Samsung dvd-tv Service Manual

DVD Television

Chassis : C16A

Model: DW21G5VDX/XEF DW21G5VDX/BWT

DW21G5VDX/XEU DW21G5VDX/NWT

DW21G5VDX/XEN DW21G5VDX/VWT

DW21G5VDX/XEG

DVD Television Cassette Recorder CONTENTS

Precautions

Specifications

Disassembly and Reassembly

Alignment and Adjustment (Electrical)

Troubleshooting

Exploded View and Parts List

Electric Parts List

Block Diagram

Schematic Diagrams

1.

2.

3.

4.

5.

6.

7.

8.

9.

1. Precautions

1-1 Safety Precautions

1. Be sure that all of the built-in protective

devices are replaced. Restore any missing

protective shields.

2. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including: nonmetallic control knobs

and compartment covers.

3. Make sure that there are no cabinet openings

through which people—particularly

children—might insert fingers and contact

dangerous voltages. Such openings include

the spacing between the picture tube and the

cabinet mask, excessively wide cabinet

ventilation slots, and improperly fitted back

covers.

If the measured resistance is less than 1.0

megohm or greater than 5.2 megohms, an

abnormality exists that must be corrected

before the unit is returned to the customer.

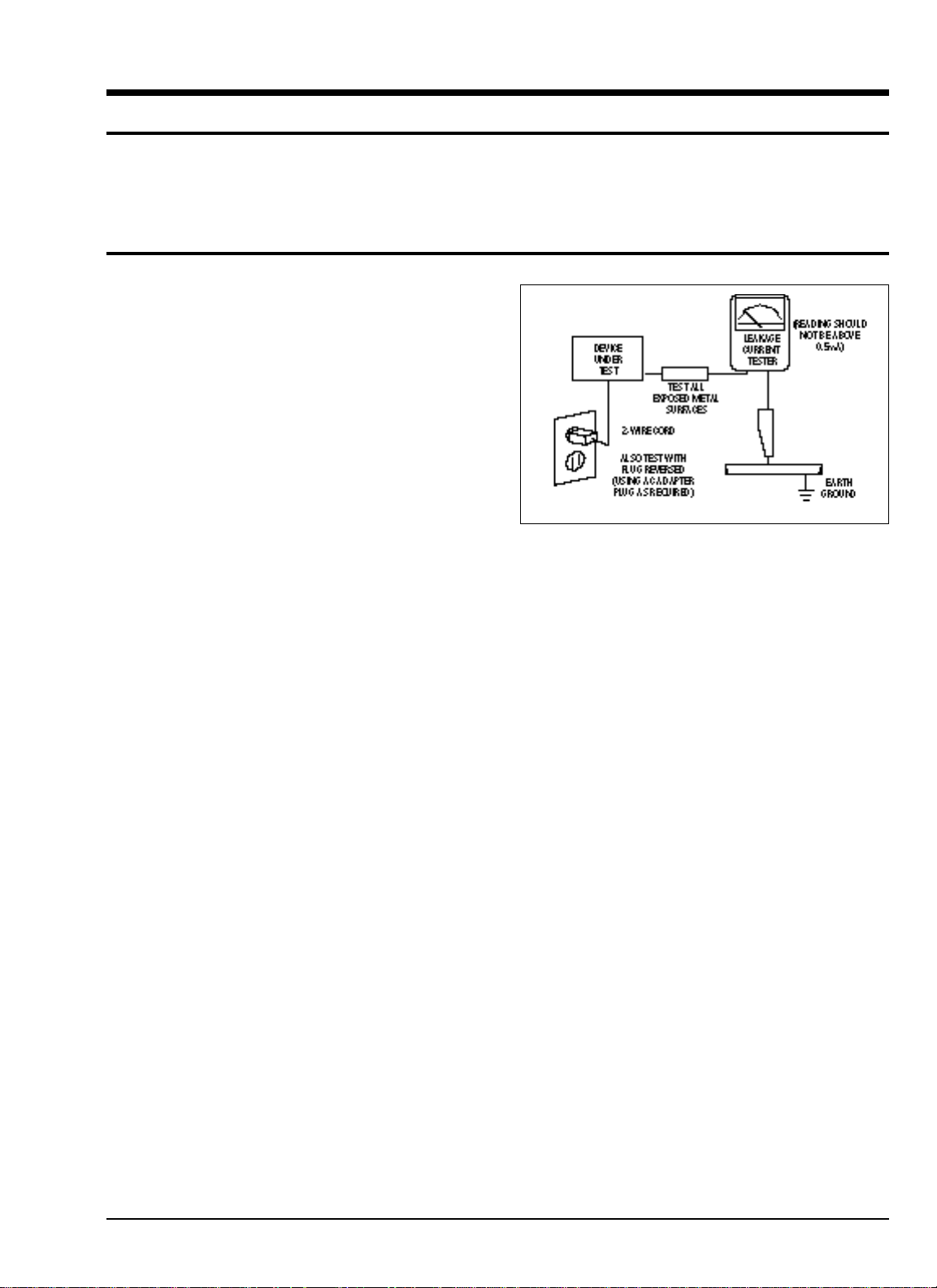

4. Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANIS C101.1, Leakage Current for

Appliances), and Underwriters Laboratories

(UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug

the AC line cord directly into the power

outlet. With the unit’s AC switch first in the

ON position and then OFF, measure the

current between a known earth ground (metal

water pipe, conduit, etc.) and all exposed

metal parts, including: antennas, handle

brackets, metal cabinets, screwheads and

control shafts. The current measured should

not exceed 0.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat the

test.

Fig. 1-1 AC Leakage Test

6. Antenna Cold Check:

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across

the two AC prongs. Connect one lead of the

ohmmeter to an AC prong. Connect the other

lead to the coaxial connector.

7. X-ray Limits:

The picture tube is especially designed to prohibit X-ray emissions. To ensure continued

X-ray protection, replace the picture tube only

with one that is the same type as the original.

Carefully reinstall the picture tube shields and

mounting hardware; these also provide X-ray

protection.

8. High Voltage Limits:

High voltage must be measured each time servicing is done on the B+, horizontal deflection

or high voltage circuits. Correct operation of

the X-ray protection circuits must be

reconfirmed whenever they are serviced.

(X-ray protection circuits also may be called

“horizontal disable” or “hold-down”.)

Heed the high voltage limits. These include

the X–ray Protection Specifications Label, and

the Product Safety and X-ray Warning Note on

the service data schematic.

Precautions

Samsung Electronics 1-1

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential

hazards such as electrical shock and X-rays.

1-1 Safety Precautions (Continued)

9. High voltage is maintained within specified

limits by close-tolerance, safety-related

components and adjustments. If the high

voltage exceeds the specified limits, check

each of the special components.

10. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of this unit. Example: Do not

add auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also,

any design changes or additions will void the

manufacturer’s warranty.

11. Hot Chassis Warning:

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only

if the AC power plug is inserted so that the

chassis is connected to the ground side of the

AC source.

To confirm that the AC power plug is inserted

correctly, do the following: Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the

reading is greater than 1.0V, remove the AC

power plug, reverse its polarity and reinsert.

Re-measure the voltage between the chassis

and ground.

12. Some TV chassis are designed to operate with

85 volts AC between chassis and ground,

regardless of the AC plug polarity. These units

can be safely serviced only if an isolation

transformer inserted between the receiver and

the power source.

13. Some TV chassis have a secondary ground

system in addition to the main chassis ground.

This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulating material that must not be defeated

or altered.

14. Components, parts and wiring that appear to

have overheated or that are otherwise

damaged should be replaced with parts that

meet the original specifications. Always

determine the cause of damage or overheating, and correct any potential hazards.

15. Observe the original lead dress, especially

near the following areas: Antenna wiring,

sharp edges, and especially the AC and high

voltage power supplies. Always inspect for

pinched, out-of-place, or frayed wiring. Do

not change the spacing between components

and the printed circuit board. Check the AC

power cord for damage. Make sure that leads

and components do not touch thermally hot

parts.

16. Picture Tube Implosion Warning:

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure

that the replacement picture tube is the same

as the original.

17. Do not remove, install or handle the picture

tube without first putting on shatterproof

goggles equipped with side shields. Never

handle the picture tube by its neck. Some

“in-line” picture tubes are equipped with a

permanently attached deflection yoke; do not

try to remove such “permanently attached”

yokes from the picture tube.

18. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

give might be lost if the replacement component differs from the original—even if the

replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( ) or ( ).

Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications.

A replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

Precautions

1-2 Samsung Electronics

1-2 Servicing Precautions

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit’s AC power cord from

the AC power source before attempting to: (a)

Remove or reinstall any component or

assembly, (b) Disconnect an electrical plug or

connector, (c) Connect a test component in

parallel with an electrolytic capacitor.

3. Some components are raised above the printed

circuit board for safety. An insulation tube or

tape is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the portion around

the serviced part has not been damaged.

5. Check the insulation between the blades of the

AC plug and accessible conductive parts

(examples: metal panels, input terminals and

earphone jacks).

6. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the

power switch ON. Connect an insulation

resistance meter (500V) to the blades of the AC

plug.

The insulation resistance between each blade

of the AC plug and accessible conductive parts

(see above) should be greater than 1 megohm.

7. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of

its assemblies) unless all solid-state heat sinks

are correctly installed.

8. Always connect a test instrument’s ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument’s ground lead last.

Precautions

Samsung Electronics 1-3

Warning1: First read the “Safety Precautions” section of this manual. If some unforeseen circumstance creates a conflict between

the servicing and safety precautions, always follow the safety precautions.

Warning2: An electrolytic capacitor installed with the wrong polarity might explode.

1. Some semiconductor (“solid state”) devices

are easily damaged by static electricity. Such

components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component damage

caused by static electricity.

2. Immediately before handling any semicon

ductor components or assemblies, drain the

electrostatic charge from your body by

touching a known earth ground. Alternatively,

wear a discharging wrist-strap device. (Be

sure to remove it prior to applying power—

this is an electric shock precaution.)

3. After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4. Do not use freon-propelled chemicals. These

can generate electrical charges that damage

ESDs.

5. Use only a grounded-tip soldering iron when

soldering or unsoldering ESDs.

6. Use only an anti-static solder removal device.

Many solder removal devices are not rated as

“anti-static”; these can accumulate sufficient

electrical charge to damage ESDs.

7. Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive materials.

8. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

9. Minimize body motions when handling

unpackaged replacement ESDs. Motions such

as brushing clothes together, or lifting a foot

from a carpeted floor can generate enough

static electricity to damage an ESD.

Precautions

1-4 Samsung Electronics

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

Precautions

Samsung Electronics 1-5

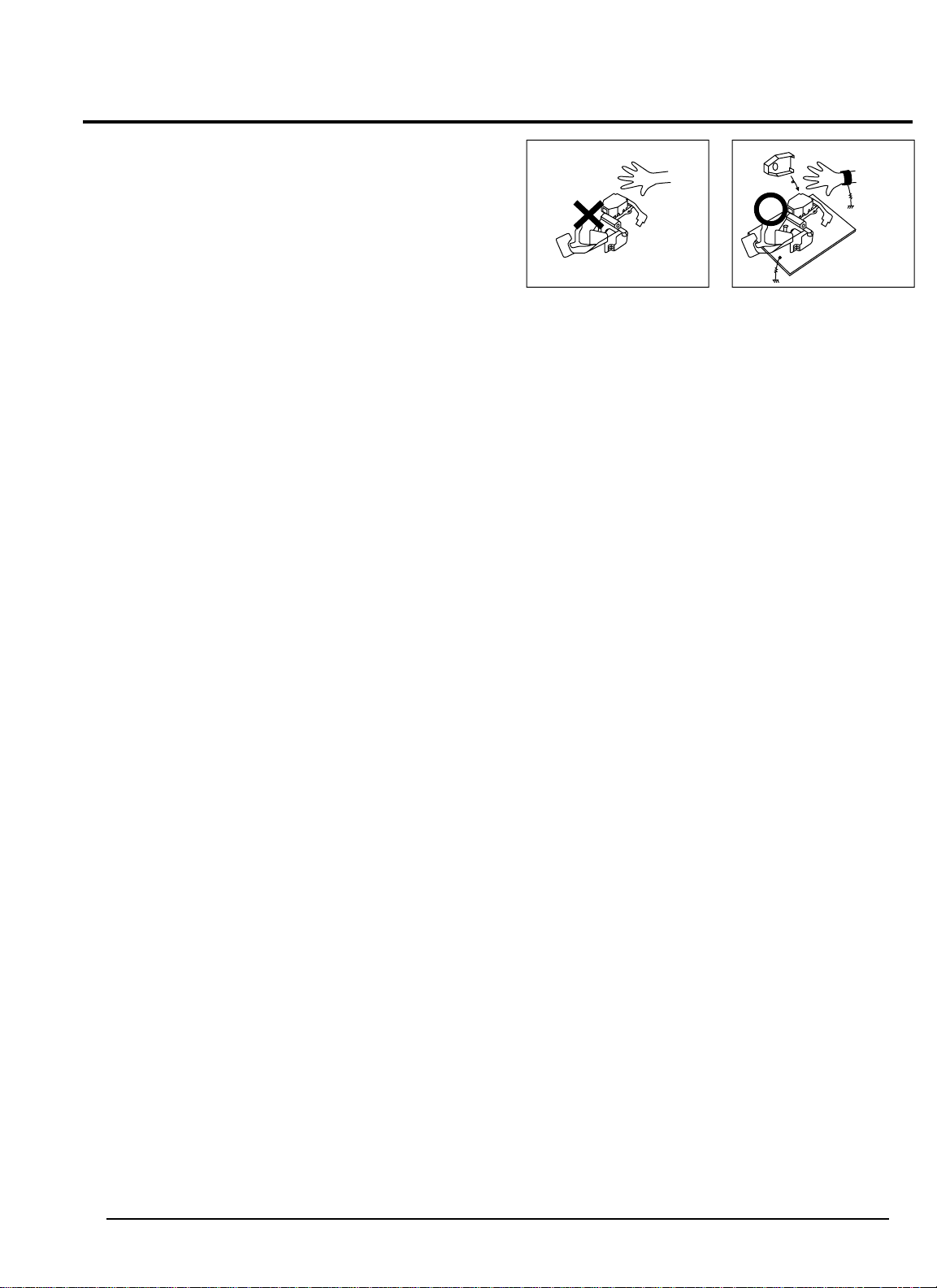

1-4 Handling the optical pick-up

The laser diode in the optical pick up may suffer electrostatic breakdown because of potential static electricity from clothing and your body.

The following method is recommended.

(1) Place a conductive sheet on the work bench (The

black sheet used for wrapping repair parts.)

(2) Place the set on the conductive sheet so that the

chassis is grounded to the sheet.

(3) Place your hands on the conductive sheet(This

gives them the same ground as the sheet.)

(4) Remove the optical pick up block

(5) Perform work on top of the conductive sheet. Be

careful not to let your clothes or any other static

sources to touch the unit.

Be sure to put on a wrist strap grounded to the sheet.

Be sure to lay a conductive sheet made of copper etc.

Which is grounded to the table.

Fig.1-3

(6) Short the short terminal on the PCB, which is in-

side the Pick-Up ASS’Y, before replacing the PickUp. (The short terminal is shorted when the PickUp Ass’y is being lifted or moved.)

(7) After replacing the Pick-up, open the short terminal

on the PCB.

THE UNIT

WRIST-STRAP

FOR GROUNDING

1M

1M

CONDUCTIVE SHEET

Precautions

1-6 Samsung Electronics

1-5 Pick-up disassembly and reassembly

1-5-1 Disassembly

1) Remove the power cable.

2) Switch SW3 on Deck PCB to “OFF” before

removing the Flat-Cable.

( Inserted into Main PCB DCN1. See Fig. 1-4)

3) Disassemble the Deck.

4) Disassemble the Deck PCB.

1-5-2 Assembly

1) Replace the Pick-up.

2) Assemble the Deck PCB.

3) Reassemble the Deck.

4) Insert Flat-Cable into Main PCB DCN1 and switch

SW3 on Deck PCB to “ON”. (See Fig 1-4)

Note : If the assembly and disassembly are not done in correct sequence, the Pick-up may be damaged.

Samsung Electronics 2-1

2-1. Specifications

TELEVISION PART

Colour systems PAL(option) / SECAM(option) (UK;PAL)

TV standards L/L’(option), B/G(option), D/K(option) (UK;I)

Number of channels 100 programmes

Reception range/cable TV Hyperband/interband tuner

Aerial input 75 Ohms, coaxial cable

DISC

DVD (DIGITAL VERSATILE DISC) Reading Speed : 3,49 m/sec.

Approx. Play Time (Single sided, Single Layer Disc) : 135 min.

CD : 12 Cm Reading Speed : 1,2 to 1,4 m/sec.

Maximum Play Time : 74 min.

CD : 8 Cm Reading Speed : 1,2 to 1,4 m/sec.

Maximum Play Time : 20 min.

CD : 12 Cm Reading Speed : 1,2 to 1,4 m/sec.

Maximum Play Time : 74 min. (Video + Audio)

GENERAL

Power supply 220-240V~, 50Hz (110-260V~, 50/60Hz; option)

Consumption 85W

Audio output power 7Watts x 2

Number of loudspeakers 2

Tube size 21” (51cm)

Tube type BLACK MATRIX

Sockets 2 SCART(SCART1 : FULL RGB SCART) ON THE REAR.

(SCART2 : MONITOR OUT) ON THE REAR.

1 RCA input (audio and video2) on the front

Earphones output (3.5 mm mini-jack)

1 aerial/cable TV coaxial input

Dimensions (W x D x H)/Weight 606 X 513 X 505mm / 39.5Kg

Operating temperature 5°C - 35°C

Relative humidity 10% - 75%

The descriptions and characteristics given in this booklet are given for information purposes only and

are subject to modification without notice.

4-2 Factory (“Service”) Mode

Alignment and Adjustments (Electrical)

4. Alignment and Adjustments (Electrical)

4-1 Preadjustment

4-1-1 Factory Mode

1. Do not attempt these adjustments in the Video

Mode.

2. The Factory Mode adjustments are necessary

when either the EEPROM (IC902) or the CRT

is replaced.

3. Do not tamper with the “Adjustment” screen

of the Factory Mode menu. This screen is

intended only for factory use.

4-1-2 When EEPROM (IC902) Is Replaced

1. When IC902 is replaced all adjustment data

revert to initial values. It is necessary to reprogram this data.

2. After IC902 is replaced, warm up the TV for

10 seconds.

4-1-3 When CRT Is Replaced

Make the following adjustments after setting up

purity and convergence:

White Balance

Sub-Brightness

Vertical Center

Vertical Size

Horizontal Size

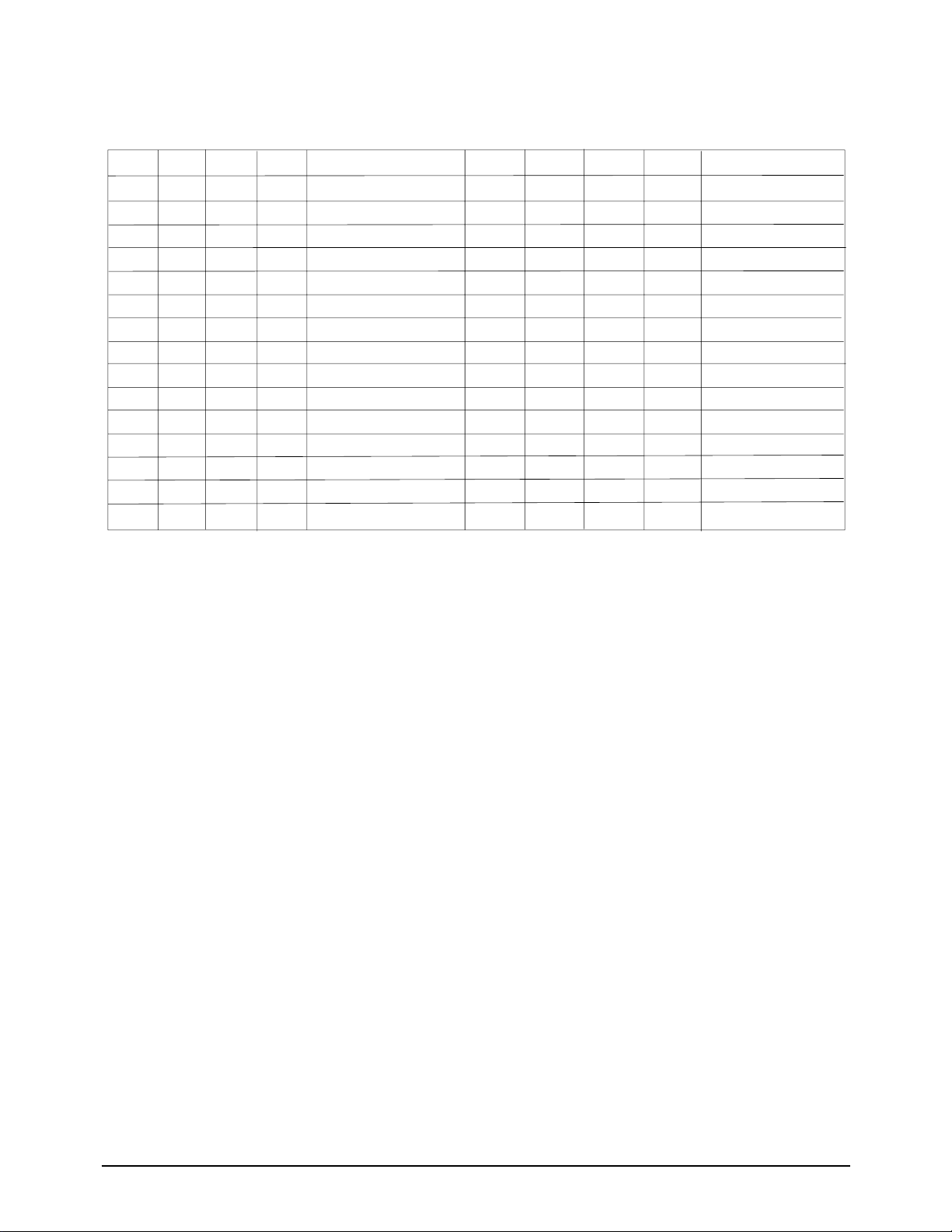

4-2-1 Procedure for the “Adjustment” Mode

1. This mode uses the standard remote control.

The Service Mode is activated by: (1) pressing

the “FACTORY” service key on the local-keyboard, or (2) by entering the following remotecontrol sequence (within 2 seconds):

STAND-BY →DISPLAY →MENU→ MUTE→

POWER ON

2. The “SERVICE (FACTORY)” message will be

displayed. The Service Mode has three components: Adjustment, Option Bytes and Reset.

3. Access the Adjustment Mode by pressing the

“VOLUME” keys ( Up or Down). The adjustment parameters are listed in the accompanying table, and selected by pressing the CHANNEL keys (▲,▼).

4. Selection sequences for the

PAL/SECAM B/G, L systems:

down or up key:

TXP>SBT>SCT>SCR>STT>BCR>BLG>RG>

GG>BG>PWL>SC>SL>VA>PUS>PHS>GRE>

BB>CDL>BKS>PEW>PEP>PEUC>PELC>

PDL>VSC>HP>HB>TC>WS

5. The VOLUME keys increase or decrease the

adjustment values, (stored in the

non-volatile memory) when Adjustment Mode

is cancelled.

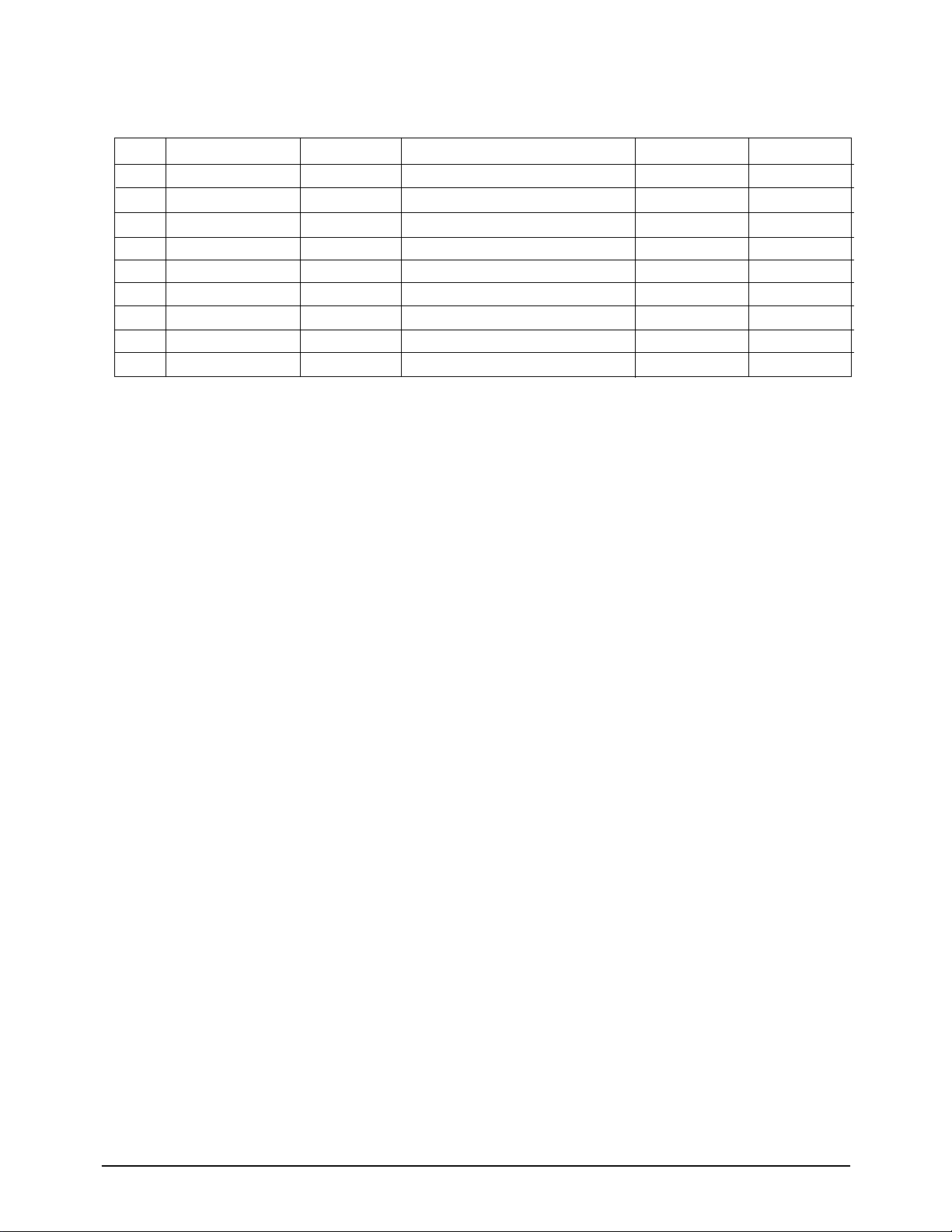

4-2-2 Adjust

NOTE : PVS, VA, PHS, NVS, NHS parameters must be aligned using

both the 50 Hz and 60 Hz vertical-field rates.

4-2-3 AGING Mode (Reference Only)

This pattern is used for pre-heating the CRT during manufacturing--it is accessed in the

factory by twice pressing the "FACTORY" key .

Even if the TV power is cut off, the Aging Mode is not cancelled.

The "AGING" marking is displayed on the screen.

The AGING mode is cancelled by repressing the "FACTORY" key.

Alignment and Adjustments (Electrical)

OSD

TXP

SBT

SCT

SCR

STT

BLR

BLG

RG

GG

BG

PWL

SC

SL

VA

PVS

Initial

4

6

10

6

9

8

8

32

32

32

15

11

27

12

26

Adjust

Fix

Fix

Fix

Fix

Fix

Fix

Fix

Range

0-7

0-23

0-23

0-13

0-13

0-15

0-15

0-63

0-63

0-63

0-15

0-63

0-63

0-63

0-63

Function

Osd Position

Sub Brigh

Sub Contrast

Sub Color

Sub Tint

Low Light R

Low Light G

High Light R

High Light G

High Light B

Peak white level

S-Correction

Vertical Slope

Vertical Amplitu

Pal vertical shift

Adjust

Fix

Fix

Fix

Fix

Fix

Fix

Fix

Fix

Fix

Fix

Fix

Fix

Initial

34

1

0

11

0

30

2

0

0

7

32

32

32

32

1

OSD

PHS

GRE

BB

CDL

BKS

REW

PEP

PEUC

PELC

PDL

VSC

HP

HB

TC

WS

Range

0-63

0-1

0-1

0-15

0-1

0-15

0-15

0-63

0-63

0-15

0-63

0-63

0-63

0-63

0-63

Function

Pal Horizon Shift

Greenish level

Blue Screen

Cathode Drive Level

Black Stretcher

EW

EW Parabola

Under Corner

Lower Corner

H-Paralleogram

Horizontal Bow

EW Trapezium

White Stretch

4-2-4 OPTION

Alignment and Adjustments (Electrical)

NO

1

2

3

4

5

6

7

8

9

OSD

HELP MSG

LANGUAGE

SYSTEM

ATS OPTION

AUTO CLOCK

S-Modulation

TTX

TTX DEFAULT

Adjust

ON

EUROPE

CF

ON

OFF(Fix)

54%

ON

FLOF

Range

ON/OFF

EUROPE/RUSSIA/ARAB

CF/CI/CW/CX/CB/CII

ON/OFF

ON/OFF

54%/80%/100%

ON/OFF

FLOF/LIST

4-2-5 RESET

The Reset Mode is used during factorying inspection

Function Reset : After Factorying Reset, the following items itens revert to their initial values.

1. Volume 11

2. Program Channel 0

3. P- STD MEMORY

4. Auto Power OFF

5. NR OFF

6. Skip(Store/Clear) ALL CLEAR

Cautim : When the EEPROM is replaced ; all items revert to their initial values.

Alignment and Adjustments (Electrical)

4-3 Other Adjustments

4-3-1 General

1. Usually, a color TV needs only slight

touch-up adjustment upon installation.

Check the basic characteristics such as height,

horizontal and vertical sync and focus.

2. The picture should have good black and white

details. There should be no objectionable

color shading; if color shading is present,

perform the purity and convergence adjustments described below.

3. Use the specified test equipment or its

equivalent.

4. Correct impedance matching is essential.

5. Avoid overload. Excessive signal from a sweep

generator might overload the front-end of the

TV. When inserting signal markers, do not

allow the marker generator to distort test

results.

6. Connect the TV only to an AC power source

with voltage and frequency as specified on the

backcover nameplate.

7. Do not attempt to connect or disconnect any

wires while the TV is turned on. Make sure

that the power cord is disconnected before

replacing any parts.

8. To protect against shock hazard, use an

isolation transformer.

4-3-2 Automatic Degaussing

A degaussing coil is mounted around the

picture tube, so that external degaussing after

moving the TV should be unnecessary. But

the receiver must be properly degaussed upon

installation.

The degaussing coil operates for about 1

second after the power is switched ON. If the

set has been moved or turned in a different

direction, disconnect its AC power for at least

10 minutes.

If the chassis or parts of the cabinet become

magnetized, poor color purity will result. If

this happens, use an external degaussing coil.

Slowly move the degaussing coil around the

faceplate of the picture tube and the sides and

front of the receiver. Slowly withdraw the coil

to a distance of about 6 feet before removing

power.

4-3-3 High Voltage Check

CAUTION: There is no high voltage

adjustment on this chassis. The B+ power

supply must be set to +130 volts (Full color

bar input and normal picture level).

1. Connect a digital voltmeter to the second

anode of the picture tube.

2. Turn on the TV. Set the Brightness and

Contrast controls to minimum (zero beam

current).

3. The high voltage should not exceed 30KV.

4. Adjust the Brightness and contrast controls to

both extremes. Ensure that the high voltage

does not exceed 30KV under any conditions.

Alignment and Adjustments (Electrical)

4-3-4 FOCUS Adjustment

1. Input a black and white signal.

2. Adjust the tuning control for the clearest picture.

3. Adjust the FOCUS control for well defined scanning lines in the center area of the screen.

4-3-5 Screen Adjustment

1. Turn to the ACTIVE channel.

2. Adjust the VR screen for a normal picture is (no blooming or flyback line).

3. Adjust the FOCUS control for well defined scanning lines in the center area of the screen.

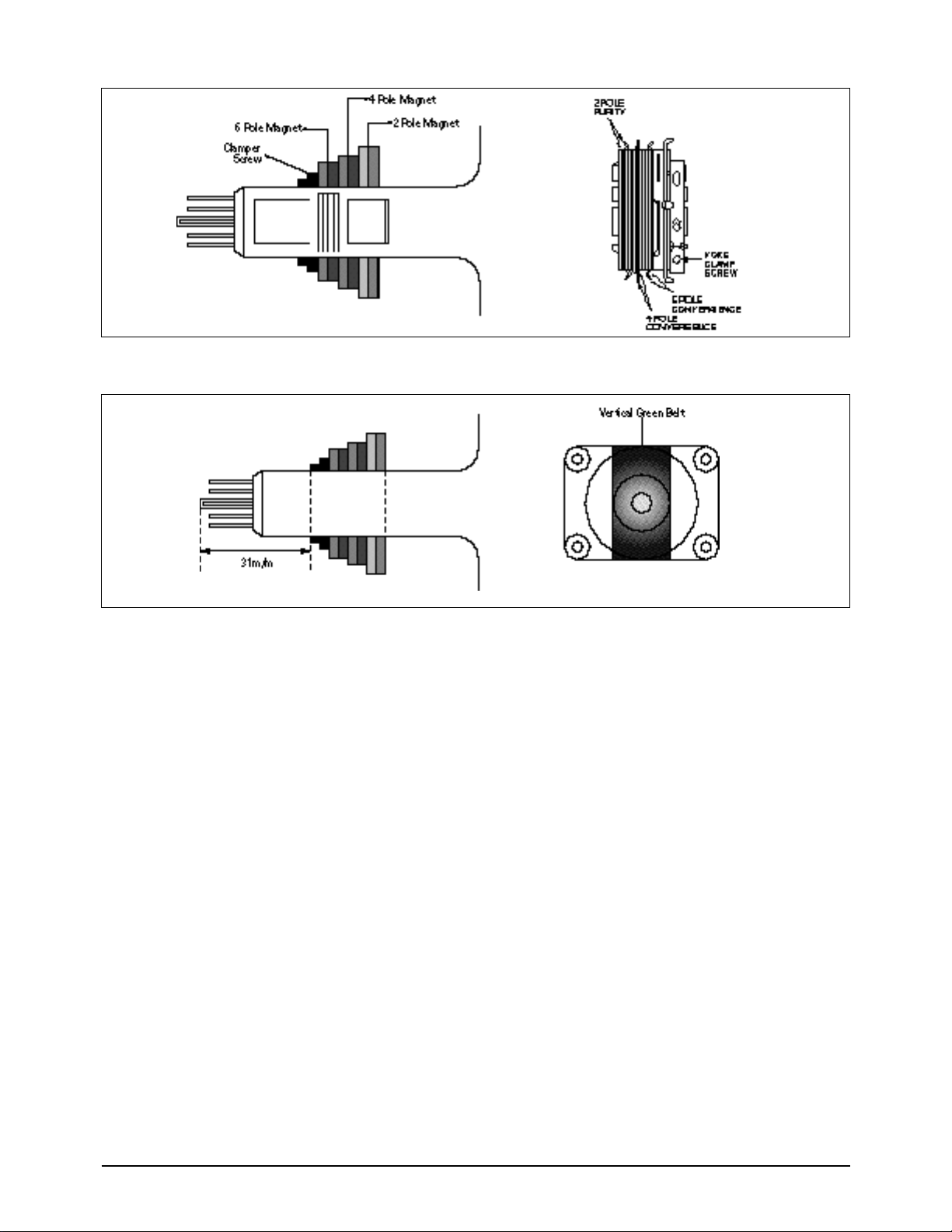

4-3-6 Purity Adjustment

1. Warm up the receiver for at least 20 minutes.

2. Plug in the CRT deflection yoke and tighten the clamp screw.

3. Plug the convergence yoke into the CRT and set in as shown in Fig. 5-1.

4. Input a black and white signal.

5. Fully demagnetize the receive by applying an external degaussing coil.

6. Turn the CONTRAST and BRIGHTNESS controls to maximum.

7. Loosen the clamp screw holding the yoke. Slide the yoke backward or forward to provide

vertical green belt. (Fig. 5-2).

8. Tighten the convergence yoke.

9. Slowly move the deflection yoke forward, and adjust for the best overall green screen.

10. Temporarily tighten the deflection yoke.

11. Produce blue and red rasters by adjusting the low-light controls. Check for good purity

in each field.

12. Tighten the deflection yoke.

Alignment and Adjustments (Electrical)

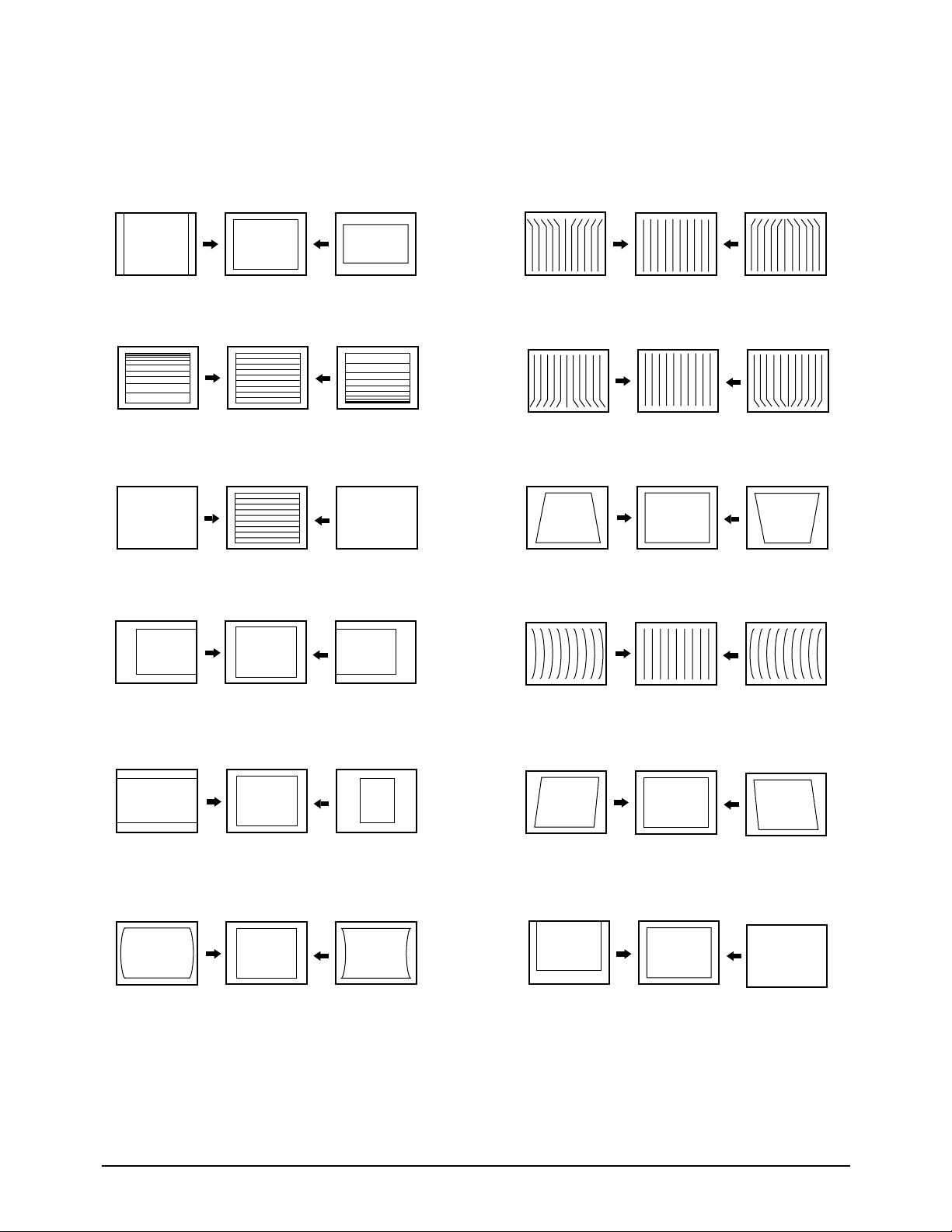

TILT (TC)

AFC BOW (HB)

H SIZE

PIN COMP (PEP)

H POSITION (PHS)

V LINEARITY (SL)

UP CPIN (PEUC)

V S CORRECTION (SC)

AFC ANGLE (HP)

V POSITION (PVS)

LO CPIN (PELC)

V SIZE(VA)

4-3-7 I C BUS GEOMETRIC Adjust

2

Alignment and Adjustments (Electrical)

4-3-8 White Balance Adjustment

4-4-7 (A) HIGH-LIGHT ADJUSTMENT

1. Input either a Lion Head or a “pure white” pattern.

2. Warm up the TV for 30 minutes.

3. Check the data in the Service Mode

4. Adjust RG, BG in the Factory Mode.

5-4-7 (B) LOW-LIGHT ADJUSTMENT

1. Automatically accomplished during the high-light adjustment.

Fig. 5 -1 Convergence Magnet Assembly

Fig. 5-2 Center Convergence Adjustment

Alignment and Adjustments (Electrical)

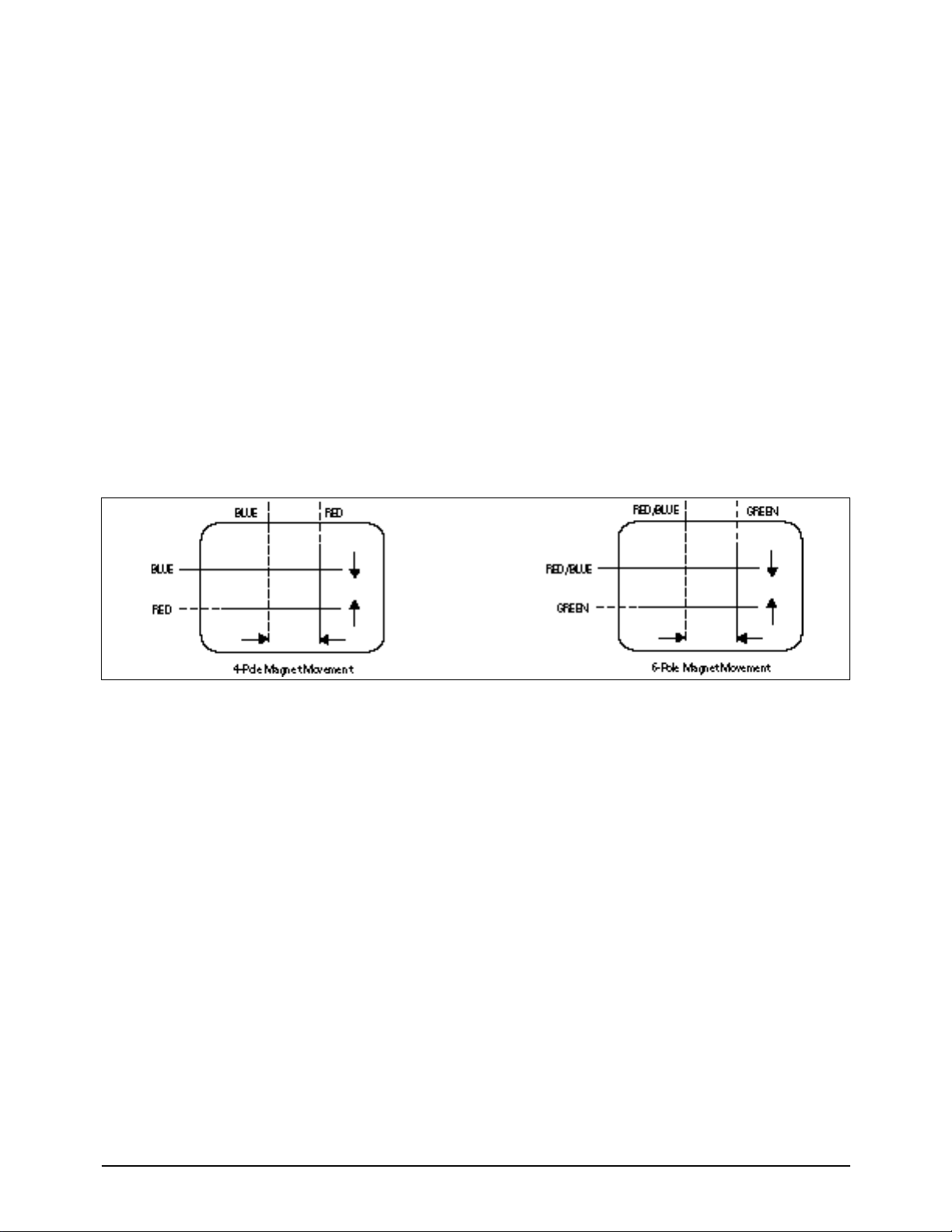

4-3-8 Center Convergence Adjustment

1. Warm up the receiver for at least 20 minutes.

2. Adjust the two tabs of the 4 pole magnets to

change the angle between them. Superimpose

the red and blue vertical lines in the center

area of the screen.

3. Adjust the Brightness and Contrast controls for

a well defined picture.

4. Adjust the two-tab pairs of the 4 pole magnets,

and change the angle between them.

Superimpose the red and the blue vertical

lines in the center area of the screen.

5. Turn the both tabs at the same time, keeping

the angle constant, and superimpose the red

and blue horizontal line in the center of the

screen.

6. Adjust the two-tab pairs of the 6-pole magnets

to superimpose the red and blue line onto the

green. (Changing the angle affects the vertical

lines, and rotating both magnets affects the

horizontal lines.)

7. Repeat adjustments 2~6, if necessary.

8. Since the 4-pole magnets and 6-pole magnets

interact, the dot movement is complex

(Fig. 5-3).

Fig 5-3 Center Convergence Adjustment

Troubleshooting

Samsung Electronics 5-1

5. Troubleshooting

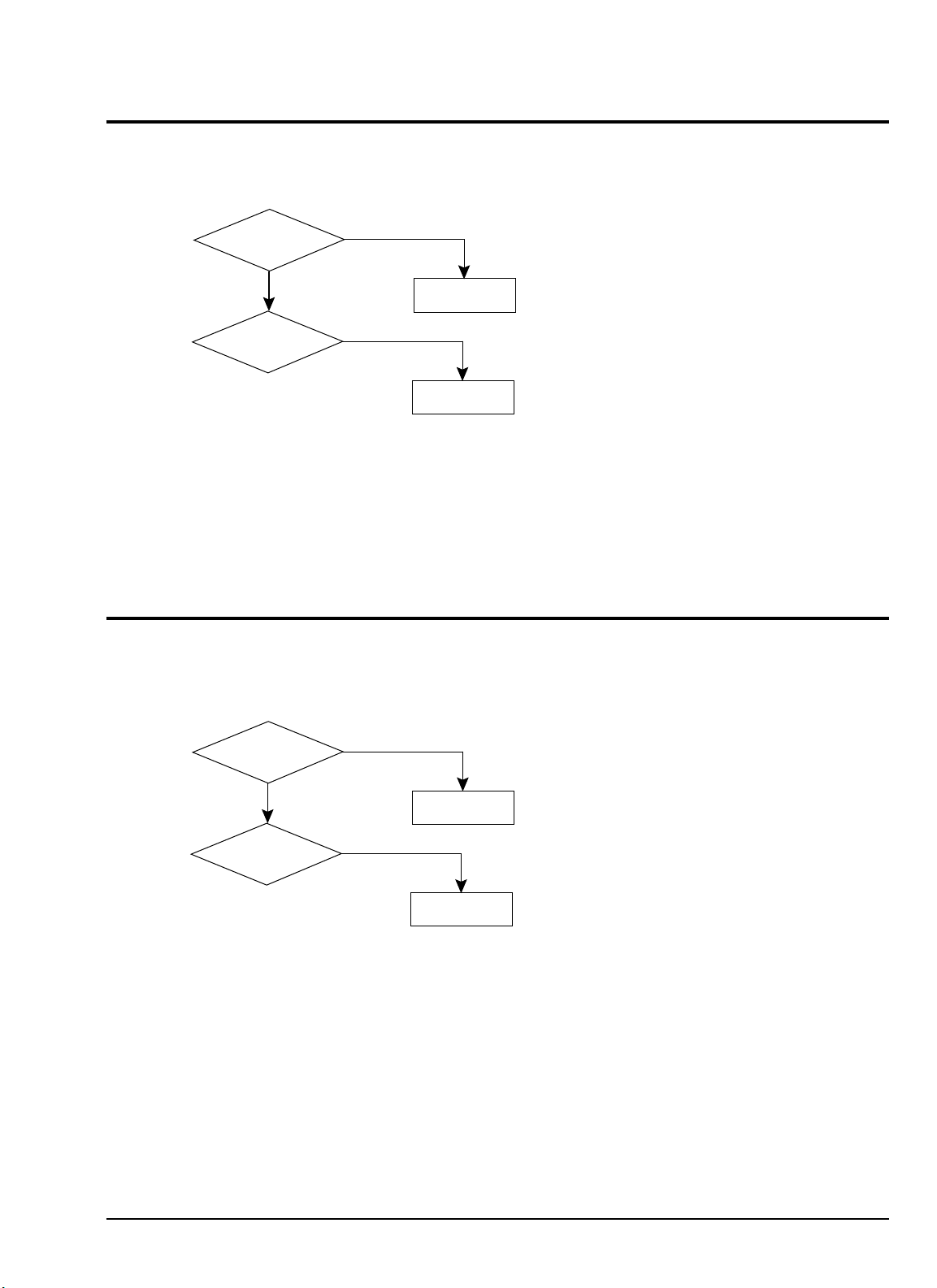

5-1 No Power (No Picture on)

Yes

Check

both terminal voltages

of C815 (130V)

Check both

terminal voltages of

C804 (280~300V).

Check D801S

F801,Q801.

No

Is IC801S Pin 3

19~22V?

Check IC801S

Check/Replace

DZ801,DZ808,

DZ802,PC801S

No

Yes

No

Yes

Check

Voltage of 80V, 15V, 20V,

13V power line..

Check whether

each power line

is short or open.

No

No

Yes

Is IC901

Pin 64 Voltage 5V?

Check H.V SYNC on

IC901 Pins 36,37

Check/Replace

IC901.

Check

IC901 Pin 20 is High

when power is On.

Check/Replace

IC902.

Check the voltage

of TU01S.

Yes

Yes

No

No

Yes

5-2 No Power (No LED On)

Troubleshooting

5-2 Samsung Electronics

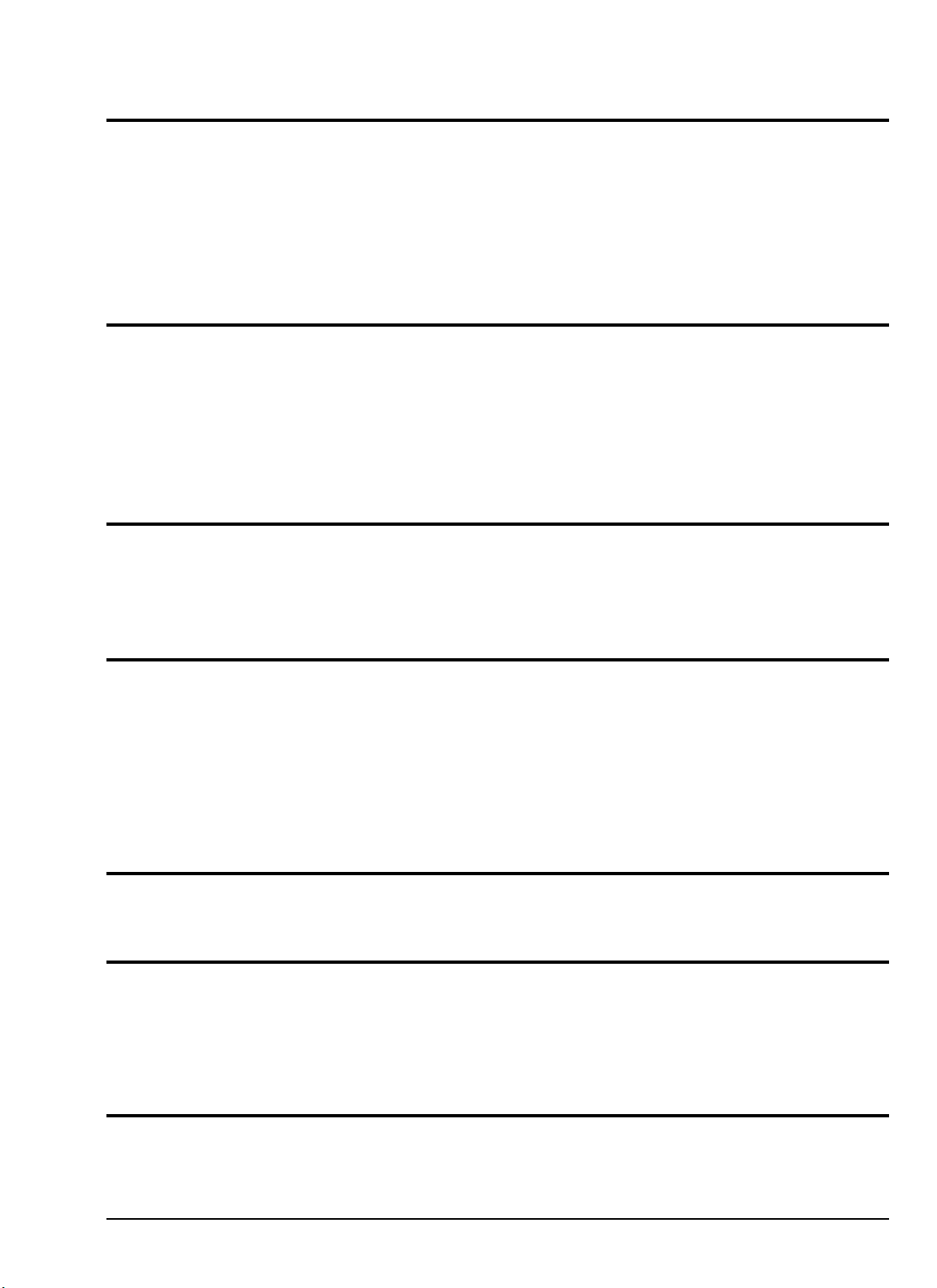

Check IC901 #31

No

Check IC901 #52, #53

Check after Bus

Line Open

Yes

Yes

Yes

Yes

Check IC904

No

Check another I2C

Bus Line.

No

No

Check IC805

Check D805

Check IC801S

Replace

Replace

Yes

No

No

Check IC901 #50~52

Replace

IC901

No

5-3 No RF Picture / Sound

Troubleshooting

Samsung Electronics 5-3

Check IC901 #52, #53

Check chroma inodule

H-out

Yes

Yes

Yes (No Sound)

Check Tuois

SDA,SCL

Check Q402,Q401

Replace

Replace

Replace

No

No

No

No

Check

c/module, R405,R435

R424,R425,D411,

D401

Yes

Check Tuner SIF

output?

No

Check Sound module

B+, 5V,8V

Check 8V, 5V

Power Line

No

No Picture

Yes

Yes

Yes

Sound Module Replace

Replace

Replace

Troubleshooting

5-4 Samsung Electronics

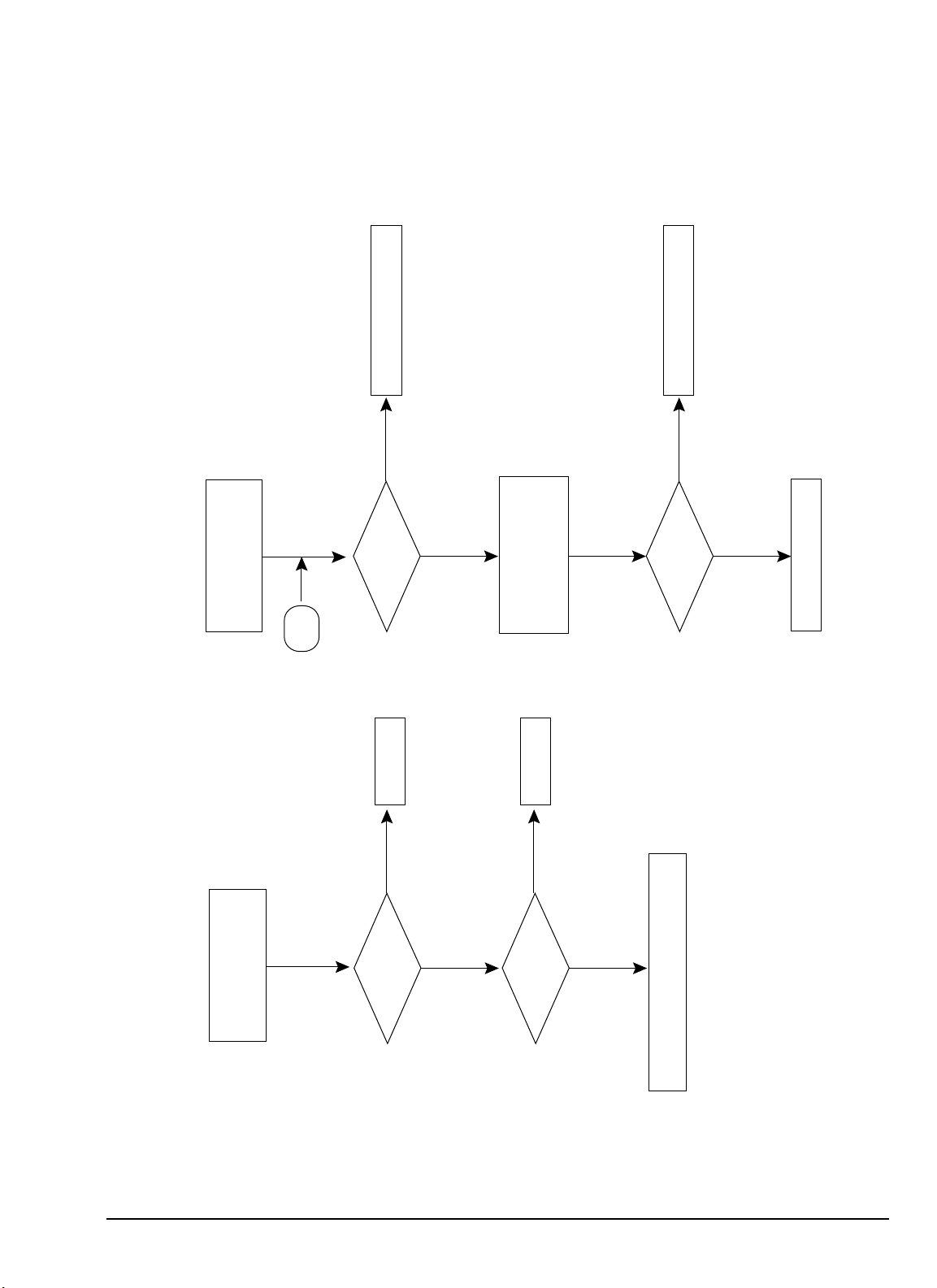

5-4 DVD PLAY NO PICTURE

Check CN201

y-cut,c-out

No

Check chroma module

No

Yes

Check DVD

Replace

Check CN201

D-L, D-R

No

Check Sound module

No

Yes

Check DVD

Replace

5-5 DVD PLAY NO SOUND

Troubleshooting

Samsung Electronics 5-5

5-6 No Picture (Sound OK)

1 Check the Brightness, Contrast and Color adjustments

2. Check: AV Picture

3. See Video Block Diagram

5-7 No Sound (Picture OK)

1. Check the Volume adjustment level.

2. Check AV Video

3. See Audio Block Diagram

5-8 RF Weak Signal (Playback, AV Mode OK)

1. Check Tuner (TU01S) B+. Check: 8V (IC802)

33V (DZ201). Check 5V (IC804)

5-9 No Vertical SCAN

1. Check R425, D401

2. Check IC301, #2

3. Check Chroma module Vertical-out Line

4. Check DY Connector

5-10 Horizontal Size

1. Check L406, C411, R421, Q403, D404, R413, R405

5-11 On-Screen Display Missing

1. Check IC901 #32, #33, 34

2. Check Chroma module

5-12 No Teletext

1. Check IC901 #30

2. Check IC901 #24 (CVBS)

Troubleshooting

5-6 Samsung Electronics

5-13 DVD Block Troubleshooting

LD is outputted

from object lens

at play key input?

Yes

Check open state from

DRIC4 to pick-up.

Check RIC1 and A,B,C,D input.

Check SIC3.

No Disc recognitionNo Disc recognition

A

B

A

No

FE om SOC1-25

is within specified

range?

Yes

No

SIC3-1,2 output

are mormal?

Yes

No

No Focus incomingNo Focus incoming

No focus incoming and

no disc occurs

Troubleshooting

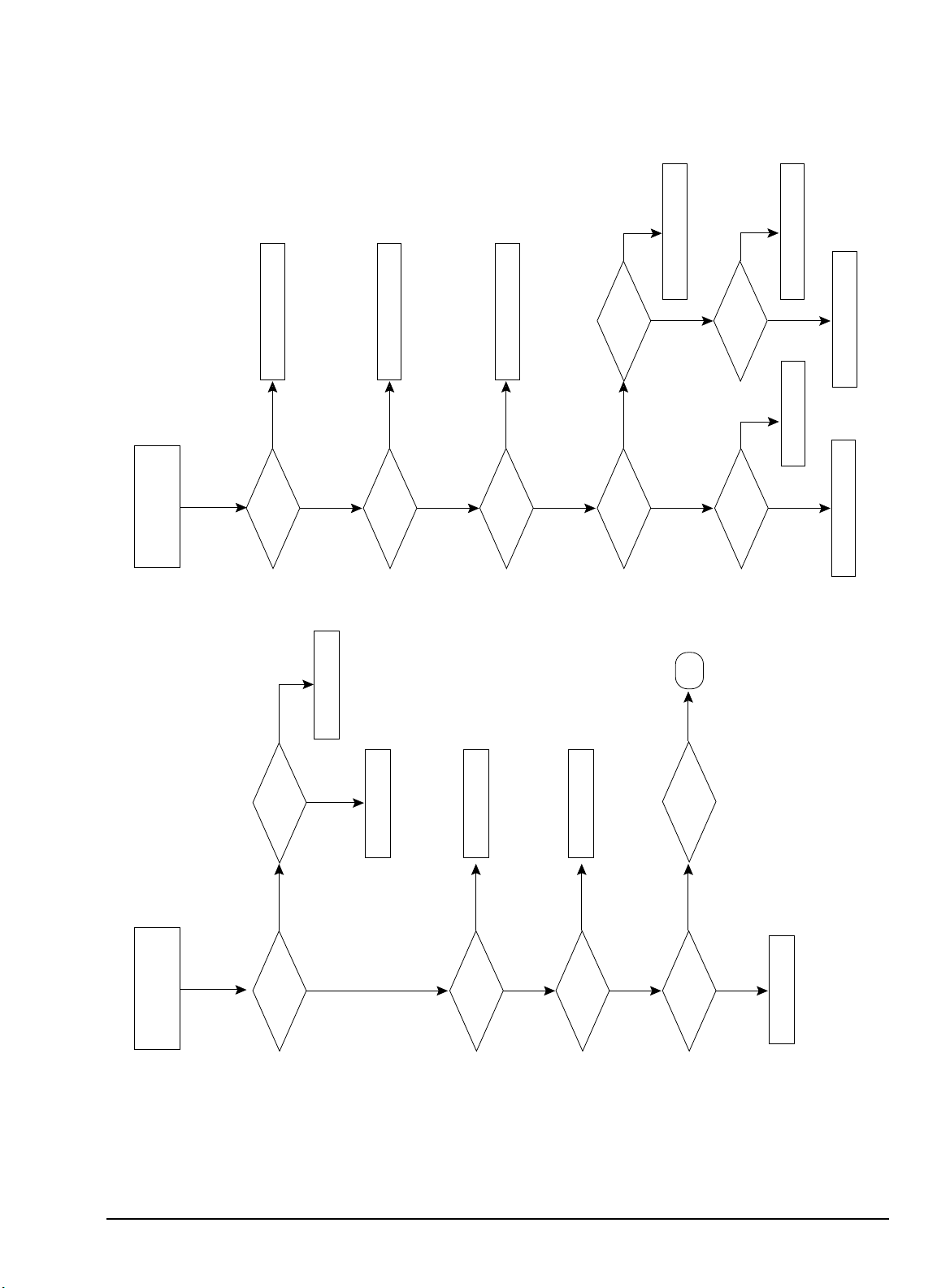

Samsung Electronics 5-7

SLD, SIC-34

output is normal?

Yes

LED+, SLED-

SIC3-32,33 output are

normal?

Yes

Check the Sled Motor and connection

No pick-up home positingNo pick-up home positing

No

No

Check MIC1

Divide RQ1 emitter terminal

voltage and 5V real voltage

difference into 10ohm.

Open check in related circuit.

LD out pick-up replace.

Check MIC1

Check SIC3

B

RIC1-21 is 5V?

Yes

Yes

No

Current exceeds 0.1A?

Yes

No

NO LD CD ON

Troubleshooting

5-8 Samsung Electronics

MIRR, SIC1-157

output is normal?

Yes

Actual velocity occurs

at SIC1-34 terminal?

Yes

Actual velocity occurs

at SIC4-32,33 terminal?

Yes

TE occurs in

search range?

Focus On?

Yes

Check RIC1 Peripheral curcuit.

Check SIC1 Peripheral curcuit.

Time out due to many jump counts

No Search Operation

A

No

No

No

No

No No

FINE SEEK MIRR

signal(RIC1-46) is missing?

Yes

Yes

No

TZCO signal

(SIC1-24)is occurs?

Yes

No

Check RIC1-26 terminal.

Check SIC3 peripheral circuit.

Check SIC1 peripheral circuit.

Check DCN1 and pick-up.

Check MECHA.

Track incomming is

delayed?

Yes

No

TE is within

2V and 3V?

SIC1-33 output

are normal?

SIC3-28,29

terminaloutputs

are normal?

Yes

Yes

Yes

No

Pick-up transfer smooth.

Yes

No

FINE SEEK Check

RF AGCO, RIC1-72

Output level is

normal?

Yes

Check RIC1 peripheral circuit.

Check SIC1 peripheral circuit.

Check SIC3 peripheral circuit.

See "Fine Seek Check"

Check pick-up.

No

No

Troubleshooting

Samsung Electronics 5-9

SPD output is normal?

(SIC1-35)

Yes

SIC3-2 output(FG)

is normal?

Yes

SIC3-9 signal

MON is "H"?

Yes

Micom(MIC1) error

Check SIC3

Abnormal rotation of Abnormal rotation of

disc motordisc motor

No

No

No

No

No

No

MIC1-84,85 is

Open;"L","L"?

Close;"H","H"?

Yes

Yes

No

Check SIC3-35,36

output open/close

Yes

No

Check signal line state from

SIC3-35,36 to tray motor.

No Tray open/closeNo Tray open/close

RIC1-70 output

are normal?

Yes

Check path to RIC1 and SIC1

After resoldering SIC1

Check SIC3 soldering and power

Check SIC1, MIC1.

Check or replace disc motor

Check RIC1 doldering and power

Input of RF signal

is normal?(SIC1-15)

RIC1-71 output

is normal?

Yes

Check RIC1 peripheral

circuit and A,B,C,D

Loading...

Loading...