Data Management Server2

MIM-D00A

BACnet Gateway

MIM-B17

LonWorks Gateway

MIM-B18

Air Conditioner

user manual

DB98-33388A(1)

E

imagine the possibilities

Thank you for purchasing this Samsung product.

Safety Precautions

• Before using the DMS2, read carefully these instructions.

• After reading the instructions, keep this user's manual in a handy and safe place.

If a user is changed, you must hand over the manuals.

• Never attempt to install the air conditioning system or to move the DMS2 by yourself.

WARNING

CAUTION

Do not attempt to install or repair this DMS2 by yourself.

This DMS2 contains no user-serviceable parts.

Always consult authorized service personnel for repairs.

When moving, consult authorized service personnel for

disconnection and installation of the DMS2.

Ensure that the wall is strong enough to support the

weight of the DMS2.

Must install the DMS2 with rated power supply.

In the event of a malfunction (burning smell, etc.),

immediately stop operation, turn off the electrical

breaker, and consult authorized service personnel.

Do not use inflammable gases near the DMS2.

Do not spill water into the DMS2.

Do not operate the DMS2 with wet hands.

Do not install the DMS2 in a location where it will come

into contact with the combustible gases, machine oil,

sulphide gas, etc.

Do not press buttons with a pointed thing.

Do not pull or bend the DMS2 cable excessively.

Do not use this DMS2 for other purpose.

Do not spray an insecticide or other combustible things

on the DMS2.

Do not clean the DMS2 with benzene, solvents or other

chemicals.

Do not give a shock to the DMS2 or disassemble it by

yourself.

E-2

Contents

General Description ....................................................... 4

ViewinG the parts ........................................................... 6

Before Use ...................................................................... 8

Main fUnction ............................................................. 10

startinG DMs2 ........................................................... 14

control anD MonitorinG ............................................. 18

Zone ManaGeMent ....................................................... 59

scheDUle ..................................................................... 64

ehp power consUMption inspection ............................ 74

control loGic ManaGeMent ........................................ 85

systeM settinGs ........................................................... 98

check Before UsinG panel .......................................... 147

settinG network inforMation ................................... 148

checkinG inDoor/oUtDoor Unit inforMation ............ 150

checkinG DMs2 Version ............................................ 151

Data BackUp settinG ................................................. 154

checkinG error inforMation ..................................... 156

reset passworD ......................................................... 157

BUtton lock .............................................................. 158

safety halt ............................................................... 159

troUBleshootinG ....................................................... 160

specifications ............................................................ 162

license ....................................................................... 163

Note

The contents and pictures used in this user manual

may be changed without advance notice for the

functional reinforcement and improvement of a

product.

E-3

General Description

Introduction of DMS2 (Data Management Server2)

The DMS2 is an Internet based device for central management of Samsung system

air-conditioners. It supports LAN & WAN and operates 24 hours without a separate PC.

Advantages of DMS2 System

The DMS2 provides the following advantages:

Everyday Device–The DMS2 is operational all year long 24 hours.

Independent Operation–The DMS2 can operate schedule control and power distribution

without a PC.

Note In order to run power distribution, relevant controllers need to be installed.

Internet Control

Web – The DMS2 has a built-in web server function and can be accessed from a

remote location to operate status

monitoring, control, trouble history, and schedule setting of the system

air-conditioners.

Using an Upper Level Controller–When a separate upper level controller (S-NET

series) is used, a number of DMS2 can be controlled with one central management

system.

Data Storage–The DMS2 has its own database built-in, therefore, trouble history,

indoor unit installation information, and power distribution data can be saved and

retrieved.

Large Scale Management–At most 256 indoor units can be connected to one DMS2

and therefore, only one DMS2 can manage small and medium size buildings.

Automatic ”e-mail” sending–When an error is occurred, inform the error details to an

e-mail saved on DMS2.

E-4

Terms

DMS2: The abbreviation of Data Management Server2.

Upper Controller: It means S-NET Series, a local controller of the DVM system.

S-NET 3, S-NET mini and RMS are linked to a DMS2.

Centralized Controller: A device that controls 16 groups of the DVM air conditioner.

A central control device of a DVM system which is located

between a DMS2 and an outdoor unit interface module.

Interface module: A data interface module of a DVM system which is located between

a central controller and an outdoor unit.

AHU(Air Handling Unit): Excutes heat exchange between air and cooling unit using

central air conditioning duct method.

ERV(Energy Recovery Ventilator): Ventilating system using heat recovery function.

E-5

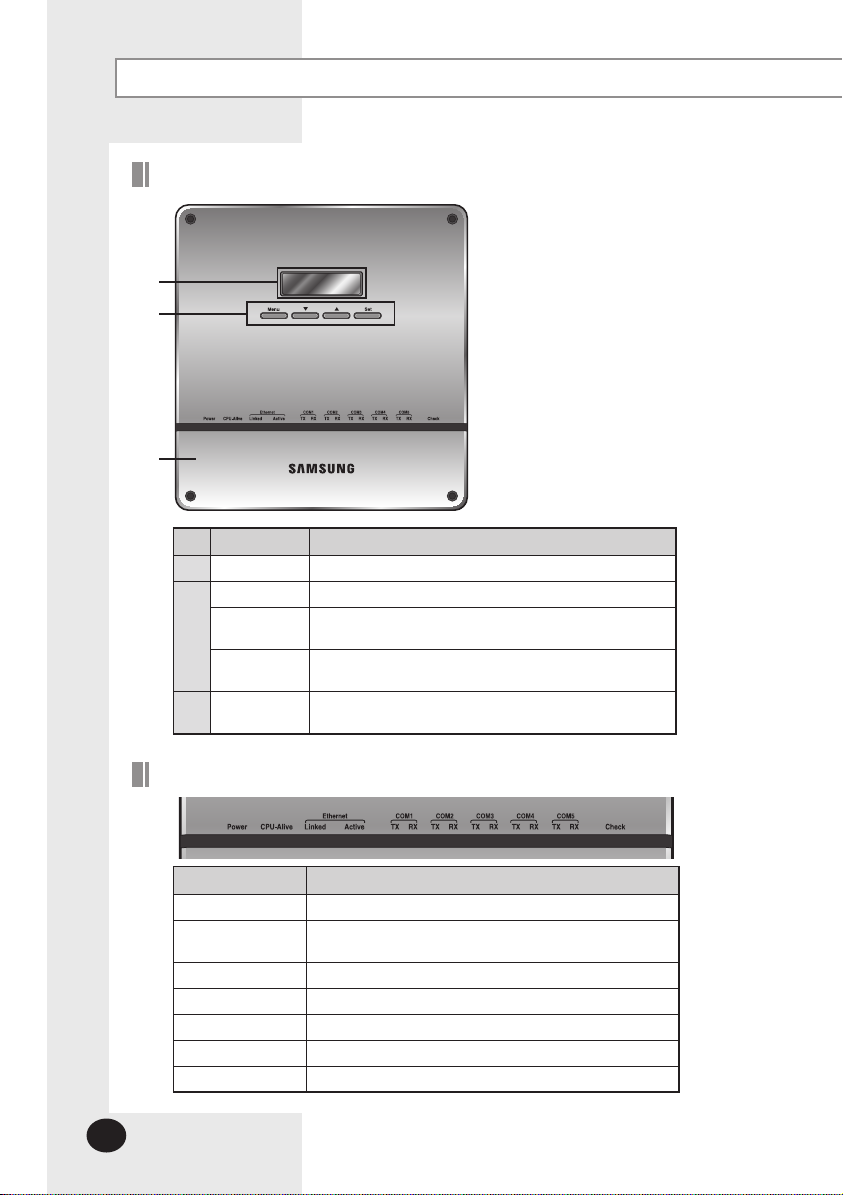

Viewing the Parts

Front View

No. Name Description

LCD Display Display current time/ Check menu

Menu button Access to main menu

▼/▲ button

Set button

Bottom cover

Select the function you want and set detailed functions in

main menu

Check the function you want from main menu

and select it

Unfasten 2 screws on the bottom and separate the bottom

cover from DMS2. Then check cable connection part.

E-6

Indicator

Name Description

Power Turns blue when the power is supplied.

CPU Alive

Ethernet–Linked Turns green during normal connection.

Ethernet–Active Blinks in orange during normal transmission/reception.

COM1~5 – TX Blinks in green during normal transmission.

COM1~5 – RX Blinks in green during normal reception.

Check Turns green when notice occurs.

Blinks in orange with 1 second intervals during normal

operation.

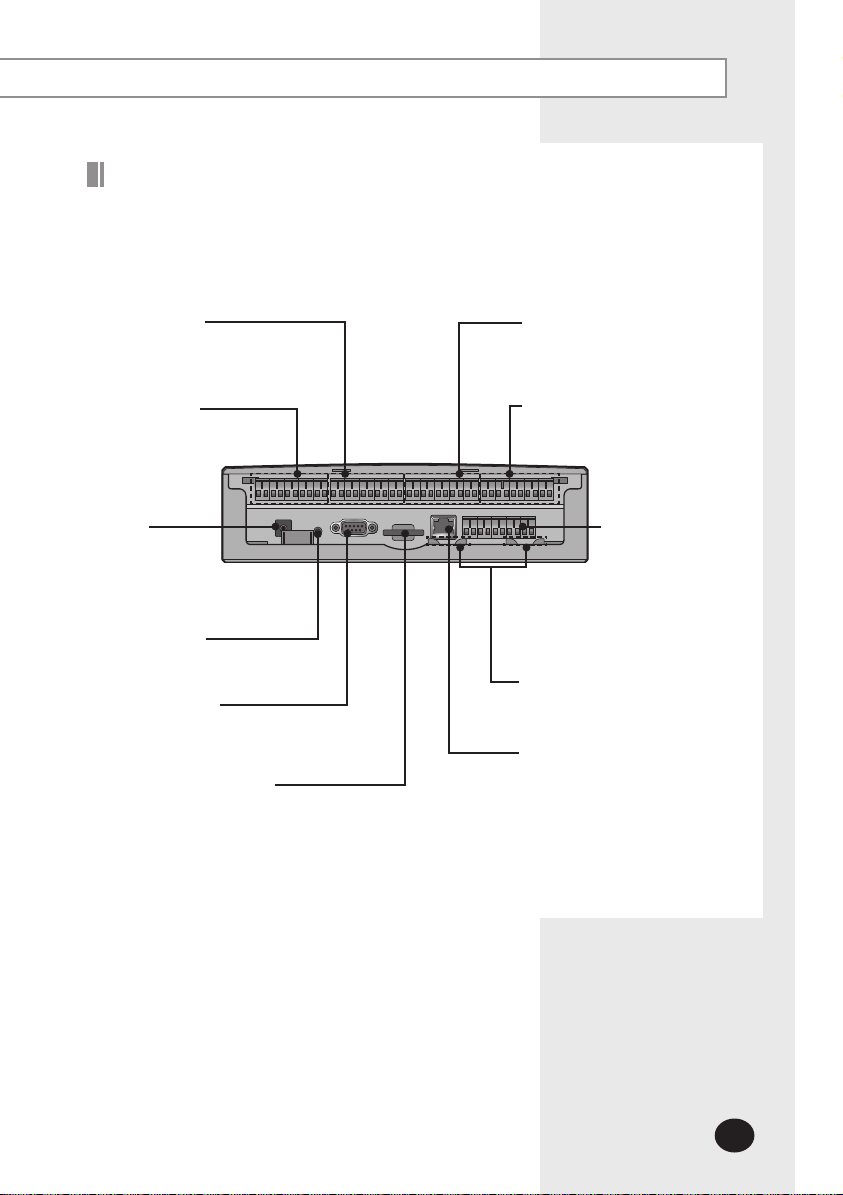

Bottom View

Separate bottom cover by unfastening 2 screws on the bottom.

DI Terminal2

Connect Digital Input

- Channel 6~Channel10

DI Terminal1

Connect Digital Input

- Channel 1~Channel 5

Power

Terminal

Connect

DMS2 adapter

Reset Button

Reset DMS2

Serial Terminal

Service agent checks error

status

SD Card Socket

Socket for sub memory (SD or MMC)

( Sub memory is for DMS2 program update and set

information saving)

※ Purchase SD card separately.

DO Terminal1

Connect Digital Output

- Channel 1~Channel 5

DO Terminal 2

Connect Digital Output

- Channel 6~Channel 10

RS485

Communication

terminal

Connect for RS485

communication

with devices such as

centralized controller/

interface module

- COM1 ~ COM5

Cable tie groove

Arrange cables connected to

DMS2

LAN Terminal

Connect LAN cable

E-7

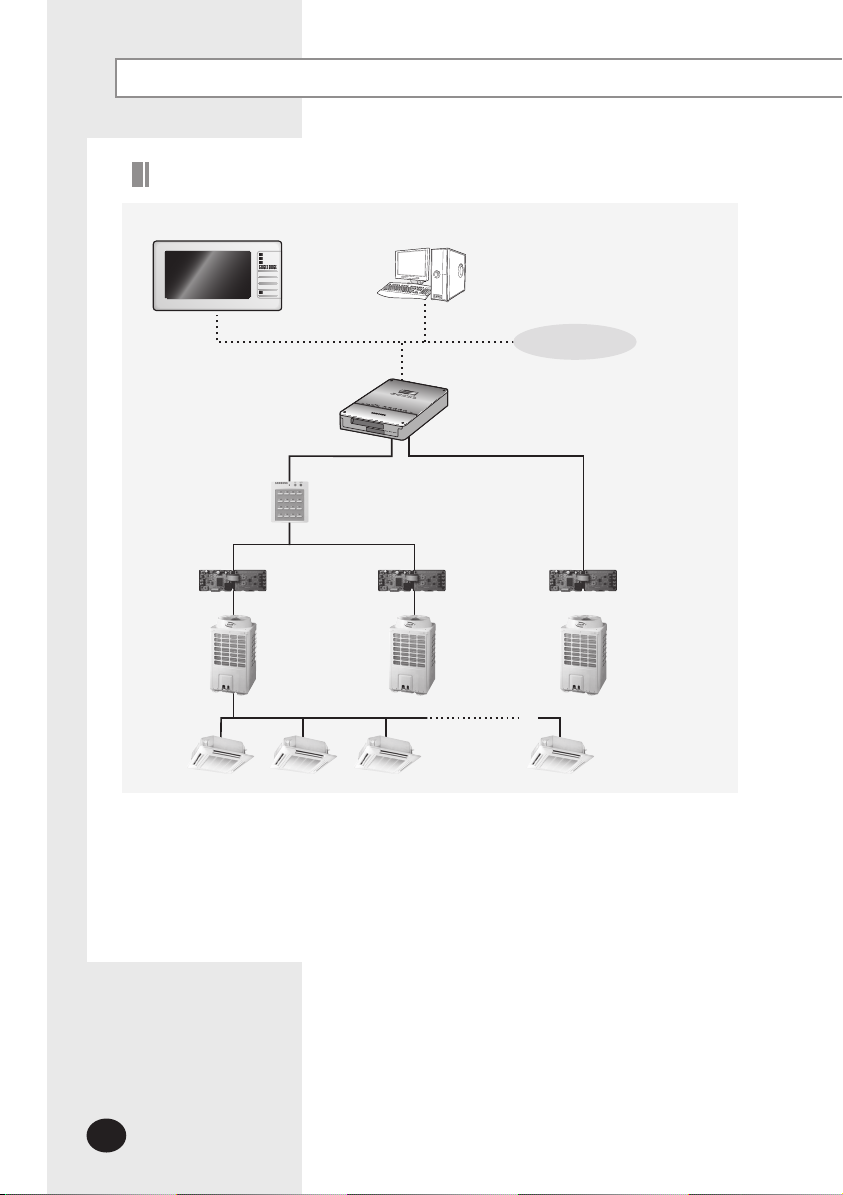

Before Use

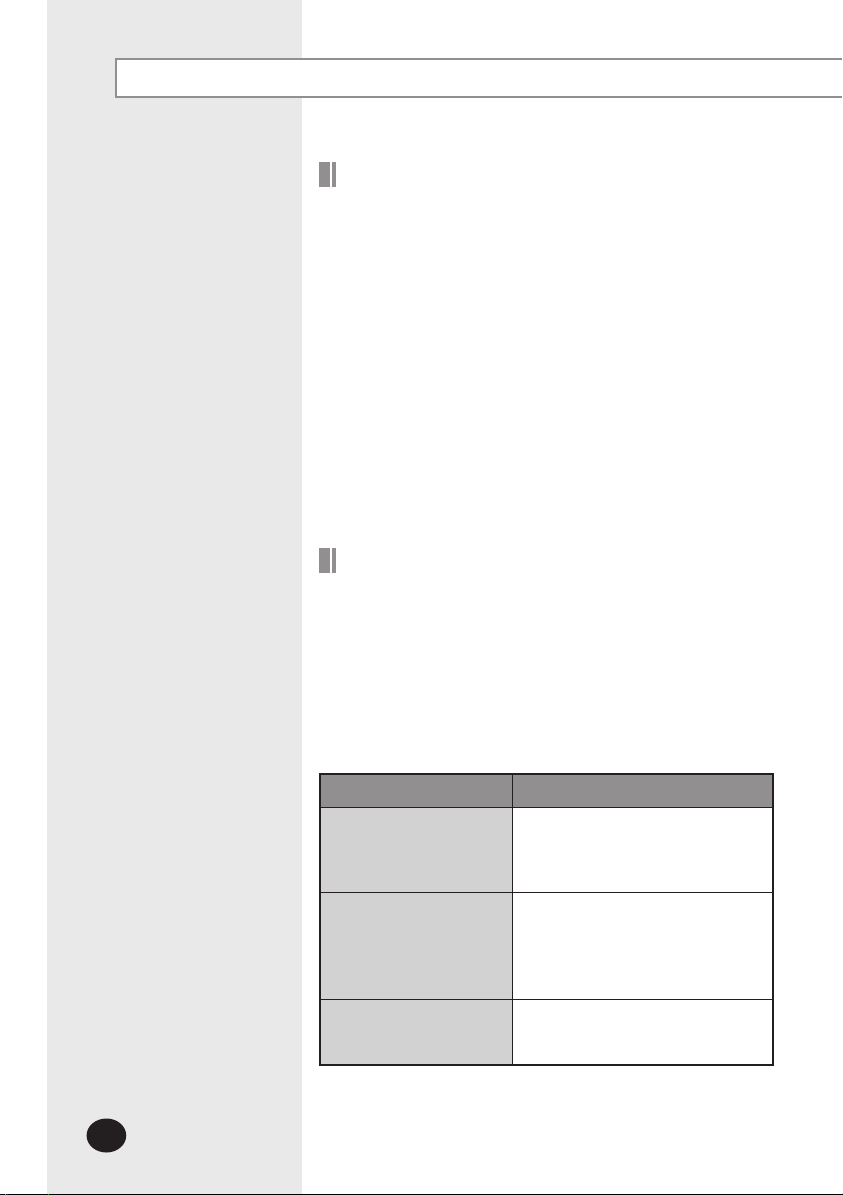

System Configuration

S-NET mini

Centralized

controller

Interface module

S-NET 3

Internet

DMS2

ⓐ ⓑ

Interface module

Interface module

Connecting centralized controller and DMS2 (ⓐ type )

You can control up to 16 centralized controllers and 256 indoor units using DMS2.

Connecting interface module and DMS2 (ⓑ type)

- You can control up to 80 interface modules and 256 indoor units using DMS2.

※ 16 interface modules can be connected to RS485 communication channel of DMS2.

- The more interface modules are connected, the longer time takes for tracking.

E-8

When connecting centralized controller and interface module to the DMS2 of same

communication channel, only one of them will communicate according to the

communication channel mode setting of [System Settings][Tracking].

Therefore, do not connect the centralized controller and interface module to the same

communication channel.

If you set the communication channel mode as interface module, virtual centralized

controller address will be assigned. Therefore if you connect centralized controller

at the same time and set the address as virtual centralized controller address, it may

cause trouble for bringing device information.

Channel 0: Virtual centralized controller 11,

Channel 1: Virtual centralized controller 12,

Channel 2: Virtual centralized controller 13,

Channel 4: Virtual centralized controller 14,

Channel 5: Virtual centralized controller 15

Web Browser Specification

Install Windows XP SP2, Windows 2000 SP4 or later version

Install Internet Explorer 7.0 or later version

※ You can use Internet Explorer 6.0 but it is not recommended.

Install Silverlight 2.0 or later version

Note

Visit internet homepage (http://www.microsoft.

com/silverlight/) to download Silverlight. Or you can

download it through the download link which is noticed

automatically when the PC is connected to the Internet

and you access to DMS2 for the first time.

Silverlight operates normally with Windows XP SP2 or

later version.

It may not operate normally with former version of

Windows.

Computer Settings for DMS2 Connection

All settings of DMS2 will be arranged in web page which built in

DMS2.

You should access to DMS2 IP to use DMS2 web page.

There are 2 ways to access DMS2 IP.

(For about settings, refer to installation manual.)

Static IP setting

Dynamic IP(DHCP) setting

E-9

Main Function

Interface with Upper Level Controller

The DMS2 receives/manages setting and control data from the

upper level controller and sends the received data to the lower

level system.

The upper level controllers of the DMS2 are the S-NET series

and the connectible S-NET series are S-NET 3, S-NET mini and

RMS.

S-NET 3: System air conditioner controlling and monitoring

program that is used by installing on a PC.

S-NET mini: System air conditioner controlling and monitoring

device with touchscreen

RMS: A device which supervises operation status and break

down status by connecting to DMS2 for system air

conditioner remote service. If break down is detected,

it notifies service agent and makes fast service possible.

Save Trouble History

The DMS2 saves at most 1024 cases of trouble history.

If the number of errors exceeds 1024, only the latest 1024 cases

are stored by deleting the oldest trouble history.

Device name, address, error occurrence time, error solvation

time, trouble history will be saved. You can check it in web

page or upper controller.

When an error occurs, it sends trouble history to e-mail saved

in DMS2.

E-10

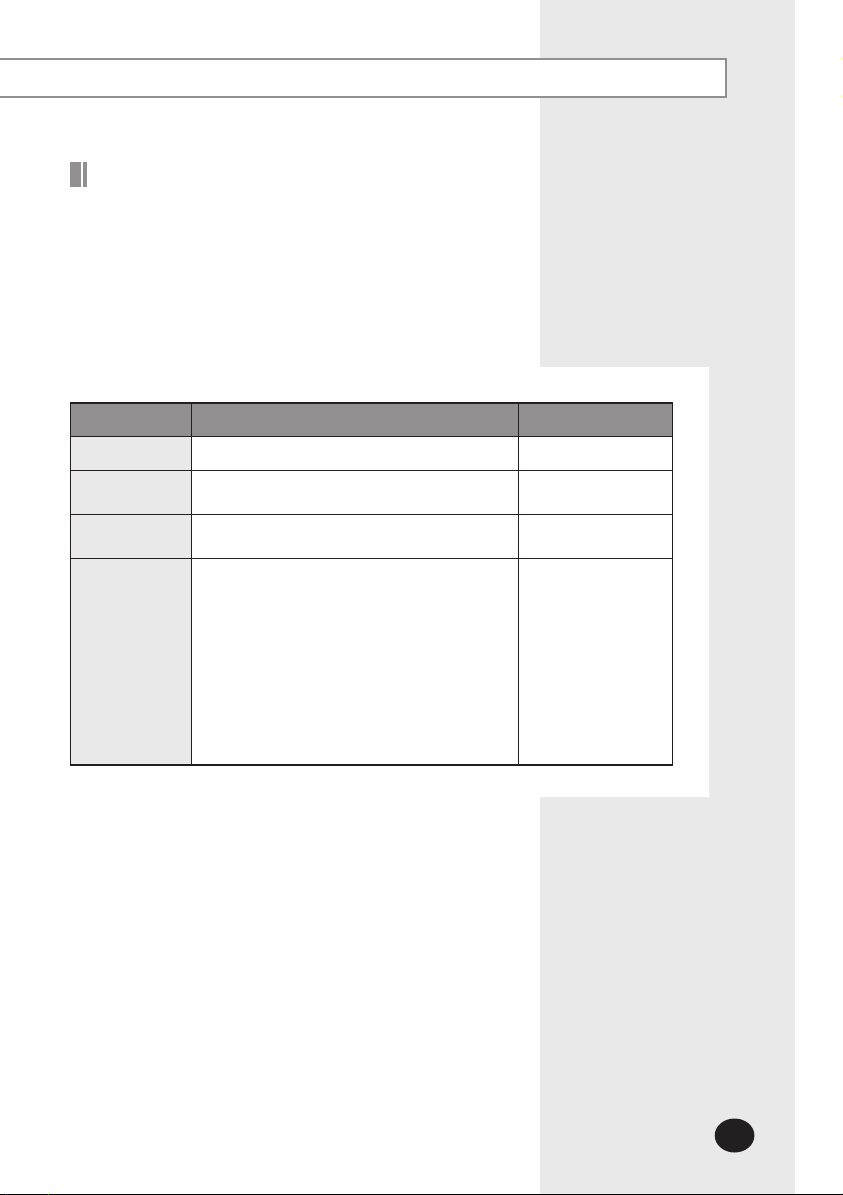

Device Type

Indoor Unit

Outdoor Unit

Communication error

such as centralized controller

Indoor unit communication error

Indoor unit sensor related error

Other errors

Outdoor unit communication error

Pipe inspection error

Outdoor unit sensor related error

Outdoor unit related other errors

Option device related communication

error

Set and Run Schedule

The schedule function of the DMS2 can be set through the Web

or using the upper level controller. 1day/Everyday/Every week

schedules can be set.

Each schedule can be used selectively by using the run

schedule/stop schedule order.

At most 256 schedules can be set.

Indoor unit control is possible at least 1 minute of interval by

set schedule.

Item Content Remark

Schedule Period Starting and ending date of a schedule

Exception Day

Setup

Devices to

be applied

Event

Set an exception day within a schedule period to

ignore the schedule control

Select devices to receive schedule control

Set indoor unit operation modes

- Device On time

- Device O time

- Desired temperature

- Operation mode: Auto/Cool/Dry/Fan/Heat/O

- Remote control usage Enable RC/ Disable RC/

Cond.RC

- Fan speed: Auto/Low/Mid/High

- Air ow: None/Vertical/Horizontal/All

- ERV operation mode: Auto/HeatEx/ByPass/Sleep

- ERV Fan speed: Low/High/Turbo

Weekly Repeat:

Maximum 10 events

per day

Daily Repeat:

Maximum 70 events

E-11

Main Function (Continued)

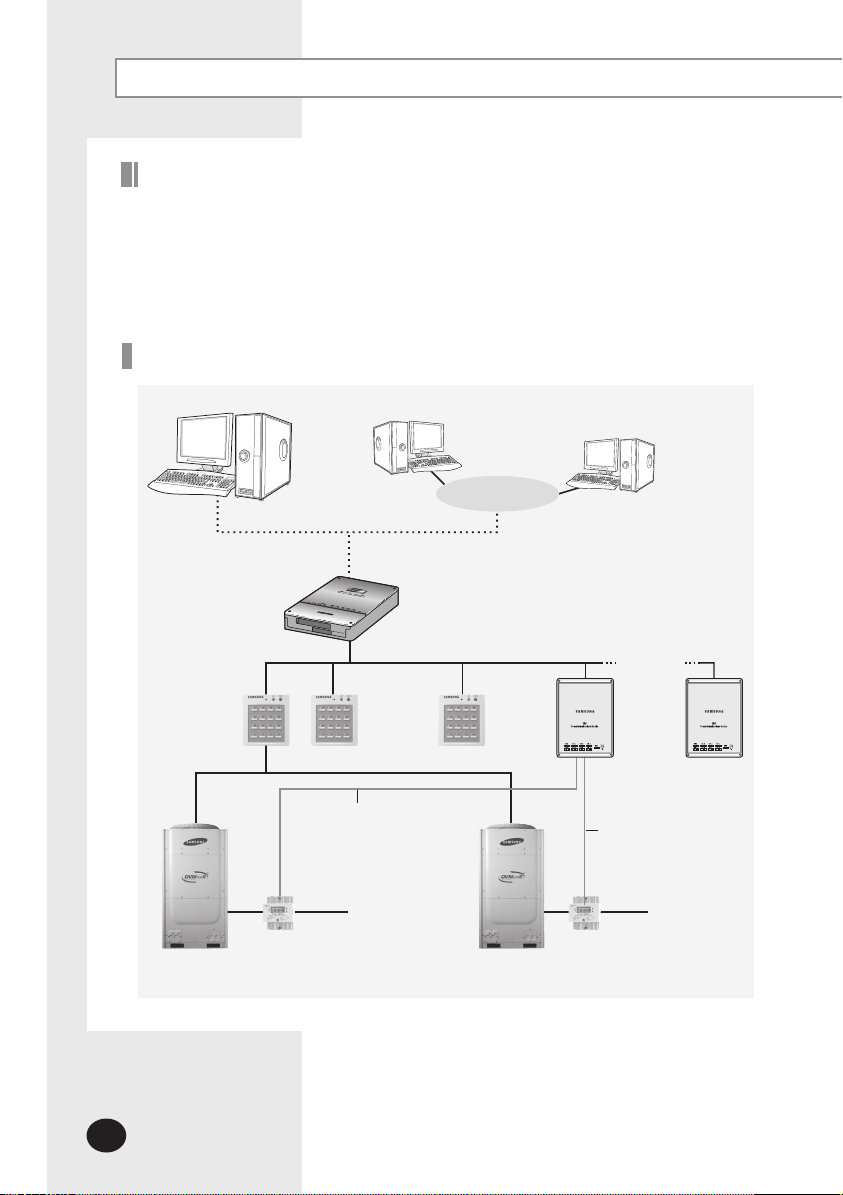

Save Integrated Power Distribution Data

The DMS2 calculates and distributes the power consumed by each indoor unit by

receiving the total power usage from the watt-hour meter interface modules (SIM/PIM)

and taking into account the operation status of the indoor units.

The DMS2 saves at most 1 year of data. After a year, the oldest data is deleted and

the latest data is saved. This data can be checked through the built-in Web page of

the DMS2 or by S-NET 3.

System Architecture

S-NET 3

Centralized controller

Watt-hour meter

DMS2

Up to

8 units

Internet

Web Client

Up to

8 units

SIM /PIM

Up to

8 units

Watt-hour meter

SIM /PIM

E-12

Time Segmentation

Time segmentation is used to divide 24 hours into different sections and to distribute

power according to each section.

This function is used when the power consumption fee is different according to

different time slots or when a building is charged differently depending on the

consumption time.

1 section (A) is set as 24hours, and the factory default setting is set as 1 section.

The time, 24hours, can also be divided into 2 sections (A,B,A), 3 sections (A,B,C,A) or

4 sections (A,B,C,D,A)

DMS2 shows the result of the power distribution for each section you set.

Input manually (When setting 2 sections, 3sections, and 4sections)

If communication error occurs between DMS and the lower level controllers,

actual power consumption and the result of power distribution value may not be

same. Make sure to solve communication error status.

- Communication error example : Between DMS2 and SIM/PIM

Between SIM/PIM and Watt-hour meter

Between DMS2 and Centralized controller

Between Centralized controller and interface

module

Between Interface module and indoor/outdoor

units Between DMS2 and interface module

E-13

Starting DMS2

Starting DMS2

Current time setting

Set the current time of DMS2 system.

“2009/01/01 01:01:01” is factory setting. Set the current time as DMS2 system time.

You can set DMS2 time in [System Settings] [System environment setting]

(Refer to page 118~119)

If DMS2 time does not set as the current time, DMS2 may cause malfunction when

using Schedule or control logic management.

Connecting centralized controller & interface module

(1) Make sure that centralized controller communication cables(C1, C2) or interface module

communication cables(R1, R2) are connected.

For communication between DMS2 and centralized controller/interface module,

centralized controller communication cable(C1, C2) or interface module

communication cable(R1, R2) should be connected.

(2) Execute tracking.

DMS2 communicates with centralized controller and interface module and

brings information about installed indoor unit and outdoor unit.

After tracking, you can use indoor unit control and other menu.

For tracking, refer to [System Settings] [Tracking] (Refer to page 134~144)

E-14

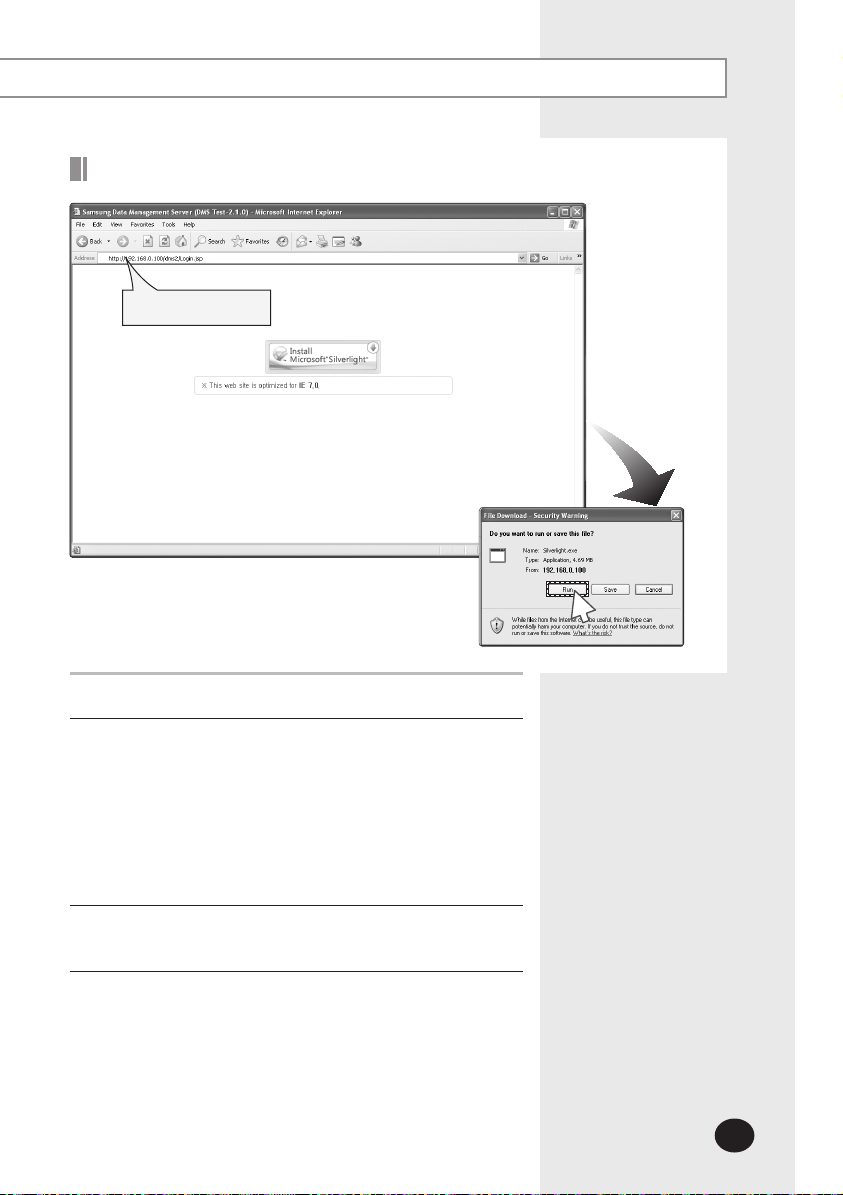

Access to DMS2 & Login

Address bar

Run internet explorer on your computer.

1

Enter IP address (http://192.168.0.100) on the address bar,

2

and then press [ENTER].

If it is the first access to DMS2, “Install Microsoft Silverlight”

message will be displayed.

- The message will not appear if Microsoft Silverlight have

already installed.

If the message window and login screen does not

appear, check PC setting status.

3

Click [Run] and continue installation.

3

Access to DMS2 again after installation.

E-15

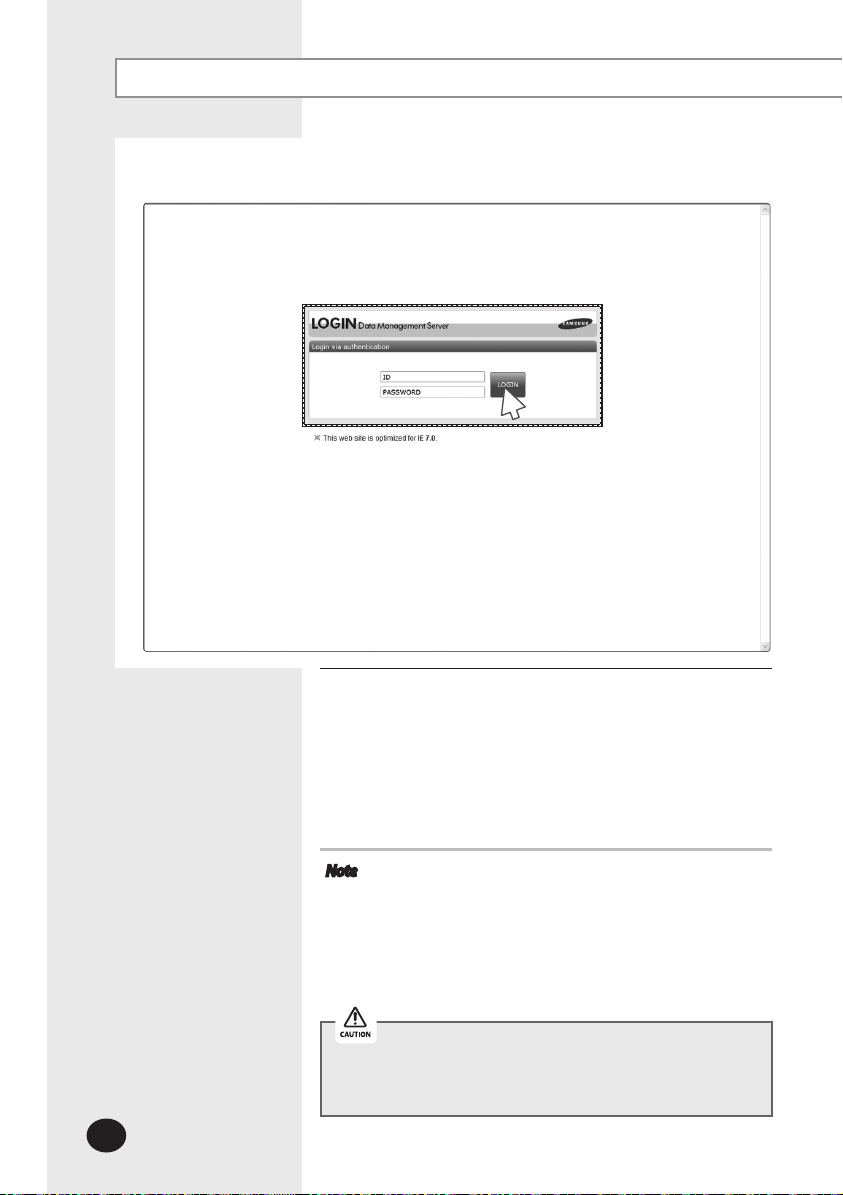

Starting DMS2 (Continued)

4

E-16

Enter ID and password when DMS2 main web page appears.

4

Then click [LOGIN].

The default DMS2 user ID is 'admin' and password is '1234'.

Depending on authorization settings which set by the

administrator, access to some functions may be restricted.

To edit user authorization, refer to [System Settings]

[User authorization management]. (Refer to page 101)

Note

Only authorized users can access to web page.

Fewer than 5 concurrent users are recommended

DMS2 manager should change ID and password for

Logout: To log out, click [LOGOUT] on the top of the

because connection speed may slow down.

security and management. (Refer to page 99)

menu.

Silverlight will run normally with Windows XP SP2 or later

version. With former version of Windows, DMS2 may not

operate normally.

Logged-in User with No Authorization

When the screen above appears, ask for manager.

1

Depending on control authorization setting, there can be

a user who does not have control authorization.

Above screen will appear when the logged-in user does

not have control authorization.

E-17

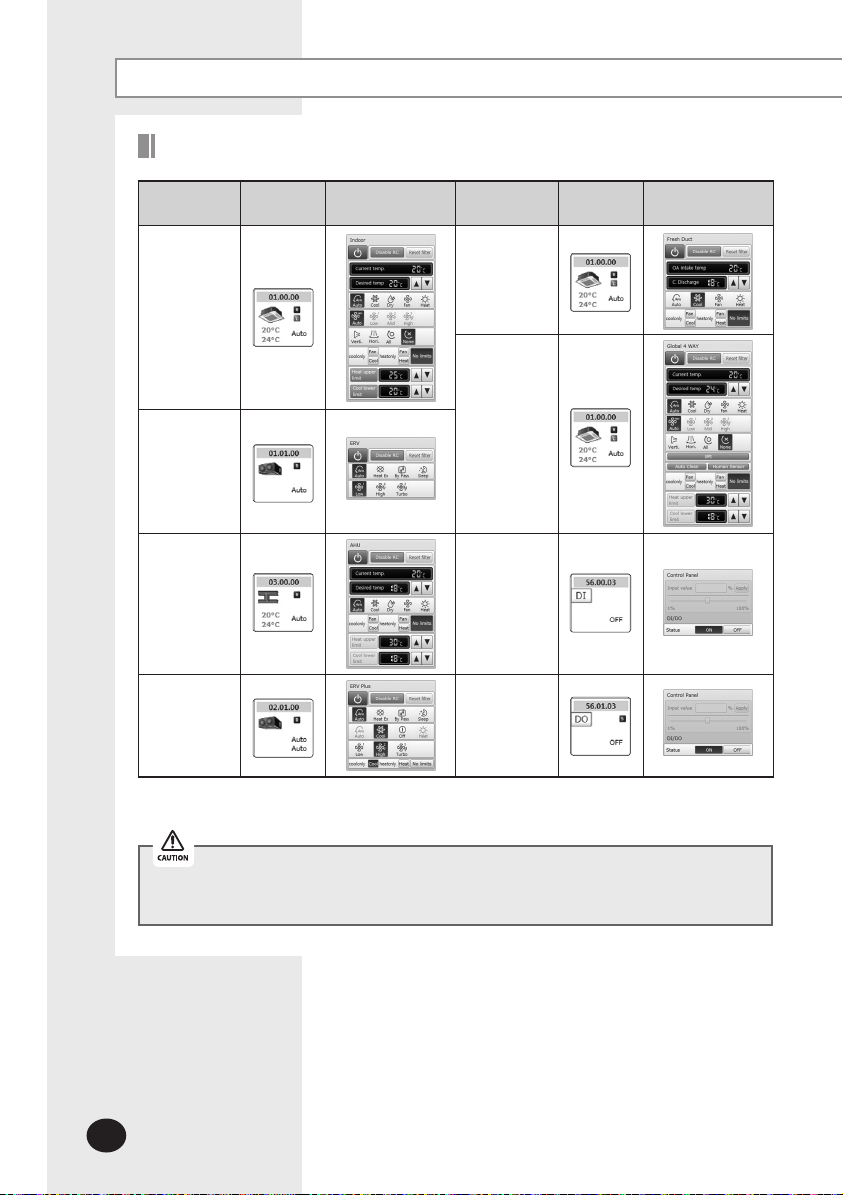

Control and Monitoring

Devices controlled and monitored by DMS2

Type Display

Indoor unit

display icon

ERV

display icon

AHU

display icon

ERV PLUS

display icon

Remote controller

(Controlling range)

Type Display

Fresh duct

display icon

Global 4 way

display icon

DI

(Digital Input)

display icon

DO

(Digital Output)

display icon

Remote controller

(Controlling range)

DMS2 can control and monitor the devices in the above table.

When users select multiple devices, 'Basic Control' will be displayed on the screen.

(This is when different types of multiple devices are selected.)

E-18

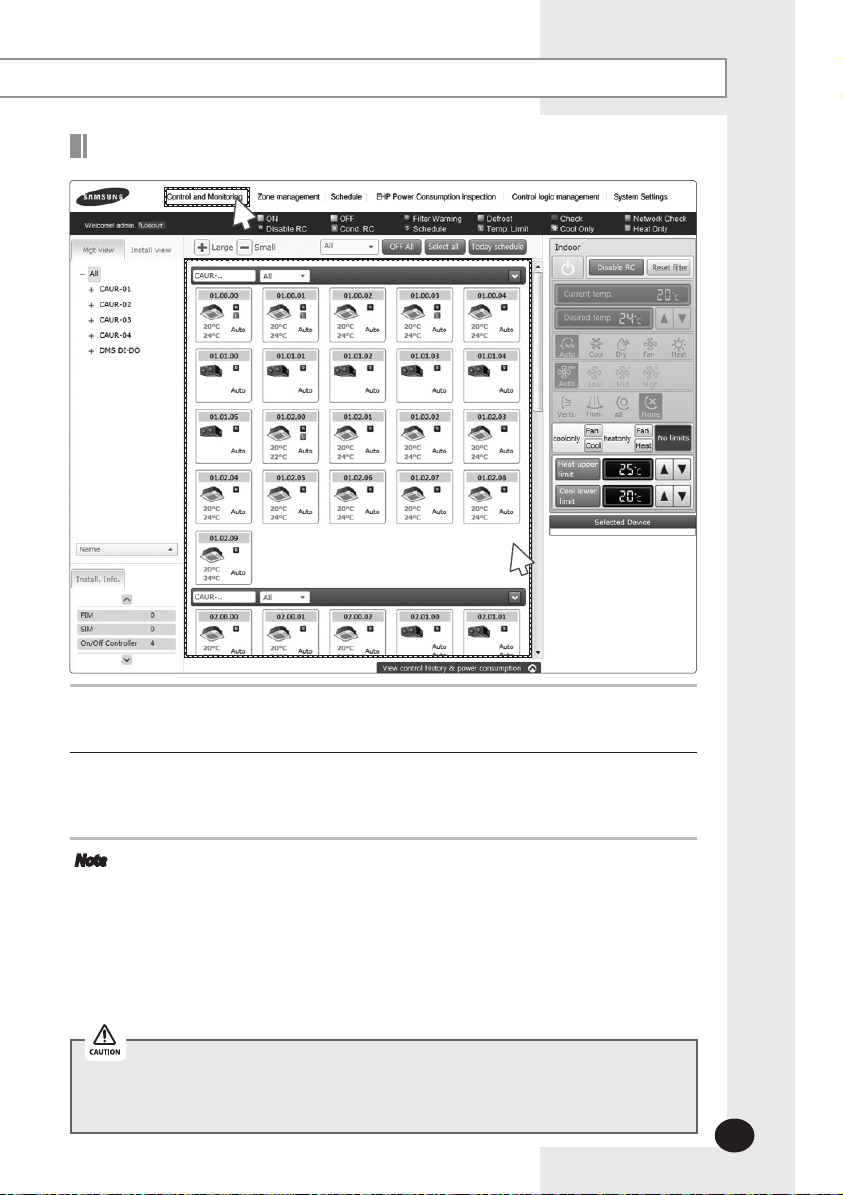

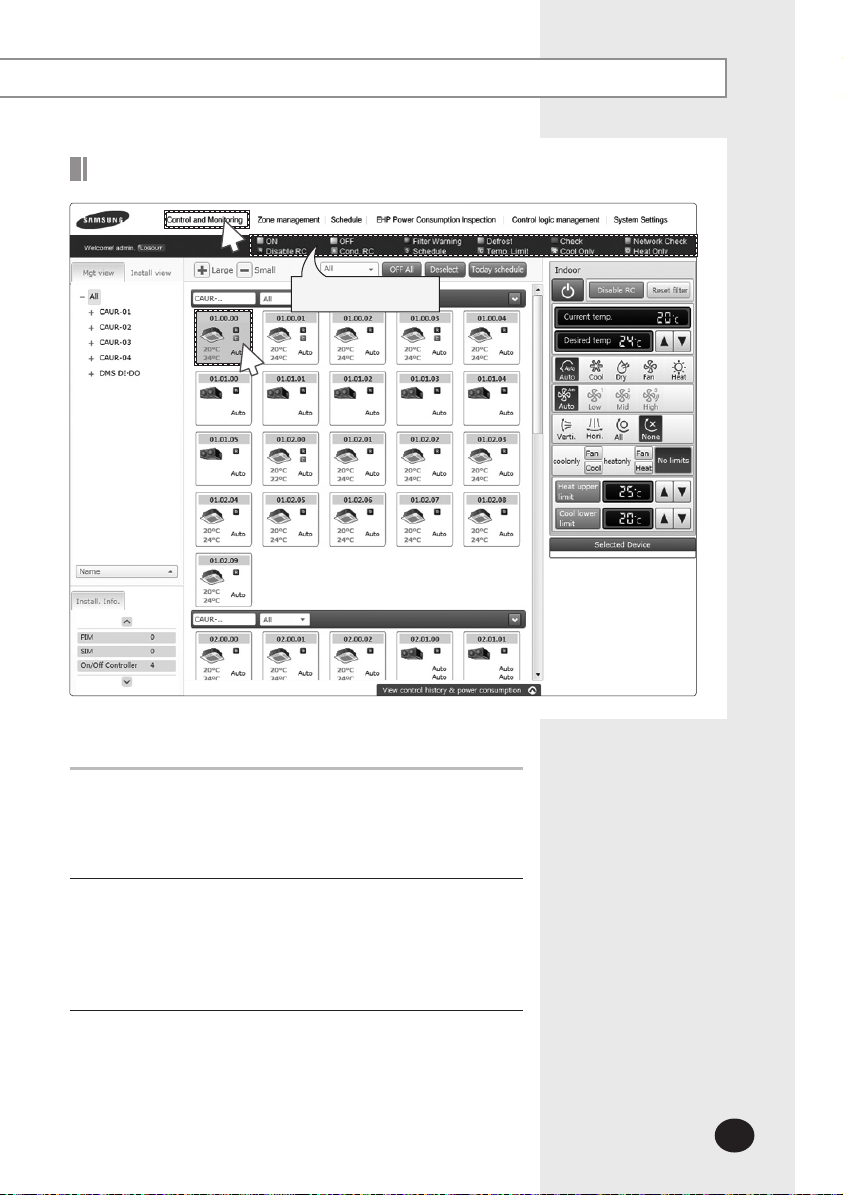

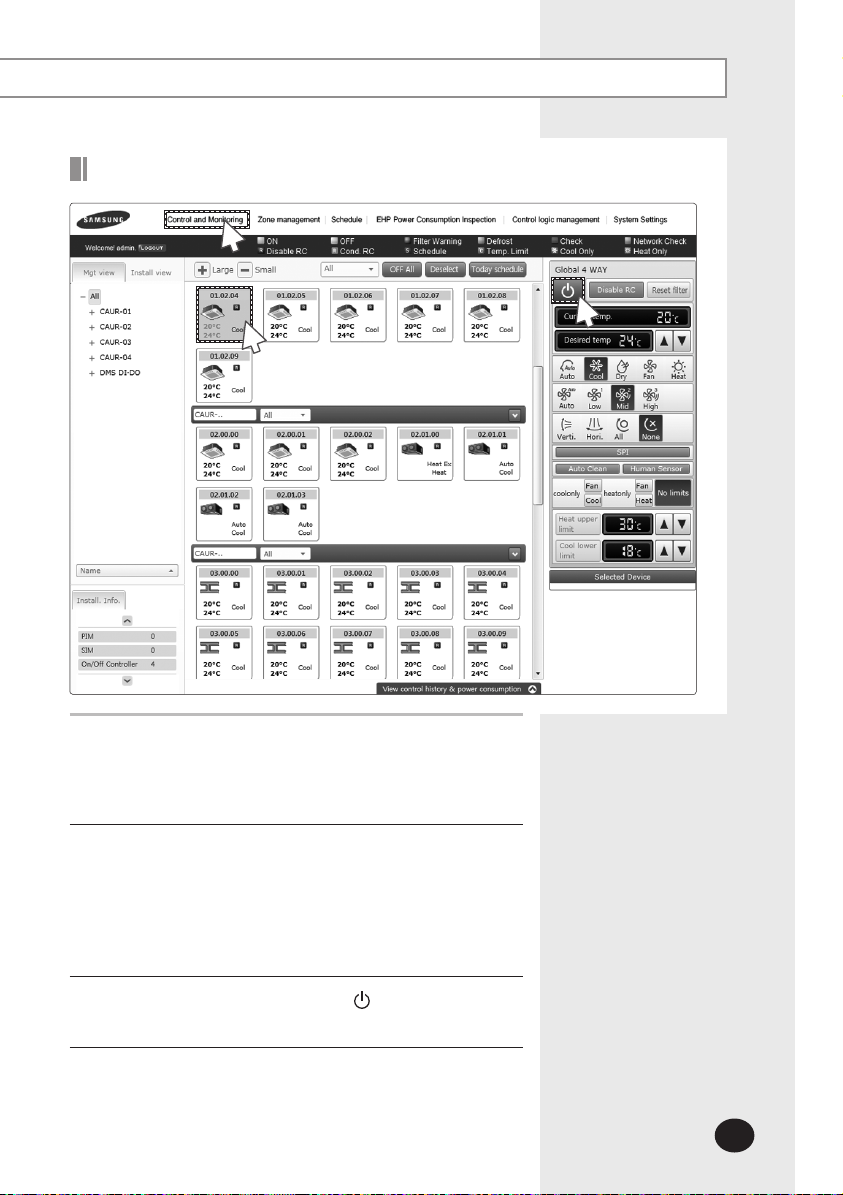

Monitoring Indoor Unit Operation Status

1

2

Click [Control and Monitoring] when DMS2 web page menu screen appears.

1

[Control and Monitoring] screen will appear when you log-in to DMS2 web page.

Check the current status of all devices.

2

You can check the current controlling status of all installed indoor units, ERV, AHU,

ERV PLUS, Fresh duct, Global 4 Way, and other devices.

Note

When the advanced functions (such as Sleep mode, Energy saving function) are

selected through wired/wireless remote controllers or indoor unit panel,

set operation mode on the remote controllers and DMS2 may be displayed

differently. Also, when controlling by DMS2, additional functions will be canceled.

Depending on the model of indoor unit, Horizontal/All air flow direction control

AHU, ERV, ERV PLUS, Global 4 Way, Fresh duct, Lighting, and other devices will be

may not be possible. In this case, vertical or fixed flow will be displayed depending

on indoor unit’s basic operation specification.

displayed only when the corresponding devices are installed.

Some functions available on DMS2 webpage may not be functional at BACnet

Gateway and LonWorks Gateway. For detailed function, refer to the installation

manual or contact Samsung Electronics.

E-19

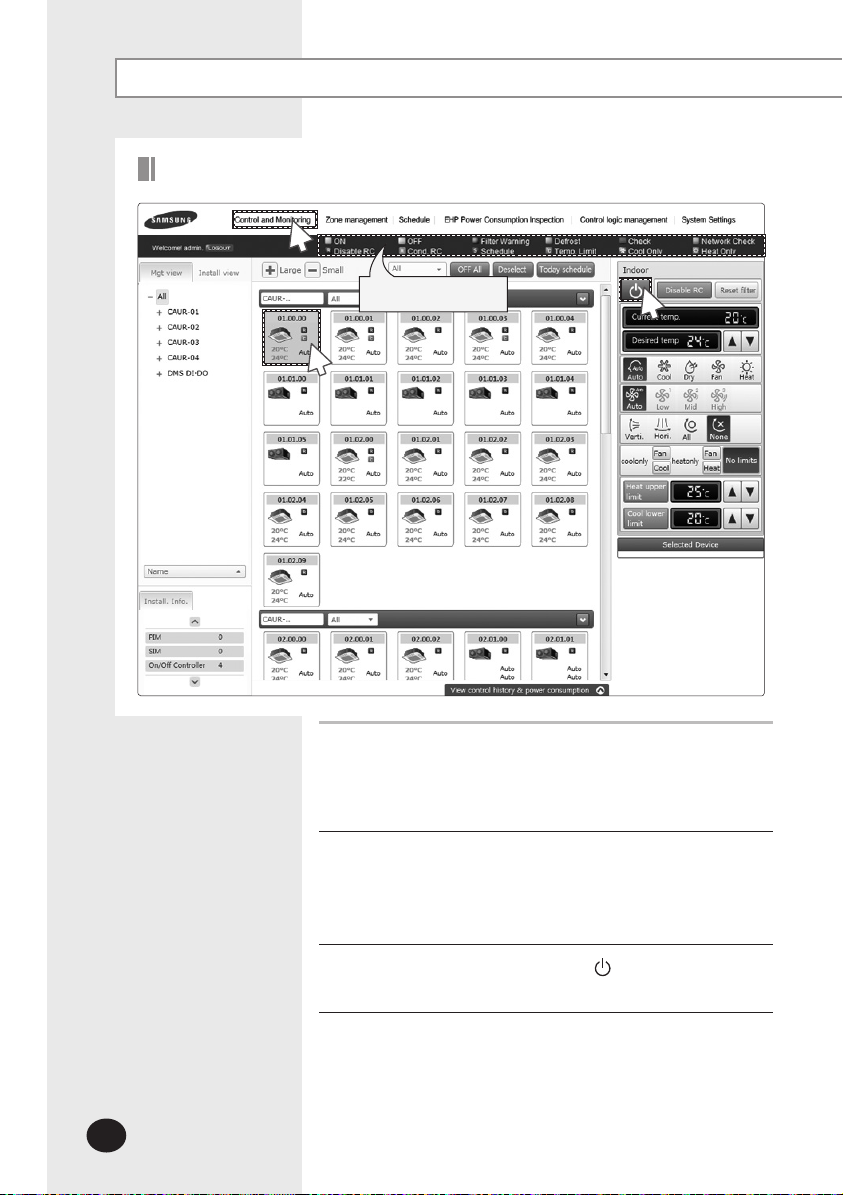

Control and Monitoring (Continued)

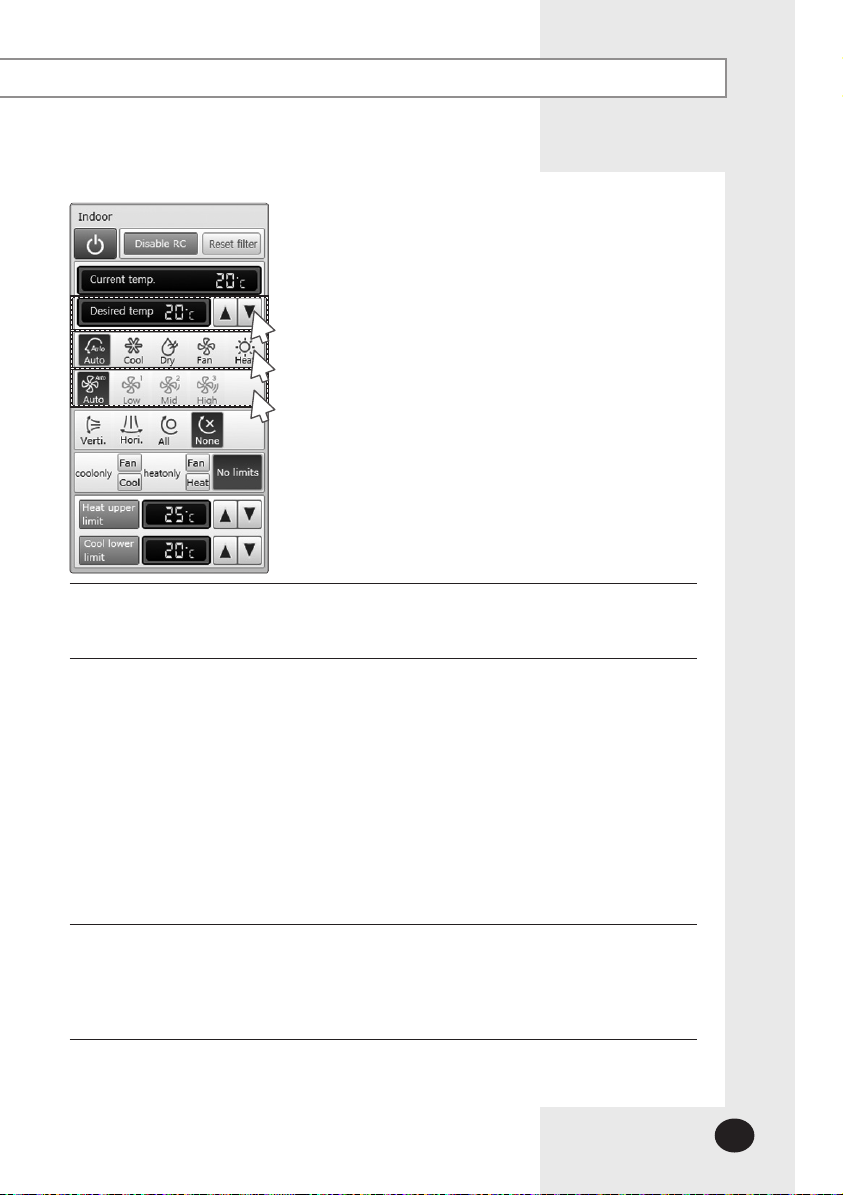

Controlling an Indoor Unit

1

Status display window

2

Click [Control and Monitoring] when DMS2 web page menu

1

screen appears.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

Select an indoor unit to control.

2

Check the indoor unit status through status display window.

When the selected indoor unit is switched on, the remote

controller panel will be automatically activated.

3

E-20

3

Turn the indoor unit on by clicking [ ].

Remote controller panel will be activated.

5

4

6

Select the operation mode.

4

You can select Auto, Cool, Dry, Fan and Heat operation mode.

Click [][] to set the desired temperature.

5

Each time you click the buttons, the temperature will be adjusted by 1℃(1°F).

If Auto/Cool/Dry mode is in operation, you can adjust the desired temperature in

the range of 18℃(65°F)~30℃(86°F).

If Heat mode is in operation, you can adjust the desired temperature in the range of

16℃(61°F)~30℃(86°F).

You cannot adjust the desired temperature in Fan mode.

When the operation mode of an indoor unit is Cool or Dry mode, you cannot set the

desired temperature lower than lower limit temperature if lower limit is enabled.

When the operation mode of indoor unit is Heat mode, you cannot set the desired

temperature higher than upper limit temperature if upper limit is enabled.

Select the fan speed.

6

You can select Auto, Low, Mid and High.

If Auto/Dry mode is in operation, fan speed will be set as Auto fan speed.

If Fan mode is in operation, you cannot select Auto fan speed.

E-21

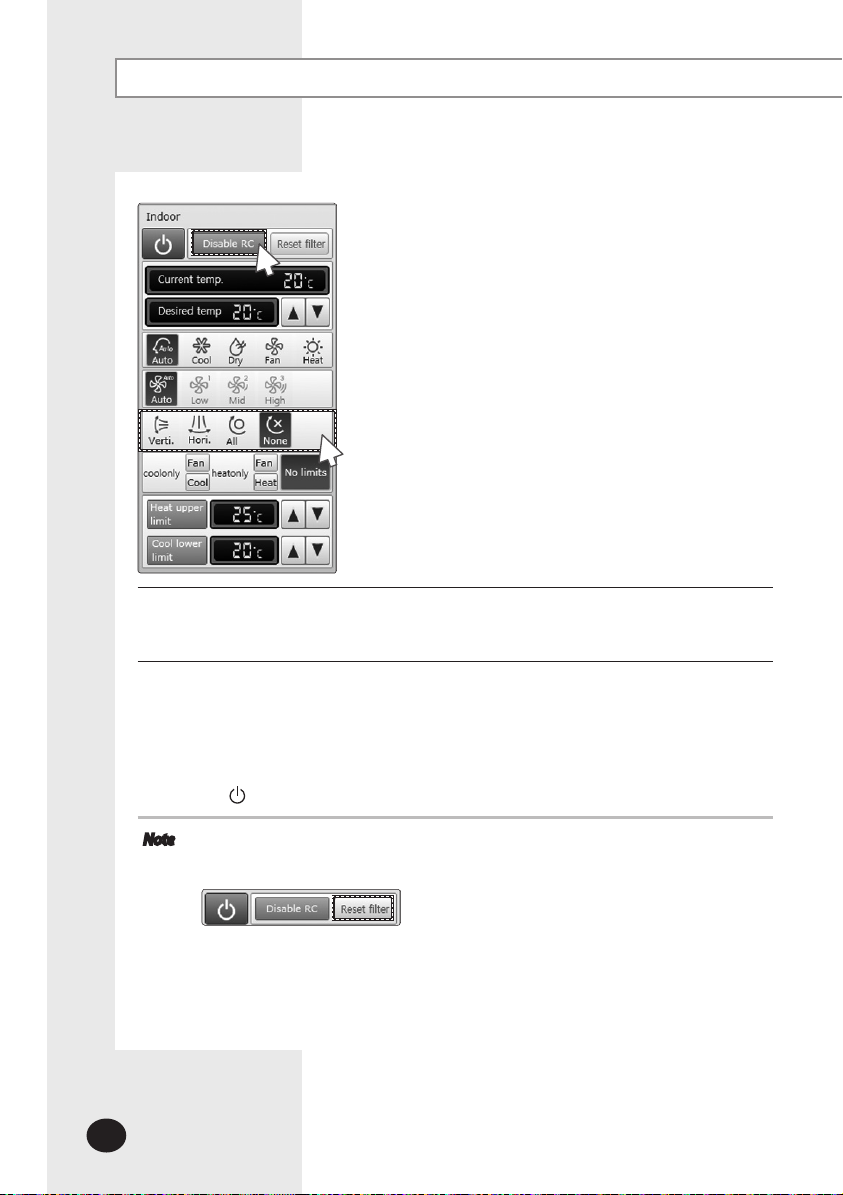

Control and Monitoring (Continued)

8

7

Select the air flow.

7

You can select Vertical, Horizontal, All and None air flow direction.

Set remote controller settings.

8

You can select Enable RC, Disable RC, and Cond. RC.

When selecting [Disable RC], indoor unit control by wired/wireless remote controller

and indoor unit panel is not possible. Indoor unit control is only available in

DMS2 web page.

Click [ ] when you want to use wired remote controller in each room.

Note

When filter warning sign is displayed on indoor unit status window

Select the indoor unit and click [Reset filter].

Filter warning will be released.

Make sure that each indoor unit must be turned on to control.

Selecting remote controller, reset filter, operation mode limits, setting lower/upper

Some air flow direction option may be restricted depending on the indoor unit

E-22

temperature limit are possible even if the power of indoor unit is off.

model.

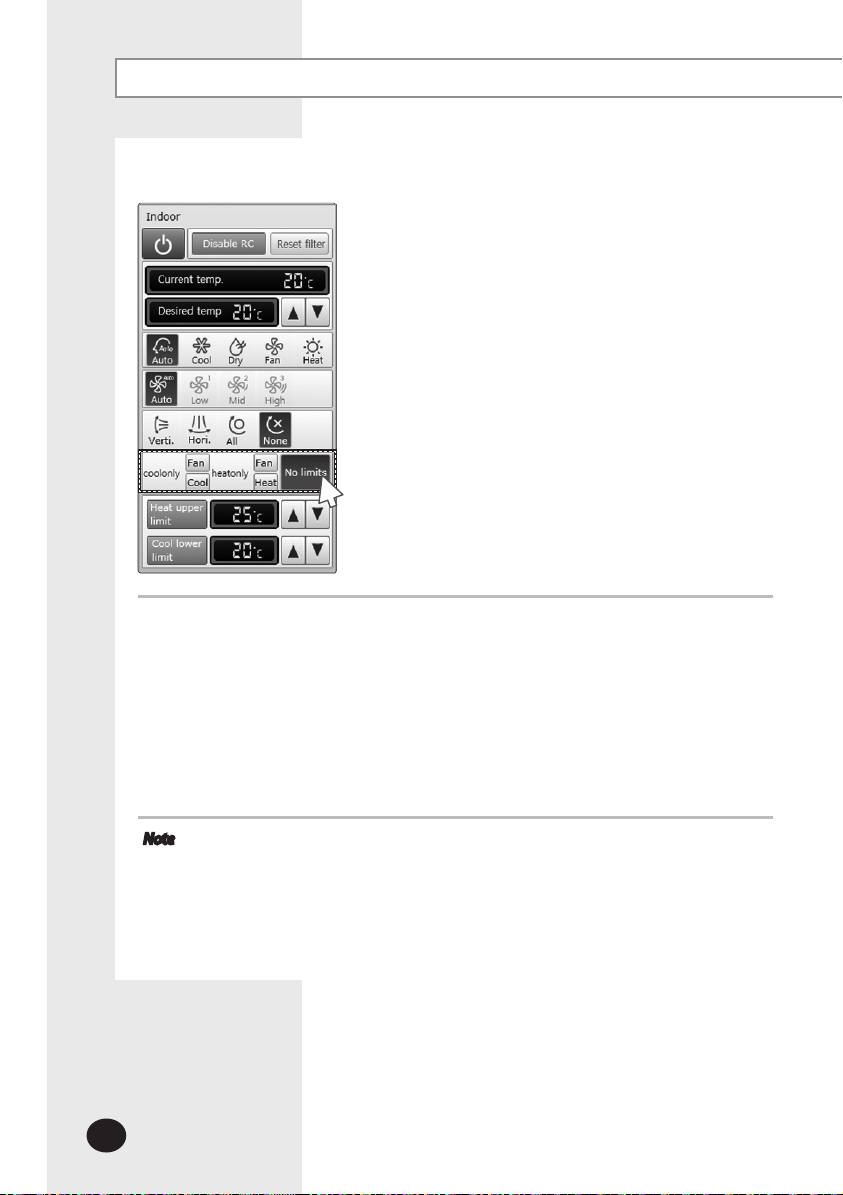

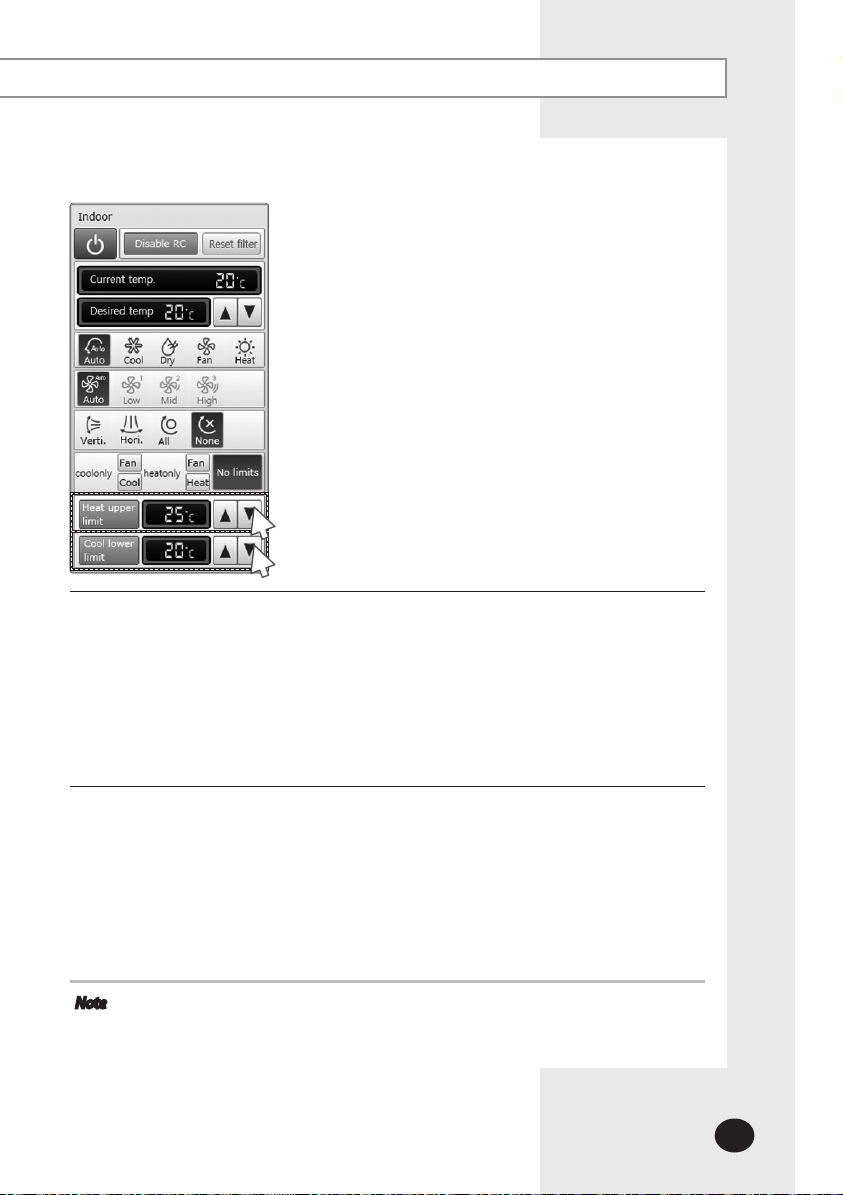

Indoor Unit Operation Mode Limit

1

Status display window

2

You can monitor the operation status of all indoor units or

have individual or whole control of the indoor units.

Click [Control and Monitoring] when DMS2 web page menu

1

screen appears.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

Select an indoor unit to control.

2

Check the indoor unit status through status display

window.

When the selected indoor unit is switched on, the remote

controller panel will be automatically activated.

E-23

Control and Monitoring (Continued)

3

Set operation mode limit.

3

You can select 'Cool only(Fan, Cool)’, ‘Heat only(Fan, Heat)’ and ‘No limits’.

- Cool only (Fan, Cool) : If cool only indoor unit operates in Heat mode,

reset the indoor unit as set operation mode.

- Heat only (Fan, Heat) : If heat only indoor unit operates in cool mode,

reset the indoor unit as set operation mode.

- No limits : You can use cool only and heat only with no limits.

- e.g : If the 'cool only fan' indoor unit operates in heating mode, DMS2 will detect it

and reset the indoor unit in Fan mode.

Note

Operation mode limits setting is not available in ERV.

ERV Plus doesn’t operate Fan mode, it only operates cool mode in ‘cool only’.

Mixed operation can occur regardless of operation mode limits setting.

E-24

ERV Plus doesn’t operate Fan mode, it only operates heat mode in ‘heat only’.

If indoor unit with operation mode limit is in mixed operation, DMS2 solves mixed

operation status automatically by controlling the indoor unit in set operation mode.

In the following circumstances, all indoor units under the

same outdoor unit should be set to the same operation

mode limits. Mixed operation can occur continuously

when you set some of indoor unit to cool only and the

other to heat only.

- If the centralized controller is MCM-A202 and is in

group mode

- If the centralized controller is in group mode and the

interface module is MIM-B13 or MIM-B04A

Except above circumstances, DMS2 changes the

operation mode limit of all indoor units under the same

outdoor unit to same operation mode limit.

- If the centralized controller is in group mode and is

above MCM-A202A and all the interface modules under

the centralized controller are above MIM-B13A

- If the centralized controller is in individual mode

If you set the cooling only indoor unit’s operation mode

limit to heating only, DMS2 may display Heating

Cooling alternately.

E-25

Control and Monitoring (Continued)

Setting Lower/Upper Temperature Limit of an Indoor Unit

1

Status display window

2

E-26

You can monitor the operation status of all indoor units, and

control the indoor units as a whole, or as individual units.

Click [Control and Monitoring] when DMS2 web page menu

1

screen appears.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

Select an indoor unit to control.

2

Check the indoor unit status through status display window.

When the selected indoor unit is switched on, the remote

controller panel will be automatically activated.

3

4

Set upper temperature limit by pressing [] and [].

3

Click 'Heat upper limit' to apply the upper temperature limit setting.

When indoor unit is operating in heat mode, DMS2 controls indoor unit as upper

temperature limit if the desired temperature is higher than upper temperature limit.

Upper temperature limit can be set in the range of 16°C(61°F)~30°C(86°F).

When an indoor unit is operating in Heat mode and the upper temperature limit is

applied, you cannot set the desired temperature higher than the upper temperature

limit.

Set lower temperature limit by pressing [] and [].

4

You can set lower temperature limit by clicking 'Cool lower limit'.

When indoor unit is operating in cool mode, DMS2 controls indoor unit as lower

temperature limit if the desired temperature is lower than lower temperature limit.

Lower temperature limit can be set in the range of 18°C(65°F)~30°C(86°F).

When indoor unit is operating in Cool or Dry mode and the low temperature limit is

applied, you cannot set the desired temperature lower than the lower temperature

limit.

Note

You cannot set the lower and upper temperature limit of ERV, ERV PLUS,

and Fresh duct.

E-27

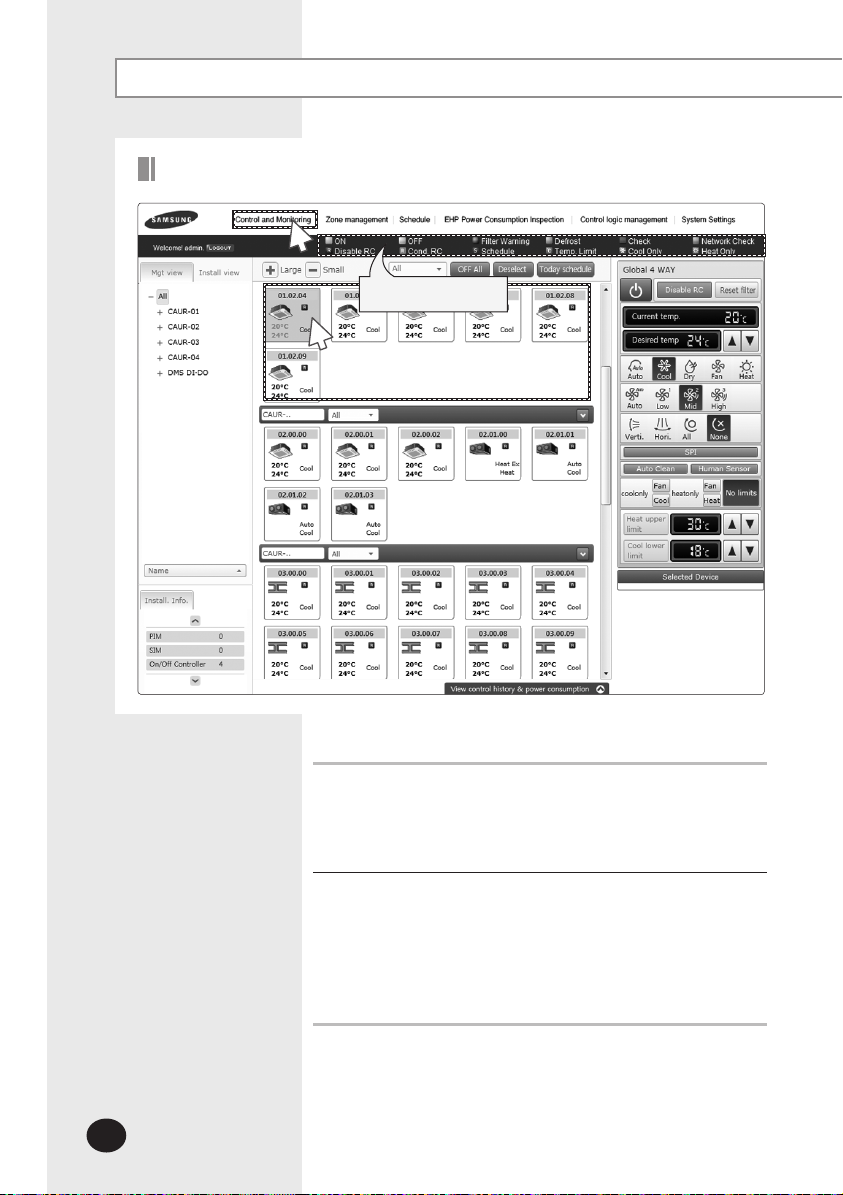

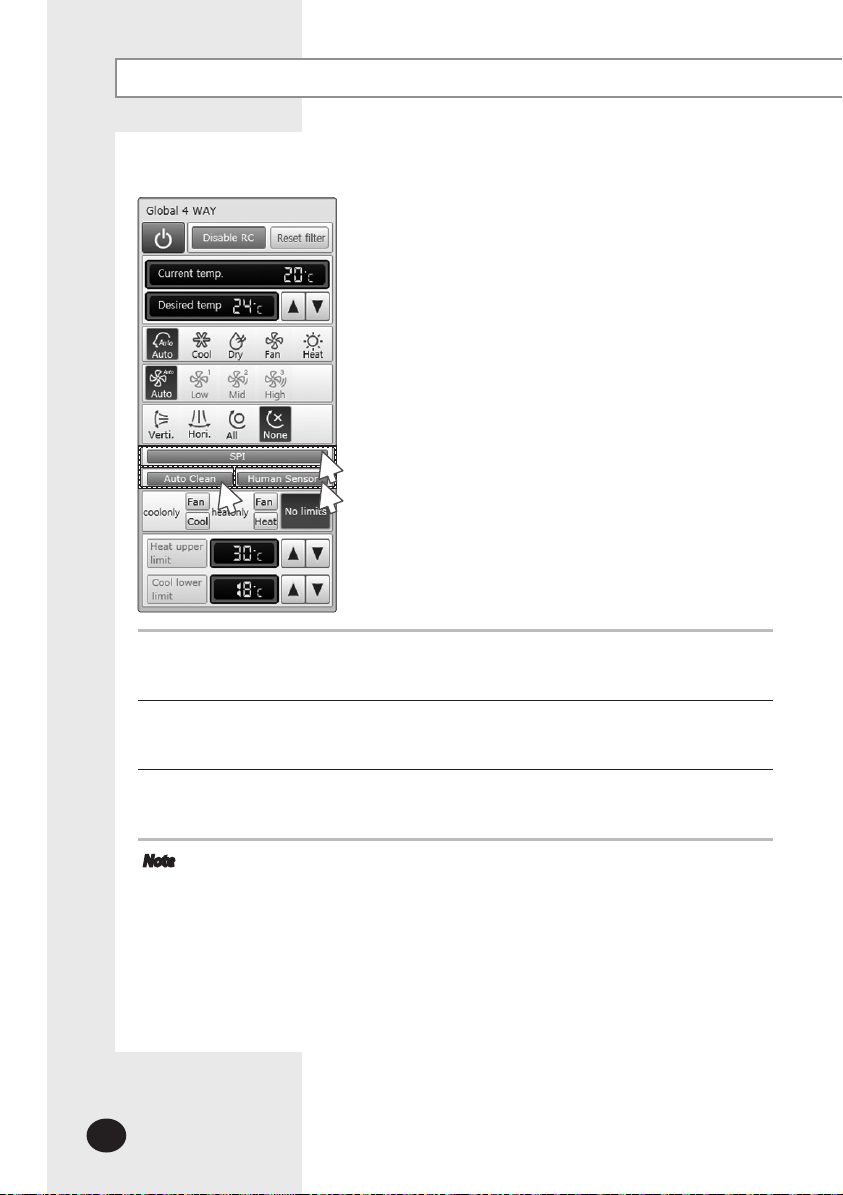

Control and Monitoring (Continued)

Monitoring the operation status of Global 4 Way

1

Status display window

2

E-28

You can monitor the operation status of Global 4 Way, and

control Global 4 Way as a whole, or as individual units.

Click [Control and Monitoring] when DMS2 web page menu

1

screen appears.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

Check the current status of Global 4 Way.

2

Check the status of Global 4 Way through the status

display window.

When the selected Global 4 way is switched on,

the remote controller panel will be automatically

activated.

Controlling Global 4Way

1

2

Click [Control and Monitoring] when DMS2 web page menu

1

screen appears.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

3

Check the current status of Global 4 Way.

2

Check the status of Global 4 Way through the

status display window.

When the selected Global 4 way is switched on,

the remote controller panel will be automatically

activated.

3

Turn the Global 4way on by clicking [ ].

Remote controller panel will be activated.

E-29

Control and Monitoring (Continued)

4

6

Select SPI setting.

4

You can set SPI through button activation / non activation.

5

Select Human Sensor setting .

5

You can set Human Sensor through button activation / non activation.

Select Auto Clean setting.

6

You can set Auto cleaning through button activation / non activation.

Note

SPI, Human Sensor, and Auto Clean will work only when the corresponding

options are installed and their normal operation is guaranteed when the

centralized controller is above MCM-A202D and Interface module is

MIM-B13D.

Refer to the ‘Controlling an indoor unit’ for Global 4 Way control. (Page 20~22)

Refer to the ‘Indoor unit operation mode limit’ for Global 4 Way operation

Refer to the ‘Setting lower/upper temperature Limit of an Indoor Unit’ for

E-30

mode limit. (Page 23~25)

setting lower or upper temperature limit of Global 4 Way. (Page 26~27)

Monitoring AHU Operation Status

1

Status display window

2

You can monitor the operation status of AHU, and control AHU as a whole,

or as individual units.

Click [Control and Monitoring] when DMS2 web page menu screen appears.

1

[Control and Monitoring] screen will appear when you log-in to DMS2 web page.

Check current status of AHU.

2

Check AHU status through status display window.

When the selected AHU is switched on, the remote controller panel will be

automatically activated.

Note

To control AHU, refer to the ‘Controlling an indoor unit’ steps.

AHU’s fan speed is fixed as high. (Refer to the page 20~22)

You cannot set air flow direction of AHU.

To set the operation mode limit of AHU, refer to the ‘Indoor unit operation mode

To set the lower/upper temperature limit of AHU, refer to the ‘Setting lower/upper

limit’ steps. (Refer to the page 23~25)

temperature limit of indoor unit’ steps. (Refer to the page 26~27)

E-31

Control and Monitoring (Continued)

Monitoring Fresh duct operation status

1

Status display window

2

You can monitor the operation status of Fresh duct, and control the Fresh duct

as a whole, or as individual units.

Click [Control and Monitoring] when DMS2 web page menu screen appear.

1

[Control and Monitoring] screen will appear when you log-in to DMS2 web page.

Check the current status of a Fresh duct.

2

Check the status of a Fresh duct through the status display window.

When the selected Fresh duct is switched on, the remote controller panel will be

automatically activated.

E-32

Controlling a Fresh duct

1

3

2

Click [Control and Monitoring] when DMS2 web page menu screen appear.

1

[Control and Monitoring] screen will appear when you log-in to DMS web page.

Check the current status of a Fresh duct.

2

Check the status of a Fresh duct through the status display window.

When the selected Fresh duct is switched on, the remote controller panel will be

automatically activated.

3

Turn the Fresh duct on by clicking [ ].

Remote controller panel will be activated.

E-33

Control and Monitoring (Continued)

4

Set cooling/heating discharge temperature by clicking []and[]

4

When the Fresh duct is in Cool mode, the Fresh duct can be set as cooling discharge

temperature and when the Fresh duct is in Heat mode, the Fresh duct can be set as

heating discharge temperature.

When the Fresh duct is in Auto or Fan mode, the discharge temperature cannot be

adjusted.

Cooling discharge temperature can be set in the range of 15°C(59°F)~25°C(77°F).

Heating discharge temperature can be set in the range of 18°C(65°F)~30°C(86°F).

Note

The normal Fresh duct operation is guaranteed when the centralized controller

is above MCM-A202D and the interface module is MIM-B13D.

Controlling or monitoring cooling/heating discharge temperature setting is

Refer to the ‘Controlling an indoor unit’ for Fresh duct control. ( Page 20~22)

The fan speed of a Fresh duct is fixed as ‘High’.

Setting air flow direction of a Fresh duct is not available.

Refer to the ‘Indoor unit operation mode limit’ for Fresh duct operation mode

available only when the DMS2 is directly connected to the Interface module

MIM-B13D. However, when the DMS2 is connected to a centralized controller,

controlling or monitoring cooling/heating discharge temperature setting is

not available.

limit. (Page 23~25)

E-34

Monitoring ERV Operation Status

1

Status display window

2

You can monitor the operation status of ERV, and control the

ERV as a whole, or as individual units.

Click [Control and Monitoring] when DMS2 web page menu

1

screen appears.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

Check current status of ERV.

2

Check the status of ERV through the status display window.

When the selected ERV is switched on, the remote controller

panel will be automatically activated.

E-35

Control and Monitoring (Continued)

Controlling ERV

1

2

3

E-36

You can monitor the operation status of ERV, and control the

ERV as a whole, or as individual units.

Click [Control and Monitoring] when DMS2 web page menu

1

screen appears.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

Select an ERV to control.

2

When the selected ERV is switched on, the remote controller

panel will be automatically activated.

3

Turn ERV on by pressing [ ].

The remote controller panel will be activated.

6

4

5

Select the operation mode.

4

You can select Auto, HeatEx, By pass and Sleep.

Select the fan speed.

5

You can select Low, High and Turbo.

Fan speed is set to Low in Sleep mode.

Set remote controller settings.

6

You can select Enable RC, Disable RC, and Cond. RC.

When selecting [Enable RC], indoor unit control by wired/

wireless remote controller is not possible. Indoor unit

control is only available in DMS2 web page.

Click [ ] when you want to use wired remote controller in

each room.

Note

When filter warning sign is displayed on ERV status

window

Select the ERV and click [Reset filter]. Filter warning will be

released.

Make sure that ERV must be turned on to control.

Selecting remote controller and filter reset are possible

even if the power of indoor unit is off.

E-37

Control and Monitoring (Continued)

Monitoring ERV PLUS operation status

1

Status display window

2

E-38

You can monitor the operation status of ERV PLUS,

and control the ERV PLUS as a whole, or as individual units.

Click [Control and Monitoring] when DMS2 web page menu

1

screen appears.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

Check the current status of ERV PLUS.

2

Check the status of ERV PLUS through the status display

window.

When the selected ERV PLUS is switched on, the remote

controller panel will be automatically activated.

Controlling ERV PLUS

1

2

Click [Control and Monitoring] when DMS2 web page menu

1

screen appear.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

3

Select ERV PLUS to control.

2

Check the status of ERV PLUS through the status display

window.

When the selected ERV PLUS is switched on, the remote

controller panel will be automatically activated.

3

Turn the ERV PLUS on by clicking [ ].

Remote controller panel will be activated.

E-39

Control and Monitoring (Continued)

4

Select the operation mode

4

You can select Auto, Cool, Off and Heat mode.

Note

The normal ERV PLUS control or monitoring is guaranteed when the

centralized controller is above MCM-A202D and the interface module is

MIM-B13D.

Refer to the ‘Controlling ERV’ for ERV PLUS control. (Page 36 ~ 37)

Refer to the ‘Indoor unit operation mode limit’ for ERV PLUS operation

ERV PLUS doesn’t operate Fan mode, so it only operates cool mode in

ERV PLUS doesn’t operate Fan mode, so it only operates heat mode in

mode limit. (Page 23 ~ 25)

‘cool only’.

‘heat only’.

E-40

Monitoring DMS DI/DO Operation Status

1

Click [Control and Monitoring] when DMS2 web page menu

1

screen appears.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

3

2

Check the current status of DI and DO device.

2

Monitor the device through the control panel.

3

Note

Entering ON/OFF becomes impossible for DI device.

Entering ON/OFF becomes possible for DO device.

Entering control value becomes impossible for DI/DO

You can control and monitor DI/DO which built-in

device.

DMS2. However, DI 1, 2 and DO 1, 2, 9, 10 are excluded

from controlling and monitoring because they are

used for the internal function of DMS.

E-41

Control and Monitoring (Continued)

Controlling DMS DO

1

2

E-42

Click [Control and Monitoring] when DMS2 web page menu screen appears.

1

[Control and Monitoring] screen will appear when you log-in to DMS2 web page.

Select DO device to control when control and monitoring screen appears.

2

Check the status of DI or DO device.

3

Turn DO device on by clicking [ON]/[OFF] button on the control panel.

3

Note

Remote controller setting is not possible for DI/DO device.

Monitoring the selected multiple devices operation status

1

Status display window

2

You can monitor the operation status of other type devices,

and control other type devices as a whole, or as individual units.

Click [Control and Monitoring] when DMS2 web page menu screen appears.

1

[Control and Monitoring] screen will appear when you log-in to DMS2 web page.

Check the status of the selected multiple devices.

2

Check the status of an indoor unit through status display window.

When the selected devices are switched on, the remote controller panel will be

automatically activated.

Note

When users select multiple devices, 'Basic Control' will be displayed

The current status of last selected indoor unit type devices (Indoor unit, AHU,

The status of last selected ERV type devices (ERV, ERV PLUS) will be displayed

The list of the selected multiple devices will be displayed on the ‘Selected Device’.

on the screen. (This is when different types of multiple devices are selected.)

Fresh duct, Global 4 way) will be displayed on the 'Indoor control'.

on the 'Ventilation Control'.

E-43

Control and Monitoring (Continued)

Controlling the selected multiple devices

1

3

2

E-44

Click [Control and Monitoring] when DMS2 web page menu

1

screen appears.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

Check the status of the selected devices.

2

Check the status of an indoor unit through status display

window.

When the selected devices are switched on, the remote

controller panel will be automatically activated.

3

Turn the selected devices on by clicking [ ].

Remote controller panel will be activated.

4

5

6

7

8

9

Select the desired temperature by clicking [][].

4

Each time you click the button, the temperature will be adjusted by 1°C(1°F).

If Auto/Cool/Dry mode is in operation, you can adjust the desired temperature in the

range of 18°C(65°F)~30°C(86°F).

If Heat mode is in operation, you can adjust the desired temperature in the range of

16°C(61°F)~30°C(86°F).

You cannot adjust the desired temperature in Fan mode.

When the operation mode of an indoor unit is in Cool or Dry mode, you cannot set

the desired temperature lower than lower limit temperature if lower limit is enabled.

When the operation mode of an indoor unit is in Heat mode, you cannot set the

desired temperature higher than upper limit temperature if upper limit is enabled.

Select the operation mode.

5

You can select Auto, Cool, Dry, Fan and Heat mode.

Select the fan speed.

6

You can select Auto, Low, Mid and High.

If Auto/Dry mode is in operation, fan speed will be set as Auto fan speed.

If Fan mode is in operation, you cannot select Auto fan speed.

E-45

Control and Monitoring (Continued)

Select the ERV operation mode.

7

You can select Auto, Heat Ex, By pass and Sleep mode.

Select the fan speed.

8

You can select Low, high and Turbo.

If Sleep mode is in operation, the fan speed will be set as

Low fan speed.

When controlling certain types of devices in detail, select

9

the device you want to control on the list of the ‘Selected

Device’.

Note

If the ERV type devices are not on the list of the

‘Selected Device’, ventilation control will not be

activated.

If the indoor unit type devices are not on the list of the

When controlling an indoor unit, ERV devices

When controlling ERV devices, Indoor unit (Indoor unit,

You can select power on/off, Disable RC, Reset filter,

Power on/off, Disable RC and Reset filter are controlled

When selecting multiple devices, the list of the selected

‘Selected Device’, Indoor control will not be activated.

(ERV, ERV PLUS) cannot be controlled.

AHU, Fresh duct, Global 4 Way) cannot be controlled.

Indoor Control (Desired temp, operation mode, fan

speed) and ERV Control in the ‘Basic control’.j

to all the devices.

devices will be displayed at the bottom of the remote

controller. When selecting the device you want to

control, the remote control panel of the selected device

will be activated and you can control the selected

device in detail. However, the rest of the devices cannot

be controlled other than the selected device.

E-46

Checking the Installation Information

1

2

3

You can check the installation status of currently connected

device.

Click [Control and Monitoring] when DMS2 web page menu

1

screen appears.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

Click ‘Install.Info’. tab at the bottom left of the screen.

2

Check installation status of currently connected device in the

3

installation information tab.

You can check installation information by pressing

[∧] and [∨] buttons.

E-47

Control and Monitoring (Continued)

View the Control History & Power Consumption

1

2

E-48

3

You can select a device and view control history and power

consumption information.

Click [Control and Monitoring] when DMS2 web page menu

1

screen appears.

[Control and Monitoring] screen will appear when you

log-in to DMS2 web page.

Select a device you want to view control history and power

2

consumption.

Click [View control history & power consumption]tab and

3

wait for a while.

Control history and power consumption information are

received from DMS2.

‘Data receiving’ message will appear on the bottom right

of the tab.

When data reception is completed from DMS2, check control

4

history and power consumption of selected device.

Note

In ‘Control history’, you can check power control and

remote controller usage status.

Operation mode, desired temperature, air flow and fan

speed control shows you the controlled time and type

of control only.

If SIM is not installed, power consumption information

may not be correct.

Power consumption information is displayed only

when SIM is installed.

If SIM is removed, value measured with SIM will be

displayed.

4

E-49

Control and Monitoring (Continued)

Cycle Monitoring

1

2

3

You can select an indoor unit and check cycle information.

E-50

Click [Control and Monitoring] [Cycle Monitoring] when DMS2 web page menu

1

screen appears.

Click [Select].

2

DMS2 installation information will be displayed.

Select a device to check cycle information.

3

If you select centralized controller, its subordinate outdoor unit which has the

earliest address will be selected.

If you select interface module, its subordinate outdoor unit will be selected.

If you select indoor unit, upper outdoor unit will be selected.

Cycle information of selected outdoor unit and subordinate indoor units.

4

If the status of outdoor unit and indoor unit is changed, status value turns into blue.

Note

You can check all the cycle information on DVM Plus 2 or DVM Plus 3 with the

centralized controller MCM-A202B and interface module MIM-B13B (or higher

version of those devices) only. However, some cycle information may not be

displayed on any other models of outdoor unit.

Indoor Unit Usage Restriction_Operation Limit

1

3

You can set the operation of indoor unit as cooling only and

heating only.

Click [Control and Monitoring] [Indoor unit usage

1

restriction] when DMS2 web page menu screen appears.

Press [Edit] button.

2

Set the limit mode.

3

You can select 'Cool-only’, ‘Heat-only’ or ‘None’.

- For cooling only indoor unit, you can select cool, dry and

fan modes only.

- For heating only indoor unit, you can select heat and fan

modes only.

2

E-51

Control and Monitoring (Continued)

4

Set the control mode.

4

If you set the control mode, indoor unit operating in limited operation mode will

be automatically set to operate in pre-set control mode. You can set the different

control mode to each of the indoor units.

- Cooling only indoor unit: You can select fan or cool mode.

- Heating only indoor unit: You can select fan or heat mode.

(Ex: When the indoor unit with fan mode is changed to heat mode, DMS2 will

perceive it and control the indoor unit in fan mode.)

ERV PLUS doesn’t operate Fan mode, so it operates only Cool or Heat mode in the

'cool only' or 'heat only' limit mode.

Note

Mixed operation can occur even if you set limit mode.

If the indoor unit with operation mode limit is in mixed operation, DMS2 will

solve the problem automatically by controlling it in control mode.

In the following circumstances, all indoor units under the same outdoor unit

should be set to the same limit mode. Mixed operation can occur continuously

when you set some of indoor unit to cool only and the other to heat only.

- If the centralized controller is MCM-A202 and is in group mode

- If the centralized controller is in group mode and the interface module is

MIM-B13 or MIM-B04A

Except above circumstances, DMS2 changes the limit mode of all indoor units

under the same outdoor unit to same limit mode.

- If the centralized controller is in group mode and is above MCM-A202A and all

the interface modules under the centralized controller are above MIM-B13A

- If the centralized controller is in individual mode

If you set the cooling only indoor unit’s limit mode to heating only, DMS2 may

display Heating Cooling alternately.

E-52

Indoor Unit Usage Restriction_Temperature Limit in Cool/Heat mode

1

2

You can set temperature lower/upper temperature limit in

cool/heat mode.

Click [Control and Monitoring] [Indoor unit usage

1

restriction] when DMS2 web page menu screen appears.

Press [Edit] button.

2

E-53

Control and Monitoring (Continued)

3

Set the lower/upper temperature limit.

3

You can set lower/upper temperature limit by selecting

'Enable'/'Disable'.

If desired temperature is lower than lower limit

temperature when the indoor unit is operating in cool

mode, DMS2 controls indoor unit to lower temperature

limit.

If desired temperature is higher than upper limit

temperature when the indoor unit is operating in heat

mode, DMS2 controls indoor unit to upper temperature

limit.

Lower temperature limit range: 18℃(65°F)~30℃(86°F)

Upper temperature limit range: 16℃(61°F)~30℃(86°F)

If the indoor unit is in Auto(Cool)/Auto(Heat) mode, lower/

upper temperature limit will be applied when the indoor

unit is operating in Auto mode.

However, if the upper temperature limit is set to

16°C(61°F)~17°C(64°F), the upper temperature limit in

Auto(Heat) mode is 18°C(65°F).

ERV plus and Fresh duct cannot set the lower temperature

limit in Cool mode or upper temperature limit in Heat mode.

4

E-54

Click [Save].

4

Indoor unit usage restriction setting will be saved.

Checking the Trouble History

1

Click [Control and Monitoring] [Trouble history]

1

when DMS2 web page menu screen appears.

Check all the trouble history.

2

You can check address, device type, occurrence time,

resolution time, code number and status.

3

You can check detailed information on trouble history by

3

selecting the item in the list.

Note

DMS2 saves maximum 1024 trouble histories.

If the number of history exceeds 1024, DMS2 will delete

the oldest history first.

If the same code trouble is detected repeatedly in the

same device on the same day, trouble history will be

shown as 1 case. If it occurs more than 2 times,

‘Resolution time’ may change every time you check.

And the number of repetition will be displayed in

‘Status’ field.

E-55

Control and Monitoring (Continued)

Checking the Trouble History by Date

1

3

DMS2 saves maximum 1024 trouble histories. If the number

of history exceeds 1024, DMS2 will delete the oldest history

first.

Click [Control and Monitoring] [Trouble history]

1

when DMS2 web page menu screen appears.

Enter the time period you want to check.

2

Enter year/month/day in order.

Click [Search].

3

You can check address, device type, occurrence time,

resolution time, code number and status in the entered

period.

2

4

E-56

You can check detailed information on trouble history by

4

selecting the item in the list.

Deleting the Trouble History

1

2

Click [Control and Monitoring] [Trouble history]

1

when DMS2 web page menu screen appears.

Select trouble history you want to delete.

2

Click [Delete].

3

Click [OK] from the confirm window. Selected trouble

history will be deleted.

3

E-57

Control and Monitoring (Continued)

Checking the Operation Status

1

3

You can check operation status of indoor unit which is

controlled by DMS2.

4

E-58

Click [Control and Monitoring] [Checking operation status]

1

when DMS2 web page menu screen appears.

Check the operation history.

2

You can check the device type, occurrence time, control

unit, control type, and controlled device address of

indoor unit which is controlled by DMS2 and subordinate

controller.

You can check operation status by entering date.

3

Enter year/month/day then click [Search]. You can check

control history that occurred on the entered date.

You can check detailed control history which is controlled by

4

the command by pressing control history in the list.

Note

DMS2 saves the information of operation history for 180 days.

However, it varies depending on saving space of DMS2.

Zone Management

Zone Setting & Edit – Individual/Group Initialization

1

3

2

Click [Zone management] [Zone Setting & Edit] when DMS2 web page menu screen

1

appears.

Same screen will be displayed even if you click [Zone management] only.

Initialize the indoor unit organization as individual by clicking [Individual].

2

Individual initialization reorganizes connected indoor unit based on installation address.

Initialize the indoor unit organization as group by clicking [Group].

3

Group initialization reorganizes connected indoor unit based on RMC address.

After group initialization, indoor units are displayed as one device when

upper zone is selected in the [Control and Monitoring] screen.

When editing zone after group initialization, moving in group is only allowed.

After group initialization, subordinate devices cannot be moved individually to

the other zone.

Note

Only the user who has authorization to edit all zones can use zone initialization.

- To the user who has no authorization to use zone initialization and manage

structure, button will not be displayed.

If the user does not have authorization to edit zone, [Inidividual], [Group] and

[Zone edit] will not be displayed.

E-59

Zone Management (Continued)

Zone Setting & Edit – Setting the User Authorization

1

2

Click [Zone management] [Zone Setting & Edit] when DMS2 web page menu

1

screen appears.

Same screen will be displayed even if you press [Zone management] only.

3

Set user authorization for each zone.

2

If the user has no authorization for the zone, controlling and monitoring of the

zone is restricted.

The user who is allowed to control and monitor zone has ‘’ sign.

Click [Save] to save.

3

The user of currently selected zone is selected in the screen.

You should set the authorization for controlling and monitoring the zone when the

user is added.

If you do not set the authorization for zone after adding a user, the zone will not be

displayed even if the user logged in.

Setting the user authorization is valid only for the zone displayed on the screen. If you

select the other zone setting without clicking save button after changing the setting,

user authorization for previously selected zone will be gone.

When initializing zone, all rights are given to all users.

E-60

Zone Setting & Edit – Zone Edit

1

2

Click [Zone management] [Zone Setting & Edit] when

1

DMS2 web page menu screen appears.

Same screen will be displayed even if you press

[Zone management] only.

Click [Zone Edit].

2

Zone edit screen will be displayed.

E-61

Zone Management (Continued)

3

6

7

4

5

8

E-62

Click [▼] to set viewing option of zone edit list.

3

You can select from viewing by 'Name’, ‘Address’ and ‘Address & Name'.

Edit item you want.

4

Create in the

above

Create in the

below

Create the sub

zone

Remove

Move up Move up the selected zone or indoor unit.

Move down Move down the selected zone or indoor unit.

Move to upper

level

Rename

Cut Cut to move the selected zone or indoor unit,

Paste Move the cut zone or indoor unit to the selected zone.

Create a new zone on top of the selected zone.

Create a new zone under the selected zone.

Create a zone one step lower than the user selected.

You cannot create a zone under 5 steps in zone edit.

Remove selected zone. If the selected zone includes device,

the device will move to the top step.

Move the selected zone or indoor unit to the upper level.

Rename the selected zone or indoor unit.

You can use maximum 16 letters.

Click [Remove disappeared] to remove all disappeared devices which were found

5

after tracking.

Change zone properties.

6

You can select “General”, “AHU”, and “Group”.

Mode Property name Description Remarks

Virtual group which is managed by

▪

installation address, not by RMC

address

The user can create and delete zone.

▪

Not applicable.

( Only supported in group initialization

mode.)

Virtual group which manages AHU kit

▪

in general zone.

The user can create and delete.

▪

Virtual group which is set and

▪

managed by the user.

The user can create and delete.

▪

Virtual group which is managed by

▪

installation address, not by RMC

address.

The user cannot create and delete.

▪

DMS2 creates it automatically.

Virtual group which manages AHU kit

▪

in general zone.

The user can create and delete.

▪

-

Not applicable.

( Only supported in group initialization

mode.)

It will be displayed as single device in

▪

the control and monitoring screen, and

it can be controlled as single device.

You cannot move subordinate device

▪

to the other zone.

-

It is displayed like as one device in the

▪

control and monitoring screen and can

be controlled.

You cannot move subordinate device

▪

to the other zone.

It is displayed like as one device in the

▪

control and monitoring screen and can

be controlled.

You cannot move subordinate device

▪

to the other zone.

Individual

initialization

mode

Group

initialization

mode

General

Group

AHU

General

Group

AHU

Click [Apply].

7

Edited zone structure will be applied.

To cancel the setting, click [Cancel].

8

E-63

Schedule

Creating New schedule

1

2

You can set, edit, delete and use the schedules for air

conditioner control.

Click [Schedule] [Schedule setting] when DMS2 web page

1

menu screen appears.

Click [Register] in the schedule setting screen.

2

Note

It is not available to provide the schedule information to

BMS system.

E-64

3

4

5

Enter the schedule name when the schedule setting screen

3

appears.

Select schedule period you want by clicking calendar.

4

If you select 'No limit' when setting end date, it means

there is no period and it displays Dec 31st, 9999.

To set the end date, remove the check of ‘No limit’ or select

calendar icon which is on the right side of date.

To set an exception date in the schedule period, click

5

[Add exception] and select date(month/day) you want.

Select an exception date on the calendar window.

E-65

Schedule (Continued)

6

E-66

To cancel the added exception date, select the exception

6

date it() and click [Delete].

Maximum 365 exception dates can be saved.

7

8

Click [Add device] to select a device to apply.

7

The list of all the connected devices will be displayed.

You can register a schedule for DMS DO as well.

8

To cancel the selected device, select () the device again

and click [Delete].

E-67

Schedule (Continued)

9

10

Click [∨] to select repeat schedule you want and set an event.

9

You can select 'Weekly', 'Everyday' and '1day'.

However, the starting and end date should be same when you select '1day'.

Enter 4 digits for ON/OFF time setting.

Ex) 8:00 0800, 9:30 0930

Remote controller setting is as follows.

●

Enable RC: Controlling indoor unit using wired/wireless remote controller or

●

Disable RC: Controlling indoor unit using wired/wireless remote controller or

●

Cond. RC

- ON by centralized controller, DMS2: Controlling indoor unit using wired/wireless

- OFF by centralized controller, DMS2: Controlling indoor unit using wired/wireless

Click [Add] to add event.

To delete event, select an event() and click [Delete].

Maximum 70 events can be set per 1 schedule. In case of week schedule, 10 events per

1 day can be set.

If starting and end time of schedule event are repeated, only the schedule event

which is made earlier will be executed.

indoor unit panel in each room is possible.

indoor unit panel in each room is not possible.

remote controller or indoor unit panel in each

room is possible.

remote controller or indoor unit panel in each

room is not possible.

E-68

Click [Save].

10

Set schedule information is saved in DMS2.

Click [Cancel] to cancel schedule setting.

Note

If you select dry mode among basic modes, auto fan

speed is only available.

When the operation mode is ‘Auto’, fan speed is always

set to ‘Auto’.

When the operation mode is ‘Fan’, you cannot control

fan speed as ‘Auto’.

When the operation mode is ‘Dry’, fan speed is always

set to ‘Auto’.

When you select sleep mode among ERV modes, ‘Mid’

fan speed is only available.

The desired temperature range is as below.

- Celsius: 16°C~30°C in heating mode, 18°C~30°C in

cooling mode

- Fahrenheit: 61°F~86°F in heating mode, 65°F~86°F in

cooling mode

If the tracking is not completed, schedule setting is not

possible. To use proper schedule function, make sure to

complete tracking with installation engineer.

‘Off’ operation works only with ERV PLUS.

E-69

Schedule (Continued)

Editing Schedule

2

1

2

1

3

Click [Schedule] [Schedule setting] when DMS2 web page

menu screen appears.

Select the schedule to edit.

For the currently operating schedule, you can only

check it.

E-70

Click [Edit].

3

Edit schedule when the schedule edit screen appears.

Editing schedule method is same as “Creating New

Schedule”. (Refer to page 64~69)

Deleting Schedule

1

2

3

Click [Schedule] [Schedule setting] when DMS2 web page

1

menu screen appears.

Select the schedule to delete.

2

Click [Delete].

3

Click [OK] in confirm window and selected schedule will

be deleted.

Deleting schedule is possible only when the schedule is in

stop status.

If you want to delete schedule which is currently applied,

stop applying the schedule first.

E-71

Schedule (Continued)

Applying schedule

2

3

1

2

3

1

Click [Schedule] [Schedule setting] when DMS2 web page

menu screen appears.

Select the schedule you want to use.

Use schedule functions by clicking [Run] and [Stop].

To apply the selected schedule, click [Run].

To stop the selected schedule, click [Stop].

E-72

Note

To stop all schedules, click [Stop all].

- Currently applied schedule will be stopped.

Checking Schedule Control History

1

2

3

Click [Schedule] [Checking schedule control history] when

1

DMS2 web page menu screen appears.

Select a date to check and then click [Search].

2

Only executed schedules can be searched.

You can check detailed setting by clicking the schedule

3

name.

Note

DMS2 saves the information or schedule control history

for 180 days.

However, it varies depending on saving space of DMS2.

E-73

EHP Power Consumption Inspection

Checking Inspection Result (with SIM/PIM)

1

2

You can check the operation history and power consumption saved in DMS for each

indoor unit.

Click [EHP Power Consumption Inspection] [Check inspection result] when DMS2 web

1

page menu screen appears.

Set date and search condition (power consumption/proportion/individual indoor unit by

2

date) when inspection result screen appears.

Select year/month/day in order.

Based on DMS2 time, you can check up to 365 days of watt-hour meter value.

Click [Search].

3

Inspection result will be displayed depending on set period and searching condition.

You can check power consumption only when watt-hour meter is connected.

If watt-hour meter is not connected, you can check operating proportion by indoor

unit only .

3

4

Click [Save as Excel].

4

Searched inspection result will be saved as MS Excel file.

Note

For data management, it is recommended to save indoor unit inspection result

periodically.

Power consumption inspection result is for reference only and should not be used

E-74

for official financial transactions.

Checking Inspection Result (without SIM/PIM)

1

2

3

Click [EHP Power Consumption Inspection] [Check

1

inspection result] when DMS2 web page menu screen

appears.

Channel setting by indoor unit must be done in advance.

Set date when inspection result screen appears.

2

Select year/month/day in order.

Based on DMS2 time, You can check up to 365 days of

inspection results.

4

Enter power consumption value during the period.

3

Virtual channel is value which is set in channel setting by

indoor unit.

Click [Calculate].

4

Power consumption by indoor unit during the period will

be displayed.

E-75

EHP Power Consumption Inspection (Continued)

E-76

Check the power consumption result of the selected period.

5

Due to rounding the actual values, actual input value and

result value may different to each other.

If you want to save the consumption result for selected

period as MS Excel file, click [Save as Excel].

Click [Calculate] to go back to inspection result screen.

Note

For data management, it is recommended to save

indoor unit inspection result periodically.

Power consumption inspection result is for reference

only and should not be used for official financial

transactions.

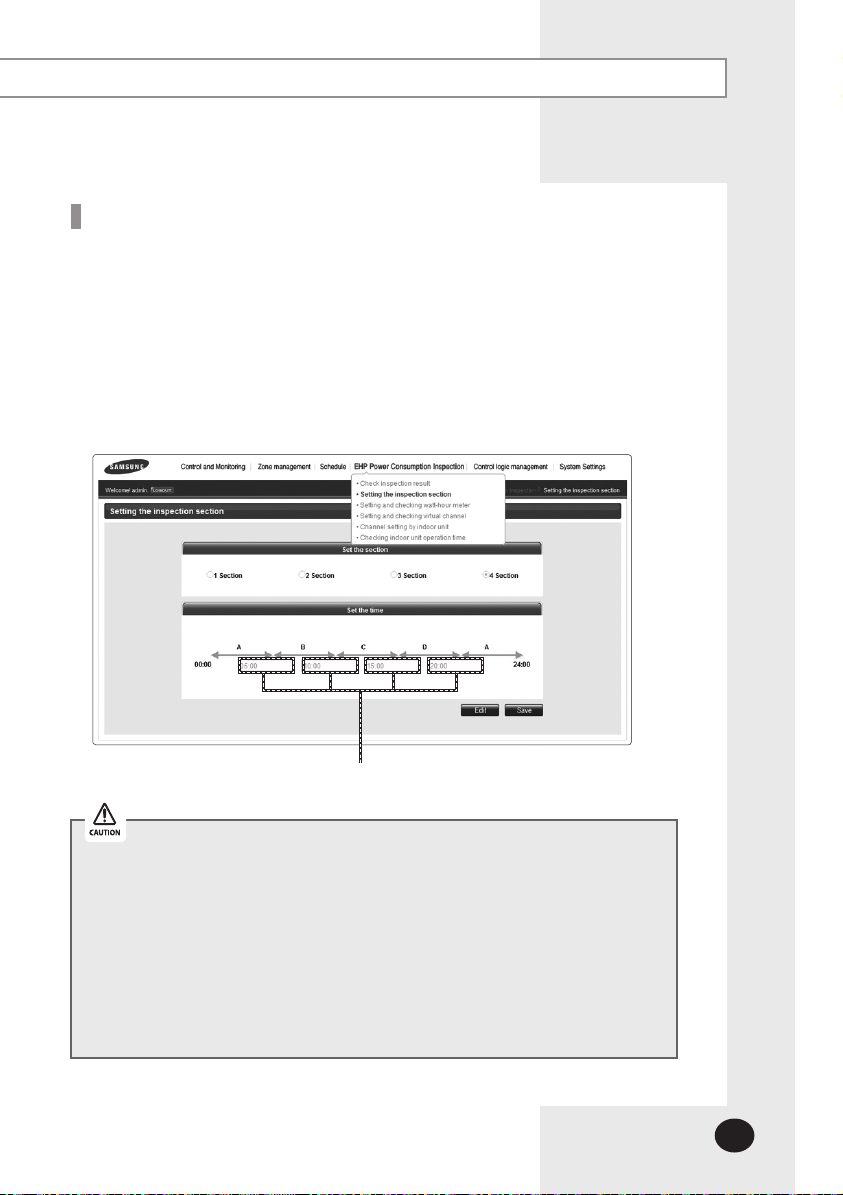

Setting the Inspection Section

3

Click [EHP Power Consumption Inspection] [Setting the

1

inspection section] when DMS2 web page menu screen

appears.

Click [Edit] when inspection result screen appears.

2

1 section is set as default.

Select a section and enter time by section.

3

You should enter time of section B when selecting 2

sections and enter time of section B and section C when

selecting 3 sections and enter time of section B, section C,

and section D when selecting 4 sections.

Correct format of time is HH:MM.

Ex) 4:30 in the af ternoon 16:30

1

4

2

Click [Save].

4

Set power section will be saved in DMS2.

If you do not click [Save], changed setting will not be

saved.

Note

Ex) When selecting 2 sections(A, B, C)

If the border time between A and B is 08:00, section A is

00:00 ~ 08:00,

section B is 08:01 ~ 18:00, and section A again is

18:01 ~ 24:00.

E-77

EHP Power Consumption Inspection (Continued)

Setting and Checking Watt-Hour Meter

1

3

4

2

Click [EHP Power Consumption Inspection] [Setting and checking watt-hour

1

meter] when DMS2 web page menu screen appears.

Setting watt-hour meter is possible only when SIM/PIM is installed.

Click [Edit] when the setting and checking watt-hour meter screen appears.

2

CT proportion ‘1’ is set as default.

Set name and CT proportion of watt-hour meter.

3

You can use maximum 16 letters.

The range of CT proportion value is positive number from 1 to 5000.

Click [Save].

4

Set watt-hour meter information will be saved in DMS2.

If you do not click [Save], changed setting will not be saved.

Watt-hour meter value shows actual value of currently connected watt-hour meter.

Watt-hour meter value will be updated automatically.

When using CT watt-hour meter, be careful that there can be difference with actual

power consumption as much as CT ratio error.

E-78

Checking Kilowatthour History

1

2

3

Click [EHP Power Consumption Inspection] [Setting and Checking watt-hour

1

meter] when DMS2 web page menu screen appears.

Click [Kilowatthour history] when the setting and checking

2

watt-hour meter screen appears.

Select SIM/PIM address and date you want when the kilowatthour history screen

3

appears.

Enter year/month/day in order.

Based on DMS2 time, you can check up to 365 days of kilowatthour history.

Click [Check].

4

Kilowatthour history of set period will be displayed.

4

E-79

EHP Power Consumption Inspection (Continued)

Setting and Checking Virtual Channel

1

3

E-80

2

4

Click [EHP Power Consumption Inspection] [Setting and

1

checking virtual channel] when DMS2 web page menu screen

appears.

Maximum 128 virtual channels can be set.

Virtual channel is written in (24 ~ 31).(1 ~ 16) format

address.

Ex) 24.1, 25.2, 31.8

Click [Edit] when the setting and checking virtual channel

2

screen appears.

Set the name of virtual channel.

3

You can use maximum 16 letters.

Click [Save].

4

Set virtual channel name will be saved in DMS2.

If you do not click [Save], changed setting will not be

saved.

Channel Setting by Indoor Unit

Click [EHP Power Consumption Inspection] [Channel

1

setting by indoor unit] when DMS2 web page menu screen

appears.

Click [Edit] when the setting channel by indoor unit screen

2

appears.

1

2

Some functions available on DMS2 webpage may not be

functional at BACnet Gateway and LonWorks Gateway.

For detailed function, refer to the installation manual or

contact Samsung Electronics.

E-81

EHP Power Consumption Inspection (Continued)

7

Check the address and channel information of SIM/PIM which is connected to watt-

3

hour meter.

If 0~7 SIM/PIM units execute tracking, it will be displayed as 16~23 in DMS2.

Below table shows the channel information of the terminal which SIM and watt-

hour meter is connected.

(Terminal block 1 is on the very left side in SIM.)

Location

Terminal block

Top part 1 2 3 4

Bottom part 5 6 7 8

PIM: Channel 1 is on the most left side and 8 channels are arranged in a line.

Terminal block 1 Terminal block 2 Terminal block 3 Terminal block 4

8

E-82

Check the information of indoor/outdoor unit which is connected to

4

watt-hour meter.

Check the SIM/PIM channel(watt-hour meter) information of indoor/outdoor unit.

5

You can set the channel when SIM/PIM is installed in DMS2.

When bringing indoor unit’s power from outdoor unit, set the ‘Outdoor unit SIM

channel’ information only.

( ‘Outdoor unit SIM channel’ is referring to watt-hour meter which is connected to

outdoor unit.)

When bringing indoor unit’s power from the other device, not from outdoor unit,

set the ‘Outdoor unit SIM channel’ and ‘Indoor unit SIM channel’ information.

(‘Indoor unit SIM channel’ is referring to watt-hour meter which is connected to

indoor unit.)

Power distribution will be executed automatically. The user does not need to check

the value of watt-hour meter.

The maximum number of SIM channels for an outdoor unit is 4.

Check the virtual channel information of indoor/outdoor unit.

6

To execute power distribution without SIM/PIM, you should set virtual channel.

When bringing indoor unit’s power from outdoor unit, set the ‘Outdoor unit virtual

channel’ information only.

( ‘Outdoor unit virtual channel’ is referring to watt-hour meter which is connected

to outdoor unit.)

When bringing indoor unit’s power from the other device, not from outdoor unit,

set the ‘Outdoor unit virtual channel’ and ‘Indoor unit virtual channel’ information.

(‘Indoor unit virtual channel’ is referring to watt-hour meter which is connected to

indoor unit.)

The number of virtual channel varies depending on the number of interface

module.

To execute power distribution, you need to check watt-hour meter value manually.

Power distribution using SIM/PIM is more accurate than using indoor/outdoor unit

virtual channel. Therefore, it is recommended to execute power distribution using

SIM/PIM.

Set indoor unit to execute power distribution.

7

If you do not set the watt-hour meter information, the power distribution result of

the indoor unit will be displayed as ‘0’.

Click [Save].

8

Set channel information will be saved in DMS2.

If you do not click [Save], changed setting will not be saved.

Information of watt-hour meter connected to indoor/outdoor unit should be accurate.

If the watt-hour meter information is not accurate when you set channel information

of indoor unit, error may occur in the power distribution result.

You should set SIM/PIM channel information in the indoor unit if you want to execute

power distribution using SIM/PIM. If not, it means that you do not execute power

distribution. In this case, the power distribution result of the indoor unit will be ‘0’.

If the information of watt-hour meter connected to indoor/outdoor unit is changed,

consult with installation engineer.

DMS2 executes power distribution based on set information.

Virtual channel is not available when you use BACnet or LonWorks Gateway function.

E-83

EHP Power Consumption Inspection (Continued)

Checking Indoor Unit Operation Time

1

2

3

4

E-84

Click [EHP Power Consumption Inspection] [Checking

1

indoor unit operation time] when DMS2 web page menu

screen appears.

Select search condition (All indoor units by period/

2

Individual indoor unit by date) when Checking indoor unit

operating time screen appears.

Select year/month/day in order.

Based on DMS2 time, you can check up to 365 days of

operation time.

Click [Search].

3

Operation time will be displayed depending on set period

and condition.

Click [Save as Excel].

4

Searched operation time result will be saved as MS Excel

file.

Note

For data management, it is recommended to save indoor