Samsung VP-L980, VP-L320, VP-L330, VP-L300, SCL320 User Manual

...

© Samsung Electronics Co.,Ltd. MAR. 1999

Printed in Korea

AD68-00079B

SERVICE MANUAL

SCL300/L310/L320/L330/L350/L800/L850/VP-L300/L320/L330/L350/L980

8mm CAMCORDER

SCL300/L310/L320/L330/L350

SCL800/L850

VP-L300/L320/L330/L350

VP-L980

SERVICE

1. Precautions

2. Service Tips

3. Product Specifications and

Comparison Chart

4. Disassembly and Reassem

5. Alignment and Adjustment

6. Exploded View and Parts L

7. Electrical Parts List

8. PCB Diagrams

9. Wiring Diagram

10. Schematic Diagrams

Manua

8mm CAMCORDER

CONTENTS

For mechanical disassembly and adjustment, refer to the “Mechanical Manual”

(DE-6 AD68-30200A).

cover 5/11/95 9:42 AM Page 1

Samsung Electronics 1-1

1. Be sure that all of the built-in protective devices

are replaced. Restore any missing protective

shields.

2. When reinstalling the chassis and its assemblies, be sure to restore all protective devices,

including :

control knobs and compartment covers.

3. Make sure that there are no cabinet openings

through which people--particularly children

--might insert fingers and contact dangerous

voltages. Such openings include the spacing

between the picture tube and the cabinet mask,

excessively wide cabinet ventilation slots, and

improperly fitted back covers.

If the measured resistance is less than 1.0

megohm or greater than 5.2 megohms, an

abnormality exists that must be corrected

before the unit is returned to the customer.

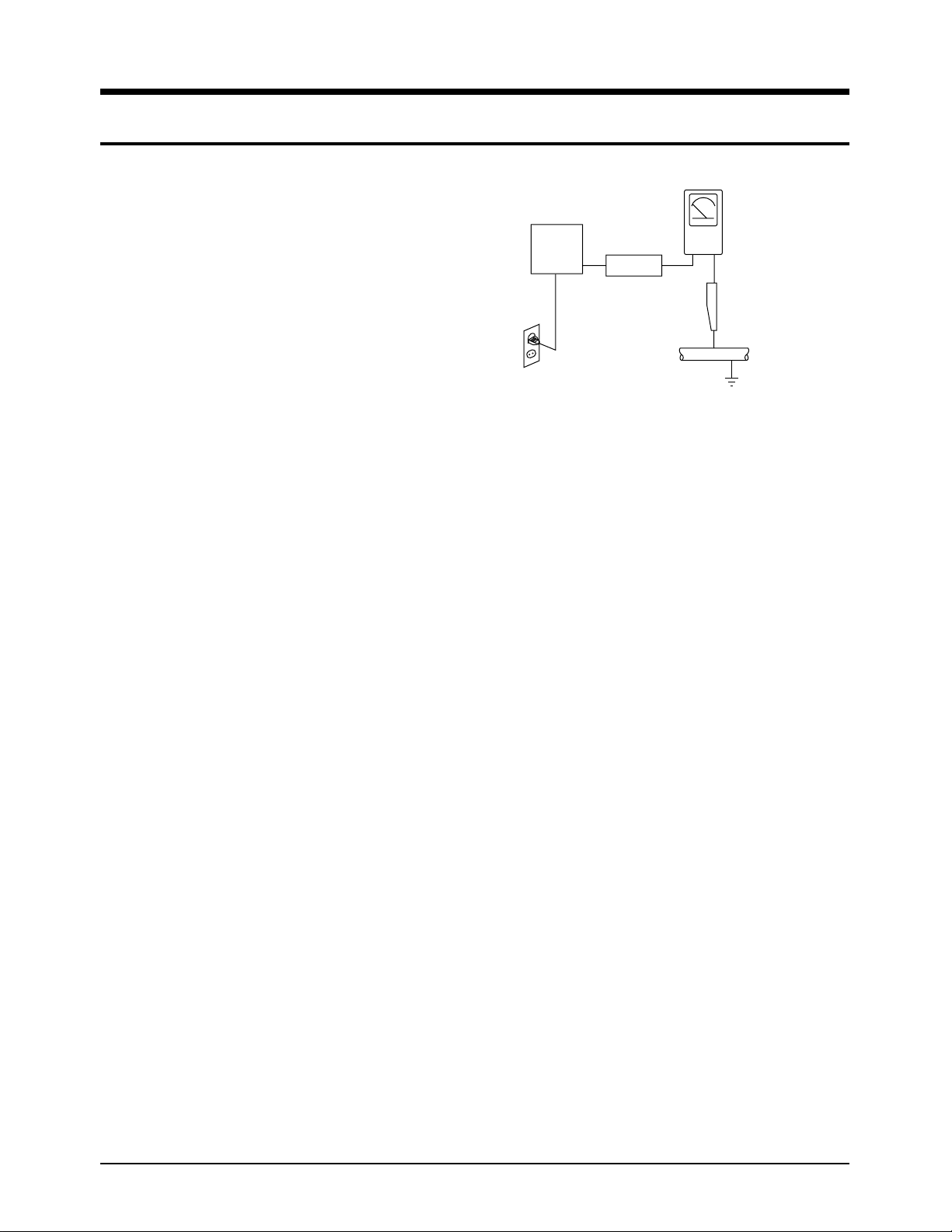

4. Leakage Current Hot Check (See Fig. 1) :

Warning : Do not use an isolation transformer

during this test. Use a leakage current tester or

a metering system that complies with American

National Standards Institute (ANSI C101.1,

Leakage Current for Appliances), and

Underwriters Laboratories (UL Publication

UL1410, 59.7).

5. With the unit completely reassembled, plug the

AC line cord directly the power outlet. With the

unit’s AC switch first in the ON position and

then OFF, measure the current between a

known earth ground (metal water pipe, conduit, etc.) and all exposed metal parts, including : antennas, handle

brackets, metal cabinets, screwheads and control shafts. The current measured should not

exceed 0.5 milliamp. Reverse the power-plug

prongs in the AC outlet and repeat the test.

6. X-ray Limits :

The picture tube is designed to prohibit X-ray

emissions. To ensure continued X-ray protection, replace the picture tube only with one that

is the same type as the original.

Fig. 1 AC Leakage Test

7. Antenna Cold Check :

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across

the two AC prongs. Connect one lead of the

ohmmeter to an AC prong.

Connect the other lead to the coaxial connector.

8. High Voltage Limit :

High voltage must be measured each time

servicing is done on the B+, horizontal deflection or high voltage circuits.

Heed the high voltage limits. These include the

X-ray protection Specifications Label, and the

Product Safety and X-ray Warning Note on the

service data schematic.

9. Some semiconductor (“solid state”) devices are

easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect transistors.

The following techniques will reduce the

occurrence of component damage caused by

static electricity.

10. Immediately before handling any semiconduc-

tor components or assemblies, drain the electrostatic charge from your body by touching a

known earth ground. Alternatively, wear a discharging Wrist-strap device. (Be sure to

remove it prior to applying power--this is an

electric shock precaution.)

1. Precautions

Device

Under

Test

(Reading should

not be above

0.5mA)

Leakage

Currant

Tester

Earth

Ground

Test all

exposed metal

surfaces

Also test with

plug reversed

(using AC adapter

plug as required)

2-Wire Cord

11. High voltage is maintained within specified

limits by close-tolerance, safety-related components and adjustments. If the high voltage

exceeds the specified limits, check each of the

special components.

12. Design Alteration Warning :

Never alter or add to the mechanical or electrical design of this unit. Example : Do not

add auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also,

any design changes or additions will void the

manufacturer’s warranty.

13. Hot Chassis Warning :

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only

if the AC power plug is inserted so that the

chassis is connected to the ground side of the

AC source.

To confirm that the AC power plug is inserted

correctly, do the following : Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the reading is greater than 1.0V, remove the AC power

plug, reverse its polarity and reinsert. Re-measure the voltage between the chassis and

ground.

14. Some TV chassis are designed to operate with

85 volts AC between chassis and ground,

regardless of the AC plug polarity. These units

can be safely serviced only if an isolation

transformer inserted between the receiver and

the power source.

15. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of

its assemblies) unless all solid-state heat sinks

are correctly installed.

16. Always connect a test instrument’s ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument’s ground lead last.

17. Observe the original lead dress, especially near

the following areas : Antenna wiring, sharp

edges, and especially the AC and high voltage

power supplies. Always inspect for pinched,

out-of-place, or frayed wiring. Do not change

the spacing between components and the

printed circuit board. Check the AC power

cord for damage. Make sure that leads and

components do not touch thermally hot parts.

18. Picture Tube Implosion Warning :

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure

that the replacement picture tube is the same

as the original.

19. Do not remove, install or handle the picture

tube without first putting on shatterproof goggles equipped with side shields. Never handle

the picture tube by its neck. Some “in-line”

picture tubes are equipped with a permanently

attached deflection yoke; do not try to remove

such “permanently attached” yokes from the

picture tube.

20. Product Safety Notice :

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

give might be lost if the replacement component differs from the original--even if the

replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( or ).

Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications.

A replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

Samsung Electronics1-2

Precautions

Samsung Electronics 2-1

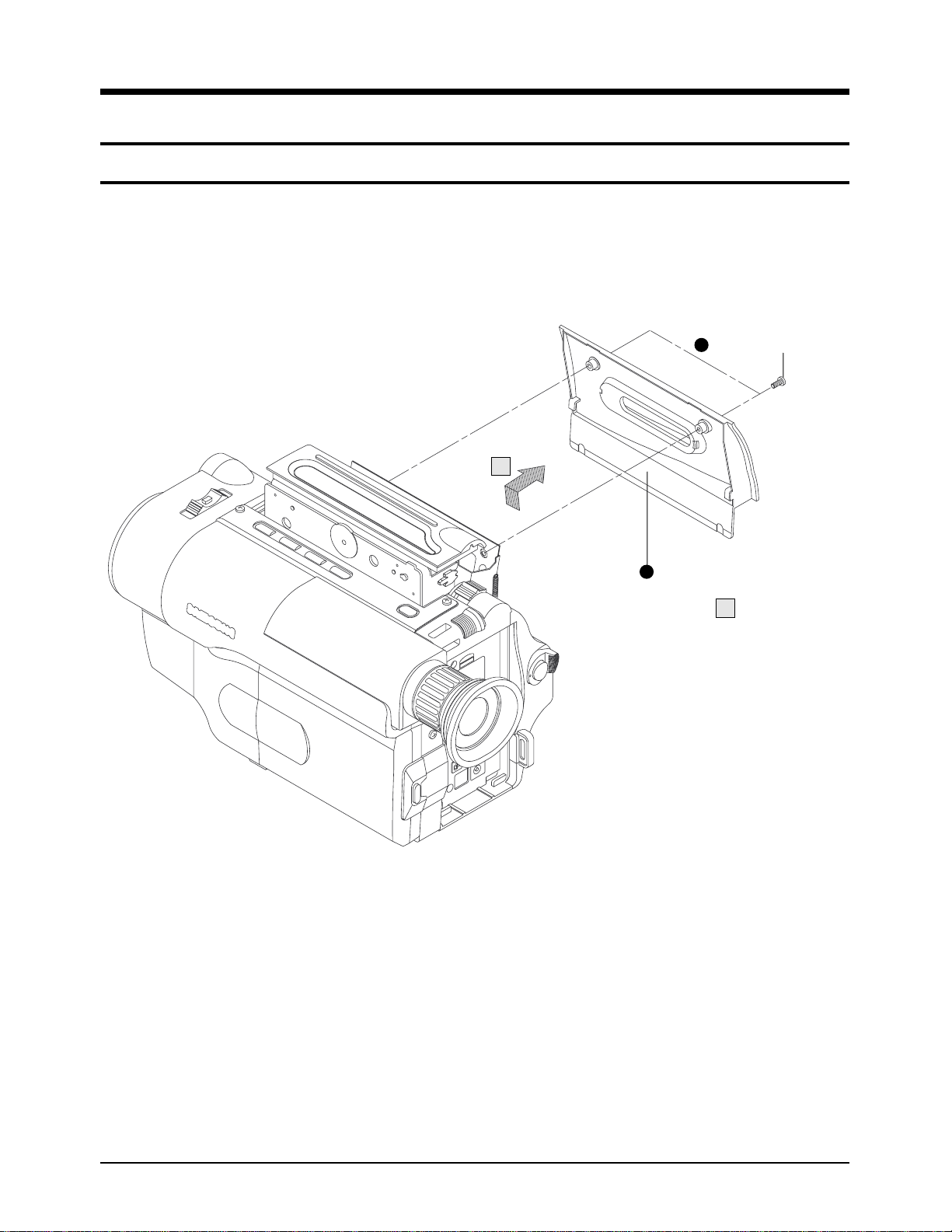

✤ The Service materials (Lamp, Plier) will be supplied by SEC Korea.

1. Disassemble the screw from the camcorder with a

small screw driver as figure.

2. Pull out the video light cover unit carefully as figure.

❚ Do not apply excessive force because the cover is

easy to be broken.

❚ The right side of the cover is fixed by hitch, and the

left by a screw.

3. Pull out the bulb with flat pliers supplied as a service

tool.

❚ Do not apply excessive force because the cover is

easy to be broken.

4. Insert a new BULB(JC 6V-3W/G2.5) with a pliers as

figure.

❚ Do not apply excessive force because the cover is

easy to be broken.

❚ Make sure that the bulb is in place exactly.

❚ To prevent the smudge of the finger prints reducing

the life of the bulb, do not touch the bulb with fingers.

5. Reassemble the video light cover unit to the camcorder carefully as figure.

❚ Do not apply excessive force because the cover is

easy to be broken.

6. Reassemble the screw with a small screw driver to

the camcorder.

2. Service Tip

2-1 Replacing The Bulb For The Video Light

1

2

3

4

5

6

Samsung Electronics2-2

Service Tips

MEMO

MEMO

Samsung Electronics 3-1

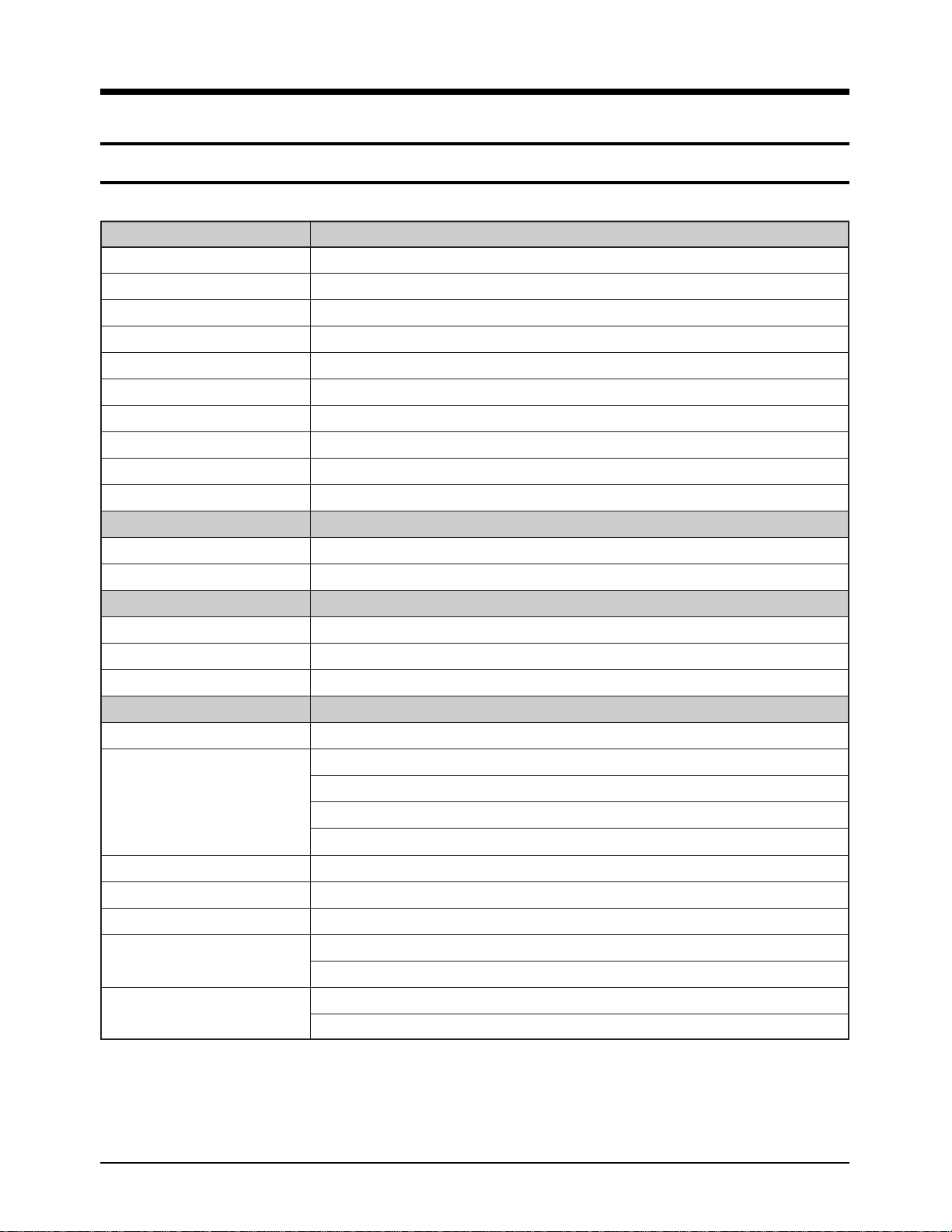

3. Product Specifications and Comparison Chart

3-1 NTSC Models (SCL300/L310/L320/L330/L350/L800/L850)

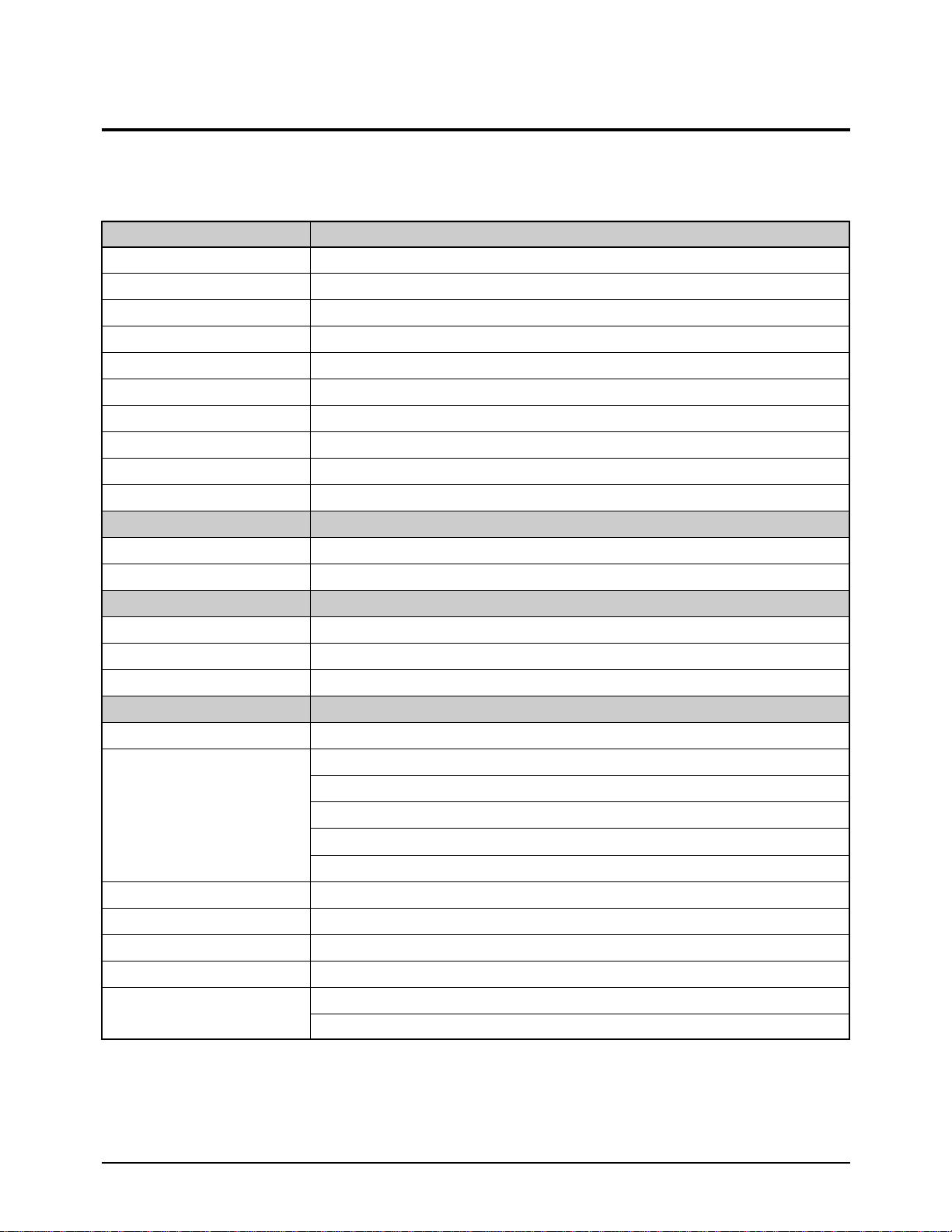

System SCL300/L310/L320/L330/L350/L800/L850

Recording time P6-120: 120 min.

FF or REW time P6-120: approx. 6.5 min.

Image device CCD (Charge Coupled Device)

Optical zoom ratio SCL300/L310/L320/L330: 16X, SCL350/L800/L850:22X

Focal length:f SCL300/L310/L320/L330: 3.9~62.6 mm, SCL350/L800.L850: 4.0~88.0 mm

F SCL300/L310/L320/L330: 1.4, SCL350/L800/L850: 1.6

Filter diameter 46 mm

Focus system Inner

Macro Auto wide macro

Min. Illumination 0.3 lux (visible)

LCD monitor

Size/Pic. cell SCL300/L310/L320: 2.5 inch/62k, SCL330/L350/L800/L850: 3 inch/89k

Method TFT

Connectors

Video out Mini jack, 1 Vp-p, 75 ohms, Unbalanced

Audio out Mini jack, 7.7 dBs, imp.: less than 2.2 kohms

External mic Monaural (SCL800/L850: stereo), ø3.5

General

Power requirement 6.0~7.2 V DC

Power consumption SCL300/L310: 5.3 W,

SCL320: 5.4 W, SCL330: 5.6 W

SCL350: 5.7 W

SCL800: 6.1 W, SCL850: 6.2 W

Built-in mic Condenser mic, omni-directional

Built-in speaker Dynamic, 0.5 W standard

Operating temperature 0°C to 40°C (32°F to 104°F)

Dimension (WXHXD) SCL300/L310/L320/L330 : 109X104X215 mm (4.29X4.09X8.46 inch)

SCL350/L800/L850 : 109X104.5X221mm (4.29X4.09X8.7 inch)

Weight SCL300/L310/L320 : 860 g (1.89 lbs), SCL330 : 870 g (1.92 lbs)

SCL350 : 900 g (1.98 lbs), SCL800/L850 : 900 g (1.98 lbs)

✤ The technical specifications and design may be changed without notice.

*Conditions:

LCD on/EVF off/EIS off/LIGHT off

Recording

System VP-L300/L320/L330/L350/L980

Recording time P5-120: 120 min.

FF or REW time P5-120: approx. 8 min.

Image device CCD (Charge Coupled Device)

Optical zoom ratio VP-L300/L320/L330: 16X, VP-L350/L980:22X

Focal length:f VP-L300/L320/L330: 3.9~62.6 mm, VP-L350/L980: 4.0~88.0 mm

F VP-L300/L320/L330: 1.4, VP-L350/L980: 1.6

Filter diameter 46 mm

Focus system Inner

Macro Auto wide macro

Min. Illumination 0.3 lux (visible)

LCD monitor

Size/Pic. cell VP-L300/L320: 2.5 inch/62k, VP-L330/L350/L980: 3 inch/89k

Method TFT

Connectors

Video out Mini jack, 1 Vp-p, 75 ohms, Unbalanced

Audio out Mini jack, 7.7 dBs, imp.: less than 2.2 kohms

External mic Monaural (VP-L980: stereo), ø3.5

General

Power requirement 6.0~7.2 V DC

Power consumption VP-L300: 5.3 W

VP-L320: 5.4 W

VP-L330: 5.6 W

VP-L350: 5.7 W

VP-L980: 6.2 W

Built-in mic Condenser mic, omni-directional

Built-in speaker Dynamic, 0.5 W standard

Operating temperature 0°C to 40°C (32°F to 104°F)

Dimension (WXHXD) VP-L300/L320/L330 : 109X104X215, VP-L350/L980 : 109X104.5X221

Weight VP-L300/L320 : 860 g, VP-L330 : 870 g

VP-L350 : 900 g, VP-L980 : 900 g

Samsung Electronics3-2

Product specifications and comparison chart

3-2 PAL Models (VP-L300/L320/L330/L350/L980)

✤ The technical specifications and design may be changed without notice.

*Conditions:

LCD on/EVF off/EIS off/LIGHT off

Recording

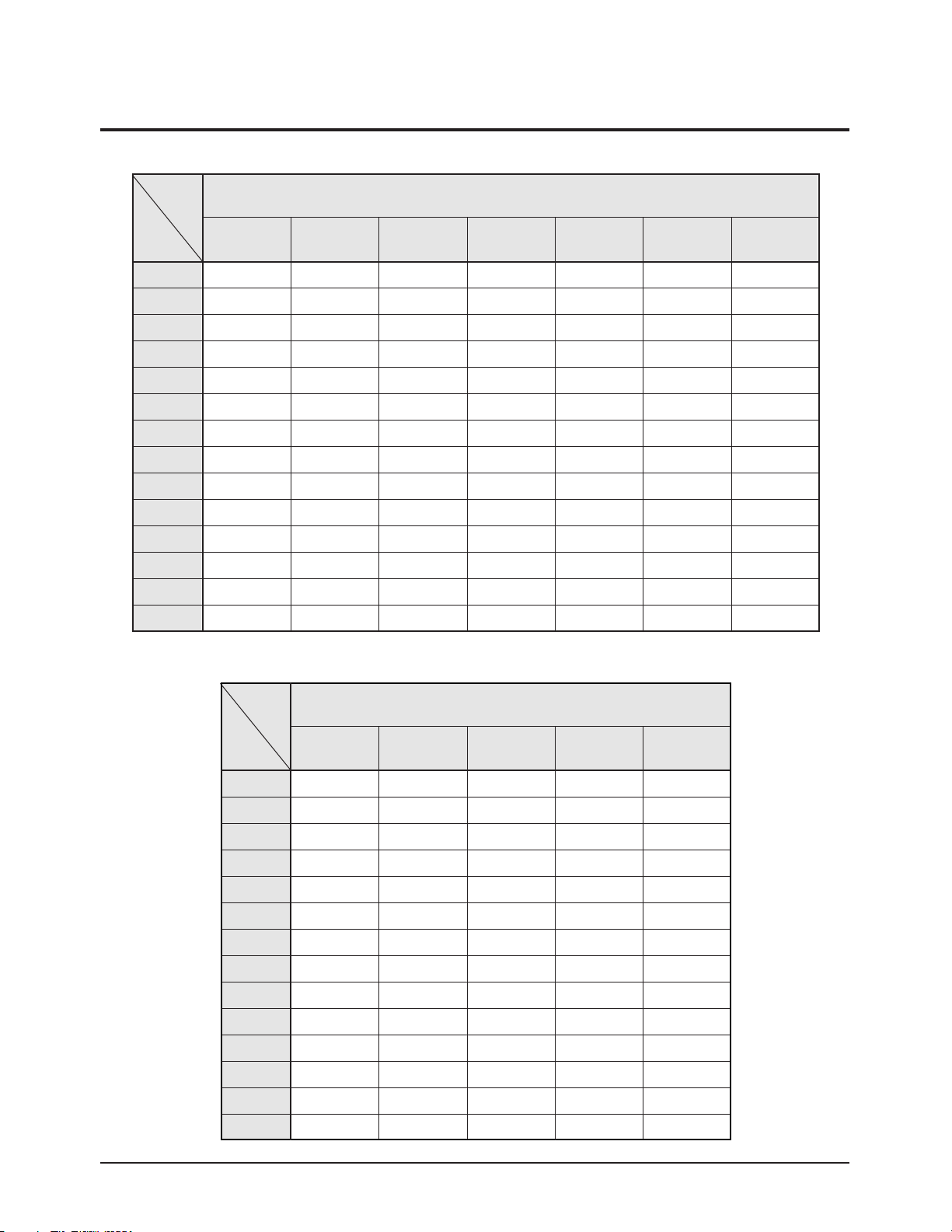

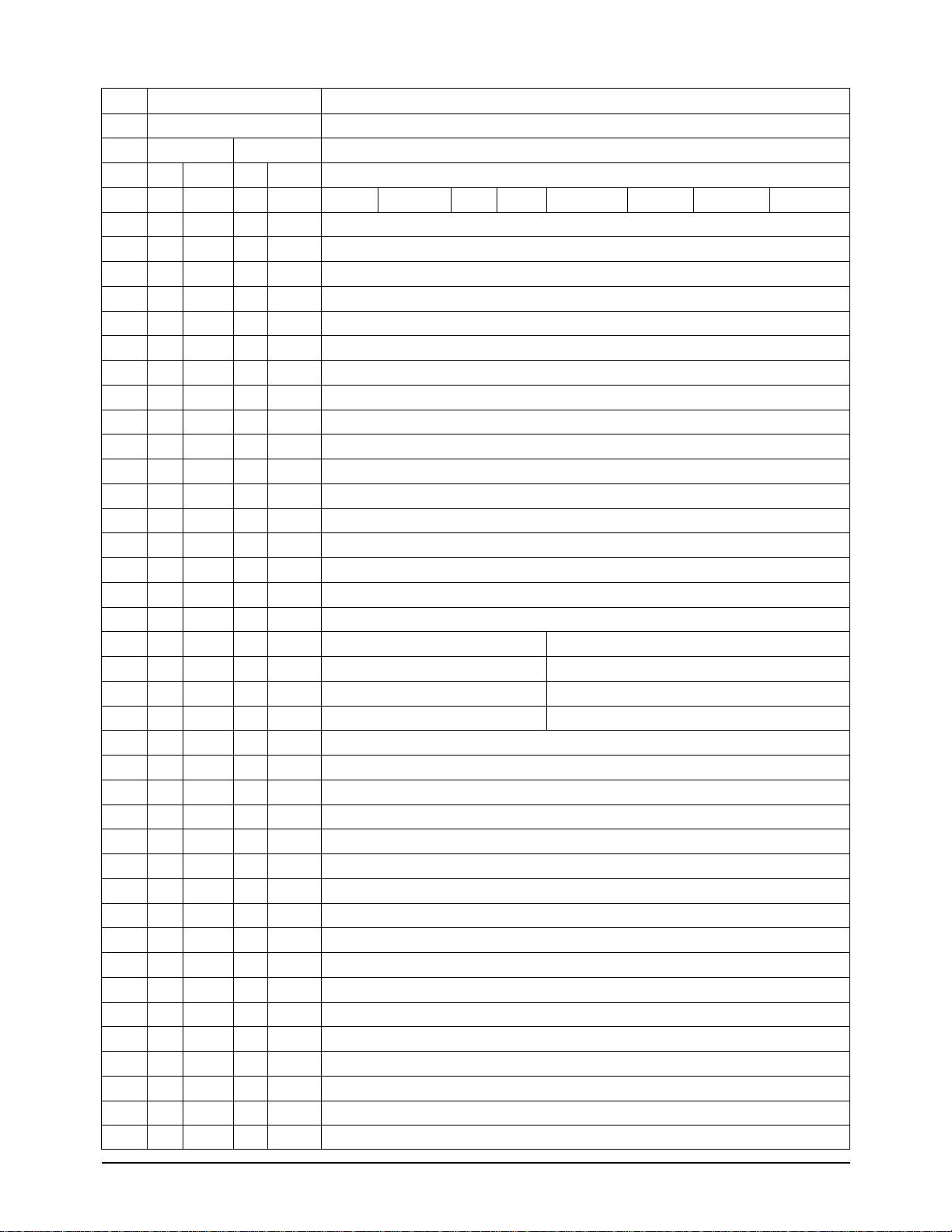

Hi8 mm

3´´

O

O

O

O

O

Ni-MH

Stereo

B & W

O

Auto

x22 (x440)

570 K

8 mm

3´´

O

O

O

O

O

Ni-MH

Mono

B & W

O

Auto

x22 (x440)

570 K

8 mm

3´´

X

X

O

O

O

Ni-MH

Mono

B & W

O

Auto

x16 (x320)

320 K

8 mm

2.5´´

X

X

X

O

O

Ni-Cd

Mono

B & W

O

Auto

x16 (x320)

320 K

NTSC

Features

Format

LCD Size

V/Light

EIS

XDR

BLC

Remocon

Battery

Audio

V/Finder

P.Title

Focus System

Z/Ratio

CCD

Model

Features

Samsung Electronics 3-3

Product specifications and comparison chart

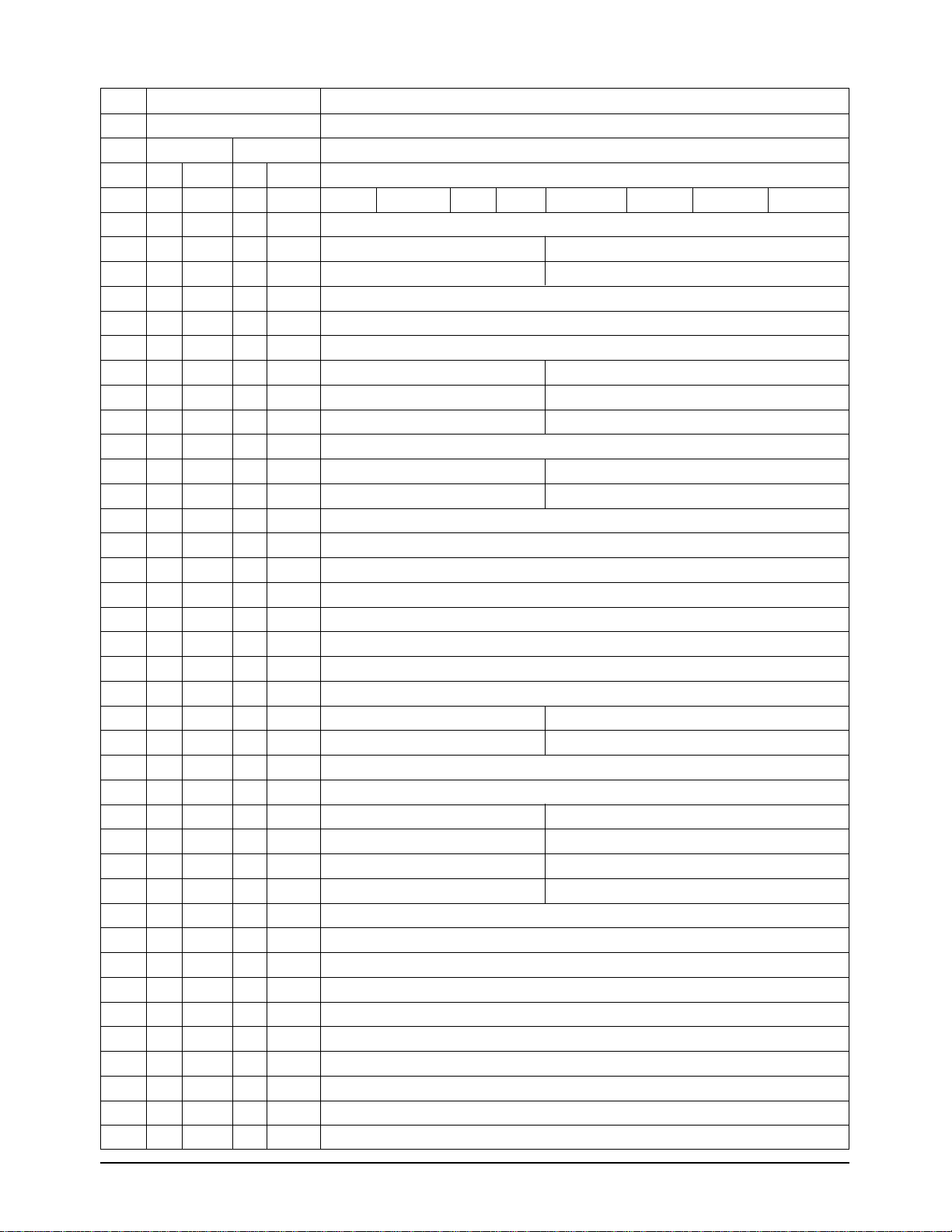

3-3 Comparison Chart

Format

LCD Size

V/Light

EIS

I-BLC

BLC

Remocon

Battery

Audio

V/Finder

P.Title

Focus System

Z/Ratio

CCD

8 mm

2.5´´

X

X

X

O

X

Ni-Cd

Mono

B & W

O

Auto

x16 (x320)

270 K

8 mm

2.5´´

X

X

X

O

O

Ni-MH

Mono

B & W

O

Auto

x16 (x220)

270 K

8 mm

2.5´´

X

O

X

O

O

Ni-Cd

Mono

B & W

O

Auto

x16 (x320)

270 K

8 mm

3´´

X

X

O

O

O

Ni-MH

Mono

B & W

O

Auto

x16 (x320)

270 K

8 mm

3´´

O

O

O

O

O

Ni-MH

Mono

B & W

O

Auto

x22 (x440)

270 K

Hi8 mm

3´´

X

X

O

O

O

Ni-MH

Stereo

B & W

O

Auto

x22 (x440)

470 K

Hi8 mm

3´´

O

O

O

O

O

Ni-MH

Stereo

B & W

O

Auto

x22 (x440)

470 K

8 mm

2.5´´

X

O

O

O

O

Ni-Cd

Mono

B & W

O

Auto

x16 (x320)

320 K

SCL300 SCL310 SCL320 SCL330 SCL350 SCL800 SCL850

VP-L300 VP-L320 VP-L330 VP-L350 VP-L980

Model

PAL

Samsung Electronics3-4

Product specifications and comparison chart

MEMO

MEMO

Samsung Electronics 4-1

4. Disassembly and Reassembly

4-1 Cabinet Disassembly

4-1-1 Ass’y Cover Housing Removal

1

Remove 2 screws.

2

Remove the ass'y cover

housing in the direction

of arrow .

A

A

Fig. 4-1 Ass’y Cover Housing Removal

*

It is recommended to eject the cassette

housing for removal the cover housing.

*

You don’t need to disassemble the Cover

Housing except that you change the Deck

Mechanism.

Samsung Electronics4-2

Disassemblr and Reassembly

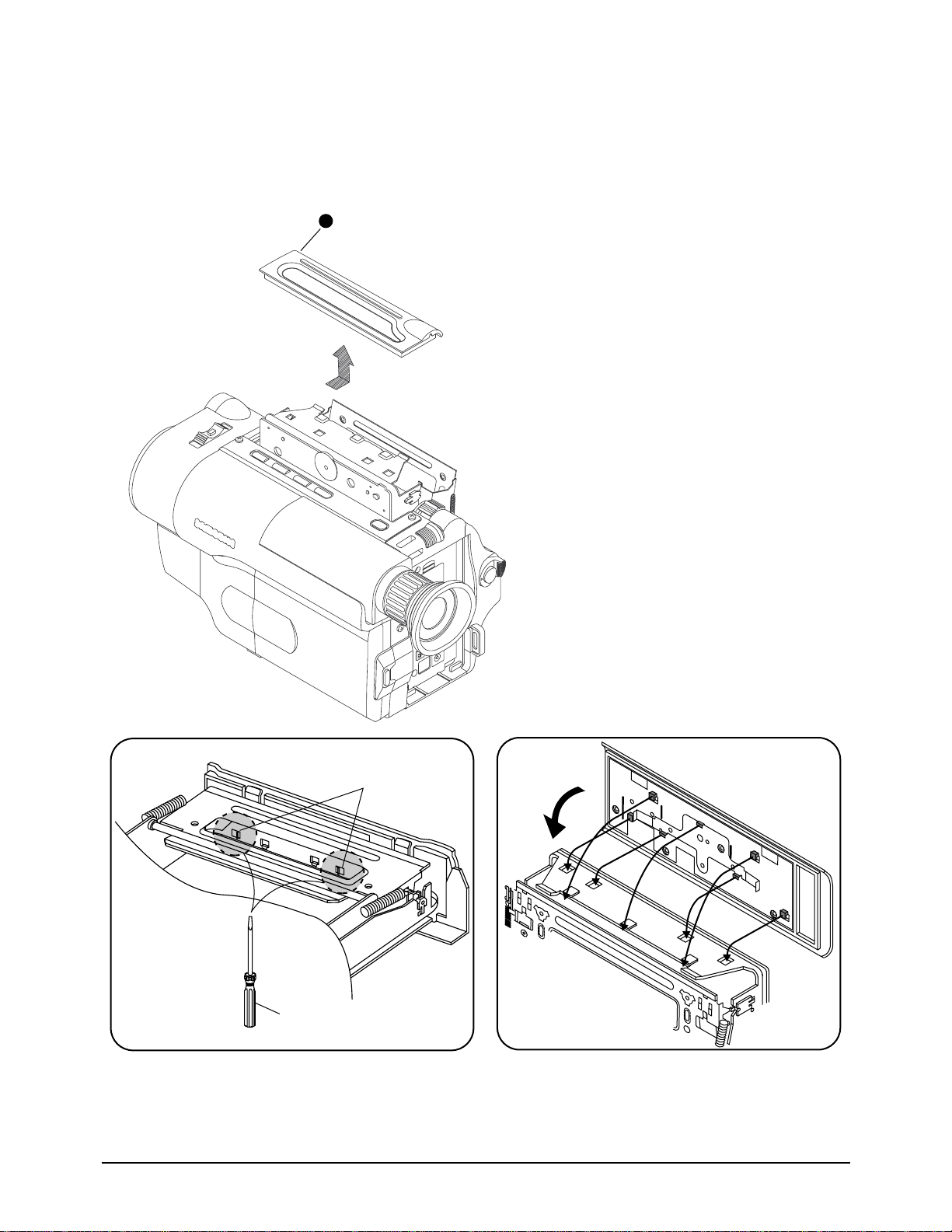

4-1-2 Ass’y Case Top Removal

1

Remove ass'y case top by gentlely releasing

2 locking tabs with a small screw driver.

(see DETAIL "A")

REASSEMBLY : Put the 7 tabs into the slot,

while sliding it as shown in DETAIL "B".

2 locking tabs

Precision screw driver

< DETAIL "A" >

"B"

< DETAIL "B" >

Fig. 4-2 Ass’y Case Top Removal

*

You don’t need to disassemble the Case Top except that

you change the Deck Mechanism.

Samsung Electronics 4-3

Disassemblr and Reassembly

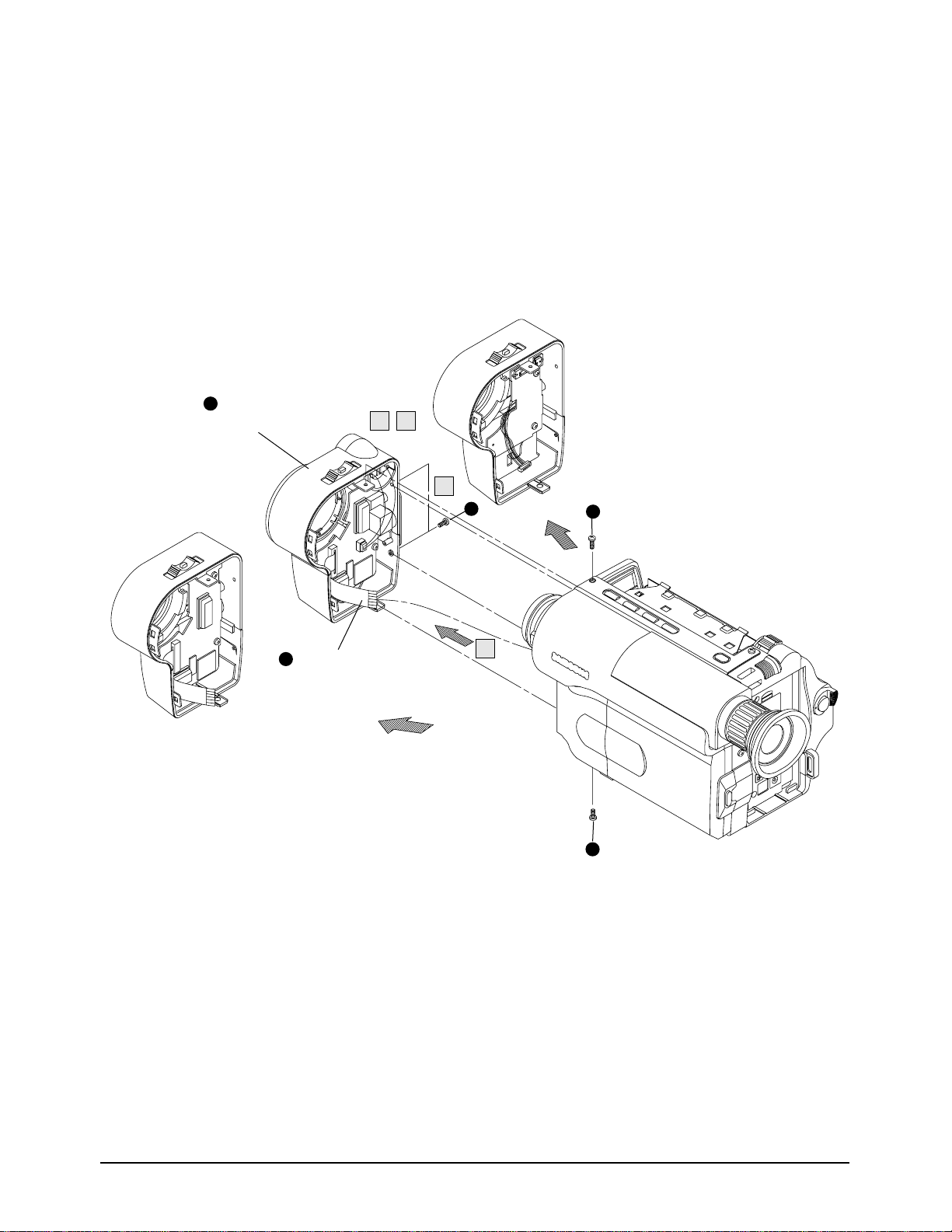

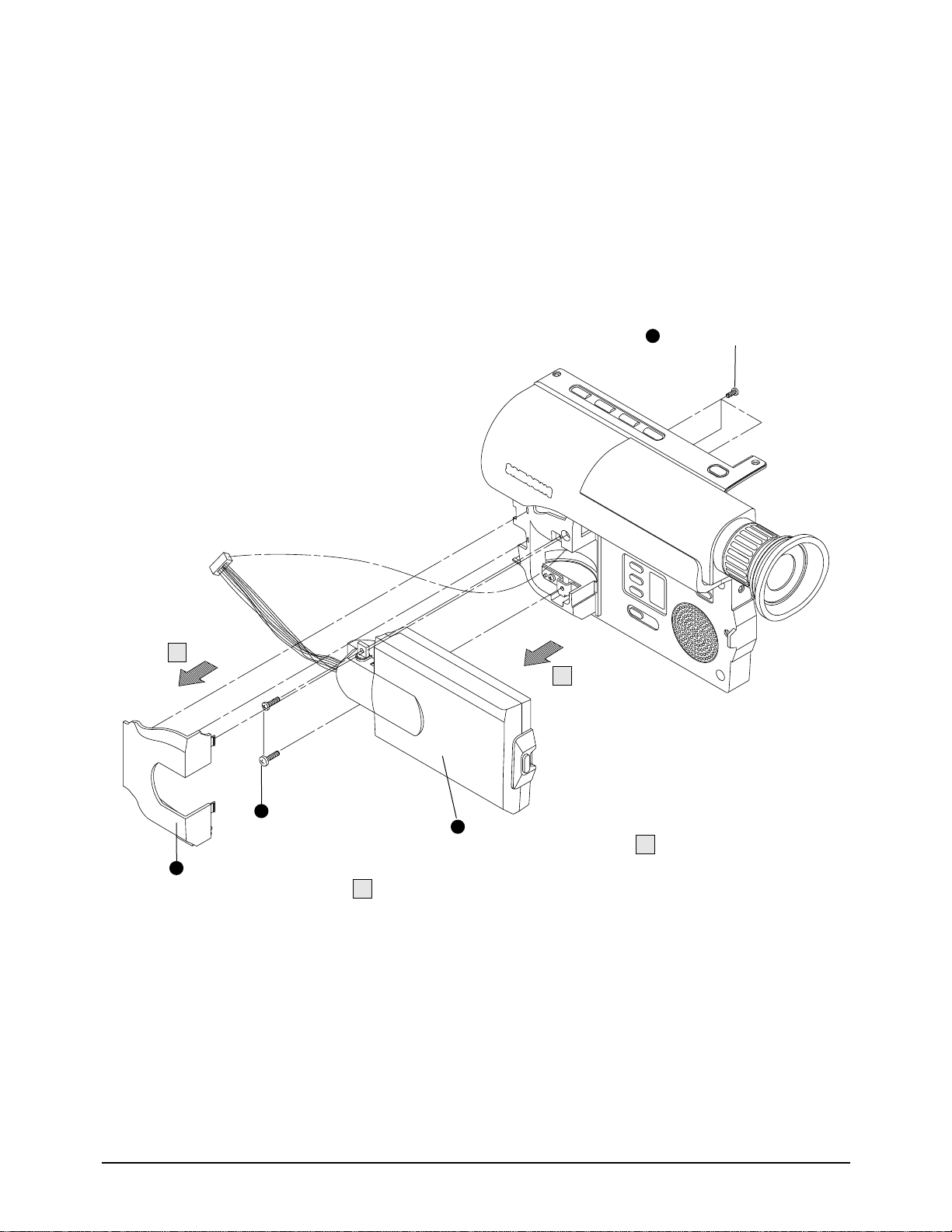

1

1

1

Remove 4 screws.

3

Disconnect the FPC

or wire from the audio block

of MAIN PCB.

(Ass'y front for

EIS models)

(Ass'y front for

Non-EIS models)

2

Pull out the ass'y front in

the direction of arrow , .

B

A

A B

4-1-3 Ass’y Front Removal

Fig. 4-3 Ass’y Front Removal

Samsung Electronics4-4

Disassemblr and Reassembly

4-1-4 Ass’y Case Right Removal

1

Remove 4 screws.

Pull out the unit case

in the direction of arrow .

Disassemble after turning

knob to be "LOCK".

1

1

2

A

A

Fig. 4-4 Ass’y Case Right Removal

Samsung Electronics 4-5

Disassemblr and Reassembly

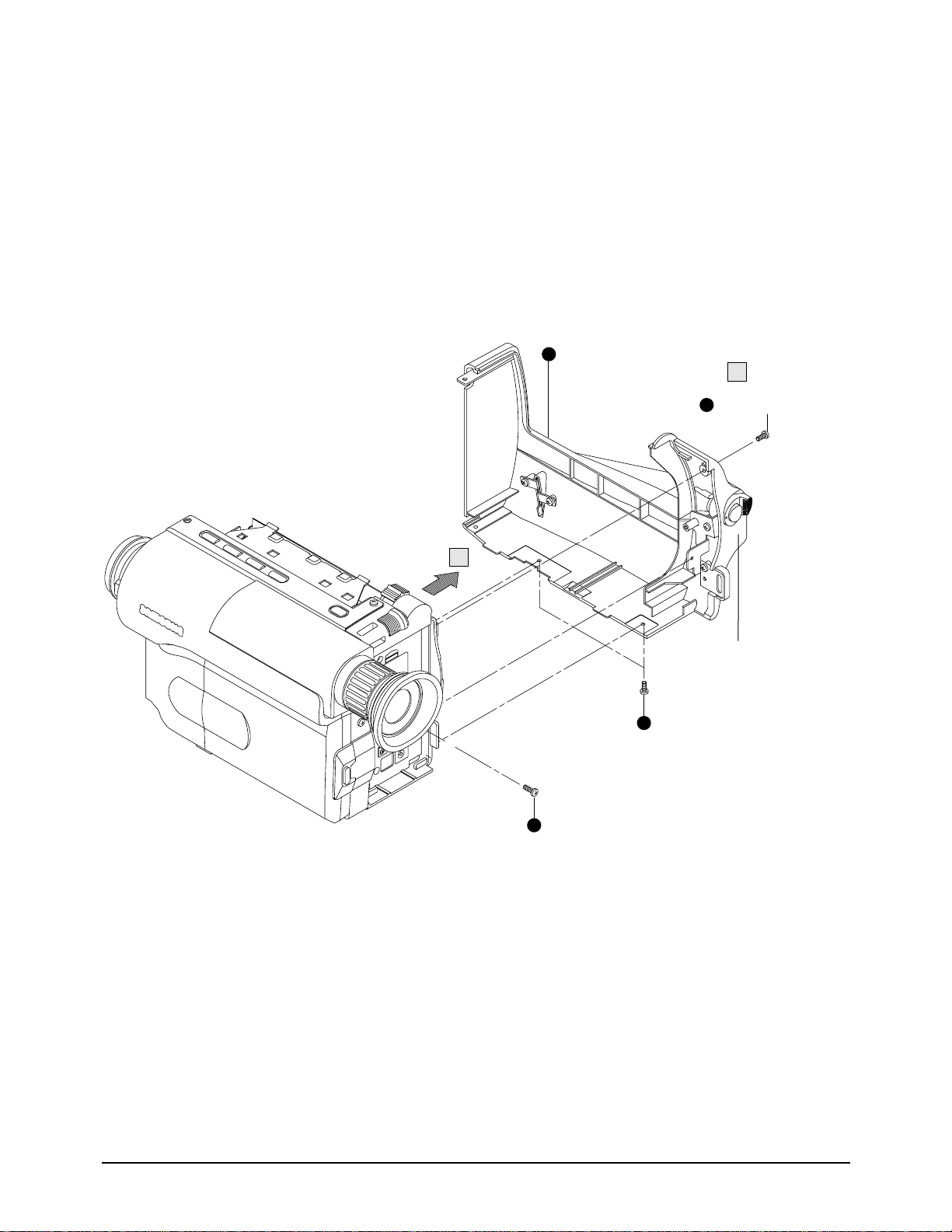

2

Pull out the case left

assembly in the direction

of arrow .

1

1

Remove 5 screws.

1

1

1

A

A

Disconnect wire

of 15 pins.

Disconnect wire

of 10 pins.

4-1-5 Ass’y Case Left Removal

Fig. 4-5 Ass’y Case Left Removal

4

Pull out the LCD assembly

in the direction of arrow .

1

Remove 1 screw.

Remove 2 screws.

3

Pull out the cover

in the direction of arrow .

2

B

B

A

A

Samsung Electronics4-6

Disassemblr and Reassembly

Fig. 4-6 Ass’y LCD Removal

4-1-6 Ass’y LCD Removal

Samsung Electronics 4-7

Disassemblr and Reassembly

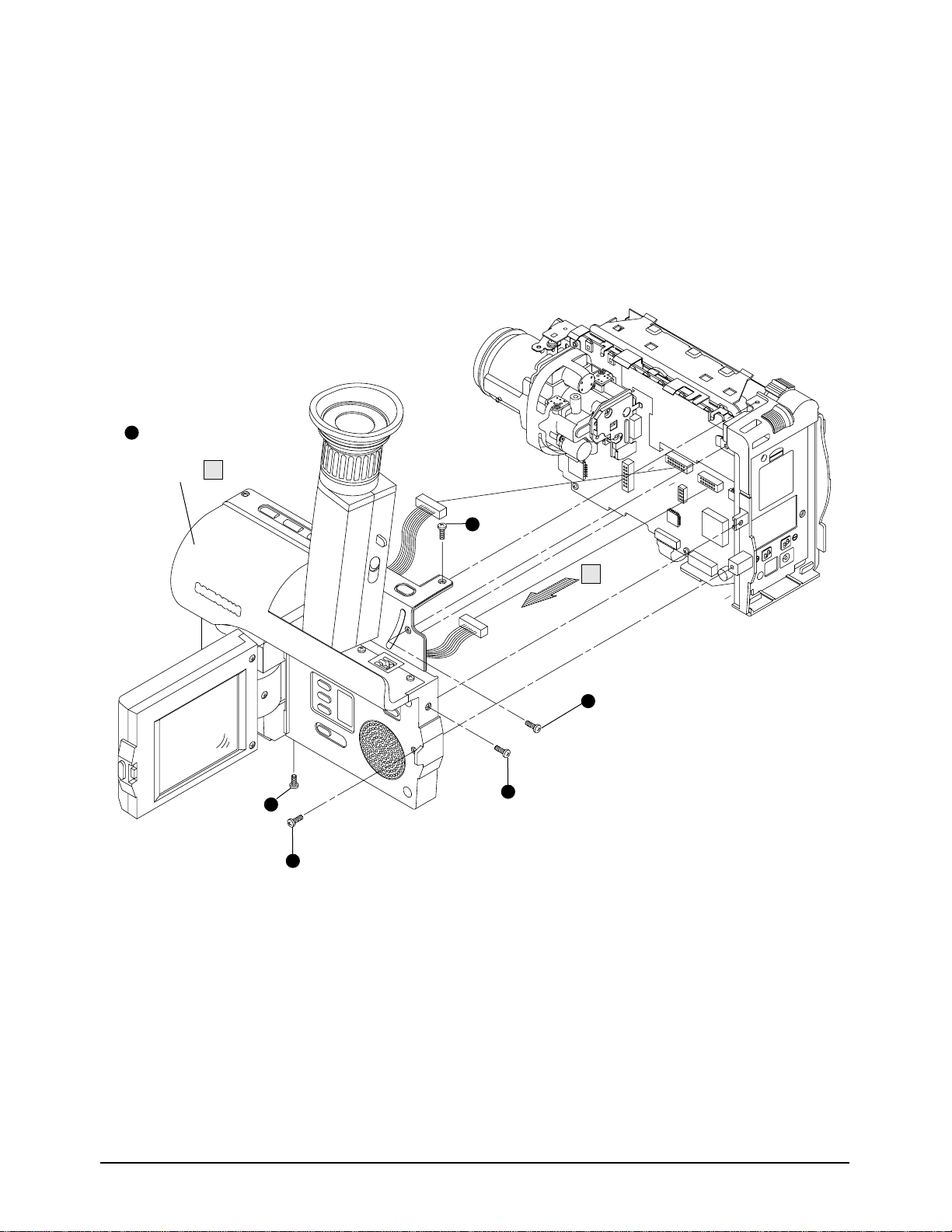

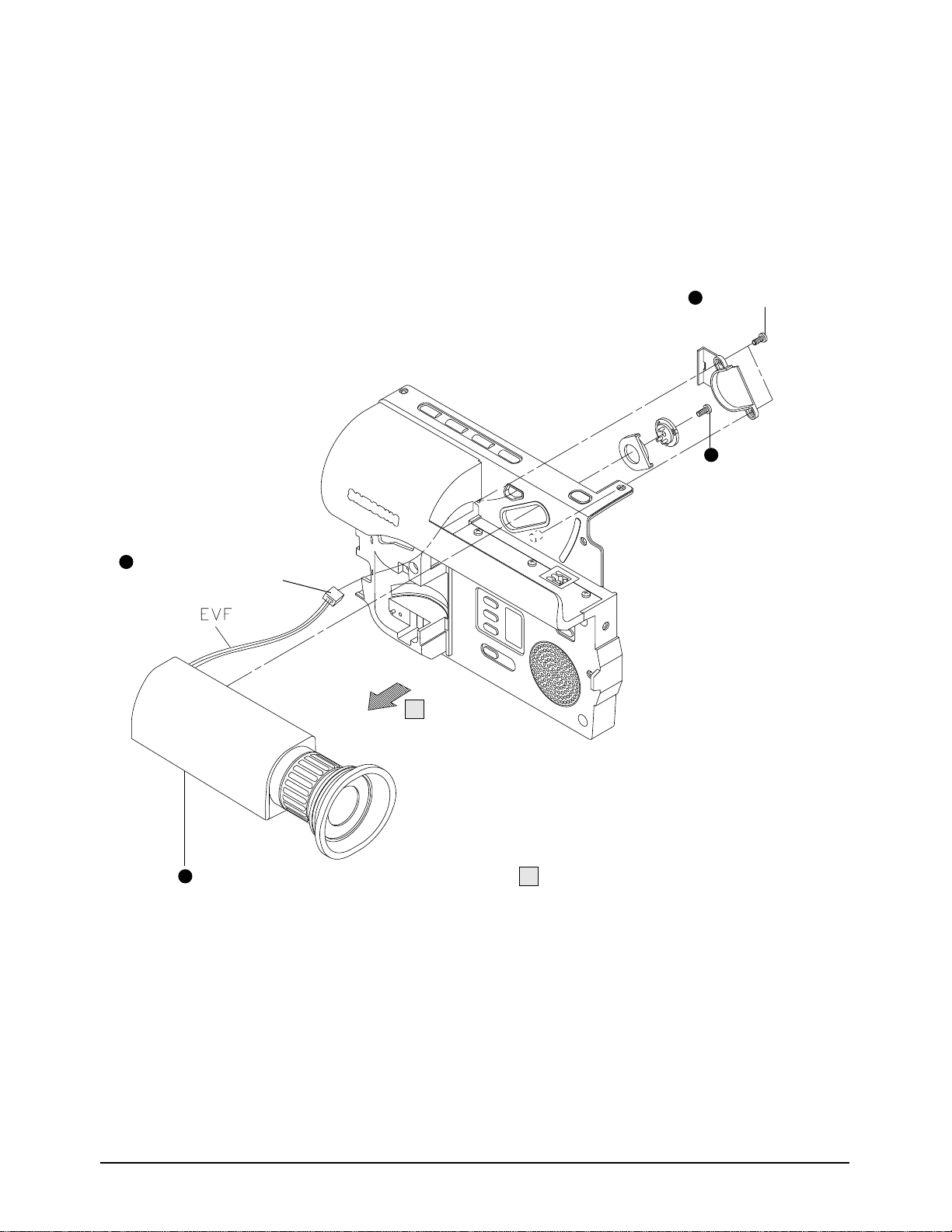

4-1-7 Ass’y EVF Removal

1

Remove 2 screws.

A

A

Remove 1 screw.

4

Pull out the EVF ass'y in the direction of arrow .

2

Disconnect wire of 3 pins from

the FUNCTION PCB.

3

Fig. 4-7 Ass’y EVF Removal

Samsung Electronics4-8

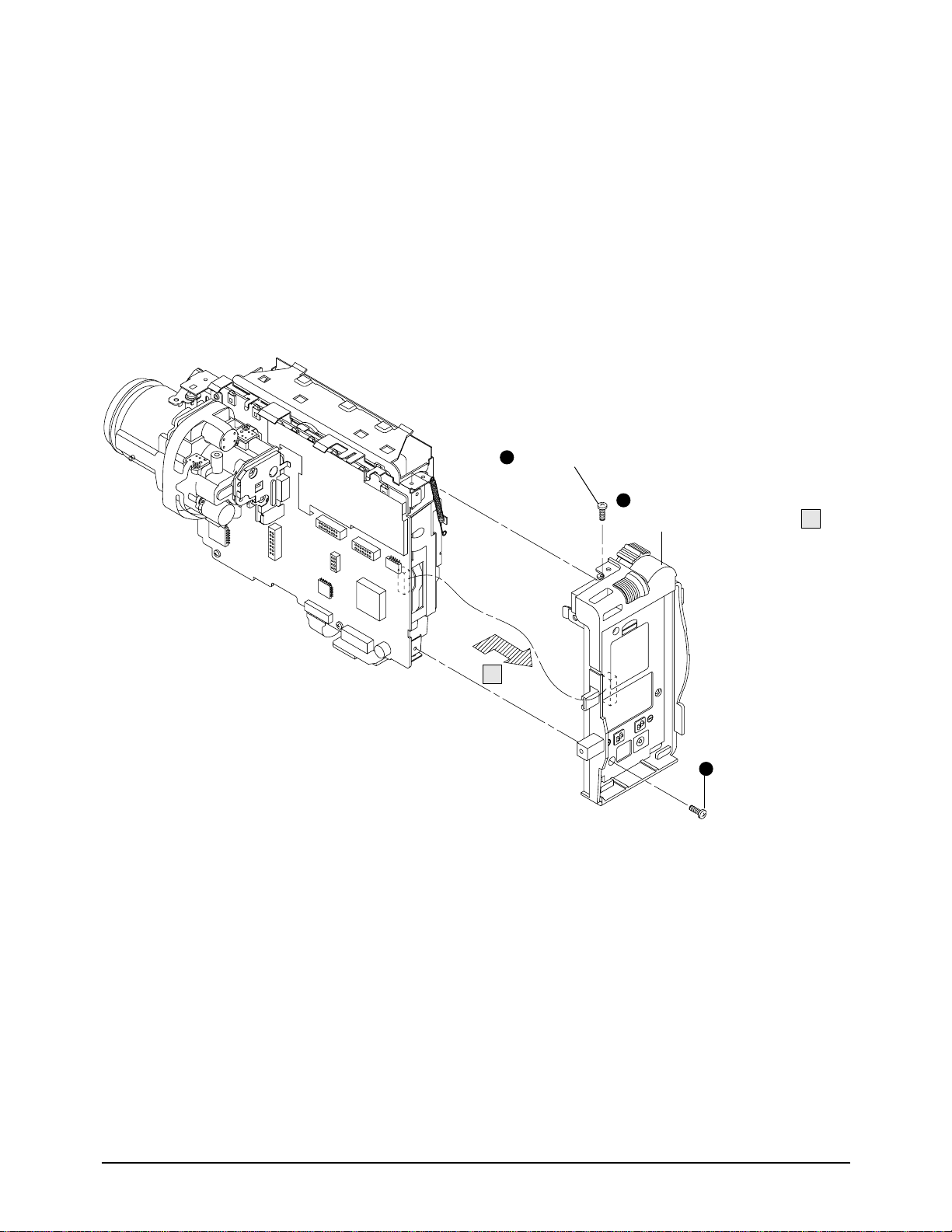

Disassemblr and Reassembly

1

Remove 1 screw.

A

A

2

Remove 1 screw.

3

Pull out the ass'y REAR board

in the direction of arrow .

4-1-8 Ass’y Rear Board Removal

Fig. 4-8 Ass’y Case Rear Removal

Samsung Electronics 4-9

Disassemblr and Reassembly

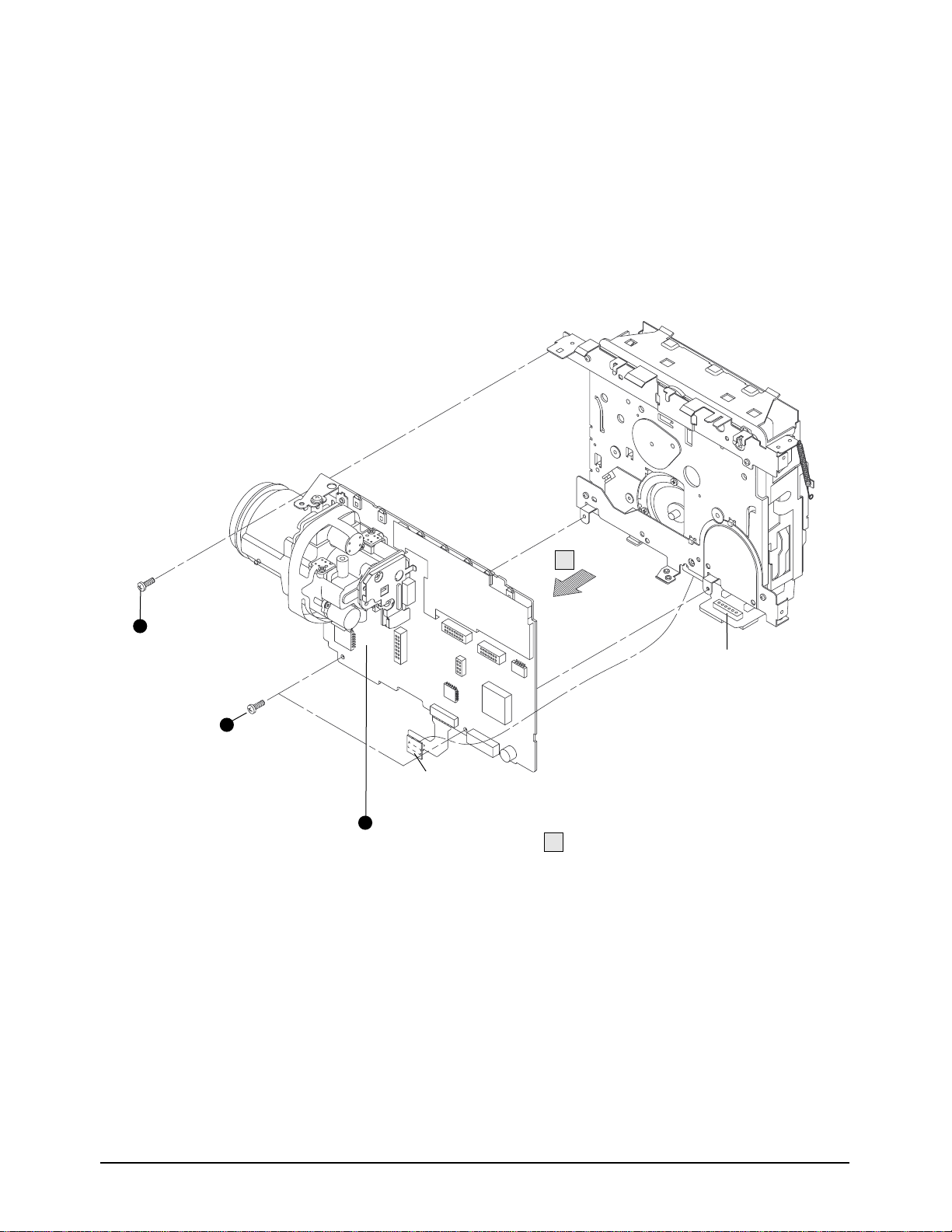

4-1-9 Ass’y 8mm Deck Removal

1

1

Remove 3 screws.

2

Pull out the MAIN PCB from the ass'y DECK

in the directiob of arrow .

A

A

Disconnect connector

from the MAIN PCB.

Disconnect connector

from the Head-Drum.

Fig. 4-9 Ass’y 8mm Deck Removal

Samsung Electronics4-10

Disassemblr and Reassembly

1

2

Remove 2 screws.

A

A

4

Disconnect connector and pull out the

ass'y LENS in the direction of arrow .

3

Disconnect FPC from the connector of the MAIN PCB.

Remove solder with an iron

to isolate PCB and LENS.

4-1-10 Ass’y Camera Removal

Fig. 4-10 Ass’y Camera Removal

Samsung Electronics 4-11

Disassemblr and Reassembly

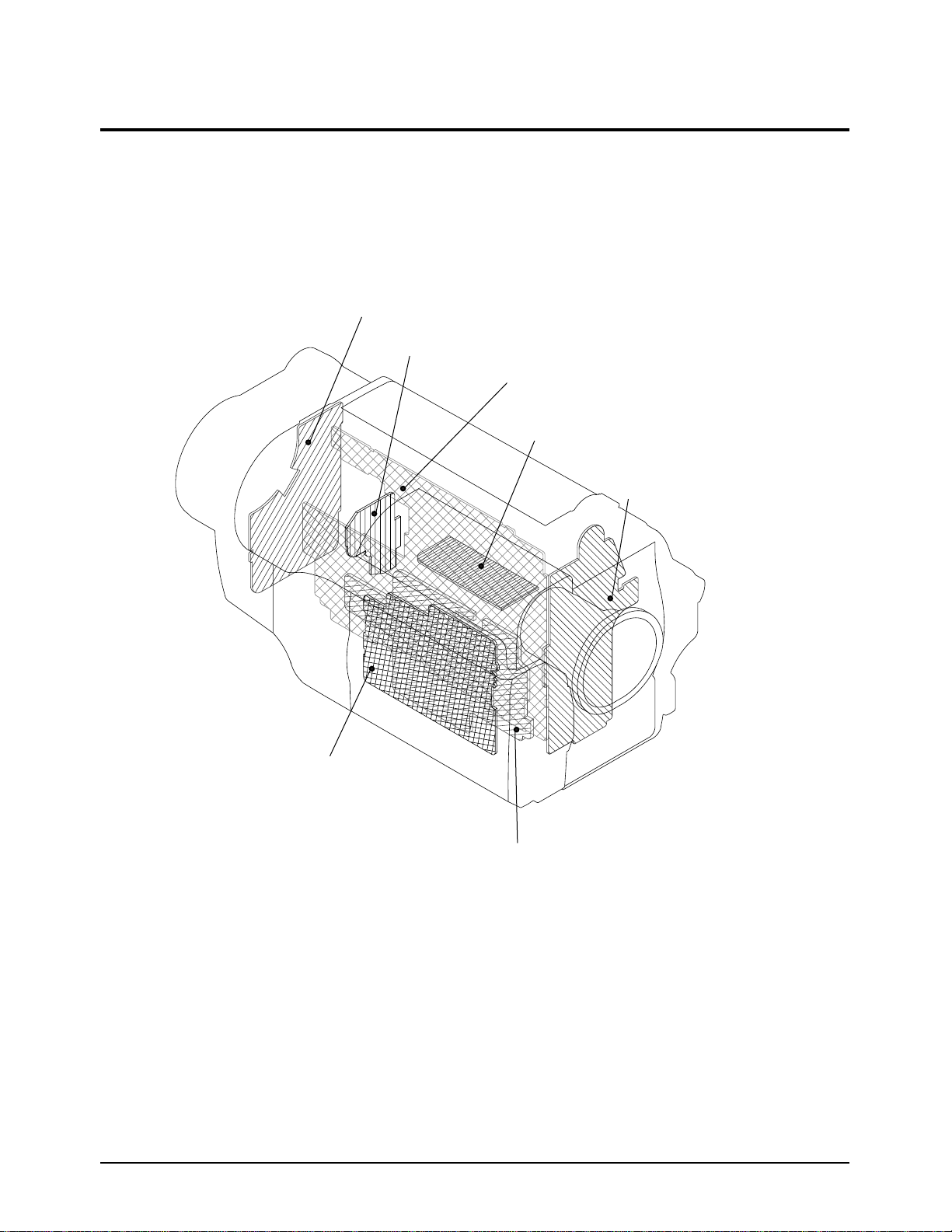

4-2 Circuit Boards Location

ASS'Y MAIN BOARD

ASS'Y CCD BOARD

ASS'Y LCD BOARD

ASS'Y FUNCTION BOARD

ASS'Y EVF BOARD

ASS'Y REAR BOARD

ASS'Y EIS BOARD (EIS MODEL)

ASS'Y FRONT BOARD (NON EIS MODEL)

Fig. 4-11 Circuit Boards Location

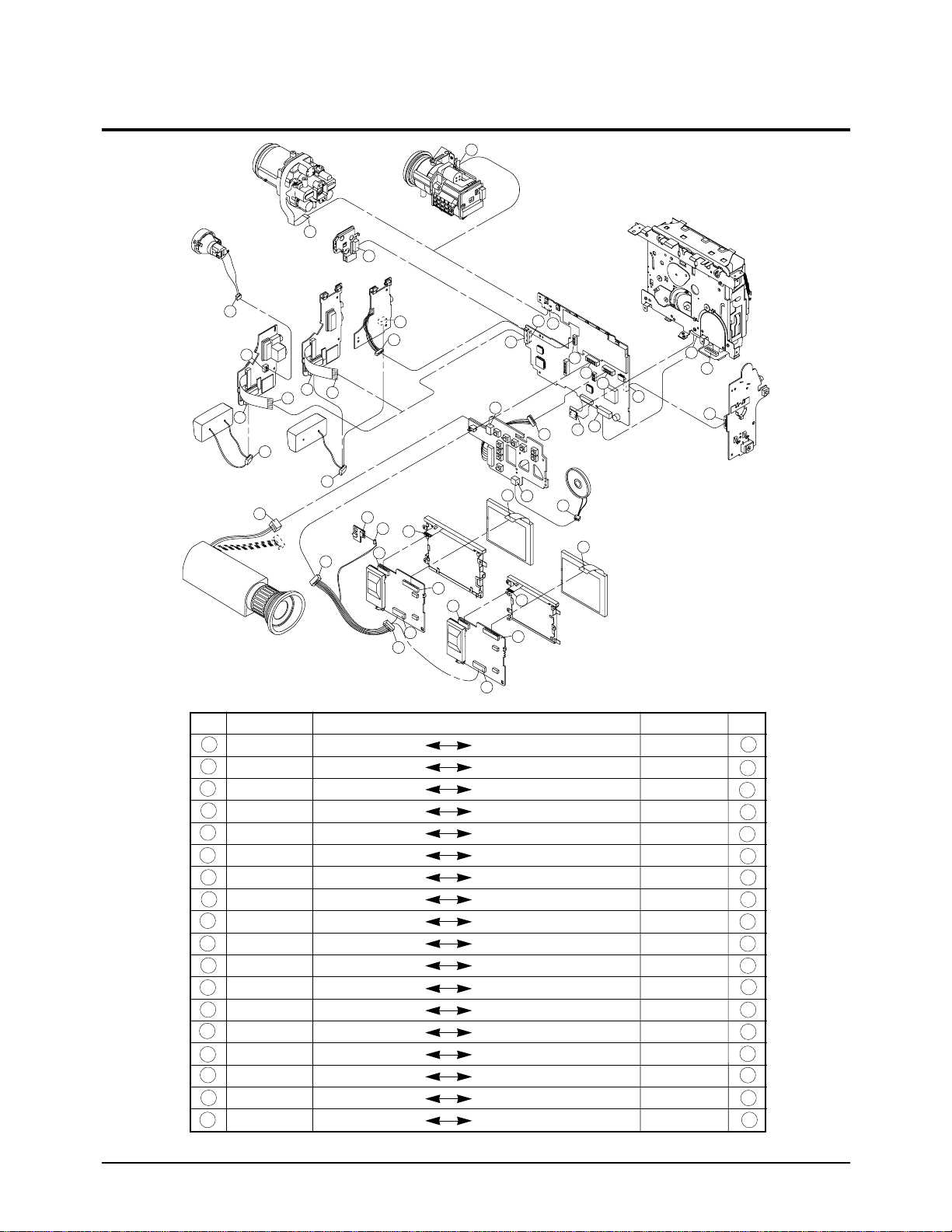

DIRECTION

DECK MAIN PCB

DECK MAIN PCB

MAIN PCB REAR PCB

MAIN PCB FUNCTION PCB

MAIN PCB LCD

MAIN PCB CCD PCB

MAIN PCB LENS FPC

MAIN PCB LENS FPC

MAIN PCB FRONT FFC (EIS,STEREO)

MAIN PCB FRONT FFC (EIS, MONO)

MAIN PCB FRONT PCB (NO EIS)

FRONT PCB MIC ASS’Y

FRONT PCB MIC ASS’Y

FRONT PCB MIC ASS’Y

FRONT PCB LIGHT ASS’Y

FUNCTION PCB EVF

FUNCTION PCB SPEAKER

LCD HINGE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

37

38

39

40

41

42

43

44

Samsung Electronics4-12

Disassemblr and Reassembly

NO. NO.

4-3 Connector Diagrams

Fig. 4-12 Connector Diagrams

CONNECTOR

CN51

––

CN601

CN603

CN604

CNP01

CNP03

CNP02

CNP801

CN801

CN802

CN891

CN893

CN893

CN895

CN472

CN473

––

CONNECTOR

CN501

CN52

CN771

––

––

CNC01

––

––

CN894

CN894

CN890

––

––

––

––

––

––

––

1

357

9

111313

16

16

19

21

23

252628

38

31

2

468

10

12

14

15

17

18

20

22

242527

29

39

30

Samsung Electronics 5-1

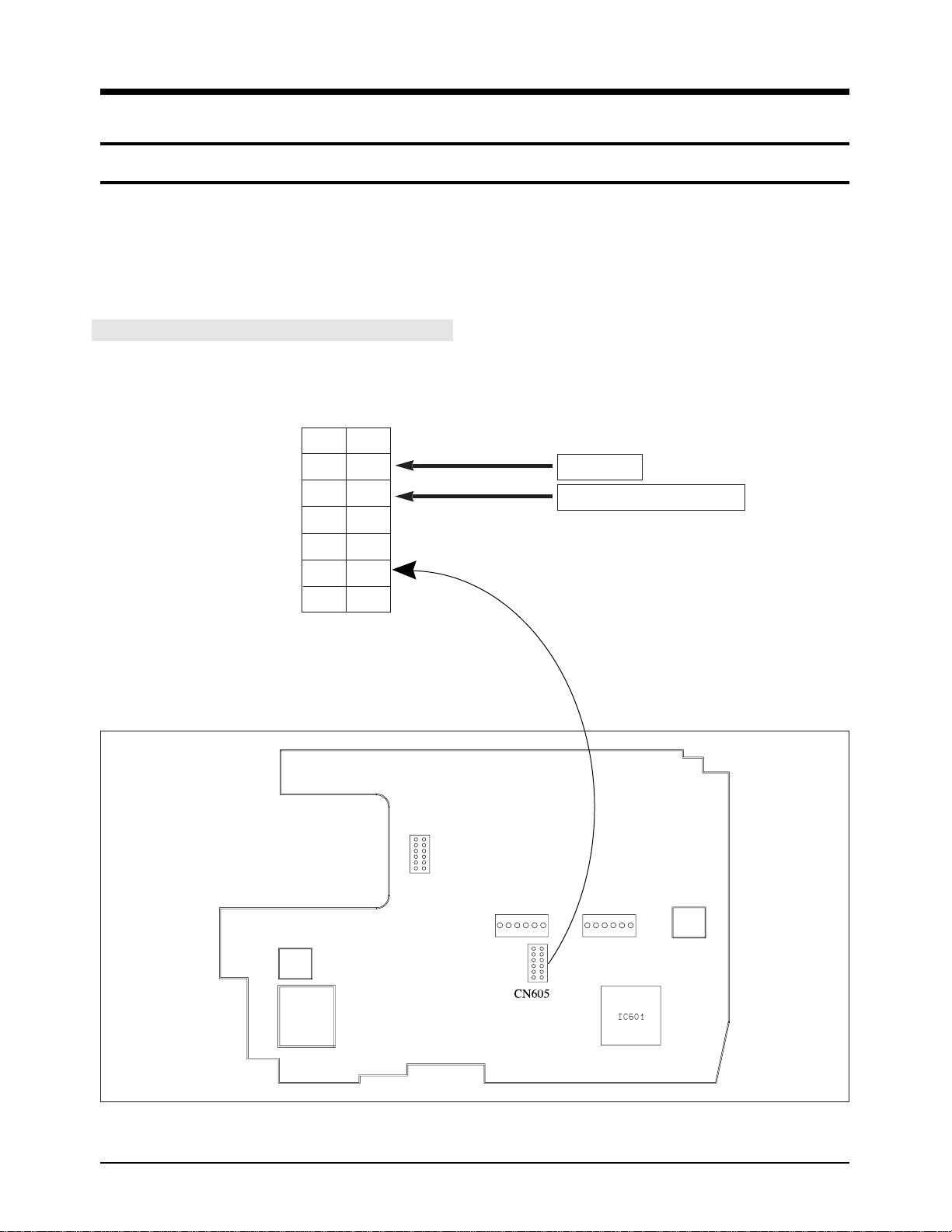

5. Alignment and Adjustment

5-1. Mechanism Alignment

¥ Refer to mechanical manual ÒDE-6 (AD68-30200A)Ófor the adjustment and checks of mechanism section.

Test Points for Mechanism Alignment

1. PB RF - Pin 11 of CN605

2. Head Switching (Trigger) - Pin 9 of CN605

14

12

10

8

6

4

2

13

11

9

7

5

3

1

PB RF

Head Switching - Trigger

CN605

Fig. 1 Test point

Fig. 2 Test location of test point

Samsung Electronics5-2

Alignment and Adjustment

POSITION

IC601 IC601 IC601

ACTION MODE

28PIN 27PIN 26PIN

L H H EJECT

L L H UNLOADING STOP

H L L LOADING STOP

H H L PLAY, FF, Z/RTN, STILL....

EJECT

UNLOADING STOP

LOADING STOP

PB

IC601

27PIN

GROUND

IC601

26PIN

COMMON

IC601

28PIN

OPEN

EJECT

PLAY

LOADING

STOP

UNLOADING

STOP

LOADING

UNLOADING

Reference

¥ Mechanical Transition Chart of MODE switch.

Samsung Electronics 5-3

Alignment and Adjustment

5-2 Camera Section Adjustment

Note :

1. This system has

1) EEPROM to store the confirmed adjustment data.

2) DSP (Digital Signal Process ; ICP01 - Main board) chip to process the signal of camera parts.

3) One test point for the frequency adjustment of DSP main clock (P. CLK).

4) The special mode for camera adjustment using the function keys on the left case.

2. Keep in mind

1) All adjustment steps should performed using the remote controller.

5-2-1 Preparations

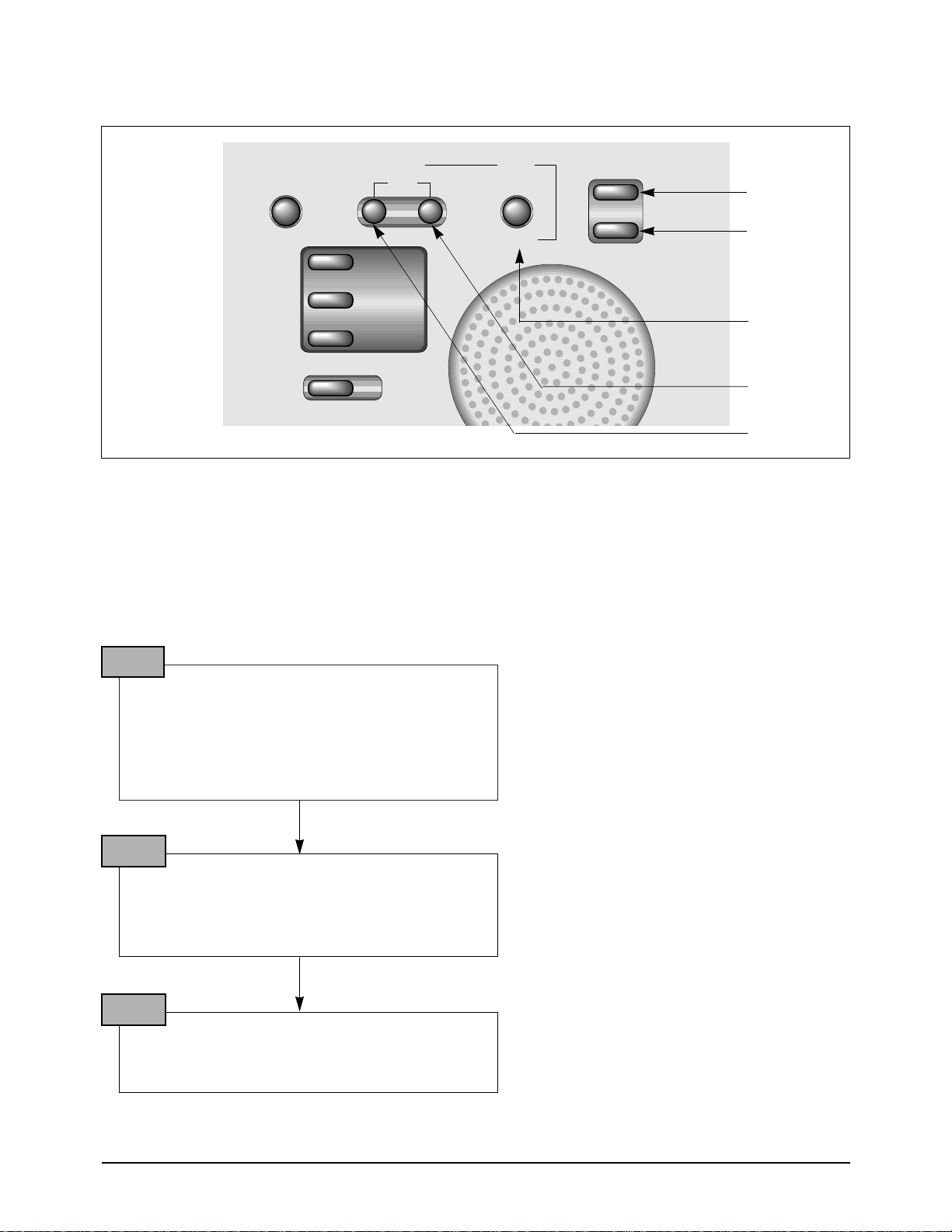

4. The function keys on the left case

The following is a chart explaining the use of each button :

1. Equipment to be used

1) DC Power supply

2) Oscilloscope

3) Frequency counter

4) Vectorscope

5) Waveform monitor

6) Color monitor or TV

7) Various charts

- Color bar chart

- Gray-scale chart, etc...

2. Composition of camera P.C.Boards

1) Main PCB

2) CCD PCB

3) EVF PCB

4) LCD PCB

3. Adjustment preparations

1) The function keys on the left case is used as a

camera adjust tool.

2) Press the confirm button when each manual

adjustment step is completed to write the

adjustment data to the EEPROM.

3) After each adjustment step is completed, OSD

shows ÒOK!Ó.

4) To cancel the adjustment mode, remove the

power source.

Using Button

MENU/ENTER (CONFIRM)

EDIT – (DATA DOWN)

EDIT + (DATA UP)

TITLE (MODE UP)

DATE/TIME (MODE DOWN)

MF

(FAR/NEAR)

ZOOM TELE/ZOOM WIDE

Adjustment

Data store after finishing adjustment by DATA UP/DOWN button.

When change data value of adjust state.

Mode change.

Manual focus adjustment.

Move the zoom position of lens.

Samsung Electronics5-4

Alignment and Adjustment

The function keys left case is required to adjust the camera section.

✤ ZOOM LEVER : ZOOM TELE/WIDE

Note : In service adjustment mode, button names are different from those in customer camera function con-

trol mode. EX) MENU/ENTER button is the same as confirm.

5. How to get into service ÒADJUSTÓ mode

1. Remove the lithium battery from the camcorder.

2. Connect the power source (battery/DC cable).

3. Eject the tape if it is in the unit.

4. Set the power switch of the camcorder to “CAMERA” position.

5. Set OSD on state.

STEP 1

1. Press and hold the “EJECT” button and “STOP”

button on the camcorder at the same time for

more than 5 seconds.

Then unit goes into service mode.

STEP 2

On screen display show “ODF. T.INI XX XX” CAMERAADJUSTMENT mode has successfully been

activated.

STEP 3

Note : When ÒXX XXÓ is shown in service adjustment procedures, this indicates variable values.

DATA DOWN

DATA UP

MODE DOWN

MODE UP

CONFIRM

ZERO RETURN

XDR/BLC

SELECT MENU

EDIT

_

DSE

ON/OFF

COUNTER

RESET

DISPLAY

+

ENTER

TITLE

DATE/TIME

ADDR OSD-DISPLAY CONTENT

0DF T.INI TABLE INITIAL

0CD HALL HALL AUTO ADJUST

0CE IRIS IRIS AUTO ADJUST

0CF AWB AWB AUTO ADJUST

0D0 LENS LENS AUTO ADJUST( WARNING! DONÕT USE WITHOUT AN INFINITE COLLIMATOR)

0D6 ZVR.C ZOOM LEVER CENTER DATA CHECKING

0DB AGCM AGC AUTO ADJUST (NORMALLY NO USED)

0DE 3MLENS 3M LENS AUTO ADJUST AT SERVICE FIELD (DISTANCE: 3M +/- 1Cm)

NO-OSD-DISPLAY

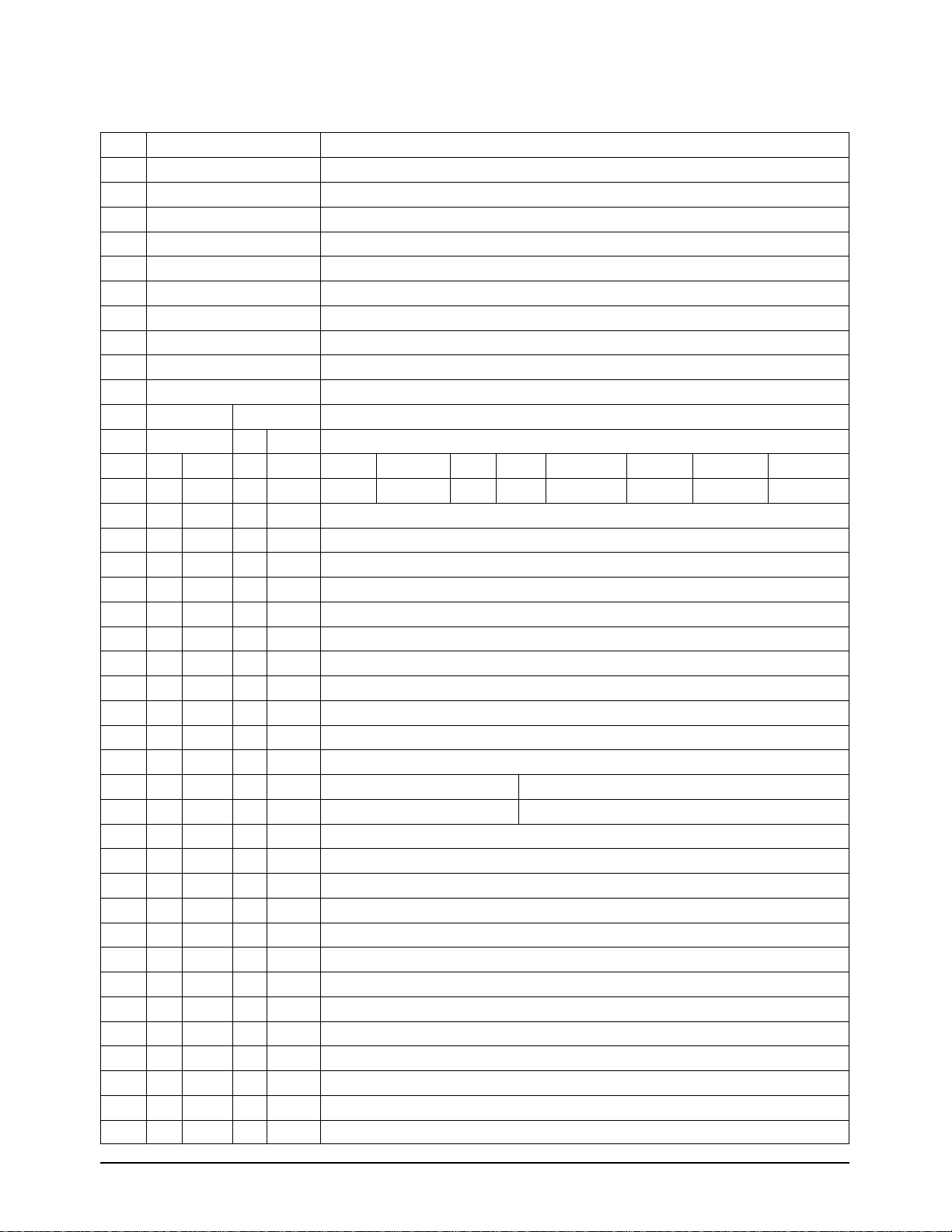

ADDR MODEL/DATA CONTENT (EEPROM DATA PAGE 0)

PAL NTSC

HI8 NORMAL HI8 NORMAL BIT SEGMENTATION EXPLAIN

ADDR DATA D7 D6 D5 D4 D3 D2 D1 D0

001 54 54 54 54 OPTION AGC TARGET- 0'=FIX WDR='1' PASTEL COLOR KEY/RING CAN/SECREM EMBOSS COLOR

002 00 00 00 00 @IRIS CONTROL-LOW

003 08 08 08 08 @IRIS CONTROL-HIGH

004 F0 F0 F0 F0 * AWB-HSS MODE * AWB STOP HALL

005 80 80 80 80 @P.CLK PWM-HIGH

006 30 30 30 30 AGC TARGET DOWN VALUE AT 001H D6='1' OPTION

007 00 00 00 00 AGC MAX, DARK SLICE-B CONTROL

008 08 08 08 08 @UPD16835 INIT 4th

009 66 66 66 66 @UPD16835 INIT 6th

00A 66 66 66 66 @UPD16835 INIT 7th

00B 00 00 00 00 @UPD16835 standard data current set A(4th.7) : D0, current set B(7th.7) : D1

00C 03 03 03 03 @CDS F-REG(f1,f0) CAM : BIT0:f0,BIT1:f1

00D A0 A0 A0 A0 changed by AUTO HALL ADJ(0CD) "@CDS F-REG(f9,f2) CAM ;PGA GAIN -HIGH(0.00dB~ 30.0dB)"

00E 60 60 60 60 changed by AUTO HALL ADJ(0CD) "@CDS G-REG CAM ;DAC1(HALL REFERENCE CONTROL;0V~3.0V);"

00F 3A 3A 3A 3A "@CDS H-REG CAM ;DAC2(HALL GAIN CONTROL;0V~3.0V); "

010 87 87 87 87 "@CDS E-R(e1,e0),J-R(j0),M-R;D0:e0,D1:e1,D2:j0(CAM),D4:e0,D5:e1,D6:j0(VCR),D7:cds-rev='1'"

011 90 90 90 90 "@CDS F-REG(f9,f2) VCR ;PGA GAIN -HIGH(0.00dB~ 10.0dB)"

012 00 00 00 00 @WDR REGISTER[7,0] *AEINSEL=D7,AELPFSEL=D6,X[5:0]

013 80 80 80 80 @WDR REGISTER[15,8] *AECLIP_TH[7:0]

014 00 00 00 00 @WDR REGISTER[23,16] *AEL_TH[7:0]

015 FF FF FF FF @WDR REGISTER[31,24] *AEH_TH[7:0]

016 8B 8B 76 76 @WDR REGISTER[39,32] *AEW2VE[7:0]

017 24 24 24 24 @WDR REGISTER[47,40] *AEW2VS[7:0]

018 ED ED F1 F1 @WDR REGISTER[55,48] *AEW2HE[7:0]

019 07 07 13 13 @WDR REGISTER[63,56] *AEW2HS[7:0]

01A 81 81 6E 6E @WDR REGISTER[71,64] *AEW1VE[7:0]

01B 26 26 20 20 @WDR REGISTER[79,72] *AEW1VS[7:0]

Samsung Electronics 5-5

Alignment and Adjustment

ÒCAMERA ADJUST MODE, EEPROM ADDRESS SEQUENCE & DATA OF PAGE 0Ó

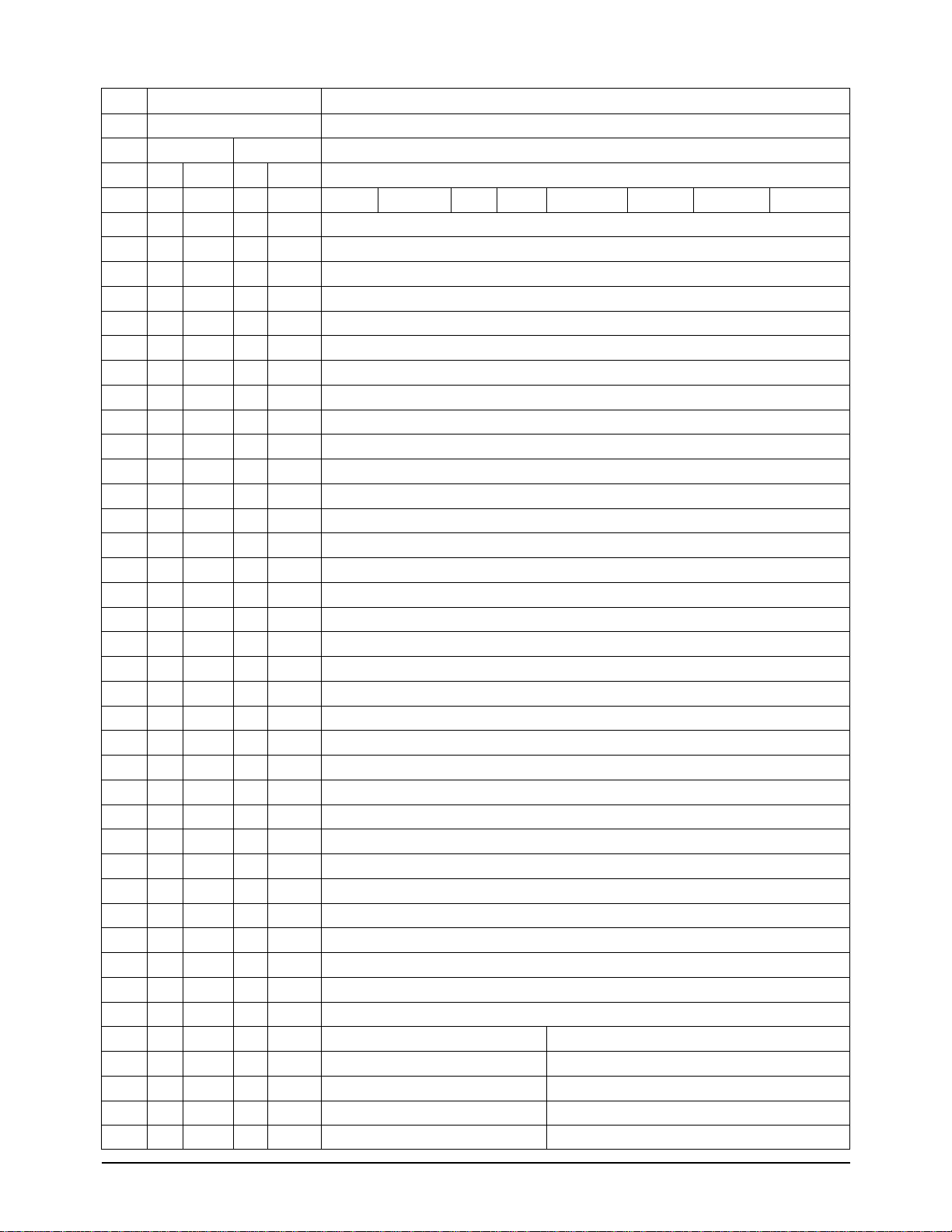

NO-OSD-DISPLAY

ADDR MODEL/DATA CONTENT (EEPROM DATA PAGE 0)

PAL NTSC

HI8 NORMAL HI8 NORMAL BIT SEGMENTATION EXPLAIN

ADDR DATA D7 D6 D5 D4 D3 D2 D1 D0

01C B4 B4 C1 C1 @WDR REGISTER[87,80] *AEW1HE[7:0]

01D 32 32 43 43 @WDR REGISTER[95,88] *AEW1HS[7:0]

01E 00 00 00 00 @WDR REGISTER[103,96] *SP_ADJ START POINT ADJUSTMENT

01F FF FF FF FF @WDR REGISTER[111,104] *TEST_ADDR[7:0]

020 00 00 00 00 @WDR REGISTER[119,112] *TEST_CNTL[7:0]

021 88 88 88 88 @WDR REGISTER[127,120] *ALPF_TH3[7:4],ALPF_TH4[3:0]

022 88 88 88 88 @WDR REGISTER[135,128] *ALPF_TH1[7:4],ALPF_TH2[3:0]

023 2A 2A 2A 2A @WDR REGISTER[143,136] *ALPF_WTSFT[7:5],ALPF_THSFT[4:3],SHPF_SFT[2:0]

024 99 99 99 99 @WDR REGISTER[151,144] *COLOR127[7:4],COLOR55[3:0]

025 99 99 99 99 @WDR REGISTER[159,152] *COLOR31[7:4],COLOR63[3:0]

026 49 49 49 49 @WDR REGISTER[167,160] *CH_SEL[7:4],COLOR12[3:0]

027 F0 F0 F0 F0 @WDR REGISTER[175,168] *BACK_SP[7:4].BACK_WT[3:0]

028 44 44 44 44 @WDR REGISTER[183,176] *LUT_TAB[7:5],LUT_HPF_SFT[4:2],X[1:0]

029 E0 E0 E0 E0 @WDR REGISTER[191,184] *LTIC[7:0]

02A C0 C0 C0 C0 @WDR REGISTER[199,192] *LIT_ON,LSI_ON,HLOG_ON,X[4:0]

02B 68 68 68 68 @WDR REGISTER[207,200] *HIST_WT HISTOGRAM WEIGHT

02C 18 18 18 18 @WDR REGISTER[215,208] *LTU-GAIN[7:0]

02D FF FF FF FF @WDR REGISTER[223,216] *LP-V[7:0] LENGTH OF VERTICAL ACTIVE AREA

02E 28 28 28 28 @WDR REGISTER[231,224] *SP-V[7:0] START OF VERTICAL ACTIVE AREA

02F B2 B2 B2 B2 @WDR REGISTER[239,232] *LP-H[7:0] LENGTH OF HORIZONTAL ACTIVE AREA

030 2E 2E 2E 2E @WDR REGISTER[247,240] *SP-H[7:0} START OF HORIZONTAL ACTIVE AREA

031 00 00 00 00 @WDR REGISTER[255,248] *GR_MODE[7:0] WDR COMMAND'00=WDR OFF, C0=WDR ON'

032 ~03F ~03F ~03F ~03F NO USED

040 10 18 18 18 * AWB- STABLE MODE THRESHOLD

041 ~048 ~048 ~048 ~048 NO USED

049 04 06 07 06 * AWB- TRACKING AREA SETTING

04A D0 D0 D0 D0 "@WDR ON ; AE A-READ(SMALL)DATA CUTTING -LOW"

04B 01 01 01 01 "@WDR ON ; AE A-READ(SMALL)DATA CUTTING -HIGH"

04C 04 04 04 04 "* AWB- R-CTRL UP/DOWN VALUE ( W/B TARGET CENTER(=80) +/- ADDR;04C )"

04D 80 80 80 80 "* AWB- B-CTRL UP/DOWN VALUE ( W/B TARGET CENTER(=80) +/- ADDR;04D )"

04E 8A 80 8A 80 * AWB- OUTDOOR HALL VALUE

04F E0 E0 E0 E0 WDR AE TARGET -LOW

050 00 00 00 00 WDR AE TARGET-HIGH

051 44 44 44 44 changed by AUTO 3MLENS ADJ(0DE) ZOOM PULSE LOW 16X LENS

052 FF FF FF FF changed by AUTO 3MLENS ADJ(0DE) ZOOM PULSE HIGH 16X LENS

053 31 33 48 2D changed by AUTO AWB ADJ(0CF) R-CONTROL 3100K

054 A0 89 C8 78 changed by AUTO AWB ADJ(0CF) B CONTROL 3100K

055 5F 60 88 5E changed by AUTO AWB ADJ(0CF) R-CONTROL 5100K

Samsung Electronics5-6

Alignment and Adjustment

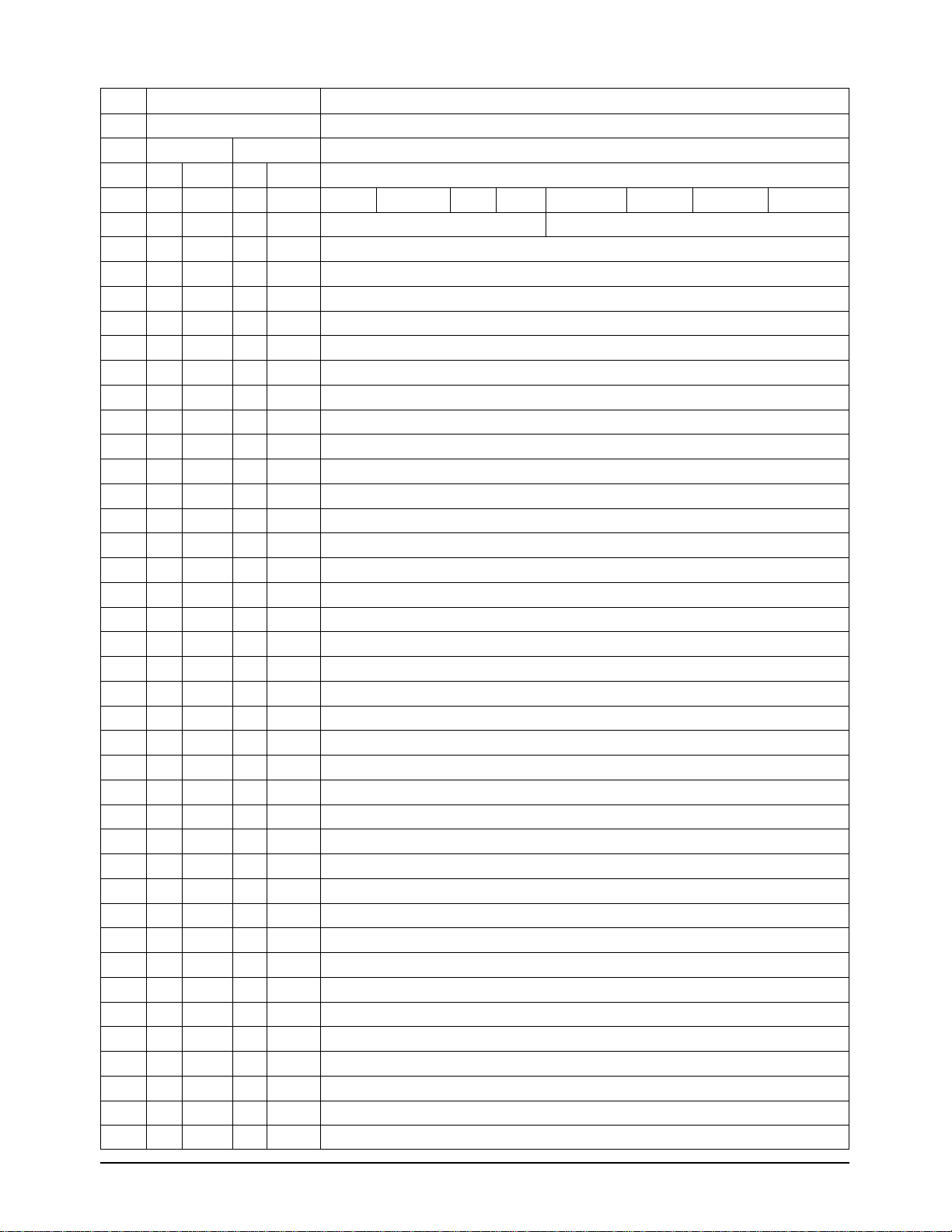

NO-OSD-DISPLAY

ADDR MODEL/DATA CONTENT (EEPROM DATA PAGE 0)

PAL NTSC

HI8 NORMAL HI8 NORMAL BIT SEGMENTATION EXPLAIN

ADDR DATA D7 D6 D5 D4 D3 D2 D1 D0

056 5A 54 68 4E changed by AUTO AWB ADJ(0CF) B CONTROL 5100K

057 00 00 00 00 @DSP#12C( HAPGN) at AGC

058 00 00 00 00 @DSP#12C (HAPGN) at AGC

059 03 03 03 03 "* AWB- RATIO ; 1/3 CENTER TRACKING"

05A 03 03 03 03 "* AWB- RATIO HIGH ; CENTER AXIS OVER 5100K(OUTDOOR)"

05B 04 04 04 04 "* AWB- RATIO LOW ; CENTER AXIS BELOW 3100K(INDOOR)"

05C E0 E0 E0 E0 SHUTTER START POINT OF IRIS CONTROL PERCENT(FF=100% IRIS MAX)

05D 80 80 80 80 "@WDR ON; AE DATA CUTTING -LOW"

05E 02 02 02 02 "@WDR ON; AE DATACUTTING -HIGH"

05F 50 50 50 50 "@WDR ON; BLACK BALANCE MAX-DATA (MIN DATA+31)"

060 40 40 40 40 "@WDR ; AE-TARGET MARGIN; #087,#088 -#060, AT CLIP-COUNTER ON "

061 10 10 10 10 "@WDR ; CLIP_COUNTER-TH-'HIGH' BYTE "

062 15 15 15 15 @EIS H-TH-COUNTER

063 35 35 35 35 @EIS H-TH

064 15 15 15 15 @EIS V-TH-COUNTER

065 35 35 35 35 @EIS V-TH

066 08 08 04 04 "@WDR ON; Y ,C GAMMA 1 "

067 0D 0D 07 07 "@WDR ON; Y ,C GAMMA 2 "

068 1B 1B 15 15 "@WDR ON; Y,C GAMMA 3 "

069 32 32 2C 2C "@WDR ON; Y ,C GAMMA 4 "

06A 57 57 4D 4D "@WDR ON; Y,C GAMMA 5 "

06B 82 82 70 70 "@WDR ON; Y,C GAMMA 6"

06C C0 C0 B4 B4 "@WDR ON; Y ,C GAMMA 7"

06D F0 F0 F8 F8 "@WDR ON; Y,C GAMMA 8"

06E EE EE EE EE "@WDR ON; ADDR#12C ;YVBKT,YVBK,HBLK,YHBK"

06F 08 08 08 08 "@WDR ON; ADDR#123;YHPSC,YAPC"

070 50 50 50 50 "@WDR ON; ADDR#126;YLPFSEL"

071 10 10 10 10 "@WDR ON; ADDR#134;RED DARK SLICE"

072 03 03 03 03 "@WDR ON; ADDR#135;BLUE DARK SLICE"

073 00 00 00 00 "@WDR ON; ADDR#136;GREEN DARK SLICE"

074 11 11 10 10 @CINEMA F-ZONE LIMIT UP

075 7D 7D 68 68 @CINEMA F-ZONE LIMIT UP

076 5A 60 4B 50 @R-GAIN POSITIVE(ADDR.147) at OUTDOOR

077 55 60 3D 4A @R-GAIN NEGATIVE(ADDR.148) at OUTDOOR

078 25 2C 12 29 @R-HUE POSITIVE (ADDR.149) at OUTDOOR

079 28 3B 17 35 @R-HUE NEGATIVE (ADDR.14A) at OUTDOOR

07A 33 39 2C 31 @B-GAIN POSITIVE(ADDR.14B) at OUTDOOR

07B 2B 30 1D 21 @B-GAIN NEGATIVE(ADDR.14C) at OUTDOOR

Samsung Electronics 5-7

Alignment and Adjustment

NO-OSD-DISPLAY

ADDR MODEL/DATA CONTENT (EEPROM DATA PAGE 0)

PAL NTSC

HI8 NORMAL HI8 NORMAL BIT SEGMENTATION EXPLAIN

ADDR DATA D7 D6 D5 D4 D3 D2 D1 D0

07C 1C 1A 24 26 @B-HUE POSITIVE (ADDR.14D) at OUTDOOR

07D 0E 0E 15 0D @B-HUE NEGATIVE (ADDR.14E) at OUTDOOR

07E 50 50 50 50 @NEGA BLC TARGET-'L'

07F 00 00 00 00 @NEGA BLC TARGET-'H'

080 04 04 04 04 "@AE; AE A-WINDOW WEIGHT '05'=50%"

081 5E 5E 5E 5E "@AE; SPOTLIGHT AE-TARGET 'L'"

082 00 00 00 00 "@AE; SPOTLIGHT AE-TARGET 'H'"

083 90 90 90 90 @DIGITAL CLAMP CONTROL START AGC

084 0C 0C 0C 0C @AGC MAX , DIGITAL CLAMP CONTROL(ADDR.#118)

085 90 90 90 90 * AWB- W/B DATA-TH

086 02 02 02 02 * AWB- LUMINANCE AREA NUMBER

087 00 00 00 00 "@AE; BLC/WDR , AE TARGET 'L'"

088 02 02 02 02 "@AE; BLC /WDR, AE TARGET 'H'"

089 75 75 75 75 @SEPIA CDS-R

08A 3A 3A 3A 3A @SEPIA CDS-G

08B 00 00 00 00 "@AE; SAND&SNOW MODE AE TARGET 'L'"

08C 02 02 02 02 "@AE; SAND&SNOW MODE AE TARGET 'H'"

08D 00 00 00 00 changed by AUTO 3MLENS ADJ(0DE) @FOCUS TELE MARGIN LOW BYTE(CANON X22 LENS)

08E 00 00 00 00 changed by AUTO 3MLENS ADJ(0DE) @FOCUS TELE MARGIN HIGH BYTE(CANON X22 LENS)

08F F0 F0 F0 F0 changed by AUTO 3MLENS ADJ(0DE) @FOCUS WIDE MARGIN LOW BYTE(CANON X22 LENS)

090 FF FF FF FF changed by AUTO 3MLENS ADJ(0DE) @FOCUS WIDE MARGIN HIGH BYTE(CANON X22 LENS)

091 F8 09 00 0A @CCD H-PIXEL NUMBER -LOW BYTE

092 02 02 03 02 @CCD H-PIXEL NUMBER -HIGH BYTE

093 23 23 F7 F7 @CCD V LINE NUMBER -LOW BYTE

094 01 01 00 00 @CCD V LINE NUMBER -HIGH BYTE

095 1C 0C 16 09 @CCD V SKIP LINE DEFAULT VALUE

096 B9 46 50 EE @CCD V LINE NUMBER LOW BYTE

097 02 02 02 01 @CCD V LINE NUMBER HIGH BYTE

098 98 98 98 98 "@DSP IC ADDR #41H ;ART DSE LEVEL"

099 B8 B8 B8 B8 "@DSP IC ADDR #1CH ;NEGA MODE WHITE CLIP LEVEL"

09A 30 30 30 30 * AWB- START HALL VALUE

09B 1C 1C 1C 1C "@DSE- MOSAIC SIZE; DSP IC ADDR #39H "

09C F4 F4 F4 F4 "@D/ZOOM MAX RATIO; CO=4X, EE=14.3X, F4= 20X "

09D 68 68 68 68 @ NOISE SLICE START AGC VALUE

09E 0B 0B 0B 0B @ HAP(DSP #10BH) MIN VALUE AT AGC MAX

09F 0B 0B 0B 0B @ VAP(DSP 310C) MIN VALUE AT AGC MAX

0A0 18 20 18 20 @ YAP(DSP #10DH) MAX VALUE AT AGC MAX

0A1 A0 A0 A0 A4 @ CHROMA SUPPRESS PERCENT

Samsung Electronics5-8

Alignment and Adjustment

NO-OSD-DISPLAY

ADDR MODEL/DATA CONTENT (EEPROM DATA PAGE 0)

PAL NTSC

HI8 NORMAL HI8 NORMAL BIT SEGMENTATION EXPLAIN

ADDR DATA D7 D6 D5 D4 D3 D2 D1 D0

0A2 60 60 60 60 @ CHROMA SUPPRESS START AGC VALUE

0A3 00 00 00 00 changed by AUTO IRIS ADJ(0CE) @ IRIS CONTROL MAX LOW BYTE

0A4 05 05 05 05 changed by AUTO IRIS ADJ(0CE) @ IRIS CONTROL MAX HIGH BYTE

0A5 B4 B4 B4 B4 * AWB -AT OUTDOOR,TRACKING AMOUNT(IN CASE,INDOOR DATAINPUT) ,B4=70%,FF=0%(NO TRACKING)

0A6 C0 C0 C0 C0 * AWB- WB AGC% , STOP POINT ( 80=50%, C0=75%)

0A7 89 89 89 89 @HALL WIDTH AT HALL ADJUST

0A8 E5 E5 E5 E5 changed by AUTO 3MLENS ADJ(0DE) @ZOOM RESET LOW(16X, 22X LENS)

0A9 88 88 88 88 changed by AUTO 3MLENS ADJ(0DE) @ZOOM RESET HIGH(16X, 22X LENS)

0AA 80 80 80 80 changed by ZOOM VR CENTER(0D6) @ZOOM VR CENTER VALUE

0AB 20 20 20 20 @ZOOM VR CENTER MARGIN( ZOOM STOP PERIOD)

0AC 34 30 34 30 changed by AUTO AGC ADJ(0DB) @AGC MIN VALUE

0AD A8 A8 A8 A8 changed by AUTO AGC ADJ(0DB) @AGC MAX VALUE

0AE 0B 0B 09 09 "REMOCON ZOOM SPEED; 22X LENS -PAL:0B NTSC:09 "

0AF 02 02 02 02 AF ZIGZAG AMOUNT AT BASIC ZOOM SPEED

0B0 68 28 5B 30 @IN AGC AUTO ADJUST (ADDR.0DB), SHUTTER CONTROL OF AGC MIN ADJUST OPERATING(D0='0'FIX)

0B1 2A 2B 08 01 @IN AGC AUTO ADJUST (ADDR.0DB), SHUTTER CONTROL OF AGC MAX ADJUST OPERATING(D7='1'FIX)

0B2 ~0B6 ~0B6 ~0B6 ~0B6 NO USED

0B7 1A 1A 16 16 "ZOOM MAX SPEED ;22X LENS PAL:19H,NTSC:15H"

0B8 3A 3A 3A 3A @HALL REF START, AT AUTO HALL ADJUST ADDR.0CD

0B9 4C 4C 4C 4C @HALL GAIN START, AT AUTO HALL ADJUST ADDR.0CD

0BA 40 40 40 40 changed by AUTO HALL ADJ(0CD) @HALL MIN VALUE

0BB C0 C0 C0 C0 changed by AUTO HALL ADJ(0CD) @HALL MAX VALUE

0BC E0 D0 D0 D0 @AE TARGET-LOW BYTE

0BD 00 00 00 00 @AE TARGET-HIGH BYTE

0BE B0 B0 B0 B0 changed by AUTO IRIS ADJ(0CE) @IRIS CONTROL MIN LOW BYTE

0BF 09 09 09 09 changed by AUTO IRIS ADJ(0CE) @IRIS CONTROL MIN HIGH BYTE

0C0 18 18 18 18 changed by AUTO 3MLENS ADJ(0DE) @FOCUS RESET LOW(16X,22X LENS)

0C1 82 82 82 82 changed by AUTO 3MLENS ADJ(0DE) @FOCUS RESET HIGH(16X,22X LENS)

0C2 40 40 40 40 @HALL CLOSE TARGET

0C3 ~C6 ~C6 ~C6 ~C6 NO USED

0C7 12 12 12 12 EIS GYRO-RESET TIME '0C=3.7SEC'

0C8 13 13 13 13 EIS START TIME ('10'=4.4SEC) AFTER EIS GYRO-RESET

0C9 65 64 65 60 @IRIS CONTROL OF ZOOM WIDE POSITION AT LENS ADJUSTMENT

0CA 24 24 24 24 @QB_GCTRL

0CB 48 48 48 48 @AETAR L (FLEX-ZONE)

0CC 00 00 00 00 @AETAR H (FLEX-ZONE)

0CD FF FF FF FF @@HALL AUTO ADJUST

0CE FF FF FF FF @@IRIS AUTO ADJUST

Samsung Electronics 5-9

Alignment and Adjustment

Loading...

Loading...