Page 1

COMPACT

155 Mbit/s

ADD-DROP

MULTIPLEXER

MULTIPLEXEUR ADD-DROP

à 155 Mbit/s COMPACT

ADR 155C

Installation and User Guide

Guide d'Installation et d'Utilisation

N56717020101

Issue : April 2000

Edition : Avril 2000

Page 2

Page 3

COMPACT

155 Mbit/s

ADD-DROP

MULTIPLEXER

MULTIPLEXEUR ADD-DROP

à 155 Mbit/s COMPACT

ADR 155C

Installation and User Guide

Guide d'Installation et d'Utilisation

N56717020101

Issue : April 2000

Edition : Avril 2000

Page 4

LIST OF CHANGES

REPERTOIRE DES MISES A JOUR

(A new edition replaces any previous versions)

(Une nouvelle édition annule et remplace la précédente)

No/

N°

0101 April 2000/

Remarque importante : La version logicielle actuelle n'offre pas la fonction RIP décrite dans ce

Important remark : The current software version does not offer the RIP function described

Date/

Date

Avril 2000

guide.

in this guide

Change description

mise à jour

Creation of original user guide/

Création du document à l'édition originale

/Description de la

Page

/Page

All pages/

Toutes pages

Page 5

COMPACT 155 Mbit/s

ADD-DROP MULTIPLEXER

ADR 155C

Installation and User Guide

Installation and User Guide - N56717020101

Reproduction and communication in any form prohibited without the written permission of

(

Page A0-1

Page 6

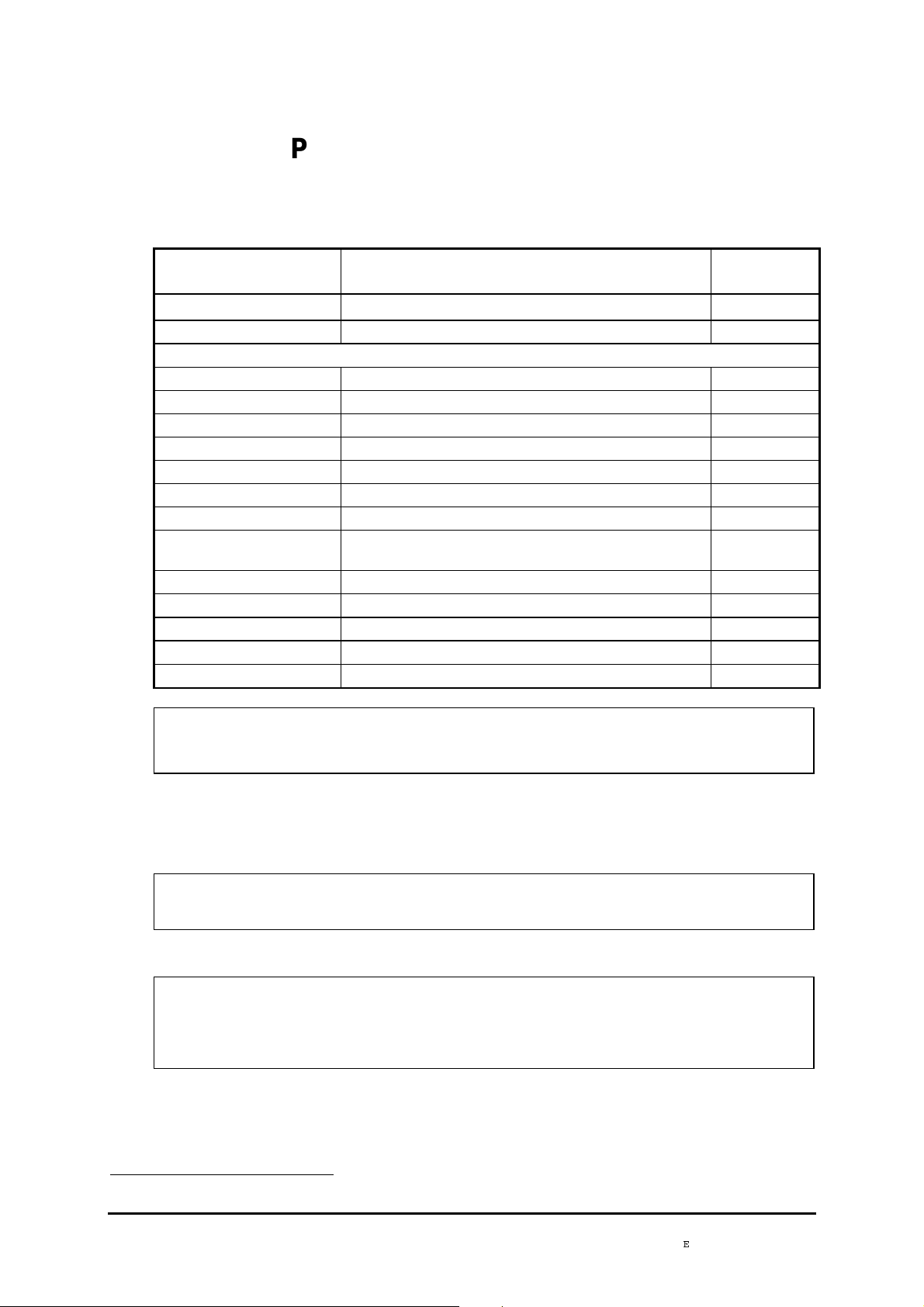

PORTS SECURITY LEVEL

Port safety level for the 19" subrack access

The connectors are identified on the front panels of the equipment (cards or motherboard).

Connectors Function

Security

level

PWRA/PWRB Power supply

PWR Power supply SELV

Motherboard

SYNC G.703 2 Mbit/s synchronization Ports SELV

E1 INPUT & E1 OUTPUT G.703 2 Mbit/s Ports SELV

MNGT Other equipment connection SELV

COMM VT100 local supervision SELV

ETH Ethernet LAN remote supervision SELV

LOOPS Loops and remote signaling SELV

ADR ICI 1.x Card

TR and REC G.957 and G.958 STM-1 IC1.1 or IC1.2 Optical Laser class 1

Dangerless

EOW and AUX Engineering Order Wire SELV

ADR LAN1 Card

ETH Ethernet Port SELV

ADR 21E120 Card

E1 INPUT & E1 OUTPUT G.703 2 Mbit/s Ports SELV

SELV

1

)

The 19" subrack must be mounted only in racks with a bottom part that is

closed or fitted with a class V1 or HF1 or better air filter, or that stand on a

non-flammable floor..

Safe earth requirement

This equipment m us t be ins talled only by skilled personnel. For compliance, the protective earth

terminal must be connected to a safe earth with an impedance Z of less than 5 Ohms.

)

Handling precaution: For any work to be carried out inside the equipment, an

antistatic wrist strap must be worn.

Lithium Battery

)

Warning : If the battery is incorrectly replaced there is a risk of explosion.

Only replace with same type battery or equivalent type recommanded by the

manufacturer

Dispose of used battery according to manufacturer instructions

In ADR155C, battery replacement may only be done by return Supply Support Department.

1

Safety Extra Low Voltage Circuit

Installation and User Guide - N56717020101

Page A0-2

Reproduction and communication in any form prohibited without the written permission of

(

Page 7

CONTENTS

CHANGE LIST 0-2

SECTION A : Installation and user guide...................... A0-1 to AA-6

PORTS SECURITY LEVEL A0-2

CONTENTS A0-3 to A0-4

1. INSTALLATION AND COMMISSIONING

1.1 - General A1-1

1.2 - Subrack

1.3 - Connecting ports A1-4

1.3.1 - Connecting Power Supply A1-4

1.3.2 - Connecting on motherboard

1.3.3 - Connecting on the ADR IC1.x card

1.3.4 - Connecting on ADR LAN1 card

1.3.5 -

1.3.6 - 75 Ω connecting strip A1-18

1.4 - Commissioning

1.4.1 - Configuration required A1-22

1.4.2 - Parameterizing the communication function A1-22

1.4.3 - Using HTTP navigator

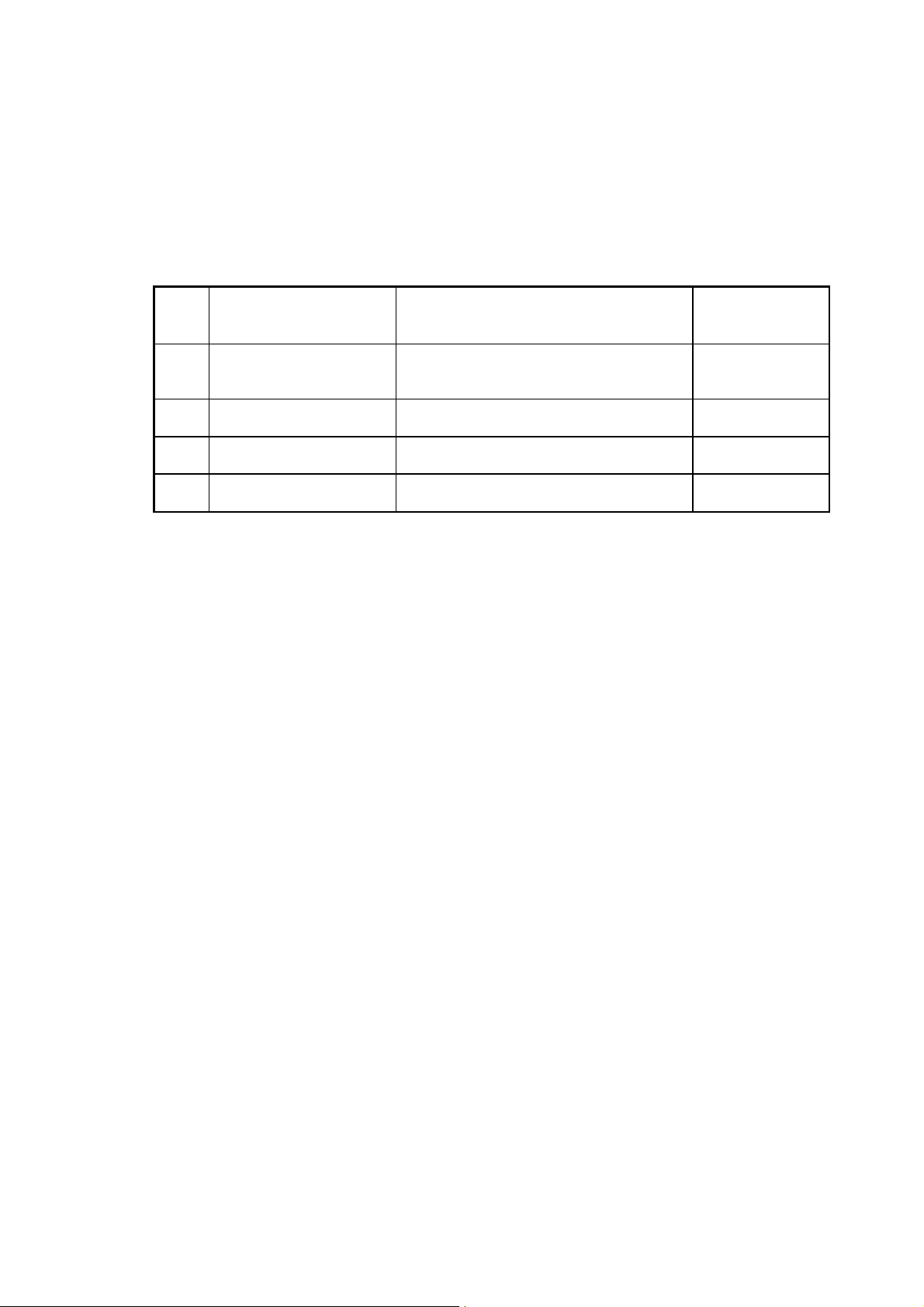

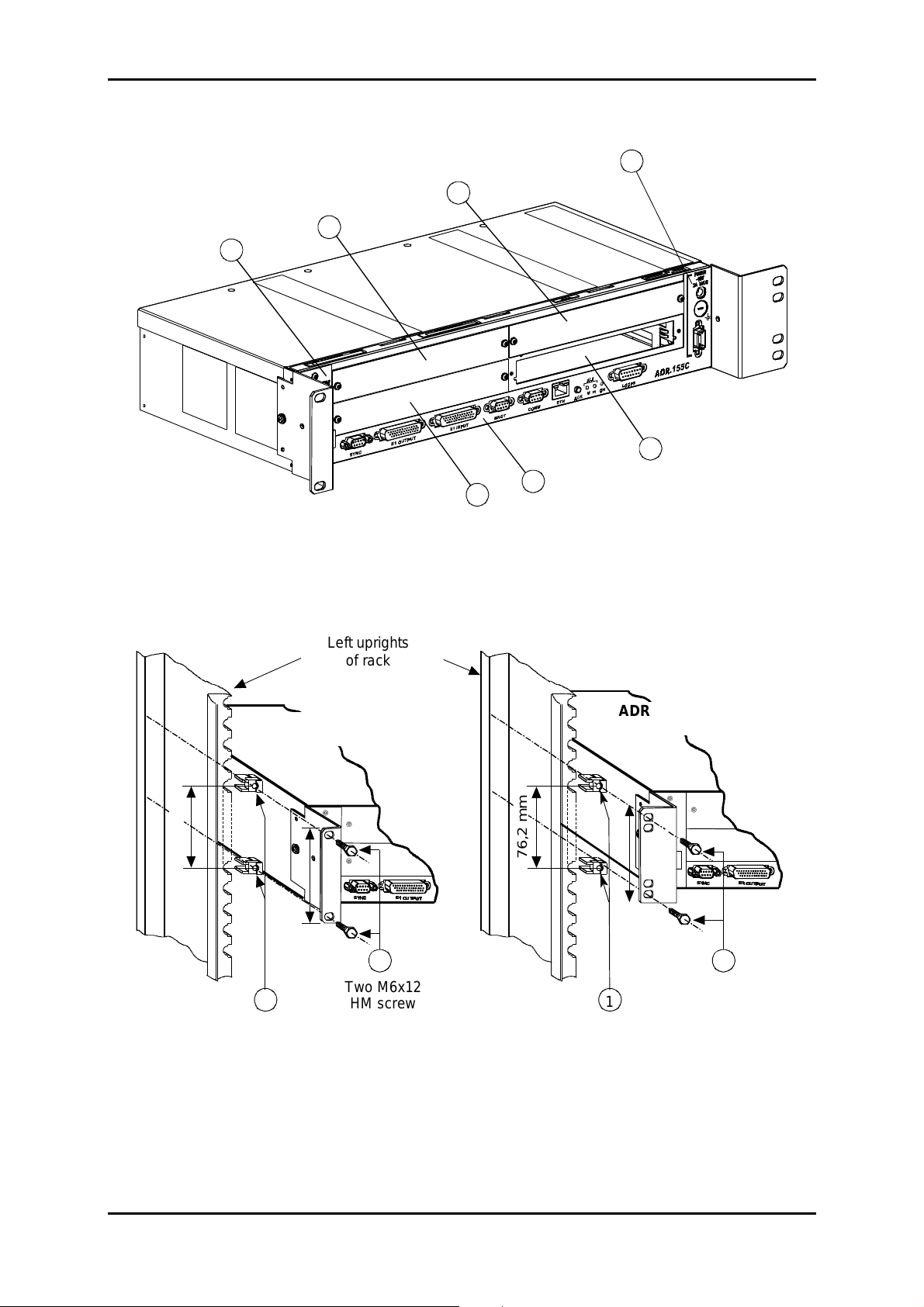

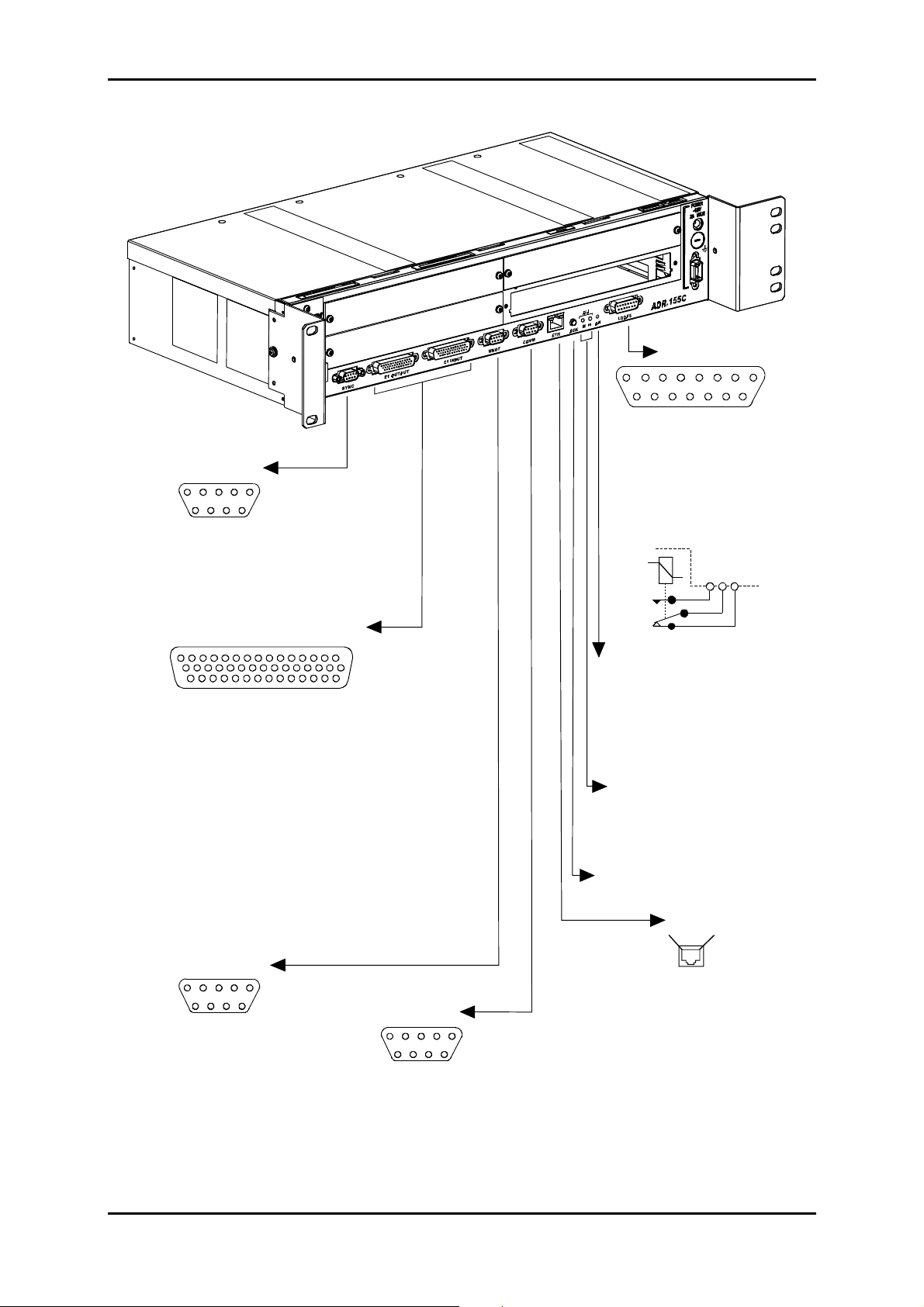

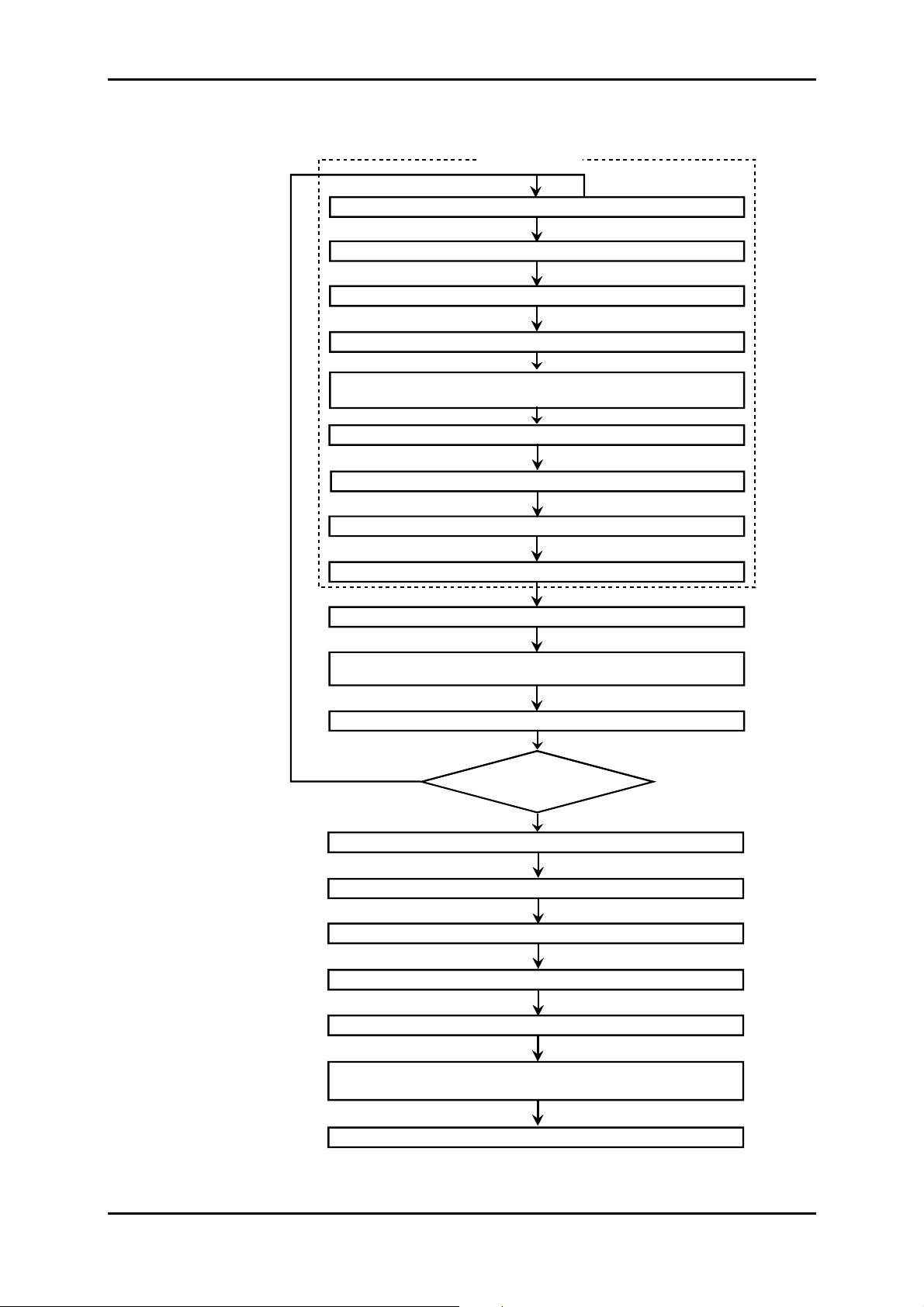

Figure 1-1 ADR155C Subrack Installation A1-2

Figure 1-2 Connecting power supply ports A1-5

Figure 1-3 Connecting motherboard inputs A1-6

Figure 1-4 Connecting ADR IC1.x card inputs A1-12

Figure 1-5 Connecting ADR LAN1 card input A1-16

Figure 1-6 Connecting ADR 21E120 card input A1-17

Figure 1-7 75 Ω connecting strip A1-18

Figure 1-8 Commissioning procedure for ADR155C network A1-19

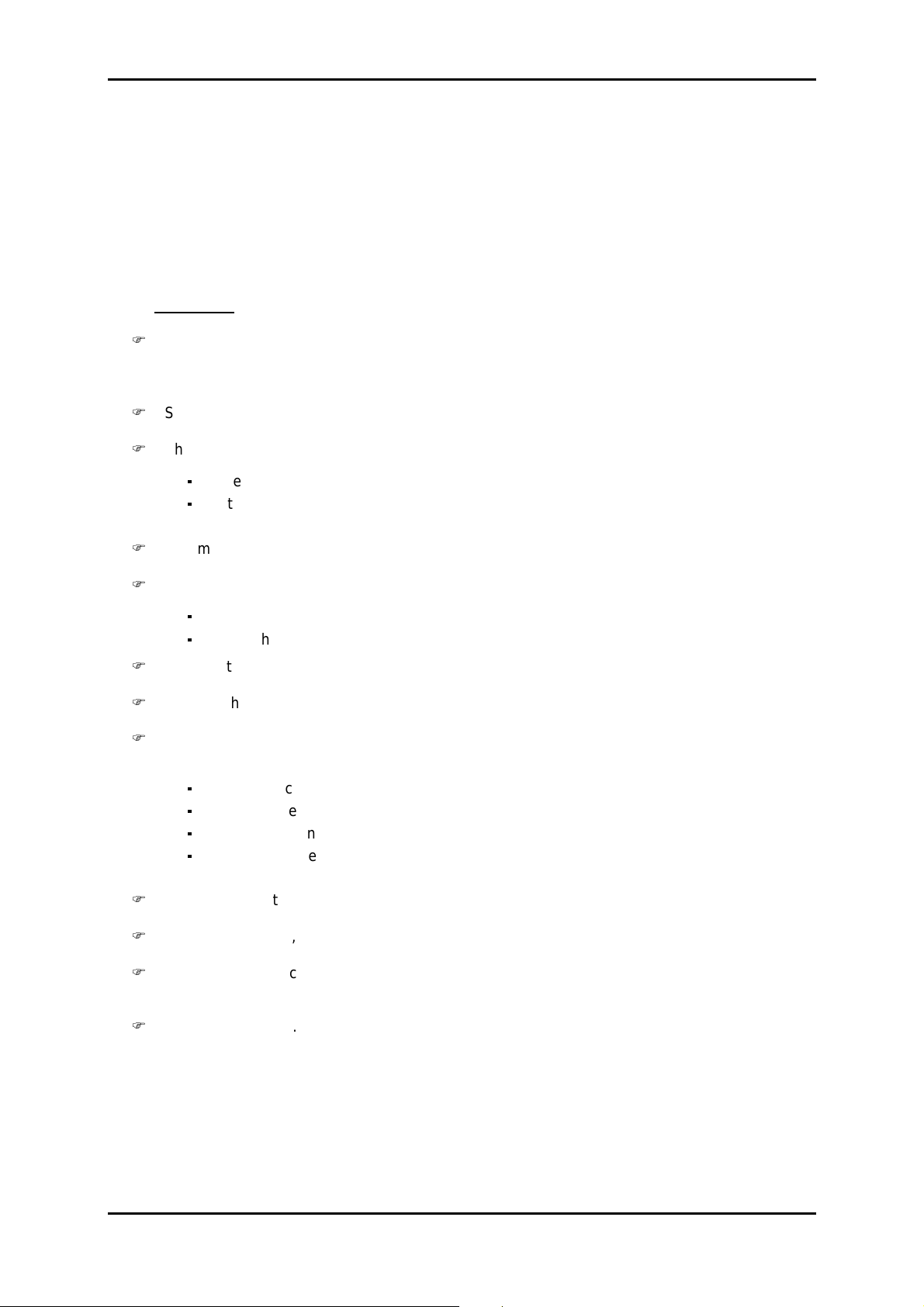

Figure 1-9 Examples of the communication function configuration A1-21

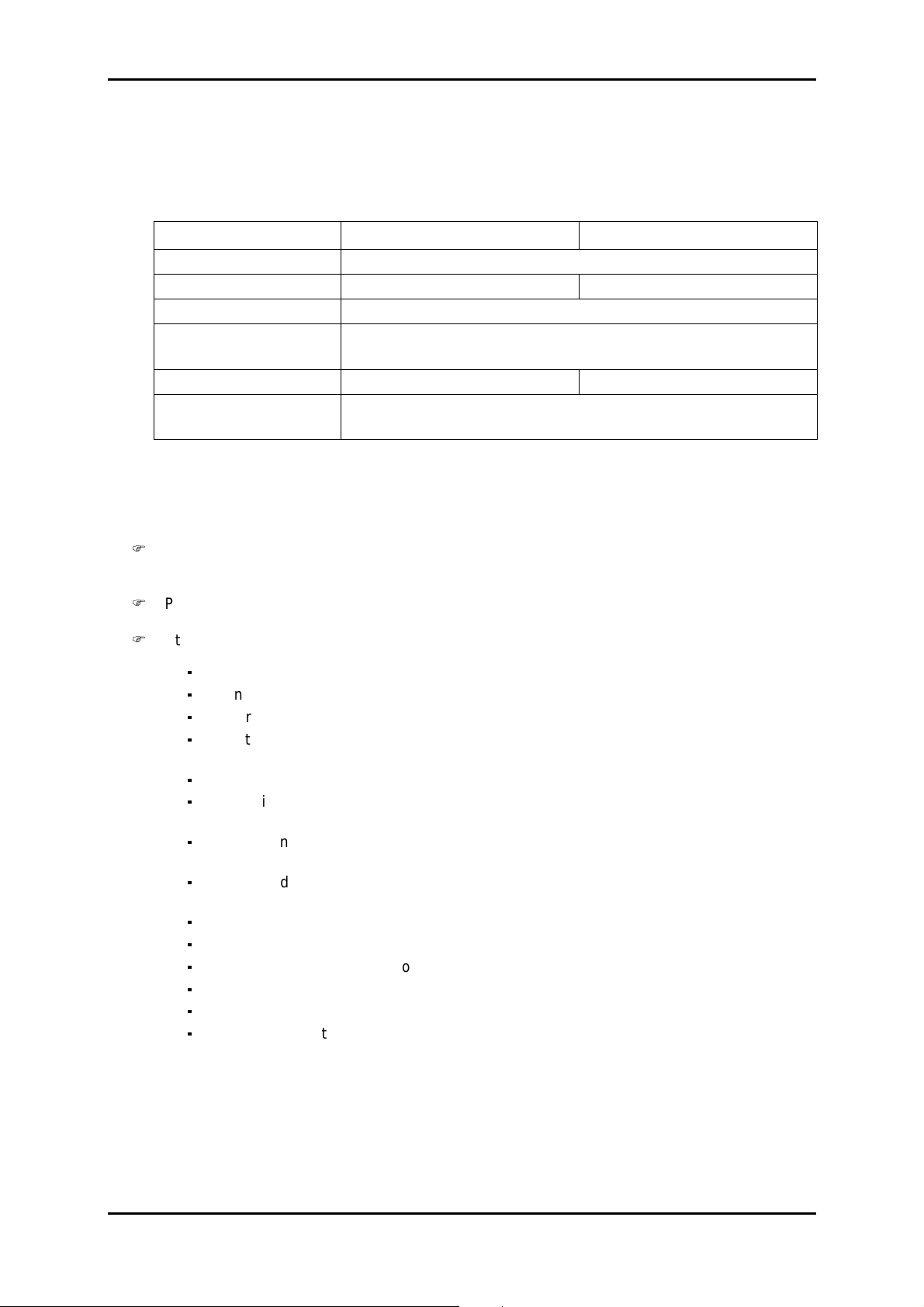

Figure 1-10 Menu structure A1-27

installation A1-3

Connecting on ADR 21E120 card

........................................................... A1-1 to A1-28

A1-7

A1-13

A1-16

A1-17

A1-20

A1-26

2. OPERATION......................................................................................................... A2-1 to A2-20

2.1 - Functional description A2-1

2.2 - General A2-2

2.3 - Operational parameters A2-2

2.4 - Predefined functions A2-9

2.5 - Alarms processing A2-12

2.6 - Performance processing A2-17

2.7 - Procedure for replacing subassemblies A2-19

Installation and User Guide - N56717020101

Reproduction and communication in any form prohibited without the written permission of

(

Page A0-3

Page 8

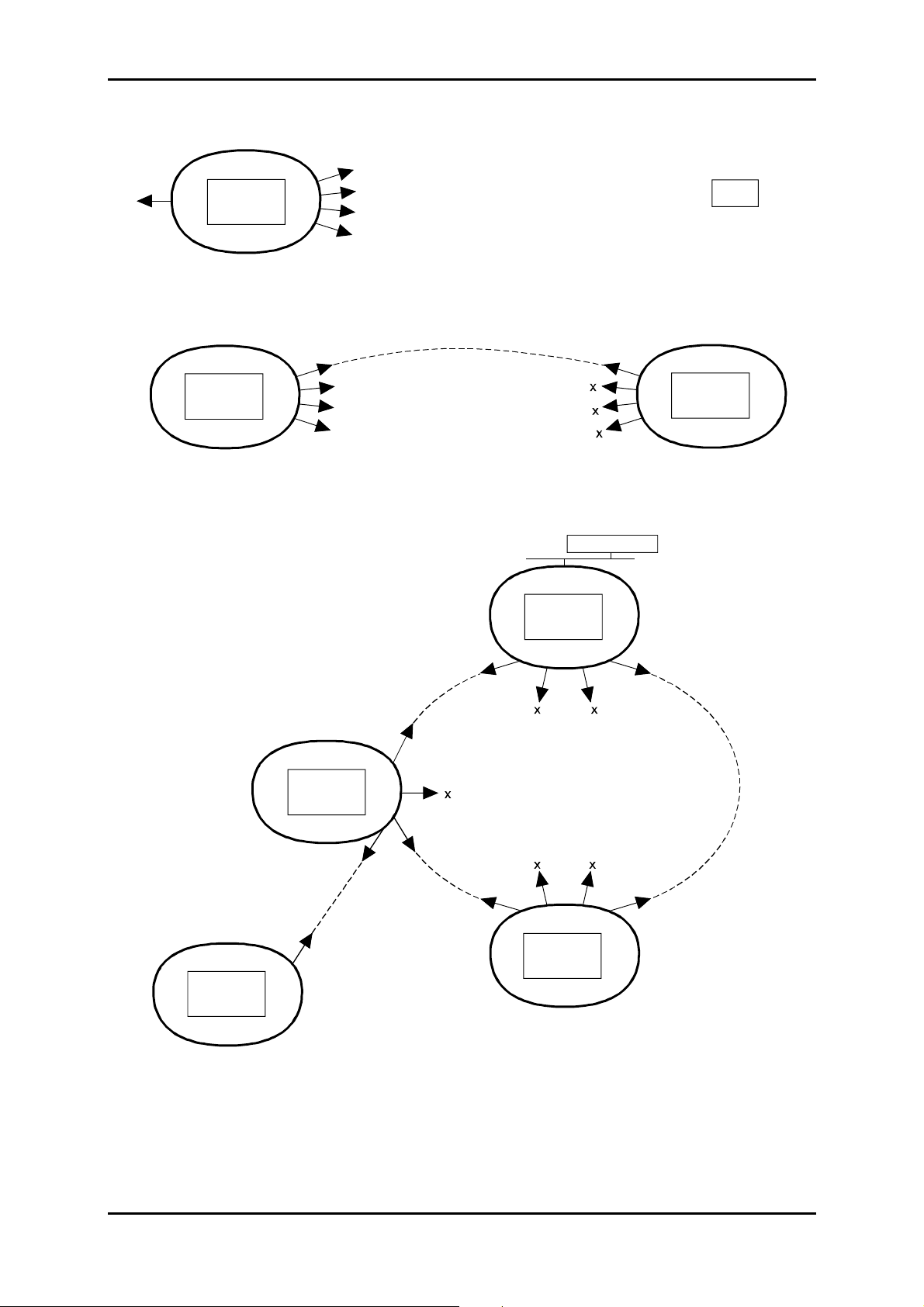

Figure 2-1 Synchronization from the 2 MHz external sync input (T3) A2-10

Figure 2-2 Synchronization from the 2 MHz port A2-10

Figure 2-3 Remote loopback function (registering alarms on central site) A2-11

Tables 2-1 to 2-6 Configuration parameters A2-2 to A2-7

Tables 2-7 to 2-8 Commands A2-8 to A2-9

Tables 2-9 to 2-10 Alarms and severity A2-13 to A2-14

3. SPARE PARTS....................................................................................................... A3-1 to A3-2

4. SPECIFICATIONS.................................................................................................. A4-1 to A4-2

ANNEX A - CONSTRUCTING AN IP NETWORK ADDRESSING PLAN AA-1 to AA-6

A.1 - Preamble AA-1

A.2 - Addressing IP AA-2

A.3 - Adressing plan AA-3

A.4 - Use of static tables AA-3

A.5 - Use of RIP routing demon AA-5

SECTION B : Guide d'installation et d'utilisation............ B0-1 à BA-6

Installation and User Guide - N56717020101

Page A0-4

Reproduction and communication in any form prohibited without the written permission of

(

Page 9

1 - INSTALLATION AND COMMISSIONING

1. INSTALLATION AND COMMISSIONING

1.1 - General

The ADR 155C is an optical STM-1 add-drop multiplexer used to build STM-1 point-to-point

links, STM-1 rings, or mesh networks with conduct (SNC) or line (MSP) protection, so

performing the conveyance of links at 2 Mbit/s, Ethernet, STM-1.

The ADR 155C can be used as:

STM-1 terminal multiplexer with maximum capacity of 63 VC12 and capability of 1+1

protection,

STM-1 repeater, capability of regenerating 2 VC4,

STM1 multiplexer with insertion/extraction, with maximum capacity of 4 STM-1 and

insertion/extraction of 21 VC12

LAN interconnection point (in exclusive function up to 3 remote links totalling 3 VC3 used).

This equipment is managed from a HTTP navigator:

either locally, via its dedicated Ethernet interface

or remotely by teleoperation

or from the IONOS- ANM network manager; in this last case, us ing the SNMP protocol also

allows global network supervision.

Using a local terminal with VT100 emulation is necessary on the first commissioning, for the

configuration of communication parameters.

Management network connections are performed via DCC D1 to D3 (or D4 to D12) of the STM1

or on Ethernet (ETH) or P (MNGT) interfaces of the equipment.

The ADR155C is placed in 19" racks or ETSI frames. It consists of:

a 2U subrack fitted with a motherboard grouping together the basic functions of the

equipment, a backplane and a secured 48V DC power supply,

an ADRFAN module, consisting of two redundant ventilation units,

four traffic cards:

IC1.1 or IC1.2 STM1 optical card (ADR IC1.1 or ADR IC1.2 card) allowing a VC4

connection or 3 VC3 connections or 63 VC12 connections or a com bination of VC3/VC12

connections

21 x 2 Mbit/s card, G.703, (ADR21E120 card), allowing 21 VC12 connections

Ethernet 10/100 card (LAN1 ADR card), allowing 2 VC3 connections.

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-1

Page 10

1 - INSTALLATION AND COMMISSIONING

g

g

B

A

V

P

D

76 ,2 mm

Left uprights

of rack

ADR 155C

19" SUBRACK

2U

C

M

ADR 155C Subrack

ADR 155C

ETSI RACK

76 ,2 mm

6

(

6<1&

(

<1&

2

28

873

7387

87

2U

6

(

6<1&

(

<1&

2

28

873

7387

87

2 2

Two M6x12

1

HM screw

Two M6

cage nuts

19" rack mountin

Figure 1-1- ADR155C Subrack Installation

Installation and User Guide - N56717020101

Page A1-2

No reproduction or communication without the written cons ent of

1

Two M6

cage nuts

ETSI rack moutin

SAGEM SA

Two M6x12

HM screw

Page 11

1 - INSTALLATION AND COMMISSIONING

- Subrack

1.2

The ADR 155C subrack can be installed in 19" rack or ETSI fram e (see Figure 1-1). It consists

of:

a motherboard located in the lower part (item M),

four non-dedicated slots (items A to D), designed to accommodate the traffic cards,

a slide located on the left of the subrack designed to accom modate the ventilation module

(item V),

a power supply (item P).

All connections are performed on front panel, either on the subrack, or on the modules.

Installation in a 19" rack

Elements attaching the subrack in 19" rack (brackets, cage nuts and attaching screws), are

provided in its package.

The ADR155C has a system of therm al contr ol by ventilation ; during the installation, provide for

sufficient space for the ventilation aperture on the left of the subrack , and also f or the aeration,

at the top and right of the subrack. On the other hand, never hinder the natur al air convec tion on

the right side.

installation

Perform the following operations:

provide a 2U place in the rack for each equipment and a 1U space between equipments,

secure the attaching brackets for mounting in 19" rack, on either side of the subrack,

clip, on either side of the rack, two M6 cage nuts (item 1),

position the 19" subrack back in front of the rack,

slide the 19" subrack until attaching brackets are in contact with uprights, opposite the 4 cage

nuts, and then secure the subrack with 4 M6x12 hex head screws (item 2).

Installation in an ETSI rack

The installation of the subrack in ETSI rack is identical with that in 19" rack.

In this case, use the set of attaching brackets specific for mounting in ETSI rack.

Installation of cards

RECALL: Prior to any operation on the cards, the operator must be provided with an

antistatic bracelet.

ADR155C slots are non-dedicated. However, in order to make wiring easier and ensure the

homogeneity among sites, it is advisable to proceed as follows:

position the tributary cards from C clockwise

position the agregate cards from D counter-clockwise

check the ventilation module presence in its reserved slide,

secure each card through M3 screws of Torx type (6-branch star), using a suited screwdriver.

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-3

Page 12

1 - INSTALLATION AND COMMISSIONING

1.3 - Connecting ports

The connections to be performed on the equipment depend on the configuration chosen:

On the power supply card:

poser supply ports: "

PWR

" or "

PWRA

" and/or "

PWRB

",

On the subrack motherboard strip:

management ports : "

Remote indication, remote control and station alarm port : "

2Mbit/s G.703 synchronization port : "

21x2Mbit/s G.703 traffic ports: "

COMM

ETH"

", "

E1 INPUT

and/or "

SYNC

" and "

MNGT

"

E1 OUTPUT

"

LOOPS

"

".

Depending on the traffic modules used

optical STM-1 ports and order wire channels ports,

Ethernet port

21x2Mbit/s G.703 traffic ports.

Connection requirements :

Ö

For a right distribution of cords on either side of the subr ack, the connections of slots A and

C, the 21 2Mbit/s accesses and synchronization access are oriented leftward. All other

connections are oriented leftward.

Ö

The run of cords must not hinder the extraction of a module; in particular, connecting

cables of the left subrack half is to be secured to the frame with enough backlash to

enable the ventilation module to be extracted during a maintenance operation.

1.3.1 - Connecting Power Supply

"PWRA" and/or "PWRB" ports, when the equipment is powered from one or two 48 V

sources, the power source(s) should be limited to 100 VA.

. "PWR" port when the equipment is powered from a mains voltage (230 V AC), via an

optional 110-240//48V 60W/ transformer.

Observe the following connection requirements :

Ö

"PWR" and "PWRA" and/or "PWRB" Power supply ports can be connected simultaneously.

Ö

The power cord or the 110-240//48V 60W/ transf orm er m us t not be connected to the prim ar y

source prior to being connected to the equipment.

Ö

The 110-240//48V 60W/ transformer must be mounted far from any heat source, and no

traction must be exerted on its connecting wires.

Installation and User Guide - N56717020101

Page A1-4

No reproduction or communication without the written cons ent of

SAGEM SA

Page 13

1 - INSTALLATION AND COMMISSIONING

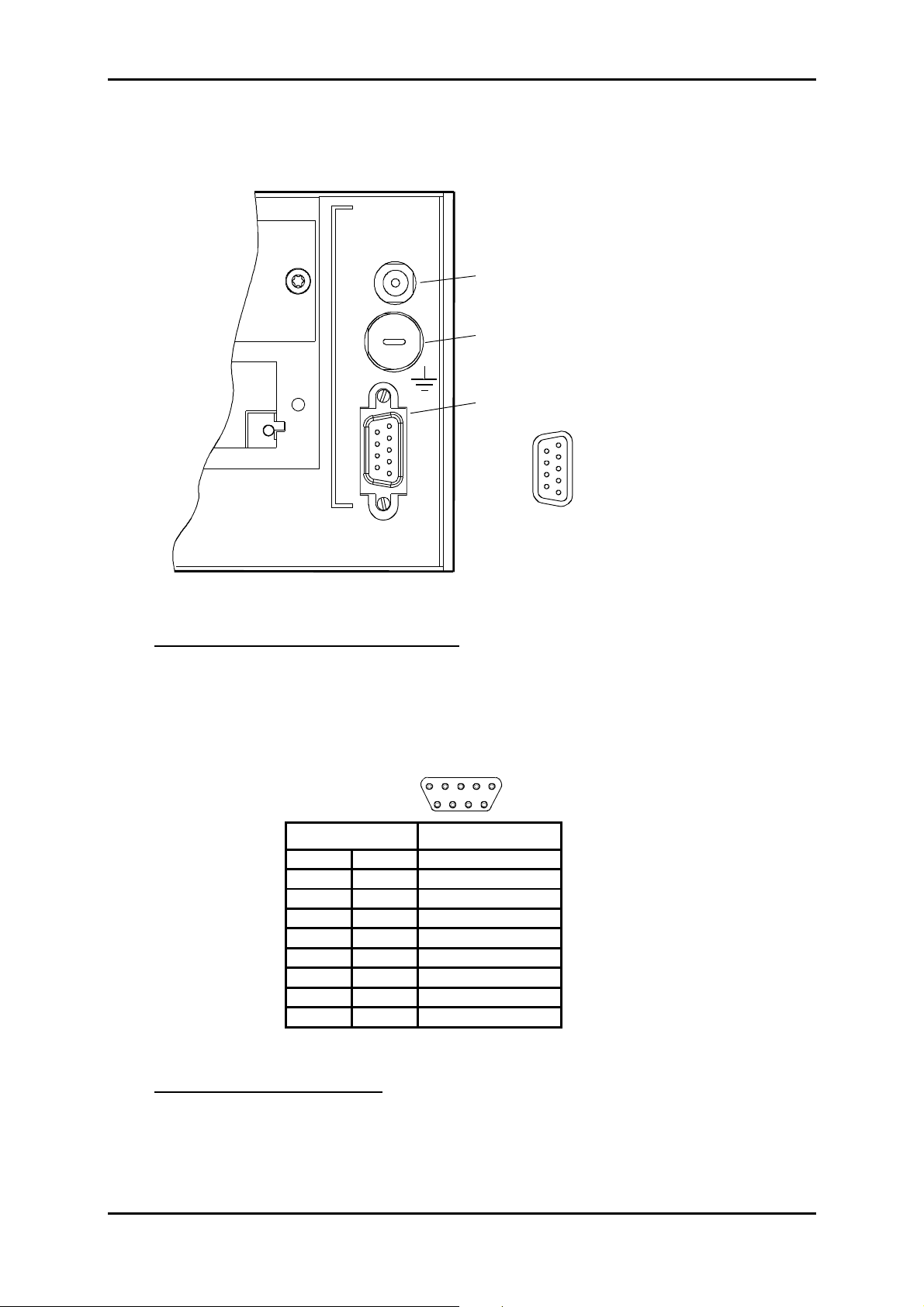

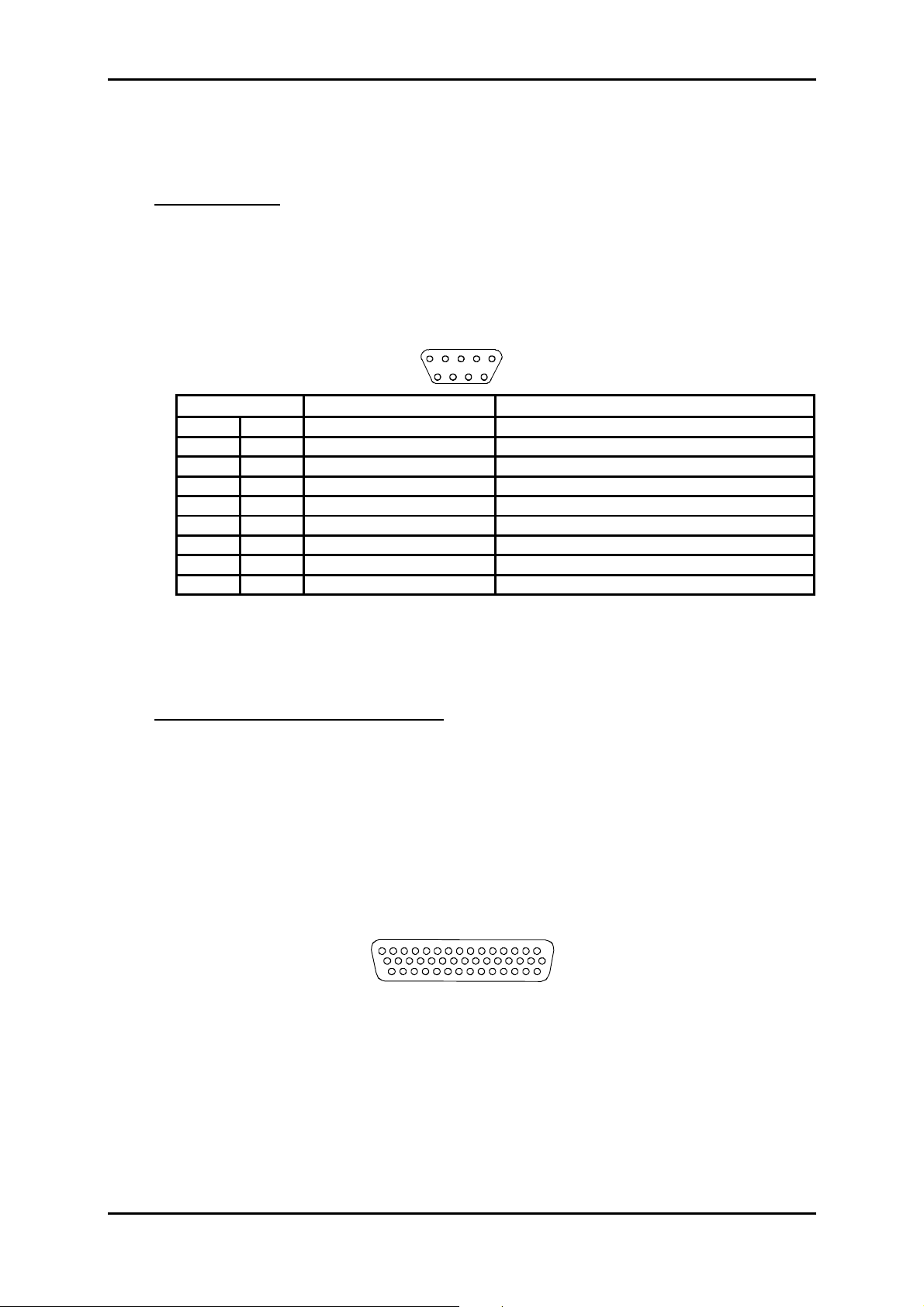

Description of power supply ports

POWER

- 48V

2A MAX

"PWR" Jack type connector

F4AL250V Fuse 4A Quick fuse

low power shutdown

250V

PWRA and PWRB

1 - 48 B1

5

9

6

1

2 - 48 B1 6 OB1

3 - Reserved 7 OB1

4 - 48 B2 8 OB2

5 - 48 B2 9 OB2

ADR-155C

Figure 1-2 – Connecting power supply ports

"PWRA"/"PWRB" power supply interface:

Input voltage : One or two Safety Extra Low Voltage (SELV) type – 48V sources

Voltage range allowed: - 36 V to - 60 V

Maximum voltage range : - 36 V to - 72 V

Power 100 VA maximum

Connector Male 9-way HE5

5

9

Pin N° Signal name

1 -48B1

6OB1

2 -48B1

7OB1

3 Reserved

8OB2

4 -48B2

9OB2

5 -48B2

1

6

NOTA : The shielding of the connector is connected to the equipment ground

"PWR" power supply interface:

Port Connecting transformer 110-240//48V 60W/

Connector Jack (core = OB1 and shield = - 48 V1).

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-5

Page 14

1 - INSTALLATION AND COMMISSIONING

"SYNC"

5

9

1 : GND

2 : TX1_TIP 6 : TX1_RING

3 : RX1_TIP 7 : RX2_TIP

4 : RX2_RING 8 : RX1_RING

5 : RESERVED 9 : RESERVED

1

6

LOOPS

8

15

1 : Break B

2 : Make B 9 : Common B

3 : Common A 10 : Break A

4 : Gnd 11 : Make A

5 : R-MON 4 N 12 : R-MON 4 P (OB)

6 : R-MON 3 N 13 : R-MON 3 P (OB)

7 : R-MON 2 N 14 : R-MON 2 P (OB)

8 : R-MON 1 N 15 : R-MON 1 P (OB)

Schematic diagram

of a dry loop

M

CB

1

9

"E1 OUTPUT"and "E1 INPUT"

15 1

30

44 31

1 : Tx(Rx) 1A

2 : Tx(Rx) 3B

3 : Tx(Rx) 4A

4 : Tx(Rx) 6B

5 : Tx(Rx) 7A

6 : Tx(Rx) 9B

7 : Tx(Rx) 10A

8 : Tx(Rx) 12B

9 : Tx(Rx) 13A

10 : Tx(Rx) 15B

11 : Tx(Rx) 16A

12 : Tx(Rx) 18B

13 : Tx(Rx) 19A

14 : Tx(Rx) 21B

15 : GND

16 : GND

17 : Tx(Rx) 2B

18 : Tx(Rx) 3A

19 : Tx(Rx) 5B

20 : Tx(Rx) 6A

21 : Tx(Rx) 8B

22 : Tx(Rx) 9A

23 : Tx(Rx) 11B

24 : Tx(Rx) 12A

25 : Tx(Rx) 14B

26 : Tx(Rx) 15A

27 : Tx(Rx) 17B

28 : Tx(Rx) 18B

29 : Tx(Rx) 20B

30 : Tx(Rx) 21A

31 : Tx(Rx) 1B

32 : Tx(Rx) 2A

33 : Tx(Rx) 4B

34 : Tx(Rx) 5A

35 : Tx(Rx) 7B

36 : Tx(Rx) 8A

37 : Tx(Rx) 10B

38 : Tx(Rx) 11A

39 : Tx(Rx) 13B

40 : Tx(Rx) 14A

41 : Tx(Rx) 16B

42 : Tx(Rx) 17A

43 : Tx(Rx) 19B

44 : Tx(Rx) 20A

"MNGT"

5

9

1 : GND

2 : RXPA 6 : RXPB

3 : TXPA 7 : TXPB

4 : TXCLKPA 8 : TXCLKPB

5 : RXCLKPA 9 : RXCLKPB

1

6

16

COMM

5

9

1 : DCD

2 : RX 6 : DSR

3 : TX 7 : RTS

4 : DTR 8 : CTS

5 : Gnd 9 : NC *

Green "ON" LED

On

Flashing

Off

or not run software

"ALA" LEDs

Red "M" LED

ON : major alarm

Yellow "m" LED

OFF : minor alarm

"ACK"

alarm acquittement

In service card

Autotest default

No powered equipment

Push button

ETH

Pin 8Pin 1

1 : TX_ETH_TIP 5 : NC

2 : TX_ETH_RING 6 : RX_ETH_RING

3 : RX _ETH _TIP 7 : NC

4 : NC * 8 : NC

1

6

Yellow LED

ON : correct link

Green LED

ON : on reception

NC * : Reserved

: link status

: traffic status

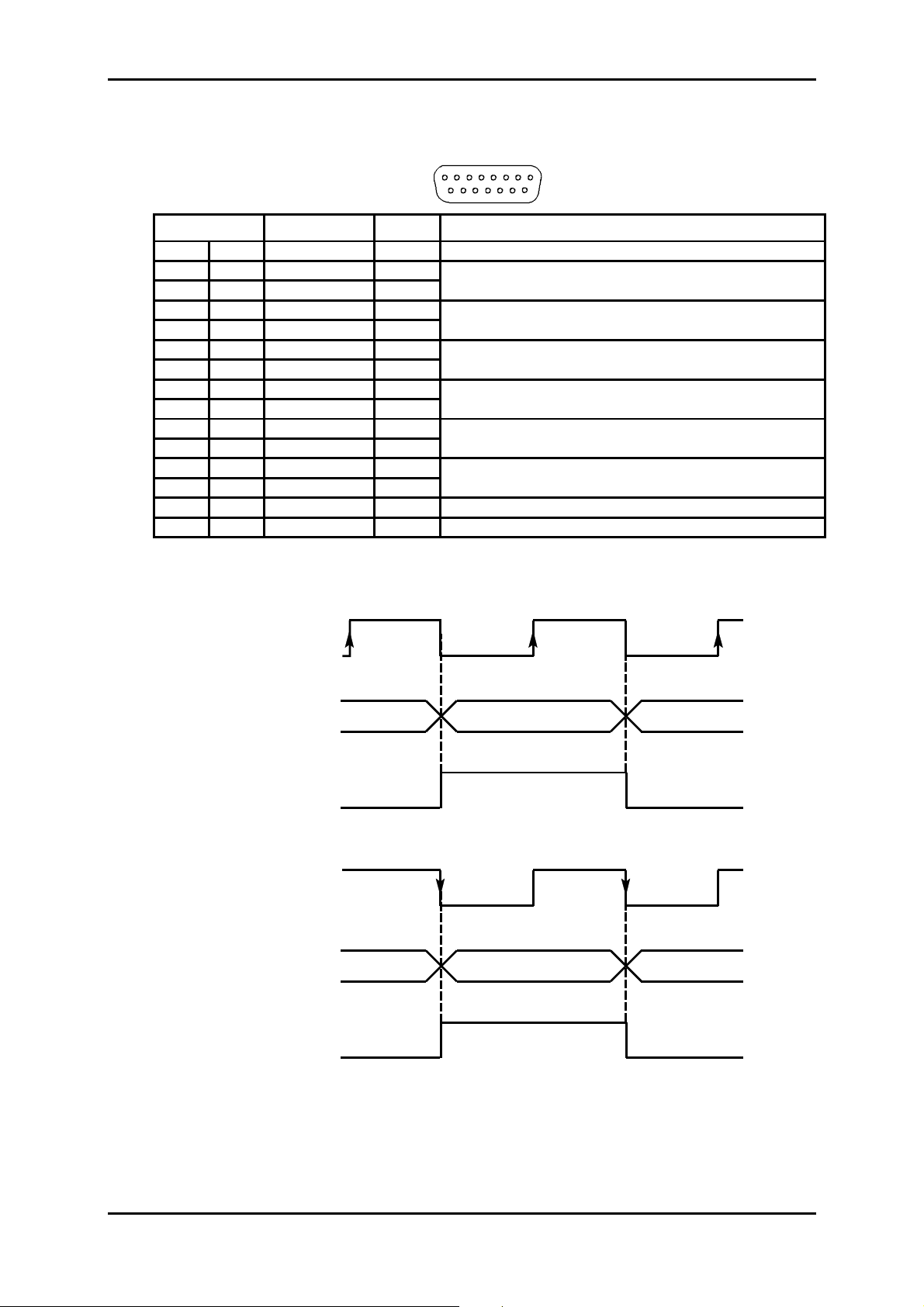

Figure 1-3 – Connecting mother board inputs

Installation and User Guide - N56717020101

Page A1-6

No reproduction or communication without the written cons ent of

SAGEM SA

Page 15

1 - INSTALLATION AND COMMISSIONING

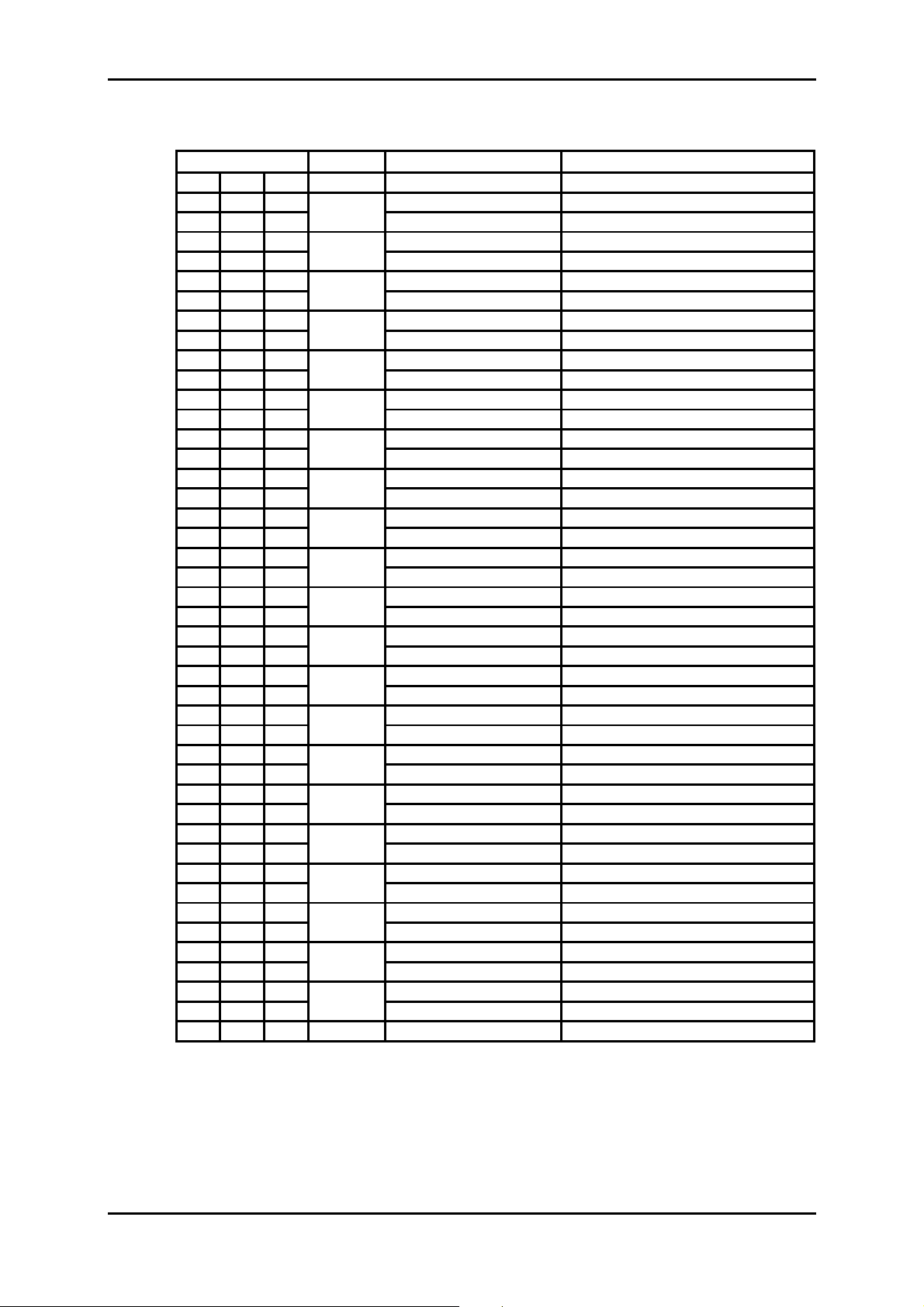

1.3.2 - Connecting on motherboard

1.3.2.1 - Remote indication, remote control and station alarm port

("LOOPS")

"LOOPS" Interface:

Ports 4 remote indication inputs for floating contacts (

-48 V internally, active when closed and with electrical isolation

(loop current = from 1 to 10 mA),

2 dry loop outputs (common, normally closed and normally open) (

outputs

) for station alarm or remote control use (maximum current = 100 mA

on resistive load),

Connector Female 15-way HE5

8

15

Pin N° Signal name Comments

1 BREAK B Normally closed contact of dry loop B

9 COMMON B Common contact of dry loop B

2 MAKE B Normally open contact of dry loop B

10 Break A Norm al l y closed contact of dry loop A

3 COMMON A Common contact of dry l oop A

11 Make A Normally open contact of dry l oop A

4 GND Ground

12 R- MON 4 P (OB) User imput N°4

5R-MON 4 N

13 R- MON 3 P (OB) User imput N°3

6R- MON 3 N

14 R- MON 2 P (OB) User imput N°2

7R- MON 2 N

15 R- MON 1 P (OB) User imput N°1

8R- MON 1 N

NOTE: OB is the result of a logical "OR" between signals OB1 and OB2 on the "PW R", "PWRA" and "PWRB"

power supply interfaces.

1

9

Local user inputs

), biased to

Local user

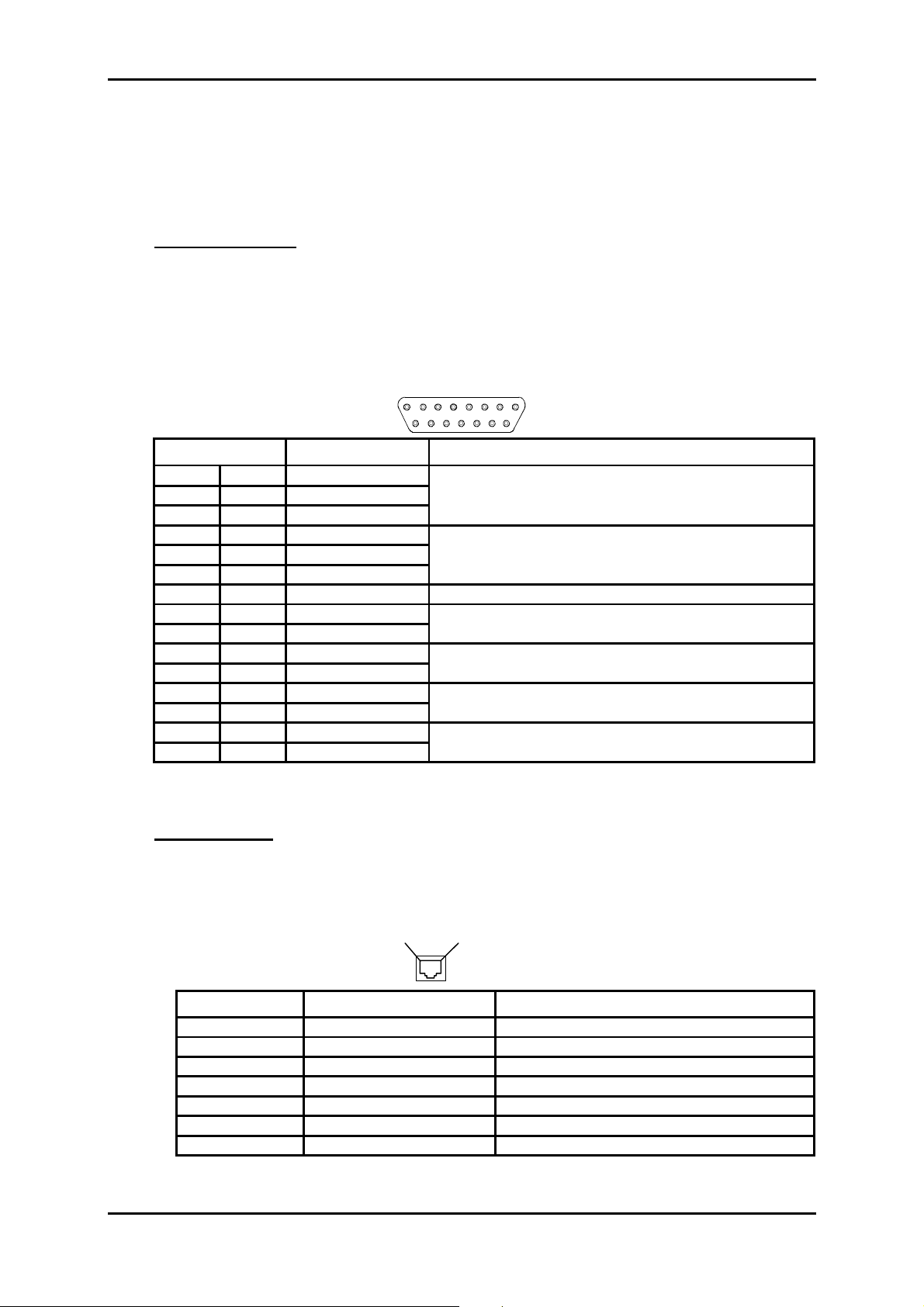

"ETH" Interface:

Port Ethernet management interface operating at 10 Mbit/s in half-duplex or full-

duplex mode according to the mode used by the interlocutor (dynamic

adaptation of the Ethernet port on each new log-in of the interlocutor),

Connector RJ48 Type (RJ45 shielded).

Pin 1

Pin N° Signal name Comments

1 TX_ETH_TIP Output (hot point)

2 TX_ETH_RING Output (cold point)

3 RX_ETH_TIP Input (hot point)

4 NC Reserved

5 NC Reserved

6 RX_ETH_RING Input (cold point)

7 and 8 NC Reserved

Pin 8

Front view

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-7

Page 16

1 - INSTALLATION AND COMMISSIONING

NOTE: Two LEDs are linked to the "ETH" port:

• LED, "Activity", green colour : Trafic status indicator,

• LED, "Link", yellow colour : Link status indicator.

1.3.2.2 - Management and Administration ports

"COMM" Interface:

Ports RS232, connecting VT100 standard console or emulation

Bit rate 19200 bauds (8 data bits, no parity bit and 1 stop bit),

Connector Female 9-way HE5

5

9

Pin N° Signal name Comments

1 DCD Connected to DSR

6 DSR Data Set Ready (to DCE)*

2 RX Received dat a (to DCE)*

7 RTS Request To Send (from DCE)*

3 TX Transmitted data (from DCE)*

8 CTS Clear To Send (to DCE)*

4 DTR Data Terminal Ready (from DCE)*

9 RI Ring Indicator (not connect ed)

5 GND Ground

* The ADR155C is seen as DCE

1

6

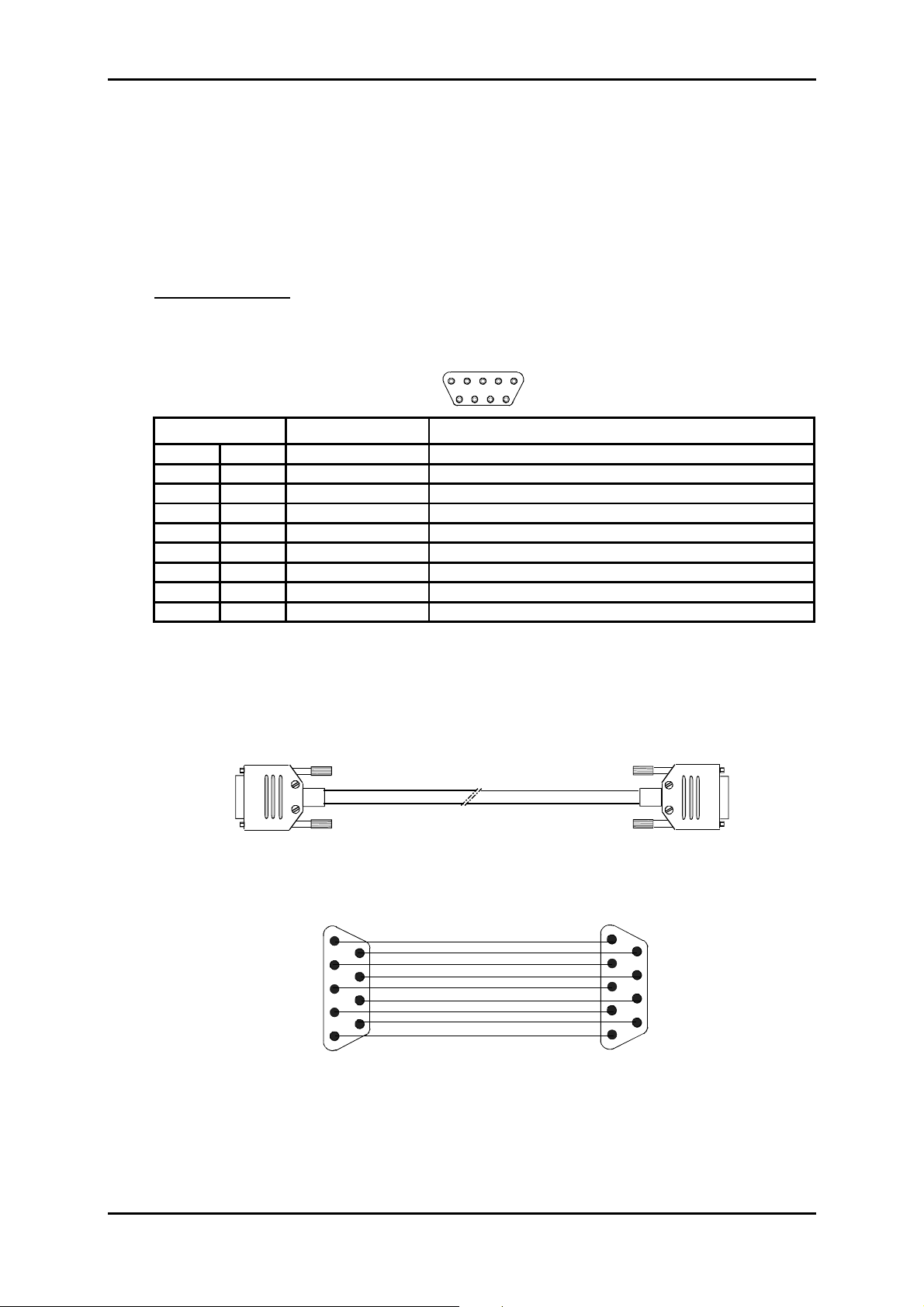

Connection cable See below.

Equipment side

"COMM"

Male 9-way connector

1

6

9

5

Wiring diagram

VT100 or PC

side

Female 9-way connector

1

6

9

5

Installation and User Guide - N56717020101

Page A1-8

No reproduction or communication without the written cons ent of

SAGEM SA

Page 17

1 - INSTALLATION AND COMMISSIONING

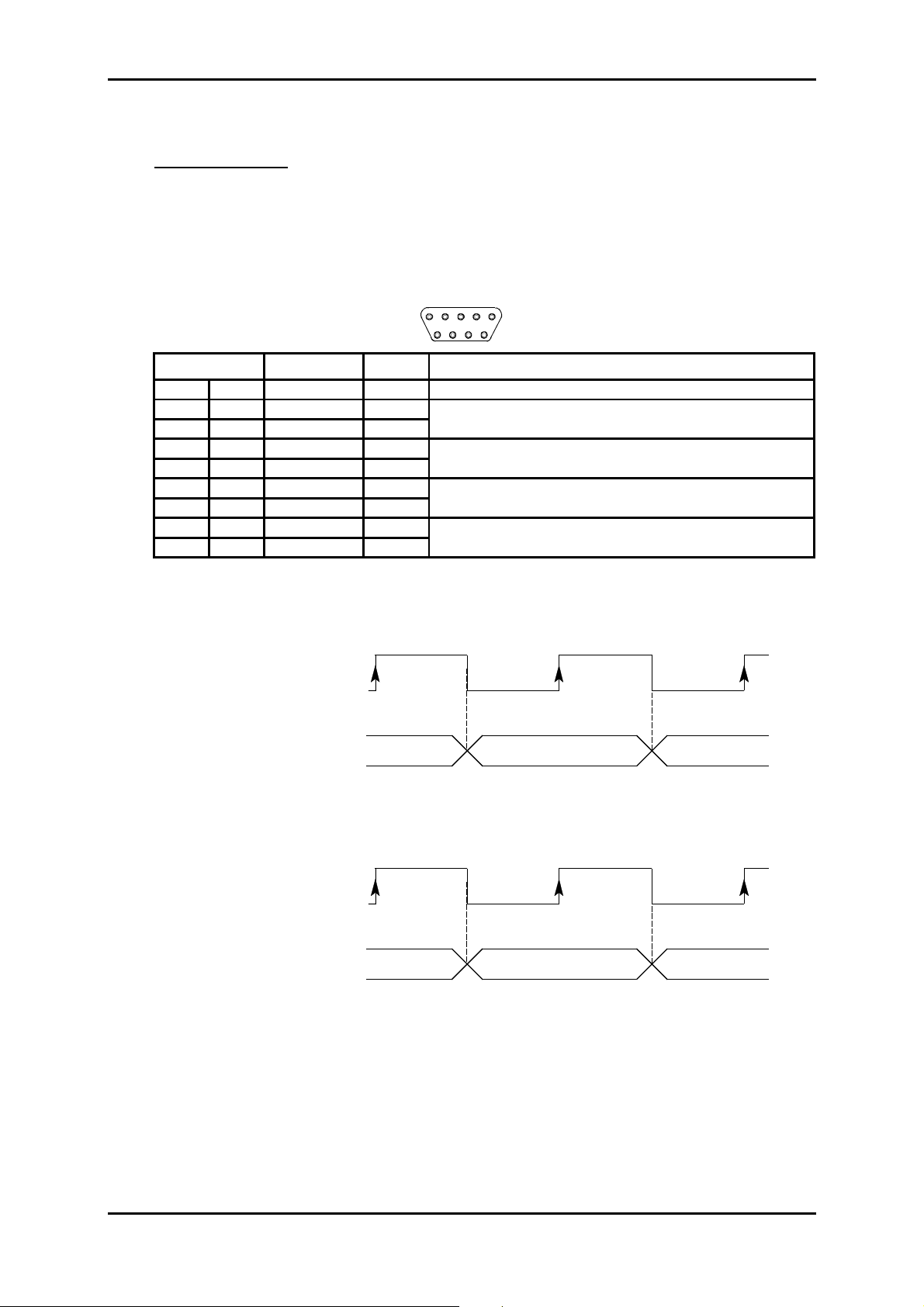

)

"MNGT" Interface:

Port V.11 synchronous (differential) interconnection possible with other SAGEM

equipment ADR155C, FOT 155C, through serial synchronous links used in

codirectional mode at 64 kbit/s or master contra-directional mode (rate

defined by the ADR 155C)

Bit rate 64 kbit/s,

Connector Female 9-way HE5.

5

9

Pin N° Signal name Polarity Comments

1 GND Ground (no connected)

6RXPB(+)

2 RXPA (-)

7TXPB(+)

3 TXPA (-)

8 TXCLKPB (+)

4 TXCLKPA (-)

9 RXCLKPB (+)

5 RXCLKPA (-)

Input for data received over the P interface and sampled on the

rising edge of receive cloc k RXCLKP (B-A)

Output for data sent over the P interface on the falling edge of

transmit clock TXCLKP (B-A)

Output for transmit cloc k; in codirectional mode, the transm it clock

timing is derived from the equipment's i nt ernal timing

Receive clock input

1

6

*In slave contradirectional mode (coming) TXCLK signals are inputs.

Timing diagram for the "MNGT" interface in codirectional mode (64 kbit/s synchronous use):

TXCLKP (B-A)

(codirectional transmit

clock output)

TXP (B-A)

(output for data transmitted

over P interface)

B8 B1 B2

RXCLKP (B-A)

(receive clock input)

RXP (B-A)

(input for data received

over the P interface

B8 B1 B2

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-9

Page 18

1 - INSTALLATION AND COMMISSIONING

1.3.2.3 - G.703 2 Mbit/s Synchronization port

"SYNC" Interface

Ports Two G.703 2MHz external synchronization inputs (T3) and one G.703 2MHz

clock output (T4) compliant with ITU-T G.703 Recommendation

(§ 10.3 for input port, § tab.10 for output port)

Bit rate 2,048 Mbit/s ± 50 ppm,

Impedance 120 Ω balanced,

Connector Female 9-way HE5 (120 Ω).

5

9

Pin N° Signal name Comments

1 GND Ground

6 TX1 RING (T4-) Output T4-1 (cold point)

2 TX1 TIP (T4+) Output T4-1 (hot point)

7 RX2 TIP (T3+) Input T3-2 (hot point)

3 RX1 TIP (T3+) Input T3-1 (hot point)

8 RX1 RING (T3-) Input T3-1 (cold point)

4 RX2 RING (T3-) Input T3-2 (cold point)

9 NC Reserved

5 NC Reserved

1

6

NOTA : The shielding of the connector case is connected to the subrack front panel ground

1.3.2.4 - G.703, 21 x 2 Mbit/s traffic port

"E1 INPUT" and "E1 OUTPUT" Interface

ports 21 x 2 Mbit/s traffic ports compliant with the ITU-T G.703 Recommendation

(§ 6.3 for input port, § tab.6 for output port)

Bit rate 2,048 Mbit/s ± 50 ppm,

Code HDB3,

Impedance 120 Ω balanced,

Connector SUB D HD female 44 pins supporting L907 cable (21 ports).

This interface uses two connectors : E1 INPUT connector for inputs (named RX) and

E1 OUTPUT connector for outputs (named TX)

15

30

44 31

1

16

Installation and User Guide - N56717020101

Page A1-10

No reproduction or communication without the written cons ent of

SAGEM SA

Page 19

1 - INSTALLATION AND COMMISSIONING

Pin N°

16

31

1

17

2

32

18

33

3

19

4

34

20

35

5

21

6

36

22

37

7

23 11

8

38

12

24

39

9

25 14

10

40

15

26

41

11

27

12

42

28

13

43

29

14

44

30

15

Ports Signal name

GND

1

2

3

4

5

6

7

8

9

10

13

16

17

18

19

20

21

TX(RX) 1B

TX(RX) 1A

TX(RX) 2B

TX(RX) 2A

TX(RX) 3B

TX(RX3A

TX(RX) 4B

TX(RX) 4A

TX(RX) 5B

TX(RX) 5A

TX(RX) 6B

TX(RX) 6A

TX(RX) 7B

TX(RX) 7A

TX(RX) 8B

TX(RX) 8A

TX(RX) 9B

TX(RX) 9A

TX(RX) 10B

TX(RX) 10A

TX(RX) 11B

TX(RX) 11A

TX(RX) 12B

TX(RX) 12A

TX(RX) 13B

TX(RX) 13A

TX(RX) 14B

TX(RX) 14A

TX(RX) 15B

TX(RX) 15A

TX(RX) 16B

TX(RX) 16A

TX(RX) 17B

TX(RX) 17A

TX(RX) 18B

TX(RX) 18A

TX(RX) 19B

TX(RX) 19A

TX(RX) 20B

TX(RX) 20A

TX(RX) 21B

TX(RX) 21A

GND

Comments

ground

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Output (Input) 2 Mbit/s (hot poi nt)

Output (input) 2 Mbit/s (cold poi nt)

Ground

NOTA : The shielding of the connector case is connected to the subrack front panel ground

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-11

Page 20

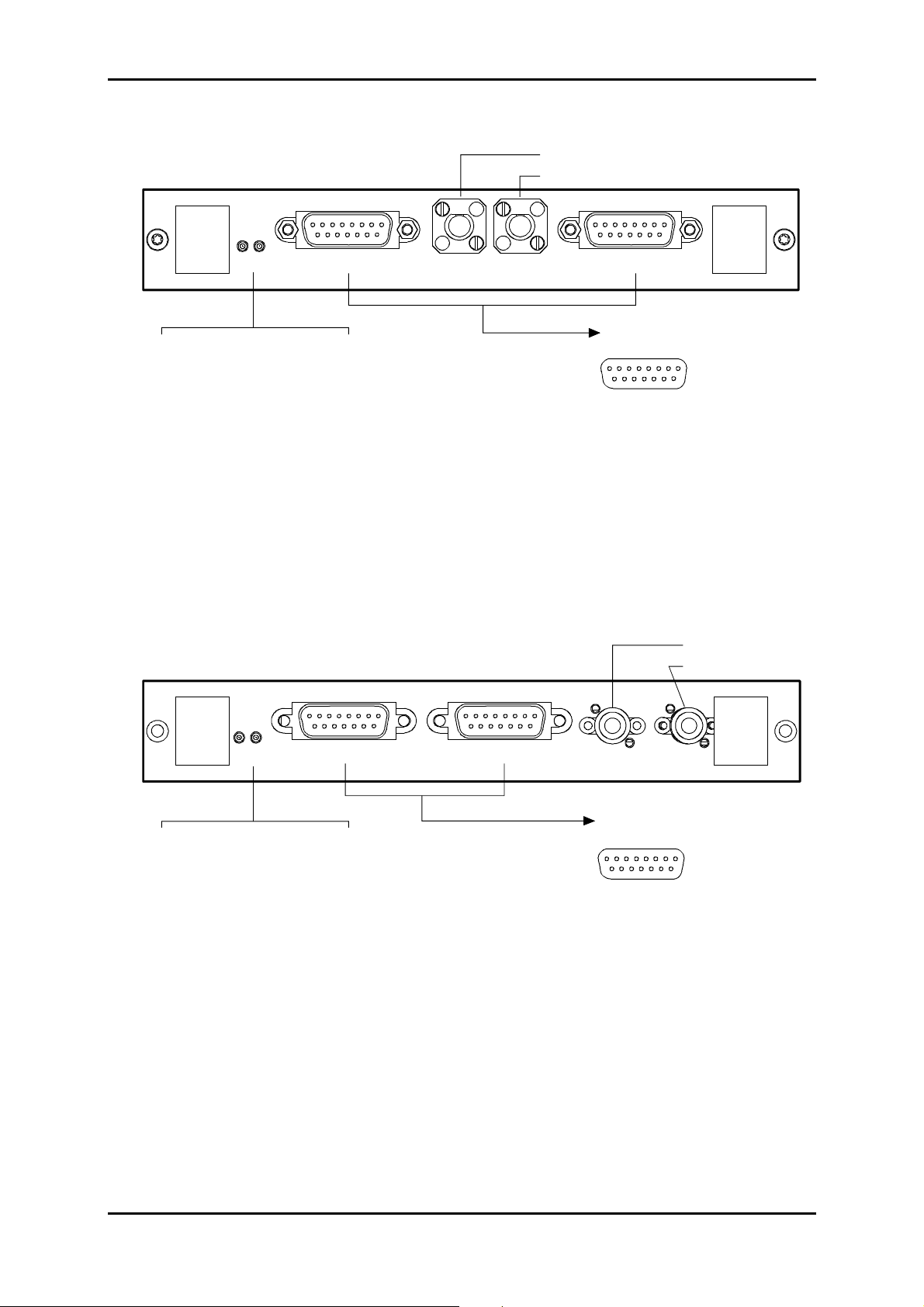

1 - INSTALLATION AND COMMISSIONING

ADR IC1

STM1 transmission port

STM1 reception port

STATUS

LED STATUS

Green Red

ON OFF Card in service

ON ON Card in alarm

OFF OFF Hardware default (fuse)

OFF ON Card out of service

Flashing Autotest default

ADR IC1.1

TR REC

Version 1

AUXEOW

"

EOW and "AUX

81

15

1 : NC

2 : TA 9 : TB

3 : TOF PA 10 : TOF PB

4 : RA 11 : RB

5 : ROF PA 12 : ROF PB

6 : R64 A 13 : R64 B

7 : T64 A 14 : T64 B

8 : GND 15 : NC

"

9

STM1 transmission port

STM1 reception port

STATUS

LED STATUS

Green Red

ON OFF Card in service

ON ON Card in alarm

OFF OFF Hardware default (fuse)

OFF ON Card out of service

Flashing Autotest default

EOW AUX

Figure 1-4 - Connecting ADR IC1.x card inputs

Version 2

TR REC

"

EOW and "AUX

81

15

1 : NC

2 : TA 9 : TB

3 : TOF PA 10 : TOF PB

4 : RA 11 : RB

5 : ROF PA 12 : ROF PB

6 : R64 A 13 : R64 B

7 : T64 A 14 : T64 B

8 : GND 15 : NC

"

9

NC: Reserved

Installation and User Guide - N56717020101

Page A1-12

No reproduction or communication without the written cons ent of

SAGEM SA

Page 21

1 - INSTALLATION AND COMMISSIONING

1.3.3 - Connecting on the ADR IC1.x card

Each ADR IC1.x module provides connection for:

an STM1 interface ("TR" transmission port and "

two order wire channels at 64 kbit/s (named "EOW" and "AUX"), which, by default, are

conveyed in E1 and F1 bytes of the SOH, respectively.

REC

1.3.3.1 - Connecting STM1 interface

Remove the contact protection connector,

Connect STM-1 interface to front panel FC/PC connectors:

Ö

Transmission TR Connector

Ö

Reception REC Connector

"TR" and "REC" ports:

" reception port)

Interface Type IC 1.1 = L 1.1 + S 1.1 or IC 1.2 = L 1.2 + S 1.2,

Bit rate 155.520 Mbit/s ± 15 ppm,

Standart ITU-T G.957/G.958,

Encoding Not encoded (NRZ),

Optical fiber* Single mode (1300 nm (IC1.1) or

1550 nm (IC1.2), ITU-T G.652),

Transmit optical power -5 to 0 dBm

Max. receive power 0 dBm

Sensibility at 10

garanteed Attenuation 0 - 28 dB with no external attenuator,

Typical range 0 - 60 km (IC1.1) or 0 - 90 km (IC1.2),

Connector all ceramic FC/PC

* : It is pos sible to use a multi-mode optical fiber with diameter sm aller than or equal to 62.5

microns. The optic al budget is then reduced to 25 % of the optical budget obtained with a

mono-mode optical f iber . T he tr ansmission optical fiber is mono-mode type and the reception

optical fiber is multi-mode type.

-10

- 34 dB

1.3.3.2 - Connecting order-wire channels

"EOW" and "AUX" Interface:

Port synchronous V.11 (differential),

Bit rate 64 kbit/s,

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-13

Page 22

1 - INSTALLATION AND COMMISSIONING

9

)

Connector Female 15-way HE5.

81

15

Pin N° Signal name Polarity Comments

1 - Not connected

9TB(+)

2 TA (-)

10 TOFPB (+)

3 TOFPA (-)

11 RB (+)

4 RA (-)

12 ROFPB (+)

5 ROFPA (-)

13 R64B (+)

6 R64A (-)

14 T64B (+)

7 T64A (-)

15 - Not connected

8 Ground

Input for data to send over the STM-1 line and sampled on the

rising edge of clock T64 (B-A)

Transmit mode byte sync output indicating the positioning of bit 1

and sent on the rising edge of clock T64 (B-A)

Output for data extracted from STM-1 line and sampled on the

falling edge of clock T64 (B -A)

Receive mode byte sync output indicating the setting of bit 1 and

sent on the falling edge of cl ock T64 (B-A)

64 kHz receive clock output

64 kHz transmit cl ock output

Timing diagram f or the "EOW /AUX" interfac e in contra-directional m ode (64 k bit/s synchronous

use):

T64 (B-A)

(transmit clock output)

T (B-A)

(input for data to transmit

over STM1 line)

TOFP (B-A)

(transmit synchro byte

pulse output)

R64 (B-A)

(receive clock output)

R (B-A)

(output for data received

from STM1 line)

B8 B1 B2

B8 B1 B2

ROFP (B-A)

(receive synchro b yte

pulse output

Installation and User Guide - N56717020101

Page A1-14

No reproduction or communication without the written cons ent of

SAGEM SA

Page 23

1 - INSTALLATION AND COMMISSIONING

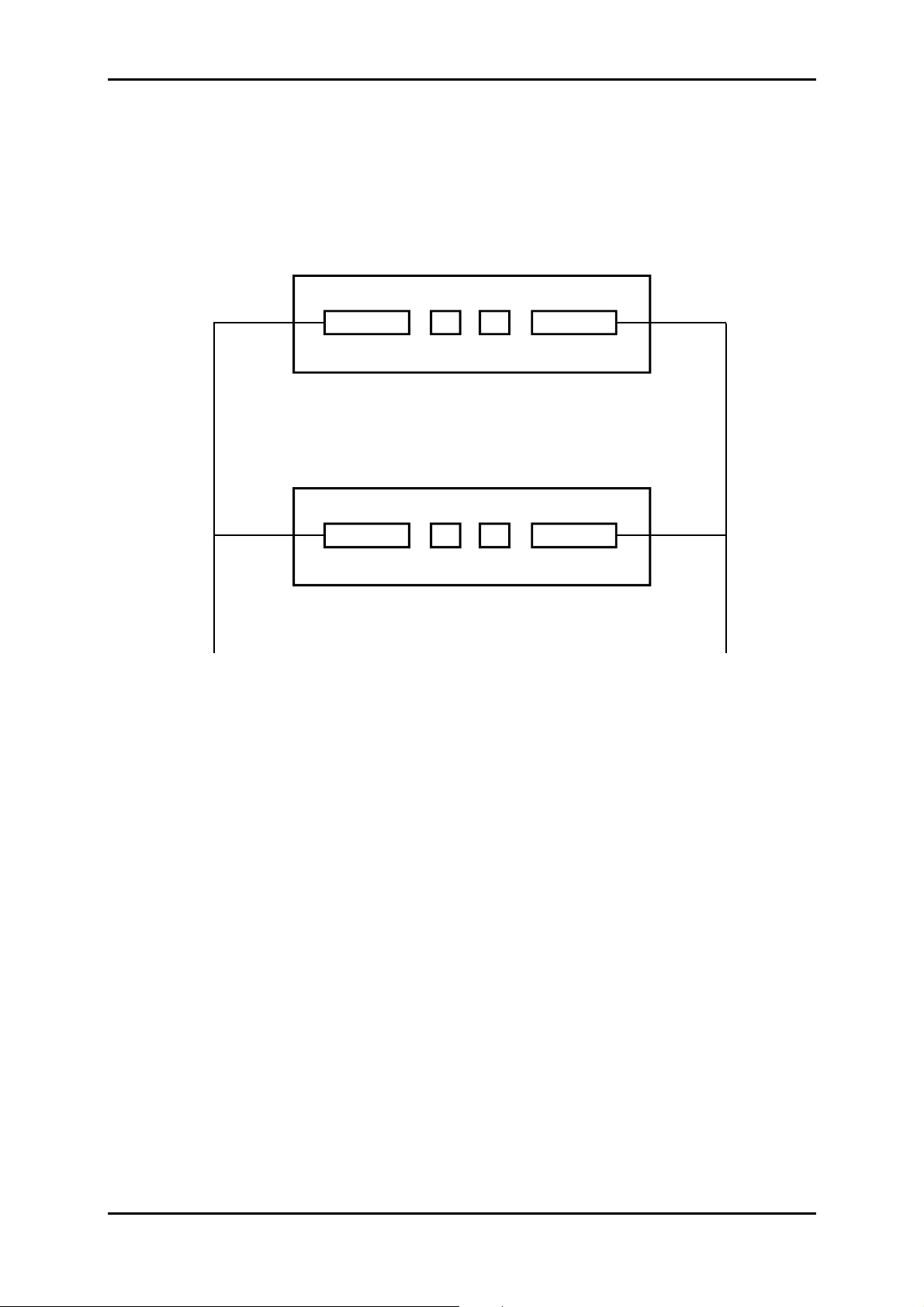

1.3.3.3 – Connecting with MSP operati on

As EOW and AUX ports are physically integral with ADR IC1.x, operating the order wire and

auxiliary channels with MSP protection requires the use of a "Y" cord elec tr ically connecting, one

by one, identically, the signals of EOW and AUX connectors.

EOW

ADR IC1.x Working

EOW

ADR IC1.x Prot ection

"Y" cord for

order wire

channel operation

TRTRREC

REC

AUX

AUX

"Y" cord for

auxiliar y wire

channel operation

Likewise, in order to ensure a good behaviour during the changeover from one m odule to the

other, the operator should take care to k eep identical c onfigur ations on both ADR IC1.x cards ; a

warning message appears in case of modification.

Only the connections are not identical. There must be no connections on the "Protection"

module, as in all the connections are made to the "Working" module.

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-15

Page 24

1 - INSTALLATION AND COMMISSIONING

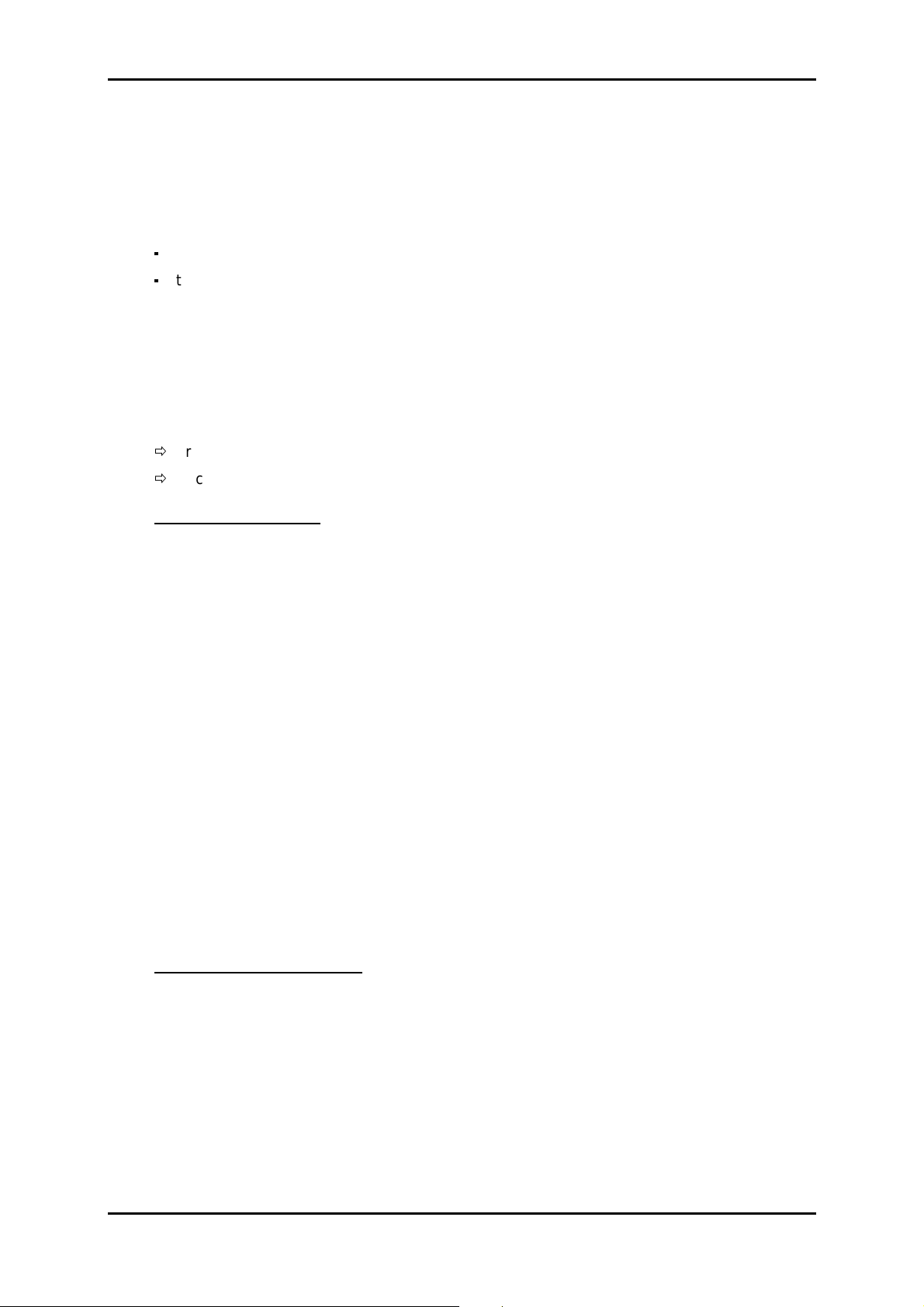

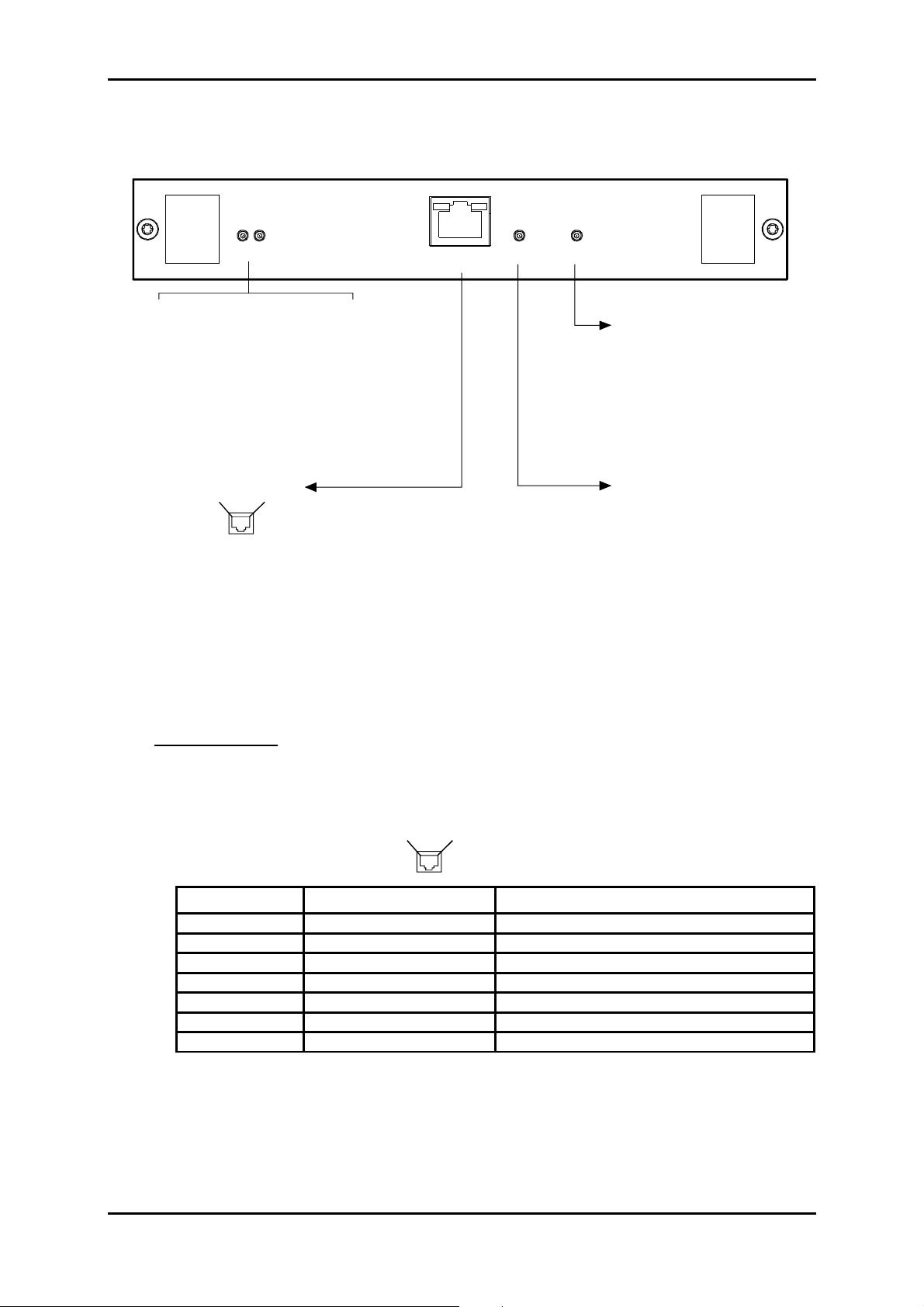

1.3.4 - Connecting on ADR LAN1 card

ADR LAN1

STATUS

ETH

/

10

100 HALF/FULL

LED STATUS

Green Red

ON OFF Card in service

ON ON Card in alarm

OFF OFF Hardware default (fuse)

OFF ON Card out of service

Flashing Autotest default

ETH

Contact 8Contact 1

1 : TX_ETH_TIP 5 : NC

2 : TX_ETH_RING 6 : RX_ETH_RING

3 : RX _ETH _TIP 7 : NC

4 : NC 8 : NC

Yellow LED

ON : correct link

Green LED

ON : on reception

: link status

: traffic status

NC : Reserved

HALF/FULL

Yellow LED :

(Half or Full Duplex)

ON : Full duplex

10/100

Yellow LED :

ON : 100 Mbit/s

Ethernet interface type

Ethernet interface bite rate

Figure 1-5 – Connecting ADR LAN1 card input

"ETH" Interface :

Port Traffic Ethernet interface operating at 10 or 100 Mbit/s in half-duplex or full-

duplex mode according to the mode used by the interlocutor (dynamic

adaptation of the Ethernet port on each new log-in of the interlocutor),

Connector Ethernet 10 or 100 BaseT - RJ48 Type (Shielded RJ45).

Pin 1

Pin 8

Front view

Pin N° Signal name Comments

1 TX_ETH_TIP Ethernet output (hot point)

2 TX_ETH_RING Ethernet output (cold point)

3 RX_ETH_TIP Ethernet input (hot point)

4 NC Reserved

5 NC Reserved

6 RX_ETH_RI NG Ethernet i nput (cold point)

7 and 8 NC Reserved

NOTE: Two LEDs are linked to the "ETH" interface:

• LED, "Activity", green colour : Trafic status indicator,

• LED, "Link", yellow colour : Link status indicator.

Electrical characteristics compliant with the IEEE 802.3U

Installation and User Guide - N56717020101

Page A1-16

No reproduction or communication without the written cons ent of

SAGEM SA

Page 25

1 - INSTALLATION AND COMMISSIONING

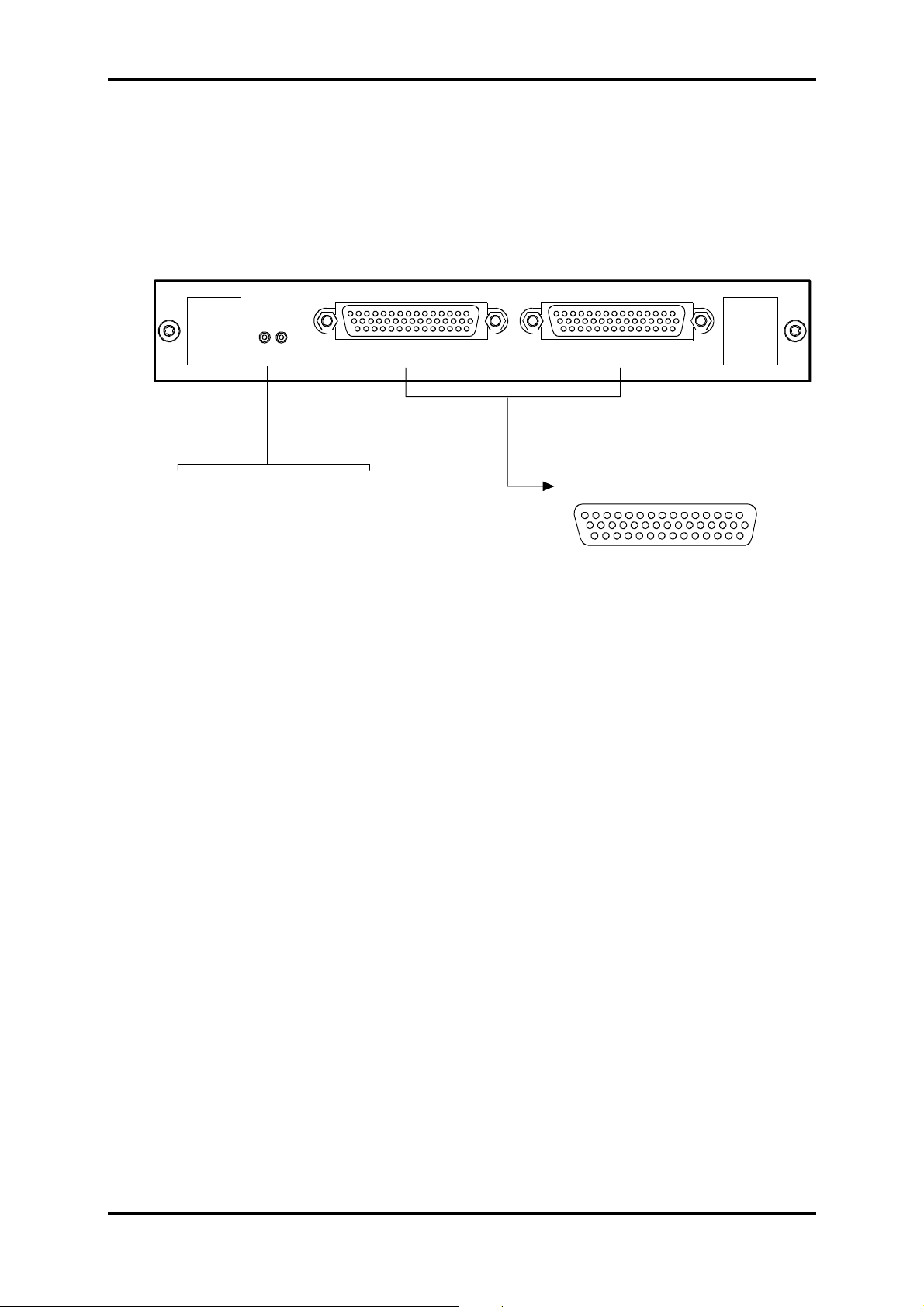

1.3.5 - Connecting on ADR 21E120 card

2 Mbit/s traffic connections, performed on "

E1 INPUT"

ADR21E120 card are identical with those perform ed on "

on the front side of the motherboard (see § 1.3.2.4)

ADR 21E120

STATUS

LED STATUS

Green Red

ON OFF Card in service

ON ON Card in alarm

OFF OFF Hardware default (fuse)

OFF ON Card out of service

Flashing Autotest default

E1 OUTPUT E1 INPUT

1 : Tx(Rx) 1A

2 : Tx(Rx) 3B

3 : Tx(Rx) 4A

4 : Tx(Rx) 6B

5 : Tx(Rx) 7A

6 : Tx(Rx) 9B

7 : Tx(Rx) 10A

8 : Tx(Rx) 12B

9 : Tx(Rx) 13A

10 : Tx(Rx) 15B

11 : Tx(Rx) 16A

12 : Tx(Rx) 18B

13 : Tx(Rx) 19A

14 : Tx(Rx) 21B

15 : GND

and

"E1 OUTPUT"

E1 INPUT"

and

ports on the

"E1 OUTPUT"

"E1 OUTPUT" and "E1 INPUT"

15 1

30

44 31

16 : GND

17 : Tx(Rx) 2B

18 : Tx(Rx) 3A

19 : Tx(Rx) 5B

20 : Tx(Rx) 6A

21 : Tx(Rx) 8B

22 : Tx(Rx) 9A

23 : Tx(Rx) 11B

24 : Tx(Rx) 12A

25 : Tx(Rx) 14B

26 : Tx(Rx) 15A

27 : Tx(Rx) 17B

28 : Tx(Rx) 18B

29 : Tx(Rx) 20B

30 : Tx(Rx) 21A

31 : Tx(Rx) 1B

32 : Tx(Rx) 2A

33 : Tx(Rx) 4B

34 : Tx(Rx) 5A

35 : Tx(Rx) 7B

36 : Tx(Rx) 8A

37 : Tx(Rx) 10B

38 : Tx(Rx) 11A

39 : Tx(Rx) 13B

40 : Tx(Rx) 14A

41 : Tx(Rx) 16B

42 : Tx(Rx) 17A

43 : Tx(Rx) 19B

44 : Tx(Rx) 20A

ports

16

Figure 1-6 – Connecting ADR 21E120 card inputs

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-17

Page 26

1 - INSTALLATION AND COMMISSIONING

1.3.6 - 75 Ω connecting strip

Drafting TBD

Figure 1-7 - 75 ΩΩ connecting strip

Installation and User Guide - N56717020101

Page A1-18

No reproduction or communication without the written cons ent of

SAGEM SA

Page 27

1 - INSTALLATION AND COMMISSIONING

LOCAL TEST

Equipment Inventory

- 48 V power Check

Aggregate optical loopback

Insertion of communication parameters (VT100)

* case of underequipped

unitary equipment

Settin g to time and insertion of the test configuration tributary accesses

Connecti on of external sync input from of an "Master" equipment

no

(HTTP browser)

Tributary Ports continuity ch eck

- 48 V redundancy Check

A and B loops and alarms check

Local tr ansmission test (30 m n ) *

Optical connection

(optional)

Configuration Elaboration

Local Test on network

of last équi pm ent ?

yes

Link established

Optical m easurements

MSP protection check

Counters reset

24 H link Performance

Equipment operational

(constitution of in stallat ion file)

Configuration Save

Figure 1-8 – Commissioning procedure for ADR155C network

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-19

Page 28

1 - INSTALLATION AND COMMISSIONING

1.4 - Commissioning

: The equipm ent can be operated from a PC fitted with VT 100 emulation and HT TP navigator;

NOTE

its minimum configuration is defined in section 1.4.1.

A local terminal with VT100 emulation is indispensable during the first commissioning, in

order to be able to access the equipment via the management function; however, this

terminal only enables the communication function to be parameterized.

Procedure.

)

On the first commissioning, the equipment scans its constitution and considers it as the

expected configuration, in service, not monitored. It is thus advisable to insert the traffic

cards before power-up, in order to speed up the commissioning.

)

Switch on the power supply connected to the equipment.

)

The equipment conducts self-tests:

When self-tests have run correctly, the "ON" indicator light is illuminating,

In the opposite case, an indicator flashing code defines the faulty self-test (c ontact the

hotline).

)

Parameterize the communication interface, using the VT100 (see § 1.4.1).

)

Using the HTTP navigator, (see § 1.4.3).

Update the equipment time and date

Set each card under monitoring: validate the "Monitoring" command.

)

Connect the 2 Mbit/s and/or Ethernet ports, according to the equipment composition,

)

Connect the AUX and EOW ports required.

)

Download a predefined configuration or prepare the desired configuration, using the HTTP

navigator:

Create the connections

Establish the wished protection (MSP protection, SNC protection ...)

Choose the synchronization source, and change its parameters if required.

Change, if necessary, the configuration parameters and the alarm configuration.

The default configuration of the various parameters is provided by § 2.1.1.

)

Conduct the tests on STM-1 links, complying with the process described in Figure 1-2.

)

From that moment, the equipment is operational.

)

Operating alarms can signal a wrong connec tion of interfaces. Chec k the connection of por ts,

the alarms corresponding to the connected ports, and correct any problems that may arise.

)

Save configuration.

REMARK: It is possible, once the commissioning is perf orm ed, to connect additional 2 Mbit/s G .703,

Ethernet or STM1 ports, and to insert or extract powered cards.

Installation and User Guide - N56717020101

Page A1-20

No reproduction or communication without the written cons ent of

SAGEM SA

Page 29

1 - INSTALLATION AND COMMISSIONING

g

T

HTP

E

T

H

R

SN PM

P

P

P

Communication function over an ADR 155C

D1 - D3 over STM1 D1 - D3 over STM1

HT PT

E

T

H

R

SN PM

P

P

P

Example 1 : communication over a point to point link

Mngt port

ETH port

.

4 PPP ports

.

(Point to Point Protocol)

x

x

x

Application

HTTP server

.

SNNP agent for

.

IONOS ANM

R

Routing

function

HT PT

P

P

P

R

SN PM

E

T

H

The TPI can be connec ted to any

Ethernet int erf ace as soon as the

parametere zing enables to reach

1 equipment to be ope rated

E

ADR

IONOS ANM in neces sary

to operate this FOT C

(but the ADR cannot be

operated from the ETH

interface of the F OT C

T

H

FOT C *

E

T

H

R

SN PM

P

P

P

HT PT

R

SN PM

- D3

D

1

on STM1

aggregate

P

P

P

- D3

D

1

on STM1

tributary

D1 - D3 STM1

on East

- D3 STM1

D

1

on West

S

N

M

P

D1 - D3

STM1

on West

- D3

D

1

STM1

on East

S

N

M

P

IONOS ANM

HT

E

R

PPP

PPP

R

HTE

H

T

T

P

- D3

D

1

STM1

on East

- D3

D

1

STM1

on West

H

T

T

P

ADR

ADR

Example 2 : communication over an ADR 155C and FOT 155C rin

Figure 1-9 – Examples of the communication function configuration

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-21

Page 30

1 - INSTALLATION AND COMMISSIONING

1.4.1 - Configuration required

The minimum configuration proposed for the operating PC is as follows:

Description Configuration 1 Configuration 2

Processor 266 MHz Pentium

Memory 32 MB 64 MB

Display 800x600, 256 colours (1024x768 recommended)

Interface Serial RS232 interface

Ethernet 10 base T network card

Operating system Windows 95 Windows NT4

Applications Hyperterminal for Windows

HTTP navigator: Netscape Communicator 4.5

1.4.2 - Parameterizing the communication function

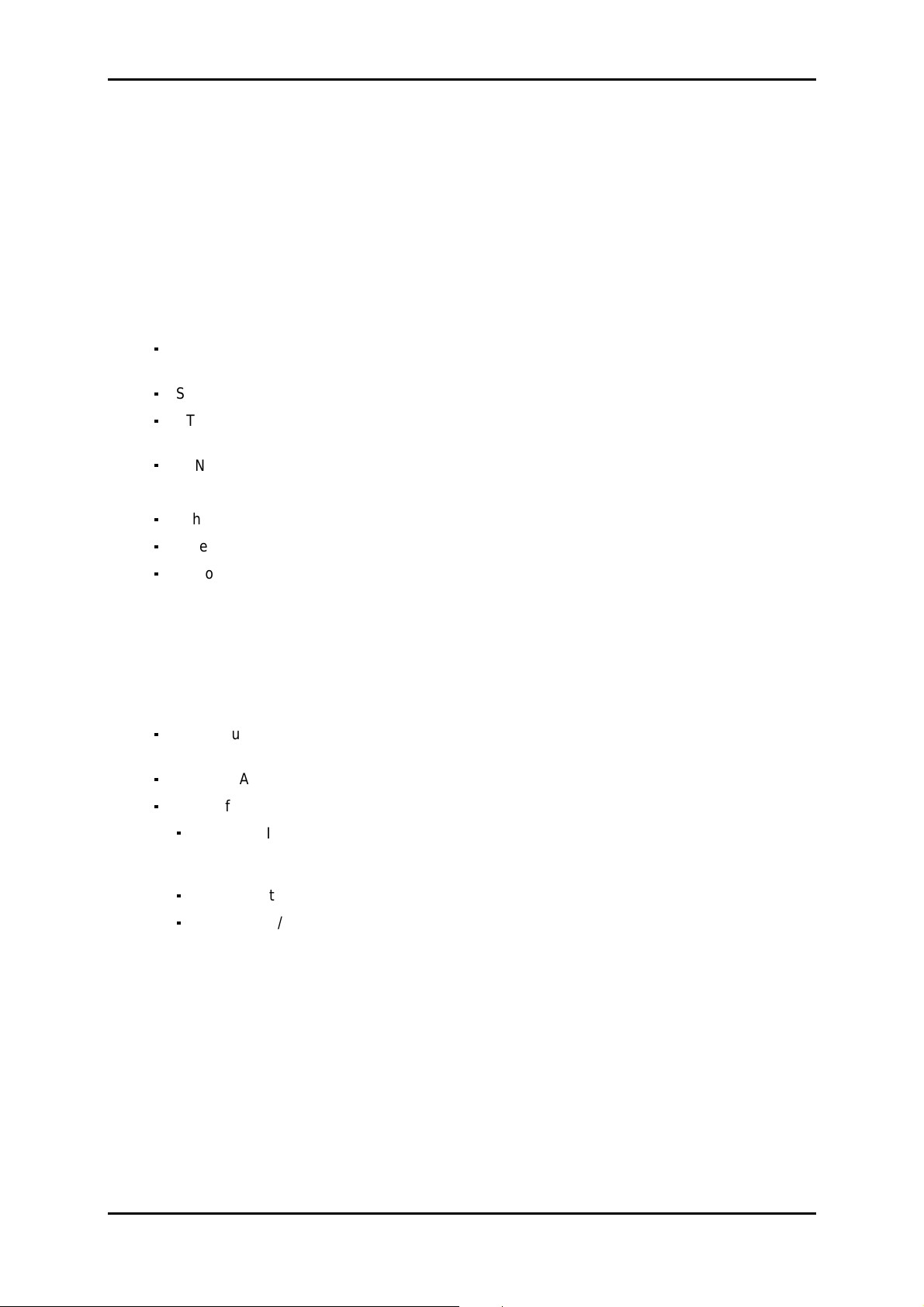

Figure 1-9 presents the available resources and various configurations possible for the

communication function;

)

Connect "

COMM

" port of the equipment to a "COM" port not used on the PC with VT100

emulation,

)

Power the PC on,

)

Start the Hyper Terminal application

on the first use, proceed as follows:

connect "

power the PC on,

select, in succession, from Windows desktop, the Start, Programs, Accessories and

COMM

" port of the equipment to a "COM" port not used on the PC,

HyperTerminal command buttons,

choose the icon representative of the HyperTerminal application,

a description window for the connection appears; give a nam e for the connection and

validate your choices,

a new window appears; choose that PC "COM" port which is connected to the

equipment and validate your choice,

a new window appears; configure the port parameters as indicated below and validate

the programming :

. Bits per second : 19200,

. Data bits : 8,

. Parity : no parity,

. Stop bits : 1,

. Flow control : none,

save the connection (Save command in the application File menu).

NOTE

: On the next opening of "Hyperterm inal" application, choosing the connection icon

will be enough to be logged on the equipment.

On the equipment power-up, the operating menu appears.

To exit the "Hyperterminal" application, select Quit command from File menu.

Installation and User Guide - N56717020101

Page A1-22

No reproduction or communication without the written cons ent of

SAGEM SA

Page 31

1 - INSTALLATION AND COMMISSIONING

)

Open a session and enter your password (to param eterize the communication f unction, it is

indispensable to have "supervisor" rights).

NOTE : By default, on the first commissioning, the password is empty.

)

The following menu appears:

To select a command, type the command number in "Choice ?" text zone, and press

"ENTER" key to validate your choice.

)

Choice "1" : Configuration of communication interface,

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-23

Page 32

1 - INSTALLATION AND COMMISSIONING

The screen displays the 5 communication interfaces possible, with their characteristics, and

proposes to change each of them by turns. These interfaces are:

- an Ethernet port –ETH

- 4 PPP (Point to Point Protocol) portes – PPP1 to PPP4 - to be chosen from the following

management paths:

either at bytes D1 to D3 of channel DCC1 of an STM1 frame (named DCC1-A, DCC1-B,

DCC1-C or DCC1-D according to the number and position of ADR IC1.x modules in the

equipment), or the MNGT interface

Each interface is defined by its characteristics:

- "Port" : physical port "ETH", "PPP1" to "PPP4"

- "Admin" or interface state: "ON" (interface active) or "OFF" (interface inactive)

- "@ IP" : IP address

- "subnet mask" : subnetwork mask

- "@ IP of dest" : destination IP address (for PPP ports only)

- "Path" : management path chosen for the PPP ports (DCC1x or MNGT)

- "RIP" : management routing self-adaptability to the network struc ture validated or not (limited

to 16 hops without gateway)

The parameterization is backed up port by port.

)

Choice "2" : Configuration of static routes,

The screen displays the already defined management routes with their characteristics:

- "No" : reference of the route

- "destination @ IP" : destination IP address (equipment or subnetwork)

- "subnet mask" : subnetwork mask

- "next hop @ IP" : IP address of the next equipment (connected on line with the given

equipment)

Installation and User Guide - N56717020101

Page A1-24

No reproduction or communication without the written cons ent of

SAGEM SA

Page 33

"interface" : interface used to reach the next equipment

"cost" : or "metric", number of hops to reach the destination.

From this screen, it is possible to change the existing routes , to delete them or to create new

ones (the static routing is necessary if FOT155C's are present on the network or for an

interconnection with a contiguous network).

)

Choice "3" : Display of routing information,

1 - INSTALLATION AND COMMISSIONING

This screen is used to view the routing table, to list the dynamic and/or static routes and also the

interface configurations

)

Choice "4" : equipment REBOOT,

This command is used to perform immediate application REBOOT and to restart with the

parameters already stored in the equipment .

)

Choice "5" : Logout

With the parameterization being complete, this command closes the current session.

An automatic session ex it is performed after a few m inutes of inactivity (time parameterizable

from the manager).

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-25

Page 34

1 - INSTALLATION AND COMMISSIONING

1.4.3 - Using HTTP navigator

1.4.3.1 - First commissioning

Start the NESCAPE application

On the Welcome screen, fill in the "Address" field with the IP address of the ADR155C

equipment.

WARNING :

With NESCAPE 4.5, the equipment IP address should include no nonsignificant '0'. Example: "http://135.11.9.30/" instead of "http://135.11.09.30/"

The navigator welcome screen "Welcome to the ADR155C's site" appears.

On the first commissioning, the password is empty; click on

Apply

to access "ADR155C shelf

view" screen.

From that moment, the navigator is operational.

1.4.3.2 - Navigator Presentation

On session opening on the HTTP navigator, the "ADR155C shelf view" represents the

equipment global view, where each slot is marked with a letter, A, B, C, D or M according to

Figure 1-1.

This screen is used to view the equipment status, in particular:

inconsistencies between configuration and composition: each slot inc ludes the name of the

expected card (top, left) and the nam e of the inserted card (in the middle, red coloured if

necessary)

alarmed modules, framed red in the case of a major alarm, yellow for a minor alarm,

modules configured out of monitoring are represented greyed.

modules configured out of service include a cross to signal this administrative status.

Installation and User Guide - N56717020101

Page A1-26

No reproduction or communication without the written cons ent of

SAGEM SA

Page 35

1 - INSTALLATION AND COMMISSIONING

This screen is also used to:

activate the common f unctions of the equipment, s uch as the synchronization, safety, traffic

information, etc. by clicking on a function in the menu bar; s ee tree structure of the general

menu,Figure 1-10.

access the functionalities related to a module in particular (for exam ple, MSP protection in

the case of an ADRIC1.x module) : double click on the module to be selec ted, the selection

arrow is blinking and its specific menu appears; see the tree structure of "card" menus in

Figure 1-10;

view the own characteristics of a port (connections performed, conf iguration of connections,

alarm states ...), by selecting the relevant connector.

For each function viewed, the configuration parameters, operating commands, active

parameters and alarm s tates are gr ouped together on the sam e s creen, with the various ac tions

possible being accessible or not by the operator according to his/her clearance level.

The upper edge of the navigator window recalls the equipm ent IP address, the clearance level

acquired and, if required, the slot concerned.

LOGIN

EQUIPMENT

Date and Time

Inventories

(hardware/Software)

Security

Management

Upload and

Download

Menu "ADR21E120"

Maintenance

Monitoring

Service

Expected Card

Performance :

VC12 Near (#1 to 21)

VC12 Far (# 1 to 21)

Board status

E1 INPUT/OUTPUT ports

TRANSMISSION

Failure hold off/on

time

Laser

VC12 Near / VC12 Far

SYNCHRONISATION

Synchronisation

sources

Menu "ADRIC1.x"

Maintenance

Monitoring

Service

Expected Card

Performance :

VC3 Near / VC3 Far

RST Near

MST Near / MST Far

Protection

Board status

TR /REC ports

EOW port

AUX port

CROSS-

CONNECTION

Configuration

Delete

Names

modifications

LAN Wizard

Menu "ADRLAN1"

Monitoring

Service

Expected Card

Performance :

VC3 Near / VC3 Far

Board status

ETH port

EVENT LOGS

Clear

Refresh

Convert

Save

Menu "CARTE-MERE"

Maintenance

Monitoring

Performance :

VC12 Near (# 1 to 21)

VC12 Far (# 1 to 21)

IP Parameters

Board status

E1 INPUT/OUTPUT ports

About

Help

?

Figure 1-10 – Menu structure

Installation and User Guide - N56717020101

No reproduction or communication without the written cons ent of

SAGEM SA

Page A1-27

Page 36

1 - INSTALLATION AND COMMISSIONING

Installation and User Guide - N56717020101

Page A1-28

No reproduction or communication without the written cons ent of

SAGEM SA

Page 37

2 - OPERATION

2. OPERATION

2.1 - Functional description

The ADR 155C is an optical STM1 add-drop multiplex er us ed to build STM-1 point-to-point links,

STM-1 rings, or mesh networks, so achieving the mismatch of links at 2 Mbit/s, Ethernet or

STM1.

The ADR 155C can also be connected to an equipment of the synchronous digital hierarchy in

accordance with UIT-T recommendations G.707 and G.783.

The ADR 155C modelling in functional blocks according to standard G.783 is presented below:

SPI : SDH Physical Interface

RST : Regeneration Section Termination OHA : OverHead Access

MST: Multiplex Section Termination

MSP : Multiplex Section Protec tion

MSA : Multiplex Section Adaptat i on

HPOM : Higher order Path Overhead Monitor

HPC : Higher order Path Connection

HPT : Higher order Path Terminati on

SETS : Synchronous Equi pment

SETPI : Synchronous Equipment

Timing Source

Timing Physical I nterface

HPA : Higher order Path Adaptation

LUG : Lower order path Unequipped Generator

LPOM : Lower order Path Overhead Monitor MCF : Message

LPC : Lower order Path Connection

LPT : Lower order Path Termination

LPA Lower order Path

Adaptation (VC12)

PPI : plesiochronous phys i cal

Interface (VC12)

SEMF : Synchronous Equipm ent

Management Function

Communication Func tion

Lower order Path

Adaptation (VC3)

plesiochronous physical

Interface (VC3)

Installation and User Guide - N56717020101

No reproduction or communi cation without the written consent of

SAGEM SA

Page A2-1

Page 38

2 - OPERATION

g

2.2 - General

The ADR155C operation and maintenance are carried out:

- either directly on the equipment, through the front panel indicator lights and two engineering

management loops (loops A and B),

- or from a PC fitted with HTTP navigator,

- or from a network manager, using the SNMP protocol.

2.3 - Operational parameters

The operational parameters include:

the configuration parameters,

the maintenance commands or operations (these actions are cleared in case of power supply

loss)

the alarms and their severity.

Configuration parameters

NOTE : The functional blocks naming, configuration parameters and their default value, noted

XXXXXX

"

", are displayed on HTTP navigator.

Configuration parameters per functional blocks Default

value

SPI : SDH Physical Interface

The Automatic Laser Shutdown function is always enabled

(equipment global functionality)

ALS

"

" (Automatic Laser Shutdown) "

enable

"

MST : Multiplex section Termination

EBER-B2 monitoring ; configurable in "

If EBER-B2 is not monitor in

, AIS, SF and MS-RDI consequent actions are

Monitoring

" or "No

Monitoring

"

Monitoring

"

"

inhibited

SD-B2 threshold: configurable from 10-6 to 10

SD-B2 threshold

"

"

-9

-6

10

"

"

MSP : Multiplex Section Protection

Link type : 1+0 or 1+1

1+0

"

"

Protection mode : bi-directional / unidirectional

Mode

"

"

BIDIR

"

"

Revertive authorization : return after a W TR time-delay to the working link

when the fault (SF or SD) causing the switch has disappeared.

Revertive

"

"

OFF

"

"

Table 2-1 – Configuration parameters (1/6)

Installation and User Guide - N56717020101

Page A2-2

No reproduction or communi cation without the written consent of

SAGEM SA

Page 39

Configuration parameters per functional blocks Default

MSP : Multiplex Section Protection - suite

Wait Time to Restore (WTR) period : in revertive mode, period following

restoration of nominal operation ; configurable from 0 to 15mn in onesecond steps

"WTR"

SF/SD priority according to Recommendation G. 783 [1994] annex A.1.2.1 ;

possible value :"high" or "low" (compatibility with MXA)

"Sf/sd priority"

SF and SD fault persistence : configurable from 0 to 10s in 100ms steps

"Hold-off time"

HPOM : Higher order path overhead monitor

Signal label expected and received (byte C2 of VC4 path overhead) ;

"Label" :

-- "Expected", possible values : "01H" (equipment not specified) or

"02H" (TUG mode structure)

-"Received".

HPT : Higher Order Path Termination

Signal label transmitted, expected and received (byte C2 of VC4 path

overhead) ; "Label" " :

-"Transmitted", possible values : "01H" (equipment not specified) or

"02H" (TUG mode structure)

-"Expected", possible values : "01H" (equipment not specified) or

"02H" (TUG mode structure)

-"Received". (hexadecimal value)

2 - OPERATION

value

"1 mn"

"low"

"0 ms"

"02H"

"02H"

"02H"

Path trace Byte J1 transmitted :

"UNNAMED VC4" + CRC7 not configurable and not treated in reception

LUG : Lower order path Unequipped Generator

Number of the unequipped VC12s transmitted in TUG3s

(by default no connection)

LPOM : Lower order path overhead monitor)

Signal label (VC12) received:

-"Label Rec".

Signal label (VC3) received:

-"Label Rec".

SD threshold : configurable from 10-5 to 10-9 for VC3

configurable from 10

-5

to 10-8 for VC12

"SD threshold"

Table 2-2 – Configuration parameters (2/6)

"UNNAMED .

VC4" + CRC7

"FFH"

-6

"

"10

Installation and User Guide - N56717020101

No reproduction or communi cation without the written consent of

SAGEM SA

Page A2-3

Page 40

2 - OPERATION

LPC : Lower order Path Connection

Connection switch

Connection name (configurable according to M.1400 §13) No name

Configuration parameters per functional blocks Default

value

Not put into

service

Type : bi-directional / unidirectional

SNC protection

Type

Protection mode

Revertive authorization (path by path) : return after a WTR tim e-delay to

the working link when the fault (SF or SD) causing the switch has

disappeared.

"Revertive"

Wait Time to Restore (WTR) period (common to all paths): in revertive

mode, period following restoration of nominal operation ; configurable

from 0 to 15mn in one-second steps

"WTR"

SF and SD fault persistence (path by path) : configurable from 0 to 10s in

100ms steps

"Hold-off time"

LPT : Lower order Path Termination

Signal label (VC12) transmitted, expected and received; "Label" :

-"Transmitted",: "000b" no connection or "010b" (asynchronous)

if connection (not configurable by the operator)

-"Expected", possible value : "001b" equipped without specification or

"010b" (asynchronous)

-"Received".

MONO

SNC/I

MONO

"no"

"1 mn"

"0 ms"

"010b"

SD-V5 threshold (VC12) configurable from 10-5 to 10-8 for VC12

"SD-V5 threshold""10

ADRLAN Card

Signal label (VC3# i) transmitted, expected and received; "Label" :

-"Transmitted", not configurable

-"Expected", not configurable

-"Received".

Bit rate : Forcing the Ethernet port bit rate

The bit rate is imposed on or self- adaptive to the connection (selection of

the maximum proposed bit rate on the half- or full-duplex bus)

Flow control

- LAN towards VC3_# i

- VC3_# i towardsVC3_# j or LAN

Table 2-3 – Configuration parameters (3/6)

Installation and User Guide - N56717020101

Page A2-4

No reproduction or communi cation without the written consent of

SAGEM SA

-6

"

"A8H"

"A8H"

10 Mbit/s

60 %

60 %

Page 41

Configuration parameters per functional blocks Default

ADRLAN Card – continue

Interface configuration

- LAN in service / no service

- Maximum route Age

- Path trace J1 transmitted :

"UNNAMED VC3" + CRC7 not configurable and not treated in reception

SETS : Synchronous Equipment Timing Source

Quality level of synchronization sources ; "Quality" :

-"PRC" (Primary Reference Clock),

-"SSUT" (Synchronisation Supply Unit Transit),

-"SSUL" (Synchronisation Supply Unit Local),

-"SEC" (Synchronisation Equipment Clock),

-"DNU" (Do Not Use),

-"SSMB" (Synchronisation Status Message Byte) (synchronization quality

carried out in S1 Byte).

2 - OPERATION

value

Service

300 s

"UNNAMED .

VC3" + CRC7

T3 : PRC

T1 : SSMB

T2 : SEC

T4 : SEC

Use of synchronization status messages (SSM) ;

"SSM" "ON"

T0 priority Table, according to enabled sources ;

possible values : 1 to 8

2 Mbit/s port number chosen for T2 ; "T2 Tributary port"

"1"

for all sources

"1"

(1 port per enabled 2 Mbit/s card)

Revertive authorization (common to all s ources) : return after a W TR tim e-

delay to the working link when the fault (SF or SD) causing the s witch has

disappeared.

"Revertive"

"yes"

Wait Time to Restore (WTR) period : in revertive mode, period following

restoration of nominal operation ; configurable from 0 to 30mn by onesecond step

"WTR" "1 mn"

Source selected for T4 ;

"Active source"

"T0"

SASE mode control (enable or disable) disabled

T3 source selection for SASE mode (T3-1 or T3-2)

Quality level for T4

T3-1

"PRC"

-"PRC" (Primary Reference Clock),

-"SSUT" (Synchronisation Supply Unit Transit),

-"SSUL" (Synchronisation Supply Unit Local),

-"SEC" (Synchronisation Equipment Clock),

Table 2-4 – Configuration parameters (4/6)

Installation and User Guide - N56717020101

No reproduction or communi cation without the written consent of

SAGEM SA

Page A2-5

Page 42

2 - OPERATION

OHA : OverHead Access

EOW interface operating mode :

CO (codirectional) or CT (contra-directional master)

"EOW configuration"

Configuration parameters per functional blocks Default

value

CT

Selection of E1/E2"

AUX interface operating mode (F1);

CO (codirectional) or CT (contra-directional master)

"AUX configuration"

MCF : Message Communications Function

MNGT interface operating mode ;

CO (codirectional) or CT (contra-directional master)

"P port configuration" CO

Equipment

Session

Selection of clearance level :

Administrator

Operator

Observer

One password by clearance level

No password

(Only the administrator may modify password)

Equipment date and time

Status of slots A, B, C, D (slot configured with an expected card)

"01/01/1970"

A, C:ADR21E120

B, D : ADRIC1.x

Monitoring

E1

CT

Admin

Monitoring of modules

A no-monitored card is indicated in the equipment view; not monitoring a

card inhibits the entire management of the faults related to this card (card

and port)

Subrack Monitoring

Monitoring of ports

Not monitoring a port inhibits the entire management of the faults related to

this port

Putting a card into/out of service

(The card is ignored by the management function)

Table 2-5 – Configuration parameters (5/6)

Installation and User Guide - N56717020101

Page A2-6

No reproduction or communi cation without the written consent of

No Monitoring

Monitoring

Monitoring

for physical port

No Monitoring

for performance

Service

SAGEM SA

Page 43

Configuration parameters per functional blocks Default

Equipment – Continue

Alarms

2 - OPERATION

value

Alarm severity

The severity of each alarm is configurable individually with the following

See tables

2-9 to 2-11

attributes: major, major reverse, minor, minor reverse, none, none reverse

Alarm Persistence

Persistence for the appearance: X = 1, 3, 10 or 30s

Persistence for the disappearance: Y = 01, 3, 10 or 30s

X = 3s

Y = 3s

Loops

Mismatch of remote indication loops 1 and 2 validated or not

Not validated

(use of bits 1 to 4 of byte S1)

Centre site (yes/no) No

Routing

Authorization to transmit traps to the management: declaration of the

manager addresses (10 addresses possible)

Tables of configured static routes Not configured

Putting ports into service: Ethernet, PPP1, PPP2, PPP3 or PPP4

Enabled / Disabled (port by port) Disabled

Port addressing (port by port) :

Interface IP address

Subnetwork mask

Destination IP address (PPP interface only)

0.0.0.0

0.0.0.0

0.0.0.0

Management paths (port by port – PPP only):

Options: MNGT, DCC1_A, DCC1_B, DCC1_C, DCC1_D Not configured

RIP routing validated or not (port by port) Not validated

Table 2-6 – Configuration parameters (6/6)

Installation and User Guide - N56717020101

No reproduction or communi cation without the written consent of

SAGEM SA

Page A2-7

Page 44

2 - OPERATION

Maintenance operation commands

Monitoring commands according to the functional blocks

SPI : SDH Physical Interface

2s laser restart on operator action

9s laser restart on operator action

Line loopback enabled/disabled (transparent type)

Equipment loopback enabled/disabled (transparent type)

MSP : Multiplex Section Protection

Operator command for MSP protection

Clear

Lockout of Protection

Forced Switch to Working

Forced Switch to Protection

Manual Switch to Working

Manual Switch to Protection

LPC : Lower order Path Connection

Operator command for SNC protection of VC12 or VC3 path (per path and in order of priority):

Clear

Lockout of Protection

Forced Switch to Working

Forced Switch to Protection

Manual Switch to Working

Manual Switch to Protection

PPI : PDH Physical Interface

Line loopback enabled/disabled (transparent type)

Equipment loopback enabled/disabled (transparent type)

ADRLAN Card

LAN statistics

VC3 # i statistics

Flow control

Interface status-

SETS : Synchronous Equipment Timing Source

Protection operator command

Clear

Lockout of Protection

Forced Switch

Manual Switch to Protection

Table 2-7- Commands (1/2)

Installation and User Guide - N56717020101

Page A2-8

No reproduction or communi cation without the written consent of

SAGEM SA

Page 45

Monitoring commands according to the functional blocks

Equipment

Alarms

Alarm acknowledgements using the front panel push-button

(such acknoledgements occur only at the level of major and minor output loops).

RESET of alarm and event logs

Performance

RESET of performance logs 15 mn # i

RESET of performance logs 24 h # i

Reset

Hot reset of the equipment, performed by software

(the reset time should be shorter than 30s)

Table 2-8 : Commands (2/2)

2.4 - Predefined functions

2 - OPERATION

On commissioning, the following mechanisms are implemented automatically:

synchronization,

management of outgoing remote indication loops.

Synchronization

The synchronisation of the local equipment and remote equipment is m anaged according to the

available synchronization sources, their quality and the priority they are allocated.

The synchronization sources possible are:

standalone operation (local oscillator),

T1 extracted from one of the incoming STM1 stream s (1 to 4 possibilities according to the

number of ADRIC1.x cards present in the equipment),

T2 : one 2 Mbit/s G.703 source per dec lared 2 Mbit/s m odule, and s elected f rom the various

2 Mbit/s G.703 accesses

T3 : two external 2 MHz G.703 sources

Installation and User Guide - N56717020101

No reproduction or communi cation without the written consent of

SAGEM SA

Page A2-9

Page 46

2 - OPERATION

q

q

The following figures give typical synchronization examples according to equipment connections.

2 MHz external

sync input (T3):

- Quality = PRC,

- Priority = 1.

ADR155C 1

STM-1port (T1-C):

- Quality = DNU

- Priority = 2.

ADR155C 2

STM-1port (T1-C):

- Quality = DNU

- Priority = 2.

Internal

synchronization

T0 = T3

T1-C = T0 = T3

SSM = PRC

ADR155C 3

T0 = T1-c

2 MHz clock output

T4= T1-N

Synchronization

of other e

uipments

T0 = T1-C

2 MHz clock output

T4= T0 = T3 (ADR155C1)

Synchronization

of other equipments

SSM = PRC

T1-C = T0 = T3 (ADR155C1)

Figure 2-1 - Synchronization from the 2 MHz external sync input (T3)

2 Mbit/s port (T2):

- Quality = PRC,

- Priority = 1.

ADR155C 1

Internal

synchronization

T0 = T2

T1-C = T0 = T2

STM-1port (T1-C):

- Quality = DNU

- Priority = 2.

SSM = SEC

ADR155C 2

T0 = T1-C West

STM-1port (T1-C):

- Quality = DNU

- Priority = 2.

T1-C = T0 - T1-c (West)

or T2 (ADR155C1)

2 MHz clock output

T4= T0 = T1c West

ADR155C 3

T0 = T1-c

2 MHz clock output

T4= T1-N

Synchronization

of other e

uipments

SSM = SEC

Synchronization

of other equipments

NOTE : Synchronization is applied to the 2 Mbit/s port of the ADR155C which is enabled first

(local ADR155C in the example).

Figure 2-2 - Synchronization from a 2 Mbit/s port

Installation and User Guide - N56717020101

Page A2-10

No reproduction or communi cation without the written consent of

SAGEM SA

Page 47

2 - OPERATION

Loops Management

On remote sites, two local outgoing loops (Local user outputs A and B) are activated on the

appearance of a local : equipment alarm or rem ote indication loops 3 and 4 (Local user input #3

or #4).

The remote loopback function allows an equipment named " central site", to register faults

present on remote sites.

This function requires eac h site to transm it to the central site an alarm pres ence m essage. This

messages which corr esponds to remote m onitoring loopback 1 or 2 (Loc al user input #1 or #2)

is transmitted in the S1 byte. To link this mes sage to equipment's alarms, the outputs of the A

and B loops (Local user outputs A and B) should be connected to remote monitoring loops 1 and

2 (Local user input #1 or #2) respectively.

Data chaining in a bus or ring type network architectur e is provided by "OR" f unction validation

between the data received (Far user inputs #1 et #2) via S1 STM1 West and S1 STM1 East, and

local data, for each site in the network.

At the "central site" equipment, "OR" function validation between the data received (Far user

inputs #1 and #2) via S1 STM1 W est and S1 ST M1 East, and loc al data (Local us er input #1 or

#2 and local alarm), enables local alarm loopbacks to be activated (Local user outputs A and B).

To configure the remote loopback function, the f ollowing parameters should be programmed :

"Line remote loopback" and " central site".

The Figure 2-3 gives an exam ple of remote m anagement of the local outgoing loops according

to the equipment connections.

A

EASTEASTWEST WEST

Activation of

Local user

inputs #1 or #2

S1 = state of local user

inputs #1 and #2

Received

West S1

#1

#2

#3

#4

Local

user inputs

AB

Acivation of local

user inputs

folowing activation

of loc a l user

outputs A or B

( équipment

or local user

inputs #3 rt #4)

ADR 155C 2

Local user outputs

#1 or # 2

alarms

S1 = state of local user

inputs #1 and #2

AB

EAST WEST

Acivation of local

user inputs

#1 or #2

folowing activation

#1

#2

#3

#4

Local user

inputs

of loc a l user

outputs A or B

( équipment

alarms

or local user

inputs #3 rt #4)

ADR 155C 3

#1

#2

#3

#4

Local

user inputs

Local user outputs

Local user outputs

B

Figure 2-3 – Remote loopback function (registering alarms on central site)

NOTE : Status of :

- incoming loops (Local user inputs #1 to #4),

- far incoming loops (Far user inputs #1 to #2),

- and outgoing loops (Local user outputs A and B),

may be displayed on HTTP navigator.

No reproduction or communi cation without the written consent of

Installation and User Guide - N56717020101

SAGEM SA

Page A2-11

Page 48

2 - OPERATION

2.5 - Alarms processing

LEDs and pushbuttons

The following tables give the meanings of the lit LEDs and the actions initiated by using the

pushbuttons.

LEDs :

Ö

Monitored

item

Motherboard "ON" Green On In service card

Ethernet "Activity" Green On On reception

(management port Off No traffic

or ADRLAN card) "Link" Yellow On Correct Link

Traffic cards "STATUS" See table below

"STATUS"LEDs on ADR IC 1.x, ADR LAN and ADR 21E120 cards :

Ö

Green LED Red LED Meaning

On Off Card in service and configured

On On Card in service and in alarm

Off Off Hardware default on card (fuse)

Off On Card out of service (not configured)

Flashing Self-test default

Designation Colour Status Meaning