SAMSUNG DVD905 Service Manual

DIGITAL VIDEO DISC PLAYER

DVD905

SERVICE

1. Precautions

2. Reference Information

3. Product Specifications

4. Disassembly and Reassembly

5. Thoubleshooting

6. Exploded Views and Parts List

7. Electrical Parts List

8.

Block Diagram

9. PCB Diagrams

10. Wiring Diagram

11. Schematic Diagrams

Manual

DIGITAL VIDEO DISC PLAYER CONTENTS

© Samsung Electronics Co., Ltd. MAY. 1997 AH68-20166A / AH68-20167A

Samsung Electronics 1-1

1. Precautions

1. Be sure that all of the built-in protective devices are

replaced. Restore any missing protective shields.

2. When reinstalling the chassis and its assemblies, be

sure to restore all pretective devices, including :

control knobs and compartment covers.

3. Make sure that there are no cabinet openings

through which people--particularly children

--might insert fingers and contact dangerous

voltages. Such openings include the spacing

between the picture tube and the cabinet mask,

excessively wide cabinet ventilation slots, and

improperly fitted back covers.

If the measured resistance is less than 1.0 megohm

or greater than 5.2 megohms, an abnormality exists

that must be corrected before the unit is returned

to the customer.

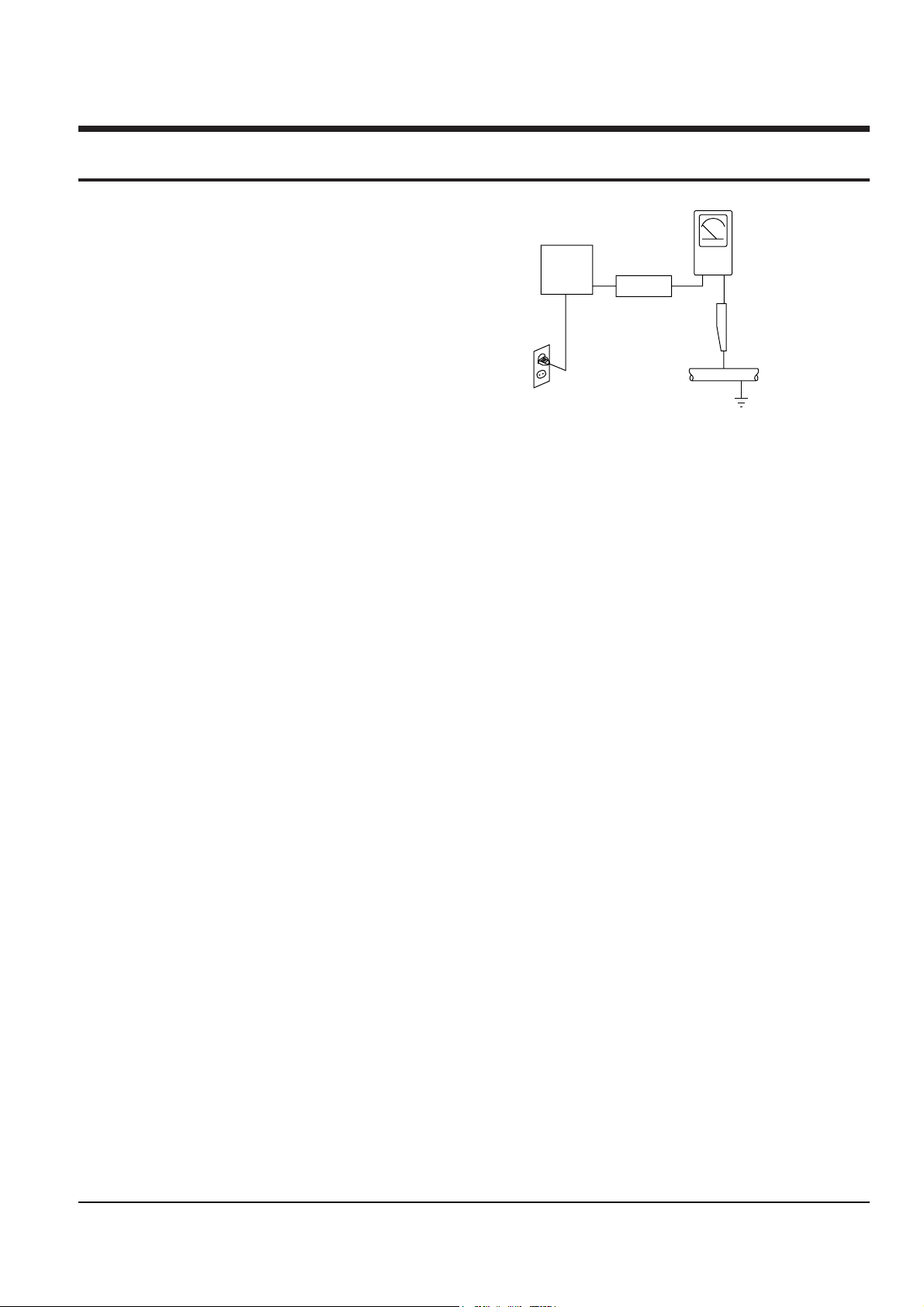

4. Leakage Current Hot Check (See Fig. 1) :

Warning : Do not use an isolation transformer

during this test. Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI C101.1,

Leakage Current for Appliances), and Underwriters

Laboratories (UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug the AC

line cord directly the power outlet. With the unitÕs

AC switch first in the ON position and then OFF,

measure the current between a known erath

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including : antennas, handle

brackets, metal cabinets, screwheads and control

shafts. The current measured should not exceed

0.5 milliamp. Reverse the power-plug prongs in the

AC outlet and repeat the test.

6. X-ray Limits :

The picture tube is designed to prohibit X-ray

emissions. To ensure continued X-ray protection,

replace the picture tube only with one that is the

same type as the original.

Fig. 1 AC Leakage Test

7. Antenna Cold Check :

With the unitÕs AC plug disconnected from the

AC source, connect an electrical jumper across the

two AC prongs. Connect one lead of the ohmmeter

to an AC prong.

Connect the other lead to the coaxial connector.

8. High Voltage Limit :

High voltage must be measured each time

servicing is done on the B+, horizontal deflection

or high voltage circuits.

Heed the high voltage limits. These include the

X-ray protection Specifications Label, and the

Product Safety and X-ray Warning Note on the

service data schematic.

9. Some semiconductor (Òsolid stateÓ) devices are

easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect transistors.

The following techniques will reduce the

occurrence of component damage caused by static

electricity.

10. Immediately before handling sny semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known

earth ground. Alternatively, wear a discharging

Wrist-strap device. (Be sure to remove it prior to

applying power--this is an electric shock

precaution.)

Device

Under

Test

(Reading should

not be above

0.5mA)

Leakage

Currant

Tester

Earth

Ground

Test all

exposed metal

surfaces

Also test with

plug reversed

(using AC adapter

plug as required)

2-Wire Cord

Precautions

1-2 Samsung Electronics

11. High voltage is maintained within specified limits

by close-tolerance, safety-related components and

adjustments. If the high voltage exceeds the

specified limits, check each of the special

components.

12. Design Alteration Warning :

Never alter or add to the mechanical or electrical

design of this unit. Example : Do not add

auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also, any

design changes or additions will void the

manufacturerÕs warranty.

13. Hot Chassis Warning :

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only if

the AC power plug is inserted so that the chassis

is connected to the ground side of the AC source.

To confirm that the AC power plug is inserted

correctly, do the following : Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the reading

is greater than 1.0V, remove the AC power plug,

reverse its polarity and reinsert. Re-measure the

voltage between the chassis and ground.

14. Some TV chassis are designed to operate with 85

volts AC between chassis and ground, regardless

of the AC plug polarity. These units can be safely

serviced only if an isolation transformer inserted

between the receiver and the power source.

15. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of its

assemblies) unless all solid-state heat sinks are

correctly installed.

16. Always connect a test instrumentÕs ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrumentÕs

ground lead last.

17. Observe the original lead dress, especially near

the following areas : Antenna wiring, sharp

edges, and especially the AC and high voltage

power supplies. Always inspect for pinched, outof-place, or frayed wiring. Do not change the

spacing between components and the printed

circuit board. Check the AC power cord for

damage. Make sure that leads and components

do not touch thermally hot parts.

18. Picture Tube Implosion Warning :

The picture tube in this receiver employs

Òintegral implosionÓ protection. To ensure

continued implosion protection, make sure that

the replacement picture tube is the same as the

original.

19. Do not remove, install or handle the picture tube

without first putting on shatterproof goggles

equipped with side shields. Never handle the

picture tube by its neck. Some Òin-lineÓ picture

tubes are equipped with a permanently attached

deflection yoke; do not try to remove such

Òpermanently attachedÓ yokes from the picture

tube.

20. Product Safety Notice :

Some electrical and mechanical parts have special

safety-related characteristics which might not be

obvious from visual inspection. These safety

features and the protection they give might be

lost if the replacement component differs from the

original--even if the replacement is rated for

higher voltage, wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( or ).

Use replacement components that have the same

ratings, especially for flame resistance and

dielectric strength specifications. A replacement

part that does not have the same safety

characteristics as the original might create shock,

fire or other hazards.

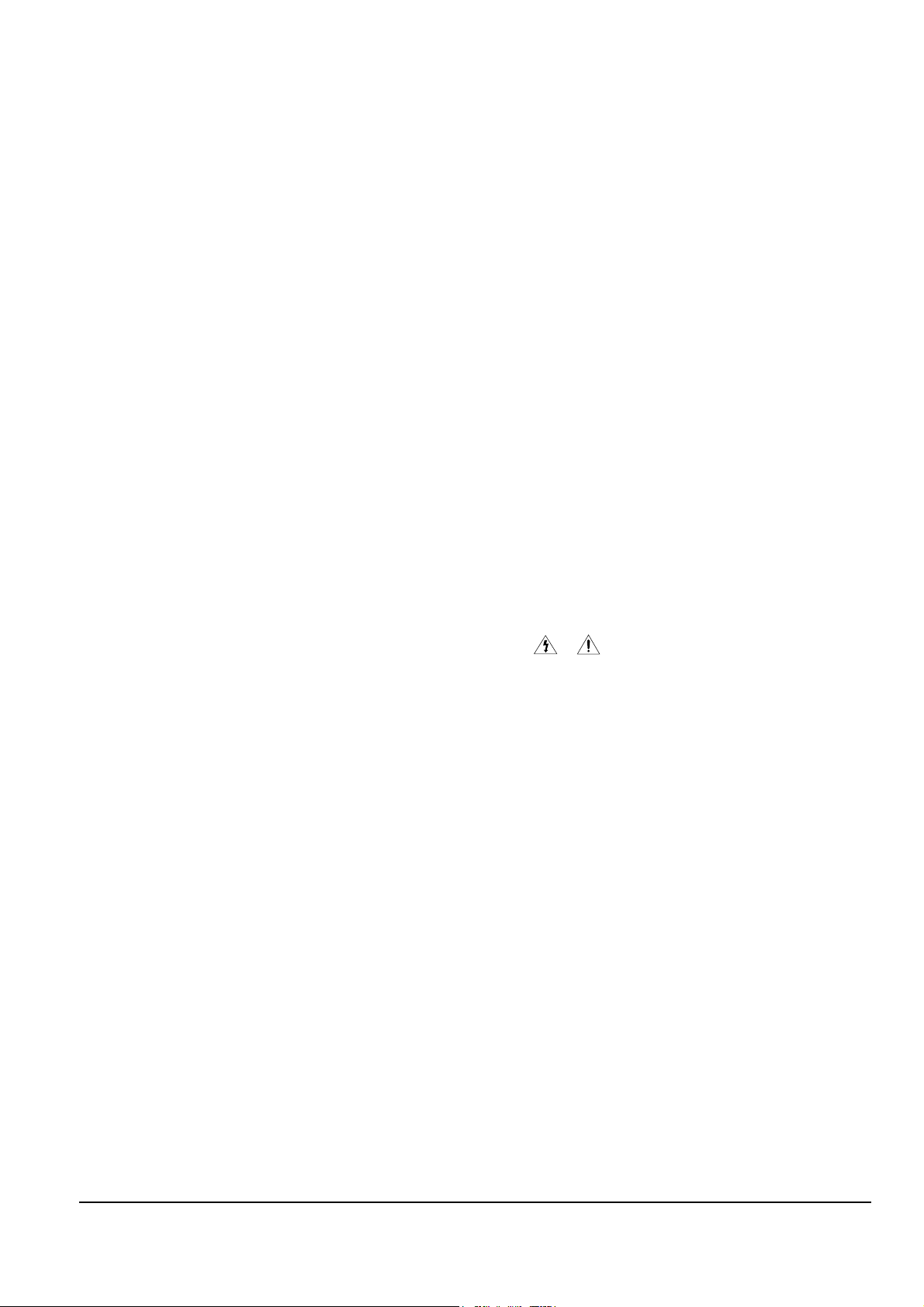

21. Cautions for handling Pick-up

Body grounding (hand) : Be sure to wear a wrist

strip with one side grounded. (Impedance :

Below 10

-8

½ )

Work table grounding : Put A grounded electric

conductor such as copper plate on tne work

table.

Caution: Do not let clothing touch the product

(to prevent possible damage from static electricty).

FPC operation : Handle the FPC carefully because

it is easily damaged.

Precautions

Samsung Electronics 1-3

1) Remove the power cable.

2) Switch LD SW3 on deck PCB to ÔSÕ before removing the FPC ( inserted into Main PCB CN1.

See Fig 1-2.)

3) Disassemble the deck.

4) Disassemble the deck PCB.

5) Replace the Pick-up.

O

S

LD

SW3

FPC

1-2-1 Disassembly

1-2 Pick-up disassembly and ressembly

1-2-2 Assembly

Note : If the assembly and disassembly are not done in correct sequence, the Pick-up may be damaged.

Fig. 1-2

1) Replace the Pick-up.

2) Assemble the deck PCB.

3) Reassemble the deck.

4) Switch LD SW3 on deck PCB to ÔOÕ and insert

FPC into Main PCB CN1 (See Fig 1-2).

Precautions

1-4 Samsung Electronics

MEMO

Samsung Electronics 3-1

3. Product Specifications

The specifications and design may be changed without notice. The weight and dimensions are approximate.

MODEL DVD905

G

E

N

E

R

A

L

D

I

S

C

V O

I U

D T

E P

O U

T

A O

U U

D T

I P

O U

T

120 Voltage, 60Hz

23W

4.4Kg

(W)420mm x (D)339mm x (H)120mm

+ 5 °C ~ 35 °C

50% ~ 95%

Reading Speed ; 1.2 ~ 1.4mm/sec

Maximum Play Time ; 135 minutes

Reading Speed ; 1.2 ~ 1.4mm/sec

Maximum Play Time ; 74 minutes

Reading Speed ; 1.2 ~ 1.4mm/sec

Maximum Play Time ; 74 minutes

Reading Speed ; 1.2 ~ 1.4m/sec

Maximum Play Time ; 74 minutes(Video + Audio)

2 channel ; 1.0Vp-p

R(Red) ; 0.714Vp-p

G(Green) ; 0.714Vp-p

B(Blue) ; 0.714Vp-p

S(Sync) ; 4.0Vp-p

Luminance Signal ;1Vp-p (75Ω load)

Color Signal ; 0.286Vp-p (75Ω load)

L(1/L), R(2/R)

F/L, F/R, R/L, R/R, C/T, S/W

Analog ; 2Vrms(1KHz)

Digital ; 5Vp-p

* Frequency Response ; 4Hz ~20KHz, S/M Ratio : 105dB

* Dynamic Range ; 95dB

* Total Harmonic Distortion 0,005%

Power Requirements

Power Consumption

Weight

Set Size

Operating Temperature Range

Operating Humidity Range

DVD

(DIGITAL VERSATILE DISC

CD : 12cm

(COMPACT DISC)

CD : 8cm

(COMPACT DISC)

VIDEO - CD

12cm

RCA JACK

SUPER VIDEO

2 channel

5 channel

Output Level

Digital Frequency

Response

Product Specifications

3-2 Samsung Electronics

MEMO

Disassembly and Reassembly

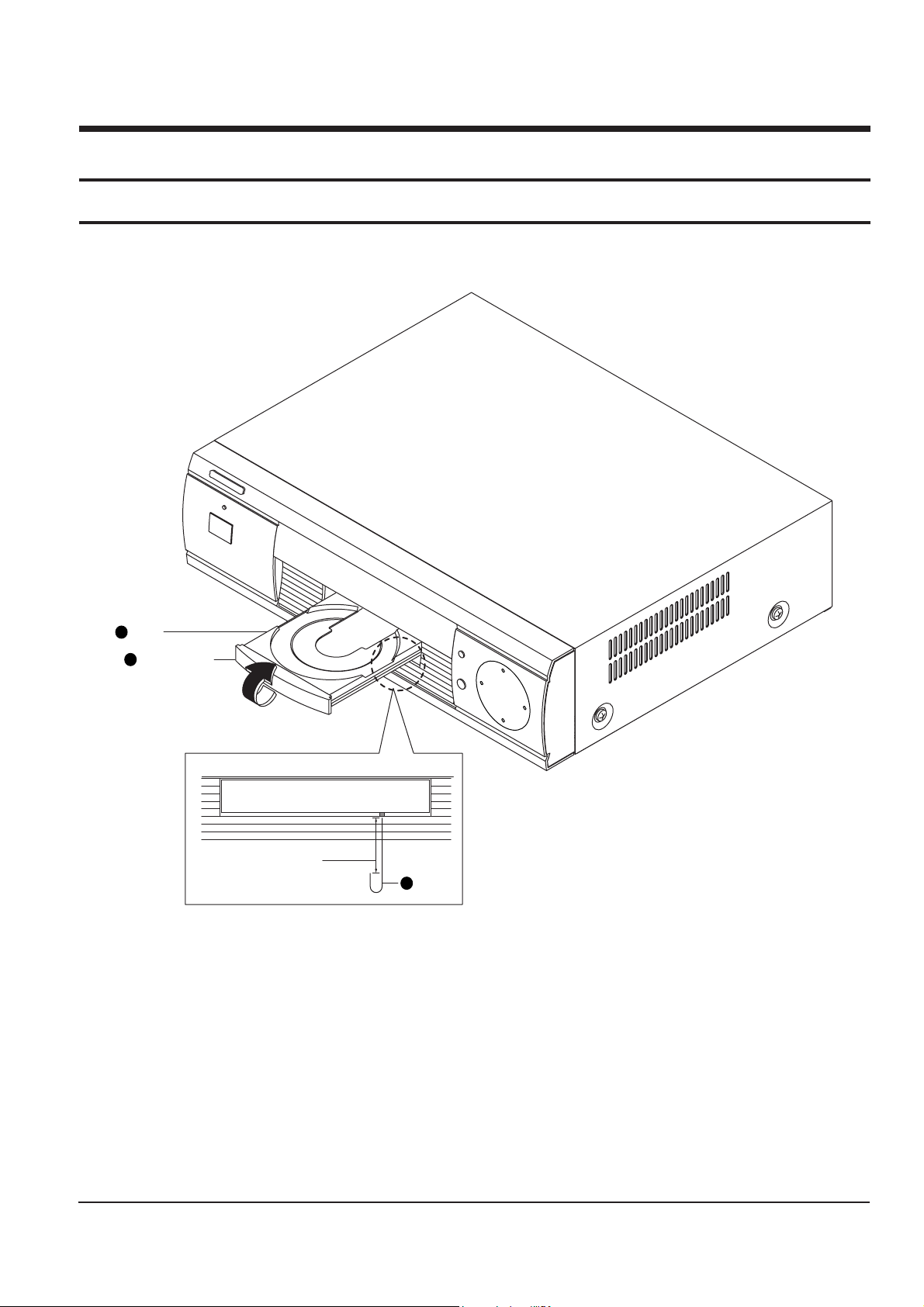

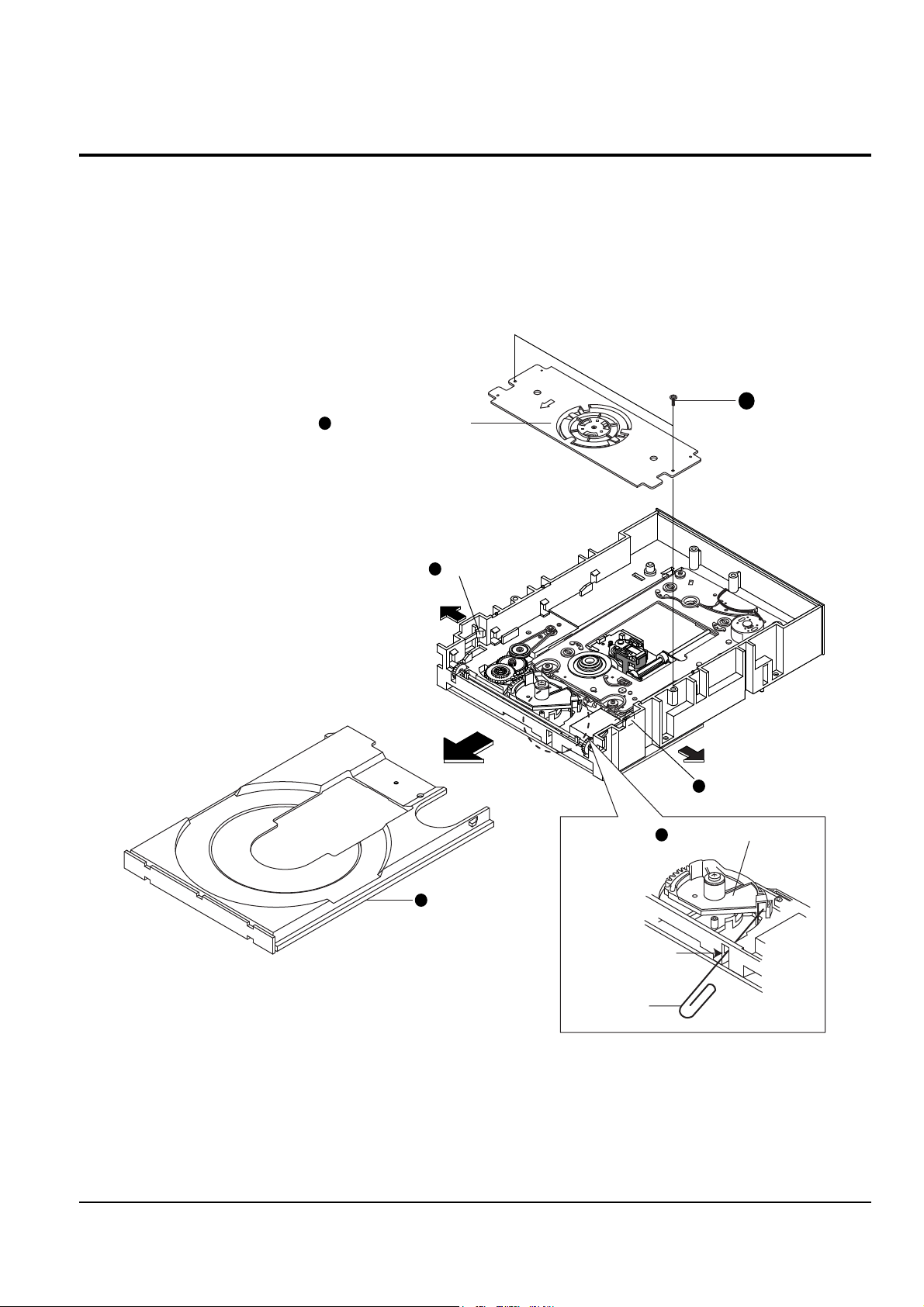

1) Supply power and open Tray Œ.

2) Disassemble the door-tray ´ in direction of arrow.

3) Close Tray Πand power off.

Note : If Tray Œ doesnÕt open, insert a clip ˇ into the hole (as shown in detailed drawing), and open Tray Œ

manually.

Fig. 4-1

Samsung Electronics 4-1

70mm

TRAY

DOOR-TRAY

CHIP

2

1

3

4. Disassembly and Reassembly

4-1 Exterior and PCB Disassembly

4-1-1 Door-tray

4-2 Samsung Electronics

Disassembly and Reassembly

4-1-2 Top cabinet

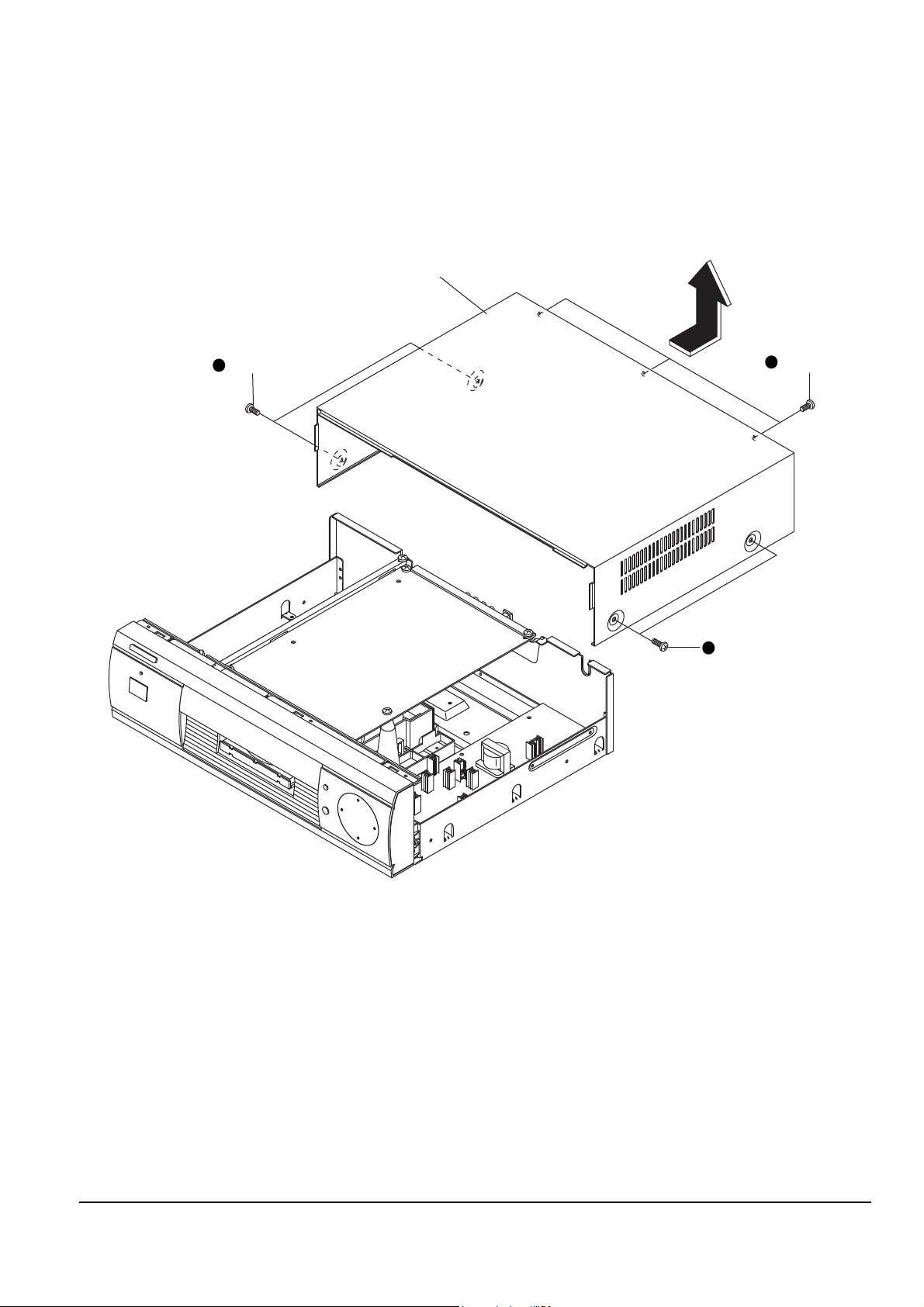

1. Remove 3 screws Πon the back panel.

2. Remove 4 screws ´, ˇ on the left and right side.

3. Lift up the top cabinet in direction of arrow.

Fig. 4-2

CABINET-TOP

2SCREWS

3SCREWS

2SCREWS

22

33

11

Samsung Electronics 4-3

Disassembly and Reassembly

4-1-3 Front

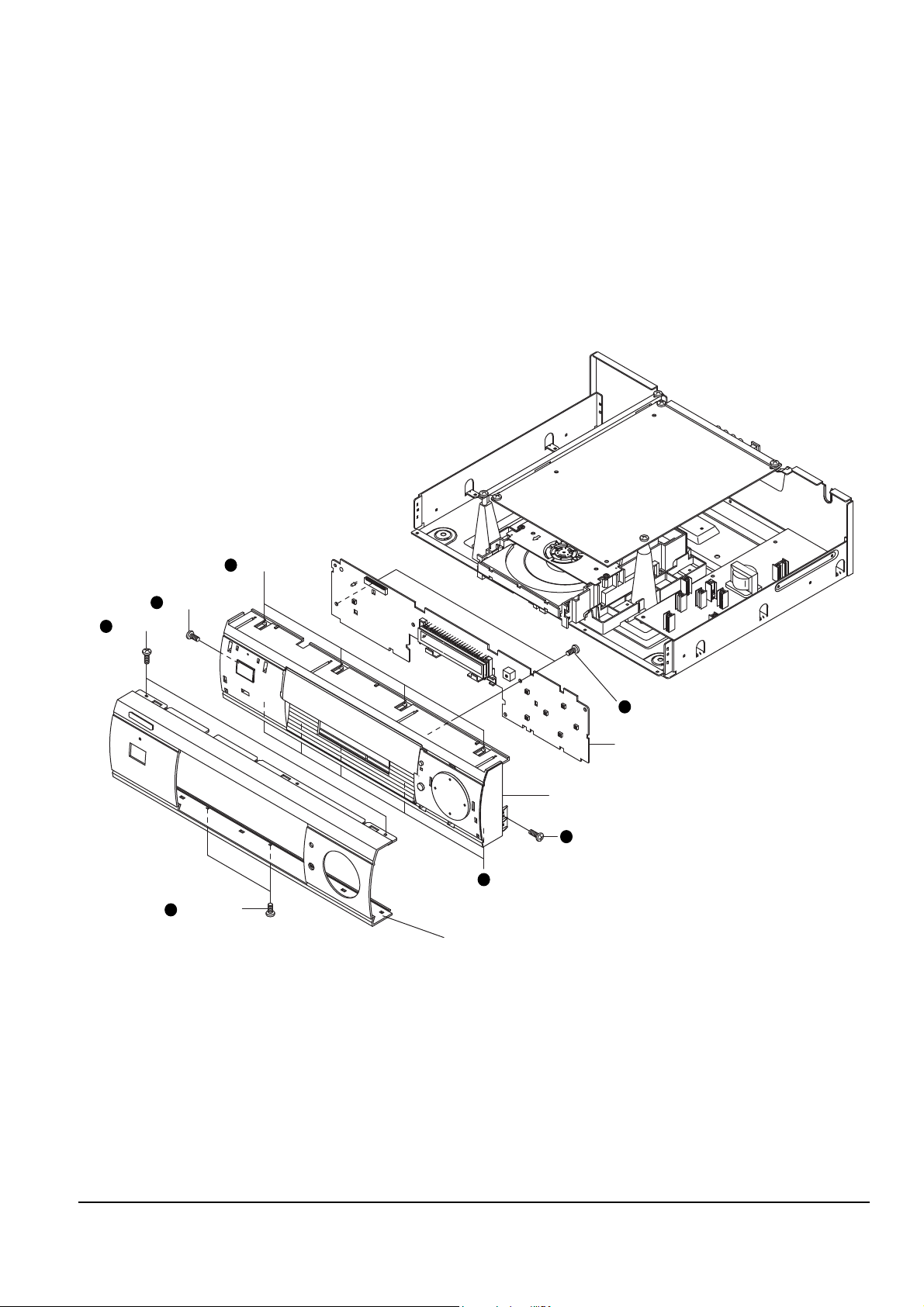

1. Remove 2 screws Œ, ´ on the left and right side of panel-front assÕy

2. Remove 2 screws ˇ on the bottom of cover-panel assÕy and disassemble the front.

3. Remove 2 screws ¨ from PCB-front.

4. Remove 9 hooks to fix PCB-front and disassemble PCB-front.

5. Remove 2 screws ˆ on the top of cover-panel assÕy

6. Remove 4 top hooks Ø and 5 bottom hooks ∏ and disassemble the cover-panel assÕy.

Fig. 4-3

2 SCREWS

1 SCREW

4 HOOKS

2 SCREWS

COVER-PANEL ASS'Y

5 HOOKS

PANEL-FRONT ASS'Y

1 SCREW

2 SCREWS

PCB-FRONT

22

66

55

44

11

77

33

4-4 Samsung Electronics

Disassembly and Reassembly

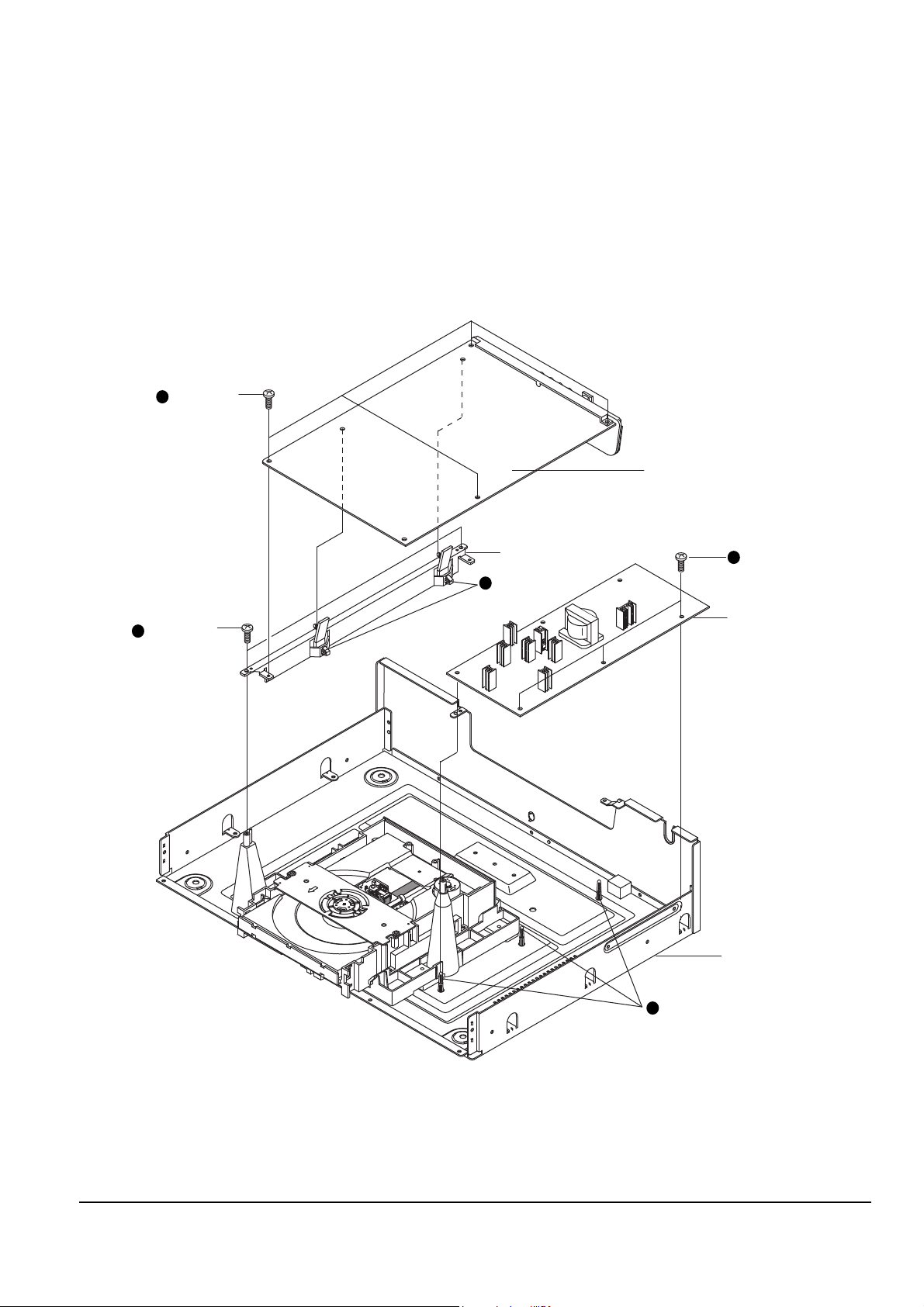

4-1-4 PCB-MAIN, PCB-SMPS

1. Remove 4 screws Πto fix PCB-MAIN.

2. Remove 2 Holder-PCB ´ inserted in PCB-MAIN and lift up PCB-MAIN.

3. Remove 3 screws ˇ from PCB-SMPS.

4. Remove 3 Spacer-PCB ¨ inserted in PCB-SMPS and lift up PCB-SMPS.

5. Remove 2 screws ˆ to fix BRKT-PCB assÕy.

Fig. 4-4

4 SCREWS

2 SCREWS

PCB-MAIN

PCB-SMPS

3 SCREWS

BRKT-PCB ASS'Y

HOLDER-PCB

SPACER-PCB

ASS'Y BOTTOM

11

55

22

44

33

Samsung Electronics 4-5

Disassembly and Reassembly

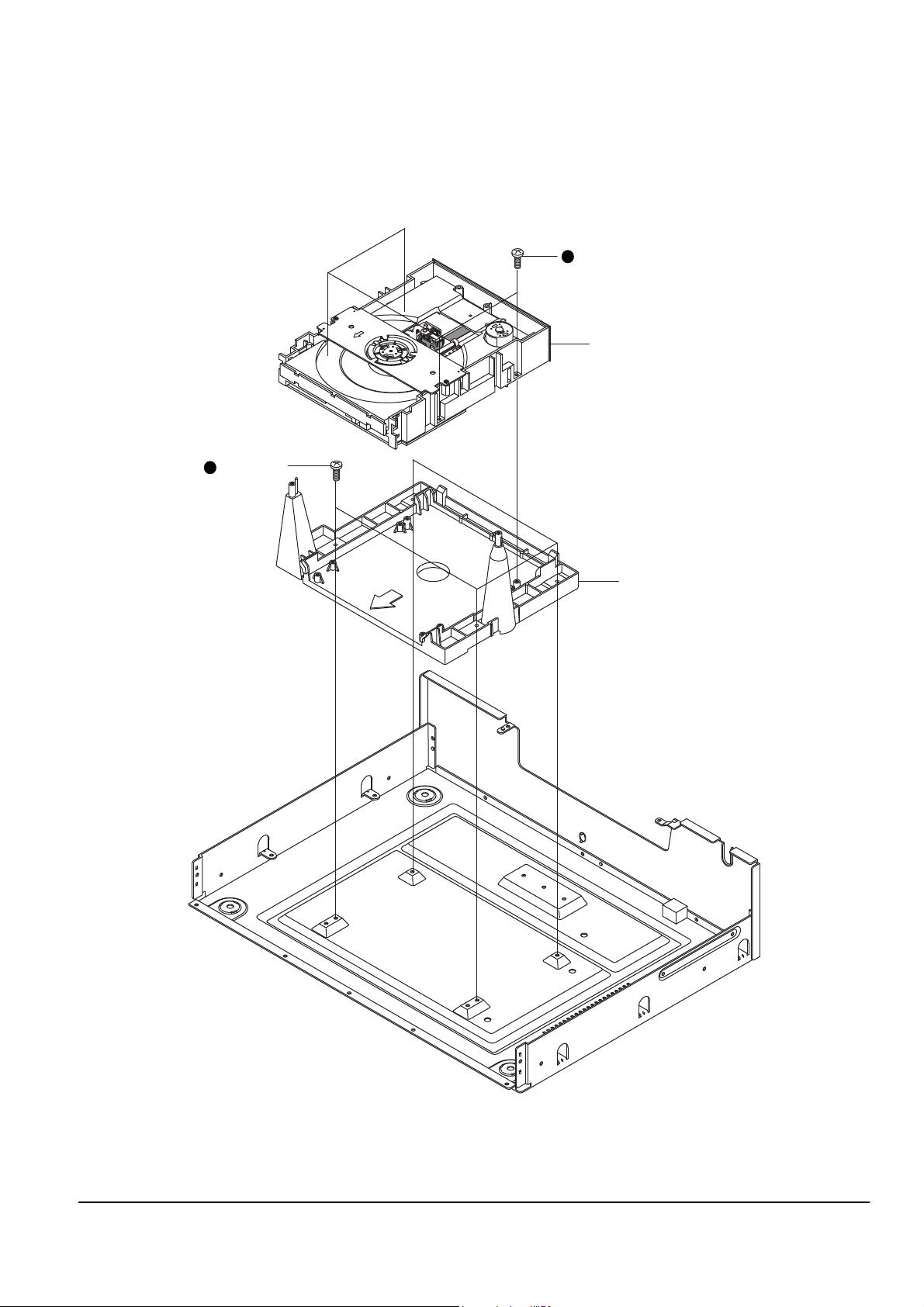

4-1-5 Deck, Frame-chassis

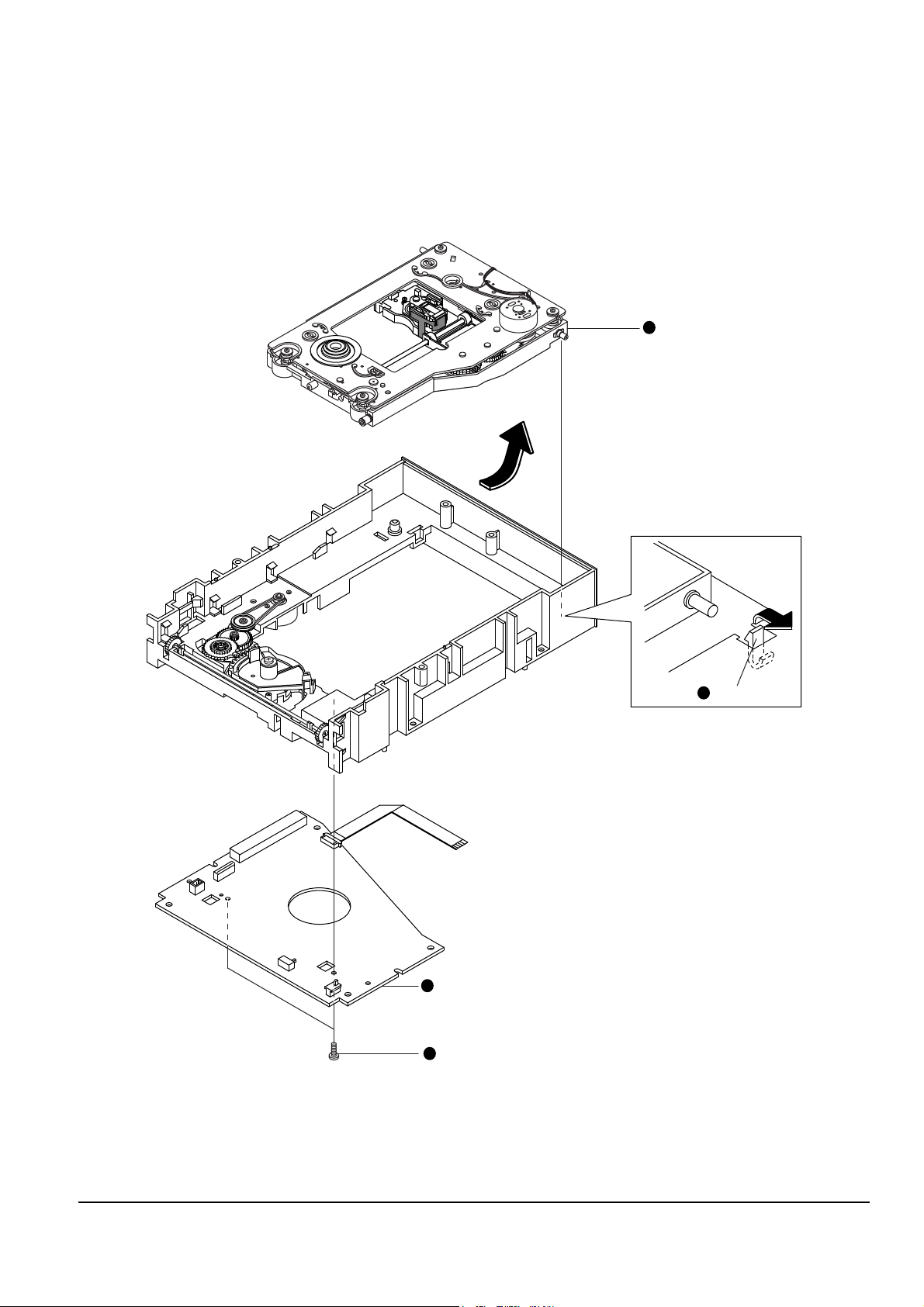

1. Remove 4 screws Πfrom the deck and lift it up.

2. Remove 4 screws ´ from the frame-chassis and lift it up.

Fig. 4-5

4 SCREWS

DECK

FRAME-CHASSIS

4 SCREWS

11

22

Disassembly and Reassembly

4-6 Samsung Electronics

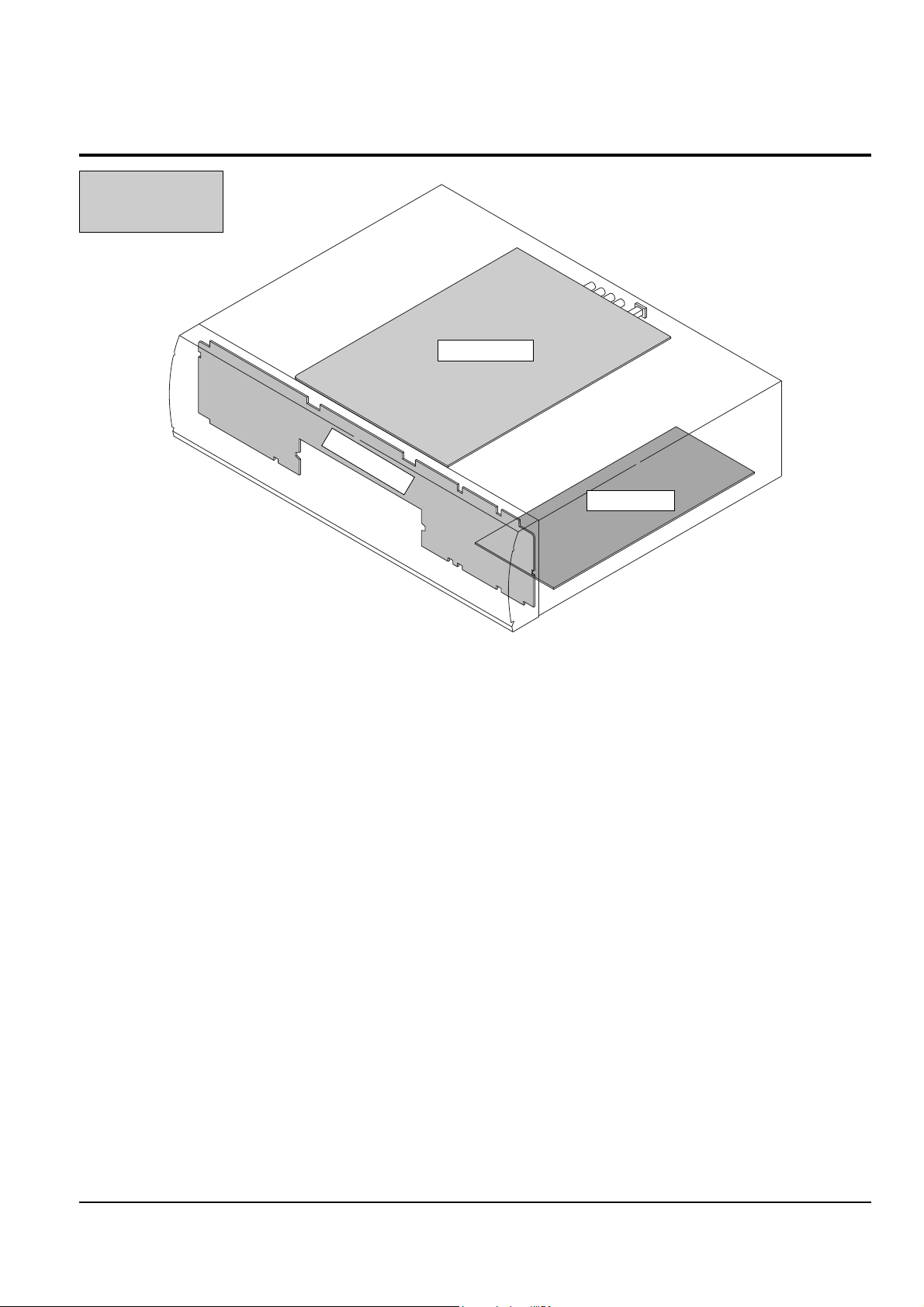

4-2 PCB Locations

PCB-MAIN

PCB-SMPS

PCB-FRONT

Fig. 4-6

DVD905

Disassembly and Reassembly

Samsung Electronics 4-7

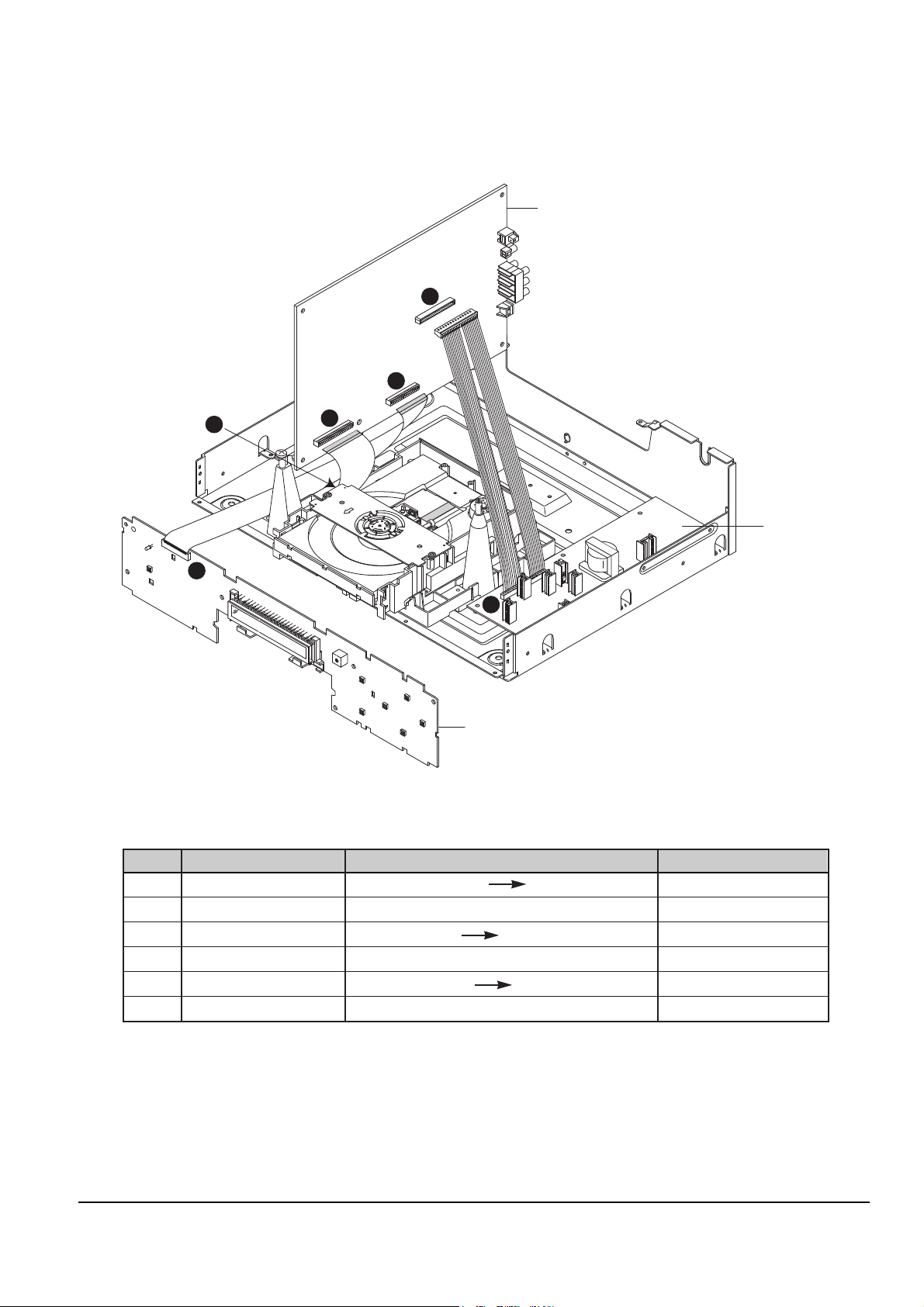

4-2-1 DVD905

Fig. 4-7

PCB-FRONT

1

PCB-SMPS

4

2

6

PCB-MAIN

3

5

No. Connector wafer No. Direction Connector wafer No.

ΠFCN1 PCB-FRONT PCB-MAIN VCN11

´ VCN11 PCB-FRONT FCN1

ˇ CN5 DECK PCB-MAIN CN1

¨ CN1 DECK CN5

ˆ PCN02 PCB-SMP PCB-MAIN VCN13

Ø VCN13 PCB-SMPS PCN02

Disassembly and Reassembly

4-8 Samsung Electronics

4-3 Deck Disassembly

4-3-1 Tray

1. Remove 2 screws Œ and lift up the assÕy-deck clamper ´.

2. Insert a clip into Emergency hole, and push Gear-Cam Center ˇ. When the tray ¨ comes out a little, pull it in

direction of arrow ÒCÓ.

3. Pull the tray ¨ to disassemble, while simultaneously pushing the hook ˆ, Ø in direction of arrow ÒAÓ, ÒBÓ.

Fig. 4-8

"A"

"C"

" B "

HOOK

EMERGENCY

HOLE

CLIP

33

GEAR-CAM CENTER

TRAY

HOOK

11

2 SCREWS

ASS'Y-DECK CLAMPER

22

55

66

33

44

Disassembly and Reassembly

Samsung Electronics 4-9

4-3-2 Ass’y-Deck DVD

1. Remove 2 screws Œ and disassemble the assÕy-PCB deck ´.

2. Disassemble the assÕy-deck DVD ¨ in direction of arrow ÒBÓ, while simultaneously pushing the hook ˇ in

direction of arrow ÒAÓ.

Fig. 4-9

"B"

"A"

ASS'Y-DECK DVD

33

HOOK

ASS'Y-PCB DECK

2 SCREWS

11

22

33

44

Disassembly and Reassembly

4-10 Samsung Electronics

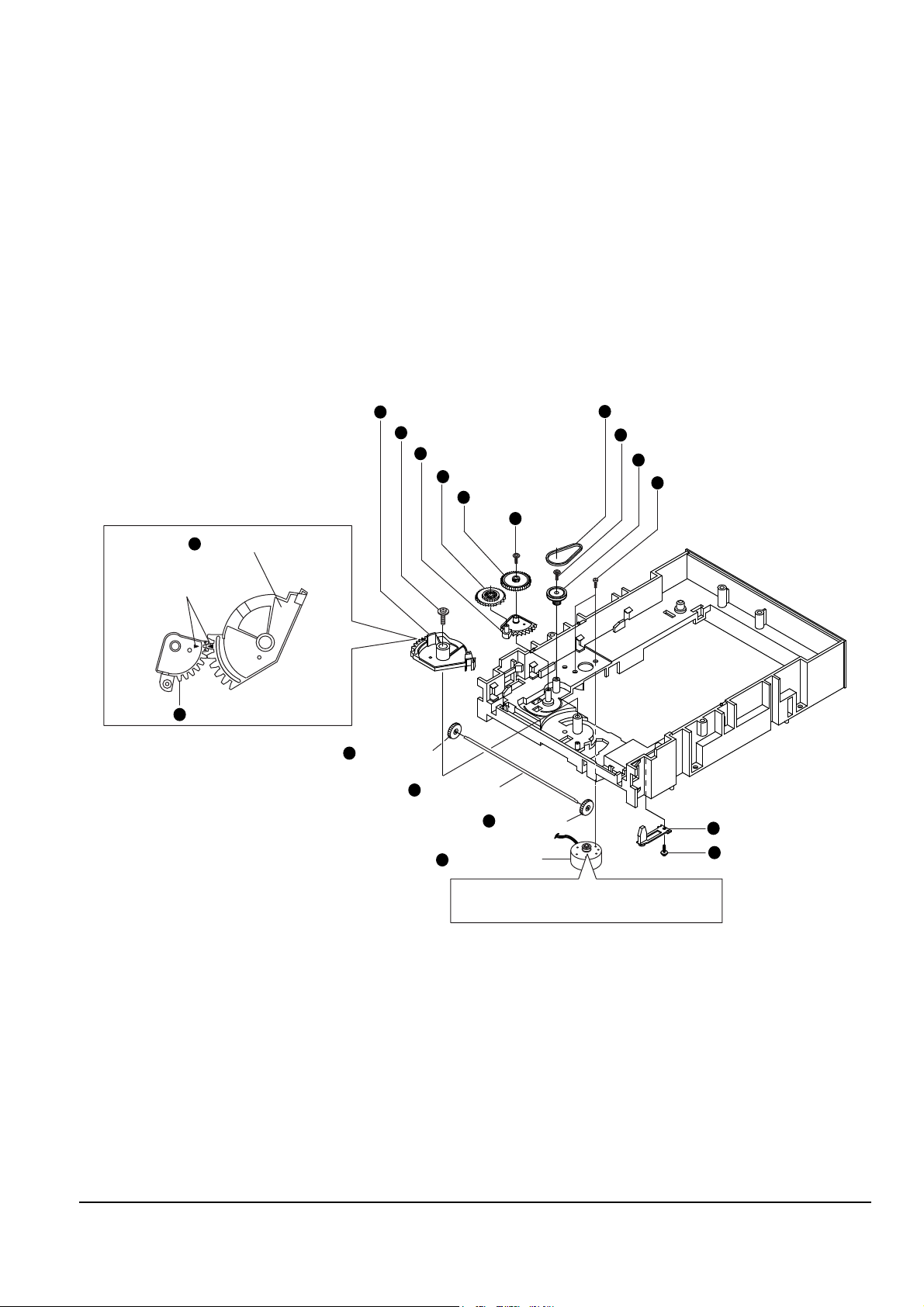

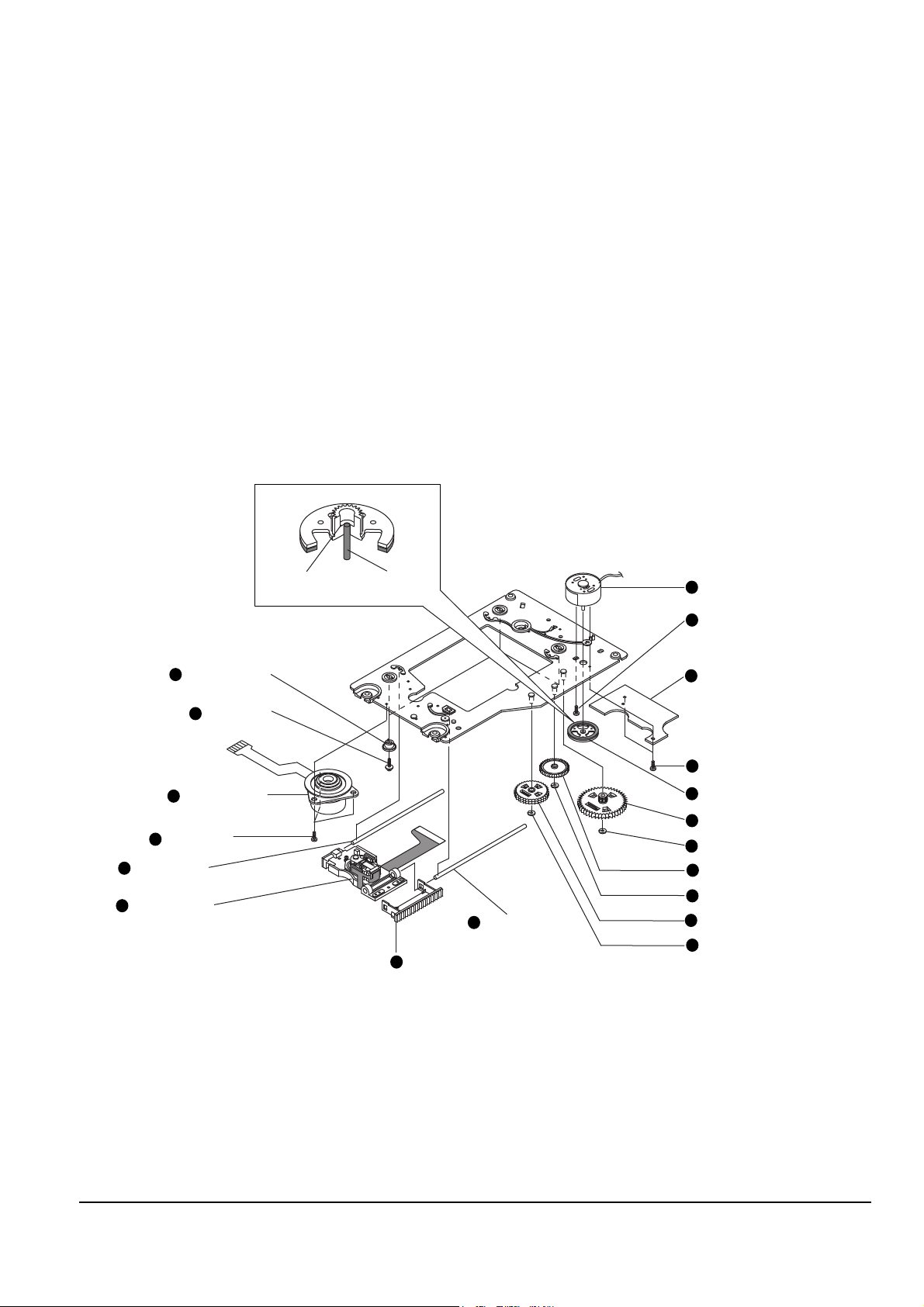

4-3-3 Chassis-Main parts

1. Lift up the gear-tray Œ, remove 1 screw ´ and lift up the gear-cam center ˇ.

2. Lift up the belt-pulley ¨, remove 1 screwˆ and lift up the pulley-gear Ø.

3. Remove 1 screw ∏ and lift up the gear-tray A ” and gear-cam sub ’.

4. Remove 2 screws ˝ and disassemble the assÕy-motor load Ô.

5. Remove 1 screw and disassemble the lever-open S/W Ò.

6. Lift up the shaft-syncro Ú and remove the 2 gear-syncro Æ in both directions.

Assembling : Adjust the shaft end of motor-feed so that it is exactly equal to the height of the hump in gear pole

of assÕy-gear magnet.

Fig. 4-10

GEAR-CAM CENTER

1 SCREW

GEAR-CAM SUB

11

GEAR-TRY

GEAR-TRY A

BELT-PULLEY

1 SCREW

PULLEY-GEAR

2 SCREWS

LEVER-OPEN S/W

1 SCREW

MOTOR,PULLEY ASSEMBLING : ADJUST THE END OF MOTOR

SHAFT SAMELY AS HEIGHT OF PULLEY AT ASSEMBLY.

ASS'Y-MOTOR LOAD

GEAR-SYNCHRO

SHAFT-SYNCHRO

GEAR-SYNCHRO

GEAR-CAM SUB

1 SCREW

33

GEAR-CAM-CENTER

POINT

1212

1313

1010

66

55

44

77

88

11

33

22

99

33

99

1515

1414

1515

1111

Disassembly and Reassembly

Samsung Electronics 4-11

4-3-4 Ass’y deck

1. Remove 4 screws Œ.

2. Lift up the assÕy-deck ´.

Fig. 4-11

4 SCREWS

ASS'Y-DECK

11

22

Disassembly and Reassembly

4-12 Samsung Electronics

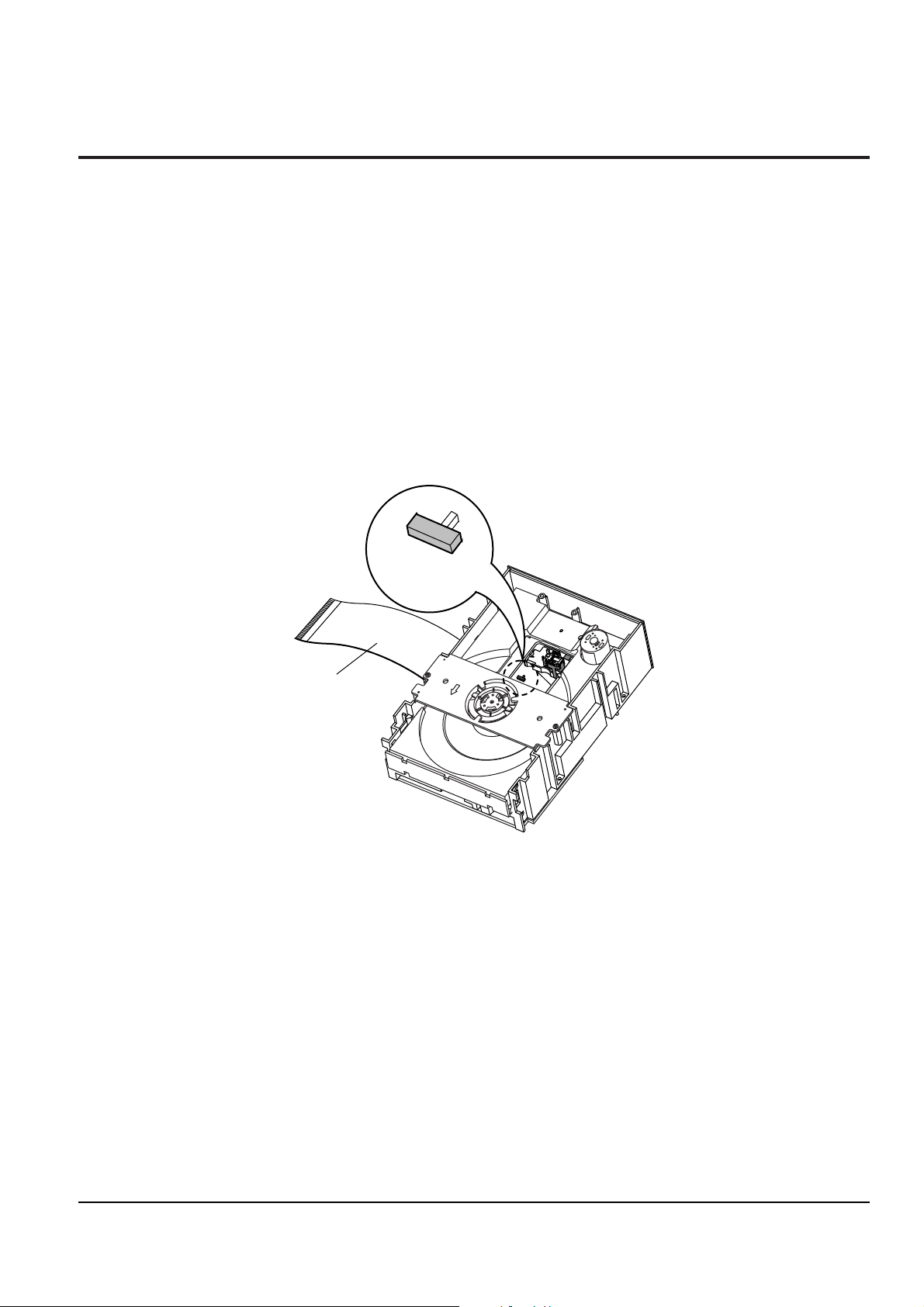

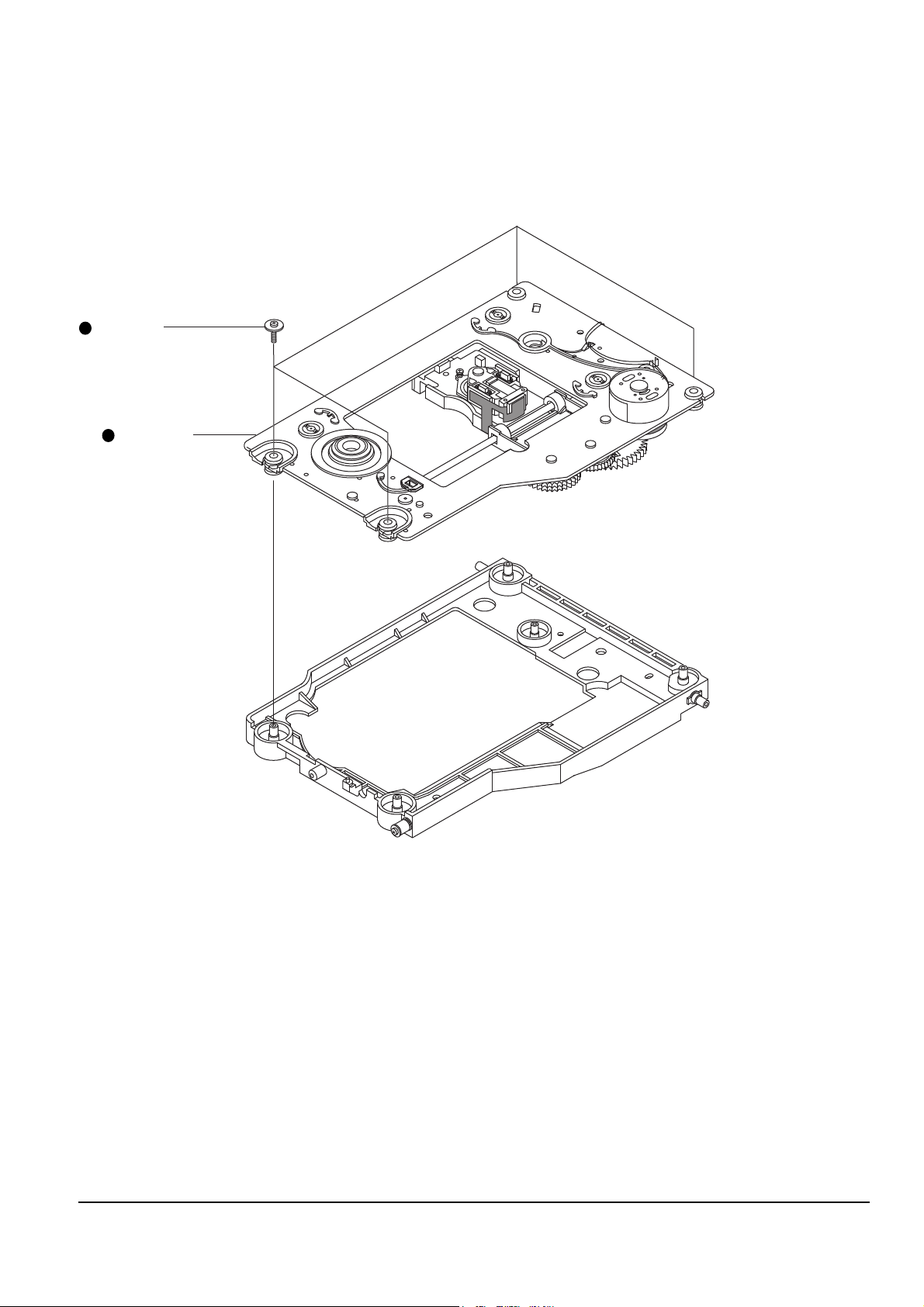

4-3-5 Ass’y-Deck parts

1. Remove 3 screws Œ and disassemble 3 holder-cams ´.

2. Disassemble the rack-slide ˆ and assÕy-pickup Ø, while simultaneously removing the shaft-P/U-L ¨,

shaft-P/U-R ¨.

3. Remove 3 screws ∏ and disassemble the assÕy-motor spindle ”.

4. Remove the washer-plain ’ and disassemble the assÕy-gear feed AU/AL ˝.

5. Remove the washer-plain Ô and disassemble the gear-feed B .

6. Remove the washer-plain Ò and disassemble the assÕy-gear feed CU/CL Ú.

7. Disassemble the assÕy-gear magnet Æ.

8. Remove 2 screws ı and disassemble the assÕy-PCB hall sensor ˜.

9. Remove 1 screw ¯ and disassemble the motor-feed ˘.

Assembling : Adjsut the shaft end of motor-feed ˘ so that it is exactly equal to the height of the hump in gear

pole of assÕy-gear magnet.

Fig. 4-12

HUMP

MOTOR SHAFT

<DETAILED DRAWING : UPPER SIDE>

HOLDER-CAM

3 SCREWS

ASS'Y-MOTOR

SPINDLE

3 SCREWS

SHAFT-P/U-L

ASS'Y-PICKUP

MOTOR-FEED

1 SCREWS

ASS'Y-PCB HALL SENSOR

2 SCREWS

ASS'Y-GEAR MAGNET

ASS'Y-GEAR FEED AU/AL

WASHER-PLANE

GEAR FEED B

WASHER-PLANE

ASS'Y-GEAR FEED CU/CL

WASHER-PLANE

SHAFT-P/U-R

RACK-SLIDE

1818

1919

1717

1616

1515

1414

9 9

1212

1111

1414

1313

5 5

44

66

33

77

88

11

22

Samsung Electronics 2-1

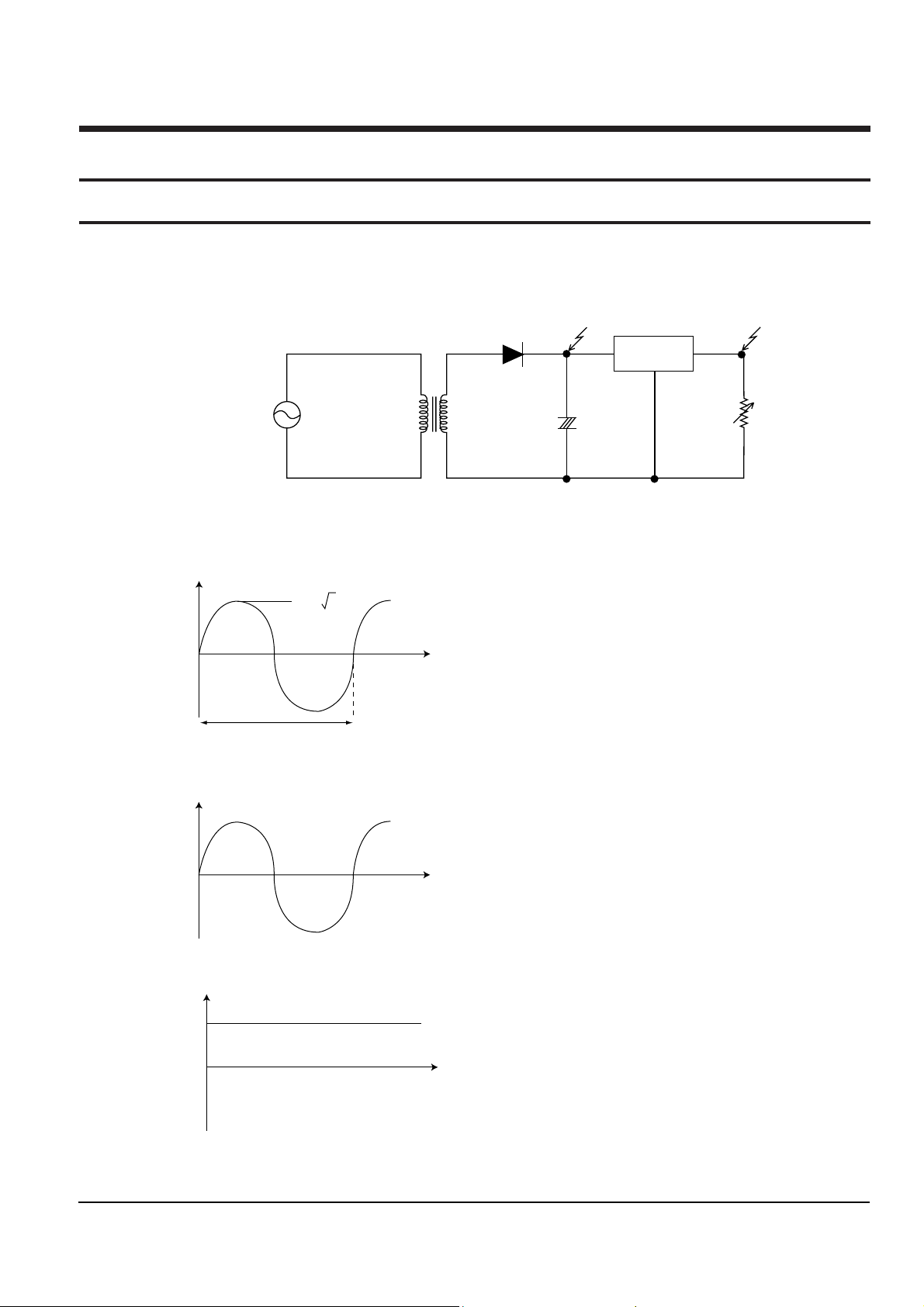

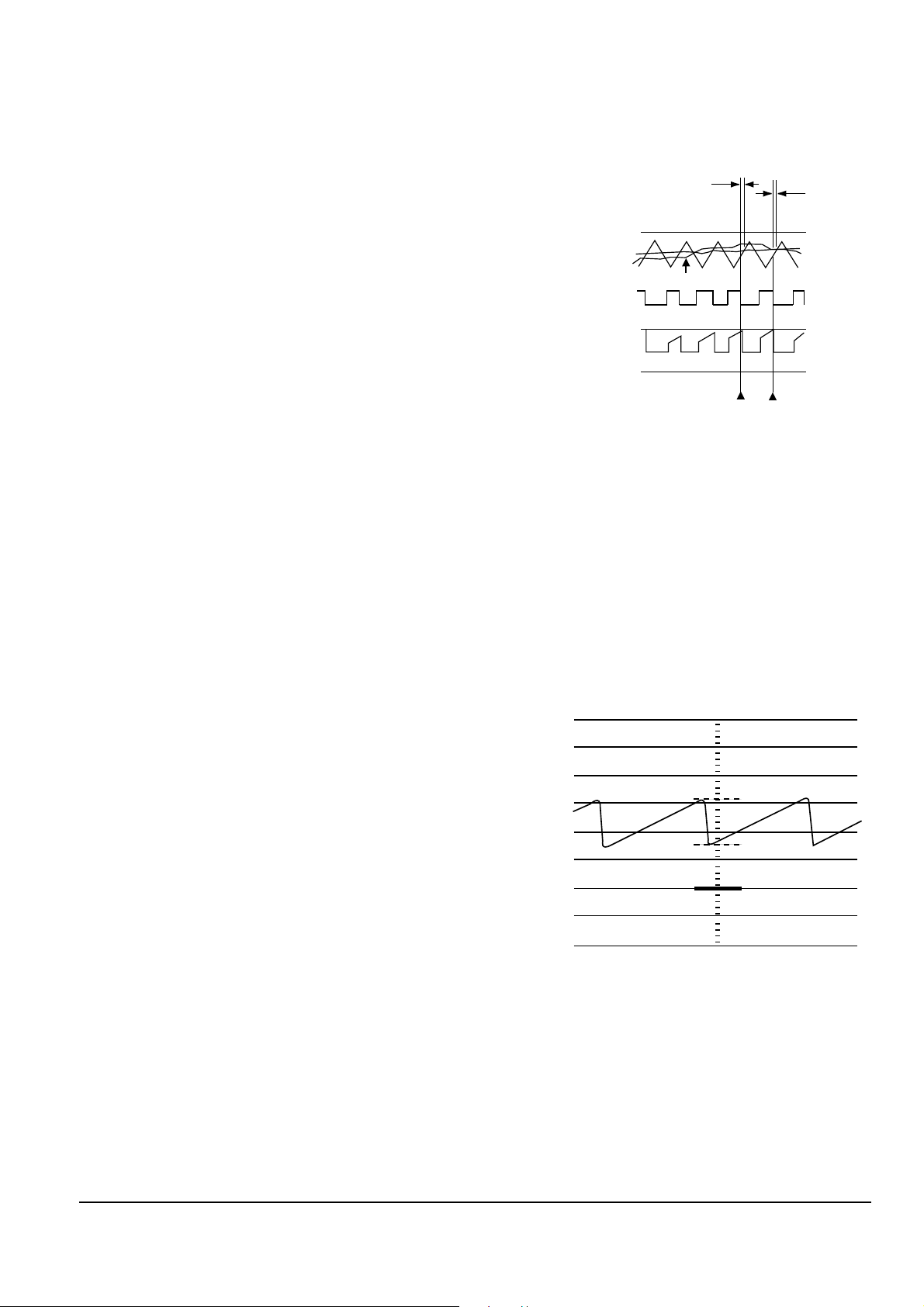

2-1-1 Comparison between linear power supply and SMPS

2-1-1(a) LINEAR

Fig. 2-1

Input : Common power to transformer(Vp)

Fig. 2-2

The output Vs of transformer is determined by the ratio of

1st Np and 2st Ns.

Vs = (Ns/Np) x Vp

Fig. 2-3

Vout is output (DC) by diode and

condensor.

Fig. 2-4

2. Circuit Operating Description

2-1 SMPS circuit description

Vreg

Vout

+

–

+

+

–

Vs

(Ns)

Vp

(Np)

Regulator

Common power

(Ex.220V60Hz)

Vs

t

0

220 2 V

20us

Vs

t

0

Vout

t

0

3 Waveform/Description

Reference Information

2-2 Samsung Electronics

3 Advantages and disadvantages of linear power supply

a. Advantages :

Little noise because the output waveform of transformer is

sine wave.

b. Disadvantages :

È Additional margin is required because Vs is changed

(depending on power source). (The regulator loss is

caused by margin design).

È Greater core size and condensor capacity are needed,

because the transformer works on a single power

frequency.

Fig. 2-5

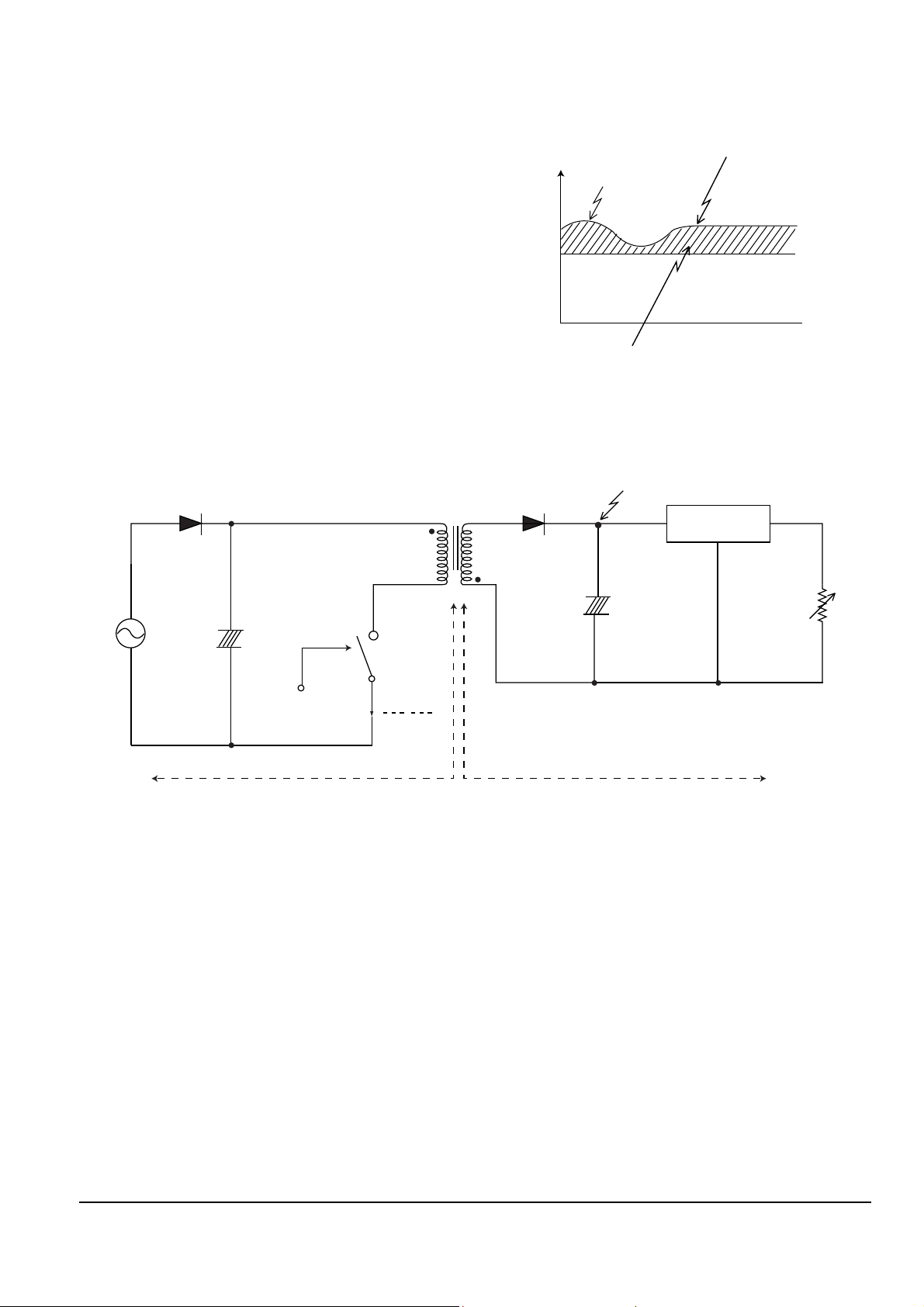

2-1-1 (B) SMPS(PULSE WIDTH MODULATION METHOD)

Fig. 2-6

3 Terms

- 1st : Common power input to 1st winding.

- 2d : Circuit followings output winding of transformer.

- f(Frequency) : Switching frequency(T : Switching cycle)

- Duty : (Ton/T) x 100

V

Vreg

Vout

0 t

Change by common power

Regulator loss

Transformer Vout

(Np)

(Vp)

Switch

Vs switch

I switch

Vin

ON/OFF Control

+

–

+

–

+

+

+

–

(Vs)

(Ns)

Regulator

Reference Information

Samsung Electronics 2-3

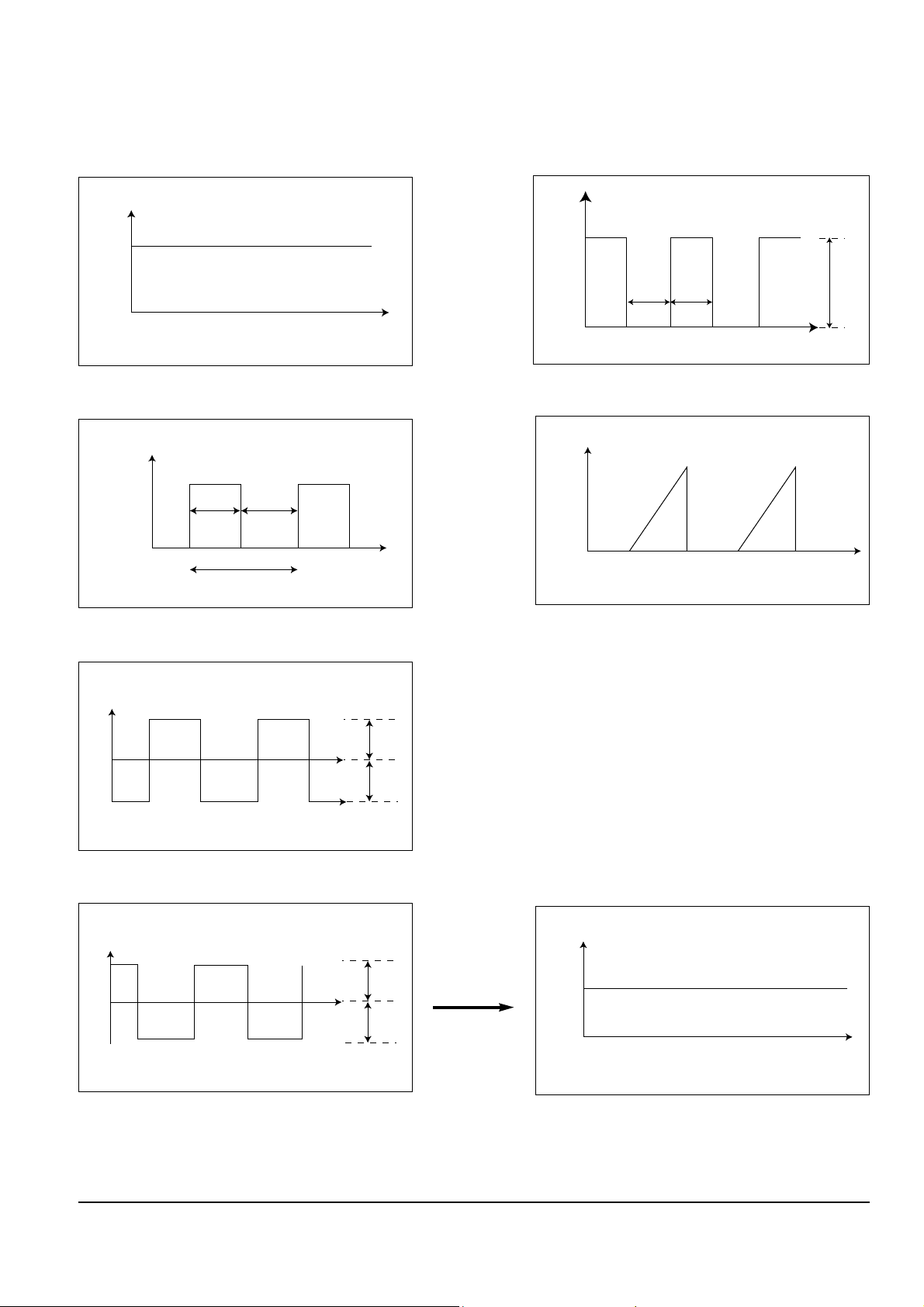

3 Waveform

Fig. 2-7 Fig.2-11

Fig. 2-8 Fig. 2-12

Fig. 2-9

Fig. 2-10 Fig. 2-13

Vin

0

t

Vswitch

ON/OFF

Control

Vp

0

Ton

Toff

0

Vin–Vp

t

Iswitch

Ton Toff

0

f t

0

t

Vin

t

Vps

Vs

0

Vs1

t

Vs2

Vout

0

t

Reference Information

2-4 Samsung Electronics

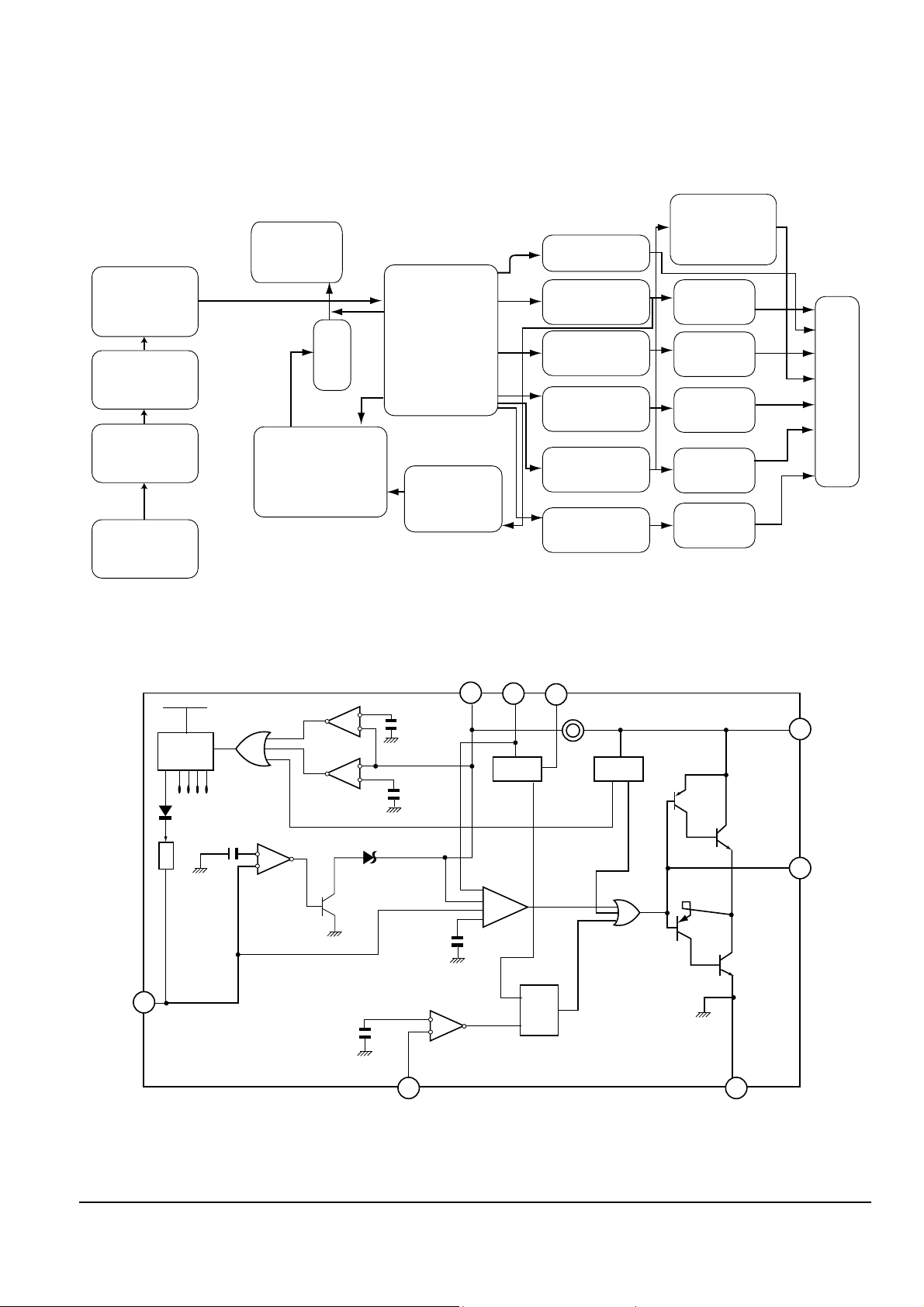

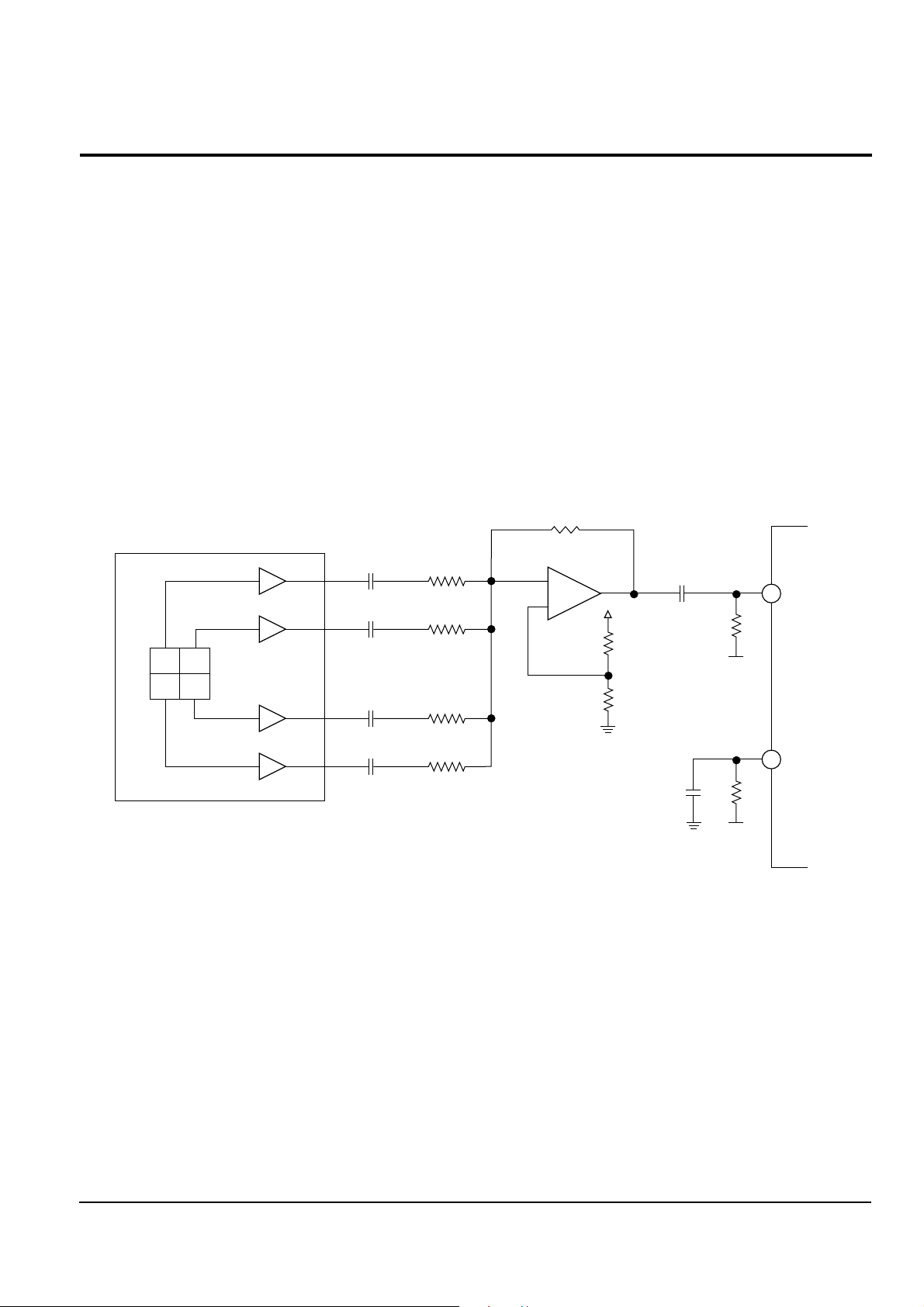

2-1-1(c) INTERNAL BLOCK DIAGRAM

1. Internal block diagram of SMPS circuit

Fig. 2-14

2. PIC1(KA7552) internal block diagram

Fig. 2-15

BIAS

OFF

2.8V

7.0V

CS

8 7

1

CT RT

10UA

OSC UVLD

VCC

OUT

GNDIS(+)

PB

4.3k

3.6V

ZD

G

D MAX

(46%, 70%)

R

S

Q

PWM

OCP

+

Ð

Ð

+

Ð

+

Ð

+

0.24V

6

5

4

3

2

Noise removing circuit at

power

input/output

Noise

removal

(SNUBBER)

Smoothing

circuit

Rectified circuit

Line filter

Power IN

(85-265V)

F

E

T

FLT driving

circuit

5V rectified

smoothing circuit

3.3V rectified

smoothing circuit

Convertor

PWM control circuit

(KA7552)

Voltage

detection

circuit

9V rectified

smoothing circuit

8V rectified

smoothing circuit

-8V rectified

smoothing circuit

5V rectified

voltage

circuit(x2)

3.3V rectified

voltage

circuit

9V rectified

voltage

circuit

8V rectified

voltage

circuit

-8V rectified

voltage

circuit

O

u

t

p

u

t

Reference Information

Samsung Electronics 2-5

2-1-2 SMPS circuit description

2-1-2(a) CIRCUIT METHOD

FLY-BACK PWM(Pulse width modulation) control

2-1-2(b) CIRCUIT DESCRIPTIONS

1. AC power rectification/smoothing terminal

- PD01 : Convert AC power to DC(Wave rectification)

- PO10 : Smooth the voltage converted to DC(Refer to Vin of Fig. 2-7)

- PC01, PC02, PC03, PC04, PC05, PC06, PL01, PL02, PL03 : Noise removal at power input/output

- PVA1 : SMPS protection at power surge input

- PVA2 : SMPS protection at 2st ground surge input(PVA1 pattern open : to remove noise)

- PR10 : Rush current limit resistance during power cord insertion.

È Rush current = (AC input voltage x 1.414 - Diode drop voltage) / Pattern resistance + PL02.01

resistance + PC10 resistance + PR10) (AC230V based : approx. 26A)

È Without PR10, the bridge diode might be damaged as the rush current increases.

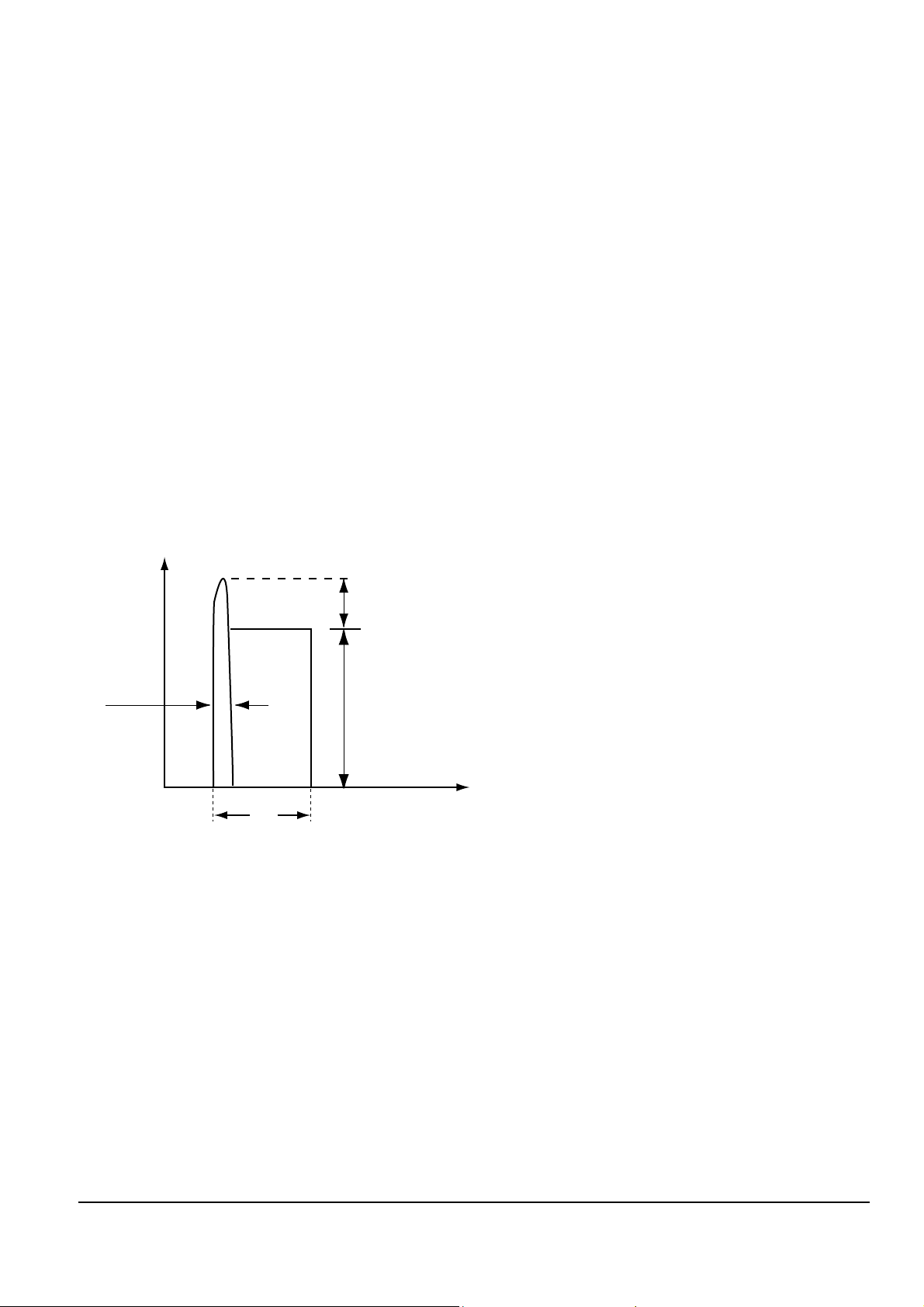

2. SNUBBER circuit : PR17, PR18, PC11, PD10

- Prevent residual high voltage at the terminals of

switch during switch off/Suppress noise.

High inverted power occurs at switch off,

because of the 1st winding of transformer:

(V=L1xdi/dt. LI : Leakage Induction)

A very high residual voltage exists on both

terminals of PQ1 because dt is a very short.

- SNUBBER circuit protects PQ1 from damage

through leakage voltage suppression by RC,

(Charges the leakage voltage to PD10 and PC11,

and discharges to PR17 and PR18).

- PC12, PL11 : For noise removal

Fig. 2-16

3. PIC1 Vcc circuit

- PR11, PR12, PR13, PR14 : PIC1 driving resistance (PIC1 works through driving resistance at power cord in)

- PIC1 Vcc : PR20, PD12, PC17

1) Use the output of transformer as Vcc, because the current starts to flow into transformer while PIC1 is active.

2) Rectify to PD12 and smooth to PC17.

3) Use the output of transformer as PIC1 Vcc : The loads are different before and after PIC1 driving.

(Vcc of PIC1 decreases below OFF voltage, using only the resistance due to load increase after PIC1 driving.)

- PR20 : For noise removal

0

Vin–Vp

Vswitch

dt

Toff

t

Inverted power

by leakage

inductance

Reference Information

2-6 Samsung Electronics

4. PIC1 function : PWM control (Refer to Switch ON/OFF Control of Fig. 2-6)

- 0.56V

- -

OFF voltage 0.75V

SHUT OFF voltage 2.8V

DUTY MAX voltage 2.3V

LIMIT voltage 0.24V

- -

- -

Maximum DUTY 70%

ON voltage 16V

OFF voltage 8.7V

- -

OFF voltage 0.42V

ON voltage 0.56V

3.6V

SHUT OFF voltage 7V

MAX DUTY voltage 2.3V

1 RT

2 F/B

3 IS

4 GND

5 OUT

6 VCC

7 CT

8 CS

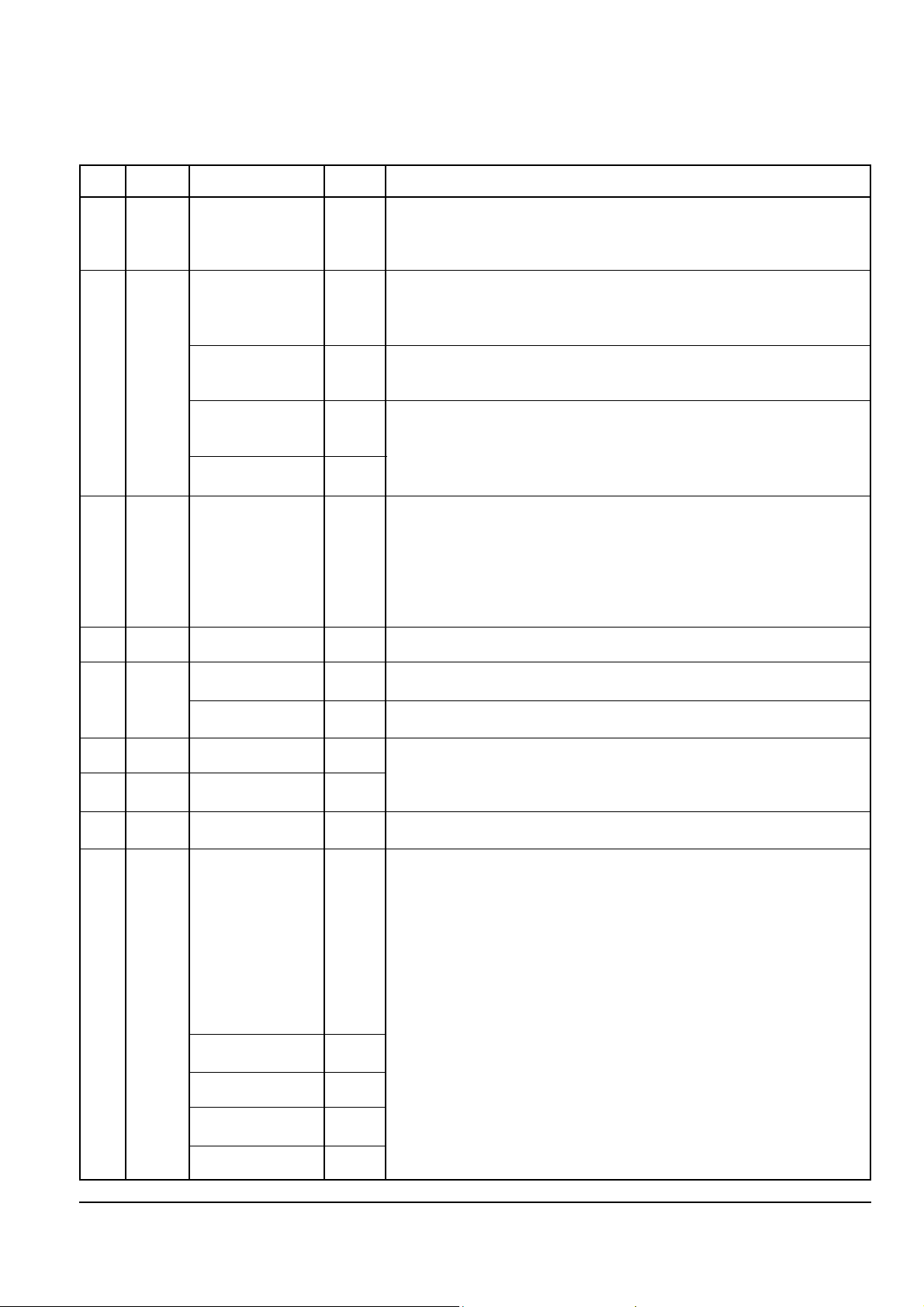

PIN NAME CLASS SPEC. FEATURES

* Resistance to determine OUT terminal(pin5) ON/OFF control frequency

- Determined with CT terminal(pin7) and for DVDP, 50KHz

RT : PR24, CT : PC13

* OUT terminal duty is determined by F/B potential

(Duty control : 2st output constant-voltage control)

* The voltage of PIC2(Output voltage freedback) is input to F/B terminal.

* If F/B terminal potential decreases below 0.75V, OUT duty is zero.

- SMPS 2st output voltage is zero.

* If F/B potential is above 2.8V, CS terminal(8pin) potential ascends in IC.

If CS potential rises above 7V, SHUT OFF mode is maintained.

* SHUT OFF mode : IC internal bias OFF state.(Operation stop)

* If IS terminal potential is above 0.24V, maintain on time only when IS

terminal potential is 0.24V without holding OUT duty determined in F/B

terminal(Duty limit).

* PQ1(F,E,T) current is distributed to PR22, PR21 in voltage, and input to IS

terminal.

* Purpose : Limit the overcurrent of PQ1(Current waveform : See Fig. 2-10)

* Ground(SMPS 1st ground)

* ON/OFF control pulse output terminal(f : fixed, ON TIME : variable)

* Maximum duty is 70% (Maximum).

* IC power supply terminal. IC function starts at exceeding 16V. Vcc less than

8.7V will be OFF after IC working.(See Clause 3. Vcc circuit)

- Vcc voltage is 10-12V at normal operation.

* ON/OFF frequency determining terminal(Refer to 1 pin RT terminal)

* OS potential setting : Connect the condenser to OS terminal(PC14)

* ON/OFF control : If CS potential is above 0.56V, IC function starts and if

below 0.42V, IC function stops.

* At normal operation : Maintain 3.6V in IC

* SHUT OFF mode : If CS potential is above 7V, shut off.(Overload

prevention)

- SHUT OFF function : When IS, F/B, CS terminal are all operated normally.

(Refer to Clause 6. MAX. POWER limiting circuit)

* SOFT START : Switch protection at initial starting

- F/B potential is 3.6V internally at initial starting.(Duty max.)

- PQ1 damage occurs due to overcurrent on switch at duty max.

- CS terminal sets the duty with F/B terminal

- Connect PC14 to CS terminal and set the voltage charging time at initial

starting.

- Increase the duty by raising the voltage gradually via PC14 at initial starting

for normal operation.

(Duty max. is limited by F/B potential at initial starting)

Normal operation

voltage

Reference Information

Samsung Electronics 2-7

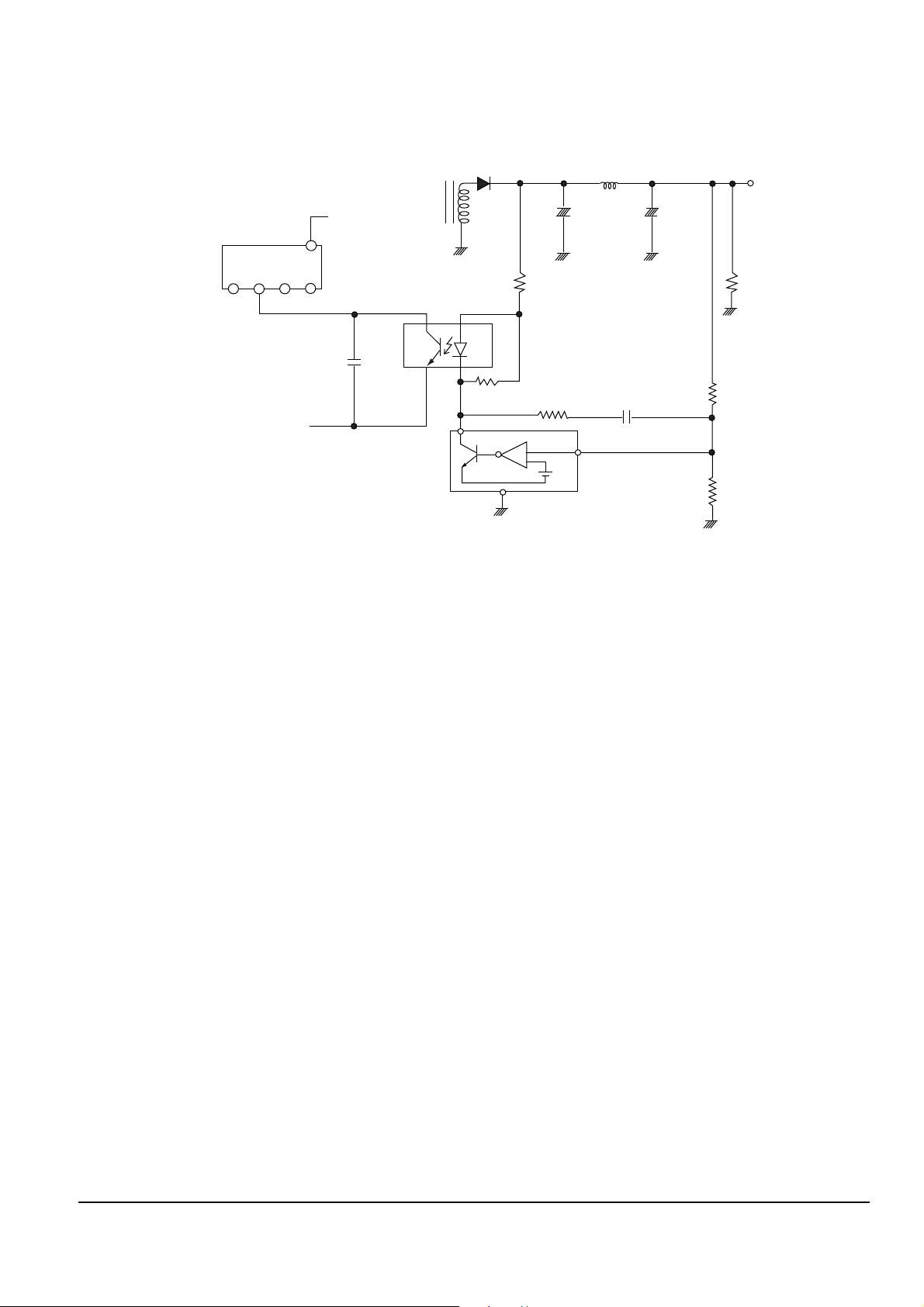

5. Feedback control circuit

Fig. 2-17

- F/B terminal of PIC1 determines output duty cycle.

- Duty definition : Refer to Vs1 in Fig4-10.(Duty up: Vs1 up, Duty down: Vs2 down)

- C-E(Collector-Emitter) of PIC2 and F/B potential of PIC1 are same.

- At F/B terminal open : SHUT OFF mode

È F/B potential is set to 3.6V internally.

F/B potential decreases to 1-2V by C-E voltage of PIC2 ( controlled by normal

operation. )

È When F/B terminal is open, shut off occurs because 2.8V is exceeded.

(Refer to clause 4.)

3 Operation descriptions

a. Internal OP-Amp Ô+Õ base potential of PIC3 is 2.5V and external Ò-Ó input potential is connected with PR38

and PR39 to maintain Vout of 5.8V. (Vout = ((PR36 x PR39) / PR39) x 2.5V)

b. If load of 5.8 V terminal increases(or AC input voltage decreases) and Vout decreases below 5.8V, then :

PIC3 ÔPÕ potential down below 2.5V --> PIC3 A-K of base current down --> PIC3 of A-K current down -->

PIC2 Diode current down --> PIC2 C-E current down --> PIC2 C-E voltage up --> PIC1 F/B voltage up -->

OUT Duty up --> Transformer 1st current up --> Transformer 1st power up --> Vout up --> Maintain

Vout 5.8V

c. If load of 5.8 V terminal decreases(or AC input voltage rises) and Vout rises above 5.8V, then :

Reverse sequence of the above description ® Duty down ® Vout down ® Maintain 5.8V

(i.e., the feedback to maintains 5.8V).

- PR35, PR36 : Reduce 5.8V overshoot

- PR37, PC43 : Prevent IC3 oscillation(for phase correction)

- PC18 : Adjust feedback response rate

PIC1

OUT

ON/OFF Control

Trans

PC18

PIC2

C

E

A

P

K

2.5V

K

PR36

PR37

A

PR35

PC38 PC39

PR40

100/2W

PL37

5 .8V

PD35

PC43

PR38

PR39

GND

++ ++

GND

F/B

1

2

3

4

5

PIC3

-

+

Reference Information

2-8 Samsung Electronics

6. Maximum power limit circuit

* Circuit configuration : PIC1 F/B, CS, IS terminal PR23, PR21,

PR22, PC13A

* Role : Switch overcurrent protection

* The current on switch inputs to IS and outputs as voltage via

PR23, PR21, PR22.

* If the current on switch increases and IS terminal input

voltage exceeds 0.24V, duty is determined by F/B terminal.

Accordingly, the current on switch is limited less than specific

current.(If 2d load rises, the switch current increases. Refer to

clause 5. in circuit description).

* If I/S terminal is open : Switch and other parts are damaged

because the switch is not limited during abnormal status (for

example, 2d ouput terminal short).

Fig. 2-18

1) Intermittent operation mode

- Definition : PIC1 canÕt deliver normal output, and repeats Vcc ON/OFF operation(Vcc voltage is swing

between 16V(ON) and 8.7V(OFF).

- Operation description : for example. 2d output terminals shorted, then :

Specific 2d terminal short --> 2d power is concentrated on short terminal --> 5.8V(PC39)

voltage down --> F/B voltage up (Refer to clause 5.) --> Duty up --> Switch current up --> Limit switch

current to IS terminal(Duty limit) --> Apply 1st supply power in comparison with 2d power -->

Concentrate on 2d power short terminal --> PIC1 Vcc terminal TRANS. output voltage down below

8.7V --> PIC1 OFF --> PIC1 ON via driving resistance --> Above operations repeated ® Maintain

intermittent operation mode (See Fig. 2-19 Waveform).

At short release : normal operation

2) Short OFF mode

- Main examples : Feedback circuit Open, Max, Power

excess(Design spec.), 5.8V Terminal short

- Operation description :

Ex - 2d load is high abnormally;

1st supply power is low in comparison with 2d output power.

5.8V down --> Duty up --> Switch current up -->

IS terminal duty limit --> 1st supply power limit --> 5.8V

voltage down --> F/B potential above 2.8V(Shut OFF voltage)

--> OS terminal potential up (Refer to Clause 4.)F/B -->

OS potential above 7V --> Shut OFF mode

- The output voltage of SMPS is zero because PIC1 doesnÕt work

during Shut OFF mode.

- Shut OFF mode release : OS potential decreases below

7V.(Charge OS terminal forcely)

- Feedback terminal open : Shut OFF (Refer to clause 5.);

PC13A : For IS terminal input noise removal Fig. 2-19

CS Voltage(3.6V)

Duty Limit sector

FB Voltage

DT Voltage

OSC OUT

OUT Voltage

COM.C4(0.24V)

Over current protection

Over current protection

Blas voltage

IS(+) Voltage

Time : 100ms / div

Volt : 5V / div

16V

8V

GND

Reference Information

Samsung Electronics 2-9

7. Shut Off mode prevention circuit at instant load increase : PC15, PZD13

- During a sudden load increase;

By means of current concentration on specific output terminal, 5.8V voltage down --> F/B potential up -->

Maintain Shut Off mode.

Stablize F/B potential (Loading completion) below 7V by lengthening CS potential rise time to 7V

(in order to prevent Shut Off mode).

- Normal operation : CS potential is 3.6V and PZD13(4.7V ZENER) is open.

- OD potential above 4.7V at instant load increase --> PZD13, PC15 work --> OS terminal condenser capacity

increases in parallel with PC14 and PC15 --> CS potential rising rate down --> Instant operation completed

--> F/B potential stable --> Normal operation

8. Maximum power limiting circuit addition : PZD11, PR19

- SMPS efficiency : Below 25W : High efficiency at AC110V input

Above 25W : High efficiency at AC230V input

- The peak value of current on switch at overload is lower than that at 110V input because SMPS is highly

efficient above 25W at 230V input. Therefore, maximum power increases at 230V as compared to

110V at overload. Add PZD11, PR19 and set to the same level as 110V.

- Higher at 230V input than at PZD11 input, limit maximum power because IS terminal potential goes up.

9. PQ1(F,E,T) Gate Drive Circuit : PR15, PR16, PD11

- PIC1 OUT is square wave but charging and discharing by PR15, PR16 occurs due to internal condenser

between gate-sources of PQ1.

- PR15, PR16 : Switch ON Time setting - PD11 is reverse : PIC1 OUT --> PR15 --> PR16 --> Charge to gate

- PR16, PD11 : Switch OFF Time setting - PD11 is proper : GATE - PR16 --> PD11 --> Discharge to PIC1

OUT(GND)

- Switch ON/OFF time : Releated to switch loss and noise

10. PIC1 overcurrent protection : PZD12

- Operate PZD12 and protect PIC1 from damage from residual overcurrent (PIC1 Vcc, due to external surge

inflow and feedback line open).

2-10 Samsung Electronics

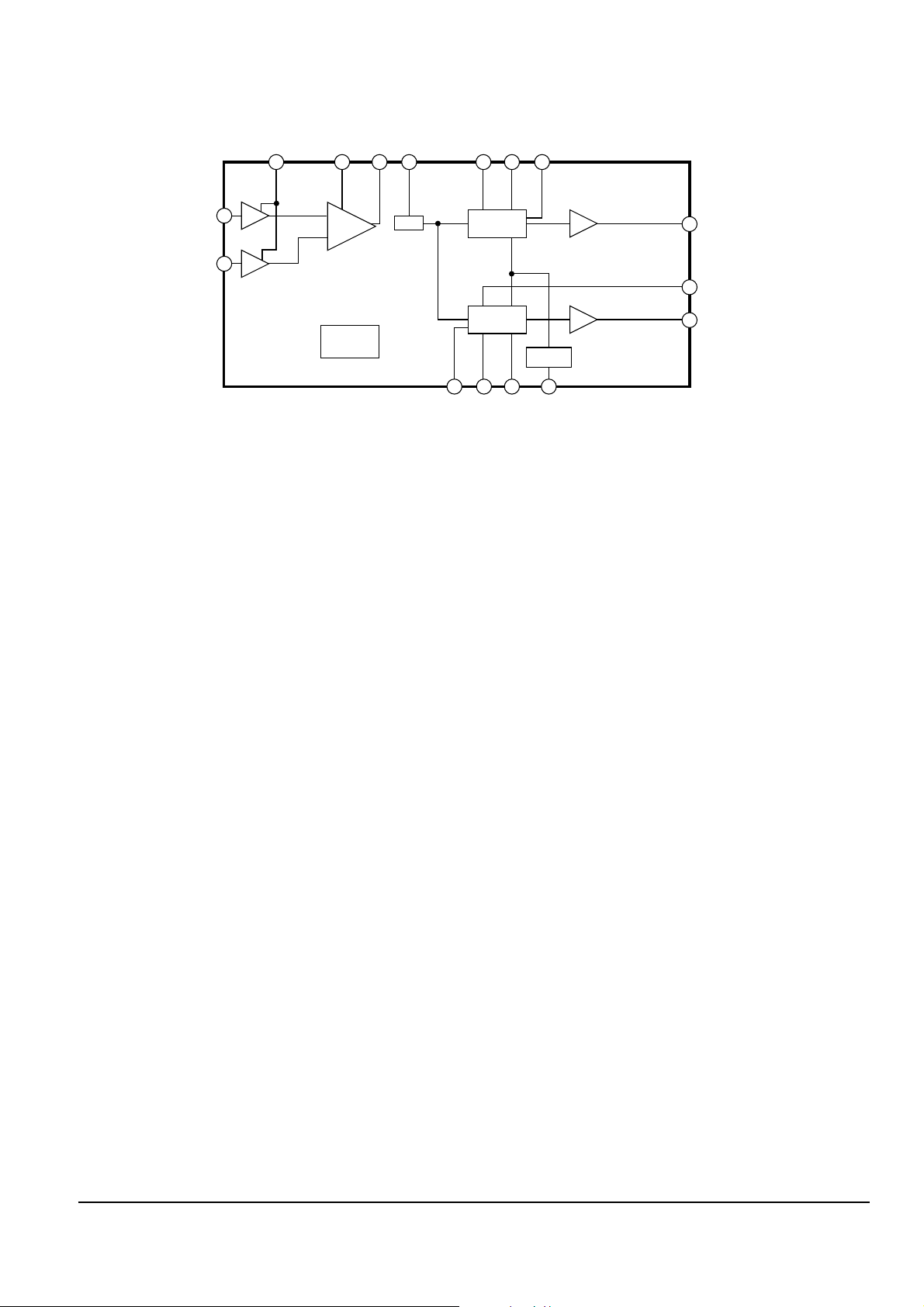

2-2-1 RIC1(TA1236F)

TA1236F is combined with TA1253FN, TC9240F and TC90A19F as bipolar IC developed for DVD SERVO system.

Main features include DVD waveform equalizing, CD waveform equalizing, focus error signal generation, 3-beam

tracking error signal generation, laser power control, etc. after receiving the pick-up output converted into I/V.

1. Basic potentiometer

TA1236F uses a single power method and each circuit is based on VREF of 2.1V. Note :

symmetrical about GND for VREF because VREF(pin20) terminal is needed for IC, which uses the peripheral VREF

and 2VREF output(pin18).

2. RF signal

Fig. 2-20 shows the flow of signal generated by the pick-up.

A, B, C, D signals detected from pick-up are converted in to RF signal(A+B+C+D) via RF summing AMP.

RF signal is inputted to RFN(pin55) among input terminals and RFP(pin54) is used for AC ground.

Fig. 2-20

Fig. 2-21 shows the waveform-equalizing block diagram for the RF signal.

It outputs to EQout(pin 46) terminal by initially changing switching AMP gain of DVD and CD, and then

adjusting the level in VCA. It controls VCA gain by means of RF gain(pin 48) and interfaces with PWM signal,

(output from RFGC terminal of TC9420F, via low-pass filter to constitute a loop for adjustment of constant

amplitude). The gain in EQout is 1.0 for DVD and 1.67 for CD.

EQout terminal is connected with EQin(pin 45) externally, and inputs into DVD EQ and CD EQ(Waveform

equalizing circuit).

55

54

PICK-UP

PD

D A

C B

I-V AMP

RC12

104

RR20

1K

RC10

104

RR19

1K

+

–

RC15

104

RR24

1K

RC14

104

RR22

1K

RR18

1.2K

RIC3 OPA 650

SUMMING AMP

2

3

6

RC11

104

RR23

10K

RR50

5.6K

RR51

5.6K

RC22

104

RR33

10K

Vref

RIC1

TA1236

RFN

Vref

RFP

+5A

2-2 RF circuit description

Reference Information

Reference Information

Samsung Electronics 2-11

Fig. 2-21

The control parameters of DVD EQ and CD EQ are as follows.

1) DVD EQ control parameter

- DVDEQ(pin 43) : Changes the gain of peak frequency with EQ frequency characteristic. Convert PWM

signal, output from TC90A19F, into DC via low-pass filter.

- DVDTIME(pin 41) : Changes the peak frequency with EQ frequency characteristic. Convert PWM signal,

output from TC90A19F, into DC via low-pass filter.

- S/Dse1(pin 64) : Changes the peak frequency (like DVD TIME) as 2d control. ( Switched according to

regeneration speed ratio of single/double layer).

- MCK(pin 15) : Input the base clock and link the peak frequency with it. The amplitude of MCK might be

small (500mVp-p).

- DVDGD(pin 25) : Changes the group delay characteristics with EQ frequency characteristic.

2) CD EQ control parameter

- CD EQ(pin 40) : Changes the gain of peak frequency with EQ frequency characteristic. The constant DC is

supplied to a resistive voltage divider.

- CD TIME(pin 42) : Changes the peak frequency with EQ frequency characteristic. The constant DC is

supplied to a resistive voltage divider.

- S/Qse1(pin 44) : Changes the peak frequency (such as CD TIME) as 2d control. (Switched according to play

linear velocity ratio of quadruple/single rate. Set to Ô0Õ because only one rate is vaild in

this system).

Note : CD and DVD signals are equalized according to the above control parameters ,and then output to CD

EQ OUT (pin39) and DVD EQ OUT (pin34). Then, CD signal is transferred to TC9420F, DVD signal is

sent to TC90A19F and detected.

DVDsel RFgain EQout EQin

CDEQCD

TIME SQsel

RFN

RFP

47 48 46 45 40 42 44

55

54

64 41 43 15

34

25

39

VCA

ATT

CD EQ

DVD EQ

RIC1

TA1236F

GEN.

T/CON

SDsel DVD

TIME

DVDEQMCK

DVD G/D

DVD EQ OUT

CD EQ OUT

2-2-2 Description of data processor for DVD

(Including DIC1 and DIC5 protection IC)

1. Outline

The data processor IC for DVD does the following :

1) Converts RF signal to digital, demodulates original signal and corrects errors,

2) PLL circuit to generate the clock for data detection in accordance with play velocity,

3) CLV control circuit to control the rotation rate of disc,

4) DIC5 Protection IC, connected with input/output of data processor, which releases the protection for the

protected data (which is then transmitted to video decoder and Micom).

Loading...

Loading...