Page 1

Automation System TROVIS 5500

Room Controller

TROVIS 5572

Electronics from SAMSON

Mounting and

Operating Instructions

EB 5572 EN

®

Firmware version 1.10

Edition February 2007

Page 2

Disclaimer of liability

Disclaimer of liability

We areconstantly developing our products and therefore, reservethe right to change the prod

uct or the information contained in this document at any time without notice.

We donot assume any liability for the accuracy or completenessof these mounting and operat

ing instructions. Moreover, we do not guarantee that the buyer can use the product for an in

tended purpose. SAMSON rejects any liability for claims by the buyer, especially claims for

compensation including lost profits or any other financial loss, except the damage was caused

intentionally or by gross negligence. If an essential term of the contract is breached by negli

gence, SAMSON’s liability is limited to the foreseeable damage.

Safety instructions

The device may only be assembled, started up or operated by trained and

4

experienced personnel familiar with the product.

Proper shipping and appropriate storage are assumed.

4

-

-

-

-

2 EB 5572 EN

Page 3

Contents

Contents

1 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Operating elements. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Setting the controller time . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Programming the time schedule . . . . . . . . . . . . . . . . . . . . . 8

1.5 Selecting the operating mode (presence button) . . . . . . . . . . . . . 9

1.6 Changing temperature set points temporarily . . . . . . . . . . . . . . 10

2 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Activate/deactivate functions . . . . . . . . . . . . . . . . . . . . . 11

2.2 Changing parameters . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Calibrating the room sensor . . . . . . . . . . . . . . . . . . . . . . 13

2.4 Checking inputs and outputs . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Reset to default settings . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1 Heating functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.1 Window contact . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.2 Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.3 Vacation period. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Cooling functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.1 Window contact . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.2 Dew point monitoring . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Operating mode override . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 Summer time/winter time changeover . . . . . . . . . . . . . . . . . 18

3.5 Key lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.6 Switching outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . 23

7 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 Function block list . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

EB 5572 EN 3

Page 4

Brief description

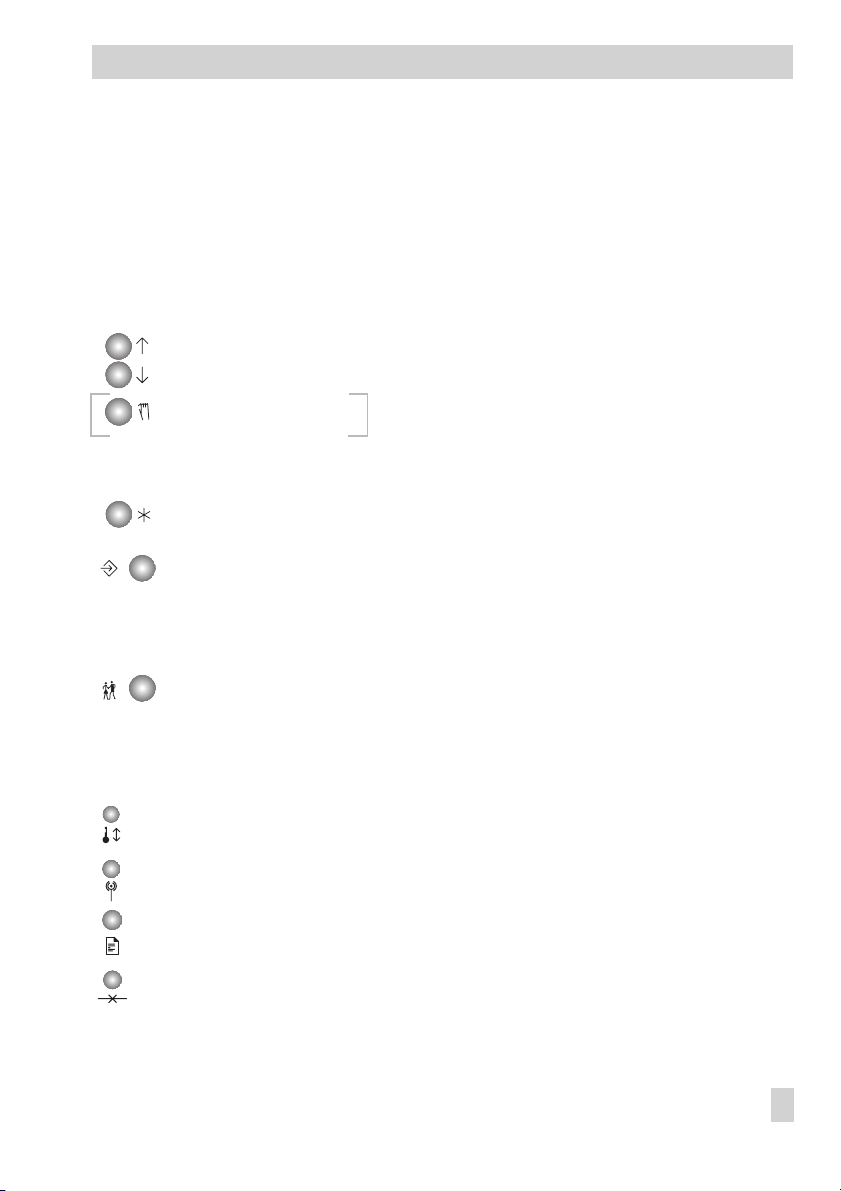

Changeover key (short = 1 s)

(time, date, time schedules)

Changeover key (long = 5 s)

(

Set points

parameter level)

Presence button

(Operating mode: Automatic – Time-of-use – Outside time-of-use)

Arrow keys

(scrolling, changing)

Reset key

Default settings

4 EB 5572 EN

Data sheet key

(configuration level)

Thermometer key

(

Control

parameter level)

Radio tower key

(

Communication

Enter key (selecting,

confirming)

parameter level, test)

Page 5

Operation

1 Operation

The room controller is ready for use after performing the connections (section 6) and start-up

(section 2).

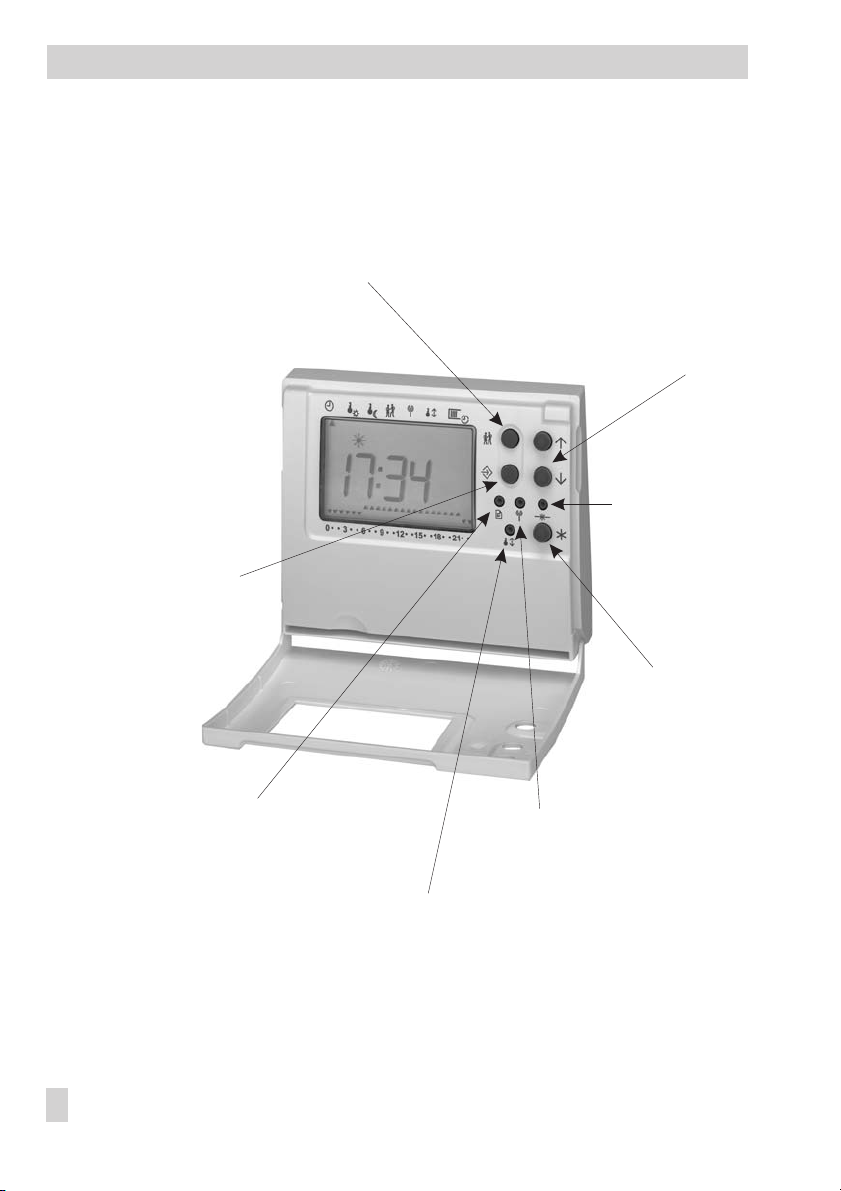

1.1 Operating elements

Operating elements when cover is closed

Arrow keys (up and down keys)

Used to select displays and parameters

Manual key

Without any function

Additional operating elements accessible with the cover open

Enter key

Used to confirm a selection or setting

Changeover key

Key pressed for approx. 1 sec.: Open controller time and programmed time

schedule

Key pressed for approx. 5 sec.: Open

tering key number)

Presence button

Used to select operating mode (Automatic – Time-of-use – Outside of time-of-use)

Set points

parameter level (only after en-

Note that you require a pointed object such as a ball-point pen in order to press the follow

ing recessed keys:

Thermometer key

Used to access

Radio tower key

Used to access

Data sheet key

Used to access configuration level (only after entering key number)

Reset key

Used to reset the room controller to its default settings (delivery state)

(only after entering key number)

Control

Communication

parameter level (only after entering key number)

parameter level (only after entering key number)

EB 5572 EN 5

-

Page 6

Operation

1.2 Display

Information on the current operation appears on the display of the controller during use:

Set point Large reading

Actual temperature Small reading on the bottom right of the display

The actual temperature reading changes in steps of 0.5 °C.

Operating mode No icon outside of time-of-use

during time-of-use

in vacation mode

Presence Arrow points to indicating that the automatic operating mode has

been interrupted (refer to section 1.5)

Time schedule 5, 6 changes in automatic operating mode depending on the

programmed time schedule: 5 Time-of-use · 6 Outside of time-of-use

555 Continuous time-of-use (automatic operating mode interrupted)

666 Continuously outside of time-of-use (automatic operatingmode

interrupted)

Communication

failure

Control station

intervention

Frost protection Actual temperature (small) blinks on the display when

6 EB 5572 EN

blinks on the display

(only when communication is configured, refer to section 4)

RC appears on the display

(only when communication is configured, refer to section 4)

– Actual room temperature < 5 °C

– Dew-point monitor alarm

– Window contact

Snow flake icon (blinking)

– Actual room temperature < 5 °C

Snow flake icon (constant)

– Dew-point monitor alarm

Page 7

Operation

1.3 Setting the controller time

The correct time and date needs to be set directly after starting up the controller or after the

power supply has been disconnected for more than 24 hours.

How to proceed:

Open the cover.

Press key briefly (approx 1 s). The time appears on the display.

An arrow on the right of the display at the same level as the changeover key indi

cates that the time can be changed.

Press this key to enter the editing mode.

The time starts to blink.

Enter the correct time.

Confirm the time.

Select date setting.

Press this key to enter the editing mode.

The date starts to blink.

Enter the correct date.

Confirm the date.

Select year setting.

Press this key to enter the editing mode.

The year starts to blink.

Enter the correct year.

Confirm the year.

Exit the parameter level.

-

Note!

If no key is pressed within five minutes, the controller display returns to the set point reading.

EB 5572 EN 7

Page 8

Operation

1.4 Programming the time schedule

Three times-of-use can be programmed for each day of the week within which the controller

regulates the room temperature to the

Set point for time-of-use

set the start and stop times of this time-of-use to the identical time.

Parameters

Times-of-use Mon to Fri

Times-of-use Sat and Sun

WE Range of values

08:00 to 20:00

00:00 to 00:00

00:00 to 24:00 h in steps of 15 minutes

00:00 to 24:00 h in steps of 15 minutes

How to proceed:

Open cover.

Press key briefly (approx 1 s). The time appears on the display.

An arrow on the right of the display at the same level as the changeover key indi

cates that the time can be changed.

The date appears on the display.

The year appears on the display.

Select time-of-use setting.

The arrow at the top of display points to .

Reading: 1–7 = daily, 1 = Monday, 2 = Tuesday, …, 7 = Sunday

Press this key to enter the editing mode.

The start time of the first time-of-use appears on the display.

Set the start time (in 15-minute steps).

Confirm the start time.

The stop time of the first time-of-use appears on the display.

Set the stop time (in 15-minute steps).

Confirm the stop time.

The start time of the second time-of-use appears on the display.

. If a time-of-use is not required,

-

Repeat the instructions highlighted in gray to set the second and third times-of-use. After all the

times-of-use have been programmed:

Exit the parameter level.

Note!

If no key is pressed within five minutes, the controller display returns to the set point reading.

8 EB 5572 EN

Page 9

Operation

1.5 Selecting the operating mode (presence button)

Press key repeatedly to cycle through the following operating modes:.

Temporary set point settings (see section 1.6) are reset when the operating mode is changed.

Automatic mode

( during time-of-use, no icon appears outside of time-of-use; 6…5…6)

Depending on the programmed time schedule, the controller regulates the room tem

perature to the

for outside of time-of-use

Set point for time-of-use

outside of the time-of-use.

Time-of-use (;55555…)

The controller regulates the room temperature to the

less of the programmed time schedule.

Outside of time-of-use (66666…)

The controller regulates the room temperature to the

time-of-use

regardless of the programmed time schedule.

The duration of the time-of-use and outside of time-of-use operating mode is set in function

block F02:

Function

Resetting operating mode 1 F02*

* F02 - 0: Operating mode settings for continuous time-of-use/outside of time-of-use

F02 - 1: Operating mode settings for time-of-use/outside of time-of-use that applies until the next

time schedule starts when the operating mode changes back to automatic mode

during the time-of-use and to the

Set point for time-of-use

Set point for outside of

WE Configuration

Set point

regard

-

-

EB 5572 EN 9

Page 10

Operation

1.6 Changing temperature set points temporarily

During the controller operation, the current set point and the actual temperature appear on the

display.

Use the arrow keys to temporarily change the current set point.

The new temporary set pointapplies until the next time-of-use starts or until the operating mode

is changed, however, eight hours at the maximum.

The following maximum set point shifts apply:

Set point for time-of-use

4

Set point for outside of time-of-use:

4

Set point for vacation mode

4

How to proceed:

Change the set point temporarily in steps of 0.5 °C.

Note!

The temporary set point can also be overwritten by a building control station (GLT) when the

communication is active (see section 4).

: ±3 °C

+8 °C

: +8 °C

10 EB 5572 EN

Page 11

2 Start-up

Start-up

The changes described in this section concerning controller configuration can only be per

formed after the valid key number has been entered.

The valid key number is specified on page 27. To prevent unauthorized access to the key num

ber, tear out or blank out the key number.

2.1 Activate/deactivate functions

A function is activated and deactivated by selecting the associated function block.

The function blocks are listed in section 7.1.

How to proceed:

Open cover.

Press the data sheet key.

Enter key number.

The configuration level is opened.

Select the function block.

Enter the editing mode.

Fb : _ _ blinks.

Activate the function block.

Reading: Fb : _ _ ON

or

Deactivate the function block.

Reading: Fb : _ _ OFF

Confirm setting.

Repeat the instructions highlighted in gray to set further function blocks.

On completing the controller configuration:

Exit the configuration level (or, alternatively, by pressing ).

-

-

Note!

If no key is pressed within five minutes, the controller display returns to the set point reading.

EB 5572 EN 11

Page 12

Start-up

2.2 Changing parameters

Depending on the active functions, not all the parameters that are specified in the parameter

lists in the appendix are accessible (–> section 7.2).

The parameters are arranged in topics in various parameter levels (PA):

PA

4

4

4

Set points

PA

Control

PA

Communication

How to proceed:

Open cover.

Select required parameter level:

Enter the key number.

The parameter level is opened.

Select parameter.

Enter the editing mode.

The display starts to blinks.

Set parameter.

Confirm setting.

Repeat the instructions highlighted in gray to set other parameters in the opened parameter

level. On completing all the parameter settings:

Exit the parameter level. Use corresponding key depending on the parameter level:

: Set points for time-of-use, outside of time-of-use, and

vacation mode

: Control parameters

: Device address, Baud rate, sensor calibration, switching

inputs and outputs

Set points

PA

Control

PA

PA

Communication

Set point

PA

Control

PA

PA

Communication

(press key approx. 5 sec.)

s

Note!

If no key is pressed within five minutes, the controller display returns to the set point reading.

12 EB 5572 EN

Page 13

Start-up

2.3 Calibrating the room sensor

If the temperature displayed on the room controller (current temperature on the bottom right of

the display) does not match the actual room temperature, the measured temperature of the

room sensor can be changed and reset. On calibration, the currently displayed sensor temper

ature needs to be changed to match the directlymeasured roomtemperature (referencetemper

ature).

Note!

An incorrectly performed calibration leads to the wrong room temperature measurements and

results in incorrect control performance. Use a thermometer with a high degree of accuracy on

measuring the reference temperature.

How to proceed:

Open cover.

Select

Communication

Enter the key number.

The parameter level is opened.

The device address appears on the display.

The Baud rate appears on the display.

The transmit/receive test appears on the display.

Select correction value for room sensor

Reading: Measured temperature (small); correction value (large)

Enter the editing mode.

The correction value starts to blink.

Set the temperature difference found.

Confirm the temperature difference.

Exit the parameter level (or, alternatively, by pressing ).

parameter level.

-

-

Note!

If no key is pressed within five minutes, the controller display returns to the set point reading.

EB 5572 EN 13

Page 14

Start-up

2.4 Checking inputs and outputs

The current state of the binary inputs, triacs and analog outputs can be displayed in the

munication

How to proceed:

parameter level. The state of triacs andanalog outputscan be changed manually.

Open cover.

Select

Communication

Enter the key number.

The parameter level is opened

Press key 4 times.

The state of the binary input BE1 appears:

E1 0 /E1 1 (BE1 open/closed)

Press the key once to change to the next input or output:

• Binary input BE2 · Reading: E2 0/E2 1 (BE 2 open/closed)

• Triac 1 · Reading: A1 0/A1 1 (triac 1 open/closed)

• Triac 2 · Reading: A2 0/A2 1 (triac 2 open/closed)

• Analog output AA1 · Reading: AA1 0 to AA1 100 (0 to 10 V voltage)

• Analog output AA2 · Reading: AA2 0 to AA2 100 (0 to 10 V voltage)

Changing triac/analog output state:

The output triac 1 (A1), triac 2 (A2), analog output AA1 or analog output AA2 ap

pear on the controller display.

Enter the editing mode.

Close triac (A_ 1) or raise voltage at the analog output.

or

Open TRIAC (A_ 0) or reduce voltage at the analog output.

parameter level.

Com

-

-

Exit the parameter level (or, alternatively, by pressing ).

Note!

If no key is pressed within five minutes, the controller display returns to the set point reading.

14 EB 5572 EN

Page 15

2.5 Reset to default settings

All parameters and functions can be reset to their default settings.

How to proceed:

Open cover.

Select default setting menu.

Enter the key number.

The default setting menu is opened.

Enter the editing mode.

Press key.

Confirm the reset.

Exit the default setting menu.

Start-up

EB 5572 EN 15

Page 16

Functions

3 Functions

3.1 Heating functions

3.1.1 Window contact

The window contact function depends on the state of binary input BE1:

BE1 = 0: The heating valve is closed.

4

BE1 = 1: Control according to the current operating mode.

4

The heating valve is opened for five minutes every 20 minutes

3.1.2 Optimization

The controller determines the

building characteristics.

Advance heating time

The

time-of-use

when the time-of-use starts, but at an earlier point in time instead.

The

side of time-of-use

finish when the outside of time-of-use starts, but at an earlier point in time instead.

Note!

Advance heating time

time

Function

Optimization 0 F03 - 1

Parameters

Maximum advance heating time 360 min PA

Maximum cooling down time 120 min PA

already when the time-of-use starts. In optimization mode, heating does not start

Cooling down time

already when the time-of-use ends. In optimization mode, heating does not

and

Maximum cooling down time

Advance heating time

is the time required to achieve the room temperature

is the time required to achieve the room temperature

and

Cooling down time

parameters respectively.

WE Configuration

WE Parameter level / Range of values

and

Cooling down time

are restricted by the

Set points

Set points

Maximum advance heating

/ 0 to 360 min

/ 0 to 120 min

depending on the

Set point for out-

Set point for

16 EB 5572 EN

Page 17

3.1.3 Vacation period

Functions

During the programmed

perature to the

The Presence alert function (section 3.3) isnot activeduring the programmed vacation period.

Parameters

Set point for vacation mode 15 °C PA

Vacation schedule – PA

Set point for vacation mode

Vacation period

WE Parameter level / Range of values

(start and stop), the controller regulates the room tem

. appears on the display.

Set points

Set points

/ 5 to 30 °C

/ –

3.2 Cooling functions

The cooling valve regulates the temperature to the current set point during the time-of-use.

The following applies for outside of time-of-use:

When F04 - 0: No cooling

When F04 - 1: The temperature is regulated to a raised set point. The setback calculated

from the set point for outside of time-of-use during heating is interpreted

as an increase.

Function

Cooling 0 F04*

* F04 - 0: No cooling outside of time-of-use

F04 - 1: Cooling also outside of time-of-use

WE Configuration

3.2.1 Window contact

The Window contact function depends on the state of binary input BE1:

BE1 = 0: The cooling valve is closed.

4

BE1 = 1: Control according to the current operating mode.

4

-

3.2.2 Dew point monitoring

The dew point monitoring uses the binary input BE2:

BE2 = 0: Temperature regulated to

4

BE2 = 1: Cooling is interrupted.

4

Function

Function BE2 0 F01 - 1

Set point for outside of time-of-use

WE Configuration

.

EB 5572 EN 17

Page 18

Functions

3.3 Operating mode override

The adjusted operating mode override is processed by binary input BE2:

BE2 = 0: Control according to the current operating mode.

4

BE2 = 1: The temperature is regulated to

4

Note!

If the vacation mode is set, the setting F01 - 1 has no function; the controller continues to regu

late the temperature to

programmed time schedule or operating mode.

Set point for vacation mode.

Set point for time-of-use

regardless of the

-

Function

Function BE2 0 F01 - 0

WE Configuration

3.4 Summer time/winter time changeover

The time changeover is performed automatically on the last Sunday in March at 02:00 h and on

the last Sunday in October at 03:00 h.

Function

Summer time/winter time changeover 1 F06 - 1

WE Configuration

3.5 Key lock

When this function is active, , , , and keys do not have any function.

Just theset point and actual temperature appear on thecontroller display. Changes to the oper

ating mode and time schedule and temporary set point changes cannot be made.

Function

Key lock 0 F05 - 1

WE Configuration

-

18 EB 5572 EN

Page 19

3.6 Switching outputs

Functions

The operating mode of the switching outputs can be selected in the

Control

parameter level.

Note!

Changes to the control signal that are smaller than the value set in

parameter

Parameter

Min. control signal 5 % PA

are not processed.

WE Parameter level / Range of values

Control

/ 1 to 100 %

Min. control signal

Three-point stepping output (heating only)

The control loop functions with a PI control algorithm. The heating valve reacts to pulses which

the controllerissues when a system deviation exists. Inparticular, the length of the first pulsedepends on the size of the system deviation and the selected

rises). Pulse length and interval time change continuously until the system deviation is

as K

P

Gain K

eliminated. The interval between pulses is influenced considerably by the

terval increases as T

rises). The

N

Valve transit time T

indicates how long the valve needs to

Y

(the pulse length increases

P

Reset time T

(the in-

N

move through the range from 0 to 100 %.

Parameters

Switching outputs function 1

Gain K

P

Reset time T

Valve transit time T

N

Y1

WE Parameter level / Range of values

PA

Control

/ Select: 1

1.0 PA

180 s PA

45 s PA

Control

Control

Control

/ 0.1 to 100

/ 0 to 1000 s

/ 0 to 1000 s

2 x On/off PPM (heating and cooling)

The control signals applied at the 0to 10 Voutput that exceedthe value enteredin the

control signal

1/T

Y1

Parameters

Switching outputs function 1

Valve transit time T

Valve transit time T

parameter, are issued as a pulse width modulated signal with the basic frequency

(heating) or 1/TY2(cooling).

WE Parameter level / Range of values

PA

Control

/ Select: 2

Y1

Y2

45 s PA

45 s PA

Control

Control

/ 0 to 1000 s

/ 0 to 1000 s

EB 5572 EN 19

Minimum

Page 20

Functions

2 x On-off thermostat (heating and cooling)

The output signal (AA1 heating, AA2 cooling) of the controller is switched on or off.

A control signal is issued when the temperature exceeds or falls below the set point, depending

on the controlled variable. If the control signal exceeds the

Min. Control signal

, the on-off ther

mostat is switched on or off.

Parameter

Switching outputs function 1

WE Parameter level / Range of values

PA

Control

/ Select: 3

Triac 1 and triac 2 switched according to the time schedule

Both triacs are switched on together depending on the time schedule or the adjusted operating

mode. Both triacs are closed outside of time-of-use.

Parameter

Switching outputs function 1

WE Parameter level / Range of values

PA

Control

/ Select: 4

Triac 1 switched according to the time schedule, triac 2 switched according the state of

AA2

Triac 1 switches according to the time schedule or adjusted operating mode.

Triac 2 switches on when the control signal for cooling = 100 % and when a system deviation

(cooling demand) continues to exist. Triac 2 functions in sequence to the control signal for cooling, for example, to connect additional cooling equipment. When the temperature reaches the

set point, triac 2 switches off again.

Parameter

Switching outputs function 1

WE Parameter level / Range of values

PA

Control

/ Select: 5

-

20 EB 5572 EN

Page 21

4 Communication

Communication

The serialsystem bus interface RS-485 enables the TROVIS 5572 Room Controller tocommuni

cate with a control system (GLT). A complete control system can be implemented using a suit

able software to visualize the process and to enable communication.

The operation of the controller requires a constant bus link (data cable).The bus line is designed

in an open ring structure to connect individual control equipment. The data cable is connected

at the end of the bus lineto thecontrol station over a RS-485/RS-232 converter (e.g.CoRe 01).

The bus connection range (cable length) is maximum 1200 m. A maximum of 128 devices can

be connected in such a segment. Repeaters must be used (for example, CoRe 01) to regenerate

the signal level over long distances or when more than 32 devices are connected to one bus

line. A maximum of 246 devices can be addressed and connected to a bus with 8-bit

addressing.

Caution!

You are required to follow the relevant standards and regulations applicable to lightning and overvoltage protection on installing the controller.

A transmitting and/or receiving test can be initiated in the

RC blinking : Receiving data telegrams from control station (GLT),

4

on the display even when they are intended for other controllers

: Controller transmitting to control station (GLT)

4

Description of the parameters that need to be set:

Device address

The

within a system.

Baud rate

The

is used to identify the controller. An address may only be assigned once

indicates the transfer rate between control systemand controllerin a bus system.

Communication

parameter level:

-

-

Functions

16-bit addressing 0 F07*

* F07 - 0: 8-bit addressing

F07 - 1: 16-bit addressing

WE Configuration

EB 5572 EN 21

Page 22

Installation

Parameters

Device address 000 PA

Baud rate 19200 PA

Transmitting/receiving test – PA

WE Parameter level / Range of values

Communication

Communication

Communication

/ 0 to 255 ( 8 bit)

0 to 999 (16 bit)

/ 19200, 9600

/ Display: RC/

5 Installation

Note!

The room controller must be mounted at a height of 1.50 m.

Make sure that the operation of the room controller is not affected by heat sources (radiators,

lights, electrical appliances) or by drafts close to doors or windows.

The room controller should not be covered by curtains or any pieces of furniture.

To mount and wire the room controller, remove the housing from the base.

How to proceed:

1. Press down the tongue on the bottom of the controller and tip the housing section forward to remove it from the base.

2. Screw the base to the wall.

3. Connect the wiring as described in section 6.

4. Push the top of the housing section onto the base and push it down.

22 EB 5572 EN

Page 23

6 Electrical connection

Important!

The room controller is operated with a 24 V AC power supply.

Terminal assignment

Electrical connection

1

2

3 0…10 V output 1

4 0…10 V output 2

5 GND for 0…10 V outputs

6 Binary input BE1

7 Binary input BE2

8 GND for binary inputs

9

10 AC 2 has GND reference

11

12

13

14

15

16

Modbus RS-485 (slave)

Power supply 24 V AC

Triac output 1 24 V AC, 1 A

Triac output 2 24 V AC, 1 A

RS-485; Modbus (master) Connection to expansion module(s)

Connection to the control station (GLT) or

to a Modbus master interface

AC 1

EB 5572 EN 23

Page 24

Appendix

7 Appendix

7.1 Function block list

F Function block WE Description

01 Function BE2 0 F01 - 0: Operating mode override by BE2

F01 - 1: Dew point monitoring

02 Resetting the operating

mode

03 Optimization 0 F03 - 0: Function is not active

04 Cooling 0 F04 - 0: Cooling not active outside of time-of-use

05 Key lock 0 F05 - 0: Function is not active

06 Summer time/winter

time changeover

07 16-bit addressing 0 F07 - 0: 8-bit addressing

1 F02 - 0: Time-of-use/outside of time-of-use operating

mode setting continuous

F02 -1 : Time-of-use/outside of time-of-use operating

mode setting that applies until the next time

schedule starts when the operating mode changes

back to automatic mode

F03 - 1: Optimization; calculation of advance heating time

or cooling down time in heating mode

F04 - 1: Cooling also active outside of time-of-use

F05 - 1: Keys (except for recessed keys) are locked

1 F06 - 0: Function is not active

F06 - 1: Automatic time changeover

F07 - 1: 16-bit addressing

24 EB 5572 EN

Page 25

7.2 Parameter list

Appendix

Set points

parameter level

Parameter WE Description

01 Set point for time-of-use 21 °C Adjustment range: 5 to 30 °C

02 Set point for outside of

17 °C Adjustment range: 5 to 30 °C

time-of-use

03 Set point for vacation

15 °C Adjustment range: 5 to 30 °C

mode

04 Maximum advance

heating time

360 min Start value for the calculation: 120 min

Can only selected when the optimization function is active

(F03 - 1).

05 Maximum cooling

down time

120 min Start value for the calculation: 60 min

Can only selected when the optimization function is active

(F03 - 1).

06 Vacation schedule –

Control

parameter level

Parameter WE Description

01 Switching outputs

function

1

Option:

1: Three-point stepping output

2: 2 x On/off PPM

3: 2 x On/off thermostat

4: Triac 1 and triac 2 switched according to the time schedule

5: Triac 1 switched according to the time schedule;

Triac 2 switched acc. to the state of triac 1 and AA2

02 Gain K

03 Reset time T

P

N

04 Derivative-action time T

05 Valve transit time T

06 Valve transit time T

Y1

Y2

1.0 Adjustment range: 0.1 to 100

180 s Adjustment range: 0 to 1000 s

0 s Adjustment range: 0 to 1000 s

V

45 s Adjustment range: 0 to 1000 s

45 s Adjustment range: 0 to 1000 s

07 Min. control signal 5.0 % Adjustment range: 1.0 to 100 %

EB 5572 EN 25

Page 26

Appendix

Communication

Parameter WE Description

01 Device address 0 Adjustment range: 0 to 255 (8 bit) 0 to 999 (16 bit)

02 Baud rate 19200 Adjustment range: 9600, 19200

03 Transmitting/receiving

test

04 Calibrating the room

sensor

05 Read/test BE1 Reading: E1 0 (open), E1 1 (closed)

06 Read/test BE2 Reading: E2 0 (open), E2 1 (closed)

07 Read/test triac 1 Reading/Adjustment range: A1 0 (open), A1 1 (closed)

08 Read/test triac 2 Reading/Adjustment range: A2 0 (open), A2 1 (closed)

09 Read/test AA1 Reading/Adjustment range: AA1 0 (0 V) to AA1 100 (10 V)

10 Read/test AA2 Reading/Adjustment range: AA2 0 (0 V) to AA2 100 (10 V)

parameter level

000 = No communication with control station (GLT)

RC blinks on display on receiving any data telegram from the

control station(GLT), even if they are intended for other con

trollers

blinks on display for transmitting to the control station

(GLT)

0.0 Adjustment range: –9.9 to + 9.9 °C (in steps of 0.1 °C)

-

26 EB 5572 EN

Page 27

7.3 Technical data

Inputs 1 room sensor (internal)

1 presence button (internal)

2 binary inputs for window contact/dew point and operating mode

override

Outputs 2 triac outputs 24 V AC, 1 A

2 outputs 0 to 10 V

Power supply 24 V AC

Interface Modbus (RS-485)

Environmental conditions Operation: 0 to 50 °C

Degree of contamination 2 according to VDE 0110

Noise immunity According to EN 61000-6-1

Noise emission According to EN 61000-6-3

Power consumption

of room controller

Power consumption

of expansion module

Maximum load for

analog output

Dimensions in mm

W x H x D 113 x 91 x 30

Storage, transportation: –10 to 60 °C

95 % rH, not condensing

Approx. 0.6 VA

Approx. 1 VA

Not smaller than 4.7 k

Ω

Appendix

Key number:

1732

EB 5572 EN 27

Page 28

Terminal assignment (refer to section 6)

Please note:

The room controller is operated with 24 V AC.

Modbus RS-485

to expansion module

RS-485; Modbus (slave)

0 … 10 V output 1

0 … 10 V output 2

GND for 0 … 10 V outputs

Binary input BE1

Binary inputs BE2

GND for binary inputs

Power supply 24 V AC

Triac output 1

Triac output 2

RS-485; Modbus (master)

Connection to the control

station (GLT) or to a

Modbus master interface

AC 1

AC 2 has GND reference

24 V AC, 1 A

24 V AC, 1 A

Connection to expansion

module(s)

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 5572 EN

2007-02

Loading...

Loading...