Page 1

Automation System TROVIS 5400

Heating and District Heating Controller

TROVIS 5475-2

®

Electronics from SAMSON

Fig. 1 ⋅ TROVIS 5475-2

Edition January 2001

Firmware Version

1.10

Mounting and operating instructions

EB 5475-2 EN

Page 2

Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page

1. General

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Notes for the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Sensor resistance values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Installing the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Installing the sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Electrical connections

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Connecting the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Connecting the sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Terminal wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. Description of the controller functions

. . . . . . . . . . . . . . . . . . . . . . 13

4.1 Optimize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Adaptation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Reduced operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 Summer time operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 Automatic clock reset summer time/winter time . . . . . . . . . . . . . . . . . . 15

4.6 Public holidays and vacations . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.7 Delayed outdoor temperature adaptation . . . . . . . . . . . . . . . . . . . . 15

4.8 Limitation of the return flow temperature . . . . . . . . . . . . . . . . . . . . . 16

4.9 Limitation of the system deviation for OPEN signal . . . . . . . . . . . . . . . . 17

4.10 Forced charging of the drinking water storage tank . . . . . . . . . . . . . . . . 17

4.11 Thermal disinfection of the drinking water storage tank . . . . . . . . . . . . . . 17

4.12 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.13 Defective sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.14 Forced operation of the pumps . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.15 Limitation of flow rate or capacity . . . . . . . . . . . . . . . . . . . . . . . . 19

5. System descriptions and diagrams

5.1 System code number 1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2 System code number 2.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System code number 2 .0 with changeover valve . . . . . . . . . . . . . . . . . 21

System code number 2.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 System code number 3.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4 System code number 4.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

System code number 4 .1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

System code number 4.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5 System code number 5.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.6 System code number 6.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2

. . . . . . . . . . . . . . . . . . . . . . . 20

Page 3

6. Operation

6.1 Operating controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2 Selecting the operating modes . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2.1 Remote controlling the heating system . . . . . . . . . . . . . . . . . . . . . 33

6.3 Control levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.1 Configuration level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.2 Parameter level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.3 Operating level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Increasing/decreasing the room temperature

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . 37

7. Starting up and configuring the controller

7.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1.1 Setting the code number . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1.2 Setting the system code number (Anl) . . . . . . . . . . . . . . . . . . . . . 39

7.1.3 Setting the function blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1.4 Function block list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.4 Sensor calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.2 Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2.1 Resetting to default values . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2.2 Entering and modifying user data . . . . . . . . . . . . . . . . . . . . . . . 48

Entering current time and date . . . . . . . . . . . . . . . . . . . . . . . . . 48

Entering parameters for heating circuit:

Heating characteristics and temperatures . . . . . . . . . . . . . . . . . . . 48

Time schedule for heating . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Public holidays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Vacations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Entering parameters for drinking water circuit:

Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Time schedule for drinking water heating . . . . . . . . . . . . . . . . . . . . 56

Time schedule for circulation pump . . . . . . . . . . . . . . . . . . . . . . 56

7.3 Personal code numbers, locking the mode switch for manual operation and

enabling the write protect function for the configuration level . . . . . . . . . . 57

7.4 Configuring the correction switch . . . . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . 38

8. Data transfer using memory module

9. Configured data

Assembly, start-up and operation of the device may only be performed

by trained and experienced personnel familiar with this product. Proper

!

shipping and appropriate storage are assumed.

The controller is designed for use in power installations. For connection

and maintenance you are required to observe the relevant safety regulations.

. . . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3

Page 4

1. General

The heating and district heating controller is designed for weather-compensated flow temperature control. This means it controls the flow temperature of a heating system based on a heating

characteristic so that the room temperature is always maintained at the desired level regardless

of the outdoor temperature. When used as a district heating controller, the controller can limit

the return flow temperature variably according to the outdoor temperature.

A drinking water heating system may be operated from the primar y heating circuit, using a second control loop, or from the secondary heating circuit.

A differential temperature control featuring a meter tracking the operating hours of the solar

circuit pump is included in three system configurations for the solar heating of drinking water

storage tanks.

The connected sensors allow the controller to measure the respective temperatures which are

transmitted to the central signal processing system. Subsequently, this system issues a three-step

or on/off control signal corresponding to the preset set points for each of the two control loops.

In addition, the controller controls the heating circulation pump and the pumps for drinking

water heating. The signal from a heat meter that is proportional to the flow rate or capacity can

be connected to a pulse or current input. This enables the limitation of a maximum and/or minimum flow rate or capacity.

These mounting and operating instructions are valid for:

Firmware version 1.0 upwards

(The firmware version installed appears for 2 seconds in the display when the controller is

switched on)

Whats new compared to the previous version?

The circulation pump ZP runs on a time schedule in all systems.

1.1 Notes for the user

The installation of the controller and its electrical connection described in the following and,

must be carried out by authorized personnel only.

The settings for configurations described in chapter 7.1 also require specialized knowledge of

heating systems and should only be performed by an expert. This also applies for the description of the controller functions and system configurations described in chapter 4 and 5.

The start-up of the controller is normally carried out by authorized personnel all configuration

data should be entered into the configured data tables in chapter 9.

The controller is programmed with default temperature values and time schedules that can be

changed on start-up or by the user at a later date over the menu described in chapter 7.2.2.

The settings for the end user

and non-expert should be restricted to changing the heatings flow

temperature to increase or decrease room temperatures (chapter 6.3.3 on page 37) and

changing the set times-of-use (chapter 7.2.2 on page 51).

The current time and date are saved in memory for at least 24 hours when the controller is

left unconnected to the power supply. Other configuration data are stored in memory indefinitely and cannot be lost.

4

Page 5

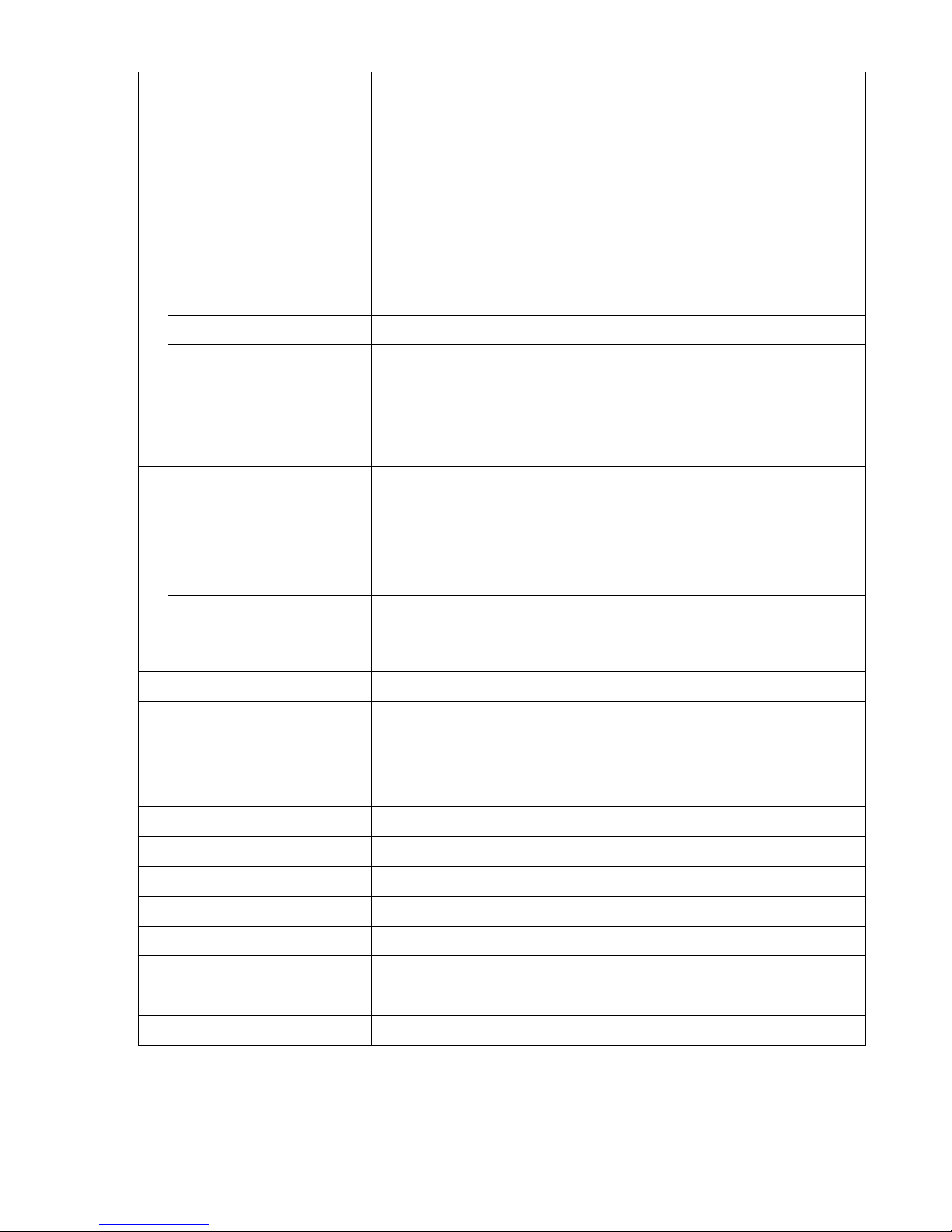

1.1 Technical data

Inputs

Sensor inputs Max. 7 PTC and Pt 100 or NTC and Pt 100, or Pt 1000 and Pt

100 sensors

2-wire circuit

(heating circuit/drinking water circuit)

2 flow temperature sensors, alternatively 1 solar collector sensor

1 room temperature sensor

1 outdoor temperature sensor

1)

1 return flow temperature sensor ( 2 in system code no. 4)

2 storage tank temperature sensors

Binary inputs Storage tank thermostat

Additional inputs Current input 4(0)...20 mA for flow rate limitation or pulse

counting input for limitation of capacity or flow rate

Current input 4(0)...20 mA for outdoor temperature

Remote control option for correcting flow temperature and

selecting the operating mode

Outputs

Control signal y Three-step signals: max. load 250 V AC, 2 A;

min. 10 mA, varistor suppression 300 V

On/off signal: max. load 250 V AC, 2 A;

min. 10 mA, varistor suppression 300 V

Binary outputs Max. 4 outputs for pump control

Load: max. 250 V AC, 2 A min. 10 mA, varistor

suppression 300 V

Control parameters K

= 0.1...50; Tn = 1...999 s; valve transit time Ty = 15...240 s

p

Operating voltage 230 V AC (+10 %/15 %), 48 to 62 Hz,

Power failure: All parameter and configuration data are saved

in an EEPROM.

Power consumption Approx. 1.5 VA

Temperature range Operation: 0...40 Storage: 20 to 60 °C

1)

Degree and class of protection IP 40 according to IEC 529 and II according to VDE 0106

Degree of contamination 2 according to VDE 0110

Overvoltage category II according to VDE 0110

Humidity rating F according to VDE 40040

Noise immunity Corresponding to EN 50082 Part 1

Noise emission Corresponding to EN 50081 Part 1

Weight approx. 0.5 kg

1)

On using Pt100 or Pt100 resistance thermometers, permissible temperature

range down to −65 °C, however, display only indicates down to −40 °C

5

Page 6

CAUTION

Safety features such as frost protection monitoring and excess temperature protection are not

active in the following cases:

Defective heating controller and failure of its functions

•

Sensors are faulty, not connected or have not been deactivated

•

No power supply to the controller

•

Mode switch set to manual operation

•

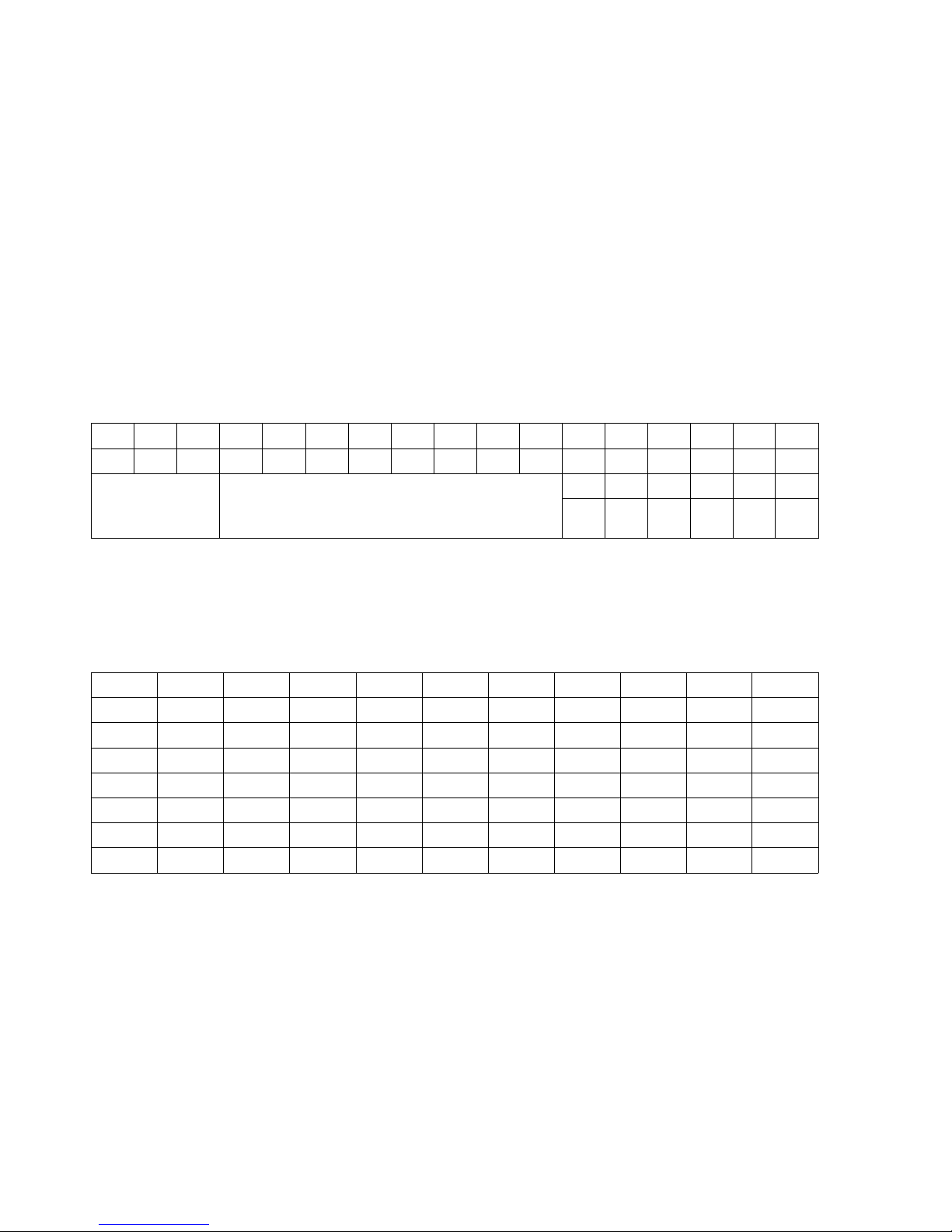

1.2 Sensor resistance values

Resistance thermometer with PTC measuring element

Sensors for outdoor temperature Type 5224, for flow and return flow temperature Types 5264

and 5265, for storage tank temperature Type 5264, sensor for room temperature with remote

control Type 5244

°C 20 10 0 +10 +20 +25 +30 +40 +50 +60 +70 +80 +90 +100 +110 +120

Ohm 694 757 825 896 971 1010 1050 1132 1219 1309 1402 1500 1601 1706 1815 1925

Room temperature

sensor with remote

control Type 5244

Switch position "clock", terminals 1 and 2 °C +10 +15 +20 +25 +30

Ohm 679 699 720 741 762

Resistance thermometer with Pt 100 measuring element

Sensors for outdoor temperature Type 5225, for flow and return flow temperature Types 5204

and 5205-47, for storage tank temperature Types 5205-46 and 5205-48, sensor for room temperature Type 5255

°C -35 -30 -25 -20 -15 -10 -5 0 5 10

Ohm 86.25 88.22 90.19 92.16 94.12 96.09 98.04 100.00 101.95 103.90

°C15202530354045505560

Ohm 105.85 107.79 109.73 111.67 113.61 115.54 117.47 119.40 121.32 123.24

°C 65 70 75 80 85 90 95 100 105 110

Ohm 125.16 127.07 128.98 130.89 132.80 134.70 136.60 138.50 140.39 142.29

°C 115 120 125 130 135 140 145 150

Ohm 144.17 146.06 147.94 149.82 151.70 153.58 155.45 157.31

Resistance values with Pt1000 measuring element

Use the resistance values in the table for the Pt100 and multiply the values by the factor of 10.

Sensor for outdoor temperature Type 5227, for flow and return flow temperature Types 5207-

21, 5207-27, 5277 (thermowells required) and Type 5267 (surface sensor),

for storage tank temperature Type 5207-46 and Type 5207-48,

sensor for room temperature Type 5257-1,

room temperature sensor with remote control Type 5257-4.

6

Page 7

2. Installation

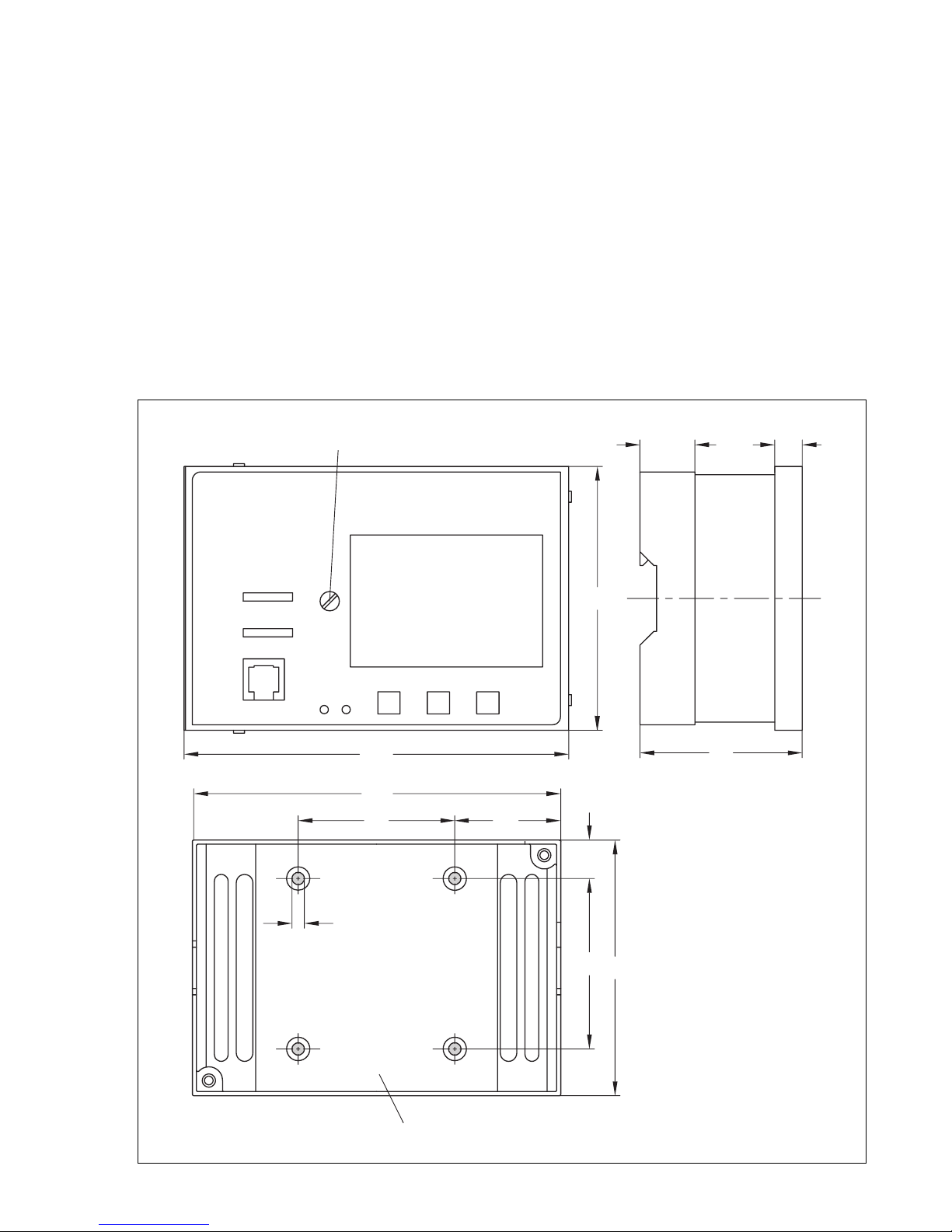

2.1 Installing the controller

The controller is made up of the controller casing which contains the electronics components

and the rear casing section with the terminal blocks. To connect the controller, remove the screws

on the front panel and separate the controller housing from the rear casing.

For wall mounting, use four screws to mount the rear casing to a wall. The distances between the

holes are shown in Fig. 2.

For top hat rail mounting, mount the controller onto the top hat rail using the spring-mounted

hook on the rear casing.

For panel mounting, push the controller casing through the panel cut-out (92 x 138 mm) and insert the fastening clips (delivered with the controller) into the notches at the top and bottom of

the casing. Then turn the threaded bolts in the direction of the control panel so that the casing is

pressed with its front frame against the control panel.

Fixing screw on controller section

30 10

98

144 59

138

57 41

15

Ø 4.5

62

93

Panel cut-out

92 x 138 mm

Fig. 2 ⋅ Dimensional diagram

Fastening section on controller rear casing

7

Page 8

2.2 Installing the sensors

2.2.1 Outdoor sensor

Use two screws to mount the outdoor sensor to the outside wall at an appropriate place. Make

sure that the sensor is mounted away from direct heat sources (windows, vents etc.). In case of

single family dwellings, preferably mount the sensor on the wall at the side of the house where

the most frequently occupied rooms are situated.

2.2.2 Flow/return flow sensor

Mount the sensor as duct sensor or surface sensor in an easily accessible location near the control valve:

Duct sensor:

Surface sensor:

polish the pipe clean. Firmly press the sensor onto the pipe and secure it to the pipe using the enclosed tightening strap.

2.2.3 Room sensor

Mount the sensor on the wall approx. 150 cm above the floor at an appropriate place. Make

sure that the air circulation is not obstructed by cupboards, curtains or similar items.

3. Electrical connections

3.1 General

!

Use separate cables for 230 V supply line and the signal lines!

•

Also use separate cables for the digital signal lines (bus lines) and the analog signal lines

•

(sensor lines).

Insert the duct sensor into a thermowell as far as it will go.

Remove insulation from the flow pipe where the sensor is to be mounted and

CAUTION!

For wiring and connection of the controller, you are required to observe the VDE

regulations and the regulations of the local power supply company. For this reason,

this type of work must be carri ed out b y a spec ia list.

In systems with a high electromagnetic noise level, we recommend that shielded cables be

•

used for the analog signal lines.

Ground the shield at the inlet or outlet of the control cabinet, using the largest possible cross

section and via the shortest possible route.

The central grounding point must be connected to the grounding conductor using a min.

10 mm

As a rule, the shield needs only be grounded on one side at the control cabinet inlet, except

when an equipotential bonding exists that has much lower resistance than the shield resistance.

To increase the noise immunity, make sure that there is a minimum distance of 10 cm be-

•

tween the power cables and signal lines. We recommend that this distance between these

lines is also kept in the control cabinet!

Inductances in the control cabinet, e.g. contactor coils, must be equipped with suitable inter-

•

ference suppressors (RC elements)!

Control cabinet elements with a high field strength, e.g. transformers or frequency converters, should be shielded by means of separators that have good chassis ground.

8

2

cable.

Page 9

Surge protection

The following measures must be taken if lines are installed outside of the building or over long

distances:

The shield of signal lines routed outside of buildings must have current carrying capacity

•

and must be grounded on both sides.

Surge diverters must be installed at the control cabinet inlet.

•

3.2 Connecting the controller

Connect the controller on the basis of the relevant terminal diagrams of the associated system

code numbers (Fig. 3 to 10).

The power supply section of the controller terminals 14 to 26 must be connected using wires

with a cross-section of 1.5 mm

2

at the minimum.

Knock out the holes marked on the rear casing for the cable entries and insert the enclosed selfsealed grommets or suitable glands.

3.3 Connecting the sensors

Connect the cables with a cross-section of min. 0.5 mm

2

to the terminal strip terminals 1

to 13 on the rear casing. See chapter 7.1.4 for Pt100 (Pt1000/PTC) on sensor calibration.

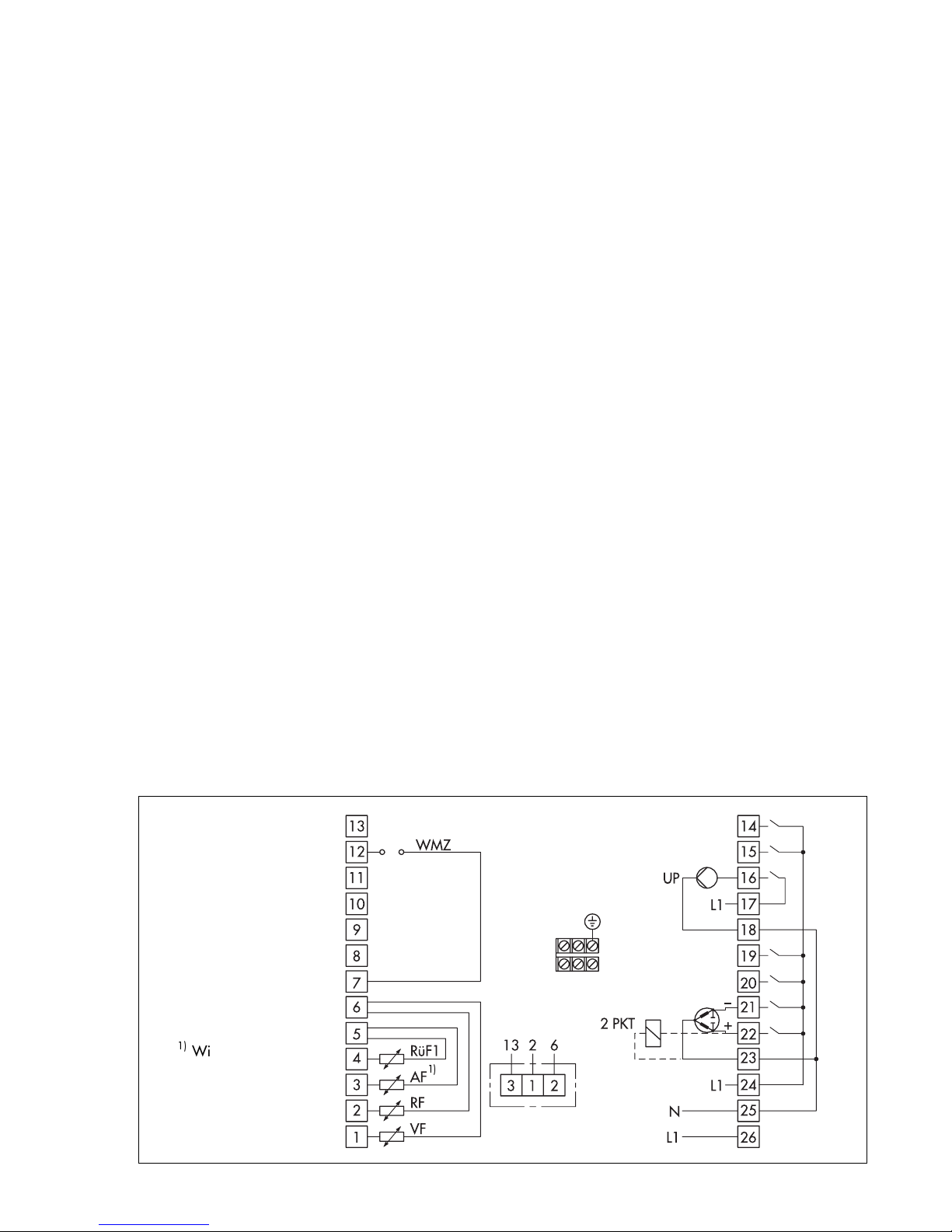

3.4 Terminal wiring diagrams

Legend for circuit diagrams:

AF Outdoor sensor SLP Storage tank charging pump

RF Room sensor UP Circulation pump of heating circuit

RÜF Return flow sensor ZP Circulation pump of drinking water circuit

SF Storage tank sensor WMZ Heat meter

VF Flow sensor Solar circuit:

TW Drinking water circuit CF Solar circuit collector sensor

HK Heating circuit CP Solar circuit pump

2 PKT On/off

With 0 …20 mA

50 Ω connect in parallel

Fig. 3

System code no. 1

Option Type 5244

Type 5257-4

9

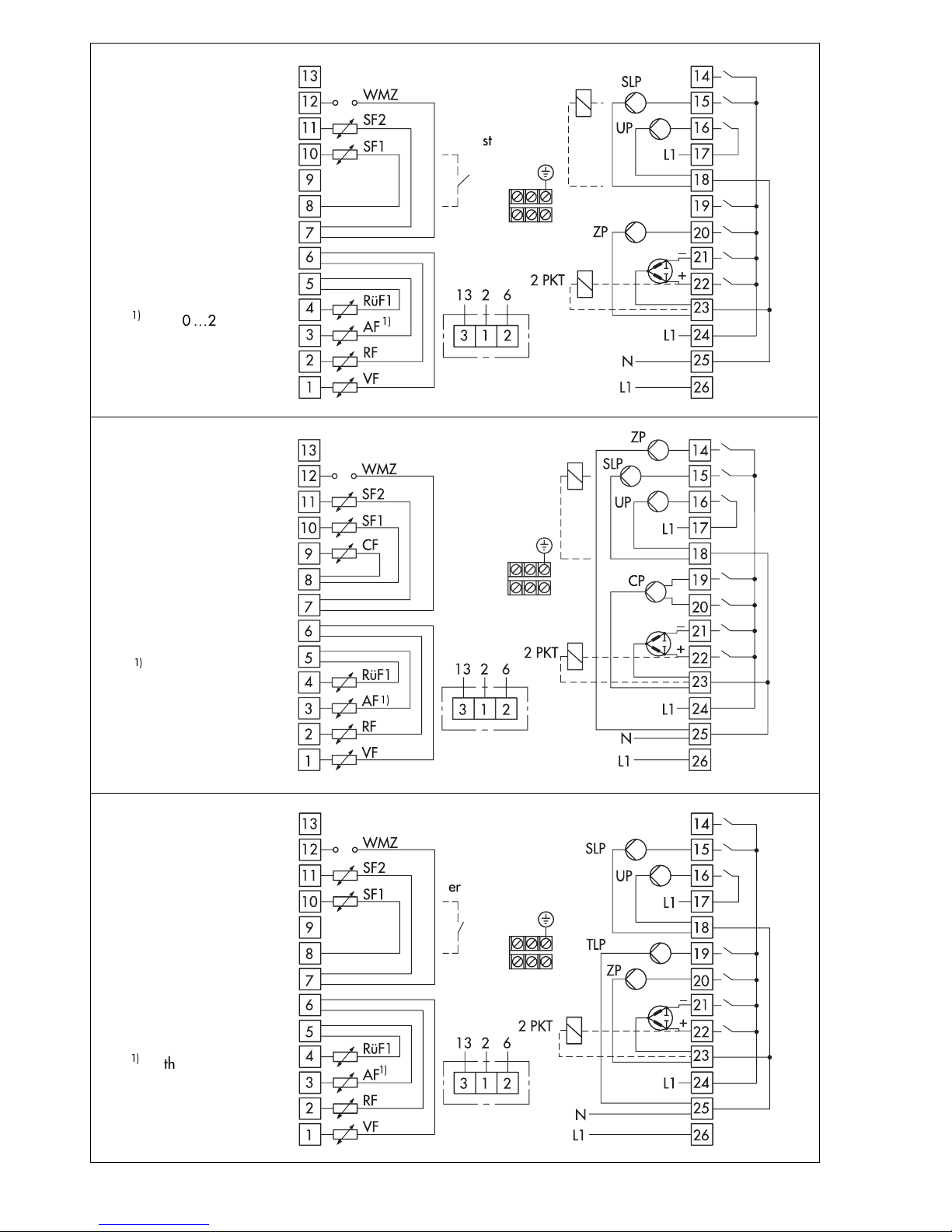

Page 10

Thermostat

Changeover

valve

With 0 …20 mA

50 Ω connect in parallel

Fig. 4

System code no. 2.0

With 0 …20 mA

50 Ω connect in parallel

Fig. 5

System code no. 2.1

Option Type 5244

Type 5257-4

Stage1

Stage 2

Option Type 5244

Type 5257-4

Wit h 0 …20 mA

50 Ω connect in parallel

Fig. 6

System code no. 3.0

10

Thermostat

Option Type 5244

Type 5257-4

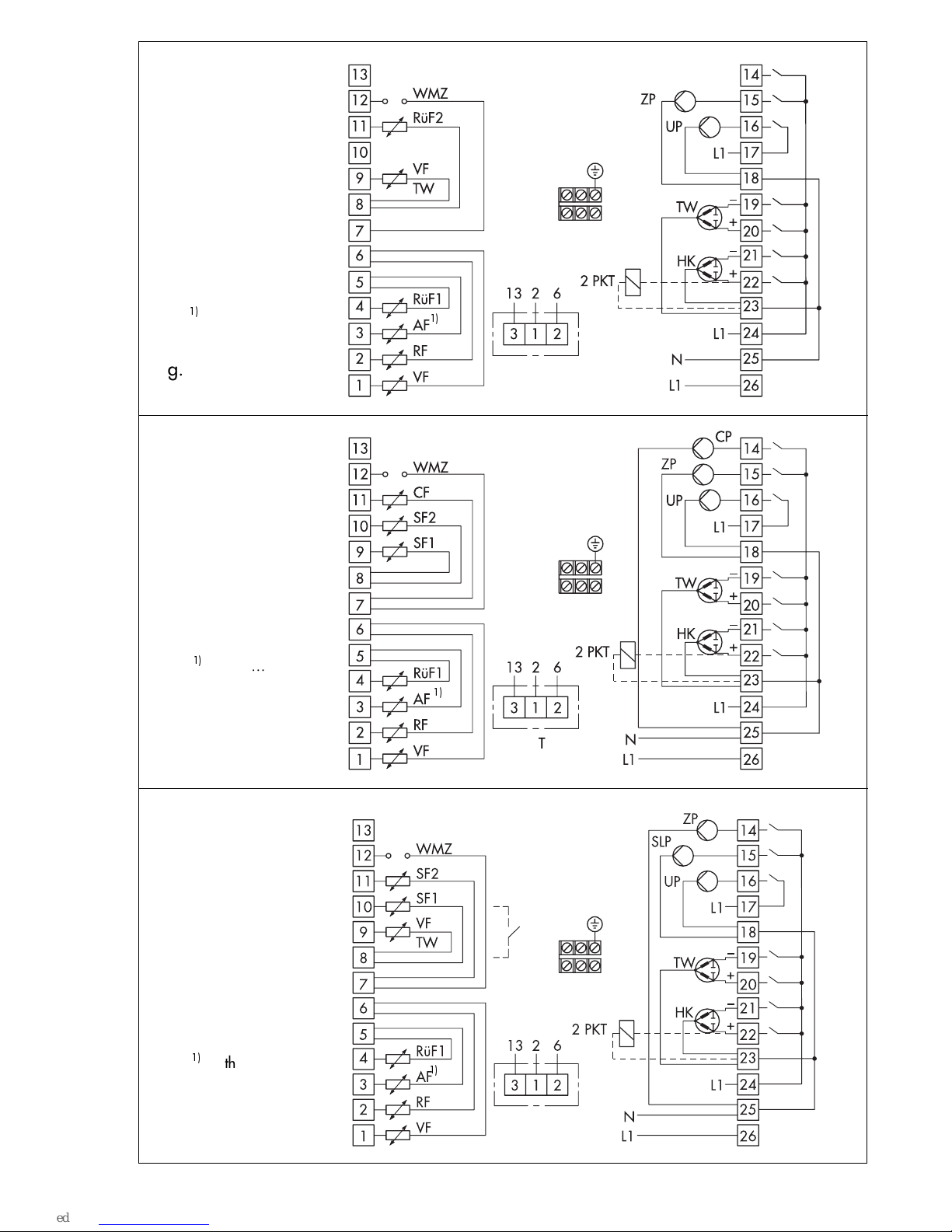

Page 11

Wit h 0 …20 mA

50 Ω connect in parallel

Fig. 7

System code no. 4.0

Wit h 0 …20 mA

50 Ω connect in parallel

Fig. 8

System code nos. 4.1,

4.2

Option Type 5244

Type 5257-4

Option Type 5244

Type 5257-4

Wit h 0 …20 mA

50 Ω connect in parallel

Fig. 9

System code no. 5.0

Thermostat

Option Type 5244

Type 5257-4

11

Page 12

* Fast-reacting

sensor/actuator

With 0 …20 mA

50 Ω connect in parallel

Fig. 10

System code no. 6.0

Option Type 5244

Type 5257-4

12

Page 13

4. Description of the controller functions

The following function descriptions are intended to help you understand the settings required for

operation.

The controller functions depend on the selected system code numbers (1 to 6). See chapter 5 for

details.

4.1 Optimize

The controller is capable of automatically determining the most favorable times for activation/deactivation of the heating system in periodically occupied buildings. To activate this function, select function block setting FB 0 = ON (linked to FB 13 = ON).

In contrast to the reduced operation, the heating system is deactivated at the latest when the

time of non-use starts. A reference room with an installed room temperature sensor is monitored in place of the entire building. Whenever the room temperature falls below an adjustable

Sustained temperature, the controller activates the heating until the temperature exceeds the

sustained temperature (plus approx. 0.5°C differential gap) again. To achieve this, the system

can be run at the maximum permissible flow temperature.

The controller determines when the heating should be activated to start rated operation of the

system so that the Room temperature set point (temperature adjustable at the controller) is just

reached when the set time-of-use begins. The heating may be activated up to 6 hours before the

set time-of-use begins (this is the case on start-up as the controller has not yet stored any information concerning the building characteristics).

Drinking water is not heated in system code numbers 2 and 3 during the preheating time. The

controller determines when the heating is to be deactivated so that the temperature does not fall

significantly below the desired room temperature towards the end of time-of-use due to the

heating being deactivated before the time-of-use ends (e.g. direct sunlight can cause an increase in room temperature, especially if the flash adaptation is not used, and this in turn leads

to the system being deactivated too soon). The heating may be deactivated up to 2 hours before

the set time-of-use ends.

If 2 rated operation times are set for one day, the controller does not monitor the Sustained temperature, but a Reduced room temperature set point (the temperature adjustable at the controller) between both time blocks.

4.2 Adaptation

The controller is capable of automatically adapting the heating characteristic to the building

characteristics. Based on the default heating characteristic (gradient value 1.8), a reference

room with an installed room temperature sensor is monitored in place of the entire building. If

the measured room temperature deviates from the adjustable Room temperature set point on

the average during the time-of-use when the mode switch is set to , the subsequent rated

operation time is based on the altered heating characteristic gradient, provided the function

block setting is set to FB 1 = ON. The corrected value is displayed in the parameter level as

Gradient of the heating; this parameter cannot be accessed to change it manually when the

adaptation mode (FB = 1) is selected.

Immediate responses to deviations in room temperature can be achieved using the function

block setting FB 2 = ON: the flash adaptation compensates for deviations in room temperature

during time-of-use when the mode switch is set to , by lowering or raising the heating characteristic by up to 30 °C (parallel displacement of the heating characteristic). Combined with

adaptation mode (FB 1 = ON), a maximum displacement of 5 °C is designated.

13

Page 14

The displacement is displayed as Level of the heating characteristic; this parameter cannot be

accessed to adjust it manually when the flash adaptation mode (FB 2 = ON) is selected.

The options on the controller and remote control to correct the set point apply to the room temperature set point in adaptation/flash adaptation mode.

4.3 Reduced operation

In reduced operation, the heating circuit generally operates on a flow temperature set point

value defined by the heating characteristic and reduced by the value set under Set-back of flow

temperature for reduced operation. If, however, during times of non-use, the outdoor temperature exceeds the value entered as the Outdoor temperature limit value for deactivation in reduced operation, the controller automatically deactivates the heating system by closing the

control valve, and the heating circulation pump UP is deactivated after the set lag time has

elapsed. If the outdoor temperature falls below the limit value (approx. 0.5 °C differential

gap), the heating system immediately starts operating again.

If the outdoor temperature falls below the Outdoor temperature limit value for reactivation of

rated operation in reduced operation during times of non-use, the value set under Set-back of

flow temperature for reduced operation is ignored: the flow set point for rated operation is

used.

4.4 Summer time operation

In summer time operation, the controller automatically deactivates the heating system, by closing the control valve and the heating circulation pump UP is switched off after the set lag time

has elapsed.

The outdoor temperature is the decisive factor for the start of summer time operation. If it exceeds the parameter Outdoor temperature limit value for summer time operation (default setting: 22 °C; setting range: 0...50 °C), summer time operation is directly activated.

When this limit value (approx. 0.5 °C differential gap) is not reached, the heating immediately

starts operating again.

The Time-controlled summer time operation function is linked to the setting the function block

FB 3 = ON and only activated when the mode switch is set to .

The decisive factors for time-controlled summer time operation to become active are:

The current date. If it lies within the effective time period of summer time operation

(settings in the configuration level linked to the function block setting FB 3 = ON. Default:

01.06. to 30.09.)

The daytime mean temperature (measured between 7:00 and 22:00 hrs) exceeds the out-

door temperature limit value on the corresponding number of subsequent days

(settings in the configuration level linked to the function block setting FB 3 = ON. Default:

outdoor temperature limit value 18 °C setting range 0 to 30 °C and 2 days to activate

the time-controlled summer time operation setting range 1...3)

14

Page 15

If the time-controlled summer time operation is active, heating operation will not start even at

lower outdoor temperatures when the t ime- of-u se st ar ts.

The time-controlled summer time operation is only deactivated when the daytime mean temperature falls below the outdoor temperature limit value on the corresponding number of subsequent days.

(Setting in the configuration level linked to the function block setting FB 3 = ON. Default: 1 day

to deactivate the time-controlled summer time operation setting range 1...3)

If the heating system is also deactivated due to the parameters Outdoor temperature limit value

for summer time operation and the Time-controlled summer time operation, the heating is not

reactivated when the temperature falls by approx. 0.5 °C below the values in the above mentioned parameters.

Info display about the time-controlled summer time operation.

If the display of the outdoor temperature is selected (function block FB 3 = ON) in the operating

level when the summer time operation is activated and the key is held down, the daytime

mean temperature is displayed.

The bars at the top of the display show the temperature curve over the past 8 days. The black

areas show where the temperature exceeded the limit value and the empty areas where the temperature fell below the limit value. A black area marked 1, for example, means that the outdoor

temperature limit was exceeded on average on the previous day.

4.5 Automatic clock reset summer time/winter time

When you set the function block FB 5 = ON, the controller automatically resets the clock on the

last Sunday in March from 2:00 to 3:00 hrs and on the last Sunday in October from 3:00 to

2:00 hrs.

4.6 Public holidays and vacations

The controller lets you define 20 public holidays and 10 vacation periods (parameter level).

There is no default setting for public holidays.

On public holidays, the heating system operates based on the data entered for Sundays (heating time schedule); during vacations, the heating runs in reduced or standby operation.

The drinking water heating is not affected by public holidays and vacations when the controller

operates using default settings. When you activate the function block FB 6 = ON, the drinking

water heating will then operate on public holidays using the same time schedule entered for

Sundays (time schedule for drinking water heating). Subsequently, the drinking water heating is

then not active during vacations (frost protection monitoring from +5 °C downwards).

4.7 Delayed outdoor temperature adaptation

This function is used to determine the flow temperature set point using a calculated outdoor temperature which is delayed either:

a) only when the outdoor temperature decreases, or

b) regardless of the outdoor temperature.

For instance, if the outdoor temperature varies by 12 °C within a very short time , the Calcu-

lated outdoor temperature is adapted to the outdoor temperature in small steps over a time

period of 4 hours with a delay setting of 3 °C/hr. This function helps to prevent heating system

overloads in combination with overheated buildings, or temporarily insufficient heating due to

short-term outdoor temperature variations, e.g. caused by warm winds or excessive solar radi-

15

Page 16

ation on the outdoor temperature sensors.

An active delayed outdoor temperature adaptation is signalized in the operating level by a

blinking outdoor temperature in the display. When you keep key pressed down, the Calculated outdoor temperature is shown in the display.

If the function Time-controlled summer time operation (FB 3 = ON) is activated, the calculated

outdoor temperature is not indicated in the display.

4.8 Limitation of the return flow temperature

For an economical operation of a district heating system, it is required that as much heat as

possible be extracted from the heat transfer medium (water) circulating through the system. The

difference in temperature between the flow and return flow in the network is used to indicate

how much energy is being consumed: a large difference in temperature indicates a high level of

energy efficiency and a small difference indicates a low level of energy efficiency. One return

flow temperature sensor is sufficient to evaluate the difference in temperature when the flow

temperature in the network is predetermined.

The function is as follows: the return flow temperature can either be limited depending on the

outdoor temperature (variable) or by a fixed value. If the return flow temperature measured at

the return flow sensor RüF1 exceeds the limit value calculated from the set return flow characteristic or the fixed limitation value by the value x, the respective calculated or fixed set point

(flow temperature of heating, charging temperature) is reduced by the value x, multiplied by return flow temperature limitation factor. As a result, the primary flow rate is reduced with the effect that the return flow temperature drops. Both the measured value of the Return flow temperature and the set point (flow temperature of heating, charging temperature) blink in the display when a limitation case occurs. The function is already activated by the function block setting FB 20 = ON.

In system code numbers 2 and 3 (drinking water heating implemented in the secondary circuit),

the controller switches during the heating up of drinking water over to the parameter Return

flow limitation temperature during drinking water heating from the return flow temperature

limitation value (calculated from the return flow temperature limitation characteristic). This ensures that the return flow limitation temperature in the heating circuit can be held low in the seasonal interim period.

In system code number 4, a separate return flow temperature limitation in the drinking water

circuit is additionally possible, provided FB 21 = ON.

System code number 5 allows you to include the return flow temperature of the drinking water

circuit. For this purpose, the return flow temperature sensor must be mounted in a return flow

pipe used in both circuits, and the function block FB 21 must be activated (ON). When FB 21 is

activated (ON), the parameter Return flow limitation temperature during drinking water heating (the temperature is adjustable at the controller) is activated. When drinking water is being

heated, the highest value from both return flow temperature limitation values (heating circuit

and drinking water circuit) is used for the limitation control. When a limitation occurs, both the

set point in the heating circuit and the set point in the drinking water circuit are reduced. If the

priority for drinking water through set-back operation is additionally activated (FB 8 = ON, setting "Ab"), the reduced heating circuit set point is also further reduced when a limitation occurs!

In system code number 6, a return flow temperature limitation is only possible in the heating circuit.

16

Page 17

4.9 Limitation of the system deviation for OPEN signal

When using the controller for steam pressure control, we recommend that you activate this function. It limits the controllers reaction to set point deviations which cause the control valve to

open. This makes it much easier to start up such systems without complications. The controllers

response to set point deviations which cause the control valve to close are not affected by this

function.

In the system code numbers 1, 2 and 3, the function must be activated via FB 11 = ON.

In the system code numbers 4, 5 and 6 set

FB 11 = ON to activate the function linked to the heating circuit, and

FB 12 = ON to activate the function linked to the drinking water circuit.

4.10 Forced charging of drinking water storage tank

Systems 2, 3 and 5 are equipped with this function as standard, provided that a storage tank

sensor (not a storage tank thermostat) is used.

To guarantee sufficient charging of the drinking water storage tank at the time when the rated

operation of the heating circuit begins (or when the preheating period in the optimize mode

begins), forced charging commences one hour before the time-of-use set of the heating circuit

begins (or one hour before the preheating period in the optimize mode), provided that the timeof-use of the drinking water circuit does not end as the time-of-use the heating circuit starts.

The drinking water heating finishes as usual when the temperature Drinking water heating

OFF is reached.

4.11 Thermal disinfection of the drinking water storage tank

This function cannot be used in conjunction with a storage tank thermostat.

The thermal disinfection is first activated by the function block setting FB 7 = ON. You can select

whether the thermal disinfection should run on a certain day of the week or daily.

Drinking water heating is started on the days concerned at the start time set to heat up the water

to disinfect it. The thermal disinfection finishes at the stop time set at the latest.

(Settings in the configuration level, linked to function block setting FB 7 = ON. Default: week

day 3 Wednesday; start time 0:00 hrs, stop time 4:00 hrs, these times can be changed in 30

min. steps; deactivating temperature 70 °C, setting range 60 to 90 °C).

Systems 2, 3 and 5 function with a 5 °C higher deactivating temperature for charging the storage tank. In System 4, the drinking water set point corresponds to the deactivating temperature

+5 °C; however, thermal disinfection also finishes when the deactivating temperature in the storage tank is reached.

If the required temperature in the storage tank is not reached before the stop time, the thermal

disinfection procedure is interrupted. However, the return flow temperature in the drinking

water circuit is not limited by it.

A parallel pump operation selected using the parameter FB 9 = ON is not carried out during

thermal disinfection. The procedure of thermal disinfection is also not interrupted by an intermediate heating operation (systems 2 and 3). The circulation pump remains in operation contrary to the default drinking water heating in systems 2 and 4 during the thermal disinfection !

4.12 Frost protection

Generally, the heating circuit circulation pump UP is activated when the outdoor temperature

falls below +3 °C. A flow temperature set point of 10 °C is used for control.

17

Page 18

The drinking water circuit circulation pump ZP is likewise activated, provided that storage tank

charging is not taking place. Outside of rated operation times for drinking water heating, the

temperature of the drinking water storage tanks is additionally kept at 5 °C, provided that a

storage tank thermostat is not used. In conjunction with a storage tank thermostat, there is no

frost protection outside of rated operation times for drinking water heating.

There is no frost protection when mode switch is set to manual!

Note:

4.13 Defective sensors

symbol appears in the display

The following described controller behavior in the event of a defect refers to a definite short-circuit and clear interruption in the sensor wiring.

Safety functions such as frost protection and excess temperature protection are therefore guaranteed when a sensor fails.

Outdoor temperature sensor AF:

If the outdoor sensor is defect, the controller either regulates a flow temperature set point of 50

°C or the maximum flow temperature, provided it is smaller than 50 °C.

Flow temperature sensor VF:

If this flow sensor fails, the controller continues to operate in the

last position the valve assumed.

Flow temperature sensor for drinking water circuit VF TW, (SF1 in systems 4.1, 4.2):

If this

sensor fails, the drinking water circuit is deactivated; the control valve of the drinking water circuit remains closed.

Return flow temperature sensor RüF:

If the return flow sensor fails, the control system functions

without return flow temperature limitation.

Room temperature sensor RF:

If this sensor fails, the controller functions according to the settings for operation without room sensor, i.e. it switches from the optimize mode to reduced

operation. If the adaptation mode has been activated, the heating characteristic most recently

determined remains unchanged.

Storage tank temperature sensor SF1 and SF 2:

If one of the two sensors fails, storage tank

charging is not carried out anymore.

Sol ar cir cuit sensor SF2 and CF:

If one of the two sensors fails, the solar circuit pump is switched

off.

4.14 Forced operation of the pumps

If the pumps are not used, they are protected from blocking by forced operation. If the heating

circuit circulation pump UP, the storage tank charging pump SLP or the heat exchanger charging pump are not activated within 24 hours, they are force-operated for one minute as follows:

The circulation pump then starts at 12:00 hrs, storage tank charging pump and the heat exchanger charging pumps start at 12:01 hrs.

18

Page 19

4.15 Limitation of flow rate or capacity

The TROVIS 5475-2 Heating and District Heating Controller can be used in conjunction with

heat meters to limit the flow rate or capacity.

To be able to limit the flow rate based on a 0 or 4-20 mA signal issued by heat meters, the heat

meters must be equipped with high-resolution measuring technology, especially the flow

measuring element, and the signal must reflect the measured value with a delay time of less than

5 seconds, if necessary, caused by signal averaging.

You can activate/deactivate function block FB 22 = ON and FB 23 = ON to determine the signal

range (0 or 4 to 20 mA), the upper measuring range value (the flow rate flowing through the

flow measuring element at 20 mA signal), the required minimum limit value (creep feed rate)

and the maximum limit value.

When the flow rate in control operation reaches the set maximum limit value, the controller switches to flow rate control with the maximum limit value as the set point; the flow temperature control then takes over from the flow rate control when the temperature at the flow sensor VF exceeds the current set point by 5 K. In system code numbers 4 to 6, the heating circuit valve is

preferably controlled via flow rate.

When the flow rate in control operation falls below the set minimum limit value, the control valve

of the heating circuit is temporarily closed. The control operation is first started again when the

temperature at the flow sensor VF falls below the current set point by 5 K.

Alternatively, the flow rate or capacity can also be limited based on a pulse signal 3 to 500

pulse/hour from the heat meter.

The function block settings FB 22 = OFF and FB 23 = ON determine the maximum pulse rate to

be limited for the mere heating operation and for drinking water heating as well as the associated influencing factors.

Since the readout of the current pulse rate which also includes the flow rate registered in the

controller or the capacity registered in the controller is calculated as a function of the distance

in time between the incoming pulses, it is natural that sudden surges in flow rate or capacity

cannot be directly registered by the controller. This applies particularly to low pulse rates!

If the pulse rate P in control operation reaches the set maximum limit, the set point of the corresponding control loop is reduced. The severity of the intervention can be determined by changing the associated influencing factor.

In system code numbers 4 to 6, the set point of the control loop with a lower limit value is reduced in principle by the pulse rate limitation.

Determining P [pulse/hr]:

For example, if a heat meter issues one pulse per kilowatt hour (resolution = 1 kWh/pulse), the

maximum pulse rate P [pulse/hr] must be set as described below for a desired limitation to

P = 30 kW:

P [pulse/hr] = P [kW] / resolution [kWh/pulse]

P [pulse/hr] = 30 kW / 1 kWh/pulse = 30 pulse/hr

19

Page 20

5. System descriptions and diagrams

Introduction

The system diagrams show possible connections for safety equipment as an example. These

examples are represented by dot-dash lines.

Should a temperature regulator (TR) or safety temperature monitor (STM) or additionally a

pressure limiter (PL) be required, you must use a control valve with fail-safe action that complies

with DIN 32730.

The heating circuit must be equipped with a TR/STM combination if it is stipulated in DIN 4747

Part 1.

A Pressure Limiter (PL) must be installed if DIN 4751requires it.

You are required to install a TR/STL combination in a primary drinking water heating circuit, if

required by DIN 4753.

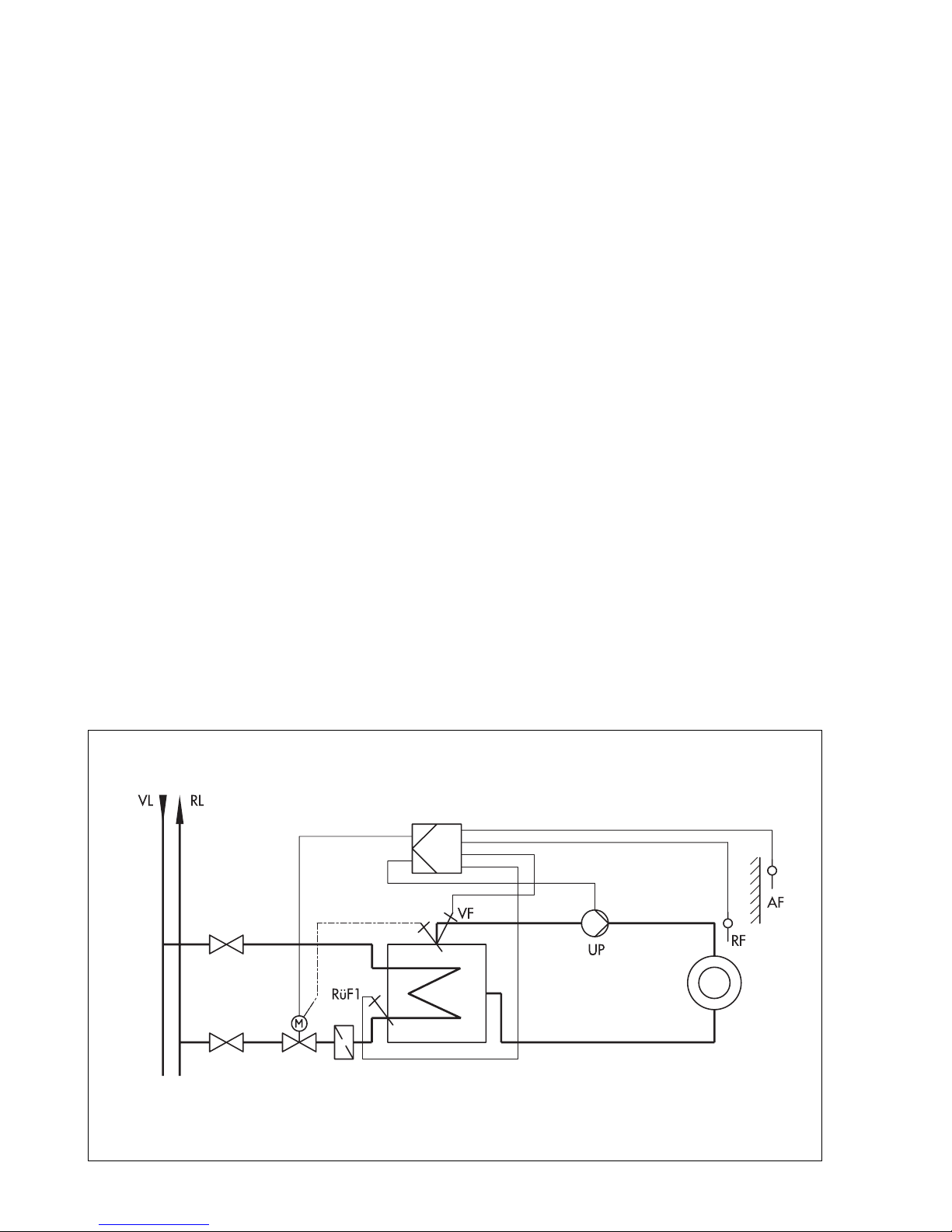

5.1 System code number 1.0

, only heating

Weather-compensated flow temperature control with variable limitation of the return flow temperature

Fig. 11 ⋅

(system code number 1.0)

Anl 1

20

Page 21

5.2 System code number 2.0

Weather-compensated flow temperature control with variable limitation of the return flow temperature and drinking water heating in a storage tank system

Fig. 12 ⋅

Anl 2.0

(system code number 2.0)

System c ode n umber 2.0 with cha ngeover valve

Weather-compensated flow temperature control with variable limitation of the return flow temperature and drinking water heating in a storage tank system with changeover valve

Fig. 13

⋅

Anl 2.0

(system code number 2.0) with changeover valve

21

Page 22

Drinking water heating process

Charging of the drinking water storage tank is started when the drinking water temperature in

the storage tank falls below the temperature value Drinking water heating ON or the value set

at a storage tank thermostat.

As a rule, the controller attempts to adapt the current flow temperature to the set Charging temperature before the storage charging pump starts to operate. In such operating situations, the

flow temperature of the heating circuit may be raised by up to 10 K, however, up to the set limit

Max. flow temperature at the maximum.

When the heating circuit is deactivated, the controller does not attempt this; the storage charging pump starts up immediately, or when a return flow sensor is connected and FB 20 = ON is

activated with the option "SLP" selected, it first starts to operate when the return flow temperature reaches the temperature at the storage tank sensor SF1.

With the default setting FB 9 = OFF harsh priority, i.e. the heating circuit is deactivated while

the drinking water heating is active long-term charging can be interrupted after 20 minutes

for 10 minute periods by the heating operation. For this, set the function block FB 9 = OFF, and

select the option "20". The same applies to the setting FB 9 = ON with the option "US" selected

system with a circulation pump and changeover valve.

With the setting FB 9 = ON and the option "PU" selected parallel pump operation the heating circulation pump only continues to run when the increase in flow temperature in the heating

circuit is maximum 10 K Max. flow temperature at the maximum.

Should the capacity available for parallel operation be too low, causing the charging temperature to remain more than 5 K under the set value, the heating operation is interrupted for 10

minutes. The time span before the parallel operation is terminated can be set in FB 9.

The storage tank charging stops when the drinking water temperature in the storage tank

reaches the temperature value Drinking water heating OFF or the preset value at the storage

tank thermostat. This occurs when the flow temperature demand of the heating circuit is correspondingly high because the storage charging pump has just been deactivated or in accordance with the parameter setting End charging process when the flow temperature demand of

the heating circuit is lower. In any case, the storage charging pump is deactivated, at the latest,

after two transit periods of the control valve 2xTy have elapsed.

22

Page 23

System code number 2.1

Weather-compensated flow temperature control system with variable limitation of the return

flow temperature and drinking water heating from the secondary circuit with differential temperature control for solar-powered heating of the drinking water storage tank system.

Solar collector

Fig. 14 ⋅

Anl 2.1

Solar collector

(system code number 2.1)

Fig. 15 ⋅

Anl 2.1

(system code number 2.1)

23

Page 24

If, in system code number 2, the drinking water heating takes place as already described with a

storage tank sensor (storage tank sensor SF1), the storage tank sensor SF2 can be used for the

solar-powered heating of the drinking water storage tank.

In addition to the "Drinking water heating process", the difference in temperature is determined

between the storage tank sensor SF2 and the solar collector sensor CF.

The solar circuit pump starts its two-stage operation depending on the parameter Solar circuit

pump ON:

Stage 2 is requested when the difference in temperature is twice as high as the value set in the

parameter Solar circuit pump ON.

If the difference in temperature falls below the value set in the parameter Solar circuit pump

ON, it switches back to stage 1.

The pump stops operating if the difference in temperature falls below the parameter Solar circuit pump OFF.

The solar circuit pump CP is, in principle, deactivated when the temperature measured at the

storage tank sensor reaches the parameter Solar charging OFF.

The time schedule for drinking water heating influences only the additional heating over the

storage tank sensor SF1, not the solar circuit.

The operating hours of the solar circuit pump CP can be retrieved by entering the code number

1990.

5.3 System code number 3.0

Weather-compensated flow temperature control with variable limitation of the return flow temperature and drinking water heating in the storage tank charging system

Fig. 16 ⋅

Anl 3.0

(system code number 3.0)

24

Page 25

Drinking wate r heating process

Charging of the drinking water storage tank is started when the drinking water temperature in

the storage tank falls below the temperature value Drinking water heating ON or the value set

at a storage tank thermostat.

The controller attempts to reduce flow temperatures that are higher than the set Charging temperature over the heating circuit before the heat exchanger charging pump together with the

storage charging pump start to operate.

When the heating circuit is deactivated as well as at lower flow temperature demands, the storage charging pump is activated immediately, while the storage charging pump is first activated

when the flow temperature reaches the temperature at the storage tank sensor SF1.

With the default setting FB 9 = OFF harsh priority, i.e. the heating circuit is deactivated while

the drinking water heating is active long-term charging can be interrupted after 20 minutes

for 10 minute periods by the heating operation. For this, set the function block FB 9 = OFF, and

select the option "20".

With the setting FB 9 = ON and the option "PU" selected parallel pump operation the heating circulation pump only continues to run when the increase in flow temperature in the heating

circuit is maximum 10 K Max. flow temperature at the maximum.

Should the capacity available for parallel operation be too low, causing the charging temperature to remain more than 5 K under the set value, the heating operation is interrupted for 10

minutes. The time span before the parallel operation is canceled can be set in FB 9.

The storage tank charging stops when the drinking water temperature in the storage tank reaches the temperature value Drinking water heating OFF or the preset value at the storage tank

thermostat. This occurs when the flow temperature demand of the heating circuit is correspondingly high because the storage charging pump has just been deactivated or in accordance

with the parameter setting End charging process when the flow temperature demand of the

heating circuit is lower. In any case, the storage charging pump is deactivated, at the latest, after two transit periods of the control valve 2xTy have elapsed; 15 seconds after the heat exchanger charging pump has been deactivated, the storage tank pump stops running.

25

Page 26

5.4 System code number 4.0

Weather-compensated flow temperature control with variable limitation of the return flow temperature and drinking water heating with return flow temperature limitation from the primary

circuit, designed as storage tank water heater

Fig. 17 ⋅

Anl 4.0

(system code number 4.0)

Drinking water heating process

The drinking water control valve causes a more or less fast charging of the drinking water storage tank from its closed position depending on the current system deviation and the set control

parameters when the drinking water temperature in the storage tank falls below the set point of

the Drinking water temperature.

Should the capacity available for a parallel operation of both circuits heating circuit and

drinking water circuit be too low when the maximum capacity is required, the function block

FB 8 can be activated.

With the setting FB 8 = ON and the option "Ab" selected Drinking water priority through setback operation the heating circuit is set to reduced operation for 20 minutes when there is a

system deviation of more than 5 K in the drinking water circuit: its capacity requirement is

moved back by reducing the current flow temperature by the value set in Set-back of flow temperature for reduced operation.

With the setting FB 8 = ON and the option "In" selected Drinking water priority through

reverse control the capacity requirement of the heating circuit is reduced when there is a system deviation of more than 5 K in the drinking water circuit. This is achieved by the three-point

stepping output of the drinking water circuit having an effect on the heating circuits control

valve in the opposite direction. The time span before the priority mode responds can be set in

Fb8.

26

Page 27

System code number 4.1

Weather-compensated flow temperature control with variable limitation of the return flow temperature and drinking water heating from the primary circuit with differential temperature control for solar-powered heating of the drinking water tank.

Solar collector

Fig. 18 ⋅

Anl 4.1

(system code number 4.1)

In addition to the "Drinking water heating process", the difference in temperature is determined

between the storage tank sensor SF2 and solar collector sensor CF. Both solar circuit pumps start

operating depending on the parameter Solar circuit pump ON. At the same time, the control

valve of the drinking water circuit is closed.

The solar circuit pumps stop running and the additional heating is enabled, provided their time

schedules allow this, when the difference in temperature drops below the value in the parameter

Solar circuit pumps OFF.

The operating hours of the solar circuit pump CP can be retrieved by entering the code number

1990.

27

Page 28

System code number 4.2

Weather-compensated flow temperature control with variable limitation of the return flow temperature and drinking water heating from the primary circuit with differential temperature control for solar-powered heating of the drinking water tank.

Solar collector

Fig. 19 ⋅

Anl 4.2

(system code number 4.2)

The difference to the system code number 4.1 is that the additional heating remains active even

during the operation of the solar circuit pumps, provided their time schedule allows it.

28

Page 29

5.5 System code number 5.0

Weather-compensated flow temperature control with variable limitation of the return flow temperature and drinking water heating from the primary circuit, designed as storage tank charging system

With FB19 = ON

Fig. 20 ⋅

Anl 5.0

(system code number 5.0)

Drinking wate r heating process

Charging of the drinking water storage tank is started when the drinking water temperature in

the storage tank falls below the temperature value Drinking water heating ON or the value set

at a storage tank thermostat. The storage tank charging pump starts operating immediately and

the Charging temperature is controlled.

Should the capacity available for a parallel operation of both circuits heating circuit and

drinking water circuit be too low when the maximum capacity is required, the function block

FB 8 can be activated.

With the setting FB 8 = ON and the option "Ab" selected Drinking water priority through setback operation the heating circuit is set to reduced operation for 20 minutes when there is a

system deviation of more than 5 K in the drinking water circuit: its capacity requirement is

moved back by reducing the current flow temperature by the value set in Set-back of flow temperature for reduced operation.

With the setting FB 8 = ON and the option "In" selected Drinking water priority through reverse

control the capacity requirement of the heating circuit is reduced when there is a system deviation of more than 5 K in the drinking water circuit. This is achieved by the three-point stepping

output of the drinking water circuit having an effect on the heating circuits control valve in the

opposite direction. The time span before the priority mode responds can be set in FB 8.

29

Page 30

Charging of the storage tank finishes when the drinking water temperature in the storage tank

reaches the temperature Drinking water heating OFF or the value preset at the storage tank

thermostat. With the default setting FB19 = OFF, the control valve of the drinking water circuit is

closed for this purpose.

The storage charging pump is deactivated when the charging temperature has dropped below

the value set in the parameter End charging process, or at the latest, after two transit periods of

the control valve in the drinking water circuit 2xTy have elapsed.

With the setting FB19 = ON Circulation via the heat exchanger the control of the charging

temperature is retained, if required, after intermediate reduction of the charging temperature as

set in the parameter End charging process.

5.6 System code number 6.0

Weather-compensated flow temperature control with variable limitation of the return flow temperature and drinking water heating from the primary circuit, designed as system with instantaneous water heater

Fig. 21 ⋅

Anl 6.0

(system code number 6.0)

30

Page 31

Drinking wate r heating process

The drinking water outlet temperature of the heat exchanger is controlled according to the set

point in the parameter Drinking water temperature. The setting of the control parameters concerning the achievable control quality is decisive for this.

Should the capacity available for a parallel operation of both circuits heating circuit and

drinking water circuit be too low when the maximum capacity is required, the function block

FB 8 can be activated.

With the setting FB 8 = ON and the option "Ab" selected Drinking water priority through setback operation the heating circuit is set to reduced operation for 20 minutes when there is a

system deviation of more than 5 K in the drinking water circuit: its capacity requirement is

moved back by reducing the current flow temperature by the value set in Set-back of flow temperature for reduced operation.

With the setting FB 8 = ON and the option "In" selected Drinking water priority through

reverse control the capacity requirement of the heating circuit is reduced when there is a system deviation of more than 5 K in the drinking water circuit. This is achieved by the three-point

stepping output of the drinking water circuit having an effect on the heating circuits control

valve in the opposite direction. The time span before the priority mode responds can be set in

FB 8.

The circulation pump ZP always runs according to its time schedule.

Observe the following for devices to be used in the drinking water control loop regarding the

drinking water temperature sensor VFTW and the control valve:

You must use a temperature sensor with fast response (we recommend a Pt100 sensor with z 09

= 2.3 seconds Type 5209) for measuring the drinking water outlet temperature. This is necessary in order to keep the duration of temperature peaks as well as the temperature peaks themselves as small as possible. In addition, an actuator with a transit time of max. 40 seconds is required.

We strongly recommend that the circulation pump be operated during times-of-use of the drinking water circuit!

31

Page 32

6. Operation

6.1 Operating controls

To access the operator controls, open the front cover of the controller.

Besides the mode switches, the following keys can be used to configure the controller.

Changeover key

Lets you change from the operating level to the parameter level or configuration

level

Reset key

Lets you reset all freely accessible parameters to default values (factory setting)

This keys function is active only on the parameter level!

Arrow keys

These keys let you adjust the displays as well as retrieve and set data by moving

up and down

Enter key

Operating level: lets you view adjusted set points

Parameter level: lets you access and acknowledge entered values and data

Configuration level: lets you access and acknowledge adjusted system code

numbers and function blocks

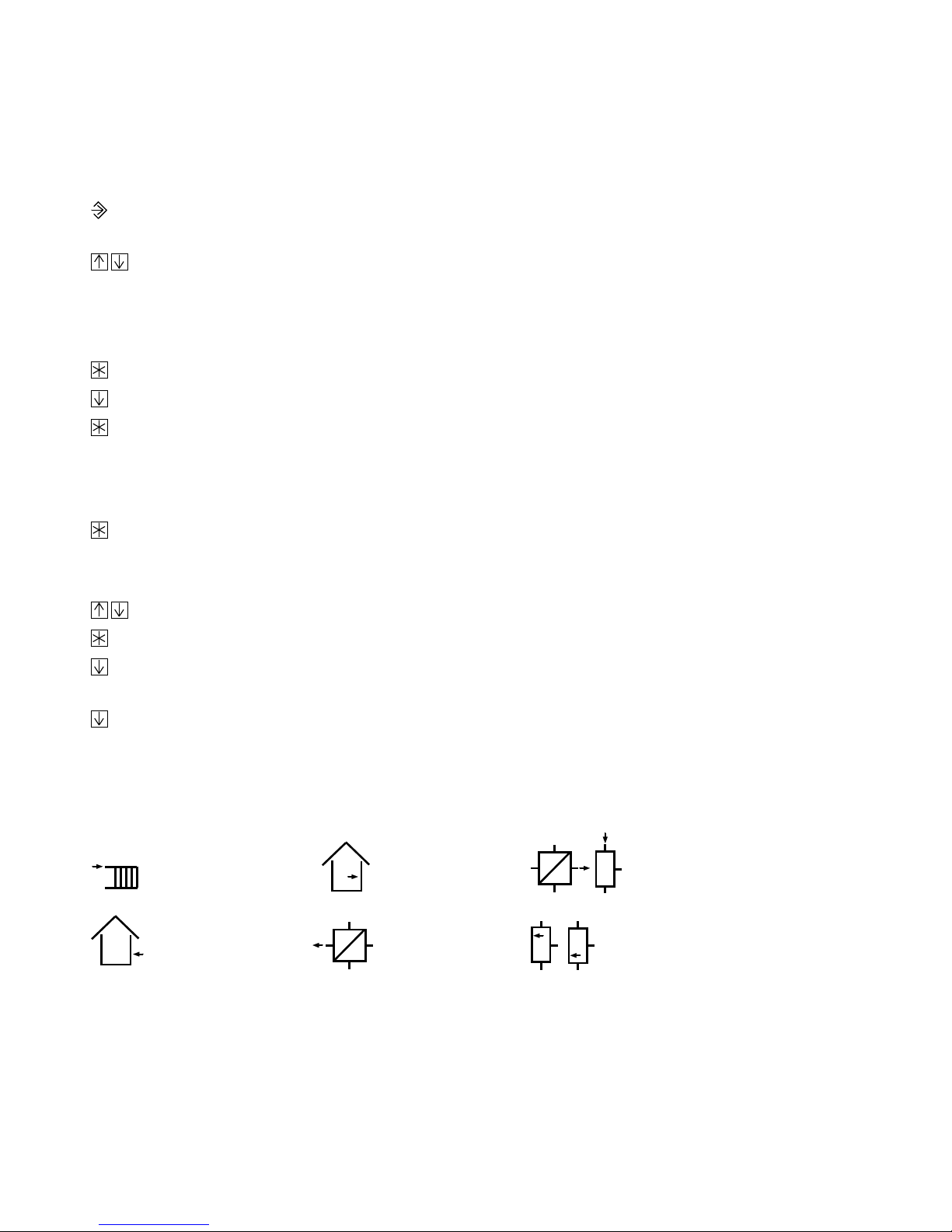

6.2 Selecting the operating modes

Use the mode switch to select the mode for each control loop (heating circuit or drinking water

heating circuit). Time-controlled operation is used as the default setting. The switch positions

with the assigned symbols mean the following:

Mode switch for the heating circuit

Time-controlled operation with switchover between

rated operation and reduced or standby operation

Rated operation

Reduced or standby operation

Manual operation: *

Control valve opens inactive closes, UP on

(for on/off control: + = ON, 0 = OFF)

32

* If the controller only reacts to these switch positions as in reduced or

standby operation, the manual level is locked. See chapter 7.3 on page

57 for more details.

Page 33

Mode switch for the drinking water heatin g circuit

Time-controlled operation with option to deactivate

drinking water heating circuit

Time-controlled operation, heating circuit deactivated,

only frost protection active

Heating and drinking water heating circuits deactivated,

only frost protection active

Manual operation: *

Control v alve opens inactiv e closes

(no function in

position 0 = drinking water circuit deactivated

position + = SLP and, if needed, TLP switched on)

* If the controller only reacts to these switch positions as in deactivated

mode (heating and drinking water heating circuits are deactivated), the

manual level is locked. See chapter 7.3 on page 57 for more details.

Set point correction switch

Heating circuit deactivated, only frost protection active

system 1

; in

system 2

and 3 only

Switch for set point correction during rated operation to

increase (+) or decrease () the set point as an alternative

to the mode switch for the drinking water heating circuit.

Switch symbol sticker is delivered with the controller.

See chapter 7.4 on page 58 about how to activate this switch

T

∆

flow max

T

∆

room max

= ±4 K x heating characteristic gradient (without adaptation)

= ±2 K (with adaptation)

6.2.1 Remote controlling the heating system

(only with room temperature sensot Type 5244 or Type 5257-4 with remote control)

You can change the operating mode or correct a set point of the heating circuit directly from the

room using the remote control.

Switch positions at the remote control are only effective when the mode switch at the controller is

set to the time-controlled operation symbol.

Time-controlled operation

Rated operation

Reduced or standby operation

Set point correction during rated operation periods

+ Increase room temperature Decrease room temperature

T

∆

flow max

T

∆

room max

= ±5 K x heating characteristic gradient (influencing range without adaptation)

= ±5 K (influencing range with adaptation)

33

Page 34

6.3 Control levels

Upon connection to the power supply during start-up, the controller automatically switches to

the operating level. To configure the controller, you must first switch over to the configuration

level and then the parameter level.

6.3.1 Configuration level:

You can adapt the controller to the individual system requirements

using the functions available.

6.3.2 Parameter level:

You can enter user data such as the time, date, heating characteristic,

set points, times-of-use, etc.

6.1.3 Operating level:

On this level, the controller is standard set to rated operation with timecontrolled switchover to reduced or standby operation.

Use the mode switches to change to other operating modes; times-of-use and current operating

states are indicated in the display.

As a rule, the basic display (Fig. 22) appears with the current time and bars indicating the current times-of-use as well as various operating states.

If you keep the key pressed down when the time appears in the display, the display alternates

between the current date and year.

If you want to display other values, e.g. current temperature values, proceed as follows:

Press the arrow key to view next display or

Press the arrow key to view the previous di splay

If you want to view the associated set point instead of the current temperature value, keep the

key pressed down.

If you continue to press the key, other images appear in the display with other symbols. These

depend on the system code entered during configuration (see chapter 7.1) as well as the adjusted function blocks.

Time schedule

Public holidays

Vaca ti on

Rated operation

Reduced or

standby operation

Frost protection

Sensor malfunction

1

Heating

demand

Heating pump

Val ve h ea ti ng

Fig. 22 ⋅ Basic display

34

10 1112 13 14 1516 17 1819123456789 20212223240

DW

circulation

pump (ZP)

Drinking water

demand

DW heat exchanger

charging pump

(TLP)/solar circuit

M

Storage charging pump (SLP)OPEN CLOSED

STOP

Summer time operation (heating circuit deactivated depending on

out sid e te mpe ratu re)

M

pump (CP)

Val ve fo r dri nk in g

water

Page 35

Operating level

Configuration level

Press both keys simultaneously

Current Anl

Fast setting

warmer/colder

1011 1213 14 1516 17 18 191 2 3 4 5 6 7 8 9 20 21 2223 240

1

M

Temperatures

heating

Temperatures

drinking water

M

Key held pressed:

Set point shown

Parameter level

Press key for 2 s

Key held pressed:

Date displayed

Enter current

time and date

Time

Enter

values

Data

heating

Function blocks

Time schedules

heating

Time schedules

drinking water

Public holidays

Vac ati ons

Time schedules

heating

Public holidays

Vac ati ons

Data

drinking water

Time schedules

drinking water

Fig. 23 ⋅ Control levels

35

Page 36

The most impor tant symbols and their mea ning:

Outdoor temperature

Meaning when key is kept pressed down.

Info Time-controlled summer time operation

Calculated outdoor temperature (only with

delayed outdoor temperature adaptation )

Flow temperature

Heating

Return flow temperature

(only with ret urn f low sensor)

(blinks when limitation is active)

Room temperature

(only with room sensor)

Storage tank temperature

(bottom)

Set point

(blinks in case of limitation of return flow,

flow rate or capacity)

Limit value

Set point

(only in adaptation and optimizing mode)

Drinking water heating ON / OFF

for system code nos. Anl 2.0, Anl 3.0 and

Anl 5.0

with just

one storage tank sensor

(SF1)

depending on deactivated/activated DW

heating

Drinking water heating OFF

for system code nos. Anl2.0, Anl3 and Anl5

with

two storage tank sensors

Solar circuit pump OFF

for system code nos. Anl 2.1, 4 .1 and 4.2

Storage tank temperature

(top)

Charging temperature

(only for Anl 2, 3 and 5)

For Anl2.1, Anl4.1, Anl4.2:

collector temperature

Drinking water temperature

(only for Anl6)

Flow rate/pulse rate

(only on flow rate or capacity

limitation)

(blinks when limitation is active)

Drinking water heating ON

for system code nos. Anl 2.0, 3.0 and 5.0

with two storage tank sensors

Drinking water heating ON / OFF

for system code no. Anl 2.1 depending on

deactivated/activated DW heating

Set point for system code no. Anl 4

Set point (for system code nos. Anl 2 and 3

only during activated DW heating)

Solar circuit pump ON

Set point

Limit value

36

Page 37

Increase/decrease heatings set point on the operating level

The room temperature can be adjusted from the operating level by simply pressing a few keys.

This is achieved by changing the flow temperature of the heating circuit via displacement of the

heating characteristic to make it warmer or cooler, or in adaptation mode, by directly changing

the room temperature set point.

This setting is only effective when the heating system is running during a rated operation period!

10 1112 13 1415 16 17 18191 2 3 4 5 6 7 8 9 20212223240

Operating level, e.g. time shown in the display

If you want to change the set point:

Press the arrow key until the gradient of the

heating characteristic or room set point (see

1

M

M

below) appears in the display.

Press the enter key. The displacement arrows

start to blink.

10 1112 13 1415 16 1718 1912345 6789 20212223240

°C

Use the arrow keys to set the required

displacement value in °C . Upwards = increase

and downwards = decrease room temperature.

A displacement by 5 °C, for example, causes a 1°C increase in the room temperature.

1

M

M

Press the enter key to acknowledge the value.

Shortly after, the display returns to the current

time.

10 1112 13 1415 16 17 18191 2 3 4 5 6 7 8 9 20212223240

°C

Press the enter key. The room temperature

arrow starts to blink.

1

M

Use the arrow keys to set the required value

in °C.

Press the enter key to acknowledge the value.

M

Shortly after, the display returns to the current

time.

37

Page 38

7. Star ting up and confi guring the control ler

Switch on the power supply to start up the controller.

After briefly switching between displays, the controller automatically goes to the operating level

and the time appears in the display.

You must first configure the controller before setti ng it.

Then enter any required user data as described in chapter 7.2 on parameterization.

7.1 Configuration

Configure the controller to adapt its functions to the requirements of the system. To do this, select

the appropriate system diagram from the system descriptions in chapter 5 (Figs. 11 to 21).

After this, determine the functions required for the chosen system diagram by activating and setting certain function blocks.

The set system code number as well as the function blocks FB 20 to FB 23 are protected by

Note:

a

code number

.

You can only access the settings for the system code numbers, function blocks and all the data

required for parameterization and configuration after entering a valid code number!

If you cannot change any function block settings in the parameter level and various par-

Note:

ameters are not shown in the display, the write protection function for the configuration level is

enabled. See chapter 7.3 on page 57 for more details.

7.1.1 Setting the code number

The valid code number is written on page 62 of this manual. If you want to keep this code number, but prevent any unauthorized person from using it, cut out or scribble out the number on

page 62.

Personal code number:

You can enter your own personal code number. See chapter 7.3 on

page 57 for more details.

0 0 0 0

appears in the display after you have selected a system code number or a protected

function block

1011 1213 141516 1718 191 2 3 4 5 6 7 8 9 2021 2223 240

Press the arrow key until you approximately

reach the code number (the longer you press the

key, the faster the displayed number changes) .

Use the arrow keys to set the number.

Press the enter key to acknowledge the set code

number.

38

Page 39

7.1.2 Setting the system code number (Anl)

Use a pencil (or similar item) to press the changeover key. A triangle (parameter level)

starts to blink in the top left-hand corner of the display.

Press the arrow keys simultaneously; two triangles (configuration level) start to blink

and the currently active system code number is shown in the display.

If you want to keep the system code number shown in the display:

Press the arrow key. Bars indicating the associated function blocks appear in the display.

If you want to change the system code number shown in the display, you must first enter the code

number. See also chapter 7.1.1:

Press the enter key.

0 0 0 0

appears in the display.

Press the arrow key until you approximately reach the code number (the longer you

press the key, the faster the displayed number changes).

Use the arrow keys to set the code number.

Press the enter key to acknowledge the set code number.

blinks in the display.

Anl

Use the arrow keys to set the system code number of the selected system diagram

(Anl 1 to Anl 6, Figs. 11 to 21).

Press the enter key to acknowledge the system code number.

Bars indicating the associated function blocks for that system appear in the display.

7.1.2 Setting the function blocks

Directly after you have set and acknowledge the system code number, bars appear in the display together with the basic setting of the associated function blocks.

If you select additional sensors and/or functions that are not included in the basic setting, do not

forget to set the corresponding function blocks (ON or OFF). Refer to the following list for further

explanations about the function blocks.

The black bars under the numbers 1...24 at the top of the display mean the function blocks are

activated (ON). Blank areas under the numbers mean the function blocks are deactivated

(OFF).

Configuration level

(blinks)

Fig. 24 ⋅ System code number and function block settings

10111213141516171819123456789 20212223240

Current

function block number

e.g.

function block 14 ON

System code number

39

Page 40

If you want to change the basic setting of a function block, proceed as follows:

Use a pencil (or similar item) to press the changeover key. A triangle (parameter level)

starts to blink in the top left-hand corner of the display.

Press the arrow keys simultaneously; two triangles (configuration level) start to blink

and the currently active system code number is shown in the display.

Press the arrow key. Bars indicating the function blocks appear in the display.

Use the arrow keys to set the number of the function block you want to change.

Press the enter key. The function block number starts to blink.

Press the arrow key to switch the function block

Press the arrow key to switch the function block

ON