Page 1

CUSTOMER

DELL

MODEL NO.

LTN156AT34

DATE OF ISSUE

2013.02.20

EXTENSION CODE

-D

Customer Approval & Feedback

Approved by

13/02/20

Prepared by

13/02/20

LCD Sales & Marketing Team

Samsung Display Co., Ltd

Product Specification

( √ ) Preliminary Specification

( ) Approval Specification

The information described in this SPEC is preliminary and can be changed

without prior notice

Page 2

————————————————————————————————————————————————–

Table of Contents

REVISION HISTORY ................................................................................................................................................ 3

1. GENERAL DESCRIPTION .................................................................................................................................... 4

2. ABSOLUTE MAXIMUM RATINGS ..................................................................................................................... 6

2.1 ENVIRONMENTAL ABSOLTE RATINGS ................................................................................................................... 6

2.2 ELECTRICAL ABSOLUTE RATINGS ........................................................................................................................... 7

2.3 THE OTHERS .............................................................................................................................................................. 7

3. OPTICAL CHARACTERISTICS............................................................................................................................. 8

4. BLOCK DIAGRAM ............................................................................................................................................. 11

4.1 TFT LCD MODULE ................................................................................................................................................... 11

4.2 THE STRUCTURE OF LED PLACEMENT.................................................................................................................. 11

5. ELECTRICAL CHARACTERISTICS ..................................................................................................................... 12

5.1 TFT LCD MODULE ................................................................................................................................................... 12

5.2 BACK LIGHT UNIT ................................................................................................................................................... 14

5.3 LED DRIVER .............................................................................................................................................................. 14

5.4 LVDS INTERFACE ..................................................................................................................................................... 16

5.5 INTERFACE TIMING ................................................................................................................................................ 18

5.6 INPUT COLOR DATA MAPPING ............................................................................................................................ 19

5.7 POWER ON/OFF SEQUENCE ................................................................................................................................. 20

5.8 INPUT TERMINAL PIN ASSIGNMENT .................................................................................................................... 22

6. PIXEL FORMAT .......................................................................................................................................................... 23

7. OUTLINE DIMENSION ..................................................................................................................................... 24

8. RELIABILITY TEST ............................................................................................................................................. 25

9. PACKING ........................................................................................................................................................... 26

9.1 CARTON ................................................................................................................................................................... 26

9.2 MARKING ................................................................................................................................................................. 27

10. GENERAL PRECAUTIONS .............................................................................................................................. 29

10.1 HANDLING ........................................................................................................................................................... 29

10.2 STORAGE ............................................................................................................................................................... 30

10.3 OPERATION ........................................................................................................................................................... 30

10.4 OTHERS ................................................................................................................................ .................................. 31

11. EDID ................................................................................................................................................................. 32

12. APPENDIX ....................................................................................................................................................... 33

12.1 SYSTEM DESIGN GUIDE ....................................................................................................................................... 33

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 2 of 36 Rev. No. 05-P01-S-130220

Page 3

————————————————————————————————————————————————–

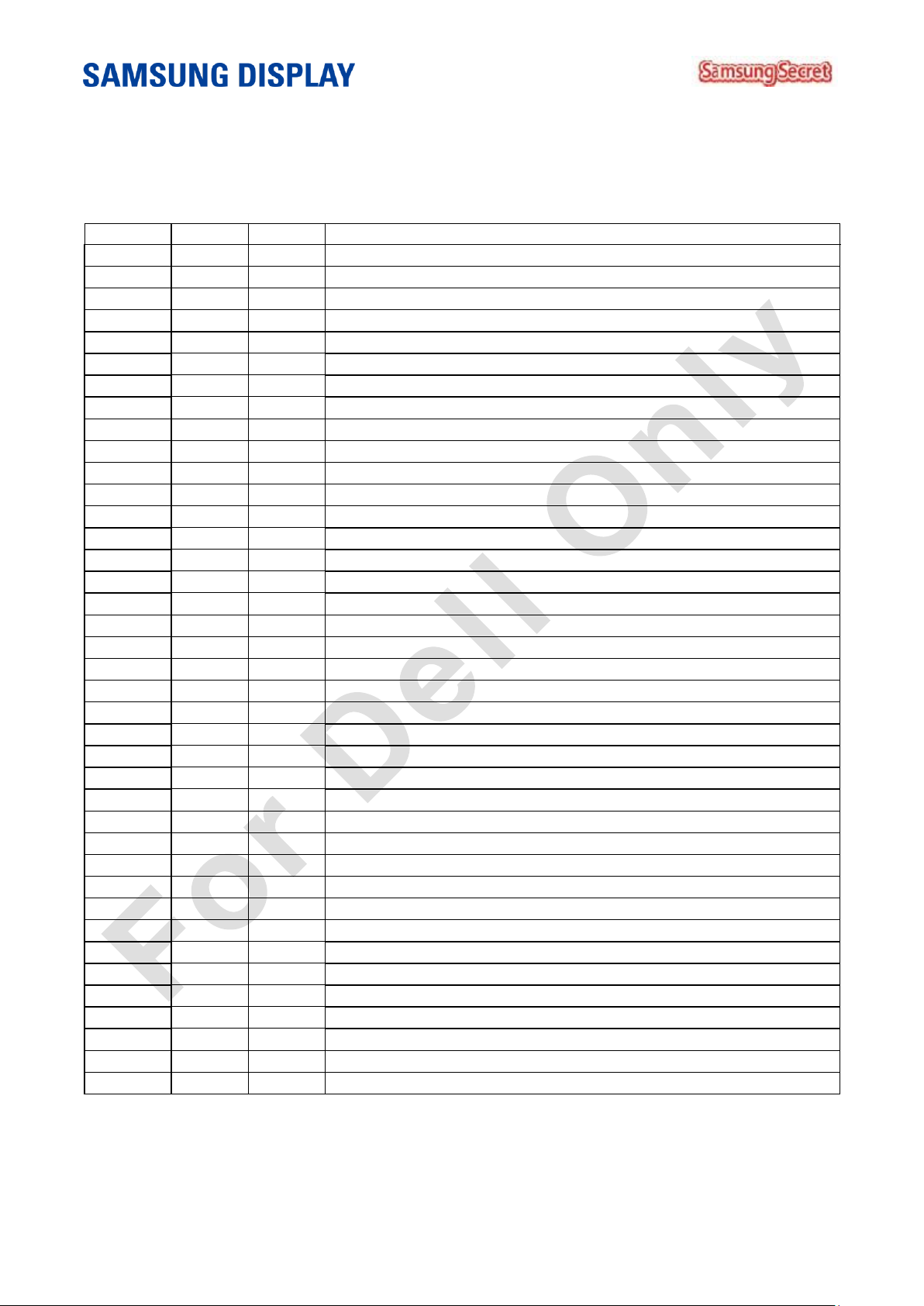

Date.

Rev.No.

Page

Revision Description

01/31/13

P00

All

Initial Release

02/20/13

P01

All

Model code was modified.

REVISION HISTORY

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 3 of 36 Rev. No. 05-P01-S-130220

Page 4

————————————————————————————————————————————————–

Item

Specification

Unit

Note

Display area

344.232 (H) x 193.536 (V) (15.6”diagonal)

mm Driver Element

a-Si TFT active matrix

Display colors

262,144 (6bit)

Number of pixel

1366 * 768

Pixel

16:9

Pixel Arrangement

RGB vertical stripe

Pixel pitch

0.252 (H) x 0.252 (V) (TYP.)

mm

Display Mode

Normally white, TN mode

Thickness of glass

0.5

mm Surface treatment

TBD Glare

Environmental safe regulation

Pb Free, Halogen Free

1. GENERAL DESCRIPTION

DESCRIPTION

The LTN156AT34-D uses a color active matrix TFT (Thin Film Transistor) liquid crystal display (LCD) that uses

amorphous silicon TFTs as switching components. This model is composed of a TFT LCD panel, a driver circuit,

and a backlight unit. This 15.6” model has a resolution of 1366 x 768 pixels and can display up to 262,144

colors.

FEATURES

High contrast ratio

HD (1366 x 768 pixels) resolution

Low power consumption

Fast Response

LED back light with an embedded LED driver

DE (Data enable) only mode

3.3V LVDS interface

Onboard EEDID chip

APPLICATIONS

Notebook PC

If the intent to use this product is for other purpose, please contact Samsung Display.

GENERAL INFORMATION

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 4 of 36 Rev. No. 05-P01-S-130220

Page 5

————————————————————————————————————————————————–

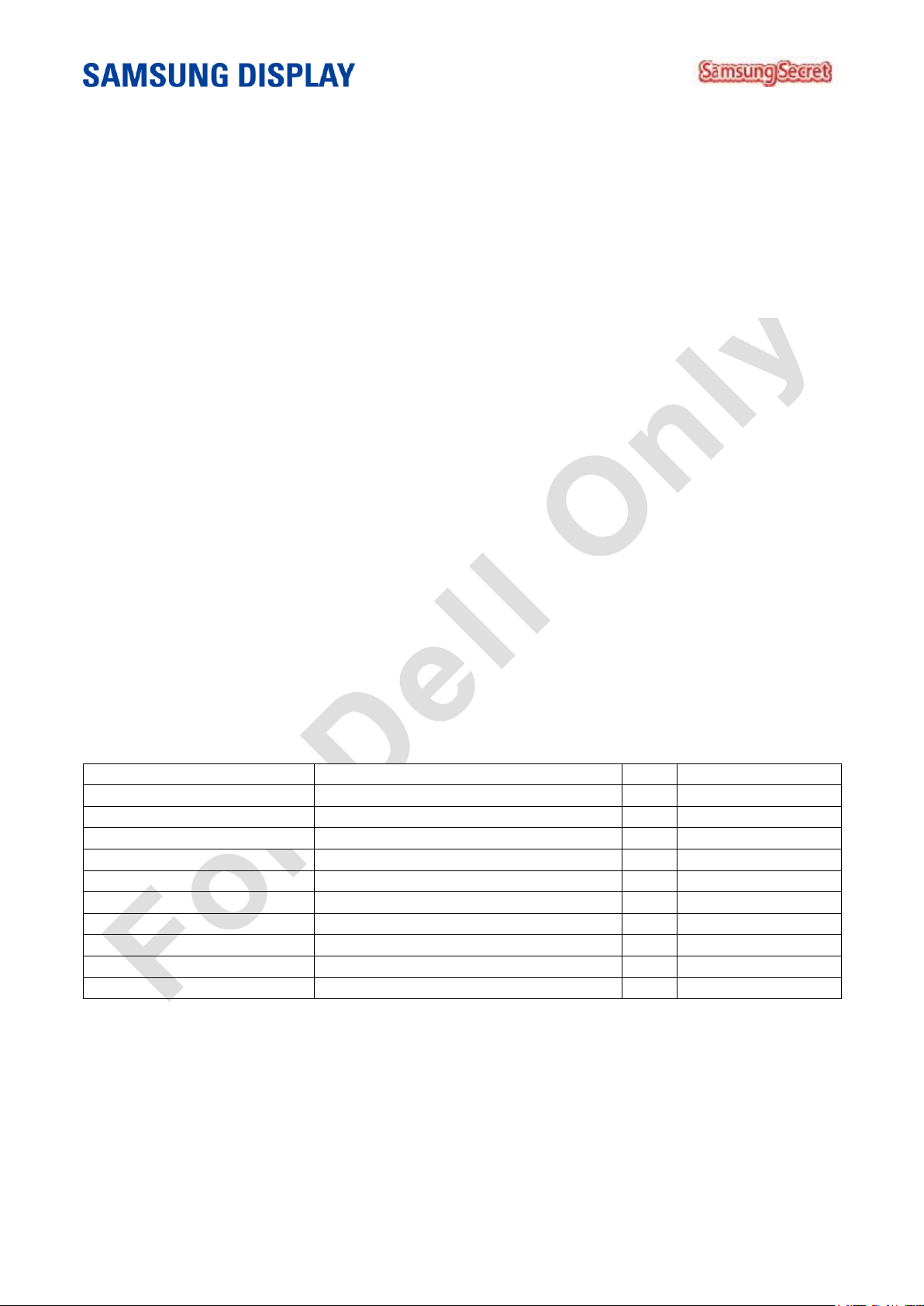

Item

Min.

Typ.

Max.

Unit

Note

Module

Size

Horizontal (H)

359.0

359.5

360.0

mm

Vertical (V)

223.3

223.8

224.3

mm

with flange

206.0

206.5

207.0

mm

w/o flange

Depth (D)

-

-

3.2

mm

(1)

Weight

- - 380 g

MECHANICAL INFORMATION

NOTE (1) Measuring method for thickness

Force to be applied for measurement : The 200gf when using the height gauge

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 5 of 36 Rev. No. 05-P01-S-130220

Page 6

————————————————————————————————————————————————–

Item

Symbol

Min.

Max.

Unit

Note

Storage temperate

TSTG

-20

60

C

(1)

Operating temperature

(Temperature of glass surface)

TOPR 0 50

C

(1)

Shock ( non-operating )

Snop - 240 G (2), (4)

Vibration (non-operating)

Vnop - 2.41 G (3), (4)

2. ABSOLUTE MAXIMUM RATINGS

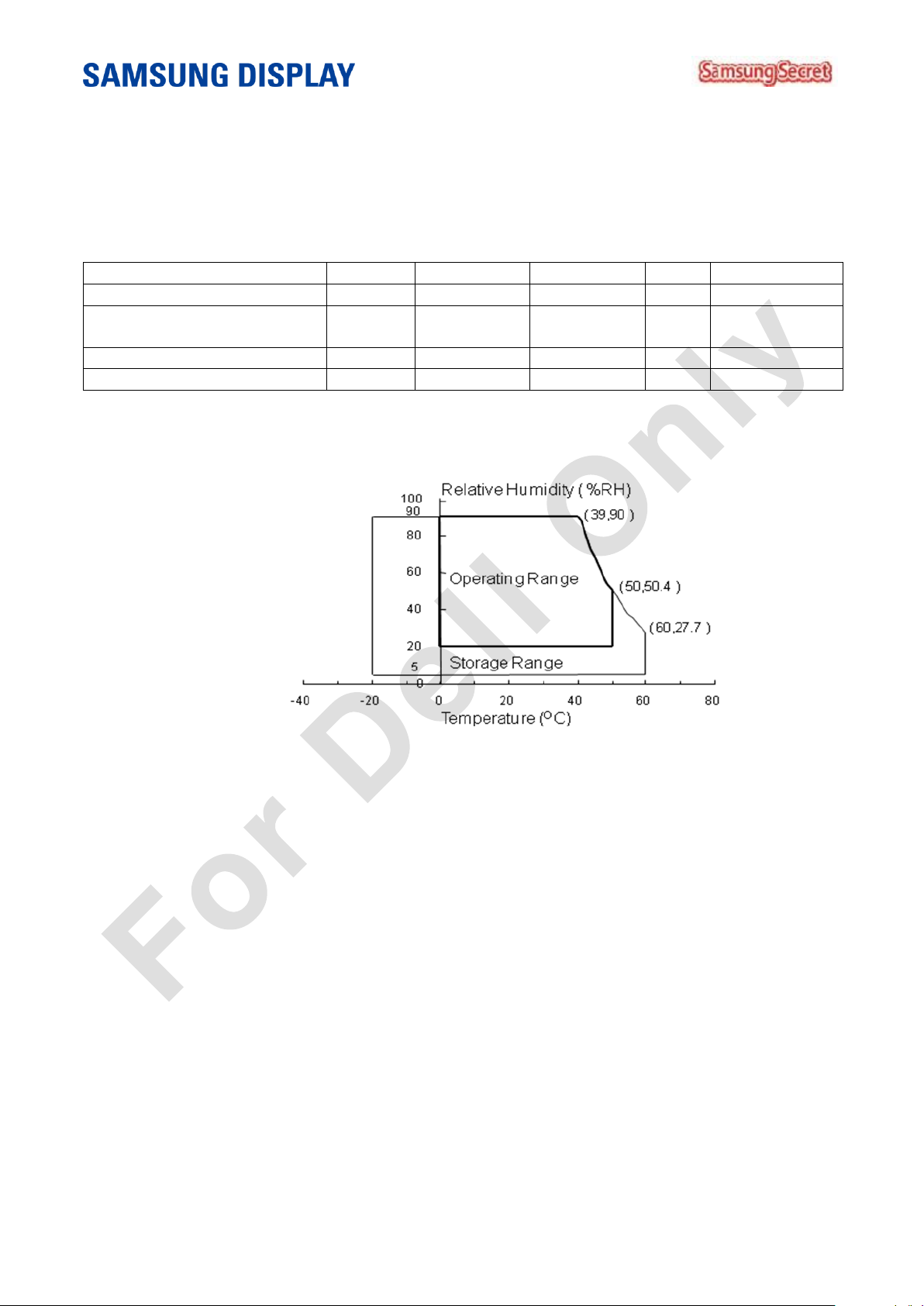

2.1 ENVIRONMENTAL ABSOLTE RATINGS

Note (1) The range of temperature and relative humidity are shown in the graph below 90% RH Max. .

(39℃ ≥ Ta) If the temperature is higher than 40 ℃, the maximum temperature of wet–bulb shall be

less than 39℃. No condensation

(2) Vibrate X, Y, and Z axis in the shape of the half sine wave one time for 2ms .

(3) Vibrate the X, Y, and Z randomly within a 5 - 500 Hz range for 30min.

(4) When testing a vibration and a shock, the fixture, which holds the module to be tested shall be

hard and rigid in order for the the module not to be twisted or bent by the fixture.

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 6 of 36 Rev. No. 05-P01-S-130220

Page 7

————————————————————————————————————————————————–

Item

Symbol

Min.

Max.

Unit

Note

Power Supply Voltage

VLCD_VCC

VSS - 0.3

TBD

V

(1),(2)

LVDS Input Voltage

VLVDS

VSS - 0.3

TBD

Item

Symbol

Min.

Max.

Unit

Note

BLU Supply Voltage

V

BL_PWR

VSS - 0.3

26.5

V

(1), (2)

BLU Supply Current

I

BL_PWR

- 0.9

A

(1), (2)

Vin=12V

Duty 100%

Item

Test Conditions

Remark

CONTACT DISCHARGE

150pF, 330, 8kV, 200points, 1 time/point

Operating

AIR DISCHARGE

150pF, 330, 15kV, 200points, 1 time/point

Operating

2.2 ELECTRICAL ABSOLUTE RATINGS

(1) TFT LCD MODULE

VLCD_VCC =3.3V, VSS = GND = 0V

Note (1) Within Ta (25 2 C )

(2) Permanent damage to the device may occur if exceed maximum values

.

(2) BACKLIGHT UNIT

VSS = GND = 0V

Note (1) Within Ta (25 2 C )

(2) Permanent damage to the device may occur if exceed maximum values

2.3 THE OTHERS

(1) STATIC ELECTRICITY PRESSURE RESISTANCE

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 7 of 36 Rev. No. 05-P01-S-130220

Page 8

————————————————————————————————————————————————–

Item

Symbol

Condition

Min.

Typ.

Max.

Unit

Note

Contrast Ratio

CR

Normal

Viewing

Angle

= 0

= 0

500 - -

-

(1),(2),(5)

Response time

( Rising + Falling )

TRT

-

16

25

msec

(1),(3)

Average Luminance

of White (5 Points)

YL,AVE

170

200

-

cd/m2

IF=100%

Duty

(1),(4)

Color

Chromaticit

y

(CIE)

Red

RX

-0.03

TBD

+0.03

(1),(5)

RY

TBD

Gree

n

GX

TBD

GY

TBD

Blue

BX

TBD

BY

TBD

Whit

e

WX

TBD

WY

TBD

Viewing

Angle

Hor.

L

CR 10

At center

40

45

-

Degrees

(1),(5)

H

40

45

-

Ver.

H

10

15

-

L

30

35

-

Color

Gamut

CG -

45 - %

White variation

(13P)

L

- TBD

(6)

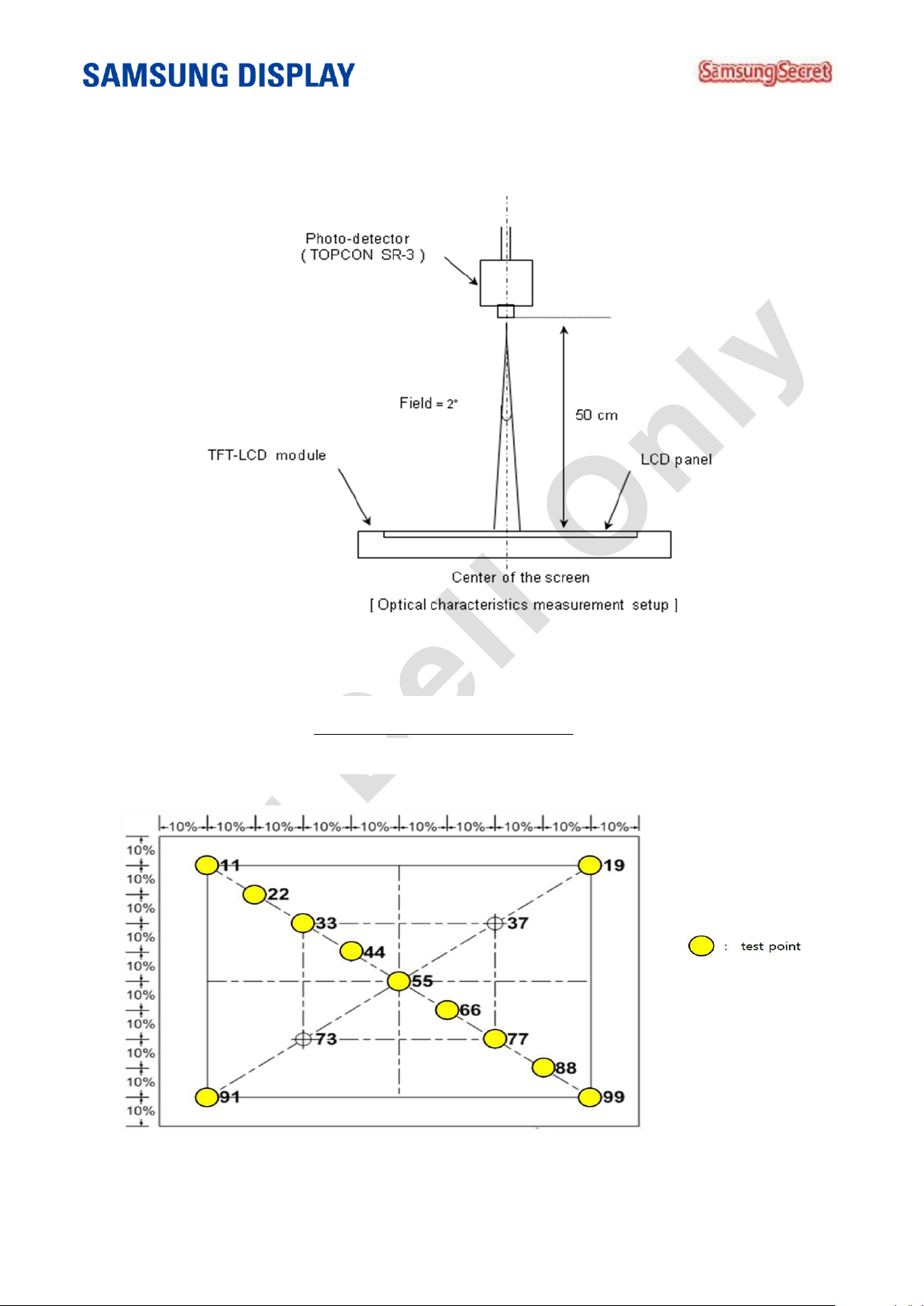

3. OPTICAL CHARACTERISTICS

The following items are measured under the stable conditions.* The optical characteristics should be measured

in the dark room or the equivalent environment by the methods shown in the Note (5).

Measuring equipment : TOPCON SR-3

Ta = 25 2 C, VLCD_VCC =3.3V, fv= 60Hz, fDCLK = (TBD)MHz, IF = 100% duty

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 8 of 36 Rev. No. 05-P01-S-130220

Page 9

————————————————————————————————————————————————–

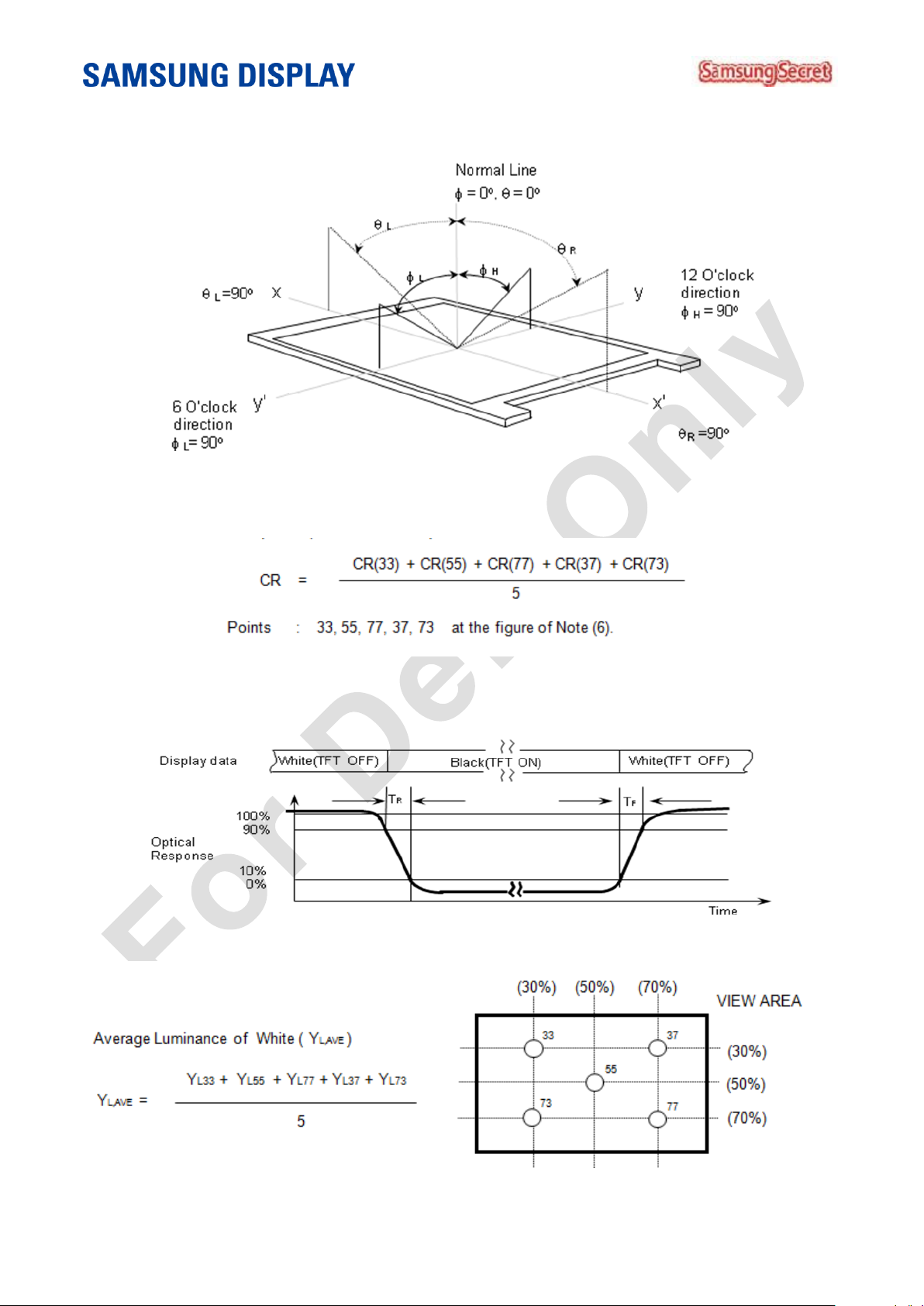

Note (1) The definition of viewing angle : The range of viewing angle (10 C/R)

Note (2) The definition of contrast ratio (CR) : The ratio of max. gray and min gray at 5 points

(33, 55, 77, 37, 73)

Note (3) The definition of Response time : Subtotal of the time, during which the transmission changes from

10% to 90% when the TFT turns on and off.

Note (4) The definition of average luminance of white : Measure the luminance of white at 5 points.

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 9 of 36 Rev. No. 05-P01-S-130220

Page 10

————————————————————————————————————————————————–

L =

Maximum luminance of 11 points

Minimum luminance of 11 points

Note (5) Measure the panel, which is left for 30 min. at the normal temp. after leaving it for 30 min with turning

the back light on at the rating. The measurement should be executed under the condition including

the ambient temp., 25℃±2℃, the dark room, windless(removed the direct wind), and no vibration.

Note (6) The definition of white variation at 11 points ( L): 11,22,33,44,55,66,77,88,99,19,91 point

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 10 of 36 Rev. No. 05-P01-S-130220

Page 11

————————————————————————————————————————————————–

LTN156AT34-D

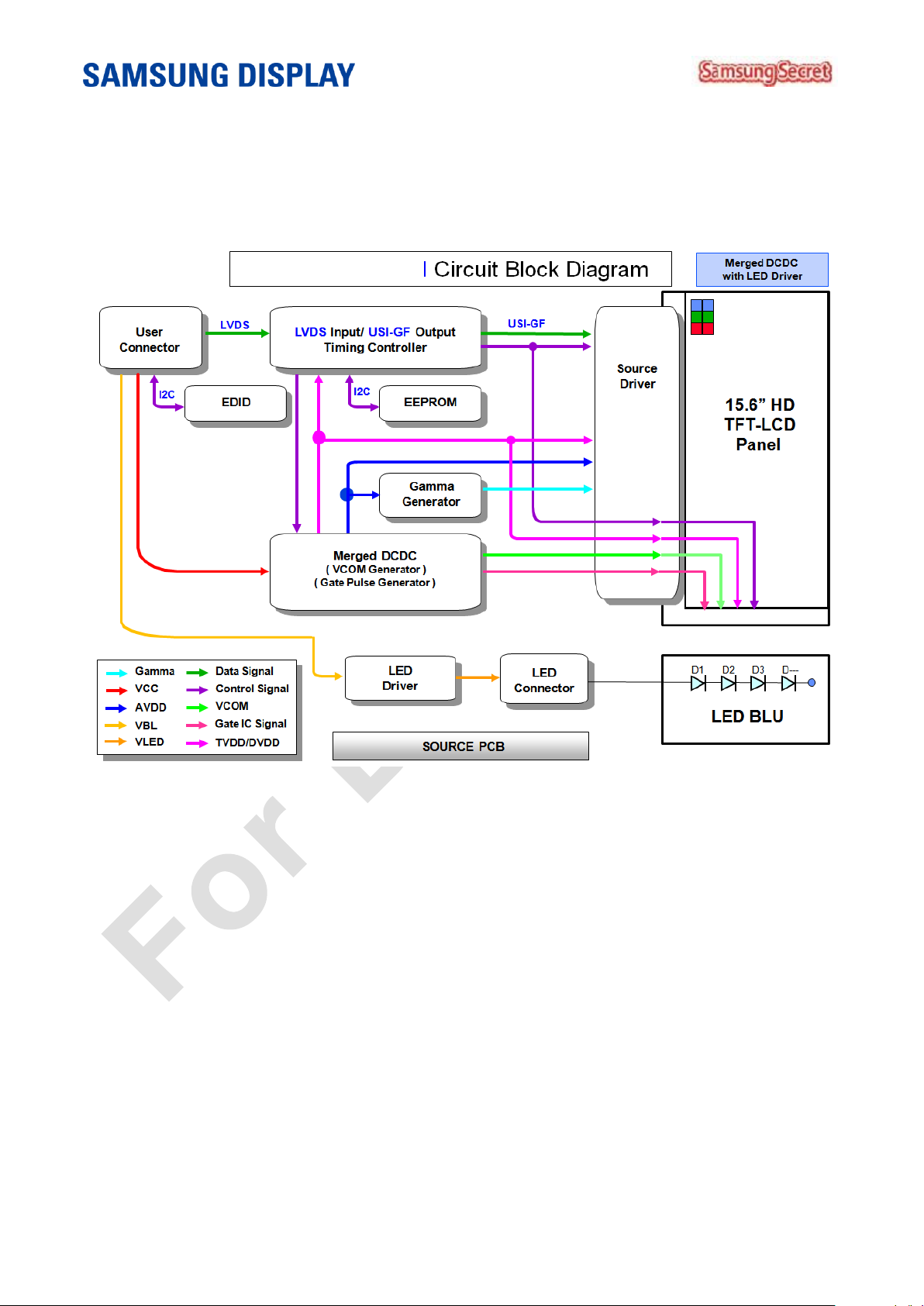

4. BLOCK DIAGRAM

4.1 TFT LCD MODULE

4.2 THE STRUCTURE OF LED PLACEMENT

(TBD)

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 11 of 36 Rev. No. 05-P01-S-130220

Page 12

————————————————————————————————————————————————–

Item

Symbol

Min.

Typ.

Max.

Unit

Note

Power Supply Voltage

VLCD_VCC

3.0

3.3

3.6 V

T-CON TTL

Input Voltage

High

VIH

TBD V

Low

VIL

TBD V Vsync

60Hz

fv

60 Hz Hsync

60Hz

fh

TBD kHz

Main Frequency

60Hz

fDCLK

TBD

MHz

Rush Current

IRUSH

TBD A

(5)

Input Current

White

ILCD_VCC

-

TBD - mA

(4)

Mosaic

ILCD_VCC

-

TBD - mA

Black

ILCD_VCC

-

TBD - mA

Red

ILCD_VCC

-

TBD mA

Green

ILCD_VCC

-

TBD mA

Blue

ILCD_VCC

-

TBD mA

5. ELECTRICAL CHARACTERISTICS

5.1 TFT LCD MODULE

* Ta = 25 ± 2 °C

Note (1) The data pins for display and signal pins for timing should be connected.(GND= 0V)

(2) fV = 60Hz, fDCLK = (TBD) MHZ, VLCD_VCC = 3.3V , DC Current.

(3) In the case of 40Hz & 50Hz, FOS, Flicker & Brightness are not guaranteed, because their level might

be different from 60Hz operation.

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 12 of 36 Rev. No. 05-P01-S-130220

Page 13

————————————————————————————————————————————————–

Note (4) The dissipation pattern for power

Note (5) The condition for measurement for rush current

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 13 of 36 Rev. No. 05-P01-S-130220

Page 14

————————————————————————————————————————————————–

Item

Symbol

Min.

Typ.

Max.

Unit

Note

LED Forward Current

IF

TBD mA

LED Forward Voltage

VF

TBD V

IF = TBD mA

LED Array Voltage

VP

TBD V

VF * LED Counts

LED Power Consumption

P -

2.6

W

LED Life time

Hr

15,000 - -

Hour

(1)

LED Counts

Q

-

TBD - EA

Item

Symbol

Min.

Typ.

Max.

Unit

Note

Input Voltage

VBL_PWR

TBD V

Input Current

IBL_PWR

TBD mA

Vin=12V Duty 100%

PWM duty Ratio

DBL_PWM_DIM

TBD %

PWM : TBD

External PWM Frequency

FBL_PWM_DIM

TBD kHz

In-Rush Current

IRUSH_BL_PWR

TBD A

(1)

5.2 BACK LIGHT UNIT

Ta = 25 2 C

Note (1) The life time (Hr) of LEDs can be defined as the time during which it continues to operate under the

condition, which the Ta is 25 2 C and IF= TBD mArms until the one of the following events

occurs when the brightness becomes 50% or lower than the original..

5.3 LED DRIVER

The manufacturer of LED driver: TBD Ta= 25 2 C

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 14 of 36 Rev. No. 05-P01-S-130220

Page 15

————————————————————————————————————————————————–

Note (1) Rush current measurement condition

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 15 of 36 Rev. No. 05-P01-S-130220

Page 16

————————————————————————————————————————————————–

Characteristics

Symbol

Min.

Typ.

Max.

Unit

Conditions

Differential input high

threshold voltage

VTH - -

+200

mV

VCM = 1.2V

Differential input low

threshold voltage

VTL

-200 - -

mV

Differential input voltage

|VID|

200

400

600

mV

Common mode voltage

VCM

0.4

1.2

1.8

V

|VID|= 100mV

Characteristics

Symbol

Min.

Typ.

Max.

Unit

Remarks

ROUTCLK frequency

fRCP

(TBD)

(TBD)

(TBD)

Mhz

LVDS RX Skew

(Strobe) Right

Margin

85MHz

T

RSRM

- - 400

ps

50MHz - -

700

ps

LVDS RX Skew

(Strobe) Left

Margin

85MHz

T

RSLM

-400 - -

ps

50MHz

-700 - -

ps

V

TL

RIN1P

RIN1P-RIN1N

Tr

Vcm

V

TH

1 1 0 1 0 1 0

RINCLKP

Vid

RINCLKN

RIN1N

0

5.4 LVDS INTERFACE

LVDS DC Specifications

LVDS AC Specifications

< The definition of LVDS DC characteristics >

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 16 of 36 Rev. No. 05-P01-S-130220

< The definition of LVDS Receiver Skew (Strobe) Margin >

Page 17

————————————————————————————————————————————————–

Characteristics

Symbol

Min.

Typ.

Max.

Unit

Remarks

Modulation Rate

Fmr

-3 0 +3 %

Modulation Frequency

Fmf

30

-

300

kHz

@ MAINCLK =

(TBD)MHz

LVDS SSC Specification

< Definition of SSC (Spread Spectrum Clock) >

Timing diagrams of LVDS transmission

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 17 of 36 Rev. No. 05-P01-S-130220

Page 18

————————————————————————————————————————————————–

Signal

Item

Symbol

Min.

Typ.

Max.

Unit

Note

Frame Frequency

Cycle

TV TBD

Lines

Vertical active

in the display term

Display Period

TVD - 768

-

Lines

Scanning time in

one line

Cycle

TH TBD

Clocks

Horizontal active

in the display term

Display Period

THD

-

1366

-

Clocks

5.5 INTERFACE TIMING

5.5.1 TIMING PARAMETERS

5.5.2 TIMING DIAGRAMS OF INTERFACE SIGNAL

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 18 of 36 Rev. No. 05-P01-S-130220

Page 19

————————————————————————————————————————————————–

5.6 INPUT COLOR DATA MAPPING

Note (1) Definition of gray : Rn: Red gray, Gn: Green gray, Bn: Blue gray (n=gray level)

Note (2) Input signal: 0 =Low level voltage, 1=High level voltage

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 19 of 36 Rev. No. 05-P01-S-130220

Page 20

————————————————————————————————————————————————–

Timing (ms)

Remarks

0.5<T1≤10

VLCD_VCC rising time from 10% to 90%

0<T2 ≤50

Interval from VLCD_VCC to valid data at power ON

0<T3 ≤50

Interval from valid data OFF to VLCD_VCC OFF at power Off

150 ≤T4

VLCD_VCC OFF time for Windows restart

200 ≤T5

Interval from valid data to B/L enable at power ON

0 ≤T6

Interval from valid data off to B/L disable at power Off

0<T7 ≤10

VLCD_VCC falling time from 90% to 10%

10<T8

Interval from valid data on to LED driver Vin rising time 10%

10<T9

Interval from LED driver Vin falling time 10% to valid data Off

0.5<T10≤10

LED V

in

rising time from 10% to 90%

0.5<T11≤10

LED V

in

falling time from 90% to 10%

0<T12

Interval from LED driver Vin rising time 90% to PWM ON

0<T13

Interval from PWM Off to LED driver Vin falling time 10%

0 ≤ T14

Interval from PWM ON to B/L Enable ON

0 ≤ T15

Interval from B/L Enable Off to PWM Off

5.7 POWER ON/OFF SEQUENCE

To prevent the product from being latched up or the DC in the LCD module from starting an operation, the

order to turn the power on and off should be changed to the order as shown in the diagram below.

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 20 of 36 Rev. No. 05-P01-S-130220

Page 21

————————————————————————————————————————————————–

The backlight may be flashed if the interface signal remains floated when the above-mentioned signal

becomes invalid.

Note (1) The power voltage from system shall be supplied to the input pin of LCD constantly.

(2) Enable the voltage to the LED within the range, which the LCD is operated. The screen becomes

white when turning the back-light on before the LCD is operated or turning the LCD off before

turning the back-light off. Operation or the LCD turns off before the back-light turns off, the display

may momentarily become white.

(3) Don’t leave the system at a high impedance state, which the interface signal is out for a long time

after the Vcc is enabled.

(4) The T4 should be measured the module is fully discharged.

(5) The interface signal shall not maintain the high impedance when the power is on.

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 21 of 36 Rev. No. 05-P01-S-130220

Page 22

————————————————————————————————————————————————–

Pin

Symbol

Function

1

NC

Hot Plug Detect or No connection (optional)

2

LCD_VCC

LCD logic and driver IC Power(3.3V typ.)

3

LCD_VCC

LCD logic and driver IC Power(3.3V typ.)

4

VCC_EDID

DDC power

5

BIST_EN (WPN)

BIST enable and Reserved for the use by LCD manufacturer. (WPN)

6

CLK_EDID

DDC clock 7 DAT_EDID

DDC data 8 RX0-

Negative LVDS differential data input for pixel

9

RX0+

Positive LVDS differential data input for pixel

10

H_GND

High speed ground

11

RX1-

Negative LVDS differential data input for pixel

12

RX1+

Positive LVDS differential data input for pixel

13

H_GND

High speed ground

14

RX2-

Negative LVDS differential data input for pixel

15

RX2+

Positive LVDS differential data input for pixel

16

H_GND

High speed ground

17

RXC-

Negative LVDS differential clock input for pixel

18

RXC+

Positive LVDS differential clock input for pixel

19

LCD_GND

LCD logic and driver IC Ground

20

NC

No connection

21

NC

No connection

22

LCD_GND

LCD logic and driver IC Ground

23

NC

No connection

24

NC

No connection

25

LCD_GND

LCD logic and driver IC Ground

26

NC

No connection

27

NC

No connection

28

LCD_GND

LCD logic and driver IC Ground

29

NC

No connection

30

NC

No connection

31

BL_GND

Backlight ground

32

BL_GND

Backlight ground

33

BL_GND

Backlight ground

34

NC

Hot Plug Detect or No connection (optional)

35

BL_PWM_DIM

Signal input for the system PWM for dimming

36

BL_ENABLE

Backlight on/off

37

APS_EN

APS on/off or No connection (optional)

38

BL_PWR

Backlight power

39

BL_PWR

Backlight power

40

BL_PWR

Backlight power

5.8 INPUT TERMINAL PIN ASSIGNMENT

5.8.1 INPUT SIGNAL & POWER

(

(LVDS, Connector : 20455-040E-0, I-PEX or the equipment with the equivalent capability)

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 22 of 36 Rev. No. 05-P01-S-130220

Page 23

————————————————————————————————————————————————–

1366

Line 768

6. PIXEL FORMAT

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 23 of 36 Rev. No. 05-P01-S-130220

Page 24

————————————————————————————————————————————————–

TBD

7. OUTLINE DIMENSION

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 24 of 36 Rev. No. 05-P01-S-130220

Page 25

————————————————————————————————————————————————–

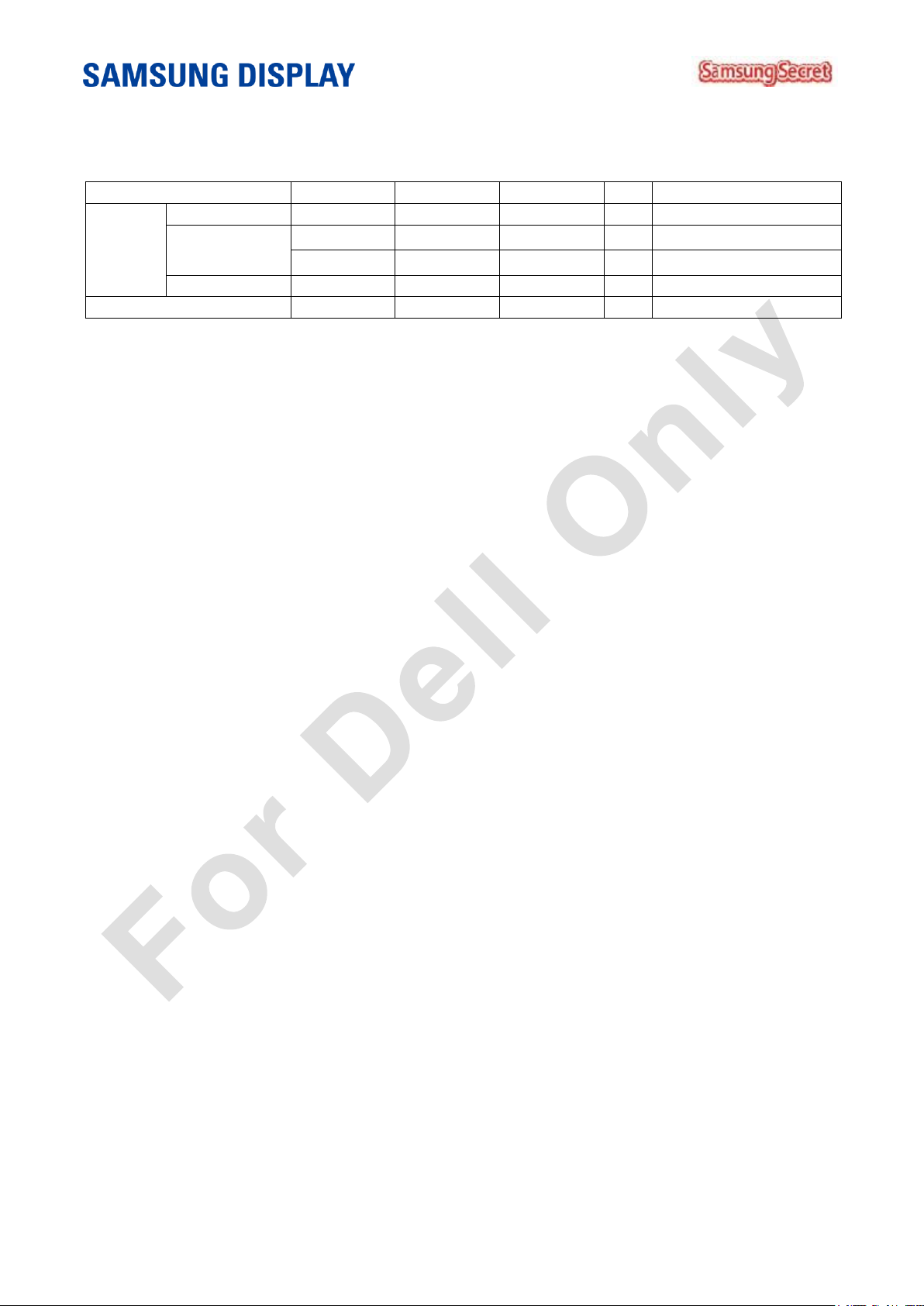

Item

Condition

Time/Cycle

HTOL

55 ℃

500 hrs

LTOL

-5 ℃

500 hrs

HTS

70 ℃

500 hrs

LTS

-25 ℃

500 hrs

THB

50 ℃, 90%

500 hrs

WHTS

60 ℃, 75%

500 hrs

T/C

-40 ℃/30min ~ 65 ℃/30min

50 cycles

ESD

Non-

operating

CDM : 150pF, 330Ω, 9point, 3 times/point

± 10kV

Operating

Contact : 150 pF, 330Ω, 100point, once/point

± 8kV

Air(non-contact) : 150pF, 330Ω, 100point, once/point

± 15kV

Box Vibration

(Non-operating)

5~200Hz, 1.05Grms, 2hr/Y

1time

Shock

(Non-operating)

240G, 2msec, ± XYZ

30min/axis

HINGE

10~170˚, Open/Close 2sec, Pause1sec

30Kcycle

Altitude

-40~50℃, 0~45,000ft

72.5Hr

8. RELIABILITY TEST

[Result Evaluation Criteria ]

Under the display quality test conditions with normal operation state,

these should be no change which may affect practical display functions.

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 25 of 36 Rev. No. 05-P01-S-130220

Page 26

————————————————————————————————————————————————–

No

Part name

Quantity

1

Static electric protective sack

36 pcs

2

Packing case (Inner box)

included shock absorber

1 set

3

Pictorial marking

2

4

Carton

1 set

9. PACKING

9.1 CARTON

(1) Packing Form

Corrugated Cardboard box and Corrupad form as shock absorber.

(2) Packing Method

Note (1) Total Weight : Approximately 18 Kg

(2) Acceptance number of piling : 36 sets

(3) Carton size : 373(W) 470(D) 372(H))

(3) Packing Material

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 26 of 36 Rev. No. 05-P01-S-130220

Page 27

————————————————————————————————————————————————–

Build Name(s)

Revision Code(s)

SST (WS)

X00, X01, X02, … X09

PT (ES)

X10, X11, X12, … X19

ST (CS)

X20, X21, X23, … X29

XB (MP)

A00, A01, A02, … A99

Panel number

Cell ID

Lot ID

Month

Year

Product Code

Line

Samsung Revision Code

9.2 MARKING

A nameplate is affixed to the specified location on each product.

(1)Parts number : LTN156AT34

(2)Revision code : 3 letters

(3)Lot number : X X X X XXX XX X D01

(4) Nameplate Indication

Parts name : LTN156AT34

Lot number : XXXXXXXXXX

Inspected work week : 1304 (2013 year 4th week)

Product Revision Code : D01

DP/N : Dell Part No (“0PT8JP” is for LTN156AT34-D)

※ Panel revision code scheme (Refer to the Red box on the label)

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 27 of 36 Rev. No. 05-P01-S-130220

Page 28

————————————————————————————————————————————————–

TBD

(5) Packing small box attach

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 28 of 36 Rev. No. 05-P01-S-130220

Page 29

————————————————————————————————————————————————–

10. GENERAL PRECAUTIONS

10.1 HANDLING

(a) When the module is assembled, It should be attached to the system firmly using every mounting holes.

Be careful not to twist and bend the modules.

(b) Refrain from strong mechanical shock and / or any force to the module. In addition to damage, this may

cause improper operation or damage to the module and CCFT back-light.

(c) Note that polarizers are very fragile and could be easily damaged. Do not press or scratch the surface

harder than a HB pencil lead.

(d) Wipe off water droplets or oil immediately. If you leave the droplets for a long time, Staining and

discoloration may occur.

(e) If the surface of the polarizer is dirty, clean it using some absorbent cotton or soft cloth.

(f) The desirable cleaners are water, IPA (Isoprophyl Alcohol) or Hexane. Do not use Ketone type materials(ex.

Acetone), Ethyl alcohol, Toluene, Ethyl acid or Methyl chloride. It might permanent damage to the polarizer

due to chemical reaction.

(g) If the liquid crystal material leaks from the panel, it should be kept away from the eyes or mouth .In case

of contact with hands, legs or clothes, it must be washed away thoroughly with soap.

(h) Protect the module from static , it may cause damage to the C-MOS Gate Array IC.

(i) Use fingerstalls with soft gloves in order to keep display clean during the incoming inspection and assembly

process.

(j) Do not disassemble the module.

(k) Do not pull or fold the LED FPC.

(l) Do not touch any component which is located on the back side.

(m) Protection film for polarizer on the module shall be slowly peeled off just before use so that the

electrostatic charge can be minimized.

(n) Pins of I/F connector shall not be touched directly with bare hands.

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 29 of 36 Rev. No. 05-P01-S-130220

Page 30

————————————————————————————————————————————————–

ITEM

Unit

Min.

Max.

Storage

Temperature

(℃)

5

40

Storage

Humidity

(%rH)

35

75

Storage Life

12 months

Storage

Condition

- The storage room should be equipped with a good ventilation facility, which has a

temperature controlling system.

- Products should be placed on the pallet, which is away from the wall not on the floor.

- Prevent products from being exposed to the direct sunlight, moisture, and water.;

Be cautious not to pile the products up.

- Avoid storing products in the environment, which other hazardous material is placed.

- If products are delivered or kept in the storage facility more than 3 months,we recommend

you to leave products under the condition including a 20℃ temperature and a humidity of

50% for 24 hours.

- If you store semi-manufactured products for more than 3 months, bake the products under

the condition including the 50℃ temp. and the 10% humidity for 24hrs after being used.

10.2 STORAGE

We highly recommend to comply with the criteria in the table below.

10.3 OPERATION

(a) Do not connect, disconnect the module in the “ Power On” condition.

(b) Power supply should always be turned on/off by following item 6.3 “ Power on/off sequence “.

(c) Module has high frequency circuits. Sufficient suppression to the electromagnetic interference shall be

done by system manufacturers. Grounding and shielding methods may be important to minimize the

interference.

(d) The FPC cable between the LED chips and its converter power supply shall be a minimized length and be

connected directly .The longer cable between the back-light and the converter may cause lower luminance

of light source (LED).

(e) The standard limited warranty is only applicable when the module is used for general notebook

applications. If used for purposes other than as specified, SEC is not to be held reliable for the defective

operations. It is strongly recommended to contact SEC to find out fitness for a particular purpose.

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 30 of 36 Rev. No. 05-P01-S-130220

Page 31

————————————————————————————————————————————————–

10.4 OTHERS

(a) Ultra-violet ray filter is necessary for outdoor operation.

(b) Avoid condensation of water. It may result in improper operation or disconnection of electrode.

(c) Do not exceed the absolute maximum rating value. ( the supply voltage variation, input voltage variation,

Variation in part contents and environmental temperature, so on) Otherwise the module may be damaged.

(d) If the module displays the same pattern continuously for a long period of time, it can be the situation when

The image “sticks” to the screen.

(e) This module has its circuitry PCB’s on the rear side and should be handled carefully in order not to be

stressed.

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 31 of 36 Rev. No. 05-P01-S-130220

Page 32

————————————————————————————————————————————————–

TBD

11. EDID

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 32 of 36 Rev. No. 05-P01-S-130220

Page 33

————————————————————————————————————————————————–

1

[Common]Gap in the rear of display

Prevent the product from being defected resulted from the interference and

the lack of gap between the rear cover of system and the LCD module.

Recommendation

A. The gap between the rear cover of system and the rear of LCD module.

: Min. 0.3mm (Recommend)

B. Based on the size of part in a maximum size between the rear cover of

system and the LCD module.

: Min. 0.3mm (Recommend)

(※ Based on the maximum thickness of module, which the tolerance is

considered.)

Risk factor

Pooling / White Spot / Being divided

2

Gap in the front of display

Prevent the product from being defected resulted from the interference and the

lack of gap between the front cover of system and the LCD module.

Recommendation

: Min. 0.3mm (Recommend)

(※ Based on the maximum thickness of module, which the tolerance is

considered.)

Risk factor

Pooling

12. APPENDIX

12.1 SYSTEM DESIGN GUIDE

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 33 of 36 Rev. No. 05-P01-S-130220

Page 34

————————————————————————————————————————————————–

3

[Common] The shape of key pad of system

Prevent the product from being defected resulted from the shape of key pad in

the system.

Recommendation

A. Make the shape of frame, which surrounds the key pad as round as possible.

B. Prevent the product from being defected resulted from the pressurization by

attaching the sponge on the cover of system not to be overlapped with the

position of the frame around key pad.

C. Prevent the product from being defected, which is resulted from the

pressurization from outside by eliminating the difference in height between

the key pad and the frame around key pad.

Risk factor

White Spot / Black Spot / Being broken in glass.

4

[Common] The arrangement of user cable (Camera, Antenna)

Prevent the product from being defected resulted from the user cable arranged

on the rear of module.

Recommendation

A. Arrange the user cable in the side not in the rear(the active area) of

LCD module.

Risk factor

Pooling / White Spot

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 34 of 36 Rev. No. 05-P01-S-130220

Page 35

————————————————————————————————————————————————–

5

[Common] The arrangement of input cable

Prevent the product from being defected resulted from the overlapping

between the input cable and the film of LCD module .

Recommendation

A. Arrange the input cable not to be overlapped with the COF film.

B. Minimization of the height of input cable and making the COF film flat.

Risk factor

A/D (The damaged COF film is cracked., The chip is broken.)

6

[ELS] Gap between the bracket and the LCD Module

Prevent the LCD module from being interfered when testing the product in

terms of the performance of hinge and the occurrence of twist.

Recommendation

A. Secure the min. 1.0mm distance between the bracket and the LCD module at

4 corners of screen respectively.

B. Control the angle of bracket on the system.

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 35 of 36 Rev. No. 05-P01-S-130220

Page 36

————————————————————————————————————————————————–

7

[ELS] Suggestion on the angle of bracket

Prevent the product from being defected resulted from the changed top

chassis by the angle and the shape of bracket on the system.

Recommendation

A. Don't form the bracket hole.

B. Control the angle in the event that the bracket, which has L-shape is applied.

(90 ± 2˚)

Risk factor

Pooling / Light leakage

8

[UMS] Control the angle of the connected part on the user flange

Prevent the user flange from not being placed horizontally, which is caused

when the LCD module, which is structured in UMS is assembled.

Recommendation

A. Prevent the product from being pooled resulted from the changed user

flange

created when assembling the LCD module to the system.

B. Insert the screw to the hole of flange vertically when LCD module is

assembled to the system.

Risk factor

Pooling

——————————————————————————————————————————————––—

Doc. No. LTN156AT34-D Page 36 of 36 Rev. No. 05-P01-S-130220

Loading...

Loading...