14MN10

SERVICE MANUAL

S20W814MN10//

COLOR TELEVISION

Chassis No. SN-000

VIDEO IN AUDIO

W

E

O

R

P

CH –

VOL

+

MODEL

14MN10

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified should be used.

CONTENTS

Page

» ELECTRICAL SPECIFICATIONS .........................................................................................................1

» IMPORTANT SERVICE SAFETY PRECAUTION .................................................................................2

» LOCATION OF USER'S CONTROL .....................................................................................................4

» INSTALLATION AND SERVICE INSTRUCTIONS ................................................................................5

» CHASSIS LAYOUT .............................................................................................................................11

» BLOCK DIAGRAM ..............................................................................................................................12

» DESCRIPTION OF SCHEMATIC DIAGRAMS....................................................................................13

» PRINTED WIRING BOARD ASSEMBLIES ........................................................................................17

» REPLACEMENT PARTS LIST ............................................................................................................20

» PACKING OF THE SET ......................................................................................................................25

ELECTRICAL SPECIFICATIONS

POWER INPUT.................................................... 120 V AC 60 Hz

POWER RATING ....................................................................69 W

PICTURE SIZE ............................................. 580cm2 (89.8sq inch)

CONVERGENCE ............................................................. Magnetic

SWEEP DEFLECTION .................................................... Magnetic

FOCUS ............................................... Hi-Bi-Potential Electrostatic

INTERMEDIATE FREQUENCIES

Picture IF Carrier Frequency ..................................... 45.75 MHz

Sound IF Carrier Frequency...................................... 41.25 MHz

Color Sub-Carrier Frequency .................................... 42.17 MHz

(Nominal)

AUDIO POWER

OUTPUT RATING ................................ 0.9W (at 10% distortion)

SPEAKER

SIZE ......................................................................8 cm (Round)

VOICE COIL IMPEDANCE............................. 32 ohm at 400 Hz

ANTENNA INPUT IMPEDANCE

VHF/UHF.....................................................75 ohm Unbalanced

TUNING RANGES

VHF-Channels...............................................................2 thru 13

UHF-Channels ............................................................14 thru 69

CATV Channels ...........................................................1 thru 125

Specifications are subject to change without

prior notice.

SHARP CORPORATION

1

14MN10

IMPORTANT SERVICE SAFETY PRECAUTION

Ë

Service work should be performed only by qualified service technicians who are thoroughly

familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

3. Semiconductor heat sinks are potential shock

hazards when the chassis is operating.

4. The chassis in this receiver has two ground systems

which are separated by insulating material. The nonisolated (hot) ground system is for the B+ voltage

regulator circuit and the horizontal output circuit. The

isolated ground system is for the low B+ DC voltages

and the secondary circuit of the high voltage

transformer.

To prevent electrical shock use an isolation

transformer between the line cord and power

receptacle, when servicing this chassis.

CAUTION: FOR CONTINUED

PROTECTION AGAINST A

RISK OF FIRE, REPLACE

4A 125V

ONLY WITH SAME TYPE 4A125V FUSE.

SERVICING OF HIGH VOLTAGE SYSTEM

AND PICTURE TUBE

When servicing the high voltage system,

remove the static charge by connecting a

10k ohm resistor in series with an insulated

wire (such as a test probe) between the picture tube ground and the anode lead. (AC

line cord should be disconnected from AC

outlet.)

1. Picture tube in this receiver employs integral

implosion protection.

2. Replace with tube of the same type number for

continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing

shatterproof goggles and after discharging the high

voltage anode completely.

X-RADIATION AND HIGH VOLTAGE LIMITS

1. Be sure all service personnel are aware of the

procedures and instructions covering X-radiation. The

only potential source of X-ray in current solid state

TV receivers is the picture tube. Howe ver , the picture

tube does not emit measurable X-Ray radiation, if

the high voltage is as specified in the "High Voltage

Check" instructions.

It is only when high voltage is excessive that Xradiation is capable of penetrating the shell of the

picture tube including the lead in the glass material.

The important precaution is to keep the high voltage

below the maximum level specified.

2. It is essential that servicemen have available at all

times an accurate high voltage meter.

The calibration of this meter should be checked

periodically.

3. High voltage should always be kept at the rated value

−no higher. Operation at higher voltages may cause

a failure of the picture tube or high voltage circuitry

and;also, under certain conditions, may produce

radiation in exceeding of desirable levels.

4. When the high voltage regulator is operating properly

there is no possibility of an X-radiation problem. Every

time a color chassis is serviced, the brightness should

be tested while monitoring the high voltage with a

meter to be certain that the high voltage does not

exceed the specified value and that it is regulating

correctly.

5. Do not use a picture tube other than that specified or

make unrecommended circuit modifications to the

high voltage circuitry.

6. When trouble shooting and taking test measurements

on a receiver with excessive high voltage, avoid being

unnecessarily close to the receiver.

Do not operate the receiver longer than is necessary

to locate the cause of excessive voltage.

2

2

2

IMPORTANT SERVICE SAFETY PRECAUTION

(Continued)

14MN10

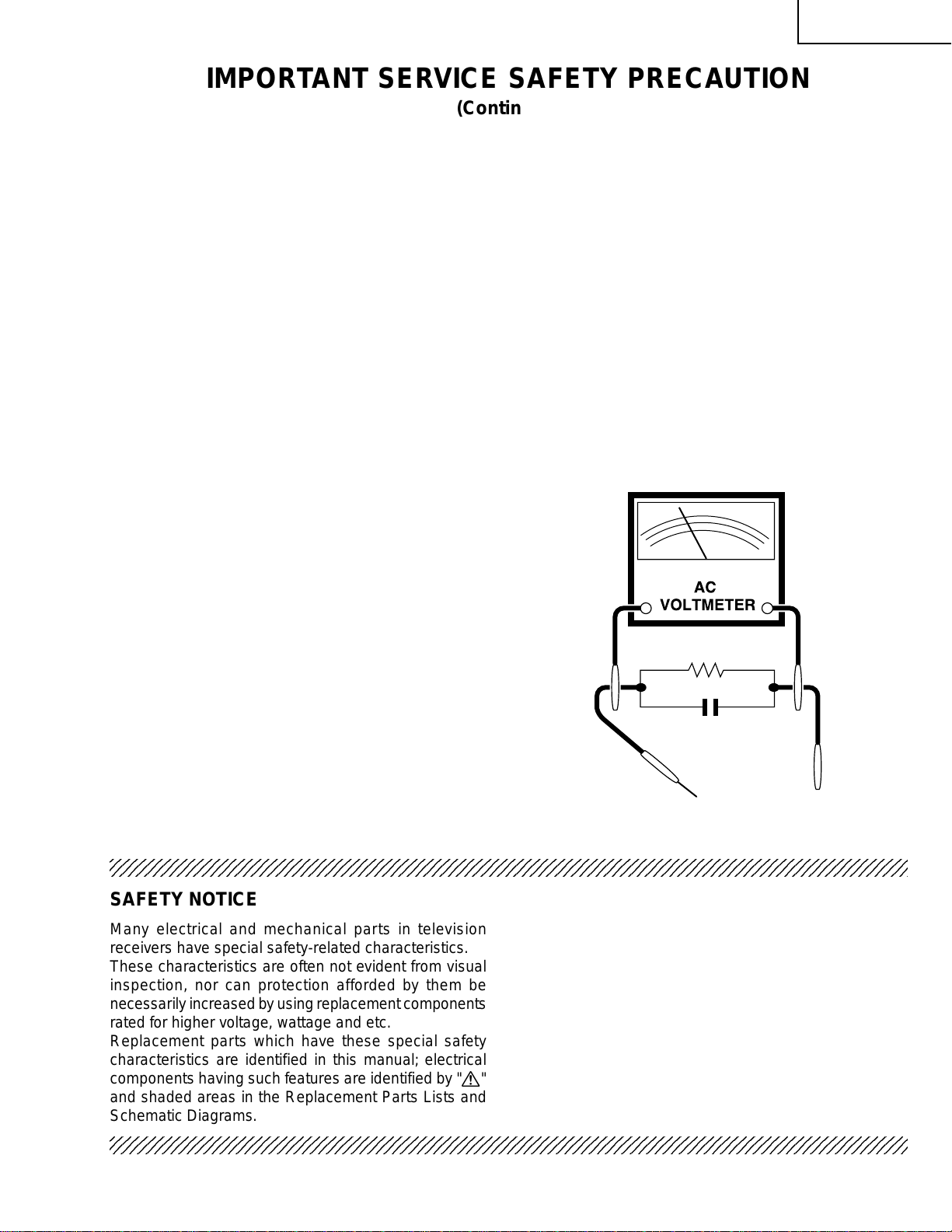

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators and etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

• Plug the AC cord directly into a 120 volt AC outlet,

(Do not use an isolation transformer for this test).

• Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as electrical conduit or electrical ground

connected to earth ground.

• Use an AC voltmeter ha ving with 5000 ohm per volt,

or higher, sensitivity to measure the A C v oltage drop

across the resistor.

• Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon and etc.) and measure the AC voltage

drop across the resistor.

AII checks must be repeated with the AC line cord

plug connection reversed. (If necessary, a nonpolarized adapter plug must be used only for the

purpose of completing these check.)

Any current measured must not exceed 0.5 milliamp .

Any measurements not within the limits outlined

above indicate of a potential shock hazard and

corrective action must be taken before returning the

instrument to the customer.

1.5k ohm

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in television

receivers have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage and etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by " å"

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

For continued protection, replacement parts must be

identical to those used in the original circuit. The use of

substitute replacement parts which do not have the same

safety characteristics as the factory recommended

replacement parts shown in this service manual, may

create shock, fire, X-radiation or other hazards.

3

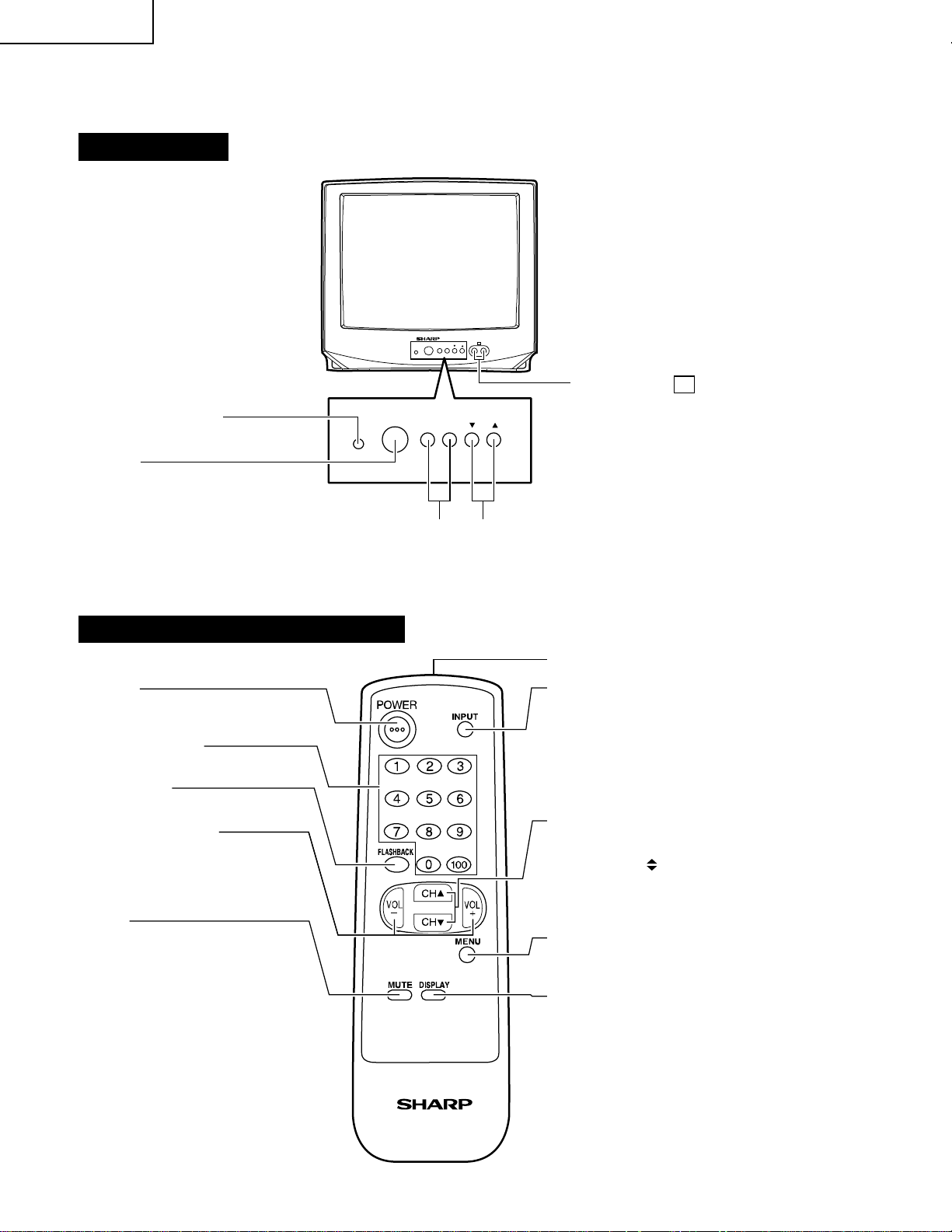

14MN10

Front Panel

SENSOR AREA FOR

REMOTE CONTROL

POWER

Press ➝ On.

Press again ➝ Off.

LOCATION OF USER'S CONTROL

VIDEO IN AUDIO

W

E

O

R

P

CH –

VOL

+

VIDEO/AUDIO IN TERMINALS

W

E

O

R

P

CH –

VOL

+

VOLUME UP/DOWN

(+) Increases sound.

(–) Decreases sound.

Basic Remote Control Functions

POWER

Press → On.

Press again → Off.

REMOTE KEYPAD

Accesses any channel from keypad.

FLASHBACK

Returns to previous channel.

VOLUME UP/DOWN

(+) Increases sound.

(–) Decreases sound.

• In menu mode, changes or selects

the TV adjustments.

MUTE

Press → Mutes sound.

Press again → Restores sound.

• CLOSED CAPTION appears when

sound is muted.

CHANNEL UP/DOWN

'

( ) Selects next higher channel.

( ) Selects next lower channel.

"

• Press both at the same time to

access the MAIN MENU screen.

Infrared Transmitter Window

INPUT

Press → Switch to e xternal video input

mode.

Press again → Switch to TV mode.

CHANNEL UP/DOWN

( ) Selects next higher channel.

'

( ) Selects ne xt lower channel.

"

• Moves the “

” mark of the MENU

screen.

MENU

Press → Accesses MAIN MENU.

Press again → Exits MAIN MENU.

DISPLAY

Press → Displa ys receiving channel for

four seconds.

Press again → Removes display .

• Temporarily displays receiving

channel when in Closed Caption

mode.

TV

4

14MN10

INSTALLATION AND SERVICE INSTRUCTIONS

Note: (1)When performing any adjustments to resistor controls and transformers use non-metallic

screwdrivers or TV alignment tools.

(2)Before performing adjustments, the TV set must be on at least 15 minutes.

CIRCUIT PROTECTION

The receiver is protected by a 4.0A fuse (F701),

mounted on PWB-A, wired into one side of the AC

line input.

X-RADIATION PROTECTOR CIRCUIT TEST

After service has been performed on the horizontal

deflection system, high v oltage system, B+ system,

test the X-Radiation protection circuit to ascertain

proper operation as follows:

1. Apply 120V AC using a variac transformer for accur ate

input voltage.

2. Allow for warm up and adjust all customer controls

for normal picture and sound.

3. Receive a good local channel.

4. Connect a digital voltmeter to TP653 and mak e sure

that the voltmeter reads 21.3 ±1.5V.

5. Apply external 27.9V DC at TP653 by using an

external DC supply, TV must be shut off.

6. To reset the protector, unplug the A C cord and mak e

a short circuit between TP651 and TP652. No w make

sure that normal picture appears on the screen.

7. If the operation of the horizontal oscillator does not

stop in step 5, the circuit must be repaired before the

set is returned to the customer.

HIGH VOLTA GE CHECK

High voltage is not adjustable but must be checked

to verify that the receiver is operating within safe

and efficient design limitations as specified checks

should be as follows:

1. Connect an accurate high voltage meter between

ground and anode of picture tube.

2. Operate receiver for at least 15 minutes at 120V AC

line voltage, with a strong air signal or a properly tuned

in test signal.

3. Enter the service mode and select the service

adjustment "S03" and Bus data "01" (Y-mute on).

4. The voltage should be approximately , 24.0kV (at z ero

beam).

If a correct reading cannot be obtained, check circuitry

for malfunctioning components. After the voltage test,

make Y-mute off to the normal mode.

5

14MN10

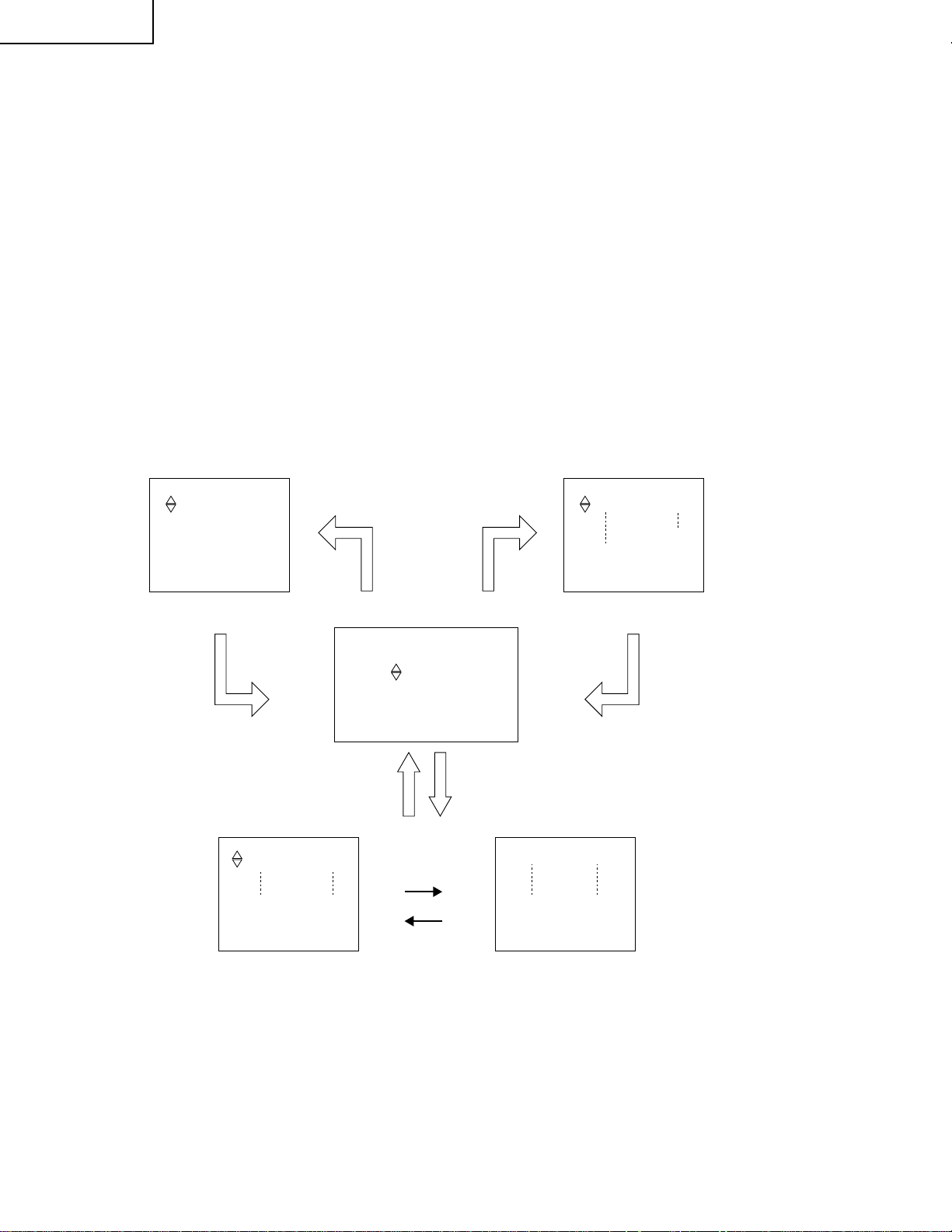

For adjustments of this model, the bus data is converted to various analog signals by the D/A converter circuit.

Note: There are still a few analog adjustments in this series such as focus and master screen voltage. Follow

the steps below whenever the service adjusment is required.

To enter the service mode and exit service mode.

While pressing the Vol-up and Ch-up buttons at the sametime, plug the AC cord into a wall socket.

Now, the TV set is switched on and enters the service mode.

To exit the service mode, turn the television off by pressing the power button.

1. Service mode.

Before putting unit into the service mode, check that customer adjustments are in the normal mode. Use the reset

function in the video adjustment menu to ensure customer control are in their proper (reset) position.

2. Service number selection.

In the service mode, you will see the window screen as window 1. There are 3 adjustment categories 2DEF,

3SIGNAL, 4FIX VALUE as show in Figure A.

Window 2: DEF

D01

D03

D05

RETURN

RETURN

Window 4: FIX VALUE

RETURN NEXT

D02

D04

D06

Window 1: ADJUSTMENT CATEGORIES

RETURN

F01 F02

F13 F14

DEF

SERVICE MODE

DEF

SIGNAL

FIX V ALUE

EEPROM

NEXT

PREVIOUS

SIGNAL

FIX V ALUE

Window 3: SIGNAL

S01

S13

RETURN

F15 F16

F25 F26

RETURNPREVIOUS

S02

S12

RETURN

Figure A: ADJUSTMENT CATEGORIES

Press CH UP/DOWN button for selection and enter by VOL UP or VOL DOWN.

Press CH UP/DOWN button to select the adjustment item and VOL UP/DOWN

to adjust the data number for each categories.

(OSD disturbance can be erased by R/C display key)

(Note: EEPROM-Factory used only)

6

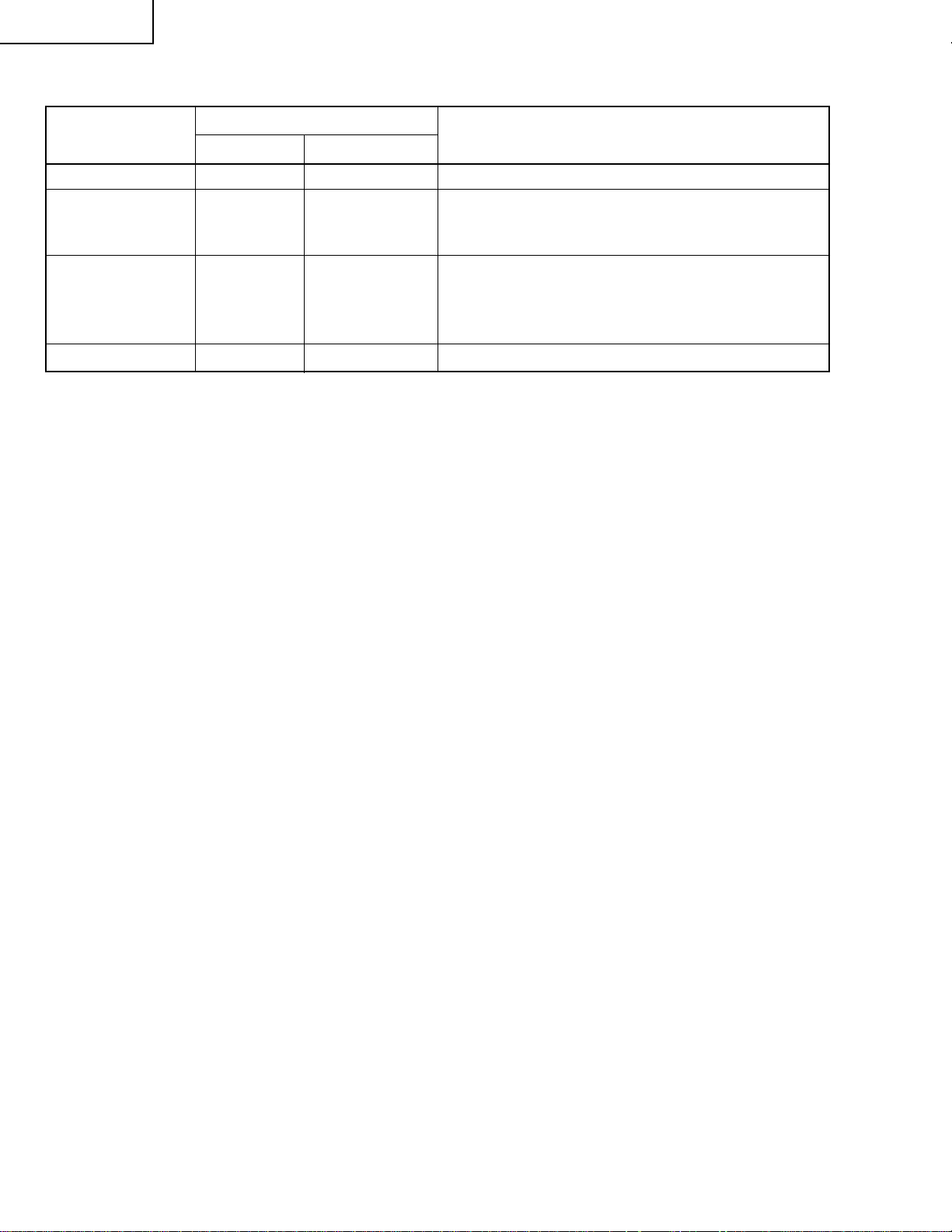

Below are the adjustments ranges and initial values for FIX VALUE category.

FIX V ALUE

SERVICE

POSITION

F01 OPTION 1 00-FF B0 A0

F02 OPTION 2 00-FF 04 0C

F03 E-SAVE 00-3F 23 1F

F04 TUNER SETUP 00, 01 00 00

F05 R-TONE RD 00-7F 19 03

F06 R-TONE BD 00-7F 00 7C

F07 B-TONE RD 00-7F 00 00

F08 B-TONE BD 00-7F 12 04

F09 FM LEVEL 00-1F 0C 0C

F10 AFC GAIN 00, 01 00 00

F11 G DRIVE 00, 0F 00 0F

F12 FBT BLK SW 00,01 01 01

F13 V COMP 00-07 07 07

F14 OSD CONT 00-03 02 01

F15 SHARPNESS 00-3F 19 19

F16 FLT SYS 00-07 00 00

F17 KILLER OP 00-07 04 02

F18 PRE SHOOT 00-03 03 00

F19 CORING 00-03 04 04

F20 DC REST 00-03 02 02

F21 BS START 00-03 01 01

F22 BS GAIN 00-03 01 01

F23 ABL START 00-07 00 00

F24 R/B ANGLE 00-0F 08 08

F25 H BLK R 00-0F 04 03

F26 H BLK L 00-0F 04 06

ADJUST ITEM

RANGE

Table - A

DATA

INITIAL VALUE

14MN10

(Hex)

Below are the ranges and initial values for each adjustment and in each categories.

DEF

SERVICE

POSITION

D01 H-PHASE 00-1F 0C

D02 V-SIZE 00-7F 40

D03 V-POSITION 00-3F 20 Must be "20"

D04 CC-POSITION 00-FF 1A

D05 V-LINEARITY 00-1F 10 Must be "12"

D06 V-S-CORRECTION 00-1F 10 Must be "0F"

ADJUST ITEM

RANGE

DATA

Table - B

INITIAL V ALUE

ADJUSTMENT CONTENTS

SIGNAL

SERVICE

POSITION

S01 RF AGC 00-3F 14

S02 VIDEO LEVEL 00-07 03

S03 Y-MUTE 00-03 00

S04 SUB BIAS 00-FF 40 Must be "60"

S05 R-BIAS 00-FF 00

S06 G-BIAS 00-FF 00

S07 B-BIAS 00-7F 00

S08 R-DRIVE 00-7F 40

S09 B-DRIVE 00-7F 40

S10 CONTRAST 00-7F 5A

S11 TINT 00-7F 40

S12 COLOR 00-7F 40

S13 BRIGHTNESS 00-7F 40

ADJUST ITEM

RANGE

Note: Refer to the SERVICE ADJUSTMENT for each corresponding values.

Table - C

DATA

INITIAL V ALUE

ADJUSTMENT CONTENTS

"01": Y-MUTE, "02": V-STOP & Y-MUTE,

"03": Activate Color Killer Circuit

7

14MN10

Holding down both the V ol-up/Ch-do wn buttons on the TV set at service mode f or more than 2 seconds will automatically

write the above initial values into IC2101.

PART REPLACED

IC2001

IC201

IC2101

CRT

ADJUSTMENT

NECESSARY

X

X

X

UNNECESSARY

X

Table - D

NOTES

Data is stored in IC2101.

The adjustment is needed to compensate for characteristics

of parts including IC201.

Holding down both the V ol-up/Ch-down b uttons on the TV set

in the service mode for more than 2 seconds will automatically

write the above initial values into IC2101.

Adjust items related to picture tube only.

8

Loading...

Loading...