Samsung MAX-870, MAX-880 Schematic

3 CD CHANGER

MINI MINI COMPONENT

MAX-870/880

SERVICE

Manual

3CD CHANGER MINI COMPONENT CONTENTS

1. Precautions

2. Specifications

3. Disassembly and Reassembly

4. Alignment and Adjustments

5. Special Circuit Descriptions

6. Troubleshooting

7. Exploded Views and Parts List

8. Electrical Parts List

9. Block Diagrams

10. PCB Diagrams

11. Wiring Diagram

12. Schematic Diagrams

ELECTRONICS

© Samsung Electronics Co.,Ltd. Jan. 1998

Printed in Korea

Code no. AH68-20177A

1. Precautions

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential hazards

such as electrical shock and X-rays.

Samsung Electronics 1-1

1-1 Safety Precautions

1. Be sure that all of the built-in protective

devices are replaced.

2. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including control knobs and

compartment covers.

3. Make sure that there are no cabinet

openings through which people-particularly children--might insert fingers

and contact dangerous voltages. Such

openings include the spacing between the

picture tube and the cabinet mask,

excessively wide cabinet ventilation slots,

and improperly fitted back covers.

4. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of the unit. Example: Do

not add auxiliary audio or video connectors. Such alterations might create a safety

hazard. Also, any design changes or additions will void the manufacturer's warranty.

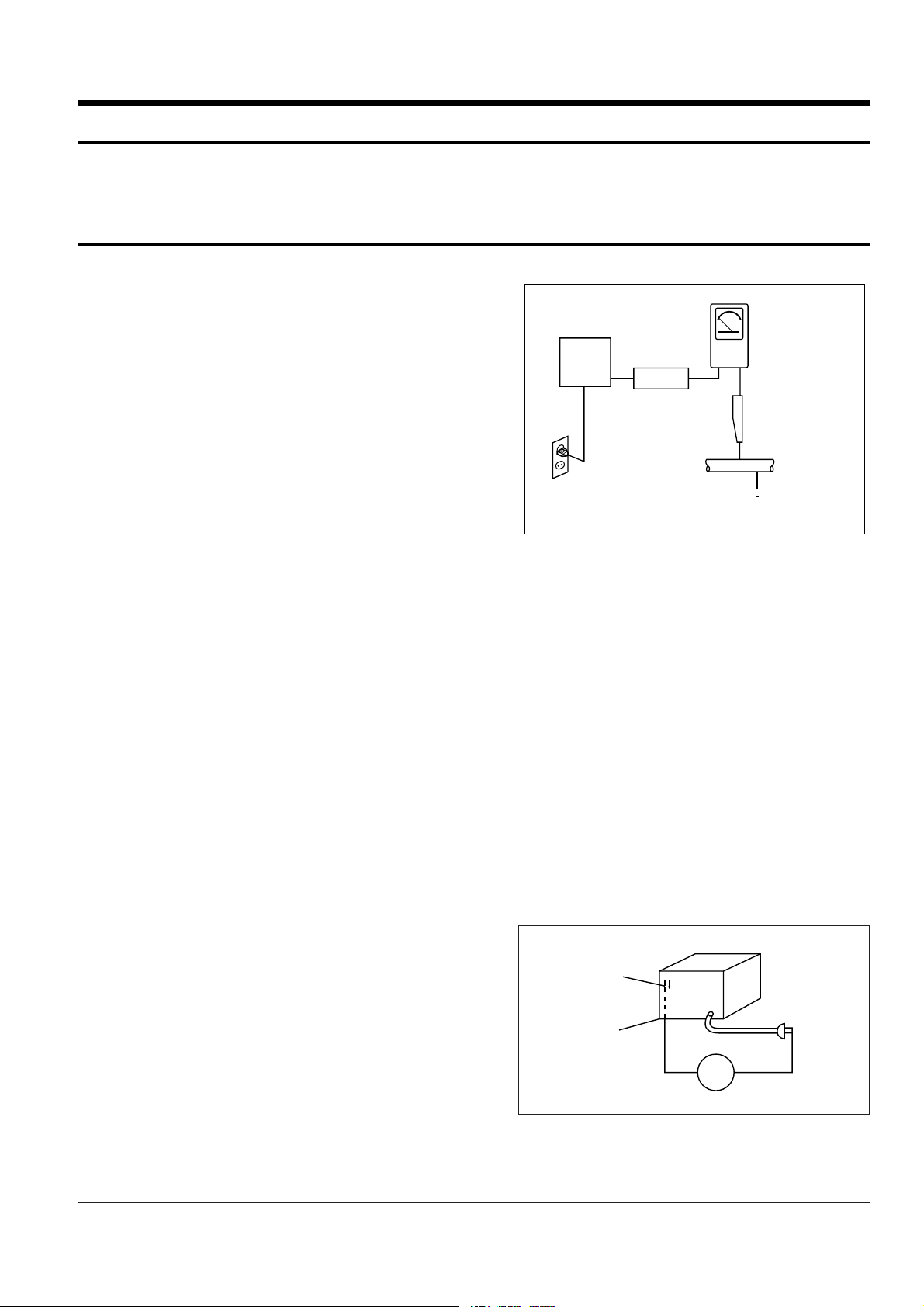

5. Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANSI C101.1, Leakage Current for

Appliances), and Underwriters Laboratories

(UL Publication UL1410, 59.7).

With the unit completely reassembled, plug

the AC line cord directly into a 120V AC

outlet. With the unit's AC switch first in

the ON position and then OFF, measure the

current between a known earth ground

(metal water pipe, etc.) and all exposed

metal parts. Examples: Handle brackets,

metal cabinets, screwheads and control

shafts. The current measured should not

exceed 0.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat.

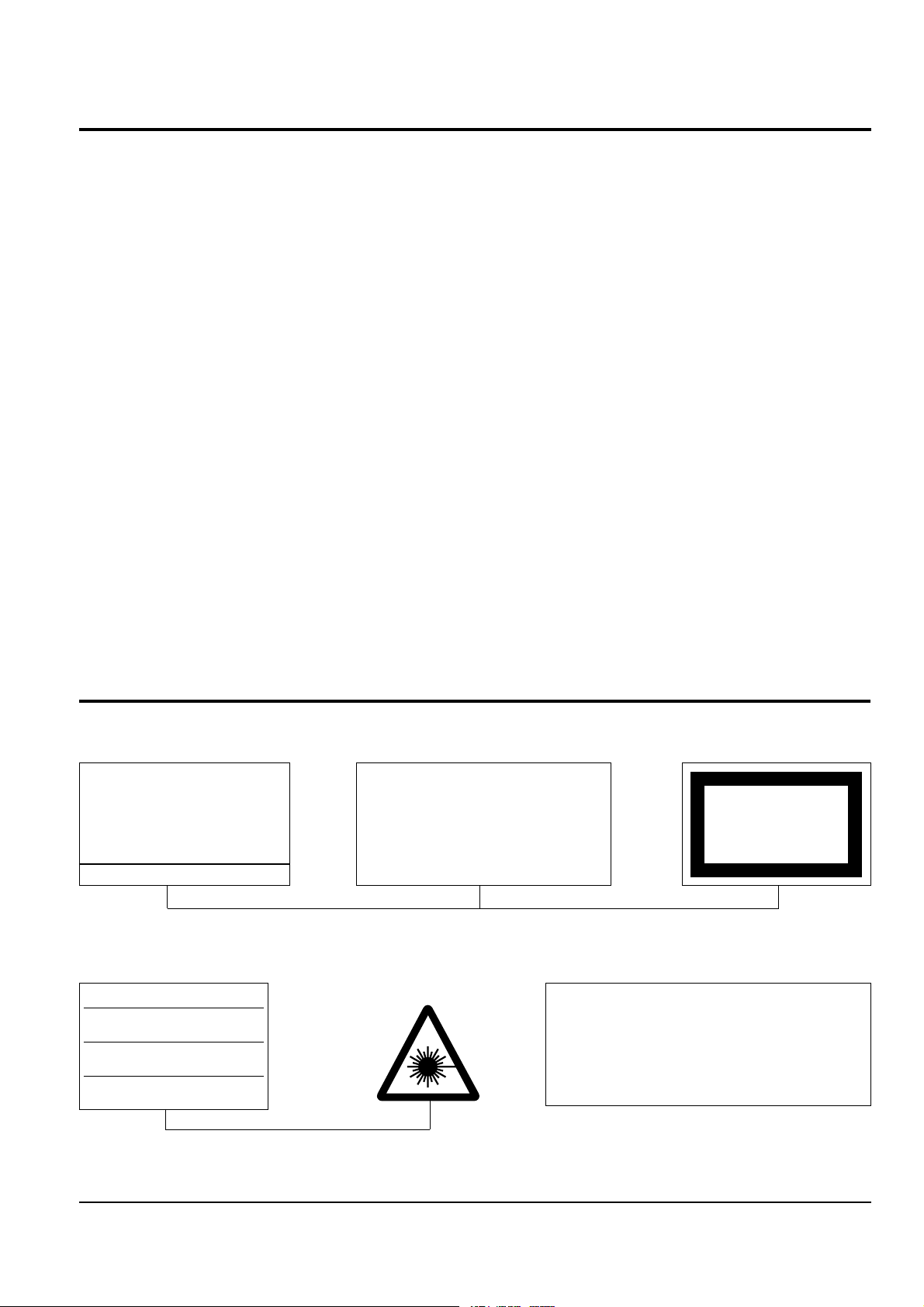

6. Insulation Resistance Cold Check:

(1) With the unit's AC plug disconnected

from the AC source, connect an electrical

jumper across the two AC prongs. (2) Set

the power switch to ON. (3) Measure the

resistance between the shorted AC plug and

any exposed metallic parts. Example:

Screwheads, antenna, control shafts or

handle brackets.

If any of the exposed metallic parts has a

return path to the chassis, the measured

resistance should be between 1 and 5.2

megohms. If there is no return path, the

measured resistance should be "infinite." If

the resistance is outside these limits, a shock

hazard might exist. See Figure 1-2

Device

Under

Test

(Reading should

not be above

0.5mA)

Leakage

Currant

Tester

Earth

Ground

Test all

exposed metal

surfaces

Also test with

plug reversed

(using AC adapter

plug as required)

2-Wire Cord

Antenna

Terminal

Exposed

Metal Part

ohm

Ohmmeter

Fig. 1-1 AC Leakage Test

Fig. 1-2 Insulation Resistance Test

Samsung Electronics1-2

1-1 Safety Precautions (Continued)

7. Components, parts and wiring that appear

to have overheated or that are otherwise

damaged should be replaced with parts

that meet the original specifications.

Always determine the cause of damage or

overheating, and correct any potential

hazards

8. Observe the original lead dress, especially

near the following areas: Antenna

wiring, sharp edges, and especially the

AC and high voltage power supplies.

Always inspect for pinched, out-of-place,

or frayed wiring. Do not change the

spacing between components and the

printed circuit board. Check the AC

power cord for damage. Make sure that

no wires or components touch thermally

hot parts.

9. Product Safety Notice:

Some electrical and mechanical parts

have special safety-related characteristics

which might not be obvious from visual

inspection. These safety features and the

protection they give might be lost if the

replacement component differs from the

original--even if the replacement is rated

for higher voltage, wattage, etc.

10 Components that are critical for safety are

indicated in the circuit diagram by

shading, or . Use replacement

components that have the same ratings,

especially for flame resistance and

dielectric strength specifications. A

replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

1-2 Servicing Precautions

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit's AC power cord

from the AC power source before

attempting to: (a) Remove or reinstall any

component or assembly, (b) Disconnect an

electrical plug or connector, (c) Connect a

test component in parallel with an

electrolytic capacitor.

3. Some components are raised above the

printed circuit board for safety. An

insulation tube or tape is sometimes used.

The internal wiring may be clamped to

prevent contact with thermally hot

components. Reinstall all such elements to

their original position.

4. After servicing, always check that the

screws, components and wiring have been

correctly reinstalled. Make sure that the

portion around the serviced part has not

been damaged.

5. Check the insulation between the blades of

the AC plug and accessible conductive parts

(examples: metal panels, input terminals

and earphone jacks).

6. Insulation Checking Procedure: Disconnect

the power cord from the AC source and

turn the power switch ON. Connect an

insulation resistance meter (500V) to the

blades of the AC plug.

The insulation resistance between each

blade of the AC plug and accessible

conductive parts (see above) should be

greater than 1 megohm.

7. Never defeat any of the B+ voltage

interlocks. Do not apply AC power to the

unit (or any of its assemblies) unless all

solid-state heat sinks are correctly installed.

8. Always connect a test instrument's ground

lead to the instrument chassis ground

before connecting the positive lead; always

remove the instrument's ground lead last.

Precautions

Warning1: First read the "Safety Precautions" section of this manual. If some unforeseen circumstance creates a conflict

between the servicing and safety precautions, always follow the safety precautions.

Samsung Electronics 1-3

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

1-4 Special Precautions and Warning Labels for Laser Products

1. Some semiconductor ("solid state") devices

are easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs). Examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component

damage caused by static electricity.

2. Immediately before handling any

semiconductor components or assemblies,

drain the electrostatic charge from your

body by touching a known earth ground.

Alternatively, wear a discharging

wrist-strap device. (Be sure to remove it

prior to applying power--this is an electric

shock precaution.)

3. After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4. Do not use freon-propelled chemicals.

These can generate electrical charges that

damage ESDs.

5. Use only a grounded-tip soldering iron

when soldering or unsoldering ESDs.

6. Use only an anti-static solder removal

device. Many solder removal devices are

not rated as "anti-static" (these can

accumulate sufficient electrical charge to

damage ESDs).

7. Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive

materials.

8. Immediately before removing the protective

material from the leads of a replacement

ESD, touch the protective material to the

chassis or circuit assembly into which the

device will be installed.

9. Minimize body motions when handing

unpackaged replacement ESDs. Motions

such as brushing clothes together, or lifting

a foot from a carpeted floor can generate

enough static electricity to damage an ESD.

Precautions

UL : Manufactured for U.S.A. Market.

CSA : Manufactured for Canadian Market.

EU : Manufactured for European Market.

SCAN : Manufactured for Scandinavian

Market.

This Product Complies with

DHHS Rules 21CFR, Sub

chapter J.At date of Manufacture

(UL)

(SCAN)

(EU)

CERTIFIED ONLY TO CANADIAN

ELECTRICAL CODE.

CERTIFIE EN VERTU DU CODE

CANADIAN DE LELETRICITE

SEULEMENT

(CSA)

CLASS 1

LASER PRODUCT

(EU)

Fig. 1-3 Warning Labels (Location: Enclosure Block)

Fig. 1-4 Warning Labels (Location: Disc Clamper, Inner Side of Unit Door or Nearby Unit Chassis )

CAUTION : INVISIBLE LASER RADIATION WHEN OPEN

AND INTERLOCKS DEFEATEO AVOIDEXPOSURE TO BEAM

ADVARSEL:USYNLIG LASERSTRÅLING VED ABNING

NÅR SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION

UNDGA UDSAETTELSE FOR STRALING

VARO:AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALTTINA NAKYMATTÖMALLE LASERSATEILYLLE ALA

KATSO SATEESEEN!

VARNING:OSYNLIG LASERSTRÅLNING NAR DENNA DEL

AR OPPNAD OCH SPARREN AR URKOPPLAD BETRAKTA

EJSTRÅLEN!

Samsung Electronics1-4

1-4 Special Precautions and Warning Labels for Laser Products (Continued)

1-4-1 Warnings

1. When servicing, do not approach the LASER

exit with the eye too closely. In case it is

necessary to confirm LASER beam emission,

be sure to observe from a distance of more

than 30 cm from the surface of the objective

lens on the optical pick-up block.

2. Do not attempt to handle the objective lens

when the DISC is not on the tray.

1-4-2 Laser Diode Specifications

Material: GaAs+ GaAlAs

Wavelength: 760-800 nm

Emission Duration: Continuous

Laser Output: 0.2 mw (measured at a

1.6 mm distance from the objective lens

surface on the optical pick-up block.)

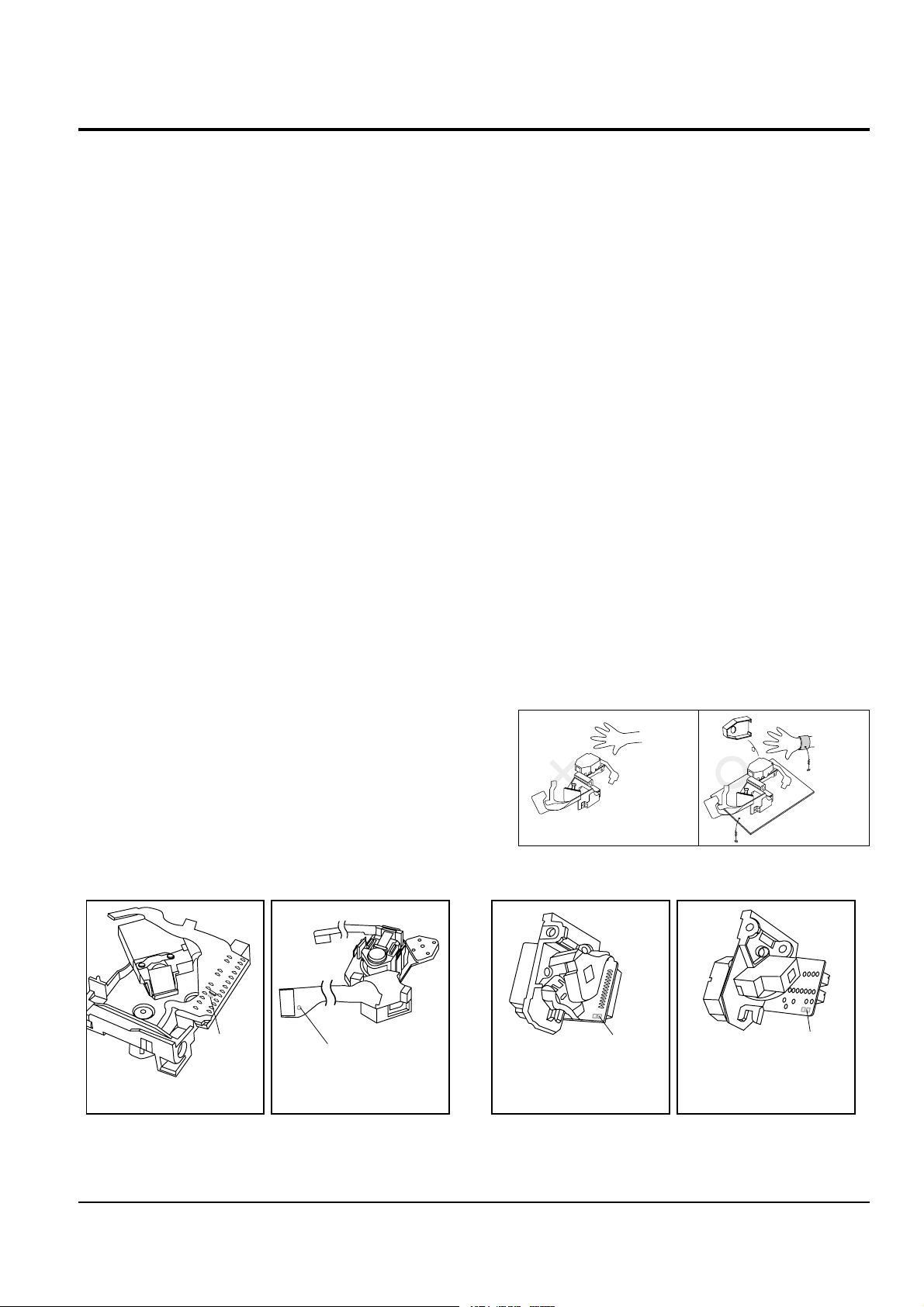

1-4-3 Handling the Optical Pick-up

1. Static electricity from clothing or the body

may cause electrostatic breakdown of the

laser diode in the Optical Pickup. Follow

this procedure:

2. Place a conductive sheet on the work bench

(i.e., the black sheet used for wrapping

repair parts.) Note: The surface of the work

bench should be covered by a copper

ground plane, which is grounded.

3. The repair technician must wear a wrist

strap which is grounded to the copper sheet.

4. To remove the Optical Pickup block:

Place the set on the conductive sheet, and

momentarily touch the conductive sheet

with both hands. (While working, do not

allow any electrostatic sources--such as

clothes--to touch the unit.)

5. Ground the "Short Terminal" (located on the

PCB, inside the Pickup Assembly) before

replacing the Pickup. This terminal should

be shorted whenever the Pickup Assembly

is lifted or moved.

6. After replacing the Pickup, reopen the Short

Terminal. See diagrams below:

Precautions

THE UNIT

(1) WRIST-STRAP

FOR GROUNDING

short

terminal

SOH91VI(LDP)

short terminal

SOH91CI(CAR,walkman)

1M

CONDUCTIVE SHEET

short

terminal

short

terminal

SOH-A1

(CMS-V10,CMS-V30)

1M

SOH94T4N

(CMS-V10,CMS-V30)

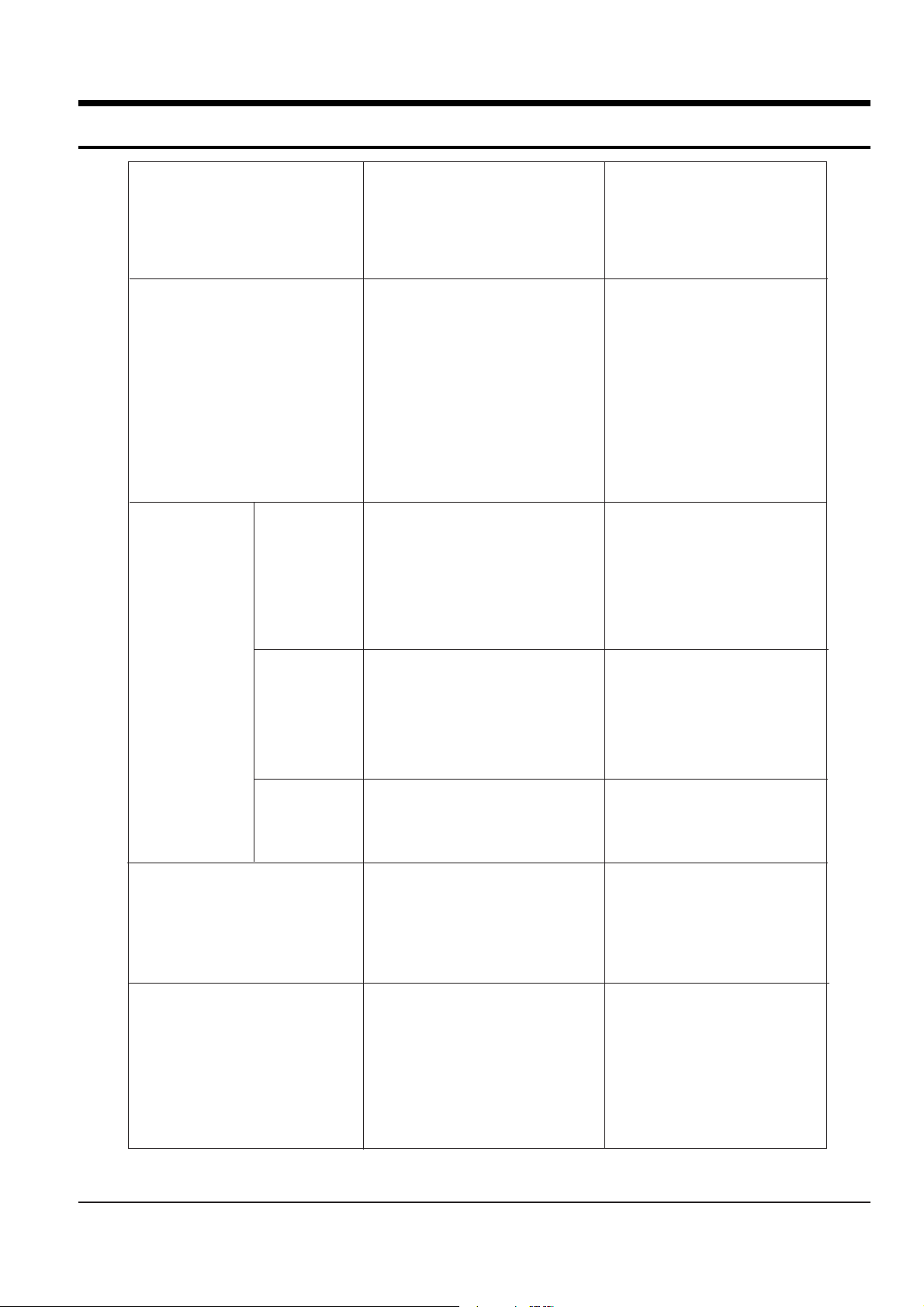

2. Product Specfications

Samsung Electronics

2-1

General

Amp

Cassette

Tuner

Compact Disc

FM

MW

(AM)

LW

(option)

Power source

Power consumption

- MAX-870

- MAX-880

Dimensions (mm)

Power output (Front)

- MAX-870

- MAX-880

Total harmonic distortion

Frequency response

Signal to noise ratio

Channel separation

Input sensitivity

- Mic

- Aux

Frequency range

Usable sensitivity

Signal to noise ratio

IF rejection ratio

Total harmonic distoration

Separation (Stereo)

Frequency range

Usable sensitivity

Signal to noise ratio

IF rejection ratio

Total harmonic distortion

Frequency range

WOW FLUTTER

Erasing effect

Signal to noise ratio

Total harmonic distortion

Frequency response

Signal to noise ratio

Channel separation

Total harmonic distortion

Audio Output

125Hz ~ 12.5KHz(-5dB)

0.15%

60 dB

40 dB

2.5%

20Hz ~ 20KHz(±1dB)

90 dB(1kHz)

75 dB(1kHz)

0.1% (100Hz)

0.05%(1kHz)

0.2% (10kHz)

1V (1kHz 0dB)

Frequency range

Usable sensitivity

Signal to noise ratio

146 ~ 290KHz

60 dB

35 dB

87.5 ~ 108MHz

6 dB

62 dB

60 dB

0.3%

35 dB

522 ~ 1611KHz

54 dB

40 dB

30 dB

2%

100W / Ch(6Ω) (THD 10%)

150W / Ch(6Ω) (THD 10%)

0.08% (1kHz)

30Hz ~ 30kHz

75 dB

50 dB (1kHz)

5mV (±3)

400mV (±80)

AC 230V 50HZ (option)

340W

550W

270(W) x 317(H) x 340(D)

Specifications are subject to change without notice.

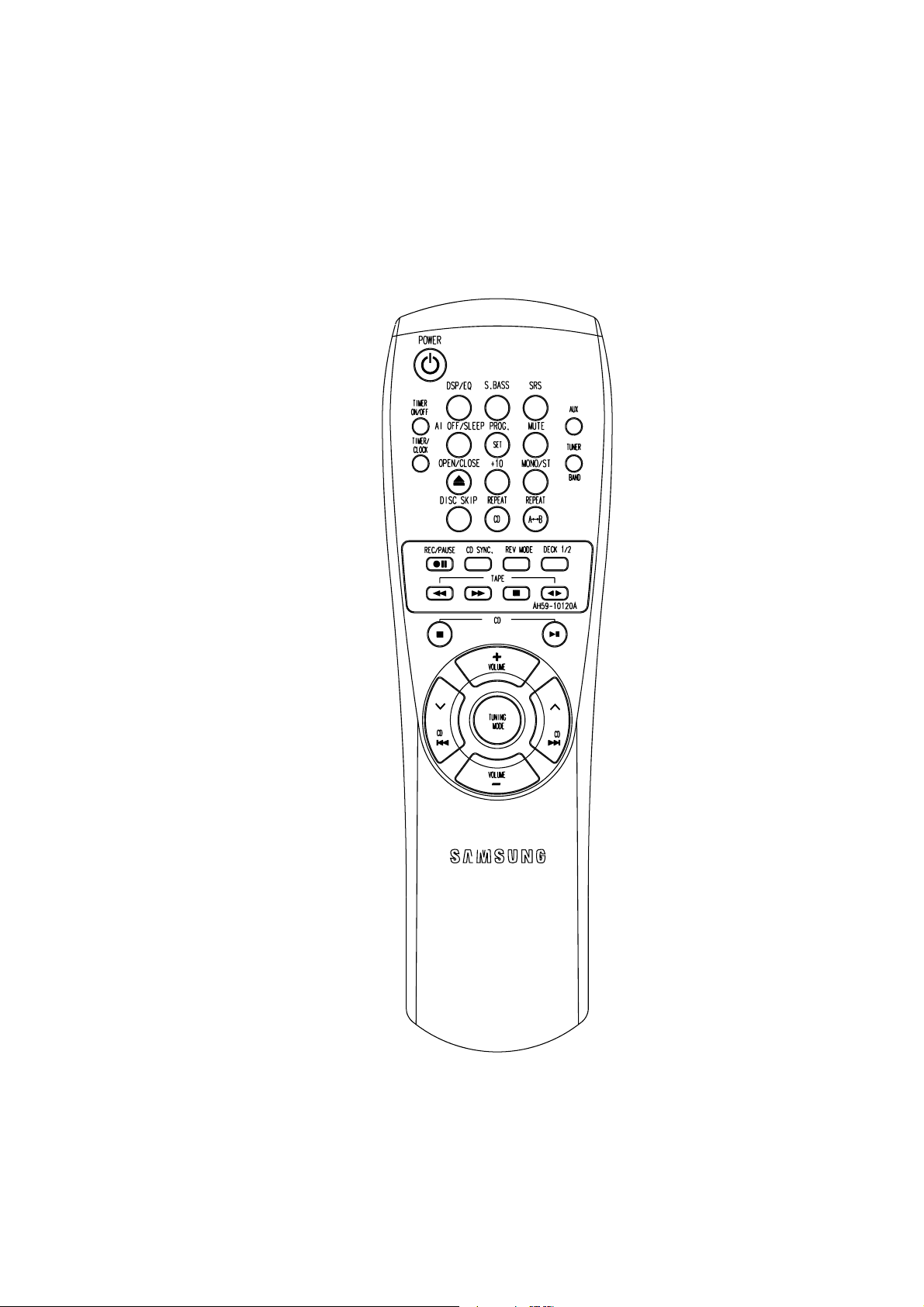

Remote Control

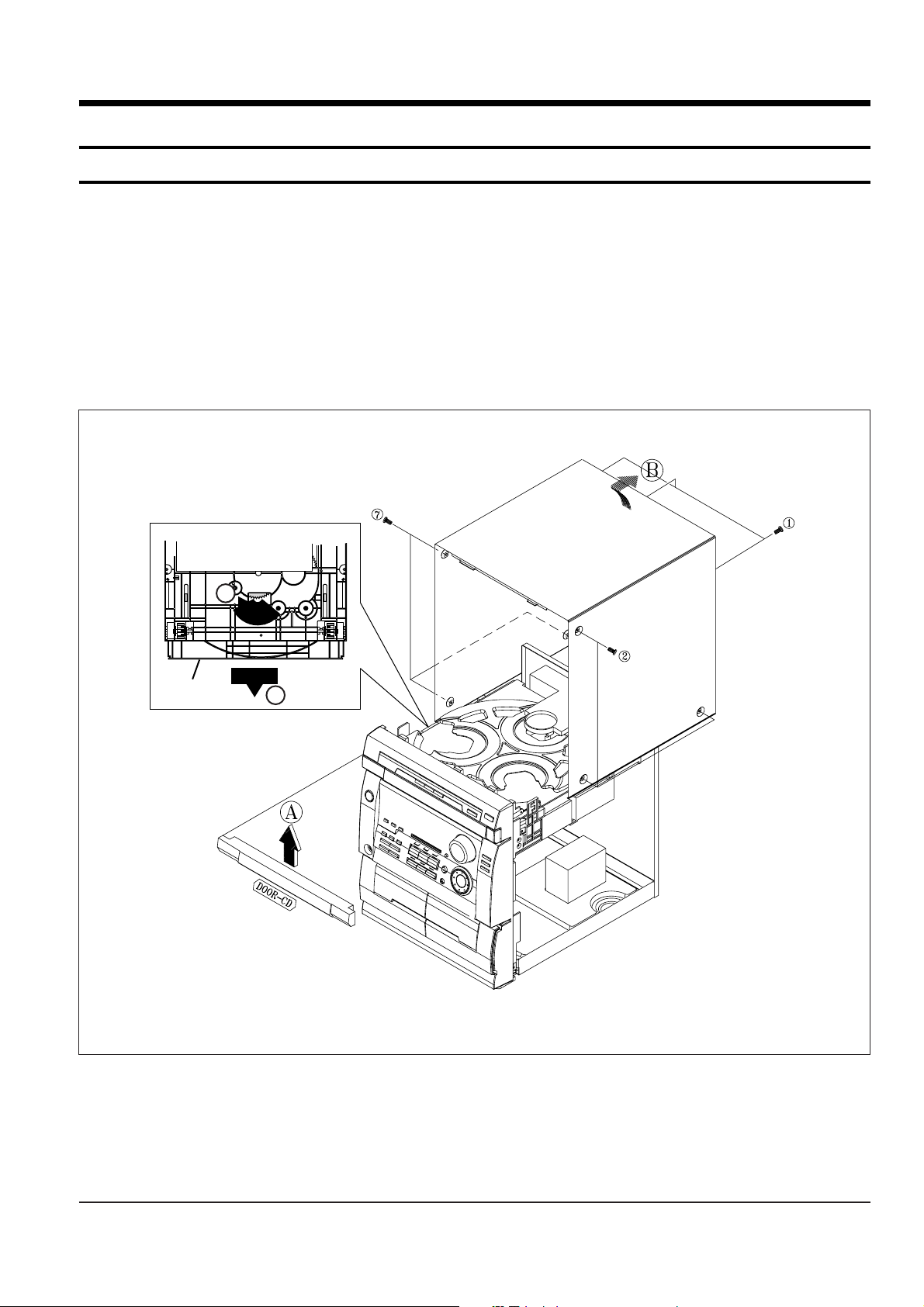

3. Disassembly and Reassembly

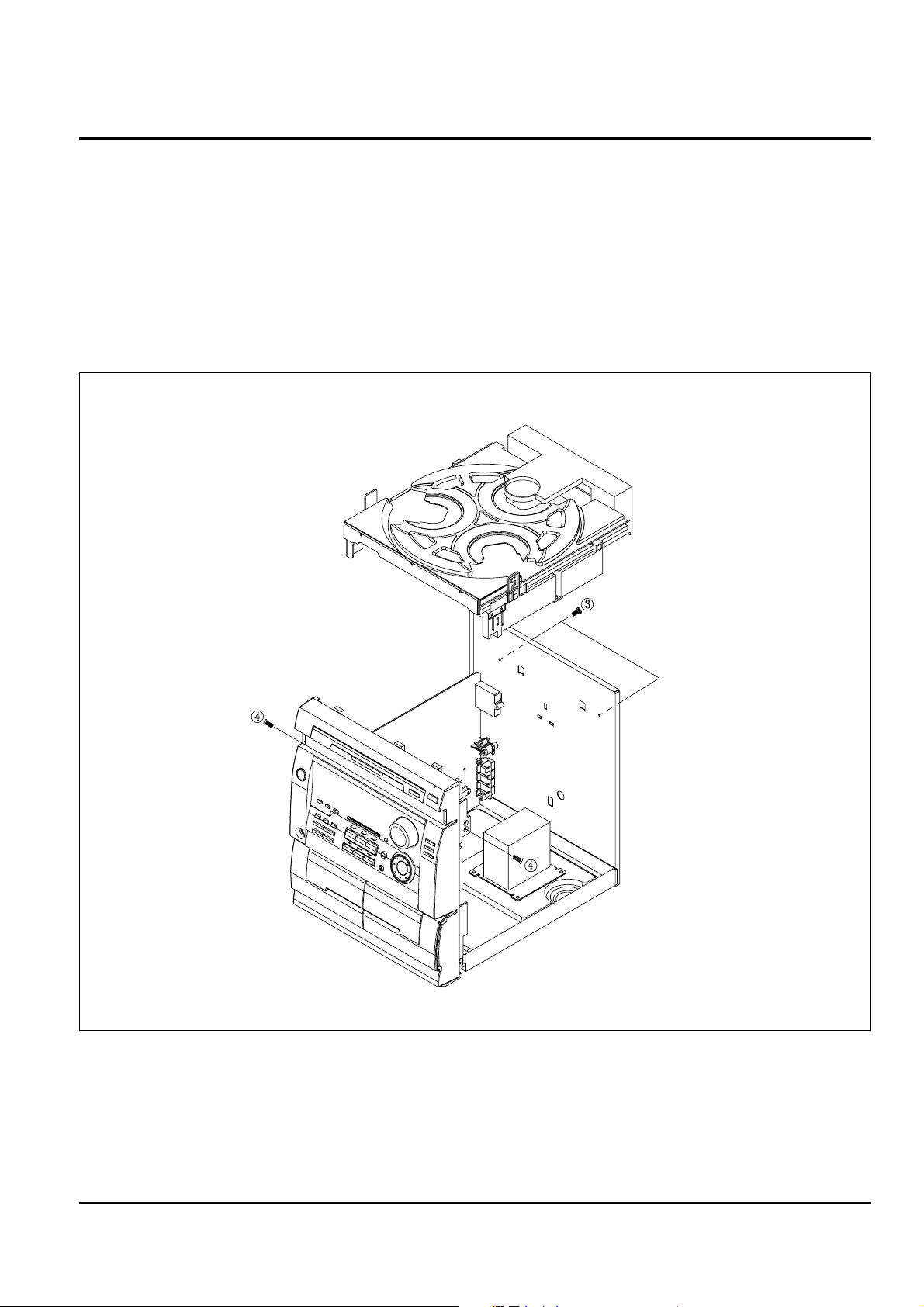

3-1 Cabinet-Top

* If power is connected ;

1. Turn power on and open the CD ,push the Door-CD in the direction of arrow to remove.

2. Remove 7 screws !, @ holding the Cabinet-Top.

Lift the back of the Cabinet-Top and shade it to the rear to remove.

* If power is not connected ;

Remove the Cabinet-Top and Turn the Gear the clockwise using the hand as shown in figure 3-1-1.

Open the Door-CD and pull the Tray in the direction of arrow @.

2

TRAY

1

Figure 3-1

Samsung Electronics 3-1

Figure 3-1-1

Figure 3-2

3-2 Samsung Electronics

3-2 CD-Mecha, Door-CD

Disassembly and Reassembly

1. Remove 4 screws #, $.

2. Lift the back of the CD-Mecha to remove.

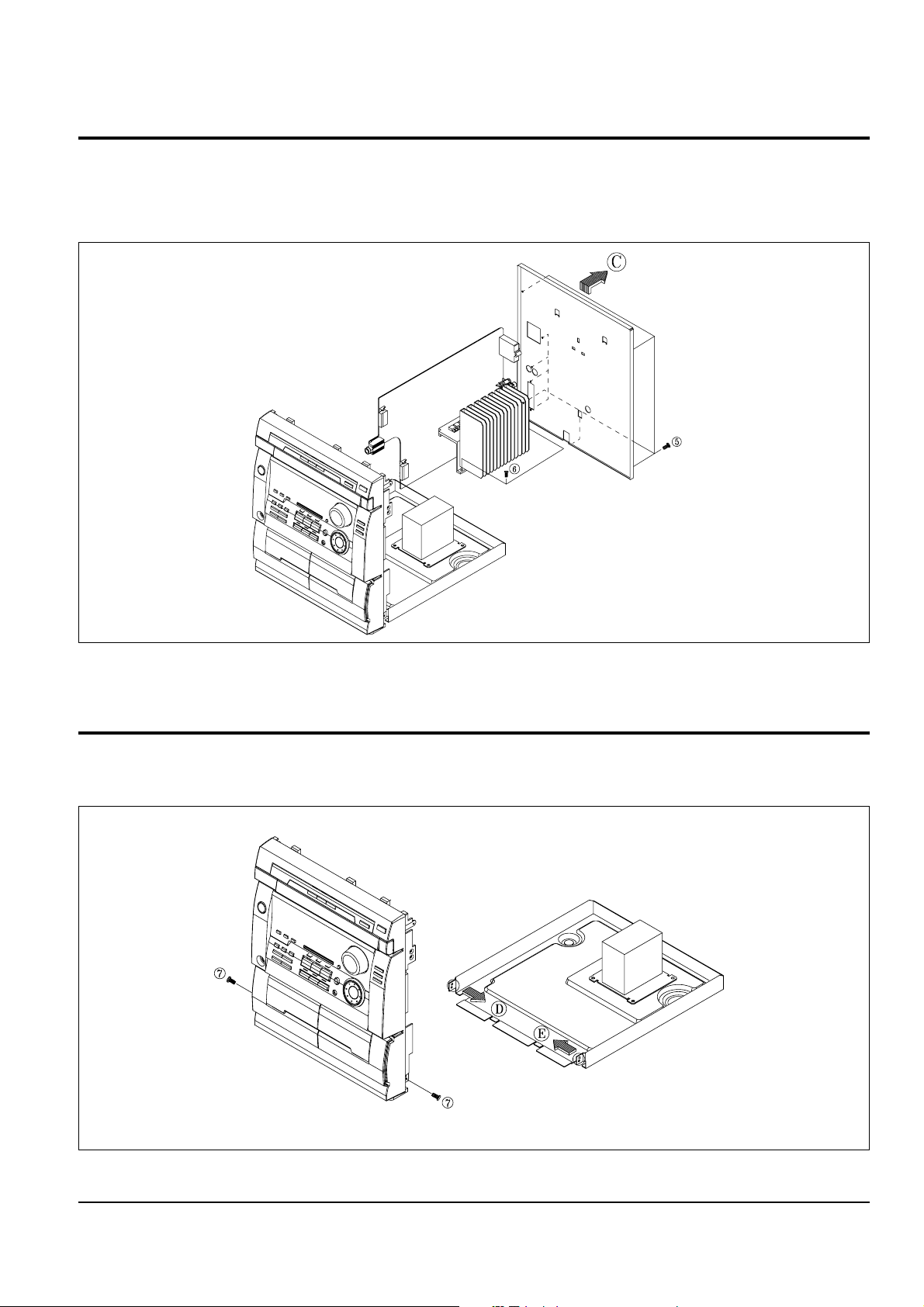

3-3 Cabinet-Rear and Main PCB

1. Remove 9 screws %.

2. Lift the Cabinet-Rear and slide it to the rear by releasing the hook of Cabinet-Bottom.

3. Remove 2 screws ^ and slide the Main PCB to the rear to remove.

1. Remove 2 screws &.

2. Slide it to the front by releasing two hooks on the bottom of Cabinet-Front to remove.

Figure 3-3

Figure 3-4

3-4 Cabinet-Front and Cabinet-Bottom

Samsung Electronics 3-3

Disassembly and Reassembly

Figure 3-5

3-4 Samsung Electronics

Disassembly and Reassembly

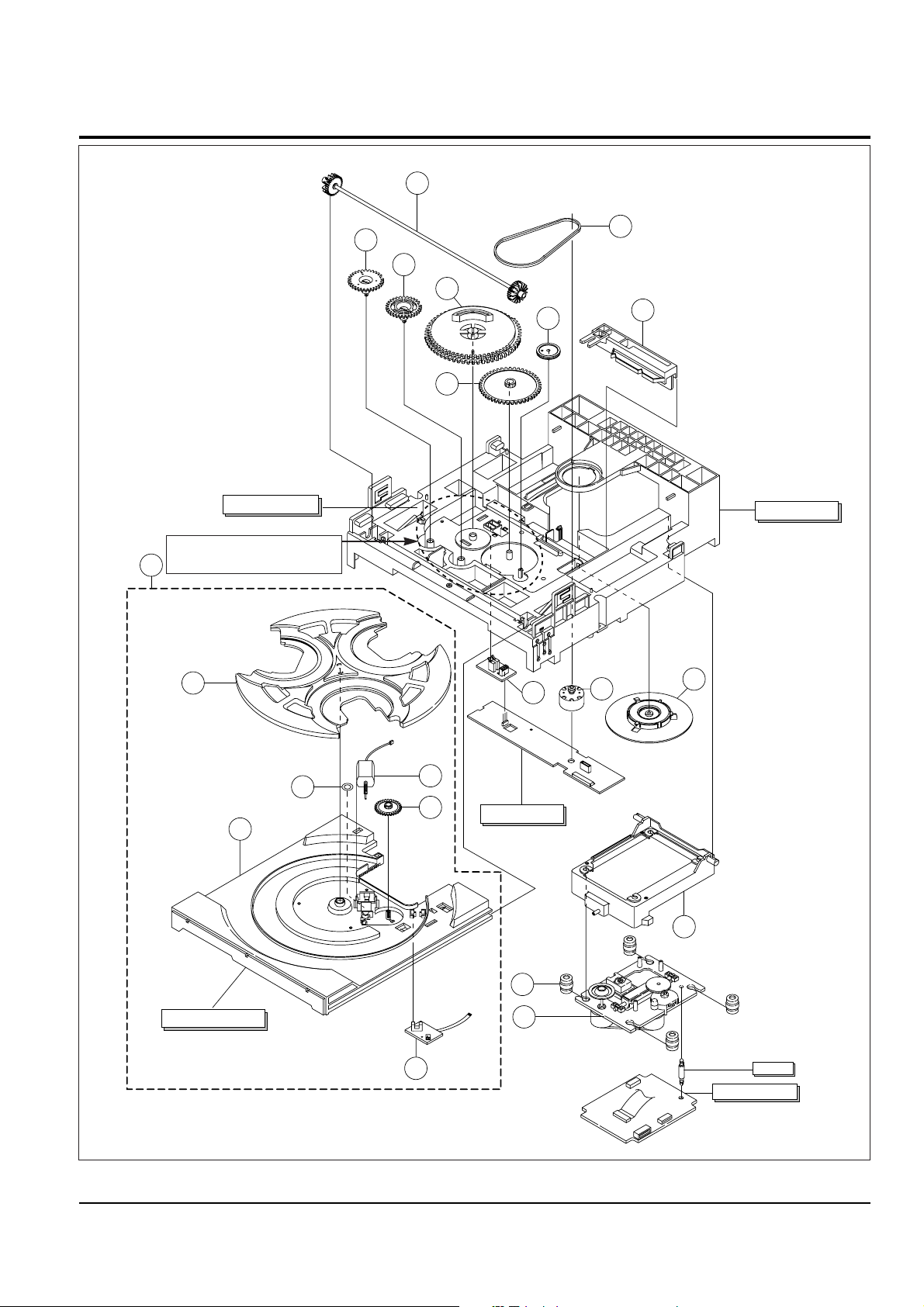

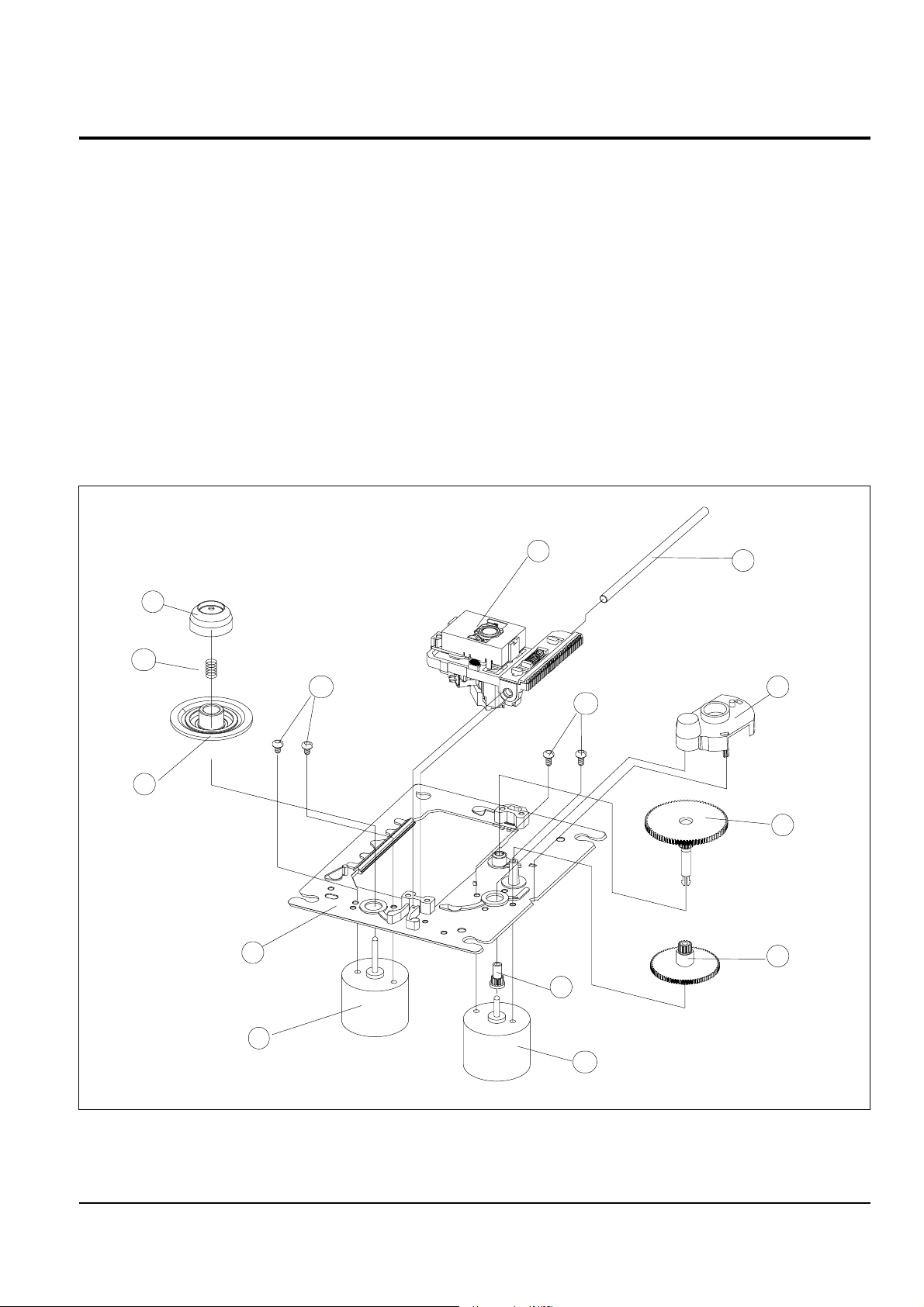

3-5 CD Mecha

13

8

2

7

6

5

4

9

3

1

10

17

16

12

11

20

15

21

14

19

CD SUB PCB

TRAY DISC ASS'Y

TRAY STOPPER

CD MAIN PCB

HOOK

BASE MAIN

18

Refer to the next page

for timming point

Samsung Electronics 3-5

Disassembly and Reassembly

3-5 CD Mecha Continued

3-5-1 Tray Disassembly

3-5-2 Main Disassembly

3-5-3 CD Main PCB Disassembly

*When removing, take extreme care not to damage the hook.

1. Open the Tray Disc AssÕy by turning the Gear-Load(%) in the direction of open,then remove the Wire-Tray(Q).

2. Remove two Tray-Stopper and tray.

1. Remove the Tray-Roulette(3) from the Tray-Disc AssÕy(4) by releasing the hook.

2. Remove the PCB-Sensor AssÕy(5) from the tray by releasing the hook.

3. Remove the Worm-Motor AssÕy())from the Tray-Disc AssÕy(4).

4. Remove the Cushion-Motor(1) from the Tray.

5. Remove the Gear-Roulette(2) from the Tray-Disc AssÕy(4) by releasing the hook.

1. Remove the Table-Chuck AssÕy(6) from the Base-Main by turning it.

2. Push the Slider-Cam(!)towards right, then lift it up to remove.

3. Remove the Gear-Tray(^) from the Base-Main by releasing the fixed hook.

4. Remove the Gear-Converter(&)from the Base-Main by releasing the fixed hook.

5. Remove the Gear-Cam(%) from the Base-Main by releasing the fixed hook.

6. Remove the Belt(@) from the Pulley-Motor AssÕy(7) & the Gear-Pulley(#).

7. Remove the Gear-Pulley(#) from the Base-Main by releasing the fixed hook.

8. Remove the Gear-Load($).

9. Remove the Gear-Synchro(*).

10. Desolder two soldering points of the CD SUB PCB, then remove it from Base-Main by

releasing the hook.

11. Remove the Pulley-Motor AssÕy(7) by releasing the hook.

12. Remove the PCB-SW AssÕy(8) by releasing the hook.

1. Remove the Lever-Lifter(9) from the Base-Main by releasing two hooks.

2. Remove four Rubber-CD(0) from the Lever-Lifter and then remove the Deck-CD(“).

3. Remove the Hook.

4. Remove the CD MAIN PCB with the soldering iron.

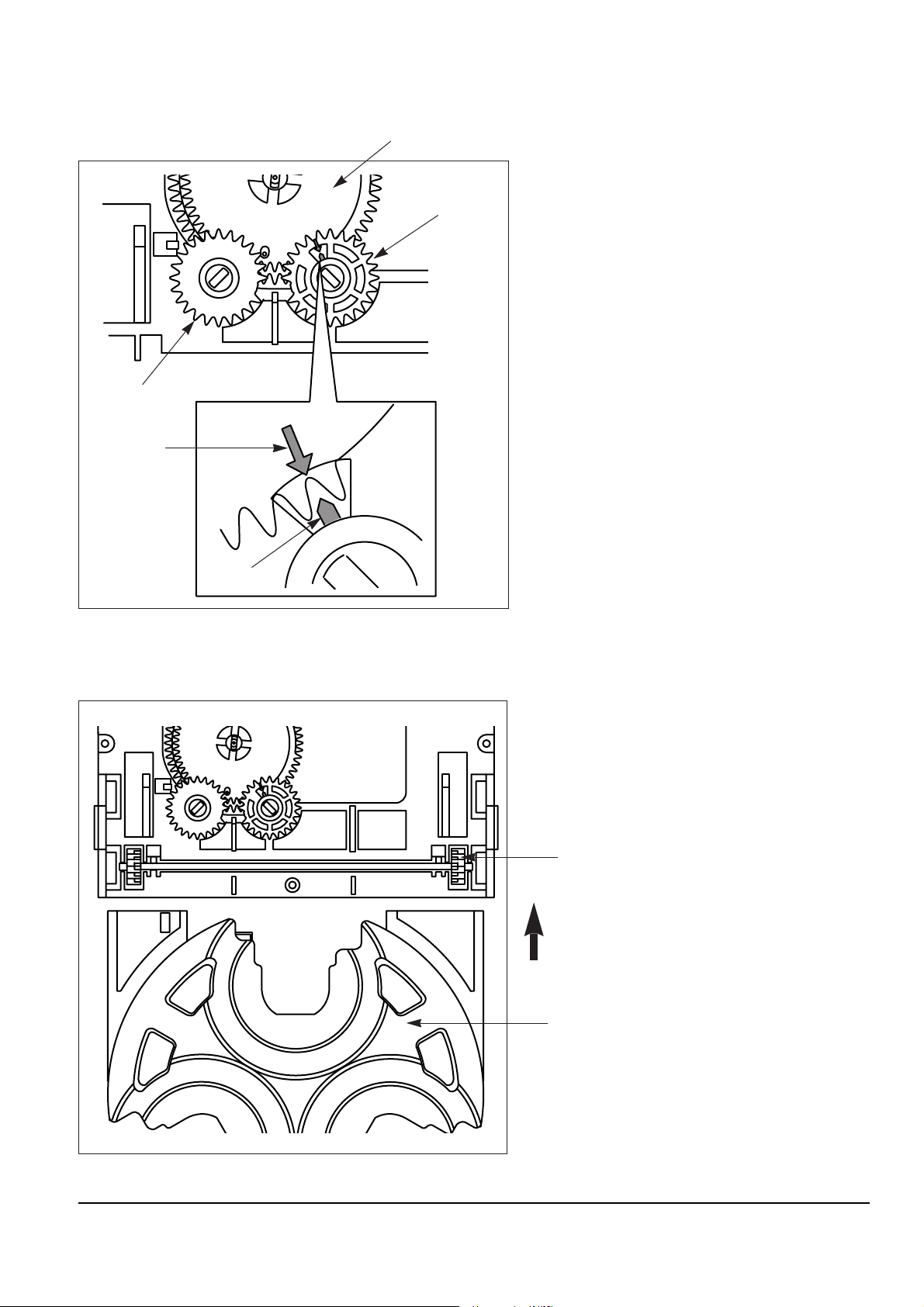

Figure 3-6

Figure 3-7

3-6 Samsung Electronics

Disassembly and Reassembly

* Reinstall in reverse order.

* Align the Gear-Cam with the Gear-Tray as

shown ing Figure 3-6, then mount the Tray-Disc.

* When assembling the Tray-Disc,take extreme

care not to engage with Gear-Synchro.

Gear-Cam

Gear-Cam

Gear-Cam

Gear-Cam

Timming Point

Gear-Cam

Gear-Synchro

Gear-Disc

Insert

Figure 3-8

Samsung Electronics 3-7

3-6 CD Deck

1. Remove the Shaft !.

2. Lift the P/U @.

Note : Take extreme care not to touch the surface of lens.

If there is an alien materials, clean it with swab smeared alcohol.

3. Lift the Center-ring #.

4. Remove the Spring-T/Table $.

5. Remove the Turn-Table (M) %.

6. Remove 2 screws ^ and then remove the Spindle-Motor &.

7. Remove the Cover-Gear * by pushing the hook.

8. Remove the Gear (c) ( by pushing the hook.

9. Lift the Gear(b) ).

10. Remove the Gear(a) 1.

11. Remove 2 screws 2 and the then remove the Feed-Motor 3.

12. Remove the Chassis-Deck (M) 4.

Disassembly and Reassembly

3

4

5

6

12

2

1

8

9

10

11

13

14

7

Figure 3-9

3-8 Samsung Electronics

3-6 CD Deck (Option)

Disassembly and Reassembly

1. Remove the Shaft !.

2. Lift the P/U @.

Note : Take extreme care not to touch the surface of lens.

If there is an alien materials, clean it with swab smeared alcohol.

3. Lift the Center-Knob #.

4. Remove the Center-ring $.

5. Remove the Spring-T/Table %.

6. Remove the Turn-Table(M) ^.

7. Remove 2 screws & and then remove the Spindle-Motor *.

8. Remove the Cover-Gear ( by pushing the hook.

9. Remove the Gear(c) ) by pushing the hook.

10. Lift the Gear(b) 1.

11. Remove the Gear(a) 2.

12. Remove 2 screws 3 and then remove the Feed-Motor 4.

13. Remove the Chassis-Deck(M) 5.

4

6

7

13

2

1

9

10

11

12

14

15

8

3

5

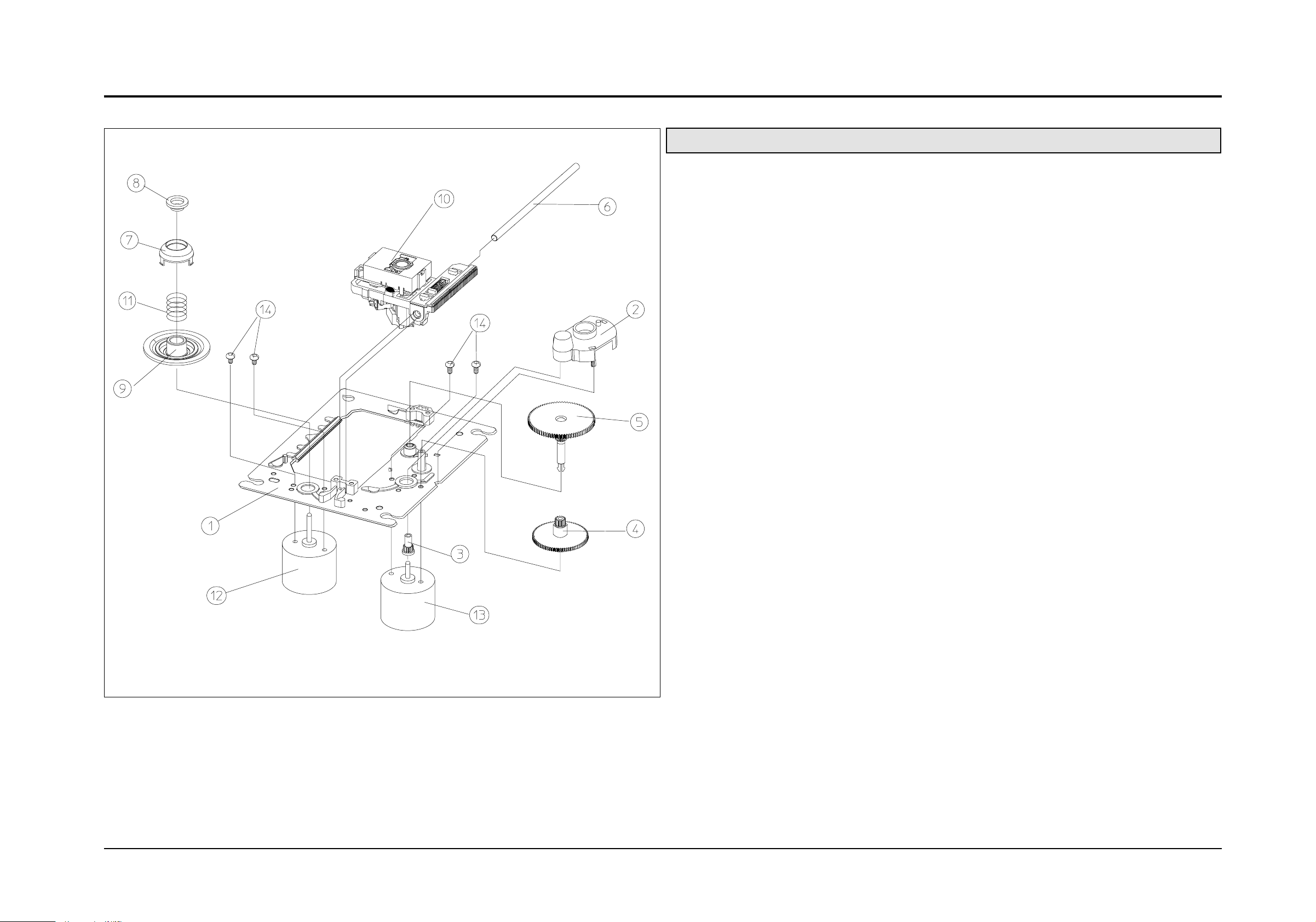

7.Exploded Views and Parts List

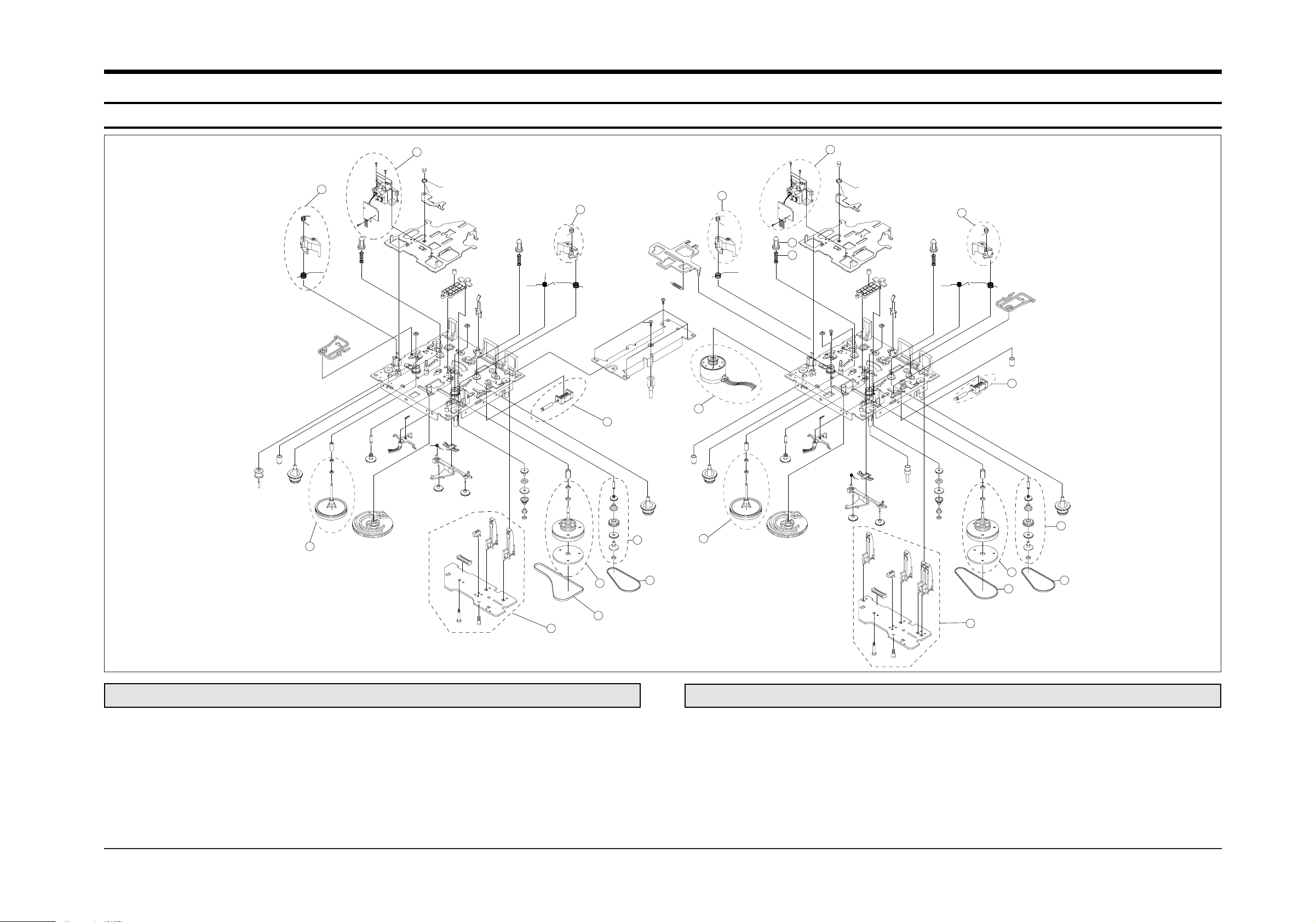

7-1 Cassette Deck Exploded View and Parts List

Samsung Electronics 7-1

45

10

9

4

5

7

12

14

11

2

3

1

11

8

9

4

6

13

11

14

3

10

7

No. Code No. Description Specification Remarks

1

2

3

4

5

6

7

AH59-20004U

AH81-11052G

AH81-11052D

AH81-10798D

AH81-10798E

AH81-11052E

AH81-11052B

AH81-10798H

DECK-CASSETTE

MOTOR ASS’Y

HEAD ASS’Y (R/P)

HEAD ASS’Y (P/B)

SOLENOID ASS’Y

CNTR ASS’Y (R/P)

CNTR ASS’Y (P/B)

FLYWHEEL ASS’Y (F)

ADR2118TW

EG530YD2BH

YK56RAA4N3

YK50PBB4N3

ADR2100-01

ADR2118TW-03

ADR2118TW-04

ADR2100-04

No. Code No. Description Specification Remarks

8

9

10

11

12

13

14

AH81-10798J

AH81-10798K

AH81-10798M

AH81-10798N

AH81-11052A

AH81-11052E

AH81-10798U

FLYWHEEL ASS’Y (R)

PINCH ARM (F)

PINCH ARM (R)

CLUTCH ASS’Y

MAIN BELT (R/P)

MAIN BELT (P/B)

SUB BELT

ADR2100-05

ADR2100-06

ADR2100-07

ADR2100-08

ADR2118TW-01

ADR2118TW-02

ADR2100-09

33

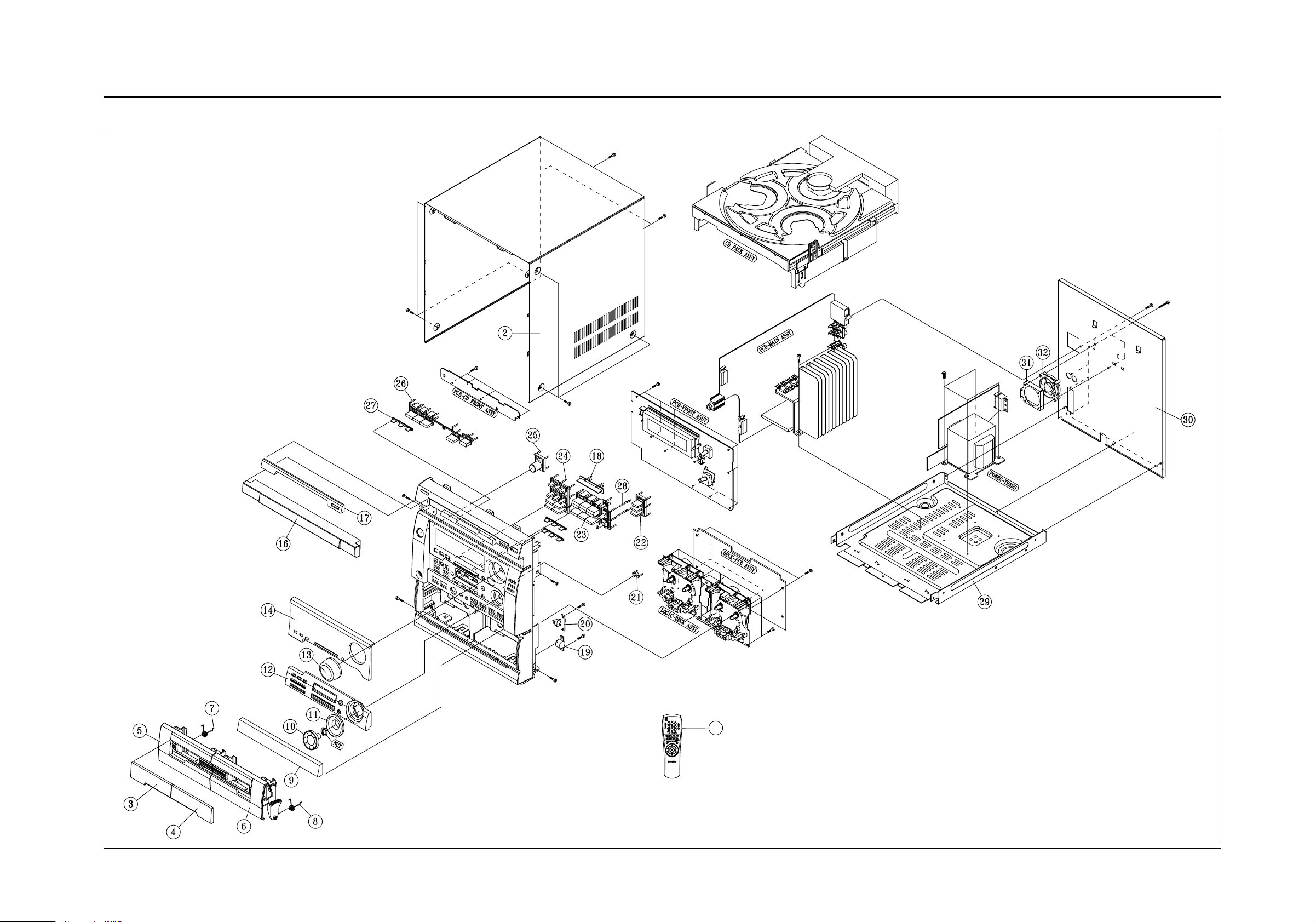

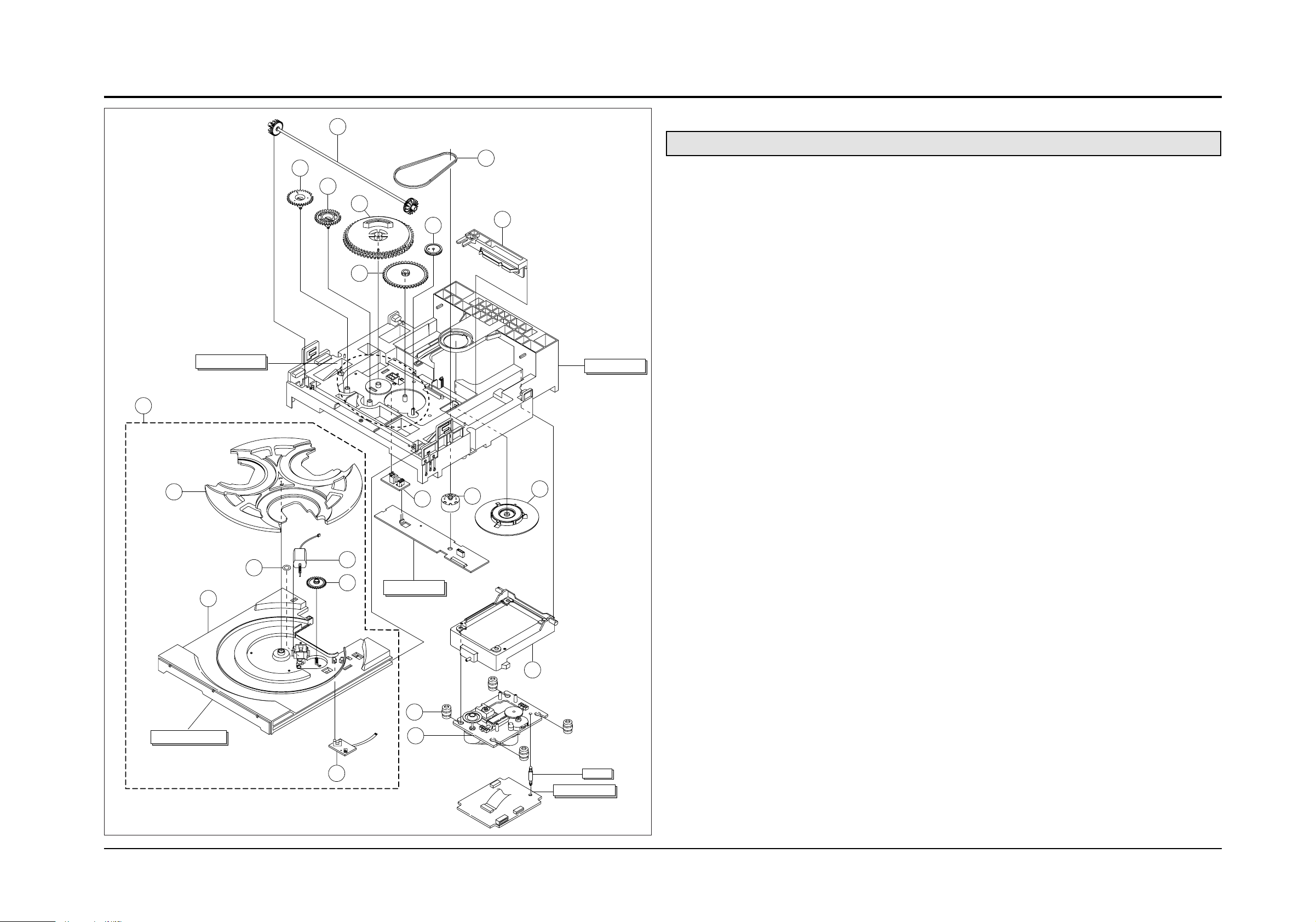

7-2 Main Exploded View and Parts List

7-2-1 Exploded View

Exploded Views and Parts List

7-2

Samsung Electronics

7-2-2 Parts List (using MAX-870)

7-2-2 Parts List (using MAX-880)

No. Code No. Description Specification Remarks

2

3

4

5

6

7

8

9

10

11

12

13

14

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

AH64-30390A

AH64-40431A

AH64-40432A

AH64-50335C

AH64-50337C

AH61-62004A

AH61-62005A

AH61-20480B

AH64-11222C

AH64-42002B

AH64-42001C

AH64-11221C

AH64-40430C

AH64-50336D

AH64-40429B

AH67-10162A

AH61-80030A

AH95-50001A

AH67-10164A

AH64-11217B

AH64-11218D

AH64-11219B

AH64-11223C

AH64-11216C

AH67-10163A

AH67-10165A

AH64-30416A

AH64-30417D

AH64-30417E

AH64-30417F

AH64-30417J

AH61-10747A

AH31-10020A

AH59-10120A

CABINET-TOP

WINDOW-DOOR,A

WINDOW-DOOR,B

DOOR-CASS,A

DOOR-CASS,B

SPRING-EJECT,A

SPRING-EJECT,B

CAP-FRONT,E

KNOB-JOG

DECO-JOG

DECO-FRONT

KNOB-VOLUME

WINDOW-VFD

DOOR-CD

WINDOW-CD

LENS-COM

DAMPER-ASSY

LATCH-ASSY

LENS-JOG

KNOB-SRS

KNOB-FUNCTION

KNOB-DECK

KNOB-POWER

KNOB-CD OPEN

LENS-CD

LENS-ECHO

CABINET-BOTTOM

CABINET-REAR

BRACKT-FAN

FAN-DC

REMOCON-ASSY

PCM 0.625T (D/GRAY)

PMMA VIOLET(LUCKY, 71129)

PMMA VIOLET(LUCKY, 71129)

ABS 94HB BLK

ABS 94HB BLK

STS Ø1.1

STS Ø1.1

MIPS 94HB BLK

ABS D/GRAY (HF-06660I,G3174)

ABS NATURAL HF-0660I,G3174

MIPS 94HB BLK

ABS D/GRAY (HF-0660I,G3174)

PMMA VIOLET(LUCKY,41802)

ABS 94HB BLK(LUCKY,41802)

PMMA VIOLET

ACRYL

HF-0660I, G3174

MAX-555

ACRYL

ABS D/GRAY (HF-0660I, G3174)

ABS D/GRAY (HF-0660I, G3174)

ABS D/GRAY (HF-0660I, G3174)

ABS D/GRAY (HF-0660I, G3174)

ABS D/GRAY (HF-0660I, G3174)

ACRYL

ACRYL

SECC 1.0T

SECC 0.8T

BRACKT-FAN

FAN-DC

REMOCON-ASSY

No. Code No. Description Specification Remarks

2

3

4

5

6

7

8

9

10

11

12

13

14

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

AH64-30390A

AH64-40431A

AH64-40432A

AH64-50335C

AH64-50337C

AH61-62004A

AH61-62005A

AH61-20480B

AH64-11222C

AH64-42002B

AH64-42001C

AH64-11221C

AH64-40430C

AH64-50336E

AH64-40429B

AH67-10162A

AH61-80030A

AH95-50001A

AH67-10164A

AH64-11217B

AH64-11218D

AH64-11219B

AH64-11223C

AH64-11216C

AH67-10163A

AH67-10165A

AH64-30416A

AH64-30417D

AH64-30417E

AH64-30417F

AH64-30417J

AH61-10747A

AH31-10020A

AH59-10120A

CABINET-TOP

WINDOW-DOOR,A

WINDOW-DOOR,B

DOOR-CASS,A

DOOR-CASS,B

SPRING-EJECT,A

SPRING-EJECT,B

CAP-FRONT,E

KNOB-JOG

DECO-JOG

DECO-FRONT

KNOB-VOLUME

WINDOW-VFD

DOOR-CD

WINDOW-CD

LENS-COM

DAMPER-ASSY

LATCH-ASSY

LENS-JOG

KNOB-SRS

KNOB-FUNCTION

KNOB-DECK

KNOB-POWER

KNOB-CD OPEN

LENS-CD

LENS-ECHO

CABINET-BOTTOM

CABINET-REAR

BRACKT-FAN

FAN-DC

REMOCON-ASSY

PCM 0.625T (D/GRAY)

PMMA VIOLET(LUCKY, 71129)

PMMA VIOLET(LUCKY, 71129)

ABS 94HB BLK

ABS 94HB BLK

STS Ø1.1

STS Ø1.1

MIPS 94HB BLK

ABS D/GRAY (HF-06660I,G3174)

ABS NATURAL HF-0660I,G3174

MIPS 94HB BLK

ABS D/GRAY (HF-0660I,G3174)

PMMA VIOLET(LUCKY,41802)

ABS 94HB BLK(LUCKY,41802)

PMMA VIOLET

ACRYL

HF-0660I, G3174

MAX-555

ACRYL

ABS D/GRAY (HF-0660I, G3174)

ABS D/GRAY (HF-0660I, G3174)

ABS D/GRAY (HF-0660I, G3174)

ABS D/GRAY (HF-0660I, G3174)

ABS D/GRAY (HF-0660I, G3174)

ACRYL

ACRYL

SECC 1.0T

SECC 0.8T

BRACKT-FAN

FAN-DC

REMOCON-ASSY

Exploded Views and Parts List

Samsung Electronics

7-3

Exploded Views and Parts List

7-4

Samsung Electronics

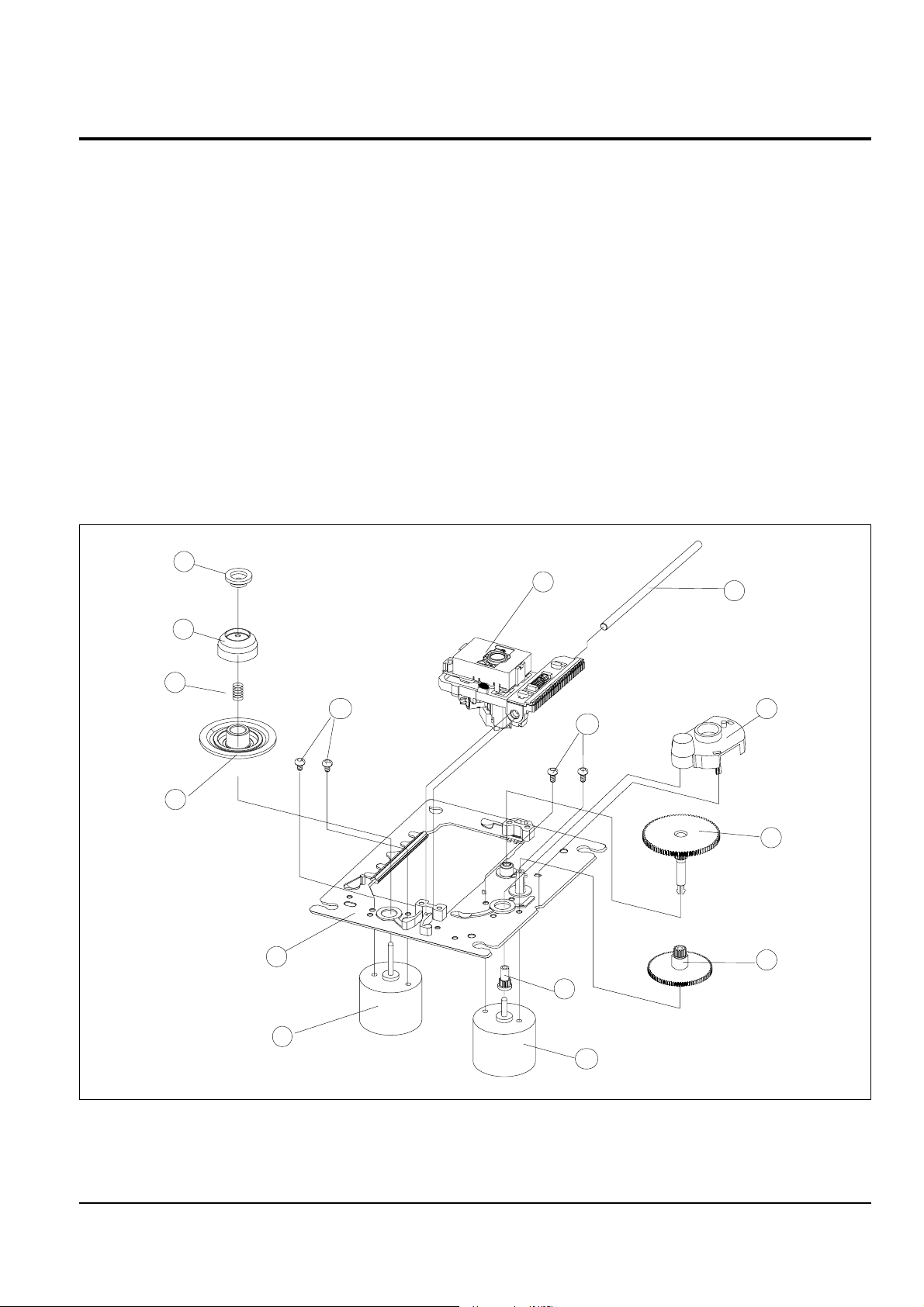

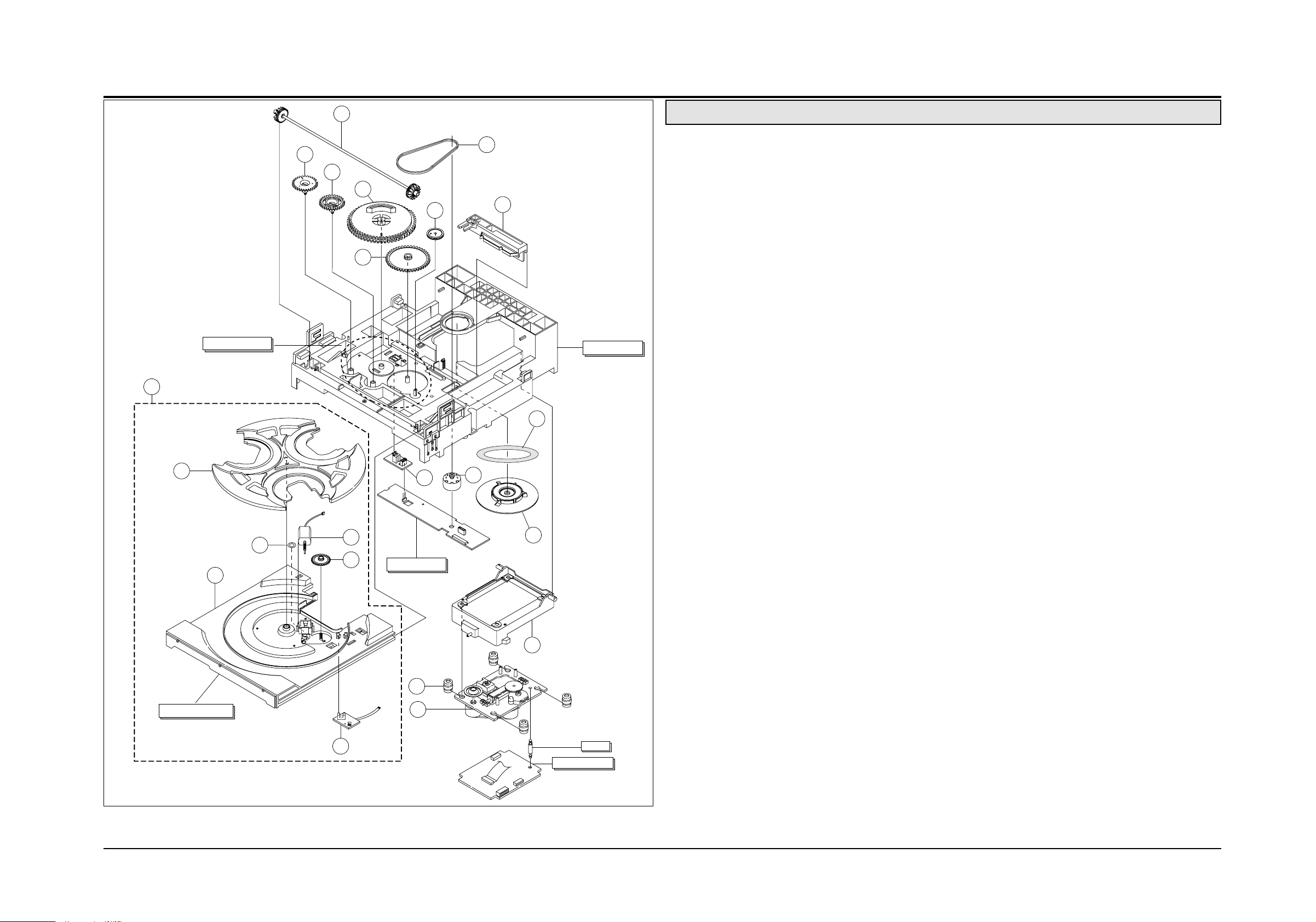

7-3 CD Mecha Exploded View and Parts List

13

8

2

7

6

5

4

9

3

1

10

17

16

12

11

20

15

21

14

19

CD SUB PCB

TRAY DISC ASS'Y

TRAY STOPPER

CD MAIN PCB

HOOK

BASE MAIN

18

No. Code No. Description Specification Remarks

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

19

20

21

AH66-80022A

AH66-60034A

AH66-20186A

AH66-20187A

AH66-20188A

AH66-20189A

AH66-20190A

AH66-20191A

AH59-10097A

AH59-10098A

AH69-20044A

AH66-20193A

AH66-90056A

AH66-90055A

AH59-10099A

AH59-10100A

AH59-10101A

AH66-30086A

AH73-10016A

AJ59-20003F

SLIDER-CAM

BELT-LOAD

GEAR-PULLEY

GEAR-LOAD

GEAR-CAM

GEAR-TRAY

GEAR-CONVERT

GEAR-SYNCRO

ASSY-TRAY DISC

ASS-WORM-MOTOR

CUSHION-MOTOR

GEAR-ROULETTE

TRAY-ROULETTE

TRAY-DISC

ASSY-PCB SENSOR

ASSY-TABLE CHUCK

ASSY-PULLEY-MOTOR

LEVER-LIFTER

RUBBER-CD

DECK-CDP

ABS HF-380 NTR

CR

POM(M90-44) WHT

POM(M90-44) BLK

POM(M90-44) WHT

POM(M90-44) BLK

POM(M90-44) WHT

ABS HF-380 NTR

CMS-300, ASS’Y-TRAY

CMS-300, ASS’Y-WORM

NBR BLK

POM(M90-44) BLK

ABS XR-401 BLK

-,ABS,-,BLK

CMS-300,ASS’Y SENSOR

CMS-300,ASS’Y CHUCK

CMS-300,ASS’Y CHUCK

ABS HF-380 BLK

IRR

DECK-CD *CMS-A30NM6

Exploded Views and Parts List

Samsung Electronics

7-5

7-3 CD Mecha Exploded View and Parts List (Option)

13

8

2

7

6

5

4

9

3

1

10

17

12

11

20

15

21

16

14

19

CD SUB PCB

TRAY DISC ASS'Y

TRAY STOPPER

CD MAIN PCB

HOOK

BASE MAIN

18

22

No. Code No. Description Specification Remarks

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

19

20

21

22

AH66-80022A

AH66-60034A

AH66-20186A

AH66-20187A

AH66-20188A

AH66-20189A

AH66-20190A

AH66-20191A

AH59-10097A

AH59-10098A

AH69-20044A

AH66-20193A

AH66-90056A

AH66-90055A

AH59-10099A

AH59-10100B

AH59-10101A

AH66-30086A

AH73-10016A

AH59-20004Y

AH63-70141A

SLIDER-CAM

BELT-LOAD

GEAR-PULLEY

GEAR-LOAD

GEAR-CAM

GEAR-TRAY

GEAR-CONVERT

GEAR-SYNCRO

ASSY-TRAY DISC

ASS-WORM-MOTOR

CUSHION-MOTOR

GEAR-ROULETTE

TRAY-ROULETTE

TRAY-DISC

ASSY-PCB SENSOR

ASSY-TABLE CHUCK

ASSY-PULLEY-MOTOR

LEVER-LIFTER

RUBBER-CD

DECK-CDP

SHEET-CHUCK

ABS HF-380 NTR

CR

POM(M90-44) WHT

POM(M90-44) BLK

POM(M90-44) WHT

POM(M90-44) BLK

POM(M90-44) WHT

ABS HF-380 NTR

CMS-300, ASS’Y-TRAY

CMS-300, ASS’Y-WORM

NBR BLK

POM(M90-44) BLK

ABS XR-401 BLK

-,ABS,-,BLK

CMS-300,ASS’Y SENSOR

CMS-300UD,TABLE-CHUCK ASSY

CMS-300,ASS’Y CHUCK

ABS HF-380 BLK

IRR

CMS-P30AM6UD

PVC 1.0

7-6

Samsung Electronics

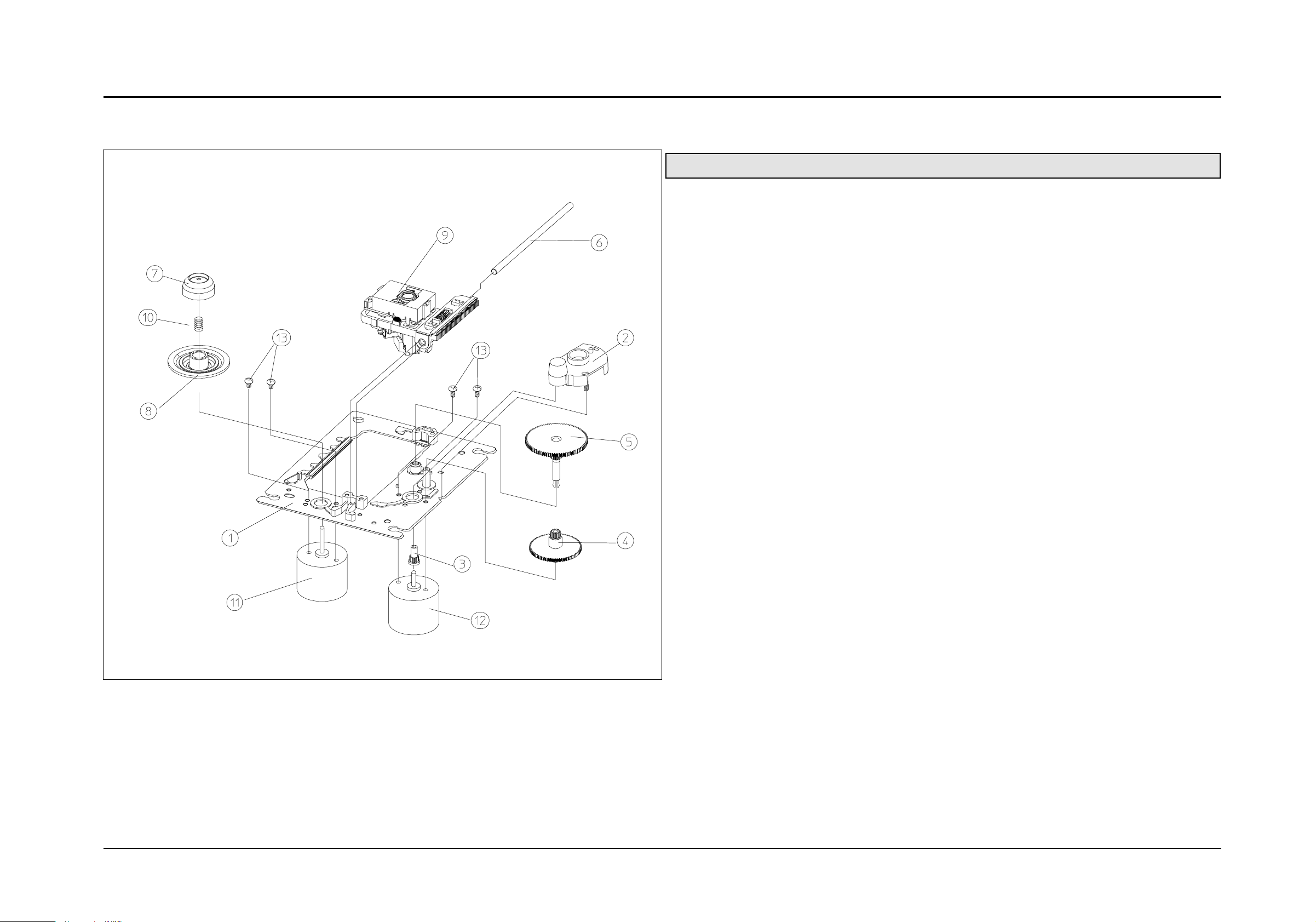

7-4 CD Deck Exploded View and Parts List

7-4-1 Exploded View

No. Code No. Description Specification Remarks

1

2

3

4

5

6

7

8

9

10

11

12

13

AJ59-20003F

AH61-10022C

AH63-30048A

AH66-20016A

AH66-20017A

AH66-20018A

AH71-50036A

15253-503-011

AH66-90018A

AJ30-20001B

AH61-60055A

AH31-10009A

AH31-10002B

AH60-10014A

DECK-CD

CHASSIS-DECK(M)

COVER-GEAR

GEAR(A)

GEAR(B)

GEAR(C)

SHAFT-PU

CENTER-RING

TURN-TABLE(M)

PICK-UP CDP

SPRING-T/TABLE

MOTOR-SPINDLE

MOTOR-FEED

SCREW-PH(+M2*3)

CMS-P30NM6

CMSA30 POM M90-44

CMS-V30 BLK ABS

CMS-V30 M0.3 Z13 SP POM

CMS-V30 M0.3 Z13 SP POM

CMS-V30 M0.3 Z16/Z90 SP POM

CMS-V30 D3 L79 SUS420J2

ABS+GS 20% CMS-V10N

ABS+GS 20% CMS-V10N

P/U SOH-A1 ROW V-P/J

CS STS-W PI0.4 D5.7 L9.3 CMS-V10N

RF-310T-11400 43L 25V 85mA

RF-310ta 30MM NDM4RA3ETL 11.0MM

+M2X3 FE FZY W700

Exploded Views and Parts List

7-4-2 Parts List

Samsung Electronics

7-7

Exploded Views and Parts List

7-4 CD Deck Exploded View and Parts List (Option)

No. Code No. Description Specification Remarks

1

2

3

4

5

6

7

8

9

10

11

12

13

14

AH59-20004Y

AH61-10022B

AH63-30048A

AH66-20016A

AH66-20017A

AH66-20018A

AH71-50036A

15253-503-011

AH64-10648A

AH66-90029A

AJ30-20001B

AH61-60055A

AH31-10009A

AH31-10002B

AH60-10014A

DECK-CD

CHASSIS-DECK(M)

COVER-GEAR

GEAR(A)

GEAR(B)

GEAR(C)

SHAFT-PU

CENTER-RING

CENTER-KNOB

TURN-TABLE(M)

PICK-UP CDP

SPRING-T/TABLE

MOTOR-SPINDLE

MOTOR-FEED

SCREW-PH(+M2*3)

CMS-P30AM6UD

CMSP30 POM M90-44

CMS-V30 BLK ABS

CMS-V30 M0.3 Z13 SP POM

CMS-V30 M0.3 Z13 SP POM

CMS-V30 M0.3 Z16/Z90 SP POM

CMS-V30 D3 L79 SUS 420J2

ABS+GS 20% CMS-V10N

ABS 94HB

-,-,-,CMS-V30

P/U SOH-A1 ROW V-P/J

CS STS-W PI0.4 D5.7 L9.3 CMS-V10N

RF-310T-11400 43L 25V 85mA

RF-310TA 30MM NDM4RA3ETL 11.0MM

+M2X3 FE FZY W700

Loading...

Loading...