Page 1

MODEL

LTA230AN03-W

Doc. No

Page

1 / 38

SAMSUNG Confidential

The Information described in this specification is for the first draft and can be changed without prior notice.

Samsung Display Co., LTD

SAMSUNG TFT-LCD

MODEL: LTA230AN03-W

Page 2

MODEL

LTA230AN03-W

Doc. No

Page

2 / 38

SAMSUNG Confidential

Contents

Revision History

General Description

1. Absolute Maximum Ratings

1.1 Environmental Absolute Ratings

1.2 Electrical Absolute Ratings

1.3 The Others Absolute Ratings

2. Optical Characteristics

3. Electrical Characteristics

3.1 TFT LCD Module

3.2 Backlight Unit

3.3 LED Module Connector

4. Block Diagram

4.1 TFT LCD Module

4.2 Back Light

5. Input Terminal Pin Assignment

5.1 Input Signal & Power

5.2 Converter Input Pin Configuration

5.3 Converter Input Power Sequence

5.4 LVDS Interface

5.5 Input Signals, Basic Display Colors and Gray Scale of Each Color

5.6 Pixel Format in the display

6. Interface Timing

6.1 The parameters of timing

6.2 Timing diagrams of interface signal

6.3 Characteristics of Input data of LVDS

6.4 The sequence of power on and off

7. Outline Dimension

8. Reliability Test

9.Marking & Others

10.General Precaution

10.1 Handling

10.2 Storage

10.3 Operation

10.4 Guide for the Operation Condition

10.5 Others

11. Special Precautions

- - - - - - - - - - - - - - - - - - - ( 3 )

- - - - - - - - - - - - - - - - - - - ( 4 )

- - - - - - - - - - - - - - - - - - - ( 6 )

- - - - - - - - - - - - - - - - - - - ( 7 )

- - - - - - - - - - - - - - - - - - - ( 13 )

- - - - - - - - - - - - - - - - - - - ( 16 )

- - - - - - - - - - - - - - - - - - - ( 17 )

- - - - - - - - - - - - - - - - - - - ( 23 )

- - - - - - - - - - - - - - - - - - - ( 32 )

- - - - - - - - - - - - - - - - - - - ( 33 )

- - - - - - - - - - - - - - - - - - - ( 35 )

- - - - - - - - - - - - - - - - - - - ( 36 )

- - - - - - - - - - - - - - - - - - - ( 39 )

Page 3

MODEL

LTA230AN03-W

Doc. No

Page

3 / 38

SAMSUNG Confidential

Date

Rev. No

Page

Summary

22. Fab. 2012

000

all

First Issued (First Draft)

The revision history

Page 4

MODEL

LTA230AN03-W

Doc. No

Page

4 / 38

SAMSUNG Confidential

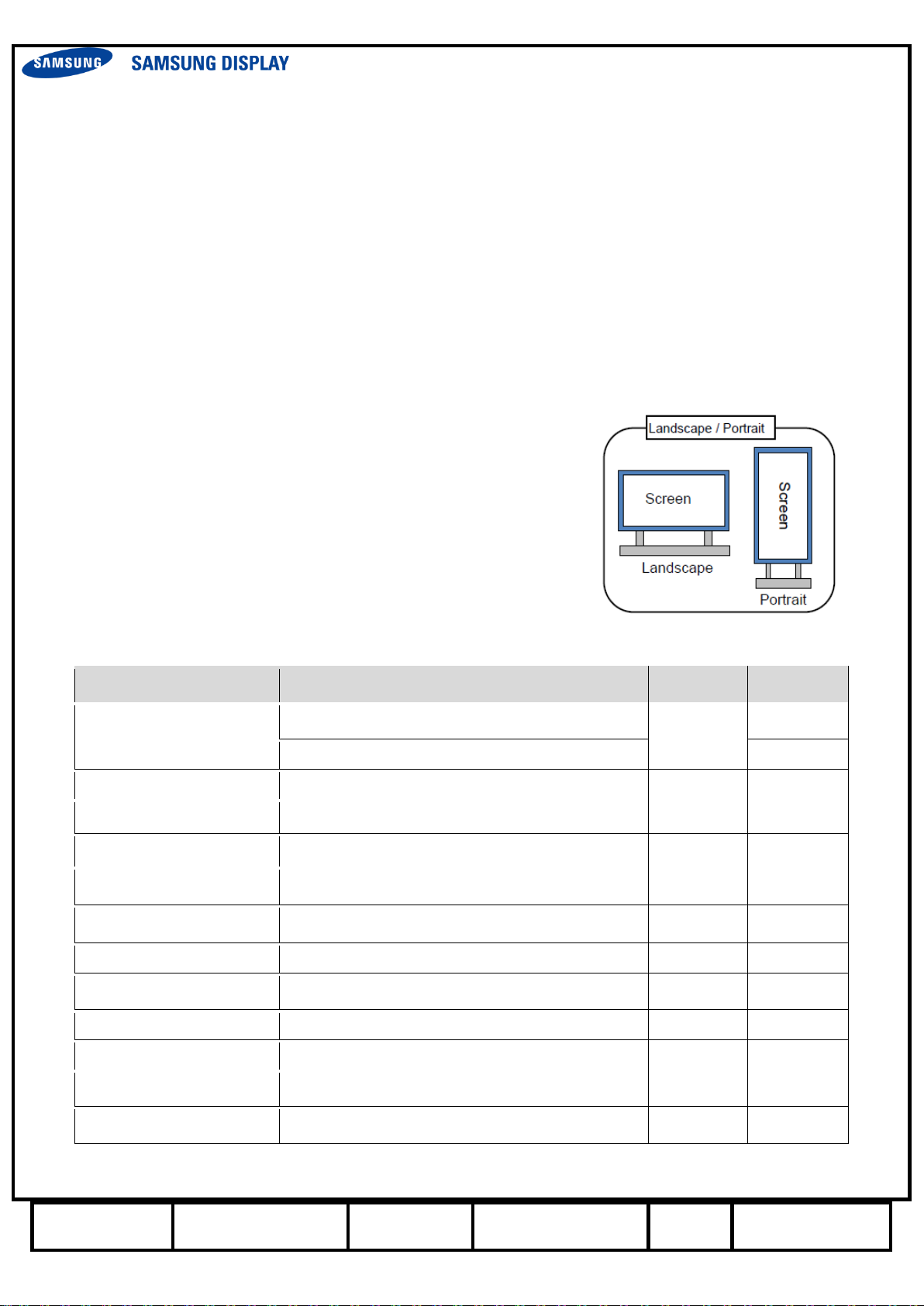

General Description

Description

LTA230AN03 is a color active matrix liquid crystal display (LCD) that uses amorphous silicon TFT(Thin Film

Transistor) as switching components. This model is composed of a TFT LCD panel, a driver circuit, and a

back-light unit. This 23.0” model has a resolution of 1366 x 768 pixels (16:9) can display up to

16.7 Million colors with the wide viewing angle of 89° or higher in all directions. This panel is intended to

support applications by providing an excellent performance for the display products with a flat panel such as

Home-alone Multimedia TFT-LCD TV and a High Definition TV.

General Information

Features

High contrast ratio & aperture ratio with the wide color gamut

PVA(Patterned Vertical Align) mode

Wide viewing angle (±178°)

High speed response (with DCC circuit)

Wide XGA (1,366 x 768 pixels, 16:9)

Edge LED BLU Unit

DE (Data enable) mode

The interface (1 pixel/clock) of LVDS serial interface

Items

Specification

Unit

Note

Module Size

534.0(H) x 311.8(V)

㎜

Max

11(D)

Max

Weight

1700

g

Typ

Pixel Pitch

0.372(H) x 0.124(W)

㎜

Active Display Area

508.152(H) x 285.696(V)

㎜

Surface Treatment

Anti-glare

Haze

2.3

%

Hardness

Hard coating 2H

Display Colors

16.7 Million colors (8 bits)

colors

Number of Pixels

1366 x 768

pixel

16 : 9

Pixel Arrangement

RGB horizontal stripe

Display Mode

Normally Black

Luminance of White

250

cd/m

2

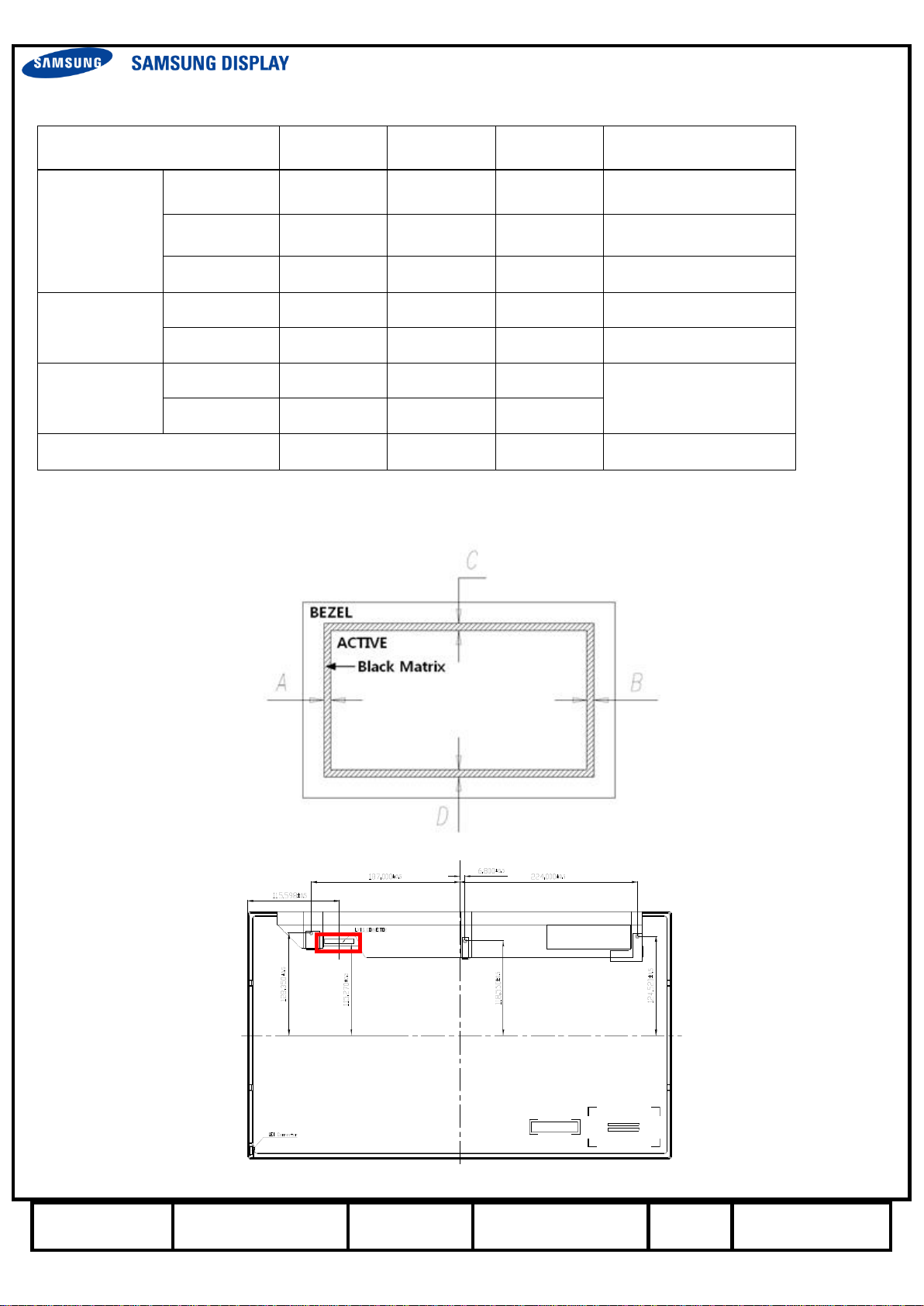

Page 5

MODEL

LTA230AN03-W

Doc. No

Page

5 / 38

SAMSUNG Confidential

Item

Min.

Typ.

Max.

Note

Module size

Horizontal(H)

533.5

534.0

534.5

mm

Vertical(V)

311.3

311.8

312.3

mm

Depth(D)

10.5

11

11.5

mm(connector 위치)

Bezel Open

Horizontal(H)

513.3

513.8

514.3

mm

Vertical(V)

290.3

290.8

291.3

mm

Black Matrix

Shift

Horizontal(H)

2

mm

(1)

Vertical(V)

2

Weight

1700

g

NOTE (1) Measure the figure for Black Matrix shift to be recorded on the spec. with referring to the drawings.

| A - B | ≤ Horizontal Spec

| C - D | ≤ Vertical Spec

<Module Depth Measure Point : Chassis bottom Base Surface>

MECHANICAL INFORMATION

Page 6

MODEL

LTA230AN03-W

Doc. No

Page

6 / 38

SAMSUNG Confidential

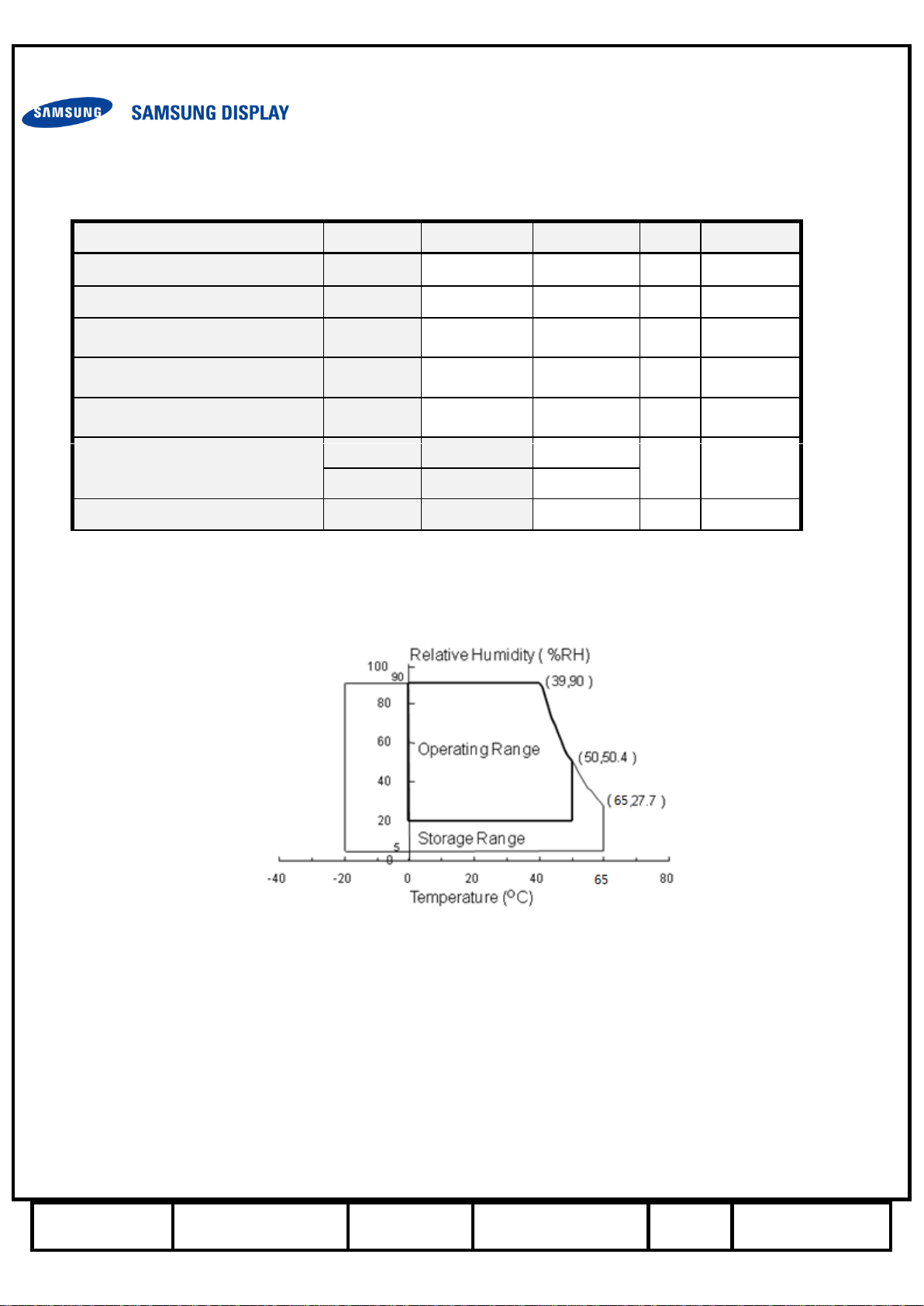

1. ABSOLUTE MAXIMUM RATINGS

1.1 Environmental Absolute Ratings

Item

Symbol

Min.

Max.

Unit

Note

Storage temperature

TSTG

-20

65

C

(1)

Operating temperature

TOPR 0 50

C

(1)

Humidity for storagure

HSTG 5 90

%RH

Operating humidity

HOPR

20

90

%RG

Endurance on static electricity

150

V

(5)

Shock (non-operating)

Snop(X,Y)

50

G

(2),(4)

Snop(Z)

-

50

Vibration (non-operating)

Vnop - 1.5

G

(3),(4)

Note (1) The ranges of temperature and relative humidity are shown in the graph below. 90% RH Max.

(The temperature of Ta shall be over 39℃.)

The maximum temperature of wet–bulb shall be less than 39℃.

No condensation

Note (2) 11ms, half sine wave, one time for X, Y, Z axis

Note (3) 10 ~ 300 Hz, Swap rate for X, Y, Z axis one time*

Note (4) The fixture for the test of the vibration and shock, which holds the module to be tested shall be hard and

rigid in order for the module not to be twisted or bent by the fixture.

Note (5) Keep the static electricity under 50V in Polarizer attaching process.(Open Cell)

Page 7

MODEL

LTA230AN03-W

Doc. No

Page

7 / 38

SAMSUNG Confidential

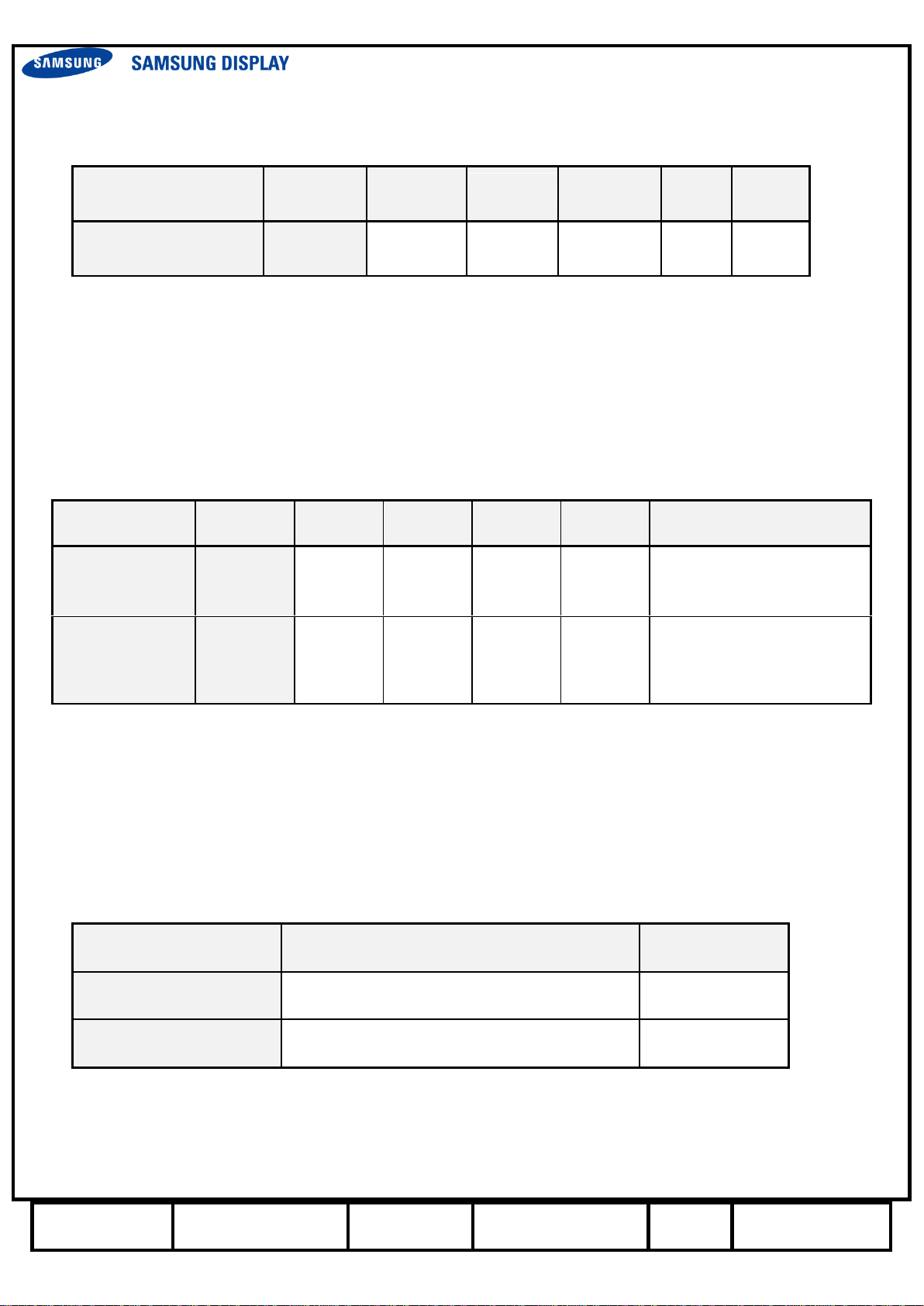

Item

Symbol

Min.

Typ.

Max.

Unit

Note

Input Supply

Voltage /

Converter

Vcc

-

- - V

Without Converter

LED Current(2D)

ILED,2D

- - 180

mAmean

120mA/sting

, 1string

1.2 Electrical Absolute Ratings

(1) TFT LCD MODULE

1.3 The Others Absolute Ratings

STATIC ELECTRICITY PRESSURE RESISTANCE

Item

Symbol

Min.

Typ.

Max.

Unit

Note

Power Supply Voltage

VDD

10.8

12

13.2

V

(1)

Item

Test Conditions

Remark

CONTACT DISCHARGE

150pF, 330, 10kV, 210points, 1 time/point

Operating

AIR DISCHARGE

150pF, 330, 20kV, 210points, 1 time/point

Operating

(2) BACK-LIGHT UNIT

Note (1) Within Ta (25 2 C)

The permanent damage or defect to the device may occur if the panel is operated at the figure set, which exceeds a limit

of maximum value stated in the former spec.

The functional operation should be limited to the conditions described above under normal operating conditions.

Ta (25 2 C)

Page 8

MODEL

LTA230AN03-W

Doc. No

Page

8 / 38

SAMSUNG Confidential

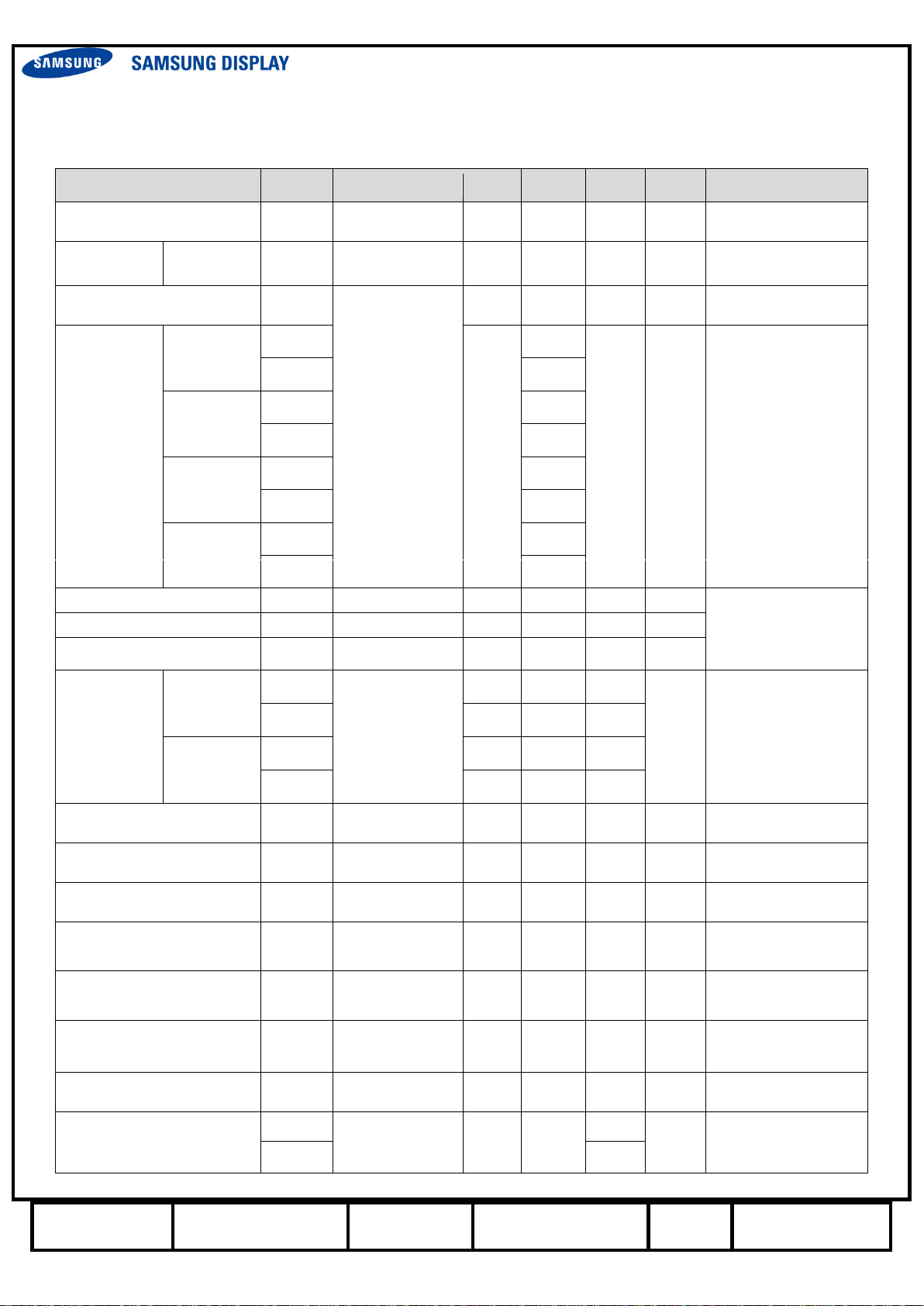

2. Optical characteristics

The optical characteristics should be measured in the dark room or the space surrounded by the similar setting.

Measuring equipment : TOPCON RD-80S, TOPCON SR-3 ,ELDIM EZ-Contrast

(Ta = 25 ± 2°C, VDD=12.0V, fv=60Hz, f

DCLK

=148.5MHz, Light source: D65 Standard light)

Item

Symbol

Condition

Min.

Typ.

Max.

Unit

Note

Contrast ratio

(At the center of screen)

C/R

3000

4000

-

(1)

SR-3

Response

time

G-to-G

Tg

T

PAN,SUR

=29.9℃

- 8 16

msec

(3)

RD-80S

Luminance of white

(At the center of screen)

YL

Normal

qL,R=0

qU,D=0

Viewing

Angle

200

250

-

cd/m2

(4)

SR-3

Chromaticity

(CIE 1931)

Red

Rx

TYP.

-0.03

0.645

TYP.

+0.03

(5),(6)

SR-3

Ry

0.338

Green

Gx

0.302

Gy

0.603

Blue

Bx

0.149

By

0.067

White

Wx

0.285

Wy

0.311

sRGB Concordance

-

97

%

(5)

SR-3

Color gamut

- - 68 - %

Color

- -

8,500 - K

Viewing

Angle

Hor.

qL

C/R≥10

70

89

-

Degree

(6)

SR-3

EZ-Contrast

qR

70

89

-

Ver.

qU

70

89

-

qD

70

89

-

Brightness uniformity

(9 Points)

B

uni

-

-

25

%

(2)

SR-3

Transmissivity

T 5.3

5.7 - %

(7)

D65/SR3

Transmissivity Uniformity

T

uni

- - 10

%

(8)

D65/SR3

Gamma Value

GMA

(@20G~200G)

1.95

2.2

2.45

(9)

SR-3

Gamma variation

Gdiff

(@20G~128G)

-0.14 - 0.14

(11)

SR-3

ACC Linearity

ACC_lin

-0.015

-

0.015

(12)

SR-3

5nit Uniformity

(38G/255G)

Buni_5nit

-30 - 30

%

(10)

SR-3

White Color Coordinate

Uniformity

Wx uni

-

-

0.012

(13)

SR-3

Wy uni

0.012

Notice

Page 9

MODEL

LTA230AN03-W

Doc. No

Page

9 / 38

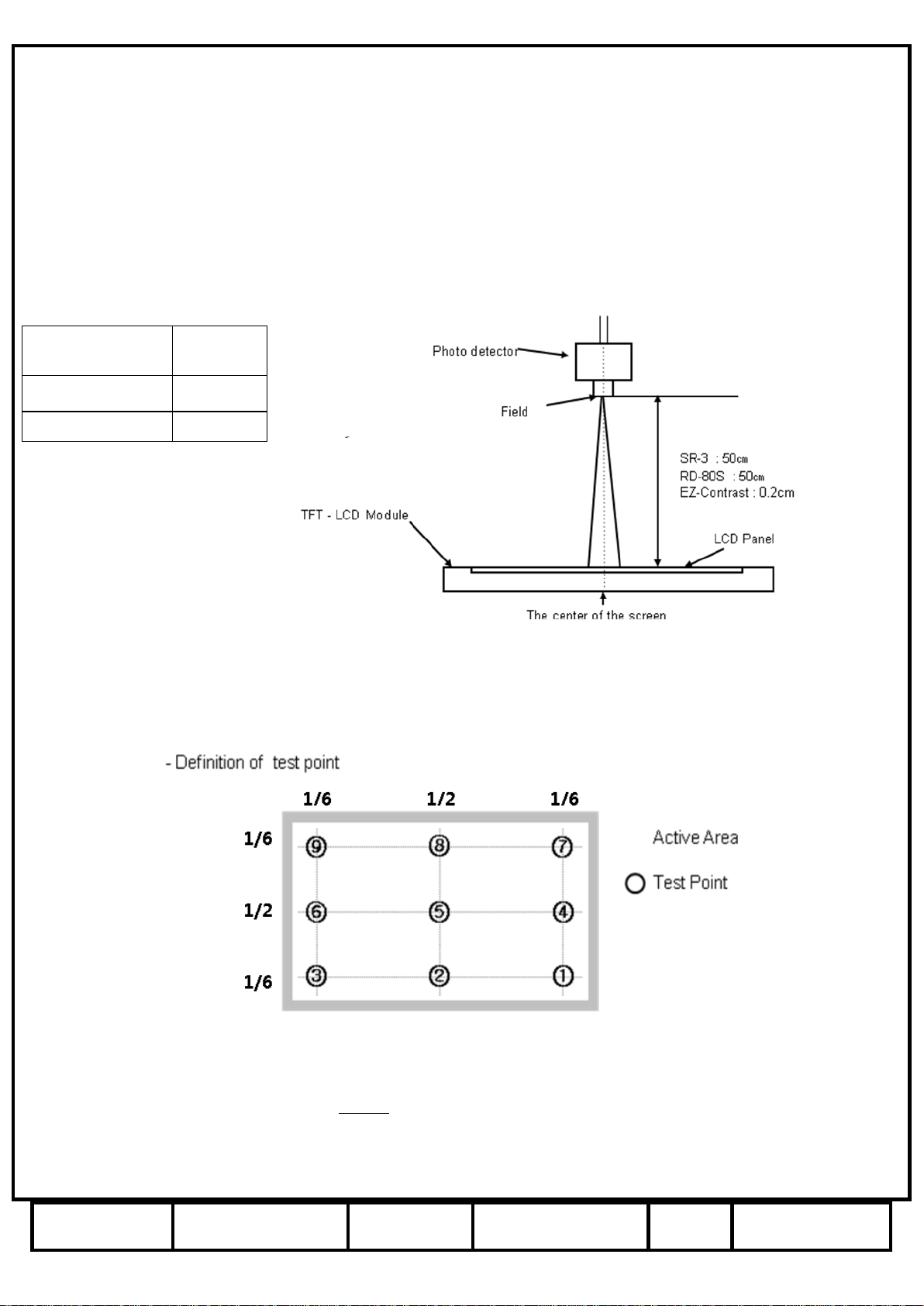

(a) Setup for test equipment

The measurement should be executed in a stable, windless, and dark room for 40min and 60min after

operating the panel at the given temperature for stabilization of the standard light. (SDC uses the standard

luminance of the D65 media).

This measurement should be measured at the center of screen.

The environment condition: Ta = 25 ± 2 °C

(b) D65 media has the general light source.

The temperature of color is 6847K. The coordinate of color is Wx 0.313, Wy 0.329

The luminance of this product is 7217cd/㎡.

Photo detector

Field

SR-3

2°/1°

RD-80S

1°

(c) The CIE positions D65 as the standard daylight illuminant:

[D65] is intended to represent average daylight and has a correlated color temperature of approximately

6500 K. CIE standard illuminant D65 should be used in all colorimetric calculations requiring

representative daylight, unless there are specific reasons for using a different illuminant.

Note (1) Definition of contrast ratio (C/R)

: The ratio of gray max (Gmax) & gray min (Gmin) at the center point ⑤ of the panel

The measurement goes in D65 Standard light source

Gmax : The luminance with all white pixels

C R

G

G

/

max

min

Page 10

MODEL

LTA230AN03-W

Doc. No

Page

10 / 38

Gmin : The luminance with all black pixels

Note (2) Definition of the brightness uniformity of 9 points (Test pattern : The full white)

The measurement shall be executed with the standard light source of D65 .

Bmax : The maximum brightness

Bmin : The minimum brightness

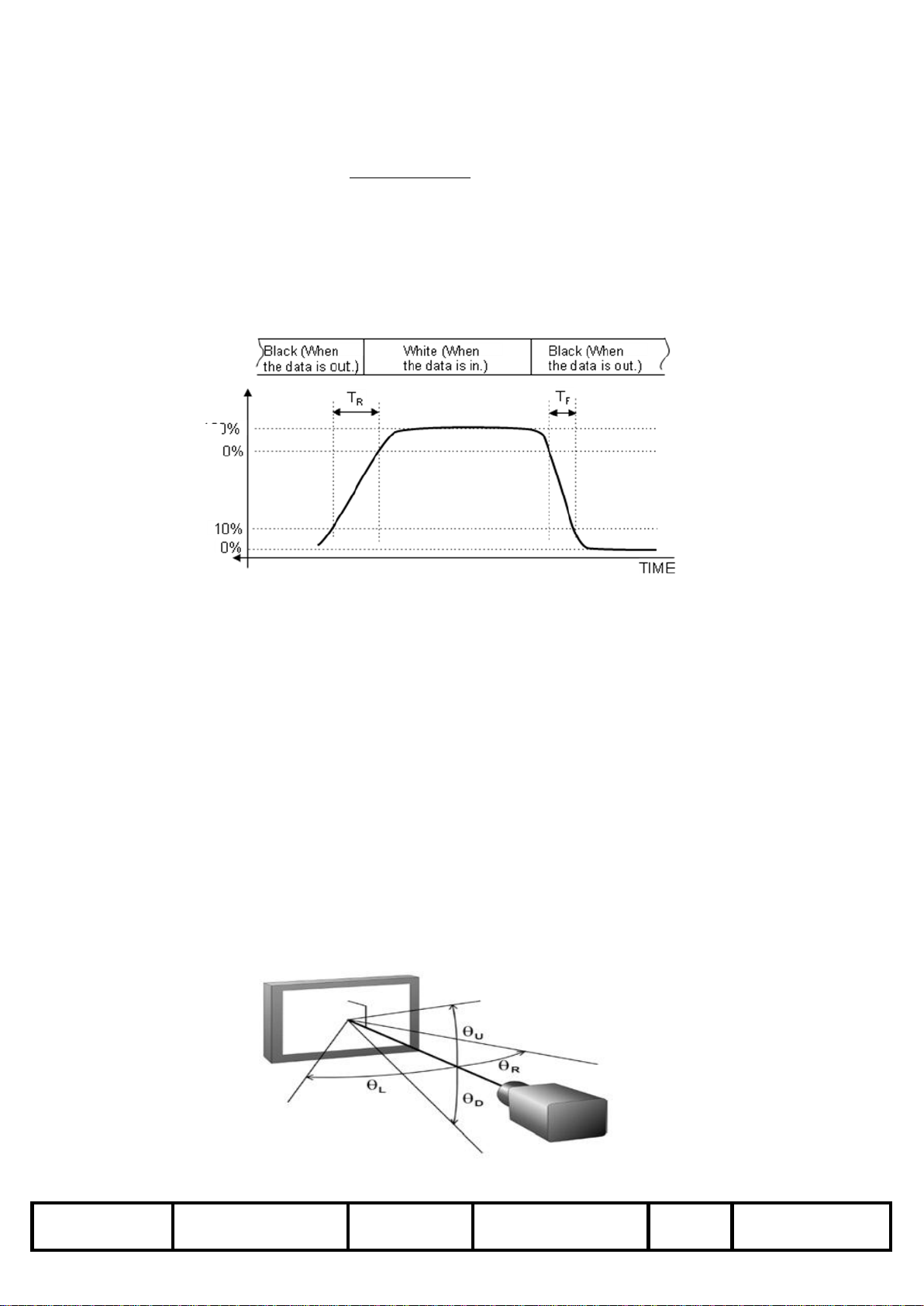

Note (3) Definition of the response time : Sum of Tr, Tf

※ G-to-G : Average response time between whole gray scale to whole gray scale.

The response time is the value that was measured after it was operated in Samsung's standard BLU for

one hour.( at room temperature)

Note (4) The definition of luminance of white: The luminance of white at the center point ⑤

The measurement shall be executed with the standard light source of D65.

Note (5) The definition of chromaticity (CIE 1931)

The color coordinate of red, green, blue and white at the center point ⑤

The measurement shall be executed with the standard light source of D65.

Note (6) Definition of viewing angle

: The range of viewing angle (C/R ≥10)

The measurement shall be executed with the standard light source of D65.

The response

Of optical instruments

Buni

B B

B

100

( max min)

max

Display data

Page 11

MODEL

LTA230AN03-W

Doc. No

Page

11 / 38

SAMSUNG Confidential

Note (7) Definition of transmissivity

The measurement shall be executed with the standard light source of D65.

Note (8) Definition of the Transmissivity uniformity of 9 points (Test pattern: The full white)

The measurement shall be executed with the standard light source of D65.

Tmax : The maximum Transmissivity

Tmin : The minimum Transmissivity

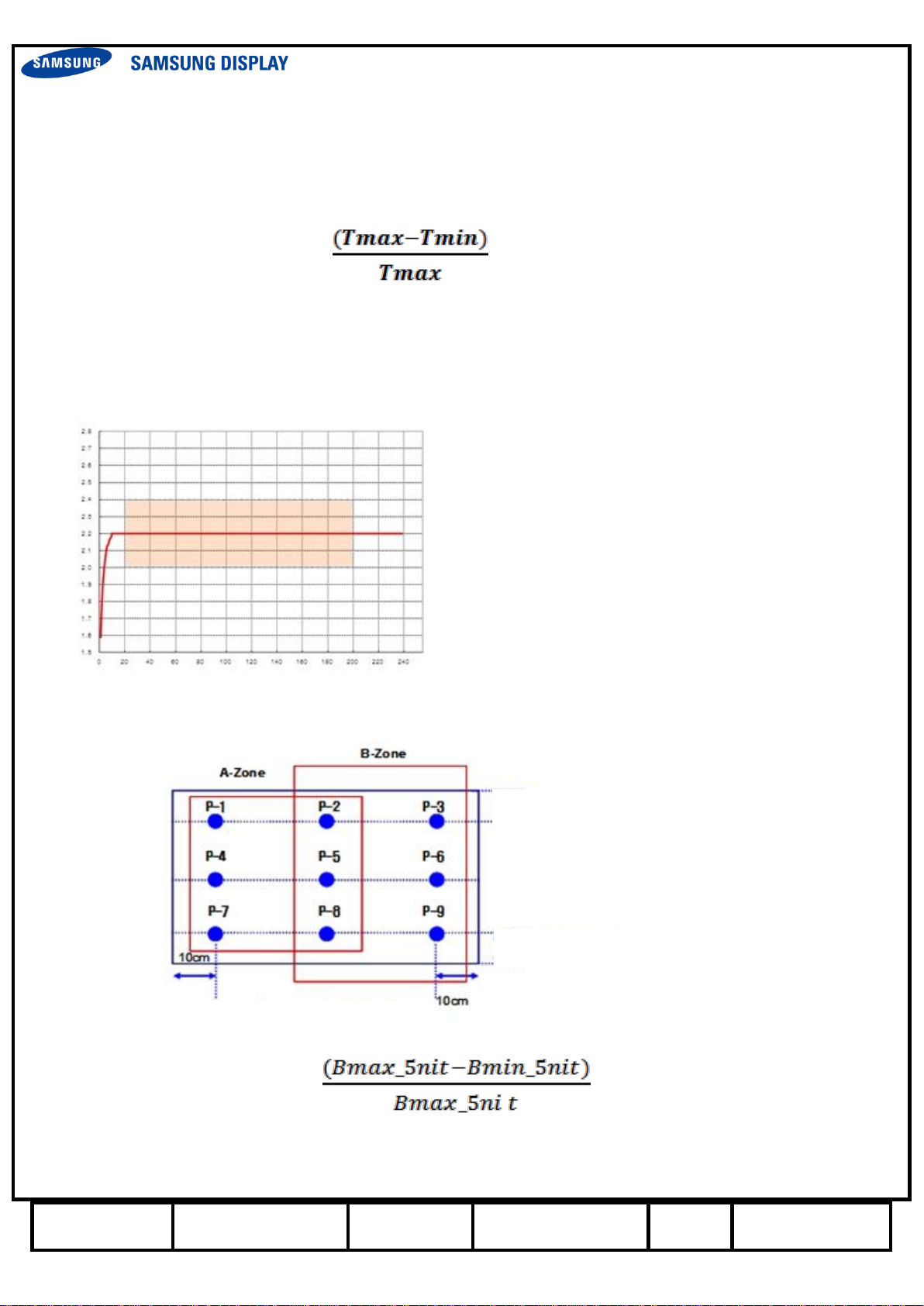

Note (9) Management Criteria of Gamma Value

Note (10) 5nit Low Gray Uniformity

Tuni

= 100*

Gamma Value :

20 ~ 200Gray : 2.0 ~ 2.4 (Typ. 2.2)

Buni_5nit

= 100*

Bmax_5nit : The maximum brightness at 5nit Gray

Bmin_5nit : The minimum brightness at 5nit Gray

Vertical 1/6 Point

[Panel Measure Point]

Vertical 1/6 Point

Page 12

MODEL

LTA230AN03-W

Doc. No

Page

12 / 38

Note (11) Gamma Variation between Center and Left (or Right)

Gamma measured at 10cm point from the left & right side is more less than 0.1 than Gamma measured

at Center

(Gamma measured at 10cm of the P-4 & P-6 is more less than 0.1 than Gamma measured at P-5)

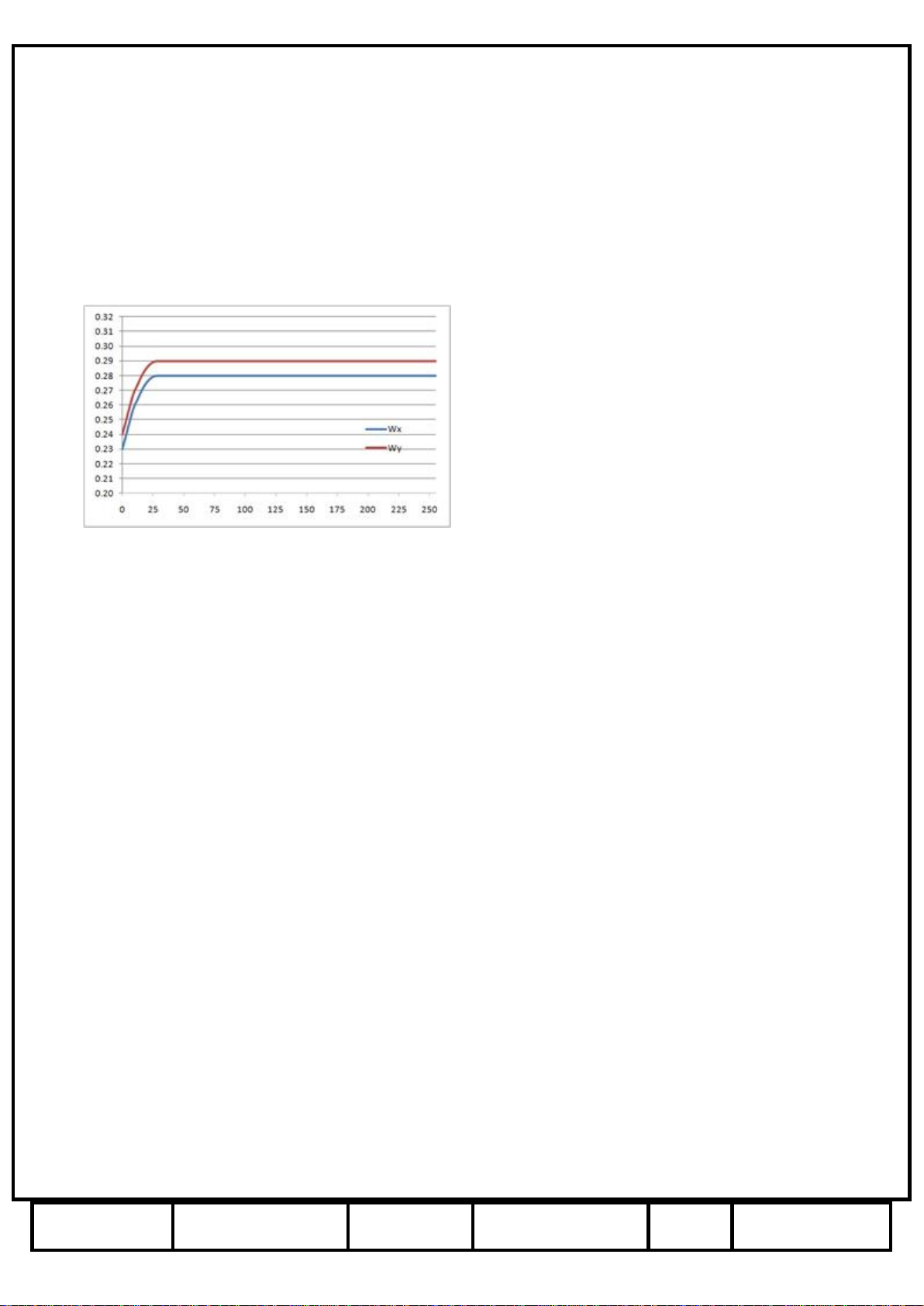

Note (12) Management Criteria of ACC Linearity

Note (13) White Color Coordinate Uniformity of 9 points (Test pattern: The full white)

< Frame Inversion >

255Gray Wx/Wy value basis (a module unit basis)

a. Color coordinate differences are less than 15/1,000 at

Any Point above 30Gray and 255Gray

b. When Wx/Wy coordinates reverse at 0Gray, it permits

an once intersection under, 30Gray

Wy, uni

= Wy max-Wy min

Wy max: The maximum Wy

Wy min: The minimum Wy

Page 13

MODEL

LTA230AN03-W

Doc. No

Page

13 / 38

SAMSUNG Confidential

3. Electrical characteristics

The connector to transmit a display data and a timing signal shall be connected.

Ta = 25°C ± 2 °C

Item

Symbol

Min.

Typ.

Max.

Unit

Note

Voltage of power supply

V

DD

10.8

12.0

13.2

V

(1)

Current

of power

supply

(a) Black

I

DD

-

201

301

mA

(2),(3)

(b) White

-

216

316

mA

(c) V-stripe

-

368

524

mA

Vsync frequency

f

V

48

60

66

Hz Hsync frequency

f

H

44

48

53

kHz Main frequency

f

dclk

72

78

85

MHz Rush current

I

RUSH

- - 4

A

(4)

Note (1) The voltage for ripple shall be controlled under the range of fewer than 10% of V

DD

voltage.

(2) fV=60Hz, f

DCLK

=78MHz, VDD = 12.0V, DC Current.

(3) The pattern for checking the power dissipation (LCD module only)

(4) Conditions for measurement

3.1 TFT_LCD Module

a) Black pattern b) White pattern c) V-stripe

Page 14

MODEL

LTA230AN03-W

Doc. No

Page

14 / 38

* The temperature range for component of the some major part of operating module

3.2 BACK-LIGHT UNIT

* Back light unit is composed of 1–LED bars .(33 pcs of LEDs).

Item

Symbol

Min.

Typ.

Max.

Unit

Note

LED Operating

Temperature range

Top

-30 - 85

℃

LED unit

LED Storage

Temperature range

Tstg

-40

-

100

℃

LED Junction

Temperature

Tj - -

145

℃

LED Forward Current

IF - 120

126

mA

1 channel

IFP

-

N/A - mA

N/A

LED Forward Voltage

VF

96.4

103.6

110.9

V

VFP

-

N/A - V

N/A

Thermal Resistance

Junction to PCB

Rth, JS

- - 18

K/W

Power Consumption

P

11.6

12.4

13.3

W

IF X VF X 1CH

Operating Life Time

Hr

>30,000

Hour

LED Counts

Q - 33 - EA

Part

Spec

Ambient Operating

Temperature

Junction Operating

Temperature

Timing Controller

LAXC021T2B-Q1

-20℃ ~ 75℃

~ 125℃

Ta=25℃

Page 15

MODEL

LTA230AN03-W

Doc. No

Page

15 / 38

* Pin Description (Connector : 104086-0410, Molex)

pin

name

description

1

Vin

LED power input

2

-

-

3

-

-

4

RTN

LED Bar return channel

3.3 LED Module Connector

Page 16

MODEL

LTA230AN03-W

Doc. No

Page

16 / 38

4. Block diagram

without converter, 33 LEDs

** Vin 120mA current supply

** I1 = 120mA(typ)

4.1 TFT LCD MODULE

4.2 Back Light

Page 17

MODEL

LTA230AN03-W

Doc. No

Page

17 / 38

SAMSUNG Confidential

5. The Pin assignment in the input terminal

connector : PTW (30Pin,SMD-A)

No

Signal

REMARK

1

WPN

WPN

2

SCL

I2C interface

3

SDA

4

GND

GND

5

LV0_N

negative LVDS differential data input (0)

6

LV0_P

positive LVDS differential data input (0)

7

GND

GND

8

LV1_N

negative LVDS differential data input (1)

9

LV1_P

positive LVDS differential data input (1)

10

GND

GND

11

LV2_N

negative LVDS differential data input (2)

12

LV2_P

positive LVDS differential data input (2)

13

GND

GND

14

LVCLK_N

negative LVDS differential data input (Clock)

15

LVCLK_P

positive LVDS differential data input (Clock)

16

GND

GND

17

LV3_N

negative LVDS differential data input (3)

18

LV3_P

positive LVDS differential data input (3)

19

GND

GND

20

N.C

21

LVDS_SEL

LVDS OPTION (Low: JEIDA, High: VESA)

22

WPN

WPN

23

GND

GND

24

GND

25

N.C

26

VIN

Power Supply : +12V

27

VIN

28

VIN

29

VIN

30

VIN

5.1 Input Signal & Power

Page 18

MODEL

LTA230AN03-W

Doc. No

Page

18 / 38

SAMSUNG Confidential

Note(1) : Pin number, which starts from the left side.

a. Pins for power GND shall be connected to the LCD’s metal chassis.

b. All input pins for power shall be connected together.

c. All NC pins shall be designed with being separated from other signal or power.

Fig . The diagram of connector

Page 19

MODEL

LTA230AN03-W

Doc. No

Page

19 / 38

Without converter product

Without converter product

5.2 Configuration of Input pin of Converter

5.3 The power sequence for inputting the Converter

Page 20

MODEL

LTA230AN03-W

Doc. No

Page

20 / 38

SAMSUNG Confidential

5.4 LVDS Interface

- LVDS Receiver : T-CON (merged)

- Data Format(Normal)

LVDS pin

JEIDA -DATA

Normal -DATA

TxOUT/RxIN0

TxIN/RxOUT0

R2

R0

TxIN/RxOUT1

R3

R1

TxIN/RxOUT2

R4

R2

TxIN/RxOUT3

R5

R3

TxIN/RxOUT4

R6

R4

TxIN/RxOUT6

R7

R5

TxIN/RxOUT7

G2

G0

TxOUT/RxIN1

TxIN/RxOUT8

G3

G1

TxIN/RxOUT9

G4

G2

TxIN/RxOUT12

G5

G3

TxIN/RxOUT13

G6

G4

TxIN/RxOUT14

G7

G5

TxIN/RxOUT15

B2

B0

TxIN/RxOUT18

B3

B1

TxOUT/RxIN2

TxIN/RxOUT19

B4

B2

TxIN/RxOUT20

B5

B3

TxIN/RxOUT21

B6

B4

TxIN/RxOUT22

B7

B5

TxIN/RxOUT24

HSYNC

HSYNC

TxIN/RxOUT25

VSYNC

VSYNC

TxIN/RxOUT26

DEN

DEN

TxOUT/RxIN3

TxIN/RxOUT27

R0

R6

TxIN/RxOUT5

R1

R7

TxIN/RxOUT10

G0

G6

TxIN/RxOUT11

G1

G7

TxIN/RxOUT16

B0

B6

TxIN/RxOUT17

B1

B7

TxIN/RxOUT23

RESERVED

RESERVED

LVDS OPTION( input : pin45 ) : IF THIS PIN : LOW (GND) → JEIDA LVDS FORMAT

OTHERWISE : HIGH (3.3V) OR OPEN(NC) → NORMAL NS LVDS FORMAT

Page 21

MODEL

LTA230AN03-W

Doc. No

Page

21 / 38

SAMSUNG Confidential

COLOR

DISPLAY

DATA SIGNAL

GRAY

SCALE

LEVEL

RED

GREEN

BLUE

R0

R1

R2

R3

R4

R5

R6

R7

G0

G1

G2

G3

G4

G5

G6

G7

B0

B1

B2

B3

B4

B5

B6

B7

BASIC

COLOR

BLACK

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 -

BLUE

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 -

GREEN

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 -

CYAN

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 -

RED

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 -

MAGENTA

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 -

YELLOW

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 -

WHITE

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 -

GRAY

SCALE

OF RED

BLACK

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R0

DARK

↑

↓

LIGHT

1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R1

0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R2 : : : : : : : : : : : : : : : : : : : : : : : :

R3~

R252

: : : : : : : : : : : : : : : : : : : : : : :

:

1 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R253

0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R254

RED

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R255

GRAY

SCALE

OF

GREEN

BLACK

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 G0

DARK

↑

↓

LIGHT

0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 G1

0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 G2

: : : : : : : : : : : : : : : : : : : : : : :

:

G3~

G252

: : : : : : : : : : : : : : : : : : : : : : : : 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0 G253

0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 G254

GREEN

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 G255

GRAY

SCALE

OF

BLUE

BLACK

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 B0

DARK

↑

↓

LIGHT

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 B1

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 B2

: : : : : : : : : : : : : : : : : : : : : : :

:

B3~

B252

: : : : : : : : : : : : : : : : : : : : : : :

:

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 B253

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 B254

BLUE

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 B255

Note ) Definition of Gra

Rn : Red Gray, Gn : Green Gray, Bn : Blue Gray (n = Gray level)

Input Signal : 0 = Low level voltage, 1 = High voltage

5.5 Input Signals, Basic display colors and Gray Scale of Each Color

Page 22

MODEL

LTA230AN03-W

Doc. No

Page

22 / 38

SAMSUNG Confidential

5.6 Pixel Format in the display

Line 1

Line 768

1

1366

Page 23

MODEL

LTA230AN03-W

Doc. No

Page

23 / 38

6. Interface timing

6.1 The parameters of timing ( DE mode )

SIGNAL

ITEM

SMBOL

MIN.

TYP.

MAX.

Unit

NOTE

Clock

Frequency

1/T

C

72

78

85

MHz

-

Hsync

F

H

44

48

53

KHz

-

Vsync

F

V

48

60

66

Hz

-

Term for the

vertical

display

Active

display

period

T

VD

-

768

-

Lines

-

Total vertical

T

V

780

802

1200

Lines

-

Term for the

horizontal

display

Active

display

period

T

HD

-

1366

-

Clocks

-

Total

Horizontal

T

H

1460

1624

2000

clocks

-

Note) The signals of Hsync and Vsync must be inputted even though this T-con is operated at DE mode.

(1) Test Point: TTL controls signal and CLK at LVDS Tx at the input terminal of system.

(2) Internal VDD = 3.3V

(3) The spread spectrum

- The limit of spread spectrum's range of SET in which the LCD module is assembled should be within ± 3 %

- Frequency for modulation : Min 30KHz

Parameter

Symbol

Value

Unit

Note

Min

Typ

Max

CMOS

Interface

Input High

Threshold

Voltage

VIH (High)

2.5

-

3.3 V

Input Low

Threshold

Voltage

VIL (Low)

0 - 0.5 V

Page 24

MODEL

LTA230AN03-W

Doc. No

Page

24 / 38

SAMSUNG Confidential

6.2 Timing diagrams of interface signal (Only DE mode)

Page 25

MODEL

LTA230AN03-W

Doc. No

Page

25 / 38

R03

RxOUT26 RxOUT25 RxOUT22

RxOUT24

RxOUT21 RxOUT20 RxOUT19

RxOUT18 RxOUT15 RxOUT13RxOUT14 RxOUT12 RxOUT9 RxOUT8

RxOUT7 RxOUT6 RxOUT3RxOUT4 RxOUT2 RxOUT1 RxOUT0

T

DE Vsync B02Hsync B05 B03 B04

G04 B01 G05 B00 G03 G02 G01

G00 R04 R05 R02 R01 R00

TxCLK OUT

RxCK IN

Rx IN1

Rx IN0

Rx IN2

RxOUT23 RxOUT17 RxOUT11

RxOUT16

RxOUT10 RxOUT5 RxOUT27

T/7

B07 R06B06 G07 R07 G06

Rx IN3

RESERVED

RECOMMENDED TRANSMITTER INPUT CHARACTERISTICS

SYMBOL

PARAMETER

MIN.

TPY.

MAX.

UNITS.

TCIT

TxCLK IN TRANSITION TIME (FIG2)

1.0

-

6.0

ns

TCIP

TxCLK IN PERIOD (FIG3)

11.76

T

50

ns

TCIH

TxCLK IN HIGH TIME (FIG3)

0.35T

0.5T

0.65T

ns

TCIL

TxCLK IN LOW TIME (FIG3)

0.35T

0.5T

0.65T

ns

TXIT

TxCLK TRANSITION TIME

1.5

-

6.0

ns

Page 26

MODEL

LTA230AN03-W

Doc. No

Page

26 / 38

TRANSMITTER SWITCHING CHARACTERISTICS

-OVER RECOMMENDED OPERATING SUPPLY AND TEMPERATURE RANGES UNLESS OTHERWISE SPECIFIED.

SYMBOL

PARAMETER

MIN.

TPY.

MAX.

UNITS.

LLHT

LVDS LOW TO HIGH TRANSITION TIME (FIG1)

-

0.75

1.5

ns

LHLT

LVDS HIGH TO LOW TRANSITION TIME (FIG1)

-

0.75

1.5

ns

TPPos0

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 0 (FIG 7)

NOTE 1

F = 40MHZ

-0.25 0 0.25

ns

TPPos1

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 1

3.32

3.57

3.82

ns

TPPos2

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 2

6.89

7.14

7.39

ns

TPPos3

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 3

10.46

10.71

10.96

ns

TPPos4

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 4

14.04

14.29

14.54

ns

TPPos5

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 5

17.61

17.86

18.11

ns

TPPos6

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 6

21.18

21.43

21.68

ns

TPPos0

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 0 (FIG 7)

NOTE 1

F = 65MHZ

-0.20 0 0.20

ns

TPPos1

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 1

2.00

2.20

2.40

ns

TPPos2

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 2

4.20

4.40

4.60

ns

TPPos3

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 3

6.39

6.59

6.79

ns

TPPos4

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 4

8.59

8.79

8.99

ns

TPPos5

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 5

10.79

10.99

11.19

ns

TPPos6

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 6

12.99

13.19

13.39

ns

TPPos0

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 0 (FIG 7)

NOTE 1

F = 85MHZ

-0.20 0 0.20

ns

TPPos1

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 1

1.48

1.68

1.88

ns

TPPos2

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 2

3.16

3.36

3.56

ns

TPPos3

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 3

4.84

5.04

5.24

ns

TPPos4

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 4

6.52

6.72

6.92

ns

TPPos5

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 5

8.20

8.40

8.60

ns

TPPos6

TRANSMITTER OUTPUT PULSE POSITION FOR BIT 6

9.88

10.08

10.28

ns

TSTC

TxIN SETUP TO TxCLK IN (FIG 3)

2.5 - -

ns

THTC

TxIN HOLD TO TxCLK IN (FIG 3)

0 - -

ns

TCCD

TxCLK IN TO TxCLK OUT DELAY (FIG4)

Ta = 25 ℃, Vcc = 3.3

V

3.8 - 6.3

ns

TxCLK IN TO TxCLK OUT DELAY (FIG4)

2.8 - 7.1

ns

TJCC

TRANSMITTER JITTER CYCLE TO CYCLE (FIG 8,9)

F=85 MHZ

-

110

150

ps

F=65 MHZ

-

210

230

ps

F=40 MHZ

-

350

370

ps

TPLLS

TRANSMITTER PHASE LOCK LOOP SET (FIG 5)

- - 10

ms

TPDD

TRANSMITTER POWER DOWN DELAY (FIG 6)

- - 100

ns

Page 27

MODEL

LTA230AN03-W

Doc. No

Page

27 / 38

note1)The minimum and maximum limits are based on statistical analysis of the device performance over process, voltage, and temperature

ranges. this parameter is functionality tested only on automatic test equipment (ATE)

note2)The limits are based onbench charaterization of the device's jitter response over the power supply voltage range. output clock jitter is

measured with a cycle to cycle jitter of ± 3ns applied to the input clock signal while data inputs are switching (fig8,9).A jitter event of 3 ns,

represents worse case jump in the clock edge from most graphics controller VGA Cihps currently available. this parameter is used when calculating

system margin as descrbed in AN-1059

Page 28

MODEL

LTA230AN03-W

Doc. No

Page

28 / 38

Page 29

MODEL

LTA230AN03-W

Doc. No

Page

29 / 38

Page 30

MODEL

LTA230AN03-W

Doc. No

Page

30 / 38

SAMSUNG Confidential

6.3 Characteristics of Input data of LVDS (S64V 기준)

(1) DC Specification

(2) AC Specification

Page 31

MODEL

LTA230AN03-W

Doc. No

Page

31 / 38

Page 32

MODEL

LTA230AN03-W

Doc. No

Page

32 / 38

SAMSUNG Confidential

6.4 The sequence of power on and off

To prevent a latch-up phenomena or the DC operation of the LCD Module, the power on/off sequence should be

accorded with the settings described in the diagram below.

T1 SPEC : 0.5 msec<T1≤10msec

T2 SPEC : 10 msec<T2≤50msec

T3 SELC : 0msec<T3≤50msec

T4 SELC : 1000msec≤T4

T5 SELC : 1000msec≤T5 (BLU ON TIME : Converter ENA Signal(ON))

T6 SELC : 100msec≤T6 (BLU OFF TIME : Converter ENA Signal(OFF))

T1 : The time, during which the level of VDD is rising from 10% to 90%.

T2 : The change for the time, during which the V

DD

start rising the level above 90% until the valid data of signal started coming in.

T3 : The change for the time, during which the valid data of signal started coming until the VDD started coming out.

T4 : The time, during which the V

DD

start coming out to restart the Windows.

T5 : The time, during which the valid data starts coming in until the power of B/L exceed 50%.

T6 : The time, during which the level of B/L’s power falls below 50% until the valid data of signal starts coming out.

The inputted V

DD

’s value for supply voltage, BLU, and signal to the external system of the module shall be

computed in observance of the former mentioned value.

The method to apply the voltage to the lamp within the range, which the LCD operates. When the back-

light is turned on before the LCD is operated or the power of LCD is turned off before the back-light is

turned off, the abnormal display on the screen may be shown momentarily.

Please keep the level of input signal low or keep the level of impedance high when the V

DD

is off.

The value shall be measured after the module has been fully discharged between the periods when the

power is on and off during the T4.

Page 33

MODEL

LTA230AN03-W

Doc. No

Page

33 / 38

SAMSUNG Confidential

7. Outline dimension

Page 34

MODEL

LTA230AN03-W

Doc. No

Page

34 / 38

SAMSUNG Confidential

8. Reliability test

Items to be evaluated

Condition for the evaluation

Quantity

Standard for evaluation

HTOL

50 ℃

4

60 ℃

8

LTOL

-5℃

4

THB

Evaluate the whole cell in the panel when examining the

panel, which is over 32" at 50℃ and 90 %RH.*

10

Margin on the operation

of ASG at a low

temperature.

(Optional)

Check the temperature when the noise occurs under the

conditions, the max. frequency and between the 40℃ and 25℃.

Each cell

Applied to products with

ASG only.

Margin on the operation

of ASG at a high

temperature. (Optional)

Examine the panel operated under the conditions, the

min. frequency and the 60℃ for 96hrs.

Each cell

Applied to products with

ASG only.

Residual image at a

normal temp.

Repeat the exam. to examine the mosaic pattern(9"*10")

of panel at 25 ℃ for 12hrs followed by the exam for the

rolling pattern at 25 ℃ for 12hrs three times.

8

New decompression

Examine the panel, which is in the temp. range of 40℃ to 50℃ between the

0m(0ft) and 13,700m(45,000ft) for

72 and half hrs.

4

HTS

Store at the 70 ℃.

4

LTS

Store at the -25 ℃.

4

Residual image at the

high temperature

(optional)

Examine the mosaic pattern(9"*10") of DID at

50℃ for 336hrs.

8

Only for DID product

Evaluation for the

panel on the pallet

Dropping(20cm)->Set the temp. and humidity(30℃~60℃ / 40℃~90%RH)->Pressurizing-

> Vibrating(Vibrate the panel within the frequency range

between 5hz and 200hz for 2hrs at the sine wave of 1.05

g.)->Dropping(20cm)

1 Pallet

Vibration

Vibrate the panel within the frequency range between

10hz and 300hz for 10min at the sine wave at 1.5G

Vibrate the panel in the direction of X, Y, and Z axis for

30min.

3

Shock

If the screen size of panel is below 40", drop the panel

with applying the 50G one time toward the direction of

±X, Y, and Z axis from the spot where the panel is

placed respectively for 11msec. (±XYZ), If the screen size

is 46“, apply the 40G for ±X and Y axis or the 30G for ±

Z. If the screen size is over 52", apply the 30G.

3

TSS

Test the TV between the -20℃ and 65℃ 440 times. Test

the DID between the -20℃ and 65℃ 220 times.

4

WHTS

Store the module at 60 ℃ and 75 %RH.

4

TS

Execute the exam for TV at -20℃ for 30 min. and at

60℃ for 30min 100 times. / Execute the exam for the

DID at -20℃ for 30 min. and at 60℃ for 30min 200

times.

4

Dust

Execute the test to observe the status of falling dust for

2

Page 35

MODEL

LTA230AN03-W

Doc. No

Page

35 / 38

5 min. after spraying the dust in the air for 5 sec. at a

normal temperature and normal humidity for 5 hrs.

Turn the panel on and off at the interval of 10 min.

Execute the test for the DID for 10hrs.

Twist

Examine the 52”-sized module by pushing the one point

of panel by 10 degrees forward and backward with

fixing other three points for 0.9s 500 times respectively.,

Examine the 46”-sized module by pushing the one point

of panel by 10 degrees forward and backward with

fixing other three points for 0.7s 500 times respectively.

Examine the 40"-sized module by pushing the one point

of panel by 20 degrees forward and backward with

fixing other three points for 0.85s 250 times

respectively., Examine the 32”-sized module by pushing

the one point of panel by 20 degrees forward and

backward with fixing other three points for 0.7s 250

times respectively.

Examine the 26”-sized module by pushing the one point

of panel by 20 degrees forward and backward with

fixing other three points for 0.6s 250 times respectively.

4

Noise

Noise occurred when the frame of instrument is

expanded as the operating module emits the heat.: Max

50dB (Below the 10 times when the level of sound is

over 36dB.)

2

Noise

Noise from machine : Under the 23dB on average.

2

The new compound

stress

Repeat the exam, which stresses the panel under the

temp. range of -20℃ to 60℃ and the humidity range

of 0%RH to 90%RH two times.

4

ESD

Shoot the ESD with the measuring gun,

which is operated at ±10 kV to the 210 points with

contacting the panel.

3

Shoot the ESD with the measuring gun, which is

operated at ±20 kV to the 210 points without

contacting the panel.

3

Input pin for inverter and converter (optional): Apply ±

15kV three times.

3

Only for the attached part

of inverter and converter.

[ Criteria on evaluation]

The components of product, which may affect to the function of display shall not be changed when the display

quality test is executed under the normal operating condition.

* HTOL/ LTOL : The operating at the high and low temperature*

* THB : The slant of temperature and humidity

* HTS/LTS : The storage at the high and low temperature

* WHTS : The storage condition at the high temperature with the high humidity

Page 36

MODEL

LTA230AN03-W

Doc. No

Page

36 / 38

SAMSUNG Confidential

10.2 Storage

ITEM

Unit

Min.

Max.

Storage

Temperature

(℃)

5

40

Storage

Humidity

(%rH)

35

75

Storage life

12 months

Storage

Condition

- The storage room shall be equipped with a good ventilation facility, which has

a temperature controlling system.

- Products shall be placed on the pallet, which is away from the wall not on the floor.

- Prevent products from being exposed to the direct sunlight, moisture, and water.;

Be cautious not to pile the products up.

- Avoid storing products in the environment where other hazardous material is placed.

- If products are delivered or kept in the storage facility more than 3 months, we recommend

you to leave products under the condition including a 20℃ temperature and a humidity of

50% for 24 hours.

10.3 Operation

(1) Do not connect or disconnect the cable to the module at the "Power On" condition.

(2) The power shall be always turned on/off by the item 6.4. "Power on/off sequence"

(3) The module has a circuit with a high frequency. The electromagnetic interference shall be suppressed by

system manufacturers sufficiently. The methods to ground and shield is important to minimize the

interference.

(4) Design the length of cable to connect between the connector for back-light and the inverter as short as possible

and the shorter cable shall be connected directly.

The cable between the back light connector and its converter power supply should be connected directly with

a minimized length. A longer cable between the back light and the converter may cause lower luminance of

LED package and may require higher startup voltage(Vs).

Page 37

MODEL

LTA230AN03-W

Doc. No

Page

37 / 38

SAMSUNG Confidential

10.4 Operation condition guide

(a) The LCD product shall be operated under normal conditions.

The normal condition is defined as below;

- Temperature : 20±15℃

- Humidity : 55±20%

- Display pattern : continually changing pattern (Not stationary)

(b) If the product will be used under extreme conditions such as under the high temperature, humidity,

display patterns or the operation time etc.., it is strongly recommended to contact SDC for the

advice about the application of engineering . Otherwise, its reliability and the function may not

be guaranteed. Extreme conditions are commonly found at airports, transit stations, banks, stock markets, and

controlling systems.

10.5 Others

(a) The ultra-violet ray filter is necessary for the outdoor operation.

(b) Avoid the condensation of water which may result in the improper operation of product or the

disconnection of electrode.

(c) Do not exceed the limit on the absolute maximum rating. (For example, the supply voltage

variation, the input voltage variation, the variation in content of parts and environmental temperature,

and so on) If not, the module may be damaged.

(d) If the module keeps displaying the same pattern for a long period of time, the image may be

remained to the screen. To avoid the image sticking, it is recommended to use a screen saver.

(e) This module has its circuitry of PCB's on the rear side and should be handled carefully in order for

a force not to be applied.

(f) Please contact the SDC in advance when the same pattern is displayed for a long time

Page 38

MODEL

LTA230AN03-W

Doc. No

Page

38 / 38

SAMSUNG Confidential

11. Special precautions

No.

Component

Expected cause

1

Upholding part for

panel

Prevent the panel from breaking by assigning gaps between the panel and the upholding part for panel on the drawing

for the upholding part for panel.

Refer to the (a), (b), (c) of 3-1 for the design of BLU.

2

The shape of the

upholding part for

panel

Design the upholding part for panel to fit to the panel appropriately when designing the BLU since the shape of the

upholding part for panel may damage the panel.

Refer to the (a), (b), (c) of 3-1 for the design of BLU.

3

The edge of

upholding part for

panel

Design the edge of panel to have a sufficient space with the upholding part for panel when designing the BLU since the

edge of the upholding part for panel may damage the panel when assembling the panel and BLU.

Refer to the (a), (b), (c) of 3-1 for the design of BLU.

4

Upholding part for

panel

Place the upholding part for the panel in order for the shape of mold, which contacts

with the panel not to interfere with the area of panel.

Refer to the (a), (b), (c) of 3-1 for the design of BLU.

5

Drive IC

Design the BLU in order for the COF not to contain the lead crack resulted from the tensioned COF created when the

product is twisted if the space between the D-IC COF and the middle mold isn't sufficient.

Refer to the (a), (b), (c),(d),(e),(f), and (g)of 3-2 for the design of BLU.

6

Drive IC

Design the BLU in order for the product not to contain the lead crack resulted from the tensioned COF caused under

the condition, which the product is twisted by fixing the source PCB.

Refer to the (a), (b), (c),(d),(e),(f), and (g)of 3-2 for the design of BLU.

7

IC

component

1) The temperature of each part of product suggested by our company and the second vendor shall meet the standard

of temperature, which is recommended not to be exceeded by our company when the product is affected under the

various temperature ranges.

Apply over 1mm long separation distance stated in the safety standard between the electric part and each conductor.

(Apply the rated separation distance when insulating.)

8

Thermal pad

Apply the thermal pad in a designated size to the product as a measure to lower the temperature of heat in order for

each part to use the rated temperature.

9

POL

The surrounding area of the POL shall be treated with an electrification treatment since the external ESD may cause a

phenomenon, which the POL is coming off.

In addition, the GND portion of source PBA shall be grounded.

10

PBA

The GND portion of each PBA shall be contacted with the GND portion of BLU.

Refer to the (a) and (b) of 3-3 for the design of BLU.

11

Circuit

The standardized approval from the client is required since the EMI is executed by a client.

Our company can only measure the reference since the client measures the BLU.

12

The height of

component

Design the BLU with considering the maximum height of parts, which our company suggests.

13

Between the FFC

and the C-PBA

Design the instrument with considering the length between the FFC and the control PBA.

(The marginal minimum length of 5mm or 8mm is required.)

14

Panel

The surface temperature of panel shall be maintained within 0℃ and 45℃ when the external ambient temperature is at

25℃. (Design the BLU with considering the increase of the temperature in the panel by the LED, CCFL, and etc.)

15

Aging

Recommend to age for over 1 hour at least in the state, which the product is driving initially to stabilize the

characteristic of the initial TFT.

16

The attachment of

gasket

The additional confirmation by our company is required If the attachment of gasket to the S-PBA of our company is

required.(To fix the S-PBA or the EMI)

17

Drive IC

Design the top chassis and the driver IC to be contacted by placing the shape of emboss inside the top chassis as a

measure to prevent the driver IC from heating. The size of emboss shall be designed in larger size than the size of IC

inside the film of the driver IC.

Refer to the (a), (b), (c),(d),(e),(f), and (g)of 3-2 for the design of BLU.

18

The prohibited

bandwidth

Design the BLU in order for the BLU not to interfere with the area, where the control PBA and the source PBA are

located densely according to the drawing for the BLU from our company.

19

S-PBA

The material, which contacts with the bottom side of S-PBA which has a pattern shall be non-conducting material or

shall be insulated.

Loading...

Loading...