Page 1

TFT-LCD MONITOR

GH15DS

SERVICE

Manual

TFT-LCD MONITOR CONTENTS

1. Precautions

2. Product Specifications

3. Disassembly & Reassembly

4. Troubleshooting

5. Exploded View & Parts List

6. Electrical Parts List

7. Block Diagram

8. Wiring Diagram

9. Schematic Diagrams

10. Panel Description

Page 2

1 Precautions

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

(READING SHOULD

NOT BE ABOVE 0.5mA)

LEAKAGE

CURRENT

TESTER

2-WIRE CORD

*ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

!

Follow these safety, servicing and ESD precautions to prevent damage and to protect against potential hazards such as

electrical shock.

1-1 Safety Precautions

1-1-1 Warnings

1. For continued safety, do not attempt to modify the

circuit board.

2. Disconnect the AC power and DC Power Jack

before servicing.

3. When the chassis is operating, semiconductor

heatsinks are potential shock hazards.

1-1-2 Servicing the LCD Monitor

1. When servicing the LCD Monitor, remove the static

charge by connecting a 10k ohm resistor in series

with an insulated wire (such as a test probe)

between the chassis and the anode lead.

(Disconnect the AC line cord from the AC outlet.)

2. It is essential that service technicians have an

accurate voltage meter available at all times. Check

the calibration of this meter periodically.

1-1-3 Fire and Shock Hazard

Before returning the monitor to the user, perform the

following safety checks:

1. Inspect each lead dress to make certain that the

leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in

the monitor.

2. Inspect all protective devices such as nonmetallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

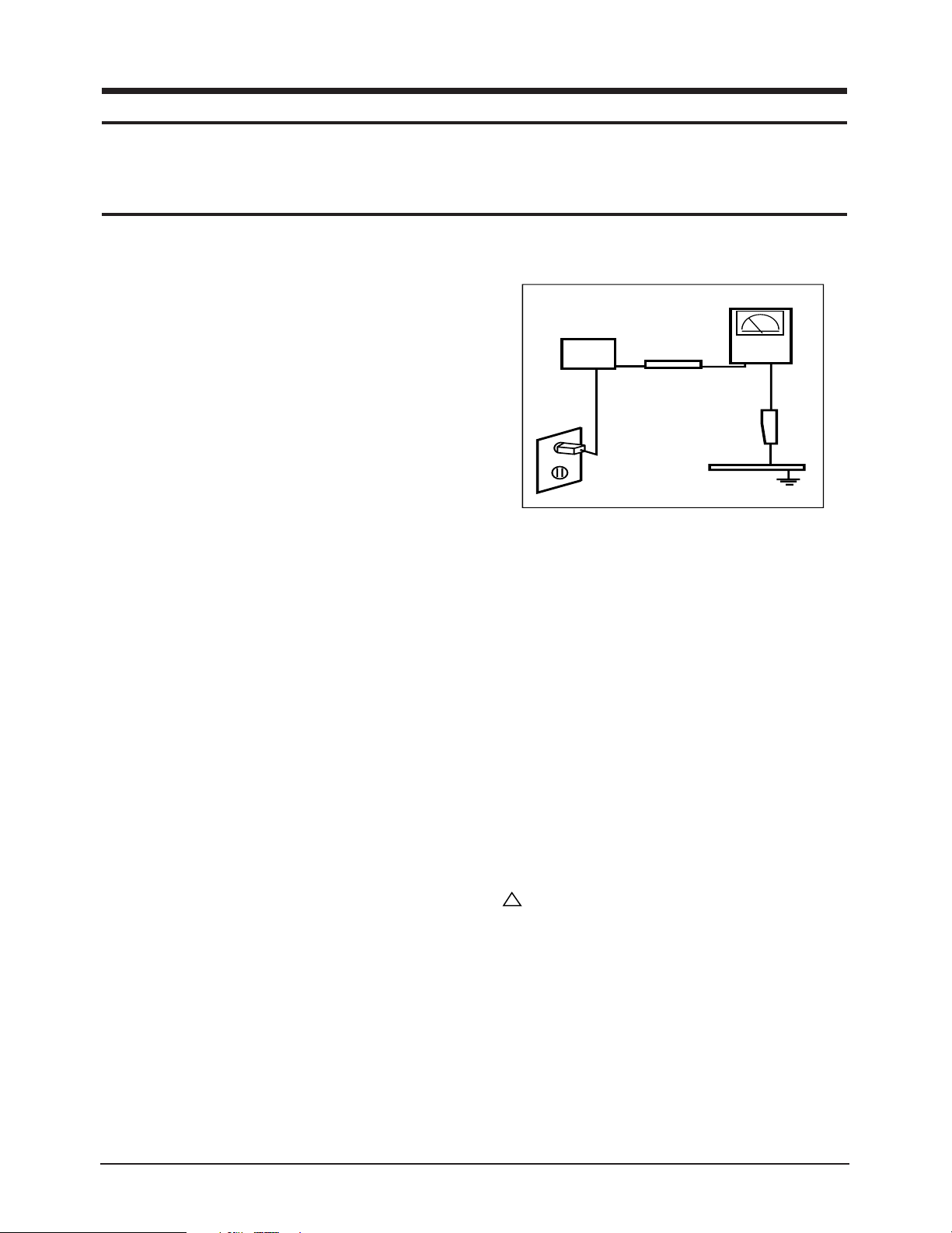

3. Leakage Current Hot Check (Figure 1-1):

WARNING: Do not use an isolation transformer

during this test.

Use a leakage current tester or a metering system

that complies with American National Standards

Institute (ANSI C101.1, Leakage Current for

Appliances), and Underwriters Laboratories (UL

Publication UL1410, 59.7).

4. With the unit completely reassembled, plug the AC

1-1-4 Product Safety Notices

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection. The protection they give

may not be obtained by replacing them with

components rated for higher voltage, wattage, etc. Parts

that have special safety characteristics are identified by

replacement that does not have the same safety

characteristics as the recommended replacement part

might create shock, fire and / or other hazards. Product

safety is under review continuously and new

instructions are issued whenever appropriate.

Figure 1-1. Leakage Current Test Circuit

line cord directly into a 120V AC outlet. With the

unit’s AC switch first in the ON position and then

OFF, measure the current between a known earth

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including: metal cabinets,

screwheads and control shafts. The current

measured should not exceed 0.5 milliamp. Reverse

the power-plug prongs in the AC outlet and repeat

the test.

on schematics and parts lists. A substitute

GH15DS 1-1

Page 3

1 Precautions

1-2 Servicing Precautions

WARNING: An electrolytic capacitor installed with the wrong polarity might explode.

Caution: Before servicing units covered by this service manual, read and follow the Safety Precautions

section of this manual.

Note: If unforeseen circumstances create conflict between the following servicing precautions and any of the

safety precautions, always follow the safety precautions.

1-2-1 General Servicing Precautions

1. Always unplug the unit’s AC power cord from the

AC power source and disconnect the DC Power

Jack before attempting to:

(a) remove or reinstall any component or assembly,

(b) disconnect PCB plugs or connectors, (c) connect

a test component in parallel with an electrolytic

capacitor.

2. Some components are raised above the printed

circuit board for safety. An insulation tube or tape

is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

3. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the area around the

serviced part has not been damaged.

4. Check the insulation between the blades of the AC

plug and accessible conductive parts (examples:

metal panels, input terminals and earphone jacks).

5. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the power

switch ON. Connect an insulation resistance meter

(500 V) to the blades of the AC plug.

The insulation resistance between each blade of the

AC plug and accessible conductive parts (see

above) should be greater than 1 megohm.

6. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrument’s

ground lead last.

1-3 Electrostatically Sensitive Devices (ESD) Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated circuits and some fieldeffect transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known earth

ground. Alternatively, wear a discharging wriststrap device. To avoid a shock hazard, be sure to

remove the wrist strap before applying power to

the monitor.

2. After removing an ESD-equipped assembly, place it

on a conductive surface such as aluminum foil to

prevent accumulation of an electrostatic charge.

3. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESDs.

4. Use only a grounded-tip soldering iron to solder or

desolder ESDs.

5. Use only an anti-static solder removal device. Some

solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage

ESDs.

6. Do not remove a replacement ESD from its

protective package until you are ready to install it.

Most replacement ESDs are packaged with leads

that are electrically shorted together by conductive

foam, aluminum foil or other conductive materials.

7. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

Caution: Be sure no power is applied to the

chassis or circuit and observe all

other safety precautions.

8. Minimize body motions when handling

unpackaged replacement ESDs. Motions such as

brushing clothes together, or lifting your foot from

a carpeted floor can generate enough static

electricity to damage an ESD.

1-2 GH15DS

Page 4

2 Product Specifications

2-1 Specifications

Item

LCD Panel TFT-LCD panel, RGB vertical stripe, normaly white,15-Inch viewable,

0.297 mm pixel pitch

Scanning Frequency Horizontal : 30 kHz ~ 60 kHz

Vertical : 56 Hz ~ 75 Hz

Display Colors 16.2 Million colors

Maximum Resolution Horizontal : 1024 Pixels

Vertical : 768 Pixels

Input Video Signal VESA TMDS

Input Sync Signal Encoded by TMDS

Maximum Pixel Clock rate 80 MHz

Active Display Horizontal : 304 mm Vertical : 228 mm

AC power voltage & Frequency AC 90 ~ 260 Volts, 60/50 Hz ± 3 Hz

Power Consumption On : 30 W (max) / Saving : 3W (max) / Switch - off : 1W (max)

Dimensions

Unit (W x D x H)

With Simple Stand

Without Simple stand

With Pivot Stand

Without Pivot Stand

15.4 x 15.1 x 6.8 Inches (391.4 x 383.6 x 173 mm)

15.4 x 11.5 x 2.5 Inches (391.4 x 292.8 x 64.0 mm)

15.4 x 15.1 x 6.8 Inches (391.4 x 383.6 x 173 mm)

15.4 x 17.1 x 6.8 Inches (391.4 x 433.6 x 173 mm)

15.4 x 11.5 x 2.5 Inches (391.4 x 292.8 x 64.0 mm)

Description

Weight (Net/Gross) 4.2 kg (9.3 lbs) / 5.2 kg (11.5 lbs)

Environmental Considerations Operating Temperature : 50°F ~ 104°F (10°C ~ 40°C)

Humidity : 10 % ~ 80 %

Storage Temperature : -3.2°F ~ 140°F (-20°C ~ 60°C)

Humidity : 5 % ~ 95 %

•GH15DS comply with SWEDAC (MPR II) recommendations for reduced electromagnetic fields.

•Designs and specifications are subject to change without prior notice.

GH15DS 2-1

Page 5

2 Product Specifications

2-2 DVI Signal Pin Assignments - Main Pin Field (GH15DS)

Pin Signal Assignment Pin Signal Assignment Pin Signal Assignment

1 T.M.D.S. Data2- 9 T.M.D.S. Data1- 17 T.M.D.S. Data0-

2 T.M.D.S. Data2+ 10 T.M.D.S. Data1+ 18 T.M.D.S. Data0+

3 T.M.D.S. Data2 Return 11 T.M.D.S. Data1 Return 19 T.M.D.S. Data0 Return

4NC 12NC 20NC

5NC 13NC 21NC

6 DDC Clock 14 +5V Power 22 T.M.D.S. Clock Return

7 DDC Data 15 Ground (Self-Raster) 23 T.M.D.S. Clock+

8 NC 16 Hot Plug Detect (+5V) 24 T.M.D.S. Clock-

2-2 GH15DS

Page 6

2 Product Specifications

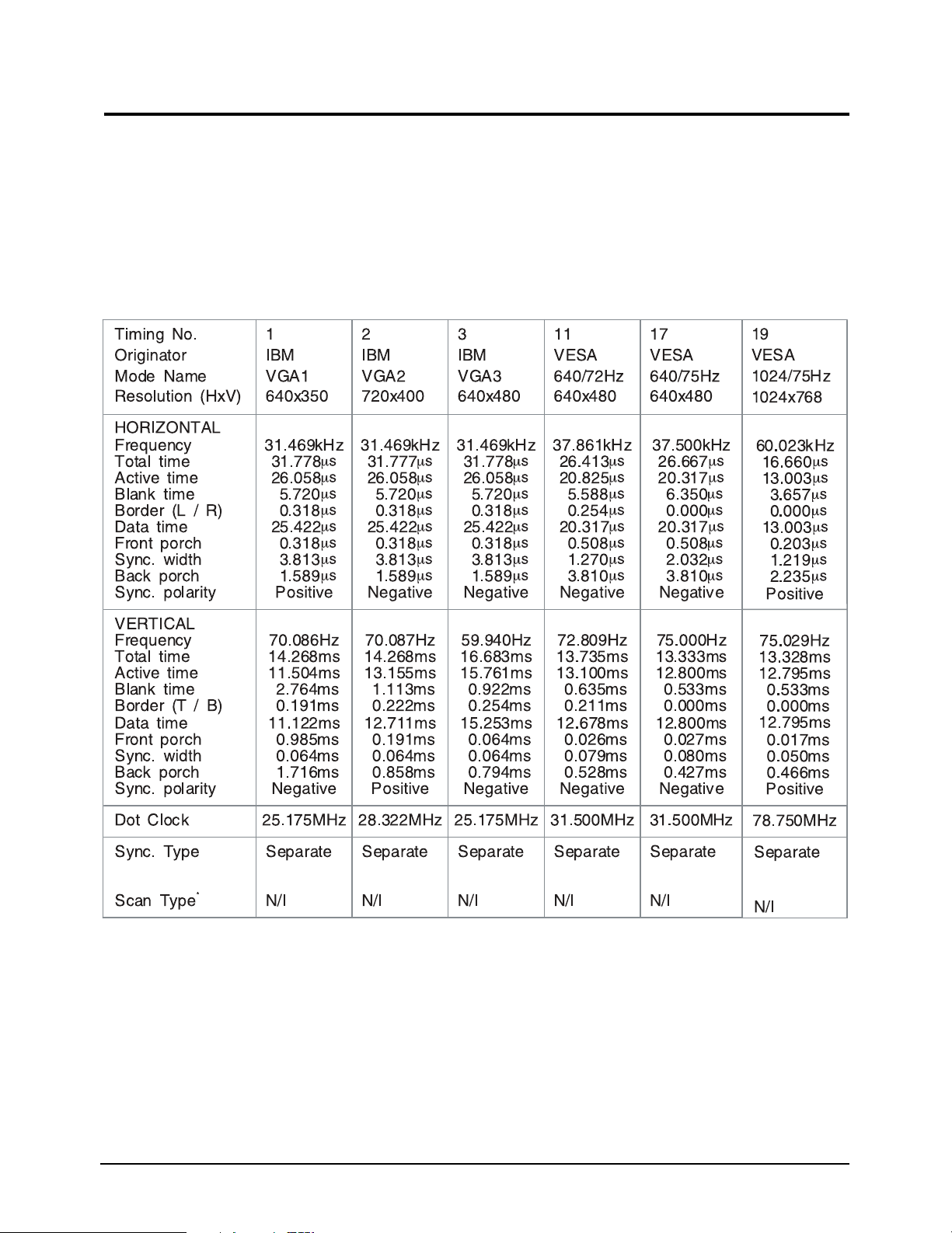

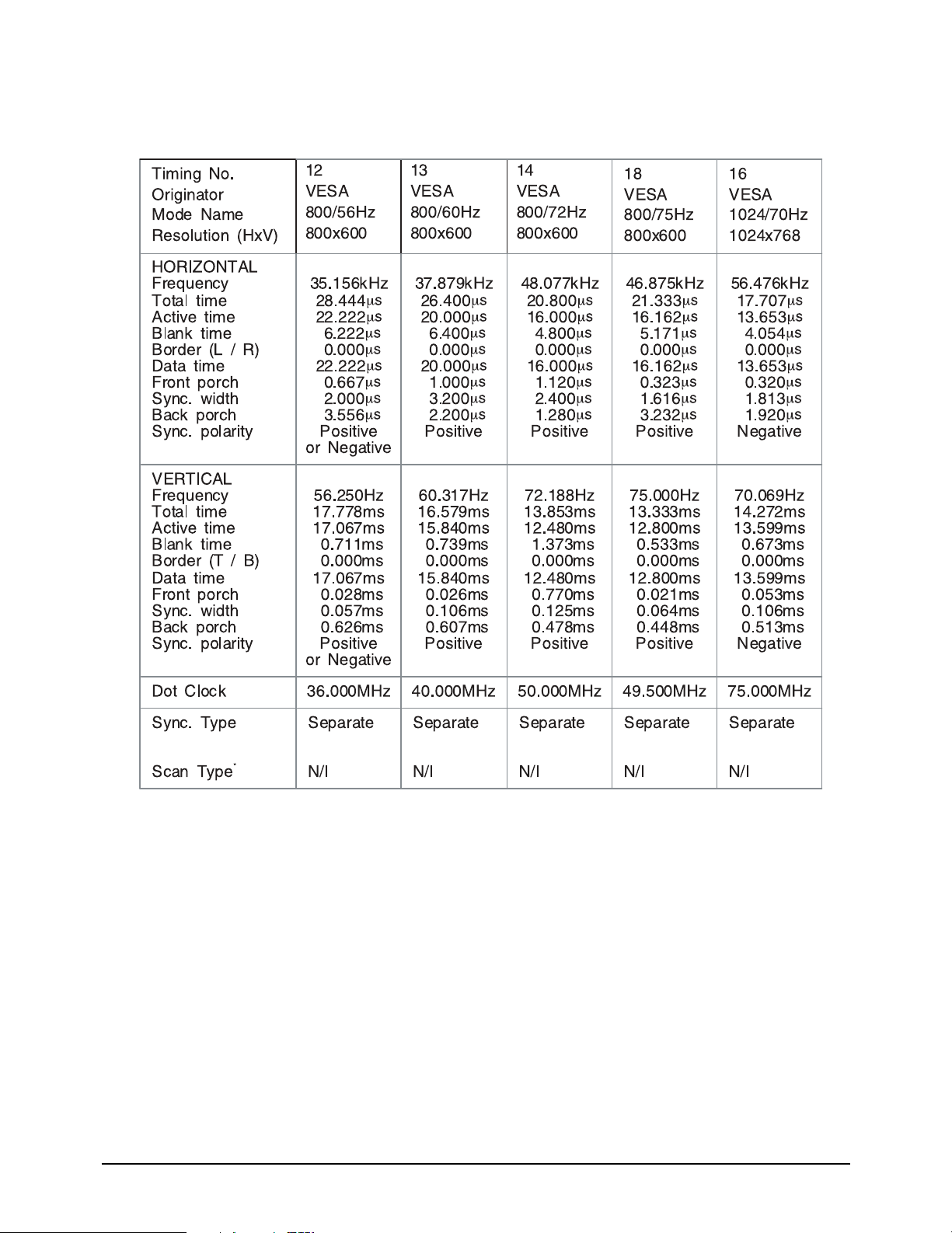

2-3 Timing Chart

This section of the service manual describes the timing that the computer industry recognizes as standard

for computer-generated video signals.

2-3-1. GH15DS

Table 2-1. Timing Chart

GH15DS 2-3

Page 7

2 Product Specifications

Table 2-2. Timing Chart

2-4 GH15DS

Page 8

3-1-1 Removing the Stand

1. Remove 4 screws in the hinge area.

2. Disconnect Power Cord and Signal Cable.

3. Pry it off the back of the monitor.

3-1-2 Main Body Disassembly

1. Remove 2 screws on the two corner of the

Rear Cover.

2. Remove Rear Cover from the Front Cover.

3. Remove 4 screws on the Shield and remove

the shield.

4. Disconnect Inverter wire, Function PCB wire

and Interface wire.

Remove 3 screws on the Main PCB and

remove 2 screws on the D sub shield.

5. Remove 3 screws on the power PCB and

remove 2 screws on the Inverter PCB.

6. Remove the Main PCB Assembly.

7. Remove 3 screws on the Function PCB from

locking area of Function knob and remove

Function PCB.

3-1-3 Standard Stand Disassembly

1. Remove 2 screws from the Stand front.

2. Remove 7 screws from the Stand Bottom.

3. Remove Stand Rear from the Stand assembly.

4. Remove 5 screws from the Stand assembly.

5. Remove the Neck front from the Stand

assembly.

6. Remove 2 screws from the Stand assembly.

7. Remove Neck Rear from the Stand assembly.

8. Remove 4 screws from the Stand assembly.

GH15DS 3-1

3 Disassembly and Reassembly

This section of the service manual describes the disassembly and reassembly procedures for the

GH15DS monitor.

WARNING: This monitor contains electrostatically sensitive devices. Use with caution when

handling these components.

3-1 Disassembly

Cautions:1. Disconnect the monitor from the power source before disassembly.

2. Follow these directions carefully; never use metal instruments to pry apart the cabinet.

Page 9

3 Disassembly and Reassembly

3-2 GH15DS

1. After confirm there is nothing

on the disk

Turn the LCD module over

and put it on a flat desk set to

the ground.

3-2 Replacement Order of Lamp Assemblies (GH15DS : Samsung Panel)

2. Push down the stopper and

slide the lamp unit.

3. Please take out the lamp

unit from the LCD

module.

Page 10

3 Disassembly and Reassembly

GH15DS 3-3

4. Please fix the new lamp

units on the LCD module :

opposite process 2 and 3

* Replacement of lamp unit should be done at the power off state and recommanded clean

bench condition.

3-3 Reassembly

Reassembly procedures are in the reverse order of Disassembly procedures.

Page 11

4 Troubleshooting

Notes: 1. Before troubleshooting, setup the PC’s display as below.

• Resolution: 1024 x 768

• H-frequency: 48 kHz

• V-frequency: 60 Hz

2. If no picture appears, make sure the power cord is correctly connected.

3. Check the following circuits.

• No raster appears: Main PCB

• 12V develop but no screen: Main PCB

• 12V does not develop: Main PCB

4. If you push and hold the EXIT button for more than 5 seconds, the monitor automatically turns back

to the factory preset(GH15DS).

4-1 Power

Does proper DC 12 V

appear at CN100?

Yes

Does proper DC 5 V appear at

output Pin of IC100?

Yes

Does proper 3.3 V - signals

appear at output Pin of IC103?

Yes

Does proper 3.3 V - signals

appear at Pin 7 of CN100?

Yes

Does proper 3.3 V - signals

appear at R300?

No

Check Power Adaptor.

No

Check IC100 and related circuit.

No

Check IC103 and related circuit.

No

Check CN100-7 and related circuit.

No

Check IC301 and related circuit.

Yes

Check IC101, IC102, IC601, IC401

and related circuit.

GH15DS 4-1

Page 12

4 Troubleshooting

4-2 Video

Power indicator is green?

Yes

Do the input signals appear at

pin 30, 31, 32 of IC401?

3 4 5

Yes

No

No

Do the input signals

appear at D201~D208?

1 2

Yes

Check X301.

Check Pin 68 of IC301 and IC102.

Check IC301.

No

Do the output signals appear

at pin 40 of IC401?

6

Yes

Replace LCD panel.

No

Check IC401.

4-2 GH15DS

Page 13

WAVEFORMS

4 Troubleshooting

D201

1

IC401 #30

3

D208

2

IC401 #31

4

IC401 #32

5

IC401 #40

6

GH15DS 4-3

Page 14

6 Electrical Parts List

6-1 Main PCB Part

Loc. No. Code No. Description Specification Remarks

CIS BN44-00053A ADAPTOR

CIS BN72-00209A SUPPORT-POWER GH15LS,ABS+PC,GR37,-,5V,-,-,- SNA

CIS BN75-00176B UNIT-SHIELD/DSUB GH15LS,-,SPTE T0.5,-,-,-,- SNA

CIS BN70-00204B SHIELD-D/SUB GH15DS,SPTE,-,T0.5,-,-,CIS BN71-00024A EARTH-PLATE GH17LS,SUS,T0.15,-,-,- SNA

CIS BN46-00008K MICOM-S/W,GOGH GH15DS,-,-,-,-,-,- SNA

CN100 3711-004853 CONNECTOR-HEADER BOX,7P,1R,2MM,ANGLE,SN,WHT SNA

CN201 3701-001173 CONNECTOR-DSUB 24P,3R,FEMALE,ANGLE,AUF

CN601 3711-001465 CONNECTOR-HEADER NOWALL,3P,1R,2.54mm,STRAIGHT,A SNA

DVI BN60-00001A SCREW-CHASSIS -,NI PLATING,-,11,HEX,HEX,-,UNC#4-40,NI PLT,- SNA

IC601 0903-001143 IC-MICROCONTROLLER

SOCK_IC601 3704-001071 SOCKET-IC 42P,DIP,SN,1.778mm

C102 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C103 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C104 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C105 2402-001042 C-AL,SMD 100uF,20%,16V,GP,TP,6.6x6.6x5.4mm

C106 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C107 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C108 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C112 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C113 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C114 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C115 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C201 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C202 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C301 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C302 2402-001042 C-AL,SMD 100uF,20%,16V,GP,TP,6.6x6.6x5.4mm

C303 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C304 2402-001042 C-AL,SMD 100uF,20%,16V,GP,TP,6.6x6.6x5.4mm

C307 2402-000135 C-AL,SMD 22uF,20%,16V,GP,TP,5.3x5.3x5.4

C308 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C309 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C310 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C311 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C312 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C313 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C314 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C315 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C316 2203-000384 C-CERAMIC,CHIP 0.015nF,5%,50V,NP0,TP,1608

C317 2203-000384 C-CERAMIC,CHIP 0.015nF,5%,50V,NP0,TP,1608

C318 2203-000384 C-CERAMIC,CHIP 0.015nF,5%,50V,NP0,TP,1608

C319 2203-000384 C-CERAMIC,CHIP 0.015nF,5%,50V,NP0,TP,1608

C320 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C321 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C322 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C323 2402-000135 C-AL,SMD 22uF,20%,16V,GP,TP,5.3x5.3x5.4

C325 2402-000135 C-AL,SMD 22uF,20%,16V,GP,TP,5.3x5.3x5.4

C326 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C327 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

DPA30L,150S,100-240VAC,47 - 63 HZ,12VDC/3.3VDC,2A/2A,-,30.6,AC-DC,-10~40C,-,-

88P6232,8BITBit,SDIP,42P,600MIL,12MHz,ST,CMOS,PLASTIC,5V,-,-40to+85C,464BYTE,32K

SNA

GH15DS 6-1

Page 15

6 Electrical Parts List

Loc. No. Code No. Description Specification Remarks

C328 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C329 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C330 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C331 2402-000135 C-AL,SMD 22uF,20%,16V,GP,TP,5.3x5.3x5.4

C332 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C333 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C334 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C335 2203-000280 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

C336 2203-000280 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

C402 2203-000440 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,C403 2203-000440 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,C404 2203-000440 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,C405 2203-000440 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,C413 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C414 2402-001042 C-AL,SMD 100uF,20%,16V,GP,TP,6.6x6.6x5.4mm

C415 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C600 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C601 2402-001042 C-AL,SMD 100uF,20%,16V,GP,TP,6.6x6.6x5.4mm

C602 2203-000626 C-CERAMIC,CHIP 0.022nF,5%,50V,NP0,TP,1608

C603 2203-000626 C-CERAMIC,CHIP 0.022nF,5%,50V,NP0,TP,1608

C604 2402-000176 C-AL,SMD 10uF,20%,16V,GP,TP,4.3x4.3x5.4

C605 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C606 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C610 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C611 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C612 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C613 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

C614 2203-005005 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

CA301 2503-001019 C-NETWORK 33PFX4,10%,50V,CHIP

CA302 2503-001019 C-NETWORK 33PFX4,10%,50V,CHIP

CA303 2503-001019 C-NETWORK 33PFX4,10%,50V,CHIP

CA304 2503-001019 C-NETWORK 33PFX4,10%,50V,CHIP

CA305 2503-001019 C-NETWORK 33PFX4,10%,50V,CHIP

CA306 2503-001019 C-NETWORK 33PFX4,10%,50V,CHIP

CN101 3711-000556 CONNECTOR-HEADER BOX,12P,1R,1.25mm,SMD-A,SN SNA

CN402 3711-003161 CONNECTOR-HEADER BOX,20P,1R,1.25mm,ANGLE,SN SNA

CN600 3711-002049 CONNECTOR-HEADER BOX,6P,1R,1.25mm,SMD-A,SN SNA

D201 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D202 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D203 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D204 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D205 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D206 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D207 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D208 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D209 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

D210 0401-001056 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

FT301 2901-001114 FILTER-EMI SMD 25VDC,2.0ADC,-,100nF,3.2x1.6x1

FT302 2901-001114 FILTER-EMI SMD 25VDC,2.0ADC,-,100nF,3.2x1.6x1

FT303 2901-001114 FILTER-EMI SMD 25VDC,2.0ADC,-,100nF,3.2x1.6x1

FT402 2901-001114 FILTER-EMI SMD 25VDC,2.0ADC,-,100nF,3.2x1.6x1

6-2 GH15DS

Page 16

6 Electrical Parts List

Loc. No. Code No. Description Specification Remarks

FT407 2901-001114 FILTER-EMI SMD 25VDC,2.0ADC,-,100nF,3.2x1.6x1

IC100 1203-001488 IC-POSI.FIXED REG. 7805,T0-252,3P,-,PLASTIC,4.8/5

IC103 1203-001293 IC-POSI.FIXED REG. 033,T0-252,3P,6.5MIL,PLASTIC,3

IC201 1103-000129 IC-EEPROM 24C02,256x8BIT,SOP,8P,150MIL,1

IC301 1003-001374 IC-LCD CONTROLLER GM3020,LQFP,128P,551MIL,SINGLE,-,-,PLASTIC,3.47V,0TO+70C,-,-,IC401 1205-001740 IC-TRANSMITTER

IC603 1103-000129 IC-EEPROM 24C02,256x8BIT,SOP,8P,150MIL,1

L100 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

L101 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

L102 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

L201 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

L303 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

L304 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

L401 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

L402 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

L602 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

L603 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

L604 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

L605 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

L606 2703-001334 INDUCTOR-SMD 1.5uH,10%,2x1.25x0.85mm

MP1.0 BN41-00093A PCB MAIN S/M150DS,FR4,2L,-,-,120*110*1.6,GH15D,-,-,Q101 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q102 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q103 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q600 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q601 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q602 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q603 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q605 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

Q606 0501-002080 TR-SMALL SIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

R100 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R101 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R102 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R103 2007-000102 R-CHIP 100Kohm,5%,1/16W,DA,TP,1608

R104 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R105 2007-000102 R-CHIP 100Kohm,5%,1/16W,DA,TP,1608

R106 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R107 2007-000102 R-CHIP 100Kohm,5%,1/16W,DA,TP,1608

R108 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R109 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R110 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R111 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R112 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R113 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R114 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R201 2007-000078 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

R202 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R203 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R204 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R205 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R300 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

DS90C385,TSSOP,56P,240MIL,PLASTIC,4V,1.63W,-10 TO +70C,ST,FPD LINK-85MHZ(LVDS)

GH15DS 6-3

Page 17

6 Electrical Parts List

Loc. No. Code No. Description Specification Remarks

R301 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R302 2007-000071 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

R303 2007-000071 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

R304 2007-000071 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

R309 2007-000071 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

R310 2007-000078 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

R311 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R312 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R313 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R314 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R315 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R316 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R317 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R318 2007-000309 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

R322 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R323 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R324 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R327 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R329 2007-000078 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

R330 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R331 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R332 2007-000109 R-CHIP 1Mohm,5%,1/16W,DA,TP,1608

R401 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R402 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R403 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R600 2007-000070 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

R601 2007-000078 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

R602 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R606 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R608 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R609 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R610 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R611 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R612 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R613 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R614 2007-000109 R-CHIP 1Mohm,5%,1/16W,DA,TP,1608

R615 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R616 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R618 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R619 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R620 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R621 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R622 2007-000084 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

R623 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R624 2007-000078 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

R625 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R626 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R627 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R628 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R629 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R630 2007-000102 R-CHIP 100Kohm,5%,1/16W,DA,TP,1608

6-4 GH15DS

Page 18

6 Electrical Parts List

Loc. No. Code No. Description Specification Remarks

R631 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R632 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R633 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R634 2007-001002 R-CHIP 510ohm,5%,1/16W,DA,TP,1608

R635 2007-001002 R-CHIP 510ohm,5%,1/16W,DA,TP,1608

R636 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R637 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R638 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R639 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R640 2007-000090 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

R641 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R642 2007-000078 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

R866 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R867 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

R868 2007-000074 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

RA301 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA302 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA303 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA304 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA305 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

RA306 2011-000002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

X301 2801-004004 CRYSTAL-SMD 20.25MHz,20ppm,28-AAN,13pF,25ohm,TP

X601 2801-003773 CRYSTAL-SMD 12MHZ,30PPM,28-AAN,20PF,50OHM,TP

ZD201 0403-000579 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

ZD202 0403-000579 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

ZD203 0403-000579 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

ZD204 0403-000579 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

ZD205 0403-000579 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

6-2 Others

Loc. No. Code No. Description & Specification Remarks

PANEL BN07-00026A LCD-DISPLAY;LTM150XH-L01,CZB,8BIT,333.6*254.76*12.5

MAIN PCB ASS’Y BN94-00128A ASSY PCB-SN;GH15DS

SIGNAL CABLE BN39-00072A CBF SIGNAL;DET,2000MM,24P/24P,IVORY,-,DVI

INVERTER HARNESS BN39-00020A CBF-HARNESS;12P/12P,170MM,BLU/YEL/WHT

LVDS HARNESS BN39-00183A LEAD CONNECTOR ASSY;UL2835#28,UL/CSA,20P,120MM

POWER CORD(115V) BN39-00141A AC POWER CORD;125VAC,10A,1800,IVORY

POWER CORD(230V) BN39-00140A AC POWER CORD;230VAC,250/10A,1.80M,3PIN EURO STRAIGH,IVORY

INVERTER BN44-00056A INVERTER;GOGH,SIC1542,48KHZ,12VDC,37*140*16,4LAMP

GH15DS 6-5

Page 19

7 Block Diagram

GH15DS 7-1

Page 20

GH15DS 8-1

1

2

3

4

5

6

7

+12V

GND

GND

+12V_INV

GND

PWR_OFF

3.3V

CN100

1

2

3

4

5

6

7

+12V

GND

GND

+12V_INV

GND

PWR_OFF

3.3V

CN2

1

2

3

4

5

6

+3.3V

LED_R

LED_G

KEY_A

KEY_B

GND

CN600

NC

DVI_+5V

DVI_GND

GND

Rx0–

Rx0+

DVI_+5V

NCNCGND

RxC+

RxC–

CN201

MAIN PCBPOWER PCB

1314151417181920212223

24

Rx2–

Rx2+

GNDNCNC

DVI_CLK

DVI_DTA

NC

Rx1–

1

2

3

4

5

6

7

8

9

10

11

Rx1+

GND

12 NC

+5V

GND

GND

+12V_INV

+12V_INV

+12V_INV

CN101 CN402

7

8

9

101112

NC

BRT_CTL_INVNCBL_ONNCGND

1

2

3

4

5

6

GND

Tx1A+

Tx1A-

GND

Tx0A+

Tx0A-

GND

GND

LCD_VCC

LCD_VCC

111213141516171819

20

NC

GND

Tx3A+

Tx3A-

GND

TxCA+

TxCA-

GND

Tx2A+

1

2

3

4

5

6

7

8

9

10 Tx2A-

CN1

1

2

3

GND

8 Wiring Diagram

Page 21

GH15DS 9-1

9 Schematic Diagrams

9-1 Main Part Schematic diagram

XG1 XG2

HPD

R300

0

1/16W

0

1/16W

R331R330

Q1

1/16W

100

R867

1/16W

0

X301

HC-49/SM5H(20.25MHz)

Q0

MO

50V

0.01nF

C335 C336

0.01nF

50V

MO

R332 1M

R329

1K

1/16W

DVI_GND

DVI_CLK

DVI_DAT

DVI_+5V

24

27

30

31

32

1/16W

0

R301

15

16

26

29

17

18

19

20

21

22

23

7

8

25

28

9

10

11

12

13

14

8

tpcon32p_1

CN201

1

2

3

4

5

6

12345

6

7

12345

678

CA306

678

CA305

CA304

1

2

345

CA303

1

2

34567

8

34567867

8

CA302

1

2

CA301

12345

16V

10uF

C415

ON+5V

C201

10uF

16V

16.000

100uF

C302

D3.3V

MO

16V

100nF

C303

L304

1.5uH

L303

1.5uH

3.3V_RX

C304

100uF

16.000

C301

100nF

16V

MO

1718192021

22

789

10111213141516

CN402

slcon22p_1

12345

6

SGM32F1E104-2A

FT407

1

A

B

2

3

C

LCD_VCC

MO

16V

100nF100uF

C414

16V

3.3V_RX

C413

12

3

MMBD4148SE

D204

12

3

12

3

D203

MMBD4148SE

MMBD4148SE

D201

12

3

D202

MMBD4148SE

2

3

D208

MMBD4148SE

12

3

12

3

MMBD4148SE

D207

112

3

MMBD4148SE

D206

BZX84C5V1

ZD203

D205

MMBD4148SE

ZD204

BZX84C5V1

BZX84C5V1

ZD202

ZD205

BZX84C5V1

C311

100nF

16V

3.3V_RX

16V

100nF

C310

3.3V_RX

16V

100nF

C308

1/16W22

3.3V_RX

C328

100nF

16V

22 1/16W

R302

R304

16V

100nF

C334

R309

1/16W22

MO

R402

R403 100

100

100

3

MO

50V

1nF

C405

R401

1.5uH

FT402

SGM32F1E104-2A

1A2

B

C

VCC1

26

VCC2

L402

7

TXIN9

47

TXOUT0+

TXOUT0-

48

45

TXOUT1+

TXOUT1-

46

41

TXOUT2+

42

TXOUT2-

37

TXOUT3+

TXOUT3-

38

VCC

1

9

25

27

TXIN24

TXIN25

28

TXIN26

30

TXIN27

50

55

TXIN3

56

TXIN4

TXIN5

2

TXIN6

3

TXIN7

4

6

TXIN8

12

TXIN14

14

TXIN15

15

16

TXIN16

TXIN17

18

19

TXIN18

TXIN19

20

TXIN2

54

TXIN20

22

TXIN21

23

TXIN22

24

TXIN23 PWRDWN

32

17

R_FB

31

TXCLKIN

39

TXCLKOUT+

TXCLKOUT-

40

TXIN0

51

TXIN1

52

8

TXIN10

10

TXIN11

TXIN12

11

TXIN13

13

GND2

GND3

21

29

GND4

53

GND5

49

LVDSGND

LVDSGND1

43

LVDSGND2

36

LVDSVCC

44

35

PLLGND

PLLGND1

33

PLLVCC

34

3.3V_LVDSTX

IC401

DS90C385MTD

GND1

5

50V

1nF

L401

1.5uH

C402

1nF

50V

MO

C404

MO

3

C403

1nF

50V

MO

R201

ZD201

BZX84C5V1

1

A

B

2

C

1/16W

1K

R203

C202

100nF

16V

4.7K

1/16W

R202

1/16W

4.7K

R205 100

R204 100

RxC

Rx0

RxC+

Rx1

Rx0+

Rx2+

Rx1+

Rx2

MMBD4148SE

D210

D209

MMBD4148SE

7

8

1.5uH

L201

NM24C02M8

IC201

1

2

3

4

5

6

R327 100

1/16W

C332

100nF

16V

MO

16V

100nF

C327

113

STI_TM2

TCLK

100

VBUFC

95

VDD1

71

VDD2

77

VDD3

83

99

XTAL

C326

100nF

16V

117

RVSS5

RVSS6

4

86

RX0

RX0-

87

80

RX1

RX1-

81

74

RX2

RX2-

75

RXC

89

90

RXC-

STI_TM1

112

RESETn

REXT

69

RVDD1

14

RVDD2

28

RVDD3

41

56

RVDD4

RVDD5

118

3

RVDD6

29

RVSS2

42

RVSS3

RVSS4

57

38

PD9

PDE

24

PHS

53

PLL-DGNDA

104

103

PLL-DVDDA

97

PLL_RGNDA

PLL_RVDDA

98

PPWR

55

52

PVS

15

PVSS1

109

124

123

PD42

PD43

122

121

PD44

PD45

116

115

PD46

PD47

114

46

PD5

PD6

45

44

PD7

PD8

43

7

PD32

PD33

6

5

PD34

PD35

2

1

PD36

PD37

128

127

PD38

PD39

126

PD4

47

125

PD40

PD41

21

PD22

PD23

20

17

PD24

PD25

16

13

PD26

PD27

12

11

PD28

PD29

10

48

PD3

9

PD30

PD31

8

35

34

PD13

PD14

33

PD15

32

31

PD16

PD17

30

27

PD18

PD19

26

PD2

49

23

PD20

PD21

22

OSD_CLK

OSD_DATA0

63

64

OSD_DATA1

60

OSD_HREF

OSD_VREF

61

54

PBIAS

25

PCLK

PD0

51

50

PD1

PD10

37

36

PD11

PD12

72

GND1

78

GND2

84

GND3

111

HCLK

HDATA

108

107

HFS

IRQ

110

OSD-DATA2

65

66

OSD-DATA3

OSD-FSW

67

62

40

CVDD2

CVDD3

59

119

CVDD4

19

CVSS1

CVSS2

39

58

CVSS3

CVSS4

120

101

DAC-DGNDA

DAC-DVDDA

102

105

DVDD

DVSS

106

AGND5

92

AGND6

93

68

AVDD1

76

AVDD2

82

AVDD3

88

AVDD4

AVDD5

91

94

AVDD6

96

CLKOUT

CVDD1

18

gm3020

IC301

AGND1

70

AGND2

73

AGND3

79

AGND4

85

10

10 1/16W

R318

1/16W

R316

R317

1/16W

R315

1/16W10

10

10

10 1/16W

R314

1/16W

R312

R313

1/16W

R311

1/16W10

10

R324

100

1/16W

R322 100

1/16W

1/16W

100R323

SGM32F1E104-2A

FT301

A

1

2

B

C

3

SGM32F1E104-2A

FT302

A

12

B

C

3

3.3V_RX

FT303

SGM32F1E104-2A

1

AB

2

3

C

22 1/16W

R303

C316

15pF

50V

MO

15pF

50V

MOMO

50V

15pF

C317

MO

50V

15pF

C318 C319

1

2

3

4

5

6

7

8

2

3

4

5

6

7

8

RA302

6

7

8

RA301

1

RA304

1

2

3

4

5

RA303

1

2

3

4

5

6

7

8

3

4

5

6

7

8

5

6

7

8

RA306

1

2

RA305

1

2

3

4

16V

100nF

C314 C315

100nF

16V16V

100nF

C312 C313

100nF

16V

C309

100nF

16V

MO

16V

100nF

C322

16V

22uF

C307

16V

MOMO

16V

100nF

C320 C321

100nF

C323

22uF

16V

16V

100nF

C329 C330

100nF

16V

C325

22uF

16V

MO

16V

100nF

C333

R310

1K

1/16W

C331

22uF

16V

DAR(0)

DAR(1)

DAR(2)

DAR(3)

DAG(4)

DAG(5)

DAG(6)

DAG(7)

DAG(0)

DAG(1)

DAG(2)

DAG(3)

DAB(4)

DAB(5)

DAB(6)

DAB(7)

DAB(0)

DAB(1)

DAB(2)

DAB(3)

DHS

DVS

DDEN

LVDS_EN

Tx0A-

Tx0A+

Tx1A-

Tx1A+

Tx2A-

Tx2A+

TxCA-

TxCA+

Tx3A-

Tx3A+

DAR(4)

DAR(5)

DAR(6)

DAR(7)

DAB(3)

DAB(4)

DAB(5)

DAB(6)

DAB(7)

Tx0ATx0A+

Tx1ATx1A+

Tx2ATx2A+

TxCATxCA+

Tx3ATx3A+

DCLK

DVI_DAT

DVI_DAT

DVI_+5V

DVI_+5V

DAR(7:0)

DAR(0)

DAR(1)

DAR(2)

DAR(3)

DAR(4)

DAR(5)

DAR(6)

DAR(7)

DAG(7:0)

DAG(0)

DAG(1)

DAG(2)

DAG(3)

DAG(4)

DAG(5)

DAG(6)

DAG(7)

DAB(7:0)

DAB(0)

DAB(1)

DAB(2)

DDEN

DCLK

DHS

HCLK

HDAT

IRQn

RESET3020

HFS

DVI_GND

Rx1+

Rx2+

Rx1-

Rx2-

RxC-

RxC+

Rx0+

Rx0-

DVI_CLK

DVI_CLK

DAB(7)

DAB(6)

DAB(5)

DAB(4)

DAB(3)

DAB(2)

DAB(7:0)

DAB(1)

DAB(0)

DAG(0)

DAG(1)

DAG(2)

DAG(3)

DAG(4)

DAG(5)

DAG(6)

DAG(7)

DAG(7:0)

DAR(7)

DAR(6)

DAR(5)

DAR(4)

DAR(3)

DAR(2)

DAR(7:0)

DAR(1)

DAR(0)

DVS

Rx2+

Rx2-

Rx1+

Rx1-

Rx0+

Rx0-

RxC+

RxC-

4

6

5

3

1

2

GH15ES/GH15MS

only

Page 22

9 Schematic Diagrams

9-2

GH15DS

1

D201

2

D208

5

IC401 #32

6

IC401 #40

3

IC401 #30

4

IC401 #31

Page 23

9-2 Video Part Schematic diagram

9 Schematic Diagrams

GH15DS 9-3

for JIG

CLK

DATA

Model Select Option

Place at distributed position

P0.0

P0.1

P0.2

P0.3

P0.4

P0.5

P0.6

P0.7

SDA1

SCL1

VDD(5V)

GND

OSC_O

OSC_I

GND(TST)

SDA0

SCL0

RESETn

P1.2

PWM0

PWM1

PWM2

PWM3

PWM4

PWM5

PWM6

CLMP_O

HSYNCO

VSYNCO

VSYNCI

HSYNCI

SOG_SYNC

GND

5V

AD0

AD1

AD2

AD3

P3.4

P3.5

P3.6

P3.7

TO FUNCTION

H=SXGA

L=XGA

(H:OFF, L:ON)

XM2

TP_ON5V

XM1

R110

0

1/16W

TP_ON3V

R102

0

1/16W

MO

CPU_VCC

3.3V_RX

TP_I12V

TP_POFF

C606

100nF

16V

TP_BL5V

TP_M12V

TP156

1

TP157

1

R109

0

1/16W

R631

10K

1/16W

Q606

B

C

E

1/16W

1K

R642

ON+5V

2SC2412K-Q

PA3.3V

ON+3.3V

3.3V_LVDSTX

C115

100nF

16V

MO

IC103

BA033FP

GND

IN OUT

PA3.3_5V

PA3.3V

R100

100

1/16W

100R868

R641 100 1/16W

1/16W

4.7K

R606

1/16W

TPF1

1

1/16W

4.7K

R602

100nF

C614

1/16W

4.7K

R622

4.7K

R609

R621

4.7K

1/16W

1.5uH

L602

1/16W

1/16W100R866

100 1/16W

R623 100 1/16W

1/16W100R612

R613

1.5uH L603

1.5uH L605

100nF

C610

100nF 100nF

C612C611 C613

100nF

1.5uH L604

L6061.5uH

1

TPF5

11

TPF3

1

TPF4

CN600

1

2

3

4

5

6

7

8

TPF2

CPU_VCC

CPU_VCC

slcon8p

MO

50V

22pF

C603

1M

1/16W

C602

22pF

50V

MO

HC-49/S-SMD(12MHz,30ppm)

X601

Q0Q1

R614

17

18

19

20

21 22

23

24

25

26

38

13

39

14

40

15

41

16

42

8

34

9

35

10

36

11

37

12

28

3

29

4

30

5

31

6

32

7

33

LCD_VCC

KS88C6232N

IC601

1

27

2

E

C112

100nF

16V

MO

2SC2412K-Q

Q101

B

C

R104

1/16W

100K

R103

R101

PA3.3_5V

1/16W

10K

B

C

E

1/16W

0

R640

10K

1/16W

Q605

2SC2412K-Q

4

1

S1

3

S2

R601

1K

1/16W

IC101

SI9933ADY-T1

D1

8

7

D1_1

D2

6

5

D2_1

G1

2

G2

1/16W

0

R112

R600

1/16W

0

R113

100nF

C107

1/16W

0

1.5uH

L102

C106

100nF

100nF

C108

L101

1.5uH

1.5uH

L100

10

11

12

13

14

TP_BL12V

1

2

3

4

5

6

7

8

9

TP_BRT

1

TP_BLON

1

CN101

slcon14p_1

4

5

6

7

DC+12V_INV

ON+5V

slcon7p

CN100

1

2

3

4.7K

1/16W1/16W

4.7K

R618

1/16W

4.7K

R620R619

CPU_VCC

16V

10uF

C604

R608

4.7K

1/16W

1K

1/16W

R624

4.7K

1/16W

CPU_VCC

1/16W

4.7K

R611

R610

1/16W

100

R628

100

R633

CPU_VCC

R632

100

R626

100

1/16W

R629

R630

100K

1/16W

1/16W

10K

R625

1/16W

10K

100

R627

6

7

8

CPU_VCC

C605

100nF

16V

MO

CPU_VCC

NM24C02M8

IC603

1

2

3

4

5

4.7K

R615

ON+3.3V

R616

4.7K

CPU_VCC

C601

100uF

16.000

GND

IN OUT

C600

100nF

16V

MO

IC100

BA17805FP

MO

16V

100nF

C114

C113

100nF

16V

MO

B

C

E

D3.3V

R108

10K

1/16W

Q103

2SC2412K-Q

R107

100K

1/16W

2SC2412K-Q

Q102

B

C

E

1/16W

100K

R105

6

D2

D2_1

5

2

G1

4

G2

S1

1

S2

3

1/16W

10K

R106

SI9933ADY-T1

IC102

8

D1

D1_1

7

R637

10K

10K

R639

R636

R638

10K

2SC2412K-Q

Q603

B

C

E

10K Q600

2SC2412K-Q

B

C

E

CPU_VCC

R635

510

1/16W

Q601

2SC2412K-Q

B

C

E

B

C

E

1/16W

510

R634

ON+5V

DC+12V

PA3.3V

2SC2412K-Q

Q602

C102

10uF

16V

R111

0

1/16W

C103

100nF

16V

MO

1/16W

0

R114

C104

TP_3VIN

16V

100uF

C105

MO

16V

100nF

BRT_CTL

LED_R

LED_G

KEY_A

KEY_B

PA3.3_5V

DET_PCPWR

BRT_CTL_INV

IRQn

EEP_SDA

SEL_MDL

BRT_CTL_INV

BL_ON

PWR_OFF

BRT_CTL

PLCD_ON

PWR_OFF

SEL_MDL

KEY_A

PLED_RED

KEY_B

LVDS_EN

RESET3020

BL_ON

PLCD_ON

HCLK

TMDS_ON

HDAT

SPWR_ON

HFS

PLED_GRN

EEP_SCL

DET_CONN

PLED_RED

PLED_GRN

SPWR_ON

TMDS_ON

DVI_DAT

DVI_CLK

EEP_SCL

EEP_SDA

DET_CONN

DVI_+5V

DVI_GND

DET_PCPWR

LED_R LED_G

PLED_RED

PLED_GRN

Loading...

Loading...