Page 1

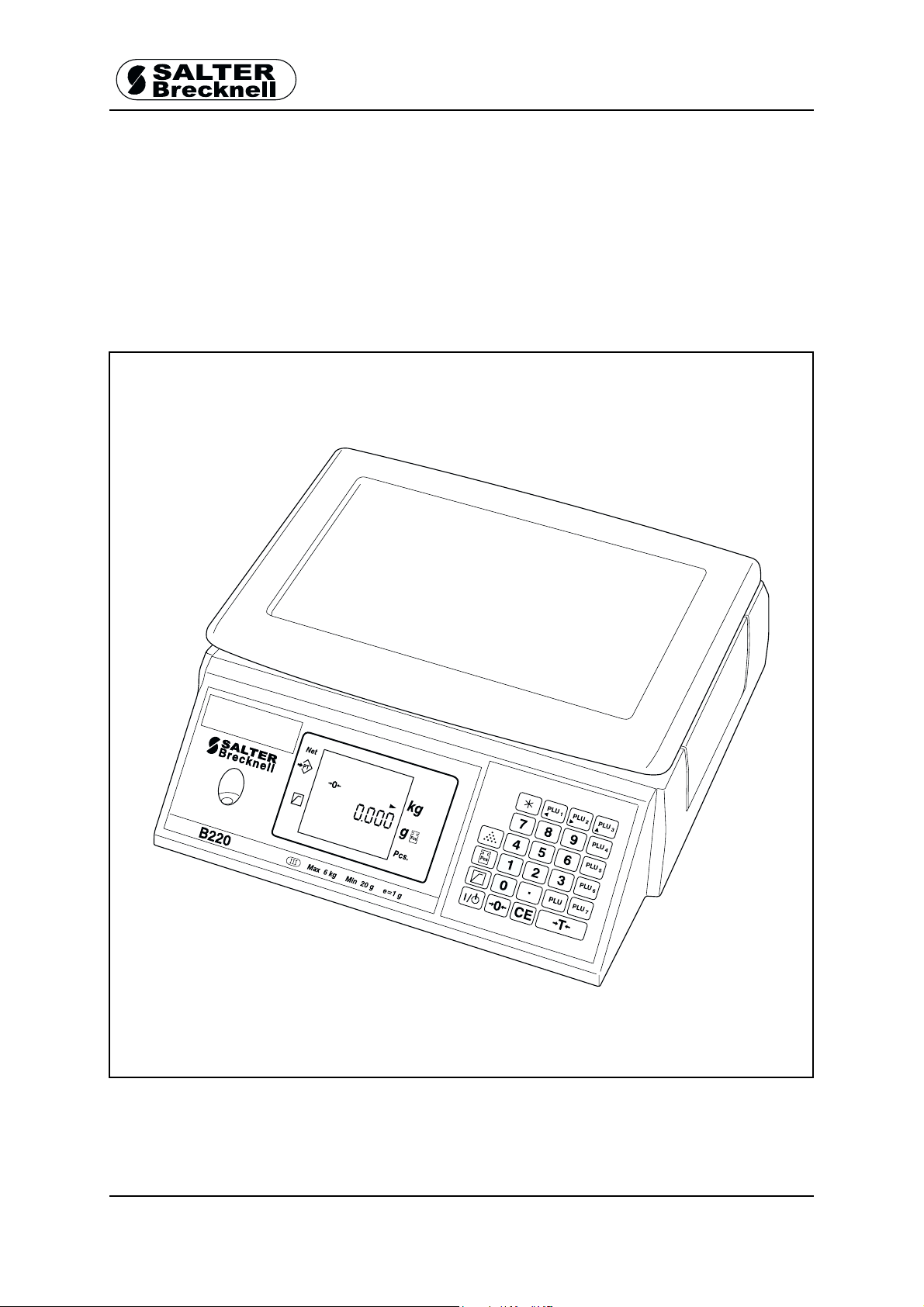

B220/S220 Parts Counter

Service Instructions

76103-382 Issue 1

*76103-382*

07.09.01

Page 2

Page 3

Table of Contents

Table of Contents

Removing the covers 1

Installing expansion boards 2

Installing a head-up display -3

Status display 4

Error messages 5

Configuring the scale 6

Management mode 6

Restricted service access 6

To enter restricted service access 7

Full service access 7

Verification mode 7

To go to the configuration menus 7

Exiting from full or restricted service access 7

Navigating service mode 8

Product configuration branches 9

Branch 0 - Edit counter 9

Branch 5 - Typical configurations 9

Branch 6 - Weighing functionality 10

Branch 7 - Weighing limits 12

Branch 08 - Gravity compensation 12

Branch 09 - Weight display 13

Branch 19 - Bleeper functions 13

Branch 20 - Power saving 13

Branch 29 - Key press duration 14

Branch 60 - Tares 14

Branch 100 - PLUs 14

Calibration 15

Aborting calibration 16

Replacing a head-up display 17

30kg scales 18

Stiffener plate 18

Base covers 18

Illustrated parts list 19

Head-up display 20

Wiring Diagram 21

B220/S220 Parts Counter Service Instructions i

Page 4

Page 5

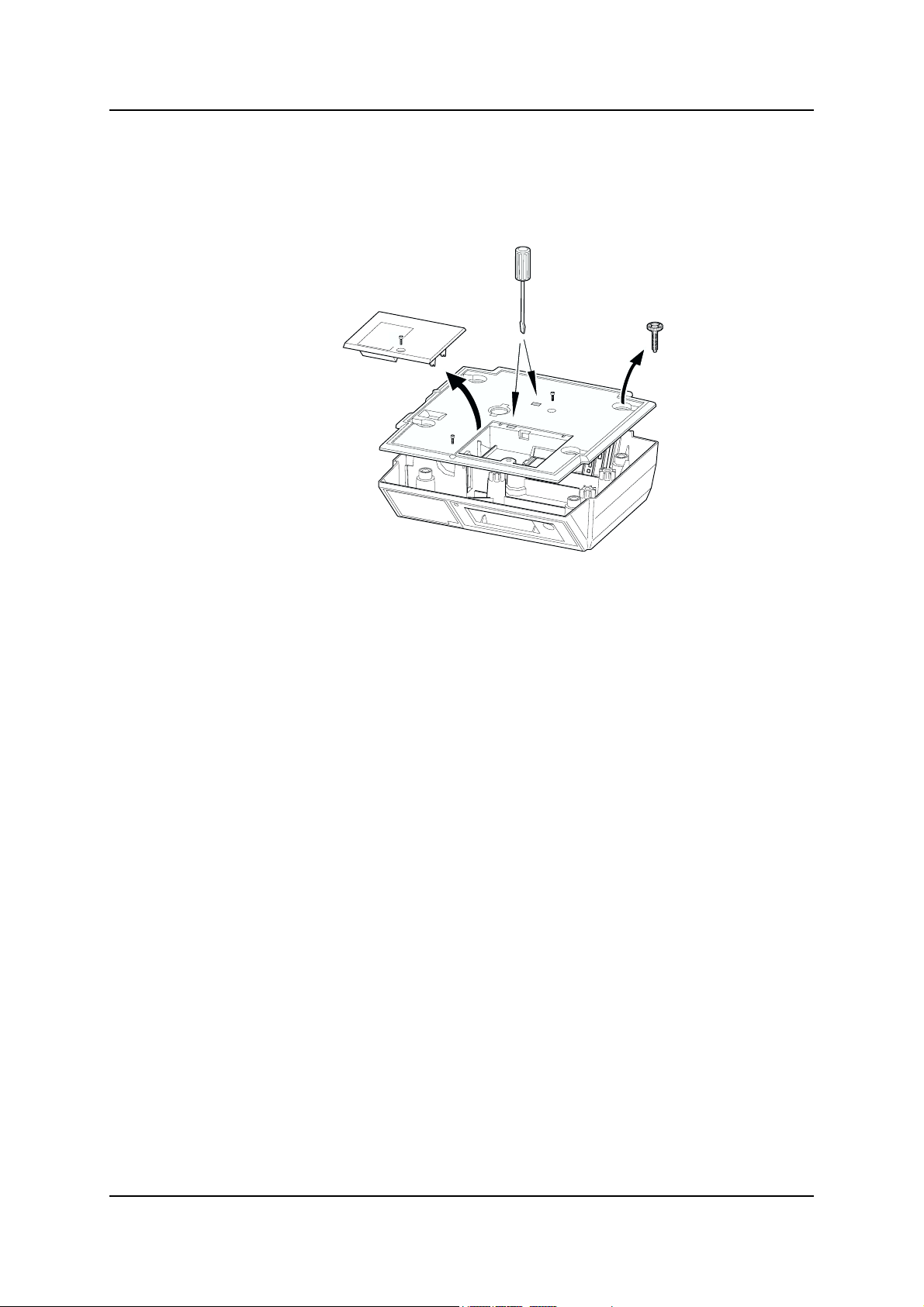

Removing the covers

Removing the covers

1. Disconnect the power supply from the scale.

2. Remove the weighplate.

3. Break the tamper seal.

4. Remove the screw (A) and remove the expansion board cover.

5. Remove the feet (and the springs if the scale is a 30kg machine).

6. Remove the screw (B) at the front edge of the scale.

7. Lever the clips holding the cover using a flat-bladed screwdriver.

NOTE: When replacing the cover, if either of the clips are damaged an M6 machine

or self-tapping screw (C) can be used to hold the cover in place.

B220/S220 Parts Counter Service Instructions 1

Page 6

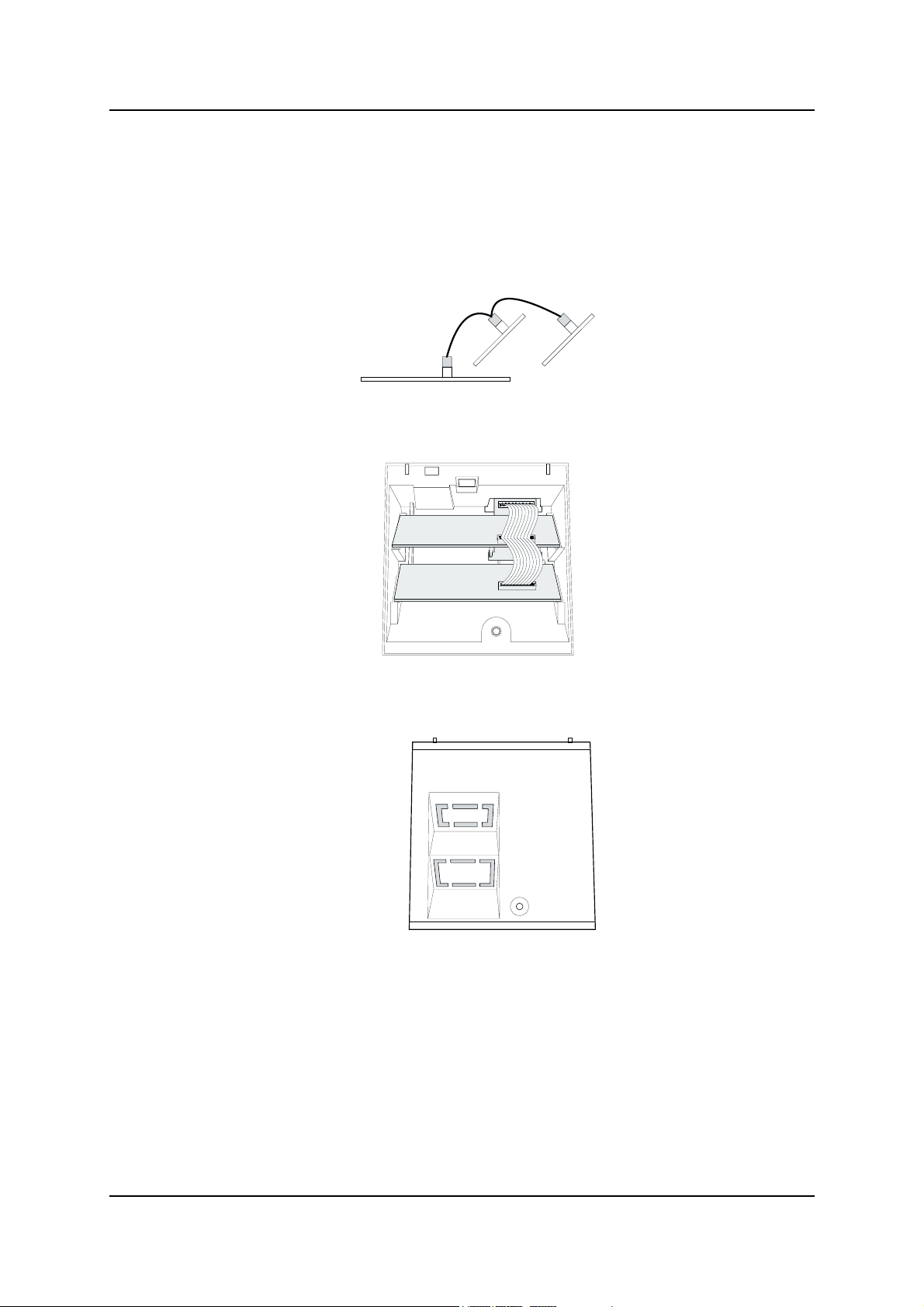

Installing expansion boards

Installing expansion boards

Refer to the fitting instructions included with each expansion board for details on

configuration settings.

1. Connect the wiring loom to the expansion boards.

2. Remove the cover and place the boards in their correct slots.

3. Break off the appropriate blanking plate and replace the cover.

2 B220/S220 Parts Counter Service Instructions

Page 7

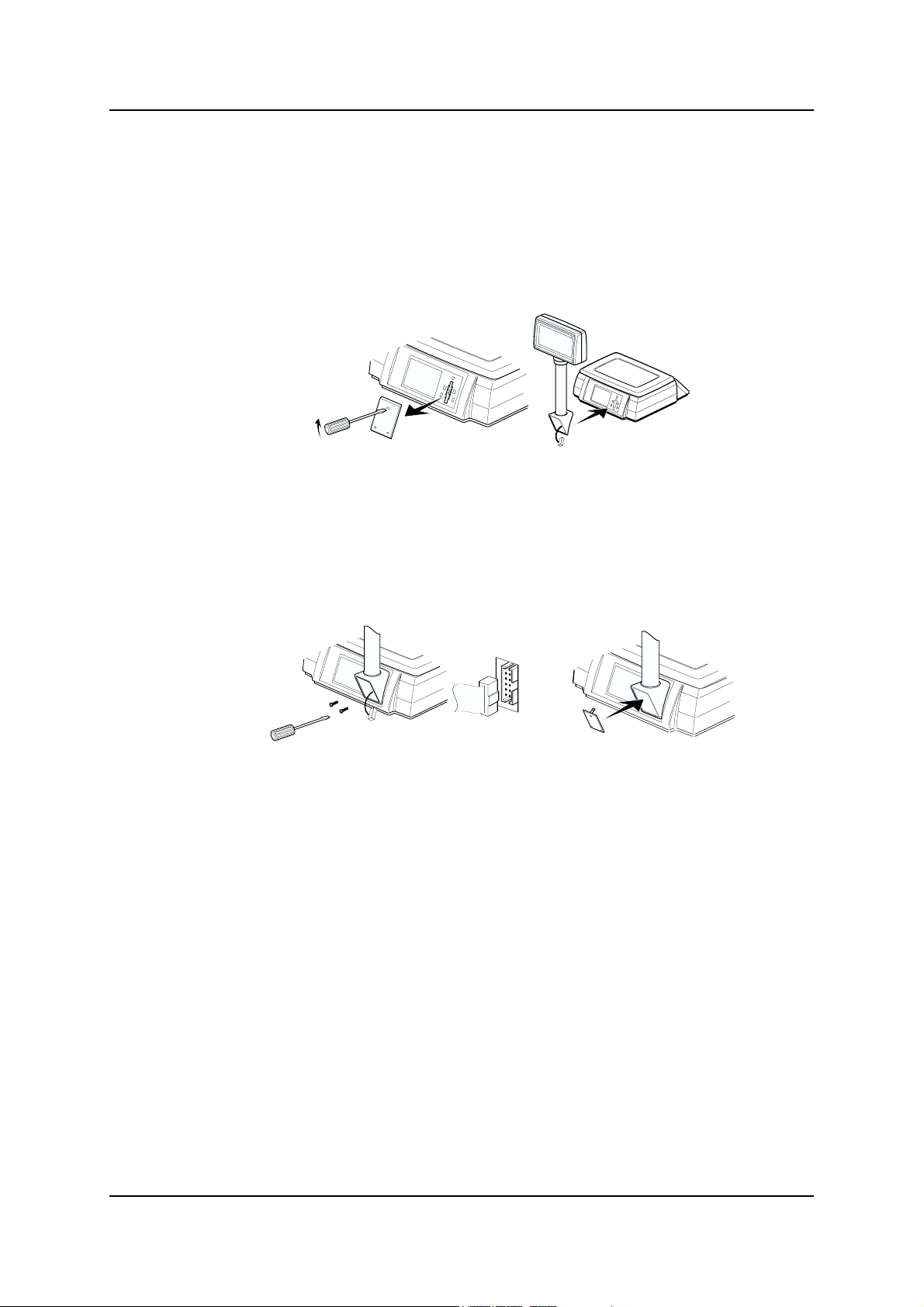

Installing a head-up display

Installing a head-up display

1. Disconnect the scale from the mains power supply, or remove the battery

pack.

2. Using a flat-bladed screwdriver, remove the blanking plate from the back of

the scale.

3. Attach the display using the two slotted screws. Carefully insert the plug from

the display into the socket at the back of the scale.

NOTE: Do not push the connector into the socket too hard as you may damage

the socket.

4. Replace the blanking plate, and reconnect the power supply.

B220/S220 Parts Counter Service Instructions 3

Page 8

Status display

Status display

The status display shows some basic information about the scale. to view this

information, press the display test key twice:

Top row Middle row Bottom row

0 Boot block product code Boot block version number

1 Application block product code Application block version number

2 Configuration block product code Configuration block version number

3 Product configuration checksum

status:

0 - OK

1 - Checksum failed

4 Mains/battery voltage Blank

5 Secondary calibration counter Blank

6 Cause of last reset:

0 - Power down

1 - Watchdog

2 - Clock monitor

If you need to contact your authorised service agent for advice, please make a

note of all the settings shown.

Product configuration edit counter

Blank

4 B220/S220 Parts Counter Service Instructions

Page 9

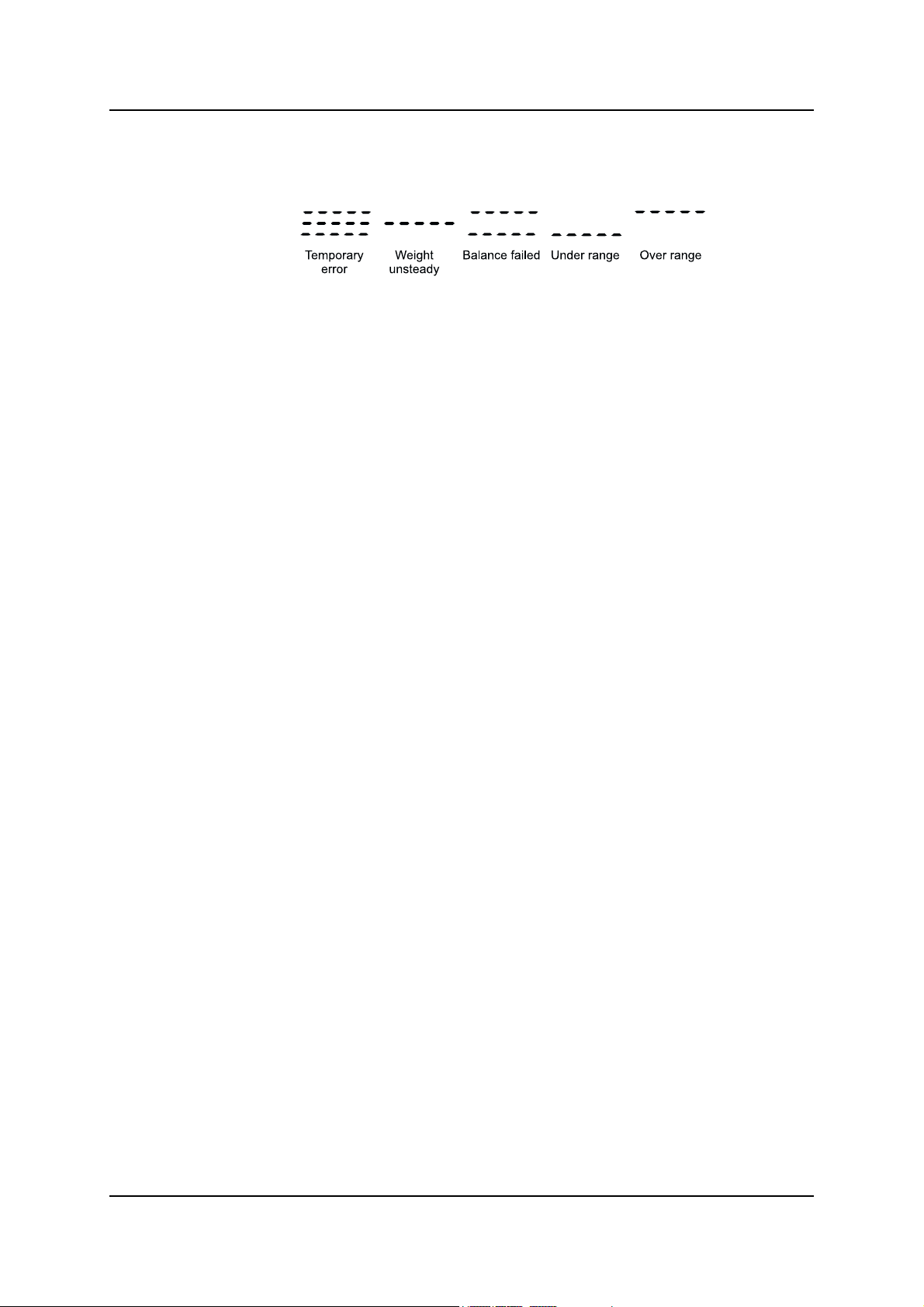

Error messages

Error messages

E5 Disconnect then reconnect the power supply.

E10 Battery failure - replace the batteries (do not use NiCad batteries).

E11 Power supply voltage too high. Make sure the correct power supply is

being used (see page ).

E15 Disconnect then reconnect the power supply.

E19 Software download tool error. Try downloading the application again.

E20 Disconnect then reconnect the power supply, if the error reappears, you

will need to replace the load cell (see page ).

E21 This could be caused by excessive vibration or an incorrect service

calibration. Either adjust the filters (see page ), or re-calibrate the scale

(see page ).

E30 Management/service mode not exited correctly. Re-enter service mode,

select the value to be changed, change the value and go to the next branch

or sub-branch to accept the change.

E35 An invalid configuration for the scale has been given in branch 5, re-enter

the configurations (see page ).

E36 An invalid capacity for the scale has been given in branch 5. Re-enter the

configurations (see page ).

E40 The weight used for user-calibration is unsteady, re-calibrate the scale.

E41 An incorrect weight is being used for user-calibration, use the correct

weights

E42 User calibration is not available for this scale.

E100 Invalid PLU contents, re-program the PLU.

E101 Transaction failed.

E102 PLU write failed. The PLU has been protected in management mode.

E103 Tare failed, re-program the tare.

E110 The counting piece-weight is greater than 10% of the capacity of the scale.

E151 A change to the configuration has failed, reprogram the configuration.

E152 User does not have access to this item (in management mode).

B220/S220 Parts Counter Service Instructions 5

Page 10

Configuring the scale

Configuring the scale

There are three ways to configure the scale:

Management mode

This mode allows the user to configure a few branches of the scale. Because the

configurations can be different for each scale, refer to the User Instructions for

details on the branches available.

To enter management mode:

To exit management mode:

Restricted service access

This will allow you to see all of the scales configuration.

You will not be able to alter the branches that are marked as 'Full service access

only', if you attempt to change these configurations you will see an error message

(E 152).

6 B220/S220 Parts Counter Service Instructions

Page 11

Configuring the scale

To enter restricted service access:

The scale will now be in verification mode (see below).

Full service access

This will give full access to the scales configuration.

1. Unplug the scale from the power supply.

2. Break the security seal and remove the blanking plate.

3. Plug the service tool (part number 18165-140) into the side of the scale.

4. Replace the weighplate and re-connect the power supply. The scale will now

be in verification mode (see below).

Verification mode

Verification mode will display the weight to four decimal places, and zero tracking

will be disabled.

To go to the configuration menus:

If you need to return to verification mode at any time, press:

Exiting from full or restricted service access

To exit:

You will need to disconnect the power supply, (remove the service tool if you are

in full service access) and reconnect the power supply.

NOTE: If you do not exit service mode correctly you will see an E 30 error

message.

B220/S220 Parts Counter Service Instructions 7

Page 12

Navigating service mode

Navigating service mode

Each configuration setting consists of a value and a location, the location consists

of a Branch number and a Sub-branch number.

Function Key

Go to the next branch.

Go to the next sub-branch.

Go to the previous branch. *

Go to the previous sub-branch. *

Go to branch 00.

Select value to be changed.

Change the value.

Note: After changing a value, you must go to the next

branch or sub-branch to accept the change.

Increment the value X10.

Exit service mode.

If you are using the service tool, disconnect the power

supply from the scale and remove the tool before

reconnecting the scale to the power supply.

* This key may not be available on some products.

8 B220/S220 Parts Counter Service Instructions

Page 13

Product configuration branches

Product configuration branches

NOTE: For older application block versions (0-5-0 or earlier) some branches or

sub-branches are not available.

Branch 0 - Edit counter

Sub-branch Value

00 - Default user mode This counter is automatically incremented whenever the product

configuration has been altered.

Branch 5 - Typical configurations

Full service access only.

NOTE: If you enter an incorrect value for these configurations you will see an E 30

or E35 error - re-enter the correct values.

Sub-branch numbers

Capacity 00 01 02 03 04 05 06 07 08 09 10 11 12

6kgx1g 6000 0 0 0 3 1 0 0 0 0 0 0 100

6kgx0.2g 6000 0 0 1 4 1 0 0 0 0 0 0 100

12kgx2g 1200000131000000100

15kgx2g 15000 0 0 1 3 1 0 0 0 0 0 0 100

15kgx0.5g 15000 0 0 2 4 1 0 0 0 0 0 0 100

30kgx1g 3000000031000000100

30kgx5g 3000000231000000100

B220/S220 Parts Counter Service Instructions 9

Page 14

Product configuration branches

Branch 6 - Weighing functionality

Full service access only.

Sub-branch Value

00 - Zero indicator. This determines when the

gross zero indicator appears on the display.

01 - Zero tracking. This is used to account for

minor weight changes over time. For

example, when weighing in dusty

environments.

02 - Balance on power up. When powered up,

the scale determines if it is within its

previous balance range, if it is, it looks at

sub-branch 03. If it is not a balance failed

indicator will appear. A typical example of

an error is if the scale is powered up without

the weighplate on the scale.

03 - Automatic zero self balance. If enabled,

the scale will automatically perform a

balance.

04 - Dual capacity switching. 0 - Allowed for all weight ranges.

0 - Gross zero appears when the range

is between ±0.25 divisions.

1 - Gross zero appears when the range

is between ±0.5 divisions.

0 - Disabled.

1 - Enabled.

0 - Disabled. No test performed.

1 - -5 to 15%.

3 - -2 to 2%.

0 - Disabled.

1 - Enabled.

1 - Only allowed at gross zero.

05 - Weight return to zero. When a weight has

been removed from the scale, this

determines how near to zero the scale must

be before displaying the zero indicator.

06 - Hysteresis. This is used to prevent the

weight display from flickering between the

top of one weight increment and the bottom

of the next.

07 - Normal balance range. This is percentage

of the capacity that the zero can move away

from the power up balance due to zero

tracking, automatic or manual balance.

08 - Filters. If the scale is in an environment

where there is vibration, for example in a

mechanical workshop, filters can be applied

so that the weight display remains steady.

The stronger the filter the longer the display

will take to display a weight.

0 - Gross zero division.

1 - Between 0 and 20 divisions.

0 - Disabled.

1 - Enabled.

0 - 200 Primary capacity (%) multiplied

by 2.

For example, 200 = 100% 50 =

25%.

0 - Default filter (3).

1 -8 1 = Slight filter, 8 = Strong filter.

10 B220/S220 Parts Counter Service Instructions

Page 15

Product configuration branches

Sub-branch Value

09 - Minimum test weight for customer

calibration. Not available.

10 - Maximum correction from customer

calibration. Not available.

11 - Alternate Units. This will convert the

displayed weight into the selected units.

12 - Weight steady. The weight must remain

within the given ± range for a set amount of

time before the weight is displayed.

13 - Tare increment. This sets the tare value

that can be accepted by the scale. For

example, on a 15kg x 5g scale if the tare

increment is set to 1, then the tare weight

must be a multip le of 5g. If the tare weight is

not a multiple, then the scale will not accept

the tare.

0 - 200 Capacity (%) multiplied by 2.

0 - 255 divisions.

0 - Disable alternate units.

1 - USA decimal Pounds.

2 - Grams.

0 - ± 0.1 divisions.

1 - ± 0.25 divisions.

2 - ± 0.5 divisions.

3 - ± 1 divisions.

4 - ± 1.5 divisions.

5 - ± 2 divisions.

6 - ± 3 divisions.

7 - ± 5 divisions.

0 - Allow any tare increment.

1 - Tare increment must be a multiple

of the weight increment.

14 - Automatic re-tare. This sets the percentage

of a tare within which subsequent tares will

also be allowed without having to press the

tare key. This is generally used where there

is minor weight variation between

containers. For example, cardboard boxes.

B220/S220 Parts Counter Service Instructions 11

0 - Disable automatic re-tare.

1- 200 tare range (%) multiplied by 2.

For example, 200 = 100% 50 = 25%

Page 16

Product configuration branches

Branch 7 - Weighing limits

Full service access only.

Sub-branch Value

00 - Minimum weight. This restricts the weight

display so that it remains blank until the

minimum weight has been exceeded.

01 - Under range limit. If the scale is set to

display negative values (Branch 9 subbranch 00) the weight display remains blank

until the negative weight has been

exceeded.

Branch 08 - Gravity compensation

Full service access only.

Sub-branch Value

00 - Calibration gravity factor. This is the

gravity factor of the location where the scale

has been calibrated..

01 - Site gravity factor. This is the gravity factor

of the location where the scale is to be used.

0 - 65535 divisions.

This is the minimum weight (shown on the

overlay) divided by the minimum weight

increment (e).

0 - 65535 divisions.

As published by the support office of your

national distributor.

Minimum value = 975000

Maximum value = 985000

You must enter a six digit value as the

gravity factors are automatically set to five

decimal places.

If the scale is to be calibrated and used in the same gravity zone, then both gravity

factors should be set to 0.

If you intend to calibrate the scale and then send the scale to a different gravity

zone, you must enter the calibration and site gravity factors.

If you do not know the site gravity factor, you must enter the calibration gravity

factor and send a note with the scale stating that the site gravity factor is to be

entered and needs to be re-verified and stamped before being sold to the

customer.

NOTE: Once the calibration and site gravity factors have been entered, the scale

may not weigh correctly until the scale is at the site.

12 B220/S220 Parts Counter Service Instructions

Page 17

Product configuration branches

Branch 09 - Weight display

Full service access only.

Sub-branch Value

00 - Blank net weight display. This sets the

display to either show a negative net weight

or to blank the display when a tare is

created and then removed from the scale.

01 - Weight decimal marker type. 0 - Comma.

Branch 19 - Bleeper functions

Sub-branch Value

00 - Bleep when below zero. 0 - Disabled.

01 - Keyboard bleep. 0 - Disabled.

02 - Target bleep. 0 - Disabled.

03 - Error bleep. 0 - Disabled.

0 - Negative net weight display.

1 - Blank net weight display.

1 - Decimal point.

1 - Enabled.

1 - Enabled.

1 - Enabled.

1 - Enabled.

04 - Bleeper volume. 0 - Quiet.

1 - Loud.

Branch 20 - Power saving

Sub-branch Value

00 - Backlight timeout. This is the length of time

between the last scale activity and the

backlight being activated.

01 - Sleep timeout. This is the length of time

between the last scale activity and the scale

going into 'SLEEP' mode.

0 - Permanently off.1 - 5 seconds.

2 - 1 minute.

3 - 5 minutes.

4 - Permanently on.

0 - No sleep timeout.

1 - 1 minute.

2 - 5 minutes.

3 - 30 minutes.

B220/S220 Parts Counter Service Instructions 13

Page 18

Product configuration branches

Branch 29 - Key press duration

Sub-branch Value

00 - ’Long’ key press duration. 1 - 255 milliseconds X10

(E.g. 200 = 2sec).

Branch 60 - Tares

Sub-branch Value

NOTE: See also, branch 6 sub-branch 13 - tare increment, and branch 6 sub-branch

14 - automatic re-tare.

00 - Manual balance whilst tare active. 0 - Manual balance disabled whilst any

tare is active.

1 - Manual balance clears the tare after

a successful balance.

01 - Minimum piece weight. Weight in grams.

02 - Minimum sample size. Weight in grams.

03 - Item count thousands separator. 0 - Disabled.

1 - Enabled.

04 - Keyboard entered (graduated) tare. 0 - Disabled.

1 - Enabled.

05 - Cumulative tare. 0 - Disabled.

1 - Enabled.

06 - Stored tare. 0 - Disabled.

1 - Enabled.

Branch 100 - PLUs

The branch number for a PLU = 100 plus the PLU number

For example, PLU 5 = 105, PLU 19 = 119

Sub-branch Value

00 - Write protect. 0 - Write enabled.

1 - Write protected.

01 - Piece weight. Weight in grams.

02 - Stored tare. Weight in grams.

14 B220/S220 Parts Counter Service Instructions

Page 19

Calibration

Calibration

You will only be allowed to calibrate the scale when using full service access.

1. Unplug the scale from the power supply.

2. Break the tamper seal, remove the blanking plate and plug the service tool

into the side of the scale.

3. Replace the weighplate and re-connect the power supply.

4. Check that the gravity factors are correct (see page 12).

5. Place a full load on the scale and remove it several times in order to 'exercise

the scale'.

6. Enter calibration mode:

7. Make sure there is no load on the scale.

8. Place a half load on the scale.

9. Place a full load on the scale.

10. Remove half the load.

11. Remove all the load.

B220/S220 Parts Counter Service Instructions 15

Page 20

Calibration

12. The calibration procedure is now complete.

13. Disconnect the scale from the power supply.

14. Remove the service tool from the side of the scale and reconnect the power

Aborting calibration

If you attempt to abandon the calibration procedure you will see:

You must start the calibration procedure again.

supply.

16 B220/S220 Parts Counter Service Instructions

Page 21

Replacing a head-up display

Replacing a head-up display

1. Slide the collar down the column.

2. Gripping the headup display firmly, press hard at the two points marked A,

and break open the covers:

3. Disconnect and remove the damaged display.

4. For the new display, make sure that both dip-switches are in the ON position.

5. Fit the new display, making sure that the loom is connected to socket 'B'.

6. Snap the covers together and re-fit the collar.

B220/S220 Parts Counter Service Instructions 17

Page 22

30kg scales

30kg scales

For 30kg scales, a stiffener plate must be used.

Stiffener plate

Base covers

If you need to replace a damaged base cover, break off all four cut-outs from the

new cover before replacing.

18 B220/S220 Parts Counter Service Instructions

Page 23

Illustrated parts list

Illustrated parts list

B220/S220 Parts Counter Service Instructions 19

Page 24

Illustrated parts list

Head-up display

20 B220/S220 Parts Counter Service Instructions

Page 25

Wiring Diagram

Wiring Diagram

B220/S220 Parts Counter Service Instructions 21

Page 26

Wiring Diagram

Power supplies

COUNTRY P/N NOTE

UK 70682-256 Low current

UK 70682-259 High current

USA 70682-257 Low current

USA 70682-260 High current

Europe 70682-258 Low current

Europe 70682-261 High current

Load cells

COUNTRY P/N NOTE

Blank 70718-623 Blank 15 kg - No software

Blank 70718-385 Blank 30 kg - No software

22 B220/S220 Parts Counter Service Instructions

Page 27

Index

Index

!

30kg scales 18

30kg stiffener plate 18

B

Bleeper functions 13

C

Calibration 15

Configurations 9

Configuring the scale 6

Covers 1

E

Edit counter 9

Error messages 5

Exiting service mode 7

Expansion boards 2

F

Full service access 7

G

Gravity factors 12

H

M

Management mode 6

N

Navigating service mode 8

P

Power saving 13

Power supplies 22

S

Service access 6

Service access Full 7

Service access Restricted 6

Status display 4

T

Tares 11, 14

V

Verification mode 7

W

Weighing functionality 10

Weighing limits 12

Weight display 13

Wiring diagram 21

Head-up display 3, 20

I

Illustrated parts list 19

K

Key press duration 14

L

Load cells 22

B220/S220 Parts Counter Service Instructions i

Page 28

Page 29

Page 30

This document contains a general guide only of the product of the product and shall not form part of any contract unless specifically agreed by Salter Brecknell Weighing

in writing in each case on the Order Acknowledgement. The specification of the products described herein may vary from time to time and may be altered without notice.

PO Box 9533, Smethwick

West Midlands, B66 2TE

Tel UK: 0870 444 6132 Fax UK: 0121 623 6629

Email: sales@salterbrecknell.co.uk Tel Int: +44 (0)121 623 6675 Fax Int: +44 (0)121 623 6629

Loading...

Loading...