Page 1

Circuit Description

Samsung Electronics

Service Manual

12-1

12

12. Circuit Description

12.1 Engine Controller

The engine controller module consists of a motor controller, a PWM controller, a LSU I/F controller, and an ADC I/F

controller.

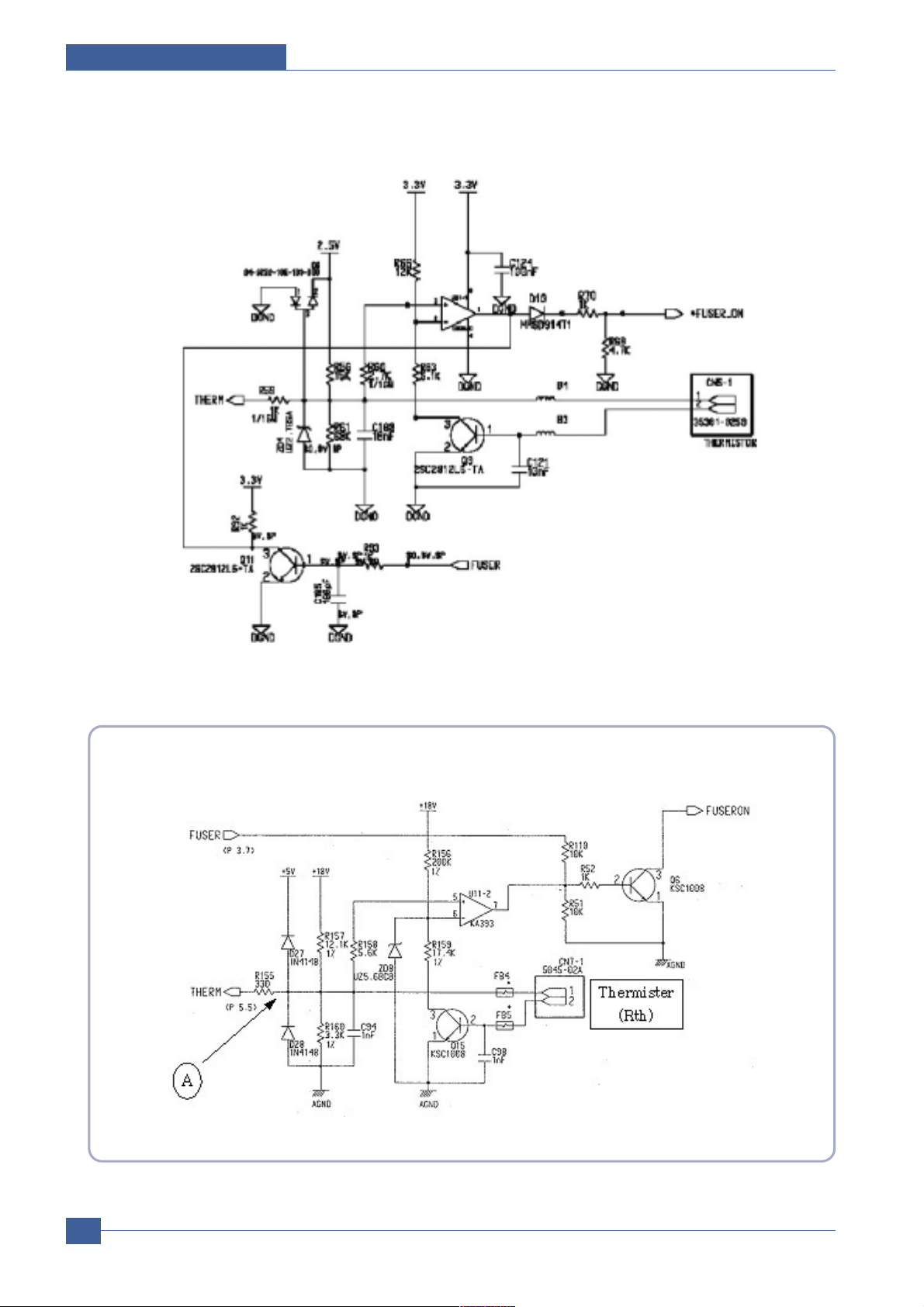

12.1.1 Heater Control

The heat lamp radiates heat by using AC power. The AC power is a TRIAC (a semiconductor switch device) which

controls a switch. The ‘ON/OFF’ control is completed by turning on/off a gate of the TRIAC through a photo TRIAC

which is insulation part.

If explaining more detail about the AC control part, it consists of passive circuit ; therefore, it turns on/off the heater

by receiving the signal from the engine control part. If the heater on signal is turned on at the engine, electricity flows

in as the LED of the PC1 (Photo TRIAC) is connected. Then, it emits light.

By this light, the TRIAC unit, a light receiving unit, becomes on, and electricity is supplied to the gate of the TRIAC.

Then, the TRIAC is turned on. As a result, AC current flows in a heat lamp, and the heat lamp radiates heat.

On the other contrary, if the signal is turned off, the PC1 becomes off, and the TRIAC is turned off due to no electricity at the gate of the TRIAC. Consequently, the heat lamp is turned off.

Special Feature of TRIAC (THY 1): 16A, 600V SWITCHING

Phototriac Coupler (PC3)

Turn On If Current: 15mA~50mA(Design: 16mA)

High Repeive Peak Off State Voltage: Min 600V

Vcc

Vcc

Vcc

R3

C2

1nF

R1

E

R5

5.6K

TR2 KSC

1008-Y

R4

BD1

Rs

C

TR1

KSC

1008-Y

BD2

3

C1

10nF

B

THERMISTOR

CN1

D1

914T1

D2

914T1

IC1

LM393D

R6

5.6K

R7

1K

R2

D3

914T1

2

1

1

2

E

C

B

HEAT

LAMP

N

H

PC1

CHOKE

C22

103

R24

120

R22 180

FUSIBLE

R23

100

C21

104

TRIAC

R21

1.5K

ENGINE CONTROL PART

AC CONTROL PART

AC

VOLTAGE

12

1

2

6 4

FUSER

THERM

+24Vs

Page 2

Samsung Electronics

Service Manual

Circuit Description

12-2

Page 3

Circuit Description

Samsung Electronics

Service Manual

12-3

Explanation about the condition of Normal Operation

If the fuser (P3.7) port becomes high, the Q6 is activated. Aheat lamp starts operating by the activity.

As the temperature of the heat lamp is increased, the resistance value of the thermister is decreased.

Therefore, the electric potential of the circled Abecomes low.

On/Off operation of the Q6 is only controlled by the fuser (P3.7) port because 5(+) of the

U11(Comparator) is always higher than 6 (-) within the normal control temperature rage.

Functions of the Malfunction Protection:

If the fuser port (P3.7) is turned on regardless of controlling due to system malfunction, the temperature of the heat roller goes abnormally high. At this time, the resistance value of the thermister becomes

low.

When the resistance value of the thermister becomes low, the electric potential of the circled Agets low,

and when the temperature goes over the certain temperature, the comparator (U11) gets a low output.

As a result, even though the fuser port is abnormally activated, it is disable to be over the regular temperature. For maintaining a regular temperature, a protect circuit consists in it (This protection is set up

to start operating at the rage between 205°~210°)

12.1.2 PWM Controller

Function Description

PWM TIMER consists of each sub block which has various functions. The sub block is divided based on

this block diagram. The entire diagram of the PWMTIMER is organized as below.

PWM TIMER OPERATION is figured out if calculating PHCLK by the value selected by the register setting

and the divider. PHCLK is created by count block at the PWM TIMER

Page 4

Samsung Electronics

Service Manual

Circuit Description

12-4

12.1.3 Motor Driver

A motor drive circuit is decided when selecting a driver IC. (Supplied by vendor) ML1610 uses the motor driver IC of

AN44060. However, the sensing resistance Rs value and the Vreference resistance value are variable according to

the motor drive current value.

12.1.4 LSU Controller

The laser scanning unit controller (LSUC) of Jupiter4E is a block for interface between PVC block and LSU.

LSUC sends the video data received from PVC and the laser diode turn On/Off signal created by inner 21 bit counter

to the laser diode of LSU. LSU creates the horizontal sync signal (nHSYNC) by sensing the inputted diode turn on/off

signal with the attached sensor. nHSYNC is inputted to PVC and LSUC as a signal that informs the beginning of one

line. Also, LSU makes the activity of nLREADY signal (ready to print) low when the polygon motor becomes regularly rotating. LSU can recognize the regular rotation status of the polygon motor by reading nLREADYFlag bit in SFR.

Once the polygon motor regularly rotates, it sends the page sync signal (nPSync) to PVC by writing ‘1’at LSUCON[5]

in LSUC, and PVC starts operating for one page printing. After that, every time nHSYNC signal is created, PVC senses the signal and outputs the video data (PVC_VDO) to LSUC. At this time, LSUC creates the video window (Printing

area) and masks it on the video data sent by PVC. LSUC sends the completed video data (LSU_VDO) to the laser

diode in LSU.

Also, LSUC supplies LSU_CLK, created by counting the system clock with the operation clock source of LSU, for the

use of substitution for oscillator. The SFR is set up in IsuSfr block by receiving the bus control signal from APB bus,

and the settled register values are redelivered to IsuCon block. IsuCon block creates a signal for controlling the laser

diode of LSU and outputs it to a pad. The digital filter module is a digital filter to provide against the noise loaded in

nHSYNC and nLREADY signal which directly get into the chip. It is three layer filter, and the delay time is 3*System

Clock Time.

The interface between PVC and LSUC is shown in the picture.

LSUC

nHSYNC

nHSYNC

LSU_VDO

PVC_VDO

nPSync

nFSYNC

nFSYNC

nLSYNC

VDO

PVC

PVC_TEST_EN

PVC_T EST_EN

1

0

0

1

LSU_VDO

Page 5

Circuit Description

Samsung Electronics

Service Manual

12-5

lsuSfr

PSEL

PENABLE

PADDR[4:0]

PWDATA[31:0]

nLREADY

DigiFilter

nHSYNC_FO

DigiFilter

lsuCon

lsuControl[8:0]

windowOnTime[20:0]

windowOffTime[20:0]

ldOffTime[20:0]

ldOnTime[20:0]

patternDuty[9:0]

lsuClkDuty[18:0]

flagClear

LSU_VDO

LSU_CLK

nPSync

nLREADYFlag

nHSYNC

nLREADY_FO

LS UC

DAC

PD

THER

THV

DAC_OUT

PI

Control

Block

PRDATA[31:0]

PWRITE

APB

BRIDGE

APCCON[11:0]

apcOnTime[20:0]

apcOffTime[20:0]

SHOffTime[20:0]

SHOnTime[20:0]

ENGIN

ADC

E

Pmax[9:0]

Pmin[9:0]

Ka[14:0]

REF[24:0]

Kp[15:0]

Ki[4:0]

Ky

YMAXH[8:0]

YMAXL[31:0]

YMINH[8: 0]

YMINL[31:0]

YINITH[8:0]

YINITL[31:0]

KU[5:0]

U_VALUE[25:0]

SEH[4:0]

SEL[4:0]

L_VALUE[9:0]

HCLR[20:0]

PVC

ADO_2[9:0]

ap

CKIN.

ADC_EN

SEL[1:0]

cOn

ADC

Contro ller

Page 6

Samsung Electronics

Service Manual

Circuit Description

12-6

The main signals used in LSU Controller are shown in the table.

12.1.5 ADC Controller

Jupiter4E ADC Controller has 3 analog input channels.

It automatically converts the 3 channels in turns with 10 bit 500KSPS adc1275x_pc, and also it makes the conversion

on the desired time by manually controlling STC of the register. After finishing the conversion, it makes the interruption to be pending. When AD conversion of 3 rd channel ends for the PI Control of LSU, it sends the 10bit digital data

converted with the latch short pulse signal to LSUC.

Name Direction Description

PVC-VDO I The video data output from PVC.

nLREADY I Its activity becomes low as the polygon motor of LSU gets the regular speed.

nHSYNC I It informs the beginning of one line. It is the same as nLSYNC of PVC.

nPSync 0 It is inputted to nFSync of PVC.

LSU_VDO 0 The completed video data output by masking video window on PVC_VOD.

first field second field

nHSYNC

window On

ldOn

window OnTim e

window Off Time

ldOnTime

ldOffT ime

count er start

testPattern

patternstart

PVC_ VDO

Laser Diode & Window On/Off Time

Loading...

Loading...