Samsung DVD-807 Reference Information

Samsung Electronics 2-1

2. Reference Information

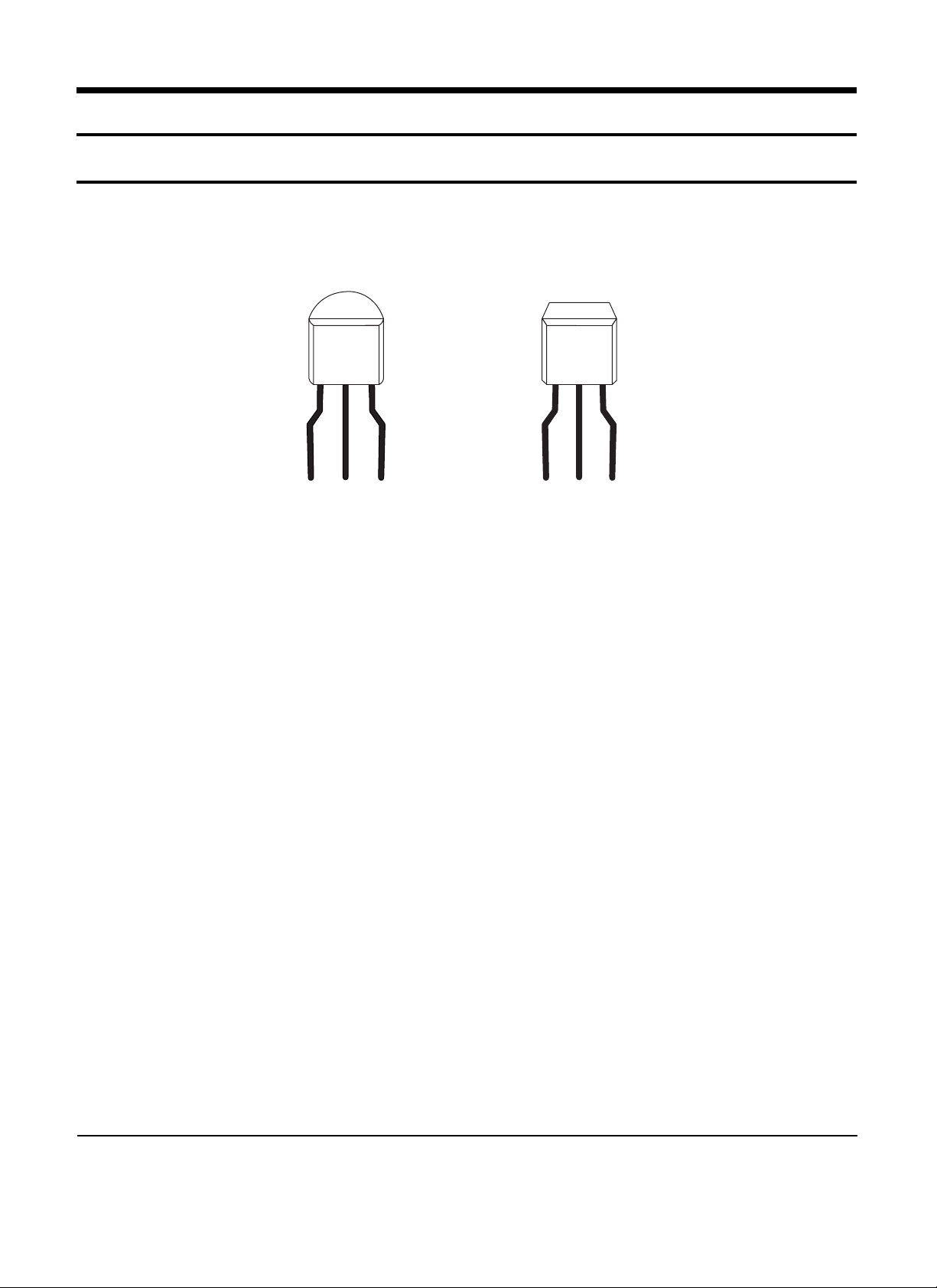

2-1 Semiconductor Base Diagram

Fig. 2-1

RQ1

SS9012

S9012

G-634

E B C

D G S

K184

Y6A

SQ1

K184

2-2 Samsung Electronics

2-2 Chip Replacement

1) Do not touch the part body directly with the soldering iron. ICs, especially TSOP, are easily damaged by heat.

2) Use care regarding soldering iron tip and avoid

repidly heating parts. Some parts can be damaged

by sudden heating. Preheat the part at about

100°… for several minutes before installing it.

3) Use soldering tip temperature of about 240°… or

larger parts, use a slightly higher temperature

(about 280°…).

4) The thin(0.3mm)solder for miniature parts does

not contain adequate flux. Supplementary flux is

thus needed in most cases.

5) Use care not to damage the circuit pattern, especially when removing.

6) Because of the many pins, cleanliness of the pattern is extremely important after removing the IC.

7) Use care to avoid solder bridges. Remove any that

occurs.

8) Position the part carefully. They will also affect the

soldering operation. Be very precise in positioning

the IC. Soldering opposite pins first holds the IC in

place and makes soldering the other pins easier.

9) Do not reuse removed parts.

10) Check for solder joints, especially miniature parts

with small lead.

11) A defective trimming resistor cannot be adjusted

externally . Replace with an ordjnary variable resistor.

12) It is important to inspect the work with a magnifier.

Check after installing (cold solder joints, etc.).

2-2-1 Precaution for the chip Replacement

The tools for the chip replacement are as follows:

1) Thin tip type soldering iron

2) Small flat-blade tip-type soldering iron

3) Special desoldering tip iron

4) Airblower unit

5) Flat Package Pick-up

6) Flux can be cleaned by water

7) 0.3mm thin solder can be cleaned by water

8) Desoldering wire

9) Tweezers

2-2-2 Tools for the Chip Replacement

2-2-3 Chip Resistors and Chip Capacitors

-- Kind of the Part

The kind of chip resistors and chip capacitors as follows:d

1) Think Film Chip Resistors

2) Carbon Film Chip Resistors

3) Metal Film Chip Resistors

4) Chip Ceramic Capacitors

5) Chip Trimming Resistors

-- Removing the Part

1) Using two soldering irons:

Use thin tip soldering irons.

Use soldering tip temperature of about 280°….

Simultaneously heat both ends of the part.

While heating, grasp the part with the tips of the

soldering irons and remove it.

Use desoldering wire to completely remove the old

solder from the part location of the board.

A clean pattern for installing the new part is very

important.

Fig 2-2

-- Installing the Part

1) Use desoldering wire to remove the previous solder.

2) Clean the location.

3) Apply flux.

4) Position the IC and solder two pins at opposite sides.

5) Use a sharp tipped soldering iron and carefully

solder each Pin.(After gaining experience, a thicker

tip can be used for better work efficiency.)

6) Remove any solder bridges with desoldering wire.

7) Inspect the work with a magnifier.

1

2

3

4

5

6

Loading...

Loading...