Page 1

Automation System 5400

Heating and District Heating Controller

TROVIS 5432

Electronics from SAMSON

Mounting and

Operating Instructions

EB 5432 EN

®

Firmware version 2.1x

Edition July 2004

Page 2

Disclaimer of liability

Disclaimer of liability

We are constantly developing our products and therefore, reserve the right to change the

product or the information contained in this document at any time without notice.

We do not assume any liability for the accuracy or completeness of these mounting and op

erating instructions. Moreover, we do not guarantee that the buyer can use the product for

an intended purpose. SAMSON rejects any liability for claims by the buyer, especially

claims for compensation including lost profits or any other financial loss, except the damage

was caused intentionally or by gross negligence. If an essential term of the contract is

breached by negligence, SAMSON’s liability is limited to the foreseeable damage.

Safety instructions

The device may only be assembled, started up or operated by trained and

4

experienced personnel familiar with the product. Proper shipping and appropriate storage are assumed.

The controller has been designed for use in electrical power systems. For

4

wiring and maintenance, you are required to observe the relevant safety

regulations.

-

2 EB 5432 EN

Page 3

Contents

Table of contents

1 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Control knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Operating modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Displaying data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Setting the system time . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6 Setting the times-of-use . . . . . . . . . . . . . . . . . . . . . . . . 10

1.7 Stand-by mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.7.1 Vacation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.7.2 Outdoor temperature dependent deactivation. . . . . . . . . . . . . . 12

1.8 Party mode

1.9 Correcting the set point . . . . . . . . . . . . . . . . . . . . . . . . 14

1.9.1 Correcting the set point temporarily . . . . . . . . . . . . . . . . . . 14

1.9.2 Correcting the set point permanently . . . . . . . . . . . . . . . . . . 14

2 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 Configuration and parameterization . . . . . . . . . . . . . . . . . . 15

3 Manual operation mode . . . . . . . . . . . . . . . . . . . . . . . 16

4 Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 Functions of the heating circuit . . . . . . . . . . . . . . . . . . . . 23

5.1 Weather-compensated control . . . . . . . . . . . . . . . . . . . . . 23

5.2 Fixed set point control . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3 Drying of jointless floors . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4 Automatic deactivation of the heating . . . . . . . . . . . . . . . . . 26

5.5 Outdoor temperature dependent advance heating . . . . . . . . . . . 27

5.6 Delayed adaptation to the outdoor temperature . . . . . . . . . . . . 27

5.7 Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.8 Flash adaptation . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.9 Room temperature-based control. . . . . . . . . . . . . . . . . . . . 29

6 Functions of the DHW circuit . . . . . . . . . . . . . . . . . . . . . 30

6.1 DHW priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 System-wide functions . . . . . . . . . . . . . . . . . . . . . . . . 32

7.1 Automatic summer time/winter time changeover . . . . . . . . . . . . 32

7.2 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.3 Forced operation of the pumps. . . . . . . . . . . . . . . . . . . . . 32

7.4 Limiting the return flow temperature . . . . . . . . . . . . . . . . . . 33

(constant rated operation)

. . . . . . . . . . . . . . . . . 13

EB 5432 EN 3

Page 4

Contents

7.5 Three-step control . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.6 On/off control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8 Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9 Infrared interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11 Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . 39

12 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

12.1 Function block list . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

12.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

12.3 Resistance values with Pt 1000 sensor . . . . . . . . . . . . . . . . . 43

12.4 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

12.5 User data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4 EB 5432 EN

Page 5

Operation

1 Operation

The controller is ready for use with the temperatures and operating time schedules preset by

the manufacturer.

On start-up, the current time and date need to be set at the controller (–> section 1.5).

1.1 Control knob

Turn q:

*

Select parameters, displays and temperature displays

Press :

Confirm adjusted selection or settings

Press for three seconds 3s:

Switch from the operating level to the user level as well as from

the user level to the installation level

1.2 Operating modes

Automatic mode

Display: and in the time-of-use periods, and outside of the times-of-use periods

The controller works in rated operation within the programmed times-of-uses and in reduced

operation outside of the times-of-use, provided that the control operation is not deactivated

due to the outdoor temperature. The controller switches automatically between both operating modes.

Day mode (constant rated operation)

Display:

Regardless of the programmed times-of-use, the set points relevant for rated operation are

used constantly by the controller.

Stand-by mode (vacation mode)

Display:

In stand-by mode, the heating is switched off regardless of the programmed times-of-use.

The frost protection mode is still active.

Night mode (reduced operation; can only be set over the room panel)

Display:

Regardless of the programmed times-of-use, the set points relevant for reduced operation are

used constantly by the controller.

PArTY

HoLidAY

or

or – – –

EB 5432 EN 5

Page 6

Operation

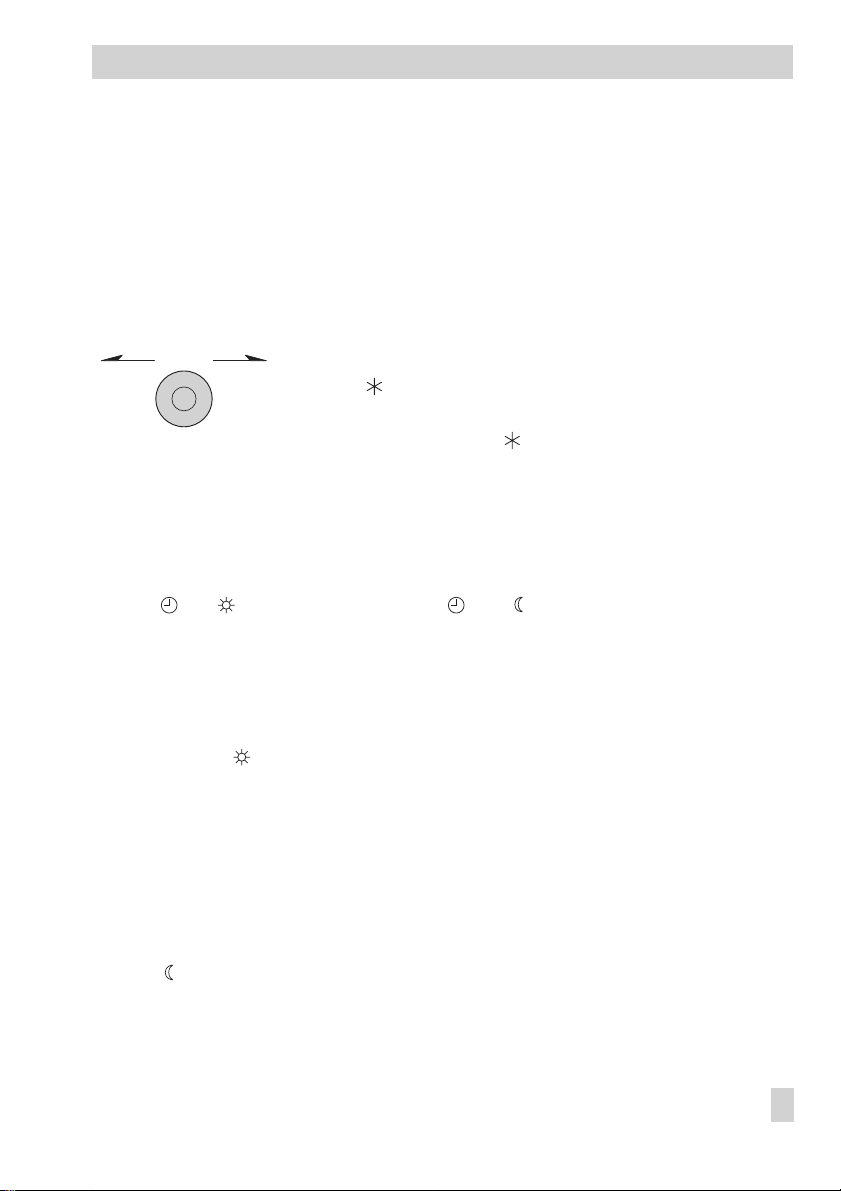

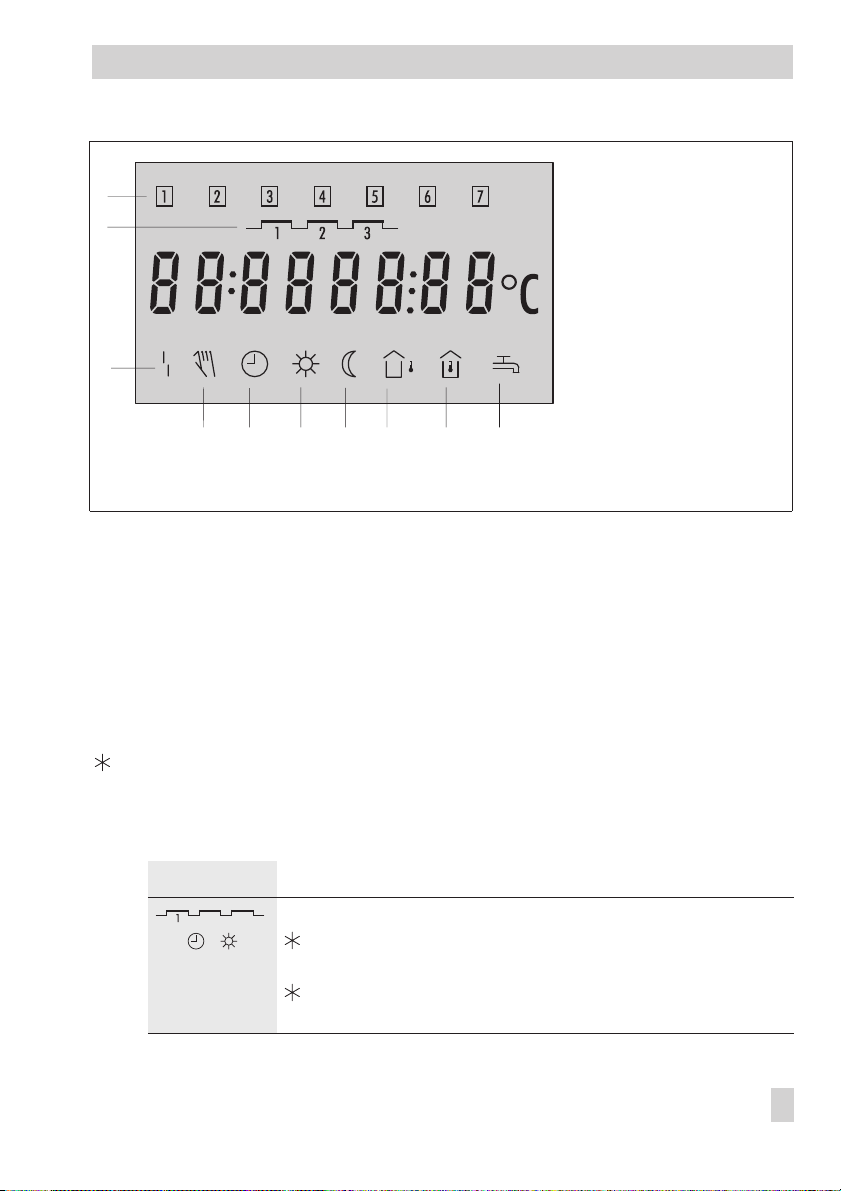

1.3 Display

The current set point appears on the display during operation.

Which set point is displayed depends on:

The configured type of control

4

The programmed times-of-use

4

Weather-compensated control, room set point mode (F1 - 1 and F9 - 1)

Day set point (time-of-use period)*

or night set point (outside of time-of-use period)

Weather-compensated control (F1 - 1 and F9 - 0), fixed set point control (F1 - 0 and F7 - 0)

Flow temperature (times-of-use period)*

or reduced flow temperature (outside of time-of-use period)

The set point (left) and the measured value (right) are

displayed in this example.

* Appears on the depicted display

Note!

The icon appears additionally on the display for a control functioning with the room

panel unit (F7- 1).

A temporarily active set point (corrected once) is indicated on the display by the icon

together with the icon (refer to section 1.9.1).

An active function for drying of jointless floors is indicated on the display by the icon

together with the icon (refer to section 5.3).

6 EB 5432 EN

Page 7

Operation

1 Days of week

1

2

3

4 5 6 7 8 9 10

Fig. 1 · Icons

Mon (1) to Sun (7)

2 Times-of-use

periods

3 Malfunction

4 Manual mode

5 Automatic mode

6 Day operation

(rated operation)

7 Night operation

(reduced operation)

8 Outdoor sensor

9 Room sensor

10 Hot water demand

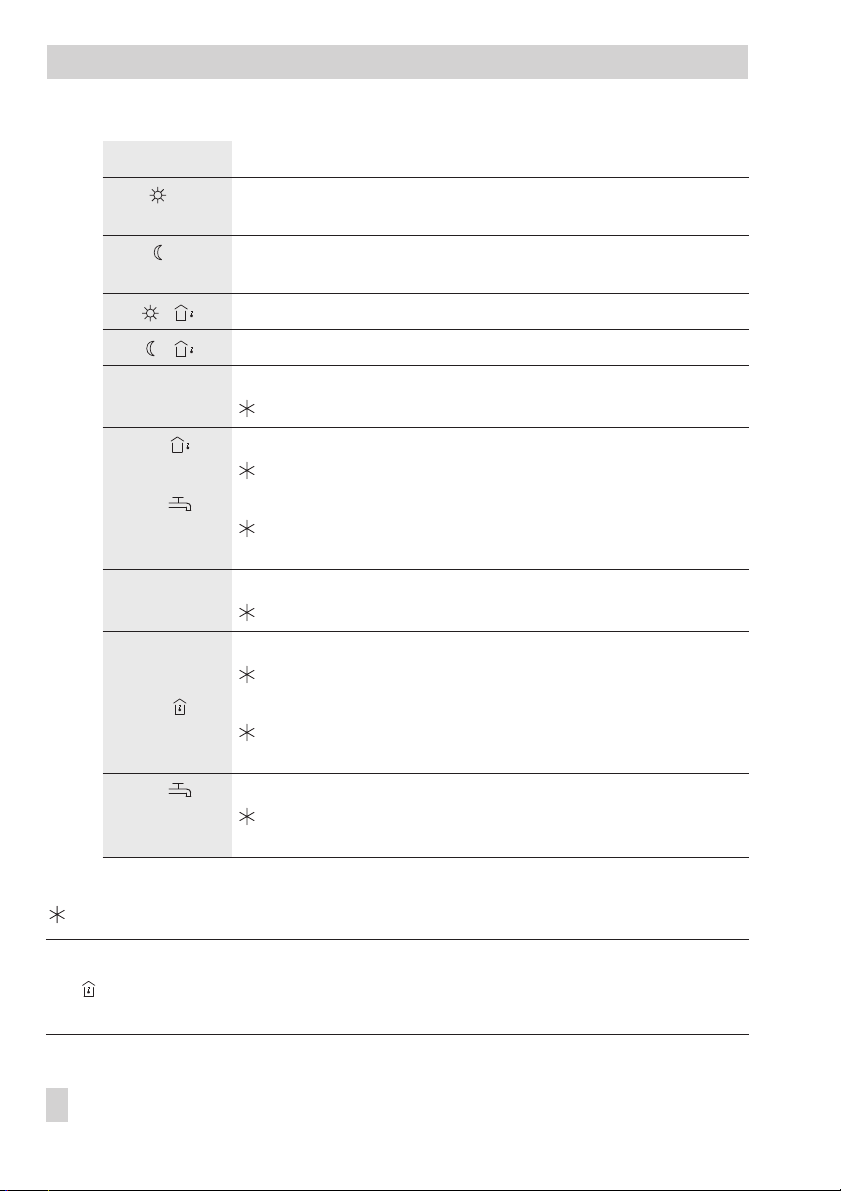

1.4 Displaying data

The times-of-use periods, measured values as well as set points or limit values can be retrieved and displayed in the user level (–> Fig. 10 on page 49). The controller configuration

determines which measured values as well as which set points or limit values appear on the

display.

Proceed as follows:

3s Switch to user level.

Display: Time

q

Select value.

The different data points appear on the display in sequence:

Display Meaning

Current time-of-use

,

Open data point

q

Display daily times-of-use.

Confirm

Times-of-use

Times-of-use

appears on the display.

.

by pressing the knob when

End

EB 5432 EN 7

Page 8

Operation

Display Meaning

* Day set point

* Night set point

or flow temperature set point (F1 - 0 and F7 - 0)

or reduced flow temperature set point (F1 - 0 and F7 - 0)

OT deactivating value in rated operation (F1 - 1 and F9 - 0)

OT deactivating value in reduced operation (F1 - 1 and F9 - 0)

t1

t2

,

t2

,

t3

t4

t4

,

t5

, Measured value: Storage tank temperature (F7 - 0)

q

Select

End

Switch to operating level.

Measured value: Flow temperature

Flow temperature set point

Measured value: Outdoor temperature

Delayed outdoor temperature (F3 - 1)

Measured value: Storage tank temperature (F1 - 0 and F7 - 1)

Activating/deactivating value for DHW system

(DHW set point + on/off differential)

Measured value: Return air temperature

Maximum return air temperature

Measured value: DHW temperature monitoring

Monitoring value

Measured value: Room temperature (F7 - 1)

Day set point or night set point

(influenced by a room panel, if applicable)

Activating/deactivating value for DHW system

(DHW set point + on/off differential)

on the display.

* Note!

The icon appears additionally on the display for a control functioning with the room

panel unit (F7- 1).

8 EB 5432 EN

Page 9

Operation

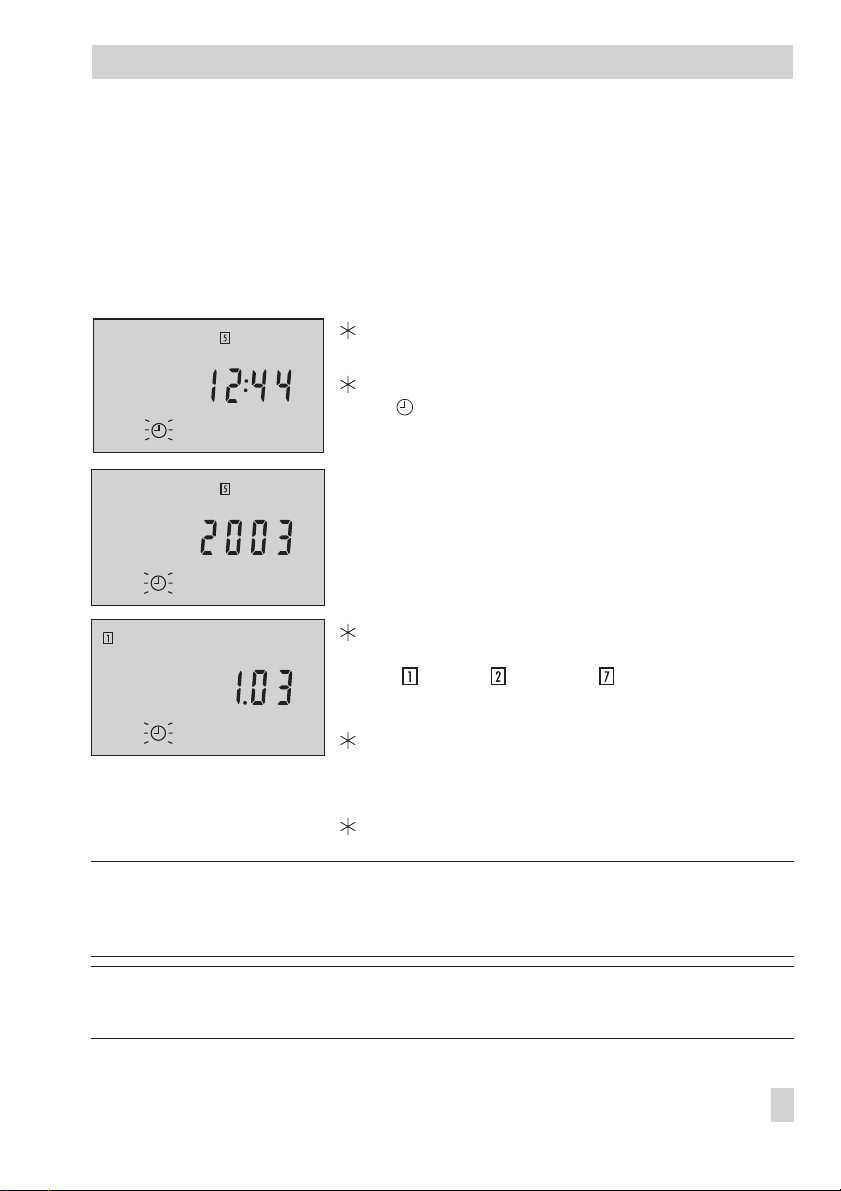

1.5 Setting the system time

The current time and date need to be set immediately after start-up and after a power failure

lasting more than 72 hours has occurred. This is indicated by the time blinking on the dis

play. The time is already in the edit mode and can be changed directly. The first two instruc

tions steps are then omitted.

Proceed as follows:

3s Switch to user level.

Display: Time.

Open time data point.

blinks.

Change time.

q

Confirm time setting.

Display: Year.

Change year.

q

Confirm year.

Display: Date (day.month) as well as day of the week

( = Mon, = Tue, …, = Sun)

q

Change date.

Confirm date.

Display: Time

q

Select

End

on the display.

Switch to operating level.

-

-

Note! On initial start-up and after a power failure lasting more than 72 hours, the controller

switches automatically to the operating level after the date has been set and confirmed. The

last two steps are omitted.

Note! The controller automatically switches to the operating level if the control knob is left

untouched for five minutes.

EB 5432 EN 9

Page 10

Operation

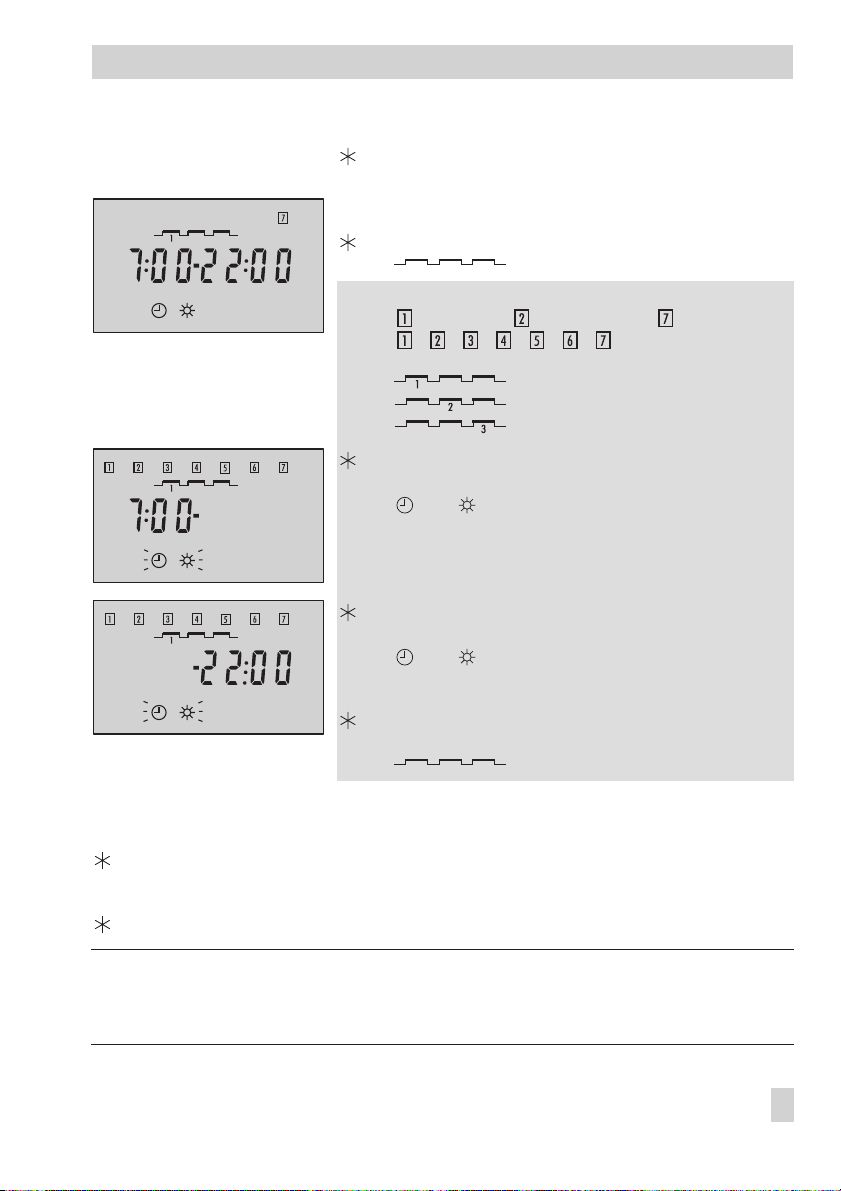

1.6 Setting the times-of-use

Three time-of-use periods can be set for each day of the week.

If not all the time-of-use periods are required, the start and stop times of the third time-of-use

period (for just two periods) must be set to identical times or, alternatively, the start and stop

times of the second time-of-use (for just one period). The controller then automatically sets the

start and stop times to the stop time of the previous time-of-use period.

The times-of-use are displayed in the user level (–> Fig. 10 on page 49).

Note!

You can set the times-of-use for each day or for an entire week. If you want to set the

times-of-use for certain days to be different than the rest of the week, we recommend you set

the times-of-use for the entire week first (display: ) and then al

ter the times-of-use for each day which require different times-of-use.

The week setting of the times-of-use writes over any already programmed times-of-use.

-

Parameter

Time period/day 1–7 = daily,

Start time of first time-of-use 07:00 00:00 to 24:00 h; in steps of 30 minutes

Stop time of first time-of-use 22:00 00:00 to 24:00 h; in steps of 30 minutes

Start time of second time-of-use 22:00 00:00 to 24:00 h; in steps of 30 minutes

Stop time of second time-of-use 22:00 00:00 to 24:00 h; in steps of 30 minutes

Start time of third time-of-use 22:00 00:00 to 24:00 h; in steps of 30 minutes

Stop time of third time-of-use 22:00 00:00 to 24:00 h; in steps of 30 minutes

WE Range of values

= Monday, = Tuesday, …, = Sunday

Note!

The controller includes an optimized activation function which makes sure the controller auto

matically changes to the valid set point ( blinks), six hours at the earliest before the pro

-

grammed time-of-use starts, to compensate for low outdoor temperatures.

10 EB 5432 EN

-

Page 11

Proceed as follows: 3s Switch to the user level.

Display: Time

Select

q

q

q

q

To set other times-of-use, repeat the instructions in the fields highlighted in gray.

q

Select

End

on the display.

Exit

Times-of-use

q

Select

End

Switch to operating level.

.

on the display.

Times-of-use

Open data point

Select time period/day and times-of-use:

= Monday, = Tuesday, …, = Sunday and

with

Open time period/day.

Display: Start time of first time-of-use period

and blink.

Change start time (in steps of 30 minutes).

Confirm start time.

Display: Stop time of first time-of-use period

and blink.

Change stop time.

Confirm stop time.

Display: Set time-of-use period

.

Times-of-use

blinks.

= first time-of-use period,

= second time-of-use period,

= third time-of-use period.

blinks.

.

= daily

Operation

Note!

The controller automatically switches to the operating level if the control knob is left un

touched for five minutes.

EB 5432 EN 11

-

Page 12

Operation

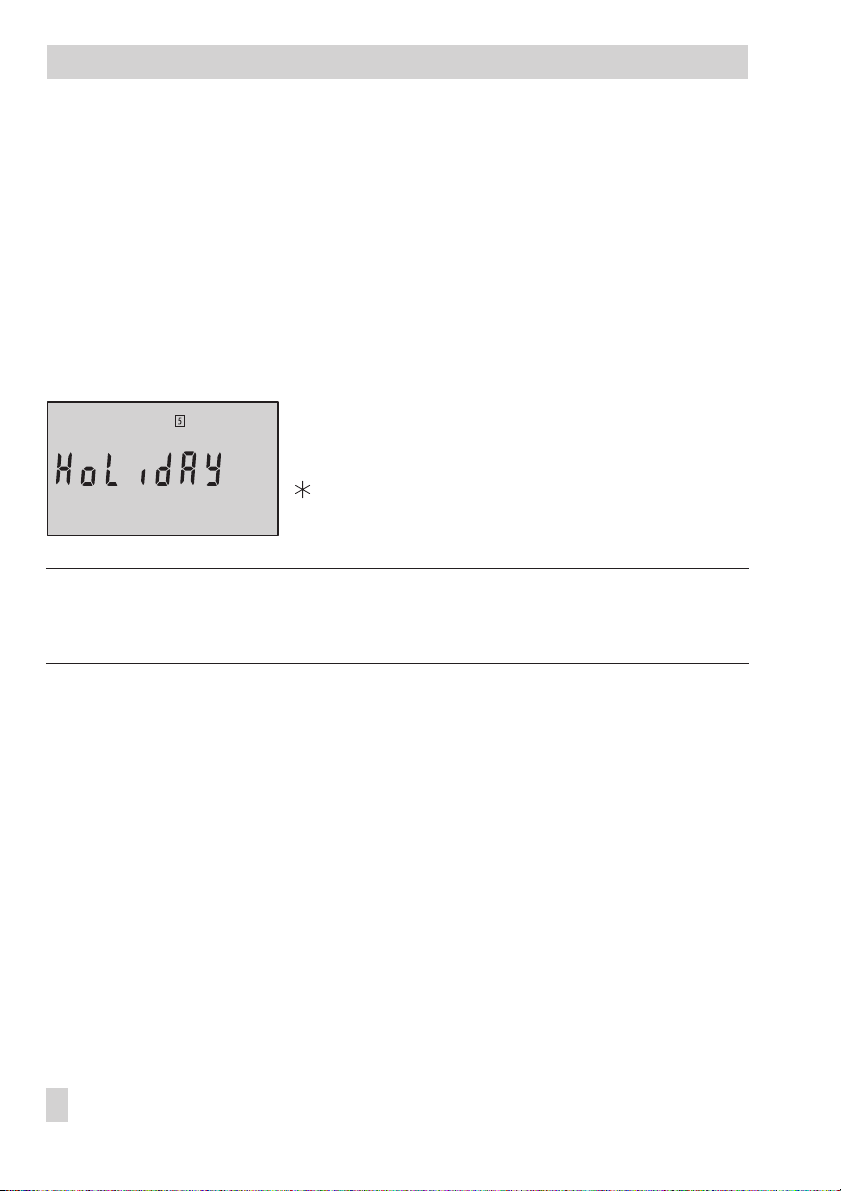

1.7 Stand-by mode

1.7.1 Vacation mode

Function independent of controller setting.

The vacation mode function places the heating circuit into the stand-by mode: the heating is

deactivated, however, frost protection is guaranteed. The functions of an existing DHW cir

cuit remain unchanged.

The vacation mode function is set in the operating level (set point display).

Proceed as follows:

Select menu

q

will go).

The display blinks.

Confirm vacation mode. Alternatively:

Wait 3 minutes until the display stops blinking.

The vacation mode is activated.

Note!

The controller is in vacation mode when HoLidAY appears on the display.

The controller exits the vacation mode when the current set point is reset (–> section 1.9).

HoLidAY

(turn knob to the left as far as it

-

1.7.2 Outdoor temperature dependent deactivation

Controller setting F1 - 1 and F9 - 1

The outdoor temperature dependent deactivation function places the heating circuit into the

stand-by mode dependent on the outdoor temperature. The heating is deactivated when the

outdoor temperature exceeds the active limit value (plus 1 °C on/off differential), however,

frost protection is still guaranteed. – – – appears on the display as the flow temperature set

point while the outdoor temperature dependent deactivation function is active. The functions

of an existing DHW circuit remain unchanged.

OT deactivating value in rated operation

The

value in reduced operation

12 EB 5432 EN

outside of the times-of-use apply and are set in the user level.

within the times-of-use and

OT deactivating

Page 13

Proceed as follows:

Vorgehen: 3s Switch to user level.

Display: Time.

Select

OT deactivating value in rated operation

OT deactivating value in reduced operation

Open data point.

Change data point.

Confirm data point.

Select

End

on the display.

Switch to operating level.

OT deactivating value in rated

operation

OT deactivating value in

reduced operation

q

q

q

Operation

or

.

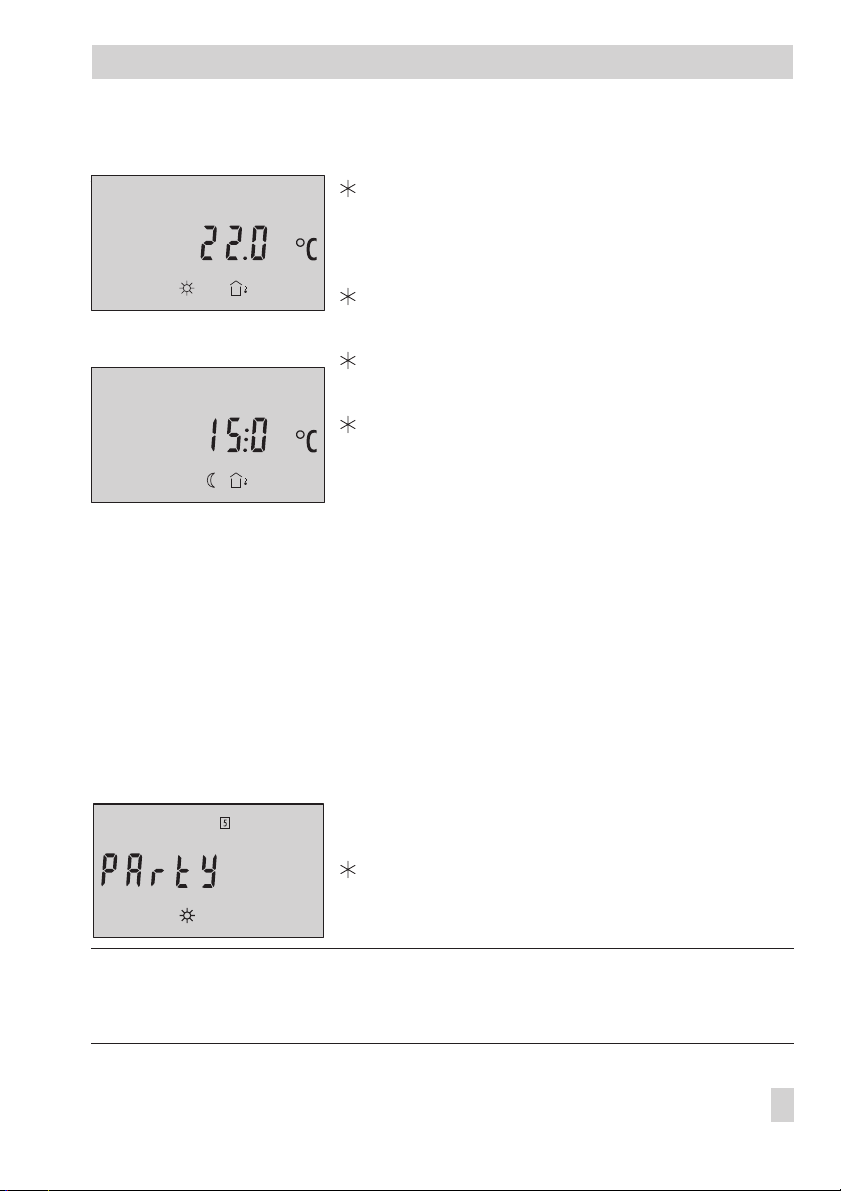

1.8 Party mode

Function independent of controller setting.

The party mode function sets the controller in rated operation mode: regardless of the pro-

grammed times-of-use, the

by the controller.

The party mode function is set in the operating level (set point display).

Proceed as follows:

Note!

The controller is in constant rated operation when PArtY appears on the display. The controller

exits the constant rated operation mode when the current set point is reset (–> section 1.9).

(constant rated operation)

Set point dayorFlow temperature set point

q

Select menu

will go). The display blinks.

Confirm party mode. Alternatively:

Wait 3 minutes until the display stops blinking.

The party mode is activated.

PArtY

(turn knob to the right as far as it

are constantly used

EB 5432 EN 13

Page 14

Operation

1.9 Correcting the set point

The current set point is displayed in the operating level. In rated operation, the

or the

Flow temperature set point

tion, the

Night set point

or the

appears on the display (–> section 1.3). In reduced opera

Reduced flow temperature set point

appears on the display.

Day set point

1.9.1 Correcting the set point temporarily

The current set point which appears on the display can be changed for just as long as the

rated operation mode (programmed time-of-use period) is running or the reduced operation

mode (outside of the time-of-use period) is running.

This temporary correction of the set point is made in the operating level (set point display).

Proceed as follows:

Turn the control knob one position.

q

The icon display blinks.

Change the parameter.

q

Confirm the new parameter setting. Alternatively:

Wait until the display stops blinking.

The new parameter setting has been saved.

The temporarily active set point (corrected once) is indicated on the display by the

icon together with the icon.

1.9.2 Correcting the set point permanently

The permanent change of

well as the

made in the user level.

Night set pointorReduced flow temperature set point

Day set pointorFlow temperature set point

in reduced operation is

in rated operation as

-

Proceed as follows:

3s Switch to user level. Display: Time

q

Select menu

Open the set point.

q

Change the set point.

Confirm the set point.

q

Select

Switch to operating level.

14 EB 5432 EN

Set point

End

on the display.

(–> page 6).

Page 15

Start-up

2 Start-up

2.1 Configuration and parameterization

The controller is configured and parameterized in the configuration and parameterization

level (–> Fig. 10 on page 49). After accessing the configuration and parameterization level

(CoPa level), the function blocks F1 to F9 appear at first, followed by the parameters P1 to

P18. The individual functions and parameters are listed in the Appendix (–> page 41).

The configuration and parameterization level is locked to prevent unintentional and unautho

rized access. This level can only be opened when the key number is known. The key number

can be found on page 48. To avoid unauthorized use of the key number, remove the page

or make the key number unreadable.

Proceed as follows:

3s Switch to user level. Display: Time

Select

End

q

3s Switch to the configuration and parameterization level (CoPa level).

Display: 0,

on the display.

nr

blinks.

q Set key number.

Confirm key number. Display: F1

q

Select function block* or parameter.

Open selected data point.

q

Change data point.

Confirm setting of the data point.

To set further function blocks and parameters, repeat the instructions in the fields highlighted

in gray.

q

Select

End

on the display.

Return to operating level.

Display: Current set point

-

* Note!

A function block is activated when F_ 1 appears on the display; it is deactivated when F_ 0

appears on the display.

EB 5432 EN 15

Page 16

Manual operation mode

3 Manual operation mode

In manual operation mode, the circulation pump UP is always switched on. The output SLP is

usually switched off. Initially, no control signal is issued for the heating circuit.

Activate the manual operation mode in the configuration and parameterization level (CoPa

level) over function block F2.

Functions

Manual operation of an actuator 0 F2 - 1

Proceed as follows:

3s Switch to user level.

Display: Time

Select

End

q

3s Switch to the configuration and parameterization level (CoPa level).

Display: 0,

Set key number.

q

Confirm key number.

Display: F1

q

Select function block F2.

Open function block F2.

q

Activate function block F2.

Display: F2 - 1.

Activate manual operation mode.

Display: and

q

Move the actuator manually:

oPEn: OPEN (3-step signal); activate output (on/off signal)

StoP: Last position (3-step signal); deactivate output (on/off signal)

cLoSE: CLOSED (3-step signal)

on the display.

nr

blinks.

StoP

WE Configuration

Note!

The frost protection function is not active in manual operation mode.

16 EB 5432 EN

Page 17

Manual operation mode

Exit manual operation mode:

Select cLoSE on the display.

q

3s Close manual operation mode and return to operating level.

Displaying measured values during manual operation mode

Select StoP on the display.

q

3s Switch to user level.

Display: Time

Select the measured values t1 to t5 in sequence.

q

Select

End

q

Switch to menu for moving actuator manually (oPEn, StoP or cLoSE).

Note!

The manual operation mode is maintained even after a power failure (display: StoP).

on the display.

EB 5432 EN 17

Page 18

Systems

4 Systems

The heating system can be designed either as a primary system, secondary system or a sin

gle-stage boiler system.

The flow temperature can either be controlled weather-compensated, based on the room

temperature or a fixed set point. The hydraulic schematics of the heating system and the con

troller configuration are the factors that determine how the flow temperature is controlled.

Primary system, indirect Primary system, direct

S3 S1UPHK_3-step S4

BE

BA

AE

RK

BE

BA

AE

RK

Secondary system Boiler system

Single-stage

boiler

S1UP S3HK_3-step S4 S2S2

-

-

BE

BA

AE

RK

18 EB 5432 EN

S2 S2

S3S1UP HK_3-step S4

BE

BA

AE

RK

UPHK_on/off S4S1

Page 19

Weather-compensated control without room panel (= default setting)

Setting F1 - 1 (with outdoor temperature sensor S2)

F7 - 0 (without room panel)

Comments With or without S3 (depending on the circuit)

F4 - 0 for single-stage boiler system

Storage tank charging/DHW priority possible (–> Figs. 2 and 3)

Weather-compensated control with room panel

Setting F1 - 1 (with outdoor temperature sensor S2)

F7 - 1 (with room panel)

Comments With or without S3 (depending on the circuit)

F4 - 0 for single-stage boiler system

Storage tank charging/DHW priority not possible

Fixed set point control

Setting F1 - 0 (without outdoor temperature sensor S2)

F7 - 0 (without room panel)

Comments With or without S3 (depending on the circuit)

F4 - 0 for single-stage boiler system

Storage tank charging/DHW priority possible (–> Figs. 2 and 3)

Room temperature-based control

Setting F1 - 0 (without outdoor temperature sensor AS)

F7 - 1 (with room panel)

Comments With or without S3 (depending on the circuit)

F4 - 0 for single-stage boiler system

Storage tank charging/DHW priority possible (–> Fig. 4)

Systems

EB 5432 EN 19

Page 20

Systems

WW

KW

HK_3-step

S3 S1

BE

BA

AE

RK

UP

S5

Fig. 2 · Weather-compensated control or fixed set point control and on/off control for storage tank

system in the primary circuit

Weather-compensated control Fixed set point control

Setting

Comments

F1 - 1 and F7 - 0 F1 - 0 and F7 - 0

With or without S3 (depending on the circuit)

Storage tank charging over storage tank sensor S5

(depending on the circuit)

Monitoring priority at S5

S2TW_on/off

20 EB 5432 EN

Page 21

Systems

WW

KW

BE

BA

AE

RK

HK_3-step

ROH

UP

S3 S1 S4

Fig. 3 · Weather-compensated control or fixed set point control and mechanical control (ROH =

self-operated regulators) for storage tank system in the primary circuit

Weather-compensated control Fixed set point control

Setting

Comments

F1 - 1 and F7 - 0 F1 - 0 and F7 - 0

With or without S3 (depending on the circuit)

Storage tank charging over storage tank sensor S5

(depending on the circuit)

Monitoring priority at S4 (depending on the circuit) or S5

S2SLP

S5

EB 5432 EN 21

Page 22

Systems

WW

KW

BE

BA

AE

RK

HK_3-step

UP

S3 S1

S4

TW_on/off

S2

Fig. 4 · Room temperature-based control and on/off control of the storage tank system in the primary

system

Room temperature-based control

Setting

Comments

With or without S3 (depending on the circuit)

F1 - 0 and F7 - 1

Storage tank charging over storage tank sensor S2

(depending on the circuit)

Monitoring priority at S2

22 EB 5432 EN

Page 23

Functions of the heating circuit

5 Functions of the heating circuit

5.1 Weather-compensated control

When weather-compensated control is used, the flow temperature is adjusted according to

the outdoor temperature. The heating characteristic in the controller defines the flow temper

ature set point as a function of the outdoor temperature (–> Fig. 5).

t

[˚C]

VL

130

120

110

100

90

80

70

60

50

40

30

20

Fig. 5 Gradient characteristics

2.62.93.2

2.4

2.2

2.0

1.8

1.6

1.4

t

1.2

1.0

0.8

0.6

0.4

0.2

-16-12-8-4048121620

-20 [

VL

t

A

t

A

C]

˚

Flow temperature

Outdoor temperature

-

Basically, the following rule applies: a drop in outdoor temperature causes the flow tempera

ture to rise. By varying the parameters

Gradient

your individual requirements. Increasing

creasing

Gradient

in a lower flow temperature. The parameter

and

Gradient

Level

, you can adapt the characteristic to

results in a higher flow temperature, de

Level

performs a parallel

shifting of the heating characteristic in upward or downward direction.

Outside the times-of-use, reduced set points are used for control:

The reduced flow set point is calculated either as the difference between the adjusted values

Day set point

for

or dependent on the parameter P9

(rated room temperature) and

(Set-back of flow temperature in reduced operation)

Night set point

(reduced room temperature)

with

the controller setting F1 - 1 and F9 - 0.

The parameters

Max. flow temperature

and

Min. flow temperature

mark the upper and lower

limits of the flow temperature.

EB 5432 EN 23

-

-

Page 24

Functions of the heating circuit

Examples for setting the characteristic:

Old building, radiator design 90/70: Gradient approx. 1.8

4

New building, radiator design 70/55: Gradient approx. 1.4

4

New building, radiator design 55/45: Gradient approx. 1.0

4

Underfloor heating depending on arrangement: Gradient smaller 0.5

4

Weather-compensated control, room set point mode

Functions

Type of control 1 F1 - 1

Room set point mode 1 F9 - 1

Parameter

Day set point 20 °C User level / 10 to 40 °C

Night set point 15 °C User level / 10 to 40 °C

Gradient 1.6

Level 0 °C

Min. flow temperature 30 °C

Max. flow temperature 80 °C

WE Configuration

WE Level / Range of values

CoPa level P1 / 0.2 to 3.2

CoPa level P2 / –30 to 30 °C

CoPa level P3 / 0 to 130 °C

CoPa level P4 / 0 to 130 °C

Weather-compensated control

Functions

Type of control 1 F1 - 1

Room set point mode 1 F9 - 0

Parameter

OT deactivating value in rated operation 22 °C User level / 0 to 50 °C

OT deactivating value in reduced operation 15 °C User level / –30 to 50 °C

Gradient 1.6

Level 0 °C

Min. flow temperature 30 °C

Max. flow temperature 80 °C

Set-back of flow temperature in reduced operation 15 °C

WE Configuration

WE Level / Range of values

CoPa level P1 / 0.2 to 3.2

CoPa level P2 / –30 to 30 °C

CoPa level P3 / 0 to 130 °C

CoPa level P4 / 0 to 130 °C

CoPa level P9 / 0 to 50 °C

24 EB 5432 EN

Page 25

Functions of the heating circuit

Note!

Particularly for control operation without room panel, the room temperatures for day

set point)

and night

(Night set point)

adjusted in the room set point mode only become effec

(Day

tive satisfactorily when the heating characteristic has been adapted to the building/heating

surface layout.

5.2 Fixed set point control

During a time-of-use period, the flow temperature can be controlled according to a fixed set

point. Outside the time-of-use periods, the controller regulates the reduced flow temperature.

-

Functions

Type of control 1 F1 - 0

Parameter

Flow temperature set point 50 °C User level / 0 to 130 °C

Reduced flow temperature set point 30 °C User level / 0 to 130 °C

WE Configuration

WE Level / Range of values

5.3 Drying of jointless floors

In compliance with Part 4 of the DIN EN 1264 standard, the first heating up is performed

with a flow temperature of 25 °C. This temperature is maintained constant for 3 days. After

that, the controller uses the maximum flow temperature as the set point for the following

4 days. When the drying of jointless floors function is activated, the set point appears on the

left-hand side of the display and the current flow temperature appears on the right-hand side

of the display.

An active function for drying of jointless floors is indicated on the display by the icon to

gether with the icon.

The function is switched off automatically when the drying is completed.

Note!

A power failure or any change in the controller setting resets the drying function to restart .

Function

Drying of jointless floors 0 F6 - 1

WE Configuration

-

EB 5432 EN 25

Page 26

Functions of the heating circuit

5.4 Automatic deactivation of the heating

The heating is automatically deactivated according to various criteria depending on whether

the heating system is equipped with or without a room panel:

Weather-compensated control, room set point mode (F1 - 1 and F9 - 1) – without room panel

Deactivation during day mode The outdoor temperature exceeds the

Deactivation during night

mode

Weather-compensated control (F1 - 1 and F9 - 0) – without room panel

Deactivation during day

mode

Deactivation during night

mode

Weather-compensated control (F1 - 1 and F7 - 1) – with room panel

Deactivation during day mode The outdoor temperature exceeds the

Deactivation during night

operating mode

Room temperature-based control

Deactivation during day mode The room temperature exceeds the

Deactivation during night

operating mode

The outdoor temperature exceeds the

The outdoor temperature exceeds

operation

The outdoor temperature exceeds

operation

The

exceeds the

The

exceeds the

The room temperature exceeds the

by 1 °C.

by 1 °C.

Night set point

Night set point

Night set point

Night set point

is 17 °C or higher and the outdoor temperature

by 1 °C.

is 17 °C or lower and the room temperature

by 1 °C.

Day set point

Night set point

OT deactivating value in rated

OT deactivating value in reduced

Day set point

Day set point

Night set point

by 1 °C.

by 1 °C.

by 1 °C.

by 1 °C.

by 1 °C.

The heating is activated immediately when the temperature falls below the relevant set point.

Note!

The table does not include any specifications for fixed set point control as the heating is

never deactivated with this type of control.

26 EB 5432 EN

Page 27

Functions of the heating circuit

5.5 Outdoor temperature dependent advance heating

Due to low outdoor temperatures, the controller starts heating before the time-of-use period

starts in rated operation. The

Advance heating time

–12 °C. The advance heating time is shortened when the outdoor temperature is higher.

The colder it is outside, the earlier the reduced operation is ended to ensure that the required

room temperature is reached at the start of the time-of-use period.

Note! During the advance heating phase, the icon blinks on the display.

uses a reference outdoor temperature of

Functions

Type of control 1 F1 - 1

Parameter

Advance heating time 120 min

WE Configuration

WE Level / Range of values

CoPa level P17 / 0 to 360 min

5.6 Delayed adaptation to the outdoor temperature

The calculated outdoor temperature is used to determine the flow temperature set point. The

heat response is delayed when the outdoor temperature either gets colder or warmer. If the

outdoor temperature varies by, for example, 10 °C within a very short period of time, the

calculated outdoor temperature is adapted to the actual outdoor temperature in small steps.

Delay

Assuming a

of 5 °C/h, the adaptation would take

The delayed adaptation to the outdoor temperature helps avoid unnecessary overloads of

central heating stations in combination with either overheated buildings occurring, for exam

ple, due to warm winds, or temporarily insufficient heating due to the outdoor sensor being

exposed to direct sunshine.

Note!

The described function can only be activated together with weather-compensated control.

Functions

Type of control 1 F1 - 1

Delayed adaptation to outdoor temperature 0 F3 - 1

Parameter

Delay 3 °C/h

WE Configuration

WE Level / Range of values

CoPa level P7 / 1 to 6 °C/h

C

°°10

/

Ch

.

2

th

==

5

-

EB 5432 EN 27

Page 28

Functions of the heating circuit

5.7 Remote control

Apart from measuring the room temperature, the Type 5257-5 Room Panel (Pt 1000 sensor)

provides the following opportunities of influencing the control process:

Selection of the operating mode: – Automatic mode

4

Set point correction: during rated operation, the room temperature set point can be in

4

creased or reduced by up to 5 °C using a continuously adjustable rotary knob

When the remote room controller (room panel) is connected and activated, the corrected

Room temperature set point

Functions

Room panel 0 F7 - 1

is shown.

– Rated operation (day)

– Reduced operation (night)

WE Configuration

5.8 Flash adaptation

A Type 5257-5 Room Panel must be connected for the Flash adaptation function.

The flash adaptation counteracts deviations in room temperature by reducing or raising the

flow temperature by up to 30 °C. The

tion of the flow temperature set point by 1 °C.

The flash adaptation is deactivated when the parameter

measured room temperature then does not have any affect on the flow temperature control.

Cycle rate

determines the time between each correc-

Cycle rate

(P18) is set to 0. The

-

Note!

We recommend setting the flash adaptation initially with a cycle rate of 10 minutes. Shorter

cycle rates are more likely to have a negative effect, particularly when cooling loads such as

drafts or an open window affect the control. Then the rooms may be temporarily overheated

when the cooling load is eliminated.

Functions

Type of control 1 F1 - 1

Room panel 0 F7 - 1

Parameter

Cycle rate 0 min

28 EB 5432 EN

WE Configuration

WE Level / Range of values

CoPa level P18 / 0 to 100 min

Page 29

Functions of the heating circuit

5.9 Room temperature-based control

A Type 5257-5 Room Panel must be connected for the Room temperature-based control

function; however, the control works without an outdoor sensor.

The flow temperature is reduced or raised by up to 30 °C when deviations in room tempera

ture occur. The

Cycle rate

ture set point by 1 °C. The default setting is 10 minutes when the room temperature-based

control is activated; the flow temperature control starts with a default set point of 50 °C, pro

vided that the parameter

Note!

We recommend not to set the cycle rate too short. Shorter cycle rates are more likely to have

a negative effect, particularly when cooling loads such as drafts or an open window affect

the control. Then the rooms may be temporarily overheated when the cooling load is elimi

nated.

determines the time between each correction of the flow tempera

Max. flow temperature

(P4) permits it.

-

-

-

-

Functions

Type of control 1 F1 - 0

Room panel 0 F7 - 1

Parameter

Cycle rate 10 min

WE Configuration

WE Level / Range of values

CoPa level P18 / 1 to 100 min

EB 5432 EN 29

Page 30

Functions of the DHW circuit

6 Functions of the DHW circuit

a) b)

Fig. 6 · DHW system in a storage tank charging system (a) and in a storage tank system (b)

The controller starts charging the storage tank as soon as the water temperature measured

at the storage tank sensor (S5 or S2) falls below the

The charging of the storage tank finishes when the water temperature measured at the storage tank sensor has reached the temperature T =

storage tank charging.

Use F8 to select the

F8 - 0: On/off differential = 5 °C

4

F8 - 1: On/off differential = 2 °C

4

Functions

On/off differential of storage tank charging 0 F8

Parameter

DHW set point 45 °C

On/off differential of storage tank charging

WE Configuration

WE Level / Range of values

DHW set point

DHW set point+On/off differential of

CoPa level P16 / 20 to 90 °C

(P16).

.

6.1 DHW priority

Should the temperature at the DHW sensor S4 or, in cases where DHW sensor S4 does not

exist, at the storage tank sensor S5/S2, fall below the

minutes, the heating capacity of the heating circuit is lowered by reducing the set point. The

heating circuit set point is then reduced in small steps every five minutes up to a minimum

30 EB 5432 EN

Monitoring value for priority

for five

Page 31

Functions of the DHW circuit

flow temperature of 20 °C, provided the temperature still lies below the

priority.

Three different operating conditions exist:

The DHW temperature at S4 (S5/S2) is under the

4

heating circuit set point is reduced.

The DHW temperature to S4 (S5/S2) is up to 5 °C above the

4

4

Functions

Room panel 0 F7 *

* F7 - 0: Monitoring value for priority at S4 (depending on the circuit) or storage tank

Parameter

Monitoring value for priority 40 °C

the heating circuit set point remains unchanged.

ity –>

The DHW temperature to S4 (S5/S2) exceeds the

than 5 °C –> the heating circuit set point which was reduced due to the priority is in

creased.

WE Configuration

charging and

Monitoring value for priority at S5

F7 - 1: Storage tank charging and monitoring value for priority at S2 (room

temperature-based control)

WE Level / Range of values

Monitoring value for priority –>

Monitoring value for priority

CoPa level P6 / 20 to 90 °C

Monitoring value for

Monitoring value for prior

the

-

by more

-

EB 5432 EN 31

Page 32

System-wide functions

7 System-wide functions

7.1 Automatic summer time/winter time changeover

The clock is automatically set one hour forward on the last Sunday in March at 2.00 h and

set one hour back on the last Sunday in October at 3.00 h.

Function

Summer time/winter time changeover 1 F5 - 1

WE Configuration

7.2 Frost protection

The frost protection function is activated with weather-compensated or room temperaturebased control.

The circulation pump is activated and a flow set point of 20 °C is used for the control when

the outdoor temperature is lower than 3 °C with weather-compensated control and the heating is switched off (stand-by mode).

The flow temperature is monitored with room temperature-based control and the heating is

switched off. If the flow temperature drops below 5 °C, the circulation pump is activated and

the flow temperature set point of 20 °C is used for the control.

Note!

The frost protection function is not active in manual operating mode or with fixed set point

control.

7.3 Forced operation of the pumps

When the circulation pumps have not been activated for 24 hours, forced operation of the

pumps is started at 12.00 h for one minute to prevent the pumps from getting stuck when

they are not operated for a longer period of time.

32 EB 5432 EN

Page 33

System-wide functions

7.4 Limiting the return flow temperature

The temperature difference between the flow and return flow in a network indicates how well

the energy is used: the greater the difference, the higher the efficiency. A return flow sensor

is sufficient to evaluate the temperature difference when the network flow temperatures are

predetermined. The flow temperature set point is reduced when the return flow temperature

measured at the return flow sensor S3 exceeds the limit temperature. As a result, the primary

flow rate is reduced and the return flow temperature falls. A PI algorithm is used to limit the

return flow temperature. The integral action cannot be parameterized.

Parameter

Maximum return flow temperature 50 °C

KPReturn flow temperature limit 1.0

WE Level / Range of values

CoPa level P5 / 20 to 90 °C

CoPa level P8 / 0.1 to 50.0

7.5 Three-step control

The flow temperature can be controlled with a PI algorithm. The motorized valve reacts to

pulses which the controller issues when a system deviation arises. In particular, the length of

the first pulse depends on the size of the system deviation and the selected

(the impulse length increases as the KPincreases). The intervals between each pulse and

gain

the interval length between pulses change continuously until the system deviation has been

eliminated.

The interval length between each pulse is greatly influenced by the

length increases as T

increases). The

N

Valve transit time T

specifies the time required by the

Y

valve to travel through the range from 0 to 100 %.

Functions

Control signal 1 F4 - 1

Parameter

KP(proportional gain) 2.0

TN(reset time) 120 s

TY(valve transit time) 45 s

WE Configuration

WE Level / Range of values

CoPa level P10 / 0.1 to 50.0

CoPa level P11 / 0 to 999 s

CoPa level P12 / 10 to 240 s

KPProportional

Reset time T

(the interval

N

EB 5432 EN 33

Page 34

System-wide functions

7.6 On/off control

The flow temperature can be controlled, for instance, by switching a burner on and off. The

burner is switched on by the controller when the flow temperature falls below the set point

T = 0.5 x

On/off differential

the burner is switched off again. The larger the

of switching involved. The default setting of

it is switched on to run permanently for this time regardless of how long. Likewise, a burner

that has just been switched off due to the temperature conditions when the programmed

imum activation time

Functions

Control signal 1 F4 - 0

Parameter

On/off differential 5 °C

Min. activation time 120 s

Min. deactivation time 120 s

. On exceeding the set point by T = 0.5 x

On/off differential

Minimum activation time

On/off differential

selected, the less amount

enables a burner once

remains switched off regardless how long for the time set.

WE Configuration

WE Level / Range of values

CoPa level P13 / 2 to 10 °C

CoPa level P14 / 0 to 600 s

CoPa level P15 / 0 to 600 s

,

Min

-

34 EB 5432 EN

Page 35

8 Malfunctions

Malfunctions

The controller’s reaction when a sensor is defective or a sensor is missing is described in fol

lowing:

Flow sensor:

4

For three-step control, the control valve takes on the valve position 30 %.

For on/off control, the controller regulates the on/off output at 30-minute intervals as

long as the time set under

The icon blinks on the display when the sensor fails.

Outdoor sensor:

4

A flow temperature set point of 50 °C is used for control, or the

is used if the maximum flow temperature (P4) is lower than 50 °C.

ture

The icon blinks on the display when the sensor fails.

Return flow sensor:

4

The return flow temperature limit function is deactivated.

Room sensor in room panel:

4

The flow temperature control is no longer affected by the measured room temperature.

The icon blinks on the display when the sensor fails.

DHW sensor:

4

The monitoring of priority changes to storage tank sensor, if necessary.

Storage tank sensor:

4

There is no storage tank charging.

Minimum activation time

(P14).

Maximum flow tempera

-

-

EB 5432 EN 35

Page 36

Infrared interface

9 Infrared interface

The TROVIS 5432 Heating and District Heating Controller can be configured and operated

over the front infrared interface using SAMSON’s TROVIS-VIEW Operator Interface soft

ware. This software’s operation is similar to Microsoft Windows Explorer.

The TROVIS-VIEW software is supplied with the device-specific module for the TROVIS 5432

Heating and District Heating Controller on CD-ROM (order no. 6661-1002).

The minimum system requirements can be found in the Data Sheet T 6661 EN for

TROVIS-VIEW as well as the readme.txt file in the main directory of the CD-ROM.

An infrared interface on the controller front panel is used for communication between PC

and controller. Data transmission between the RS-232 serial port on a PC and the integrated

controller infrared interface requires an infrared adapter (order no. 8864-0900).

-

2

1

Fig. 7 · Data transfer over the infrared interface

36 EB 5432 EN

0.7 m

˚

25

1 Infrared adapter

2 Connect to PC at optionally

COM1 to COM4 ports

Page 37

10 Installation

Installation

The controller consists of the housing section and base. The housing section contains the en

tire electronics, the display as well as the control knob. The base contains the terminal strip.

The controller is suitable for mounting in control panels or on walls (–> Fig. 8).

Note!

An adapter is available to mount the controller on top-hat rails.

Control panel mounting

1. Press down the tongue on top of the controller.

2. Tip the housing forward and remove it from the base.

3. Make a cut-out of 138 x 92 mm (W x H) in the control panel.

4. Insert the controller housing through the panel cut-out.

5. Use the two threaded bolts located at the side of the housing and the clips to clamp the

housing in the panel.

6. Install the electrical connections in the base as described in section 11.

7. First attach the lower part of the base to the housing and then snap on the top part.

Wall mounting

1. Press down the tongue on top of the controller.

2. Tip the housing forward and remove it from the base.

3. If necessary, drill holes at the intended place using the specifications given. Fasten

base with screws.

4. Install the electrical connections in the base as described in section 11.

5. First attach the lower part of the base to the housing and then snap on the top part.

-

EB 5432 EN 37

Page 38

Installation

96

15

Holes for

adapter to

mount on

top-hat rail

Fig. 8 · Installation

140

5044.3

22

3

35

15

29.3

55.5

91

10

137

8

38 EB 5432 EN

Page 39

Electrical connection

11 Electrical connection

!

Caution!

For electrical installation, you are required to observe the relevant electrotechnical regula

tions of the country of use as well as the regulations of the local power suppliers. Make sure

all electrical connections are installed by trained and experienced personnel!

Notes on installing the electrical connections

-

Install the 230 V power supply lines and the signal lines separately! To increase noise im

4

munity, observe a minimum distance of 10 cm between the lines. Make sure the minimum

distance is also observed when the lines are installed in a cabinet.

The lines for digital signals (bus lines) and analog signals (sensor lines, analog outputs)

4

must also be installed separately!

In plants with a high electromagnetic noise level, we recommend to use shielded cables

4

for the analog signal lines. Ground the shield at one side, either at the control cabinet inlet or outlet, using the largest possible cross-section. Connect the central grounding point

and the PE grounding conductor with a cable≥10 mm² using the shortest route.

Inductances in the control cabinet, e.g. contactor coils, are to be equipped with suitable

4

interference suppressors (RC elements).

Control cabinet elements with high field strength, e.g. transformers or frequency convert-

4

ers, should be shielded with separators providing a good ground connection.

Overvoltage protection

If signal lines are installed outside buildings or over large distances, make sure appropri

4

ate surge or overvoltage protection measures are taken. Such measures are indispens

able for bus lines!

The shield of signal lines installed outside buildings must have current conducting capac

4

ity and must be grounded on both sides.

Surge diverters must be installed at the control cabinet inlet.

4

Connecting the controller

The controller is connected as illustrated in the wiring diagram.

Open the housing to connect the cables. To connect the feeding cables, make holes in the

marked locations underneath on the base and fit suitable grommets or cable glands.

-

-

-

-

Connecting the sensors

Cables with a minimum cross-section of 2 x 0.5 mm² can be connected to the terminals at

the controller base unit.

EB 5432 EN 39

Page 40

Electrical connection

Note!

The controller can only be operated with Pt 1000 sensors.

Connecting the actuators

Connect cables with at least 1.5 mm² suitable for damp locations to the terminals of the con

troller output. The direction of travel needs to be checked at start-up (–> section 3).

Connecting the pumps

Connect all cables with at least 1.5 mm² to the terminals of the controller as illustrated in the

connection diagram.

-

12345678910

NL

UP SLP HK_3-step

56 89

TW_on/off HK_on/off

+

_

Fig. 9 · Electrical connection

40 EB 5432 EN

11 12

13

14 15 16 17 18

S4 S5S3S2S1

16 17 18

Type 5257-5

123

Room Panel

Page 41

Appendix

12 Appendix

12.1 Function block list

F Function WE Comments

F1 Type of control 1 F1 - 1: Weather-compensated control

F1 - 0: Fixed set point control or

F1 - 0 and F7 - 1: Room temperature-based control

F2 Manual operation of

actuator

F3 Delayed adaptation to

outdoor temperature

F4 Control signal 1 F4 - 1: 3-step control

F5 Summer time/winter time

changeover

F6 Drying of jointless floors 0 F6 - 1: Drying of jointless floors active

F7 Room panel 0 F7 - 1: Connection of Type 5257-5 Room Panel to S4/S5

F8 On/off differential of

storage tank charging

F9 Room set point mode 1 Only effective with F1 - 1:

F Function block, WE default setting

0 F2 - 1: Manual operation mode active

0 F3 - 1: Delayed adaptation to outdoor temperature,

only effective with F1 - 1

F4 - 0: On/off control

1 F5 - 1: Changeover active

After the function’s running time has elapsed, F6 - 0 is set.

F7 - 0: DHW priority, storage tank charging over S4/S5

(depending on circuit)

0 F8 - 1: On/off differential = 2 °C

F8 - 0: On/off differential = 5 °C

F9 - 1: Room set point assignable

F9 - 0: Set-back and outdoor temperature dependent

deactivating values assignable

EB 5432 EN 41

Page 42

Appendix

12.2 Parameter list

P Designation WE Range of value

P1 Gradient 1.6 0.2 to 3.2

P2 Level 0 °C –30 to 30 °C

P3 Min. flow temperature 30 °C 0 to 130 °C

P4 Max. flow temperature 80 °C 0 to 130 °C

P5 Max. return flow

temperature

P6 Monitoring value for priority 40 °C 20 to 90 °C

P7 Delay 3 °C/h 1 to 6 °C/h

P8 KPReturn flow temperature

limit

P9 Set-back of flow tempera-

ture in reduced operation

P10 KPThree-step control 2.0 0.1 to 50.0

P11 TNThree-step control 120 s 0 to 999 s

P12 TYThree-step control 45 s 10 to 240 s

P13 On/off differential

P14 Min. activation time for

on/off control

P15 Min. deactivation time for

on/off control

P16 DHW set point 45 °C 20 to 90 °C

P17 Advance heating time 120 min 0 to 360 min

P18 Cycle rate 0 min

P Parameter, WE Default setting

50 °C

1.0

15 °C

5 °C

120 s

120 s

and

10 min

20 to 90 °C

0.1 to 50.0

0 to 50 °C

2 to 10 °C

0 to 600 s

0 to 600 s

01to 100 min/

to 100 min

42 EB 5432 EN

Page 43

Appendix

12.3 Resistance values with Pt 1000 sensor

°C –35 –30 –25 –20 –15 –10 –5 0 5 10

862.5 882.2 901.9 921.6 941.2 960.9 980.4 1000.0 1019.5 1039.0

Ω

°C 15 20 25 30 35 40 45 50 55 60

1058.5 1077.9 1097.3 1116.7 1136.1 1155.4 1174.7 1194.0 1213.2 1232.4

Ω

°C 65 70 75 80 85 90 95 100 105 110

1251.6 1270.7 1289.8 1308.9 1328.0 1347.0 1366.0 1385.0 1403.9 1422.9

Ω

°C 115 120 125 130 135 140 145 150

1441.7 1460.6 1479.4 1498.2 1517.0 1535.8 1554.5 1573.1

Ω

12.4 Technical data

Inputs 5 inputs for Pt 1000 sensors

Outputs

Control signal Y Three-step or on/off signal, non-floating: 230 V AC, 0.3 A AC

Binary output 2 outputs to control heating circuit pump and to release DHW system

Operating voltage 230 V AC (+ 10 %/ – 15 %), 48 to 62 Hz,

Ambient temperature

Operation 0 to 50 °C

Transport/storage –10 to 60 °C

Relative humidity Normal, no dew

Degree of protection IP 40 according to EN 60529

Class of protection I according to EN 50178

Degree of contamination 2 according to EN 50178

Overvoltage category II according to EN 50178

Noise immunity According to EN 61000-6-1

Noise emission According to EN 61000-6-3

Weight Approx. 0.4 kg

(triac outputs with varistor for surge suppression)

(double-throw contact), non-floating: 230 V AC, 2 A

(relay output with varistor for surge suppression)

Power consumption, approx. 1 VA

EB 5432 EN 43

Page 44

Appendix

12.5 User data

Station

Operator

Responsible SAMSON office

Function blocks

F1 F2 F3 F4 F5 F6 F7 F8 F9

Parameters

P Designation Setting Range of values

P1 Gradient 0.2 to 3.2

P2 Level –30 to 30 °C

P3 Min. flow temperature 0 to 130 °C

P4 Max. flow temperature 0 to 130 °C

P5 Max. return flow temperature 20 to 90 °C

P6 Monitoring value for priority 20 to 90 °C

P7 Delay 1 to 6 °C

P8 KPReturn flow temperature limit 0.1 to 50

P9 Set-back of flow temperature in reduced

P10 KPThree-step control 0.1 to 50

P11 T

P12 TYThree-step control 10 to 240 s

P13 On/off differential 2 to 10 °C

P14 Minimum activation time for on/off control 0 to 600 s

P15 Minimum deactivation time for on/off control 0 to 600 s

P16 DHW set point 20 to 90 °C

P17 Advance heating time 0 to 360 min

P18 Cycle rate

operation

Three-step control 0 to 999 s

N

0 to 50 °C

01to 100 min/

to 100 min

44 EB 5432 EN

Page 45

Times-of-use

Monday (1)

Tuesday (2)

Wednesday (3)

Thursday (4)

Friday (5)

Saturday (6)

Sunday (7)

Appendix

Start – Stop (1) Start – Stop (2) Start – Stop (3)

EB 5432 EN 45

Page 46

Index

Index

A

Activation

dependent on outdoor temperature . . 27

Automatic mode. . . . . . . . . . . . . . . . . . . . 5

C

Configuration . . . . . . . . . . . . . . . . . . . . 15

Connection

Actuator. . . . . . . . . . . . . . . . . . . . . . 40

Controller. . . . . . . . . . . . . . . . . . . . . 39

Pump. . . . . . . . . . . . . . . . . . . . . . . . 40

Sensor . . . . . . . . . . . . . . . . . . . . . . . 39

Constant rated operation . . . . . . . . . . . . 13

Control

On/off. . . . . . . . . . . . . . . . . . . . . . . 34

Three-step . . . . . . . . . . . . . . . . . . . . 33

Control knob . . . . . . . . . . . . . . . . . . . . . . 5

Correcting the set point. . . . . . . . . . . . . . 14

D

Data

displaying . . . . . . . . . . . . . . . . . . . . . 7

Day mode . . . . . . . . . . . . . . . . . . . . . . . . 5

Deactivation

automatic. . . . . . . . . . . . . . . . . . . . . 26

outdoor temperature dependent. . . . . 12

Delayed adaptation to the outdoor

temperature. . . . . . . . . . . . . . . . . . . . . . 27

DHW priority override . . . . . . . . . . . . . . 30

Display . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Drying jointless floors . . . . . . . . . . . . . . . 25

E

Electrical connection . . . . . . . . . . . . 39 - 40

F

Fixed set point control. . . . . . . . . . . . . 6, 25

Flash adaptation . . . . . . . . . . . . . . . . . . 28

Forced operation of pumps . . . . . . . . . . . 32

Frost protection . . . . . . . . . . . . . . . . . . . 32

Function block . . . . . . . . . . . . . . . . . . . . 15

Function block list. . . . . . . . . . . . . . . . . . 41

G

Gradient characteristics . . . . . . . . . . . . . 23

I

Infrared interface . . . . . . . . . . . . . . . . . . 36

Installation

control panel mounting . . . . . . . . . . . 37

wall mounting . . . . . . . . . . . . . . . . . 37

J

Jointless floors . . . . . . . . . . . . . . . . . . . . 25

M

Malfunctions . . . . . . . . . . . . . . . . . . . . . 35

Manual operation mode . . . . . . . . . 16 - 17

N

Night mode . . . . . . . . . . . . . . . . . . . . . . . 5

O

On/off control . . . . . . . . . . . . . . . . . . . . 34

Outdoor temperature dependent advance

heating . . . . . . . . . . . . . . . . . . . . . . . . . 27

Overvoltage protection . . . . . . . . . . . . . . 39

P

Parameter list. . . . . . . . . . . . . . . . . . . . . 42

Parameters . . . . . . . . . . . . . . . . . . . . . . 15

Party mode . . . . . . . . . . . . . . . . . . . . . . 13

46 EB 5432 EN

Page 47

R

Rated operation . . . . . . . . . . . . . . . . . 5, 13

Reduced operation. . . . . . . . . . . . . . . . . . 5

Remote control. . . . . . . . . . . . . . . . . . . . 28

Resistance values . . . . . . . . . . . . . . . . . . 43

Return flow temperature limit . . . . . . . . . 33

Room panel. . . . . . . . . . . . . . . . . . . . . . 28

Room sensors

Pt 1000 . . . . . . . . . . . . . . . . . . . . . . 28

S

Sensor

defective . . . . . . . . . . . . . . . . . . . . . 35

Set point

Day . . . . . . . . . . . . . . . . . . . . . . . . . 23

Night. . . . . . . . . . . . . . . . . . . . . . . . 23

Setting the system time . . . . . . . . . . . . . . . 9

Stand-by mode . . . . . . . . . . . . . . . . . 5, 12

Summer time/winter time changeover . . . 32

System description . . . . . . . . . . . . . 18 - 22

T

Technical data . . . . . . . . . . . . . . . . . . . . 43

Three-step control. . . . . . . . . . . . . . . . . . 33

Times-of-use

setting . . . . . . . . . . . . . . . . . . . . . . . 10

TROVIS-VIEW . . . . . . . . . . . . . . . . . . . . 36

U

User data . . . . . . . . . . . . . . . . . . . . . . . 44

V

Vacation mode . . . . . . . . . . . . . . . . . . . 12

W

Weather-compensated control. . . . . . . 6, 23

Index

47

Page 48

Abbreviations

Abbreviations

AE Analog input

BA Binary output

BE Binary input

HK Heating circuit

KW Cold water

OT Outdoor temperature

RK Control circuit

ROH Self-operated regulators

S1..5 Sensors 1...5

SLP Storage charging pump

TW Domestic hot water (DHW)

UP Circulation pump

WW Hot water

48 EB 5432 EN

Key number 1732

Page 49

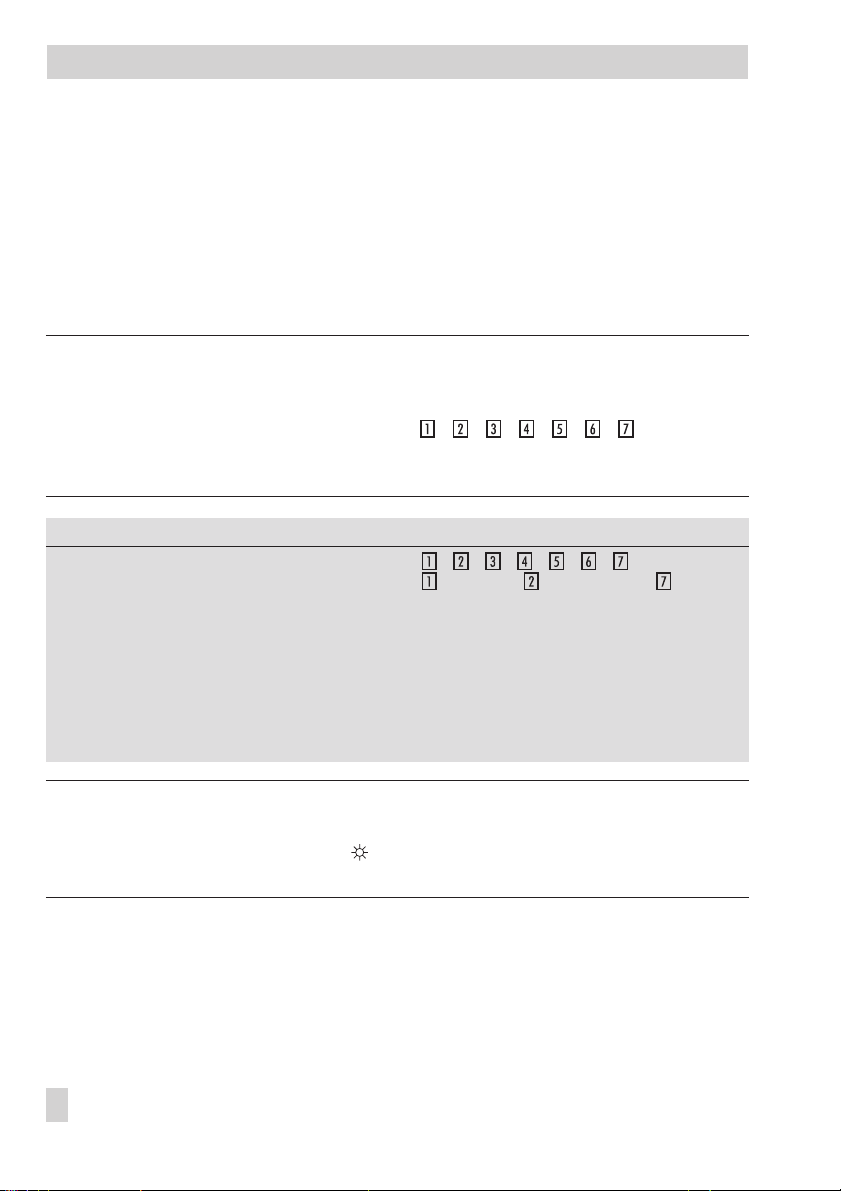

Operating level

Current set point

q

Temporary

set point change

q

(turn knob to left)

HoLidAY

q

(turn knob to right)

PArtY

User level

3s

System time

q

Current time-of-use

q

Set point rated operation

OT deactivating value

in rated operation

q

Set point red. operation

OT deactivating value

in reduced operation

q

t1 to t5

q

End

Appendix

Configuration and

parameterization level

F1 to F9

q

P1 to P18

q

End

or

or

3s

Fig. 10 · Level structure

EB 5432 EN 49

Page 50

50 EB 5432 EN

Page 51

Appendix

EB 5432 EN 51

Page 52

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 5432 EN

2008-02

Loading...

Loading...