Page 1

Automation System 5400

Boiler Controller

TROVIS 5474

Electronics from SAMSON

Mounting and

Operating Instructions

EB 5474 EN

®

Firmware version 2.0x

Edition July 2004

Page 2

Disclaimer of liability

Disclaimer of liability

We areconstantly developing our products and therefore, reservethe right to change the prod

uct or the information contained in this document at any time without notice.

We do not assume any liability for the accuracy or completeness of these mounting and

operating instructions. Moreover, we do not guaranteethat thebuyer can use the product for an

intended purpose. SAMSON rejects any liability for claims by the buyer, especially claims for

compensation including lost profits or any other financial loss, except the damage was caused

intentionally or by gross negligence. If an essential term of the contract is breached by

negligence, SAMSON’s liability is limited to the foreseeable damage.

Safety instructions

The device may only be assembled, started up or operated by trained and

4

experienced personnel familiar with the product. Proper shipping and

appropriate storage are assumed.

The controller has been designed for use in electrical power systems. For

4

wiring and maintenance, you are required to observe the relevant safety

regulations.

The Safety shutdown function (section 8.10) does not replace the safety tem-

4

perature limiter as the boiler controller is not a safety-relevant component.

-

2 EB 5474 EN

Page 3

Contents

Contents

1 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Operating elements. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.1 Operating keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.2 Operating switches . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Operating modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 Displaying data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5 Setting the controller time . . . . . . . . . . . . . . . . . . . . . . . 11

1.6 Setting the times-of-use . . . . . . . . . . . . . . . . . . . . . . . . 13

1.6.1 Entering vacation periods . . . . . . . . . . . . . . . . . . . . . . . 15

1.6.2 Entering public holidays . . . . . . . . . . . . . . . . . . . . . . . . 16

2 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1 Setting the system code number and the boiler rating . . . . . . . . . . 18

2.2 Activating and deactivating functions. . . . . . . . . . . . . . . . . . 19

2.3 Changing parameters . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.4 Enter key number . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5 Calibrating sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.6 Resetting to default values . . . . . . . . . . . . . . . . . . . . . . . 24

3 Manual operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4 Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 Boiler functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.1 Boiler switching behavior . . . . . . . . . . . . . . . . . . . . . . . 32

5.2 Lag/lead sequence control. . . . . . . . . . . . . . . . . . . . . . . 34

5.2.1 Control without sensor VFg . . . . . . . . . . . . . . . . . . . . . . 34

5.2.2 Outdoor temperature-dependent sequence . . . . . . . . . . . . . . . 34

5.2.3 Capacity-dependent sequence . . . . . . . . . . . . . . . . . . . . . 35

5.2.4 Sequence lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.5 Lag delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.3 Change in lag/lead sequence (Anl 4 to 7) . . . . . . . . . . . . . . . 36

5.3.1 Outdoor temperature-dependent change (Anl 5 and 7) . . . . . . . . . 36

5.3.2 Capacity-dependent change (Anl 5 and 7) . . . . . . . . . . . . . . . 36

5.3.3 Operating hours-dependent change (Anl 5 and 7) . . . . . . . . . . . 37

5.3.4 Change with binary input (Anl 4 to 7) . . . . . . . . . . . . . . . . . 37

5.4 Return flow boost . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.4.1 Common return flow boost . . . . . . . . . . . . . . . . . . . . . . 38

5.5 Parallel operation (Anl 7) . . . . . . . . . . . . . . . . . . . . . . . 38

EB 5474 EN 3

Page 4

Contents

5.6 Operating hours counter. . . . . . . . . . . . . . . . . . . . . . . . 38

5.7 Boiler pump control . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.8 Boiler sensor acting as a thermostat . . . . . . . . . . . . . . . . . . 39

5.9 Modulation feedback . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.10 Operational alarm . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.11 Return flow sensor acting as a thermostat. . . . . . . . . . . . . . . . 41

6 Functions of the heating circuit . . . . . . . . . . . . . . . . . . . . 42

6.1 Outdoor temperature-dependent advance heating . . . . . . . . . . . 42

6.2 Optimization using a room sensor . . . . . . . . . . . . . . . . . . . 42

7 Functions of the DHW circuit. . . . . . . . . . . . . . . . . . . . . . 44

7.1 DHW heating in the storage tank system (Anl 1 to 3) . . . . . . . . . . 44

7.1.1 Priority circuit (Anl 1 to 3) . . . . . . . . . . . . . . . . . . . . . . . 45

7.2 Forced charging of the DHW storage tank (Anl 1 to 7) . . . . . . . . . 46

7.3 Thermal disinfection (Anl 1 to 3) . . . . . . . . . . . . . . . . . . . . 47

7.4 External DHW demand (Anl 1 to 7) . . . . . . . . . . . . . . . . . . 48

8 System-wide functions . . . . . . . . . . . . . . . . . . . . . . . . 49

8.1 Weather-compensated control . . . . . . . . . . . . . . . . . . . . . 49

8.1.1 Gradient characteristic . . . . . . . . . . . . . . . . . . . . . . . . 50

8.1.2 4-point characteristic . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.2 Fixed set point control . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.3 Differential temperature control using variable weighting factors. . . . . 53

8.4 Deactivation depending on outdoor temperature . . . . . . . . . . . . 53

8.5 Summer mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.6 Delayed outdoor temperature adaptation. . . . . . . . . . . . . . . . 54

8.7 Automatic summer time/winter time changeover . . . . . . . . . . . . 55

8.8 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.9 Forced operation of the pumps. . . . . . . . . . . . . . . . . . . . . 56

8.10 Flow temperature limitation . . . . . . . . . . . . . . . . . . . . . . 56

8.11 Control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.11.1 Three-step control . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.11.2 On/off control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.11.3 Continuous control . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.12 Control signal deactivation. . . . . . . . . . . . . . . . . . . . . . . 59

8.13 Processing of external demand. . . . . . . . . . . . . . . . . . . . . 59

8.14 Feedforwarding the outdoor temperature . . . . . . . . . . . . . . . . 59

8.15 Locking of changed settings . . . . . . . . . . . . . . . . . . . . . . 60

9 Operational faults . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4 EB 5474 EN

Page 5

Contents

9.1 Error list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.2 Sensor failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.3 Displaying the lead/collective error alarm . . . . . . . . . . . . . . . 62

9.4 Error status register . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.5 Error alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.5.1 Sending text message in case of error . . . . . . . . . . . . . . . . . 64

9.5.2 Sending fax in case of a fault alarm . . . . . . . . . . . . . . . . . . 65

10 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.1 Controller with RS-232 port . . . . . . . . . . . . . . . . . . . . . . 67

10.2 System bus interface in conjunction with cable converters

RS-232/RS-485 (for four-wire bus) . . . . . . . . . . . . . . . . . . 68

10.3 Description of communication parameters to be adjusted . . . . . . . . 69

10.4 Meter bus interface . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.4.1 Activating the meter bus . . . . . . . . . . . . . . . . . . . . . . . . 71

10.5 Memory module. . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

11 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

12 Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . 76

13 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.1 Function block list . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.2 Parameter lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

13.3 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

13.4 Sensor resistance tables . . . . . . . . . . . . . . . . . . . . . . . 115

13.5 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

13.6 Customer data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

EB 5474 EN 5

Page 6

Operation

1 Operation

The controller is ready for use with the temperatures and time schedules preset by the manufac

turer.

On start-up, the current time and date need to be set at the controller (–> section 1.5).

1.1 Operating elements

The operating controls are located in the front panel of the controller and protected by a Plexi

glas door.

1.1.1 Operating keys

Changeover key

(press using a pointed object such as a pen)

Switch from the info level to the parameter and configuration level and back

Reset key

(press using a pointed object such as a pen)

Press to reset accessible parameters to their default settings; the controller

must be in the configuration level

Arrow keys

– To scroll within levels

– To change values

Enter key

– To access levels

– Access parameters and functions to edit them

– Confirm settings

– Display set points in the info level

-

-

6 EB 5474 EN

Page 7

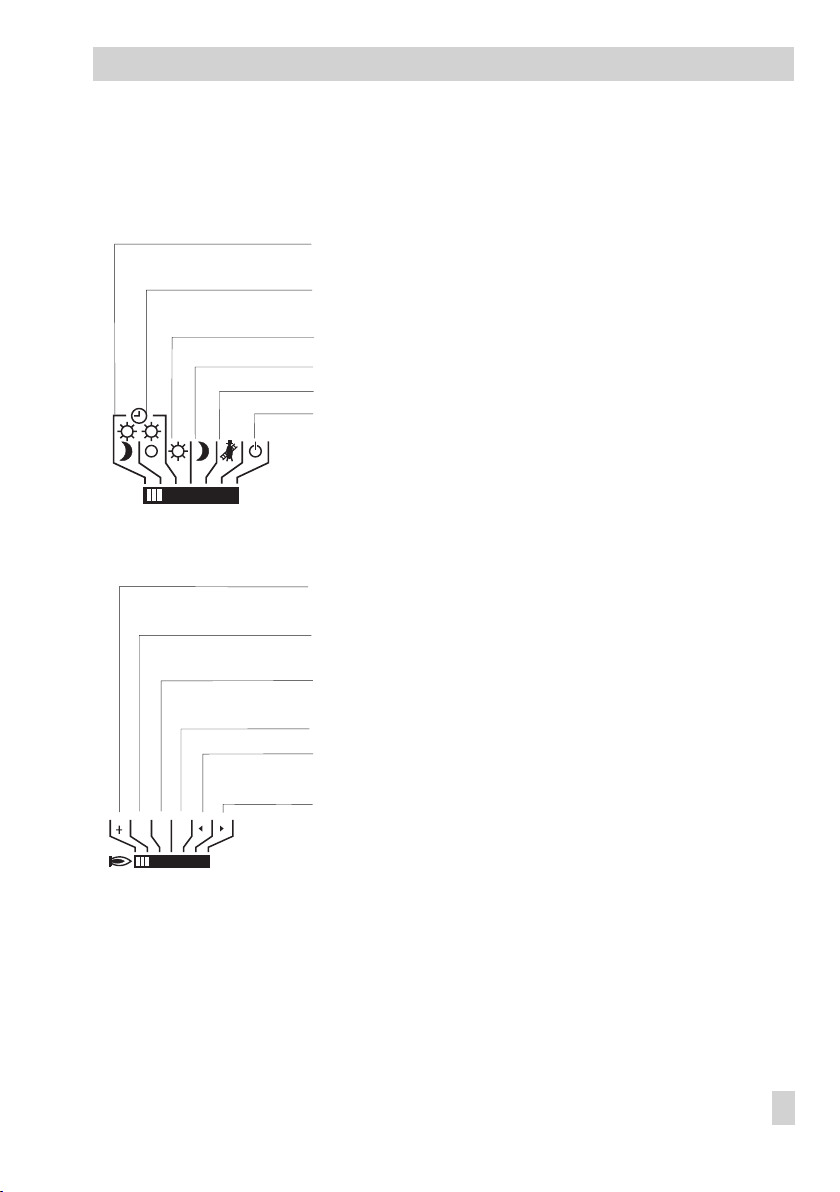

1.1.2 Operating switches

Mode selector switch

Selector switch

2

1

1 1

22O12

Operation

Automatic mode with switchover between

day mode and night mode

Automatic mode with switchover between

day mode and stand-by mode

Day mode (rated operation)

Night mode (reduced operation)

Manual/maintenance mode

Stand-by mode

Boiler 1 and 2 in operation;

automatic lag/lead sequence change

Boiler 1 in operation,

Boiler 2 switched off

Boiler 2 in operation,

Boiler 1 switched off

Boiler 1 and 2 switched off

Boiler 1 and 2 in operation;

Boiler 2 as lead boiler

Boiler 1 and 2 in operation;

Boiler 1 as lead boiler

EB 5474 EN 7

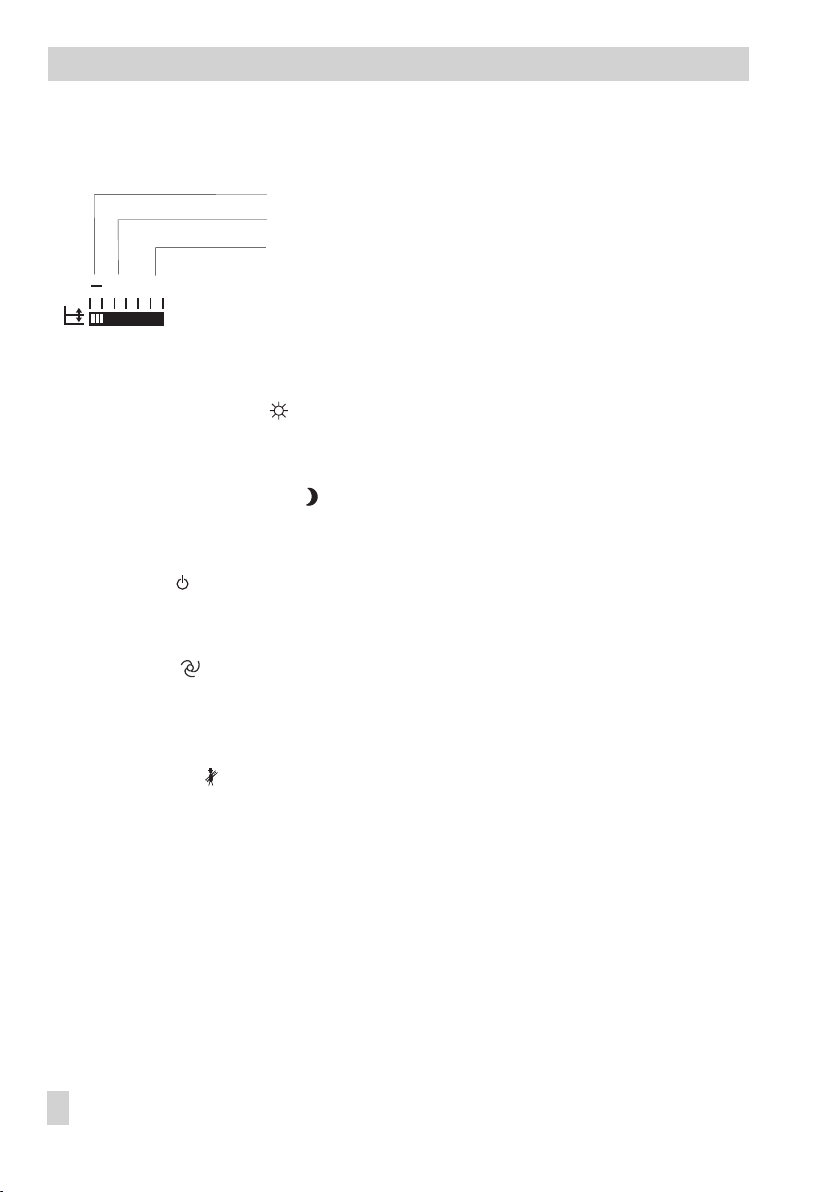

Page 8

Operation

Correction switch for the flow temperature

Set point set-back by 2.5 °C per notch

No change in set point

Set point raised by 2.5 °C per notch

+

0

1.2 Operating modes

Day mode (rated operation)

Regardless ofthe programmed times-of-use and summer mode,the set points relevant for rated

operation are used by the controller.

Night mode (reduced operation)

Regardless of the programmed times-of-use and summer mode, the set points relevant for reduced operation are used by the controller.

Stand-by mode

The controller is switched off. The boilers only work when there is a demand for DHW or a demand for an external set point. The protective functions remain active.

Automatic mode

During the programmed times-of-use, the controller works in rated operation. Outside these

times-of-use, the controller is in reduced operation or stand-by mode, depending on the set

tings. The controller switches automatically between both operating modes.

Maintenance mode

Pumps are controlled manually (–> section 3).

Control is not possible. Use the maintenancemode just for maintenance purposes and for emis

sion measurements.

The default setting of the circulation pumps is set for constant operation.

-

-

8 EB 5474 EN

Page 9

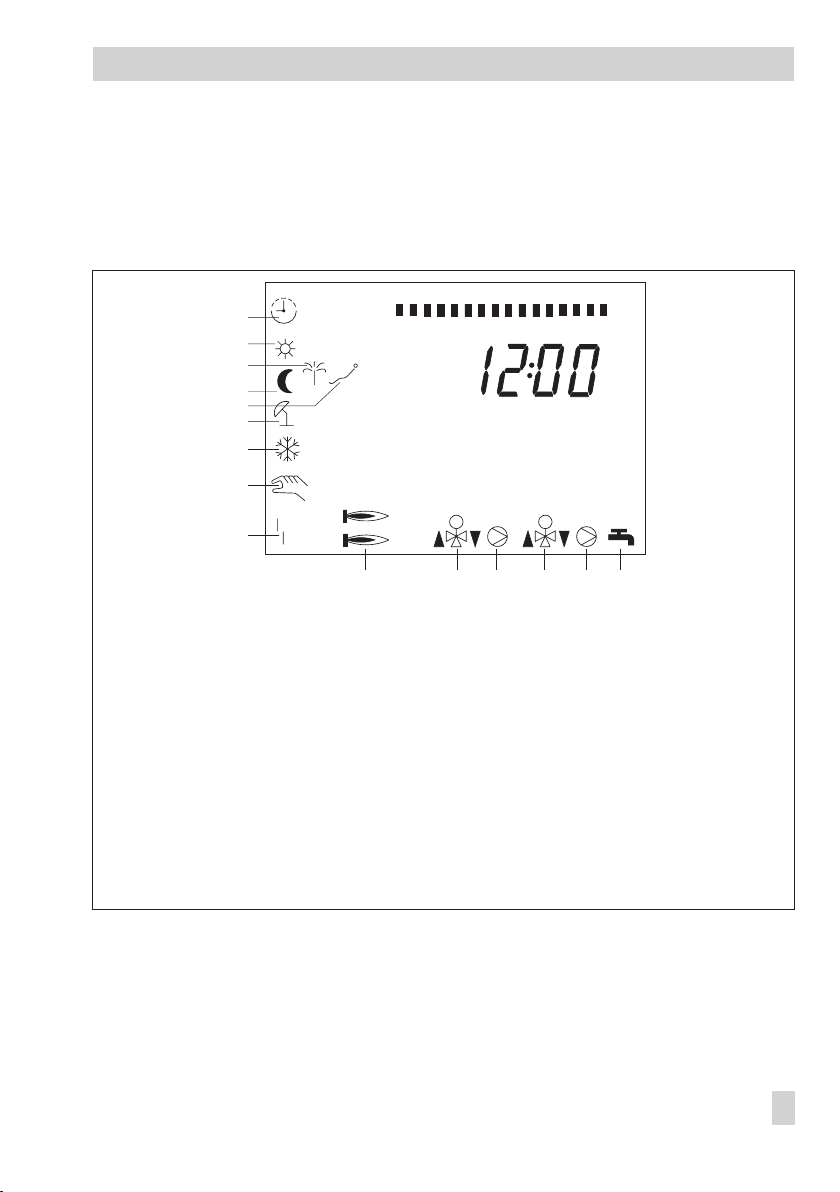

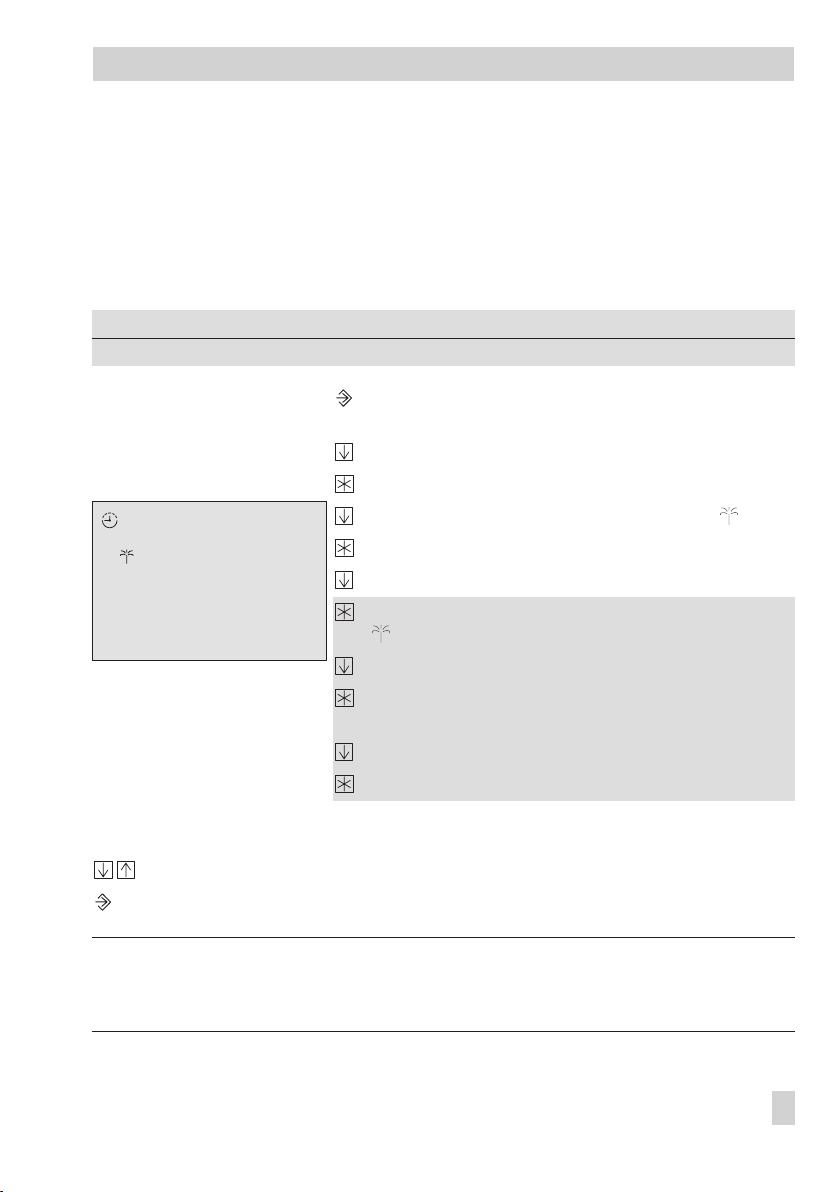

1.3 Display

Operation

During operation, the display indicates the current time as well as informationabout the opera

tion of the controller. The times-of-use are represented by black squares below the row of num

bers at the top of the display. Icons indicate the operating status of the controller.

8

1

2

3

4

5

6

7

8

9

1 Automatic operation

2 Rated operation

3 Vacation mode

4 Reduced operation

5 Public holiday mode

6 Summer mode

7 Frost protection

0

123

1

4

2

10

9

10

7

1

2

1

2

56

8 Manual/maintenance

mode

9 Malfunction

10 Boiler and boiler stages

11 Valve in control circuit 1

Open: Left arrow

Closed: Right arrow

12 Boiler pump 1 ON

1211 1314

1617181920

15

1

11 12 13 14 15

2122

24

23

2

13 Valve in control circuit 2

Open: Left arrow

Closed: Right arrow

14 Boiler pump 2 ON

15 DHW heating

-

-

Fig. 1 · Icons

The controller status can be displayed in the operating level (–> section 1.4).

EB 5474 EN 9

Page 10

Operation

1.4 Displaying data

Controller time, measured values, set points and limits, times-of-use, public holidays and vaca

tion periods can be retrieved and displayed in th

131). The various levels are listed in section 13.3.

InF1: Boiler 1

4

InF2: System Anl 1 to 3, Co5 -> Fb13 = ON: Separate heating circuit

4

4

4

4

4

4

Proceed as follows:

System Anl 4 to 7: Boiler 2

InF3: System Anl 1 to 3, Co5 -> Fb13 = ON: Direct heating circuit

InF4: DHW heating

InF5: General information, e.g. times-of-use

InF8: Error initialization

InF9: Modbus and meter bus communication

Select info level.

Open info level.

Scroll to read the various datapoints of the selected info level that appear one after

the other.

Compare the set point/limit with the actual value.

Press both arrows keys simultaneously:

Return to the display with time.

e InF1toInF9

info levels (-> Fig. 10 on page

-

10 EB 5474 EN

Page 11

Operation

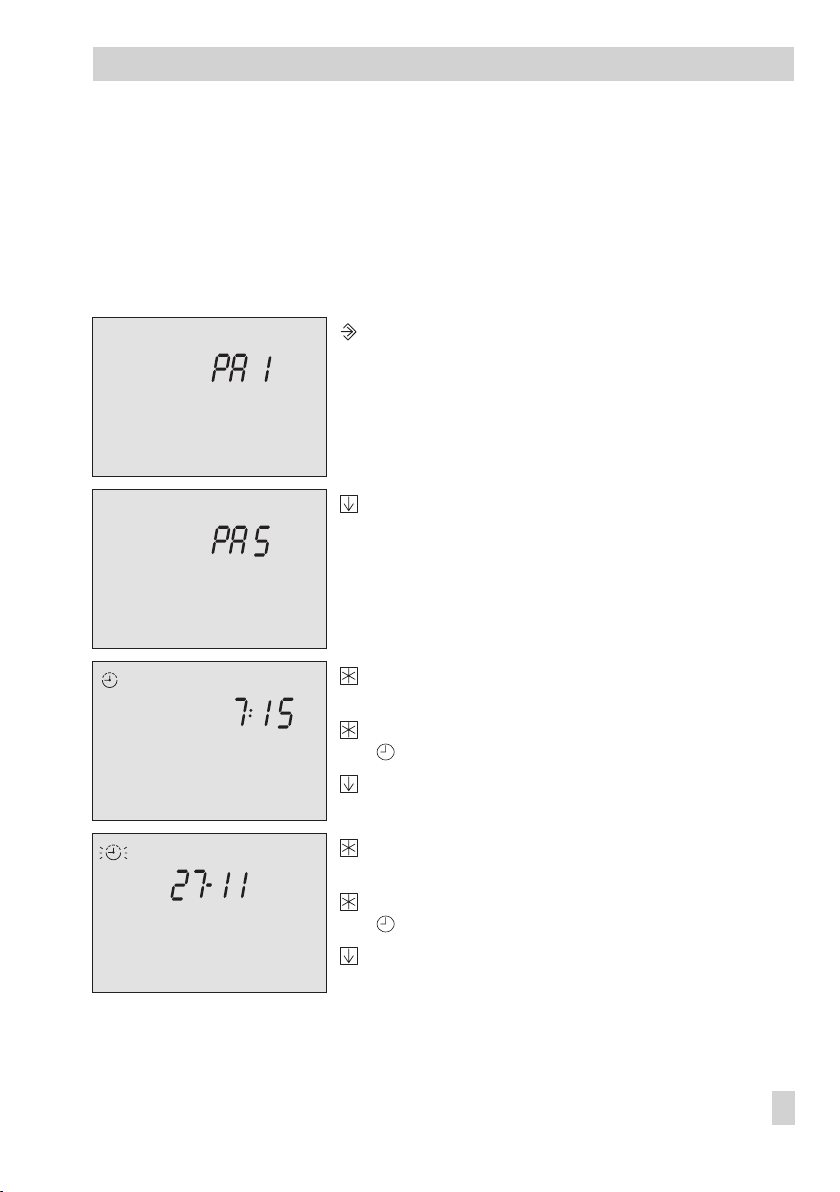

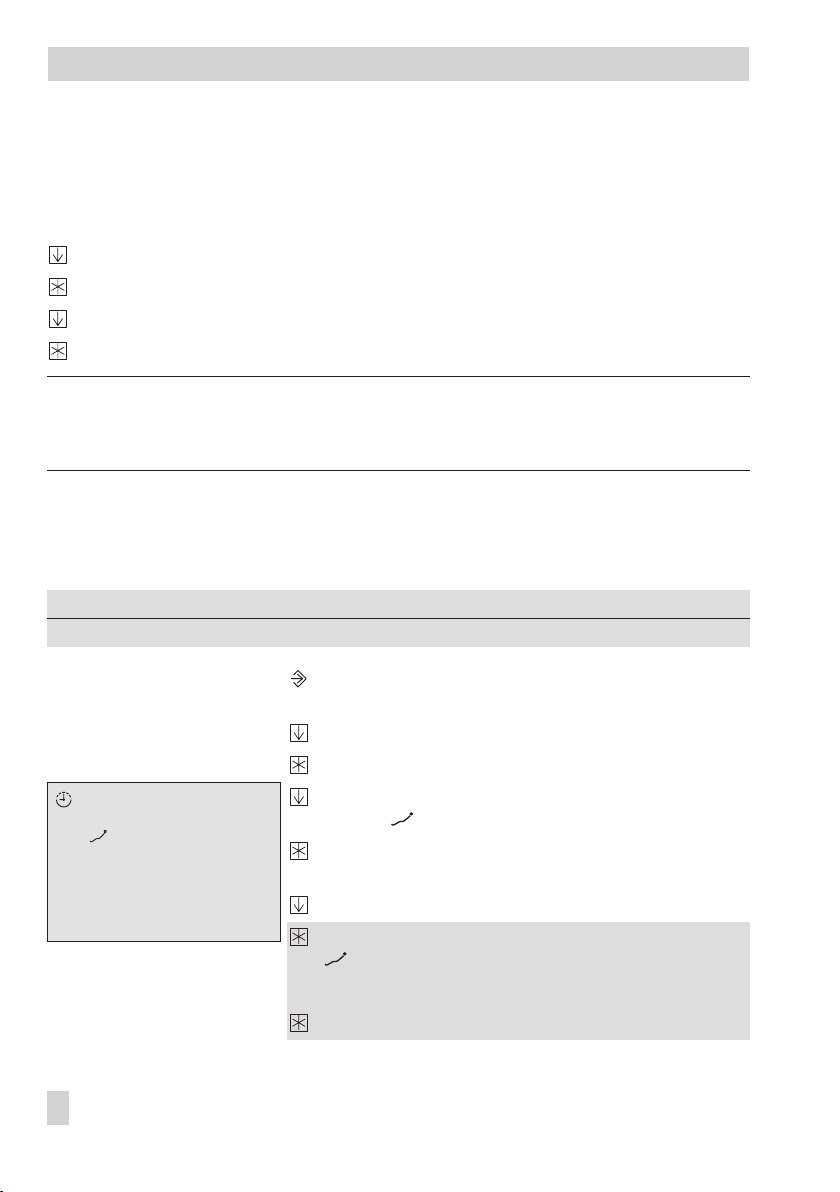

1.5 Setting the controller time

The current time and date need to be set immediately after start-up and after a power failure

lasting longer than 24 hours. This is indicated by the time blinking on the display.

PA5

The time is set in the

Proceed as follows:

9876543210

parameter level.

242322212019181716151413121110

Switch to the configuration and parameter level.

Display:

PA1

9876543210

1

9876543210

242322212019181716151413121110

242322212019181716151413121110

Select PA5 parameter level.

Open PA5 parameter level.

Display: Time

Activate editing mode for the controller time.

blinks.

Change time.

9876543210

242322212019181716151413121110

Confirm time.

Display: Date (Day-Month)

Activate editing mode for the date.

blinks.

Change date.

EB 5474 EN 11

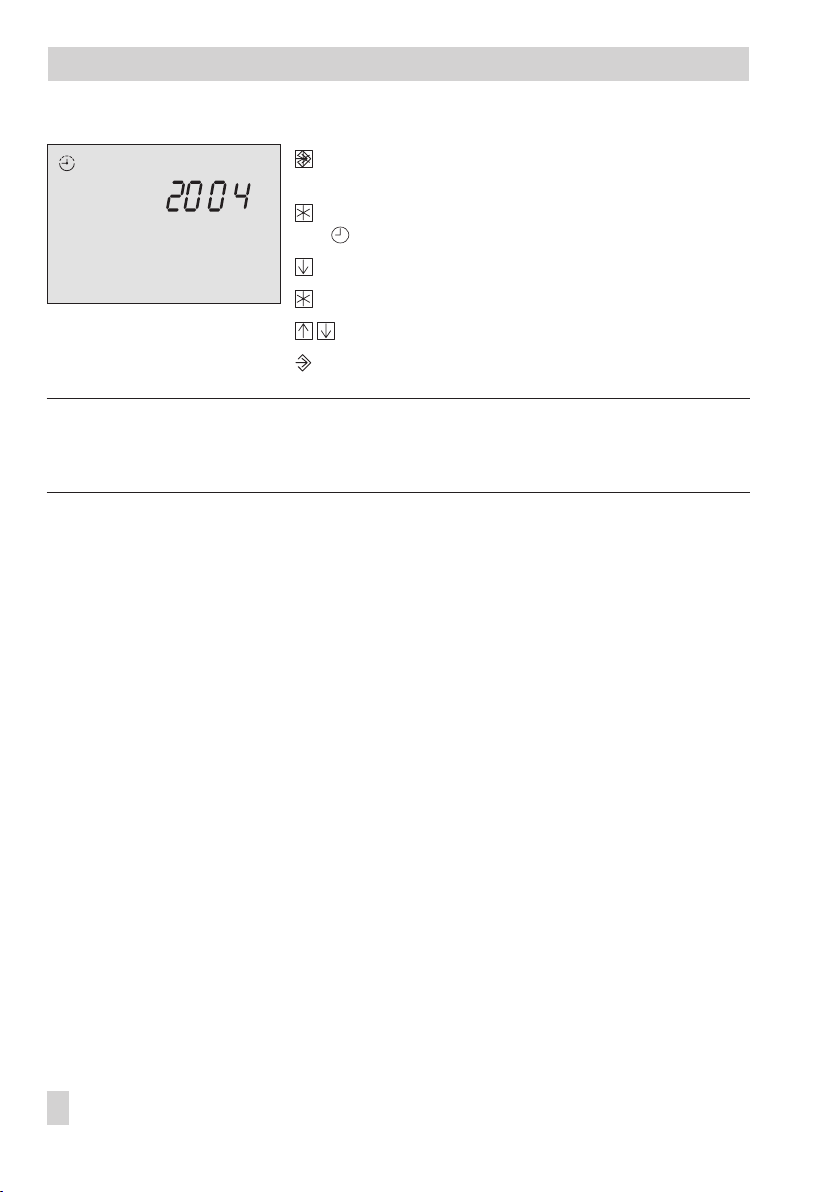

Page 12

Operation

9876543210

242322212019181716151413121110

Confirm date.

Display: Year

Activate editing mode for the controller time.

blinks.

Change year.

Confirm year.

Exit PA5 parameter level.

Return to the operating level.

Note!

The controller automatically returns to the operating level if the keys are left unpressed for two

minutes.

12 EB 5474 EN

Page 13

Operation

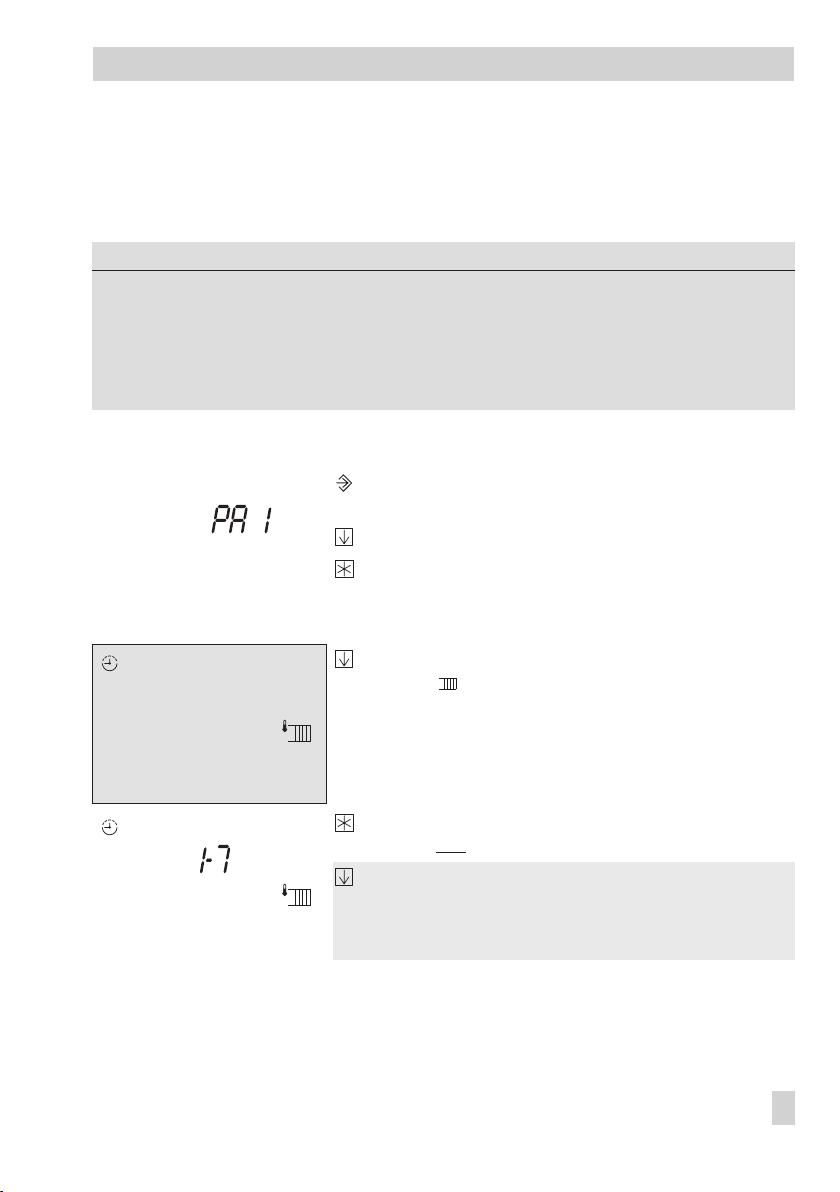

1.6 Setting the times-of-use

Two times-of-use can be set for each day of the week. If only one time-of-use is required, the

start and stop times of the second time-of-use must be programmed to identical times.

Parameters

Period/day 1–7 PA5 / 1–7, 1 to 7

Start first time-of-use 7:00 PA5 / 00:00 to 24:00h; in steps of 30 minutes

Stop first time-of-use 12:00 PA5 / 00:00 to 24:00h; in steps of 30 minutes

Start second time-of-use 12:00 PA5 / 00:00 to 24:00h; in steps of 30 minutes

Stop second time-of-use 22:00 PA5 / 00:00 to 24:00h; in steps of 30 minutes

Proceed as follows:

9876543210

242322212019181716151413121110

WE Parameter level / Range of values

Switch to the configuration and parameter level.

Display:

PA1

Select PA5 parameter level.

Open PA5 parameter level.

Display: Controller time

9876543210

9876543210

242322212019181716151413121110

242322212019181716151413121110

Select datapoint for times-of-use.

Display:

1

Activate editing mode for times-of-use.

Display: 1–7

Select period/day for which the times-of-use are to be

valid:

1–7 = Monday to Sunday,

1 = Monday, 2 = Tuesday, …, 7 = Sunday

EB 5474 EN 13

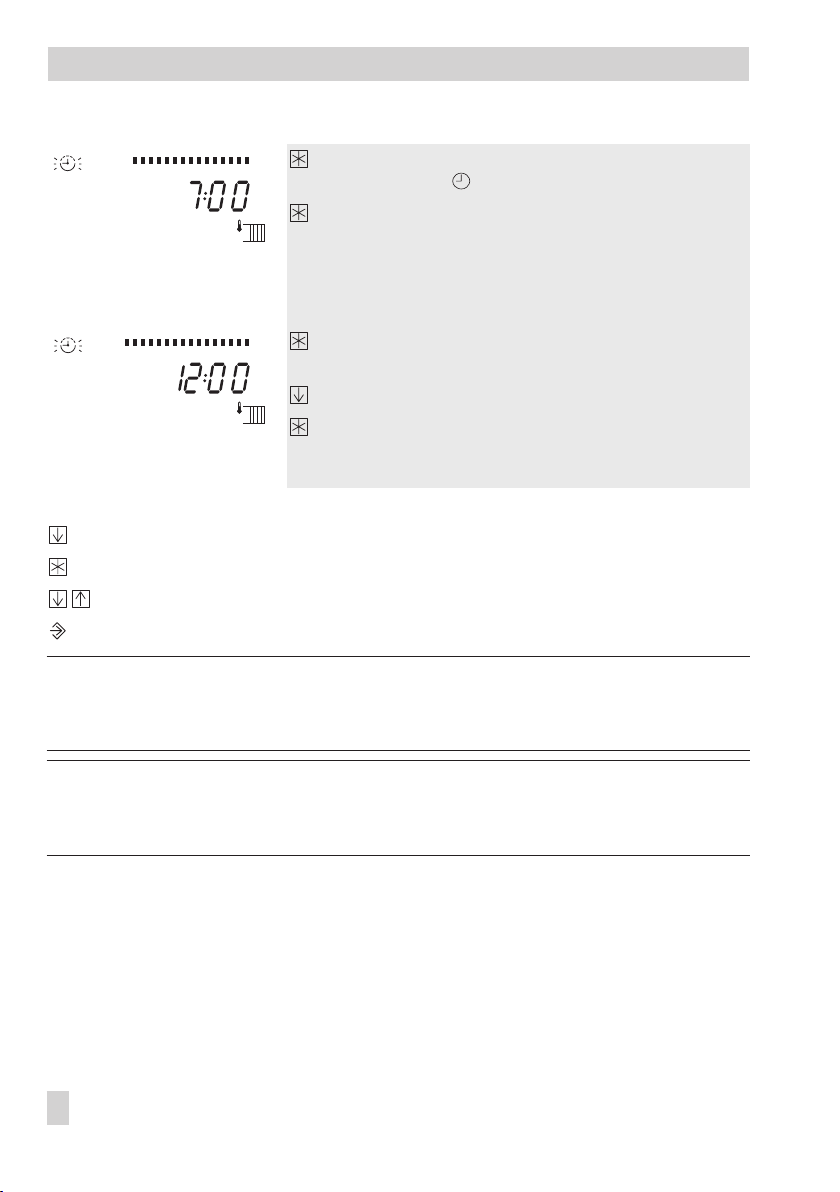

Page 14

Operation

9876543210

START

242322212019181716151413121110

Activate editing mode for period/day.

Display: START; blinks.

Edit start time (steps of 30 minutes).

9876543210

STOP

242322212019181716151413121110

Confirm start time.

Display:

STOP

Edit stop time (steps of 30 minutes).

Confirm stop time.

Display:

START

The second time-of-use is set like the first time-of-use.

To set the times-of-use for each day, repeat the instructions in the fields highlighted in gray.

Select

End

on the display.

Exit the datapoint for times-of-use.

Exit the parameter level.

Return to the operating level.

Note!

Do notuse the 1–7 menu to check the programmed times-of-use. On openingthis menu, the ti

mes-of-use are reset to their default settings.

-

Note!

The controller automatically returns to the operating level if the keys are left unpressed for two

minutes.

14 EB 5474 EN

Page 15

Operation

1.6.1 Entering vacation periods

When the switch position Automatic operation with switchover between day mode and night

mode is selected, night set points (reduced set points) are used by the controller. When the

switch position Automatic operation with switchover between day mode and stand-by mode

is selected, the system is switched off. The frost protection function remains active.

A maximum of 10 vacation periods may be entered.

Parameter

Vacation periods – PA5 / 01.01 to 31.12

Proceed as follows: Switch to the parameter and configuration level.

9876543210

242322212019181716151413121110

To enter additional vacations, re-select

in the fields highlighted in gray.

Exit the parameter level.

Return to the operating level.

WE Parameter level / Range of value

Display:

PA1

Select PA5 parameter level.

Open PA5 parameter level. Display: Controller time

Select datapoint for vacation period. Display:

Open data point for vacation period. Display:

If applicable, select

– – – –

.

START

Activate editing mode for vacation periods.

blinks.

Set start date of vacation period.

Confirm start date of the vacation period.

Display:

STOP

Set end of vacation period.

Confirm end of the vacation period.

––––

(between 31.12 and 01.01) and repeat the steps

Note!

In systems Anl 1 to 3 with integrated DHW heating (Co5 -> Fb13 = ON), the vacations entered

also apply to the DHW heating with the setting Co4 -> Fb10 = ON.

EB 5474 EN 15

Page 16

Operation

Vacation periods that are not assigned to a specific date should be deleted by the end of the

year so that they are not carried on into the following year.

Deleting vacation periods:

Select the vacation period you wish to delete in the datapoint for vacation periods.

Confirm selection.

Select

– – – –

.

Delete vacation period.

Note!

The controller automatically returns to the operating level if the keys are left unpressed for two

minutes.

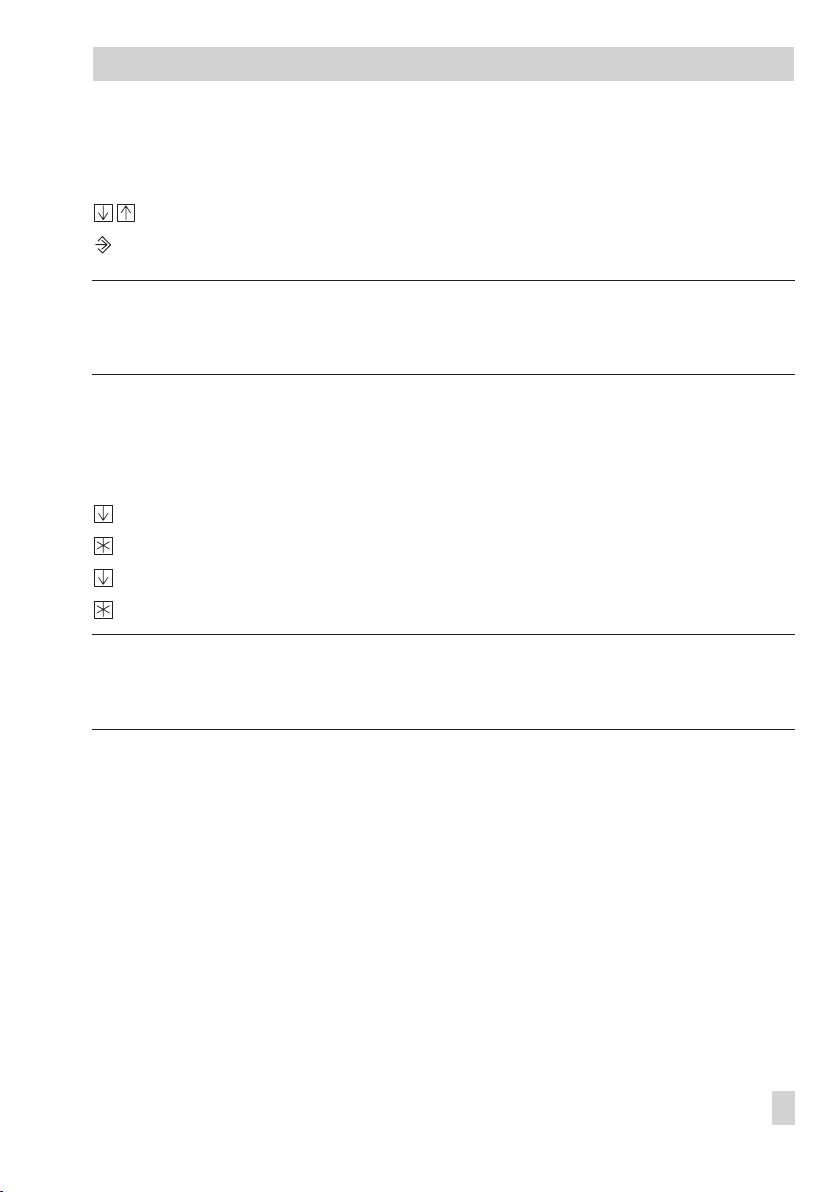

1.6.2 Entering public holidays

The times-of-use programmed for Sunday apply on public holidays. A maximum of 20 public

holidays can be entered.

Parameter

Public holidays – PA5 / 01.01 to 31.12

WE Parameter level / Range of value

Proceed as follows: Switch to the parameter and configuration level.

Display:

PA1

Select PA5 parameter level.

Open PA5 parameter level. Display: Controller time

8

56

4

0

123

9

1211 1314

10

7

1617181920

15

2122

24

23

Select datapoint for public holidays.

Display:

Open datapoint for public holidays.

Display:

If applicable, select

START

– – – –

.

Activate editing mode for public holiday.

blinks.

Edit public holiday.

Confirm public holiday.

16 EB 5474 EN

Page 17

Operation

To enter additional public holidays, re-select

––––

(between 31.12 and 01.01) and repeat the

steps in the fields highlighted in gray.

Exit the parameter level.

Return to the operating level.

Note!

In systems Anl 1 to 3 with integrated DHW heating (Co5 ->Fb13 =ON), thepublic holidaysen

tered also apply to the DHW heating with the setting Co4 -> Fb10 = ON.

Public holidays that are not assigned to a specific date should be deleted by the end of the year

so that they are not carried on into the following year.

Deleting a public holiday:

Select the holiday you wish to delete in the datapoint for public holidays.

Confirm selection.

– – – –

Select

.

Delete the public holiday.

Note!

The controller automatically returns to the operating level if the keys are left unpressed for two

minutes.

-

EB 5474 EN 17

Page 18

Start-up

2 Start-up

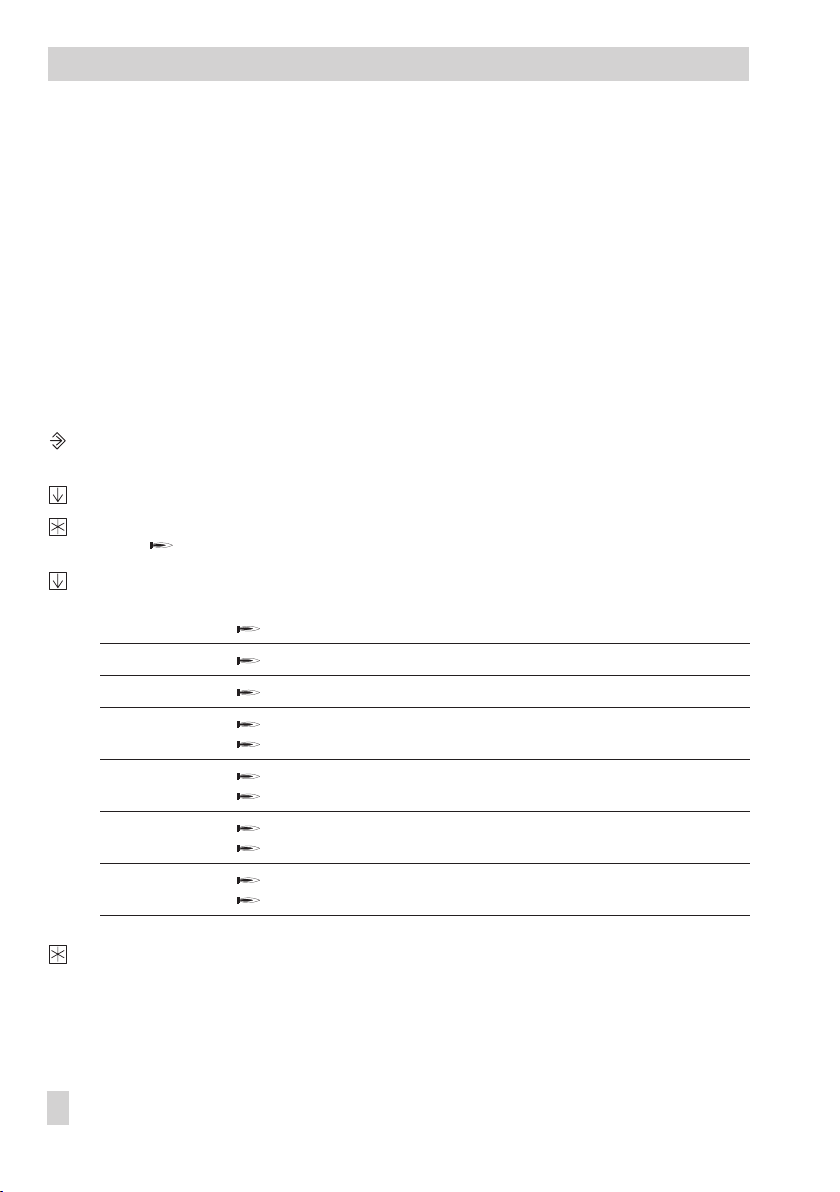

2.1 Setting the system code number and the boiler rating

7 different hydraulic schematics are available. Each system configuration is represented by a

system code number (Anl). The different schematics are dealt with in section 4. Available con

troller functions are described in sections 5 to 8.

Changing the system code number resets previously adjusted function blocks to their default set

tings (WE). Function block parameters and settingsin theparameter level remain unchanged.

The system code number is set in the parameter and configuration level.

Proceed as follows:

Switch to the parameter and configuration level.

level.

level.

1

Anl 1

PA1

Display shows:

Select

Anl

Open

Anl

Display:

Select system code number (Anl).

-

-

System Anl 1

System Anl 2

System Anl 3

System Anl 4

System Anl 5

System Anl 6

System Anl 7

1

Anl 1

1

Anl 2

2

1

Anl 3

2

1

1

2

Anl 4

1

1

2

1

2

Anl 5

2

1

1

2

2

Anl 6

1

1

2

2

Anl 7

Confirm system code number (Anl).

The burner and stage icons for burner 1 blink.

The boiler rating is shown.

18 EB 5474 EN

Single boiler for one-stage burner

Single boiler for two-stage burner

Single boiler for modulating burner

Double boiler for one-stage condensing boiler and

two-stage low-temperature boiler

Double boiler for 2 two-stage burners

Double boiler for modulating and two-stage burner

Double boiler for two modulating burners

Page 19

Start-up

Set the required rating.

Set first the capacity of the basic stage and then the total capacity of the burner of

two-stage and modulating burners.

Confirm the rating.

Set the capacity of the second burner in systems Anl 4 to 7.

End

Select

Exit the

Display:

on the display.

Anl

level.

Co1

2.2 Activating and deactivating functions

A function is activated or deactivated in the associated function block. The numbers 0 to 24 in

the top row of the display represent the respective function block numbers. When a configura

tion level is opened, the activated function blocks are indicated by a black square on the

right-hand side below the function block number. The function blocks are described in section 13.2.

The functions are arranged in topic groups:

Co1: Boiler 1

4

Co2: Systems Anl 1 to 3, Co5 -> Fb13 = ON: separate heating circuit

4

Systems Anl 4 to 7: Boiler 2

Co3: Systems Anl 1 to 3, Co5 -> Fb13 = ON: direct heating circuit

4

Co4: DHW heating

4

Co5: General functions

4

Co6: Sensor initialization

4

Co8: Error initialization

4

Co9: Modbus and meter bus communication

4

-

Proceed as follows:

Switch to the parameter and configuration level.

Display shows:

Switch to the configuration level (-> Fig. 10, page 131).

Open the configuration level.

PA1

EB 5474 EN 19

Page 20

Start-up

Select function block.

Activate editing mode for function block.

The function block number starts to blink.

0 0 0 0

If

section 2.4).

Activate function block (Fb = ON).

An activated function block is indicated by a black square below (right) the function

block number in the top row of the controller display.

or:

Deactivate function block (Fb = OFF).

Confirm setting.

If the function block is not closed, further function block parameters can be adjusted.

Proceed as follows:

Make the desired changes and confirm.

If applicable, the next function block parameter is displayed.

Confirm all parameters to exit the opened function block.

To adjust additional function blocks within the configuration level, repeat the steps in the fields

highlighted in gray.

Exit the configuration level.

Return to the operating level.

appears on the display, the key number needs to be entered first (refer to

Note!

The controller automatically returns to the operating level if the keys are left unpressed for two

minutes.

20 EB 5474 EN

Page 21

2.3 Changing parameters

Start-up

Depending on the activated functions, not all parameters listed in the parameter list in the Ap

pendix (–> section 13.2) might be available.

The parameters are arranged in topic groups:

PA1: Boiler 1

4

PA2: Systems Anl 1 to 3, Co5 -> Fb13 = ON: separate heating circuit

4

4

4

4

4

Proceed as follows:

To adjust additional parameters, repeat the steps in the fields highlighted in gray.

Systems Anl 4 to 7: Boiler 2

PA3: Systems Anl 1 to 3, Co5 -> Fb13 = ON: direct heating circuit

PA4: DHW heating

PA5: General parameters

PA9: Modbus and meter bus communication

Switch to the parameter and configuration level. Display:

Select parameter level (-> Fig. 10, page 131).

Open the parameter level.

Select parameter.

Activate editing mode for parameter.

Change parameter.

Confirm parameter setting.

Exit the parameter level.

Return to the operating level.

PA1

-

Note!

The controller automatically returns to the operating level if the keys are left unpressed for two

minutes.

EB 5474 EN 21

Page 22

Start-up

2.4 Enter key number

Some functions are protected against unintentional or unauthorized access. These functions can

only be activated or deactivated after the valid key number has been entered. The valid key

number for initial start-up can be found on page 127. To avoid unauthorized use of the key

number, remove the page or make the key number unreadable.

Proceed as follows:

0 0 0 0

The key number remains active for approx. 10 minutes.

blinks on the display.

Set valid key number.

Confirm key number.

When the correct key number is entered, the function block to be changed blinks on the

display.

When an incorrect key number is entered, the controller returns to the next configuration

level.

2.5 Calibrating sensors

The connected sensors are calibrated in the Co6 configuration level. The following applies:

Co6 -> Fb00 = ON: Pt 100/Pt 1000 sensors mixed (default setting)

4

Co6 -> Fb00 = OFF: Pt 100/PTC sensors mixed

4

The resistance values of the sensors can be found on page 115.

Each universal input can be configured separately.

The function block parameter includes the following types: Ni 200/1000, PTC, NTC,

Pt 100/1000, (0/4 to 20) mA. The function blocks Co6 -> Fb01 to Fb17 correspond to the bi

nary inputs BE1 to BE17 in the terminal wiring plan (–> page 78 onwards).

Activate the function block for the required sensor and select the function block parameter

which matches the type of the input signal.

Note!

Pt 100 orPt 1000 sensor should be used to measure theflow temperature as only these types of

sensor are able to measure temperatures reaching up to 160 °C (maximum temperature of the

flow temperature set point).

-

22 EB 5474 EN

Page 23

Start-up

If the temperature values displayed at the controller differ from the actual temperatures, the

measured values of all connected sensors can be changed or readjusted. To calibrate a sensor,

the currently displayed sensor value must be changed such that it matches the temperature (ref

erence temperature) measured directly at the point of measurement.

Perform the calibration in function block Fb23 in Co6.

Proceed as follows:

Switch to the parameter and configuration level.

Display:

PA1

Select Co6 configuration level.

Open Co6 configuration level.

Select function block Fb23.

Confirm setting.

Display:

0 0 0 0

Enter currently valid key number.

The function block Fb23 blinks on the display.

Activate function block.

Confirm setting.

Select the function block for the sensor to be calibrated:

The function blocks Co6 -> Fb01 to Fb17 correspond to the binary inputs BE1 to BE17

in the terminal wiring plan (–> page 78 onwards) depending on the selected system

code number (Anl), e.g. Co6 -> Fb03 for sensor VFg (all systems).

Activate editing mode for sensor.

Fb_ blinks on the display.

Display measured temperature.

Activate editing mode for measured temperature.

Measured temperature blinks.

Correct measured temperature.

Read the actual temperature directly from the thermometer at the point of measure

-

ment and enter this value as the reference temperature.

Confirm corrected measured temperature.

Additional sensors are calibrated similarly.

-

EB 5474 EN 23

Page 24

Start-up

Select function block Fb23.

Activate editing mode for function block Fb23.

Deactivate function block Fb23.

Confirm setting.

Select

End

on the display.

Exit the configuration level.

Return to the operating level.

Note!

The adjusted sensor values are not reset by the function for resetting to default values.

2.6 Resetting to default values

All parametersand function blocks that can be setwithout entering the key number can bereset

to their default settings (WE).

Proceed as follows:

Reset to default settings.

Function blocks and parameters are reset to their default settings (WE).

Note!

Resetting protected parameters to their default settings is only possible when the key number is

still active.

The controller isready foroperation with its default settings. You just need to set the correctdate

and current time.

24 EB 5474 EN

Page 25

Manual operation

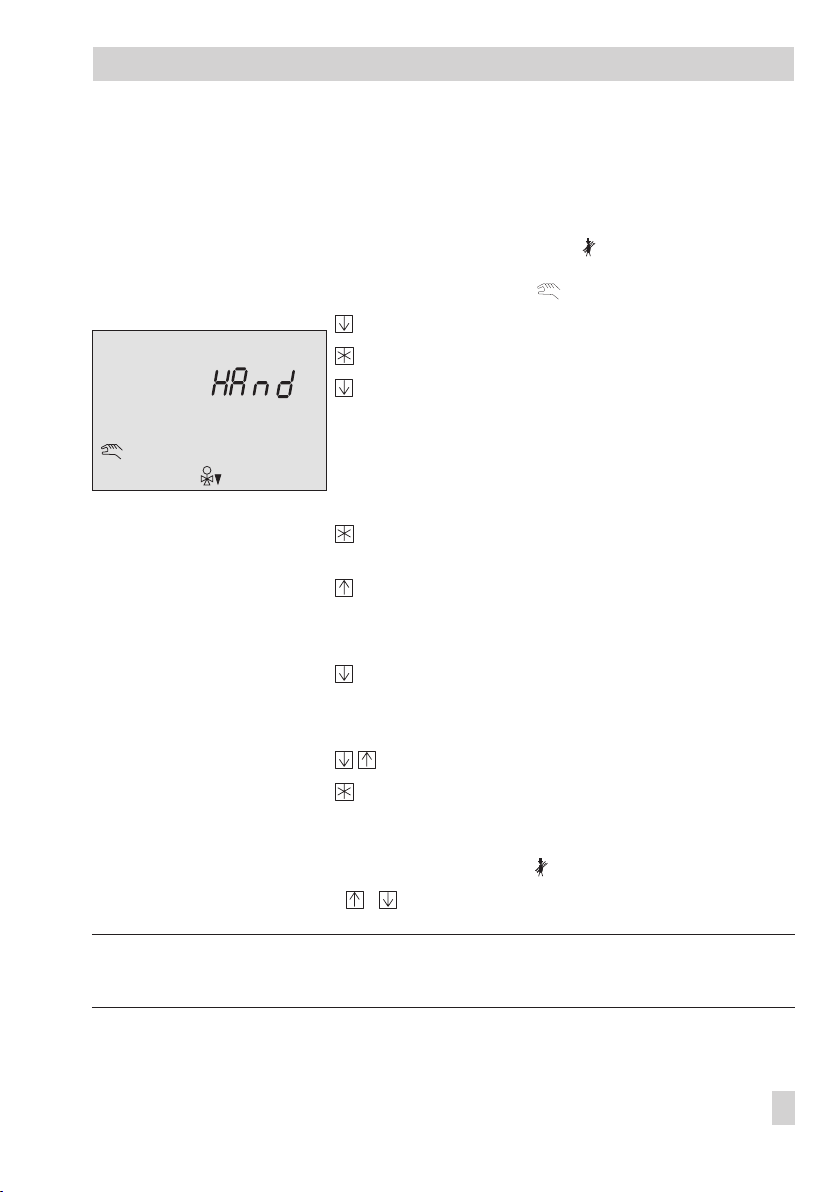

3 Manual operation

All the settings of the outputs canbe setin the manual mode, see wiring plan(-> section12).

Proceed as follows: Set mode selector switch to .

After approx. 10 seconds the boilers start operation at

full capacity. Display:

HAnd

9876543210

242322212019181716151413121110

Select

Open the manual level. Display:

Select output:

bA: 1, 2 BA1 and BA2

3-Pt: 1, 2 BA3 and BA4, BA5 and BA6

1

PU: 1, 2 BA7 and BA8

StUF: 1, 2, 3, 4 BA9 to BA12

AnAL: 1, 2 AA 1, 2 (RK1, RK2)

Activate editing mode for output.

The display blinks.

Activate output, increase value.

Three-point stepping output: OPEN

or:

Deactivate output, decrease value.

Three-point stepping output: CLOSED

and:

Three-point stepping output: STOP

Confirm setting.

The changed values remain valid as long as the manual

mode is active.

Slide mode switch to .

Exit the manual level.

on the display.

bA1

Note!

In manual mode, frost protection does not function.

EB 5474 EN 25

Page 26

Systems

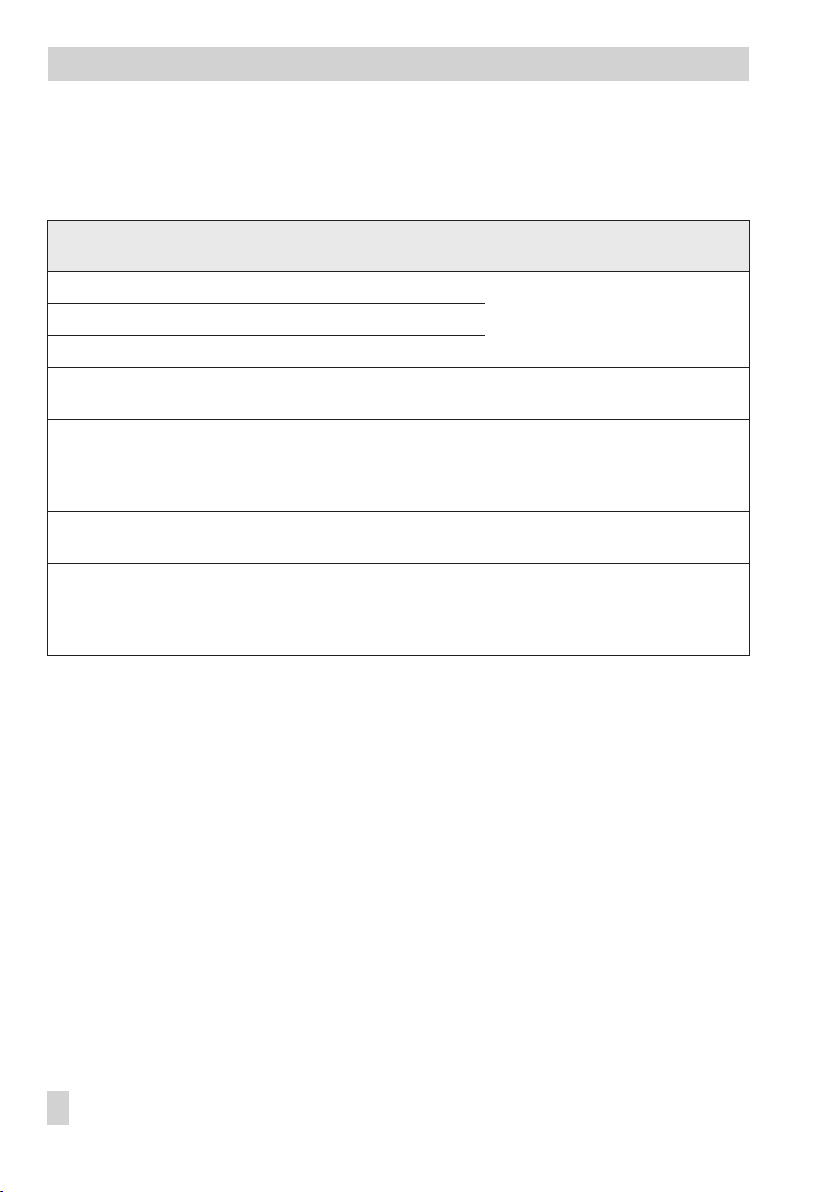

4 Systems

7 hydraulic schematics are available.

System code

number (Anl)

1

2

3

4

5 Double boiler for 2 two-stage burners Change in lag/lead sequence either

6 Double boiler for modulating und

7 Double boiler for two modulating

System description Comments

Single boiler for one-stage burner

Single boiler for two-stage burner

Single boiler for modulating burner

Double boiler for one-stage condensing boiler

and two-stage low-temperature boiler

two-stage burners

burners

Optionally separate heating circuit

and DHW heating can be controlled

Lag sequence without automatic

lag/lead sequence change

depending on operating hours, on

outdoor temperature or boiler

capacity

Lag sequence without automatic

lag/lead sequence change

Change in lag/lead sequence either

depending on operating hours, on

outdoor temperature or boiler

capacity

26 EB 5474 EN

Page 27

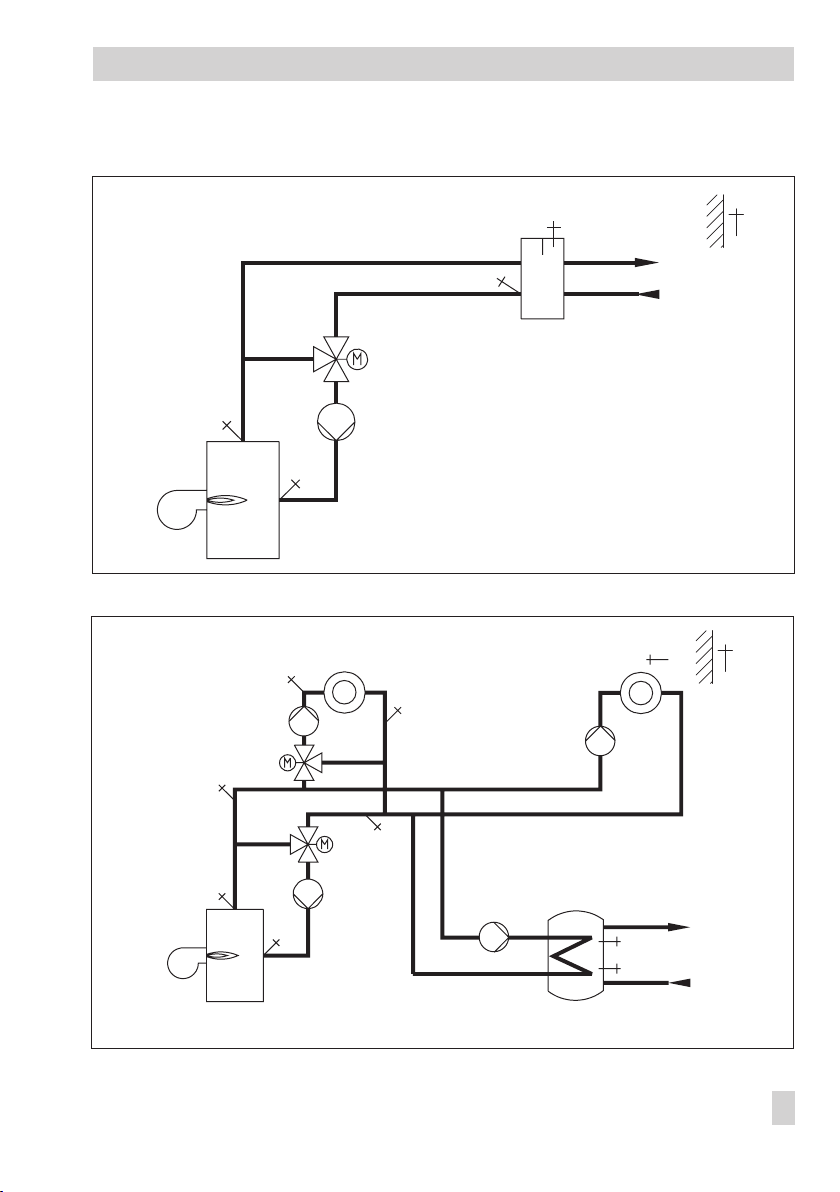

System Anl 1 with Co5 -> Fb13 = OFF

RK1

RüFg

Systems

VFg

AF

VL

RL

KF1

RüF1

1

Pu1

System Anl 1 with Co5 -> Fb13 = ON

VF2

Pu2

RK2

VFg

RK1

KF1

RüF1

1

Pu1

RüFg

RüF2

K1 One-stage burner

Pu3

SLP

RF

SF1

SF2

AF

K1 One-stage burner

EB 5474 EN 27

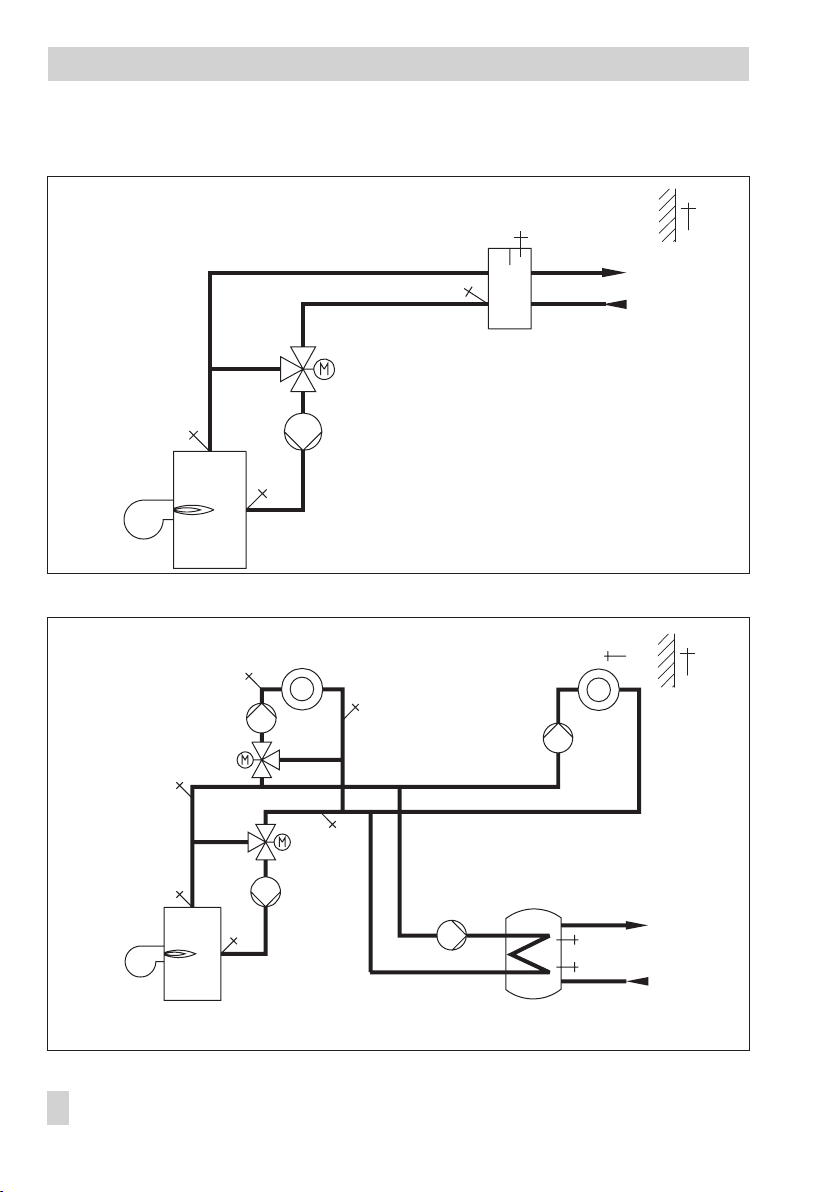

Page 28

Systems

System Anl 2 with Co5 -> Fb13 = OFF

KF1

RüF1

1

2

System Anl 2 with Co5 -> Fb13 = ON

VF2

Pu2

RK2

VFg

Pu1

RK1

RüF2

RüFg

VFg

K1 Two-stage burner

RF

Pu3

AF

VL

RL

AF

28 EB 5474 EN

KF1

RüFg

RK1

Pu1

RüF1

1

2

SLP

SF1

SF2

K1 Two-stage burner

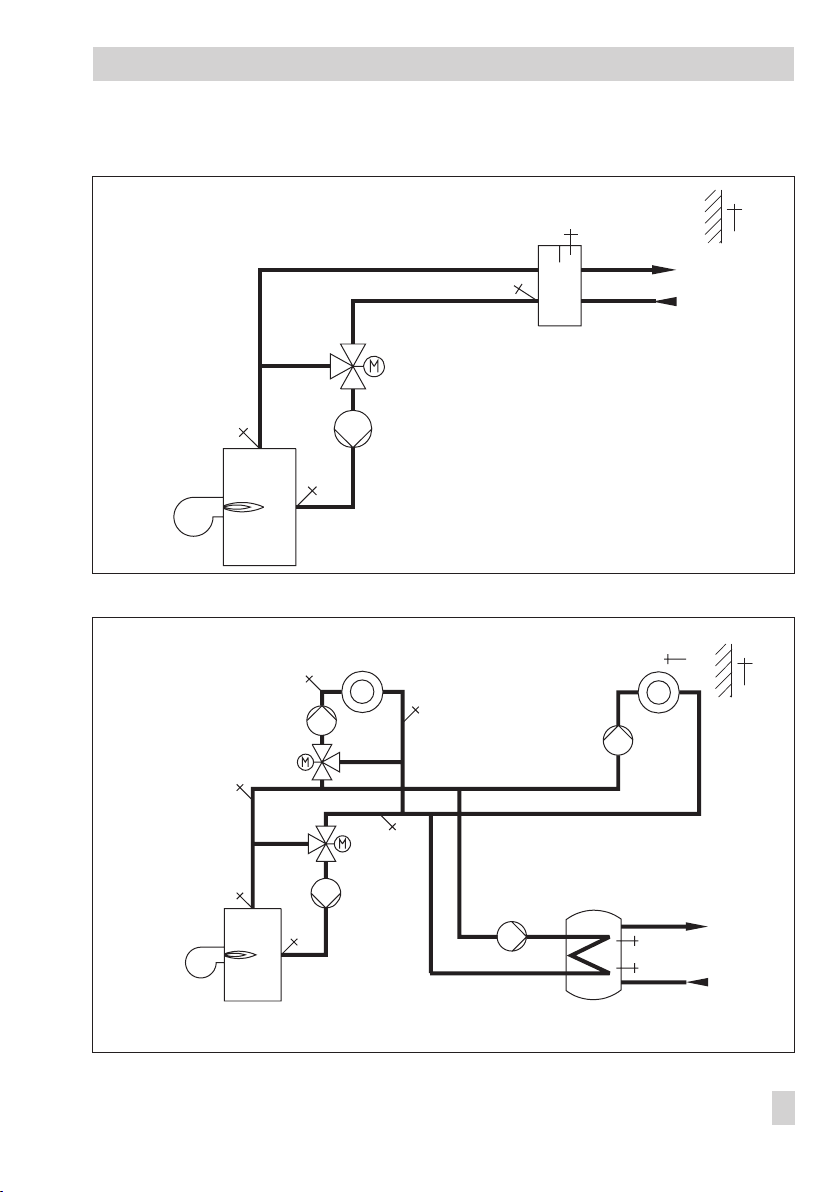

Page 29

System Anl 3 with Co5 -> Fb13 = OFF

Systems

KF1

RüF1

System Anl 3 with Co5 -> Fb13 = ON

VF2

Pu2

RK2

VFg

Pu1

RK1

RüF2

VFg

RüFg

K1 Modulating burner

Pu3

AF

VL

RL

RF

AF

KF1

RüF1

RK1

Pu1

RüFg

SLP

SF1

SF2

K1 Modulating burner

EB 5474 EN 29

Page 30

Systems

System Anl 4

System Anl 5

KF1

VFg

RüFg

RK1 RK2

Pu1 Pu2

1

RüF1

KF2

1

2

RüF2

K1 One-stage condensing boiler

VL

RL

AF

K2 Two-stage low-temperature boiler

VFg

RüFg

VL

RL

AF

30 EB 5474 EN

KF1

RK1 RK2

Pu1 Pu2

1

2

RüF1

KF2

1

2

RüF2

K1, K2 Two-stage burner

Page 31

System Anl 6

Systems

KF1

System Anl 7

RK1 RK2

Pu1 Pu2

RüF1

KF2

1

2

RüF2

RüFg

K1 Modulating burner

K2 Two-stage burner

RüFg

VFg

VFg

VL

RL

VL

RL

AF

AF

KF1

RK1 RK2

Pu1 Pu2

RüF1

KF2

RüF2

K1, K2 Modulating burner

EB 5474 EN 31

Page 32

Boiler functions

5 Boiler functions

5.1 Boiler switching behavior

The

Minimum activation and deactivation time

ters described in following.

To be able to keep the cooling off periods between two activation phases, a boiler is first

switched on when the time entered in

Minimum deactivation time

activation.

To ensurethe burning of residues left over during the start-upphase, a boiler is switched off first

after the time entered in

Parameters

Minimum activation time 1 min PA1, PA2* / 0 to 90 min

Minimum deactivation time 2 min PA1, PA2* / 0 to 90 min

Minimum activation time

On/off boiler

A boiler is activated when the flow temperature falls below the flow temperature set point by

Hysteresis

the

Lockout time

the

(Fig. 3). After the operational feedback message (burner firing –> section 5.10),

must elapse before the boiler is switched to the next stage. If the flow temperature is expected toreach theset pointrange withinthe

to the next stage.

A boiler stage is switched off when the flow temperature exceeds theflow temperature set point

by the

Hysteresis

.

Modulating boiler

A boiler starts to operate with its minimum capacity if the flow temperature falls below the flow

temperature set point by the

firing –>section 5.10), the

Hysteresis

Lockout time

(Fig. 2). After the operational feedback message (burner

troller modulates the boiler capacity to match the actual energy requirement according to the

flow temperature set point.

parameters have priority over allother parame

has passed since the last de

has elapsed.

WE Parameter level / Range of values

* Only in systems Anl 4 to 7

Tolerance time

, the boiler doesnot switch

must elapsebefore the modulation is enabled. The con

-

-

-

Parameters

Hysteresis 3 °C PA5 / 1 to 20 °C

Tolerance time 30 min PA5 / 0 to 99 min

Lockout time 2 min PA5 / 0 to 99 min

WE Parameter level / Range of values

32 EB 5474 EN

Page 33

Flow temperature set point +

Hysteresis

Boiler functions

t

[°C]

VL

Flow temperature set point

Flow temperature set point –

Hysteresis

Burner start

Activation of

boiler stage

Fig. 3 · Criteria for switching the boiler stages

tVL[°C]

Flow temperature set point +

Hysteresis

Flow temperature set point

Flow temperature set point –

Hysteresis

Lockout time

Operational alarm

f. burner

t [s]

Tolerance time

t [s]

Burner start

Activation of

boiler stage

Lockout time

Operational alarm

f. burner

Fig. 2 · Criteria for switching the modulating boiler

Tolerance time

EB 5474 EN 33

Page 34

Boiler functions

5.2 Lag/lead sequence control

The boilers are released depending on the configuration:

Co1, Co2* -> Fb00 = OFF: Boiler released according to the position of the mode selector

4

switch

Co1, Co2* -> Fb00 = ON: Boiler 1 is not released if binary input BE17 is closed, pro

4

vided Boiler 1 is not locked by the mode switch.

Boiler 2* is released if binary input BE16 is closed, provided Boiler 2 is not locked by the

mode switch.

Function

Release of boiler K1, 2 OFF Co1, Co2* -> Fb00

WE Configuration

* Only in systems Anl 4 to 7

5.2.1 Control without sensor VFg

The Burner activation independent from sensor VFg function allows the boiler to be switched

on independently from sensor VFg, i.e. exclusively according to boiler sensors VF1 and VF2.

Other functions which have an effect on the lag and lead sequence control of the boiler in

two-boiler systems do not affect the boiler which works independently any more.

On activating the Continuous running of pump function, the boiler pumps react like the pumps

of master controller in normal systems.

Functions

Burner activation not dependent on

sensor VFg

Continuous running of pump OFF Co5 -> Fb14

WE Configuration

OFF Co5 -> Fb20 = ON

-

5.2.2 Outdoor temperature-dependent sequence

If the outdoor temperature is above the limit entered in

just the lead boiler always remains in operation. The lag boiler is not even activated when the

maximum capacity of the lead boiler is insufficient to achieve an increased flow temperature.

The lag boiler is first released when the outdoor temperature is lower than the limit entered in

Temperature tAfor releasing sequence

The limit entered in

short-term demand above the limit can be compensated for without any loss in comfort by pro

longing the operating time of the lead boiler. This depends on the performance of the lead

boiler.

34 EB 5474 EN

Temperature tAfor releasing sequence

after t = 2 x

Temperature tAfor releasing sequence,

Lockout time

.

must be selected to ensure that a

-

Page 35

Boiler functions

Function

Releasing sequence ON Co5 -> Fb07 = ON

Parameters

Lockout time 2 min PA5 / 0 to 99 min

Temperature tAfor releasing sequence 12 °C PA5 / –40 to 50 °C

WE Configuration

WE Parameter level / Range of values

5.2.3 Capacity-dependent sequence

The lead boiler is activated when theflow temperaturefalls belowthe flowtemperature setpoint

Hysteresis

by the

the second stage. The second boiler is also activated if 90 % of its maximum load is not sufficient

over thetime period oft=2x

temperature set point and the set point hysteresis is not reached within the tolerance time.

The lag boiler is switched off when one of the following conditions is fulfilled:

The current load of both boilers is less than 90 %.

4

The actualtemperature is greater than the set point and hysteresis added together as wellas

4

its tendency shows that the temperature willnot fallbelow this total within the tolerance time.

Function

Releasing sequence ON Co5 -> Fb07 = OFF

Parameter

Lockout time 2 min PA5 / 0 to 99 min

. In the event of a demand for increased capacity, the lead boiler switches to

Lockout time

to increasethe flow temperature to therequired flow

WE Configuration

WE Parameter level / Range of values

5.2.4 Sequence lock

The binary input BE11 is used to lock the sequence. The input of the outdoor temperature is de

termined by the binary input. The outdoor sensor is not required.

Function

Outdoor sensor ON Co5 -> Fb00 = OFF, select: FoAUS

WE Configuration

5.2.5 Lag delay

The

Lag delay

mands. The second boiler is first switched on when required after the time in

elapsed. The time countdown is shown in the InF5 level.

parameter helps minimize losses during start-up in the event of short-term de

Lag delay

EB 5474 EN 35

has

-

-

Page 36

Boiler functions

Parameter

Lag delay 10 min PA5 / 0 to 90 min

WE Parameter level / Range of values

5.3 Change in lag/lead sequence (Anl 4 to 7)

The lag/lead sequence can be changed depending on the outdoor temperature, operating

hours or capacity. The change in lag/lead sequence is only effective when the mode selector

switch is set to and with the configuration Co5 -> Fb20 = OFF.

Note!

A change in lag/lead always takes place when the controller detects a fault in the lead boiler

regardless of the configuration.

2

1

5.3.1 Outdoor temperature-dependent change (Anl 5 and 7)

The outdoor temperature-dependent change in lag/lead sequence is only appropriate when

boilers with varying capacity are used.

The lead boiler is determined by comparing the mean outdoor temperature overthree dayswith

Reverse sequence limit t

the

Outdoor temperature >

4

boiler is the boiler with the smallest unit capacity

Outdoor temperature <

4

boiler is the boiler with the largest unit capacity

Functions

Automatic change in lag/lead sequence ON Co5 -> Fb09 = ON

Condition for change in lag/lead sequence ON Co5 -> Fb10 = OFF, select: 1

Parameter

Outdoor temperature limit for lag/lead

sequence change

parameter:

A

Outdoor temperature limit for lag/lead sequence change

Outdoor temperature limit for lag/lead sequence change

WE Configuration

WE Parameter level / Range of values

15 °C PA5 / –40 to 50 °C

: Lead

: Lead

5.3.2 Capacity-dependent change (Anl 5 and 7)

The lead boiler is the boiler which had the lowest average capacity over the past three days.

Functions

Automatic change in lag/lead sequence ON Co5 -> Fb09 = ON

36 EB 5474 EN

WE Configuration

Page 37

Boiler functions

Condition for change in lag/lead sequence ON Co5 -> Fb10 = OFF, select: 2

5.3.3 Operating hours-dependent change (Anl 5 and 7)

After a fixed amount of time haselapsed, countingin hoursfrom the time when the last lag/lead

sequence tookplace (

role as lead boiler.

The elapsed operating hours since the last change in lag/lead sequence are shown in the InF5

level.

Functions

Automatic change in lag/lead sequence ON Co5 -> Fb09 = ON

Condition for change in lag/lead sequence ON Co5 -> Fb10 = ON

Parameter

Time interval for lag/lead sequence change 168 h PA5 / 1 to 999 h

Time intervalfor lag/lead sequence change)

WE Configuration

WE Parameter level / Range of values

, theother boiler takes on the

5.3.4 Change with binary input (Anl 4 to 7)

The binary input BE4 can be used for the change in lag/lead sequence when the DHW heating

is not being controlled:

BE4 = OFF: Boiler 1 as lead boiler

4

BE4 = ON: Boiler 2 as lead boiler

4

Functions

DHW demand – active ON Co4 -> Fb00 = OFF

Automatic change in lag/lead sequence OFF Co5 -> Fb09 = OFF

WE Configuration

Note!

In system Anl 7 the binary input BE4 can be used either for modulation feedback, for an exter

nal demand for DHW or for an external change in lag/lead sequence.

5.4 Return flow boost

On fulfilling the criteria for activation (–> section 5.1) the return flow control circuit is closed at

the valve RK1/RK2. In the released boiler K1/K2 (see above), the first stage of the boiler and

the boiler pump Pu1/Pu2 is switched on. The water is circulated in the boiler circuit.

The return control circuit is released if the temperature at the sensor RüF1/RüF2 exceeds the

limit entered in

Minimum return flow temperature.

The mixing valve opens and release the cor

EB 5474 EN 37

-

-

Page 38

Boiler functions

responding flow rateto theplant untilthe valve is completely opened and the boiler pump deliv

ers the maximum flow rate in the plant.

Parameter

Minimum return flow temperature 50 °C PA1, PA2* / 20 to 120 °C

WE Parameter level / Range of values

* Only in systems Anl 4 to 7

Depending on the configuration, the return flow boost can be controlled with a continuous

signal, on/off signal or three-point stepping signal (–> section 8.11).

5.4.1 Common return flow boost

In systems with two boilers (systems Anl 4, 5, 6 and 7), a common return flow boost can be im

plemented. This is done by using the return flow control circuit of the first boiler K1, depending

on whether the boiler is in operation.

Function

Common return flow boost OFF Co5 -> Fb12 = ON

WE Configuration

5.5 Parallel operation (Anl 7)

This function leads to both boilers working constantly in parallel (no lag/lead sequence

control).

The boilersstart operatingone after the other, taking into account the programmed times:

and

mum deactivation time for boiler K1, 2

for releasing sequence

ture t

A

Function

Parallel operation of boilers OFF Co5 -> Fb19 = ON

Parameters

Minimum deactivation time f. boiler K1, 2 0 min PA1, 2 / 0 to 90 min

Lag delay 10 min PA5 / 0 to 90 min

Temperature tAfor releasing sequence 12 °C PA5 / –40 to 50 °C

Lag delay

WE Configuration

WE Parameter level / Range of values

as well as taking into account

Mini-

Tempera-

-

-

5.6 Operating hours counter

This function allows the performed operating hours of boilers K1, 2 to be shown in the Inf1, 2

levels. The control is not affected by the counted operating hours. If the operating hours should

be selected to start at a certain initial value, this can be programmed separately.

38 EB 5474 EN

Page 39

Boiler functions

Function

Operating hours counter OFF

WE Configuration

Co1, Co2* -> Fb02 = ON

0 h

Initial value / Configurable as required

count Counting the operating hours

rESEt Reset operating hours to initial value

* Only in systems Anl 4 to 7

5.7 Boiler pump control

The boiler pump control is connected with the boiler control loop.

When a boiler is switched on to the first stage, the associated boiler pump is also switched on.

When the boiler is switched off, the boiler is switched off too either after the

elapsed or when the temperature falls below

Boiler flow limit

.

Pump lag time

In summer mode, the boiler pump is switched off together with the boiler when the deactivation

criteria are fulfilled.

In systems without hydraulic separator, in which the heating water must be circulated through

the boiler, the boiler pump may notbe switchedoff. For this purpose, the Continuous running of

pump function is activated. The boiler pump continues to run when the lead boiler is switched

off and the valve is opened. As a result, the cold system water can reach the boiler return flow

pipe. If the return flow temperature is a factor that needs to be monitored in theboiler, theinstallation of an hydraulic separator is recommended.

Function

Continuous running of pump OFF

WE Configuration

Co5 -> Fb14 = ON

5 min

Pump lag time / 0 to 90 min

55 °C

Boiler flow limit / 20 to 120 °C

has

5.8 Boiler sensor acting as a thermostat

The boiler sensors KF1 and KF2 control the safety deactivation (–> section 8.10), which is trig

gered whenever the maximum flow temperature is exceeded, as well as the temperature-de

pendent pump lag of the boiler pumps Pu1 and Pu2 (–> section 5.7).

The maximum permissible flow temperature can also be monitored in systems Anl 4, 5 and 6

with thermostats. The inputs of the boiler sensors must be defined as binary inputs for this pur

pose. The thermostats are connected to the same terminals as the boiler sensors.

EB 5474 EN 39

-

-

-

Page 40

Boiler functions

Function

Boiler sensor KF1, 2 ON Co1, Co2* -> Fb03 = OFF

WE Configuration

StEiG: Thermostat closes

FALL: Thermostat opens

*Only in systems Anl 4 to 7

5.9 Modulation feedback

The modulation feedback in systems Anl 3, 6 and 7 can be implemented by a potentiometer (1

to 2 kΩ) or by a limit switch for maximum boiler capacity output.

Modulation feedback with potentiometer

The inputsfor the potentiometer are marked in thewiring diagrams (–> section 12) with SG_K1

(potentiometer 1) and with SG_K2 (potentiometer 2).

Function

Modulation feedback K1, 2 ON Co1, Co2* -> Fb07 = ON

WE Configuration

* Only in system Anl 7

Note!

In system Anl 7, the binary input BE4 can be used either for modulation feedback, for external

DHW demand or for external change in lag/lead sequence.

5.10 Operational alarm

The boiler controller waits for an operational alarm before it continues (–> section 5.1). The

operational alarm can optionally be issued over a binary input or after fixed time entered in

Start-up time for boiler

parameter.

40 EB 5474 EN

Page 41

Boiler functions

Operational alarm over a binary input

The inputs for the operational alarm are marked in the wiring diagrams (section 12) with BE2

BM_K1 for Boiler 1 and with BE1 BM_K2 for Boiler 2.

Function

Operational alarm K1, 2 ON Co1, Co2* -> Fb01 = ON

WE Configuration

* Only in systems Anl 4 to 7

Operational alarm after start-up

Function

Operational alarm K1, 2 ON

WE Configuration

Co1, Co2* -> Fb01 = OFF

0 s

Start-up time for boiler / 0 to 5400 s

* Only in systems Anl 4 to 7

5.11 Return flow sensor acting as a thermostat

The return flow sensors can optionally be replaced by thermostats. For this purpose, the inputs

for the return flow sensors are defined as binary inputs. The thermostats are connected to the

same terminals as the return flow sensors.

Function

Return flow sensor RüF1, 2 ON Co1, Co2* -> Fb04 = OFF

WE Configuration

StEiG: Thermostat closes

FALL: Thermostat opens

* Only in systems Anl 4 to 7

EB 5474 EN 41

Page 42

Functions of the heating circuit

6 Functions of the heating circuit

6.1 Outdoor temperature-dependent advance heating

Only selectable for systems Anl 1 to 3 with Co5 -> Fb13 = ON.

The controller switchesthe heatingon beforethe time-of-use starts in normal operation depend

ing onthe outdoor temperature. The

of –12 °C. The advance heating time is shortened in case of higher outdoor temperatures.

Functions

Heating circuit with DHW heating OFF Co5 -> Fb13 = ON

Optimization OFF

Outdoor sensor ON Co5 -> Fb00 = ON

Advance heatingtime

WE Configuration

Co3 -> Fb05 = ON,

120 min

Advance heating time / 0 to 360 min

is basedon an outdoor temperature

select: 1

6.2 Optimization using a room sensor

Only selectable for systems Anl 1 to 3 with Co5 -> Fb13 = ON.

Both thefunctions describedshould only be used if the room in which theroom sensor is located

(reference room) has a heating characteristic that is similar to the rest of the building.

No thermostat valves should be mounted on the radiators in the reference room.

There are two types of optimization depending on the activation conditions:

Outdoor temperature-dependent advance heating, room temperature-dependent deacti-

4

vation

The controller activates the heating depending on the outdoor temperature before the

time-of-use starts in normal operation. The

temperature of –12 °C. The advance heating time is shorter whenthe outdoortemperature is

higher (see section 6.1).

Room temperature-dependent advance heating and deactivation

4

The controller calculates the required advance heating time (max. 6 hours) adapted to the

building characteristics, resulting in the

reached in the reference room when the time-of-use starts. The heating is heated with the

maximum flowtemperature duringthe advance heating phase. As soon as the

is reached, outdoor temperature-dependent control starts.

Advance heating time

Day set point

(rated room temperature) being

is based on an outdoor

Day setpoint

-

The controllerdeactivates the heating in both types of optimization dependingon the room sen

sors up to two hours before the time-of-use finishes.

The controller chooses the deactivation time such in a way that the room temperature does not

drop significantly below the desired temperature until the time-of-use ends.

42 EB 5474 EN

-

Page 43

Functions of the heating circuit

Outside the times-of-use, the controller monitors the

Sustained temperature

or the

in the case of room temperature-dependent deactivation. When

Night set point

(reduced room temperature)

the temperature falls below the night set point, the controller heats with the max. flow tempera

ture until the measured room temperature exceeds the adjusted value by 1 °C.

Note!

Direct sunshine can cause theroom temperatureto increaseand thusresult inthe prematurede

activation of the heating system.

A drop in room temperature within a brief period outside of the time-of-use may lead to the ad

vance heating to reach the room temperature being activated too early.

Functions

Heating circuit with DHW heating OFF Co5 -> Fb13 = ON

Room sensor OFF Co3 -> Fb00 = ON

Outdoor temperature-dependent advance heating, room temperature-dependent deactivation:

Optimization OFF

Outdoor sensor AF1 to 3 ON Co5 -> Fb00 = ON

Room temperature-dependent advance heating and deactivation:

Optimization OFF

Parameter

Day set point 20 °C PA3 / 10 to 40 °C

Night set point 17 °C PA3 / 10 to 40 °C

Sustained temperature 10 °C PA3 / 10 to 40 °C

WE Configuration

Co3 -> Fb05 = ON,

120 min

WE Parameter level / Range of values

Advance heating time / 0 to 360 min

Co3 -> Fb05 = ON,

select: 2

select: 3

-

-

-

EB 5474 EN 43

Page 44

Functions of the DHW circuit

7 Functions of the DHW circuit

Only systems Anl 1 to 3 have their own DHW heating (DHW heating in storage system with

Co5 -> Fb13 = ON).

The systems Anl 4 to 7 do not have their own DHW heating; they are, however, able to process

an external DHW demand (-> section 7.4) and to reduce an excessively high flow temperature

over a DHW forced charging in the external system (-> section 7.2).

7.1 DHW heating in the storage tank system (Anl 1 to 3)

WW

SLP

Fig. 4 · DHW heating in a storage tank system

SF1

SF2

ZP

KW

SLP Storage tank charging pump

SF1 Storage tank sensor 1

SF2 Storage tank sensor 2

ZP Circulation pump

WW Hot water

KW Cold water

Operation with storage tank sensor SF1

The controller begins charging the storage tank when the water temperature measured at sensor SF1 falls below the set point

DHW demand ON

. The controller stops charging the storage

tank when the water temperature in the storage tank measured at sensor SF1 reaches the value

DHW demand ON+Hysteresis

T =

The set point

Functions

Heating circuit with DHW heating OFF Co5 -> Fb13 = ON

Storage tank sensor SF1 OFF Co4 -> Fb03 = ON

Storage tank sensor SF2 OFF Co4 -> Fb04 = OFF

Parameters

Boiler set point for DHW demand 65 °C PA4 / 20 to 120 °C

DHW demand ON 40 °C PA4 / 20 to 90 °C

Hysteresis 5 °C PA4 / 0 to 30 °C

Boiler set point for DHW demand

.

determines the set point at sensor VFg.

WE Configuration

WE Parameter level / Range of values

44 EB 5474 EN

Page 45

Functions of the DHW circuit

Operation with two storage tank sensors SF1 and SF2

The controller begins charging the storage tank when the water temperature measured at sen

sor SF1 falls below the set point

DHW demand ON

. The controller stops charging the storage

tank when the water temperature in the storage tank measured at sensor SF2 reaches the value

DHW demand OFF

The set point

Functions

Heating circuit with DHW heating OFF Co5 -> Fb13 = ON

Storage tank sensor SF1 OFF Co4 -> Fb03 = ON

Storage tank sensor SF2 OFF Co4 -> Fb04 = ON

Parameters

Boiler set point for DHW demand 65 °C PA4 / 20 to 120 °C

DHW demand ON 40 °C PA4 / 20 to 90 °C

DHW demand OFF 45 °C PA4 / 20 to 90 °C

.

Boiler set point for DHW demand

WE Configuration

WE Parameter level / Range of values

determines the set point at sensor VFg.

Operation with storage tank thermostat

The storage tank thermostat is connected to SF1 and switches the storage tank charging on and

off. The set point

Functions

Heating circuit with DHW heating OFF Co4 -> Fb13 = ON

Storage tank sensor SF1 OFF Co4 -> Fb03 = OFF

Storage tank sensor SF2 OFF Co4 -> Fb04 = OFF

Parameter

Boiler set point for DHW demand 65 °C PA4 / 20 to 120 °C

Boiler set point for DHW demand

must still be predetermined.

WE Configuration

WE Parameter level / Range of values

-

7.1.1 Priority circuit (Anl 1 to 3)

The DHW heating can be switched with priority over the separate heating circuit 2 or directly

over the heating circuit (heating circuit 3, Pu3).

Heating circuit 2:

During the storage tank charging, the separateheating circuit2 is placed in reduced operation.

EB 5474 EN 45

Page 46

Functions of the DHW circuit

Functions

Heating circuit with DHW heating OFF Co5 -> Fb13 = ON

DHW priority over HK2 OFF Co4 -> Fb06 = ON

WE Configuration

Heating circuit 3:

During the storage tank charging, the direct heating circuit is switched off. The separate heating

circuit runs in parallel.

Functions

Heating circuit with DHW heating OFF Co5 -> Fb13 = ON

DHW priority over HK3 OFF Co4 -> Fb07 = ON

WE Configuration

Note!

When the DHW priority over HK3 function is deactivated, the direct heating circuit also runs in

parallel to the DHW charging. The heating circuit may, however, only be overheated by 10 °C .

In other words, the heating circuit is supplied with not enough heat when the boiler set point for

the heating circuit is greater than

Boiler set point for DHW demand

off during storage tank charging when the

Boiler set point for DHWdemand

. The heating circuit is switched

is 10 °C higher than

the boiler set point.

7.2 Forced charging of the DHW storage tank (Anl 1 to 7)

A forced charging of the DHW storage tank can prevent that the safety equipment place the

boiler out of operation in case of excessively high flow temperature.

The forced charging of the DHW storage tank takes place when the

forced charging

is exceeded at the flow sensor together with sensor VFg or at one of the two

boiler sensors KF1 or KF2.

In systems without their own DHW heating (systems Anl 4 to 7) the demand for a forced charg

ing is passed on to the connected controllers atbinary outputBA1. The actual forced charging is

started by the controllers that are responsible for the DHW heating.

Functions

Heating circuit with DHW heating OFF Co5 -> Fb13 = ON*

Forced charging of DHW storage

tank

WE Configuration

OFF

Co4 -> Fb02 = ON

80 °C

Maximum limit f. DHW forced charging/20 to 120 °C

* Not in systems Anl 4 to 7

Maximum limit for DHW

-

46 EB 5474 EN

Page 47

Functions of the DHW circuit

7.3 Thermal disinfection (Anl 1 to 3)

In all systems with DHW heating, the DHW storage tank is thermally disinfected on the selected

Day of week

The charging temperature is always 5 °C higher than the

Thermal disinfection starts at the adjusted

Disinfection temperature

the

display. The error alarm is automatically reset when the

during the next thermal disinfection.

Thermal disinfection for preventing legionella infection causes

high return flow temperatures during the disinfection cycle (return flow temperature limita

4

tion suspended),

high storage tank temperatures after thermal disinfection has been concluded,

4

lime scale (possibly), which can have a negative effect on heat exchanger performance.

4

Note!

This function is not available when a storage tank thermostat is used.

or daily. The storage tank is heated up to the adjusted

Disinfection temperature

Start time

is not reached at the end of thermal disinfection, blinks on the

and finishes at the

Disinfection temperature

Disinfection temperature

.

Stop time

at the latest. If

is reached

.

-

Functions

Heating circuit with DHW heating OFF Co5 -> Fb13 = ON

Storage tank sensor SF1 OFF Co5 -> Fb03 = ON

Thermal disinfection OFF

WE Configuration

Co4 -> Fb08 = ON

Day of week / 0, 1 to 7 (daily, Mon to Sun)

3

Disinfection temperature / 50 to 80 °C

70 °C

Start time / 00:00 to 23:59 h

00:00

Stop time / 00:00 to 23:59 h

04:00

EB 5474 EN 47

Page 48

Functions of the DHW circuit

7.4 External DHW demand (Anl 1 to 7)

This function allows the boiler controller to switch over to the

Boiler set point for DHW demand

when the binary input BE4 (WWA) is closed. The thermal disinfection has priority when the ex

ternal DHW demand and thermal disinfection coincide.

Functions

Modulation feedback K2 ON Co2 -> Fb07 = OFF

DHW demand – active ON Co4 -> Fb00 = ON

Parameter

Boiler set point for DHW demand 65 °C PA4 / 20 to 120 °C

WE Configuration

WE Parameter level / Range of values

Note!

In system Anl 7, the binary input BE4 can be used either for modulation feedback, for external

DHW demand or for external change in lag/lead sequence.

-

48 EB 5474 EN

Page 49

System-wide functions

8 System-wide functions

8.1 Weather-compensated control

When weather-compensated control is used, the flow temperature is controlled according to the

outdoor temperature. The boiler characteristic in the controller defines the flow temperature set

point as a function of the outdoor temperature (–> Fig. 5). The outdoor temperature required for

weather-compensated control is measured at the outdoor sensor at the input AF or received

over a 0 to 10 V signal at the input AE2.

[

C] t

˚

VL

130

120

110

100

90

80

70

60

50

40

30

20

20 16 12 8 4 0 -4 -8 -12 -16 -20

Fig. 5 · Gradient characteristic

3.2 2.9 2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.4

0.2

t

C]

[

˚

tVLFlow temperature

t

A

A

Outdoor temperature

Caution!

Pt 100or Pt1000 sensorshould be used for measuring the flow temperature as only these sensors

guarantee measurements up to 160 °C (max. temperature of the flow temperature set point).

Function

Outdoor sensor ON

WE Configuration

Co5 -> Fb00 = ON

FUEHL: Outdoor temperature sensor AF

0–10: 0 to 10 V signal

3 °C

Frost protection limit / –30 to 20 °C*

* See section 8.8

EB 5474 EN 49

Page 50

System-wide functions

8.1.1 Gradient characteristic

Basically, the following rule applies: a decrease in the outdoor temperature causes the flow tem

perature to increase. By varying the

teristic to your individual requirements. Increasing

ture, decreasing

transport of the heating characteristic in an upward or downward direction.

Outside the times-of-use, reduced set points are used for control:

Reduced flow set point

Max. flowtemperature

The

its of the flow temperature. A separate gradient characteristic can be selected for the limitation

of the return flow temperature.

Examples for adjusting the characteristic:

Old building, radiator design 90/70: Gradient approx. 1.8

4

New building, radiator design 70/55: Gradient approx. 1.4

4

New building, radiator design 55/45: Gradient approx. 1.0

4

Underfloor heating depending on arrangement: Gradient smaller 0.5

4

Functions

Type of characteristic OFF Co5 -> Fb03 = ON, select: 2

Type of characteristic for separate/direct

heating circuit*

Parameters

Gradient, flow 1.8 PA2*, PA3*, PA5 / 0.4 to 3.2

Level, flow 0 °C PA2*, PA3*, PA5 / –30 to 30 °C

Set-back difference 15 °C PA2*, PA3*, PA5 / 0 to 30 °C

Max. flow temperature 90 °C PA2*, PA3* / 20 to 160 °C

Min. flow temperature 20 °C PA2*, PA3* / 20 to 120 °C

Gradient

in alower flowtemperature. The

= Flow set point–Set-back difference

and

Gradient

Min. flowtemperature

and

Level

WE Configuration

ON Co2, Co3 -> Fb10 = ON, select: 2*

* Only in systems Anl 1 to 3 with Co5 -> Fb13 = ON

WE Parameter level / Range of values

* Only in systems Anl 1 to 3 with Co5 -> Fb13 = ON

parameters, you can adapt the charac

Gradient

parameters markthe upperand lowerlim

results in a higher flow tempera

Level

parameter performsa parallel

.

-

-

-

-

50 EB 5474 EN

Page 51

System-wide functions

[˚C]

8.1.2 4-point characteristic

The 4-point characteristic allows you to define your own heating characteristic.

It is defined by 4 points for the

set-back difference

is predetermined for points P1 and P2 and for points P3 andP4 inthe corre

Outdoor temperature

sponding parameter level, resulting in the dashed line in Fig. 6.

Max. flowtemperature

The

and

Min. flowtemperature

its of the flow temperature.

t

[˚C]

VL

100

t

VLmax

90

80

70

60

50

t

VLmin

40

30

20

10

P4

20 15 10 5 0 –5 –10 –15 –20

Fig. 6 · 4-point characteristic

P2

P3

P1

and the

Flow temperature

parameters markthe upperand lowerlim

P1 to 4 Points 1 to 4

Flow temperature

t

VL

Outdoor temperature

t

A

..min Min. flow temperature

..max Max. flow temperature

4-point characteristic

-------- Reduced 4-point characteristic

t

A

. The

Boiler

-

-

Functions

WE Configuration

Type of characteristic OFF Co5 -> Fb03 = ON, select: 1

Type of characteristic for separate/

OFF Co2, Co3 -> Fb10 = ON, select: 1*

direct heating circuit*

* Only in systems Anl 1 to 3 with Co5 -> Fb13 = ON

EB 5474 EN 51

Page 52

System-wide functions

Parameters

Outdoor temperature Point 1

Point 2

Point 3

Point 4

Flow temperature Point 1

Point 2

Point 3

Point 4

Set-back difference Points

½

Points

3/4

Max. flow temperature 90 °C PA2*, PA3* / 20 to 160 °C

Min. flow temperature 20 °C PA2*, PA3* / 20 to 120 °C

WE Parameter level / Range of values

–10 °C

– 5 °C

10 °C

90 °C

80 °C

68 °C

50 °C

15 °C

20 °C

* Only in systems Anl 1 to 3 with Co5 -> Fb13 = ON

PA2*, PA3*, PA5 / –20 to 50 °C

5 °C

PA2*, PA3*, PA5 / 20 to 160 °C

PA2*, PA3*, PA5 / 0 to 30 °C

8.2 Fixed set point control

During the times-of-use, the flow temperature can be controlled according to a fixed

Outside the times-of-use, this

Set point

is reduced by the

Set-back difference

The fixed set point control is activated when there is no outdoor sensor AF connected to the system or when it has been configured in the function block Type of characteristic. In the case that

the fixed set point control is configured and an outdoor sensor is connected, the outdoor temperature is displayed in the InF5 level. The outdoor temperature does not have any effect on the

control loop.

Functions

Type of characteristic OFF Co5 -> Fb03 = OFF

Type of characteristic for separate/

direct heating circuit*

Parameters

Flow temperature set point 70 °C PA2*, PA3*, PA5 / 20 to 160 °C

Set-back difference 15 °C PA2*, PA3*, PA5 / 0 to 30 °C

WE Configuration

OFF Co2, Co3 -> Fb10 = OFF*

* Only in systems Anl 1 to 3 with Co5 -> Fb13 = ON

WE Parameter level / Range of values

* Only in systems Anl 1 to 3 with Co5 -> Fb13 = ON

Set point

.

.

52 EB 5474 EN

Page 53

System-wide functions

8.3 Differential temperature control using variable weighting factors

This functionallows thereturn flow temperature, total (RüFg) to be taken into account in the con

trol loop, in addition to the flow temperature, total (VFg).

The difference between the flow temperature, total (VFg) and return flow temperature, total

(RüFg) is specified using the

Intended temperature difference

parameter. It is a measure for the

energy consumption in a heating circuit. The greater the temperature difference, the larger the

energy required by a heating circuit. If the actual temperature difference is not the same as the

intended temperature difference, it is evaluated by the

. After initial signs for a deviation occur, the flow temperature is raisedor reducedby this

control

Kp factor for differential temperature

factor.

When the

Kp factor for differential temperature control

is set to 0, the return flow temperature

does not have any effect on the control of the flow temperature.

When the

Kp factor for differential temperature control

is set to 1, a pure return flow tempera

ture limitation takes place.

Function

Return flow sensor, total RüFg OFF

WE Configuration

Co5 -> Fb02 = ON

10 °C

Intended temperature difference / 0 to 90 °C

0.5

Kp factor for differential temperature control /

0 to 1

8.4 Deactivation depending on outdoor temperature

The controller switches to the stand-by mode when

to summer mode in rated operation

during times-of-use or

change to summer mode in reduced operation

Should the temperature fall below the limit, the heating is started again. The function for deacti

vation depending outdoor temperature is set by default.

Parameter

Outdoor temperature limit causing change

to summer mode in rated operation

Outdoor temperature limit causing change

to summer mode in reduced operation

WE Parameter level / Range of values

22 °C PA5 / 0 to 50 °C

10 °C PA5 / –10 to 50 °C

Outdoor temperature limit causing change

Outdoor temperature limit causing

outside times of use is exceeded.

-

-

-

EB 5474 EN 53

Page 54

System-wide functions

8.5 Summer mode

Summer mode is activated depending on the mean daytime temperature (measured between

7.00h and 22.00h) during the desired period.

If the mean daytime temperature exceeds the

Outdoor temperature limit

on two consecutive

days, summer mode is activated on the following day: the heating is switched off. If the mean

daytime temperature remains below the

Outdoor temperature limit

on the next day, summer