Samsung S6B0718 Datasheet

S6B0718

permission of LCD Driver IC Team.

104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD

Contents in this document are subject to change without notice. No part of this document may be reproduced or

transmitted in any form or by any means, electronic or mechanical, for any purpose, without the express written

Feb. 2000.

Ver. 2.1

Prepared by: Hyoung-Seok Lee

lhs98@samsung.co.kr

104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD S6B0718

S6B0718 Specification Revision History

Version Content Date

0.0 Original Nov.1998

Modify syntax errors

0.1

Append n-line inversion wave form to figure 11 on page 19.

Dec.1998

Modify figure 12 on page 20

Change the number of COM/SEG (85COM / 100SEG -> 81COM /

1.0

104SEG)

Mar.1999

Modify PAD location

1.1

Append PAD center coordinates to table 1, 2 on page 4, 5

Append referential instruction setup flow on page 48 to 51

Apr.1999

Change bumped PAD size (modify figure 2 and table 1 on page 3)

Change the PAD Center Coordinates of COM39 and COMS1.

1.2

(modify table 2 on page 4)

May.1999

Change LCD power supply voltage

(modify VOUT and V0 voltage on page1, 52, 53, 54, 55)

Modify Set partial display duty ratio (refer to page 32)

Modify N-line Inversion Register “2 to 32” -> “3 to 33” (refer to page 41)

1.3

Change Consumption Current “2mA” -> “2uA”, “10mA” -> “10uA”

(refer to page 47)

Jun.1999

Add Partial Duty Changing “Waiting for Discharging the LCD Power

Levels (refer to figure 39)

1.4

1.4

Fix the TBD Value of DC/AC Characteristics.

Remove N-line Inversion function.

Aug.1999

Oct. 1999

2.0 Change the supply voltage(VDD) range (2.4 to 5.5 -> 2.4 to 3.6) Nov. 1999

2.0 Repair the COG/ILB align key coordinate. Dec. 1999

2.1

Change sales/product code to integration code (KS0718 -> S6B0718)

Feb. 2000

2

S6B0718 104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD

CO

NTENTS

INTRODUCTION ..................................................................................................................................................1

BLOCK DIAGRAM...............................................................................................................................................2

PAD CONFIGURATION .......................................................................................................................................3

PAD CENTER COORDINATES ............................................................................................................................5

PIN DESCRIPTION ..............................................................................................................................................7

POWER SUPPLY ..........................................................................................................................................7

LCD DRIVER SUPPLY..................................................................................................................................7

SYSTEM CONTROL .....................................................................................................................................8

MICROPROCESSOR INTERFACE...............................................................................................................9

LCD DRIVER OUTPUTS.............................................................................................................................11

FUNCTIONAL DESCRIPTION............................................................................................................................ 12

MICROPROCESSOR INTERFACE.............................................................................................................12

DISPLAY DATA RAM (DDRAM)..................................................................................................................15

LCD DISPLAY CIRCUITS............................................................................................................................19

LCD DRIVER CIRCUIT ...............................................................................................................................21

POWER SUPPLY CIRCUITS ......................................................................................................................24

REFERECE CIRCUIT EXAMPLES..............................................................................................................29

RESET CIRCUIT.........................................................................................................................................31

INSTRUCTION DESCRIPTION...........................................................................................................................32

SPECIFICATIONS..............................................................................................................................................51

ABSOLUTE MAXIMUM RATINGS...............................................................................................................51

DC CHARACTERISTICS .............................................................................................................................52

AC CHARACTERISTICS.............................................................................................................................55

REFERENCE APPLICATIONS........................................................................................................................... 59

MICROPROCESSOR INTERFACE.............................................................................................................59

CONNECTIONS BETWEEN S6B0718 AND LCD PANEL............................................................................60

3

S6B0718 104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD

INTRODUCTION

The S6B0718 is a driver & controller LSI for graphic dot-matrix liquid crystal display systems. It contains 81 common

and 104 segment driver circuits. This chip is connected directly to a microprocessor, accepts serial or 8-bit parallel

display data and stores in an on-chip display data RAM of 89 x 104 bits. It provides a highly flexible display section

due to 1-to-1 correspondence between on-chip display data RAM bits and LCD panel pixels. And it performs display

data RAM read/write operation with no externally operating clock to minimize power consumption. In addition,

because it contains power supply circuits necessary to drive liquid crystal, it is possible to make a display system

with the fewest components.

FEATURES

Driver Output Circuits

− 81 common outputs / 104 segment outputs

Applicable Duty Ratios

Programmable duty ratio Applicable LCD bias Maximum display area

1/9 to 1/81 1/4 to 1/11

− Various partial display

− Partial window moving & data scrolling

On-chip Display Data RAM

81 × 104

− Capacity: 89 x 104 = 9,256 bits

− Bit data "1": a dot of display is illuminated.

− Bit data "0": a dot of display is not illuminated.

Microprocessor Interface

− 8-bit parallel bi-directional interface with 6800-series or 8080-series

− Serial interface (only write operation) available

On-chip Low Power Analog Circuit

− On-chip oscillator circuit

− Voltage converter (x3, x4, x5 or x6)

− Voltage regulator (temperature coefficient: -0.05%/°C or external input)

− On-chip electronic contrast control function (64 steps)

− Voltage follower (LCD bias: 1/4 to 1/11)

Operating Voltage Range

− Supply voltage (VDD): 2.4 to 3.6 V

− LCD driving voltage (VLCD = V0 - VSS): 4.0 to 15.0 V

Low power Consumption

− 150 µΑ Max. (VDD = 3V, x5 boosting, V0 = 12V, internal power supply on and display OFF)

− 15 µΑ Max. (during power save [standby] mode)

Package Type

− Gold bumped chip or TCP

1

104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD S6B0718

DB0

DB1

COMS1

COM

BLOCK DIAGRAM

SEG103

SEG102

VDD

V0

V1

V2

V3

V4

VSS

:

SEG101

:

SEG2

SEG1

SEG0

104 SEGMENT

DRIVER CIRCUITS

COMS

COM0

:

:

:

82 COMMON

DRIVER CIRCUITS

79

HPMB

V0

VR

INTRS

VEXT

REF

VOUT

C1-

C1+

C2C2+

C3+

C4+

C5+

VCI

V / F

CIRCUIT

V / R

CIRCUIT

V / C

CIRCUIT

INTERNAL

POWER

SUPPLY

PAGE

ADDRESS

CIRCUIT

SEGMENT CONTROLLER

DISPLAY DATA RAM

89 X 104 = 9,256 Bits

COLUMN ADDRESS

CIRCUIT

INSTRUCTION DECODER & REGISTER

MPU INTERFACE (PARALLEL & SERIAL)

COMMON CONTROLLER

DISPLAY

LINE

ADDRESS

CIRCUIT

STATUS REGISTERBUS HOLDER

TIMING

GENERATOR

CIRCUIT

STATIC

DRIVER

OSCILLATOR

MS

CL

SYNC

M

FRS

FR

DB2

DB3

DB4

DB5

DB6(SCLK)

DB7(SID)

RW_WR

E_RD

RS

CS2

CS1B

PS

C68

RESETB

Figure 1. Block Diagram

2

S6B0718 104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD

Y

(0,0)

X

ðððð

- - - -

ððð

ð

ðððð

- - - -

ððð

ð

PAD CONFIGURATION

113242

243

рр ррррррррррррррррррр

S6B0718

(TOP VIEW, PADS UP)

- - - - - - - - - -

ррррррррррррррррррр

ðð

112

274

рррррррррррррррррррррр

1

Figure 2. S6B0718 Chip Configuration

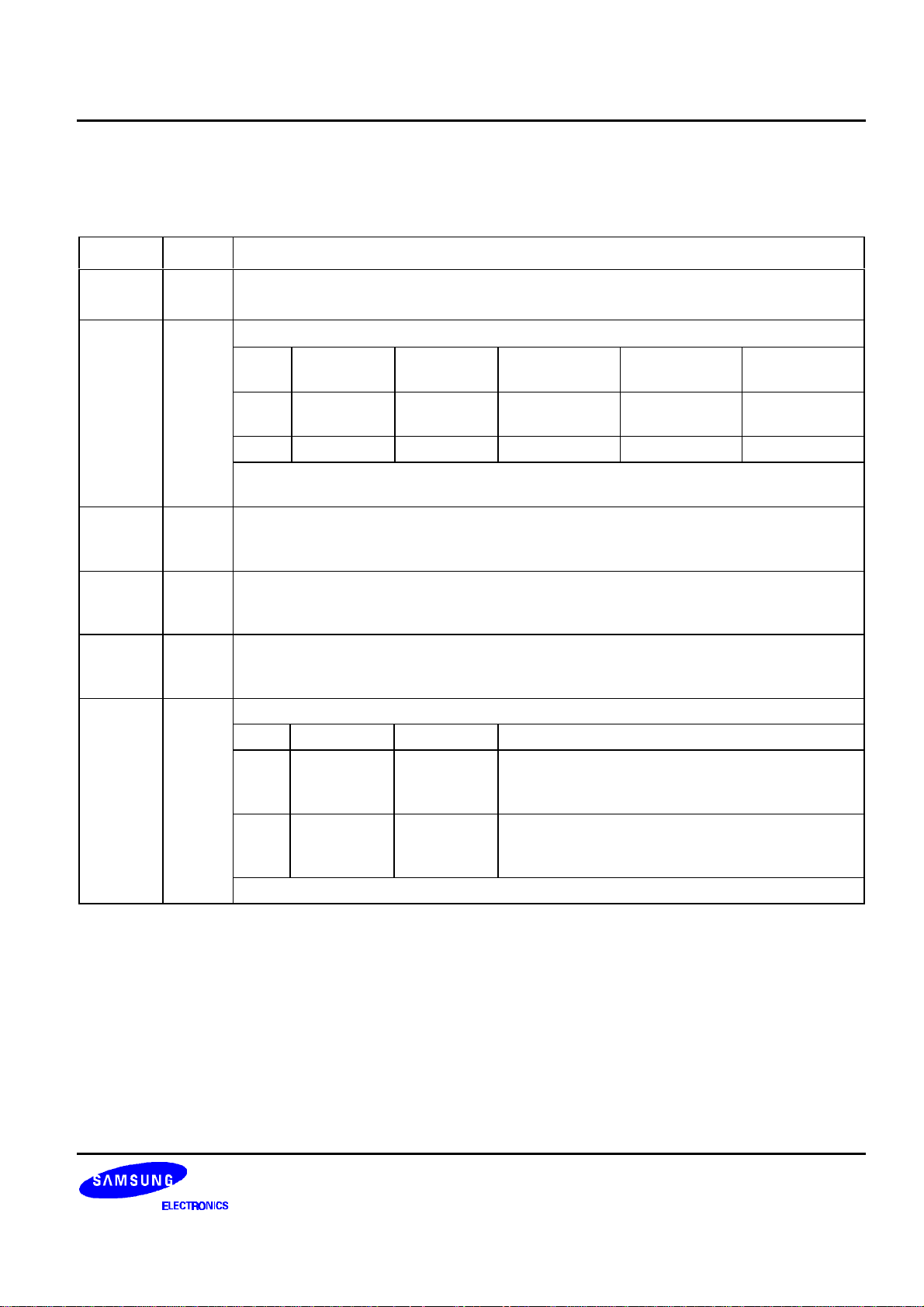

Table 1. S6B0718 Pad Dimensions

Item Pad No.

Chip size - 8350 2380

Pad pitch

- - - - - - - - - -

1 to 80 90

82 to 110

115 to 240

245 to 273

81

111 to 114

241 to 244

274

1 to 80 54 112

81 110 80

ррррррррррррррррррррррр

X Y

81

80

Size

Unit

60

80

µm

82 to 110 110 40

111 to 112 110 60

Bumped pad size (Max.)

Bumped pad height All pad 14 (Typ.)

113 to 114 60 110

115 to 240 40 110

241 to 242 60 110

243 to 244 110 60

245 to 273 110 40

274 110 80

3

104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD S6B0718

30µm

30µm

30µm

42µm

108µm

42µm

108µm

COG Align Key Coordinate ILB Align Key Coordinate

30µm 30µm 30µm

(+3565, +640)

42µm 108µm

(-3493.5, +488.5)

42µm108µm

(+3493.5, -408.5)

4

S6B0718 104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD

50

C5+

855

-1066

100

COM20

4028

130

150

SEG24

1650

1043

PAD CENTER COORDINATES

Table 2. Pad Center Coordinates

[Unit: µm]

No. Name X Y No. Name X Y No. Name X Y

1 FRS -3555 -1066 51 C3+ 945 -1066 101 COM19 4028 190

2 FR -3465 -1066 52 C3+ 1035 -1066 102 COM18 4028 250

3 TEST1 -3375 -1066 53 C1- 1125 -1066 103 COM17 4028 310

4 TEST2 -3285 -1066 54 C1- 1215 -1066 104 COM16 4028 370

5 TEST3 -3195 -1066 55 C1+ 1305 -1066 105 COM15 4028 430

6 CL -3105 -1066 56 C1+ 1395 -1066 106 COM14 4028 490

7 M -3015 -1066 57 C2+ 1485 -1066 107 COM13 4028 550

8 SYNC -2925 -1066 58 C2+ 1575 -1066 108 COM12 4028 610

9 VSS -2835 -1066 59 C2- 1665 -1066 109 COM11 4028 670

10 HPMB -2745 -1066 60 C2- 1755 -1066 110 COM10 4028 730

11 MS -2655 -1066 61 C4+ 1845 -1066 111 DUMMY 4028 810

12 VDD -2565 -1066 62 C4+ 1935 -1066 112 DUMMY 4028 890

13 PS -2475 -1066 63 VSS 2025 -1066 113 DUMMY 3910 1043

14 C68 -2385 -1066 64 REF 2115 -1066 114 DUMMY 3830 1043

15 VSS -2295 -1066 65 VEXT 2205 -1066 115 COM9 3750 1043

16 CS1B -2205 -1066 66 VDD 2295 -1066 116 COM8 3690 1043

17 CS2 -2115 -1066 67 INTRS 2385 -1066 117 COM7 3630 1043

18 VDD -2025 -1066 68 VSS 2475 -1066 118 COM6 3570 1043

19 RESETB -1935 -1066 69 V4 2565 -1066 119 COM5 3510 1043

20 RS -1845 -1066 70 V4 2655 -1066 120 COM4 3450 1043

21 VSS -1755 -1066 71 V3 2745 -1066 121 COM3 3390 1043

22 RW_WR -1665 -1066 72 V3 2835 -1066 122 COM2 3330 1043

23 E_RD -1575 -1066 73 V2 2925 -1066 123 COM1 3270 1043

24 VDD -1485 -1066 74 V2 3015 -1066 124 COM0 3210 1043

25 DB0 -1395 -1066 75 V1 3105 -1066 125 COMS 3150 1043

26 DB1 -1305 -1066 76 V1 3195 -1066 126 SEG0 3090 1043

27 DB2 -1215 -1066 77 V0 3285 -1066 127 SEG1 3030 1043

28 DB3 -1125 -1066 78 V0 3375 -1066 128 SEG2 2970 1043

29 DB4 -1035 -1066 79 VR 3465 -1066 129 SEG3 2910 1043

30 DB5 -945 -1066 80 VR 3555 -1066 130 SEG4 2850 1043

31 DB6 -855 -1066 81 COM39 4028 -1030 131 SEG5 2790 1043

32 DB7 -765 -1066 82 COM38 4028 -950 132 SEG6 2730 1043

33 VDD -675 -1066 83 COM37 4028 -890 133 SEG7 2670 1043

34 VDD -585 -1066 84 COM36 4028 -830 134 SEG8 2610 1043

35 VDD -495 -1066 85 COM35 4028 -770 135 SEG9 2550 1043

36 VDD -405 -1066 86 COM34 4028 -710 136 SEG10 2490 1043

37 VDD -315 -1066 87 COM33 4028 -650 137 SEG11 2430 1043

38 VCI -225 -1066 88 COM32 4028 -590 138 SEG12 2370 1043

39 VCI -135 -1066 89 COM31 4028 -530 139 SEG13 2310 1043

40 VSS -45 -1066 90 COM30 4028 -470 140 SEG14 2250 1043

41 VSS 45 -1066 91 COM29 4028 -410 141 SEG15 2190 1043

42 VSS 135 -1066 92 COM28 4028 -350 142 SEG16 2130 1043

43 VSS 225 -1066 93 COM27 4028 -290 143 SEG17 2070 1043

44 VSS 315 -1066 94 COM26 4028 -230 144 SEG18 2010 1043

45 VOUT 405 -1066 95 COM25 4028 -170 145 SEG19 1950 1043

46 VOUT 495 -1066 96 COM24 4028 -110 146 SEG20 1890 1043

47 VOUT 585 -1066 97 COM23 4028 -50 147 SEG21 1830 1043

48 VOUT 675 -1066 98 COM22 4028 10 148 SEG22 1770 1043

49 C5+ 765 -1066 99 COM21 4028 70 149 SEG23 1710 1043

5

104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD S6B0718

200

SEG74

-1350

1043

250

COM56

-4028

430

Table 2. Pad Center Coordinates (Continued)

[Unit: µm]

No. Name X Y No. Name X Y No. Name X Y

151 SEG25 1590 1043 201 SEG75 -1410 1043 251 COM57 -4028 370

152 SEG26 1530 1043 202 SEG76 -1470 1043 252 COM58 -4028 310

153 SEG27 1470 1043 203 SEG77 -1530 1043 253 COM59 -4028 250

154 SEG28 1410 1043 204 SEG78 -1590 1043 254 COM60 -4028 190

155 SEG29 1350 1043 205 SEG79 -1650 1043 255 COM61 -4028 130

156 SEG30 1290 1043 206 SEG80 -1710 1043 256 COM62 -4028 70

157 SEG31 1230 1043 207 SEG81 -1770 1043 257 COM63 -4028 10

158 SEG32 1170 1043 208 SEG82 -1830 1043 258 COM64 -4028 -50

159 SEG33 1110 1043 209 SEG83 -1890 1043 259 COM65 -4028 -110

160 SEG34 1050 1043 210 SEG84 -1950 1043 260 COM66 -4028 -170

161 SEG35 990 1043 211 SEG85 -2010 1043 261 COM67 -4028 -230

162 SEG36 930 1043 212 SEG86 -2070 1043 262 COM68 -4028 -290

163 SEG37 870 1043 213 SEG87 -2130 1043 263 COM69 -4028 -350

164 SEG38 810 1043 214 SEG88 -2190 1043 264 COM70 -4028 -410

165 SEG39 750 1043 215 SEG89 -2250 1043 265 COM71 -4028 -470

166 SEG40 690 1043 216 SEG90 -2310 1043 266 COM72 -4028 -530

167 SEG41 630 1043 217 SEG91 -2370 1043 267 COM73 -4028 -590

168 SEG42 570 1043 218 SEG92 -2430 1043 268 COM74 -4028 -650

169 SEG43 510 1043 219 SEG93 -2490 1043 269 COM75 -4028 -710

170 SEG44 450 1043 220 SEG94 -2550 1043 270 COM76 -4028 -770

171 SEG45 390 1043 221 SEG95 -2610 1043 271 COM77 -4028 -830

172 SEG46 330 1043 222 SEG96 -2670 1043 272 COM78 -4028 -890

173 SEG47 270 1043 223 SEG97 -2730 1043 273 COM79 -4028 -950

174 SEG48 210 1043 224 SEG98 -2790 1043 274 COMS1 -4028 -1030

175 SEG49 150 1043 225 SEG99 -2850 1043

176 SEG50 90 1043 226 SEG100 -2910 1043

177 SEG51 30 1043 227 SEG101 -2970 1043

178 SEG52 -30 1043 228 SEG102 -3030 1043

179 SEG53 -90 1043 229 SEG103 -3090 1043

180 SEG54 -150 1043 230 COM40 -3150 1043

181 SEG55 -210 1043 231 COM41 -3210 1043

182 SEG56 -270 1043 232 COM42 -3270 1043

183 SEG57 -330 1043 233 COM43 -3330 1043

184 SEG58 -390 1043 234 COM44 -3390 1043

185 SEG59 -450 1043 235 COM45 -3450 1043

186 SEG60 -510 1043 236 COM46 -3510 1043

187 SEG61 -570 1043 237 COM47 -3570 1043

188 SEG62 -630 1043 238 COM48 -3630 1043

189 SEG63 -690 1043 239 COM49 -3690 1043

190 SEG64 -750 1043 240 COM50 -3750 1043

191 SEG65 -810 1043 241 DUMMY -3830 1043

192 SEG66 -870 1043 242 DUMMY -3910 1043

193 SEG67 -930 1043 243 DUMMY -4028 890

194 SEG68 -990 1043 244 DUMMY -4028 810

195 SEG69 -1050 1043 245 COM51 -4028 730

196 SEG70 -1110 1043 246 COM52 -4028 670

197 SEG71 -1170 1043 247 COM53 -4028 610

198 SEG72 -1230 1043 248 COM54 -4028 550

199 SEG73 -1290 1043 249 COM55 -4028 490

6

S6B0718 104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD

PIN DESCRIPTION

POWER SUPPLY

Table 3. Power Supply Pins

Name I/O Description

VDD Supply Power supply

VSS Supply

V0

V1

V2

V3

V4

I/O

Ground

LCD driver supplies voltages

The voltage determined by LCD pixel is impedance converted by an operational amplifier

for application.

Voltages should have the following relationship;

V0 ≥ V1 ≥ V2 ≥ V3 ≥ V4 ≥ VSS

When the internal power circuit is active, these voltages are generated as following table

according to the state of LCD bias.

LCD bias

1/N bias

NOTE: N = 4 to 11

V1

(N-1) / N x V0

V2 V3 V4

(N-2) / N x V0 (2/N) x V0 (1/N) x V0

LCD DRIVER SUPPLY

Table 4. LCD Driver Supply Pins

Name I/O Description

C1- O Capacitor 1 negative connection pin for voltage converter

C1+ O Capacitor 1 positive connection pin for voltage converter

C2- O Capacitor 2 negative connection pin for voltage converter

C2+ O Capacitor 2 positive connection pin for voltage converter

C3+ O Capacitor 3 positive connection pin for voltage converter

C4+ O Capacitor 4 positive connection pin for voltage converter

C5+ O Capacitor 5 positive connection pin for voltage converter

VOUT I/O Voltage converter input / output pin

VCI I

VR I

REF I

VEXT I

Voltage converter input voltage pin

Voltages should have the following relationship: VDD ≤ VCI ≤ V0

V0 voltage adjustment pin

It is valid only when on-chip resistors are not used (INTRS = "L")

Selects the external VREF voltage via VEXT pin

− REF = "L": using the external VREF

− REF = "H": using the internal VREF

Externally input reference voltage (VREF) for the internal voltage regulator

It is valid only when REF is "L".

7

104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD S6B0718

SYSTEM CONTROL

Table 5. System Control Pins

Name I/O Description

Master / slave operations select pin

− MS = "H": master operation

− MS = "L": slave operation

The following table depends on the MS status.

MS I

CL I/O

SYNC I/O

M I/O

FR O

FRS O

INTRS I

HPMB I

TEST1

to

TEST3

MS

H Enabled Enabled Output Output Output

L Disabled Disabled Input Input Input

Display clock input / output pin

When the S6B0718 is used in master/slave mode (Multi-chip), the CL pins must be

connected each other.

Display sync input / output pin

When the S6B0718 is used in master/slave mode (Multi-chip), the SYNC pins must be

connected each other.

LCD AC signals input / output pin

When the S6B0718 is used in master/slave mode (Multi-chip), the M pins must be

connected each other.

Static driver common output pin

This pin is used together with the FRS pin.

Static driver segment output pin

This pin is used together with the FR pin.

Internal resistors select pin

This pin selects the resistors for adjusting V0 voltage level.

− INTRS = "H": use the internal resistors

− INTRS = "L": use the external resistors

VR pin and external resistive divider control V0 voltage.

Power control pin of the power supplies circuit for LCD driver

− HPMB = "L": high power mode

− HPMB = "H": normal mode

This pin is valid in master operation.

Test pins

I

Don’ t use these pins.

Internal analog circuits Display timing signals

Oscillator Power supply CL SYNC M

8

S6B0718 104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD

MICROPROCESSOR INTERFACE

Table 6. Microprocessor Interface Pins

Name I/O Description

RESETB I

PS I

C68 I

CS1B

CS2

RS I

RW_WR I

Reset the input pin

When RESETB is "L", initialization is executed.

Parallel/Serial data input select input

PS

H Parallel RS DB0 to DB7

L Serial RS SID(DB7) Write only SCLK(DB6)

*NOTE: When PS is "L", DB0 to DB5 are high impedance and E_RD and RW_WR

must be fixed to either "H" or "L".

Microprocessor interface select input pin

− C68 = "H": 6800-series MPU interface

− C68 = "L": 8080-series MPU interface

Chip select input pins

Data/instruction I/O is enabled only when CS1B is "L" and CS2 is "H". When chip

I

select is non-active, DB0 to DB7 may be high impedance.

Register select input pin

− RS = "H": DB0 to DB7 are display data

− RS = "L": DB0 to DB7 are control data

Read / Write execution control pin

C68 MPU Type RW_WR Description

H 6800-series RW

L 8080-series /WR

Interface

Mode

Data/

Instruction

Data Read / Write Serial Clock

E_RD

RW_WR

Read/Write control input pin

− RW = "H": read

− RW = "L": write

Write enable clock input pin

The data on DB0 to DB7 are latched at the rising

edge of the /WR signal.

-

9

104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD S6B0718

Table 6 (Continued)

Name I/O Description

Read / Write execution control pin

C68 MPU Type E_RD Description

Read/Write control input pin

− RW = "H": When E is "H", DB0 to DB7 are in an

E_RD I

H 6800-series E

output status.

− RW = "L": The data on DB0 to DB7 are latched at

the falling edge of the E signal.

DB0

to

DB7

I/O

L 8080-series /RD

Read enable clock input pin

When /RD is "L", DB0 to DB7 are in an output status.

8-bit bi-directional data bus that is connected to the standard 8-bit microprocessor data

bus. When the serial interface selected (PS = "L");

− DB0 to DB5: high impedance

− DB6: serial input clock (SCLK)

− DB7: serial input data (SID)

When chip select is not active, DB0 to DB7 may be high impedance.

10

S6B0718 104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD

LCD DRIVER OUTPUTS

Table 7. LCD Driver Outputs Pins

Name I/O Description

LCD segment driver outputs

The display data and the M signal control the output voltage of segment driver.

SEG0

to

SEG103

COM0

to

COM79

COMS

(COMS1)

Display data M

H H V0 V2

O

LCD common driver outputs

The internal scanning data and M signal control the output voltage of common driver.

O

O

Common output for the icons

The output signals of two pins are same. When not used, these pins should be left open.

H L VSS V3

L H V2 V0

L L V3 VSS

Power save mode VSS VSS

Scan data M Common driver output voltage

H H VSS

H L V0

L H V1

L L V4

Power save mode VSS

Segment driver output voltage

Normal display Reverse display

NOTE: DUMMY – These pins should be opened (floated).

11

104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD S6B0718

FUNCTIONAL DESCRIPTION

MICROPROCESSOR INTERFACE

Chip Select Input

There are CS1B and CS2 pins for chip selection. The S6B0718 can interface with an MPU only when CS1B is "L"

and CS2 is "H". When these pins are set to any other combination, RS, E_RD, and RW_WR inputs are disabled and

DB0 to DB7 are to be high impedance. And, in case of serial interface, the internal shift register and the counter are

reset.

Parallel / Serial Interface

S6B0718 has three types of interface with an MPU, which are one serial and two parallel interface. This parallel or

serial interface is determined by PS pin as shown in table 8

Table 8. Parallel / Serial Interface Mode

PS Type CS1B CS2 C68 Interface mode

H Parallel CS1B CS2

L Serial CS1B CS2

Parallel Interface (PS = "H")

The 8-bit bi-directional data bus is used in parallel interface and the type of MPU is selected by C68 as shown in

Table 9. The type of data transfer is determined by signals at RS, E_RD and RW_WR as shown in table 10.

Table 9. Microprocessor Selection for Parallel Interface

C68 CS1B CS2 RS E_RD RW_WR DB0 to DB7 MPU bus

H CS1B CS2 RS E RW DB0 to DB7 6800-series

L CS1B CS2 RS /RD /WR DB0 to DB7 8080-series

Table 10. Parallel Data Transfer

Common 6800-series 8080-series Description

RS

E_RD

(E)

RW_WR

(RW)

E_RD

(/RD)

RW_WR

(/WR)

H 6800-series MPU mode

L 8080-series MPU mode

*×

Serial-mode

*×: Don't care

H H H L H Display data read out

H H L H L Display data write

L H H L H Register status read

L H L H L Writes to internal register (instruction)

12

S6B0718 104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD

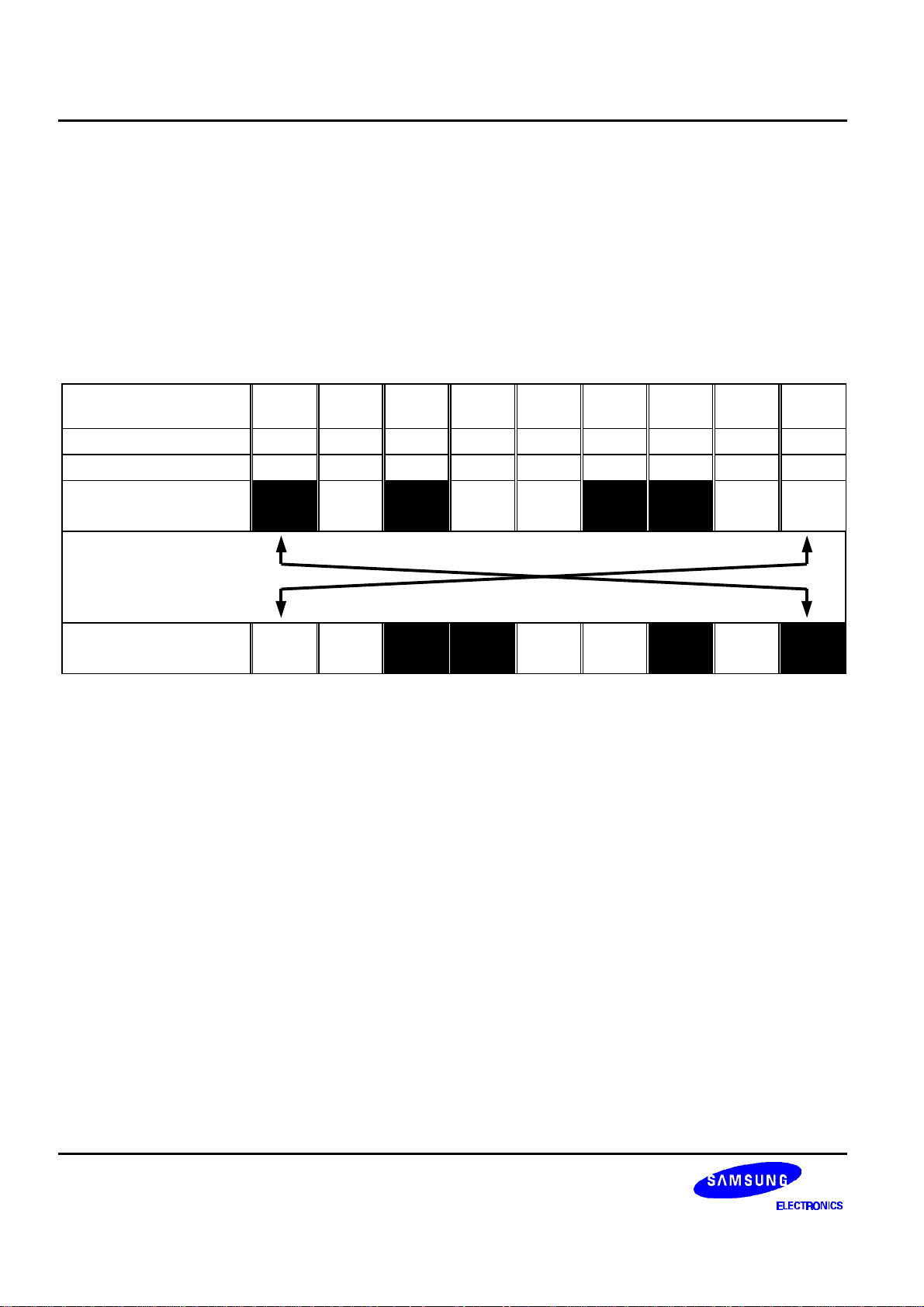

Serial Interface (PS = "L")

When the S6B0718 is active, serial data (DB7) and serial clock (DB6) inputs are enabled. And not active, the internal

8-bit shift register and the 3-bit counter are reset. Serial data can be read on the rising edge of serial clock going into

DB6 and processed as 8-bit parallel data on the eighth serial clock. Serial data input is display data when RS is high

and control data when RS is low. Since the clock signal (DB6) is easy to be affected by the external noise caused by

the line length, the operation check on the actual machine is recommended.

CS1B

CS2

SID

SCLK

RS

DB6DB7DB0DB1DB2DB3DB4DB5DB6DB7

Figure 3. Serial Interface Timing

Busy Flag

The Busy Flag indicates whether the S6B0718 is operating or not. When DB7 is "H" in read status operation, this

device is in busy status and will accept only read status instruction. If the cycle time is correct, the microprocessor

needs not to check this flag before each instruction, which improves the MPU performance.

13

104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD S6B0718

D(N)

D(N+1)

D(N+2)

N

N+1

N+2

N+3

Data Transfer

The S6B0718 uses bus holder and internal data bus for Data Transfer with the MPU. When writing data from the

MPU to on-chip RAM, data is automatically transferred from the bus holder to the RAM as shown in figure 4. And

when reading data from on-chip RAM to the MPU, the data for the initial read cycle is stored in the bus holder

(dummy read) and the MPU reads this stored data from bus holder for the next data read cycle as shown in figure 5.

This means that a dummy read cycle must be inserted between each pair of address sets when a sequence of

address sets is executed. Therefore, the data of the specified address cannot be output with the read display data

instruction right after the address sets, but can be output at the second read of data.

MPU signals

RS

/WR

DB0 to DB7

Internal signals

/WR

BUS HOLDER

COLUMN ADDRESS

MPU signals

RS

/WR

/RD

DB0 to DB7

Internal signals

/WR

N D(N) D(N+1) D(N+2) D(N+3)

N D(N) D(N+1) D(N+2) D(N+3)

N N+1 N+2 N+3

Figure 4. Write Timing

N

Dummy D(N) D(N+1)

14

/RD

BUS HOLDER

COLUMN ADDRESS

N

Figure 5. Read Timing

S6B0718 104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD

- -

- -

- -

- -

001

- -

0

011

- -

0

101

- -

0

000

- -

1

DISPLAY DATA RAM (DDRAM)

The Display Data RAM stores pixel data for the LCD. It is 89-row by 104-column addressable array. Each pixel can

be selected when the page and column addresses are specified. The 89 rows are divided into 11 pages of 8 lines

and the 12th page with a single line (DB0 only). Data is read from or written to the 8 lines of each page directly

through DB0 to DB7. The display data of DB0 to DB7 from the microprocessor correspond to the LCD common lines

as shown in figure 6. The microprocessor can read from and write to RAM through the I/O buffer. Since the LCD

controller operates independently, data can be written into RAM at the same time as data is being displayed without

causing the LCD flicker.

DB0

DB1

DB2

DB3

DB4

1 0 0 - - 1

COM0

COM1

COM2

COM3

COM4

- -

Display Data RAM LCD Display

Figure 6. RAM-to-LCD Data Transfer

Page Address Circuit

This circuit is for providing a Page Address to Display Data RAM shown in figure 8. It incorporates 4-bit Page

Address register changed by only the "Set Page" instruction. Page Address 11 (DB3, DB1 and DB0 are "H", DB2 is

"L") is a special RAM area for the icons and display data DB0 is only valid.

Line Address Circuit

This circuit assigns DDRAM a Line Address corresponding to the first line (COM0) of the display. Therefore, by

setting line address repeatedly, it is possible to realize the screen scrolling and page switching without changing the

contents of on-chip RAM as shown in figure 8 & figure 9. It incorporates 7-bit Line Address register changed by only

the initial display line instruction and 7-bit counter circuit. At the beginning of each LCD frame, the contents of

register are copied to the line counter which is increased by CL signal and generates the Line Address for

transferring the 104-bit RAM data to the display data latch circuit. However, display data of icons are not scrolled

because the MPU can not access Line Address of icons.

15

104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD S6B0718

Column Address Circuit

Column address circuit has a 7-bit preset counter that provides column address to the Display Data RAM as shown

in figure 8. When set Column Address MSB / LSB instruction is issued, 7-bit [Y6:Y0] is updated. And, since this

address is increased by 1 each a read or write data instruction, microprocessor can access the display data

continuously. However, the counter is not incremented and locked if a non-existing address above 67H. It is

unlocked if a Column Address is set again by set Column Address MSB / LSB instruction. And the Column Address

counter is independent of page address register.

ADC Select instruction makes it possible to invert the relationship between the column address and the segment

outputs. It is necessary to rewrite the display data on built-in RAM after issuing ADC Select instruction. Refer to the

following figure 7.

SEG output

SEG

0

SEG

1

SEG

2

SEG

3

... ...

SEG

100

SEG

101

SEG

102

SEG

103

Column address [Y6:Y0] 00H 01H 02H 03H ... ... 64H 65H 66H 67H

Display data 1 0 1 0 1 1 0 0

LCD panel display

... ...

( ADC = 0 )

LCD panel display

( ADC = 1 )

... ...

Figure 7. The Relationship between the Column Address and the Segment Outputs

Segment Control Circuit

This circuit controls the display data by the Display ON / OFF, reverse display ON / OFF and entire display ON / OFF

instructions without changing the data in the display data RAM.

16

S6B0718 104 SEG / 81 COM DRIVER & CONTROLLER FOR STN LCD

Page Address

DB3 DB0DB1DB2

0 0 0 0

0 0 0 1

0 0 1 0

0 0 1 1

0 1 1 1

1 0 0 0

1 0 0 1

1 0 1 0

1 0 1 1

Column

Address

LCD Output

Data

ADC=0

ADC=1

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB0

00

01 02 03 04 05 62 63 64 65 66 67

SEG1

SEG0

SEG2

SEG3

SEG4

SEG5

Page 0

Page 1

Page 2

Page 3

Page7

Page8

Page9

Page10

Page 11

- - - - -

- - - - -

- - - - -

SEG99

SEG98

SEG100

SEG101

00

0102030405626364656667

SEG103

SEG102

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

40H

41H

42H

43H

44H

45H

46H

47H

48H

49H

4AH

4BH

4CH

4DH

4EH

4FH

50H

51H

52H

53H

54H

55H

56H

57H

register = 00H

1/81

When Initial line address = 00H

Initial line

Duty

1/73

Duty

COM

Output

COM0

COM1

COM2

COM3

COM4

COM5

COM6

COM7

COM8

COM9

COM10

COM11

COM12

COM13

COM14

COM15

COM16

COM17

COM18

COM19

COM20

COM21

COM22

COM23

COM24

COM25

COM26

COM27

COM28

COM29

COM30

COM31

COM56

COM57

COM58

COM59

COM60

COM61

COM62

COM63

COM64

COM65

COM66

COM67

COM68

COM69

COM70

COM71

COM72

COM73

COM74

COM75

COM76

COM77

COM78

COM79

COMS

Figure 8. Display Data RAM Map (Initial Line Address = 00H)

17

Loading...

Loading...