Samsung ML-3550N Service manual

Samsung Laser Printer

ML-3550N

SERVICE

Manual

LASER PRINTER

CONTENTS

1. Precautions

2. Outline

3. Construction and Operation

4. Disassembly and Assembly

5. Maintenance

6. Troubleshooting

7. Exploded view and Part List

Samsung Electronics Co.,Ltd. May 2003

Printed in Korea.

VERSION NO. : 1.02 CODE : JC-0070A

Copyright(c) 2003. 5.

1-1Samsung Electronics

1. Precautions

Read the following cautions before repairing this printer. Please read and understand the cautions for your safety.

1.1 Cautions for safety

Warning 1

LCD contains harmful materials.

Liquid in LCD is harmful to humans.

1.2 Cautions of safety

Do not touch the damaged LCD.

This printer has LCD on the Operating panel. In

the LCD, there is a liquid, bad for human body. If

the liquid contacts to a mouth, please rinse off

immediately and go to see a doctor. Also, if it

contacts to eyes, rinse it off with flowing water over

15 minutes and go to see a doctor.

Warning 2

If you don't follow this manual, you can get

burned or an electronic shock.

Do use proper power voltage.

The outlet for power supply must have appointed

current or voltage. If not, a fire or a leakage of

electricity can be occurred.

Do use specified power cord.

Do use the cord supplied with the printer.

If higher current than regular power flows through

the power cord, a fire can be occurred.

Do not connect many plugs into one

outlet.

This higher current flow in the outlet may cause a

fire.

Do not put water or foreign objects into

printer.

Do not put foriegn object or liquid in or on the

priner. It may cause fire, electric shock, or

malfunction. If this accidently occurs remove the

power immediately remove plug from the outlet.

Do not look into the inner side of the

printer.

This printer uses laser diode. Do not look into the inner side

of the machine when power is on, or put mirror, metal, etc.

into the printer. If the laser beam contacts a human's eye, it

can cause blindness. (Laser beam cannot be observed by

human's eyes)

Do not disassemble, repair, or rebuild the

printer.

Do not disassemble, repair or rebuild parts, which are not

mentioned in this service manual. Doing so can cause

malfunctions and an electric shock and a fire can occurr.

If there are strange smell or sound...

If there are strange smells or sounds turn off the power and

pull out the plug from an outlet. If continually using the

machine may cause a fire.

Do not put any foreign object into the

printer.

Do not put any foreign objects into the printer.

It may cause an electric shock or fire.

Precautions

1-2 Samsung Electronics

Do not touch the power plug with wet

hands.

Please remove the power plug from an outlet when

servicing. Also, do not put in or pull out the plug with wet

hands. It can cause an electric shock.

When you put in or pull out the plug...

When you put in or pull out the plug, you should do it

by grabbing the plug part. If you put in or pull out the

plug by grabbing the cord part, the cord can be

damaged and it can cause a fire or an electric shock.

When you put in the plug, put in it securely.

Do put the plug securely.

If not, fire can be occurred due to connecting inferiority.

Do handle the power cord carefully ...

Do not bend, twist, or tie it or put heavy object on it.

Also, do not fix it by staple. If a cord is damaged, fire

or electric shock can be occurred.

Do replace the damaged power cord

immediately .

A damaged power cord must be replaced immediately

with a same type of cord. Do not repair and use it. If

you repair it with a tape, a fire or electric shock can be

occurred.

Do not spray any kind of medical stuff.

Do not spray an insecticide or other medical stuff on

the power cord. The cover of the cord can be thinner

due to the behavior. It can cause a fire or electric

shock.

When there is thunder and lightening...

Those can cause a fire or an electric shock. Pull out

the power plug from an outlet and do not touch a cable

or other parts when thundering and lightening.

Do avoid dusty and high moist place.

Do not install the printer at place where has dust or

high moist place (around a humidifier). It is possible to

occur a fire. Pull out the plug separately and clean it

with dry fabric. If water drops on the dusty place, a fire

can be occurred.

Do avoid direct sunlight.

Do not install the printer at place exposes to a direct

sunlight like near by a window. It do, inner

temperature is getting higher. Therefore, a

malfunction or a fire can be occurred.

Be careful with the high temperature part.

The fuser unit works at a high temperature. Use caution

when working on the printer. Wait for the fuser to cool off

before disassebly.

Do not put finger or hair into the rotating

parts.

When operating a printer, do not put hand or hair into

the rotating parts (Paper feeding entrance, motor, fan,

etc.). If do, you can get harm.

When you move the printer ...

This printer is 60 kg including developing cartridge

and cassette. If you wish to move it, it must be

moved by two people. Do grab the handle at each

side and hold the front. If one person tries to move it,

it can cause a physical injury (back born).

Do not install printer on an unstable place.

Do not install the printer on an unstable place. This can

cause bodily harm, or damage the printer. It is 60 kg, so if

you wish to put it on a table, check the table bo be sure

the tablet is strong enough to support the printet.

Do not install a printer on an inclined floor or

an unbalanced place. After installation,

double check that the printer is stable.

Warning 3

Disregarding this warnning may cause bodly

injury.

Precautions

1-3Samsung Electronics

1.3 ESD Cautions

Several semiconductor devices can be damaged easily by static electricity. Such parts are called ESD (Electrostatically

sensitive devices), and IC, semiconductor chip, etc. are ESD.

Please read the cautions shown in the below. Damages from static electricity can be prevented.

1. Static electricity, remains on a body, must be removed before handle semiconductors or parts attach a semiconductor.

Touch a ground or tie a leather belt on a wrist, which prevent static electricity,.

2. After separate the ESD part, put it on the surface of aluminum or copper, which have conductivity ability, to prevent

static electricity.

3. Do use a soldering wire when you connect or disconnect the ESD.

4. Do use a soldering remover treated with 'static electricity breaker' function. If not, ESD can be damaged due to a static

electricity.

5. Do not use chemical product has the Freon ingredient. When the Freon gas is jetting, a static electricity is occurred.

Therefore, it can damage the ESD.

6. Do unpack the ESD package right before install it. The most of ESD are packed with conductive box, aluminum plate,

and etc., which prevent static electricity.

7. Before take off the tape for preventing current from the soldering part of ESD, do make the soldering part to get in touch

with the circuit part.

8. An electric connection between ESD and the part must be maintained until the ESD is securely put-in or it is attached

on circuit plate.

9. Be careful to move your body when you handle the unpacked ESD replacement part. To rub clothes or to step on a

carpet occur a static electricity, which can damage the ESD.

1.4

Cautions for replacement and management of the inferior parts

1. When you replace the video controller PBA, you must disassemble the NVRAM(U2) from the used PBA and attach it to

the new PBA. The NVRAM stores several important information such as history of printout counts, jam occurring

counts, unit replacing counts, and so on. If you replace the NVRAM with a new one, all the information is erased as

initial status as from factory.

In this case, it is difficult to maintain or to repair the product properly.

When replace the video controller PBA, the NVRAM must be attached to a new PBA.

2. This printer is easy to repair and to replace because the most of parts are modularized, and has functions to check the

using amount and the life span of each unit.

After replacing the inferior parts, initialize the using amount of the part, which stored in system.

(Chapter 6 Troubleshooting - Service Mode - Reset Unit CNT: refer to the 6-51 page)

3. Some parts are consumption parts such as engine oil or belt of car. The parts' life span is stored in NVRAM, and you

can check the using amount of parts when you need.

After replacing the parts, the life count value must be initialized for informing the replacement to the machine.

(Chapter 6 Troubleshooting - Service Mode - Reset Unit CNT: refer to the 6-51 page)

Warning : Do pull out all the power and keep the cautions for safety.

Precautions

1-4 Samsung Electronics

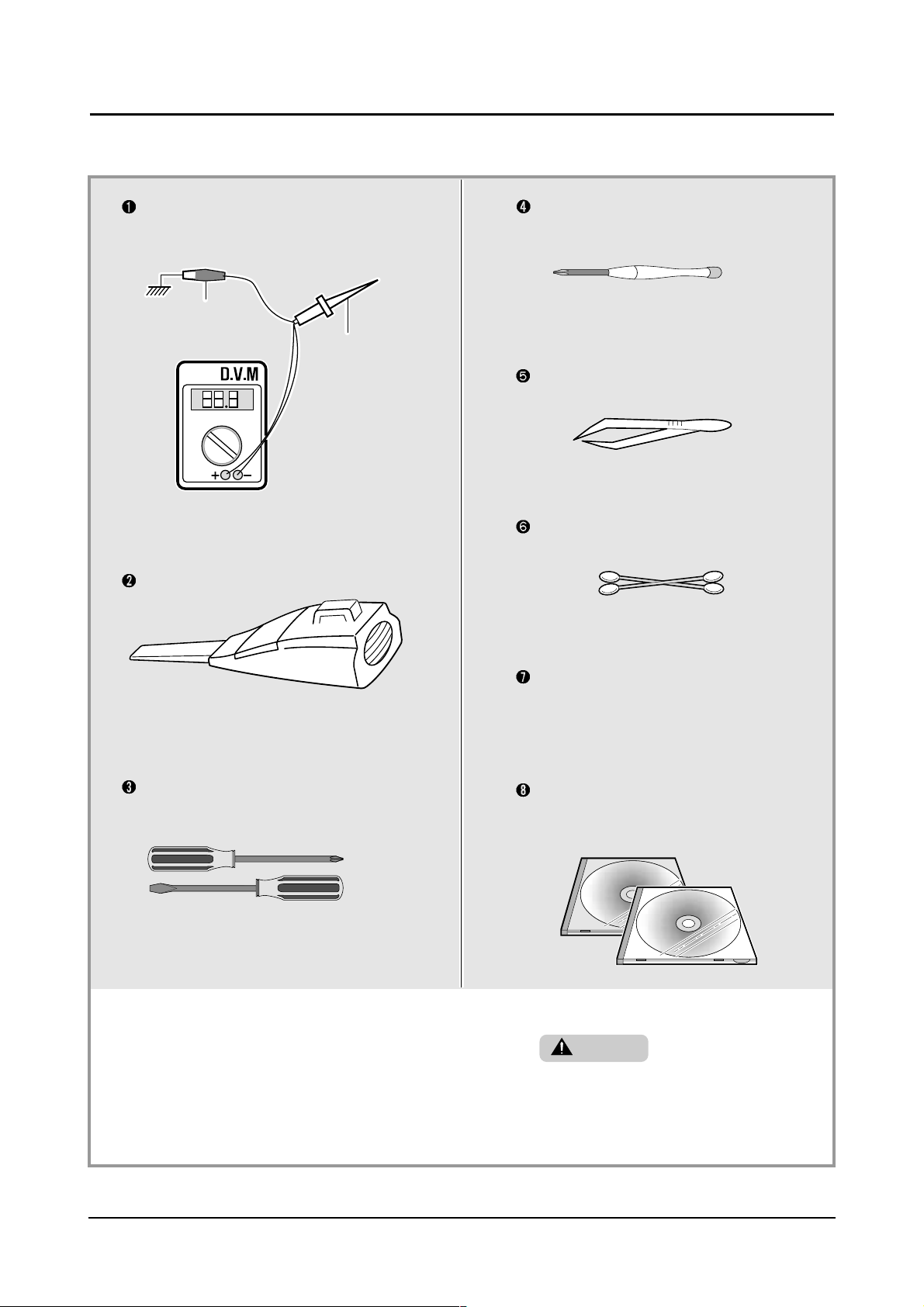

1.5 Tool list for repair

It is recommend to use the tools shown in the below for proper repair explained in this service manual.

DVM (Digital Volt Meter)

• Standard: Displays over 4 digits (DC, AC)

Vacuum

Driver

• Standard: "-" shape type, "+" shape type (M3

long, M3 short, M2 long, M2 short)

Timer driver

• Standard: "+" shape type (M3)

Tweezers

• Standard: For home use, small type

Cotton swab

• Standard: For home use, For medical use

Cleaning tool

• Dry fabric or soft fabric.

• IPA: Isopropyl Alcohol)

Software(Driver) installing CD-ROM

• Installing driver CD-ROM

• Networking installing CD-ROM

Warning

When disassembling or assembling the

PBA Ass’y, be careful not to touch the part

due to its sensitiveness for the electric

static.

Ground

Ground

High Volt Probe

High Volt Probe

1G

1G

1,000 : 1

1,000 : 1

Samsung Electronics

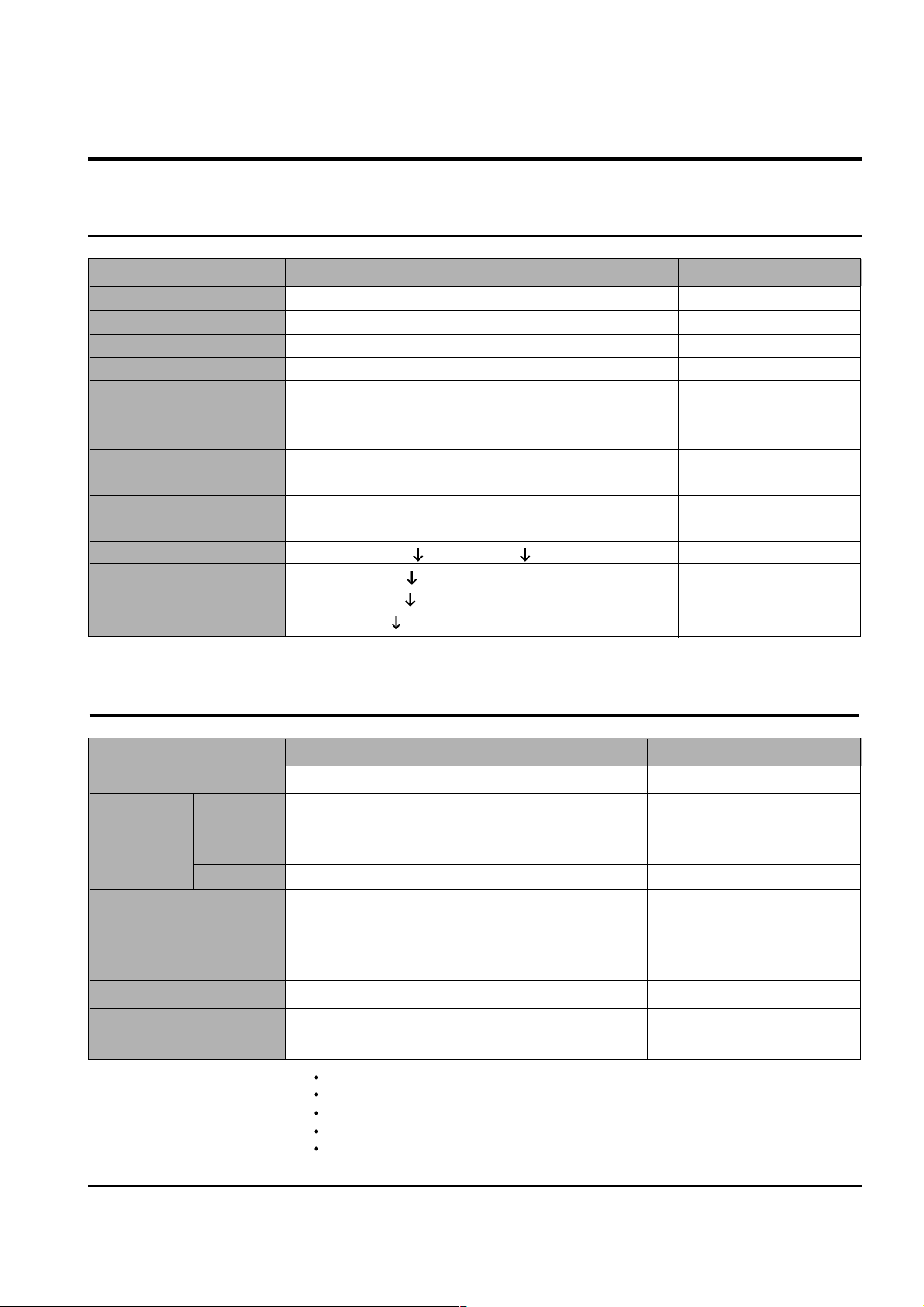

Outline

2-1

2. Outline

2.1 Printer Engine

2.2 Controller

ITEM SPEC REMARK

Printing Speed 35 PPM (A4)

Resolution 600 DPI, 1200 DPI Class

Scanning LSU

Technology

Electronic Photo Process

Toner, Fusing 2 Components Toner, Heat/Pressure

Operating time

Cold WarmUp : 60 sec Less than

FPOT : 12.5 sec Less than

Dimension 560 (W) X 498 (D) X 560 (H) mm

Weight 60 Kg (convert to LBS.)

Gross Weight

Power Supply EURO : 220 ~ 240 VAC 50 ~ 60 Hz

USA : 100 ~ 120 VAC

Consumption Power Standby : 250 W , Sleep : 40 W , Printing : 850 W

Noise Simplex : 55 dB

Duplex : 58 dB

Stand by : 40 dB

ITEM SPEC REMARK

Processor Power PC 603e 266 MHz

Memory RAM

Basic

: 32 M 64/128MB

Option : 2 DIMM SLOT

Refer to the 7.15 others

(Separately purchase)

ROM 1 DIMM SLOT

Emulation PCL6, PS3

Fonts 10 True T ype Outlines

1 PCL Bitmap

136 PS3 Font

Interface

Basic type

: IEEE1284, USB, Ethernet 10/100 TX Auto interface switching

Device Driver PCL for WIN 9x/NT, 2000, Mac, Linux

(1)

PS 3 for WIN 9x/NT, 2000, Mac, Linux

(1)

MAC OS : Network Connection : Power Macintosh or higher

Macintosh OS 8.6 or higher

USB Connection :

G3 or higher

Macintosh OS 8.6 or higher

USB port

Samsung Electronics

Outline

2-2

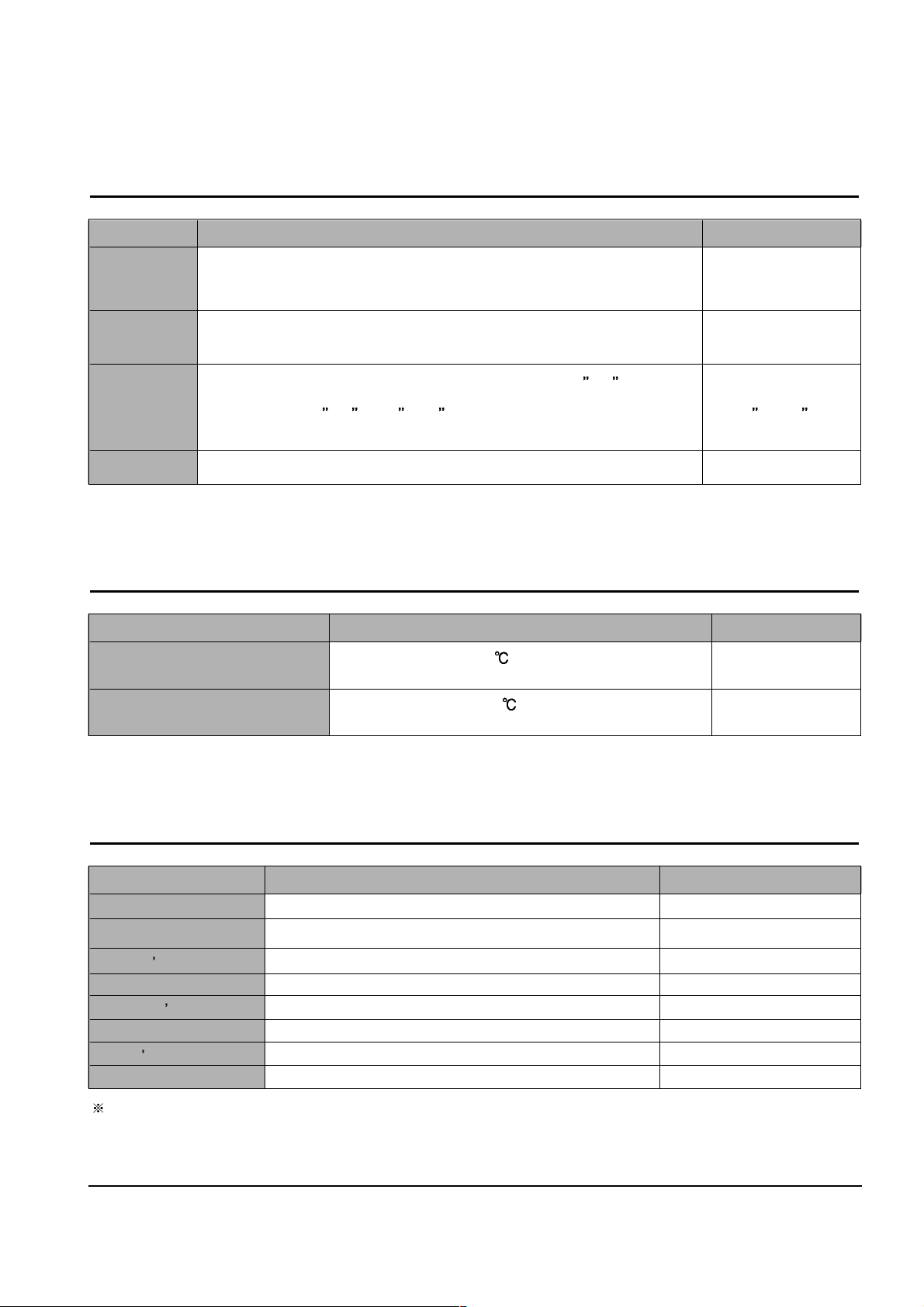

2.3 Print paper

ITEM SPEC REMARK

Input Tray 2 x 500 Sheets CST (75 g/m

2

or 20 lb) : 60 to 105 g/m2 (16 to 28 lb)

Sheets Maximum 2,000 sheets

Option Cassette

(SCF) : 2x500 Sheets : 60 to 105 g/m2 (16 to 28 lb)

Sheets

:

75g loading amount

50 Sheets MPF (75 g/m

2

or 20 lb) : 60 to 165 g/m2 (16 to 43 lb)

Sheets

Output Tray

Maximum

500 Sheets F/D (

Standard of

75 g/m

2

(20 lb)

paper

)

Sheet Size CST : A5, B5, B4, Exec, A4, Letter, Folio, State, Legal, A3,11 x17 Max Print Line

MPF : A6 ~ A3, 11 x17 ,12.28 x18.5 (306mm x 465mm), B4, B5, LTR : 12.05 x18.31

Folio, State

Duplex 32 IPM (Image Per Minute) :

Standard of horizontal output of the A4 paper(LTR)

2.5 Consumption parts

ITEM SPEC REMARK

Toner Container 25,000 Sheets Container (40,000 Economy),

5% density standard User can replace it

Developer unit 50,000 Sheets (

For sale

),

A4 Sheet, 5% density standard

Service person should replace it.

Fuser Ass y 200,000 Sheets : A4

standard

Service person should replace it.

Pick-up roller rubber

100,000 Sheets : A4

standard

Service person should replace it.

Transfer Ass y 100,000 Sheets : A4

standard

Service person should replace it.

MPF Roller &

Rubbing Pad

100,000 Sheets : A4

standard

Service person should replace it.

Exit Ass y 500,000 Sheets : A4

standard

Service person should replace it.

Main Fan 750,000 Sheets : A4

standard

Service person should replace it.

2.4 Environment

ITEM SPEC REMARK

Operating Environments Temperature : 10 ~ 32

Humidity : 20 ~ 80 %

Storage Environments Temperature : -20 ~ 50

Humidity : 0 ~90 %

Please refer to the [Chapter 5 Maintenance] for the consumption parts and the life span parts.

Samsung Electronics

Outline

2-3

2.6 Network Type

ITEM SPEC REMARK

OS support

• Windows 95/98/ME/XP

(Network Operating Systems) • Windows NT 4.0/2000

• NetWare (3.x,4.x,5.x), NDS and Bindery

Mode/PSERVER and PRINTER

• UNIX(LPR)- LINUX(LPR)

• OS 400(LPR)

• Macintosh(7.0 higher)

Protocols

support

• TCP/IP(Port 2000) : For Printing

(Network Protocols Supported) Windows 95/98/ME/XPWindows NT 4.0/2000

• LPR(Port 515):

Windows NT4.0/2000/XP, UNIX, LINUX, Macintosh, OS-400

• 9100 Port : Windows 2000/XP, UNIX, LINUX

• IPP : Windows 95/98/ME/XP, NT4.0/2000

• IPX/SPX : Windows 95/98/ME/XP/NetWare 3.x/4.x/5.x

• DLC/LLC: Windows 95/98/Windows NT 4.0/2000

• EtherTalk: Macintosh(7.0 higher)

• SMB(NetBEUI,NetBIOS):

Windows95/98/ME/XP/Windows NT 4.0/2000.

• SNMP (Based on DLC/LLC, TCP/IP, IPX/SPX) For Management

Network Card Interface • Ethernet 10/100 Base TX (Auto Negotiation)

Administrator Program • SyncThru :

(Network Management S/W) Samsung' Admin Software Utility. Based on Windows

Operating System.

• SNMP and MIB-II Support.

• HTTP server for web browser based network management

(can manage NPC and printer options on web browser)

Application Program for user • JMS(Job Management System) : can manage print job.

• Status Monitor : can monitor printer's status.

• Port Monitor: can print some job by Samsung Network Print Port

• IPP (Internet Printing Protocol) Port Monitor and Client :

can print some job over Internet.

• SetIP : can set IP address.

2.7 Panel Type

ITEM SPEC REMARK

User Panel 8 Keys, LED Key(2 Color), 2x16 ICON LCD

3. Construction and Operation

The Samsung ML-3550N is a high-speed laser printer that prints 35 pages per minute. (A4 horizontal standard) The ML3550N has a print resolution of 600dpi. It also has a duplex printing function and a offset catch function, that automatically

arranges document for convenience of the network user.

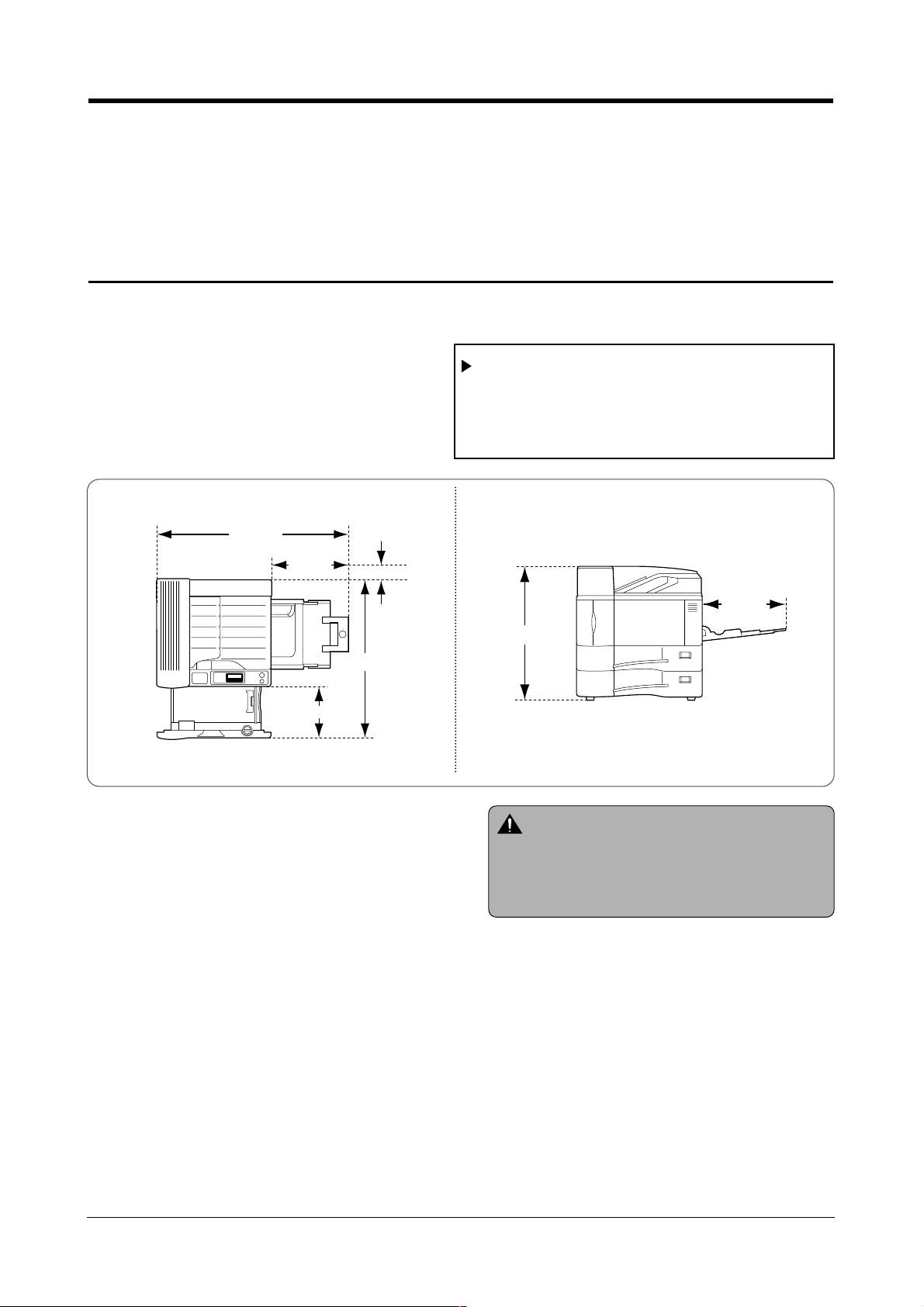

3.1 Printer size and Installation

The printers location should allow enough space to open covers, Multi-cassettes, and cassettes.

3-1Samsung Electronics

Warning

1. Do move this printer with at least two people

due to its heavy weight.

2. Do install this printer in balance.

Do not install it on the inclined surface.

837 mm

292 mm

100 mm

889 mm

368 mm

292 mm

583 mm

Do avoid the place mentioned in the below.

• Bad ventilated place • Near to heater

• Exposed by direct sunlight • Moist place

• Inclined place

Construction and Operation

Samsung Electronics

3-2

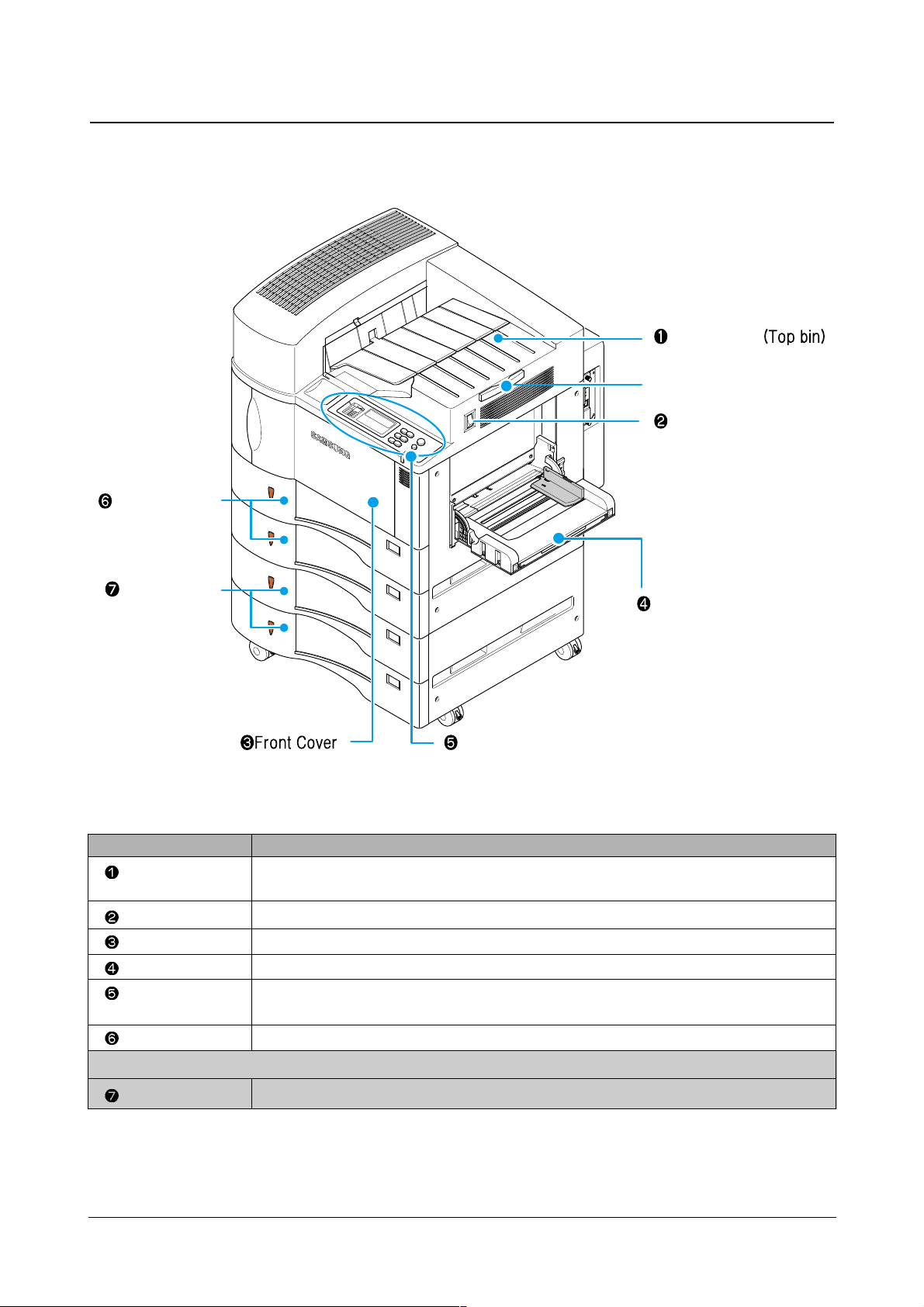

Standard bin

Power Switch

Multi-cassette

OPE panel

Cassette 1,2

Cassette 3,4

Use it when printing

longer paper such as A3.

Name Functions

Standard bin This is the basic (standard) output tray.

(Top bin)

The printed side is always faced down.

Power Switch It is a function to turn the power ON/OFF.

Front Cover

It needs to be opened when installing the developer or toner cartridge.

Multi-cassette It is used when various paper types are fed such as envelops, OHP, etc.

OPE panel It has display a window for displaying the present status, buttons for selecting functions of

printer, and a lamp.

Cassette 1, 2 500 standard sheets can be fed from the each cassette (75g sheets standard).

Optional Feeding Device

Cassette 3,4 The each cassette can feed 500 standard sheets. (75g sheets standard)

3.1.1 Front part of the printer

Construction and Operation

3-3Samsung Electronics

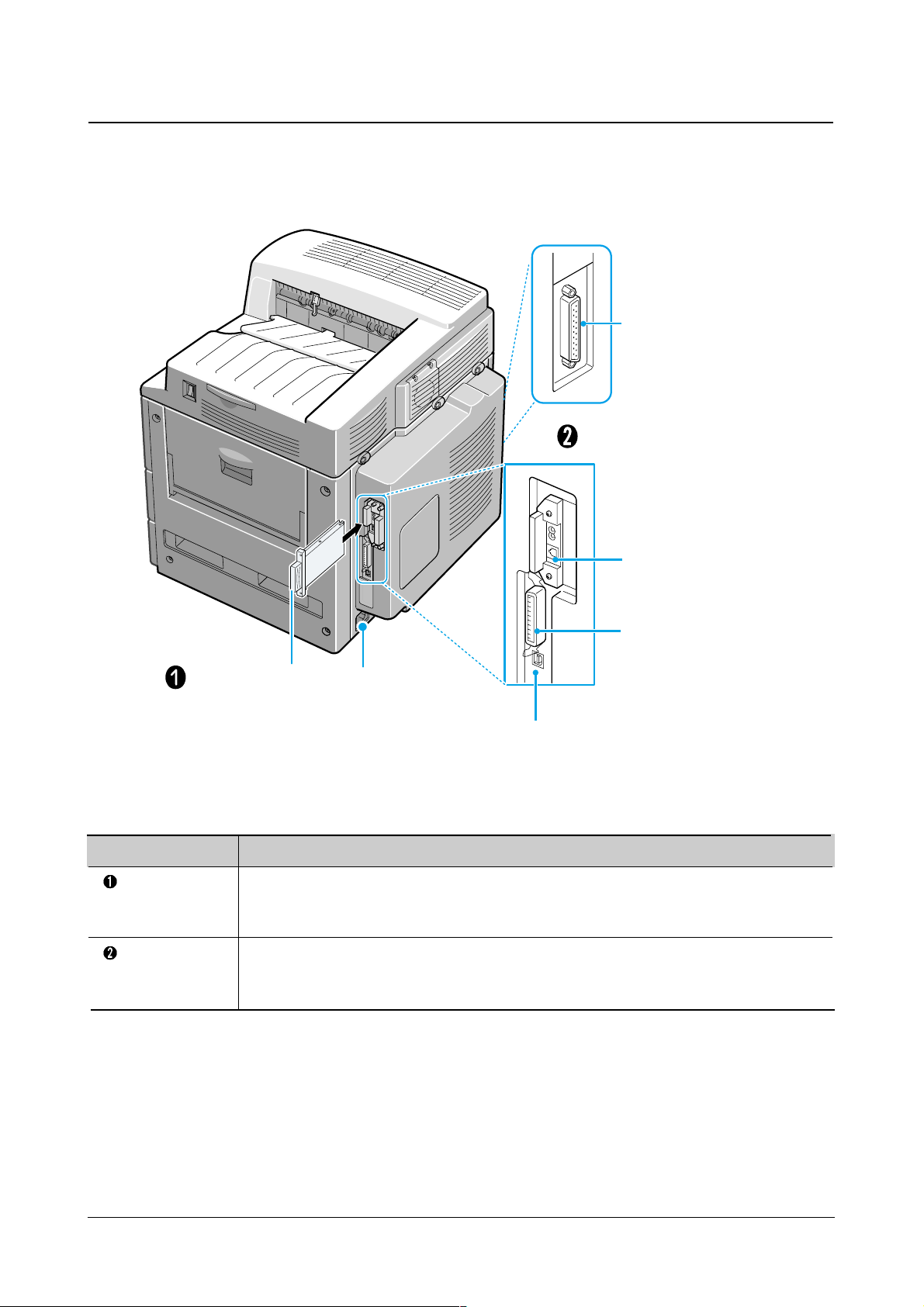

3.1.2 Rear part of the printer

10/100 Base-TX

Network Ethernet Port

IEEE 1284 Parallel

Printer Port

USB Port

power input socket

Hard Disk (HDD)

(Option)

To second cassette

feeder connector.

Name Functions

Hard disc

(Option)

Computer

connecting

interface

It is 10 Gbytes, enough to download all files which user sends, so it reduces the standby

time for print. After printing, it can store the information, and the other various functions such

as printing confidential document function can be used.

It services the IEEE 1284 Parallel Port and 10/100 Base TX network Ethernet Port.

It means that it is well interfaced with a personal (local type) computer environment and a

network environment.

Construction and Operation

Samsung Electronics

3-4

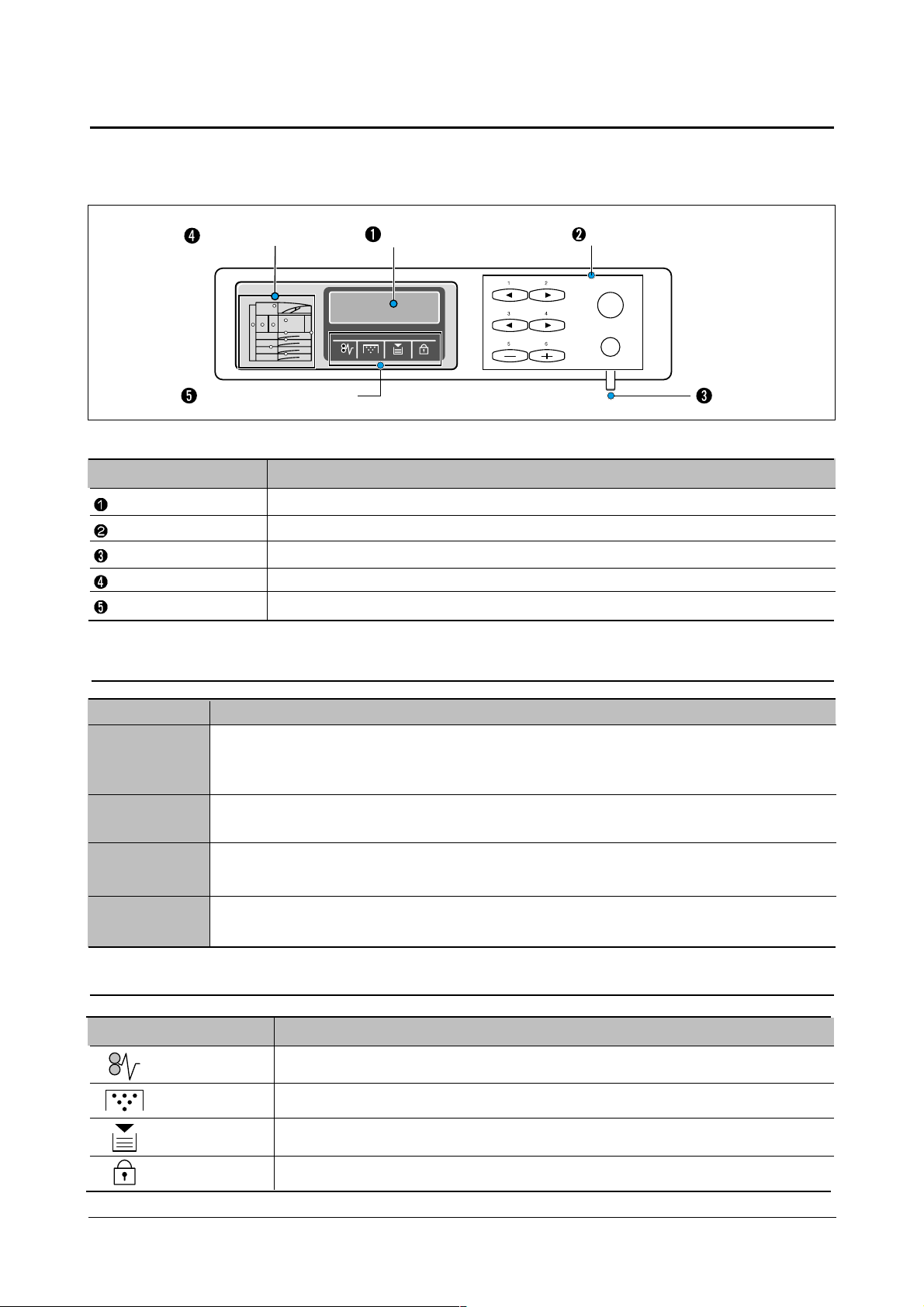

3.2 OPE Panel

A switch for displaying the status of the printer and for operation, LED, and LCD for displaying the status of the device,

errors, and so on are attached on the panel.

<Error display unit tells at where an error is occurred>

Display window Button

Lamp

Error content display

Jam location display

MENU

Online / Continue

Select / Stop

ITEM

VALUE

Name Functions

Display window

Button

Lamp

Jam location display

Error content display

It shows the present status of the printer and the menu.

Refer to the function of the OPE panel button.

Refer to the table of the error display status.

It tells where the jam occurs.

An icon for each error status is on.

3.2.1 Error display window

3.2.2 Error display icon

Status of lamp

Conditions

READY

OFFLINE

PRINTING XXX

(XXX : file_name)

SLEEPING

• It is an online status, Ready to print.

• If pushing the [Online] button, it becomes an offline status, and if pushing a [Menu] button,

it becomes a menu status.

•

It is offline standby status, tells it is impossible to print.

• when pushing a [Menu] button, it becomes a menu status.

•

It tells the machine is printing. On the last line, the file name is displayed.

Also, a page name can be displayed when a page provided by computer is being printed.

• Power save mode. Power save is canceled when the machine receives a data or any button is

pushed.

Status of lamp

Conditions

(Paper Jam)

(Toner Low)

(Paper Empty)

(Interlock)

When the jam occurs, the Red light is on.

When the toner is low, the Red light is on.

When there is no paper, the Red light is on.

When cover is open, the Red light is on.

Construction and Operation

3-5

Samsung Electronics

3.2.4 Function of the OPE panel

Status of lamp Conditions

Meun

Item

Value

•

The button is for selecting online or offline. The online is standby status for print, and

the offline is impossible status to print.

When data doesn't be needed for a while, select offline status.

•

Select the Continue button if you wish to keep printing even though a warning error is

showing up.

•

After changing a value of item while using the menu, press it to select value. For

example, if changing paper count for printing several pages, press the [Enter/Stop]

button. The papers will be printed as many as selected paper counts since a screen

displays designation.

•

Press it when canceling the menu status or erasing the received data while printing.

•

Press it when operating the menu.

Press [ ] to move to next menu and press [ ] to move to previous menu.

•

In case of pressing a secret number for printing confidential document, use [1] & [2]

button to enter

• Used to scroll through the menu.

Press [ ] to move to next item and press [ ] to move to previous item.

•

In case of pressing a secret number for printing confidential document, use [3] & [4]

button to enter figure 3 & 4.

•

In the menu, the values and items of each item are repeated.

Press [+] to move to next value and press [-] to move to previous value.

•

In case of pressing a secret number for printing confidential document, use [5] & [6]

button to enter figure 5 & 6.

3.2.3 Error display status

Off

.

•

The machine is offline status, tells impossible status to receive data.

Press the [Online/Continue] button to become an online status.

•

The machine is power save mode status, tells possible status to receive data.

Green Light On

.

•

The machine is online status, tells possible status to print.

Green Light Flashing.•

(Slow flashing) Data is being received to the printer.

•

(Fast flashing) The machine is printing.

It is flashing swiftly while receiving data and printing at the same time.

Orange Light On

.

•

The machine is stopped due to an error. The error can be discriminated by checking the

error display icon or messaged in the display window.

Orange Light Flashing.• It is a warning error, and the machine waits until user clears the error.

Check the error contents from a window and clear it. After clearing the errorr, the printing

process is continues.

Status Conditions

Select / Stop

Online / Continue

Construction and Operation

Samsung Electronics

3-6

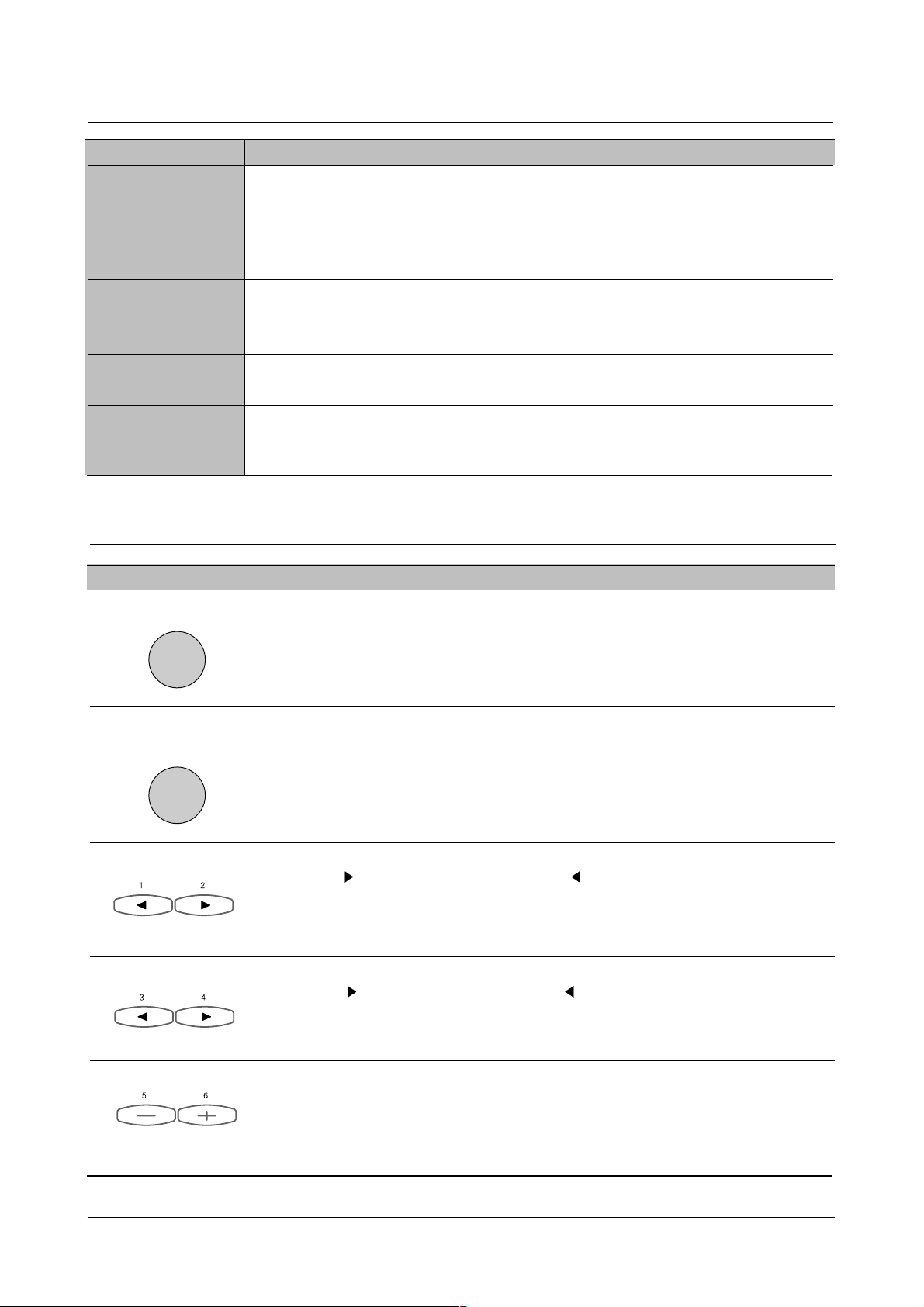

3.3 Other supplies list

Drum Cartridge Toner Cartridge

Printer Cable

(Parallel cable)

Power Code

CD ROM

Discharged paper

support bin

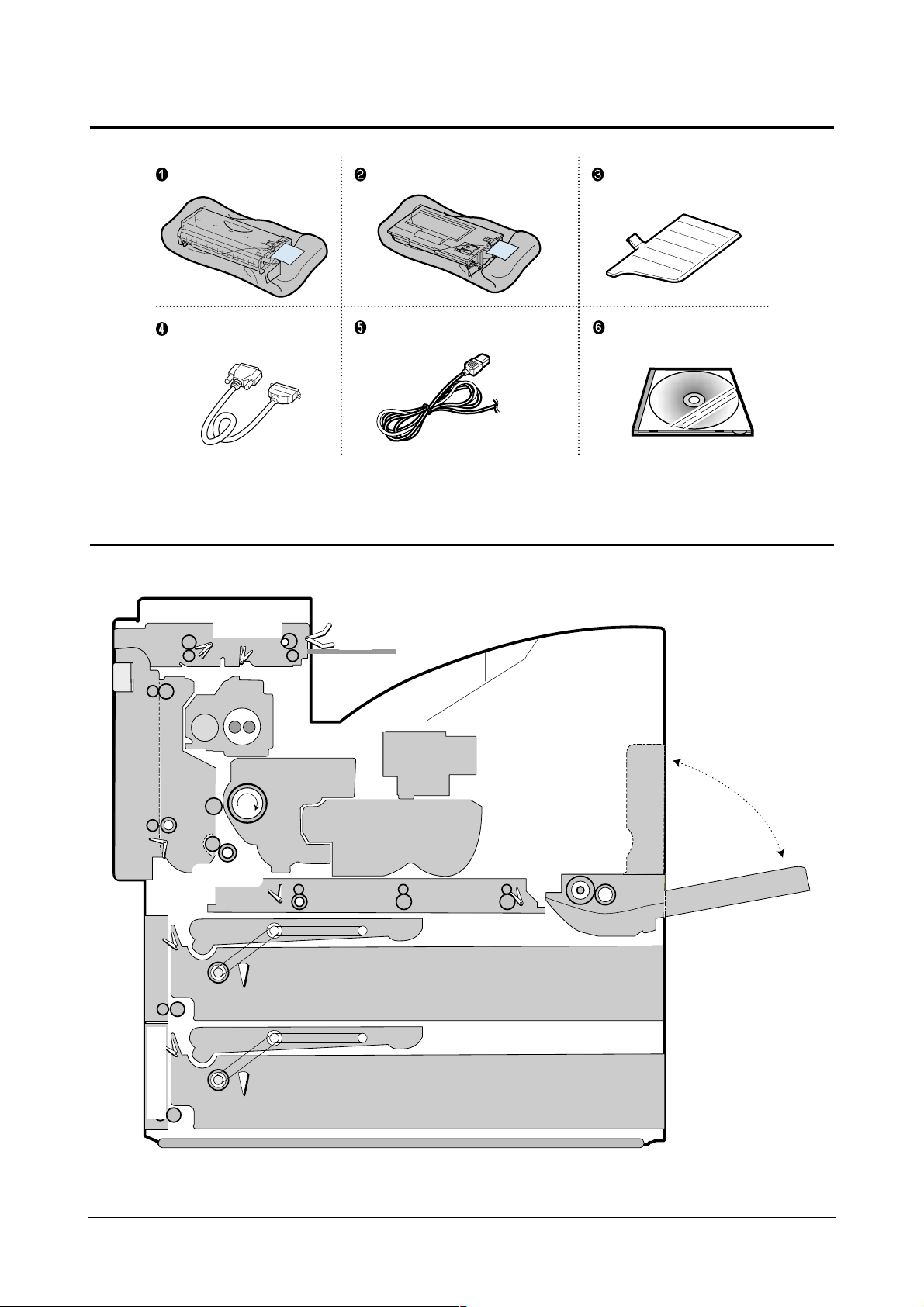

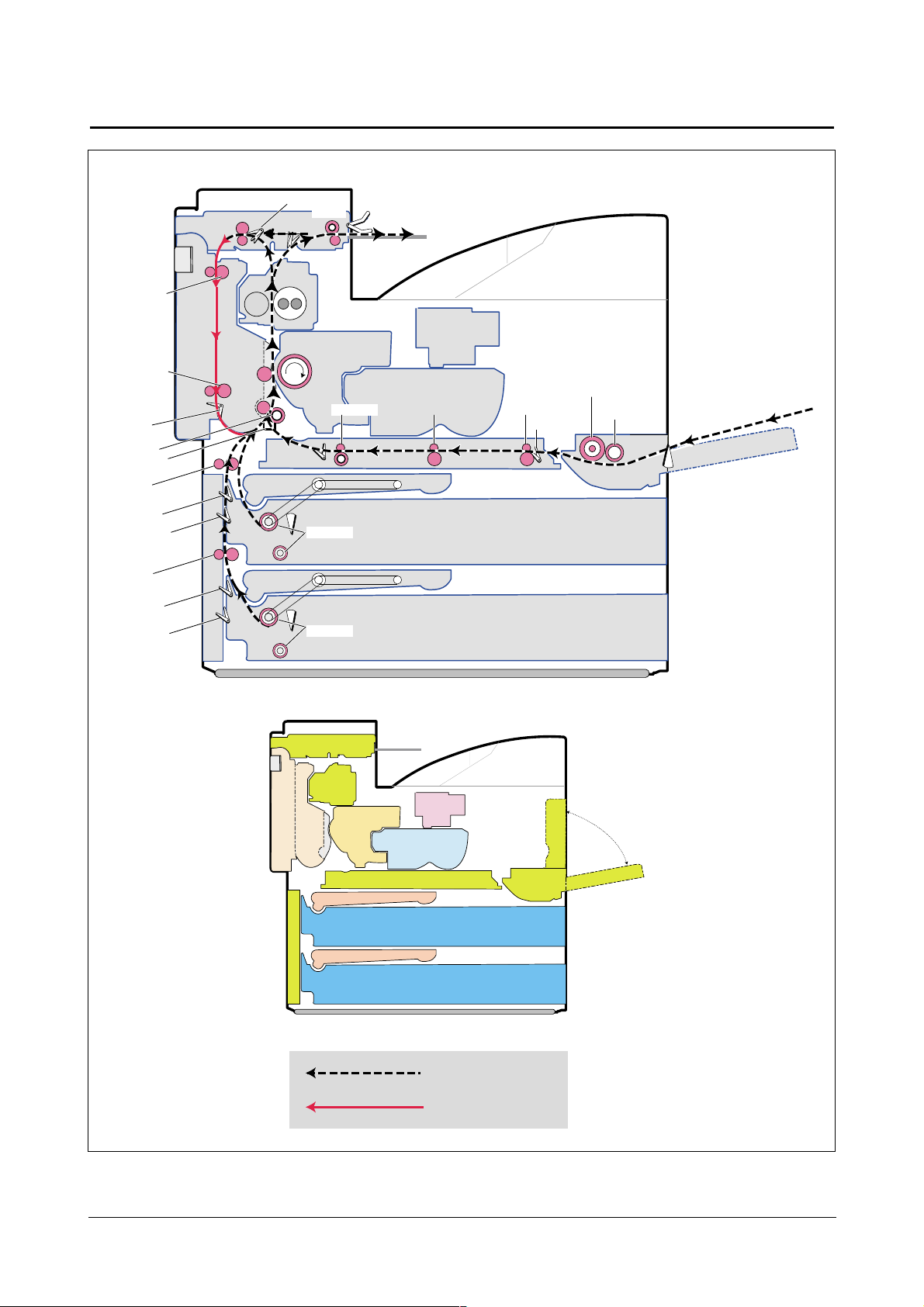

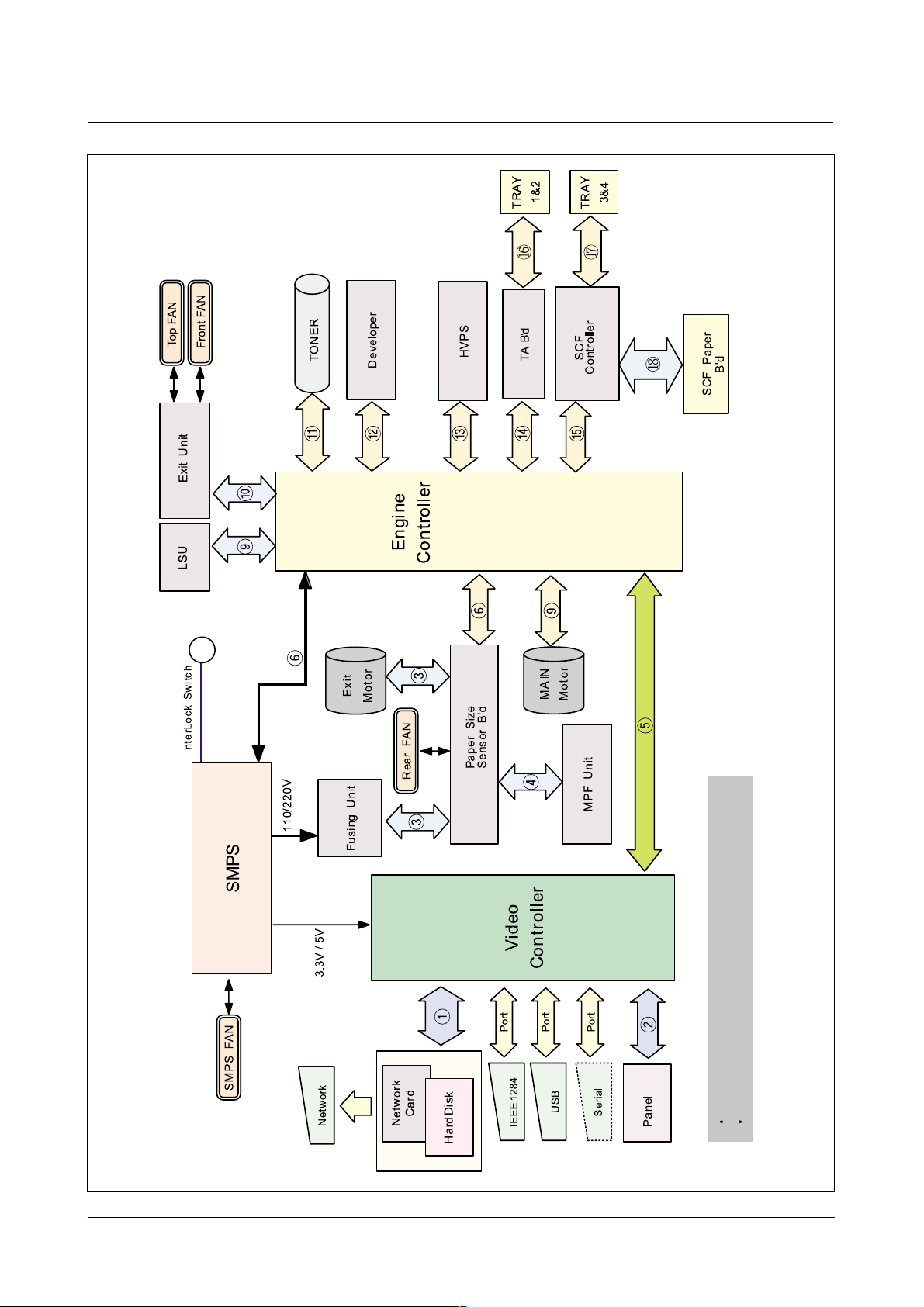

3.4 Construction and operation of the system

FUSER

OPC DRUM UNIT

TONER CONTAINER

LSU

MPF PICK-UP UNIT

CASSETTE 1

CASSETTE 2

DUPLEX UNIT

REGISTRATION

EXIT UNIT

MPF TR

PICK UP

PICK UP

LEFT DOOR ASS’Y

TOP BIN

T AKE A W AY UNIT

Construction and Operation

3-7

Samsung Electronics

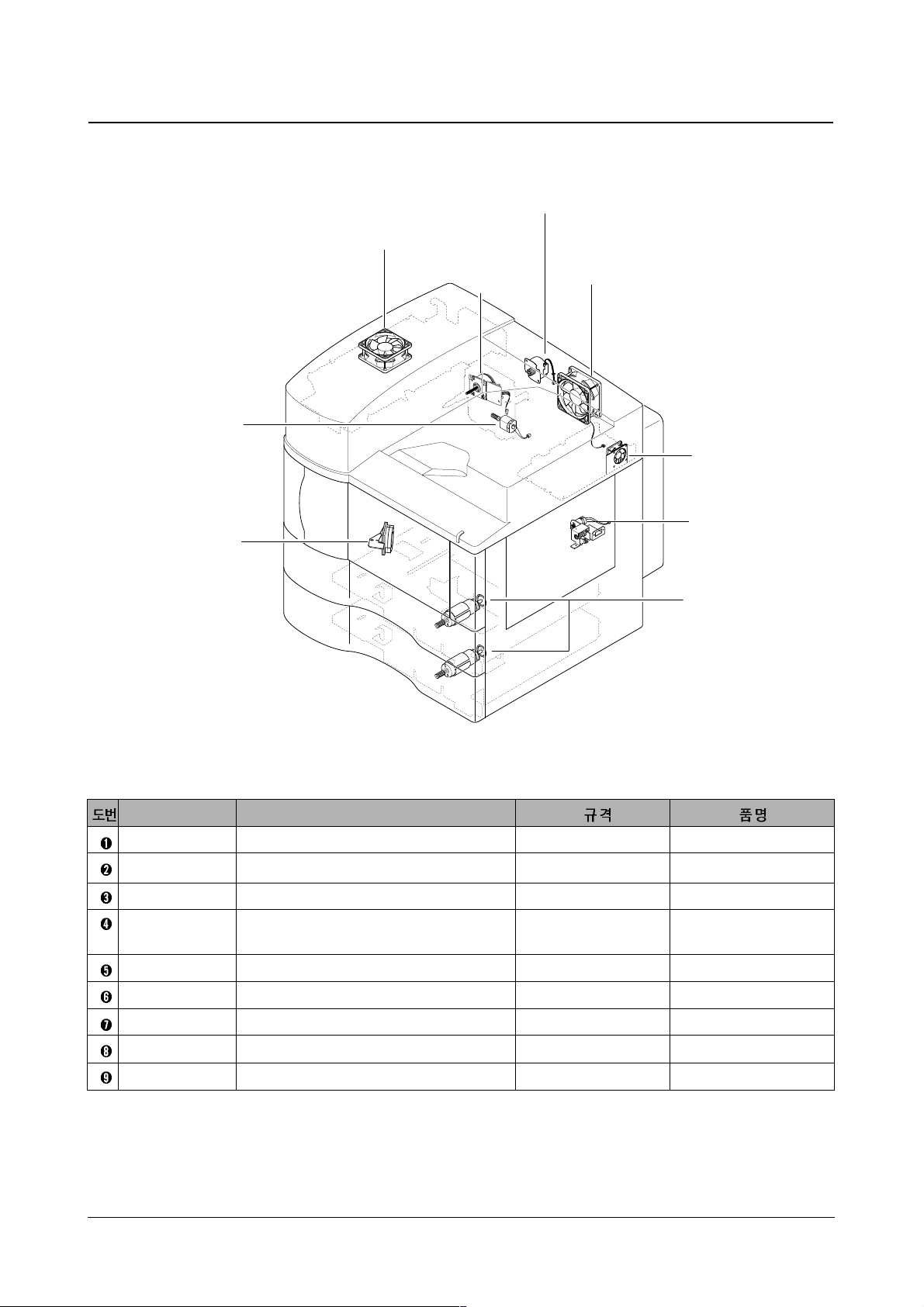

3.4.1 Motor and Fan layout

➑ Top Fan

➐ Main Fan

➍ Duplex Motor

➌ Main Motor

➒ SMPS Fan

➋ MPF Motor

➊ Pick Up Motor

➎ DC Toner Motor

➏ Front Fan

Name Functions

PICK UP MOTOR

Transfers the cassette paper

24V/17.9Ω/6900rpm AC385XLOT-00E4030

MPF MOTOR

Transfers the MPF paper

30V/19.4Ω/7500rpm HC385MOT-01E4012

MAIN MOTOR

Rotates the OPC

24V DNQ 18A88D20A

DUPLEX MOTOR

Transfers papers to the duplex unit for duplex

24V/4Ω M49SP-1

print and paper discharge

DC TONER MOTOR

Supplies toner

24V/59.4Ω/5900rpm MF203G-00E4039

FRONT FAN

Supplies the air to the inner set

24V/5500rpm AB5024MB-CO3

MAIN FAN

Discharges the heat from fuser unit to outside

24V/3800rpm AD0924XB-A73GL

TOP FAN

Supplies the air to the inner set when printing

24V/3800rpm AD0924XB-A73GL

SMPS FAN

Discharges the heat from SMPS to outside

24V/45rpm AD 0624MB-A76GL

Construction and Operation

Samsung Electronics

3-8

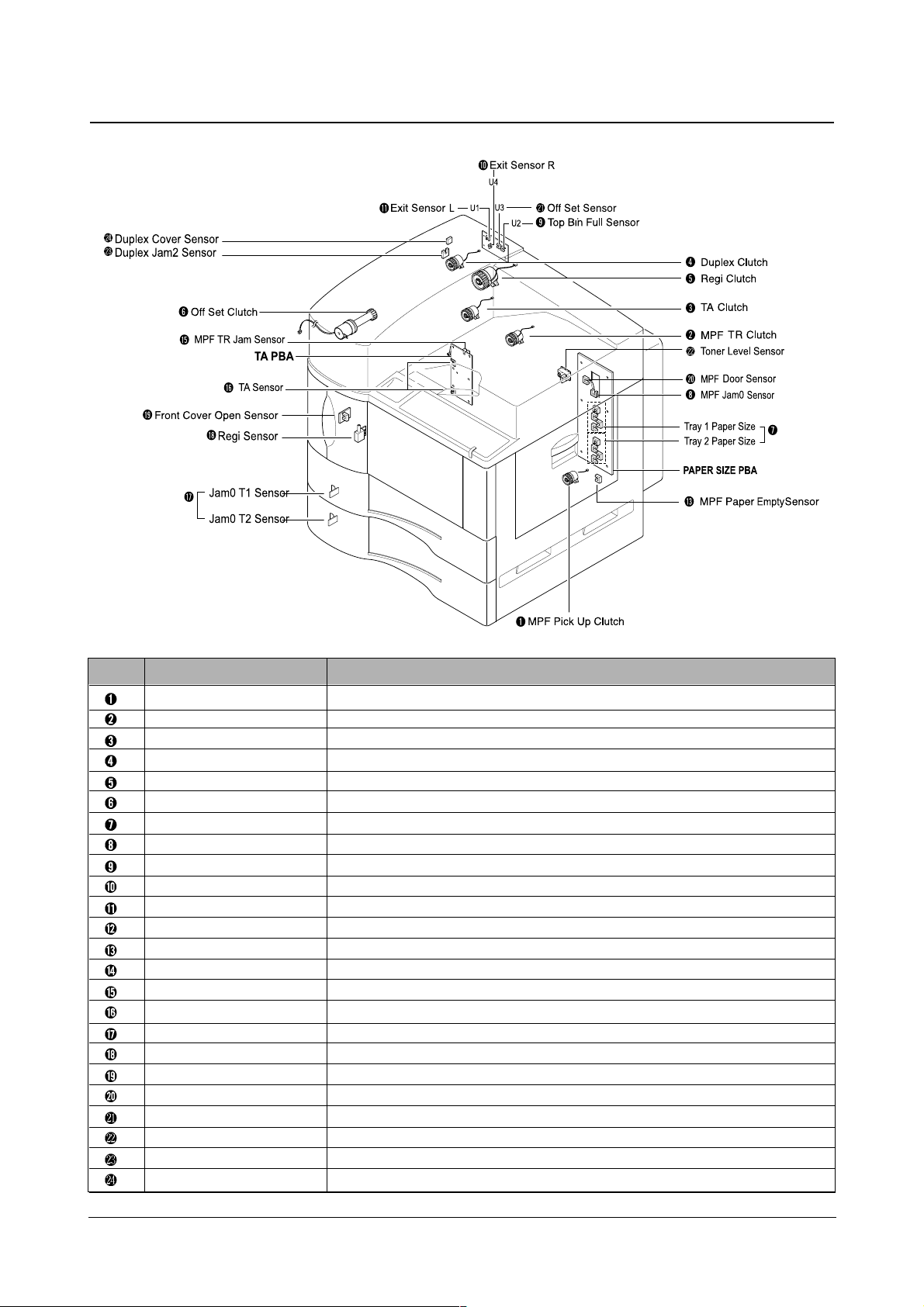

3.4.2 Sensor and Clutch layout

No.

Name Functions

MPF PICK UP CLUTCH

Drives the MPF Pick Up.

MPF TR CLUTCH

Drives the MPF Transfer Roller.

TA CLUTCH

Transfers the paper to the Registration Sensor.

DUPLEX CLUTCH

Transfers papers from Exit unit to the Duplex Pick up.

REGI CLUTCH

Transfers paper from Registration sensor to the Developer.

OFF SET CLUTCH

Separate and loads papers.

PAPER SIZE SENSOR

Detects paper size.

MPF JAM0 SENSOR

Detects paper jam while it is transferred from pick up to MPF tray.

TOP BIN FULL SENSOR

Detects paper whether it is full.

EXIT SENSOR R

Detects paper jam while paper is transferred from Exit to Top bin direction.

EXIT SENSOR L

Detects paper jam while paper is transferred from Exit to Left bin direction.

Left Cover Sensor

Detects Left cover status.

MPF PAPER SENSOR

Detects paper at MPF whether there is paper or not.

TA Cover Sensor

Detects status of TA Cover.

MPF TR JAM SENSOR

Detects paper jam at MPF tray.

TA SENSOR

Detects paper jam between Jam0sensor and Registration sensor via tray.

JAM O SENSOR

Detects paper jam while paper is transferred to the registration sensor.

Regi Sensor

Detects paper jam while paper is transferred from TA Sensor to Exit R Sensor.

Front Cover Open Sensor

Detects the front cover whether it is closed or opened.

MPF Door Sensor

Detects MPF Transfer Unit whether it is attached or not.

Off Set Sensor

Manages the offset location.

Toner Level Sensor

Detects toner amount (low) in the toner cartridge.

Duplex Jam Sensor

Detects paper jam between Exit sensor and Registration sensor.

Duplex Cover Sensor

Detects Duplex cover status.

Construction and Operation

3-9

Samsung Electronics

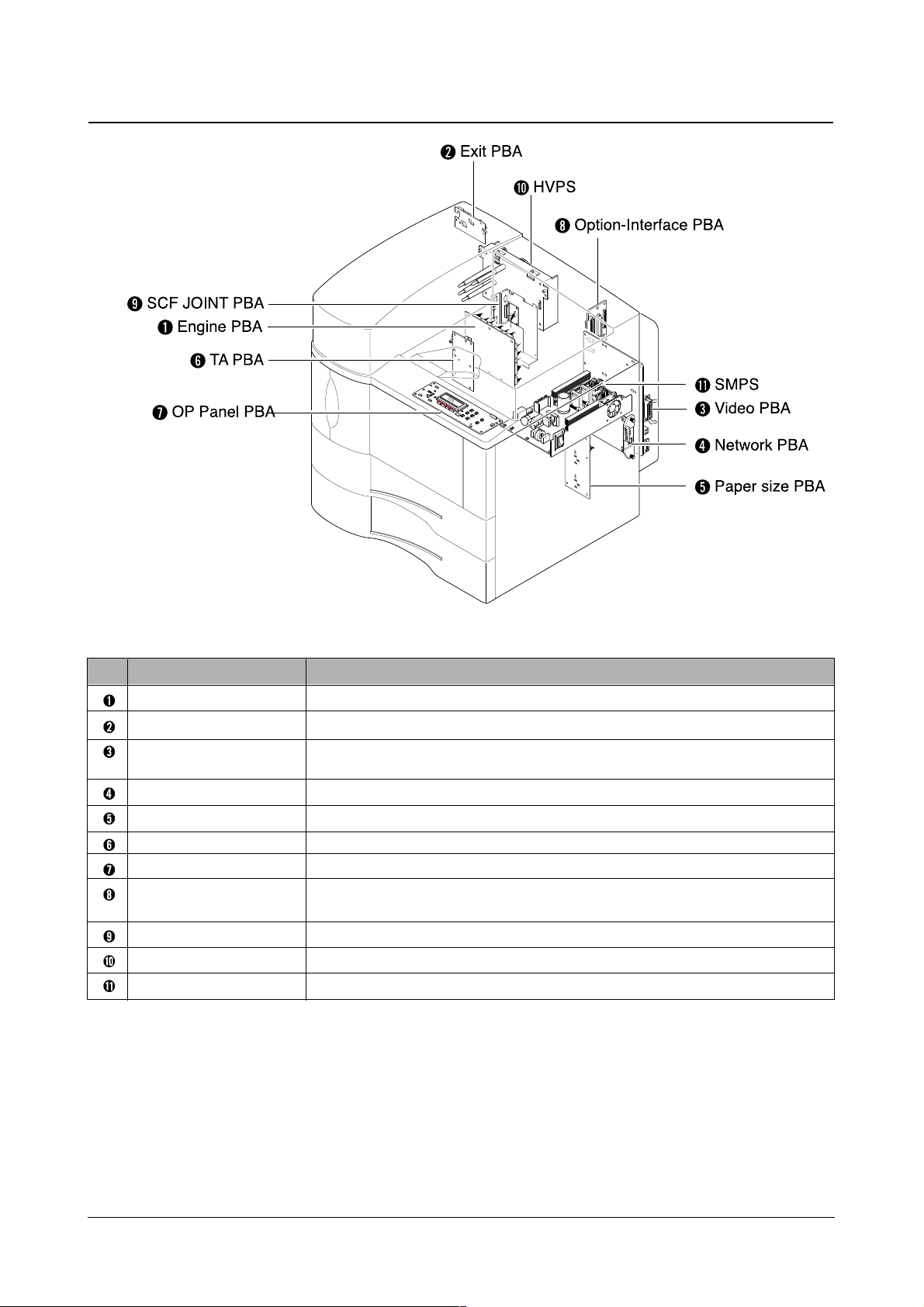

3.4.3 Board (PBA) layout

No.

Name Functions

ENGINE PBA Controls engine functions to print the video data from video controller.

EXIT PBA

It checks the paper discharged from fuser unit.

VIDEO PBA 1) It sends the video data from the host (PC) to the engine for print.

2) Perfomers emulations.

NETWORK PBA Network card and physical connetion to LAN.

PAPER SIZE PBA

It is a board to drive paper size motor, exit motor, and MPF Pick up motor.

TA PBA

It is a board to operate the clutch. (Drives the tray 1,2, the pick up motor, the TA sensor, etc.)

OP PANEL PBA

It is a board to display the set status.

OPTION-INTERFACE

1) It interfaces with the HDD for storing data.

PBA

2) It interfaces with Operation panel.

SCF JOINT PBA

It is a board to connect the engine board to the SCF.

HVPS Provides high voltage to the electrostatic print process unit.

SMPS Supplies power to all DC power and AC power circuits.

Construction and Operation

Samsung Electronics

3-10

3.5 Operation

7. Full Sensor R

8. Exit Sensor L

5. Exit Sensor R

15. Duplex

Jam2 Sensor

4. Fuser Roll

OPC Drum

3. Transfer Roll

13. Wait Roll

12. Trans Roll 2

12. Trans Roll 1

9. Duplex Inter Roll

Press Roll

2. Regi Roll

1. Regi Sensor

TA Roll 1

TA Sensor 1

TA Roll 2

TA Sensor 2

Jam0 T1 Sensor

Jam0 T

2

Sensor

MPF Jam Sensor2

MPF Jam Sensor1

Seperate MPF Roll

Pickup MPF Roll

MPF Paper Empty Sensor

MPF Trans Roll 1MPF Trans Roll 2MPF Trans Roll 3

6. Exit Roll

Pickup Tray Roll 1

Pickup Tray Roll 2

TAKE A W AY UNIT

PICK UP

PICK UP

MPF TRANSFER

OPC DRUM UNIT

LSU

TONER CONTAINER

EXIT UNIT

TOP BIN

CASSETTE1

CASSETTE2

DUPLEX UNIT

LEFT DOOR ASS’Y

MPF TRAY

MPF TRAY

Front-side print

Backside print

Construction and Operation

3-11

Samsung Electronics

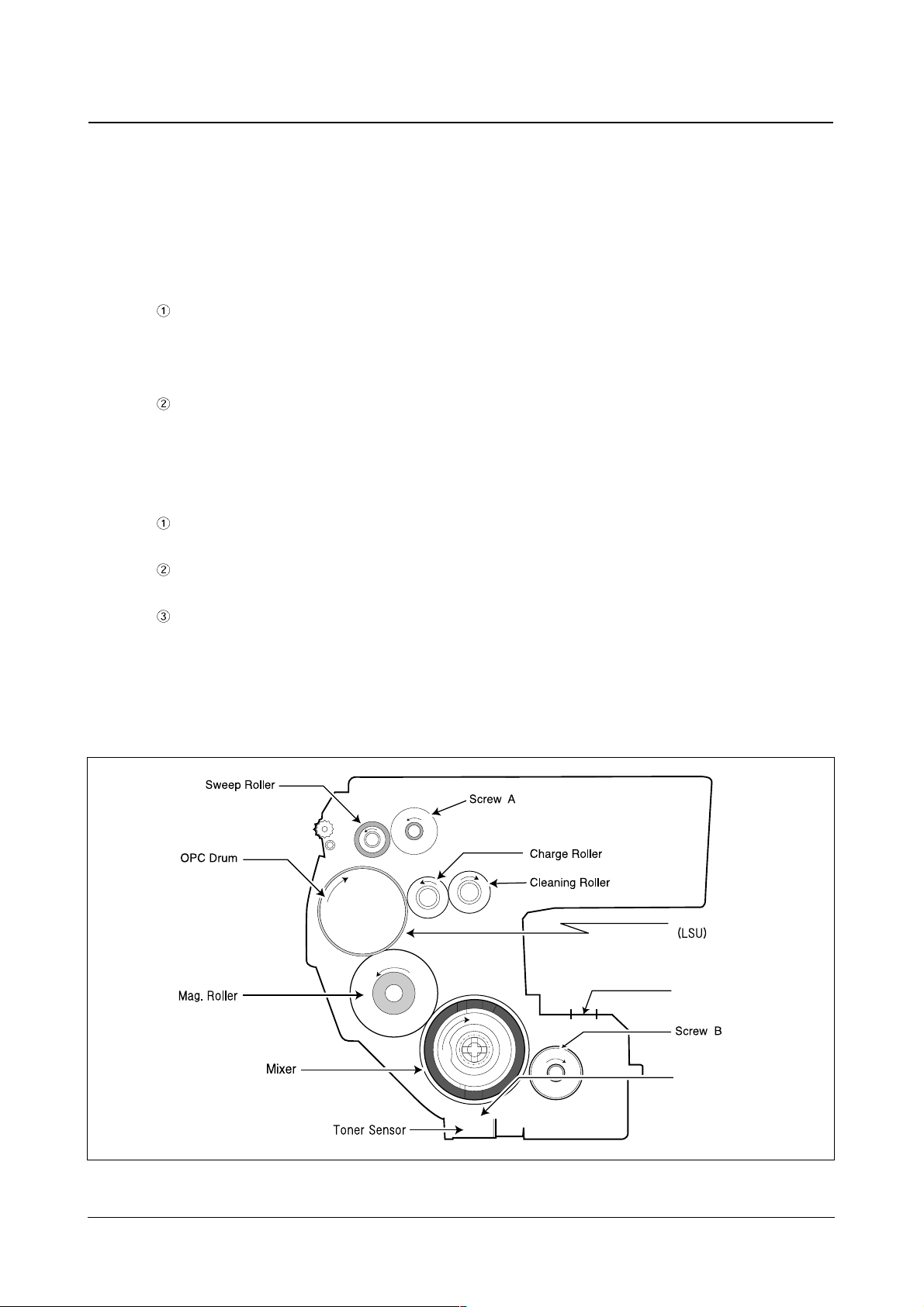

3.5.1 Developing process

The developing process consists of the drum cartridge and the toner cartridge. It allows the creation of a visual image.

• Developing method : Two components magnetic developing method.

• Checking Existence or nonexistence of developer unit: The MICOM chip verifiies status of developer.

If the developing unit is not attached the message will be displayed.

• Checking life span of consumption parts

The life span of the drum cartridge: 50,000 sheets (A4 5% pattern standard)

- Life span check : The running count is always stored in the MICOM in the Deve_ID board attached to the

drum cartridge. When a service report file is outputted, the counter is displayed at the

development cartridge under consumables status (Remainder).

The life span of the toner cartridge: 25,000 sheets (A4 5% pattern standard)

- Life span check : The running count is always stored in the MICOM in the Toner_ID board attached to the

outside of the toner cartridge. When a service report file is outputted, the counter is

displayed at the Toner Remainder under consumables status (Remainder)

• Checking toner density

By using the toner sensor, which detects the supplying changes according to the toner's and carrier's mixing

rate, the machine detects and displays toner emptiness.

The toner density is evenly maintained by checking the toner density level. The toner density level is

checked with the duty of V dig output. (If the density is low, drives the toner motor to supply toner)

Toner Sensor : Rated input voltage : DC 24V

Vcont Voltage : DC 2~12V Possibly change

Vod : Digital

Voa : Analog

Laser

Toner

Supply Unit

Toner

<Drum cartridge organization diagram>

Construction and Operation

Samsung Electronics

3-12

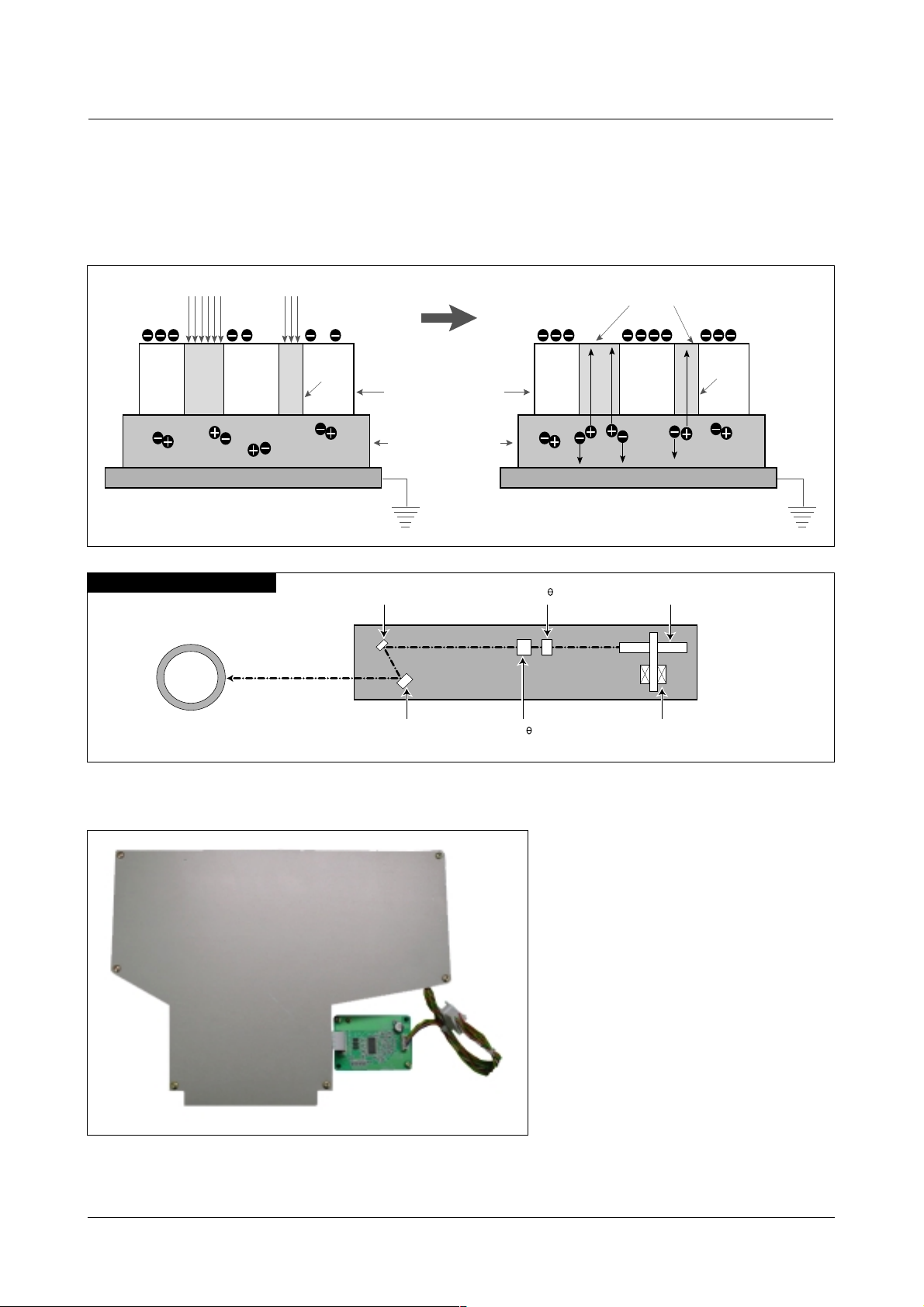

(1) Charging process

It is the first step of electronic photo process. The surface of the OPC is evenly charged with a negitive (-) voltage to

preparing for the next laser exposure. When a negitive (-1300V~-1550V) volts is reached on the charge roller,

the surface of the OPC should be charged to about a negitive (-700V) volts.

This is the first step to create the electrostatic photo process.

DEVELOPING

ROLLER

TRANSFER ROLLER

<Developing Process>

Charge Roller

-1300V ~ -1550V

Construction and Operation

3-13

Samsung Electronics

Plastic f- Lens

Glass f- LensCylinderical Mirror

OPC Drum

Polygon Mirror : 7

Polygon Motor

Air Bearing(35,000rpm)

Plane Mirror

LSU Theory

The LSU unit is controlled by the video

controller. It scans the video data received

from video controller with laser beam by using

the rotation principal of the polygon mirror to

create the latent image on the OPC drum. It

is the core part of LBP.

• Resolution : 600 X 600 DPI

• Scanning width : A3

(2) Exposure process

The exposure process creates an image on the drum. The video board enables the LSU (Laser Scan Unit) to expose the

drum. At this point the image is invisible. This electric image is created on the surface of the OPC. As the drum is exposed

by light, a path is created on CTL layer, and through it, negitive charged particles in the CGL layer move to erase the

charge on the exposed section, and the latent image is created. The AL Substrate must be grounded for smooth

movement of positive charges.

Photo_Conductive Material

CTL : Charge Transport Layer

CGL : Charge Generating Layer

Light (LASER)

PATH genesis

AL SUBSTRATE AL SUBSTRATE

Latent Image

PATH genesis

< LSU Unit>

Construction and Operation

Samsung Electronics

3-14

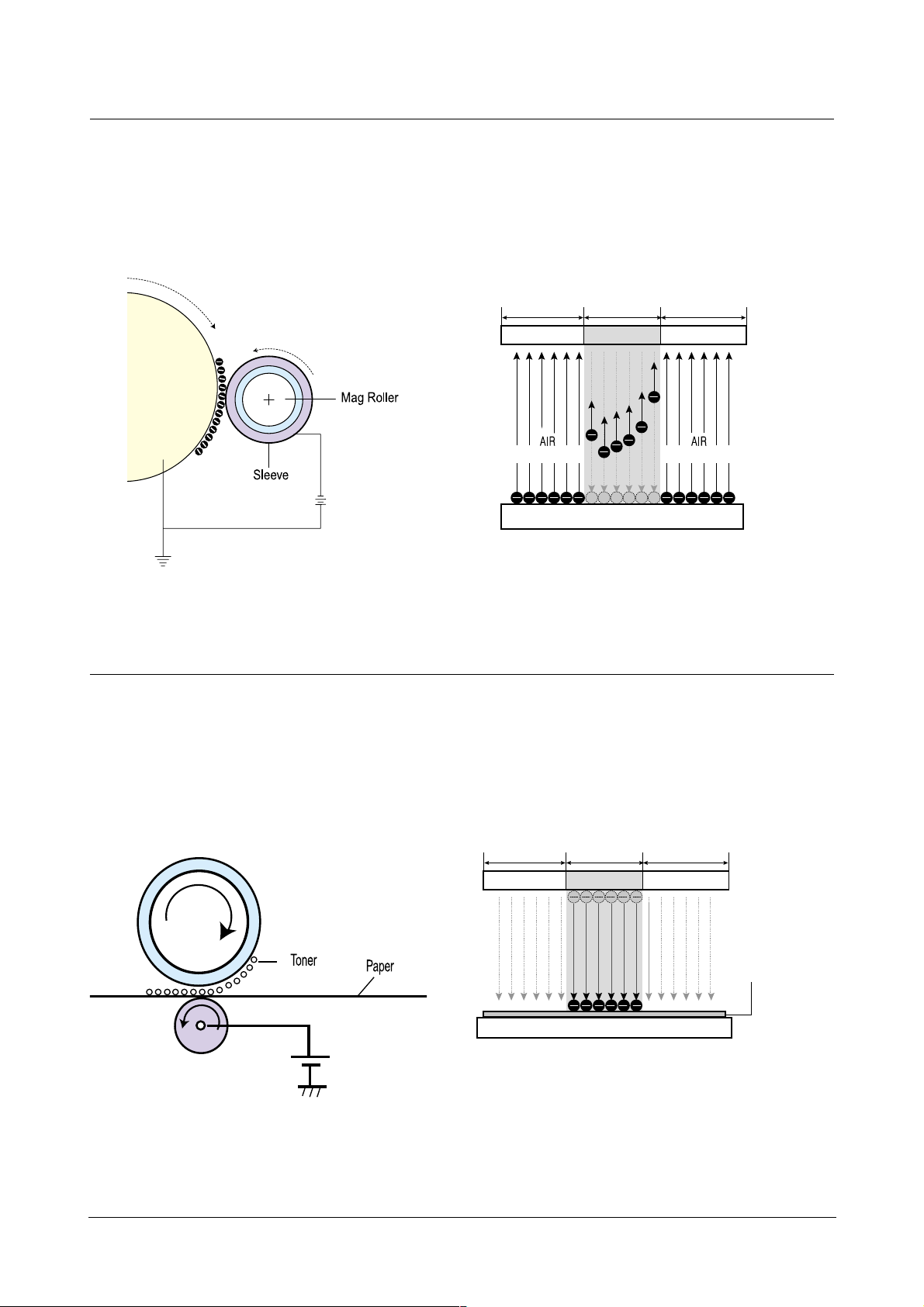

(3) Development Process

The development process moves the toner particle to the latent image created in the exposure process. After this step,

the image will be visible on the drum surface. The latent image is a more positive voltage and therefore the more negitive

charged toner is attracted to exposed portions of the drum. The developing voltage should be lower than the unexposed

section and higher than exposed section. (The density is controlled by this voltage.)

As the picture shown in the below, the electronic field is formed, and the negitive charged toner moves to the OPC.

The picture is shown the dry method EP case.

OPC

Unexposed

section

Exposed

section

OPC

Unexposed

section

Dry method EP case Dry method EP case

Moving direction

Transfer roller

OPC

Transfer Roller

OPC

Paper

Unexposed

section

Exposed

section

Unexposed

section

Developing roller

(4) Image Transferring Process

The transfer process "transfers" or moves the toner from the image on the drum to the paper. This is accomplished by

attracting the toner from the drum to the positively charged transfer roller. The voltage is changed by environmental

conditions such as temperature, humidity, etc. At this point the image is still "wet copy". The toner is only held to the paper

electrostaticly. The toner can be brushed off.

Construction and Operation

3-15

Samsung Electronics

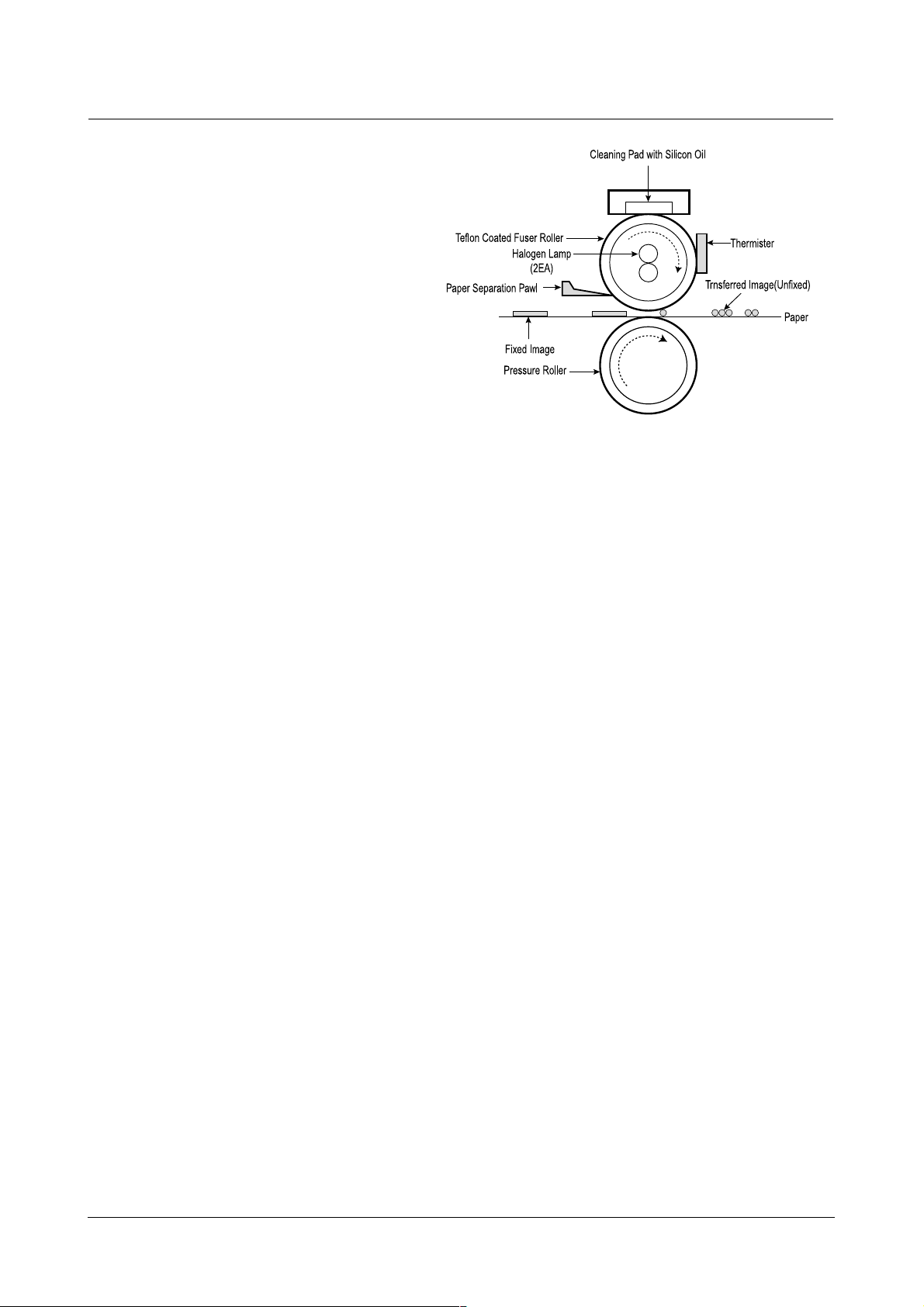

(5) Fusing Process

Fusing or Fixing is accomplished by using both heat

and pressure. Heating and pressure adhears the

toner to the paper.

While the toner on the paper is passing the fuser, the

toner is melted and adhered to the paper by heat

and pressure.

In the fusing process, temperature, pressure, and

passing time are important. Usually, temperature is

140~160 ˚C, and the NIP width is taken 2~5 mm

more to get longer contacting time. The thermistor

controls the temperature of the fuser roller.

The temperature ±5 ˚C in norma to properly fix the

toner to the paper.

To prevent adirty fuser roller, clean the surface of the

fuser roller with the cleaning pad and silicon oil.

The Separation Pawl is used to prevent the roll-up of

paper.

• Fusing method : Pressure fusing method. It has Heater lamp, Heat roller, pressure roller, etc.

• Heater lamp consisted of the Main lamp and the sub lamp both are halogen lamps.

• Thermostat :The thermostat is a bi-polar metal that opens to prevent over heating.

• Overheat prevention : If the thermistor detects over 200 °C, the heater is off by using OP AMP.

(TRIAC and Relay off)

Construction and Operation

Samsung Electronics

3-16

CHARGE

ROLLER

OPC

OPR

CLEANING

BLADE

DEVELOPING

TRANSFER

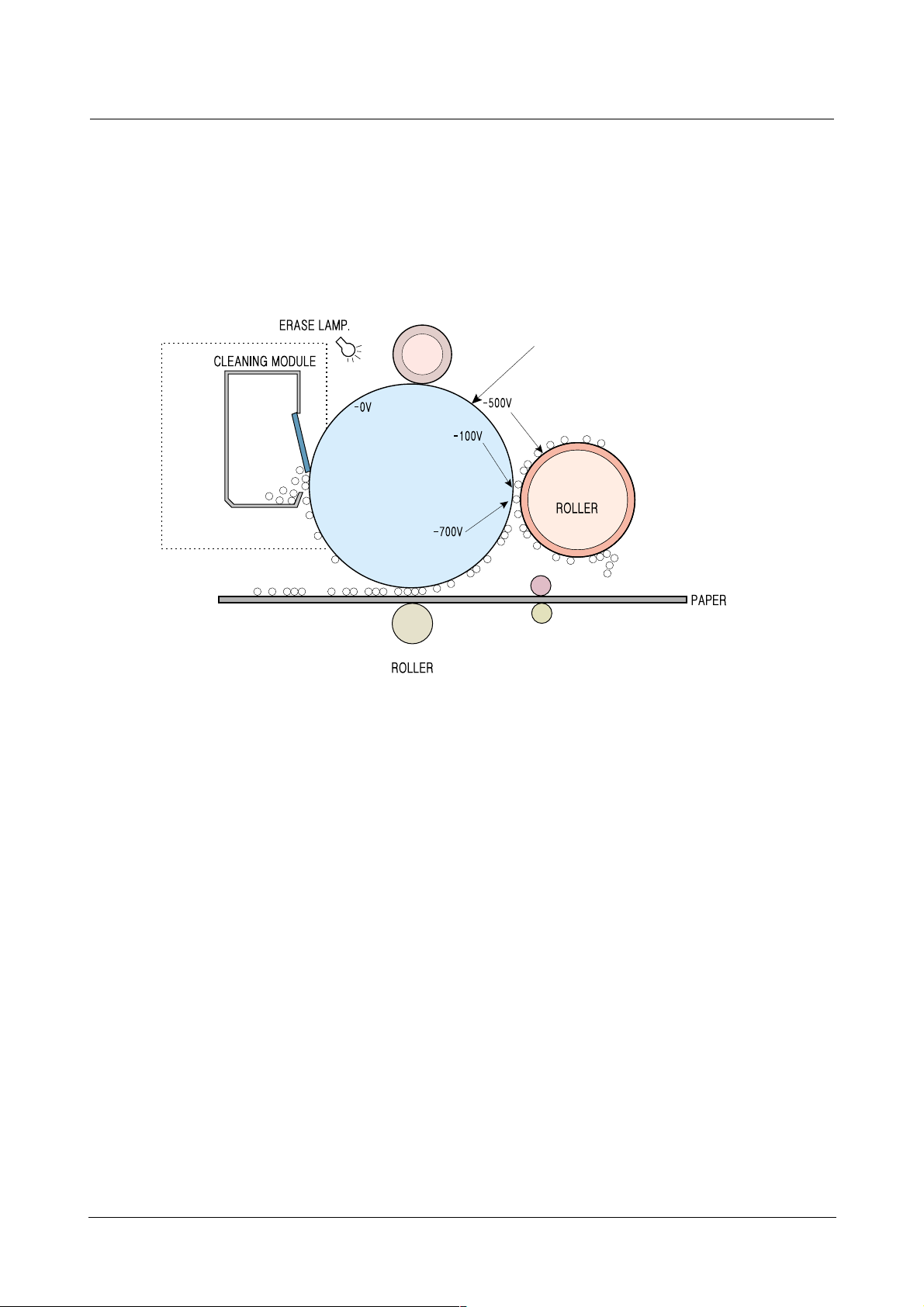

(6) Cleaning process and Erase process

This step removes the remaining charge and the toner particles from the OPC. In the cleaning process, the remaining

toner on the OPC is cleaned by the cleaning blade and by the erase process. The remaining charges on the OPC are

erased.

The LED is used for the erase lamp. In case to use OPR (Organic Photo_Receiptor) for OPC, the wave-length is around

640~680nm.

Light must be handled perfectly not to interrupt the other processes.

Construction and Operation

3-17

Samsung Electronics

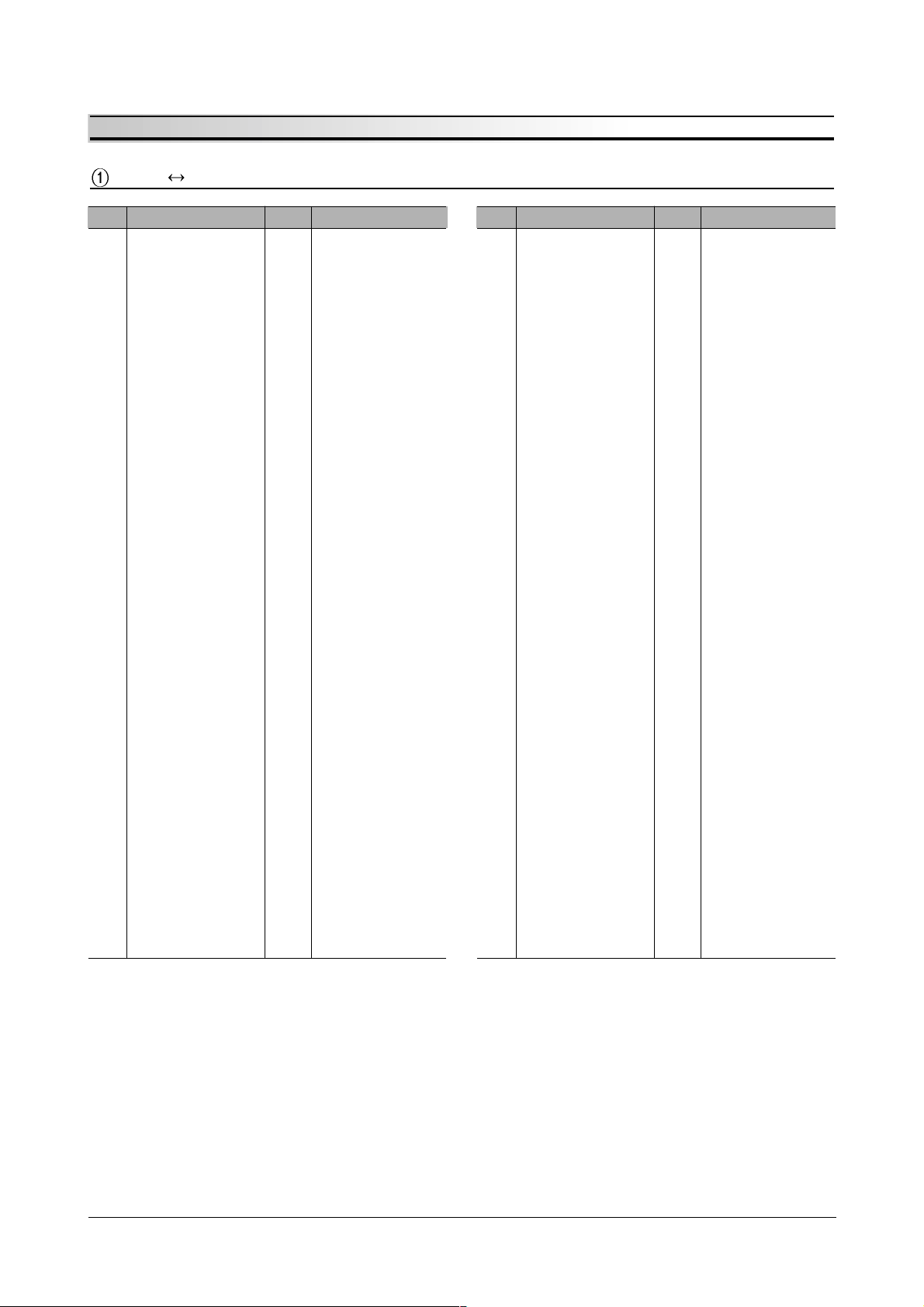

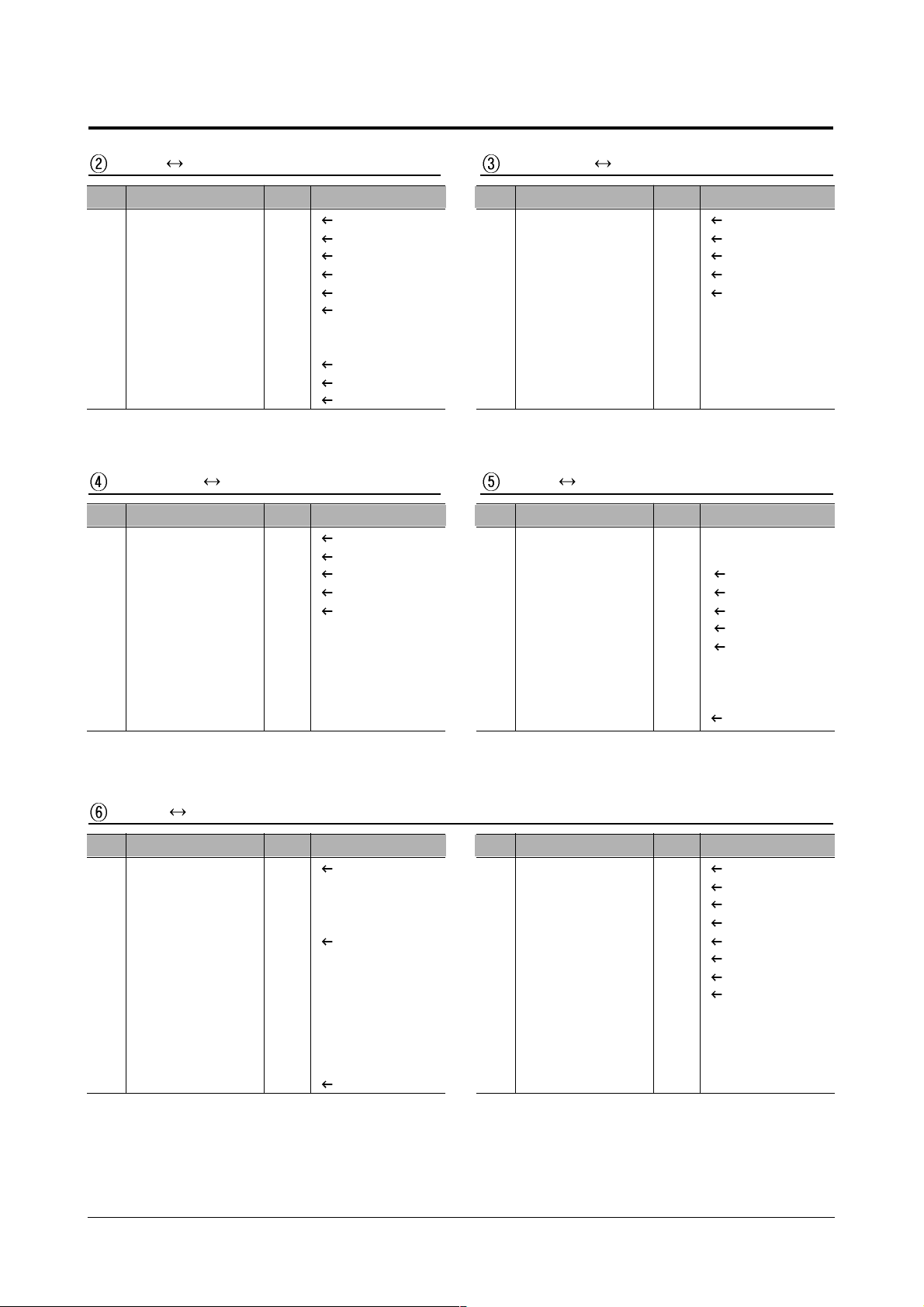

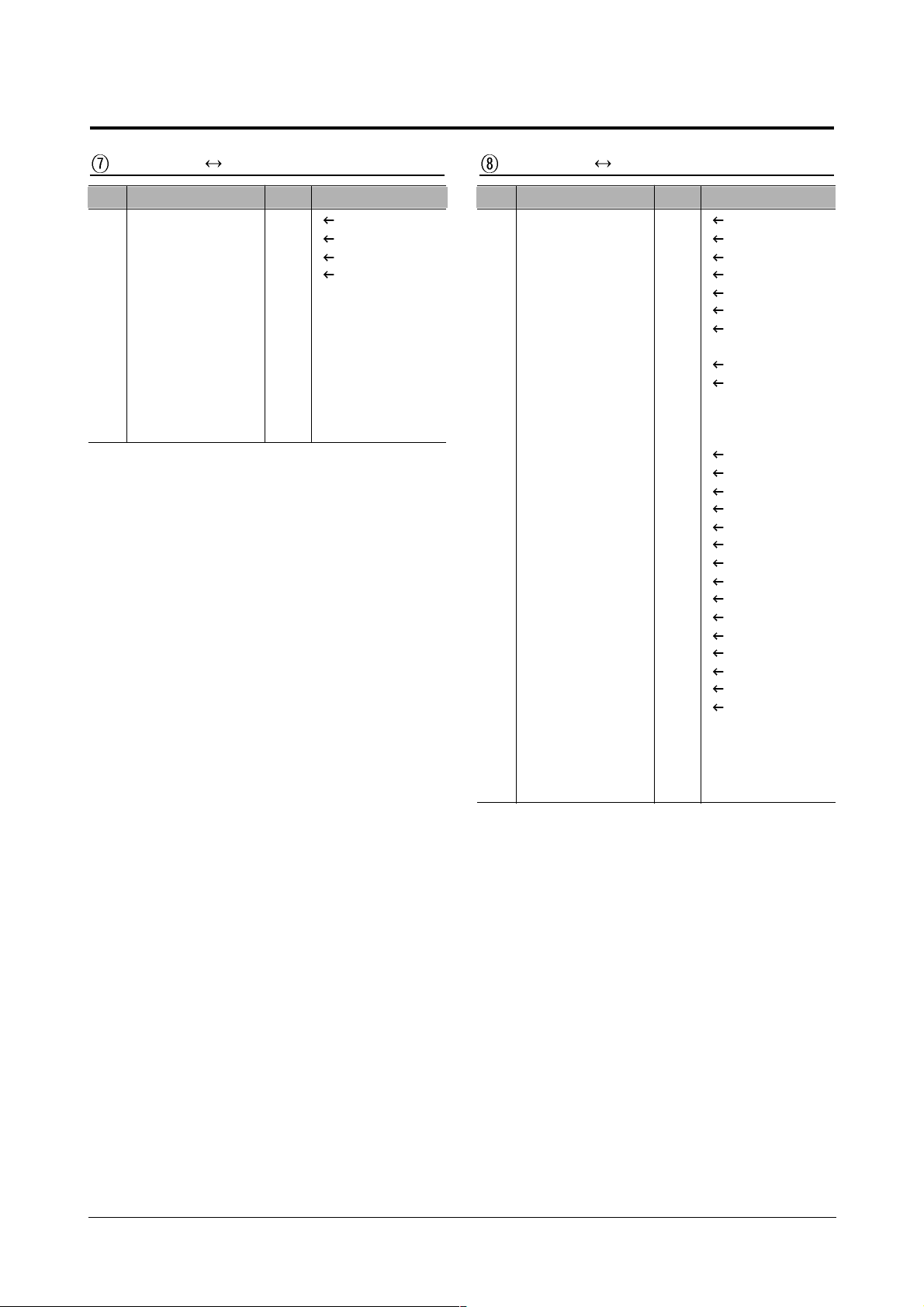

3.5.2 CONNECTION DIAGRAM

There are no sensors and clutches.

Please refer to the signal description table in the next page.

CN402

CN401

CN306

CN307

CN308

CN1

CN5

CN3 CN2

CN5

CN2

CN11 CN15

CN5

CN6

CN7

CN12

CN13

CN14

CN101

CN2

CN9

CN5

CN1

CN1

CN2

CN18

CN7

CN13

CN19

CN5

CN6

CN4

CN3

CN4

CN1

CN1

CN1

CN1

CN6

Construction and Operation

Samsung Electronics

3-18

• Signal Description Table

Video Vertical(HDD&Network)

Pin Signal Name Pin Signal Name

1 DRAMD X(16) 1 DRAMD X(16)

2 DRAMD X(17) 2 DRAMD X(17)

3 DRAMD X(18) 3 DRAMD X(18)

4 DRAMD X(19) 4 DRAMD X(19)

5 DRAMD X(20) 5 DRAMD X(20)

6 DRAMD X(21) 6 DRAMD X(21)

7 DRAMD X(22) 7 DRAMD X(22)

8 DRAMD X(23) 8 DRAMD X(23)

9 HDD_RST* 9 HDD_RST*

10 nHDD_DMARQ 10 nHDD_DMARQ

11 nDRAMWE_HDD 11 nDRAMWE_HDD

12 S_DRAMA(2) 12 S_DRAMA(2)

13 S_DRAMA(1) 13 S_DRAMA(1)

14 S_DRAMA(0) 14 S_DRAMA(0)

15 VCC 15 VCC

16 VCC 16 VCC

17 VCC 17 VCC

18 VCC 18 VCC

19 GND 19 GND

20 GND 20 GND

21 nNETWORK_CS 21 nNETWORK_CS

22 nWAIT 22 nWAIT

23 DPO_RST* 23 DPO_RST*

24 nNETWORK_IRQ 24 nNETWORK_IRQ

25 nDATA(31) 25 nDATA(31)

26 nDATA(30) 26 nDATA(30)

27 nDATA(29) 27 nDATA(29)

28 nDATA(28) 28 nDATA(28)

29 nDATA(27) 29 nDATA(27)

30 nDATA(26) 30 nDATA(26)

31 nDATA(25) 31 nDATA(25)

32 nDATA(24) 32 nDATA(24)

33 nDATA(23) 33 nDATA(23)

34 nDATA(22) 34 nDATA(22)

35 nDATA(21) 35 nDATA(21)

36 nDATA(20) 36 nDATA(20)

37 nDATA(19) 37 nDATA(19)

38 nDATA(18) 38 nDATA(18)

39 nDATA(17) 39 nDATA(17)

40 nDATA(16) 40 nDATA(16)

Pin Signal Name Pin Signal Name

41 DRAMD X(24) 41 DRAMD X(24)

42 DRAMD X(25) 42 DRAMD X(25)

43 DRAMD X(26) 43 DRAMD X(26)

44 DRAMD X(27) 44 DRAMD X(27)

45 DRAMD X(28) 45 DRAMD X(28)

46 DRAMD X(29) 46 DRAMD X(29)

47 DRAMD X(30) 47 DRAMD X(30)

48 DRAMD X(31) 48 DRAMD X(31)

49 DASP 49 DASP

50 nDRAMOE 50 nDRAMOE

51 HDD_IORDY 51 HDD_IORDY

52 nHDD_DMAACK 52 nHDD_DMAACK

53 nHDD_IRQ 53 nHDD_IRQ

54 PDIAG 54 PDIAG

55 CS0 55 CS0

56 CS1 56 CS1

57 GND 57 GND

58 GND 58 GND

59 GND 59 GND

60 BRDIN* 60 BRDIN*

61 NT_nRD 61 NT_nRD

62 NT_nWR 62 NT_nWR

63 NT_TT1 63 NT_TT1

64 NT ADDR(2) 64 NT ADDR(2)

65 NT ADDR(3) 65 NT ADDR(3)

66 NT ADDR(4) 66 NT ADDR(4)

67 NT ADDR(5) 67 NT ADDR(5)

68 NT ADDR(6) 68 NT ADDR(6)

69 NT ADDR(7) 69 NT ADDR(7)

70 NT ADDR(8) 70 NT ADDR(8)

71 NT ADDR(9) 71 NT ADDR(9)

72 NT ADDR(10) 72 NT ADDR(10)

73 NT ADDR(11) 73 NT ADDR(11)

74 NT ADDR(12) 74 NT ADDR(12)

75 NT ADDR(13) 75 NT ADDR(13)

76 NT ADDR(14) 76 NT ADDR(14)

77 NT ADDR(15) 77 NT ADDR(15)

78 NT ADDR(16) 78 NT ADDR(16)

79 NT ADDR(17) 79 NT ADDR(17)

80 NT ADDR(18) 80 NT ADDR(18)

Construction and Operation

3-19

Samsung Electronics

Video Panel PaperSize Fusing Unit

Pin Signal Name Pin Signal Name

1 VCC 1

2 VCC 2

3 PANEL_MSG 3

4 PANEL_CMD 4

5 LCD_DRV_EN 5

6 RESET_LCD 6

7 ERROR_LED 7 LCD_LED0

8 ON_LINE_LED 8 PRINTER_ERR

9 GND 9

10 GND 10

11 GND 11

Pin Signal Name Pin Signal Name

1 24VS 1

2N.C 2

3 FU_FANON 3

4N.C 4

5 FU_FANFB 5

Pin Signal Name Pin Signal Name

15V 1

2 DGND 2

3 DGND 3

4 24VS 4

5 MPF_PE* 5

6 MPF_PICKUP 6 MPF_PICK_CLUT

Pin Signal Name Pin Signal Name

1 ENGINE_MSG 1 EMSG*

2 nPRINT 2 PRINT*

3 EVIDEO+ 3

4 EVIDEO- 4

5 RDY* 5

6 LSYNC+ 6

7 LSYNC- 7

8 ENGINE_CMD 8 CMSG*

9 nFSYNC 9 PSYNCRQ*

10 nENDPAGE 10 END_PAGE

11 GND 11

PaperSize MPF Unit V ideo Engine

Pin Signal Name Pin Signal Name

1 12V 2

2 12V GND 1 DGND

3 3.3V 4 3.3VB

4 3.3V GND 3 DGND

5 -5V 6

6 -5V GND 7 DGND

7 5.1V GND 8 DGND

8 5.1V GND 7 DGND

9 5.1V 10 5V

10 5.1V GND 9 DGND

11 5.1V 12 5V

12 5.1V 11 5V

13 24VS 14

Pin Signal Name Pin Signal Name

14 24VS 13

15 24VS GND 16

16 24VS GND 15

17 24V GND 18

18 24V GND 17

19 24V 20

20 24V 19

21 24V 22

22 FAN-FB 21 FAN_FBP

23 RLY-CON 24 RELAY_CON*

24 FAN-CON 23 FAN_PS

25 HT2 26 HEAT2_ON

26 HT1 25 HEAT1_ON

SMPS Engine

Construction and Operation

Samsung Electronics

3-20

Exit Motor PaperSize PaperSize Engine

Pin Signal Name Pin Signal Name

11A 1

21B 2

32A 3

42B 4

Pin Signal Name Pin Signal Name

11 24V 2

2 24V 1

3 DPX_MA 4

4 MPF_DOOR* 3

5 DPX_MA* 6

6 MPF_JAM1 5

7 DPX_MB 8

8 MPF_MOTON 7 MPF_MOTON*

9 DPX_MB* 10

10 MPF_PE* 9

11 THERMISTER1 12 THERM

12 MPF_PICKUP 11 MPF_PICKUP*

13 THERMISTER2 14 HEAT_ON

14 5V 13

15 FU_FANON 16

16 5V 15

17 FU_FANFB 18

18 T1_SIZE0* 17

19 T2_SIZE0* 20

20 T1_SIZE1* 19

21 T2_SIZE2* 21

22 T1_SIZE2* 22

23 T2_SIZE2* 24

24 T1_SIZE3* 23

25 DGND 26

26 T2_SIZE3* 25

27 DGND 28

28 DGND 27

Loading...

Loading...