Page 1

Mounting and

Operating Instructions

EB 5573-1 EN

Firmware version 2.26

®

Electronics from SAMSON

Edition July 2015

TROVIS 5500 Automation System

TROVIS 5573-1

Heating and District Heating Controller

With graphics display

Page 2

Denition of signal words

DANGER!

Hazardous situations which, if not

avoided, will result in death or serious injury

WARNING!

Hazardous situations which, if not

avoided, could result in death or serious injury

NOTICE

Property damage message or malfunction

Note:

Additional information

Tip:

Recommended action

2 EB 5573-1 EN

Controller versions

The TROVIS5573-1 Heating and District Heating Controller is available in various versions.

The type designation on the nameplate indicates the controller version:

Type designation (nameplate) Version

TROVIS 5573-100x Heating and district heating controller with plain-text readings on a

graphics display

TROVIS 5573-110x Heating and district heating controller with graphics display and

M-bus interface for three M-bus units

These mounting and operating instructions are valid for both controller versions.

Firmware revisions

Old New

2.20 2.24

Internal revisions

2.24 2.26

New error indication function (CO5 > F07)

0 to 10V signal for outdoor temperature function extended (CO5 > F23)

Outdoor temperatures can be received and sent by a 0 to 10V signal.

Page 3

Contents

EB 5573-1 EN 3

1 Safety instructions .........................................................................................6

1.1 Disposal ........................................................................................................6

2 Operation .....................................................................................................7

2.1 Operating controls .........................................................................................7

2.1.1 Rotary pushbutton .......................................................................................... 7

2.1.2 Rotary switch ................................................................................................. 7

2.2 Reading information ......................................................................................8

2.2.1 Adapting the Trend-Viewer ...........................................................................10

2.3 Selecting operating modes ............................................................................11

2.4 Setting the time and date ..............................................................................13

2.5 Setting the times-of-use .................................................................................15

2.6 Setting special times-of-use ...........................................................................17

2.6.1 Party timer ...................................................................................................17

2.6.2 Public holidays ............................................................................................18

2.6.3 Vacations ....................................................................................................19

2.7 Entering day and night set points ..................................................................21

3 Start-up ......................................................................................................23

3.1 Setting the system code number.....................................................................24

3.2 Activating and deactivating functions ............................................................25

3.3 Changing parameters ..................................................................................27

3.4 Calibrating sensors ......................................................................................28

3.5 Altering the display contrast ..........................................................................30

3.6 Changing the display language ....................................................................30

3.7 Loading default setting .................................................................................31

4 Manual mode .............................................................................................32

5 Systems ......................................................................................................33

6 Functions of the heating circuit .....................................................................71

6.1 Weather-compensated control .......................................................................71

6.1.1 Gradient characteristic .................................................................................72

6.1.2 Four-point characteristic ...............................................................................74

6.2 Fixed set point control...................................................................................75

6.3 Underoor heating/drying of jointless oors ..................................................76

6.4 Outdoor temperature for continuous day mode ..............................................77

Page 4

4 EB 5573-1 EN

Contents

6.5 Buffer tank systems Anl 16.x .........................................................................78

6.6 Summer mode .............................................................................................79

6.7 Delayed outdoor temperature adaptation .......................................................80

6.8 Remote operation .........................................................................................80

6.9 Optimization ...............................................................................................81

6.10 Flash adaptation ..........................................................................................82

6.10.1 Flash adaptation without outdoor sensor (based on room temperature) ............83

6.11 Adaptation ..................................................................................................84

6.12 Cooling control ............................................................................................84

7 Functions of the DHW circuit ........................................................................87

7.1 DHW heating in the storage tank system ........................................................87

7.1.1 DHW circuit additionally controlled by a globe valve ......................................89

7.2 DHW heating in the storage tank charging system ..........................................90

7.3 DHW heating in instantaneous heating system ...............................................92

7.4 Domestic hot water heating with solar system .................................................93

7.5 Intermediate heating ....................................................................................94

7.6 Parallel pump operation ...............................................................................94

7.7 Speed control of charging pump ...................................................................94

7.8 Circulation pump during storage tank charging .............................................95

7.9 Priority position ............................................................................................95

7.9.1 Reverse control ............................................................................................95

7.9.2 Set-back operation .......................................................................................96

7.10 Forced charging of DHW storage tank ...........................................................97

7.11 Thermal disinfection of DHW storage tank .....................................................97

8 System-wide functions .................................................................................99

8.1 Automatic summer/standard time switchover .................................................99

8.2 Frost protection ............................................................................................99

8.3 Forced pump operation ..............................................................................100

8.4 Return ow temperature limitation ...............................................................100

8.5 Condensate accumulation control ................................................................101

8.6 Three-step control .......................................................................................102

8.7 On/off control ...........................................................................................102

Page 5

EB 5573-1 EN 5

Contents

8.8 Continuous control in control circuit RK1 ......................................................103

8.9 Releasing a control circuit/controller with binary input .................................. 103

8.10 Processing an external demand in control circuit RK1 ....................................104

8.11 Creep feed rate limitation with a binary input ...............................................105

8.12 Locking manual level ..................................................................................106

8.13 Locking the rotary switch ............................................................................106

8.14 Feeder pump operation ..............................................................................106

8.15 External demand for heat due to insufcient heat supply ...............................106

8.16 Entering customized key number .................................................................107

9 Operational faults .....................................................................................109

9.1 Error list ....................................................................................................109

9.2 Sensor failure ............................................................................................109

9.3 Temperature monitoring ..............................................................................110

9.4 Error status register ....................................................................................110

9.5 Alarm notication by text message ..............................................................111

10 Communication .........................................................................................113

10.1 RS-232 to modem communication module ...................................................114

10.2 RS-485 communication module ...................................................................115

10.3 Description of communication parameter settings..........................................116

10.4 Meter bus ..................................................................................................117

10.4.1 Activating the meter bus .............................................................................117

10.4.2 Flow rate and/or capacity limitation with meter bus......................................118

10.5 Memory module ........................................................................................121

10.6 Data logging .............................................................................................122

11 Installation ................................................................................................124

12 Electrical connection ..................................................................................127

13 Appendix ..................................................................................................132

13.1 Function block lists .....................................................................................132

13.2 Parameter lists ...........................................................................................144

13.3 Resistance values .......................................................................................150

13.4 Technical data ...........................................................................................151

13.5 Customer setting ........................................................................................152

Page 6

6 EB 5573-1 EN

Safety instructions

1 Safety instructions

For your own safety, follow these instructions concerning the mounting, start up and operation of the controller:

− The controller is to be mounted, started up or operated only by trained and experienced

personnel familiar with the product.

− For electrical installation, you are required to observe the relevant electrotechnical regu-

lations of the country of use as well as the regulations of the local power suppliers. Make

sure all electrical connections are installed by trained and experienced personnel. Before

performing any such work on the controller, disconnect it from the power supply.

− The controller is designed for use in low voltage installations. For wiring and mainte-

nance, you are required to observe the relevant regulations concerning device safety and

electromagnetic compatibility.

To avoid damage to any equipment, the following also applies:

− Proper shipping and storage are assumed.

− Before start-up, wait until the controller has reached the ambient temperature.

1.1 Disposal

Waste electrical and electronic equipment may still contain valuable substances. They may

also, however, contain harmful substances which were necessary for them to function. For

this reason, do not dispose this kind of equipment together with your other household waste.

Instead, dispose of your waste equipment by handing it over to a designated collection point

for the recycling of waste electrical and electronic equipment.

Page 7

EB 5573-1 EN 7

Operation

2 Operation

The controller is ready for use with the default temperatures and operating schedules. On

start-up, the current time and date need to be set at the controller (refer to section2.4).

2.1 Operating controls

The operating controls are located in the front panel of the controller.

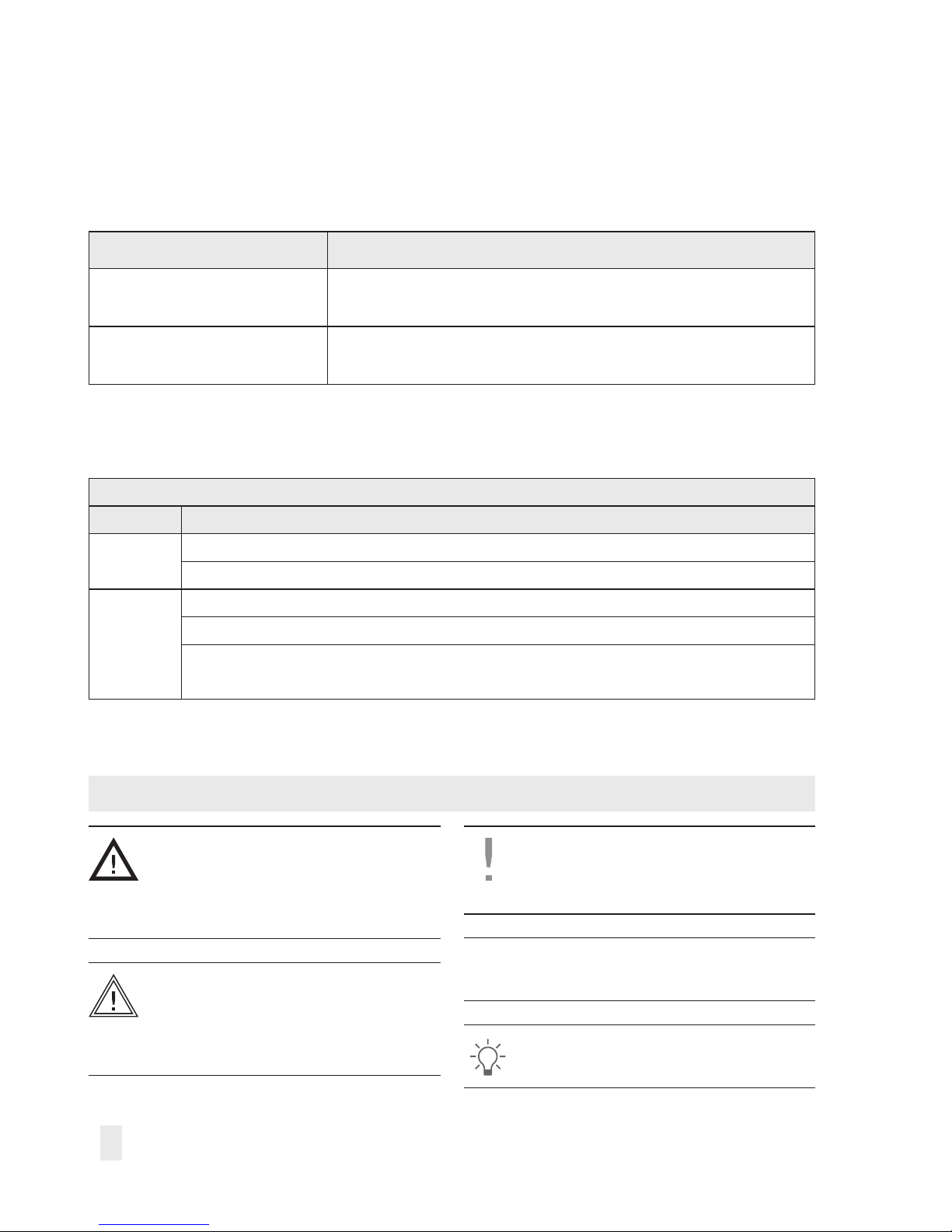

2.1.1 Rotary pushbutton

*

Rotary pushbutton

Turn [q]:

Select readings, parameters and function blocks

Press [Û]:

Conrm adjusted selection or settings

2.1.2 Rotary switch

The rotary switch is used to set the operating mode and the relevant parameters for each

control circuit.

Operating level

Operating modes

Manual level

Day set point (rated room temperature)

Night set point (reduced room temperature)

Times-of-use for heating/DHW

Special time-of-use

Time/date

Settings

Page 8

8 EB 5573-1 EN

Operation

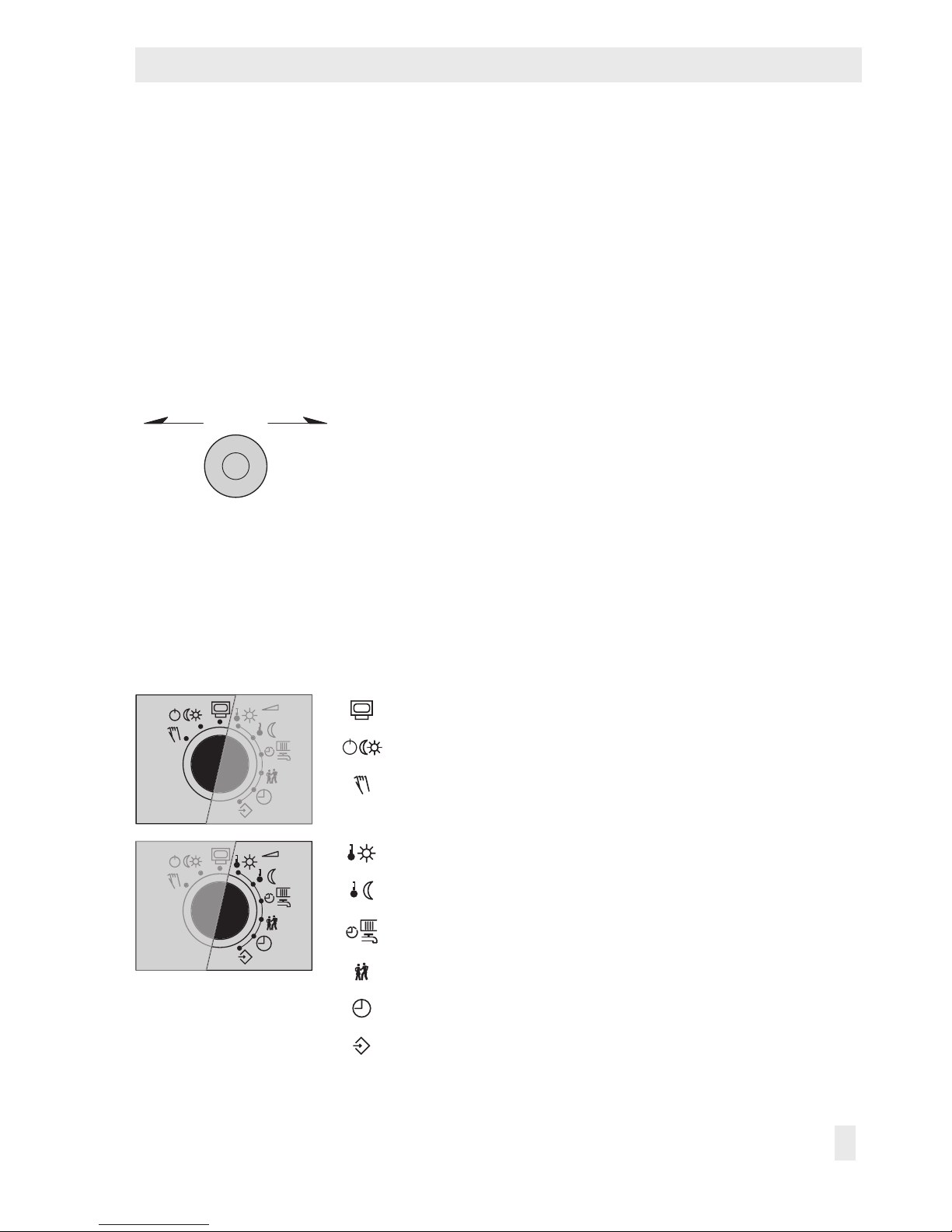

2.2 Reading information

The display indicates the date, time and actual temperature when the rotary switch is posi-

tioned at

(operating level).

Weather-compensated control

current temperature = outdoor temperature

Fixed set point control

current temperature = ow temperature

Further information can be obtained by turning the rotary pushbutton:

q Operating state

The following applies for heating circuits HC1 and HC2:

Heating

circuit

Current

operating

mode

Valve

opens

closes

Actual position-

ing value

Circulation pump

(heating) ON/OFF

The following applies for DHW heating:

Current operating

mode

Pump ON/OFF

Storage tank charging pump

Circulation pump (DHW)

Solar circuit pump

For further details, refer to section2.3.

Page 9

EB 5573-1 EN 9

Operation

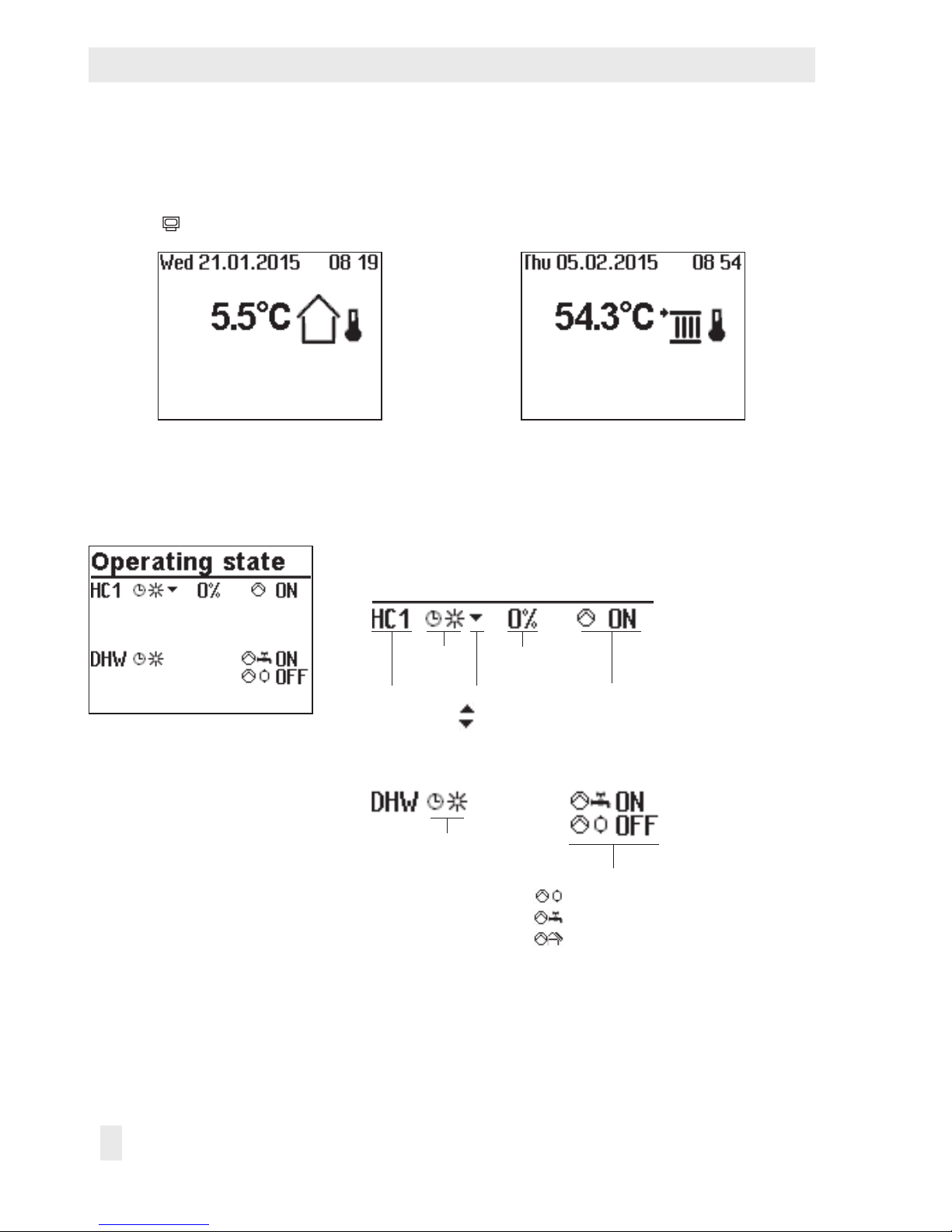

q Selected system code number

For further details, refer to section3.1.

¼ Important measured values of the entire system, e.g. out-

door temperature, ow temperature and return ow temperature, are displayed.

q Times-of-use (depending on system code number)

– Heating circuit HC1

– Heating circuit HC2

– DHW heating

The day mode times is highlighted in black on the time

chart.

Night mode and deactivation times are highlighted in

gray on the time chart.

For further details, refer to section2.5.

¼ Measured values, set points and limits of the system sec-

tion shown are displayed.

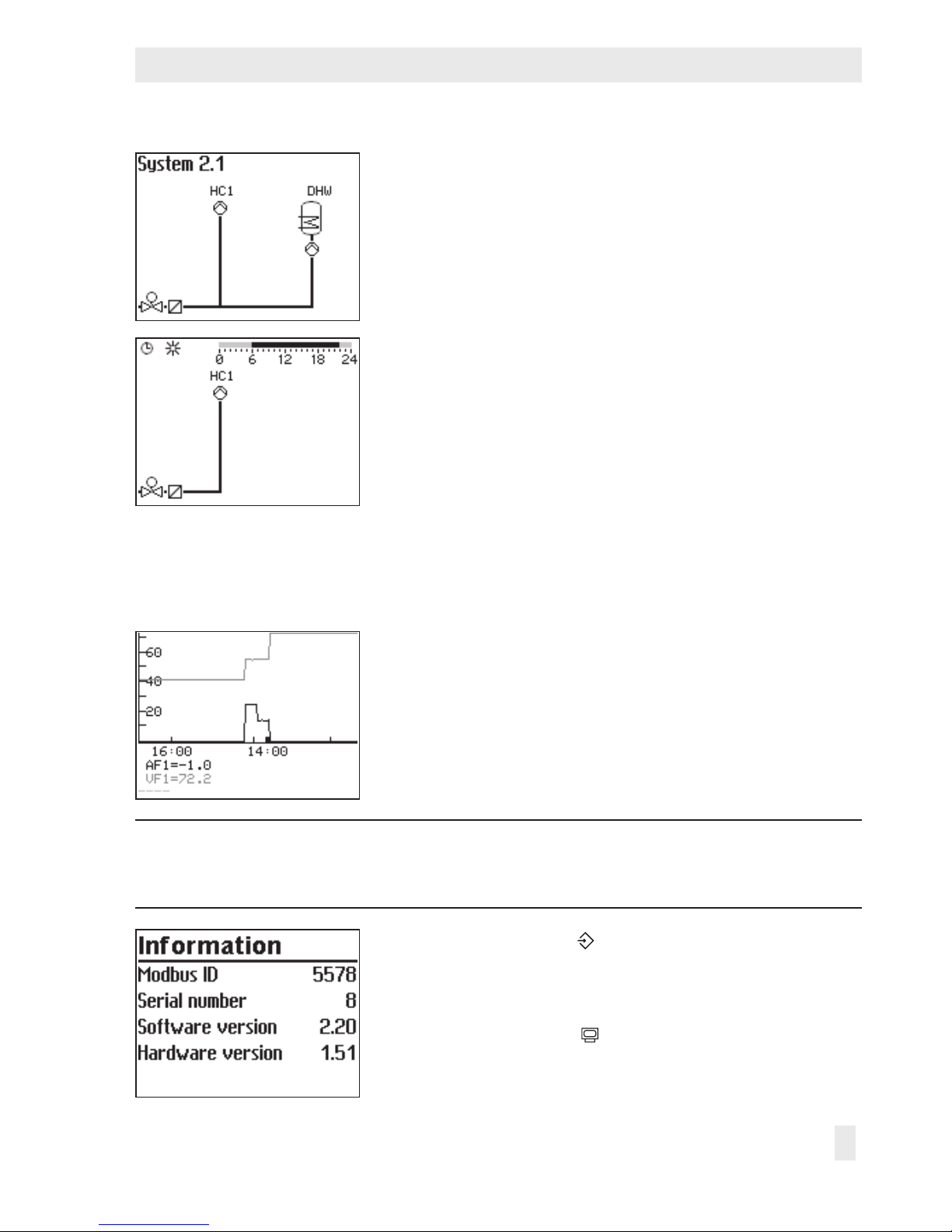

q Trend-Viewer

The standard graph shows the data measured at the out-

door sensor AF1 and ow sensor VF1 plotted over time.

For further details, refer to section2.2.1.

Note:

Details on the controller version (device identication, serial number, software and

hardware versions) are displayed in the extended operating level.

Turn the rotary switch to (settings).

q Enter key number 1999.

¼ Conrm key number.

Turn the rotary switch to

(operating level).

q Select 'Information'.

Page 10

10 EB 5573-1 EN

Operation

2.2.1 Adapting the Trend-Viewer

The standard graph shows the data measured at the outdoor sensor AF1 and ow sensor

VF1 plotted over time.

¼ Open the Trend-Viewer.

Adding measuring data

q Select – – – – on the display.

¼ Activate editing mode for sensor selection.

q Select sensor.

¼ Conrm selected sensor.

Deleting measured data:

q Select the sensor whose measured data are no longer to

be displayed.

¼ Activate editing mode for sensor.

q Select – – – – on the display.

¼ Conrm deletion.

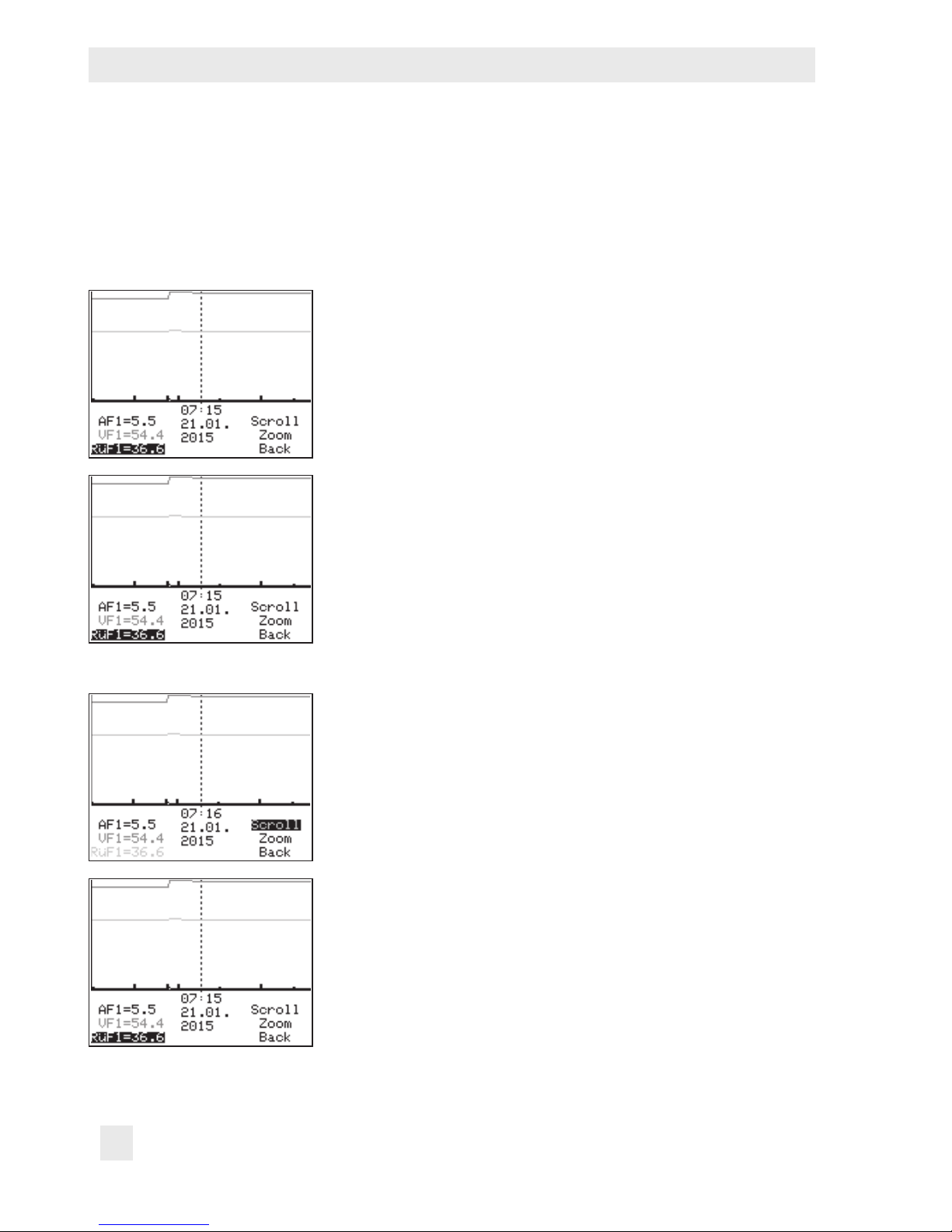

Shifting the time line:

q Select 'Scroll'.

¼ Activate editing mode for scroll function.

q Shift the time line.

¼ Conrm time display.

Page 11

EB 5573-1 EN 11

Operation

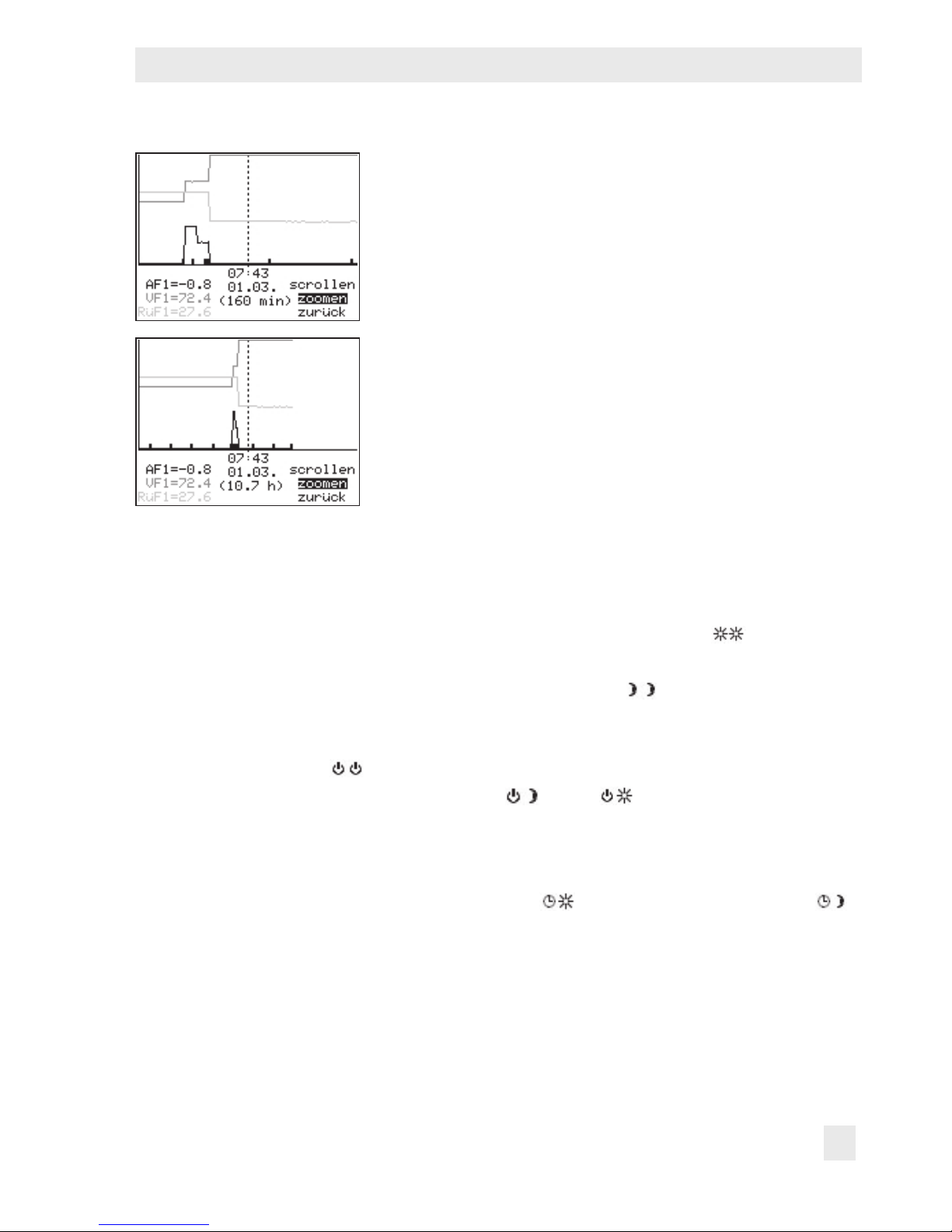

Zooming in/out

q Select 'Zoom'.

¼ Open zoom function.

q Zoom in or out.

¼ Conrm display.

Closing the Trend-Viewer

q Select 'Back'.

¼ Close the Trend-Viewer

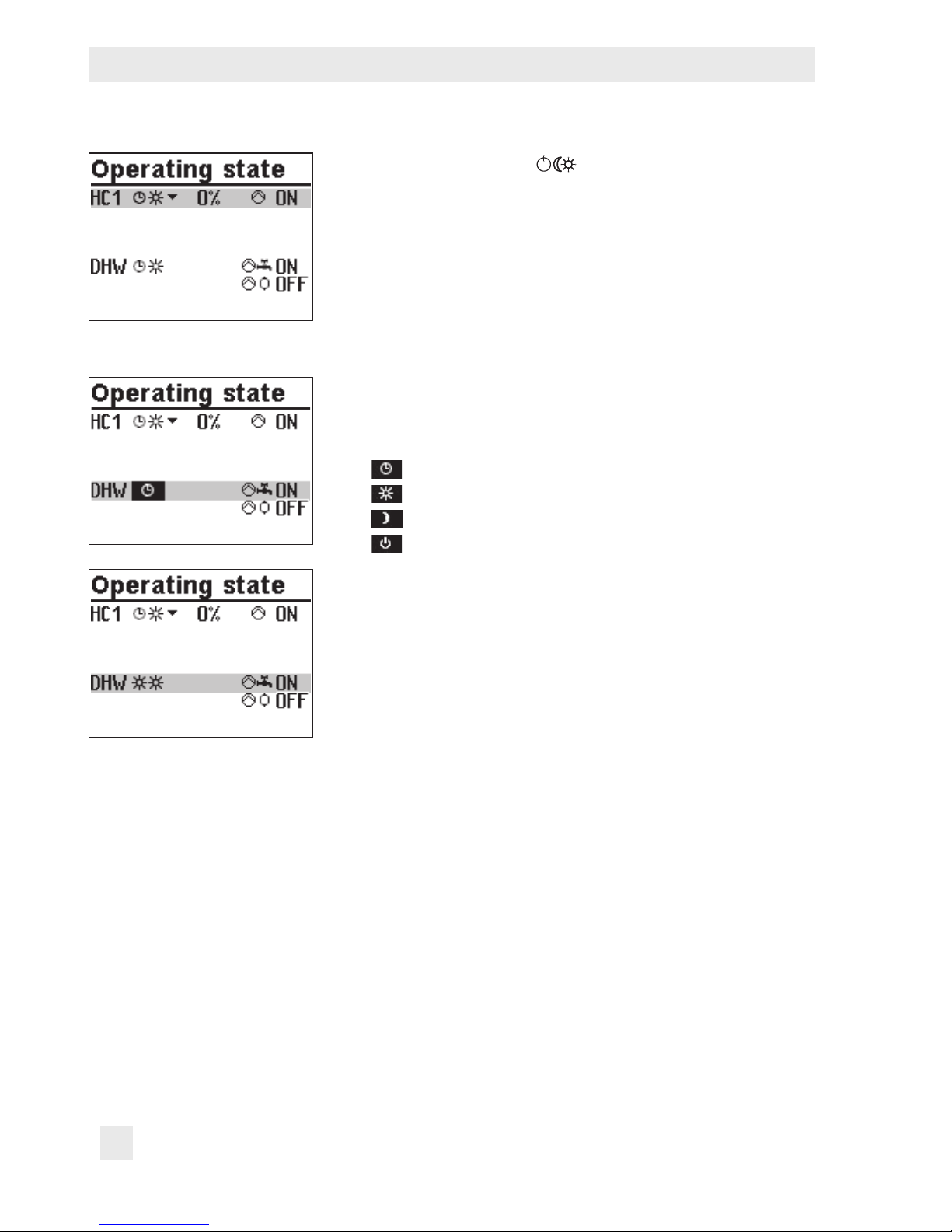

2.3 Selecting operating modes

Day mode (rated operation): regardless of the programmed times-of-use and summer mode,

the set points relevant for rated operation are used by the controller. Icon:

Night mode (reduced operation): regardless of the programmed times-of-use, the set points

relevant for reduced operation are used by the controller. Icon:

Control operation deactivated: regardless of the programmed times-of-use, control opera-

tion of the heating circuits and DHW heating remains deactivated. The frost protection is activated, if need be. Icon:

Icons when the frost protection is activated: HC

, DHW

Automatic mode: during the programmed times-of-use, the controller works in day mode.

Outside these times-of-use, the controller is in night mode, unless control operation is deactivated depending on the outdoor temperature. The controller switches automatically between

both operating modes. Icon within the times-of-use:

, icon outside the times-of-use:

Manual mode: valves and pumps can be controlled manually. For further details, refer to

section4.

Page 12

12 EB 5573-1 EN

Operation

Turn the rotary switch to (operating modes). The operating states of all system control circuits are displayed:

− Heating circuit HC1

− Heating circuit HC2

− DHW heating

Î Only those control circuits are available for selection

which can be controlled by the selected system.

q Select the control circuit.

¼ Activate editing mode for the control circuit. The operat-

ing mode is shown inverted on the display.

q Select the operating mode:

Automatic mode

Day mode

Night mode

System deactivated

¼ Conrm the operating mode.

Page 13

EB 5573-1 EN 13

Operation

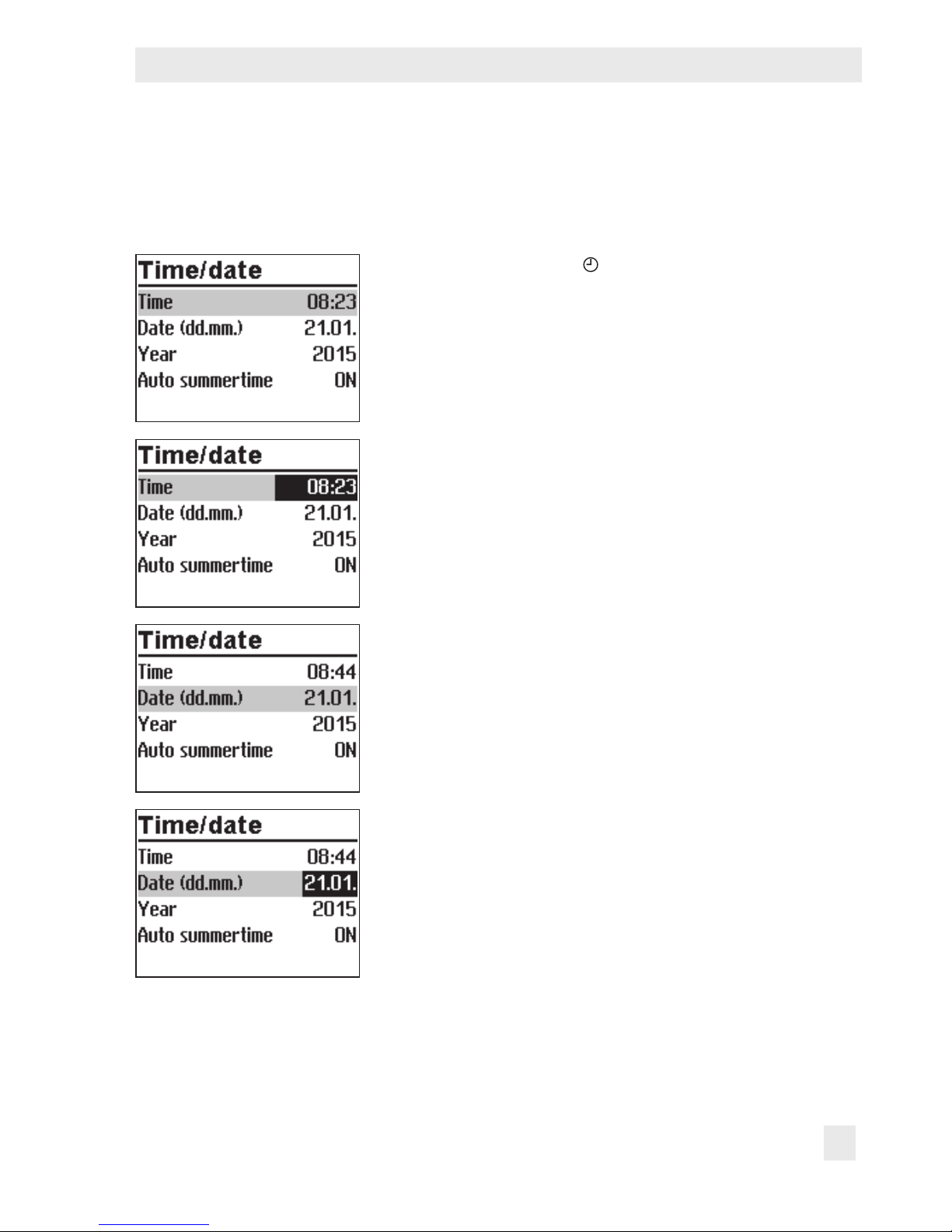

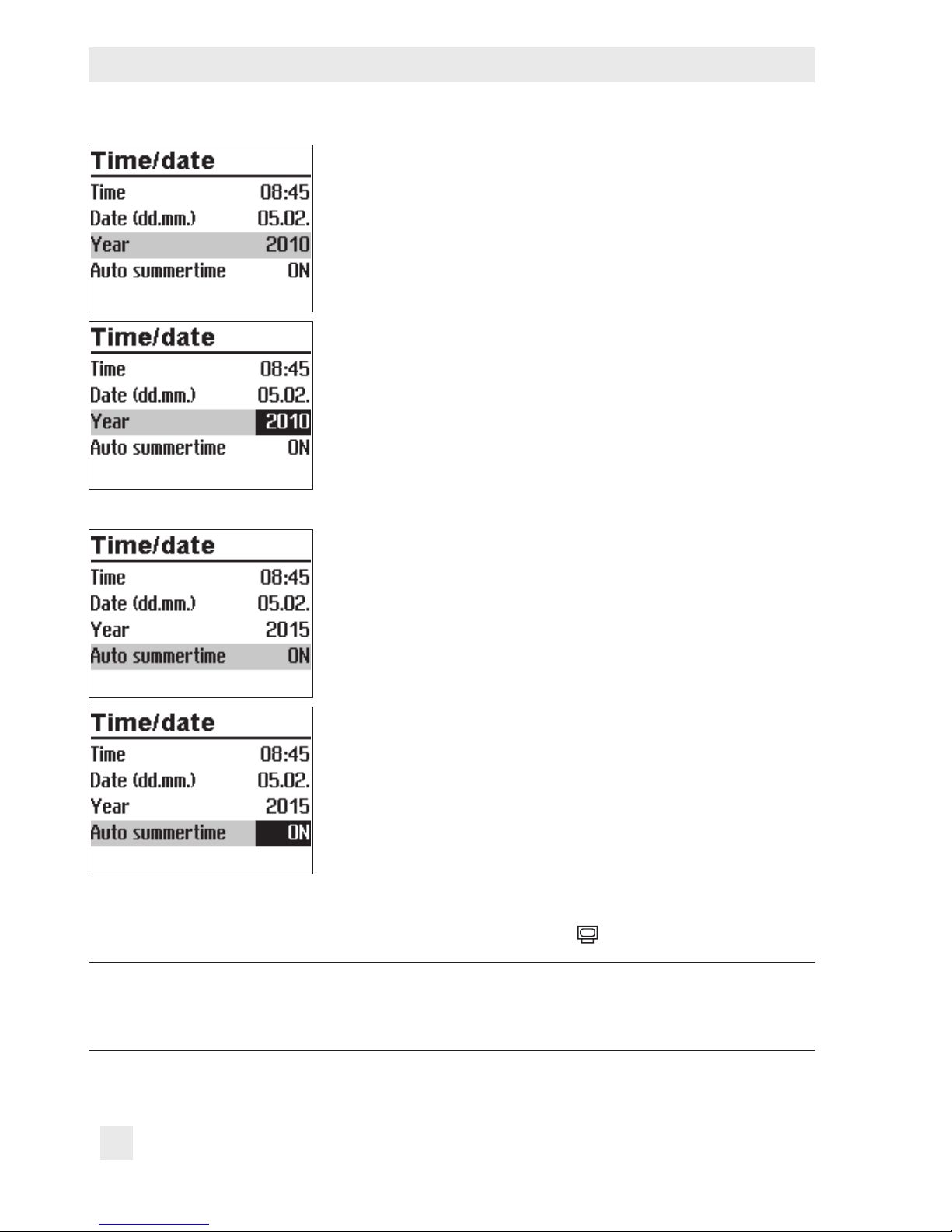

2.4 Setting the time and date

The current time and date need to be set immediately after start-up and after a power failure

lasting more than 24 hours. This is the case when the time blinks on the display.

Turn the rotary switch to (time/date). The current time is

selected (gray background).

¼ Activate editing mode for the time. The time reading is

inverted.

q Change the time.

¼ Conrm the time setting.

q Select 'Date' (dd.mm) [q].

¼ Activate editing mode for the date. The date reading is

inverted.

q Change date (day.month).

¼ Conrm the date setting.

Page 14

14 EB 5573-1 EN

Operation

q Select 'Year'.

¼ Activate editing mode for the year. The year reading is

inverted.

q Change the year.

¼ Conrm the year setting.

Deactivate or activate the automatic summer/standard time

switchover as required. Refer to section8.1:

q Select 'Auto summertime'.

¼ Activate the editing mode for automatic summer/stan-

dard time switchover. The current setting is shown inverted on the display:

ON = Summer/standard time switchover active

OFF = Summer/standard time switchover not active

q Deactivate or activate the automatic summer/standard

time switchover.

¼ Conrm deactivation/activation.

Turn the rotary switch back to

(operating level).

Note:

The correct time is guaranteed after a power failure of 24 hours. Normally, the correct time is still retained at least 48 hours after a power failure.

Page 15

EB 5573-1 EN 15

Operation

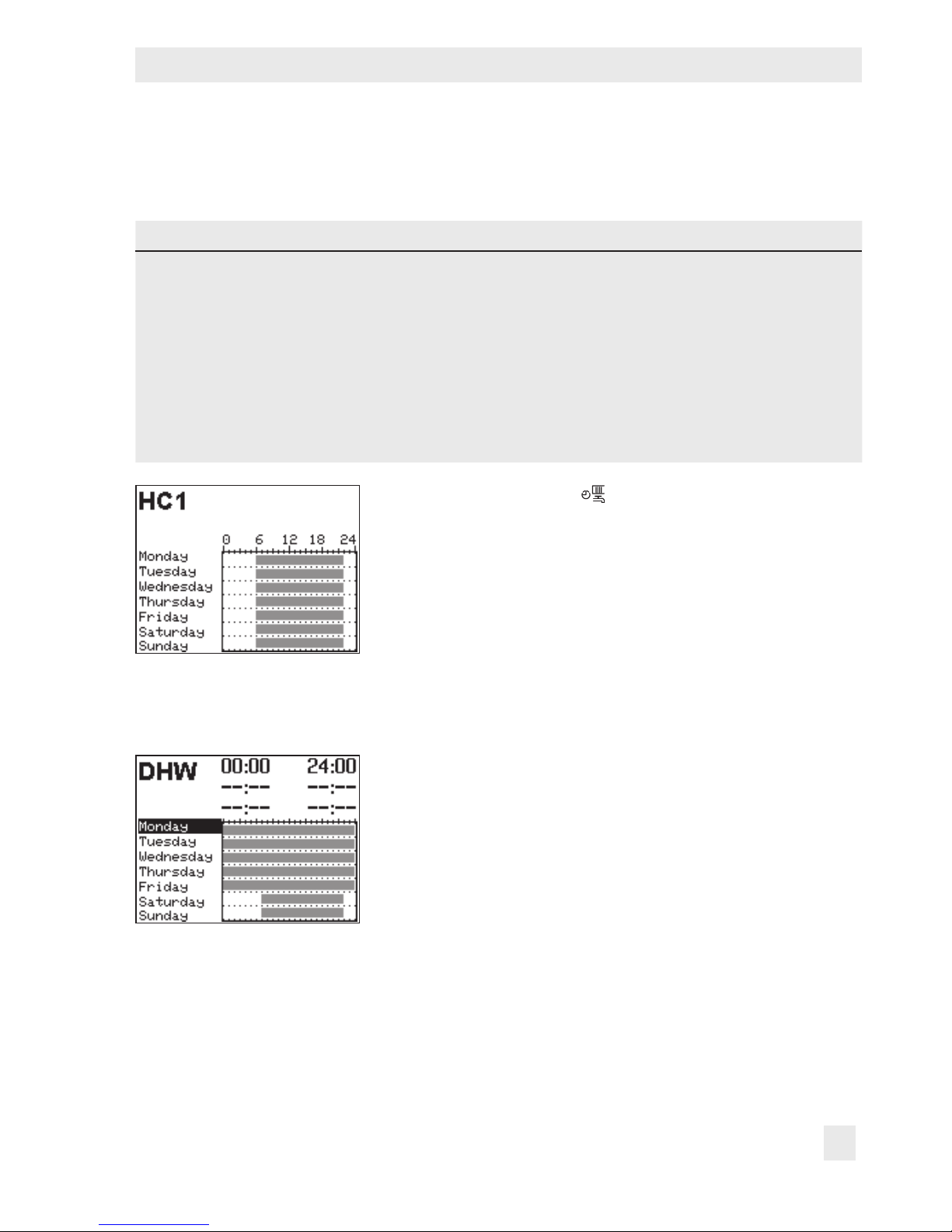

2.5 Setting the times-of-use

Three times-of-use can be set for each day of the week.

Parameters WE Value range

HC1, HC2 DHW, CP

Start rst time-of-use 06:00 00:00 00:00 to 24:00 h; in steps of 15 minutes

Stop rst time-of-use 22:00 24:00 00:00 to 24:00 h; in steps of 15 minutes

Start second time-of-use --:-- --:-- 00:00 to 24:00 h; in steps of 15 minutes

Stop second time-of-use --:-- --:-- 00:00 to 24:00 h; in steps of 15 minutes

Start third time-of-use --:-- --:-- 00:00 to 24:00 h; in steps of 15 minutes

Stop third time-of-use --:-- --:-- 00:00 to 24:00 h; in steps of 15 minutes

Turn the rotary switch to (times-of-use). The rst control

circuit is displayed together with its programmed times-of-

use.

q Program the times-of-use of another control circuit, if re-

quired:

– Heating circuit HC2

– DHW heating

– Circulation pump (DHW) CP

Î Only those control circuits are available for selection

which can be controlled by the selected system.

¼ Activate editing mode for the control circuit. The times-

of-use for Monday are displayed.

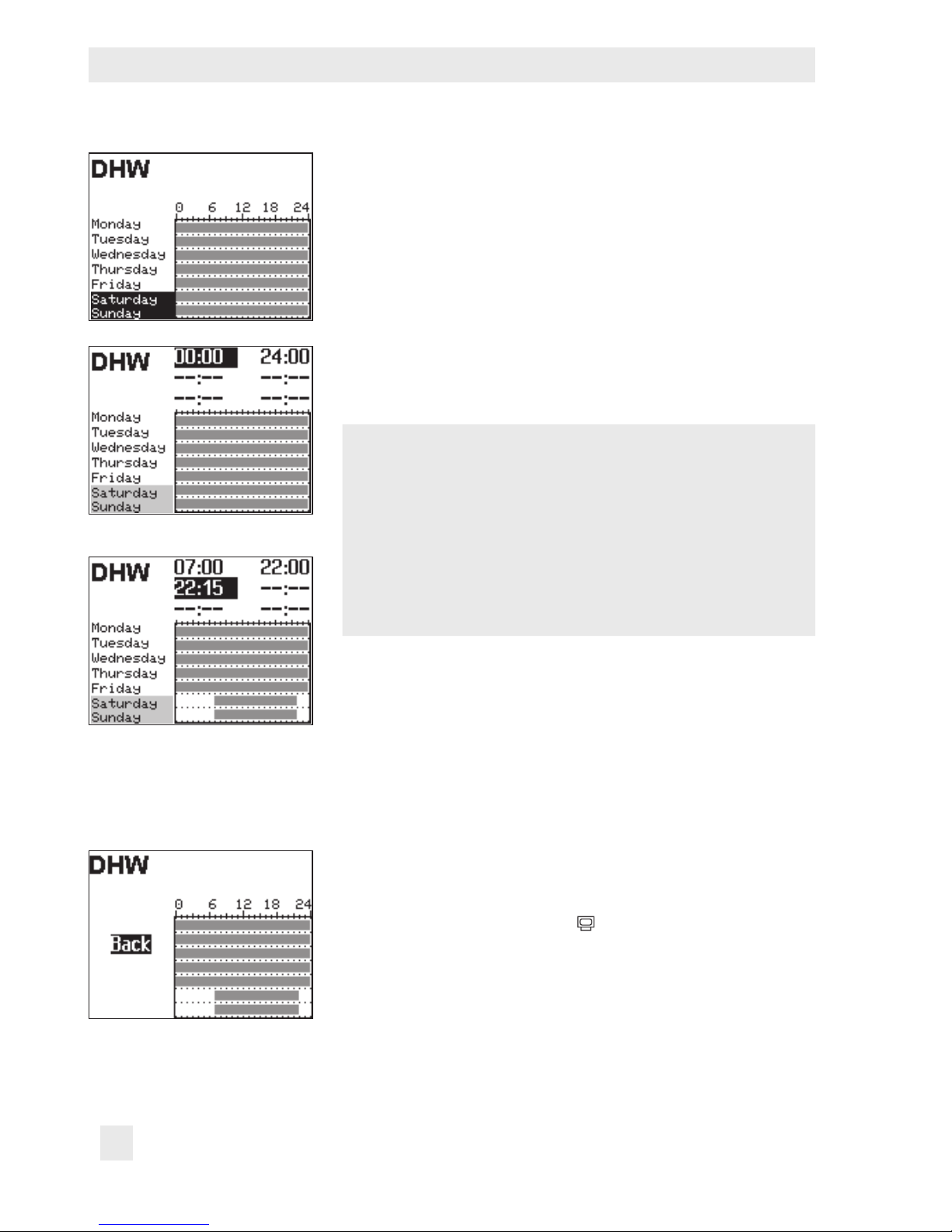

Page 16

16 EB 5573-1 EN

Operation

q Select period/day for which the times-of-use are to be

valid. The times-of-use can be programmed for individual days or for a block of days, e.g. Monday to Friday,

Saturday and Sunday or Monday to Sunday. The selected days are shown inverted on the display.

¼ Activate editing mode for the period/day.

The start time of the rst time-of-use period can now be

edited (inverted reading).

q Change start time (in steps of 15 minutes).

¼ Conrm the start time. The stop time of the rst time-of-

use period can now be edited.

q End stop time (in steps of 15 minutes).

¼ Conrm the stop time. The start time of the second time-

of-use period can now be edited.

To set the second and third times-of-use periods, repeat

steps with gray background. If no further times-of-use are to

be programmed for the selected time period/day, exit the

menu by conrming the indicated start time twice (2x Û).

Proceed in the same manner to program further periods/

days.

After setting all times-of-use:

q Select 'Back'.

¼ Exit the times-of-use setting.

Turn the rotary switch back to

(operating level).

Page 17

EB 5573-1 EN 17

Operation

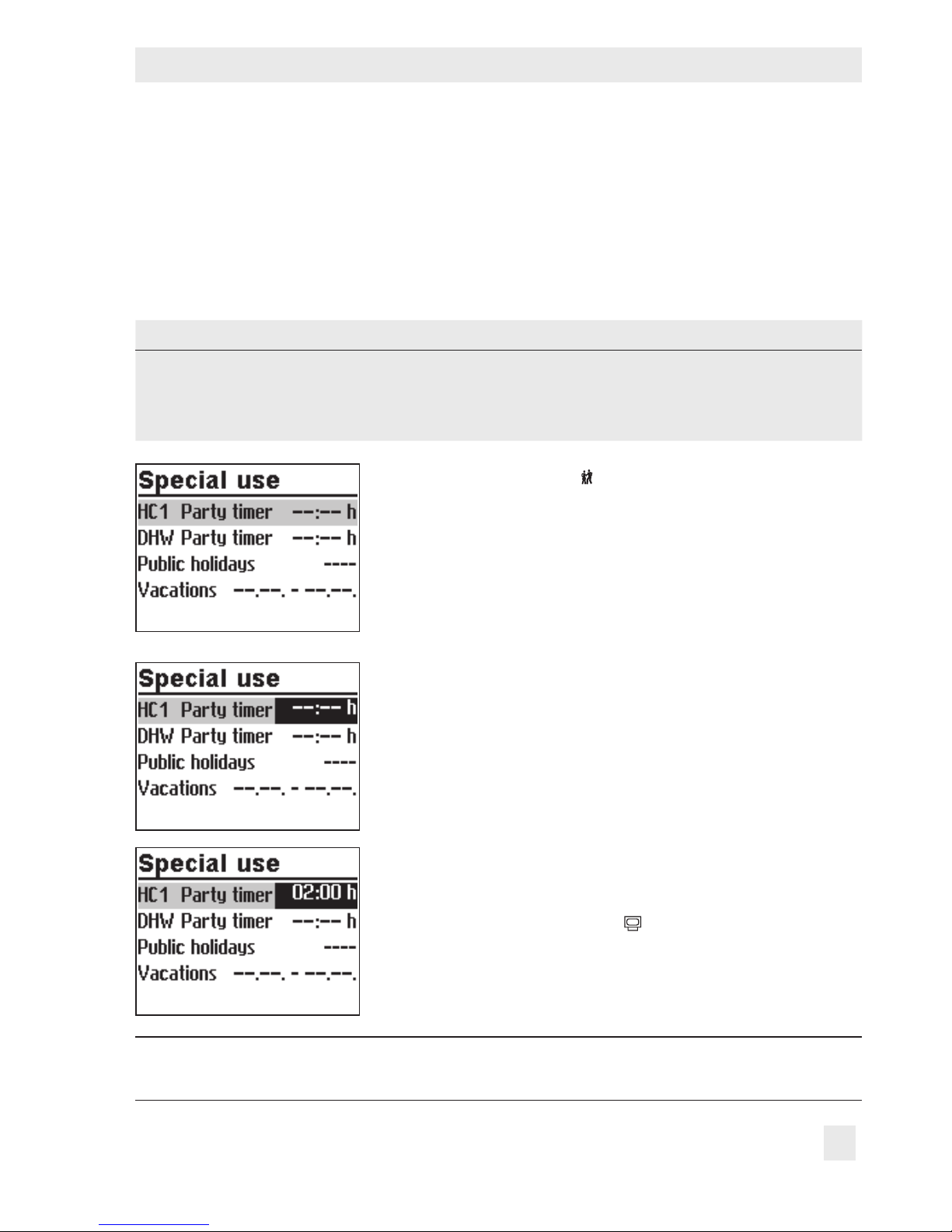

2.6 Setting special times-of-use

2.6.1 Party timer

Rated operating in the corresponding control circuit (HC1, HC2 or DHW) is started or continued for the time period set in the party timer. When the party timer has elapsed, the party

timer returns to --:--.

Parameters WE Value range

HC1 party timer --:-- h 0 to 48h; in steps of 15 minutes

HC2 party timer --:-- h 0 to 48h; in steps of 15 minutes

DHW party timer --:-- h 0 to 48h; in steps of 15 minutes

Turn the rotary switch to (special times-of-use). The party

timer for the rst control circuit is now selected.

q Set party timer of another control circuit, if required:

– Heating circuit HC2

– DHW heating

Î Only those control circuits are available for selection

which can be controlled by the selected system.

¼ Activate editing mode for the party timer. The party tim-

er is now in the editing mode (inverted display).

q Extend day operation as required (in steps of 15 min-

utes).

¼ Conrm setting.

After setting the party timer:

Turn the rotary switch back to

(operating level).

Note:

Party timer runs down in steps of 15 minutes.

Page 18

18 EB 5573-1 EN

Operation

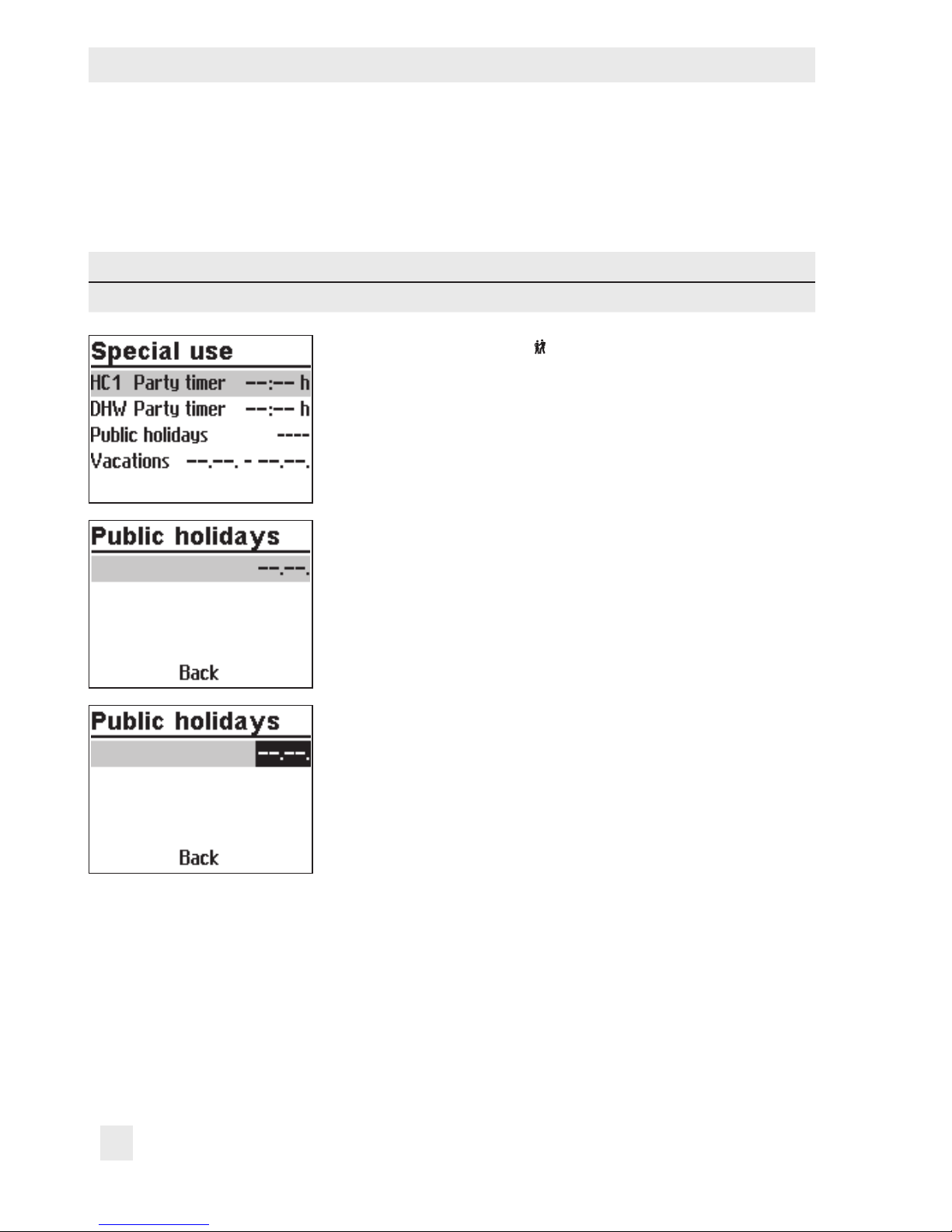

2.6.2 Public holidays

On public holidays, the times-of-use specied for Sunday apply.

A maximum of 20 public holidays may be entered.

Parameters WE Value range

Public holidays --:-- 01.01 to 31.12

Turn the rotary switch to (special times-of-use). The party

timer for the rst control circuit is now selected.

q Select 'Public holidays'.

¼ Start the public holiday setting. The rst public holiday

setting is now selected. --:-- is displayed if no public holidays (default setting) have been programmed.

q Select --:--, if applicable.

¼ Activate editing mode for public holidays.

q Set the date of the public holiday.

¼ Conrm the date.

Proceed in the same manner to program further public holi-

days.

Deleting a public holiday:

q Select the holiday you wish to delete.

¼ Conrm the date.

q Select --:--.

¼ Conrm setting.

The public holiday is deleted.

Page 19

EB 5573-1 EN 19

Operation

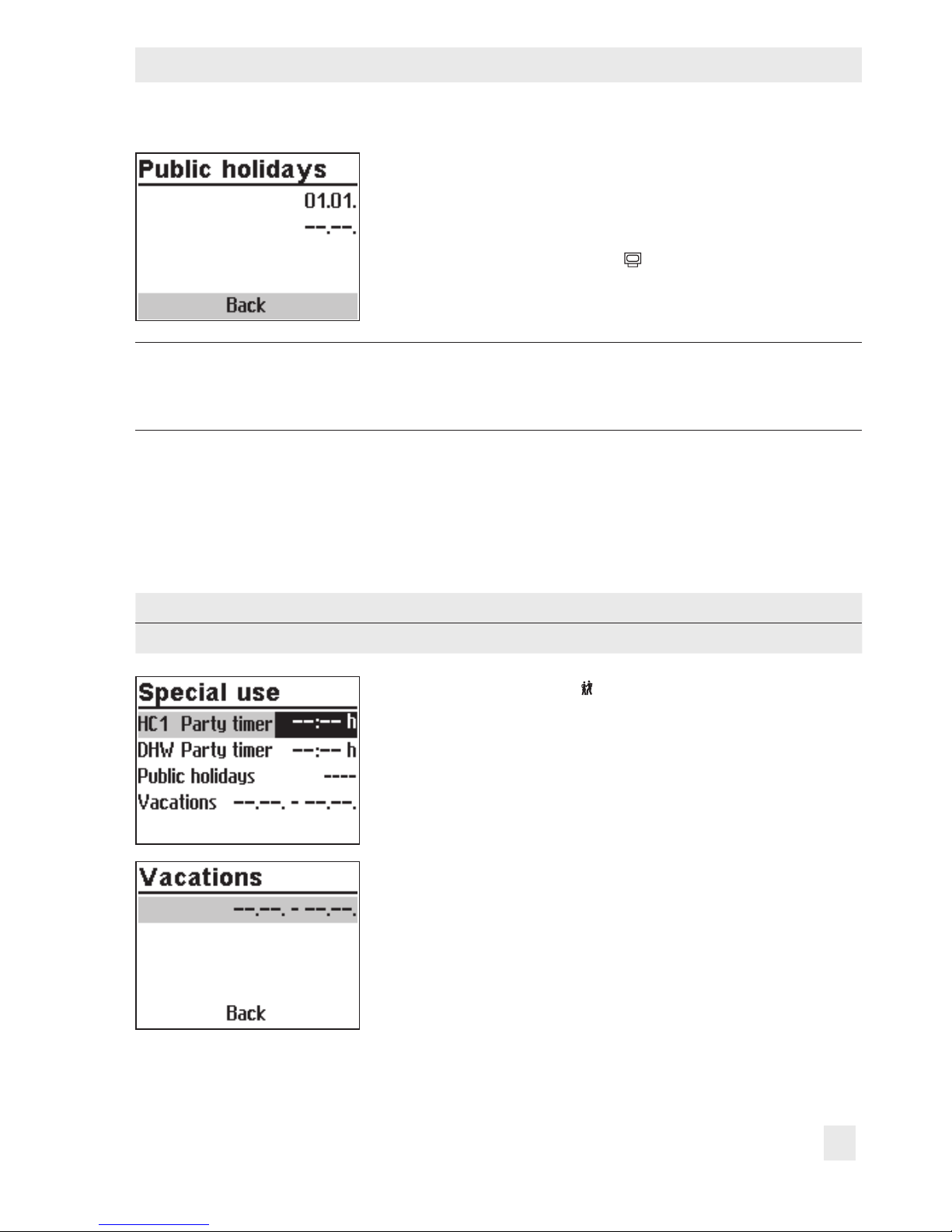

After programming all public holidays:

q Select 'Back'.

¼ Exit the public holiday setting.

Turn the rotary switch back to

(operating level).

Note:

Public holidays that are not assigned to a specic date should be deleted by the end

of the year so that they are not carried on into the following year.

2.6.3 Vacations

The system runs constantly in reduced mode during vacation periods. A maximum of ten vacation periods can be entered. Each vacation period can be separately assigned to the heating circuits HC1, HC2 and DHW circuit or to all control circuits.

Parameters WE Value range

Vacation period --.-- - --.-- 01.01 to 31.12

Turn the rotary switch to (special times-of-use). The party

timer for the rst control circuit is now selected.

q Select 'Vacations'.

¼ Start the vacations setting. The rst vacations setting is

now selected. --.-- - --.--.is displayed if no vacations (default setting) have been programmed.

q Select --.-- - --.--, if applicable.

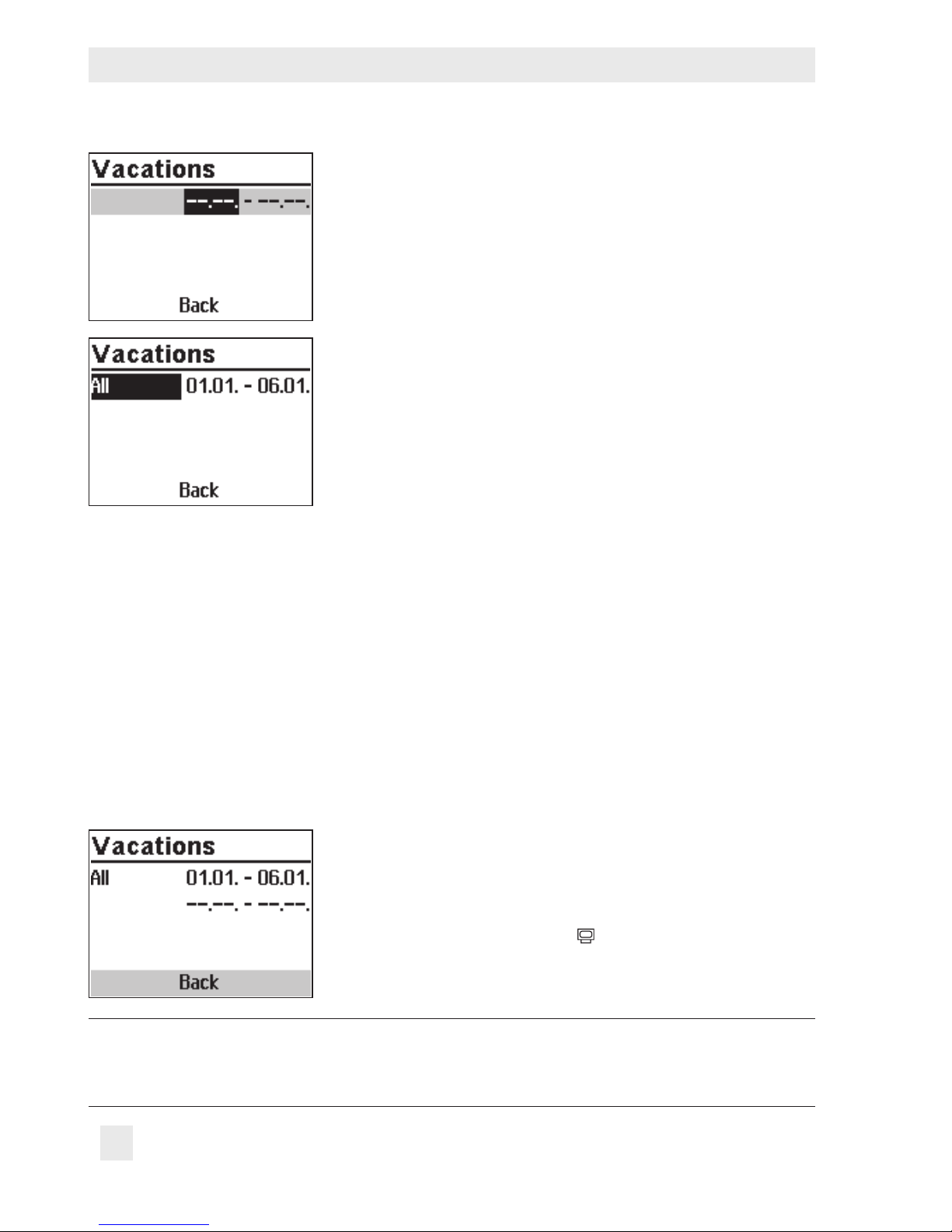

Page 20

20 EB 5573-1 EN

Operation

q Activate editing mode for vacations.

The start date can now be edited (inverted reading).

q Set the start date.

q Conrm the start date.

The end date can now be edited.

q Set the end date.

q Conrm the year setting. 'All' is selected. The vacation

period then applies to all control circuits.

q If the vacation period is to be only valid for one control

circuit, select the required control circuit:

– Heating circuit HC1

– Heating circuit HC2

– DHW heating

Î Only those control circuits are available for selection

which can be controlled by the selected system.

¼ Conrm the control circuit.

Proceed in the same manner to program further vacations.

Deleting vacation periods:

q Select the start date of the period you wish to delete.

¼ Conrm vacation period.

q Select --.-- - --.--.

¼ Conrm setting.

The vacation period is deleted.

After programming all vacation periods:

q Select 'Back'.

¼ Exit the vacations setting.

Turn the rotary switch back to

(operating level).

Note:

Vacations should be deleted by the end of the year so that they are not carried on into the following year.

Page 21

EB 5573-1 EN 21

Operation

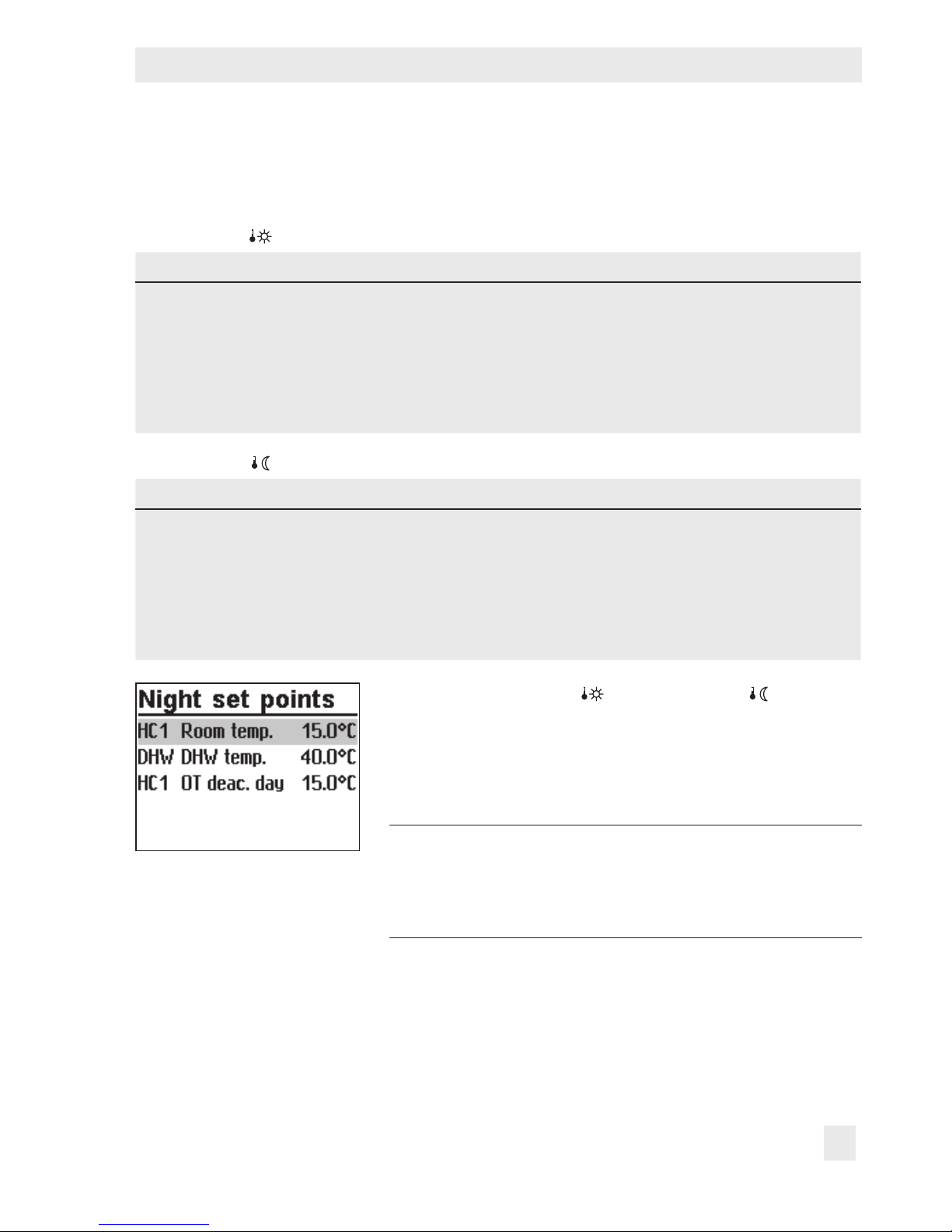

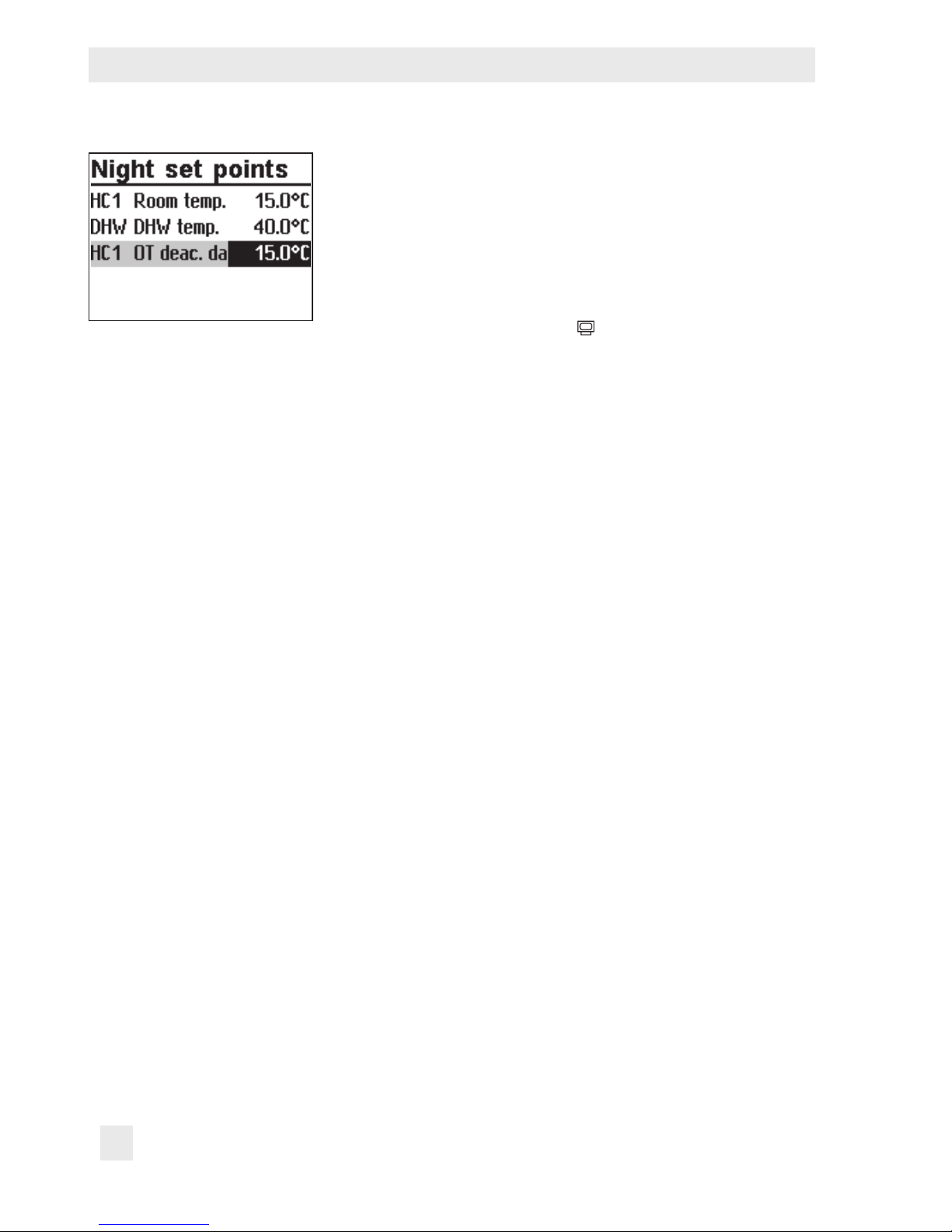

2.7 Entering day and night set points

The desired room temperature for the day and night set points can be programmed.

Switch position

Parameters WE Value range

HC1 room temperature 20.0°C 0.0 to 40.0°C

HC2 room temperature 20.0°C 0.0 to 40.0°C

DHW temperature 55.0°C Min. to max. DHW temperature

HC1 OT deactivation value 22.0°C 0.0 to 50.0°C

HC2 OT deactivation value 22.0°C 0.0 to 50.0°C

Switch position

Parameters WE Value range

HC1 room temperature 15.0°C 0.0 to 40.0°C

HC2 room temperature 15.0°C 0.0 to 40.0°C

DHW temperature 40.0°C Min. to max. DHW temperature

HC1 OT deactivation value 15.0°C 0.0 to 50.0°C

HC2 OT deactivation value 15.0°C 0.0 to 50.0°C

Turn the rotary switch to (day set point) or (night set

point).

The day or night set points are listed on the display.

Î Only those day and night set points are available for se-

lection which can be controlled by the selected system.

Note:

The deactivation values are located in a separate

menu (deactivation values) for systems with three

control circuits.

q Select the set point.

Page 22

22 EB 5573-1 EN

Operation

¼ Activate editing mode for set point.

q Adjust the set point.

¼ Conrm setting.

Proceed in the same manner to adjust further set points.

After adjusting all the set points:

Turn the rotary switch back to

(operating level).

Page 23

EB 5573-1 EN 23

Start-up

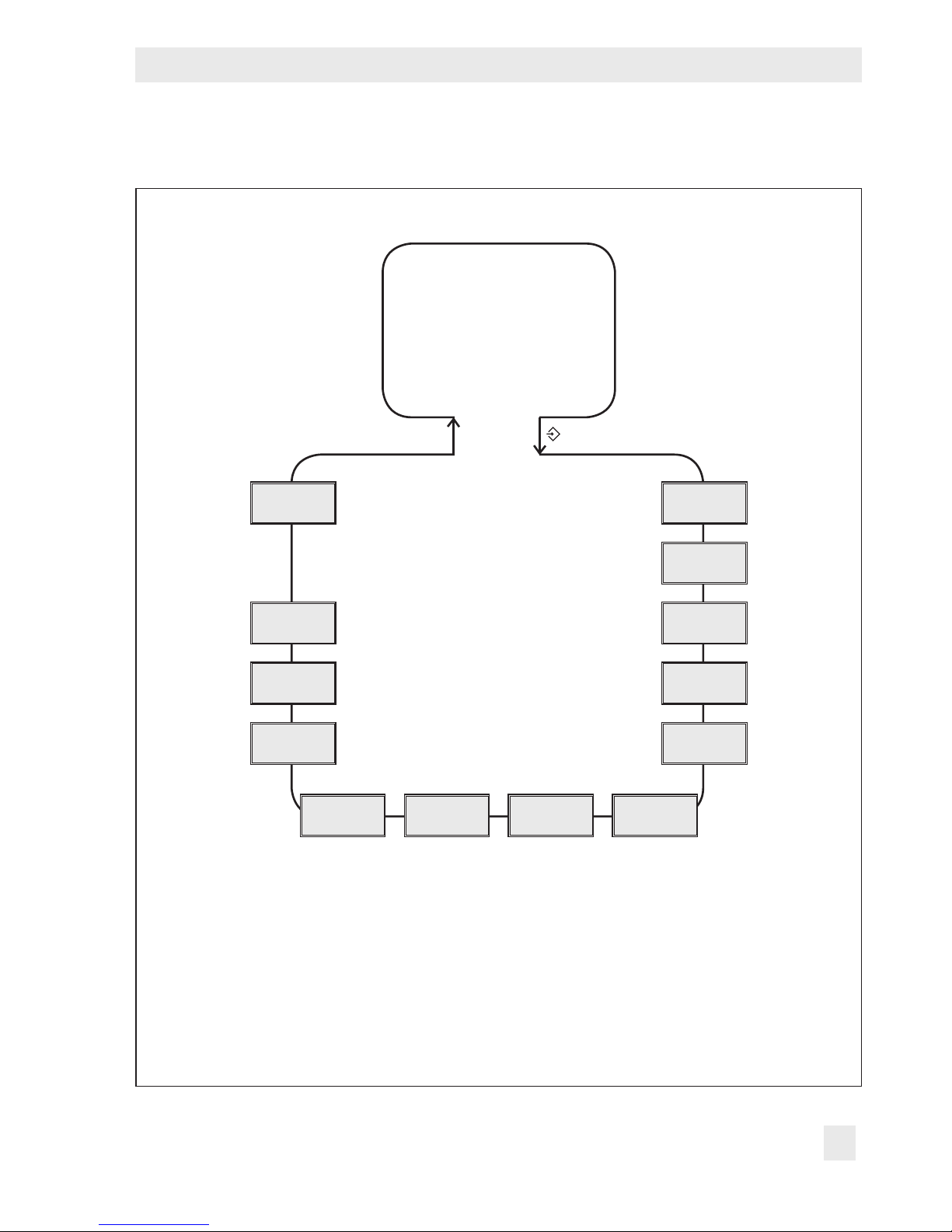

3 Start-up

q

Operating level

q

Conguration and

parameter level

Perform start-up. Refer to section3.

Back

System

CO6

CO5

CO4 CO2 CO1 PA6

PA1

PA2

PA4

Display

contrast

Display

language

& key number

¼

PA1/CO1:

PA2/CO2:

PA4/CO4:

CO5:

PA6/CO6:

Anl:

RK1 (heating circuit 1)

RK2 (heating circuit 2)

DHW circuit

System-wide

Modbus communication

System code number

Fig. 1: Level structure of TROVIS 5573

Page 24

24 EB 5573-1 EN

Operation

The modications of the controller conguration and parameter settings described in this section can only be performed after the valid key number has been entered.

The key number that is valid on the rst start-up can be found on page163. To avoid unauthorized use of the service key number, remove the page or make the key number unreadable. In addition, it is possible to enter a new, customized key number (refer to section8.16).

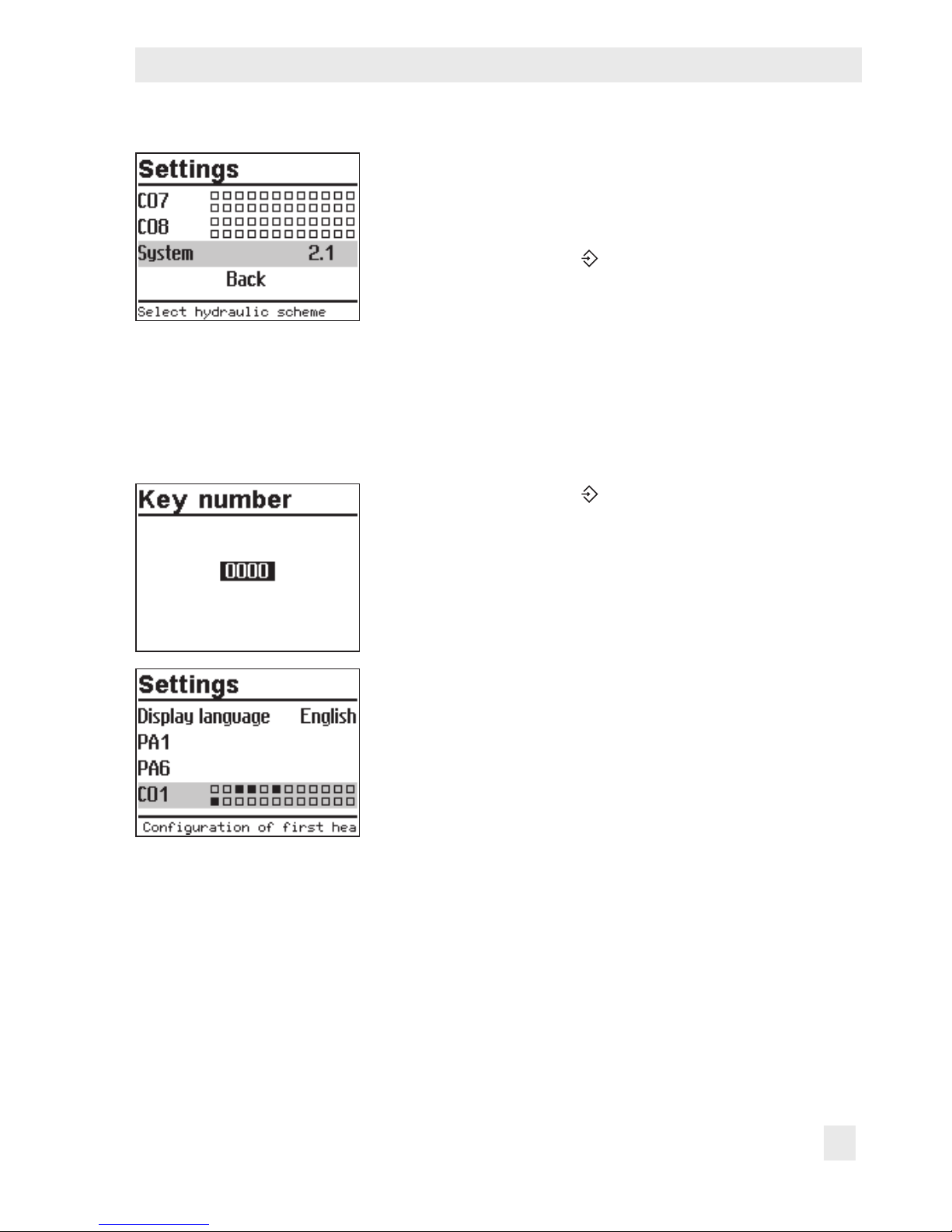

3.1 Setting the system code number

31 different hydraulic schematics are available. Each system conguration is represented by

a system code number. The different schematics are dealt with in section5. Available controller functions are described in sections6, 7 and 8.

Changing the system code number resets previously adjusted function blocks to their default

settings (WE). Function block parameters and parameter level settings remain unchanged.

The system code number is set in the conguration and parameter level.

Turn the rotary switch to (settings).

q Enter the currently valid key number.

¼ Conrm key number.

q Select 'System'.

¼ Open 'System'.

q Select the required system.

Page 25

EB 5573-1 EN 25

Operation

¼ Conrm the system selected.

q Select 'Back'.

¼ Exit menu.

Turn the rotary switch to

(settings).

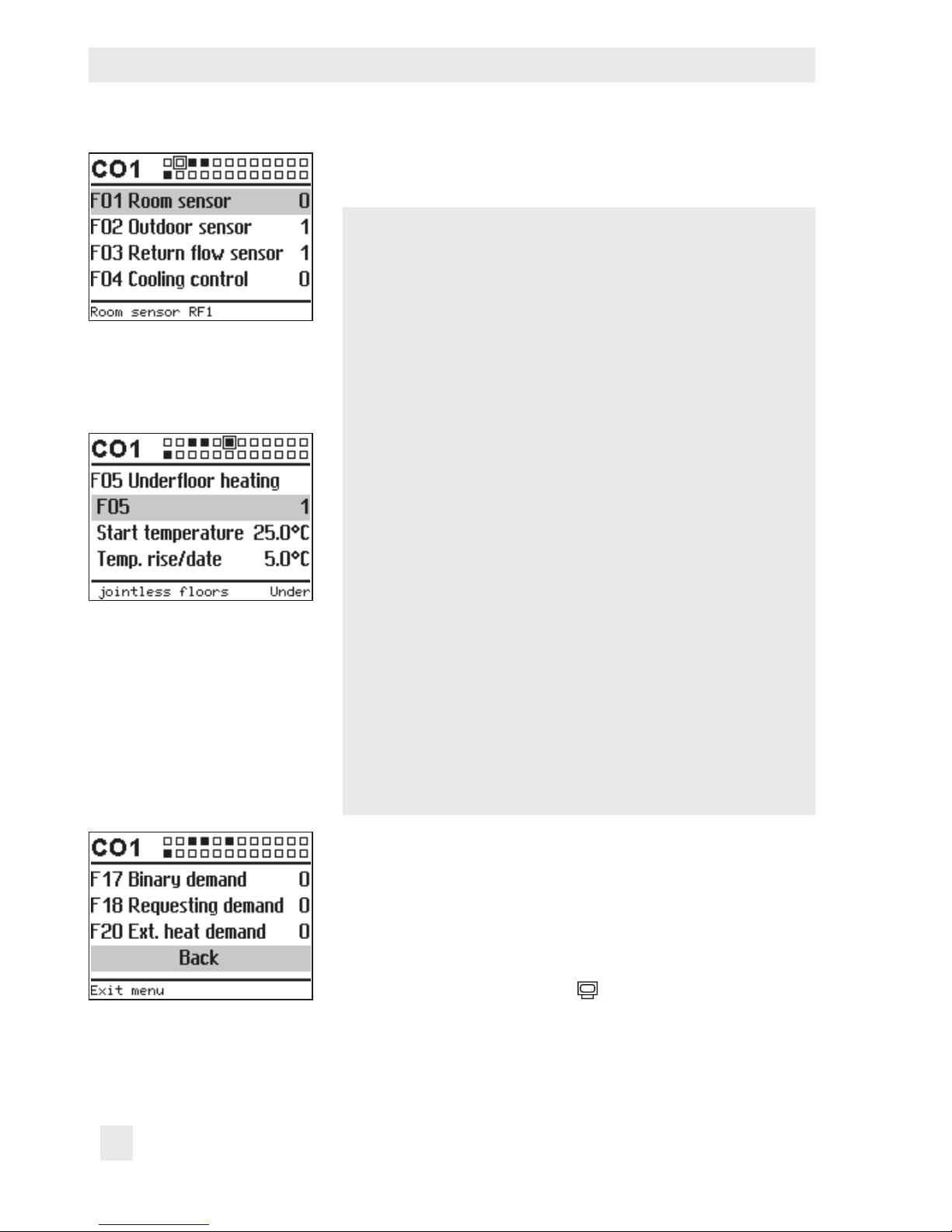

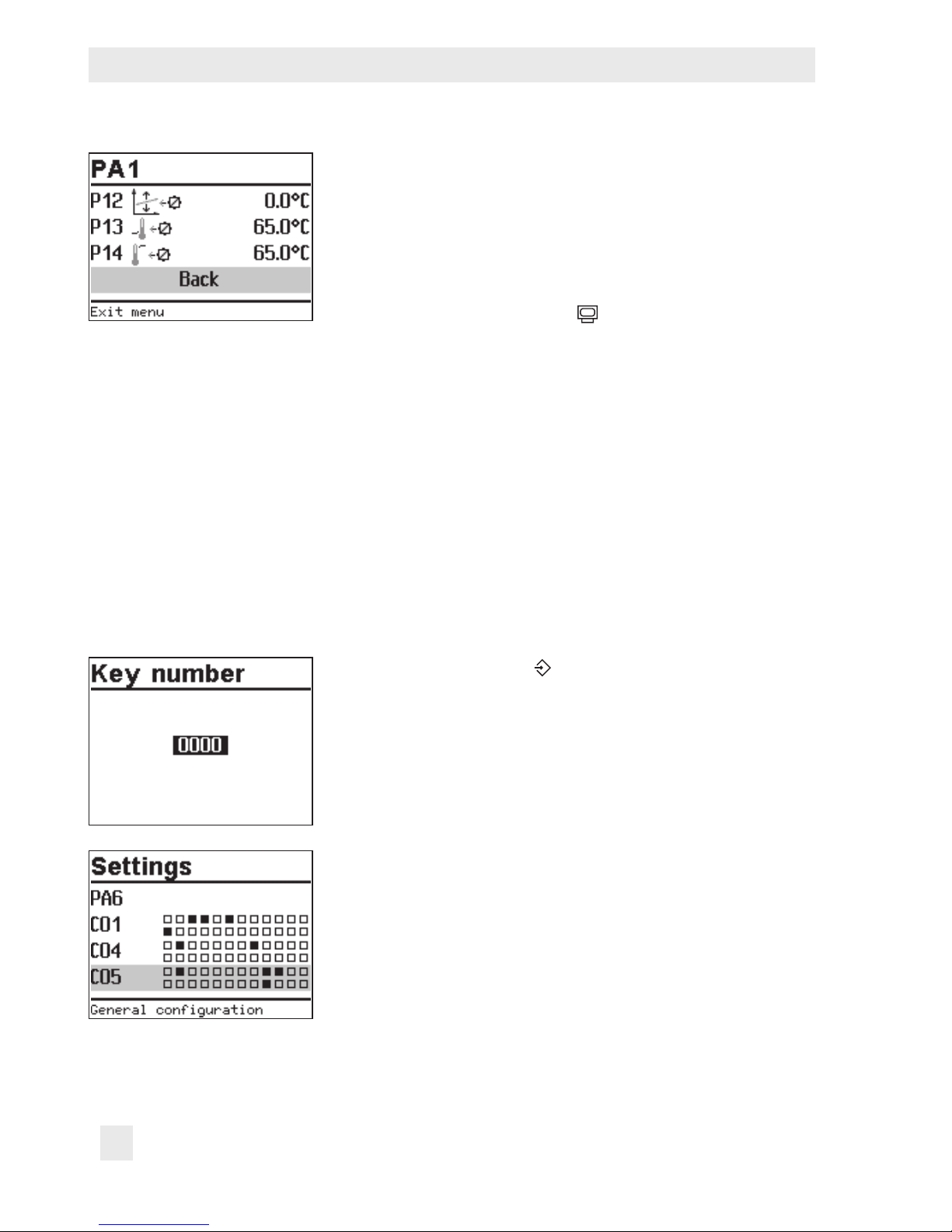

3.2 Activating and deactivating functions

A function is activated or deactivated in the associated function block. For more details on

function blocks, refer to section13.1.

Turn the rotary switch to (settings).

q Enter the currently valid key number.

¼ Conrm key number.

q Select the required conguration level:

– CO1: Heating circuit HC1

– CO2: Heating circuit HC2

– CO3: Not applicable

– CO4: DHW heating

– CO5: System-wide functions

– CO6: Modbus communication

Active function blocks are indicated by the black

squares.

Î Only those conguration levels are available for selec-

tion which can be controlled by the selected system.

Page 26

26 EB 5573-1 EN

Operation

¼ Open conguration level.

The rst function block is selected (marked gray).

q Select function.

Functions without function block parameters:

¼ Activate editing mode for the function.

The currently active conguration '0' or '1' is shown in-

verted on the display.

q Activate function (1) or deactivate function (0).

¼ Conrm conguration.

Functions with function block parameters:

¼ Open function.

q Select conguration.

¼ Activate editing mode for conguration.

The currently active conguration '0' or '1' is shown in-

verted on the display.

q Activate function (1) or deactivate function (0).

¼ Conrm conguration.

q Select function block parameter.

¼ Activate editing mode for function block parameter.

The current setting is shown inverted on the display.

q Set function block parameter.

Proceed in the same manner to set further function blocks.

Exit conguration level:

q Select 'Back'.

q Exit conguration level.

To adjust further function blocks in other conguration levels,

repeat steps with gray background.

Turn the rotary switch back to

(operating level).

Page 27

EB 5573-1 EN 27

Operation

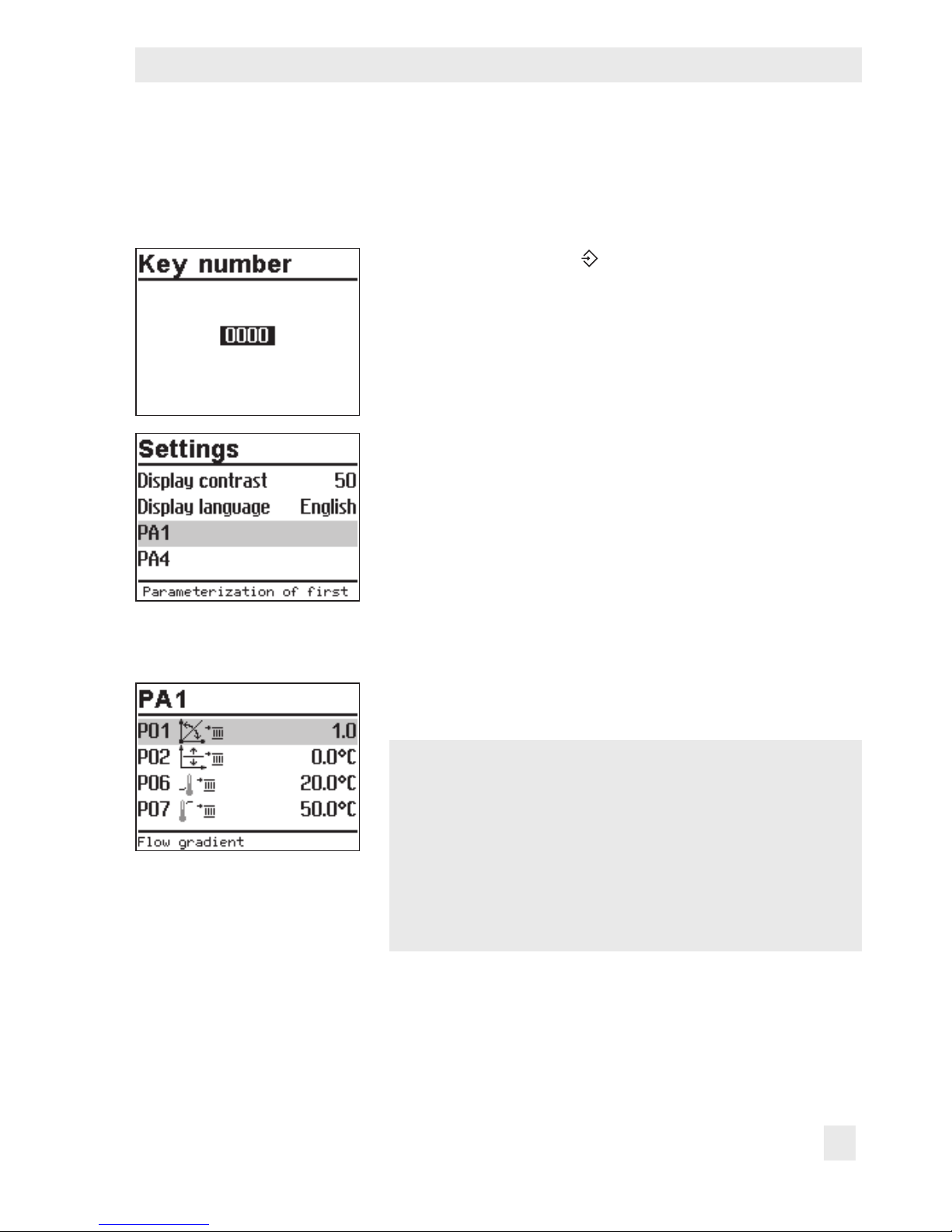

3.3 Changing parameters

Depending on the system code number selected and the activated functions, not all parameters listed in section13.2 might be available.

Turn the rotary switch to (settings).

q Enter the currently valid key number.

¼ Conrm key number.

q Select the required parameter level:

– PA1: Heating circuit HC1

– PA2: Heating circuit HC2

– PA3: Not applicable

– PA4: DHW heating

– PA5: Not applicable

– PA6: Modbus communication

Î Only those parameter levels are available for selection

which can be controlled by the selected system.

¼ Open parameter level.

The rst parameter is selected (marked gray).

q Select parameter.

¼ Activate editing mode for the parameter.

The current setting is shown inverted on the display.

q Set the parameter.

¼ Conrm setting.

¼ Proceed in the same manner to change further parame-

ters.

Page 28

28 EB 5573-1 EN

Operation

Exit parameter level.

q Select 'Back'.

q Exit conguration level.

To adjust further function blocks in other conguration levels,

repeat steps with gray background.

Turn the rotary switch back to

(operating level).

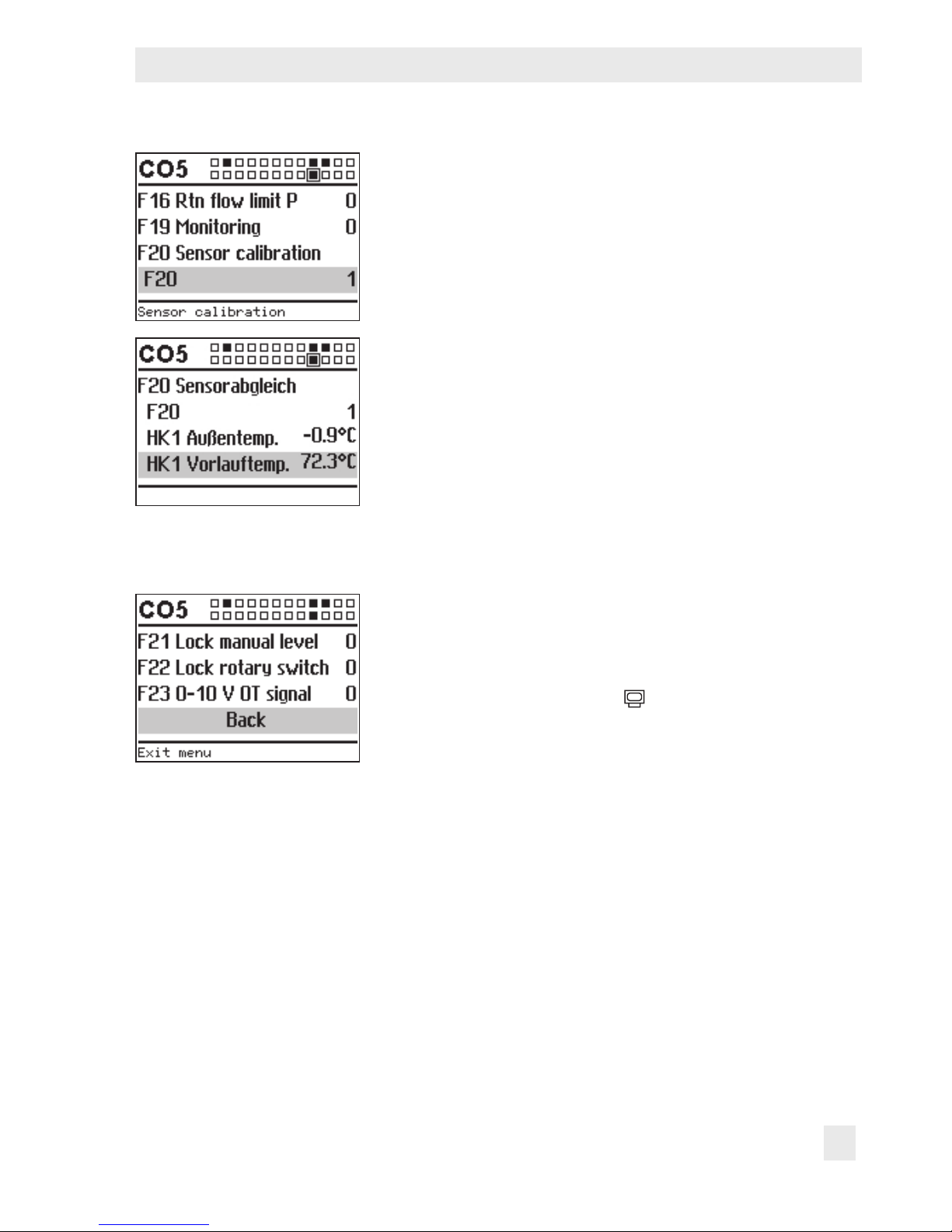

3.4 Calibrating sensors

The controller is designed for connection of Pt1000 sensors. The Pt 1000 resistance values

are listed on page150.

If the temperature values displayed at the controller differ from the actual temperatures, the

measured values of all connected sensors can be recalibrated. To calibrate a sensor, the currently displayed sensor value must be changed such that it matches the temperature (reference temperature) measured directly at the point of measurement. Sensor calibration is activated in CO5 in F20 function block.

An incorrect sensor calibration can be deleted by setting F20 - 0.

Turn the rotary switch to (settings).

q Enter the currently valid key number.

¼ Conrm key number.

¼ Select CO5 conguration level.

¼ Open CO5 conguration level.

¼ Select F20 function block.

¼ Activate editing mode for F20 function block.

Page 29

EB 5573-1 EN 29

Operation

q Select F20 conguration.

¼ Activate editing mode for conguration.

The currently active conguration '0' or '1' is shown in-

verted on the display.

q Activate function block ('1').

¼ Conrm activation.

¼ Select the temperature that you want to calibrate.

¼ Open calibration.

The temperature is shown inverted on the display.

¼ Correct measured value.

Read the actual temperature directly from the thermometer at the point of measurement and enter this value as

the reference temperature.

¼ Conrm corrected measured value.

¼ Proceed in the same manner to calibrate further sensors.

Exit conguration level:

q Select 'Back'.

q Exit conguration level.

Turn the rotary switch back to

(operating level).

Page 30

30 EB 5573-1 EN

Operation

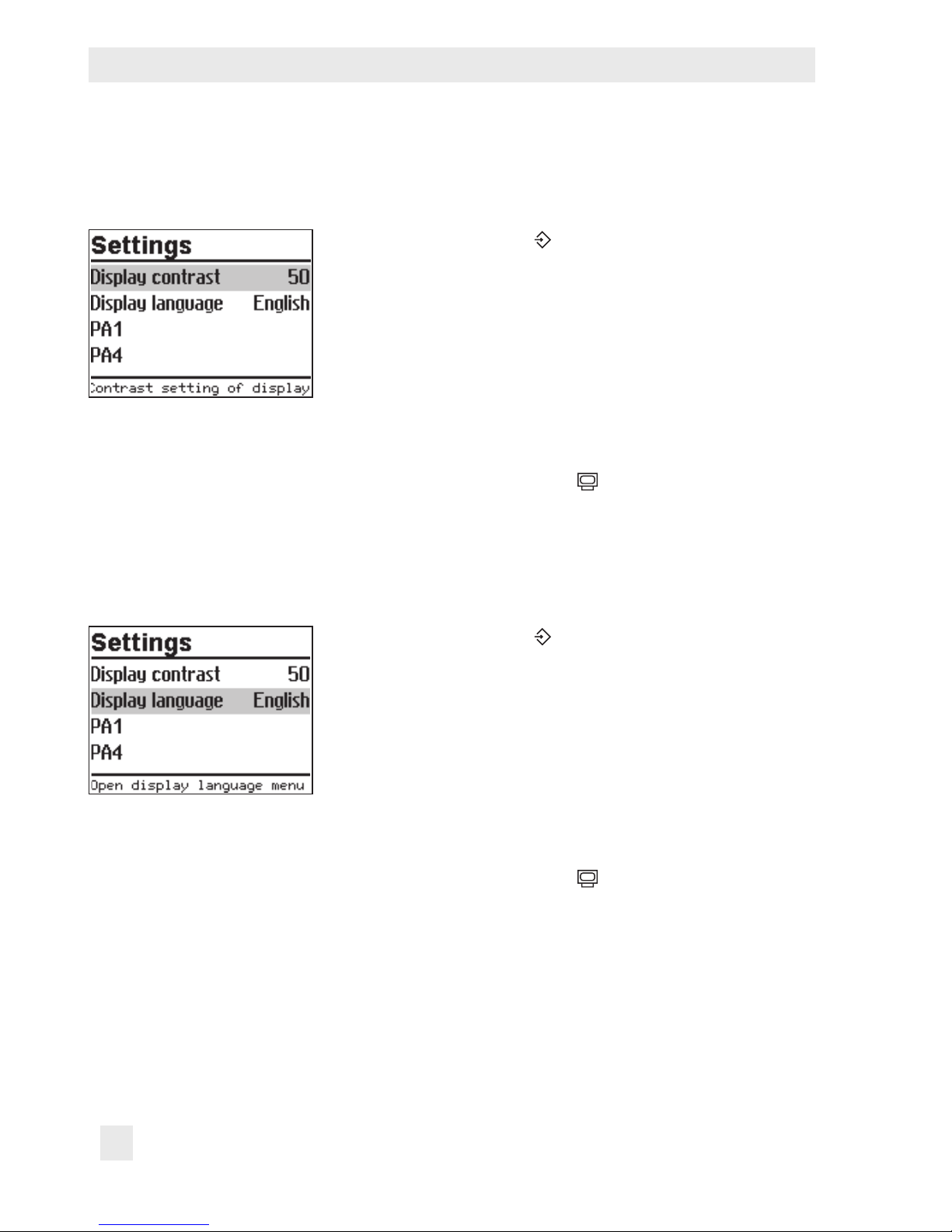

3.5 Altering the display contrast

You can alter the contrast of the display.

Turn the rotary switch to (settings).

q Enter the currently valid key number.

¼ Conrm key number.

q Select 'Display contrast'.

¼ Activate editing mode for the display contrast.

The current setting is shown inverted on the display.

q Set the display contrast

¼ Conrm setting.

Turn the rotary switch back to

(operating level).

3.6 Changing the display language

The default display language is German. The setting can be changed to English.

Turn the rotary switch to (settings).

q Enter the currently valid key number.

¼ Conrm key number.

q Select 'Display language'.

¼ Activate editing mode for the language setting.

The currently valid language is selected.

q Change language setting.

¼ Conrm setting.

Turn the rotary switch back to

(operating level).

Page 31

EB 5573-1 EN 31

Operation

3.7 Loading default setting

All parameters set over the rotary switch as well as parameters in the PA1 and PA2 parameter levels can be reset to their default settings (WE), except for the maximum ow temperature and the return ow temperature limits in PA1 and PA2.

Turn the rotary switch to (settings).

q Enter key number 1991.

¼ Conrm key number.

The settings are reset when the following icon appears

on the controller display:

Page 32

32 EB 5573-1 EN

Manual mode

4 Manual mode

Switch to manual mode to congure all outputs (refer to section12).

NOTICE

The frost protection does not function when the controller is in manual mode.

Changing positioning value/switching state manually:

Turn the rotary switch to (manual mode).

The outputs of the congured system are listed on the

display.

q Select the output

Positioning value

Circulation pump (heating)

Storage tank charging pump

Circulation pump (DHW)

Solar circuit pump

q Activate editing mode for the output.

q Change the positioning value/switching state.

q Conrm the positioning value/switching state.

The modied values remain active as long as the control-

ler is in manual mode.

Turn the rotary switch to

(operating level). The manual

mode is deactivated.

Note:

The outputs of the controller are not affected by merely turning the rotary switch to

(manual mode). The outputs are only changed by entering or changing the position-

ing values or switching states.

Page 33

EB 5573-1 EN 33

Systems

5 Systems

31 different hydraulic schematics are available.

Boiler systems:

Single-stage boiler systems can be congured from any system whose heating circuits and

DHW circuit include just one heat exchanger. These systems are Anl 1.0-1, 1.5-1, 1.6-1,

1.6-2, 1.9-1, 1.9-2, 2.x, 3.0, 3.5, 4.0 and 4.1.

The boiler can be controlled by an on/off output (CO1 > F12 - 0).

RK1/Y1 RüF1 VF1 UP1 RF1

BE

BA

AE

RK

RK1_2 Pkt VF1 UP1 RF1

BE

BA

AE

RK

Single-stage boiler

Fig. 2: Conguration of a boiler system

Page 34

34 EB 5573-1 EN

Systems

System Anl 1.0-1

BE

BA

AE

RK

AF1

RüF1 VF1

UP1RK1/Y1

RF1

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 35

EB 5573-1 EN 35

Systems

System Anl 1.0-2

BE

BA

AE

RK

AF1

RF1

RüF1

VF1

UP1

RK1/Y1

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 36

36 EB 5573-1 EN

Systems

System Anl 1.1-1

AF1

BE

BA

AE

RK

WW

KW

VF4 ZP SF1RF1UP1 RK1/Y1

VF1

RüF1

SLP (RK2)

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 0 (without SF2)

CO4 > F05 - 0 (without VF4)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 37

EB 5573-1 EN 37

Systems

System Anl 1.1-2

UP1 SLP

AF1

RK1/Y1 VF1 RüF1 RF1

BE

BA

AE

RK

WW

KW

SF1ZPVF4

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 0 (without SF2)

CO4 > F05 - 0 (without VF4)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 38

38 EB 5573-1 EN

Systems

System Anl 1.2

BE

BA

AE

RK

WW

KW

UP1

RK1/Y1

VF1

RüF1

RF1

TLP

AF1

VF4

SLP

SF2ZPSF1

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 0 (without RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 1 (with SF2)

CO4 > F05 - 0 (without VF4)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 39

EB 5573-1 EN 39

Systems

System Anl 1.3-1

BE

BA

AE

RK

AF1

WW

KW

CP

VF3

SF2

ZP

SF1

SLP (RK2)

RK1/Y1

VF1

UP1

RüF1

RF1

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 40

40 EB 5573-1 EN

Systems

System Anl 1.3-2

BE

BA

AE

RK

UP1

RK1/Y1

VF1

RüF1

RF1

AF1

WW

KW

CP

VF3 SF2

ZP

SF1

SLP

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 41

EB 5573-1 EN 41

Systems

System Anl 1.5-1

BE

BA

AE

RK

WW

KW

ZP

SLP

RüF1

VF1 SF1

RK1/Y1

Default settings

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 0 (without SF2)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 42

42 EB 5573-1 EN

Systems

System Anl 1.5-2

BE

BA

AE

RK

WW

KW

ZP

VF1

SF1

SLP

RüF1RK1/Y1

Default settings

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 0 (without SF2)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 43

EB 5573-1 EN 43

Systems

System Anl 1.6-1

BE

BA

AE

RK

WW

KW

SF2

ZP SLP

VF1 SF1RK1/Y1

RüF1

Default settings

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 1 (with SF2)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 44

44 EB 5573-1 EN

Systems

System Anl 1.6-2

BE

BA

AE

RK

WW

KW

SF2

ZP SLP

UP1 VF1

VF4 SF1

RK1/Y1

RüF1

Default settings

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 1 (with SF2)

CO4 > F05 - 0 (without VF4)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 45

EB 5573-1 EN 45

Systems

System Anl 1.6-3

BE

BA

AE

RK

WW

KW

SF2

ZP SLP

VF1 SF1

RüF1

RK1/Y1

UP1

Default settings

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 1 (with SF2)

CO4 > F05 - 0 (without VF4)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 46

46 EB 5573-1 EN

Systems

System Anl 1.9

BE

BA

AE

RK

RK2

WW

KW

ZP

VF2

SF1RüF2

BE2

Default settings

CO4 > F01 - 0 (without SF1)

CO4 > F03 - 0 (without RüF2)

CO4 > F04 - 0 (without ow rate sensor)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 47

EB 5573-1 EN 47

Systems

System Anl 2.0

BE

BA

AE

RK

WW

KW

AF1

ZP

RüF1

VF1

UP1

SLP (RK2)

SF1

RK1/Y1

RF1

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 0 (without SF2)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 48

48 EB 5573-1 EN

Systems

System Anl 2.1

BE

BA

AE

RK

AF1

RüF1 VF1

UP1RK1/Y1 RF1

SLP

WW

KW

ZP

SF1

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 0 (without SF2)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 49

EB 5573-1 EN 49

Systems

System Anl 2.2

BE

BA

AE

RK

AF1

RüF1 VF1

UP1RK1/Y1 RF1

TLP

WW

KW

SF2

ZP SLP

VF4 SF1

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 1 (with SF2)

CO4 > F05 - 0 (without VF4)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 50

50 EB 5573-1 EN

Systems

System Anl 2.3

BE

BA

AE

RK

AF1

RüF1 VF1

UP1RK1/Y1 RF1

SLP

WW

KW

VF3

CP SF2 SF1ZP

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 51

EB 5573-1 EN 51

Systems

System Anl 3.0

BE

BA

AE

RK

AF1

RüF1 VF1 UP2

RK2RK1/Y1

RF2

VF2

RüF2UP1 UP1

Default settings

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO2 > F01 - 0 (without RF2)

CO2 > F03 - 0 (without RüF2)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 52

52 EB 5573-1 EN

Systems

System Anl 3.5

BE

BA

AE

RK

RüF1 VF1

RK1/Y1 UP1

Note Closed control circuit and UP1 are only active during the process-

ing for an external demand

Default settings

CO1 > F03 - 1 (with RüF1)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 53

EB 5573-1 EN 53

Systems

System Anl 4.0

BE

BA

AE

RK

AF1

RüF1

VF1

UP2

RK2RK1/Y1

RF2

VF2

RüF2

RF1

UP1

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO2 > F01 - 0 (without RF2)

CO2 > F03 - 0 (without RüF2)

CO5 > F07 - 0 (without error indication at terminal 23)

Page 54

54 EB 5573-1 EN

Systems

System Anl 4.1

BE

BA

AE

RK

AF1

RüF1

VF1

UP2

RK2RK1/Y1

RF2

VF2

RüF2

RF1

UP1

WW

SLP SF1

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO2 > F01 - 0 (without RF2)

CO2 > F03 - 0 (without RüF2)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 0 (without SF2)

Page 55

EB 5573-1 EN 55

Systems

System Anl 4.5

BE

BA

AE

RK

AF1

RüF1

VF1

UP2

RK2RK1/Y1

RF2

VF2

RüF2

RF1

UP1

WW

SF1SLP

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO2 > F01 - 0 (without RF2)

CO2 > F03 - 0 (without RüF2)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 0 (without SF2)

Page 56

56 EB 5573-1 EN

Systems

System Anl 10.0-1

BE

BA

AE

RK

AF1

RüF1

VF1

UP1RK1/Y1

RF1RüF2

VF2

UP2RK2

RF2

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO2 > F01 - 0 (without RF2)

CO2 > F03 - 1 (with RüF2)

CO5 > F07 - 0 (without error indication at terminal 23)

Page 57

EB 5573-1 EN 57

Systems

System Anl 10.0-2

BE

BA

AE

RK

AF1

UP1

RF1

UP2

RF2

RK1/Y1

RK2

VF1

RüF1

VF2

RüF2

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO2 > F01 - 0 (without RF2)

CO2 > F03 - 1 (with RüF2)

CO5 > F07 - 0 (without error indication at terminal 23)

Page 58

58 EB 5573-1 EN

Systems

System Anl 11.0

BE

BA

AE

RK

AF1

RüF1 VF1 UP1RK1/Y1 RK2 RF1

WW

KW

SF1ZPRüF2

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F03 - 0 (without RüF2)

CO5 > F07 - 0 (without error indication at terminal 23)

Page 59

EB 5573-1 EN 59

Systems

System Anl 11.1-1

BE

BA

AE

RK

WW

KW

SLP

VF2 SF1

RK1/Y1

RüF1 VF1

AF1

ZP

RüF2RK2

UP1

RF1

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 0 (without SF2)

CO4 > F03 - 0 (without RüF2)

Page 60

60 EB 5573-1 EN

Systems

System Anl 11.1-2

BE

BA

AE

RK

WW

KW

UP1

RK1/Y1

VF1

RüF1

RF1 AF1 ZP

SLP

RüF2

VF2 SF1

RK2

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 0 (without SF2)

CO4 > F03 - 0 (without RüF2)

Page 61

EB 5573-1 EN 61

Systems

System Anl 11.1-3

WW

KW

BE

BA

AE

RK

AF1

RüF2

VF2RK2 ZP SF1

SF2SLP RK1/Y1 RF1VF1

RüF1UP1

Default settings System Anl 11.1 System Anl 11.2

CO1 > F01 - 0 (without RF1) - 0 (without RF1)

CO1 > F02 - 1 (with AF1) - 1 (with AF1)

CO1 > F03 - 1 (with RüF1) - 1 (with RüF1)

CO4 > F01 - 1 (with SF1) - 1 (with SF1)

CO4 > F02 - 0 (without SF2) - 1 (with SF2)

CO4 > F03 - 0 (without RüF2) - 0 (without RüF2)

Page 62

62 EB 5573-1 EN

Systems

System Anl 11.2

BE

BA

AE

RK

WW

KW

AF1

SF2

ZP SLPRüF1 VF1

VF2

RüF2

UP1 SF1

RK1/Y1

RK2 RF1

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 1 (with SF2)

CO4 > F03 - 0 (without RüF2)

Page 63

EB 5573-1 EN 63

Systems

System Anl 11.6

BE

BA

AE

RK

WW

KW

RK2

Z

RK1/Y1 RüF1

VF2VF1 SF2 UP1 AF1

RüF2 SLP/ZP SF1 RF1

*

* Note:

Install a continuously running pump in the DHW circuit and con-

nect it directly to the main power supply.

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 1 (with SF1)

CO4 > F02 - 1 (with SF2)

CO4 > F03 - 0 (without RüF2)

Page 64

64 EB 5573-1 EN

Systems

System Anl 11.9

BE

BA

AE

RK

AF1

RüF1

VF1

UP1RK1/Y1

RK2 RF1

WW

KW

ZP

VF2

SF1

RüF2

BE2

Default settings

CO1 > F01 - 0 (without RF1)

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO4 > F01 - 0 (without SF1)

CO4 > F03 - 0 (without RüF2)

CO4 > F04 - 0 (without ow rate sensor)

CO5 > F07 - 0 (without error indication at terminal 23)

Page 65

EB 5573-1 EN 65

Systems

System Anl 16.0

BE

BA

AE

RK

SF2

SF1RüF1 SLP/Y1

VF1RK1/Y1 UP1 AF1

Default settings

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 66

66 EB 5573-1 EN

Systems

System Anl 16.1

BE

BA

AE

RK

SF2

SF1RüF1 SLP/Y1

VF1RK1/Y1 UP1 AF1

RK2

UP2

VF2

RüF2

Default settings

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO2 > F03 - 0 (without RüF2)

Page 67

EB 5573-1 EN 67

Systems

System Anl 16.2

BE

BA

AE

RK

SF2

SF1RüF1

SLP/Y1

VF1RK1/Y1 UP1 AF1

VF2

UP2

Default settings

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 68

68 EB 5573-1 EN

Systems

System Anl 16.3

BE

BA

AE

RK

SF2

SF1

SLP/Y1

VF1RK1/Y1 AF1

UP1

RüF2

CP

RüF1

Default settings

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 69

EB 5573-1 EN 69

Systems

System Anl 16.4

BE

BA

AE

RK

SF2

RüF1

SLP/Y1

VF1RK1/Y1 AF1

VF2

UP2

UP1

RüF2

CP

SF1

Default settings

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO5 > F07 - 0 (without error indication at terminal 29)

Page 70

70 EB 5573-1 EN

Systems

System Anl 16.6

BE

BA

AE

RK

SF2

SF1

RüF1

SLP/Y1

VF1RK1/Y1 AF1

RK2

UP2

VF2

RüF2

UP1

Default settings

CO1 > F02 - 1 (with AF1)

CO1 > F03 - 1 (with RüF1)

CO2 > F02 - 0 (without AF2 for RK2)

CO2 > F03 - 0 (without RüF2)

Page 71

EB 5573-1 EN 71

Functions of the heating circuit

6 Functions of the heating circuit

Which controller functions are available depends on the selected system code number (Anl).

6.1 Weather-compensated control

When weather-compensated control is used, the ow temperature is controlled based on the

outdoor temperature. The heating characteristic in the controller denes the ow temperature

set point as a function of the outdoor temperature (seeFig. 3). The outdoor temperature required for weather-compensated control can either be measured at an outdoor sensor or received over the 0 to 10V input.

20

30

0.2

2.4

2.62.93.2

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.4

0.6

40

50

60

70

80

90

100

110

120

130

[°C]

–20

[

°

C]

–16–12–8–4048121620

140

150

–24 –28 –32 –36 –40

t

VL

t

A

tVL Flow temperature

tA Outdoor temperature

Fig. 3: Gradient characteristics

Functions WE Conguration

Outdoor sensor 0 CO1 > F02 - 1

0 to 10V signal for outdoor temperature 0

Input

–20°C

50°C

CO5>F23 - 1

Direction: Input

Lower transmission range: –30 to 100°C

Upper transmission range: –30 to 100°C

Page 72

72 EB 5573-1 EN

Functions of the heating circuit

6.1.1 Gradient characteristic

Basically, the following rule applies: a decrease in the outdoor temperature causes the ow

temperature to increase in order to keep the room temperature constant. By varying the gradient and level parameters, you can adapt the characteristic to your individual requirements:

20 0 –20

t

VL

[˚C]

[

˚

C]

t

A

The gradient needs to be increased if the room temperature

drops when it is cold outside.

20 0 –20

t

VL

[˚C]

[

˚

C]

t

A

The gradient needs to be decreased if the room temperature

drops when it is cold outside.

20 0 –20

t

VL

[˚C]

[

˚

C]

t

A

The level needs to be increased and the gradient decreased

if the room temperature drops when it is mild outside.

20 0 –20

[

˚

C]

t

A

[˚C]

t

VL

The level needs to be decreased and the gradient increased

if the room temperature rises when it is mild outside.

Page 73

EB 5573-1 EN 73

Functions of the heating circuit

Outside the times-of-use, reduced set points are used for control: the reduced ow set point is

calculated as the difference between the adjusted values for 'Day set point' (rated room temperature) and 'Night set point' (reduced room temperature). The 'Max. ow temperature' and

'Min. ow temperature' parameters mark the upper and lower limits of the ow temperature.

A separate gradient characteristic can be selected for the limitation of the return ow tem-

perature.

Examples for adjusting the characteristic:

− Old building, radiator design 90/70: Gradient approx. 1.8

− New building, radiator design 70/55: Gradient approx. 1.4

− New building, radiator design 55/45: Gradient approx. 1.0

− Underoor heating depending on arrangement: Gradient smaller than 0.5

Note:

Particularly for control operation without room sensor, the room temperatures set for

day ('Day set point') and night ('Night set point') only become effective satisfactorily

when the heating characteristic has been adapted to the building/heating surface

layout.

Functions WE Conguration

Four-point characteristic 0 CO1, 2 > F11 - 0

Parameters WE Switch position: value range

Day set point 20.0°C

: –5.0 to 150.0°C

Night set point 15.0°C

: –5.0 to 150.0°C

Parameters WE Parameters: value range

Flow gradient 1.8* PA1, 2 > P01: 0.2 to 3.2

Level (parallel shift) 0.0°C PA1, 2 > P02: –30.0 to 30.0°C

Min. ow temperature 20.0°C PA1, 2 > P06: –5.0 to 150.0°C

Max. ow temperature 90.0°C* PA1, 2 > P07: –5.0 to 150.0°C

* With CO1, 2 > F05 - 1 the following

applies:

Gradient: 0.2 to 1.0 (1.0)

Max. ow temperature: –5.0 to 50.0°C (50.0°C)

Page 74

74 EB 5573-1 EN

Functions of the heating circuit

6.1.2 Four-point characteristic

The four-point characteristic allows you to dene your own heating characteristic. It is dened by four points for the outdoor temperature, ow temperature, reduced ow temperature

and return ow temperature. The 'Max. ow temperature' and 'Min. ow temperature' parameters mark the upper and lower limits of the ow temperature.

t

VLmax

t

VLmin

t

VL

100

90

80

70

60

50

40

30

20

10

[˚C]20 15 10 50–5 –10 –15 –20

P1

P2

P3

P4

[˚C]

t

A

P1 to P4 Points 1 to 4

tVL Flow temperature

tA Outdoor temperature

- - -min Min. ow temperature

- - - max Max. ow temperature

––––––––– Four-point characteristic

– – – – – – Reduced four-point

characteristic

Fig. 4: Four-point characteristic

Note:

− The 'Day set point' and 'Night set point' parameters are no longer available when

the four-point characteristic has been selected, provided no additional functions

(e.g. optimization, ash adaptation) have been selected.

− The four-point characteristic function can only be activated when the adaptation

function is not active (CO1, 2 > F08 - 0).

Functions WE Conguration

Adaptation 0 CO1, 2 > F08 - 0

Four-point characteristic 0 CO1, 2 > F11 - 1

Parameters WE Parameters: value range

Outdoor temperature Point 1

Point 2

Point 3

Point 4

–15.0°C

–5.0°C

5.0°C

15.0°C

PA1, 2 > P05: –50.0 to 50.0°C

Page 75

EB 5573-1 EN 75

Functions of the heating circuit

Parameters WE Parameters: value range

Flow temperature Point 1

Point 2

Point 3

Point 4

70.0°C

55.0°C

40.0°C

25.0°C

PA1, 2 > P05: –5.0 to 150.0°C

Reduced ow temperature Point 1

Point 2

Point 3

Point 4

60.0°C

40.0°C

20.0°C

20.0°C

PA1, 2 > P05: –5.0 to 150.0°C

Return ow temperature Points 1 to 4 65.0°C PA1, 2 > P05: 5.0 to 90.0°C

Min. ow temperature 20.0°C PA1, 2 > P06: –5.0 to 150.0°C

Max. ow temperature 90.0°C* PA1, 2 > P07: –5.0 to 150.0°C

* With CO1, 2 > F05 - 1 the following

applies: Max. ow temperature: –5.0 to 50.0°C (50.0°C)

6.2 Fixed set point control

During the times-of-use, the ow temperature can be controlled according to a xed set

point. Outside the times-of-use, the controller regulates to a reduced ow temperature. Set

the desired rated ow temperature as 'Day set point', and the reduced ow temperature as

'Night set point'.

Functions WE Conguration

Outdoor sensor CO1 > F02 - 0

Parameters WE Switch position: value range

Day set point 50.0°C

: Min. to max. ow temperature

Night set point 30.0°C

: Min. to max. ow temperature

Parameters WE Parameters: value range

Min. ow temperature 20.0°C PA1, 2 > P06: –5.0 to 150.0°C

Max. ow temperature 90.0°C PA1, 2 > P07: –5.0 to 150.0°C

Note:

A xed set point control in heating circuit HC2 can only be congured with CO2 >

F02 - 0 when CO1 > F02 - 0 is also congured since heating circuit HC2 congured

with CO2 > F02 - 0 only uses the measured outdoor temperature provided by heat-

ing circuit HC1.

Page 76

76 EB 5573-1 EN

Functions of the heating circuit

6.3 Underoor heating/drying of jointless oors

Using function block setting CO1, 2 > F05 - 1, the respective heating circuit is congured as

an underoor heating circuit. In doing so, the controller at rst only limits the value ranges of

the heating characteristic gradient and the maximum ow temperature in PA1, 2 parameter

levels:

− Value range of the gradient: 0.2 to 1.0

− Value range of the maximum ow temperature: 5 to 50°C

In addition, it is possible to activate the drying of jointless oors function. In connection with

this, the function block parameters are listed which appear after activating this function

block. They determine the drying process: the rst heating up phase starts at the entered Start

temperature, which has a ow temperature of 25°C in its default setting. In the course of 24

hours, this temperature is raised by the value entered in 'Temp. rise/day', i.e. the default setting causes the ow temperature set point to rise to 30°C. If the maximum temperature is

reached, it is kept constant for the number of days entered in 'Duration'. The 'Temp. reduction/day' parameter determines the temperature reduction downwards. If the 'Temp. reduction/day' is set to 0, the temperature maintaining phase moves directly to automatic mode. If

the function block parameter 'Start temperature' is set to 25°C and 'Temp. rise/day' to

0.0°C, the drying functions runs as specied in Part 4 of DINEN1264: the drying of jointless oors function starts with a ow temperature of 25°C, which is kept constant for three

days. Afterwards, the controller switches to the maximum adjusted temperature. The further

process remains unchanged. The drying of jointless oors function is activated using the ad-

justed 'Start temperature' by changing the setting 'Stop' to 'Start'. 'Start' is displayed when

the drying function starts. The restarting stages 'Hold' and 'Reduction' can be be selected to

continue an interrupted drying process. The course of the drying process can be monitored in

the operating level by reading the measured data of the associated heating circuit.

Page 77

EB 5573-1 EN 77

Functions of the heating circuit

The drying process has been successfully completed when 'Done' is displayed. This disappears from the display after resetting the display to Stop in CO1, 2 > F05 or after interrupting the power supply. Any power failure that occurs while the function is running automatically restarts the drying function. In systems in which the drying function had to be interrupted due to DHW heating (e.g. system Anl2.1), storage tank charging does not occur while

the drying function is active, provided it is not used for frost protection of the storage tank.

NOTICE

The function block parameter can only be accessed after starting the function by resetting to 'Stop' in CO1, 2 > F05.

Functions WE Conguration

Underoor heating/drying of jointless

oors

0

25.0°C

5.0°C

45.0°C

4

0.0°C

Stop

CO1, 2>F05 - 1

Start temperature: 20.0 to 60.0°C

Temp. rise/day: 1.0 to 10.0°C

Maximum temperature: 25.0 to 60.0°C

Duration: 0 to 10 days

Temp. reduction/day: 0.0 to 10.0°C

Start condition: Stop, Start, Hold, Reduction

6.4 Outdoor temperature for continuous day mode

If a heating circuit is in night mode (automatic mode, ), this circuit is switched to day mode

whenever the outdoor temperature falls below 'Outdoor temperature for continuous day

mode'. Reduced operation restarts after the outdoor temperature rises above the limit (plus

0.5°C hysteresis).

This function is activated at very low temperatures to avoid that the building cools down ex-

cessively outside the times-of-use when low outdoor temperatures occur.

Parameters WE Parameters: value range

Outdoor temperature for continuous day

mode

–15.0°C PA1, 2 > P09: –50.0 to 5.0°C

Page 78

78 EB 5573-1 EN

Functions of the heating circuit

6.5 Buffer tank systems Anl 16.x

The systems Anl 16.x are tted with a butter tank. The buffer tank can be charged by the district heating system according to an adjustable characteristic or to an adjustable xed set

point. The storage tank charging pump SLP is controlled to the storage tank set point (e.g.

45.3°C), which is based on the outdoor temperature. Storage tank charging starts when

temperature falls below the outdoor-temperature-based set point at SF1. The charging temperature results from the outdoor-temperature-based set point plus 6°C (e.g. 51.3°C). The

storage tank charging is nished when the temperature at SF2 exceeds the outdoor-temperature-based set point by 3°C (e.g. 48.3°C).

With CO1>F21-1, Y1 for speed control of the storage tank charging pump is available.

All storage tank charging actions start with the minimum pump speed (function block parameter: 'Min. speed signal'). As soon as the charging temperature at VF1 is nearly reached, the

speed of the storage tank charging pump is increased and the valve controls the ow rate. If

the temperature at SF2 reaches the value entered in Start speed reduction, the signal level at

Y1 is reduced within the range between the limits entered in Start speed reduction and Stop

speed reduction. Y1 is set to 0V when the storage tank charging pump is switched off.

For systems without a downstream control circuit, a transmitted external demand causes the

feeder pump UP1 to be activated and can override the current buffer tank set point, if necessary. For systems with a downstream control circuit, either a transmitted external demand or

the demand of the downstream control circuit causes the feeder pump UP1 to be activated,

regardless of the CO5 > F14 setting. Regardless of the CO5 > F14 setting, the external demand and the demand of the downstream control circuit can override the current buffer tank

set point.

The pump UP2 of the solid-fuel boiler circuit starts to run when the temperature reaches 'Start

temperature for boiler pump' at VF2. The boiler pumps is switched off again when the temperature at VF2 falls below the temperature T = 'Start temperature for boiler pump' – 'Boiler

pump hysteresis'.

In systems Anl 16.3, 16.4 and 16.6, a solar circuit is integrated, which uses sensor SF2 for

control. The collector circuit pump CP is activated when the temperature at the collector sensor RüF2 is higher than that at storage tank sensor SF2 by the value entered in 'Solar circuit

pump ON'. It is deactivated when the temperature difference falls below the valve entered in

'Solar circuit pump OFF' or when the temperature at the storage tank sensor SF2 reaches

'Max. storage tank temperature'.

Page 79

EB 5573-1 EN 79

Functions of the heating circuit

Note:

The buffer tank control circuit is deactivated as described in section6.4. When predened gradients of heating characteristic (CO1 > F11-0) are used, night mode is

not possible in the buffer tank control circuit. In contrast to an active four-point characteristic (CO1 > F11-1): in this case, a four-point characteristic exists for day and

night modes.

Functions WE Conguration

Speed reduction of charging pump based

on charging progress

0

40°C

50 °C

2V

CO1 > F21

Start speed reduction: 5 to 90°C

Stop speed reduction: 5 to 90°C

Min. speed signal: 0 to 10V

Parameters WE Parameters: value range

Solar circuit pump ON 10.0°C PA4 > P10: 1.0 to 30.0°C

Solar circuit pump OFF 3.0°C PA4 > P11: 0.0 to 30.0°C

Max. storage tank temperature 80.0°C PA4 > P12: 20.0 to 90.0°C

Start temperature for boiler pump 60.0°C PA5 > P01: 20.0 to 90.0°C

Boiler pump hysteresis 5.0°C PA5 > P02: 0.0 to 30.0°C

6.6 Summer mode

Summer mode is activated depending on the mean daytime temperature (measured between

7.00h and 22.00h) during the adjusted summer time period. If the mean daytime temperature exceeds the 'Boost' on the number of successive days set in 'No. days until activation',

summer mode is activated on the following day. This means that the valves in all heating circuits are closed and the circulation pumps are switched off after t = 2 x valve transit time. If

the mean daytime temperature falls below the 'Limit' on the number of successive days set in

'No. days until deactivation', summer mode is deactivated on the following day.

Functions WE Conguration

Summer mode 0

01.06 - 30.09

2

1

18.0°C

CO5 > F04 - 1

Time: Adjustable as required

No. days until activation: 1 to 3

No. days until deactivation: 1 to 3

Limit: 0.0 to 30.0°C

Page 80

80 EB 5573-1 EN

Functions of the heating circuit

Note:

Summer mode only becomes effective when the controller is in automatic mode (

).

6.7 Delayed outdoor temperature adaptation

The calculated outdoor temperature is used to determine the ow temperature set point. The

heat response is delayed when the outdoor temperature either increases or decreases or

both. If the outdoor temperature varies by, for example, 12°C within a very short period of

time, the calculated outdoor temperature is adapted to the actual outdoor temperature in

small steps (delay time of 3°C/h) over a time period of

t=

12 C

3C/h

°

°

=4h

.

Note:

The delayed outdoor temperature adaptation helps avoid unnecessary overloads of

central heating stations in combination with either overheated buildings occurring, for

example, due to warm winds, or temporarily insufcient heating due to the outdoor

sensor being exposed to direct sunshine. In the operating level, the outdoor temperature blinks on the display while delayed outdoor temperature adaptation is active. A

small hour glass appears next to the thermometer on the display when this function is

active. The calculated outdoor temperature is displayed.

Functions WE Conguration

Delayed outdoor temperature adaptation

(decreasing)

0 CO5>F05 - 1

Delay/h: 1.0 to 6.0°C

Delayed outdoor temperature adaptation

(increasing)

0

3.0°C

CO5>F06 - 1

Delay/h: 1.0 to 6.0°C

6.8 Remote operation

Apart from measuring the room temperature, the Type5257-5 Room Panel (Pt 1000 sensor)

provides the following opportunities of inuencing the control process:

− Selection of the operating mode: Automatic mode

Day mode

Night mode

− Set point correction: during rated operation, the room temperature set point can be in-

creased or reduced by up to 5°C using a continuously adjustable rotary knob.

Page 81

EB 5573-1 EN 81

Functions of the heating circuit

With an activated room sensor, the measured room temperature is displayed when the remote operation is connected and activated. Nevertheless, it is not used for control when either the optimization, adaptation or ash adaptation function is activated.

Type 5257-5

TROVIS 5573-1

RK1 RK2

Terminal 1 Terminal 5 Terminal 3

Terminal 2 Terminal 12 Terminal 12

Terminal 3 Terminal 9 Terminal 10

Fig. 5: Wiring plan for Type5257-5 Room Panel to TROVIS 5573-1 for RK1 or RK2

Functions WE Conguration

Room sensor 0 CO1, 2 > F01 - 1

6.9 Optimization

This function requires the use of a room sensor. Depending on the building characteristics,

the controller determines and adapts the required advance heating time (maximum 8 hours)

to ensure that the desired 'Day set point' (rated room temperature) has been reached in the

reference room when the time-of-use starts. During the advance heating period, the controller

heats with the max. ow temperature. This temperature is built up in steps of 10°C. As soon

as the 'Day set point' has been reached, weather-compensated control is activated.

Depending on the room sensor, the controller switches off the heating system up to one hour

before the time-of-use ends. The controller chooses the deactivation time such that the room

temperature does not drop signicantly below the desired value until the time-of-use ends.

During the advance heating period and the premature deactivation of the heating system, the

or icon blink on the display.

Outside the times-of-use, the controller monitors the 'Night set point' (reduced room temperature). When the temperature falls below the night set point, the controller heats with the max.

ow temperature until the measured room temperature exceeds the adjusted value by 1°C.

Page 82

82 EB 5573-1 EN

Functions of the heating circuit

Note:

− Direct sunshine can cause the room temperature to increase and thus result in the

premature deactivation of the heating system.