sahinler metal HKM-115 User Manual

L

E

U

N

A

M

S

`

R

E

S

U

E

S

U

E

S

U

D

O

M

M

M

O

R

I

O

R

I

O

R

I

N

N

N

O

O

W

W

W

D

D

O

O

O

R

R

E

E

E

L

R

R

R

`

`

L

L

S

S

K

K

K

H

H

H

E

E

M

M

E

K

K

K

R

R

R

A

A

M

M

M

M

M

M

N

N

–

–

–

U

U

A

A

A

E

E

1

1

1

C

C

C

1

1

1

L

L

5

H

H

H

5

5

E

N

I

I

I

N

N

E

E

C

a

d

.

1

6

2

8

5

B

U

R

S

A

/

T

U

R

K

E

Y

İ

z

m

i

r

Y

o

l

u

2

2

.

k

m

M

ü

m

i

n

G

e

n

c

o

ğ

l

u

C

a

d

.

1

6

2

8

5

B

U

R

S

A

/

T

U

İ

z

m

i

r

Y

o

l

u

2

2

.

k

m

M

ü

m

i

n

G

e

n

c

o

ğ

l

u

C

a

d

.

1

6

2

8

5

B

U

R

S

:

:

@

l

e

l

e

l

e

A

9

0

-

2

+

9

0

-

2

+

9

0

-

2

+

s

a

h

i

n

s

a

h

i

s

a

h

i

r

m

e

t

r

m

e

t

r

m

e

t

İ

z

m

i

r

Y

o

l

u

2

2

.

k

m

M

ü

m

i

n

G

e

n

c

o

ğ

l

u

0

-

2

2

4

-

4

7

0

0

1

5

8

(

6

l

i

n

e

s

p

b

x

)

F

a

x

T

e

l

:

+

9

0

-

2

2

4

-

4

7

0

0

1

5

8

(

6

l

i

n

e

s

p

b

x

)

T

e

l

:

+

9

-

2

2

4

-

4

7

0

0

1

5

8

(

6

l

i

n

e

T

e

l

:

+

9

0

W

e

b

:

w

w

w

.

s

a

h

i

n

l

e

r

m

e

t

a

l

.

W

e

b

:

w

w

w

.

s

a

h

i

n

l

e

r

W

e

b

:

w

w

w

.

s

a

h

S

p

a

r

e

S

S

p

p

a

r

e

p

p

a

r

e

m

i

n

l

e

r

m

a

r

t

s

&

a

r

t

s

p

&

a

r

t

s

&

c

e

t

a

l

.

e

t

a

l

.

s

e

r

v

s

e

r

v

s

e

r

v

s

o

m

c

o

m

c

o

m

i

c

e

:

s

e

i

c

e

:

s

i

c

e

:

s

p

b

x

)

E

m

a

i

l

E

m

a

i

l

E

m

a

i

l

r

v

i

c

e

@

e

r

v

e

r

v

s

i

c

e

@

i

c

e

@

:

F

a

x

F

a

x

:

i

n

f

o

@

:

i

n

f

o

@

:

i

n

f

o

a

h

i

n

s

a

h

i

n

s

a

h

i

n

R

/

T

U

R

2

4

-

4

7

2

4

-

4

7

2

4

-

4

7

l

e

r

m

n

n

a

a

a

e

l

e

r

m

e

l

e

r

m

e

l

.

c

o

m

l

.

c

o

m

l

.

c

o

m

K

E

Y

K

E

Y

0

0

7

7

0

0

0

t

a

t

a

t

0

7

7

0

0

7

7

0

l

.

c

o

m

l

a

.

c

o

m

l

.

c

o

m

E

ECC

C

M

M

C

C

E

ESS

S DD

D

R

REE

ECC

CTT

T

V

VEE

E

8

8 //

/

/

/

E

ECC

C

C E D E C L A R A T I O N

We as

ŞAHİNLER METAL MAKİNE END. A.Ş.

İzmir Yolu 22.km

Mümin Gençoğlu Caddesi

Bursa / TÜRKİYE

confirm that the machine

HHKKMM 111155

Serial Number :

Production Year :

complies with

and the machine also harmonized with the standards

DIN EN 60204 Part 1

Position : General Director

Name : Orhan ŞAHİN

BURSA, on ..............................

r

A

H

I

C

N

H

I

N

C

H

I

N

E

w

i

t

h

E

C

-

w

i

t

h

w

i

t

h

-

C

E

-

C

E

-

C

E

s

i

o

s

i

o

s

i

o

i

D

-

i

D

-

i

D

-

D

E

C

-

D

E

C

-

D

4

/

3

9

4

/

3

9

/

3

9

9

9

9

o

V

w

o

L

L

L

e

e

e

e

r

r

r

o

V

w

o

o

V

w

o

l

e

v

e

L

l

e

v

e

L

l

e

v

e

L

t

c

s

e

v

i

t

c

e

e

s

e

v

i

i

t

c

e

v

E

e

p

r

e

p

r

e

p

A

M

A

l

a

c

e

d

l

a

c

e

d

l

a

c

e

d

N

-

C

E

N

-

C

E

N

-

C

E

C

E

C

E

E

I

I

I

R

i

r

e

c

i

r

e

c

i

r

e

c

/

4

/

4

/

4

4

6

/

3

6

/

3

6

/

3

g

a

t

l

g

a

t

l

g

a

t

l

i

D

e

r

D

r

i

i

D

r

M

E

M

E

E

s

t

t

E

E

e

e

M

I

9

I

9

I

V

9

8

3

i

v

e

s

i

v

e

s

t

i

v

e

s

G

W

G

W

G

W

E

E

C

/

8

E

C

/

8

E

C

/

8

e

3

7

e

3

7

e

3

7

e

v

i

t

c

e

v

i

t

c

e

v

i

t

c

9

8

V

9

8

V

9

8

V

6

9

1

/

/

3

6

9

1

3

/

/

s

s

6

9

1

/

a

d

n

a

d

n

n

a

d

E

E

E

E

/

3

2

E

/

3

2

E

/

3

2

/

1

/

6

8

1

/

6

8

/

6

8

s

6

3

3

/

6

3

3

/

6

3

3

/

1

8

W

/

/

/

8

8

W

W

8

8

8

3

7

/

W

G

G

W

W

G

E

a

n

d

a

n

d

a

n

d

G

G

G

3

7

3

7

/

E

W

/

E

W

/

E

W

G

G

G

E

/

8

E

/

8

E

/

8

G

W

E

G

W

E

G

W

E

CONTENTS Page

General notes 1 - 2

General warranty terms 3

Safety and accident prevention instructions 4

Transportation 5

Setting up the machine 6

Adjustment of the shear blade 7

View of the delivery side 8

Technical properties 9

Additional tools 10

Five work stations 11 - 12

Safety explanations 13 - 15

Operation of the machine 16

Punching table 17

Punching tools 18 - 19

Arrangement of the punch tools in general 20 - 21

Punch capacity 22

Safety precautions of the work stations 22

Steel bar and profile cutting installation 23

Shearing installation 24

Angle cutting installation 25 - 26

Grooving, grooving tools and parts 27 - 28

Stroke adjustment 29

Machine rod and lever readjustment 30

Hydraulic system, maintenance, lubrication 31 - 32

Hydraulic schema 33 – 34

Special accessories 35

Optional punch die and blade

Blade adjustment and part list

Electrical

GENERAL NOTES

1. Introduction

Thank you for choosing a Şahinler Sheet / Metal Working Machine. We are proud to have you

in our long list of satisfied customers all over the world.

This User’s Manual is absolutely for your safety and is essential for the machine to have a

long production life. As long as you keep up with our Manual you will be able to run your machine

smoothly and safely. Keep in mind that the machine is designed absolutely to perform maximum safety and for efficient working.

In this Manual you can find instructions and information about:

Correct installations of the machine

Description of the functional parts of the machine

Set-up and start-up adjustments

Correct standard and scheduled maintenance

Simple safety regulations and accident prevention.

Therefore, as far as the user’s safety is concerned, in this handbook the possible risks con-

nected with machine operation are pointed out as follows:

Attention: Showing the risks of accident, if instructions are not followed.

Warring: Showing the probable damages to the machine or equipment, if the in-

structions are not strictly followed.

Note: It gives useful information.

It is certainly necessary that the operator should read and understand all the Attention,

ring,

Note specified in this Manual before starting with operation of the machine and before any lubri-

cation or maintenance intervention

On all steps of installation, operation and maintenance safety must be your first concern for

the protection of yourself, other users and the service of the machine. In case of any failure please first

refer to this Manual, and then if a solution cannot be found contact first of all the distributor where you

purchased our product. Do not forget to refer to the drawings and the numbers for any spare part

needed or to define any problem. Make sure you have the serial number and production year of the

machine.

Our technical staff will make their best to help you in the most convenient way.

2. Transport

As soon as you receive the machine, check for any visible transport damages. Should there

be any visible damages; report it straight away to the transporter company and of course Şahinler

Metal Mak. End. A.Ş. or your supplier.

War-

Remove any protective crates around the machine and read the instructions on related chap-

ters of this Manual carefully to set up the machine. If the machine is damaged while transport, imme-

diately take some photographs for insurance claims.

Take precautions while loading / unloading or moving the machine to avoid any injuries. Refer

also to related chapter of this Manual for the best way of handling the machine.

3. Electrical Information

All necessary connection procedure can be found on this Manual. Do not try to connect the

machine before reading these procedures and fully understanding the drawings. For any unclear matters get in touch with Şahinler Metal Mak. End. A.Ş. or any of the Şahinler distributors. Have the machine connected by a qualified electric technician. For, as we made clear in the “general conditions of

guarantee”, under no circumstances installing mistakes, including electrical connection mistake, can

not be covered by guarantee agreement. Always turn off power before making any connections or

disconnecting the machine.

4. Maintenance

Your machine is designed and produced to work efficiently and smoothly. To achieve this you

should also take care while operating the machine. Regard Maintenance sections to have the longest

life from your machine. Try and use original spare parts where necessary and most importantly do not

overload the machine or do not make any unauthorized modifications.

5. Safety

Take all precautions possible to avoid any personal injury while using the machine. Keep in

mind to protect the third party people around the machine. Refer to safety directives.

GENERAL WARRANTY TERMS

Your machine is covered by manufacturer’s guarantee for a period of

of purchase against manufacture defects. The warranty period does not exceed 18 months from

the date of delivery from the manufacturer’s factory.

Warranty covers only manufacture defective parts and / or components that are reported as

“defective” by a Sahinler Technician or the Agent Technician and must be reported to Sahinler in

writing by fax or email.

The manufacturer is responsible for the supply of free of charge spares only and cannot be held

responsible for loss of work.

Shipping and customs fees for the spare part must be paid by the end-user.

If a technician travel is necessary Sahinler will not c harge for lab or a nd work manship c os ts but the

customer must pay traveling and accommodation charges.

A Warranty claim does not relieve the Customer from payment obligations.

12 months from the date

The Customer can not ask or demand any reimbursement of damage nor the Cus tomer will have

the right to extend or delay payment obligations nor the cancellation of order and the refunding of

damages as the guarantee is given for the defective parts of the machine and not for the job.

Note: All warranty claims must be applied with the Model, Serial Number and the

Manufacture Year of the mac hine.

-4 -

SAFETY AND ACCIDENT PREVENTION INSTRUCTIONS

General Safety Instructions

Following instructions are meant for the operator of the machine and it is the End-User’s

responsibility to make sure the operator reads and understands the following and the User’s Manual

for safe operation.

Read the User’s manual before operating the machine.

Always inform electric faults to electric technicians.

Keep your working dress or long hair or necklace etc away from rotating parts.

Make sure you know the position of Emergency Stop Buttons on the machine.

Switch off the machine when NOT worki ng .

Work with necessary safety clothes if necessary (safety shoes, glasses , earplugs etc).

Control the Safety features before working and ensure they are working properly.

See and understand Safety Labels on the machine.

Perform periodic maintenance.

DO NOT overload the machine.

If you see abnormal behavior of the machine, stop the machine and inform your supervisor

immediately.

Be careful of other people around the machine during operation.

Never modify electric unit.

Never remove any mechanic or electronic safety features from the machine.

Be extremely careful during transport or re-placement of the machine and follow transport

instructions in the manual to safety handle the machine.

Machine Specific Safety Instruction

Safety Features

Position of Emergency Stops.

Position of Safety Labels.

Position of the operator during operation.

Danger zones

We recommend you to use upper listed rules. If you use upper listed rules, we hope you will

not take industrial accident. Shows danger zones below the picture and these zones workstation of the

machine. You don’t touch into the danger zones

-4 -

SAFETY AND ACCIDENT PREVENTION INSTRUCTIONS

General Safety Instructions

Following instructions are meant for the operator of the machine and it is the End-User’s

responsibility to make sure the operator reads and understands the following and the User’s Manual

for safe operation.

Read the User’s manual before operating the machine.

Never touch rotating or moving parts.

Always inform electric faults to electric technicians.

Keep your working dress or long hair or necklace etc away from rotating parts.

Make sure you know the position of Emergency Stop Buttons on the machine.

Switch off the machine when NOT worki ng .

Work with necessary safety clothes if necessary (safety shoes, glasses , earplugs etc).

Control the Safety features before working and ensure they are working properly.

See and understand Safety Labels on the machine.

Perform periodic maintenance.

DO NOT overload the machine.

If you see abnormal behavior of the machine, stop the machine and inform your supervisor

immediately.

Be careful of other people around the machine during operation.

Never modify electric unit.

Never remove any mechanic or electronic safety features from the machine.

Be extremely careful during transport or re-placement of the machine and follow transport

instructions in the manual to safety handle the machine.

Machine Specific Safety Instruction

Safety Features

Position of Emergency Stops.

Position of Safety Labels.

Position of the operator during operation.

Danger zones

We recommend you to use upper listed rules. If you use upper listed rules, we hope you will

not take industrial accident. Shows danger zones below the picture and these zones workstation of the

machine. You don’t touch into the danger zones

-4 -

p

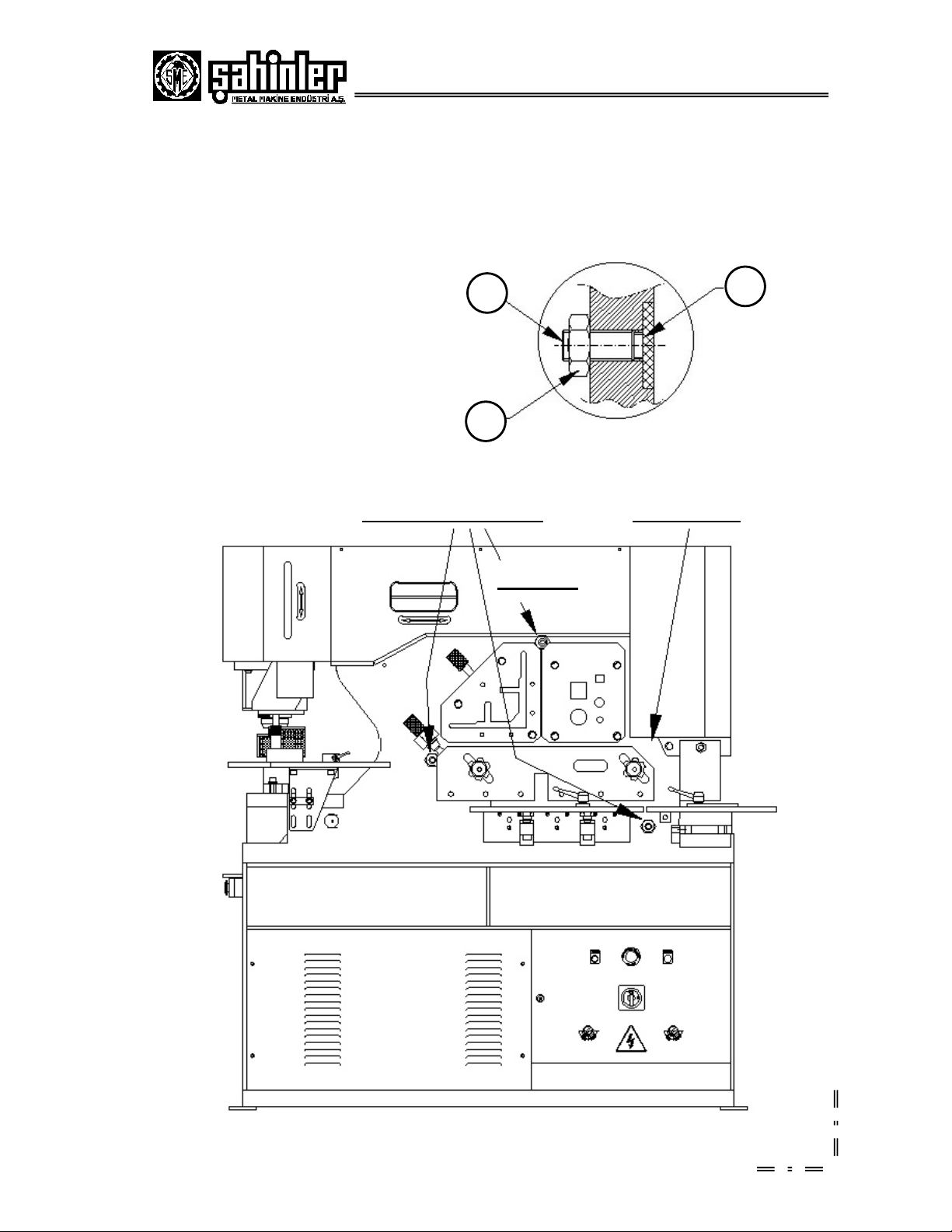

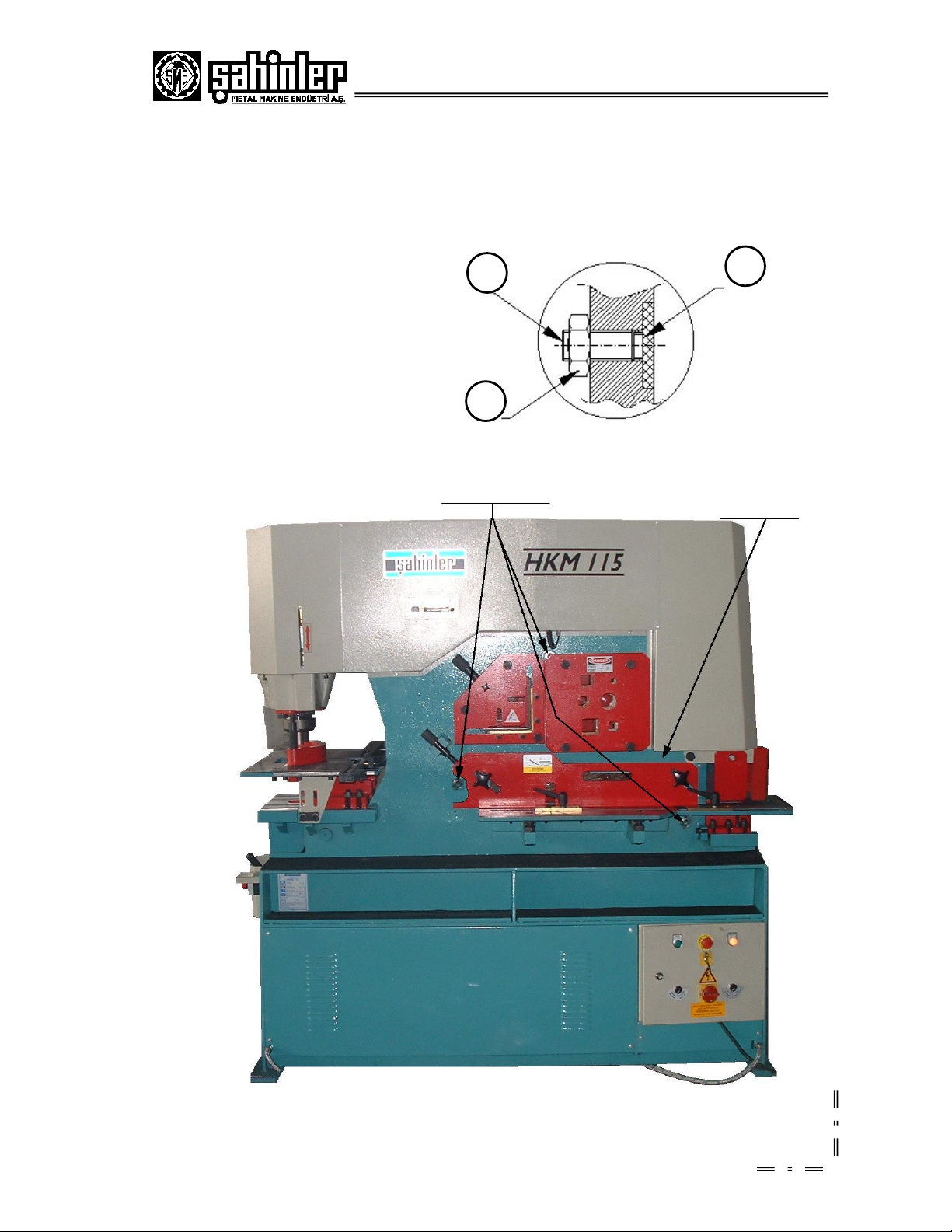

VIEW OF THE DELIVERY SIDE

Shear cylinder

Punch cylinder

Punch Unit

VIEW OF THE NOTCHING SIDE

Shear Unit

Lever Grou

Notching Unit

Hydraulic Unit

Adjustment of the shear blade

The adjustment of the shear levers should be carried out before any adjustment of the shear blade. The

adjustment explain as shown below.

Explanation of figure

1. Adjustment screw

2. Safety nut

3. Bronze pressure pl ate

1

2

Not to tension Shear lever adjustment

3

HKM115

-3-

Adjustment of the shear blade

The adjustment of the shear levers should be carried out before any adjustment of the shear blade. The

adjustment explain as shown below.

Explanation of figure

1. Adjustment screw

2. Safety nut

3. Bronze pressure pl ate

1

2

Shear lever adjustment

3

Not to tension

-3 -

SETTING UP THE MACHINE

Ask for the help of an experienced and qualified technician while setting up the machine.

1-) Fundamental Plan of the Machine

Four holes (Refer to the drawing below) Dia.15mm

2-) Instructions

For an effective machine, the position and the base of the machine are important. Be careful on

these points while placing the machine:

The machine must be placed on a flat, preferab ly cement base. To fix the machine use bolts.

There must be plenty of room all around the machine for easy working.

The machine height is ideal for any workingman.

There must be plenty of Light on top of the machine

855

1830

1870

DELİK ZIMBAS I PUNCHING

Max. Kalınlıkt a çap Diamet er x max. t hickn ess

Çap x kalınlık (Øxt) Diameter x thickness

Min. Kalınlıkta çap (Özel) (*) Diameter x min. Thickness Optional) (*)

İş kursu Stroke

Kurs adeti (20mm) Stroke count in (20mm)

Oluk derinliği Throat depth

Çalışma yüksekliği Working height

MAKA S SHEET METAL SHEAR

Düz sac Sheet metal

Düz sac Sheet metal

Bıçak uzunluğu Blade lenght

Açılı Kesim Shearing with angle

Çalışma yüksekliği Working height

PROFİL KESM E MAKASI ANGLE SHEAR

Dik köşebent (90º) Angle section (90º)

Açılı köşebent (45º) Angle section (45º)

Çalışma yüksekliği Working height

DOLU M ALZEME MAKA SI STEEL BAR SHEARI NG

Yuvarlak / Dörtköşe Round / Square

ÇENTİK AÇM A NOTCHING

Malzeme kalınlığı T hickness

Genişlik Width

Derinlik Depth

V Derinliği

Köşe flanşı Angle flange

Çalışma yüksekliği Working height

ÖZEL KALIPL AR

U - I profil bıçakları U-I Section blades

V Depth

OPTIONAL TOOLS

HKM 45 HKM 60 HKM 65 HKM 85 HKM 115 HPM 65 HPM 85

Ø22x15mm Ø28x15mm Ø26x20mm Ø33x20mm Ø34x26mm Ø26x20mm Ø33x20mm

Ø38x8mm Ø38x11mm Ø57x10mm Ø55x12mm Ø55x16mm Ø55x10mm Ø55x12mm

Ø100x3mm Ø110x3mm Ø110x3mm Ø110x5mm Ø110x5mm Ø110x3mm Ø110x5mm

50mm 55mm 55mm 80mm 80mm 55mm 80mm

x 20 x26 x 25 x25 x25 x25 x25

175mm 220mm 305mm 355mm 355mm 625mm 625mm

940mm 940mm 1030mm 1050mm 1050mm 1075mm 1050mm

200x15mm 200x20mm 300x20mm 380x20mm 380x25mm

300x12mm 300x15mm 375x15mm 480x15mm 600x15mm

316mm 317mm 380mm 482mm 610mm

80x10mm 80x10mm 100x15mm 120x15mm 120x15mm

940mm 940mm 890mm 900mm 900mm

100x100x10mm 120x120x12mm 130x130x13mm 150x150x15mm 150x150x18mm

70x6mm 80x8mm 70x10mm 80x8mm 80x10mm

1140mm 1140mm 1130mm 1155mm 1160mm

Ø30mm- 25mm Ø40mm- 35mm Ø45mm- 45mm Ø50mm- 50mm Ø55mm- 50mm

8mm 10mm 10mm 13mm 13mm

35mm 42mm 45mm 52mm 60mm

75mm 100mm 90mm 100mm 100mm

60mm 60mm 60mm 70mm 80mm

80x8mm 100x10mm 100x10mm 100x13mm 100x13mm 100x10mm 100x10mm

940mm 940mm 890mm 890mm 900mm

80x45mm 80x45mm 130x65mm 160x90mm 200x100mm

T profil bıçakları T Section blades

Özel çentik takımı Special V-notching tooling

Lama kıvırma

V kıvı rma

Sac kıvırma

Çentik

kısmında

zımba

TEKNİK ÖZELLİKLER TECHNICAL D ATA

derinliğ

max. Kapasite

max.

max.

Çene

V bending

Press brake

Punching on

notcher

Bar bend. max.

Sheet bend.

max.capacity

Bar bend. max.

max capacity

Motor gücü Motor power

Ağırlık Weight

Makine ölçüleri Machine dimensions

Basınç Power (Pressure)

Capacity

Capacity

40x6mm 80x10 90x12mm 100x12mm 120x12mm

100x100x8mm 100x100x10mm 100x100x10mm 100x100x13mm 100x100x13mm 100x100x10mm 100x100x13mm

100x12mm 150x12mm 250x15mm 250x20mm 250x22mm 250x15mm 250x20mm

500x3mm 500x3mm 700x3mm 500x3mm 500x3mm

85mm 110mm 125mm 125mm 125mm 125mm 125mm

18x12mm 20x12mm 38x8mm 38x10mm 38x12mm

4kW 4kW 5.5kW 7.5kW 7.5kW 5.5kW 7.5kW

1300kg 1250kg 1600kg 2430kg 3100kg 1900kg 2900kg

1200x600x1400mm 1510x590x1570mm 1625x750x1800mm 1900x790x1910mm 1880x790x1990mm 1450x850x1614mm 1670x855x1763mm

45 ton 60ton 65ton 85ton 115ton 65ton 85ton

7

ADDITIONAL TOOLS

PUNCHING AT THREADING STATION

Maximum capacity ( Diameter x Max. thickness ) 34x26 [mm]

Maximum capacity (Max. diameter x thickness ) 110x5 [mm]

Throat depth 355 [mm]

PROFILE CUTT ING

U – I Section blades 200x100 [mm]

T Sections blades 120x12 [mm]

NOTCHING

Thickness 13

Width 60

Depth 100

V Depth 80

Working height 900

[mm]

[mm]

[mm]

[mm]

[mm]

Special V-notching tooling 100x100x13 [mm]

Sheet bending max. capacity 700x3 [mm]

Based on material strength 45 [kg/mm2]

The maximum punching pressure of this machine is 1150 kN ( 115 ton )

The following tools are included in the basic equipment of the machine;

1 C – Spanner 120/130

4,5,6,8,10,14,19 mm. Allen keys

Punch adapter

Punch holder

Stamp and matrix ( 26 mm )

Scraper

Round square blade ( 1 set )

Angle cutting blade ( 1 set )

Profile cutting blade ( 1 set )

Notching tools

-7-

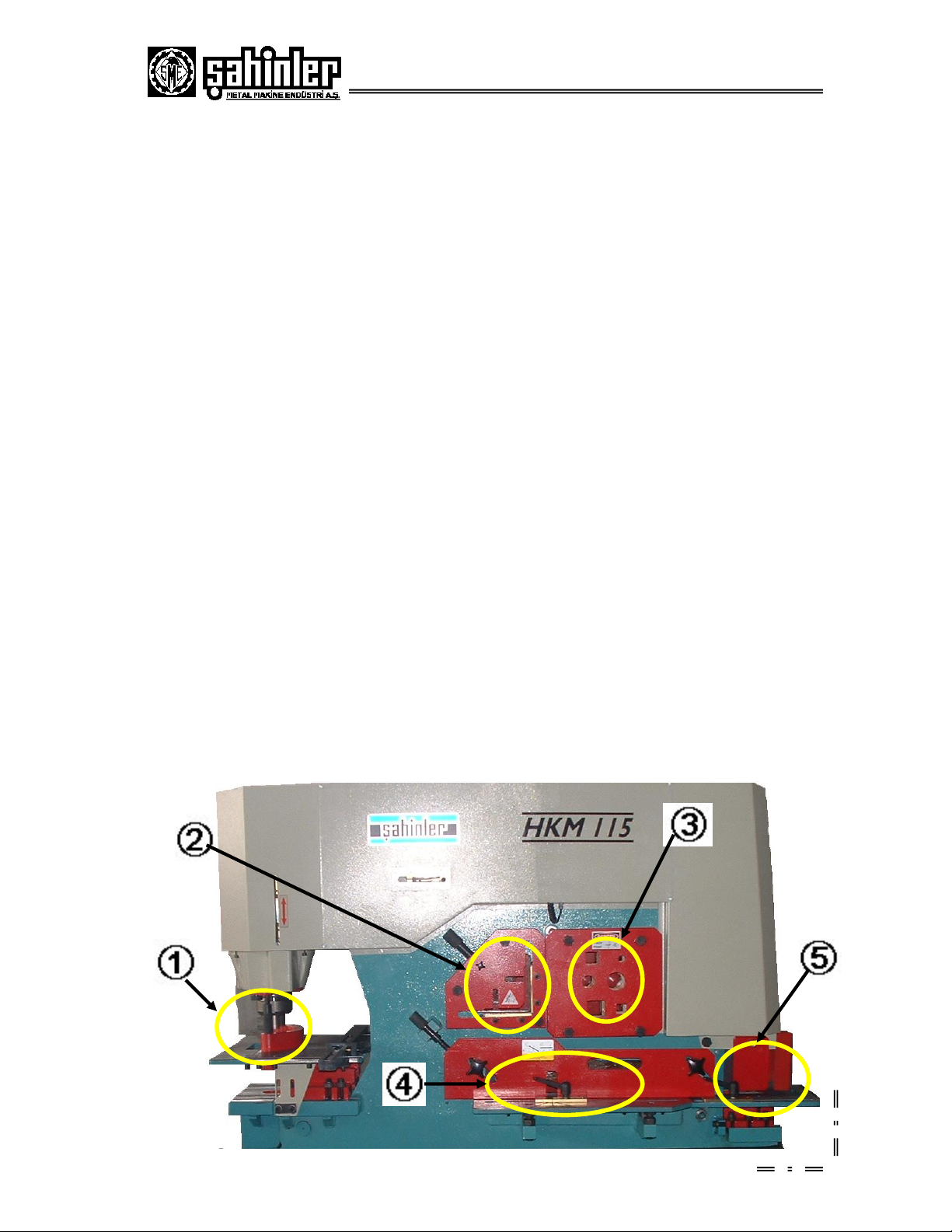

FIVE WORK STATIONS

1. 1-PUNCHING STATION

All punching operating are processed by means of hydraulic power thus giving the machine

the ability to punch very efficiently and silently. It can either be used to punch thick materials

or thin materials in layers together. Punching is silent, powerful, efficient. The waste materials

in layers together. The punching table consists two parts. First is the punching flange. The

second is holder. The holder is a device that holds the material after punching not to come

back with the punch. It must be equally adjusted or it can break the punch. There are different

holders for different materials. However the standard holder which we supply is suitable for

punching is between 6-55 mm.

SAFETY PRECAUTIONS

All power and depth and other adjustment must be done under full control of an

experienced technician

Please check all the moving parts before working

Check the punch and die that they are in the same direction

Adjust the holder equally and according to the material

always use the protective plastics

on small and accuracy needing works use special protection

while replacing the punch or die or holder shut the main switch

never leave the machine unattended

do NOT overload the machine

2. SHEARING STATION

The shearing unit has been equipped with a simple and robust fixing installation, which can be

adjusted for any material thickness within the cutting the cutting capacity of the machine. A

shearing up to 45

0

for flat bars or the cutting of the flanges of angle profiles, which have

previously been cut at inclined-angle cutting stations.

The shearing blades constructed for mass production can be used on both sides ( the upper

blade has 2 cutting edges, the lower blade has 4 cutting edges ) and ensure a clean cutting

with the minimum deformation, from the full capacity till a material thickness of only 2 mm.

SAFETY PRECAUTIONS

Always use the bolder

Never place any part of your body under the blade

Do NOT overload the machine

3. CUTTING STATION

This station enables the cutting of big angles with a capacity of up to 9 0

up to 45

0

. The angle between 45

at the shearing station of the flange will be cut at the required angle. The fixing installation

supports the material in a manner to provide a correct cutting.

SAFETY PRECAUTIONS

Never place your hand or fingers inside the blade.

Do NOT overload the machine

Use holder fitted on this station for a better work

0

and 90

0

0

will be obtained, these will be cut first at 90

and smaller angles

0

and then

4. PROFILE CUTTING STATION

The machine are equipped as standard with the blades for cutting round and quadrangle bars.

Through additional equipment, it is possible to cut at the machine U-section, I-section and T-

section profiles in this clearance. The blades are held by simple squeezing jaws which ensure

an easy equipment arrangement at the machine without any detailed adjustment.

SAFETY PRECAUTIONS

Never place your hand or fingers inside the blade.

Do NOT overload the machine

Use holder fitted on this station for a better work

5. NOTCHING STATION

The notching station has been equipped as standard with a rectangle unit and threading table

having adjustable counter holders, which enable a repeatable positioning. Additional

installations are available for narrow widths or V notching of angles up to 45

it is possible to have units for forming at bar ends and for easy notching works.

SAFETY PRECAUTIONS

Never put any part of your body under the blade

Use protective gloves or protective cages for very small works

Do NOT overload the machine

0

(V). Furthermore ,

SHOWS OF THE FIVE WORK STATIONS

STANDARD SPECIFICATIONS

Punch and die Ø26

Punch holder

Flange cut ting blade

Notching blade

Centralized lubrication

Crescent key

User’s manual

Loading...

Loading...