Page 1

2. Reference Information

2-1 Abbreviations and Acronyms

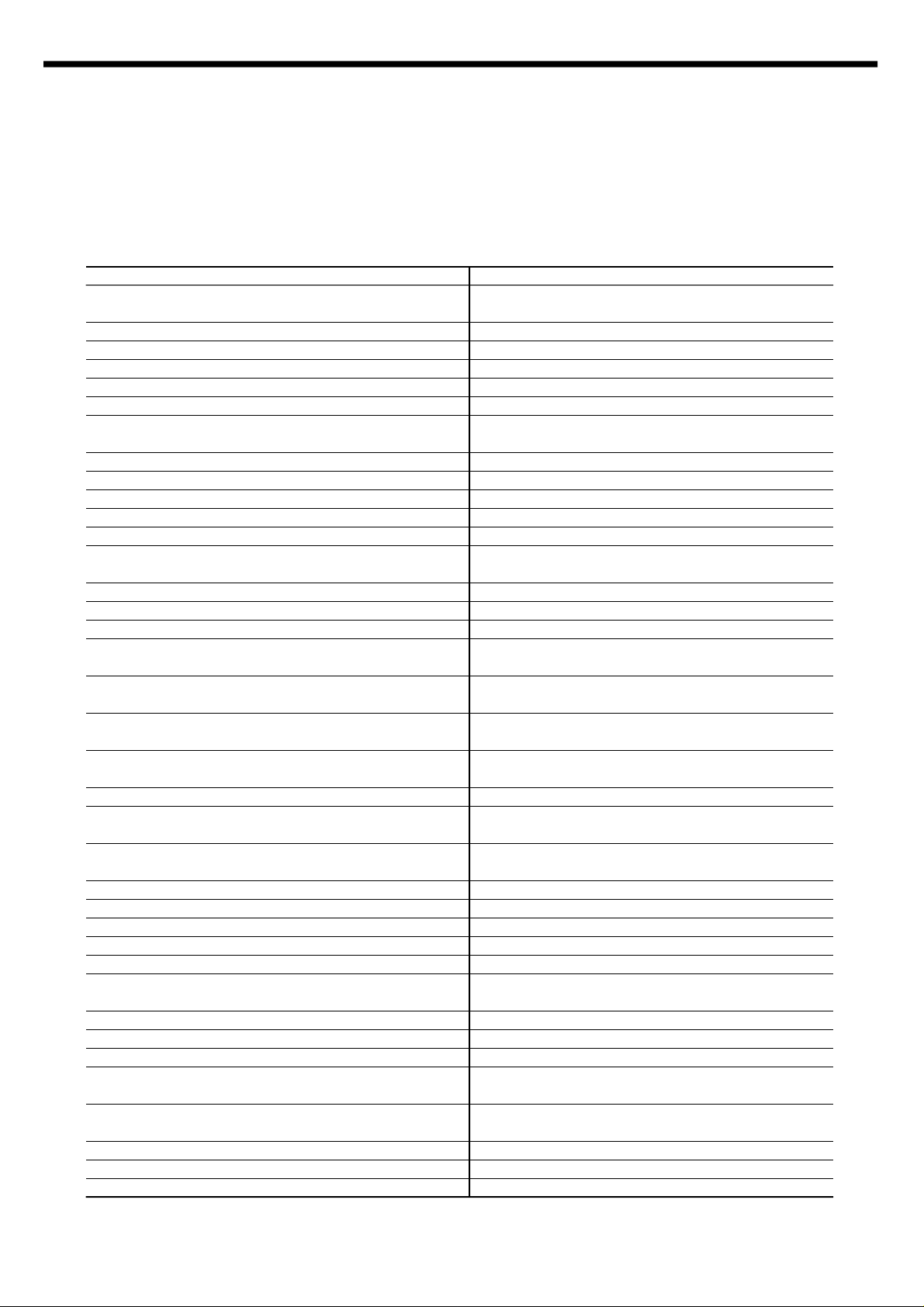

Tables 2-1 and 2-2 List abbreviations and acronyms which may be found in this sevice manual.

Table 2-1. Abbreviations

Abbv Definition Abbv Definition

amps amperes lb pound(s)

lin linearity

ass’y assembly lock bus lock

badac bad assess mm millimeter(s)

neg negative

bps bits per second od open drain

clk clock OSC oscillator

cm centimeter(s) OUT output

CON connector PIC picture

GND ground pos positive or position

HLDA hold acknowledge pot potential

HLDAR hold acknowledge received psynrq page synchronizaton request

HLDR hold request pwr power

HOR horizontal qty quantity

in inch(es) or input sw switch

INTA interrupt Acknowledge sync synchronous or

synchronization

INT Interrupt tach tachometer

INTR Interrupt request Vcc collector supply valtage(dc)

I/O Input and Output vert vertical

mpx multiplex Vp-p peak-to-peak voltage

VR variable resistor

Page 2

Table 2-2. Acronyms

Acronym Definition Acronym Definition

ABL Automatic Blanking Limiter IDE Intelligent Drive electronics or

Imbedded Drive Electronics

ACC Automatic Color Control IF Intermediate Frequency

ADC Analog to Digital Converter IPM Images Per Minute

ADS Address/Data Status ISA Industry Standard Architecture

ALE Address-Latch Enable KBC Keyboard Controller

ASCII American Standard Code for LAD Local Address/Data Bus

Information interchange

BIOS Basic Input/Output System LCD Liquid Crystal Display

BPF Band Pass Second LED Light Emitting Diode

BPS Bits Per Second MCA Micro Channel Architecture

CCFT Cold Cathode Fluorescent Tube MDA Monochrome Display Adapter

CGA Color Graphics Adapter NC No Connection

CMOS Complementary Metal Oxide NF Noise Fiqure or Noise Factor

Semiconductor

CPU Central Processing Unit PA Power Amplifier

CRT Cathode Ray Tube PBA Printed Board Assembly

CRU Customer Replacement Unit

DMA Direct Memory Access or PBM Primary Bus master

Dynamic Memory Address

DMAC Direct Memory Access PCB Printd Circuit Board

Controller

DVM Digital Voltmeter PCMCIA Personal Computer Memory

Card International Association

EEPROM Electronically Erasable Pro- PLCC Plastic Leaded Chip Carrier

grammable read Only Memory

EGA Enhanced Graphics Adapter PMS Power Management System

EISA Extended Industry Standard POST Power On Self Test

Architecture

ESDI Enhanced Small Device PPM Pages Per Minute

Interface

FDC Floppy Disk Controller PQFP Plastic Quad Flat Package

FDD Floppy Disk Drive QFP Quad Flat Package

FL Fluorescent Light(Lamp) RAM Random Access Memory

HDD Hard Disk Drive ROM Read Only Memory

HPF High Pass Filter RTC Real-Time Clock

SCSI Small Computer Systems SBM Secondary Bus Master

Interface

SIO Serial Input/Output Controller TSTN Triple Super Twisted Nematic

SOP Small Outline Package UHF Ultrahigh Frequency

SSOP Shrink Small Outline Package VCO Voltage Controlled Oscillator

STN Super Twisted Nematic VESA Video Electronics Standard

Association

SCC Serial Communications VGA Video Graphics Array

Controller

TFT Thin Film Transistor VHF Very High Frequency

TS Tri-State XO Crystal Oscillator

TSOP Thin Small Outline Package

Page 3

2-2. Diagnostic Control Unit

2-2-1. Abstract

The diagnostic Control Unit(DCU) is useful for troubleshooting the Laser beam printer ML Series engines,

and for checking printer status.

The DCU can be used in common for ML series, but each model has several different code description.

Refer to the code description for ML-7000 in next page.

< Fig 1-1. ML-80 DCU >

Page 4

2-2-2. List of code description

Code Description

1. DIAGNOSTIC CODE 2.STATUS CODE

00 MAIN MOTOR OPERATING 78 SYSTEM ERROR

01 MAIN HIGH VOLT ON / OFF TEST 00 Ready to print from LEGAL paper tray

02 THV (- ) ON / OFF TEST 01 Ready to print form LETTER paper tray

03 THV (+) ON / OFF TEST 02 Ready to print form A4 paper tray

04 DEV, SUPPLY ON / OFF TEST 03 Ready to print form EXEC paper tray

05 LSU OPERATING TEST 04 Ready to print from B5 paper tray

06 PICK UP CLUTCH ON 05 Ready to print from FOLIO paper tray

07 PE, DS1, DS2 SENSOR TEST 20 PRINT START (1st CASSETTE)

08 MP, EXIT, FEED SENSOR TEST 21 PRINT START (MULTI PURPOSE)

09 TOP & REAR COVER OPEN, 22 PRINT START (2’nd CASSETTE)

OUT BIN SENSOR TEST 23 PRINT START (DUPLEX)

10 FUSER TEST 50 PAPER OUT

11 HOT BURN TEST 60 OPEN FUSER ERROR

12 DUPLEX CLUTCH TEST 62 LOW HEATER ERROR

13 MULTI PURPOSE CLUTCH TEST 68 OVER HESTER ERROR

14 THERMISTER 2 TEST 61 WARM-UP

15 PAPER SIZE SENSOR TEST 64 COVER OPEN ERROR

69 SLEEP MODE

70 NO PAPER or CASSETTE

71 PAPER JAM “0”

72 PAPER JAM “1”

73 PAPER JAM “2”

74 DUPLEX JAM “1”

75 DUPLEX JAM “2”

76 OUT BIN FULL

95 LSU NOT READY

Page 5

2-2-3. The Diagnostic Control Unit (DCU) Operating Guide

¶°Display the engine status and error status code. Refer to List of Code Description.

2) Self-Test mode.

¶°When the engine is ready, this button starts printing a streak pattern.

3) Green mode

¶°Transfer high Voltage adjustment mode

With the power off, hold down the Self-Test button and turn on the pinter. Continue holding down the button

for 5 seconds to start Green mode.

4) Diagnostic Control mode.

¶°With the power off, hold down the 3 button (up/down, shift, stop/enter) and turn on the printer

Continue holding down the button for 5 seconds to start Diagnostic Control mode on the engine.

¶°The DCU has three diagnostic control buttons.

UP : Steps the function of the other two buttons:

SHIFT : Controls the function of the other two buttons:

SHIFT+UP means step down and SHIFT+START means stop.

START : Stasrts or stops the current diagnostic test.

Code Key Operation LED Display

00 ENTER Run Main Motor Lighten ON LED

SHIFT+STOP Stop Main Motor Lighten OFF LED

UP Increment DCU Code No. (01, MHV)

SHIFT+DOWN Decrement DCU code No. (13, MP)

01 ENTER MHV ON Lighten ON LED

SHIFT+STOP MHV OFF Lighten OFF LED

UP Increment DCU Code No. (02, THV Negative)

SHIFT+DOWN Decrement DCU code No. (00, Main Motor)

02 ENTER THV Negative ON Lighten ON LED

SHIFT+STOP THV Negative OFF Lighten OFF LED

UP Increment DCU Code No. (03, THV)

SHIFT+DOWN Decrement DCU code No. (02, MHV)

03 ENTER THV ON Lighten ON LED

SHIFT+STOP THV OFF Lighten OFF LED

UP Increment DCU Code No. (04, Dev)

SHIFT+DOWN Decrement DCU code No. (02, THV Negative)

04 ENTER DEV, SUPPLY ON Lighten ON LED

SHIFT+STOP DEV, SUPPLY ON Lighten OFF LED

UP Increment DCU Code No. (05, LSU)

SHIFT+DOWN Decrement DCU code No. (03, THV)

05 ENTER LSU Motor On Lighten 3rd LED

UP LSU Leady and LD On Lighten 1, 2nd LED

SHIFT+STOP LSU Motor OFF

UP Increment DCU Code No. (06, Pickup Clutch)

SHIFT+DOWN Decrement DCU code No. (04, Dev)

The DCU has functions as follows:

1) Engine Status and Error Code Display mode

Page 6

Code Key Operation LED Display

ßZ15°…1st LED ON

No Action 15°…¶ZTemperature ¶Z30°…2nd LED ON

No Action Temperature ß[30°…3nd LED ON

No Action Thermister 2 Open All LED ON

No Action Thermister 2 Short All LED OFF

UP Increment DCU code No.

(15, Cassette sensor TEST)

SHIFT + DOWN Decrement DCU Code No. (13, MP Clutch TEST)

15 No Action Cassette Sensor 1 ON/OFF 1st LED ON/OFF

No Action Cassette Sensor 2 ON/OFF 2nd LED ON/OFF

No Action Cassette Sensor 3 ON/OFF 3nd LED ON/OFF

UP Increment DCU Code No. (00, Main Motor)

SHIFT + DOWN Decrement DCU Code No. (14, Thermister 2 Test)

06 ENTER Pickup Clutch ON Lighten ON LED

SHIFT+STOP Pickup Clutch OFF Lighten OFF LED

UP Increment DCU Code No. (07, Sensor TEST)

SHIFT+DOWN Decrement DCU code No. (06, Pickup Clutch)

07 No Action Paper Empty Sensor ON/OFF 1st LED ON/OFF

No Action Duplex 1 Sensor ON/OFF 2nd LED ON/OFF

No Action Duplex 2 Sensor ON/OFF 3rd LED ON/OFF

UP Increment DCU Code No. (08, Sensor TEST)

SHIFT+DOWN Decrement DCU Code No. (06, Pickup Clutch)

08 No Action Multi Purpose Sensor ON/OFF 1st LED ON/OFF

No Action Exit Sensor ON/OFF 2nd LED ON/OFF

No Action Feed Sensor ON/OFF 3rd LED ON/OFF

UP Increment DCU Code No. (09, Sensor TEST)

SHIFT+DOWN Decrement DCU Code No. (07, Sensor TEST)

09 No Action Cover Open Sensor ON/OFF 1st LED ON/OFF

No Action Cover Open Sensor ON/OFF 2nd LED ON/OFF

No Action Out Bin Sensor ON/OFF 3rd LED ON/OFF

UP Increment DCU Code No. (10, Fuser TEST)

SHIFT+DOWN Decrement DCU Code No. (08, Sensor Clutch)

10 ENTER Fuser ON Lighten ON LED

SHIFT+STOP Fuser OFF Lighten OFF LED

UP Increment DCU Code No. (04, Dev)

SHIFT+DOWN Decrement DCU code No. (02, THV Negative)

12 ENTER Duplex Clutch ON Lighten ON LED

SHIFT+STOP Duplex Clutch OFF Lighten OFF LED

UP Increment DCU Code No. (13, MP Cluth)

SHIFT+DOWN Decrement DCU code No. (11, Self-Test)

13 ENTER Multi Purpose Clutch ON Lighten ON LED

SHIFT+STOP Multi Purpose Clutch OFF Lighten OFF LED

UP Increment DCU Code No. (14,Thermister 2 Test)

SHIFT+DOWN Decrement DCU code No. (12, Duplex Clutch)

14 No Action Temperature

Loading...

Loading...