Page 1

Automation System TROVIS 5400

Ventilation Controller

TROVIS 5477

Electronics from SAMSON

Mounting and

Operating Instructions

EB 5477 EN

®

Firmware version 2.0x

Edition April 2004

Page 2

Disclaimer of liability

Disclaimer of liability

We are constantly developing our products and therefore, reserve the right to change the

product or the information in this document at any time without notice.

We do not assume any liability for the accuracy or completeness of these mounting and op

erating instructions. SAMSON rejects liability for claims by the buyer, especially claims for

compensation including lost profits or any other financial loss, except the damage was

caused intentionally or by gross negligence. If an essential term of the contract is breached

by negligence, SAMSON's liability is limited to the foreseeable damage.

Safety instructions

Assembly, start-up and operation of this device may only be performed by

4

trained and experienced personnel familiar with this product. Proper transportation and storage are assumed.

The controller is intended for use in electrical power installations. For wiring

4

and maintenance, you are required to observe the relevant safety regulations.

-

What’s new compared to previous version (1.9)

Compared to the firmware version 1.9, the following changes have been made:

A two-second delay before a sensor failure is detected and before a binary input state

4

changes to suppress error messages caused by signal distortion.

The system bus interface can be switched over from 8-bit addressing to 16-bit addressing

4

(Fb44).

When the modem is in operation, if you keep the enter key pressed when the time ap

4

pears on the display, the current connection status “Free”, “Call”, “Conn” or “Ring” is

shown.

2 EB 5477 EN

-

Page 3

Contents

Table of contents

1 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Operating controls . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.1 Operating keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.2 Mode switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Operating modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 Data retrieval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5 Setting the time and date . . . . . . . . . . . . . . . . . . . . . . . 10

1.6 Programming the time schedule . . . . . . . . . . . . . . . . . . . . 12

1.6.1 Entering public holidays . . . . . . . . . . . . . . . . . . . . . . . . 14

1.6.2 Entering vacations. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1 Setting the system code number and control method . . . . . . . . . . 17

2.2 Activating and deactivating functions. . . . . . . . . . . . . . . . . . 19

2.3 Changing parameters . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Calibrating sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5 Entering the key number . . . . . . . . . . . . . . . . . . . . . . . . 22

2.6 Resetting default setting . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Manual operation. . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1 System code number 9 . . . . . . . . . . . . . . . . . . . . . . . . 36

5 Control methods and system components . . . . . . . . . . . . . . . 37

5.1 Ventilation and temperature control in air-conditioning systems . . . . . 37

5.1.1 Supply air temperature control . . . . . . . . . . . . . . . . . . . . . 37

5.1.2 Exhaust air temperature control . . . . . . . . . . . . . . . . . . . . 37

5.1.3 Exhaust air temperature cascade control . . . . . . . . . . . . . . . . 38

5.1.4 Room temperature control . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.5 Room temperature cascade control. . . . . . . . . . . . . . . . . . . 40

5.2 Humidity control in air-conditioning systems (Anl 6, 8 and 9) . . . . . . 41

5.2.1 Supply air humidity control . . . . . . . . . . . . . . . . . . . . . . 41

5.2.2 Exhaust air/room humidity control . . . . . . . . . . . . . . . . . . . 42

5.2.3 Exhaust air or room humidity cascade control

5.3 Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4.1 Heating coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4.2 Mixed air chamber . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.4.3 Heat recovery unit (HRU) . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . 42

EB 5477 EN 3

Page 4

Contents

5.4.4 Cooling coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.5 Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.6 Fans with variable speed . . . . . . . . . . . . . . . . . . . . . . . 51

6 Control functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1 Supply air temperature limit . . . . . . . . . . . . . . . . . . . . . . 53

6.2 Supply air humidity limit . . . . . . . . . . . . . . . . . . . . . . . 53

6.3 Return air temperature limit . . . . . . . . . . . . . . . . . . . . . . 54

6.4 Variable return air temperature maximum limit . . . . . . . . . . . . . 54

6.5 Sustained room temperature . . . . . . . . . . . . . . . . . . . . . . 55

6.6 Night purge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.7 Summer compensation. . . . . . . . . . . . . . . . . . . . . . . . . 57

6.8 Fan operation dependent on room temperature/room humidity . . . . . 57

6.9 Air quality control via the mixed air chamber . . . . . . . . . . . . . 58

6.10 Outdoor temperature-compensated control . . . . . . . . . . . . . . . 59

6.10.1 Outdoor temperature-compensated supply air control . . . . . . . . . . 59

6.10.2 Summer deactivation . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.10.3 Summer time operation

6.11 Control functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.11.1 System start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.11.2 Circulating air mode after system start-up . . . . . . . . . . . . . . . 62

6.11.3 Enabling fan speed 1 . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.11.4 Enabling fan speed 2 . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.11.5 Fan operation feedback . . . . . . . . . . . . . . . . . . . . . . . . 64

6.11.6 Enabling the cold storage . . . . . . . . . . . . . . . . . . . . . . . 64

6.11.7 Controlling the direct expansion evaporator . . . . . . . . . . . . . . 65

6.11.8 Controlling the chiller . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.11.9 Condensation detection . . . . . . . . . . . . . . . . . . . . . . . . 66

6.11.10 Circulation pump control for the heating coil . . . . . . . . . . . . . . 66

6.11.11 Circulation pump control for the HRU. . . . . . . . . . . . . . . . . . 67

6.11.12 Electric air heater . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7 System-wide functions . . . . . . . . . . . . . . . . . . . . . . . . 68

7.1 Switchover between summer time and winter time . . . . . . . . . . . 68

7.2 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.2.1 System frost protection. . . . . . . . . . . . . . . . . . . . . . . . . 68

7.2.2 Frost protection HRU. . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.2.3 Stand-by monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.2.4 Stand-by control . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.3 Forced-operation of the pumps . . . . . . . . . . . . . . . . . . . . 69

7.4 External correction of the temperature set point . . . . . . . . . . . . . 70

. . . . . . . . . . . . . . . . . . . . . . . . 60

4 EB 5477 EN

Page 5

Contents

7.5 External setting of the outdoor air rate . . . . . . . . . . . . . . . . . 70

7.6 External correction of the humidity set point . . . . . . . . . . . . . . 70

7.7 External setting of the air volume . . . . . . . . . . . . . . . . . . . 71

7.8 External demand for operation . . . . . . . . . . . . . . . . . . . . 71

7.9 External demand for fan speed 2. . . . . . . . . . . . . . . . . . . . 72

7.10 External selection of the operating mode . . . . . . . . . . . . . . . . 73

7.10.1 External selection of the operating mode using the four-staged switch . . 73

7.10.2 External selection of the operating mode using Type 5257-6 Room Panel 73

7.11 Request for externally required signal . . . . . . . . . . . . . . . . . 75

7.12 Outdoor temperature output . . . . . . . . . . . . . . . . . . . . . . 76

7.13 Locking settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8 Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.1 Sensor failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.1.1 Status register (FSR) . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

9.1 RS-232-C serial interface . . . . . . . . . . . . . . . . . . . . . . . 80

9.2 RS-485 interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9.3 Description of the communication parameters to be set . . . . . . . . . 82

9.4 Memory module. . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

10 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

11 Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . 86

12 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

12.1 Function block list CO . . . . . . . . . . . . . . . . . . . . . . . . . 89

12.2 List of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

12.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

12.4 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

12.5 Resistance values. . . . . . . . . . . . . . . . . . . . . . . . . . . 110

12.6 Customer data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

EB 5477 EN 5

Page 6

Operation

1 Operation

1.1 Operating controls

The TROVIS 5477 Ventilation Controller can be operated using the operating controls on the

front panel.

The controller is ready for operation using its default temperature and time schedule settings.

On start-up, after switching on the power supply, the correct time and date must be set in

the controller (–> section 1.5).

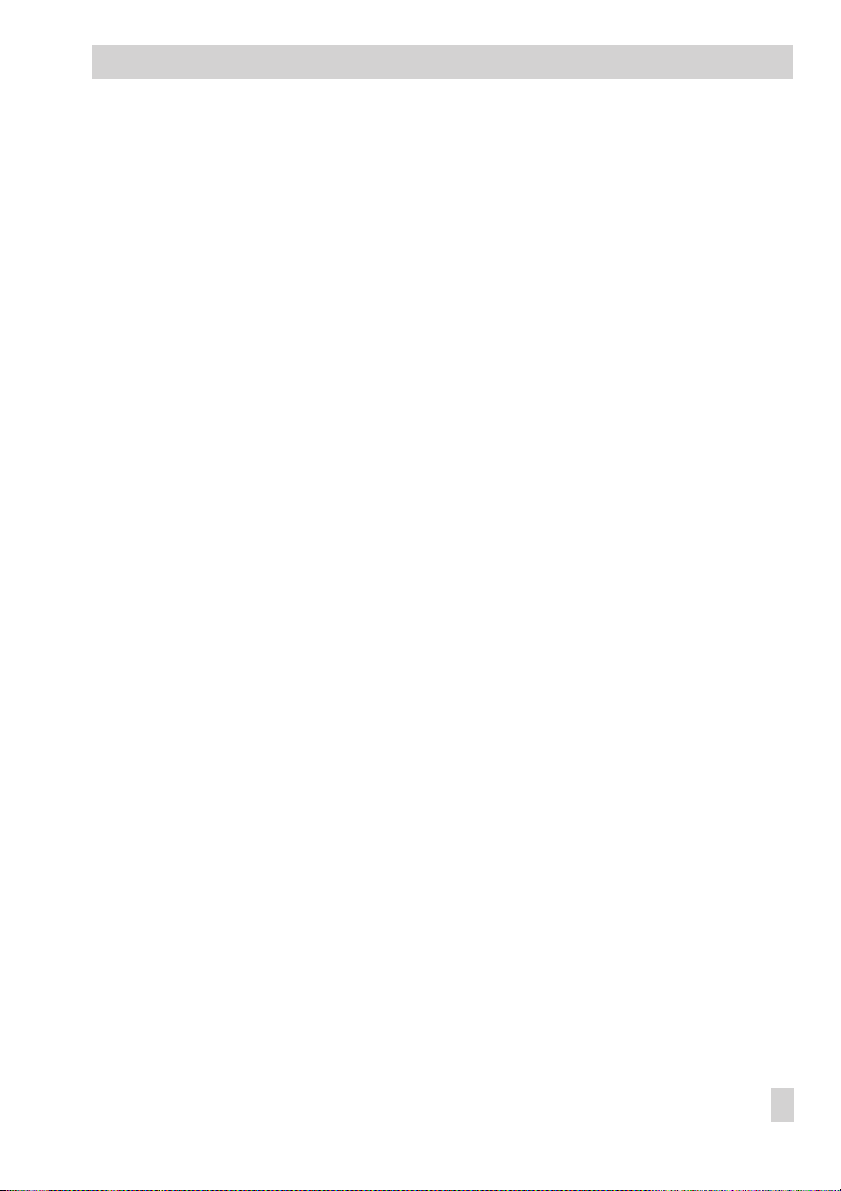

1.1.1 Operating keys

The operating keys are located on the front of the controller and protected by a transparent

cover.

Changeover key

(press with pencil or similar pointed object)

Allows you to change between the operating level, parameter level and

configuration level.

Reset key

(press with pencil or similar pointed object)

Allows you to reset all freely accessible parameters to default values (factory

setting). This key’s function is only active on the parameter level

6 EB 5477 EN

Arrow keys

Allow you to retrieve and set parameters

Enter key

Operating level: allows you to read set points

Parameter level: allows you to access and acknowledge parameters

Configuration level: allows you to access and acknowledge function

blocks

Page 7

Operation

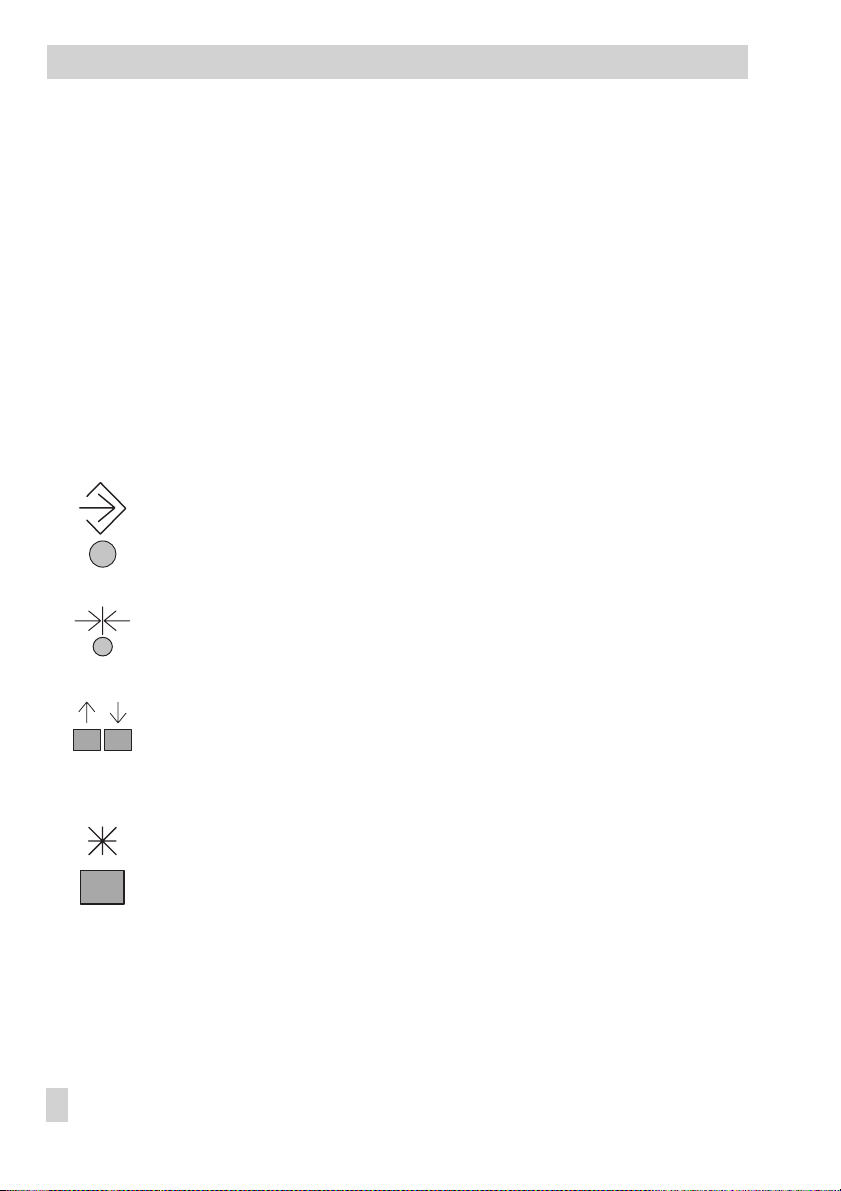

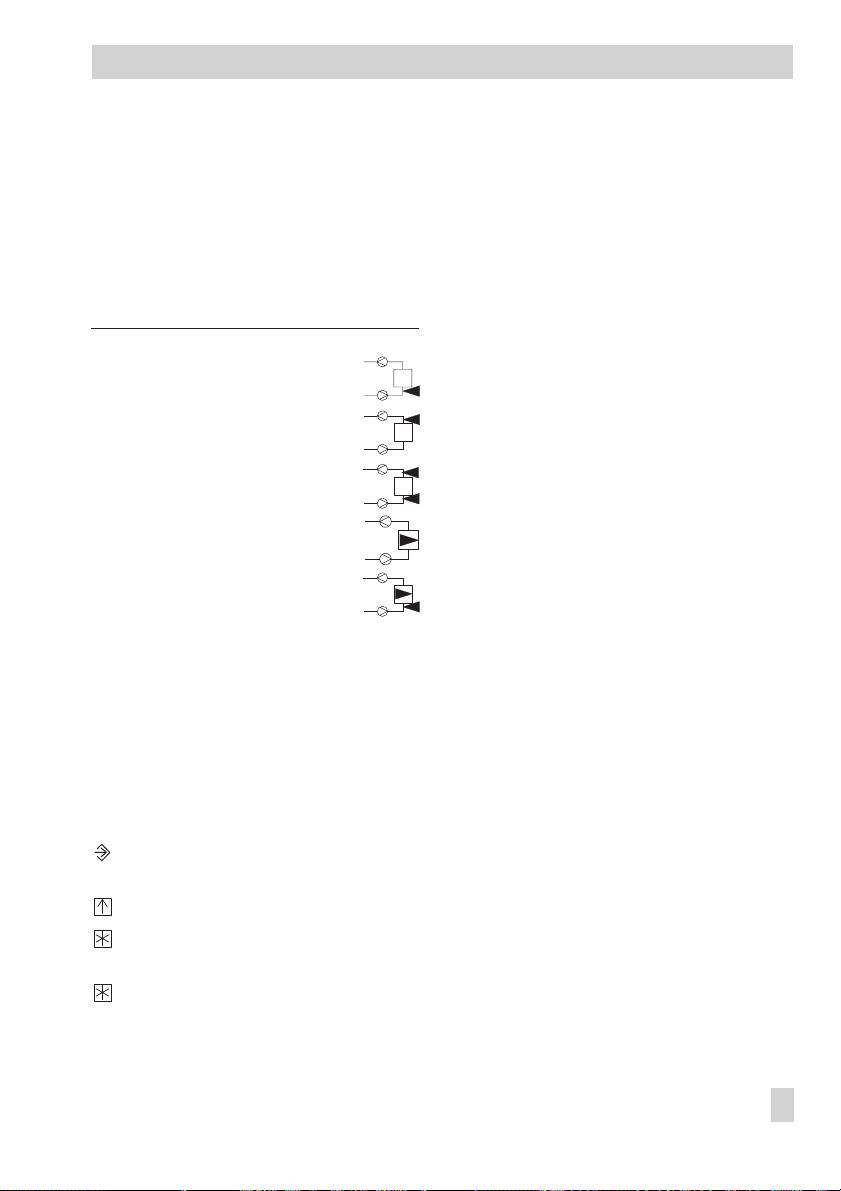

1.1.2 Mode switches

Operating mode switch

Automatic operation with switchover between rated and re

duced operation

Rated operation

Reduced operation

Manual operation

Selection switch for manual operation

The function of the selection switch depends on the position of the operating mode switch

(see above).

Position Function

at operating mode switch at selection switch for manual operation

-

Operation of selected output

,, Display of output states

Control output Y1 (heating coil)

Control output Y2 (humidifier, mixed air chamber, heat

recovery unit)

Control output Y3 (cooling coil)

Pump(s)

Fans

Y

Y

Y

2

1

3

EB 5477 EN 7

Page 8

Operation

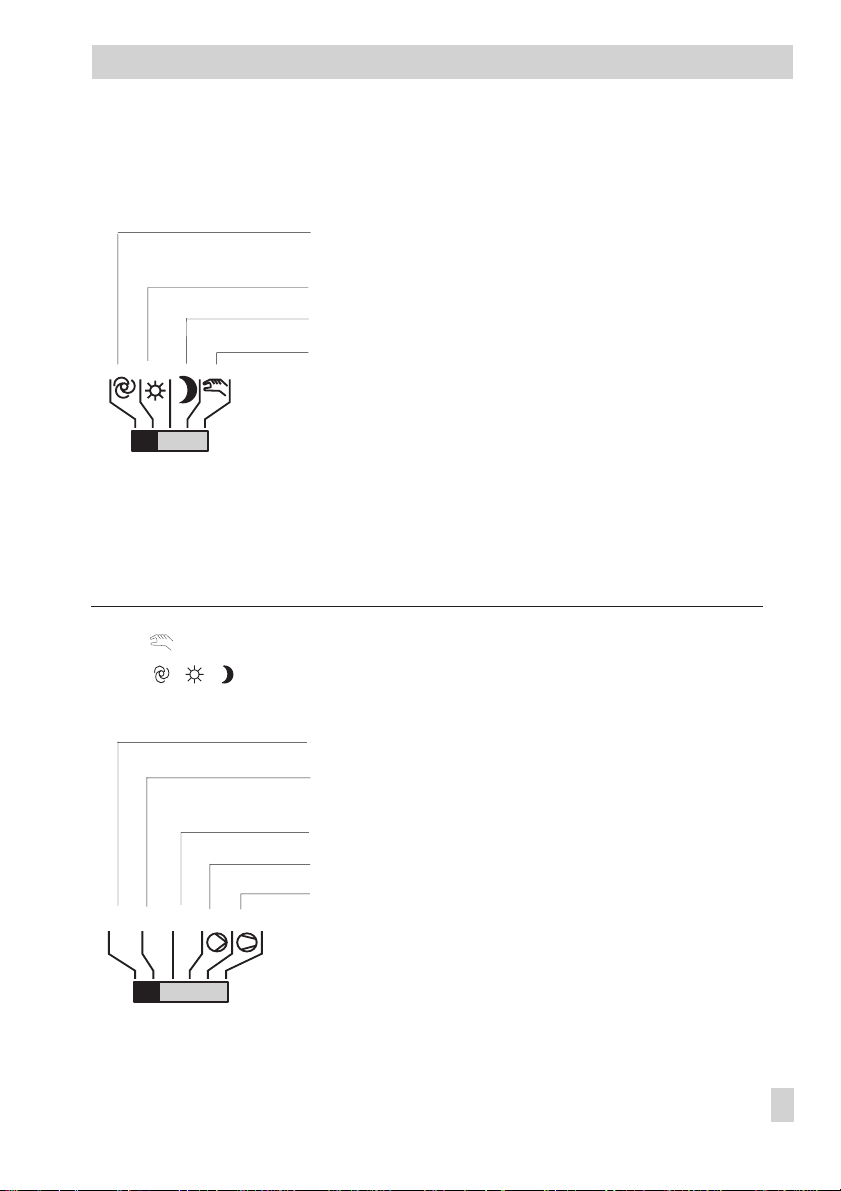

Set point correction switch

Changes remain effective until the switch position is changed again

–: Set point reduction in 1 °C increments per notch

0: No change in set point

+: Set point increase in 1 °C increments per notch

1.2 Operating modes

Day mode (rated operation) ( )

The set points set for rated operation are constantly used by the controller irrelevant of the

programmed time-of-use or summer mode.

Stand-by operation ( )

The ventilation is deactivated. The frost protection is active.

Manual operation ( )

Manual operation of valves and pumps.

8 EB 5477 EN

Page 9

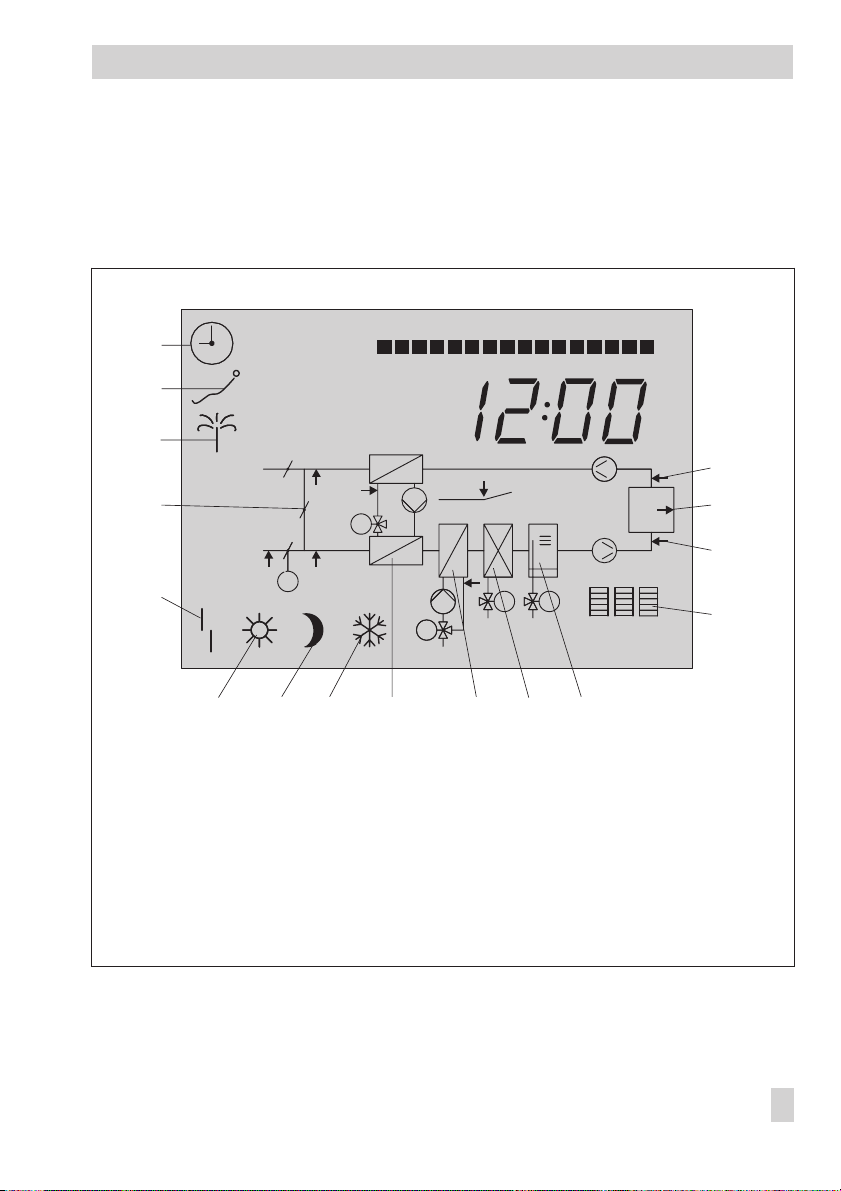

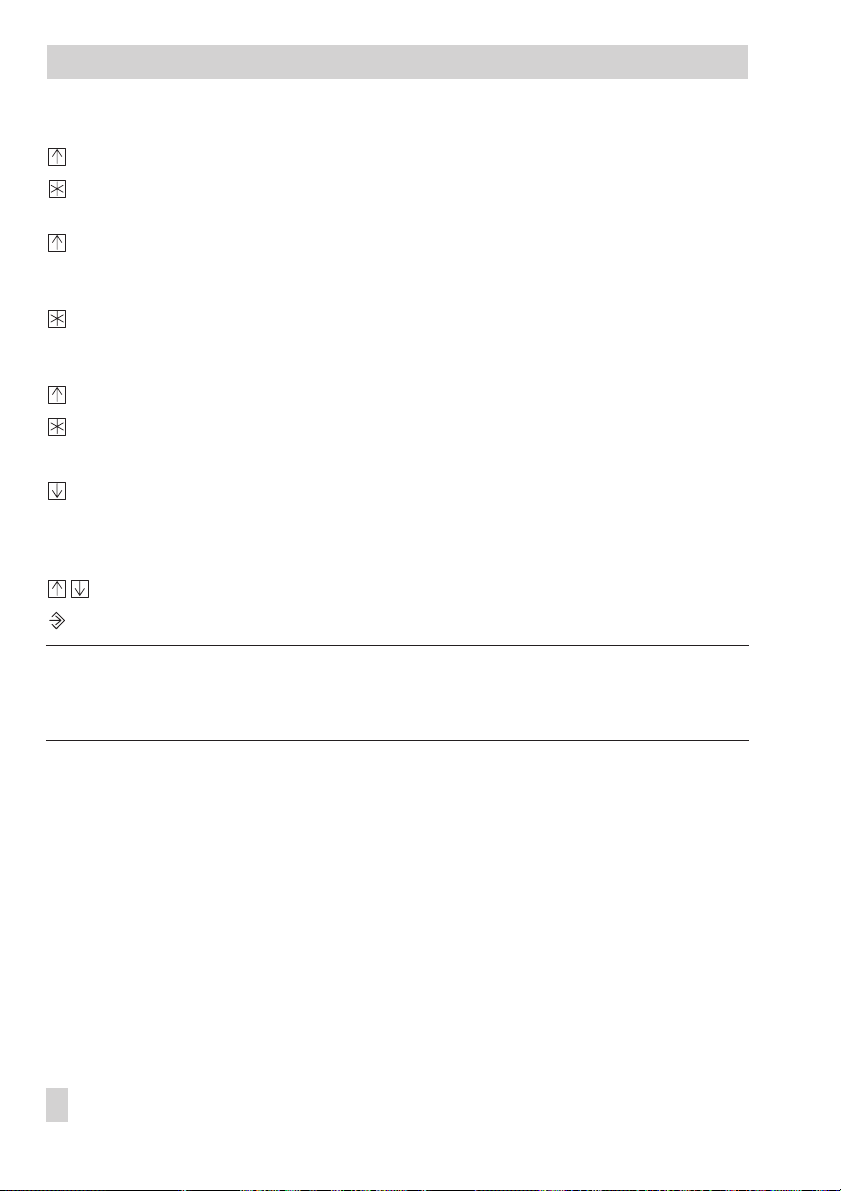

1.3 Display

Operation

During operation, the display indicates the current time as well as information about the op

eration of the controller. The times-of-use are represented by black squares below the row of

numbers at the top of the display. Symbols indicate the operating status of the controller.

24

Y1 Y2 Y3

2322212019181716151413121110987654210

16

15

14

13

1

2

3

4

32˚C

5

6

7

1 Time schedule

2 Public holidays

3 Vacation

4 Mixed air chamber

5 Malfunction

6 Rated operation

7 Reduced operation

8 Frost protection

3

M

Y2

M

Y2

M

Y1

8

9

10

M

Y3MY2

11

12

9 Heat recovery unit

10 Heating coil

11 Cooling coil

12 Humidifier

13 Control outputs

14 Supply air temperature/humidity

15 Room temperature/humidity

16 Exhaust air temperature/humidity

-

Fig. 1 · Display while the controller is operating (example)

See section 1.4 for more information about how to read the current status of the controller in

the operating level.

EB 5477 EN 9

Page 10

Operation

1.4 Data retrieval

You can view information in the operating level concerning various temperatures, control

signals, times-of-use, public holidays, states of the binary inputs as well as the baud rate

(–> Fig. 30). Which temperatures are shown depends on the system code number and the

configuration.

You will find a list of the various displays in section .

How to proceed:

The controller shows the time.

Press the arrow key.

Every time you press the key, another dat point appears on the display.

If required, you can view other information concerning a data point.

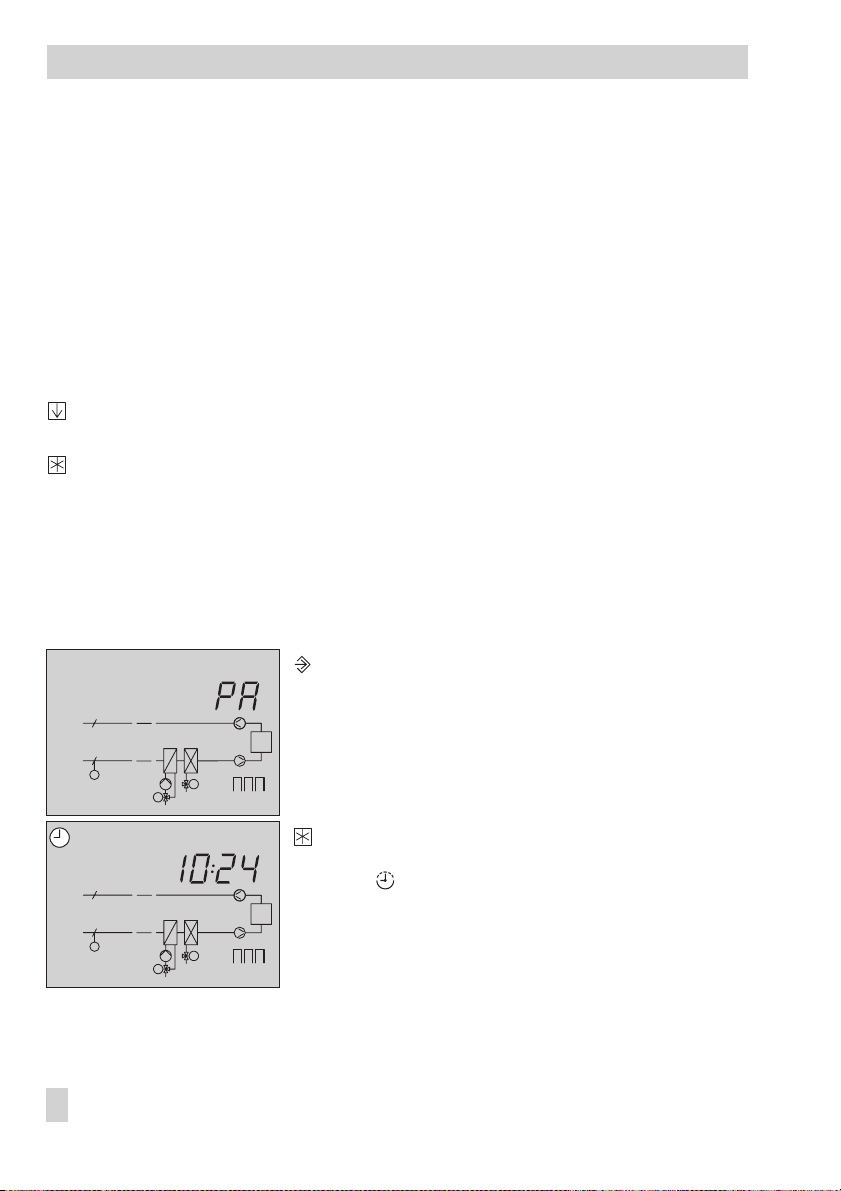

1.5 Setting the time and date

Set the current date and time directly after start-up and after a power failure, if necessary.

You must set the time and date in the parameter level.

How to proceed:

24

23222120191817161514131211109876542103

Switch to the configuration and parameter level.

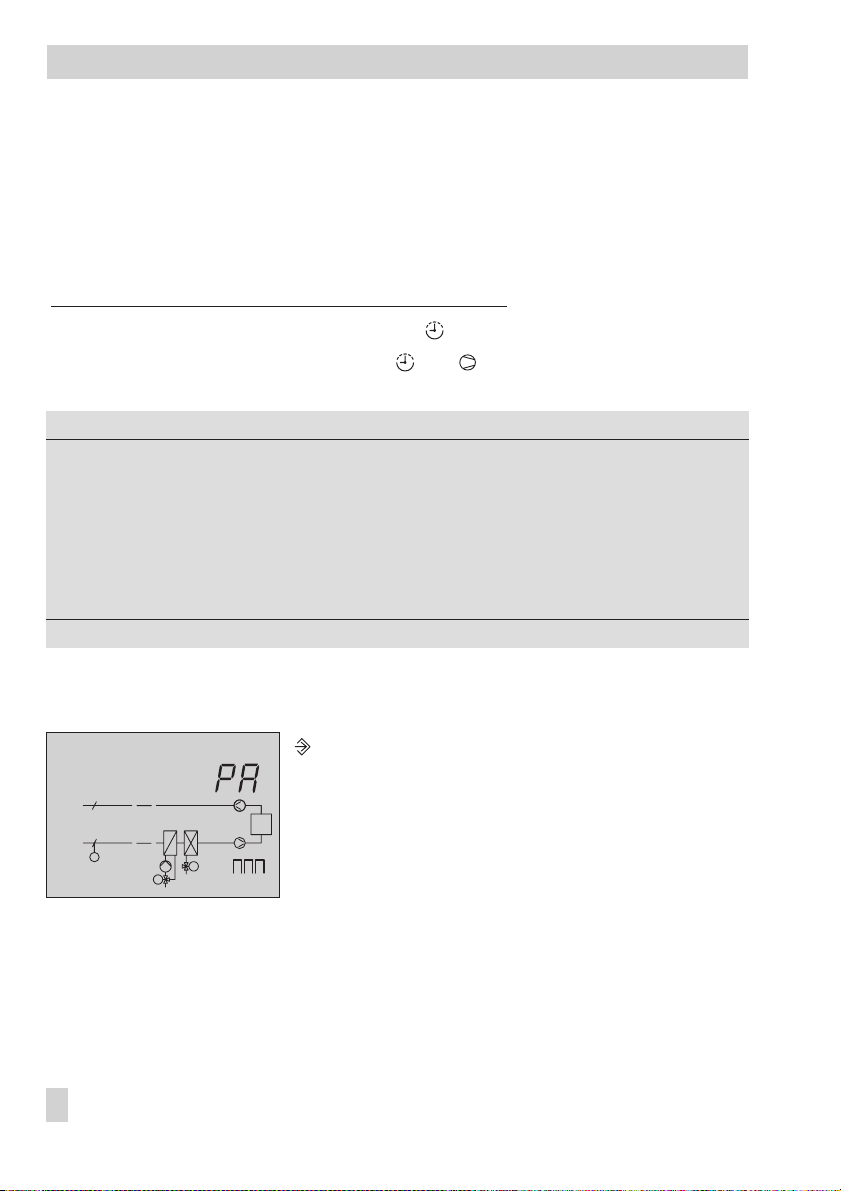

PA

appears on the display.

CO

M

PA

M

10 EB 5477 EN

M

Y3

M

Y1

Y1 Y2 Y3

24

23222120191817161514131211109876542103

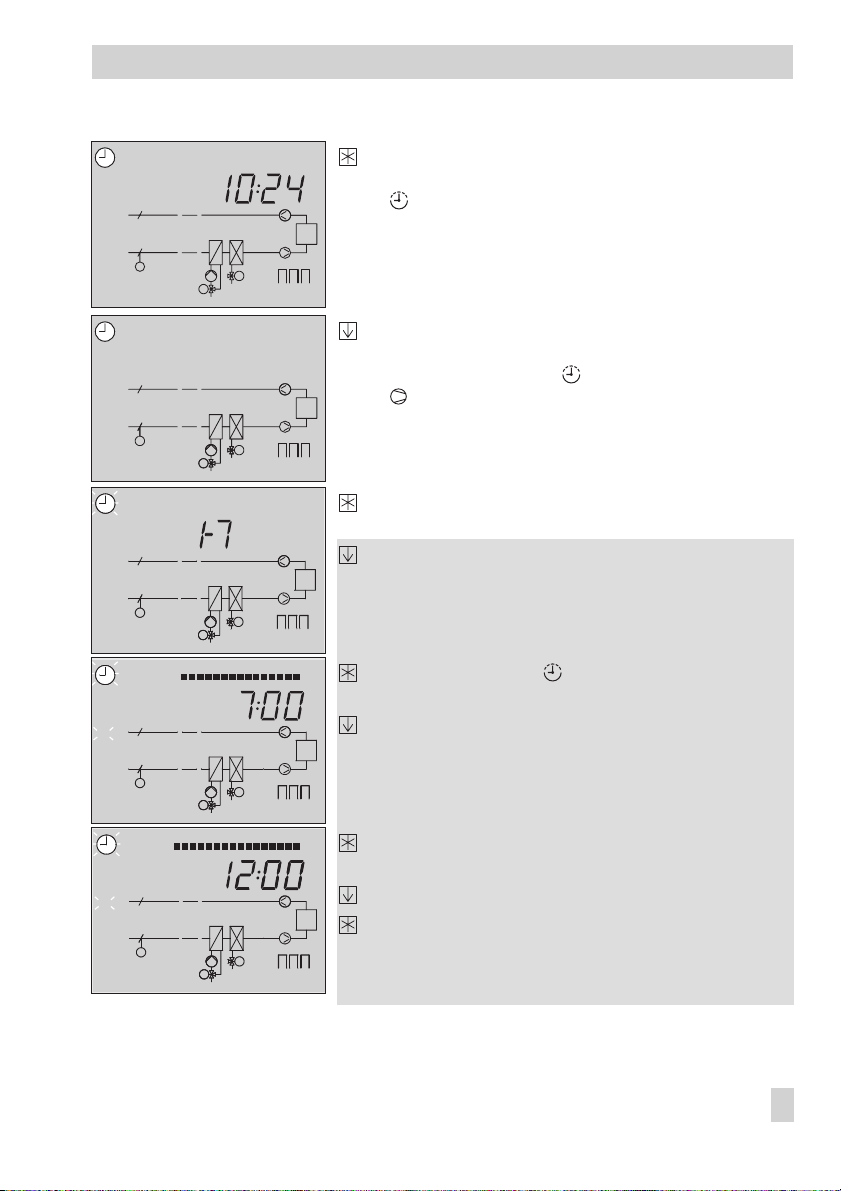

Press the enter key.

The time appears on the display.

The symbol starts to blink slowly.

M

Y3

M

Y1

Y1 Y2 Y3

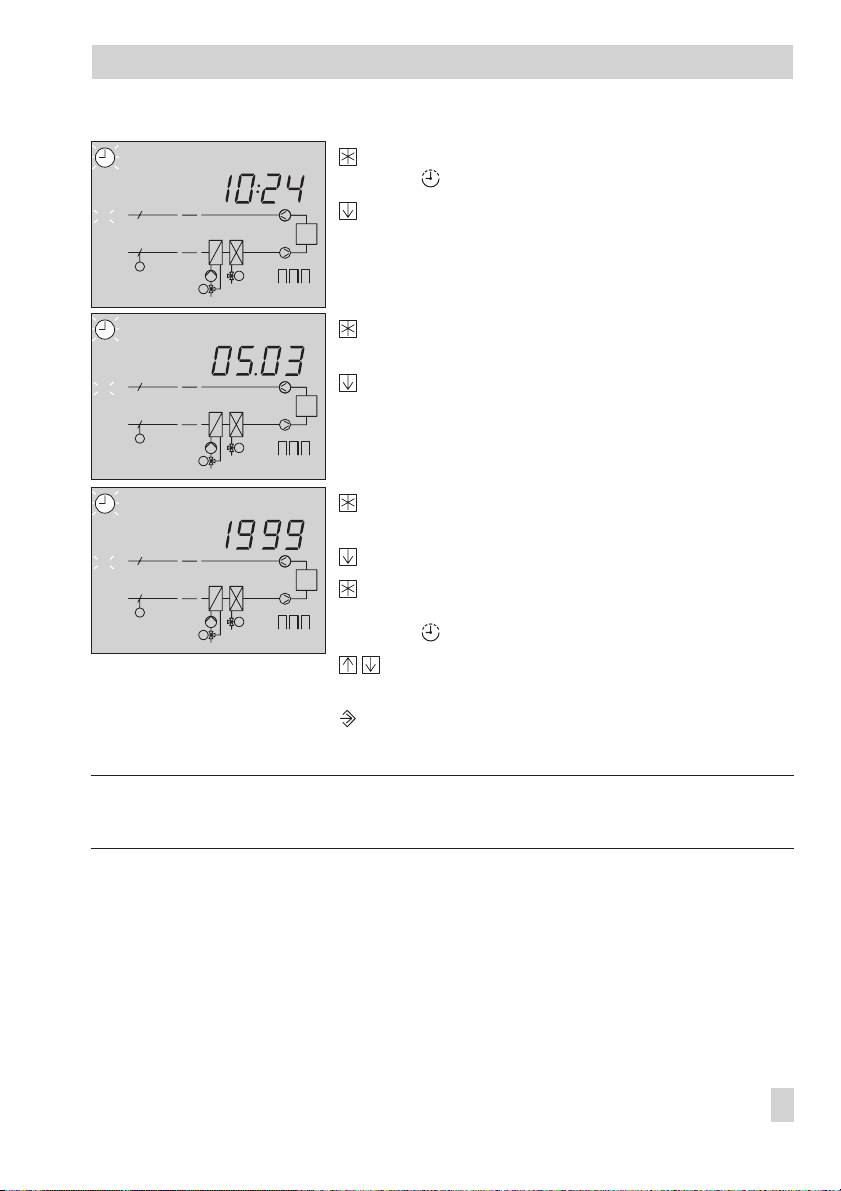

Page 11

Operation

24

23222120191817161514131211109876542103

PA

Press the enter key.

PA

The symbol and

blink quickly.

Use the arrow key to set the correct time.

M

M

Y3

M

Y1

Y1 Y2 Y3

24

23222120191817161514131211109876542103

Press the enter key to acknowledge the time.

A date appears on the display

PA

M

M

Y3

M

Y1

Y1 Y2 Y3

24

23222120191817161514131211109876542103

Use the arrow key to set the correct date.

Press the enter key to acknowledge the date.

The year appears on the display.

PA

Use the arrow key to set the correct year.

Press the enter key to acknowledge the year.

M

M

Y3

M

Y1

Y1 Y2 Y3

The time appears on the display again.

The symbol blinks slowly.

Press both arrow keys simultaneously.

PA

appears on the display again.

Press the changeover key to return to the operating

level.

Note:

The controller returns to the operating level two minute after the last key has been pressed.

EB 5477 EN 11

Page 12

Operation

1.6 Programming the time schedule

You can enter two time periods for every day of the week.

If you need just one continuous time-of-use period, set the same time for the start of the sec

ond time period and the end of the first time period.

You can set separate times-of-use for the system and, if required, for the fan speed 2.

Times-of-use Display

System

Fan speed 2

START, STOP

START, STOP

and blink

, and blink

-

Parameters

WE* Range of values

Period/day 1–7 1–7, 1, 2, 3, 4, 5, 6, 7 with 1–7 = every day,

1–5 = Monday to Friday, 6–7= Saturday and Sunday,

1 = Monday, 2 = Tuesday, ..., 7 = Sunday

Start first time-of-use 7:00 0:00 to 24:00 h; in steps of 30 minutes

Stop first time-of-use 12:00 0:00 to 24:00 h; in steps of 30 minutes

Start second time-of-use 12:00 0:00 to 24:00 h; in steps of 30 minutes

Stop second time-of-use 22:00 0:00 to 24:00 h; in steps of 30 minutes

* Default setting (WE) valid for system

How to proceed:

24

23222120191817161514131211109876542103

CO

M

M

Y3

M

Y1

Y1 Y2 Y3

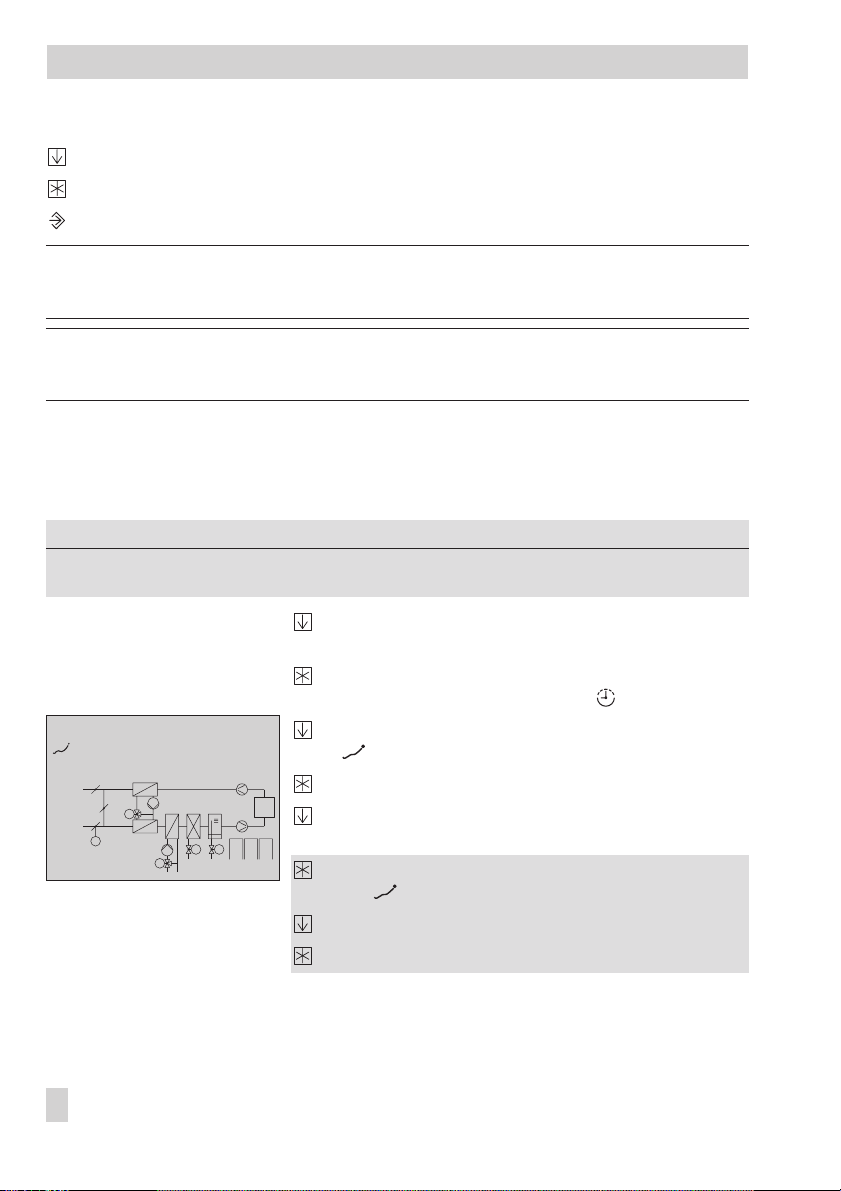

Switch to the configuration and parameter level.

PA

appears on the display.

12 EB 5477 EN

Page 13

Operation

24

23222120191817161514131211109876542103

Press the enter key to enter the parameter level.

The time appears on the display.

PA

blinks slowly.

M

STOP

START

PA

M

STOP

START

PA

M

Y3

M

Y1

Y1 Y2 Y3

24

23222120191817161514131211109876542103

Press the arrow key until the same display as shown

appears for changing the system times-of-use.

START, STOP

(

and the symbol start to blink,

additionally blinks with fan speed 2).

M

Y3

M

Y1

Y1 Y2 Y3

24

23222120191817161514131211109876542103

Press the enter key.

1–7

appears on the display.

Select the duration/day for the times-of-use.

1–7 = Monday to Sunday

M

START

PA

M

STOP

PA

M

Y3

M

Y1

M

Y1

Y1 Y2 Y3

24

23222120191817161514131211109876542103

M

Y3

Y1 Y2 Y3

24

23222120191817161514131211109876542103

1–5 = Monday to Friday

6–7 = Saturday and Sunday

1 = Monday, 2 = Tuesday, …, 7 = Sunday

Press enter key. The symbol andPAstart to blink

START

quickly.

and a time appear on the display.

Set the start time (30-minute steps).

Press the enter key.

STOP

and a time appear on the display.

Set the stop time (30-minute steps).

Press the arrow key

START

M

M

Y3

M

Y1

Y1 Y2 Y3

and a time appear on the display.

The second time-of-use period can set in the same

way as the first time-of-use period.

Repeat the steps in the gray box to enter times-of-use for other days not yet programmed.

EB 5477 EN 13

Page 14

Operation

Select

End

.

Exit the parameter level.

Return to the operating level.

Note! The controller automatically returns to the operating level when keys are left unpressed

for longer than two minutes.

Note! Use just the menu for the individual days to check the programmed time schedules. When

time blocks are selected, the times-of-use for the days selected are reset to default settings!

1.6.1 Entering public holidays

The controller uses the times-of-use programmed for Sundays on public holidays.

You can enter a maximum of 20 public holidays.

Parameter

Public holidays 01.01; 01.05;

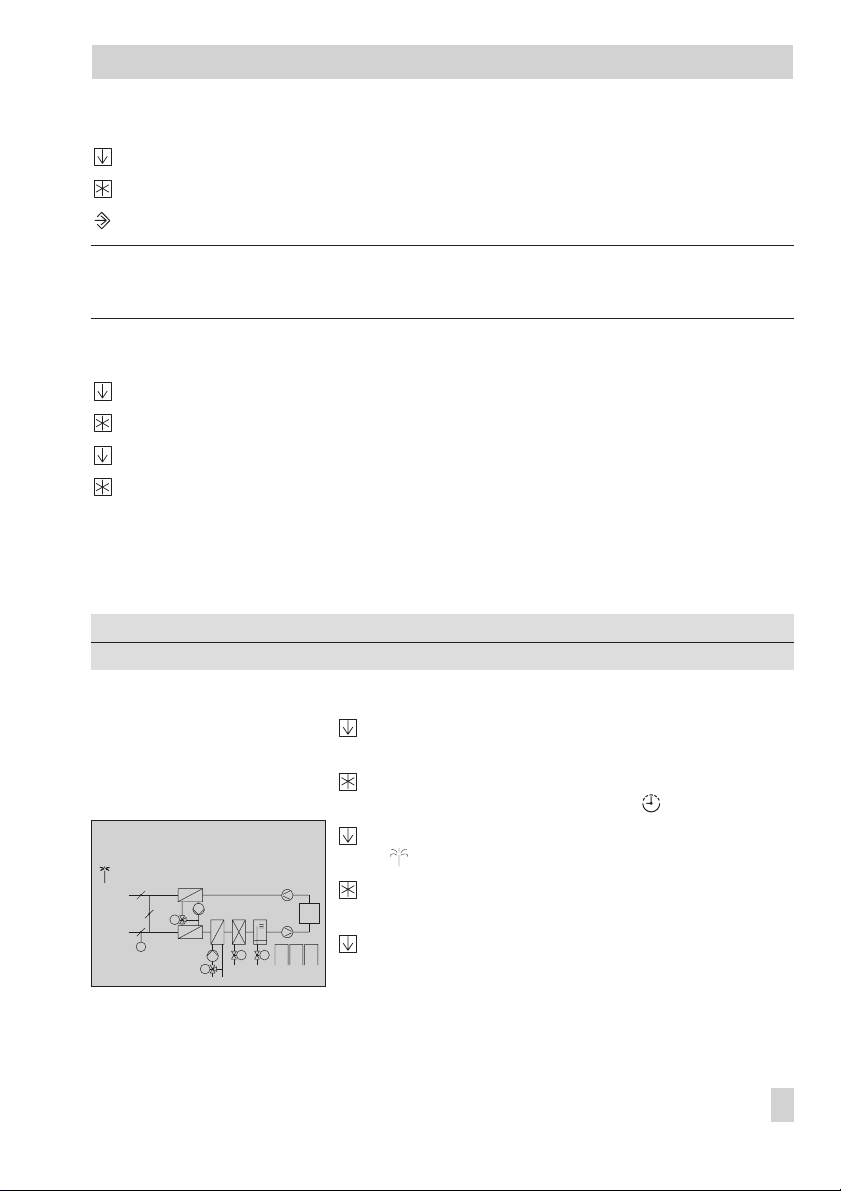

How to proceed: Switch to the configuration and parameter level.

0123456789101112131415161718192021222324

PA

M

Y2

M

Y2

Y1

M

To enter other public holidays, press the arrow key until

again. Repeat the steps in the gray box.

WE Range of values

01.01 (1 Jan) to 31.12 (31 Dec)

25.12; 26.12

PA

appears on the display.

Press the enter key.

The time appears on the display, blinks slowly.

Select public holidays data point.

appears on the display.

Press the enter key to access data point.

Press the arrow key until

M M

Y3 Y2

Y1 Y2 Y3

sary.

Press the enter key.

The symbol blinks quickly.

Change the date of the public holiday.

Confirm the date of the public holiday.

– – – –

– – – –

appears, if neces

appears on the display

-

14 EB 5477 EN

Page 15

Operation

Select

End

.

Exit the parameter level.

Return to the operating level.

Note! Public holidays that are not assigned to a specific date should be deleted by the end of

the year so that they are not carried on into the following year.

Deleting a public holiday:

Use the arrow key to select the public holiday you want to delete.

Press the enter key.

Press the arrow key until

– – – –

appears.

– – – –

is between 31.12 and 01.01.

Press the enter key. The public holiday is deleted.

1.6.2 Entering vacations

During vacation periods, the controller constantly remains in stand-by mode.All safety functions are activated. A maximum of 10 vacation periods can be entered.

Parameter

Vacation period (START, STOP) – 01.01 to 31.12

WE Range of values

How to proceed: Switch to the configuration and parameter level.

PA

appears on the display.

Press the enter key.

The time appears on the display, blinks slowly.

0123456789101112131415161718192021222324

Select vacation data point.

appears on the display.

PA

M

Y2

M

Y2

M M

Y1

Y3 Y2

M

Y1 Y2 Y3

Press the enter key to access vacation data point.

START

appears on the display.

Press the arrow key until

– – – –

appears, if neces

sary.

EB 5477 EN 15

-

Page 16

Operation

Press the enter key.

The symbol blinks quickly.

Set when the vacation period should start.

Press the enter key to confirm the start of the vacation period.

STOP

appears on the display.

Set when the vacation period should end.

Press the enter key to confirm the end of the vacation period.

To enter other vacations, press the arrow key until

peat the steps in the gray box.

End

Select

Exit the parameter level.

Return to the operating level.

.

– – – –

appears on the display again. Re

Note!

Vacations that have been entered should be deleted by the end of the year so that they are

not carried on into the following year.

Deleting a vacation period:

-

Select the start of the vacation period to be deleted.

Press the enter key.

Press the arrow key until

– – – –

Press the enter key.

The vacation period has been deleted.

16 EB 5477 EN

is between 31.12 and 01.01.

– – – –

appears on the display.

Page 17

2 Start-up

2.1 Setting the system code number and control method

Start-up

This ventilation controller allows ten different systems to be controlled. Each system is as

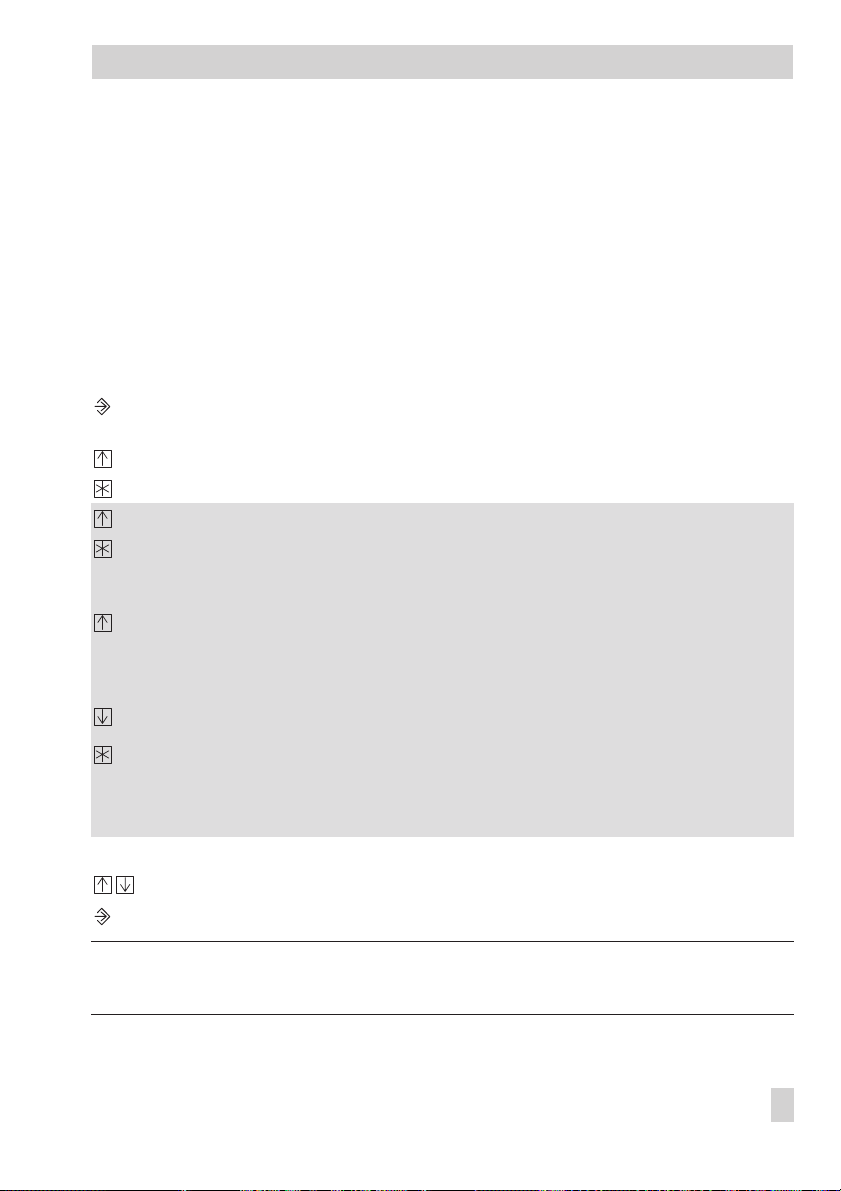

signed a system code number. You can find a list of the different systems in section 4. In ad

dition, the control method can be determined. The following control methods are available:

Control method Display

Supply air control

Exhaust air control

Exhaust air cascade control

Room control

Room cascade control

The control methods and functions of the controller are described in sections 5, 6 and 7.

Every change in system code number or control method causes the assignment of sensors to

be reprogrammed: the sensor inputs required for the function blocks are activated and the

sensor inputs not used are deactivated. These settings can be changed manually.

You must set the system code number in the configuration level (see Fig. 30).

How to proceed:

-

-

Change to the configuration and parameter level.

PA

appears on the display.

Select

CO

level.

Press the enter key.

The currently active system code number, e.g. Anl 1, blinks on the display.

Press the enter key.

Anl

andCOblink quickly.

EB 5477 EN 17

Page 18

Start-up

Select the required system code number.

Confirm the system you have selected.

Anl

starts to blink slowly on the display.

Press upward arrow key.

The components of the system and the arrows indicating the control method start to

blink on the display.

Press the enter key.

The components of the system and the control method arrows start to blink quickly on

the display.

Select the control method.

Confirm the control method you have selected.

System code numbers 6, 8 and 9:

Select the control method for the humidity control loop.

The humidity control loop is set in the same manner as the temperature control loop.

On selecting options, humidifying and dehumidifying mode or just humidifying mode

are differentiated between. In the humidifying mode, just the humidifier blinks.

CO

Press both arrow keys simultaneously.

Press the changeover key to return to the operating level.

appears on the display again.

Note!

The controller automatically returns to the operating level when keys are left unpressed for

longer than two minutes.

18 EB 5477 EN

Page 19

Start-up

2.2 Activating and deactivating functions

The controller is configured by setting the function blocks (Fb). You can activate or deactivate

CO

function blocks in the configuration level

square located to the right of a function block number at the top of the display indicates

whether function block is activated. The initial display shows the function blocks 1 to 24.

Scroll to the function blocks 25 to 47 to display the setting of these function blocks.

Proceed as described below to set the function block parameters.

How to proceed:

Change to the configuration and parameter level.

PA

appears on the display.

CO

Select

Enter the configuration level.

Select the required function block.

Confirm the function block you have selected.

If a function is protected,

(–> section 2.5) before a protected function block can be changed.

Press the upward arrow key to activate the function block (Fb = ON).

A black square to the right of the function block number at the top of the display indicates that the function block is activated.

or alternatively:

Press the downward arrow key to deactivate the function block (Fb = OFF).

Press the enter key to acknowledge the setting.

If the function block is left open, other parameters can be set. Proceed:

The parameter appears: Carry out change and confirm it.

Exit the function block.

Repeat the steps in the gray box to set other function blocks in the open configuration level.

Press both arrow keys simultaneously to exit parameter level.

Press the changeover key to return to the operating level.

configuration level.

0

Anl

appears on the display. The code number must be entered

. On opening the configuration level, a black

appears on the display.

Fb_

blinks.

Note! The controller automatically returns to the operating level when keys are left unpressed

for longer than two minutes.

EB 5477 EN 19

Page 20

Start-up

2.3 Changing parameters

Depending on the system code number set and the active functions, not all the parameters

are accessible which are listed in the parameter lists in the appendix (−> section 12.2).

How to proceed:

Change to the configuration and parameter level.

PA

appears on the display.

Press the enter key.

The time appears on the display.

Select the parameter you want to set.

Access the parameter.

Change the parameter.

Confirm the new parameter.

Repeat the steps in the gray box to set other parameters.

Press both arrow keys simultaneously to exit the parameter level.

Return to the operating level.

Note!

The controller automatically returns to the operating level when keys are left unpressed for

longer than two minutes.

20 EB 5477 EN

Page 21

Start-up

2.4 Calibrating sensors

The sensor calibration is performed in the configuration level.

Fb17 = ON: Pt 100 and Pt 1000 sensors

4

Fb17 = OFF: Pt 100 and PTC sensors

4

The values measured by all the connected sensors can be changed or reset. To proceed, set

the sensor value displayed to the temperature measured directly at the measuring point (ref

erence temperature).

Activate calibration with Fb1 to Fb7.

An incorrect calibration can be deleted by setting Fb1 to F7 = OFF.

How to proceed:

Change to the configuration and parameter level.

CO

Select

Enter the configuration level.

Press the upward arrow key until Fb25 appears on the display.

(This function block is merely selected to enter the code number. Another function

block that is protected by the code number can be also used.)

Press the enter key.

Enter and confirm the code number (–> section ) .

Close function block Fb 25.

Select the function block of the sensor that is to be calibrated (Fb1 to Fb7):

Fb1: Supply air sensor

Fb2: Exhaust air sensor

Fb3: Outdoor sensor

Fb4: Return flow sensor, heating coil

Fb5: Room sensor

Fb6: Return flow sensor, HR (system 3 and 5)

Fb7: Mixed air or extract air sensor (system 2 and 4)

Press the enter key.

A temperature appears on the display.

Set the temperature measured at the actual point of measurement.

The actual temperature at a thermometer direct at the point of measurement can be

used as the reference temperature.

configuration level.

0

appears on the display.

Anl

appears on the display.

Fb_

starts to blink.

-

EB 5477 EN 21

Page 22

Start-up

Confirm the new temperature.

End sensor calibration.

Other sensors can be calibrated in the same manner.

Press both arrow keys simultaneously to exit parameter level.

Return to the operating level.

2.5 Entering the key number

Several functions are protected against unintentional and unauthorized access. These func

tions can only be altered when the code number is known. The code number is written on

page 116. Tear out this page or blank out the code number to prevent its unauthorized use.

How to proceed:

0

appears on the display.

Press the arrow key until the correct code number appears on the display.

Confirm the code number.

When the correct code number is confirmed, the function block that should be

changed starts to blink quickly on the display.

The code number remains active for approx. three minutes.

2.6 Resetting default setting

Parameters from the parameter level can be reset to their default values (factory settings).

How to proceed:

Press the reset key with a pencil, etc.

All the parameters are reset to the factory setting (WE).

-

22 EB 5477 EN

Page 23

Manual operation

3 Manual operation

In manual operation mode, all outputs are set, see wiring plan (-> section 11 ).

How to proceed:

1. Set the operating mode switch to .

2. Slide the selector switch to the output you want to change:

Y1 to 3: control signal output 1 to 3

: pump(s) output

: fan(s) output

In systems with several pumps, select the pumps using the key.

The associated symbol blinks in the system diagram.

When the pumps are deactivated, just the pump circuit blinks on the display.

– – – – appears on the display when the output is not relevant for the system code num

ber selected.

3. Change the output:

Increase the control signal: activate pumps, fan

Reduce the control signal: deactivate pumps, fan .

For two-speed fans, you can select

The value does not need to be confirmed. It is kept even if you slide the selector switch to

another setting.

ON1,ON2orOFF

.

-

4. Slide the operating mode switch from to exit the manual operating mode.

Note!

In manual operation mode, the user can set the outputs anyway as required. On selecting

the manual operation mode, all limit temperatures and logical links ceased to be in force.

The user has absolute control and takes on responsibility for interaction between all the out

puts and the resulting consequences. A frost protection thermostat (Fb15 = ON) connected to

the controllers keeps functioning even in manual operation mode.

EB 5477 EN 23

Page 24

Systems

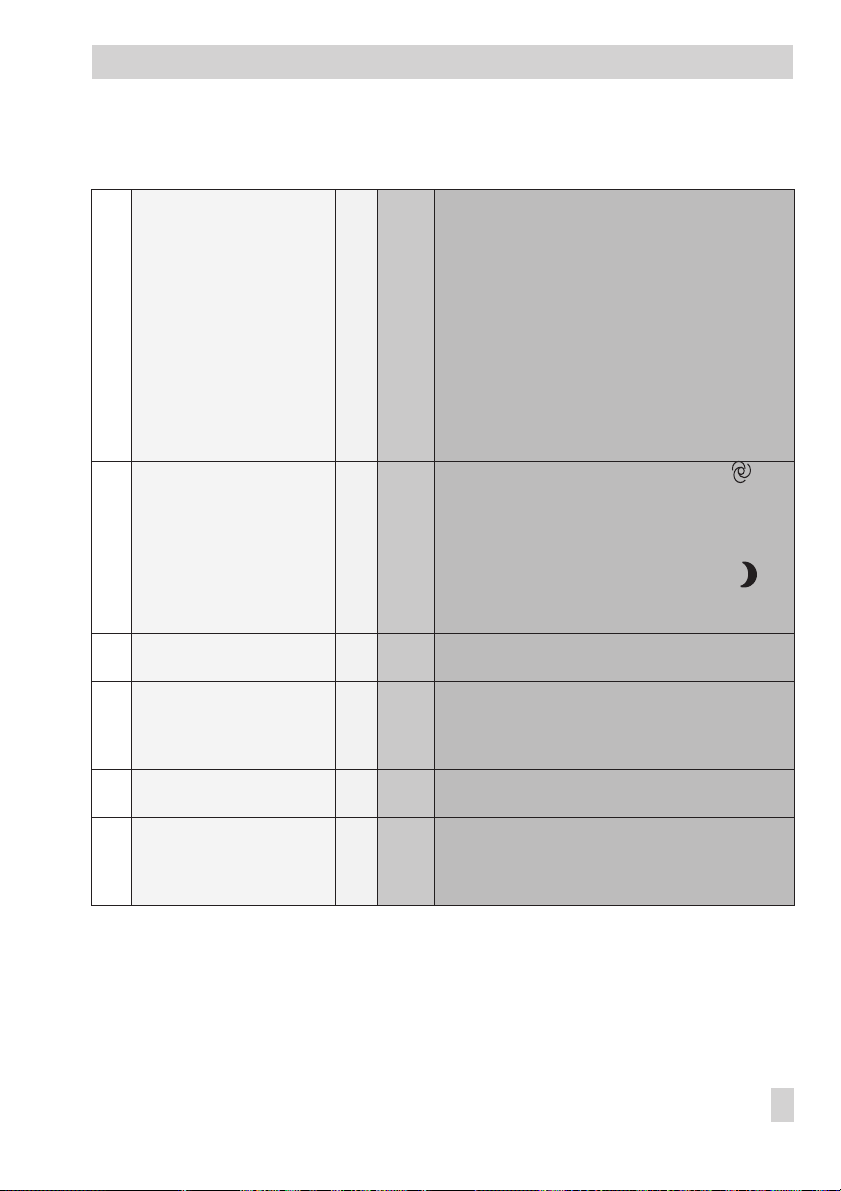

4 Systems

The ventilation controller can be used to control ten different types of systems which are as

signed system code numbers in the controller.

System code

number

0

1

2

3

4

5

6

7

8

9

* Also chilled ceiling or direct expansion evaporator (single-speed)

System description

Heating coil Ventilation

4

Heating coil

4

Cooling coil*

4

Heating coil

4

Mixed air chamber

4

Heating coil

4

Heat recovery unit

4

Heating coil

4

Cooling coil*

4

Mixed air chamber

4

Heating coil

4

Cooling coil*

4

Heat recovery unit

4

Heating coil

4

Cooling coil

4

Humidifier

4

Cooling coil* Ventilation

4

Heating coil

4

Cooling coil

4

Mixed air chamber

4

Humidifier

4

Heating coil

4

Cooling coil

4

Heat recovery unit

4

Humidifier

4

System type

Ventilation

Ventilation

Ventilation

Ventilation

Ventilation

Air-conditioning

Air-conditioning

Air-conditioning

-

24 EB 5477 EN

Page 25

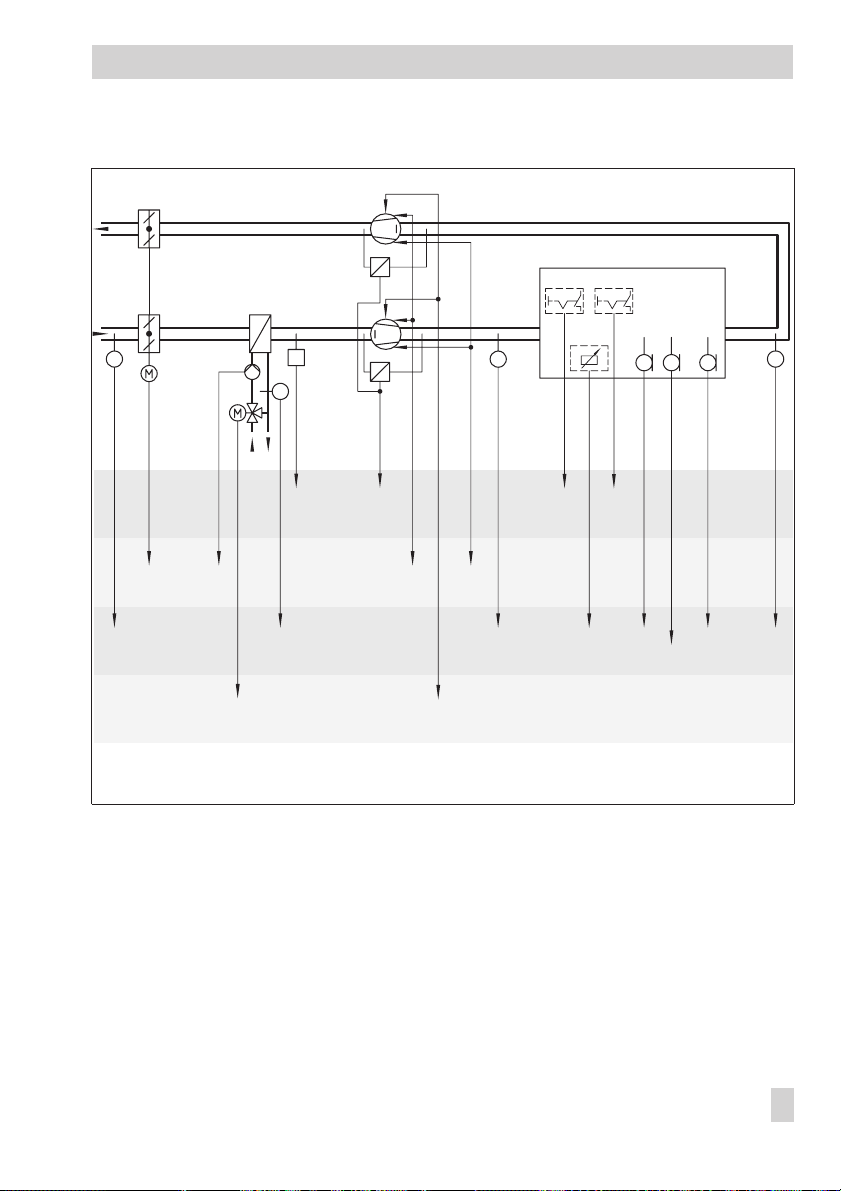

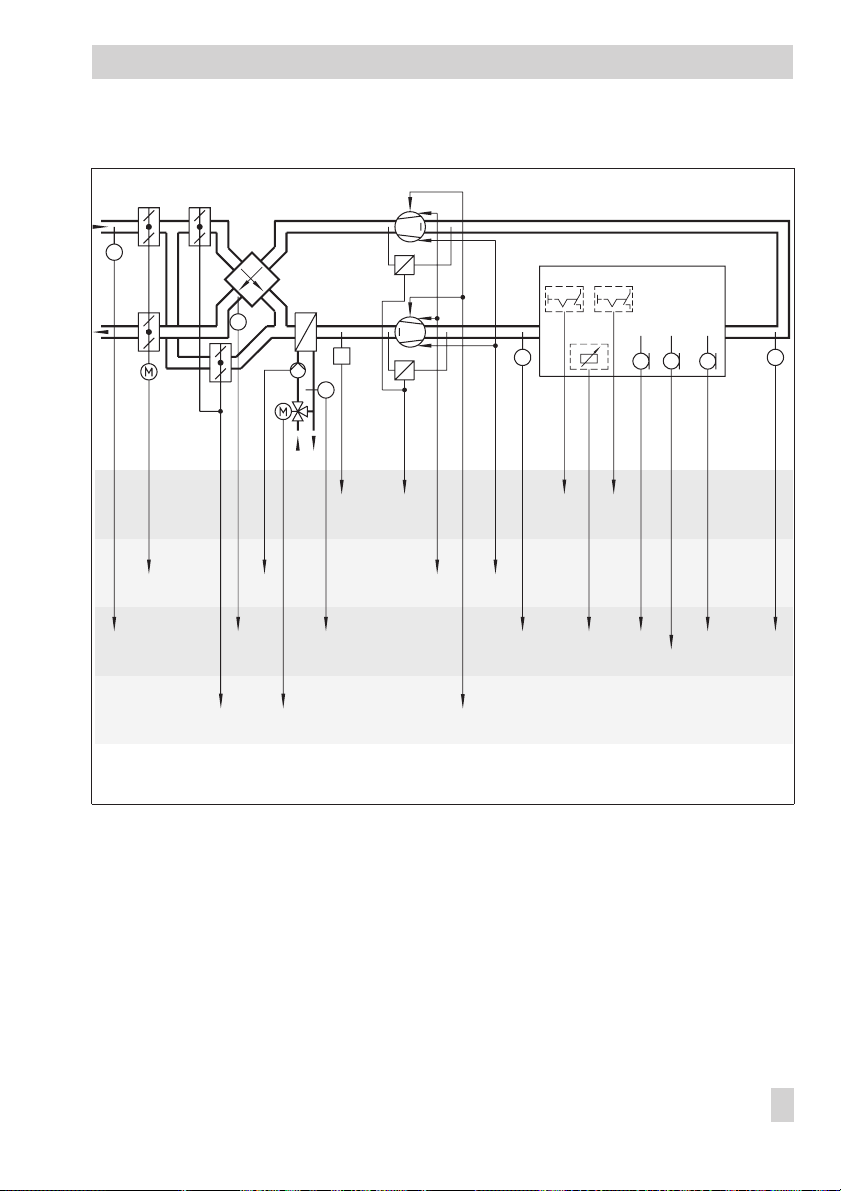

System code number 0

T

Systems

Ext. ON Ext. speed 2

Set point

T

T

T

rF

L

T

T

BE2

BA2 BA3

Speed 1 Speed 2

(AA)

BE1

F1

(AE1)

F3

(AE2)

BA2

BE3

BA1

F4

Y1

Fig. 2 · Anl 0 (system code no. 0) (ventilation)

Control of the heating coil

Outdoor temperature-compensated supply air control (–> section 6.10.1)

4

Fan operation, 2-speed or 0 to 10 V (–> section 6.8 and 6.11.4)

4

BE4

(BE7)

AE4

F5

(AE3)

F7F8

F2

(AE3)

EB 5477 EN 25

Page 26

Systems

System code number 1

T

T

Ext. ON Ext. speed 2

Set point

T

T

L

TrF

T

F3

(AE2)

BA2

BA1 (BA4)

F4

BE3

BE2

BA2 BA3

Speed 1On/off Speed 2

F1

(AE1)

Y3Y1

(AA)

BE1 BE4

(BE7)

F8 F2

F7

AE4

Specifications in parentheses

can be selected as an alternative

Fig. 3 · Anl 1 (system code no. 1) (ventilation)

Control of the heating and cooling coils

Summer compensation (–> section 6.7)

4

Sequence operation of heating/cooling or overlapping operation (–> section 6.11.8)

4

Fan operation, 2-speed or 0 to 10 V (–> section 6.8 and 6.11.4)

4

F5

(AE3)

(AE3)

26 EB 5477 EN

Page 27

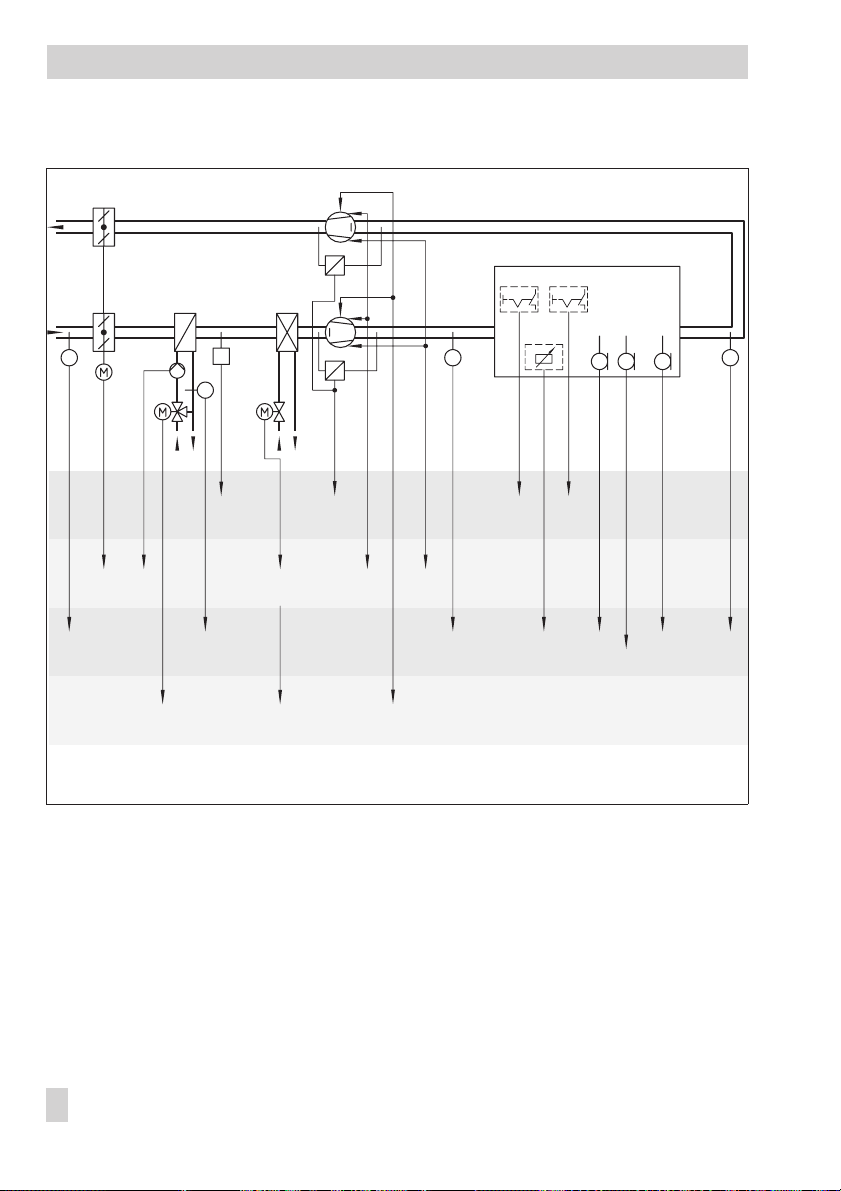

System code number 2

(F7)

T

TT

Systems

Ext. ON Ext. speed 2

Outdoor

Set point

air rate

T

T

T

rF

L

T

T

BE1 BE4

(BE7)

F8 F9 F2

AE4

Specifications in parentheses

can be selected as an alternative

F3

(AE2)

Y2

BE3 BE2

BA1

F7

F4

Y1

BA2 BA3

Speed 1 Speed 2

F1

(AE1)

(AA)

Fig. 4 · Anl 2 (system code no. 2) (ventilation)

Control of mixed air chamber and heating coil

Summer time operation (–> section 6.10.3)

4

Sequence operation of heating/dampers or mixed air temperature control (–> section

4

5.4.2)

Automatic reversal of operating action for mixed air chamber (–> section 5.4.2)

4

Fan operation, 2-speed or 0 to 10 V (–> section 6.8 and 6.11.4)

4

(F7)

F5

(AE3)

(AE3)

EB 5477 EN 27

Page 28

Systems

System code number 3

T

Antifreeze required in

HRU.

T

Ext. ON Ext. speed 2

Set point

T

T

T

LrF

T

T

F3

(AE2)

BA2

BA5 BA1

F6

Y2 Y1

BE3 BE2

F4

BA2 BA3

Speed 1 Speed 2

AA

F1

(AE1)

BE1 BE4

(BE7)

F8 F2

Specifications in parentheses

can be selected as an alternative

Fig. 5 · Anl 3 (system code no. 3) (ventilation)

Control of heat recovery unit (HRU) and heating coil

Frost protection for HRU (–> section 7.2.2)

4

Automatic reversal of operating action for HRU configurable (–> section 5.4.2)

4

Fan operation, 2-speed or 0 to 10 V (–> section 6.8 and 6.11.4)

4

AE4

F5

(AE3)

(AE3)

F7

28 EB 5477 EN

Page 29

Systems

T

Ext. ON Ext. speed 2

F3

(AE2)

BA2

T

T

T

BE3 BE2

BA1

F6

F4

Y1Y2

BA2 BA3

Speed 1 Speed 2

AA

(AE1)

Set point

T

BE1 BE4

(BE7)

F1

F8 F2

Specifications in parentheses

can be selected as an alternative

Fig. 6 · Anl 3 (system code no. 3) with cross-flow heat exchanger (ventilation)

Control of heat recovery unit (HRU) and heating coil

Heat recovery unit designed as a cross-flow heat exchanger

4

Frost protection for HRU (–> section 7.2.2)

4

Automatic reversal of operating action for HRU configurable (–> section 5.4.2)

4

Fan operation, 2-speed or 0 to 10 V (–> section 6.8 and 6.11.4)

4

LrF

T

AE4

F5

(AE3)

F7

T

(AE3)

EB 5477 EN 29

Page 30

Systems

System code number 4

(F7)

T

T

T

Ext. ON Ext. speed 2

rF

Set point T Set point rH

T

T

T

L

T

T

F3

(AE2)

Y2

BE3 BE2

BA1 (BA4)

F4F7

Y1 Y3

BA2 BA3

Speed 1On/off Speed 2

F1

(AE1)

(AA)

BE1 BE4

(BE7)

F8 F9

Specifications in parentheses

can be selected as an alternative

F7

AE4

Fig. 7 · Anl 4 (system code no. 4) (ventilation)

Control of mixed air chamber, heating and cooling coils

Summer compensation (–> section 6.7)

4

Summer time operation (–> section 6.10.3)

4

Sequential operation of heating/dampers/cooling or sequence of heating/cooling and

4

mixed air temperature control

Automatic reversal of operating action for mixed air chamber (–> section 5.4.2)

4

Fan operation, 2-speed or 0 to 10 V (–> section 6.8 and 6.11.4)

4

F5

(AE3)

F2

(AE3)

30 EB 5477 EN

Page 31

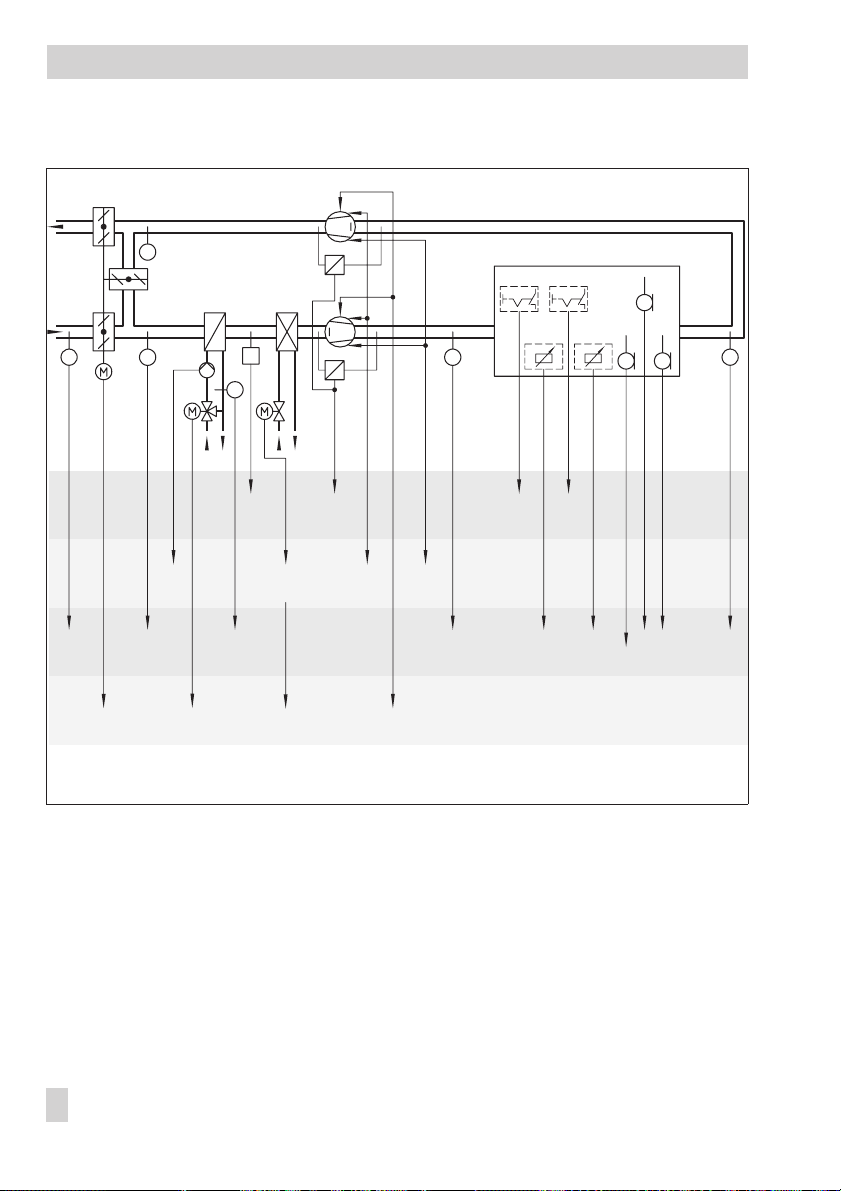

System code number 5

T

T

Systems

Ext. ON Ext. speed 2

Set point

T

T

T

L

rF

T

T

BE4

BE1

(BE7)

F8 F2

F3

(AE2)

BA2

BA5 BA1

Y2 Y1 Y3

BE3

F4F6

BE2

BA2BA4 BA3

Speed 1On/off Speed 2

AA

F1

(AE1)

Fig. 8 · Anl 5 (system code no. 5) (ventilation)

Control of heat recovery unit (HRU) as well as heating and cooling coils

Summer compensation (–> section 6.7)

4

Frost protection for HRU (–> section 7.2.2)

4

Automatic reversal of operating action for HRU configurable (–> section 5.4.2)

4

Fan operation, 2-speed or 0 to 10 V (–> section 6.8 and 6.11.4)

4

F7

AE4

F5

(AE3)

(AE3)

EB 5477 EN 31

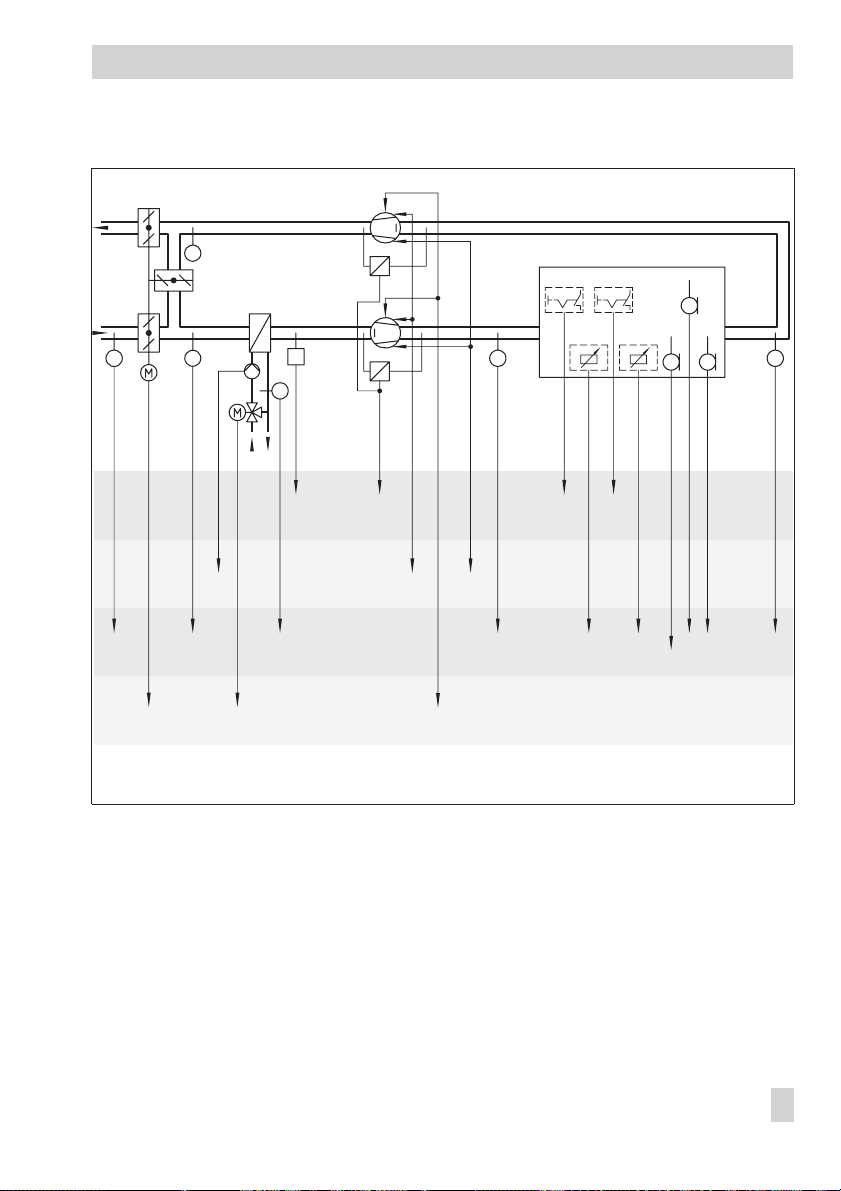

Page 32

Systems

System code number 6

T

T

Ext. ON Ext. speed 2

rF

Set point T Set point rH

T

T

rF

L

rF

T

T

BE1

BE4

(BE7)

F8 F9 F7

Specifications in parentheses

can be selected as an alternative

F3

(AE2)

BA2

BA1 (BA4)

Y1

BE3

F4

Y2

Y3

BE2

BA2 BA3

Speed 1On/off Speed 2

F1

(AE1)F6(AE2)

(AA)

Fig. 9 · Anl 6 (system code no. 6) (air-conditioning, only humidification)

Control of heating coil, cooling coil and humidification (only humidification)

Two control loops: Temperature and humidity control

4

Only humidification configurable (–> section 5.2)

4

Summer compensation (–> section 6.7)

4

Fan operation, 2-speed or 0 to 10 V (–> section 6.8 and 6.11.4)

4

AE4

(F7)

F5

(AE3)

(AE4)F2(AE3)

32 EB 5477 EN

Page 33

Systems

Antifreeze required

heat exchanger.

T

T

T

T

rF

Ext. ON Ext. speed 2

Set point T Set point rH

Set point T Set point rH

rF

rF

L

T

T

F3

(AE2)

BA2

BE3

BA1

F4

Y1Y3 Y2

BE2

BA2 BA3

Speed 1 Speed 2

(AA)

BE1 BE4

(BE7)

F1

(AE1)F6(AE2)

Note: The position of the cooling coil is not shown

on the display of the controller as here.

Specifications in parentheses

can be selected as an alternative

F8 F9 F7

AE4

(F7)

F5

(AE3)

(AE4)F2(AE3)

Fig. 10 · Anl 6 (system code no. 6) (air-conditioning, humidifying and dehumidifying)

Control of cooling and heating coils and humidification (humidifying and dehumidifying)

Two control loops: Temperature and humidity control

4

Humidification or humidifying and dehumidifying operation configurable (–> section 5.2)

4

Summer compensation (–> section 6.7)

4

Fan operation, 2-speed or 0 to 10 V (–> section 6.7 and 6.11.4)

4

EB 5477 EN 33

Page 34

Systems

System code number 7

T

T

Ext. ON Ext. speed 2

Set point

L

rF

T

T

BE2

BA2

F3

(AE2)

BA2(BA4) BA3

Speed 1On/off Speed 2

F1

(AE1)

(AA)Y3

Fig. 11 · Anl 7 (system code no. 7) (ventilation)

Cooling coil control

Summer compensation (–> section 6.7)

4

Fan operation, 2-speed or 0 to 10 V (–> section 6.8 and 6.11.4)

4

BE1 BE4

(BE7)

F8 F2

F7

Specifications in parentheses

can be selected as an alternative

AE4

F5

(AE3)

(AE3)

34 EB 5477 EN

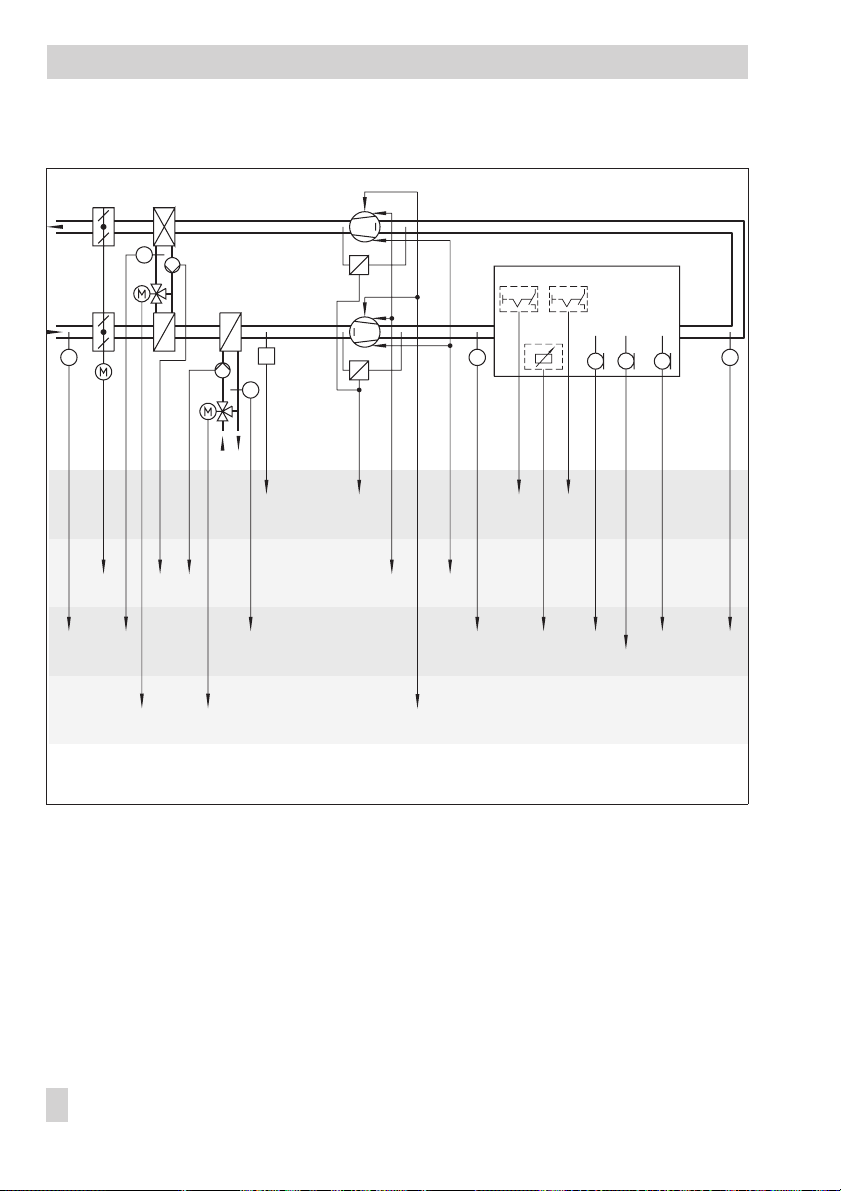

Page 35

System code number 8

T

Systems

Ext. ON Ext. speed 2

rF

Set point T Set point rH

T

T

T

rF

L

rF

T

T

BE3

BA1

F3

(AE2)

Y2

Fig. 12 · Anl 8 (system code no. 8) (air-conditioning, only humidification)

Y1

(BA4)

F4

BE2

BA2 BA3

Speed 1Speed 2

F1

(AE1)F6(AE2)

AAY3

BE1 BE4

(BE7)

F8 F9 F7

Specifications in parentheses

can be selected as an alternative

(F7)

AE4

F5

(AE3)

Control of mixed air chamber, heating coil, cooling coil and humidification

Two control loops: Temperature and humidity control

4

Humidification or humidifying and dehumidifying operation configurable (–> section 5.2)

4

Summer compensation (–> section 6.7)

4

Summer time operation (–> section 6.10.3)

4

Automatic reversal of operating action for mixed air chamber (–> section 5.4.2)

4

Fan operation, 2-speed (–> section 6.8 and 6.11.4)

4

(AE4)F2(AE3)

EB 5477 EN 35

Page 36

Systems

4.1 System code number 9

T

F3

(AE2)

BA2

Y2 Y1

BA5 BA1

Antifreeze required

heat exchanger.

T

T

BE3

(BA4)

F4

BE2

BA2 BA3

Speed 1On/off Speed 2

(AE1)F6(AE2)

AAY3

T

F1

Ext. ON Ext. speed 2

Set point T Set point rH

rF

BE1 BE4

(BE7)

F8 F9 F7

Specifications in parentheses

can be selected as an alternative

AE4

rF

L

(F7)

(AE3)

Fig. 13 · Anl 9 (system code no. 9) (air-conditioning, only humidification)

Control of heat recovery unit (HRU), heating coil, cooling coil and humidification

T

F5

(AE4)F2(AE3)

rF

T

Two control loops: Temperature and humidity control

4

Humidification or humidifying and dehumidifying operation (–> section 5.2)

4

Summer compensation (–> section 6.7)

4

Automatic reversal of operating action for HRU configurable (–> section 5.4.2)

4

Fan operation, 2-speed (–> section 6.8 and 6.11.4)

4

36 EB 5477 EN

Page 37

Control methods and system components

5 Control methods and system components

5.1 Ventilation and temperature control in air-conditioning systems

In temperature control, various control methods are differentiated between: Supply air tem

perature control, exhaust air temperature control, exhaust air cascade control, room and

room cascade control.

5.1.1 Supply air temperature control

The sensor input F1 is the control variable input by default. Alternatively, the supply air tem

perature can also be guided over the analog input AE1 to the controller.

The supply air temperature is controlled by a PID algorithm with an adjustable

temperature set point

. Depending on the system code number, the temperature control loop

has between 1 and 3 sequence outputs that are adapted to the dynamics of the correspond

ing system components by means of the

KP, T

and

T

N

control parameters. Functions such as

V

return air temperature limit, summer compensation, manual set point correction or condensation detection can shift the set point. The supply air can be controlled dependent on the outdoor temperature.

Functions

Control method Supply air control (–> page 17)

Sensor F1, supply air temperature

Assignment of inputs AE1 to AE4

Parameters

Supply air temperature set point 22 °C 0 to 50 °C

K

P

T

N

T

V

or

WE Configuration

Fb1 = ON or

OFF

Fb18 = ON,

WE Range of values

0.5 0.1 to 99.9

60 sec 1 to 999 sec

– – – – – – to 999 sec

option

: AE1F1

Supply air

-

-

5.1.2 Exhaust air temperature control

The sensor input F2 is the control variable input by default. Alternatively, the exhaust air tem

perature can also be guided over the analog input AE3 to the controller.

The exhaust air temperature is controlled by a PID algorithm with an adjustable

temperature set point

. Depending on the system code number, the temperature control loop

has between 1 and 3 sequence outputs that are adapted to the dynamics of the correspond

ing system components by means of the

KP, T

and

T

N

control parameters.

V

Exhaust air

EB 5477 EN 37

-

-

Page 38

Control methods and system components

Functions such as return air temperature limit, summer compensation, manual set point cor

rection or condensation detection can shift the set point.

Functions

Control method Exhaust air control (–> page 17)

Sensor F2, exhaust air temperature

assignment of inputs AE1 to AE4

Parameters

Exhaust air temperature set point 22 °C 0 to 40 °C

K

P

T

N

T

V

or

WE Configuration

OFF

WE Range of values

0.5 0.1 to 99.9

60 sec 1 to 999 sec

– – – – – – to 999 sec

Fb2 = ON or

Fb18 = ON,

option:

AE3F2

5.1.3 Exhaust air temperature cascade control

The sensor input F2 is the control variable input for the exhaust air temperature and the sensor input F1 is the control variable input for the supply air temperature by default. Alternatively, the exhaust air temperature can also be guided over the analog input AE3 and the

supply air temperature over the analog input AE1 to the controller.

The exhaust air temperature control loop is implemented as a P control loop with adjustable

Exhaust air temperature set point

perature is controlled by a PID control algorithm with adjustable

slave loop.

Depending on the system code number, the supply air temperature control loop

has between 1 and 3 sequence outputs that are adapted to the dynamics of the corresponding system components by means of the

Supply air temperature minimum limit

the set point shift which arises when the exhaust air temperature control loop takes influence

on the supply air temperature control loop:

Each deviation in exhaust air temperature by the amount x causes a shift of the supply air

temperature set point by the amount x multiplied by the parameter

master loop

x = Exhaust air temperature set point – Exhaust air temperature actual value

4

Temperature set point of slave loop

4

.

Temperature set point of slave loop

Note!

If the calculated set point is not within the limit, the minimum or maximum limit applies as

the new set point.

and

KPTemperature of the master loop

KP, T

and

T

N

and

Supply air temperature maximum limit -

calculated

=

+ x ·

KPTemperature master loop

control parameters. The parameters -

V

. The supply air tem-

Temperature set point of

restrict

KPTemperature of the

-

38 EB 5477 EN

Page 39

Control methods and system components

Shifts in the set point which are caused by manual set point correction, return air tempera

ture limit, summer compensation or by condensation detection, have unrestricted effects on

the exhaust air temperature set point.

Functions

Control method Exhaust air cascade control (–> page 17)

Sensor F1, supply air temperature

assignment of inputs AE1 to AE4

Sensor F2, exhaust air temperature

assignment of inputs AE1 to AE4

Parameters

Exhaust air temperature set point 22 °C 0 to 40 °C

Temperature set point of the slave loop 22 °C 0 to 50 °C

KPTemperature master loop 1 0.1 to 99.9

Supply air temperature minimum limit 18 °C 0 °C up to Supply air temp. maximum limit

Supply air temperature maximum limit 26 °C Supply air temp. minimum limit up to 50 °C

K

P

T

N

T

V

or

or

WE Configuration

Fb1 = ON or

OFF

Fb18 = ON,

Fb2 = ON or

OFF

Fb18 = ON,

WE Range of values

0.5 0.1 to 99.9

60 sec 1 to 999 sec

– – – – – – to 999 sec

option

option:

: AE1F1

AE3F2

5.1.4 Room temperature control

The sensor input F5 is the control variable input by default. Alternatively, the room temperature can also be guided over the analog input AE3 to the controller.

The room temperature is controlled by a PID algorithm with an adjustable

set point

. Depending on the system code number, the temperature control loop has between

1 and 3 sequence outputs that are adapted to the dynamics of the corresponding system

KP, T

and

T

components by means of the

N

control parameters. Functions such as return air

V

temperature limit, summer compensation, manual set point correction or condensation detec

tion can shift the set point.

Functions

Control method Room control (–> page 17)

Sensor F5, room temperature

assignment of inputs AE1 to AE4

or

WE Configuration

Fb5 = ON or

OFF

Fb18 = ON, option AE3F5

Room temperature

-

EB 5477 EN 39

Page 40

Control methods and system components

Parameters

Room temperature set point 22 °C 0 to 40 °C

K

P

T

N

T

V

WE Range of values

0.5 0.1 to 99.9

60 sec 1 to 999 sec

– – – – – – to 999 sec

5.1.5 Room temperature cascade control

The sensor input F5 is the control variable input for the room temperature and the sensor

4

input F1 is the control variable input for the supply air temperature by default. Alterna

tively, the room temperature can also be guided over the analog input AE3 and the sup

ply air temperature over the analog input AE1 to the controller.

The room temperature control loop is implemented as a P control loop with adjustable

Room temperature set point

is controlled by a PID control algorithm with adjustable

Depending on the system code number, the temperature control loop has between 1

loop.

and 3 sequence outputs that are adapted to the dynamics of the corresponding system

components by means of the

air temperature minimum limit

point shift which arises when the room temperature control loop takes influence on the

supply air temperature control loop: each deviation in room temperature by the amount

x causes a shift of the supply air temperature set point by the amount x multiplied by the

parameter

x =

4

Supply air temperature set point

4

KPTemperature master loop

Room temperature set point

Supply air temperature set point + x · KPTemperature master loop

Note!

If the calculated set point is not within the limit, the minimum or maximum limit applies as

the new set point.

Shifts in the set point which are caused by manual set point correction, return air tempera

ture limit, summer compensation or by condensation detection, have unrestricted effects on

the room temperature set point.

Functions

Control method Room cascade control (–> page 17)

Sensor F1, supply air temperature

assignment of inputs AE1 to AE4

Sensor F5, room temperature

assignment of inputs AE1 to AE4

and

KPTemperature master loop

. The supply air temperature

Temperature set point of the slave

KP,T

and

T

N

and

Supply air temperature maximum limit -

control parameters. The parameters -

V

Supply

restrict the set

.

– Room temperature actual value

calculated

or

or

=

WE Configuration

Fb1 = ON or

OFF

Fb18 = ON,

Fb5 = ON or

OFF

Fb18 = ON,

option:

option:

AE1F1

AE3F5

-

-

-

40 EB 5477 EN

Page 41

Control methods and system components

Parameters

Room temperature set point 22 °C 0 to 40 °C

Temperature set point of the slave loop 22 °C 0 to 50 °C

KPTemperature master loop 1.0 0.1 to 99.9

Supply air temperature minimum limit 18 °C 0 °C up to supply air temp. maximum limit

Supply air temperature maximum limit 26 °C Supply air temp. minimum limit up to 50 °C

K

P

T

N

T

V

WE Range of values

0.5 0.1 to 99.9

60 sec 1 to 999 sec

– – – – – – to 999 sec

5.2 Humidity control in air-conditioning systems (Anl 6, 8 and 9)

In humidity control, various control methods are differentiated between: Supply air, exhaust

air/room temperature control, exhaust air cascade control and room cascade control.

5.2.1 Supply air humidity control

The sensor input F6 is the control variable input by default. Alternatively, the analog input

AE2 can be used.

The supply air humidity is controlled by a PID control algorithm with an adjustable

humidity set point

. The humidity control loop can be used for just humidifying or for humidifying and dehumidifying depending on the control method. In humidifying and dehumidifying mode, the cooling coil is controlled in sequence to the humidifier.

The requirements of the humidity control loop for dehumidifying and the temperature control

loop for cooling are converted internally into a common control signal Y3 for the cooling

coil. Each output can be adapted to the dynamics of the corresponding system components

KP, T

and

T

by means of the

N

control parameters that are adjustable.

V

A manual set point correction has an unrestricted effect on the control by the shifting the set

point.

Supply air

Functions

Control method Supply air control (–> page 17)

Sensor F6, supply air humidity

assignment of inputs AE1 to AE4

or

WE Configuration

Fb6 = ON or

OFF

Fb18 = ON,

option:

AE2F6

EB 5477 EN 41

Page 42

Control methods and system components

Parameters

Supply air humidity set point 50 %rH 0 to 100 %rH

K

P

T

N

T

V

WE Range of values

0.5 0.1 to 99.9

60 sec 1 to 999 sec

– – – – – – to 999 sec

5.2.2 Exhaust air/room humidity control

The sensor input F7 is the control variable input by default. Alternatively, the analog input

AE4 can be used.

The exhaust air or room humidity control is implemented as a PID control algorithm with ad

justable

Exhaust air humidity set pointorRoom humidity set point

can be used just for humidifying or for humidifying and dehumidifying depending on the

control method. In humidifying and dehumidifying mode, the cooling coil is controlled in se

quence to the humidifier.

The requirements of the humidity control loop for dehumidifying and the temperature control

loop for cooling are converted internally into a common control signal Y3 for the cooling

coil. Each output can be adapted to the dynamics of the corresponding system components

KP, T

and

T

by means of the

N

control parameters that are adjustable. A manual set point

V

correction has an unrestricted effect on the control by the shifting the set point.

Functions

Control method Exhaust air/room control (–> page 17)

Sensor F7, exhaust air/room control

assignmet of inputs AE1 to AE4

Parameters

Exhaust air humidity set point

room humidity set point

K

P

T

N

T

V

or

or

WE Configuration

OFF

WE Range of values

50 %rH

50 %rH

0.5 0.1 to 99.9

60 sec 1 to 999 sec

– – – – – – to 999 sec

Fb7 = ON or

Fb18 = ON,

0 to 100 %rH

0 to 100 %rH

. The humidity control loop

option:

AE4F7

-

-

5.2.3 Exhaust air or room humidity cascade control

The sensor input F7 is the control variable input for exhaust air or room humidity and the

sensor input F6 is the control variable input for supply air humidity by default. Alternatively,

the analog input AE4 can be used for exhaust air or room humidity or the analog input AE2

for the supply air humidity.

42 EB 5477 EN

Page 43

Control methods and system components

The master loop has a P control response with adjustable

Room humidity set point

by a PID control algorithm with adjustable

and

Kp Humidity master loop

Humidity set point of the slave loop

Exhaust air humidity set point

. The supply air control is implemented

. The humidity

control loop can be used either just for humidifying or for humidifying and dehumidifying by

involving the cooling coil in sequence to the humidifier. The requirements of the humidity

control loop for dehumidifying and the temperature control loop for cooling are converted

internally into one common control signal Y3 for the cooling unit. Each output can be adap

KP,T

ted to the dynamics of the corresponding system components by means of the

and

N

control parameters that are adjustable. The set point of the supply air humidity control loop

is shifted depending on the system deviation in the exhaust air or room humidity control

loop:

Each deviation in humidity by the amount x shifts the supply air humidity set point by the

amount x multiplied by the parameter

and

humidity minimum limit

x = Exhaust air humidity set point – Exhaust air humidity actual value

4

Humidity set point of the slave loop

4

Supply air humidity maximum limit

KPHumidity master loop

calculated

=

within the range

.

Supply air

Humidity set point of the master loop + x · KPTemperature of the master loop

Note!

If the calculated set point is not within the limit, the minimum or maximum limit applies as

the new set point.

Functions

Control method Exhaust air/room cascade control (–> page 17)

Sensor F6, supply air humidity

assignment of inputs AE1 to AE4

Sensor F7, exhaust air or room humidiy

assignment of inputs AE1 to AE4

Parameters

Exhaust air humidity set point

room humidity set point

Humidity set point of the slave loop 50 %rH 0 to 100 %rH

KPHumidity master loop 1.0 0.1 to 99.9

Supply air humidity minimum limit 40 %rH 0 %rF up to supply air humidity maximum limit

Supply air humidity maximum limit 60 %rH Supply air humidity min. limit up to 100 %rH

K

P

T

N

T

V

or

or

WE Configuration

Fb6 = ON oder

OFF

Fb18 = ON,

OFF

Fb7 = ON oder

Fb18 = ON,

0 to 100 %rH

0 to 100 %r

or

WE Range of values

50 %rH

50 %rH

0.5 0.1 to 99.9

60 sec 1 to 999 sec

– – – – – – to 999 sec

option:

option:

AE2F6

AE4F7

or

-

T

V

EB 5477 EN 43

Page 44

Control methods and system components

5.3 Inputs

The assignment of the inputs depends on the system code number and the control method

(–> section 4). Sensors that are required for the selected control methods are always acti

vated. You must determined separately all the other sensors as well as the functions of the bi

nary inputs by configuring them (–>section 2). Alternatively, you can also assign up to four

analog inputs (0 to 10 V) to some of the resistance sensors. The analog inputs are suitable

for active temperature, humidity and air quality sensors.

Functions

Assignment of inputs

AE1 to AE4

WE Configuration

OFF Fb18 = ON

AE_--: Not asssigned AE1F1: Supply air temp. F1

AE3F2: Exhaust air temp. F2 AE2F3: Outdoor temperature F3

AE3F5: Room temperature F5 AE2F6: Supply air humidity F6

AE4F7: Exh. air/room humidity AE4L: Air quality L

MIN: Lower measuring range value

MAX: Upper measuring range value

5.4 Outputs

5.4.1 Heating coil

The heating coil is controlled from the control output Y1. The heating coil control is imple-

and

TV.

mented by a PID control algorithm with the adjustable parameters K

P,TN

ing action of the control output Y1 can be reversed. The default setting of the operating action: heating capacity 0 to 100 % = 0 to 10 V.

An electric air heater can be controlled via the binary output BA5 subject to Y1 (–> sec

tion 6.11.12).

The operat-

-

-

Control signal

Y1

– System deviation +

Fig. 14 · Output signal in Anl. 0

44 EB 5477 EN

Controlled variable

Page 45

Control methods and system components

Functions

Operating action Y1 OFF Fb21

Parameters

KPHeating coil 0.5 0.1 to 99.9

TNHeating coil 60 sec 1 to 999 sec

TVHeating coil – – – – – – to 999 sec

WE Configuration

WE Range of values

5.4.2 Mixed air chamber

Mixed air chamber in sequential operation

The mixed air chamber is controlled from the Y2 output which can be adapted to the dynam

ics of the mixed air chamber by means of the parameters

air chamber

TvMixed air chamber.

The parameter

and

tees an minimum proportion of outdoor air. The operating action of the control output Y2

can be reversed. The default setting is an outdoor air rate of 0 to 100 % which corresponds

to a control signal of 0 to 10 V. By activating Fb22, the operating action is reversed: the outdoor air rate 0 to 100 % then corresponds to 10 to 0 V. On feedforwarding the outdoor

temperature, the summer time operation function is taken into account (–> section 6.10.3).

By additionally feedforwarding the exhaust air temperature, the automatic reversal of the

operating action takes effect.

If the operating action of the control output Y2 is automatically reversed due to changing

temperatures, while the control is in the sequence range Y1 or Y3, the mixed air chamber is

then reversed with a constant changing rate of 15 % per minute. If there is a considerable

difference in temperature between exhaust air and extract air due to the heat given off by

the fan, the extract air temperature can also be selected as the measured variable in place of

the exhaust air temperature.

KpMixed air chamber,TNMixed

Minimum outdoor air rate

guaran-

-

Note:

The proportion of outdoor air can be suppressed during the warm-up phase with Fb43 = ON.

Functions

Sensor F7, mixed air or extract air

temperature

Operating action Y2 OFF Fb22

Circ. air mode after system start-up OFF Fb43 (not with supply air control)

WE Configuration

Fb7 = ON,

Fb7 = OFF,

option:

SEQ (with extract air sensor)

option:

SEQ (without extract air sensor)

EB 5477 EN 45

Page 46

Control methods and system components

Control

signal

Control

signal

Without outdoor air and exhaust air/

extract air temperature feedforwarding

Y1 Y2 Y3

– System deviation +

With outdoor temperature

feedforwarding

Y1 Y2 Y3

– System deviation +

Control variable

Control variable

Outdoor temperature

Control

signal

With outdoor air and exhaust air/extract

air temperature feedforwarding

tA > t Ab

Y2

Y1

Fig. 15 · Various output signals, e.g. in system code number 4

Parameters

WE Range of values

KPMixed air chamber 0.5 0.1 to 99.9

TNMixed air chamber 60 sec 1 to 999 sec

TVMixed air chamber – – – – – – to 999 sec

Minimum outdoor air rate 20 % 0 to 100 %

tA < t Ab

Control variable

Outdoor temperature

Y3

Independent mixed air temperature control

The independent mixed air temperature control is implemented by a PID control algorithm

with adjustable

Mixed air temperature set point.

the mixed air chamber with the parameters

and

TVMixed air chamber

. The parameter

The output Y2 is adapted to the dynamics of

KPMixed air chamber,TNMixed air chamber

Minimum outdoor air rate

guarantees a mini

mum proportion of outdoor air.

The operating action of the control output Y2 can be reversed. The default setting is an out

door air rate of 0 to 100 % which correspond to a control signal of 0 to 10 V. By activating

the function block Fb22, the operating action is reversed: an outdoor air rate 0 to 100 %

corresponds to 10 to 0 V. On feedforwarding the outdoor temperature, the summer time op

eration function is taken into account (–> section 6.10.3). By additionally feedforwarding the

exhaust temperature, the automatic reversal of the operating action takes effect.

46 EB 5477 EN

-

Page 47

Control

signal

Without outdoor and exhaust air temperature

feedforwarding

Y2 Y1

Y3

Control methods and system components

– System deviation

With outdoor temperature feedforwarding

Outdoor temperature

+

Control variable

With outdoor and exhaust air temperature

feedforwarding

Control

Y2

Y1

– System +

deviation

signal

Y3

Control variable

Outdoor temperature

tA > t Ab

Y2

tA < tAb

Y1

– System +

deviation

Y3

Control variable

Fig. 16 · Various output signals, e.g. in system code number 4

Note!

The proportion of outdoor air can be suppressed during the warm-up phase with Fb43 = ON.

Functions

Sensor F7, mixed air or extract air temperature

Operating action Y2 OFF Fb22

Circulating air mode after system start-up OFF Fb43 (not with supply air control)

Parameters

KPMixed air chamber 0.5 0.1 to 99.9

TNMixed air chamber 60 sec 1 to 999 sec

TVMixed air chamber – – – – – – to 999 sec

Minimum outdoor air rate 20 % 0 to 100 %

Mixed air temperature set point 18 °C 10 to 30 °C

WE Configuration

Fb7 = ON,

option:

WE Range of values

mixed air sensor

EB 5477 EN 47

Page 48

Control methods and system components

Outdoor temperature-controlled mixed air chamber

For the outdoor temperature-controlled mixed air chamber, two outdoor temperature basic

values are determined with the parameters

perature is smaller

and

100 % outdoor when the outdoor temperature is greater

in a characteristic curve for controlling the mixed air chamber. The parameter

door air rate

guarantees the required minimum proportion of the outdoor air.

Minimum outdoor air rate when the outdoor tem

which result

Minimum out

The summer time operation (–> section 6.10.3) is always available with this operation mode.

Control signal

Y2 %

Outdoor temperature

Fig. 17 · Outdoor temperature-controlled mixed air chamber

Note:

The proportion of outdoor air can be suppressed during the warm-up phase with Fb43 = ON.

-

-

Functions

Sensor F7, mixed air or extract air temperature

Operating action Y2 OFF Fb22

Circulating air mode after system start-up OFF Fb43 (not with supply air control)

Parameters

Min. outdoor air rate when the outdoor

temperature is smaller

100 % outdoor air when the outdoor temp. is greater 18 °C –10 to 50 °C

Minimum outdoor air rate 20 % 0 to 100 %

WE Configuration

Fb7 = OFF,

WE Range of values

0 °C –10 to 50 °C

option:

AT

5.4.3 Heat recovery unit (HRU)

The heat recovery unit is controlled from the control output Y2. It is implemented by a PID

control algorithm with the parameters

48 EB 5477 EN

KPHRU,TNHRU

and

TVHRU.

Page 49

Control methods and system components

Control

signal

Control variable

Fig. 18 · Output signals, e.g. in system code number 6 (humidifier only)

The operating action of the control output Y2 can be reversed.

The default setting is a heat recovery capacity of 0 to 100 % which corresponds to a control

signal from 0 to 10 V. By activating the function block Fb22, the operating action is re

-

versed: HRU capacity 0 to 100 % then corresponds to 10 to 0 V.

If the measured outdoor temperature and exhaust air temperature are available, the auto-

matic reversal of the operating action for the heat recovery unit can be activated with

Fb41 = ON.

Functions

Operating action Y2 OFF Fb22

Automatic reversal of the operating action OFF Fb41

Parameters

KPHRU 0.5 0.1 to 99.9

TNHRU 60 sec 1 to 999 sec

TVHRU – – – – – – to 999 sec

WE Configuration

WE Range of values

5.4.4 Cooling coil

The cooling coil is controlled from the control output Y3. It is implemented by a PID control

algorithm with the parameters K

Cooling coil,TNCooling coil

P

system code numbers 6, 8 and 9, the demands made by the humidity control loop for hu

midifying or the temperature control loop for cooling are converted internally into one com

mon control signal Y3 for the cooling coil. The operating action of the control output Y3 can

be reversed. The default setting is a cooling capacity of 0 to 100 % which corresponds to a

control signal from 0 to 10 V.

By activating the function block Fb23, the operating action is reversed: the cooling capacity

0 to 100 % then corresponds to 10 to 0 V.

and

TVCooling coil.

In the

-

EB 5477 EN 49

-

Page 50

Control methods and system components

Control

signal

Humidifying

– System deviation +

Fig. 19 · Output signals, e.g. in system code number 6 (humidifying and dehumidifying)

Dehumidifying

Heating

- System deviation +

Cooling

Control

variable

Cooling can also be controlled using an on/off signal which is issued at the binary output

BA4 (–> section 6.11.7). Control of a chiller is likewise possible (–> section 6.11.8).

Functions

Operating actionY3 OFF Fb23

Parameters

KPCooling coil 0.5 0.1 to 99.9

TNCooling coil 60 sec 1 to 999 sec

TVCooling coil – – – – – – to 999 sec

WE Configuration

WE Range of values

5.5 Humidifier

The humidifier is controlled in system code number 6 from the control output Y2 and in system

code numbers 8 and 9 from the analog output AA. The allocation of the control output Y2 to

the humidifier shown in the controller display does not apply to system code numbers 8 and 9!

The humidifier control is implemented by a PID control algorithm with the parameters

,

midifier

TNHumidifier

and

TVHumidifier

.

The operating action of the control output Y2 can be reversed. The default setting is a humid

ifier capacity of 0 to 100 % which corresponds to a control signal of 0 to 10 V. By activating

the function block Fb22, the operating action is reversed: a humidifier capacity 0 to 100 %

then corresponds to 10 to 0 V.

The operating action at the analog output AA cannot be reversed.

Function

Operating action Y2 OFF Fb22

WE Configuration

KPHu

-

-

50 EB 5477 EN

Page 51

Control methods and system components

Parameters

KPHumidifier 0.5 0.1 to 99.9

TNHumidifier 60 sec 1 to 999 sec