Page 1

Automation System TROVIS 6400

Process Control Stations TROVIS 6412 and 6442

Edition July 2007

Firmware C 1.3

Firmware Si 1.4

Mounting and Operating Instructions

EB 6412 EN

Page 2

Page 3

Contents

1. Notes on these mounting and operating instructions...................................... 5

1.1. Documentation ............................................................................................. 5

1.2. Abbreviations used in this manual.................................................................. 5

2. Description................................................................................................... 6

2.1. Features ....................................................................................................... 6

2.2. Versions ....................................................................................................... 6

2.3. The process control station (overview)............................................................. 7

2.4. Technical data .............................................................................................. 8

3. Installing the process control stations .......................................................... 11

3.1. TROVIS 6412 (panel-mounting unit)............................................................. 11

3.2. TROVIS 6442 (rack-mounting unit for 19inch racks)...................................... 12

3.3. Opening the controller case......................................................................... 12

4. Soldering jumpers...................................................................................... 14

4.1. Determining the input signals....................................................................... 14

4.1.1. Input board 1 (IB1)...................................................................................... 14

4.1.2. Input board 2 (IB2)...................................................................................... 15

4.1.3. Input board 3 (IB3)...................................................................................... 16

4.1.4. Input board 4 (IB4)...................................................................................... 17

4.2. Soldering jumpers on the logic board........................................................... 19

4.3. Soldering jumper for implementing the code number..................................... 19

4.4. Soldering jumpers on the interface board ..................................................... 20

5. Electrical connections.................................................................................. 22

5.1. TROVIS 6412 (panel-mounting unit)............................................................. 22

5.2. TROVIS 6442 (rack-mounting unit for 19inch racks)...................................... 24

5.3. Balancing the line resistance for the connection of Pt 100 sensors................... 26

5.4. Wiring technique with regard to electromagnetic compatibility....................... 26

6. Operation.................................................................................................. 28

6.1. Process display and control panel elements................................................... 28

6.2. OPERATING level........................................................................................ 28

6.2.1. Modifying the internal set point (reference variable) ...................................... 29

6.2.2. Power supply failure.................................................................................... 30

6.2.3. Manual adjustment of the output variable ..................................................... 30

6.3. PARAMETER level........................................................................................ 32

6.3.1. Operating the PARAMETER level .................................................................. 32

6.3.2. Example how to modify a parameter............................................................ 34

6.4. CONFIGURATION level .............................................................................. 36

6.4.1. Operating the CONFIGURATION level......................................................... 36

6.4.2. Example how to modify a configuration block............................................... 38

6.5. I-O level (displaying all input and output variables) ....................................... 40

6.6. Si level (setting the RS-485 interface)............................................................ 40

6.7. Ai level (adjustment and calibration) ............................................................ 41

6.8. Fir level (displaying the firmware number) .................................................... 43

6.9. CHE level (checking the display panel).......................................................... 43

3

Page 4

6.10. PA level (code number for the PARAMETER level) ..............................44

6.11. CO level (code number for the CONFIGURATION level)....................44

6.12. Ini level (resetting the process control station to its default values) ....................45

6.13. AdP level (adaptation of the control parameters) ............................................46

6.13.1. Single adaptation (adaptation during the start-up phase)................................48

6.13.2. Scheduling dependent on the actual value signal or output variable signal.......51

6.13.3. Scheduling dependent on an external signal..................................................53

6.13.4. Notes on adaptation....................................................................................53

6.13.5. Summary of the adaptation parameters.........................................................54

7. TROVIS 6482 Configuration and Parameterization Program.........................56

8. COPA pen...................................................................................................58

9. Interface RS-485 .........................................................................................60

9.1. Interface mode ............................................................................................60

9.2. Network construction ...................................................................................60

9.3. Network interconnections .............................................................................62

9.4. Operation...................................................................................................62

9.5. Functions supported by the Modbus protocol .................................................62

9.5.1. Function code 01 (Read Coil Status)..............................................................62

9.5.2. Function code 02 (Read Input Status).............................................................63

9.5.3. Function code 05 (Force Single Coil).............................................................63

9.5.4. Function code 03 (Read Holding Register) .....................................................63

9.5.5. Function code 04 (Read Input Register)..........................................................64

9.5.6. Function code 06 (Preset Single Register).......................................................64

9.5.7. Function code 15 (Force Multiple Coils).........................................................64

9.5.8. Function code 16 (Preset Multiple Register) ....................................................65

9.5.9. Error messages ...........................................................................................65

9.5.10. Other functions............................................................................................66

9.6. Retrofitting the RS-485 interface....................................................................66

10. Start-up procedure......................................................................................67

10.1. Optimization (tuning the process control station to the controlled system) .........67

Appendix A Data point list for the RS-485 interface.......................................................71

Appendix B Error messages ..........................................................................................90

Appendix C Checklist....................................................................................................94

4

Page 5

Notes on these mounting and operating instructions Documentation

1.Notes on these mounting and operating instructions

1.1.Documentation

Two manuals constitute the documentation for the TROVIS 6412 and 6442 Process Control

Stations: Mounting and Operating Instructions EB 6412 EN and Configuration Manual KH

6412 EN.

EB 6412 EN contains information about the installation, electrical connection and operation of

the control stations. Also introduced is how to work with the COPA pen, the COPA adapter and

the associated TROVIS 6482 Configuration and Parameterization Program. In addition, the

function of the RS-485 interface is described.

Configuration Manual KH 6412 EN presents a detailed description of the optional control

modes of the process control station, which can be defined by selecting the corresponding

configuration blocks and parameters.

1.2.Abbreviations used in this manual

The parameter names and input and output abbreviations used in this manual are those

appearing on the front-panel display of the TROVIS 6412 Process Control Station. These are

not always the same as the ones defined in the relevant DIN standards or often used in other

documents.

Caution!

!

Assembly, commissioning and operation of this process control station may only

be performed by experienced personnel.

5

Page 6

2.Description

2.1.Features

The TROVIS 6412 and 6442 Process Control Stations are microprocessor-controlled devices

used to automate industrial and process engineering plants. They are suitable not only for

constructing simple control loops, but for solving complex control problems as well. The TROVIS

6412 and TROVIS 6442 Process Control Stations only differ from each other in their design

(see section 2.2.).

Function blocks which are permanently stored in memory allow the user to easily define

pre-configured control systems and select various functions. The control mode selected determines which configuration blocks can be set, and these configuration blocks in turn determine

the adjustable parameters.

The process control stations are available with various input boards with either three or four

analog inputs. Furthermore, each control station has three binary inputs.

The analog inputs of the input boards are suitable for either standardized current and voltage

signals, potentiometers, Pt 100 temperature sensors, thermocouples or transmitter supply. The

input board 4 in the Technical data (page 8 and following) is no longer available. As a result,

the use of thermocouples is restricted.

Standard outputs include: One continuous control output, one on-off/three-step output and one

binary output for error messages.

The functional range of the process control stations can be optionally enhanced with the

following: One additional continuous control output, one analog output, two limit switches and

two binary outputs.

The process control stations can be operated, configured, and parameterized directly on the

control panel via several keys. The functions associated with the respective keys can be

disabled.

An optional program - TROVIS 6482 - allows configuration and parameterization of the

process control station via a PC (see page 56). Apart from this, all configuration blocks and

parameters can also be transferred to the process control stations, using a configuration and

parameterization pen (COPA pen) (see page 58).

The process control stations can be equipped with a RS-485 serial interface for use in a higher

level process control system.

2.2.Versions

TROVIS 64 2

Panel-mounting unit

1

Rack-mounting unit

4

Features Description

6

Page 7

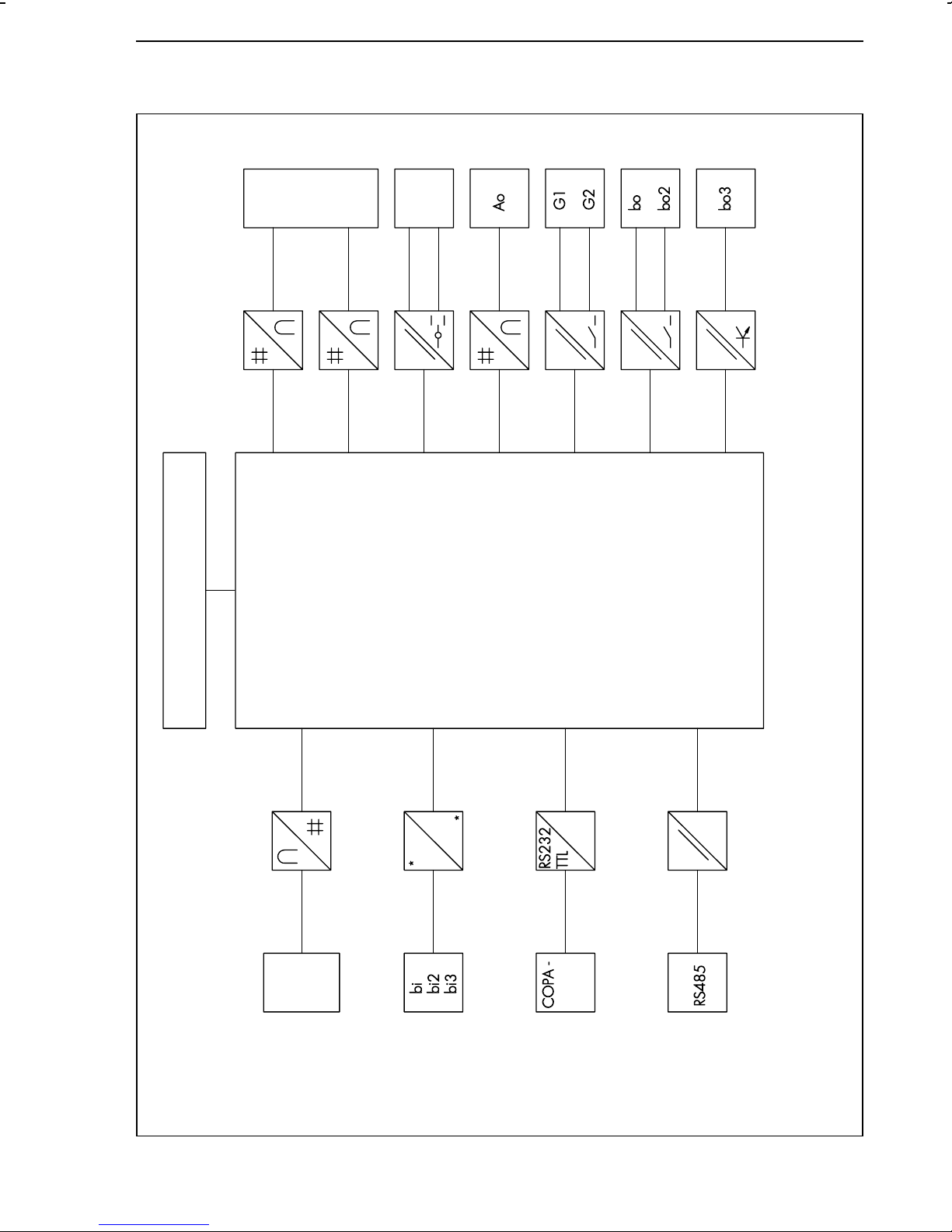

Description The process control station (overview)

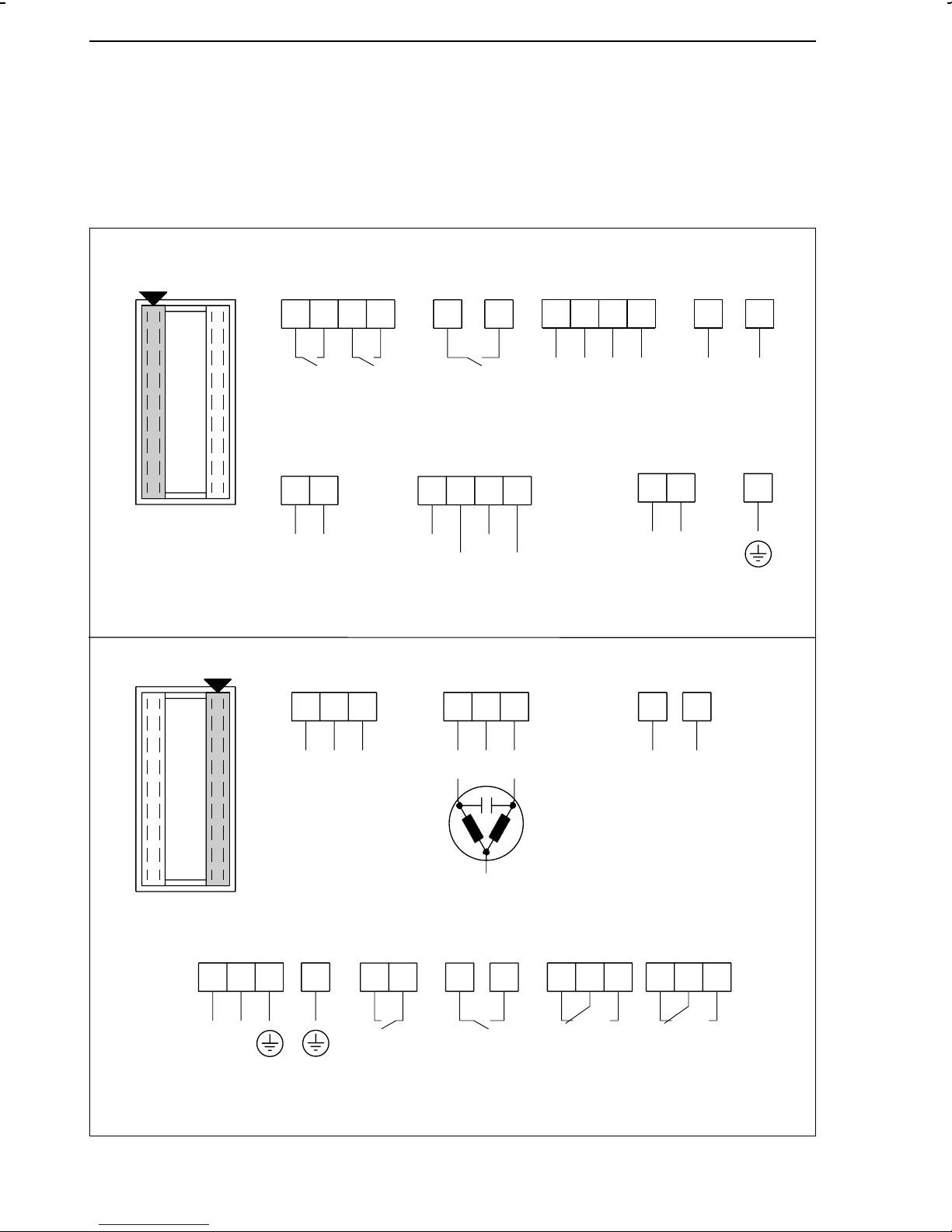

2.3.The process control station (overview)

Y1

4)

Y2

Y +

Y -

4)

4)

1

4)

4)

1

4)

Control elements

Control mode−Filtering, root extraction, func-

Software functions:

−

Ai 1

Ai 2

tion generation of input variables−Combination of input variables

Ai 3

Ai 4

(addition, subtraction, multiplica-

tion, calculation of mean value,

comparison, ratio)

Operation with two set points−Set point ramp and output

variable ramp

−

1

Optionally linear and non-linear

control algorithms and compen-

sation algorithms−Output signal limitation (fixed,

−

variable or by means of an input

variable)

Split-range operation−Definition of starting and

−

1)

pen/

adapter

restart conditions, limit alarms

Adaptation of control parameters

or parameter control by an

external signal−Selection control (limiting control)

−

2)

3)

Optional equipment

4)

,

3)

,

2)

,

1)

Fig. 1 ⋅ Block diagram of the process control station

7

Page 8

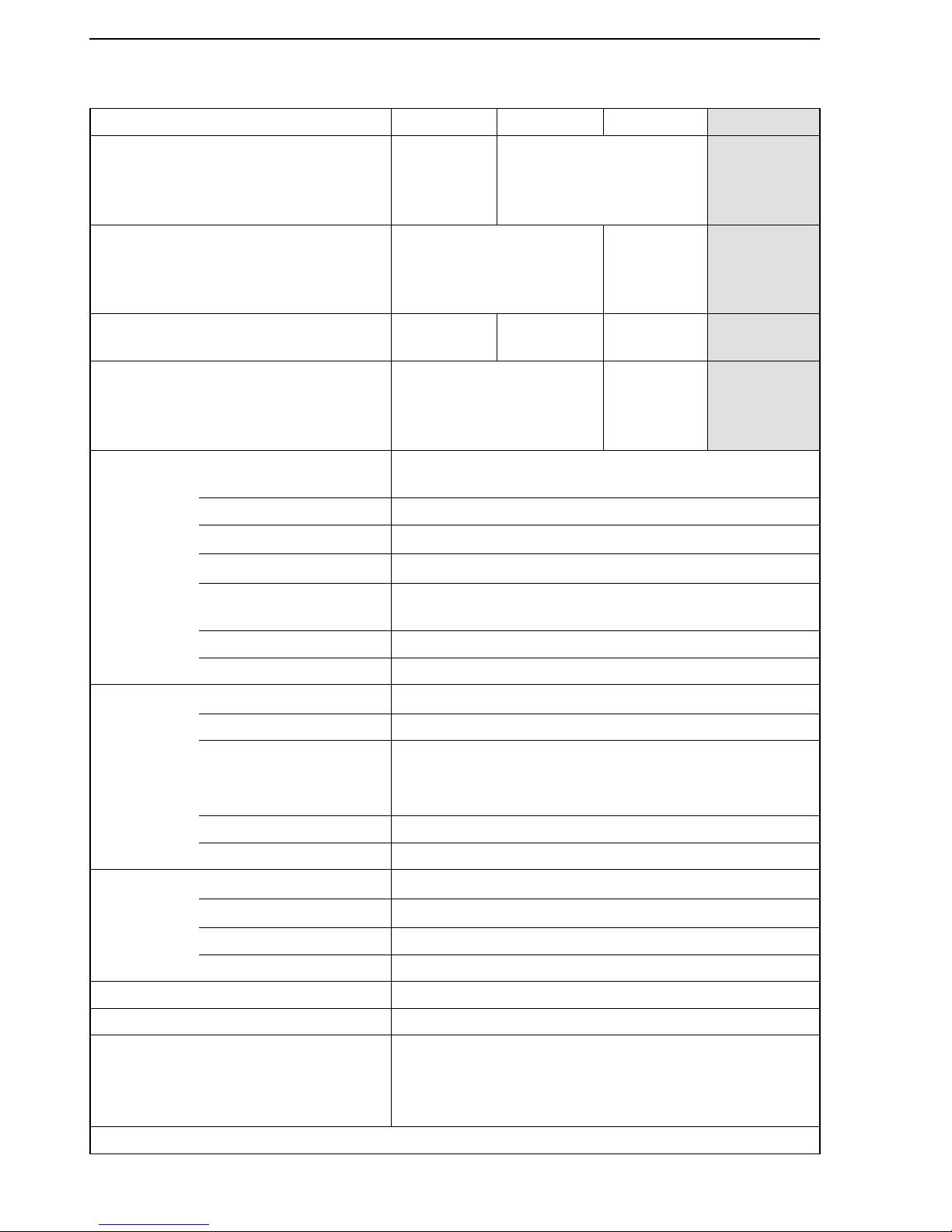

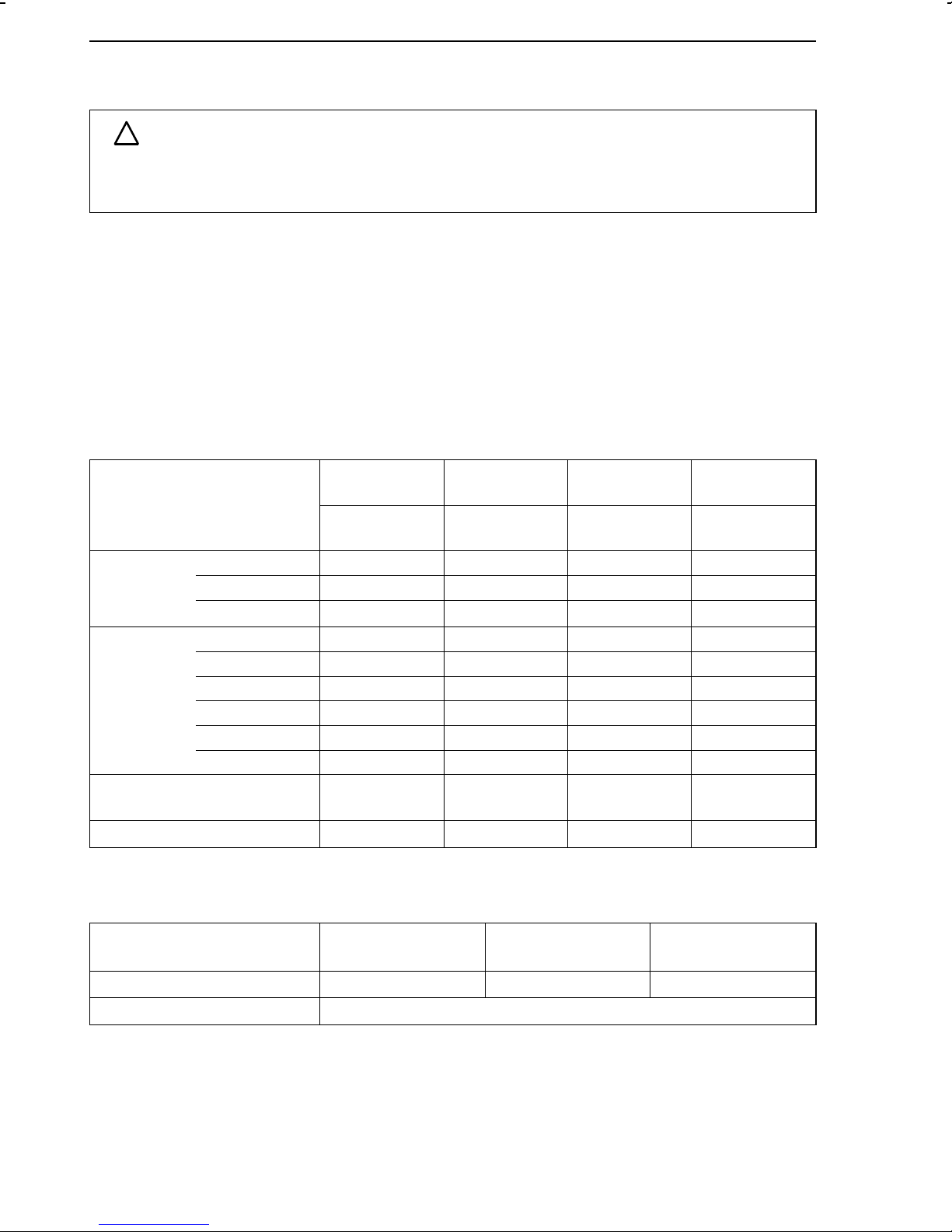

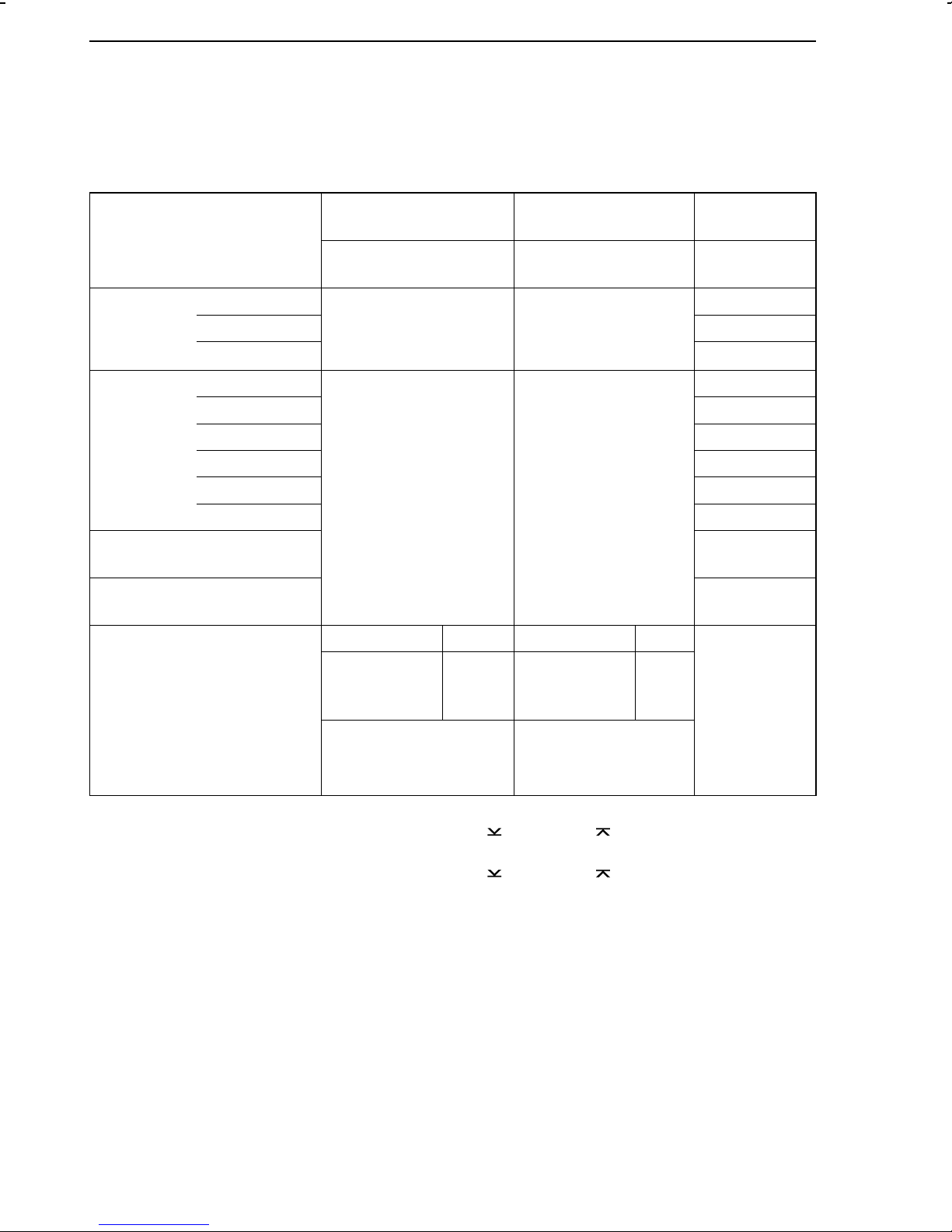

2.4.Technical data

Inputs

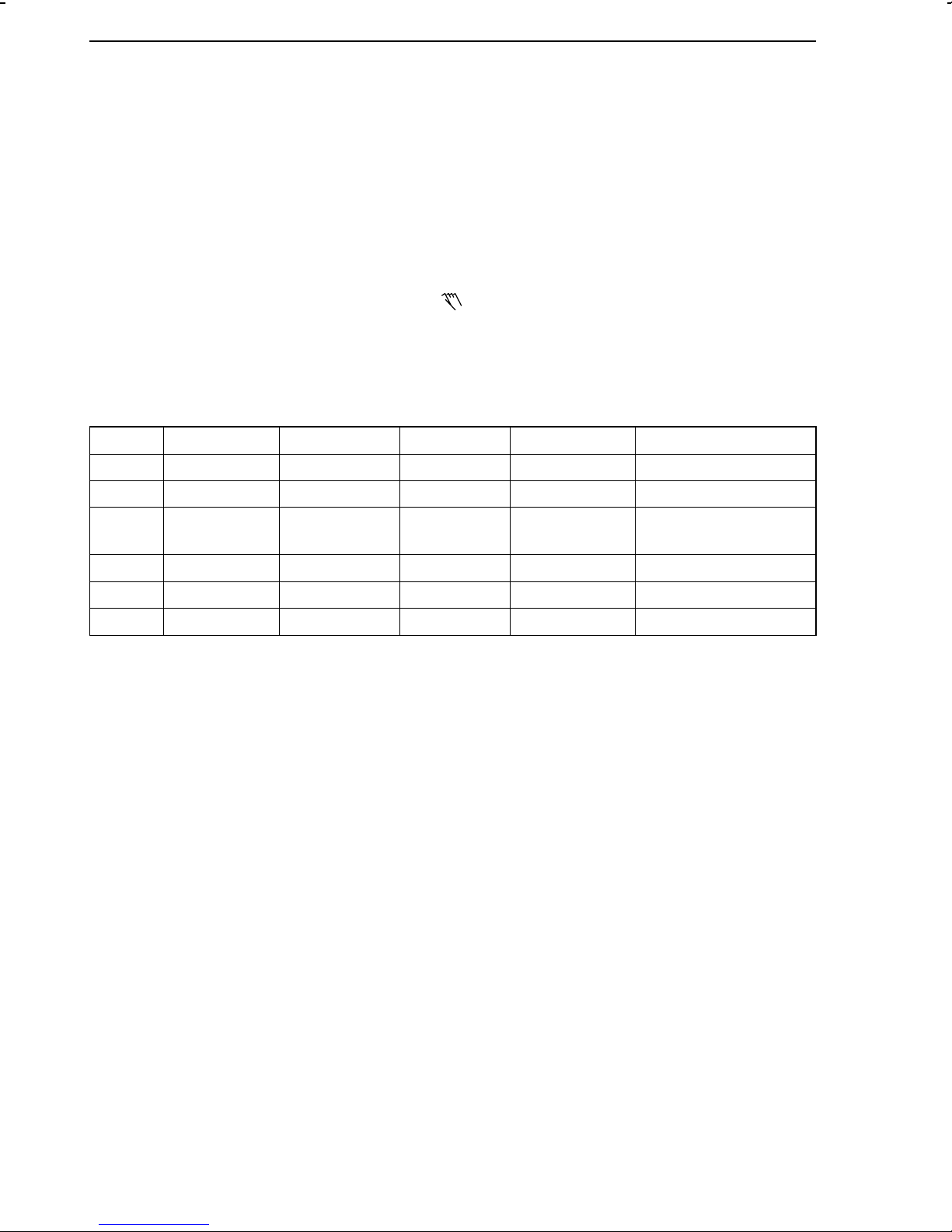

Input board 1 2 3 4

1)

Input 1 mA, V,

potentiometer,

transmitter

supply

Pt 100 in 2/3 or 4-wire

circuit

Thermocouple

(int./ext.

reference

junction)

Input 2

mA, V input,

transmitter supply

Pt 100

in 2/3

or 4-wire

circuit

mA, V,

transmitter

supply

Input 3 mA or V

input

mA, V,

transm. supply

Omitted Omitted

Input 4

mA, V or potentiometer

mA, V,

potentiometer,

transmitter

supply

mA, V or

potentiometer

mA or V

input

Measuring ranges 4(0) to 20 mA or

2(0) to 10 V; 0.2(0) to 1 V; 1(0) to 5 V

Meas. range switch-over Soldering jumpers

Max. permissible values

Current ± 50 mA, voltage ± 25 V

Internal resistance

Current R

i

= 50 Ω; voltage Ri = 200 k

Ω

Permissible

DC voltage

0 to 10 V

Error Zero point < 0.2 %, span < 0.2 %, linearity < 0.2 %

Temperature influence Zero point < 0.1 %/10 K; span < 0.1 %/10 K

Pt 100

temperature

sensors

Measuring ranges

2)

−

50 to 100 °C; 0 to 200 °C; 100 to 600 °C

Meas. range switch-over Soldering jumpers and configuration

Line resistances

Two-wire R

L1

+ R

L2

< 10 Ω,

Three-wire R

L1

= RL2 = RL3 < 50 Ω,

Four-wire, each R

L

< 100

Ω

Error Zero point, gain, linearity < 0.2 %

Temperature influence Zero point < 0.2 %/10 K; span < 0.2 %/10 K

Potentiometer Measuring range

0 to 1kΩ, ± 100 Ω, three-wire

Line resistance

R

L

< 10 Ω each

Error Zero point < 0.2 %, gain < 0.2 %

Temperature influence Zero point < 0.1 %/10 K; gain < 0.2 %/10 K

Thermocouple

1)

Specifications on request

Transmitter supply 16 to 23 V, max. 50 mA, short-term short-circuit protected

Binary inputs 3 binary inputs,

switching contacts (load 36 V DC, approx. 3 mA) or

external switching voltage (24 V DC, ± 30 %,

maximum 6 mA), selection via soldering jumpers

Technical data Description

8

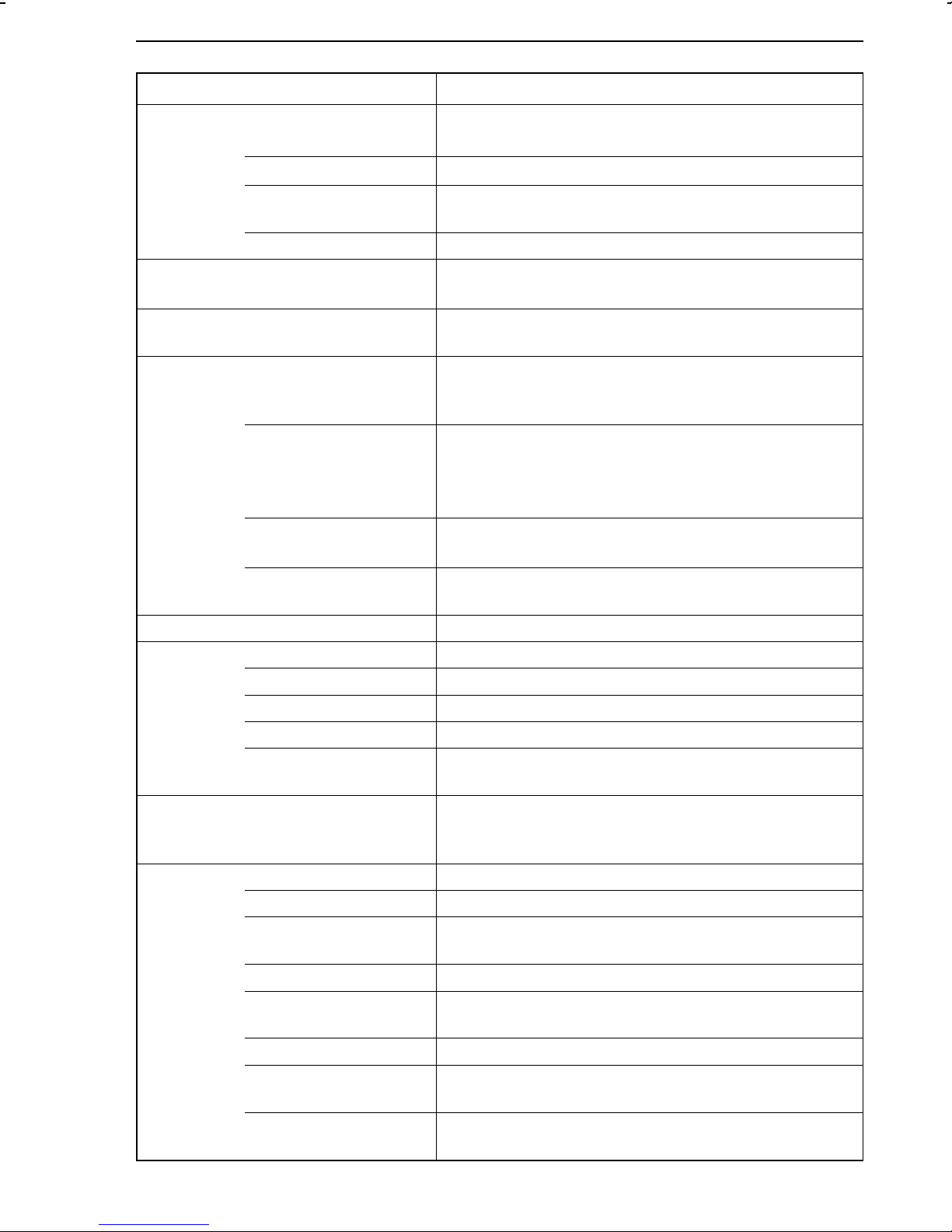

Page 9

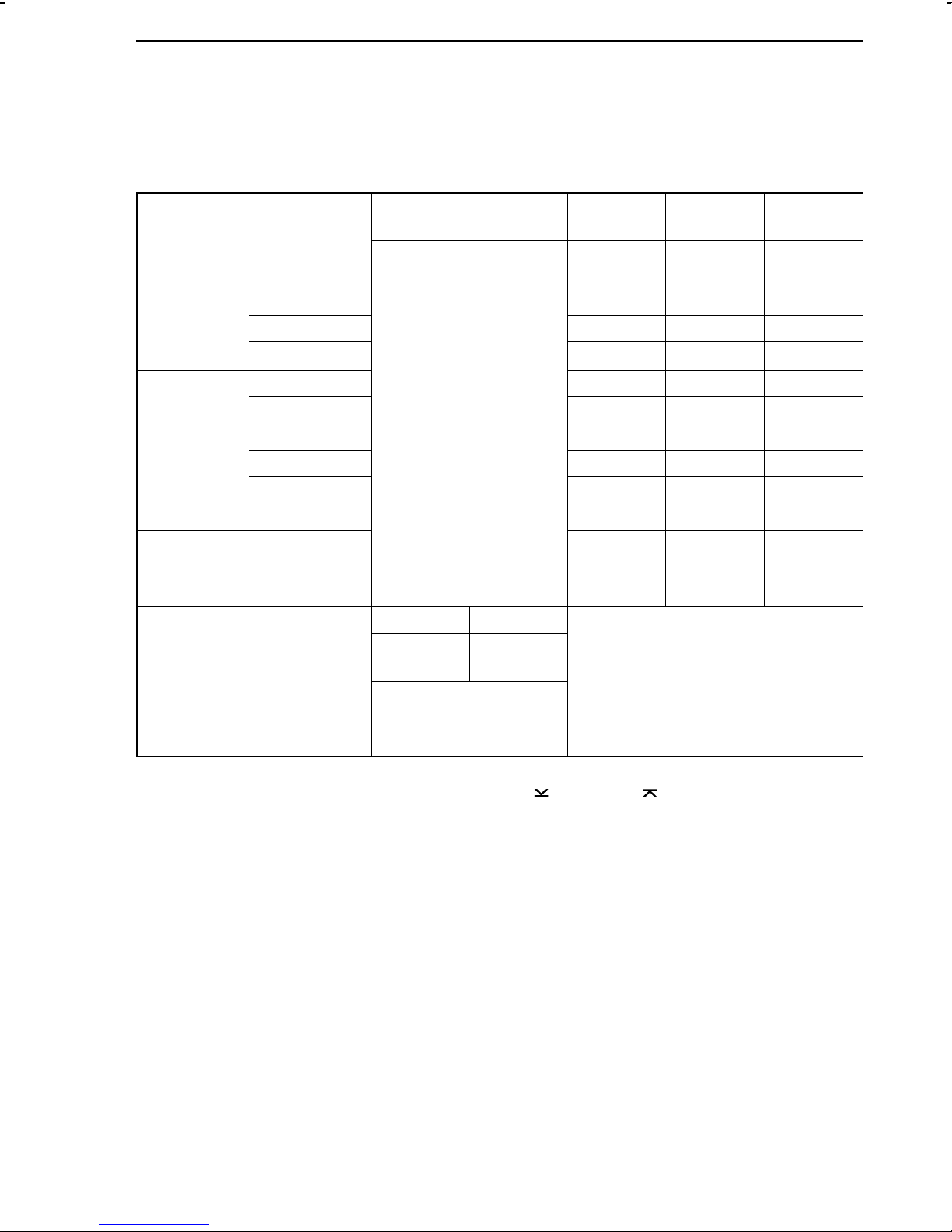

Description Technical data

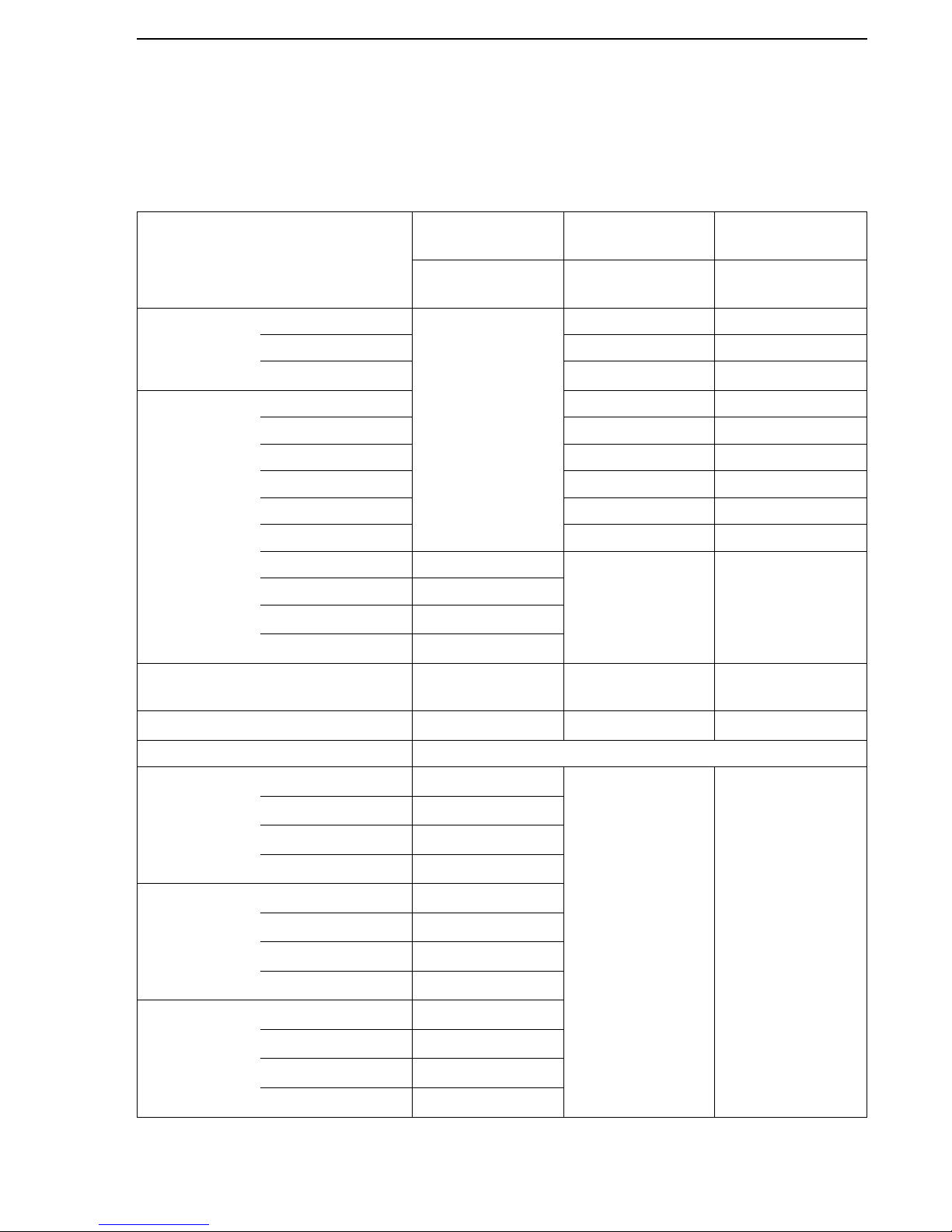

Outputs

Continuous

control output

Signal range

Output control range

4(0) to 20(22) mA, permissible load < 750 Ω or

2(0) to 10 V, permissible load > 3 kΩ

−10 to 110 %

Error Zero point < 0.3 %, nominal end value < 0.3 %,

linearity < 0.3 %

Temperature influence Zero point < 0.1 %/10 K; nominal end value < 0.1 %/10 K

Switching output 1 on-off or three-step output,

250 V AC (1A AC, cos ϕ = 1)

Binary output (BO 3) Electrically isolated transistor output,

U

= 3 V DC,U

min

= 42 V DC, I

max

= 30 mA DC

max

Options Control output 1 continuous control output for split-range operation;

signal range, output control range, error and temperature

influence same as first continuous control output (see above)

Analog output

4(0) to 20 mA, permissible load < 750 Ω or

2(0) to 10 V or −10 to 10 V, permissible load > 3kΩ

Error and temperature influence same as first continuous

control output (see above)

Limit relay 2 relays, floating contacts, maximum 250 V AC

(1 A AC, cos ϕ = 1) or maximum 250 V DC (0.1 A DC)

Binary outputs 2; floating contacts; maximum 42 V AC (0.1 A AC);

42 V DC (0.05 A DC)

Interfaces

Serial

interface

on the

front-panel

Communications protocol TROVIS 6482 SAMSON Protocol

Number of stations 1

RS-232 in conjunction w. SAMSON cable no. 1170-1141

Length of cable < 2 m

Transmittable data Configuration, parameters, input and output signals for

graphic display

COPA pen Read/write pen for transmitting the CONFIGURATION and

PARAMETER data to/from the process controls station via

the front-panel serial interface

Serial

interface

RS-485

(optional)

Communications protocol Modbus RTU 584

Data transmission Asynchronous, half duplex, 4-wire or 2-wire

Character format RTU (8 bit), 1 start bit, 8 data bits, 1(2) stop bit(s),

optional parity bit

Baud rate 300 to 19200 bit/s

Number of addressable

246

stations

Number of stations 32 (can be extended with repeater)

Length of cable and

transmitting medium

Transmittable data Configuration, parameters, operating state,

< 1200 m, with repeater maximum 4800 m, 4-wire (2

wires twisted, stranded in pairs, with static screen)

process variables, error messages

9

Page 10

General specifications

Displays Read-off angle Readable from all sides, high-contrast and lighted

Liquid Crystal Display (LCD)

Displays

3

1

⁄

2

-digit set point (reference variable) display and

3

1

⁄

2

-digit controlled variable display; bar graph displays

for deviation (i.e. error) and output variable; LED displays

for range exceeding, alarm messages when limits are

exceeded, manual operation, faults etc.;

parameter display (only in the PARAMETER level)

Configuration Permanently stored function blocks for fixed set point

control, follow-up control with or without internal/external

set point change-over, cascade control, synchro control,

ratio control, SPC control, limiting control, DDC backup

fixed set point control via binary contact

Power supply 230 V AC (200 to 250 V AC),

120 V AC (102 to 132 V AC),

24 V AC (21.5 to 26.5 V AC),

Option 24 V DC (19 to 34 V DC);

48 to 62 Hz

Power consumption Approx. 18 VA

Temperature range

0 to 50 °C (operation),

−

20 to 70 °C (shipping and storage)

Degree of

protection

Panel-mounting unit: Front IP 54, case IP 30,

terminals IP 00;

Rack-mounting unit: IP 00

Overvoltage category II

Degree of contamination 2

Conformance to European standards EN 61010, edition March 1994

Electrical

connection

Functional earthing Panel-mounting unit: On case w. Cu-flex. lead > 2.5 mm

2

Rack-mounting unit: Connector, Type F

(DIN 41 612), Cu-flex. lead > 2.5 mm

2

Power voltage and

process signals

Panel-mounting unit: Screw terminals 1.5 mm2;

Rack-mounting unit: Two connectors, Type F

(DIN 41 612), soldering or crimp types

Total delay time

3)

Approx. 100 ms

Resolution Input and output, approximately 11 bits

Dimensions See Fig. 3 and Fig. 4

Weight Panel-mounting unit, approx. 1.9 kg; rack-mounting unit, 1 kg

1)

The input board 4 (thermocouple at input 1) is no longer available

2)

Specific measuring ranges on request

3)

Depending on how many functions are configured

Technical data Description

10

Page 11

Installing the process control stations TROVIS 6412 (panel-mounting unit)

3.Installing the process control stations

3.1.TROVIS 6412 (panel-mounting unit)

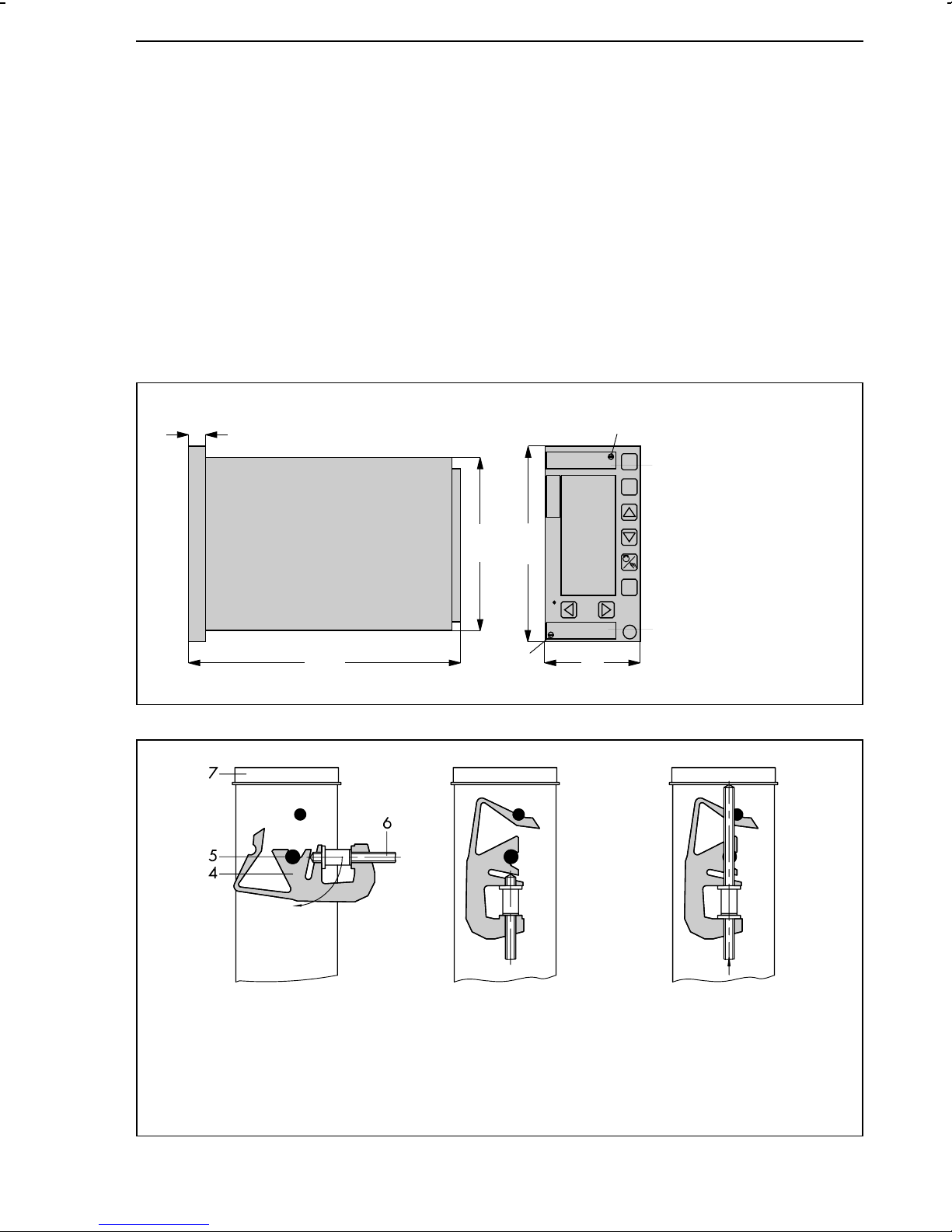

The TROVIS 6412 Process Control Station is designed for panel-mounting and has the front-frame

dimensions 72 x 144 mm. Perform the following steps in order to mount the controller:

1. Make a panel cut-out with the dimensions 68

+0.7

x 138

2. Push the process control station in the panel cut-out from the front side.

3. Install one supplied mounting bracket, both on the top and bottom of the control station

following steps 1) and 2) shown in Fig. 2 .

4. Turn the threaded rods in the direction of the control panel, using a screwdriver so that the

case is clamped against the panel ((step 3), Fig. 2 ).

16.5

(0.65)

+1.0

2

mm.

1

226

(8.90)

Fig. 3 ⋅ Dimensions (panel-mounting unit)

137.5

(5.41)

144

(5.67)

2

72

(2.83)

1

1 Label

2Screws

1) Insert on pin

(pivot) and turn

Fig. 2 ⋅ Installation (panel-mounting unit)

2) Click into

place

3) Screw tight

4 Mounting bracket

5Pin

6 Threaded rods

7 Front-panel bezel

11

Page 12

TROVIS 6442 (rack-mounting unit for 19inch racks) Installing the process control stations

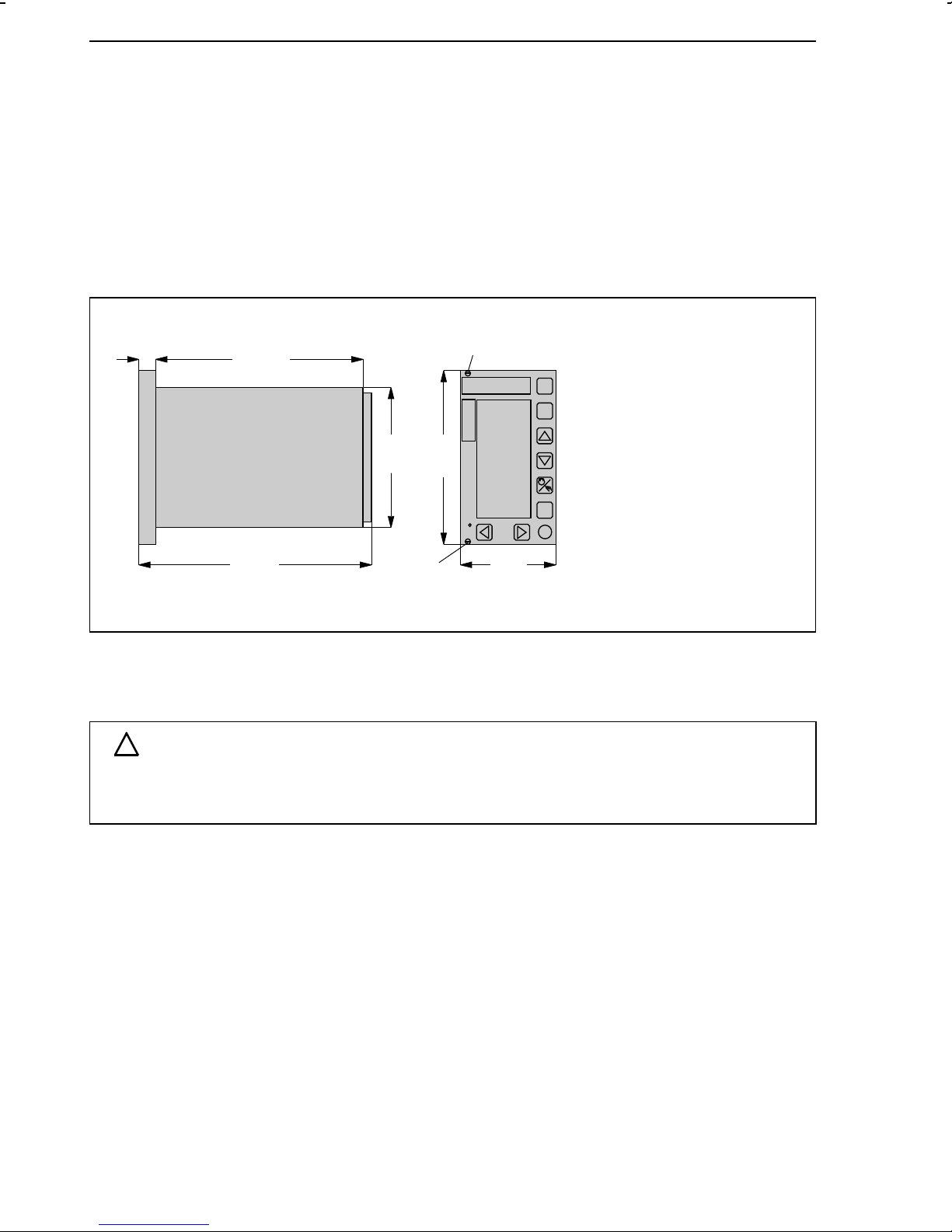

3.2.TROVIS 6442 (rack-mounting unit for 19inch racks)

The TROVIS 6442 Process Control Station is a rack-mounting unit designed for mounting in

19inch racks. It has to be installed as follows:

1. Push the control station along the guiding rails into the corresponding rack unit, making

sure it does not become tilted. Push until the connectors connect.

2. Secure the process control station to the rack unit by fastening it from the front, using two

screws (see 1, Fig. 4 ).

3 Press one protective nipple (enclosed in the delivery) into each bore made for the screws.

14.5

(0.57)

Fig. 4 ⋅ Dimensions of the 19inch rack-mounting unit

162.5

(6.40)

190

(7.48)

100

(3.94)

128.5

(5.06)

1

1

70.5

(14 HP)

(2.77)

1Screw with

protective nipple

3.3.Opening the controller case

ATTENTION!

!

The case may only be opened by experienced personnel when the power to the process

control station has been cut off!

Re-jumpering (see section 4.) or retrofitting the process control station with an interface board

requires that the case be opened as follows:

1. With panel-mounting cases, remove small paper labels (see 1, Fig. 3 ) if necessary. With

19inch rack-mounting units, remove the two protective nipples. Unscrew the two screws

located on the front-panel of the case (see Fig. 3 or Fig. 4 , depending on the type of

case).

2. Withdraw controller section towards the front. Then, proceed as described for the

respective PCB to be modified.

12

Page 13

Installing the process control stations Opening the controller case

Modify input (5, Fig. 5 ) or/ and interface board (6, Fig. 5 ):

3. Unscrew the four screws (1, 2) and remove the two distance bolts (4).

4. Carefully withdraw the input and/or interface board from the case.

5. Modify the board as desired (see sections 4.1., 4.4.).

6. Carefully reinstall the interface or/and input board by plugging it/them into the associated

connectors. Make sure the connections are made correctly! Terminals 1 and 21 of each

connector are marked.

7. Reinstall the two distance bolts (3) and the four screws (1, 2).

Proceed as described under 8. to 10.

Modify the logic board (7, Fig. 5 ) as follows:

3. Unscrew the two screws (1).

4. Remove cover plate (3).

5. Modify the board as desired (s. sections 4.2. and 4.3.).

6. Reinstall cover plate, making sure that its curved part bends towards the outside.

7. Reinstall the two screws (1).

Proceed as described under 8. to 10.

8. Record any modifications made on the label located on the cover plate. With panel-mounting units, additionally mark modifications on the label on the outside case wall!

9. Insert controller section and fasten it with the two associated screws.

10. If necessary, reinsert small labels and protective nipple on the front-panel of the control

station.

4

4

2

1

1Screws

2Screws

3 Cover plates

4 Distance bolts

5Input board

6Interface board

7Logic board

8 Power supply board

9 Case section (only

panel-mount. unit)

Fig. 5 ⋅ Location of the boards in the controller case

13

Page 14

Determining the input signals Soldering jumpers

4.Soldering jumpers

ATTENTION!

!

The soldering jumpers may only be modified by experienced personnel when the power

to the process control station has been cut off!

Several functions of the process control station are determined by means of soldering jumpers.

Open the case as described in section 3.3. to modify the jumpers. The soldering jumpers are

marked on the soldering sides of the PCBs.

4.1.Determining the input signals

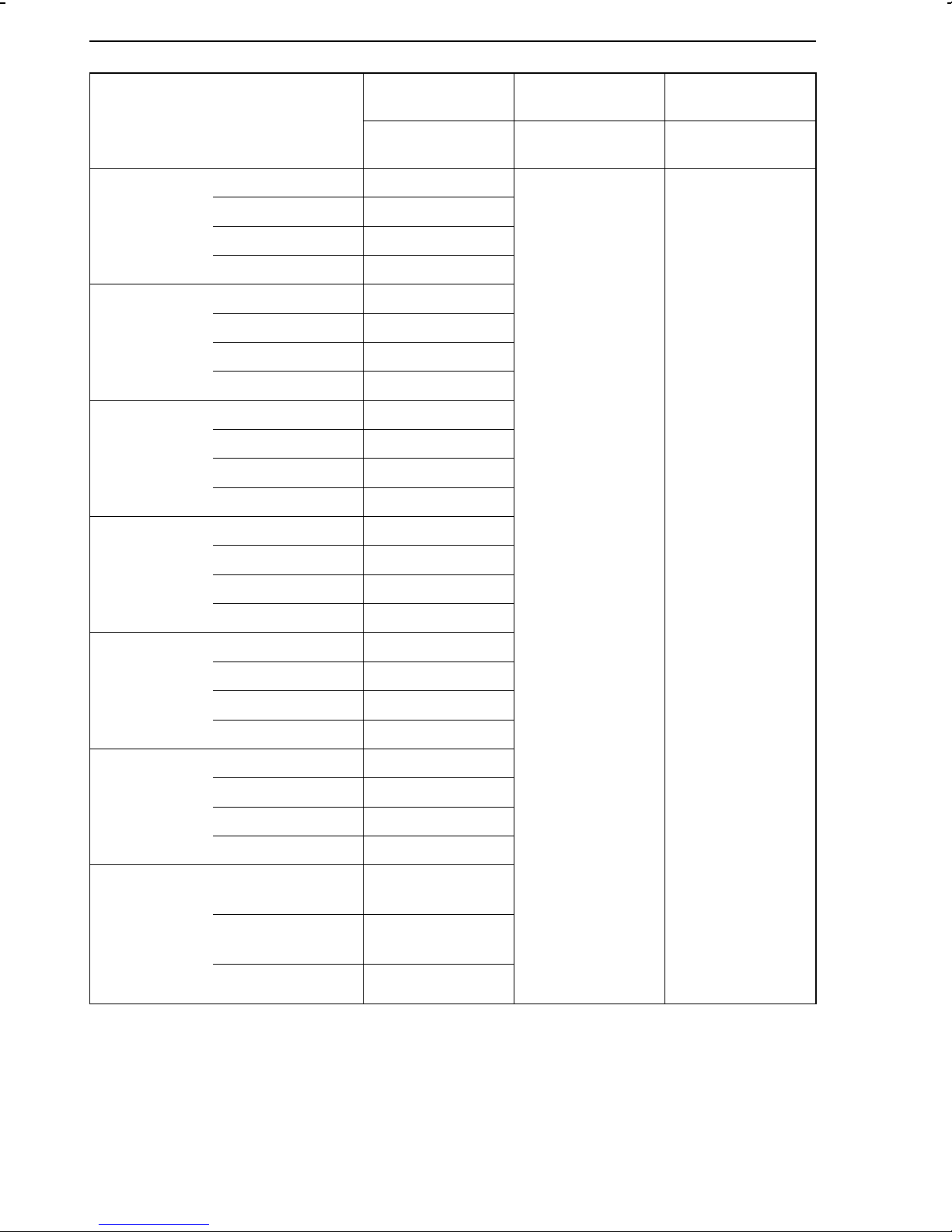

4.1.1.Input board 1 (IB1)

Note: Select the desired input signal and close the related soldering jumpers listed in line 3 or the following

ones of the table below (depending on type of signal selected)! Open all remaining jumpers associated with

the corresponding input (line 2)! See Fig. 5 for the location of the input board.

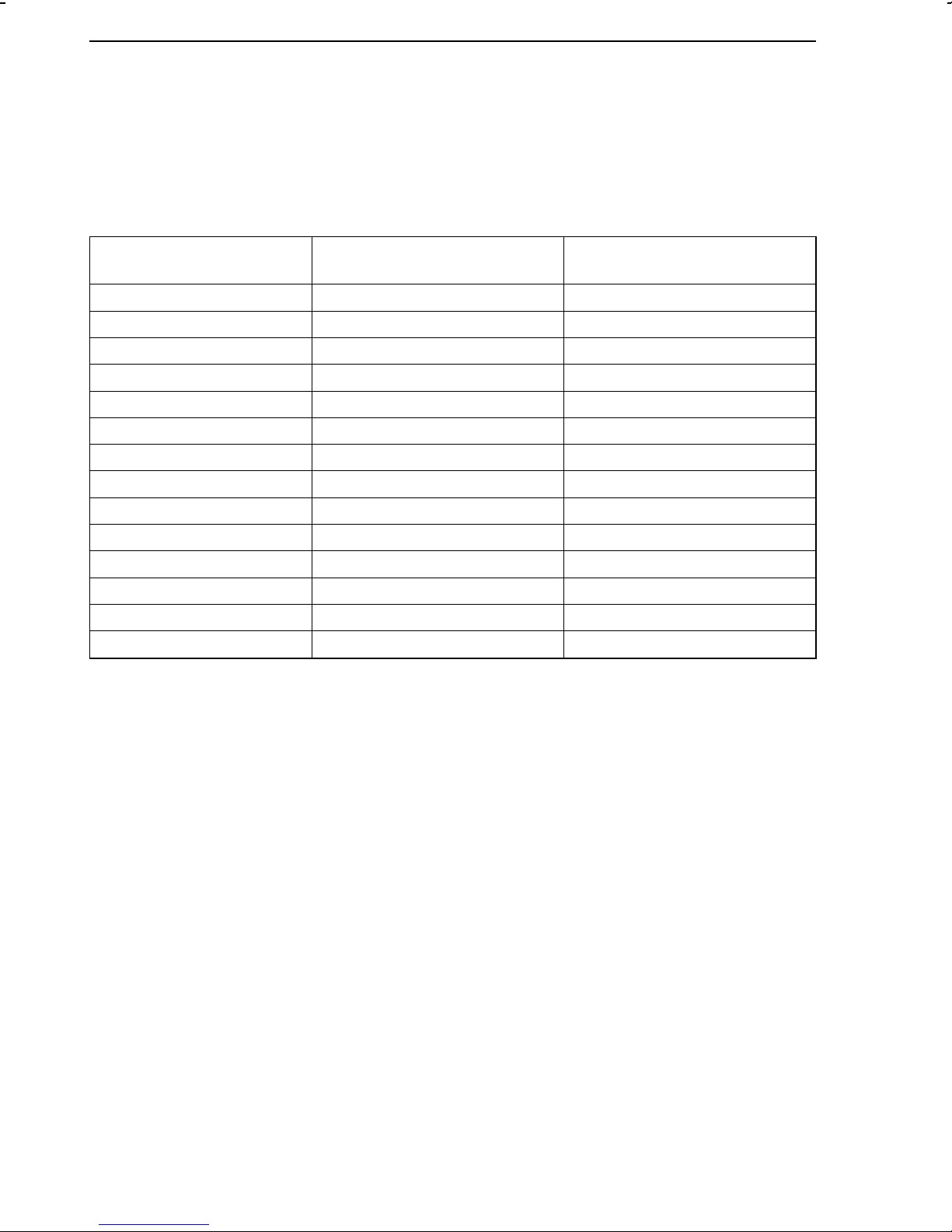

Input signal Input 1

(Ai 1)

Jumpers:

10 to 19

Current 0 to 20 mA 11 21 31 41, 45

4 to 20 mA 11, 14 21, 24 31, 34 41, 44, 45

−20 to 20 mA

Voltage 0 to 1 V11213141

0 to 5 V 12 22 32 42

0 to 10 V 13 23 33 43

0.2 to 1 V 11, 14 21, 24 31, 34 41, 44

1 to 5 V 12, 14 22, 24 32, 34 42, 44

2 to 10 V 13, 14 23, 24 33, 34 43, 44

Potentiometer

0 to 1kΩ

11, 15, 16 21, 25, 26

12, 17, 18

Input 2

(Ai 2)

Jumpers:

20 to 26

−−

Input 3

(Ai 3)

Jumpers:

31 to 34

−−

Input 4

(Ai 4)

Jumpers:

41 to 47

42, 46, 47

Transmitter supply 10, 11, 14, 19

Soldering jumpers associated with the binary inputs for all input boards:

Switching contact 50, 51 60, 61 70, 71

External switching voltage Jumpers mentioned above are open

14

Binary input 1 (bi 1)

Jumpers

20, 21, 24

Binary input 2 (bi 2)

Jumpers

−−

Binary input 3 (bi 3)

Jumpers

Page 15

Soldering jumpers Determining the input signals

4.1.2.Input board 2 (IB 2)

Note: Select the desired input signal and close the related soldering jumpers listed in line 3 or the following

ones of the table below (depending on type of signal selected)! Open all remaining jumpers associated with

the corresponding input (line 2)! See Fig. 5 for the location of the input board. The soldering jumpers

associated with the binary inputs are described in section 4.1.1., page 14

Input signal Input 1

(Ai 1)

Input 2

(Ai 2)

Input 3

(Ai 3)

Input 4

(Ai 4)

Jumpers:

10 to 19

Current 0 to 20 mA

Jumpers:

20 to 26

Jumpers:

30 to 34

Jumpers:

41 to 47

21 31 41, 45

4 to 20 mA 21, 24 31, 34 41, 44, 45

−20 to 20 mA

21, 25, 26

−−

Voltage 0 to 1 V 213141

0 to 5 V 22 32 42

0 to 10 V 23 33 43

−

0.2 to 1 V 21, 24 31, 34 41, 44

1 to 5 V 22, 24 32, 34 42, 44

2 to 10 V 23, 24 33, 34 43, 44

Potentiometer

Transmitter supply

0 to 1kΩ−−

20, 21, 24

30, 31, 34

42, 46, 47

−

Pt 100 2 /3-wire 4-wire

10, 12, 13,

2)

15, X

Measuring

ranges

1)

−50 to 100 °C

0 to 200 °C

100 to 600 °C

1)

Select one measuring range and the corresponding soldering jumper. In the PA level, adjust the

measuring range by means of the parameters GWK

2)

For specific measuring ranges (on request), soldering jumper X must be open and soldering jum-

11, 14, 16,

2)

X

1)

19

1)

18

1)

17

and GWK1 .

1

−

per 17 must be closed.

15

Page 16

Determining the input signals Soldering jumpers

4.1.3.Input board 3 (IB 3)

Note: Select the desired input signal and close the related soldering jumpers listed in line 3 or the following

ones of the table below (depending on type of signal selected)! Open all remaining jumpers associated with

the corresponding input (line 2)! See Fig. 5 for the location of the input board. The soldering jumpers

associated with the binary inputs are described in section 4.1.1., page 14.

Input signal Input 1

(Ai 1)

Input 2

(Ai 2)

Input 4

(Ai 4)

Current 0 to 20 mA

4 to 20 mA 41, 44, 45

Jumpers:

10 to 19

−−

Jumpers:

20 to 29

Jumpers:

41 to 47

41, 45

−20 to 20 mA −

Voltage 0 to 1 V 41

0 to 5 V 42

0 to 10 V 43

0.2 to 1 V 41, 44

1 to 5 V 42, 44

2 to 10 V 43, 44

Potentiometer

0 to 1kΩ

42, 46, 47

Transmitter supply 40, 41, 44,

45, 48

Pt 100 2 /3-wire 4-wire 2 /3-wire 4-wire

10, 12, 13,

3)

15, X

Measuring

ranges

−50 to 100 °C

0 to 200 °C

100 to 600 °C

1)

Select one measuring range and the corresponding soldering jumper. In the Pa level, adjust the

measuring range by means of the parameters GWK

2)

Select one measuring range and the corresponding soldering jumper. In the PA level, adjust the

measuring range by means of the parameters GWK

3)

For specific measuring ranges (on request), soldering jumper X must be open and soldering jum-

19

18

17

1)

1)

1)

11, 14,

16, X

1

2

20, 22, 23,

3)

25, XX

and GWK1 .

and GWK2 .

21,24,

4)

29

28

27

26,

4)

XX

2)

2)

2)

−

per 17 must be closed.

4)

For specific measuring ranges (on request), soldering jumper XX must be open and soldering jumper 27 must be closed.

16

Page 17

4.1.4.Input board 4 (IB 4)

Input board 4 is no longer available.

Note: Select the desired input signal and close the related soldering jumpers listed in line 3 or the following

ones of the table below (depending on type of signal selected)! Open all remaining jumpers associated with

the corresponding input (line 2). See Fig. 5 for the location of the input board. The soldering jumpers

associated with the binary inputs are described in section 4.1.1., page 14.

Input signal

Input 1

(Ai 1)

Input 2

(Ai 2)

Input 3/4

(Ai 3/4)

Jumpers:

10 to 19

Jumpers:

20 to 26

Jumpers:

41 to 47

Current 0 to 20 mA

−

21 41, 45

4 to 20 mA 21, 24 41, 44, 45

−

20 to 20 mA

21, 25, 26

−

Voltage 0 to 1 V 21 41

0 to 5 V 22 42

0 to 10 V 23 43

0.2 to 1 V 21, 24 41, 44

1 to 5 V 22, 24 42, 44

2 to 10 V 23, 24 43, 44

0 to 50 mV 17

−−

0 to 100 mV 16

−

50 to 50 mV

15

−

100 to 100 mV

14

Potentiometer

0 to 1k

Ω− −

42, 46, 47

Transmitter supply

−

20, 21, 24, 29

40, 41, 44, 45, 49

Thermocouples

Type U

0 to 200 °C

17

−−

150 to 400 °C

16

300 to 600 °C

15

0 to 600 °C

14

Type R

0 to 700 °C

17

500 to 1200 °C

16

1000 to 1700 °C

15

0 to 1700 °C

14

Type T

0 to 150 °C

17

100 to 250 °C

16

200 to 400 °C

15

0 to 400 °C

14

Soldering jumpers Determining the input signals

17

Page 18

Determining the input signals Soldering jumpers

Input signal Input 1

(Ai 1)

Jumpers:

10 to 19

Type S

Type L

Type B

Type J

0 to 700 °C

500 to 1200 °C

1000 to 1700 °C

0 to 1700 °C

0 to 350 °C

250 to 600 °C

500 to 900 °C

0 to 900 °C

200 to 1200 °C

1000 to 1500 °C

1300 to 1800 °C

200 to 1800 °C

0 to 400 °C

350 to 800 °C

17

16

15

14

17

16

15

14

17

16

15

14

17

16

Input 2

(Ai 2)

Jumpers:

20 to 26

Input 3/4

(Ai 3/4)

Jumpers:

41 to 47

−−

Type E

Type K

Reference

junction

temperature

for external

reference

junction

700 to 1200 °C

0 to 1200 °C

0 to 400 °C

300 to 700 °C

600 to 1000 °C

0 to 1000 °C

0 to 500

°C

400 to 900 °C

800 to 1300 °C

0 to 1300 °C

0 °C

20 °C

50 °C

15

14

17

16

15

14

17

16

15

14

11

12

13

18

Page 19

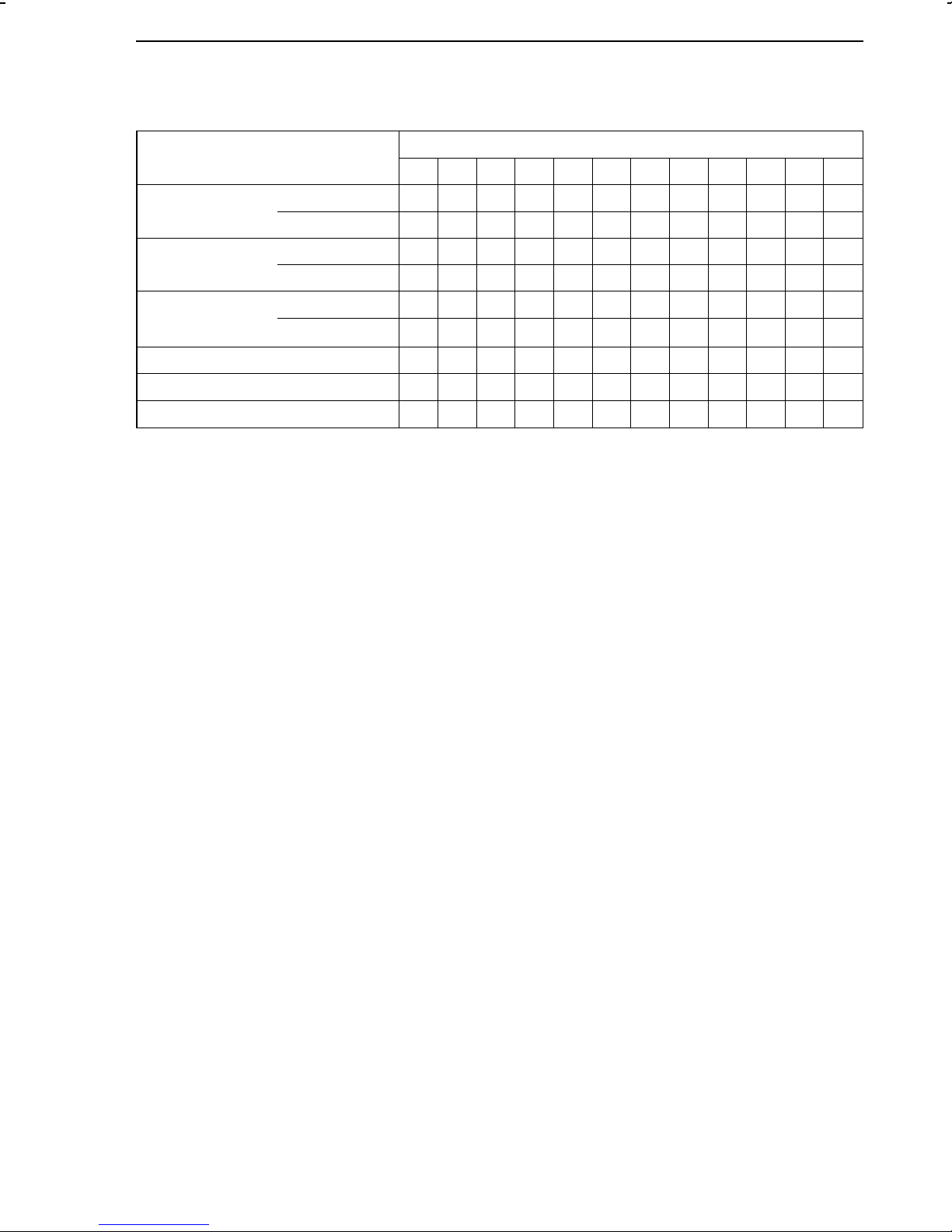

Soldering jumpers Soldering jumpers on the logic board

4.2.Soldering jumpers on the logic board

See Fig. 5 for the location of the logic board

Soldering jumper: X closed, 0 open

11 13 21 23 31 33 37 38 SZ LB 1 LB 2 LB 3

Continuous

control output Y1

Continuous

control output Y2

Analog output

Ao1

Operation with code number X

Operation with interface X X X

0(4) to 20 mA X 0

0(2) to 10 V 0 X

0(4) to 20 mA X 0

0(2) to 10 V 0 X

0(4) to 20 mA X 0 X 0

−10 to 10 V

0(2) to 10 V 0 X X 0

0X0X

4.3.Soldering jumper for implementing the code number

The CONFIGURATION level and the PARAMETER level can be protected against unauthorized

use by means of code numbers. To activate this function, the soldering jumper SZ located on

the logic board must be closed (see table in section 4.2.). This jumper SZ is open when the

controller is delivered, meaning that the configuration and parameter data of the process

control station can be modified without having to enter a corresponding code number.

Refer to section 6.10 and 6.11 on how to define the code numbers for CONFIGURATION level

and the PARAMETER level.

19

Page 20

Soldering jumpers on the interface board Soldering jumpers

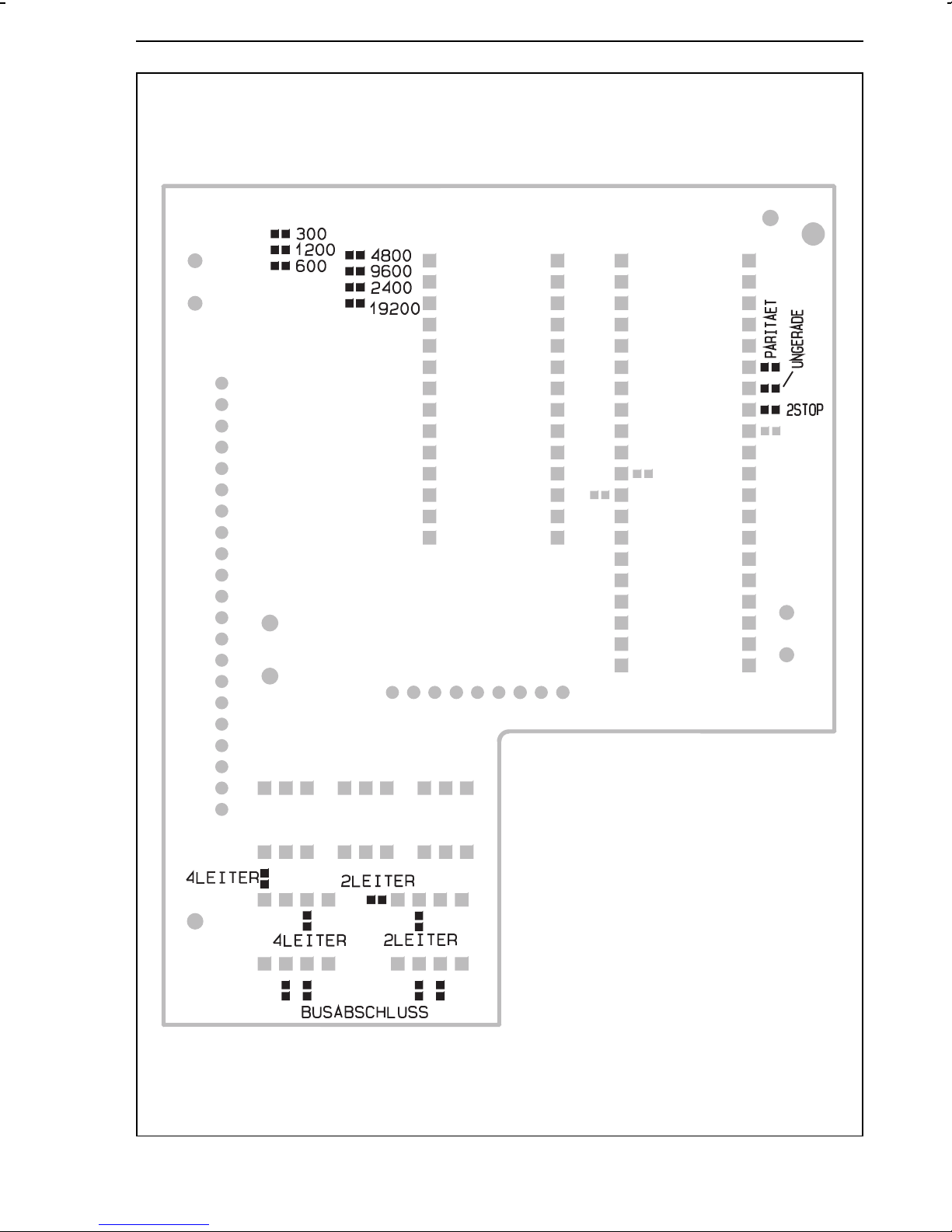

4.4.Soldering jumpers on the interface board

See. Fig. 5 for the location of the interface board and Fig. 6 for the location of the soldering

jumpers.

Important! In the interface mode, the soldering jumpers LB1, LB2 and LB3 on the logic board

must also be closed (see section 4.2., page 19). This must be observed when retrofitting the

process control station with the interface board.

Soldering jumper (LB) Default setting:

X closed, 0 open

Enable parity bit PARITAET 0

Parity odd UNGERADE 0

2 stop bits RES 0

Baud rate Modbus Select a soldering jumper

300 bit/s 300 0

600 bit/s 600 0

1200 bit/s 1200 0

2400 bit/s 2400 0

4800 bit/s 4800 0

9600 bit/s 9600 X

19200 bit/s 19200 0

Termination BUSABSCHLUSS (4 LBs) 0

Two-wire mode 2LEITER (2 LBs) 0

Four-wire mode 4LEITER (2 LBs) X

20

Page 21

Soldering jumpers Soldering jumpers on the interface board

Fig. 6 ⋅ Location of the soldering jumpers on the interface board

21

Page 22

TROVIS 6412 (panel-mounting unit) Electrical connections

5.Electrical connections

When making the electrical connections, note the VDE 0100 regulations and the regulations

valid in the country where the control station is intended to be installed.

Use shielded cables for the signal lines of the analog and binary inputs, which are installed

outside the control cabinets, in order to avoid measuring errors or other interferences. Inside

the control cabinets, these lines have to be installed separately from the control and power

supply lines.

The shieldings of the lines are to be grounded on one side at the neutral point of the measuring

and control system.

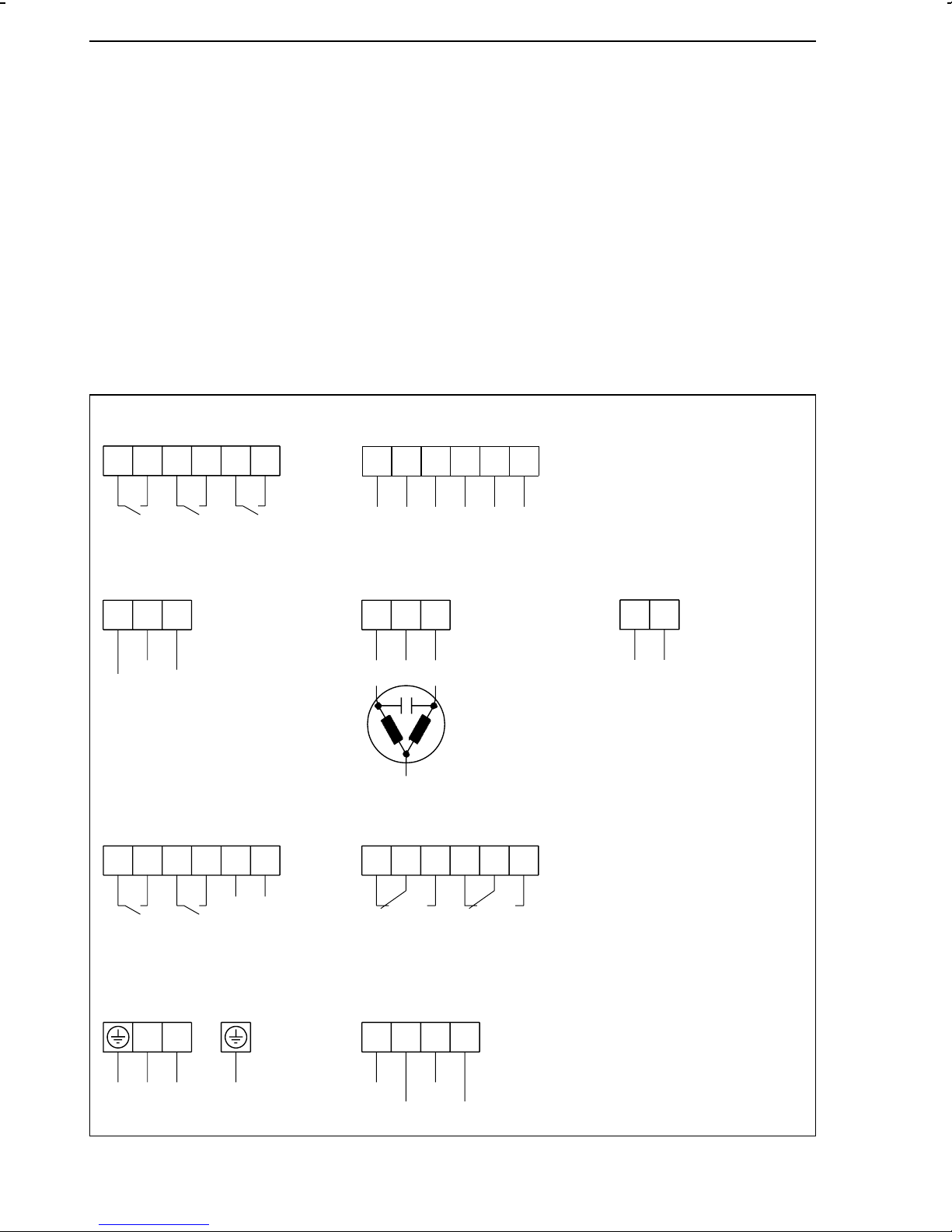

5.1.TROVIS 6412 (panel-mounting unit)

The device has plug-in terminals for wires with cross-sections of 0.5 to 1.5 mm2 (DIN 45 140).

Binary inputs

Switching contact External switching voltage

81 82

bi 1

83

bi 2

84

85

bi 3

86

81 82

+

bi 1

83

84

+

–

–

bi 2

85

+

86

–

bi 3

Continuous control outputs Switching output Analog output

33

32

31

0

Y2

1)

Y1

Binary outputs Limit relay

88 89

87

1)

bo 1

bo 2

90

91

92

+

1)

–

bo 3

47 48

–

41

49

+

L1

N

1)

43

42

G1 G2

51

52

53

34 35

–

Ao 1

1),2)

1)

+

Optional equipment

Power supply Serial interface RS-485

N

L

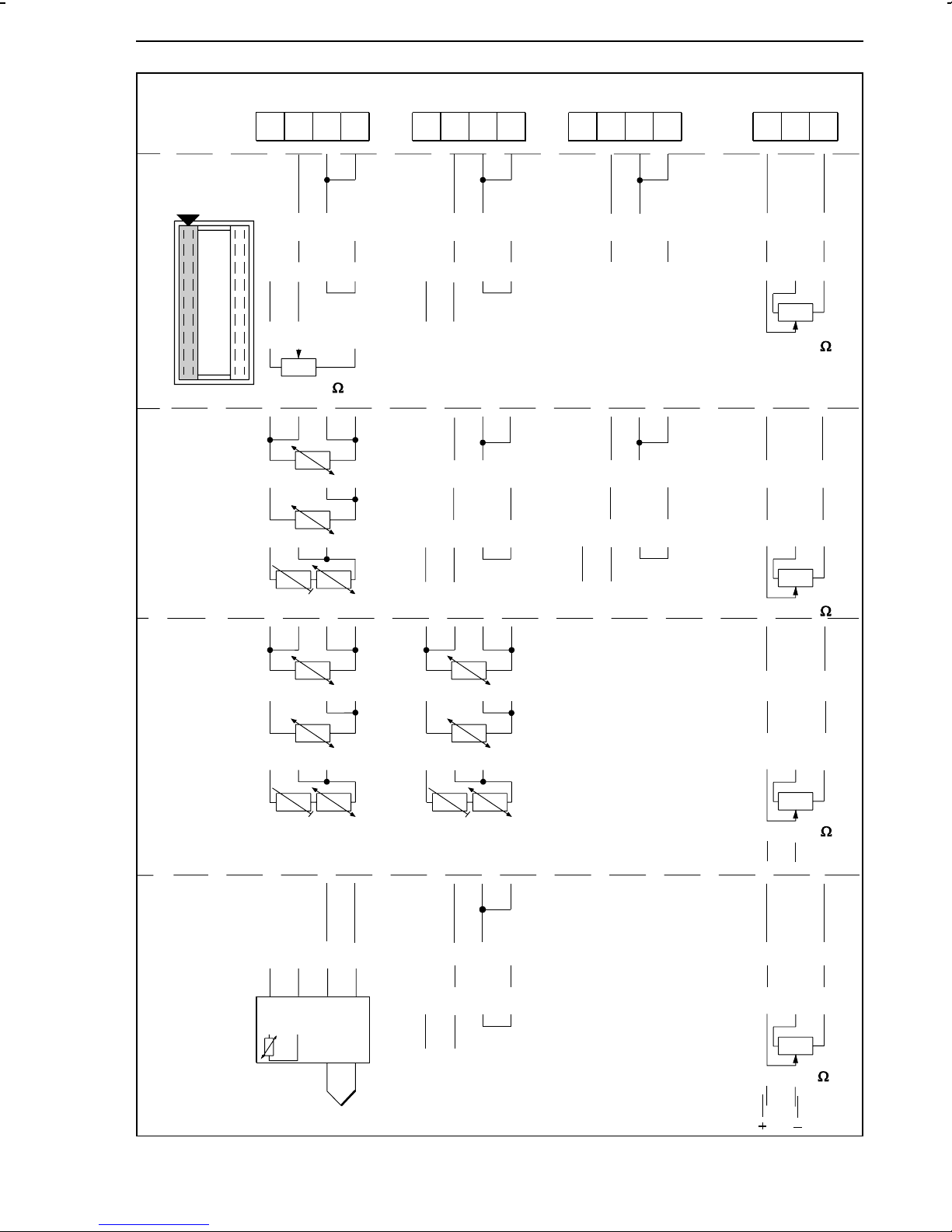

Fig. 7 ⋅ Terminal assignment of TROVIS 6412

22

96

T(A)

97

T(B)

98

R(B)

99

R(A)

2)

For 2-wire bus

Terminals 96 and 97

Page 23

Electrical connections TROVIS 6412 (panel-mounting unit)

Inputs

Input

board 1

(IB 1)

Input

board 2

(IB 2)

Ai 1

–

mA

–

V

+

0...1000

13 14

15

16

+

mA

+

V

–

+

mA

+

V

11 12

+

+

2-wire transmitter 2-wire transmitter

4W

3W

Ai 2

–

+

–

–

Ai 3

18

18

17

–

–

19

+

+

+

+

mA

V

mA

V

20

21

–

–

0%

–

–

Ai 4

23

24

+

mA

+

V

0...1000

+

mA

+

V

25

–

–

–

–

Input

board 3

(IB 3)

Input

board 4

(IB 4)

With reference

junction sensor

(item no.

1070-8472)

2W

4W

3W

2W

+

Ri

Ri

–

mV source

1

2

8

7

Pt 100

Pt 100

34

+

2-wire transmitter 2-wire transmitter

Ri

+

–

mA

+

–

V

+

2-wire transmitter

–

Pt 100

–

–

+

2-wire transmitter

0%

0%

0%

0...1000

+

mA

+

V

0...1000

+

mA

+

V

0...1000

–

–

+

–

–

–

–

+

Fig. 8 ⋅ Terminal assignment of TROVIS 6412 (continued)

2-wire transmitter + −

+

–

23

Page 24

TROVIS 6442 (rack-mounting unit for 19inch racks) Electrical connections

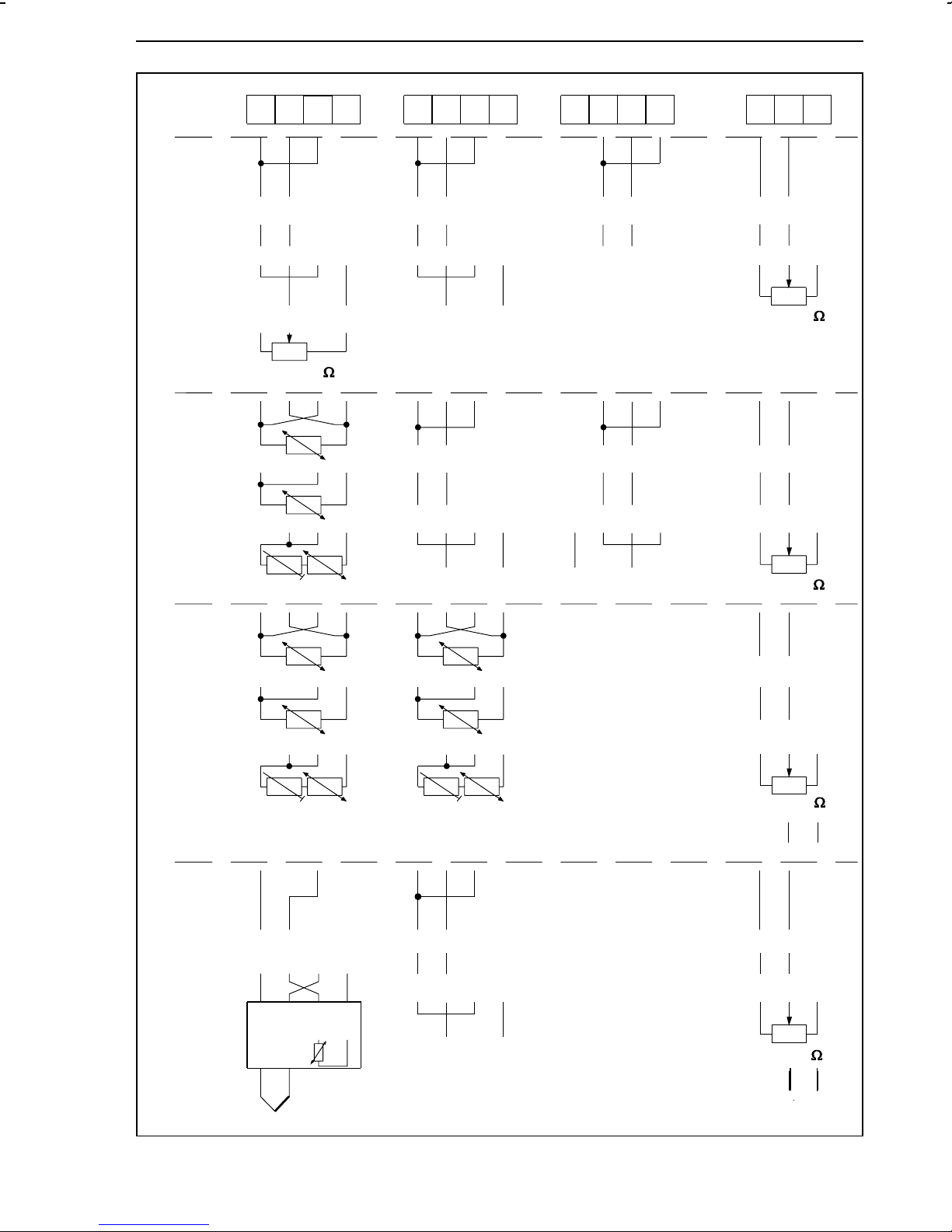

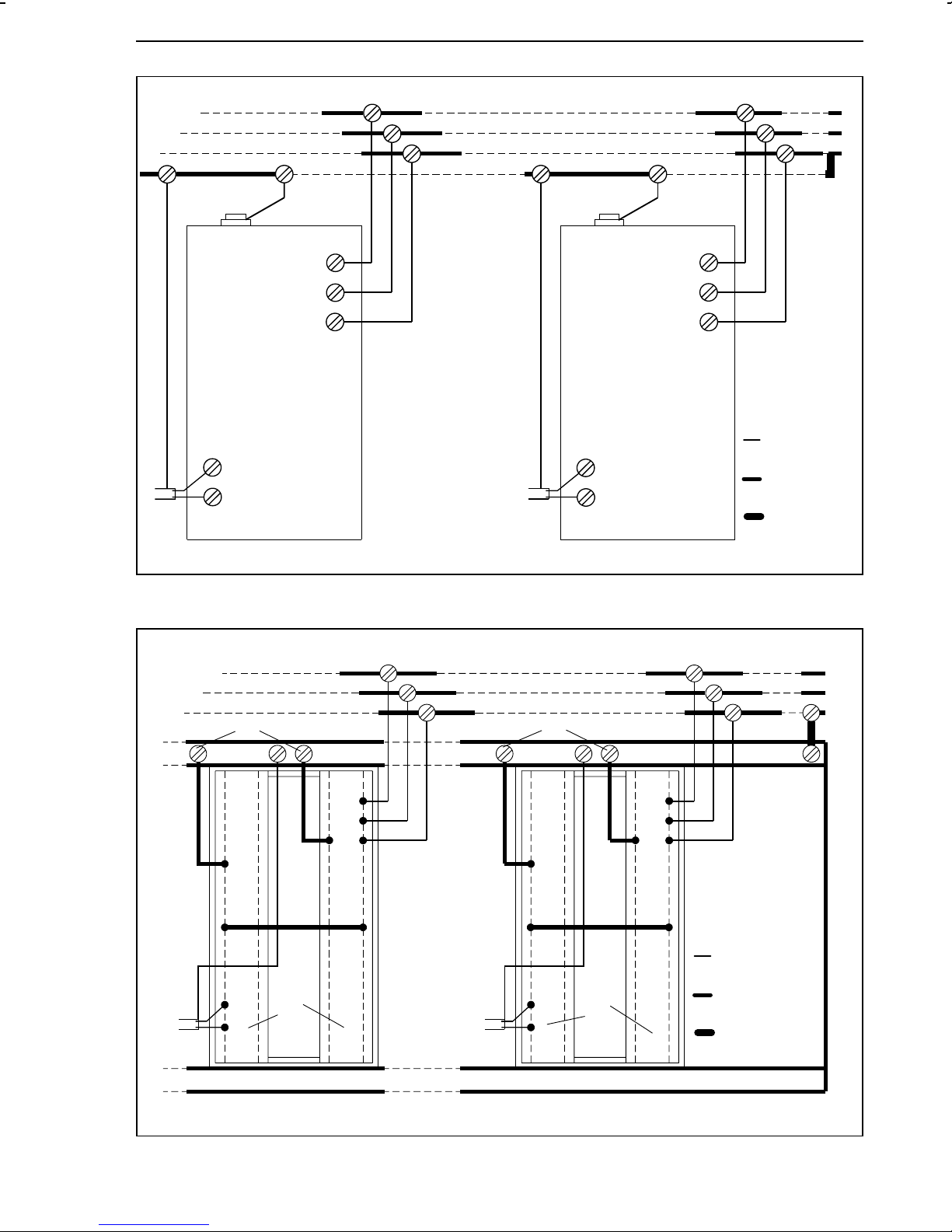

5.2.TROVIS 6442 (rack-mounting unit for 19inch racks)

The device has two plug connectors, style F (DIN 41612). The signal lines are assigned to one

of these two connectors, whereas the power supply lines are assigned to the other one, meaning

these lines are installed separately (see Fig. 9 and Fig. 10 ).

Binary inputs

Switching contact External switching voltage

d

4

2

6

8

d

10

z

16

d

4

2

6

8

d

10

z

16

bi1

bi2

bi3

+

Binary output 3 Serial interface RS-485

d

30

+

32

–

bo3

d

26

28

R(B)

R(A)

For 2-wire bus terminals

d 22 and d 24

24

T(A)

22

T(B)

bi1

2)

–

–

+

bi2

dd

18

00

+

16

Continuous control outputs Switching output Analog output

d

14 16

1)

Y1

Y2

18

–

z

810

+

L1

12

d

z

16

18

–

+

–

Ao 1

–

bi3

12

1)

Power supply Binary outputs

z

24

N

d

6

6

FE

Fig. 9 ⋅ Terminal assignment of TROVIS 6442

24

N

1)

Limit relay

zd

28

30

bo1

32

z

32

bo2

d

24 26 28

G1 G2L

1)

z

20 22 24

Page 25

Electrical connections TROVIS 6442 (rack-mounting unit for 19inch racks)

Inputs

Input

board 1 (IB 1)

Input

4W

board 2

(IB 2)

3W

Ai 1

z

–

mA

–

+

0...1000

28 26

+

V

+

32 30

–

2-wire transmitter 2-wire transmitter

z

24

Ai 2

20

22

+

–

mA

–

V

+

–

+

–

mA

–

V

18

Ai 3

z

24

14

–

+

+

–

–

–

mA

mA

12

V

V

10

+

+

+

+

Ai 4

z

6

–

–

0...1000

–

mA

–

4

2

+

+

0%

+

+

V

Input

board 3

(IB 3)

Input

board 4

(IB 4)

With reference

junction sensor

(item no.

1070-8472)

2W

4W

3W

2W

1

Ri

Ri

Pt 100

Pt 100

–

mV source

34

2

7

–

+

–

2-wire transmitter 2-wire transmitter

Pt 100

Ri

+

8

+

–

2-wire transmitter

+

–

mA

–

+

+

V

+

–

2-wire transmitter

2-wi re transmit te r

0...1000

–

–

0...1000

+

–

–

0...1000

+

0%

+

mA

+

V

0%

–

+

mA

+

V

0%

–

Fig. 10 ⋅ Terminal assignment of TROVIS 6442 (continued)

25

Page 26

Balancing the line resistance for the connection of Pt 100 sensors Electrical connections

5.3.Balancing the line resistance for the connection of Pt 100 sensors

When Pt 100 sensors are connected to the control station in a two-wire circuit, the line

resistance is to be balanced to 10 Ω at the external resistor Rj in order to avoid measuring

errors:

1. Short-circuit the line at the Pt 100 sensor or potentiometer.

2. Switch the resistor R

in the line.

j

3. Measure the resistance in the total circuit, using a suitable ohmmeter.

4. Adjust the resistor R

until the line resistance is 10 Ω.

j

In three-wire circuits, the line resistance must not be balanced. Zero and span, however, should

be checked and re-adjusted if necessary.

In four-wire circuits, balancing the line resistance is also not necessary.

5.4.Wiring technique with regard to electromagnetic compatibility

All input, output and data lines have to be run in shielded cables for reasons of electromagnetic

compatibility (EMC).

The power supply lines, as well as the protective conductors and the functional earthing line

(FE) are to be connected separately from each controller to the corresponding multi-terminal

bus bar.

With 19inch racks, a conductive connection between the functional earthing line and the rack

has to be made.

The shielded cables are to be grounded at one end (see Fig. 11 and Fig. 12 ).

26

Page 27

Electrical connections Wiring technique with regard to electromagnetic compatibility

L

N

PE

FE

L

N

PE

Controller 1 Controller n

Fig. 11 ⋅ Electrical connections for panel-mounting units

FE

N

L

PE

Cu-flex. lead

≥ 1.5 mm

Cu-flex. lead

≥ 2.5 mm

Cu-flex. lead

≥ 10 mm

2

2

2

FE

d12

d18

z2

z4

d6

z6

d18

2

1

FE

d12

d18

z2

z4

z6

d6

d18

2

1

Controller 1 Controller n

1Plug connector

Signal lines

2Plug connector

Control lines

Cu-flex. lead

≥ 1.5 mm

Cu-flex. lead

≥ 2.5 mm

Cu-flex lead

≥ 10 mm

2

2

2

L

N

PE

Fig. 12 ⋅ Electrical connections for 19inch rack-mounting units

27

Page 28

Process display and control panel elements Operation

6.Operation

This section describes how to operate the process control stations directly on the control panel.

Unfold the last page of this manual to obtain a better understanding of this description!

The process control stations are designed according to a three-level, logic operating structure:

1) OPERATING level, 2) PARAMETER level and 3) CONFIGURATION level. These levels are

described in sections 6.2. to 6.13. Depending on the selected level (mode), the visual displays

on the LCD panel and the keys assume different functions.

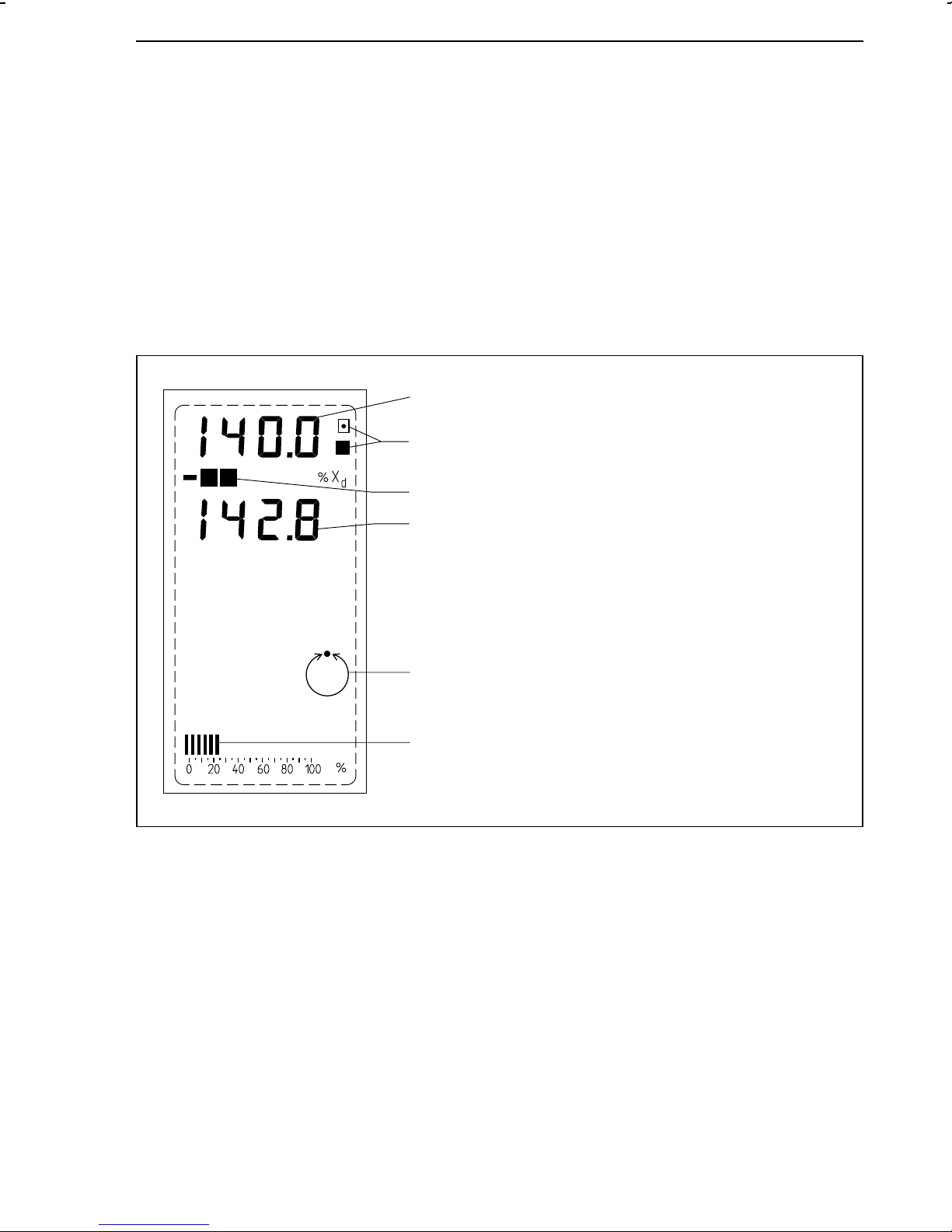

6.1.Process display and control panel elements

The process control station is operated via eight front-panel keys. The front panel also contains

a clear display field, which shows different variables and symbols, depending on the selected

operating level. Note that some parameters available in the PARAMETER and ADAPTATION

PARAMETER level can be a combination of several variables and symbols.

All process display and control panel elements are listed and explained on the last two pages

of this manual. Optional error messages are described in Appendix B .

6.2.OPERATING level

This is the standard operating level of the process control station (control mode). In this level,

the control station operates according to the pre-set control mode and the defined parameters.

The values of the set point (reference variable) (3) and the controlled variable (8) are

numerically indicated on the display panel. The control deviation (error) (7) and the output

variable (14) are represented as a percentage by means of bar graphs. In addition, a LED (19)

indicates whether the control station is in the AUTOMATIC or MANUAL mode. If the F key is

pressed, the numerical value of the output variable appears in the upper line of the display field

(3).

The OPERATING level allows the operator to modify the value of the internal set point (reference

variable), abort the restart condition option after a start-up procedure or a power supply failure

has occurred, or open the cascade when the controller is in the follow-up control mode. The

output variable can be modified manually when having changed over the process control

station to the MANUAL mode. These functions are described in the following sections.

All other levels can be accessed from the OPERATING level.

28

Page 29

Operation OPERATING level

6.2.1.Modifying the internal set point (reference variable)

In the OPERATING level, the internal set point WIN can be modified by pressing the C or D key,

provided that these keys have not been disabled in the CONFIGURATION level (C59-2 or

C59-4). Pressing the respective key briefly modifies the last digit of the indicated number by

one. The key must be held down to further advance the number. In this case, the displayed value

changes more quickly. While this modification is made, W

display. W

be configured to display other values than W

disappears after approximately 3 s. Note that the digital display field (3) can also

IN

(see configuration block C4).

IN

Pressing the C key increases the set point (reference variable).

Pressing the D key decreases the set point (reference variable).

3

16

is additionally indicated on the

IN

7

8

19

14

Fig. 13 ⋅ Display of the set point (reference variable) in the OPERATING level

3 Set point (reference variable)

7 Control deviation (error)

8 Controlled variable

14 Manipulated variable display

16 Indicator "internal set point valid"

19 AUTOMATIC mode

29

Page 30

OPERATING level Operation

6.2.2.Power supply failure

Configuration block C 43 (restart condition) defines the behaviour of the process control station

after switching on the power supply in the start-up phase or after detecting a power supply

failure (> approx. 1 s). This restart condition determines the operating mode, the set point

(reference variable) and the output variable for output Y1 or Y2.

If one of the restart conditions C43-1 to C43-6 is set, it is necessary to confirm the setting by

pressing the F key in order to return to the normal control mode. In both cases, the digital

displays for the set point and the controlled variable flash until the F key is pressed. The settings

C43-5 and C43-6 cause the process control station to remain in the MANUAL mode, even when

the F key is pressed. This is indicated by the symbol in (19).

The settings C43-7 to C43-12 must not be confirmed in order to return to the normal control

mode. The process control station automatically operates in the control mode according to the

restart conditions implemented with configuration block C 43.

The following table is a short summary of the optional restart conditions.

C43 Set point Output variable Oper. mode Press F-key Comment

-1, -2 Last active Y

-3, -4 W

-5, -6 Last active Y1K1, Y2K

-7, -8 Last active Y

-9, -10 Internal Y

-11, -12 External Y

S

, Y2K

1K1

Y1K1, Y2K

, Y2K

1K1

, Y2K

1K1

, Y2K

1K1

1

1

1

1

1

1

Automatic Yes

Automatic Yes WS overwrites W

Manual Yes

Automatic No

Automatic No

Automatic No

After pressing F,

still MANUAL mode

IN

6.2.3.Manual adjustment of the output variable

In MANUAL mode, the connected control valve can be manually moved to the desired position,

using the G and H keys, provided that these keys have not been disabled in the configuration

mode (C59-2 or C59-4). The corresponding key must be pressed until the desired output

variable is adjusted. The bar graph (13) indicates the change in the output variable. If the F key

is pressed, the numerical value of the output variable is also displayed in the digital display

field (2).

Bumpless change-over from MANUAL to AUTOMATIC mode and vice versa is carried out via

the MANUAL/AUTOMATIC key (E).

Pressing the G key increases the output variable.

Pressing the H key decreases the output variable.

30

Page 31

Page 32

PARAMETER level Operation

6.3.PARAMETER level

The control parameters can be displayed and modified in the PARAMETER level. When the

control station operates with a code number (code number mode) (see 4.3.), the parameters

can only be modified after having entered the valid code number.

Only parameters that are supported by the controller’s configuration can be displayed and

modified. All dynamic parameters (e.g.. X, W

, Z, XD, Y1, Y2), however, cannot be modified.

EX

6.3.1.Operating the PARAMETER level

See last page of this manual for the designations of the keys and displays! The process control

station is in the OPERATING level. Fig. 14 is a simplified representation of how to set a

parameter.

Accessing the PARAMETER level and displaying the parameter values

1. Press A key. I-O appears on the display.

2. Press C key. PA appears on the display.

3. Press A key. Now, the control station is in the parameter mode. The LCD panel additionally

shows the value of the currently selected parameter in the digital display field (3), the

control deviation (error) bar graph (7), the parameter table (21), and the bar graph

representing the output variable (14). The selected parameter flashes. When accessing the

PARAMETER level for the first time, the flashing parameter is always the one which was

selected last during a former modification process.

4. All parameters can be displayed by pressing the C or D key. Attention: the parameters can

be combinations of several symbols, e.g. Y

1K1

.

Modifying parameter values

1. Follow steps 1 to 3 listed under "Accessing the PARAMETER level and displaying the

parameter values".

2. Select the parameter to be modified by pressing the C or D key.

3. Press A key when the selected parameter flashes in the parameter table.

What comes up on the display now depends on whether the process control station

operates either with or without a code number.

If no code number was entered, PA flashes on the display. Hold down the A key for approx.

3 s. Continue as described under 4.

If a code number was entered, PA and flash on the display. Use the C and D keys to

set the code number in the upper line of the display (3). Then, press A key. Now the

parameter table should reappear on the display. If not, the wrong code number was

entered. Re-enter the code number, using the C and D keys or cancel by pressing the F key.

4. The selected parameter and PA flash on the display. Now a new parameter value can be

set by pressing the C and D keys. Then, press A key to accept.

5. Select next parameter with the C and D keys. Press A key, and modify them as described

under 4.

Exiting the PARAMETER level

1. Press F key.

The process control station returns to the OPERATING level.

32

Page 33

Operation PARAMETER level

Fig. 14 ⋅ Simplified parameter setting diagram

…

keys

33

Page 34

PARAMETER level Operation

6.3.2.Example how to modify a parameter

This section describes how to modify a parameter, using KP as an example. All other parameters

have to be modified accordingly.

Fig. 15

The process control station is in the standard

operating mode and the display is, for example as shown in Fig. 15 .

Fig. 16

Press A key. I-O comes up on the display.

Fig. 15 Fig. 16

Fig. 17 Fig. 18

Fig. 19 Fig. 20

Fig. 17

Press C key. PA appears on the display.

Fig. 18

Press A key. The LCD panel shows, for example this display. The parameter which was

changed last (here T

) flashes.

N

Fig. 19

Press C or D key several times until K

(only K

!). The valid KP value, here 1.8, is

P

flashes

P

displayed in the upper line of the display.

Fig. 20

Press A key.

If no code number was entered (factory default) PA flashes on the display. Hold down

the A key for approximately 3 s.

If a code number was entered (not shown in

this figure), PA and flash. Use C and D

keys to set the code number in the upper line

of the display (3). Then, press A key.

34

Page 35

Operation PARAMETER level

Fig. 21

K

and PA flash.

P

Enter new K

value by pressing the C and D

P

keys (in this example, 3.2).

Fig. 22

Press A key to accept.

The new K

Fig. 21 Fig. 22

value is stored. Only K

P

flashes.

P

Fig. 23

Press F key.

The process control station has returned to the

OPERATING level.

Fig. 23

35

Page 36

CONFIGURATION level Operation

6.4.CONFIGURATION level

The configuration blocks can be displayed and modified in the CONFIGURATION level. When

the control station operates with a code number (code number mode), the configuration blocks

can only be modified after having entered the valid code number. Configuration blocks

determine the control functions. These blocks and the associated functions are described in more

detail in Configuration manual KH 6412 E.

The configuration blocks are designated C1 to C59. The control mode selected determines

which configuration blocks are relevant. Only these blocks can be displayed and modified.

6.4.1.Operating the CONFIGURATION level

See last page of this manual for the designations of the keys and displays! Operation of this

CONFIGURATION level is described, starting from the OPERATING level. Fig. 24 is a simplified

representation of how to set a configuration block.

Accessing the CONFIGURATION level and displaying the configuration blocks

1. Press A key. I-O appears on the display.

2. Press C key several times until CO appears on the display.

3. Press A key. Now, the upper line of the display shows the setting of the configuration block

(e.g. - 1), and the associated designation of this block (e.g. C 1) is indicated in the lower

line of the display. When accessing the CONFIGURATION level for the first time, the

display always shows the configuration block which was viewed or modified last.

4. The individual configuration blocks can be viewed by pressing the C or D key.

Modifying configuration blocks

1. Follow steps 1 to 3 listed under "Accessing the CONFIGURATION level and displaying the

configuration blocks".

2. Select the configuration block to be modified by pressing the C or D key.

3. Press A key.

What comes up on the display now depends on whether the process control station

operates either with or without a code number.

If no code number was entered, CO flashes on the display. Hold down the A key for

approx. 3 s. Continue as described under 4.

If a code number was entered, CO and flash on the display. Use the C and D keys to

set the code number in the upper digital display field (3). Then, press A key. Should CO

and still flash on the display, the wrong code number was entered. Re-enter the code

number or exit the CONFIGURATION level as described below.

4. C and − flash on the display.

5. Select new value for the configuration block, using the C and D keys. Then, press A key to accept.

6. Select other configuration block with the C and D keys. Press A key. Continue as described

under 5. or exit the CONFIGURATION level.

Exiting the CONFIGURATION level

1. Press F key.

After having modified the configuration blocks, the control station returns to the OPERATING level and is in the MANUAL mode.

36

Page 37

Operation CONFIGURATION level

Fig. 24 ⋅ Simplified configuration diagram

…

keys

37

Page 38

CONFIGURATION level Operation

6.4.2.Example how to modify a configuration block

This section describes how to modify a configuration block, using C5 (configuration of controller

outputs) as an example. All other configuration blocks have to be modified accordingly.

Fig. 25

The process control station is in the standard

operating mode and the display is, for example as shown in Fig. 25 .

Fig. 26

Press A key. I-O comes up on the display.

Fig. 25 Fig. 26

Fig. 27 Fig. 28

Fig. 29 Fig. 30

Fig. 27

Press C key twice. CO appears on the display.

Fig. 28

Press A key. The configuration block modified

last and its setting are displayed (here C 8

and -1).

Fig. 29

Press C or D several times until C 5 is displayed. The valid setting for C 5 (here - 2) is

shown in the upper line of the display.

Fig. 30

Press A key.

If no code number was entered (factory default) CO flashes on the display. Hold down

the A key for approximately 3 s.

If a code number was entered (not shown in

this figure), CO and flash. Use C and D

keys to set the code number in the upper line

of the display (3). Then, press A key.

38

Page 39

Operation CONFIGURATION level

Fig. 31

C and - flash.

Select new setting for C 5 by pressing the C

and D keys (in this example 7).

Fig. 32

Press A key to accept.

The new setting C 5-7 is stored. The display

stops flashing.

Fig. 31 Fig. 32

Fig. 33

Press F key.

The process control station has returned to the

OPERATING level and is in the MANUAL

mode.

Fig. 33

39

Page 40

I-O level (displaying all input and output variables) Operation

6.5.I-O level (displaying all input and output variables)

In the I-O level (Input-Output), all input and output signals of the process control station, except

of bo3, can be displayed as absolute values.

This level is also used to check the software assignment of the respective analog inputs to an

internal signal.

Accessing the I-O level

The process control station is in the OPERATING level.

1. Press A key. I-O appears on the display.

2. Press A key to open the I-O level. "in 1" for analog input 1 comes up on the display.

3. Press C key to display other inputs and outputs.

By pressing the D key, it is possible to go through the displays in a reverse order.

Exiting the I-O level

1. Press F key.

The process control station returns to the OPERATING level.

6.6.Si level (setting the RS-485 interface)

The station number (Stn), the timeout period information (tiF), the status timeout period

information (tiF on/oFF) and the status of the RS-485 interface (Si on/oFF) are defined in this

level. For further details, see section 9.1., p. 60.

Accessing the Si level

The process control station is in the OPERATING level.

1. Press A key. I-O appears on the display.

2. Press C several times until Si appears on the display.

3. Press A key. Si is indicated in the lower line of the display and the status of the RS-485

interface is shown in the upper line of the display (on or oFF).

4. Press A key.

What comes up on the display now depends on whether the process control station

operates either with or without code number.

If no code number was entered, Si flashes on the display. Hold down the A key for approx.

3 s. Continue as described under 5.

If a code number was entered, CO and flash on the display. Use C and D keys to set

the code number in the upper line of the display (3). Then, press A key. Should CO and

still flash, the wrong code number was entered. Re-enter the code number or leave the

Si level as described below.

5. The Si level is open. Stn (for station number) comes up in the lower line of the display and

the entered number is indicated in the upper line of the display.

6. The parameters of the Si level can be viewed by pressing the C or D key.

40

Page 41

Operation Ai level (adjustment and calibration)

Modifying parameters in the Si level

1. Access the Si level as described above.

2. Select a parameter (Stn, TiF, TiF on/oFF, Si on/oFF) by pressing either the C or D key .

3. Press A key. The parameter flashes.

4. Modify setting or value, using the C or D key. Then, press A key to accept.

5. If an other parameter is to be modified, continue as described under 2.

Proceed as described below to exit the Si level.

Exiting the Si level

1. Press F key.

The process control station returns to the OPERATING level.

6.7.Ai level (adjustment and calibration)

This level is used to display the inputs Ai 1 to Ai 4 as standardized values.

When setting configuration block C14-2, the user can adjust zero and span for inputs Ai 1 to

Ai 4 or calibrate the input characteristic via 5 coordinates. This calibration procedure can

compensate for small non-linearities in the measurement of the connected transmitters. The span

can be calibrated for the controller outputs Y1 and Y2 and the analog output Ao 1.

The zero adjustment range is ±3 %, the span adjustment range is ±6 %.

Accessing the Ai level

The process control station is in the OPERATING level.

1. Press A key. I-O appears on the display.

2. Press C key several times until Ai appears on the display.

3. Press A key. Ai 1 appears in the lower line of the display, and the associated value is

indicated in the upper line of the display.

Exiting the Ai level

1. Press F key.

The process control station returns to the OPERATING level.

Displaying the analog inputs Ai 1 to 4 as standardized values

1. Access the Ai level as described above.

2. Select an input Ai 1 to Ai 4, using the C key. The associated value is indicated in the upper

line of the display.

3. Exit the Ai level as described above.

Requirements for calibration

In principle, the soldering jumpers used to define the inputs and outputs are assumed to be set

as required for the respective application (see section 4., p.14).

In addition, the following steps have to be carried out:

1. Set C14-2 in the CONFIGURATION level (see section 6.4., p. 36).

2. Press F key to exit the CONFIGURATION level.

41

Page 42

Ai level (adjustment and calibration) Operation

Zero and span adjustment for the inputs Ai 1 to Ai 4

1. Make the settings required for calibration (see previous section).

2. Access the Ai level as described above.

3. Select the input to be adjusted ( Ai 1 to Ai 4) by pressing the C key. CAL oFF appears on

the display (see "Calibrating the input characteristic" below).

4. Use a highly-accurate adjustment device to adjust the initial value of the input signal range.

When the input signal is within the adjustment range, three black bars appear in the left

bottom corner of the display. In addition, the selected input, e.g. Ai 1 and AdJ (for adjust)

alternate in the lower line of the display.

5. Press A key to accept the zero point adjustment. 0.0 appears in the upper line of the

display.

6. Use a highly-accurate adjustment device to adjust the maximum value of the input signal

range (span adjustment). When the input signal is within the adjustment range, three black

bars appear in the right bottom corner of the display field. In addition, the selected input,

e.g. Ai 1 and AdJ (for adjust) alternate in the lower line of the display.

7. Press A to accept the span adjustment. 100.0 appears in the upper line of the display.

8. Repeat steps 3. to 6. to adjust zero and span for the next input or exit the Ai level (see

above).

Calibrating the input characteristic via 5 coordinates

The five coordinates for the calibration curve are set at 0; 25; 50; 75 and 100 % of the input

signal. For an input signal in the range from 4 to 20 mA, these coordinates are, for example,

4; 8; 12; 16 and 20 mA.

Proceed as follows:

1. Make the settings required for calibration.

2. Access the Ai level as described above.

3. Press C key until CAL oFF appears on the display.

4. Press A key. "on" flashes in the upper line of the display.

5. Press A key until "on" stops flashing (approx. 5 s).

6. Press C key. Ai 1 for input 1 and CAL alternate on the display.

7. Select the desired input (Ai 1 to Ai 4), using the C key.

8. Use a highly-accurate adjustment device to set the input signal to 0 %. In the above

mentioned example, this would be 4 mA. When the input signal is within the calibration

range, a scale (0 to 100 %) comes up at the bottom of the display and two black bars

appear over the valid value (0 %). CAL and the selected input alternate in the lower line

of the display.

9. Press A key to accept the first coordinate value.

10. Repeat steps 8 and 9 in order to set the other four coordinate values (25; 50; 75; 100 %)

one after the other.

11. Repeat steps 7. to 10. for the next input or exit the Ai level by pressing the F key.

Note:

The inputs must be re-calibrated in the Ai level after exchanging the EPROM or the input board.

42

Page 43

Operation Fir level (displaying the firmware number)

Calibrating the span for the outputs Y1, Y2 and Ao1

When calibrating the span for the outputs Y1, Y2 and Ao1, proceed as follows:

Connect a highly-accurate meter to the output to be calibrated.

First, follow steps 1. to 6. listed under "Calibrating the input characteristic via 5 coordinates"

(see above).

7. Select desired output Y1, Y2 or Ao1 by pressing the C key. A scale from 0 to 100 % comes

up at the bottom of the display.

8. Use the G and H keys to adjust the desired end value of the output signal range. Check

this value with the highly-accurate meter. When the output signal is within the calibration

range, CAL and the selected output alternate in the lower line of the display.

9. Press A key to accept the calibrated end value.

10. Repeat steps 7 to 9 to calibrate the other outputs or exit the Ai level by pressing the F key.

6.8.Fir level (displaying the firmware number)

This level is used to view the version number of the EPROM used in the process control station,

as well as the current RS-485 interface version. Should you have any inquiry about the device,

always specify the version number of your process control station because the software might

have been modified for the following versions.

Proceed as follows:

The process control station is in the OPERATING level.

1. Press A key. I-O appears on the display.

2. Press D key until "Fir" comes up on the display.

3. Press A key. C (for controller = process control station) appears in the lower line of the

display, and the valid version number is indicated in the upper line of the display.

Press C key. Si (for serial interface) appears in the lower line of the display, and the valid

version number is indicated in the upper line of the display. If 0.0 appears here, this means

that no interface board is installed.

5. Press F key to exit the Fir level.

6.9.CHE level (checking the display panel)

This level is used to check proper functioning of all the display elements shown on the last page

of this manual.

Proceed as follows:

The process control station is in the OPERATING level.

1. Press A key. I-O appears on the display.

2. Press D key until CHE comes up on the display.

3. Press A key. All display elements are indicated on the display, as shown on the last page

of this manual.

4. Press F key to exit the CHE level.

43

Page 44

PA level (code number for the PARAMETER level) Operation

6.10.PA level (code number for the PARAMETER level)

This level can be used to define the code number for the PARAMETER level. The level is only

accessible, however, when the process control station operates in the code number mode (see

section 4.3., p. 19) and the operator knows the code number for servicing. In order to prevent

this code number for servicing from being accessed by unauthorized persons, either cut out or

scribble over the number on page 97.

To modify the code number for the PARAMETER level, take the following steps:

The process control station is in the OPERATING level.

1. Press A key. I-O appears on the display.

2. Press C or D key until PA and are displayed.

3. Press A key. flashes on the display. "1" comes up in the upper line of the display.

4. Enter the code number for servicing in the upper line of the display, using the C or D key.

5. Press A key. The currently valid code number is displayed and PA flashes.

6. Enter the new code number with the C or D key.

7. Press A key. PA no longer flashes.

8. Press F key to exit this level.

6.11.CO level (code number for the CONFIGURATION level)

This level can be used to define the code number for the CONFIGURATION level. The level is

only accessible, however, when the process control station is in the code number mode (see

section 4.3., S. 19) and the operator knows the code number for servicing. In order to prevent

this code number for servicing from being accessed by unauthorized persons, either cut out or

scribble over the number on page 97.

To modify the code number for the CONFIGURATION level, take the following steps:

The process control station is in the OPERATING level.

1. Press A key. I-O appears on the display.

2. Press C or D key until CO and are displayed.

3. Press A key. flashes on the display. "1" comes up in the upper line of the display.

4. Enter the code number for servicing in the upper line of the display, using the C or D key.

5. Press A key. The currently valid code number is displayed and CO flashes.

6. Enter the new code number with the C or D key.

7. Press A key. CO no longer flashes.

8. Press F key to exit this level.

44

Page 45

Operation Ini level (resetting the process control station to its default values)

6.12.Ini level (resetting the process control station to its default values)

Resetting the process control station to its default values can be useful in the start-up phase or

when the control tasks to be solved with the process control station have changed. This function

is based on the setting of configuration block C56. The Ini level can only be accessed when

C56 > 1.

C56 Resetting to default values

-1 No

-2 Configuration and parameterization

-3 Configuration

-4 Parameterization

-5 Zero and span adjustment of the analog inputs

-6 Span adjustment of the analog outputs

-7 Code number

-8 Controller ID number

-9 Adaptation parameters

The following steps have to be carried out:

The process control station is in the OPERATING level.

1. Set configuration block C56>1 (see above and section 6.4., p.36), then exit the CONFIGURATION level again.

2. Press A key. I-O appears on the display.

3. Press D key. Ini appears on the display.

4. Press A key twice. End and Ini appear on the display.

5. Press F key to exit this level.

Note:

After having executed this function, configuration block C56 is only reset to C56-1 when it was

previously set to C56-2 or C56-3! With all other settings, the Ini level remains active! We

therefore recommend to reset the configuration block to C56-1 after carrying out the function,

in order to prevent the control station from starting up by mistake.

45

Page 46

AdP level (adaptation of the control parameters) Operation

6.13.AdP level (adaptation of the control parameters)

The objective of this adaptation function is to calculate the optimum control parameters without

the need to make many adjustments on the process control station or without having much

previous knowledge of the process to be controlled.

The TROVIS 6412/42 Process Control Station supports the following adaptation procedures:

– Single adaptation (adaptation during the start-up phase) (see section 6.13.1.)

– Scheduling dependent on the actual value signal or output variable signal (see section

6.13.2.)

– Scheduling dependent on an external signal (see section 6.13.3.)

These adaptation procedures are suitable to be used for self-regulating processes, simple

integrating controlled systems, and systems with dead times, as well as for oscillating systems.

After having terminated the adaptation procedure, the process control station uses the calcula-