SAMSUNG CKF5607LXXXAC Service Manual

COLOR MONITOR

CKF5607L

(SyncMaster 500b )

Manual

SERVICE

COLOR MONITOR CONTENTS

1. Precautions

2. Reference Information

3. Product Specifications

4. Operating Instructions

5. Disassembly & Reassembly

6. Alignment & Adjustments

7. Troubleshooting

8. Exploded View & Parts List

9. Electrical Parts List

10. Block Diagram

11. PCB Diagrams

12. Wiring Diagram

13. Schematic Diagrams

Samsung Electronics Co., Ltd. March 1998

Printed in Korea

Code No.: BH68-61036A

WARNINGS

1. For continued safety, do not attempt to modify the

circuit board.

2. Disconnect the AC power before servicing.

3. When the chassis is operating, semiconductor

heatsinks are potential shock hazards.

1-1-1 Servicing the High Voltage VR

and CRT :

WARNING: A high voltage VR replaced in the wrong

direction may cause excessive X-ray

emissions.

Caution:

When replacing the high voltage

adjustment VR, it must be fixed by a

soldering iron after it is properly set.

1. When servicing the high voltage system, remove

the static charge by connecting a 10 kohm resistor

in series with an insulated wire (such as a test

probe) between the chassis and the anode lead.

2. If the HV VR requires adjustment, (a) Replace the

VR and adjust the high voltage to the specification.

(b) Use a soldering iron to melt the adjustment cap

on the HV VR to prevent any movement.

3. When troubleshooting a monitor with excessively

HV, avoid being unnecessarily close to the monitor.

Do not operate the monitor for longer than is

necessary to locate the cause of excessive voltage.

4. High voltage should always be kept at the rated

value, no higher. Only when high voltage is

excessive are X-rays capable of penetrating the shell

of the CRT, including the lead in glass material.

Operation at high voltages may also cause failure of

the CRT or high voltage circuitry.

5. When the HV regulator is operating properly, there

is no possibility of an X-ray problem. Make sure the

HV does not exceed its specified value and that it is

regulating correctly.

6. The CRT is especially designed to prohibit

X-ray emissions. To ensure continued X-ray

protection, replace the CRT only with one that is

the same or equivalent type as the original.

7. Handle the CRT only when wearing shatterproof

goggles and after completely discharging the high

voltage anode.

8. Do not lift the CRT by the neck.

1-1-2 Fire and Shock Hazard :

Before returning the monitor to the user, perform the

following safety checks:

1. Inspect each lead dress to make certain that the

leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in

the monitor.

2. Inspect all protective devices such as nonmetallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

3. Leakage Current Hot Check (Figure 1-1):

WARNING: Do not use an isolation transformer during

this test.

Use a leakage current tester or a metering system

that complies with American National Standards

Institute (

ANSI C101.1, Leakage Current for

Appliances), and Underwriters Laboratories (UL

Publication UL1410, 59.7).

4. With the unit completely reassembled, plug the AC

line cord directly into a 120V AC outlet. With the

unit’s AC switch first in the ON position and then

OFF, measure the current between a known earth

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including: metal cabinets,

screwheads and control shafts. The current

measured should not exceed 0.5 milliamp. Reverse

the power-plug prongs in the AC outlet and repeat

the test.

Figure 1-1. Leakage Current Test Circuit

1-1-4 Product Safety Notices

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection. The protection they give

may not be obtained by replacing them with

components rated for higher voltage, wattage, etc. Parts

that have special safety characteristics are identified by

on schematics and parts lists. A substitute

replacement that does not have the same safety

characteristics as the recommended replacement part

might create shock, fire and / or other hazards. Product

safety is under review continuously and new

instructions are issued whenever appropriate.

Components identified by on schematics and parts

lists must be sealed by a soldering iron after

replacement and adjustment.

CKF5607L 1-1

1 Precautions

1-1 Safety Precautions

!

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

(READING SHOULD

NOT BE ABOVE 0.5mA)

LEAKAGE

CURRENT

TESTER

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

1. Servicing precautions are printed on the cabinet,

and should be followed closely.

2. Always unplug the unit’s AC power cord from the

AC power source before attempting to: (a) remove

or reinstall any component or assembly, (b)

disconnect PCB plugs or connectors, (c) connect all

test components in parallel with an electrolytic

capacitor.

3. Some components are raised above the printed

circuit board for safety. An insulation tube or tape

is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the area around the

serviced part has not been damaged.

1. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known earth

ground. Alternatively, wear a discharging wriststrap device. To avoid a shock hazard, be sure to

remove the wrist strap before applying power to

the monitor.

2. After removing an ESD-equipped assembly, place it

on a conductive surface such as aluminum foil to

prevent accumulation of an electrostatic charge.

3. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESDs.

4. Use only a grounded-tip soldering iron to solder or

desolder ESDs.

5. Use only an anti-static solder removal device. Some

solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage

ESDs.

5. Check the insulation between the blades of the AC

plug and accessible conductive parts (examples:

metal panels, input terminals and earphone jacks).

6. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the power

switch ON. Connect an insulation resistance meter

(500 V) to the blades of the AC plug.

The insulation resistance between each blade of the

AC plug and accessible conductive parts (see

above) should be greater than 1 megohm.

7. Never defeat any of the +B voltage interlocks. Do

not apply AC power to the unit (or any of its

assemblies) unless all solid-state heat sinks are

correctly installed.

8. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting the

positive lead; always remove the instrument’s

ground lead last.

6. Do not remove a replacement ESD from its

protective package until you are ready to install it.

Most replacement ESDs are packaged with leads

that are electrically shorted together by conductive

foam, aluminum foil or other conductive materials.

7. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

Caution: Be sure no power is applied to the

chassis or circuit and observe all

other safety precautions.

8. Minimize body motions when handling

unpackaged replacement ESDs. Motions such as

brushing clothes together, or lifting your foot from

a carpeted floor can generate enough static

electricity to damage an ESD.

9. Indicates ESDs on the Schematic Diagram in

this manual.

1 Precautions

1-2 CKF5607L

1-3 Electrostatically Sensitive Devices (ESD) Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated circuits and some fieldeffect transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

1-2 Servicing Precautions

WARNING1: First read the “Safety Precautions” section of this manual. If unforeseen circumstances

create conflict between the servicing precautions and safety precautions, always

follow the safety precautions.

WARNING2: A high voltage VR replaced in the wrong direction may cause excessive X-ray

emissions.

WARNING3: An electrolytic capacitor installed with the wrong polarity might explode.

CKF5607L 2-1

2 Reference Information

2-1 List of Abbreviations, Symbols and Acronyms

2-1-1 Abbreviations

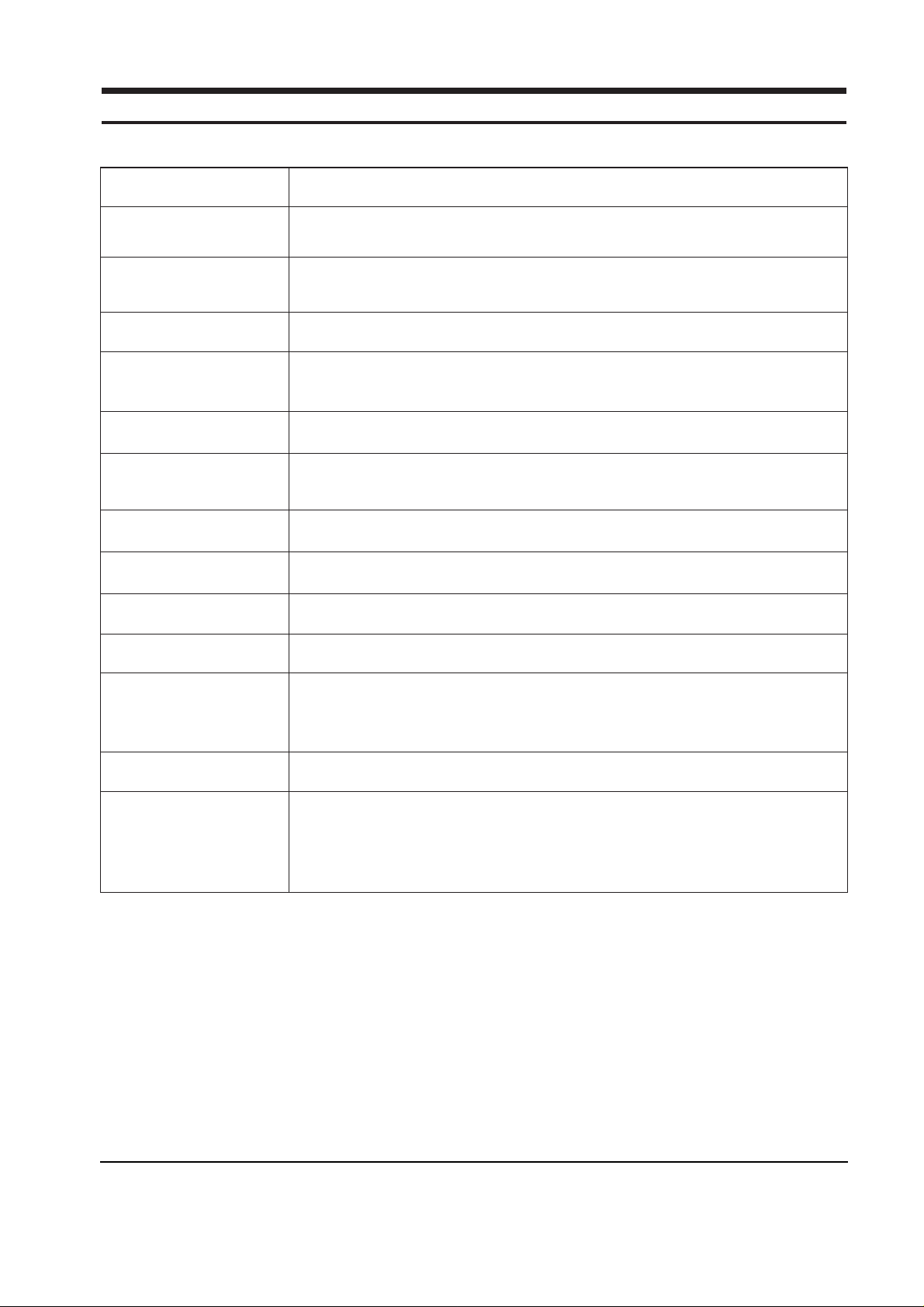

Abbreviation Definition Abbreviation Definition

ASS’Y Assembly

B Blue

B+ ADJ B+ Adjustment

B-CUT Blue-Cutoff

B-GAIN Blue Gain

BRIGHT Brightness

C R-Composition

C-MIC Condenser Microphone

CLK Clock

CM R-Cement

CN Connector

CONT Contrast

D-SUB D-Subminiature

EEP-CLK Electrically Erasable and

Programmable Clock

EXT External

EXT-MIC External Microphone

Freq. Frequency

FU Fusible

G Green

G-CUT Green-Cutoff

G-GAIN Green Gain

GND Ground

H Horizontal

H Heater

H-DRV Horizontal Drive

H-DY Horizontal Deflection Yoke

H-FLB Horizontal Flyback

H-FV Horizontal-Feedback Voltage

H-LIN Horizontal Linearity

H-POSI Horizontal Position

H-SIZE Horizontal Size

H/PHONE Headphone

Hz Hertz

I-SENSE Current-Sense

lb Pound

MAX Maximum

MIC Microphone

MIN Minimum

MP C-Metalized Polyester

MPP Metal Polypropylene

MO R-Metal Oxide

OSC Oscillator

P C-Polyester

PARA Parabola

PARALL Parallelogram

PIN-BAL Pincushion Balance

PRE-AMP Pre-Amplifier

PS1 Power Saving1 (suspend)

PS2 Power Saving2 (off)

PWR Power

R Red

R-CUT Red-Cutoff

R-GAIN Red Gain

RST Reset

S-PIN Side Pincushion

S-RASTER Self Raster

S/W Switch

SCAP S Correction Capacitor

SPK Speaker

SYNC Synchronization

T C-Tantalum

TR Transistor

TRAP Trapezoid

U-COM Microprocessor

V Vertical

V-DY Vertical Deflection Yoke

V-FLB Vertical Flyback

V-LIN Vertical Linearity

V-MUTE Video Mute

V-OUT Vertical Output

V-PARA Vertical Parabola

V-POL V-Polarity

V-POSI Vertical Position

V-SENSE Voltage-Sense

V-SIZE Vertical Size

WW R-Wire Wound

X-TAL Crystal

Ω ohm

KΩ 1000 ohm

MΩ 1000 KΩ

uF microfarad (10-6F)

nF nanofarad (10-9F)

pF picofarad (10

-12

F)

2 Reference Information

2-2 CKF5607L

Acronym Definition Acronym Definition

ABL Automatic Brightness Limits

AC Alternating Current

ACL Automatic Contrast Limit

AFC Automatic Frequency Control

ANSI American National Standards Institute

CMOS Complementary Metal Oxide

Semiconductor

CRT Cathode Ray Tube

DC Direct Current

DDC Data Display Channel

DF Dynamic Focus

DMM Digital Multimeter

DPMS Display Power Management Signaling

DVM Digital Voltmeter

DY Deflection Yoke

EEPROM Electrically Erasable and

Programmable Read only Memory

ESD Electrostatically Sensitive Device

ESF Electronic Static Field

FBT Flyback Transformer

FET Field Effect Transistor

FH Horizontal Frequency

FS Fail Safe

FV Vertical Frequency

GD Geometric Distortion

H/V Horizontal/Vertical

HV High Voltage

I/O Input/Output

IC Integrated Circuit

LED Light Emitting Diode

MAC Macintosh

MOFA Mask Outside Frame Assembly

OCP Over Current Protection

OP AMP Operational Amplifier

OSD On Screen Display

P-P Peak to Peak

PCB Printed Circuit Board

PLL Phase Locked Loop

PWM Pulse Width Modulation

SMPS Switch Mode Power Supply

SVGA Super Video Graphics Array

SWEDAC

TP Test Point

UL Underwriters Laboratories

USB Universal Serial Bus

VESA Video Electronics Standard

Association

VGA Video Graphics Array

VR Variable Registor

W/B White Balance

2-1-2 Acronyms

2-1-2 Symbols

Can emit X-radiation

Hot Ground

Cold Ground

Electrostatically Sensitive Device (ESD)

Provides special safety considerations

!

CKF5607L 3-1

3 Product Specifications

3-1 Specifications

Picture Tube: 15-Inch (38 cm): 13.8-inch (35 cm) viewable; Full-square flat-face tube, 90˚ Deflection,

0.28 mm Dot pitch, Semi- tint, Non-glare, Invar shadow mask, Anti-static silica coating

Scanning Frequency Horizontal : 30 kHz to 70 kHz (Automatic)

Vertical : 50 Hz to 160 Hz (Automatic)

Display Colors Unlimited colors

Maximum Resolution Horizontal : 1280 Dots

Vertical : 1024 Lines

Input Video Signal Analog, 0.714 Vp-p positive at 75 Ω, internally terminated

Input Sync Signal Separate Sync : TTL level positive/negative

Composite Sync : TTL level positive/negative

Maximum Pixel Clock rate 110 MHz

Active Display Horizontal : 267 mm ± 3 mm, Vertical : 200 mm ± 3 mm

Input Voltage AC 90 to 264 Volts, 60 Hz or 50 Hz ± 3 Hz

Power Consumption 85 Watt (max)

Dimensions

Unit (W x D x H) 14.6 x 16.2 x 15.2 Inches (370 x 410.6 x 385 mm)

Carton (W x D x H) 18.3 x 20.4 x 17.7 Inches (465 x 517 x 450 mm)

Weight (Net/Gross) 29.9 lbs (13.6 kg) / 34.8 lbs (15.8 kg)

Environmental Considerations Operating Temperature : 32°F to 104°F (0°C to 40°C)

Humidity : 10 % to 80 %

Storage Temperature : -4°F to 113°F (-20°C to 45°C)

Humidity : 5 % to 95 %

• Above models comply with SWEDAC (MPR II) recommendations for reduced electromagnetic fields.

• Designs and specifications are subject to change without prior notice.

Item Description

3 Product Specifications

3-2 CKF5607L

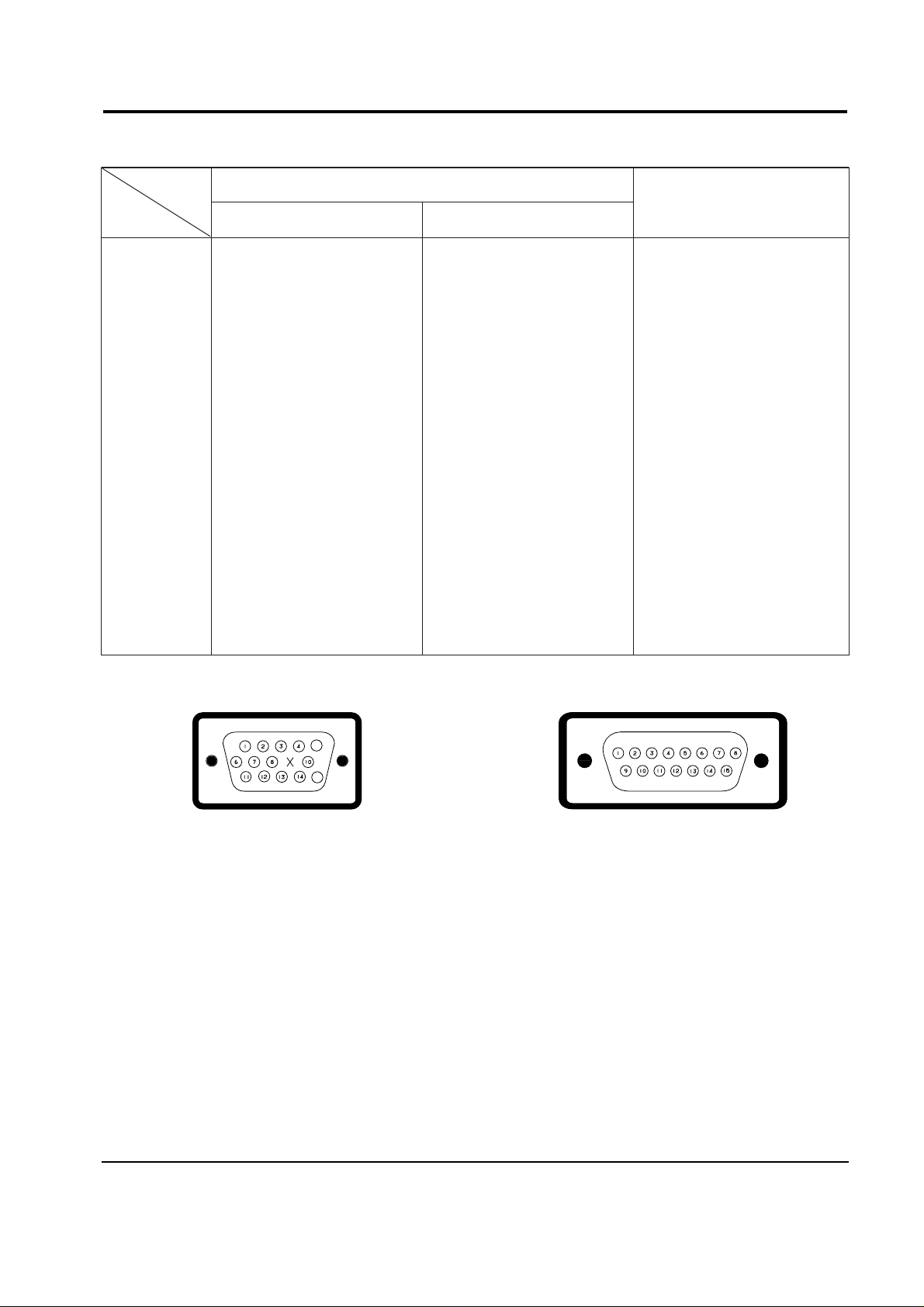

3-2 Pin Assignments

5

15

Figure 3-1. Male Type Figure 3-2. Male Type

Sync

Type

Pin No.

15-Pin Signal Cable Connector (Figure 3-1)

Cable Adapter (Figure 3-2)

Macintosh

Separate Composite

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Red

Green

Blue

GND

DDC Return

GND-R

GND-G

GND-B

Reserved

GND-Sync/Self-raster

GND

DDC Data

H-Sync

V-Sync

DDC Clock

Red

Green

Blue

GND

DDC Return

GND-R

GND-G

GND-B

Reserved

GND-Sync/Self-raster

GND

DDC Data

H/V-Sync

Not Used

DDC Clock

GND-R

Red

H/V Sync

Sense 0

Green

GND-G

Sense 1

Reserved

Blue

Sense 2

GND

V-Sync

GND-B

GND

H-Sync

3 Product Specifications

CKF5607L 3-3

QRS

P

O

Video

Sync

Sync

Horizontal

Vertical

CDE

P

O

B

A

Video

Sync

Sync

Separate Sync

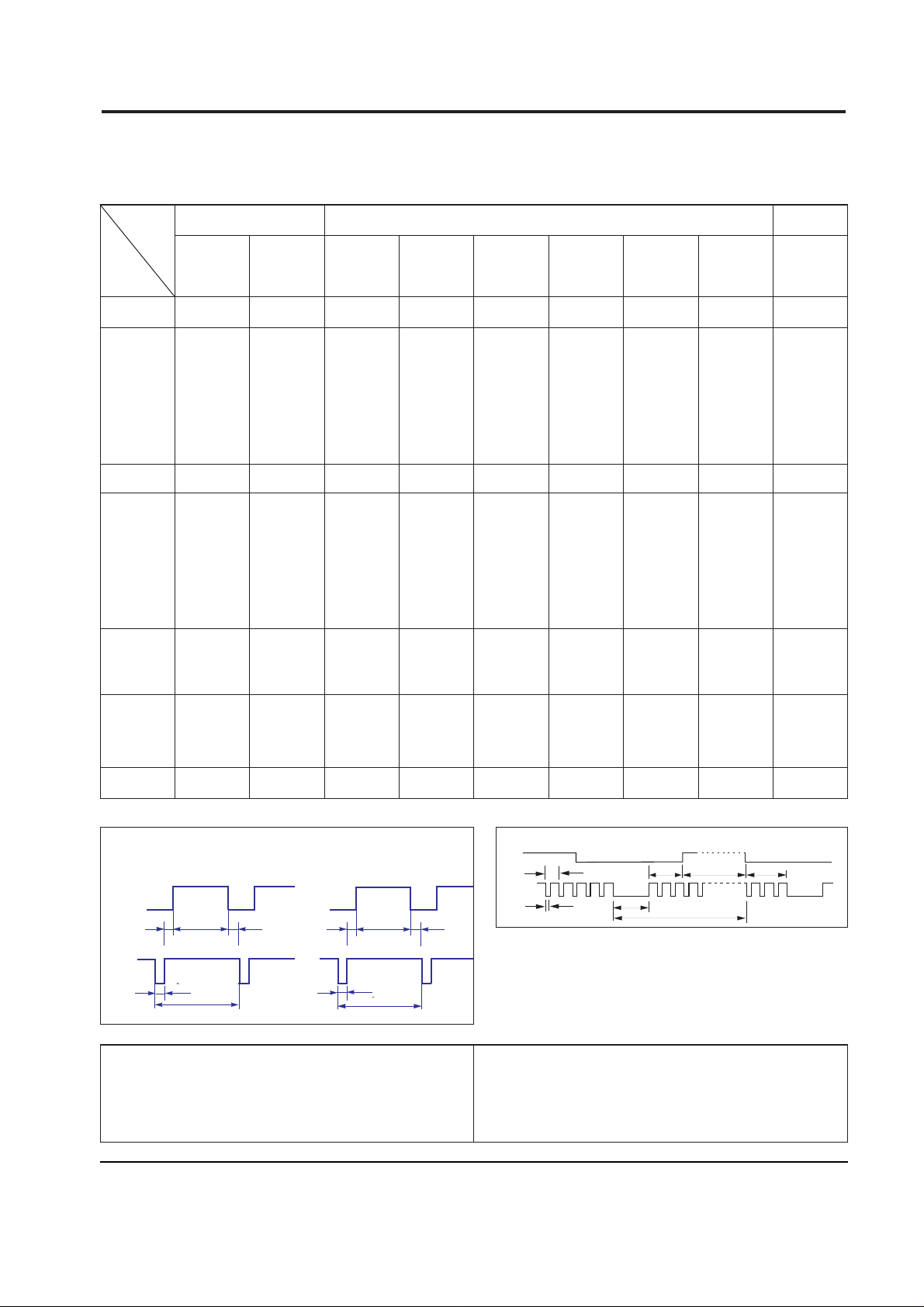

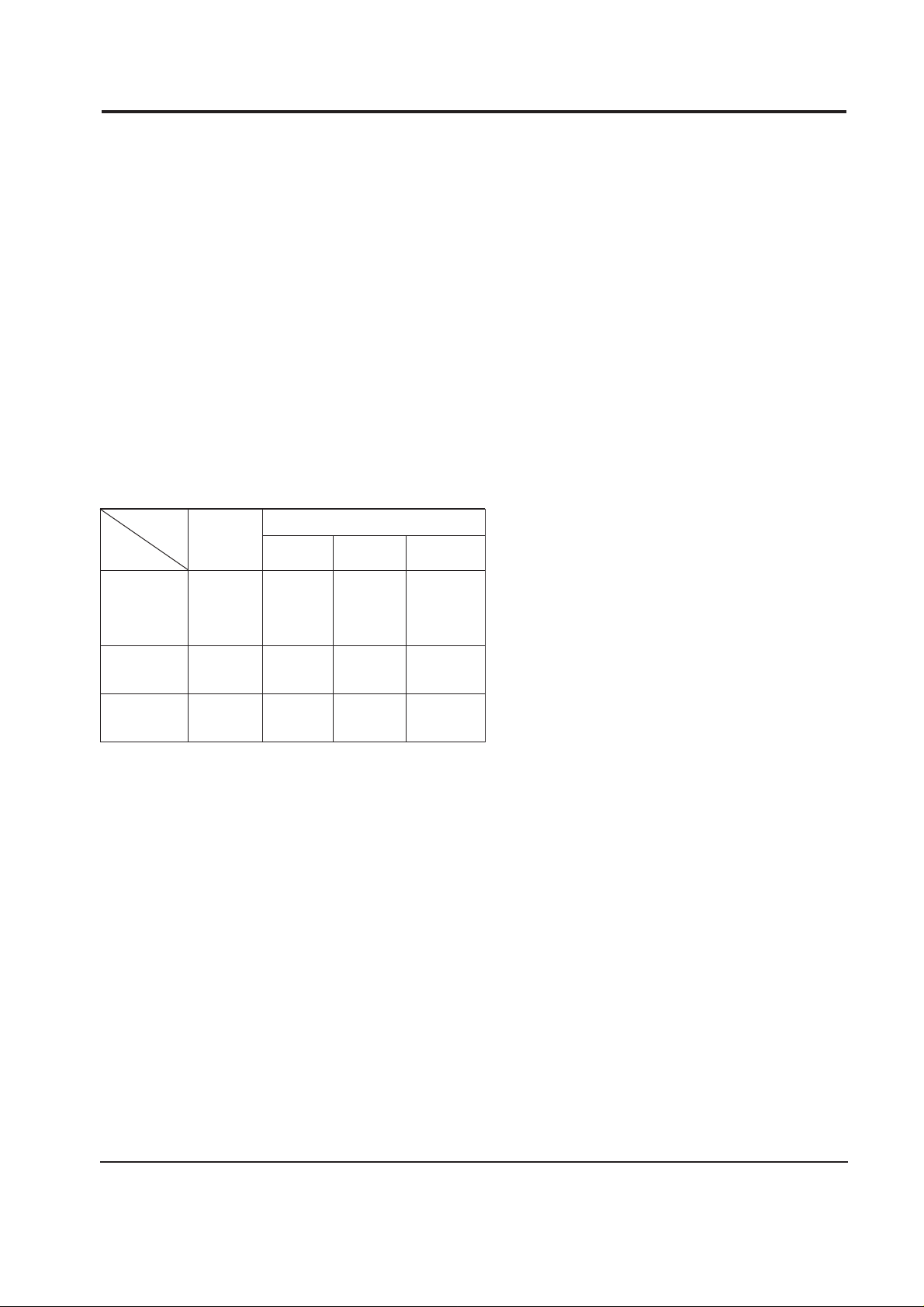

3-3 Timing Chart

This section of the service manual describes the timing that the computer industry recognizes as standard

for computer-generated video signals.

C D

A

O

E

B

P

Video

Sync

Sync

Video

Q R S

A : Line time total B : Horizontal sync width O : Frame time total P : Vertical sync width

C : Back porch D : Active time Q : Back porch R : Active time

E : Front porch S : Front porch

fH (kHz)

A µsec

B µsec

C µsec

D µsec

E µsec

fV (Hz)

O msec

P msec

Q msec

R msec

S msec

Clock

Frequency

(MHz)

Polarity

H.Sync

V.Sync

Remark

IBM VESA

Apple Mac.

800/85 Hz

800 x 600

1280/60 Hz

1280 x 1024

1024/85 Hz

1024 x 768

640/67 Hz

640 x 480

VGA3/60 Hz

640 x 480

VGA2/70 Hz

720 x 400

31.469

31.778

3.813

1.907

25.422

0.636

70.087

14.268

0.064

1.080

12.711

0.413

28.322

Negative

Positive

Separate

31.469

31.778

3.813

1.907

25.422

0.636

59.940

16.683

0.064

1.048

15.253

0.318

25.175

Negative

Negative

Separate

37.500

26.667

2.032

3.810

20.317

0.508

75.000

13.333

0.080

0.427

12.800

0.027

31.500

Negative

Negative

Separate

43.269

23.111

1.556

2.222

17.778

1.556

85.008

11.764

0.671

0.578

11.093

0.023

36.000

Negative

Negative

Separate

46.875

21.333

1.616

3.232

16.162

0.323

75.000

13.333

0.064

0.448

12.800

0.021

49.500

Positive

Positive

Separate

53.674

18.631

1.138

2.702

14.222

0.569

85.061

11.756

0.056

0.503

11.179

0.019

56.250

Positive

Positive

Separate

63.980

15.630

1.040

2.300

11.850

0.440

60.020

16.66

0.050

0.590

16.010

0.020

108.000

Positive

Positive

Separate

68.677

14.561

1.016

2.201

10.836

0.508

84.997

11.765

0.044

0.524

11.183

0.015

94.500

Positive

Positive

Separate

35.000

28.571

2.116

3.175

21.164

2.116

66.667

15.000

0.086

1.114

13.714

0.086

30.240

Negative

Negative

Composite

800/75 Hz

800 x 600

640/75 Hz

640 x 480

640/85 Hz

640 x 480

Table 3-1. Timing Chart

Mode

Timing

VIDEO

A

B

O

P

Q

R

S

Horizontal

Vertical

H/V Composite Sync

3 Product Specifications

3-4 CKF5607L

Memo

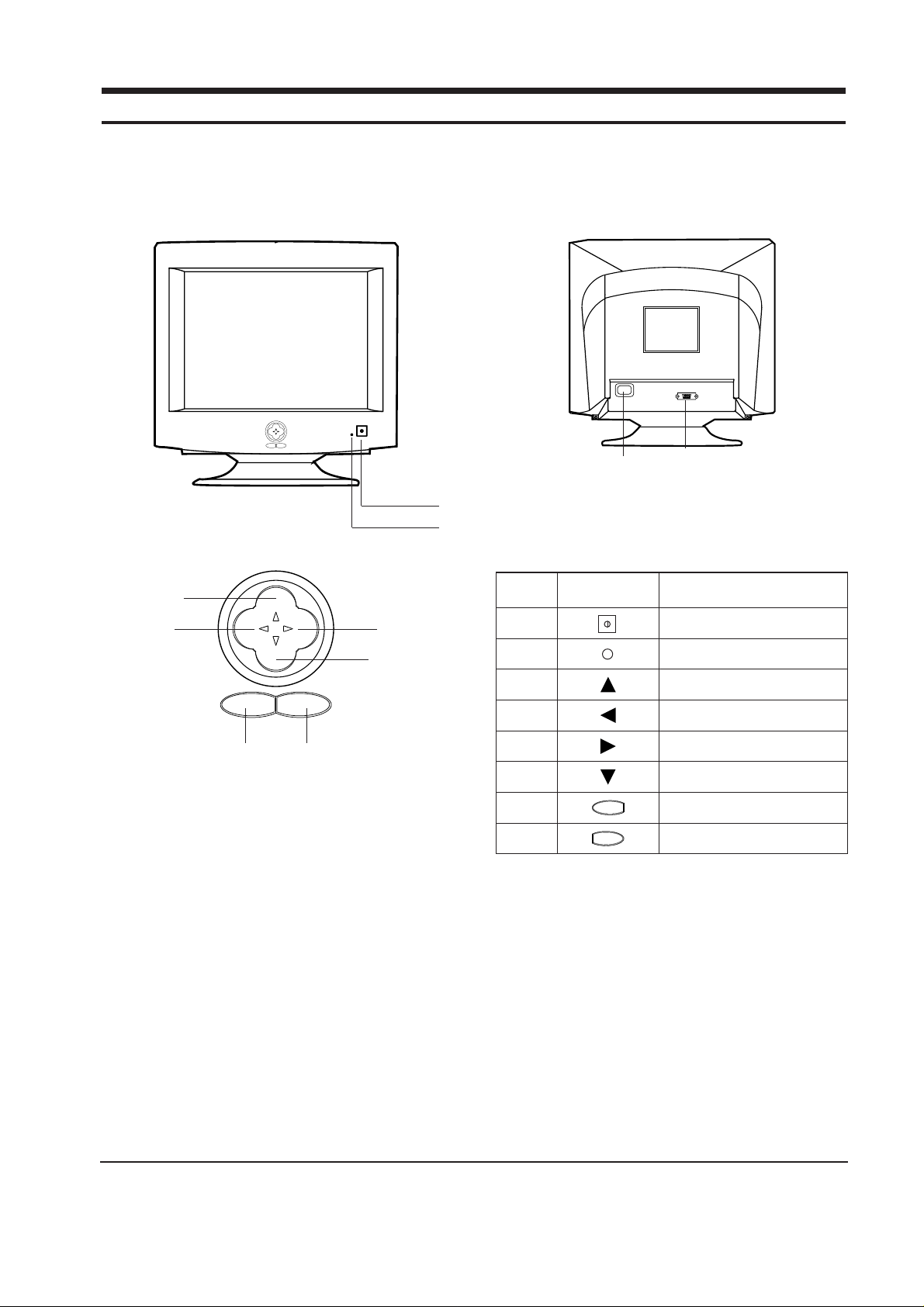

4-1 Front View and Control

4-1-1 Front View

CKF5607L 4-1

4 Opearating Instructions

1

2

Figure 4-1. Front Control Panel

Figure 4-2. Rear View

3

5

6

78

4

AC Cord Inlet

Signal Input

1 Power Button

Power Indicator LED (Dual Color)

Up Button

Left Button

Right Button

Down Button

Exit Button

Menu (

↵) Button

3

4

5

6

7

8

2

Location Symbol Description

Table 4-1. Front Panel Controls

This monitor has factory preset display settings

for each of the signals listed in the standard

Display Modes Timing Chart (see page 3-3).

As a result, when the monitor senses one of the

standard signal timings, it automatically adjusts to

an optimum size and position.

However, the user may wish to adjust the monitor

to their own preferred settings rather than use

those preset at the factory. The monitor saves up

to 11 user defined settings.

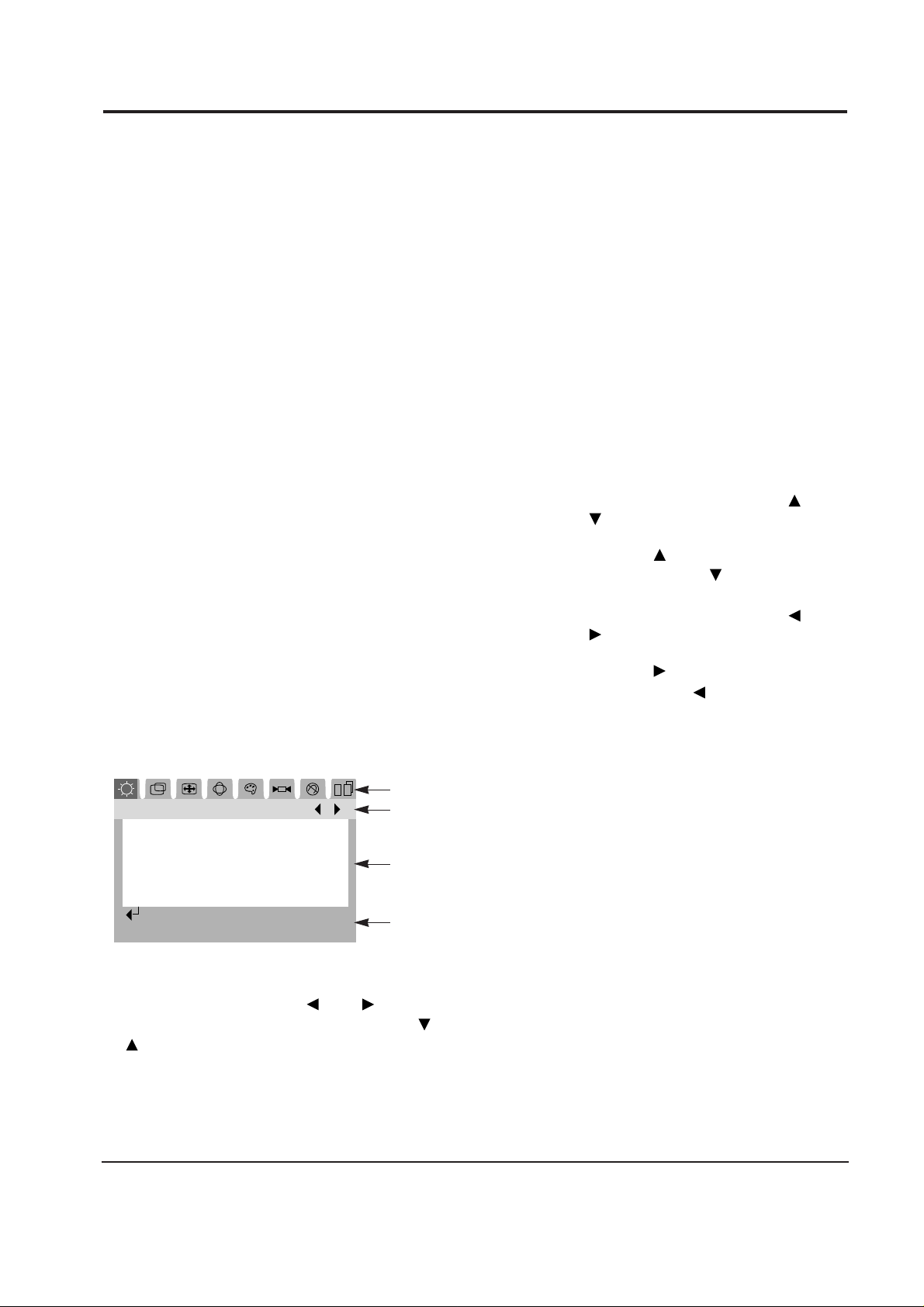

4-2-1 On Screen Display

This monitor features an On-Screen Display (OSD)

that shows information about the display setting.

The OSD appears on the screen when you select a

function button. The OSD can show the name,

range and current setting of the control function.

In addition, the OSD shows the current input

signal frequency and the list of user and factory

preset timings. The OSD remains active for

approximately 7 seconds after the completion of

any adjustment.

4-2-2 OSD Window

Push the ↵ button to open the OSD. The Main

Menu shows all of the adjustment icons along the

top of the window. The Title Bar displays Main

Menu and the icon for the last accessed function

appears highlighted. The window shows one or

more adjustment names in the Adjustment Box

and instructions display in the Information Bar.

To access a function, use the and buttons to

move to its associated icon, and then use the

or button to highlight the adjustment type.

Then, push the ↵ button to access the function.

All OSD windows change color to indicate that

the associated adjustment control is active. When

the OSD displays the name of the adjustment, for

example, Pincushion/Trap, with a green border,

adjustments for pincushion or trapezoidal effects

are available. Each OSD window shows directions

for use along the bottom of the window. When

you are satisfied with the adjustments you have

made to the current control, select the Exit button

to return to the OSD Menu where you can select

another control, or exit from the OSD system and

save your changes. The OSD remains active for

approximately 7 seconds after completion of any

adjustments.

4-2-3 Direct Controls

The on-screen Direct controls have the following

two functions:

•Brightness:With the menu off, push the or

button. The brightness

display will appear.

Push the button to increase the

brightness or the button to

decrease the brightness.

•Contrast: With the menu off, push the or

button. The contrast

adjustment display will appear.

Push the button to increase the

contrast or the button to decrease

the contrast.

4 Operating Instructions

4-2 CKF5607L

4-2 Microprocessor Controls and Functions

Main Menu

Brightness

:Access Function

Exit:Exit Menu

Figure 4-3. OSD Windows

Icon Bar

Title Bar

Adjustment Box

Information Bar

This monitor has a built-in power management

system called PowerSaver. This system saves

energy by switching your monitor into a lowpower mode when it has not been used for a

certain amount of time. The available modes are

“On,” “Standby,” “Suspend,” and “Off.”

This system operates with a VESA DPMS

compliant video card installed in your computer.

You use a software utility installed on your

computer to set up this feature. See the table

below for details.

Note 1:This monitor automatically returns to

normal operation when horizontal and

vertical sync return. This occurs when you

move the computer's mouse or press a key

on the keyboard.

Note 2:This monitor is EPA Energy Star

compliant and NUTEK compliant when

used with a computer equipped with

VESA DPMS functionality. If your

computer system cannot support a display

power management function, you can

purchase an optional DPMS software

program to enable the power saving

function. Please contact Samsung or your

dealer for more information.

Note 3:For energy conservation, turn your

monitor OFF when it is not needed, or

when leaving it unattended for long

periods.

Note 4:The PowerSaver functions do not apply to

sound functions and may cause sound

abnormalities during its power saving

modes.

4 Operating Instructions

CKF5607L 4-3

State

Items

Normal

Operation

Horizontal Sync

Vertical Sync

Video

Power

Indicator

Power

Consumption/hr

Active

Active

Active

Green Amber

Amber/Green

Blinking

Amber

Blinking

85 W (max.)

65 W

(nominal)

Less than

15 W

50 W

(nominal)

Less than

5 W

Inactive

Active

Blanked

Active

Inactive

Blanked

Power saving function EPA/NUTEK

Stand By

Mode

Suspend Mode

Position A

Power Off Mode

Position B

Inactive

Inactive

Blanked

4-3 Power Management System

Table 4-2. Display Power Management Signaling (DPMS)

Memo

4 Operating Instructions

4-4 CKF5607L

5-1-1 Cabinet Disassembly

1. With a pad beneath it, stand the monitor on its

front with the screen facing downward and

the base close to you. Make sure nothing will

damage the screen.

2. Working from the back of the monitor remove

the 2 screws.

3. To uncover the 2 uppermost screws, press in

the end of each screw cover cap and pull it

away from the cabinet. Remove the Rear

cover.

4. Using pinch-nosed pliers or long-nosed pliers,

carefully disconnect the Anode Cap from the

CRT.

Caution: Do not touch the anode contact on

the CRT.

5-1-2 Removing the Video PCB

1. Complete all previous steps.

2. Remove the screw on the Main PCB which

secures the braided ground wire on the Video

Shield. Remove all other ground wires.

3. Unsolder the center tabs on the underside of

the Video PCB Shield and remove the Video

PCB Shield.

4. Using a knife, cut the silicone bond and lift off

the CRT Socket PCB.

5. Lift off the Video PCB Ass’y.

6. Disconnect connectors CN101 and CN102 on

the Video PCB.

7. Disconnect the red screen (G2) wire on the

Video PCB.

8. Hold the Video PCB while you lift the cap on

the CRT Socket. Disconnect the red Focus wire

(G3).

5-1-3 Removing the Main PCB

1. Complete all previous steps.

2. Disconnect the Degaussing Coil at CN600 on

the Main PCB.

3. Disconnect all easily accessible ground wires

from the CRT GND Assembly and Bottom

Chassis.

4. Disconnect the DY connector between the DY

and the CN300, CN301, CN401, CN402 and

CN403 connectors on the Main PCB.

5. Remove the 2 screws on the left and right

sides of the PCB Bracket.

6. Carefully lift the Main PCB Ass’y.

7. Carefully lift off the Power Shaft from the

Main PCB.

8. Disconnect the adjustment control connector

CN201 on the Main PCB.

9. Remove the 6 screws on the top side of the

Main PCB.

10. Lift the Main PCB and place it on a flat, level

surface that is protected from static electricity.

CKF5607L 5-1

5 Disassembly and Reassembly

This section of the service manual describes the disassembly and reassembly procedures for the

CKF5607L monitor.

WARNING: This monitor contains electrostatically sensitive devices. Use caution when handling

these components.

5-1 Disassembly

Cautions:1. Disconnect the monitor from the power source before disassembly.

2. Follow these directions carefully; never use metal instruments to pry apart the cabinet.

5-2-1 Replacing the CRT

1. Loop the CRT Ground Assembly around the

back of the CRT and under the 4 corner, metal

ears. Position the corner with the spring last.

2. With the Front Cover Assembly lying face

down on a protective pad, position the CRT so

that the corner metal ears fit properly in the

Front Cover Assembly.

3. Replace the 4 corner screws.

4. Replace the Degaussing Coil Assembly and

wrap the coil with the plastic coated matal ties

to hold the coil in place.

5. Replace the CRT Ground Assembly.

6. Replace the Unit Bracket Assembly.

5-2-2 Replacing the Main PCB

1. Stand the monitor on its front with the screen

facing downward.

2. Replace the Power Shaft on the Main PCB.

3. Replace the 6 screws on the top side of the

Main PCB.

4. Replace connector CN201 on the Main PCB.

5. Position the Main PCB Ass’y in the Front

Cabinet and secure it on both sides with the

screws between the Bottom Chassis and CRT

Unit Bracket.

6. Replace the DY connector at the CN300,

CN301, CN401, CN402 and CN403 connectors

on the Main PCB.

7. Replace all easily accessible ground wires on

the CRT GND Assembly and Bottom Chassis.

8. Replace the Degaussing Coil at CN600 on the

Main PCB.

9. Replace the Anode Cap.

5-2-3 Replacing the Video PCB

1. Replacing the Focus (G3) wire on the CRT

Socket and the screen (G2) wire on the Video

PCB.

2. Replace connectors CN101 and CN102 on the

Video PCB.

3. Reconnector the CRT Socket on the Video

PCB.

4. Solder the center tab on the underside of the

Video PCB Shield and replace the Video PCB

Shield.

5. Replace the screw on the Main PCB which

secures the braided ground wire from the

Video Shield and replace all other ground

wires.

5-2-4 Cabinet Reassembly

1. Complete all previous steps.

2. Position the Rear Cover making sure that the

tabs along the front edge are properly

snapped in place. Replace the 4 screws.

3. Set the monitor on its Base and make sure that

the CRT faceplate was not scratched or

otherwise damaged.

5 Disassembly and Reassembly

5-2 CKF5607L

5-2 Reassembly

With the CRT facing downward on a protective pad, use the steps that follow to reassemble the monitor.

6-1-1 Before Making Adjustments

6-1-1 (a) ORIENTATION

When servicing, always face the monitor to the

east.

6-1-1 (b) MAGNETIC FIELDS

Whenever possible, use magnetic field isolation

equipment such as a Helmholtz field to surround

the monitor. If a Helmholtz field is not available,

frequently degauss the unit under test.

Caution: Other electrical equipment may cause

external magnetic fields which may

interfere with monitor performance.

Use an external degaussing coil to limit magnetic

build up on the monitor. If an external degaussing

coil is not available, use the internal degaussing

circuit. However, do not use the internal

degaussing circuit more than once per 30 minutes.

6-1-1 (c) WARM-UP TIME

The monitor must be on for 30 minutes before

starting alignment. Warm-up time is especially

critical in color temperature and white balance

adjustments.

6-1-1 (d) SIGNAL

Analog, 0.714 Vp-p positive at 75 ohm, internal

termination

Sync: Separate, Composite

(TTL level negative/positive)

6-1-1 (e) SCANNING FREQUENCY

Horizontal: 30 kHz to 70 kHz (Automatic)

Vertical: 50 Hz to 160 Hz (Automatic)

Unless otherwise specified, adjust at the 800 x 600

mode (53.6 kHz/85 Hz) signals.

Refer to Table 3-1 on page 3-3.

6-1-1 (f) HIGH VOLTAGE ADJUSTMENT

Signal: 53.6 kHz/85Hz

Display image: crosshatch pattern

Contrast: Maximum

Brightness: Maximum

Limit: 25 kV ±0.2 kV

Adjust VR501 to DC –204.0 V ± 0.5 V at EY14 and

GND.

Measure the hight voltage level at the anode cap.

High voltage should be within the limit as above.

If the high voltage needs adjustment use the

following procedure.

PROCEDURE

1. Turn the power off and disconnect the AC line

cord from the power source.

2. Unsolder and remove VR501 on the Main

PCB.

3. Replace VR501 and adjust the high voltage to

the specification.

4. Using a soldering iron, melt the adjustment

cap on VR501 to prevent any movement.

6-1-1 (g) G2 (SCREEN) VOLTAGE ADJUSTMENT

Signal: 53.6 kHz/85Hz

Display image: crosshatch pattern

Contrast: Maximum

Brightness: Maximum

Adjust the Screen VR of the FBT so that the G2

(Screen) Voltage for Toshiba CRT is 630 V ± 10 V.

6-1-1 (h) CENTER RASTER

Adjust SW401 so that the back raster comes to the

center when you apply a signal of 53.6 kHz/85Hz.

CKF5607L 6-1

6 Alignment and Adjustments

This section of the service manual explains how to make permanent adjustments to the monitor. Directions

are given for adjustments using the monitor Interface Board Ver. 2.0 and software (SoftJig).

6-1 Adjustment Conditions

Caution: Changes made without the SoftJig are saved only to the user mode settings. As such, the

settings are not permanently stored and may be inadvertently deleted by the user.

6-1-2 Required Equipment

The following equipment may be necessary for

adjustment procedures:

6-1-2 (a) DISPLAY CONTROL ADJUSTMENT

1. Non-metallic (–) screwdriver: 1.5 mm

Non-metallic (–) screwdriver: 3 mm

2. Philips (+) screwdriver: 1.5 mm

3. Non-metallic hexkey: 2.5 mm

4. Digital Multimeter (DMM), or

Digital Voltmeter (DVM)

5. Signal generator, or

Computer with a video board that uses the

ET-4000 chipset (strongly recommended if

using Samsung DM 200 software) and that

displays: 1024 x 768 @ 85 Hz, or 800 x 600

@ 85 Hz (minimum).

6. Personal computer

7. Required software: Softjig.exe from Samsung

which includes the cg15b.c data file

Samsung DM200, or DisplayMate for

Windows from Sonera Technologies

8. Interface Board Ver. 2.0 Code No.

BH81-90001K

9. Parallel communications cable (25-pin to

25-pin); Code No. BH81-90001H

10. Signal cable (15-pin to 15-pin cable with

additional 3-pin connector); Code No.

BH81-90001J

11. 5 V DC adapter, not supplied

Note: SoftJig Ass’y (includes items 8, 9 and 10)

Code No. BH81-90001L

6-1-2 (b) COLOR ADJUSTMENTS

1. All equipment listed in 6-1-2 (a), above

2. Color analyzer, or any luminance

measurement equipment

6-1-3 Connecting the SoftJig

Connect the monitor to the signal generator and/

or PC as illustrated in Figures 6-1 and 6-2.

Note: The signal cable connector which includes

the 3-wire cable must connect to the

monitor. If you use Setup 2 (PC only, no

signal generator) you can only make

adjustments to the signal timing available

on that computer system. To make

corrections to all factory timings requires

the use of an additional signal generator.

6-1-4 After Making Adjustments

After finishing all adjustments, test the monitor in

all directions. If, for example, the monitor does not

meet adjustment specifications when facing north,

reposition the monitor to face east and readjust.

This time, try for an adjustment closer to the ideal

setting within the tolerance range. Test the unit

again in all directions. If the monitor again fails to

meet specifications in every direction, contact

your Regional After Service Center for possible

CRT replacement.

6 Alignment and Adjustments

6-2 CKF5607L

MONITOR

INTERFACE

BOARD VER. 2.0

PC

SIGNAL

GENERATOR

3-WIRE

CABLE

SIGNAL CABLE

5V DC

ADAPTOR

PARALLEL CABLE

Figure 6-1. Setup 1, With Signal Generator

MONITOR

INTERFACE

BOARD VER. 2.0

PC

3-WIRE CABLE

SIGNAL CABLE

PARALLEL CABLE

D-SUB

CONNECTOR

5V DC

ADAPTOR

Figure 6-2. Setup 2, Without Signal Generator

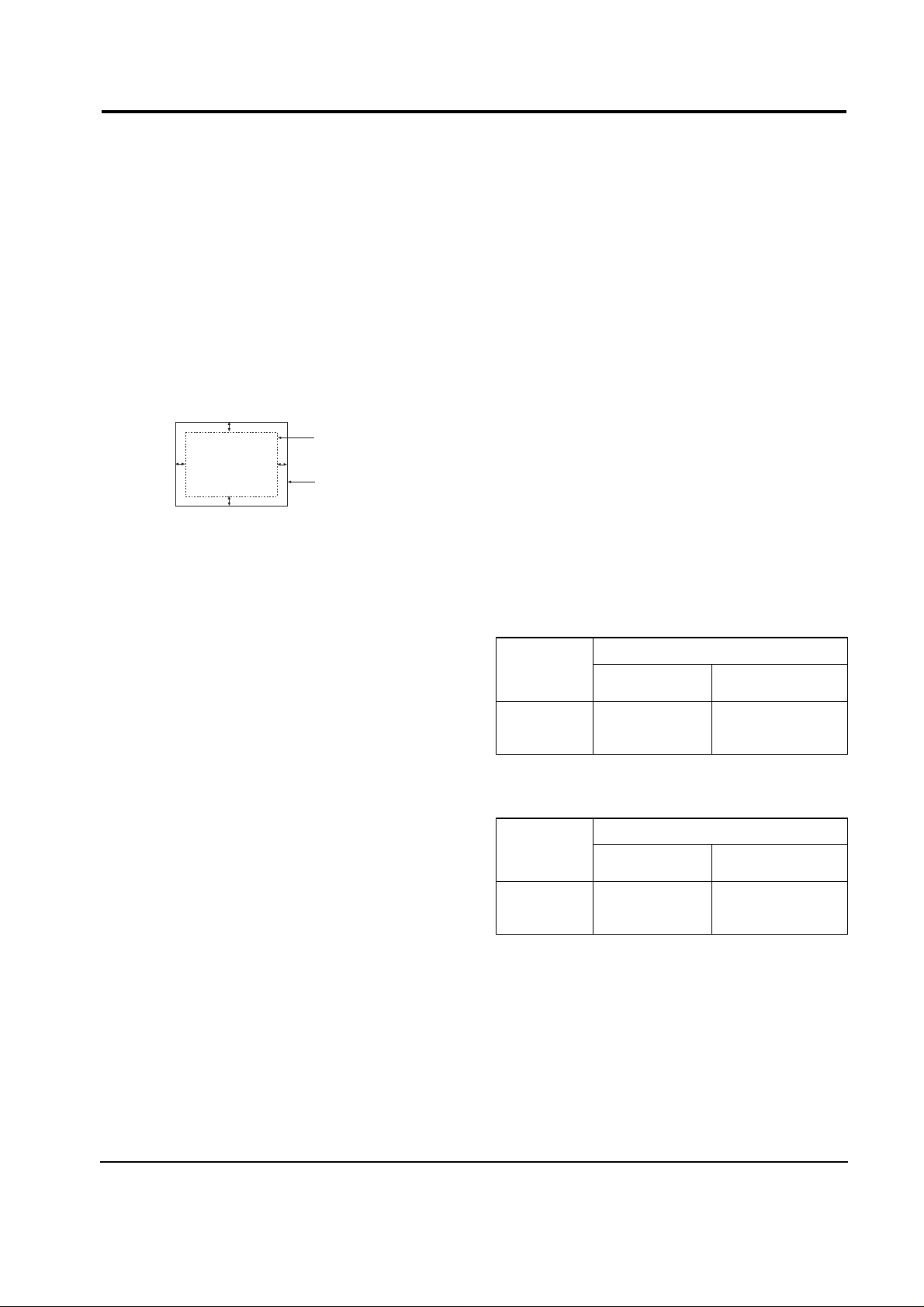

6-2-1 Centering

Centering means to position the center point of

the display in the middle of the display area.

Horizontal size and position and vertical size and

position control the centering of the display.

Adjust the horizontal size and vertical size to their

optimal settings: 267 mm (H) x 200 mm (V)

Adjust the horizontal position and vertical

position to ≤ 4.0 mm of the center point of the

screen.

|A-B| ≤ 4.0 mm.

|C-D| ≤ 4.0 mm.

Figure 6-3. Centering

6-2-1 (a) HORIZONTAL SIZE ADJUSTMENT

CONDITIONS

Scanning frequency: 53.6 kHz/85Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Click on the << or >> box next to B+OUT to

adjust the horizontal size of the display pattern to

267 mm. (Tolerance: ± 3 mm.)

6-2-1 (b) VERTICAL SIZE ADJUSTMENT

CONDITIONS

Scanning frequency: 53.6 kHz/85Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Click on the << or >> box next to V_SIZE to

adjust the vertical size of the display pattern to

200 mm. (Tolerance: ± 3 mm.)

6-2-1 (c) HORIZONTAL POSITION ADJUSTMENT

CONDITIONS

Scanning frequency: 53.6 kHz/85Hz

Display image: Crosshatch pattern

Click on the << or >> box next to H_POSI to

center the horizontal image on the raster.

6-3-1 (d) VERTICAL POSITION ADJUSTMENT

CONDITIONS

Scanning frequency: 53.6 kHz/85Hz

Display image: Crosshatch pattern

Click on the << or >> box next to V_POSI to

center the vertical image on the raster.

6-2-2 Linearity

Linearity affects the symmetry of images as they

appear on the screen. Unless each row or column

of blocks in a crosshatch pattern is of equal size,

or within the tolerances shown in Tables 6-1 and

6-2, an image appears distorted, elongated or

squashed.

Table 6-1. Standard Modes Linearity: 640x480/75Hz,

800x600/85Hz and 1024x768/85Hz

Table 6-2. Other Modes Linearity: VGA, SVGA, XGA,

MAC, etc.

6 Alignment and Adjustments

CKF5607L 6-3

6-2 Display Control Adjustments

C

A

DISPLAY AREA

EDGE OF BEZEL

B

D

4 : 3

Horizontal: 15.5~17.9

Vertical : 15.5~17.9

Supported Timing Mode

Each block (14 %)

Difference between

adjacent blocks (5 %)

Horizontal: Less than 0.83 mm

Vertical : Less than 0.83 mm

4 : 3

Horizontal: 15.9~17.5

Vertical : 15.9~17.5

Standard Modes Linearity

Each block (10 %)

Difference between

adjacent blocks (4 %)

Horizontal: Less than 0.67 mm

Vertical : Less than 0.67 mm

6-2-2 (a) HORIZONTAL LINEARITY ADJUSTMENT

The CKF5607L monitor offer only Vertical

Linearity adjustments. Horizontal Linearity is

fixed on the Chassis and is not adjustable.

6-2-2 (b) VERTICAL LINEARITY ADJUSTMENT

CONDITIONS

Scanning frequency: 53.6 kHz/85Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

To adjust the Vertical Linearity, refer to Tables 6-1

and 6-2 for the tolerance range.

Click on the << or >> box next to V_LIN to

optimize the image.

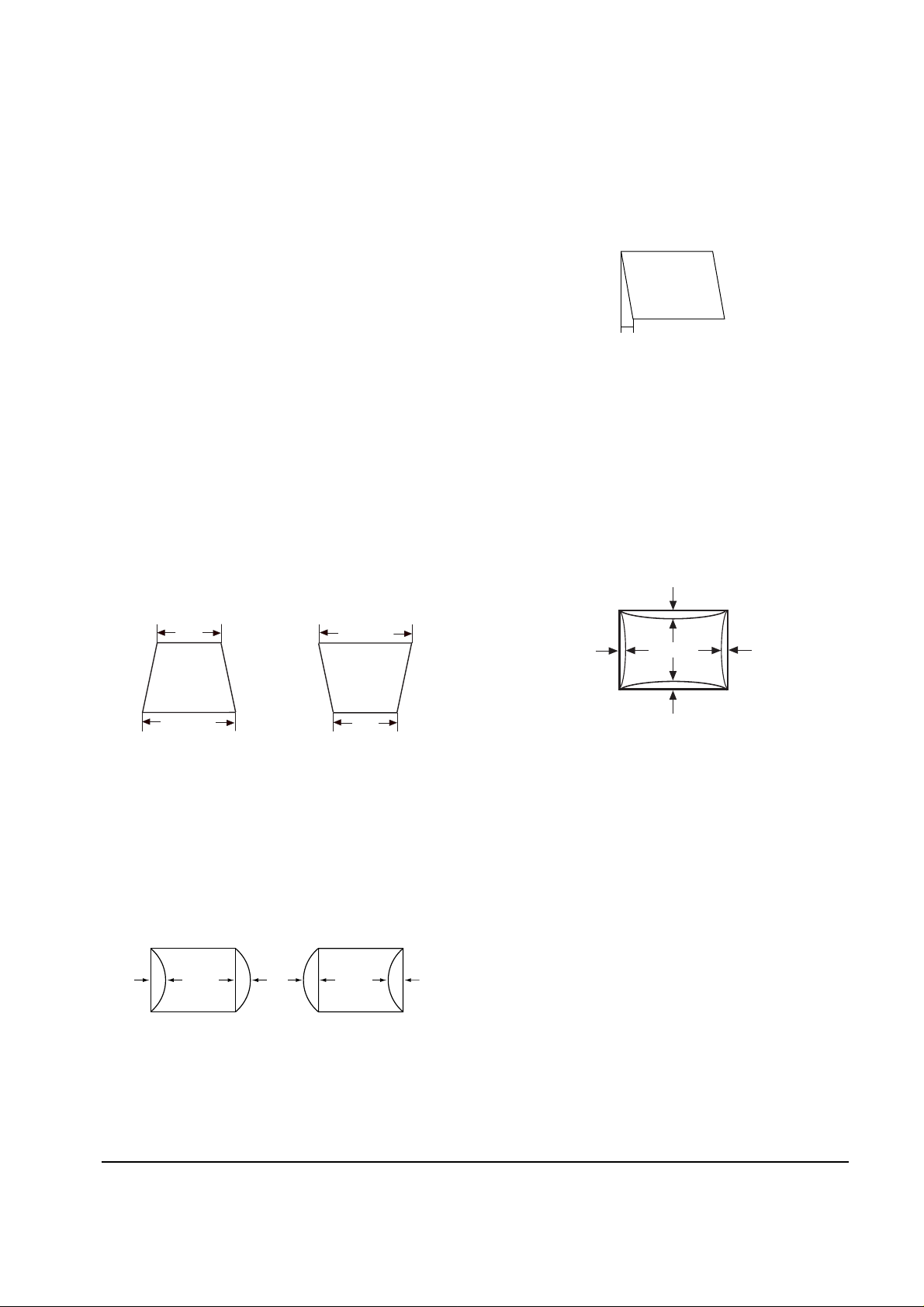

6-2-3 Trapezoid Adjustment

CONDITIONS

Scanning frequency: 53.6 kHz/85Hz

Brightness: Maximum

Contrast: Maximum

Click on the << or >> box next to TRAPE to make

the image area rectangular.

Figure 6-4. Trapezoid

6-2-4 Pinbalance Adjustment

CONDITIONS

Scanning frequency: 53.6 kHz/85Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Click on the << or >> box next to PIN_BAL to

optimize the image.

6-2-5 Parallelogram Adjustment

CONDITIONS

Scanning frequency: 53.6 kHz/85Hz

Brightness: Maximum

Contrast: Maximum

Click on the << or >> box next to PARALL to

make the image area rectangular.

Figure 6-6. Parallelogram

6-2-6 Side Pincushion Adjustment

CONDITIONS

Scanning frequency: 53.6 kHz/85Hz

Display image: Crosshatch pattern

Click on the << or >> box next to BARREL to

straighten the sides of the image area.

6-2-7 Degauss

No adjustments are available for the degaussing

circuit. The degaussing circuit can effectively

function only once per 30 minutes.

6-2-8 To Delete the User Mode Data

To delete the adjustment data from the user

modes, click USER DELETE.

6-2-9 Save the Data

To save the adjustment data for a mode, press

FACTORY SAVE.

6 Alignment and Adjustments

6-4 CKF5607L

| C1 |, | C2 | ≤ 2.0 mm, | D1 |, | D2 | ≤ 2.0 mm.

Figure 6-7. Pincushion

| A - B | < 4 mm

A

4 mm

B

B

A

D1 D2 D1

Figure 6-5. Pinbalance

| D1 |, |D2 | ≤ 2 mm

D2

C2

D1

C1

Loading...

Loading...