Samsung SC09AWH, SC09ZWH, AS09WHWE, AS09WHWD, KF-25G/SWA Service Manual

...

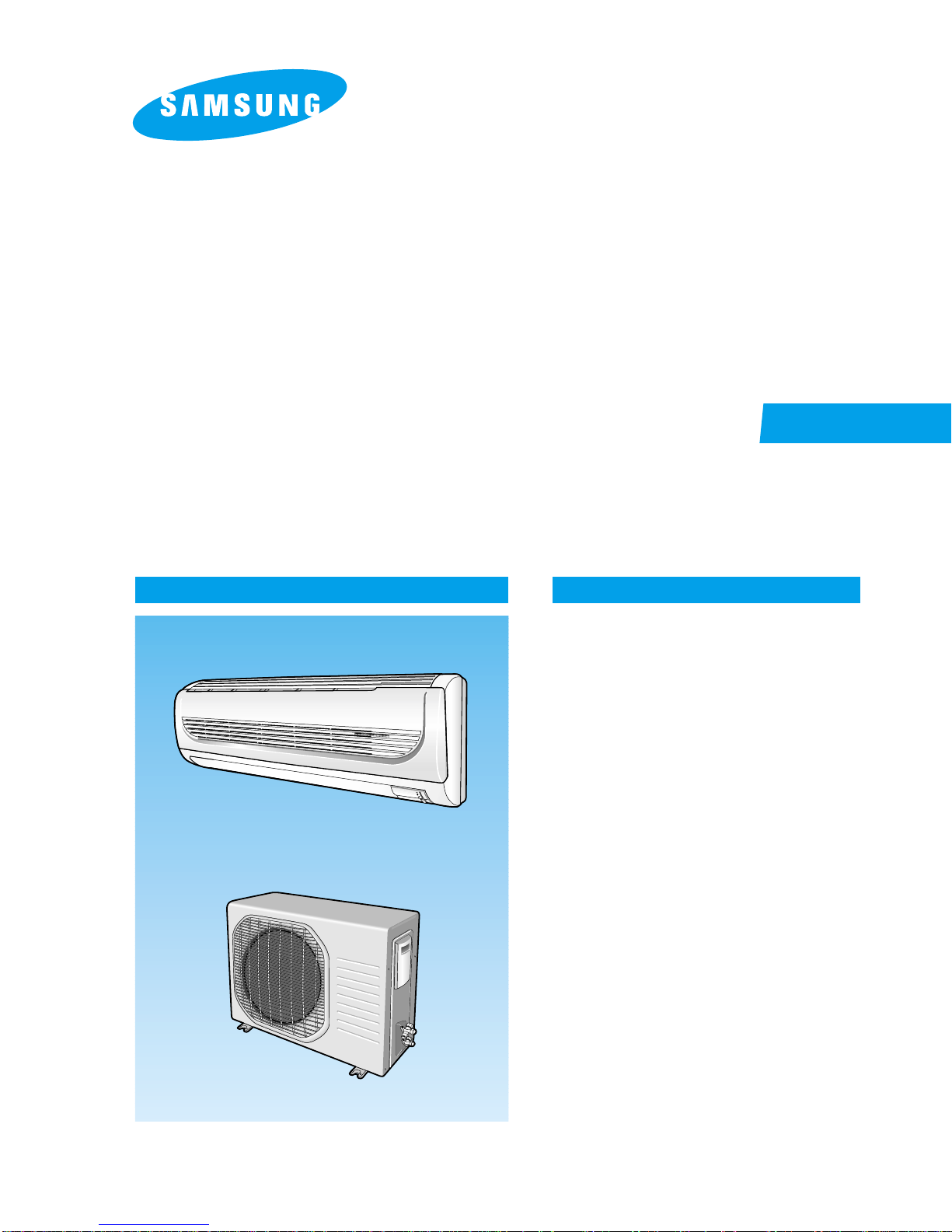

ROOM AIR CONDITIONER

INDOOR UNIT

SC09AWH

SC09ZWH

AS09WHWE

AS09WHWD

KF-25G/SWA

SC12AWH

SC12ZWH

AS12WHWE

AS12WHWD

KF-35G/SWA

SERVICE

OUTDOOR UNIT

SC09AWHX

SC09ZWHX

US09WHWE

US09WHWD

KF-25W/SWA

SC12AWHX

SC12ZWHX

US12WHWE

US12WHWD

KF-35W/SWA

Manual

CONTENTSAIR CONDITIONER

1. Product Specifications

2. Disassembly and Reassembly

3. Refrigerating Cycle Diagram

4. Set Up the Model Option

5. T roubleshooting

6. Exploded Views and Parts List

7. Block Diagram

8. Wiring Diagram

9. Schematic Diagram

ELECTRONICS

This Service Manual is a property of Samsung Electronics Co., Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

© Samsung Electronics Co., Ltd. Apr. 2004.

Printed in Korea.

Code No. DB98-16569A(2)

4m

15m

7m

ROOM AIR CONDITIONER

INDOOR UNIT

SC09AWH

SC09ZWH

AS09WHWE

AS09WHWD

KF-25G/SWA

SC12AWH

SC12ZWH

AS12WHWE

AS12WHWD

KF-35G/SWA

SERVICE

OUTDOOR UNIT

SC09AWHX

SC09ZWHX

US09WHWE

US09WHWD

KF-25W/SWA

SC12AWHX

SC12ZWHX

US12WHWE

US12WHWD

KF-35W/SWA

Manual

CONTENTSAIR CONDITIONER

1. Product Specifications

2. Disassembly and Reassembly

3. Refrigerating Cycle Diagram

4. Set Up the Model Option

5. T roubleshooting

6. Exploded Views and Parts List

7. Block Diagram

8. Wiring Diagram

9. Schematic Diagram

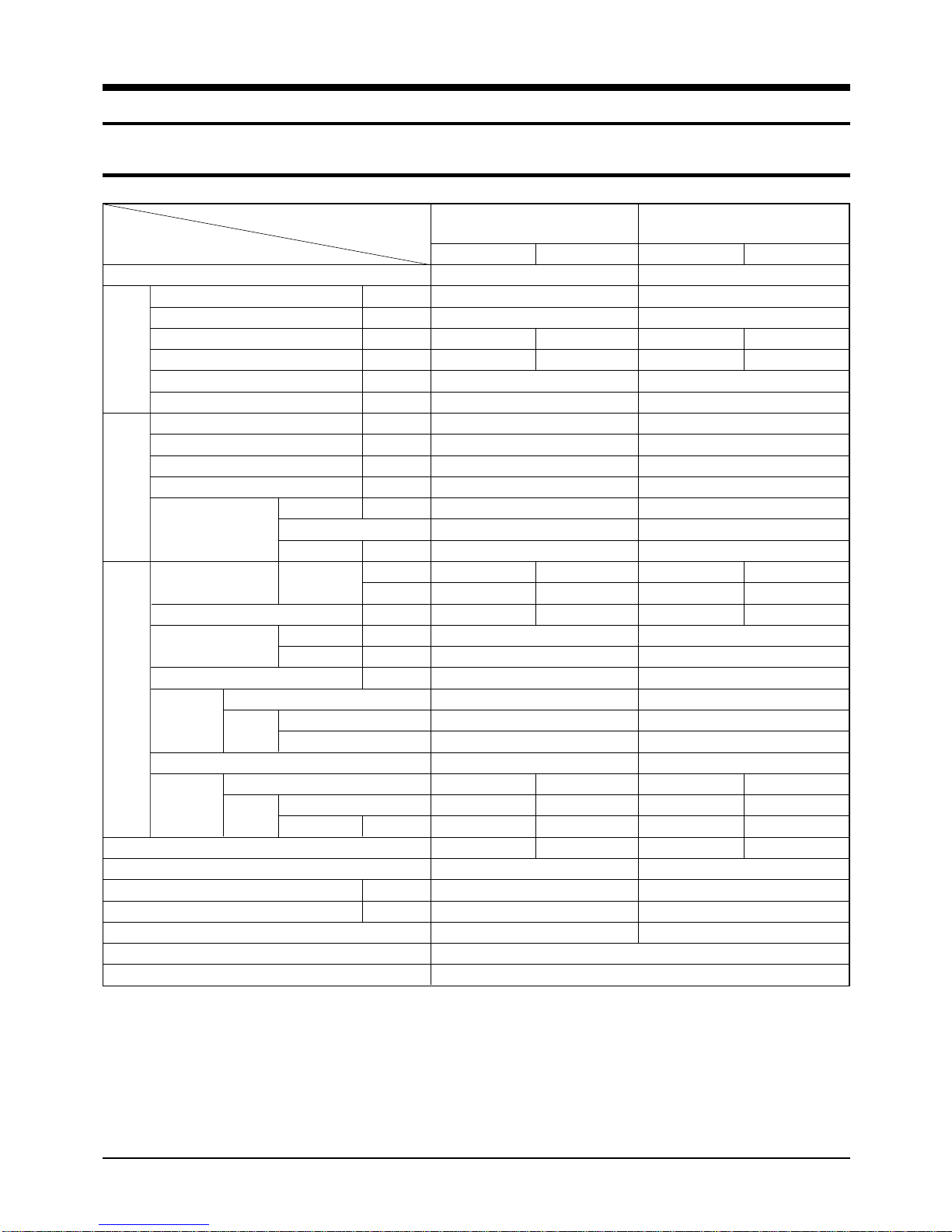

1. Product Specifications

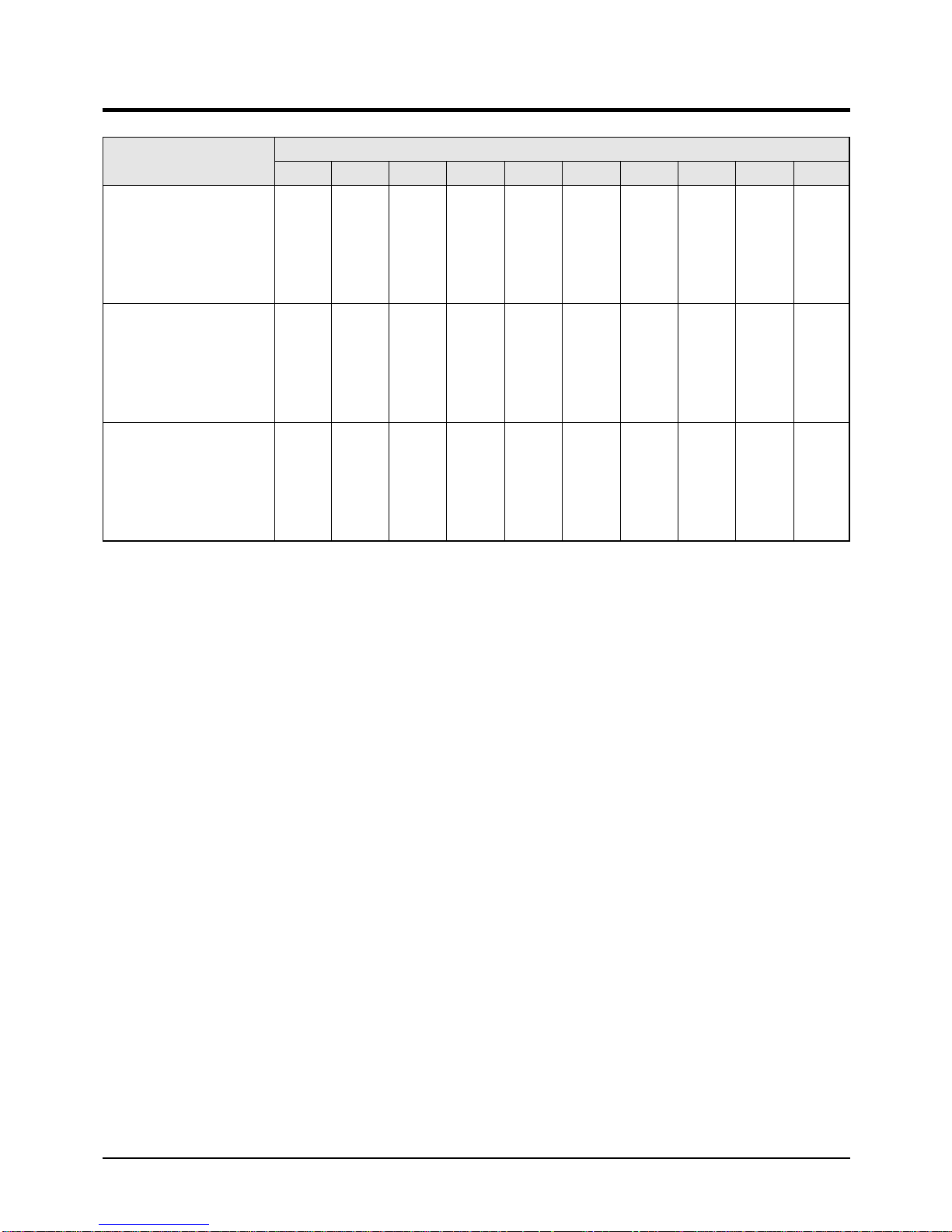

1-1 Table

Item

Type

Cooling kW

Dehumidifying |/h

Air Volume m

Performance

Noise dB

Energy Efficiency Ratio W/W

Power V-Hz

Power Consumption W

Operating Current A

Power Factor %

Starting Current A

Power

Length m

Power Cord Number of Core Wire

Capacity A

Outer Dimension W x H x D

Weight(Net) kg

Refrigerant Pipe

Drain Hose D x L(mm)

Size

Compressor Motor Type

Oil Type

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R410A) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

Type

Type

Liquid mm x L(m)

GAS mm x L(m)

Rated Output

Rated Output W

Model

3

/min

mm

inch

SC09AWH

Indoor unit Outdoor unit

Wall-mounted

2.7

1.0

7.3 25

38 / 36 / 34 51 / 51

2.70

1-220 / 240-50

1,000

4.5

98.2

21.0

-

-

250V-10A

825x285x189 720x548x265

32.5x11.2 x7.44 28.4x21.6x10.4

8.2 33.0

ø6.35 x 7.5

ø9.52 x 7.5

ø18 x 550

Rotary

Induction Motor(PSC)

900

DAPHNE FV68S(PVE)

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 1ROW 24STEP

CAPILLARY TUBE

350

580

MRA99134-9201

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB23˚C OUTDOOR UNIT : DB43˚C WB28˚C

Indoor unit Outdoor unit

41 / 39 / 37 53 / 53

825x285x189 720 x 548 x 265

32.5x11.2x7.44 28.4x21.6x10.4

Cross-flow Propeller

2ROW 14STEP 1ROW 24STEP

SC12AWH

Wall-mounted

3.5

1.4

8.3 25

2.99

1-220 / 240-50

1,170

5.7

96.9

30.0

-

-

250V-10A

8.4 33.8

ø6.35 x 7.5

ø9.52 x 7.5

ø18 x 550

Rotary

Induction Motor(PSC)

1,075

DAPHNE FV68S(PVE)

steel steel

15 50

CAPILLARY TUBE

520

830

MRA99908-9201

1Samsung Electronics

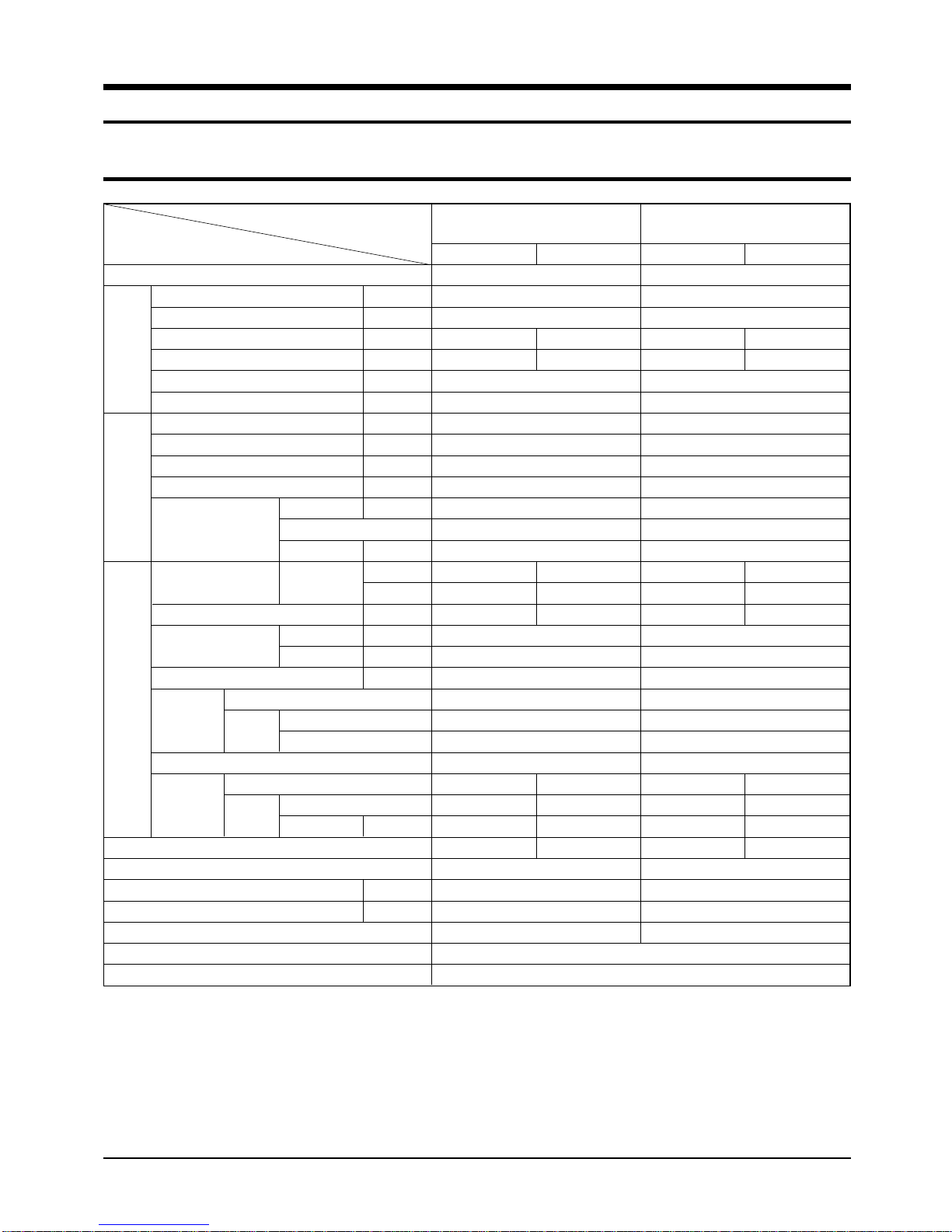

Table(cont.)

Item

Type

Cooling kW

Dehumidifying |/h

Air Volume m

Perfor-

mance

Noise dB

Energy Efficiency Ratio W/W

Power V-Hz

Power Consumption W

Operating Current A

Power Factor %

Starting Current A

Power

Length m

Power Cord Number of Core Wire

Capacity A

Outer Dimension W x H x D

Weight(Net) kg

Refrigerant Pipe

Drain Hose D x L(mm)

Size

Compressor Motor Type

Oil Type

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R22) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

Type

Type

Liquid mm x L(m)

GAS mm x L(m)

Rated Output

Rated Output W

Model

3

/min

mm

inch

SC09ZWH/AS09WHWE

Indoor unit Outdoor unit

Wall-mounted

2.7

1.0

7.3 25

38 / 36 / 34 51 / 51

2.70

1-220 / 240-50

1,000

4.5

98.2

21.0

-

-

250V-10A

825x285x189 720x548x265

32.5x11.2 x 7.44 28.4x21.6x10.4

8.2 33.0

ø6.35 x 5.0

ø9.52 x 5.0

ø18 x 550

Rotary

Induction Motor(PSC)

1,005

SUNISO-4GSD

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 1ROW 24STEP

CAPILLARY TUBE

360

580

RAC12110-9622

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB23˚C OUTDOOR UNIT : DB43˚C WB28˚C

SC12ZWH/AS12WHWE

Indoor unit Outdoor unit

Wall-mounted

3.5

1.4

8.3 25

41 / 39 / 37 53 / 53

2.99

1-220 / 240-50

1,170

5.2

96.9

30.0

-

-

250V-10A

825x285x189 720x548x265

32.5x11.2 x7.44 28.4x21.6x10.4

8.4 33.8

ø6.35 x 5.0

ø12.7 x 5.0

ø18 x 550

Rotary

Induction Motor(PSC)

1,206

SUNISO-4GSD

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 1ROW 24STEP

CAPILLARY TUBE

600

830

RAC12074-9622

Samsung Electronics2

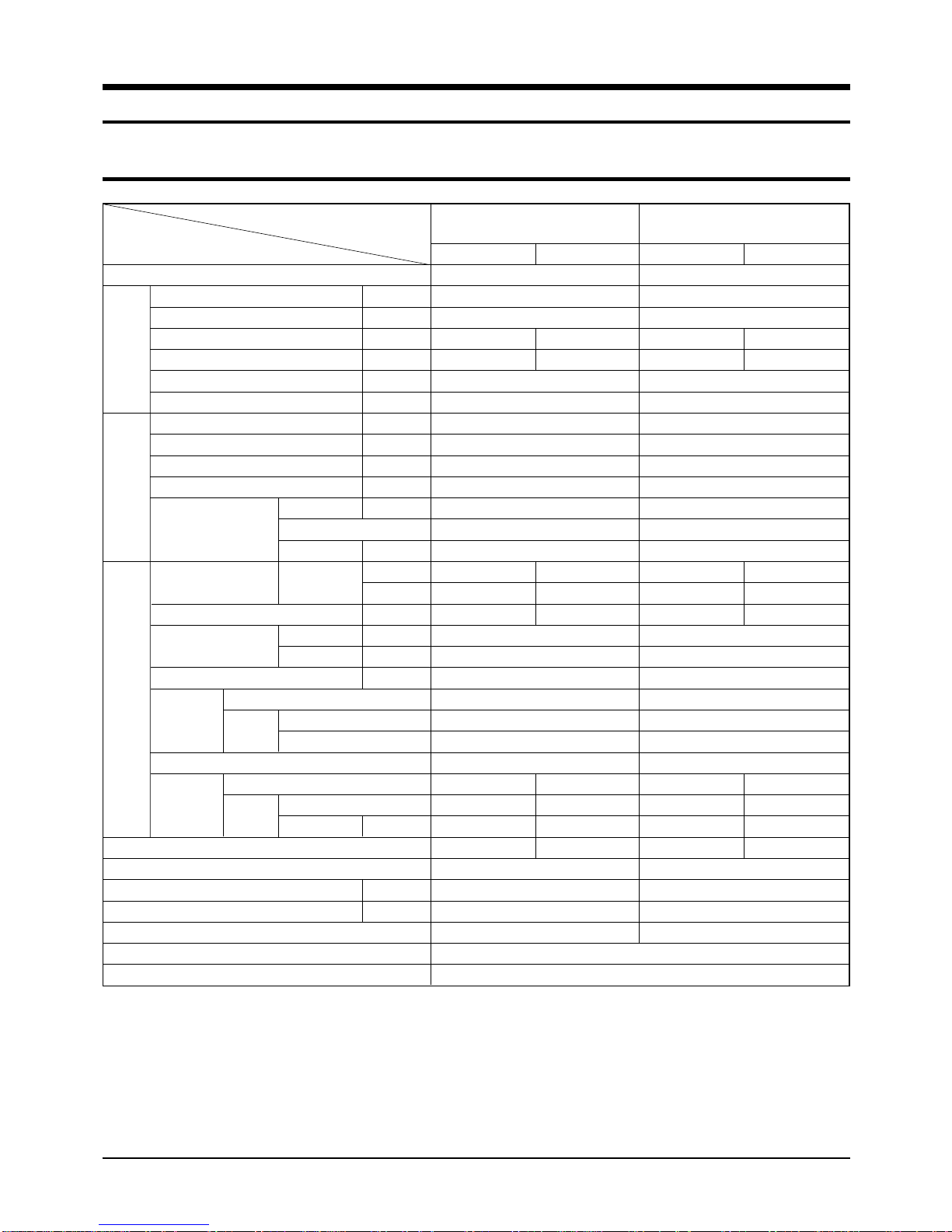

Item

Type

Cooling kW

Dehumidifying |/h

Air Volume m

Performance

Noise dB

Energy Efficiency Ratio W/W

Power V-Hz

Power Consumption W

Operating Current A

Power Factor %

Starting Current A

Power

Length m

Power Cord Number of Core Wire

Capacity A

Outer Dimension W x H x D

Weight(Net) kg

Refrigerant Pipe

Liquid mm x L(m)

GAS mm x L(m)

Drain Hose D x L(mm)

Size

Type

Compressor Motor Type

Rated Output

Oil Type

Type

Blower Motor Type

Rated Output W

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R22) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

Model

3

/min

mm

inch

AS09WHWD

Indoor unit Outdoor unit

Wall-mounted

2.65

1.0

7.3 25

38 / 36 / 34 51 / 51

2.82

1-220-50

940

4.6

97.0

21.0

-

-

250V-10A

825x285x189 720x548x265

32.5x11.2 x7.44 28.4 x21.6x10.4

8.2 33.0

ø6.35 x 5.0

ø9.52 x 5.0

ø18 x 550

Rotary

Induction Motor(PSC)

1,005

SUNISO-4GSD

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 1ROW 24STEP

CAPILLARY TUBE

360

580

RAC12054-9622

Indoor unit Outdoor unit

41 / 39 / 37 53 / 53

825x285x189 720x548x265

32.5x11.2 x7.44 28.4 x21.6x10.4

Cross-flow Propeller

2ROW 14STEP 1ROW 24STEP

AS12WHWD

Wall-mounted

3.5

1.4

8.3 25

2.99

1-220-50

1,170

5.8

92.0

30.0

-

-

250V-10A

8.4 33.8

ø6.35 x 5.0

ø12.7 x 5.0

ø18 x 500

Rotary

Induction Motor(PSC)

1,206

SUNISO-4GSD

steel steel

15 50

CAPILLARY TUBE

600

920

RAC12074-9622

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB23˚C OUTDOOR UNIT : DB43˚C WB28˚C

3Samsung Electronics 3Samsung Electronics

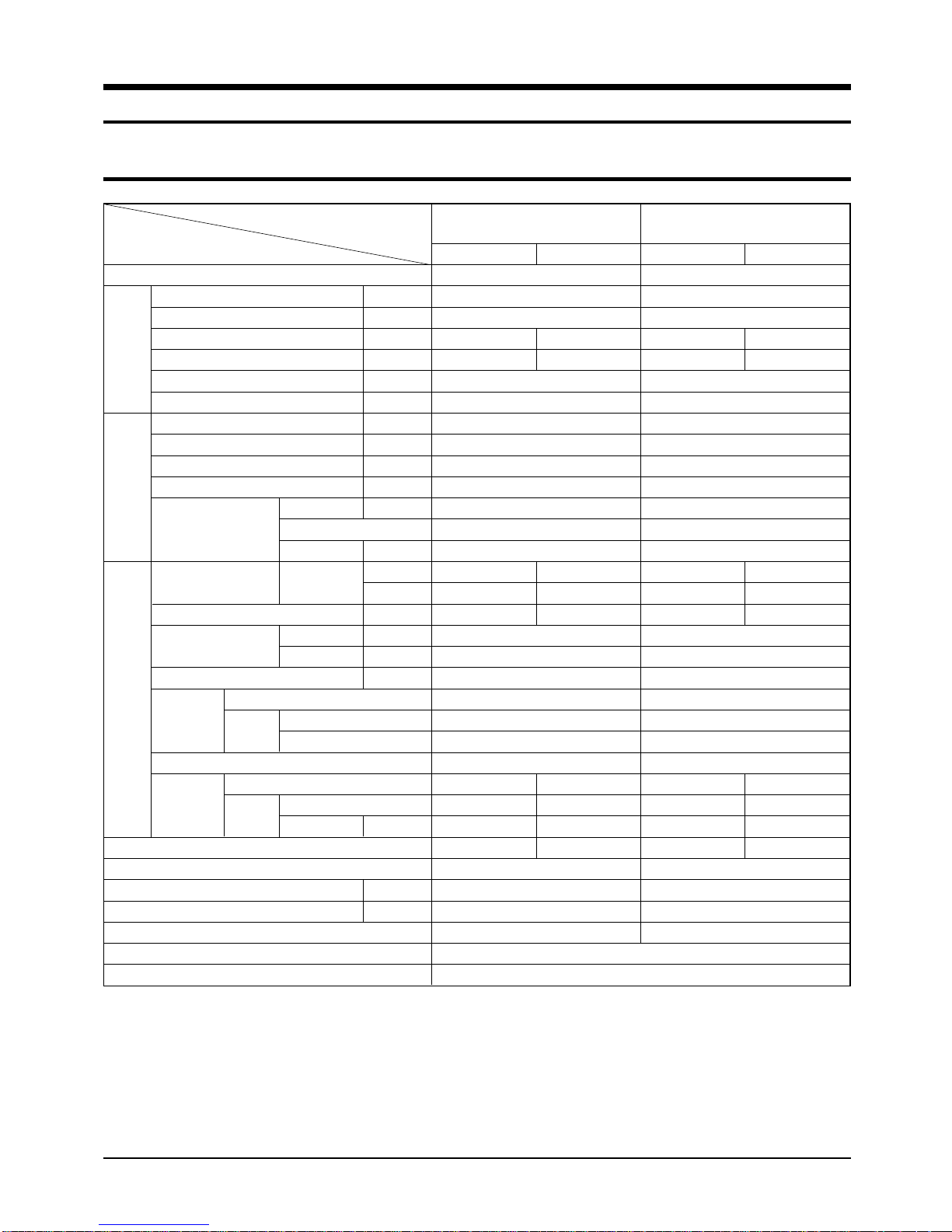

Table(cont.)

Item

Type

Cooling kW

Dehumidifying |/h

Air Volume m

Perfor-

mance

Noise dB

Energy Efficiency Ratio W/W

Power V-Hz

Power Consumption W

Operating Current A

Power Factor %

Starting Current A

Power

Length m

Power Cord Number of Core Wire

Capacity A

Outer Dimension W x H x D

Weight(Net) kg

Refrigerant Pipe

Drain Hose D x L(mm)

Size

Compressor Motor Type

Oil Type

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R22) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

Type

Type

Liquid mm x L(m)

GAS mm x L(m)

Rated Output

Rated Output W

Model

3

/min

mm

inch

KF-25G/SWA

Indoor unit Outdoor unit

Wall-mounted

2.65

1.0

7.3 25

38 / 36 / 34 51 / 51

2.82

1-220-50

940

4.6

97.0

21.0

-

-

250V-10A

835x285x189 720x548x265

32.5x11.2 x7.44 28.4 x21.6x10.4

8.2 33.0

ø6.35 x 4.0

ø9.52 x 4.0

ø18 x 550

Rotary

Induction Motor(PSC)

1,005

SUNISO-4GSD

Cross-flow Propeller

steel steel

15 50

2ROW 14STEP 1ROW 24STEP

CAPILLARY TUBE

360

580

RAC12054-9622

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB23˚C OUTDOOR UNIT : DB43˚C WB28˚C

41 / 39 / 37 53 / 53

835x285x189 720x548x265

32.5x11.2 x7.44 28.4 x21.6x10.4

2ROW 14STEP 1ROW 24STEP

KF-35G/SWA

Indoor unit Outdoor unit

Wall-mounted

3.5

1.4

8.3 25

2.99

1-220-50

1,170

5.8

92.0

30.0

-

-

250V-10A

8.4 33.8

ø6.35 x 4.0

ø12.7 x 4.0

ø18 x 550

Rotary

Induction Motor(PSC)

1,206

SUNISO-4GSD

Cross-flow Propeller

steel steel

15 50

CAPILLARY TUBE

600

920

RAC12074-9622

Samsung Electronics4

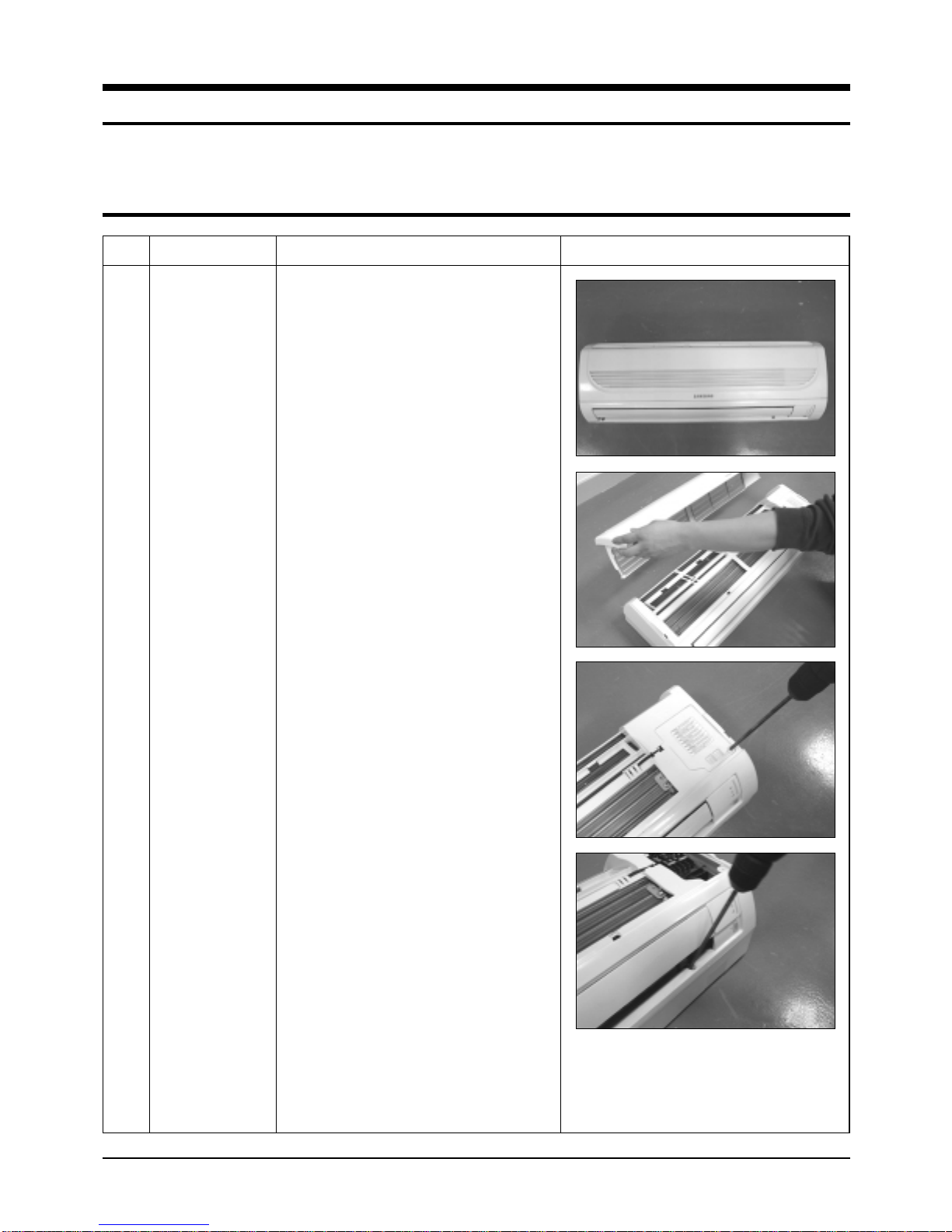

2. Disassembly and Reassembly

Stop operation of the air conditioner and remove the power cord before repairing the unit.

2-1 Indoor Unit

No Parts Procedure Remark

1 Front Grille

1) Stop the air conditioner operation and

block the main power.

2) Open the Front Grille by pulling right and

left sides of the hook.

3) Loosen 1 of the right screw and detach

the Terminal Cover.

4) Detach the thermistor from the Front

Grille.

5) Loosen 2 fixing screws of Front Grille.

5Samsung Electronics

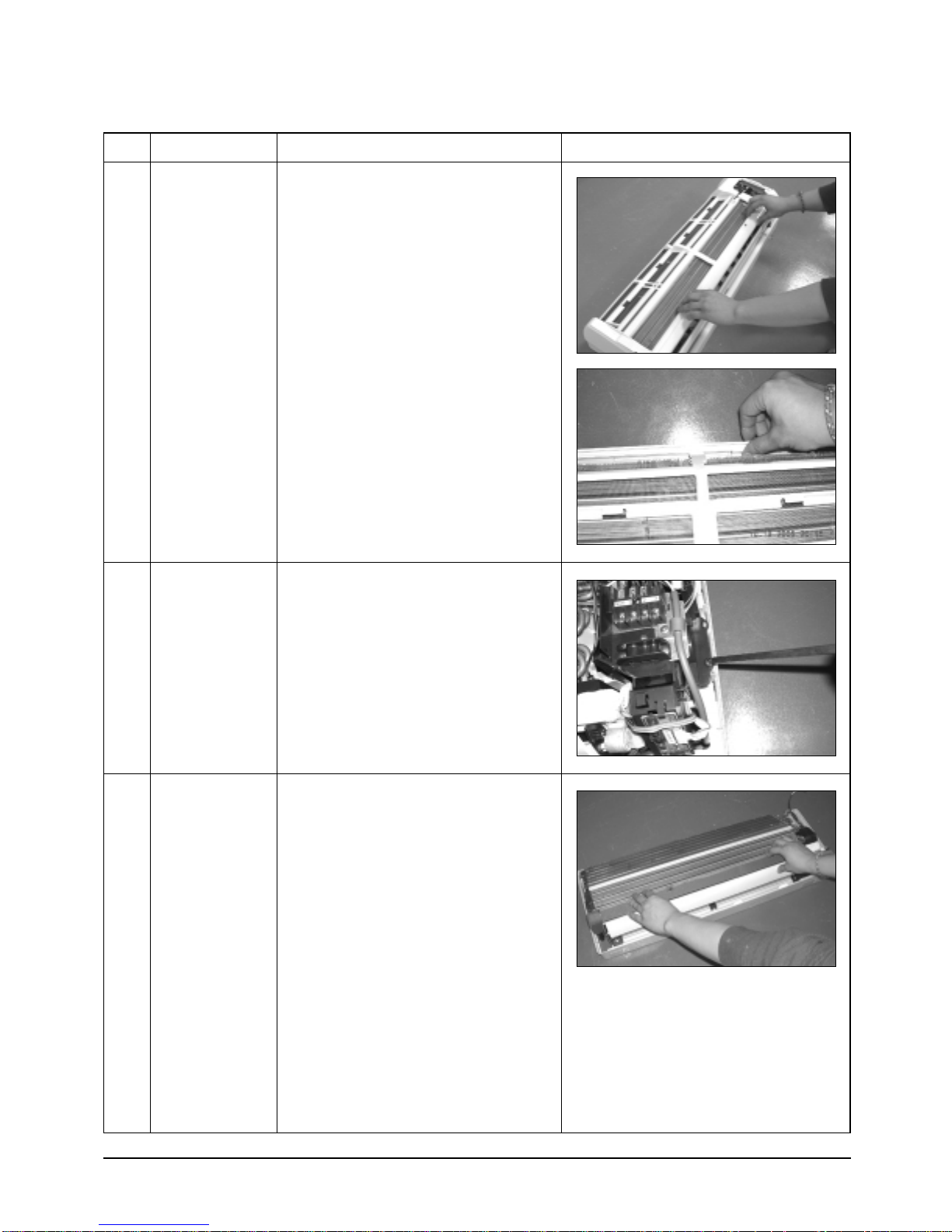

Disassembly and Reassembly

No Parts Procedure Remark

6) Unlock 2 hooks to fix Panel Front and

Tray Drain.

7) Unlock 3 hooks to fix Panel Front and

Back-Body.

2

Control-In

(Main PCB)

1) Take all the connector of PCB upper side

out. (Inclusion Power Cord)

2) Detach the outdoor unit connection wire

from the Terminal Block.

3) Loosen 4 fixing screws of Ass'y Control-In.

3

Tray Drain

1) Pull Tray Drain out from the Back Body.

Samsung Electronics6

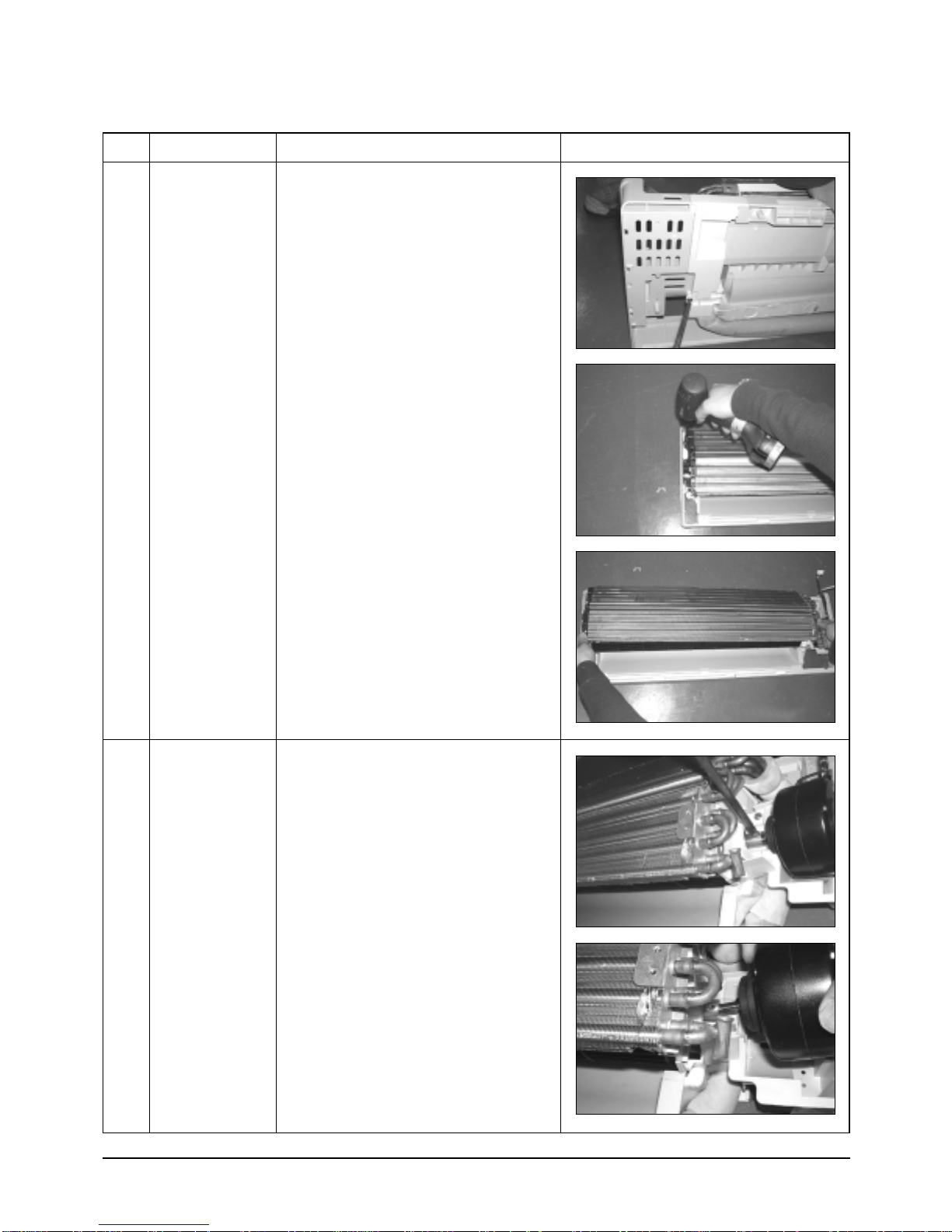

Disassembly and Reassembly

No Parts Procedure Remark

4

Heat Exchanger

1) Loosen 2 fixing earth screws of right side.

2) Detach the Connection Pipe.

3) Detach the Holder Pipe at the rear side.

4) Loosen the 3 fixing screws of right and left

side.

5) Lifting the Heat Exchanger up a little to

push the up side for separation from the

indoor unit.

5

Fan Motor

&

Cross Fan

1) Loosen the fixing screw and detach the

Motor Holder.

2) Detach the Fan Motor from the Fan.

3) Detach the Fan From the left Holder

Bearing.

7Samsung Electronics

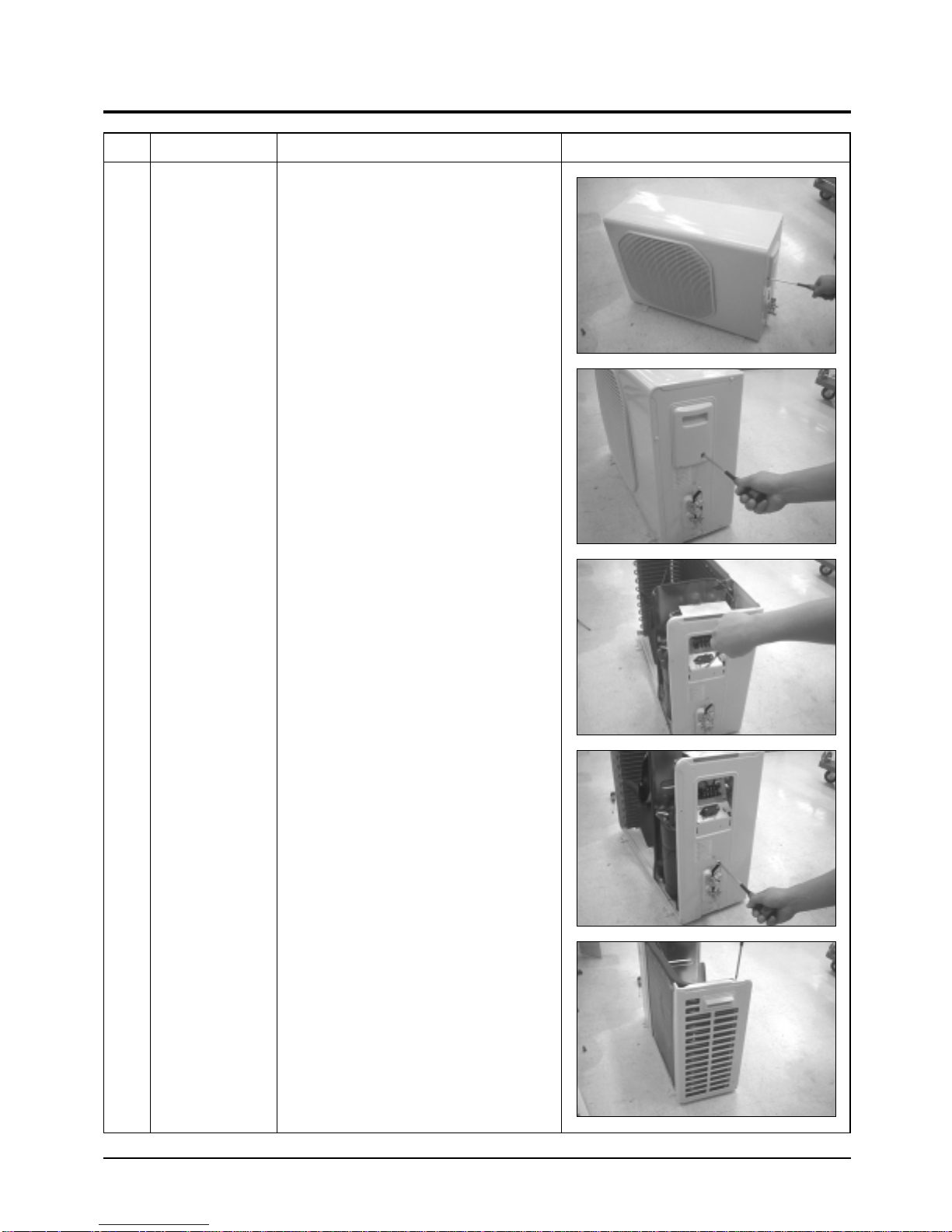

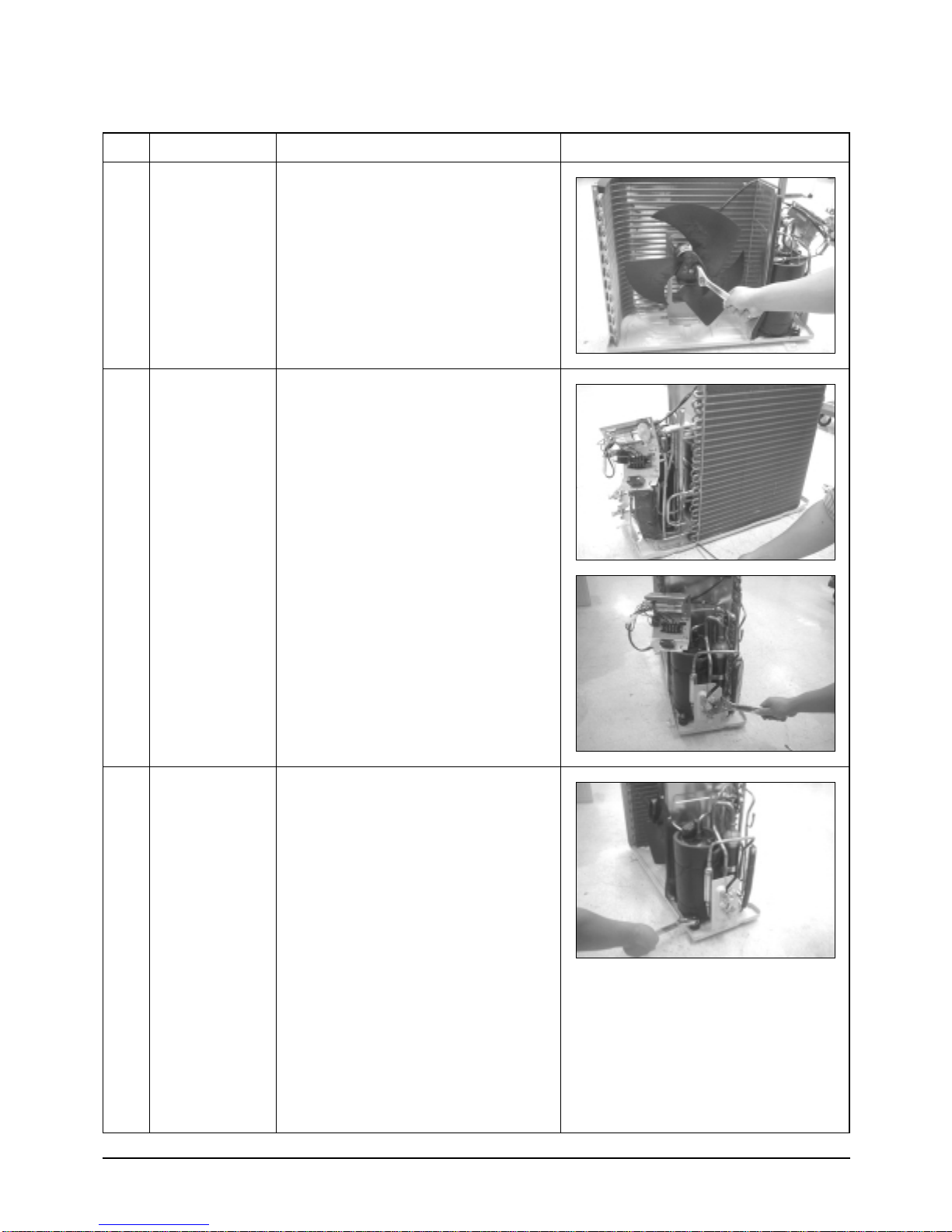

2-2 Outdoor Unit

No Parts Procedure Remark

1 Common Work

1) Loosen each 3 fixing screws on both right

and left Cabinet-Side edge and a fixing

screw on the Cabinet-Front lower to detach

the Cabinet-Front.

2) Loosen 2 fixing screws of the

Ass'y-Control.

3) Loosen 6 fixing screws of the Cabinet-Side

RH.

4) Loosen 2 fixing screws of the Cabinet-Side

LF.

Samsung Electronics8

Disassembly and Reassembly

No Parts Procedure Remark

2

3

Fan

&

Motor

Heat Exchanger

1) Detach the Nut Flange.(Turn counterclockwise because the screw is right-handed)

2) Detach the Fan.

3) Loosen 4 fixing screws to detach

the Motor.

1) Loosen 2 fixing screws on both sides.

2) Disassemble the pipe in both inlet and

outlet with welding torch.

3) Detach the Heat Exchanger.

4

Compressor

1) Loosen the Terminal Cover nut to open the

Terminal Cover.

2) Disassemble the cloth sound felt.

3) Disassemble the pipe in both inlet and

outlet of the Compressor with welding

torch.

4) Disassemble the pipe in both inlet and

outlet of the Condenser with welding torch.

5) Loosen the 3 bolts at the bottom.

6) Detach the Compressor.

9Samsung Electronics

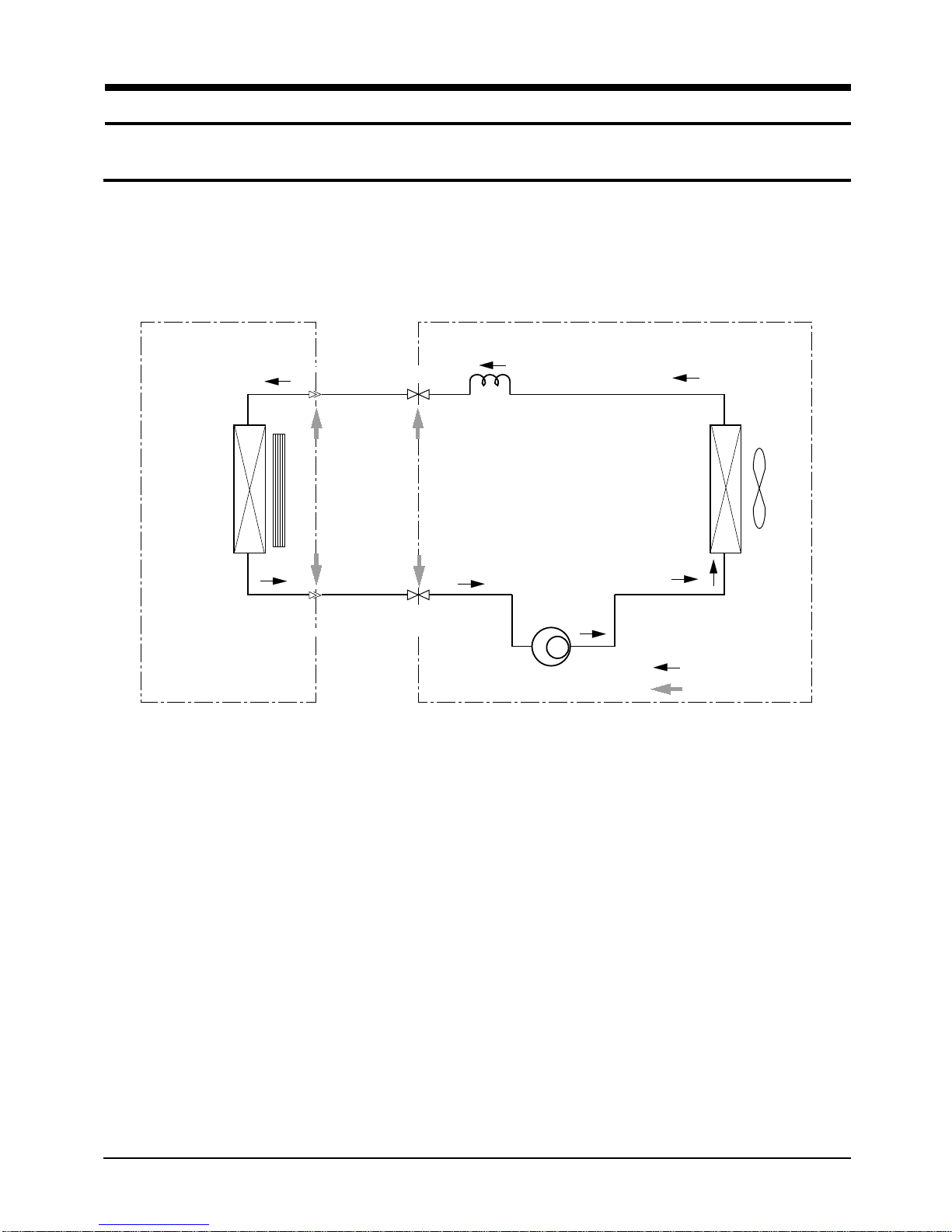

3. Refrigerating Cycle Diagram

3-1 Refrigerating Cycle Diagram

Indoor Unit

Heat

Exchanger

(Evaporator)

Outdoor Unit

Capillary tube

1

T

Liquid side

Cross fan

T2

Gas side

2-Way valve

3-Way valve

Compressor

Heat

Exchanger

(Condenser)

Propeller fan

Cooling

Gas Leak Check Point

Samsung Electronics10

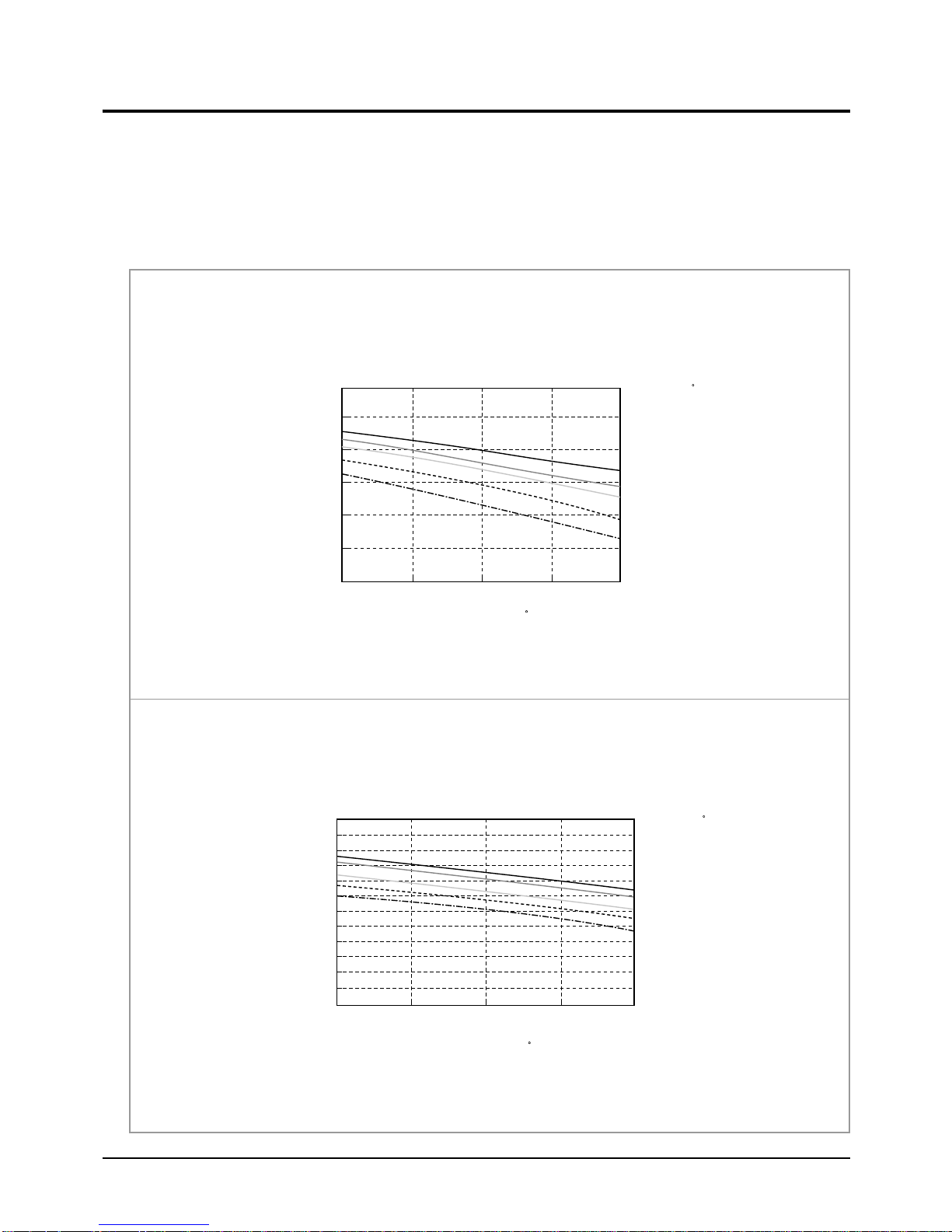

3-2 Refrigerant Cycle Characteristic

DB32.4/WB24.0

DB30.6/WB22.5

DB27.0/WB19.0

DB24.0/WB17.0

DB21.0/WB15.0

Cooling Capacity(kW)

Cooling Capacity Distribution

6.0

5.0

4.0

3.0

2.0

1.0

0.0

25 35 45

Outdoor Temp.(DB C)

Indoor Temp.( C)

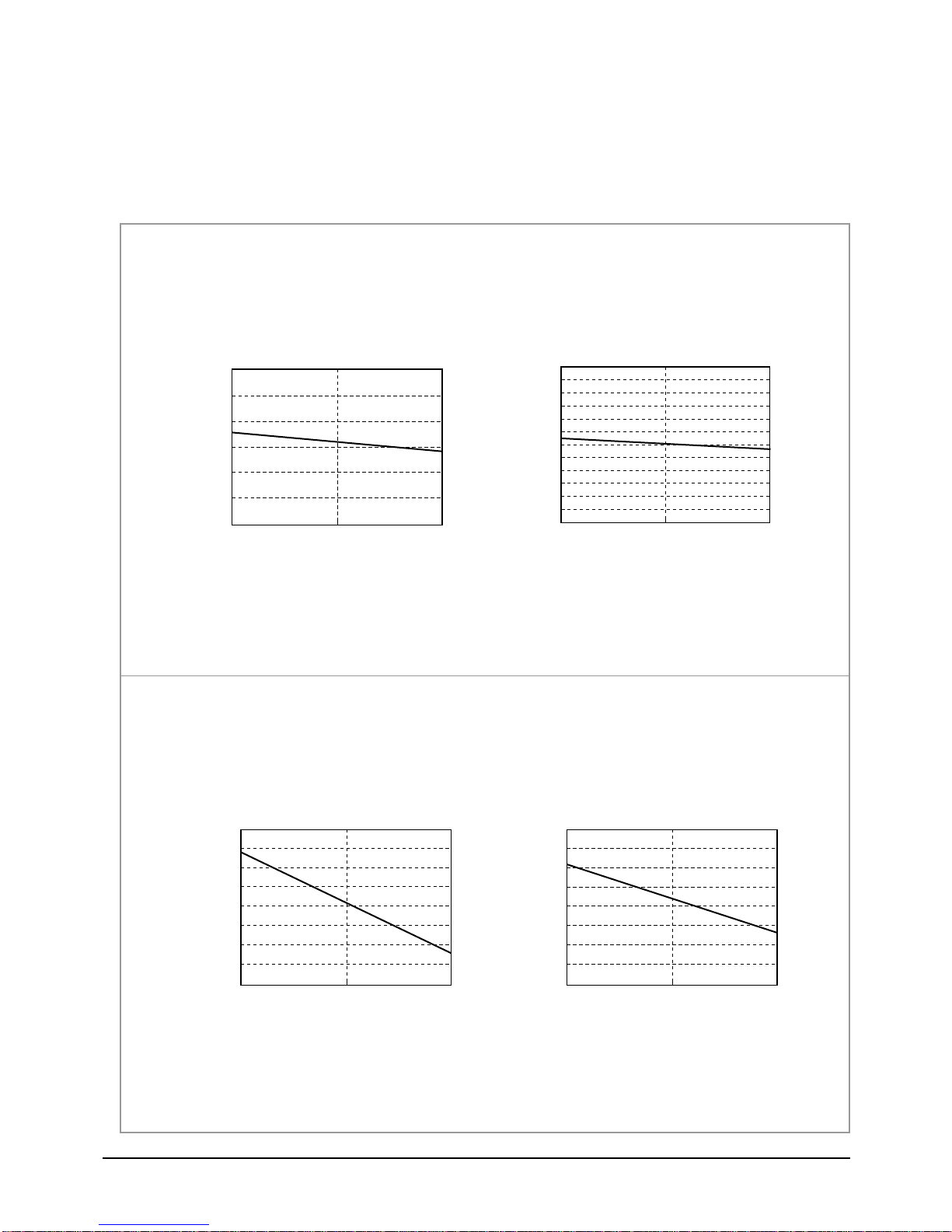

3-2-1 Capacity Distributions

Capacity Distributions according to indoor and outdoor temperature variation.

- Indoor Temp. Variation : 21.0˚C ~ 32.4˚C

- Outdoor Temp. Variation : 25.0˚C ~ 45.0˚C

■ 9,000Btu

Cooling Capacity Distribution

■ 12,000Btu

4.0

3.0

2.0

Cooling Capacity(kW)

1.0

25.0 35.0 45.0

Outdoor Temp.(DB C)

Indoor Temp.( C)

DB32.4 / WB24.0

DB30.6 / WB22.5

DB27.0 / WB19.0

DB24.0 / WB17.0

DB21.0 / WB15.0

11Samsung Electronics

Refrigerating Cycle Diagram

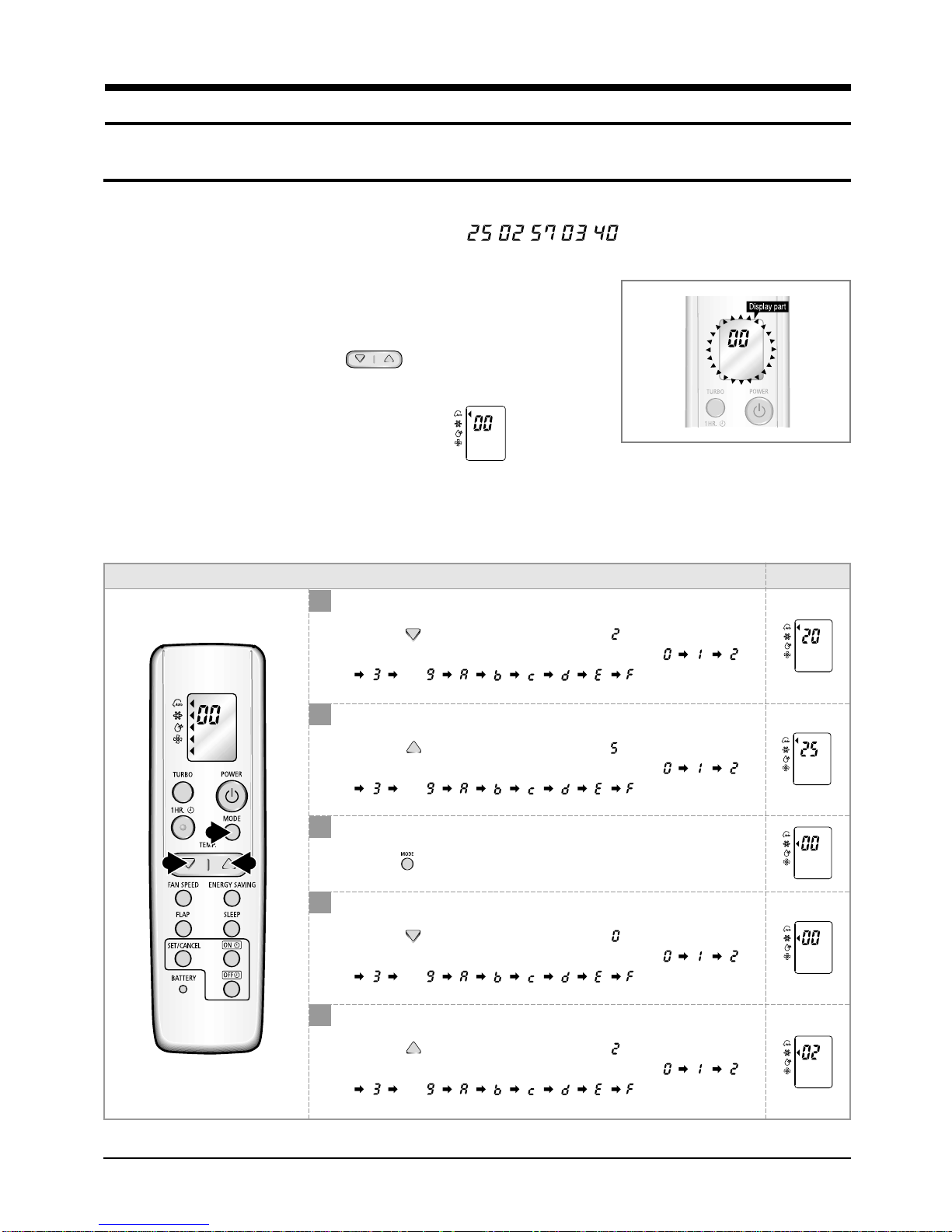

3-2-2 Power Consumption Distributions

Power Consumption Distributions according to indoor and outdoor temperature variation.

- Indoor Temp. Variation : 21.0˚C ~ 32.4˚C

- Outdoor Temp. Variation : 25.0˚C ~ 45.0˚C

■ 9,000Btu

Power consumption Distribution(Cooling mode)

■ 12,000Btu

1,300

1,200

1,100

1,000

900

Power consumption(W)

800

700

25 35 45

1,600

1,500

Outdoor Temp.(DB C)

Power consumption Distribution(Cooling mode)

Indoor Temp.( C)

DB32.4 / WB24.0

DB30.6 / WB22.5

DB27.0 / WB19.0

DB24.0 / WB19.0

DB21.5 / WB15.0

Indoor Temp.( C)

DB32.4 / WB24.0

DB30.6 / WB22.5

DB27.0 / WB19.0

DB24.0 / WB19.0

DB21.5 / WB15.0

1,400

1,300

1,200

Power consumption(W)

1,100

1,000

25 35 45

Outdoor Temp.(DB C)

Samsung Electronics12

Refrigerating Cycle Diagram

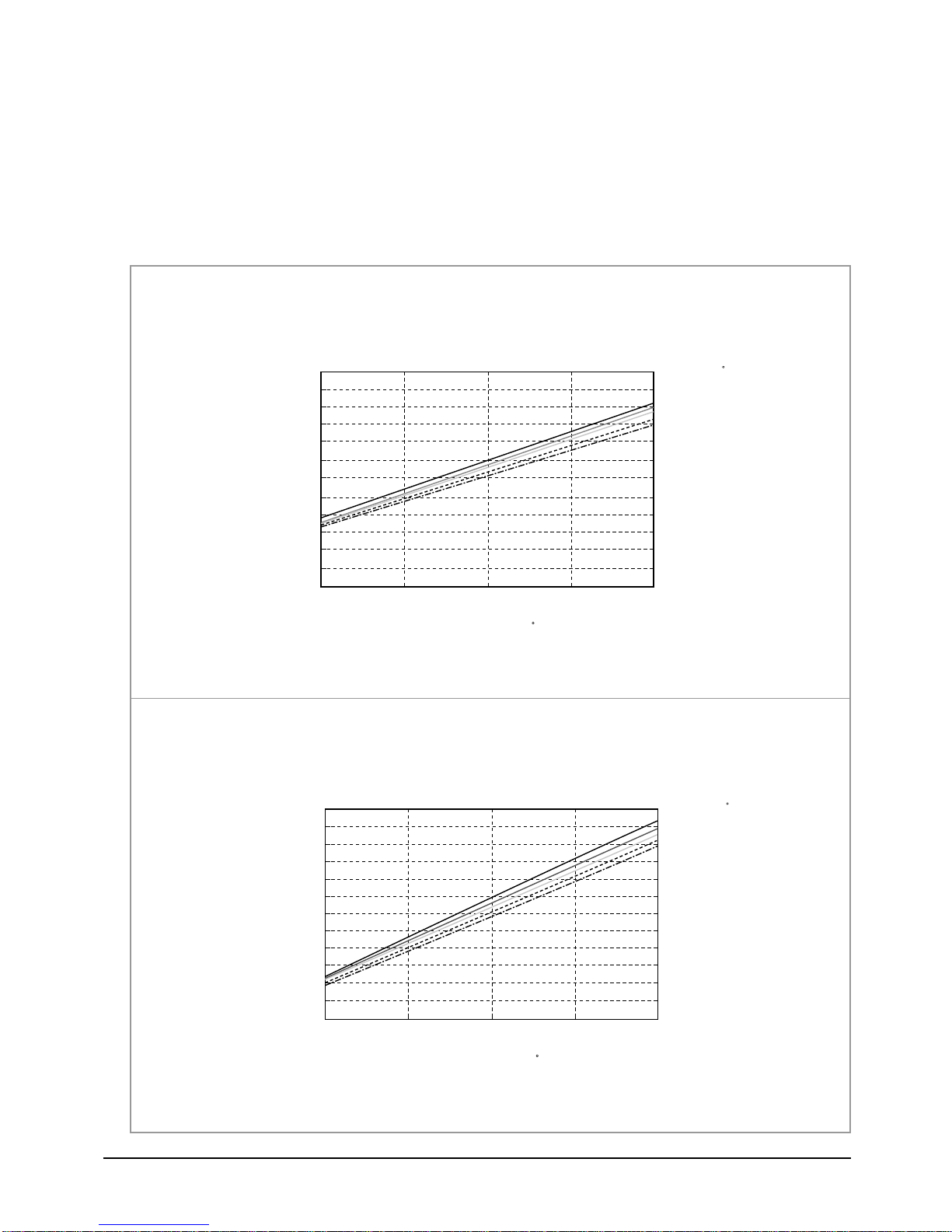

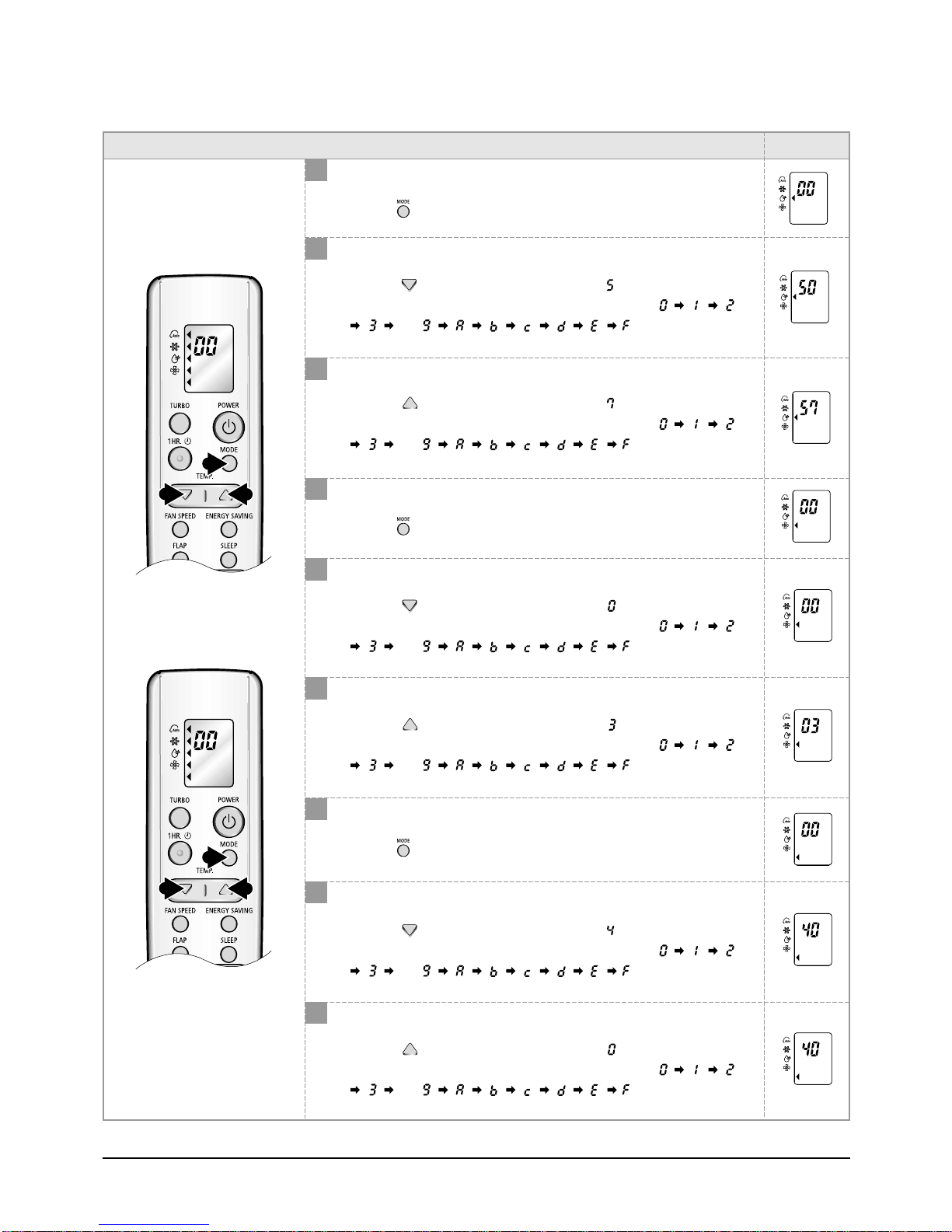

3-2-3 Capacity and Power Consumption Distributions

Capacity and power Consumption distributions according to the length of connecting Pipe between indoor unit and outdoor unit.

■ 9,000Btu

4

3

2

Coooling Capacity(kW)

1

■ 12,000Btu

Cooling Capacity

7.5 15.0

Length of Connecting Pipe(m)

Power consumption(Cooling)

1,300

1,200

1,100

1,000

900

800

Power consumption(W)

700

7.5 15.0

Length of Connecting Pipe(m)

Cooling Capacity

3.70

3.50

3.30

3.10

Cooling Capacity(kW)

2.90

7.5 15.0

Length of Connecting Pipe(m)

Power consumption(Cooling)

1,350

1,300

1,250

1,200

Power consumption(W)

1,150

7.5 15.0

Length of Connecting Pipe(m)

13Samsung Electronics

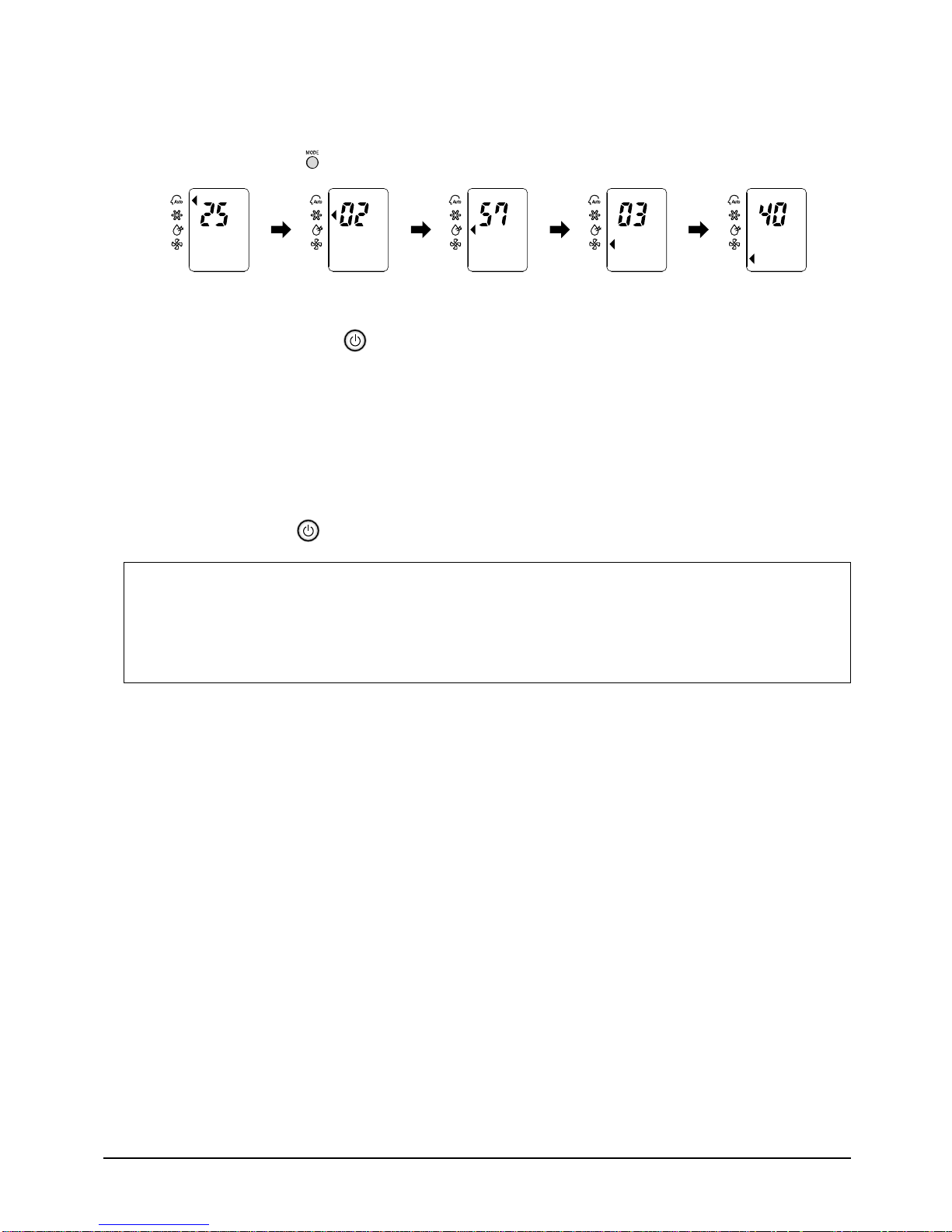

4. Set Up the Model Option

4-1 Setting Option Setup Method

ex) Option No. :

Step 1 : Enter the Option Setup mode.

st

1

nd

2

Take out the batteries of remote control.

Press the temperature button simultaneously and

insert the battery again.

rd

3

Make sure the remocon display shown as .

Step 2 : Enter the Option Setup mode and select your option according to the following procedure.

Feature Display

1

Setting Option SEG1.

Push the button to set the display panel to .

Every time you push the button, the display panel reads

3

1,4 2,5

. . .

2

Setting Option SEG2.

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

3

Change it into the set display of Option SEG3 and SEG4

with the button.

repeatedly.

repeatedly.

4

5

Setting Option SEG3.

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

Setting Option SEG4.

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

repeatedly.

repeatedly.

Samsung Electronics14

Feature Display

6,9

7,10 8,11

12

13 14

6

Change it into the set display of Option SEG5 and SEG6

with the button.

7

Setting Option SEG5.

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

8

Setting Option SEG6.

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

9

Change it into the set display of Option SEG7 and SEG8

with the button.

Set Up the Model Option

repeatedly.

repeatedly.

10

Setting Option SEG7.

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

11

Setting Option SEG8.

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

12

Change it into the set display of Option SEG9 and SEG10

with the button.

13

Setting Option SEG9.

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

14

Setting Option SEG10.

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

repeatedly.

repeatedly.

repeatedly.

repeatedly.

15Samsung Electronics

Set Up the Model Option

Step 3 : Upon completion of the selection, check you made right selections.

Whenever you press the button, the set Option will be displayed.

Step 4 : Pressing the ON/OFF button ( )

When pressing the operation ON/OFF key with the direction of remote controller for unit, the sound "Ding" is heard and the

OPERATION LED lamp is flickering at the same time, then the input of option is completed. (If the "ding" sound isn't heard,

try again pressing the ON/OFF button.)

Step 5 : Unit operation test-run

First, Remove the battery from the remote controller.

Second, Re-insert the battery into the remote controller.

Third, Press ON/OFF ( ) key with the direction of remote controller for set.

• Error Mode

st

1

If all lamps of indoor unit are flickering, Plug out, plug in power plug again and press ON/OFF key to retry.

nd

2

If the unit is not working properly or all lamps are continuously flickering after setting the option code, see if the

correct option code is set up for its model.

Samsung Electronics16

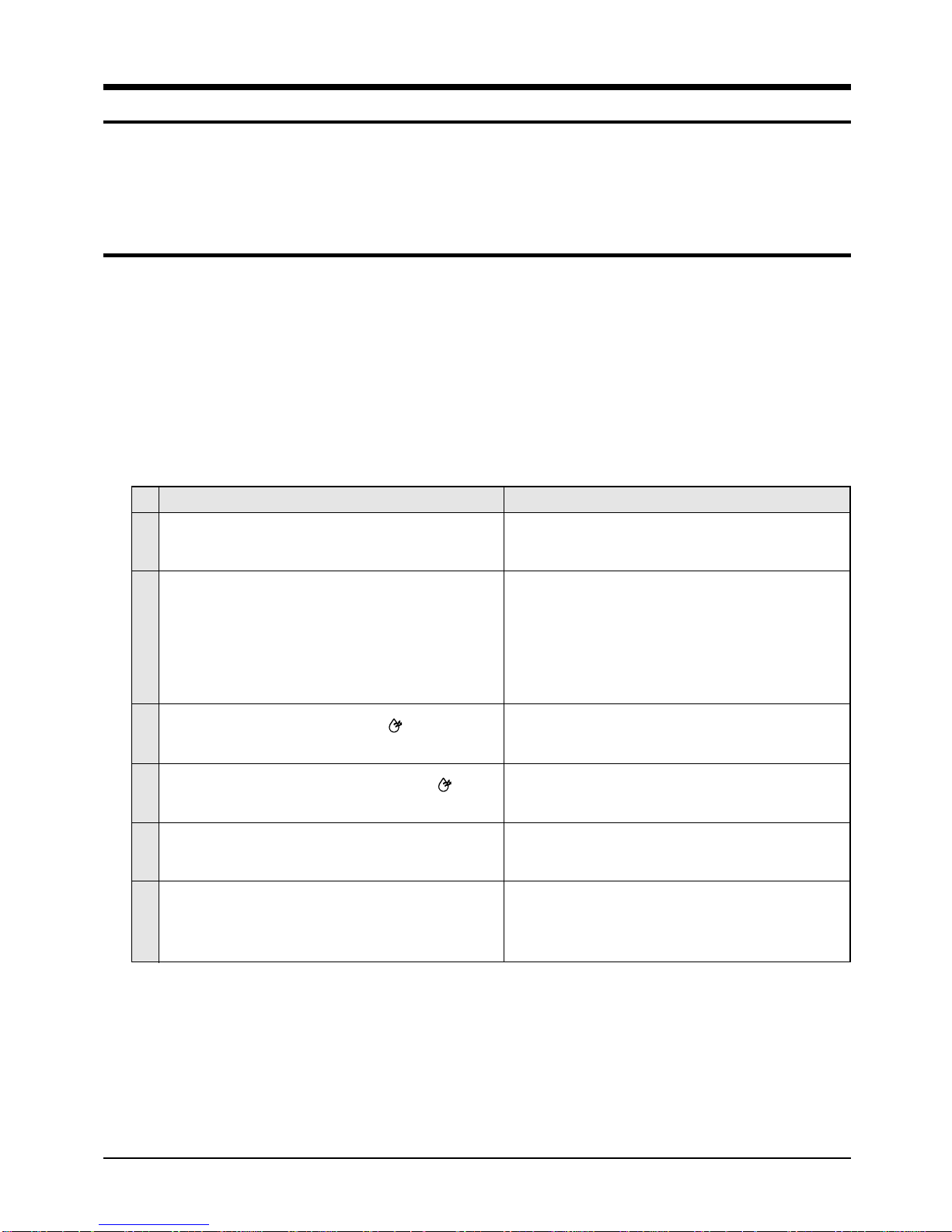

4-2 Table of the option Code

Model

SC09AWH

SC09ZWH

AS09WHWD

AS09WHWE

KF-25G/SWA

SC12AWH

SC12ZWH

AS12WHWD

AS12WHWE

KF-35G/SWA

Option Code

SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 SEG7 SEG8 SEG9 SEG10

20000A00c8

20000A00Fb

20000A0340

17Samsung Electronics

5. Troubleshooting

Check the basic items first to judge if the problem was caused by breakdown or misuse. If none of the basic items are related to the

problem, please scrutinize the machine according to the 'Breakdown Diagnosis by Symptoms' method.

5-1 Basic Breakdown Diagnosis Items

1. The input voltage should be rating voltage ±10% range.

The airconditioner may not operate properly if the voltage is out of this range.

2. Is the link cable linking the indoor unit and the outdoor unit linked properly?

The indoor unit and the outdoor unit shall be linked by 5 cables.

Check the terminals if the indoor unit and outdoor unit are properly linked by the same number of cables.

Otherwise the airconditioner may not operate properly.

3. When a problem occurs due to the contents illustrated in the table below it is a symptom not related to the malfunction of the

airconditioner.

No

1

The OPERATION indication LED(GREEN) blinks when a

power plug of the indoor unit is plugged in for the first time.

2

In a COOL operation mode, the compressor does not

operate at a room temperature higher than the setting

temperature that the INDOOR FAN should operate.

3

Fan speed setting is not allowed in DRY( ) mode.

4

Compressor stops operation intermittently in DRY( )

mode.

5

Timer LED(GREEN) of the indoor unit lights up and the

air conditioner does not operate.

6

The compressor stops intermittently in a COOL mode or

DRY mode, and fan speed of the indoor unit decreases.

Operation of air conditioner Explanation

It indicates power is on. The LED stops blinking if the operation ON/OFF button on the remote control unit is pushed.

In happens after a delay of 3 minutes when the compressor

is reoperated. The same phenomenon occurs when a power

is on.

As a phenomenon that the compressor is reoperated after a

delay of 3 minutes, the indoor fan is adjusted automatically

with reference to a temperature of the air blew.

The speed of the indoor fan is set to LL in DRY mode.

Fan speed is selected automatically in AUTO mode.

Compressor operation is controlled automatically in DRY

mode depending on the room temperature and humidity.

Timer is being activated and the unit is in ready mode.

The unit operates normally if the timer operation is cancelled.

The compressor stops intermittently or the fan speed of the

indoor unit decreases to prevent inside/outside air frozen

depending on the inside/outside air temperature.

Samsung Electronics18

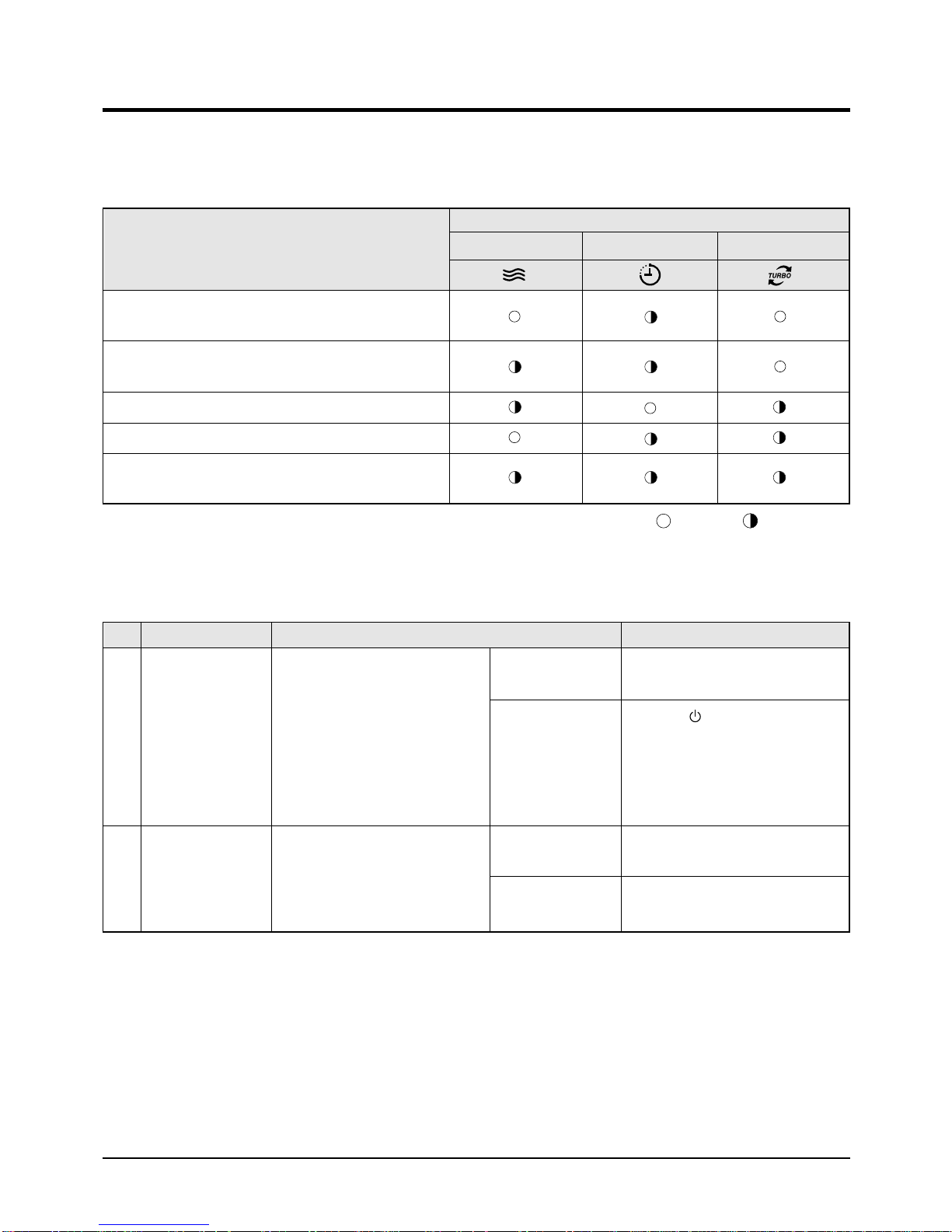

5-2 Trouble check in the initial status

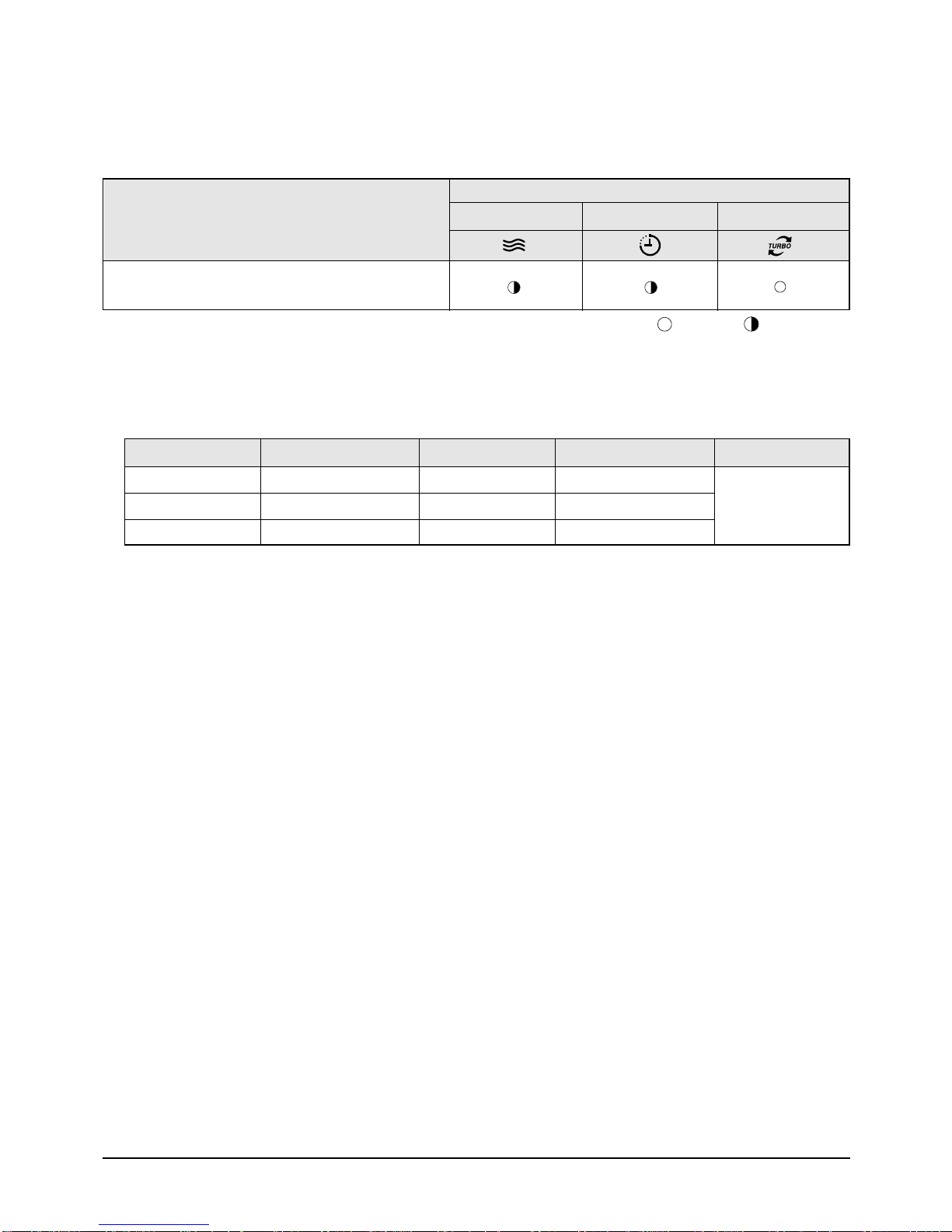

5-2-1 Diagnosis and marking of the part in trouble.

Please check the air conditioner operation status and write the check result in the chart in the room.

LAMP

Description

Indoor unit room temperature sensor error

(open or short)

Indoor unit heat exchanger temperature sensor error

(open or short)

Indoor fan motor mal function

EEPROM error

Option error

(option wasn't set up or option data error)

OPERATION TIMER TURBO

: Lamp off

5-2-2 Operation with abnormal motion

No Abnormal condition Inspection Initial Diagnosis

1

No response from

the remote control

operation signal.

2

Unable to operate the

outdoor unit

• Plug out and plug in 5 seconds later.

• Press the TURBO button with the

remote control.

• In 3 minutes, check the voltage

between the indoor unit terminal

block N(1) and 1.

Able to operate the

remote control.

Unable to operate

the remote control.

AC200V ~ AC240V

No power source

displayed.

OK

Press the button in the indoor unit.

• If it operates, the remote control and

indoor unit receiver are in trouble.

• If not, the indoor unit is in trouble.

Problem with the outdoor unit or PCB

Problem with the relay (RY71) or PCB

: Lamp flickering

19Samsung Electronics

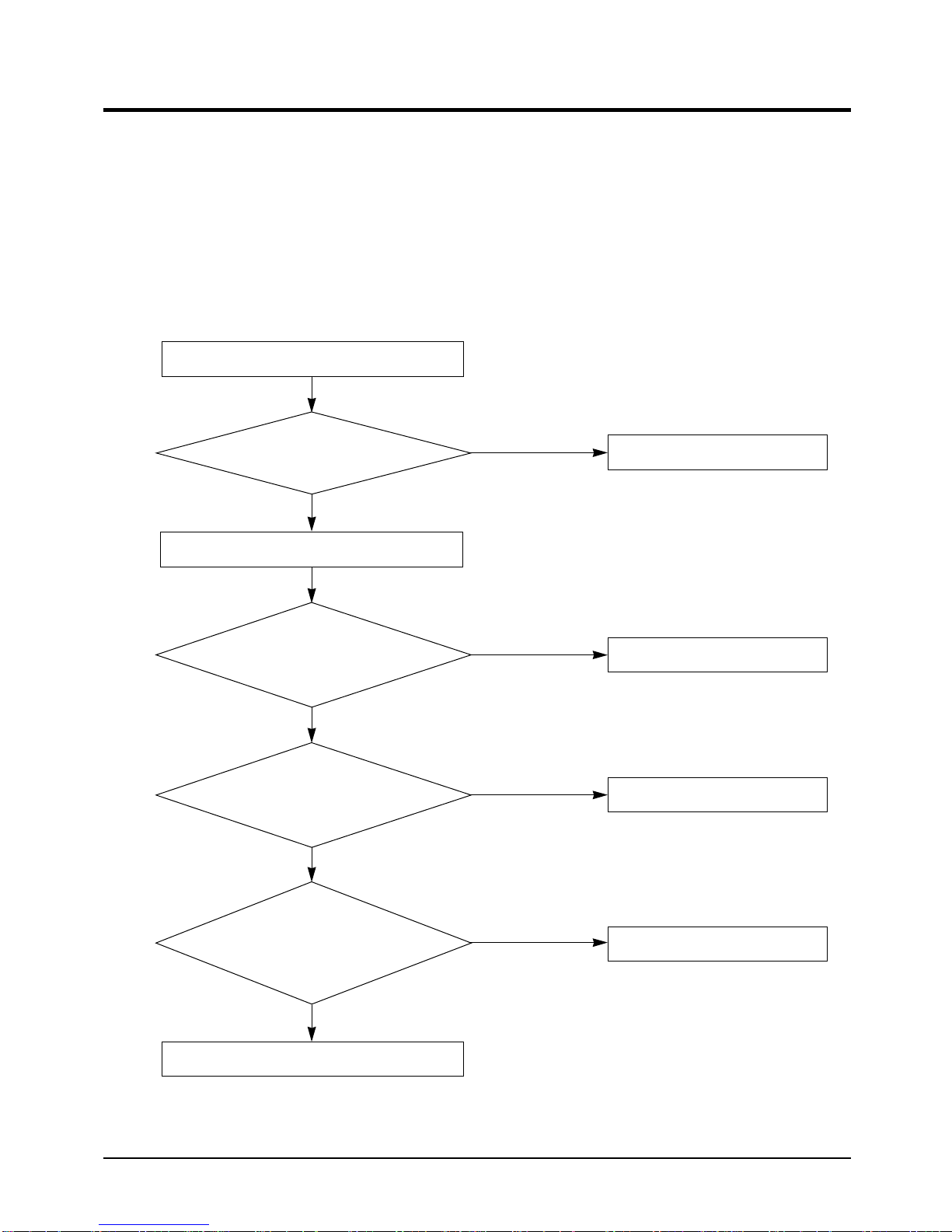

5-3 Breakdown diagnosis by symptoms

5-3-1 No Power (completely dead)-Initial diagnosis

1. Checklist :

1) Is input voltage normal?

2) Is AC power linked correctly?

3) Is input voltage of DC regulator IC KA7805 (IC02) normal? (11VDC-12.5VDC)

4) Is output voltage of DC regulator IC KA7805 (IC02) normal? (4.5VDC-5.5VDC)

2. Troubleshooting procedure

Unplug the power cord and plug it after 5 seconds

Press the Power Button on

the remote control unit to operate the air

conditioner

does not operate

◆ Check the indoor unit control board

Check whether two wires

of power cord are connected correctly to the

terminal block and control board.

Yes

Check whether the fuse on the

control board is normal.

F701: 3.15[A]/250[V]

Yes

operate

No

No

◆ Check the display board

Reconnect wires correctly

Replace fuse

Check the output of

SMPS on the control board.

Input power: AC230±15%[V]

IC02 Input: DC 12[V]

IC02 output: DC 5[V]

Yes

◆ Check the setting temperature

No

Replace the control board

Samsung Electronics20

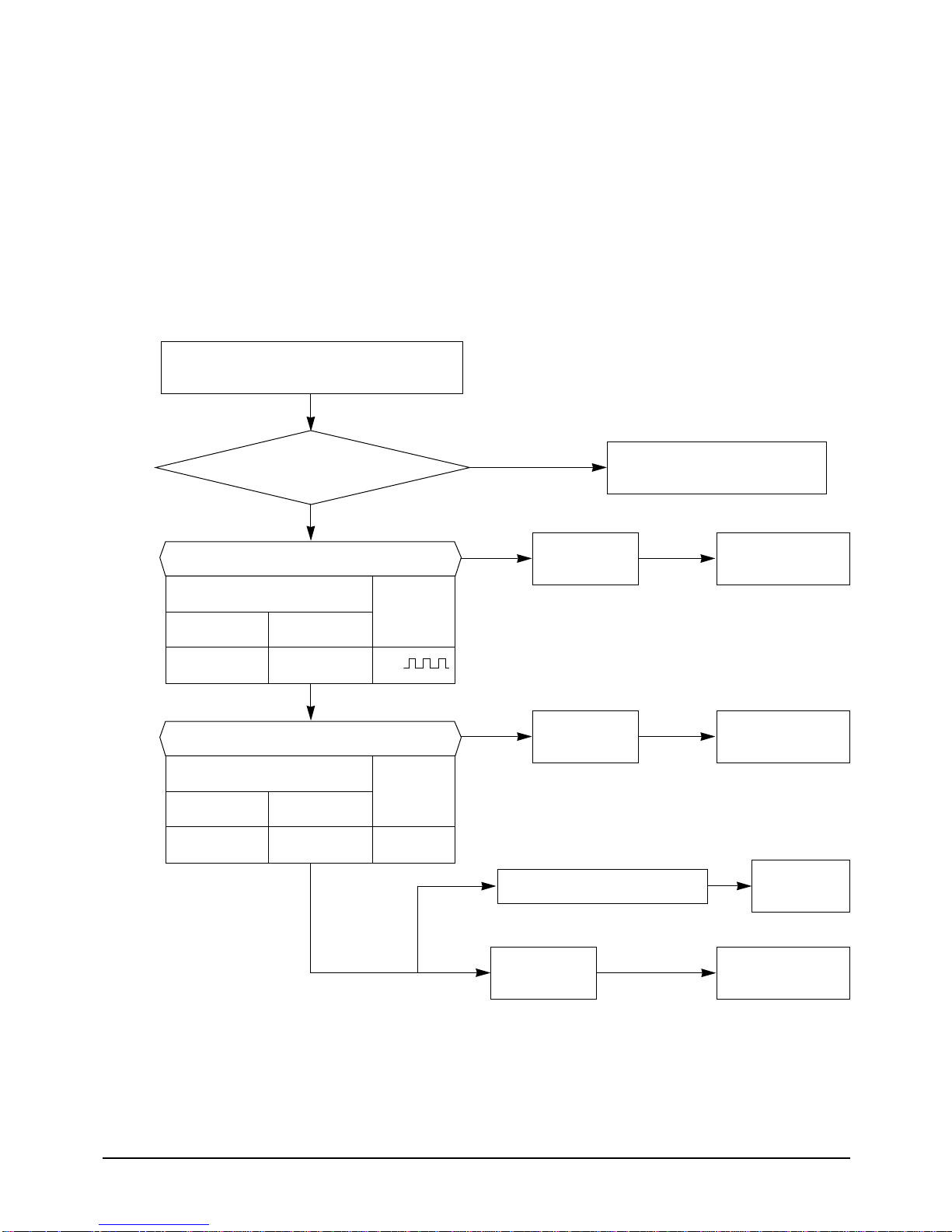

5-3-2 When the Indoor Unit Fan Does Not Operate. (Initial Diagnosis)

1. Checklist :

1) Is the indoor unit fan motor properly connected with the connector (CN72)?

2) Is the AC voltage correct?

3) Is HALL IC in indoor fan motor properly connected with the connector (CN44)?

4) Is the running capacitor (CR71) properly connected with PCB board?

2. Troubleshooting procedure

After unplugging out the power cord should

be reconnected within 5 seconds.

Yes

Troubleshooting

Does the OPERATION lamp blink?

Yes

Does the Solid State Relay(SS71) work properly?

Test rod location

+

SS71- SS71- 12V

Is the supply voltage of the fan motor sufficient?

Test rod location

PCB CN72 Condition

pin #3 and #5 Fan operate

-

Yes

Yes

Normal

Voltage

Normal

Voltage

About AC

180V

No

No

No

Motor Fan-Capacitor is out of order

Micom is

out of order.

PCB is

out of order.

Check as in the procedure

"NO power parts"

Micom

should be replaced

PCB should be

replaced.

Replace Motor

Fan-Capacitor

Fan motor

is out of order.

Fan motor

should be replaced.

21Samsung Electronics

Troubleshooting

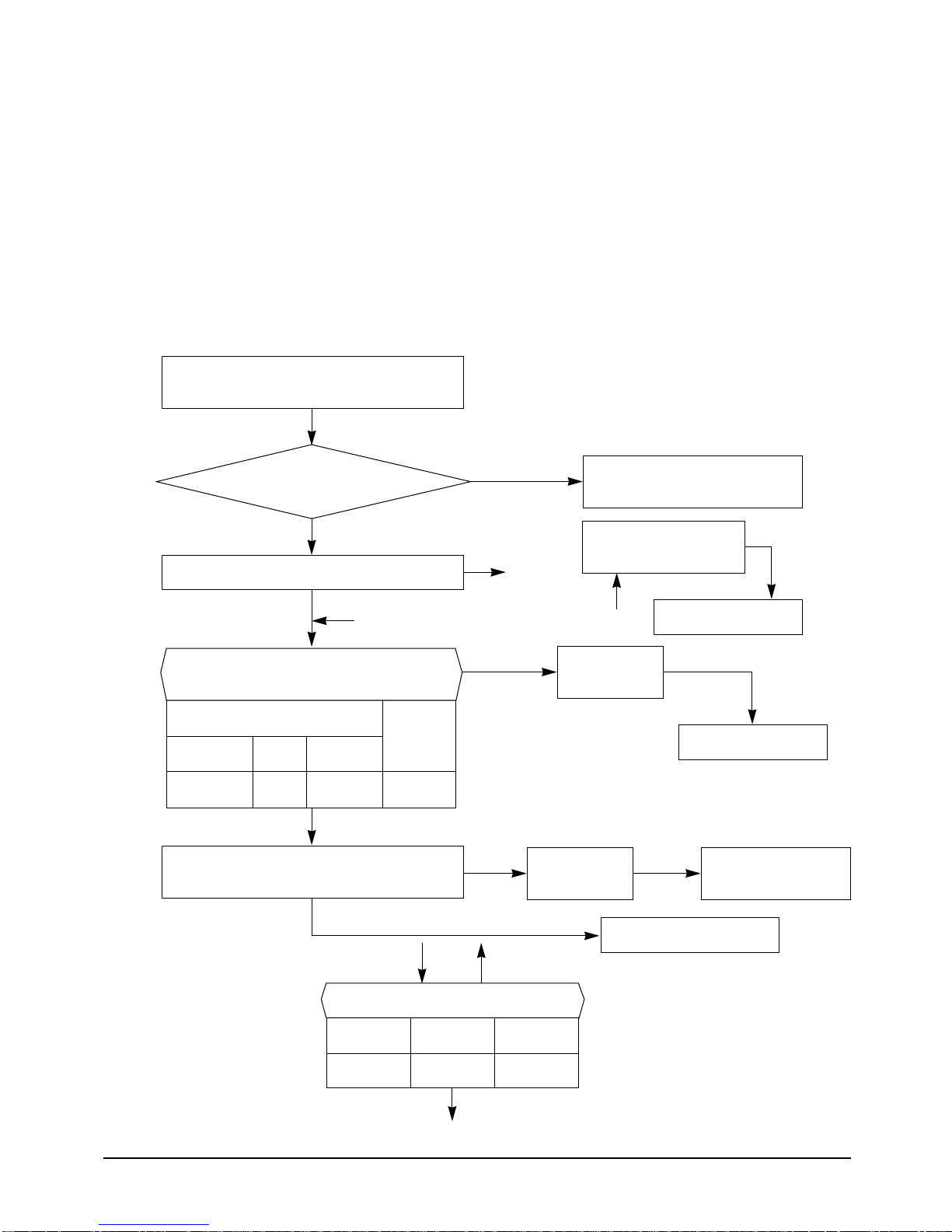

5-3-3 When the Outdoor Unit Does Not Operate. (Initial Diagnosis)

1. Checklist :

1) Is input voltage normal?

2) Is the set temperature of the remote control higher than room temperature in COOL mode?

3) Is the set temperature of the remote control lower than room temperature in HEAT mode?

4) Is the POWER IN connector (CN71) linked correctly?

5) Is the outdoor unit properly connected with the TERMINAL BLOCK connector(N(1), 1, 2, 3)?

2. Troubleshooting procedure

After unplugging out the power cord should be

reconnected within 5 seconds.

Does the OPERATION lamp blink

Yes

Does the timer lamp blink during operation?

No

#

Is the power relay RY71 operated by adjusting

the room temperature?

Test rod location

+ Condition-

Normal

Voltage

IC04 Pin No.38 RY71 ONGND DC 4.8V

Yes

Is rating voltage ±10% range applied relay between

Terminal block No. N(1) and No. 1

Yes

!

Yes

Yes

No

No

No

@

No

!

Power relay is

Check as in the procedure

"No Power parts"

Room temperature sensor is

out of order

@

PCB should be checked.

Micom is

out of order.

out of order

Outdoor unit is out of order.

PCB should be checked.

Power relay should be

replaced.

Is the room sensor normal register?

10°C20°C

30°C

12.09kΩ17.96kΩ 8.3kΩ

#

Samsung Electronics22

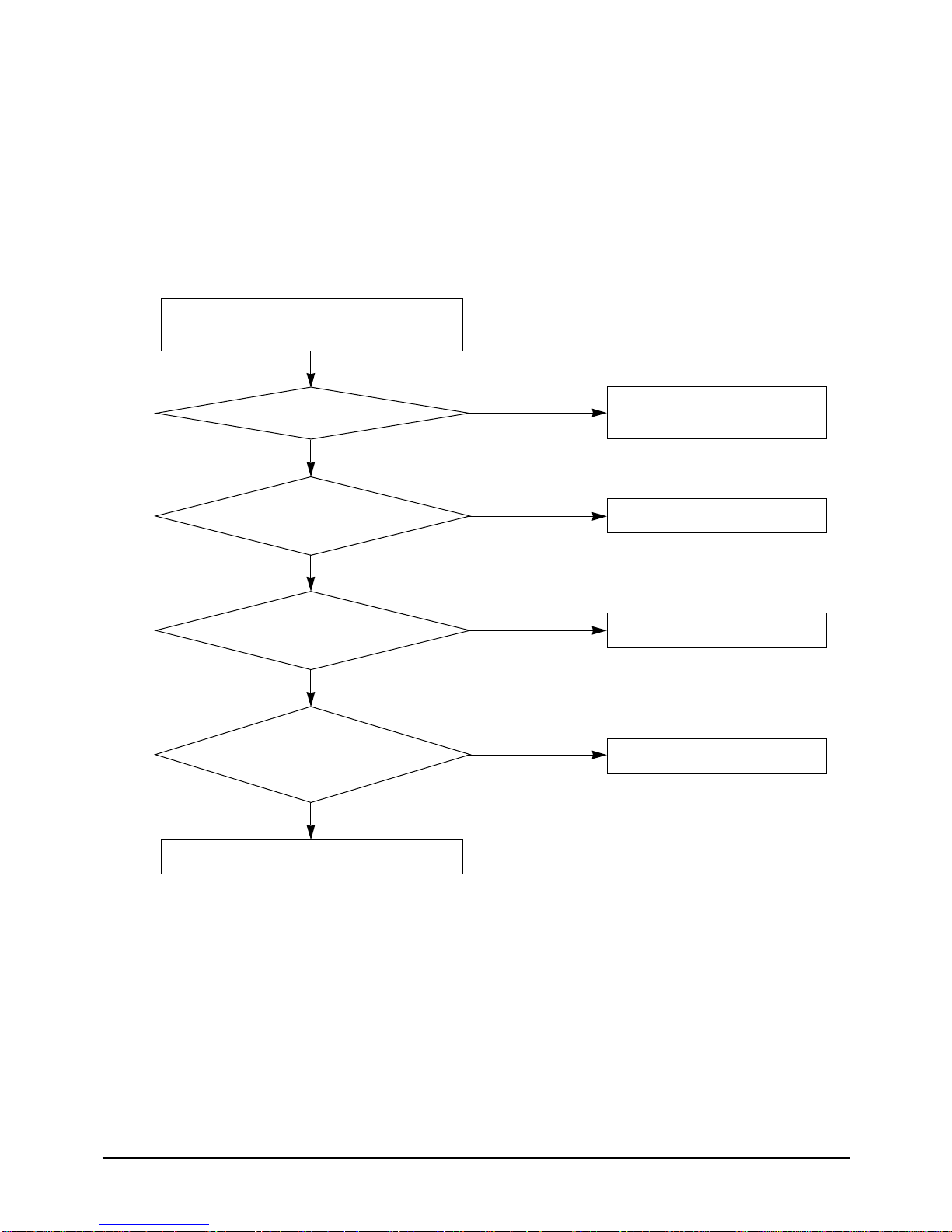

5-3-4 When the UP/DOWN Louver Motor Does Not Operate. (Initial Diagnosis)

1. Checklist :

1) Is input voltage normal?

2) Is the UP/DOWN louver motor properly connected with the connector (CN61)?

2. Troubleshooting procedure

Troubleshooting

Remove power cord and plug in again in approx.

5 seconds.

Is STD lamp blinking?

Yes

Does operation start when

swing button of the remote control unit

pushed?

No

Voltage at pin #57~#60

of micom (IC04) change?

(Squarewave)

Yes

Voltage at pin #16 of

IC06(ULN2003A) and #10~#12 of

IC08(ULN2003A) change?

(Squarewave)

No

Yes

No

No

Check as in the procedure

"No Power parts".

Normal

Micom (IC04) is faulty.

Driver IC06/08 (ULN2003A) is faulty.

Yes

UP/DOWN louver motor is faulty.

23Samsung Electronics

Troubleshooting

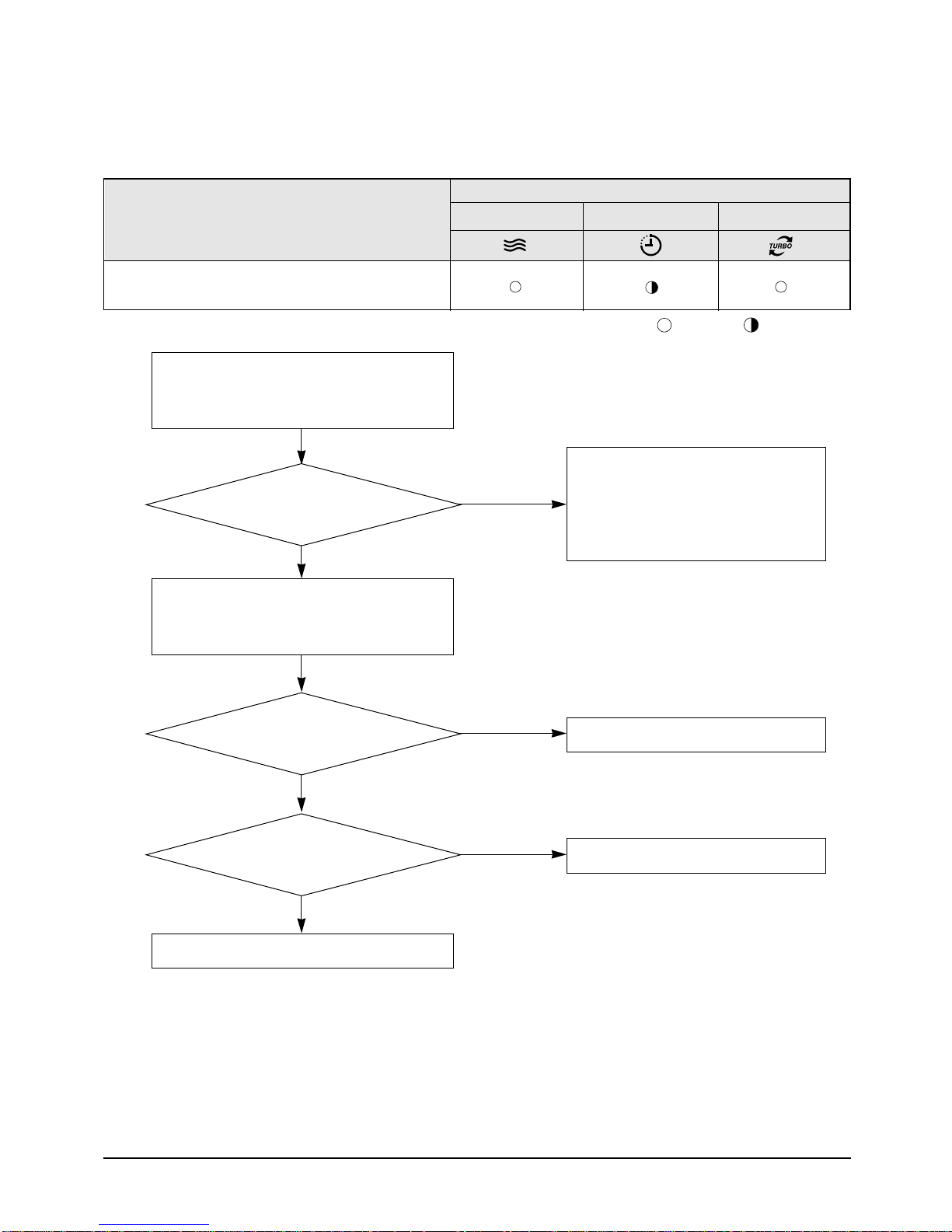

5-3-5 Room temperature sensor failure

Description

Indoor unit room temperature sensor error(open or short)

LAMP

OPERATION TIMER TURBO

Detach the assembly sensor from the

ASS'Y PCB CN43 connector and measure

the sensor resistance with an ohmmeter (tester).

Is the sensor resistance value

10KΩ ±3% at the room temperature

of 25˚C?

Yes

Connect the sensor to CN43,

supply power, and measure the voltage of

#1 and #2 of the CN43 connector.

Below 0.5V?

No

Yes

: Lamp off

ASS'Y Sensor Replace

SENSOR Resistance Value : 20˚C-12.09kΩ

SENSOR Resistance Value : 30˚C-8.31kΩ

SENSOR Resistance Value : 35˚C-6.94kΩ

SENSOR Resistance Value : 40˚C-5.83kΩ

Poor ASS'Y PCB Replace

: Lamp flickering

No

Over 4.9V?

No

MICOM Error or Connector(CN43) check

Yes

Poor ASS'Y PCB Replace

Samsung Electronics24

5-3-6 Room Pipe sensor failure

Description

Indoor unit heat exchanger temperature sensor error

(open or short)

Troubleshooting

LAMP

OPERATION TIMER TURBO

: Lamp off

: Lamp flickering

1. Check the assembly condition of the sensor connector(CN43) on the indoor unit Main PCB and if not assembled, reassemble the

connector accurately.

2. Detach the room pipe sensor connector(CN43) and check the resistance between connector 3 and 4.

Temperature(˚C)

15

20

25

Resistance Value(Kohm)

14.68

12.09

10

Temperature(˚C)

30

35

40

Resistance Value(Kohm)

8.31

6.94

5.83

Others

The data tolerance

is ±3%.

If the above data is not met, replace the room pipe sensor.

3. Assemble the room pipe sensor to PCB, plug in, and check the voltage of connector 3 and 4. If the resistance is below 0.5V or

over 4.9V, replace the indoor Main PCB. (short or disconnected in the PCB board)

5-3-7 When the remote control is not receiving.

1. Check if the connector was normally assembled.

2. Put the set in operation and check the voltage of No. 3(+) and No. 2(-) of the main PCB CN91 while operating the

remote control. When the voltage descends below 3V, the assembly module PCB is normal and the main PCB is poor.

Then replace the main PCB.

3. Replace the assembly display PCB because the module PCB is poor if the voltage between No. 2~3 of CN91

maintains 5V after the remote control starts operation.

25Samsung Electronics

5-4 PCB Inspection Method

5-4-1 Pre-inspection Notices

1. Check if you pulled out the AC power plug when you eliminate the PCB or front panel.

2. Don't hold the PCB side not impose excessive force on it to eliminate the PCB.

3. Don't pull the lead wire but hold the whole housing to connect or disconnect a connector to the PCB.

5-4-2 Inspection Procedure

1. Check connector connection and peeling of PCB or bronze coating pattern when you think the PCB is broken.

2. The PCB is composed of the 3 parts.

● Main PCB Part : MICOM and surrounding circuit, relay, room fan motor driving circuit and control circuit,

sensor driving circuit, power circuit of DC12V and DC5V, and buzzer driving circuit.

● Display part : LED lamp

● Switch part : Switch

5-4-3 Detailed Inspection Procedure

No Procedure Inspection Method Cause

1

Plug out and pull the PCB

out of the electronic box.

Check the PCB fuse.

Supply power.

2

If the operating lamp

twinkles at this time,

the above 1)~3) have

no relation.

3

Press the ON/OFF button

and operate TURBO

mode.

But, exclude the

RESERVE operation.

Press the ON/OFF button.

4

1. FAN Speed [High]

2. Continuous Operation

1) Is the fuse disconnected? (F701)

Checking the power voltage.

1) Is the DB71input voltage AC200V~AC240V?

2) Is the voltage between both terminals of the

C102 on the 2

±0.5V?

3) Is the voltage between both terminals of OUT

and GND of IC02(KA78L05) DC5V ±0.5V?

Checking the power voltage.

1) Check the voltage of the relay(RY71) coil(IC05 PIN

#11 and GND : 0V, PIN#6 and GND : 5V) during

operation(3 minutes after TURBO operation).

2) Check the voltage of both terminals of

terminal block 1 and N(1) after 3 minute

operation.: AC220V

1) Is the voltage over AC180V being imposed

on terminal #3 and #5 of the fan motor

connector(CN72)?

nd

side of the transformer AC12V

• Overcurrent

• Indoor Fan Motor Short

• AC Part Pattern Short of the MAIN PCB

• Power Cord is fault, Fuse open. Wrong

Power Cable Wiring, AC Part is faulty.

• Switching Trans or Power Circuit is faulty

• Power Circuit is faulty, Load Short

• Relay(RY71) Coil Disconnection, IC05 is

faulty

• Relay(RY71) Contact is faulty

• Fan Motor of the indoor is faulty

2) The fan motor of the indoor unit doesn't run.

3) The power voltage between terminal #3 and #5

of the connector(CN72) is 0V.

• Fan Motor Connector(CN72) is faulty

• ASS'Y Main PCB is faulty

• Connection is faulty

Samsung Electronics26

Loading...

Loading...