MULTI AIR CONDITIONER

INDOOR UNIT

MH18AP1(P2)-09

MH19AP1(P2)-07

MH19AP1(P2)-12

MH24AP1(P2)-12

MH26AP1(P2)-07

MH26AP1(P2)-12

SERVICE

OUTDOOR UNIT

MH18AP1(P2)X

MH19AP1(P2)X

MH24AP1(P2)X

MH26AP1(P2)X

Manual

CONTENTSAIR CONDITIONER

11.Product Specifications

12.Operating Instructions &

Technical Document

13. Disassembly and Reassembly

14. Refrigerating Cycle Diagram

15. Set Up the Model Option

16. Troubleshooting

17. Exploded Views and Parts List

18. PCB Diagram

19.Wiring Diagram

10.Schematic Diagram

1. Product Specifications

1-1 Table

Item

Type

Cooling/Heating 1 Unit(A)

1 Unit(B/C)

2 Unit(A+B/C) kW

Performance

Dehumidifying(A+B/C) \ /h

Noise Cooling / Heating dB

Power ø/V/Hz

Power Consumption 1 Unit(A)

(Cooling/Heating) 1 Unit(B/C)

Power

Operating Current 1 Unit(A)

(Cooling/Heating) 1 Unit(B/C)

Starting Current(Cooling/Heating) A

Outer Dimension WxHxD

Weight kg

Refrigerant Pipe

Drain Hose ID(mm)

Size

Compressor

Blower Motor Type

Heat Exchanger

2 Unit(B+C)

3 Unit(A+B+C)

2 Unit(A+B/C) W

2 Unit(B+C)

3 Unit(A+B+C)

2 Unit(A+B/C) A

2 Unit(B+C)

3 Unit(A+B+C)

Liquid

Gas

Type

Model Name

Capacitor

Motor Type(Model)

Rated Output(A+B/C)

Type

Rated Input W

Model

mm

inch

OD(mm)xL(m)

W

MH18AP1(P2)

INDOOR UNIT OUTDOOR UNIT

MH18AP1(P2)-09 MH18AP1(P2)X

WALL-MOUNTING MULTISPLIT

2.65 / 2.78

2.65 / 2.78

5.30 / 5.56

-

-

1.1+1.1 39 / 39 57 / 57

1 / 220-240V~ / 50

1,020 / 980

1,020 / 980

1,940 / 1,900

-

-

4.5 / 4.4

4.5 / 4.4

8.6 / 8.4

-

-

30

795 x 258 x 179 880 x 638 x 310

31 x 10 x 7 35 x 25 x 12

7.5 59.5

ø6.35 x 7.5

ø9.52 x 7.5

ø17

- ROTARY

-

- 35 / 35

-

-

CROSS-FAN PROPELLER

RESIN STEEL

30 100

2ROW 10STEP 2ROW 28STEP

G4A097JU1EP

INDUCTION MOTOR

925+925

MH19AP1(P2)

INDOOR UNIT OUTDOOR UNIT

MH19AP1(P2)-07

MH19AP1(P2)-12

WALL-MOUNTING MULTISPLIT

1.0+1.4 -

(–07):36 / 36,

(–12):43 / 43

1 / 220-240V~ / 50

795 x 258 x 179

890 x 285 x 179

31 x 10 x 7

35 x 11 x 7

7.5 / 8.5 60

- ROTARY

-

- 30 / 35

-

-

CROSS-FAN PROPELLER

RESIN STEEL

30 100

2ROW 10STEP 2ROW 10STEP

2ROW 12STEP 2ROW 18STEP

MH19AP1(P2)X

2.05 / 2.25

3.51 / 3.60

5.56 / 5.85

-

-

57 / 57

870 / 780

1,270 / 1,420

2,100 / 2,120

-

-

3.9 / 3.5

5.7 / 6.3

9.3 / 9.4

-

-

30

880 x 638 x 310

35 x 25 x 12

ø6.35 x 7.5

ø9.52 x 7.5

ø17

G4A080JU1EP

G8C124JU1EL

INDUCTION MOTOR

820+1,060

Refrigerant Control Unit

Refrigerant to Change(R410A)

Additional Refrigerant

(Refrigerant must be added if the piping)

Protection Device

Standard Conditions

g/m

A,B-UNIT:CAPILLARY TUBE

A-UNIT:770g / B-UNIT:770g

20(A,B-UNIT) -

- RAC12131-9622

ISO R5151 STANDARD

A,B-UNIT:CAPILLARY TUBE

A-UNIT:620g / B-UNIT:1,080g

18(A-UNIT)

25(B-UNIT)

-

ISO R5151 STANDARD

RAC12126-9622

RAC12128-9622

-

1Samsung Electronics

Table(cont.)

Item

Type

Cooling/Heating 1 Unit(A)

1 Unit(B/C)

2 Unit(A+B/C) kW

Performance

Power

Dehumidifying(A+B/C) \ /h

Noise Cooling / Heating dB

Power ø/V/Hz

Power Consumption 1 Unit(A)

(Cooling/Heating) 1 Unit(B/C)

Operating Current 1 Unit(A)

(Cooling/Heating) 1 Unit(B/C)

Starting Current(Cooling/Heating) A

Outer Dimension WxHxD

Weight kg

Refrigerant Pipe

Drain Hose ID(mm)

Size

Compressor

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Refrigerant to Change(R410A)

Additional Refrigerant

(Refrigerant must be added if the piping)

Protection Device

Standard Conditions

2 Unit(B+C)

3 Unit(A+B+C)

2 Unit(A+B/C) W

2 Unit(B+C)

3 Unit(A+B+C)

2 Unit(A+B/C) A

2 Unit(B+C)

3 Unit(A+B+C)

Liquid

Gas

Type

Model Name

Capacitor

Motor Type(Model)

Rated Output(A+B/C)

Type

Rated Input W

Model

mm

inch

OD(mm)xL(m)

W

g/m

MH24AP1(P2)

INDOOR UNIT OUTDOOR UNIT

MH24AP1(P2)-12 MH24AP1(P2)X

WALL-MOUNTING MULTISPLIT

3.51 / 3.8

3.51 / 3.8

7.02 / 7.6

-

-

1.4+1.4 43 / 43 60 / 60

1 / 220-240V~ / 50

1,280 / 1,280

1,280 / 1,280

2, 560 / 2, 560

-

-

5.7 / 5.7

5.7 / 5.7

11.4 / 11.4

-

-

35

890 x 285 x 179 1,000 x 790 x 310

35 x 11 x 7 39 x 31 x 12

8.5 69

ø6.35 x 7.5

ø9.52 x 7.5

ø17

-ROTARY

-

- 35 / 35

-

-

CROSS-FAN PROPELLER

RESIN STEEL

30 150

2ROW 12STEP 2ROW 36STEP

A,B-UNIT:CAPILLARY TUBE

A-UNIT:1,000g / B-UNIT:1,000g

16(A,B-UNIT) -

- RAC12128-9622

ISO R5151 STANDARD

G8C124JU1EL

INDUCTION MOTOR

1,060+1,060

MH26AP1(P2)

INDOOR UNIT OUTDOOR UNIT

MH26AP1(P2)-12

MH26AP1(P2)-07

WALL-MOUNTING MULTISPLIT

1.4+1.0 / 1.0 -

(–12):43 / 43,

(–07):36 / 36

1 / 220-240V~ / 50

890 x 285 x 179

795 x 258 x 179

35 x 11 x 7

31 x 10 x 7

8.5 / 7.5 71

-ROTARY

-

- 35 / 35

-

-

CROSS-FAN PROPELLER

RESIN STEEL

30 150

2ROW 12STEP 2ROW 16STEP

2ROW 10STEP 2ROW 20STEP

A-UNIT:CAPILLARY TUBE

B,C-UNIT:ELEC.EXPANSION V/V

A-UNIT:910g / B-UNIT:1,290g

16(A-UNIT)

21(B+C-UNIT)

-

ISO R5151 STANDARD

MH26AP1(P2)X

3.51 / 3.65

2.05 / 2.06

5.56 / 5.71

4.1 / 4.12

7.61 / 7.77

60 / 60

1,370 / 1,310

1,590 / 1,720

2,780 / 2,840

1,640 / 1,490

2,900 / 2,630

6.0 / 5.8

7.2 / 7.8

12.4 / 12.7

7.5 / 6.9

13.0 / 11.7

40

1,000 x 790 x 310

39 x 31 x 12

ø6.35 x 7.5

ø9.52 x 7.5

ø17

G8C124JU1EL

G8C150JU1EH

INDUCTION MOTOR

1,060+1,250

-

RAC12128-9622

RAC12122-9622

Samsung Electronics2

MEMO

3Samsung Electronics

Low Medium High

Automatic(rotated : )

2. Operating Instructions & Technical Document

2-1 Operating Instructions

2-1-1 The Feature of Key in remote control

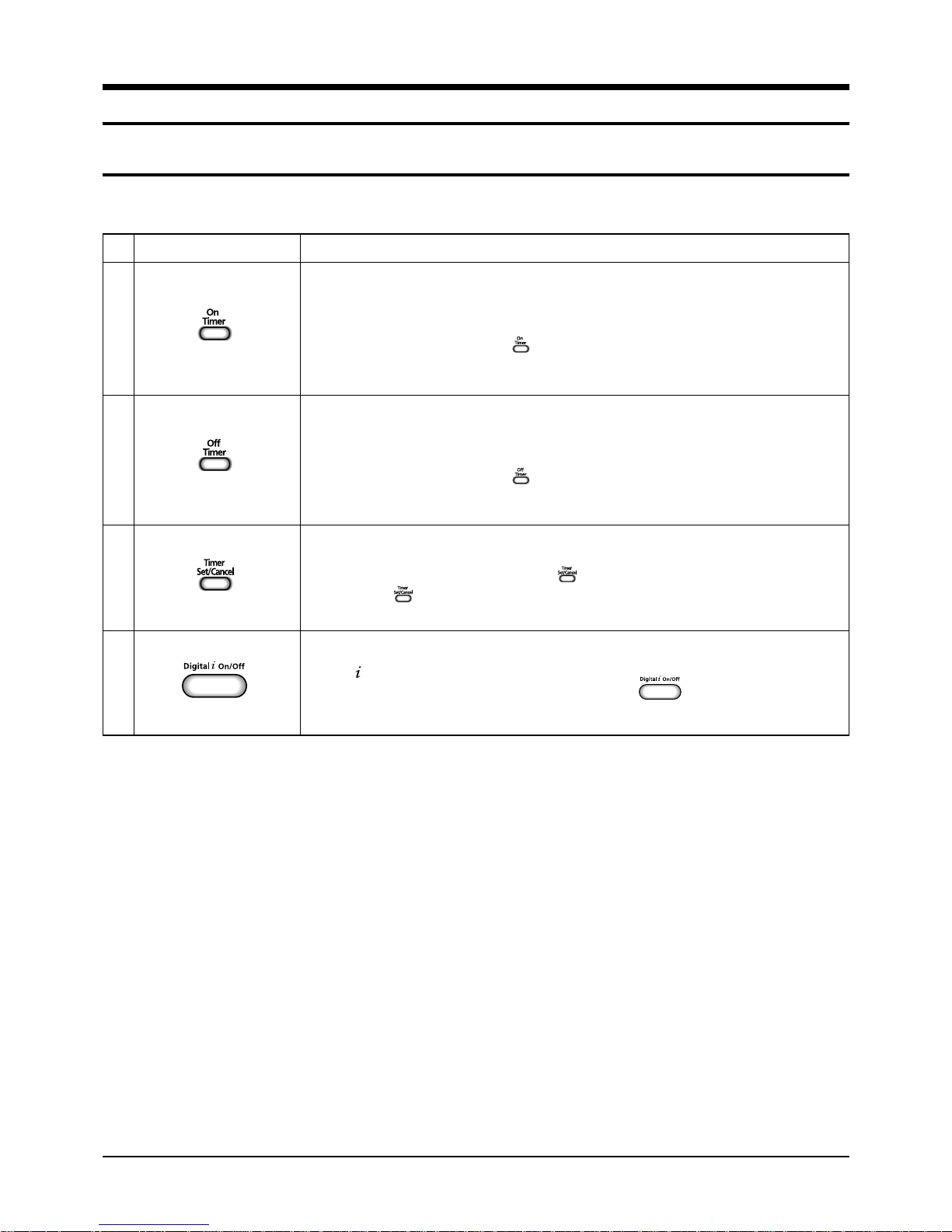

NAMED OF KEYNo

1

2

3

(On/Off)

(UP)

(DOWN)

On/Off button.

Press the button to stop or run the air conditioner.

Temperature adjustment button(UP).

To increase the temperature by the pressing the temperature button.

Temperature adjustment button(DOWN).

To decrease the temperature by the pressing the temperature button.

Mode selection button.

Each time you press this button

Mode is changed in the following order

Fan speed adjustment button.

Each time you press this button, FAN SPEED is changed in the following order.

FUNCTION OF KEY

: Auto Mode : Fan Only

: Cool Mode : Heat Mode

: Dry Mode

4

5

6

7

Swing button.

It adjusts the airflow to upward and downward.

Turbo button.

The air conditioner cools or heats the room as quickly as possible.

After 30minutes, the air conditioner is reset automatically to the previous mode.

Sleep button.

The sleep timer can be used when you are cooling or heating your room to switch the

air conditioner off automatically after a period of 6 hours.

Samsung Electronics4

The Feature of Key in remote control(cont.)

On Timer button.

The On Timer enables you to switch on the air conditioner automatically after

8

9

10

a given period of time that is from 30 minutes to 24 hours.

To set the operating time, press the button one or more times until the required

time display.

Off Timer button.

The Off Timer enables you to switch off the air conditioner automatically after

a given period of time that is from 30 minutes to 24 hours.

To set the operating time, press the button one or more times until the required

time display.

Timer Set/Cancel button.

After setting On Timer or Off Timer, press the button to set it completely.

And press the button again to cancel On Timer or Off Timer set.

FUNCTION OF KEYNAMED OF KEYNo

11

Digital On/Off button.

If you want to turn off the display during operation press the button.

5Samsung Electronics

Operating Instructions & Technical Document

2-1-2 Name & Function of Key in remote control

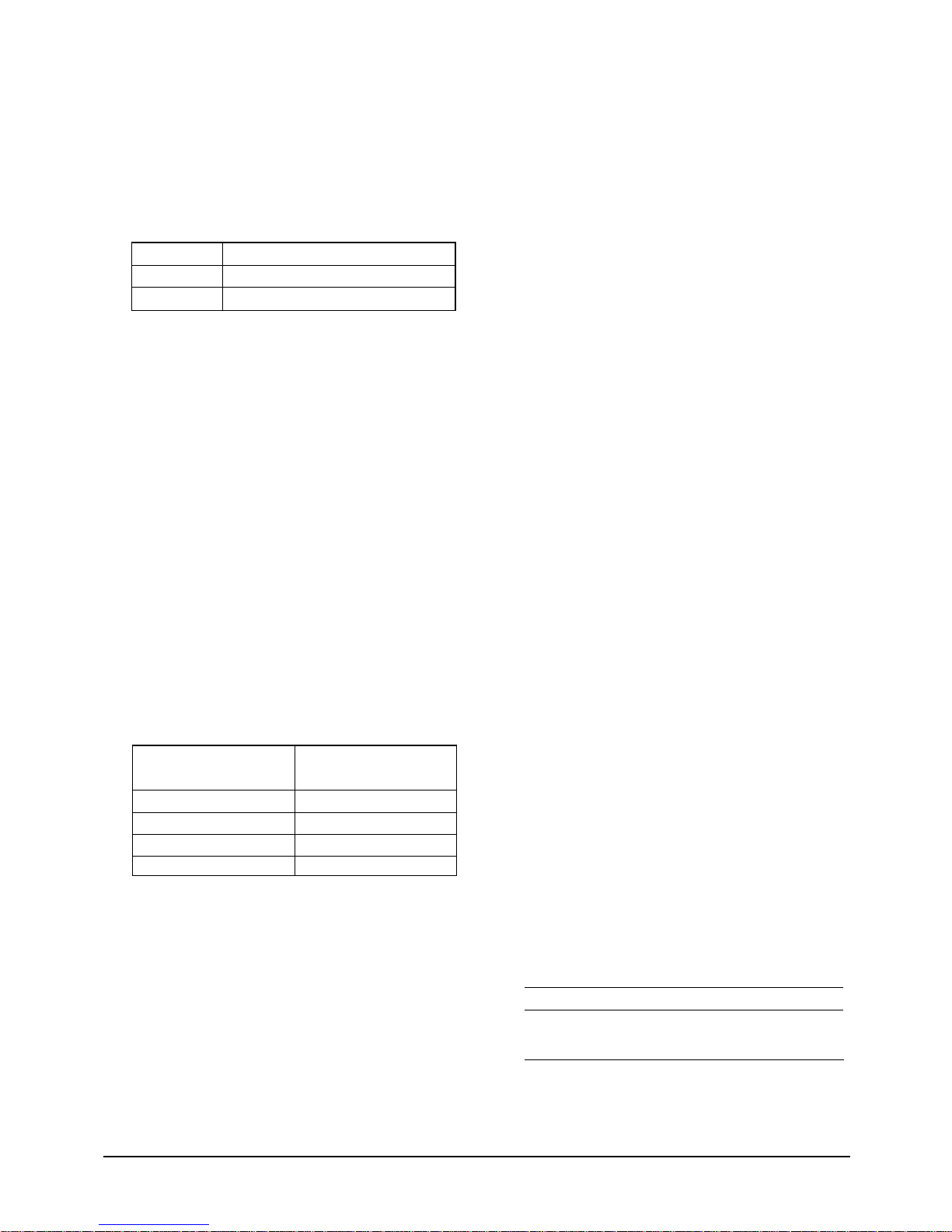

1. AUTO MODE : In this mode, operation mode(COOL,

HEAT) is selected automatically by the room temperature

of initial operation.

Room Temp

Tr≥ 21°C+∆T

21°C +∆T>Tr

Cool Operation (Set Temp:24˚C+∆T)

Heat Operation (Set Temp:22˚C+∆T)

Operation Type

∆T= -1°C, -2°C, 0°C, +1°C, +2°C

∆T is controlled by setting temperature up/down key of

remote control

2. COOL MODE : The unit operates according to the

difference between the setting and room temperature.

(18°C~30°C)

3. HEAT MODE : The unit operates according to the

difference between the setting and room temperature.(16°C~30°C)

*Prevention against cold wind : In order to prevent the

cool air from flowing out at the heat mode, the indoor fan

does not operate or operates very slowly in the

following cases. At this time, the indoor heat exchanger

will be preheating.

- For 3~5 minutes after the initial operation

- For deicing operation

- The operation of an indoor fan in accordance with

the temperature of an indoor heat exchanger

The temperature of

indoor heat exchanger

below 28˚C

28˚C~below 34˚C

34˚C~below 40˚C

above 40˚C

Indoor fan speed

off

LL Speed

L Speed

Setting Speed

*High temperature release function : It is a function to

detect an outdoor overload by the sensor of an indoor

heat exchanger and to turn the outdoor fan or the

compressor ON/OFF for safety.

*Deice : Deicing operation is controlled by indoor unit's

heat exchanger temperature and accumulating time of

compressor's operation.

Deice ends by sensing of the processing time by deice

condition.

4. DRY MODE : Has 3 states, each determined by room

temperature.

The unit operates in DRY mode.

*Compressor ON/OFF Time is controlled compulsorily

(can not set up the fan speed, always breeze).

*Protective function : Low temperature release.

(Prevention against freeze)

5. TURBO MODE : This mode is available in AUTO, COOL,

HEAT, DRY, FAN MODE.

When this button is pressed at first, the air conditioner is

operated "powerful" state for 30 minutes regardless of the

set temperature, room temperature.

When this button is pressed again, or when the operating

time is 30 minutes, turbo operation mode is canceled and

returned to the previous mode.

*But, if you press the TURBO button in DRY or FAN

mode that is changed with AUTO mode automatically.

6. SLEEP MODE : Sleep mode is available only in COOL or

HEAT mode.

The operation will stop after 6 hours.

*In COOL mode : The setting temperature is automatical-

ly raised by 1°C each 1hour When the temperature

has been raised by total of 2°C, that temperature is

maintained.

*In HEAT mode : The setting temperature is automatically

dropped by 1°C each 1hour.

When the temperature has been dropped by total of 2°C,

that temperature is maintained.

7. FAN SPEED : Manual (3 step), Auto (4 step)

Fan speed automatically varies depending on both the

difference between setting and the room temperature.

8. COMPULSORY OPERATION :

For operating the air conditioner without the remote

control.

*The air conditioner starts up in the most suitable mode

for the room temperature:

Room Temperature

Less than 21˚C

21˚C or above

Operating Mode

Heat

Cool

Temperature Setting

24˚C approx.

22˚C approx.

Samsung Electronics6

Operating Instructions & Technical Document

9. SWING : BLADE-H is rotated vertically by the stepping

motor.

*Swing Set : Press the button under the remote

control is displayed on LCD the and the blades

move up and down. If the one more time press the

button, blades location is stop.

10. SETTING THE ON/OFF TIMER. :

*ON TIMER : The On Timer enables you to switch on the

air conditioner automatically after a given period of time.

You can set the period of time from 30 minutes to 24

hours.

*OFF TIMER : The Off Timer enables you to switch off

the air conditioner automatically after a given period of

time. You can set the period of time from 30 minutes to

24 hours.

11. SELF DIAGNOSIS

Error Mode

Indoor unit room temperature sensor

error (open or short)

Indoor unit heat exchanger

temperature sensor error(open or short)

Indoor FAN MOTOR error :

Keep the RPM value 450 below for

15 seconds

EEPROM error

Error in option

In case of No option set-up

In case of option data error

DISPLAY 7-SEGMENT

Operation Off Operation On

OFF E1

OFF E2

OFF E3

OFF E6

All lamp

blinking

All lamp

blinking

Remark

12. BUZZER SOUND : Whenever the On/Off button is

pressed or whenever change occurs to the condition

which is set up or select, the compulsory operation mode,

buzzer is sounded "beep".

7Samsung Electronics

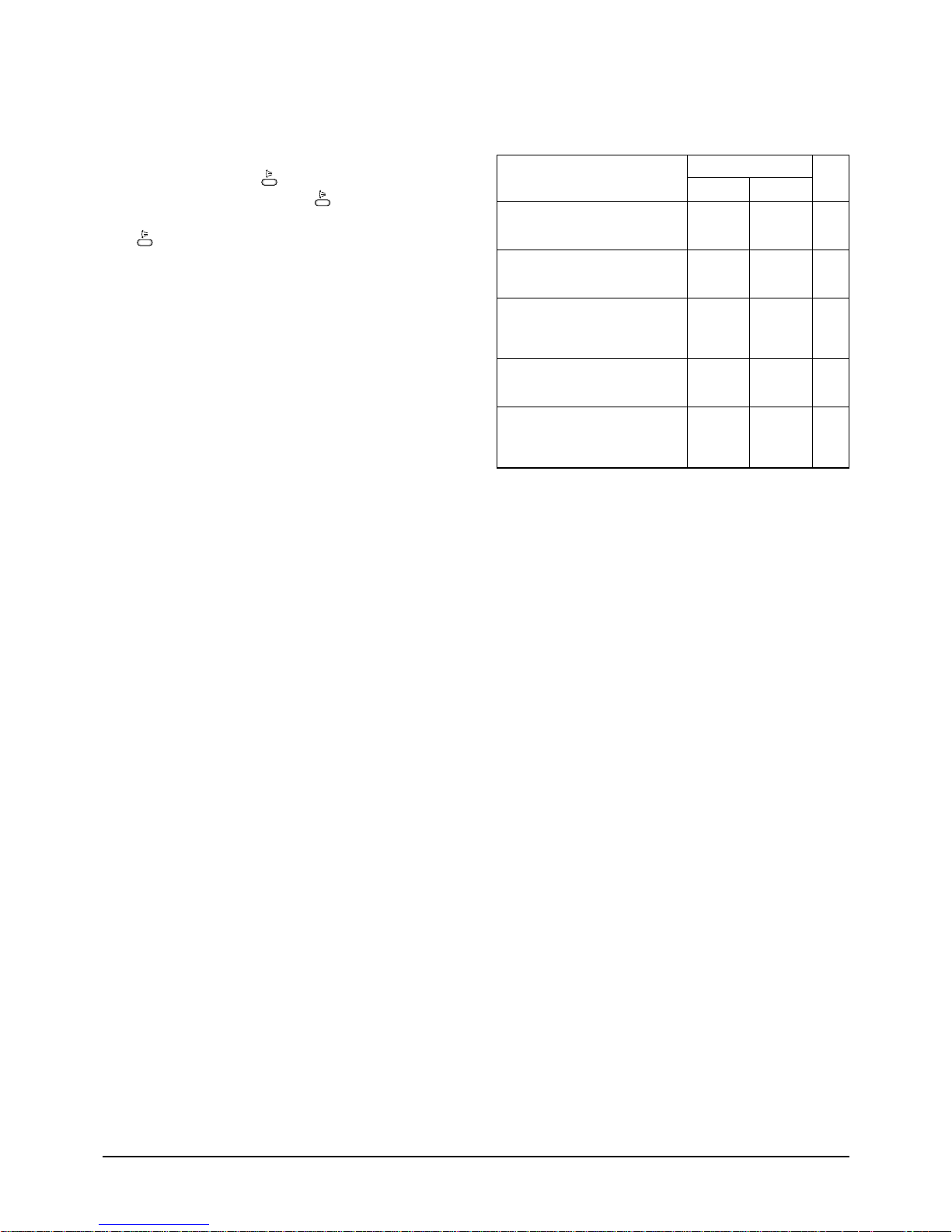

2-2 Technical Document (Pressure Graph)

20

27.2

26.5

31.6

30.4

38.8

38.5

25 30

Outdoor Temperature (ßC)

High Pressure (kgf/cm

2

G)

35 40 45

43

39

35

31

27

23

19

15

A-unit

B-unit

25.225.225.2

28.828.828.8

20 25 30

Outdoor Temperature (ßC)

Low Pressure (kgf/cm

2

G)

35 40 45

9.8

9.6

9.4

9.2

9

8.8

8.6

8.4

8.2

8

8.2

8.2

8.3

9.4

A-unit

B-unit

8.518.51

8.288.28

8.5

8.3

8.738.738.7

9.529.529.5

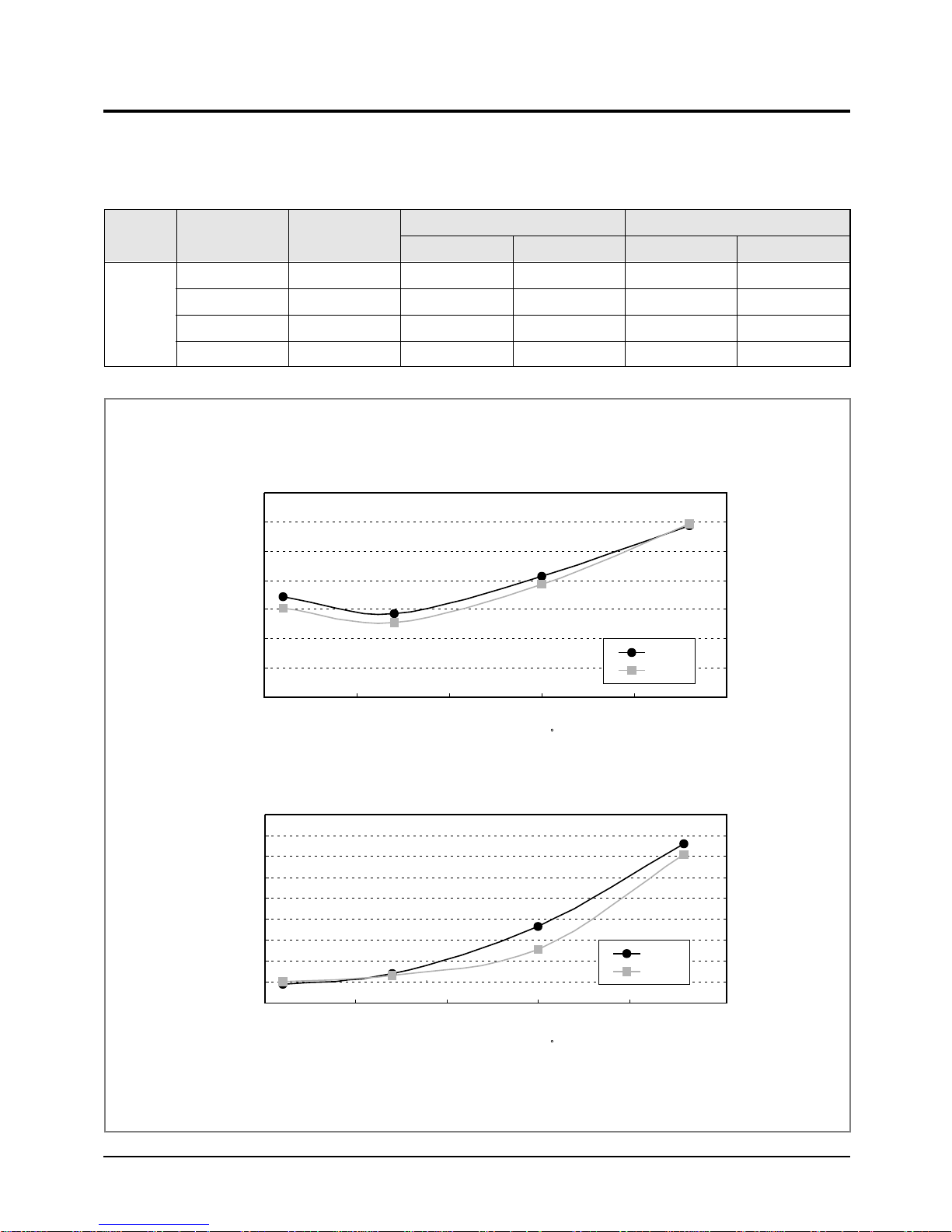

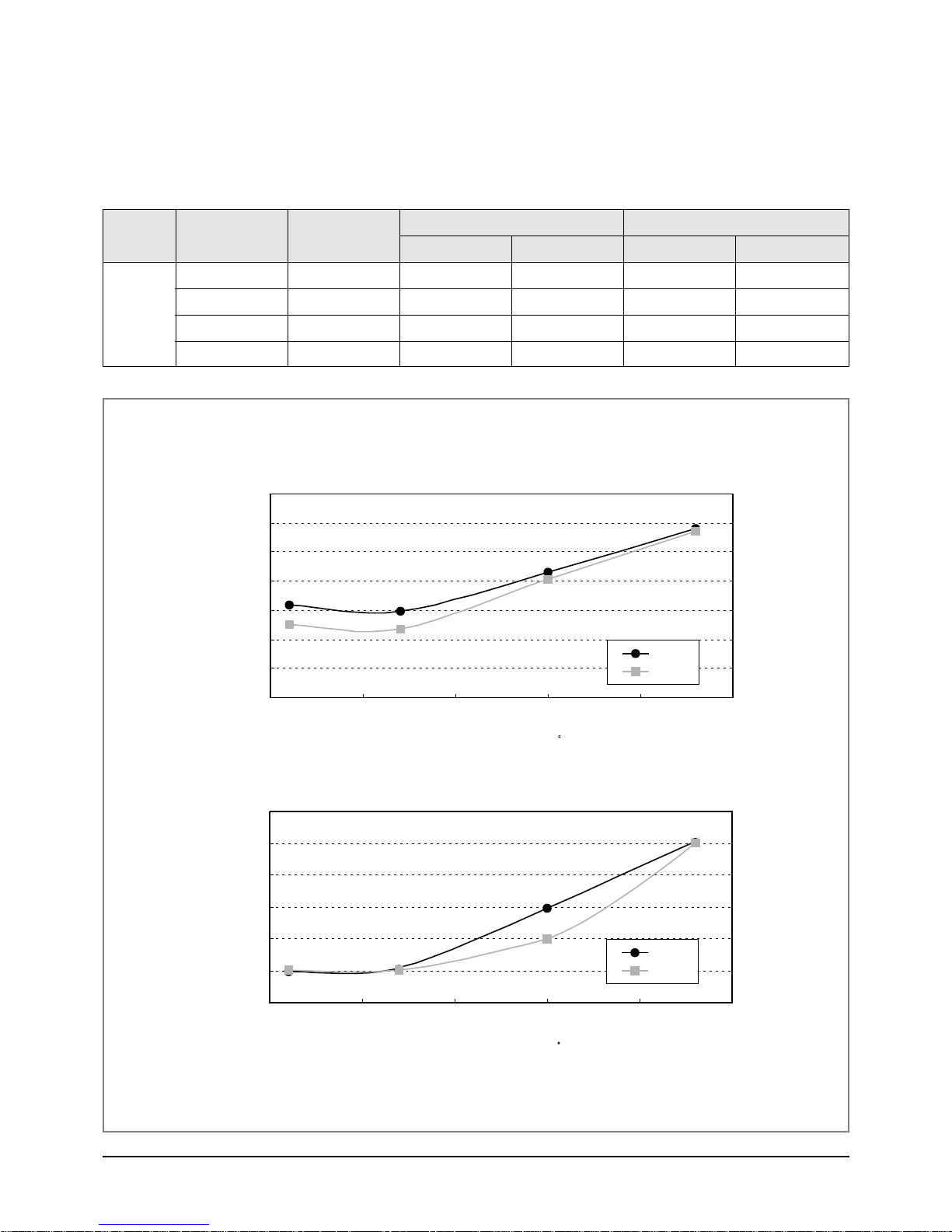

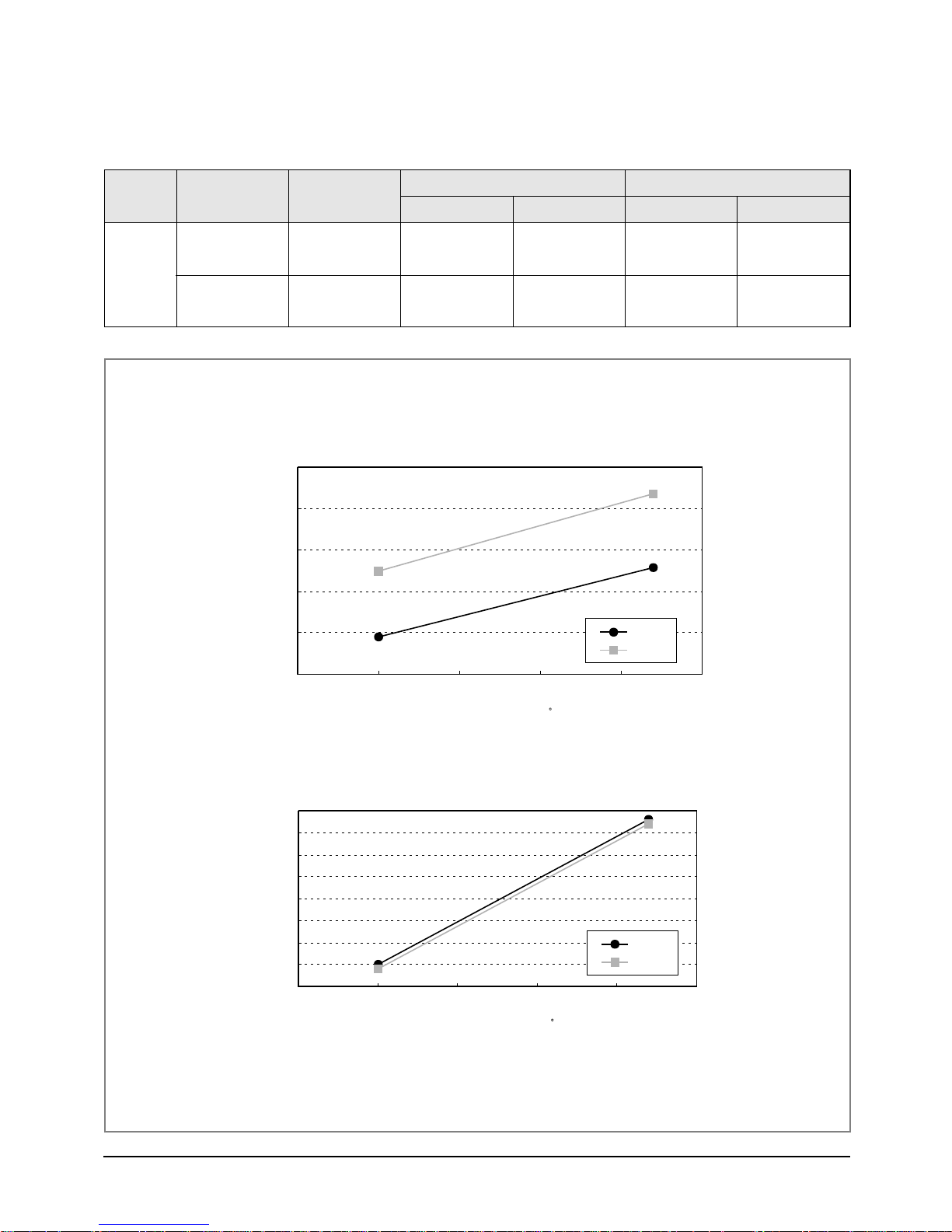

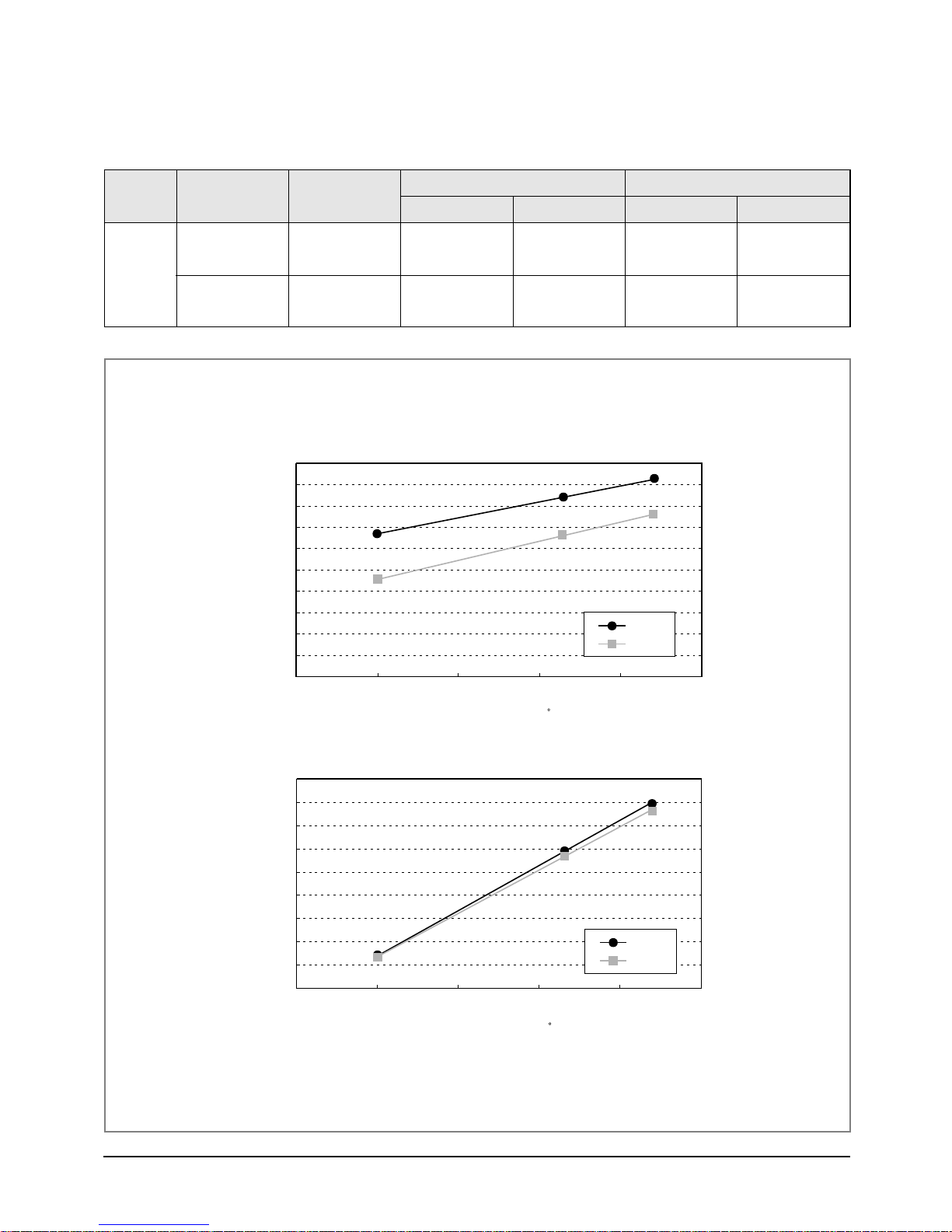

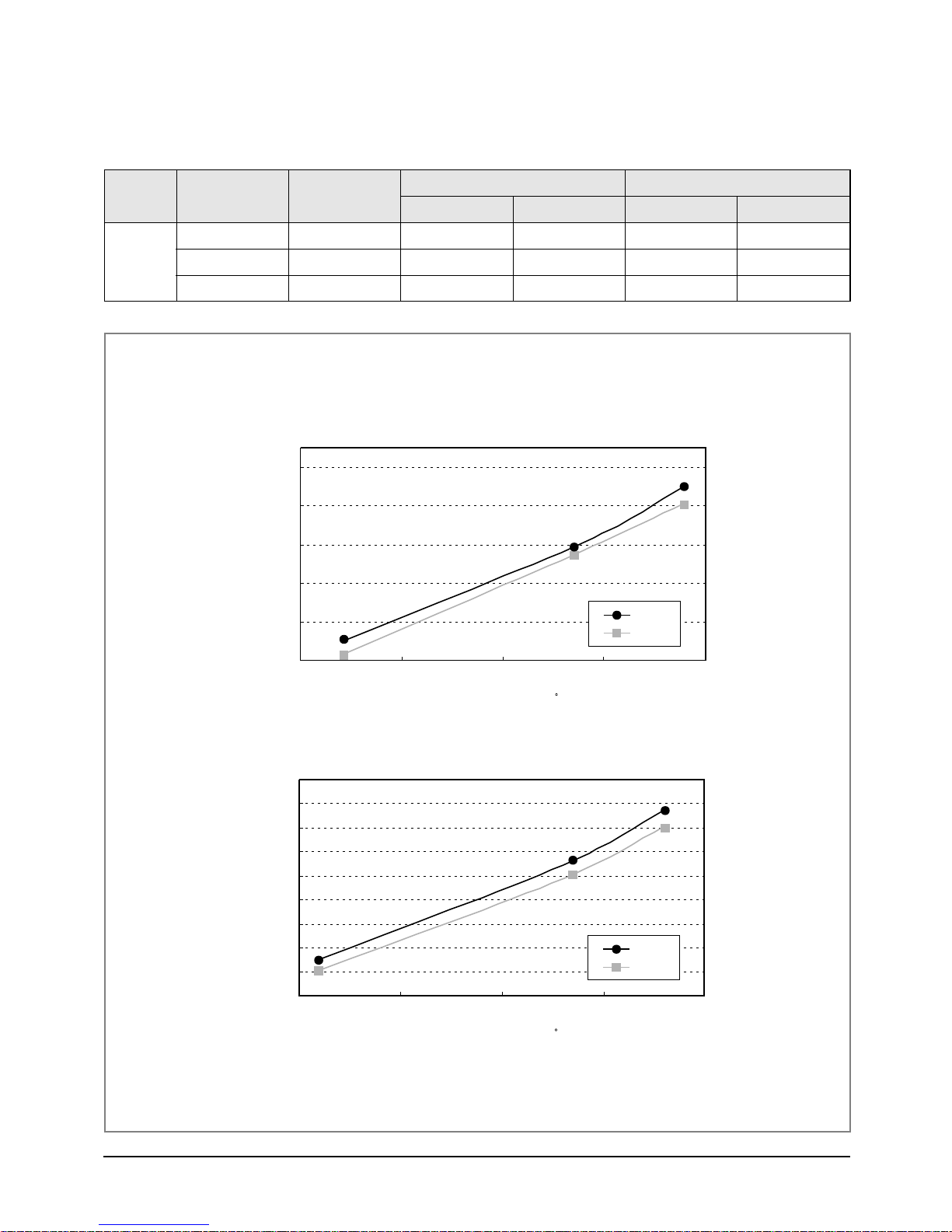

2-2-1 MH18AP1(P2)

■ Cooling(7.5m–Piping)

Cooing

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

27/19 21/15 28.8 27.2 8.2 8.2

27/19 27/20 26.5 25.2 8.3 8.3

27/19 35/24 31.6 30.4 8.7 8.5

27/19 43/26 38.5 38.8 9.5 9.4

Samsung Electronics8

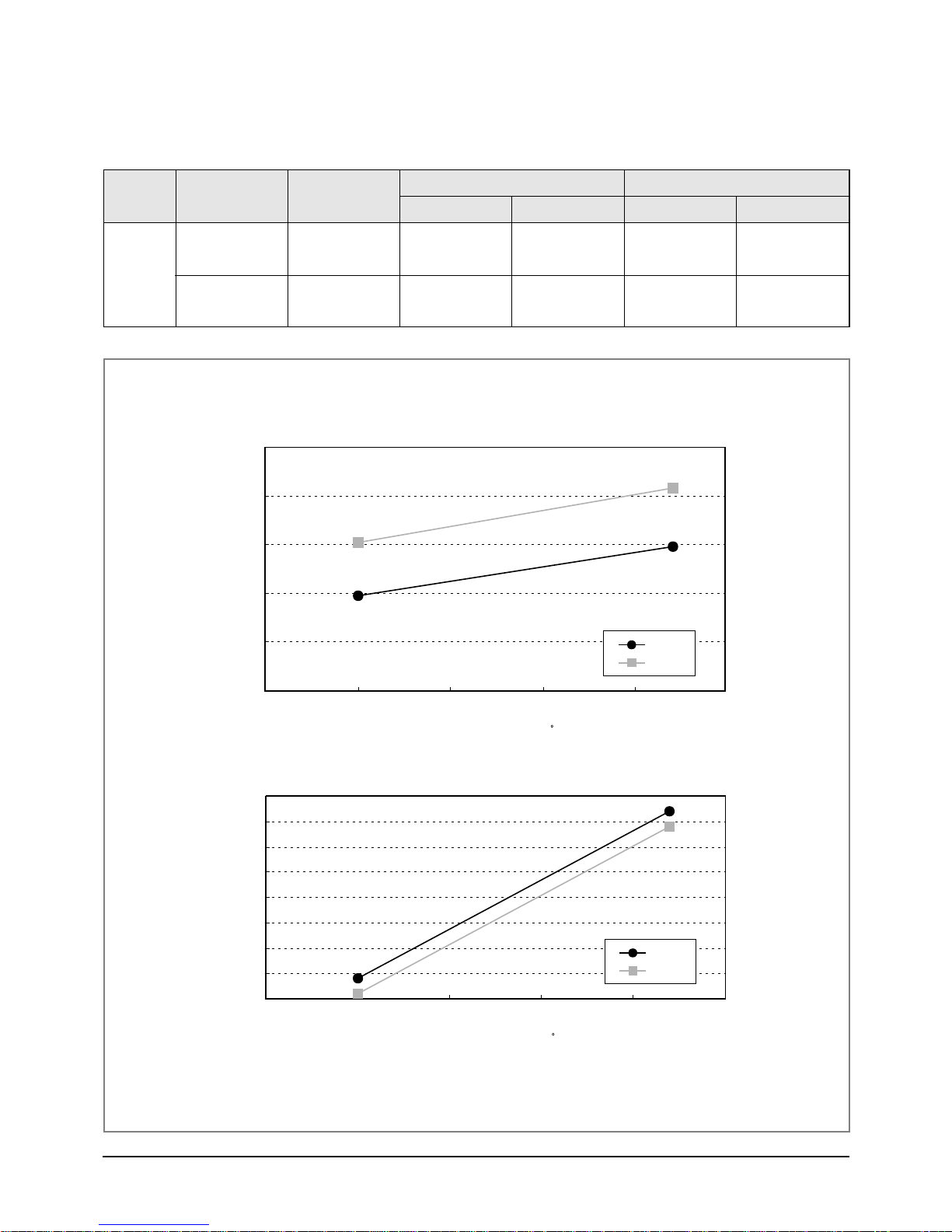

2-1-1 MH18AP1(P2)

20 25 30

Outdoor Temperature (ßC)

35 40 45

High Pressure (kgf/cm

2

G)

43

39

35

31

27

23

19

15

27.8

26.8

32.3

31.3

38.2

37.9

A-unit

B-unit

2525

24.424.4

25.025.025.0

24.4

20 25 30

Outdoor Temperature (ßC)

35 40 45

Low Pressure (kgf/cm

2

G)

9

8.8

8.6

8.4

8.2

8

7.8

8.0

8.0

8.0

8.4

8.8

8.8

8.2

8.0

A-unit

B-unit

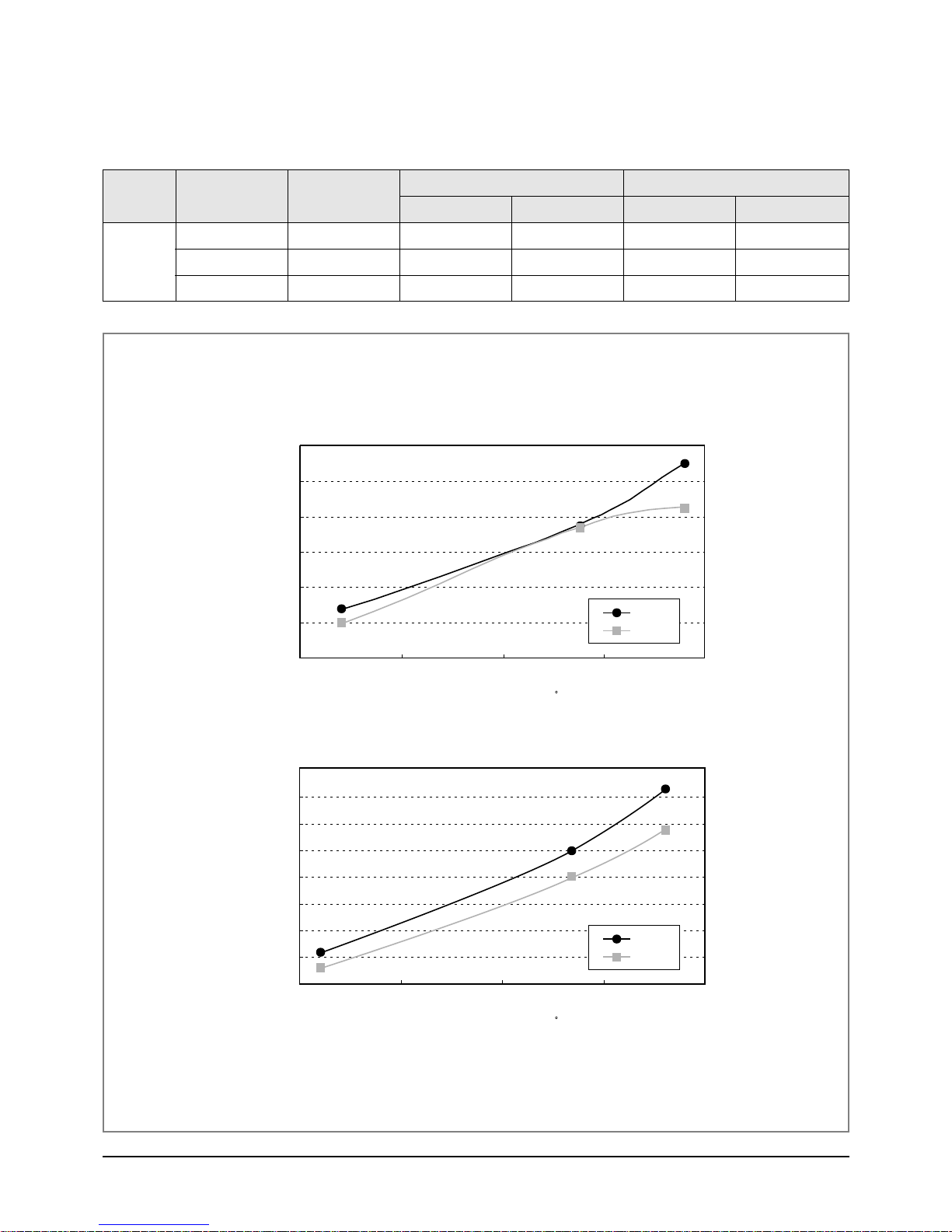

■ Cooling(15m–Piping)

Operating Instructions & Technical Document

Cooing

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

27/19 21/15 27.8 25.0 8.0 8.0

27/19 27/20 26.8 24.4 8.0 8.0

27/19 35/24 32.3 31.3 8.4 8.2

27/19 43/26 38.2 37.9 8.8 8.8

9Samsung Electronics

Operating Instructions & Technical Document

-15 -10 -5

Outdoor Temperature (ßC)

0510

High Pressure (kgf/cm

2

G)

29.5

27.5

25.5

23.5

21.5

19.5

17.5

15.5

13.5

11.5

23.8

28.6

20.2

A-unit

B-unit

23.8523.85

(27.8)(27.8)

25.6925.69

23.9

27.8

25.7

-15 -10 -5

Outdoor Temperature (ßC)

0510

Low Pressure (kgf/cm

2

G)

7.5

7

6.5

6

5.5

5

4.5

4

3.5

3

6.0

6.8

A-unit

B-unit

(5.9)(5.9)

6.846.84

3.683.68

3.723.72

5.9

6.8

3.7

3.7

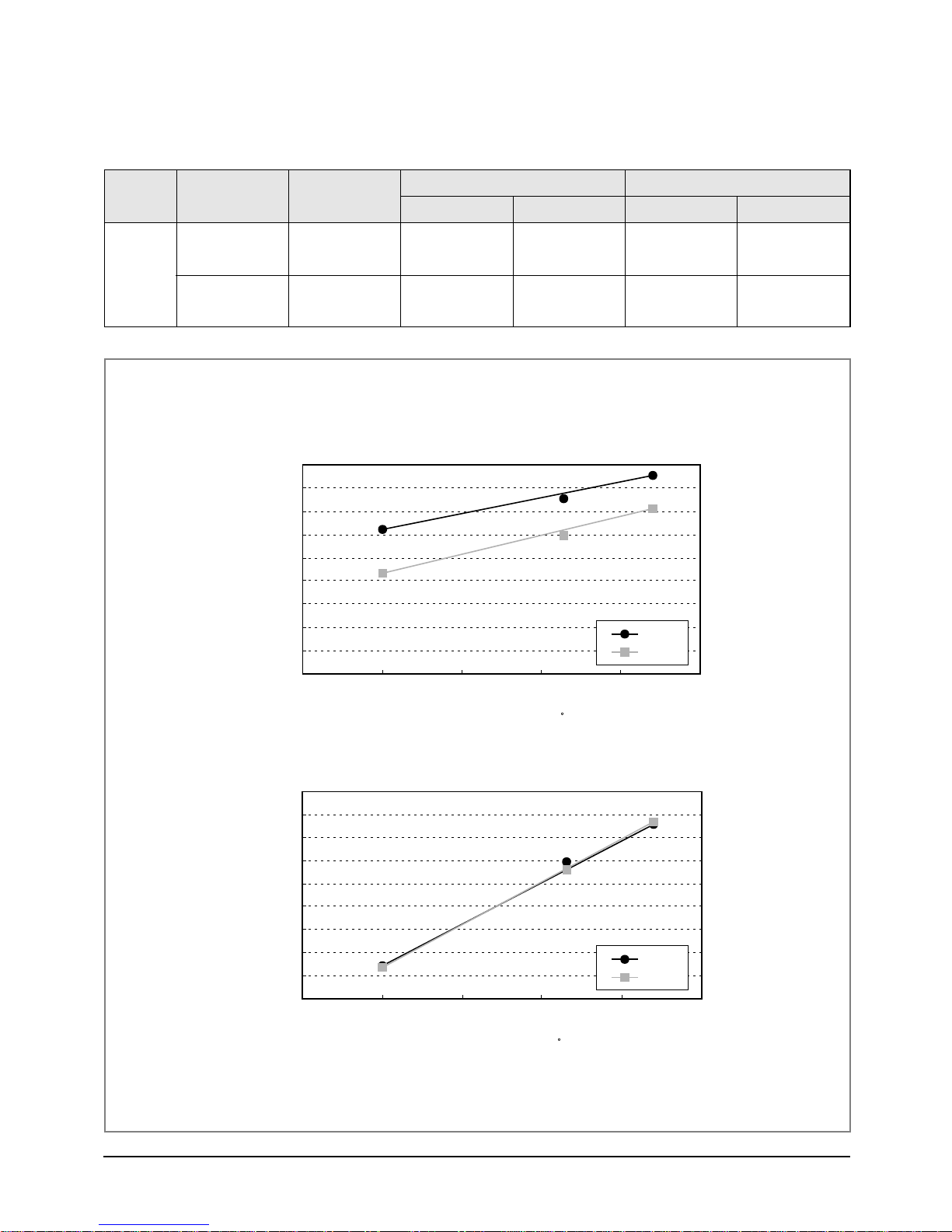

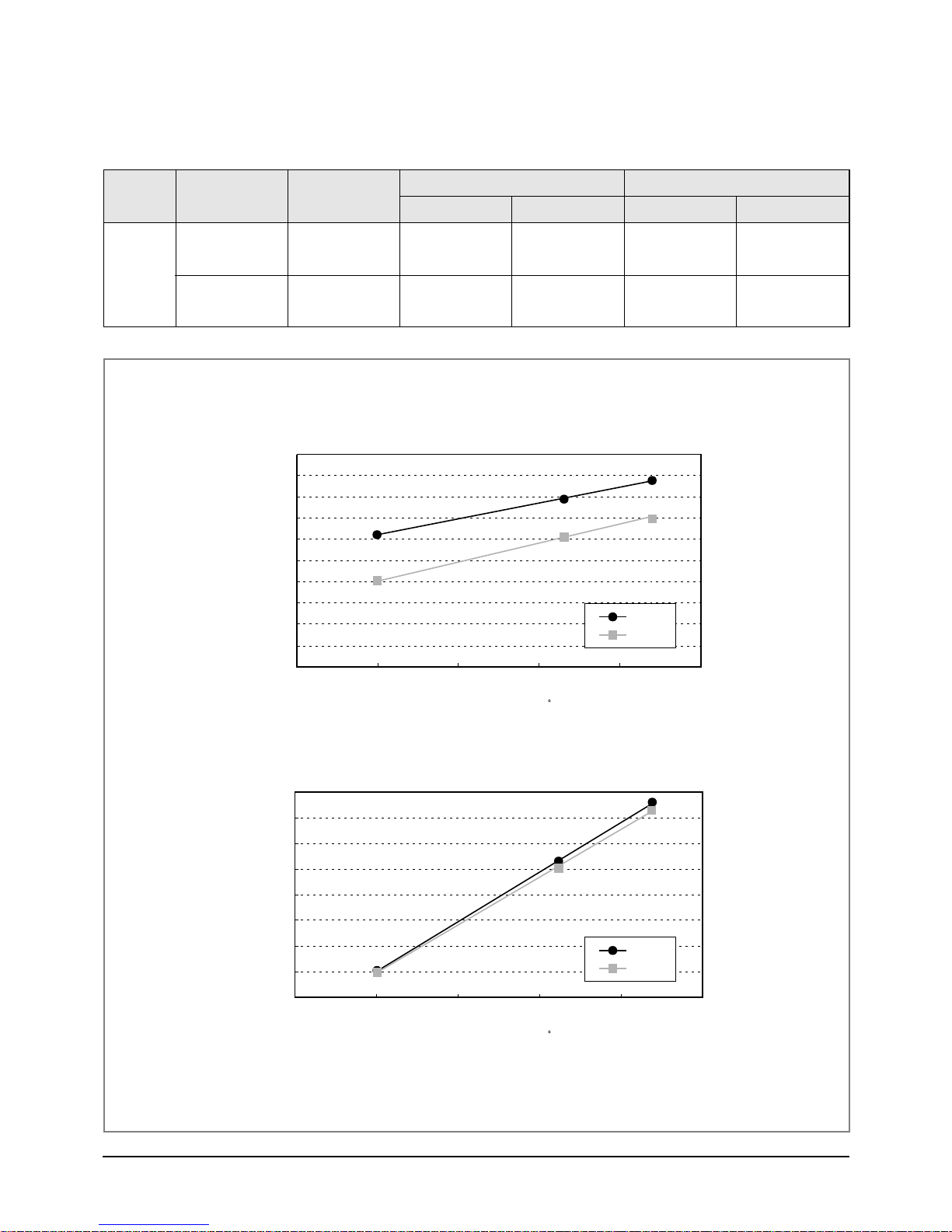

■ Heating(7.5m–Piping)

Heating

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

20/15 –10 23.9 20.2 3.7 3.7

20/15 7 28.6 25.7 6.8 6.8

Samsung Electronics10

■ Heating(15m–Piping)

-15 -10 -5

Outdoor Temperature (ßC)

0510

High Pressure (kgf/cm

2

G)

31.5

29.5

27.5

25.5

23.5

21.5

19.5

17.5

15.5

13.5

11.5

29.0

25.7

19.6

27.4

23.8

A-unit

B-unit

23.9323.9323.9

-15 -10 -5

Outdoor Temperature (ßC)

0510

Low Pressure (kgf/cm

2

G)

7

6.5

6

5.5

5

4.5

4

3.5

3

3.5

3.4

A-unit

B-unit

(5.9)(5.9)

(27.4)(27.4)

5.9

6.7

6.7

5.8

Operating Instructions & Technical Document

Heating

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

20/15 –10 23.9 19.6 3.5 3.4

20/15 7 29.0 25.7 6.7 6.7

11Samsung Electronics

Operating Instructions & Technical Document

20 25 30

Outdoor Temperature (ßC)

35 40 45

High Pressure (kgf/cm

2

G)

43

39

35

31

27

23

19

15

27.2

27.0

26.8

26.6

31.8

31.6

38.4

37.6

A-unit

B-unit

20 25 30

Outdoor Temperature (ßC)

35 40 45

Low Pressure (kgf/cm

2

G)

9.4

9.2

9

8.8

8.6

8.4

8.2

8

8.8

9.2

A-unit

B-unit

8.58.5

8.58.5

8.38.3

8.38.3

8.98.9

9.39.3

8.5

8.5

8.3

8.9

9.3

8.3

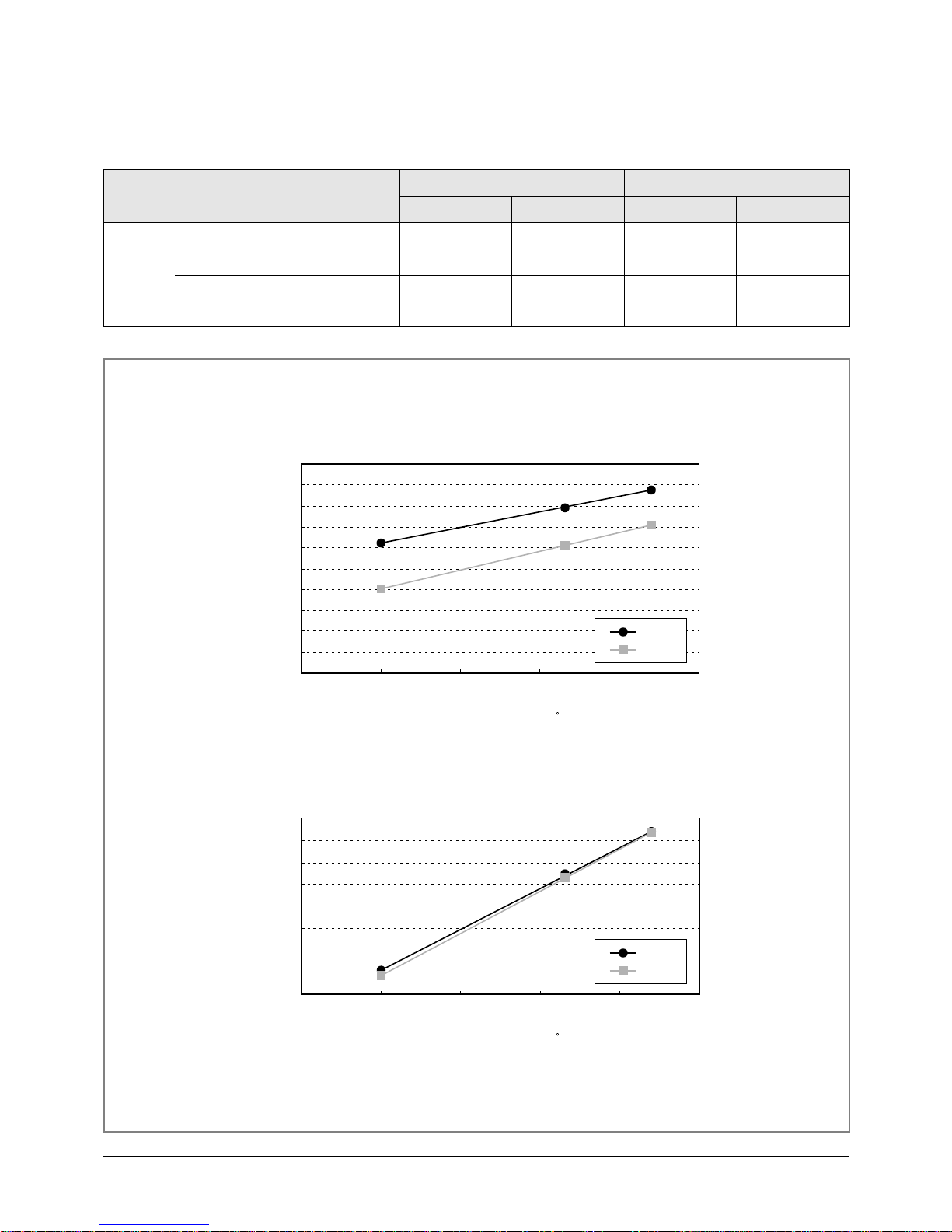

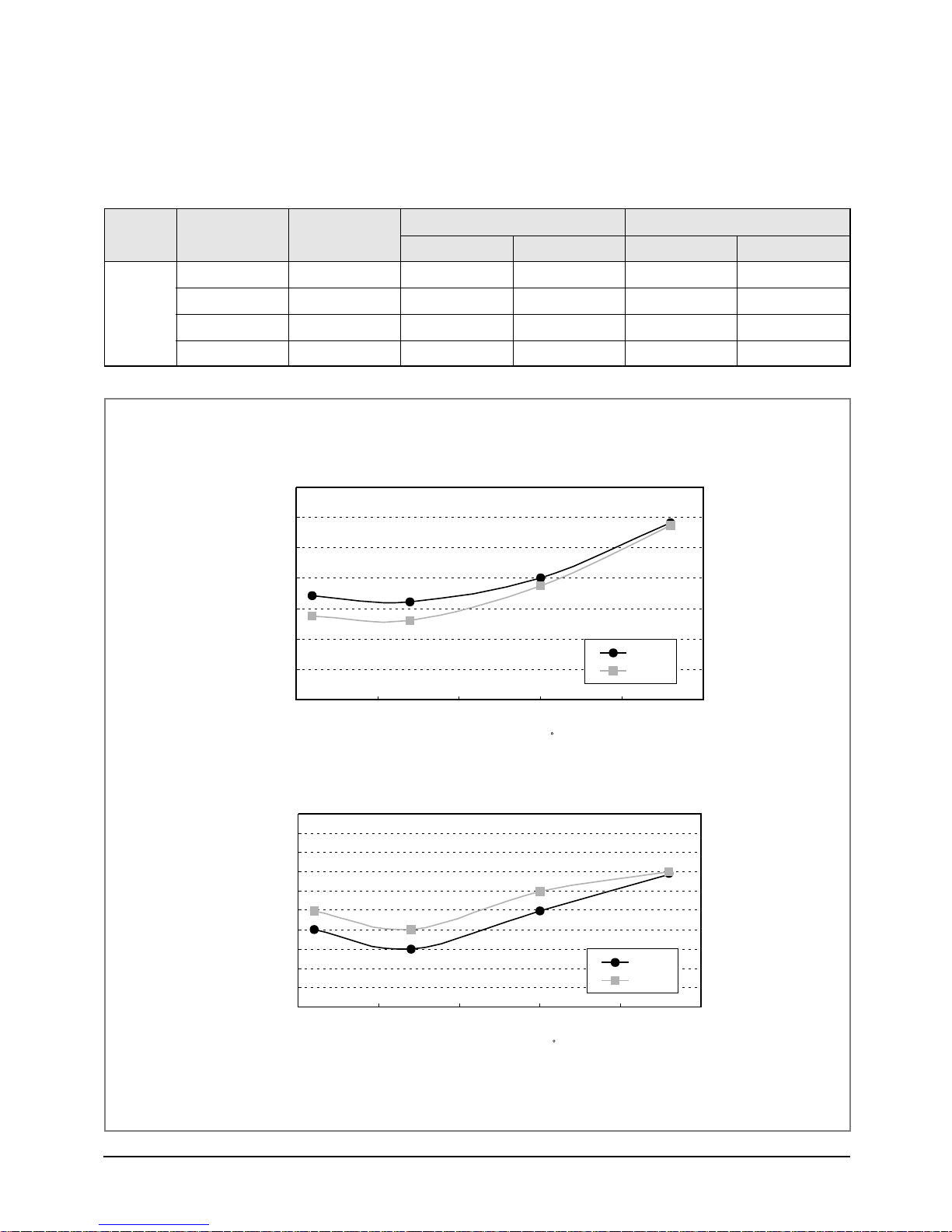

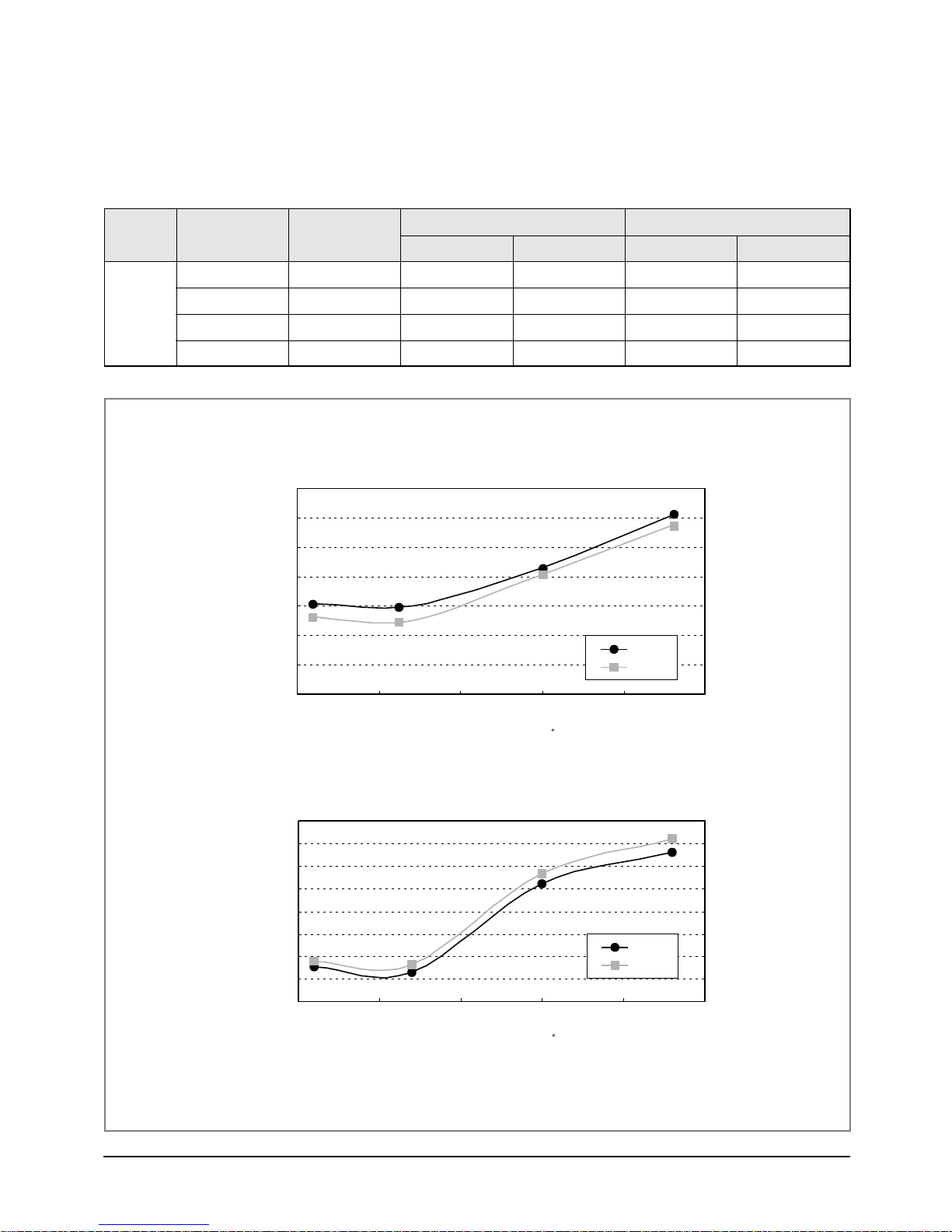

2-2-2 MH19AP1(P2)

■ Cooling(7.5m–Piping)

Cooing

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

27/19 21/15 27.2 27.0 8.5 8.5

27/19 27/20 26.8 26.6 8.3 8.3

27/19 35/24 31.8 31.6 8.9 8.8

27/19 43/26 38.4 37.6 9.3 9.2

Samsung Electronics12

2-1-1 MH18AP1(P2)

20 25 30

Outdoor Temperature (ßC)

35 40 45

High Pressure (kgf/cm

2

G)

43

39

35

31

27

23

19

15

27.4

27.2

27.0

26.8

32.0

31.8

38.6

37.8

A-unit

B-unit

20 25 30

Outdoor Temperature (ßC)

35 40 45

Low Pressure (kgf/cm

2

G)

9.4

9.2

9

8.8

8.6

8.4

8.2

8

8.4

8.2

8.4

9.2

8.8

8.2

8.1

A-unit

B-unit

8.78.78.7

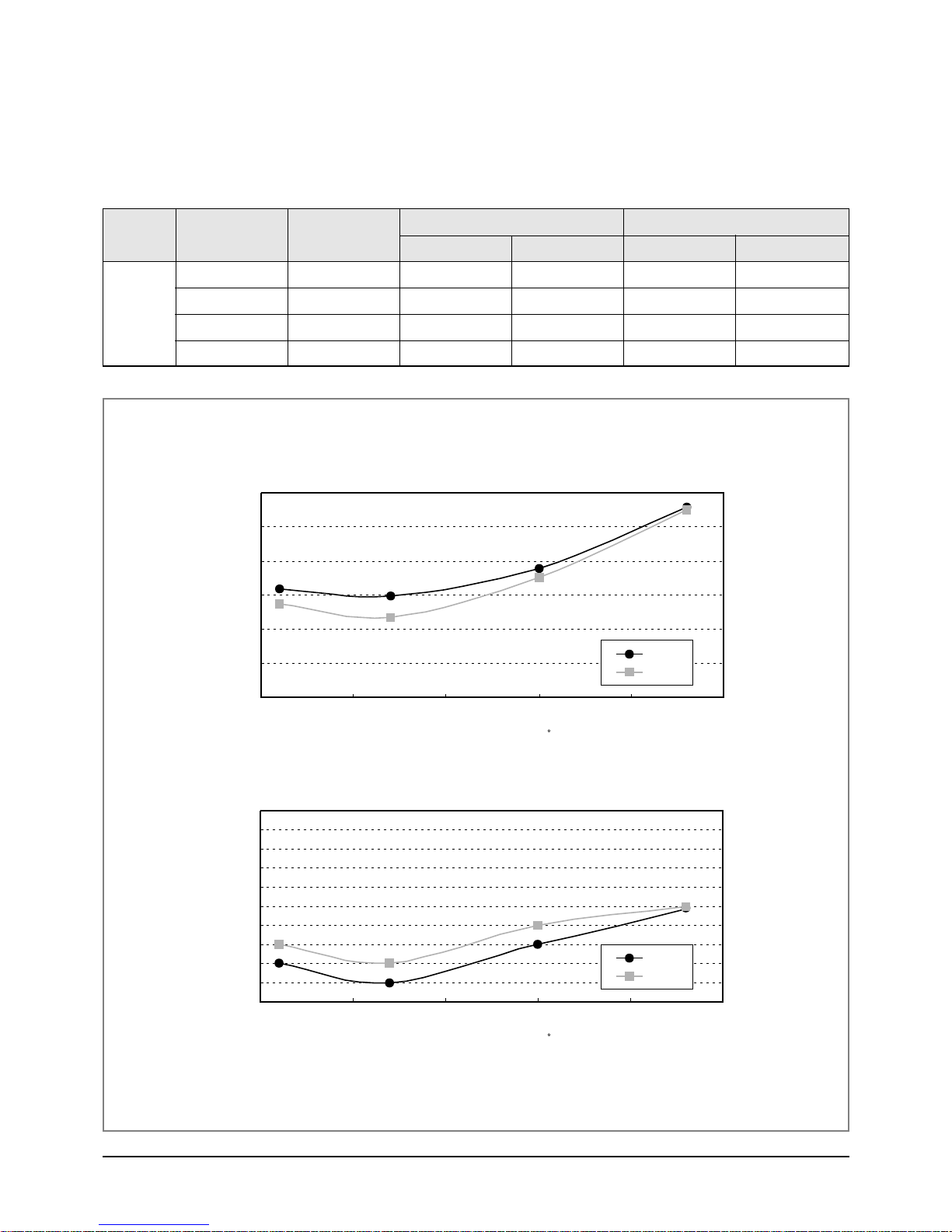

■ Cooling(15m–Piping)

Operating Instructions & Technical Document

Cooing

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

27/19 21/15 27.4 27.2 8.4 8.2

27/19 27/20 27.0 26.8 8.2 8.1

27/19 35/24 32.0 31.8 8.7 8.4

27/19 43/26 38.6 37.8 9.2 8.8

13Samsung Electronics

Operating Instructions & Technical Document

-15 -10 -5

Outdoor Temperature (ßC)

0510

High Pressure (kgf/cm

2

G)

35

32

29

26

23

20

27.5

22.7

33.1

27.7

A-unit

B-unit

-15 -10 -5

Outdoor Temperature (ßC)

0510

Low Pressure (kgf/cm

2

G)

7

6.5

6

5.5

5

4.5

4

3.5

3

3.5

6.8

6.7

3.4

A-unit

B-unit

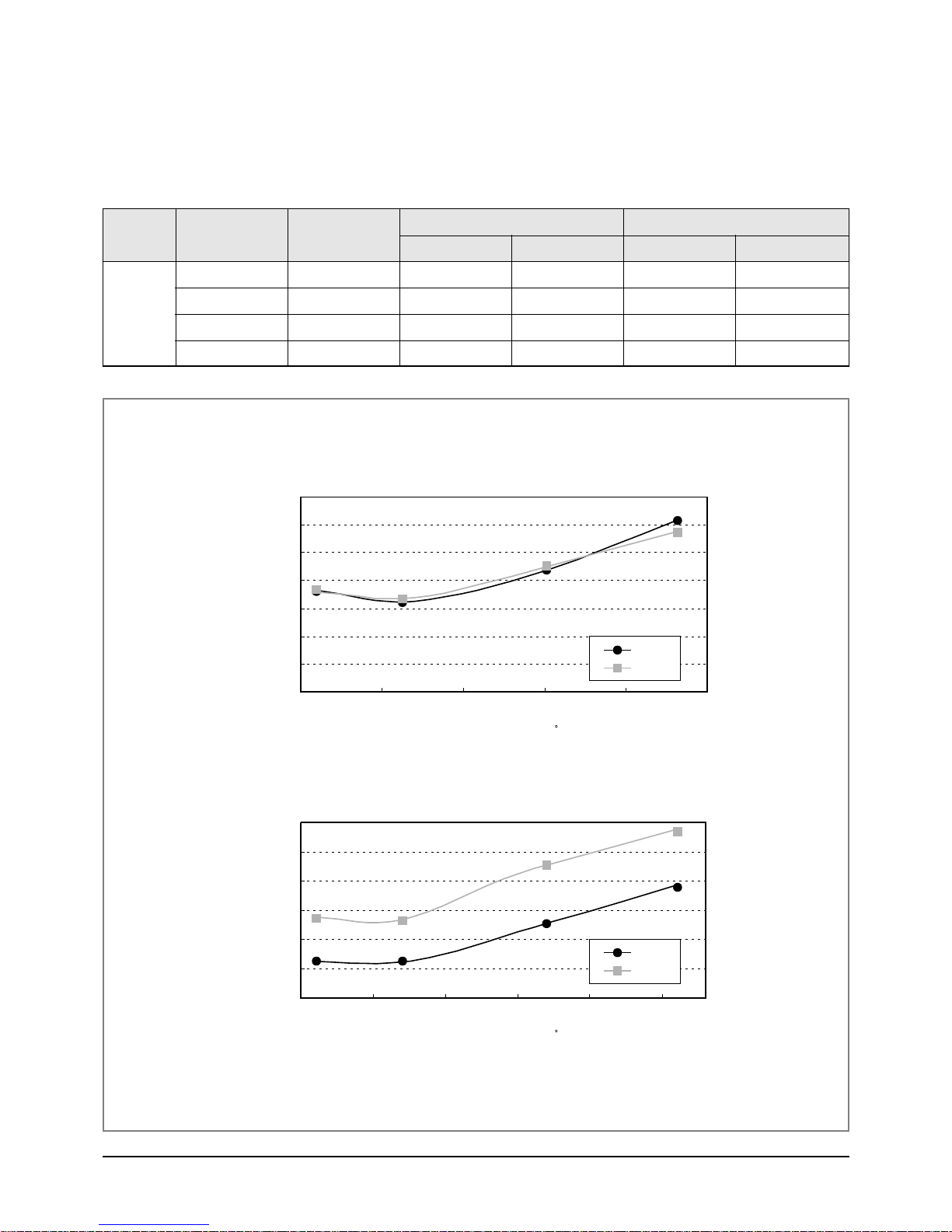

■ Heating(7.5m–Piping)

Heating

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

20/15 –10 22.7 27.5 3.5 3.4

20/15 7 27.7 33.1 6.8 6.7

Samsung Electronics14

■ Heating(15m–Piping)

-15 -10 -5

Outdoor Temperature (ßC)

0510

High Pressure (kgf/cm

2

G)

36.5

31.5

26.5

21.5

16.5

11.5

26.7

21.3

32.3

26.3

A-unit

B-unit

-15 -10 -5

Outdoor Temperature (ßC)

0510

Low Pressure (kgf/cm

2

G)

7

6.5

6

5.5

5

4.5

4

3.5

3

3.4

6.7

3.1

A-unit

B-unit

6.46.46.4

Operating Instructions & Technical Document

Heating

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit (7.5m) B-unit (32.5m)

20/15 –10 21.3 26.7 3.4 3.1

20/15 7 26.3 32.3 6.7 6.4

15Samsung Electronics

Operating Instructions & Technical Document

20 25 30

Outdoor Temperature (ßC)

35 40 45

High Pressure (kgf/cm

2

G)

43

39

35

31

27

23

19

15

27.9

31.1

38.0

38.0

30.1

28.7528.75

25.425.4

28.8

26.0

25.4

A-unit

B-unit

20 25 30

Outdoor Temperature (ßC)

35 40 45

Low Pressure (kgf/cm

2

G)

9.5

9.4

9.3

9.2

9.1

9

8.9

8.8

8.7

8.6

8.5

9.0

8.9

9.1

9.2

9.2

9.0

8.8

8.9

A-unit

B-unit

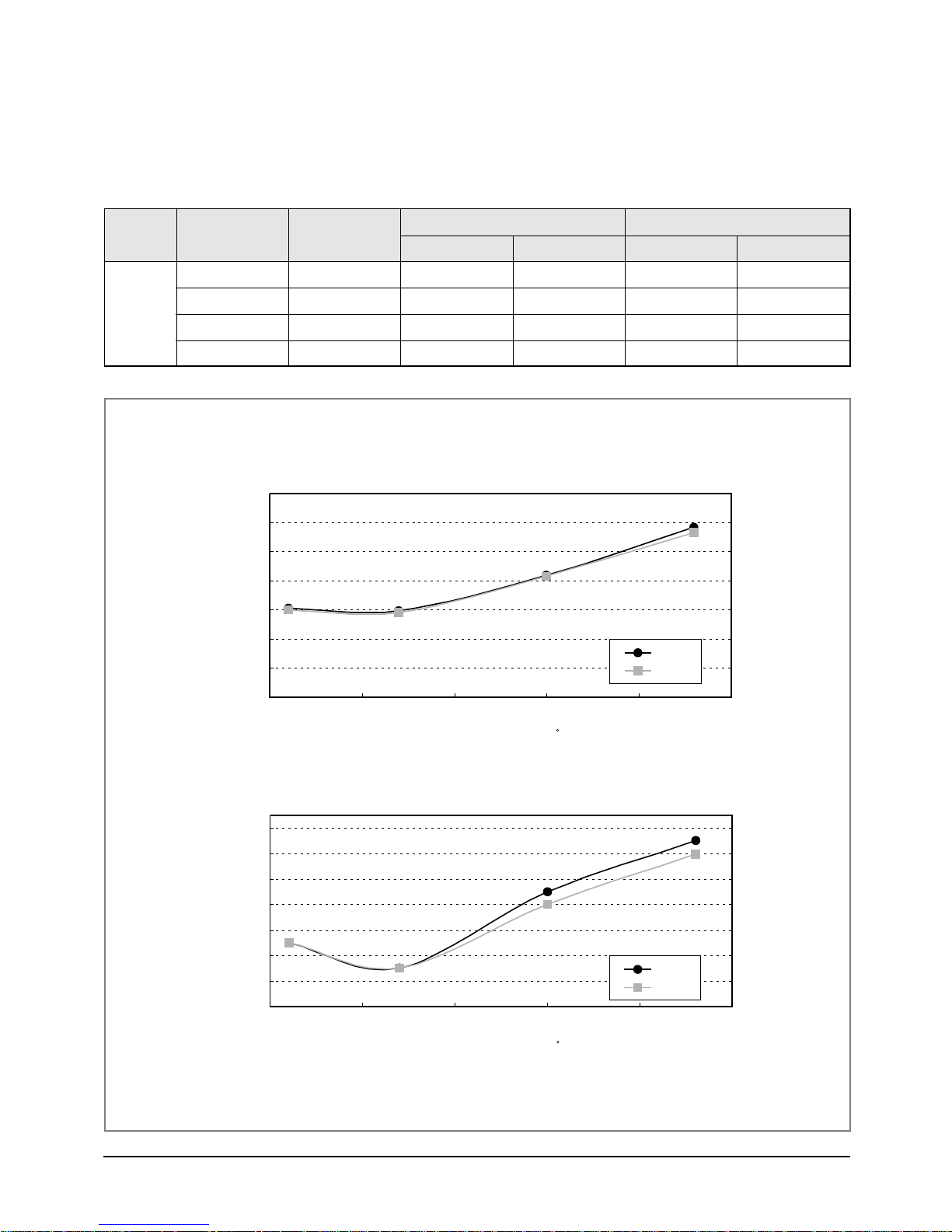

2-2-3 MH24AP1(P2)

■ Cooling(7.5m–Piping)

Cooing

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

27/19 21/15 28.8 26.0 8.9 9.0

27/19 27/20 27.9 25.4 8.8 8.9

27/19 35/24 31.1 30.1 9.0 9.1

27/19 43/26 38.0 38.0 9.2 9.2

Samsung Electronics16

2-1-1 MH18AP1(P2)

20 25 30

Outdoor Temperature (ßC)

35 40 45

High Pressure (kgf/cm

2

G)

39

35

31

27

23

19

15

27.8

26.9

29.1

37.3

26.0

A-unit

B-unit

24.424.4

30.130.1

3737

24.4

30.1

37.0

20 25 30

Outdoor Temperature (ßC)

35 40 45

Low Pressure (kgf/cm

2

G)

9.5

9.4

9.3

9.2

9.1

9

8.9

8.8

8.7

8.6

8.5

8.8

8.7

8.7

8.6

8.9

8.8

9.0

A-unit

B-unit

9.0

■ Cooling(15m–Piping)

Operating Instructions & Technical Document

Cooing

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

27/19 21/15 27.8 26.0 8.7 8.8

27/19 27/20 26.9 24.4 8.6 8.7

27/19 35/24 30.1 29.1 8.8 8.9

27/19 43/26 37.3 37.0 9.0 9.0

17Samsung Electronics

Operating Instructions & Technical Document

-15 -10 -5

Outdoor Temperature (ßC)

0510

High Pressure (kgf/cm

2

G)

31.5

29.5

27.5

25.5

23.5

21.5

19.5

17.5

15.5

13.5

11.5

24.9

30.0

26.7

A-unit

B-unit

20.6120.61

(28.4)(28.4)

(24.8)(24.8)

20.6

28.4

24.8

-15 -10 -5

Outdoor Temperature (ßC)

0510

Low Pressure (kgf/cm

2

G)

7.5

7

6.5

6

5.5

5

4.5

4

3.5

3

A-unit

B-unit

6.0

7.0

3.7

6.856.85

3.73.7

(5.9)(5.9)

6.9

3.7

5.9

■ Heating(7.5m–Piping)

Heating

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

20/15 –10 24.9 20.6 3.7 3.7

20/15 7 30.0 26.7 7.0 6.9

Samsung Electronics18

■ Heating(15m–Piping)

-15 -10 -5

Outdoor Temperature (ßC)

0510

High Pressure (kgf/cm

2

G)

31.5

29.5

27.5

25.5

23.5

21.5

19.5

17.5

15.5

13.5

11.5

A-unit

B-unit

19.6

29.0

25.7

27.4

23.8

23.9123.9123.9

-15 -10 -5

Outdoor Temperature (ßC)

0510

Low Pressure (kgf/cm

2

G)

7

6.5

6

5.5

5

4.5

4

3.5

3

A-unit

B-unit

3.5

3.5

5.9

6.8

5.8

6.7

Operating Instructions & Technical Document

Heating

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

20/15 –10 23.9 19.6 3.5 3.5

20/15 7 29.0 25.7 6.8 6.7

19Samsung Electronics

Operating Instructions & Technical Document

High Pressure (kgf/cm

2

G)

43.0

39.0

35.0

31.0

27.0

23.0

19.0

15.0

27.3

27.1

32.2

31.3

39.5

38.0

20 25 30

Outdoor Temperature (ßC)

35 40 45

A-unit

B-unit

25.4625.46

25.0625.06

25.5

25.1

Low Pressure (kgf/cm

2

G)

10.0

9.5

9.0

8.5

8.0

7.5

7.0

6.5

6.0

20 25 30 35 40 45

6.9

6.8

8.8

8.6

9.6

A-unit

B-unit

9.319.319.3

6.646.646.6

6.776.776.8

Outdoor Temperature (ßC)

2-2-4 MH26AP1(P2)

■ Cooling(7.5m–Piping)

Cooing

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

27/19 21/10 27.3 25.5 6.8 6.9

27/19 27/19 27.1 25.1 6.6 6.8

27/19 35/24 32.2 31.3 8.6 8.8

27/19 45/26 39.5 38.0 9.3 9.6

Samsung Electronics20

2-1-1 MH18AP1(P2)

High Pressure (kgf/cm

2

G)

43.0

39.0

35.0

31.0

27.0

23.0

19.0

15.0

20 25 30

Outdoor Temperature (ßC)

35 40 45

39.5

28.1

38.0

A-unit

B-unit

28.6

29.5729.57

32.8732.87

32.4032.40

29.3229.32

29.6

32.9

32.4

29.3

Low Pressure (kgf/cm

2

G)

10.0

9.5

9.0

8.5

8.0

7.5

7.0

20 25 30

Outdoor Temperature (ßC)

35 40 45

A-unit

B-unit

8.9

7.67.67.6

9.8

8.33

9.129.12

8.148.14

8.338.33

9.1

8.1

7.62

8.3

7.627.627.6

8.48.48.4

■ Cooling(15m–Piping)

Operating Instructions & Technical Document

Cooing

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

27/19 21/10 29.6 29.3 7.6 8.4

27/19 27/19 28.1 28.6 7.6 8.3

27/19 35/24 32.4 32.9 8.1 9.1

27/19 45/26 39.5 38.0 8.9 9.8

21Samsung Electronics

Operating Instructions & Technical Document

High Pressure (kgf/cm

2

G)

29

27

25

23

21

19

-12 -7 -2

Outdoor Temperature (ßC)

38

A-unit

B-unit

19.3

20.0

24.8

24.7

28.0

27.2

High Pressure (kgf/cm

2

G)

7

6.5

6

5.5

5

4.5

4

3.5

3

2.5

-11 -6 -1

Outdoor Temperature (ßC)

49

A-unit

B-unit

3.0

3.273.27

(5.22)(5.22)

4.9

6.386.38

6.0

3.3

5.2

6.4

■ Heating(7.5m–Piping)

Heating

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

20/15 –10 20.0 19.3 3.3 3.0

20/15 2 24.8 24.7 5.2 4.9

20/15 7 28.0 27.2 6.4 6.0

Samsung Electronics22

■ Heating(15m–Piping)

High Pressure (kgf/cm

2

G)

29

27

25

23

21

19

17

-12 -7 -2

Outdoor Temperature (ßC)

38

A-unit

B-unit

19.0

25.5

27.7

24.4

24.3

19.7

Low Pressure (kgf/cm

2

G)

6.5

6

5.5

5

4.5

4

3.5

3

2.5

-11 -6 -1

Outdoor Temperature (ßC)

49

A-unit

B-unit

2.8

4.5

5.4

6.2

3.1

5.0

Operating Instructions & Technical Document

Heating

Indoor

(DB/WB)

Outdoor

(DB)

High Pressure Low Pressure

A-unit B-unit A-unit B-unit

20/15 –10 19.7 19.0 3.1 2.8

20/15 2 24.4 24.3 5.0 4.5

20/15 7 27.7 25.5 6.2 5.4

23Samsung Electronics

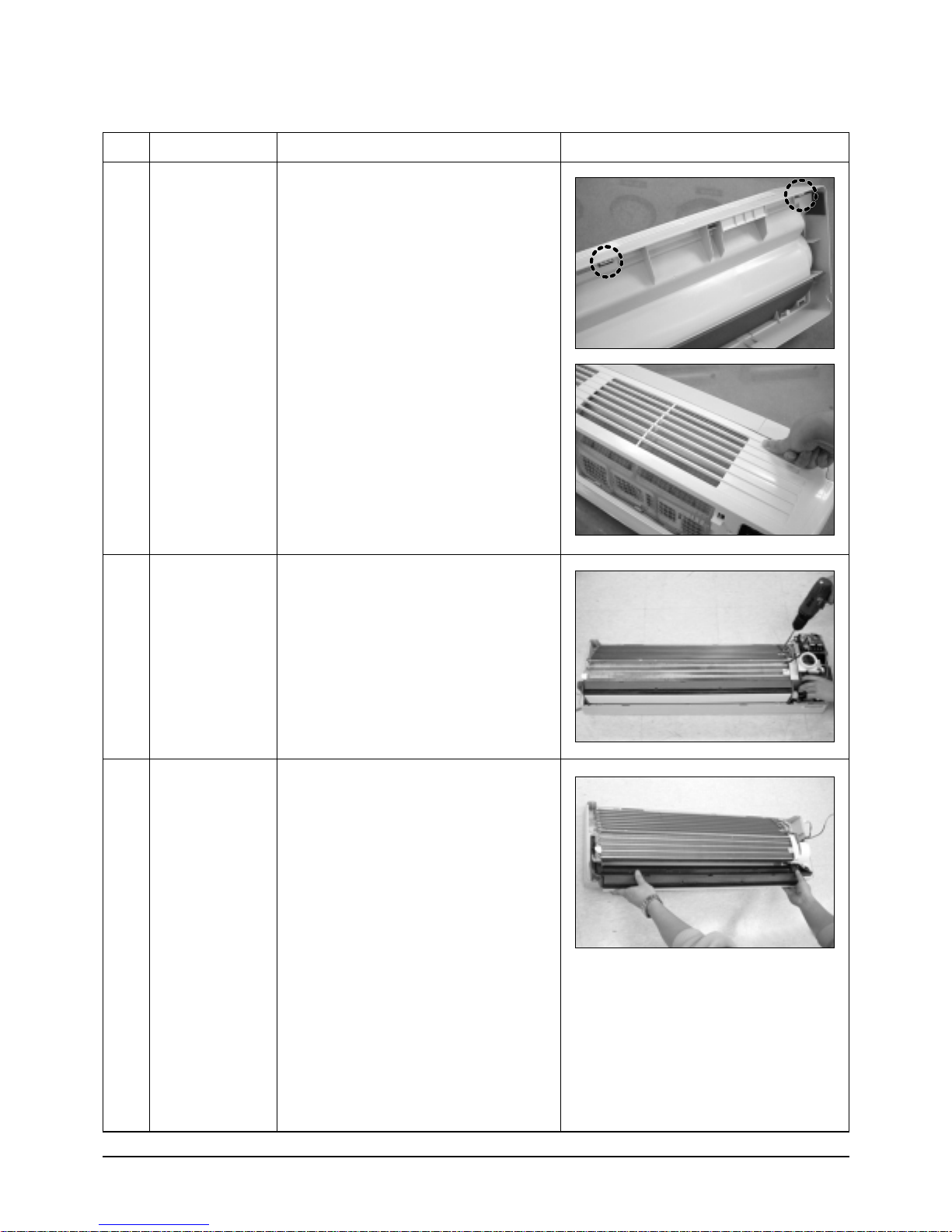

3. Disassembly and Reassembly

Stop operation of the air conditioner and remove the power cord before repairing the unit.

3-1 Indoor Unit

No Parts Procedure Remark

1 Front Panel

1) Stop the air conditioner operation and

block the main power.

2) Detach tape of Front Panel upper.

3) Slide the lower Front Grille down, then

disassemble it by pulling it forwards.

4) Open the upper Front Grille by pulling right

and left sides of the Grille.

5) Take the left and right Filter out.

6) Loosen one of the right screw and detach

the Terminal Cover.

7) Detach the thermistor from the Front Grille.

8) Loosen 5 fixing screws of Front Grille.

9) Pull the lower left and right of discharge

softly for the outside cover to be pulled out.

Samsung Electronics24

Disassembly and Reassembly

No Parts Procedure Remark

10) At first, press the left and center hook of

the back side of the Panel Grille with the

thumb to remove the hook. And press the

right of the upper side of the Panel Grille

with the fingers. And then disassemble the

Panel Grille.

2

Electrical Parts

(Main PCB)

1) Take all the connector of PCB upper side

out.(Including Power Cord)

2) Detach the outdoor unit connection wire

from the Terminal Block.

3) If pulling the main PCB up, it will be taken

out.

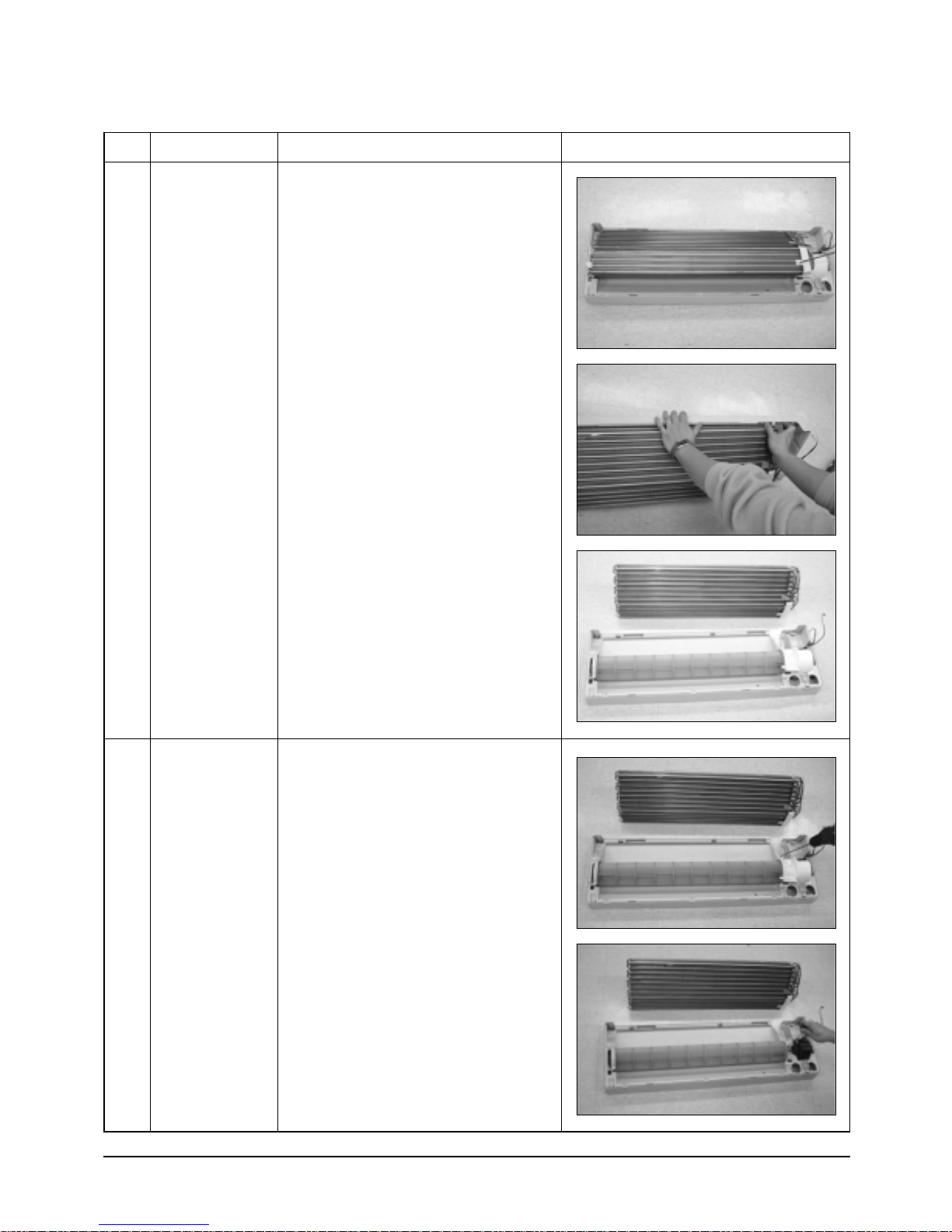

3

Tray Drain

1) Pull Tray Drain out from the Back Body.

25Samsung Electronics

Disassembly and Reassembly

No Parts Procedure Remark

4

Heat Exchanger

1) Loosen 2 fixing earth screws of right side.

2) Detach the Connection Pipe.

3) Detach the Holder Pipe at the rear side.

4) Loosen 3 fixing screws of right and left

side.

5) Detach the Heat Exchanger from the

indoor unit.

5

Fan Motor

&

Cross Fan

1) Loosen 2 fixing screws and detach the

Motor Holder.

2) Loosen 1 fixing screw of Fan Motor.

(with a M3 wrench)

3) Detach the Fan Motor from the Fan.

4) Detach the Fan from the left Holder

Bearing.

Samsung Electronics26

3-2 Outdoor Unit

No Parts Procedure Remark

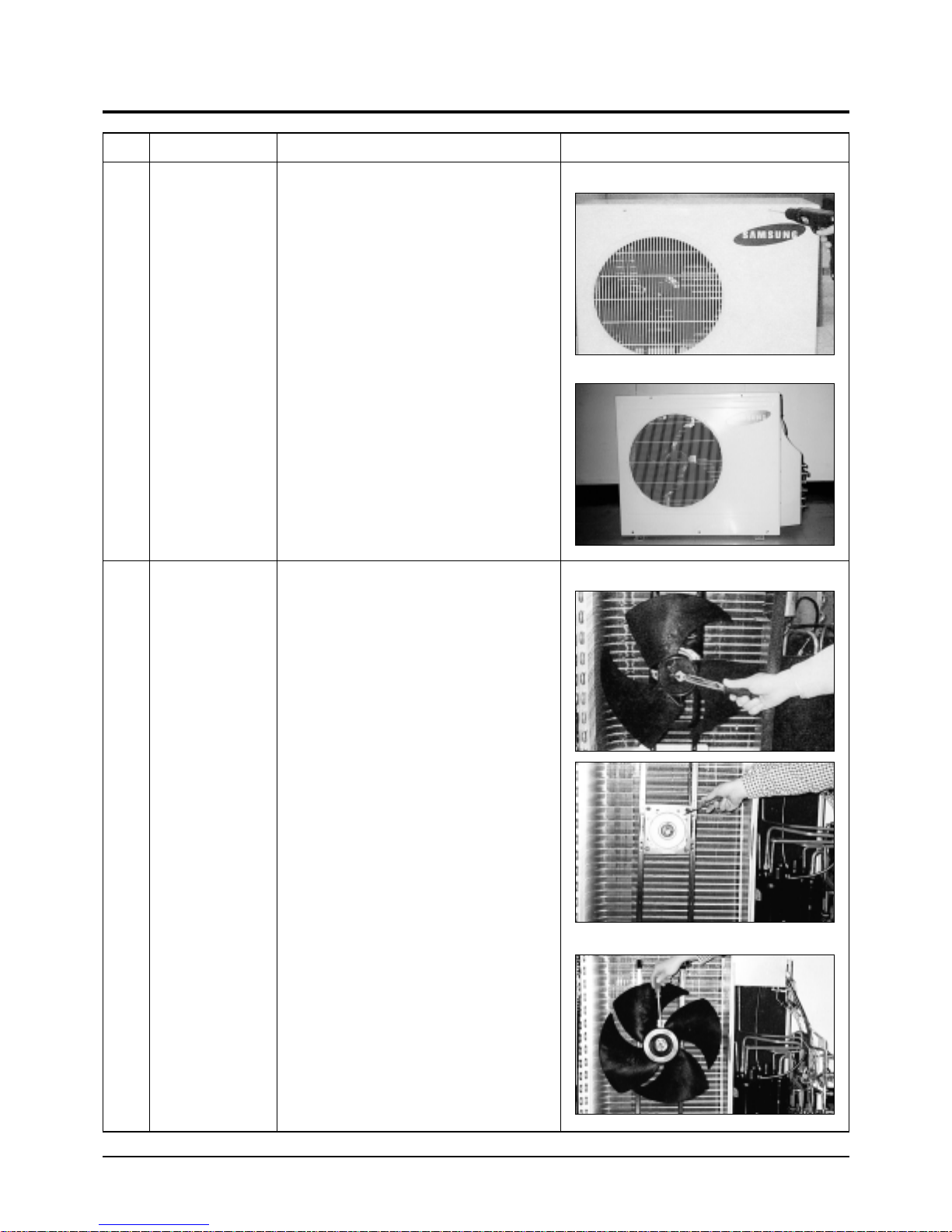

1

2

Cabinet

Fan Motor

&

Propeller Fan

1) Turn off the unit and remove the power

cable.

2) Detach the Top Cover.

3) Detach the Control Box Cover.

4) Unplug the Ass'y Cable.

5) Detach the Cabinet-Side.

6) Detach the Cabinet-Front.

* When you assemble the parts, check if the

each parts and Component Electric Box

are fixed firmly.

1) Detach the Nut Flange.

(Turn to the clockwise)

2) Disassemble the Propeller Fan.

<MH18AP1(P2)X/MH19AP1(P2)X>

<MH24AP1(P2)X/MH26AP1(P2)X>

<MH18AP1(P2)X/MH19AP1(P2)X>

<MH24AP1(P2)X/MH26AP1(P2)X>

27Samsung Electronics

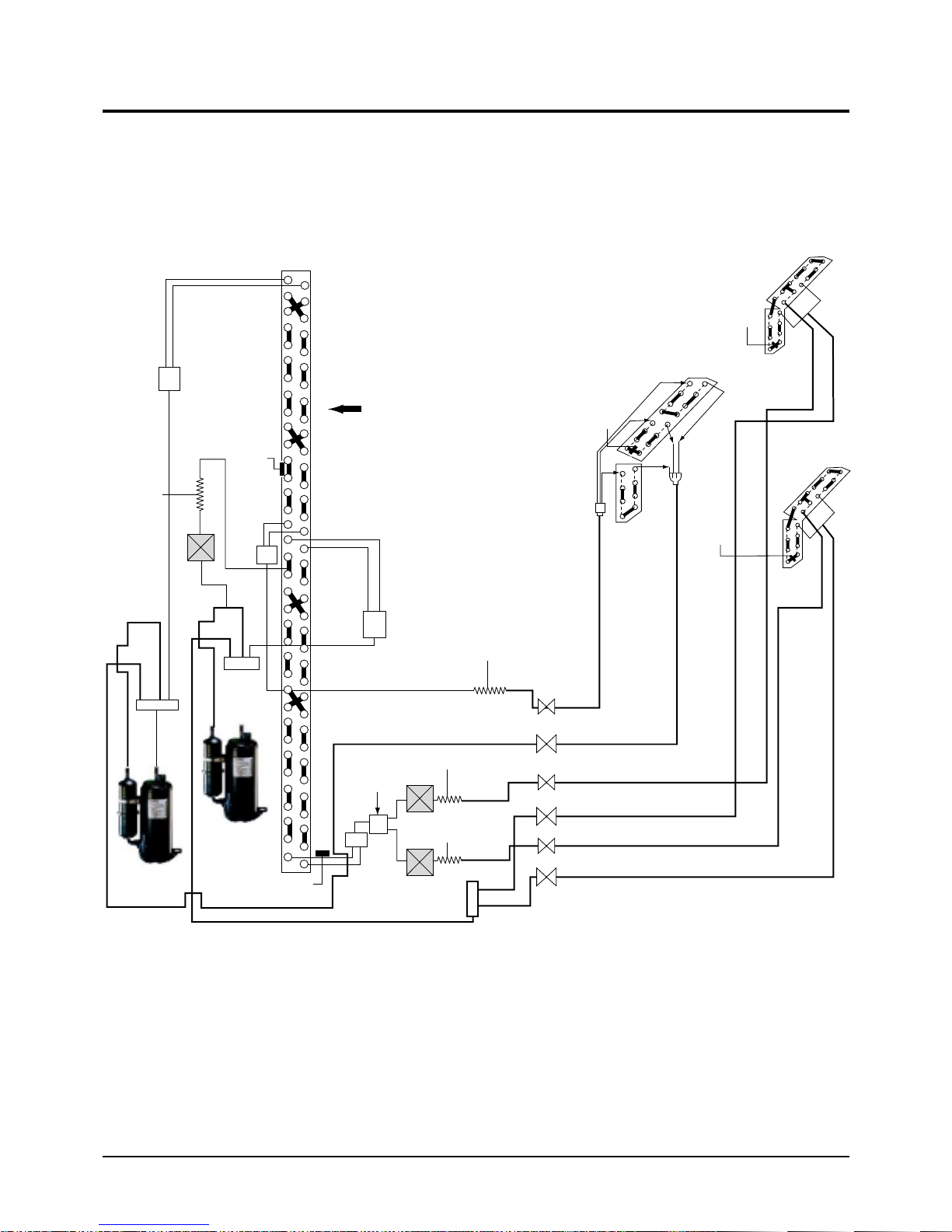

4. Refrigerating Cycle Diagram

3/8"

3/8"

3/8"

3/8"

3/8"

3/8"

1/4" 3/8"

1/4" 3/8"

7.94mm

sensor

Comp-A

A-Room

B-Room

Comp-B

7.94mm

sensor

sensor

ID1.3*650L

sensor

ID1.3*650L

4-1 MH18AP1(P2)X

Samsung Electronics28

4-2 MH19AP1(P2)X

3/8"

3/8"

1/4"

1/4"

1/4"

¿4.76

5/16"

3/8"

3/8"

3/8"

7.94mm

3/8"

1/4" 3/8"

3/8"

sensor

A-Room

B-Room

Comp-B

Comp-A

7.94mm

sensor

sensor

sensor

ID 1.3*800L

ID 1.3*500L

ID1.3*550L

29Samsung Electronics

4-3 MH24AP1(P2)X

3/8"

3/8"

3/8"

7.94mm

B-Room

Comp-B

Comp-A

3/8"

3/8"

3/8"

7.94mm

sensor

sensor

sensor

ID 1.3*550

ID1.3*650

1/4"

3/8"

A-Room

sensor

1/4" 3/8"

Samsung Electronics30

4-4 MH26AP1(P2)X

Comp-A

Comp-B/C

ID1.3*650

ID1.3*500

A-Room

(MH26AP2-12)

B-Room

(MH26AP2-07)

C-Room

(MH26AP2-07)

Distributor

Elec.expansion valve

Elec.expansion valve

1/4"(7.5m)

3/8"(7.5m)

1/4"(7.5m)

3/8"(7.5m)

1/4"(7.5m)

3/8"(7.5m)

ID1.5*700

Air

ID1.3*650

sensor

sensor

sensor

sensor

sensor

31Samsung Electronics

5. Set Up the Model Option

5-1 Setting Option Setup Method

ex) Option No. :

Step 1 : Enter the Option Setup mode.

st

1

Take out the batteries of remote control.

nd

2

Press the temperature button simultaneously and

insert the battery again.

rd

3

Make sure the remocon display shown as .

Step 2 : Enter the Option Setup mode and select your option according to the following procedure.

1

The default value is .

Otherwise, push the button to .

Every time you push the button, the display panel reads or

repeatedly.

2

Push the button to set the display panel to .

3 2

1

4

5 6

Every time you push the button, the display panel reads

. . .

3

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

repeatedly.

repeatedly.

4

Do not touch the button because its default is .

Unless the display panel reads , push the button to .

✳ Setting is not required if you must

a value which has a default.

5

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

6

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

repeatedly.

repeatedly.

Samsung Electronics32

7

9 8

7

10

11 12

Press button, then the default value is .

8

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

9

Do not touch the button because its default is .

Unless the display panel reads , push the button to .

10

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

11

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

Set Up the Model Option

repeatedly.

repeatedly.

repeatedly.

12

✳ Setting is not required if you must

a value which has a default.

Step 3 : Upon completion of the selection, check you made right selections.

Press the Mode Selection key, to set the display part to and check the display part.

The display part shows .

Press the Mode Selection key, to set the display part to and check the display part.

The display part shows .

Step 4 : Pressing the ON/OFF button ( )

When pressing the operation ON/OFF key with the direction of remote controller for unit, the sound ''Ding'' or ''Diriring'' is

heard and the OPERATION ICON( ) lamp of the display is flickering at the same time, then the input of option is completed. (If the diriring sound isn't heard, try again pressing the ON/OFF button.)

Step 5 : Unit operation test-run

First, Remove the battery from the remote controller.

Second, Re-insert the battery into the remote controller.

Third, Press ON/OFF key with the direction of remote controller for set.

• Error Mode

st

If all lamps of indoor unit are flickering, Plug out and plug in again and pressing ON/OFF key to retry.

1

2ndIf the unit is not working properly or all lamps are continuously flickering after setting the option code, see if the correct option code is

set up for it's model.

Push the button to set the display panel to .

Every time you push the button, the display panel reads

. . .

repeatedly.

33Samsung Electronics

Set up the Model Option

■ Table of the option code

MODEL OPTION CODE

MH18AP1(P2)-09

MH19AP1(P2)-07

MH19AP1(P2)-12

MH24AP1(P2)-12

MH26AP1(P2)-07

MH26AP1(P2)-12

024553-106340

023553-10620c

067503-106362

067533-106362

023753-10420c

067553-104351

Samsung Electronics34

6. Troubleshooting

6-1 Items to be checked first

1. The input voltage should be rating voltage ±10% range.

The airconditioner may not operate properly if the voltage is out of this range.

2. Is the link cable linking the indoor unit and the outdoor unit linked properly?

The indoor unit and the outdoor unit shall be linked by 4 cables.

Check the terminals if the indoor unit and outdoor unit are properly linked by the same number of cables.

Otherwise the airconditioner may not operate properly.

3. When a problem occurs due to the contents illustrated in the table below it is a symptom not related to the malfunction of the

airconditioner.

Operation of air conditionerNo

In a COOL operation mode, the compressor does not

1

operate at a room temperature higher than the setting

temperature that the INDOOR FAN should operate.

In a HEAT operation mode, the compressor does not

operate at a room temperature lower than the setting

temperature that indoor fan should operate.

Fan speed setting is not allowed in AUTO( ) or

2

DRY( ) mode.

Compressor stops operation intermittently in

3

DRY( ) mode.

Compressor of the outdoor unit is operating although

4

it is turned off in a HEAT mode.

Timer LED( ) only of the indoor unit lights up and

5

the air conditioner does not operate.

The compressor and indoor fan stop intermittently in

6

HEAT mode.

Explanation

In happens after a delay of 3 minutes when the compressor is

reoperated. The same phenomenon occurs when a power is on.

As a phenomenon that the compressor is reoperated after a

delay of 3 minutes, the indoor fan is adjusted automatically with

reference to a temperature of the air blew

The speed of the indoor fan is set to LL in DRY mode.

Fan speed is 5 steps is selected automatically in AUTO mode.

Compressor operation is controlled automatically in DRY mode

depending on the room temperature and humidity.

When the unit is turned off while de-ice is activated, the

compressor continues operation for up to 10 minutes (maximum)

until the deice is completed.

Timer is being activated and the unit is in ready mode.

The unit operates normally if the timer operation is cancelled.

The compressor and indoor fan stop intermittently if room

temperature exceeds a setting temperature in order to protect

the compressor from overheated air in a HEAT mode.

Indoor fan and outdoor fan stop operation

7

intermittently in a HEAT mode.

The compressor stops intermittently in a

8

COOL mode or DRY mode, and fan speed of the

indoor unit decreases.

The compressor operates in a reverse cycle to remove

exterior ice in a HEAT mode, and indoor fan and outdoor fan

do not operate intermittently for within 20% of the total heater

operation.

The compressor stops intermittently or the fan speed of the

indoor unit decreases to prevent inside/outside air frozen

depending on the inside/outside air temperature.

35Samsung Electronics

6-2 Checking and Testing operations

To complete the installation, perform the following checks and tests to ensure that the air conditioner is operating correctly.

1. Review all the following elements in the installation:

• Installation site strength

• Piping connection tightness to detect any gas leakages

• Connection wiring

• Heat-resistant insulation of the piping

• Drainage

• Earthing wire connection

• Correct operations (follow the steps below)

• Room select switch in the indoor unit

INDOOR UNIT

Room select switch

(A, B, C unit)

ROOM NO

A unit

A unit

B unit

C unit

Room select switch

1(#51) 2(#52)

ON

ON

OFF

OFF

ON

OFF

OFF

ON

2. Apply the power to the outdoor unit.

- Check the fuse (250V~, 5A) : The fuse is opened when the power line (L, N) is short.

Samsung Electronics36

Troubleshooting

TEST OPERATING

C

B

A

S/W-A S/W-B S/W-C

3. Check the connection of PCB communication of outdoor unit.

(Check whether the red LED of outdoor unit PCB is flickering.)

• The communication lamp is flickering after the display of each unit on the outdoor PCB display part. (every one second).

LED is not flickering, if the connection is bad or the room select switch is located in the wrong position.

- LED lamp (red) flickering after display of A(0.5 sec)

- LED lamp (red) flickering after display of B (0.5 sec)

- LED lamp (red) flickering after display of C (0.5 sec)

Note : PCB switch C is used for triple split multi air conditioner.

Result: If all of three units display lamps are flickering, the connection wires and the room option connections are good.

● If the lamp is not flickering, check as follows:

A. Check the display part of indoor unit of each unit (A,B) after outdoor unit PCB switch S/W-A is on.

Check the status of each unit indoor room select switch. (Adjust the select switch suitable to the unit A, B.)

- A unit :

- B unit :

- C unit :

B. Check the communication connection of outdoor unit PCB (Check whether the red LED of outdoor unit PCB is flickering).

The communication lamp is flickering after the display of each unit on the outdoor unit PCB. (every one second)

- LED lamp (red) is flickering after display of A(0.5 sec)

- LED lamp (red) is flickering after display of B (0.5 sec)

- LED lamp (red) is flickering after display of C (0.5 sec)

Result: If all of three units display lamps are flickering, the connection wires and the room option connections are good.

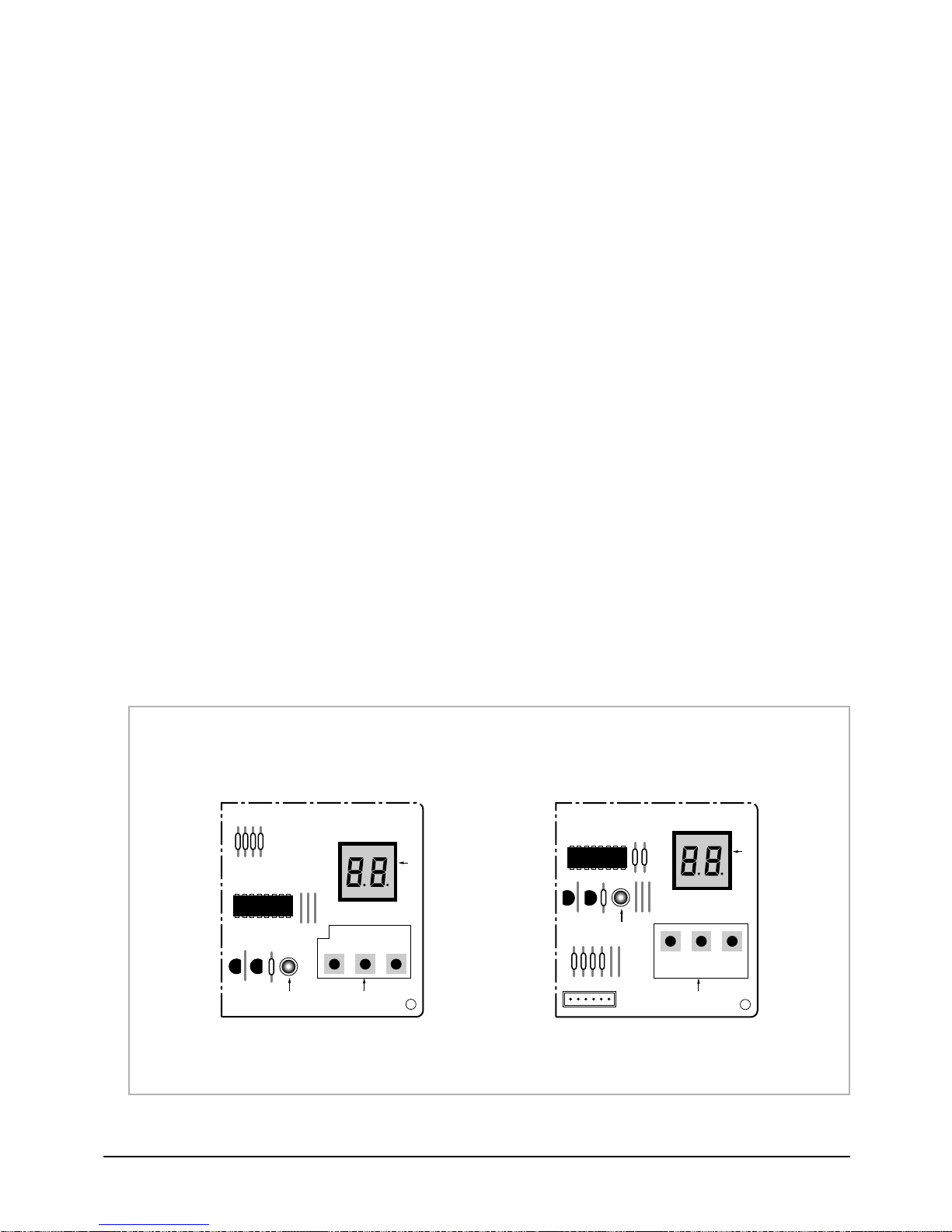

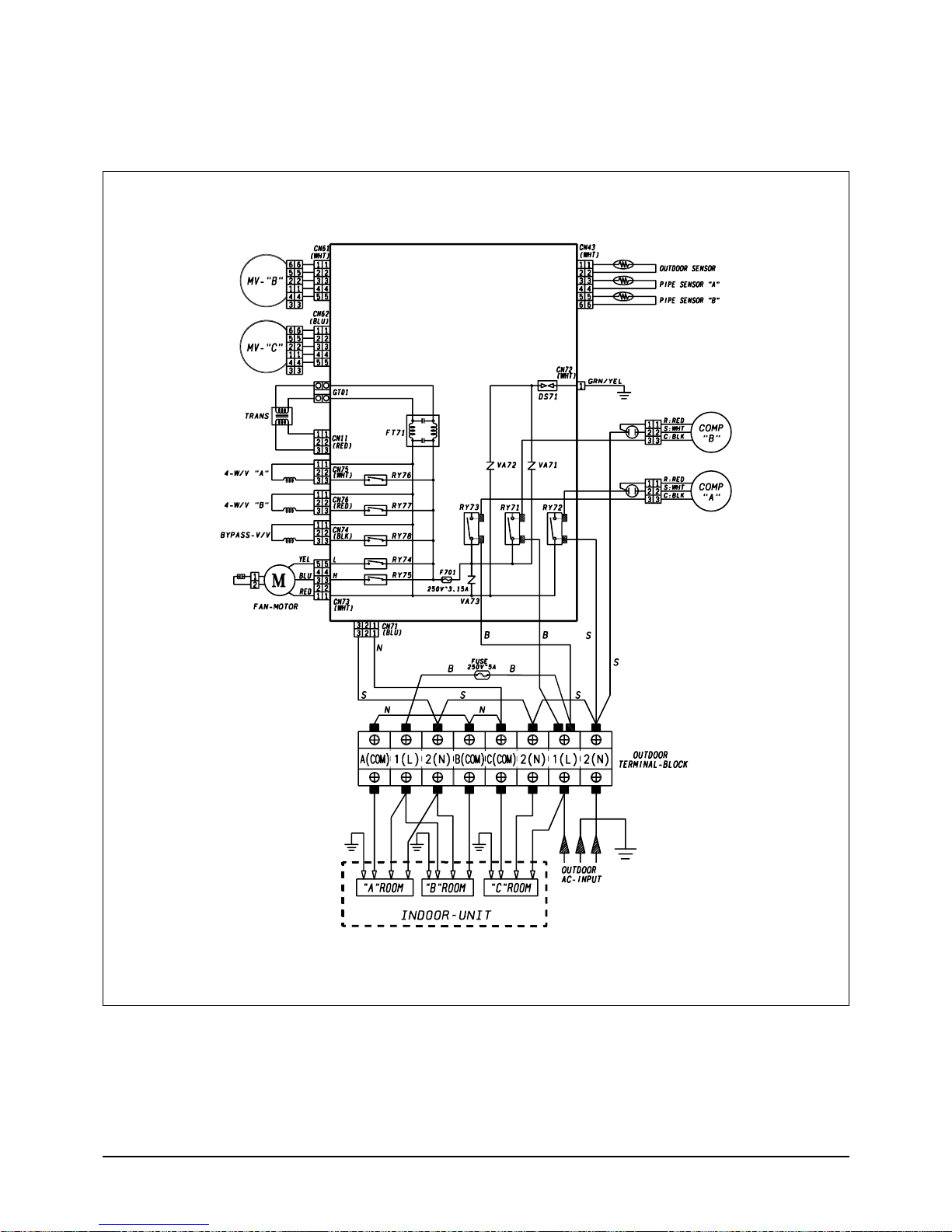

■ MH18–/MH19–/MH24– ■ MH26–

OUTDOOR UNIT

OUTDOOR UNIT

A

TEST OPERATING

CB

A

B

A : PCB display

B : Red LED

C : PCB switch

C

A : PCB display

B : Red LED

C : PCB switch

37Samsung Electronics

Troubleshooting

ABC

The error indicated on the PCB display of outdoor unit

Display

Explanation

Outdoor sensor error (Short/Open)

Outdoor Acond pipe sensor error (Short/Open)

Outdoor B cond pipe sensor error (Short/Open)

Outdoor C cond pipe sensor error (Short/Open)

A unit test operation error

B unit test operation error

C unit test operation error

A unit test communication error

B unit test communication error

C unit test communication error

Remark

Be sure to check after applying the power

to the outdoor unit.

Display when the test operation finishes.

• When the pipe temperature difference of

• indoor unit (pipe temperature 4 minutes before

• - Actual pipe temperature) is less than 5˚C.

Be sure to check during the test operation.

A,B,C unit all communication error

A room test operation OK

B room test operation OK

C room test operation OK

Communication unit number display : Aunit

Communication unit number display : B unit

Communication unit number display : C unit

(In case of triple split multi air conditioner)

High temperature of the Acond

High temperature of the B cond

Display of power application.

Display 4 minutes after the COMP is on.

• Normal operation

Unit A,B and C are changed every one second.

The communication lamp is flickering after

display of each unit.

(possibility to check the communication status)

• During the test operation the unit under test

is on and off every 0.25s.

Samsung Electronics38

The error indicated on the display panel of indoor unit

Troubleshooting

Display

ALL LAMP

is flickering

Explanation

Indoor unit room temperature sensor error

IN sensor of indoor unit heat exchanger error

Indoor unit fan motor

Indoor unit communication error

Indoor unit EEPROM error

Indoor unit EEPROM option error

•Indoor unit B, C cools and heats simultaneously

•(Indoor unit B, C mode must be same)

•Indoor unit B, C mode change simultaneously

Outdoor unit pipe is wrong connected

Outdoor unit sensor error(short/open)

Outdoor unit sensor error(short/open)

Remark

When inputting MICOM over 4.9V and below

0.4V

15 seconds after the fan being operating below

450RPM

Wrong data for 60 seconds

In this case, both indoor unit B and C remocon

off and after 2~3 second remocon on.

The pipes or the cables are wrong connected.

Check the temperature sensor of B

condenser pipe.

Check the temperature sensor of A

condenser pipe.

Outdoor unit sensor error(short/open)

Error in setting indoor unit's address & outdoor unit

communication error

Check the outdoor temperature sensor.

Check the indoor unit's address.

39Samsung Electronics

Troubleshooting

TEST OPERATING

C

B

A

S/W-A S/W-B S/W-C

4. Check the test operation status by pressing the PCB switch S/W-A and S/W-B of outdoor unit.

• Check the operation status by pushing the switch one at time.

• Perform the test operation only for the unit selected last.

• Check the pipe pressure and the other operation status during the test operation.

• Check items when the error occurs during the test operation (each unit)

- Check there is enough refrigerant.

- Check pipe connections.

EXAMPLE

◆ In case of unit A test, push once the PCB switch S/W-A (same for unit B).

- In such a case, the indoor unit of unit Ais operated automatically by the outdoor unit.

- In case the unit Atest stops, push once more the switch S/W-A.

< Operation >

1. Once the test is started, the COMP is on and Good (displayed Gd) or Error (displayed Er) is displayed after 4 minutes .

: Taking difference between the present temperature of indoor heat exchanger and the temperature 4 minutes later, if the temperature

difference is over 5°C, the connection is good or if the temperature difference is below 5°C, the connection is bad.

2. If the result of the test operation is good operation, is possible for 30 minutes max.

If there is an error, the outdoor unit shall be stopped immediately.

If an error occurs, push switch S/W-A or S/W-B once to resume from the error status. Restart is then possible.

3. Once the test operation is completed, push switch S/W-Aor S/W-B to finish the test.

4. Once the test is completed, operate the indoor unit normally.

5. Check the operation is normal. Start up is over.

■ MH18–/MH19–/MH24– ■ MH26–

OUTDOOR UNIT

OUTDOOR UNIT

A

TEST OPERATING

CB

A

B

A : PCB display

B : Red LED

C : PCB switch

C

A : PCB display

B : Red LED

C : PCB switch

Samsung Electronics40

6-3 Fault Diagnosis by Symptom

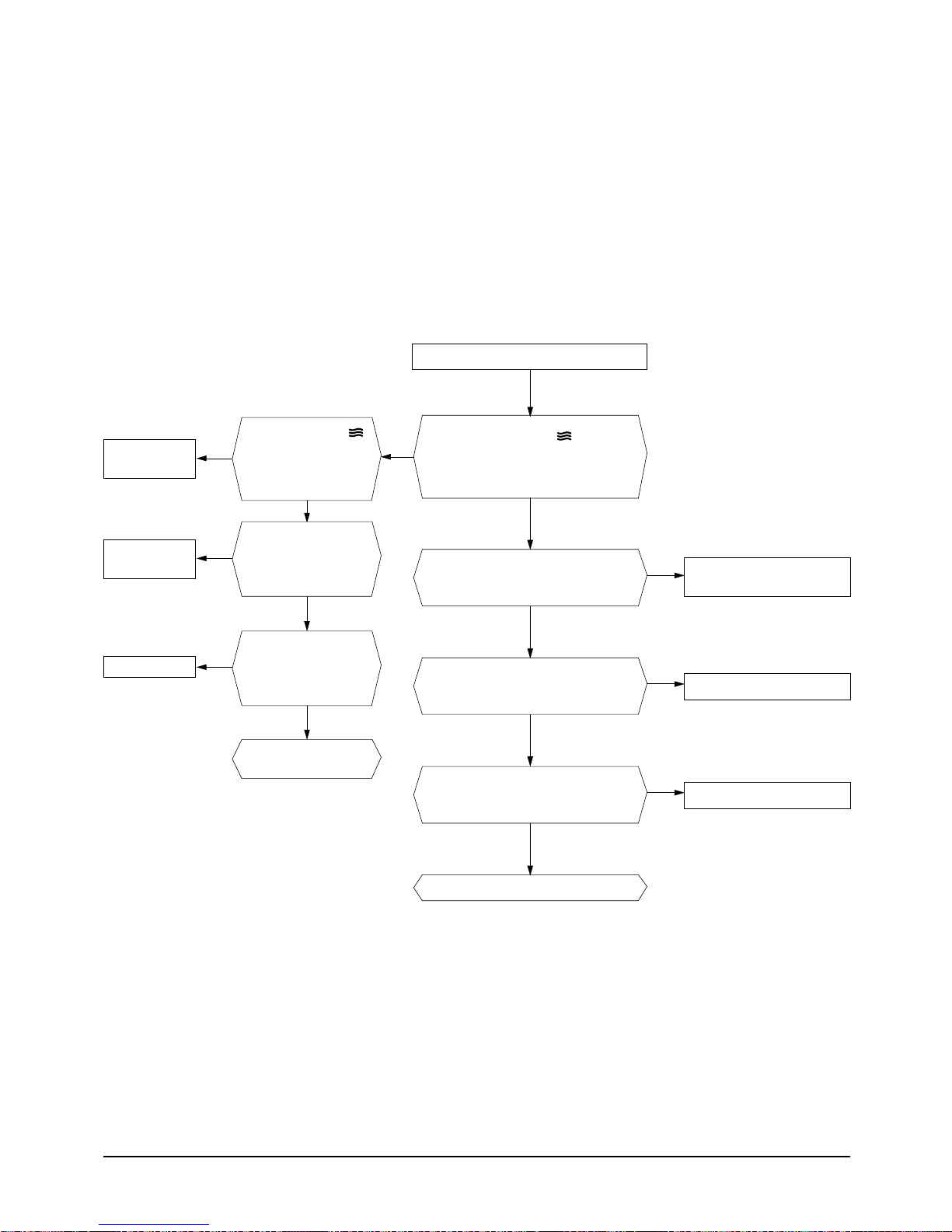

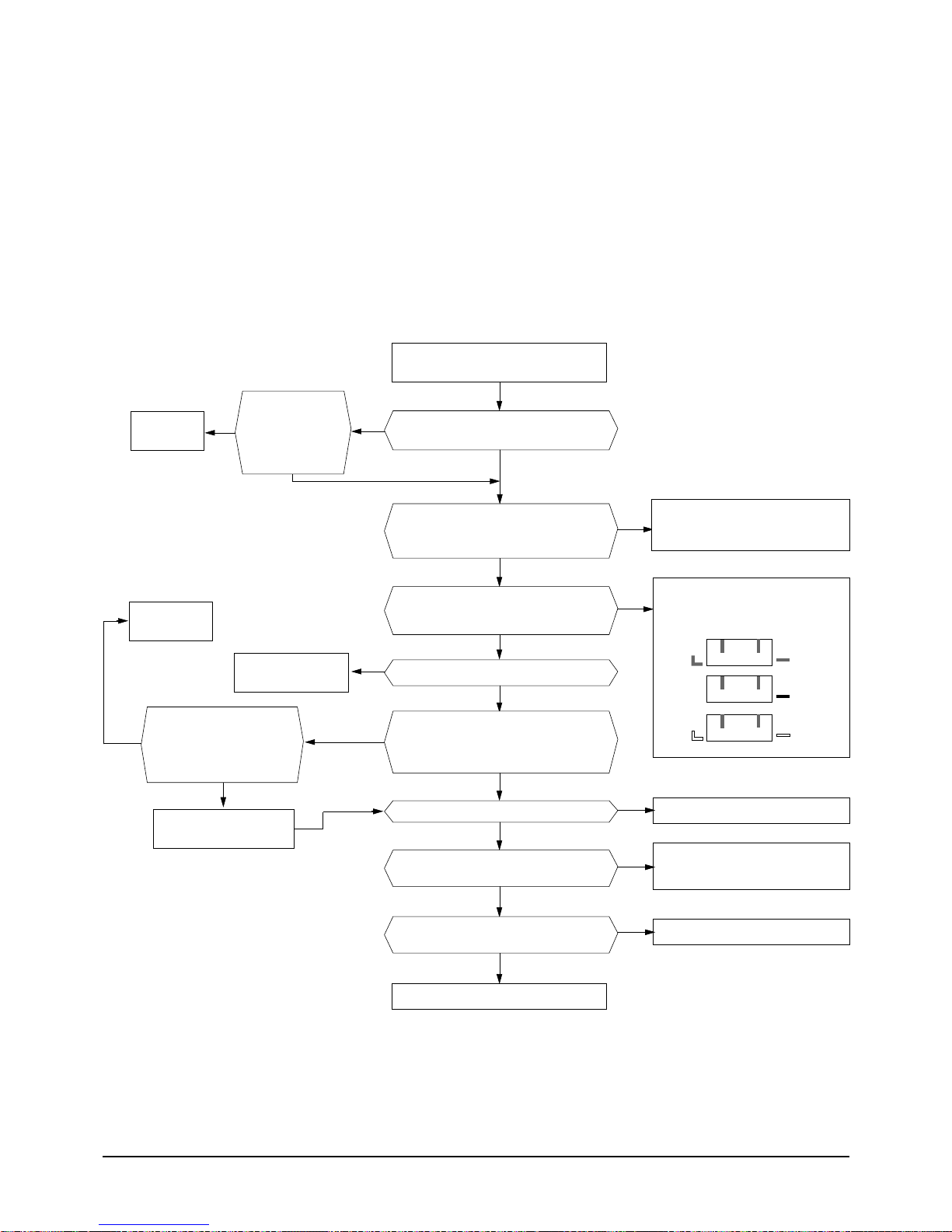

6-3-1 No Power (completely dead)-Initial diagnosis

1. Checklist :

1) Is input voltage normal?

2) Is AC power linked correctly?

3) Is output voltage of DC regulator IC KA7805 (IC02) normal? (4.5VDC-5.5VDC)

2. Troubleshooting procedure

Remove power cord and plug in

again in approx. 5 seconds

Is the operation icon( ) lamp

flickering with the sound of "ting"?

<MH26– ; Doesn't it flicker but come

out the sound of "ting"?>

Does operation start when

run/stop button on the remote controller

No

5VDC Is voltage of #48 (indoor fan)

unit pushed?

Is transmission display of the

remote controller unit blinking?

Is "beep"sound heard from the

main unit?

Is DC voltage of the PCB module

normal?

of the micom normal?

DC5V

10ms

Yes

Replace

PCB display

Is DC voltage of PCB

display normal?

No

Is rating voltage ±10%

range applied to the primary

side (~,~) of the "BD71"

No

• Check linkage between

power cord and

terminal tap

• Check fuse

Is 300V DC appear in

the secondary side (+, -)

of "BD71"

YesNo

Replace

SMPS PARTS

No

No

Yes

No

Yes

Yes

Yes

Yes

No

No

Yes

Check connections

compressor 4-Way

valve, outdoor fan

and indoor fan.

Normal

Refer to remote control

unit fault diagnosis

Replace PCB module.

DC12V

Is voltage at SS71(indoor fan)

Yes

Replace

RY71, RY73,

RY72 and

No

SS71

Replace resonator (X301)

Is operation normal?

Yes

OK

No

No

Is voltage at #16 terminal of the

micom normal?

10ms

Yes

Are voltage at #23 and #24 of the

micom normal?

250ns

Yes

Replace

micom

No

Is output voltage of IC02 normal?

Yes

Check PCB pattern.

Replace main PCB.

Is voltage output terminal of

PC814(PC02) normal?

Yes

OK

Replace IC02

No

Replace

PC814(PC02)

No

41Samsung Electronics

Troubleshooting

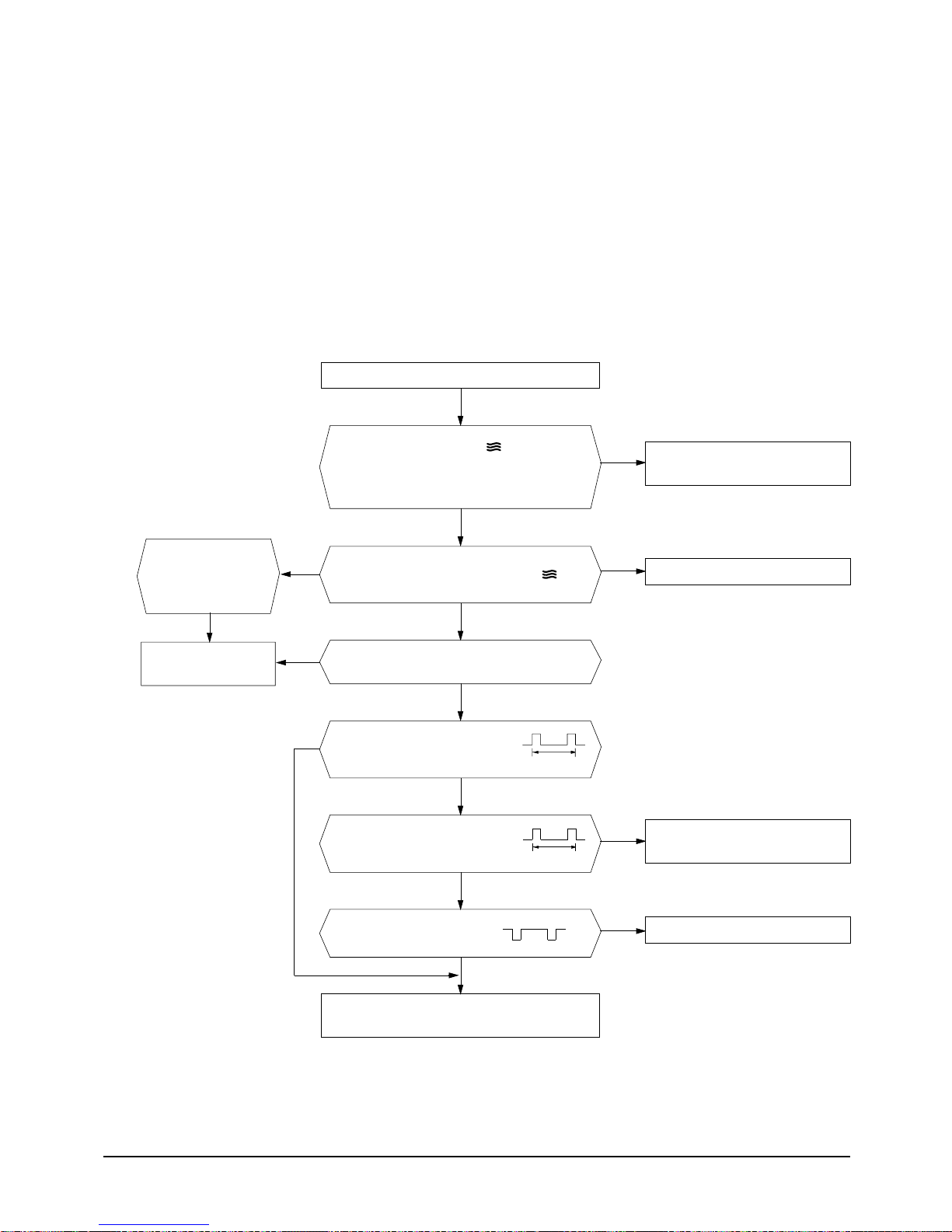

6-3-2 When the power voltage is not available

1. Checklist :

1) Is the power voltage is normal? (The rating voltage ±10% range)

2) Is the power cord is correctly connected and is the contact good?

3) Does the sound "ting" come out?

If it doesn't come out the sound "ting", do inspect and repair in accordance with the following inspection sequence.

2. Troubleshooting procedure

Apply the power

No trouble

(normal)

Check of remote

controller

Normal

Is the operation lamp( )

Yes

No

Yes

of indoor unit on when

the operation /stop button

of remote controller

is pressed?

Is the communication

signal of remote controller

surely sent and received ?

Is there no problem

between the connector of

Ass’y display PCB and the

receiving module?

Replace of

Ass'y display PCB

No

Yes

No

Yes

Is the operation icon( ) lamp

flickering with the sound of "ting"?

<MH26– ; Doesn't it flicker but come out

the sound of "ting"?>

No

Is the outdoor power connected normally?

Yes

Is the fuse (F701, 250V, 3.15A) of PCB open?

No

Is the output voltage of electrostatic voltage

regulator IC (KA7805) DC 4.5V ~ 5.5V?

Yes

No

Check of the installation method

and electrical circuit

Yes

Replace the fuse (250V, 3.15A).

No

KA7805 is out of order - replace

Replace the main PCB of indoor unit

Samsung Electronics42

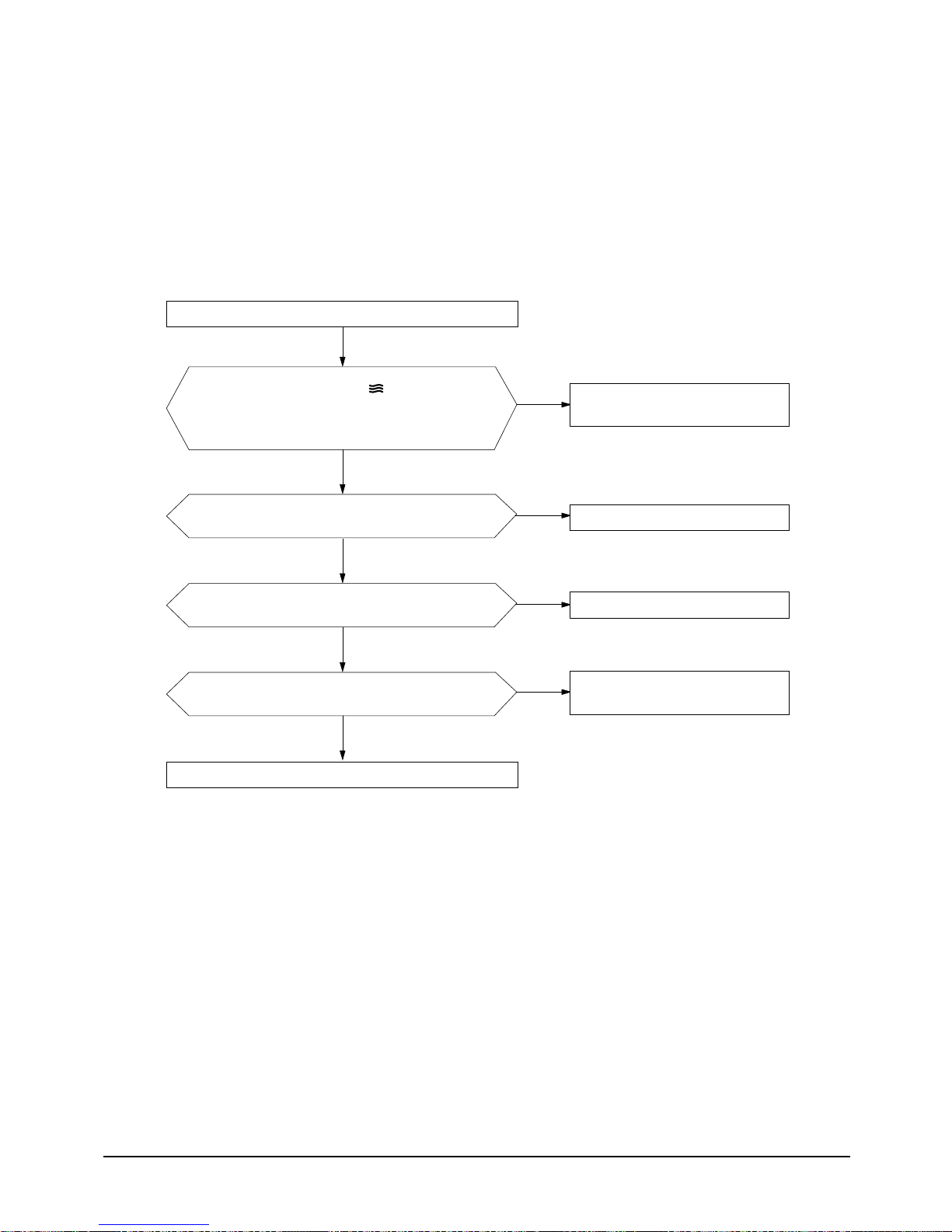

6-3-3 No Power (Outdoor unit)

1. Checklist :

1) Is the power source normal (The rating Voltage ±10% range)?

2) Is the outdoor power connected normally? ((1) of terminal : L, (2) of terminal : N, (3) of terminal : communication)?

3) Check whether the display of outdoor PCB(SEG1) is shown in the order of A- B - C when the power is applied.

If the display (SEG1) is not shown the inspection and repair shall be performed in the sequence of the following:

2. Troubleshooting procedure

Check the commu-

Normal of

outdoor PCB

Replace the

transformer

Measurement of resistance of

No No

power transformer

Are they as follows?

1st side 190 ~ 210Ω

2nd side 0.9 ~ 1.1Ω

Assemble the transformer

in the normal way.

nication of PCB

and whether the

LED 1 is continu-

ously flickering.

No

Replace the fuse

(F701) 250V 3.15A.

Yes

Put the power off and put it on

after 5 seconds.

YesYes

Yes

Is the display of PCB shown in the

sequence of A-B-C?

No

Are the power cord ((1) L, (2) N) and

communication line (3) of outdoor terminal

block connected correctly?

Yes

Is the terminal of PCB terminal (RY71, 72,

73) are assembled in the correct position?

Yes

Is the fuse open? (F701)

No

Insert the primary side of power

transformer in the terminal GT01 and

then is the voltage of secondary side

normal? (AC 15V- AC 25V)

Yes

Is the fuse (F101, 250V 2A) blown out?

No

Check whether the output voltage of IC01

(KA7812) is DC 12V.

Yes

Check whether the output voltage of IC02

(KA7805) is DC 5V.

Yes

Troubleshooting

No

No

Yes

No

No

Reinstall the power cord and

communication line with the reference

of installation manual.

After watching the display of PCB

board, assemble the color and shape

of housing correctly as follows:

BLK

WHT

RED

Replace the fuse F101 (250V 2A).

Check and Replace the rectifying

diode of power side (D101-D104)

and KA7812.

Replace the IC02 (KA7805)

BLK

RED

Replace the outdoor unit Ass'y main PCB.

43Samsung Electronics

Troubleshooting

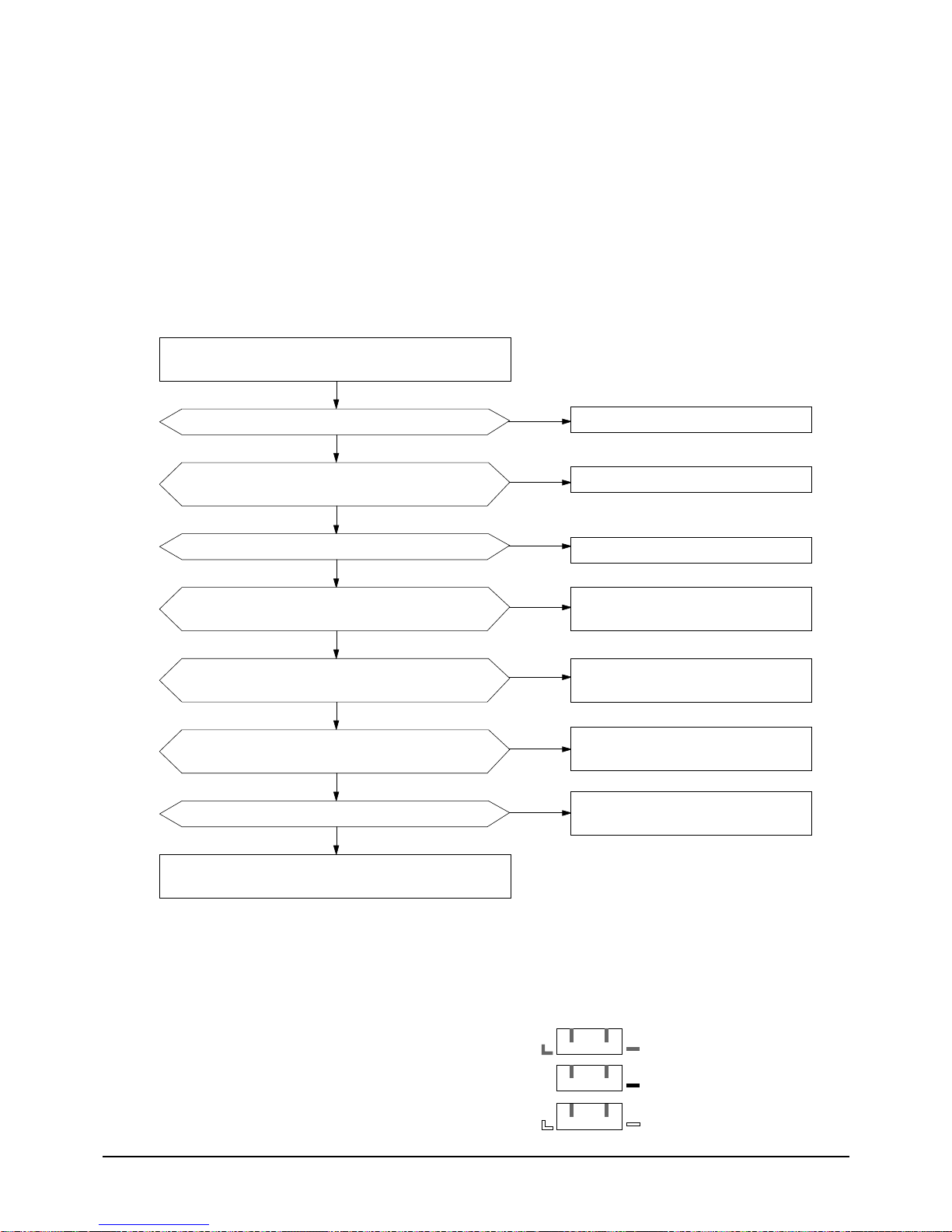

6-3-4 When the fan of indoor unit does not operate

1. Checklist :

1) Is the power voltage normal?

2) Is the connector of indoor fan with the good contact? (CN72)

3) Is the soldering status of running condenser (CR71) with the good contact?

4) Is connector of the Hall IC with the good contact (CN44)?

5) Is the indoor fan rotating when it is under operation mode?

2. Troubleshooting procedure

Put the power off and put it on after 5 seconds.

Yes

Error(Error Code : E3)

occurs after the indoor

unit fan motor is rotating

for 15 seconds?

Yes

Replacement of indoor unit

fan motor.

Yes

Yes

Is the operation icon( ) lamp

flickering with the sound of "ting"?

<MH26– ; Doesn't it flicker but come out

the sound of "ting"?>

Yes

If the operation/stop button of the remote

controller is pressed, is the operation lamp( ) and

then is the indoor fan rotating after 5~6 seconds?

Yes

Is AC 120V and higher shown across the indoor fan

No

Is the type of MICOM (IC04)

pin #48 old type ?

Is the pin #15 of IC07(ULN2003A)

the old type?

connector (CN72) ?

No

Yes

Yes

120Hz

120Hz

No

If the power is not available (indoor unit),

No

No

refer to page 41.

Replace of indoor unit PCB Ass'y.

Replace the IC07(ULN2003A) and

SS71(G3MB202PL or AQG22212)

Is the pin #17 of MICOM the

old type?

Replace the indoor unit PCB Ass'y due to the

Micom defect.

No

Replace Q501(2SC2412K)

Samsung Electronics44

6-3-5 When the outdoor unit fan does not operate

1. Checklist :

1) The outdoor unit fan motor operates only when the operating conditions are satisfied and is selected by the

RY74(LOW) and RY75(HI) to rotate.

2) Is the power voltage normal?

3) Is the contact of outdoor unit fan motor (CN73) good?

4) Is the winding resistance of outdoor unit fan motor 58Ω at Hi side and 143Ω at low side?

5) The outdoor unit fan motor operates with Hi at over 28°C and low at below 26°C during the cooling operation, and

operates with Hi at below 14°C and low at over 15°C during the heating operation.

2. Troubleshooting procedure

Apply the power to the outdoor unit and operate the indoor unit.

Troubleshooting

Is the indoor unit under operating conditions?

Yes

Is it operating in the High speed?

No

Is the voltage shown across the connector (1)↔(3) ((1)↔(5))(the

rating voltage ±10% range)?

No

Is pin #11(12) of IC06 at low? (DC 0.7V)

No

Is pin #48(49) of IC04 (MICOM) at High (DC 5V)?

No

Is the outdoor unit fan motor under the

operating conditions?

No

Normal

No

Yes

Yes

Yes

Yes

Yes

Normal (operation off)

Normal

Check the winding resistance of outdoor unit

fan motor winding resistance → Replace

Contact bad of RY74(Low), RY75(High)

→ Replace

Defect of IC06 output

→ Replace

Defect of IC04(MICOM) -

replace the IC04 or PCB ass’y

✳ Operating specification of the FAN of outdoor unit

(1) When the COMP is under the COMP ON condition during the cooling and heating operation, Hi or LOW operation is selected

according to the temperature condition of outdoor room.

(2) When Aroom and B room are mixed to operate , it is always under low operation.

(3) Perform the comp ON/OFF control in the dry mode.

(4) When it is under the operation of anti-freezing, overload protection, defrost operation, it may be Low, high or Off.

(5) Hi = High speed, Low = Low speed

45Samsung Electronics

Troubleshooting

6-3-6 When the UP/DOWN louver motor does not operate. (Initial Diagnosis)

1. Checklist :

1) Is input voltage normal?

2) Is the UP/DOWN louver motor properly connected with the connector (CN61)?

2. Troubleshooting procedure

Remove power cord and plug in again in approx. 5 seconds.

Is the operation icon( ) lamp

flickering with the sound of "ting"?

<MH26– ; Doesn't it flicker but come out

the sound of "ting"?>

Yes

Does operation start when swing button of the

remote control unit pushed?

No

Voltage at pin #26~#29 of micom (IC04) change?

(Squarewave)

Yes

Voltage at pin #10~#12 of IC06, #16 of IC07(ULN2003A)

change? (Squarewave)

Yes

UP/DOWN louver motor is faulty.

No

Check as in the procedure "No Power parts".

Yes

No

No

Refer to page 41.

Normal

Micom (IC04) is faulty.

Driver IC06(ULN2003A) or

IC07(ULN2003A) is faulty.

Samsung Electronics46

6-3-7 If Operation by remote control unit is impossible. (Initial Diagnosis)

1. Troubleshooting procedure

Remove power cord and plug in again in approx. 5 seconds.

Troubleshooting

Is the operation icon( ) lamp

flickering with the sound of "ting"?

<MH26– ; Doesn't it flicker but come out

the sound of "ting"?>

Yes

" " sound heard from the indoor unit when ON/OFF button

on the remote control unit pushed?

No

Voltage of battery less than 2.5V (Remote Control Unit)?

No

LCD display status of REMOCON normal?

Yes

Transmission display lamp ( ) blinking when

ON/OFF button on the remote control unit pushed?

Yes

No

Check as in the procedure "No Power parts".

Yes

Yes

No

No

Refer to page 41.

Normal

Replace battery.

LCD is faulty.

Replace button.

Voltage at pin #30 of Remocon Micom change?

Voltage at collector of Q601 or Q602 change?

Voltage at pin #15 of micom (IC04) change (INDOOR UNIT)?

Micom (IC04) is faulty.

Yes

Yes

Yes

No

No

Q601(C4375Y) or Q602(C1623Y) is faulty.

No

Micom is faulty.

IR LED(CL-1L5EU) is faulty.

Receiver module is faulty.

47Samsung Electronics

Troubleshooting

6-3-8 When the 4-Way valve (A,B) is not operating

1. Checklist :

1) Are the 4-Way valve A and B under the operating conditions?

When the COMP A (4-Way valve A) and COMP B (4-Way valve B) are on during the heating operating)

2) Is the power voltage normal?

3) Is the connecting of 4-Way valve A (CN75) and B (CN76) good?

2. Troubleshooting procedure

Put off the outdoor unit power and put it on again after 5 seconds.

Select the heating operation of A(B) room by the remote controller.

Has 3 minutes passed after selection of A(B) room heating?

Yes

Is the 4-Way valve A(B) on?

No

Is the voltage shown across the 4-Way valve A(B) connector

(CN75, CN76) ?

No

Is the pin #47(46) of IC04 (MICOM) at high (DC 5V) ?

No

Is the 4-Way valve A (B) under operating conditions?

No

Normal

No

Yes

Yes

Yes

Yes

Keep 4-Way valve off.

Normal

Defect of RY76 (RY77) contact and coil

→ Replace the Relay

Defect of IC06 (IC07) output

→ Replace

Defect of IC04(MICOM) -

replace the IC04 or PCB ass’y

✳ 4-Way valve operating conditions

(1) During the defrost control, put the 4-Way valve A(B) off.

(2) During the heating operation put the 4-Way valve A(B) on.

(3) The changeover of heating to cooling : put the 4-Way valve off immediately (in case of B and C room).

(4) The changeover of cooling to heating : it is on after 170 seconds delay.

Samsung Electronics48

6-3-9 When the compressor does not operate

1. Checklist :

1) Is the COMP A under the operating conditions? (cooling operating of A, B(C) room)

2) Is the power voltage normal? (the rating voltage ±10% range)

3) Are the connector connection of COMPA(RY72, 73) and B(RY71) good?

4) The COMPA(B) is operated on and off in accordance with the operating conditions of indoor unit of A(B, C) room.

2. Troubleshooting procedure

Troubleshooting

Apply the outdoor power and operate the indoor unit A(B.,C)

Is the comp Aunder the operating condition?

Has 3 minutes passed COMP A(B) after the power initial and

Is the voltage (the rating voltage ±10% range) shown across the

Is the voltage of pin #50, 51(52) of IC04 (micom) at

Is comp A(B) under the operating condition?

in the cooling mode.

Yes

COMP on/off

Yes

Is comp A(B) on?

No

*Refer to the power measuring terminal

terminal of Comp A(B) power applied?

No

Is the voltage of pin #14, 13(15) at low

(DC 0.7V)?

No

high (DC 5V)?

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Normal (comp A(B) off)

Keep Comp A(B) off

Normal

Defect of comp A(B) and running condenser

→ Replace

Defect of RY72, 73 (Comp B) and

RY71(comp A) contact and coil → Replace

Defect of IC06 output

→ Replace

Defect of IC04 (micom)

→ Replace

Normal

(comp A (B) off)

✳ Comp A (B) operating conditions

(1) Comp A: Comp on /off control in accordance with the A room during the heating and cooling indoor unit operation

(2) Comp B : Comp on /off control in accordance with the B(C) room during the heating and cooling indoor unit operation

✳ Comp A(B) power measuring terminal

(1) Comp Ameasuring ; RY73 (4) ↔ RY72 (4)

(2) Comp B measuring ; RY71 (4) ↔ RY72 (4)

(3) Power input ; RY72 (3) ↔ RY73(3)

BLK

RED

(3)

(3)

(3)

RY73

RY71

RY72

(4)

(4)

(4)

BLK

WHT

RED

49Samsung Electronics

6-4 PCB Inspection

6-4-1 Cautions for Part Replacement

1. The human body carries much static electricity. Before

touching a part for repair, replacement or the similar

purpose, be sure to touch a grounded metallic portion by

hand to let the static electricity go through the metallic

portion to the earth.

Especially when handling any micro computer or IC,

carefully remove such static electricity before touching

them.

2. When repairing any part on a work bench, be sure to

place an insulative sheet on the bench and always keep

the sheet surface neat without any metal fragments.

If any such fragment touches a part, a secondary trouble

will possibly be caused in the part.

3. Before replacing any parts, be sure to turn off the power

supply. If such replacement is done with the power supply

kept on, an electric shock, short circuit or destruction of a

part may result.

4. During replacement or repair of a part, carefully handle it

: The printed circuit board has fine lead wires (jumper

wires) and glass-made parts (diode) on its substrate.

So if a circuit board is roughly handled, such

lead wires and parts will be easily broken or damaged by

bending or shock.

5. When soldering the lead wires of any new part, be sure

to polish them using an emery paper or the like before

soldering them.

Since the lead wires of any new part are covered with an

oxide film, solder cannot adhere to the lead wires if not

polished.

6. When soldering any part, care should be exercised not to

apply any high-wattage soldering iron to the part for a

long time. Some parts are of so low a heat resistance

that they may be broken or have the properties changed

if a soldering iron is so applied (Otherwise, the pattern

may possibly be separated and raised).

7. The heat of the soldering iron should be transferred to

the entire object to be soldered. If the solder pieces are

not well fused due to insufficient transfer of the heat from

the soldering iron, no satisfactory electrical continuity can

be assured even if the soldered objects appear well connected to each other.

8. The solder used should be limited to a minimum.

If excessive solder is used, it will cause inter-pattern

contact, which may cause malfunction of the circuit.

6-4-2 Procedure

The parts should be replaced in the following procedure.

Check for any faulty part.

Detach the faulty part.

Replace it with a new part.

Check the operation of the new part.

The repair is completed.

Samsung Electronics50

6-4-3 Detailed Inspection Procedure

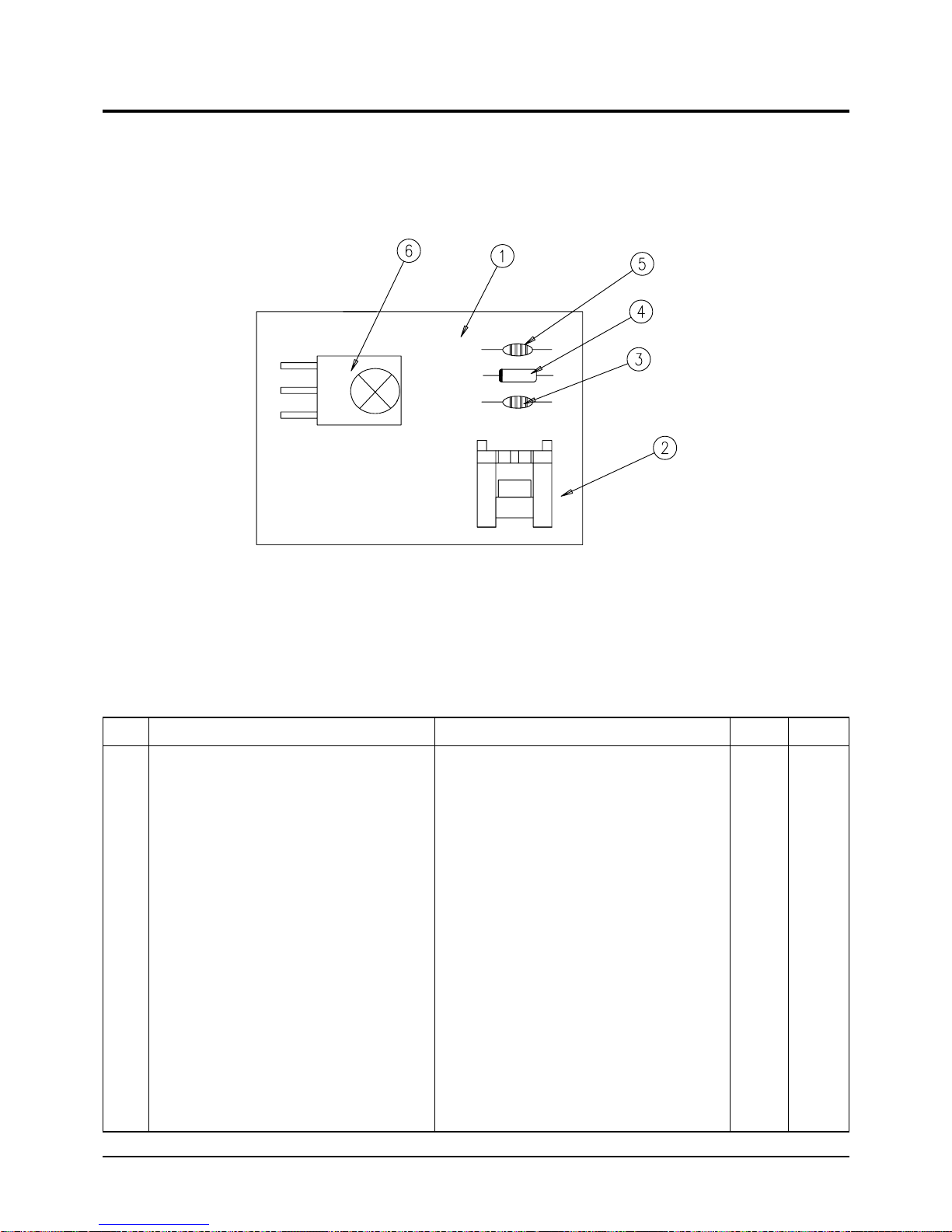

No Procedure Inspection Method Cause

Troubleshooting

1

Pull out the power plug

from the AC terminal and

confirm the fuse on the

PCB assembly.

Turn the power on.

2

If lamp blinks trouble is

not related to the items

1 through 4 on the right.

Set TURBO operating

3

mode when RMC switch

pushed after a delay of

3 minutes

(A-unit and B-unit)

1) Is the broken?

Voltage check

1) AC voltage at both end of transformer Primary?

the rating voltage ±10% range

2) AC voltage at both end of transformer secondary?

14~18Vac

3) DC voltage at OUT and GND of IC01

(KA7812)? 12VDC

4) DC voltage at OUT and GND of IC02? 5VDC

5) DC voltage at Q201 Base and GND change?

5) squarewave

Voltage check

1) Voltage of relay (RY71, 72, 73) coil Voltage at

pin #13, 14, 15 of IC07 : 12VDC

2) Voltage at RY72 No # and RY71 No #,

RY72 No # and RY73 No #, the rating voltage

±10% range

• Voltage over

• Indoor unit fan motor short-circuit.

• Irregular power code or power fuse,

• Transformer is faulty.

• Power circuit is faulty.

• Power circuit is faulty.

• Q201 is faulty.

• D101~D104 (IN4007)

• Relay(RY71) coil is open.

• IC6(KID65003A) is faulty.

• Relay contactor is faulty or Relay is faulty

or poor wiring.

Set operating mode when

4

RMC switch pushed.

1. TURBO mode

Set operating mode

5

when RMC switch

pushed.

1. [FAN] mode

2. Fan speed [Hi]

3. Continuously operation

1) Compressor does not operate.

1) Voltage at # % both ends of CN72 :

above 180V~

2) Indoor unit fan motor does not operate.

• Temperature of Heat exchange is lower.

• PCB is faulty.

• Room sensor or Heat exchanger

temperature sensor is faulty

• Indoor unit fan motor is faulty.

• Poor connection of indoor fan motor and

connector of RPM sensing (CN44)

51Samsung Electronics

4

6

15-1

15-3

15-2

15-5

15-4

15-6

2

11

5

1

1-1-2

1-1-3

1-1-4

1-1-5

1-1-6

15

1-4

1-3

1-2

1-1-1

1-1

3

3-1

7

10

7-2

7-3

7-1

8

9

13

14

12

7. Exploded Views and Parts List

7-1 Indoor Unit

You can search for the updated part code

number through the ITSELF.

URL : http://itself.sec.samsung.co.kr

Samsung Electronics52

■

Parts List

No. Code No. Description Specification

1 DB92-00558A ASS'Y PANEL FRONT TOTAL ASS'Y 1 -

DB92-00561A ASS'Y PANEL FRONT TOTAL ASS'Y - 1

1-1 DB92-00557A ASS'Y PANEL FRONT SUB P ASS'Y 1 -

DB92-00560A ASS'Y PANEL FRONT SUB P ASS'Y - 1

1-1-1 DB92-00556A ASS'Y PANEL FRONT ASS'Y 1 -

DB92-00559A ASS'Y PANEL FRONT ASS'Y - 1

1-1-2 DB31-00166B MOTOR STEP - 1 1

1-1-3 DB61-01123A HOLDER-MOTOR DC HIPS 1 -

DB61-01114A HOLDER-MOTOR DC HIPS - 1

1-1-4 DB61-01132A HINGE GRILLE HIPS 1 -

DB61-01115A HINGE GRILLE HIPS - 1

1-1-5 DB61-01133A GUIDE LINK HIPS 1 -

DB61-01116A GUIDE LINK HIPS - 1

1-1-6 DB66-00365A LINK MOTOR ABS 1 -

DB66-00364A LINK MOTOR ABS - 1

1-2 DB64-00655A GRILLE UP ABS 1 -

DB64-00640A GRILLE UP ABS - 1

1-3 DB63-00590B FILTER PRE LF PP 1 -

DB63-00585B FILTER PRE LF PP - 1

1-4 DB63-00591B FILTER PRE RH PP 1 -

DB63-00586B FILTER PRE RH PP - 1

2 DB92-00538A ASS'Y GRILLE LOW ASS'Y 1 -

DB92-00540A ASS'Y GRILLE LOW ASS'Y - 1

3 DB96-02145A ASS'Y EVAP TOTAL ASS'Y 1 -

DB96-03243A ASS'Y EVAP TOTAL ASS'Y - 1

3-1 DB96-02146A ASS'Y EVAP ASS'Y 1 -

DB96-02091B ASS'Y EVAP ASS'Y - 1

4 DB95-00367E ASS'Y FILTER BIO ASS'Y 1 1

5 DB63-00588A COVER TERMINAL HIPS 1 -

DB63-00581A COVER TERMINAL HIPS - 1

6 DB93-02531P ASS'Y REMOCON ASS'Y 1 1

7 DB94-00486A ASS'Y BACK BODY SUB ASS'Y 1 -

DB94-00488A ASS'Y BACK BODY SUB ASS'Y - 1

7-1 DB61-01119A BODY BACK HIPS 1 -

DB94-00488A BODY BACK HIPS - 1

7-2 DB63-00580A COVER-IONIZER HIPS 1 1

7-3 DB94-00258A ASS'Y BEARING ASS'Y 1 1

8 DB94-00040F ASS'Y CROSS FAN ASS'Y 1 -

DB94-00040R ASS'Y CROSS FAN ASS'Y - 1

9 DB31-00152A MOTOR FAN IN - 1 -

DB31-00152B MOTOR FAN IN - - 1

10 DB61-01120A HOLDER-MOTOR PP 1 -

DB61-01099A HOLDER-MOTOR PP - 1

11 DB67-60030A SPRING-SENSOR STS301 1 1

12 DB70-00288A PLATE HANGER SGCC-M 1 -

DB70-00276A PLATE HANGER SGCC-M - 1

13 DB93-02567A ASS'Y CONTROL IN ASS'Y 1 -

DB93-02568A ASS'Y CONTROL IN ASS'Y - 1

DB93-02567B ASS'Y CONTROL IN ASS'Y - -

DB93-02568B ASS'Y CONTROL IN ASS'Y - -

14 DB61-01121A HOLDER-PIPE HIPS 1 -

DB61-01100A HOLDER-PIPE HIPS - 1

15 DB94-00465A ASS'Y TRAY DRAIN ASS'Y 1 -

DB94-00468A ASS'Y TRAY DRAIN ASS'Y - 1

15-1 DB63-00592A TRAY DRAIN HIPS 1 -

DB63-00587A TRAY DRAIN HIPS - 1

15-2 DB94-00062E ASS'Y DRAIN HOSE ASS'Y 1 1

15-3 DB61-01125A BLADE-H HIPS 1 -

DB61-01103A BLADE-H HIPS - 1

15-4 DB61-01126A BLADE-V PP 1 -

DB61-01104A BLADE-V PP - 1

15-5 DB95-20138A ASS'Y MOTOR STEPPING ASS'Y 1 1

15-6 DB63-00635A GUARD-SAFETY WIRE STS27 1 -

DB63-00634A GUARD-SAFETY WIRE STS28 - 1

MH18AP1(P2)-09

MH19AP1(P2)-07

MH19AP1(P2)-12

MH24AP1(P2)-12

Exploded Views and Parts List

Q'TY

MH26AP1(P2)-07 MH26AP1(P2)-12

1

-

1

-

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

-

-

1

1

1

1

1

1

1

1

1

-

-

1

-

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

-

-

1

1

1

1

1

1

1

1

1

53Samsung Electronics

7-2 Outdoor Unit

1

7(7-1)

9

14

4

5

3

12

7-2

7-3

13

8(8-1~8-7)

7-4

7-5

6

2

10

11(11-1~11-5)

■ MH18AP1(P2)X/MH19AP1(P2)X

Samsung Electronics54

■

Parts List

Exploded Views and Parts List

No. Code No. Description Specification

1 DB90-00734A ASS'Y CABI FRONT ASS'Y 1 1

2 DB67-50063A FAN-PROPELLER AS+G/F20%,D405 1 1

3 DB31-00001B MOTOR-FAN IC-9630SLJ5A 1 1

4 DB61-20008C BASE-MOTOR SGCC-M,T1.2 1 1

5 DB90-40176B ASS'Y-COVER CONTROL ASS'Y 1 1

6 DB90-00733A ASS'Y BASE OUT ASS'Y 1 -

DB90-00733B ASS'Y BASE OUT ASS'Y - 1

7 DB99-00422A ASS'Y VALVE ASS'Y 1 -

DB99-00424A ASS'Y VALVE ASS'Y - 1

7-1 DB61-00889A BRACKET-VALVE SECC-P,T1.6 1 1

7-2 DB96-03154A ASS'Y TUBE CAPILLARY-A ASS'Y 1 -

DB96-03235A ASS'Y TUBE CAPILLARY-A ASS'Y - 1

7-3 DB96-03155A ASS'Y TUBE CAPILLARY-B ASS'Y 1 -

DB99-00427A ASS'Y VALVE CHECK-B ASS'Y - 1

7-4 DB99-00408A ASS'Y VALVE 4WAY-A ASS'Y 1 -

DB99-00425A ASS'Y VALVE 4WAY-A ASS'Y - 1

7-5 DB99-00409A ASS'Y VALVE 4WAY-B ASS'Y 1 -

DB99-00426A ASS'Y VALVE 4WAY-B ASS'Y - 1

8 DB93-02609A ASS'Y CONTROL OUT ASS'Y 1 -

DB93-02610A ASS'Y CONTROL OUT ASS'Y - 1

8-1 DB61-00891A CASE CONTROL OUT SGCC-M,T0.8 1 1

8-2 DB61-00585A CASE PCB OUT ABS,T2.5 1 1

8-3 2501-001237 C-OIL 35µF,450V 2 1

8-4 2501-001238 C-OIL 30µF,450V - 1

8-5 DB65-40072A TERMINAL-BLOCK 8P 1 1

8-6 2301-001370 C-FILM 2.5µF,450VAC 1 1

8-7 DB93-02252D ASS'Y PCB MAIN ASS'Y 1 1

9 DB94-00180A ASS'Y PARTITION ASS'Y 1 1

10 DB90-00742A ASS'Y CABI-UPPER ASS'Y 1 1

11 G4A097JU1EP ROTARY COMPRESSOR G4A097JU1EP 2 -

G4A080JU1EP ROTARY COMPRESSOR G4A080JU1EP - 1

G8C124JU1EL ROTARY COMPRESSOR G8C124JU1EL - 1