Page 1

TFT-LCD TV/MONITOR

Chassis Model

NF26UO LT-P266W

SERVICE

Manual

TFT-LCD TV/MONITOR CONTENTS

1. Precautions

2. Product Specifications

3. Disassembly & Reassembly

4. Alignment & Adjustments

5. Troubleshooting

6. Exploded View & Parts List

7. Parts List

8. Block Diagram

9. Wiring Diagram

10. PCB Layout

11. Schematic Diagrams

12. Panel Description

Page 2

❈ This Service Manual is a property of Samsung

Electronics Co., Ltd.

Any unauthorized use of Manual can be punished

under applicable International and/or domestic law.

Samsung Electronics Co.,Ltd.

416, Maetan-3Dong, Yeongtong-Gu, Suwon City, Kyungki-Do, Korea, 443-742

Printed in Korea

P/N : BN82-00109N-00

URL : http://itself.sec.samsung.co.kr/

Page 3

1 Precautions

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

(READING SHOULD

NOT BE ABOVE 0.5mA)

LEAKAGE

CURRENT

TESTER

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

!

Follow these safety, servicing and ESD precautions to prevent damage and to protect against potential hazards such as

electrical shock.

1-1 Safety Precautions

1-1-1 Warnings

1. For continued safety, do not attempt to modify the

circuit board.

2. Disconnect the AC power and DC Power Jack

before servicing.

1-1-2 Servicing the LCD Monitor

1. When servicing the LCD Monitor Disconnect the

AC line cord from the AC outlet.

2. It is essential that service technicians have an

accurate voltage meter available at all times. Check

the calibration of this meter periodically.

1-1-3 Fire and Shock Hazard

Before returning the monitor to the user, perform the

following safety checks:

1. Inspect each lead dress to make certain that the

leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in

the monitor.

2. Inspect all protective devices such as nonmetallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

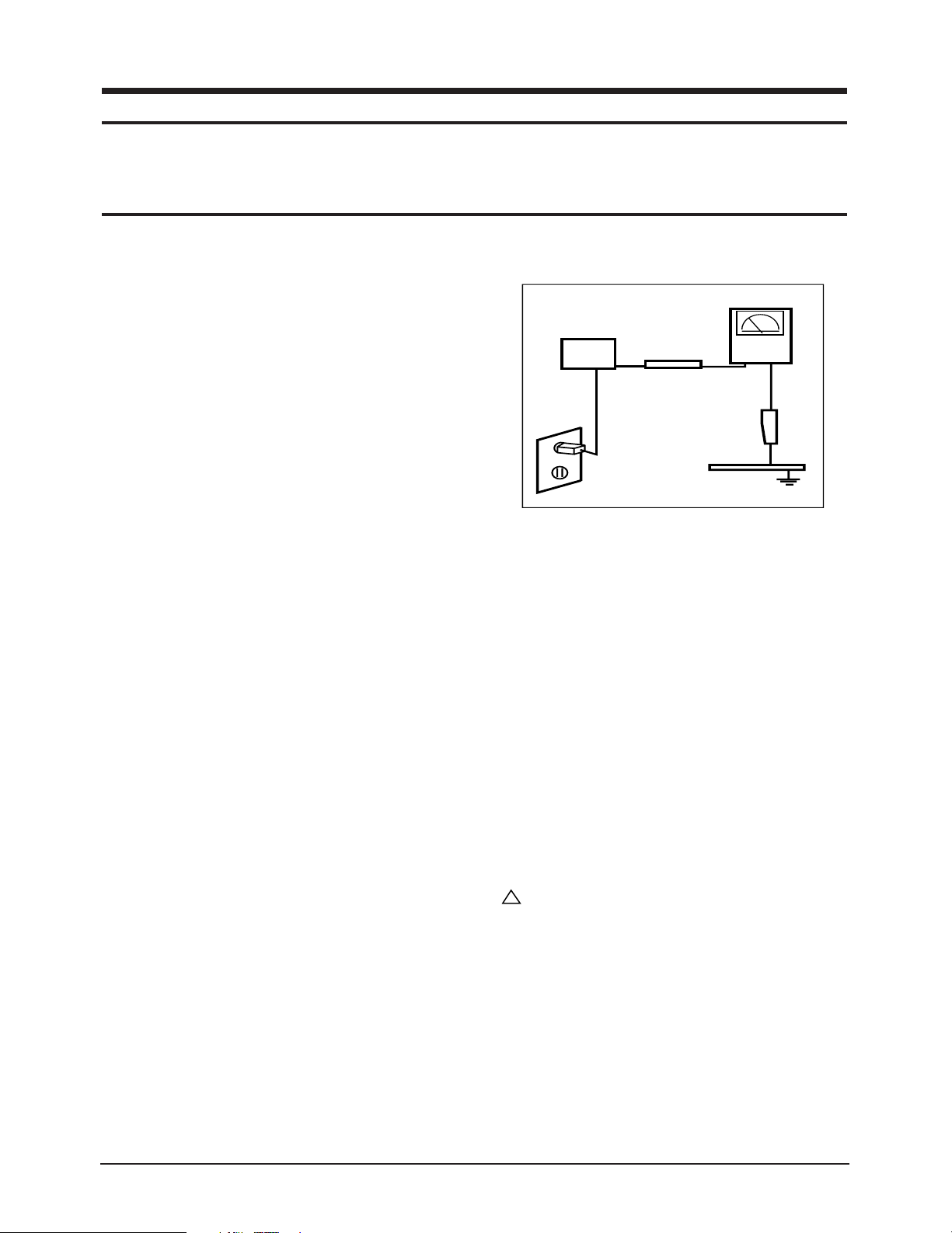

3. Leakage Current Hot Check (Figure 1-1):

WARNING: Do not use an isolation transformer during

this test.

Use a leakage current tester or a metering system

that complies with American National Standards

Institute (ANSI C101.1, Leakage Current for

Appliances), and Underwriters Laboratories (UL

Publication UL1410, 59.7).

Figure 1-1. Leakage Current Test Circuit

4. With the unit completely reassembled, plug the AC

line cord directly into a 120V AC outlet. With the

unit’s AC switch first in the ON position and then

OFF, measure the current between a known earth

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including: metal cabinets,

screwheads and control shafts. The current

measured should not exceed 0.5 milliamp. Reverse

the power-plug prongs in the AC outlet and repeat

the test.

1-1-4 Product Safety Notices

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection. The protection they give

may not be obtained by replacing them with

components rated for higher voltage, wattage, etc. Parts

that have special safety characteristics are identified by

on schematics and parts lists. A substitute

replacement that does not have the same safety

characteristics as the recommended replacement part

might create shock, fire and/or other hazards. Product

safety is under review continuously and new

instructions are issued whenever appropriate.

LT-P266W 1-1

Page 4

1 Precautions

1-2 Servicing Precautions

WARNING: An electrolytic capacitor installed with the wrong polarity might explode.

Caution: Before servicing units covered by this service manual, read and follow the Safety Precautions

section of this manual.

Note: If unforeseen circumstances create conflict between the following servicing precautions and any of the

safety precautions, always follow the safety precautions.

1-2-1 General Servicing Precautions

1. Always unplug the unit’s AC power cord from the

AC power source and disconnect the DC Power

Jack before attempting to:

(a) remove or reinstall any component or assembly,

(b) disconnect PCB plugs or connectors, (c) connect

a test component in parallel with an electrolytic

capacitor.

2. Some components are raised above the printed

circuit board for safety. An insulation tube or tape

is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

3. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the area around the

serviced part has not been damaged.

4. Check the insulation between the blades of the AC

plug and accessible conductive parts (examples:

metal panels, input terminals and earphone jacks).

5. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the power

switch ON. Connect an insulation resistance meter

(500 V) to the blades of the AC plug.

The insulation resistance between each blade of the

AC plug and accessible conductive parts (see

above) should be greater than 1 megohm.

6. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrument’s

ground lead last.

1-3 Electrostatically Sensitive Devices (ESD) Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD are integrated circuits and some field-effect

transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known earth

ground. Alternatively, wear a discharging wriststrap device. To avoid a shock hazard, be sure to

remove the wrist strap before applying power to

the monitor.

2. After removing an ESD-equipped assembly, place it

on a conductive surface such as aluminum foil to

prevent accumulation of an electrostatic charge.

3. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESDs.

4. Use only a grounded-tip soldering iron to solder or

desolder ESDs.

5. Use only an anti-static solder removal device. Some

solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage

ESDs.

6. Do not remove a replacement ESD from its

protective package until you are ready to install it.

Most replacement ESDs are packaged with leads

that are electrically shorted together by conductive

foam, aluminum foil or other conductive materials.

7. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

Caution: Be sure no power is applied to the

chassis or circuit and observe all

other safety precautions.

8. Minimize body motions when handling

unpackaged replacement ESDs. Motions such as

brushing clothes together, or lifting your foot from

a carpeted floor can generate enough static

electricity to damage an ESD.

1-2 LT-P266W

Page 5

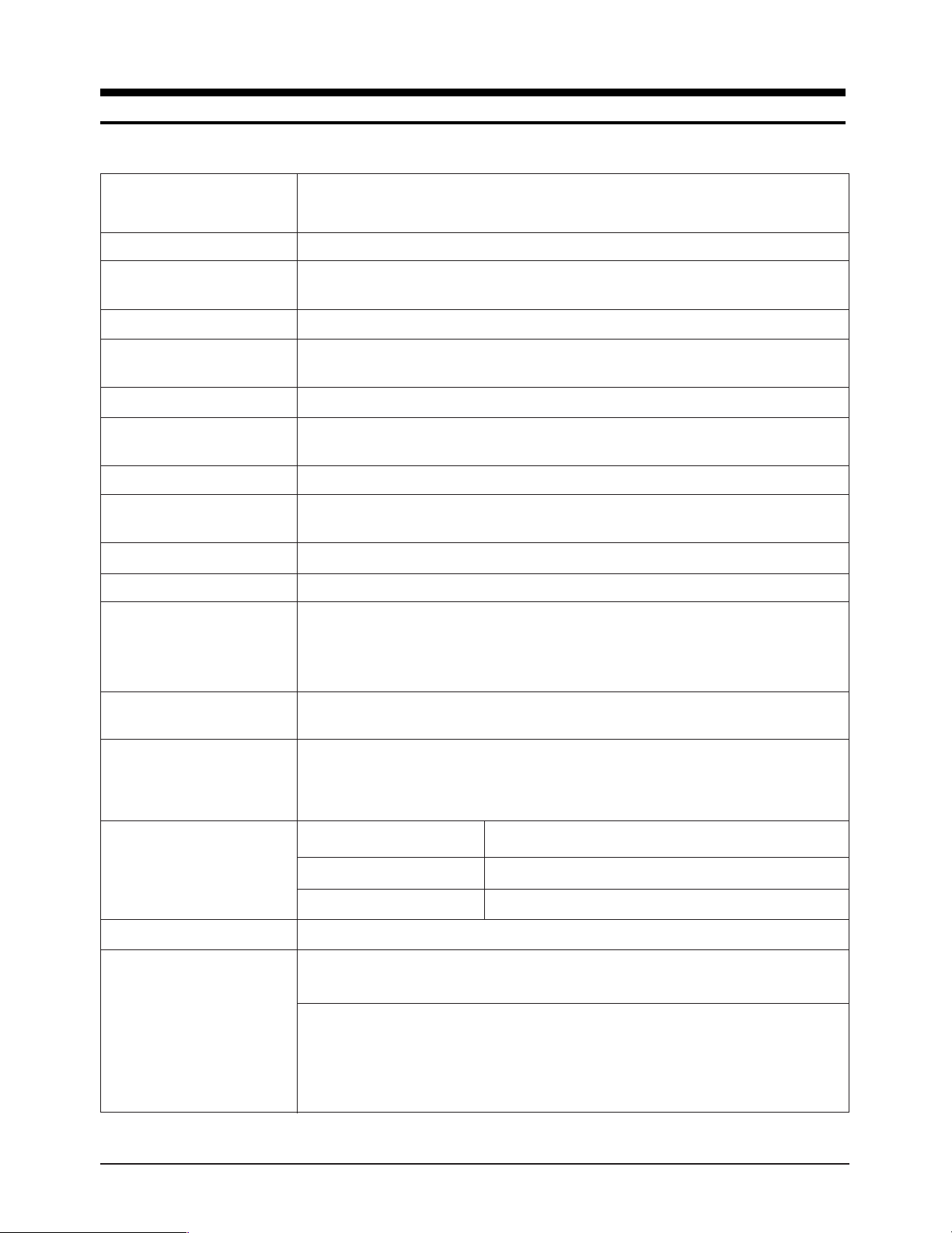

2 Product Specifications

2-1 Specifications

Item

LCD Panel TFT-LCD Panel, RGB vertical stripe, normaly Black, 26-Inch viewable, 0.537 mm pixel pitch

Scanning Frequency Horizontal : 30 kHz ~ 68 kHz (Automatic)

Vertical : 56 Hz ~ 85 Hz (Automatic)

Display Colors 16.7 Million colors

Maximum Resolution Horizontal : 1280 Pixels

Vertical : 768 Pixel

Input Video Signal Positive at 75 Ω

Input Sync Signal Type : Seperate H/V

Level : TTL level

Maximum Pixel Clock rate 80 MHz

Active Display

Horizontal/Vertical

AC power voltage & Frequency

Power Consumption 130 W

Dimensions (W x H x D)

Set 29.17 x 10.89 x 20.70 Inches (741.0 X 276.8 X 526.0 mm) State of stand installed

Package

Weight

Set / Package 15.0 kg (33.07 lbs) / 16.8 kg (37.04 lbs)

687.36 mm/ 412.42 mm

AC 100 - 240V ~, 50/60 Hz

29.17 x 4.68 x 16.92 Inches (741.0 X 119.0 X 498.5 mm) State of stand disassembled

34.49 x 13.35 x 28.11 Inches (876.0 X 339.0 X 714.0 mm)

Description

Environmental Considerations Operating Temperature : 50 °F ~ 104 °F (10 °C ~ 40 °C)

Operating Humidity : 10 % ~ 80 %

Storage Temperature : -4 °F ~ 113 °F (-20 °C ~ 45 °C)

Storage Humidity : 5 % ~ 95 %

Tunning Frequency Synthesize

TV System

Antena Input 75Ω

– MAX Internal speaker Out : Right => 5W

Sound Characteristic

– BASS Control Range : -8 dB ~ + 8dB

– TREBLE Control Range : -8 dB ~ +8 dB

– Headphone Out : 10 mW MAX

– Output Frequency : RF : 80 Hz ~ 15 kHz

LT-P266W 2-1

System NTSC-M

Sound STEREO

Left => 5W

A/V : 80 Hz ~ 20 kHz

Page 6

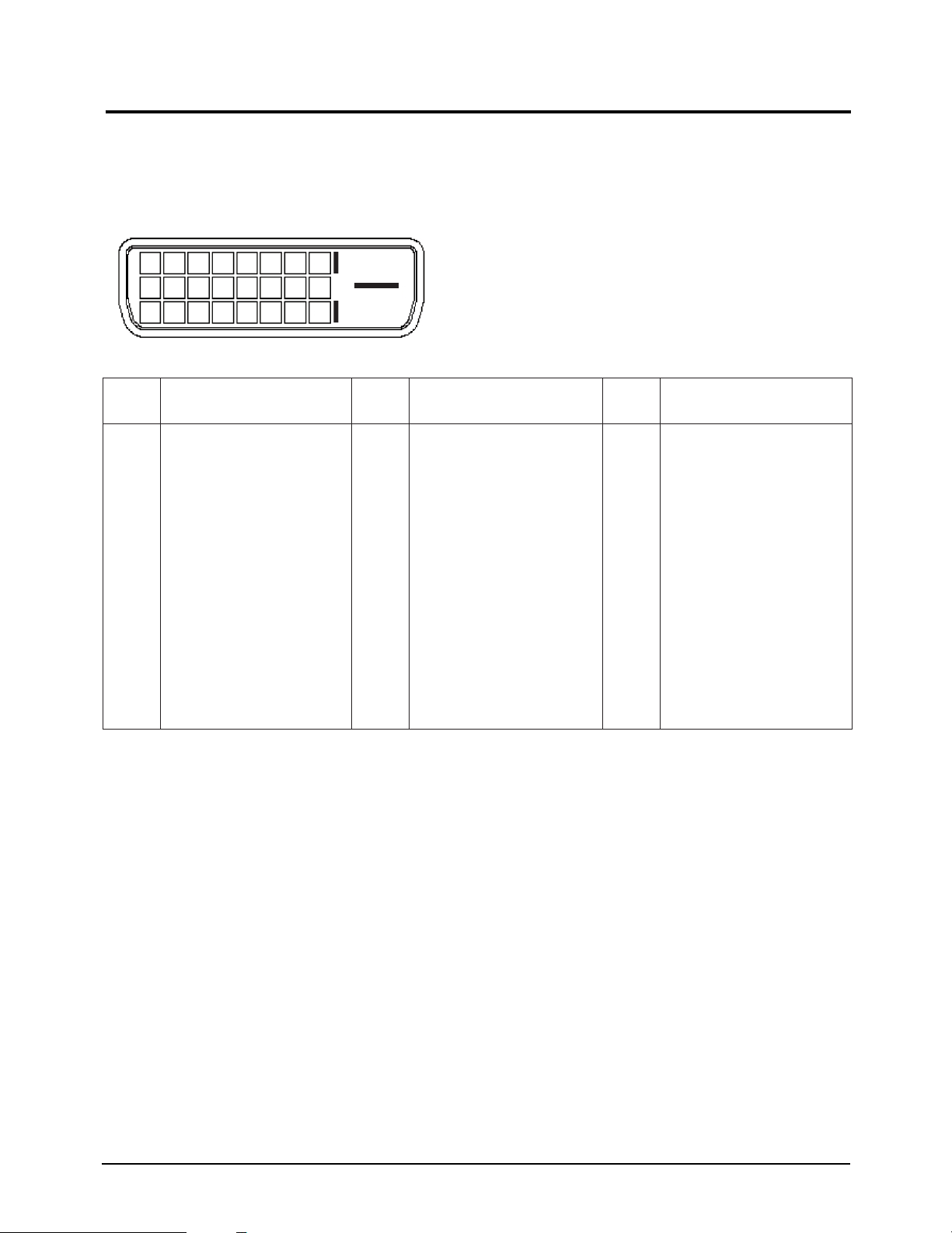

2 Product Specifications

12 345 67 8

9 10111213141516

17 18 19 20 21 22 23 24

2-2 Pin Assignments

2-2-1 DVI-D (Digital)

Ref) DVI-D : Digital only

Pin No.

1

2

3

4

5

6

7

8

9

10

Signal Assignment

RX2-

RX2+

GND

NC

NC

DDC Clock (SCL)

DDC Data (SDA)

Analog Vertical Sync.

RX1-

RX1+

Pin No.

11

12

13

14

15

16

17

18

19

20

Signal Assignment

GND

NC

NC

DDC Input Power(+5V)

IDENT_PC

5V

RX0-

RX0+

GND

NC

Pin No.

21

22

23

24

Signal Assignment

NC

GND

RXC+

RXC-

2-2 LT-P266W

Page 7

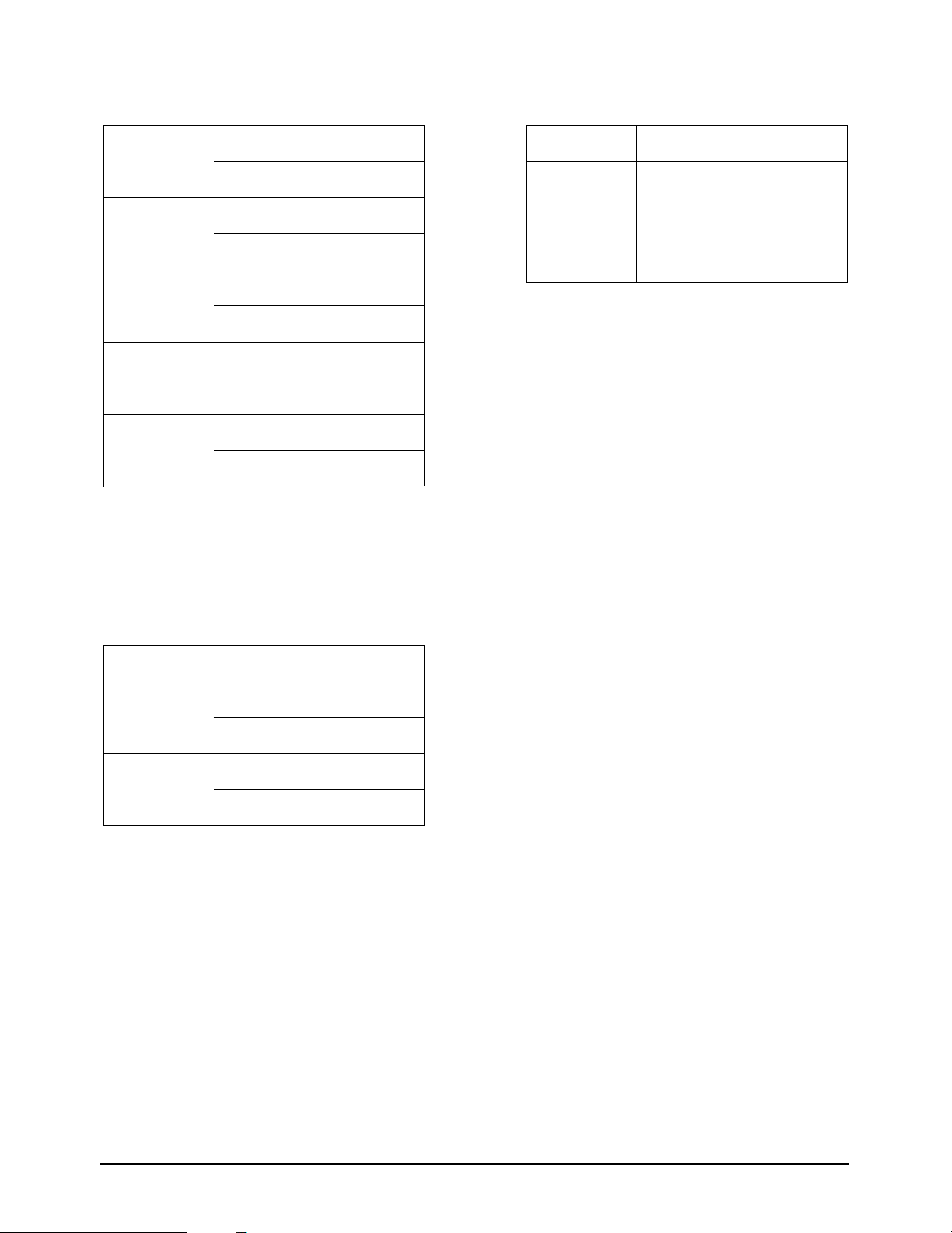

2 Product Specifications

2-2-2 Component 1, 2

RCA Green

RCA Blue

RCA Red

RCA White

RCA Red

Y

GND

Pb (Cb)

GND

Pr (Cr)

GND

Audio L

GND

Audio R

GND

2-2-3 S-Video

Pin

1

2

3

4

5

Separate

GND

Y

C

GND

GND

2-2-4 A/V

RCA Yellow

RCA White

RCA Red

CVBS

Audio L

GND

Audio R

GND

LT-P266W 2-3

Page 8

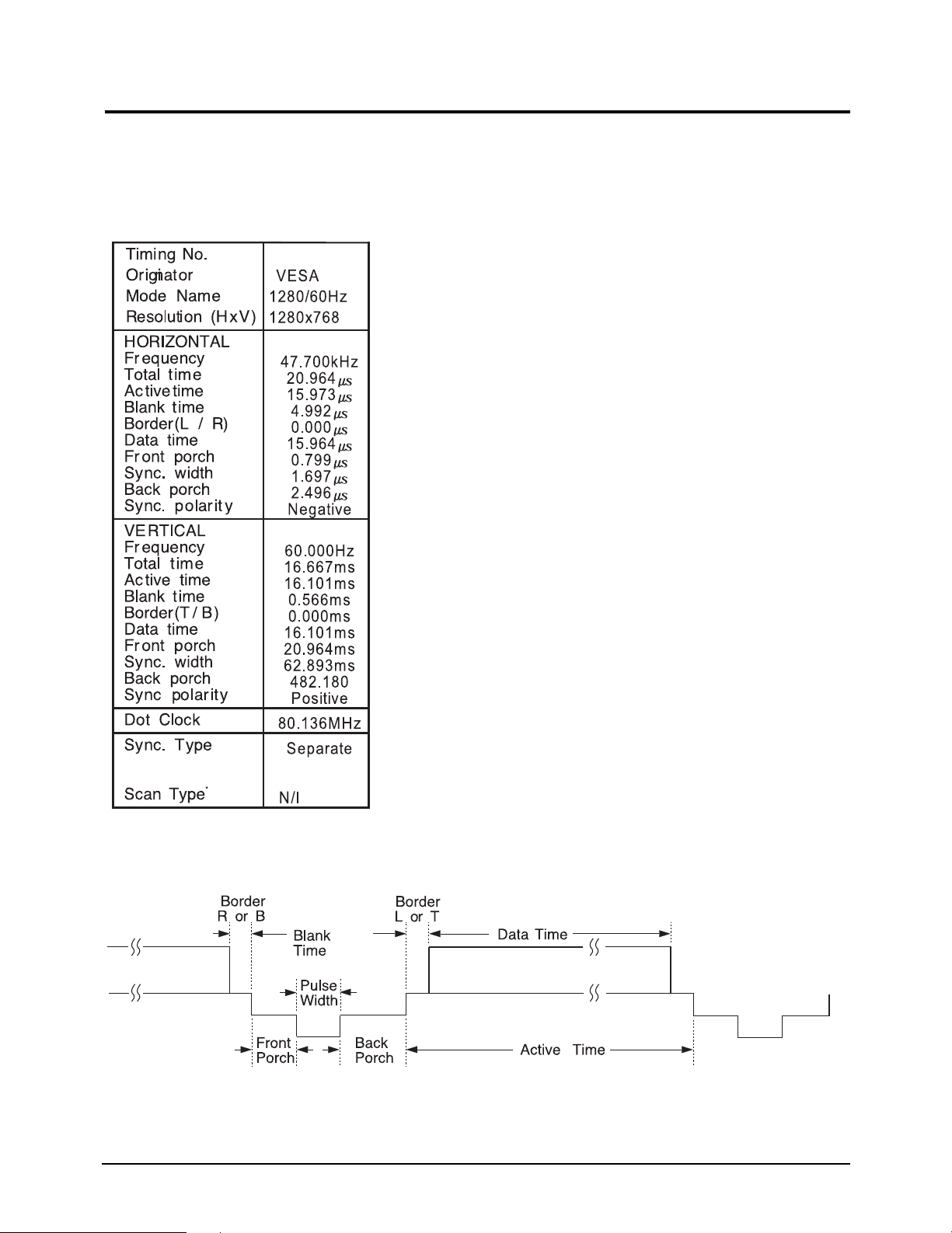

2 Product Specifications

2-3 Timing Chart

This section of the service manual describes the timing that the computer industry recognizes as standard

for computer-generated video signals.

2-3-1 LCD Panel Mode1 mode

2-4 LT-P266W

Page 9

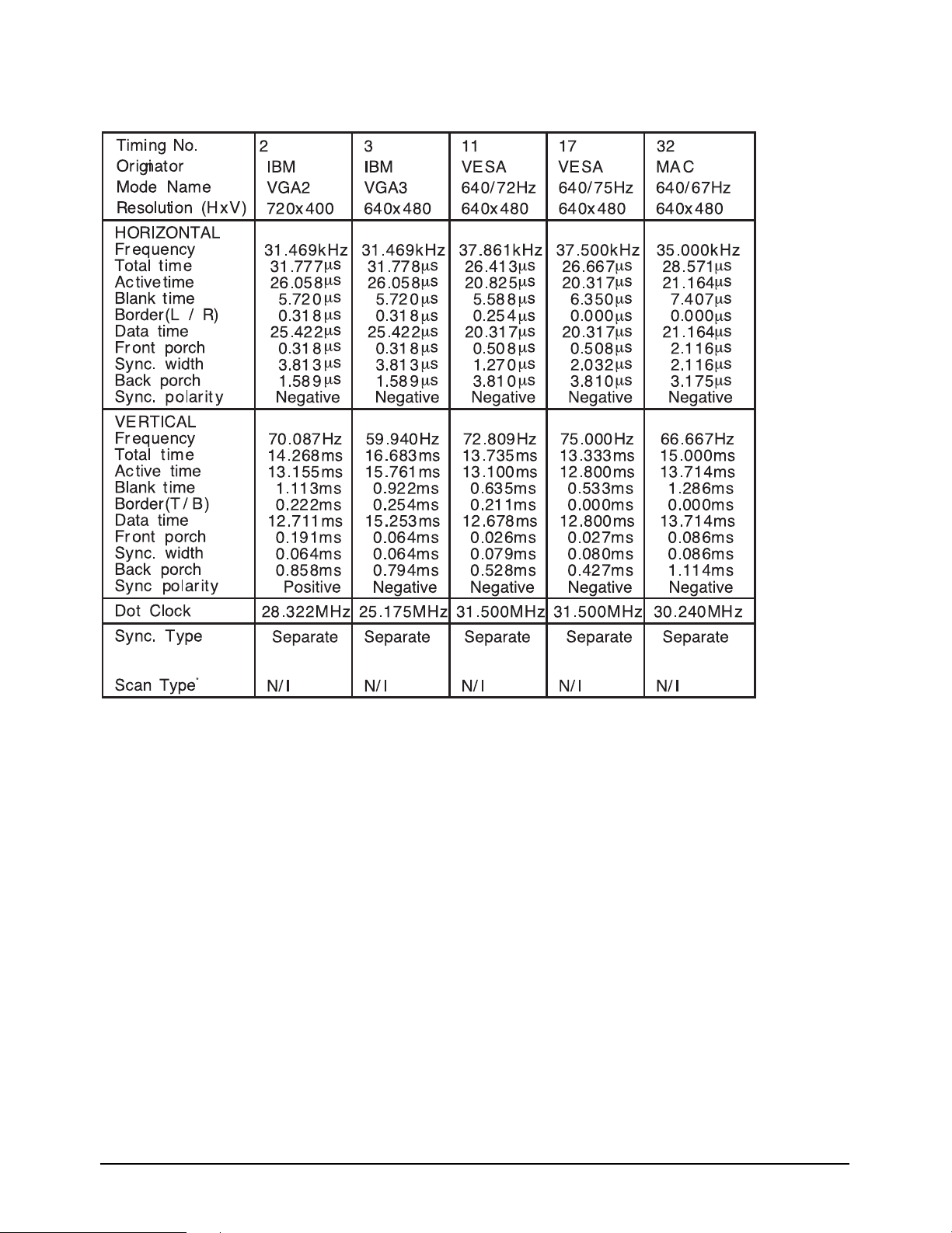

2-3-1 Supported Modes (1)

2 Product Specifications

LT-P266W 2-5

Page 10

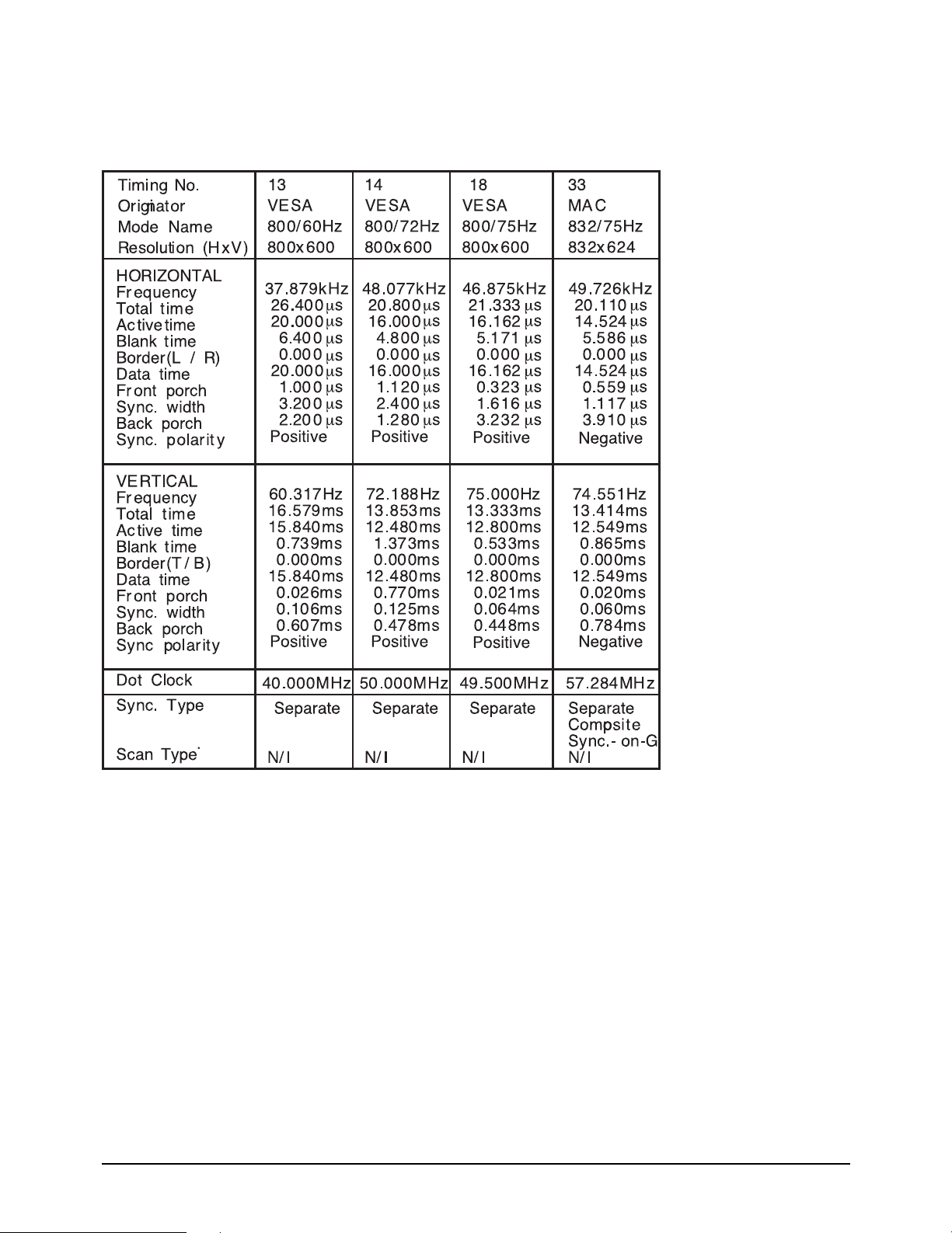

2 Product Specifications

2-3-1 Supported Modes (2)

2-6 LT-P266W

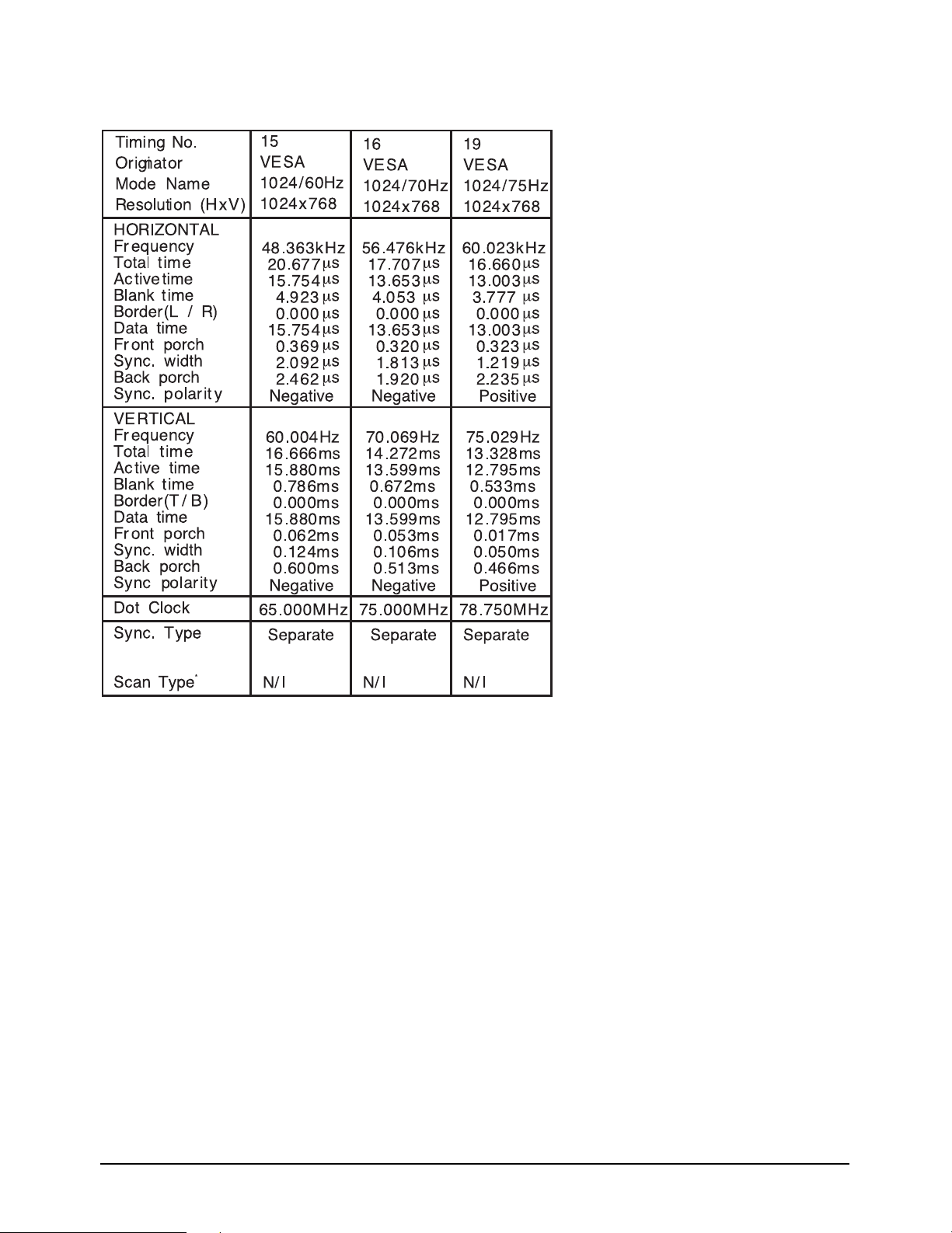

Page 11

2-3-1 Supported Modes (3)

2 Product Specifications

LT-P266W 2-7

Page 12

2 Product Specifications

Memo

2-8 LT-P266W

Page 13

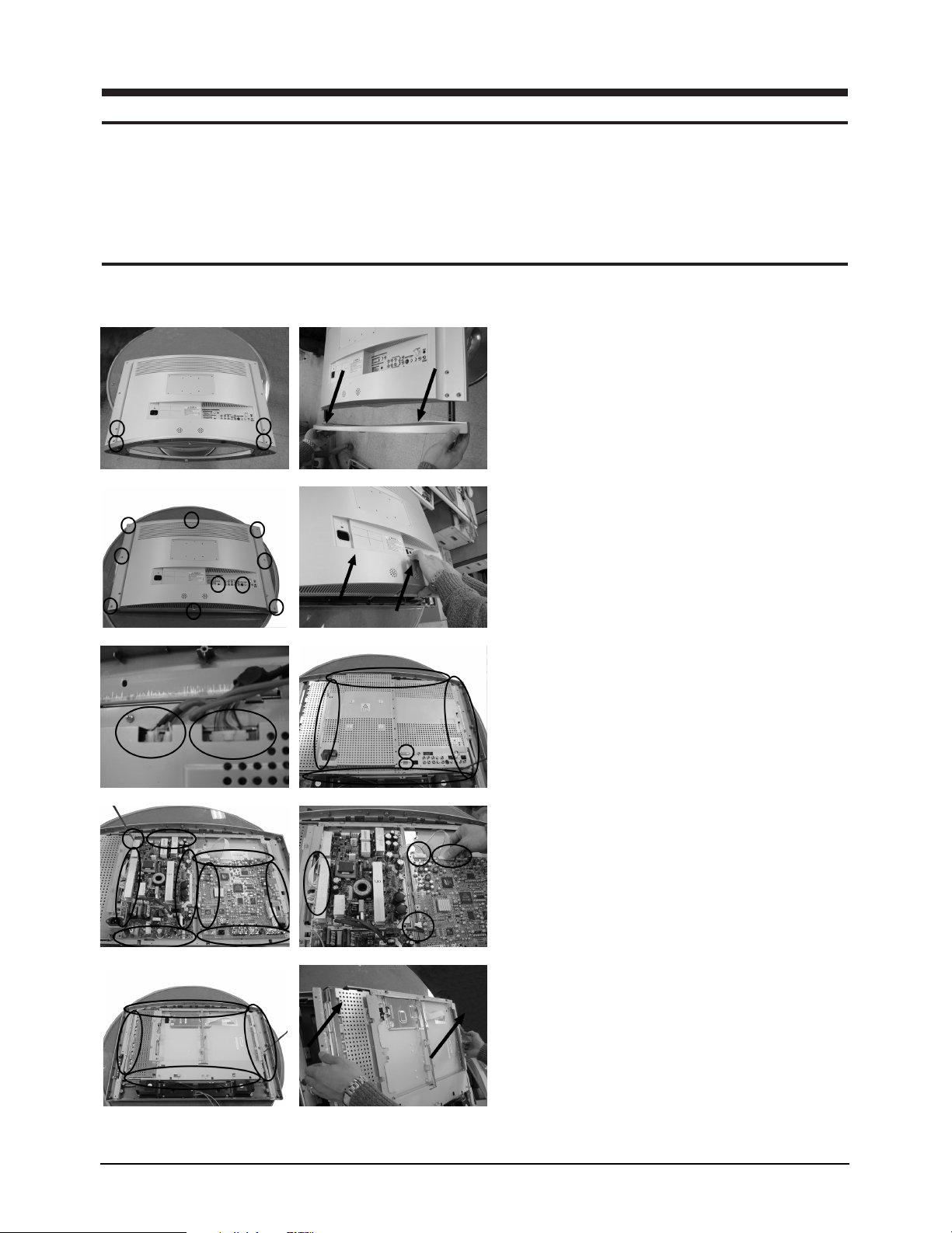

3 Disassembly and Reassembly

This section of the service manual describes the disassembly and reassembly procedures for the

LT-P266W monitor.

WARNING: This monitor contains electrostatically sensitive devices. Use caution when handling

these components.

3-1 Disassembly

Cautions:1. Disconnect the monitor from the power source before disassembly.

1. Place LCD TV face down on cushioned table.

Remove 4 screws from grip on the stand and

remove the stand.

2. Remove 10 screws from the rear cover and lift

up the rear cover.

3. Disconnect speaker cable, function cable from

the shield and remove 19 screws from the

shield.

4. Remove 18 screws from the boards and

disconnect LVDS cable, inverter cable from the

boards.

5. Remove 18 screws from the cabinet BRKT and

lift up the panel.

LT-P266W 3-1

Page 14

3 Disassembly and Reassembly

3-2 Reassembly

6. Remove 4 screws from the panel BRKT.

(Top/Bottom)

Disconnect BRKT from the panel.

7. Remove 4 screws from the panel BRKT.

(Lelt/Right)

Disconnect BRKT from the panel.

Reassembly procedures are in the reverse order of dissasembly procedures.

3-2 LT-P266W

Page 15

4 Alignments and Adjustments

4-1 General Alignment Instuction

1. Usually, a color TV-VCR needs only slight touch-up adjustment upon installation.

Check the basic characteristics such as height, horizontal and vertical sync.

2. Use the specified test equipment or its equivalent.

3. Correct impedance matching is essential.

4. Avoid overload. Excessive signal from a sweep generator might overload the front-end

of the TV. When inserting signal markers, do not allow the marker generator to distort

test result.

5. Connect the TV only to an AC power source with voltage and frequency as specified on

the backcover nameplate.

6. Do not attempt to connect or disconnect any wire while the TV is turned on. Make sure

that the power cord is disconnected before replacing any parts.

7. To protect aganist shock hazard, use an isolation transform.

LT-P266W 4-1

Page 16

4 Alignments and Adjustments

4-2 Factory Mode Adjustments

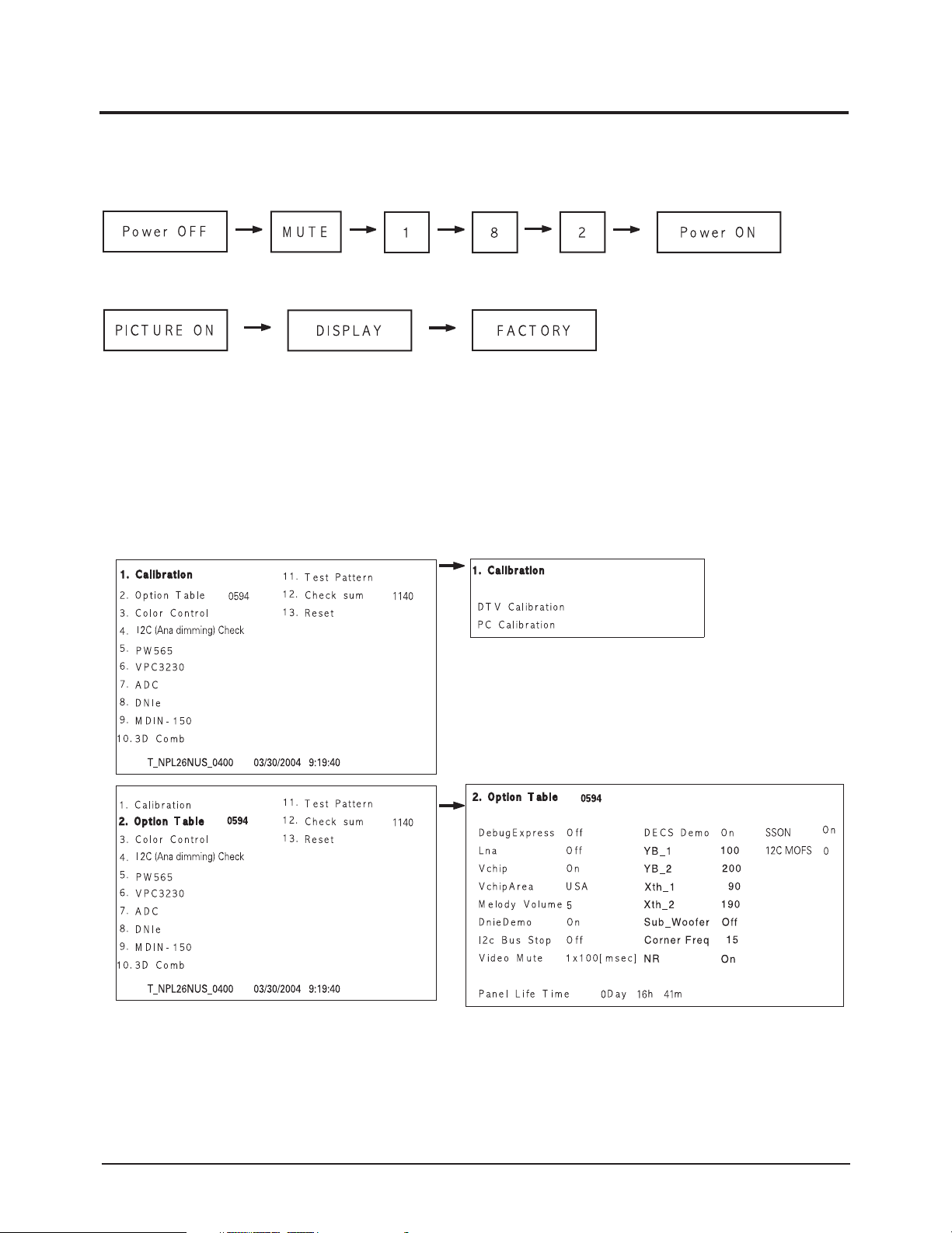

4-2-1 Entering Factory Mode

1. To enter “Service Mode” Press the remote -control keys in this sequence :

- If you do not have Factory remote - control

- If you have Factory remote - control

- The buttons are active in the service mode.

1. Remote - Control Key : Power, Arrow Up, Arrow Down, Arrow Left

Arrow Right, Menu, Enter, Number Key(0~9)

2. Function - Control Key : Power, CH +, CH -, VOL +, VOL -,

Menu, TV/VIDEO(Enter)

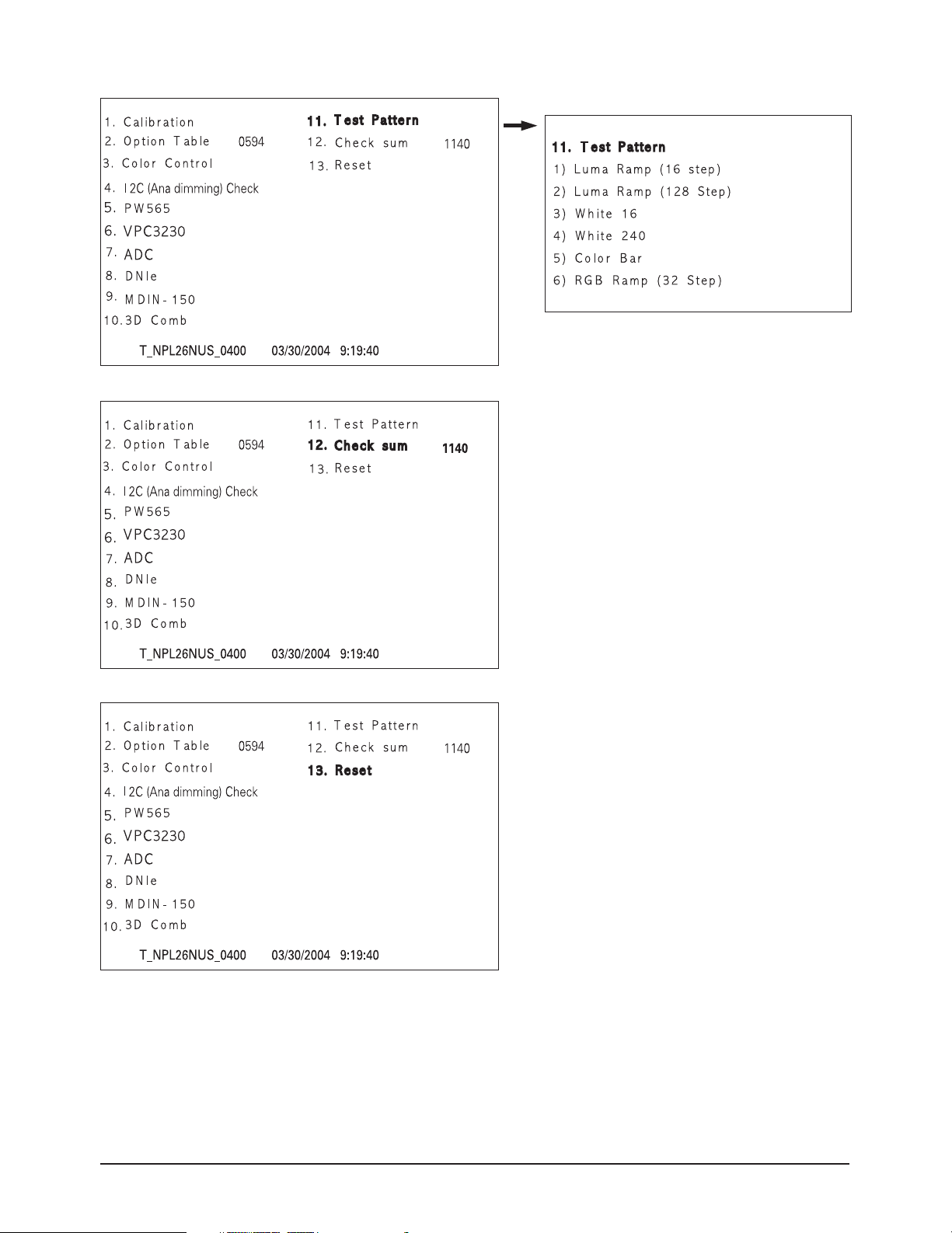

4-2-2 Factory Mode Tree

4-2 LT-P266W

Page 17

4 Alignments and Adjustments

LT-P266W 4-3

Page 18

4 Alignments and Adjustments

4-4 LT-P266W

Page 19

4 Alignments and Adjustments

LT-P266W 4-5

Page 20

4 Alignments and Adjustments

4-6 LT-P266W

Page 21

4 Alignments and Adjustments

LT-P266W 4-7

Page 22

4 Alignments and Adjustments

4-8 LT-P266W

Page 23

4 Alignments and Adjustments

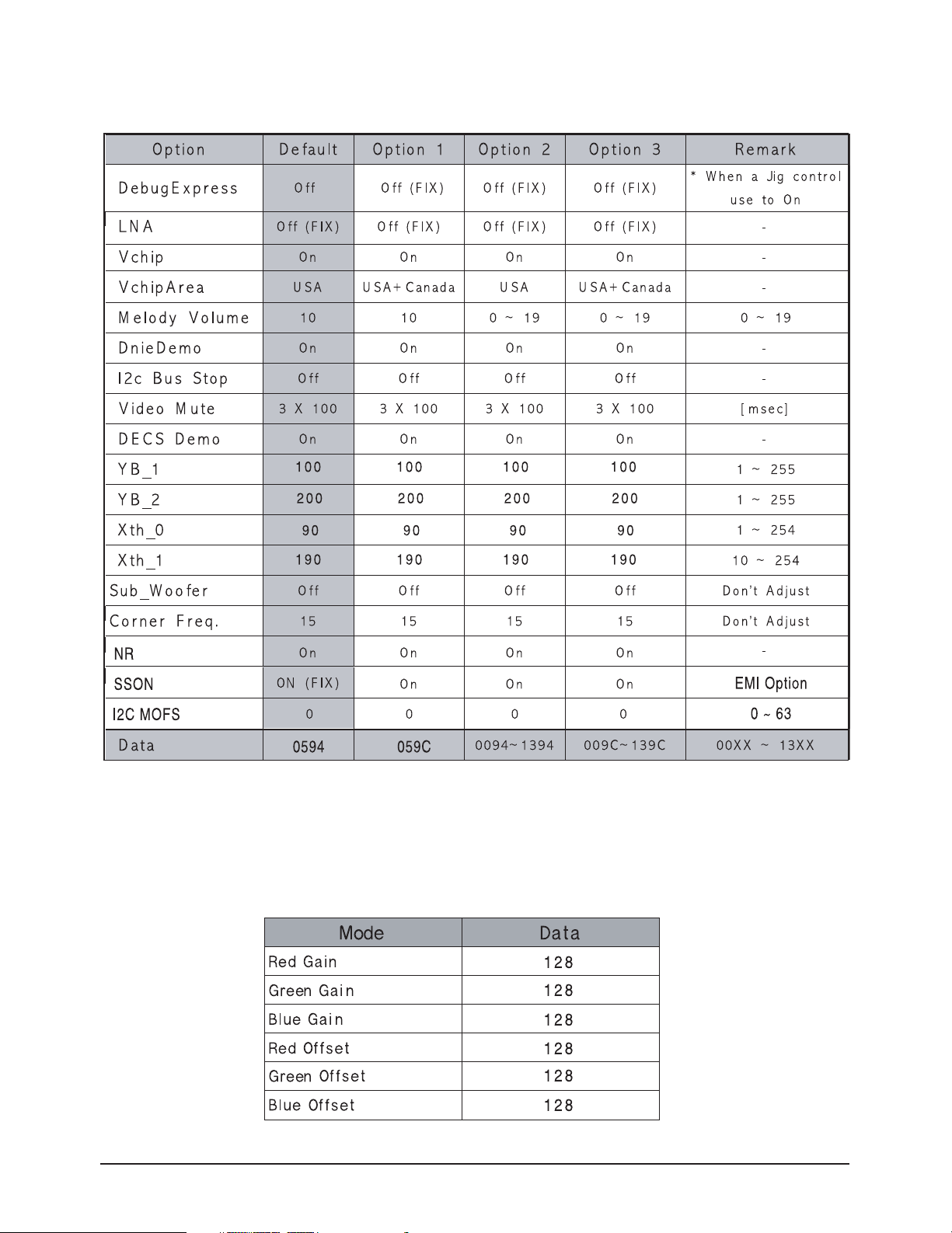

* Unless otherwise specifid, do not adjust data in Factory Mode.

* Data may be changed for display improvement.

LT-P266W 4-9

Page 24

4 Alignments and Adjustments

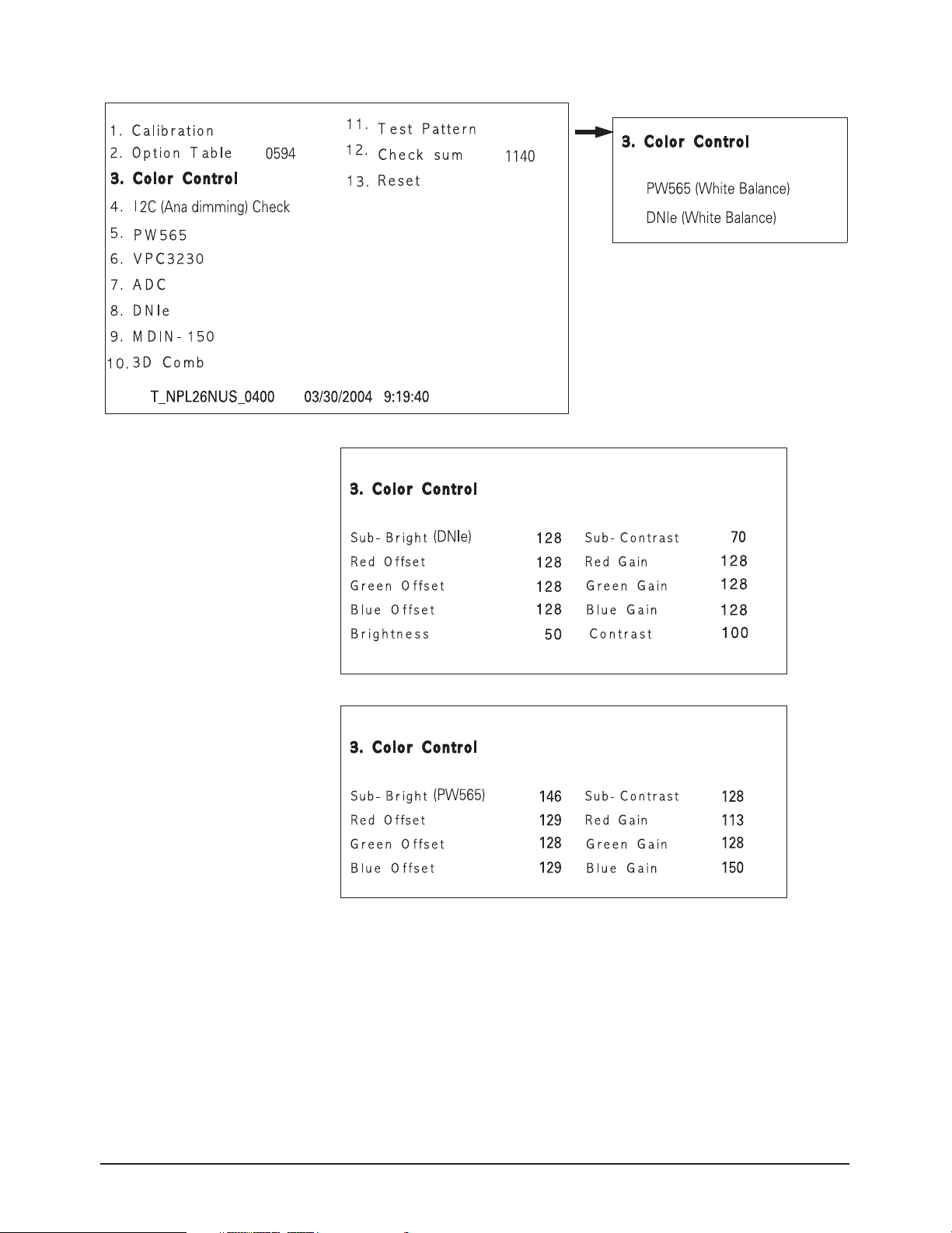

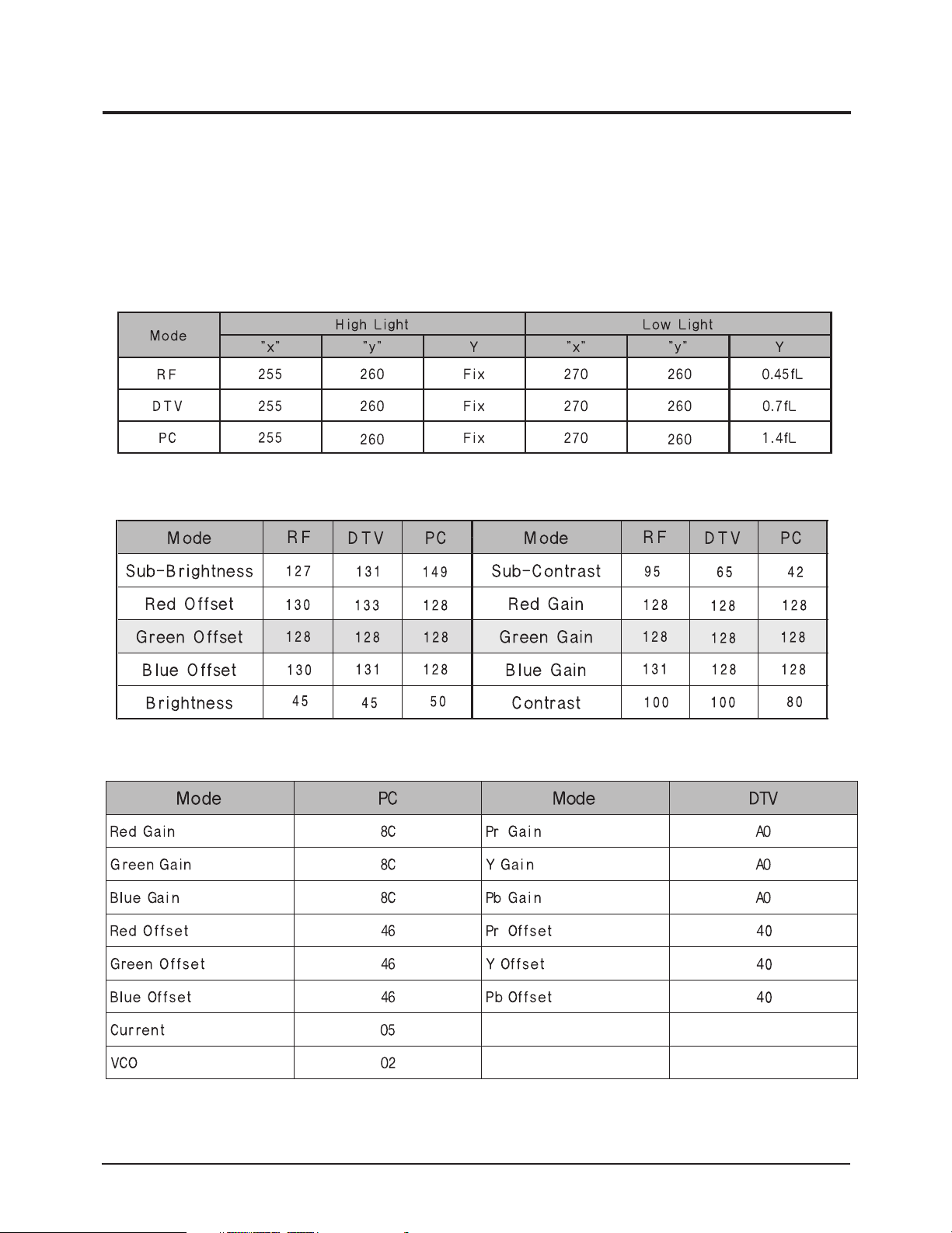

4-3 White Balance Adjustment

1. In factory mode (1, 3, 6), you can adjust the white balance.

2. As the adjustment and data values differ depending on input sources, different adjustments are

requried for RF, DTV (Component 1, 2) and PC/DVI modes.

3. Optimum condition data for each mode are saved as default values. (Refer to Table 2, 3)

4. As the RF mode is applied with the same vlaues as for VIDEO and S-VIDEO, adjustment can be

made in any of RF, VIDEO and S-VIDEO modes.

Table 4-1. White Balance Setting Conditions

Table 4-2. Color Control Default Vlaue

Table 4-3. Color Control Default Vlaue

4-10 LT-P266W

Page 25

4-3-1 Conditions for Measurement

1. On the basis of toshiba ABL pattern : High Light level (57 IRE)

- INPUT SIGNAL GENERATOR : MSPG-925LTH

* Mode NO 1 : 750X480@60 Hz

NO 6 : 1280X720@60 Hz

NO 21 : 1024X768@60 Hz

* Pattern NO 36 : 16 Color Pattern

NO 16 : Toshiba ABL Pattern

2. Optical measuring device : CA210 (FL)

Please use the MSPG-925 LTH generator for model LT-P266W.

4-3-2 Method of Adjustment

1. Adjust the basic level of DTV and PC input signals.

a) Set the input to the mode in which the adjustment will be made (DTV PC).

* Input signal - DTV Mode : Model #6 (1280*720 Mode), Pattern #36

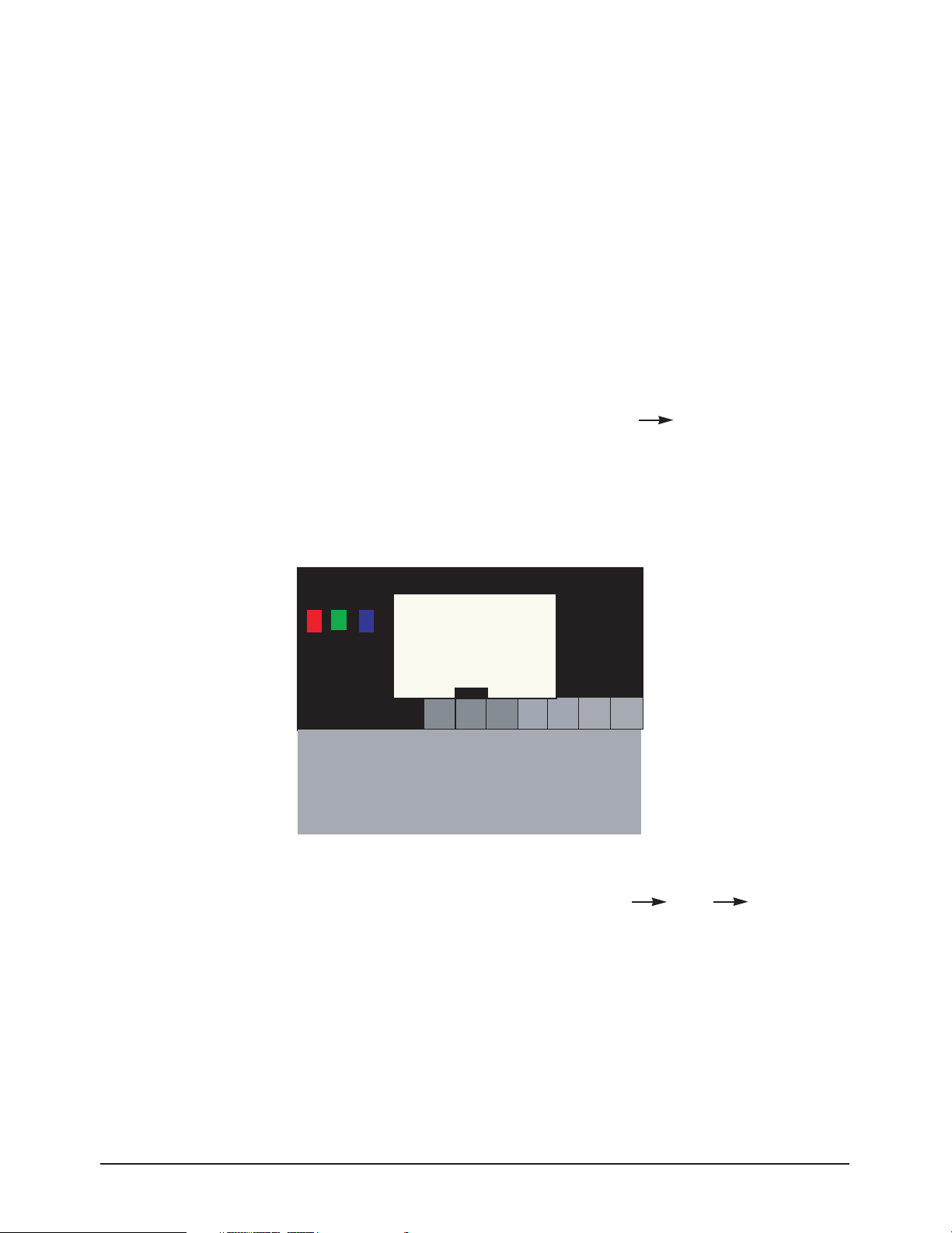

- PC Mode : Model #21 (1024*768 Mode), Pattern #16 (Picture 4-1)

b) Enter factory Calibration, confirm the ADC data (DTV, PC Mode Only).

* ADC default value : Table 4-3.

4 Alignments and Adjustments

Picture 4-1 Toshiba ABL Pattern

2. Adjust the white balance of RF, DTV and PC Modes.

a) Set the input to the mode in which the adjustment will be made (RF DTV PC).

* Input signal - VIDEO Mode : Model #1 (750*480 Mode), Pattern #16

- DTV Mode : Model #6 (1280*720 Mode), Pattern #16

- PC Mode : Model #21 (1024*768 Mode), Pattern #16

b) Enter factory color control, confirm the data.

LT-P266W 4-11

Page 26

4 Alignments and Adjustments

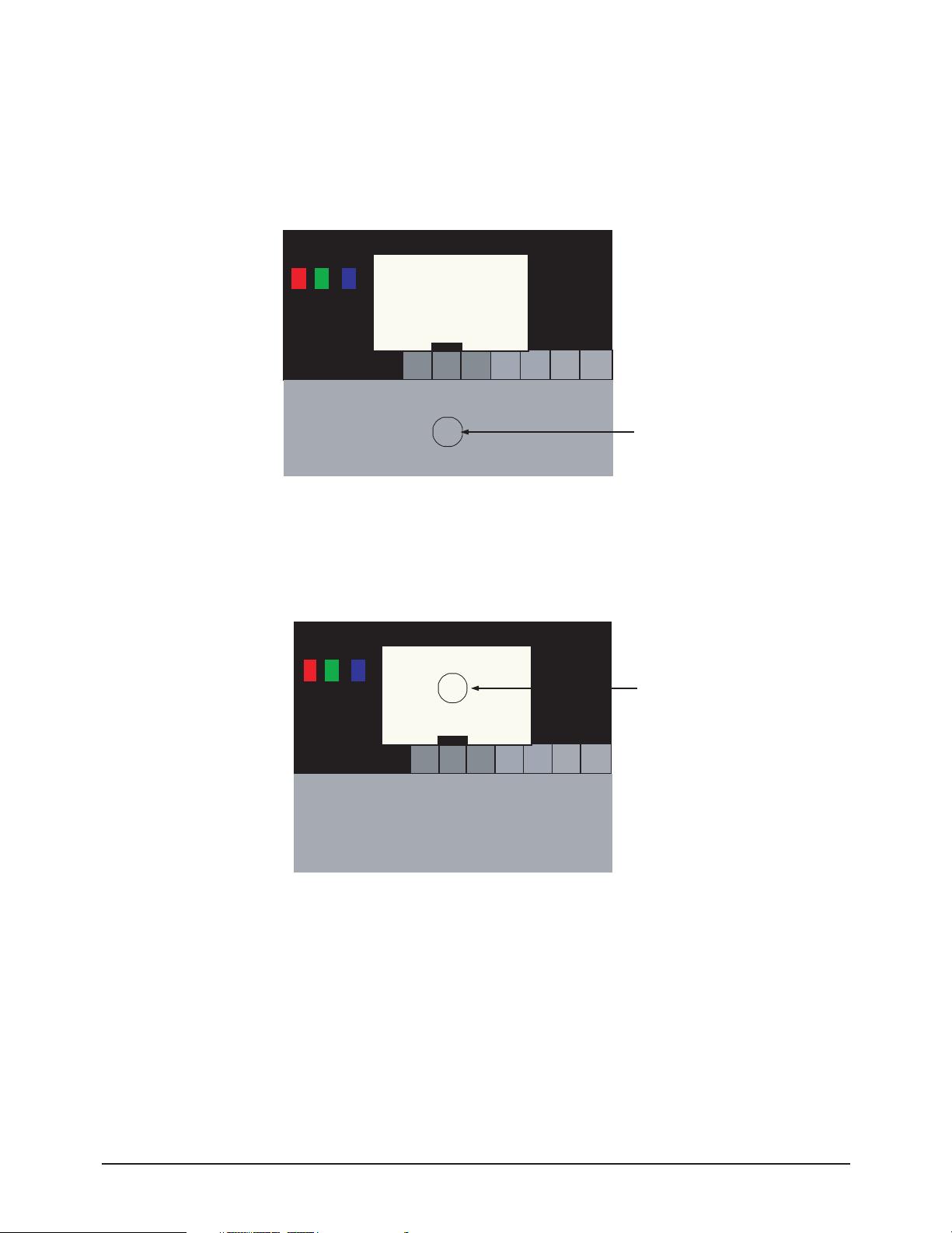

c) Adjust the low light. (Refer to table 1, 2 in adjustment position by mode)

- Adjust sub - Brightness to set the 'Y' value.

- Adjust red offset ('x') and blue offset ('y') to the color coordinates.

* Do not adjust green offset data.

Picture 4-2 Toshiba ABL Pattern

Low light

Measurement point

d) Adjust the high light. (Refer to table 1, 2 in adjustment position by mode)

- Adjust red gain ('x') and blue gain ('y') to the color coordinates.

* Do not adjust the green gain and sub-contrast (Y) data.

Picture 4-3 Toshiba ABL Pattern

High light

Measurement point

4-12 LT-P266W

Page 27

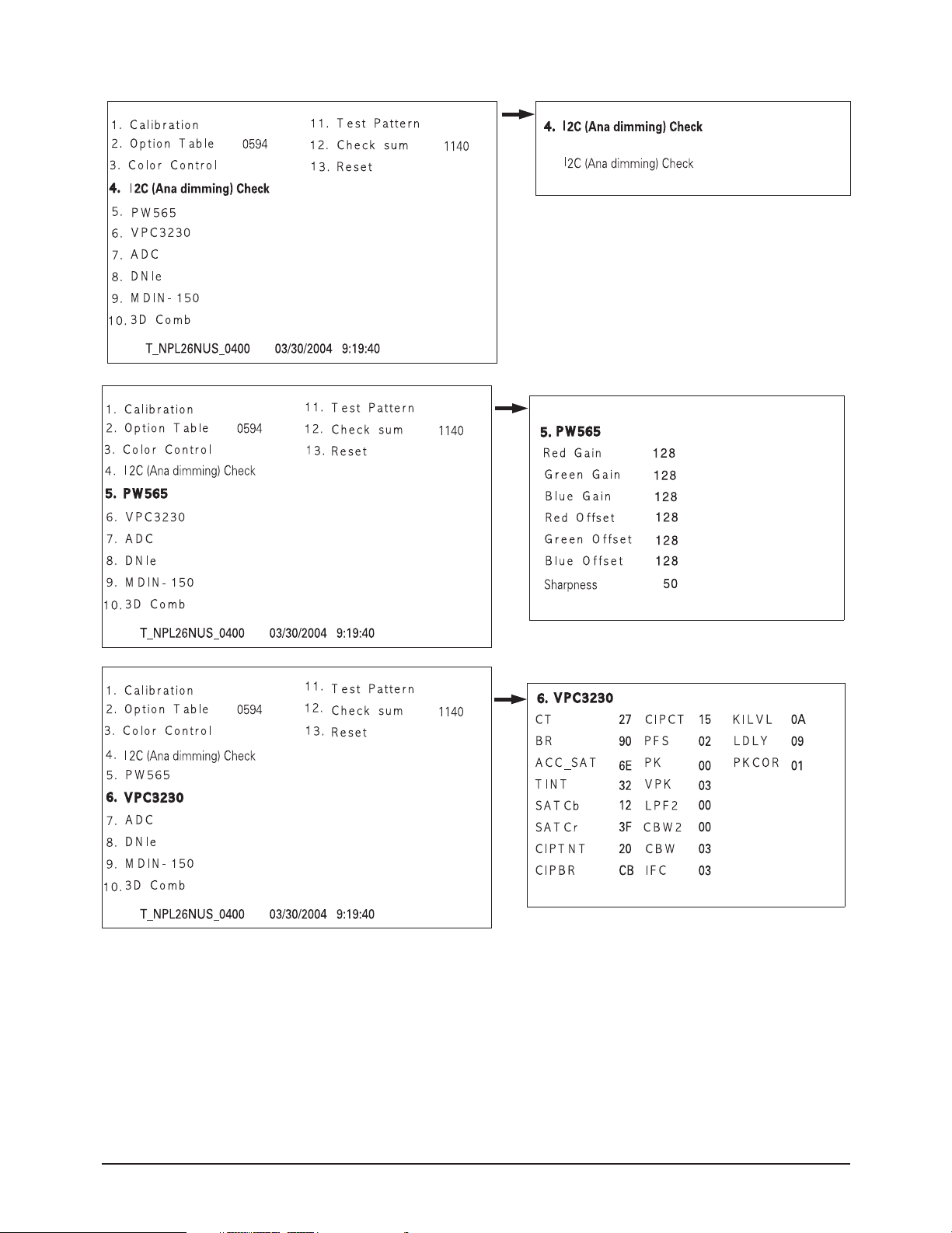

4-3-3 Option Table

4 Alignments and Adjustments

* The default settings are most recommended for Option Data. Each data may be adjusted.

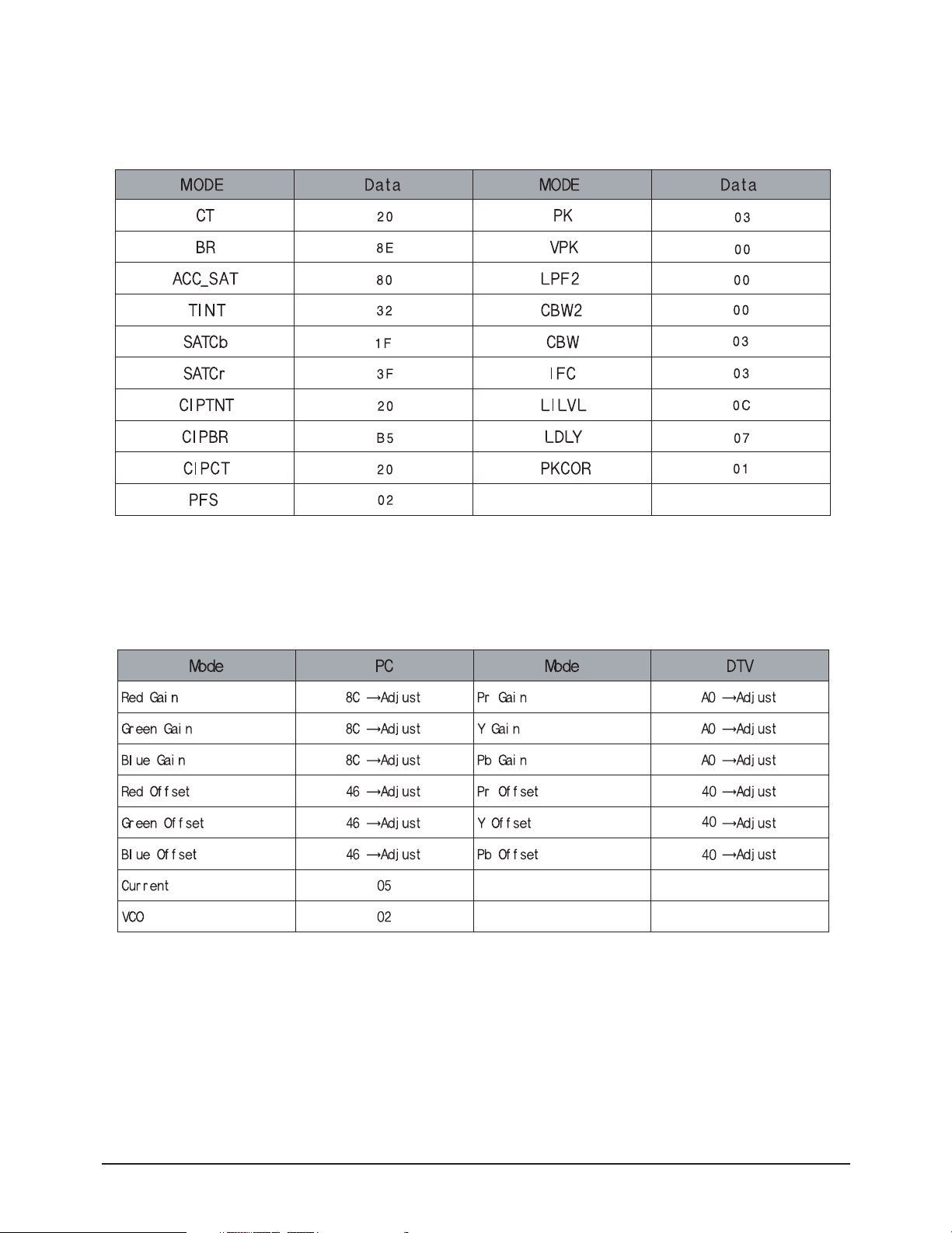

4-3-4 PW565

* Below figures are for contrast adjustment of PW565 (IC565). Do not change the data.

LT-P266W 4-13

Page 28

4 Alignments and Adjustments

4-3-5 VPC 3230-MAIN

* Data may be adjusted.

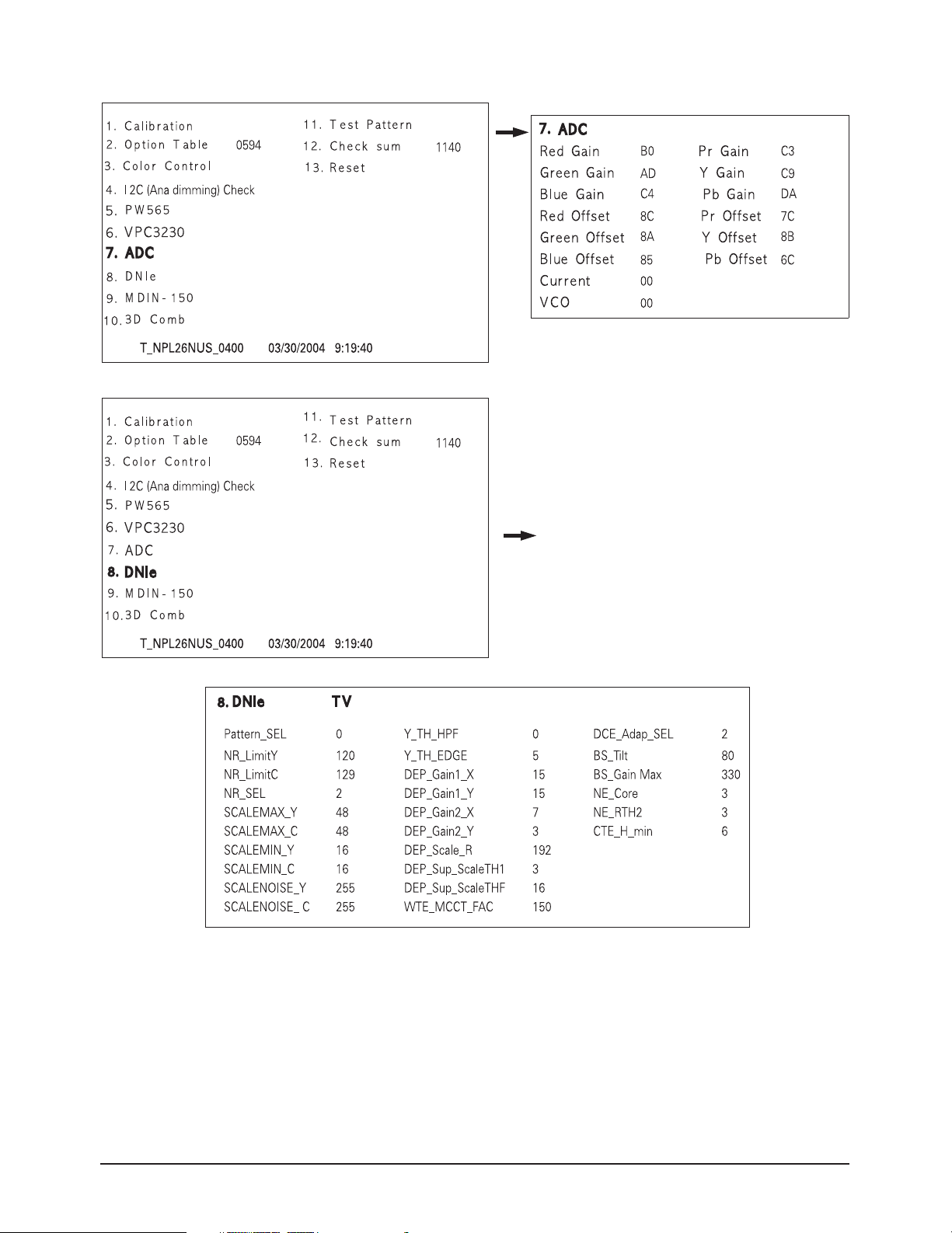

4-3-6 ADC

*Adjust the R(Pr), G(Y), B(Pb) gain and offset to the basic level of DTV and PC Input signals.

4-14 LT-P266W

Page 29

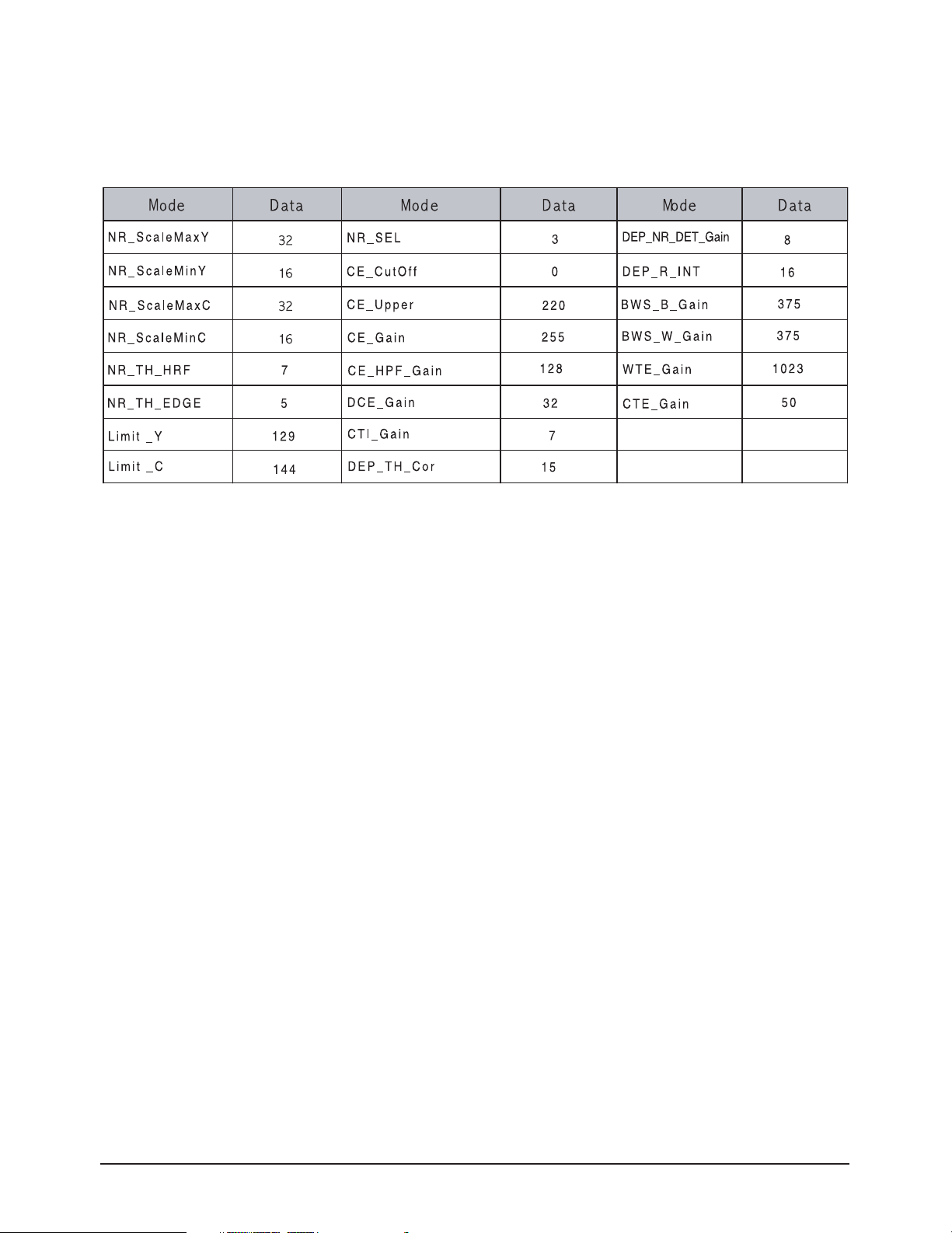

4-3-7 DNIe

* Control the specify item that a output signals of scalar (PW565).

* This data can be changed without notice.

4 Alignments and Adjustments

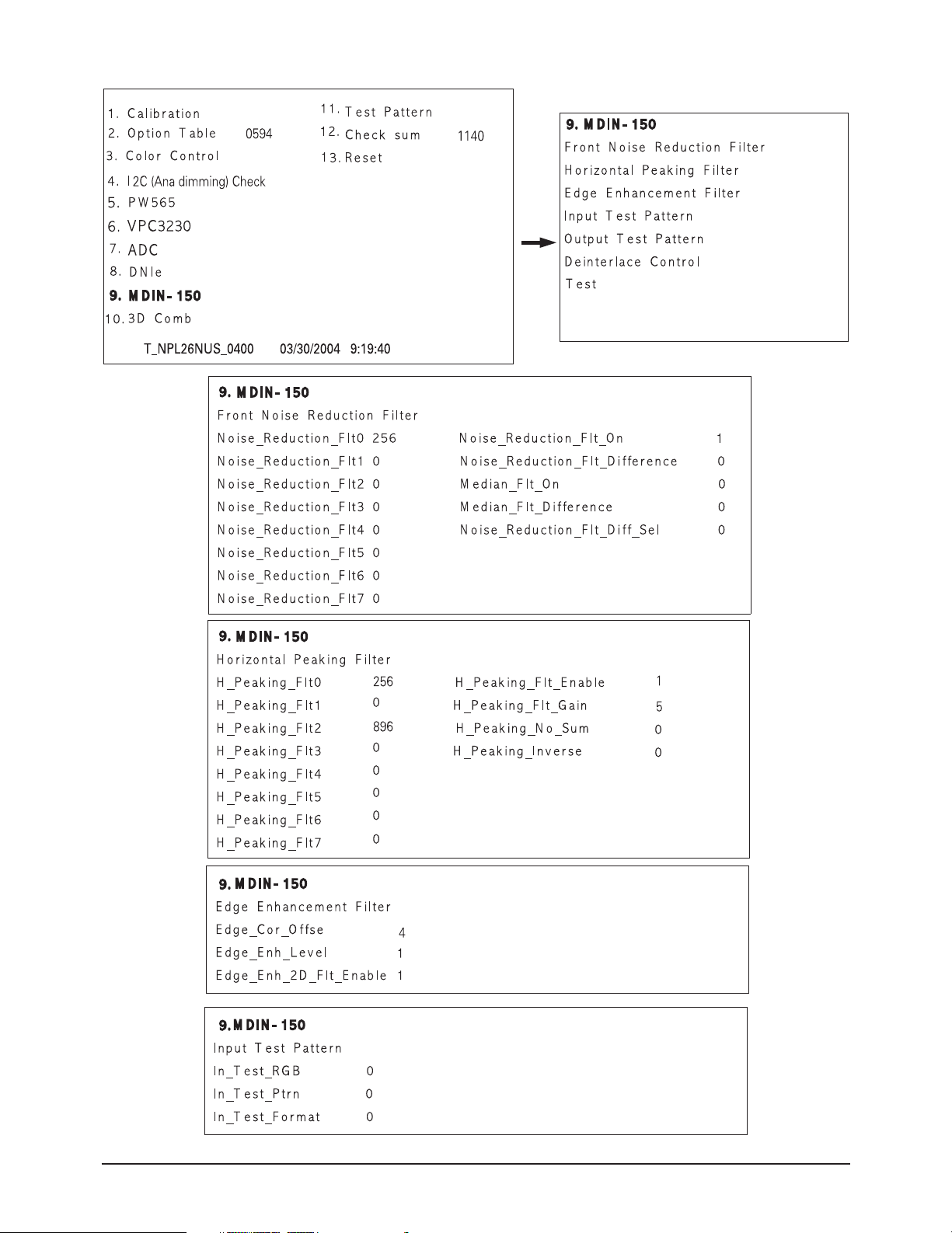

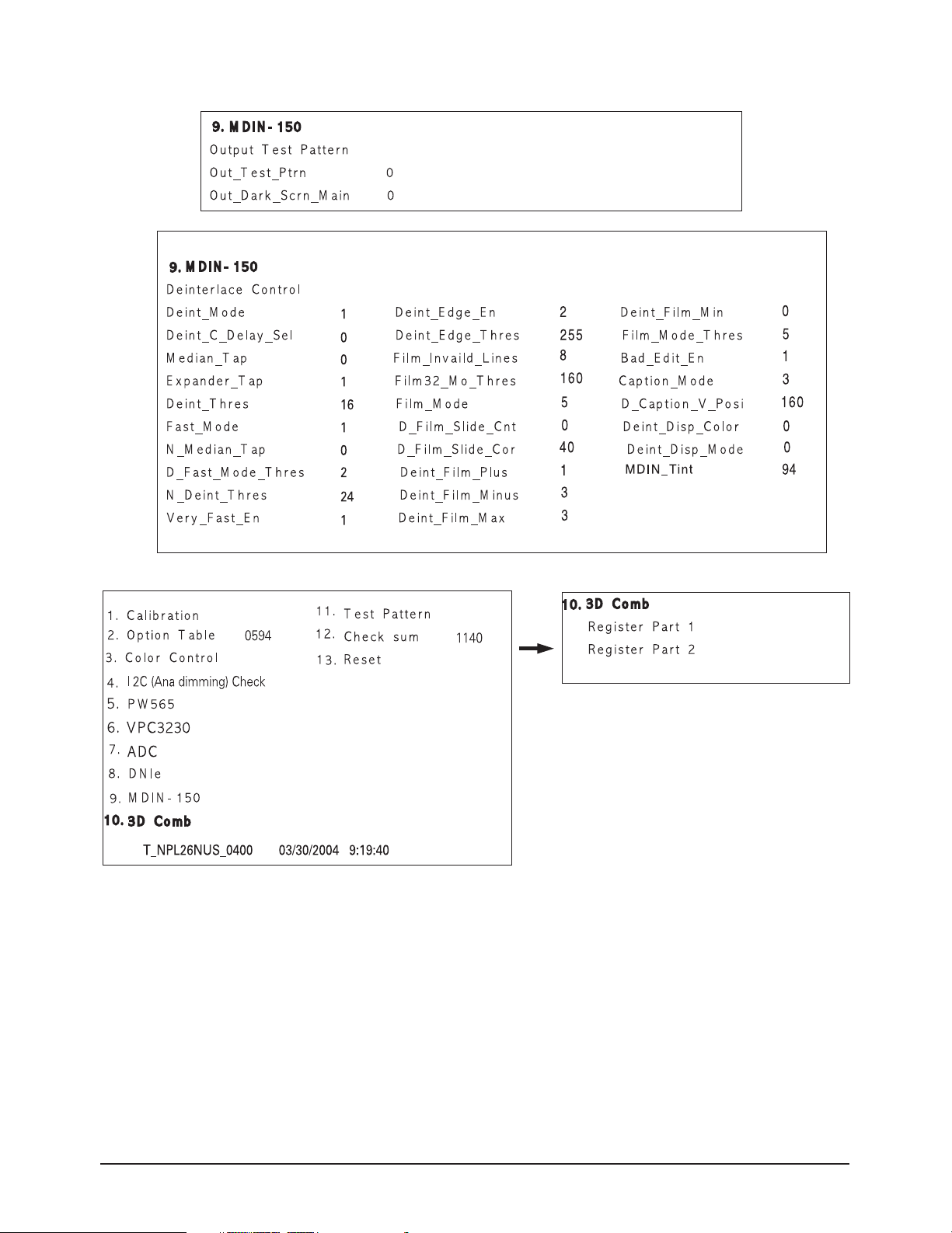

4-3-8 MDIN-150

* Control the specify item that a output signals (RF, CVBS, S-VHS Modes) of MDIN-150 (IC405).

* This data can be changed without notice.

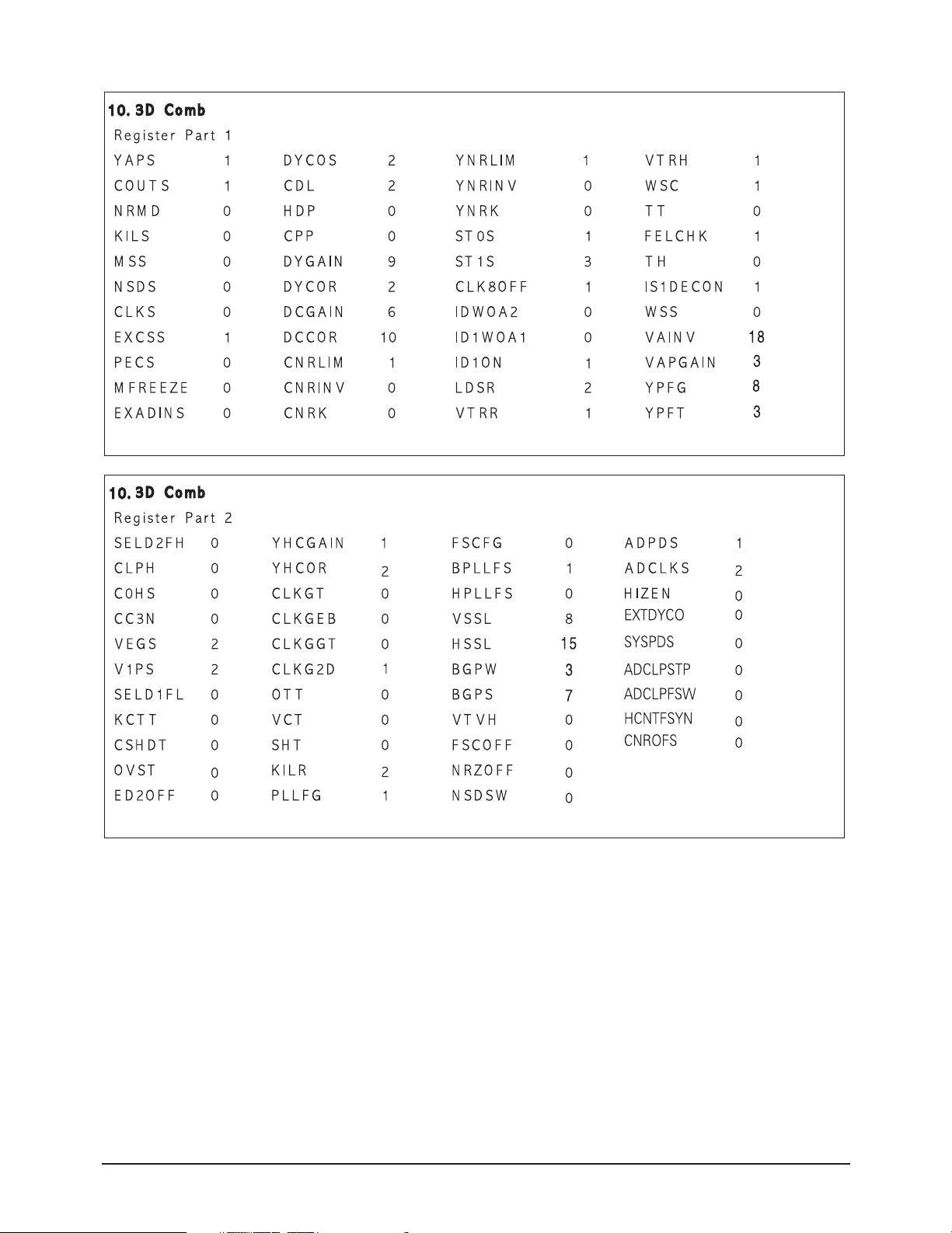

4-3-9 3D Comb

* Control the specify item that a input signals (RF, CVBS, S-VHS Modes) of D64083 (IC303).

* This data can be changed without notice.

4-3-10 Test Pattern

* Use below test patters to demonstrate the image display of PW565 (IC602).

1) Luma Ramp (16 step)

2) Luma Ramp (128 Step)

3) White 16

4) White 240

5) Color Bar

6) RGB Ramp (32 Step)

4-3-11 Check sum

* XXXX : Displays the current check sum size of the MICOM.

(Varies depending on program update)

4-3-12 Reset

* Initializes the data in the MICOM. (Set to default value)

Use ‘Reset’ to restore adjustmints made in Factory Mode to the original settings.

4-3-13 T_NPL26NUS_0400 03/30/2004 9:19:40

* Displays the MICOM program version

LT-P266W 4-15

Page 30

4 Alignments and Adjustments

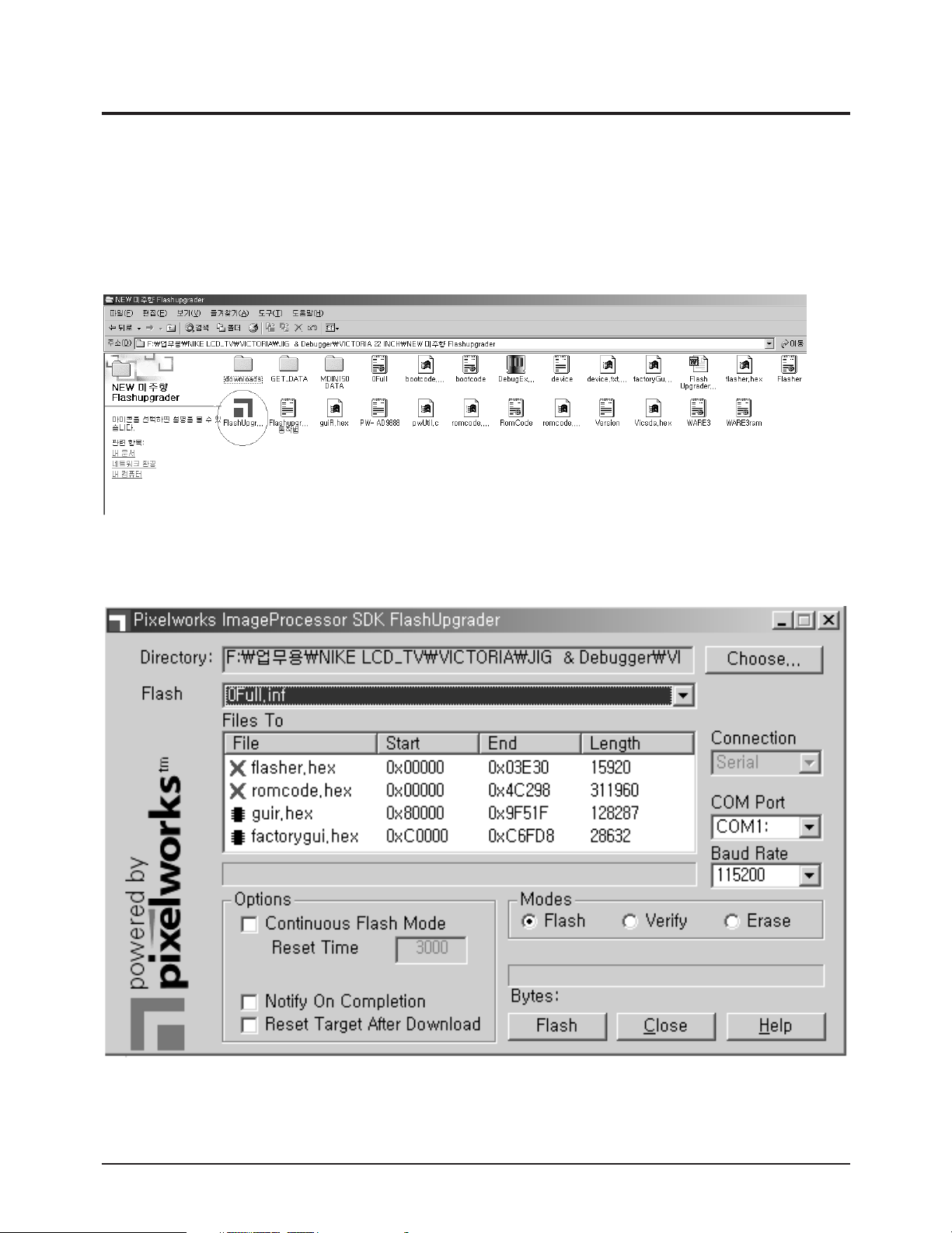

4-4 How to use SW(FlashupgradNT) for LT-P266W Set program update

1. Store program practice file in new folder.

2. Connect Set and Jig Cable to execute Program Update.

(Refer to the Picture 4-4 attachment)

3. After completing the JIG Cable connection, store Update practice program (hex file 3EA) in new folder.

(guiR, romcode, factoryGui).

4. Click FlashupgradNT.exe icon 2 times and execute it.

(Upgrader OSD screen is marked)

Picture 4-4

5. Select OFull.inf in Flash.

(flaher, romcode, guir, factorygui items look in Files To)

Picture 4-5

4-16 LT-P266W

Page 31

3

2

1

4

6. Click the “Flash” that is under right of OSD screen.

(if warning message comes out, Click the “Yes”(Y).)

4 Alignments and Adjustments

Picture 4-6

7. After acting No.6, extract Set’s Power Cable and connect it again.

8. During acting No.7, program Update sledding is marked sequentially on OSD screen.

9. After Program Update completion, act NO.7 again.

10. Program Update is completed.

Picture 4-7

<Attachment Picture 4-7 : JIG Cable Connection Explain>

1. Connect with PC Pattern Generator’s output.

(Connect only when you want to see PC screen.)

2. Connect with JIG Output (15 pins) and PC Input (PC/DVI 24 pins) terminal.

3. Connect with COM Port1 of PC (9 Pins).

4. Connect 14V 4.5A Adaptor Cable.

LT-P266W 4-17

Page 32

4 Alignments and Adjustments

Memo

4-18 LT-P266W

Page 33

5 Troubleshooting

5-1 No Power

LAMP off, power indicator

LED red color?

Yes

Does proper DC 12V

appear at C812, C813, C814?

Yes

Does proper DC A3.3V,

A5V, A1.8V, D1.8V appear at

C873, C861, C884?

Yes

Does proper DC 5V, 3.3V,

2.5V, 9V, A1.8V appear at

C831, C835, C850, C895, C884?

No

No

No

No

Check a connection a power cable.

(BH39-10339X)

Change a ass’y PCB Power.

(BN94-00443F)

Check a IC816, IC814, IC818.

Change a main PCB ass'y.

(BN94-00539D)

Check a IC811, IC812, IC813,

IC606, IC818.

Change a main PCB ass'y.

(BN94-00539D)

Yes

Does proper DC 33V, 1.2_SNI_D,

1.2V_SNI_PLL, 3.3V_SNI_D,

3.3_SNI_PLL, +3.3V_MD,

+2.5V_MD1, MDIN_APLL,

MDIN_DPLL appear at C827,

C865, C878, C551, C570,

C416, C429, C447, C451?

Yes

A power is supplied to set?

No

No

Check a IC812, IC815, IC817, FT522,

FT512, FT406, FT407, FT410, FT411.

Change a main PCB ass'y.

(BN94-00539D)

Check a other function.

(No picture part)

Replace a lcd panel.

(BN07-00121A)

LT-P266W 5-1

Page 34

5 Troubleshooting

5-2 No Video (Analog PC Signal)

Power Indicator is off.

Lamp on, no video.

Yes

Check a PC source and check

the connection of DSUB?

Yes

Does the signal appear at

1

#54, 48, 43 (R, G, B) of IC101?

Yes

Does the digital data

2

appear at output of

RA101~RA104, RA106, RA107 ?

Yes

Does the digital data

appear at output of RA605,

3

RA606, RA608, RA611,

RA613, RA615?

Yes

Does the digital data appear at

output of RA512, RA514, RA516,

4

RA518, RA520, RA521?

No

No

No

No

No

Input a analog PC signal and

connected cable.

Check IC101, PC cable. Change a PC

cable. Change a main PCB ass'y

(BN94-00539D).

Check a IC101.

Change a main PCB ass'y

(BN94-00539D).

Check a IC602, IC601.

Change a main PCB ass'y

(BN94-00539D).

Check a IC501.

Change a main PCB ass'y

(BN94-00539D).

Yes

Does the digital data appear at

5

output of FT516~FT520?

No

Check a IC515.

Change a main PCB ass'y

(BN94-00539D).

Yes

Check a LVDS cable?

Replace a lcd panel?

No

Please, Call to Samsung Co. LTD.

(BN07-00121A)

5-2 LT-P266W

Page 35

WAVEFORMS

5 Troubleshooting

1

R,G,B Intput Signal (#54,48,43) Of IC101

3

Output Digital Signal of IC602

2

R,G,B Output Signal Of IC101

4

Output Digital Signal of IC501

5

Digital Output Data of IC515

LT-P266W 5-3

Page 36

5 Troubleshooting

5-3 No Video (DVI - Digital Signal)

Power Indicator is off.

Lamp on, no video.

Yes

DVI-D check the connectionn

of DVI-D cable?

Yes

Does the digital data appear

at #80, #81, #85, #86, #90~#94

6

of IC102(Data, Clk +/-)?

Yes

Does the digital data

appear at output of RA111,

7

RA112, RA123 ~ RA126?

Yes

Does the digital data appear

at output of RA605, RA606,

3

RA608, RA611, RA613, 615?

Yes

Does the digital data appear at

output of RA512, RA514, RA516,

4

RA518, RA520, RA521?

No

No

No

No

No

Input DVI-D cable.

Check a DVI-D cable.

Check a IC102.

Change a main PCB ass'y

(BN94-00539D).

Check a IC602, IC601

Change a main PCB ass'y

(BN94-00539D).

Check a IC501.

Change a main PCB ass'y

(BN94-00539D).

Yes

Does the digital data appear at

5

output of FT516~FT520?

No

Check a IC515.

Change a main PCB ass'y

(BN94-00539D).

Yes

Check a LVDS cable?

Replacea lcd panel?

No

Please, Call to Samsung Co. LTD.

(BN07-00121A)

5-4 LT-P266W

Page 37

WAVEFORMS

5 Troubleshooting

3

Output Digital Signal of IC602

5

Digital Output Data of IC515

4

Output Digital Signal of IC501

6

Signal of DVI_RX 0~2 (Data)

6-1

Signal of DVI_RXC (CLK)

LT-P266W 5-5

7

Digital Output Signal Of IC102

Page 38

5 Troubleshooting

5-4 No Picture (Tuner_CVBS)

Power Indicator is off.

Lamp on, no picture.

Yes

8

Dose the signal

appear at #1 of IC202?

Yes

Does the signal appear at

9

#72 (Y), #71 (C) of IC201?

Yes

Does the digital data

10

appear at output of

RA201, 202 (Y), RA203, 204 (C)?

Yes

Does the digital data

11

appear at output of

RA408, 409 (Y), RA416, 417(C)?

No

No

No

No

No

Connect the RF cable and

check RF signal. (AA39-00039A)

Check a B+ voltage (#9, #7 of Tuner) :

33V, 5V change a main PCB ass'y

(BN94-00539D).

Check a IC202 and IC303.

Change a main PCB ass'y

(BN94-00539D).

Check a IC201.

Change a main PCB ass'y

(BN94-00539D).

Check a IC405 and IC406.

Change a main PCB ass'y

(BN94-00539D).

Yes

Does the digital data

appear at output of RA605,

3

RA606, RA608, RA611,

RA613, RA615?

Yes

Does the digital data appear at

output of RA512, RA514, RA5116,

4

RA518, RA520 RA521?

Yes

Does the digital data appear at

5

output of FT516~FT520?

Yes

Check a LVDS cable?

Replacea lcd panel?

(BN07-00121A)

No

No

No

No

Check a IC602, IC601.

Change a main PCB ass'y

(BN94-00539D).

Check a IC501.

Change a main PCB ass'y

(BN94-00539D).

Check a IC515.

Change a main PCB ass'y

(BN94-00539D).

Please, Call to Samsung Co. LTD.

5-6 LT-P266W

Page 39

WAVEFORMS

5 Troubleshooting

3

Output Digital Signal of IC602

5

Digital Output Data of IC515

4

Output Digital Signal of IC501

8

Tuner_CVBS Output Signal

LT-P266W 5-7

Page 40

5 Troubleshooting

WAVEFORMS

9

Analog Signal (Y,C) to IC201

11

Digital Output Y,C_OUT (0:7) Data Of IC405

10

3230 Y,C_OUT (0:7) Data

5-8 LT-P266W

Page 41

5-5 No Picture (Video_CVBS)

5 Troubleshooting

Power Indicator is off.

Lamp on, no picture.

Yes

8

Dose the signal

appear at #6 of IC202?

Yes

Does the signal appear at

9

#72 (Y), #71 (C) of IC201?

Yes

Does the digital data

10

appear at output of

RA201, 202 (Y), RA203, 204 (C)?

Yes

Does the digital data

11

appear at output of

RA408, 409 (Y), RA416, 417(C)?

No

No

No

No

No

Check a A/V cable and video signal.

(BN39-00057A)

Check a A/V cable and video signal.

Check a IC202.

Change a main PCB ass'y

(BN94-00539D).

Check a IC201 and IC902.

Change a main PCB ass'y

(BN94-00539D).

Check a IC405 and IC406.

Change a main PCB ass'y

(BN94-00539D).

Yes

Does the digital data

appear at output of RA605,

3

RA606, RA608, RA611,

RA613, RA615?

Yes

Does the digital data appear at

output of RA512, RA514, RA516,

4

RA518, RA520, RA521?

Yes

Does the digital data appear at

5

output of FT516~FT520 ?

Yes

Check a LVDS cable?

Replacea lcd panel?

(BN07-00121A)

No

No

No

No

Check a IC601, IC602.

Change a main PCB ass'y

(BN94-00539D).

Check a IC501.

Change a main PCB ass'y

(BN94-00539D).

Check a IC515.

Change a main PCB ass'y

(BN94-00539D).

Please, Call to Samsung Co. LTD.

LT-P266W 5-9

Page 42

5 Troubleshooting

WAVEFORMS

3

Output Digital Signal of IC602

5

Digital Output Data of IC515

4

Output Digital Signal of IC501

8

Tuner_CVBS Output Signal

5-10 LT-P266W

Page 43

WAVEFORMS

5 Troubleshooting

9

Analog Signal (Y,C) to IC201

11

Digital Output Y,C_OUT (0:7) Data Of IC405

10

3230 Y,C_OUT (0:7) Data

LT-P266W 5-11

Page 44

5 Troubleshooting

5-6 No Picture (S-VIDEO_Y,C)

Power Indicator is off.

Lamp on, no picture.

Yes

No

Connect the s-video cable.

Operating a video player.

(BN39-00060A)

Dose the signal appear at

9

#8 (Y), #10 (C) of IC202?

Yes

Does the signal appear at

12

#16 (Y), #17 (C) of IC202?

Yes

Does the signal appear at

9

#72 (Y), #71 (C) of IC201?

Yes

Does the digital data

10

appear at output of

RA201, 202 (Y), RA203, 204 (C)?

Yes

Does the digital data

11

appear at output of

RA408, 409 (Y), RA416, 417 (C)?

No

No

No

No

No

Check a s-video cable.

Check a IC202.

Change a main PCB ass'y

(BN94-00539D).

Check a IC201.

Change a main PCB ass'y

(BN94-00539D).

Check a IC201 and IC902.

Change a main PCB ass'y

(BN94-00539D).

Check a IC405 and IC406.

Change a main PCB ass'y

(BN94-00539D).

Yes

Does the digital data

appear at output of RA605,

3

RA606, RA608, RA611,

RA613, RA615?

Yes

Does the digital data appear at

Output of RA512, RA514,

4

RA516, RA518?

Yes

Does the digital data appear at

5

Output of FT516~FT520?

Yes

Check a LVDS cable?

Replacea lcd panel?

(BN07-00121A)

No

No

No

No

Check a IC601, IC602.

Change a main PCB ass'y

(BN94-00539D).

Check a IC501.

Change a main PCB ass'y

(BN94-00539D).

Check a IC515.

Change a main PCB ass'y

(BN94-00539D).

Please, Call to Samsung Co. LTD.

5-12 LT-P266W

Page 45

WAVEFORMS

5 Troubleshooting

3

Output Digital Signal of IC602

5

Digital Output Data of IC515

4

Output Digital Signal of IC501

9

Analog Signal (Y,C) to IC201

LT-P266W 5-13

Page 46

5 Troubleshooting

WAVEFORMS

10

3230 Y,C_OUT (0:7) Data

12

SVHS_Y,C Input Signal to IC202

11

Digital Output Y,C_OUT (0:7) Data Of IC405

5-14 LT-P266W

Page 47

5-7 No Picture (Component1, 2 : 480i, 480p, 720p, 1080i [Y, Pb, Pr])

5 Troubleshooting

Power Indicator is off.

Lamp on, no video.

Yes

Dose the signal appear at

output Pin (#19_Y, #15_Pb,

13

#21_Pr) of IC103 ?

Yes

Does the signal appear at

14

output #15_Pr, 19_Y,

21_Pb of IC105 ?

Yes

Does the digital data

2

appear at output of

RA101 ~RA104, RA106, RA107 ?

Yes

Does the digital data

appear at output of RA605,

3

RA606, RA608, RA611,

RA613, RA615?

No

Connect the RCA cable.

Operating a DTV STB and DVD player.

(BN39-00279A)

No

Check a IC103 and IC903.

Change a main PCB ass'y

(BN94-00539D).

No

Check a IC105 .

Change a main PCB ass'y

(BN94-00539D).

No

Check a IC101.

Change a main PCB ass'y

(BN94-00539D).

No

Check a IC601, IC602.

Change a main PCB ass'y

(BN94-00539D).

Yes

Does the digital data appear at

output of RA512, RA514,

4

RA516, RA518?

Yes

Does the digital data appear at

5

output of FT516~FT520 ?

Yes

Check a LVDS cable?

Replacea lcd panel?

(BN07-00121A)

No

No

No

Check a IC501.

Change a main PCB ass'y

(BN94-00539D).

Check a IC515.

Change a main PCB ass'y

(BN94-00539D).

Please, Call to Samsung Co. LTD.

LT-P266W 5-15

Page 48

5 Troubleshooting

WAVEFORMS

2

R,G,B Output Signal Of IC101

4

Output Digital Signal of IC501

3

Output Digital Signal of IC602

5

Digital Output Data of IC515

13

Output Signal of IC103 (Y,Pb,Pr)

5-16 LT-P266W

14

Input Signal (Y,Pb,Pr) to IC105

Page 49

5-8 No Sound

5 Troubleshooting

Picture is display, no sound.

Yes

Does the signal appear at

Pin 67 (Tuner Sound signal) and

Pin 56, 57 (CH1_L, R Sound) and

15

Pin 53, 54 (CH2_L, R Sound) and

of IC703 (MSP3420G)?

Yes

Check the DC 8V, 9VS, 9V

16

of IC703, IC701?

Yes

Does the signal appear at

17

L701 ~L704 ?

No

No

No

No

Connect a sound cable.

(BN39-00148A,BN39-00448A)

control a volume.

Check a connection harness and

headphone jack.

Check a IC809, IC606, IC811 and

IC810. Change a main PCB ass'y

(BN94-00539D).

Check a IC701.

Change a main PCB ass'y

(BN94-00539D).

Yes

Replace the speaker ass'y?

(BN96-01015A(L),

BN96-01016A(R))

LT-P266W 5-17

Page 50

5 Troubleshooting

WAVEFORMS

15

The Signal are Inputed to IC703

17

Output WaveForm

16

DC +8V

5-18 LT-P266W

Page 51

LT-P266W 6-1

6 Exploded View and Parts List

❈ You can search for updated part codes through ITSELF web site.

URL : http://itself.sec.samsung.co.kr/

Page 52

Memo

6 Exploded View & Parts List

6-2 LT-P266W

Page 53

7 Electrical Parts List

7-1

0 LTP266WX/XAP LT-P266W,NF26U,26,LCD-TV,PANAMA 0

0.1 M0216 BN90-00486F ASSY STAND;VN32JO 1 S.N.A

..2 M0003 BN96-01128A ASSY STAND P;NF26**,ABS HB GR503 1

...3 M0081 6003-001321 SCREW-TAPTITE;BH,+,B,M4,L8,ZPC(BLK),SWRC 8

...3 T0524 6902-000519 BAG PE;HDPE/NITRON(DOUBLE),T0.015/T0.05( 1 S.N.A

...3 STD BN61-01146A SUPPORT-TOP R;NAPLES 26",PPS,5.0 1 S.N.A

...3 STD BN61-01147A SUPPORT-TOP L;NAPLES 26",PPS,5.0 1 S.N.A

...3 M0115 BN61-01153A BRACKET-STAND;NAPLES 26",SECC,2.4 1 S.N.A

...3 M0111 BN63-01280A COVER-STAND;NAPLES 26",ABS,T3.0,V0,GR60 1 S.N.A

...3 T0132 BN73-00052A RUBBER FOOT;ARES 17,SILICON,DIA 17 * T1. 6 S.N.A

...3 M0081 6003-001239 SCREW-TAPTITE;FH,+,B,M4,L10,ZPC(YEL),SWR 8

...3 M0081 6003-001347 SCREW-TAPTITE;FH,+,B,M4,L16,ZPC(YEL),SWR 2 S.N.A

0.1 M0002 BN90-00641U ASSY COVER REAR;NF26UO 1 S.N.A

..2 M0081 6003-001323 SCREW-TAPTITE;BH,+,B,M4,L12,NI PLT,SWRCH 8 S.N.A

..2 M0013 BN96-01127B ASSY COVER P-REAR;NF26UO,HIPS V0 GR503 1

...3 M0081 6003-001188 SCREW-TAPTITE;BH,+,B,M4,L10,YEL,SWRCH18A 2 S.N.A

...3 M0113 BN61-01156A BRACKET-VESA;NAPLES 26",SECC,2.0 1 S.N.A

...3 M0006 BN63-01277B COVER-REAR;NF26**,HIPS V0 GR503 1 S.N.A

...3 C/R BN64-00268A INLAY-REAR NTSC;NAPLES 26",PC,0.8 1 S.N.A

0.1 M0001 BN90-00647C ASSY COVER FRONT;NF26UO 1 S.N.A

..2 M0081 6003-000122 SCREW-TAPTITE;BH,+,B,M4,L12,ZPC(YEL),SWR 4 S.N.A

..2 T0003 BN96-01125B ASSY COVER P-FRONT;NF26UO,ABS HB GR503 1

...3 M0112 BN63-01274A COVER-FRONT;NF26**,ABS HB GR503 1 S.N.A

...3 C/F BN63-01276B COVER-ACRYL;NF26UO,ACRYL,T2.5 1 S.N.A

...3 M0105 BN67-00116A LENS-LED;NAPLES 32",ACRYL,CLEAR 1 S.N.A

..2 T0852 BN96-01126B ASSY COVER P-MIDDLE;NF26**,ABS V0 GR503 1

...3 M0081 6003-000276 SCREW-TAPTITE;BH,+,B,M3,L10,ZPC(YEL),SWC 4 S.N.A

...3 M0081 6003-001233 SCREW-TAPTITE;PWH,+,P,M3,L8,ZPC(BLK),SWC 4 S.N.A

...3 M0162 6502-000121 CABLE CLAMP;DAMC-101,D7~8,L19,SCP-1,NTR 1 S.N.A

...3 T0069 BN63-01275B COVER-MIDDLE;NF26**,ABS V0 GR503 1 S.N.A

...3 T0501 BN63-01278B COVER-TOP;NF26**,ABS V0 GR503 1 S.N.A

...3 T0382 BP61-00495C HOLDER-CARE;PJT,ACRYL-FOAM,T0.25,W30.0mm 0.32 S.N.A

...3 T0186 BN96-01570B ASSY COVER P-GRILLE;NF26,ABS VO,FELT 1

..2 T0382 BP61-00495C HOLDER-CARE;PJT,ACRYL-FOAM,T0.25,W30.0mm 0.2 S.N.A

0.1 M0019 BN91-00403Y ASSY LCD-E2;GS17 1 S.N.A

..2 M0215 BN07-00121A LCD-PANEL;LTA260W1-L01,VENUS,1280*768,62 1

0.1 M0112 BN91-00785Z ASSY SHIELD;NF26UO 1 S.N.A

..2 CCM1 6001-000157 SCREW-MACHINE;BH,+,M4,L8,ZPC(YEL),SM20C, 2 S.N.A

..2 CCM1 6001-000157 SCREW-MACHINE;BH,+,M4,L8,ZPC(YEL),SM20C, 2 S.N.A

..2 CCM1 6001-000157 SCREW-MACHINE;BH,+,M4,L8,ZPC(YEL),SM20C, 2 S.N.A

..2 CCM1 6001-000157 SCREW-MACHINE;BH,+,M4,L8,ZPC(YEL),SM20C, 2 S.N.A

..2 T0081 6002-000514 SCREW-TAPPING;RH,+,2,M4,L15,ZPC(BLK),SWR 3 S.N.A

..2 T0081 6002-000514 SCREW-TAPPING;RH,+,2,M4,L15,ZPC(BLK),SWR 2 S.N.A

..2 T0081 6002-000514 SCREW-TAPPING;RH,+,2,M4,L15,ZPC(BLK),SWR 3 S.N.A

..2 T0081 6002-000514 SCREW-TAPPING;RH,+,2,M4,L15,ZPC(BLK),SWR 2 S.N.A

..2 T0081 6002-000514 SCREW-TAPPING;RH,+,2,M4,L15,ZPC(BLK),SWR 4 S.N.A

..2 T0081 6002-000514 SCREW-TAPPING;RH,+,2,M4,L15,ZPC(BLK),SWR 4 S.N.A

..2 M0081 6003-000117 SCREW-TAPTITE;BH,+,B,M3,L6,ZPC(YEL),SWRC 2

..2 M0081 6003-000117 SCREW-TAPTITE;BH,+,B,M3,L6,ZPC(YEL),SWRC 2

7 Electrical Parts List

You can search for updated part codes through ITSELF web site.

URL : http://itself.sec.samsung.co.kr/

Level Loc. No. Code No. Description & Specification Q'ty SA/SNA

Page 54

..2 M0081 6003-000117 SCREW-TAPTITE;BH,+,B,M3,L6,ZPC(YEL),SWRC 2

..2 M0081 6003-000117 SCREW-TAPTITE;BH,+,B,M3,L6,ZPC(YEL),SWRC 2

..2 M0081 6003-000117 SCREW-TAPTITE;BH,+,B,M3,L6,ZPC(YEL),SWRC 6

..2 M0081 6003-000117 SCREW-TAPTITE;BH,+,B,M3,L6,ZPC(YEL),SWRC 3

..2 M0081 6003-000117 SCREW-TAPTITE;BH,+,B,M3,L6,ZPC(YEL),SWRC 6

..2 M0081 6003-000117 SCREW-TAPTITE;BH,+,B,M3,L6,ZPC(YEL),SWRC 14

..2 M0081 6003-000122 SCREW-TAPTITE;BH,+,B,M4,L12,ZPC(YEL),SWR 2 S.N.A

..2 M0081 6003-000256 SCREW-TAPTITE;BWH,+,B,M3,L10,ZPC(YEL),SM 10 S.N.A

..2 M0081 6003-000276 SCREW-TAPTITE;BH,+,B,M3,L10,ZPC(YEL),SWC 2 S.N.A

..2 M0081 6003-001323 SCREW-TAPTITE;BH,+,B,M4,L12,NI PLT,SWRCH 2 S.N.A

..2 CCM1 6006-000245 SCREW-MACHINE;WSP,PH,+,M4,L8,ZPC(YEL),SW 1 S.N.A

..2 M2893 BN39-00028C LEAD CONNECTOR;CK40PS,UL1007#26,UL/CSA,1 1

..2 M2893 BN39-00525A LEAD CONNECTOR;NF26EO,UL1061#28,15P,130M 2

..2 M2893 BN39-00526A LEAD CONNECTOR;NF20EO,UL2835#28,12/15P,9 1

..2 M2893 BN39-00527A LEAD CONNECTOR;NF20EO,UL1571#30,30P,150m 1

..2 T0081 BN61-01151A BRACKET-POWER;NAPLES 26",SECC,1.2 1 S.N.A

..2 T0081 BN96-01129B ASSY MISC P-SHIELD PCB;NF26UO,SECC T0.5 1 S.N.A

...3 CIS BN63-01288A SHIELD-PCB 2;NAPLES 26",SECC,T0.5 1 S.N.A

...3 T0178 BN63-01281A SHIELD-PCB;NAPLES 26",SECC,T0.5 1 S.N.A

..2 CIS BN96-01179A ASSY MISC P-BRKT SIDE/R;NF26**,SECC T1.2 1 S.N.A

...3 T0525 BN61-01155A BRACKET-SIDE R;NAPLES 26",SECC,1.6 1 S.N.A

...3 CIS BN61-01216A BRACKET-BOSS;NF26**,SECC,T1.2 1 S.N.A

..2 CIS BN96-01180A ASSY MISC P-BRKT SIDE/L;NF26**,SECC T1.2 1 S.N.A

...3 T0524 BN61-01154A BRACKET-SIDE L;NAPLES 26",SECC,1.6 1 S.N.A

...3 CIS BN61-01216A BRACKET-BOSS;NF26**,SECC,T1.2 1 S.N.A

..2 M0145 BN96-01186A ASSY BOARD P-FUNCTION IR;NAPLES 2,FUNCTI 1

..2 T0081 BN61-01148A BRACKET-TOP;NAPLES 26",SECC,1.2 1 S.N.A

..2 MP1.4 BN61-01149A BRACKET-BOTTOM;NAPLES 26",SECC,1.2 1 S.N.A

..2 T0081 BN61-01150A BRACKET-MAIN;NAPLES 26",SECC,1.2 1 S.N.A

..2 T0562 6046-001007 STAND OFF;M3,L5,NI PLT,SUM24L,#4-40 4 S.N.A

..2 CIS BN96-01175A ASSY MISC P-BRKT POWER/SUB;NF26**,SECC T 1 S.N.A

...3 T0073 AA63-00773A GASKET-EMI;LCD,CONDUCTIVE FABRIC,6mm,10m 1 S.N.A

...3 T0081 BN61-01152A BRACKET-POWER SUB;NAPLES 26",SECC,1.2 1 S.N.A

..2 T0175 BN96-01015A ASSY SPEAKER P;8ohm,Victoria22",Left,5W, 1

..2 T0175 BN96-01016A ASSY SPEAKER P;8ohm,Victoria22",Right,5W 1

0.1 M0113 BN92-00982N ASSY P/MATERIAL;NF26EO 1 S.N.A

..2 T0214 AA60-40006A PIN-STAPLE;AUTO,33X17.8X2.4,H18,33X17.8X 6 S.N.A

..2 T0214 AA61-20285A HOLDER-BOX;3456,PP,-,-,-,WHT,VO 4 S.N.A

..2 T0172 AA69-02609A BAND-PP;W18,CLEA,1G 10.3 S.N.A

..2 T0524 6902-000584 BAG PE;HDPE/NITRON(DOUBLE),T0.015/T0.8,W 1 S.N.A

0.1 M0019 BN92-01063M ASSY LABEL;NEW 1 S.N.A

0.1 M0045 BN92-01211V ASSY ACCESSORY;LTP266WX/XAP 1 S.N.A

..2 M0045 BN96-01612X ASSY ACCESSORY;LTP266WX/XAP 1

...3 T0268 3903-000085 CBF-POWER CORD;DT,US,BP3/YES,I(IEC C13/C 1

...3 T0524 6902-000110 BAG PE;LDPE,T0.05,L356,W240,TRP,28,2,PE 1 S.N.A

...3 T0116 AA39-00039A CABLE IF;-,C2680R-H,S,1P,-,3C-2V,BLK,F-C 1

...3 T0152 AA68-00987A CARD WARRANTY;-,-,W/P100,-,-,-,-,-,A4,1P 1 S.N.A

...3 T0074 BN59-00409B REMOCON;VIOCTORIA,TM76A,NF26UO,47,G6148, 1

....4 T0119 AA09-00371A IC MICOM;SZTM-839C R-52MX,28PIN,16KBYTE, 1

....4 T0122 2802-000194 RESONATOR-CERAMIC;8MHz,1.0%,TP,8.5x4.5x5 1

...3 M0148 BN68-00656B MANUAL USERS-05;LT-P266W,SAMSUNG,E/S/P,S 1 S.N.A

...3 T0376 BN69-00350A BOX-00,ACCESSORY;AL29NO/AO,CB SW-1,YEL,K 1 S.N.A

...3 ACCESSORY BN96-01013A ASSY ACCESSORY-SCREW;NA32EO 1

....4 M0081 6003-001323 SCREW-TAPTITE;BH,+,B,M4,L12,NI PLT,SWRCH 4 S.N.A

....4 CIS 6902-000128 BAG ZIPPER;LDPE,T0.05,L150,W200,TRP,8,2, 1 S.N.A

...3 ACCESSORY AA68-03242F MANUAL-SAFETY GUIDE;All Model,SAMSUNG,En 1 S.N.A

7 Electrical Parts List

7-2

Level Loc. No. Code No. Description & Specification Q'ty SA/SNA

Page 55

7 Electrical Parts List

7-3

0.1 M0003 BN92-01212M ASSY BOX;NF26UO 1 S.N.A

0.1 M0017 BN91-00826H ASSY CHASSIS;NEW 1 S.N.A

..2 M0014 BN94-00443F ASSY PCB POWER-CH;VN30EO,EUROPE 1

...3 T0245 0202-001366 SOLDER-WIRE FLUX;-,RS60S,D1.2,63Sn/37Pb, 0.1 S.N.A

...3 DM805 0402-000250 DIODE-RECTIFIER;RG4C,1KV,2A,-,- 1

...3 DS805 0402-000250 DIODE-RECTIFIER;RG4C,1KV,2A,-,- 1

...3 DP803 0402-000562 DIODE-RECTIFIER;UF5406,600V,3A,DO-201AD, 1

...3 T0086 1203-002828 IC-PWM CONTROLLER;4981,DIP,20P,25.4X7.1M 1

...3 T0900 1404-001195 THERMISTOR-NTC;5.1ohm,15%,2900,27mW/C,BK 1

...3 CP803 2306-000321 C-FILM,LEAD-PPF;470NF,20%,275V,BK,31X11X 1

...3 CP823 2401-003915 C-AL;82uF,20%,450V,WT,BK,25.4x25mm,5.8 1

...3 CP824 2401-003915 C-AL;82uF,20%,450V,WT,BK,25.4x25mm,5.8 1

...3 CN906 3711-002855 CONNECTOR-HEADER;BOX,2P,1R,7.92mm,STRAIG 1

...3 CN906 3711-004122 CONNECTOR-HEADER;BOX,14P,1R,2mm,STRAIGHT 1

...3 CN906 3711-004182 CONNECTOR-HEADER;BOX,10P,1R,2MM,STRAIGHT 1

...3 CN906 3711-004352 CONNECTOR-HEADER;BOX,15P,1R,2MM,STRAIGHT 1

...3 CN906 3711-004352 CONNECTOR-HEADER;BOX,15P,1R,2MM,STRAIGHT 1

...3 T0010 AA27-00119A COIL CHOKE;10uH,-,10uH,10%,0.07,0.1ohm M 1

...3 T806S BN26-00007B TRANS-SOUND;EER 3019,LCD TV,12PIN,1mH,40 1

...3 T803S BN26-00009A TRANS-MULTI(VIC);EER 3019,LCD TV,12PIN,1 1

...3 T801S BN26-00010A TRANS-INVERTER;EER 3543,LCD TV,16PIN,1mH 1

...3 T0010 BN27-00014A COIL CHOKE;10uH, 0.02ohm, 14.5T,10uH,+/- 1

...3 T0010 BN27-00015B COIL CHOKE;VD063-1,COIL-CHOKE,23uH,+/-10 1

...3 LP801 BN27-00016A COIL CHOKE-PFC;1.5mH,1.5 mH,10%,HIGH-FLU 1

...3 LP806 BN29-00006A FILTER LINE-COMMON MODE;LCDTV,5uH,0.15oh 1

...3 M0020 BN96-00324A ASSY BOARD P;PDB20049A M,CONTROLLER ASS' 1

...3 T0852 BN97-00207J ASSY AUTO-POWER;VN30EO,EUROPE 1 S.N.A

....4 DP801 0401-000005 DIODE-SWITCHING;1N4148,75V,150MA,DO-35,T 1

....4 DI809 0401-000005 DIODE-SWITCHING;1N4148,75V,150MA,DO-35,T 1

....4 DI808 0401-000005 DIODE-SWITCHING;1N4148,75V,150MA,DO-35,T 1

....4 DS806 0401-000006 DIODE-SWITCHING;BAV21,250V,200MA,DO-35,T 1

....4 DS804 0401-000006 DIODE-SWITCHING;BAV21,250V,200MA,DO-35,T 1

....4 DS803 0401-000006 DIODE-SWITCHING;BAV21,250V,200MA,DO-35,T 1

....4 DM809 0401-000006 DIODE-SWITCHING;BAV21,250V,200MA,DO-35,T 1

....4 DM804 0401-000006 DIODE-SWITCHING;BAV21,250V,200MA,DO-35,T 1

....4 DM803 0401-000006 DIODE-SWITCHING;BAV21,250V,200MA,DO-35,T 1

....4 DM807 0402-000534 DIODE-RECTIFIER;RG10V,400V,1.2A,DO-201,T 1

....4 DP802 0402-000540 DIODE-RECTIFIER;RU20A,600V,1.5A,-,TP 1

....4 DS802 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T 1

....4 DS801 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T 1

....4 DP806 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T 1

....4 DM806 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T 1

....4 DM802 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T 1

....4 DM801 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T 1

....4 ZDP804 0403-000510 DIODE-ZENER;MTZJ6.2B,5.96-6.27V,500MW,DO 1

....4 ZDI808 0403-000510 DIODE-ZENER;MTZJ6.2B,5.96-6.27V,500MW,DO 1

....4 ZDP801 0403-001211 DIODE-ZENER;MTZJ12B,11.8-12.3V,500MW,DO- 1

....4 ZDP802 0403-001318 DIODE-ZENER;MTZJ4.3B,4.17-4.43V,500MW,DO 1

....4 ZDP803 0403-001325 DIODE-ZENER;MTZJ15C,14.42-15.02V,500MW,D 1

....4 ZDP805 0403-001325 DIODE-ZENER;MTZJ15C,14.42-15.02V,500MW,D 1

....4 ZDS801 0403-001327 DIODE-ZENER;MTZJ18A,16.22-17.06V,500MW,D 1

....4 ZDM801 0403-001327 DIODE-ZENER;MTZJ18A,16.22-17.06V,500MW,D 1

....4 ZDI809 0403-001327 DIODE-ZENER;MTZJ18A,16.22-17.06V,500MW,D 1

....4 ZDS802 0403-001328 DIODE-ZENER;MTZJ22A,20.15-21.2V,500MW,DO 1

....4 ZDM802 0403-001328 DIODE-ZENER;MTZJ22A,20.15-21.2V,500MW,DO 1

....4 ZDI801 0403-001328 DIODE-ZENER;MTZJ22A,20.15-21.2V,500MW,DO 1

....4 DP807 0404-001207 DIODE-SCHOTTKY;SB140,40V,1000MA,DO-41,TP 1

....4 DP805 0404-001207 DIODE-SCHOTTKY;SB140,40V,1000MA,DO-41,TP 1

....4 DP804 0404-001207 DIODE-SCHOTTKY;SB140,40V,1000MA,DO-41,TP 1

Level Loc. No. Code No. Description & Specification Q'ty SA/SNA

Page 56

....4 QP803 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,T 1

....4 QP802 0501-000369 TR-SMALL SIGNAL;KSC2331-Y,NPN,1000mW,TO- 1

....4 QI807 0501-000369 TR-SMALL SIGNAL;KSC2331-Y,NPN,1000mW,TO- 1

....4 QP804 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T 1

....4 QP801 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T 1

....4 QM813 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T 1

....4 QM801 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T 1

....4 QI810 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T 1

....4 IC012 1203-001217 IC-POSI.ADJUST REG.;431,TO-92,3P,4.58MIL 1

....4 IC012 1203-001217 IC-POSI.ADJUST REG.;431,TO-92,3P,4.58MIL 1

....4 IC012 1203-001217 IC-POSI.ADJUST REG.;431,TO-92,3P,4.58MIL 1

....4 RS809 2001-000003 R-CARBON;330ohm,5%,1/8W,AA,TP,1.8x3.2mm 1

....4 RM809 2001-000003 R-CARBON;330ohm,5%,1/8W,AA,TP,1.8x3.2mm 1

....4 RM804 2001-000009 R-CARBON;20KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RP827 2001-000010 R-CARBON;68KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RP819 2001-000019 R-CARBON(S);10OHM,5%,1/2W,AA,TP,2.4X6.4M 1

....4 RP828 2001-000107 R-CARBON(S);150KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 RI817 2001-000117 R-CARBON(S);68ohm,5%,1/2W,AA,TP,2.4x6.4m 1

....4 RS815 2001-000241 R-CARBON;1.5KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RM815 2001-000241 R-CARBON;1.5KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RP821 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RI810 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RI808 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RI807 2001-000302 R-CARBON;10OHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RP818 2001-000302 R-CARBON;10OHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RM811 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RS823 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RP830 2001-000472 R-CARBON;2.7KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RI818 2001-000472 R-CARBON;2.7KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RI830 2001-000522 R-CARBON;22KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RP823 2001-000527 R-CARBON;22OHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RP822 2001-000527 R-CARBON;22OHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RM805 2001-000577 R-CARBON;2KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RM806 2001-000645 R-CARBON;330KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RS817 2001-000660 R-CARBON;33KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RP817 2001-000660 R-CARBON;33KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RM817 2001-000660 R-CARBON;33KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RM807 2001-000660 R-CARBON;33KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RI827 2001-000660 R-CARBON;33KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RP808 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RI835 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RI831 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RI802 2001-000745 R-CARBON;4.7OHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RP825 2001-000773 R-CARBON;470KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RI820 2001-000780 R-CARBON;470OHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RI801 2001-000786 R-CARBON;47KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RP826 2001-001078 R-CARBON(S);15KOHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RM816 2001-001088 R-CARBON(S);1KOHM,5%,1/2W,AA,TP,2.4X6.4M 1

....4 RS811 2001-001088 R-CARBON(S);1KOHM,5%,1/2W,AA,TP,2.4X6.4M 1

....4 RS816 2001-001088 R-CARBON(S);1KOHM,5%,1/2W,AA,TP,2.4X6.4M 1

....4 RI837 2001-001088 R-CARBON(S);1KOHM,5%,1/2W,AA,TP,2.4X6.4M 1

....4 RI832 2001-001088 R-CARBON(S);1KOHM,5%,1/2W,AA,TP,2.4X6.4M 1

....4 RI821 2001-001088 R-CARBON(S);1KOHM,5%,1/2W,AA,TP,2.4X6.4M 1

....4 RP809 2001-001093 R-CARBON(S);2.2KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 RM818 2001-001093 R-CARBON(S);2.2KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 RI805 2001-001096 R-CARBON(S);2.2OHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RS810 2001-001097 R-CARBON(S);2.4KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 RP820 2001-001099 R-CARBON(S);2.7KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 RS804 2001-001103 R-CARBON(S);20KOHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RS805 2001-001117 R-CARBON(S);2KOHM,5%,1/2W,AA,TP,2.4X6.4M 1

7 Electrical Parts List

7-4

Level Loc. No. Code No. Description & Specification Q'ty SA/SNA

Page 57

7 Electrical Parts List

7-5

....4 RS806 2001-001129 R-CARBON(S);330KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 RS808 2001-001131 R-CARBON(S);33KOHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RP831 2001-001146 R-CARBON(S);4.7OHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RI809 2001-001146 R-CARBON(S);4.7OHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RP816 2001-001150 R-CARBON(S);470KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 RP811 2001-001161 R-CARBON(S);560KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 RP810 2001-001161 R-CARBON(S);560KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 RP815 2001-001191 R-CARBON(S);820KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 RP814 2001-001191 R-CARBON(S);820KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 RS801 2001-001194 R-CARBON(S);82KOHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RS802 2001-001194 R-CARBON(S);82KOHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RS803 2001-001194 R-CARBON(S);82KOHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RS822 2001-001194 R-CARBON(S);82KOHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RM824 2001-001194 R-CARBON(S);82KOHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RM803 2001-001194 R-CARBON(S);82KOHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RM802 2001-001194 R-CARBON(S);82KOHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RM801 2001-001194 R-CARBON(S);82KOHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RY801S 2002-001012 R-COMPOSITION;8.2Mohm,5%,1/2W,AA,TP,3.7x 1

....4 RM820 2003-001023 R-METAL OXIDE(S);120ohm,5%,2W,AF,TP,3.9x 1

....4 RP802 2003-001038 R-METAL OXIDE(S);4.7ohm,5%,2W,AF,TP,3.9x 1

....4 RP804 2003-002044 R-METAL OXIDE(S);100ohm,5%,1W,AF,TP,2.5x 1

....4 RS820 2003-002071 R-METAL OXIDE;560ohm,5%,2W,AF,TP,3.9x10m 1

....4 RM821 2003-002071 R-METAL OXIDE;560ohm,5%,2W,AF,TP,3.9x10m 1

....4 RS814 2003-002186 R-METAL OXIDE(S);22Kohm,5%,2W,AG,TP,3.9x 1

....4 RS813 2003-002186 R-METAL OXIDE(S);22Kohm,5%,2W,AG,TP,3.9x 1

....4 RS812 2003-002186 R-METAL OXIDE(S);22Kohm,5%,2W,AG,TP,3.9x 1

....4 RM814 2003-002186 R-METAL OXIDE(S);22Kohm,5%,2W,AG,TP,3.9x 1

....4 RM813 2003-002186 R-METAL OXIDE(S);22Kohm,5%,2W,AG,TP,3.9x 1

....4 RM812 2003-002186 R-METAL OXIDE(S);22Kohm,5%,2W,AG,TP,3.9x 1

....4 RP845 2003-002239 R-METAL OXIDE(S);100KOHM,5%,2W,AF,TP,3.9 1

....4 RP844 2003-002239 R-METAL OXIDE(S);100KOHM,5%,2W,AF,TP,3.9 1

....4 RP843 2003-002239 R-METAL OXIDE(S);100KOHM,5%,2W,AF,TP,3.9 1

....4 RP841 2004-000216 R-METAL;10Kohm,1%,1/4W,AA,TP,2.4x6.4mm 1

....4 RI826 2004-000216 R-METAL;10Kohm,1%,1/4W,AA,TP,2.4x6.4mm 1

....4 RP838 2004-000643 R-METAL;270Kohm,1%,1/4W,AA,TP,2.4x6.4m 1

....4 RP839 2004-000643 R-METAL;270Kohm,1%,1/4W,AA,TP,2.4x6.4m 1

....4 RP824 2004-001099 R-METAL;56Kohm,1%,1/4W,AA,TP,2.4x6.4mm 1

....4 RI819 2004-001371 R-METAL(S);1.5Kohm,1%,1/2W,AA,TP,2.4x6.4 1

....4 RP837 2004-001395 R-METAL(S);330Kohm,2%,1/2W,AA,TP,2.4x6.4 1

....4 RP833 2004-001399 R-METAL(S);5.1Kohm,1%,1/2W,AA,TP,2.4x6.4 1

....4 RS819 2004-001983 R-METAL(S);2.49Kohm,1%,1/2W,AA,TP,2.4x6. 1

....4 RI828 2004-001983 R-METAL(S);2.49Kohm,1%,1/2W,AA,TP,2.4x6. 1

....4 RP836 2004-002018 R-METAL(S);220Kohm,1%,1/2W,AA,TP,2.4x6.4 1

....4 RP835 2004-002018 R-METAL(S);220Kohm,1%,1/2W,AA,TP,2.4x6.4 1

....4 RP834 2004-002018 R-METAL(S);220Kohm,1%,1/2W,AA,TP,2.4x6.4 1

....4 RP832 2004-002234 R-METAL;560ohm,1%,1/4W,AA,TP,2.4x6.4mm 1

....4 RP840 2004-004015 R-METAL(S);9.1Kohm,1%,1/2W,AA,TP,2.5x6.5 1

....4 RS818 2004-004029 R-METAL(S);10Kohm,1%,1/2W,AA,TP,2.5x6.5m 1

....4 RS821 2008-000206 R-FUSIBLE(S);1ohm,5%,1/2W,AF,TP,2.5x6.5m 1

....4 RM823 2008-000206 R-FUSIBLE(S);1ohm,5%,1/2W,AF,TP,2.5x6.5m 1

....4 RP801 2008-000261 R-FUSIBLE(S);150ohm,5%,1W,AF,TP,3.9x10mm 1

....4 VRM801 2103-000670 VR-SEMI;1Kohm,25%,1/5W,TOP 1

....4 CS813 2201-000129 C-CERAMIC,DISC;0.1nF,10%,1000V,Y5P,-,7x4 1

....4 CS812 2201-000129 C-CERAMIC,DISC;0.1nF,10%,1000V,Y5P,-,7x4 1

....4 CP807 2201-000129 C-CERAMIC,DISC;0.1nF,10%,1000V,Y5P,-,7x4 1

....4 CM811 2201-000129 C-CERAMIC,DISC;0.1nF,10%,1000V,Y5P,-,7x4 1

....4 CM810 2201-000129 C-CERAMIC,DISC;0.1nF,10%,1000V,Y5P,-,7x4 1

....4 CI809 2201-000132 C-CERAMIC,DISC;0.1NF,10%,500V,Y5P,TP,6.5 1

....4 CI802 2201-000132 C-CERAMIC,DISC;0.1NF,10%,500V,Y5P,TP,6.5 1

....4 CS815 2201-000556 C-CERAMIC,DISC;0.47NF,10%,500V,Y5P,TP,5. 1

Level Loc. No. Code No. Description & Specification Q'ty SA/SNA

Page 58

....4 CM815 2201-000556 C-CERAMIC,DISC;0.47NF,10%,500V,Y5P,TP,5. 1

....4 CM814 2201-000556 C-CERAMIC,DISC;0.47NF,10%,500V,Y5P,TP,5. 1

....4 CI808 2201-000930 C-CERAMIC,DISC;0.22NF,10%,500V,Y5P,TP,5. 1

....4 CP817 2201-000961 C-CERAMIC,DISC;0.01NF,0.5PF,50V,RH,TP,4X 1

....4 CY802S 2201-002026 C-CERAMIC,DISC;1NF,20%,400V,Y5P,TP,11X6M 1

....4 CY801S 2201-002026 C-CERAMIC,DISC;1NF,20%,400V,Y5P,TP,11X6M 1

....4 CP831 2201-002026 C-CERAMIC,DISC;1NF,20%,400V,Y5P,TP,11X6M 1

....4 CP805 2201-002026 C-CERAMIC,DISC;1NF,20%,400V,Y5P,TP,11X6M 1

....4 CP829 2201-002026 C-CERAMIC,DISC;1NF,20%,400V,Y5P,TP,11X6M 1

....4 CP830 2201-002026 C-CERAMIC,DISC;1NF,20%,400V,Y5P,TP,11X6M 1

....4 CS809 2202-000231 C-CERAMIC,MLC-AXIAL;0.33NF,10%,50V,Y5P,T 1

....4 CS808 2202-000231 C-CERAMIC,MLC-AXIAL;0.33NF,10%,50V,Y5P,T 1

....4 CM807 2202-000231 C-CERAMIC,MLC-AXIAL;0.33NF,10%,50V,Y5P,T 1

....4 CM806 2202-000231 C-CERAMIC,MLC-AXIAL;0.33NF,10%,50V,Y5P,T 1

....4 CS806 2301-000192 C-FILM,LEAD-PEF;1nF,5%,50V,TP,5.3x10mm,5 1

....4 CP816 2301-000192 C-FILM,LEAD-PEF;1nF,5%,50V,TP,5.3x10mm,5 1

....4 CM803 2301-000192 C-FILM,LEAD-PEF;1nF,5%,50V,TP,5.3x10mm,5 1

....4 CM824 2301-000224 C-FILM,LEAD-PEF;22nF,5%,50V,TP,7.4x3.9x1 1

....4 CP819 2301-000342 C-FILM,LEAD-PEF;2.2nF,5%,50V,TP,7.4x3.9x 1

....4 CM808 2301-000356 C-FILM,LEAD-PEF;47nF,5%,50V,TP,7.5x4.0x6 1

....4 CS810 2301-000356 C-FILM,LEAD-PEF;47nF,5%,50V,TP,7.5x4.0x6 1

....4 CS805 2301-000445 C-FILM,LEAD-PEF;4.7nF,5%,50V,TP,5.5x7x3m 1

....4 CM804 2301-000445 C-FILM,LEAD-PEF;4.7nF,5%,50V,TP,5.5x7x3m 1

....4 CI810 2301-001268 C-FILM,LEAD-PPF;33nF,5%,630V,TP,20x11x17 1

....4 CI801 2301-001396 C-FILM,LEAD-PEF;100nF,10%,630V,TP,18x6.5 1

....4 CM821 2301-001396 C-FILM,LEAD-PEF;100nF,10%,630V,TP,18x6.5 1

....4 CS802 2301-001396 C-FILM,LEAD-PEF;100nF,10%,630V,TP,18x6.5 1

....4 CS811 2303-000122 C-FILM,LEAD-PEF;10nF,5%,630V,TP,19x12.5m 1

....4 CM809 2303-000122 C-FILM,LEAD-PEF;10nF,5%,630V,TP,19x12.5m 1

....4 CP804 2303-000331 C-FILM,LEAD-PPF;4.7nF,5%,630V,TP,19.5x12 1

....4 CI811 2303-001001 C-FILM,LEAD-PPF;22nF,5%,630V,TP,18x14.5x 1

....4 CP810 2305-000285 C-FILM,LEAD-PEF;220NF,5%,100V,TP,10.5X5. 1

....4 CS822 2305-000289 C-FILM,LEAD-PEF;220nF,5%,63V,TP,-,5mm 1

....4 CP811 2305-000289 C-FILM,LEAD-PEF;220nF,5%,63V,TP,-,5mm 1

....4 CM828 2305-000289 C-FILM,LEAD-PEF;220nF,5%,63V,TP,-,5mm 1

....4 CI819 2305-000289 C-FILM,LEAD-PEF;220nF,5%,63V,TP,-,5mm 1

....4 CI804 2305-000289 C-FILM,LEAD-PEF;220nF,5%,63V,TP,-,5mm 1

....4 CI815 2305-000411 C-FILM,LEAD-PEF;470nF,5%,50V,TP,7.3x4.8x 1

....4 CP815 2305-000411 C-FILM,LEAD-PEF;470nF,5%,50V,TP,7.3x4.8x 1

....4 CS819 2305-000412 C-FILM,LEAD-PEF;470nF,5%,63V,TP,-,5mm 1

....4 CS821 2305-000665 C-FILM,LEAD-PEF;100nF,5%,63V,TP,7.5x4.0x 1

....4 CP818 2305-000665 C-FILM,LEAD-PEF;100nF,5%,63V,TP,7.5x4.0x 1

....4 CI813 2305-000665 C-FILM,LEAD-PEF;100nF,5%,63V,TP,7.5x4.0x 1

....4 CM827 2306-000122 C-FILM,LEAD-PPF;100nF,5%,50V,TP,7.3x4.0x 1

....4 CM826 2306-000122 C-FILM,LEAD-PPF;100nF,5%,50V,TP,7.3x4.0x 1

....4 CM812 2306-000122 C-FILM,LEAD-PPF;100nF,5%,50V,TP,7.3x4.0x 1

....4 CI823 2306-000122 C-FILM,LEAD-PPF;100nF,5%,50V,TP,7.3x4.0x 1

....4 CI821 2306-000122 C-FILM,LEAD-PPF;100nF,5%,50V,TP,7.3x4.0x 1

....4 CI812 2401-000302 C-AL;100uF,20%,25V,GP,TP,6.3x11,5 1

....4 CP822 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5 1

....4 CP820 2401-000603 C-AL;1UF,20%,50V,GP,TP,5X11,2 1

....4 CP808 2401-000603 C-AL;1UF,20%,50V,GP,TP,5X11,2 1

....4 CP809 2401-002300 C-AL;47uF,20%,50V,GP,TP,6.3x11,5 1

....4 CP814 2401-002619 C-AL;47uF,20%,25V,GP,TP,5x11,5 1

....4 CS817 2401-003872 C-AL;2200UF,20%,25V,LZ,TP,18X20MM,7.5 1

....4 CS816 2401-003872 C-AL;2200UF,20%,25V,LZ,TP,18X20MM,7.5 1

....4 CM818 2401-003872 C-AL;2200UF,20%,25V,LZ,TP,18X20MM,7.5 1

....4 CI818 2401-003872 C-AL;2200UF,20%,25V,LZ,TP,18X20MM,7.5 1

....4 CM823 2401-003874 C-AL;1000UF,20%,25V,LZ,TP,12.5X20MM,5 1

....4 CM822 2401-003874 C-AL;1000UF,20%,25V,LZ,TP,12.5X20MM,5 1

7 Electrical Parts List

7-6

Level Loc. No. Code No. Description & Specification Q'ty SA/SNA

Page 59

7 Electrical Parts List

7-7

....4 CI817 2401-003874 C-AL;1000UF,20%,25V,LZ,TP,12.5X20MM,5 1

....4 CM820 2401-003875 C-AL;2200UF,20%,16V,LZ,TP,16X20MM,7.5 1

....4 CM819 2401-003875 C-AL;2200UF,20%,16V,LZ,TP,16X20MM,7.5 1

....4 L2514 3301-001223 BEAD-AXIAL;62ohm,3.5x0.8x5mm,,TP,,, 1 S.N.A

....4 L2514 3301-001223 BEAD-AXIAL;62ohm,3.5x0.8x5mm,,TP,,, 1 S.N.A

....4 FD801S 3601-001064 FUSE-AXIAL LEAD;125V,4A,FAST-ACTING,GLAS 1

....4 FD803S 3601-001064 FUSE-AXIAL LEAD;125V,4A,FAST-ACTING,GLAS 1

....4 T0077 BN41-00414A PCB MAIN;VENUS 30",FR4,2,A,1.6T,245*197, 1 S.N.A

....4 RM819 2001-001050 R-CARBON(S);1.5KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 CM813 2401-000015 C-AL;33uF,20%,50V,WT,-,6.3x11mm,2.5 1

....4 CM801 2401-000481 C-AL;10uF,20%,50V,WT,TP,5x11,5 1

....4 CM805 2401-000481 C-AL;10uF,20%,50V,WT,TP,5x11,5 1

....4 CS803 2401-000481 C-AL;10uF,20%,50V,WT,TP,5x11,5 1

....4 CM802 2401-000970 C-AL;22uF,20%,50V,WT,TP,5x11,5 1

....4 CS804 2401-000970 C-AL;22uF,20%,50V,WT,TP,5x11,5 1

....4 CS807 2401-000970 C-AL;22uF,20%,50V,WT,TP,5x11,5 1

....4 FD802S 3601-001163 FUSE-AXIAL LEAD;125V,7A,-,EPOXY,2.4X7.1M 1

....4 CI820 2201-000376 C-CERAMIC,DISC;0.22NF,5%,50V,SL,TP,6.3X3 1

....4 CM825 2201-000376 C-CERAMIC,DISC;0.22NF,5%,50V,SL,TP,6.3X3 1

....4 CP812 2201-000376 C-CERAMIC,DISC;0.22NF,5%,50V,SL,TP,6.3X3 1

....4 CS820 2201-000376 C-CERAMIC,DISC;0.22NF,5%,50V,SL,TP,6.3X3 1

....4 CP801 2201-000315 C-CERAMIC,DISC;2.2NF,+80-20%,250V,Y5U,TP 1

....4 CP802 2201-000315 C-CERAMIC,DISC;2.2NF,+80-20%,250V,Y5U,TP 1

...3 IC804S BP96-00194A ASSY HEAT SINK P;BP62-00018B,SPRING,STR- 1 S.N.A

....4 CIS1 0205-001154 OIL-SILICON;G746,-,- 0.2 S.N.A

....4 M0144 BH61-00004A SPRING ETC-TR;CDA,CDB,SUS304,-,-,-,-,-,T 2 S.N.A

....4 T0066 BP62-00018B HEAT SINK-ES;VENUS,A6063S,T2.0,20,70 1 S.N.A

....4 T0086 1203-002827 IC-PWM CONTROLLER;STR-W6853,TO-220(FORMI 2

...3 D801S BP96-00201A ASSY HEAT SINK P;BP62-00019B,SCREW,RBV60 1 S.N.A

....4 CIS1 0205-001154 OIL-SILICON;G746,-,- 0.2 S.N.A

....4 M0081 6003-000334 SCREW-TAPTITE;RH,+,2S,M3,L6,ZPC(YEL),SWR 1 S.N.A

....4 T0066 BP62-00019B HEAT SINK-ES;VENUS,A6063S,T2.0,20,40,WHI 1 S.N.A

....4 T0105 AA60-30001A WASHER-PLATE;M3,ID3.5,15X8.5,T1.0,SBHG 1 S.N.A

....4 CIS 0402-000116 DIODE-BRIDGE;RBV606,600V,6A,SIP-4,ST 1

...3 DI810 BP96-00286A ASSY HEAT SINK P;BP62-00019C,SPRING,MBR2 1 S.N.A

....4 T0066 BP62-00019C HEAT SINK-ES;VENUS,A6063S,T2.0,20,133,WH 1 S.N.A

....4 M0144 BH61-00004A SPRING ETC-TR;CDA,CDB,SUS304,-,-,-,-,-,T 4 S.N.A

....4 CCMM1 BN73-00047A SILICON/RUBBER;VENUS,TC1370,17*19*T0.4, 4 S.N.A

....4 CIS 0402-000240 DIODE-RECTIFIER;MBR2045,45V,20A,TO-220,S 4

...3 CN906 3711-003043 CONNECTOR-HEADER;BOX,4P,1R,2.5MM,STRAIGH 1

...3 PC804S 0604-001032 PHOTO-COUPLER;TR,170-260%,300mW,DIP-4,ST 1

...3 PC803S 0604-001032 PHOTO-COUPLER;TR,170-260%,300mW,DIP-4,ST 1

...3 PC802S 0604-001032 PHOTO-COUPLER;TR,170-260%,300mW,DIP-4,ST 1

...3 PC801S 0604-001032 PHOTO-COUPLER;TR,170-260%,300mW,DIP-4,ST 1

...3 DM808 BP96-00196B ASSY HEAT SINK P;BP62-00019D,SCREW,MBRF1 1 S.N.A

....4 T0066 BP62-00019D HEAT SINK-ES;VITORIA,A6063S,T2.0,20,70,W 1 S.N.A

....4 M0081 6003-000334 SCREW-TAPTITE;RH,+,2S,M3,L6,ZPC(YEL),SWR 3 S.N.A

....4 CIS1 0205-001154 OIL-SILICON;G746,-,- 0.3 S.N.A

....4 CIS 0402-001383 DIODE-RECTIFIER;MBRF10100CT,100V,10A,ITO 3

...3 RP807 2001-001049 R-CARBON(S);1.3KOHM,5%,1/2W,AA,TP,2.4X6. 1

...3 RP806 2001-001088 R-CARBON(S);1KOHM,5%,1/2W,AA,TP,2.4X6.4M 1

...3 RM810 2001-001097 R-CARBON(S);2.4KOHM,5%,1/2W,AA,TP,2.4X6. 1

...3 CIS 6902-000314 BAG AIR CAP;LDPE,T0.05,W400,L400,TRP,-,- 1 S.N.A

...3 IC801S BP96-00197B ASSY HEAT SINK P;BP62-00018F,SPRING,SCRE 1 S.N.A

....4 CIS1 0205-001154 OIL-SILICON;G746,-,- 0.1 S.N.A

....4 M0081 6003-000334 SCREW-TAPTITE;RH,+,2S,M3,L6,ZPC(YEL),SWR 1 S.N.A

....4 M0144 BH61-00004A SPRING ETC-TR;CDA,CDB,SUS304,-,-,-,-,-,T 5 S.N.A

....4 CCMM1 BN73-00047A SILICON/RUBBER;VENUS,TC1370,17*19*T0.4, 4 S.N.A

....4 T0066 BP62-00018F HEAT SINK-ES;VENUS,A6063S,T2.0,20,133,WH 1 S.N.A

....4 H/S 0402-001573 DIODE-RECTIFIER;UGF15JT,600V,15A,TO-220, 1

Level Loc. No. Code No. Description & Specification Q'ty SA/SNA

Page 60

....4 Q409 0505-001736 FET-SILICON;FQP18N50V2,N,500V,18A,0.265O 4

....4 P803T 1404-001252 THERMISTOR-PTC;85OHM,25%,16V,30VAC,-,-,B 1

...3 RM808 2009-000022 R-METAL PLATE;0.47ohm,10%,5W,CL,TP,5x14x 1

...3 RS807 2009-000022 R-METAL PLATE;0.47ohm,10%,5W,CL,TP,5x14x 1

...3 RP805 2009-001096 R-METAL PLATE;0.07ohm,5%,5W,CL,BK,5x14x1 1

..2 M0018 BN94-00444N ASSY PCB POWER-SUB PCB;NF26" 1

...3 T0245 0202-001366 SOLDER-WIRE FLUX;-,RS60S,D1.2,63Sn/37Pb, 0.05 S.N.A

...3 D811S 0402-000102 DIODE-BRIDGE;D2SB60,200V,1.5A,SIP-4,ST 1

...3 DB814 0402-000586 DIODE-RECTIFIER;RK49,90V,3.5A,DO-201AD 1

...3 PC811S 0604-001038 PHOTO-COUPLER;TR,130-260%,200mW,DIP-4,ST 1

...3 T0086 1203-003077 IC-PWM CONTROLLER;STR-G5551,TO-220,5P,16 1

...3 T0900 1404-001195 THERMISTOR-NTC;5.1ohm,15%,2900,27mW/C,BK 1

...3 CY814S 2201-000963 C-CERAMIC,DISC;1NF,20%,400V,Y5U,TP,9.5X6 1

...3 CX811S 2306-000318 C-FILM,LEAD-PPF;220NF,20%,250V,BK,-,22.5 1

...3 CX812S 2306-000318 C-FILM,LEAD-PPF;220NF,20%,250V,BK,-,22.5 1

...3 CB813 2401-003920 C-AL;47uF,20%,450V,WT,BK,18x31.5mm,7.5 1

...3 RL811S 3501-001053 RELAY-POWER;5VDC,530MW,10000MA,1FORMA,15 1

...3 FD802 3601-001007 FUSE-CARTRIDGE;250V,6.3A,TIME-LAG,GLASS, 1

...3 CN906 3711-002855 CONNECTOR-HEADER;BOX,2P,1R,7.92mm,STRAIG 1

...3 CN906 3711-002855 CONNECTOR-HEADER;BOX,2P,1R,7.92mm,STRAIG 1

...3 CN906 3711-003043 CONNECTOR-HEADER;BOX,4P,1R,2.5MM,STRAIGH 1

...3 LX813S AA29-00011A FILTER LINE NOISE;CZ32W8,-,0.20MAX,1.5KV 1

...3 LX816S AA29-00011A FILTER LINE NOISE;CZ32W8,-,0.20MAX,1.5KV 1

...3 T811S BN26-00014A TRANS SWITCHING-DPMS;EE 2520,LCD-Monitor 1

...3 T0010 BN27-00015A COIL CHOKE;VD063,COIL-CHOKE,80uH,+/-10%, 1

...3 L820S BN27-00024A COIL CHOKE-PFC;VD078-02,CK32PS,10mH,+-10 1

...3 LB810 BN29-00006A FILTER LINE-COMMON MODE;LCDTV,5uH,0.15oh 1

...3 T0275 BN96-00588A ASSY MISC P-INLET;Chagall,Inlet : BN39-0 1 S.N.A

...3 BN97-00208P ASSY AUTO-SUB PCB;NA26" 1 S.N.A

....4 DB812 0401-000006 DIODE-SWITCHING;BAV21,250V,200MA,DO-35,T 1

....4 DB815 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP 1

....4 DB817 0402-000254 DIODE-RECTIFIER;RGP10J,600V,1A,DO-41,TP 1

....4 DB813 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T 1

....4 Q813 0501-000010 TR-SMALL SIGNAL;KSC1008,NPN,800mW,TO-92, 1

....4 QB811 0501-000369 TR-SMALL SIGNAL;KSC2331-Y,NPN,1000mW,TO- 1

....4 QB812 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T 1

....4 VX811S 1405-000187 VARISTOR;750V,1250A,12.5x7mm,TP 1

....4 RB820 2001-000085 R-CARBON(S);100KOHM,5%,1/2W,AA,TP,2.4X6. 1

....4 RB816 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RB815 2001-000591 R-CARBON;3.3KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RB817 2001-000591 R-CARBON;3.3KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RB821 2001-000660 R-CARBON;33KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

....4 RB814 2001-001072 R-CARBON(S);12OHM,5%,1/2W,AA,TP,2.4X6.4M 1

....4 RB812 2001-001165 R-CARBON(S);56OHM,5%,1/2W,AA,TP,2.4X6.4M 1

....4 RB825 2001-001178 R-CARBON(S);680OHM,5%,1/2W,AA,TP,2.4X6.4 1

....4 RX811S 2002-001010 R-COMPOSITION;1.8Mohm,5%,1/2W,AA,TP,3.7x 1

....4 RB823 2002-001068 R-COMPOSITION;180Kohm,5%,1/2W,AA,TP,3.9x 1

....4 RB824 2002-001068 R-COMPOSITION;180Kohm,5%,1/2W,AA,TP,3.9x 1

....4 RB822 2003-001040 R-METAL OXIDE(S);47Kohm,5%,2W,AF,TP,3.9x 1

....4 RB811 2003-002239 R-METAL OXIDE(S);100KOHM,5%,2W,AF,TP,3.9 1

....4 RB826 2005-001066 R-WIRE WOUND;1.2OHM,5%,1W,AA,TP,3.3X9MM 1

....4 RB813 2008-000206 R-FUSIBLE(S);1ohm,5%,1/2W,AF,TP,2.5x6.5m 1

....4 CB807 2201-000014 C-CERAMIC,DISC;0.33NF,10%,1KV,Y5P,TP,6.3 1

....4 CB811 2201-000315 C-CERAMIC,DISC;2.2NF,+80-20%,250V,Y5U,TP 1

....4 CB812 2201-000315 C-CERAMIC,DISC;2.2NF,+80-20%,250V,Y5U,TP 1

....4 CB809 2201-000556 C-CERAMIC,DISC;0.47NF,10%,500V,Y5P,TP,5. 1

....4 CB810 2201-000556 C-CERAMIC,DISC;0.47NF,10%,500V,Y5P,TP,5. 1

....4 CY811S 2201-002026 C-CERAMIC,DISC;1NF,20%,400V,Y5P,TP,11X6M 1

....4 CY812S 2201-002026 C-CERAMIC,DISC;1NF,20%,400V,Y5P,TP,11X6M 1

....4 CY813S 2201-002026 C-CERAMIC,DISC;1NF,20%,400V,Y5P,TP,11X6M 1

7 Electrical Parts List

7-8

Level Loc. No. Code No. Description & Specification Q'ty SA/SNA

Page 61

7 Electrical Parts List

7-9

....4 CB806 2202-000263 C-CERAMIC,MLC-AXIAL;470pF,10%,50V,Y5P,TP 1

....4 CB808 2305-000665 C-FILM,LEAD-PEF;100nF,5%,63V,TP,7.5x4.0x 1

....4 CB819 2306-000122 C-FILM,LEAD-PPF;100nF,5%,50V,TP,7.3x4.0x 1

....4 F101 2901-000299 FILTER-EMI ON BOARD;-,6A,UL/CSA,-,9x7.5, 1

....4 FD811S 3601-001064 FUSE-AXIAL LEAD;125V,4A,FAST-ACTING,GLAS 1

....4 FS811A 3602-000114 FUSE-HOLDER;-,-,30mohm 1

....4 FS811B 3602-000114 FUSE-HOLDER;-,-,30mohm 1

....4 GT811 AA60-40014A PIN-GT,ASSY;AUTO 1

....4 CB817 2401-000142 C-AL;1000uF,20%,16V,WT,TP,10x20,5 1

....4 CB818 2401-000142 C-AL;1000uF,20%,16V,WT,TP,10x20,5 1

....4 CB815 2401-003046 C-AL;47uF,20%,50V,WT,TP,6.3x11,2.5 1

....4 CB816 2401-003046 C-AL;47uF,20%,50V,WT,TP,6.3x11,2.5 1

....4 RB819 2001-000016 R-CARBON(S);1OHM,5%,1/2W,AA,TP,2.4X6.4MM 1

....4 MP2.0 BN41-00456B PCB SUB-POWER;NAPLES 26",FR-4,2 LAYER,B, 1 S.N.A

...3 M2893 BN39-00354A LEAD CONNECTOR;VN40*,UL1007#26,UL/CSA,4P 1

...3 M2893 BN39-00355A LEAD CONNECTOR;VN40*,UL1617#22,UL/CSA,3( 1

...3 M2893 BN39-00383B LEAD CONNECTOR;NAPLES2,UL1007#26,UL/CSA, 1

...3 CN906 3711-000024 CONNECTOR-HEADER;BOX,3P,1R,2.5MM,STRAIGH 1

..2 M0014 BN94-00629J ASSY PCB MAIN;NF26UO 1

...3 T0245 0202-001366 SOLDER-WIRE FLUX;-,RS60S,D1.2,63Sn/37Pb, 0.01 S.N.A

...3 C701 2305-000196 C-FILM,LEAD-PEF;150nF,5%,63V,TP,-,5mm 1

...3 C704 2305-000196 C-FILM,LEAD-PEF;150nF,5%,63V,TP,-,5mm 1

...3 C724 2305-000196 C-FILM,LEAD-PEF;150nF,5%,63V,TP,-,5mm 1

...3 C725 2305-000196 C-FILM,LEAD-PEF;150nF,5%,63V,TP,-,5mm 1

...3 C5105 2305-000665 C-FILM,LEAD-PEF;100nF,5%,63V,TP,7.5x4.0x 1

...3 C5114 2305-000665 C-FILM,LEAD-PEF;100nF,5%,63V,TP,7.5x4.0x 1

...3 CN012 3701-001292 CONNECTOR-DVI;24P,3R,FEMALE,STRAIGHT,AU1 1

...3 CN009 3701-001294 CONNECTOR-DSUB;15P,3R,FEMALE,STRAIGHT,AU 1

...3 CN906 3705-001329 CONNECTOR-COAXIAL;NT(F),ADAPTOR,-,75ohm, 1

...3 CN906 3711-000057 CONNECTOR-HEADER;BOX,3P,1R,2.5mm,ANGLE,S 1

...3 CN906 3711-004121 CONNECTOR-HEADER;BOX,14P,1R,2mm,ANGLE,SN 1

...3 CN005 3722-001734 JACK-VHS;4P,-,SN,BLK,- 1

...3 CN001 3722-001903 JACK-PIN;2P,-,AU,WHT/RED,- 1

...3 CN004 3722-001903 JACK-PIN;2P,-,AU,WHT/RED,- 1

...3 CN013 3722-001903 JACK-PIN;2P,-,AU,WHT/RED,- 1

...3 CN703 3722-001931 JACK-PIN;1P,-,AU,BLK,- 1

...3 CN002 3722-001938 JACK-PIN;3P,-,AU,GRN/BLU/RED,- 1

...3 CN003 3722-001938 JACK-PIN;3P,-,AU,GRN/BLU/RED,- 1

...3 CN006 3722-002063 JACK-PIN;3P,AU,YEL/WHT/RED,STRAIGHT 1

...3 CN011 3722-002066 JACK-PHONE;6P,-,SnPb,BLK,- 1

...3 CN704 3722-002066 JACK-PHONE;6P,-,SnPb,BLK,- 1

...3 CIS3 BN40-00050A TUNER;TMQH6-003B,PDP-NELSON,NTSC,181CH,4 1

...3 CCMM1 BN97-00360E ASSY MICOM-SUB;NF26UO 1

....4 IC902 1102-001129 IC-EPROM;M27W401,512KX8BIT,PLCC,32P,11.3 1 S.N.A

...3 T0174 BN97-00361R ASSY SMD;NEW 1 S.N.A

....4 D053 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D054 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D055 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D068 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D069 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D071 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D072 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D073 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D074 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D075 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D077 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D105 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D324 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D601 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D702 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

Level Loc. No. Code No. Description & Specification Q'ty SA/SNA

Page 62

....4 D901 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D915 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D916 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D922 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200MA,SO 1

....4 D606 0402-000553 DIODE-RECTIFIER;SS24,40V,2.0A,DO-214AA 1

....4 D811 0402-000553 DIODE-RECTIFIER;SS24,40V,2.0A,DO-214AA 1

....4 D812 0402-000553 DIODE-RECTIFIER;SS24,40V,2.0A,DO-214AA 1

....4 D813 0402-000553 DIODE-RECTIFIER;SS24,40V,2.0A,DO-214AA 1

....4 D815 0402-000553 DIODE-RECTIFIER;SS24,40V,2.0A,DO-214AA 1

....4 D818 0402-000553 DIODE-RECTIFIER;SS24,40V,2.0A,DO-214AA 1

....4 D106 0403-000579 DIODE-ZENER;BZX84C5V1,4.8-5.4V,200MW,SOT 1

....4 D912 0403-000579 DIODE-ZENER;BZX84C5V1,4.8-5.4V,200MW,SOT 1

....4 D819 0403-000614 DIODE-ZENER;RLZ8.2B,8.2,500mW,LL-34,TP 1

....4 D929 0403-000620 DIODE-ZENER;RLZ5.6B,5.45-5.73V,500MW,LL- 1

....4 D926 0403-001016 DIODE-ZENER;RLZ6.2B,5.96-6.27V,500mW,LL- 1

....4 D927 0403-001016 DIODE-ZENER;RLZ6.2B,5.96-6.27V,500mW,LL- 1

....4 D928 0403-001016 DIODE-ZENER;RLZ6.2B,5.96-6.27V,500mW,LL- 1

....4 D001 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D002 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D003 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D004 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D005 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D006 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D007 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D008 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D009 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D010 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D011 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D031 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D032 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D033 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D034 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D035 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D036 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D037 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D038 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D039 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D041 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D042 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D043 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D044 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D045 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D046 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D047 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D048 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D049 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D051 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D056 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D057 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D058 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D059 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D061 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D062 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D063 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D064 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D066 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D067 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D078 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D079 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

....4 D081 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200MW,SOT-2 1

7 Electrical Parts List

7-10