Page 1

Controller with Electric Actuator

Type 5757-7

Fig. 1 · Type 5757-7 Controller with Electric Actuator for heating applications

Mounting and

Operating Instructions

EB 5757-7 EN

Firmware version 1.0x

Edition August 2005

Page 2

Contents

Contents Page

1 Design and principle of operation . . . . . . . . . . . . . . . . . . . 5

1.1 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Connection to the valve . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Dimensions in mm . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Outdoor temperature compensated control . . . . . . . . . . . . . . . 13

5.1.1 Override using potentiometer . . . . . . . . . . . . . . . . . . . . . 15

5.1.2 Summer mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.3 Delayed outdoor temperature adaptation. . . . . . . . . . . . . . . . 16

5.2 Fixed set point control . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.1 Room temperature influence . . . . . . . . . . . . . . . . . . . . . . 16

5.3 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3.1 Switchover via binary input . . . . . . . . . . . . . . . . . . . . . . 18

5.3.2 Switchover via room panel . . . . . . . . . . . . . . . . . . . . . . 19

5.3.3 Switchover via binary input in room panel . . . . . . . . . . . . . . . 19

5.4 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.5 Return flow temperature limitation . . . . . . . . . . . . . . . . . . . 19

5.6 Pump forced operation . . . . . . . . . . . . . . . . . . . . . . . . 20

5.7 External request for heat demand . . . . . . . . . . . . . . . . . . . 20

5.8 Control principle . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.9 Direction of action. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Configuration and operation using TROVIS-VIEW interface . . . . . . 23

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1.1 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2 Installing TROVIS-VIEW software . . . . . . . . . . . . . . . . . . . 24

6.3 Starting TROVIS-VIEW and performing settings . . . . . . . . . . . . 25

6.3.1 Activating/deactivating functions . . . . . . . . . . . . . . . . . . . 27

6.3.2 Setting parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3.3 Reading operational information. . . . . . . . . . . . . . . . . . . . 29

7 Data transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.1 Data transmission between TROVIS-VIEW and the actuator

(connecting cable). . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.1.1 Offline operation (indirect data transmission) . . . . . . . . . . . . . . 33

2 EB 5757-7 EN

Page 3

Contents

7.1.2 Online operation (direct data transmission). . . . . . . . . . . . . . . 33

7.2 SAMSON memory pen . . . . . . . . . . . . . . . . . . . . . . . . 34

7.2.1 Data transfer between TROVIS-VIEW and memory pen . . . . . . . . . 34

7.2.2 Data transmission between actuator and memory pen. . . . . . . . . . 35

7.2.3 Copy function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2.4 Manual operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.1 Function block list . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.3 Customer settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

EB 5757-7 EN 3

Page 4

Safety instructions

General safety instructions

4

4

4

4

4

Assembly, start-up and operation of this device may only be performed by

trained and experienced personnel familiar with the product.

According to these mounting and operating instructions, trained personnel

refers to individuals who are able to judge the work they are assigned to

and recognize possible hazards due to their specialized training, their

knowledge and experience as well as their knowledge of the applicable

standards.

Any hazards which could be caused in the connected valve by the process

medium, operating pressure or moving parts are to be prevented by means

of the appropriate measures.

Proper transportation and storage are assumed.

The actuators has been designed for use in electrical power installations.

For wiring and maintenance, you are required to observe the relevant safety

regulations. The actuator must be protected against unintentional

reconnection of the power supply.

Note:

Actuators with a CE marking fulfill the requirements of the Directives

94/9/EC and 89/336/EEC.

The Declaration of Conformity is available on request.

4 EB 5757-7 EN

Page 5

Design and principle of operation

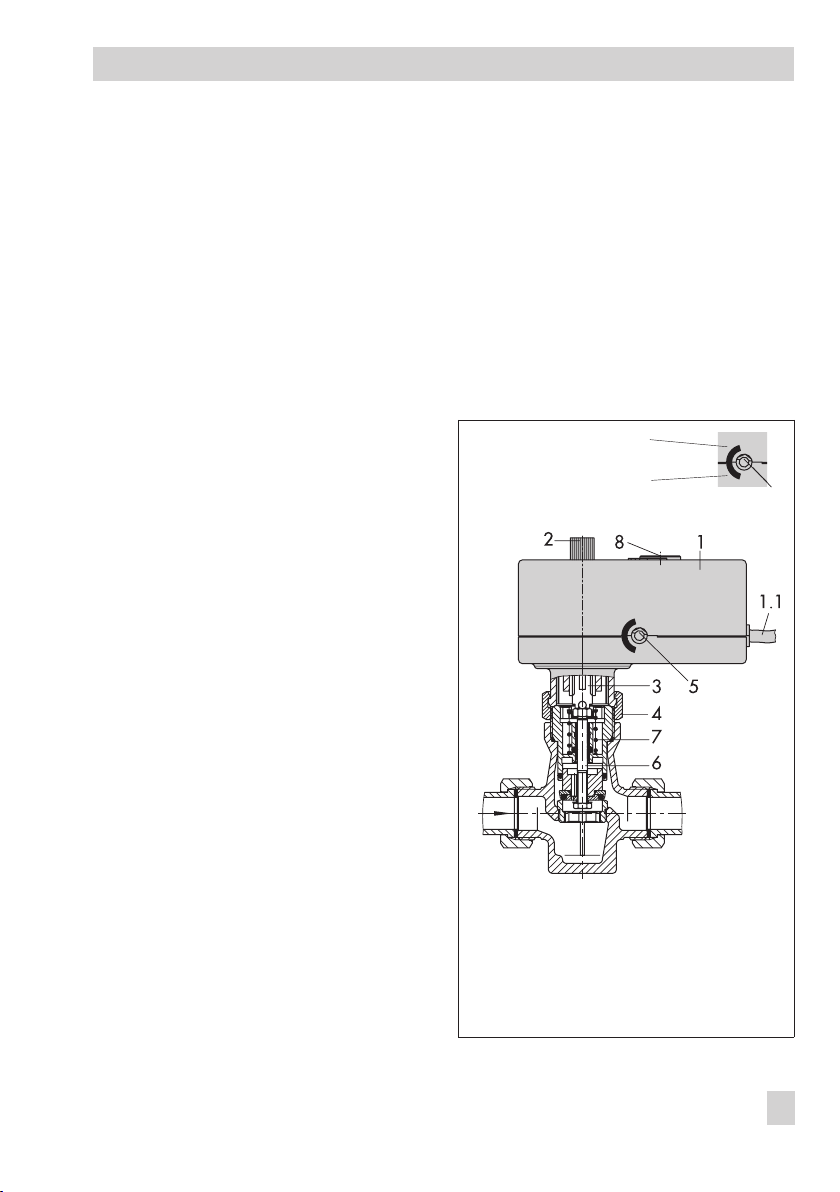

1 Design and principle of

operation

The Type 5757-7 consists of a digital con

troller integrated into the housing of an elec

tric actuator.

The combination is especially designed for

heating applications as well as for fixed set

point control of heating systems in small to

medium-sized buildings. It is particularly

suitable for mounting to SAMSON

Type 3222, Type 3222 N, Type 2488 and

Type 3267 Valves (DN 15 to 25) and to

special versions of Type 3226 and

Type 3260 Valves.

The digital controller is connected to a flow

sensor on the input side, which can be optionally upgraded by a return flow, outdoor

or room sensor.

In addition to the Pt 1000 input, the digital

controller has a potentiometer input (1000

to 1100Ωor 1000 to 2000Ω) to measure

the flow temperature. This input influences

the heating characteristic in the case of outdoor temperature compensated control and

the room temperature set point in the case of

fixed set point control with room tempera

ture influence.

Heating characteristic and set point parame

ters can be changed over the TROVIS-VIEW

Operator Interface.

The output signal of the integrated digital

controller is applied as a three-point step

ping signal to the synchronous motor of the

actuator. The signal is transferred over the

connected gear to the actuator stem (3) and

used as the positioning force.

The motor is switched off by torque-depend

ent switches when an end position is

reached or in case the motor is overloaded.

-

-

-

The actuator is mounted onto the valve using

a coupling nut (4).

When the actuator stem extends, the valve is

closed, opposing the force of the valve

spring (7). When the actuator stem retracts,

the valve is opened as the plug stem (6) fol

lows the motion of the return spring.

The valve can be moved to any position

when the power supply is disconnected by

the handwheel (2). Travel and direction of

action can be read off the travel indicator

(5) on the side of the actuator housing.

Stem retracts

Stem extends

-

1 Controller/actuator

1.1 Connecting lead

2 Handwheel (only to

be used when power

is disconnected)

3 Actuator stem

-

Fig. 2 · Functional diagram

4 Coupling nut

5 Travel indicator

6 Plug stem

7 Valve spring

8 Cover, serial

interface connection

-

5

EB 5757-7 EN 5

Page 6

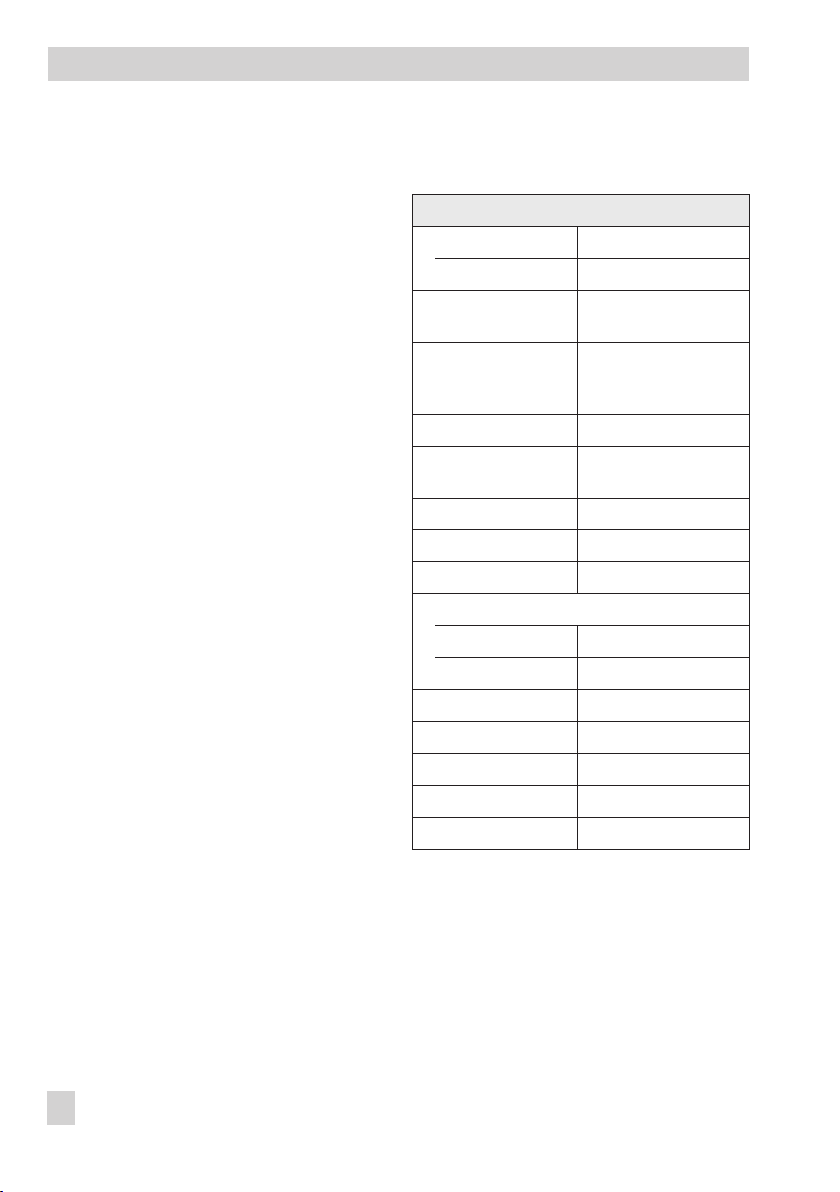

Design and principle of operation

1.1 Accessories

Heating applications, see section 5

Type 5267-2 Pt 1000 Contact Sensor

4

Permissible temperatures:

Medium –20 to 120 °C

Ambient –20 to 120 °C

Degree of protection IP 42

Type 5257-2 Pt 1000 Room Sensor

4

with potentiometer (remote adjuster)

Permissible temperatures:

Medium –35 to 70 °C

Ambient –35 to 70 °C

Degree of protection IP 20

Type 5257-7 Room Panel with

4

potentiometer and mode selector switch

Permissible temperatures:

Medium –20 to 60 °C

Ambient –20 to 60 °C

Degree of protection IP 30

Type 5227-2 Pt 1000 Outdoor Sensor

4

Permissible temperatures:

Medium –35 to 85 °C

Ambient –35 to 85 °C

Degree of protection IP 44

Communication, refer to section 6

TROVIS-VIEW Configuration and Opera

4

tor Interface (6661-1066) for

Type 5757-7 Controller with Electric Actu

ator

Hardware package

4

Accessories for direct and indirect data

transmission (including a memory pen,

connecting cable and modular adapter),

order no. 1400-7704

Memory pen

4

Indirect data transmission,

order no. 1400-7697

1.2 Technical data

Type 5757-7 Controller with Electric Actuator

Temperature sensor Max. 3 x Pt 1000

Setting range 0 to 150 °C

Potentiometer input 1000 to 1100Ωor

Binary output 230 V/50 Hz/1 A

Rated travel 6 mm

Transit time for

rated travel

Nominal thrust 300 N

Supply voltage 230 V (±10 %) / 50 Hz

Power consumption Approx. 3 VA

Permissible temperatures

Ambient 0 to 50 °C

Storage –20 to 70 °C

Degree of protection IP 42

Mounting position Any, but not suspended

Noise immunity EN 61000-6-2

-

Noise emission EN 61000-6-3

-

Weight Approx. 0.7 kg

1000 to 2000

Circulation pump or

external heat demand

20 s

Ω

6 EB 5757-7 EN

Page 7

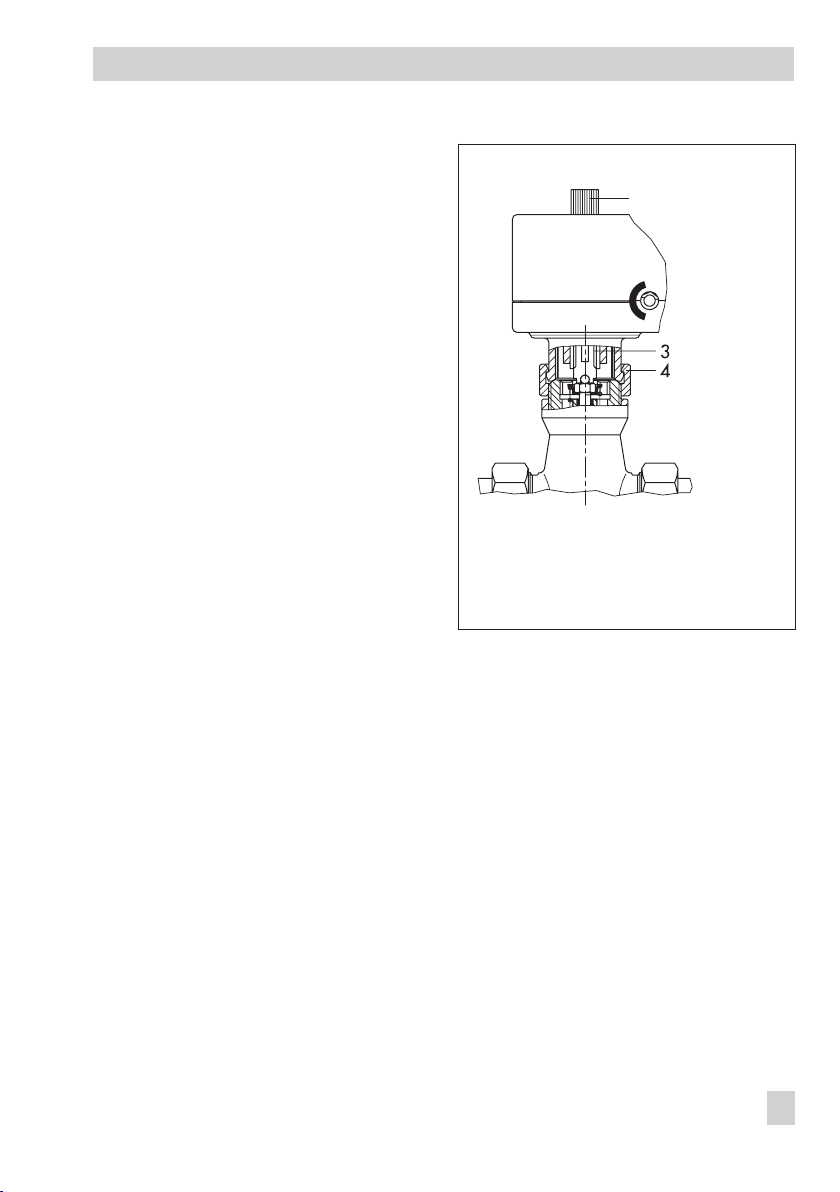

2 Connection to the valve

The actuator has a force-locking connection

to the valve in de-energized state.

Turn the handwheel (2) counterclockwise

4

to retract the actuator stem as far as it

will go.

Place the actuator on the valve connec

4

tion and screw coupling nut (4) tight

(tightening torque 20 Nm).

2.1 Mounting position

Connection to the valve

2

-

Any mounting position may be used, how

ever, may not be installed in a suspended

position.

-

2 Handwheel

3 Actuator stem

4 Coupling nut

Fig. 3 · Connecting actuator and valve

EB 5757-7 EN 7

Page 8

Electrical connection

3 Electrical connection

When installing electric lines, you

are required to observe the regula

tions governing electrical power

plant installation according to

DIN VDE 0100 as well as the regu

lations of your local power supply

company.

Use a suitable power supply which

guarantees that no dangerous volt

ages reach the device in standard

operation or in case of a fault in the

system or any other system parts.

The controller with electric actuator requires

a Pt 1000 temperature sensor (e.g. Type

5267-2) to be connected to measure the

flow temperature.

Depending on the control task, an outdoor

sensor (e.g. Type 5227-2) or a room sensor

(e.g. Type 5257-2) or a room panel

(Type 5257-7 only) can be connected. Combining one of these sensors with a return

flow sensor (e.g. Type 5267-2) is usually

possible.

Additionally, the controller with electric ac

tuator has a potentiometer input 1000 to

1100Ω(e.g. Type 5257-7) or 1000 to

2000Ω(e.g. Type 5257-2). This input is

used to correct the room set point (±5 K) in

case of fixed set point control with room

temperature influence (see section 5.2). On

using an outdoor sensor, it can change the

adjusted heating characteristic (see sec

tion 5.1).

The non-floating pump output can alterna

tively be used as an binary output for an ex

ternal request for heat demand.

-

-

-

-

-

-

The connected sensors are monitored for

line breakages.

A fault in the line of a sensor is indicated by

the red LED blinking slowly.

Caution!

Connect the actuator to the electrical

network only after the power supply

has first been switched off. Make

sure the power cannot be switched

on unintentionally!

The pump output L’ is non-floating

(230 V~).

Perform the electrical connection de-

4

pending on the heating application according to one of the following wiring diagrams (Figs. 4 and 5).

As soon as the actuator is connected to

the power supply, the initialization procedure starts.

The actuator stem extends (with operating direction selected for globe valves)

and the red and yellow LEDs are illumi

nated located under the cover on top of

the actuator.

As soon as the actuator stem has

reached the final position, the red LED is

turned off. The yellow LED remains illu

minated and indicates that the controller

with electric actuator is ready for opera

tion.

-

-

-

-

8 EB 5757-7 EN

Page 9

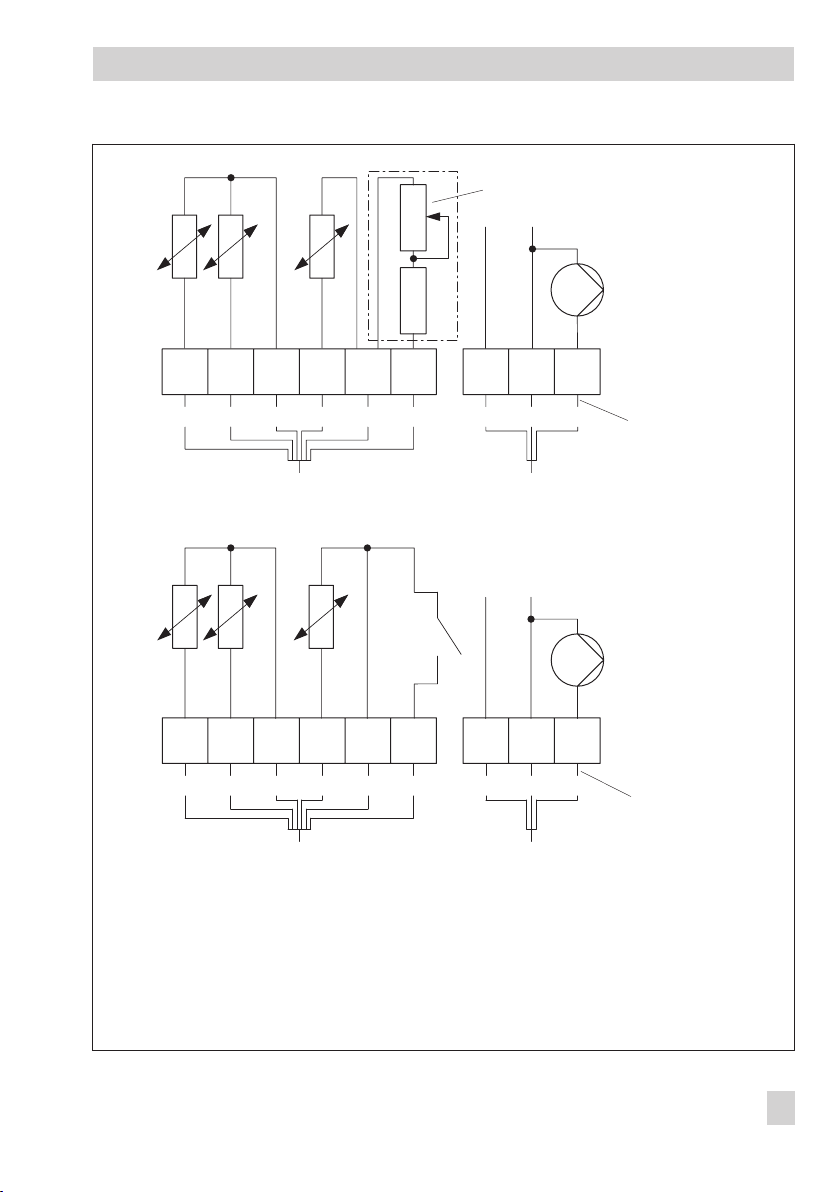

Electrical connection

VS

Pt 1000

Pt 1000

ASRüS

Pt 1000

100/

1000 Ω

1000 Ω

230 V,

50 Hz

34 6521LL´N

or ye rd br blk gr br bl blk

Application with flow, return flow, and outdoor sensors as well as potentiometer

to adjust the set point

e.g. Type 5257-2 with remote adjuster

VS

Pt 1000

Pt 1000

ASRüS

Pt 1000

230 V,

50 Hz

34 6521LL´N

Caution!

Live wires

or ye rd br blk gr br bl blk

Application with flow, return flow, and outdoor sensors as well as binary input

to switch between operating modes

or orange

ye yellow

rd red

br brown

blk black

gr green

Fig. 4 · Wiring diagrams Note:

Caution!

Live wires

br brown

bl blue

blk black

Terminals at point of installation, not included in scope of delivery

EB 5757-7 EN 9

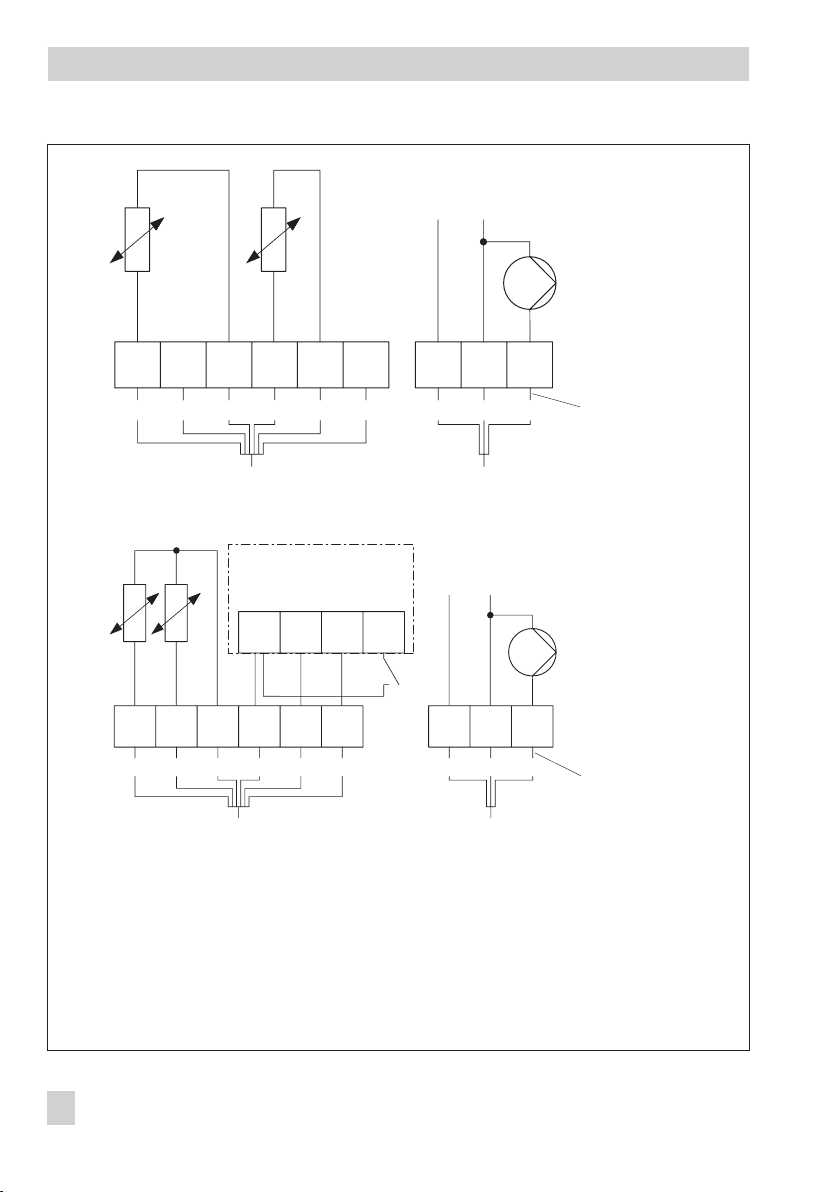

Page 10

Electrical connection

VS

Pt 1000

AS

230 V, 50 Hz

Pt 1000

34 6521LL´N

or ye rd br blk gr br bl blk

Application with flow sensor and outdoor sensors

VS

RüS

Pt 1000

Pt 1000

34 65

21LL´N

or ye rd br blk gr br bl blk

Type 5257-7

Room Panel

1432

230 V, 50 Hz

Caution!

Live wires

Caution!

Live wires

Application with flow, return flow, and room sensors with mode selector switch and set point adjuster

or orange

ye yellow

rd red

Fig.5·Wiring diagrams Note:

br brown

blk black

gr green

br brown

bl blue

blk black

Terminals at point of installation, not included in scope of delivery

10 EB 5757-7 EN

Page 11

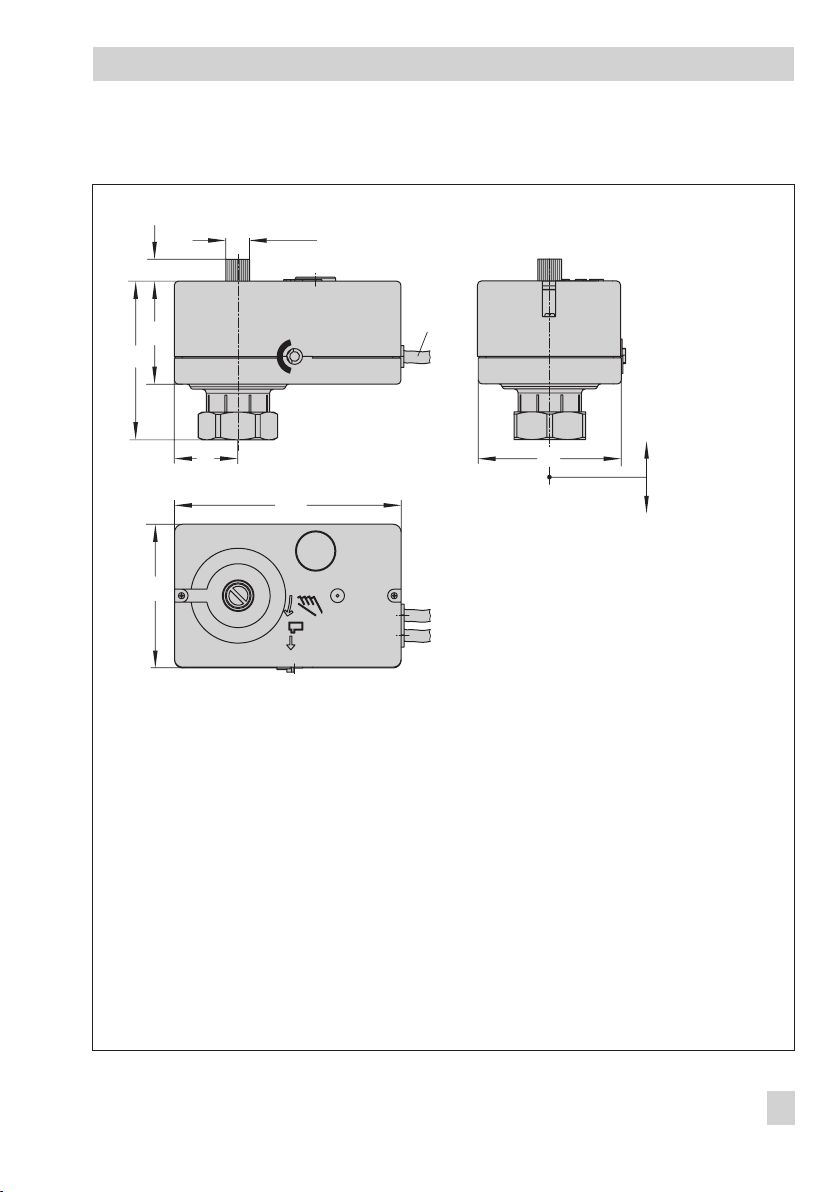

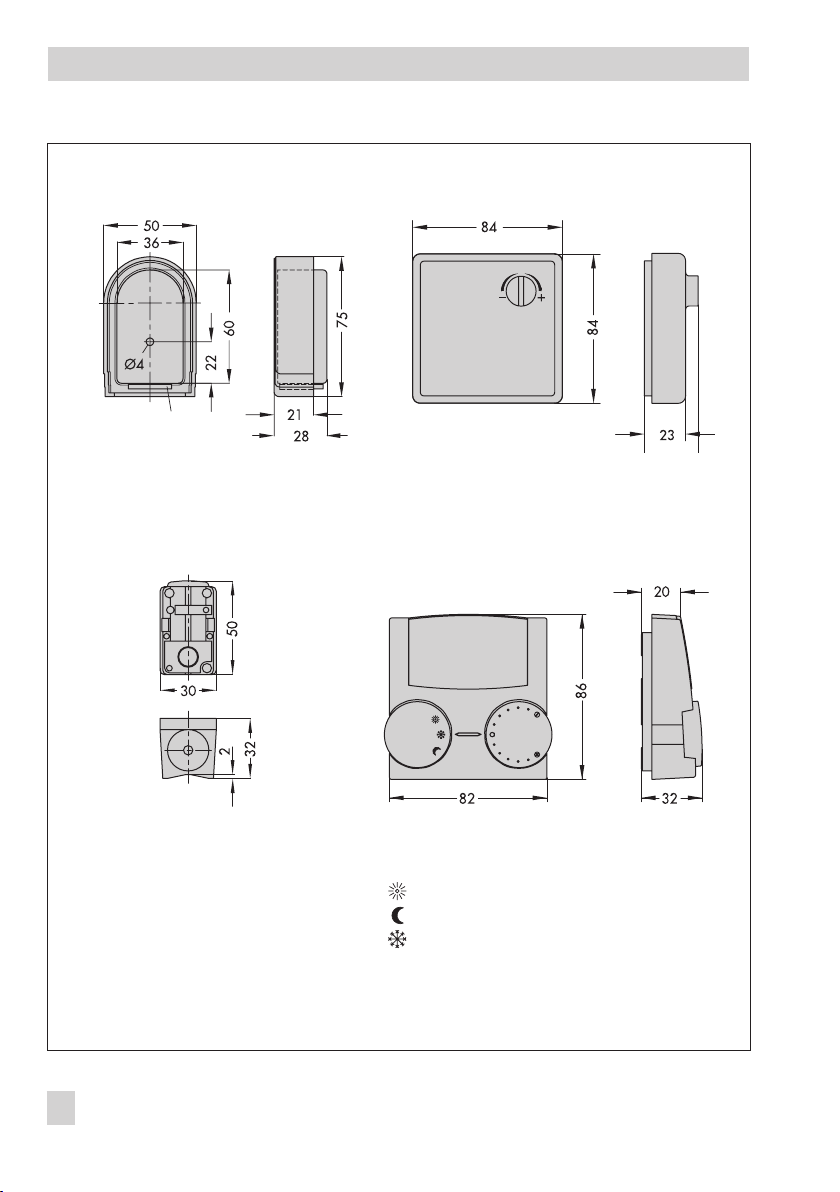

4 Dimensions in mm

Ø 12

11

Dimensions in mm

55

80

32 70 eL einfahrend

114

70

2.5 m

aL ausfahrend

Fig. 6 · Type 5757-7 Controller with Electric Actuator

EB 5757-7 EN 11

Page 12

Dimensions in mm

Type 5227-2 Outdoor Sensor,

Pt 1000

Color: RAL 9016

Type 5267-2 Contact

Sensor, Pt 1000

(flow and return flow

temperature measurement)

Fig. 7 · Accessories for heating applications

Type 5257-2 Room Sensor, Pt 1000

(remote adjustment)

Color: RAL 9010

Type 5257-7 Room Panel, Pt 1000

Color: Cover and knobs RAL 9016 · Base RAL 7047

Continuous day mode (rated operation)

Continuous night mode (reduced operation)

Off/frost protection

12 EB 5757-7 EN

Page 13

Functions

5 Functions

Functions and parameters are entered in the TROVIS-VIEW Operator Interface (see

section 6).

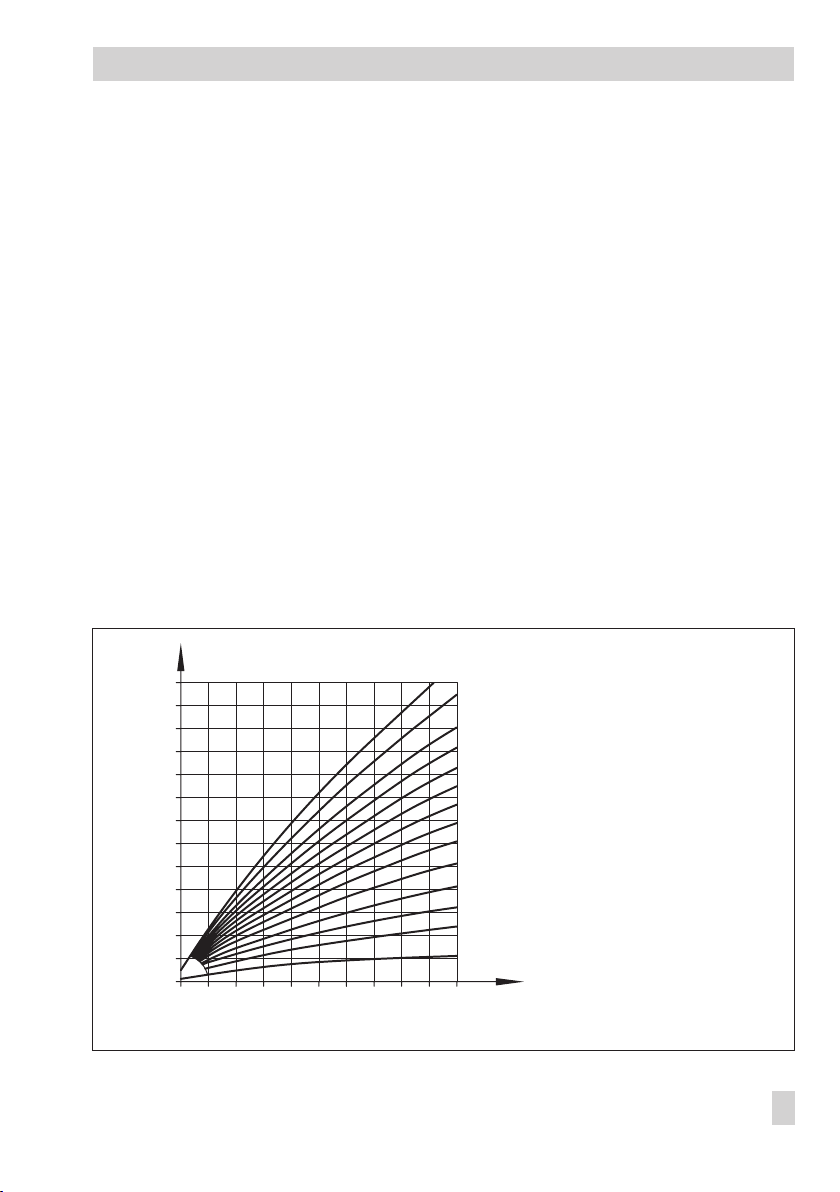

5.1 Outdoor temperature compensated control

In the outdoor temperature compensated control, the flow temperature (tVL) is automatically

adjusted in relationship to the outdoor temperature (t

troller defines the set point for flow temperature as a function of the outdoor temperature

(Fig. 8).

Basically, the following correlation exists: If the outdoor temperature drops, the flow temper

ature rises. By varying the

Gradient

to individual requirements: An increased

whereas a reduced

Gradient

and

Level

Gradient

causes a lower flow temperature. The

heating characteristic parallely upwards or downwards.

In reduced operation, the flow temperature is reduced by the amount set in

setback in reduced operation. The Maximum flow temperature

e parameters limit the flow temperature range. Return flow temperature limitation (see

tur

section 5.5) is an exception as it can reduce the flow temperature without restriction down to

20 °C flow temperature set point.

). The heating characteristic in the con

A

parameters, the characteristic can be adapted

causes an increase in flow temperature,

Level

parameter shifts the

Flow temperature

and

Minimum flow tempera-

-

-

[

C] t

VL

˚

150

140

130

120

110

100

90

80

70

60

50

40

30

20

20 16 12 8 4 0 -4 -8 -12 -16 -20

Fig. 8 · Heating characteristics

3.2

2.9

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.4

0.2

tVLFlow temperature

Outdoor temperature

t

A

t

A

[

C]

˚

EB 5757-7 EN 13

Page 14

Functions

Functions WE Configuration

F01 – Control mode 1 F01 - 1

F02 – Selecting the reference variable 0 F02 - 0

Parameters WE Range of values

P02 – Flow temperature set-back in reduced

operation

P03 – Min. flow temperature 20 °C 0 to 150 °C

P04 – Max. flow temperature 120 °C 0 to 150 °C

P05 – Heating characteristic gradient 1.6 0.2 to 3.2

P06 – Heating characteristic level 0 K –30 to 30 K

Examples for setting the heating characteristic:

Old building, radiator design 90/70: Gradient approx. 1.8

4

New building, radiator design 70/55: Gradient approx. 1.4

4

New building, radiator design 55/45: Gradient approx. 1.0

4

Underfloor heating depending on arrangement: Gradient smaller than 0.5

4

15 K 0 to 50 K

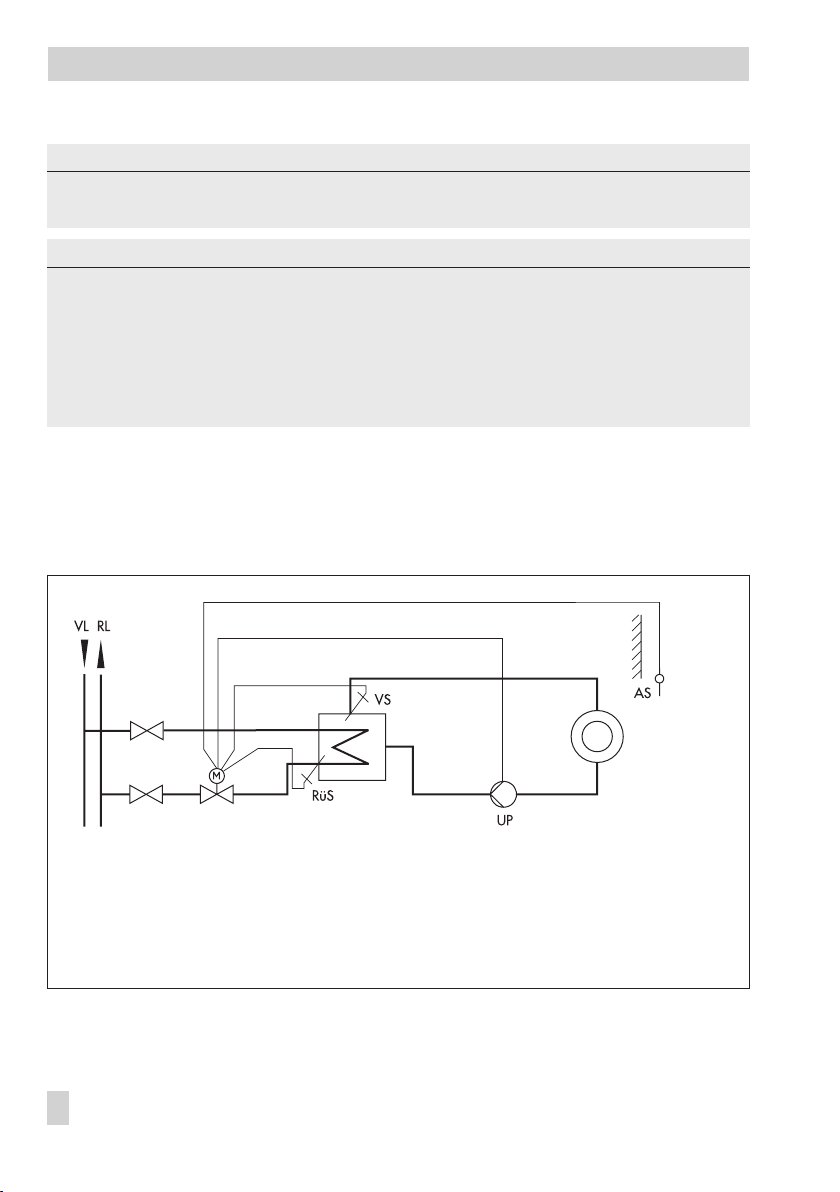

Fig. 9 · Typical application: Outdoor temperature compensated flow temperature control with return flow limitation;

switching between operating modes using a binary contact

14 EB 5757-7 EN

Page 15

Functions

5.1.1 Override using potentiometer

The potentiometer input (e.g. by connecting Type 5257-2 with remote adjustment) can

change either the heating characteristc level or gradient, depending on the configuration.

The parameters

are used to adjust the range (±) in which the influence is to take place.

ter

Functions WE Configuration

F05 – Potentiometer input 0 F05 - 1

F06 – Resistance range of potentiometer 0 F06 - 1 (Type 5257-2)

F07 – Potentiometer function 0 F07 - 0: Level shift

Parameters WE Range of values

P07 – Gradient shift range via potentiometer 1.0 0.0 to 1.5 (only with F 07 - 1)

P08 – Level shift range via potentiometer 15 K 0 to 30 K (only with F 07 - 0)

Examples:

Potentiometer function F07 - 0

4

Heating characteristic gradient

Gradient shift range via potentiometer

The gradient can be shifted between 0.6 and 2.6 (±1.0).

⇒

Potentiometer function F07 - 1

4

Heating characteristic level

Level shift range via potentiometer

The level can be adjusted between –15 K and +15 K (±15 K). The limits adjusted

⇒

for the flow temperature still apply.

Gradient shift range via potentiometer

P05 = 1.6

P07 = 1.0

P06 = 0 K

P08 = 15 K

and

Level shift range via potentiome

F07 - 1: Gradient shift

-

5.1.2 Summer mode

Should the outdoor temperature exceed the

tion/reduced operation

the circulation pump is switched after the

The heating is switched on again when the outdoor temperature falls below the set point.

Parameters WE Range of values

P17 – Outdoor temperature limit value at rated operation 22 °C 0 to 50 °C

P18 – Outdoor temp. limit value at reduced operation 15 °C 0 to 50 °C

P22 – Pump lag time 5 min 1 to 999 min

), the controller switches off the heating, i.e. the valve is closed and

Outdoor temperature limit value(rated opera

Pump lag time

has elapsed.

EB 5757-7 EN 15

-

Page 16

Functions

5.1.3 Delayed outdoor temperature adaptation

The calculated outdoor temperature is used to determine the flow temperature set point. The

heat response is delayed when the outdoor temperature either decreases, increases or in

creases and decreases.

If the outdoor temperature varies by, for example, 12 °C within a very short period of time,

the calculated outdoor temperature is adapted to the actual outdoor temperature in small

Delay

steps. Assuming a

of 3 °C/h, the linear adaptation would take =

123°°C

C/h

= 4 h.

Note!

The delayed outdoor temperature adaptation helps avoid unnecessary overloads of central

heating stations caused by either overheated buildings occurring, for example, due to warm

winds, or temporarily insufficient heating due to the outdoor sensor being exposed to direct

sunshine.

Functions WE Configuration

F04 – Delayed outdoor temperature 0 F04 - 1

Parameter WE Range of values

P16 – Delayed value for outdoor temp. adaptation 3 °C/h 1 to 6 °C/h

-

5.2 Fixed set point control

The flow temperature is controlled to the fixed value in

duced operation, the flow set point is used for the control reduced by the amount in

temperature set-back in reduced operation.

A connected outdoor sensor does not have any

effect on the control.

Functions WE Configuration

F01 – Control mode 1 F01 - 0

Parameters WE Range of values

P01 – Flow temperature set point 70 °C 0 to 150 °C

P02 – Flow temp. set-back in reduced operation 15 K 0 to 50 K

Flow temperature set point

5.2.1 Room temperature influence

On connecting a Type 5257-7 Room Panel, the

the room temperature:

16 EB 5757-7 EN

Flow temperature set point

is influenced by

. In re

Flow

-

Page 17

Functions

AS Outdoor sensor

RüS Return flow sensor

VS Flow sensor

Fig. 10 · Typical application: Fixed set point control with room temperature influence and return flow temperature

limitation; switching between operating modes at room panel (Type 5257-7)

UP Circulation pump

RL District heating network return flow

VL District heating network supply

The heat supply is matched to the required amount over a permanently active flash adaptation. The room sensor is polled at regular intervals (

ature is lower than the

at reduced operation,

.

point

Room temperature limit at rated operationorRoom temperature limit

the flow temperature is raised based on the

TrFlash adaptation).

If the room temper-

Flow temperature set

If the room temperature exceeds the room temperature set point (rated operation/reduced

operation) by the amount in

Maximum room temperature boost

i.e. the valve is closed and the circulation pump is switched off after the

, the heating is switched off,

Pump lag time

has

elapsed.

In the event, the parameter P12 –

TrFlash adaptation

is set to 0, the control is a pure fixed set

point control without room temperature influence.

Note!

We recommend not to select a value that is too low for parameter P12. In particular, in cases

where cooling loads, such as drafts or open windows, affect the control process, short cycles

usually have a negative effect. The heating is directly switched off after the cooling stops.

EB 5757-7 EN 17

Page 18

Functions

Note!

The set points for room temperature entered in TROVIS-VIEW can be reduced or raised by

5 K at the room panel.

Functions WE Configuration

F01 – Control mode 1 F01 - 1

F02 – Selecting the reference variable 0 F02 - 1

Parameters WE Range of values

P01 – Flow temperature set point 70 °C 0 to 150 °C

P12 – TrFlash adaptation 10 min 0 to 100 min

P19 – Room temperature limit at rated operation 20 °C 10 to 40 °C

P20 – Room temperature limit at reduced operation 15 °C 10 to 40 °C

P21 – Maximum room temperature boost 1 K 1 to 6 K

P22 – Pump lag time 5 min 1 to 999 min

5.3 Operating modes

5.3.1 Switchover via binary input

The active binary input determines which operating mode is used. Depending on the configuration, the following applies:

F08 - 0 Open binary input – Rated operation

4

Closed binary input – OFF/Frost protection

F08 - 1 Open binary input – Rated operation

4

Closed binary input – Reduced operation

Note!

It is not possible to connect the Type 5257-7 Room Panel at the same time in this case (see

section 5.3.3 on Switchover via binary input in room panel).

Functions WE Configuration

F05 – Potentiometer input 0 F05 - 0

F08 – Binary input function 0 F08 - 0: Rated operation + OFF/Frost protect.

18 EB 5757-7 EN

F08 - 1: Rated and reduced operation

Page 19

Functions

5.3.2 Switchover via room panel

The operating mode of the controller is determined at the mode selector switch on the

Type 5257-7 Room Panel:

Rated operation (day mode)

Reduced operation (night mode)

OFF/Frost protection

Functions WE Configuration

F05 – Potentiometer input 0 F05 - 1

F06 – Resistance range of potentiometer 0 F06 - 0 (Type 5257-7 Room Panel)

5.3.3 Switchover via binary input in room panel

The terminals 1 and 4 of the Type 5257-7 Room Panel can be bridged by means of an external floating contact (e.g. by a time switch with downstream contactor relay with floating

make or break contact). This enables the controller to switch to the rated operation mode

when the mode selector switch is set to reduced operation or OFF/Frost protection .

The following applies:

BI break contact Operating mode is the same as the mode set at the mode selector

4

switch

BI make contact Operating mode is rated operation,

4

regardless of the mode set at the mode selector switch

Functions WE Configuration

F05 – Potentiometer input 0 F05 - 1

F06 – Resistance range of potentiometer 0 F06 - 0 (Type 5257-7 Room Panel)

5.4 Frost protection

If the controller is in the operating mode OFF/Frost protection (see section 5.3), frost protec

tion measures are initiated if the following applies:

Outdoor temperature < 3 °C (outdoor temperature compensated control) or flow

4

temperature < 15 °C (fixed set point control with room temperature influence)

The circulation pump is switched off and the flow temperature is kept at 20 °C.

5.5 Return flow temperature limitation

The temperature difference between the flow and return flow in a network indicates how well

the energy is used: the greater the difference, the higher the efficiency.

EB 5757-7 EN 19

-

Page 20

Functions

A return flow sensor is sufficient to evaluate the temperature difference when the network

flow temperatures are predetermined. The flow temperature set point is reduced when the

Maximum return flow temperature

measured at the return flow sensor exceeds the limit tem

perature:

The reduction amount is calculated from the deviation of the return flow temperature multi

plied by the factor

Kp Return flow temperature limitation

temperature is reduced by the calculated amount is determined by

ture limitation

.

. The rate at which the return flow

Tn Return flow tempera

The yellow LED blinks slowly if the flow temperature is reduced due to the Return flow tem

perature limitation function

The return flow is not limited if the parameter setting

Tn Return flow temperature limitation

0 even if a return flow sensor is connected.

Function WE Configuration

F11 – Return flow temperature sensor 1 F11 - 1

Parameter WE Range of values

P13 – Maximum return flow temperature 50 °C 10 to 90 °C

P14 – Kp Return flow temperature limitation 1.0 0.1 to 50.0

P15 – Tn Return flow temperature limitation 400 s 0 to 999 s

-

-

-

-

=

5.6 Pump forced operation

A deactivated circulation pump is forced-operated every 24 hours for one minute. This function is disenabled by selecting F10 - 0 or F09 - 1.

Functions WE Configuration

F09 – Binary output function 0 F09 - 0

F10 – Anti-block protection of pump 1 F10 - 1

5.7 External request for heat demand

The controller with electric actuator can issue a heat demand to a higher-level controller

over the binary output BO in rated or reduced operation. In this case, a coupling relay

(contactor relay with floating contact) must be used to adapt the electrical connection.

This function is only possible when the binary output is not configured as a pump output.

Function WE Configuration

F09 – Binary output function 0 F09 - 1

20 EB 5757-7 EN

Page 21

5.8 Control principle

Functions

The controller with electric actuator functions with a PI algorithm (three-point stepping con

trol). The valve reacts to pulses which the digital controller issues when a system deviation

occurs. In particular, the length of the first pulse depends on the size of the system deviation

and the selected gain

rises). Pulse lengths and intervals change until the system deviation is eliminated. The interval

between individual pulses is influenced considerably by the reset time

(the interval time increases as the Tn rises).

control

The valve transit time

needs to move through its travel range from 0 to 100 %.

Note!

Do not change the default setting WE of P11 (Ty = 25 s) for this device.

Parameters WE Range of values

P09 – Kp flow temperature control 2.0 0.1 to 50.0

P10 – Tn flow temperature control 120 s 0 to 999 s

P11 – Ty actuator transit time at rated travel 25 s 10 to 240 s

Kp flow temperature control

Ty actuator transit time at rated travel

(the pulse length increases as the Kp

Tn flow temperature

reflects the time that the valve

-

5.9 Direction of action

Specify the direction of action depending on the valve used.

Function WE Configuration

F03 – Direction of stem action 0 F03 - 0: SAMSON globe valve

F03 - 1: SAMSON three-way valve

Globe valve (F03 - 0)

Actual value < Set point: Actuator stem retracts (globe valve opens)

4

Actual value > Set point: Actuator stem extends (globe valve closes)

4

EB 5757-7 EN 21

Page 22

Functions

Three-way mixing valve (F03 - 1)

Mixing valve for:

Mixing service

Flow

Return flow

Fig. 11 · Type 3226 Three-way Valve mounted onto Type 5757-7 Controller with Electric Actuator

Actual value < Set point: Actuator stem extends (three-way mixing valve opens port

4

AB

A

B

A -> AB and closes port B -> AB)

Actual value > Set point: Actuator stem retracts (three-way mixing valve closes port

4

A -> AB and opens port B -> AB)

22 EB 5757-7 EN

Page 23

Configuration and operation using TROVIS-VIEW interface

6 Configuration and operation using TROVIS-VIEW interface

6.1 General

The TROVIS-VIEW software allows various smart SAMSON devices to be configured over a

common operator interface. It consists of the operator interface, communication server, and

the device-specific module. The software has a Windows Explorer look and feel.

The entire configuration of the controller with electric actuator can be performed over the

TROVIS-VIEW Configuration and Operator Interface.

The TROVIS-VIEW software containing online help and the database module for

Type 5757-7 Controller with Electric Actuator is delivered on a CD-ROM (order number

6661-1066).

Software updates are available in Internet (http://www.samson.de) in Products > Support

and downloads.

Note!

The following instructions include a description on the key functions of the TROVIS-VIEW

software in conjunction with controllers with electric actuators. Refer to the online help in the

? menu for a detailed description.

6.1.1 System requirements

Hardware requirements

PC with Pentium II processor or equivalent (300 MHz or higher), 500 MHz recommended

4

Serial interface or USB/RS-232 adapter

4

Min. 64 MB RAM, 96 MB RAM recommended

4

Min. 150 MB free hard disk space plus approx. 10 to 15 MB additional hard disk space

4

per SAMSON module

SVGA graphic card (min. 800 x 600)

4

CD-ROM drive

4

Software

Operating system: Windows 98, ME, NT 4.xxSP6, 2000 SP2, XP

4

Microsoft.NET Framework Version 1.1 (included on the installation CD-ROM)

4

Internet browser: MS Internet Explorer, version 6.0 and higher

4

EB 5757-7 EN 23

Page 24

Configuration and operation using TROVIS-VIEW interface

6.2 Installing TROVIS-VIEW software

1. Insert the installation CD-ROM to start the installation program.

Once inserted, the CD-ROM usually starts the installation program automatically, de

pending on the configuration of the operating system. If the program does not start auto

matically, double-click setup.exe in the root directory of the CD-ROM in order to install

TROVIS-VIEW.

2. Follow the on-screen prompts and instructions of the installation program.

The TROVIS-VIEW Operator Interface can be used for different SAMSON devices. Note that

the installation program also offers you the option of installing a demo module. To use the

software without restrictions, the software needs to be activated by entering a CD key as fol

lows:

3. After installation, a dialog box will appear, prompting you to enter the CD key, which

you will find on the cover of the original CD-ROM.

Once you have entered the correct CD key and initiated the activation process, a request

code will be automatically generated which contains computer identification details.

Activation

4. The

Internet link to SAMSON’s activation server. Enter the request code and a unique activation code will then be generated and displayed.

(http://support.samson-ag.com: 8082/activate_eng.html)

5. Enter this activation code in TROVIS-VIEW’s

The software is now ready for use without any restrictions in the purchased scope.

dialog box will come up displaying the generated request code and an

Activation

dialog box.

-

-

-

Note!

Refer to the readme.txt file in the root directory of the CD-ROM for further information on in

stallation, software updates and current system requirements.

24 EB 5757-7 EN

-

Page 25

Configuration and operation using TROVIS-VIEW interface

6.3 Starting TROVIS-VIEW and performing settings

You can perform the settings in TROVIS-VIEW either when the actuator is connected (online)

to the PC or without direct connection (offline) (refer to section 7).

Note!

When the device is not connected, the default settings appear on the operator interface or,

alternatively, a stored TROVIS-VIEW file (*.tro) can be loaded and overwritten by selecting

Open in File menu.

1. Start TROVIS-VIEW. The operator interface appears with menubar and toolbar as well as

various folders.

Options

2. In

change the interface language.

Note!

Languages in gray are not available.

3. Select

ter data relevant to the plant, e.g. project

name, plant location, operator.

4. Select

(see sections 8.1 and 8.2) if you want to

load default settings onto the operator

interface.

menu, select

Customer datainEdit

Languages

menu to en

Load Factory DefaultsinEdit

to

-

menu

EB 5757-7 EN 25

Page 26

Configuration and operation using TROVIS-VIEW interface

Properties of data points are indicated by icons on clicking on a folder:

Icon Meaning

Data cannot be changed

Data can be changed

Data point can be executed

Data point is user-defined

Mark to indicate error

Value has exceeded maximum limit

Value has fallen below minimum limit

Connection to the device is interrupted or there is a write protection error

Source of data:

Value has been modified manually

Value has been uploaded from the controller with electric actuator.

In online mode,

Value originates from a stored file

Value has been adopted from memory pen

Value has been changed by the software

X

in the icon indicates a value has been updated.

26 EB 5757-7 EN

Page 27

Configuration and operation using TROVIS-VIEW interface

6.3.1 Activating/deactivating functions

1. Click on

2. Double-click the function block status (0 or I) to change the status of the function.

Right-click on a row to open pop-up window to modify configuration settings:

Modify

Read

Write

Default: ...

Configuration

To change the status of the function block.

Uploads status of the function block from device.

Downloads status of the function block to device.

Resets function block to default setting

(setting in gray to indicate that the status of the

function block is the same as the default setting)

folder to view the function block settings.

EB 5757-7 EN 27

Page 28

Configuration and operation using TROVIS-VIEW interface

6.3.2 Setting parameters

1. Click on

Note! The parameters listed in the screenshot below are default settings.

2. Double-click on the required parameter

to open pop-up window to modify pa

rameter settings.

Parameter

folder to view the parameter settings.

-

28 EB 5757-7 EN

Page 29

Configuration and operation using TROVIS-VIEW interface

Right-click on the required parameter to

open pop-up window to modify parame

ter settings:

Modify

Read

Write

Default: ...

Min ...

Max ...

Opens pop-up window to

modify parameter set

tings.

Uploads parameter value from device.

Downloads parameter value to device.

Resets parameter to default setting (setting in gray to indicate that the

parameter value is the same as the default setting)

Set parameter to the displayed minimum value.

Set parameter to the displayed maximum value.

-

-

6.3.3 Reading operational information

Note!

Operational information can only be read when TROVIS-VIEW is directly connected to the

controller with electric actuator (i.e. in online mode, refer to section 7).

Select

4

Sensors

from the binary input and output.

folder to display actual data measured by the connected sensors as well as

EB 5757-7 EN 29

Page 30

Configuration and operation using TROVIS-VIEW interface

Select the

4

ing the actuator.

Select the

4

Information

Error

subfolder in the

subfolder in the

Diagnostics

Diagnostics

folder to display information concern

folder to display current error messages.

-

30 EB 5757-7 EN

Page 31

Data transmission

7 Data transmission

The TROVIS-VIEW software installed on your PC allows you to configure the controller with

electric actuator either in offline mode (device not connected to a PC) or in online mode (de

vice connected to a PC). To activate online mode, click on the device toolbar. The commu

nication port must be set (see section 7.1)

Online mode (direct data transmission)

The actuator and TROVIS-VIEW are con

nected constantly in online operation. Cur

rent configuration and operating data are

uploaded from the actuator cyclically and

displayed in TROVIS-VIEW. The settings

configured in TROVIS-VIEW can be directly

transferred to the controller with electric ac

tuator.

To enable communication with the PC, connect the serial interface (COM port) to the

serial interface (RJ-12 jack) of the controller

with electric actuator using a SAMSON connecting cable.

In case the PC does not have a COM port, a

USB/RS-232 adapter can be used when

Windows 98, ME, 2000, or XP operating

systems are installed.

-

-

Connecting cable

-

Modular adapter

Memory pen

(also available separately:

order no. 1400-7697)

-

-

Offline mode (indirect data transmission)

There is no constant data communication

between the PC and actuator. Communica

tion must first be established to upload from

the actuator or download data to the actua

tor.

Data can be transferred to the serial

interface over the SAMSON connecting ca

ble or over a memory pen together with a

modular adapter.

A memory pen allows you to simply copy

and download configuration data onto

other devices.

Hardware package

order no. 1400-7704

-

-

-

USB/RS-232 adapter

order no. 8812-0016

Fig. 12 · Accessories for data transmission

EB 5757-7 EN 31

Page 32

Data transmission

Note!

You can only transfer data to the controller with electric actuator after the electrical connec

tion has been made as described in section 3.

7.1 Data transmission between TROVIS-VIEW and the actuator

(connecting cable)

1. Connect the serial port of the PC using

the SAMSON connecting cable to the se

rial interface connection of the actuator.

2. Select

3. Check

4. Click

5. The settings window opens and

CommunicationsinOptions

to open the server settings window. Click

Server settings

Local connection

matically local connect

on OK button to confirm server settings.

Communication

The

Port settings

State: not yet searched appears in the

Automatic detection field.

Click on

TROVIS-VIEW has found the actuator

when State: Device found on ....

appears, click on OK button twice to

confirm settings.

Start

button.

and

boxes and click

window reappears.

button.

button.

Auto-

-

menu

-

32 EB 5757-7 EN

Page 33

Data transmission

7.1.1 Offline operation (indirect data transmission)

In offline mode, there is no constant data communication between the PC and actuator.

Communication must first be established to upload from the actuator and download data to

the actuator.

Downloading data to the actuator:

Download to the deviceinDevice

Select

starts to control after data are downloaded from TROVIS-VIEW.

Uploading data from the actuator:

Select

Upload from deviceinDevice

Uploaded data are indicated in TROVIS-VIEW by the icon.

menu to transfer data to the actuator. The actuator

menu to transfer all the data from the actuator.

Note!

Data transmission can also be performed by clicking the icons in the device toolbar:

click to download data from TROVIS-VIEW to the actuator and, click to upload data

from the actuator and to display them in TROVIS-VIEW.

7.1.2 Online operation (direct data transmission)

The actuator and TROVIS-VIEW are constantly connected in online operation. Current configuration and operating data are uploaded from the actuator cyclically and displayed in

TROVIS-VIEW. Likewise, any settings performed in TROVIS-VIEW are directly transferred to

the actuator.

In the event of a sensor breakage, the interruption in sensor connection is shown without de

lay in the

Activate online operation:

Select

In online mode, in the device toolbar is animated.

Deactivate online operation:

Select

The online mode is cancelled.

Sensors

OnlineinDevice

OnlineinDevice

folder.

menu to activate online mode.

menu while the online mode is activated.

Note!

Alternatively, click in the device toolbar to activate and deactivate online operation.

EB 5757-7 EN 33

-

Page 34

Data transmission

7.2 SAMSON memory pen

The SAMSON memory pen serves as a data carrier and is able to load and store data in its

non-volatile memory.

The memory pen can be loaded with data configured in TROVIS-VIEW and the settings

transferred to one or several controllers with electric actuators. In the same way, the memory

pen can be used to upload data from the actuator allowing you to simply copy the

configuration data from one actuator to another actuator of the same type.

Note!

On inserting a memory pen that is empty or that contains data from another type of device

into the serial interface port of the actuator, the data from the actuator are uploaded to the

memory pen regardless of the status of the memory pen and any other data on the memory

pen will be overwritten.

7.2.1 Data transfer between TROVIS-VIEW and memory pen

1. Plug memory pen (3) together with modular adapter (2) into the serial interface (COM

port) of the PC (Fig. 13).

Fig. 13 · Connecting PC – memory pen

34 EB 5757-7 EN

1 Serial interface

2 Modular adapter

3 Memory pen

Page 35

Data transmission

2. Select

3. Click the

Interface

Start

in the

Memory Pen

menu.

button in Automatic detection field of the dialog box. The computer auto

matically searches for the interface assigned to the memory pen.

Message: “Memory pen found at COM …“

OK

Confirm interface setting by clicking

button.

Downloading data from TROVIS-VIEW to the memory pen

4. Select

5. Click

Download to Memory peninMemory pen

OK

button to start data transmission.

menu

Uploading data from memory pen to TROVIS-VIEW

4. Select

Upload from Memory peninMemory pen

menu to start data transmission.

7.2.2 Data transmission between actuator and memory pen

Perform steps 1 to 3 described in section 7.2.1.

4

3

-

4

Fig. 14 · Type 5757-7 – memory pen

3 Memory pen

4 Serial interface

(RJ 12 jack)

EB 5757-7 EN 35

Page 36

Data transmission

Uploading data from the actuator to

memory pen

4. Select

5. Remove memory pen from PC and plug it

Downloading data from the memory pen

to the actuator

4. Select

5. Remove memory pen from PC and plug it

Modify memory pen status

Memory pen

Check

in the dialog box.

pen

Click

into the serial interface of the actuator

(Fig. 14).

Actuator data are uploaded onto the

memory pen.

The yellow LED under the serial interface

blinks twice several times to indicate that

data transmission is in progress.

Data transmission is completed when the

LED is illuminated continuously.

Remove the memory pen from the actuator.

menu.

Automatically write to memory

OK

button to confirm.

Modify memory pen status

Memory pen

Check

in the dialog box.

pen

Click

into the serial interface of the actuator

(Fig. 14).

Data are downloaded from the memory

pen into the actuator.

The yellow LED under the serial interface

blinks several times to indicate that data

transmission is in progress.

Data transmission is completed when the

LED is illuminated continuously.

Remove the memory pen from the actuator.

menu.

Automatically read from memory

OK

button to confirm.

in

in

36 EB 5757-7 EN

Page 37

Data transmission

7.2.3 Copy function

The memory pen can be used to copy setting data to other Type 5757-7 Actuators as soon

as the data from the actuator have been transferred to the memory pen (indicated by the yel

low LED blinking twice several times).

first data transmission from the actuator.

Automatically write to memory pen

is reset after the

7.2.4 Manual operation

Caution!

Activate the handwheel (red knob) only when the actuator is de-energized.

The controller with electric actuator can be set to manual operation using the memory pen

while the control operation is running:

Perform steps 1 to 3 described in section 7.2.1.

4

4. Select

5. Check either

6. Click

7. Remove memory pen from PC and plug it

8. After removing the memory pen from the

Modify manual operation status

Memory pen

tracts

into the serial interface of the actuator

(Fig. 14).

The valve stem extends or retracts ac

cording to the option selected previously.

actuator, the actuator returns to its nor

mal control state.

menu.

Stem extendsorStem re-

in the dialog box.

OK

button to confirm.

in

-

-

-

Reset manual operation status in memory pen

1. Plug memory pen (3) together with modular adapter (2) into the serial interface (COM

port) of the PC (Fig. 13).

2. Check

3. Click

No manual operation

OK

button to confirm.

in the dialog box.

EB 5757-7 EN 37

Page 38

Appendix

8 Appendix

8.1 Function block list

The function blocks F01 to F11 have the following listed function.

F = Function block WE = Default setting 0 = OFF, 1 = ON

F

Function

01 Control mode 1 0 – Fixed set point control→Section 5.2

02 Selecting the reference

variable

03 Direction of stem action 0 0 – SAMSON globe valve→Section 5.9

04 Delayed outdoor

temperature

05 Potentiometer input 0 0 – Inactive, binary input active→Section 5.3.1

06 Resistance range of

potentiometer

07 Function of potentiometer 0 0 – Heating characteristic level shift→Section 5.1.1

08 Function of binary input 0 0 – BI short-circuited: OFF w. frost protection→Section 5.3.1

09 Function of binary output 0 0 – BO as circulation pump control→Section 5.6

10 Anti-block protection of

pumps

11 Return flow temperature

sensor

WE

Comment

1 – Control with reference variable→Section 5.1

0 0 – Outdoor sensor→Section 5.1

1 – Room sensor→Section 5.2.1

1 – SAMSON three-way valve→Section 5.9

0 0 – Without delay

1 – With delay→Section 5.1.3

1 – Active→Section 5.1.1, 5.3.2, 5.3.3

0 0 – Type 5257-7 Room Panel (1000 … 1100 Ohm)

1 0 – No anti-block protection

1 0 – OFF

Section 5.3.2, 5.3.3

→

1 – Type 5257-2 w. remote adjuster (1000 … 2000 Ohm)

Section 5.1.1

→

1 – Gradient shift→Section 5.1.1

1 – BI short-circuited: Reduced operation→Section 5.3.1

1 – BO as heat demand→Section 5.7

1 – When pumps are deactivated: switched on every 24 h

for 1 min→Section 5.6

1 – ON→Section 5.5

38 EB 5757-7 EN

Page 39

8.2 Parameter list

The parameters have the setting ranges as listed below.

P = Parameter WE = Default setting

Appendix

P

Parameter

01 Flow temperature set point 70 °C 0 to 150 °C

02 Flow temperature set-back in reduced operation 15 K 0 to 50 K

03 Minimum flow temperature 20 °C 0 to 150 °C

04 Maximum flow temperature 120 °C 0 to 150 °C

05 Heating characteristic gradient 1.6 0.2 to 3.2

06 Heating characteristic level 0 K –30 to 30 K

07 Gradient shift range via potentiometer 1.0 0.0 to 1.5

08 Level shift range via potentiometer 15 K 0 to 30 K

09 Kp flow temperature control 2.0 0.1 to 50.0

10 Tn flow temperature control 120 s 0 to 999 s

11 Ty actuator transit time at rated travel 25 s 10 to 240 s

12 Tr flash adaptation 10 min 0 to 100 min

13 Max. return flow temperature 50 °C 10 to 90 °C

14 Kp return flow temperature limitation 1.0 0.1to 50.0

15 Tn return flow temperature limitation 400 s 0 to 999 s

16 Delayed time for outdoor temperature 3.0 °C/h 1.0 to 6.0 °C/h

17 Outdoor temperature limit at rated operation 22 °C 0 to 50 °C

18 Outdoor temperature limit at reduced operation 15 °C 0 to 50 °C

19 Room temperature limit at rated operation 20 °C 10 to 40 °C

20 Room temperature limit at reduced operation 15 °C 10 to 40 °C

21 Max. room temperature boost 1 K 1 to 6 K

22 Pump lag time 5 min 1 to 999 min

WE

Setting range

EB 5757-7 EN 39

Page 40

Appendix

8.3 Customer settings

Function blocks Parameters

FWE

01 1 01 70 °C 0 to 150 °C

02 0 02 15 K 0 to 50 K

03 0 03 20 °C 0 to 150 °C

04 0 04 120 °C 0 to 150 °C

05 0 05 1.6 0.2 to 3.2

06 0 06 0 K –30 to 30 K

07 0 07 1.0 0.0 to 1.5

08 0 08 15 K 0 to 30 K

09 0 09 2.0 0.1 to 50.0

10 1 10 120 s 0 to 999 s

11 1 11 25 s 10 to 240 s

Setting

performed P WE

12 10 min 0 to 100 min

13 50 °C 10 to 90 °C

14 1.0 0.1 to 50.0

15 400 s 0 to 999 s

16 3.0 °C/h 1.0 to 6.0 °C/h

17 22 °C 0 to 50 °C

18 15 °C 0 to 50 °C

19 20 °C 10 to 40 °C

20 15 °C 10 to 40 °C

21 1 K 1 to 6 K

22 5 min 1 to 999 min

Setting

performed

Setting range

40 EB 5757-7 EN

Page 41

EB 5757-7 EN 41

Page 42

Index

Index

A

Accessories

Communication . . . . . . . . . . . . . . . . . 6

Heating applications . . . . . . . . . . . . . 6

Activation code. . . . . . . . . . . . . . . . . . . 24

Actuator stem . . . . . . . . . . . . 5, 7, 21 - 22

Anti-block protection . . . . . . . . . . . . . . . 20

C

Contact sensor (Type 5267-2)

Dimensional drawing. . . . . . . . . . . . 12

Control

Fixed set point. . . . . . . . . . . . . . . . . 16

Outdoor temperature compensated. . 13

Controller with electric actuator

Design and principle of operation. . . . 5

Dimensional diagram. . . . . . . . . . . . 11

Copy function with memory pen. . . . . . . 37

Coupling nut. . . . . . . . . . . . . . . . . . . . 5, 7

Customer data . . . . . . . . . . . . . . . . . . . 25

Customer settings . . . . . . . . . . . . . . . . . 40

D

Data transmission . . . . . . . . . . . . . 31 - 37

Accessories . . . . . . . . . . . . . . . . . . . 31

Offline mode. . . . . . . . . . . . . . . 31, 33

Online mode. . . . . . . . . . . . . . . 31, 33

with connecting cable . . . . . . . . . . . 32

with memory pen. . . . . . . . . . . . . . . 34

Delayed outdoor temperature

adaptation . . . . . . . . . . . . . . . . . . . . . . 16

E

Electrical connection . . . . . . . . . . . . . . . . 8

Wiring diagram . . . . . . . . . . . . . . . 10

Electrical connections

Wiring diagram . . . . . . . . . . . . . . . . 9

External request for heat demand. . . . . . 20

F

Fixed set point control . . . . . . . . . . . . . . 16

Room temperature influence . . . . . . . 16

Flow temperature . . . . . . . . . . . . . . . . . 13

Forced operation of pump . . . . . . . . . . . 20

Frost protection. . . . . . . . . . . . . . . . . . . 19

Function block list . . . . . . . . . . . . . . 16, 38

H

Handwheel. . . . . . . . . . . . . . . . . . . . . . . 7

Hardware package . . . . . . . . . . . . . . 6, 31

Hardware requirements. . . . . . . . . . . . . 23

Heating characteristic . . . . . . . . . . . . . . 13

Gradient. . . . . . . . . . . . . . . . . . . . . 13

Level. . . . . . . . . . . . . . . . . . . . . . . . 13

I

Installating the software . . . . . . . . . . . . . 24

M

Manual operation . . . . . . . . . . . . . . . . . 37

Memory pen. . . . . . . . . . . . . . . . . . . . . . 6

Copy function . . . . . . . . . . . . . . . . . 37

Downloading data

Actuator . . . . . . . . . . . . . 36

TROVIS-VIEW . . . . . . . . . . 35

Manual operation . . . . . . . . . . . . . . 37

Uploading data

TROVIS-VIEW . . . . . . . . . . 35

Mounting position . . . . . . . . . . . . . . . . . . 7

O

Offline mode . . . . . . . . . . . . . . . . . . . . 33

Online mode . . . . . . . . . . . . . . . . . . . . 31

Operating direction

Globe valve . . . . . . . . . . . . . . . . . . 21

Three-way valve . . . . . . . . . . . . . . . 22

Operating mode switchover

Binary input . . . . . . . . . . . . . . . . . . 18

Binary input on room panel . . . . . . . 19

42 EB 5757-7 EN

Page 43

Room panel. . . . . . . . . . . . . . . . . . . 19

Outdoor sensor (Type 5227-2)

Dimensional diagram. . . . . . . . . . . . 12

Outdoor temperature compensated control

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Outdoor temperature adaptation . . . 16

Override using potentiometer . . . . . . 15

Outdoor temperature limit . . . . . . . . . . . 15

P

Parameter list . . . . . . . . . . . . . . . . . . . . 39

Plug stem . . . . . . . . . . . . . . . . . . . . . . . . 5

Potentiometer input . . . . . . . . . . . . . . . . . 9

Pump anti-block protection. . . . . . . . . . . 20

R

Request for heat demand (external) . . . . 20

Return flow temperature limitation . . . . . 19

Room panel (Type 5257-7)

Dimensional drawing. . . . . . . . . . . . 12

Electrical connection . . . . . . . . . . . . 10

Room sensor (Type 5257-2). . . . . . . . . . . 8

Dimensional drawing. . . . . . . . . . . . 12

Electrical connection . . . . . . . . . . . . . 9

Permissible temperatures/degree of pro-

tection . . . . . . . . . . . . . . . . . . . . . . . 6

Room temperature influence

Fixed set point control . . . . . . . . . . . 16

Outdoor temperature compensated

control . . . . . . . . . . . . . . . . . . . . . . 15

RS-232 adapter . . . . . . . . . . . . . . . . . . 31

T

Three-point stepping control. . . . . . . . . . 21

Toolbar . . . . . . . . . . . . . . . . . . . . . . . . 25

Travel indicator. . . . . . . . . . . . . . . . . . . . 5

TROVIS-VIEW. . . . . . . . . . . . . . . . . . . . . 6

Icons. . . . . . . . . . . . . . . . . . . . . . . . 26

Operation . . . . . . . . . . . . . 26 - 27, 29

Starting and setting . . . . . . . . . . . . . 25

System requirements . . . . . . . . . . . . 23

V

Valve spring . . . . . . . . . . . . . . . . . . . . . . 5

S

Serial interface connection. . . . . . . . . . . 35

Summer mode . . . . . . . . . . . . . . . . . . . 15

System requirements . . . . . . . . . . . . . . . 23

EB 5757-7 EN 43

Page 44

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 5757-7 EN

S/Z 2005-10

Loading...

Loading...