Page 1

RFX Keypad

n

/

n

n

/

i

n

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Parts and Technical Service guide

Guía de servicio técnico y recambio

Guide d’instructions et pièces de rechange

Ref.:

Model 2190

Descriptio

Descripción/ Descriptio

E

The Samson RFX is designed to control and monitor the consumption

and inventory balances of automotive fluid products with minimal

installation and programming costs. The wall mounted keypad module

consists of a 12-button keypad, LCD display and integral ticket printer.

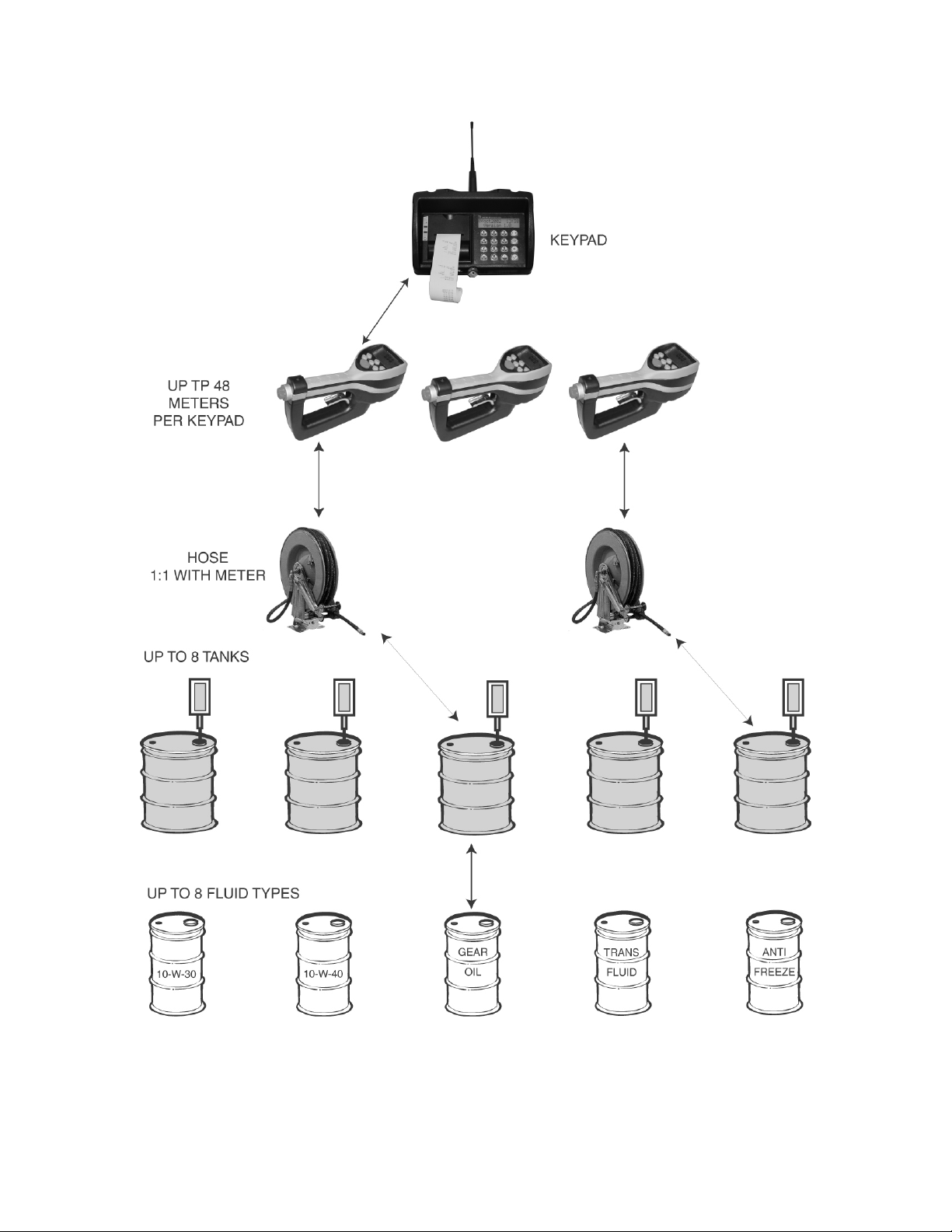

The RFX keypad can control up to 48 meters and track 8 different

fluids and tanks. It is capable of send ing and receiving data typically

up to 300 feet in a service facility installation. A unique, patented

feature of the control system is that the dispense trigger of the RFX

Meter is locked until authorization from the keypad is received. After

the dispense is completed, the user can top off the dispense and the

actual amount used is sent back to the keypad and this meter returns

to the locked status. Additionally, the meter can be installed on

portable dolly systems offering control and monitoring of often highcost lubrication products. Up to 50 operators can be defined with their

own unique PIN number for accessing the system. The system

provides dispense reports by operator, fluid type, meter or tank. This

allows for flexibility in reviewing system activity.

E

The operator enters his PIN number and selects the hose that the fluid is to be dispensed fro m.

The operator then enters the required quantity and presses ENTER to confirm. The meter is then

authorized to automatically dispense and shut off when the authorized amount of fluid is

dispensed. The operator may then top off the vehicle for the proper fill, if necessary. The operator

may allow the meter to “time out” or may depress “Reset” which sends all actua l dispense data

back to the keypad and puts the meter into a secure “Locked” status until the next authorized

dispense work order is received from the keypad. After each dispense, a transaction ticket is

printed showing the fluid and quantity dispensed along with the operator's name.

E

Mount the keypad to the wall either inside the shop on a wall facing the shop. In either case

mount the included remote antenna INSIDE the shop up high on the wall with line of sight to all

the meters.

Range is 300 feet unobstructed, be sure to test the keypad/antenna mounting position with a 2188

meter at all positions in the shop, and try to simulate a ‘worst case scenario’ with vehicle

obstructions during testing. Performing this important step will ensure trouble-free service for the

End User and no callbacks for the Installer.

Operatio

Modo de empleo/ Moded’emplo

Installation and Configuratio

2190

1

Page 2

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Table of Contents

Diagram of RFX Logical Set-up..........................................................................................3

Keyboard Description..........................................................................................................4

Default Screens....................................................................................................................5

Supervisor Menu..................................................................................................................5

Initialization Menu Screens (INI)........................................................................................8

Configuration Menu (CNF) ...............................................................................................16

Meter Reset Menu (MET)..................................................................................................22

Report Menu Screens (REP)..............................................................................................23

Internal Printer Reports......................................................................................................30

Fluid Type Definitions.......................................................................................................31

Tank Definitions ................................................................................................................32

Hose/Meter Definitions......................................................................................................33

User Definitions.................................................................................................................35

Page 3

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

PICTORAL DIAGRAM OF RFX LOGICAL SET-UP

Page 4

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) this device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

FCC ID: GIF-RFKEYPAD

FCC CERTIFIED, PART 15, SUBPART C

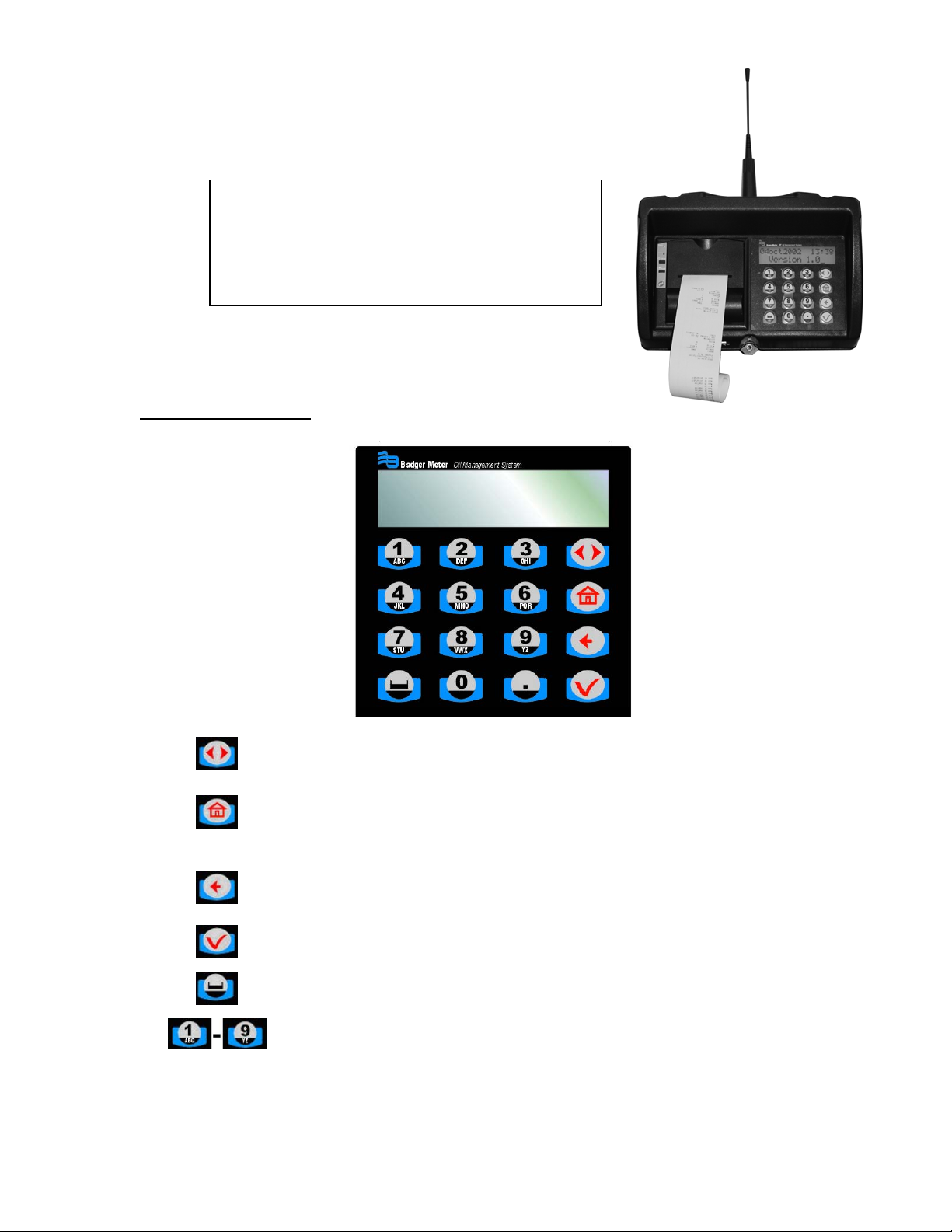

Keyboard Description:

Scroll Key: Used to select options on active display

Home Key: Pressing this key will return display to the PIN Number

and Time/Date screens

Backspace Key: Used to backspace when entering data

Enter Key: Used to enter data and move to the next screen

Space Key: Used to enter a space character when entering data

Alphanumeric Keys: Used to enter data on display. Hold down key

until the desired character is on display. Then release the key.

Page 5

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

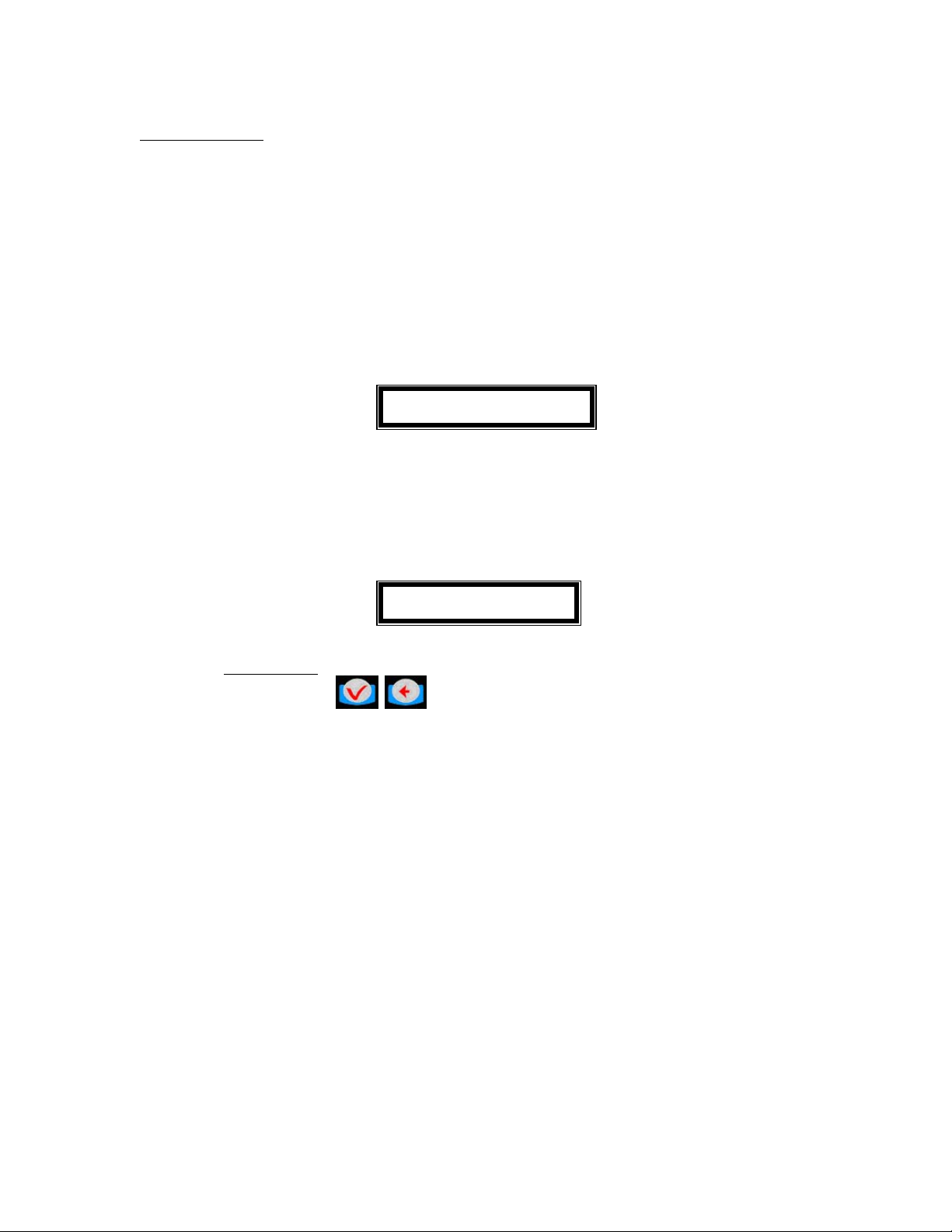

Default Screens:

• The Personal Identification Number (PIN) number is 4 numeric digits

• 1 supervisor account

• Maximum of 50 operators

• The supervisor account has access to the management screens

(initialization, configuration, communication, report, external printer and

internal printer reports)

• The operator account only has access to the dispense order screens

At power up, the following screens will be displayed:

01Jan2002 01:05

Version 1.0 US

This screen is displayed for system information only.

It is displayed during 1 seconds every 5 seconds. The 4 other seconds the

Enter Pin No. Screen will be displayed.

Enter Pin No.

****

Active keys:

Numeric keys,

,

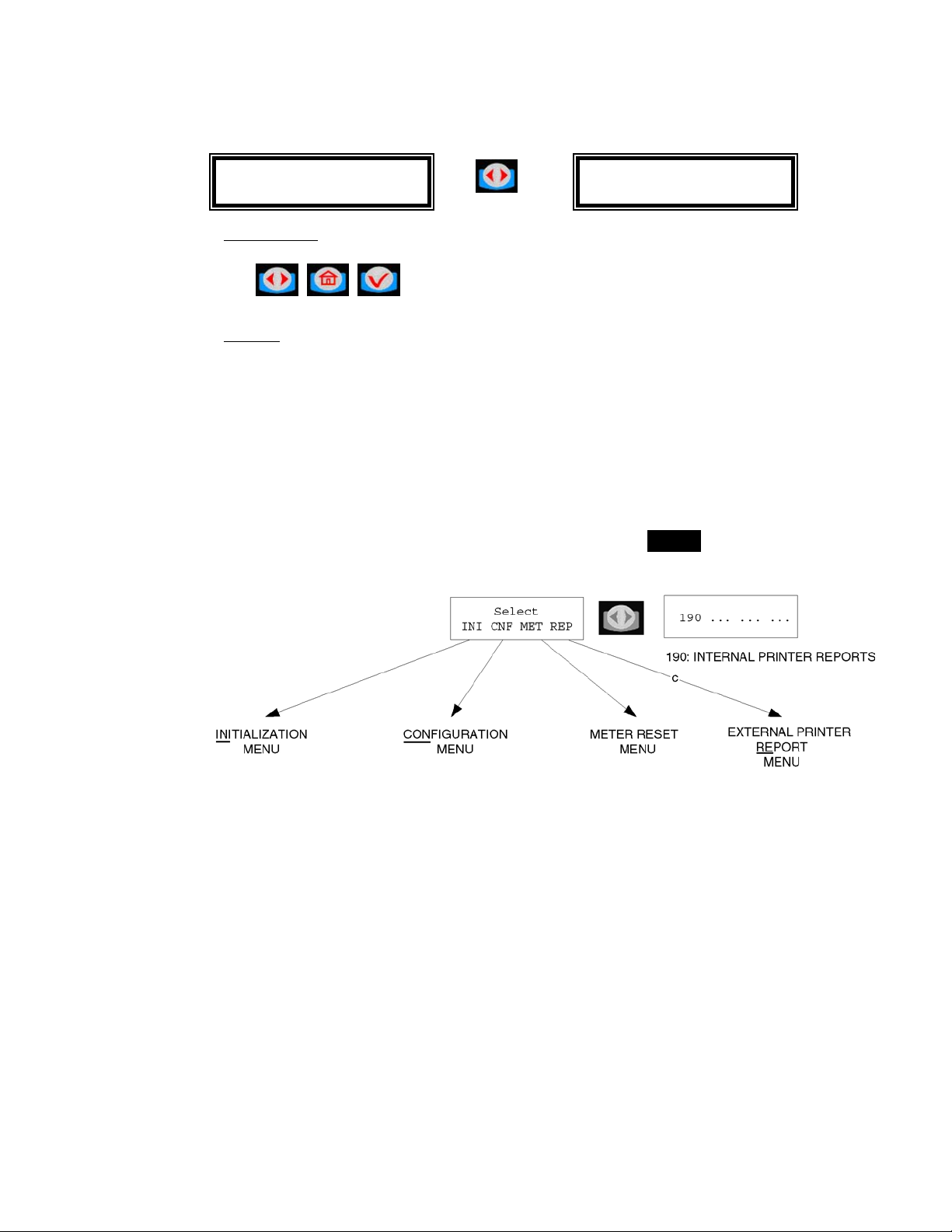

Supervisor Menu:

To access the management menu, enter the Supervisor PIN Number.

The Supervisor PIN is 4 numeric digits; default is 0000 at initial power-up.

Page 6

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Management Menu: The management menu displays after entering the

supervisor PIN Number

Select

INI CNF MET REP

190 - - - - - - - - -

Active keys:

, ,

Action:

• Choose which menu option is desired

Screens in INI can be accessed only when the Dispense Order list is

empty. If the supervisor wants to change one of these parameters whereas

the list is not empty, a screen message will be displayed. The supervisor

must clear all transaction records through the CNF menu prior to entering

the INI (initialization) menu.

For screens with multiple choices, the selection is in inverse video. (i.e.

The selection is green on black.)

The scroll key is used to select an answer (Example Yes – No). The

selection is in inverse video, it is validated with the ENTER key.

To go to the desired menu, move the scroll key to your choice and press

the ENTER key

Page 7

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Initialization Menu: Flow Chart

aThe parameter changes will affect all data in memory (example: if we

change the quantity unit from liters to gallons, the general quantity will be

simply switched from liters to gallons (no conversion from the previous

quantity unit to the new quantity unit)

aNo pending dispense order

Page 8

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

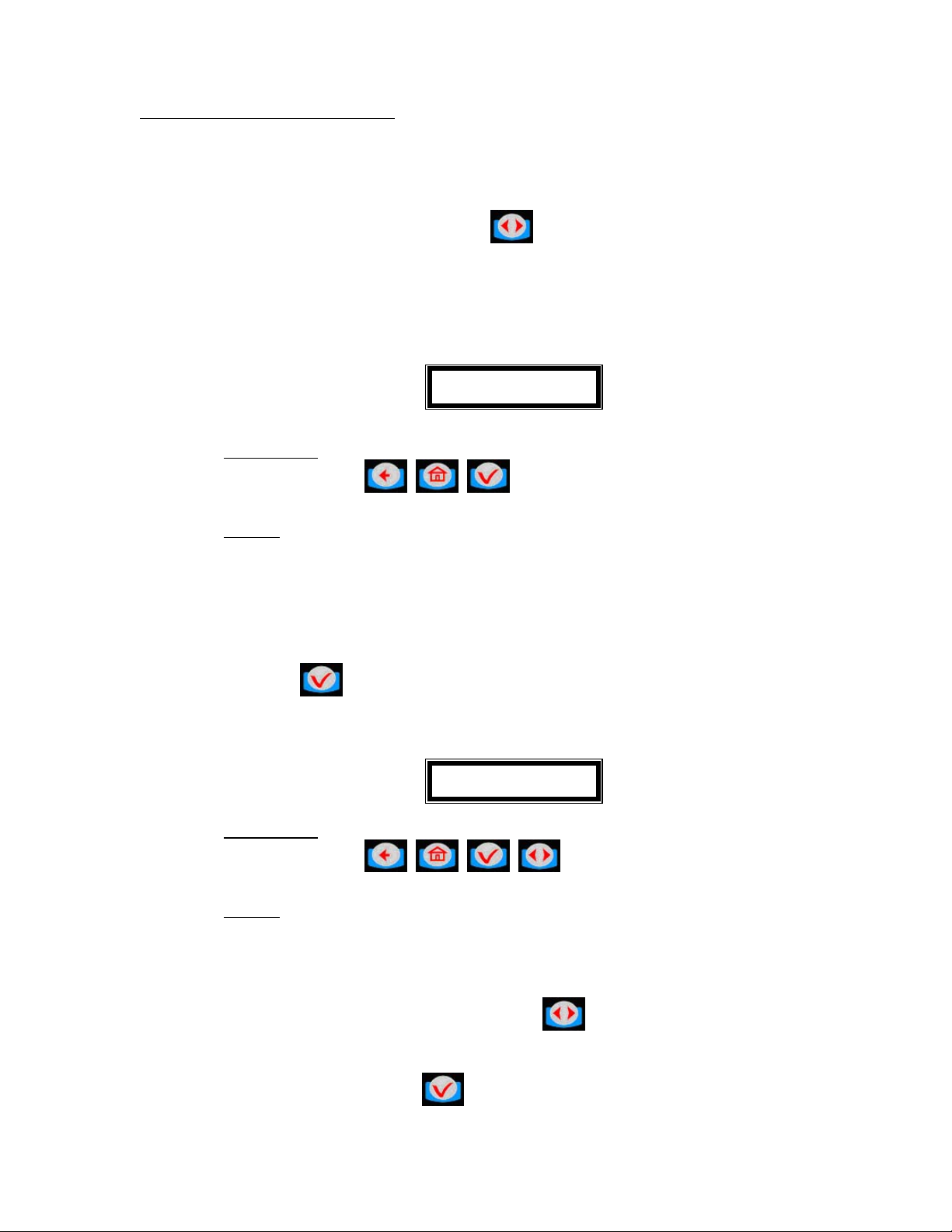

Initialization Menu Screens (INI):

• System date and time are initially blank

• System time is in military standard

• System date is in format DD/MMM/YYYY (in English)

• To change month, press to increment month

Enter Time:

Enter Time

--:--

Active keys:

Numeric keys,

, ,

Action:

• Enter key with no entry Æ Jumps to TANK UNIT screen

• If the time/date are already entered into the system, press enter

with no date to move to the next screens.

Enter time by using the numeric keys to set a 24-hour military time of day.

Press

when finished to move to the next initialization screen.

• Enter Date:

Enter Date

--/jan/----

Active keys:

Numeric keys,

, , ,

Action: Date is changed and tank unit screen is displayed.

Enter date by first entering the two digit day of the month. The cursor will

automatically jump to the month. Use

to select month, then enter a

four-digit year.

After date is set, press

to move to the next initialization screen.

Page 9

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

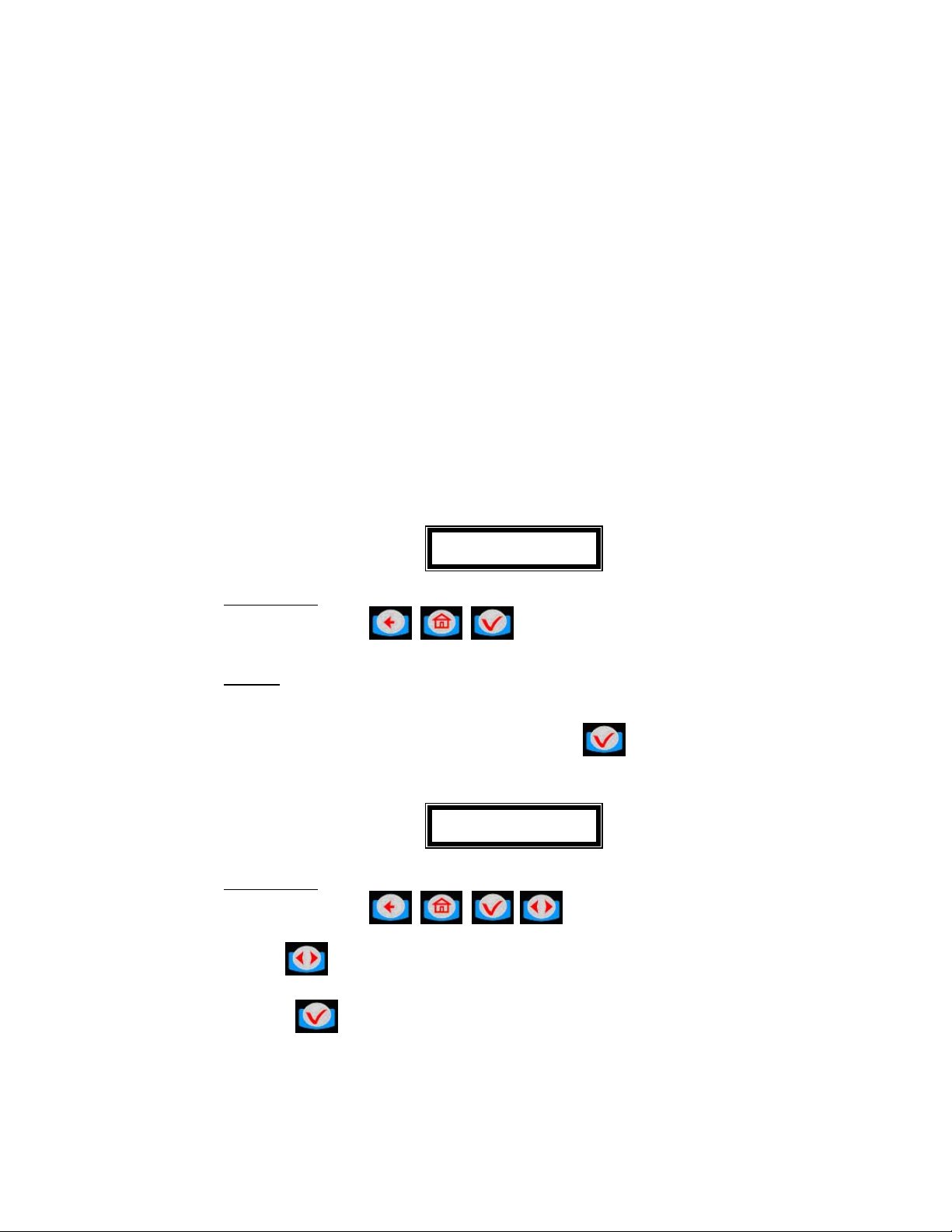

Tank Initialization:

The tank screens are used to set up the tanks in the system. Each tank is

assigned a number and a starting quantity level in the desired unit of

measure. The following is the process for installing a tank:

• Maximum of 8 Tanks

• Tank ID’s are numbered 1 thru 8

• Tank unit of measure can be quarts, liters, pints or gallons

• By default, the unit of measure is liters

• Set the dispensing unit of measure to the proper value

• The tank stock level setting is updated after each dispense from the

associated tank.

• The tank stock level quantity setting Format is 5.3 digits

(99999.999)

• The remaining tank stock level quantity will be printed out to the

nearest whole number after each dispense on the ticket.

• The Supervisor may update the tank stock level quantity setting at

any time by entering these screens to change stock levels

Tank Unit

Tank No -

Active keys:

Numeric keys,

, ,

Action:

• Enter key with no entry jumps to Fluids Screens

Enter a numeric value from 1 to 8 and press

Tank Unit

LITERS

Active keys:

Numeric keys,

, , ,

Use to select between LITERS, GALLONS, PINTS, QUARTS and

REMOVE (REMOVE option will delete the tank from the system.)

Press

to move to the next screen.

Page 10

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Tank Stock Level

No X: ---------

Active keys:

Numeric keys,

, ,

Use the numeric keys to enter a stock level from 00000.000 to 99999.999.

Press

to move to next screen.

Alphanumeric keys are validated only for some of the display menus. In

these menus to enter a letter just hold the related key and the letters scroll.

Then release the key when the letter you want is displayed.

Fluid Initialization:

This screen is used to set initial tank stock level or when ever supplier

delivers fluid. The fluid screens allow the supervisor to set the fluid

names used in the system. The parameters are:

• Maximum of 8 Fluid types

• The fluid type ID number ranges from 1 to 8

• The fluid type name is a 16 alphanumeric string

• Initially, the fluid type name is blank

Select Fluid

No -

Active keys:

Numeric keys, , ,

Action:

• Enter key with no entry Æ moves to Tank/Fluid relationship

screen

Fluid No. 1

----------------

Active keys:

Alphanumeric keys,

, ,

Page 11

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Tank-Fluid Relationship Screens:

The relationship between tank id and fluid type id will be 1:1 (one tank

assigned to one fluid type id). For example, the supervisor may associate

tank #1 with fluid #1 or tank #1 with fluid #2. Each tank must be

associated with one and only one fluid type.

Tank-Fluid

Tank No -

Active keys:

Numeric keys,

Action:

• Enter key with no entry Æ moves to Create Hose screens

Active keys:

Numeric keys,

The user must enter a valid number for a fluid in the system. Pressing enter

after a valid fluid number will bring the Tank-Fluid Tank No-, screen.

, ,

Tank-Fluid

Fluid No -

, ,

Page 12

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Adding and Deleting RF Meters: (Meter and Hose are synonymous)

This set of screens allows the Supervisor to add or delete RF Meters from

the keypad system.

• The RF Meter identification number can be found on the RF Meter

under the battery pack

• The RF Meter identification number format is 10 decimal digits

(-.---.---.---)

• Leading zeros must be entered

X.XXX.XXX.XXX

• RF Meters can be added and deleted

• Maximum of 48 RF Meters

• A given keypad can exchange data only with RF Meters whose

identification number is in this list.

• All RF Meters addresses and ids are unique

• The relationship between tank and RF Meter will be 1:n (one tank

assigned to n RF Meters). Since there will be a relationship

between tank and fluid type, the RF Meter will be assigned to one

fluid type.

• Initially the RF Meter address list is empty

Create Hose

-.---.---.---

Active keys:

Numeric keys,

, ,

Action:

• After validated RF Meter address is entered the tank-hose screen is

displayed

• Enter key with no entry Æ moves to Delete Hose screen

• If RF Meter address already used Hose Address Already Used Screen is

displayed

Hose Address

Already Used

Active keys:

There is no active key.

This screen is displayed if another RF Meter already uses the last three

number of the RF Meter.

If this screen displays check RF Meters in system to make some duplicate

RF Meters do not exist, then check to see if this RF Meter has already been

created in the system.

It is displayed for 3 seconds and it comes back to create hose screen.

Page 13

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

No Action

The relationship between tank and RF Meter will be 1:n (one tank

assigned to n meters). Since there will be a relationship between tank and

fluid type, the RF Meter will be assigned to one fluid type. Assign the RF

Meter to the tank in which it is connected.

Tank-Hose

Tank No -

Active keys:

Numeric keys,

, ,

Action:

Create hose screen is displayed

Hose ID

_ _

The system will automatically insert the created hose into the next

available slot (1-48) in the system. The user has the option to

change this hose number to any number (1-48) not currently in use.

Note: The Hose ID is the number used to create dispense orders

for the meter by the operator.

The supervisor has the option to delete a hose/RF Meter through

this screen. This is necessary when there is a change to the

system; whereby, a RF Meter needs replacement for any reason.

The supervisor should delete from the keypad the removed RF

Meter prior to creating the new RF Meter. This will put the new

RF Meter in the same logical position with the keypad and the

dispense order process will remain the same.

Delete Hose

-.---.---.---

Active keys:

Numeric keys, , ,

Action:

• If a RF Meter is deleted, the Delete Hose screen is displayed

• Enter key with no entry Æ Create Operator screen is displayed

Page 14

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Adding and Deleting Operators:

• Only an operator with valid PIN can dispense fluid

• A Maximum of 50 operators may be active in the system at a time

• The operator id (PIN number) format is 4 numeric digits

• The operator name format is 16 alphanumeric digits

• Initially, the operator list is empty

New operator

----

Active keys:

Numeric keys,

, ,

Action:

• If a new operator has been added, the Operator name screen is

displayed

• Enter key with no entry Æ Delete Operator screen is displayed

Operator XXXX

----------------

Active keys:

Alphanumeric keys,

, ,

Action:

• The New operator screen is displayed

• Enter the operator’s name using the keypad and then press enter to add.

To delete an operator, enter the four-digit id number for the operator to be

deleted and press enter.

Delete operator

----

Active keys:

Numeric keys, , ,

Page 15

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Page 16

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Configuration Menu: (CNF)

The Configuration Menu allows the supervisor to set-up all parameters for

the Keypad Operation. The Supervisor is the only user with access to

these screens.

Clearing Transactions from Keypad Memory:

• Removes all transactions (Dispense Orders) previously recorded in

memory

• Clear transactions will erase WO results data, Data will be cleared

confirmation.

Clear Transacts

YES / NO

Active keys:

The selection is in reverse video

, ,

Use the scroll key to select between YES/NO.

Confirm Clear

YES / NO

Active keys:

The selection is in reverse video

, ,

Action: The keypad will automatically return to the Clear Transacts screen on

YES or NO confirmation

Page 17

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

System Reset:

Allows the user to reset all the configuration parameters to default values:

System Reset

YES / NO

Active keys:

, ,

Action:

• If yes, the keypad asks the user to confirm

• If no, the keypad displays the mileage type screen

Confirm Reset

YES / NO

Active keys:

, ,

Action: The keypad returns to the System Reset screen

Mileage Type:

Allows the user to select how mileage is stored in the keypad

• KM/MILES

• The mileage type by default is KM.

Mileage Type

KM / MILES

Active keys:

, ,

Action:

• Press enter key to move to Mileage Info screen

Page 18

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Mileage and Registration Information Option:

Allows the supervisor to select the storage of vehicle mileage and

registration information for each dispense order.

• 16 numeric digit field

• YES/NO to the option of entering the vehicle mileage information for

each dispense order

• Mileage information by default is NO

Mileage Info

YES / NO

Active keys:

, ,

Action: Use the scroll key to select YES/NO, press enter key to move to the

Registration option screen

• 16 numeric digit field

• YES/NO to the option of entering the vehicle registration information

for each dispense order

• Registration information by default is NO

Regist. Info

YES / NO

Active keys:

, ,

Action:

Use the scroll key to select YES/NO, press enter key to move to the

keypad timeout screen

Page 19

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Keypad Timeout Option:

• Timeout parameter corresponding to the time it takes to validate after

all dispense order data has been entered. If the enter button is not

pressed within the time allocated, the keypad display goes back to the

initial menu, and the input data is erased.

• The keypad timeout is between 0 to 255 seconds (0 no timeout) and

the default for this feature is 10 seconds

Keypad Timeout

10-

Active keys:

Numeric keys,

, ,

Action:

• Press Enter key to move to Hose Inactive Timeout Option

Hose Inactive Timeout Option:

• Essentially, this is the time the user has to top-off the dispense and

completing the automatic batch.

• Timeout parameter corresponding to the time that a RF Meter could

stay inactive after the reset key has been pressed on the meter.

• If the user has not pressed reset on the RF Meter within the timeout

period, the RF Meter will transmit the dispense order quantity to the

keypad and lockout the RF Meter.

• Meter inactive timeout is sent to the RF meter. It’s the meter (ER) that

is responsible of tracking this timer.

• The meter inactive timeout is set for all RF Meters.

• The meter inactive timeout is between 0 to 65534 seconds (0 = no

timeout) and the default value is 10 minutes.

Hose Inactive

600

Active keys:

Numeric keys,

, ,

Action:

• Press Enter key to move to Display Timeout Option

Page 20

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Display Timeout Option: (Do Not Change)

• Timeout parameter corresponding to the time for displaying

information on the keypad LCD before it is refreshed with new

information

• The display timeout is set at 2 seconds

Display Timeout

2--

Active keys:

Numeric keys,

, ,

Action:

• Press Enter key to move to Internal Printer Option

Internal Printer Option:

• YES / NO. Parameter indicating the existence of an internal printer

(CUSTOM FT190).

• The internal printer value is set by default NO (a The keypad will not

detect the existence of a printer)

Internal printer

YES / NO

Active keys:

, ,

Action:

• Use scroll key to select the internal printer setting

• Press Enter key to select the internal printer setting and move to

External Printer Option

External Printer Option:

• YES / NO. Parameter indicating the existence of an external printer

(EPSON LX300).

• The external printer value is set by default NO

External Printer

YES / NO

Active keys:

, ,

Page 21

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Action:

• Use scroll key to select the external printer setting

• Press Enter key to move to select the external printer setting and

Supervisor Password Option

Supervisor Password Option:

The default supervisor password for protecting the modification of the

supervisor id is 0000.

The Supervisor can change this password during the initial set-up of the

system.

Maximum of 1 Supervisor login password

Super new pass

****

Active keys:

Numeric keys,

, ,

Action:

• Use numeric keys to enter the new password then press enter.

• Enter key with no entry Æ No change to password and displays

buzzer option.

Super Confirm

----

Active keys:

Numeric keys,

, ,

Action: reenter new password to confirm.

Buzzer Option:

This screen provides the user with the option to have a beep on

every key entry. The default is YES.

Buzzer

YES / NO

Active keys:

, ,

Page 22

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Action:

keypad will display the Supervisor Menu

Select YES or NO by using the scroll key, then press Enter. The

.

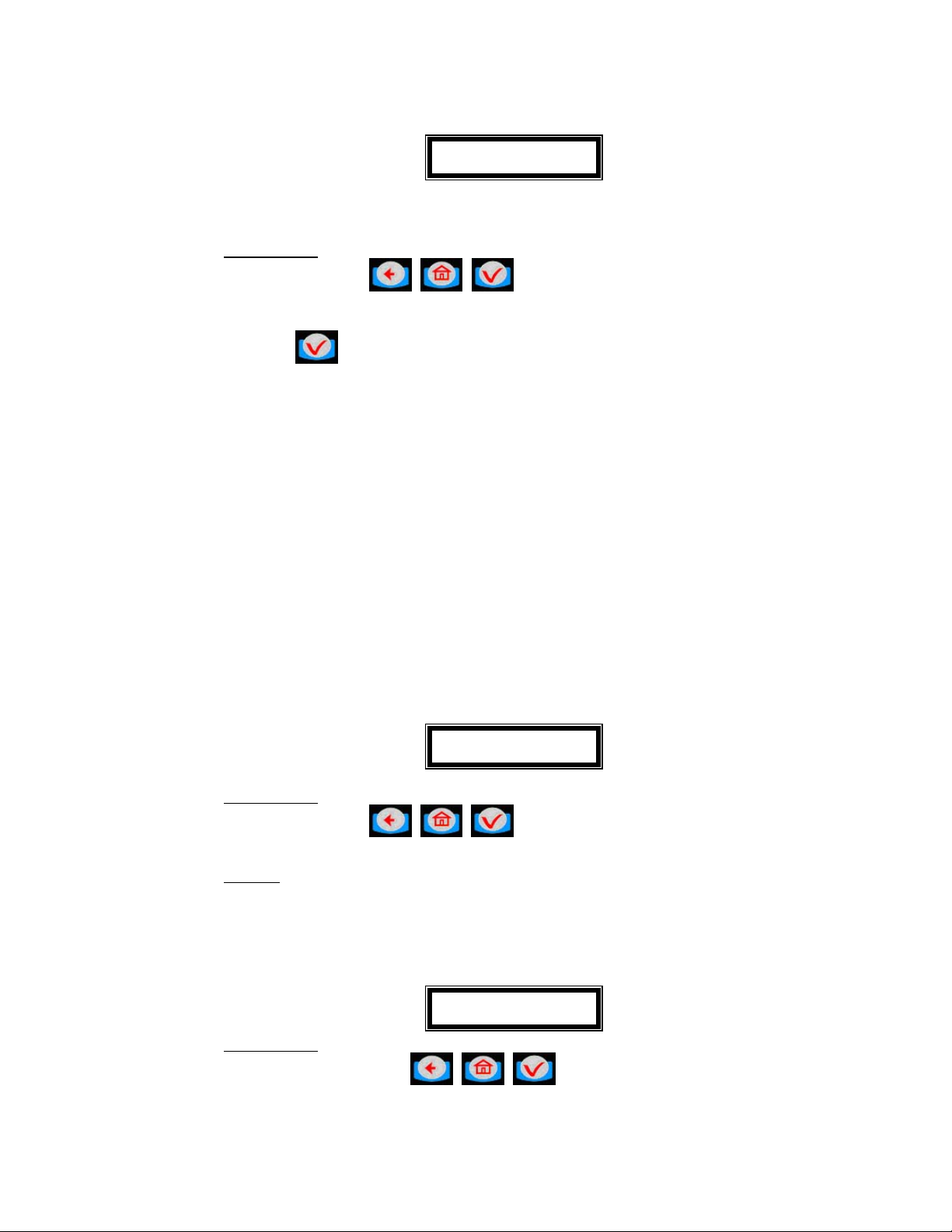

Meter Reset Menu (MET):

• Only the supervisor has access to this process.

• The supervisor may delete a dispense order in the keypad que for a

single hose or all hoses in the system.

• If the supervisor selects all RF Meters, all dispense orders in the que

will be deleted and all meters may be programmed for a dispense

order.

Init all Hose

YES / NO

Active keys:

, ,

Action:

• If YES Æ Start (Hoses Init) is displayed

• If NO Æ User is prompted for a hose number to reset

Start Hoses Init

Press enter

• Press ENTER to reset the hose

Meter Reset Menu Flowchart:

Page 23

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Report Menu Screens: (REP)

The supervisor has the opportunity to print out a variety of reports, if there

is an external printer

connected to the keypad.

INI: Prints all parameters associated with the system initialization

CNF: Prints all parameters selected for the configuration of the keypad

MET: Prints the status of all hoses/meters

REP: Prints the dispense order history

The external printer has to be activated and connected.

aWhen the keypad is printing out a report or a receipt, the keypad

keyboard will be locked for all new data entry (i.e. the operator will not be

able to enter a new Dispense Order List while the keypad is printing).

aIf the keypad detects an error on the internal printer or the external

printer (not connected, out of paper or off line), the keypad keyboard will

be locked for all new data entry and an error will displayed on the keypad

LCD. The user should check the printers for off-line or out of paper

conditions.

aIf an error is detected while printing, the keypad will not purge the

memory (especially in the case of the Dispense Order List report)

aAfter printing out the Dispense Order List report, the Dispense Order

list memory is erased automatically

The dispense order receipt is automatically (after a user prompt message)

printed out after the RF reception of the dispense order result

Select Report

INI CNF MET WO

Active keys:

, ,

Action:

• Use the scroll key to select report option

• Enter key with no entry Æ keypad returns to Supervisor Menu screen

Page 24

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Initialization Report:

DD/MMM/YYYY INITIALIZATION REPORT HH:MI

TNK PRODUCT LEVEL UNT

=== ================ ===== ======

1 Fluid 1 name 99999 LITERS

2 Fluid 2 name 99999 LITERS

(…) (…) (…) (…)

7 Fluid 7 name 99999 LITERS

8 Fluid 8 name 99999 LITERS

ID ADDR TNK

=== ================ ===

123 124456 1

234 561444 2

(…) (…) (…)

ID PIN NAME

=== ==== ================

1 1234 John SMITH

2 1235 Paul GREEN

3 1236 Mike BROWN

(…) (…) (…)

ID PRODUCT

=== ================

1 Fluid 1 name

2 Fluid 2 name

(…) (…)

7 Fluid 7 name

8 Fluid 8 name

DD/MMM/YYYY

Date of the printout

HH:MI Time of the printout

TNK Tank No

PRODUCT Fluid type name

QTY Quantity dispensed

UNT Unit

ADDR Meter RF address

ID RF Meter Id (Last 3 address characters)

TNK Tank No

PIN User pin number

NAME User name

Page 25

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Configuration Report:

DD/MMM/YYYY CONFIGURATION REPORT HH:MI

Mileage Type KM

Registration Info NO

Mileage Info NO

Internal printer Yes

External printer Yes

Address printer

Buzzer Yes

Approved PTB NO

Supervisor pass 1234

Hose Inactive 600

Keypad Timeout 10

Display Timeout 2

On-Off sequence 999999

Select Report

INI CNF COM WO

Active keys:

, ,

Action:

• Use scroll key to move to CNF and press Enter key

• Enter key with no entry Æ Supervisor Menu screen is displayed

Start

CNF Report

Active keys:

,

Action:

After Report is completed the Select Report screen is displayed

Page 26

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Communications Report:

DD/MMM/YYYY COMMUNICATION REPORT HH:MI

ADDR ID STA

====== ==== ===

0.000.000.101 1 inactive

0.000.000.137 2 inactive

0.000.000.111 3 inactive

0.000.000.126 4 inactive

0.000.000.127 5 inactive

0.000.000.109 6 inactive

0.000.000.100 7 inactive

0.000.000.135 8 inactive

DD/MMM/YYYY

Date of the printout

HH:MI Time of the printout

ADDR Meter RF address

ID RF Meter Id (Last 3 address characters)

STA Status of the RF link:

• OK Î RF link is established

• KO Î RF link not established

• ? Î RF link doubtful

Select Report

INI CNF COM WO

Active keys:

, ,

Action:

• Use scroll to move to COM and press Enter

• Enter key with no entry Æ Supervisor Menu screen is displayed

Active keys:

,

Action: After printing Select Report Menu is displayed

Start

COM report

Page 27

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Dispense Order Reports:

Select Report

INI CNF COM WO

Active keys:

, ,

Action:

• Scroll to WO and press Enter key

• Enter key with no entry Æ Supervisor Menu screen is displayed

Select REP

USR PRO HOS TNK

Active keys:

, ,

Action: Scroll to report to print and press the Enter key

There are four reports that may be printed associated with Dispense Orders:

• USR: Print dispense orders by Operator

• PRO: Print dispense orders by Fluid Type

• HOS: Print dispense orders by Hose/Meter

• TNK: Print dispense orders by Tank

User Report (USR):

DD /MMM/YYYY STATISTICAL REPORT BY USER HH:MI

USER PRODUCT QTY

================ ================ =====

JOHN SMITH FLUID TYPE 1 99999

FLUID TYPE 2 99999

FLUID TYPE 3 99999

FLUID TYPE 4 99999

PAUL GREEN FLUID TYPE 5 99999

FLUID TYPE 6 99999

FLUID TYPE 7 99999

FLUID TYPE 8 99999

(…)

Start

Report

Active keys:

,

Action: After printing the Select Report Screen is displayed

Page 28

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Product Report (PRO):

DD/MMM/YYYY STATISTICAL REPORT BY PRODUCT HH:MI

PRODUCT USER QTY

================ ================ =====

FLUID TYPE 1 JOHN SMITH 99999

PAUL GREEN 99999

FLUID TYPE 2 JOHN SMITH 99999

PAUL GREEN 99999

FLUID TYPE 3 JOHN SMITH 99999

PAUL GREEN 99999

(…)

Start

Report

Active keys:

,

Action: After printing the Select Report Screen is displayed

Hose/Meter Report (HOS):

DD/MMM/YYYY STATISTICAL REPORT BY RF METER HH:MI

ADDR ID USER QTY

====== === ================ =====

123456 456 JOHN SMITH 99999

PAUL GREEN 99999

234561 561 JOHN SMITH 99999

PAUL GREEN 99999

(…)

Start

Report

Active keys:

,

Action:

After printing the Select Report Screen is displayed

Page 29

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Tank Report (TNK):

DD/MMM/YYYY STATISTICAL REPORT TANK LEVEL HH:MI

TNK PRODUCT LEVEL UNT

=== ================ ===== =======

1 5W30 OIL 123 LITERS

2 GEAR OIL 1111 LITERS

3 ATF 111 11111 GALLONS

4 HYDRAULIC FLUID 232 QUARTS

5 10W40 OIL 3466 PINTS

6 WASHER FLUID 1 LITERS

7 5W40 OIL 2344 LITERS

8 BEER 43234 PINTS

Start

Report

Active keys:

,

Action: After printing the Select Report Screen is displayed

Report Menu Flowchart

REPORT

MENU

Select Report

INI CNF COM WO

Start

INI Report

Start

CNF Report

Start

COM Report

Select REP

USR PRO HOS TNK

Start

Report

Page 30

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Internal Printer Reports:

FLU: Prints all fluids created in the system

HDS: Prints all hose numbers with meter serial numbers

TNK: Prints all tanks created in the system

USE: Prints all operators created in the system

WO: Prints all work orders pending

PEN: Prints the current meter status

“INACTIVE”: Hose is ready

“ACTIVE”: A dispense order is pending

“UNREACHABLE”: Hose is not ready

- Hit reset button on meter to begin communications test

and reset meter.

PAR: Prints the current setting in configuration menu

MEM: Prints the memory configuration for system

NOTE: It is recommended that the supervisor print all internal reports and store hard

copies after setting up the system.

Page 31

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Fluid Type Definitions

Fluid id Name

1

2

3

4

5

6

7

8

Maximum Fluid types is 8

The Fluid name can be 16 characters in length

Page 32

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Tank Definitions

Tank id Tank Level

1

2

3

4

5

6

7

8

Maximum of 8 Tanks

Tank Capacity

The Tank Capacity value is formatted 00000.000

Page 33

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Hose/Meter Definitions

Hose/Meter id Address Number x.xxx.xxx.xxx

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Maximum of 48 Hose/Meters

Hose/Meters address is a 10 digit number

Address Data Format is x.xxx.xxx.xxx

Page 34

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Hose/Meter Definitions

Hose/Meter id Address Number x.xxx.xxx.xxx

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Maximum of 48 Hose/Meters

Hose/Meters address is a 10 digit number

Address Data Format is x.xxx.xxx.xxx

Page 35

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

User Definitions

User id User Name

1 Reserved Supervisor

2

3

4

5

6

7

8

9

10

11

Pin id

0000

12

13

14

15

16

17

18

19

20

21

22

23

24

25

The User Name is up to 16 characters

The User Pin id is a 4 digit number with leading 0’s required

Page 36

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

User Definitions

User id User Name

26

27

28

29

30

31

32

33

34

35

36

Pin id

37

38

39

40

41

42

43

44

45

46

47

48

49

50

The User Name is up to 16 characters

The User Pin id is a 4 digit number with leading 0’s required

Maximum of 50 users

Page 37

Samson Corporation-Swannanoa, NC 28778 800.311.1047 www.samsoncorporation.com

Loading...

Loading...