Page 1

FOUNDATION

TM

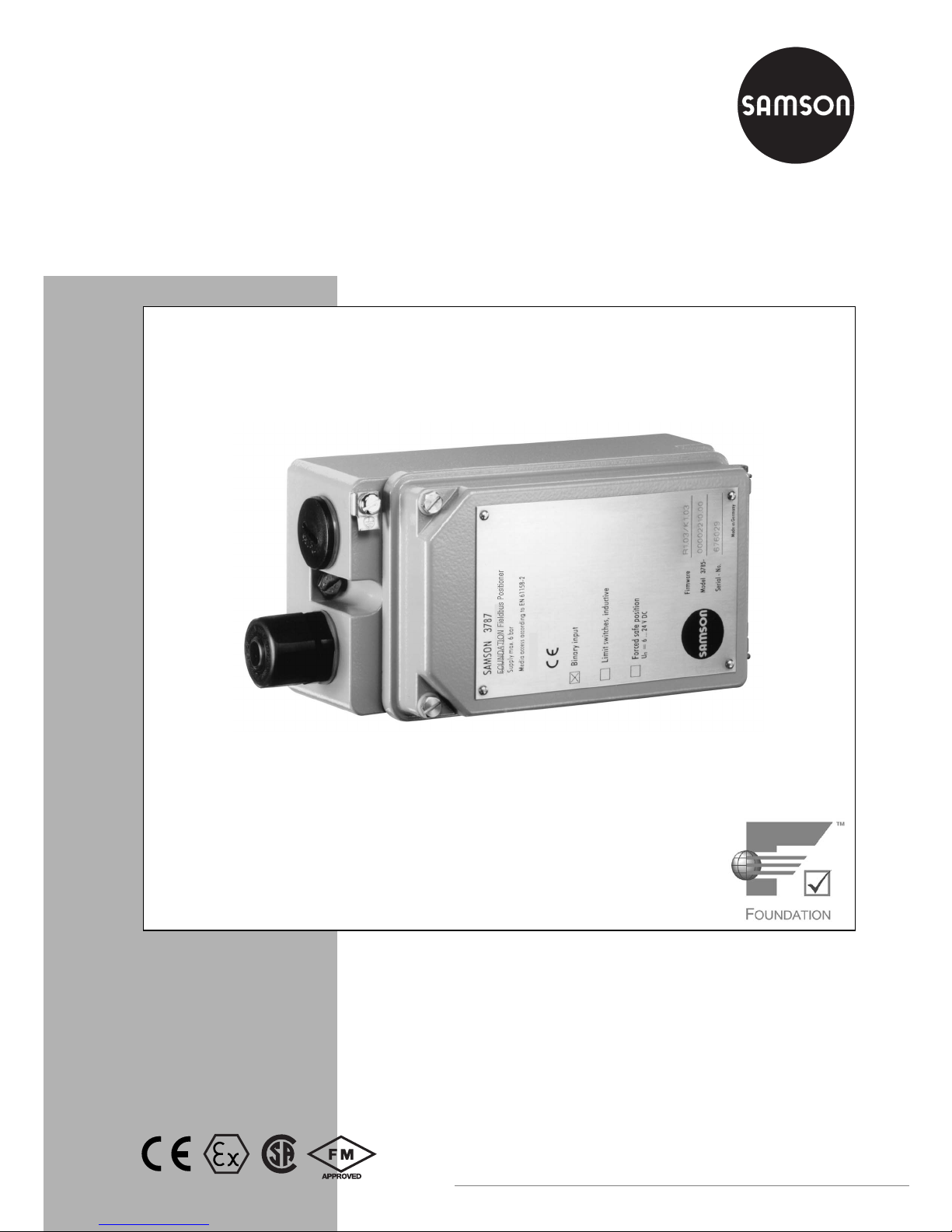

FIELDBUS Positioner

Type 3787

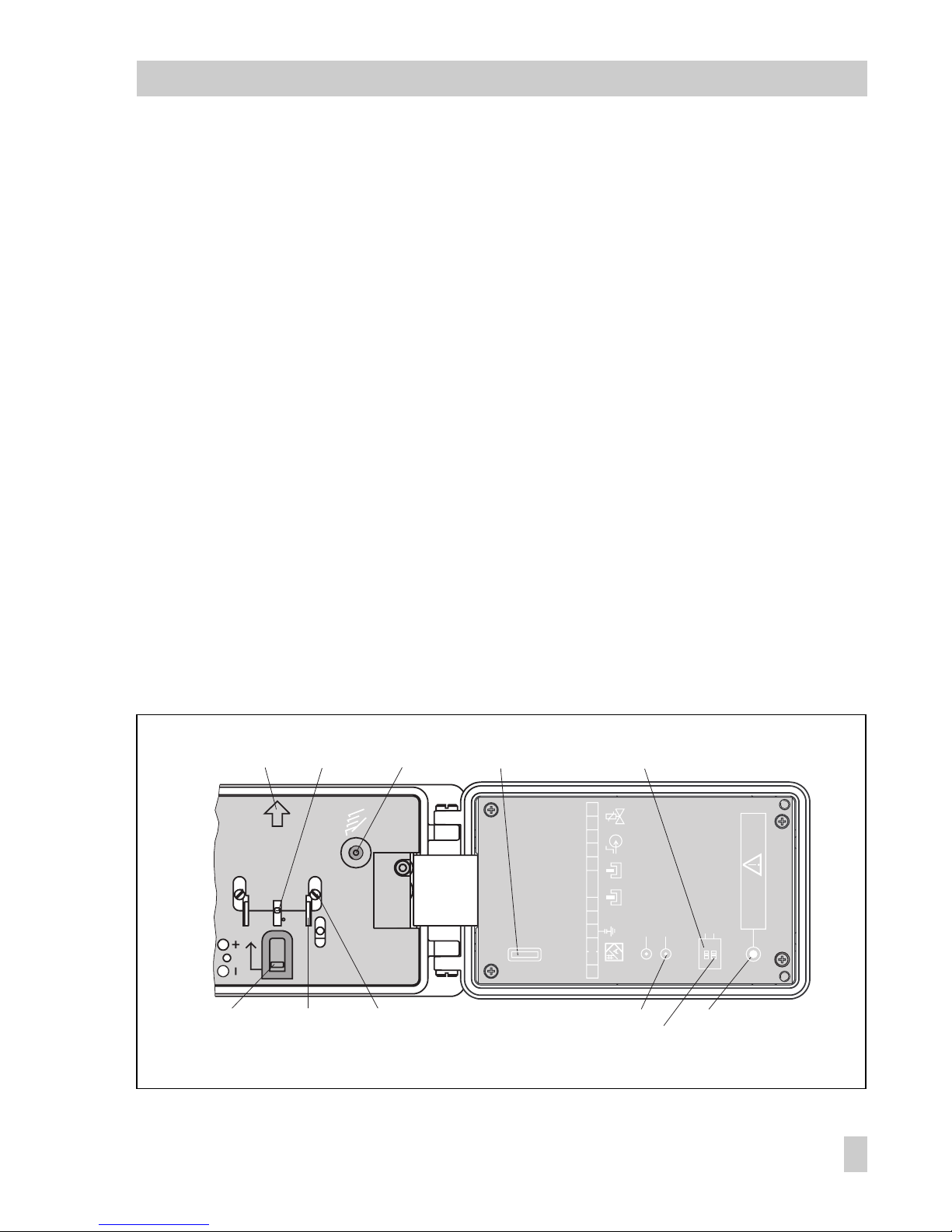

Fig. 1 ⋅Type 378 7

Mounting and

Operating Instructions

EB 8383-1 EN

Firmware R 1.4x/K 1.4x

Edition November 2004

Page 2

Contents Page

1 Design and principle of operation

. . . . . . . . . . . . . . . . . . . . . . 8

1.1 Optional limit switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Attachment to the control valve

. . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Direct attachment to Type 3277 Actuator . . . . . . . . . . . . . . . . . . . 10

2.2 Attachment acc. to IEC 60534-6 . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.1 Mounting sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.2 Presetting the valve travel . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3 Attachment to rotary actuators . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.1 Mounting the lever with feeler roll . . . . . . . . . . . . . . . . . . . . . . . 18

2.3.2 Mounting the intermediate piece . . . . . . . . . . . . . . . . . . . . . . . 18

2.3.3 Aligning and mounting the cam disk . . . . . . . . . . . . . . . . . . . . . 20

2.3.4 Reversing amplifier for double-acting actuators . . . . . . . . . . . . . . . . 22

2.4 Fail-safe action of the actuator . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Connections

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1 Pneumatic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1.1 Pressure gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1.2 Supply air pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.1 Establishing communication . . . . . . . . . . . . . . . . . . . . . . . . . 28

4Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2 Write protection and simulation switches . . . . . . . . . . . . . . . . . . . 30

4.3 Activate/deactivate forced venting function . . . . . . . . . . . . . . . . . . 30

4.4 Default setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4.1 Adjusting mechanical zero . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4.2 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.5 Operation via TROVIS-VIEW . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5.1 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5.2 Testing the control valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.6 Setting the inductive limit switches . . . . . . . . . . . . . . . . . . . . . . 34

Contents

2

EB 8383-1 EN

Page 3

5 Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6 Servicing explosion-protected versions

. . . . . . . . . . . . . . . . . . . 35

7 Parameter description

. . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.2 Device Description (DD) . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3 Notes on the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3.1 Legends assigned to the parameters . . . . . . . . . . . . . . . . . . . . . 37

7.3.2 Notes on parameter storage classes S, N and D . . . . . . . . . . . . . . . 37

7.4 Block structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.4.1 Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.4.2 Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.4.3 Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.4.3.1 Analog Output Function Block . . . . . . . . . . . . . . . . . . . . . . . 57

Parameters of the Analog Output Function Block . . . . . . . . . . . . . . . 59

7.4.3.2 PID Function Block (PID controller) . . . . . . . . . . . . . . . . . . . . . . 65

Parameters of the PID Function Block . . . . . . . . . . . . . . . . . . . . 67

7.5 Other parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.5.1 Stale counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.5.2 Link objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.5.3 LAS capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8Diagnostic messages

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.1 Messages of the XD_ERROR_EXT parameter (Transducer Block) . . . . . . . 79

8.2 Messages of the XD_ERROR parameter (Transducer Block) . . . . . . . . . . 80

8.3 Messages of the SELF_CALIB_STATUS parameter (Transducer Block) . . . . . 81

Dimensional drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

EC Type Examination Certificate . . . . . . . . . . . . . . . . . . . . . . 83

CSA/FM certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Contents

EB 8383-1 EN

3

Page 4

Safety instructions

The device may only be assembled, started up, and operated by experienced

personnel familiar with this product.

In these mounting and operating instructions, the term "experienced personnel" refers to individuals who are able to evaluate the responsibilities assigned

to them as well as recognize potential hazards due to their specialized training, knowledge, and experience as well as their special knowledge of the relevant standards.

Explosion-protected versions of this device may only be operated by personnel who have undergone special training or instructions, or who are authorized to work on explosion-protected devices in hazardous areas.

Any hazards which could be caused by the process medium, the operating

pressure, the signal pressure and moving parts of the control valve, must be

prevented by means of appropriate measures.

Should inadmissible motions or forces be produced in the pneumatic actuator

as a result of the level associated with the supply air pressure, these must be

restricted by means of a suitable pressure reducing station.

Proper shipping and appropriate storage of the device are assumed.

Note:

Devices with the CE mark meet the requirements specified in the Directive

94/9/EC and the Directive 89/336/EEC.

The Declaration of Conformity can be viewed and downloaded from the

SAMSON website at www.samson.de.

Modifications of positioner firmware in comparison to previous versions

Previous New

Positioner R 1.41 R 1.42

Correction in the zero calibration activated over software

communication

4

EB 8383-1 EN

Page 5

Firmware modifications

Communication

K1.00 K1.20

Version compatible with user interface software version number:

Fisher-Rosemount DeltaV in version 5.1 or higher

National Instruments Fieldbus Configurator in version 2.3 or

higher.

All host systems certified by the Fieldbus Foundation

Alteration to default values of the following parameters:

AO Function Block CHANNEL, PID Function Block GAIN,

PID Function Block RESET, PID Function Block BYPASS

Resource Block parameter extended:

BLOCK_ERROR, page 40

Transducer Block parameters changed/extended:

BLOCK_ERR, page 46.

Communication

K 1.00 K1.31

The output parameters of the function blocks can be

interconnected within a device and with blocks in other devices at

the same time. In the previous version, it was only possible to

either interconnect function blocks within a device or with blocks

in other devices.

An Output Failure in BLOCK_ERR of the AO Function Block

generates a Block Alarm.

The automatic resetting control loop monitor (previously not

automatic resetting) is evaluated for the control loop error

indication via LED or the message "Calibration Error". This means

this alarm or message is automatically reset as soon as the control

loop monitor cannot find an error anymore.

Communication

K 1.31 K1.40

The default value for RESET in the PID Block has been changed

from 0 to 3402823466 x 10

38

(maximum possible value). The

integral-action component of the PID is ineffective at this value as

well as at 0. On switching over the operating mode from MAN to

AUTO, a smooth switchover is achieved.

EB 8383-1 EN

5

Page 6

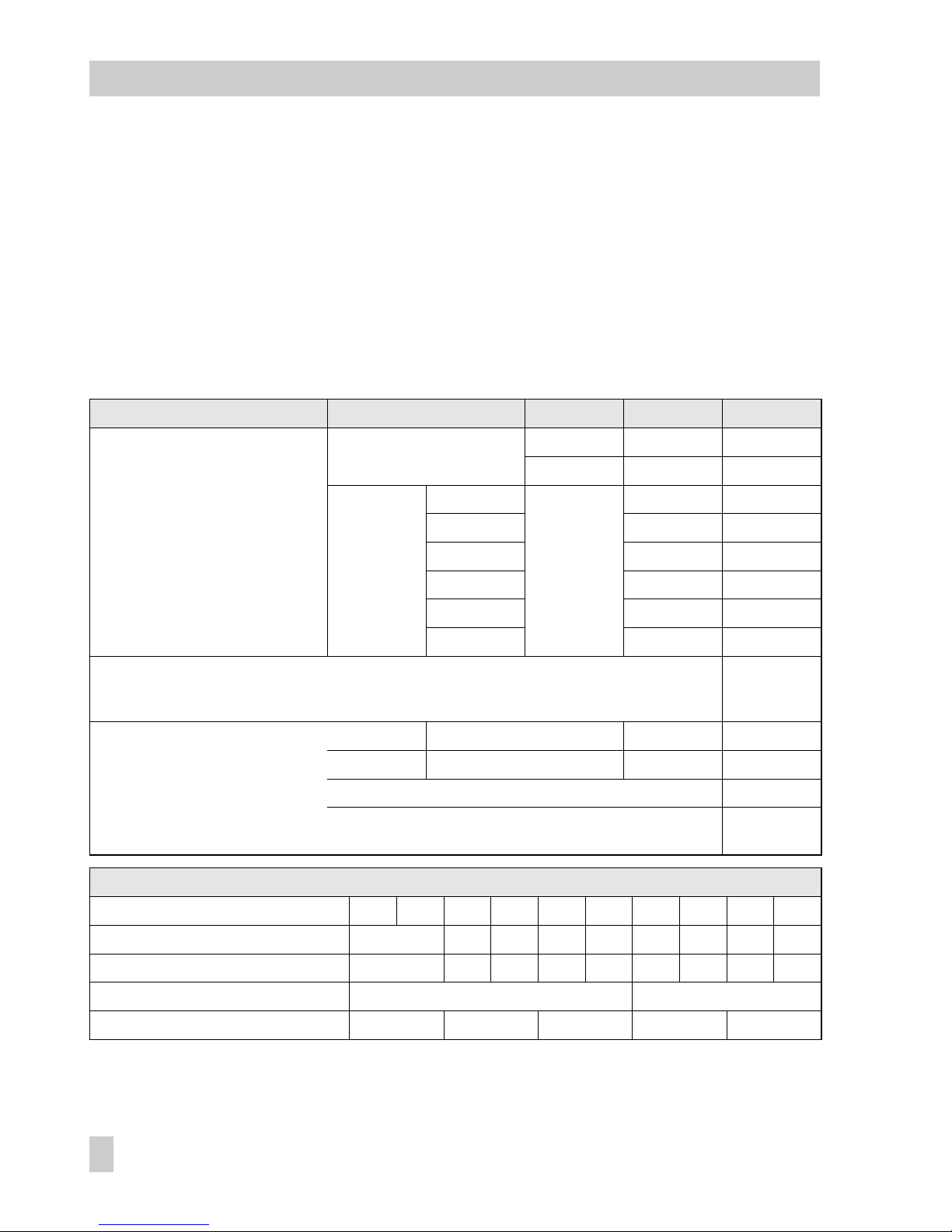

Technical data

Positioner

Travel

Direct attachment to Type 3277

Attachment acc. to IEC 60534-6

Adjustable

5 to 30 mm

5 to 255 mm or 30 to 120° for rotary actuators

Bus connection Fieldbus interface as per IEC 61158-2, bus-powered

Physical Layer Class: 113 (not explosion-protected version) and 111 (Ex-version)

Field device according to FM 3610 entity and FISCO.

Per m issib le o perati ng v oltage 9 to 32 V DC; The speci f icatio ns i n the EC Type E xamina tion Certif i cate addit ionally

apply for explosion-protected devices. Power supply over bus cable

Max. operating current 13 mA

Additional current in case of fault 0 mA

Supply air Supply air from 1.4 to 6 bar (20 to 90 psi);

Air quality as per ISO 8573-1: Max. particle size and density: Class 4;

Oil co nt ents: C la ss 3; Pr es sure de w p oint: C la ss 3

Signal pressure (output) 0 bar up to the pressure of the supply air

Characteristic, adjustable

Deviation

Globe valve: linear, equal percentage, reverse equal percentage,

SAMSON butterfly valve: linear, equal percentage

VETEC plug rotary valve: linear, equal percentage

≤1 %

Dead band

(based on rated travel/angle

Adjustable from 0.1 to 10.0 % , default 0.5 %

Resolution (internal measurement) < 0.05 %

Tran sit time re quired For v al ve tra ns it time up to 75 s

Set point ramp for exhaust and supply air separately adjustable

Operating direction Reversible, setting by software

Air consumption Independent of supply air <90l

n

/h

Air s upply A ctuat or f illed: wh en Δp = 6 bar 9.3 m

n

3

/h, when Δp = 1.4 bar 3.5 m

n

3

/h

Actu at or vented : w hen Δp = 6 bar 15.5 m

n

3

/h, when Δp = 1.4 bar 5.8 m

n

3

/h

Permissible ambient temperature 40 to 80 °C

The specifi cation s in t h e EC Typ e Examin ation Certif icate addi tionally app ly f o r

explosion-protected devices

Effects Temperature: ≤0.15 %/10 K, supply air: none,

Vibrations: none up to 250 Hz and 4 g

Deg re e o f prote ct io n IP 65 us ing fil te r check va lve inc luded

Electromagnetic compatibility Requirements acc. to EN 61000-6-2, EN 61000-6-3 and

NAMUR Recommendations NE 21 are met

Bin ar y in pu t Inte rn al powe r s upply 5 V DC , R

i

= 100 kΩ for a la rm func ti on

Forced venting

(activated over an internal switch)

Input 6 to 24 V DC, R

i

approx. 6 kΩ at 24 V D C ( depend in g on volt age)

Switching point for "1" signal ≥ 3 V, switc hi ng poin t f or "0" sign al only at 0 V,

K

V

0.17

6

EB 8383-1 EN

Page 7

Versions

Accessories

Inductive limit switches Two Type SJ 2 SN Proximity Switches for connection to a switching amplifier acc. to

EN 60947-5-6

Communication

Data transmission In accordance with FOUNDATION

TM

Fieldbus specification

Communication Profile Class: 31 PS, 32: Interoperability Test System (I TS) Revision 4.0

Materials

Case Die -c as t alumi num, chr om ized an d p lastic -c oated

External parts Stainless steel 1.4571 and 1.4301

Weigh t Appr ox 1. 3 kg

Versions of the positioner

Model

3787 -

XXX

0

X3X

Explosion protection Without

II 2 G EEx ia IIC T6/

II 2 D IP 65 T 80 °C acc. to ATEX

Ex ia FM/CSA

II 3 G EEx ia IIC T6/

II 3 D IP 54 T 80 °C acc. to ATEX

0

1

3

8

Accessories Limit switches Without

2 inductive

0

22

Forced venting Without (deactivated)

With (activated)

0

12

Pneumatic

connections

NPT 1/4- 18

ISO 228/1-G 1/4

1

2

Electric connections Cable gland M20 x 1.5

Nickel-plated brass

Quantity: 1

2

1

2

EB 8383-1 EN

7

Page 8

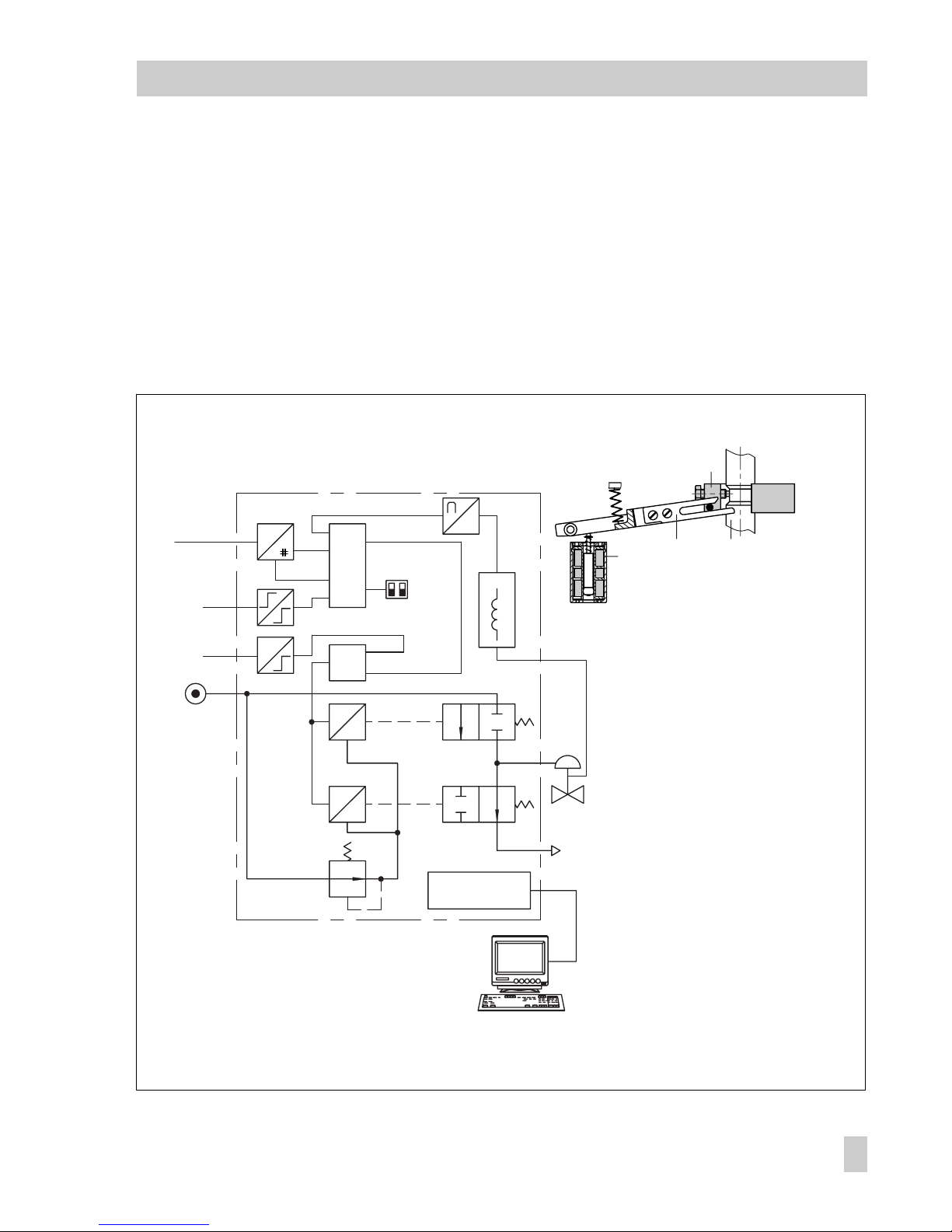

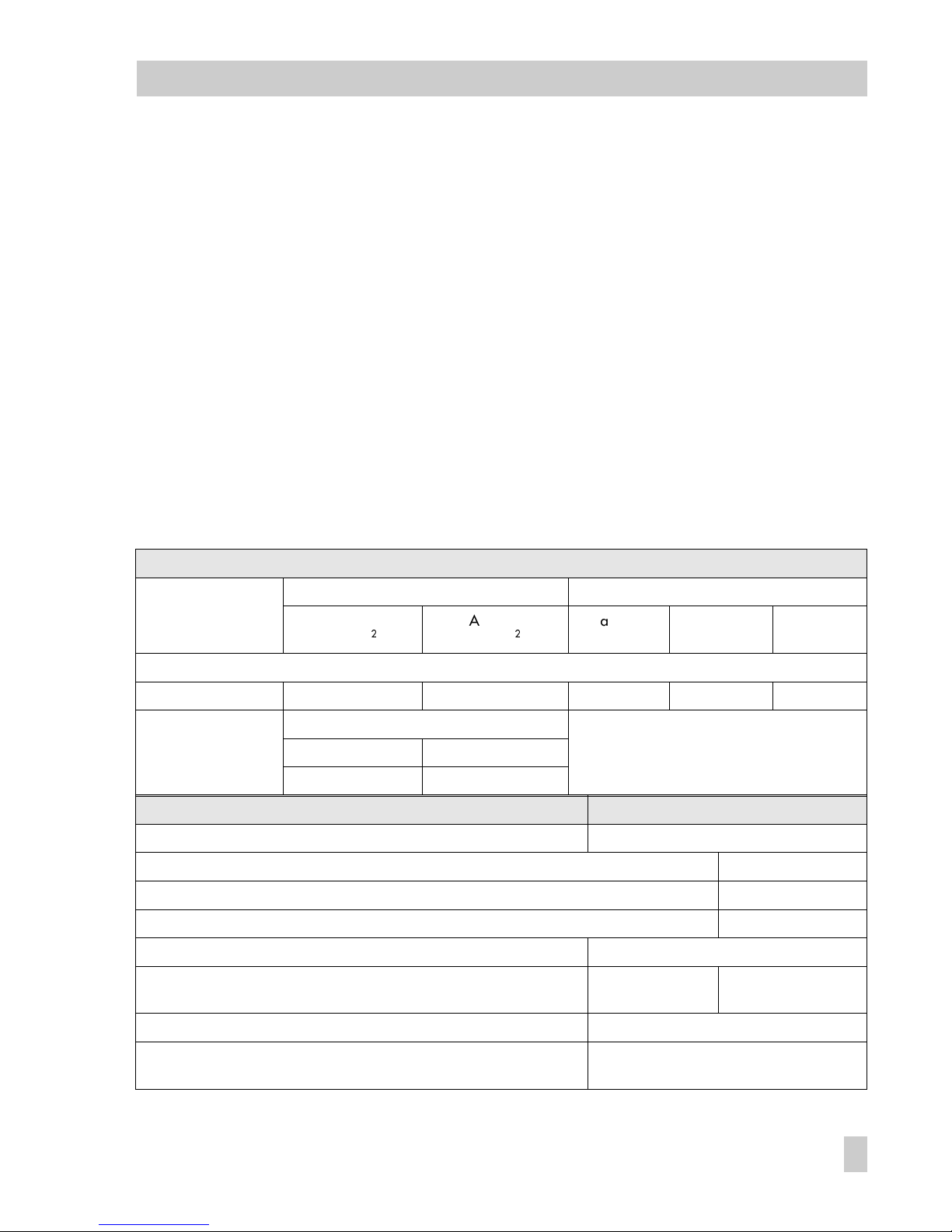

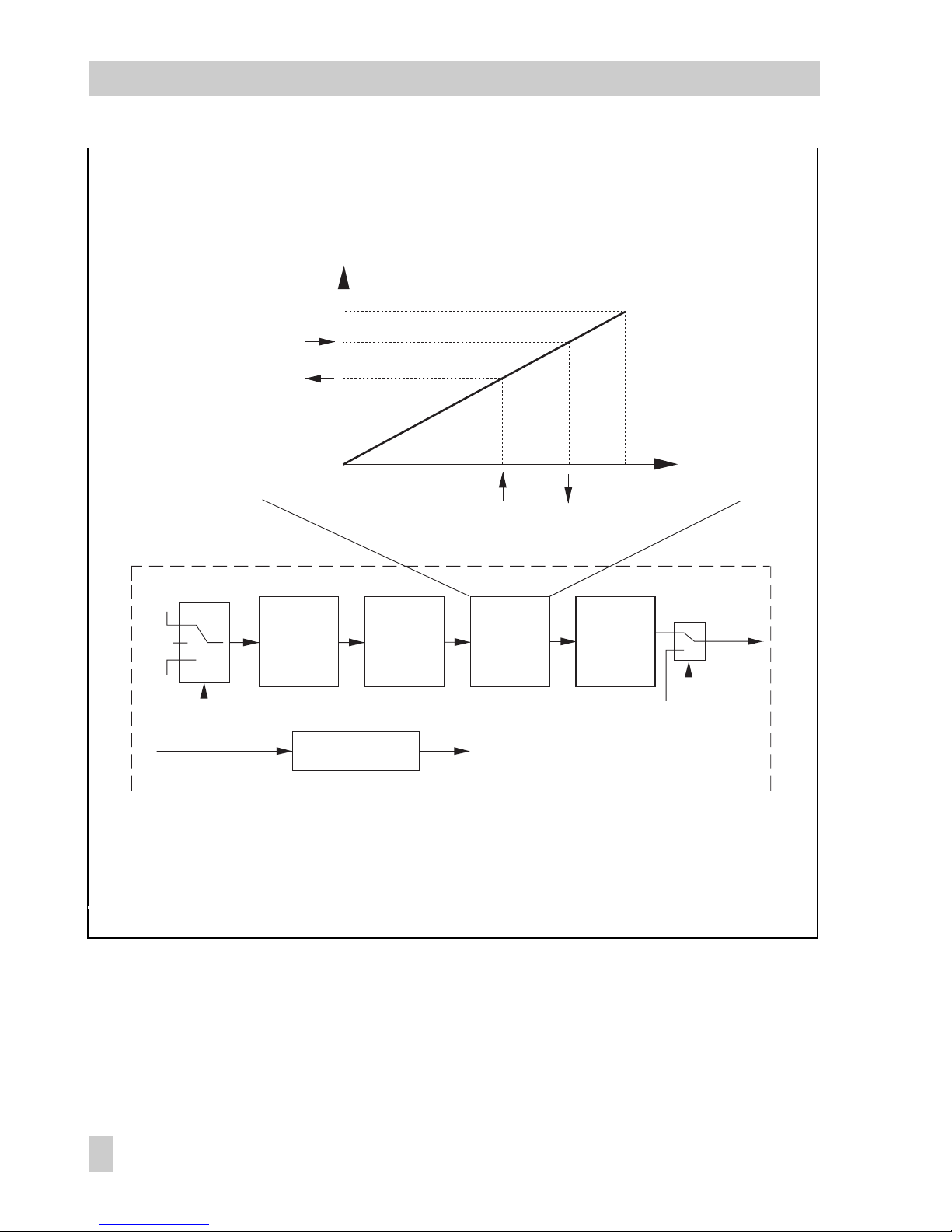

1 Design and principle of operation

The digital positioner compares the reference variable, which is cyclically transmitted over the FOUNDATION

TM

Fieldbus,

with the travel or opening angle of the control valve. It then delivers a corresponding

signal pressure. It is suitable for attachment

to linear and rotary actuators.

The Type 3787 Positioner communicates as

per FOUNDATION

TM

Fieldbus specification

with field devices, programmable logic controllers and process management systems.

An integrated PID Function Block allows the

control of required process variables directly in the field.

The travel of the control valve is picked up

by the inductive displacement sensor (1)

and supplied to the microcontroller (2) via a

converter.

The microcontroller compares the travel

with the reference variable and controls the

two pneumatic 2/2-way on-off valves (3, 4)

when a system deviation occurs. The on-off

valves fill (3) or vent (4) the pneumatic actuator via corresponding amplifiers corresponding to the system deviation.

Two LEDs on the inside of the cover indicate

the operating status of the positioner.

The positioner is equipped with a standard

binary input over which any process information can be signaled via the FOUNDATION

TM

Fieldbus.

The write protection switch (6) located on

the inside of the cover prevents stored configuration data from being overwritten.

Forced venting:

The positioner is controlled over a 6 to 24 V

signal which causes the corresponding signal pressure to be applied to the actuator. If

the voltage signal drops, the signal pressure

is shut off and the actuator is vented. The

control valve moves to its fail-safe position

regardless of the output variable issued by

the microcontroller.

1.1 Optional limit switches

Limit switches can be retrofitted to the standard positioner.

Two proximity switches can be used for failsafe circuits to indicate the valves end positions.

1.2 Communication

The positioner is completely controlled via

digital signal transmission according to the

FOUNDATION

TM

Fieldbus specification

based on the E EN 50170/A1 draft. Data

is transmitted as bit synchronous current

modulation at a transmission rate of

31.25 kbit/s over twisted pairs according

to IEC 61158-2.

Configuration with TROVIS-VIEW

The positioner can be configured using the

SAMSON Configuration and Operator Interface, TROVIS-VIEW.

To configure the positioner, connect its additional

SERIAL INTERFACE

to the RS-232 interface of a PC using an adapter cable.

After adapting the positioner to the process

requirements, TROVIS-VIEW enables the

process to be controlled online.

8

EB 8383-1 EN

Design and principle of operation

Page 9

Configuration with NI-FBUSTM Configurator

The positioner can also be configured using

the NI-FBUS

TM

Configurator from National

Instruments.

An interface card installed in a PC is required to connect it to FOUNDATION

TM

Fieldbus.

The NI-FBUS

TM

Configurator can be used to

configure the whole FOUNDATION

TM

Fieldbus network.

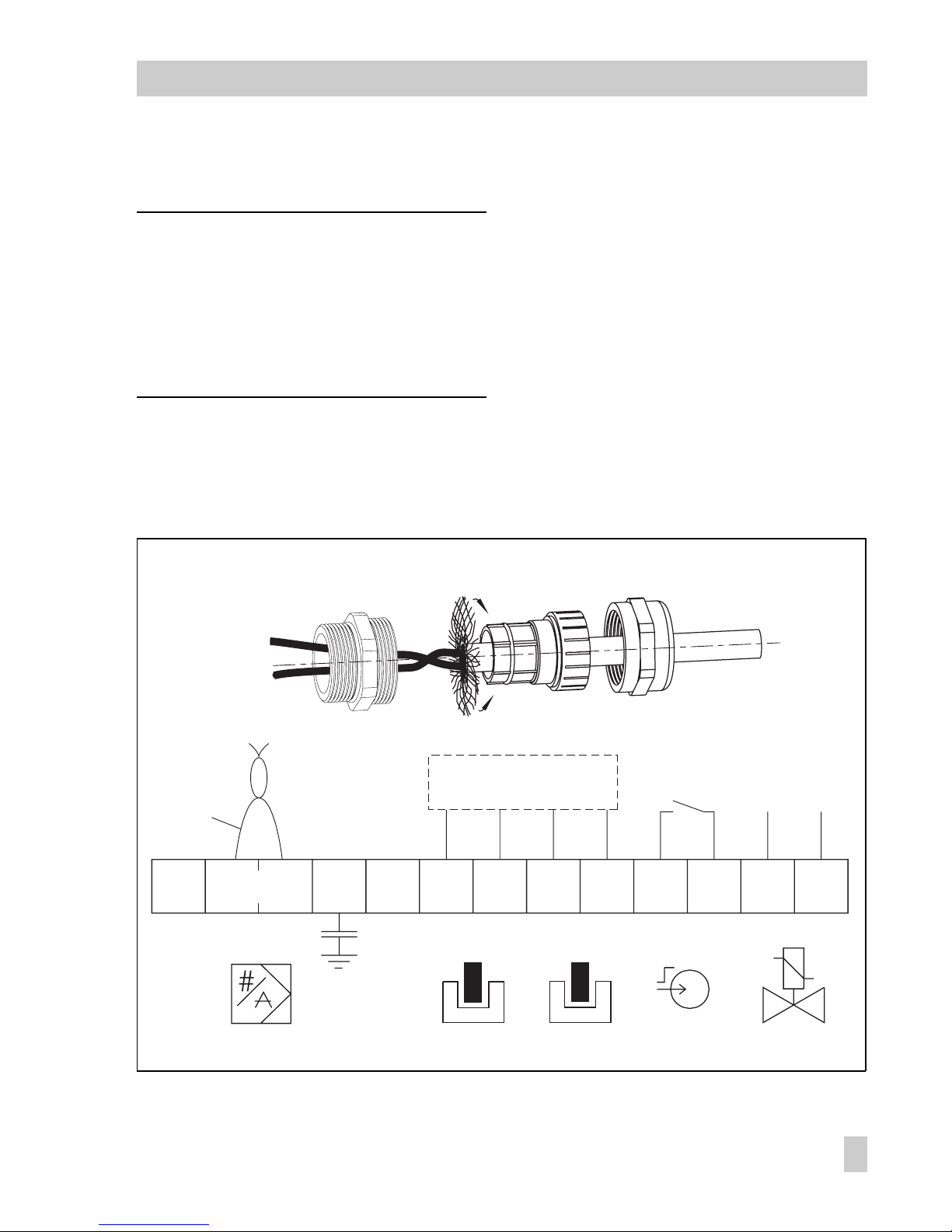

Fig. 2 ⋅Functional diagram

e

p

3

4

2

9

7

8

6

1

G

μC

&

IEC 61158-2

e

p

G

Fieldbus

Foundation

8

TROVIS

VIEW

11

10

1

12

u

13

Forced

venting

Binary

input

Supply

air

Exhaust

air

Serial Interface

1 Inductive displacement sensor

2 Microcontroller

3 On-off valve for supply air

4 On-off valve for exhaust air

5 Microcontroller

6 Switches for write protection and

simulation mode

7 Binary input

8 Forced venting

9 IEC 61158-2 interface module

10 Actuator stem

11 Lever

12 Clamp

13 Configuration interface

EB 8383-1 EN

9

Design and principle of operation

Page 10

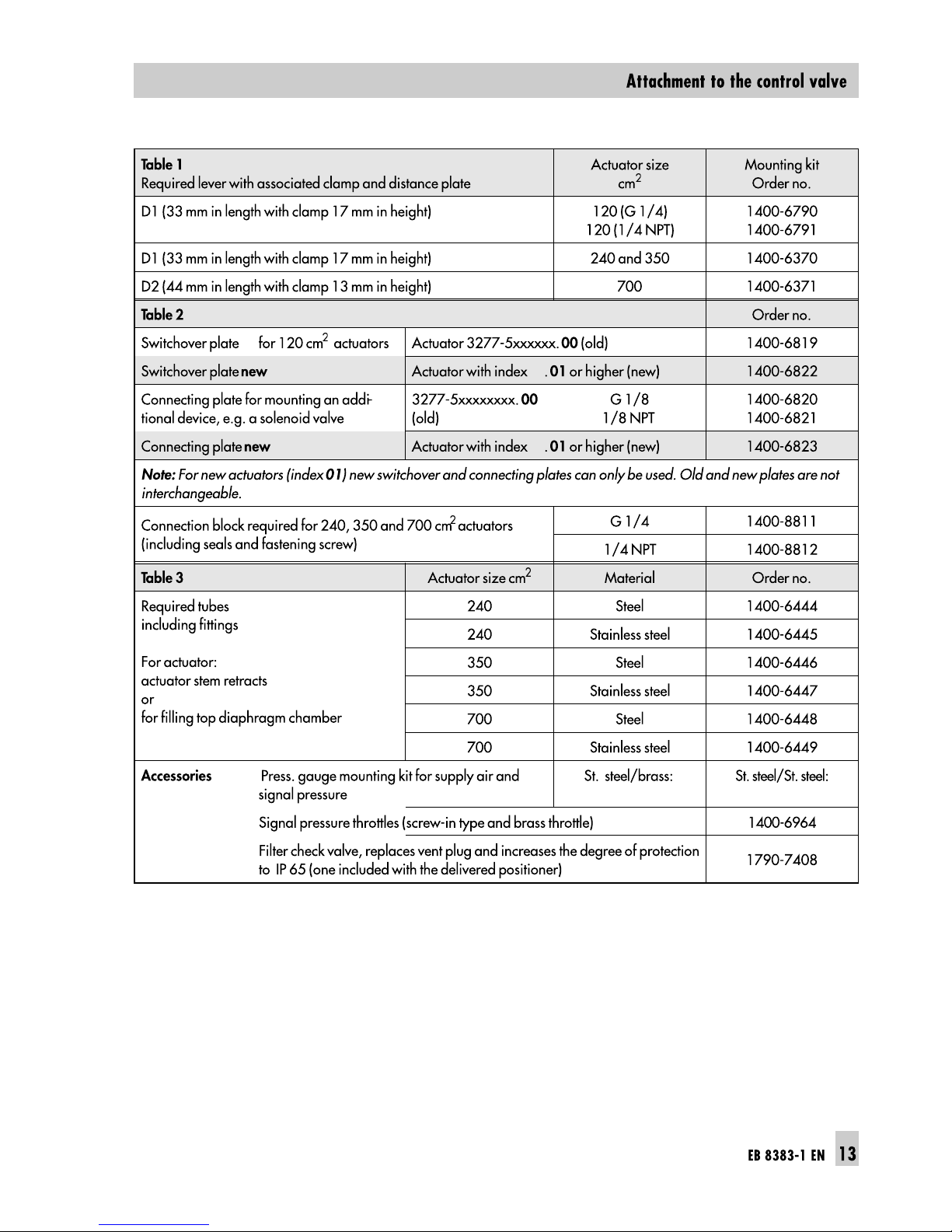

2 Attachment to the control valve

The positioner can be attached either directly to a SAMSON Type 3277 Actuator

or to control valves with cast yokes or rodtype yokes according to IEC 60534-6

(NAMUR).

In connection with an intermediate piece,

the positioner can also be attached to rotary actuators.

Since the standard positioner is delivered

without accessories, please refer to the

tables for required mounting parts and their

order numbers.

Note!

For fast control valves with small travel volumes (transit time < 0.6 sec.), replace the filter in the signal pressure output with a

screw-in throttle, if necessary, to improve

the control properties. See also sections

2.1, 2.2 and 2.3.

Important!

The positioner does not have its own venting plug, instead vented air has to escape

through venting plugs located on the mounting parts (see Figs. 3, 5 and 7).

A filter check valve for the vented air is included in every positioner delivery (under

the transparent protective cap on the back

of the positioner). Replace the standard venting plug included in the accessories with

this filter check valve. This is the only way to

achieve the degree of protection IP 65 by

preventing dirt and moisture from entering

the device.

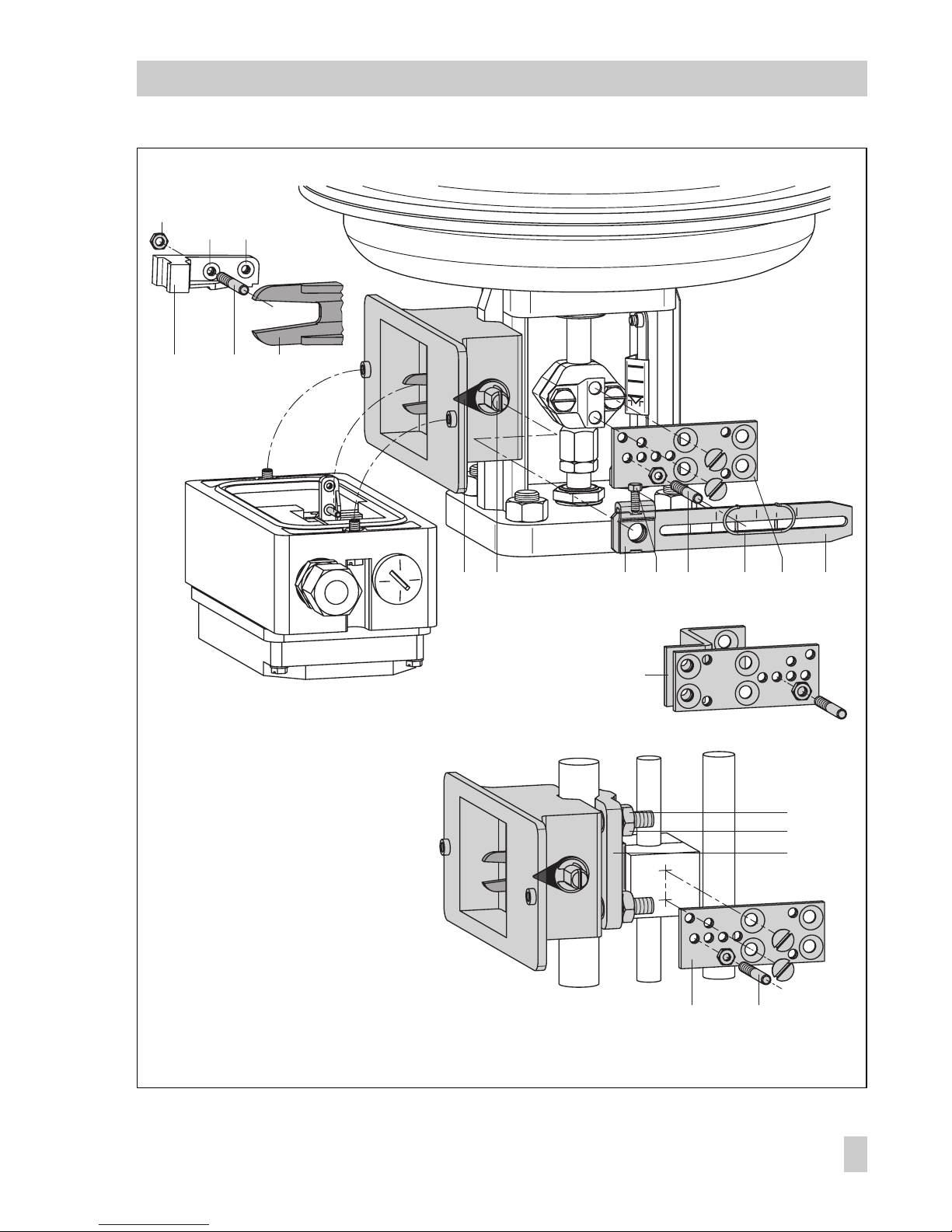

2.1 Direct attachment to Type

3277 Actuator

The necessary accessories are listed in the

Tables 1, 2 and 3 on page 13

.

When looking at the signal pressure connection or the switchover plate (actuator 120

cm

2

), the positioner must be attached to the

left side of the actuator.

The

arrow

on the black cover of the case

(Fig. 11) should point

towards the dia-

phragm chamber

.

Exception:

Control valves in which the plug

closes the seat area when the actuator stem

retracts. In this case, the positioner has to

be attached to the right side of the actuator

and the arrow points away from the diaphragm chamber.

1. Screw the clamp (1.2) to the actuator

stem, ensuring that the fastening screw

is located in the groove of the actuator

stem.

2. Screw the assigned pick-up lever D1 or

D2 to the transmission lever of the positioner.

3. Fasten the distance plate (15) with seal

pointing towards the actuator yoke.

4. Place the positioner on the plate so that

the lever D1 or D2 slides centrally over

the pin of the clamp (1.2). Then screw

tight to the distance plate (15).

5. Mount cover (16).

Actuators with 240, 350 and 700 cm

2

6. Check whether the tongue of the seal

(17) is properly aligned at the side of

the connection block (Fig. 3, center)

10

EB 8383-1 EN

Attachment to the control valve

Page 11

Actuator stem retracts

Side view of connection block

with seal

(ne w

) with switch plate (old)

Fig. 3 ⋅Attachment and signal pressure connection for Type 3277 Actuators (top) and 3277-5 with 120 cm (bottom)

SUPPLY

1817 19

1.2

D2

D1

17

16

15

1.2

16

17

15

Actuator stem retracts

Internal signal pressure

connection

Signal pressure tube

1.2 Clamp

D1 Lever

D2 Lever

15 Distance plate

16 Cover

17 Seal

18 Cover plate

19 Switch plate

Signal pressure bore

Connection block

Marking

Marking

Symbol "actuator

stem extends"

"Actuator stem

retracts"

Switchover

plate

Switchover plate

Signal pressure input

Signal pressure

input with brass

throttle, if required

Actuator stem extends

Ventin g

Actuator stem extends

EB 8383-1 EN

11

Attachment to the control valve

Page 12

with the actuator symbol "actuator stem

extends" or "actuator stem retracts" to

match the actuator version used.

If not, remove the three fastening

screws and the cover plate (18), turn

the seal (17) by 180° and reinsert it.

When the

old

connection block is used,

turn the switch plate (19) to align the actuator symbol with the arrow.

7. Place the connection block with its seal

rings on the positioner and actuator

yoke and screw it tight using the fastening screw.

For actuators with "actuator stem retracts", additionally attach the readymade signal pressure line.

Actuator with 120 cm

2

For the Type 3277-5 Actuator with 120 cm

2

effective diaphragm area, the signal pressure is transmitted to the diaphragm chamber via the switchover plate (Fig. 3 bottom).

For a rated travel of 7.5 mm, a brass

throttle (see Accessories table on page 13)

must be pressed into the seal located in the

signal pressure input on the actuator yoke.

For a rated travel of 15 mm, this is only required when the supply pressure exceeds

4 bar.

6. Remove the screw plug on the rear of

the positioner case and seal the signal

pressure output (Output 38) with the

plug from the accessories.

7. Mount the positioner so that the bore in

the distance plate (15) is aligned with

the seal located in the bore of the actuator yoke.

8. Align the switchover plate with the

corresponding symbol for left attachment and screw the plate to the actuator yoke.

Important!

If, in addition to the positioner, a solenoid

valve or a similar device is attached to the

120 cm

2

actuator, the rear M3 screw must

not be removed. In this case, the signal

pressure has to be fed from the signal pressure output to the actuator via the required

connecting plate (see Table 2). The switchover plate is no longer required.

Note!

For faster control valves with a transit time

less than 0.6 seconds, replace the filter in

the signal pressure output (output 38) with a

screw-in throttle (see Accessories table), if

necessary.

Filling the diaphragm chamber with air

If the Type 3277 Actuators diaphragm

chamber must be filled with air exhausted

from the positioner, the diaphragm chamber (for version with "actuator stem extends") can be connected to the connection

block using a tube (see Table 3). To do

this, first remove the screw plug from the

connection block.

For the Type 3277-5 Actuator with "actuator stem retracts", the air exhausted from

the positioner is constantly supplied to the

diaphragm chamber through an internal

bore.

12

EB 8383-1 EN

Attachment to the control valve

Page 13

1402-0938 1402-0939

1)

Order with every pressure gauge kit: 2 restrictions (1790-6121)

1)

Page 14

2.2 Attachment acc. to IEC 60534-6

The positioner is attached according to

NAMUR as shown in Fig. 4 using an adapter housing. The valve travel is transmitted

via the lever (18) and the shaft (25) to the

bracket (28) in the adapter housing and

then to the coupling pin (27) located on the

lever of the positioner.

To attach the positioner, you will require the

mounting parts listed in Table 4. Which

lever should be used depends on the rated

valve travel.

The positioner must be attached to the

adapter housing with the

arrow

on the

black case cover pointing

away from the

diaphragm actuator

towards the valve.

Exception: Control valves in which the plug

closes the seat area when the actuator stem

retracts. In this case, the arrow must point

towards the diaphragm actuator.

If the adapter housing cannot be mounted

between

the actuator and valve (e.g. because the actuator is from another manufacturer), the

arrow

on the case cover must

point towards the valve!

Note!

For faster control valves with a transit time

less than 0.6 seconds, replace the filter in

the signal pressure output (output 38) with a

screw-in throttle (see Accessories table).

2.2.1 Mounting sequence

Refer to Tables 4 and 5 on page 16 for required mounting parts.

Note!

Prior to mounting the parts, apply signal

pressure to the actuator so that the valve is

set to 50 % of its travel. This is the only way

to make sure that the lever (18) and bracket

(28) are exactly aligned.

Control valve with cast yoke

1. Use countersunk screws to fix the plate

(20) to the coupling which connects the

plug stem and actuator stem. With actuators 2100 and 2800 cm

2

, use addi-

tional mounting bracket (32).

2. Remove rubber plug from the adapter

housing and fasten the housing to the

NAMUR rib with hexagon head screw.

Control valve with rod-type yoke

1. Screw plate (20) to the follower clamp

of the plug stem.

2. Screw the studs (29) into the adapter

housing.

3. Place the housing with the plate (30) on

either the right or left side of the valve

stem and fasten tight using the nuts

(31). On doing so, make sure the housing is aligned at a height which will

still allow the lever (18) to be attached

horizontally.

4. Screw the pin (19) into the center row

of holes in the plate (20) and lock into

place so that it is located approximately

above the correct lever marking (1 to 2)

14

EB 8383-1 EN

Attachment to the control valve

Page 15

Fig. 4 ⋅Attachment according to IEC 60534-6 (NAMUR)

2

1,5

1

2826

AB

24 25 22

32

31

20 19

19 21 2023 18

27b

27a

29

30

Attachment to

NAMUR rib

Mounting position

Attachment to rod

18 Lever N1, N2

19 Pin

20 Plate

21 Clamp

22 Clamping plate

23 Screw

24 Pointer

25 Shaft

26 Lever of positioner

27a Transmission pin

27b Lock nut

28 Bracket

29 Studs

30 Plate

31 Nuts

32 Mounting bracket

EB 8383-1 EN

15

Attachment to the control valve

Page 16

for the assigned travel, see Table 5.

Intermediate values must be calculated.

Move the clamp (21) beforehand to

clasp the pin.

5. Measure the distance from the middle

of the shaft (25) to the middle of the pin

(19). This value must be entered later

when the positioner is being configured.

2.2.2 Presetting the valve travel

1. Adjust the shaft (25) in the adapter

housing so that the black pointer (24) is

aligned with the casted marking on the

adapter housing.

2. Screw the clamping plate (22) tight in

this position using the screw (23).

3. Screw the coupling pin (27) into the positioner lever (26) on the side with the

Table 4

Attach. acc. to IEC 60534-6 Control valve Travel in mm With lever Order no.

NAMUR mounting kit

See Fig. 4 for parts

Valve w it h cast yoke

7.5 to 60 N1 (125 mm) 1400-6787

30 to 120 N2 (212 mm) 1400-6789

Valve with

rod-type

yoke with

rod diameter

in mm

20 to 25 N1 1400-6436

20 to 25 N2 1400-6437

25 to 30 N1 1400-6438

25 to 30 N2 1400-6439

30 to 35 N1 1400-6440

30 to 35 N2 1400-6441

Attachment to Fisher and Masoneilan linear actuators

(one ea ch of bo th mo un ting ki ts is need ed per one ac tuator )

1400-6771

and

1400-6787

Accessories

Press. gauge mounting block G 1/4: 1400-7458 1/4 NPT: 1400-7459

Pressure gauge set St. st./brass: 1400-6957 St. st./St. st.: 1400-6958

Signal pressure throttles (screw-in type and brass throttle) 1400-6964

Filter check valve, replaces vent plug and increases the degree of protection

to IP 65 (one included with the delivered positioner)

1790-7408

Table 5

Attachment according to IEC 60534-6

Travel mm *) 7.51515303060306060120

Pin on mark *) 1 12121212

Corresp. distance: pin/lever pivot 42 42 84 42 84 84 168 84 168

With lever N1 (125 mm in length) N2 (212 mm in length)

Tran sm is sion pi n ( 27 ) a t posit io n A A B A B

*) Deviating travels (intermediate values) must be calculated accordingly

16

EB 8383-1 EN

Attachment to the control valve

Page 17

insert nuts and secure the pin on the

other side with a hex nut. Observe the

mounting position A or B explained in

Table 5 and Fig. 4.

4. Place the positioner onto the adapter

housing, making sure the coupling pin

(27) is positioned within the arms of the

bracket (28).

To do so, insert a 2.5 mm Allen key or

a screwdriver from the front into the

bore located below the oblong hole on

the cover plate, and push the positioner

lever into the required position.

5. Screw positioner to the adapter housing.

6. Relieve signal pressure from the actuator.

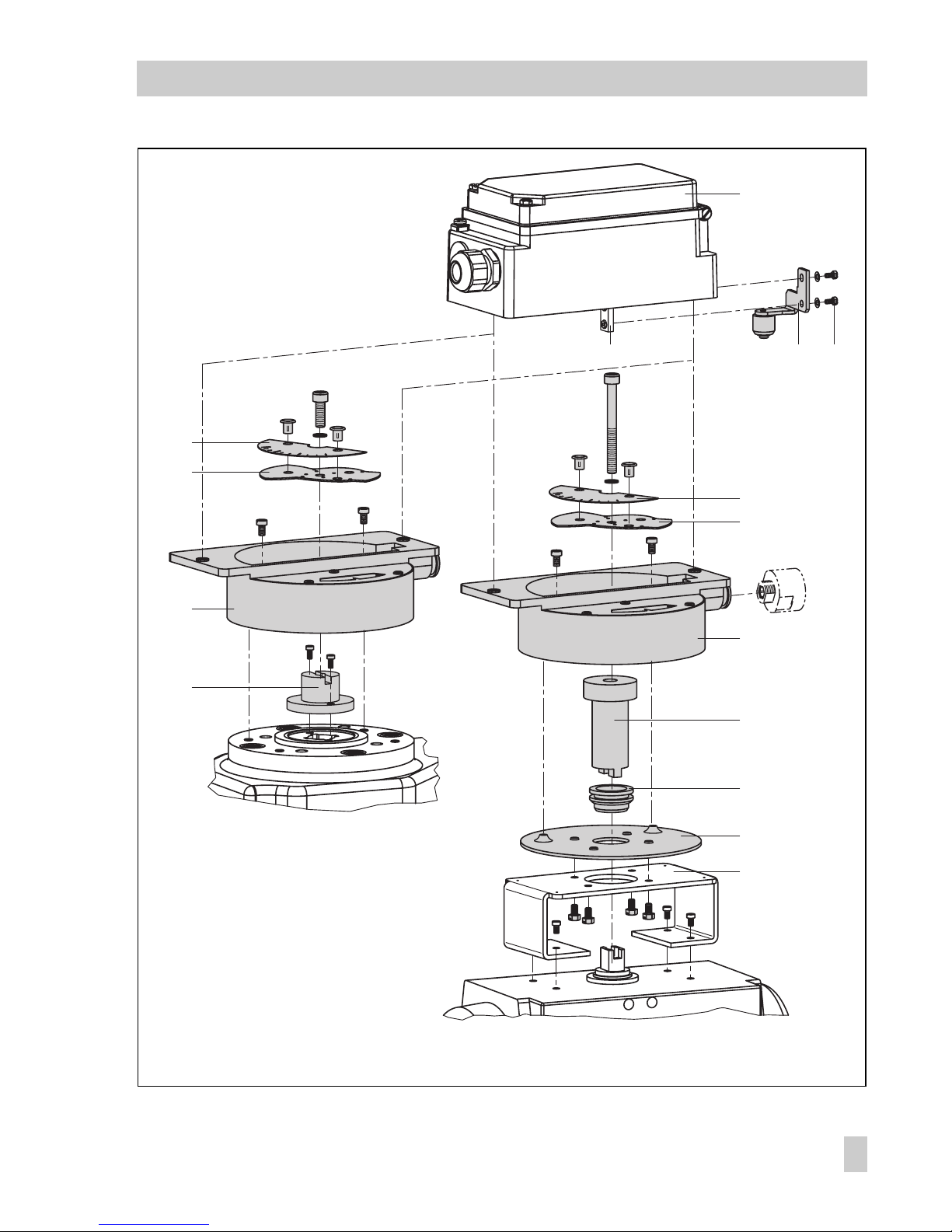

2.3 Attachment to rotary actuators

The positioner can also be attached to rotary actuators in accordance with VDI/VDE

3845 by using the mounting parts and accessories listed in Table 6. In this arrangement, the actuators rotary motion is converted via the cam disk of the actuator stem

and the feeler roll of the positioner lever

into a linear motion which is required for

the inductive displacement sensor.

Each cam disk has two curves for the

ranges of rotational angle from 0 to 90°

(recommended for all angles of rotation

smaller than 90°) and 0 to 120° (recommended for all angles of rotation larger

than 90°).

Ta bl e 6

Rotary actuators (Complete mounting parts, but without cam disks)

Attachment acc. to

VDI/VDE 3845, level

1

SAMS ON Type Actu at or Atta ch me nt to Mas on eilan ac tu ator

Actuator

160 cm

2

Actuator

320 cm

2

Camflex I

DN 25 ...100

Camflex I

DN 125...250

Camflex II

Order no.

1400-8815 1400-7103 1400-7104 1400-7118 1400-7119 1400-7120

Pip ing k it 8 x 1 stainle ss st eel

G: 1400-6670 NPT: 1400-6672

G: 1400-6669 NPT: 1400-6671

Accessories

Order no.

Reversing amplifier for double-acting actuators without springs G: 1079-1118 NPT: 1079-1119

Cam disk (0050-0089) with accessories, angle of rotation 0 to 90° and 0 to 120° 1400-6959

Cam disk (0050-0089) specially for VETEC, adjustable per software from 0 to 75° 1400-6960

Cam disk (0050-0090) specially for Camflex, adjustable per software from 0 to 50° 1400-6961

Pressure gauge mounting block G 1/4: 1400-7458; 1/4 NPT: 1400-7459

Pressure gauge set St. steel/Brass:

1400-6957

St. steel/St. steel:

1400-6958

Signal pressure throttles (screw-in type and brass throttle) 1400-6964

Filter check valve, replaces vent plug and increases the degree of protection to IP 65 (o ne inc lu ded wit h t he deliv er ed posi ti on er)

1790-7408

EB 8383-1 EN

17

Attachment to the control valve

Page 18

For double-acting, springless rotary actuators, a reversing amplifier must be attached

to the positioner housing on the side where

it is connected to the actuator (see section

2.3.4).

If the positioner is attached to a SAMSON

Type 3278 Rotary Actuator, the air exhausted from the positioner is admitted to

the inside of the actuator without any additional tubing.

If the positioner is attached to actuators

from other manufacturers (NAMUR), the air

is applied to the diaphragm chamber

through a tube with a tee connecting the actuator and the exhaust connection of the intermediate piece.

Note!

For faster control valves with a transit time

less than 0.6 seconds, replace the filter in

the signal pressure output (output 38) with a

screw-in throttle (see Accessories Table 6).

2.3.1 Mounting the lever with

feeler roll

1. Place lever with attached feeler roll

(35) on the transmission lever (37) and

secure it with the supplied screws (38)

and washers.

2.3.2 Mounting the intermediate

piece

SAMSON Type 3278 Actuator:

1. Screw adapter (36) to the free end of

the rotary actuator shaft, using two

screws.

2. Position intermediate piece (34) on the

actuator housing and secure it with two

screws. Align the intermediate piece so

that the air connections of the positioner face the side of the diaphragm

case.

Actuators according to VDI/VDE 3845

1. Place the whole intermediate piece (34,

42, 44 and 45) onto the bracket included in the delivery scope of the actuator (fixing level 1 VDI/VDE 3845) and

secure with screws.

2. Align the cam disk (40) and scale (39)

as described in section 2.3.3 and screw

tight.

With springless actuators, the reversing amplifier must be screwed to the side of the positioner case. See section 2.3.4.

18

EB 8383-1 EN

Attachment to the control valve

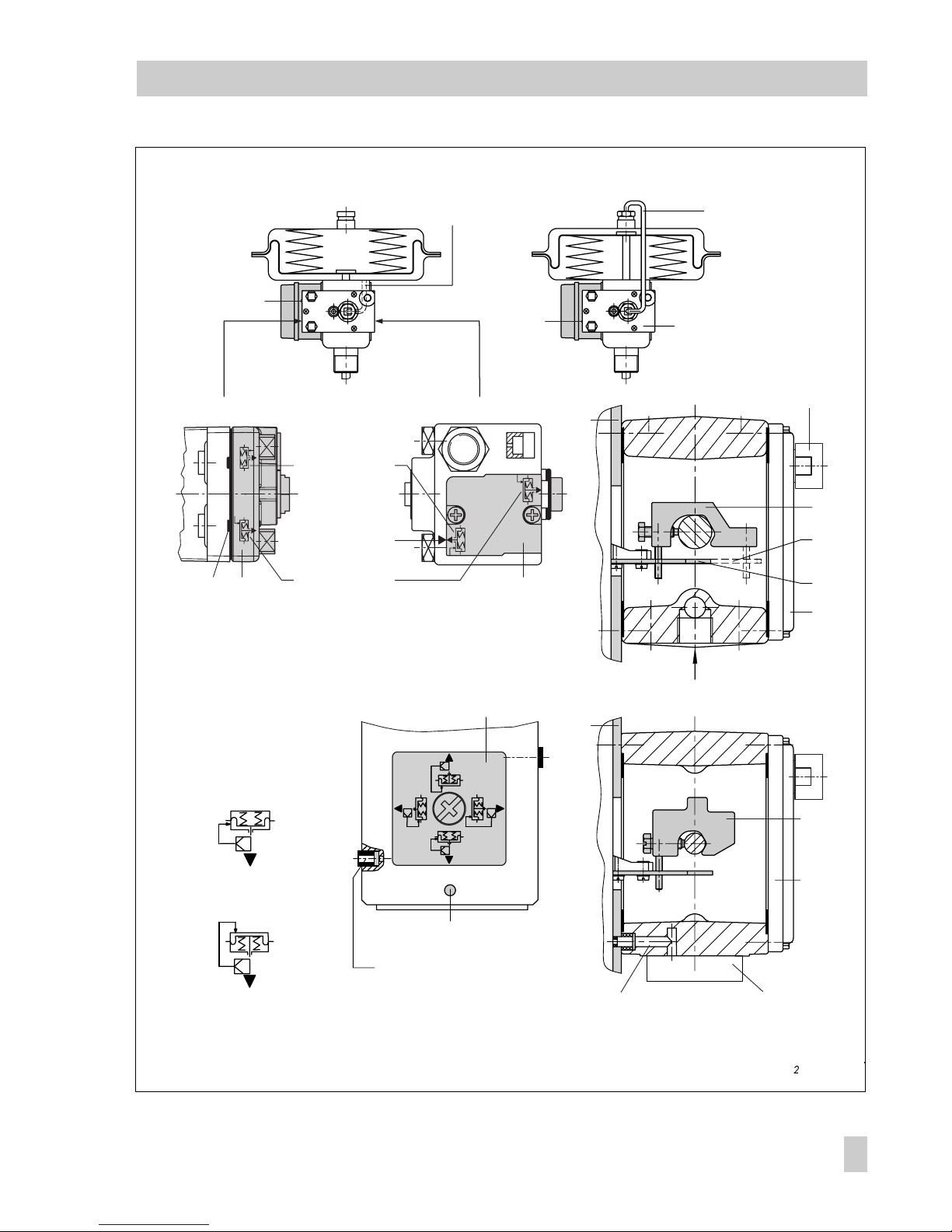

Page 19

Vent p lu g o r

filter check valve

Fig. 5 ⋅Attachment to rotary actuators

33

3835

39

39

40

34

36

40

34

44

45

42

43

37

Attachment to

SAMSON Type 3278

Attachment acc. to

VDI/VDE 3845

33 Positioner

34 Intermediate piece

35 L ev er with ca m f ollowe r r oll

36 Adapter

37 Transmission lever

38 Screws

39 Scale

40 Cam disk

41 Actuator shaft

42 Plate

43 Bracket

44 Coupling

45 Seal

EB 8383-1 EN

19

Attachment to the control valve

Page 20

2.3.3 Aligning and mounting the

cam disk

In rotary actuators with spring-return mechanism, the actuator springs determine the

fail-safe position and the direction of rotation of the control valve.

With double-acting, springless rotary actuators, the direction of rotation depends on

both the actuator and valve version used.

The initial position is always based on a

closed valve!

Whether the control valve should open or

close when the reference variable increases

must be set in the software (direction of action increasing/increasing or increasing/decreasing).

1. Place the cam disk with scale on the

adapter (36) or coupling (34), and

fasten the screws loosely at first.

The cam disk has two cam sections. The

starting point of each section is marked by

a small hole.

Note!

When the valve is closed, the starting point

(hole) of the disk must be aligned so that the

pivot of the cam disk, the 0° position of the

scale and the arrow mark on the viewing

window are in one line.

The starting point for the closed valve position should never be below the 0° position!

In actuators with fail-safe position "valve

OPEN", the maximum signal pressure must

be applied to the actuator prior to aligning

the cam disk.

In springless actuators, the supply air must

be connected.

2. On aligning the cam disk, clip on the

double-sided scale disk so that the scale

matches the direction of rotation of the

control valve. Only then secure the cam

disk with the fastening screws.

Securing the aligned cam disk

If you want to additionally secure the cam

disk to prevent it from being turned, proceed as follows:

There are four holes arranged around the

center hole on the cam disk. Select a suitable hole from the four holes to secure the

cam disk.

Drill a hole in the adapter (36) or coupling

(44) through the hole chosen and insert a

2 mm dowel pin.

3. Attach the positioner to the intermediate

piece (34) so that the lever (35) touches

the cam disk with its feeler roll.

To do so, insert a 2.5 mm Allen key or

screwdriver from the front into the bore

hole located below an oblong hole in

the cover plate and bring the positioner

lever in the required position.

4. Screw positioner to the intermediate

piece.

20

EB 8383-1 EN

Attachment to the control valve

Page 21

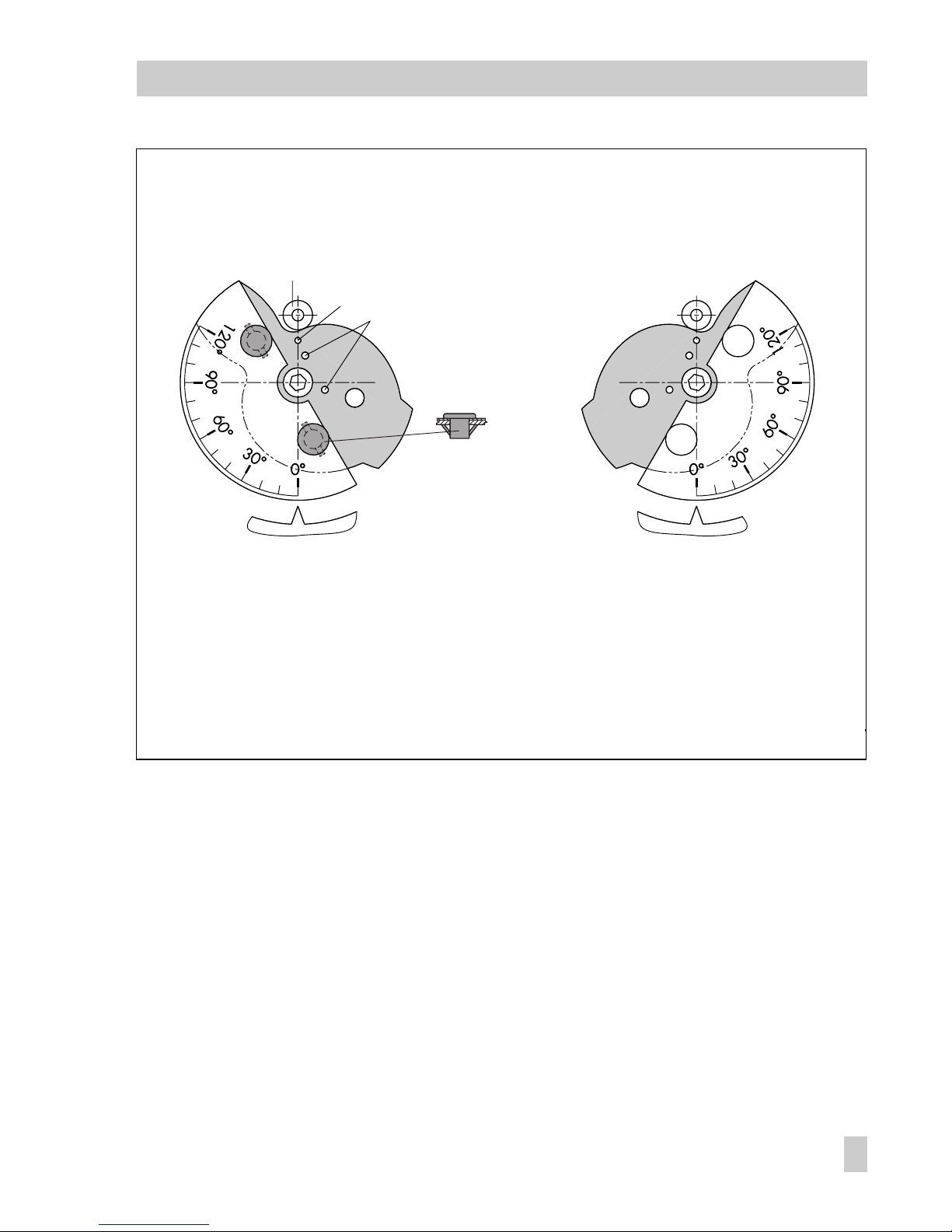

Fig. 6 ⋅Aligning the cam disk

Control valve opens

counterclockwise

Control valve opens

clockwise

Feeler roll

Starting point

Holes to secure the cam disk

View onto the actuator shaft from the positioner

Insert clip and then

press tongues outwards

EB 8383-1 EN

21

Attachment to the control valve

Page 22

2.3.4 Reversing amplifier for

double-acting actuators

For the use with double-acting actuators,

the positioner must be fitted with a reversing amplifier.

The reversing amplifier is listed as an accessory in the Table 6 on page 17.

The output signal pressure of the positioner

is supplied at the output A

1

of the reversing

amplifier. An opposing pressure, which

equals the required supply pressure when

added to the pressure at A

1,

is applied at

output A

2

. The rule A1 + A2 = Z applies.

Mounting

Note!

Prior to mounting the reversing amplifier,

remove the sealing plug (1.5). The rubber

seal (1.4) must be remain attached.

1. Thread the special nuts (1.3) from the

accessories of the reversing amplifier

into the threaded ports of the positioner.

2. Insert the gasket (1.2) into the recess of

the reversing amplifier and push both

the hollowed special screws (1.1) into

the connecting ports A1 and Z.

3. Place the reversing amplifier onto the

positioner and screw tight using both

the special screws (1.1).

4. Screw the supplied filter (1.6) using a

screwdriver (8 mm wide) into the connecting bore holes A1 and Z.

Signal pressure connections

A

1

: Output A1 leading to the signal pressure connection at the actuator which opens

the valve when the pressure increases

A

2

: Output A2 leading to the signal pressure connection at the actuator which closes

the valve when the pressure increases

Enter the actuator as "Double-acting

without spring-return mechanism" in the

user interface software under Start-up

→

Type of actuator.

2.4 Fail-safe action of the actuator

Note!

If the fail-safe action of the actuator is

changed subsequently by converting the actuator springs from "actuator stem extends"

to "actuator stem retracts", the mechanical

zero must be recalibrated and the positioner reinitialized.

22

EB 8383-1 EN

Reversing amplifier for double-acting actuators

Page 23

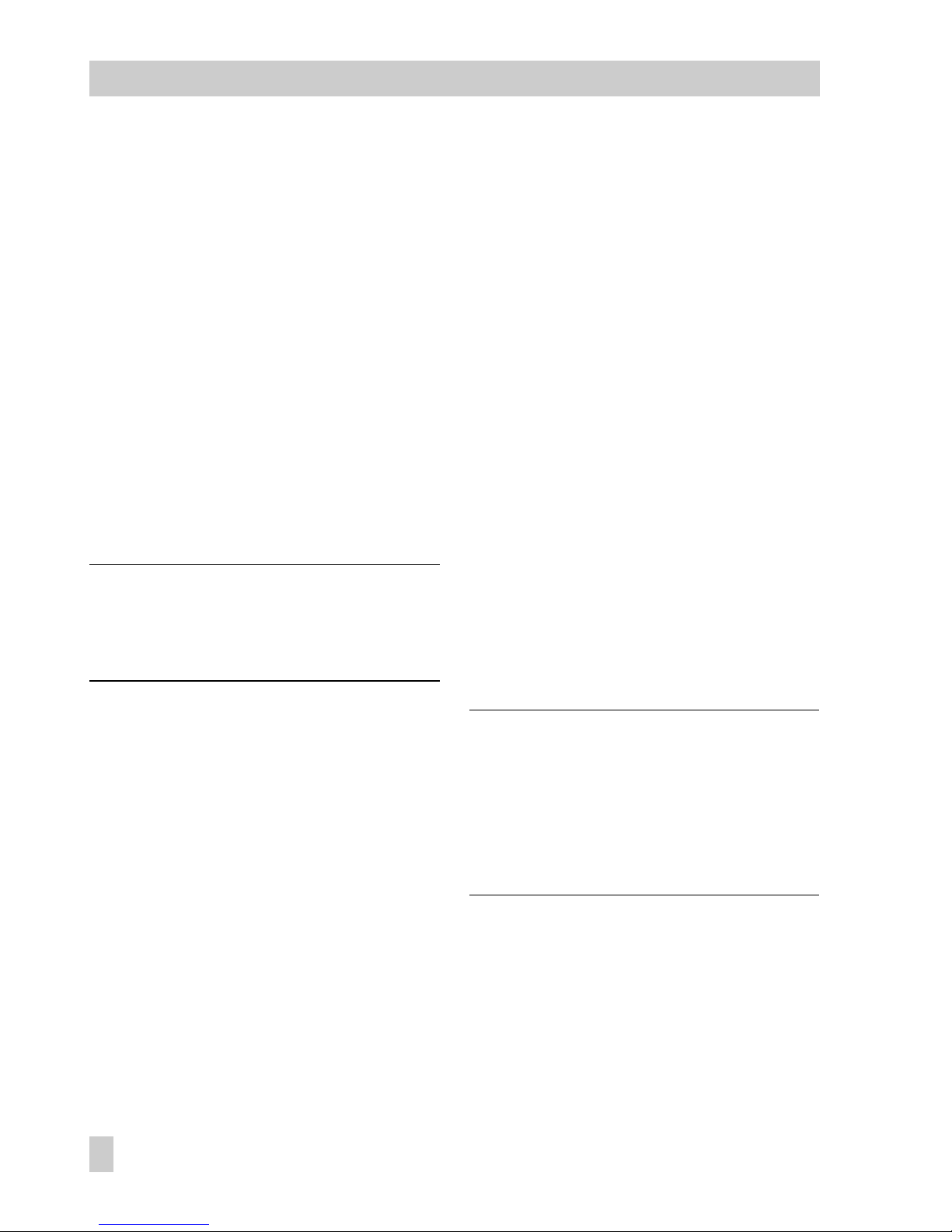

Fig. 7 ⋅Mounting a reversing amplifier

1.3 1.2 1.1 1

Output 38 Supply 9

A

1

1.5 1.6

Z

A

2

1.4

A

1

A

2

Output 38 Supply 9

1.3 1.21.1

1.6

Z

A

1

From the positioner

To the actuator

1 Reversing amplifier

1.1 Special screws

1.2 Gasket

1.3 Special nuts

1.4 Rubber seal

1.5 Plug

1.6 Filter

EB 8383-1 EN

23

Reversing amplifier for double-acting actuators

Page 24

3 Connections

3.1 Pneumatic connections

The air connections are either 1/4 NPT or

G 1/4 tapped holes. Customary fittings for

metal and copper pipes or plastic tubes can

be used.

Note!

The supply air must be dry and free from oil

and dust. Observe the maintenance instructions for upstream pressure reducing stations. Carefully purge all tubes before connecting them.

If the positoner is attached directly to Type

3277 Actuator, the connection for the signal pressure is fixed. For NAMUR attachment, the signal pressure can be applied to

either the top or bottom diaphragm chamber depending on the fail-safe position "actuator stem extends or retracts".

Exhaust air: The exhaust air connection of

the positioner is included in the mounting

parts. For direct attachment of the positioner, there is a vent plug on the plastic

cover of the actuator. For NAMUR attachment, this plug is on the adapter housing

and for attachment to rotary valves, it is on

the intermediate piece or reversing amplifier.

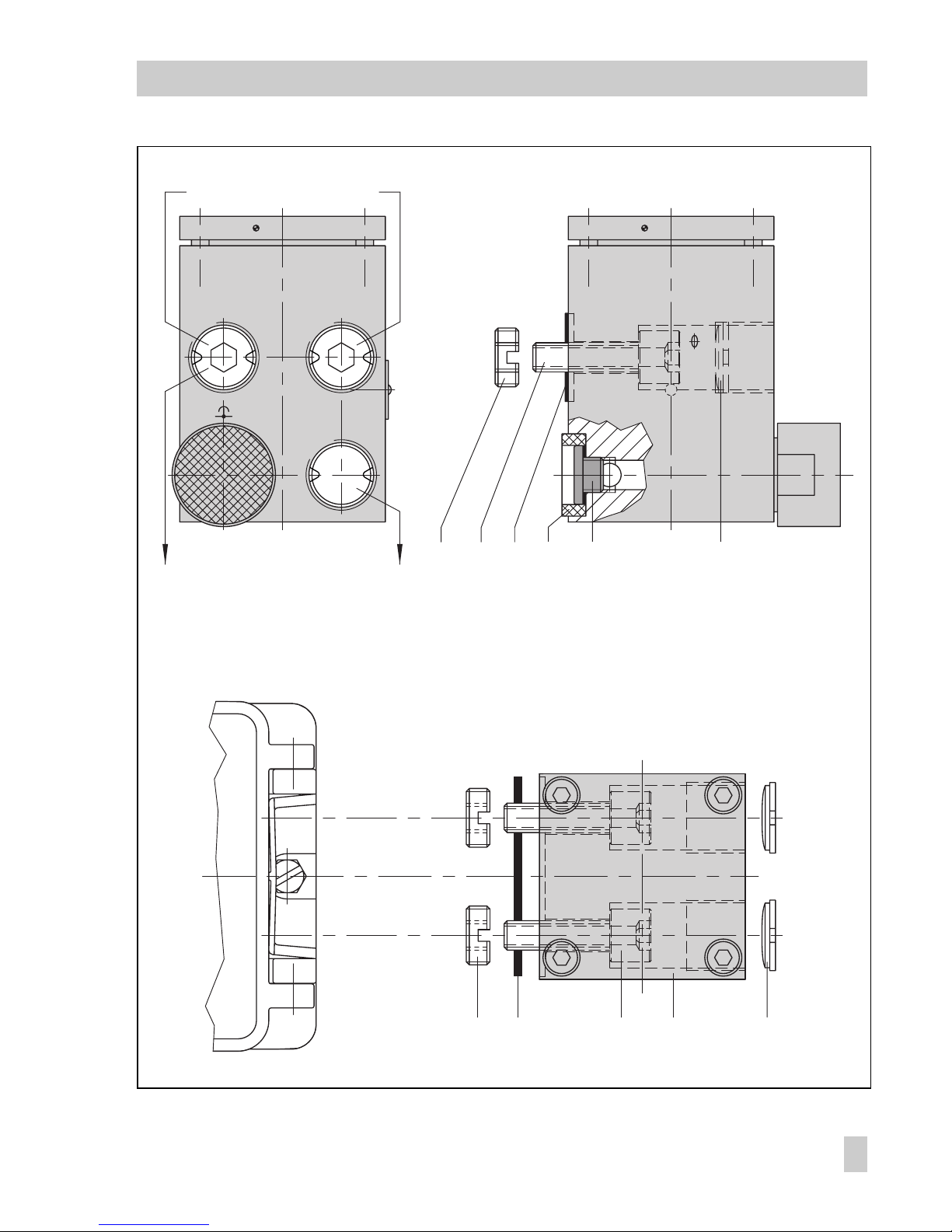

3.1.1 Pressure gauge

We recommend mounting pressure gauges

for supply air and signal pressure to monitor the positioner. The parts are listed as accessories in Tables 3, 4 and 6.

Fig. 8 ⋅Mounting the pressure gauge

2...3mm

Nut Throttle with filter

Order no. 0250-1090 1790-6121

24

EB 8383-1 EN

Connections

Page 25

3.1.2 Supply air pressure

The required supply air pressure depends

on the bench range and the operating direction (fail-safe position) of the actuator.

The bench range is mentioned on the nameplate as spring range or signal pressure

range.

Actuator stem extends:

Required supply air pressure =

Upper bench range value + 0.2 bar,

min. 1.4 bar.

Actuator stem retracts:

The required supply air pressure for tightclosing valves is calculated from the maximum signal pressure pst

max

pst

max

= F +

d

2

⋅ π ⋅ Δp

4 ⋅ A

[bar]

d = Seat diameter [cm]

Δ

p = Differential pressure across the valve [bar]

A = Actuator area [cm

2

]

F = Upper bench range value of the actuator [bar]

If there are no specifications, calculate as

follows:

Required supply air pressure = Upper

bench range value + 1 bar

3.2 Electrical connections

For electrical installation, you are required to observe the relevant electrotechnical regulations and the accident prevention regulations that

apply in the country of use. In Germany, these are the VDE regulations

and the accident prevention regulations of the employers liability insurance association.

The following standards apply for installation in hazardous areas:

EN 60079-14: 2003 (VDE 0165

Part 1)

"Electrical apparatus for ex-

plosive gas atmospheres"

and

EN 50281-1-2: 1999 (VDE 0165

Part 2)

"Electrical apparatus for use

in the presence of combustible

dust"

.

For the interconnection of intrinsically safe electrical equipment, the

permissible maximum values specified in the EC type examination certificate apply (U

i

or U0; Ii or I0; Pi or

P

0

; Ci or C0, and Li or L0).

For EEx nA equipment (non-sparking apparatus), the standard

EN 50021: 1999 specifies that connecting, interrupting, or switching

circuits while energized is only

allowed during installation, maintenance or repair work.

For EEx nL equipment (energylimited apparatus), the standard

EN 50021: 1999 allows this type of

equipment to be switched under normal operating conditions.

EB 8383-1 EN

25

Connections

Page 26

Caution!

The terminal assignment specified in

the certificate must be adhered to.

Reversing the assignment of the electrical terminals may cause the explosion protection to become ineffective!

Do not tamper with enameled

screws inside or on the housing.

Note on the selection of cables and

wires:

To install intrinsically safe circuits,

observe section 12 of the standard

EN 60079-14: 2003 (VDE 0165

Part 1).

To run multi-core cables or lines

with more than one intrinsically

safe circuit, section 12.2.2.7 of

this standard applies.

An additional cable gland can be

installed when connecting the device over two separate cables.

Cable entries left unused must be

sealed with blanking plugs.

Devices used at ambient temperatures down to 40 °C must have

metal cable entries.

The terminal assignment can be found in

Fig. 9 as well as on the labels on the cover

plate of the positioner case.

Cable entries

The cable entry with M20x1.5 cable gland,

7 to 12 mm clamping range.

There is a second M20x1.5 cable gland in

the housing that can be used for additional

connection, if required.

The screw terminals are designed for wire

cross-sections of 0.2 to 2.5 mm

2

. Tighten

by at least 0.5 Nm.

Bus line

The shielding of the Fieldbus connecting

cable is connected to the equipotential

bonding system on the process control system side. At the positioner side, the shielded

cable must be routed over the EMI-proof

brass cable gland (standard) of the positioner to the terminals. The shield which is

placed over the clamping insert is connected over a large area to the gland and

housing.

To connect the bus line, loosen the coupling nut and the clamping insert from the

positioner and remove the dust cap.

Slide the coupling nut and clamping insert over the connecting cable.

Insulate the end of the bus line to the required connecting length and cut the

wire shield off up to a length of approx.

13 mm. If necessary, cut off any cable

core filling as well.

Disentangle the braided shield and pull

it over the clamping insert.

Press the clamping insert into the connecting screw gland and screw tight the

coupling nut until the connecting cable is

clamped tight.

Route the two-wire bus line to the screw

terminals marked "IEC 1158-2",

whereby no polarity has to be observed.

In exceptional cases, when the plant may

not allow such a connection, feed the cable

shield through the cable gland and connect

it to be capacitive over the terminal "S".

However, make sure that a conducting connection cannot occur from the shield to the

cable gland or housing.

If the shielding is not placed on both sides,

we recommend installing an additional sup-

26

EB 8383-1 EN

Connections

Page 27

pressor kit (order no. 1400-9324). Separate installation instructions are included.

Note!

The connection of limit switches, binary

input and forced venting function requires

an additional cable gland that must replace

the cap fitted on the housing.

Accessories:

Cable gland M20 x 1.5, nickel-

plated brass, order no. 8808-0143

Limit switches

For operation of the limit switches, switching amplifiers have to be connected in the

output circuit. Their function is to control the

limit values of the control circuit according

to NAMUR, thus ensuring operational reliability of the positioner.

If the positioner is installed in hazardous

areas, the relevant regulations must be observed.

Binary input

A passive floating contact can be used at

the binary input. The positioner signals the

status over the bus protocol.

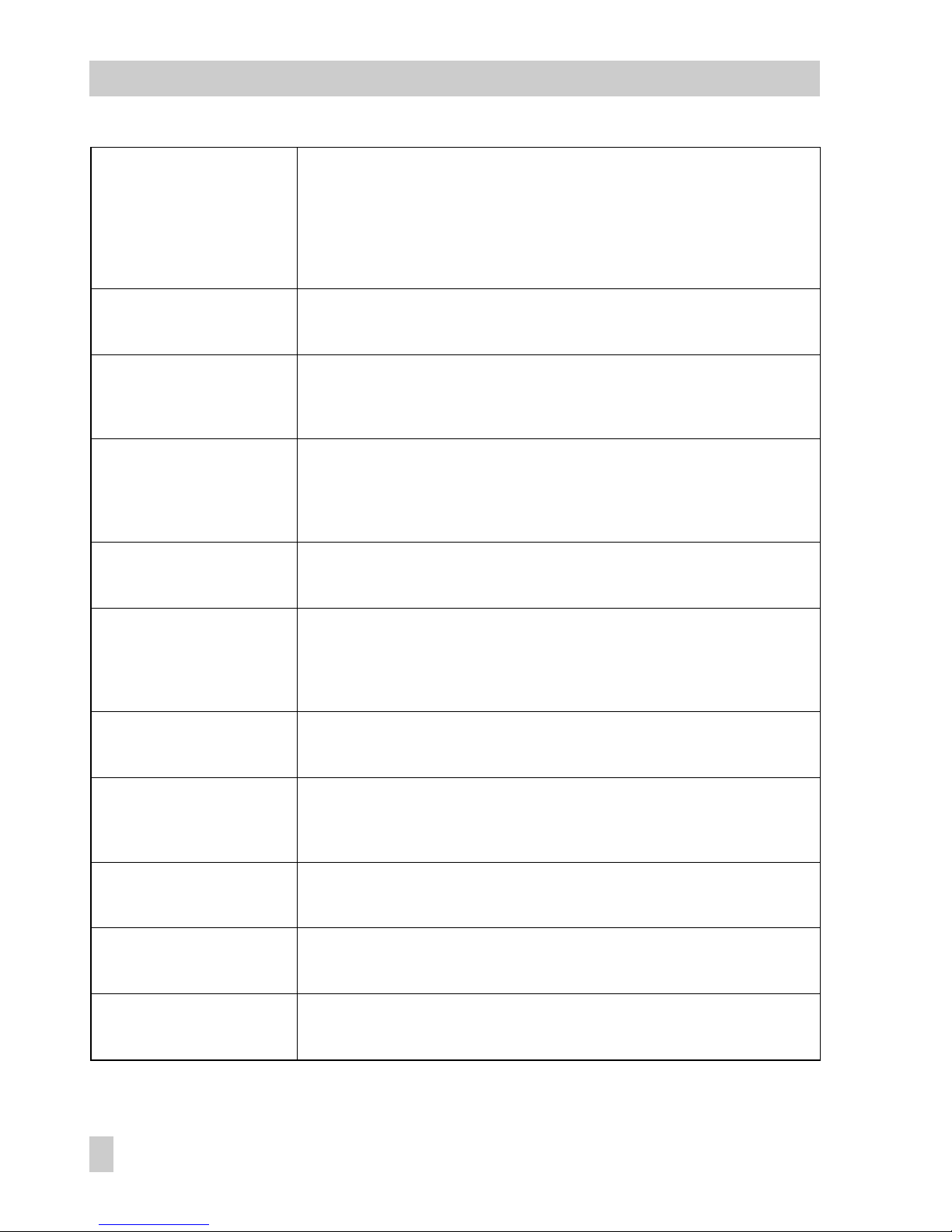

Fig. 9 ⋅Bus line connection and terminal assignment (terminal markings according to DIN 45140)

Brass screw fitting Shield Clamping insert Coupling nut

GW2 GW1

PE

S

NC

-52

+51

-42

+41 -86

+85

-82 +81

IEC 1158-2

FOUNDATION

TM

Fieldbus

Bus cable

Switching amplifier

acc. to EN 60 947-5-6

6 to 24 VDC

Limit switches Binary input Forced venting

EB 8383-1 EN

27

Connections

Page 28

Forced venting

For the positioners with forced venting function, a voltage between 6 and 24 V DC

must be connected to the terminals 81 and

82.

Note!

If there is no voltage connected or the voltage drops, the positioner vents the actuator

and does not respond to the reference variable.

28

EB 8383-1 EN

Connections

Page 29

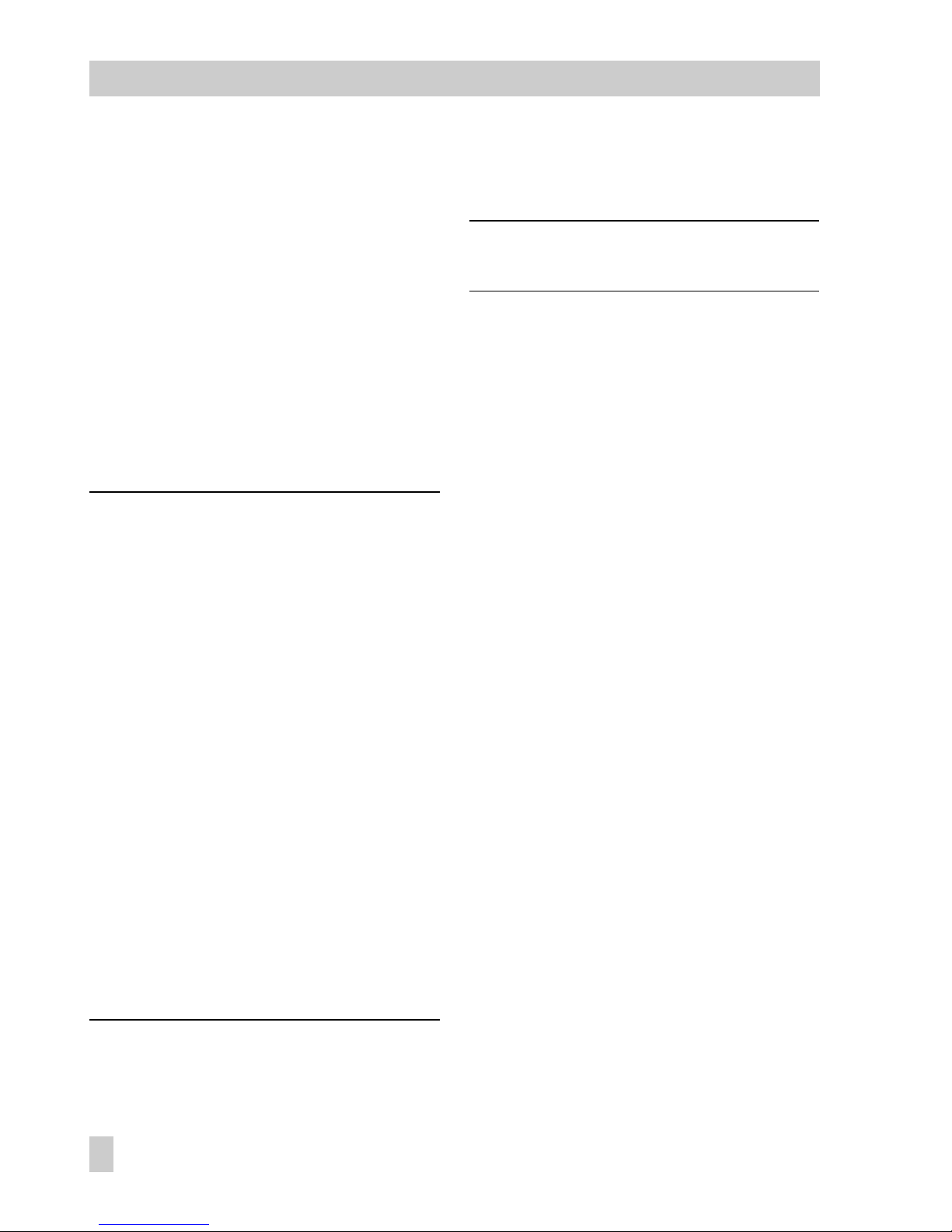

3.2.1 Establishing communication

Communication between positioner, programmable logic controller or automation

system or between PC and workstation and

positioner(s) is established in accordance

with IEC 61158-2.

If positioners are used in hazardous areas,

ex-barriers must be used.

A maximum of 32 control valves can be

operated in one segment. The number of positioners that can be connected is reduced

when they are used in hazardous areas.

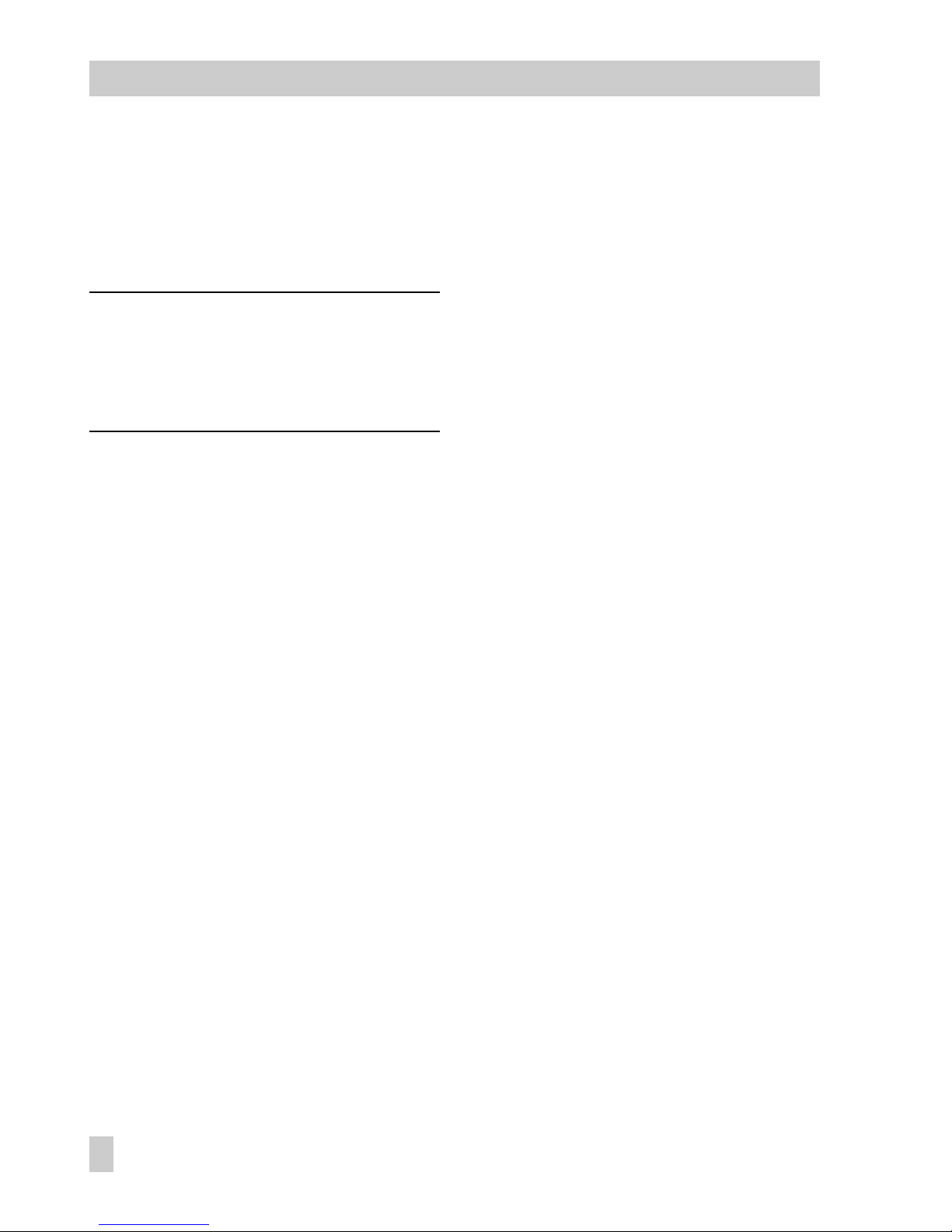

Fig. 10 ⋅ FOUNDATIONTM Fieldbus connection, for non-hazardous areas (top) and for hazardous areas (bottom)

3787

3787

3787

3787

FOUNDATION

TM

Fieldbus IEC 61158-2

FOUNDATION

TM

Fieldbus IEC 61158-2

3787-1

3787-1

3787-1

3787-1

FOUNDATION

TM

Fieldbus IEC 61158-2

FOUNDATION

TM

Fieldbus

IEC 61158-2

Process

management

system

Process

management

system

Te rm in at i o n

Ex-fieldbus barriers

Termination

Hazardous area

Supply unit

Non-hazardous area

Supply unit

Termination

EB 8383-1 EN

29

Connections

Page 30

4Operation

Warning!

Before you take the control valve

into operation, carefully move the

control valve to its end position by

covering the hole (manual operation) on the cover plate (Fig. 11).

On doing so, check whether the

lever mechanism works properly.

If the maximum angle of rotation is

exceeded because the wrong lever

mechanism has been selected or incorrectly sized, the positioner may

be ruined.

4.1 LEDs

There are two LEDs located inside the cover

used to monitor the positioner during startup, operation and to indicate possible faults.

General meaning of LEDs:

Red

Device start-up or error,

no control operation possible

Green

No error detected, control operation

or fail-safe position

(e.g. if not initialized)

Red and green

Error detected,

control operation possible

See table below for detailed description.

Description LED

Device start-up:

Red on

No error detected:

Device connected to bus, cold start completed,

initialization required

Initialization or zero calibration running

Device is initialized, no valid set point

Device is initialized, valid set point, control operation

Green, generally

Green blinks slowly

Green blinks quickly

Green blinks 3x quickly + long interval

Green on

Error in the control loop:

Zero point error

Control loop fault

Red and green

Red and green blink slowly

Red and green blink quickly

Error leading to first initialization being cancelled

(Device does not go to standard operation)

Zero point error

Mechanics/pneumatics failure

Control loop fault

Red, generally

Red blinks slowly

Red on

Red blinks quickly

Device errors causing the control operation to be

left

Device has detected an internal fault Red blinks 3x quickly + long interval

30

EB 8383-1 EN

Operation

Page 31

4.2 Write protection and simulation switches

There are two microswitches inside the

hinged cover to activate the write protection

and enable simulation.

When the write protection switch is ON, the

configuration data of the positioner are

write-protected and cannot be overwritten.

The switch must be set to OFF before any

configuration data can be changed over the

communications.

The simulation switch enables the simulation

of the position value for Analog Output

Function Block using the Simulate parameter.

4.3 Activate/deactivate forced

venting function

For models with index .03 or higher:

1. Remove cover plate on the inside of the

positioner lid by unscrewing the four

screws.

2. Unscrew the central screw on the board

and push the board to one side.

3. Set switch to desired position:

1 ENABLED > Function activated

2 DISABLED > Function deactivated.

Dimensions

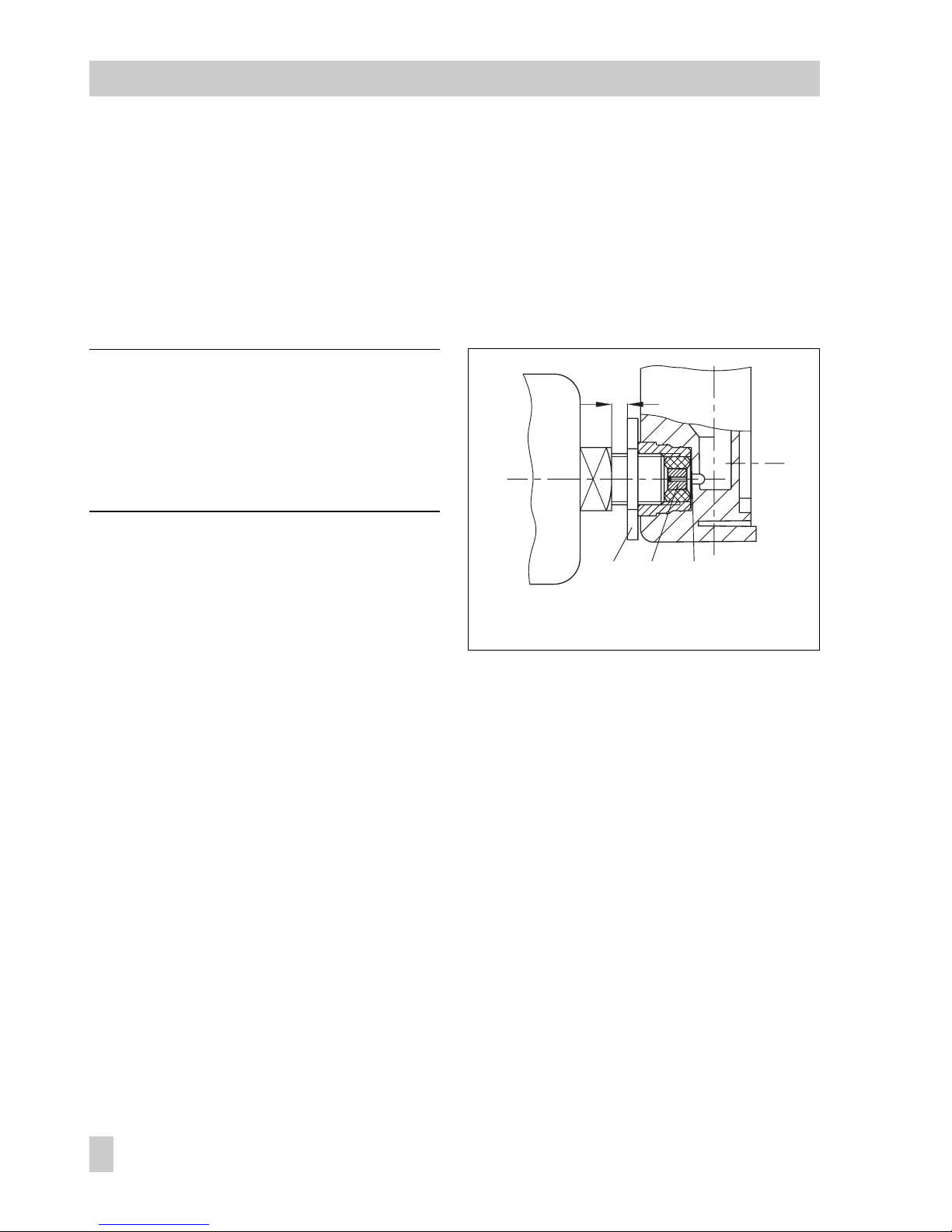

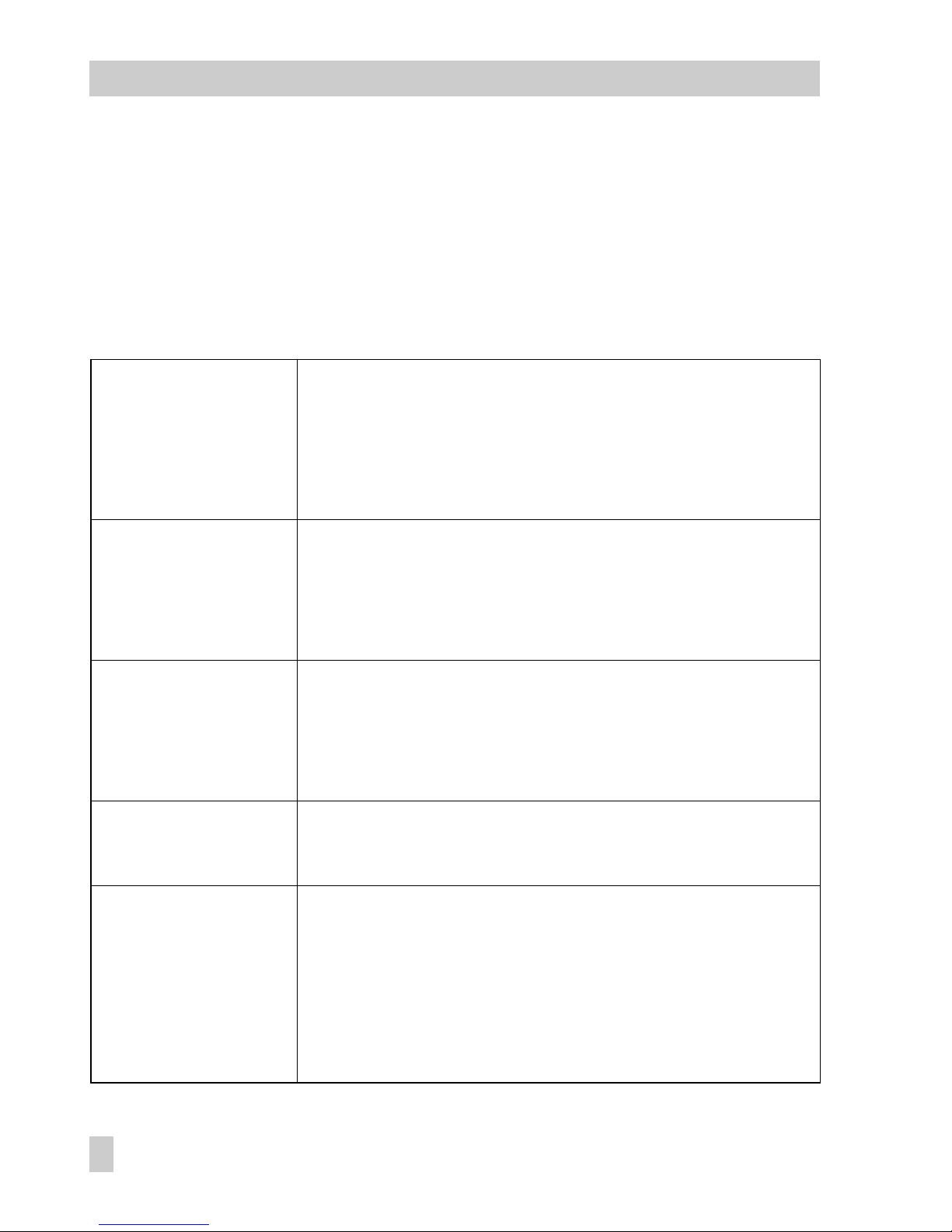

Fig. 11 ⋅View of the positioner cover open

GW1

GW2

3785

LED 1

LED 2

0

PE

IEC 1158-2

S

NC -52

+51

-42

+41

-86

+85

-82

+81

0N0FF

0FF

Caution!

Valve

actuates

Init/Zero

SERIAL

INTERFACE

FOUNDATION

Fieldbus

Simulation enable

Write protection

GW2 GW1

Arrow for mounting

position

Manual operation

Zero switch

Pointer

Adjustment screws for

limit switches

Key for initialization

and zero calibration

Metal tags

LED

Serial interface

Simulation switch

Write protection

switch

EB 8383-1 EN

31

Page 32

4.4 Default setting

All parameters are set to default values. See

chapter 7 on description of parameters.

Note!

Manual operation and activated final position functions can cause the actuator to

filled with the maximum supply pressure.

Should this lead to impermissible forces occurring, the supply pressure must be restricted by a reducing station.

4.4.1 Adjusting mechanical zero

Note!

Zero must be calibrated when the valve is

closed (with actuator stem extended in threeway valves).

Firmly push the zero switch, located on

the cover plate inside the positioner, in

the direction indicated by the arrow as

far as it will go once. The yellow pointer

will then be aligned with the white line.

For control valves which are open in their initial position, e.g. when the actuators failsafe position is "actuator stem retracts", the

positioner must be first supplied with air.

The manual operation function must then be

activated so that the supply pressure builds

up and moves the valve to the closed position. Then press the zero switch.

32

EB 8383-1 EN

Operation

Page 33

4.4.2 Initialization

After connecting the supply air and electrical connections to the bus cable, initialization must be started. During initialization,

the positioner adapts itself optimally to the

friction conditions and signal pressure requirements of the control valve.

Caution!

Initialization takes several minutes to

complete. During this time, the control valve moves. Therefore, never initialize while a process is running,

but only during the start-up phase

when the shut-off valves in the plant

section are closed. Alternatively,

remove the control valve with positioner from the plant and initialize

on a test bench.

Enter data on valve and actuator under

"Start-up" in the operating software.

Set "Type of initialization" to "Rated

range", select "Maximum range" only

for three-way valves.

Start initialization.

A successful initialization is indicated in the

operating software and over the LEDs (see

chapter 4.1).

Carry out the configuration suitable for

the valve type.

The following setting is recommended:

Fail-safe position "Actuator stem extends":

Direction of action: increasing/increasing (>>), the globe valve opens with increasing reference variable

Final position at a reference variable

less than 1% (tight closing),

Final position at a reference variable

larger than 125 % (function deactivated).

Fail-safe position "Actuator stem retracts":

Direction of action: increasing/decreasing (<>), the globe valve closes with increasing reference variable

Final position at a reference variable

less than −2.5% (function deactivated),

Final position at a reference variable

larger than 99 % (tight closing).

Set delay time to 30 s at the minimum.

Enter tag reference.

If necessary, other configuration, e.g.

special characteristics for rotary valves.

If there is

no communication

set up on the

valve, initialization directly at the valve is

also possible.

Connect positioners that are not

mounted on a valve to a power supply

and initialize the positioner as described

in chapter 4.4.2.

If communication is not possible, the default setting must be used.

Mount positioner and set the mechanical

zero as described in chapter 4.4.1.

Start initialization by pressing the

Init/Zero

key on the positioner case cover using a

suitable tool.

The initialization is completed when the positioner takes on the position predetermined

by the reference variable.

EB 8383-1 EN

33

Operation

Page 34

Note!

After the positioner has been initialized successfully for the first time, pressing the

Init/Zero

key subsequently only starts a

zero calibration.

A new initialization routine can only be

started after this when the communication is

connected.

A completed initialization can be cancelled

via the communication with the command

"Reset to default values". After this, the

Init/Zero key can be pressed to start a complete initialization.

Electric zero calibration

If, during the valves operation, the mechanical zero has shifted, an electric zero calibration can be carried out. To do this, press

the Init/Zero key located on the inside of

the cover (Fig. 11).

Caution!

The control valve moves to its final

position.

Firmly press the zero switch, located on

the cover plate of the positioner, in the

direction indicated by the arrow as far

as it will go once. The yellow pointer will

then be aligned with the white line.

Press the key again to start the electric

calibration.

After the key is pressed twice, it is locked

for approximately one minute!

The electric calibration has been completed

when the positioner takes on the position

predetermined by the reference variable.

34

EB 8383-1 EN

Operation

Page 35

4.5 Operation via TROVIS-VIEW

In addition to using the fieldbus configuration or operating system via fieldbus communication, the positioner can also be operated with SAMSONs TROVIS-VIEW user interface via the serial port integrated in the

device.

You can configure all the parameters using

the device module intended for the TROVISVIEW software.

For connection of the positioner to the serial

port of the PC, you will need an adapter

(order no. 1400-7700).

You can either connect the power supply to

the device using a fieldbus segment, or by

connecting a voltage source (9 to 32 V) to

the bus terminals on the device.

When the device is connected to a Foundation Fieldbus bus segment, you can simultaneously operate TROVIS-VIEW and the

fieldbus system without any restrictions.

4.5.1 Initialization

When you initialize the device via the

fieldbus system or TROVIS-VIEW, the initialization routine is started over the parameter

SELF_CALIB_CMD.

You can select an initialization routine

based on either the nominal range or maximum range by setting the parameter

INIT_METHOD accordingly.

During initialization based on nominal

range, the following parameters must be set:

VALVE_TYPE

Option: Rotary or linear actuator

MOUNTING_POSITION

Positioner alignment to actuator (for linear actuator).

ATTACHMENT

Defines the attachment of the positioner

(Select: Namur/integrated).

RATED_TRAVEL

Rated travel or nominal angle of the

valve

ACTUATOR_VERSION

Determines whether the actuator is single

acting or double acting.

Options for linear actuator with NAMUR attachment:

TRANSM_LENGTH

Specifies the length of the lever

TRANSM_PIN_POS

Specifies the position of the pin on the

lever.

Options for linear actuator with integrated

attachment:

TRANSM_CODE

Determines the size of the travel pick-off

for integrated attachment.

Options for rotary actuator:

TRANSM_CODE

Determines the cam disk used.

During initialization, the following parameters are determined:

ACT_FAIL_ACTION

Fail-safe action of the actuator when the

supply air fails.

ACT_STROKE_TIME_DEC

Minimum transit time to CLOSED position

ACT_STROKE_TIME_INC

Minimum transit time to OPEN position

EB 8383-1 EN

35

Operation

Page 36

MAX_HUB

Maximum travel/angle of rotation in percent of the rated travel/nominal angle.

The integrated LEDs and the parameters

SELF_CALIB_STATUS

SELF_CALIB_WARNUNG

indicate if the initialization has been successfully completed or whether errors have

occurred.

4.5.2 Testing the control valve

Upon successful initialization, you can easily test the control valve using TROVIS-VIEW

software. This function allows you to run the

valve for test purposes without the use of a

complex fieldbus system and without requiring knowledge about the function blocks

and their configuration.

Proceed as follows:

1. Set the Transducer Block to

"Local override" mode:

In the menu "Positioner-> Operating

mode TRD" under "Required operating

mode" select "Local override (LO)".

Deactivate the option "Fail safe position

(O/S)".

2. Defining a positioning value:

In the menu "Positioner-> Process

data", you can select a positioning

value for the valve over "Positioning

value TRD" (FINAL_VALUE).

Note that the status of the positioning

value must be set to "Good".

The position feedback can be retrieved

via "Current valve position"

(FINAL_POSITION_VALUE).

3. Set the Transducer Block to the "Auto"

mode.

In the menu "Positioner-> Operating

mode TRD" under "Required operating

mode" select "Automatic (AUTO)".

Deactivate the option "Local override

(LO)".

4.6 Setting the inductive limit swit-

ches

The positioner version with inductive limit

switches has two adjustable tags that are

mounted on the shaft of the positioner lever

and operate the associated proximity switches.

For operation of the inductive limit switches,

the corresponding switching amplifiers have

to be connected to the output. If the tag is in

the inductive field of the switch, the switch

assumes a high resistance. If the tag is out

of the field, the switch assumes a low resistance.

Normally, the limit switches are adjusted

such that they will provide a signal in both

end positions of the valve. These switches,

however, can also be adjusted to indicate

intermediate valve positions.

The desired switching function, i.e. whether

the output relay shall be picked up or released when the tag has entered the field,

has to be selected, if necessary, at the

switching amplifier.

36

EB 8383-1 EN

Operation

Page 37

Adjusting the switching point:

The limit switches are marked GW1 and

GW2 on the inside of the case cover. Yellow tags and the associated adjustment

screws (Fig. 11) are located below these

markings.

Each switching position can optionally be indicated when the tag has entered the field, or

when it has left the field.

Move the valve to the switching position

and adjust the tag of the required limit

switch GW1 or GW2 by turning the related adjustment screw until the switching

point is reached. This is indicated by the

LED at the switching amplifier.

In so doing, one edge of the yellow tag will

be in alignment with the white, horizontal

line on the case cover. This indicates the

side from which the tag enters the inductive

field of the proximity switch.

To ensure safe switching under any ambient

conditions, the switching point should be adjusted to a value of approx. 5% before the

mechanical stop (OPEN - CLOSED).

5 Maintenance

The positioner is maintenance-free.

Pneumatic connection 9/Supply contains a

sieve with a mesh size of 100 μm. If required, the sieve can be unscrewed and

cleaned.

Please also observe the maintenance instructions for upstream pressure reducing

stations for supply air, if applicable.

6 Servicing explosion-protected

versions

If a part of the positioner on which the explosion protection is based needs to be serviced, the positioner must not be put back

into operation until an expert has inspected

the device according to explosion protection requirements, has issued a certificate

stating this or given the device a mark of

conformity.

Inspection by an expert is not required if the

manufacturer performs a routine test on the

device prior to putting it back into operation. The passing of the routine test must

be documented by attaching a mark of conformity to the device.

Explosion-protected components may only

be replaced by original, checked components from the manufacturer.

Devices that have already been used outside of hazardous areas and are intended

for use in hazardous areas in future must

comply with the safety demands placed on

repaired devices. Prior to operation, they

must be tested according to the specifications stipulated for "Repairing explosionprotected devices".

EB 8383-1 EN

37

Maintenance

Page 38

7 Parameter description

7.1 General

The section is based on:

Fieldbus Foundation Specification "Function Block Application Process Part 1 to 3"

Revision 1.4.

Fieldbus Foundation Specification "Transducer Block Application Process Part 1 to 2"

Revision PS 3.0.

7.2 Device Description (DD)

The following Device Description files are required for integrating the device described into

host systems:

Device Description: < 0201.ffo >, < 0201.sym >

Capabilities File: < 020101.cff >

You can order these Device Description files on disk (3 1/2") from SAMSON under the pro-

duct number 1400-7705 or you can download them from the Internet at

www.samson.de

or

www.fieldbus.org

.

Note:

The file < Positioner 3787_Rev2.fhx > is required for integration into the System DeltaV from Fisher-Rosemount, instead of the capabilities file from Fieldbus Foundation.

This file can be provided by SAMSON.

7.3 Notes on the parameters

All times specified in the Resource Block are in 1/32 ms units in accordance with the

Fieldbus specification Version 1.4.

In the Device Description Library supplied by the Fieldbus Foundation on which the Device

Description of the Type 3787 is based, these parameters are incorrectly shown with the ms

unit. The numerical values supplied by the device should, however, always be interpreted as

units of 1/32 ms.

Due to the same reason, the IO_OPTS parameter in the AO Block displays "Fault state to

value" as "Fault state type".

Several parameters can only be altered in certain modes (see "Access" in Parameter description).

Therefore, it is important that the Target Mode is set and not the Actual Mode.

38

EB 8383-1 EN

Parameter description

Page 39

7.3.1 Legends assigned to the parameters

r= Read

w= Write

Index = Relative index of the parameter in each block

O/S = Out of Service

MAN = Manual

AUTO = Automatic

CAS = Cascade

RCAS = Remote Cascade

ROUT = Remote Output

S = Static parameter

N = Non-volatile parameter

D = Dynamic parameter

7.3.2 Notes on parameter storage classes S, N and D

Static and non-volatile parameters are stored in the positioners EEPROM.

If such parameters are changed over acyclic FOUNDATION Fieldbus communication, the changes are saved in the EEPROM.

The number of write accesses granted to the EEPROM is limited due to technical restrictions.

Writing of transducer block parameters is limited to 10,000 accesses. For all other

blocks, the limit is 1 million.

These access limits must be observed. If they are exceeded, integrity of the stored

data and thus the function of the positioner can no longer be guaranteed due to data

being overwritten.

Make sure these parameters are not constantly overwritten by acyclic FOUNDATION

Fieldbus transfers.

When transferring data to the positioner using cyclic, scheduled FOUNDATION

Fieldbus publishing (Publisher/Subscriber), these data are not saved in the EEPROM.

EB 8383-1 EN

39

Parameter description

Page 40

7.4 Block structure

FOUNDATION Fieldbus assigns all functions and data of a device to three different block

types. Each block type has a different area of application.

A FOUNDATION Fieldbus device has the following block types:

One Resource Block

The Resource Block contains all the hardware specific characteristics.

One or more Transducer Blocks

The Transducer Block contains all the data and device-specific parameters to link the

device to the process data (sensor or actuator).

One or more Function Blocks

Function Blocks provide generally useable automation functions.

There are various different types of Function Block, e.g. Analog Input Function Block,

Analog Output Function Block, PID Function Block and other input, output and processing

blocks.

Each of these Function Blocks can be used for processing various application functions in

the entire automation system.

Various tasks can be solved depending on how individual blocks are arranged and connected.

40

EB 8383-1 EN

Parameter description

Page 41

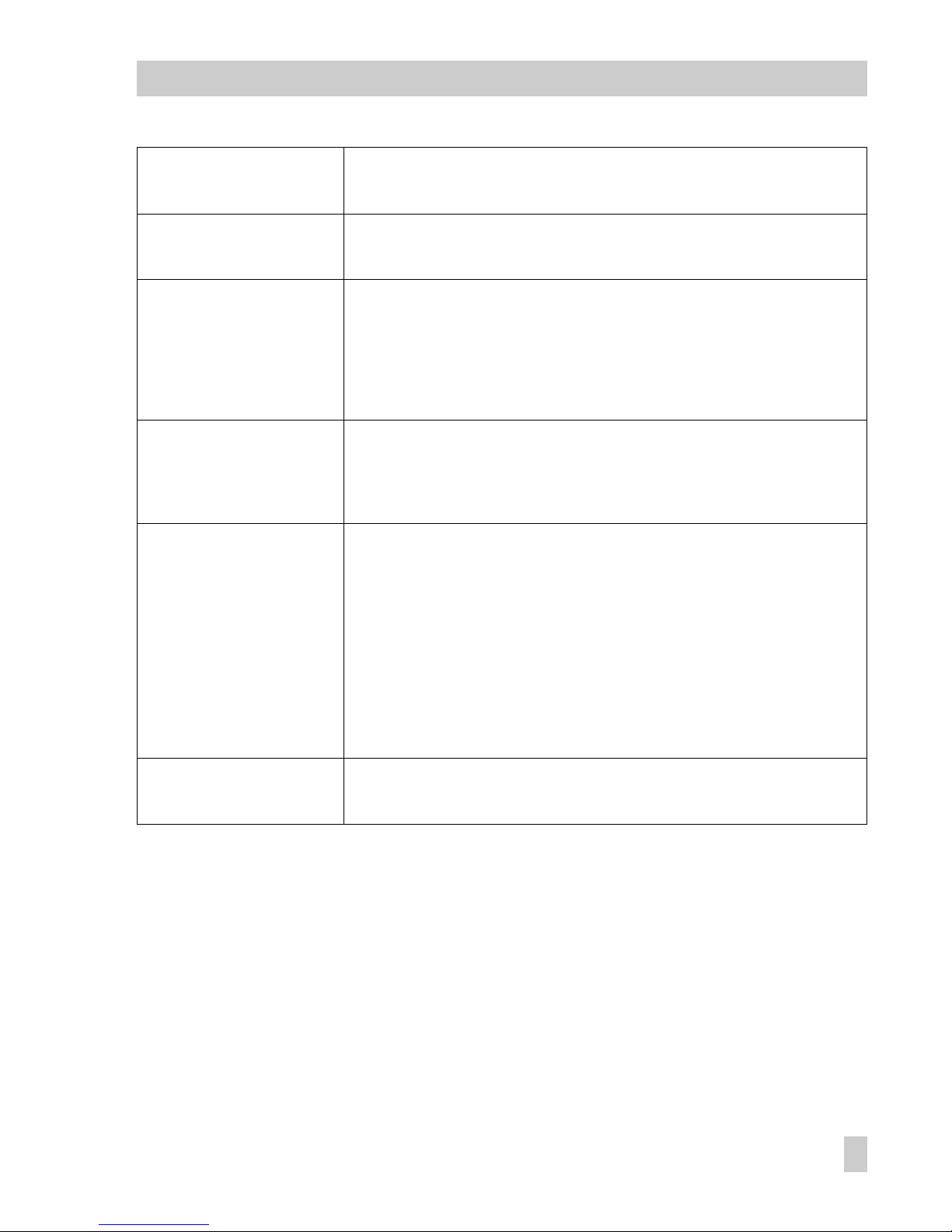

The SAMSON Type 3787 Foundation Fieldbus Positioner contains the following blocks:

One Resource Block.

One Standard Advanced Positioner Valve Transducer Block.

Two Function Blocks:

one Analog Output Function Block,

one PID Function Block.

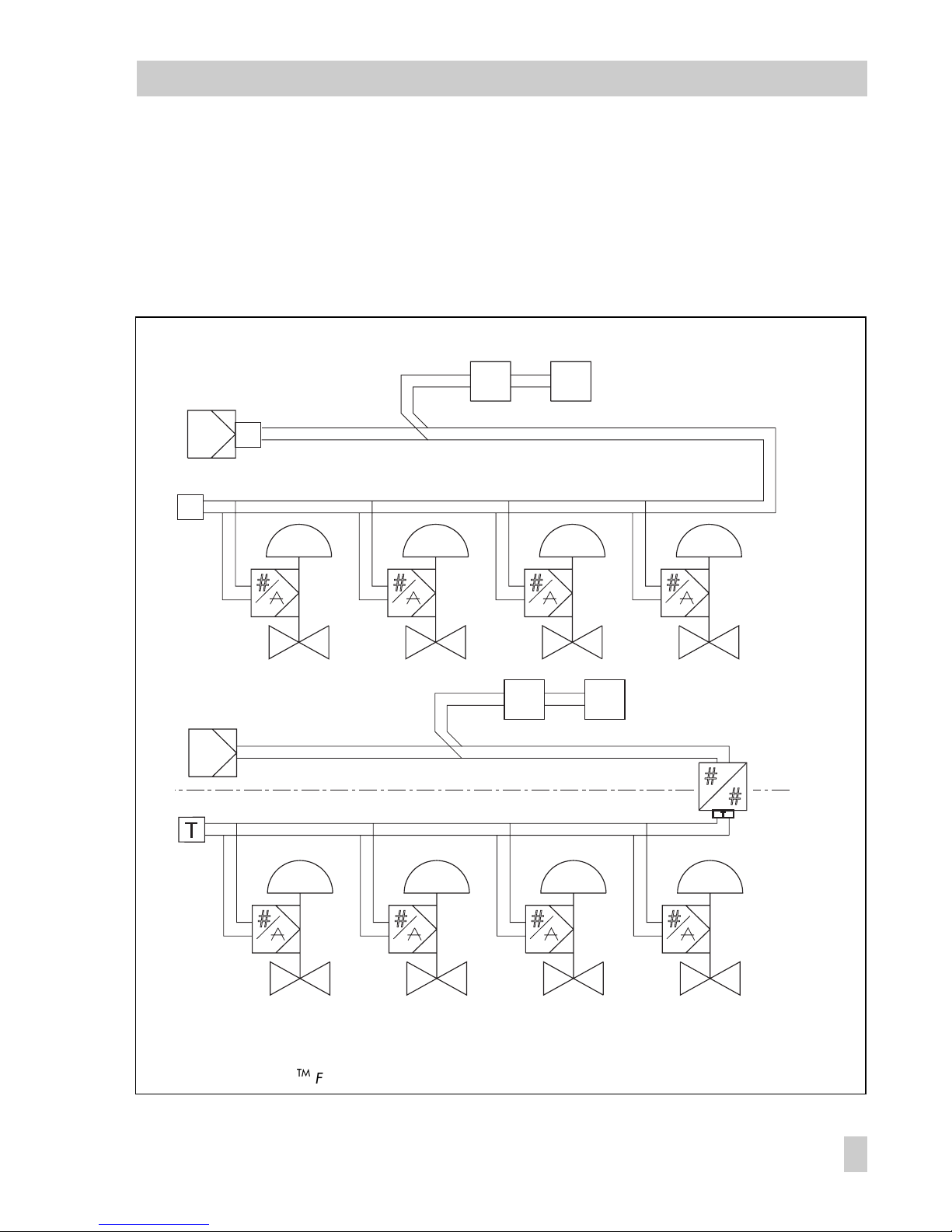

Fig. 12 ⋅Block structure

RCAS_IN

CAS_IN

OUT

MODE_BLK

(manual)

Analog Output Block

PV

Final Value

>

_

&

1

>

_

1

e

p

e

p

&

&

PWM

PWM

FINAL POSITION VALUE

Transducer Block

Pneumatik

Block

MODE_BLK

SP

>

_

OUT

FINAL_VALUE_CUTOFF_LO

FINAL_VALUE_CUTOFF_HI

READBACK

SP

Set point

ramps

Sp_RATE_DN

Sp_RATE_UP

PV, XD

scaling

XD_SCALE

PV_SCALE

high

To o u ts i de

RATED_TRAVEL

Fail-safe action

ACT_FAIL_ACTION

PD controller

SERVO_GAIN_1

SERVO_GAIN_2

SERVO_RATE

Forced venting

Fail-safe position

Hardware, firmware error

Characteristic

selection

Charact

XD, PV scaling

XD_SCALE, PV_SCALE

Set point

limits

SP_HI_LIM

SP_LO_LI

Output

options

IO_OPTS

low

1: active 0: inactive

Supply air

Filter

EB 8383-1 EN

41

Parameter description

Page 42

7.4.1 Resource Block

The Resource Block contains all the data that clearly identifies the device. It is, so to speak,

the electronic nameplate of the device.

The Resource Blocks parameters include, for example, device type, device name, manufacturer ID, serial number as well as parameters which affect the behavior of all other Blocks in

the device.

Parameters of the Resource Block

Storage class:

ACK_OPTION

S

Index: 38

Access: r, w

Options:

Default:

This parameter allows you to choose whether an alarm associated with this block

should be automatically acknowledged, i.e. without any influence from fieldbus host

system.

Undefined No option

DISC ALM Write protection has been changed

BLOCK ALM Block alarm

Undefined

Note : T he alar m i s s ent to th e f ieldbu s host sy st em, but it is not ack no wl edged by it .

ALARM_SUM

S

Index: 37

Access: r, w

Display:

Shows current status of process alarms in the Resource Block.

DISC ALM Write protection has been changed

BLOCK ALM Block alarm

Note:

Additionally, the process alarms can be cleared in this parameter group.

ALERT_KEY

S

Index: 4

Access: r; w

Input:

Default:

The identification number of the plant unit. This information may be used in the

fiel dbus ho st sy stem fo r s or ti ng alar ms an d event s.

1...255

0

Note: The value 0 (default) is not a tolerated value and is therefore rejected with an

error message when writing to the device.

BLOCK_ALARM

D

Index: 36

Access: r; w

Sho ws th e curre nt block s ta tu s with i nf or mation ab ou t exist in g c onfigu ra tion,

hardware or system errors.

Note: Additionally, the active block alarm can be manually acknowledged in this

parameter group.

BLOCK_ERR

D

Index: 6

Access: r

Display:

Sho ws th e activ e b lo ck erro r.

SIMU LATE A CTIVE Sim u latio n possib le, Simulation En able se t.

OUT OF SE RVICE T h e b lock model is O/S .

LOST STATIC DATA D ata loss in E EPROM

DEVICE NEEDS MAINTENANCE SOON

(Zero error, control loop disturbed or total valve travel.

exce ed ed). Th is alert tr ig gers a b lo ck alar m ( BL OCK_ALM ) o f

the ResourceBlock.

42

EB 8383-1 EN

Parameter description

Page 43

CLR_FSTATE

D

Index: 30

Access: r, w

Writing a Clear to this parameter will clear the fault state of the Analog Output

Function Block.

CONFIRM_TIME

S

Index: 33

Access: r, w

Default:

Defa ult of co nf ir mation t im e f or eve nt re port.

If the device does not receive any confirmation within this time, the event report is sent

again.

640000 1/32 ms

CYCLE_TIME

S

Index: 20

Access: r, w

Options:

Default:

Block execution methods predetermined by fieldbus host system.

SCHEDULED

COMPLETION OF BLOCK EXECUTION

SCHEDULED

Note: The execution method is selected directly in the fieldbus host system.

CYCLE_TYPE

S

Ind ex: 1 9

Access: r

Display:

Shows the block execution methods supported by the device.

SCHEDULED

COMPLETION OF BLOCK EXECUTION

DD_RESOURCE

S

Index: 9

Access: r

Shows the string for the Device Description in the device.

Not e: If there is not Devic e Description in th e dev ice, "null" ap pear s in the di spla y.

DD_REV

S

Index: 13

Access: r

Shows revision number of Device Description.

DESCRIPTOR

S

Index: 46

Access: r, w

Description,

freely available space for entering text to describe the application, stored in the field

device.

DEV_REV

S

Index: 12

Access: r

Shows the revision number of the device.

DEV_TYPE

S

Index: 11

Access: r

Display: