Page 1

4. Disassembly and Reassembly

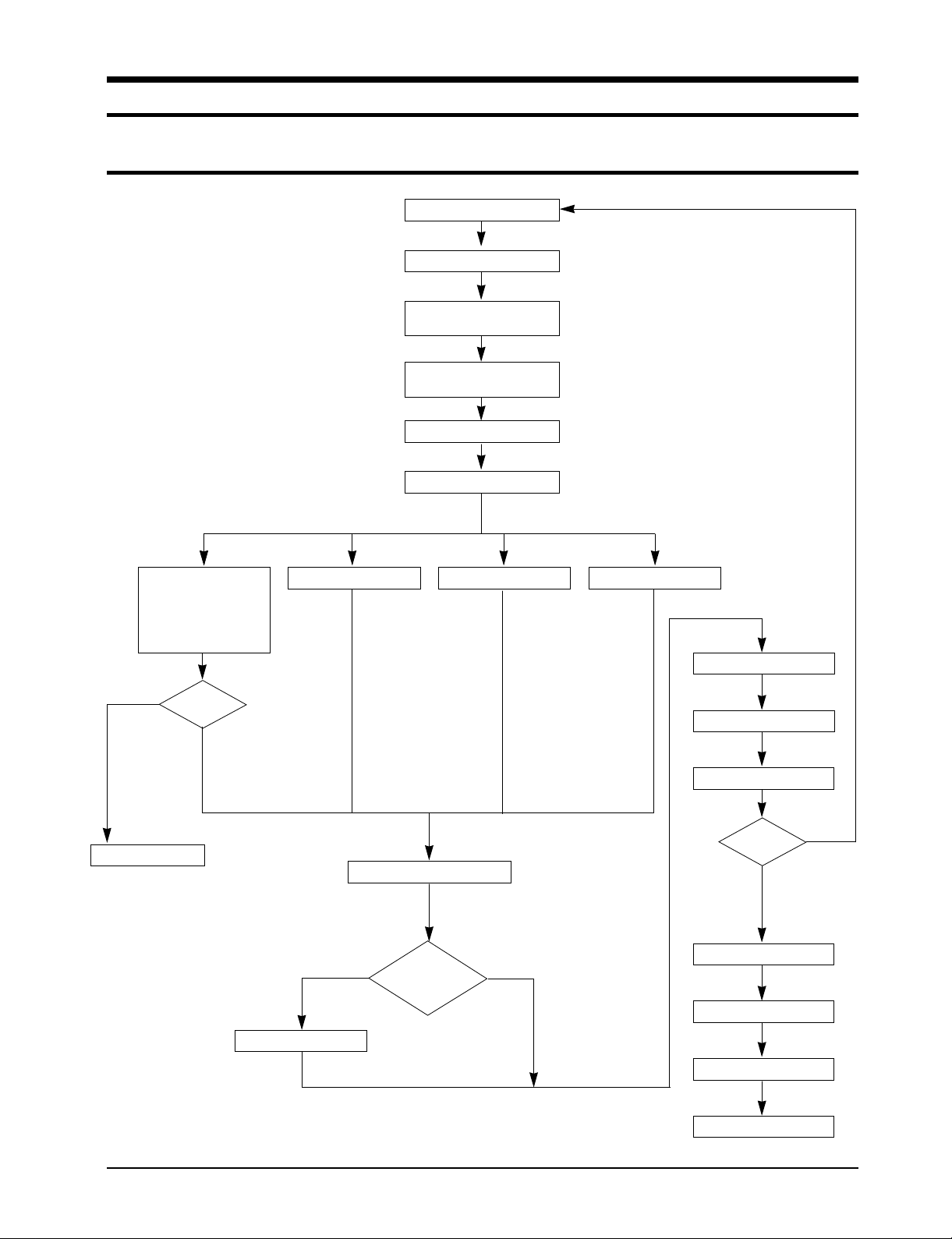

4-1 Compressor Replacement Flow Chart

Locate cause of defect

Release refrigerant

Disconnect electrical wiring

from compressor

Cut refrigerant lines

from compressor

Plug disconnected lines

Replace compressor

Inspect electrical

wiring for defects,

and terminals for

correct and secure

connections

Problem?

Y N

Corrective action

Solder discharge line

Check refrigerant oil level

Low oil level?

Solder suction line Use nitrogen gas

NY

Perform soldering function

Fill system with nitrogen gas

Check for leakage

Y

Leakage?

N

Release nitrogen gas?

Evacuate system

Add oil as necessary

Recharge system

Pinch and braze filling tube

Samsung Electronics 4-1

Page 2

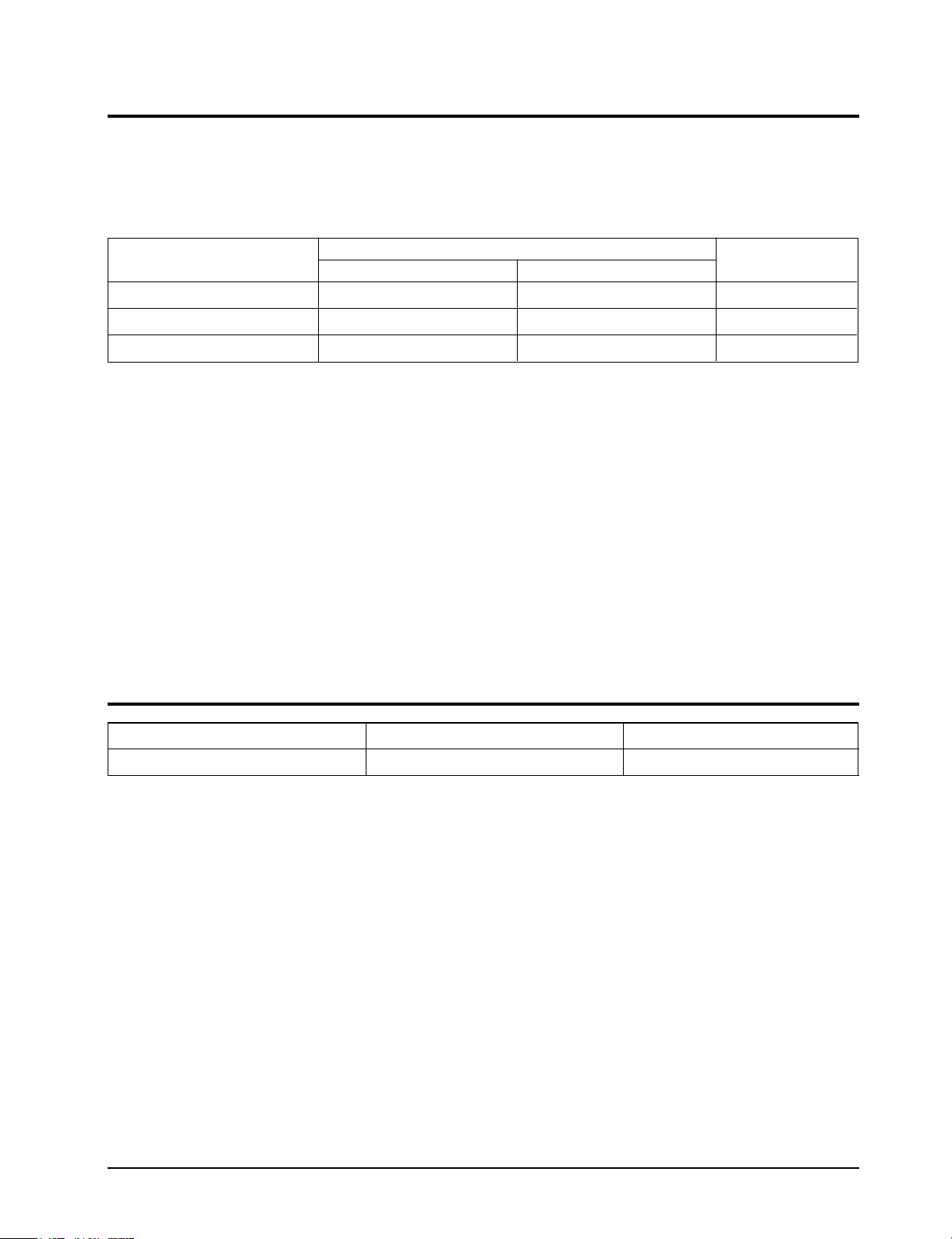

4-2 Checking the Oil

Put approximately 10cc oil into a transparent container and test it.

4-2-1 Oil quality

Condition of

Refrigerant Cycle

Normal

Overheat

Motor Damage

Color

Light Yellow

Brown Color

Dark Brown

Condition of Oil

4-2-2 Changing and adding refrigerant oil

1. Change the compressor - DO NOT recharge the oil as the compressor itself is

already charged.

2. Change the condenser .... add 50cc

3. Change the evaporator .... add 50cc

4. When the refrigerant is replaced .... add 30cc oil.

5. After vacuum is completed, the oil is filled through the high pressure side.

6. In the event of a refrigerant leak, generally it is not necessary to add oil

(unless the oil has leaked significantly).

4-3 Refrigerant Oil Specifications

Odor

No Odor

-

Pungent Oil

Remarks

Return with the system

Oil Change

Oil Change

Model Oil Specification Oil Change

AW05B0LA(AW0519) SONTEX 200LT 280CC

4-2 Samsung Electronics

Page 3

4-4 Disassembly and Reassembly Procedure

Stop operating of the air conditioner and remove the power cord before repairing the unit.

No. Part name Procedures Remarks

Ass'y - Grille 1. Remove the knobs and the grille screw

①

located behind the knob on right.

2. Remove the grille from the cabinet by pushing

in on the grille tabs on both cabinet sides, and

then lift the grille off the top latches.

Ass'y - Frame 1. Remove the 8 screws on each of the cabinet

➁

Ass'y - Evaporator 1. Remove foam-seal on the top of the unit.

➂

Ass'y - Blower 1. Loose the bolt to disassemble the blower.

➃

and lift the cabinet upward.

2. After unfolding evaporator cover upwardly,

remove screw on top of right side.

3. Separate the evaporator from the unit.

Samsung Electronics 4-3

Page 4

Disassembly and Reassembly

No. Part name Procedures Remarks

Ass'y - Control 1. Remove the 2 screws at the bottom of

➄

Ass'y - Condenser 1. Remove the 6 screws on the condenser.

➅

between the base-pan and the control-box.

2. Separate the power cord from the base pan.

2. Separate the cond-casing from the base-pan.

Ass'y - Fan Propeller 1. Loose the bolt to disassemble the fan-propeller.

➆

2. Separate the fan-propeller from the motor and

the cond-casing.

Ass'y - Motor 1. Separate the motor and the bulk-head from the

⑧

base pan.

2. Loose the 4 nuts on the bulk-head.

4-4 Samsung Electronics

Loading...

Loading...