Page 1

TROVIS 5500 Automation System

TROVIS 5576 Heating and

District Heating Controller

Mounting and

Operating Instructions

EB 5576 EN

Firmware version 2.41

Edition July 2018

®

Electronics from SAMSON

Page 2

Safety instructions

4

The device may only be assembled, started up or operated by trained and

experienced personnel familiar with the product. Proper shipping and ap

-

propriate storage are assumed.

4

The controller has been designed for use in electrical power systems. For

wiring and maintenance, you are required to observe the relevant safety

regulations.

2 EB 5576 EN

Safety instructions

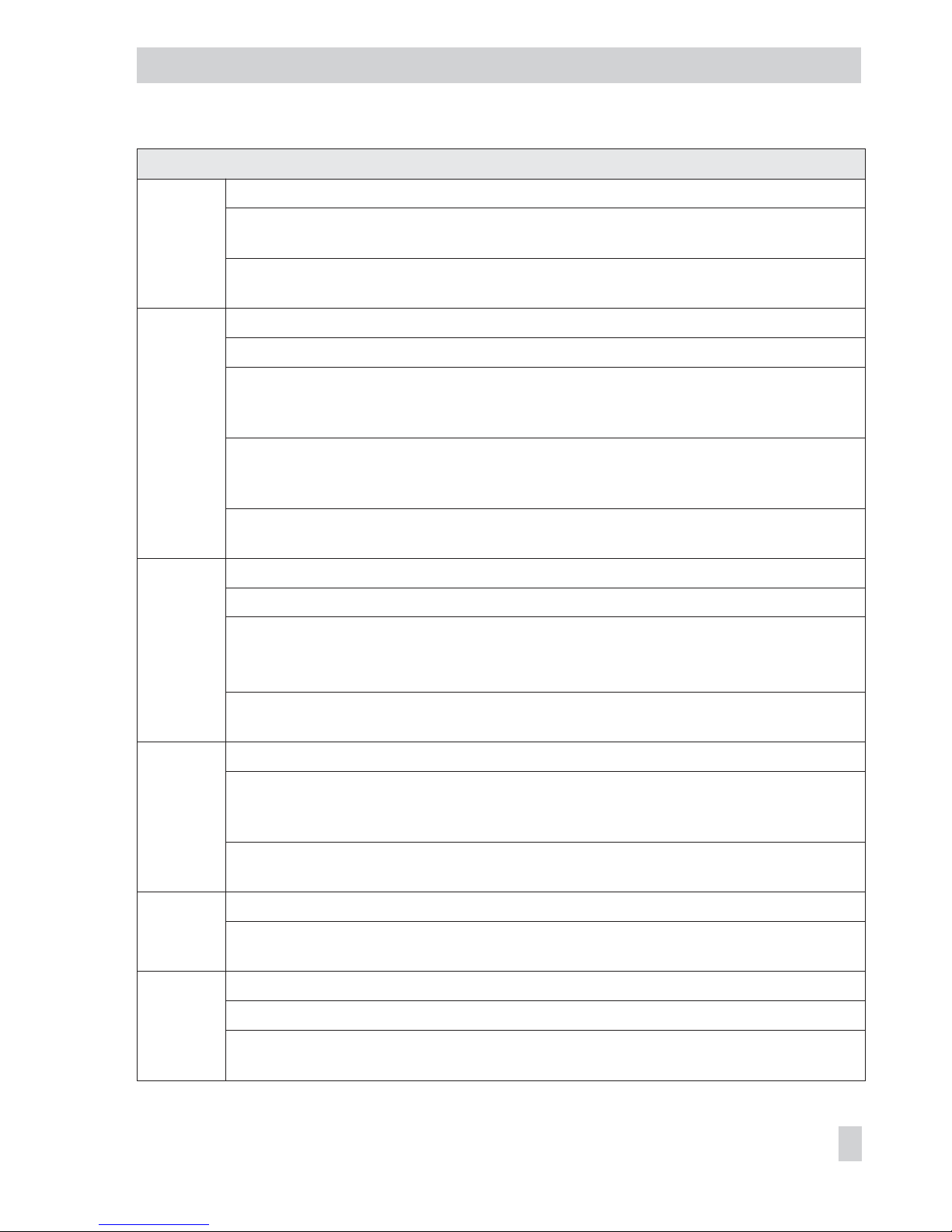

Revisions to controller firmware in comparison to previous versions

1.70

(previous)

1.71 (new)

Err 2 message (default setting loaded) is not displayed anymore. See section 8.1.

Single error messages to be forwarded over the device bus can be selected.

1.71

(previous)

1.82 (new)

An interrupted drying of jointless floors can be continued by selecting the restarting stages

START temperature maintaining phase or START temperature reduction phase. See section

5.3.

During thermal disinfection, the

Hold time of disinfection temperature can be used to determine how long the disinfection temperature must be maintained within the adjusted time

period to rate the process successful. See section 6.11.

Besides the release of single control circuits, the release of the controller is possible over

the binary input. See section 7.9.

1.82

(previous)

1.90 (new)

The new system code numbers Anl 14.1 to 14.3 increase the total of different hydraulic

schematics to 43. The new systems are all fitted with a buffer tank and a DHW storage

tank. System Anl 14.3 additionally contains a solar circuit with reroutable heat flow. See

sections 4 and 6.4.

For firmware 1.90 and higher, the maximum flow set point of the controller can be de

-

manded by issuing up to two analog signals for requesting external demand with se

-

quence control. See section 7.14.

1.90

(previous)

1.95 (new)

The priority operation (reverse control and set-back operation) can be set regardless of the

time and temperature in the system. Refer to sections 6.9.1 and 6.9.2.

The setting CO1 -> F20 - 1 allows an external demand for heat to be made when insuffi

-

cient heat is supplied. Refer to section 7.17.

Page 3

EB 5576 EN 3

Revisions to controller firmware in comparison to previous versions

Revisions to controller firmware in comparison to previous versions

1.90

(previous)

1.95 (new)

The priority operation (reverse control and set-back operation) can be set regardless of the

time and temperature in the system. Refer to sections 6.9.1 and 6.9.2.

The setting CO1 -> F20 - 1 allows an external demand for heat to be made when insuffi

-

cient heat is supplied. Refer to section 7.17.

1.95

(previous)

2.00 (new)

New system (Anl 10.5) added. Refer to section 4.

The limit switch for creep feed rate limitation can also be connected to input RüF1. In pre

vious versions, it could only be connected to the binary input (terminals 04/12). Refer to

section 7.12.3.

A primary controller linked over the device bus can receive and process the demand of

downstream controllers (version 2.00 and higher) optionally in control circuit Rk1 and/or

Rk2. Refer to section 7.13.1.

The

Boiler pump OFF parameter has been replaced by the Hysteresis parameter. Refer to

section 6.4.

2.00

(previous)

2.12 (new)

New hydraulic schematic (Anl 11.6) added. Refer to page 64.

New cooling control function (refer to section 5.13)

The cooling circuit causes a reversal of the operating direction and a minimum limitation

of the return flow temperature in Rk1/2.

The demand processing using a 0 to 10 V signal can be applied to the 0 to 130 °C trans

-

mission range. Refer to section 7.11.

2.12

(previous)

2.13 (new)

The priority operation (reverse control and set-back operation) can be activated for system

Anl 4.5 either for only one heating circuit (Rk1or Rk2) or for both heating circuits (Rk1and

Rk2). Refer to section 6.9.

New function to control the speed of the charging pump based on the charging progress.

Refer to section 6.7.

2.13

(previous)

2.14 (new)

The flow rate and capacity limitation over meter bus can be performed in control circuit

Rk1 and additionally in Rk2. Refer to section 9.3.2.

2.14

(previous)

2.20 (new)

New hydraulic schematics Anl 16.x (buffer tank system) added. Refer to page 68.

The drying of jointless floors cannot be cancelled due to a different flow temperature. Refer

to section 5.3.

Page 4

4 EB 5576 EN

Revisions to controller firmware in comparison to previous versions

2.20

(previous)

2.24 (new)

Internal modifications

2.24

(previous)

2.26 (new)

Outdoor temperature using 0 to 10 V signal function extended

Outdoor temperatures can be received or sent using a 0 to 10 V signal.

2.26

(previous)

2.28 (new)

New system Anl 11.5

2.28

(previous)

2.41 (new)

New functions and parameters in buffer tank systems (see section 5.5):

CO1>F22: SLP depending on return flow temperature

CO5´>F01: Y1 reverse

CO5´>F02: Y2 reverse

CO5´>F07: AE1 zero shift

New functions and parameters in buffer tank systems (continued):

PA1: Min. set point for buffer tank charging

PA1: Stop buffer tank charging

PA1: Charging temperature boost

PA1: Lag time of charging pump

PA4: Maximum buffer tank temperature

New Differential temperature control function (CO1>F23) in systems Anl 1.0 and 16.0.

Refer to section 5.14.

TROVIS5570 Control Panel is discontinued.

Restrictions when using a mini module (accessories no. 1400-7436). Refer to section 9.4.

Page 5

Contents

1 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1.1 Rotary pushbutton and changeover key . . . . . . . . . . . . . . . . . 9

1.1.2 Rotary switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 Displaying data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5 Setting the controller time . . . . . . . . . . . . . . . . . . . . . . . 17

1.6 Setting the times-of-use . . . . . . . . . . . . . . . . . . . . . . . . 18

1.7 Setting the party mode. . . . . . . . . . . . . . . . . . . . . . . . . 20

1.8 Activating extended operating level . . . . . . . . . . . . . . . . . . 21

1.8.1 Setting public holidays. . . . . . . . . . . . . . . . . . . . . . . . . 22

1.8.2 Setting vacation periods . . . . . . . . . . . . . . . . . . . . . . . . 23

1.9 Setting room and DHW temperature set points . . . . . . . . . . . . . 25

2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.1 Setting the system code number . . . . . . . . . . . . . . . . . . . . 27

2.2 Activating and deactivating functions. . . . . . . . . . . . . . . . . . 28

2.3 Changing parameters . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.4 Calibrating sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.5 Resetting to default values . . . . . . . . . . . . . . . . . . . . . . . 35

3 Manual operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4 Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5 Functions of the heating circuit. . . . . . . . . . . . . . . . . . . . . 74

5.1 Weather-compensated control . . . . . . . . . . . . . . . . . . . . . 74

5.1.1 Gradient characteristic. . . . . . . . . . . . . . . . . . . . . . . . . 75

5.1.2 Four-point characteristic . . . . . . . . . . . . . . . . . . . . . . . . 77

5.2 Fixed set point control . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.3 Underfloor heating/drying of jointless floors . . . . . . . . . . . . . . 79

5.4 Deactivation depending on outdoor temperature . . . . . . . . . . . . 80

5.4.1 OT deactivation value in rated operation . . . . . . . . . . . . . . . . 80

5.4.2 OT deactivation value in reduced operation. . . . . . . . . . . . . . . 80

5.4.3 OT activation value in rated operation . . . . . . . . . . . . . . . . . 81

5.5 Buffer tank systems . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.6 Summer mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.7 Delayed outdoor temperature adaptation. . . . . . . . . . . . . . . . 85

5.8 Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.9 Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5 EB 5576 EN

Contents

Page 6

5.10 Flash adaptation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.10.1 Flash adaptation without outdoor sensor (room temperature dependent) . 88

5.11 Adaptation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.12 Pump management . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.13 Cooling control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.14 Differential temperature control. . . . . . . . . . . . . . . . . . . . . 92

6 Functions of the DHW circuit . . . . . . . . . . . . . . . . . . . . . . 93

6.1 DHW heating in the storage tank system . . . . . . . . . . . . . . . . 93

6.1.1 DHW circuit additionally controlled by a globe valve . . . . . . . . . . 95

6.2 DHW heating in the storage tank charging system . . . . . . . . . . . 96

6.2.1 Cold charging protection. . . . . . . . . . . . . . . . . . . . . . . . 98

6.3 DHW heating in instantaneous heating system . . . . . . . . . . . . . 99

6.4 DHW heating with solar system. . . . . . . . . . . . . . . . . . . . 100

6.5 Intermediate heating operation . . . . . . . . . . . . . . . . . . . . 100

6.6 Parallel pump operation . . . . . . . . . . . . . . . . . . . . . . . 100

6.7 Speed control of the charging pump . . . . . . . . . . . . . . . . . 101

6.8 Circulation pump operation during storage tank charging . . . . . . . 101

6.9 Priority operation. . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.9.1 Reverse control. . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.9.2 Set-back operation . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.10 Forced charging of the DHW storage tank. . . . . . . . . . . . . . . 103

6.11 Thermal disinfection . . . . . . . . . . . . . . . . . . . . . . . . . 104

7 System-wide functions . . . . . . . . . . . . . . . . . . . . . . . . 106

7.1 Automatic summer/standard time swichover . . . . . . . . . . . . . 106

7.2 Frost protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7.3 Forced operation of the pumps . . . . . . . . . . . . . . . . . . . . 107

7.4 Return flow temperature limitation. . . . . . . . . . . . . . . . . . . 107

7.5 Condensate accumulation control . . . . . . . . . . . . . . . . . . . 108

7.6 Three-step control . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.7 On/off control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.8 Continuous control . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.9 Releasing a control circuit/controller over the binary input . . . . . . . 110

7.10 Speed control of the charging pump . . . . . . . . . . . . . . . . . 111

7.11 Processing an external demand . . . . . . . . . . . . . . . . . . . . 111

7.12 Flow rate/capacity limitation in Rk1. . . . . . . . . . . . . . . . . . 113

7.12.1 Limitation using pulse input . . . . . . . . . . . . . . . . . . . . . . 113

7.12.2 Limitation using 0/4 to 20 mA signal . . . . . . . . . . . . . . . . . 114

7.12.3 Creep feed rate limitation using a binary input . . . . . . . . . . . . 115

EB 5576 EN 6

Contents

Page 7

7.12.4 Limitation of the calculated capacity. . . . . . . . . . . . . . . . . . 116

7.13 Device bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

7.13.1 Requesting and processing an external demand . . . . . . . . . . . . 117

7.13.2 Sending and receiving outdoor temperatures . . . . . . . . . . . . . 119

7.13.3 Synchronizing the clock . . . . . . . . . . . . . . . . . . . . . . . 119

7.13.4 Priority over all controllers . . . . . . . . . . . . . . . . . . . . . . 120

7.13.5 Connecting a TROVIS 5570 Room Panel . . . . . . . . . . . . . . . 120

7.13.6 Display error messages issued by the device bus. . . . . . . . . . . . 121

7.14 Requesting an external demand by issuing a 0 to 10 V signal . . . . . 122

7.15 Connecting potentiometers for valve position input. . . . . . . . . . . 122

7.16 Feeder pump operation. . . . . . . . . . . . . . . . . . . . . . . . 123

7.17 External demand for heat due to insufficient heat supply . . . . . . . . 123

7.18 Locking manual level . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.19 Locking the rotary switches . . . . . . . . . . . . . . . . . . . . . . 124

7.20 Setting a customized key number . . . . . . . . . . . . . . . . . . . 124

8 Operational faults . . . . . . . . . . . . . . . . . . . . . . . . . . 125

8.1 Error list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

8.2 Sensor failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

8.3 Temperature monitoring . . . . . . . . . . . . . . . . . . . . . . . 126

8.4 Collective error message . . . . . . . . . . . . . . . . . . . . . . . 126

8.5 Error status register. . . . . . . . . . . . . . . . . . . . . . . . . . 127

9 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

9.1 System bus interface in combination with RS-232/RS-485

cable converters (for two-wire or four-wire bus) . . . . . . . . . . . . 128

9.2 Description of communication parameter settings . . . . . . . . . . . 129

9.3 Meter bus interface. . . . . . . . . . . . . . . . . . . . . . . . . . 130

9.3.1 Activating the meter bus . . . . . . . . . . . . . . . . . . . . . . . 130

9.3.2 Flow rate/capacity limitation using meter bus . . . . . . . . . . . . . 131

9.4 Memory module/mini module . . . . . . . . . . . . . . . . . . . . 134

9.5 Data logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

10 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

11 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . 138

12 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

12.1 Function block lists . . . . . . . . . . . . . . . . . . . . . . . . . . 142

12.2 Parameter lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

12.3 Assignment of the rotary switches . . . . . . . . . . . . . . . . . . . 169

12.4 Sensor resistance tables . . . . . . . . . . . . . . . . . . . . . . . 170

12.5 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

7 EB 5576 EN

Contents

Page 8

12.6 Customer data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Frequently used abbreviations . . . . . . . . . . . . . . . . . . . . 190

8 EB 5576 EN

Contents

Page 9

1 Operation

The controller is ready for use with the default temperatures and operating schedules.

On start-up, the current time and date need to be set at the controller (–> section 1.5).

1.1 Operating elements

The operating controls are located in the front panel of the controller and protected by a

Plexiglas door.

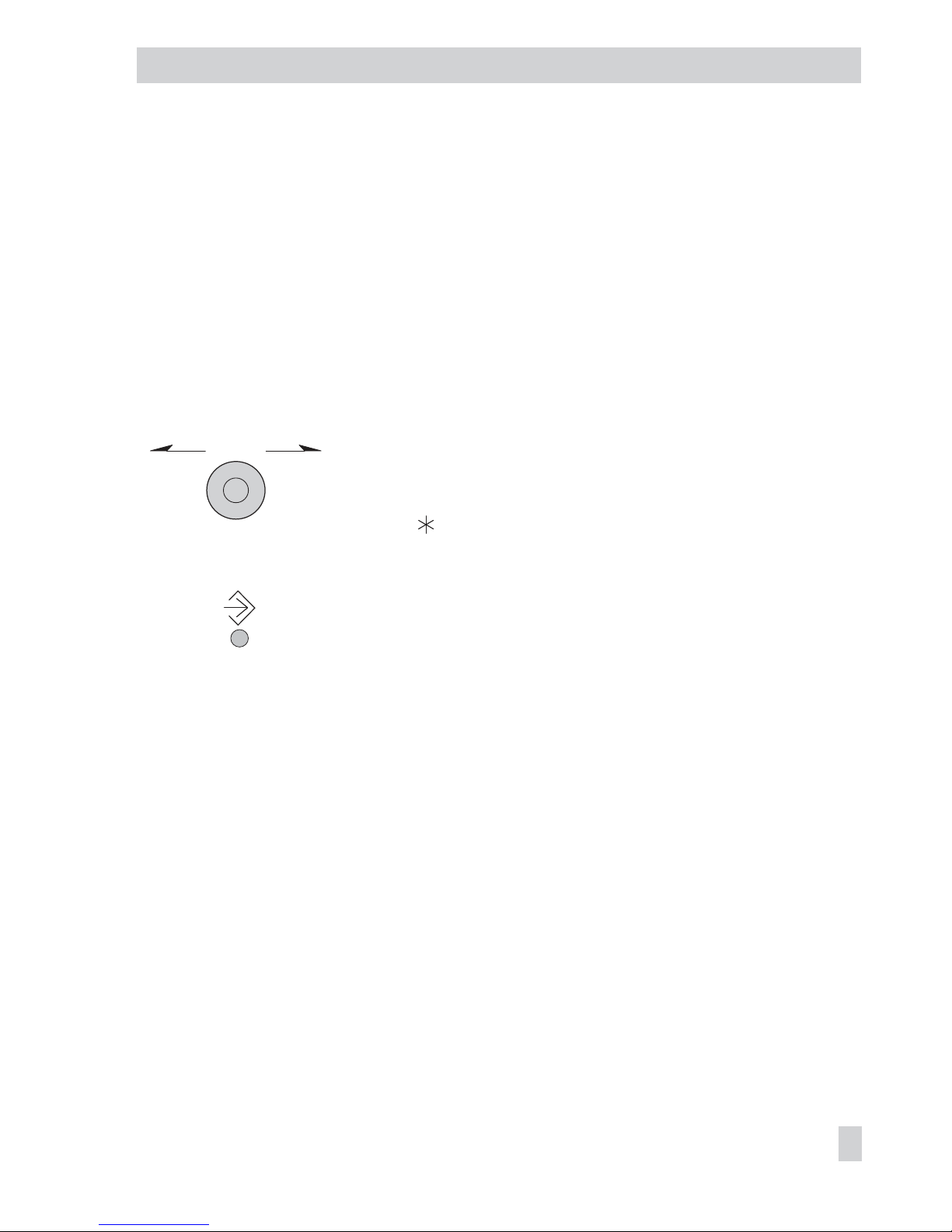

1.1.1 Rotary pushbutton and changeover key

Rotary pushbutton

Turn q:

Display, select parameters and function blocks

Press :

Confirm adjusted selection or settings

Changeover key

(use pen or any other pointed item to press)

Press to switch between operating level and

configuration/parameter level

EB 5576 EN 9

Operation

*

Page 10

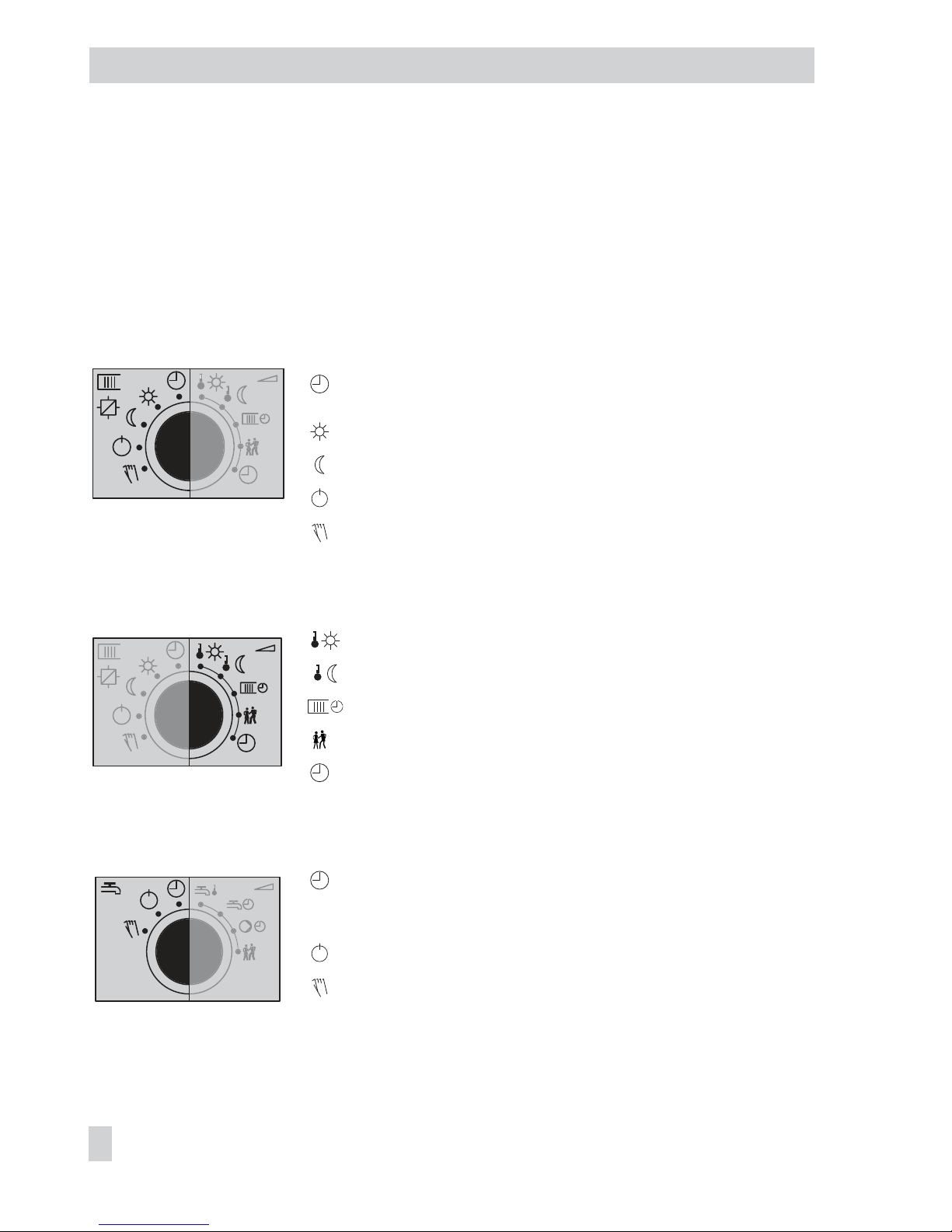

1.1.2 Rotary switches

Use the three rotary switches to adjust the required operating mode (icons on the left) and the

relevant parameters (icons on the right).

The top and middle switches are assigned to the heating circuits (see page 169). The rotary

switch in the middle is not used in systems without a second heating circuit.

The bottom switch is assigned to the DHW circuit.

Rotary switch to set the operating modes of the heating circuit

Automatic/time-controlled operation

with switchover between rated and reduced operation

Day mode (rated operation)

Night mode (reduced operation)

Control operation deactivated, frost protection only

Manual operation: correction value adjusted in percent

and activation/deactivation of the pumps

Rotary switch to set the parameters of the heating circuit

Day set point (rated room temperature)

Night set point (reduced room temperature)

Times-of-use for heating

Party mode

Controller time: setting current time, date and year

Rotary switch to set the operating modes of the DHW circuit

Automatic/time-controlled operation

with switchover between times when DHW heating

is permissible/impermissible

DHW heating deactivated, frost protection only

Manual operation: correction value adjusted in percent

and activation/deactivation of the pumps

10 EB 5576 EN

Operation

Page 11

Rotary switch to set the parameters of the DHW circuit

Set point for DHW temperature

Times-of-use for DHW heating

Times-of-use for DHW circulation pump

Party mode

Note: If more than one rotary switch is set to position “Parameter“ (right side) at the same

time, blinks on the display. The controller cannot be operated.

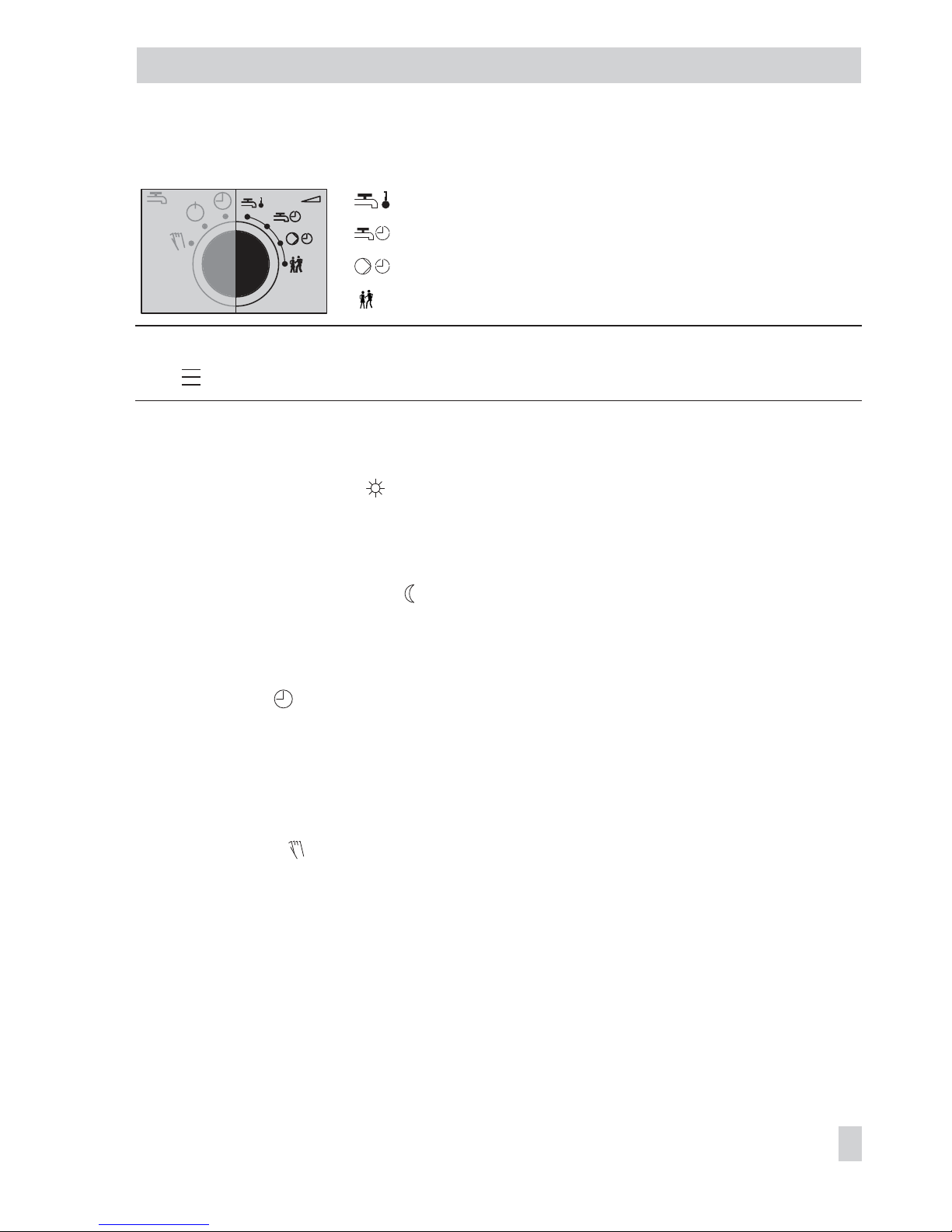

1.2 Operating modes

Day mode (rated operation)

Regardless of the programmed times-of-use and summer mode, the set points relevant for

rated operation are used by the controller.

Night mode (reduced operation)

Regardless of the programmed times-of-use, the set points relevant for reduced operation are

used by the controller.

Automatic mode

During the programmed times-of-use, the controller works in rated operation. Outside these

times-of-use, the controller is in reduced operation, unless control operation is deactivated

depending on the outdoor temperature. The controller switches automatically between both

operating modes.

Manual operation

Valves and pumps can be controlled manually (–> section 3).

EB 5576 EN 11

Operation

Page 12

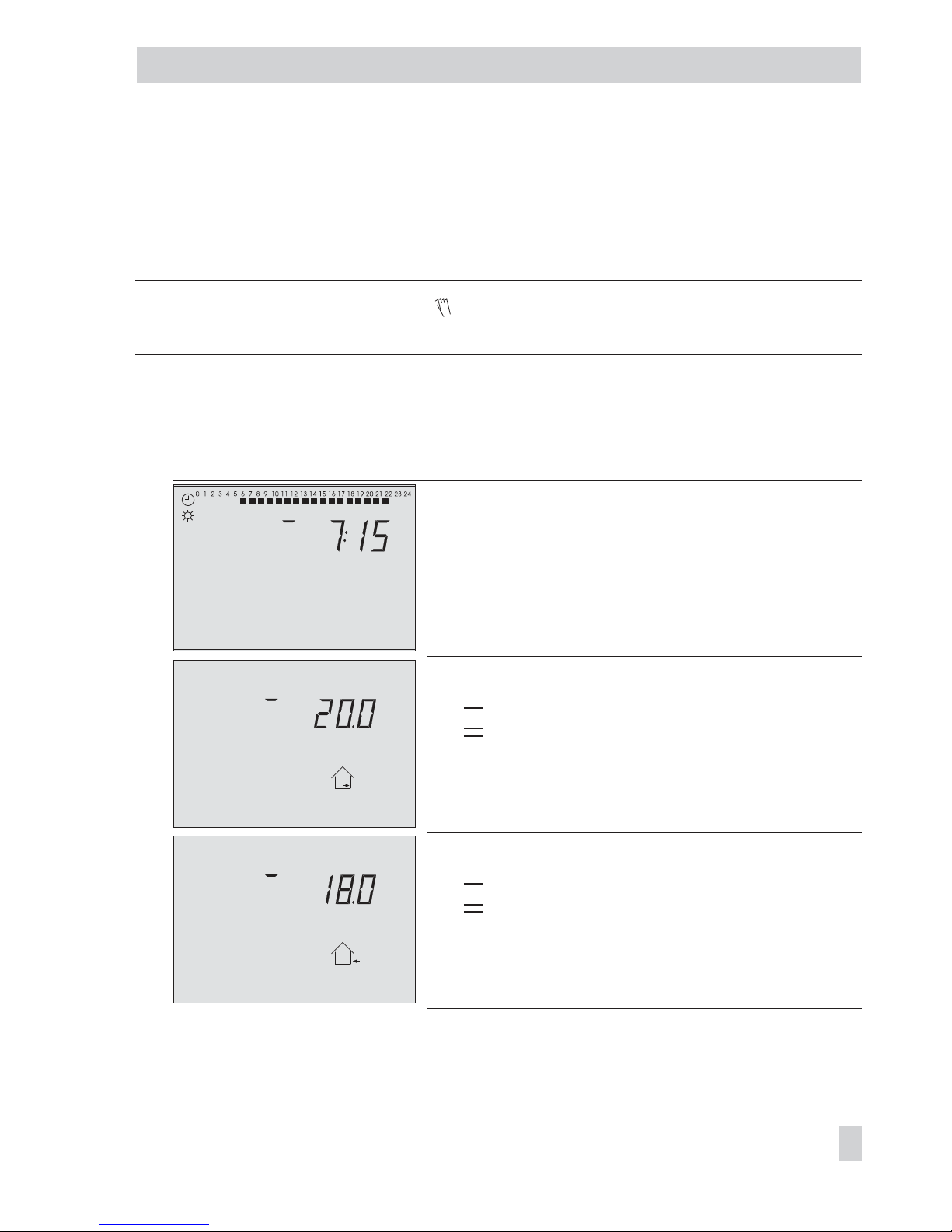

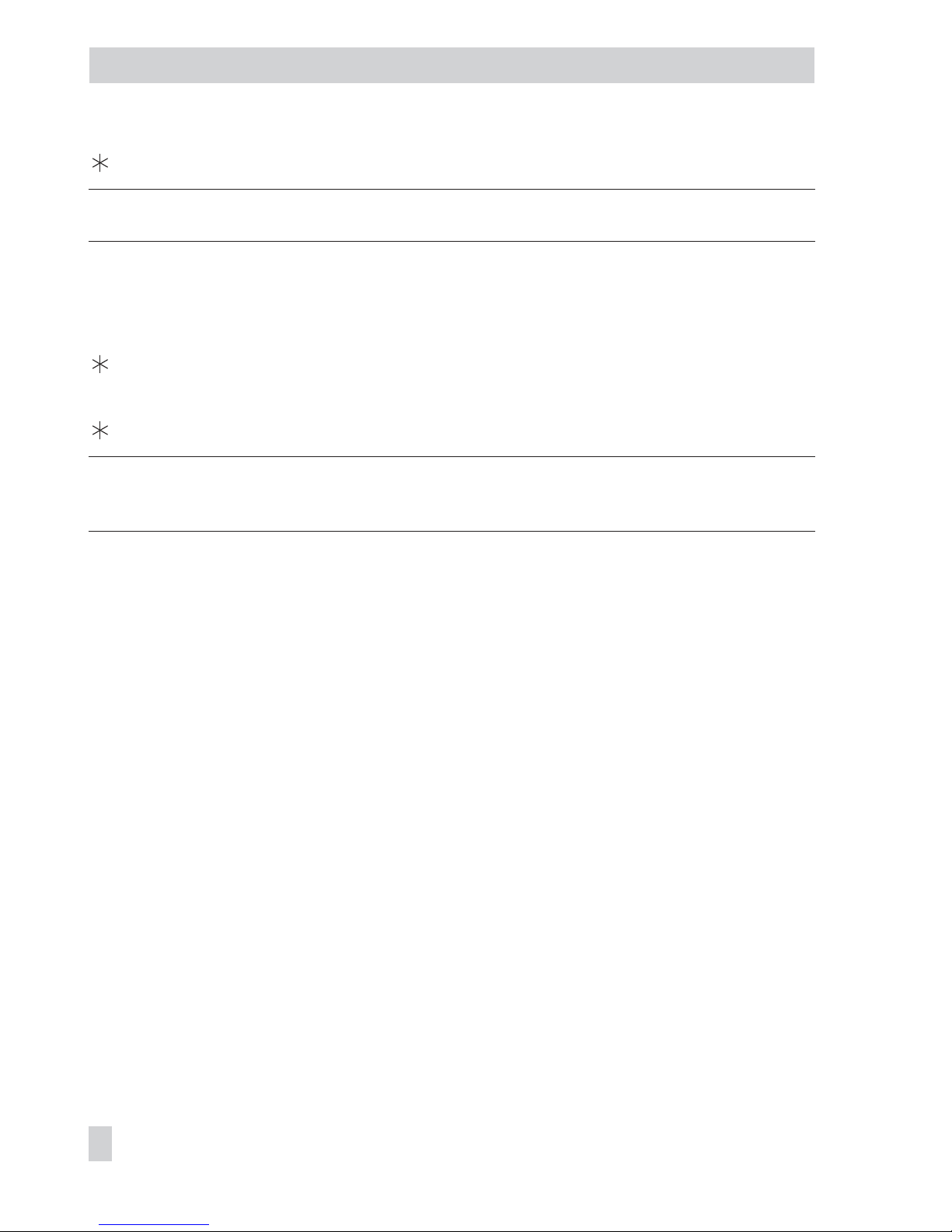

1.3 Display

During operation, the display indicates the current time as well as information about the op

eration of the controller. The times-of-use are represented by black squares below the row of

numbers at the top of the display. Icons indicate the operating status of the controller.

The controller status can be displayed in operating level (–> section 1.4).

12 EB 5576 EN

Operation

STOP

1

18

2

3

6

7

8

9

4

5

10 11 12 13 14 15 16 17

19

20

21

Fig. 1 · Icons

1 Automatic operation

2 Day mode

3 Night mode

4 Vacation mode

5 Public holiday mode

6 Frost protection

7 Operational fault

8 Output bA9

9 Valve Rk1: OPEN

10 Valve Rk1: CLOSED

11 Storage tank charging

pump SLP

12 Output BA9*

13 Circulation pump UP5*

14 DHW demand

15 Circulation pump UP2*

16 Valve Rk2: OPEN,

output bA9: ON

17 Valve Rk2: CLOSED

output bA8: ON

18 Time-of-use

19 Control circuit assignment:

: Heating circuit Rk1

: Heating circuit Rk2

20 Outdoor temperature

dependent control

deactivated

21 Demand with sequence control:

1: One output active

2: Two outputs active

* UP1, UP2, SLP, UP5, bA9 indicate possible choices for pump selection in manual mode.

Page 13

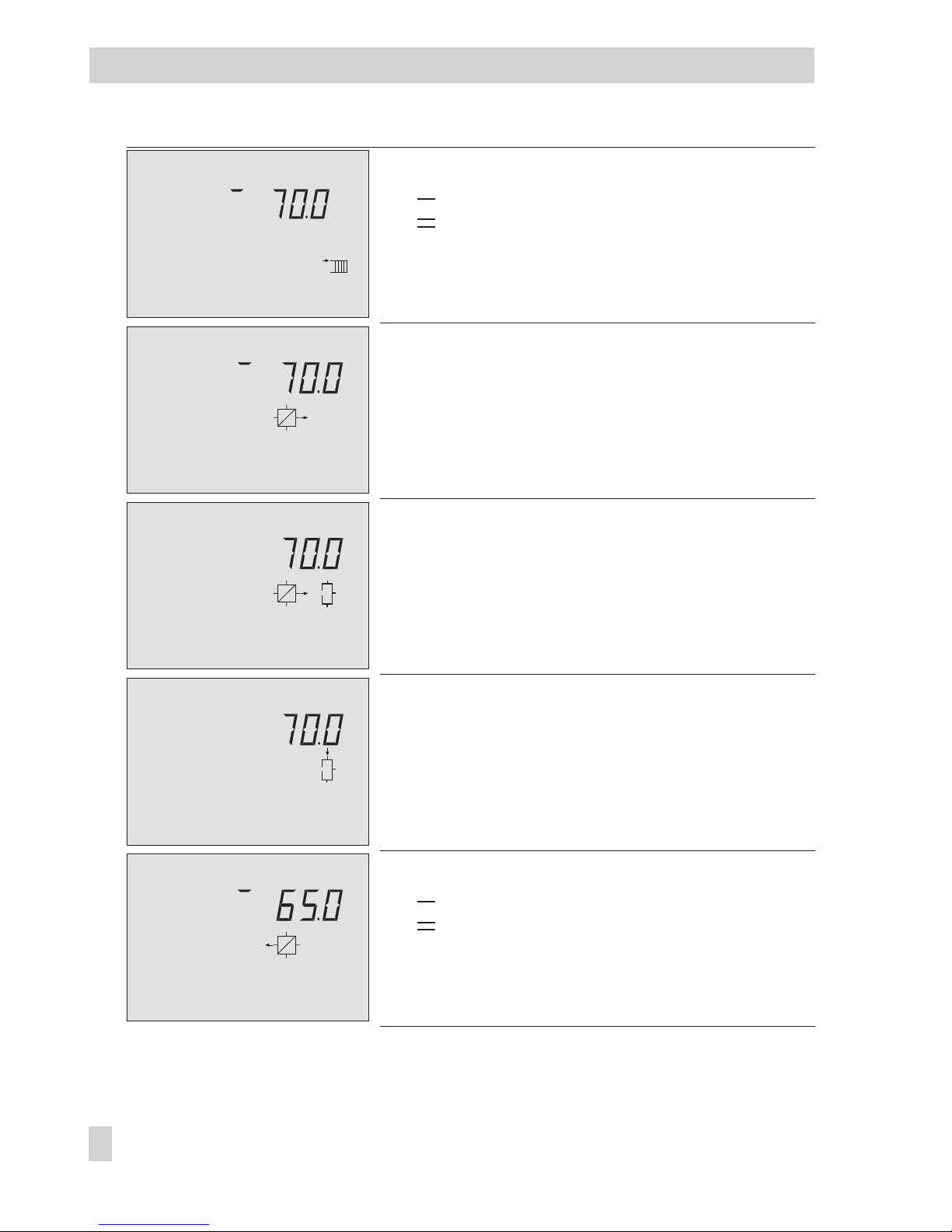

1.4 Displaying data

The time, date, public holidays and vacation periods as well as the temperatures measured

by the connected sensors and their set points can be retrieved and displayed with the help of

the rotary pushbutton.

Note: Data can also be viewed in the manual mode in the operating level.

To do so, select Info, confirm and proceed as described below.

Proceed as follows:

q

Select value.

Depending on the configuration of the controller, the different data points are displayed:

Controller time.

Room temperature

: Heating circuit Rk1

: Heating circuit Rk2

Outdoor temperature

: Heating circuit Rk1

: Heating circuit Rk2

EB 5576 EN 13

Operation

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

°C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

°C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

°C

Page 14

Temperature at the flow sensor VF

: Heating circuit Rk1

: Heating circuit Rk2

Temperature at the flow sensor VF1, primary exchanger

circuit

Temperature at the flow sensor VF2, DHW circuit

Temperature at the solar collector sensor VF3

Temperature at the return flow sensor RüF

: Heating circuit Rk1

: Heating circuit Rk2

14 EB 5576 EN

Operation

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

°C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

Page 15

Temperature at the return flow sensor RüF, DHW circuit

Temperature at the storage tank sensor SF1 (DHW storage

tank)

Temperature at the storage tank sensor SF2 (DHW storage

tank)

Temperature at the storage tank sensor SF3 (DHW storage

tank)

Temperature at the storage tank sensor SF2, SF3 (buffer tank)

EB 5576 EN 15

Operation

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

°C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

Page 16

Temperature at the storage tank sensor SF4 (buffer tank)

Temperature at the flow sensor VF4

Compare set point/limit and actual value.

By pressing the rotary pushbutton when the time is displayed, the date appears on the

display.

16 EB 5576 EN

Operation

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

°C

Page 17

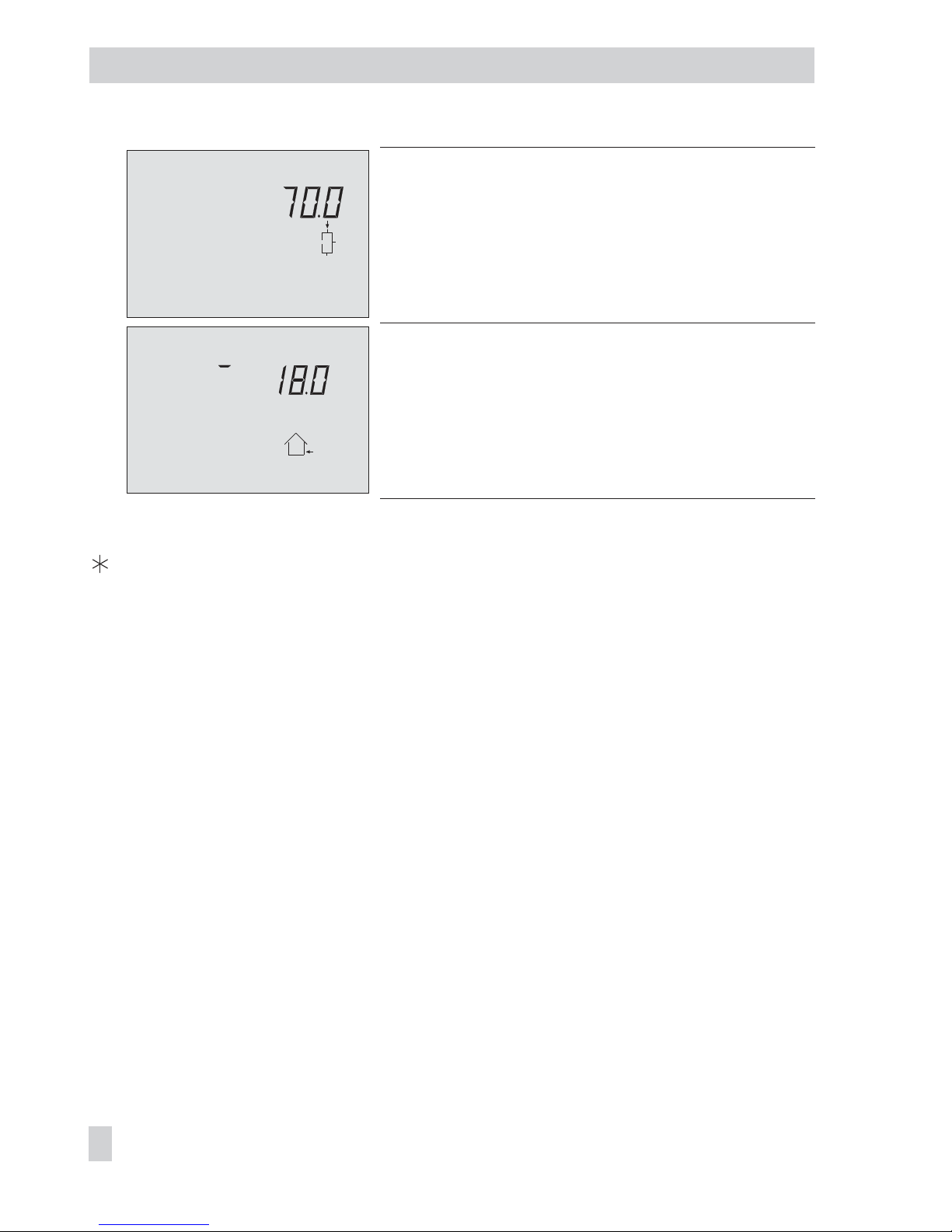

1.5 Setting the controller time

The current time and date need to be set immediately after start-up and after a power failure

of more than 24 hours has occurred. This is the case when the time blinks on the display.

Proceed as follows:

Turn the top rotary switch to position “Controller

time“ (right side).

Display shows: time

q

Edit the controller time.

Confirm the adjusted time.

Display shows: year

q

Edit the year.

Confirm the adjusted year.

Display shows: date (day.month)

q

Edit the date.

Confirm the adjusted date.

Display shows: time

Return the rotary switch to the desired operating mode

(left side).

Note: The correct time is guaranteed after a power failure of 24 hours. Normally, the correct

time is still retained at least 48 hours after a power failure.

EB 5576 EN 17

Operation

2423222120191817161514131211109876543210

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

242322212019181716151413121110

9876543210

Page 18

1.6 Setting the times-of-use

Three times-of-use can be set for each day of the week.

If only one time-of-use is required, the start and stop times of the second time-of-use must be

set to identical times. In this case, the third time-of-use is not displayed.

If only two times-of-use are required, the start and stop times of the third time-of-use must be

set to identical times.

The times-of-use for the different control circuits are set at the rotary switches one after the

other:

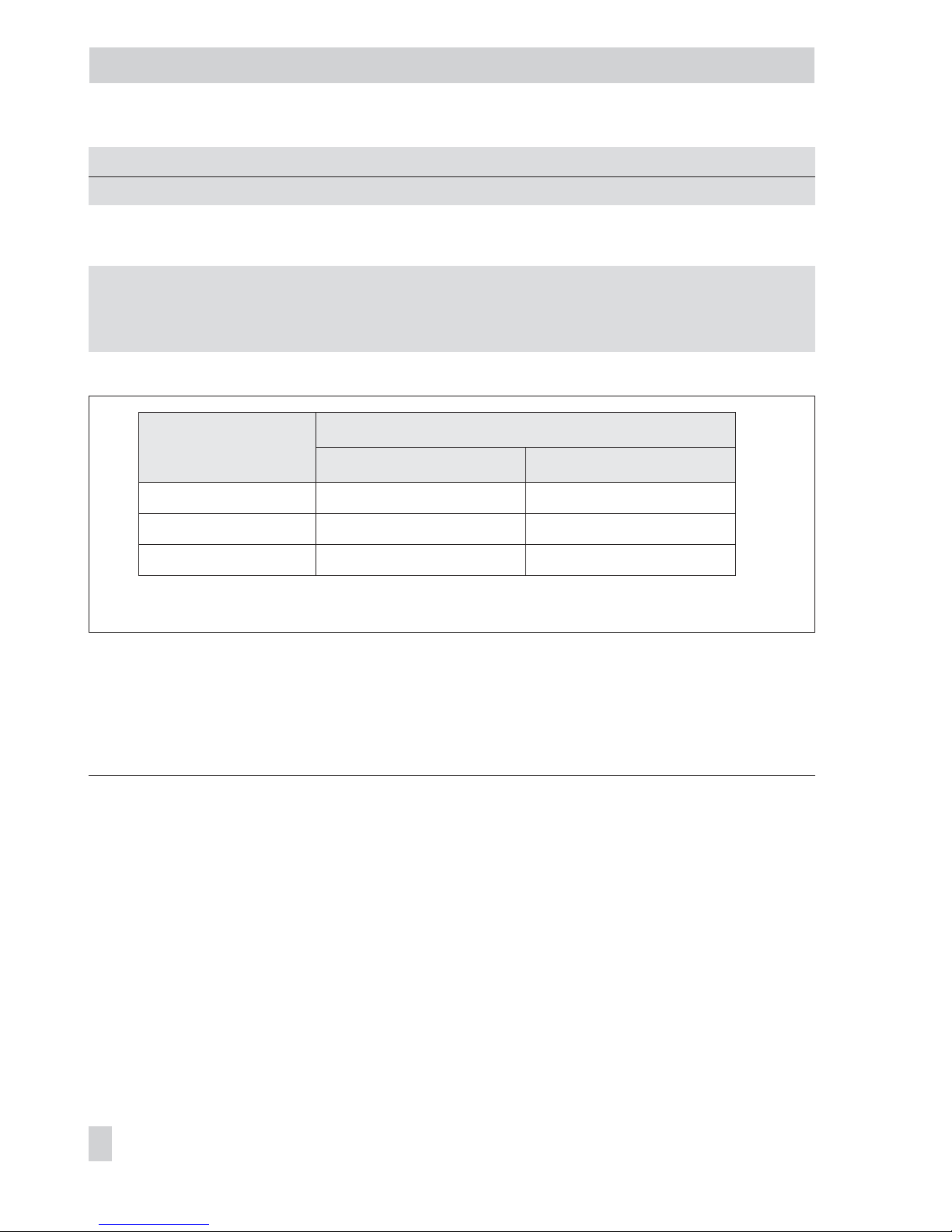

Times-of-use Rotary switch Position

Heating circuit 1* Top

Heating circuit 2* Middle

DHW heating* Bottom

Circulation pump Bottom

* Refer to page 169 for assignment

Parameters

WE* Range of values

Period/day 1–7 1–7, 1, 2, 3, 4, 5, 6, 7 with 1–7 = every day,

1 = Monday, 2 = Tuesday, ..., 7 = Sunday

Start first time-of-use 6:00 0:00 to 24:00h; in steps of 15 minutes

Stop first time-of-use 22:00 0:00 to 24:00h; in steps of 15 minutes

Start second time-of-use 22:15 0:00 to 24:00h; in steps of 15 minutes

Stop second time-of-use 22:15 0:00 to 24:00h; in steps of 15 minutes

Start third time-of-use – 0:00 to 24:00h; in steps of 15 minutes

Stop third time-of-use – 0:00 to 24:00h; in steps of 15 minutes

* Default values (WE) valid for heating circuit 1/primary heat exchanger circuit (top rotary switch)

18 EB 5576 EN

Operation

Page 19

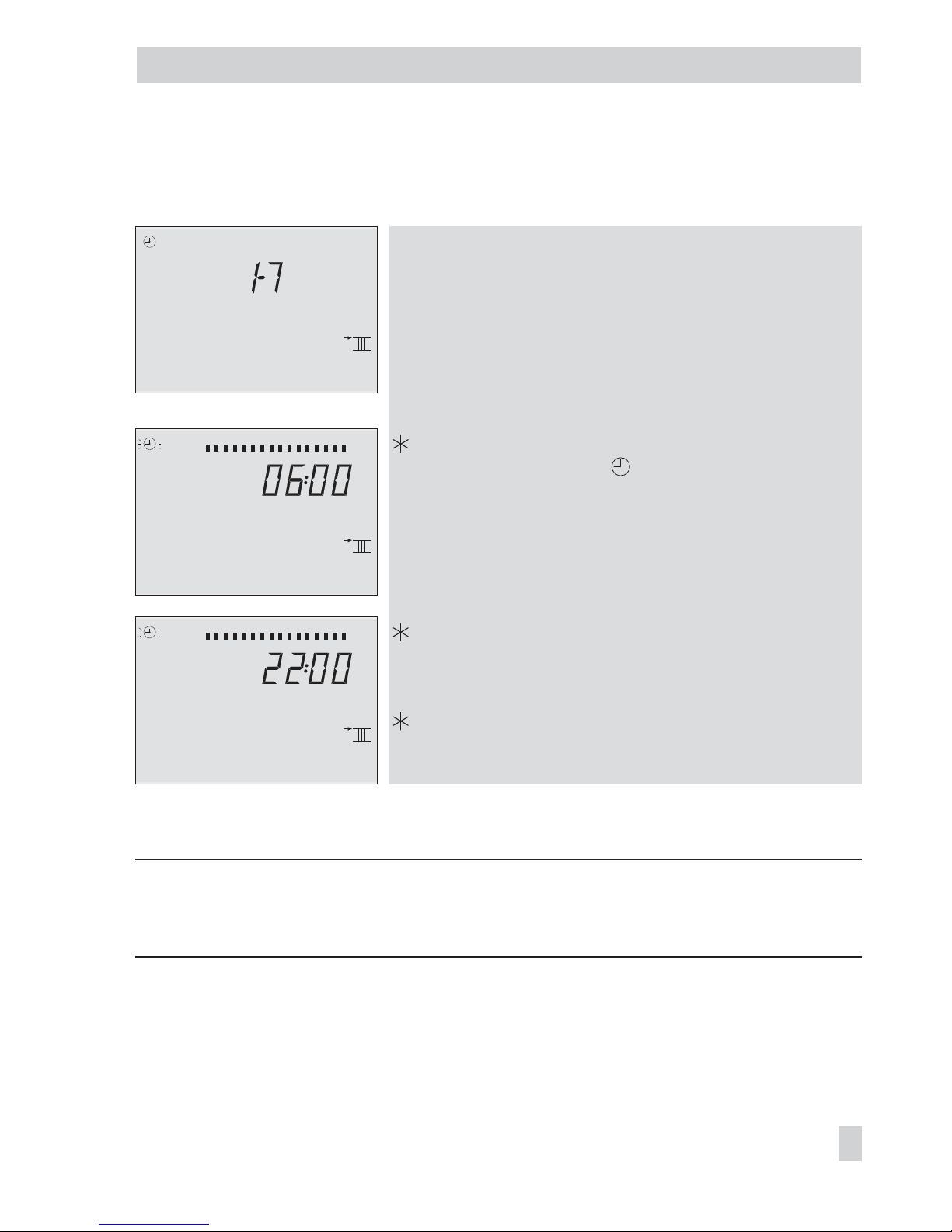

Proceed as follows: Turn appropriate rotary switch to position

“Times-of-use”.

Display shows: 1–7

q

Select period/day for which the times-of-use are to be

valid:

1–7 = every day,

1 = Monday, 2 = Tuesday, ..., 7 = Sunday

Activate editing mode for period/day.

Display shows: START, blinks

q

Edit start time (steps of 15 minutes).

Confirm start time.

Display shows: STOP

q Edit stop time (steps of 15 minutes).

Confirm stop time.

Display shows:

START

The second time-of-use is set like the first time-of-use.

To set the times-of-use for each day, repeat the instructions in the fields highlighted in gray.

Return the rotary switch to the desired operating mode (left side).

Note: Do not use the 1–7 menu to check the programmed times-of-use.

If this menu is opened after the times-of-use have been set, the schedule programmed for

Monday is also adopted for all other days of the week.

EB 5576 EN 19

Operation

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

ST OP

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

ST A RT

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Page 20

1.7 Setting the party mode

Using the Party mode function, the controller continues or activates the rated operation of the

controller during the time when the party timer is active, regardless of the programmed

times-of-use. The party timer begins when the rotary switch has been returned to operating

mode “Automatic“. When the party timer has elapsed, the party timer is reset to 00:00.

The party modes for the different control circuits are set at the rotary switches one after the

other:

Party timer Rotary switch Position

Heating circuit 1* Top

Heating circuit 2* Middle

DHW circuit* Bottom

* Refer to page 169 for assignment

Parameter

WE Range of values

Continue/activate rated operation 0 h 0 to 48 hours

Proceed as follows:

Turn appropriate rotary switch to “Party mode“.

Display shows: 00:00 or the remaining time of the party timer

q

Edit desired length of the one-off time-of-use.

Return the rotary switch to operating mode “Automatic“ (left side).

Note: The party timer counts down in steps of 15 minutes.

20 EB 5576 EN

Operation

Page 21

1.8 Activating extended operating level

After the key number 1999 has been entered, the following information can be viewed and

edited after the data points listed in section 1.4 have been displayed:

4

Heat capacity

4

Flow rate

4

Public holidays (can be changed)

4

Vacation periods (can be changed)

4

Valve positions

4

Modem status information

4

Meter bus status information

4

Switching states of the binary inputs

4

Info 2 · The following data are shown in the same sequence as shown below:

Controller ID (refer to section 8.6)

Memory capacity of data logging module (section 9.5)

Modbus station address (refer to section 9.2)

Operating hours of solar circuit pump (refer to section 6.4)

Water flow sensor (refer to section 6.3)

Opening the extended operating level:

Switch to configuration and parameter level.

Display shows:

0 0 0 0

q

Set key number 1999.

Confirm key number.

Display shows: time

Note:

–

The additional information is hidden when the key number 1999 is entered again.

–

The key number 1999 cannot be used to change the controller configuration and

parameterization. A separate key number exists for configuration and parameterization.

Refer to section 2.

EB 5576 EN 21

Operation

Page 22

1.8.1 Setting public holidays

On public holidays, the times-of-use specified for Sunday apply. A maximum of 20 public

holidays may be entered.

Parameter

WE Level / Range of values

Public holidays – Extended operating level / 01.01 (1 Jan) to 31.12 (31 Dec)

Proceed as follows:

q

In extended operating level, select “Public holidays“.

Display shows:

Open data point for public holidays.

q

If applicable, select – – – –.

Activate editing mode for public holiday. blinks.

q

Edit desired public holiday.

Confirm public holiday.

To enter additional public holidays, re-select – – – – and repeat the steps in the fields highlighted in gray.

Exit data point for public holidays.

Note: Public holidays can also be entered in parameter level PA5 (–> section 2.3).

Deleting a public holiday:

q

Under data point for public holidays, select the holiday you wish to delete.

Confirm selection.

q

Select – – – – .

Delete the public holiday.

Note: Public holidays that are not assigned to a specific date should be deleted by the end of

the year so that they are not carried on into the following year.

22 EB 5576 EN

Operation

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Page 23

1.8.2 Setting vacation periods

During vacation periods, the controller constantly remains in reduced operating mode. A

maximum of 10 vacation periods can be entered. Each vacation period can be separately

assigned to the heating circuits Rk1 and Rk2 and/or the DHW circuit.

Parameters

WE Level / Range of values

Vacation period (START, STOP) – Extended operating level / 01.01 to 31.12

Proceed as follows:

q

In extended operating level, select “Vacation periods“.

Display shows:

Open data point for vacation periods.

Display shows:

START, – –.– – (day.month)

q

If applicable, select – – – – .

Activate editing mode for start date of vacation period.

blinks.

q Edit start date of vacation period.

Confirm start date of the vacation period.

Display shows: STOP, – –.– – (day.month)

q

Edit end of vacation period.

Confirm end of vacation period.

Black squares under 1 to 4 at the top of the display

indicate the assignment of the vacation periods to the

individual control circuits.

q

Select the control circuit to which the current vacation

period should apply.

Current vacation period applies to circuit Rk1

Current vacation period applies to circuit Rk2

–

Current vacation period applies to DHW circuit

The vacation period can be assigned to a single control

circuit or any combination of all three control circuits

(Rk1 and Rk2, DHW circuit).

To enter additional vacation periods, re-select

– – – – and repeat the steps in the fields

highlighted in gray.

EB 5576 EN 23

Operation

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Page 24

Exit data point for vacation periods.

Note: Vacation periods can also be entered in parameter level PA5 (–> section 2.3).

Deleting vacation periods:

q

Under data point for vacation periods, select the start date of the period you wish to de

-

lete.

Confirm selection.

q

Select – – – – .

Delete vacation period.

Note: Vacation periods should be deleted by the end of the year so that they are not carried

on into the following year.

24 EB 5576 EN

Operation

Page 25

1.9 Setting room and DHW temperature set points

For the heating circuits, the desired room temperatures during the day (Day set point) and

during the night (Night set point) can be entered into the controller.

In the DHW circuit, the temperature you wish the DHW to be heated to can be set.

The temperature set points for the different control circuits are set at the rotary switches one

after the other:

Desired temperature set point Switch Position

Heating circuit 1*: Day set point Top

Heating circuit 1*: Night set point Top

Heating circuit 2*: Day set point Middle

Heating circuit 2*: Night set point Middle

DHW circuit*: DHW temperature set point Bottom

* Refer to page 169 for assignment

Parameters

WE Rotary switch / Range of values

Day set point 20 °C Top, middle / –5 to 150 °C

Night set point 15 °C Top, middle / –5 to 150 °C

DHW temperature set point 60 °C Bottom / Min. to max. DHW temperature

Proceed as follows:

Turn appropriate rotary switch to “Set point temperature“.

Display shows: temperature

q

Set temperature value.

Return the rotary switch to the desired operating mode (left side).

EB 5576 EN 25

Operation

Page 26

26 EB 5576 EN

Operation

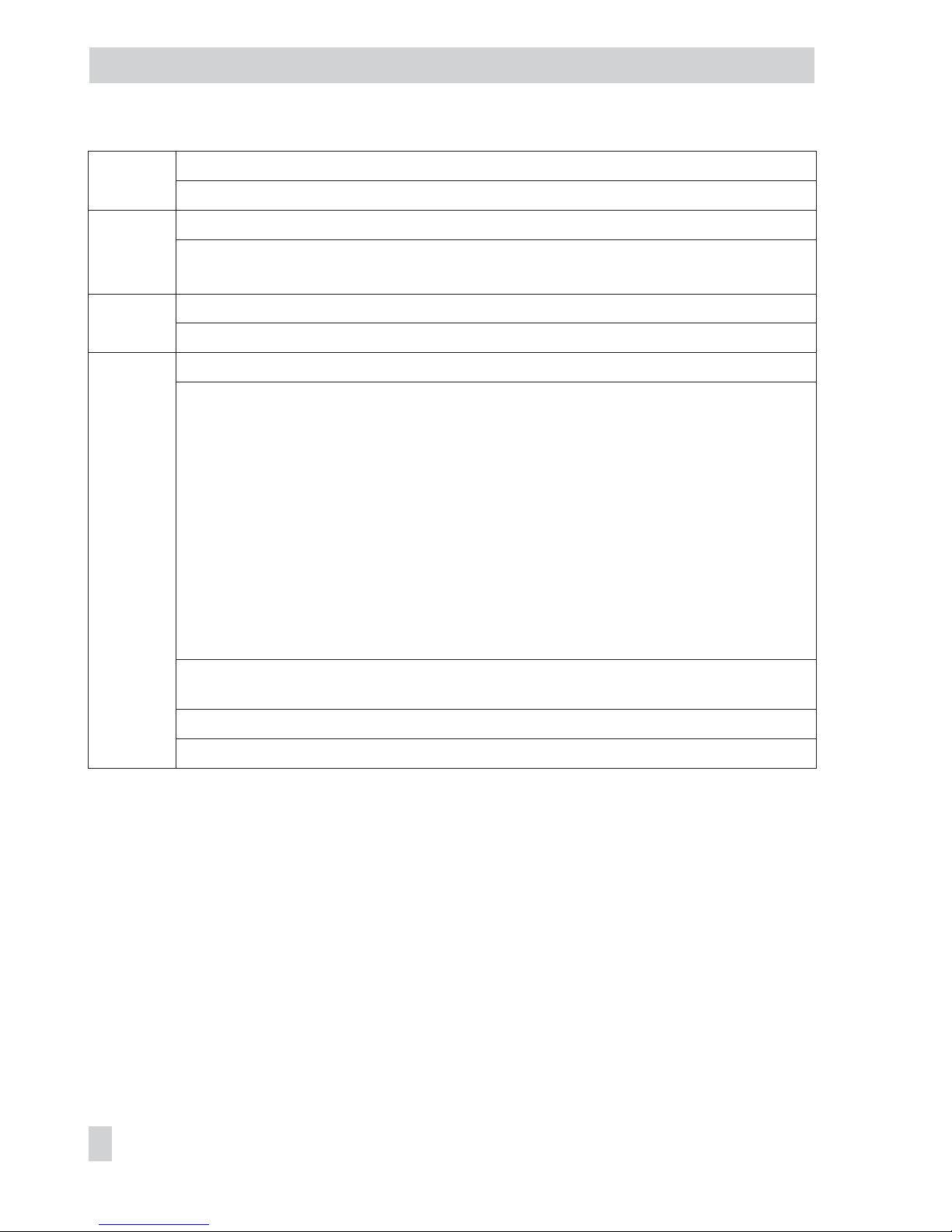

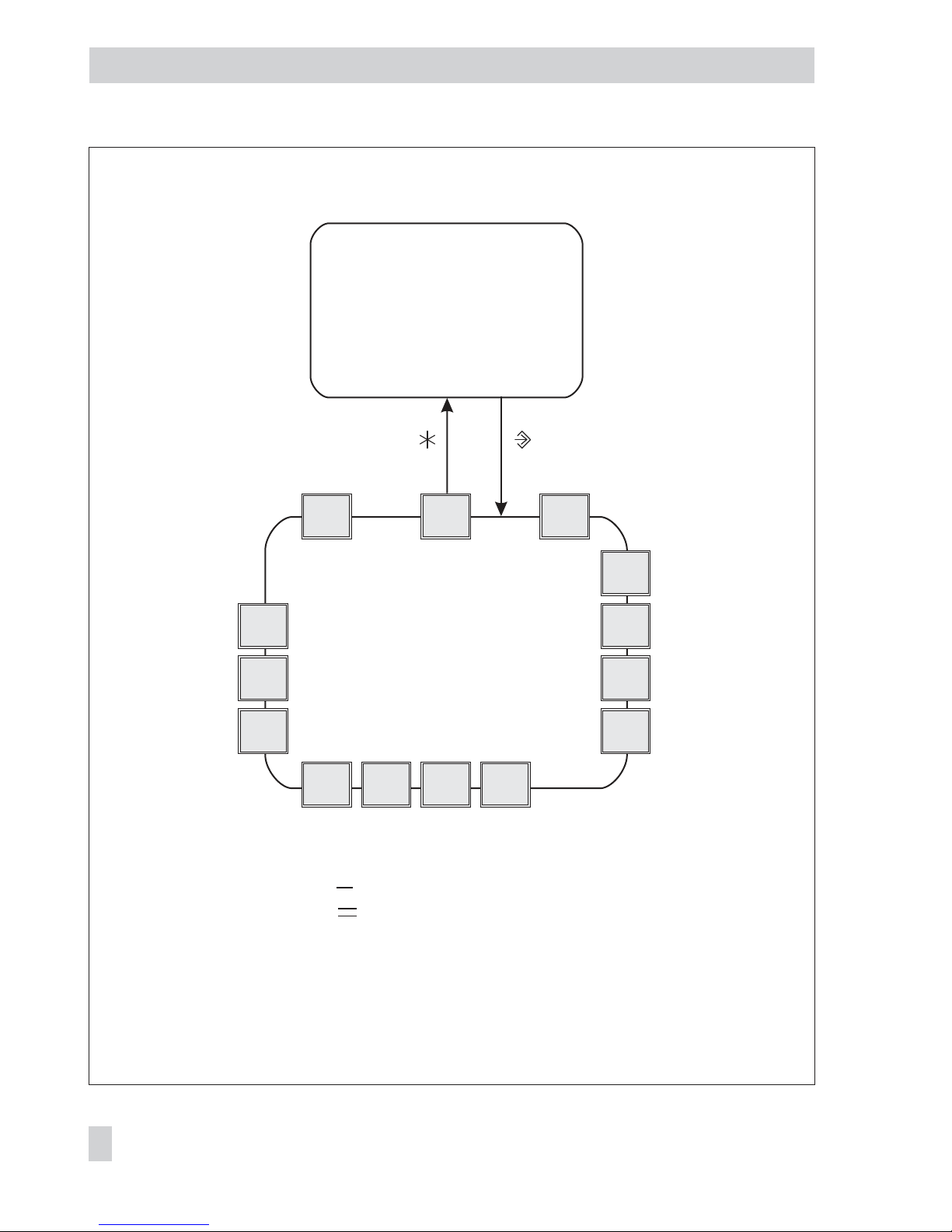

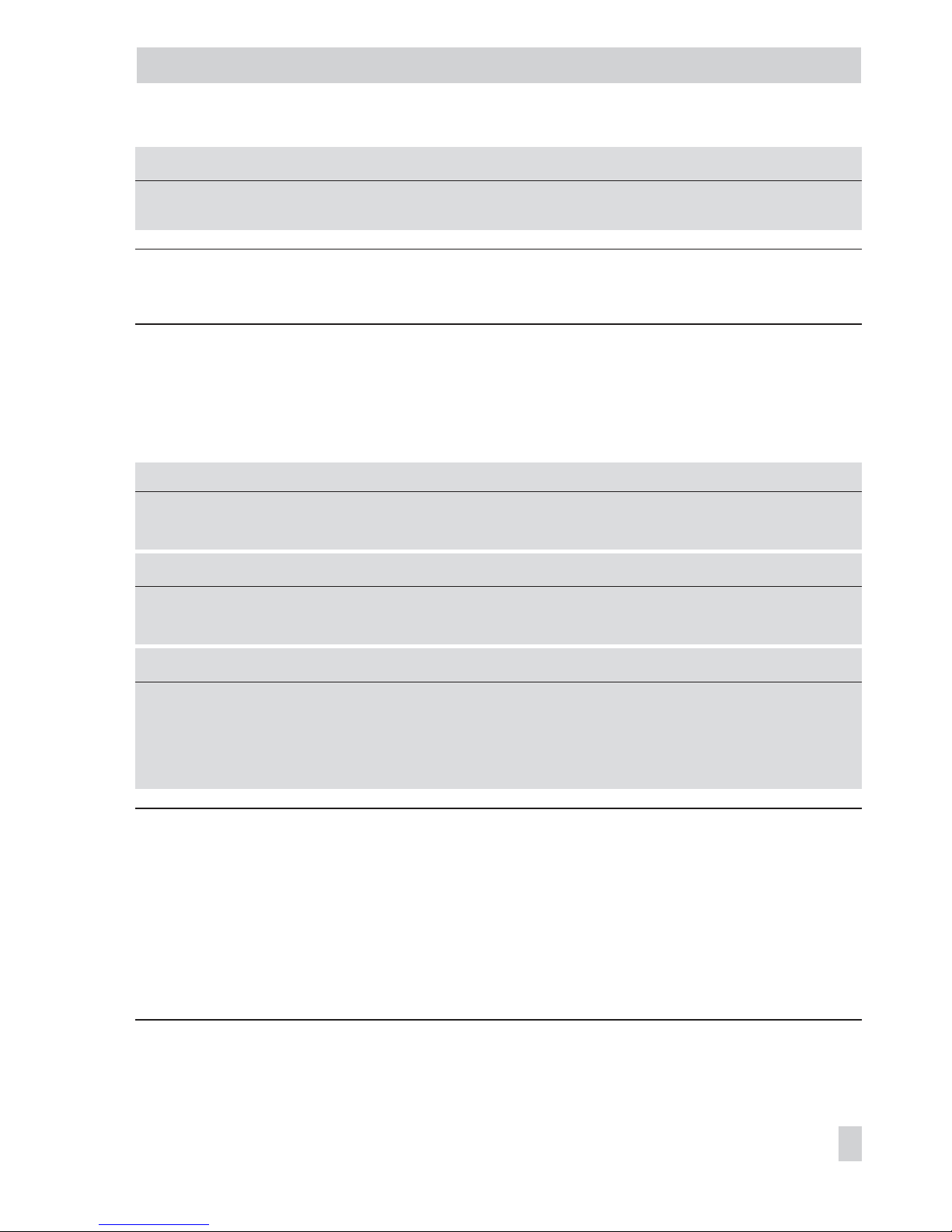

Fig. 2 · Level structure of TROVIS 5576

q

Configuration and

parameter level

(start-up, see section 2)

PA4

PA5

PA6

CO7

CO6

CO1

PA2

Anl

CO2CO4CO5

End PA1

CO8

q

Operating level

(display of time and

operation, see section 1)

& key number

PA1/CO1: Heating circuit Rk1 ( )

PA2/CO2: Heating circuit Rk2 ( )

PA4/CO4: DHW heating

PA5/CO5: System-wide parameters

PA6/CO6: Communication parameters/

Modbus/meter bus communication

CO7: Device bus

CO8: Initialization of free

inputs

Anl: System code number

Page 27

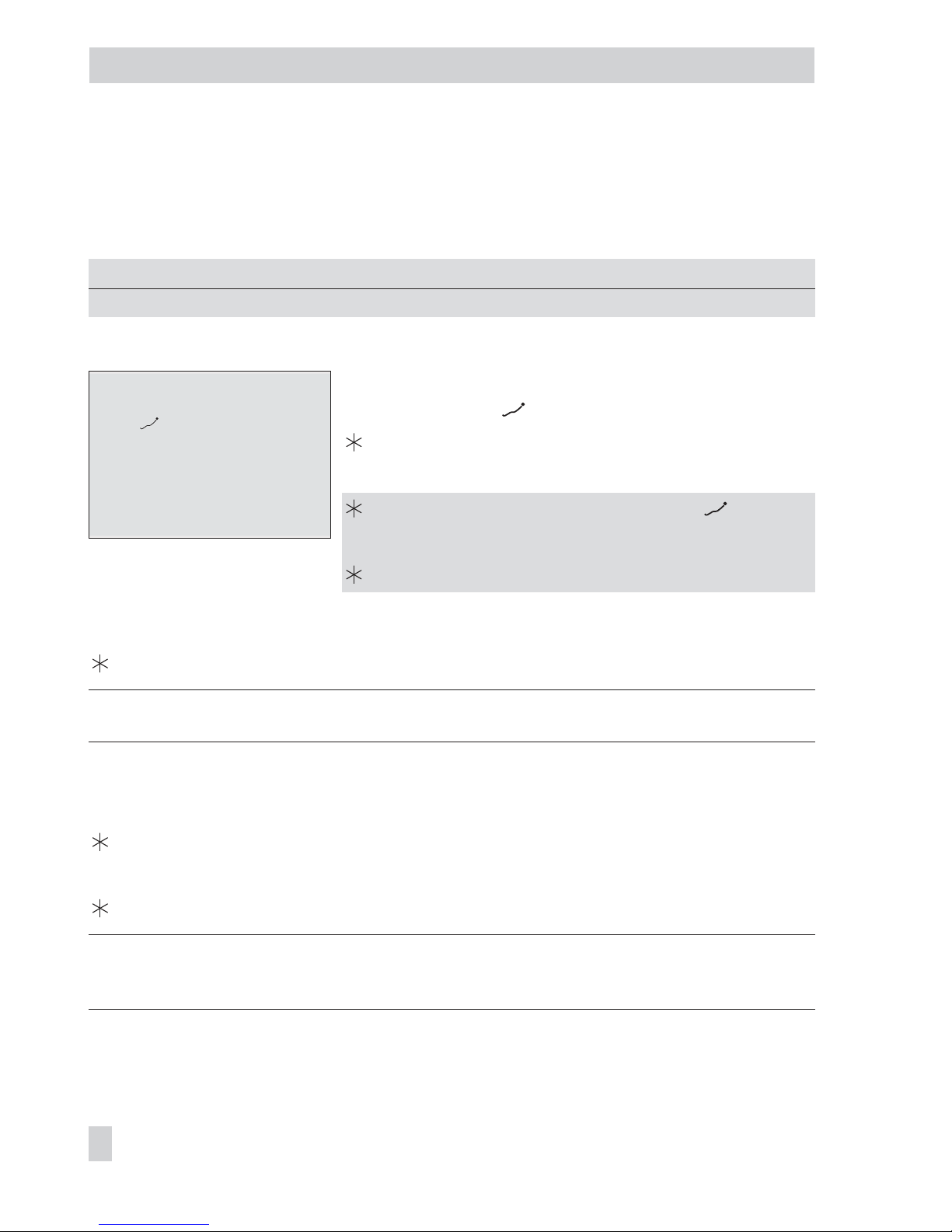

2 Start-up

The modifications of the controller configuration and parameter settings described in this sec

-

tion can only be performed after the valid key number has been entered.

The valid key number for initial start-up can be found on page 191. To avoid unauthorized

use of the key number, remove the page or make the key number unreadable. In addition, it

is possible to enter a new, customized key number (–> section 7.20).

2.1 Setting the system code number

Various hydraulic schematics are available. Each system configuration is represented by a

system code number. The different schematics are dealt with in section 4. Available controller

functions are described in sections 5, 6 and 7.

Changing the system code number resets previously adjusted function blocks to their default

settings (WE). Function block parameters and parameter level settings remain unchanged.

The system code number is set in the configuration level.

Proceed as follows:

Switch to configuration and parameter level.

Display shows: 0 0 0 0

q

Set valid key number.

Confirm key number.

Display shows: PA1

q

Select Anl (-> Fig. 2).

Activate editing mode for the system code number.

q

Edit system code number.

Confirm system code number.

Display shows: End

Return to operating level.

EB 5576 EN 27

Start-up

Page 28

2.2 Activating and deactivating functions

A function is activated or deactivated in the associated function block. The numbers 0 to 24

in the top row of the display represent the respective function block numbers. When a config

uration level is opened, the activated function blocks are indicated by a black square on the

right-hand side below the function block number. For more details on function blocks, refer to

section 12.1.

The functions are grouped by topics:

4

CO1: Heating circuit Rk1 ( )

4

CO2: Heating circuit Rk2 ( )

4

CO3: Not used

4

CO4: DHW heating

4

CO5: System-wide functions

4

CO6: Modbus and meter bus communication

4

CO7: Device bus

4

CO8: Initialization of free inputs

Proceed as follows:

Switch to configuration and parameter level.

Display shows: 0 0 0 0

q

Set valid key number.

Confirm key number.

Display shows: PA1

q

Select configuration level (-> Fig. 2).

Open configuration level.

q

Select function block.

Activated function blocks are marked by “- 1“.

Deactivated function blocks are marked by “- 0“.

Activate editing mode for the function block.

F__ blinks.

q

Activate the function block.

Display shows:

F__ - 1

An activated function block is indicated by a black square below (right) the function

block number in the top row of the controller display.

Or:

28 EB 5576 EN

Start-up

Page 29

q

Deactivate the function block.

Display shows: F__ - 0

Confirm settings.

If the function block is not closed, further function block parameters can be adjusted.

Proceed as follows:

Make the desired changes and confirm.

If applicable, the next function block parameter is displayed.

Confirm all parameters to exit the opened function block.

To adjust additional function blocks, repeat the steps in the fields highlighted in gray.

q

Select End.

Exit configuration level.

q

Select End.

Return to operating level.

Note: All function block settings are saved in the non-volatile memory of the controller.

2.3 Changing parameters

Depending on the set system code number and the activated functions, not all parameters

listed in the parameter list in the Appendix (–> section 12.2) might be available.

The parameters are grouped by topics:

4

PA1: Heating circuit Rk1 ( )

4

PA2: Heating circuit Rk2 ( )

4

PA3: Not used

4

PA4: DHW heating

4

PA5: Parameters for various systems

4

PA6: Communication parameters

4

PA7: Not used

4

PA8: Not used

EB 5576 EN 29

Start-up

Page 30

Proceed as follows:

Switch to configuration and parameter level.

Display shows: 0 0 0 0

q

Set valid key number.

Confirm key number.

Display shows: PA1

q

Select parameter level (-> Fig. 2).

Open parameter level.

q

Select desired parameter.

Activate editing mode for the parameter.

q

Edit the parameter.

Confirm the parameter.

To adjust additional parameters, repeat the steps in the fields highlighted in gray.

q Select End.

Exit parameter level.

q Select End.

Return to the operating level.

Note: All function block settings are saved in the non-volatile memory of the controller.

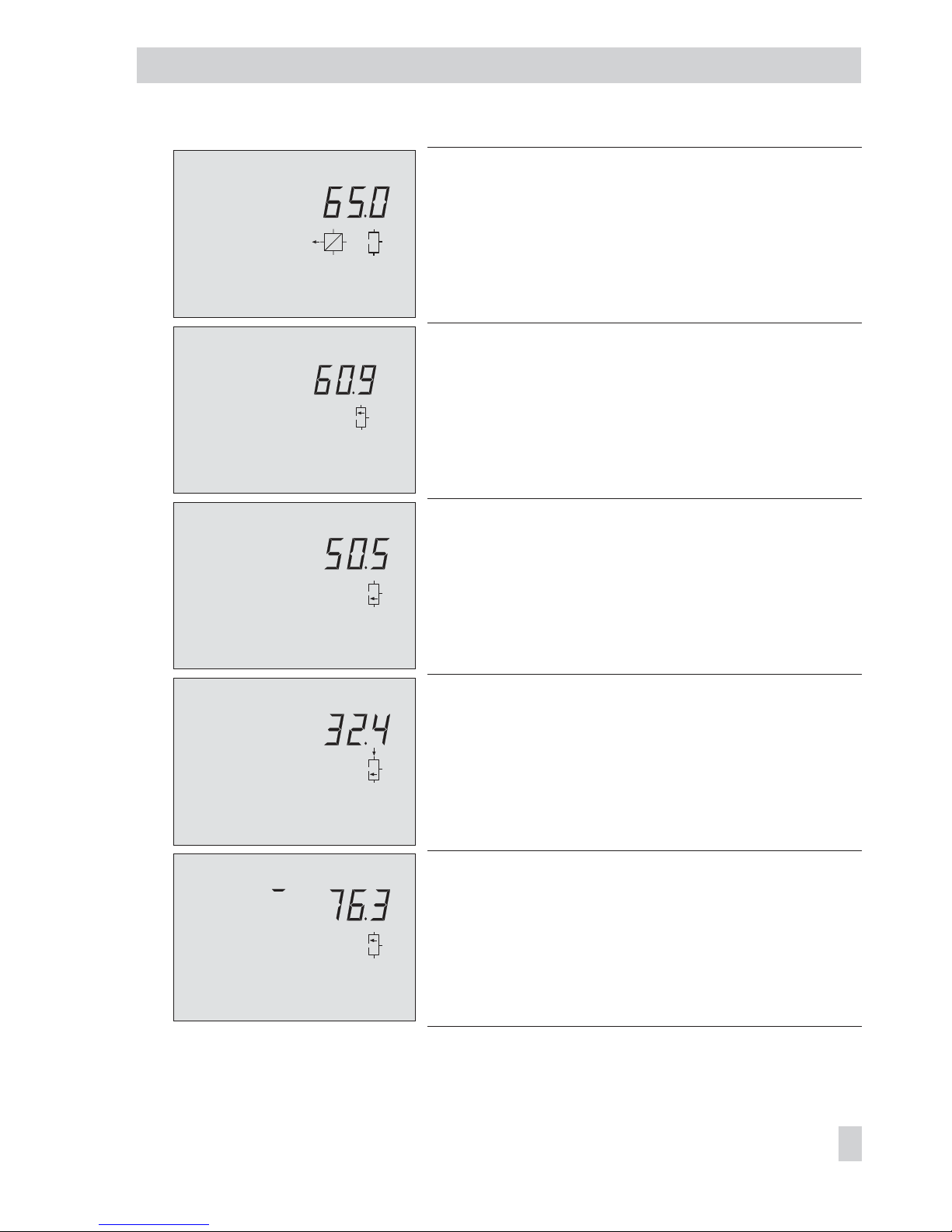

2.4 Calibrating sensors

The connected sensors are calibrated in configuration level CO5.

The following applies:

4

CO5 -> F01 - 1, CO5 -> F02 - 0, CO5 -> F03 - 0: Pt 1000 (Pt 100) sensors (default)

4

CO5 -> F01 - 0, CO5 -> F02 - 0, CO5 -> F03 - 0: PTC (Pt 100) sensors

4

CO5 -> F01 - 0, CO5 -> F02 - 1, CO5 -> F03 - 0: NTC (Pt 100) sensors

4

CO5 -> F01 - 1, CO5 -> F02 - 1, CO5 -> F03 - 0: Ni 1000 (Pt 100) sensors

4

CO5 -> F01 - 0, CO5 -> F02 - 0, CO5 -> F03 - 1: Pt 500 (Pt 100) sensors

The resistance values of the sensors can be found on page 170.

If the temperature values displayed at the controller differ from the actual temperatures, the

measured values of all connected sensors can be changed or readjusted. To calibrate a sen

-

30 EB 5576 EN

Start-up

Page 31

sor, the currently displayed sensor value must be changed such that it matches the tempera

ture (reference temperature) measured directly at the point of measurement.

Sensor calibration is to be activated in CO5 via function block F20.

An incorrect sensor calibration can be deleted by setting F20 - 0.

Proceed as follows:

Switch to configuration and parameter level. Display shows:

0 0 0 0

q

Set valid key number.

Confirm key number. Display shows: PA1

q

Select CO5 configuration level.

Open CO5 configuration level.

q

Select function block F20.

Activate editing mode for function block F20.

q Select appropriate sensor icon:

Room sensor

: Heating circuit Rk1

: Heating circuit Rk2

Outdoor sensor

: Heating circuit Rk1

: Heating circuit Rk2

EB 5576 EN 31

Start-up

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

°C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

°C

Page 32

Flow sensor VF

: Heating circuit Rk1

: Heating circuit Rk2

Flow sensor VF1, primary heat exchanger circuit

Flow sensor VF2, DHW circuit

Solar collector sensor VF3

Return flow sensor RüF

: Heating circuit Rk1

: Heating circuit Rk2

32 EB 5576 EN

Start-up

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

°C

Page 33

Return flow sensor RüF, DHW circuit

Storage tank sensor SF1 (DHW storage tank)

Storage tank sensor SF2 (DHW storage tank)

Storage tank sensor SF3 (DHW storage tank)

EB 5576 EN 33

Start-up

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

°C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

Page 34

Storage tank sensor SF2, SF3 (buffer tank)

Storage tank sensor SF4 (buffer tank)

Flow sensor VF4

Display measured value.

Measured value blinks.

q

Correct measured value.

Read the actual temperature directly from the thermometer at the point of measurement

and enter this value as the reference temperature.

Confirm corrected measured value.

Additional sensors are calibrated similarly.

q

Select End.

Exit configuration level.

q

Select End.

Return to operating level.

34 EB 5576 EN

Start-up

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

˚C

Page 35

2.5 Resetting to default values

All parameters in parameter levels PA1, PA2 and PA5 set over the rotary switches, except

for the maximum flow temperature and the return flow temperature limits in PA1/PA2, can

be reset to their default settings (WE).

Proceed as follows:

Switch to configuration and parameter level.

q

Set key number 1991.

Confirm key number.

EB 5576 EN 35

Start-up

Page 36

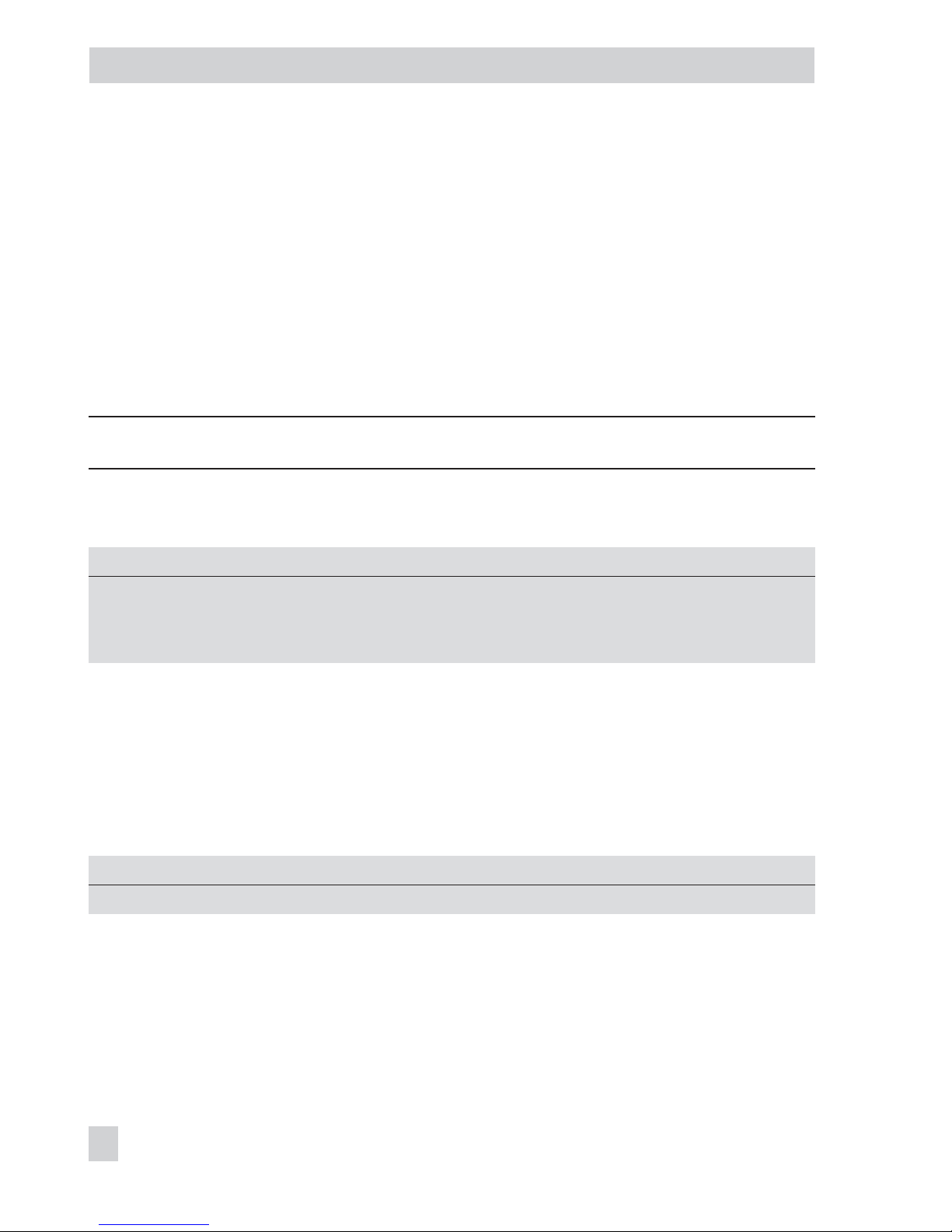

3 Manual operation

Switch to manual mode to configure all outputs (see wiring diagram in section 11).

The manual operation for the different control circuits is set at the rotary switches:

Manual operation Rotary switch Position

Heating circuit 1* Top

Heating circuit 2* Middle

DHW heating* Bottom

* Refer to page 169 for assignment

Proceed as follows:

Turn appropriate rotary switch to position “Manual operation“.

q

Select:

POS_ : Correction value in percent

UP_: Activation of the circulation pump

SLP: Activation of the storage tank charging pump

Confirm selection.

Display blinks.

q

Edit the correction value or activate/deactivate the circulation pump, etc.

Confirm edited settings.

The modified values remain active as long as the controller is in manual mode.

Return the rotary switch to the desired operating mode (left side).

Manual operation of the selected control circuit is deactivated by switching to any other

operating mode.

Note: Simply setting the rotary switch to position “Manual operation“ has no influence on

the outputs. You have to actually enter a correction value or activate/deactivate the pumps to

configure the outputs.

In manual mode, frost protection (–> section 7.2) cannot be activated.

36 EB 5576 EN

Manual operation

BE

BA

AE

AA

BE

BA

AE

AA

RüF1 VF1UP1RK1/Y1 RK1/Y1RF1 VF1UP1 RüF1 RF1

BE

BA

AE

AA

WW

KW

SF1SLP

BE

BA

AE

AA

WW

KW

SF1SLP

1.

Primary system

Secondary system

Primary system

2.

Secondary system

Page 37

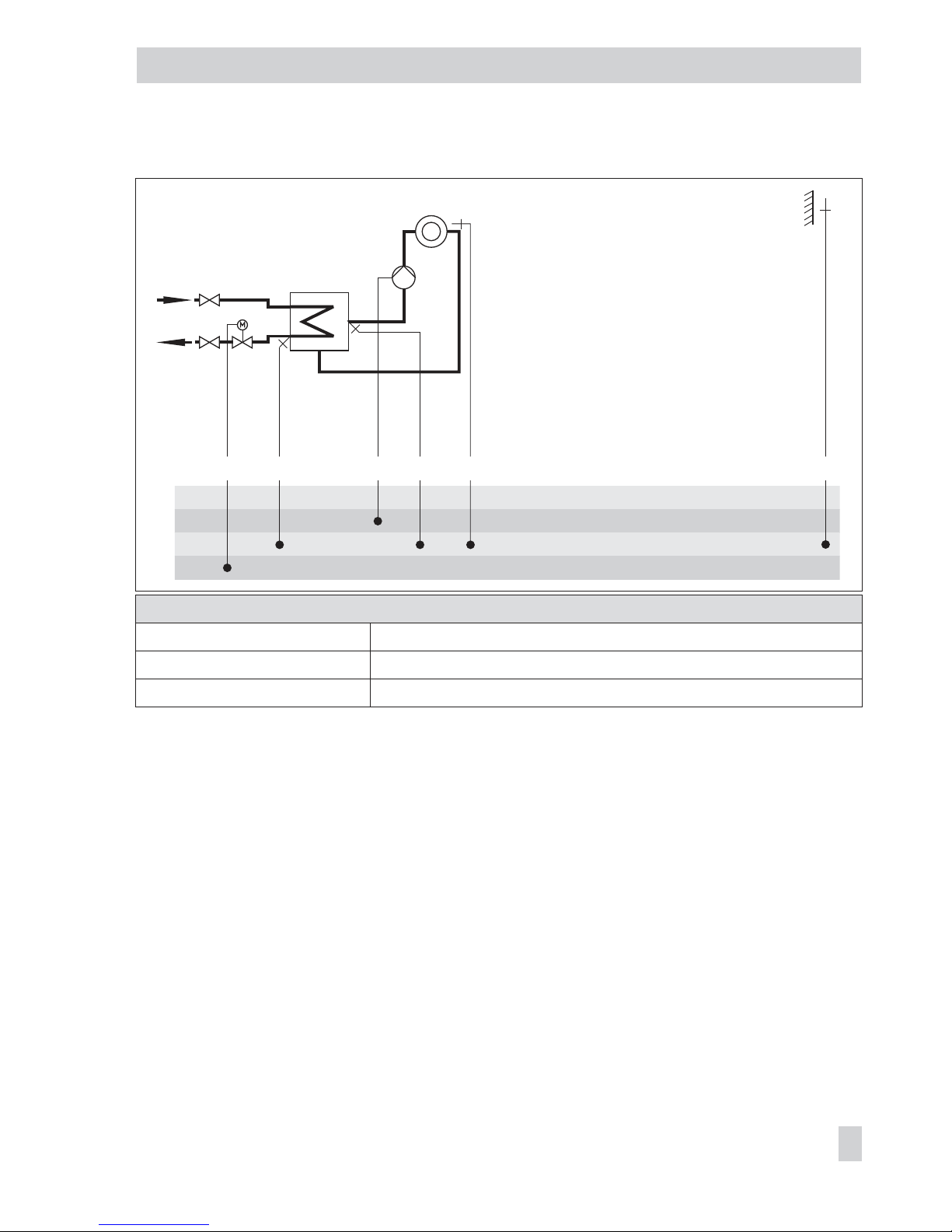

4 Systems

Various hydraulic schematics are available.

The systems can be configured both as primary and secondary systems. The fundamental hy

-

draulic differences between a primary and a secondary system are illustrated in Fig. 3.

4

1. A mixing valve replaces the heat exchanger in the heating/DHW circuit

4

2. A storage tank charging pump replaces the primary solenoid/thermoelectric valve

The controller settings do not have to be changed.

EB 5576 EN 37

Systems

Single-stage

boiler

Fig. 3 · Differences between primary and secondary systems

Page 38

Boiler systems:

Single-stage boiler systems can be configured to include any system whose heating circuits

and DHW circuit include just one heat exchanger. These systems are Anl 1.0, 1.5 to 1.8,

2.x, 3.x, 4.0 to 4.3, 7.x, 8.x and 16.x.

The boiler can be controlled by an on/off output (CO1 -> F12 - 0).

38 EB 5576 EN

Systems

RK1/Y1 RüF1 VF1 UP1 RF1

BE

BA

AE

AA

RK1_on/off VF1 UP1 RF1

BE

BA

AE

AA

Fig. 4 · Configuration of a boiler system

Page 39

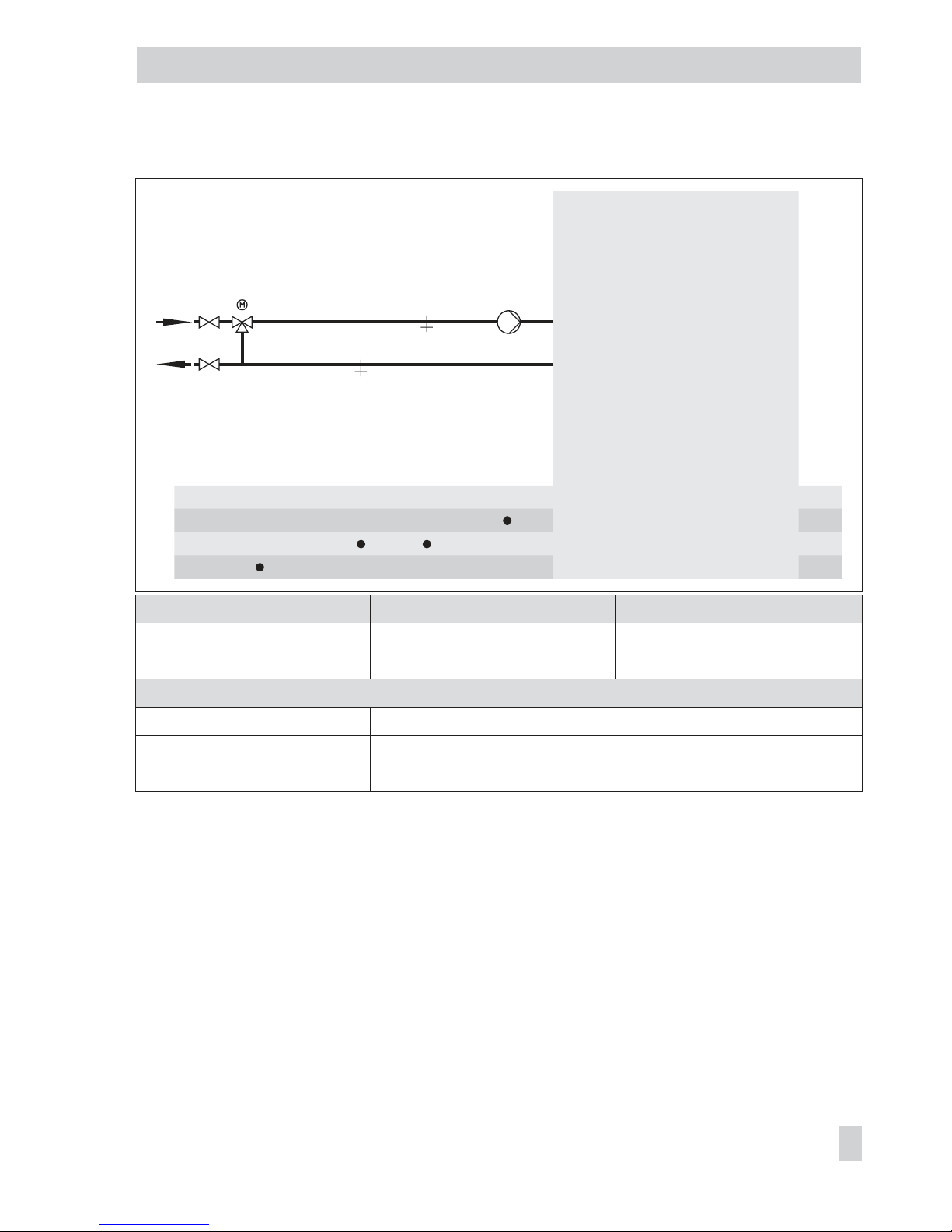

System Anl 1.0

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

EB 5576 EN 39

Systems

BE

BA

AE

AA

AF1RüF1 VF1UP1RK1/Y1 RF1

Page 40

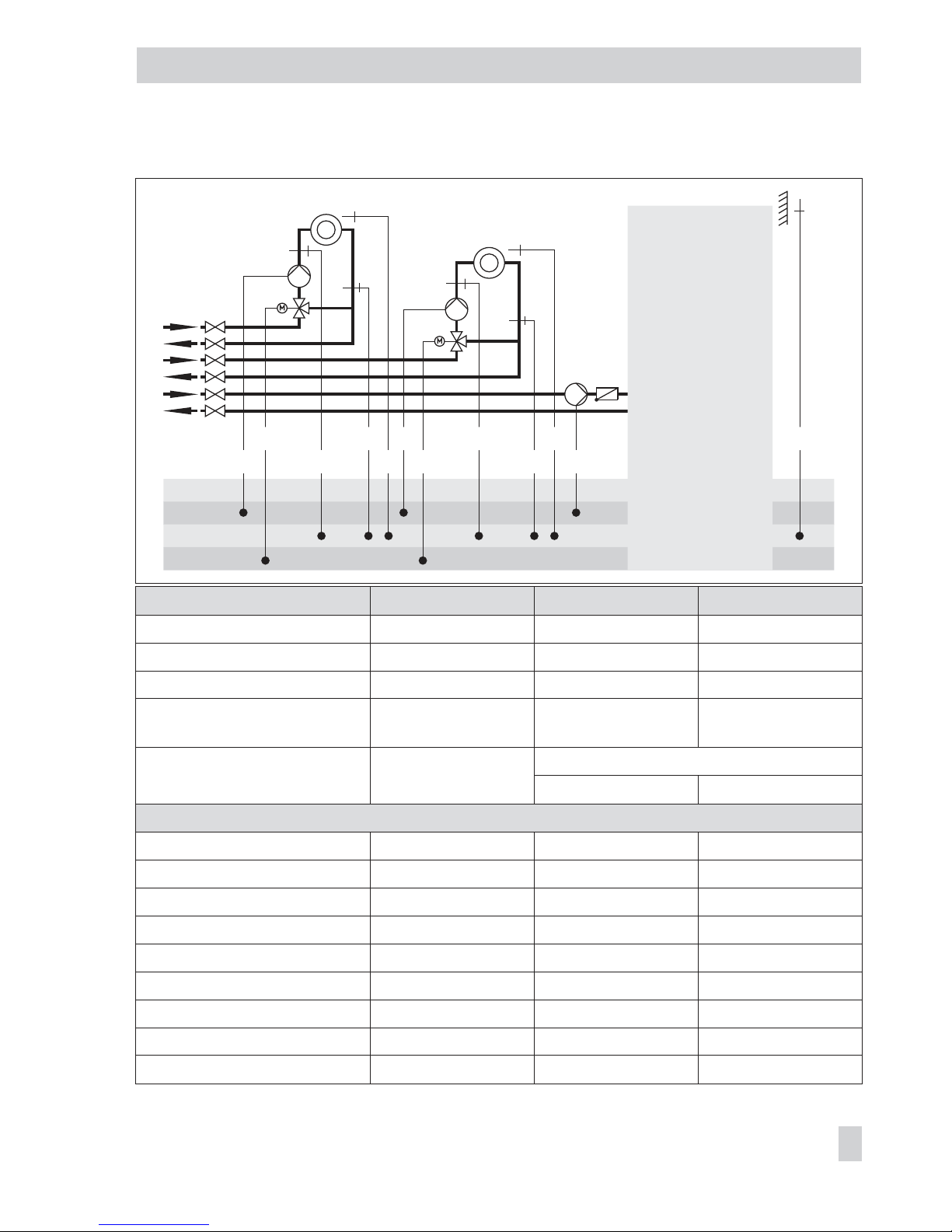

Systems Anl 1.1 to 1.4

System Anl 1.1 Anl 1.2 Anl 1.3 Anl 1.4

Type of DHW heating Type 1 Type 2 Type 3 Type 4

1)

XX = SLP UP2 SLP UP2

Integration of flow sensor VF4 Possible Possible Possible Possible

ZP integration (broken line)

with CO4 -> F10 - 1

– Not possible – Not possible

Note –

Only second

-

ary system

–

Only second

-

ary system

Default settings

CO1 -> F01 - 0 (w/o RF1) - 0 (w/o RF1) - 0 (w/o RF1) - 0 (w/o RF1)

CO1 -> F02 - 1 (with AF1) - 1 (with AF1) - 1 (with AF1) - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1) - 0 (w/o RüF1) - 1 (with RüF1) - 0 (w/o RüF1)

CO4 -> F01 - 1 (with SF1) - 1 (with SF1) - 1 (with SF1) - 1 (with SF1)

CO4 -> F02 - 0 (w/o SF2) - 1 (with SF2) - 0 (w/o SF2) - 1 (with SF2)

CO4 -> F05 - 0 (w/o VF4) - 0 (w/o VF4) - 0 (w/o VF4) - 0 (w/o VF4)

40 EB 5576 EN

Systems

UP1 XX

1)

AF1 RK1/Y1 VF1 RüF1 RF1

BE

BA

AE

AA

DHW

heating

Unfold back cover!

Page 41

Systems Anl 1.5 and 1.7

System Anl 1.5 Anl 1.7

Type of DHW heating Type 1 Type 3

Integration of flow sensor VF4 Not possible Not possible

Default settings

CO1 -> F03 - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1)

CO4 -> F02 - 0 (without SF2)

EB 5576 EN 41

Systems

BE

BA

AE

AA

SLPRüF1 VF1RK1/Y1

DHW

heating

Unfold back cover!

Page 42

Systems Anl 1.6 and 1.8

System

Anl 1.6

With pre-control

Anl 1.8

With pre-control

Anl 1.6

W/o pre-control

Anl 1.8

W/o pre-control

Type of DHW heating Type 2 Type 4 Type 2 Type 4

Integration of VF4, UP1 • –

ZP integration (broken line)

with CO4 -> F10 - 1

Possible Possible

Note –

VF1 takes the position of VF4;

RüF1 is to be installed in the heat

exchanger

Default settings

CO1 -> F03 - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1)

CO4 -> F02 - 1 (with SF2)

CO4 -> F05 - 0 (without VF4)

42 EB 5576 EN

Systems

BE

BA

AE

AA

RüF1RK1/Y1

UP1 VF1

DHW

heating

Unfold back cover!

Page 43

System Anl 1.9

System

Anl 1.9

With pre-control

Anl 1.9

Without pre-control

Integration of VF4, UP2 Yes No

Note

–

VF2 takes the position of VF4

Default settings

CO4 -> F01 - 0 (without SF1)

CO4 -> F03 - 0 (without RüF2)

CO4 -> F04 - 0 (without water flow sensor at BE17)

CO4 -> F05 - 0 (without VF4)

EB 5576 EN 43

Systems

BE

BA

AE

AA

RK2/Y2

UP2 VF2

WW

KW

ZP

VF4

BE17

SF1

RüF2

Page 44

System Anl 2.0

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1)

CO4 -> F02 - 0 (without SF2)

44 EB 5576 EN

Systems

BE

BA

AE

AA

WW

KW

AF1ZP RüF1 VF1 UP1

SLP (Rk2) SF1RK1/Y1 RF1

Page 45

Systems Anl 2.1 to 2.4

System Anl 2.1 Anl 2.2 Anl 2.3 Anl 2.4

Type of DHW heating Type 1 Type 2 Type 3 Type 4

1)

XX = SLP UP2 SLP UP2

Integration of flow sensor VF4 Not possible Possible Not possible Possible

ZP integration (broken line)

with CO4 -> F10 - 1

– Not possible – Not possible

Default settings

CO1 -> F01 - 0 (w/o RF1) - 0 (w/o RF1) - 0 (w/o RF1) - 0 (w/o RF1)

CO1 -> F02 - 1 (with AF1) - 1 (with AF1) - 1 (with AF1) - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1) - 1 (with RüF1) - 1 (with RüF1) - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1) - 1 (with SF1) - 1 (with SF1) - 1 (with SF1)

CO4 -> F02 - 0 (w/o SF2) - 1 (with SF2) - 0 (w/o SF2) - 1 (with SF2)

CO4 -> F05 - 0 (w/o VF4) - 0 (w/o VF4)

EB 5576 EN 45

Systems

BE

BA

AE

AA

AF1

RüF1 VF1

UP1RK1/Y1 RF1

XX

1)

DHW-

heating

Unfold back cover!

Page 46

System Anl 3.0

Default settings

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO2 -> F01 - 0 (without RF2)

CO2 -> F03 - 0 (without RüF2)

46 EB 5576 EN

Systems

BE

BA

AE

AA

AF1RüF1 VF1 UP2

RK2/Y2RK1/Y1

RF2

VF2

RüF2UP1 UP1

Page 47

Systems Anl 3.1 to 3.4

System Anl 3.1 Anl 3.2 Anl 3.3 Anl 3.4

Type of DHW heating Type 1 Type 2 Type 3 Type 4

1)

XX = SLP UP1 SLP UP1

Integration of flow sensor VF4 Not possible Possible Not possible Possible

ZP integration (broken line)

with CO4 -> F10 - 1

– Possible – Not possible

Note –

–

Binary output

BA9 replaced

by UP1

Only 0 to 10 V

output signal

available (Y2)

Default settings

CO1 -> F02 - 1 (with AF1) - 1 (with AF1) - 1 (with AF1) - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1) - 1 (with RüF1) - 1 (with RüF1) - 1 (with RüF1)

CO2 -> F01 - 0 (w/o RF2) - 0 (w/o RF2) - 0 (w/o RF2) - 0 (w/o RF2)

CO2 -> F03 - 0 (w/o RüF2) - 0 (w/o RüF2) - 0 (w/o RüF2) - 0 (w/o RüF2)

CO4 -> F01 - 1 (with SF1) - 1 (with SF1) - 1 (with SF1) - 1 (with SF1)

CO4 -> F02 - 0 (w/o SF2) - 1 (with SF2) - 0 (w/o SF2) - 1 (with SF2)

CO4 -> F05 - 0 (w/o VF4) - 0 (w/o VF4)

EB 5576 EN 47

Systems

BE

BA

AE

AA

AF1

RüF1

VF1

UP2

RK2/Y2RK1/Y1

RF2

VF2

RüF2 XX

1)

DHW

heating

Unfold back cover!

Page 48

System Anl 3.5

Note

Control and UP1 are only active during processing for external

demand.

Default setting

CO1 -> F03 - 1 (with RüF1)

48 EB 5576 EN

Systems

BE

BA

AE

AA

RüF1 VF1

RK1/Y1 UP1

Page 49

System Anl 4.0

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO2 -> F01 - 0 (without RF2)

CO2 -> F02 - 0 (without AF2)

CO2 -> F03 - 0 (without RüF2)

EB 5576 EN 49

Systems

BE

BA

AE

AA

AF1

RüF1

VF1

UP2

RK2/Y2RK1/Y1

RF2

VF2

RüF2

RF1

UP1

Page 50

Systems Anl 4.1 to 4.3

System Anl 4.1 Anl 4.2 Anl 4.3

Type of DHW heating Type 1 Type 2 Type 3

1)

XX = SLP BA9 SLP

Integration of VF4 Not possible Possible Not possible

ZP integration (broken line)

with CO4 -> F10 - 1

– Not possible –

Note –

Only 0 to 10 V output signal available (Y2)

Default settings

CO1 -> F01 - 0 (w/o RF1) - 0 (w/o RF1) - 0 (w/o RF1)

CO1 -> F02 - 1 (with AF1) - 1 (with AF1) - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1) - 1 (with RüF1) - 1 (with RüF1)

CO2 -> F01 - 0 (w/o RF2) - 0 (w/o RF2) - 0 (w/o RF2)

CO2 -> F02 - 0 (w/o AF2) - 0 (w/o AF2) - 0 (w/o AF2)

CO2 -> F03 - 0 (w/o RüF2) - 0 (w/o RüF2) - 0 (w/o RüF2)

CO4 -> F01 - 1 (with SF1) - 1 (with SF1) - 1 (with SF1)

CO4 -> F02 - 0 (w/o SF2) - 1 (with SF2) - 0 (w/o SF2)

CO4 -> F05 - 0 (w/o VF4)

50 EB 5576 EN

Systems

BE

BA

AE

AA

AF1RüF1

VF1

UP2

RK2/Y2RK1/Y1

RF2

VF2

RüF2 RF1UP1

XX1)

DHW heating

Unfold

back cover!

Page 51

System Anl 4.5

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO2 -> F01 - 0 (without RF2)

CO2 -> F02 - 0 (without AF2)

CO2 -> F03 - 0 (without RüF2)

CO4 -> F01 - 1 (with SF1)

CO4 -> F02 - 0 (without SF2)

EB 5576 EN 51

Systems

BE

BA

AE

AA

AF1

RüF1

VF1

UP2

RK2/Y2RK1/Y1

RF2

VF2

RüF2

RF1

UP1

WW

KW

SF1SLP ZP

Page 52

Systems Anl 7.1 and 7.2

System Anl 7.1 Anl 7.2

Type of DHW heating Type 1 Type 2

1)

XX = SLP UP2

Integration of VF4 Not possible Possible

ZP integration (broken line)

with CO4 -> F10 - 1

– Possible

Default settings

CO1 -> F03 - 1 (with RüF1) - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1) - 1 (with SF1)

CO4 -> F02 - 0 (without SF2) - 1 (with SF2)

CO4 -> F03 - 0 (without RüF2) - 0 (without RüF2)

CO4 -> F05 - 0 (without VF4)

52 EB 5576 EN

Systems

BE

BA

AE

AA

RüF1 VF1

RK2/Y2RK1/Y1

VF2 RüF2

XX1)UP1 UP1

DHW

heating

Unfold back cover!

Page 53

Systems Anl 8.1 and 8.2

System Anl 8.1 Anl 8.2

Type of DHW heating Type 1 Type 2

1)

XX = SLP UP2

Integration of VF4 Not possible Possible

ZP integration (broken line)

with CO4 -> F10 - 1

– –

Default settings

CO1 -> F01 - 0 (without RF1) - 0 (without RF1)

CO1 -> F02 - 1 (with AF1) - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1) - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1) - 1 (with SF1)

CO4 -> F02 - 0 (without SF2) - 1 (with SF2)

CO4 -> F03 - 0 (without RüF2) - 0 (without RüF2)

CO4 -> F05 - 0 (without VF4)

EB 5576 EN 53

Systems

BE

BA

AE

AA

AF1

RüF1

VF1

UP1

RK1/Y1 RF1

RK2/Y2

VF2 RüF2

XX1)

DHW heating

Unfold back cover!

Page 54

System Anl 10.0

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO2 -> F01 - 0 (without RF2)

CO2 -> F02 - 0 (without AF2)

CO2 -> F03 - 1 (with RüF2)

54 EB 5576 EN

Systems

BE

BA

AE

AA

AF1RüF1

VF1

UP1RK1/Y1

RF1

RüF2

VF2 UP2

RK2/Y2 RF2

Page 55

Systems Anl 10.1 to 10.3

System Anl 10.1 Anl 10.2 Anl 10.3

Type of DHW heating Type 1 Type 2 Type 3

1)

XX = SLP BA9 SLP

Integration of VF4 Possible Possible Possible

ZP integration (broken line)

with CO4 -> F10 - 1

– Not possible –

Note

–

Only 0 to 10 V output signal available (Y2)

Only second. system

Default settings

CO1 -> F01 - 0 (w/o RF1) - 0 (w/o RF1) - 0 (w/o RF1)

CO1 -> F02 - 1 (with AF1) - 1 (with AF1) - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1) - 0 (w/o RüF1) - 1 (with RüF1)

CO2 -> F01 - 0 (w/o RF2) - 0 (w/o RF2) - 0 (w/o RF2)

CO2 -> F02 - 0 (w/o AF2) - 0 (w/o AF2) - 0 (w/o AF2)

CO2 -> F03 - 1 (with RüF2) - 0 (w/o RüF2) - 1 (with RüF2)

CO4 -> F01 - 1 (with SF1) - 1 (with SF1) - 1 (with SF1)

CO4 -> F02 - 0 (w/o SF2) - 1 (with SF2) - 0 (w/o SF2)

CO4 -> F05 - 0 (w/o VF4) - 0 (w/o VF4) - 0 (w/o VF4)

EB 5576 EN 55

Systems

BE

BA

AE

AA

UP1 XX

1)

AF1 RK1/Y1

VF1

RüF1

RF1

UP2

RK2/Y2

VF2

RüF2

RF2

DHW heating

Unfold

back cover!

Page 56

System Anl 10.5

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F03 - 1 (with RüF1)

CO2 -> F01 - 0 (without RF1)

CO2 -> F03 - 1 (with RüF2)

56 EB 5576 EN

Systems

BE

BA

AE

AA

RüF1 VF1RK1/Y1

RüF2 VF2RK2/Y2

UP1

UP2

Page 57

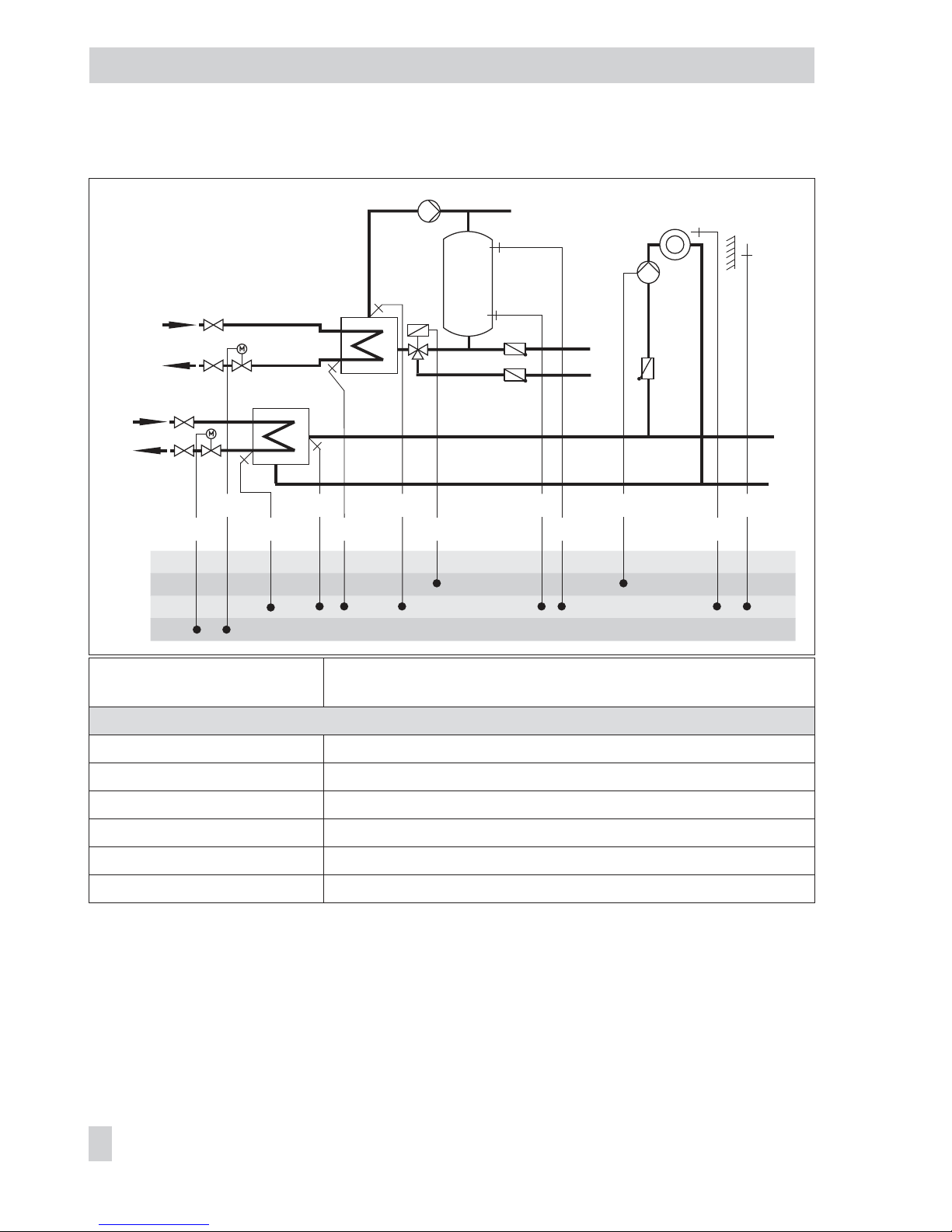

Systems Anl 11.0 and 11.3

System Anl 11.0 Anl 11.3

Type of DHW heating Type 1 Type 3

Integration of VF4 Not possible Not possible

ZP integration (broken line)

with CO4 -> F10 - 1

– –

Note

–

Binary output BA9

replaced by UP2

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO4 -> F03 - 0 (without RüF2)

EB 5576 EN 57

Systems

BE

BA

AE

AA

AF1RüF1 RüF2

VF1

UP1RK1/Y1

RF1

RK2/Y2

DHW heating

Unfold back cover!

Page 58

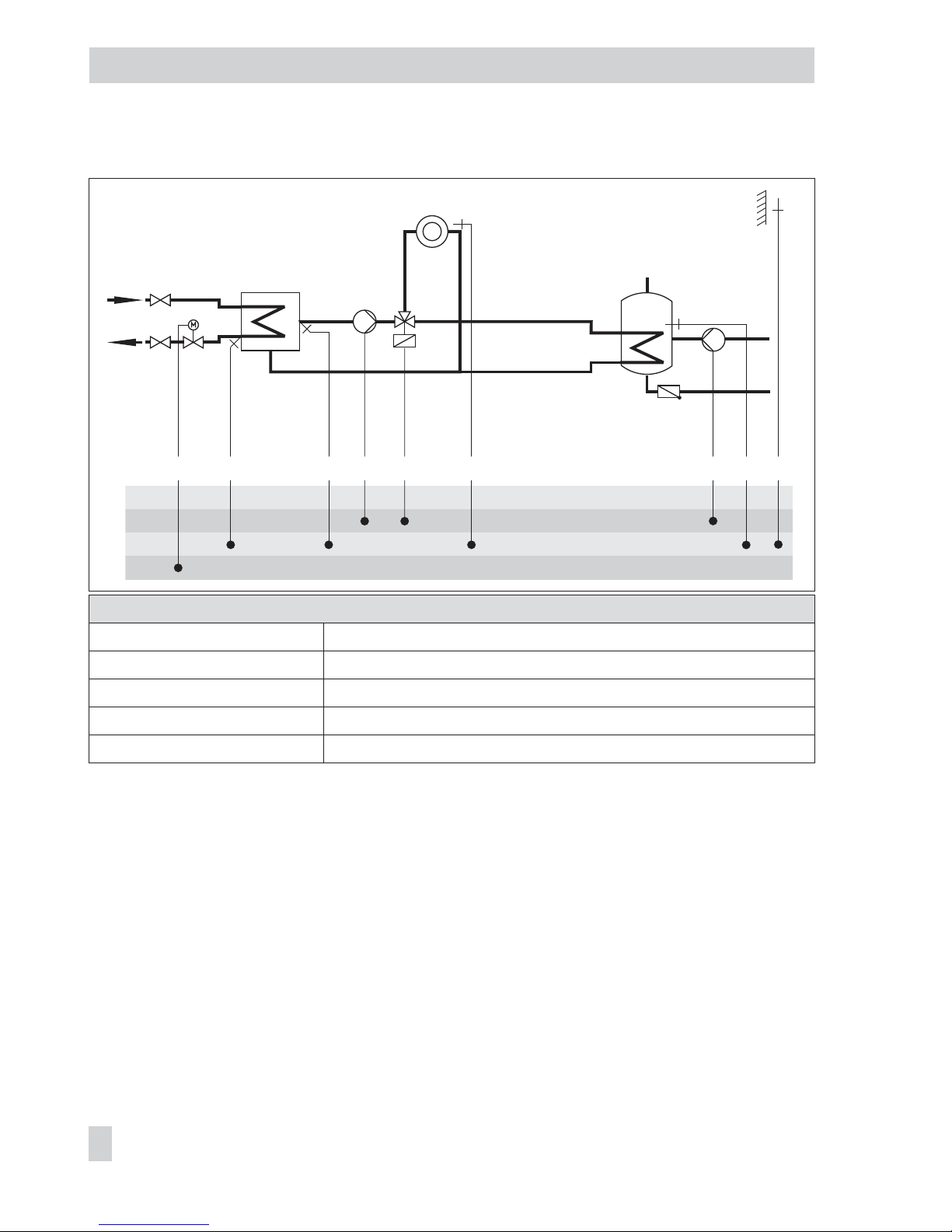

System Anl 11.1

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1)

CO4 -> F02 - 0 (without SF2)

CO4 -> F03 - 0 (without RüF2)

The system code Anl 11.1 can also be used for systems with buffer tank. See page 60.

58 EB 5576 EN

Systems

BE

BA

AE

AA

WW

KW

UP1 RK1/Y1 VF1 RüF1 RF1 AF1 ZP SLPRüF2 VF2 SF1RK2/Y2

Page 59

System Anl 11.2

System

Anl 11.2

With pre-control

Anl 11.2

Without pre-control

Type of DHW heating Type 2 Type 2

Integration of VF4, UP2 • –

ZP integration (broken line)

with CO4 -> F10 - 1

Possible Possible

Note

–

VF2 takes the position of VF4

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1)

CO4 -> F02 - 1 (with SF2)

CO4 -> F03 - 0 (without RüF2)

CO4 -> F05 - 0 (without VF4)

The system code Anl 11.2 can also be used for systems with buffer tank. See page 60.

EB 5576 EN 59

Systems

BE

BA

AE

AA

WW

KW

AF1

SF2

ZP SLPRüF1

VF1 VF4

RüF2UP1

SF1

RK1/Y1

RK2/Y2 RF1

UP2

VF2

Page 60

System Anl 11.1/11.2 with buffer tank

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1)

CO4 -> F02

Anl 11.1 - 0 (without SF2)

Anl 11.2 - 1 (with SF2)

CO4 -> F03 - 0 (without RüF2)

60 EB 5576 EN

Systems

WW

KW

BE

BA

AE

AA

AF1

RüF2

VF2RK2 ZP SF1

SF2SLP RK1 RF1VF1

RüF1UP1

Page 61

System Anl 11.4

ZP integration (broken line)

with CO4 -> F10 - 1

Possible

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1)

CO4 -> F02 - 1 (with SF2)

CO4 -> F03 - 0 (without RüF2)

The system code Anl 11.4 can also be used for systems with buffer tank. See page 62.

EB 5576 EN 61

Systems

BE

BA

AE

AA

SLPRüF1

VF1 VF2

AF1

RüF2UP1RK1/Y1

RK2/Y2 RF1

WW

KW

SF1ZP

UP2 SF3 SF2

VF3

Page 62

System Anl 11.4 with buffer tank

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1)

CO4 -> F02 - 1 (with SF2)

CO4 -> F03 - 0 (without RüF2)

62 EB 5576 EN

Systems

WW

KW

BE

BA

AE

AA

AF1RüF2

VF2

VF3

RK2 ZP

SF1

SF2

SF3SLP

RK1UP2 RF1VF1

RüF1UP1

Page 63

System Anl 11.5

Note DHW circuit with adjustable valve position for storage tank charging

in absolute priority operation. By using RüF2, the ready-adjusted

valve position is governed by the return flow temperature limitation.

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO4 -> F02 - 0 (without SF2)

CO4 -> F03 - 1 (with RüF2)

EB 5576 EN 63

Systems

BE

BA

AE

AA

RK1/Y1

RüF1

VF1 UP1 AF1

RF1

WW

KW

ZP

RüF2

SF1

RK2

Page 64

System Anl 11.6

*Note: The pump in the DHW circuit is designed to run constantly. There-

fore, it must connected directly to the mains supply.

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1)

CO4 -> F02 - 1 (with SF2)

CO4 -> F03 - 0 (without RüF2)

64 EB 5576 EN

Systems

BE

BA

AE

AA

WW

KW

Z

RK1/Y1

VF2VF1 SF2 UP1 AF1

RüF2 SLP/ZP SF1 RF1

*

RK2/Y2

RüF1

Page 65

System Anl 11.9

System

Anl 11.9

With pre-control

Anl 11.9

Without pre-control

Integration of VF4, UP2 Yes No

Note

–

VF2 takes the position of VF4

Default settings

CO1 -> F01 - 0 (without RF1)

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO4 -> F01 - 0 (without SF1)

CO4 -> F03 - 0 (without RüF2)

CO4 -> F04 - 0 (without water flow sensor at BE17)

CO4 -> F05 - 0 (without VF4)

EB 5576 EN 65

Systems

BE

BA

AE

AA

AF1

RüF1

VF1

UP1RK1/Y1

RK2/Y2 RF1

UP2

VF2

WW

KW

ZP

VF4

BE17

SF1

RüF2

Page 66

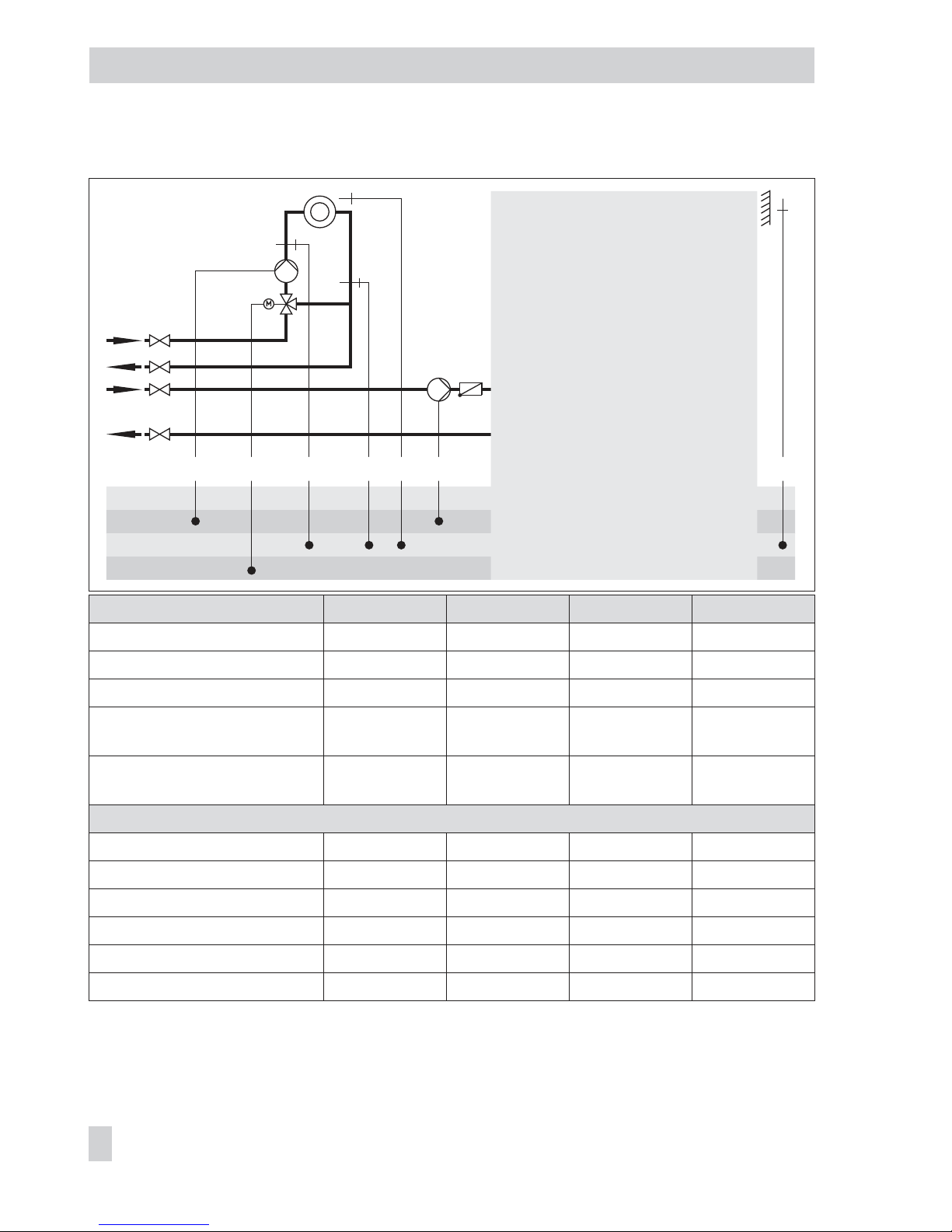

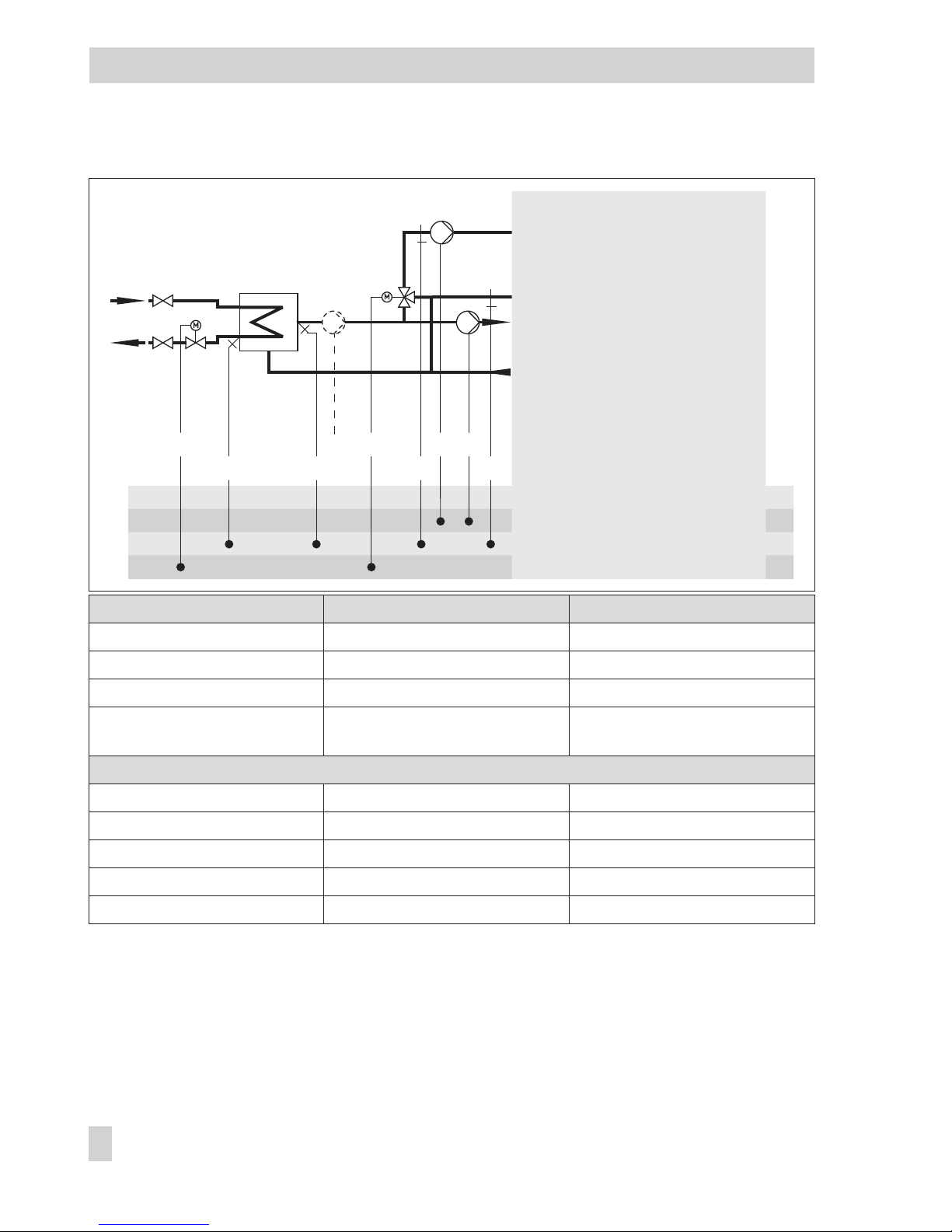

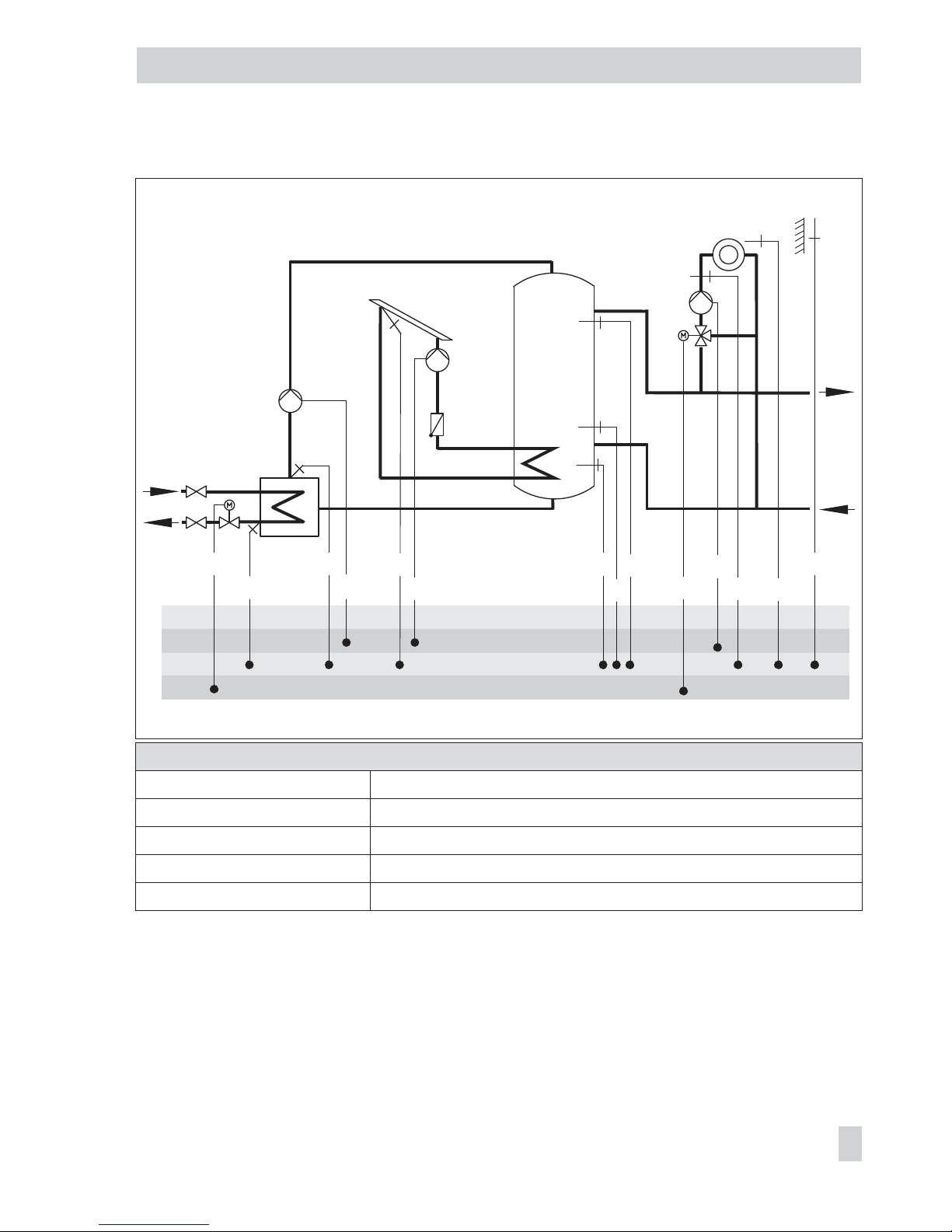

Systems Anl 14.1 and 14.2

System Anl 14.1 Anl 14.2

Type of DHW heating Type 1 Type 2

1)

XX = SLP UP1

Integration of UP1 Possible Not possible

Default settings

CO1 -> F02 - 1 (with AF1) - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1) - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1) - 1 (with SF1)

CO4 -> F02 - 0 (w/o SF2) - 1 (with SF2)

66 EB 5576 EN

Systems

BE

BA

AE

AA

RÜF1

XX1) RK1/Y1 VF2

BA8 BA9

UP1

AF1

VF1

SF3UP2

DHW

heating

Unfold

back

cover!

Page 67

System Anl 14.3

Default settings

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO4 -> F01 - 1 (with SF1)

EB 5576 EN 67

Systems

BE

BA

AE

AA

RÜF1

SLP RK1/Y1

BA8 BA9

AF1VF1

RÜF2

ZP UP1SF3

SF4/VF4SF1 UP2

SF2

KW

WW

Page 68

System Anl 16.0

Default settings

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

68 EB 5576 EN

Systems

BE

BA

AE

AA

SF2

SF1RüF1 SLP

VF1RK1/Y1 UP1 AF1

Page 69

System Anl 16.1

Default settings

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO2 -> F01 - 0 (without RF2)

CO2 -> F02 - 0 (without AF2 for Rk2)

CO2 -> F03 - 0 (without RüF2)

EB 5576 EN 69

Systems

BE

BA

AE

AA

SF2

SF1RüF1 SLP

VF1RK1/Y1 UP1 AF1

RK2/Y2

UP2

VF2

RüF2

RF2

Page 70

System Anl 16.2

Default settings

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

70 EB 5576 EN

Systems

BE

BA

AE

AA

SF2

SF1RüF1

SLP

VF1RK1/Y1 UP1 AF1

VF2

UP2

Page 71

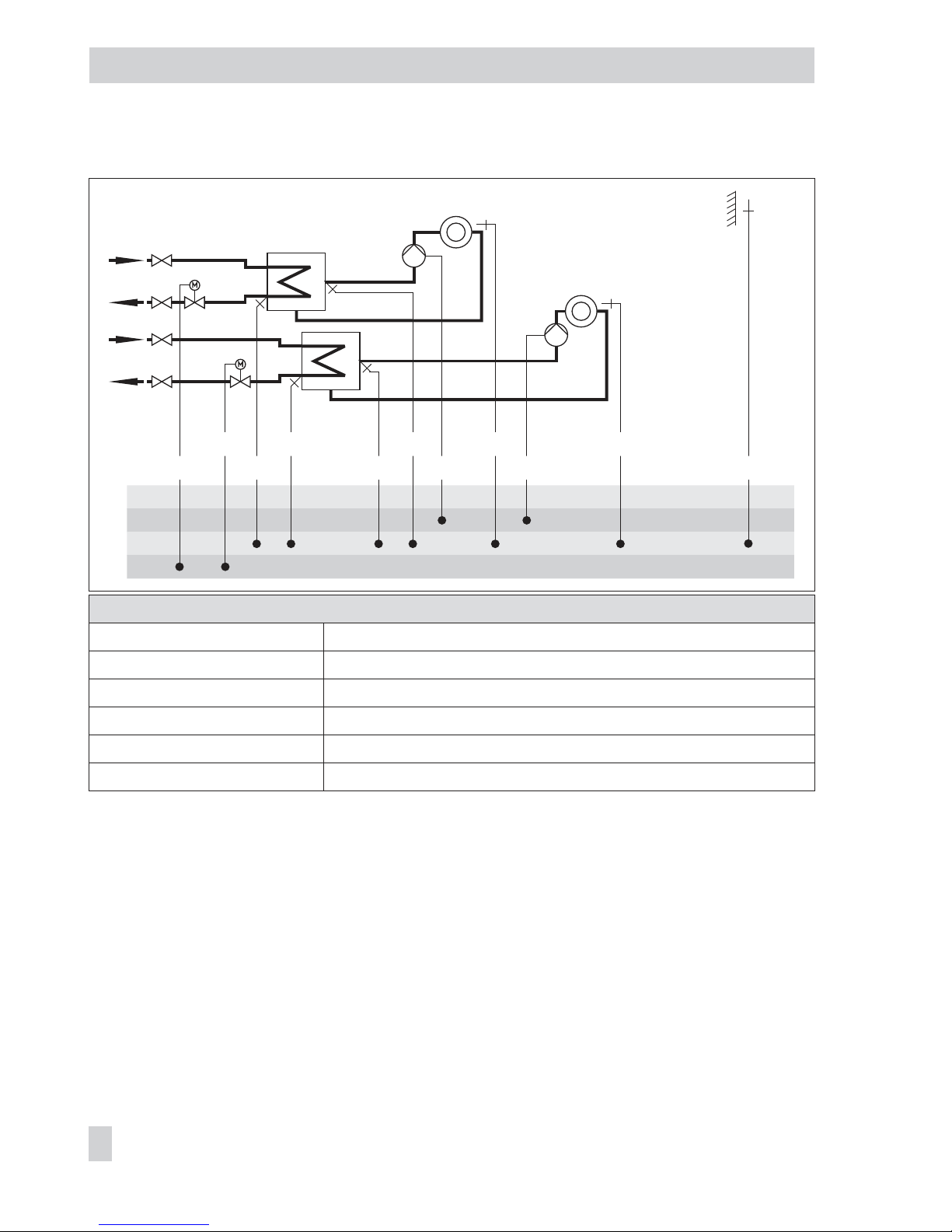

System Anl 16.3

Default settings

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

EB 5576 EN 71

Systems

BE

BA

AE

AA

SF3

SF1

SLP

VF1RK1/Y1 AF1

UP1

RüF2

BA9

SF2

RüF1

Page 72

System Anl 16.4

Default settings

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

72 EB 5576 EN

Systems

BE

BA

AE

AA

SF3

SF2RüF1

SLP

VF1RK1/Y1 AF1

VF2

UP2

UP1

RüF2

BA9

SF1

Page 73

System Anl 16.6

Default settings

CO1 -> F02 - 1 (with AF1)

CO1 -> F03 - 1 (with RüF1)

CO2 -> F01 - 0 (without RF2)

CO2 -> F02 - 0 (without AF2 for Rk2)

CO2 -> F03 - 0 (without RüF2)

EB 5576 EN 73

Systems

BE

BA

AE

AA

SF3

SF1

RüF1

SLP

VF1RK1/Y1 AF1

RK2/Y2

UP2

VF2

RF2

RüF2

UP1

SF2

Page 74

5 Functions of the heating circuit

Which controller functions are available depends on the selected system code number (Anl).

5.1 Weather-compensated control

When weather-compensated control is used, the flow temperature is controlled according to

the outdoor temperature. The heating characteristic in the controller defines the flow tempera

ture set point as a function of the outdoor temperature (–> Fig. 5). The outdoor temperature

required for weather-compensated control can either be measured at an outdoor sensor or

received over the 0 to 10 V input or from a connected device bus.

Functions

WE Configuration

Outdoor sensors AF1/2 1 CO1, 2 -> F02 - 1

Outdoor temperature received

over 0 to 10 V input

0

AE

–20 °C

50 °C

CO5 -> F23 - 1

Direction/AE for receiving temperature

Lower transmission range / –50 to 100 °C

Upper transmission range / –50 to 100 °C

If you wish to alternatively receive the outdoor temperature over the device bus, the follow

-

ing additional configurations must be made:

Device bus 0 CO7 -> F01 - 1; device bus address

Receive value AF1 0 CO7 -> F07 - 1; register no.

74 EB 5576 EN

Functions of the heating circuit

20

30

0.2

2.4

2.62.93.2

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.4

0.6

40

50

60

70

80

90

100

110

120

130

[°C]

–20

[°C]–16–12–8–4048121620

140

150

–24 –28 –32 –36 –40

t

VL

t

A

Fig. 5 · Gradient characteristics

t

VL

Flow temperature

t

A

Outdoor temperature

Page 75

Receive value AF2 0 CO7 -> F09 - 1; register no.

5.1.1 Gradient characteristic

Basically, the following rule applies: a decrease in the outdoor temperature causes the flow

temperature to increase.

By varying the parameters Gradient and Level, you can adapt the characteristic to your indi

-

vidual requirements:

The gradient needs to be increased if the room temperature

drops when it is cold outside.

The gradient needs to be decreased if the room tempera-

ture rises when it is cold outside.

The level needs to be increased and the gradient decreased

if the room temperature drops when it is mild outside.

EB 5576 EN 75

Functions of the heating circuit

t

VL

t

A

[°C]

[°C]

20 0 –20

t

VL

t

A

[°C]

[°C]

20 0 –20

t

VL

t

A

[°C]

[°C]

20 0 –20

Page 76

The level needs to be decreased and the gradient increased

if the room temperature rises when it is mild outside.

Outside the times-of-use, reduced set points are used for control:

The reduced flow set point is calculated as the difference between the adjusted values for Day

set point (rated room temperature) and Night set point (reduced room temperature).

The Max. flow temperature and Min. flow temperature parameters mark the upper and lower

limits of the flow temperature. A separate gradient characteristic can be selected for the limi

-

tation of the return flow temperature.

Examples for adjusting the characteristic:

4

Old building, radiator design 90/70: Gradient approx. 1.8

4

New building, radiator design 70/55: Gradient approx. 1.4

4

New building, radiator design 55/45: Gradient approx. 1.0

4

Underfloor heating depending on arrangement: Gradient smaller than 0.5

Note: Particularly for control operation without room sensor, the room temperatures set for

day (Day set point) and night (Night set point) only become effective satisfactorily when the

heating characteristic has been adapted to the building/heating surface layout.

Function

WE Configuration

Four-point characteristic 0 CO1, 2 -> F11 - 0

Parameters

WE Rotary switch / Range of values

Day set point 20 °C Top, middle / 0 to 40 °C

Night set point 15 °C Top, middle / 0 to 40 °C

Parameters

WE Parameter level / Range of values

Gradient, flow 1.8* PA1, 2 / 0.2 to 3.2

Level, flow 0 °C PA1, 2 / –30 to 30 °C

Min. flow temperature 20 °C PA1, 2 / –5 to 150 °C

Max. flow temperature 90 °C* PA1, 2 / 5 to 150 °C

* With CO1, 2 -> F05 - 1, the following applies: Gradient, flow / 0.2 to 1.0 (1.0)

Max. flow temperature / 5 to 50 °C (50 °C)

76 EB 5576 EN

Functions of the heating circuit

t

VL

t

A

[°C]

[°C]

20 0 –20

Page 77

5.1.2 Four-point characteristic

The four-point characteristic allows you to define your own heating characteristic.

It is defined by four points each for the Outdoor temperature, the Flow temperature, the Re

-

duced flow temperature

and the Return flow temperature. The Max. flow temperature and Min.

flow temperature parameters mark the upper and lower limits of the flow temperature.

Note: The Day set point and Night set point parameters are no longer available when the

four-point characteristic has been selected, provided no additional functions (e.g. Optimiza

-

tion, Flash adaptation) have been selected.

Function

WE Configuration

Four-point characteristic 0 CO1, 2 -> F11 - 1

Parameters

WE Parameter level / Range of values

Outdoor temperature Point 1

Point 2

Point 3

Point 4

–15 °C

–5 °C

5 °C

15 °C

PA1, 2 / –50 to 50 °C

EB 5576 EN 77

Functions of the heating circuit

t

VLmax

t

VLmin

t

VL

100

90

80

70

60

50

40

30

20

10

[˚C]20 15 10 5 0 –5 –10 –15 –20

P1

P2

P3

P4

[˚C]

t

A

Fig. 6 · Four-point characteristic

P1 to P4 Points 1 to 4

t

VL

Flow temperature

t

A

Outdoor temperature

---min Min. t

VL

---max Max. t

VL

Four-point characteristic

Reduced four-point characteristic

Page 78

Parameters

WE Parameter level / Range of values

Flow temperature Point 1

Point 2

Point 3

Point 4

70 °C

55 °C

40 °C

25 °C

PA1, 2 / –5 to 150 °C

Reduced flow temperature Point 1

Point 2

Point 3

Point 4

60 °C

40 °C

20 °C

20 °C

PA1, 2 / –5 to 150 °C

Return flow temperature Points 1 to 4 65 °C PA1, 2 / 5 to 90 °C

Min. flow temperature 20 °C PA1, 2 / –5 to 150 °C

Max. flow temperature 90 °C* PA1, 2 / 5 to 150 °C

* With CO1, 2 -> F05 - 1, the following applies: Max. flow temperature / 5 to 50 °C (50 °C)

Note: The four-point characteristic function can only be activated when the Adaptation func

-

tion is not active (CO1, 2 -> F08 - 0).

5.2 Fixed set point control

During the times-of-use, the flow temperature can be controlled according to a fixed set

point. Outside the times-of-use, the controller regulates to a reduced flow temperature.

Set the desired rated flow temperature as Day set point, and the reduced flow temperature as

Night set point.

Functions

WE Configuration

Outdoor sensor AF1 1 CO1 -> F02 - 0

Parameters

WE Rotary switch / Range of values

Day set point 50 °C Top, middle / Min. to max. flow temperature

Night set point 30 °C Top, middle / Min. to max. flow temperature

Parameters

WE Parameter level / value range

Min. flow temperature 20 °C PA1, 2 / –5 to 150 °C

Max. flow temperature 90 °C PA1, 2 / 5 to 150 °C

78 EB 5576 EN

Functions of the heating circuit

START

Page 79

Note: A fixed set point control in heating circuit 2 with CO2 -> F02 - 0 can only be config

ured if CO1 -> F02 - 0 is set as well, because the heating circuit 2 with CO2 -> F02 - 0 only

uses the measured outdoor temperature provided by heating circuit 1.

5.3 Underfloor heating/drying of jointless floors