Samsung WS32Z30HP, WS32Z40HT, CW29Z308T, S63B Schematic

1. Make sure all protective devices are properly installed

including non-metallic handles and compartment covers

when installing or re-installing the chassis or chassis

assemblies.

2. Make sure that no gaps exist between the cabinets for

children to insert their fingers in to prevent children from

receiving electric shocks. Gaps mentioned above include

ventilation holes of a too great magnitude between the

vaccum tube and the cabinet mask, and the improper

installation of the rear cabinet.

Errors may occur when the resistance is below 1.0 ㏁ or

over 5.2 ㏁.

In these cases, make sure that the device is repaired

before sending it back to the customer.

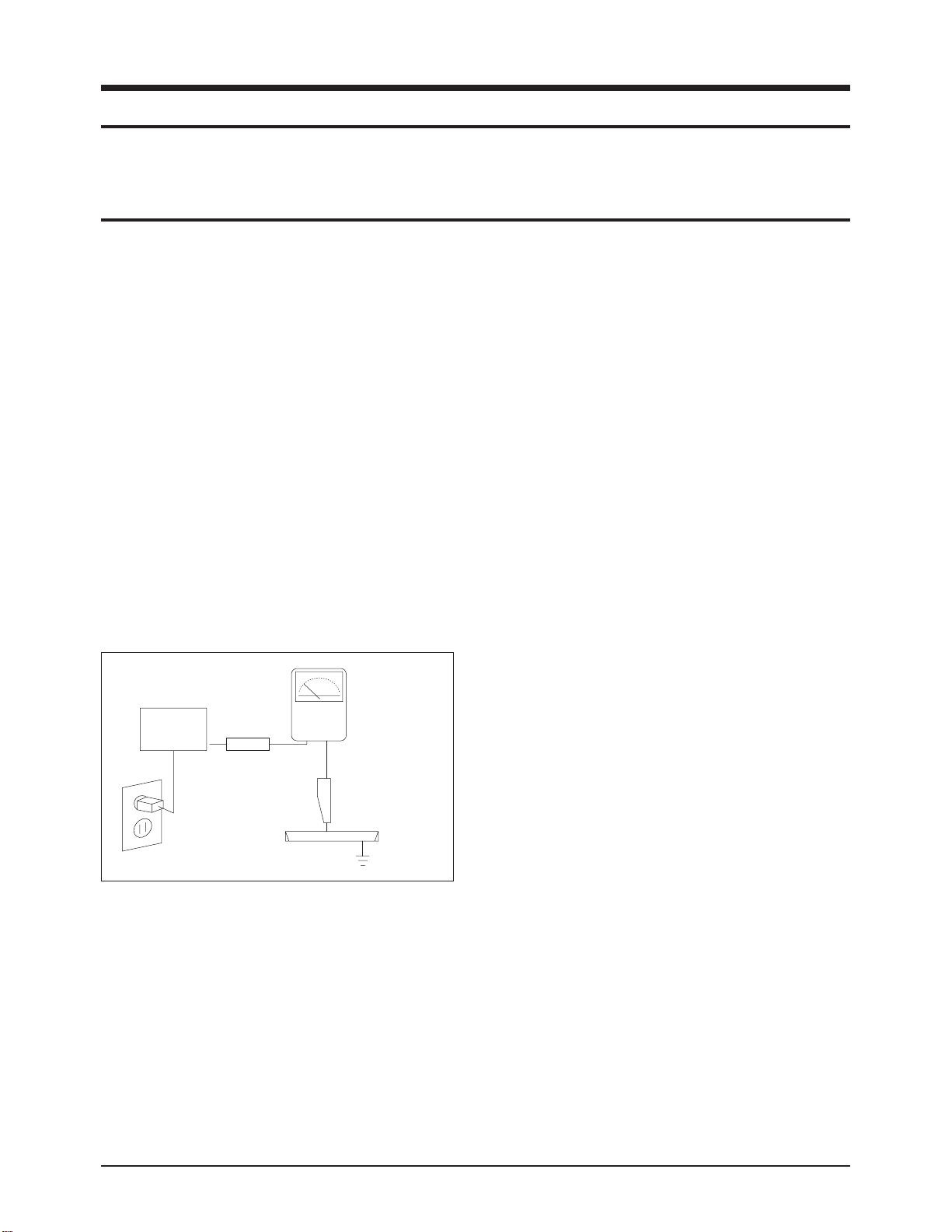

3. Check for Electricity Leakage (Figure 1-1)

Warning: Do not use an insulated transistor for checking

the leakage. Use only those current leakage testers or

mirroring systems that comply with ANSIC 101.1 and the

Underwriter Laboratory's specifications (UL1410, 59.7).

Fig. 1-1 AC Leakage Test

4. A high voltage is maintained within the specified limits

using safety parts, calibration and tolerances. When

voltage exceeds the specified limits, check each special

part.

5. Warning for Engineering Changes:

Never make any changes or additions to the circuit

design or the internal part for this product.

Ex: Do not add any audio or video accessory

connectors. This might cause physical damage.

Furthermore, any changes or additions to the original

design/engineering will invalidate the warranty.

6. Warning - Hot Chassis:

Some TV chassis are directly connected to one end of

the AC power cord for electrical reasons.

Without insulated transistors, the product can only be

repaired safely when the chassis is connected to the

earthed end of the AC power source.

To make sure the AC power cord is properly connected,

follow the instructions below. Use the voltmeter to

measure the voltage between the chassis and the

earthed ground. If the measurement is over 1.0V, unplug

the AC power cord and change the polarity before reinserting it. Measure the voltage between the chassis

and the ground again.

7. Some TV chassis are shipped with an additional

secondary grounding system. The secondary system is

adjacent to the AC power line. These two grounding

systems are separated in the circuit using an

unbreakable/unchangeable insulation material.

8. When any parts, material or wiring appear overheated or

damaged, replace them with new regular ones

immediately. When any damage or overheating is

detected, correct this immediately and make a regular

check of possible errors.

9. Check for the original shape of the lead, especially that

of the antenna wiring, any sharp edges, the AC power

and the high voltage power. Carefully check if the wiring

is too tight, incorrectly placed or loose. Never change the

space between the part and the printed circuit board.

Check the AC power cord for possible damages. Keep

the part or the lead away from any heat-emitting

materials.

Precaution

Samsung Electronics 1-1

To avoid possible damages or electric shocks or exposure to radiation, follow the instructions below with regard to safety,

installation, service and ESD..

1. Precaution

1-1 Safety Precautions

(READING SHOULD

DEVICE

UNDER

TEST

EXPOSED METAL

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

TEST ALL

SURFACES

LEAKAGE

CURRENT

TESTER

NOT BE ABOVE

0.5mA)

EARTH

GROUND

10. Safety Indication:

Some electrical circuits or device related materials

require special attention to their safety features, which

cannot be viewed by the naked eye. If an original part is

replaced with another irregular one, the safety or

protective features will be lost even if the new one has a

higher voltage or more watts.

Critical safety parts should be bracketed with ( ).

Use only regular parts for replacements (in particular,

flame resistance and dielectric strength specifications).

Irregular parts or materials may cause electric shock or

fire.

Precaution

1-2 Samsung Electronics

!

1. The service instructions are printed on the cabinet, and

should be followed by any service personnel.

2. Make sure to unplug the AC power cord from the power

source before starting any repairs.

(a) Remove or re-install parts or assemblies.

(b) Disconnect the electric plug or connector, if any.

(c) Connect the test part in parallel with the electrolytic

capacitor.

3. Some parts are placed at a higher position than the

printed board. Insulated tubes or tapes are used for this

purpose. The internal wiring is clamped using buckles to

avoid contact with heat emitting parts. These parts are

installed back to their original position.

4. After the repair, make sure to check if the screws, parts

or cables are properly installed. Make sure no damage is

caused to the repaired part and its surroundings.

5. Check for insulation between the blade of the AC plug

and that of any conductive materials (i.e. the metal

panel, input terminal, earphone jack, etc).

6. Insulation Check Process: Unplug the power cord from

the AC source and turn the switch on. Connect the insulating resistance meter (500v) to the AC plug blade.

The insulating resistance between the blade of the AC

plug and that of the conductive material should be more

than 1 ㏁.

7. Any B+ interlock should not be damaged.

If the metal heat sink is not properly installed, no

connection to the AC power should be made.

8. Make sure the grounding lead of the tester is connected

to the chassis ground before connecting to the positive

lead. The ground lead of the tester should be removed

last.

9. Beware of risks of any current leakage coming into

contact with the high-capacity capacitor.

10. The sharp edges of the metal material may cause

physical damage, so ensure wearing protective gloves

during the repair.

Precaution

Samsung Electronics 1-3

Warning 1: First carefully read the "Safety Instruction" in this service manual.

When there is a conflict between the service and the safety instructions, follow the safety instruction at all times.

Warning 2: Any electrolytic capacitor with the wrong polarity will explode.

1-2 Servicing Precautions

1-3 Static Electricity Precautions

1. Some semi-conductive ("solid state") devices are

vulnerable to static electricity. These devices are known

as ESD. ESD includes the integrated circuit and the field

effect transistor. To avoid any materials damage from

electrostatic shock, follow the instructions described

below.

2. Remove any static electricity from your body by

connecting the earth ground before handling any

semi-conductive parts or ass'ys. Alternatively, wear a

dischargeable wrist-belt.

(Make sure to remove any static electricity before

connecting the power source - this is a safety instruction

for avoiding electric shock)

3. Remove the ESD ass'y and place it on a conductive

surface such as aluminum foil to prevent accumulating

static electricity.

4. Do not use any Freon-based chemicals.

Such chemicals will generate static electricity that

causes damage to the ESD.

5. Use only grounded-tip irons for soldering purposes.

6. Use only anti-static solder removal devices.

Most solder removal devices do not support an

anti-static feature. A solder removal device without an

anti-static feature can store enough static electricity to

cause damage to the ESD.

7. Do not remove the ESD from the protective box until the

replacement is ready. Most ESD replacements are

covered with lead, which will cause a short to the entire

unit due to the conductive foam, aluminum foil or other

conductive materials.

8. Remove the protective material from the ESD

replacement lead immediately after connecting it to the

chassis or circuit ass'y.

9. Take extreme caution in handling any uncovered ESD

replacements. Actions such as brushing clothes or lifting

your leg from the carpet floor can generate enough static

electricity to damage the ESD.

Precaution

1-4 Samsung Electronics

CAUTION

These servicing instructions are for use by

qualified service personnel only.

To reduce the risk of electric shock do not

perform any servicing other than that contained in the

operating instructions unless you are qualified to do so.

Precaution

Samsung Electronics 1-5

1-4 Installation Precautions

1. For safety reasons, more than two people are required

for carrying the product..

2. Keep the power cord away from any heat emitting

devices, as a melted covering may cause fire or electric

shock.

3. Do not place the projector in areas with poor ventilation

such as a bookshelf or closet. The increased internal

temperature may cause fire.

4. Bend the external antenna cable when connecting it to

the product. This is a measure to protect it from being

exposed to moisture. Otherwise, it may cause a fire or

electric shock.

5. Make sure to turn the power off and unplug the power

cord from the outlet before removing the product. Also

check the antenna cable or the external connectors if

they are fully unplugged. Damage to the cord may cause

fire or electric shock.

6. Keep the antenna far away from any high-voltage cables

and install it firmly. Contacting the high-voltage cable or

the antenna falling over may cause fire or electric shock.

7. When connecting the RF antenna, check for a DTV

receiving system and install a separate DTV reception

antenna for areas with no DTV signal.

8. Check the basics of the screen test.

- Image position/size, Tilt adjustment

1-6 Samsung Electronics

MEMO

Product Specification

Samsung Electronics 2-1

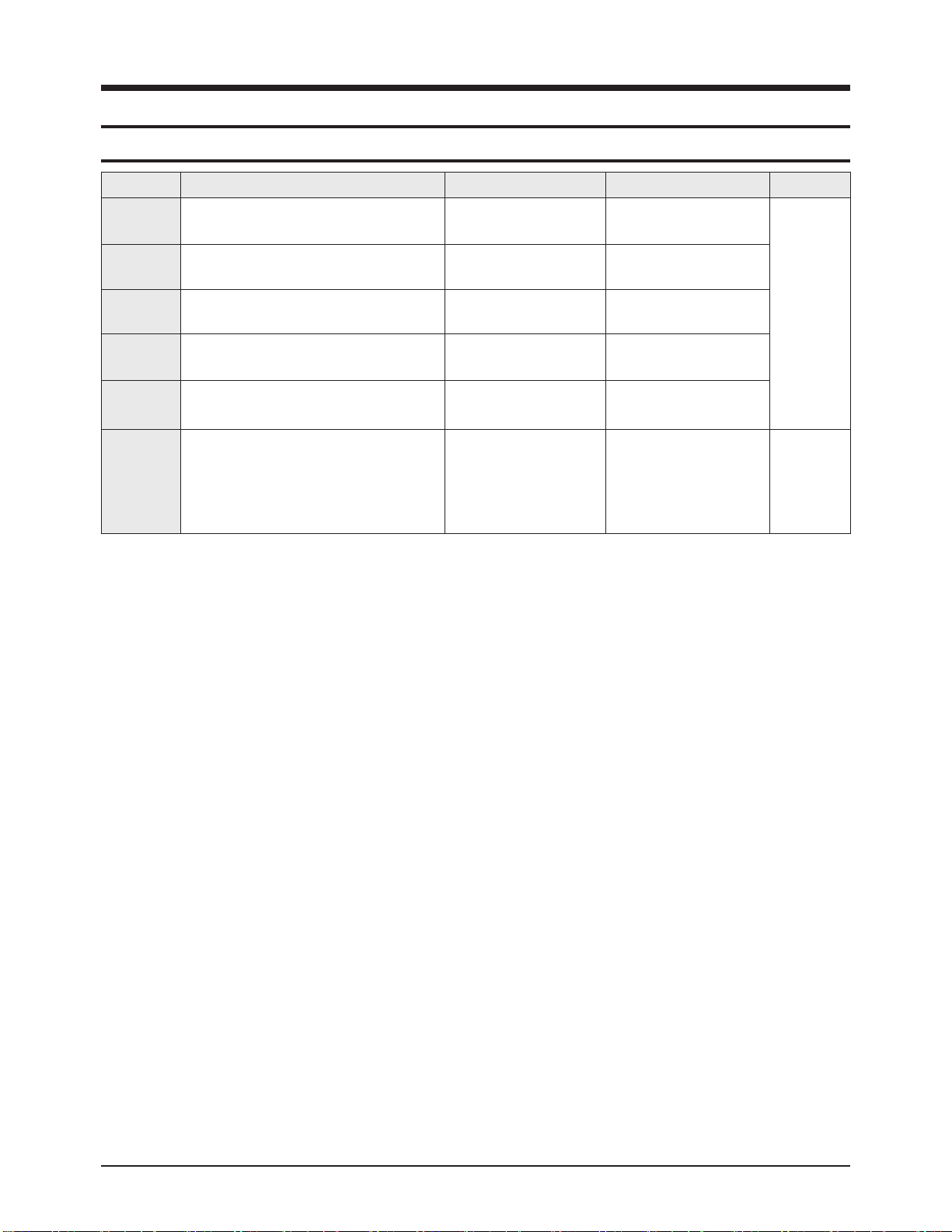

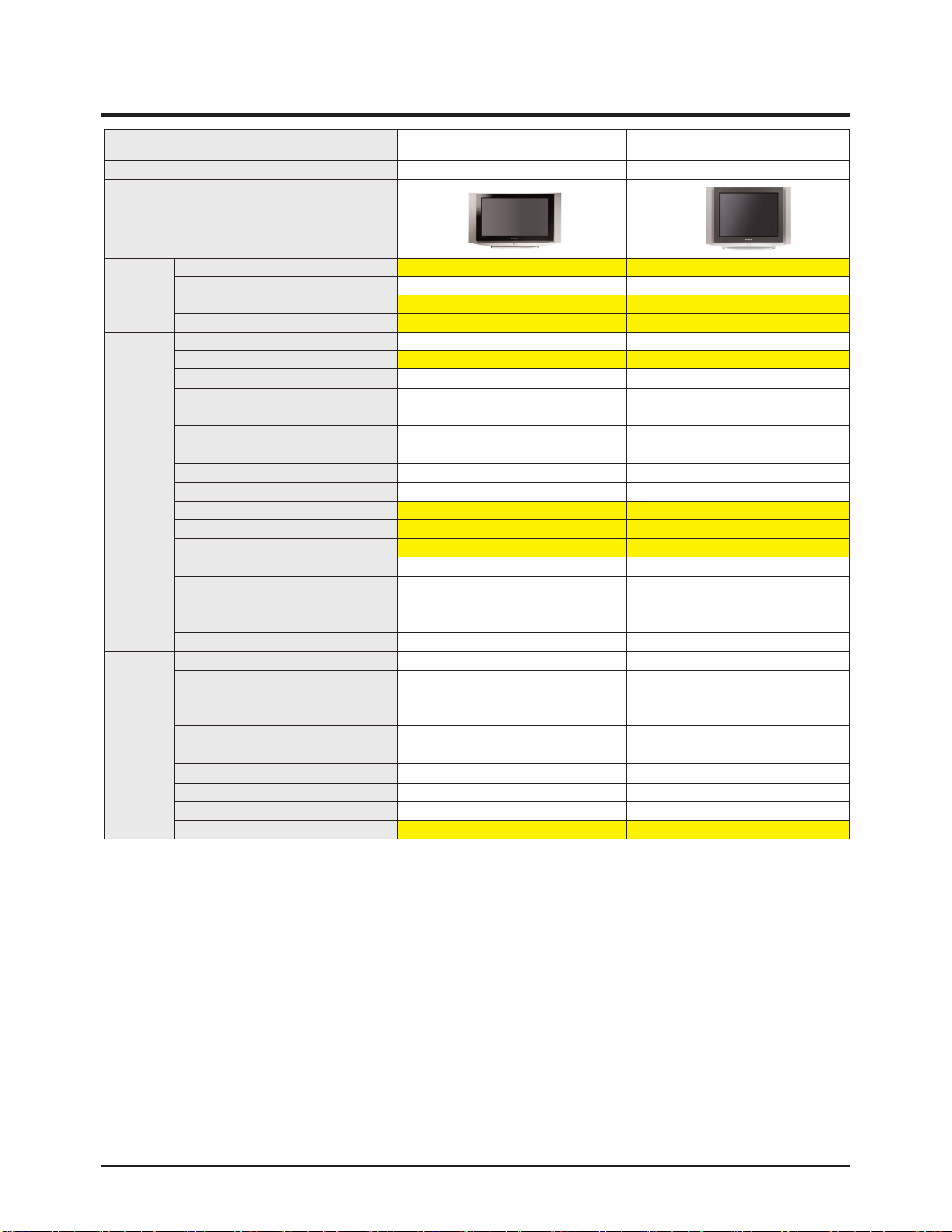

2. Product Specification

2-1 Product Features

Block Specfication EU East asia/CIS Remark

CRT

- Slimmer than existing CRTs

Existing: 495mm → Slimfit : 365mm

Vixlim CRT Vixlim CRT

RF Part - Same as for the OZ(S62A) Model TMQZ2-402A, PAL-CW TMQZ2-401A, PAL-CS

Power

- Input Voltage : AC 160~300V

- Stand-By : Less than 3W

STR-X6750 STR-X6750

Video

- PAL/SECAM/NT4.43/NT3.58

- Progressive 100Hz(Full 100Hz)

VCT69xyP

CXA2165

VCT69xyP

CXA2165

Audio

- Output : 10W x 2

- Function : SRS-TRUSURROUND

VCT69xyP VCT69xyP

Cabinet

- New Front and Back Cabinets

- 184mm of saved space compared to

the existing model

A11:580mm → Z40:396mm

Z30 Design Applied

FPTV Looking Design

Black Bezel 2Tone

Color Design

Z30(OZ) Design Applied

FPTV Looking Design

Black Bezel 2Tone

Color Design

■ Core Parts Functions

- VCT69xyP : RF-CVBS,EXT-CVBS,FRONT Y,C,SCART1 R/G/B input and Video Signal Processing.

Provides S-IF Analog audio And Digital audio signal input and decoding functions.

I2C-Comunication,Master Control Micom, Rom Micom

- CXA2165 : H-out,VD-P,VD-N,RGB output,Video and Deflection Signal Processing.

- MST3383M : HDMI decoding Functions

- TW9906 : PIP Processor

Product Specification

2-2 Samsung Electronics

2-2 Key Features

Model

WS32Z40 / CW29Z40

(Europe)

WS32Z40 / CW29Z40 / CS29Z40

WS32Z30 / CW29Z30 (CIS)

Voltage AC230V 160~300V

Frequency of Operation 50/60 Hz 50/60 Hz

Dimensions(mm)

934X399X568 (32")

796X421X593 (29")

934X399X568 (32")

796X421X593 (29")

Weight

54.5Kg (32")

43.0Kg (29")

54.5Kg (32")

43.0Kg (29")

■ H/W Configuration

- Slimfit(Low Depth) CRT adopted

- Progressive 100Hz (Full 100Hz)

■ S/W Configuration

- Multi System PAL/SECAM(CIS Option:NTSC4.43/NTSC3.58)

- ATS, Auto Wide, Pre Channel, On/Off Timer, Zoom, Blue Screen

■ Picture

- System

Video : PAL/SECAM/ NTSC3.58(CIS Option)

Sound : B/G, D/K, I, L/L', M(CIS Option)

- Black Level expansion, CTI, VM, Dynamic focus

- AKB(Auto kinetic Bias)

- Still picture, Digital Noise reduction

- PIP (2Tuner) : Option

- Auto Wide

■ Sound

- System : A2+Niacam Stereo, SRS Trusurround

- Output : 10W+10W

- Speaker : 2EA

- AVL, Melody, Auto Stereo, Auto Mute, Equalize

■ In/Out Terminals

- Side : 1 CVBS Input, 1 S-Video Input, Sound L/R

- Rear : 2 Scart, 1 Component(480i/480P/576i/576P/720P/1080i/1080P 50Hz/60Hz), 1 HDMI Input(Option)

■ Remocon : TM86

■ Power Supply

- Europe(230V), CIS(160V- 300V)

■ Power Consumption

- Stand-by : 3W

- Max Power : 180W

Product Specification

Samsung Electronics 2-3

2-3 Specifications Analysis

Model WS32Z30/CW29Z30 CW-29Z338T

Chassis S62B S63B

Design

Basic

Product Type Slimfit CRT Slimfit CRT

Digital Display - -

Screen Size 32 / 29 inch 29 inch

Aspect Ratio 16:9 / 4:3 4:3

Visual Quality

Digital Comb Filter -

O

Screen Pitch 0.73 0.73

AKB

O O

Digital Noise Reduction

O O

DNIe - -

3:2 Pull Down Support - -

Audio

Base/Treble/Balance - -

Equalizer 5 Band 5 Band

AVL

O O

Surround SRS-WOW SRS-TRUSURROUND

Speaker System Direct Direct

Speaker Output 10W + 10W 10W + 10W

Function

Dual Screen Function - -

Double Screen - -

TTX 10page/200page(Option) 750page(Option)

Still Picture

O O

Auto Jack Recognition - -

Ports

Antenna In Rear : 1 Rear : 1

External In Rear:2, Side:1 Rear:2, Side:1

S-Video Side : 1 Side : 1

Y/Pb/Pr - Rear : 1

PC - -

DVI - -

HDMI - -

Digital Audio Out - -

Video Out Rear : 1 Rear : 1

Audio Out - -

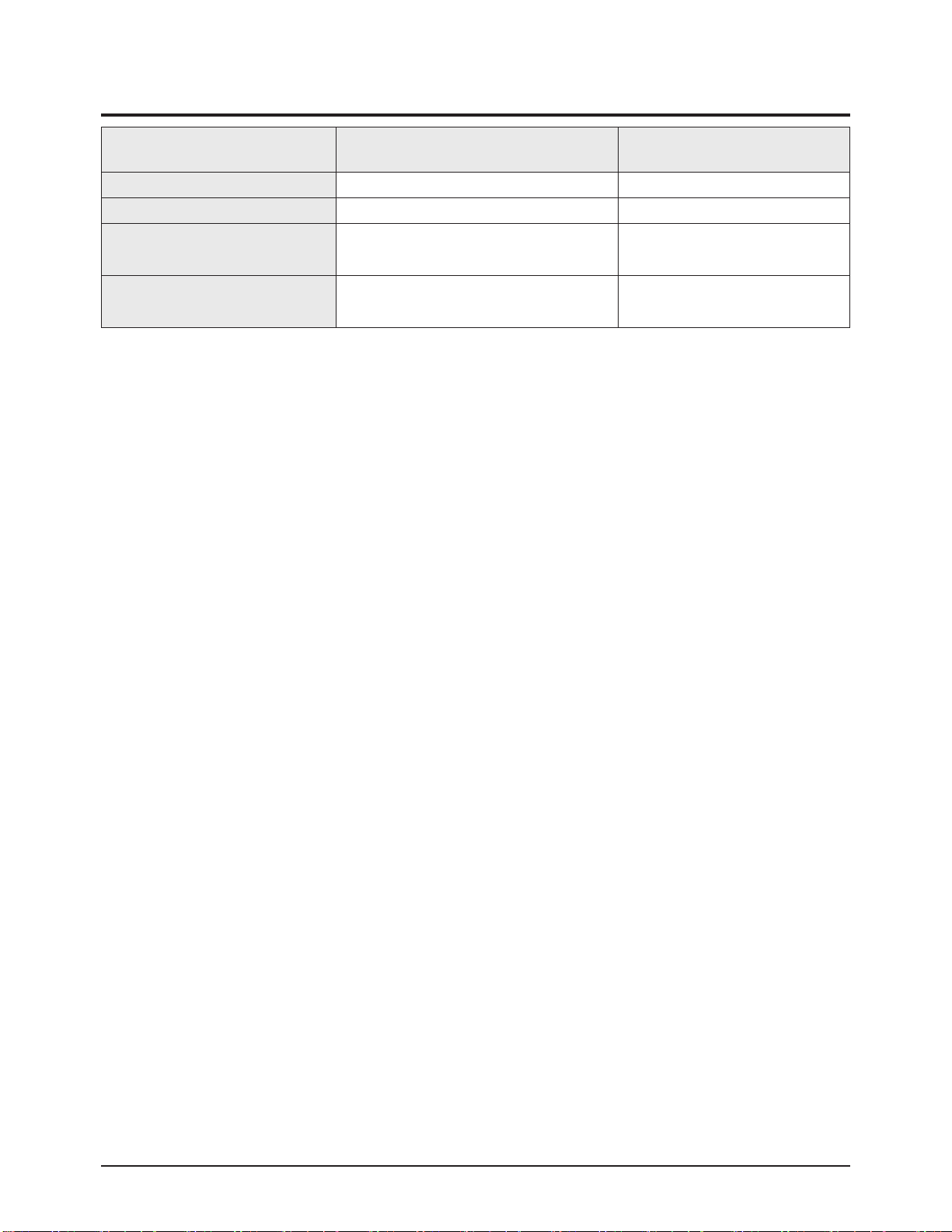

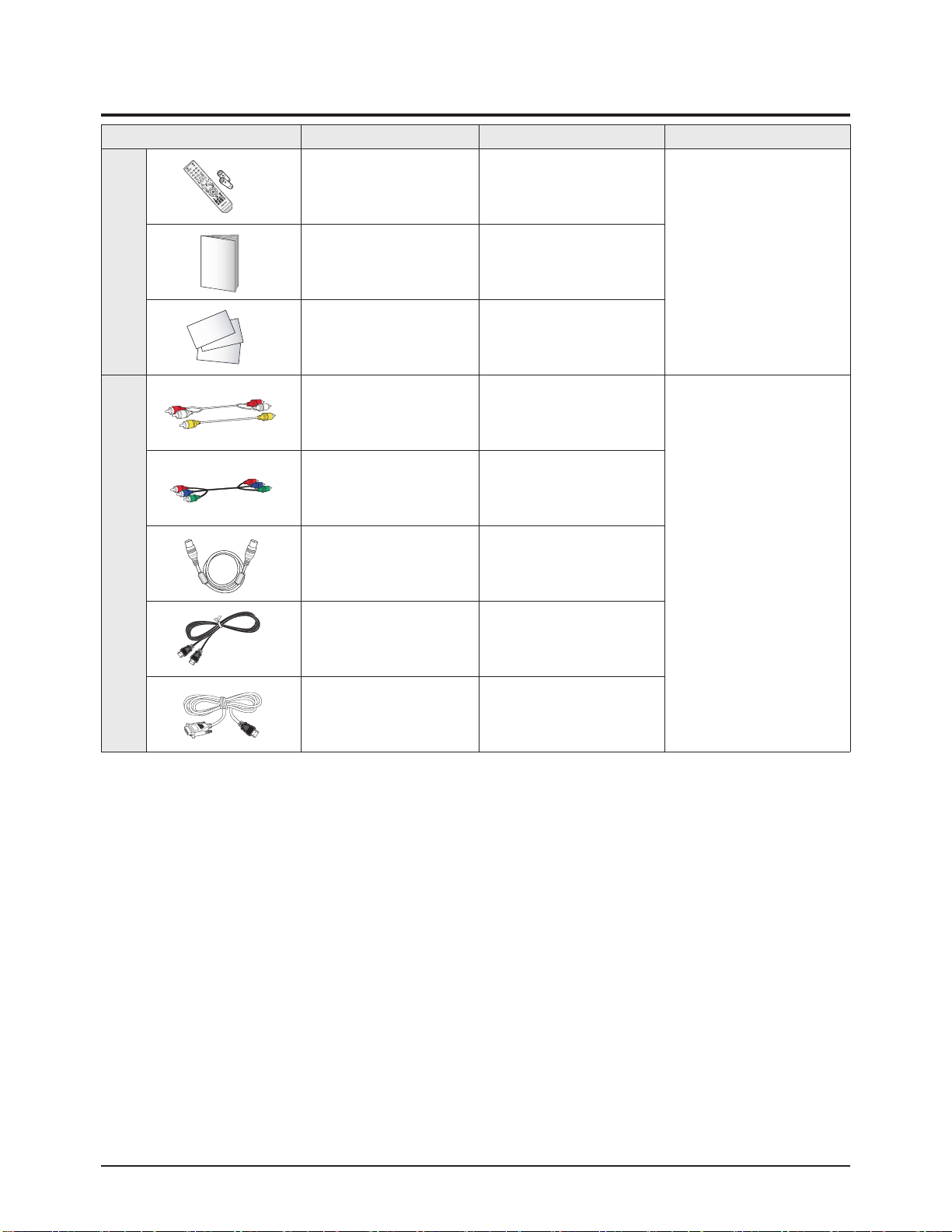

2-4 Accessories

Accessories Item Item code Remark

Supplied Accessories

Remote Control

Batteries

AA59-00382A

4301-000121

Samsung Service centerOwner's Instructions AA68-03784A

Warranty Card

Registration Card

Safety Guide Manual

BN68-00514D

AA68-03575D

AA68-03242E

Accessories that can be

purchased additionally

Video Cable

Audio Cable

-

Internet shopping mall

Component Cable(RCA) -

Antenna Cable -

HDMI Cable -

HDMI/DVI Cable -

Product Specification

2-4 Samsung Electronics

Alignment & Adjustment

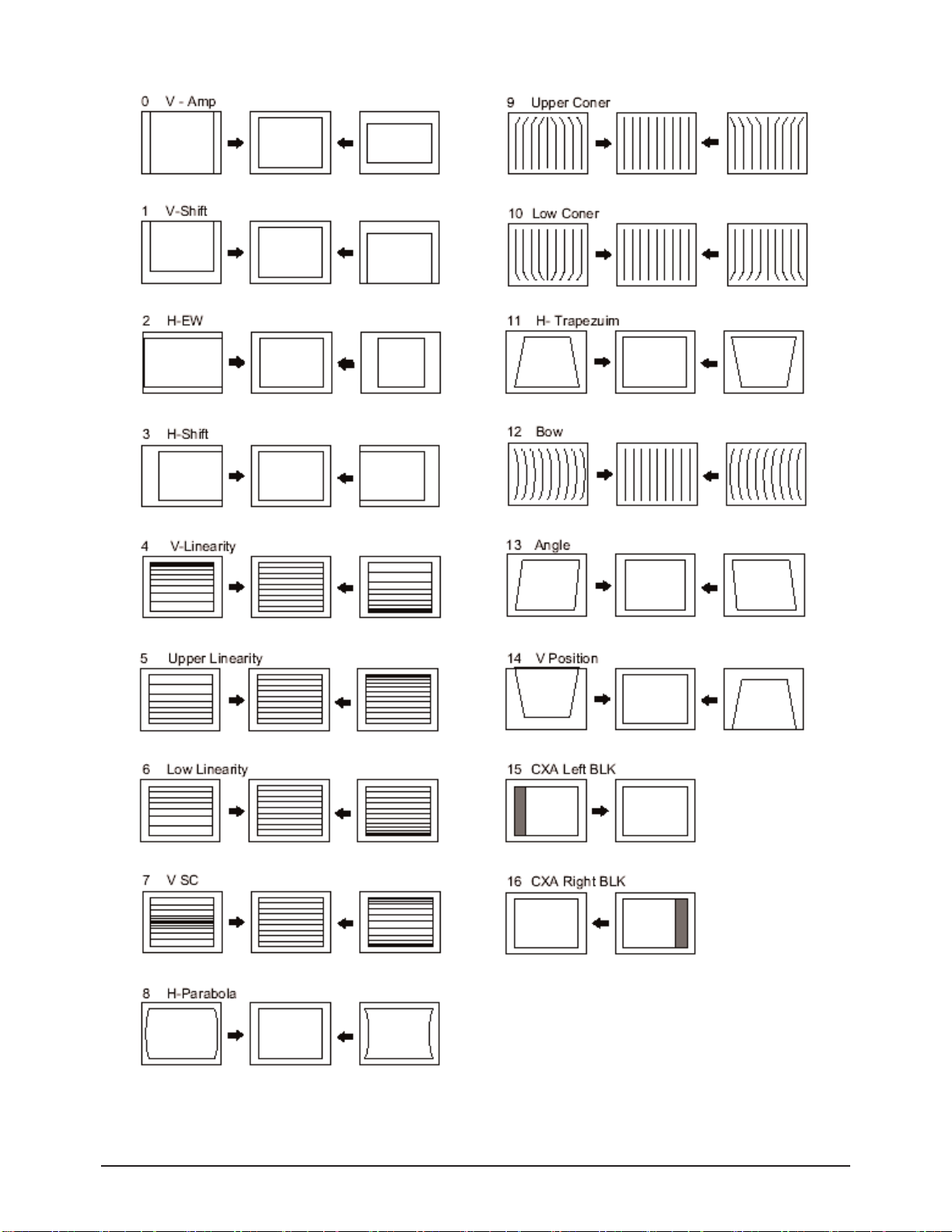

3. Alignment & Adjustment

3-1 Service Instruction

1. General Adjustment :

In general, a color TV can provide ideal visual quality by adjusting the basic settings such as the vertical size, horizontal size,

focus, etc.

Display a black and white picture on the screen to check if the picture is clearly displayed.

If there are some 'spotted' points on the screen when displaying a black and white picture, degauss the screen using the

degauss coil. If the spotted points remain, re-adjust the purity and the convergence. This completes the basic performance

examination.

Notice.

■ These adjustments and the check list are only applied to S63A chassis-applied models.

■ Only use 230V for the measurement set. It is recommended using an insulation transformer when supplying power to

the set so as to prevent shock to the set or to yourself.

■ These adjustment specifications have been created on the basis of the domestic S63A chassis-applied remote control

model. Some of the contents may be changed subject to the sales location and the product specifications.

2. When replacing the F_Box Board :

Since the software is loaded to the EPROM of the F_box board, check the version of the

software of the EPROM.

To check the version of the software, Enter service mode presee the key on the reomte

control according to the following seguenu.

(in stand-by status) Info→Menu→Mute→Power→ON

The software information will then be displayed below the OSD menu.

The notation of the software information : For example, T_SHPEU_1009 refers to

"CORSET BASIC MODEL Europe. ver.1009".

Since the settings including the Channel

information, Deflection, etc. are saved to the

nvRAM, reconfigure these settings when

replacing the System Board

3. When replacing the Main Board : No adjustments required. Except that Tilt adjustment, focus adjustment, screen voltage

setting and W/B adjustment are all required.

4. When replacing the CRT Ass'y : No adjustments required.

5. When replacing the front panel master power switch : No adjustments required.

6. When replacing the Side AV : No adjustments required.

7. When replacing the control switch : No adjustments required.

Samsung Electronics 3-1

Alignment & Adjustment

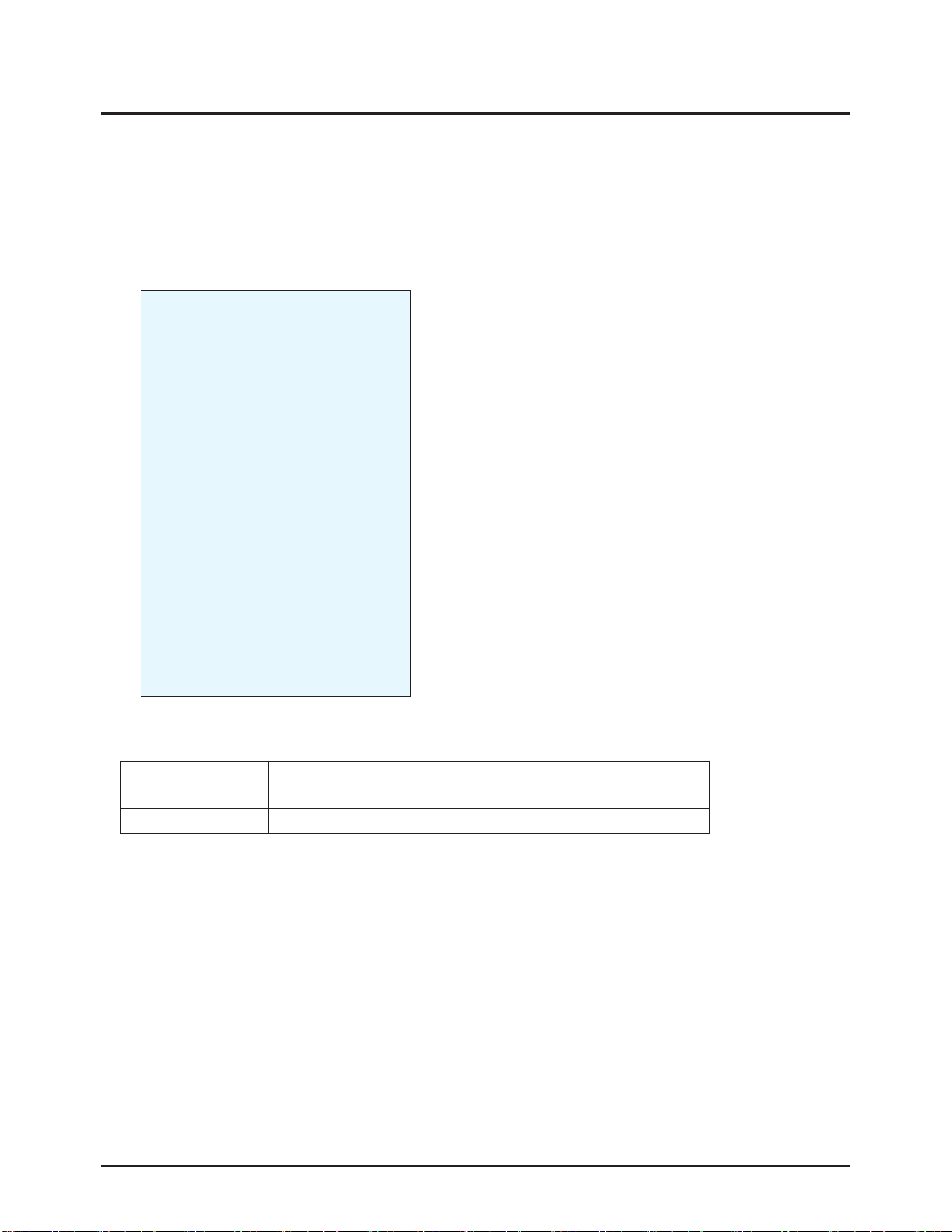

3-2 How to Access Service Mode

1. To enter Service Mode, press the keys on the remote control according to the following sequence. (in Stand-by status)

Info → Menu → Mute → Power On

※ When failing to enter Service Mode, repeat the procedure above.

2. The initial screen of Service Mode.

< Europe>

1. Deflection

2. 480p/576p

3. 720p/1080i

4. 4:3 offset--Vixlm

5. Video Adkust1

6. Video Adkust2

7. Video Adkust3

8. Video Adkust4

9. Video Adkust5

10. Video Adkust6

11. Video Adkust7

12. Video Adkust8

13. OPTION (55 OB 00)

14. YC Delay

15. EEPROM

16. Bus Stop

17. checksum 0000

18. RESET

3. Functions of the Keys within Service Mode

MENU Show all menus

▲ / ▼

◀ / ▶

3-2 Samsung Electronics

Move the cursor to select an item.

Adjust the selected configuration value

Alignment & Adjustment

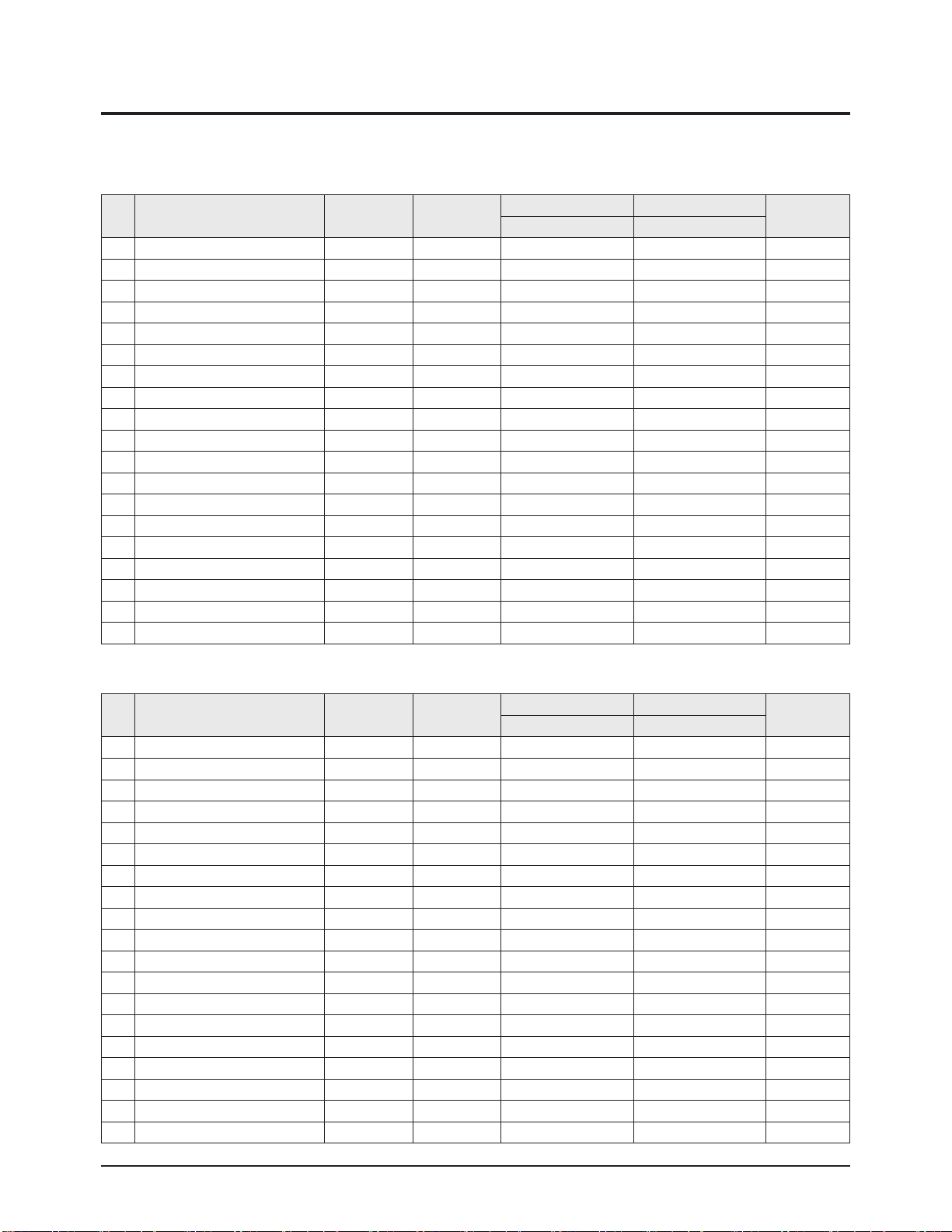

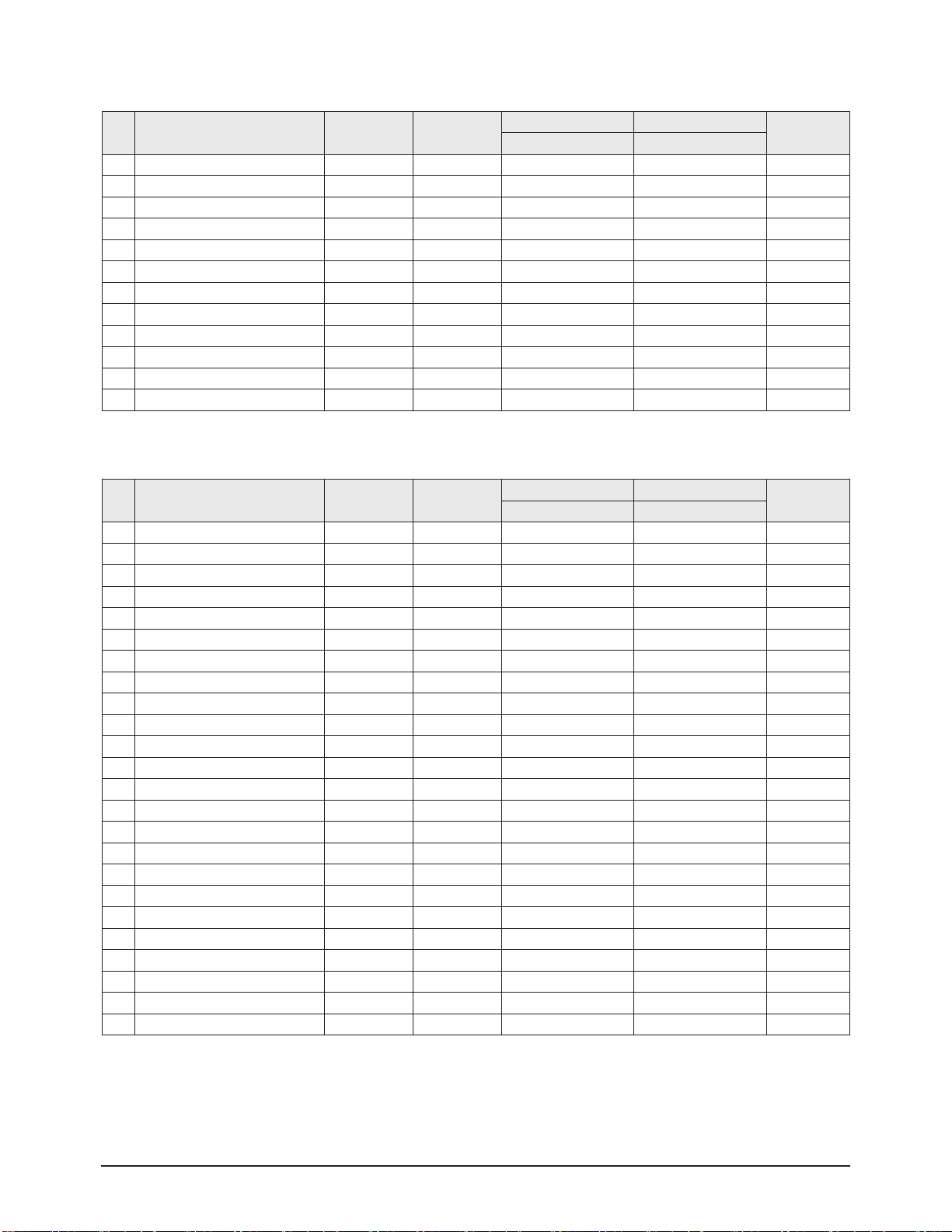

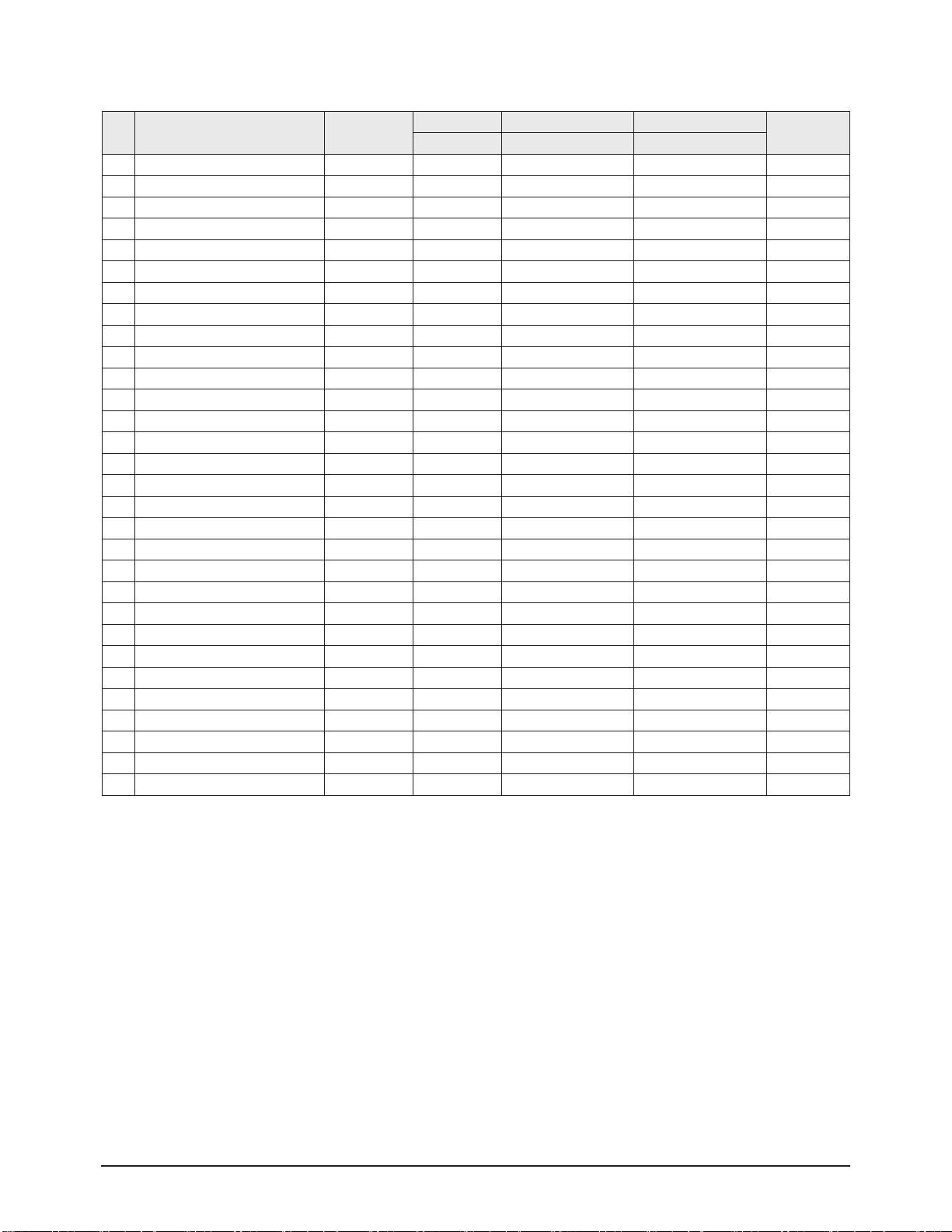

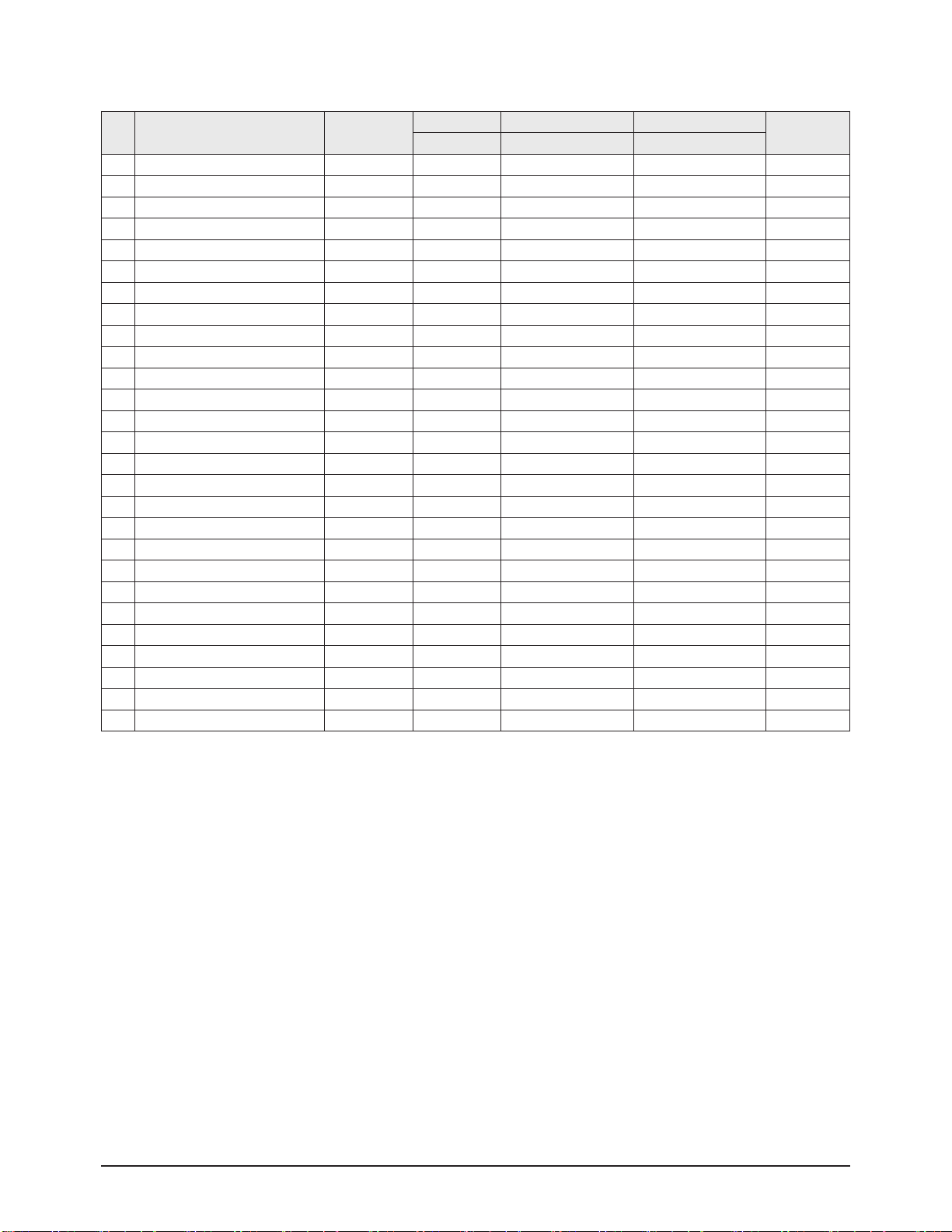

3-3 Factory Data

■ Europe

1. DEFLECTION(PAL)

No item Range intial

0 V Amp 0~63 30 30 34 Adjust

1 V Shift 0~63 26 26 27 Adjust

2 H EW 0~63 30 30 21 Adjust

3 H Shift 0~63 36 36 42 Adjust

4 V Linearity 0~15 6 6 6 FIX

5 Upper Linearity 0~15 0 0 0 FIX

6 Lower Linearity 0~15 1 1 1 FIX

7 V SC 0~15 3 3 4 FIX

8 H Parabola 0~63 32 32 48 Adjust

9 Upper Corner 0~63 37 37 38 Adjust

10 Lower Corner 0~63 34 34 35 Adjust

11 H Trapezium 0~63 40 40 37 Adjust

12 Bow 0~63 32 32 34 Adjust

13 Angle 0~63 30 30 28 Adjust

14 V Position 0~63 32 32 32 FIX

15 H Parablar_Pal(Offset) 0~63 0 0 0 FIX

16 Upper Corner_Pal(Offset) 0~63 0 0 0 FIX

17 Lower Corner_Pal(Offset) 0~63 0 0 0 FIX

18 Bow(Offset) 0~63 0 0 0 FIX

WS32Z30/40 (32") CW29Z30/40 (29")

Data Data

Remark

2. DEFLECTION(NTSC)

No item Range intial

0 V Amp 0~63 -4

1 V Shift 0~63 -3 -3 -3 Adjust

2 H EW 0~63 0

3 H Shift 0~63 -3

4 V Linearity 0~15 0 0 0 Adjust

5 Upper Linearity 0~15 0 0 0 FIX

6 Lower Linearity 0~15 0 0 0 FIX

7 V SC 0~15 0 0 0 FIX

8 H Parabola 0~63 0 0 0 Adjust

9 Upper Corner 0~63 0 0 0 Adjust

10 Lower Corner 0~63 0 0 0 Adjust

11 H Trapezium 0~63 4 4 4 Adjust

12 Bow 0~63 0 0 0 Adjust

13 Angle 0~63 0 0 0 Adjust

14 V Position 0~63 0 0 0 FIX

15 H Parablar_Pal(Offset) 0~63 0 0 0 FIX

16 Upper Corner_Pal(Offset) 0~63 0 0 0 FIX

17 Lower Corner_Pal(Offset) 0~63 0 0 0 FIX

18 Bow(Offset) 0~63 0 0 0 FIX

WS32Z30/40 (32") CW29Z30/40 (29")

Data Data

-6 → -4

-2 → 0

0 → -3

-6 Adjust

-2 Adjust

0 Adjust

Remark

Samsung Electronics 3-3

Alignment & Adjustment

3-4 Samsung Electronics

Alignment & Adjustment

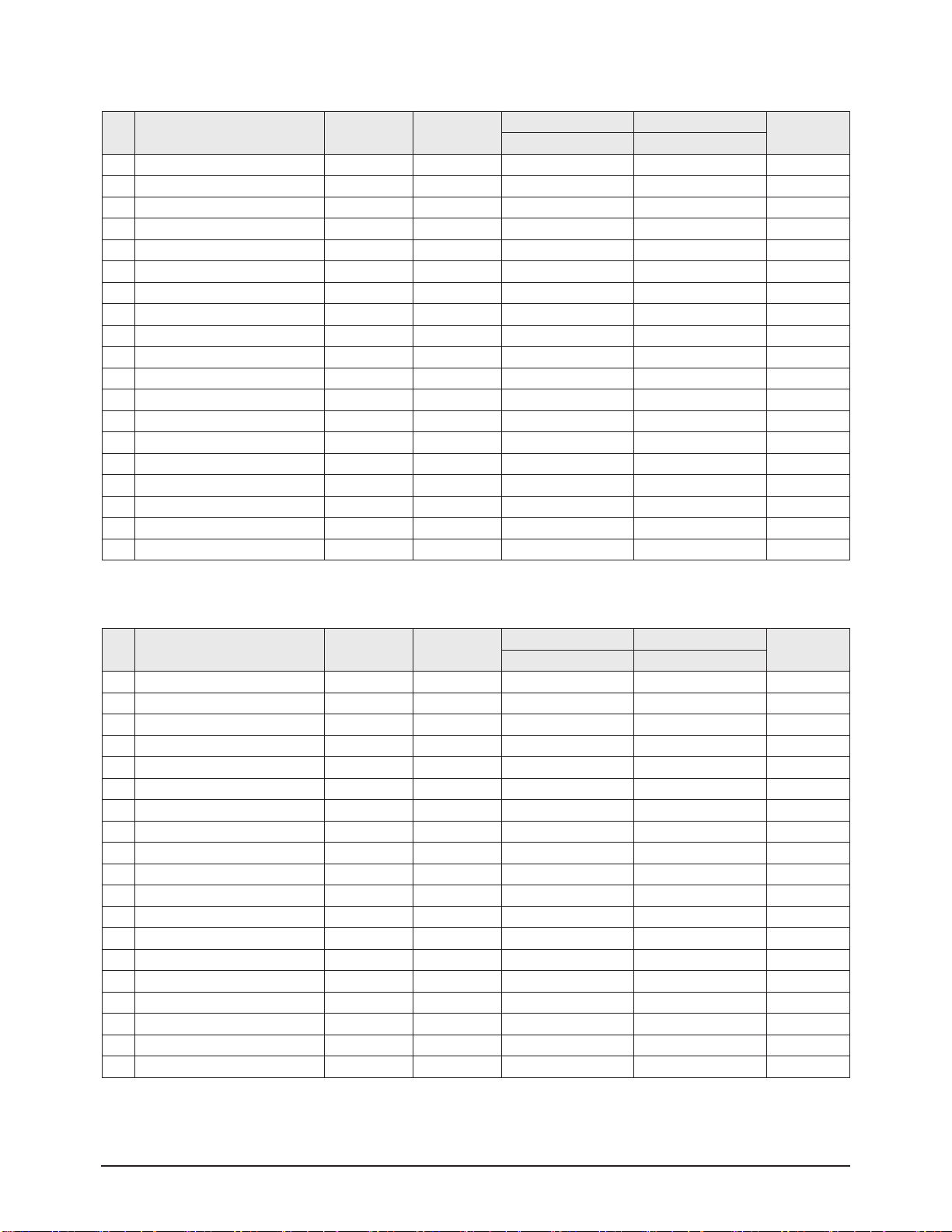

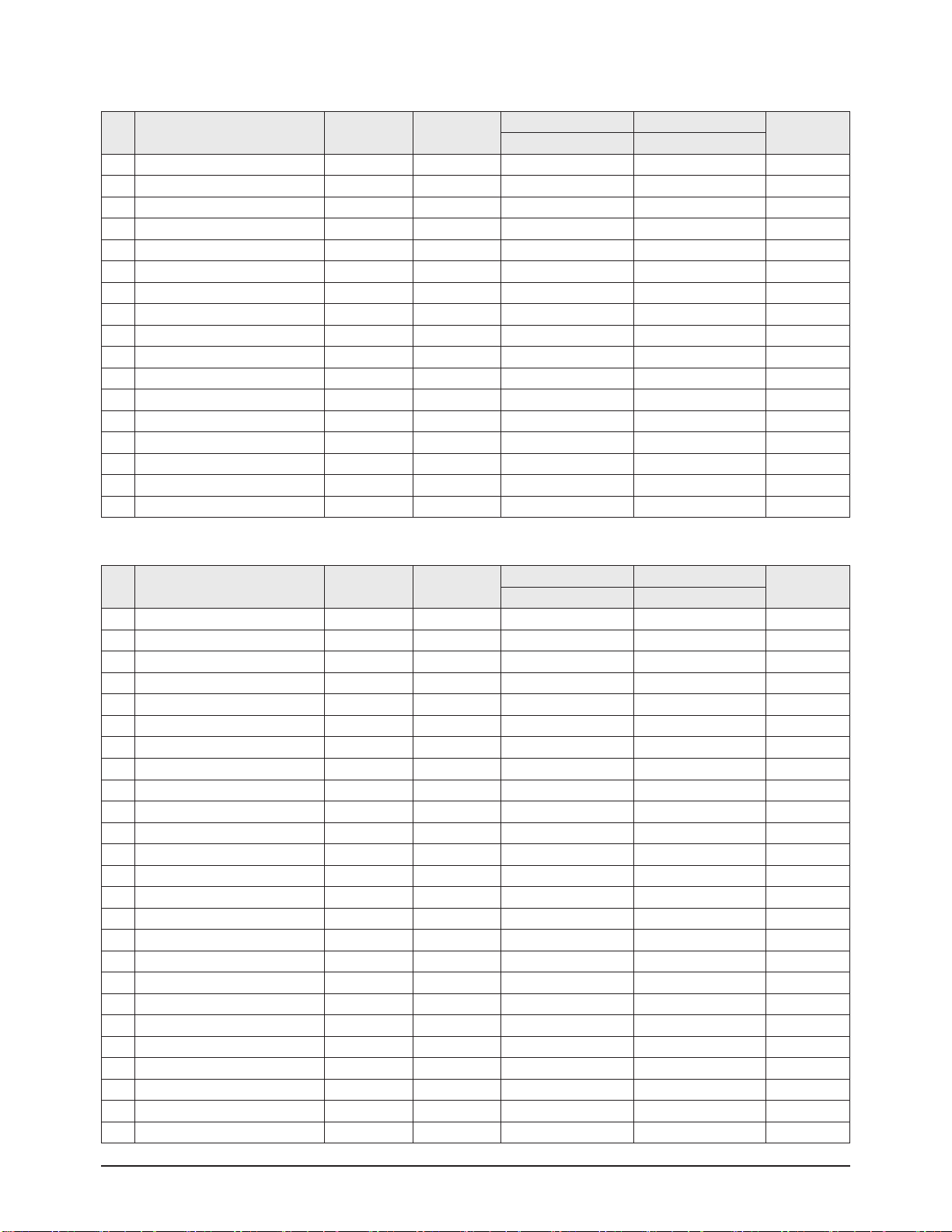

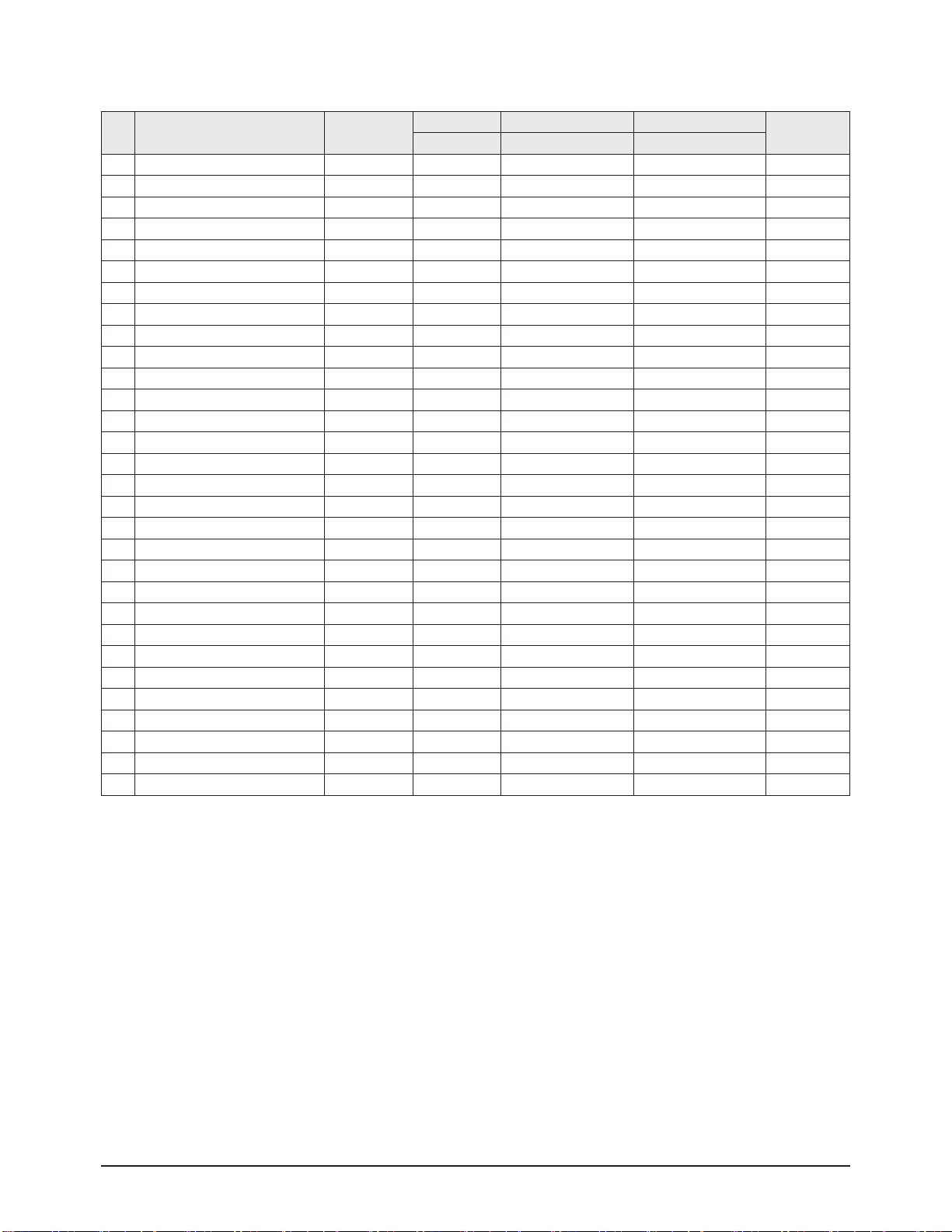

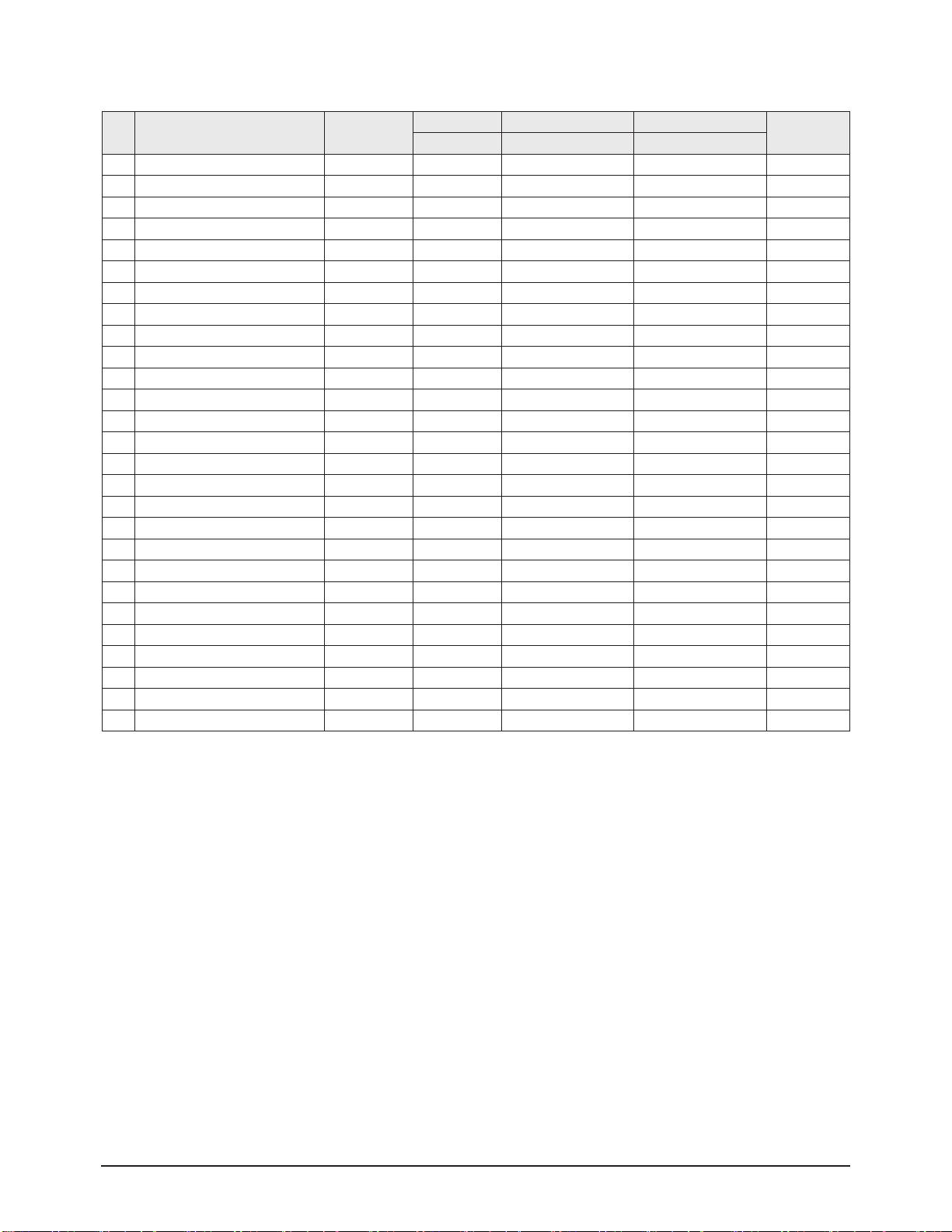

3. DTV DEFLECTION OFFSET(480P)

No item Range intial

0 V Amp -63~63 2 2 0 Adjust

1 V Shift -63~63 0 0 0 Adjust

2 H EW -63~63 0 0 0 Adjust

3 H Shift -63~63 0 0 0 Adjust

4 V Linearity -15~15 0 0 0 Adjust

5 Upper Linearity -15~15 0 0 0 FIX

6 Lower Linearity -15~15 0 0 0 FIX

7 V SC -15~15 0 0 0 FIX

8 H Parabola -63~63 0 0 0 Adjust

9 Upper Corner -63~63 0 0 0 Adjust

10 Lower Corner -63~63 0 0 0 Adjust

11 H Trapezium -63~63 0 0 0 Adjust

12 Bow -63~63 0 0 0 Adjust

13 Angle -63~63 0 0 0 Adjust

14 V Position -63~63 0 0 0 FIX

15 UP-UCG (Up Corner Semi Control) -3~3 0 0 0 FIX

16 LO-UCG (Low Corner Semi Control) -3~3 0 0 0 FIX

17 UP-UCP (Up Corner posiotion Control) -3~3 0 0 0 FIX

18 LO-UCP (Low Corner posiotion Control) -3~3 0 0 0 FIX

WS32Z30/40 (32") CW29Z30/40 (29")

Data Data

Remark

4. DTV DEFLECTION OFFSET(576P)

No item Range intial

0 V Amp -63~63 6 6 6 Adjust

1 V Shift -63~63 -4 -4 -4 Adjust

2 H EW -63~63 0 0 0 Adjust

3 H Shift -63~63 0 0 0 Adjust

4 V Linearity -15~15 0 0 0 Adjust

5 Upper Linearity -15~15 0 0 0 FIX

6 Lower Linearity -15~15 0 0 0 FIX

7 V SC -15~15 0 0 0 FIX

8 H Parabola -63~63 0 0 0 Adjust

9 Upper Corner -63~63 0 0 0 Adjust

10 Lower Corner -63~63 0 0 0 Adjust

11 H Trapezium -63~63 3 3 8 Adjust

12 Bow -63~63 0 0 0 Adjust

13 Angle -63~63 0 0 0 Adjust

14 V Position -63~63 0 0 0 FIX

15 UP-UCG (Up Corner Semi Control) -3~3 0 0 0 FIX

16 LO-UCG (Low Corner Semi Control) -3~3 0 0 0 FIX

17 UP-UCP (Up Corner posiotion Control) -3~3 0 0 0 FIX

18 LO-UCP (Low Corner posiotion Control) -3~3 0 0 0 FIX

WS32Z30/40 (32") CW29Z30/40 (29")

Data Data

Remark

Samsung Electronics 3-5

Alignment & Adjustment

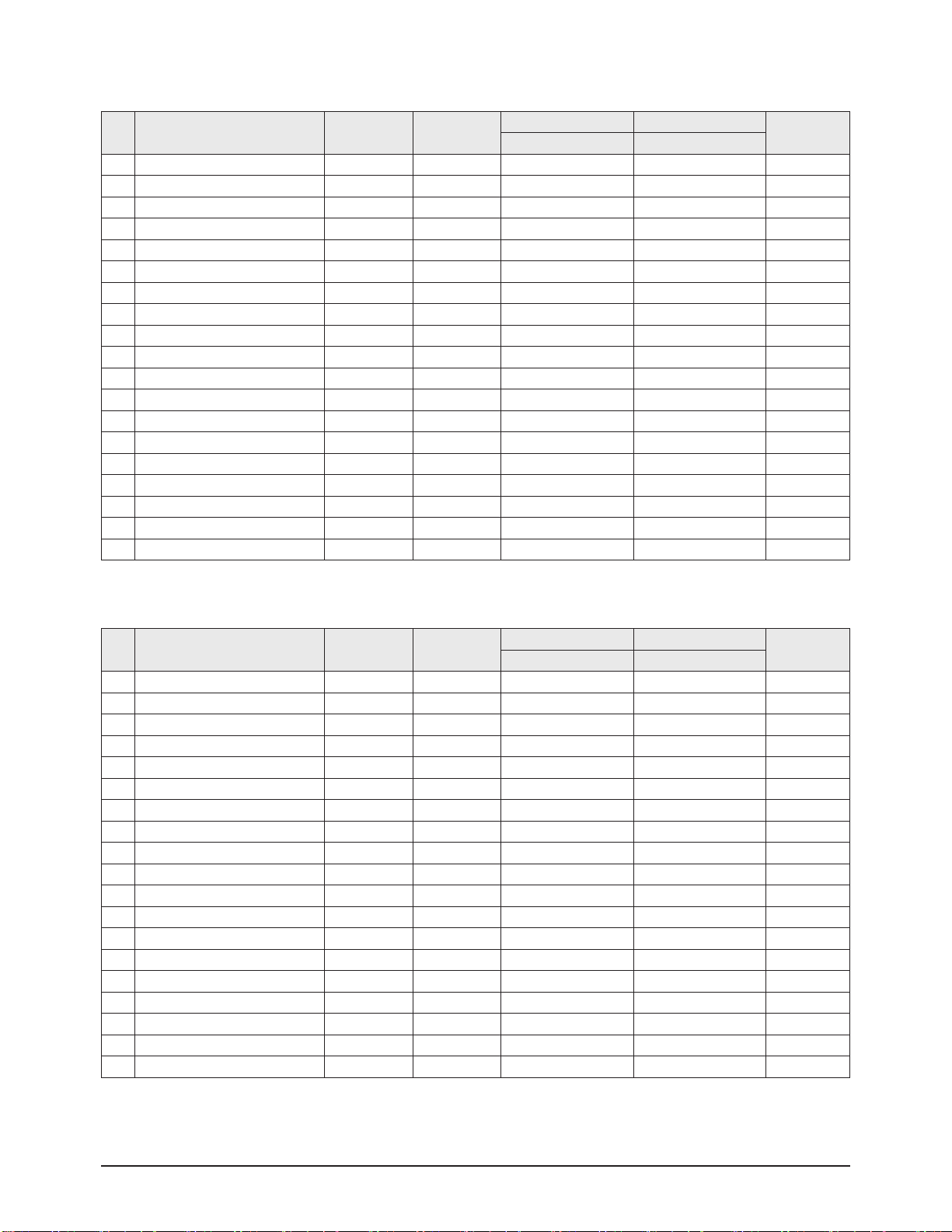

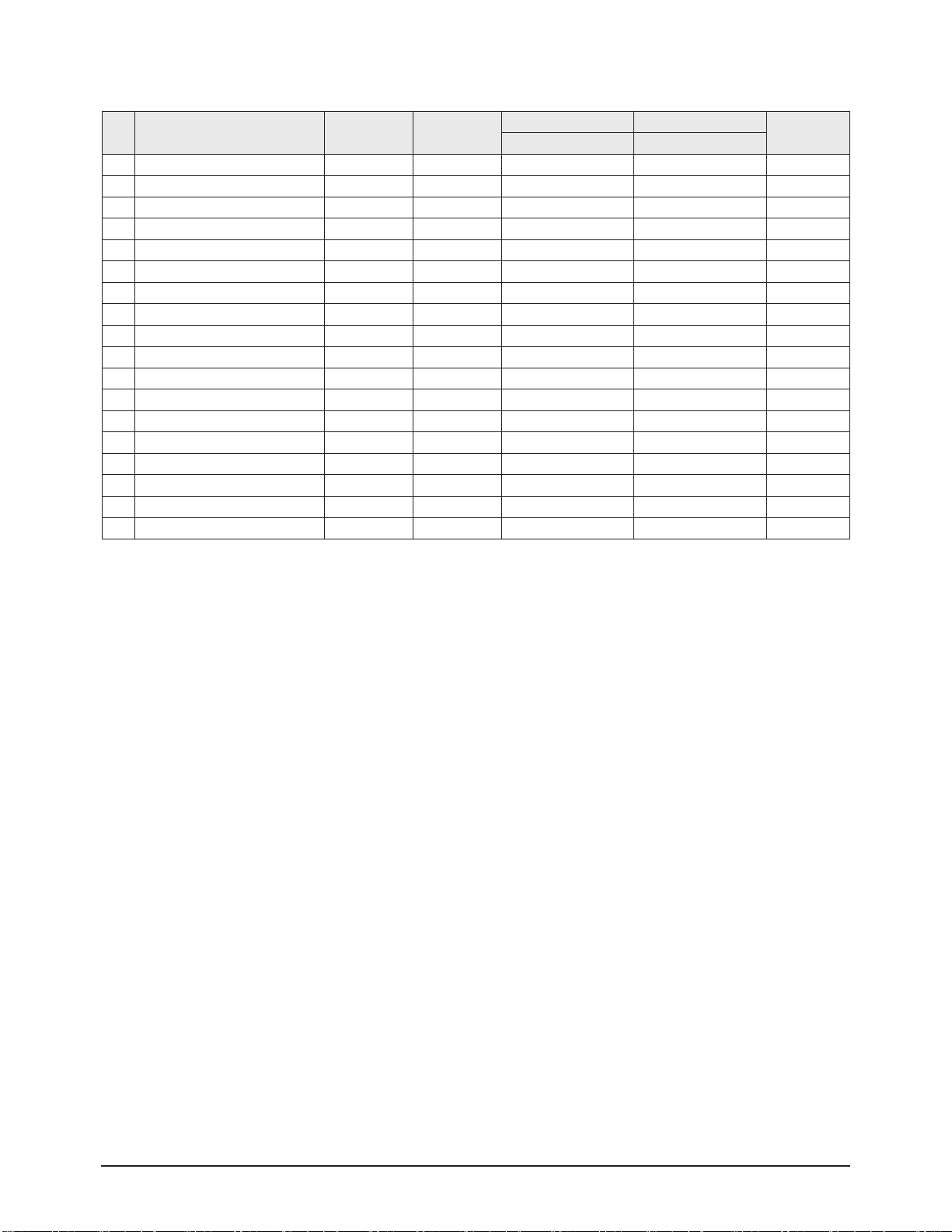

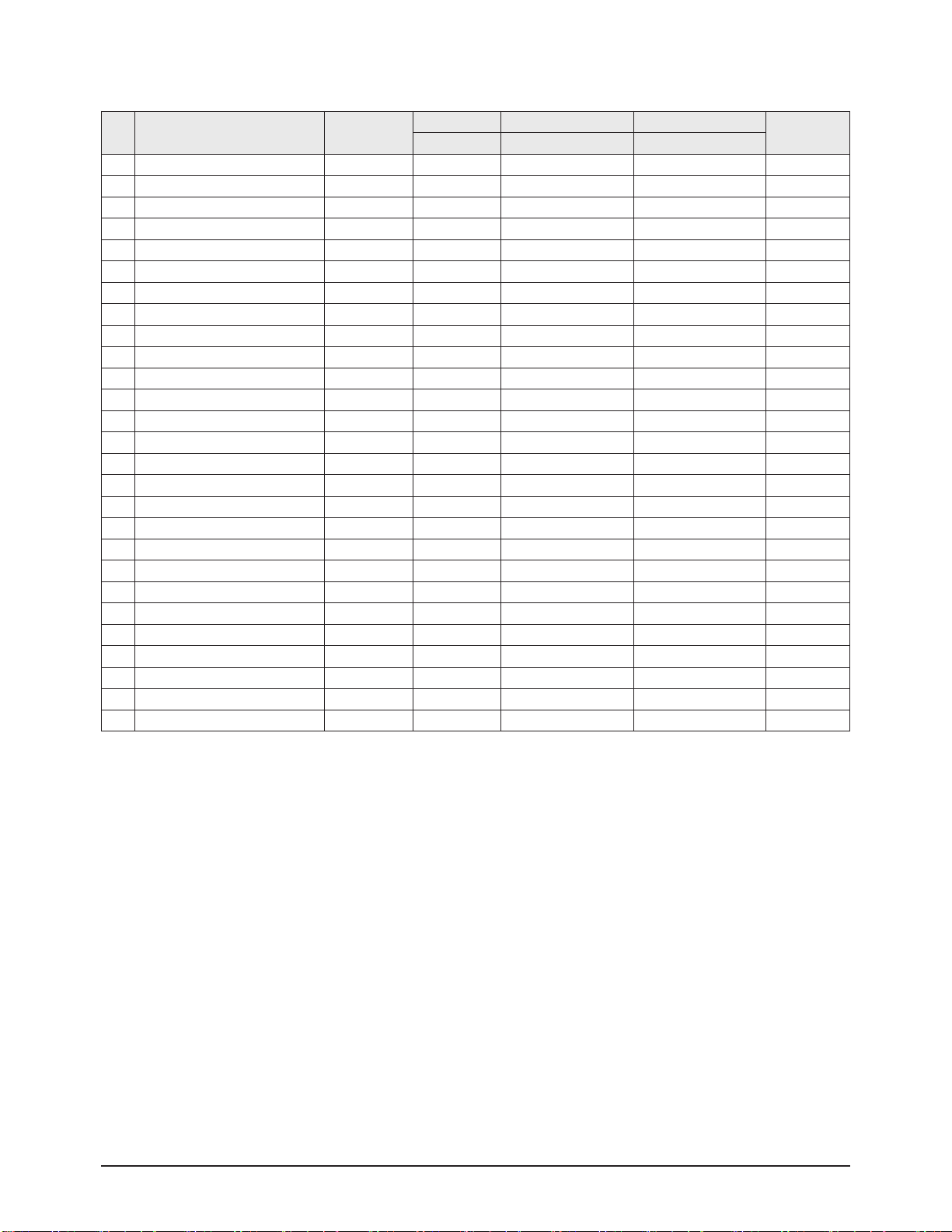

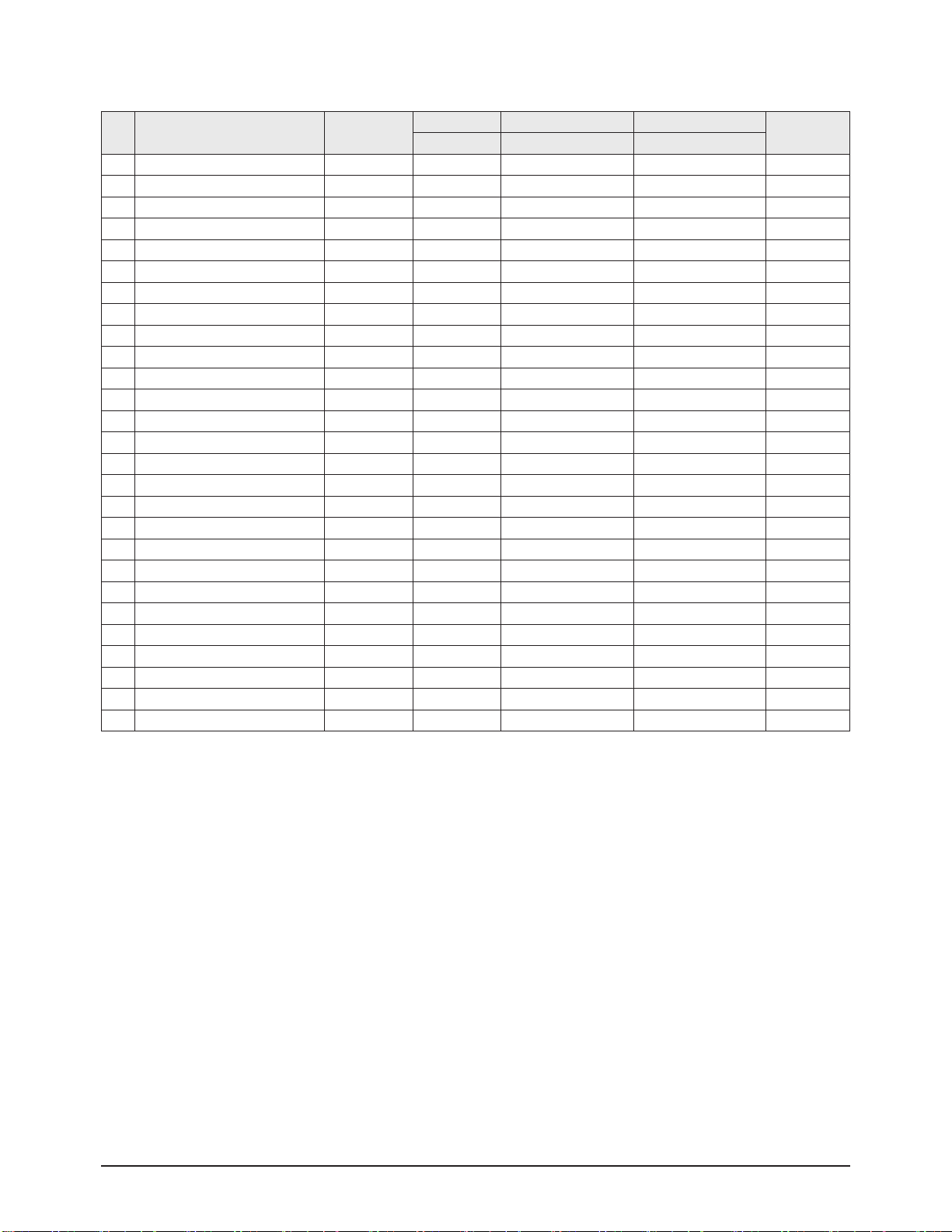

5. DEFLECTION OFFSET(720P)

No item Range intial

0 V Amp 0~63 0 0 0 Adjust

1 V Shift 0~63 0 0 0 Adjust

2 H EW 0~63 0 0 0 Adjust

3 H Shift 0~63 0 0 0 Adjust

4 V Linearity 0~15 0 0 0 Adjust

5 Upper Linearity 0~15 0 0 0 FIX

6 Lower Linearity 0~15 0 0 0 FIX

7 V SC 0~15 0 0 0 FIX

8 H Parabola 0~63 0 0 0 Adjust

9 Upper Corner 0~63 0 0 0 Adjust

10 Lower Corner 0~63 0 0 0 Adjust

11 H Trapezium 0~63 0 0 0 Adjust

12 Bow 0~63 0 0 0 Adjust

13 Angle 0~63 0 0 0 Adjust

14 V Position 0~63 0 0 0 FIX

15 UP-UCG (Up Corner Semi Control) 0~3 0 0 0 FIX

16 LO-UCG (Low Corner Semi Control) 0~3 0 0 0 FIX

17 UP-UCP (Up Corner posiotion Control) 0~3 0 0 0 FIX

18 LO-UCP (Low Corner posiotion Control) 0~3 0 0 0 FIX

WS32Z30/40 (32") CW29Z30/40 (29")

Data Data

Remark

6. DEFLECTION OFFSET(1080I)

No item Range intial

0 V Amp 0~63 -15 -15 -15 Adjust

1 V Shift 0~63 -5 -5 -5 Adjust

2 H EW 0~63 4 4 4 Adjust

3 H Shift 0~63 -3 -3 -3 Adjust

4 V Linearity 0~15 0 0 0 Adjust

5 Upper Linearity 0~15 0 0 0 FIX

6 Lower Linearity 0~15 0 0 0 FIX

7 V SC 0~15 0 0 0 FIX

8 H Parabola 0~63 0 0 0 Adjust

9 Upper Corner 0~63 0 0 0 Adjust

10 Lower Corner 0~63 0 0 0 Adjust

11 H Trapezium 0~63 5 5 5 Adjust

12 Bow 0~63 0 0 0 Adjust

13 Angle 0~63 0 0 0 Adjust

14 V Position 0~63 0 0 0 FIX

15 UP-UCG (Up Corner Semi Control) 0~3 0 0 0 FIX

16 LO-UCG (Low Corner Semi Control) 0~3 0 0 0 FIX

17 UP-UCP (Up Corner posiotion Control) 0~3 0 0 0 FIX

18 LO-UCP (Low Corner posiotion Control) 0~3 0 0 0 FIX

WS32Z30/40 (32") CW29Z30/40 (29")

Data Data

Remark

3-6 Samsung Electronics

Alignment & Adjustment

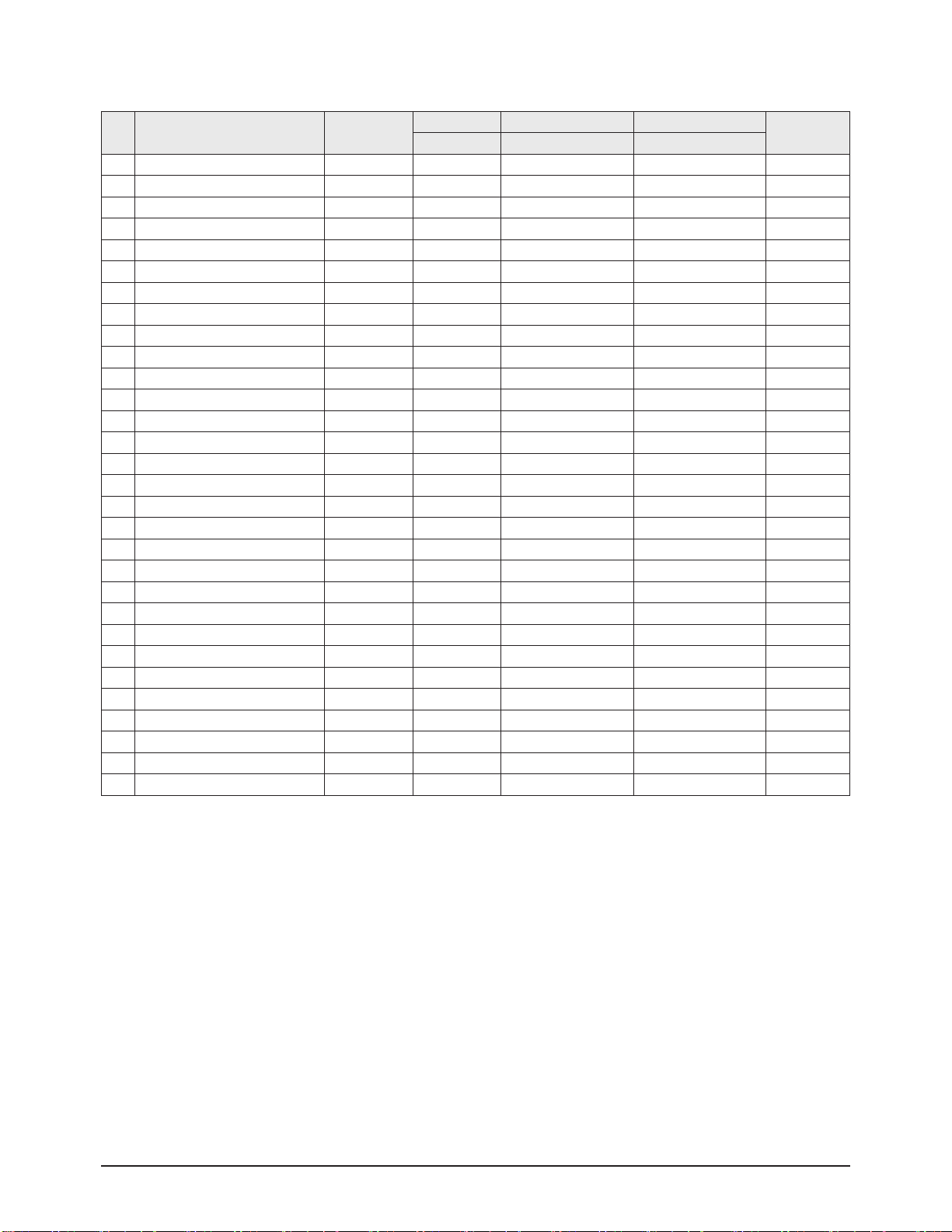

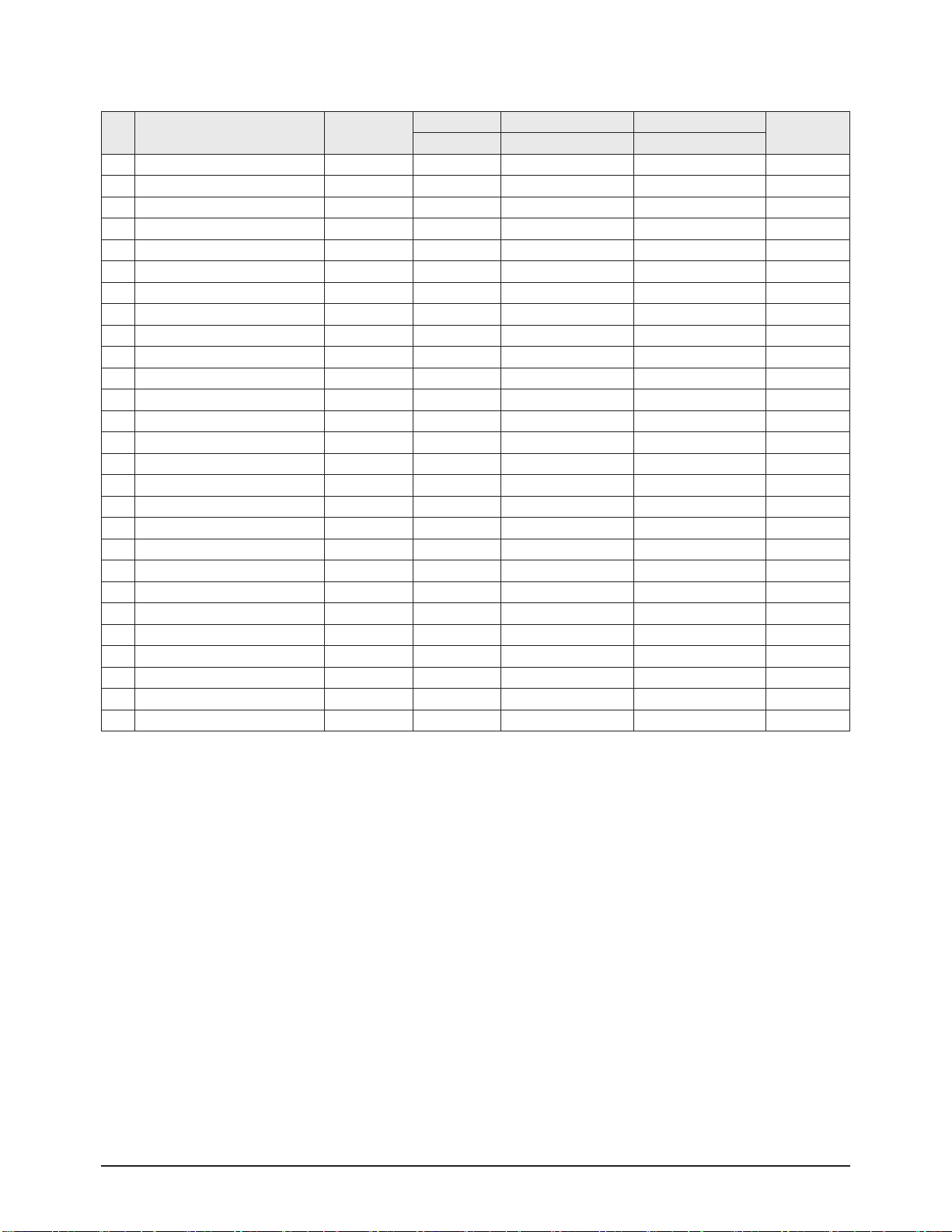

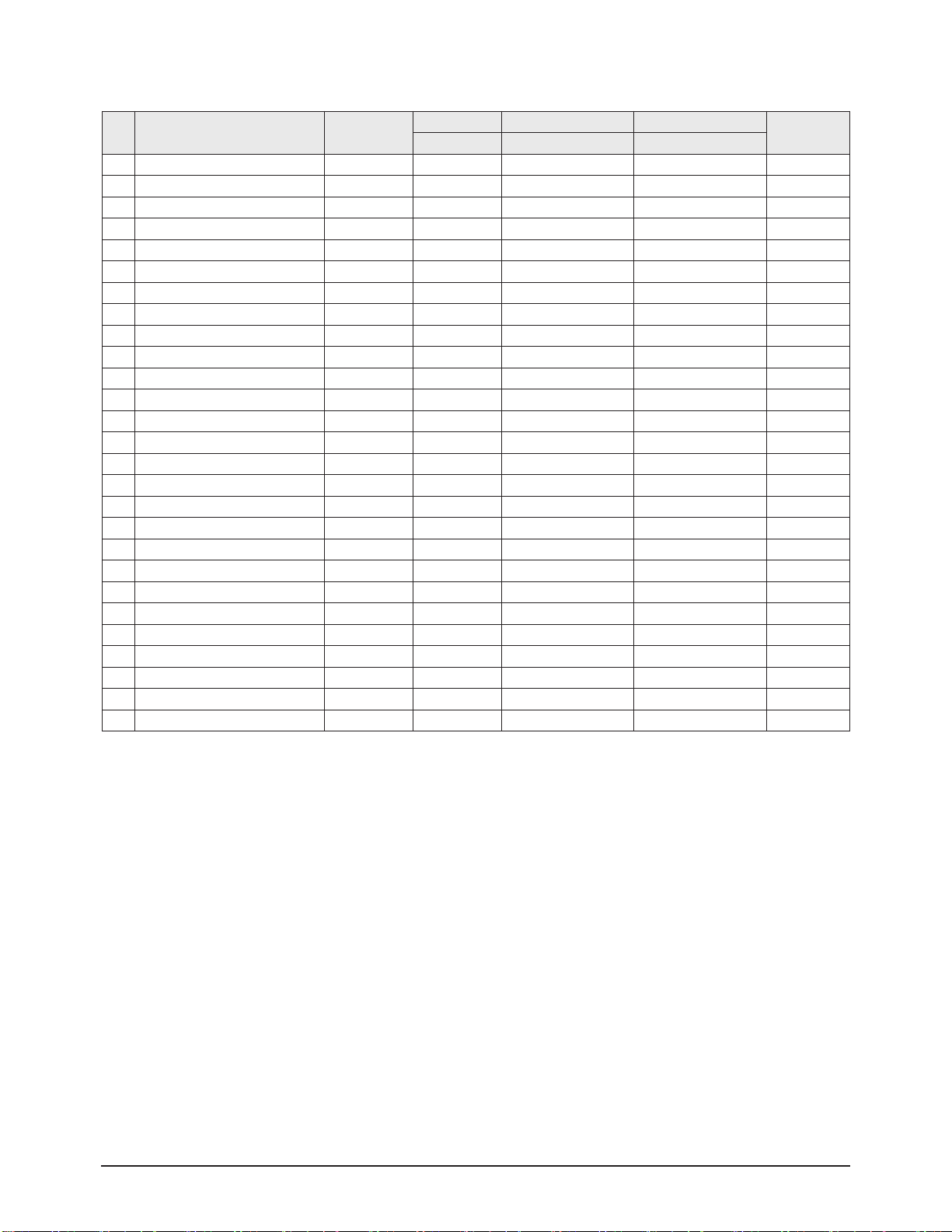

7. 4:3 OFFSET_VIXLIM

No item Range intial

1 H Parabola -20~20 0 0 0 Adjust

2 Upper Corner -20~20 0 0 0 Adjust

3 Lower Corner -20~20 0 0 0 Adjust

4 Bow -20~20 0 0 0 Adjust

5 Angle -20~20 0 0 0 Adjust

6 H Shift -20~20 0 0 0 Adjust

7 H Parabola NT -20~20 0 0 0 Adjust

8 Upper Corner NT -20~20 0 0 0 Adjust

9 Lower Corner NT -20~20 0 0 0 Adjust

10 Bow NT -20~20 0 0 0 Adjust

11 Angle NT -20~20 0 0 0 Adjust

12 H Shift -20~20 0 0 0 Adjust

WS32Z30/40 (32") CW29Z30/40 (29")

Data Data

Remark

8. VIDEO ADJUST 1

No item Range intial

0 R CutOff 0~63 20 20 20 Adjust

1 G CutOff 0~63 20 20 20 FIX

2 B CutOff 0~63 20 20 20 Adjust

3 R Drive 0~63 32 32 32 Adjust

4 G Drive 0~63 32 32 32 FIX

5 B Drive 0~63 32 32 32 Adjust

6 Sub Bright 0~63 15 15 15 Adjust

7 Sub Contrast 0~15 9 9 9 Adjust

8 Bright VCTP 0~256 140 140 140 FIX

9 Contrast VCTP 0 ~ 63 28

10 SAT-VCTP 0 ~ 63 23

11 Tint VCTP 0 ~ 23 10 10 10 FIX

12 SC_RGB_ BRTADJ -128 ~ 127 128 128 128 FIX

13 SC_RGB_ CONADJ 0 ~ 63 45 45 45 FIX

14 SC_RGB_ USATADJ 0 ~ 63 42

15 SC_RGB_ VSATADJ 0 ~ 63 42

16 RGB24_BRTADJ 0~255 14

17 RGB24_CONADJ 0 ~ 63 30 30 30 FIX

18 RGB24_ USATADJ 0 ~ 63 30

19 RGB24_ VSATADJ 0 ~ 63 30

20 RGB24_BR_HD 0~255 0

21 RGB24_CO_HD 0 ~ 63 30 30 30 FIX

22 RGB24_ USA_HD 0 ~ 63 30

23 RGB24_ VSA_HD 0 ~ 63 30

WS32Z30/40 (32") CW29Z30/40 (29")

Data Data

28 → 30

15 → 11

42 → 32

42 → 32

16 → 14

32 → 30

32 → 30

16 → 14

32 → 30

32 → 30

30 FIX

11 FIX

32 FIX

32 FIX

14 FIX

30 FIX

30 FIX

14 FIX

30 FIX

30 FIX

Remark

Samsung Electronics 3-7

Alignment & Adjustment

9. VIDEO ADJUST 2

No item Range intial

0 ABL Mode 0~03 3 3 3 FIX

1 Gamma 0~03 0 0 2 FIX

2 ABL TH 0~15 14 14 3 FIX

3 AKB Time 0~31 15 15 15 FIX

4 S - ABL 3 3 3 FIX

5 P - ABL 6

6 VSU 0 0 0 FIX

7 LNA EXE 0 ~ 4 3 3 3 FIX

8 H_EHT comp 0~15 3 3 3 FIX

9 V_EHT comp 0~15 5 5 5 FIX

10 PIN EHT comp 0~07 3

11 AFC EHT comp 0~07 0 0 0 FIX

12 Sync Phase 0~1 0 0 0 FIX

13 Sync Phase (480) 0~1 1 1 1 FIX

14 Sync Phase (576P) 0~1 0 0 0 FIX

15 Sync Phase (720P) 0~1 1 1 1 FIX

16 Sync Phase (1080) 0~1 0 0 0 FIX

WS32Z30/40 (32") CW29Z30/40 (29")

Data Data

9 → 6

2 → 3

9 FIX

3 FIX

Remark

10. VIDEO ADJUST 3

No item Range intial

0 TNR Enable 0 ~ 1 1 1 1 FIX

1 TNR Chroma 0 ~ 15 10 11 10 FIX

2 TNR Luma 0 ~ 15 11 11 7 FIX

3 LTI Enable 0 ~ 1 1 1 1 FIX

4 LTI Gain 0 ~ 15 15 15 15 FIX

5 LTI Gain x2 0 ~ 1 1 1 1 FIX

6 LTI Coring 0 ~ 7 2

7 Lmix gain 3 3 3 FIX

8 Lmix offset 0 ~ 31 13

9 Peak Center Freq 0~3 3 3 3 FIX

10 Peaking Coring 0 ~ 31 2 2 2 FIX

11 CTI BW 0 ~ 1 4

12 CTI LP 0 ~ 1 1 1 1 FIX

13 CTI Gain 0 ~ 15 5 5 5 FIX

14 CTI Coring 0 ~ 15 2

15 V Peaking 0 ~ 15 3

16 V Peak Coring gain 0~7 0 0 0 FIX

17 V Peak high gain 0~15 0 0 0 FIX

18 V Peak coring high 0~15 0 0 0 FIX

19 IF Comp Filter 0 ~ 7 4 4 4 FIX

20 DHYAPRESC 0~3 2 2 2 FIX

21 DHCAPRESC 0~3 2 2 2 FIX

22 Neg Peaking 0 ~ 15 11 11 11 FIX

23 DCE Gain 0~255 45 45 45 FIX

24 CORBP 0~1 0 0 0 FIX

WS32Z30/40 (32") CW29Z30/40 (29")

Data Data

3 → 2

12 → 13

1 → 4

3 → 2

2 → 3

3 FIX

13 FIX

4 FIX

2 FIX

3 FIX

Remark

3-8 Samsung Electronics

Alignment & Adjustment

11. VIDEO ADJUST 4

No item Range intial

0 SVM RW 0 ~ 7 2 2 2 FIX

1 SVM Delay 0 ~ 7 0 0 0 FIX

2 SVM Coring 0 ~ 15 2 2 2 FIX

3 SVM Gain 0 ~ 63 45 45 45 FIX

4 SVM C_Gain 0 ~ 3 0 0 0 FIX

5 OSD Contrast 0 ~ 127 30 30 30 FIX

6 OSD Bright -512 ~ 511 127 127 127 FIX

7 TTX Contrast 0 ~ 127 17 17 17 FIX

8 TTX Bright ` 127 127 127 FIX

9 Melody Volume 0 ~ 127 10 10 10 FIX

10 VCR Mode Cnt 30 30 30 FIX

11 SLLTHD 2 2 2 FIX

12 SLLTHDV 3 3 3 FIX

13 THRSEL 0 0 0 FIX

14 LPCDEL 0 0 0 FIX

15 Pilot High 13 13 13 FIX

16 Pilot Low 7 7 7 FIX

17 AM_Prescale 22 22 22 FIX

WS32Z30/40 (32") CW29Z30/40 (29")

Data Data

Remark

Samsung Electronics 3-9

Alignment & Adjustment

12. Video Adjust5 (60i/100i)

No item Range

0 HORWIDTHP_H 5 5 5

1 HORWIDTHP_L 50 50 50 FIX

2 VERIWDTHP_H 1 1 1 FIX

3 VERIWDTHP_L 26 26 26 FIX

4 HORPOSP_H 1 1 1 FIX

5 HORPOSP_L 65 65 65 FIX

6 VERPOSP_H 0 0 0 FIX

7 VERPOSP_L 29 29 29 FIX

8 NAPPLIP_H 2 2 2 FIX

9 NAPPLIP_L 94 94 94 FIX

10 NALPFIP_H 0 0 0 FIX

11 NALPFIP_L 18 18 18 FIX

12 HSCPOSC_H 8 8 8 FIX

13 HSCPOSC_L 70 70 70 FIX

14 VSCPOSC_H 31 31 31 FIX

15 VSCPOSC_L 100 100 100 FIX

16 HORWIDTH_M_H 5 5 5 FIX

17 HORWIDTH_M_L 50 50 50 FIX

18 VERWIDTH_M_H 1 1 1 FIX

19 VERWIDTH_M_L 39 39 39 FIX

20 HORPOS_M_H 1 1 1 FIX

21 HORPOS_M_L 60 60 60 FIX

22 VERPOS_M_H 0 0 0 FIX

23 VERPOS_M_L 23 23 23 FIX

24 VSCPRESC_H 0 0 0 FIX

25 VSCPRESC_L 0 0 0 FIX

26 SD_BRTADJ 128 128 128 FIX

27 SD_CONADJ 32 32 32 FIX

28 SD_USATADJ 32 32 32 FIX

29 SD_VSATADJ 32 32 32 FIX

PAL_RF WS32Z30/40 (32") CW29Z30/40 (29")

Initial Data Data

Remark

3-10 Samsung Electronics

Alignment & Adjustment

13. Video Adjust5 (NTSC)

No item Range

0 HORWIDTHP_H 5 5 5

1 HORWIDTHP_L 75 75 75 FIX

2 VERIWDTHP_H 1 1 1 FIX

3 VERIWDTHP_L 235 235 235 FIX

4 HORPOSP_H 1 1 1 FIX

5 HORPOSP_L 50 50 50 FIX

6 VERPOSP_H 0 0 0 FIX

7 VERPOSP_L 30 30 30 FIX

8 NAPPLIP_H 2 2 2 FIX

9 NAPPLIP_L 18 18 18 FIX

10 NALPFIP_H 0 0 0 FIX

11 NALPFIP_L 10 10 10 FIX

12 HSCPOSC_H 8 8 8 FIX

13 HSCPOSC_L 45 45 45 FIX

14 VSCPOSC_H 12 12 12 FIX

15 VSCPOSC_L 20

16 HORWIDTH_M_H 5 5 5 FIX

17 HORWIDTH_M_L 88 88 88 FIX

18 VERWIDTH_M_H 2 2 2 FIX

19 VERWIDTH_M_L 5 5 5 FIX

20 HORPOS_M_H 1 1 1 FIX

21 HORPOS_M_L 30 30 30 FIX

22 VERPOS_M_H 0 0 0 FIX

23 VERPOS_M_L 10

24 VSCPRESC_H 4 4 4 FIX

25 VSCPRESC_L 0 0 0 FIX

26 SD_BRTADJ 128 128 128 FIX

27 SD_CONADJ 32 32 32 FIX

28 SD_USATADJ 32 32 32 FIX

29 SD_VSATADJ 32 32 32 FIX

NTSC WS32Z30/40 (32") CW29Z30/40 (29")

Initial Data Data

20 → 80

10 → 15

20 FIX

10 FIX

Remark

Samsung Electronics 3-11

Alignment & Adjustment

14. Video Adjust5 (576i)

No item Range

0 HORWIDTHP_H 5 5 5

1 HORWIDTHP_L 50 50 50 FIX

2 VERIWDTHP_H 1 1 1 FIX

3 VERIWDTHP_L 30 30 30 FIX

4 HORPOSP_H 1 1 1 FIX

5 HORPOSP_L 65 65 65 FIX

6 VERPOSP_H 0 0 0 FIX

7 VERPOSP_L 26 26 26 FIX

8 NAPPLIP_H 1 1 1 FIX

9 NAPPLIP_L 176 176 176 FIX

10 NALPFIP_H 0 0 0 FIX

11 NALPFIP_L 16 16 16 FIX

12 HSCPOSC_H 8 8 8 FIX

13 HSCPOSC_L 125 125 125 FIX

14 VSCPOSC_H 31 31 31 FIX

15 VSCPOSC_L 100 100 100 FIX

16 HORWIDTH_M_H 5 5 5 FIX

17 HORWIDTH_M_L 50 50 50 FIX

18 VERWIDTH_M_H 1 1 1 FIX

19 VERWIDTH_M_L 38 38 38 FIX

20 HORPOS_M_H 1 1 1 FIX

21 HORPOS_M_L 55 55 55 FIX

22 VERPOS_M_H 0 0 0 FIX

23 VERPOS_M_L 23 23 23 FIX

24 VSCPRESC_H 0 0 0 FIX

25 VSCPRESC_L 0 0 0 FIX

26 SD_BRTADJ 146 145 145

27 SD_CONADJ 46 45 45

28 SD_USATADJ 32 52 52

29 SD_VSATADJ 32 54 54

576i 576i_32" 576i_29"

Initial Data Data

Remark

3-12 Samsung Electronics

Alignment & Adjustment

15. Video Adjust5 (480i)

No item Range

0 HORWIDTHP_H 5 5 5

1 HORWIDTHP_L 48 48 48 FIX

2 VERIWDTHP_H 1 1 1 FIX

3 VERIWDTHP_L 246 246 246 FIX

4 HORPOSP_H 1 1 1 FIX

5 HORPOSP_L 60 60 60 FIX

6 VERPOSP_H 0 0 0 FIX

7 VERPOSP_L 21 21 21 FIX

8 NAPPLIP_H 1 1 1 FIX

9 NAPPLIP_L 101 101 101 FIX

10 NALPFIP_H 0 0 0 FIX

11 NALPFIP_L 16 16 16 FIX

12 HSCPOSC_H 8 8 8 FIX

13 HSCPOSC_L 125 125 125 FIX

14 VSCPOSC_H 12 12 12 FIX

15 VSCPOSC_L 0 0 0 FIX

16 HORWIDTH_M_H 5 5 5 FIX

17 HORWIDTH_M_L 48 48 48 FIX

18 VERWIDTH_M_H 1 1 1 FIX

19 VERWIDTH_M_L 241 241 241 FIX

20 HORPOS_M_H 1 1 1 FIX

21 HORPOS_M_L 41 41 41 FIX

22 VERPOS_M_H 0 0 0 FIX

23 VERPOS_M_L 24 24 24 FIX

24 VSCPRESC_H 4 4 4 FIX

25 VSCPRESC_L 0 0 0 FIX

26 SD_BRTADJ 146 146 146 FIX

27 SD_CONADJ 45

28 SD_USATADJ 52

29 SD_VSATADJ 52

480i 480i_32" 480i_29"

Initial Data Data

46 → 45

32 → 52

32 → 52

45 FIX

52 FIX

52 FIX

Remark

Samsung Electronics 3-13

Alignment & Adjustment

16. Video Adjust6 (comp_HD)

No item Range

0 HORWIDTHP_H 5 5 5 FIX

1 HORWIDTHP_L 45 45 45 FIX

2 VERWIDTHP_H 1 1 1 FIX

3 VERWIDTHP_L 226 226 226 FIX

4 HORPOSP_H 1 1 1 FIX

5 HORPOSP_L 104 104 104 FIX

6 VERPOSP_H 0 0 0 FIX

7 VERPOSP_L 26 26 26 FIX

8 DHSCPRESC_H 11 11 11 FIX

9 DHSCPRESC_L 100 100 100 FIX

10 DNAPPLIP_H 1 1 1 FIX

11 DNAPPLIP_L 11 11 11 FIX

12 DVOFPOSC 128 128 128 FIX

13 VERPOS_S 6 6 6 FIX

14 VEROFFS_S 0 0 0 FIX

15 HORPOS_S_H 1 1 1 FIX

16 HORPOS_S_L 41 41 41 FIX

HPULLINMODE 0 0 0 FIX

17 DVSCPOSC_HI 64 64 64 FIX

18 DVSCPOSC_LO_H 131 131 131 FIX

19 DVSCPOSC_LO_L 17 17 17 FIX

20 DHSCPOSC_HI 14 14 14 FIX

21 DHSCPOSC_LO 255 255 255 FIX

22 HD_BRTADJ 145 145 145 FIX

23 HD_CONADJ 45

24 HD_USATADJ 52

25 HD_VSATADJ 52

480P_HD 480P_HD_32" 480P_HD_29"

intial Data Data

47 → 45

32 → 52

32 → 52

45 FIX

52 FIX

52 FIX

Remark

3-14 Samsung Electronics

Alignment & Adjustment

17. Video Adjust6 (comp_HD)

No item Range

0 HORWIDTHP_H 5 5 5 FIX

1 HORWIDTHP_L 20 20 20 FIX

2 VERWIDTHP_H 2 2 2 FIX

3 VERWIDTHP_L 68 68 68 FIX

4 HORPOSP_H 1 1 1 FIX

5 HORPOSP_L 85 85 85 FIX

6 VERPOSP_H 0 0 0 FIX

7 VERPOSP_L 26 26 26 FIX

8 DHSCPRESC_H 11 11 11 FIX

9 DHSCPRESC_L 210 210 210 FIX

10 DNAPPLIP_H 1 1 1 FIX

11 DNAPPLIP_L 35 35 35 FIX

12 DVOFPOSC 100 100 100 FIX

13 VERPOS_S 5 5 5 FIX

14 VEROFFS_S 6 6 6 FIX

15 HORPOS_S_H 1 1 1 FIX

16 HORPOS_S_L 1 1 1 FIX

HPULLINMODE 0 0 0 FIX

17 DVSCPOSC_HI 64 64 64 FIX

18 DVSCPOSC_LO_H 66 66 66 FIX

19 DVSCPOSC_LO_L 203 203 203 FIX

20 DHSCPOSC_HI 14 14 14 FIX

21 DHSCPOSC_LO 215 215 215 FIX

22 HD_BRTADJ 146

23 HD_CONADJ 46

24 HD_USATADJ 53

25 HD_VSATADJ 54

576P_HD 576P_HD_32" 576P_HD_29"

intial Data Data

145 → 146

47 → 46

32 → 53

32 → 54

146 FIX

46 FIX

53 FIX

54 FIX

Remark

Samsung Electronics 3-15

Alignment & Adjustment

18. Video Adjust6 (comp_HD)

No item Range

0 HORWIDTHP_H 4 4 4 FIX

1 HORWIDTHP_L 226 226 226 FIX

2 VERWIDTHP_H 2 2 2 FIX

3 VERWIDTHP_L 125 125 125 FIX

4 HORPOSP_H 1 1 1 FIX

5 HORPOSP_L 50 50 50 FIX

6 VERPOSP_H 0 0 0 FIX

7 VERPOSP_L 26 26 26 FIX

8 DHSCPRESC_H 2 2 2 FIX

9 DHSCPRESC_L 30 30 30 FIX

10 DNAPPLIP_H 0 0 0 FIX

11 DNAPPLIP_L 240 240 240 FIX

12 DVOFPOSC 128 128 128 FIX

13 VERPOS_S 6 6 6 FIX

14 VEROFFS_S 0 0 0 FIX

15 HORPOS_S_H 1 1 1 FIX

16 HORPOS_S_L 15 15 15 FIX

HPULLINMODE 1 1 1 FIX

17 DVSCPOSC_HI 71 71 71 FIX

18 DVSCPOSC_LO_H 60 60 60 FIX

19 DVSCPOSC_LO_L 178 178 178 FIX

20 DHSCPOSC_HI 15 15 15 FIX

21 DHSCPOSC_LO 255 255 255 FIX

22 HD_BRTADJ 142

23 HD_CONADJ 50 50 50 FIX

24 HD_USATADJ 50

25 HD_VSATADJ 50

720P 50_HD 720P 50_HD_32" 720P 50_HD_29"

intial Data Data

144 → 142

32 → 50

32 → 50

142 FIX

50 FIX

50 FIX

Remark

3-16 Samsung Electronics

Alignment & Adjustment

19. Video Adjust6 (comp_HD)

No item Range

0 HORWIDTHP_H 4 4 4 FIX

1 HORWIDTHP_L 225 225 225 FIX

2 VERWIDTHP_H 2 2 2 FIX

3 VERWIDTHP_L 16 16 16 FIX

4 HORPOSP_H 1 1 1 FIX

5 HORPOSP_L 53 53 53 FIX

6 VERPOSP_H 0 0 0 FIX

7 VERPOSP_L 26 26 26 FIX

8 DHSCPRESC_H 3 3 3 FIX

9 DHSCPRESC_L 210 210 210 FIX

10 DNAPPLIP_H 0 0 0 FIX

11 DNAPPLIP_L 214 214 214 FIX

12 DVOFPOSC 128 128 128 FIX

13 VERPOS_S 24 24 24 FIX

14 VEROFFS_S 1

15 HORPOS_S_H 0 0 0 FIX

16 HORPOS_S_L 240 240 240 FIX

HPULLINMODE 1 1 1 FIX

17 DVSCPOSC_HI 85 85 85 FIX

18 DVSCPOSC_LO_H 70

19 DVSCPOSC_LO_L 255 255 255 FIX

20 DHSCPOSC_HI 14 14 14 FIX

21 DHSCPOSC_LO 162 162 162 FIX

22 HD_BRTADJ 142

23 HD_CONADJ 50 50 50 FIX

24 HD_USATADJ 50

25 HD_VSATADJ 50

720P 60_HD 720P 60_HD_32" 720P 60_HD_29"

intial Data Data

0 → 1

70 → 90

144 → 142

32 → 50

32 → 50

0 FIX

70 FIX

142 FIX

50 FIX

50 FIX

Remark

Samsung Electronics 3-17

Alignment & Adjustment

20. Video Adjust6 (comp_HD)

No item Range

0 HORWIDTHP_H 4 4 4 FIX

1 HORWIDTHP_L 220 220 220 FIX

2 VERWIDTHP_H 2 2 2 FIX

3 VERWIDTHP_L 129 129 129 FIX

4 HORPOSP_H 0 0 0 FIX

5 HORPOSP_L 250 250 250 FIX

6 VERPOSP_H 0 0 0 FIX

7 VERPOSP_L 26 26 26 FIX

8 DHSCPRESC_H 15 15 15 FIX

9 DHSCPRESC_L 30 30 30 FIX

10 DNAPPLIP_H 0 0 0 FIX

11 DNAPPLIP_L 0 0 0 FIX

12 DVOFPOSC 128 128 128 FIX

13 VERPOS_S 6 6 6 FIX

14 VEROFFS_S 0 0 0 FIX

15 HORPOS_S_H 0 0 0 FIX

16 HORPOS_S_L 131 131 131 FIX

HPULLINMODE 1 1 1 FIX

17 DVSCPOSC_HI 53 53 53 FIX

18 DVSCPOSC_LO_H 69 69 69 FIX

19 DVSCPOSC_LO_L 255 255 255 FIX

20 DHSCPOSC_HI 13 13 13 FIX

21 DHSCPOSC_LO 246 246 246 FIX

22 HD_BRTADJ 143

23 HD_CONADJ 49 49 49 FIX

24 HD_USATADJ 50

25 HD_VSATADJ 50

1080i 50_HD 1080i 50_HD_32" 1080i 50_HD_29"

intial Data Data

145 → 143 145 → 143

32 → 50 32 → 50

32 → 50 32 → 50

Remark

FIX

FIX

FIX

3-18 Samsung Electronics

Alignment & Adjustment

21. Video Adjust6 (comp_HD)

No item Range

0 HORWIDTHP_H 5 5 5 FIX

1 HORWIDTHP_L 30 30 30 FIX

2 VERWIDTHP_H 2 2 2 FIX

3 VERWIDTHP_L 17 17 17 FIX

4 HORPOSP_H 0 0 0 FIX

5 HORPOSP_L 180 180 180 FIX

6 VERPOSP_H 0 0 0 FIX

7 VERPOSP_L 26 26 26 FIX

8 DHSCPRESC_H 14 14 14 FIX

9 DHSCPRESC_L 130 130 130 FIX

10 DNAPPLIP_H 0 0 0 FIX

11 DNAPPLIP_L 100 100 100 FIX

12 DVOFPOSC 128 128 128 FIX

13 VERPOS_S 6 6 6 FIX

14 VEROFFS_S 0 0 0 FIX

15 HORPOS_S_H 0 0 0 FIX

16 HORPOS_S_L 190 190 190 FIX

HPULLINMODE 1 1 1 FIX

17 DVSCPOSC_HI 64 64 64 FIX

18 DVSCPOSC_LO_H 0 0 0 FIX

19 DVSCPOSC_LO_L 183 183 183 FIX

20 DHSCPOSC_HI 14 14 14 FIX

21 DHSCPOSC_LO 66 66 66 FIX

22 HD_BRTADJ 143

23 HD_CONADJ 49 49 49 FIX

24 HD_USATADJ 50

25 HD_VSATADJ 50

1080i 60_HD 1080i 60_HD_32" 1080i 60_HD_29"

intial Data Data

145 → 143 145 → 143

32 → 50 32 → 50

32 → 50 32 → 50

Remark

FIX

FIX

FIX

Samsung Electronics 3-19

Alignment & Adjustment

22. VIDEO ADJUST 7(color tone setting)

No item Range intial

0 R drive offset Warm2 -20~+20 3

1 B drive offset Warm2 -20~+20 -9 -9 -9 FIX

2 R cutoff offset Warm2 -20~+20 6 6 6 FIX

3 B cutoff offset Warm2 -20~+20 -11 -11 -11 FIX

4 R drive offset Warm1 -20~+20 2

5 B drive offset Warm1 -20~+20 -2

6 R cutoff offset Warm1 -20~+20 3

7 B cutoff offset Warm1 -20~+20 -2

8 R drive offset Normal -20~+20 0 0 0 FIX

9 B drive offset Normal -20~+20 0 0 0 FIX

10 R cutoff offset Normal -20~+20 0 0 0 FIX

11 B cutoff offset Normal -20~+20 0 0 0 FIX

12 R drive offset Cool 1 -20~+20 0

13 B drive offset Cool 1 -20~+20 4 4 4 FIX

14 R cutoff offset Cool 1 -20~+20 2

15 B cutoff offset Cool 1 -20~+20 6 6 6 FIX

16 R drive offset Cool 2 -20~+20 -2 -2 -2 FIX

17 B drive offset Cool 2 -20~+20 6 6 6 FIX

18 R cutoff offset Cool 2 -20~+20 0 0 0 FIX

19 B cutoff offset Cool 2 -20~+20 9 9 9 FIX

WS32Z30/40 (32") CW29Z30/40 (29")

Data Data

3 → 8

2 → 4

-2 → -3

3 → 4

-2 → -3

0 → -5

2 → 0

8 FIX

4 FIX

-3 FIX

4 FIX

-3 FIX

-5 FIX

0 FIX

Remark

3-20 Samsung Electronics

Loading...

Loading...