Page 1

Supply Pressure Regulators

Type 4708

Mounting and

Operating Instructions

EB 8546 EN

Edition June 2012

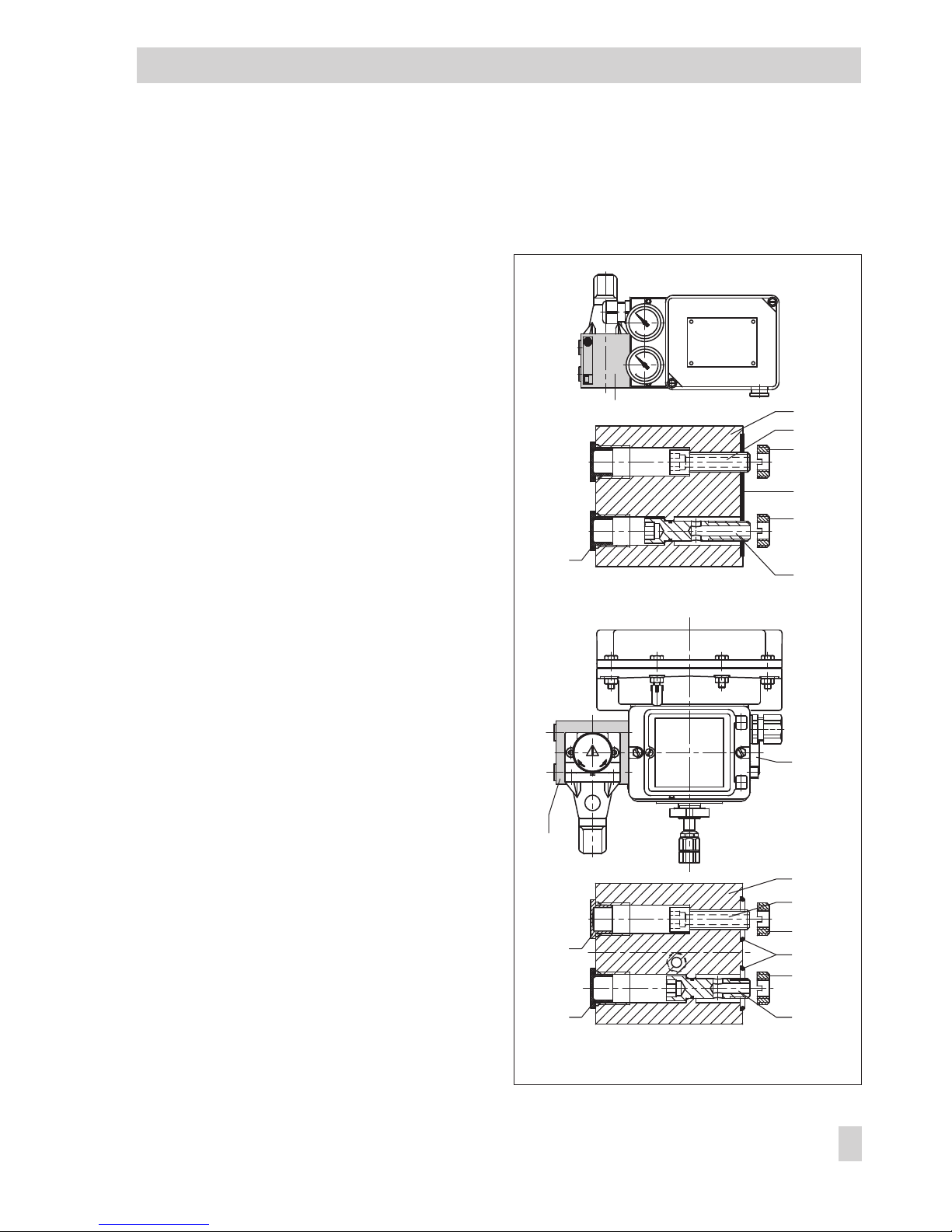

Fig. 1 · Supply pressure regulators

Type 4708-1152 with filter receptacle

Type 4708-5352 on Type 3730 Positioner

Type 4708-6252 on Type 3372 Actuator

Page 2

Contents Page

1 Design and principle of operation. . . . . . . . . . . . . . . . . . . . 4

1.1 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Mounting the supply pressure regulator. . . . . . . . . . . . . . . . . 8

2.1 Compact supply pressure regulator . . . . . . . . . . . . . . . . . . . 8

2.1.1 Direction of flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.2 Turning the supply pressure regulator . . . . . . . . . . . . . . . . . . 9

2.2 Supply pressure regulators for attachment to positioners and actuators. . 10

3 Pneumatic connections . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Pressure gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Additional connection for a solenoid valve . . . . . . . . . . . . . . . 15

3.3 Manual/automatic transfer. . . . . . . . . . . . . . . . . . . . . . . 18

3.3.1 Mounting on positioners . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3.2 Mounting using an adapter plate. . . . . . . . . . . . . . . . . . . . 19

3.3.3 Operating the manual/automatic transfer . . . . . . . . . . . . . . . 20

3.4 Filter with filter receptacle . . . . . . . . . . . . . . . . . . . . . . . 20

3.4.1 Mounting the air filter . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5 Rotatable supplementary filter . . . . . . . . . . . . . . . . . . . . . 21

3.5.1 Mounting the rotatable supplementary filter. . . . . . . . . . . . . . . 21

4 Set point adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8 Dimensions in mm. . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2 EB 8546 EN

Contents

Page 3

EB 8546 EN 3

Safety instructions

General safety instructions

4

The supply pressure regulators may only be mounted, started up or serviced

by fully trained and qualified personnel, observing the accepted industry

codes and practices. Make sure employees or third persons are not exposed

to any danger. All safety instructions and warnings in these mounting and

operating instructions, particularly those concerning assembly, start-up and

maintenance, must be observed.

4

Proper shipping and appropriate storage of the regulators are assumed.

Page 4

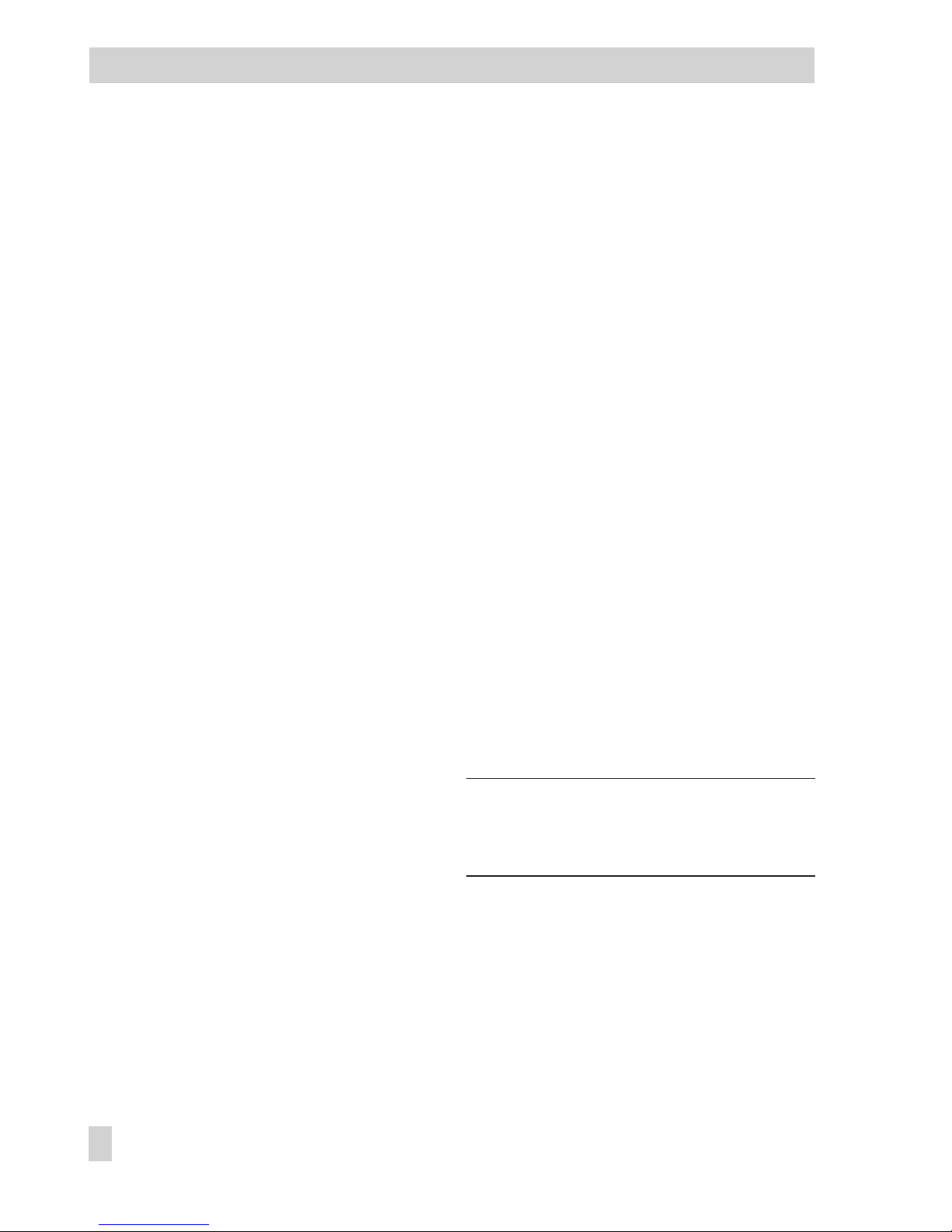

1 Design and principle of

operation

The supply pressure regulator is used to supply pneumatic measuring and control equipment with a constant air supply.

The maximum 12 bar pressure of the compressed air network in a plant is reduced to

an adjustable minimum pressure of 0.2 to

1.6 bar or 0.5 to 6 bar.

At the inlet side, the supply pressure regula-

tor is equipped with a filter cartridge with a

mesh size of 20 µm. In addition, the regulator can also be equipped with a filter receptacle and a pressure gauge on the outlet

side.

The compressed air at the inlet flows across

the filter and through the free cross-sectional

area between the seat (1.1) and plug (1.2).

It leaves the outlet with a reduced pressure

depending on the plug position.

The output pressure to be controlled is transferred through the bore (1.3) to the operating diaphragm (2) where it is converted into

a positioning force. This force is used to

move the valve plug depending on the force

of the positioning spring (4).

Turning the set point screw (7) causes the

spring force to change and, as a result, the

required set point is adjusted.

The set point ranges of the supply pressure

regulator from 0.2 to 1.6 bar and 0.5 to

6 bar are determined by various tensions of

the installed positioning spring (4).

Condensed water contained in the compressed air can be collected and drained

when the filter cartridge (9) is mounted horizontally or the filter receptacle (12) is suspended downwards. The stopper (10) can

be unscrewed or the manual drainage can

be activated (drain plug (15) in old versions)

to drain condensed water.

Note: Tighten the drain plug by hand only.

The maximum permissible tightening torque

is 3 Nm.

4 EB 8546 EN

Design and principle of operation

Page 5

EB 8546 EN 5

Design and principle of operation

15

1.11 1.2 1.3 2 3 4 5 6 7 8

9

10

10.1

11

11.1

12.1

12

13

9

16

Fig. 2 · Sectional drawings

1 Body

1.1 Seat

1.2 Plug

1.3 Bore in body

2 Operating diaphragm

3 Venting bore

4 Positioning spring

5 Cap

6 Lock nut

7 Set point screw

8 Adjustment knob

(accessories in Section 7)

9 Filter cartridge

10 Stopper

11 Bushing

11.1 Gasket

12 Filter receptacle

12.1 Gasket

13 Screw

15 Drain plug (max. 3 Nm)

16 Manual drainage

Old version

Adapter plate/connecting plate

Diverting gasket

Page 6

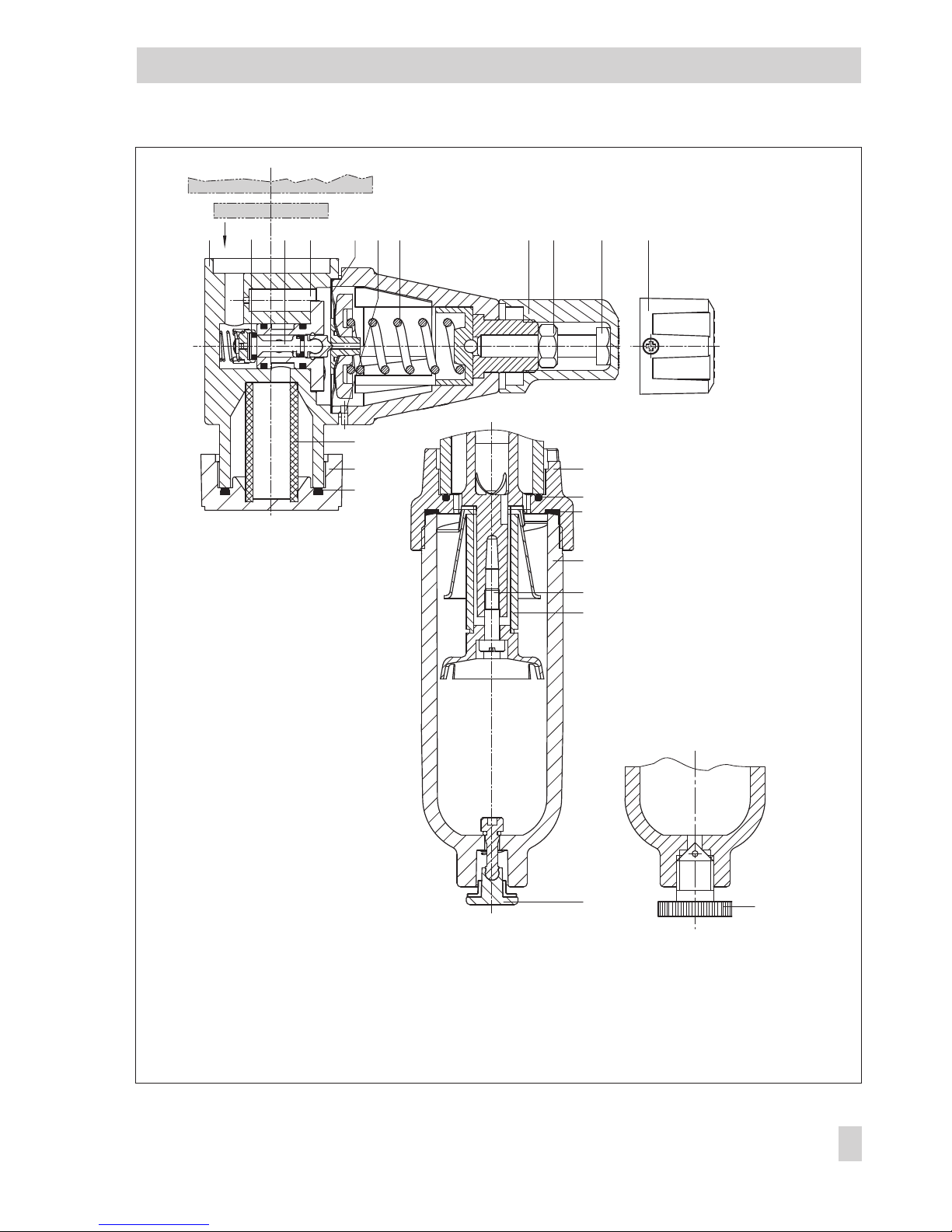

1.1 Versions

Standard version Type 4708-

xxxx

Filter on aluminum basis without

filter receptacle

10

With plastic filter receptacle

11

With aluminum filter receptacle

12

Stainless steel supply pressure regulator

Filter on stainless steel basis with

stainless steel receptacle

13

With plastic filter receptacle

14

Without filter receptacle

17

Connection

G ¼

2

¼-18 NPT

5

Set point range 0.5 to 6 bar (8 to 90 psi)

Without pressure gauge

0

With pressure gauge,

completely free of copper

1

With pressure gauge,

copper-free housing

2

Set point range 0.2 to 1.6 bar (3 to 23 psi)

Without pressure gauge

3

With pressure gauge, completely free of copper

4

With pressure gauge,

copper-free housing

5

Supply pressure regulator with adapter plate

for positioners

Type 3730, 3766, 3767, 3780,

3785, 3787

53

Type 3730, 3766, 3767, 3780,

3785, 3787

54

Type 4763/4765

55 0

Type 3760

57

Type 3761

58

Supply pressure regulator with adapter plate

for pneumatic actuators

Type 3277 (240 to 700 cm²)

with Type 3730, 3766, 3767,

3780, 3785 or 3787 Positioner

62 0

Type 3372

62

Type 3277 with connection

block

64

Manual/automatic transfer

Bypass for positioner

82

Filter without pressure gauge

Type 4708-

xxx0

Aluminum housing and plastic

filter receptacle

83 0

Aluminum housing and aluminum filter receptacle

84 0

Stainless steel housing and

plastic filter receptacle

86 0

Stainless steel housing and

stainless steel filter receptacle

87 0

6 EB 8546 EN

Design and principle of operation

Page 7

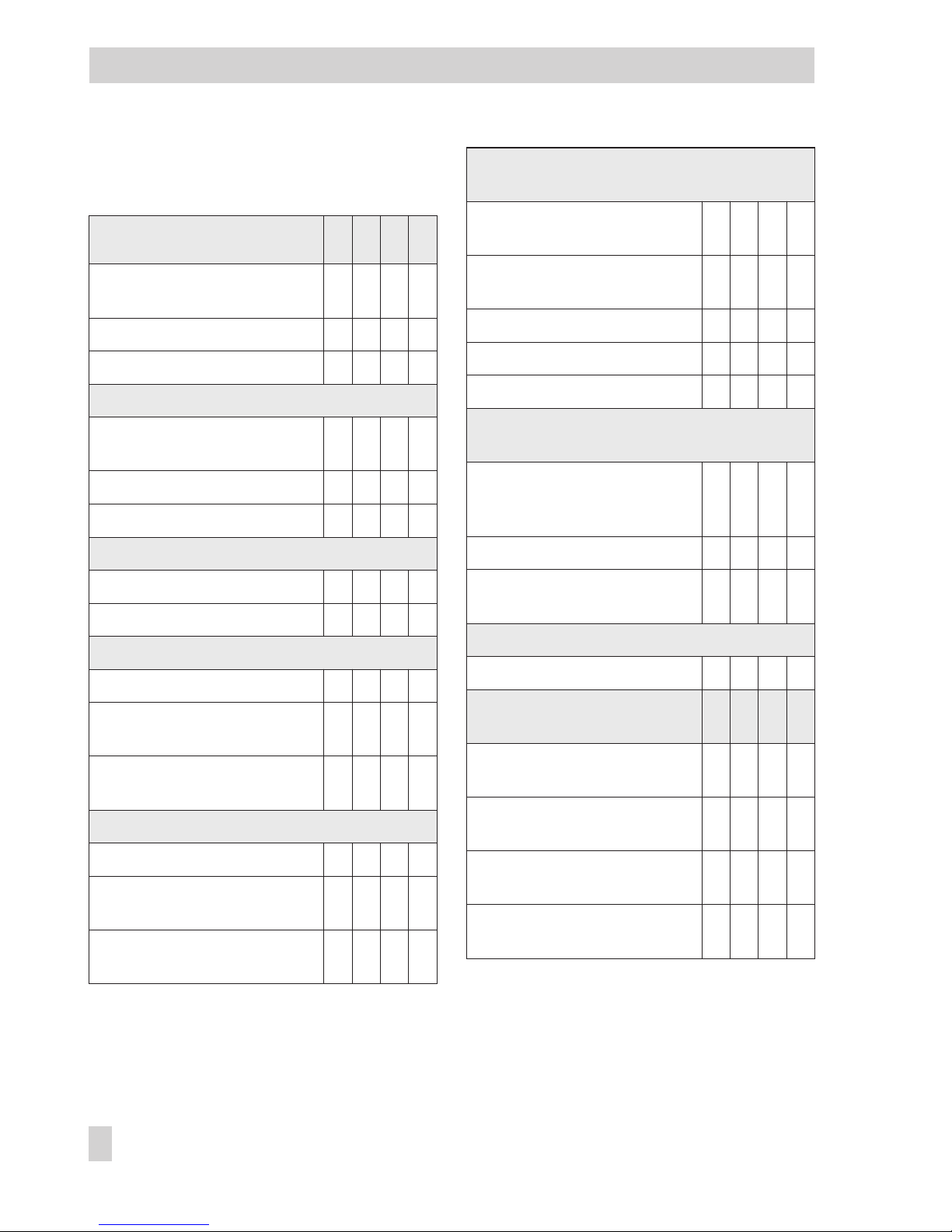

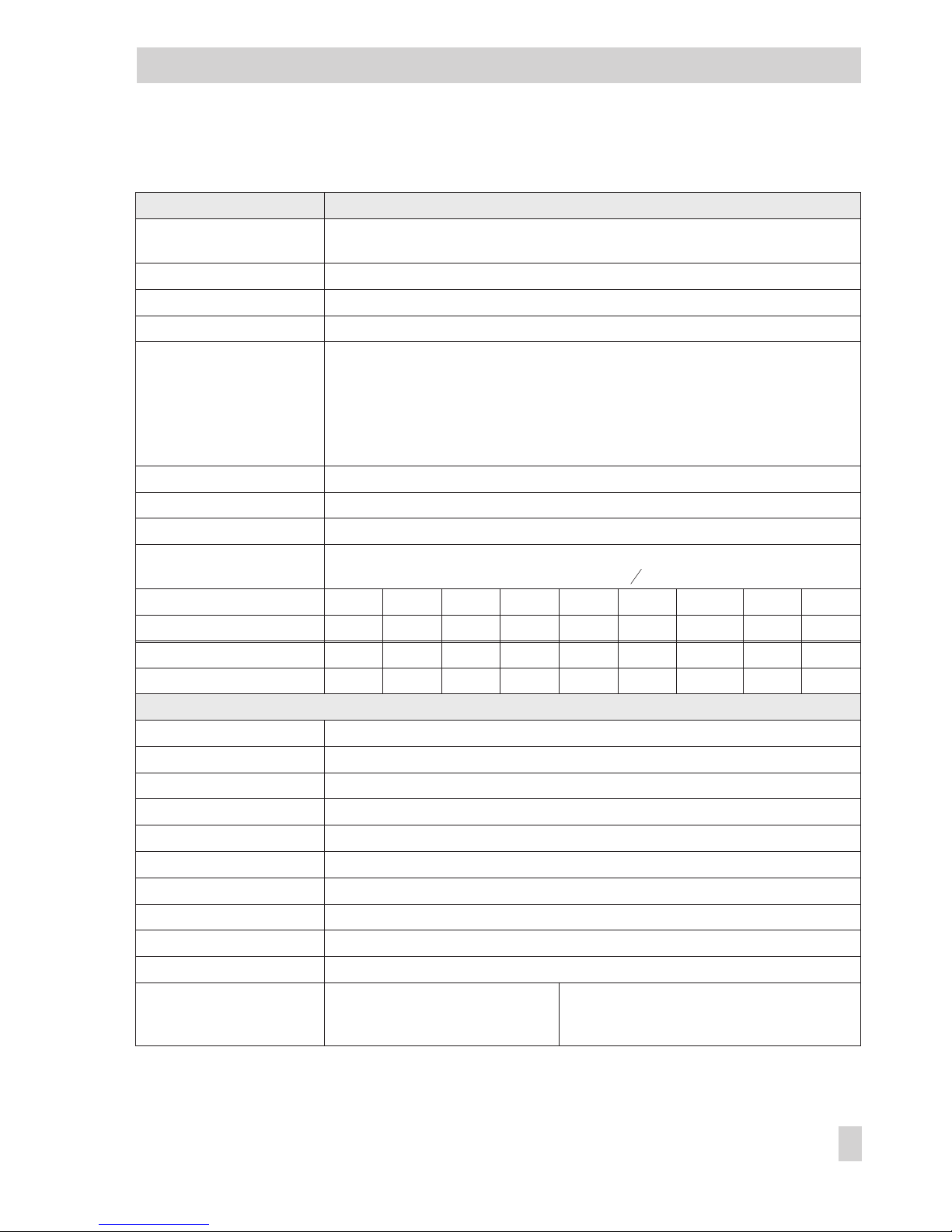

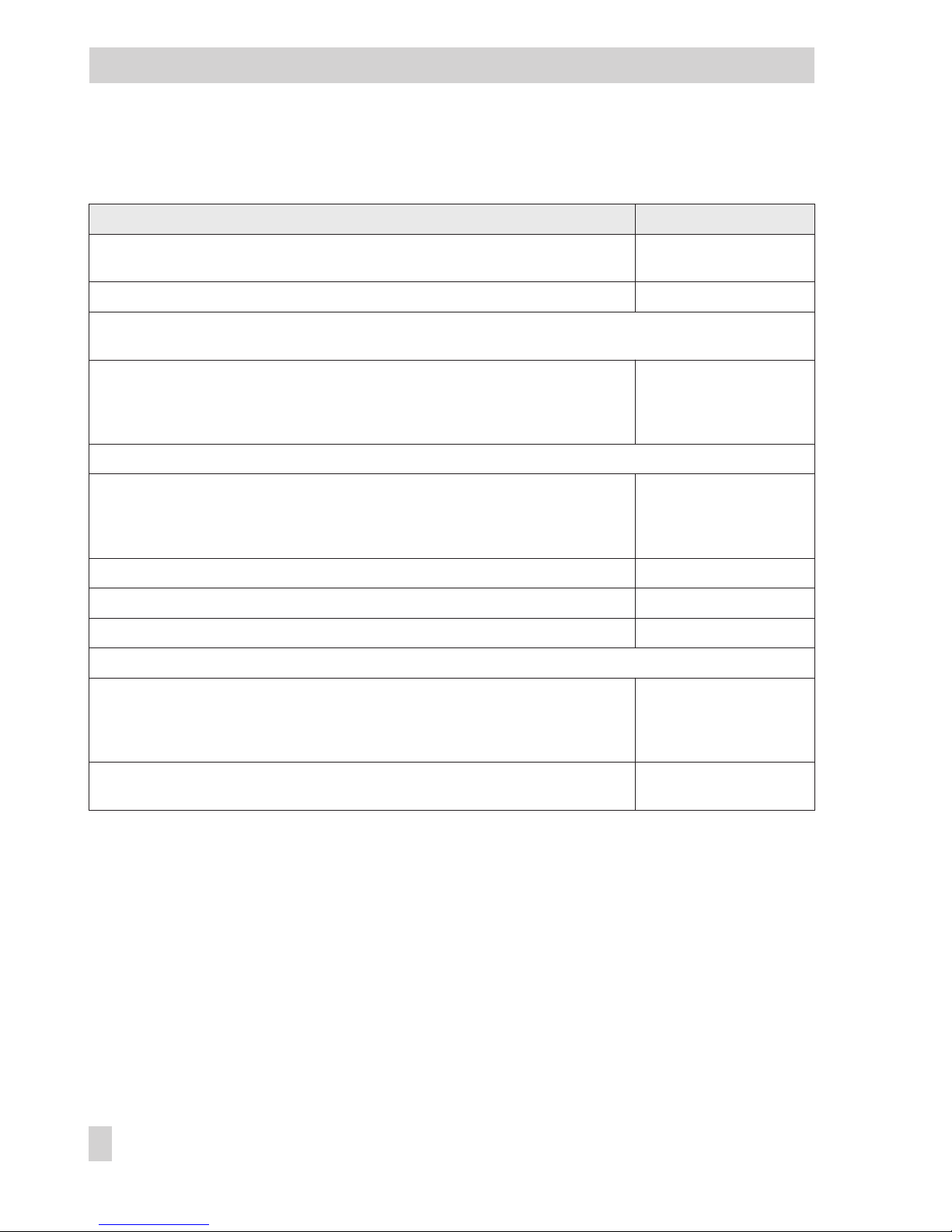

1.2 Technical data

EB 8546 EN 7

Design and principle of operation

Supply pressure regulator Type 4708-xx

Supply pressure

1 bar (15 psi) above the adjusted set point,

however, at least 1.6 bar (24 psi) · Max. 12 bar (180 psi)

Output pressure Adjustable from 0 to 1.6 bar (0 to 24 psi) or 0 to 6 bar (0 to 90 psi)

Set point range 0.2 to 1.6 bar (3 to 24 psi) or 0.5 to 6 bar (8 to 90 psi)

Air consumption

£

0.05 m

n

3

/h (with 7 bar supply air)

Permissible ambient

temperature

(values in brackets apply to

low-temperature version)

–25 to 70 °C (–50 to 70 °C) for Types 4708-11, -14, -45, -83, -86

–25 to 80 °C (–40 to 80 °C) for Type 4708-64

–25 to 80 °C (–50 to 80 °C) for Types 4708-10, -12, -13, -17, -53, -54, -55, -57,

-58, -62, -82, -84, -87

(–30 °C possible, but in this case, air consumption reaching up to 0.3 m

n

3

/h with

7 bar supply pressure)

Input pressure dependance < 0.01 bar/Dp = 1 bar

Reversing error 0.1 bar to 0.4 bar (depending on the set point)

Hysteresis < 0.1 bar

Pressure gauge Ø40

indication range

0 to 1.6 bar (0 to 24 psi) or 0 to 6 bar (0 to 90 psi)

Connection G

1

8

Type 4708- 10 11 12 13 14 17 53 54 55

Weight, approx. 0.48 0.58 0.66 1.65 1.2 1.0 0.68 0.95 0.37

Type 4708- 57 58 62 64 82 83 84 86 87

Weight, approx. 0.47 0.4 0.4 0.5 0.4 0.24 0.32 0.59 0.95

Materials

Body Polyamide, glass fiber reinforced

Adapter plate Aluminum alloy, anodized black

Stopper and gasket Polyamide, glass fiber reinforced and NBR

Cover Polyamide, glass fiber reinforced

Cap Polyamide, glass fiber reinforced

Plug Polyamide, glass fiber reinforced and polyoxymethylene

Plug sealing NBRT and VMQ

Diaphragm NBR

Diaphragm plate Polyamide, glass fiber reinforced

Filter cartridge 20 µm: Polypropylene · 5 µm: Stainless steel

Pressure gauge

Housing

Connection

Stainless steel

St. steel (version free of copper)

Brass, nickel-plated

Page 8

2 Mounting the supply

pressure regulator

To prevent excessive amounts of condensed

water from collecting, the distance between

the compressor and supply pressure regulator should be kept as short as possible.

Make sure the drain plug faces downwards

in versions with a filter receptacle.

2.1 Compact supply pressure

regulator

The supply pressure regulator can either be

mounted directly in the pipeline of the air

supply or on rails or brackets using the corresponding mounting parts (see accessories

table in section 7).

Observe the direction of flow of the supply

air. An arrow on the nameplate indicates

the direction.

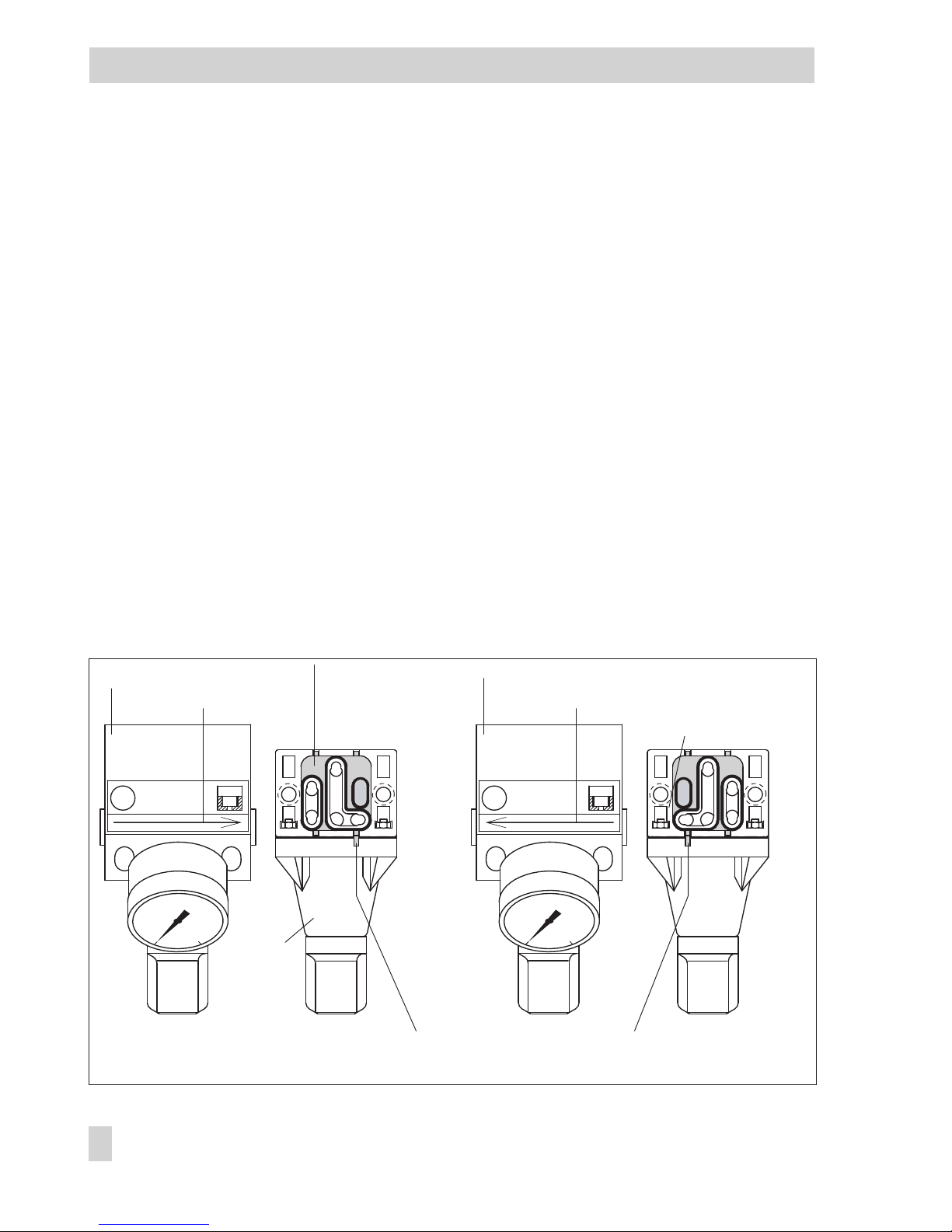

2.1.1 Direction of flow

In the compact supply pressure regulators

4708-10xx/-11xx/-14xx and -17xx the

direction of flow can be changed as follows:

1. Unscrew both fixing screws and lift the

supply pressure regulator off its connecting plate.

2. Remove the diverting gasket, turn it

180 degrees and reposition it as shown

in Fig. 3.

Note: The long rubber finger of the gasket must always point in the direction of

the regulator outlet.

3. Fasten the supply pressure regulator

onto the connecting plate.

4. Stick the enclosed adhesive label over

the arrow of the nameplate, ensuring the

arrow indicates that the supply air flows

in the opposite direction.

8 EB 8546 EN

Mounting the supply pressure regulator

G

4708-112.

0

6

3-....

0

6

3-....

4708-112.

G

Fig. 3 · Changing the direction of flow in compact supply pressure regulators

Connecting plate

Standard label

Diverting gasket

Connecting plate

Label with arrow

Fixing screws

Long rubber finger always pointing towards the regulator outlet

Supply

pressure

regulator

Page 9

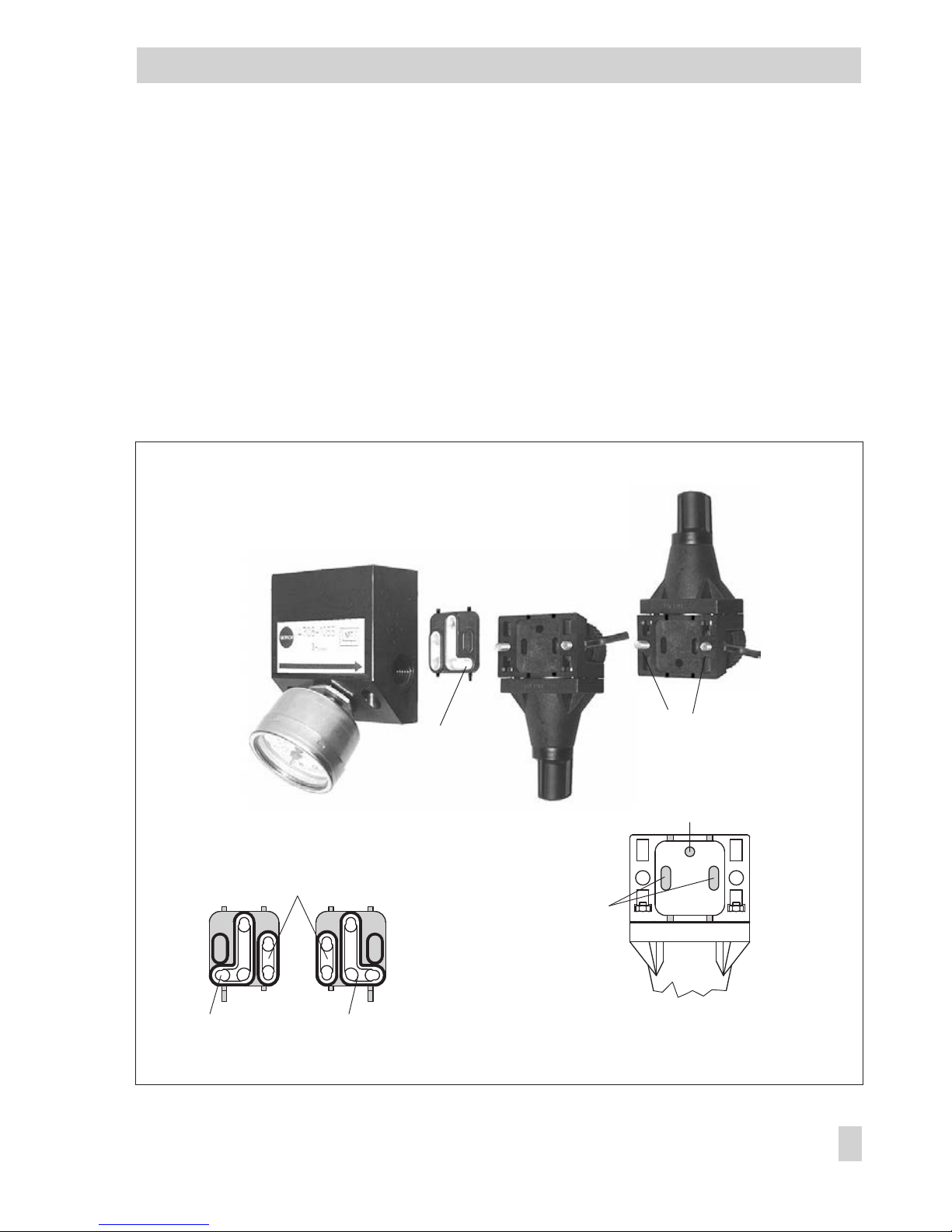

2.1.2 Turning the supply pressure

regulator

The supply pressure regulator can be turned

on its connecting plate to allow the set point

screw to face either up or down.

1. Unscrew both fixing screws and lift the

supply pressure regulator off its connecting plate.

2. Pull the diverting gasket out of the regu-

lator and keep it in this position.

3. Turn the regulator 180 degrees and reinsert the gasket. In this way, you keep

the bore assignment of the gasket for

supply air input and regulator outlet.

Note: The long rubber finger of the gasket must always point in the direction of

the regulator outlet (reduced supply

pressure).

4. Fasten the regulator onto the connecting

plate.

EB 8546 EN 9

Mounting the supply pressure regulator

Fig. 4 · Turning the supply pressure regulator on its connecting plate or adapter plate

Supply air input

Connecting plate or adapter plate

Supply air input

(Supply) >

Regulator facing downward

Diverting gasket

Long rubber finger

always pointing

towards outlet

Regulator facing upward

Fixing screws

Regulator outlet

Diverting gasket

Front and back view

Regulator outlet (long rubber finger)

Supply air input

depending on the

position of the

gasket

Page 10

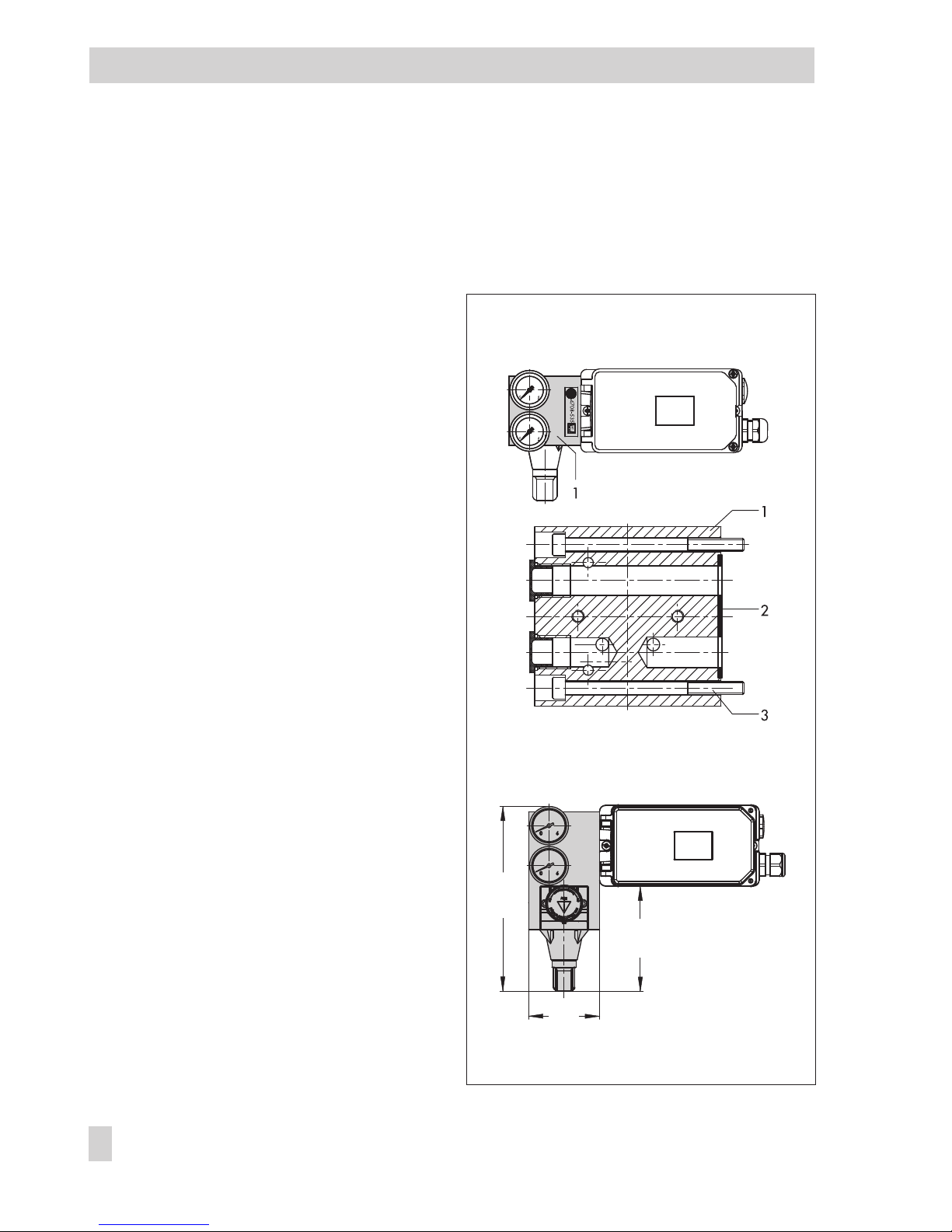

2.2 Supply pressure regulators

for attachment to positioners

and actuators

The supply pressure regulator versions intended for attachment to positioners and actuators are equipped with various adapter

plates for the attachment.

If required, the installation position of the

supply pressure regulator can be changed

by turning it 180° on its adapter plate to allow the set point screw/adjustment knob to

face either up or down. This applies particularly for positioners which can be attached

either to the left or right side of the valve

yoke to determine the operating direction

and fail-safe action of the actuator.

To turn the supply pressure regulator, proceed as described for the compact supply

pressure regulator in section 2.1.2. The regulator is turned on its adapter plate instead

of on the connecting plate.

Regulators for Types 3730/3766/3767/

3780/3785/3787 Positioners

Type 4708-53xx for Type 3271 Actuator

and Type 3277 Actuator with 120 cm² as

well as 240 to 700 cm² with hooked-up

valve accessories.

1. Insert the gasket (2) into the recess of the

adapter plate (1).

2. Place the supply pressure regulator on

the positioner on the side where the

pneumatic connections SUPPLY and

OUTPUT are located. Screw tight using

both M5 screws (3).

Type 4708-54xx for rotary actuators.

Proceed to mount as Type 4708-53xx.

Type 4708-54xx has a second output

sealed with a stopper. This is intended for

reduced supply air. It can be used to supply

a second device, if required (e.g. a pilot-operated solenoid valve).

10 EB 8546 EN

Mounting the supply pressure regulator

Fig. 5 · Attachment onto positioners

Type 4708-53xx

73

194

111

Type 4708-54xx

Page 11

Type 4708-55xx for Type 4763 and

Type 4765 Positioner

1. Screw the special nuts (5) into the connecting holes of the positioner.

2. Insert the gasket (2) into the recess of the

adapter plate (1).

3. Push the special hollow screws (6) for

SUPPLY and (7) for OUTPUT into the

connecting holes of adapter plate (1).

4. Place the supply pressure regulator onto

the positioner and fasten it using both

special screws.

5. Seal the spare connections with stoppers

(4) to prevent dirt from entering the device.

Type 4708-57xx for Type 3760 Positioner

The attachment for a positioner mounted on

the left side of the valve yoke (seen from the

black switchover plate) is shown. For a

positioner mounted on the right side, the

adapter plate is attached in the same way,

except the supply pressure regulator must be

turned by 180° (see bottom of page 28).

1. Screw the special nuts (5) into the connecting holes of the positioner.

2. Insert the O-rings (9) into the recess of

the adapter plate (1).

3. Push the special hollow screws (6) for

SUPPLY and (7) for IN. SIGNAL into

connecting holes of adapter plate (1).

4. Place the supply pressure regulator onto

the positioner and fasten it using both

special screws.

5. Seal the IN. SIGNAL connection of i/p

positioner with stainless steel stopper

(10).

6. Seal the spare connections with stoppers

(4) to prevent dirt from entering the device.

EB 8546 EN 11

Mounting the supply pressure regulator

6

0

SAMSON 4763

4708-552.

6

0

G

1

7

6

5

5

2

1

4

4

10

1

7

9

6

1

5

5

Fig. 6 · Attachment to positioners

Switchover

plate

Page 12

Type 4708-58xx for Type 3761 Positioner

1. Screw the special nut (5) into the SUPPLY

connecting hole of the positioner.

2. Push the special hollow screw (6) into

the connection hole of the adapter plate

(1).

3. Insert the O-ring (9). Position the supply

pressure regulator and fasten it to the

positioner using the special screw.

4. Seal the spare connections with stoppers

(4) to prevent dirt from entering the device.

Type 4708-64xx for Type 3277 Actuator

Before attaching the supply pressure regulator, check whether the tongue of the gasket

(1.2) is aligned at the connection block (1)

in such a way that the actuator symbol (1.3)

indicating “Actuator stem extends” or “Actuator stem retracts” matches the fail-safe action of the actuator.

If this is not the case, proceed as follows:

1. Unscrew the three Phillips screws (3.1),

lift off the cover plate (1.1) and turn the

gasket (1.2) by 180° and reinsert it.

2. Place the connection block with inserted

O-ring on the positioner and actuator

yoke and fasten it with hexagonal socket

screw (3).

3. Place the supply pressure regulator with

O-ring on the connection block and fasten it with hexagonal socket screw (2).

12 EB 8546 EN

Mounting the supply pressure regulator

3

1

1.1

1.2

1.3

3.1

3.1

2 1

G3/8

1

38

238

G

Output

Output

S

Input

6

5

4

3

2

1

0

27

1

6

9

4

1

5

Fig. 7 · Attachment of supply pressure regulator

Page 13

Type 4708-62xx for Type 3372 Actuator

1. Screw the special nut (5) into the SUPPLY

connecting hole of the actuator.

2. Push the special hollow screw (6) into

the connecting hole of the adapter plate.

3. Insert the O-ring (9). Position the supply

pressure regulator and fasten it onto actuator using the special screw.

4. Seal the spare connections with stoppers

(4) to prevent dirt from entering the device.

EB 8546 EN 13

Mounting the supply pressure regulator

1

9

5

6

4

1

6

5

9

4

Fig. 8 · Attachment to Type 3372 Actuator

Page 14

3 Pneumatic connections

The pneumatic connections are designed either as G ¼ or ¼ NPT-18 threads. On compact supply pressure regulators, an arrow

on the adhesive label indicates the direction

from the supply air input to the output.

In supply pressure regulators with two connecting holes in the adapter plate (Figs. 5

and 6, top), the supply air connection is

marked SUPPLY. The positioner's output signal is routed in these versions over the

OUTPUT port through the adapter plate to

the actuator.

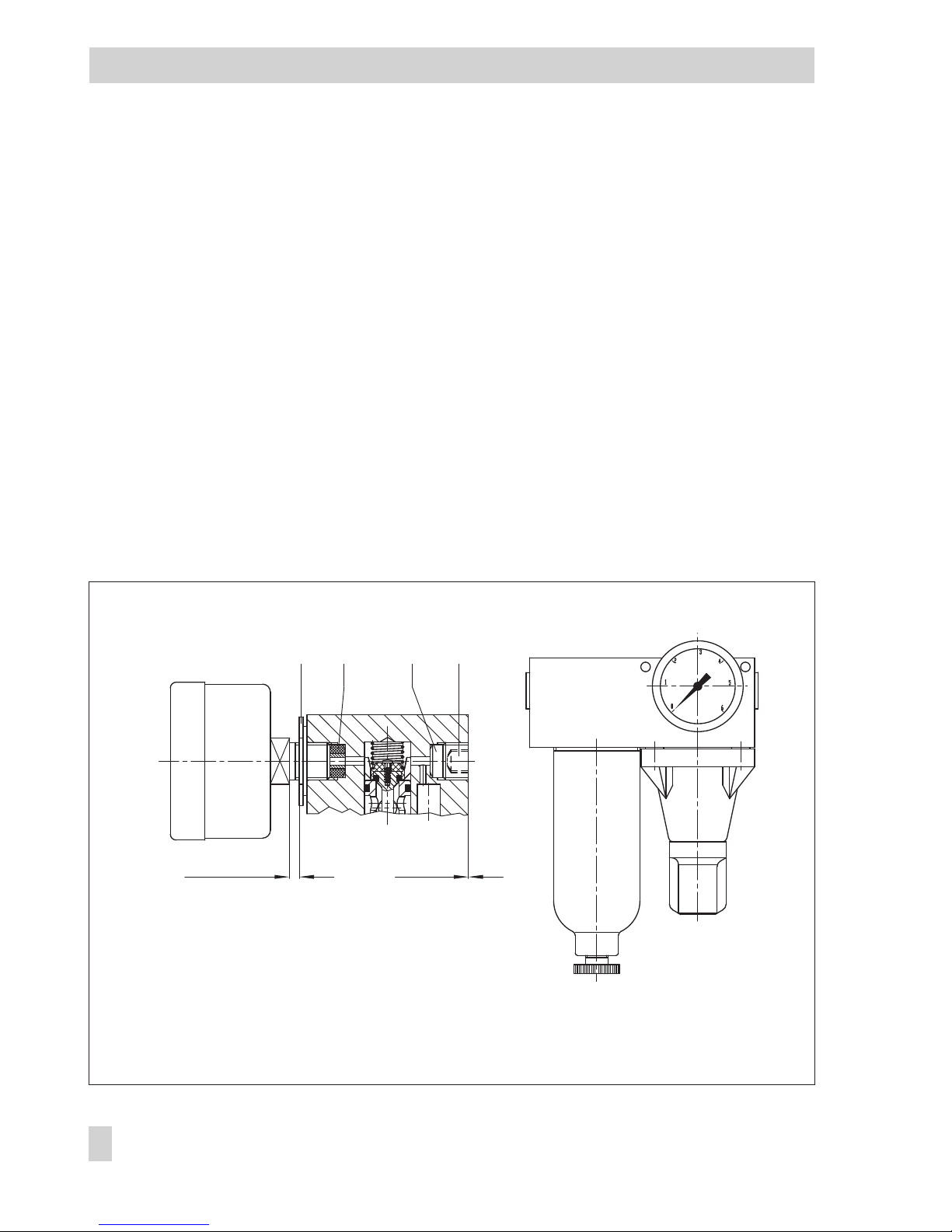

3.1 Pressure gauge

Mount the pressure gauge in such a way

that there is a 2-3 mm gap between the lock

nut and pressure gauge's square end after

tightening the lock nut (20).

In the compact versions (Type 4708-12xx/

-13xx), make sure additionally that the

stopper (23) is only screwed in to the point

where it becomes aligned with the housing,

otherwise the gaskets (21, 22) will be damaged. Each gasket is assigned either to the

pressure gauge or to the stopper and must

be changed correspondingly if you change

the location of the pressure gauge and

stopper to the other side.

14 EB 8546 EN

Pneumatic connections

20 22

2...3 mm 0 mm

21 23

Fig. 9 · Pressure gauge attachment, e.g. with Type 4708-12xx/13xx Supply Pressure Regulators

Page 15

3.2 Additional connection for a

solenoid valve

An additional output for reduced air pressure is required to allow the supply pressure

regulator to supply two pneumatic devices.

In some versions of Type 4708 (see section 7 on accessories), a second output can

be made available by using an intermediate

plate.

Example: Pneumatic actuator with positioner

and pilot-operated

solenoid valveÞSupply

air must be supplied separately to the pilot

control.

The reduced supply pressure of the supply

pressure regulator is additionally routed to

the threaded connection at the side over the

corresponding holes in the intermediate

plate. All supply pressure regulators have

the same intermediate plate, except for

Type 4708-57xx, designed for attachment

to Type 3760 Positioner (Fig. 12), its intermediate plate has a different hole assignment for the air ducts.

All versions can be ordered made of aluminum or stainless steel and with either G or

NPT threads. See section 7 for more details.

EB 8546 EN 15

Pneumatic connections

1

1.1

A

A

A

A

E

SUPPLY

2

2.1

3

4

4.1

E

E

E

Fig. 10 · Mounting an intermediate plate for Types 3730/3766/3767/3780 Positioners

Intermediate plate (2) with

additional connection

Output for

reduced supply air

Page 16

Mounting the intermediate plate

1. Remove the fixing screws and lift the

supply pressure regulator (4) together

with the diverting gasket (3) off the

adapter plate (1).

Make sure you do not change the position of the diverting gasket in the supply

pressure regulator.

Note: The long rubber finger of the diverting

gasket (3) must always point in the direction

of the regulator outlet (reduced supply air).

See Figs. 10, 11 and 12.

2. Insert O-rings (2.1) in the holes of the intermediate plate (2).

3. Place the intermediate plate onto the

adapter plate in such a way that the

three holes located next to one another

are positioned over both 5 mm holes on

16 EB 8546 EN

Pneumatic connections

1

1.1

E

A

M

A

2

2.1

3

4

4.1

A

A

E

A

E

A

E

Fig. 11 · Mounting an intermediate plate on Type 3372 Actuator

Output for

reduced supply air

Supply air input

Intermediate

plate (2)

Page 17

the adapter plate and the bores (1.1) for

the fixing screws are aligned.

4. Place the supply pressure regulator (4)

with the diverting gasket (3) onto the intermediate plate (2). Insert the longer fixing screws and fasten the parts.

EB 8546 EN 17

Pneumatic connections

SUPPLY

A

M

A

2

1

2.1

1.1

E

E

3

E

4

4.1

E

A

A

A

A

Fig. 12 · Mounting an intermediate plate on Type 3760 Positioner

Page 18

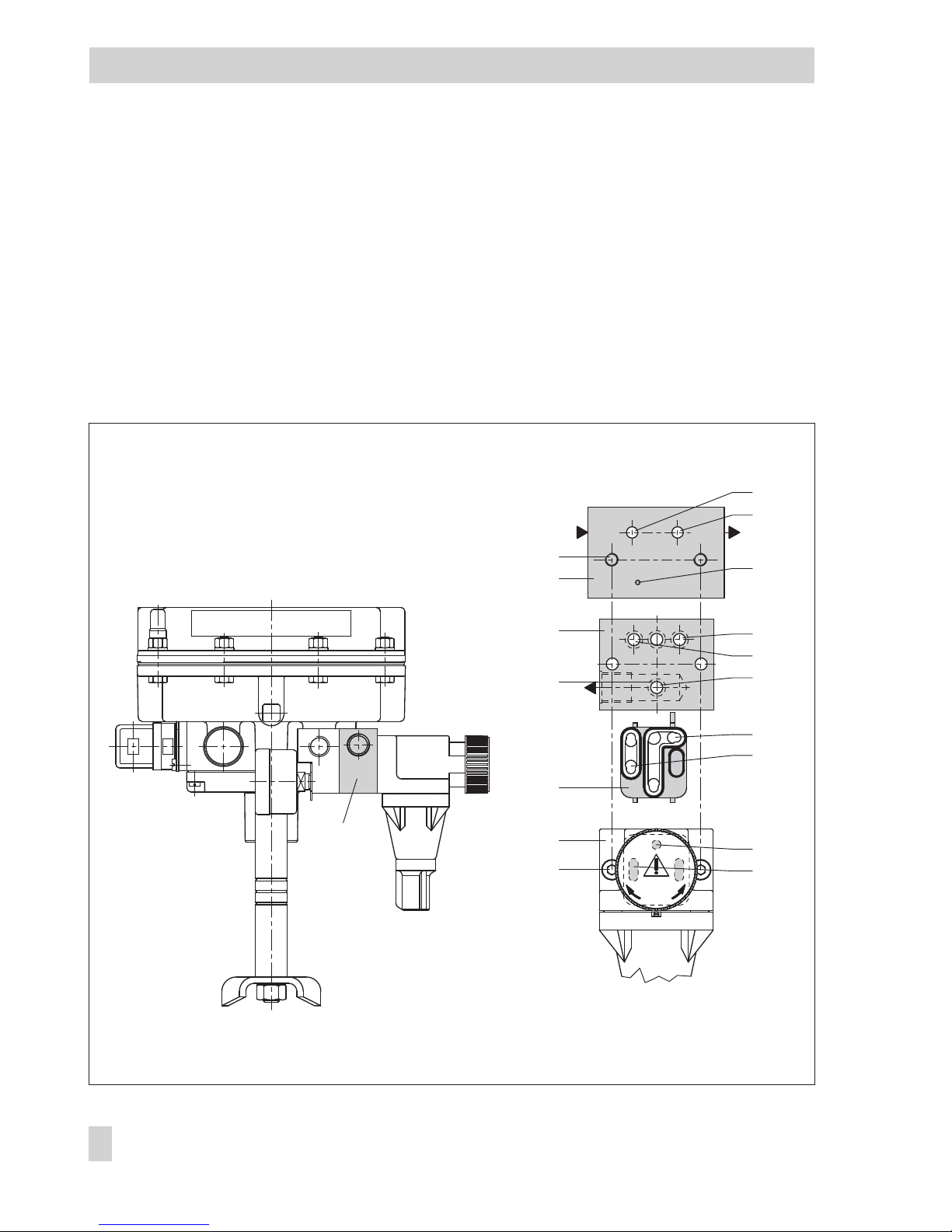

3.3 Manual/automatic transfer

The positioner output is routed to the actuator over the manual/automatic transfer. In

automatic mode, the positioner is in

closed-loop operation. In manual mode, the

output pressure of any supply pressure regulator is directly applied to the actuator. This

creates a manual bypass for the positioner.

The manual/automatic transfer unit is

mounted directly onto Types 376x, 378x

and 373x (Fig. 14) or on an adapter plate

with hook-up to the actuator (Fig. 13).

The Type 4708-53 (Fig. 15) or Type

4708-54 Supply Pressure Regulator can be

fastened onto the regulator. All other supply

pressure regulators can be connected to the

manual/automatic transfer by a piping

(hook-up).

3.3.1 Mounting on positioners

4

Insert flat gasket into recess of the manual/automatic transfer unit (Fig. 14).

4

Fasten manual/automatic transfer unit to

the positioner using the two hexagon

socket screws.

4

Connect hook-up to the Supply and Output connections of the manual/automatic

transfer unit.

18 EB 8546 EN

Pneumatic connections

1

Output (38)

Supply (9)

2

3

4

Supply

Output

Fig. 13 · Mounting the manual/automatic transfer using an adapter plate

1 Pneumatic control

valve with positioner

2 Adapter plate

1400-9605 (G)

1400-9606 (NPT)

3 Manual/automatic

transfer

Type 4708-82

in AUTO mode

4 Supply pressure regu-

lator with filter

(e.g. Type 4708-10)

Fig. 14 · Mounting on a positioner

Page 19

Optionally, a Type 4708-53 Supply Pressure Regulator can be mounted upstream of

the manual/automatic transfer unit

(Fig. 15).

3.3.2 Mounting using an adapter

plate

4

Fasten adapter plate, for example to a

NAMUR rib using a hexagon socket

screw.

4

Fit the flat gasket on the manual/automatic transfer unit. Fasten it to the

adapter plate using the two hexagon

socket screws.

4

Connect hook-up for positioner and actuator as shown in Fig. 13.

EB 8546 EN 19

Pneumatic connections

Fig. 15 · Type 4708-82 Manual/Automatic Transfer

Unit, Type 4708-53 Supply Pressure

Regulator with pressure gauges and

rotatable filter receptacle

Fig. 16 · Mounting using adapter plate

Page 20

3.3.3 Operating the manual/

automatic transfer

In normal operation, the manual/automatic

transfer runs in automatic mode, during

which the positioner supplies air to the

pneumatic actuator.

To switch to manual mode, twist off the plastic cap. Turn the switchover pin counterclockwise and pull it (approx. 1 cm) out of

the bayonet lock. The compressed air is then

routed directly from the supply pressure regulator or from the air supply network to the

pneumatic actuator.

To switch back to automatic mode, push in

the switchover pin again. To do this, insert

the lock pin completely into the bayonet and

lock it. Replace plastic cap and tighten.

3.4 Filter with filter receptacle

The Types 4708-83, 4708-84, 4708-86

and 4708-87 Air Filters are designed for

universal use. They have either G ¼ or

¼-18 NPT threaded connections.

3.4.1 Mounting the air filter

Mount the air filter directly into the pipeline,

while ensuring the direction of flow (printed

on the device) is kept.

The filter receptacle must face downwards to

function correctly.

20 EB 8546 EN

Pneumatic connections

Fig. 17 · Cap and switchover pin

Fig. 18 · Types 4708-83 to -87 Air Filters

Page 21

3.5 Rotatable supplementary

filter

The rotatable supplementary filter (see

Fig. 15) is designed for mounting to Type

4708-53 and Types 4708-55 to -64 Supply

Pressure Regulators. They replace the small

integrated filter cartridge. The entire filter

housing can be rotated by 360° to ensure

that the condensate drain is always facing

downwards.

Filter versions

Aluminum housing with filter in transparent

plastic receptacle

Temperature range: –

–20 to 70 °C

Order no. 1400-9460

Special version

Temperature range:

–40 to 70 °C

Order no. 1400-9461

3.5.1 Mounting the rotatable

supplementary filter

4

Remove the cover and filter cartridge

from the supply pressure regulator.

4

Place the supplied seal carefully onto the

groove (see arrow) of the connection.

4

Insert connecting pipe together with seal

into the supply pressure regulator and

tighten the plastic coupling nut.

Note: Make sure that the seal does not fall

out of the groove during mounting, otherwise the filter will not function properly.

4

Align the supplementary filter in the vertical direction.

4

Secure the position by tightening the

hexagonal socket screw (6 mm).

EB 8546 EN 21

Pneumatic connections

Fig. 19 · Connection and seal for supplementary filter

Page 22

4 Set point adjustment

(Fig. 2)

Depending on the version, the set point of

the supply pressure regulator can be adjusted either at the adjustment knob (8), or

after screwing off the cap (5), at the set

point screw (7).

4

Turning the knob or screw clockwise increases the output pressure and turning it

counterclockwise reduces the output

pressure.

4

Use the lock nut (6) to secure the setting.

Note: When using the version with the adjustment knob (8) to adjust the set point,

make sure that the Phillips screws are

screwed tight to prevent the knob from coming loose due to vibration.

5 Maintenance

(Fig. 2)

We recommend you check the filter as often

as possible.

Drain condensed water that has collected:

4

Remove the stopper (10) or

4

Unscrew the drain plug (15) by about

half a turn or

4

Activate the manual drainage (16).

Note: Tighten the drain plug by hand only.

The maximum permissible tightening torque

is 3 Nm.

When faults occur, e.g. a pressure drop, unscrew the stopper (10) or the filter receptacle

(12) and replace the filter cartridge (order

no. 8504-9027).

Prior to carrying out any maintenance work,

shut off the air supply!

In the version with a filter receptacle, screw

the fixing screw (13) tight so that the filter

cartridge sits properly. Replace the gasket

(12.1) order no. 0439-0061, if necessary.

In the versions 4708-11xx/14xx, do not unscrew the bushing (11), if at all possible. If,

however, you needed to unscrew it, you can

replace the gasket (11.1) order no.

0439-0287 as well.

If there is any leakage at the stopper (10),

the entire stopper including the seal (10.1)

must be replaced. Refer to section 6.1 on

spare parts.

22 EB 8546 EN

Set point adjustment

Page 23

6 Troubleshooting

4

Leakage between supply pressure regulator and adapter plate:

Check whether the diverting gasket

(Figs. 3 and 4) is installed and both fixing screws are tightened properly.

4

Excessive blow-off over the venting bore

(3 in Fig. 2):

Check whether the diverting gasket

(Figs. 3 and 4) is installed correctly.

4

The air supply decreases and the output

pressure drops:

Check the filter cartridge (9 in Fig. 2) for

dirt and make sure the set point is correctly adjusted.

6.1 Spare parts

EB 8546 EN 23

Troubleshooting

Article

Order no.

Filter

Filter cartridge 20 µm

Filter cartridge 5 µm including seal

8504-9027

8504-9030

Filter receptacle

Filter receptacle, plastic

Filter receptacle, aluminum

Filter receptacle, stainless steel

1199-0423

1199-0424

1199-0425

Filter compatible with paint on request

Seal for filter receptacle

0439-0061

Stopper including seal (10 and 10.1 in Fig. 2)

1099-5055

Pressure gauge

Pressure gauge, entirely made of stainless steel

Pressure gauge, made of brass/stainless steel

0089-0009

0089-0018

Pressure gauge seal

1099-4305

Page 24

7 Accessories

24 EB 8546 EN

Accessories

Accessories Order no.

Mounting parts for mounting on rail acc. to EN 50022

acc. to EN 50035

1400-7341

1400-7342

Mounting parts for mounting on bracket for Type 3271 or Type 3277 Actuator 1400-7343

Intermediate plate for additional connection

with Types 4708-10xx/-11xx/-53xx/-55xx/-58xx/-62xx/-64xx (not required for Type 4708-54xx)

Aluminum with G ¼ thread

Aluminum with ¼ NPT thread

Stainless steel with G ¼ thread

Stainless steel with ¼ NPT thread

1400-7400

1400-7404

1400-7402

1400-7406

Intermediate plate for additional connection with Type 4708-57xx Supply Pressure Regulator

Aluminum with G ¼ thread

Aluminum with ¼ NPT thread

Stainless steel with G ¼ thread

Stainless steel with ¼ NPT thread

1400-7401

1400-7405

1400-7403

1400-7407

Special screw to mount Type 4708-54xx on Type 3710 Reversing Amplifier 1400-7806

Adjustment knob for set point adjustment 1400-7408

Nut for panel mounting 1400-7725

Adapter plate for manual/automatic transfer (Type 4708-82)

Aluminum with G ¼ thread

Aluminum with ¼ NPT thread

Stainless steel with G ¼ thread

Stainless steel with ¼ NPT thread

1400-9605

1400-9606

1400-9607

1400-9608

Adapter plate (from Type 3710) to mount Type 4708-53 on old models of Types 3733,

3767 and 3780 Positioners

1400-9621

Page 25

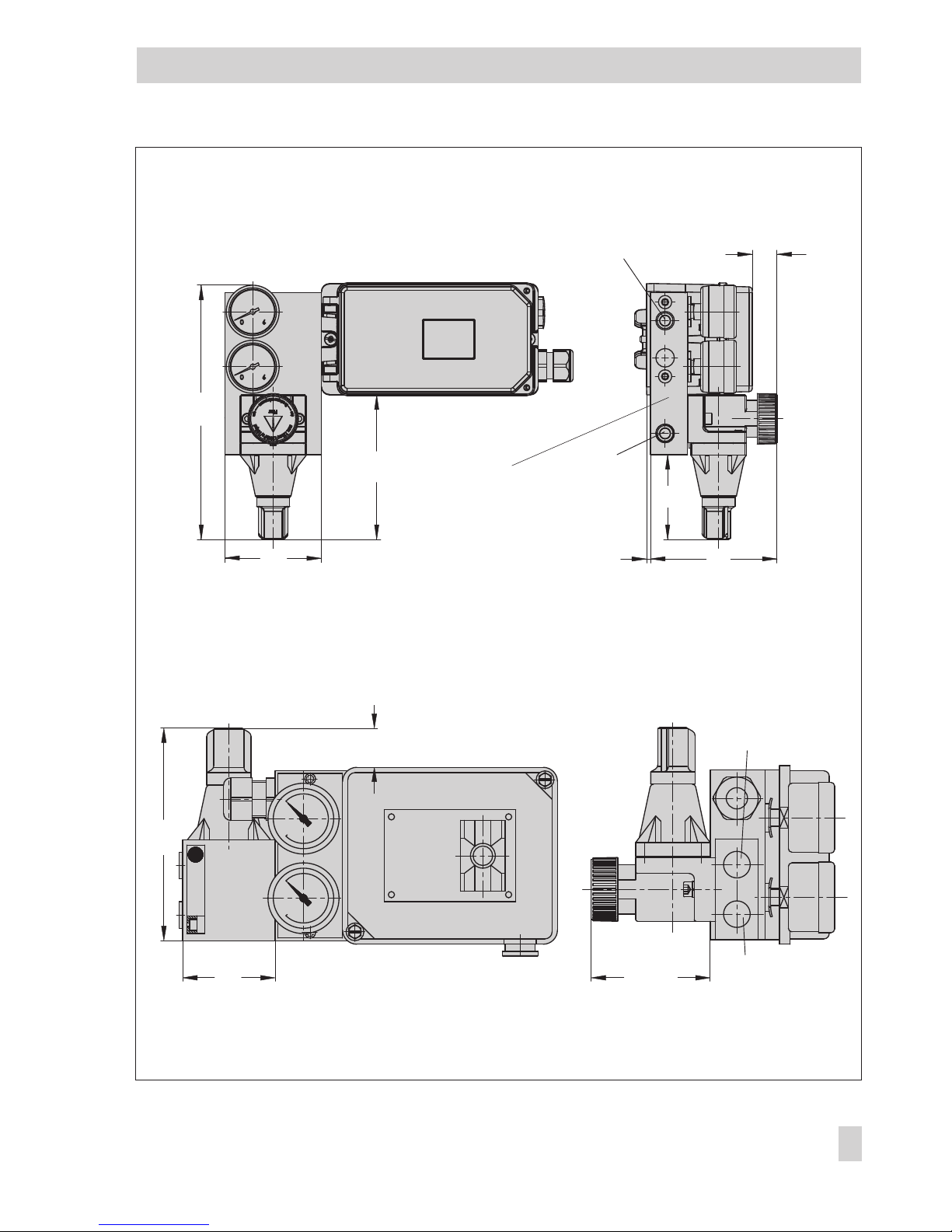

8 Dimensions in mm

EB 8546 EN 25

Dimensions in mm

79

524339

19

51

4460

90

126

78 (102)

79

5243

19

51

60 44

182 (206)

Type 4708-11xx/14xx Supply Pressure Regulator

Supply pressure regulators with intermediate plate

The overall height increases by 24 mm for the

additional connection.

In this case, the dimensions in parentheses () apply.

Mounting bracket

(accessories)

Type 4708-10xx/17xx Supply Pressure Regulator

Page 26

26 EB 8546 EN

Dimensions in mm

06

06

80

65(89)

Output

Supply

51

25

70

4708-535.

NPT

44

59

42

15

116

99

42

44

Ø41

102

123

12

59

Type 4708-12xx/13xx Supply Pressure Regulator

Type 4708-83xx/84xx/86xx/87xx

Supply Pressure Regulator

Type 4708-53xx Supply Pressure Regulator

for Types 3730/3766/3767/3780/3785/3787 Positioners

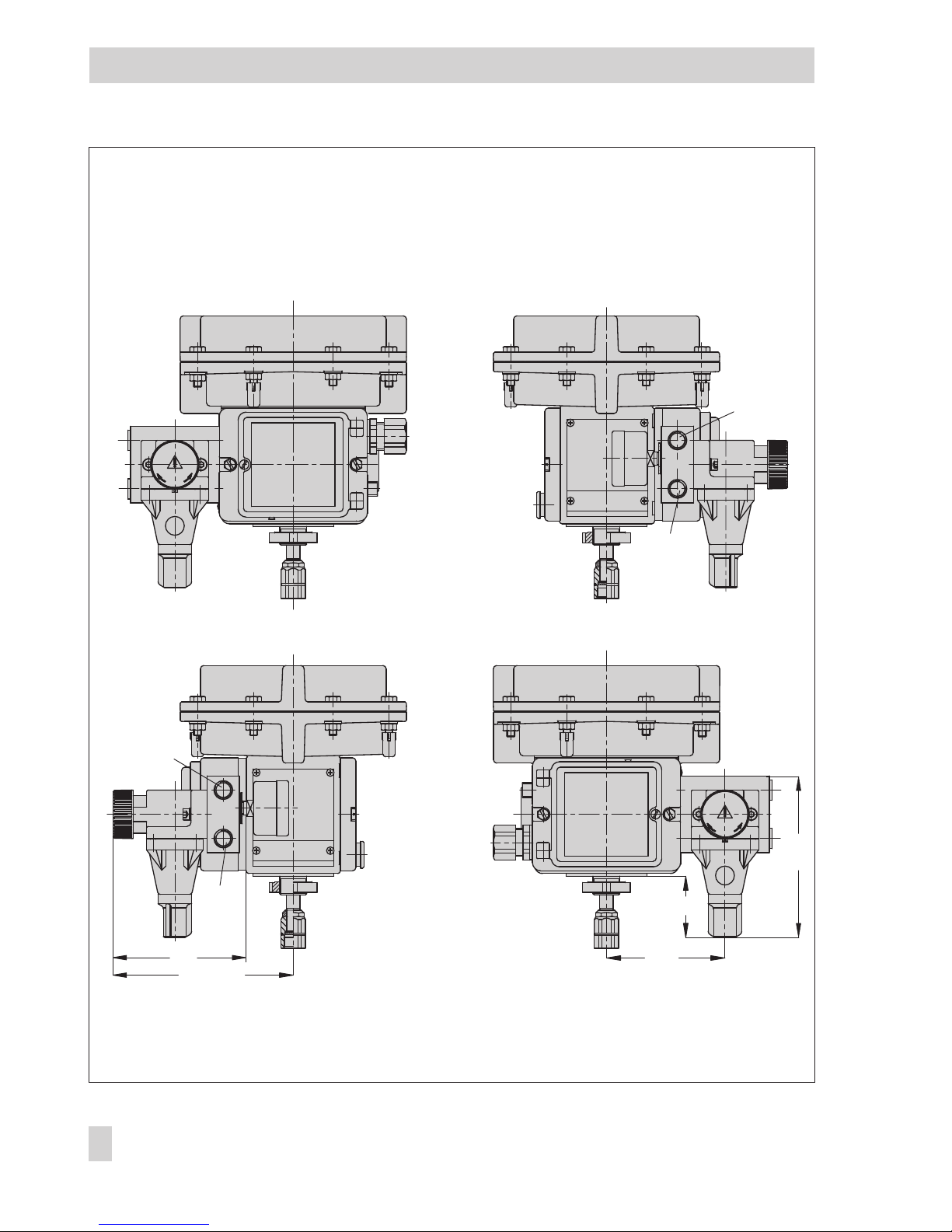

Page 27

EB 8546 EN 27

Dimensions in mm

73

192

111

66

96

19

3

Output

Supply

Type 4708-54xx Supply Pressure Regulator

for Types 3730/3766/3767/3780/3785/3787 Positioners

Type 4708-55xx

for Types 4763/4765 Positioners

G

6

0

SAMSON 4763

4708-552.

6

0

Output

Supply

66 (90)55

27

122

Output

(reduced supply)

Page 28

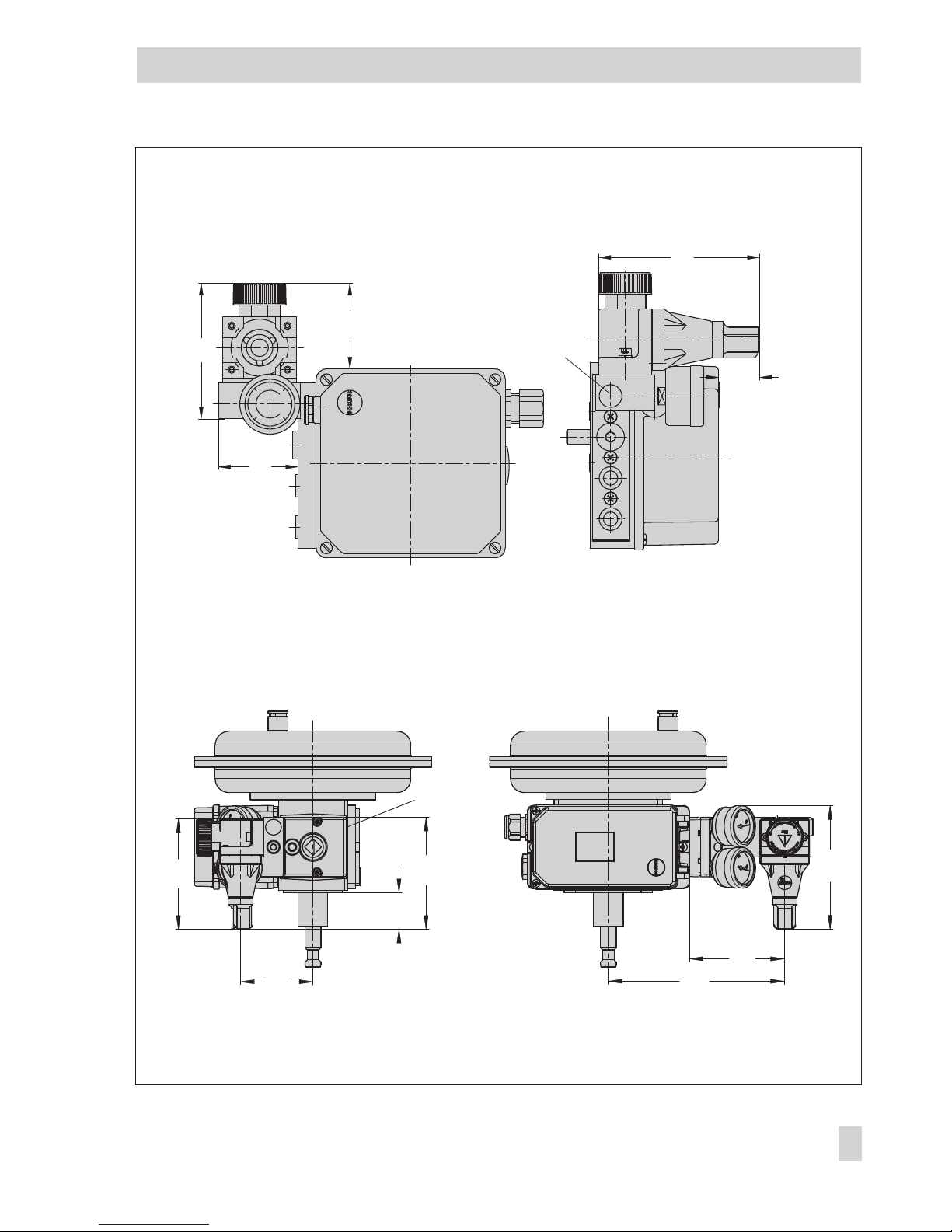

28 EB 8546 EN

Dimensions in mm

99 122

133 (157)

Supply

Input

Signal

Input

Signal

Supply

927

927

47

122

Type 4708-57xx Supply Pressure Regulator

for Type 3760 Positioner

Page 29

EB 8546 EN 29

Dimensions in mm

1

38

238

G

Output

Output

S

Input

6

5

4

3

2

1

0

SAMSON

27

60

(84)

Supply

56

111

30

93

74 207

111

125

113

37

125

Supply

G3/8

Type 4708-64xx

for Type 3277 Actuator

Attachment on left or right

Type 4708-58xx

for Type 3761 Positioner

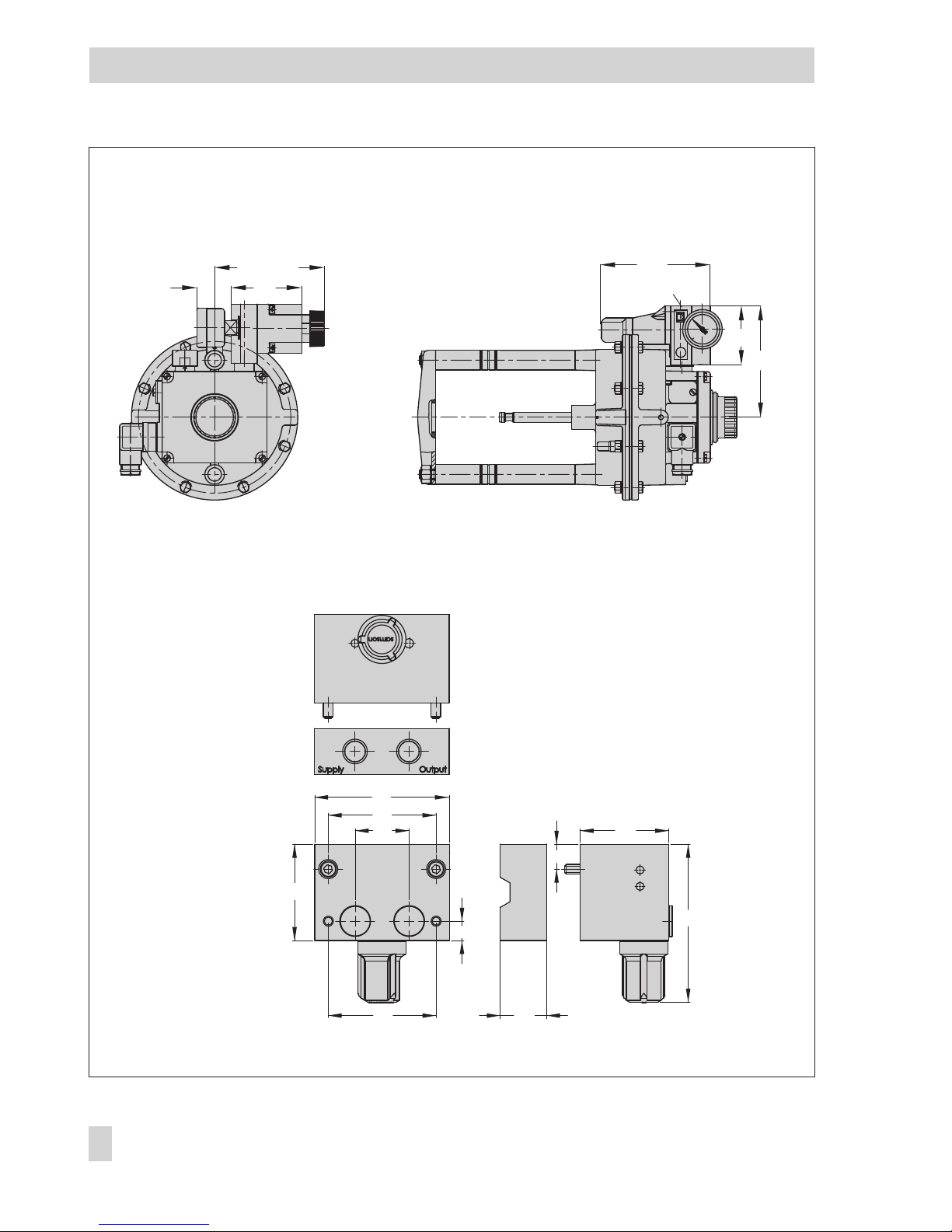

Page 30

30 EB 8546 EN

Dimensions in mm

0

6

G

4708-622X

Supply

19 94

111(135)

113

60

Supply

113

Type 4708-6221

for Type 3372-031x Actuator

70

56

56

46

24

82

28

50

13

10

Type 4708-82

Manual/automatic transfer unit with adapter plate

Page 31

EB 8546 EN 31

Page 32

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 8546 EN

S/Z 2012-08

Loading...

Loading...