Page 1

Automation System TROVIS 5500

Programmable Logic Controller (PLC)

TROVIS 5571

Electronics from SAMSON

Mounting and

Operating Instructions

EB 5571 EN

®

Firmware version 1.21

Edition March 2009

Page 2

Disclaimer of liability

Disclaimer of liability

We are constantly developing our products and therefore, reserve the right to change the

product or the information contained in this document at any time without notice.

We do not assume any liability for the accuracy or completeness of these mounting and

operating instructions. Moreover, we do not guaranteethat thebuyer can use the product for an

intended purpose. SAMSON rejects any liability for claims by the buyer, especially claims for

compensation including lost profits or any other financial loss, except the damage was caused

intentionally or by gross negligence. If an essential term of the contract is breached by

negligence, SAMSON’s liability is limited to the foreseeable damage.

Safety instructions

The device may only be assembled, started up or operated by trained and

4

experienced personnel familiar with the product. Proper shipping and

appropriate storage are assumed.

The device has been designed for use in electrical power systems. For wiring

4

and maintenance, you are required to observe the relevant safety

regulations.

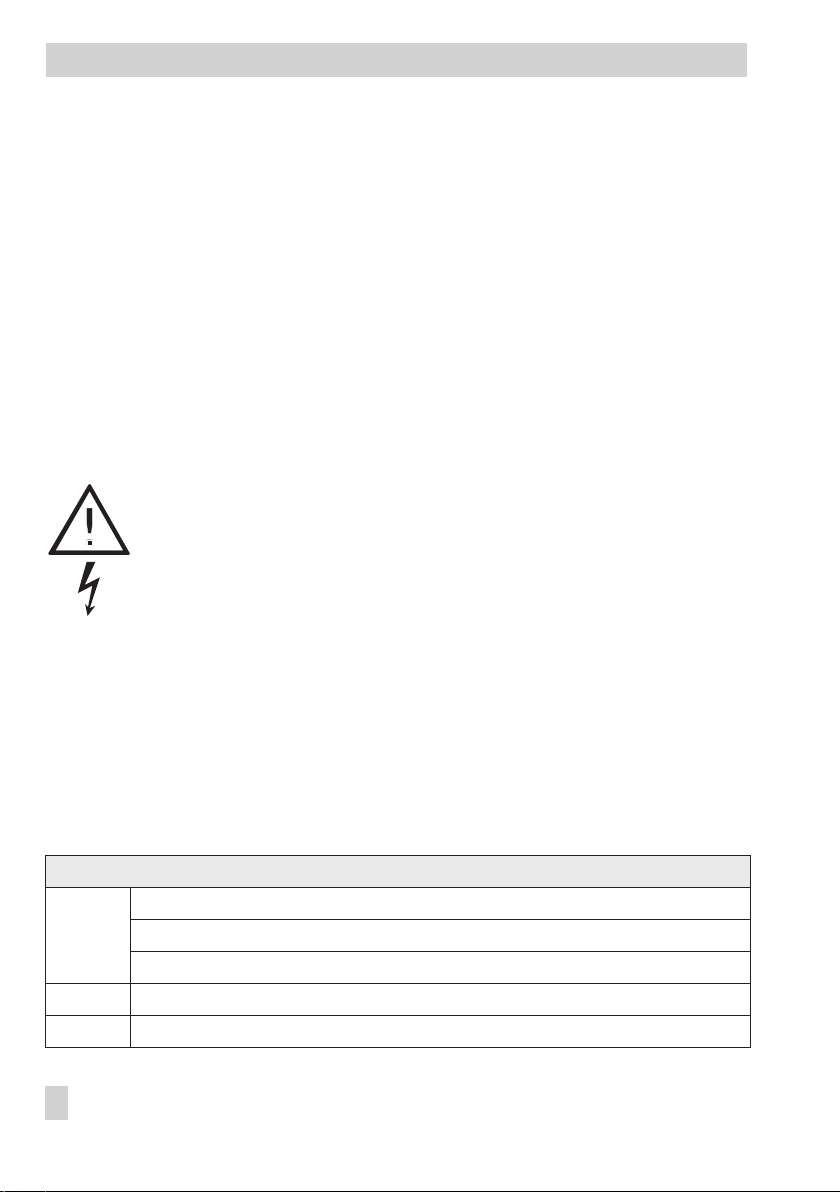

Modifications of the PLC firmware compared to the previous version

1.10 (old) 1.11 (new)

New default setting for parameter

Expansion of the data logging function (see section 5.5)

1.11 (old) 1.21 and lower (new)

Internal modifications

2 EB 5571 EN

Gateway

= Off

Page 3

Contents

Contents Page

1 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Operating elements. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.1 Operating keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 Adjusting the contrast of the display . . . . . . . . . . . . . . . . . . . 6

1.3 Displaying data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Setting the system time . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Changing PLC settings. . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Configuring universal inputs . . . . . . . . . . . . . . . . . . . . . . 13

2.4 Resetting to default values . . . . . . . . . . . . . . . . . . . . . . . 15

3 Manual operation. . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Operational faults . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Modbus slave interface . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Modbus master interface . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Description of communication parameters to be adjusted . . . . . . . . 21

5.4 Meter bus interface . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4.1 Activating the meter bus . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5 Data logging module . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5.1 Data logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5.2 Saving and loading firmware and applications . . . . . . . . . . . . . 26

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7 Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . 29

8 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.1 Settings level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.3 Special key codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.4 Expansion modules . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.4.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.4.2 Terminal assignment. . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.4.3 Integrating the expansion modules . . . . . . . . . . . . . . . . . . . 37

8.5 Sensor resistance tables . . . . . . . . . . . . . . . . . . . . . . . . 38

8.6 Customer data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

EB 5571 EN 3

Page 4

Operation

1 Operation

The programmable logic controller (PLC) is freely programmable. The controller is delivered

without an executable application in the memory. The application must be developed sepa

®

rately for the desired purpose on a personal computer using ISaGRAF

(programming as in

IEC 61131-1) and then transferred to the controller.

On start-up, after transferring the generated application, the current time and date must be set

in the controller (–> section 1.4).

1.1 Operating elements

1.1.1 Operating keys

The keys are located in the front panel of the PLC and protected by a Plexiglas door.

Changeover key

(press with pen or other pointed item)

Switch between levels (after entering the key code)

Reset key

(press with pen or other pointed item)

Reset freely accessible parameters and function blocks to their default values

(factory settings)

-

4 EB 5571 EN

Cursor key(s)

Pressing both keys together:

– Switch to information level

Pressing one of the keys separately:

– Navigate in levels (also in the application developed with ISaGRAF

– Set data points

Enter key

– Open levels (also in the application developed with ISaGRAF

®

– Activate editing mode for parameters and function blocks

– Confirm entered settings

®

)

)

Page 5

Operation

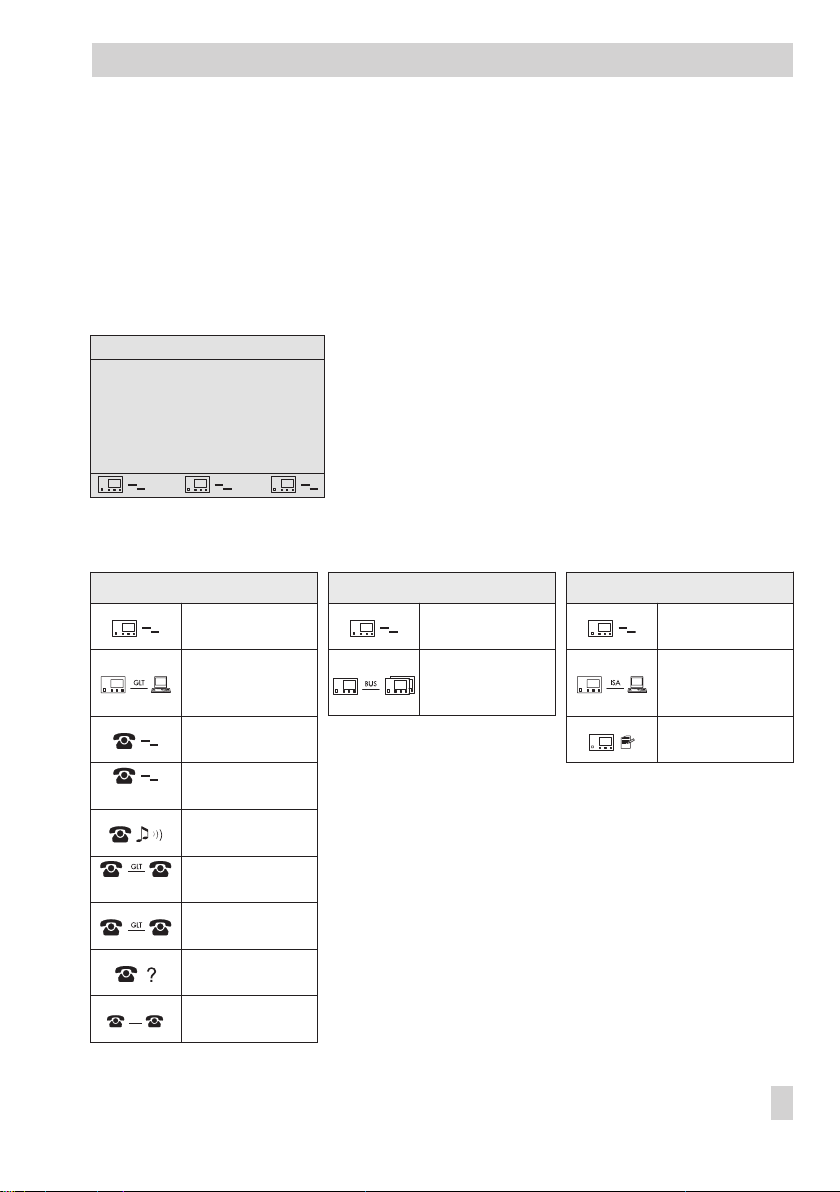

1.2 Display

The programmable logic controller has a plain text display.

The display is automatically illuminated when entering or setting the controller.

After connecting the controller to the power supply, “System is being initialized…“ appears

briefly on the display.

Should the display not be illuminated or the contrast is too strong/weak, you can adapt the dis

play illumination. Refer to section 1.2.1.

28.11.2005 10:00:05 V1.1xx

Application: …

Version: …

Date: …

CRC: …

Size: … kB

Cycle time: … ms

The current status of the three communication interfaces “RS-232/Slave“, “RS-485/Master“

and “RS-232/Prog“ appears at the bottom of the display:

RS-232/Slave (left) RS-485/Master (middle) RS-232/Prog (right)

Interface inactive Interface inactive Interface inactive

If an application is not saved on the PLC, the normal display

(left) contains the date, time and current firmware version.

If an application is saved on the PLC, the normal display

contains application-related information.

-

blinking

blinking

SMS

Direct connection

to control station

active

Modem inactive

Modem initializa

tion active

RING,

calling active

Connection estab

lished/canceled

Connection to con

trol station active

Error

SMS sending

active

Modbus master

active

-

-

-

Connection to

ISaGRAF

®

bench active

Data logging

active

EB 5571 EN 5

Work-

Page 6

Operation

Note!

If no key is pressed for two minutes, the PLC returns to the normal display. The background

illumination of the display is switched off automatically.

Any settings that have not been confirmed are not saved and must be re-entered.

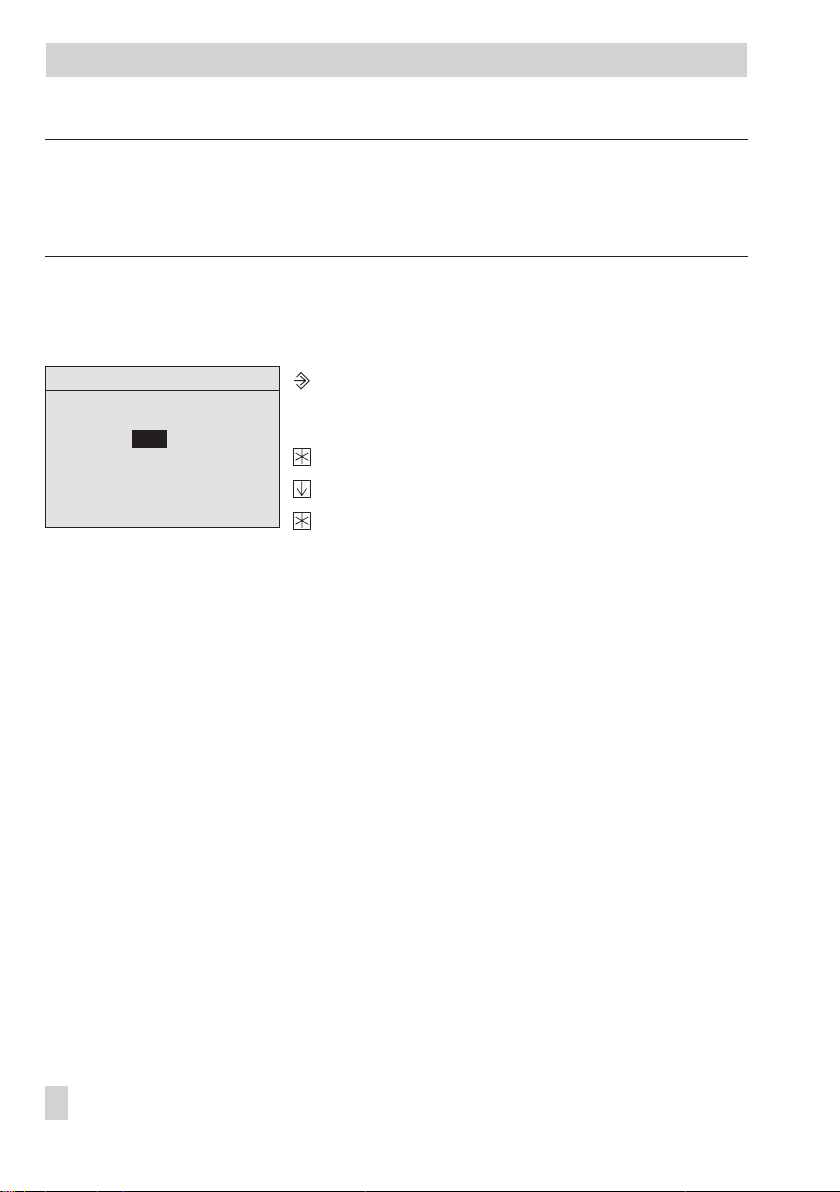

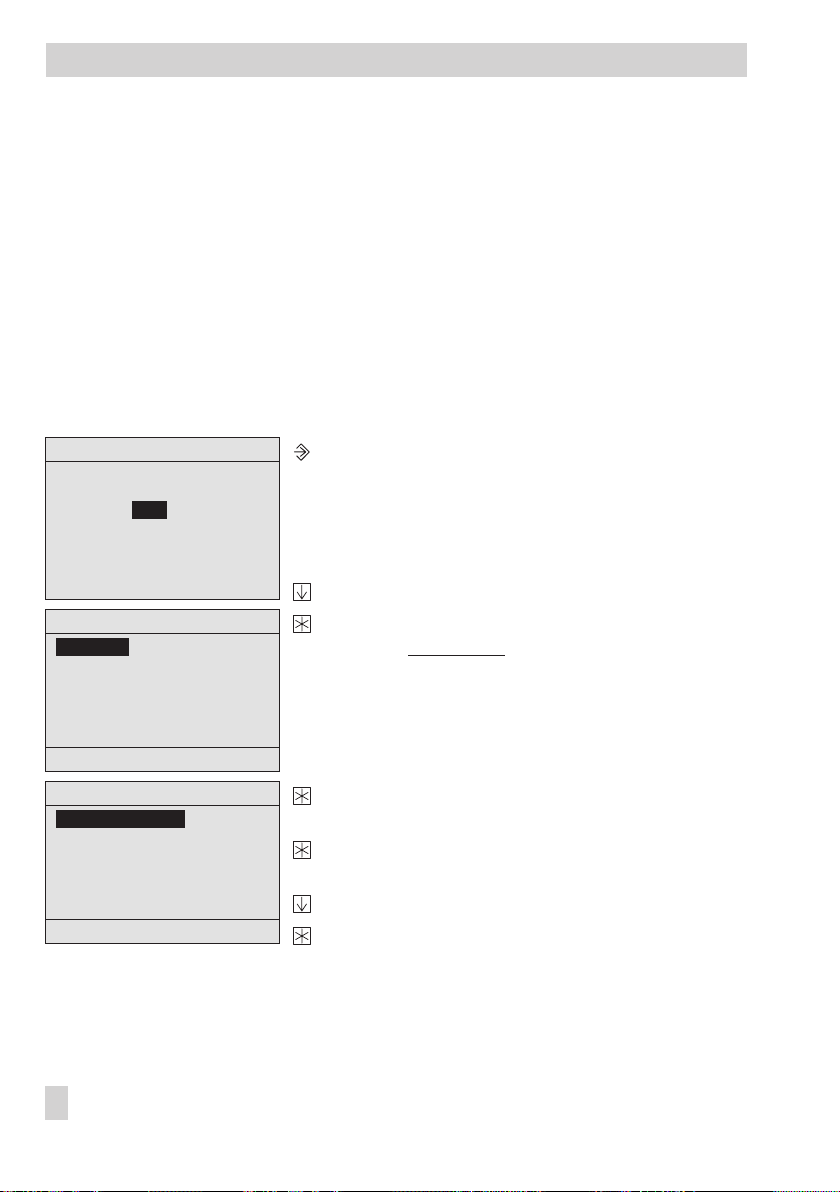

1.2.1 Adjusting the contrast of the display

Entering the key code

0000

Activate the editing mode.

Display: Entering the key code

0000

blinks

Confirm the

0000

reading.

Set the contrast.

Confirm the changed setting.

Display: Normal display (depending on the

application)

6 EB 5571 EN

Page 7

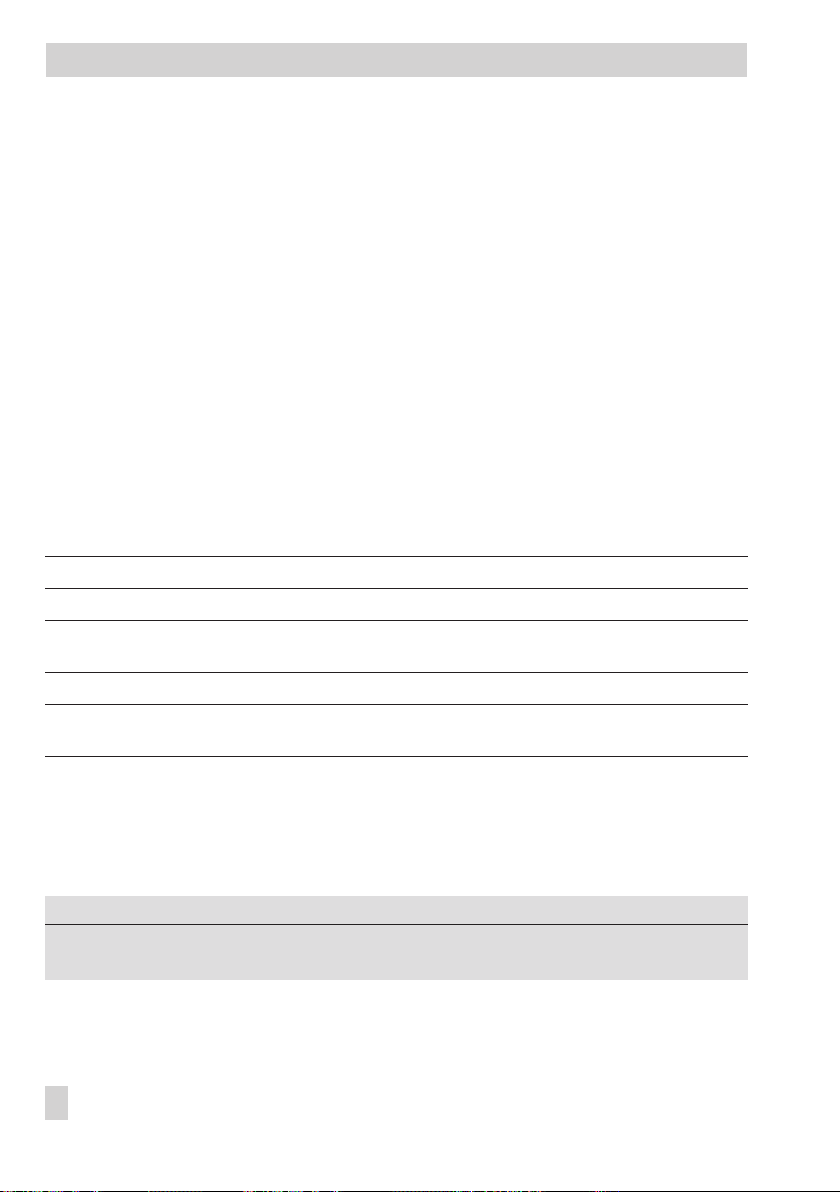

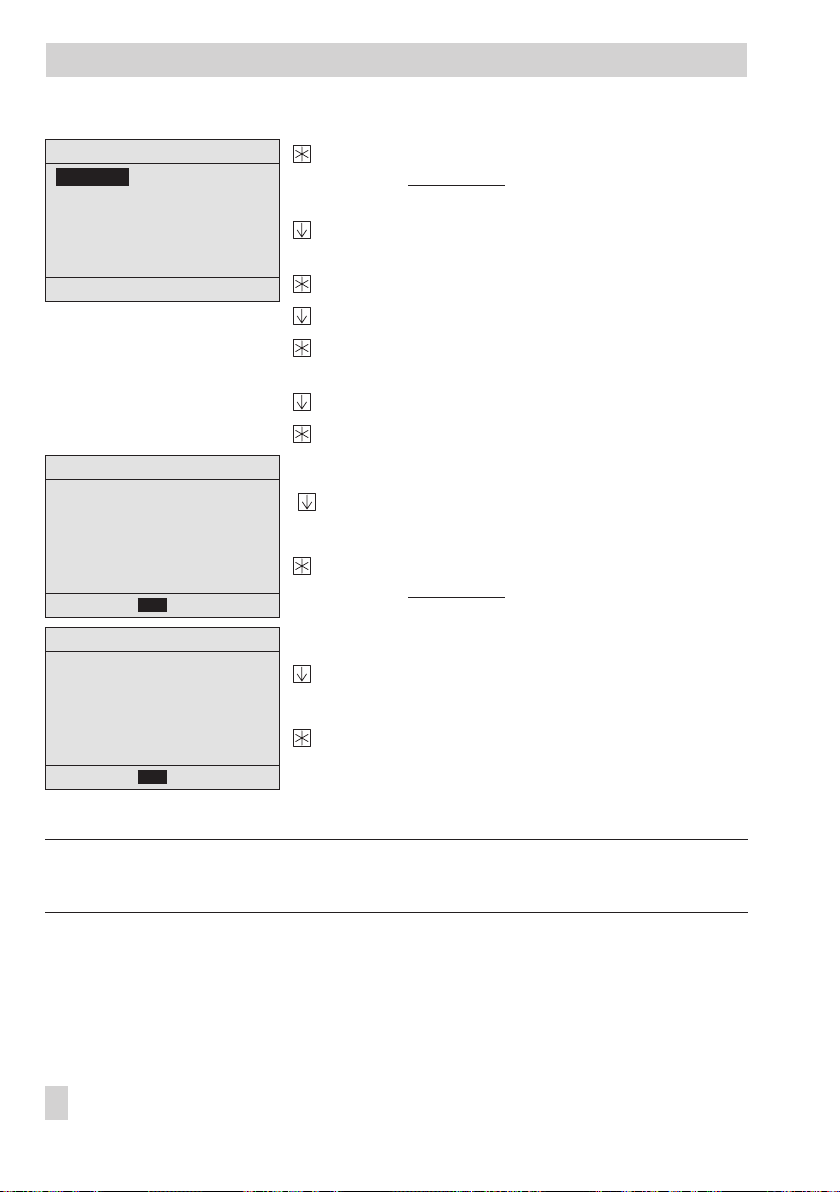

1.3 Displaying data

Operation

The states of the inputs and outputs as well as information on the connected meter bus instru

ments can be retrieved in the information level. In addition, the analog and binary outputs can

be changed (refer to section 3 on manual operation).

The information level is divided into individual menu items:

Analog inputs · Measured data from connected sensors

4

Analog outputs · Output data from four analog outputs *

4

Binary inputs · States of the binary sensors (on/off)

4

Binary outputs · States of the binary outputs (on/off) *

4

Meter bus · Output data of the meters connected over meter bus

4

*)The analog and binary output settings can be changed after entering the key code.

)

)

Proceed as follows:

Information level

Analog inputs

Analog outputs

Binary inputs

Binary outputs

Meter bus

System info

Back

Binary outputs

BA07=OFF

BA08=OFF

BA09=OFF

BA10=OFF

BA11=OFF

BA12=OFF

Back

Information level

Analog inputs

Analog outputs

Binary inputs

Binary outputs

Meter bus

System info

Back

Switch to the information level.

Display: Information level

The menu item “Analog inputs“ is highlighted.

Select required menu item, e.g. binary outputs.

Activate the menu item.

Select required data point.

Returning to the information level

Select

Back

to return to the information level.

Exit the menu item.

Display: Information level

Exiting the information level

Select

Back

.

Exit the information level.

Display: Normal display (depending on the

application)

-

Note!

If no key is pressed for two minutes, the PLC automatically returns to the normal display.

EB 5571 EN 7

Page 8

Operation

1.4 Setting the system time

The current time and date need to be set immediately after start-up and after a power failure

lasting more than 24 hours.

Set the system time in the settings level under the menu item “Date / time”. The Automatic sum

mer time function can also be activated or deactivated in this menu item.

System time: Time-dependent functions of the saved application are based on the system

4

time set in the PLC.

Automatic summer time: The summer time is automatically set on the last Sunday in

4

March at 02:00 h and the winter time on the last Sunday in October at 03:00 h.

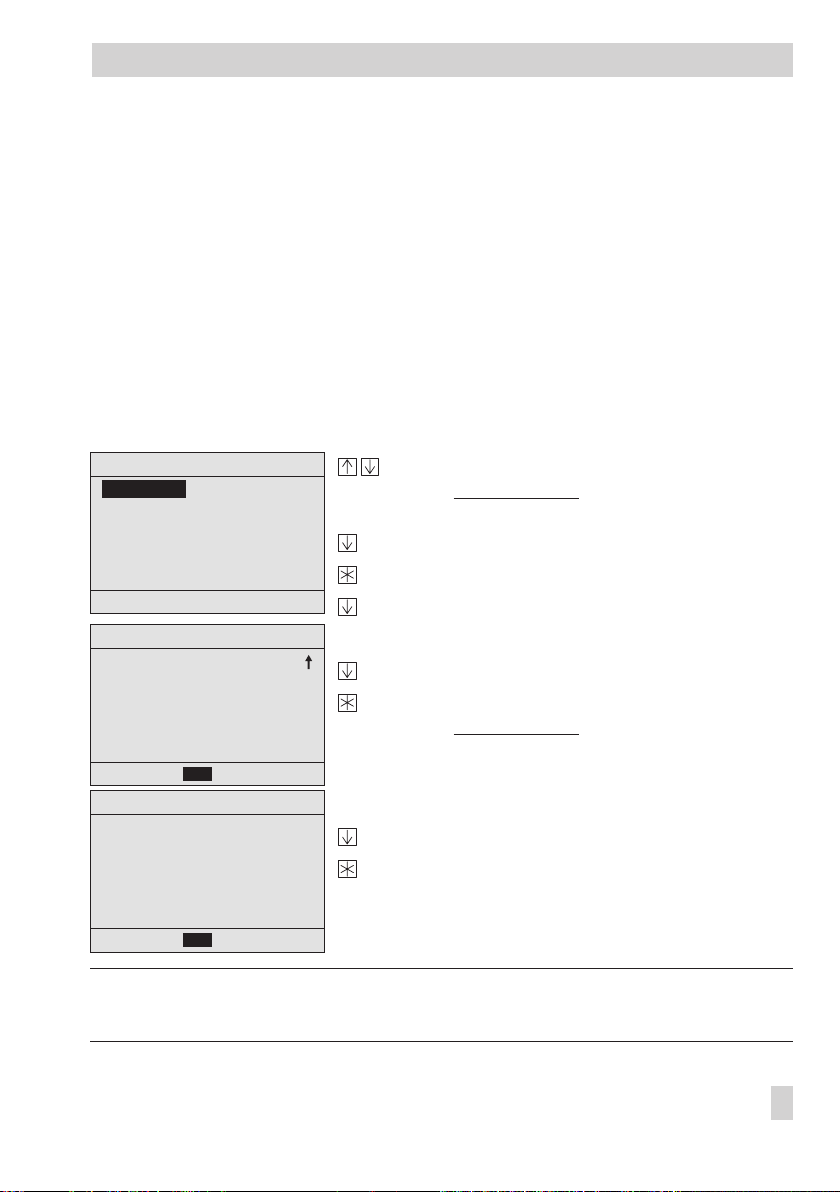

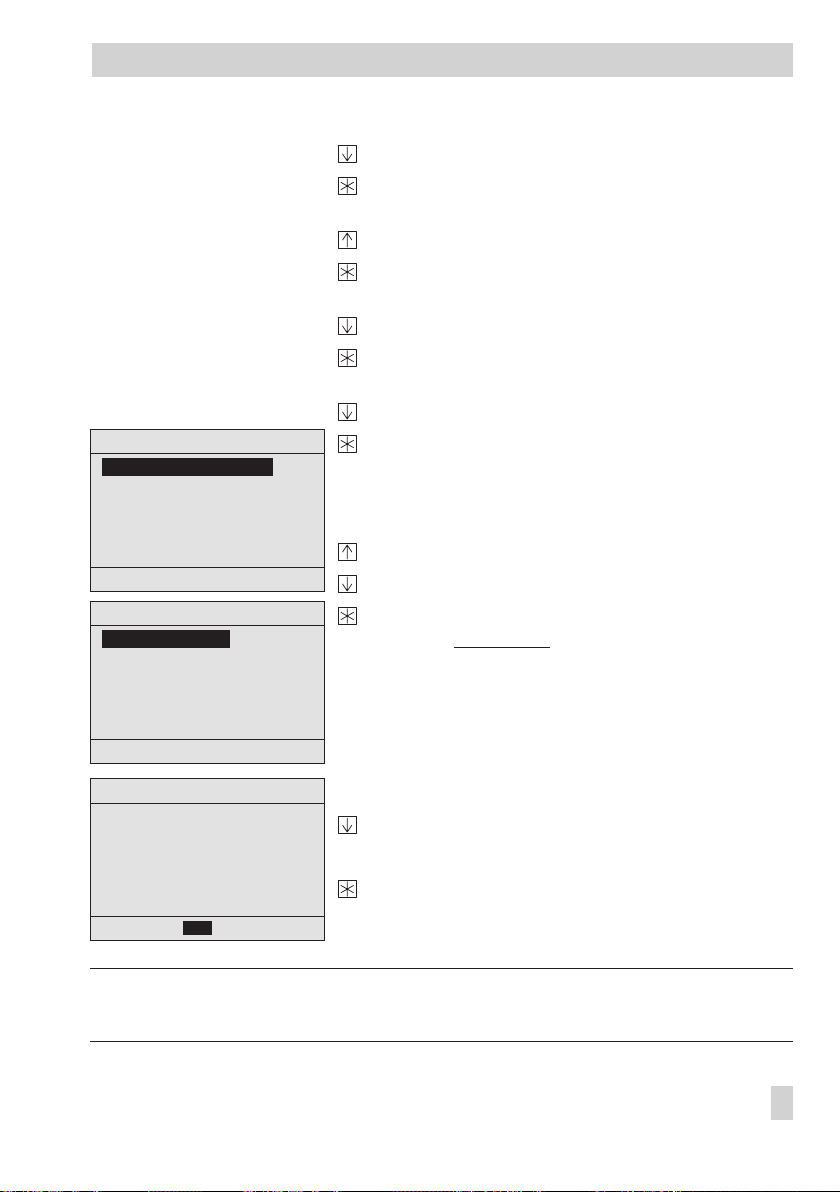

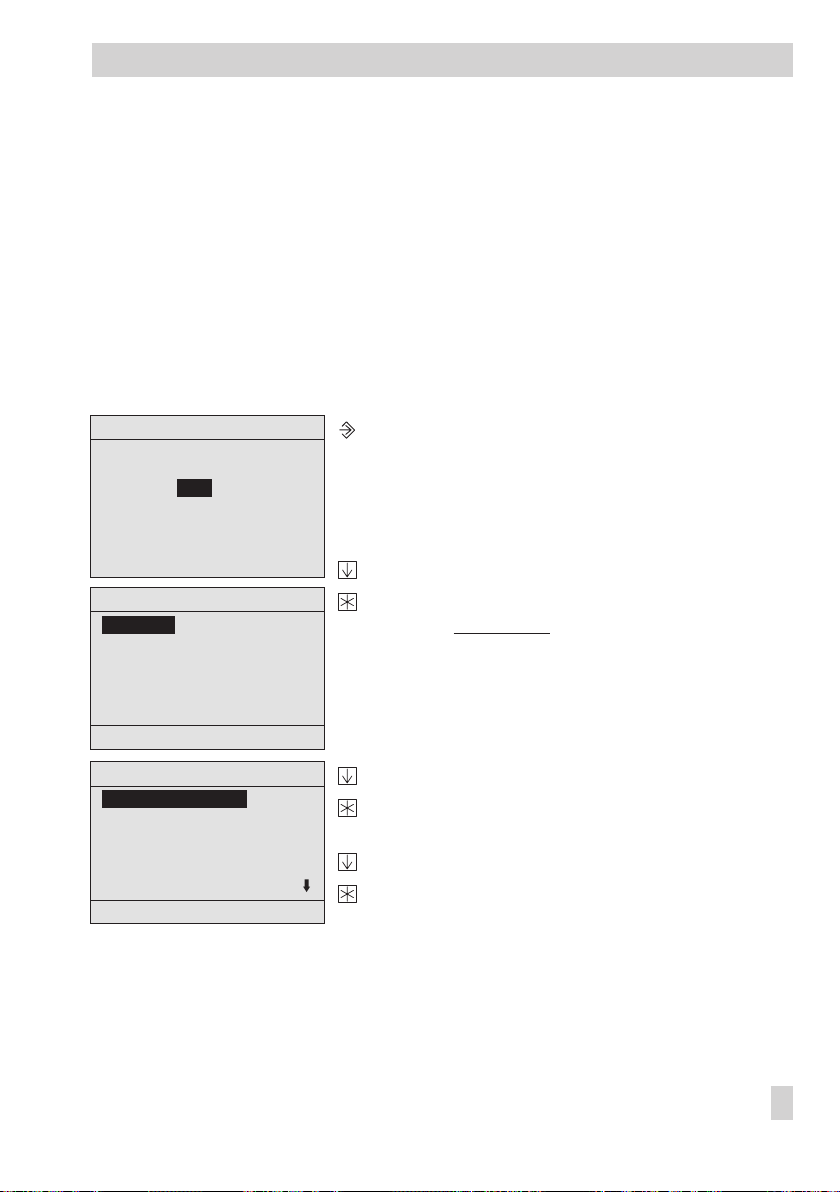

Proceed as follows:

-

Entering the key code

0000

Settings level

Date / time

RS-232/Slave

RS-485/Master

RS-232/Prog

Meter bus

Universal input type

Back

Settings level

28.11.2005 10:00

RS-232/Slave

RS-485/Master

RS-232/Prog

Meter bus

Universal input type

Back

Activate the editing mode.

Display: Entering the key code

0000

blinks

Enter the key code.

Confirm the key code entered.

Display: Settings level

The “Date / time“ menu item is highlighted.

Activate the menu item “Date / time“.

Display: System time (DD.MM.YYYY HH:MM)

Activate the editing mode for the system time.

DD

Display: Date (

) blinks.

Enter date.

Confirm date entered.

MM

Display: Month (

) blinks.

8 EB 5571 EN

Page 9

Settings level

Automatic summer time? On

RS-232/Slave

RS-485/Master

RS-232/Prog

Meter bus

Universal input type

Back

Settings level

28.11.2005 10:00

RS-232/Slave

RS-485/Master

RS-232/Prog

Meter bus

Universal input type

Back

Operation

Enter month.

Confirm month entered.

YYYY

Display: Year (

) blinks.

Enter year.

Confirm year entered.

HH

Display: Time (

) blinks.

Enter hour.

Confirm hour entered.

MM

Display: Minutes (

) blink.

Enter minutes.

Confirm minutes entered.

Display: “Automatic summer time? __“ blinks

If required, change the current setting (on/off) of the

Automatic summer time function.

Activate function: Automatic summer time? On

Deactivate function: Automatic summer time? Off

Exit the menu item “Date / time“.

Display: Settings level

Settings level

Date / time

RS-232/Slave

RS-485/Master

RS-232/Prog

Meter bus

Universal input type

Back

Exiting the settings level

Select

Back.

Exit the settings level.

Display: Normal display (depending on the

application)

Note!

If no key is pressed for two minutes, the PLC automatically returns to the normal display.

EB 5571 EN 9

Page 10

Start-up

2 Start-up

2.1 Programming

Programming the PLC requires a PC with ISaGRAF®software.

®

The ISaGRAF

needs of your plant (ISaGRAF

software enables you to program a control system that is tailored to the specific

®

development environment 1400-7621). Programming must fol

low the structures and rules stipulated in IEC 61131-3. The PLC may be programmed with the

languages defined in the standard: Sequential Function Chart (SFC), Instruction List (IL), Flow

Chart (FC), Function Block Diagram (FBD), Ladder Diagram (LD), and Structured Text (ST).

®

There are 128 KB of memory available in the PLC for the ISaGRAF

application.

The application is complied to machine code in the PC environment. This code is then trans

ferred to the PLC over the front RJ-45 jack (connecting cable 1400-7620).

Programming languages:

Sequential Function Chart

(SFC):

Instruction List (IL): Low-level textual language for logic and arithmetic operations

Flow Chart (FC): High-level language used to visualize the data flow

Function Block Diagram

(FBD):

Ladder Diagram (LD): Simple graphics-based language for logical operations (boolean)

Structured Text (ST): High level language similar to PASCAL and C especially designed for

Used to describe operations of a sequential process with a simple graphic representation

Graphics-based language for building and combining complex functions

(logical, arithmetic)

control applications

For operation and application of the ISaGRAF®environment, refer to the documentation in

cluded in the software package. To enable simple and clear programming, ready-made func

tions and function blocks, e.g. for boiler systems, heat exchanger sequence control, ventilation

systems, heating circuits or domestic hot water systems, are available from SAMSON.

-

-

-

-

Parameters*

Station address 255 RS-232/Prog / 1 to 247, 255

Baud rate 9600 RS-232/Prog / 9600, 19200

WE Settings level / Range of values

* –> Section 5.3 (Description of communication parameters to be adjusted)

10 EB 5571 EN

Page 11

Start-up

Note!

In ISaGRAF

status or value of the internal variable is written to the associated holding or coil register and

can be read or written over Modbus.

Important! The PLC application must be reloaded after a cold start.

®

, internal variables can be assigned (integer or bool) network addresses. The

2.2 Changing PLC settings

PLC settings can only be changed after entering the valid key code.

The valid key code can be found on page 42. To avoid unauthorized use, remove the page or

make the key code unreadable.

Change PLC settings in the settings level, which contains the following menu items:

Date / time, refer to section 1.4

4

RS-232/Slave, refer to section 5.1

4

RS-485/Master, refer to section 5.2

4

RS-232/Prog, refer to section 2.1

4

Meter bus, refer to section 5.4

4

Universal input type, refer to section 2.3

4

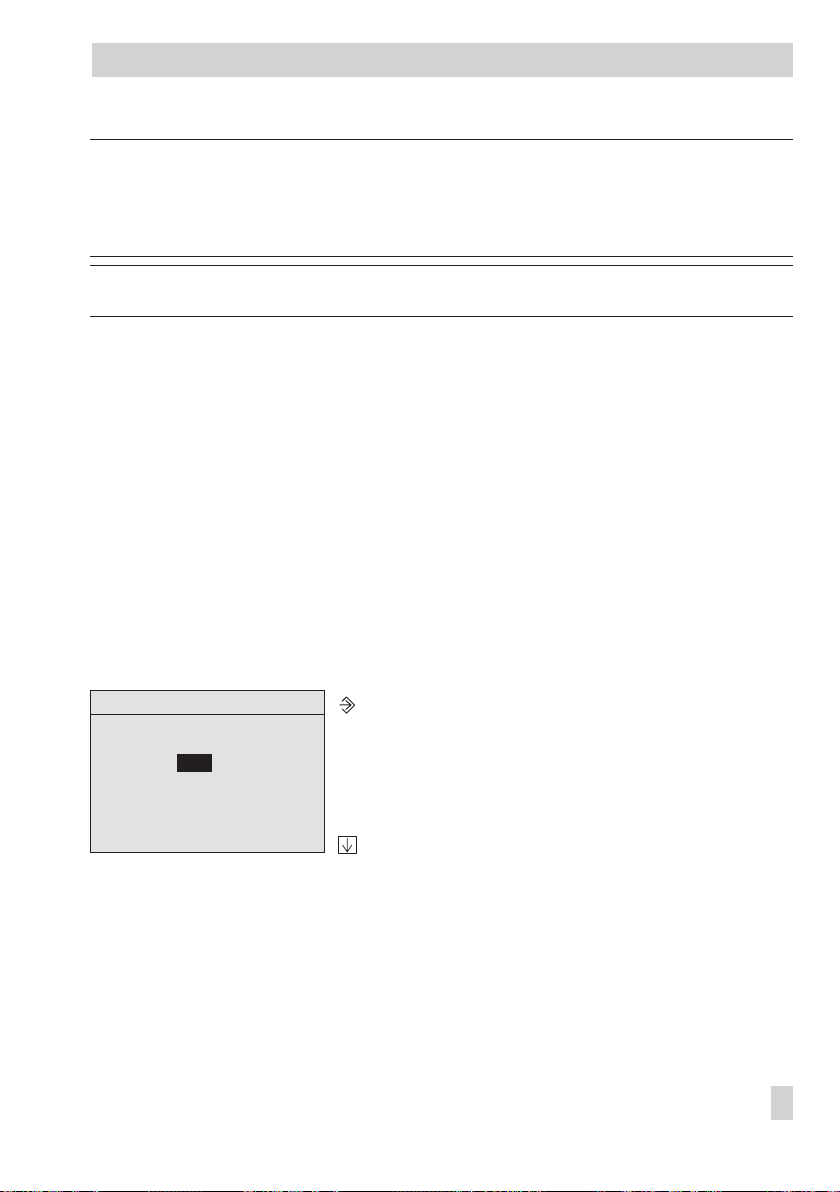

Proceed as follows:

Entering the key code

0000

Activate the editing mode.

Display: Entering the key code

0000

blinks

Enter the valid key code.

EB 5571 EN 11

Page 12

Start-up

Settings level

Date / time

RS-232/Slave

RS-485/Master

RS-232/Prog

Meter bus

Universal input type

Back

RS-232/Slave

Modbus Slave

Modem

Baud rate

Back

Settings level

Date / time

RS-232/Slave

RS-485/Master

RS-232/Prog

Meter bus

Universal input type

Back

Confirm the key code.

Display: Settings level

The menu item “Date / time“ is highlighted.

Select the menu item in which the settings are to be

changed, e.g. “RS-232/Slave“.

Activate the selected menu item.

Select the data point which you want to change.

Activate the editing mode of the data point.

Display: Data point blinks.

Set the data point.

Confirm the setting.

Returning to the settings level

Back

Select

to return to the settings level.

Exit the menu item.

Display: Settings level

Exiting the settings level

Select

Back

to return.

Exit the settings level.

Display: Normal display (depending on the

application)

Note!

If no key is pressed for two minutes, the PLC automatically returns to the normal display.

12 EB 5571 EN

Page 13

Start-up

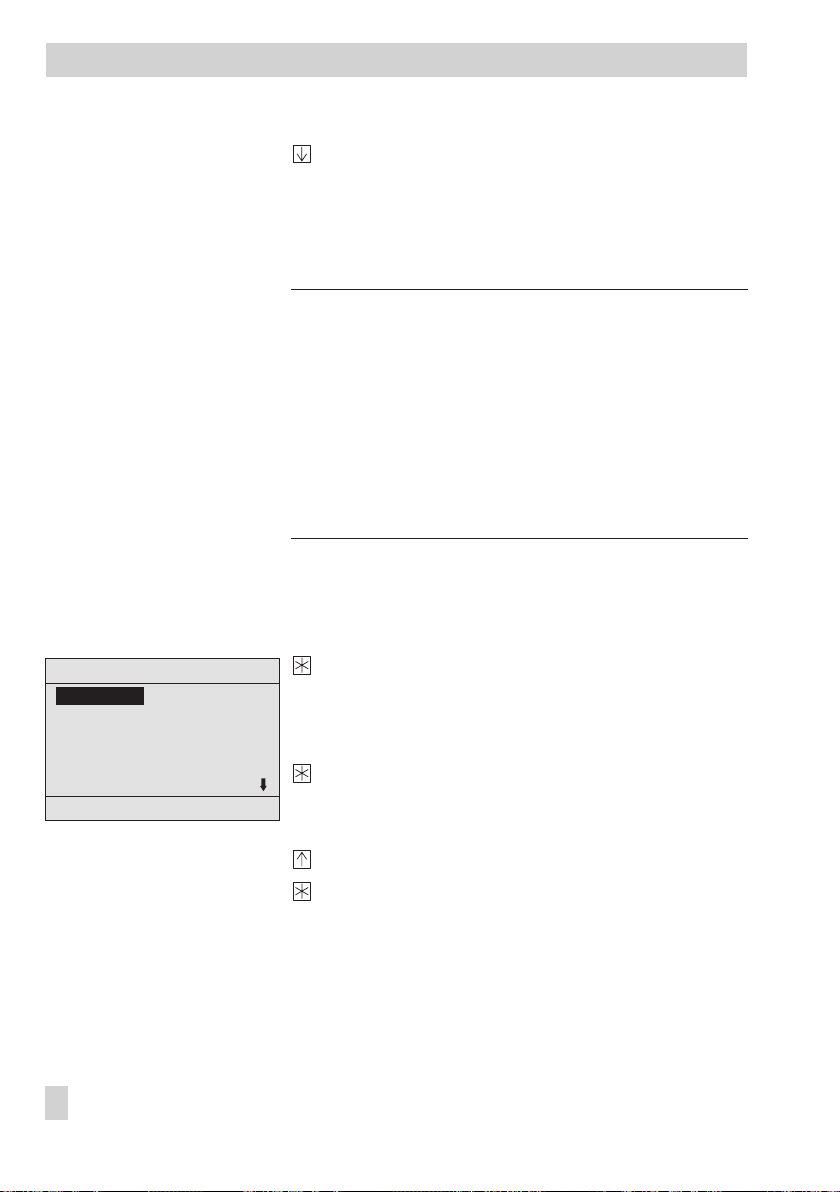

2.3 Configuring universal inputs

There are 17 universal inputs, which may be used as binary inputs, analog inputs (0 to 10 V,

0/4 to 20 mA) or as sensor inputs. The hardware must be configured accordingly (sensor ini

tialization).

Refer to page 38 for the resistance values of the PTC, Pt 100 and Pt 1000 sensors.

You can also configure each universal input separately.

The following configurations are available: Pt 100/500/1000/2000, Ni 200/1000/2000,

PTC, NTC, 1–2 kΩ, BE, 0/4 to 20 mA (with 50Ωparallel resistor) and 0 to 10 V.

Proceed as follows:

-

Entering the key code

0000

Settings level

Date / time

RS-232/Slave

RS-485/Master

RS-232/Prog

Meter bus

Universal input type

Back

Universal input type

UE01=PT100↔PT1000

UE02=PT100↔PT1000

UE03=PT100↔PT1000

UE04=PT100↔PT1000

UE05=PT100↔PT1000

UE06=PT100↔PT1000

Back

Activate the editing mode.

Display: Entering the key code

0000

blinks

Enter the valid key code.

Confirm the key code.

Display: Settings level

The “Date / time“ menu item is highlighted.

Select the menu item “Universal input type“.

Activate this selected menu item.

The first universal input UE01is highlighted.

Select the universal input.

Activate the universal input.

UE__

Display:

blinks.

EB 5571 EN 13

Page 14

Manual operation

Select the type of universal input.

The inputs are available in the following order:

PT100↔PT1000, PT100↔PTC, NI2000, PT2000,

PT500, 0 – 10V, BE, 1000 – 2000Ω, PT100,

PT1000, NTC, PTC, NI1000, NI200, 4 – 20mA,

0 – 20mA

Note!

On selecting the universal input types PT100

PT100

PTC, this configuration applies then to all 17 uni

↔

PT1000 or

↔

versal inputs. Any inputs that have a different type need to

be configured separately afterwards.

Binary inputs with terminal 10 functioning as GND are slow

(delay of approx. 3 s).

Binary inputs with terminal 9 functioning as GND are fast

(ms).

If a resistance input has been selected:

(PT100↔PT1000, PT100↔PTC, NI2000, PT2000,

PT500, PT100, PT1000, NTC, PTC, NI1000 or NI200)

Universal input type

Calibrate? No

UE02=PT100↔PT1000

UE03=PT100↔PT1000

UE04=PT100↔PT1000

UE05=PT100↔PT1000

UE06=PT100↔PT1000

Back

14 EB 5571 EN

Confirm the type of universal input.

Display: ”Calibrate? No“ blinks.

If the temperature sensor connected at the input is not to be

calibrated:

Exit the universal input.

If the temperature sensor connected at the input is to be

calibrated:

Set to “Calibrate? Yes“.

Confirm calibration.

Display:

Temperature measured

by the sensor blinks.

Compare the temperature measured by the sensor

with the temperature measured by a reference ther

mometer installed directly at the point of measure

-

-

ment.

Page 15

If both temperatures are not the same:

Correct the sensor temperature.

Confirm corrected temperature.

Appendix

Universal input type

UE12=PT100↔PT1000

UE13=PT100↔PT1000

UE14=PT100↔PT1000

UE15=PT100↔PT1000

UE16=PT100↔PT1000

UE17=PT100↔PT1000

Back

If another type of universal input is selected:

Confirm the universal input type.

Returning to the settings level

Select

Back

to return to the settings level.

Exit the menu item.

Display: Settings level

Settings level

Date / time

RS-232/Slave

RS-485/Master

RS-232/Prog

Meter bus

Universal input type

Back

Exiting the settings level

Select

Back

to return.

Exit the settings level.

Display: Normal display (depending on the

application)

2.4 Resetting to default values

The values in the settings level can be reset to their default values.

Important!

Resetting to default values causes a application saved in the PLC to be deleted.

Proceed as follows:

1. Cut the power supply to the PLC.

2. Restart the PLC, while pressing down the reset key with a pointed object.

“System is being initialized… Cold start values loaded!“ appears briefly on the display

before the normal display with the current firmware version (displays on page 5) ap

pears.

The values of the setting level are the same as the default values (see section 8.1).

EB 5571 EN 15

-

Page 16

Manual operation

3 Manual operation

All outputs configured in manual operating mode. Refer to the wiring plan (–> section 7).

Note!

If the analog and binary output menus are activated without entering the key code before

hand, the key icon appears at the top of the display when you press the enter key to con

firm the setting. This setting is locked.

You can only change this setting after entering the key code first.

Proceed as follows:

Entering the key code

Activate the editing mode.

Display: Entering the key code

0000

0000

blinks

Enter the valid key code.

Confirm the key code.

Display: Settings level

The “Date / time“ menu item is highlighted.

Select

Back

to return.

Exit the editing mode.

Display: Normal display (depending on application )

Information level

Analog inputs

Analog outputs

Binary inputs

Binary outputs

Meter bus

System info

Back

Switch to the information level.

Display: Information level

“Analog inputs“ menu item is highlighted.

Select required menu item “Analog outputs” or

“Binary outputs”.

Activate the menu item.

Select the required output.

Activate the selected output.

Display:

AA...orBA...

blinks.

-

-

16 EB 5571 EN

Page 17

Operational faults

Analog output setting: 0 to 10 V

Increase the value.

Reduce the value.

Setting with binary outputs: on/off

Binary input = on

Binary input = off

Exit the output.

Display: indicates manual intervention.

Information level

Analog inputs

Analog outputs

Binary inputs

Binary outputs

Meter bus

System info

Back

Exiting the information level

Select

Back

to return.

Exit the information level.

Display: Normal display (depending on application)

4 Operational faults

Displaying errors in the error status register and sending fault alarms to a mobile phone over

the SMS function or to a fax machine can be configured in ISaGRAF

tion.

The corresponding function blocks exist for this purpose.

®

to match the applica

-

EB 5571 EN 17

Page 18

Communication

5 Communication

5.1 Modbus slave interface

The PLC can communicate with a control system using the RS-232 Modbus slave interface. To

gether with the suitable process visualization software and communication software, a com

plete control system can be implemented.

The following interface settings are possible:

– Operation with a dial-up modem on the RS-232 Modbus slave interface

Basically, communication is only establishedautomatically when the application has been con

figured to dial when a fault occurs. The controller works autonomously. Nevertheless, the mo

dem can dial up to the controller at any time to read data from it or change settings, if neces

sary. The use of the modem connecting cable (1400-7139) is recommended.

– Operation with a leased line modem on the RS-232 Modbus slave interface

Communication is established over a permanent connection between two leased line modems.

This setup is applied for long-distance transmissions or when different signal level converters

are used. The connection between the controller and the modem can also be established over

the modem connecting cable (1400-7139).

– Operation on a four-wire bus

To link the controller and the bus line, the signal level needs to be converted by an appropriate

converter (SAMSON cable converter 1400-7308).

-

-

-

-

-

Fig. 1 · Network structure

18 EB 5571 EN

Page 19

Communication

GND TD DTR RTSRDDCD

Fig. 2 · Pin assignment, RJ-12 system bus interface

Modbus slave interface RS-232

The Modbus connection is located on the rear panel of the controller housing (RJ 12 jack). The

controller can be connected either directly to the serial interface of a PC (point-to-point connection) or to a (dial-up) modem. A dial-up modem is required if the controller is to be connected to

the telecommunications network. In this case, the controller operates autonomously and issues

an alarm to the building control station (GLT) when faults occur. In addition, the building control

station can dial up to the controller and read data from it.

Parameters*

Station address

16-bit addressing?

Control system

monitoring

Modem Off RS-232/Slave

Cyclical initialization 30 min RS-232/Slave > Modem = On / 1 to 300 min

Automatic disconnection 5 min RS-232/Slave > Modem = On / 1 to 300 min

Baud rate 9600 RS-232/Slave / 9600, 19200

* –> Section 5.3 (Description of communication parameters to be adjusted)

WE Settings level / Range of values

255

No

30 min

RS-232/Slave > Modbus Slave / 1 to 247, 255

RS-232/Slave > Modbus Slave > Station address / Yes, No

RS-232/Slave > Modbus Slave / 1 to 300 min

Modem = On: PLC connected to telecommunications network

Modem = Off: PLC directly connected to a computer

EB 5571 EN 19

Page 20

Communication

Modbus slave interface

in combination with RS-232/RS-485 cable converters (for four-wire bus)

Operating the PLC in combination with cable converters requires a permanent bus connec

tion (data cable). The bus line links the devices/control units in an open ring. At the end of

the bus line, the data cable is connected to the control station using an RS-485/RS-232 con

verter (e.g. TROVIS 5484). The maximum extension (cable length) of the bus line is 1,200 m.

A maximum of 32 devices can be connected to such a segment. If you wish to use more than

32 devices or need to bridge greater distances, make sure repeaters (e.g. TROVIS 5482) are

installed to replicate the signal. In all, a maximum of 246 devices can be connected to a bus

line.

!

Caution!

Make sure that the relevant standards and regulations concerning lightning and overvoltage

protection are observed upon installation.

Parameters*

Station address

16-bit addressing?

Control system

monitoring

Modem Off RS-232/Slave / Modem = Off

Baud rate 9600 RS-232/Slave / 9600, 19200

* –> Section 5.3 (Description of communication parameters to be adjusted)

WE Settings level / Range of values

255

No

30 min

RS-232/Slave > Modbus Slave / 1 to 247, 255

RS-232/Slave > Modbus Master > Station address / Yes, No

RS-232/Slave > Modbus Slave / 1 to 300 min

5.2 Modbus master interface

Modbus instruments can be connected to the PLC using the RS-485 Modbus master interface.

The maximum bus line is 1,200 m. If you need to bridge greater distances, make sure repeaters

(e.g. TROVIS 5482) are installed to replicate the signal.

Terminals 1 and 2 are used for connection (see Fig. 4).Up to four expansion modules can also

be connected in parallel to these terminals. Refer to section 8.4.3 for more details.

-

!

Caution!

Make sure that the relevant standards and regulations concerning lightning and overvoltage

protection are observed upon installation.

20 EB 5571 EN

Page 21

Communication

Parameters*

Gateway Off RS-485/Master / On, Off

Addressing 8 bit RS-485/Master / 8-bit, 16-bit

Baud rate 9600 RS-485/Master / 9600, 19200

Frame Off RS-485/Master / On, Off

Bias voltage Off RS-485/Master / On, Off

Validity 600 s RS-485/Master / 0 to 600 s

Pause 0 ms RS-485/Master / 0 to 100 ms

Timeout 100 ms RS-485/Master / 100 to 10000 ms

Expansion module Broadcast RS-485/Master > Station address / 0 to 255, broadcast

* –> Section 5.3 (Description of communication parameters to be adjusted)

WE Settings level / Range of values

5.3 Description of communication parameters to be adjusted

Station address

This address is used to identify the PLC in bus or modem operation. In a system, each controller

needs to be assigned a unique address.

Addressing/16-bit addressing

Selection between 16-bit addressing or 8-bit addressing

Select RS-232/Slave menu item (under

16-bit addressing? Yes – 16-bit addressing

4

16-bit addressing? No – 8-bit addressing

4

Station address

):

Baud rate

The baud rate setting refers to the transfer speed between the Modbus instruments.

Control system monitoring

Any intervention made by the control system on dynamic processes are restricted in time, pro

vided that communication between the control system and the controller is not established. The

controller resets the time monitoring after every valid retrieval of the station address. After the

defined maximum time has elapsed, all even bits are reset to “autonomous“.

EB 5571 EN 21

-

Page 22

Communication

Modem

Modem = On:

4

PLC connected to telecommunications network over a modem (RS-232 Modbus slave in

terface)

Modem = Off:

4

PLC directly connected to a computer (RS-232 Modbus slave interface) and on operating

the PLC in combination with cable converters (RS-232/RS-485)

Cyclical initialization

This parameter defines the period of time for a cyclical issue of the initialization command

“ATZ“. The command is not issued during dial-up or when connected.

Automatic disconnection

When the controller connects to the building control station but without addressing a Modbus

data point, the PLC closes the connection after the time specified for

has elapsed.

Gateway

Gateway = On:

4

Any polling by the building control station to the Modbus instruments connected to the

PLC is passed directly on to the slaves.

Gateway = Off:

4

Any polling by the building control station to the Modbus instruments connected to the

PLC is not passed directly on to the slaves.

Automatic disconnection

-

Frame

Frame = On: Framing function activated

4

Frame = Off: Framing function deactivated

4

Bias voltage

We recommend applying a bias voltage on the bus to keep the signal level stable. This bias volt

age is usually applied to the bus by the Modbus master.

Bias voltage = On: Bias voltage on the bus

4

Bias voltage = Off: No bias voltage on the bus

4

22 EB 5571 EN

-

Page 23

Communication

Validity

The values saved in the PLC, which have been sent by the slaves, have a time-dependent

Validity

.

If the building control station polls the saved data within the valid period of time, the PLC sends

the saved data directly to the building control station. However, if the polling to the PLC is

outside of this valid time period, the PLC first polls the slaves and then sends these updated data

to the building control station.

Pause

Pause

The time entered in

responded to the last polling by the PLC.

Timeout

is the time that elapses before the PLC polls a slave after it has

If the slave does not respond to a PLC polling after the time in

generated.

Expansion module (1400-9386)

Expansion modules are connected by specifying their station address. This station address can

be entered in default state (reset over the jumpers) using the last two figures of the serial numbers.

Example:

The serial number 600116 means that the station address is 16.

This can only be dialed by the broadcast function when one expansion module is connected.

Timeout

has elapsed, an alarm is

5.4 Meter bus interface

Thanks to the meter bus interface, the PLC can communicate with up to 3 heat and water meters

according to EN 1434-3.

Details onthe useof the different heat and water meters can be found in the technicaldocumen

tation TV-SK 6311.

5.4.1 Activating the meter bus

To successfully transfer data from the heat meter (WMZ) to the PLC, the heat meter must use a

standardized protocol in accordance with EN 1434-3. It is impossible to make a general state

ment about which specific data can be accessed in each meter.For detailson thedifferent meter

makes, refer to the technical documentation TV-SK 6311.

-

-

EB 5571 EN 23

Page 24

Communication

Meter bus

WMZ#1: EN1434/Cont. 250

WMZ#2: None

WMZ#3: None

Back

Model code [None, P15, PS2, EN1434, CAL3, APAto, SLS]

4

The model code, which needs to be set for the respective heat meter, can be found in

TV-SK 6311. In general, the default setting of 1434 can be used for most devices.

Reading mode [Coil, Cont, 24h]

4

The meters can be read either automatically approx. every 24 hours (24h), continuously

(con) or when the coils (= Modbus data points) assigned to the heat meters WMZ1 to

WMZ3 are overwritten with the value 1 over the system bus interface (Coil).

All settings that are made for communication with heat or

water meters are stored in Settings level > Meter bus >

WMZ#_.

Set the parameters in the following sequence:

– Model code

– Reading mode

– Meter bus address

Note!

With reading mode “24h“, the displayed values are not updated by reading the status

information again; the values read during the last cycle remain unchanged.

With reading mode “con“, the values in the levels are not continuously updated. Reopen

the specific level to get current values.

Meter bus address (Addr?) [0 to 255]

4

A meter bus address must be unique and correspond with the address preset in the

WMZ. If the preset meter bus address is unknown, a single heat meter connected to the

controller can be assigned meter bus address 254. Address 255 deactivates communica

tion with the respective heat meter.

-

Parameters

Model code None Meter bus > WMZ#_ /

Reading mode Meter bus > WMZ#_ / Coil, Cont, 24h

Meter bus address Meter bus > WMZ#_ / 0 to 255

In theinformation level,“EN1434“ is displayed when the meter bus is activated. Press the enter

key toget to the display referring to themeter bus. The following information is displayed about

the selected heat meter:

24 EB 5571 EN

WE Settings level / Range of values

None, P15, PS2, EN1434, CAL3, APAto, SLS

Page 25

Communication

WMZ#1 (EN1434)

ID no.: FFFFFFFF

Flow rate: _.___ l/h

Total capacity: –.––– m3

Capacity: –.––– kW

Energy: –.––– Mwh

Flow pipe: – °C

Back

Note!

A blinking icon at the end of the header “WMZ#_ (EN1434)“ indicates an operational

fault.

Check the heat/water meter connection to the meter bus interface and check the parameters

set in the Settings level > Meter bus > WMZ#_.

ID no.

4

Flow rate [l/h]

4

Total capacity [m3]

4

Capacity [kW]

4

Energy [Mwh]

4

Flow pipe [°C]

4

Return flow pipe [°C]

4

Meter bus address

4

Status

4

5.5 Data logging module

Data logging module inserted

L: Data logging

A: wtf_a02 (V90)

A: kesf_a01 (V20)

F: Firmware (V1.11)

F: Firmware (V1.12)

Back

A data logging module (order no. 1400-9378) allows the

firmware versions and applications to be saved and loaded

in addition to data logging.

The data loggingmodule isconnected to the RJ-45 jack at the

front of the controller. The menu shown here *) appears on

the display as soon as the data logging module is inserted.

*) The menu items A: … (application) and F: … (firmware) depend on the current firmware and

application of the PLC as well as on the firmware and application saved in the data logging module.

5.5.1 Data logging

The data logging module allows controller data to be saved. Without any additional program

ming, the controllersaves thephysical inputs 1 to 7 every minute. When the memory of the data

logging module is full, the controller starts to write over the oldest data.

After connecting the data logging module, the “Data logging” menu item must be selected for

this function.

EB 5571 EN 25

-

Page 26

Communication

Note!

The Data logging function causes all the data previously saved in the module to be deleted.

The data logging viewer software allows the data to be viewed in graph format. The USB-Con

verter 3 (order no. 1400-9377) is required to connect the data logging module to a computer.

The data logging viewer software is supplied with the USB-Converter 3.

5.5.2 Saving and loading firmware and applications

On loading (represented by ) a firmware or application, dataare downloadedfrom thedata

logging module onto the PLC.

Note!

An application or firmware can only be loaded after the key code has been entered.

4

4

4

4

A: … Downloading an application onto the PLC.

The application in the PLC is overwritten.

F: … Downloading a firmware onto the PLC.

The firmware in the PLC is overwritten.

On saving (represented by ) afirmware or application, data are uploaded from the PLC onto

the data logging module.

A: … Uploading a current application onto the data logging module.

F: … Uploading the firmware onto the data logging module.

-

26 EB 5571 EN

Page 27

Installation

6 Installation

The controller consists of the housing with the electronics and the back panel with the terminals.

It is suitable for panel, wall, and top hat rail mounting (Fig. 3).

Panel mounting

1. Remove both screws (1).

2. Pull apart the controller housing and back panel.

3. Make a cut-out of 138 x 92 mm (width x height) in the control panel.

4. Insert the controller housing through the panel cut-out.

5. Insert one mounting clamp (2) each at the top and bottom or at the sides. Screw the

threaded rod towards the panel with a screwdriver such that the housing is clamped

against the control panel.

6. Install the electrical connections at the back of the housing as described in section 7.

7. Fit the controller housing.

8. Fasten both screws (1).

Wall mounting

1. Remove both screws (1).

2. Pull apart the controller housing and back panel.

3. If necessary, bore holes with the specified dimensions in the appropriate places. Fasten

the back panel with four screws.

4. Install the electrical connections at the back of the housing as described in section 7.

5. Fit the controller housing.

6. Fasten both screws (1).

Top hat rail mounting

1. Remove both screws (1).

2. Pull apart the controller housing and the back panel.

3. Fasten the spring-loaded hook (4) at the bottom of the top hat rail (3).

4. Slightly push the controller upwards and pull the upper hook (5) over the top hat rail.

5. Install the electrical connections at the base as described in section 7.

6. Remount the controller housing.

7. Fasten both screws (1).

EB 5571 EN 27

Page 28

Installation

Wall mounting

Panel mounting

57

42

2

Back panel of the

controller

1

2

Controller housing

Top hat rail mounting

62

15

5

Dimensions in mm

WxHxD=144x96x111

Fig. 3 · Installation

28 EB 5571 EN

5

4

3

Page 29

Electrical connection

7 Electrical connection

Caution!

For electrical connection of the PLC, you are required to observe the relevant electrotechnical

regulations of the country of use as well as the regulations of the local power supplier. Make

sure all electrical connections are installed by trained and qualified personnel!

Notes on installing the electrical connections

Install the 230 V power supply lines and the signal lines separately! To increase noise im

4

munity, observe a minimum distance of 10 cm between the lines. Make sure the minimum

distance is also observed when the lines are installed in a cabinet.

The lines for digital signals (bus lines) and analog signals (sensor lines, analog outputs)

4

must also be installed separately.

In plants with a high electromagnetic noise level, we recommend to use shielded cables

4

for the analog signal lines. Ground the shield at one side, either at the control cabinet inlet or outlet, using the largest possible cross-section. Connect the central grounding point

and the PE grounding conductor with a cable≥10 mm² using the shortest route.

Inductances in the control cabinet, e.g. contactor coils, are to be equipped with suitable

4

interference suppressors (RC elements).

Control cabinet elements with high field strength, e.g. transformers or frequency conver-

4

ters, should be shielded with separators providing a good ground connection.

Overvoltage protection

If signal lines are installed outside buildings or over large distances, make sure appro

4

priate surge or overvoltage protection measures are taken. Such measures are indispen

sable for bus lines!

The shield of signal lines installed outside buildings must have current conducting

4

capacity and be grounded on both sides.

Surge diverters must be installed at the control cabinet inlet.

4

Noise suppression

The TROVIS 5571 Controller with SAMSON actuator is interference suppressed according to

VDE 0875. If different actuator makes are used, or moreover, further actuators with interfer

ence sourcesare usedin a plant, the operator/supplier of a custom-made plant must makesure

that the entire plant complies with VDE0875 regulations due to thelegal obligation of ensuring

interference suppression.

-

-

-

-

EB 5571 EN 29

Page 30

Electrical connection

Legend

AA Analog output

AE Analog input

BA Binary output

BE Binary input

GND Ground

30 EB 5571 EN

Note!

If the universal inputs are used as

current or voltage inputs, terminal

13 instead of terminal 10 must be

used as ground.

Do not connect terminals 9, 10

and 13!

Meter bus

Supply + 15 V

Fig. 4 · Wiring plan of TROVIS 5571

Page 31

Electrical connection

Connecting the PLC

Open the housing to connect the cables. Make holes in the marked locations at the top, bottom

or back of the housing’s back panel and fit suitable grommets or screw joints.

Observe the diagram (Fig. 4) for connection. The connection diagram contains all possible in

puts and outputs. The assignment of the corresponding inputs and outputs is determined by the

respective application.

Inputs

When wiring the universal inputs (BE1/AE1 to BE17/AE17), make sure to use terminal 13 as

ground in case of active inputs (current and voltage inputs). If the universal inputs are used as

passive inputs (sensors or binary inputs), terminal 10 must be used as ground.

Binary inputs with terminal 10 functioning as ground (GND) are slow (a delay of approx. 3 sec

onds).

Binary inputs with terminal 9 functioning as ground (GND) are fast (ms).

Outputs

The binary low-voltage outputs (BA1 and BA2) are used for signaling. As a result, only a minimal load can be applied to these outputs (50 V DC, max. 100 mA ohmic load). If greater loads

are to be applied, it is recommended to control relays over theoutputs whichthen switchthe elevated load.

The 10 binary outputs (BA3 to BA12) can be loaded with max. 250 V AC, 2 A.

Modbus

The control station is connected over a serial RS-232 interface at the back of the controller.

Further Modbus instruments (slaves) are connected to the PLC over the RS-485 interface

(terminals 1 and 2).

-

-

Connecting the sensors

Cables with a minimum cross-section of 2 x 0.5 mm² can be connected to the terminals at the

back panel of the housing.

EB 5571 EN 31

Page 32

Appendix

8 Appendix

8.1 Settings level

Menu item Functions/parameters Setting range WE

section

Date/time System time (date and time) freely configurable

Automatic summer time On / Off On

See

RS-232/Slave

Modbus slave 5.1

Station address

16-bit addressing

Control system

1 to 247, 255

Yes / No

255

No

1 to 300 min 30 min

monitoring

)

Only with

*

modem = On

Modem

Cyclical initialization *

Auto. disconnection *

On / Off

)

1 to 300 min

)

1 to 300 min

Off

30 min

5 min

Baud rate 9600, 19200 9600

RS-485/Master Gateway On / Off Off 5.2

Addressing 8 bit, 16 bit 8 bit

Baud rate 9600, 19200 9600

Frame On / Off Off

Bias voltage On / Off Off

Validity 0 to 600 s 0 s

Pause 0 to 100 ms 0 ms

Timeout 100 to 10000 ms 100 ms

Expansion module

Station address 0 to 255 0

RS-232/Prog Station address 1 to 247, 255 255 2.1

Baud rate 9600, 19200 9600

32 EB 5571 EN

Page 33

Appendix

Menu item Functions/parameters Setting range WE

Meter bus WMZ#1 to WMZ#3

Model code

None, P15, PS2, EN1434,

None

CAL3, APAto, SLS

Reading mode

Meter bus address

Universal input type UE01 to UE17 PT100↔PT1000

Coil, Cont, 24h

0 to 255

1) 2)

,

PT100↔PTC

PT2000

0–10V, BE, 1000–2000Ω,

PT100

NI1000

1) 2)

, NI20002),

2)

, PT5002),

2)

, NTC2), PTC2),

2)

, NI2002),

PT100

PT1000

4–20mA, 0–20mA

1)

Settling valid for all UE

2)

Calibration? Yes / No

↔

See

section

5.4

2.3

EB 5571 EN 33

Page 34

Appendix

8.2 Technical data

TROVIS 5571 Programmable Logic Controller (PLC)

Universal inputs 17 universal inputs, separately configurable as:

Outputs 10 binary relay outputs,

Interfaces

Modbus slave interface

Optional:

Modbus master interface RS-485 for communication with other Modbus instruments (connected

Meter bus Connected over terminals 48/49/50

Programming interface For installing an application created in IsaGraf®(front RJ-45 jack)

Voltage supply 230 V AC, 48 to 62 Hz

Power consumption Approx. 8 VA

Ambient temperature 0 to 40 °C

Storage temperature –20 to 60 °C

Degree of protection IP 40

Class of protection II

Degree of contamination 2

Overvoltage category II

Humidity rating F

Noise emission According to EN 61000-6-3

Noise immunity According to EN 61000-6-1

Noise suppression According to DIN VDE 0875

Weight Approx. 0.6 kg

– Resistance input

Pt 100/500/1000, Ni 200/1000/2000, PTC/NTC, 1–2 k

– Current input

0/4 to 20 mA (50Ωparallel resistor)

– Voltage input 0–10 V

– Binary input, floating

non-floating in pairs, 2 A/250 V AC

2 low-voltage binary outputs, 100 mA/50 V AC

4 analog outputs (0 to 10 V),

non-floating in pairs (max. load > 4.7 kΩ)

RS-232 for modem or point-to-point communication with PC

(RJ-12 jack at the back)

Modbus interface RS-485 over cable converter 1400-7308

over terminals 1/2)

and data logging

Ω

34 EB 5571 EN

Page 35

8.3 Special key codes

Description Key codes

Task info 21

Delete PLC application 17

Interface protocols 20

Restart controller 15

Error memory 23

8.4 Expansion modules

8.4.1 Technical data

Extension of the inputs and outputs at the programmable logic controller (PLC)

Inputs

Binary inputs 6 · Optionally can be used as:

Outputs

Binary outputs 4 · 230 V/2 A (relay)

Interfaces Modbus RS-485

Operating voltage 24 V AC

Dimensions [mm]

Width 140

Height 93

Depth 30

1)

Note!

The expansion module 1400-9386 (power supply 24 V AC) can be used in conjunction with

TROVIS 5571 PLC (power supply 230 V AC) or with TROVIS 5572 Room Controllers (power supply

24 V AC).

A 230 V AC/24 V AC transformer is required for the expansion module when it is used in

conjunction with the TROVIS 5571 Programmable Logic Controller!

– 0 to 10 V input (inputs 1, 2, 5, 6)

– Pt 1000 input (inputs 3, 4)

– 0 to 1000Ωinput (inputs 3, 4)

– Counter inputs, max. 1 kHz (inputs 1, 2)

– 0 to 10 V outputs (inputs 5, 6)

1)

Appendix

EB 5571 EN 35

Page 36

Appendix

8.4.2 Terminal assignment

1 BA1 Binary output 1 230 V/2 A

2 BA2 Binary output2 230 V/2 A

3 COM1/2 COM binary output 1/2

4 BA3 Binary output 3 230 V/2 A

5 BA4 Binary output 4 230 V/2 A

6 COM3/4 COM binary output 3/4

7 AC1 24V

8 AC2 24V AC 2 has GND reference

Power supply 24 V AC

9 BE1 Binary input 1 or

0 to 10 V input

10 BE2 Binary input 2 or

0 to 10 V input

11 ( GND input 1/2

12 BE3 Binary input 3 or

Pt 1000 or 0 to 1000

Ω

13 BE4 Binary input 4 or

Pt 1000 or 0 to 1000

Ω

14 ( GND input 3/4

15 BE5 Binary input 5 or

0 to 10 V input

16 BE6 Binary input 6 or

0 to 10 V input

17 ( GND input/output 5/6

18 A1

19 B1

RS-485/MODBUS (slave) Connection to TROVIS 5571/5572

20 A2

21 B2

1)

Only with smart expansion module, functioning similar to a basis device

RS-485/MODBUS (master) Connection to expansion module(s)

AC 1

Or counter input

Or counter input

Or 0 to 10 V output

Or 0 to 10 V output

1)

36 EB 5571 EN

Page 37

8.4.3 Integrating the expansion modules

Appendix

A maximum of four expansion modules (1400-9386) can be integrated over the Modbus mas

ter interface (Fig. 5)

TROVIS

5571

PLC

Terminals

21

RS-485

RS-232

TROVIS

5576

Module 1

1

RS-485

AB

Module 2

RS-485

1

AB

Module 3

RS-485

1

AB

Module 4

RS-485

1

AB

RS-485

2

AB

Fig. 5 · Integration of expansion modules (1400-9386)

The expansion modules are integrated in the Settings level under the menu item RS-485/Master

-> Expansion module.

The following menu appears when an expansion module has been found:

Expansion module

Serial no.: 116

Station address: – –– –

E1 = BE

E2 = BE

E3 = BE

E4 = BE

Back

The station address can be assigned (to match the ISaGRAF

project) in this menu and the inputs or outputs (0 to 10 V) E1 to

E6 of the expansion modules can be configured.

-

®

EB 5571 EN 37

Page 38

Appendix

8.5 Sensor resistance tables

Resistance values with PTC resistors

Type 5224 Outdoor Temperature Sensors, Types 5264 and 5265 Flow and Return Flow Tem

perature Sensors, Type 5264 Storage Tank Temperature Sensors

°C –20 –10 0 10 20 25 30 40 50 60 70 80 90 100 110 120

694 757 825 896 971 1010 1050 1132 1219 1309 1402 1500 1601 1706 1815 1925

Ω

Resistance values with Pt 1000 resistors

Type 5227-2 Outdoor Temperature Sensors, Type 5277-2 (thermowell required) and

Type 5267-2 (contact sensor) Flow, Return Flow and Storage Tank Temperature Sensors.

Type 5257-1, Type 5257-5 (room panel) Room Temperature Sensors.

–35 –30 –25 –20 –15 –10 –5 0 5 10

°C

862.5 882.2 901.9 921.6 941.2 960.9 980.4 1000.0 1019.5 1039.0

Ω

15 20 25 30 35 40 45 50 55 60

°C

1058.5 1077.9 1097.3 1116.7 1136.1 1155.4 1174.7 1194.0 1213.2 1232.4

Ω

65 70 75 80 85 90 95 100 105 110

°C

1251.6 1270.7 1289.8 1308.9 1328.0 1347.0 1366.0 1385.0 1403.9 1422.9

Ω

115 120 125 130 135 140 145 150

°C

1441.7 1460.6 1479.4 1498.2 1517.0 1535.8 1554.5 1573.1

Ω

Resistance values with Pt 100 resistors

-

Refer to the table for Pt 1000 resistors and divide the specified values by 10.

Type 5225 Outdoor Temperature Sensors, Types 5204, 5205-46 to -48 Flow and Return Flow

Temperature Sensors, Types 5205-46 to -48 Storage Tank Temperature Sensors, Type 5255

Room Temperature Sensors.

38 EB 5571 EN

Page 39

8.6 Customer data

Station

Operator

Relevant SAMSON office

Settings

Functions/parameters Setting range Setting

Date/time

System time (date and time) freely configurable

Automatic summer time On/Off

RS-232/slave

Station address 1 to 247, 255

16-bit addressing Yes/No

Control system

monitoring

Modem On/Off

Cyclical initialization 1 to 300 min

Auto. disconnection 1 to 300 min

Baud rate 9600, 19200

RS-485/master

Gateway On/Off

Addressing 8 bit, 16 bit

Baud rate 9600, 19200

Frame On/Off

Bias voltage On/Off

Validity 0 to 600 s

Pause 0 to 100 ms

Timeout 100 to 10000 ms

Expansion module

Station address 0 to 255, broadcast

1 to 300 min

Appendix

EB 5571 EN 39

Page 40

Appendix

Meter bus WMZ#1 WMZ#2 WMZ#3

Model code None, P15, PS2, EN1434,

Reading mode Coil, cont, 24h

Meter bus address 0 to 255

Universal input UE 1234567891011121314151617

PT100↔PT1000

PT100↔PTC

NI2000

PT2000

PT500

0–10V

BE

1000–2000

PT100

NTC

PTC

NI1000

NI200

4–20mA

0–20mA

Ω

CAL3, APAto, SLS

40 EB 5571 EN

Page 41

Index

16-bit addressing. . . . . . . . . . . . . . . . . . 22

8-bit addressing. . . . . . . . . . . . . . . . . . . 22

A

Addressing . . . . . . . . . . . . . . . . . . . . . . 22

Application

saving/loading. . . . . . . . . . . . . . . . . 27

Automatic disconnection. . . . . . . . . . . . . 23

B

Baud rate . . . . . . . . . . . . . . . . . . . . . . . 22

Bias voltage. . . . . . . . . . . . . . . . . . . . . . 23

C

Changeover key. . . . . . . . . . . . . . . . . . . . 4

Communication parameters . . . . . . . . . . 22

Configuring inputs . . . . . . . . . . . . . . . . . 13

Connection

PLC . . . . . . . . . . . . . . . . . . . . . . . . . 32

Sensors . . . . . . . . . . . . . . . . . . . . . . 32

Slaves . . . . . . . . . . . . . . . . . . . . . . . 32

Contrast (display). . . . . . . . . . . . . . . . . . . 6

Control system monitoring. . . . . . . . . . . . 22

Controller time . . . . . . . . . . . . . . . . . . . . . 8

Cursor key(s) . . . . . . . . . . . . . . . . . . . . . . 4

Customer data . . . . . . . . . . . . . . . . . . . . 40

Cyclical initialization . . . . . . . . . . . . . . . 23

D

Data logging module . . . . . . . . . . . . . . . 26

data logging . . . . . . . . . . . . . . . . . . 26

saving/loading applications . . . . . . . 27

saving/loading firmware versions . . . 27

Display . . . . . . . . . . . . . . . . . . . . . . . . . . 5

E

Enter key . . . . . . . . . . . . . . . . . . . . . . . . . 4

Expansion module . . . . . . . . . . . . . . . . . 24

integrating . . . . . . . . . . . . . . . . . 21, 38

technical data. . . . . . . . . . . . . . . . . . 36

terminal assignment . . . . . . . . . . . . . 37

Index

F

Firmware version . . . . . . . . . . . . . . . . . . . 5

saving/loading. . . . . . . . . . . . . . . . . 27

Flow Chart. . . . . . . . . . . . . . . . . . . . . . . 10

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Function Block Diagram . . . . . . . . . . . . . 10

G

Gateway . . . . . . . . . . . . . . . . . . . . . . . . 23

I

Information level . . . . . . . . . . . . . . . . . . . 7

Installation

Panel mounting. . . . . . . . . . . . . . . . . 28

Top hat rail mounting . . . . . . . . . . . . 28

Wall mounting . . . . . . . . . . . . . . . . . 28

Instruction List . . . . . . . . . . . . . . . . . . . . 10

Interface

RS-232 (Modbus slave) . . . . . . . 19 - 20

RS-232/RS-485 (Modbus slave) . . . . 21

RS-485 (Modbus master). . . . . . . . . . 21

Internal variable. . . . . . . . . . . . . . . . . . . 11

ISaGRAF . . . . . . . . . . . . . . . . . . . . . . . . 10

L

Ladder Diagram. . . . . . . . . . . . . . . . . . . 10

M

Manual operation . . . . . . . . . . . . . . 16 - 17

Meter bus . . . . . . . . . . . . . . . . . . . . . . . 24

Modbus master interface. . . . . . . . . . . . . 21

Modbus slave interface. . . . . . . . . . . . . . 19

Modem

Dial-up modem . . . . . . . . . . . . . . . . 19

Leased line. . . . . . . . . . . . . . . . . . . . 19

Modem on/off. . . . . . . . . . . . . . . . . . . . 23

N

Noise suppression . . . . . . . . . . . . . . . . . 30

EB 5571 EN 41

Page 42

Index

O

Operating elements . . . . . . . . . . . . . . . . . 4

Operational faults . . . . . . . . . . . . . . . . . 18

Overvoltage protection . . . . . . . . . . . . . . 30

P

Pause . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Plain text display . . . . . . . . . . . . . . . . . . . 5

Programming. . . . . . . . . . . . . . . . . . . . . 10

R

Reset key. . . . . . . . . . . . . . . . . . . . . . . . . 4

Resistance input

Calibration. . . . . . . . . . . . . . . . . . . . 14

S

Sensor resistance values . . . . . . . . . . . . . 39

Sequential Function Chart . . . . . . . . . . . . 10

Station address . . . . . . . . . . . . . . . . . . . 22

Structured Text. . . . . . . . . . . . . . . . . . . . 10

T

Technical data . . . . . . . . . . . . . . . . . . . . 35

Timeout . . . . . . . . . . . . . . . . . . . . . . . . . 24

V

Validity . . . . . . . . . . . . . . . . . . . . . . . . . 24

W

Wiring plan. . . . . . . . . . . . . . . . . . . . . . 31

42 EB 5571 EN

Key code 1732

Page 43

EB 5571 EN 43

Page 44

Operating level

(created application)

Entering the key code

Information level

Analog inputs

Analog outputs

Binary inputs

Binary outputs

Meter bus

System info

Back

0000

XXXX

Settings level

Date / time

RS-232/Slave

RS-485/Master

RS-232/Prog

Meter bus

Universal input type

Back

0000

Contrast

Back

BackBack

Back

Normal display

(depending on application)

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main

Telefon: 069 4009-0 · Telefax: 069 4009-1507

Internet: http://www.samson.de

EB 5571 EN

2009-03

Loading...

Loading...