Sammic SV-810CCS User Manual

FOOD PRESERVATION AND SOUSVIDE

VACUUM PACKING MACHINES - S RANGE

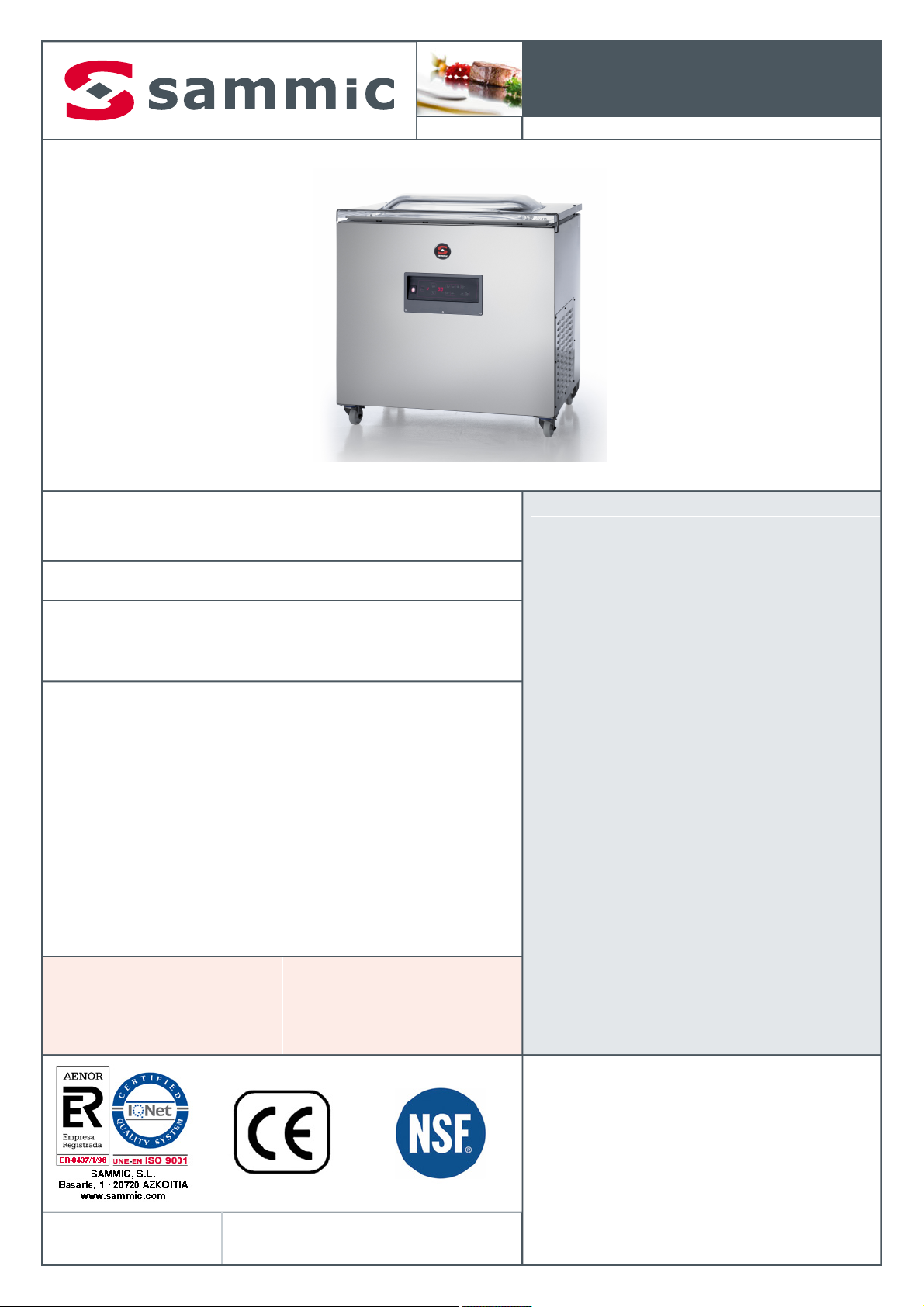

Vacuum Sealer SV-810CCS

FLOORSTANDING UNIT. 100M³/H. 580 + 580 MM.

Two sealing bars (580 + 580 mm.)

100 m³/h Busch vacuum pump.

· Improves the durability of cooked or raw food, with no loss of weight.

· All functions are controlled by a microprocessor, which allows control of the exact

desired vacuum percentage in the chamber.

· Vacuum PLUS: allows to program an extra vacuum time once 99% vacuum has

been reached.

· Easy to program. 10-program-memory.

· Stainless steel body.

· Stainless steel chamber.

· Cordless sealing bars.

· Softair as standard.

· Gas flush as standard.

· Digital keyboard.

· LED’s indicate each cycle stage whilst performing.

· STOP key allows the interruption of the cycle at any stage, moving on to the next

step.

· Pump drying program: improves the durability of the machine.

· Working hours counter display, which allows to know when oil must be replaced.

· NSF-International certified appliance (complying with Hygiene, Cleaning and Food

Material regulations).

TECHNICAL SPECIFICATIONS

Pump capacity: 100 m3/h

Useful length of the sealing bar: 580 mm + 580 mm

Total loading: 2200 W

Vacuum pressure (maximum): 0.5 mbar

Internal dimensions

·Width: 864 mm

·Depth: 603 mm

·Height: 210 mm

External dimensions (WxDxH)

·Width: 990 mm

·Depth: 760 mm

·Height: 995 mm

Net weight: 250 Kg

Noise level (1m.): 75 dB(A)

Background noise: 32 dB(A)

DEFAULT EQUIPMENT OPTIONAL EQUIPMENT

· Filling plate.

2006/95/EC, 2004/108/EC, NSF/ANSI

Standard 169.

UNE-EN 60335-1:1997. UNE-EN 60335-2-64:2001

EN 55014-1 (2000), EN 55014-2 (1997)

EN 61000-3-2 (1995)

· Vac-Norm external vacuum kit.

· Bag cutting kit.

· Liquid insert plate set.

· Vacuum sealing bags.

Loading...

Loading...