sahinler metal 4R HSS 320 User Manual

HYDRAULIC 4 ROLLS PLATE BENDING MACHINE

USER’S MANUAL

4R HSS 320

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 1 -

E

ECC

C

M

M

C

C

E

ESS

S DD

D

R

REE

ECC

CTT

T

V

VEE

E

8

8 //

/

/

/ EE

EWW

WGG

G //

/ CC

CEE

EEE

E

CE DECLARATION

We as

confirm that the machine

HYDRAULIC 4 ROLLS PLATE BENDING MACHINE

4R HSS 320

Serial Number :

Production Year :

complies with

and the machine also harmonized with the standards .

NAME : MUSTAFA PINARBAŞI

POSITION : PRODUCTION MANAGER

BURSA, ..............................

A

H

I

E

A

M

A

REPLACED WITH EC – DIRECTIVES 91 / 368 / EWG ;

EC – NOISE LEVEL DIRECTIVES 86 / 188 / EWG

N

H

I

N

C

H

I

N

EC – LOW VOLTAGE 73 / 23 / EWG

I

E

93 / 44 EWG ; 93 / 68 CEE

I

I

R

TS EN 60204 Part 1

I

9

3

I

9

I

V

9

7

3

7

8

3

7

/

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 2 -

DANGER OF ELECTRIC EMERGENCY STOP

GROUNDING SYSTEM WORKING VOLTAGE

ATTENTION

BEFORE OPERATING MACHINE

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 3 -

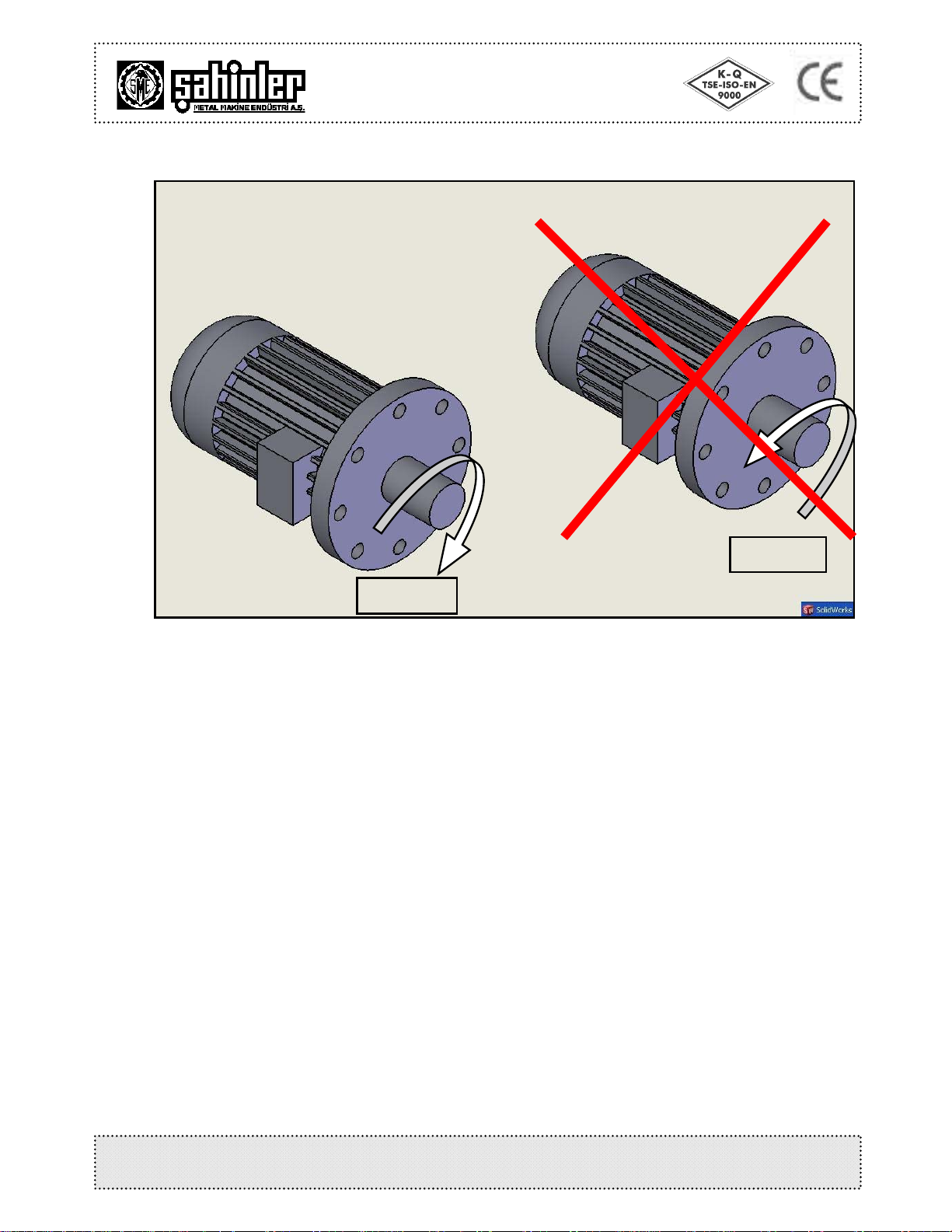

YOU MUST FOLLOW THESE IMPORTANT STEPS

RIGHT

1. Open the cover and check the direction of motor rotation.

2. If motor rotation direction is wrong , then change L1 – L2 cables with each other.

WRONG

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 4 -

İNDEX PAGE NO

GENERAL NOTES

1 .

IMPORTANT SAFETY TERMS

2 .

GENERAL DRAWING OF THE MACHINE

3 .

TRANPORTATION

4 .

SETUP INSTRUCTIONS

5 .

TECHNICAL PROPERTIES

6 .

7 .

8 .

9 .

10 .

11 .

12 .

13 .

TECHNICAL SPECIFICATIONS and STANDARD EQUIPMENTS

6 . 1

OPERATING INSTRUCTIONS

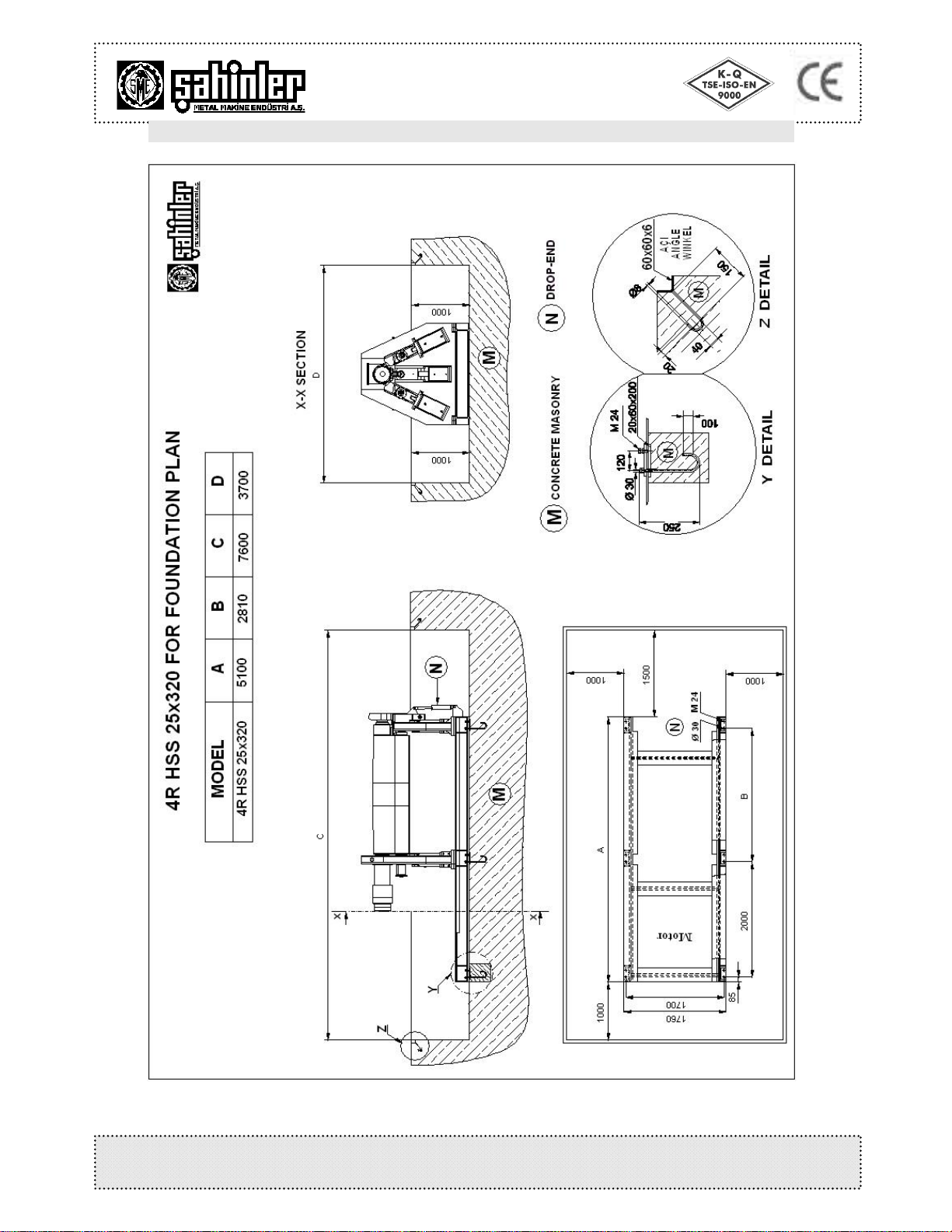

EXPLANATION OF FOUNDATION PLAN

7 . 1

EMERGENCY STOP

7 . 2

THERMAL OVERLOAD or OIL TEMPRATURE

7 . 3

ELECTRIC CONNECTION

7 . 4

SAFETY DIRECTIVES

DANGER ZONES

8 . 1

INVERSE ELECTRIC PROTECTION

8 . 2

EXPLANATION FOR SAFETY SWITCH

8 . 3

DROP - END

8 . 4

IMPORTANT POINTS ON WELDING OPERATION

8 . 5

BENDING OPERATIONS

PRE - BENDING

9 . 1

BENDING

9 . 2

CONICAL BENDING

9 . 3

PERIODIC CONTROLS

PERIODIC CONTROLS and SCHEME

10 . 1

LUBRICATION

10 . 2

HYDRAULIC MAINTENANCE

PERIODICALLY CONTROL THE FILTER

11 . 1

HYDRAULIC PLAN and LIST

GENERAL WARRANTY TERMS

6

7

8

9

10

10

11

12

13

14

14

14

15

15

16

17

18

19

20 - 21

22 - 23

24

25

26

27 - 28

29

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 5 -

1. GENERAL NOTES

Thank you for choosing a Şahinler sheet / Metal Working Machine. We are proud to have you in

our long list of satisfied customers all over the world.

In this manual you can find instructions and information about ;

Correct installations of the machine

Description of the functional parts of the machine

Set – up and start – up adjustments

Correct standard and schedules maintenance

Simple safety regulations and accident prevention

Attention : Showing the risks of accident , if instructions are not followed.

Warring : Showing the probable damages to the machine or equipment , if the

instructions are not strictly followed

Note : It gives useful information

It is certainly necessary that the operator should read and understand all the attention , warring ,

note specified in this manual before starting with operation of the machine and before any lubrication

or maintenance intervertion.

Remove any protective crates around the machine and read the intructions on related chapters of

this manual carefully to set up the machine. If the machine is damaged while transport , immediately

take some photographs for insurance claims.

All necessary connection procedure can be found on this manual. Have the machine connected

by a qualified electric technician. Our factory is not responsible for damages because of electricity

connections.

Your machine is designed and produced to work efficiently and smoothly. To achieve this you

should also take care while operating the machine. Regard maintenance sections to have the longest

live from your machine. Try and use original spare parts where necessary and most importantly do not

overload the machine or do not make any unauthorized modifications.

Take all precautions possible to avoid any personnel injury while using the machine. Keep in mind

to Project the third party people around the machine. Refer to safety directives

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 6 -

2. IMPORTANT SAFETY TERMS

Following instructions are meant for the operator of the machine and it is the end user’s

responsibility to make sure that the operator reads and understands the following.

Machine must be used by a trained operator who can notice working risks.

Use the machine according to the factory working rules and directions in catalogue.

Machine is designed for working only in technical capacities which are shown in catalogue.

Machine must not be used out of it’s technical capacities. Manufacturer is not responsible for

damages that can happen.

Manufacturer is not responsible for the damages that can happen for wrong electricity

connections.

Never touch rotating or moving parts.

Keep your working dress or long hair or necklace etc away from rotation parts.

Make sure you know the position of emergency stop buttons on the machine.

In any emergency situation please push the emergency button and follow the emergency rules.

Work with necessary safety clothes if necessary ( safety shoes , glasses , earplugs etc ).

See and understand safety labels on the machine.

Be careful of other people around the machine during operation.

Never modify electric units and table

Do not remove any electronic or mechanical parts of the machine.

Do not make any modifications on the machine without manufacturer’s acceptance. These

modifications can effect the machine safety specifications and CE regulations.

Do not overload the machine

Switch off the machine when not working.

Be extremely careful during transport or replacement of the machine and follow transport

instructions in the manual to safely handle the machine.

During the bending operation do not touch and approach the material.

Do not operate the machine in rusty places and do not use rust materials.

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 7 -

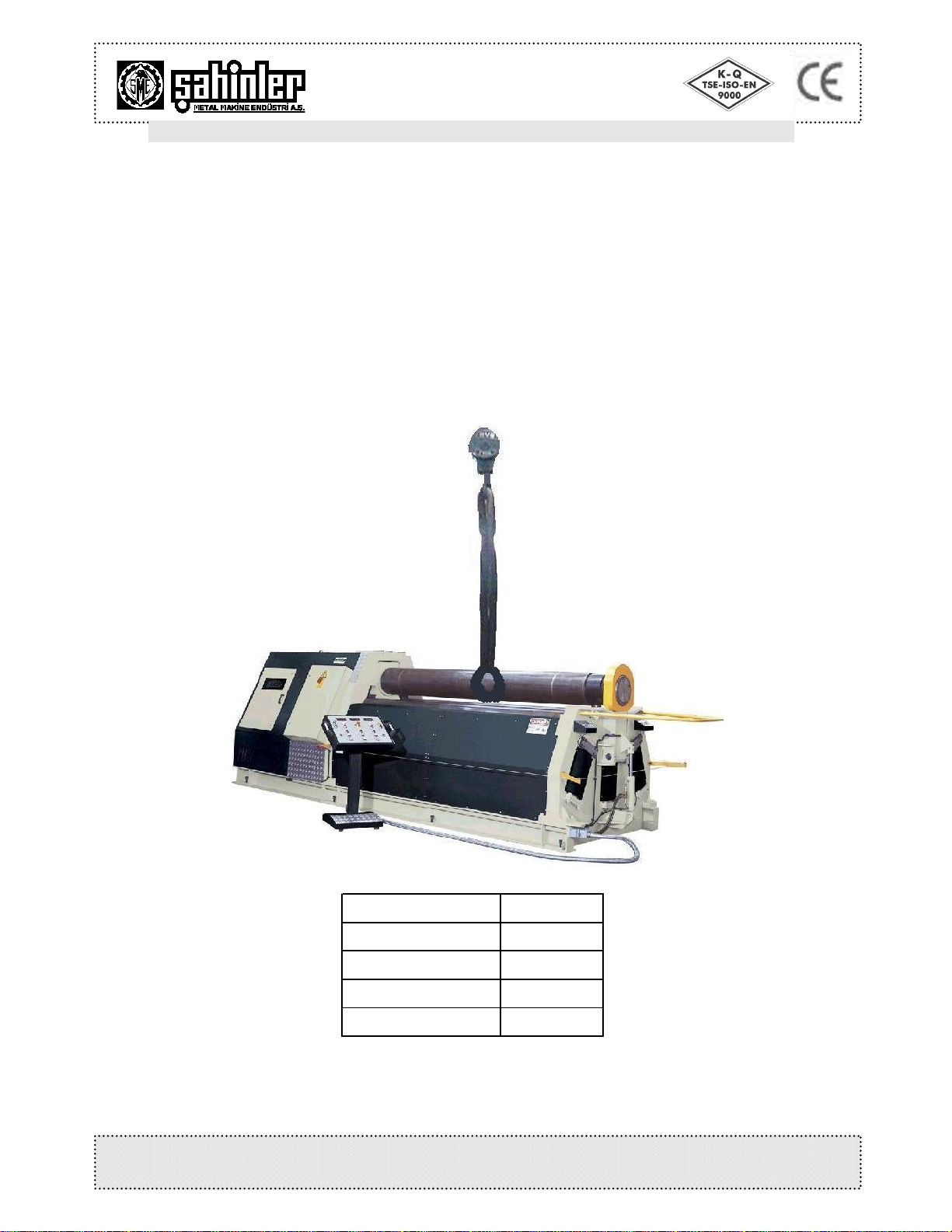

3. GENERAL DRAWING OF THE MACHINE

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 8 -

4. TRANSPORTATION

Machine must be carried with crane and must be lift up from the centre of gravity. Keep away from

sudden actions that damage the machine.

Customer must control the machine functions after transportation to see if everything is O.K.

Always carry and lift up the machine following Shown points. Take precaution on the carrying

and lifting situations.

If the machine’s balance position is not suitable set it to the suitable position.

Lift up the machine carefully keep away from sudden speed and sudden side changing’s.

In the mounting place move slowly when the machine touch with the floor.

Machine Type Weight

4R HSS 20 - 320 9 Ton

4R HSS 25 - 320 11 Ton

4R HSS 30 - 320 13 Ton

4R HSS 40 - 320 16 Ton

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 9 -

5. SETUP INSTRUCTIONS

Control the electricity Lines before the machine arrives.

For machine place consider your best and easy production area

Machine mounting floor must be flat , strong and without holes. Defective and insecure places

can spoil machine balance.

Provide a suitable and enough lightened place

Make sure that your machine is balanced on the ground.

6. TECHNICAL PROPERTIES

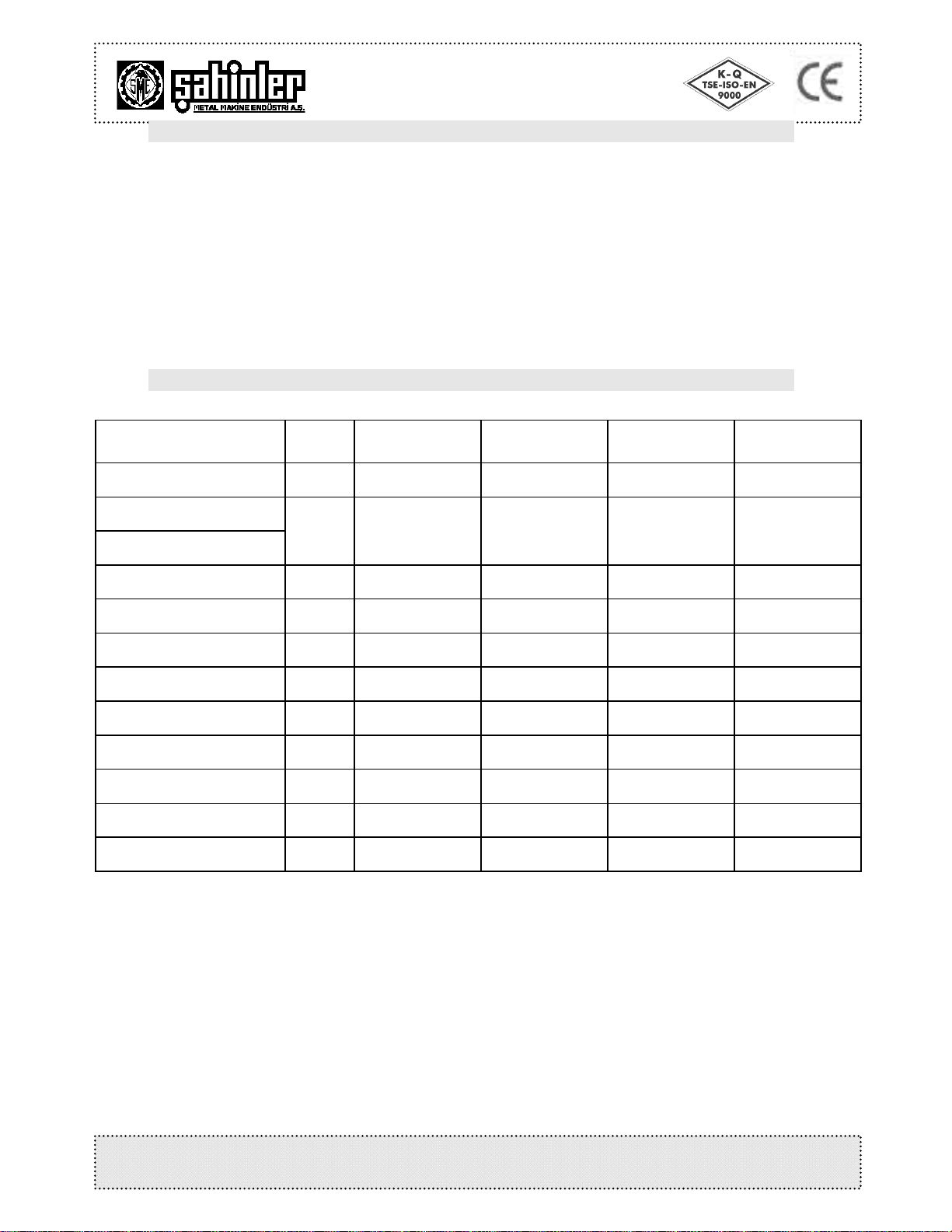

Model Unit

Without Prebending Ø x 5

Diameter

With Prebending Ø x 5

Without Preb ending

Ø x 1,5

With Prebending Ø x 1,5

Diameter

Bottom Roll Diameter Ø mm 320 320 320 320

Side Rolls Diameter Ø mm 240 240 240 240

Motor Power Kw 18 , 5 18 , 5 18 , 5 18 , 5

Working Speed m/Min 1,5 - 5 1 ,5 - 5 1 ,5 - 5 1,5 - 5

Machine Dimensions mm 4700x1800x1900 5200x1800x1900 5700x1800x1900 6700x1800x1900

Roll Lenght mm 2050 2550 3100 4100

Useful Lenght mm 2000 2500 3000 4000

Weight Kg 9000 11000 13000 16000

mm 25 20 16 10

mm 16 12 10 6

4R HSS 20

320

4R HSS 25

320

4R HSS 30

320

4R HSS 40

320

8mm 20 16 12

Note : Machine dimensions are approximate.

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 10 -

6 . 1 TECHNICAL SPECIFICATIONS AND STANDARD EQUIPMENT’S

The machine is particularly suitable for medium plate for the production of ferrules in

automatic cycle with or without cnc system varying radiused parts with or without axis

interpolation.

Bottom pinching roll with hydraulic positioning.

Two lateral rolls with double pinch pyramid action ( Bottom pinching and lateral rolls

with balancing system to guarantee perfect parallelism and high quality production ).

Top roll is driven by hydraulic motor coupled to the planetary speed reducer.

Movement of the lateral rolls is carried out by means of pistons.

Digital displays are provided for locating setting of roll positions.

Hydraulic drop end for ease of cylinder removal.

All control operations are conveniently located on an independent control console.

Steel welded heavy frame construction , thermally stress relieved

Induction hardened rolls are of high tensile carbon steel forging , heat treated and

submitted ton on destructive structure controls.

Conical bending device.

Hydraulic elements ; motor and pump group , pressure valves , solenoid valves , oil

display and etc. Bosch , Rexroth or Duplomatic used.

Emergency system ; safety string barrier around the machine and emergency push

button

Electric equipment’s ; Siemens or Telemecanique

Machine equipped with two speed working system which is controlled from independent

control console.

Built according to EC safety directives ( CE Mark )

User’s manual

Roll material is SAE 1050 and it is hardened

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 11 -

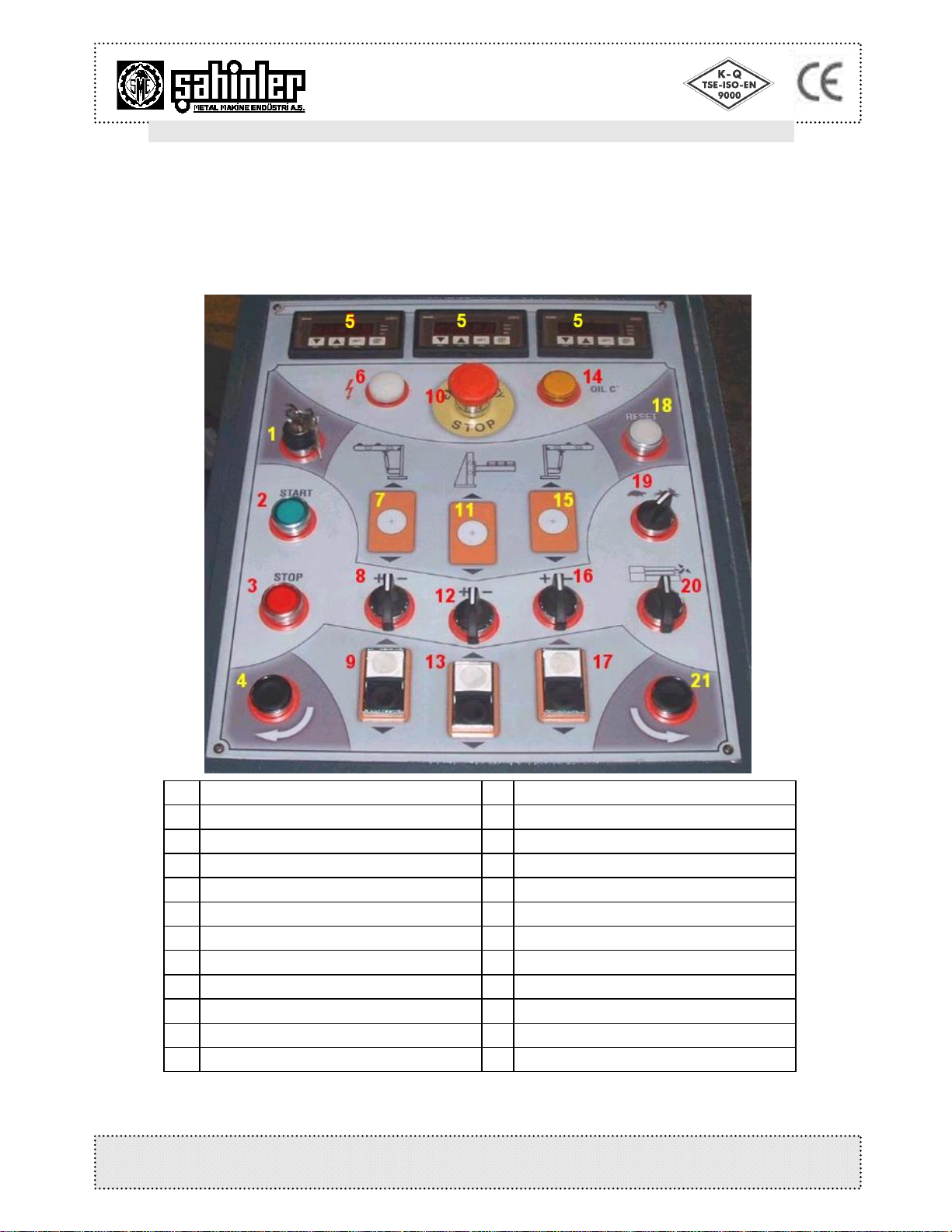

7. OPERATING INSTRUCTIONS

Your machine is equipped with a phase sequencer. If the electric connection is wrong the

machine will not start up . Reverse the main electric cables and try again.

When you see the power on indicator press the start button. The motor should start up and after a

few seconds you should hear the machine running.

Test the movements of the machine by pressing rotation and piston buttons.

No Button Name No Button Nam e

1 Switch On / Off 12 Pinching Roll Conical Up - Down

2 Start Button 13 Pinching Roll Up - Down

3 Stop Button 14 Oil Temperature Indicator

4 Rolls Clock Wise Rotation Button 15 Right Support Up - Down

5 Digital Read - Outs 16 Right Roll Conical

6 Power On 17 Right Roll Up - Down

7 Left Support Up - Down 18 Reset

8 Left Roll Conical Up - Down 19 Fast - Slow Rotation Swich

9 Left Roll Up - Down 20 Brack et Open - Close Swich

10 Emergency Stop 21 Rolls Counter Clock Wise Rotation Button

11 Lift Up - Down

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 12 -

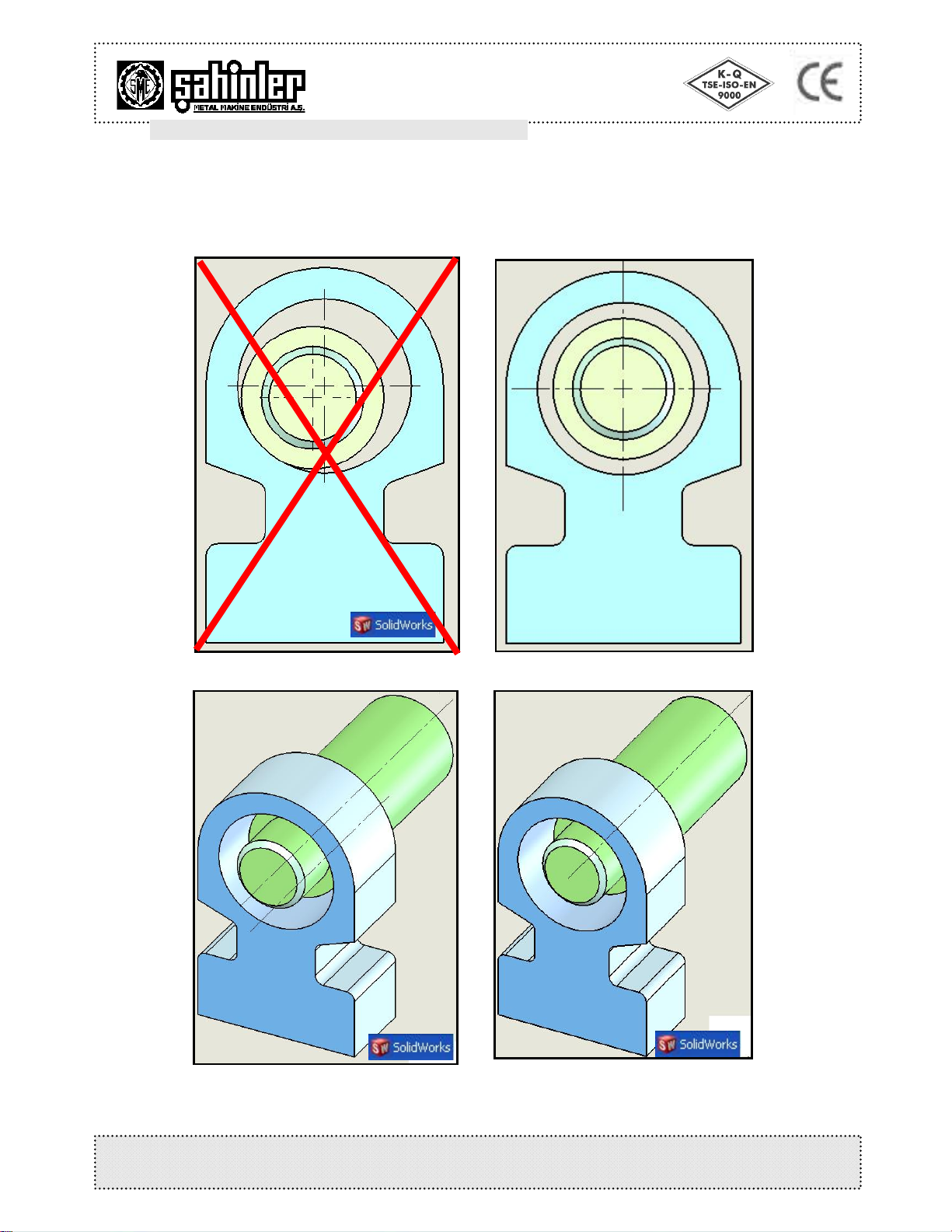

7 . 1 EXPLANATION OF FOUNDATION PLAN

Before proceeding to the bending operation in the machine, open the bracket on the front part and

verify if the upper roll enters the bracket in a symmetrical manner. If there is any deviation, first of all

adjust such deviation through the balancing bolts in the safe and then start to work.

WRONG RIGHT

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 13 -

7 . 2 EMERGENCY STOP

The machine has one emergency stop and emergency stop wire around the machine If the

machine is stopped by pushing one of these the PLC must be Reset before starting

Release the emergency stop button or switch on the emergency wire

Push Reset button

Push start button.

7 . 3 THERMAL OVERLOAD OR OIL TEMPERATURE

If the thermal overload indicator is on it means the motor is disabled by the system to protect it

from burning. The motor is overheated due to a problem and must cool down before restarting. Do not

restart the motor at least 10 minutes. Let it cool down and try to find the problem. Do not restart the

machine until the problem is solved.

7 . 4 ELECTRIC CONNECTION

Please bring the plug near the machine and connect like as shown below.

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 14 -

8. SAFETY DIRECTIVES

The ŞAHİNLER A.Ş. four – roll plate bending machine is supplied with necessary guards to

protect from injuries by worm – type gearbox and other gears. The only other area which needs to

carefully monitored during use is the rotational area of the rolls.

8 . 1 DANGER ZONES

The below shown danger zones must be kept clear during operation

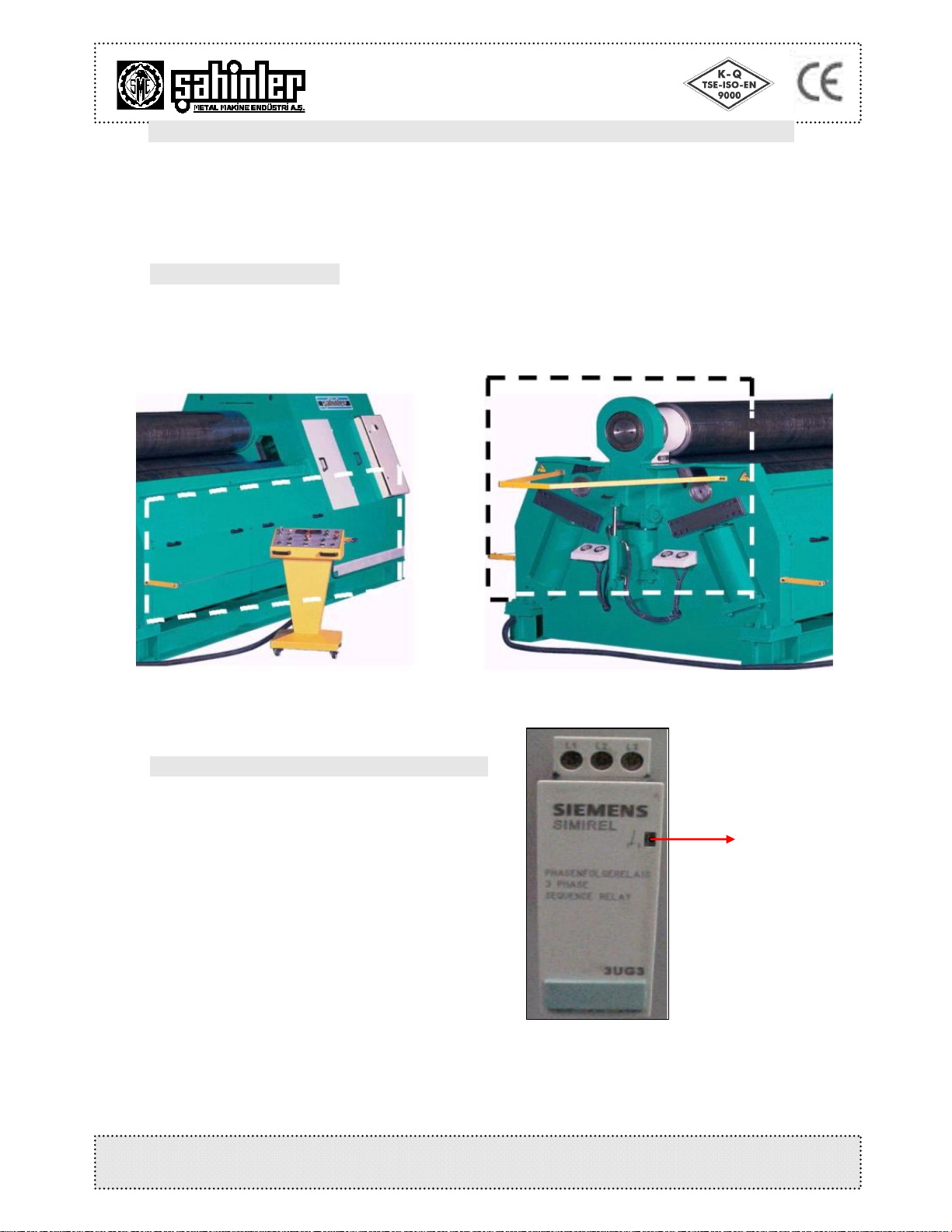

8 . 2 INVERSE ELECTRIC PROTECTION

If the electrical connection of the machine is

wrong the phase protection device activates and

cuts off any electric supply to protect the hydraulic

pumps from inverse rotating and burning out. Only

when its connected Correct the relay light will light

YELLOW - OK

up and the machine will operate

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 15 -

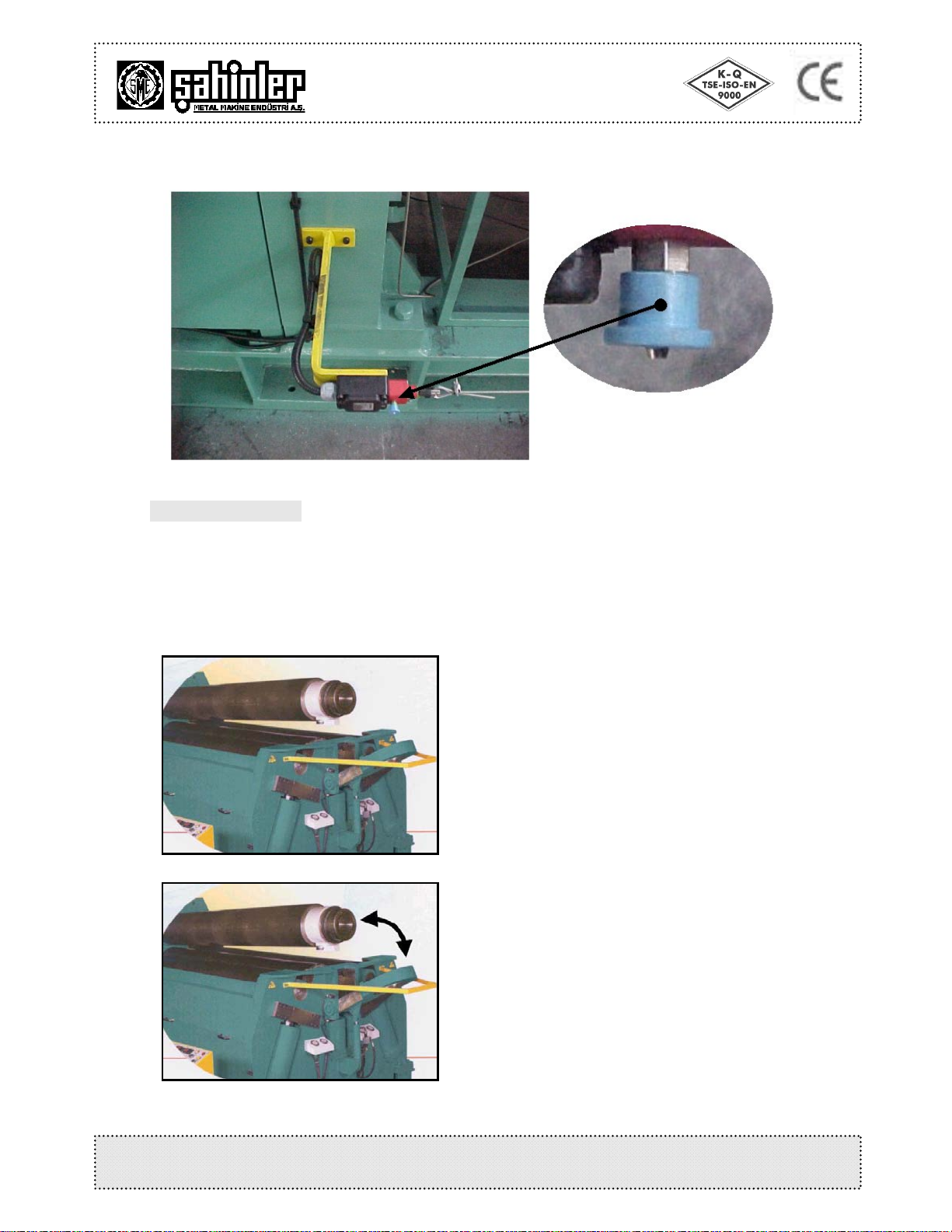

8 . 3 EXPLANATION FOR SAFETY SWITCH

The machine has been equipped with a security switch and wire for the operators safety when the

safety wire is pushed it pulls the below shown ring this act as emergency stop and stops all machine

activity.

GREEN LINE

BLUE

BUTTON

To restart the blue knob ( fig. 1 )

While pulling the safety wire when

engaged you should see green

( fig. 2 )line under the blue knob

Now you can restart the machine from

control panel.

Safety switch’s on and off positions as given below

Switch on position.

Switch off position

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 16 -

The safety wire comes unassembled for packing reasons and must be assembled by the

customer as shown above to completely surround the machine

8 . 4 DROP - END

If for any reason emergency button is used during opening and closing of the drop end arm , it will

stop instantly

After the emergency button is released and Reset button is pushed you must use the start button

to restart the machine.

Emergency stop pushed

Emergency stop released

Reset pushed

Start pushed

MACHINE CODE : 4R HSS 320

DATE : MARCH 2006 PAGE

- 17 -

Loading...

Loading...