Page 1

Specifications

Alignment and Adjustments

Troubleshooting

Exploded View and Parts List

Service Item

Block Diagrams

Schematic Diagrams

1.

2.

3.

4.

5.

6.

7.

DLP TV

Chassis : L64A(N_L5)_Robocop-1

Model : HLR4677WX/XAA (HL-R4677W)

HLR5677WX/XAA (HL-R5677W)

SERVICE

Manual

DLP TV CONTENTS

Page 2

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

© Samsung Electronics Co., Ltd. DEC. 2004

Printed in Korea

AA82-01909A

ELECTRONICS

Page 3

Specifications

Samsung Electronics

1-1

1. Specifications

Model HL-R4677W HL-R5677W

Voltage AC 120V

Frequency of Operation 60Hz

Power Consumption 230 Watts

Dimensions

(W x D x H)

1094x339x814 mm

43.07x13.35x32.05 inches

1330x396x962.5 mm

52.36x15.59x37.89 inches

Weight 71.65lbs/32.5Kg 93.7lbs/42.5Kg

Page 4

1-2

Samsung Electronics

MEMO

Page 5

Alignment and Adjustments

Samsung Electronics 2-1

Factory

DDP1011(L5)

DNIe

ADV7402(M)

ADV7402(S)

uPD64083

MSP4440

CCA

Cinema CCA

SP Actuator

CHECKSUM 0000

OPTION

SERVICE

T_RoboAUS0_XXXX

20XX_XX_XX

T-DTVUCOM5-XXXX

T-RoboAUS1_XXXX

2-1 When Entering Service Mode:

2-1-1 Service Mode Entry Method

1. Turn off the power to make the SETSTAND-BY mode.

2. In order to enter the Service Mode, Press "Mute" → "1” → "8" → "2" → "POWER" button on the Remote Control.

In case entry into SERVICE MODE is unsuccessful, repeat the procedures above.

2-1-2 Initial DISPLAY State in times of SERVICE MODE Switch overs

2-1-2(A) OSD DISPLAY

2-1-2(B) BUTTONS OPERATIONS WITHIN SERVICE MODE

2. Alignment and Adjustments

MENU Full Menu Display / Move to Parent Menu

Direction keys ▲ / ▼

Item Selection by Moving the Cursor

Direction keys ◀ / ▶

Data Increase/Decrease for the Selected Item

Source Cycles through the active input source that are connected to the unit

Page 6

Alignment and Adjustments

2-2 Samsung Electronics

2-1-3 Factory Data

1) DDP1011

No Item Range Default Remark

1 V-Position 0~60 30 Screen upper and lower adjustment

2 H-Position 0~120 60 Screen left right adjustments

3 LAMP SYNC Pulse(P) Pulse(P), Pass(T)

4 INDEX DELAY 0~359 100 Index Delay adjustment

5 SEQ SELECT 0~15 7 Sequence Selection

6 V-FLIP Normal/Flip Normal Vertical Flip Operation

7 H-FLIP Normal/Flip Normal Horizontal Flip Operation

8 GAMMA 0~15 2 Gamma Table Selection

9 SLR OFF/ON OFF SLR Function Selection

10 DMD_BIAS B,C,D,E E DMD Bias bin vlotage selection

11 Lamp Boost 0~63 20 Lamp Boost value selection

12 Lamp Sync Delay 0~4095 0 Lamp Sync delay value selection

13 Test Pattern 0 Test Pattern Selection

Page 7

Alignment and Adjustments

Samsung Electronics 2-3

2) DNIe

No Item Range Default Remark

1 Test Pattern 0 Test Pattern Selection

2 NR_MAX Y/C 0~255 48 Temporal NR Gain

3 NR_MIN Y/C 0~255 16 Temporal NR Gain

4 Core 0~15 4 NEOnDCE User Set Up

5 B_RATIO 12000 Low level information for the minimum value

6 BLACK_TILT 0~255 120 Black Stretch Area

7 W_RATIO 12000 High level information for the minimum value

8 WHITE_TILT 0~255 200 White Stretch Area

9 GAIN1X 0~63 16 Gain of horizontal high frequency region

10 GAIN1Y 0~63 12 Gain of vertical high frequency region

11 GAIN2X 0~63 8 Gain of horizontal middle frequency region

12 GAIN2Y 0~63 4 Gain of vertical middle frequency region

13 GAIN3X 0~63 1 Gain of horizontal low frequency region

14 NDON ON

ON,OFF Background Noise Detection ON/OFF

Switch

15 CORING_ON ON ON,OFFCoring On/Off

16 SCALE_R 0~255 92 Log Mapping Gain

17 WTE_CSC YCCRGB YCCRGB,YPPRGB

18 DITHER_MOD 0 1,2,3

19 RED_C_COEFF 128 Gain adjustment of the contrast for the Red signal

20 GRN_C_COEFF 128 Gain adjustment of the contrast for the Green signal

21 BLU_C_COEFF 128 Gain adjustment of the contrast for the Blue signal

22 RED_B_COEFF 128

Gain adjustment of the brightness for the Red

signal

23 GRN_B_COEFF 128

Gain adjustment of the brightness for the Green

signal

24 BLU_B_COEFF 128

Gain adjustment of the brightness for the Blue

signal

25 Sub Contrast 0~150 105

Brightness adjustment for the high-light parts of the

screen

26 Sub Brightness 235

Brightness adjustment for the low-light parts of the

screen

Page 8

Alignment and Adjustments

2-4 Samsung Electronics

4) CCA

No Item Range Default Remark

1 CCA On/Off On CCAOn/Off Selection

2 Red-x 0~32768 651 Red-x adjustment

3 Red-y 0~32768 340 Red-y adjustment

4 Red-Y 0~32768 128 Red-Y adjustment

5 Green-x 0~32768 290 Green-x adjustment

6 Green-y 0~32768 709 Green-y adjustment

7 Green-Y 0~32768 455 Green-Y adjustment

8 Blue-x 0~32768 148 Blue-x adjustment

9 Blue-y 0~32768 53 Blue-y adjustment

10 Blue-Y 0~32768 67 Blue-Y adjustment

11 White-x 0~32768 272 White-x adjustment

12 White-y 0~32768 285 White-y adjustment

13 White-Y 0~32768 703 WHite_Y adjustment

14 WB Spread Spread CCAvalue to all mode

15 Move HDMI Move to the HDMI Mode

16 DRedX 640 Target Red X value for CCA

17 DRedY 330 Target Red Y value for CCA

18 DGreenX 300 Target Green X value for CCA

19 DGreenY 670 Target Green Y value for CCA

20 DBlueX 150 Target Blue X value for CCA

21 DBlueY 60 Target Blue Y value for CCA

22 DCyanX 200 Target Cyan X value for CCA

23 DCyanY 268 Target Cyan Y value for CCA

24 DMagentaX 275 Target Magenta X value for CCA

25 DMagentaY 130 Target Magenta Y value for CCA

26 DYellowX 435 Target Yellow X value for CCA

27 DYellowY 535 Target Yellow Yvalue for CCA

28 D_White_X 291 Target White X value for CCA

29 D_White_Y 300 Target White Y value for CCA

30 DTV/HDMI 0

3) MSP4440

No Item Range Default Remark

1 MDB Effect 0~127 56 Micronas Dynamic Bass

2 SRS Dialog 0~127 64 SRS Dialog clarity adjustment

3 PLL Pilot low adjustment

4 PLH Pilot high adjustment

Page 9

Alignment and Adjustments

Samsung Electronics 2-5

6) CHECKSUM 0000

Excute Checksum calcuation

5) Cinema CCA

No Item Range Default Remark

1 DRedX 640 Target Red X value for CCA

2 DRedY 330 Target Red Y value for CCA

3 DGreenX 300 Target Green X value for CCA

4 DGreenY 670 Target Green Y value for CCA

5 DBlueX 150 Target Blue X value for CCA

6 DBlueY 60 Target Blue Y value for CCA

7 DCyanX 200 Target Cyan X value for CCA

8 DCyanY 268 Target Cyan Y value for CCA

9 DMagentaX 275 Target Magenta X value for CCA

10 DMagentaY 130 Target Magenta Y value for CCA

11 DYellowX 435 Target Yellow X value for CCA

12 DYellowY 535 Target Yellow Y value for CCA

13 D_White_X 313 Target White X value for CCA

14 D_White_Y 329 Target White Y value for CCA

Page 10

Alignment and Adjustments

2-6 Samsung Electronics

7) OPTION

No Item Range Default Remark

1 Lamp Clear Initialize lamp using time. Lamp Life is set to zero

2 User Reset All setting is back to the default

3 WB Reset OFF Initialize the White Balance value

4 EER Reset Clear the EEPROM

5 Lamp Life 0h Time for which the lamp has been used

6 AUTO POWER ON/OFF ON

The sets turns on automatically when the power cord

is plugged in

7 DNle DEMO ON/OFF ON DNle Demo function selection

8 Lamp Control Dynamic Dynamic, Always

9 MUTE TIME 600ms

Time which the screen will be black while switching

channels

10 EDID WRITE

11 DELAYMOD ON/OFF OFF Sound Delay Module ON/OFF selection

12 DBG/ANY SEL Debug/AnyNet Select the use of the Aynet jack

13 GEM/GEMIR SEL GemIR/Gemstar Not used

14 226 TEST PATT Xilleon 226 test pattern

15 Set Default Data Initialize Service Data

16 DDC protection OFF DDC write ON/OFF selection

17 LNADefault AUTO LNAsetting OFF/Auto selection

18 PROTECT ON Protection ON/OFF selection

19 WATCH DOG Watch Dog ON/OFF selection

20 WD COUNT 0 Count for Watch Dog event

21 Auto Pgm Range Not used

8) SERVICE

No Item Range Default Remark

1 V-Position 30 Screen upper and lower adjustment

2 H-Position 60 Screen left right adjustment

3 LAMP SYNC Pulse(P)

4 Actuator Gain Actuator Gain adjustment

5 INDEX DELAY 100 Index delay adjustment

6 AUTO COLOR Auto Color function execution

7 CCA CCAmenu

8 Lamp Clear Initialize Lamp using time

9 User Reset All setting is back to the default

Page 11

Samsung Electronics 2-7

Alignment and Adjustment

2-2 CCA Adjustment Service Methods

CCAAdjustment is needed after changing a light engine or digital board

2-2-1 CCA

In DLP TV, even the same RGB color may differ depending on the light engine. CCA(Color Coordinate Adjustment) corrects the

color to achieve the color accuracy. CCAperforms color correction after measuring and inputting the current light engine's data on

actual color coordinates for displayed Red, Green, Blue, and White color patterns, using a color coordinate measuring equipment.

At this moment, color correction is performed on the basis of previously inputted Desired Color Coordinates and Measured Color

Coordinates. Measured Data on Service Engine's color coordinates is presented on the CCAlabel. Input the label values to per-

form CCAcolor correction.

2-2-2 Condition of the CCA Label upon Receipt of the Service Engine

*"CCALABEL" describes the measured color coordinates on the light engine.

CCA LABEL

R G B W

X X X X

X X X X

X X X X

Page 12

Alignment and Adjustments

2-8 Samsung Electronics

2-3 INDEX DELAY Adjustment

1. Turn off the power to make the SETSTAND-BY mode.

2. In order to enter the Service Mode, Press "Mute" → "1” → "8" → "2" → "POWER" button on the Remote Control.

3. Select "Service" on the first display of the Service mode menu.

4. Press the ▲▼(Up or Down) button to move to INDEX DELAY, then press ENTER to select.

5. The INDEX DELAY setup screen (with a red bar at the bottom of the screen) will be displayed.

6. Press the ◀▶ (Left of Right) button to check the red color at the bottom of the screen at its minimum and maximum values of

changing from red to magenta, then adjust to the mean value.

2-4 Projected Image Adjustment

1. Turn off the power to make the SETSTAND-BY mode.

2. In order to enter the Service Mode, Press "Mute" → "1” → "8" → "2" → "POWER" button on the Remote Control.

3. Select "Service" on the first display of the Service mode menu.

4. Select the V-position for vertical positioning and H-position for horizontal positioning by using the ▲▼(up, down) buttons.

※ Do not set the V-position value to 34 or 35.

(Setting to these values will cause horizontal lines on the right side of the screen.)

2-2-3 CCAService Procedures

CCAON/OFF

Red - x : ???

Red - y : ???

Red - Y : ???

Green - x : ???

Green - y : ???

Green - Y : ???

Blue - x : ???

Blue - y : ???

Blue - Y : ???

White - x : ???

White - y : ???

White - Y : ???

WB SPREAD

Move HDMI

CCAMenu in FACTORY Mode

To execute CCAadjustment , perform the following steps:

1. Turn off the power to make the SETSTAND-BY mode.

2. In order to enter the Service Mode, Press "Mute" → "1” → "8" →

"2" → "POWER" button on the Remote Control.

3. Select FACTORY > SERVICE > CCA mode on the SET.

4. Switch the CCAOFF.

5. Input the CCAbasic engine data to the SET.

6. Input the D-White -x, y values in the coordinates per destination.

(if necessary)

7. Select WB SPREAD, then press Enter to activate the WB Spread

SET ensuring that you adjust until you get the OK sign.

After adjusting, exit Factory Mode.

8. When the adjustment is complete, check the picture quality.

*Attention

Performing CCAis independent on current display's resolution and input signal type if you don't measure color coordinates data.

Measuring color coordinates data requires specific equipment not possessed by service personnel, what makes performing manual

adjustment impossible. Adjusting CCAis applied to all the signal mode. Don't change Desired value because it will be hamful to

the color of the SET.

Page 13

Alignment and Adjustments

Samsung Electronics 2-9

2-5 POD Channel Board

* Analog Channel Tuning

* Digital(VSB, QAM) Channel Tuning

* 3wire(CLK,Data,Select) control in method tuner control

2-5-1 Assy POD Channel Board

CN600

Transporting video stream

Pin Name PIN No. Pin Name

S_5V 1 32 NRESET

GND 2 31 GND

QAM_SCL 3 30 VSB_SDA

QAM_SDA 4 29 VSB_SCL

GND 5 28 CH_RST

DRX 6 27 CRX

QTX 7 26 ETX

ITX 8 25 CTX

GND 9 24 GND

TS_CLK 10 23 TS_SEL

TS_SYNC 11 22 TS_VAL

TS_D7 12 21 TS_D6

TS_D5 13 20 TS_D4

TS_D3 14 19 TS_D2

TS_D1 15 18 TS_D0

D3.3V 16 17 GND

Pin Name PIN No. Pin Name

S_A30V 1 32 GND

GND 2 31 GND

S_A9V 3 30 TU_CLK

GND 4 29 TU_EN

GND 5 28 TU_DAT

S_A6.5V 6 27 GND

GND 7 26 XTAL_ON_OFF

NTSC_AFT 8 25 GND

GND 9 24 GND

CVBS 10 23 Crystal_CTL

GND 11 22 TU_AGC

SIF 12 21 GND

GND 13 20 GND

GND 14 19 GND

GND 15 18 GND

GND 16 17 GND

CN601

Connecting the control signal between Digital & Channel board

QAM-Demod

8VSB-Demod

Tuner

RF_Splitter

IF_NT_Demod

Page 14

Alignment and Adjustments

2-10 Samsung Electronics

2-6 ASSY PCB POWER Service Manual

CN804

CN805

*Supply DC Voltage

CN805

Connecting Power to Analog Board

Pin Name PIN No.

STD 5V 1

GND 2

STD 5V 3

GND 4

12VA 5

GND 6

12VA 7

GND 8

33VA 9

POD-SW 10

Pin Name PIN No. Pin Name

STD 5V 1 2 S-MUTE

GND 3 4 S14.5V

33V 5 6 GND

GND 7 8 S14.5V

POWER-SW 9 10 GND

5.5VB 11 12 5.5VB

GND 13 14 GND

12VB 15 16 12VB

GND 17 18 GND

12VB 19 20 12VB

GND 21 22 GND

GND 23 24 80VB

CN804

Connecting Power to Analog Board

2-6-1 Assy Power Board

Page 15

Alignment and Adjustments

Samsung Electronics 2-11

2-7 ASSY PCB DIGITAL Service Manual

RS232 - S/W Upgrarde and Anynet

HDMI - A/V Input

* Microprocessor (Generates turn on signal to power board)

* Monitor LED's

* All Digital Video Processing

* Sensor / Switch Controls

* OSD / Menu

* Reset Switch

* Connected with POD channel Board. See the right picture.

2-7-1 Assy Digital Board

Page 16

Alignment and Adjustments

2-12 Samsung Electronics

Pin Name PIN No. Pin Name

I2SWS_OUTA 1 2 TxDM

I2SSD_OUTA 3 4 RxDM

I2SCLK_OUTA 5 6 GND

GND 7 8 SDA_M5

SDA_PANNEL 9 10 SCL_M5

SCL_PANNEL 11 12 NT_I2S_SCLK

GND 13 14 NT_I2S_LRCLK

NT_I2S_DATA 15 16 USB_SW_UP_P

nMICOM_INIT 17 18 USB_SW_UP_N

nRESET 19 20 S_nRESET

ANALOG_nRST 21 22 DDP_READY

MD_nRESET 23 24 PWRGOOD

LAMP_ERROR 25 26 DTV_Lt

DLP_SYNCVAL 27 28 DTV_Rt

GND 29 30 GND

CN16

Connecting the control signal between Digital & Analog Board

Pin Name PIN No. Pin Name

MD3.3V 1 2 MD3.3V

MD3.3V 3 4 D3.3V

GND 5 6 D3.3V

GND 7 8 GND

STB_6.5V 9 10 GND

GND 11 12 GND

STB_9V 13 14 D5.7V

GND 15 16 D5.7V

STB_30V 17 18 GND

STB_5V 19 20 GND

5VA 21 22 D12V

GND 23 24 GND

GND 25 26 D9V

33V 27 28 GND

CN17

Connecting Power to the Digital Board

Pin Name PIN No. Pin Name

MAIN_Y 1 2 GND

MAIN_C 3 4 GND

SUB_Y 5 6 GND

SUB_C 7 8 GND

DTV_CVBS 9 10 GND

COMP1_Y 11 12 GND

COMP1_Pb 13 14 GND

COMP1_Pr 15 16 GND

COMP2_Y 17 18 GND

COMP2_Pb 19 20 GND

COMP2_PR 21 22 GND

M_CVBS 23 24 GND

M_SIF 25 26 GND

S_CVBS 27 28 GND

S_SIF 29 30 GND

CN21

Connecting the audio / video signal from the rear input terminal

Digital Board Connector Pin

Page 17

Alignment and Adjustments

Samsung Electronics 2-13

2-8 ASSY PCB ANALOG Service Manual

* Distributes supply voltage from the Power Board to Digital Board

* Transfers Turn-On Command from Digital Board to Power Board

* Encompasses the majority of the Audio Circuit

* Analog Video Switching / Processing

* Analog AudioSwitching / Processing

* 3D Comb Processing

2-8-1 Assy Analog Board

Page 18

Alignment and Adjustments

2-14 Samsung Electronics

CN275

Connecting USB cable for Software Upgrade

Analog Board Pin Assignment

Pin Name PIN No.

GND 1

5VB 2

USB-NEG 3

USB-POS 4

GND 5

CN249

For Debugging

Pin Name PIN No.

SDA-A 1

SCL-A 2

GND 3

5VA 4

CN250

For Debugging

Pin Name PIN No.

SDA-DMD 1

SCL-DMD 2

GND 3

5VA 4

CN259

Connecting Power to the DMD

Pin Name PIN No.

5VB 1

5VB 2

GND 3

GND 4

12VB 5

12VB 6

GND 7

GND 8

GND 9

CN266

Connecting Power and the Control Signal to the Actuator

Protection Board

Pin Name PIN No.

GND 1

12VB 2

GND 3

SDA-M1 4

SCL-M1 5

GND 6

5VA 7

GND 8

70VB 9

GND 10

Pin Name PIN No. Pin Name

3.3V-ATI 1 2 3.3V-ATI

3.3VB-D 3 4 3.3V-ATI

3.3VB-D 5 6 GND

GND 7 8 GND

GND 9 10 6.5VA-D

GND 11 12 GND

5.7VB 13 14 9VA

5.7VB 15 16 GND

GND 17 18 30VA

GND 19 20 5VA

12VB 21 22 5VA

GND 23 24 GND

9VB 25 26 GND

GND 27 28 33VB

GND 29 30 GND

CN268

Connecting Power to the Digital Board

Page 19

Alignment and Adjustments

Samsung Electronics 2-15

CN265

Connecting the IR signal

Pin Name PIN No.

IR 1

GND 2

5VA 3

CN261

Connecting front LED indicators

Pin Name PIN No.

5VA 1

KEY-PWR 2

GND 3

LED1 4

LED2 5

LED3 6

CN273

Connecting Side Buttons

Pin Name PIN No.

GND 1

KEY1 2

KEY2 3

GND 4

CN228

Connecting and transmitting Audio signal to Speaker

Pin Name PIN No.

-L-OUT 1

+L-OUT 2

-R-OUT 3

+R-OUT 4

Pin Name PIN No.

FAN-ERROR 1

GND 2

8VA-FNA 3

CN223

Transmitting Video Signal from Side Terminal

Pin Name PIN No.

SIDE-Y 1

SIDE-C 2

GND 3

SIDE-V 4

GND 5

SIDE-L 6

GND 7

SIDE-R 8

GND 9

SIDE-SDET 10

SIDE-VDET 11

CN274

Connecting the Power and Control Signal to the POD Fan

Page 20

Alignment and Adjustments

2-16 Samsung Electronics

Pin Name PIN No. Pin Name

MAIN_Y 1 2 GND

MAIN_C 3 4 GND

SUB_Y_V 5 6 GND

SUB_C 7 8 GND

DTV_CVBS 9 10 GND

COMP1_Y 11 12 GND

COMP1_Pb 13 14 GND

COMP1_Pr 15 16 GND

COMP2_Y 17 18 GND

COMP2_Pb 19 20 GND

COMP2_Pr 21 22 GND

MTNR_CVBS 23 24 GND

MTNR_SIF 25 26 GND

STNR_CVBS 27 28 GND

STNR_SIF 29 30 GND

CN257

Connecting the audio / video signal from the rear input terminal

Pin Name PIN No. Pin Name

TxDM 1 2 ATI-I2S-WS

RxDM 3 4 ATI-I2S-DATA

GND 5 6 ATI-I2S-CLK

SDA_A 7 8 GND

SCL_A 9 10 SDA_DMD

I2SCLK 11 12 SCL_DMD

I2S_WS 13 14 GND

USB_POS 15 16 I2S_DATA

USB_NEG 17 18 CPU_INIT

SOUND_RESET 19 20 CPU_RESET

DDP_READY 21 22 RESET_D

PWRGOOD 23 24 MD_nRESET

DTV_L 25 26 LAMP_ERROR

DTV_R 27 28 DLP_SYNCVAL

GND 29 30 GND

CN258

Connecting the control signal between Digital and Analog

Pin Name PIN No. Pin Name

5VA 1 2 POWER-MUTE

GND 3 4 S16VB

33VB 5 6 GND

GND 7 8 S16VB

POWER-SW 9 10 GND

5.7VB 11 12 5.7VB

GND 13 14 GND

12VB 15 16 12VB

GND 17 18 GND

12VB 19 20 12VB

GND 21 22 GND

GND 23 24 70VB

CN267

Connecting Power

Pin Name PIN No.

5VA 1

GND 2

5VA 3

GND 4

12VA 5

GND 6

12VA 7

GND 8

30VA 9

POD-SW 10

CN270

Connecting Power

Page 21

Alignment and Adjustments

Samsung Electronics 2-17

2-9 ASSY PCB DMD Service Manual

* Control Lamp Turn-On

* Powers Color Wheel Motor

* Drives DMD Panel

* Sensor Control

* Attached to optical Engine

2-9-2 Block Diagram

2-9-1 Assy DMD Board

Page 22

Alignment and Adjustments

2-18 Samsung Electronics

PIN NAME DESCRIPTION

SCTRL_BN/P B channel LVDS serial control

DCLK_BN/P B channel LVDS CLOCK

SCPDI SERIALCONTROLDATAINPUT

SCPDO SERIAL CONTROLDATAOUTPUT

SCPENB SERIAL CONTROL ENABLE

SCPCK SERIAL CONTROL CLOCK

DMD RESETB DMD LOGIC RESET

MBRST(14:0) MIRROR BIAS RESET

MBRST_EXTRA UNUSED MIRROR BIAS RESET

SCR_CLR TEST CLEAR PINS(NORMALGND)

READOUTA(1:0) A-CHANNEL SERIAL DATAOUT DURING SPAM READ TEST OPERATION

READOUTB(1:0) B-CHANNEL SERIAL DATAOUT DURING SPAM READ TESTOPERATION

TP(2:0) MANUFACTORING TEST POINT(NO CONNECTED DURING NORMAL CPERATION)

RSV_A(4:0)/RSV_B(4:0) RESERVED PINS(NORMAL:GND)

EVCC REFERENCE VOLTAGE DURING SPAM READ TEST OPERATION(NORMALGND)

VCC2 MIRROR ELECTRODE VOLTAGE(7.3V)

VCC LOGIC SUPPLY

VSS LOGIC GROUND

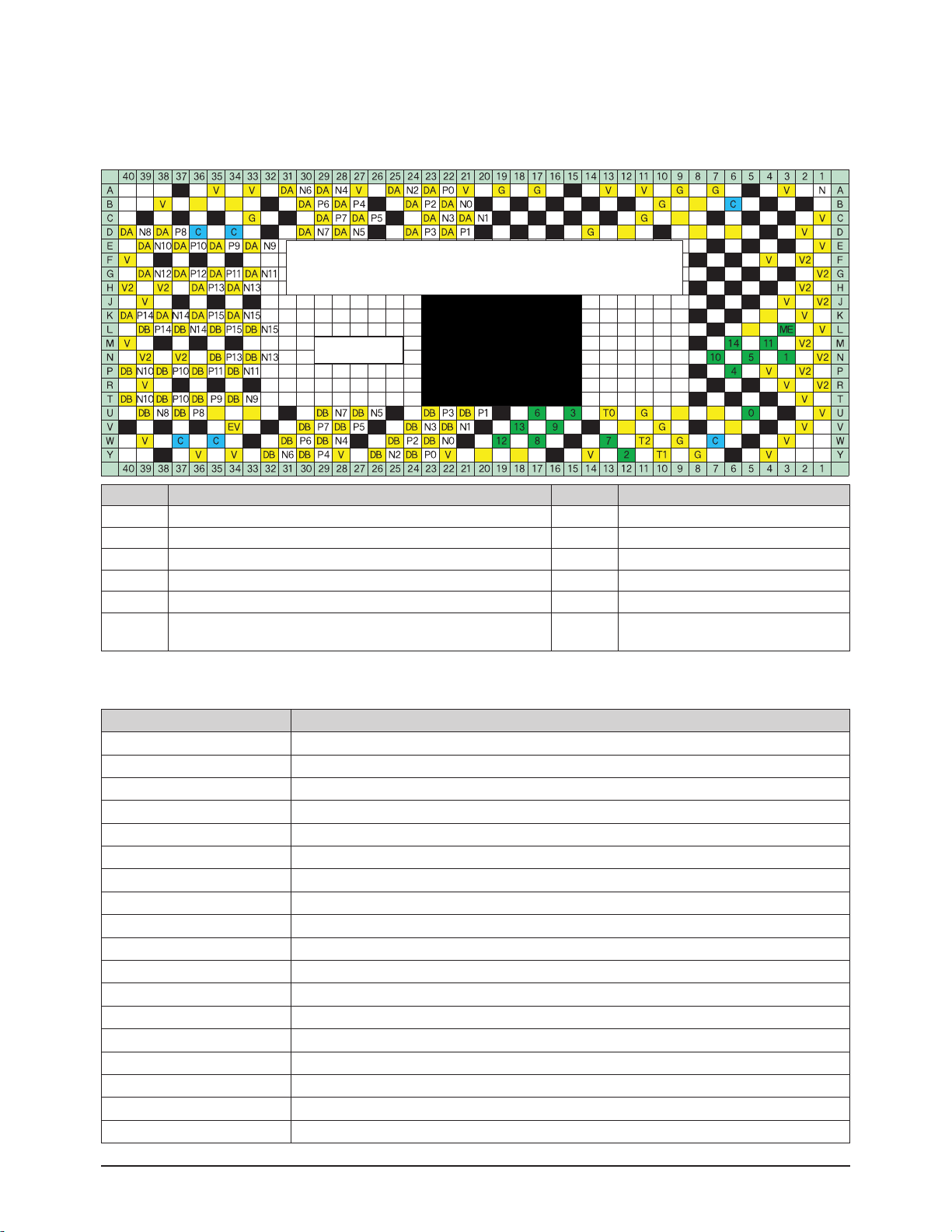

2-9-3 DMD Panel Pin Terminal Characteristics Diagram

2-9-4 Description of Terminal Characteristics

※ Remove the heat sink attached to the DMD Board and tighten the screws in four places and then inspect the characteristics of

each pin terminal.

Pin Name Description Pin Name Description

V Voltage : 3.3V T Test Point

V2 VCC2 : 8V ME Mirror Bias Extra

DA AChannel Data Bus [When measured, there should be a waveform] C Clock

DB B Channel Data Bus [When measured, there should be a waveform] P# A,B Channel Positive

No. MBRST# (Mirror Bias Rest) 26V N# A,B Channel Negative

G

The part from the present position to the GND

(The black part is also a GND.)

The vertical lines, which may occur due to improper connections between the panel and the

PCB, occur with intervals of 50 inches(26mm). If vertical lines occur with intervals of more than

26mms, it indicates a failure of the DDP1011 IC itself. If they occur with intervals of less than

26mm, it means that more than two pins have bad connections.

DA,DB output wave

[Screen:WHITE]

Page 23

Alignment and Adjustments

Samsung Electronics 2-19

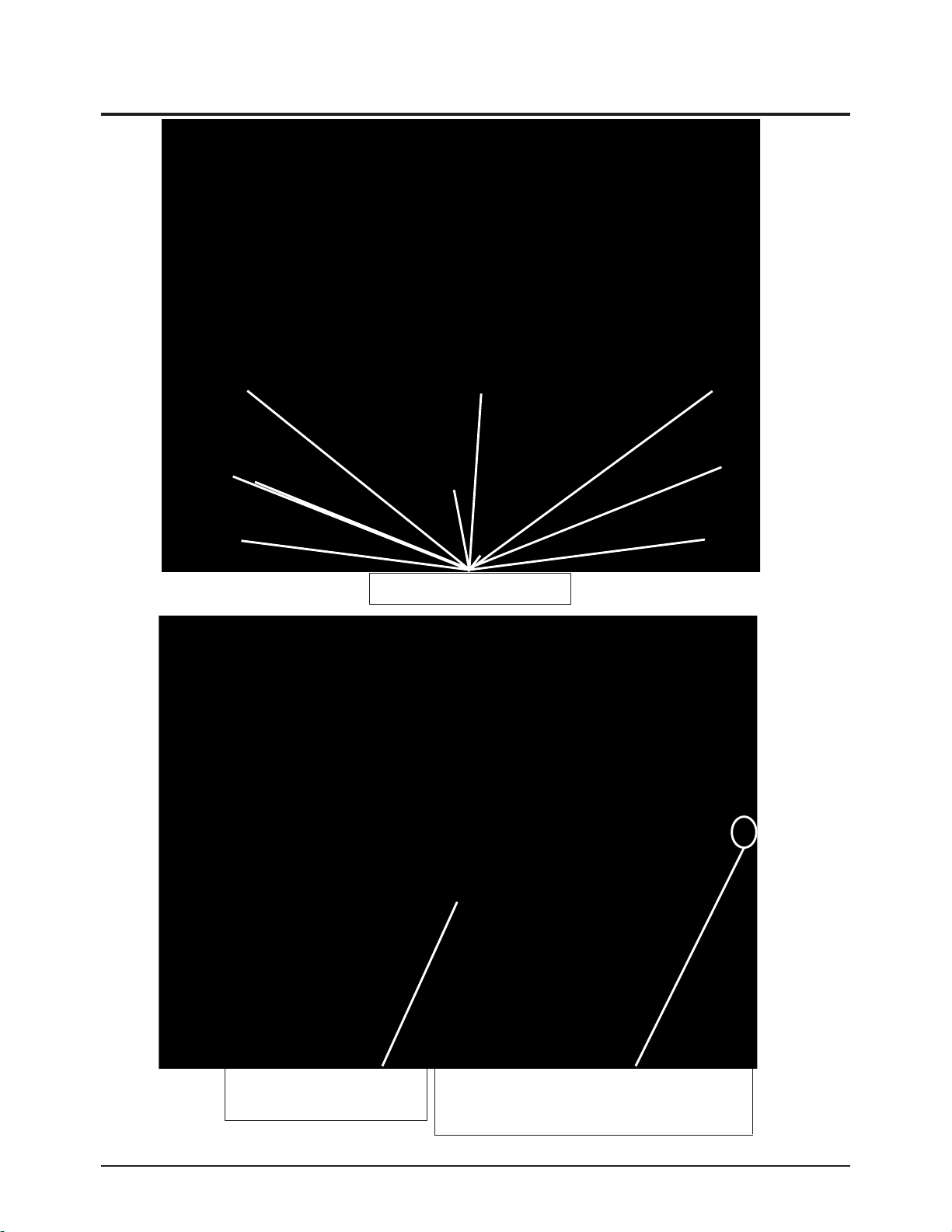

No Description Key Point Remark

1

1) When the power cord is plugged in,

2) DC 380V is automatically supplied to the ballast.

Check whether the DC380V

power is supplied to the ballast.

2

1) When the power key is pressed via the remote control, the micom

of the digital board outputs high (5V) PWR signals.

2) The power board operates normally.

5V and 12V are supplied to the DMD CN105 terminal.

Check whether 5V and 12V are

supplied to the CN105 terminal.

* 12V must be supplied to operate the motor.

(The voltage of the motor driving power is 12V.)

3

1) The MTR Reset signal is supplied to the R161 terminal of the

motor IC101 from the micom on the digital board and then the

motor starts to drive.

2) If the color wheel rotates for a certain time and then stops, check

whether the color wheel sensor is normal.

(Check the waveform on the No.2 terminal below CN102.)

After the set is powered on, check

whether 5V is detected on pin

No.49 of IC101.

→ After a while, the sound

generated by the rotating color

wheel is heard.

* If 5V is not detected, the motor will not operate.

4

1) Check whether the signal (SCI: STARTCONTROL INPUT)

that turns on lamp #2 of CN109 on the DMD board is high (5V).

Check whether CN109 #2 signal

is 5V.

* When SCI is high (5V), the lamp litz of CN109

is low (0V).

* CN109 #2 terminal voltage changes to pulse

wave form 14 seconds after (for 50 inch TV)

the time that the voltage is 5V.

* When about 4 seconds have passed after

changing to pulse waveform, the screens are

displayed on the set.

5 1) Method for checking whether the DDP1010 IC RESET is normal.

If the voltage between R254 and

R255 is 3V, it is normal.

2-9-5 Engine Failure Inspection Flow Chart for the DMD Board

2-9-6 Output Voltage States of the DMD Board Parts

Output terminal

Wave form for

RA101,102,103,104

Page 24

Alignment and Adjustments

2-20 Samsung Electronics

2-10 Optical Science

2-10-1 Engine

2-10-2 Optical Specification

Parameter Nominal Value Unit Connent

Brightness 450 nits

6-segment color wheel, TI development board,

no spoke light recapture, reference lamp

Uniformity (ANSI)

- Typical

- Minimal

+/- 15

+/- 25

%

%

+ : brightest of 13 ANSI points/average of 9 points

- : darkest of 13 ANSI points/average of 9 points

Contrast full on/off

- Typical

1000 to 1 n.a.

6-segment color wheel, TI development board,

no spoke light recapture

Color Temperature 7,500 K (Warm 1) n.a. measured in image center

F-number

≥ 2.6

n.a. design value

Projection distance at 50"

screen size

680 mm

projection distance : distance from vertex of front

lens to projection screen

Exit pupil position 48.69 mm design value, distance to vertex of front lens

F.O.V (Field of View) 84 deg. design value

Panel size 17.5104x9.8496 mm Diamond Pixel Configuration

Lateral color aberration

@ 50" (R-G ; B-G)

≤ 7

≤ 7

㎛

㎛

Desion value

440/546/640 ㎛

TV distortion

- in horizontal direction

- in vertical direction

≤│0.3│

≤│0.3│

%

%

Pin Cushion or Barrel condition

folding angle 62 deg. mechanical design value

Lamp Module

Color Wheel Cover

DMD Module

Optical Module

Page 25

Alignment and Adjustments

Samsung Electronics 2-21

2-11 Service

2-11-1 Service Hint #1 - DMD Board Assy

2-11-2 Service Hint #2 - ColorWheel Assy

Problem : PIXEL DEFECT, VERTICALLINE

Solution : Change the DMD Board assembly

Problem : INCREASED NOISE

Solution : Change the Color wheel module

G

Page 26

Alignment and Adjustments

2-22 Samsung Electronics

2-11-3 Service Hint #3 - LAMP Assy

Problem : LOW BRIGHTNESS or No Power

Solution : Change the Lamp module

Page 27

Alignment and Adjustments

Samsung Electronics 2-23

2-12 Tilt the Screen

Remove the bottom cover.

Remove the cover of the

signal terminal.

Fix the safety switch on the right with tape

so that the set can be turned on after

removing the bottom cover.

Page 28

Alignment and Adjustments

2-24 Samsung Electronics

Remove the four screws on the upper and lower part

of the power board, and remove the whole assembly

without removing the cable.

Page 29

Alignment and Adjustments

Samsung Electronics 2-25

Place the power board on the back, and

keep the cables connected.

Remove the two screws on the left and the one screw

on the bottom right, without removing the engine.

※ Even when those screws are removed, the board

does not separate, it can be moved within the

adjustable range because there is a spring screw

at the center that holds it.

Fix the safety switch on the right with tape

so that the set can be turned on after removing

the bottom cover.

Page 30

Alignment and Adjustments

2-26 Samsung Electronics

Turn on the TV to send signals.

Then, adjust the screen position,

by holding both of the upper corners

of the DMD board.

※ When adjusting the screen, it is better for two people to work together.

On person should direct the picture position while the other person looks

at the screen.

※ The movement direction of the board and the picture are opposite.

- When the board is lifted upward, the screen descends down.

- When it is tilted to the left, the screen tilts to the right.

※ When the picture adjustment is completed:

First, tighten the two screws on the left of the DMD board

and then slowly tighten the one screw on the bottom right.

Be careful not to touch the board while screwing.

(When using an electric-powered screwdriver, be careful that

the torque is not too high.)

Page 31

Alignment and Adjustments

Samsung Electronics 2-27

2-13 Side Panel Buttons

The buttons on the right side panel control your TV's basic features, including the on-screen menu system. To use the more

advanced features, you must use the remote control.

2-14 Side Panel Jacks

Use the right side panel jacks to connect a component that is used only occasionally (a camcorder or video game, for example).

①

SOURCE

Press to switch between viewing TV programs and signals from connected

components.

②②

MENU

Press to see the on-screen menu.

③

+ VOL –

Press to lower or raise the volume and to select items when using the on-screen

menu.

④④ ∧

CH

∨∨

Press to change channels and move between items on the on-screen menu.

⑤

Press to activate (or change) a particular item.

⑥⑥

POWER

Press to turn the TV on and off.

①

VIDEO Input jack

Connect the video signal from a camcorder or video game.

②②

AUDIO Input jacks

Connect the audio signal from a camcorder or video game.

③

S-VIDEO Input jack

Connect an S-video signal from a camcorder or video game.

(S-Video 3 jack and Audio L/R input 3 are used in conjunction.)

Page 32

Alignment and Adjustments

2-28 Samsung Electronics

2-15 Rear Panel Jacks

Use the rear panel jacks to connect components such as a VCR. You can connect different components such as VCRs, Set-Top

Box and a DVD player etc., because there are two sets of video input jacks and two sets of component video input jacks on the

rear panel of your TV. For more information, please see "Connections".

① ANTENNAterminals

Two independent cables or antennas can be connected to these

terminals. Use "Cable IN" and "Air IN" terminals to receive a

signal from VHF/UHF antennas or your cable system. Use the

"Cable OUT" terminal to send the signal being received by the

"Cable IN" terminal out to another component (such as a Cable

Set-Top Box).

② S-VIDEO INPUT jacks

Connects an S-Video signal from an S-VHS VCR or DVD player.

③ DVI (Digital Video Interface) AUDIO INPUT jacks

Connect to the digital audio output jacks of a device with DVI

output.

④ VIDEO/AUDIO INPUT jacks

Connect video/audio signals from external sources, such as VCR

or DVD players.

⑤ VIDEO/AUDIO OUTPUT jacks

Sends video/audio signals from the TV to an external source,

such as a VCR. These jacks are available only in RF, Video and

S-Video modes.

⑥ Component1, 2 jacks (Y, PB, PR, L, R)

Use these jacks to connect the component video/audio signals

from a DVD player or a Set-Top Box.

⑦ DIGITALAUDIO OUT(OPTICAL) jack

Connect to a Digital Audio Component.

⑧ Anynet

Please refer to the Anynet Owner's Instruction.

⑨ HDMI (High Definition Multimedia Interface)/

DVI INPUT jack

Connect to the HDMI jack of a device with HDMI output.

Connect to the digital video output jack for device with DVI

output.

⑩ CableCARD™

Insert the CableCARD into the slot.

⑪ SERVICE

This jack is for repair and software upgrades.

Page 33

Alignment and Adjustments

Samsung Electronics 2-29

17.EXIT

Press to exit the menu.

18.▲, ▼, ◀, ▶, ENTER

Press to select highlight up, down, left, or

right. While using the on-screen menus,

press the ENTER to activate (or change) a

particular item.

19.MTS(Multichannel Television

Stereo

)

Press to choose Stereo, Mono or SAP

(Secondary Audio Program).

20.PIP(Picture In Picture)

Displays the available channels in

sequence.

(These buttons change channels in the PIP

window only.)

21.STILL

Press to pause the current screen.

22.ASPECT

Press to change the screen size.

23.SRS

Activates TruSurround.

24.DNIe

(Digital Natural Image engine)

Activates DNIe.

25.SET

Used during set up of this remote control, so

that it will work compatibly with other

devices.

(Set-Top box, VCR, Cable box, DVD, etc.)

26.SLEEP

Press to select a preset time interval for

automatic shutoff.

27.PIP Controls

CH ∧∧/

∨

; Press to displays the available

channels in sequence. (These buttons

change channels in the PIP window only.)

28.CAPTION

Controls the caption decoder.

29.VCR/DVD Controls

Controls VCR or DVD functions: Rewind,

Stop, Play/Pause, Fast Forward.

27.RESET

If your remote control is not functioning

properly, take out the batteries and press

the reset button for about 2~3 secons.

Re-insert the batteries and try using the

remote control again.

1. POWER

Turns the TV on and off.

2. P.MODE

Adjust the TV picture by selecting one of

the preset factory settings (or select your

personal, customized picture settings.)

3. ANTENNA

Press to select "AIR" or "CABLE".

4. CHANNEL NUMBER

Press to directly tune to a particular

channel.

5. -

Press to select additional channels

(digital and analog) being broadcast by

the same station. For example, to select

channel "54-3", press "54", then press

"-" and "3".

6. VOL+, VOL-

Press to increase or decrease the

volume.

7. MUTE

Press to mute the TV sound.

8. ANYNET

Runs the Anynet view functions and sets

up Anynet devices.

9. MENU

Displays the main on-screen menu.

10.CH.LIST

Displays the channel list.

11.FAV.CH (Favorite Channel)

Press to switch between your favorite

channels.

12.MODE

Selects a target device to be controlled

by the Samsung remote control (i.e., TV,

STB, VCR, CABLE, or DVD).

13.PRE-CH

Tunes to the previous channel.

14.SOURCE

Press to display all of the available video

sources (i.e., TV, Set-Top box, VCR,

DVD, DTV).

15.CH

Press to change channels.

Moves from one set of screen information to the next in TV Guide menu.

16.INFO

Press to display information on the TV

screen.

2-16 Remote Control

You can use the remote control up to about 23 feet from the TV. When using the remote control, always point it directly at the TV.

You can also use your remote control to operate your VCR, Cable box, DVD player or Samsung Set-Top Box.

Page 34

2-30 Samsung Electronics

MEMO

Page 35

Troubleshooting

Samsung Electronics 3-1

3. Troubleshooting

3-1 Flow Chart for Malfunction

If the DLP turns on

No

Check the Power Cord

Yes

Can you see anything

in the screen?

No

Yes

Can you see OSD menu

running in the screen?

Check Cables connected to

Digital Board. If necessary,

replace Digital Board

Yes

No

Can you see Digital

Channel broadcast ?

No

Replace POD Channel Board

Does the LAMP turn on?

No

2)

Check if LED1 on the

Analog Board turns on?

Yes

Replace LAMP

Check Cables connected to

BALLAST. If necessary,

replace BALLAST.

Check Cables connected to

DMD Board.

If necessary, replace DMD Board.

Yes

1)

Check DVI Cable.

If necessary, replace DVI Cable.

No

3)

Check if DMD Fan is running?

Check Cables connected to

Power Board. If necessary,

replace Power Board.

No

Check Cables connected to

DMD Board. If necessary,

replace DMD Board.

Yes

Check Cables connected to

Analog Board.

If necessary, Analog Board.

1) DVI Cable

2) LED1

3) DMD Fan

Page 36

Troubleshooting

3-2 Samsung Electronics

3-2 Front Panel LED Indicators

The three lights on the front panel indicate the status of your TV.

• It takes about 30 seconds for the TV to warm up, so normal brightness may not appear immediately.

• The TV has a fan to keep the inside lamp from overheating. You'll occasionally hear it working.

Indicator Light Key

: Light is On

: Light is Blinking

: Light is Off

TIMER LAMP STAND BY/TEMP

Standby state.

The picture will automatically appear in about 15 seconds.

Auto Timer ON/OFF has been set and the set will automatically be

turned on in about 25 seconds.

A cooling fan inside the set is not operating normally.

Lamp cover on rear of the set is not properly shut.

Check if the ventilation hole on the rear of the set is blocked, because

if the inner temperature is too high, the power will shut off.

Lamp may be defective. Please contact a certified technician.

Indication

Page 37

Troubleshooting

Samsung Electronics 3-3

3-3 Blinking Temp & Timer LED

Are fans running?

No

Check for 8Vdc at

CN103 & 104 on Actuator

Board

No

Check CN802 pins 8&10 on

the Power board for 12VB

Yes

Replace

the Analog board

Yes

Replace Actuator board

Yes

Replace fan(s)

No

Replace Power Board

Page 38

Troubleshooting

3-4 Samsung Electronics

3-4 Blinking Temp LED

CN106

Temperature

Sensor

Ablinking lamp LED is the most common failure indication. It can be caused by no lamp, no color wheel, no

fan(s), or other defective components.

CN106

Check Temp Sensor

connector CN106

on Sub Detector Board

Yes

Install jumper across

Temp Sensor Terminals

Does it work?

Yes

Replace Temp. Sensor

No

No

Reinsert

the Connector

Replace

Sub Detector Board

Temperature

Sensor

Yes

Yes

Does color wheel run?

No

Yes

Yes

Yes

Is lamp on?

Does lamp

No

come on, then

shut off?

No

Yes

No

Replace DMD Board

Do fan(s) run?

Replace color wheel assy'

Check 280V DC to lamp ballast(CN1)

Measure with DC meter

No

Replace Power Board Re-install lamp assy'

No

Check pin 1 on CN503

on DMD Board for 5V DC

No NoYes Yes

Check 5Vpp at CN503

pin 3 on DMD Board

Replace lamp assy' or ballast Replace DMD Board Replace ballast or lamp assy'

Page 39

Troubleshooting

Samsung Electronics 3-5

3-5 Blinking Lamp and Temp LEDs

Is lamp cover installed?

Make sure lamp cover

switch is activating

Yes

Short CN107

on Actuator Board

No

Install lamp cover

Yes

No

Check boss

on Lamp Cover

No

Replace the Actuator Driver Board

No

Replace the Digital Board

CN107

Page 40

Troubleshooting

3-6 Samsung Electronics

3-6 Disassemble and Reassemble

① Remove screws and back cover.

③ Separate a GT-Wire and DVI cable.

⑤ Chassis.

② Remove the screws and the terminal.

④ Separate the cables.

3-6-1 Separation of the back cover and the chassis

Page 41

Troubleshooting

Samsung Electronics 3-7

① Remove the screws and cables.

③ Analog, Digital Board and Fan.

⑤ Remove the nuts.

② Remove the screws and cables.

④ Remove the nuts.

⑥ Remove the screws.

3-6-2 Separation of the Analog and Digital Board

Page 42

Troubleshooting

3-8 Samsung Electronics

⑦ After removing a Top Shield case.

① Remove the screws and cables.

② Power Board.

3-6-3 Separation of the Power Board

Page 43

Troubleshooting

Samsung Electronics 3-9

* For replacement, you will need a 5.91 Inches-long Phillips screwdriver and a pair of gloves.

1. Unplug TV, then use a screwdriver to remove

the screw as shown in the picture.

(Remove the rubber cap and unscrew the

screw. )

2. Remove the Lamp cover.

(Exert a bit of force to the right and pull for easy

opening.)

3. Use a screwdriver to remove the screws

securing the Lamp.

There are 2 screws: one on the left and one on

the right. When the screws have been

completely unfastened, they will still be

connected to the body of the Lamp.

4. Separate the Lamp from the engine by holding

the handle and pulling it out.

5. To reinstall the Lamp, follow these steps in

reverse order.

☞ NOTES

1. Be sure the replacement Lamp is the same model.

2. After replacing the lamp align the lamp cover with the groove and secure the screw.

3. The TV will not turn on if the lamp cover is not correctly closed (as this will activate the protective circuit).

3-6-4 Lamp Replacement

Page 44

Troubleshooting

3-10 Samsung Electronics

3-6-5 BALLAST replacement Method

■ Failure type : The lamp does not operate.

1. Loosen the two screws which hold the lamp in place, and then remove the lamp.

2. Loosen the screw which holds the connector in place.

3. Loosen the four screws on the ballast board.

4. Replace it with a new board and re-assemble it in the reverse order.

1

2

3

4

Page 45

Troubleshooting

Samsung Electronics 3-11

3-6-6 Color Wheel Ass'y Replacement

1. Remove the three screws

2. Remove the dust preventing tape.

3. Lift up the C/W

cover.

Loosen the two screws

and remove the lamp.

Page 46

Troubleshooting

3-12 Samsung Electronics

Remove the five screws.

Lift up the bracket and the light tunnel.

※ Be careful not to dirty the light tunnel with foreign materials.

Remove the screw

at the side of the

light tunnel.

Remove the three screws

and replace the

color wheel ASSY.

*Caution: Never touch the color wheel.

Touch only the instruments.

Page 47

4. Exploded View & Parts List

4-1 HLR4677WX/XAA

Exploded View & Parts List

Samsung Electronics 4-1

You can search for the updated part code through ITSELF web site.

URL : http://itself.sec.samsung.co.kr

Loc.No. Code No. Description;Specification Q'ty S.N.A

M0256 BP96-00849D ASSY BRACKET P-MAIN PCB;L5,SECC,T1.0,SEA 1 S.N.A

T0003 BP96-00321E ASSY COVER P-FRONT;46L5(L62B),AL EXTR,DG 1

T0053 BP67-00051A SCREEN FRESNEL;46W,PMMA,1021*580.5,2T 1

T0054 BP67-00107A SCREEN LENTI;46W,MS,1021*580.5,2T 1

T0066 AA96-20129A ASSY POWER CORD;-,EP2/YES,H/C300,ME301P, 1 S.N.A

T0068 BP61-00337A BRACKET-MIRROR ASSY;SECC,46L5 1 S.N.A

T0070 BP61-00899A HOLDER-CHASSIS;HLP4674W,ABS V0,T2.5,W60, 1 S.N.A

T0074 BP59-00076A REMOCON;ROBOCOP,TM76A,200*54*21,47,Light 1

T0120 BP94-02141P ASSY PCB POWER; 1 S.N.A

T0129 BP96-00305P ASSY ENGINE P-DLP PL46;46L5 DLP,PHILIPS 1

T0130 BP96-00947A ASSY COVER P-TERMINAL BOARD;L5(L64A),HIP 1 S.N.A

T0131 BP96-00324C ASSY COVER P-BACK TOP;46L5,HIPS,V0,GRY,D 1

T0131 BP96-00328A ASSYCOVER P-BACK BOT;46L5,HIPS,V0,GR503 1

T0134 BP67-00040A MIRROR-FRONT,DM1;43",GLASS,810*472*434,F 1

T0132 BP94-01853A ASSY PCB MISC-DIGITAL;HLR4677WX/XAA,L64A 1 S.N.A

T0137 BP94-02211A ASSY PCB S-SUB DETECTOR S/W;HLP4674WX/XA 1 S.N.A

T0145 BP94-02037A ASSY PCB MISC-ANALOG;HLR4677WX/XAA,L64A, 1 S.N.A

T0147 BP96-00325G ASSY COVER P-SIDE L;46L5,HIPS,HB,GRY,DGM 1

T0158 BP96-00322J ASSY COVER P-MAIN;46L5(L64A),HIPS,V0,GRY 1 S.N.A

T0177 BP63-00072B COVER-FRONT JERSEY;46L5,AL6063,BLK,EXTR 1 S.N.A

T0186 BP96-00431B ASSYCOVER P-GRILLE HOLE;46L5,HIPS,HB,GR 1

T0211 BP61-00383A BRACKET-SCREEN BOT;46L5,AL 6063 EXT,BLK 1 S.N.A

T0214 BP63-00144S COVER SIDE-R ASSY;46L5,HIPS,HB,GRY,DGM12 1 S.N.A

T0264 AA63-00021G SPACER-MIRROR;524J,434J,PVC,-,-,-,BLK,-, 3 S.N.A

T0265 AA63-00021U SPACER-MIRROR BOT;47Q7,PVC HB,L770,BLK 1 S.N.A

T0409 BP61-00338A BRACKET-FRONTTOP ASSY;AL6063,46L5,EXTR, 1 S.N.A

T0890 BP96-00855A ASSY FAN P;1B1S,50*50*0.5,1.9,0.19,24,-1 1 S.N.A

T0928 BP61-00259A BRACKET-MIRROR TOP(T);46L5,AL6063,BLK,EX 1 S.N.A

T0074 T0066

T0053

T0003

T0211

T0186

T0054

T0928

T0177

T0264

T0265

T0068

T0134

T0409

T0158

T0147

T0129

T0070

T0137

T0132

T0120

T0131

T0890

T0145

T0214

M0256

T0131

T0130

Page 48

Exploded View & Parts List

4-2 Samsung Electronics

4-2 HLR5677WX/XAA

You can search for the updated part code through ITSELF web site.

URL : http://itself.sec.samsung.co.kr

Loc.No. Code No. Description;Specification Q'ty S.N.A

M0256 BP96-00849D ASSY BRACKET P-MAIN PCB;L5,SECC,T1.0,SEA 1 S.N.A

T0003 BP96-00300C ASSY COVER P-FRONT;56L5,AL EXTR,DGN8422, 1

T0053 BP67-00155A SCREEN FRESNEL;56W,1257*713.5,2T 1

T0054 BP67-00110A SCREEN LENTI;56W,MS,1257*713.5,2T 1

T0066 AA96-20129A ASSY POWER CORD;-,EP2/YES,H/C300,ME301P, 1 S.N.A

T0068 BP61-00305A BRACKET-MIRROR ASSY;BLK,56L5 1 S.N.A

T0070 BP61-00899A HOLDER-CHASSIS;HLP4674W,ABS V0,T2.5,W60, 1 S.N.A

T0074 BP59-00076A REMOCON;ROBOCOP,TM76A,200*54*21,47,Light 1

T0120 BP94-02141P ASSY PCB POWER; 1 S.N.A

T0129 BP96-00305P ASSY ENGINE P-DLP PL46;46L5 DLP,PHILIPS 1

T0130 BP96-00947A ASSY COVER P-TERMINAL BOARD;L5(L64A),HIP 1 S.N.A

T0131 BP96-00299A ASSYCOVER P-BACK BOT;56L5,HIPS,V0,GR503 1

T0131 BP96-00302B ASSY COVER P-BACK TOP;56L5,HIPS V0,GRY,D 1

T0132 BP94-01853A ASSY PCB MISC-DIGITAL;HLR4677WX/XAA,L64A 1 S.N.A

T0137 BP94-02211A ASSY PCB S-SUB DETECTOR S/W;HLP4674WX/XA 1 S.N.A

T0145 BP63-00122P COVER SIDE-RIGHTASSY;56L5,HIPS,HB,GRY,D 1 S.N.A

T0145 BP94-02037A ASSY PCB MISC-ANALOG;HLR4677WX/XAA,L64A, 1 S.N.A

T0147 BP96-00303G ASSY COVER P-SIDE L;56L5,HIPS,HB,GRY,DGM 1

T0158 BP96-00297M ASSY COVER P-MAIN;56L5,HIPS,V0,GRY,SEA(L 1 S.N.A

T0186 BP96-00432B ASSYCOVER P-GRILLE HOLE;56L5,HIPS,HB,GR 1

T0260 BP67-00059A MIRROR-FRONT;Mirror Front 56",glass,1048 1

T0264 AA63-00021L SPACER-MIRROR,TOP;50J6,PVC HB,BLK,L1020 1 S.N.A

T0264 AA63-00021N SPACER-MIRROR,SIDE;50J6,PVC HB,L545,BLK 3 S.N.A

T0409 BP61-00382A BRACKET-FRONT TOPASSY;AL6063+ABS,56L5 1 S.N.A

T0890 BP96-00855A ASSY FAN P;1B1S,50*50*0.5,1.9,0.19,24,-1 1 S.N.A

T0925 BP61-00384A BRACKET-SCREEN HOLE;AL6063 EXTR BLK,56 1 S.N.A

T0927 BP63-00149A COVER-FRONT HOLE;56L5,AL6063 EXTR BLK 1 S.N.A

T0928 BP61-00223A BRACKET-MIRROR TOP(T);46L5,AL6063,BLK,EX 1 S.N.A

T0074 T0066

T0409

T0068

T0928

T0927

T0264

T0264

T0260

T0158

T0054

T0053

T0003

T0925

T0186

T0147

T0129

T0070

T0137

T0132

T0120

T0131

T0890

T0145

T0145

M0256

T0131

T0130

Page 49

Exploded View & Parts List

Samsung Electronics 4-3

Exploded View & Parts List

4-3 ENGINE ASS'Y

L3 Engine Exploded View List

NO. Description CODE NO. Specification Q'TY

1 ASSY LAMP P BP96-00826A L3,LAMPSERVICE,PHILIPS 120W,E22 1

1-1 SCREW-MACHINE 6006-001039 WSP,PH,+,M4,L12,ZPC(YEL),SM10C 1

2 ASSY DMD BOARD P BP96-00678B L3 PHILIPS,DMD BOARD,SERVICE 1

2-1 SPRING ETC-COIL,DMD AA61-01195A B3K,SPRING STEEL 4

2-2 SCREW-MACHINE 6001-000819 PWH,+,-,M3,L30,ZPC(YEL),SWRCH10A,UP,- 4

2-3 SCREW-TAPTITE 6006-000248 PWH,+,-,S,M3,L8,ZPC(YEL),SWRCH18A,P0 2

2-4 SCREW-TAPTITE 6003-000264 PWH,+,B,M3,L6,ZPC(YEL),SWRCH18 1

3 ASSY BALLAST P BP96-00690A L3,SERVICE BALLST 1

3-1 SCREW-TAPTITE 6003-001023 PWH,+,B,M3,L10,ZPC(YEL),SWRCH18A,- 2

4 ASSY K/D-COLOR WHEEL BP98-00489A L3 ENGINE,SERVICE 1

5 ASSY K/D-OPTIC MODULE BP98-00490B L3 ENGINE(FDB),SERVICE 1

5-1 SCREW-TAPTITE 6003-000277 BH,+,B,M3,L12,ZPC(YEL),SWRCH18 5

6 COVER DUCT-TOP23 BP63-00295A SVP-50L3HR,PC G/F20 1

6-1 COVER DUCT-BOTTOM23 BP63-00296A SVP-50L3HR,PC G/F20 1

6-2 FAN-DC BP31-00010B SVP-50L7XHD,UL94V-0, PBT,Wire Length = 500mm 1

6-3 RUBBER-FAN,LAMP BP73-00012A SHP700,NBR,50,LOSS FACTOR>0.02 2

6-4 SCREW-TAPTITE 6003-001023 PWH,+,B,M3,L10,ZPC(YEL),SWRCH18A,- 3

6-5 SCREW-MACHINE 6006-001039 WSP,PH,+,M4,L12,ZPC(YEL),SM10C 3

7 GUIDE-BALLAST 23 BP61-00732A SVP-50L3HR,PC G/F 20 1

7-1 HOLDER-BALLAST 23 BP61-00728A SVP-50L3HR,PC G/F20 1

7-2 SCREW-MACHINE 6006-001039 WSP,PH,+,M4,L12,ZPC(YEL),SM10C 3

8 HOUSING-LAMP,BOTTOM 23 BP61-00726A SVP-50L3HR,AL D/C 1

8-1 SCREW-TAPTITE 6006-000249 PWH M/S (S.P/W) M3*L7 P0.75 3

9 ASSY MISC-THERMOSTAT BP91-00612A HLP5063W,L62B 1

9-1 SCREW-MACHINE 6006-001035 PH M/S (S.P/W) M3*L8 P0.5 2

10 COVER-CW 23 BP63-00299A SVP-50L3HR,PC G/F20 1

10-1 SCREW-MACHINE 6006-001035 PH M/S (S.P/W) M3*L8 P0.5 2

11 COVER-LENS PROJECTION BP63-00338A SVP-50L3,PS,T0.3 1

11-1 SCREW-TAPTITE 6003-001023 PWH B-T M3*L10 2

12 HOLDER-INTERFACE BP61-00668A SVP-50L3HR,ABS V0 BLK 1

12-1 SCREW-MACHINE 6006-001039 WSP,PH,+,M4,L12,ZPC(YEL),SM10C 3

12-2 ASSY PCB S-ACTUATOR BP94-02149K DP,BP41-00121A,L62B,ATLANTIS 1

12-3 SCREW-TAPTITE 6003-001023 PWH B-T M3*L10 4

12-4 ASSY MISC-DETECTOR S/W BP91-00775A ASSY MISC-DETECTOR S/W 1

12-5 SCREW-TAPTITE 6003-001023 PWH B-T M3*L10 1

13 BRACKET-BASE 23 BP61-00730A SVP-50L3HR,SECC,1.6 1

14 HOLDER-BASE BP61-00590A DLP L3,PPS G/F30 1

14-1 SCREW-MACHINE 6006-001039 WSP,PH,+,M4,L12,ZPC(YEL),SM10C 6

15 FAN-DC BP31-00011A AD0612LB-D72GL,P.B.TUL94-Vo,Wire+Metal Bracket 1

15-1 BRACKET-FAN DMD BP61-00595A DLP L3,SECC,T1.0 1

15-2 SCREW-TAPTITE 6006-000250 BH,+,WT,B,M3,L20,ZPC(YEL),SWRCH18A,- 2

15-3 SCREW-TAPTITE 6003-000199 PWH,+,B,M3,L14,ZPC(YEL),SWRCH1 2

15-4 HOLDER-SPACER,RUBBER BN61-00236A B3K,BSBM 2

15-5 RUBBER-DAMPFAN BP73-00040A HLN507W,CR,30,BLACK,V0 2

3

2-

2

2-1,2-

4

2-

12

15

15-1

15-2

15-3

15-4

5

15-

1

11-

1

1

1

5

42

12-

12-1

12-4

2

1-1

12-

5-

6-

1

0

1

10-

1

4

4

6

3

6-

2

6-

1

6-

14-

5

1

6-

12-3

9

1

9-

8

8-

1

5

3

7-2

13

7-1

1

1

3-

Page 50

Electrical Parts List

Samsung Electronics

5-1

5. Service Item

5-1 HLR4677WX/XAA

Yon can search for the updated part code through ITSELF web site.

URL:http://itself.sec.samsung.co.kr

Loc.No. Code No. Description;Specification Q'ty

D0254 AA32-00015A MODULE REMOCON;FRP-3521H31,38KHZ,940MM,M 1

T0268 AA39-10007Y CBF-POWER CORD;-,EP2/YES,SPT-2 18AWGx2C, 1

CIS3 AA40-00122A TUNER;TMQH2-003A,C-TV TM(SUB),NTSC,181CH 1

T0952 AA59-00365A MODULE-RF SPLITTER;UMX-NT-040,2in/2out/l 1

M0114 BP39-00106E CBF SIGNAL;HLP4674WX,24P/24P,UL20276-D,4 1

T0049 BP47-00016A LAMP-BALLAST;EUC 120 P/H 11,120W P/H 11, 1

T0074 BP59-00076A REMOCON;ROBOCOP,TM76A,200*54*21,47,Light 1

T0453 BP61-00244A HOLDER-BALLAST PHILIPS;PPS,NATURAL 1

T0269 BP64-00225A CABINET-BACK BOT;46L5,HIPS,V0,GRAY 1

T0268 BP64-00226A CABINET-BACK TOP;46L5,HIPS,V0,GRAY 1

T0134 BP67-00040A MIRROR-FRONT,DM1;43",GLASS,810*472*434,F 1

T0053 BP67-00051A SCREEN FRESNEL;46W,PMMA,1021*580.5,2T 1

T0512 BP67-00093A LENS-PRJ ASSYVE;HLN507W1X,GLASS,NTR,N/A 1

T0054 BP67-00107A SCREEN LENTI;46W,MS,1021*580.5,2T 1

T0511 BP68-00460A MANUAL USERS;HL-R4677W,SEM,ENG,C.S. Amer 1

T0091 BP94-00502S ASSY PCB MISC-SIDE A/V;HLN467WX/XAA,L62A 1

T0132 BP94-01853A ASSY PCB MISC-DIGITAL;HLR4677WX/XAA,L64A 1

T0145 BP94-02037A ASSY PCB MISC-ANALOG;HLR4677WX/XAA,L64A, 1

T0120 BP94-02141P ASSY PCB POWER; 1

T0245 BP94-02203A ASSY PCB MISC-KEY CONTROL;HLP4674WX/XAA, 1

T0175 BP96-00076A ASSY SPEAKER P;,8OHM,25W,001282/001144,1 1

T0128 BP96-00224C ASSY COVER P-LAMP(PJ);43"50"46"56" DLP P 1

T0127 BP96-00249F ASSY COVER P-DMD;L5(L62B),SVC ASSY 1

T0126 BP96-00250A ASSY COVER P-COLOR WHEEL;DLP(SVC),COLOR 1

T0296 BP96-00251A ASSY COVER P-DUCT FAN;DLP(SVC),FAN ASSY 1

T0129 BP96-00305P ASSY ENGINE P-DLP PL46;46L5 DLP,PHILIPS 1

T0003 BP96-00321E ASSY COVER P-FRONT;46L5(L62B),AL EXTR,DG 1

T0158 BP96-00322J ASSY COVER P-MAIN;46L5(L64A),HIPS,V0,GRY 1

T0131 BP96-00324D ASSY COVER P-BACK TOP;46L5,HIPS,V0,GR503 1

T0147 BP96-00325G ASSY COVER P-SIDE L;46L5,HIPS,HB,GRY,DGM 1

T0131 BP96-00328A ASSY COVER P-BACK BOT;46L5,HIPS,V0,GR503 1

T0186 BP96-00431B ASSY COVER P-GRILLE HOLE;46L5,HIPS,HB,GR 1

CN269 BP96-00547C ASSY BOARD P-JACK;ROBOCOP_1,NTSC,AV+S.VH 1

M0018 BP97-00873A ASSY MICOM;L62B,29W800D,T-AT2MWWS-1001,0 1

Page 51

Electrical Parts List

5-2

Samsung Electronics

5-2 HLR5677WX/XAA

Yon can search for the updated part code through ITSELF web site.

URL:http://itself.sec.samsung.co.kr

Loc.No. Code No. Description;Specification Q'ty

D0254 AA32-00015A MODULE REMOCON;FRP-3521H31,38KHZ,940MM,M 1

T0268 AA39-10007Y CBF-POWER CORD;-,EP2/YES,SPT-2 18AWGx2C, 1

CIS3 AA40-00122A TUNER;TMQH2-003A,C-TV TM(SUB),NTSC,181CH 1

T0952 AA59-00365A MODULE-RF SPLITTER;UMX-NT-040,2in/2out/l 1

M0114 BP39-00106E CBF SIGNAL;HLP4674WX,24P/24P,UL20276-D,4 1

T0049 BP47-00016A LAMP-BALLAST;EUC 120 P/H 11,120W P/H 11, 1

T0074 BP59-00076A REMOCON;ROBOCOP,TM76A,200*54*21,47,Light 1

T0453 BP61-00244A HOLDER-BALLAST PHILIPS;PPS,NATURAL 1

T0269 BP64-00212A CABINET-BACK BOT;56L5,HIPS,V0,,,,,GRAY, 1

M0045 BP64-00213B CABINET BACK-TOP;56L5,HIPS,V0,GRAY,DGM-1 1

T0260 BP67-00059A MIRROR-FRONT;Mirror Front 56",glass,1048 1

T0512 BP67-00093A LENS-PRJ ASSYVE;HLN507W1X,GLASS,NTR,N/A 1

T0054 BP67-00110A SCREEN LENTI;56W,MS,1257*713.5,2T 1

T0053 BP67-00155A SCREEN FRESNEL;56W,1257*713.5,2T 1

T0511 BP68-00460A MANUAL USERS;HL-R4677W,SEM,ENG,C.S. Amer 1

T0091 BP94-00502S ASSY PCB MISC-SIDE A/V;HLN467WX/XAA,L62A 1

T0132 BP94-01853A ASSY PCB MISC-DIGITAL;HLR4677WX/XAA,L64A 1

T0145 BP94-02037A ASSY PCB MISC-ANALOG;HLR4677WX/XAA,L64A, 1

T0120 BP94-02141P ASSY PCB POWER; 1

T0245 BP94-02203A ASSY PCB MISC-KEY CONTROL;HLP4674WX/XAA, 1

T0175 BP96-00076A ASSY SPEAKER P;,8OHM,25W,001282/001144,1 1

T0128 BP96-00224C ASSY COVER P-LAMP(PJ);43"50"46"56" DLP P 1

T0127 BP96-00249F ASSY COVER P-DMD;L5(L62B),SVC ASSY 1

T0126 BP96-00250A ASSY COVER P-COLOR WHEEL;DLP(SVC),COLOR 1

T0296 BP96-00251A ASSY COVER P-DUCT FAN;DLP(SVC),FAN ASSY 1

T0158 BP96-00297M ASSY COVER P-MAIN;56L5,HIPS,V0,GRY,SEA(L 1

T0131 BP96-00299A ASSY COVER P-BACK BOT;56L5,HIPS,V0,GR503 1

T0003 BP96-00300C ASSY COVER P-FRONT;56L5,AL EXTR,DGN8422, 1

T0131 BP96-00302B ASSY COVER P-BACK TOP;56L5,HIPS V0,GRY,D 1

T0147 BP96-00303G ASSY COVER P-SIDE L;56L5,HIPS,HB,GRY,DGM 1

T0129 BP96-00305P ASSY ENGINE P-DLP PL46;46L5 DLP,PHILIPS 1

T0186 BP96-00432B ASSY COVER P-GRILLE HOLE;56L5,HIPS,HB,GR 1

CN269 BP96-00547C ASSY BOARD P-JACK;ROBOCOP_1,NTSC,AV+S.VH 1

M0018 BP97-00873A ASSY MICOM;L62B,29W800D,T-AT2MWWS-1001,0 1

Page 52

Block Diagram

Samsung Electronics 6-1

6. Block Diagram

6-1 Digital Block Diagram

S

O

U

U

T

o

g

S

o

a

u

e

(

)

PO

slo

t

o

d

(

s

m

igl

Page 53

Block Diagram

6-2 Samsung Electronics

6-2 DLP-Builtin Module

X226

MP

UNE

nnel

400

400

DN

LVD

MD_

ntr

MEMO

(1

B)

128

AUD

PCMCIA

Cable Card

POD Channel

(NT &AT SC& QAM)

TUNE

R

#2

TS_1_DATA[ 7:0]

CLK,VLD,SY

(NT )

TUNER SIGNAL

M_CVBS

S_CVBS

M_SIF

S_SIF

VIDEO-1

3D-Y

3D-C

VIDEO-2

SUB-V/Y

SUB-C

Componet-1

COMP1_Y

COMP1_Pb

COMP1_Pr

Componet-2

COMP2_Y

COMP2_Pb

COMP2_Pr

HDMIRx

RS-232

MICOM_Rx

MICOM_Tx

RS-232(Debug)

Rx

Tx

TMDS

COMP1 Y,Pb,Pr

COMP2 Y,Pb,

TMDS

Scramle TS UN Scramle TS

NC

TS_2_DATA[7:0]

CLK,VLD,SYNC

Pr

HDMI

Sii9993

HDMI Rx

M

CImax

U

X

Card I/F

M

U

X

3D- Y/C

SUB- Y/C

VBS

S_C

COMP1 Y,Pb,Pr

COMP2 Y,Pb,

BA7657

7657

COM P

Y,Pb,

S/ W

M

U

X

M

U

X

M

U

X

M

U

X

Pr

Pr

3D- Y/C

SUB- Y/C

S_CVBS

7657 Y,Pb,

PC R,G,B,

HSYNC,VSYNC

I2C_M

SDA_M5

SCL_M5

Pr

TS_A_DATA[ 7:0]

CLK,VLD,SYNC

TS_B_DATA[ 7:0]

CLK,VLD,SYNC

ADV7400

#2

(NT & ADC)

ADV7400

#1

(NT & ADC)

I2C

SDA_PANNEL

NNEL

SCL_PA

MUX

656[7 :0] ,CLK

LK

656[7 :0] ,C

or

24bit[ 7:0],CLK ,

c

HSync,Vsyn

DE

HDMI_I2S_CLK,

CLK

DATA,LR

AUDIO

I2S_CLK,DATA,LRCLK

NT_I2S_CLK,

DATA,LRCLK

TS #A

TS #B

&

Ext

VIDEO

IN #A

Ext

VIDEO

IN #B

FLFLASH

(16MB)

28F128

(CPCPU

MP

Ext

AUDI

IN

MUX

K4D551638Dx2

X226

B

&

EG.G.decode r

&

Video Scaler

&

OSD )

RS- 232 A

O

RS- 232 B

NT_I2S_CLK ,

DATA,L RCLK

RARAM

MB)

(128

Digital

AUDIO

AC 3/PCM

OUT

MICOM_Rx, Tx

OUT

OUT

12bit

[11:0]

CLK 0

Rx,Tx

CONTROL

CPU_RESET

12bit[24:12]

H,VSYN C,CL K 1

D-Flip

-Flo p

AC 3/PCM

OUT

MEMO

K4S643232 x

DN

Enhanc

12bit

[11:0]

I2S_CL K,DATA

LRC LK

6MB)

(1

Ie Pro

Image

OPT ICAL

I2C_5V

RY

2

24bit

[23:0]

H,VSYNC ,

er

CLK

/RCA

LVD

S &

Contr

MD_

TX[3:0]+DLP_SYNCVAL

MD_nRESET

DDP_READY

PWRGOOD

LVDS_EN

LAMP+Txn,Rx

SDA,SCLPANNEL

AUD

SPDIF

SDA_M5

SCL_M5

ol

IO

THC 63LVDH63

LVDS Tx

Page 54

Block Diagram

Samsung Electronics 6-3

6-3 Analog Block Diagram

278

RA0

278

RA0

317SX-ADAD

(1

2VB

DCDC

(12

.3

VB-D)

317SX-ADAD

(12

Si

2.0mm

2.0mm

30p,#2

6

7p,#26

2.0mm

4p,#26

2.0mm

6p,#

190mm

26

2.0mm

3p,#

2.0mm

26

30p,#2

6

2.5mm

p,#26

30

2

3

0

m

m

2.0mm

5p,#

26

U

p

g

r

a

d

e

KA78RH33

(5V→3.3V)

LF25C

(5V→2.5V)

LM317SX-

(1

2VB

→ 9VBVB)

Regulator

LF25

D-to-A (2R)

(AV Signals

KEY

for L7

)

KEY

Micom

Block

Micom/EPG Slicer

DA555X)

(S

J

Video Switching(Y/C, Adder)

3D Comb

Block

& LED

LM317SX-

(12

PWR

VA- >9VAVA)

I/O Expander

(PCF8574)

de AV

Si

Regulator

78D05F

IR

J

D-to-A (2R) D-to-A (2R)

(Control Sign

DCDC

(12

VB- >3.3

VB-D)

als)

DCDC

(12VA->6.5VA-D)

Speaker

Sound Amp Block

ReRegugulator

(278

RA0

5)

ReRegugulator

(278

RA0

MSP4440

Audio Processing

(Power)

DCDC

12VA->3.3V-ATI

5)

(

S

P

T

B

)

(

B

+

)

DMD

PWR

D

E

U

T

°

B

W

R

P

O

W

E

R

S

2.5mm

10

p,#22

2.5mm

24

p,#22

2.0mm

9p,#

2.0mm

10p,#26

26

)

Regulator

BA033

2.0mm

3p,#26

Video Switching(CVBS)

Analog Board

(Built-In)

Audio Switching

I/O Expander

(PCF8574)

(SVHS1/SVHS2)

FAN

AV INPUT/OUTPUT

(V1/V2/V out)

Component1/2

Page 55

Block Diagram

6-4 Samsung Electronics

6-4 RF SWITCH POD LNA BLOCK

6-5 AV Switching(TEA64XX) BLOCK

TEA64

Y/C

TEA64

Video

3D-COMB

TEA64

Mixer

TEA64

Audio

MSP44X

B+(9V)

LNA

S/

W#1

GND

S/W#2

AIR

CABLE LOOP OUT

LNA

SPLIT

RELAY#1

RELAY#2

MAIN SUB

CABLE

BS S/W OFF

LOOP

AMP

SPLIT

SVHS1-Y

SVHS1-C

SVHS2-Y

SVHS2-C

3D-Y

3D-C

MTNR-V

STNR-V

V1-V

V2-V

N.C

SIDE-V

V1-LR

V2-LR

N.C

SIDE-LR

COMP1- LR

COMP2- LR

TEA64

(ADDER

Tri-State)

(96h)

Y/C

TEA64

(ADDER

Tri-State)

(90h)

Video

TEA64

(98h)

Audio

25

SW

25

SW

22

SW

MAIN-V- OUT

SUB

CAP-V-OUT

MON-V-OUT

MAIN-Y- OUT

MAIN-C-OUT

SUB-Y-OUT

SUB-C-OUT

-V-OUT

MAIN-LR

SUB- LR

PC

DVI-LR

3D-C

3D-Y

3D-COMB

-LR

SIDE-Y

SIDE-C

MSP44X

MAIN-Y

MAIN-C

TEA64

(ADDER

Tri-State)

(94h)

Mixer

25

SW

+

+

SUB- V(MIXED)

CAP-V(Y) CAP-Y-OUT

MONOUT-V MON-Y-OUT

MONITOR-LR

X

Page 56

7. Schematic Diagrams

Samsung Electronics

Schematic Diagrams

7-1

7-1 Analog

This Document can not be used without Samsung's authorization.

7-1-1 PowerSignal

C681

4.7uF

50V

Power Signal

from SMPS Board

CN267

SMW250-24V

1

3

56

78

9

11 12

13 14

15

17 18

19

21 22

23 24

2

4

10

16

20

R949 R950

13Kohm

1/10W

13Kohm

1/10W

Regulator

for Audio Amp-Left

Regulator

for Audio Amp-Right

CN259

1

2

3

4

5

6

7

8

9

To DMD Board Assy (B+ Power)

CN270

1

2

3

4

5

6

7

8

9

10

Power Signal from SMPS Board

(only for USA)

FAN-SW

FAN-SW..

High : Output enabled

Low : Output disabled

CN268

VOUT

3

2

VOUTVIN

ADJ

1

R760

845ohm

1/10W

R762

5.1Kohm

1/10W

Thermal Resistance (10 X 10)

IC158

MIC39102BM

1

2

3

4

EN

IN

OUT

ADJ5GND

8

GND

7

GND

6

GND

VOUT

3

2

VOUTVIN

ADJ

1

R808

845ohm

1/10W

R809

5.1Kohm

1/10W

IC154

KIA78D05F

1

3

I

O

G

2

IN-30-BR200

1

34

56

7

11 12

13

15 16

17 18

19

21 22

23 24

25 26

27

2

10

14

20

28

Angle and EMI Shielding Type

(3711-005567)

To Digital Board Assy (Power Signal)

R921

1.2Kohm

1/10W

CableCard Fan Power Control

If a CableCard inserted, IC158 is enabled

to drive the Fan and cool a CableCard

Power Check Indicator LED

Page 57

Schematic Diagrams

7-2 Samsung Electronics

This Document can not be used without Samsung’s authorization.

7-1-2 DCDC

USA

KOR

BD156 BD184

O

X

X

O

IC139

1

2

3

4

MP1583DN

BS

IN

SW

GND5FB

8

SS

7

EN

6

COMP

DCDC Converter for Power of ATI-CPU

USA : STD power

KOR : B+ power

R1122

3Kohm

1/10W

IC140

1

2

3

4

MP1583DN

BS

IN

SW

GND

8

SS

7

EN

6

COMP

5

FB

DCDC Converter for Power of ATI-CPU

USA/KOR Common B+ power

R803

47Kohm

1/10W

IC142

MP1583DN

1

BS

2

IN

3

SW

4

GND5FB

COMP

8

SS

7

EN

6

R807

1.5K

1/16W

DCDC Converter for Power of Channel Board

Only for USA

Page 58

Samsung Electronics

Schematic Diagrams

7-3

This Document can not be used without Samsung’s authorization.

7-1-3 AV_Input

S1-DET

L1

S1-DET

V1-DET

S1-C

S1-Y

V1-IN(EXT2-V(Y))

N.C.(EXT2-VOUT)

N.C.(EXT2-RED(C))

V1-DET

S1-C

S1-Y

V1

MON-ROUT

R1

S2-DET

L2

COMP1-R

COMP2-R

N.C.(EXT2-LOUT)

V1-LIN(EXT2-LIN)

S2-DET

N.C.(EXT3-LOUT)

V2-LIN(EXT3-LIN)

N.C.(EXT3-FB)

MON-ROUT(AUDIO-ROUT)

COMP1-R

COMP2-R

N.C.(EXT2-ROUT)

V1-RIN(EXT2-RIN)

N.C.(EXT2-DET)

V2-DET

S2-C

S2-Y

V2-IN(EXT3-V(Y))

N.C.(EXT3-VOUT)

N.C.(EXT3-RED(C))

N.C.(EXT3-GRN)

N.C.(EXT3-BLU)

N.C.(EXT3-ROUT)

V2-RIN(EXT3-RIN)

N.C.(EXT3-DET)

MON-LOUT(AUDIO-LOUT)

MON-VOUT

COMP1-Y

COMP1-Pb

COMP1-Pr

COMP1-DET

COMP1-L

COMP2-Y

COMP2-Pb

COMP2-Pr

COMP2-DET

COMP2-L

V2-DET

S2-C

S2-Y

V2

R2

MON-LOUT

MON-VOUT

COMP1-Y-IN

COMP1-Pb-IN

COMP1-Pr-IN

COMP1-DET

COMP1-L

CN223

1

2

3

4

5

6

7

8

9

10

11

From Side AV Board Assy

CN269 is a new Item and the Code Number is...

BP96-00547B, full Jack including "PC-L/R"

BP96-00547C, changed Jack removing "PC-L/R"

COMP2-Y-IN

COMP2-Pb-IN

COMP2-Pr-IN

COMP2-DET

COMP2-L

Page 59

Schematic Diagrams

7-4 Samsung Electronics

This Document can not be used without Samsung’s authorization.

7-1-4 AV_Switching

IC159

BA178M08FP

1

I

O

G

2

3

8V-6425

8V-6425

SDA-A

SCL-A

S1-Y

S1-C

S2-Y

S2-C

COMB-Y-OUT

COMB-C-OUT

100R1065

100R1070

100

R1064

R1071

100

100R1066

100R1067

R1068

100

R1069

100

8V-6425

C697

C702 10uF

C699

C700

C701

10uF

16V

16V

10uFC698

16V

10uF

16V

10uF

16V

10uF

16V

R1036

10

C766

100nF

25V

1K

1

3

4

5

6

7

8

9

Y/C Switching-1st

IC148

TEA6425D

IN1

SDA

IN2

SCL

IN3

IN4

SUB

IN5

VCCP

IN6 GND

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT8

20

VCC

192

18

17

16

15

14

13

12

11

C767

100nF

25V

R1056

4.7K

4.7K

8V-6425

R1058R1057

4.7K

R994

R992 0

R991

R1059

4.7K

SDA-A

SCL-A

0

0R993

0

SIDE-Y

SIDE-C

MAIN-Y-OUT

MAIN-COUT

SUB-YOUT

SUB-COUT

R975

75

R1080

R1079 100

C712 10uF

C708

C709

100

R1077

R1078 100

R976

75

100

16V

10uFC713

16V

10uF

16V

10uF

16V

C710 10uF

C711

Y/C Switching-2nd

IC147

TEA6425D

16V

10uF

16V

1

2

3

4

5

6

7

8

9

10 11

C770

100nF

25V

IN1

IN2

SCL

IN3

IN4

SUB

IN5

VCCP

IN6

OUT1SDA

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT8

VCC

GND

9VB

MAIN-V-OUT

SUB-V-OUT

C771

100nF

25V

20

19

18

17

16

15

14

13

12

SUB-Y-OUT

SUB-C-OUT

MAIN-Y-OUT

MAIN-C-OUT

SUB-Y-V

SUB-C

MAIN-Y

MAIN-C

CAP-Y-OUT

MON-MIXED-V-OUT

MTNR-CVBS

STNR-CVBS

DTV-CVBS

R1154

150ohm

1/10W

R1156

150ohm

1/10W

R1155

150ohm

1/10W

R1158

150ohm

1/10W

R1157

150ohm

1/10W

R1159

150ohm

1/10W

SDA-A

SCL-A

SIDE-V

3.3uH

L187

1

2

3

4

5

6

7

8

9

10

11

12

13

14

C774

1nF

50V

MO

IC149

TEA6422D

SDA

GND

SCL

CAP

VS

ADDR

L1

L2

L3

NC

NC

L4

L5

L6

LOUT1

ROUT3

LOUT3

RPUT1

LOUT2 ROUT2

SWITCHING

28

27

26

25

R1

24

R2

23

R3

22

NC

21

NC

20

R4

19

R5

18

R6

17

16

15

100R1076

100R1075

IC146

C707 10uF

16V

C706 10uF

16V

100R1072

V1

V2

R1073 100

C703 10uF

16V

10uF

C704 C720

16V

R1074 100

R974

75

C705

10uF

16V

1

IN1

SDA

3

IN2

4

SCL

5

IN3

6

IN4

7

SUB

8

IN5

9

VCCP

10

IN6 GND

C768

100nF

25V

TEA6425D

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT8

20

VCC

192

18

17

16

15

14

13

12

11

CVBS Switching

C769

100nF

25V

R998 0

R9951K0

MAIN-V-OUT

SUB-V-OUT

CAP-V-OUT

MON-V-OUT

L1 R1

R1038

L2

DTV-L

SIDE-L

COMP1-L

COMP2-L

R1039 1K

R1041 1K

C684

100uF

25V

1KR1037

C714 10uF

1K

C716 10uF

1KR1040

C717

C718 10uF

C772

100nF

25V

16V

10uFC715

16V

16V

10uF

16V

16V

R997

D289

RLZ12B

0

AUDIO

100

R1081

R1082 100

C719

C721

C722

C723

0R996

10uF

16V

10uF

16V

10uF

16V

10uF

16V

10uF

16V

R1042

R1046

SDA-A

SCL-A

1K

1KR1043

1KR1044

1KR1045

R2

DTV-R

SIDE-R

COMP1-R

COMP2-R

SUB-RSUB-L

MAIN-L

MAIN-R

Page 60

Samsung Electronics

Schematic Diagrams

7-5

This Document can not be used without Samsung’s authorization.

7-1-5 AV_Comp_Buffer

L188

3.3uH

MON-MIXED-V-OUT

MON-V-OUT

MON-VOUT

CAP-Y-OUT

CAP-V-OUT

CAP-CVBS

Page 61

7-1-6 3D_Comb

Schematic Diagrams

7-6 Samsung Electronics

This Document can not be used without Samsung’s authorization.

6

M_IN OUT

5

NC

4

NC

3

M_OUT

2

IN

NC1GND

MGND1MGND2

GND

GND

7

8

9

10

IC128

UPD64083GF-3BA

3D-Comb

IC122

LF25CDT

1

3

I

O

G

2

NC1GND

IN

2

M_OUT

3

NC

4

NC

5

M_IN7OUT

6

MGND1 MGND2

GND

GND

10

1

O3I

9

C795

47uF

16V

8

G

2

Page 62

Samsung Electronics

Schematic Diagrams

7-7

7-1-7 Sound_Processor & Amp

This Document can not be used without Samsung’s authorization.

D295

1N4148WS

D294

1N4148WS

1N4148WS

D293

IC160

KIA7042AF-RTF

1

IC150

74LCX125MX

1

2

3

4

ATI-I2S-DATA

5

6

7

ATI-I2S-WS

ATI-I2S-CLK

GND

3

IN

OUT

GND

2

/OE1

D1

O1

/OE2

D2

O2

GND

VCC

/OE4

/OE3

14

13

12

D4

11

O4

10

9

D3

8

O3

Don't stuff

when JBL-EQ is NOT used

JBL-EQ Module

IC124

Use 1204-002179, MSP4440G

Sound Processor

C396

220uF

35V

C436

470nF

63V

C437

470nF

63V

C813

680nF

63V

IC127

BA178M08FP

3

1

I

O

G

2

CN228's right side pin is No.1

left side pin is No.4

C397

220uF

35V

C438

470nF

63V

C439

470nF

63V

C812

680nF

63V

4

3

2

1

(8 Ohm speaker)

To Sound Delay Module

[Use BN95-00368A]

Page 63

Samsung Electronics

Schematic Diagrams

7-8

This Document can not be used without Samsung’s authorization.

7-1-8 M1_PCF8574_UART

IC137

LF25CDT

1

3

O

I

G

2

I/O Expander

for Jack ID

IC133

AT24C16AN-10SI-2.7

1

VCC

NC

2

NC