Page 1

TFT-LCD MONITOR

GH17LS

GH17ES

SERVICE

Manual

TFT-LCD MONITOR CONTENTS

1. Precautions

2. Product Specifications

3. Disassembly & Reassembly

4. Alignments & Adjustments

5. Troubleshooting

6. Exploded View & Parts List

7. Electrical Parts List

8. Block Diagram

9. Wiring Diagram

10. Schematic Diagrams

11. Panel Description

Page 2

Samsung Electronics Co.,Ltd.

416, Maetan-3Dong, Paldal-Gu, Suwon City, Kyungki-Do, Korea.

Printed in Korea

P/N : BN68-00225C-00

http://www.samsungmonitor.com (SyncMaster Worldwide)

http://www.samsung-monitor.com (SyncMaster USA)

http://www.sec.co.kr/monitor (Korea)

Page 3

Copyright

Trademarks

© 2001 by Samsung Electronics Co., Ltd.

All rights reserved.

This manual may not, in whole or in part, be

copied, photocopied, reproduced, translated, or

converted to any electronic or machine readable

form without prior written permission of

Samsung Electronics Co., Ltd.

GH17LS/GH17ES Service Manual

First edition July 2001.

Printed in Korea.

ii GH17LS/GH17ES

Samsung is the registered trademark of Samsung

Electronics Co., Ltd.

GH17LS/GH17ES and MacMaster Cable Adapter

are trademarks of Samsung Electronics Co., Ltd.

Macintosh, Centris, Quadra, Duo Douk, and

Power Macintosh are trademarks of Apple

Computer, Inc.

All other trademarks are the property of their

respective owners.

Page 4

1 Precautions

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

(READING SHOULD

NOT BE ABOVE 0.5mA)

LEAKAGE

CURRENT

TESTER

2-WIRE CORD

*ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

!

Follow these safety, servicing and ESD precautions to prevent damage and to protect against potential hazards such as

electrical shock.

1-1 Safety Precautions

1-1-1 Warnings

1. For continued safety, do not attempt to modify the

circuit board.

2. Disconnect the AC power and DC power jack

before servicing.

1-1-2 Servicing the LCD Monitor

1. When servicing the LCD Monitor, Disconnect the

AC line cord from the AC outlet.

2. It is essential that service technicians have an

accurate voltage meter available at all times. Check

the calibration of this meter periodically.

1-1-3 Fire and Shock Hazard

Before returning the monitor to the user, perform the

following safety checks:

1. Inspect each lead dress to make certain that the

leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in

the monitor.

2. Inspect all protective devices such as nonmetallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

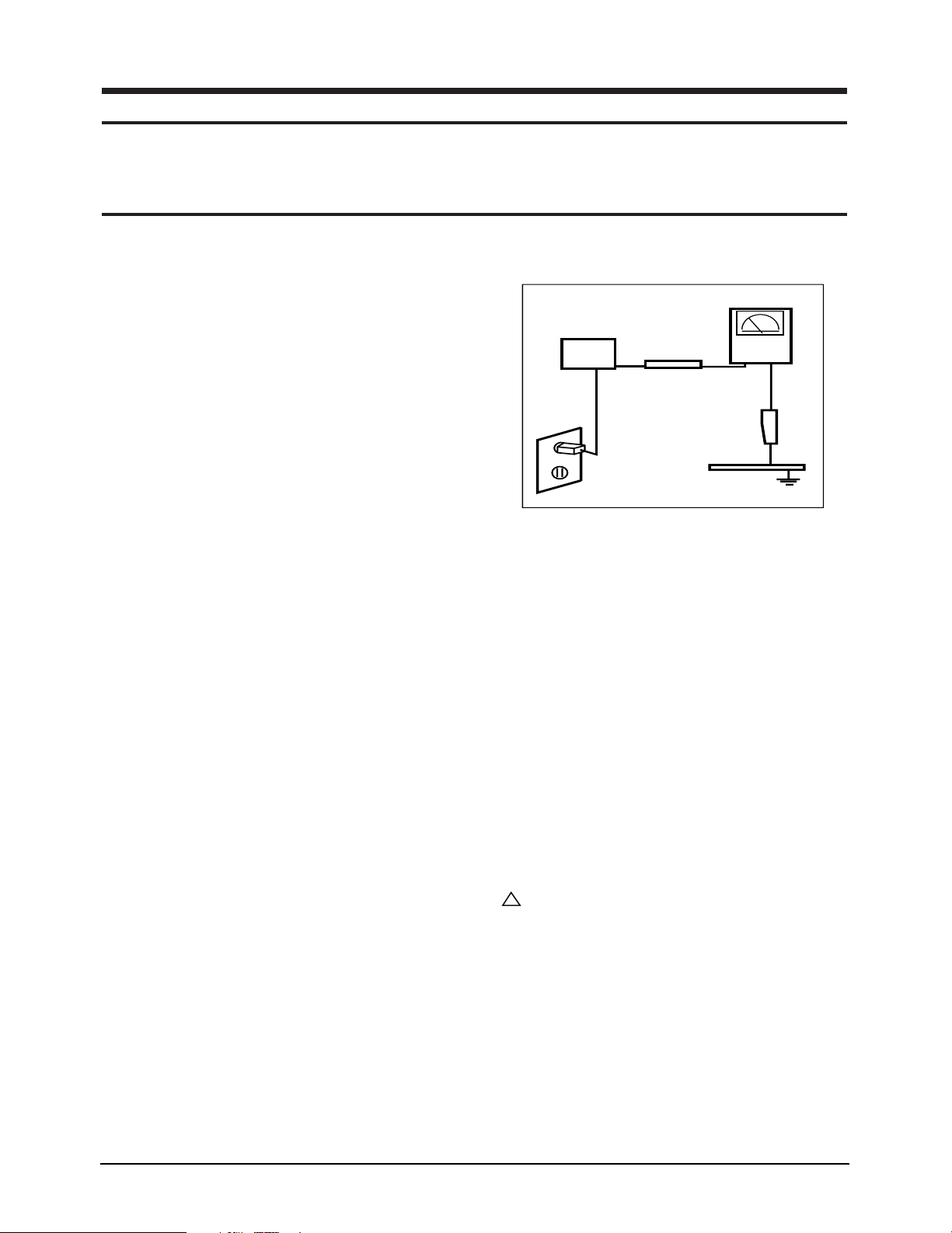

3. Leakage Current Hot Check (Figure 1-1):

WARNING:

Do not use an isolation transformer during this test.

Use a leakage current tester or a metering system

that complies with American National Standards

Institute (ANSI C101.1, Leakage Current for

Appliances), and Underwriters Laboratories (UL

Publication UL1410, 59.7).

Figure 1-1. Leakage Current Test Circuit

4. With the unit completely reassembled, plug the AC

line cord directly into a 120V AC outlet. With the

unit’s AC switch first in the ON position and then

OFF, measure the current between a known earth

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including: metal cabinets,

screwheads and control shafts. The current

measured should not exceed 0.5 milliamp. Reverse

the power-plug prongs in the AC outlet and repeat

the test.

1-1-4 Product Safety Notices

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection. The protection they give

may not be obtained by replacing them with

components rated for higher voltage, wattage, etc. Parts

that have special safety characteristics are identified by

on schematics and parts lists. A substitute

replacement that does not have the same safety

characteristics as the recommended replacement part

might create shock, fire and / or other hazards. Product

safety is under review continuously and new

instructions are issued whenever appropriate.

GH17LS/GH17ES 1-1

Page 5

1 Precautions

1-2 Servicing Precautions

WARNING: An electrolytic capacitor installed with the wrong polarity might explode.

Caution: Before servicing units covered by this service manual, read and follow the Safety Precautions

section of this manual.

Note: If unforeseen circumstances create conflict between the following servicing precautions and any of the

safety precautions, always follow the safety precautions.

1-2-1 General Servicing Precautions

1. Always unplug the unit’s AC power cord from the

AC power source and disconnect the DC Power

Jack before attempting to:

(a) remove or reinstall any component or assembly,

(b) disconnect PCB plugs or connectors, (c) connect

a test component in parallel with an electrolytic

capacitor.

2. Some components are raised above the printed

circuit board for safety. An insulation tube or tape

is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

3. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the area around the

serviced part has not been damaged.

4. Check the insulation between the blades of the AC

plug and accessible conductive parts (examples:

metal panels, input terminals and earphone jacks).

5. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the power

switch ON. Connect an insulation resistance meter

(500 V) to the blades of the AC plug.

The insulation resistance between each blade of the

AC plug and accessible conductive parts (see

above) should be greater than 1 megohm.

6. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrument’s

ground lead last.

1-3 Electrostatically Sensitive Devices (ESD) Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated circuits and some fieldeffect transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known earth

ground. Alternatively, wear a discharging wriststrap device. To avoid a shock hazard, be sure to

remove the wrist strap before applying power to

the monitor.

2. After removing an ESD-equipped assembly, place it

on a conductive surface such as aluminum foil to

prevent accumulation of an electrostatic charge.

3. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESDs.

4. Use only a grounded-tip soldering iron to solder or

desolder ESDs.

5. Use only an anti-static solder removal device. Some

solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage

ESDs.

6. Do not remove a replacement ESD from its

protective package until you are ready to install it.

Most replacement ESDs are packaged with leads

that are electrically shorted together by conductive

foam, aluminum foil or other conductive materials.

7. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

Caution: Be sure no power is applied to the

chassis or circuit and observe all

other safety precautions.

8. Minimize body motions when handling

unpackaged replacement ESDs. Motions such as

brushing clothes together, or lifting your foot from

a carpeted floor can generate enough static

electricity to damage an ESD.

1-2 GH17LS/GH17ES

Page 6

2 Product Specifications

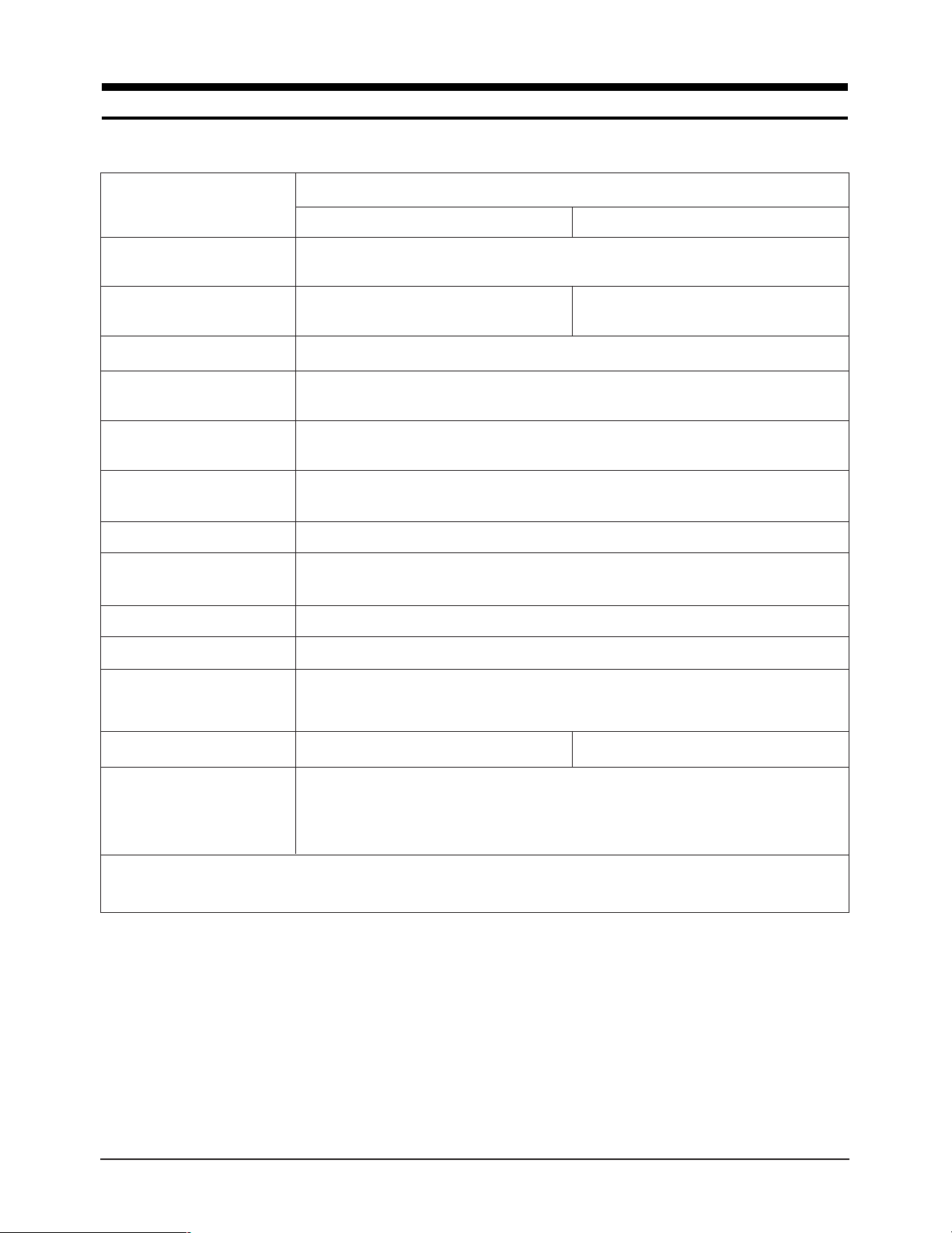

2-1 Specifications

Description

Item

LCD Panel TFT-LCD panel, RGB vertical stripe, normally black transmissive,

17-Inch viewable, 0.264 (H) x 0.264 (V) mm pixel pitch

Scanning Frequency Horizontal : 30 kHz ~ 81 kHz (Automatic)

Vertical : 56 Hz ~ 85 Hz (~XGA), 76 Hz (SXGA); GH17ES

Display Colors 16,7 Million colors

Maximum Resolution Horizontal : 1280 Pixels

Vertical : 1024 Pixels

Input Video Signal Analog, 0.714 Vp-p ± 5% positive at 75 Ω,

internally terminated

Input Sync Signal Type : Seperate H/V sync, Composite H/V, Sync-on-Green

Level : TTL level (V high ≥ 2.0 V, V low ≤ 0.8 V), Sync-on-Green (≤ –0.25 V)

Maximum Pixel Clock rate 135 MHz

GH17LS

Vertical : 56 Hz ~ 76 Hz; GH17LS

GH17ES

Active Display

Horizontal/Vertical 338 ± 3 mm/270 ± 3 mm

AC power voltage & Frequency AC 90 ~ 264 Volts, 60/50 Hz ± 3 Hz

Power Consumption 42 W (max), 40W (normal)

Dimensions

Unit (W x D x H) 17.5 x 18.0 x 8.2 Inches (444 x 457 x 208.4 mm)

Carton (W x D x H) 20.7 x 10.7 x 20.9 Inches (527 x 271 x 532 mm)

Weight (Net/Gross)

Environmental Considerations Operating Temperature : 50°F ~ 104°F (10°C ~ 35°C)

• GH17LS/GH17ES comply with SWEDAC (MPRII) recommendations for reduced electromagnetic fields.

• Designs and specifications are subject to change without prior notice.

5.4 kg (11.9 lbs) / 7.9 kg (17.4 lbs)

Humidity : 10 % ~ 80 %

Storage Temperature : -68°F ~ 113°F (-20°C ~ 45°C)

Humidity : 5 % ~ 95 %

5.8 kg (12.8 lbs) / 8.3 kg (18.3 lbs)

GH17LS/GH17ES 2-1

Page 7

2 Product Specifications

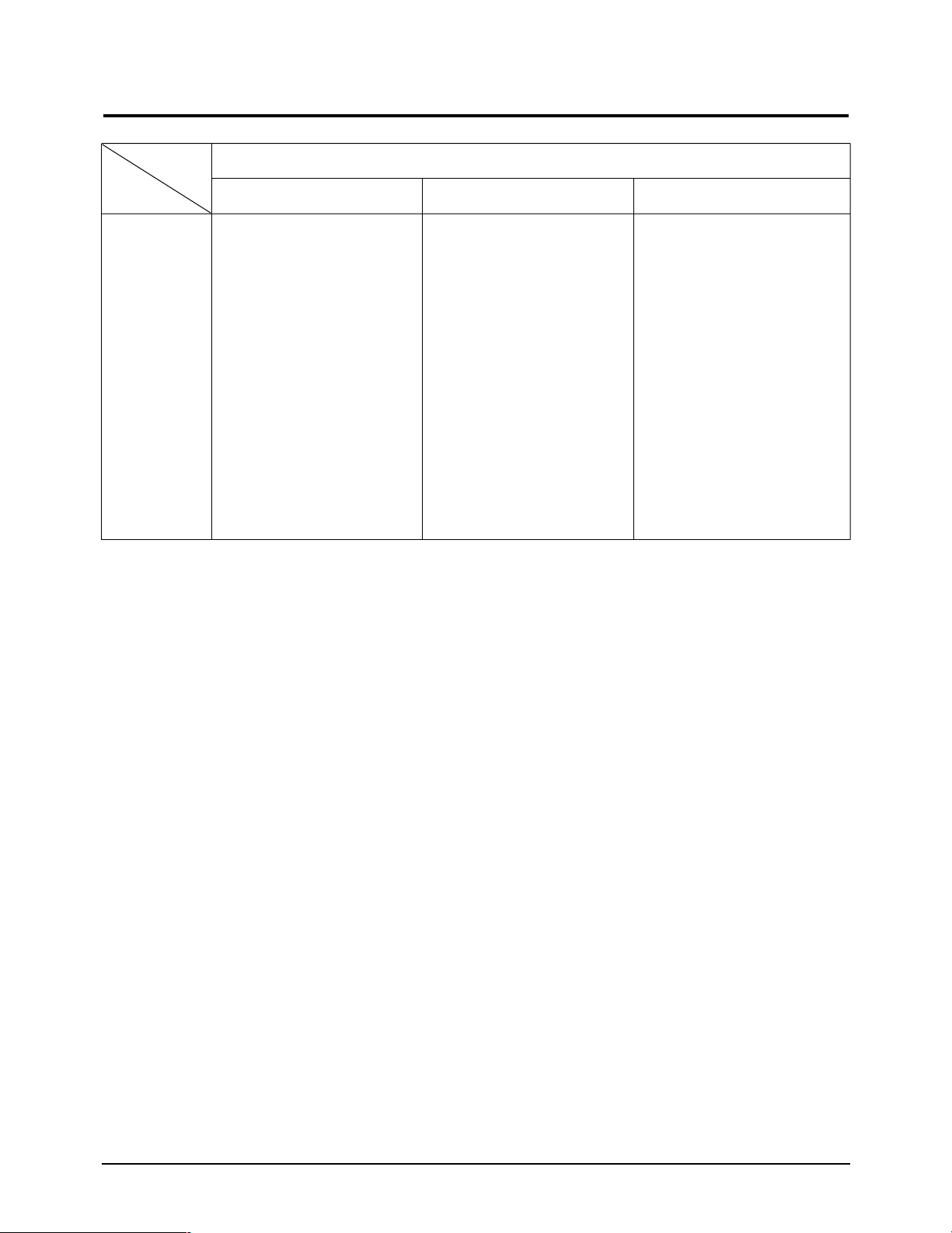

2-2 Pin Assignments

Pin No.

10

11

12

13

14

15

Sync

Type

Separate Composite

1

2

3

4

5

6

7

8

9

Red

Green

Blue

GND

DDC Return (GND)

GND-R

GND-G

GND-B

DDC Power Input (+5V)

Self Raster

GND

Bi-Dr Data (SDA)

H-Sync.

V-Sync.

DDC Clock (SCL)

15-Pin D-Sub Signal Cable Connector

Red

Green

Blue

GND

DDC Return (GND)

GND-R

GND-G

GND-B

DDC Power Input (+5V)

Self Raster

GND

Bi-Dr Data (SDA)

H/V-Sync.

Not Used

DDC Clock (SCL)

Sync-on-green

Red

Green + H/V Sync.

Blue

GND

DDC Return (GND)

GND-R

GND-G

GND-B

DDC Power Input (+5V)

Self Raster

GND

Bi-Dr Data (SDA)

Not Used

Not Used

DDC Clock (SCL)

2-2 GH17LS/GH17ES

Page 8

2 Product Specifications

QRS

P

O

Video

Sync

Sync

Horizontal

Vertical

CDE

P

O

B

A

Video

Sync

Sync

VIDEO

A

B

O

P

Q

R

S

Horizontal

Vertical

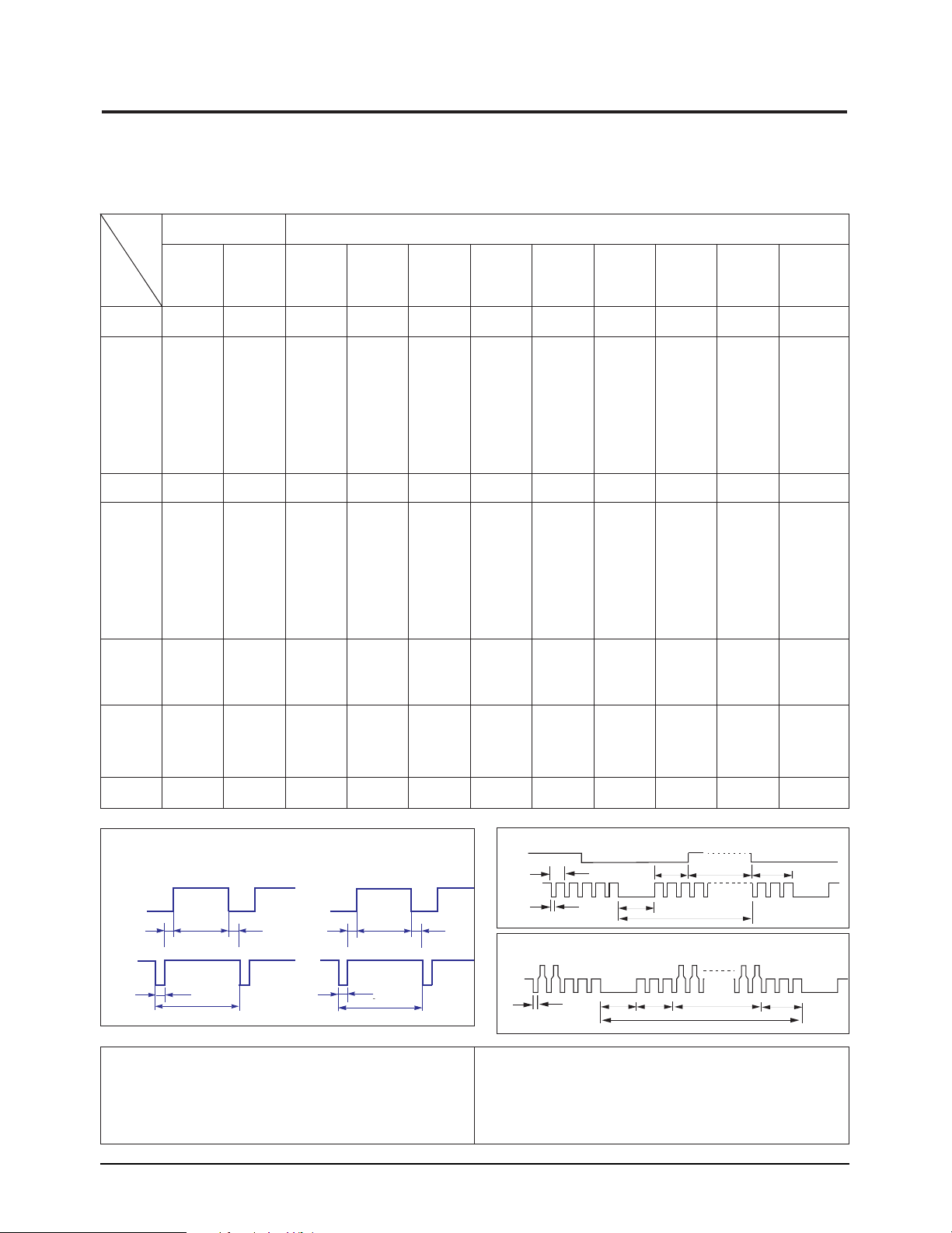

2-3 Timing Chart

This section of the service manual describes the timing that the computer industry recognizes as standard

for computer-generated video signals.

Table 2-1. Timing Chart

Mode

Timing

fH (kHz)

A µsec

B µsec

C µsec

D µsec

E µsec

fV (Hz)

O msec

P msec

Q msec

R msec

S msec

Clock

Freq.

(MHz)

VGA2/

70 Hz

720 x 400

31.469

31.777

3.813

1.589

26.058

0.318

70.087

14.268

0.064

0.858

13.155

0.191

28.322

IBM

640 x 480

VGA3/

60 Hz

31.469

31.778

3.813

1.589

26.058

0.318

59.940

16.683

0.064

0.794

15.761

0.064

25.175

640/75 Hz

640 x 480

37.500

26.667

2.032

3.810

20.317

0.508

75.000

13.333

0.080

0.427

12.800

0.027

31.500

640/85 Hz

640 x 480

43.269

23.111

1.556

2.222

17.778

1.556

85.008

11.764

0.671

0.578

11.093

0.023

49.500

800/75 Hz

800 x 600

46.875

21.333

1.616

3.232

16.162

0.323

75.000

13.333

0.064

0.448

12.800

0.021

49.500

800/85 Hz

800 x 600

53.674

18.631

1.138

2.702

14.222

0.569

85.061

11.756

0.056

0.503

11.179

0.019

56.250

VESA

1024/60Hz

1024 x 768

48.363

20.677

2.092

2.462

15.754

0.369

60.004

16.666

0.124

0.600

15.880

0.062

75.000

1024/75Hz

1024 x 768

60.023

16.660

1.219

2.235

13.003

0.203

75.029

13.328

0.050

0.466

12.795

0.017

78.750

1024/85Hz

1024x768

68.677

14.561

1.016

2.201

10.836

0.508

84.997

11.765

0.044

0.524

11.183

0.015

94.500

1280/76Hz

1280x1024

(Analog Only) (Analog Only)

81.129

16.640

6.400

2.880

1280/75Hz

1280x1024

79.976

12.504

1.067

1.837

9.481

3.200

76.106

10.660

0.080

3.200

0.119

75.025

13.329

0.038

0.475

12.804

0.020

135.000

0.013

135.000

Polarity

H.Sync

V.Sync

Remark

A : Line time total B : Horizontal sync width O : Frame time total P : Vertical sync width

C : Back porch D : Active time Q : Back porch R : Active time

E : Front porch S : Front porch

GH17LS/GH17ES 2-3

Sync

Negative

Positive

Separate

Video

C D

Negative

Negative

Separate

Separate Sync

E

Negative

Negative

Separate

Negative

Negative

Separate

Video

Q R S

Positive

Positive

Separate

Positive

Positive

Separate

Negative

Negative

Separate

Positive

Positive

Separate

Positive

Positive

Separate

H/V Composite Sync

Negative

Negative

Com.

Positive

Positive

Separate

Sync-on-Green

Sync

B

A

P

O

Green

Horizontal

Vertical

P

B

Q

R

O

S

Page 9

2 Product Specifications

Memo

2-4 GH17LS/GH17ES

Page 10

3 Disassembly and Reassembly

This section of the service manual describes the disassembly and reassembly procedures for the

GH17LS/GH17ES TFT-LCD monitors.

WARNING: This monitor contains electrostatically sensitive devices. Use caution when handling

these components.

3-1 Disassembly

Cautions:1. Disconnect the monitor from the power source before disassembly.

2. Follow these directions carefully; never use metal instruments to pry apart the cabinet.

3-1-1 Removing the Stand

1. With a pad beneath it, stand the monitor on its

front with the screen facing downward and

the base close to you. Make sure nothing will

damage the screen.

2. Remove the 4 screws on the Stand.

Caution: Be careful. The signal cable and

power cable are still attached to the

monitor.

3. Disconnect the Signal Cable and Power Cord.

3-1-2 Main Body Disassembly

1. Remove 2 screws on the Rear Cover.

2. Pull the Rear Cover up and off the monitor.

3. Remove 7 screws on the PCB Shield.

4. Disconnect the Function PCB wire (10P)

between the Function PCB and the CN103

connector on the Main PCB.

5. Disconnect 4 Inverter wires between the Panel

and the CN2, 3, 4, 5 connectors on the Inverter

PCB.

6. Disconnect the interface wire (30P) between

the Panel and the CN102 connector on the

Main PCB.

7. Remove 3 screws on the Main PCB and 2

screws on the Inverter PCB and 2 screws on

the Power Adapter PCB.

8. Disconnect the 12P harness between CN1

connector on the inverter and CN104

connector on the Main PCB.

9. Carefully lift the Main PCB Assembly and

Inverter PCB and place them on a flat, level

surface that is protected from static electricity.

10. Remove 4 screws on the Bracket Guide.

(GH17LS only)

11. Remove 3 screws on the Function PCB from

the Front Cover and remove the Function PCB

and Function Knob.

GH17LS/GH17ES 3-1

Page 11

3 Disassembly and Reassembly

3-2 Reassembly

Reassembly procedures are in the reverse order of Disassembly procedures.

3-2 GH17LS/GH17ES

Page 12

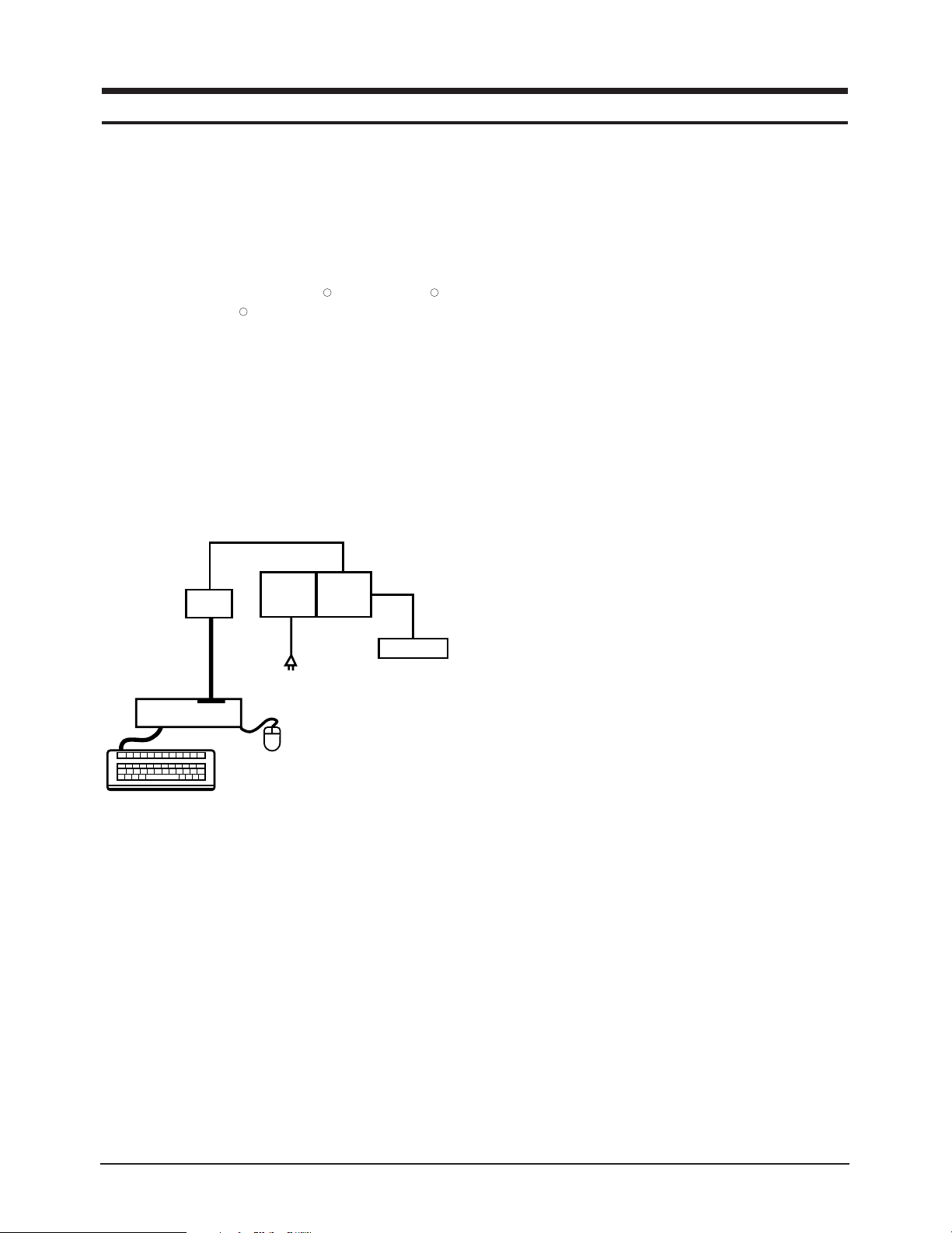

4 Alignments and Adjustments

PC

Serial cable

Function

Board

Power

cable

RS232

JIG

Power

AdapterADBoard

This section of the service manual explains how to use the RS232 JIG.

This function is needed when AD Board Change and program memory (IC110) change.

4-1 Required Equipment

The following equipment is necessary for

adjusting the monitor:

• Computer with Windows 95 , Windows 98 ,

or Windows NT .

R

R R

• RS232 JIG.

4-2 RS232 Jig Setup

1. Install Hyper Terminal program from

windows system.

2. Configure Baud rate to 19200, select

appropriate COM port.

3. Make the Hardware setup as per

figure shown.

4-3 Changing Board

Before replacing the AD Board, read all Panel

information data by using RS232 JIG and hyper

terminal.

1. Type character `B`.

Service Menu for Gogh 17 Model.

1. Read.

2. Modify upper Back Light Value.

3. Modify Lower back Light Value.

4. Modify Panel On Time Value.

5. Exit Service Menu

Enter 1

Upper Backlight Time Expired (in hours) : ***

Lower Backlight Time Expired (in hours) : ***

Panel On Time (in hours) : ***

Please note down these values. Than change to

new board. Execute the command `B`, read the

values. You will see these are set to default

values. Change the values to the recorded

values. Exit the service menu by `B` command.

Figure 4-1.

4. Establish the connection by selecting

“Connect” from hyper Terminal.

5. Power on the board, now you see messages in

the application window.

If no messages than check for 1, 2 and 3 again.

Message :

Gogh 17*** fw. copyright (c) 2000, 2001 Sage.

Date : ****. **. **.

Chip ID : b1.

Panel : Samsung 17 SXGA.

2. Color Auto Adjustment

After function `1`. Assemble the monitor.

And display 16-Gray pattern or black and white

mixed pattern. Then push “Exit”, “-” and “+”

key of function same time.

During normal execution of Auto Algorithm

the screen image may changed.

4-4 Program memory (IC110) change

Follow same method as changing Board (4-3).

GH17LS/GH17ES

4-1

Page 13

4 Alignments and Adjustments

Memo

4-2 GH17LS/GH17ES

Page 14

5 Troubleshooting

Notes: 1. Before troubleshooting, setup the PC’s display as below.

• Resolution: 1280 x 1024

• H-frequency: 64 kHz

• V-frequency: 60 Hz

2. If no picture appears, make sure the power cord is correctly connected.

3. If you push and hold the EXIT button for more than 5 seconds, the monitor automatically turns back

to the factory preset.

5-1-1 No Power

When Pin 6 of CN105 is 0V

does proper DC 12V, 5V

appear at Pin 1, 2 and 7 of

CN105 seperately?

Yes

Does proper DC 5 V appear at

Pin 3 of IC115?

Yes

Does proper DC 3.3 V appear at

Pin 3 of IC112?

Yes

Does proper DC 2.5 V appear at

Pin 2 of IC116 and IC117?

❇

No

No

No

No

Change power Adaptor.

Check IC115 and related circuit.

Check IC112 and related circuit.

Check IC116, IC117

and related circuit.

❇ 0V means power on state.

GH17LS/GH17ES 5-1

Page 15

5 Troubleshooting

5-1-2 No Power

When Pin 6 of CN105 is

❇❇

around 2V, does proper DC 8V,

3V appear at Pin 1 and 7 of

CN105 seperately?

No

Change power Adaptor.

Yes

Does proper DC 5 V appear at

Pin 3 of IC115?

Yes

Push Power button.

Does proper 0V at Pin 6 of

CN105?

Yes

Does proper DC 3.3 V appear at

Pin 3 of IC112?

Yes

Does proper DC 2.5 V appear at

Pin 2 of IC116, IC117?

No

No

No

No

Check IC115 and related circuit.

Check function PCB Assy

and related circuit.

Check IC112 and related circuit.

Check IC116, IC117

and related circuit.

❇❇ 2V means soft power off or DPMS state.

5-2 GH17LS/GH17ES

Page 16

5-2 No Video

Check signal cable connection and power.

5 Troubleshooting

Does the X101 and X201 oscillate properly?

1

2

Yes

There R, G, B input are at R103, R107 and R108?

Yes

There sync. and data output are

R260, R261, R211, R213, and RA201 ~ RA212?

6

3 4

5

Yes

There proper signal input are

Pin 66, 65, 64, and 11 of IC102?

5

3 4

6

Yes

Does the output signal appear at

R121 ~ R130 R132, R135, R136, and R138 ~ R144?

7

No

Replace that or

check related circuit.

No

Check input part.

No

Please check the power related

IC202 and output part.

No

Check IC102 and related circuit.

No

Check the LVDS_EN at

R118 is high or not.

Normal state is high.

Yes

There are DC 5V at Pin 1, 2 and 3 of CN102?

Yes

There are DC 12V, DC5V and DC 3.3V at

Pin 10, 11, 12 ; Pin 7 and Pin 4 of CN104?

No

No

Check the Power

and related circuit.

Please check the Inverter

and related circuit.

GH17LS/GH17ES 5-3

Page 17

5 Troubleshooting

WAVEFORMS

1

3

2

4

5

6

7

5-4 GH17LS/GH17ES

Page 18

GH17LS/GH17ES 6-1

6 Exploded View and Parts List

6-1 GH17LS

Page 19

6 Exploded View & Parts List

6-2 GH17LS/GH17ES

6-2 GH17ES

Page 20

7 Electrical Parts List

7-1 Main PCB Parts

Loc. No. Code No. Description Specification Remarks

CIS 0201-001223 ADHESIVE-TS HT-130S,RED,700+/- 50,- SNA

CIS 0202-001044 SOLDER-WIRE. S63S-W3.0,S63S,D3,63Sn/37Pb,- SNA

CIS 0202-001046 SOLDER-WIRE FLUX CF-110VH-2A,-,-,-,- SNA

CIS 0202-001162 SOLDER-CREAM RMA-20-21L,S63,-,SN63/PB36.6/AG0.4,FLUX9.5% SNA

CIS 0202-001172 SOLDER-WIRE FLUX RS-107,RS60,D1.2,SN60/PB40,- SNA

CIS 0204-001095 THINNER #4520,-,-,- SNA

CIS BN44-00054A ADAPTOR

CIS BN72-00209A SUPPORT-POWER GH15LS,ABS+PC,GR37,-,5V,-,-,- SNA

CIS BN75-00177A UNIT-SHIELD/DSUB GH17LS,-,SPTE T0.5,-,-,-,- SNA

CIS BN46-00008H MICOM-S/W,GOGH GH17LS,-,-,-,-,-,- SNA

CN101 3701-001219 CONNECTOR-DSUB 15P,3R,FEMALE,ANGLE,AUF

CN105 3711-004853 CONNECTOR-HEADER BOX,7P,1R,2MM,ANGLE,SN,WHT SNA

CN106 3711-000056 CONNECTOR-HEADER BOX,2P,1R,2.5mm,ANGLE,SN SNA

CN108 3711-001465 CONNECTOR-HEADER NOWALL,3P,1R,2.54mm,STRAIGHT,A SNA

IC110 1102-001097 IC-EPROM

BD101 3301-001145 CORE-FERRITE BEAD AB,4.5x1.6x1.6mm,-,- SNA

BD104 3301-001145 CORE-FERRITE BEAD AB,4.5x1.6x1.6mm,-,- SNA

BD105 3301-001145 CORE-FERRITE BEAD AB,4.5x1.6x1.6mm,-,- SNA

BD106 3301-001163 CORE-FERRITE BEAD AB,80ohm,2x1.25x1mm,300mA,TP,FERRITE,0.08ohm SNA

BD107 3301-001163 CORE-FERRITE BEAD AB,80ohm,2x1.25x1mm,300mA,TP,FERRITE,0.08ohm SNA

BD108 3301-001163 CORE-FERRITE BEAD AB,80ohm,2x1.25x1mm,300mA,TP,FERRITE,0.08ohm SNA

C101 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C102 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C103 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C104 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C105 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C106 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C107 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C111 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C112 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C113 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C114 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C115 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C116 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C117 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C118 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C121 2203-000257 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

C122 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C123 2203-000257 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

C124 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C125 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C126 2402-001042 C-AL,SMD 100uF,20%,16V,GP,TP,6.6x6.6x5.4mm

C127 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C128 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C129 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C130 2203-000257 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

C131 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C132 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

DPA34L,170S,100-240VAC,47-63HZ,12V/5V,2A/2A,-,34W,AC-DC,-10~+40C,-,-

27C010,128KX8BIT,PLCC,32P,-,90NS,5V,10%,PLASTIC,0TO+70C,0.1MA,CMOS,TR

GH17LS/GH17ES 7-1

Page 21

7 Electrical Parts List

Loc. No. Code No. Description Specification Remarks

C136 2203-000626 C-CERAMIC,CHIP 0.022nF,5%,50V,NP0,TP,1608

C143 2203-000257 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

C144 2402-001044 C-AL,SMD 100uF,20%,25V,-,TP,8.3x8.3x6.3

C145 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C146 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C147 2203-000257 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

C148 2203-000257 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

C149 2203-000257 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

C150 2203-000257 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

C151 2203-000257 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

C152 2203-000257 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

C153 2203-000626 C-CERAMIC,CHIP 0.022nF,5%,50V,NP0,TP,1608

C162 2203-005533 C-CERAMIC,CHIP 1000nF,20%,6.3V,X7R,TP,1608

C163 2203-005533 C-CERAMIC,CHIP 1000nF,20%,6.3V,X7R,TP,1608

C164 2203-005533 C-CERAMIC,CHIP 1000nF,20%,6.3V,X7R,TP,1608

C165 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C166 2402-000144 C-AL,SMD 3.3uF,20%,50V,GP,TP,4.3x4.3x5.

C168 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C169 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C170 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C171 2402-000179 C-AL,SMD 47uF,20%,16V,GP,TP,6.6x6.6x5.4

C172 2402-000179 C-AL,SMD 47uF,20%,16V,GP,TP,6.6x6.6x5.4

C173 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C174 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C175 2409-001029 C-ORGANIC 120uF,20%,6.3V,WT,TP,10.3x10.3x10.3mm,9

C176 2402-000179 C-AL,SMD 47uF,20%,16V,GP,TP,6.6x6.6x5.4

C177 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C178 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C179 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C180 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C181 2402-000179 C-AL,SMD 47uF,20%,16V,GP,TP,6.6x6.6x5.4

C182 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C183 2203-000236 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

C184 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C185 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C187 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C188 2203-000697 C-CERAMIC,CHIP 0.002nF,0.25pF,50V,NP0,TP,1608

C189 2203-000697 C-CERAMIC,CHIP 0.002nF,0.25pF,50V,NP0,TP,1608

C190 2203-000697 C-CERAMIC,CHIP 0.002nF,0.25pF,50V,NP0,TP,1608

C191 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C192 2402-001044 C-AL,SMD 100uF,20%,25V,-,TP,8.3x8.3x6.3

C193 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C194 2402-000179 C-AL,SMD 47uF,20%,16V,GP,TP,6.6x6.6x5.4

C201 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C202 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C207 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C208 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C209 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C210 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C211 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C212 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

7-2 GH17LS/GH17ES

Page 22

7 Electrical Parts List

Loc. No. Code No. Description Specification Remarks

C213 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C214 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C216 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C218 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C219 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C220 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C221 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C222 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C223 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C224 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C225 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C226 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C227 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C228 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C229 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C230 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C231 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C236 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C237 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C238 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C239 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C240 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C241 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C242 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C243 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C244 2203-000440 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,C245 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C246 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C247 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C248 2203-000440 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,C249 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C250 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C251 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C252 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C253 2203-000440 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,C254 2203-000440 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,C255 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C256 2203-000440 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,C257 2402-001006 C-AL,SMD 4.7uF,20%,25V,GP,TP,3.6x6.3x3.

C258 2203-000440 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,C259 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C260 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C264 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C265 2402-001006 C-AL,SMD 4.7uF,20%,25V,GP,TP,3.6x6.3x3.

C267 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C268 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C269 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C270 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C271 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C272 2409-001029 C-ORGANIC 120uF,20%,6.3V,WT,TP,10.3x10.3x10.3mm,9

CN102 3711-004070 CONNECTOR-HEADER BOX,30P,1R,1.25mm,SMD-A,SN SNA

GH17LS/GH17ES 7-3

Page 23

7 Electrical Parts List

Loc. No. Code No. Description Specification Remarks

CN103 3711-002050 CONNECTOR-HEADER BOX,10P,1R,1.25mm,SMD-A,SN SNA

CN104 3711-000556 CONNECTOR-HEADER BOX,12P,1R,1.25mm,SMD-A,SN SNA

CN107 3711-002049 CONNECTOR-HEADER BOX,6P,1R,1.25mm,SMD-A,SN SNA

D101 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D102 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D103 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D104 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D105 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D106 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D107 0402-000553 DIODE-RECTIFIER SS24,40V,2.0A,DO-214AA

FT101 2901-001114 FILTER-EMI SMD 25VDC,2.0ADC,-,100nF,3.2x1.6x1

FT102 2901-001114 FILTER-EMI SMD 25VDC,2.0ADC,-,100nF,3.2x1.6x1

FT103 2901-001114 FILTER-EMI SMD 25VDC,2.0ADC,-,100nF,3.2x1.6x1

FT104 2901-001114 FILTER-EMI SMD 25VDC,2.0ADC,-,100nF,3.2x1.6x1

FT105 2901-001114 FILTER-EMI SMD 25VDC,2.0ADC,-,100nF,3.2x1.6x1

FT106 2901-001114 FILTER-EMI SMD 25VDC,2.0ADC,-,100nF,3.2x1.6x1

FT109 3301-001145 CORE-FERRITE BEAD AB,4.5x1.6x1.6mm,-,- SNA

FT110 3301-001145 CORE-FERRITE BEAD AB,4.5x1.6x1.6mm,-,- SNA

FT112 3301-001145 CORE-FERRITE BEAD AB,4.5x1.6x1.6mm,-,- SNA

FT113 3301-001145 CORE-FERRITE BEAD AB,4.5x1.6x1.6mm,-,- SNA

FT201 3301-001145 CORE-FERRITE BEAD AB,4.5x1.6x1.6mm,-,- SNA

FT202 3301-001145 CORE-FERRITE BEAD AB,4.5x1.6x1.6mm,-,- SNA

FT203 3301-001145 CORE-FERRITE BEAD AB,4.5x1.6x1.6mm,-,- SNA

FT204 3301-001145 CORE-FERRITE BEAD AB,4.5x1.6x1.6mm,-,- SNA

FT205 3301-001145 CORE-FERRITE BEAD AB,4.5x1.6x1.6mm,-,- SNA

IC101 1103-001164 IC-EEPROM

IC102 1205-001870 IC-TRANSMITTER

IC103 1103-000138 IC-EEPROM 24C16,2Kx8BIT,SOP,8P,150MIL,10

IC104 0803-000106 IC-TTL 74F132,TRIGGER,SOP,14P,150MIL,

IC105 1203-001109 IC-VOL. DETECTOR 7045,SOT-89,3P,-,PLASTIC,4.3/4

IC106 0903-001215 IC-MICROCONTROLLER

IC107 0505-001170 FET-SILICON SI9933ADY-T1,P,-20V,3.4A,0.06ohm,2W,SO-8

IC109 0802-001108 IC-BICMOS LOGIC

IC110_SOCK 3704-000249 SOCKET-IC 32P,PLCC,SN,1.27mm

IC112 1203-001293 IC-POSI.FIXED REG. 033,T0-252,3P,6.5MIL,PLASTIC,3

IC115 1203-001488 IC-POSI.FIXED REG. 7805,T0-252,3P,-,PLASTIC,4.8/5

IC116 1203-001465 IC-POSI.ADJUST REG. 317,TO-263,3P,-,PLASTIC,1.2/37

IC117 1203-001465 IC-POSI.ADJUST REG. 317,TO-263,3P,-,PLASTIC,1.2/37

IC118 0505-001170 FET-SILICON SI9933ADY-T1,P,-20V,3.4A,0.06ohm,2W,SO-8

IC202 1205-002028 IC-LCD CONTROLLER

L201 2703-001778 INDUCTOR-SMD 3.3UH,20%,3.2X2.5X2.2MM

L206 2703-001778 INDUCTOR-SMD 3.3UH,20%,3.2X2.5X2.2MM

L207 2703-001778 INDUCTOR-SMD 3.3UH,20%,3.2X2.5X2.2MM

MP1.0 BN41-00089A PCB MAIN GH17LS,FR4,4L,1.0,1.6,120X110,GH17LS,-,-,Q101 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q103 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q105 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q106 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q107 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q108 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q109 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

24LC21A,128X8BIT,SOP,8P,150MIL,-,5V,10%,PLASTIC,0 TO +70C,100UA,CMOS,TP

DS90C387VJD,QFP,100P,550MIL,PLASTIC,3.6V,2.8W,-10to+70C,TR,Dual Pixel LVDS

80C32X2,8Bit,PLCC,44P,-,40MHz,TR,CMOS,PLASTIC,5V,1W,0to+70C,256BYTE,-,8Bit,300nS

74ABT573,LATCH,TSSOP,20P,173MIL,8,TR,PLASTIC,3-STATE,-,0.55V,-65TO+150C,-,0.8V,5

JAGASM,BGA,388P,208MIL,PALATIC,3.45V,2.5W,-40TO+125C,TR,DIGITAL DISPLAY PRO.

SNA

7-4 GH17LS/GH17ES

Page 24

7 Electrical Parts List

Loc. No. Code No. Description Specification Remarks

Q110 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q111 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q201 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

R101 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R102 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R103 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R104 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R105 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R106 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R107 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R108 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R109 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R110 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R111 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R112 2007-001167 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

R113 2007-001167 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

R114 2007-001167 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

R115 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R116 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R117 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R118 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R119 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R120 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R121 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R122 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R123 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R124 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R125 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R126 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R127 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R128 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R129 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R130 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R131 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R132 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R133 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R134 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R135 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R136 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R137 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R138 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R139 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R140 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R141 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R142 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R143 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R144 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R145 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R146 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R147 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R148 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

GH17LS/GH17ES 7-5

Page 25

7 Electrical Parts List

Loc. No. Code No. Description Specification Remarks

R149 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R150 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R151 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R152 2007-000078 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

R153 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R154 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R155 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R156 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R157 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R158 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R159 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R160 2007-000102 R-CHIP 100Kohm,5%,1/16W,DA,TP,1608

R162 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R165 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R166 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R167 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R168 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R169 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R170 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R171 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R172 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R173 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R174 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R175 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R176 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R184 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R185 2007-000102 R-CHIP 100Kohm,5%,1/16W,DA,TP,1608

R187 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R188 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R189 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R190 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R191 2007-000132 R-CHIP 180Kohm,5%,1/16W,DA,TP,1608

R192 2007-000132 R-CHIP 180Kohm,5%,1/16W,DA,TP,1608

R193 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R194 2007-000125 R-CHIP 3.9Kohm,5%,1/16W,DA,TP,1608

R195 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R196 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R197 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R198 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R199 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R201 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R202 2007-000071 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

R204 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R208 2007-000075 R-CHIP 220ohm,5%,1/16W,DA,TP,1608

R211 2007-000071 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

R212 2007-000071 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

R213 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R214 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R215 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R216 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R217 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

7-6 GH17LS/GH17ES

Page 26

7 Electrical Parts List

Loc. No. Code No. Description Specification Remarks

R219 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R220 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R221 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R222 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R223 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R224 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R225 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R226 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R227 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R228 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R229 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R230 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R231 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R232 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R233 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R234 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R235 2007-000124 R-CHIP 2.2Kohm,5%,1/16W,DA,TP,1608

R236 2007-000134 R-CHIP 33Kohm,5%,1/16W,DA,TP,1608

R237 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R238 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R239 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R240 2007-000072 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

R242 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R243 2007-000071 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

R244 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R245 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R246 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R247 2007-000088 R-CHIP 7.5Kohm,5%,1/16W,DA,TP,1608

R248 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R249 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R250 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R251 2007-000102 R-CHIP 100Kohm,5%,1/16W,DA,TP,1608

R253 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R254 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R255 2007-000071 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

R259 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R260 2007-000071 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

R261 2007-000071 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

R263 2007-000077 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

R264 2007-000077 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

R265 2007-000077 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

R266 2007-000077 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

R267 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R268 2007-001167 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

R269 2007-000102 R-CHIP 100Kohm,5%,1/16W,DA,TP,1608

R270 2007-000119 R-CHIP 560ohm,5%,1/16W,DA,TP,1608

R273 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R274 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R275 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R276 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R277 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

GH17LS/GH17ES 7-7

Page 27

7 Electrical Parts List

Loc. No. Code No. Description Specification Remarks

R278 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R279 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R297 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R298 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R299 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R307 2007-000076 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

R309 2007-001002 R-CHIP 510ohm,5%,1/16W,DA,TP,1608

R310 2007-001002 R-CHIP 510ohm,5%,1/16W,DA,TP,1608

R311 2007-001002 R-CHIP 510ohm,5%,1/16W,DA,TP,1608

R315 2007-000076 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

R316 2007-000076 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

R317 2007-001002 R-CHIP 510ohm,5%,1/16W,DA,TP,1608

R318 2007-000078 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

R327 2007-000077 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

R328 2007-000078 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

R330 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R331 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R332 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R333 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R338 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R339 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R340 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R344 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R345 2007-000078 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

R347 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R348 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R360 3301-001236 CORE-FERRITE BEAD AB,60ohm,1.6x0.8x0.8mm,200mA,TP,H,0.7ohm

R361 3301-001236 CORE-FERRITE BEAD AB,60ohm,1.6x0.8x0.8mm,200mA,TP,H,0.7ohm

R362 3301-001236 CORE-FERRITE BEAD AB,60ohm,1.6x0.8x0.8mm,200mA,TP,H,0.7ohm

RA201 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA202 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA203 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA204 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA205 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA206 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA207 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA208 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA209 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA210 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA211 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA212 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA213 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA214 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

X101 2801-003667 CRYSTAL-SMD 14.3182MHZ,50PPM,28-AAN,16,50OHM,TP

X201 2804-001474 OSCILLATOR-CLOCK 14.31818MHZ,100PPM,30PF,TP,3.3V,15MA

ZD101 0403-000579 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

ZD102 0403-000579 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

ZD103 0403-000579 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

ZD104 0403-000579 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

ZD105 0403-000579 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

ZD106 0403-000579 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

7-8 GH17LS/GH17ES

Page 28

7 Electrical Parts List

7-2 Others

Loc. No. Code No. Description Specification Remarks

CIS BN39-00114A CBF-SIGNAL NL150MO,15P/15P,2990,1830MM,UL2990,IVORY,D-SUB

CIS BN44-00029A INVERTER

CIS BN41-00045A PCB MAIN

CN301+PAN BN39-00102A CBF-HARNESS

CN302+INV BN39-00002A CBF-HARNESS -,60,BLU/WHT,-,26,-

SIC1801,4LAMP,SIC1801,18.1,14V DC,160x45x17

CEZANNE-II,FR-4 ,4,-,1.6T,117.0*172.4*1.6,CN,-,-,-,CN17MS,-,-,-,1.6+,223x118.9,-,-,-,CN17MSS,UL1571,UL/CSA,30P,90MM,BLU/WHT,AWG30,DF14-30S-1.25C,F1-X30H,-,-,-,-,-,-

GH17LS/GH17ES 7-9

Page 29

7 Electrical Parts List

Memo

7-10 GH17LS/GH17ES

Page 30

8 Block Diagram

ANALOG

PC

Scaller + ADC

LCD

Panel I/F

CLOCK

MCU

Setup Data & User I/F

User Key

Jag - ASM

Back Light Control

Power Sequence Control

GH17LS/GH17ES 8-1

Page 31

8 Block Diagrams

Memo

8-2 GH17LS/GH17ES

Page 32

GH17LS/GH17ES 9-1

9 Wiring Diagram

Page 33

Memo

9 Wiring Diagram

9-2 GH17LS/GH17ES

Page 34

GH17LS/GH17ES 10-1

10 Schematic Diagrams

10-1 Main Part Schematic Diagram

RxO0RxO0+

RxO1RxO1+

RxO2RxO2+

GND

RxOCRxOC+

RxO3RxO3+

RxE0RxE0+

GND

RxE1RxE1+

GND

RxE2RxE2+

RxECRxEC+

RxE3-

GND

RxE3+

NC

NC

NC

5V

5V

5V

12V_BL

H:WHITE

L:BLACK

BASIC TOUCH SCREEN

H:NORMAL

L:DPMS

R258

10K10K

R257

+5V

1

R256

10K

TP137

1

TP138

1

TP139

560

R270

10nF

C121

CPU+5V

F

7

G

8

H

10uF

C122

NM24C17FM8X

IC103

1

A

2

B

3

C

4

D

5

E

6

R346

0

+5V

TP153

1

TP156

1

TP146

1

TP163

1

TP161

1

TP162

1

1

TP159

1

TP160

1

1

TP157

1

TP158

1

TP154

1

TP155

1

TP151

1

TP152

TP148

1

TP149

1

TP150

TP145

1

TP147

1

TP143

1

TP144

1

1

TP141

1

TP142

1

1

TP166

1

TP140

1

TP164

1

TP165

TP167

100

100

R330

R334

R336 R337

100

100

100

100

R335

R342

R343

CPU+5V

R341 100

100

1K

R344

4.7K

2SC2412K-Q

Q111

B

C

E

R345

R262

22

0R338

R339

0

0

0

R340

0

R332

R333

R331

0

510

1/16W

1/16W

330

R315

R310

R317

1/16W

510

R311

1/16W

510

R309

510

1/16W

1K

1/16W

R328

Q109

2SC2412K-Q

B

C

E

R307

330

1/16W

R316

1/16W

470

R327

1/16W

1K

1/16W

330

2SC2412K-Q

Q110

B

C

E

R318

R192

R191

180K

180K

FT113

A1B

2

3.3VJP

slcon3p

CN108

123

16V

47uF

C194

B

16V

10uF

C193

BD107

B

BD108

BD106

B

100

R107

R108 100

R103 100

C189

C190

0.002nF

0.002nF

100uF

25V

C188

0.002nF

R296

1K

CPU+5V

C192

CPU+5V

R297

10K

10K

4.7K

R298

100nF

C191

R299

1

100nF

C187

1

TP132

1

TP133

1

TP130

1

TP128

TP126

1

TP135

1

TP136

TP134

1

TP125

1

TP129

1

TP131

1

TP109

1

TP127

1

TP107

1

TP108

1

1

TP102

1

TP101

1

1

TP104

1

TP103

1

TP106

1

TP105

1

TP123

1

TP124

TP117

1

TP121

1

TP122

TP114

1

TP115

1

TP112

1

TP113

1

TP110

1

TP111

1

1

TP119

1

TP120

1

TP116

1

TP118

+12V_INVERTER+12V_MAIN

10uF

C185

R204 100

C184

100nF

2.5VJA1

R202

22

100K

R201 10K

S2

3

2SC2412K-Q

Q108

B

C

E

R269

SI9933ADY-T1

IC118

8

D1

D1_1

7

6

D2

D2_1

5

2

G1

4

G2

S1

1

75R268

+5V

+5V

C183

100pF

3.3uF

C166

+5V

CPU+5V

CPU+5V

C145

100nF

MAIN5V

SS24

D107

CPU+5V

CPU+5V

10K

MAIN5V

Q107

B

C

E

R199

GND

IN OUT

R251

100K

FT109

1A2

B

IC115

BA17805FP

B

FT110

A1B

2

+3.3V

LVDS3.3V

FT112

1A2

C181

47uF

C180

100nF

C182

100nF

IN OUT

C179

10uF

+5V

BA033FP

IC112

GND

C177

100nF

120uF

C175 C176

47uF

+2.5V

100nF

C178

R265

470

R266

ADJ

3

1

VIN2VOUT_1

4

VOUT_2

470

100nF

C173

IC117

LM317SX

47uF

C172C171

47uF

PLL_2.5V

C174

100nF

470

R264

470

LM317SX

IC116

3

ADJ

VIN

1

VOUT_1

2

VOUT_2

4 R263

C169

100nF

100nF

C170

C168

10uF

CPU+5V

+12V_MAIN

CPU+5V

R198

4.7K

R250

4.7K

R197

R249

4.7K

4.7K

4.7K

R248

4.7K

R193 4.7K

4.7K

R245

R246

10K

R195

1000nF

C164

1000nF

C162

C163

1000nF

2.5VJA1

3.9K

R194

100nF

C165

R185

100K

7.5K

R247

E

10K

R184

B

C

E

Q106

B

C

CPU+5V

Q105

0

0R190

R188

R189

8

R187 0

0

slcon8p

CN107

1

2

3

4

5

6

7

R176

10K

10K

R175

10K

R173

R174

10K

R172

10K

C150

10K

R171

10nF

10nF

10nF

C151 C152C149 C148

10nF

10nF

10nF

CPU+5V

CPU+5V

C147

10K

1/16W

10K

R110

100R168

R167

R147 100

100

100R146

100R159

R145

R158 100

100

100R157

100R155

R156

R154 100

100

100R153

100R150

R151

R149 100

1A2

B

I+5V

100R148

10K

CPU+5V

BD105

4.7K

R170

Q103

2SC2412K-Q

B

C

E

R169

6

5

D2_1

G1

2

G2

4

1

S1

3

S2

LCD+5V

IC107

SI9933ADY-T1

D1

8

7

D1_1

D2

R160

10K

R162

Q101

B

C

E

100K

100nF

C146

10

11

12

slcon2p

CN106

1

2

1

2

3

4

5

6

7

8

9

4

5

6

7

+5V

+12V_INVERTER

slcon12p

CN103

I+5V

slcon7p

CN105

1

2

3

BD104

BLM41P600S

1A2

B

10nF

C143

10

11

12

13

14

C144

100uF

25V

1

2

3

4

5

6

7

8

9

CN104

slcon14p_1

C123

10nF

CPU+5V

CPU+5V

R166R165

4.7K

28

A14

29

NC/A17

30

*WE

31

VCC

32

4.7K

20

DQ7

21

*CE

22

A10

23

*OE

24

A11

25

A9

26

A8

27

A13

DQ0

13

DQ114DQ2

15

VSS

16

DQ317DQ418DQ519DQ6

A7

5

A6

6

A5

7

A4

8

A3

9

A2

10

A1

11

A0

12

20

IC110

AT27C010-90JC

VPP

1

A162A153A12

4

12

M

13

N

14

15

O

16

P

17

Q

18

R

S

19

T

4

E

5

F

6

7

G

H

8

I

9

J10K

11

L

IC109

SN74ABT573

A

1

B

2

C

3

D

1K

CPU+5V

ZD106

A

1

2

B

3

C

R152

C130

10nF

R208

C132

10uF

10uF

C131

CPU+5V

220

OUT

C129

100nF

CPU+5V

KIA7045RTF

IC105

GND_1

GND_2

IN

4.7KR134

R137

R133

4.7K

100

100

22pF

C136

R131

X101

Q0 Q1

22pF

C153

32

RST

10

VCC

44

35

VPP

22

VSS

1

VSS1

21

XTAL120XTAL2

P2_6

30

P2_7

31

P3_0

11

13

P3_1

14

P3_2

15

P3_3

16

P3_4

17

P3_5

18

P3_619P3_7

PSEN_

5

P1_36P1_4

P1_5

7

P1_6

8

P1_7

9

P2_024P2_125P2_226P2_327P2_4

28

P2_5

29

43

P0_142P0_241P0_3

40

39

P0_4

38

P0_5

37

P0_6

36

P0_7

2

P1_03P1_14P1_2

IC106

TS80C32X2-MCB

ALE

33

NIC1

12

NIC2

23

34

NIC3

P0_0

C128

100nF

C127

100nF

100nF

C114

C126

100uF

100nF

C112 C113

100nF

18

19

20

21

22

23

24

25

26

C111

10uF

8

9

10

11

12

13

14

15

16

17

27

28

29

30

1

2

3

4

5

6

7

R123 0

CN102

slcon30p

0R122

R121 0

0

R126 0

R124 0

R125

R144 0

0R142

R143 0

0R141

R140 0

0

R139 0

R136 0

R138

0R135

0R130

0R132

0R129

R127

0R128

47

R118

0

10K

LVDS3.3V

10KR119

R120

R116

R117 10K

10K

10K

10KR111

R115

SGM32F1E104-2A

FT102

A

12

B

C

3

LVDS3.3V

C117

100nF 100nF

C118

100nF

C116

C115

10uF

LVDS3.3V

100nF

SGM32F1E104-2A

FT104

1

A

B

2

3

C

C102 C104

100nF

C103

100nF

C106

100nF

C105

10uF

C107

LVDS3.3V

100nF

SGM32F1E104-2A

FT101

A

1

2

B

C

3

77 76

R26

R27

75

R_FB

20

21

R_FDE

Vcc_1

53

Vcc_2

67

82

Vcc_3

Vcc_4

97

Vsync

55

7

R13

R14

6

5

R15

R16

4

3

R17

84

R20

R21

8180

R22

R23

79 78

R24

R25

22

PLLGND_1

16

17

PLLGND_2

19

PLLGND_3

15

PLLSEL

PLLVCC_1

12

PLLVCC_2

18

PRE

14

R10

10

9

R11

R12

8

GND_2

GND_3

8398

GND_4

54

Hsync

25

LVDSGND_1

35

LVDSGND_243LVDSGND_3

LVDSGND_4

51

LVDSVCC_1

30

LVDSVCC_240LVDSVCC_3

48

PD_

74

G20

G21

73

72

G22

G23

71

70

G24

G25

69

66

G26

G27

65

13

GND

52

GND_1

68

CLKIN

56

DE

23

DUAL

G10

2

1

G11

100

G12

G13

99 96

G14

G15

9594

G16

G17

93

B22

B23

61

60

B24

B25

59

58

B26

B27

57

BAL

24

CLK1M

4241

CLK1P

27

CLK2M

CLK2P

26

11

92

B10

B11

9190

B12

B13

8988

B14

B15

8786

B16

B17

85

64

B20

B21

63

62

4439

A3M

A3P

3837

A4M

A4P36A5M

3433

A5P

A6M

3231

A6P29A7M

A7P

28

DS90C387VJD

IC102

A0M

5049

A0P47A1M

A1P

4645

A2M

A2P

LCD+5V

BD101

1AB2

R196 100

C125

100nF

C124

10uF

VCC

14

FT106

SGM32F1E104-2A

A

12

B

C

3

IN

4

A2

13

A3

10

B0

IN

2

B1

IN

5

B2

12

B3

9

GND

IN

7

O_1

IN

6

O_2

11

O_3

8

B

2

C

3

74F132D(REEL)

IC104

0_0

IN

3

A0

IN

1

A1

ZD102

1

A

B

2

C

3

ZD103

1

A

ZD101

1

A

B

2

C

3

100nF

C101

R101

100

R104

4.7K

4.7K

100

R106

R102

4

7

WC_

R105

100

24LC21AT-/SN

IC101

NC_1

1

NC_2

2

NC_3

3

6

SCL

5

SDA

8

VCC

VSS

6

7

8

9

10

11

12

13

14

15

CN101

d_sub15p

1

2

3

4

5

12

3

100R109

FT103

A

12

B

C

3

D1043D102

12

3

12

3

D103

12

D105

12

3

D101

3

FT105

1

A

B

2

3

C

1

2

3

D106

12

1

2

3

ZD105

R114

75

ZD104

75

R113R112

75

LED1

LED

LED_R

LED_G

CREF

CTRL

LED1

SELFRAST_D_SUB

PANEL_ON_OFF

BL_ON

AUTO

MCALE

MAIN_ON_OFF

MAIN_ON_OFF

JAG_RST

AHS

CTRL

LED_R

MENU

GREEN1N

BLUE1N

BLUE1N

AUTO

POWER

LEFT

EXIT

RXD

TXD

RESET

MCA16

RIGHT

LED_G

MENU

PANEL_ON_OFF

RED1P

GREEN1P

BLUE1P

CTRL

MCAD(3)

MCRD

RED1N

RED1N

GREEN1N

MCA(11)

MCA(9)

MCA(8)

MCA(13)

MCA(14)

MCA(8:15)

MCAD(3)

MCA(7)

MCAD(0:7)

MCA(8:15)

MCA(0:7)

LEFT

LED

POWER

RXD

TXD

BL_ON

BL_CNT

MCA(6)

MCA(6)

MCA(5)

MCA(5)

MCA(4)

MCA(4)

MCA(3)

MCA(3)

MCA(2)

MCA(2)

MCA(1)

MCA(1)

MCA(0)MCA(0)

MCALE

MCAD(0:7)

MCA16

MCAD(0)

MCAD(4)

MCAD(5)

*PSEN

MCAD(0:7)

MCAD(1)

MCAD(2)

MCAD(6)

MCAD(7)

MCA(15)

MCA(12)

MCA(10)

MCA(10)

MCA(11)

MCA(12)

MCA(13)

MCA(14)

MCA(15)

CTRL

MCWR

*PSEN

RESET

MCAD(7)

MCAD(5)

MCAD(3)

MCAD(1)

MCAD(6)

MCAD(4)

MCAD(2)

MCAD(0)

MCA(7)

DCLK

LVDS_EN

MCALE

MCAD(0)

MCAD(1)

MCAD(2)

MCAD(4)

MCAD(5)

MCAD(6)

MCAD(7)

RIGHT

EXIT

MCA(8)

MCA(9)

DAGRN(4)

DAGRN(5)

DAGRN(6)

DAGRN(7)

DABLU(0:7)

DABLU(0)

DABLU(1)

DABLU(2)

DABLU(3)

DABLU(4)

DABLU(5)

DABLU(6)

DABLU(7)

DEN

DVS

DHS

DBGRN(0:7)

DBGRN(0)

DBGRN(1)

DBGRN(2)

DBGRN(3)

DBGRN(4)

DBGRN(5)

DBGRN(6)

DBGRN(7)

DBBLU(0:7)

DBBLU(0)

DBBLU(1)

DBBLU(2)

DBBLU(3)

DBBLU(4)

DBBLU(5)

DBBLU(6)

DBBLU(7)

DARED(0:7)

DARED(0)

DARED(1)

DARED(2)

DARED(3)

DARED(4)

DARED(5)

DARED(6)

DARED(7)

DAGRN(0:7)

DAGRN(0)

DAGRN(1)

DAGRN(2)

DAGRN(3)

AHS

AVS

V_SYNC

H*V_SYNC

DBRED(0:7)

DBRED(0)

DBRED(1)

DBRED(2)

DBRED(3)

DBRED(4)

DBRED(5)

DBRED(6)

DBRED(7)

RED1N

GREEN1N

BLUE1N

SELFRAST_D_SUB

AVS

1

7

Page 35

10 Schematic Diagrams

10-2 GH17LS/GH17ES

1 7

Page 36

10 Schematic Diagrams

GH17LS/GH17ES 10-3

10-2 Main Part Schematic Diagram

1

10K

+5V

TP168

10K

R347 R348

FT205

A

1

B

2

6.3V

120uF

C272

L201

3.3UH

R224 0

3.3VJF

22

R255

1A2

B

100nF

C267

R243

22

FT203

X201

GND

2NC1

OUT3VDC

4

100

R254

R278 10K

10KR279

0

R253 10K

0R274

R273

R275 0

0

0R276

N4

Y4

VSSC8

A22

VSSP1

D22

VSSP2

XIN

A6

XOUT

A7

XVDD

D7

XVSS

B7

R277

VSS49

VSS5

L16

VSS50

AC5

M11

VSS6

VSS7

M12

M13

VSS8

VSS9

M14

VSSC3

G23

N23

VSSC4

VSSC5

W23

D4

VSSC6

VSSC7

T15

VSS34

VSS35

T16

VSS39

A23

L15

VSS4

VSS40

F26

VSS41

L26

VSS42

R26

VSS43

AC26

VSS44

AF23

VSS48

C1

N1

VSS24

VSS25

R12

R13

VSS26

VSS27

R14

R15

VSS28

VSS29

R16

VSS3

L14

T11

VSS30

VSS31

T12

T13

VSS32

VSS33

T14

VSS14

VSS15

N14

N15

VSS16

VSS17

N16

P11

VSS18

VSS19

P12

L13

VSS2

P13

VSS20

VSS21

P14

P15

VSS22

VSS23

P16

R11

VDDC8

H4

R4

VDDC9

B22

VDDP1

C22

VDDP2

L11

VSS0

VSS1

L12

M15

VSS10

VSS11

M16

N11

VSS12

VSS13

N12

N13

AF26

VDD9

A5

AC20

VDDC0

VDDC1

AC14

VDDC10

AB4

AC8

VDDC2

D23

VDDC3

VDDC4

K23

T23

VDDC5

VDDC6

AB23

D21

VDDC7

D1

VDD0

AF21

AF16

VDD1

K1

VDD10

AA1

VDD11

VDD2

AF10

A26

VDD3

VDD4

J26

N26

VDD5

VDD6

U26

Y26

VDD7

VDD8

SDD62

A24

A25

SDD63

SDD7

AE24

SDD8

AF24

SDD9

AC25

SDRAS

P24

R25

SDWE

D19

SVDD

B19

SVSS

E1

SYSRST

TEST

D25

D26

SDD53

SDD54

C23

C24

SDD55

SDD56

C25

C26

SDD57

SDD58

B23

B24

SDD59

SDD6

AD24

SDD60

B25

B26

SDD61

G25

G26

SDD43

SDD44

F23

F24

SDD45

SDD46

F25

E23

SDD47

SDD48

E24

E25

SDD49

SDD5

AC24

SDD50

E26

D24

SDD51

SDD52

K26

SDD33

SDD34

J23

J24

SDD35

SDD36

J25

H23

SDD37

SDD38

H24

H25

SDD39

SDD4

AE23

SDD40

H26

G24

SDD41

SDD42

Y24

SDD24

Y25

SDD25

W24

SDD26

W25

SDD27

W26

SDD28

L23

SDD29

L24

SDD3

AD23

SDD30

L25

SDD31

K24

SDD32

K25

AD26

SDD14

AE26

SDD15

AB24

SDD16

AB25

SDD17

AB26

SDD18

AA23

SDD19

AA24

SDD2

AC23

SDD20

AA25

SDD21

AA26

SDD22

Y23

SDD23

SDCKE

R24

T25

SDCKFB

P23

SDCKN

SDCKP

R23

SDCS0

M26

SDD0

AD22

SDD1

AE22

SDD10

AD25

SDD11

AE25

SDD12

AF25

SDD13

V24

SDA10

N25

SDA2

V25

SDA3

V26

SDA4

U23

SDA5

U24

SDA6

U25

SDA7

P25

SDA8

P26

SDA9

N24

T26

SDCAS

R2P

C15

RREFH

C14

RREFL

D14

RVDD1

D13

RVDD2

B14

RVSS1

B13

RVSS2

SCDT_GPIO0

E2

SCL

F3

F4

SDA

SDA0

V23

SDA1

PHSYNC

AE21

AF12

PNLCLK

PSHFCLK

AC13

D20

PVDD1

B20

PVSS1

AC21

PVSYNC

PWM1

B1

A12

R1N

A13

R1P

A10

R2N

A11

PD6

PD60

AC22

AC17

PD61

PD62

AC11

AF19

PD63

PD64

AF13

AF8

PD65

PD7

AE15

AF15

PD8

PD9

AC16

AF20

PDE

AC10

AF14

PD4

AD10

PD40

PD41

AE10

AD11

PD42

PD43

AE11

AF11

PD44

PD45

AC12

AD12

PD46

PD47

AE12

PD5

AC15

AD15

PD3

AE14

AD7

PD30

PD31

AE7

AF7

PD32

PD33

AD8

AE8

PD34

PD35

AC9

AD9

PD36

PD37

AE9

AF9

PD38

PD39

PD2

AD19

PD20

PD21

AE19

AD20

PD22

PD23

AE20

AF5

PD24

PD25

AC6

AD6

PD26

PD27

AE6

AF6

PD28

PD29

AC7

AE13

AD16

PD10

PD11

AE16

AD17

PD12

PD13

AE17

AF17

PD14

PD15

AC18

AD18

PD16

PD17

AE18

AF18

PD18

PD19

AC19

AD14

AD2

PC9

PCFIELD_GPIO3

AE5

AB2

PCHREF

PCHSYNC

AB3

PCLKA

G4

PCLKB

P4

PCLKC

AA4

AD5

PCVREF_GPIO2

AB1

PCVSYNC

AD13

PD0

PD1

AC1

AC2

PC13

PC14

AC3

AC4

PC15

PC2

AF3

AF4

PC3

PC4

AE1

AE2

PC5

PC6

AE3

AE4

PC7

PC8

AD1

Y3

PB5W1PB6W2PB7W3PB8W4PB9

V1

P3

PBVSYNC

PC0

AF1

AF2

PC1

PC10

AD3

AD4

PC11

PC12

PB16U4PB17T1PB18T2PB19

T3

PB2

Y1

PB20

T4

R1

PB21

PB22

R2

R3

PB23

PB3Y2PB4

M4

PA8L1PA9

L2

PB0

AA2

PB1

AA3

PB10V2PB11V3PB12V4PB13U1PB14U2PB15

U3

J4

PA19

H1

PA2

N2

PA20H2PA21H3PA22G1PA23

G2

PA3N3PA4M1PA5M2PA6M3PA7

PA0P1PA1

P2

PA10L3PA11L4PA12K2PA13K3PA14K4PA15J1PA16J2PA17J3PA18

A4

B4

MCAD5

MCAD6

A3

B3

MCAD7

MCAD8

C3

A2

MCAD9D3MCALE

MCCSC4MCRD

E3

E4

MCWR

MEMCLK

T24

D2

C13

IREFH

C12

IREFL

D12

IVDD1

D11

IVDD2

B12

IVSS1

B11

IVSS2

MCAD0

B6

B5

MCAD1

MCAD2

C5

D5

MCAD3

MCAD4

D16

GVDD1

D15

GVDD2

B16

GVSS1

B15

GVSS2

HSYNC0

F2

D6

HSYNC1

HSYNC2

C6

HSYNCOUT

C2

A8

I1

A9

I2

INTR

AF22

AD21

ENVDD

A16

G1N

A17

G1P

A14

G2N

A15

G2P

B2

GPIO4

C21

GPVDD

B21

GPVSS

C17

GREFH

C16

GREFL

CLAMPOUT

CVDD1

D9

CVDD2

D8

CVSS1

B9

CVSS2

B8

DEIN

F1

M23

DQM

M25

DQS

DVDD

D10

DVSS

B10

DVSYNC

G3

ENBKL

A21

B1P

A18

B2N

A19

B2P

BANK

M24

C19

BREFH

C18

BREFL

D18

BVDD1

D17

BVDD2

B18

BVSS1

B17

BVSS2

A1

C10

AVDD1

AVDD2

C11

AVDD3

C8

AVDD4

C9

C20

AVSS1

AVSS2

C7

A20

B1N

IC202

JAGASM

100

100nF

R267

100nF

C242

C241

C238 C239

100nF

100nF

100nF

2.5VJA2

+2.5V

PLL_2.5V

2.5VJS

2.5VJS

C240

L207

3.3UH

3.3UH

L206

2.5VJA1

C218

10uF

10uF

C216

1A2

B

100

R244

FT202

A1B

2

FT204

10uF

C247

100nF

C245

FT201

1A2

B