Page 1

EB 5206 EN

Translation of original instructions

Type 5343 Safety

Temperature Monitor

(STM)

Type5347 Double

Thermostat (TR/STL)

Type5344 Temperature

Regulator (TR)

Type5348 Double

Thermostat (TR/STM)

Thermostats

Type5343 · Type5344 · Type5345

Type5347 · Type5348 · Type5349

Edition October 2017

Type 5345 Safety

Temperature Limiter (STL)

Type5349 Double

Thermostat (STM/STL)

Page 2

Note on these mounting and operating instructions

These mounting and operating instructions assist you in mounting and operating the device

safely. The instructions are binding for handling SAMSON devices.

Î For the safe and proper use of these instructions, read them carefully and keep them for

later reference.

Î If you have any questions about these instructions, contact SAMSON‘s After-sales Service

Department (aftersalesservice@samson.de).

The mounting and operating instructions for the devices are included in

the scope of delivery. The latest documentation is available on our website

at www.samson.de > Service & Support > Downloads > Documentation.

Denition of signal words

!

DANGER

Hazardous situations which, if not avoided,

will result in death or serious injury

!

WARNING

Hazardous situations which, if not avoided,

could result in death or serious injury

2 EB 5206 EN

!

NOTICE

Property damage message or malfunction

Note

Additional information

Tip

Recommended action

Page 3

Contents

1 General safety instructions .............................................................................4

2 Design and principle of operation ..................................................................5

2.1 Typetesting ....................................................................................................5

2.2 Technical data ...............................................................................................6

2.3 Mounting accessories .....................................................................................9

3 Installation ..................................................................................................10

3.1 Mounting position ........................................................................................10

3.2 Contact thermostat .......................................................................................11

3.3 Mounting the thermowell ..............................................................................11

3.3.1 Wall mounting with the capillary tube to the thermowell ..................................12

3.3.2 Mounting on tanks or in pipes .......................................................................12

4 Electrical connection ....................................................................................14

5 Operation ...................................................................................................15

5.1 Temperature regulator (TR) ............................................................................15

5.2 Safety temperature monitor (STM) .................................................................15

5.3 Safety temperature limiter (STL) .....................................................................15

7 Lead sealing ................................................................................................16

6 Dimensions in mm .......................................................................................16

8 EU declarations of conformity ......................................................................20

EB 5206 EN 3

Page 4

General safety instructions

1 General safety instructions

For your own safety, follow these instructions concerning the mounting, start up, and opera-

tion of the thermostat:

− The thermostat is to be mounted, started up or operated only by trained and experienced

personnel familiar with the product.

According to these mounting and operating instructions, trained personnel refers to

individuals who are able to judge the work they are assigned to and recognize possible

dangers due to their specialized training, their knowledge and experience as well as

their knowledge of the applicable standards.

− Upon installation of the electric cables and connecting the device, observe the VDE

regulations as well as the regulations of your local power supplier. Make sure all

electrical connections are installed only by trained and experienced personnel.

To avoid damage to any equipment, the following also applies:

− Proper shipping and storage are assumed.

Note

The device with a CE marking fullls the requirements of the Directives 2014/30/EU and

2014/30/EU, 2014/35/EU and 2011/65/EU.

The EU declarations of conformity are included in the Appendix of these instructions.

4 EB 5206 EN

Page 5

Design and principle of operation

2 Design and principle of oper-

ation

The thermostats are equipped with a

changeover contact. When the thermostat is

triggered, the connection between connections 1 and 2 are interrupted and the connections 1 and 4 are connected (see Fig.5

on page14).

Safety temperature monitor (STM)

A snap-action switch in the STM is triggered

when the temperature at the temperature

sensor rises above the adjusted set point.

When the temperature falls below the set

point by approximately 8K, the switch re-

turns to its original position.

The contact opens or closes when the temperature at the temperature sensor falls below –20°C. It automatically closes or opens

again when the temperature at the temperature sensor rises above –20°C.

The STM is triggered when the capillary tube

breaks.

Temperature regulator (TR)

The snap-action switch is triggered when the

temperature at the temperature sensor rises

above the adjusted set point. When the temperature falls below the set point by approximately 4K, the switch returns to its original

position.

Safety temperature limiter (STL)

The snap-action switch is triggered and

locked when the temperature at the temperature sensor rises above the adjusted set

point. When the temperature falls below the

set point by approximately 10%, the

snap-action switch can be unlocked manual-

ly.

The contact opens or closes when the temperature at the temperature sensor falls below –20°C. It automatically closes or opens

again when the temperature at the temperature sensor rises above –20°C.

The contact opens or closes when the system

fails. It is not possible to unlock the device.

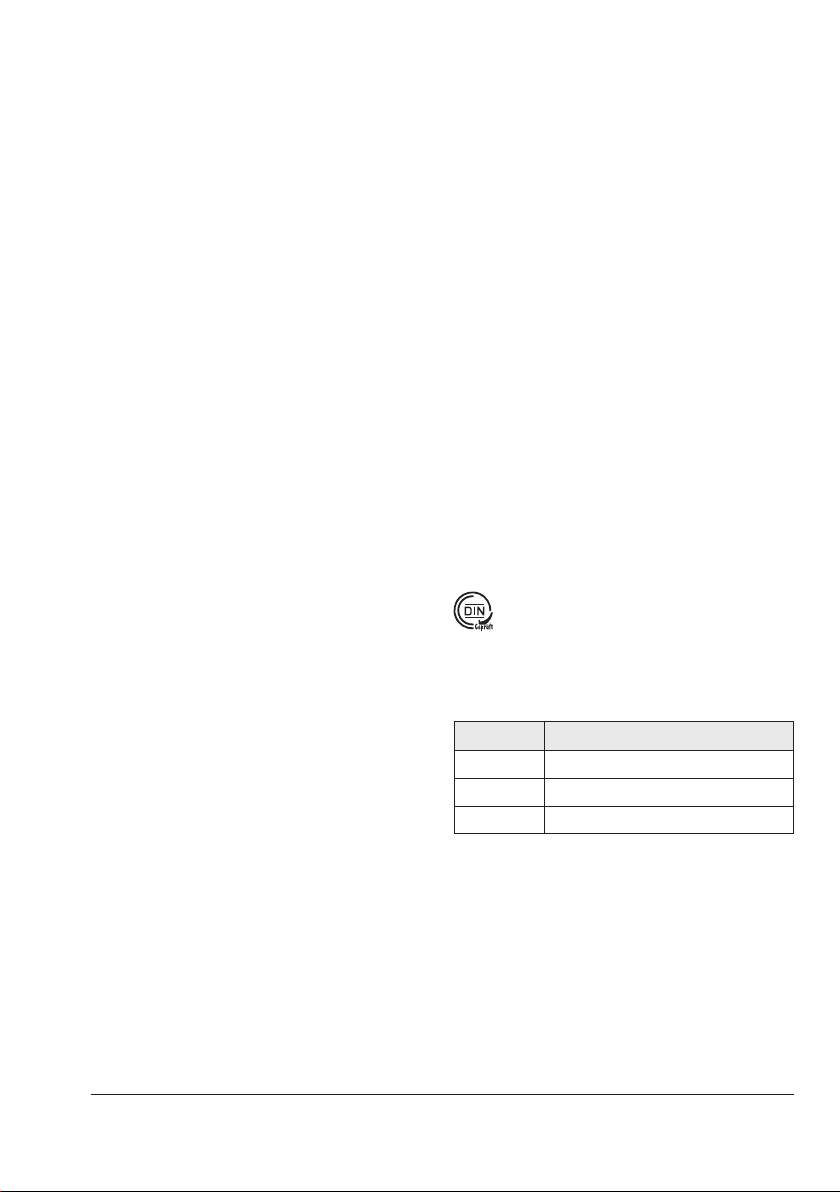

2.1 Typetesting

The thermostats are tested by the German

Technical Inspectorate (TÜV) according to

DINEN14597.

Type DIN register number

5343 STW1209

5344 TR1208

5345 STB1207

EB 5206 EN 5

Page 6

General safety instructions

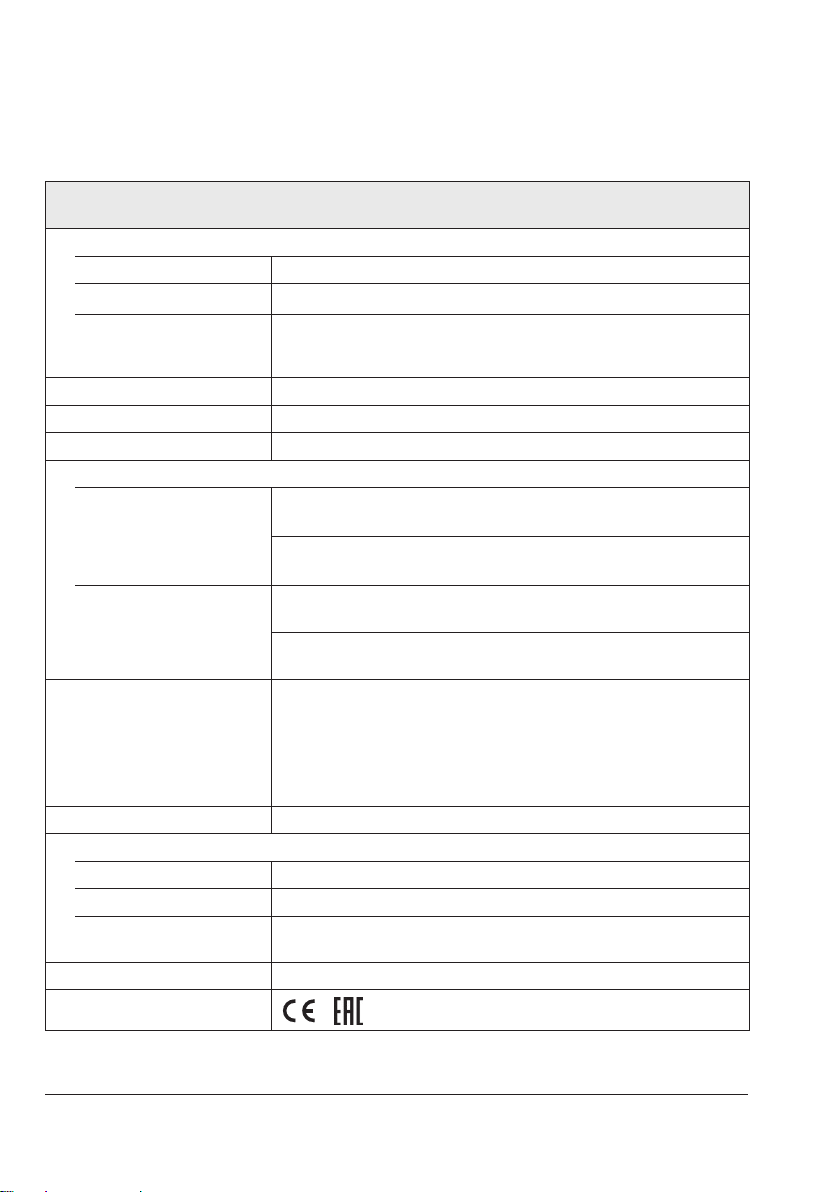

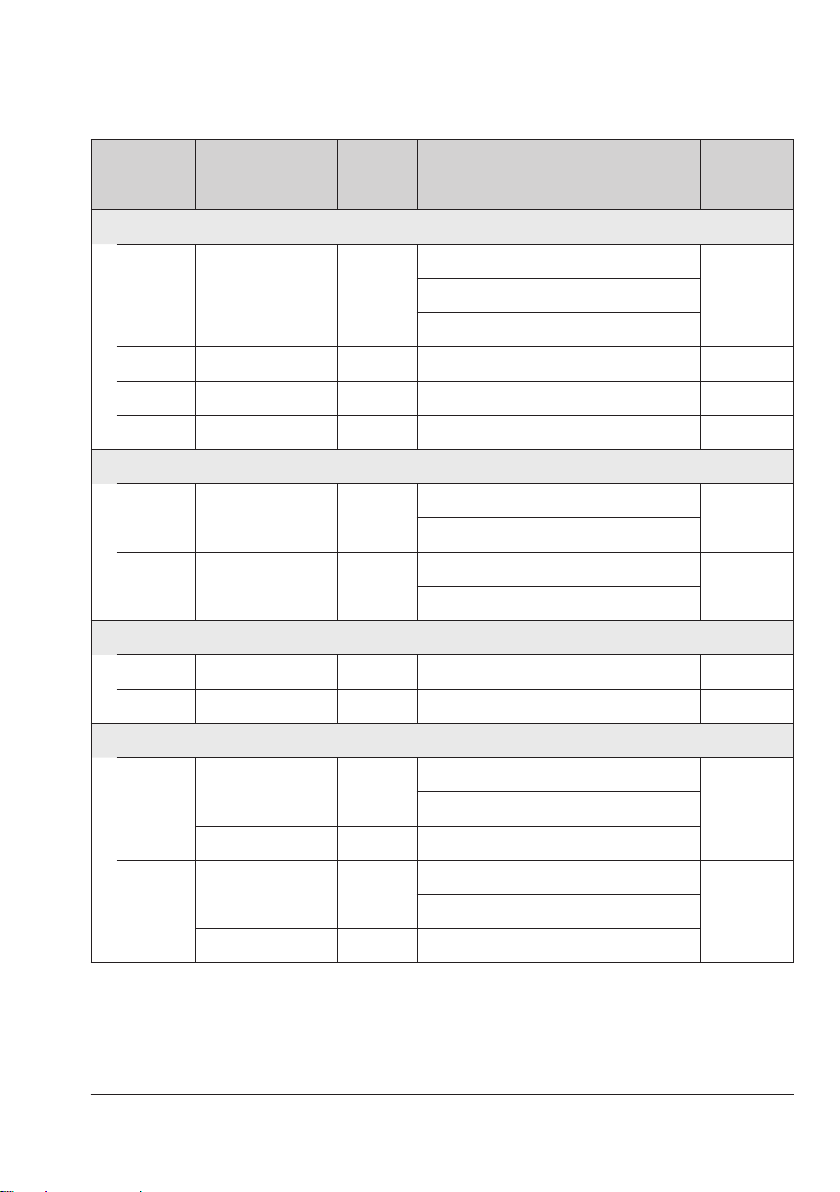

2.2 Technical data

Single thermostats: Type5343 (STM), Type5344 (TR), Type5345 (STL)

Double thermostats: Type5347 (TR/STL), Type5348 (TR/STM), Type5349 (STM/STL)

Permissible ambient temperature

Transportation and storage –30 to +80°C

Service Max. 80°C

Max. pipe temperature when

mounted as a contact

thermostat

Degree of protection IP 54 according to EN60529

Cable entry M20x1.5 cable gland, suitable for 6 to 12mm cable diameter

Minimum switching capacity AC/DC = 24V, 100mA

Maximum switching capacity

Temperature regulator (TR),

safety temperature monitor

(STM)

Safety temperature limiter

(STL)

Inuence of mean ambient

temperature based on the set point

Connection Spring-cage terminals, 0.75 to 2.5mm² wire cross-section

Materials

Bottom section of the housing PA (reinforced)

Housing cover ABS with window (PMMA)

Temperature sensor, capillary

tube

Weight Single thermostat approx. 0.225kg · Double thermostat approx. 0.45kg

Compliance

Max. 120°C

With 230VAC +10%

With 230VDC +10%

With 230VAC +10%

With 230VDC +10%

A shift of the switching point arises when the ambient temperature at the

knob and at the capillary tube deviates from the calibration ambient temperature of +22°C:

Higher ambient temperature g Lower switching point

Lower ambient temperature g Higher switching point

This inuence is minimized by temperature compensation.

Cu (copper)

1)

·

NC contact: 16A (2.5); cos φ = 1 (0.6)

NO contact: 6.3A (2.5); cos φ = 1 (0.6)

NC contact: 0.25A

NO contact: 0.25A

NC contact: 16A (2.5); cos φ = 1 (0.6)

Signal contact: 2A (2.5); cos φ = 1 (0.4)

NC contact: 0.25A

Signal contact: 0.25A

1)

No EAC compliance for Type5349

6 EB 5206 EN

Page 7

General safety instructions

Type Set point range

Safety temperature monitors (STM)

5343-1 0 to 60°C 8K

5343-2 40 to 100°C 8K Range: 40 to 100 °C 0K –8.5K 125°C

5343-3 70 to 130°C 8K Range: 70 to 130 °C 0K –8.5K 155°C

5343-4 35 to 95°C 8K Range: 35 to 95 °C 0K –8.5K 120°C

Temperature regulators (TR)

5344-1 0 to 120°C 3K

5344-2 20 to 150°C 4K

Safety temperature limiters (STL)

5345-1 70 to 130°C 8K Range: 70 to 130 °C +8.5K –8.5K 155°C

5345-2 30 to 90°C 8K Range: 30 to 90 °C 0K –8.5K 115°C

Switching dif-

ferential

Switching point accuracy

Range: 0 to 25 °C 0K –8.5K

Range: 35 to 60 °C 0K –8.5K

Range: 0 to 80 °C +7.2K –7.2K

Range: 80 to 120 °C +3.6K –3.6K

Range: 20 to 106 °C +7.8K –7.8K

Range: 106 to 150 °C +3.9K –3.9K

Max.

medium

temperature

85°CRange: 25 to 35 °C 0K –6.0K

145°C

175°C

Double thermostats (TR/STL)

5347-1

TR: 0 to 120°C 3K

STL: 70 to 130°C 8K Range: 70 to 130 °C 0K –8.5K

TR: 0 to 120°C 3K

5347-2

STL: 30 to 90°C 8K Range: 30 to 90 °C 0K –8.5K

Range: 0 to 80 °C +7.2K –7.2K

145°CRange: 80 to 120 °C +3.6K –3.6K

Range: 0 to 80 °C +7.2K –7.2K

115°CRange: 80 to 120 °C +3.6K –3.6K

EB 5206 EN 7

Page 8

General safety instructions

Type Set point range

Double thermostats (TR/STM)

TR: 0 to 120°C 3K

5348-1

STM: 70 to 130°C 8K Range: 70 to 130 °C 0K –8.5K

TR: 0 to 120°C 3K

5348-2

STM: 40 to 100°C 8K Range: 40 to 100 °C 0K –8.5K

Double thermostats (TR/STM)

STM: 70 to 130°C

5349-1

STL: 30 to 90°C Range: 30 to 90 °C 0K –8.5K

Switching dif-

ferential

8K

Switching point accuracy

Range: 0 to 80 °C +7.2K –7.2K

Range: 0 to 80 °C +7.2K –7.2K

Range: 70 to 130 °C 0K –8.5K

Max.

medium

temperature

145°CRange: 80 to 120 °C +3.6K –3.6K

125°CRange: 80 to 120 °C +3.6K –3.6K

145°C

8 EB 5206 EN

Page 9

General safety instructions

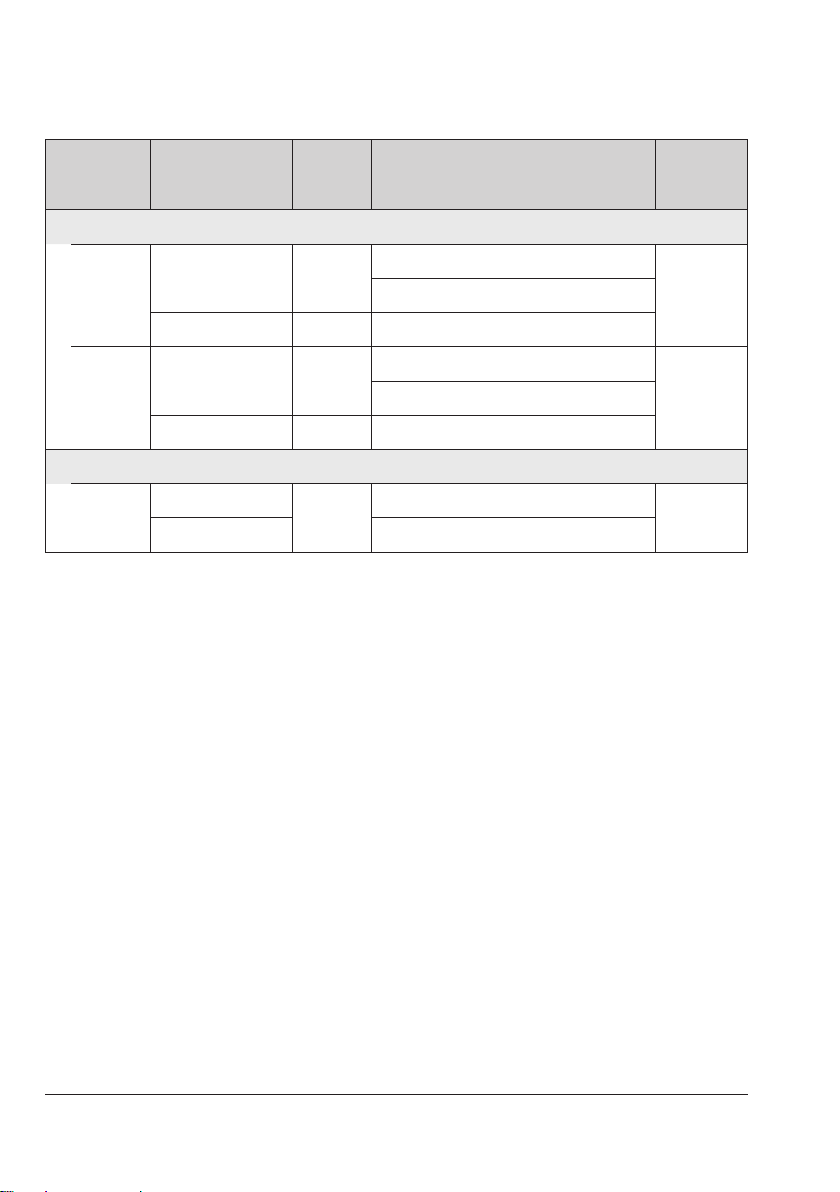

2.3 Mounting accessories

Thermowells

The thermostat is supplied without a thermowell. The following thermowells are available for

single and double thermostats as accessories:

Thermowell for single thermostat Max. pressure at 150°C Order no.

Nickel-plated brass · CuZn (2.0401)

100x8mm 48bar 1400-9844

150x8mm 48bar 1400-9845

200x8mm 48bar 1400-9846

CrNiMo steel (1.4571)

100x8mm 88bar 1400-9848

150x8mm 88bar 1400-9849

300x8mm 88bar 1400-9850

Thermowell for double thermostat Max. pressure at 150°C Order no.

Nickel-plated brass · CuZn (2.0401)

100 x (2x 8) mm 48bar 1400-9901

150 x (2x 8) mm 48bar 1400-9851

CrNiMo steel (1.4571)

100x15mm 48bar 1402-0340

150x15mm 48bar 1400-9853

300x15mm 48bar 1400-9854

Note

The scope of delivery of the thermowell includes:

− A clip to fasten the capillary tube to the thermowell (see section3.3.1)

− A small metal plate with screw to attach the thermostat to the thermowell (see sec-

tion3.3.2)

Strap

Strap for mounting the contact thermostat (15 to 100mm

Order no.: 1400-9865

pipe diameter)

EB 5206 EN 9

Page 10

Installation

2

5a

6

3 Installation

!

NOTICE

Inadequate protection against water jets

through insufcient sealing.

− Do not remove the seals in the housing

(1) and on the set point adjuster of the

temperature regulator (4). See Fig.1.

− The thermostat must only be operated

with an inserted seal (6). See Fig.1.

!

NOTICE

Risk of thermostat malfunction due to

measuring uid escaping upon breakage of

the capillary tube.

− Do not bend or cut the capillary tube.

− Do not use a smaller bending radius

than 5mm.

Table 1: Properties of the measuring uid

Dangerous reaction No

Ignition temperature 375°C

Water hazard Class 1

Slightly contaminating

Toxicological specications

Irritant No

Health hazard No

Toxic No

3.1 Mounting position

Contact thermostat

The thermostat must not be suspended with

the bottom of the housing (containing the

sensor) facing upwards.

Thermostat with thermowell

The valve can be mounted in any desired

position.

1 Thermostat

2 Sensor

3 Capillary tube

4 Set point adjuster (TR only)

5a Spring for unlocking (STL only)

6 Seal

Necessary seals for degree of

protection IP54

Fig.1: Necessary seals for degree of protection IP54

3

1

TR

4

10 EB 5206 EN

Page 11

Installation

1

8

3.2 Contact thermostat

3.3 Mounting the thermowell

Single thermostats can be mounted onto

pipes with diameters between 15 and

100mm. A strap is required in this case (see

section2.3, Mounting accessories).

Note

The sensors of double thermostats share the

same thermowell. See section2.3.

1. Insert seal (6) as shown in Fig.2.

2. Thread the strap (8) behind the sensor

holder at the back of the housing (1).

3. Use the strap to attach the thermostat to

the pipe.

4. Unscrew the front cover of the thermo-

stat.

5. Connect the wiring as described in sec-

Before fastening the thermostat, uncoil the

capillary tube to the required length:

− For wall mounting, the required length

depends on the required capillary tube

and length of the thermowell

− For mounting the thermostat on tanks/in

pipes, the required length depends on

the length of the thermowell

tion4.

6. Screw the front cover back onto the ther-

mostat.

TR: Place the set point adjuster onto the tem-

perature regulator.

!

NOTICE

Risk of thermostat malfunction due to measuring uid escaping upon breakage of the capillary tube.

Do not pull at the sensor on uncoiling the

capillary tube.

1. Unscrew the front cover of the thermostat.

2. Detach the sensor from the back of the

6

thermostat.

3. Route the sensor through the back of the

housing to the front.

2

4. Uncoil the capillary to the required

length (Fig.4a).

5. Route the sensor again through the back

1 Thermostat

2 Sensor

6 Seal

8 Strap

Fig.2: Mounting a contact thermostat

of the housing (Fig.4a).

6. Insert seal (6) as shown in Fig.4b or

Fig.4c.

Î Proceed as described in section3.3.1 or

in section3.3.2 depending on how the

thermostat is to be mounted.

EB 5206 EN 11

Page 12

Installation

95

42.4 95.4

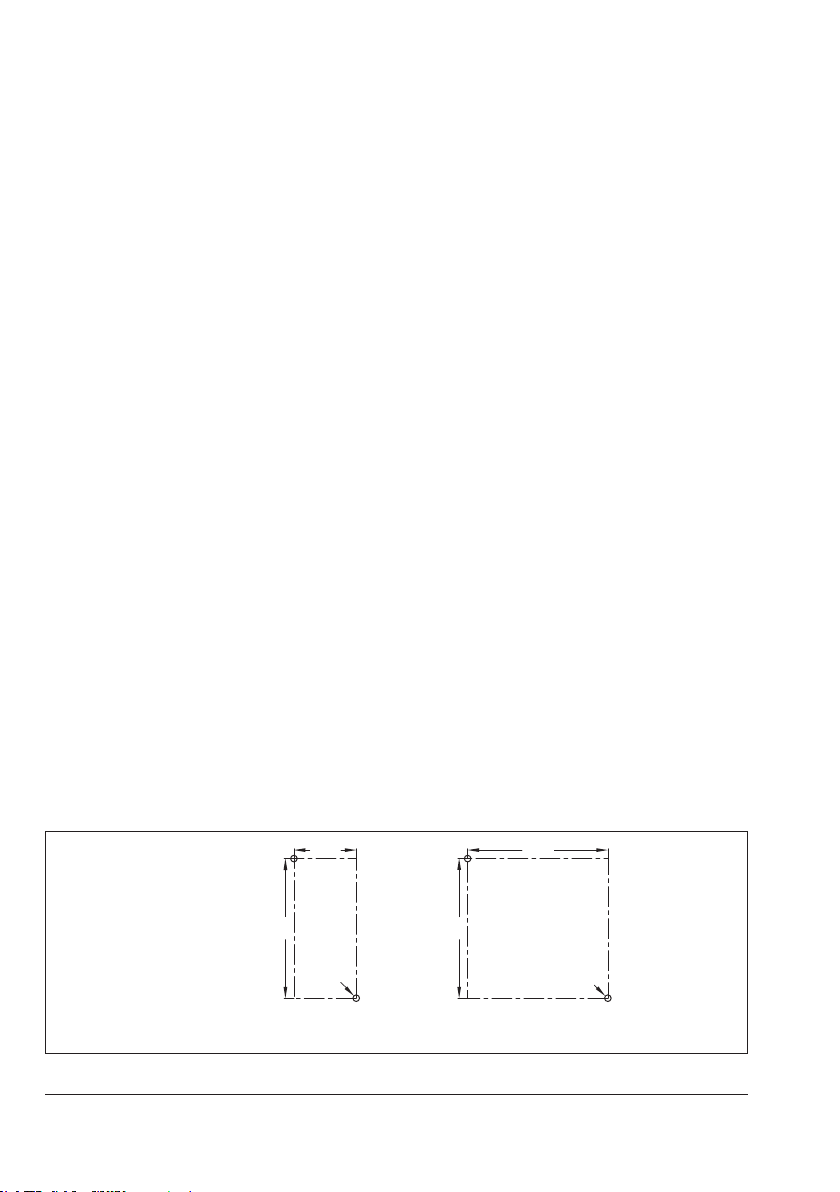

3.3.1 Wall mounting with the capillary tube to the thermowell

The thermostats are fastened to the wall using two screws (not included in the scope of

delivery).

7. Drill holes in wall as shown in Fig.3.

8. Insert the seal (6).

9. Fix the capillary tube in the notch at the

side of the thermostat housing or let it

run down the middle (Fig.4b).

10. Fasten the back of the housing (1) using

two screws to the wall.

11. Screw the thermowell (7) into the pipe or

tank.

12. Push the sensor (2) as far as it will go in-

to the thermowell (7).

13. Fasten the capillary tube (3) to the ther-

mowell (7) using the supplied clip (7a).

14. Connect the wiring as described in sec-

tion4.

15. Screw the front cover back onto the ther-

mostat.

TR: Place the set point adjuster onto the tem-

perature regulator.

3.3.2 Mounting on tanks or in pipes

The thermostats are fastened to the thermowells which are screwed into place.

7. Insert the seal (6).

8. Screw the thermowell (7) into the pipe or

tank.

9. Insert the small metal plate (7b) at the

back of the housing (1) and secure in

place with the screw (7c).

10. Push the sensor (2) as far as it will go in-

to the thermowell (7), making sure that

the round hole at the back of the housing

(1) rests on the collar on the thermowell.

11. Push the thermostat approx. 2mm

lengthways toward the SAMSON logo to

allow the thermowell to engage.

12. Tighten screw (7c) until the housing is

xed into place on the thermowell.

13. Connect the wiring as described in sec-

tion4.

14. Screw the front cover back onto the ther-

mostat.

TR: Place the set point adjuster onto the tem-

perature regulator.

Single thermostat Double

Ø 4.5

Fig.3: Drill templates

12 EB 5206 EN

thermostat

95

Ø 4.5

Page 13

Fig.4a: Uncoiling the capillary tube

7

6

2

1

Installation

Fig.4b Wall mounting with the capillary tube to the

Fig.4c Mounting on tanks or in pipes

thermowell

7c

7a 3

6

7b

7

2

1

1 Thermostat

2 Sensor

3 Capillary tube

6 Seal

7 Thermowell

7a Clip

7b Metal plate

7c Screw

Fig.4: Mounting the thermowell

EB 5206 EN 13

Page 14

Electrical connection

4 Electrical connection

!

DANGER

Risk of electric shock.

− Upon installation of the electric cables,

you are required to observe the regulations concerning low-voltage installations

according to DINVDE0100 as well as

the regulations of your local power supplier.

− Only use a suitable power supply which

guarantees that no dangerous voltages

reach the device in normal operation

and in the event of a fault in the system

or any other system parts.

− Connect the grounding conductor to the

PE terminal.

− The wires of double thermostats are routed

through the opening in the intermediate

wall to the second thermostat. Seal the

opening not used for cable entry with a

blanking cap.

Cable entry

Route the wires through the cable gland

(M20x1.5) into the inside of the thermostat.

The spring-clamp terminals are designed for

a wire cross-section of 0.75 to 2.5mm².

Wiring

Open the thermostat housing and wire the

thermostat according to Fig.5:

− Rigid wire ends: strip 11 to 13mm insu-

lation off the cable and place it into the

terminal point (

) as far it will go.

− Flexible wire ends without ferrules: use a

slotted screwdriver to keep the spring

open (in

the terminal point (

) and place the wire ends into

) as far they will

go.

− Flexible wire ends with ferrules: t

ferrules to the wire ends. Refer to

EN60947-1. Use a suitable crimping

tool.

Place the wire ends into the terminal point

(

) as far they will go.

Note

The wire ends can be pulled out by holding

the spring open with a slotted screwdriver (in

).

NC contact

NO contact

Temperature regulator (TR)

Safety temperature monitor

Safety temperature limiter

Fig.5: Electrical connection

1 – 2

1 – 4

(STM)

(STL)

24 1

1

42

1

42

14 EB 5206 EN

Page 15

Operation

4a

5a

5 Operation

5.1 Temperature regulator (TR)

Adjust the set point at the set point adjuster

(4).

Limiting the set point range

The lower range value and upper range value of the set point range can be limited.

4

4 Set point adjuster

4a Pin to limit the set point range

5.2 Safety temperature monitor (STM)

Open the thermostat housing and adjust the

set point using a at-blade screwdriver.

5.3 Safety temperature limiter (STL)

Open the thermostat housing and adjust the

set point using a at-blade screwdriver.Open

the thermostat housing and adjust the set

point using a at-blade screwdriver.

Unlocking safety temperature limiters

Note

The safety temperature limiter can only be

reset after the temperature has fallen below

the adjusted limit by approximately 10%.

Use a at-blade screwdriver to unlock the

thermostat.

1. Turn the set point adjuster (4) to a value

within the required temperature range.

2. Pull the set point adjuster (4) off the tem-

perature regulator.

3. Break off the pin (4a).

4. Insert the pin (4a) at the point where the

temperature is to be limited (min./max.

temperature).

5. Place the set point adjuster back on the

temperature regulator.

EB 5206 EN 15

1. Unscrew the screw lid (5).

2. Use a at-blade screwdriver to move the

spring (5a) from the bottom to the top as

far as it will go.

5

5 Screw lid

5a Spring for unlocking

Page 16

Lead sealing

16

30

Ø 6

95

**

Ø8

5

300

7 Lead sealing

!

NOTICE

Impaired thermostat functioning due to incorrectly attached lead-seal.

Only lead-seal in the gray-colored area.

Note

Drill the holes for lead sealing. The lead-seal

is not included in the scope of delivery.

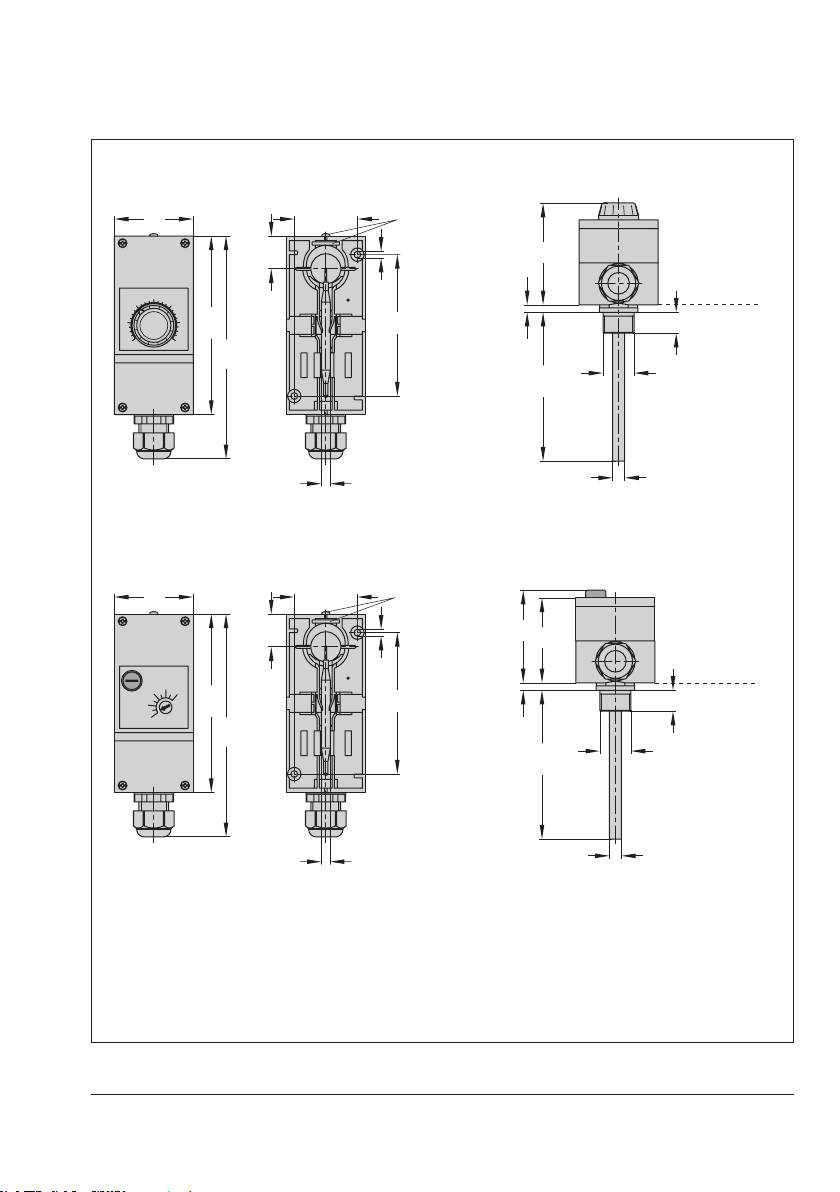

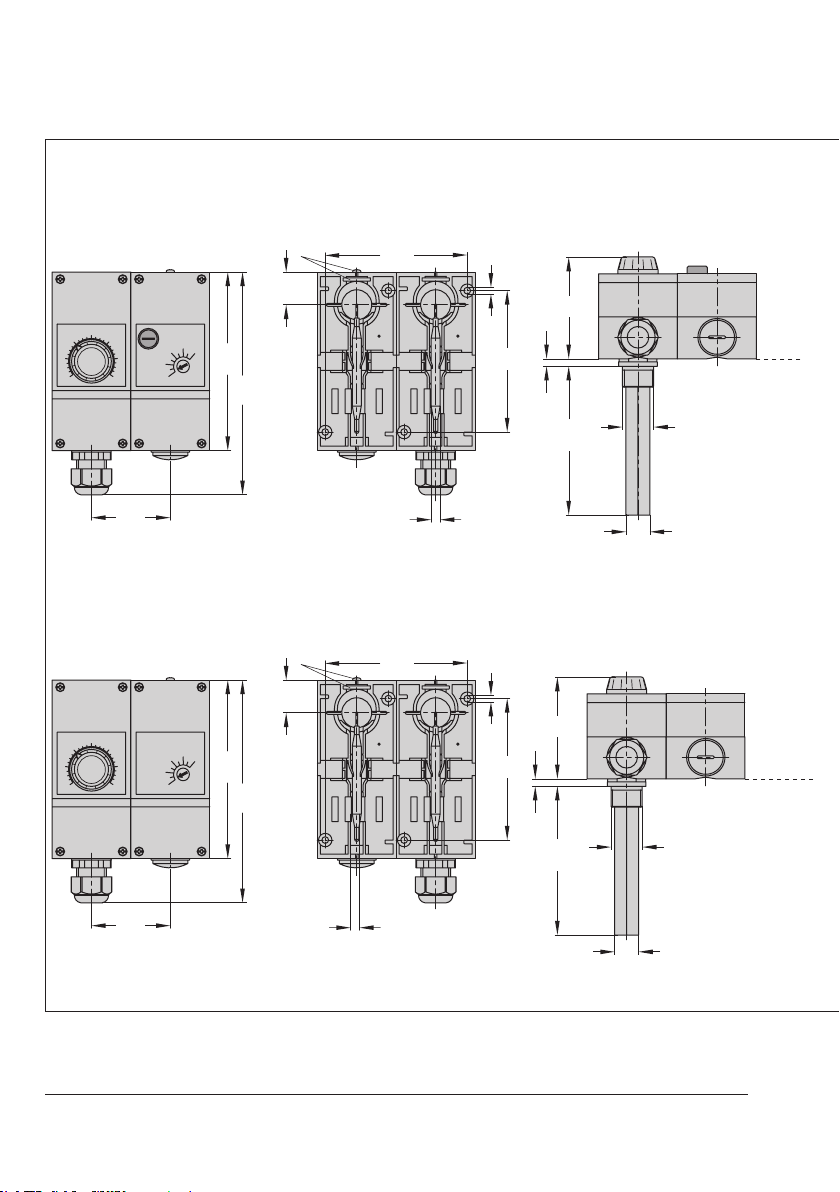

6 Dimensions in mm

15

8

Single thermostats

Type 5343 Safety Temperature Monitor (STM) Dimensions with thermowell (accessories)

53 42.4

22

58

Housing without thermowell

120

˚C

150

16 EB 5206 EN

Ø 4.5

200

150

100

15

G1/2

Page 17

Dimensions in mm

**

95

Ø 6

Ø8

5

95

**

Ø 6

Ø8

300

Type5344 Temperature Regulator (TR) Dimensions with thermowell (accessories)

53 42.4

22

Ø 4.5

120

150

300

70

200

150

Housing

without ther-

mowell

15

G1/2

100

Type 5345 Safety Temperature Limiter (STL) Dimensions with thermowell (accessories)

53 42.4

22

120

˚C

150

Ø 4.5

635

58

200

150

100

Housing

without ther-

mowell

15

G1/2

** Metal plate and screw for fastening the

thermostat onto the thermowell (wall

mounting)

EB 5206 EN 17

Page 18

Dimensions in mm

95

**

Ø 6

Ø15

5

˚C

120

150

106

95.4

22

Ø 4.5

95

**

Ø 6

G1/2

Ø15

100

150

300

63

58

5

95

**

Ø 6

Ø15

5

Double thermostats

Type5347 Double Thermostat (TR/STL)

22

120

˚C

150

106

Type5348 Double Thermostat (TR/STM)

22

120

˚C

150

95.4

95.4

Dimensions with thermowell (accessories)

70

Ø 4.5

100

150

300

G1/2

Dimensions with thermowell (accessories)

70

Ø 4.5

Housing

without ther-

mowell

Housing

without

thermowell

G1/2

106

100

150

300

18 EB 5206 EN

Page 19

Dimensions in mm

95

**

Ø 6

Ø15

100

63

5

Type5349 Double Thermostat (TR/STM)

22

120

˚C

150

106

95.4

Dimensions with thermowell (accessories)

58

Ø 4.5

150

300

G1/2

** Metal plate and screw for fastening

the thermostat onto the thermowell

(wall mounting)

Housing

without

thermowell

EB 5206 EN 19

Page 20

EU declarations of conformity

SAMSON AKTIENGESELLSCHAFT

Weismüllerstraße 3

Telefon: 069 4009-0 · Telefax: 069 4009-1507

E

Revison 07

ce_5344-0_de_en_fra_rev07.pdf

Revison 07

ce_5343-0_de_en_fra_rev07.pdf

8 EU declarations of conformity

61000-6-2:2005, EN 61000-6-3:2007

+A1:2011, EN 61326-1:2013

EN 50581:2012

Au nom du fabricant.

-Mail: samson@samson.de

Typ/Type/ Type 5344

Régulateur de température (TR)

Weismüllerstraße 3

D-60314 Frankfurt am Main

Deutschland/Germany/Allemagne

SAMSON AKTIENGESELLSCHAFT

Déclaration UE de conformité

Temperaturregler (TR) / Temperature Controller (TR) /

60314 Frankfurt am Main

EU Konformitätserklärung / EU Declaration of Conformity /

EMC 2014/30/EU

Die alleinige Verantwortung für die Ausstellung dieser Konformitätserklärung trägt der Hersteller/

This declaration of conformity is issued under the sole responsibility of the manufacturer/

La présente déclaration de conformité est établie sous la seule responsabilité du fabricant.

Für das folgende Produkt/ For the following product /Nous certifions que le produit

the conformity with the relevant Union harmonisation legislation is declared with/

wird die Konformität mit den einschlägigen Harmonisierungsrechtsvorschriften der Union bestätigt/

est conforme à la législation d'harmonisation de l'Union applicable selon les normes:

Typ/Type/ Type 5343

Déclaration UE de conformité

EU Konformitätserklärung / EU Declaration of Conformity /

Die alleinige Verantwortung für die Ausstellung dieser Konformitätserklärung trägt der Hersteller/

This declaration of conformity is issued under the sole responsibility of the manufacturer/

Contrôleur de température de sécurité (STW)

Sicherheitstemperaturwächter (STW) / Safety Temperatur Monitor (STW) /

EMC 2014/30/EU

La présente déclaration de conformité est établie sous la seule responsabilité du fabricant.

Für das folgende Produkt/ For the following product /Nous certifions que le produit

the conformity with the relevant Union harmonisation legislation is declared with/

wird die Konformität mit den einschlägigen Harmonisierungsrechtsvorschriften der Union bestätigt/

est conforme à la législation d'harmonisation de l'Union applicable selon les normes:

RoHS 2011/65/EU

LVD 2014/35/EU EN 60730-1:2016, EN 61010-1:2010

Hersteller/Manufacturer /Fabricant:

61000-6-2:2005, EN 61000-6-3:2007

+A1:2011, EN 61326-1:2013

EN 50581:2012

LVD 2014/35/EU EN 60730-1:2016, EN 61010-1:2010

RoHS 2011/65/EU

Hersteller/Manufacturer /Fabricant:

Frankfurt /Francfort, 2017-07-29

Gert Nahler Hanno Zager

Zentralabteilungsleiter/Head of Department/Chef du département Leiter Qualitätssicherung/Head of Quality Managment/

Entwicklung Automation und Integrationstechnologien/ Responsable de l'assurance de la qualité

Development Automation and Integration Technologies

Im Namen des Herstellers/ On behalf of the Manufacturer/

Au nom du fabricant.

Weismüllerstraße 3

D-60314 Frankfurt am Main

Deutschland/Germany/Allemagne

SAMSON AKTIENGESELLSCHAFT

Frankfurt /Francfort, 2017-07-29

Im Namen des Herstellers/ On behalf of the Manufacturer/

-Mail: samson@samson.de

60314 Frankfurt am Main

Entwicklung Automation und Integrationstechnologien/ Responsable de l'assurance de la qualité

Gert Nahler Hanno Zager

Zentralabteilungsleiter/Head of Department/Chef du département Leiter Qualitätssicherung/Head of Quality Managment/

Development Automation and Integration Technologies

20 EB 5206 EN

Page 21

EU declarations of conformity

SAMSON AKTIENGESELLSCHAFT

Weismüllerstraße 3

Revison 07

+A1:2011, EN 61326-1:2013

RoHS 2011/65/EU

EN 50581:2012

ce_5347-0_de_en_fra_rev07.pdf

Revison 07

+A1:2011, EN 61326-1:2013

RoHS 2011/65/EU EN 50581:2012

ce_5345-0_de_en_fra_rev07.pdf

61000-6-2:2005, EN 61000-6-3:2007

Au nom du fabricant.

-Mail: samson@samson.de

Typ/Type/ Type 5347

Thermostat double TR/STB

Weismüllerstraße 3

D-60314 Frankfurt am Main

Deutschland/Germany/Allemagne

SAMSON AKTIENGESELLSCHAFT

Déclaration UE de conformité

Doppelthermostat TR/STB / Double Thermostat TR/STB /

60314 Frankfurt am Main

EU Konformitätserklärung / EU Declaration of Conformity /

EMC 2014/30/EU

LVD 2014/35/EU EN 60730-1:2016, EN 61010-1:2010

Die alleinige Verantwortung für die Ausstellung dieser Konformitätserklärung trägt der Hersteller/

This declaration of conformity is issued under the sole responsibility of the manufacturer/

La présente déclaration de conformité est établie sous la seule responsabilité du fabricant.

Für das folgende Produkt/ For the following product /Nous certifions que le produit

the conformity with the relevant Union harmonisation legislation is declared with/

wird die Konformität mit den einschlägigen Harmonisierungsrechtsvorschriften der Union bestätigt/

est conforme à la législation d'harmonisation de l'Union applicable selon les normes:

Typ/Type/ Type 5345

Déclaration UE de conformité

EU Konformitätserklärung / EU Declaration of Conformity /

Die alleinige Verantwortung für die Ausstellung dieser Konformitätserklärung trägt der Hersteller/

This declaration of conformity is issued under the sole responsibility of the manufacturer/

Limiteur de température de sécurité (STB)

Sicherheitstemperaturbegrenzer (STB) / Safety Temperatur Limiter (STB) /

EMC 2014/30/EU

La présente déclaration de conformité est établie sous la seule responsabilité du fabricant.

Für das folgende Produkt/ For the following product /Nous certifions que le produit

the conformity with the relevant Union harmonisation legislation is declared with/

wird die Konformität mit den einschlägigen Harmonisierungsrechtsvorschriften der Union bestätigt/

est conforme à la législation d'harmonisation de l'Union applicable selon les normes:

Hersteller/Manufacturer /Fabricant:

61000-6-2:2005, EN 61000-6-3:2007

SAMSON AKTIENGESELLSCHAFT

LVD 2014/35/EU EN 60730-1:2016, EN 61010-1:2010

Hersteller/Manufacturer /Fabricant:

Frankfurt /Francfort, 2017-07-29

Im Namen des Herstellers/ On behalf of the Manufacturer/

Au nom du fabricant.

Weismüllerstraße 3

D-60314 Frankfurt am Main

Deutschland/Germany/Allemagne

Frankfurt /Francfort, 2017-07-29

Im Namen des Herstellers/ On behalf of the Manufacturer/

Entwicklung Automation und Integrationstechnologien/ Responsable de l'assurance de la qualité

Development Automation and Integration Technologies

Gert Nahler Hanno Zager

Zentralabteilungsleiter/Head of Department/Chef du département Leiter Qualitätssicherung/Head of Quality Managment/

-Mail: samson@samson.de

60314 Frankfurt am Main

Entwicklung Automation und Integrationstechnologien/ Responsable de l'assurance de la qualité

Development Automation and Integration Technologies

Gert Nahler Hanno Zager

Zentralabteilungsleiter/Head of Department/Chef du département Leiter Qualitätssicherung/Head of Quality Managment/

EB 5206 EN 21

Page 22

EU declarations of conformity

SAMSON AKTIENGESELLSCHAFT

Weismüllerstraße 3

Telefon: 069 4009-0 · Telefax: 069 4009-1507

E

Revison 07

ce_5349-0_de_en_fra_rev07.pdf

Revison 07

ce_5348-0_de_en_fra_rev07.pdf

61000-6-2:2005, EN 61000-6-3:2007

+A1:2011, EN 61326-1:2013

EN 50581:2012

Au nom du fabricant.

-Mail: samson@samson.de

Typ/Type/ Type 5349

Thermostat double STW/STB

Weismüllerstraße 3

D-60314 Frankfurt am Main

Deutschland/Germany/Allemagne

SAMSON AKTIENGESELLSCHAFT

Déclaration UE de conformité

Doppelthermostat STW/STB / Double Thermostat STW/STB /

60314 Frankfurt am Main

EU Konformitätserklärung / EU Declaration of Conformity /

EMC 2014/30/EU

Die alleinige Verantwortung für die Ausstellung dieser Konformitätserklärung trägt der Hersteller/

This declaration of conformity is issued under the sole responsibility of the manufacturer/

La présente déclaration de conformité est établie sous la seule responsabilité du fabricant.

Für das folgende Produkt/ For the following product /Nous certifions que le produit

Thermostat double TR/STW

the conformity with the relevant Union harmonisation legislation is declared with/

wird die Konformität mit den einschlägigen Harmonisierungsrechtsvorschriften der Union bestätigt/

est conforme à la législation d'harmonisation de l'Union applicable selon les normes:

Typ/Type/ Type 5348

RoHS 2011/65/EU

LVD 2014/35/EU EN 60730-1:2016, EN 61010-1:2010

Hersteller/Manufacturer /Fabricant:

61000-6-2:2005, EN 61000-6-3:2007

+A1:2011, EN 61326-1:2013

EN 50581:2012

Frankfurt /Francfort, 2017-07-29

Im Namen des Herstellers/ On behalf of the Manufacturer/

Au nom du fabricant.

Weismüllerstraße 3

D-60314 Frankfurt am Main

Deutschland/Germany/Allemagne

SAMSON AKTIENGESELLSCHAFT

Entwicklung Autom ation und Integrationstechnologien/ Responsable de l'assurance de la qualité

Gert Nahler Hanno Zager

Zentralabteilungsleiter/Head of Department/Chef du département Leiter Qualitätssicherung/Head of Quality Managment/

Development Automation and Integration Technologies

-Mail: samson@samson.de

Déclaration UE de conformité

Doppelthermostat TR/STW / Double Thermostat TR/STW /

60314 Frankfurt am Main

EU Konformitätserklärung / EU Declaration of Conformity /

EMC 2014/30/EU

LVD 2014/35/EU EN 60730-1:2016, EN 61010-1:2010

Die alleinige Verantwortung für die Ausstellung dieser Konformitätserklärung trägt der Hersteller/

This declaration of conformity is issued under the sole responsibility of the manufacturer/

La présente déclaration de conformité est établie sous la seule responsabilité du fabricant.

Für das folgende Produkt/ For the following product /Nous certifions que le produit

the conformity with the relevant Union harmonisation legislation is declared with/

wird die Konformität mit den einschlägigen Harmonisierungsrechtsvorschriften der Union bestätigt/

est conforme à la législation d'harmonisation de l'Union applicable selon les normes:

RoHS 2011/65/EU

Hersteller/Manufacturer /Fabricant:

Frankfurt /Francfort, 2017-07-29

Im Namen des Herstellers/ On behalf of the Manufacturer/

Entwicklung Automation und Integrationstechnologien/ Responsable de l'assurance de la qualité

Development Automation and Integration Technologies

Gert Nahler Hanno Zager

Zentralabteilungsleiter/Head of Department/Chef du département Leiter Qualitätssicherung/Head of Quality Managment/

22 EB 5206 EN

Page 23

EB 5206 EN 23

Page 24

EB 5206 EN

SAMSON AKTIENGESELLSCHAFT

Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

samson@samson.de · www.samson.de

2018-07-03 · English

Loading...

Loading...