Operation, Maintenance,

and Parts Manual

TLV Series Liftgate

• 2750 Lb. Capacity

XL-TG10156UD-en-US Rev A

Contents

Contents Page

Introduction ......................................................................... 3

Warranty .............................................................................. 3

Notes, Cautions, and Warnings ............................................. 3

Section 1 – General Safety Precautions ................................ 4

Section 2 – Model and Serial Number .................................. 6

Section 3 – Decal Part Numbers ........................................... 7

TLV Liftgate Terminology ...................................................... 8

Section 4 – Pre-Operation Information ................................. 9

Section 5 – Control Switch Operation ................................... 9

Section 6 – Raising or Lowering the Platform ..................... 10

Introduction

This manual provides you with the information necessary for

the care, maintenance, inspection, and safe operation of the

SAF-HOLLAND TL and TG Series Liftgate.

NOTE: For liftgate components replacement, contact

SAF-HOLLAND Customer Service at:

U.S. 888-396-6501

Canada 800-503-9847

Warranty

Refer to the complete warranty for the country in which

the product will be used. A copy of the warranty certificate

is included with the product as well as on the SAF-HOLLAND

website (www.safholland.us and www.safholland.ca). It may

also be ordered directly from SAF-HOLLAND; the address is

shown on the back cover.

Notes, Cautions, and Warnings

Contents Page

Section 7 – Unfolding the Platform .................................... 11

Section 8 – Platform Loading ............................................. 12

Section 9 – Stowing the Platform ....................................... 13

Section 10 – Filling the Hydraulic Reservoir ........................ 14

Section 11 – Routine Service and Inspection....................... 15

Section 12 – Troubleshooting ............................................. 16

Section 13 – Pump Hydraulic and Electrical Diagrams ......... 18

Section 14 – Pump Hydraulic and Electrical Schematic........ 20

Section 15 – Liftgate Components ...................................... 22

Section 16 – Hydraulic Components ................................... 24

IMPORTANT: Read this manual before using this

product. Keep this manual in a safe

location for future reference.

Failure to follow the instructions and

safety precautions in this manual can

result in death or serious injury.

Throughout this manual, you will notice the terms

“NOTE,” “IMPORTANT,” “CAUTION,” and “WARNING”

followed by useful product information. So that you may

better understand the manual, those terms are as follows:

NOTE: Includes additional information to enable

accurate and easy performance of procedures.

IMPORTANT: Includes additional information that if

not followed could lead to hindered

product performance.

You must read and understand all of the safety procedures presented

in this manual before operating or starting any work on the liftgate.

NOTE: In the United States, workshop safety requirements

are defined by federal and/or state Occupational

Safety and Health Act. Equivalent laws may exist

in other countries. This manual is written based

on the assumption that OSHA or other applicable

employee safety regulations are followed by the

location where work is performed.

Proper tools must be used to perform the maintenance and

repair procedures described in this manual. Many of these

procedures may require special tools.

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Used without the safety alert symbol,

indicates a potentially hazardous situation

which, if not avoided, could result in

property damage.

Indicates a potentially hazardous situation

which, if not avoided, could result in minor

or moderate injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury.

3

General Safety Precautions

1. General Safety Precautions

Read and observe all Warning and Caution hazard alert messages

in this publication. They provide information that can help

prevent serious personal injury, damage to components, or both.

Please observe the following safety instructions in order

to maintain the operational and road safety of your

SAF-HOLLAND Liftgate:

1. You must be fully trained on the capabilities and the limitations

of this equipment to operate the equipment properly.

2. When operating the liftgate, always stand to one side of

the platform. Make sure that the area is clear of obstacles,

other personnel, fingers, arms, hands, legs, and/or feet.

Failure to keep area near your liftgate

clear could create a crush and/or pinch

hazard which, if not avoided, could result

in death or serious injury.

IMPORTANT: DO NOT exceed liftgate capacity when

raising or lowering platform.

Failure to avoid overloading the liftgate

may result in platform failure which,

if not avoided, could result in death or

serious injury.

3. Make sure liftgate is in stowed position when not in use.

4. NEVER step off moving equipment. Only step off the

platform when it is in contact with the ground or at deck

height when entering the vehicle.

Failure to lower the platform to ground

level before stepping on or off platform

could result in mild to moderate injury.

We highly recommend the use of only SAF-HOLLAND

Original Parts.

A list of SAF-HOLLAND Technical Support locations to

supply SAF-HOLLAND Original Parts can be found at

www.safholland.us or by contacting SAF-HOLLAND

Customer Service at U.S. 1-888-396-6501 or Canada

1-800-503-9847.

Servicing Safety Precautions

1. DO NOT work underneath the liftgate without properly

supporting the raised platform and liftframe in

accordance with workplace safety requirements.

2. Never strike any part of the liftgate with a steel hammer.

3. Safety protection should always be worn as protection

from pressurized fluid spray, flying debris, and other

airborne matter when working with tools, power tools,

welding equipment, and dangerous chemicals.

NOTE: Never operate the liftgate with the vehicle running

unless instructed to by this manual for specific

service items.

Failure to turn off vehicle motor before

commencing work could allow vehicle to

move which, if not avoided, could result

in death or serious injury.

4. While servicing or repairing equipment, always disconnect

the electrical power to the pump motor and ensure that

the platform and liftframe is supported on the ground or

secured in the travel lugs.

5. Check for slippery surfaces before stepping off the

liftgate platform.

6. NEVER jump off the liftgate.

7. In an emergency situation, release the control switch to

stop the liftgate operation.

8. SAF-HOLLAND Liftgates require routine service, inspection,

and maintenance in order to maintain optimum performance,

proper operation, and to identify normal wear.

Failure to properly engage the vehicle

parking brake prior to operating or

maintaining liftgate may allow vehicle

movement which, if not avoided, could

result in death or serious injury.

4

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

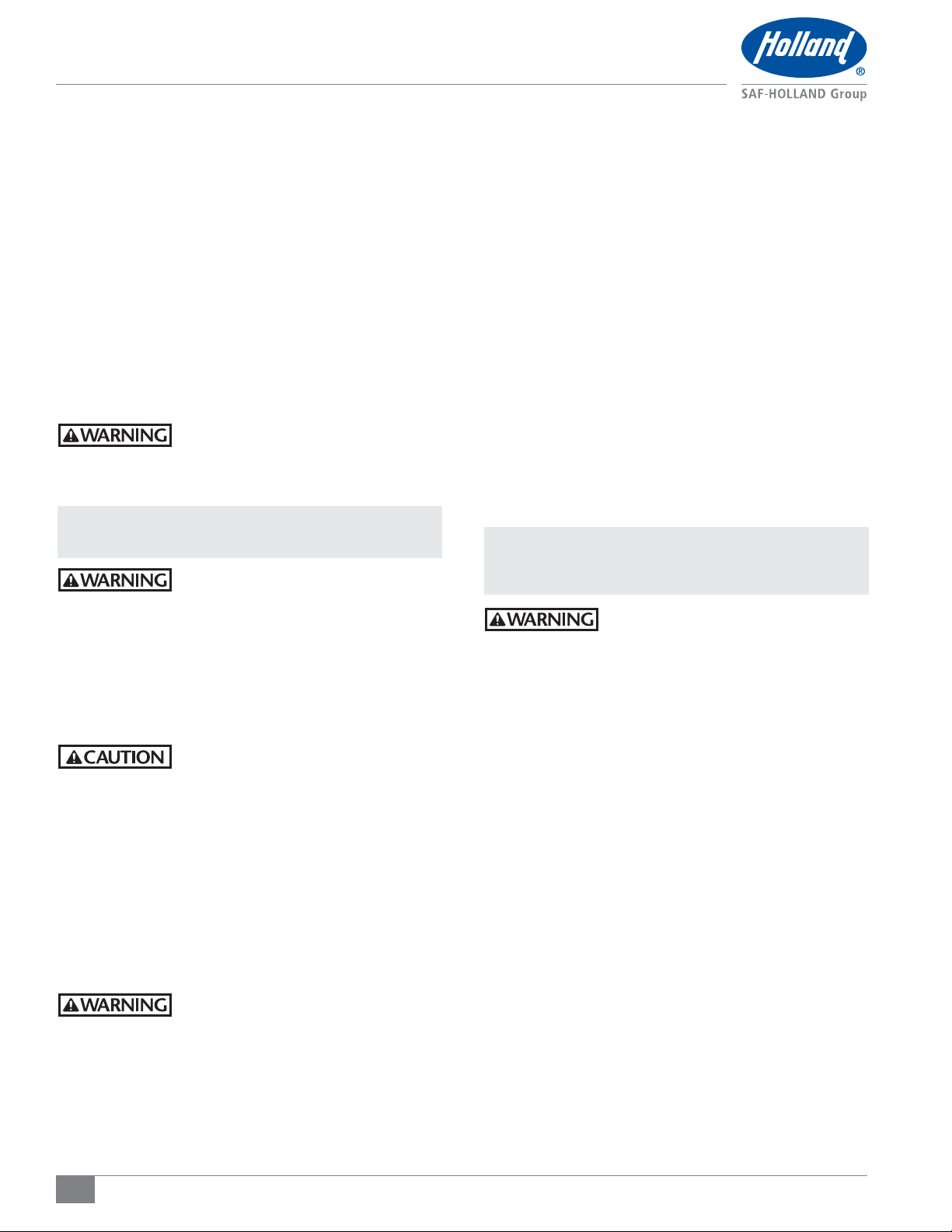

General Safety Precautions

5. When welding is required, ensure that the battery ground

cable is disconnected and that all electrical equipment is

completely electrically isolated before welding is initiated

(Figure 1).

6. Before starting any welding, ensure that the area to be

repaired is cleaned of debris and combustible material.

Have a charged fire extinguisher available and know

how to use it.

7. When searching for an oil leak, wear work gloves and

use a piece of cardboard or wood as a detector. Wear a

safety face shield or goggles for eye protection. NEVER

use your bare hands to check for fluid leaks (Figure 2).

Failure to properly protect yourself when

searching for hydraulic leaks could result

in fluid injection into the skin which,

if not avoided, could result in death or

serious injury.

8. Pressure can remain in a hydraulic system after the power

source and pump have been shut down. Ensure that there

is no pressure in any of the hydraulic cylinders or hoses

before performing work on components, or disconnecting

any hoses (Figure 3).

Failure to depressurize the hydraulic

system could result in fluid injection into

the skin which, if not avoided, could

result in death or serious injury.

Figure 1

Figure 2

NOTE: Batteries contain acid that can burn and they

also produce gas that can explode, follow battery

manufacturers’ provided safety instructions when

working on your battery.

Failure to follow manufacturers’ safety

instructions when handling batteries may

result in explosion which, if not avoided,

could result in minor to moderate injury.

9. Inspect the equipment daily for potential fire hazards and

make any necessary repairs immediately.

10. Inspect electrical wiring and connections, and hydraulic

hose runs to ensure they are secure and not rubbing

against other components.

11. Clean up any excess grease, oil accumulation and spillage

immediately. Use only non-flammable products for cleaning

the liftgate or components.

Figure 3

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

5

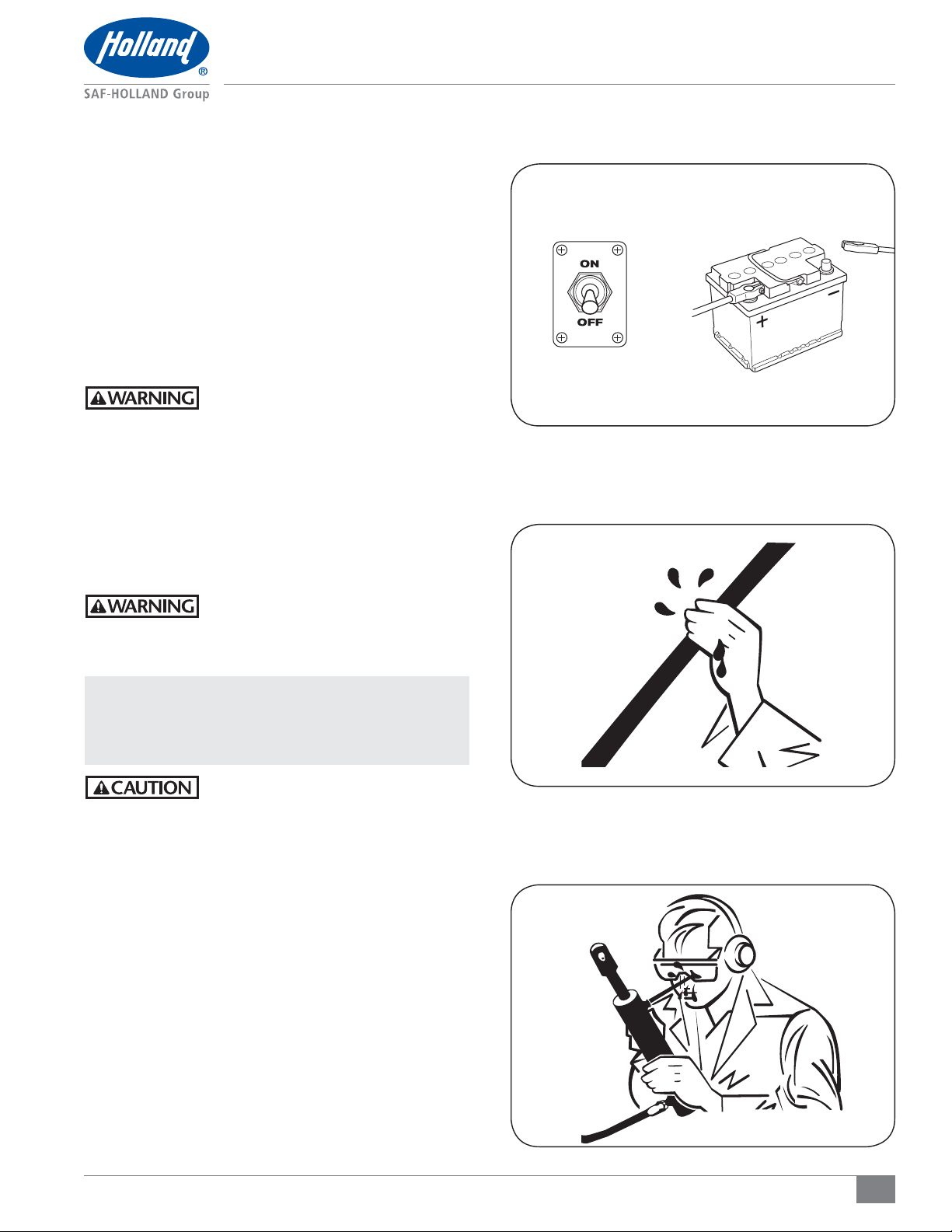

Model and Serial Number Information

2. Liftgate Model and Serial

Number Location

Each SAF-HOLLAND liftgate has a stamped metal tag that

identifies the liftgate model and serial number (Figure 4).

This tag is attached to the front roadside of the main tube

(Figure 5). In order to properly identify your HOLLAND

liftgate and its components when communicating with

SAF-HOLLAND or your dealer, please record the model, serial

numbers, dealer, and purcahse date and refer to them when

ordering replacement parts.

Model Number

TLV 27 48

Platform Size

48" long

Capacity

2,750 lbs.

Figure 4

Figure 5

MODEL NUMBER

XXXXXXXXXX-XXXX

SERIAL NUMBER

XXXXX

Model

Serial Number after November 1, 2008

98 02 312 0123

Sequence Number

Day of Year

Year Code

Facility Code

Equipment Model No.: _______________________________

Serial No.: _________________________________________

Purchase Date: _____________________________________

Dealer: ____________________________________________

LIFTGATE MODEL AND SERIAL

NUMBER TAG LOCATION

6

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

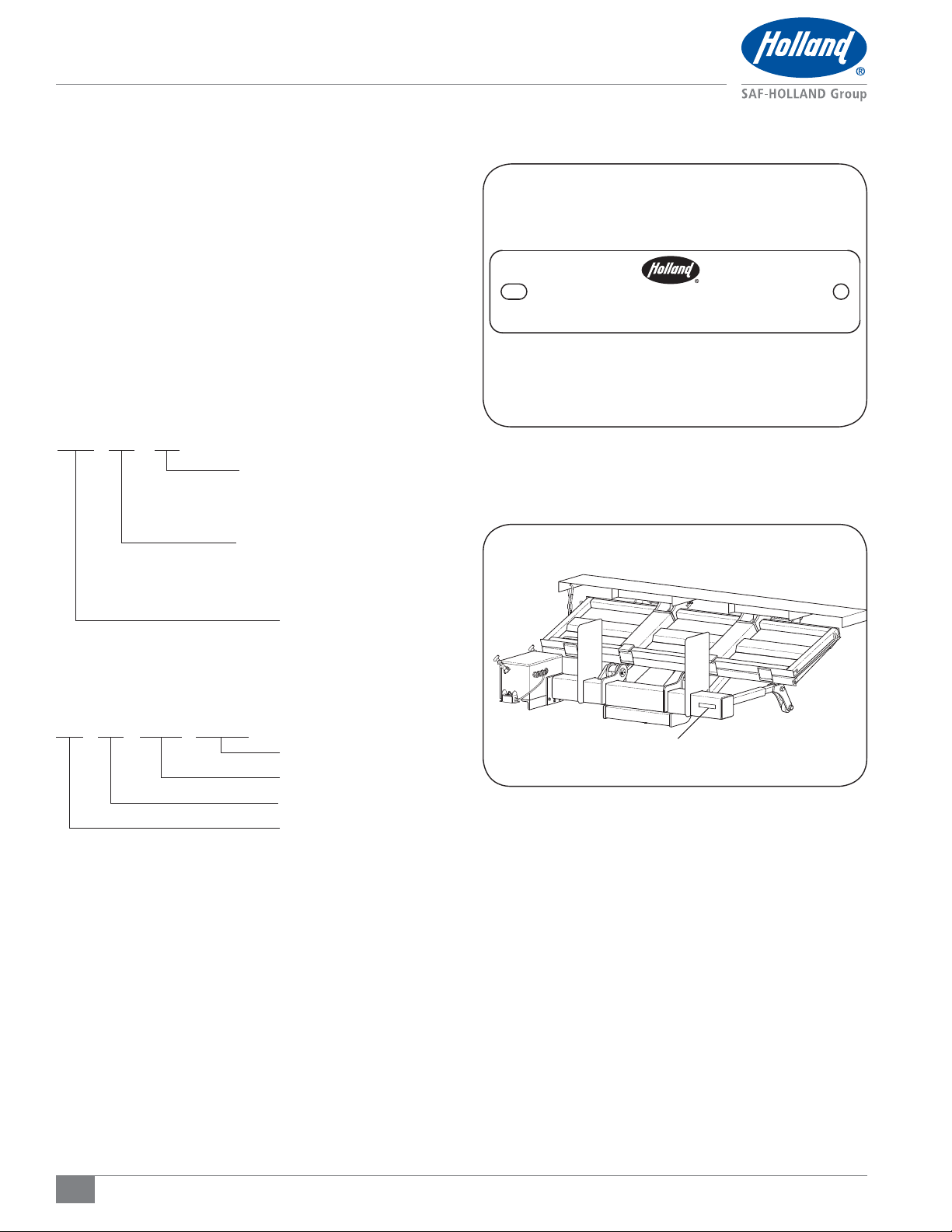

Decal Requirements

3. Decal Part Numbers

IMPORTANT: All decals must be installed, maintained,

and kept visible and legible.

Prior to placing the vehicle into service, inspect all decals

listed below. Ensure the decals are in the correct location and

are legible (Figures 6 and 7). Replace any damaged and/or

missing decals.

It is the responsibility of the end user to periodically inspect

all decals and ensure that they are clean and completely

legible. If any decals are missing, loose, damaged, or difficult

to read, contact SAF-HOLLAND Customer Service to order

replacements immediately.

DECAL QTY ENGLISH FRENCH DESCRIPTION

A 2 XB-59726 XB-59727 Maximum Capacity 2,750

B 2 XB-51170 XB-57067 Pinch Point

C 1 XB-54995 XB-64388 High Pressure Fluid

D 1 XB-50346 XB-50353 Warning

Figure 6

CURBSIDE

A

Figure 7

C

E

F

D

B

G

ROADSIDE

B

E 1 XB-62815 XB-62878 Warning - Riding Platform

F 1 XB-50345 XB-50352 Instructions

G 1 XB-50344 XB-50349 Caution - Always Stand Clear

A

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

7

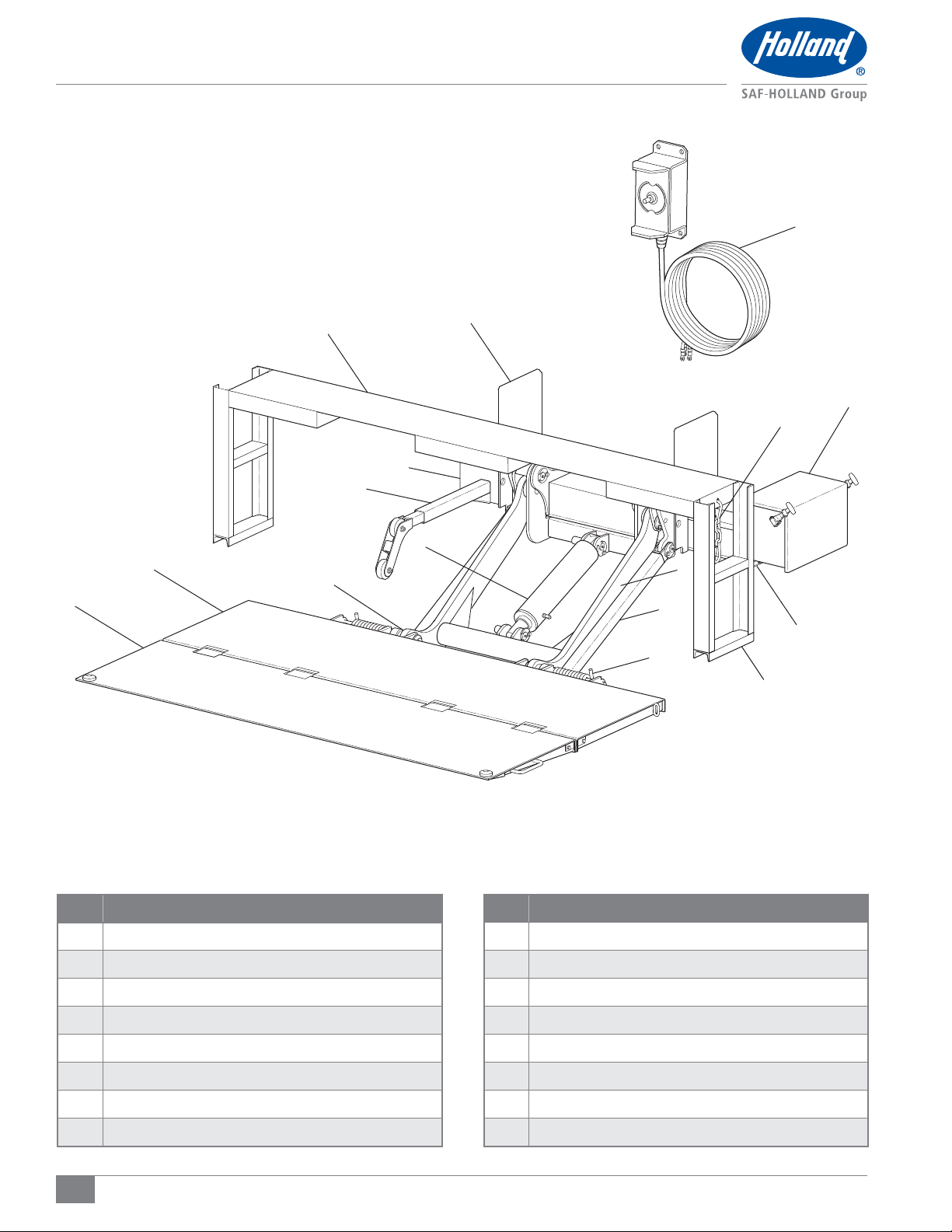

Liftgate Terminology

1

16

14

7

2

4

3

15

12

13

9

8

6

11

5

10

ITEM DESCRIPTION

Control Station

1

2 Inner Platform

3 Outer Platform

4 Adjusting Bolts

5 Torsion Spring

6 Compression Member

7 Roller Opener

8

Lift Frame

8

ITEM DESCRIPTION

9 Lift Cylinder

10 Step Brace

11 Pump Box Mount

12 Pump Box

13 Travel Hook

14 Main Tube

15 Attaching Plates

16

Deck Extension

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Liftgate Operation Instructions

4. Pre-Operation Information

1. Ensure the platform is clear of obstacles and other personnel.

2. Inspect liftgate for any damage, bruised paint or

bent components.

3. Inspect electrical cables and hydraulic hoses, repair or

secure as necessary.

Failure to repair and/or replace worn or

damaged components before use could

result in liftgate failure which, if not avoided,

could result in death or serious injury.

4. Read and understand the decals referenced in Section 3.

5. Vehicle must be on flat, level ground before operating liftgate.

6. Ensure that the vehicle parking brake is securely engaged.

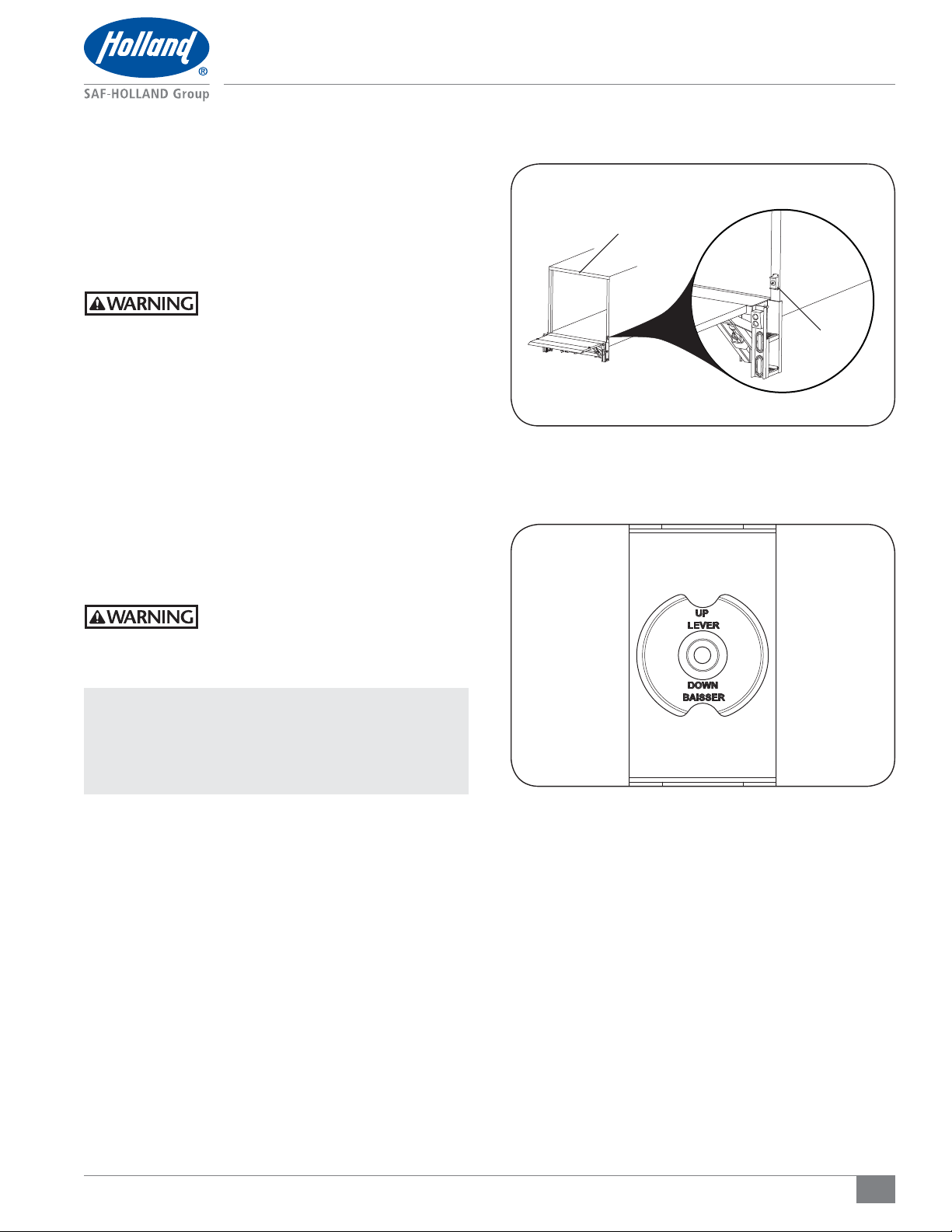

5. Control Station Switch Operation

To operate the liftgate, use the toggle switch on the control

station located at the rear of the vehicle (Figure 8).

This toggle switch enables the operator to raise and lower the

liftgate platform (Figure 9).

Figure 8

REAR OF VEHICLE

CONTROL

STATION

Figure 9

Failure to keep clear of the moving liftgate

could create a crush and/or pinch hazard

which, if not avoided, could result in death

or serious injury.

NOTE: If the Operator is required to ride the liftgate,

observe and familiarize yourself with the liftgate

operation, decals and manuals. Ensure stable

footing at all times. The switch only allows the

operator to raise or lower the platform.

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

9

Liftgate Operation Instructions

6. Raising or Lowering the Platform

Failure to secure load prior to operating

platform could allow load to shift and

strike operator which, if not avoided,

could result in minor or moderate injury.

IMPORTANT: This unit is intended for loading and

unloading cargo only. If personnel are

required to ride the liftgate, familiarize

yourself with this liftgate manual.

Failure to ensure stable footing while

riding the liftgate could allow the

operator to fall which, if not avoided,

could result in death or serious injury.

6.1 Raising the Platform

1. Stand to the side of the vehicle and clear of the platform,

push the control station toggle switch in the UP direction

(Figure 10).

NOTE: The toggle switch must remain engaged for the

platform to continue moving upward.

2. To stop the platform from moving upward, release the

toggle switch.

Figure 10

CONTROL STATION

UP

TOGGLE SWITCH

Figure 11

CONTROL STATION

6.2 Lowering the Platform

1. Stand to the side of the vehicle and clear of the platform,

push the control station toggle in the DOWN direction

(Figure 11).

NOTE: The toggle switch must remain engaged for the

platform to continue moving downward.

2. To stop the platform from moving downward, release the

toggle switch.

DOWN

TOGGLE SWITCH

10

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Liftgate Operation Instructions

7. Unfolding the Platform

1. Stand clear of the liftgate, and using the control station,

raise the stowed platform to relieve any tension on the

travel chain (Figure 12).

2. Disengage the travel latch chain hook from the platform

(Figure 13).

3. With the travel chain clear, lower the unit until the

liftgate firmly contacts the ground.

Failure to ensure stable footing while

engaging the foot pedal could result

in slipping which, if not avoided, could

result in minor or moderate injury.

4. Grasp the platform to rotate it down. As the platform

starts to rotate, step back to allow the platform to fall

into a horizontal position (Figure 14).

Failure to keep feet clear of platform

during operation could create a crush

and/or pinch hazard which, if not avoided,

could result in death or serious injury.

5. While standing clear and to the side grasp the flip

over section and rotate it allowing it to fall into a

horizontal position.

Figure 12

CONTROL STATION

UP

TOGGLE SWITCH

Figure 13

TRAVEL LATCH

CHAIN HOOK

PLATFORM

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Figure 14

PLATFORM

11

Liftgate Operation Instructions

8. Platform Loading

Failure to keep load within platform edge

could create a crush hazard which, if not

avoided, may result in damage to the load.

Failure to keep loads stable and within

design capacity could result in falling objects

or component failure which, if not avoided,

could result in death or serious injury.

When riding the platform, failure to keep

feet within front edge of platform could

create a crush hazard which, if not avoided,

could result in death or serious injury.

8.1 Loading from the Ground

1. Using the control station, open the platform from the

stowed position and lower it to the ground (Refer to

Sections 6 and 7).

IMPORTANT: Never operate a fork lift truck on or over

the platform.

Failure to remove fork lift trucks from

the liftgate platform area could cause

component failure which, if not avoided,

could result in death or serious injury.

2. Load the platform by placing the load center as close to the

center of the platform as possible and placing the heaviest

part of the load to the front of the platform (Figure 15).

3. Using the control station toggle switch at the rear of the

vehicle, raise the platform to deck height and unload

(Figure 16). If required, repeat procedures to continue

with additional loads.

4. When the liftgate has been unloaded, lower and stow the

platform (Refer to Sections 6 and 9).

Figure 15

PLACE LOAD

ON CENTER

OF PLATFORM

FRONT OF

PLATFORM

Figure 16

DECK HEIGHT

8.2 Loading from the Vehicle

1. Using the control station, open and raise the platform to

deck height (Refer to Sections 6 and 7).

2. Load the platform by placing the load center as close to the

center of the platform as possible and placing the heaviest

part of the load to the front of the platform (Figure 17).

IMPORTANT: Never operate a fork lift truck on or over

the platform.

Failure to remove fork lift trucks from

the liftgate platform area could cause

component failure which, if not avoided,

could result in death or serious injury.

3. Using the control station toggle switch on the rear of the

vehicle, lower the platform to the ground.

4. When the liftgate has been unloaded, stow the platform

(Refer to Section 9).

12

Figure 17

PLACE LOAD

ON CENTER

OF PLATFORM

FRONT OF PLATFORM

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Liftgate Operation Instructions

9. Stowing the Platform

1. Lower the platform to below waist level, lift the end of

the flipover section, rotating it about the pivot bolts and

allow the flipover to fall onto the platform (Figure 18).

Failure to keep feet clear of platform

during operation could create a crush

and/or pinch hazard which, if not avoided,

could result in death or serious injury.

2. Lower the platform to the ground and rotate the inner

platform allowing it to rest against the platform roller

openers (Figure 19).

3. Stand clear and using the control station, raise the

platform until the platform is in fully raised position.

NOTE: When the liftgate is fully retracted to the stored

position, release the control switch.

4. Position the travel latch chain hook into the latch hook

hole in the side of the platform (Figure 20).

Figure 18

FLIPOVER

SECTION

PIVOT BOLTS

Figure 19

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

ROLLER OPENERS

Figure 20

HOLE IN

PLATFORM

TRAVEL

LATCH

HOOK

13

Filling the Hydraulic Reservoir

10. Filling the Hydraulic Reservoir

IMPORTANT: Keep dirt, water, and other contaminants

from entering the hydraulic system; clean

the area to prevent contamination of the

hydraulic fluid and use a clean funnel with

a fine screen mesh.

1. Set the vehicle parking brake.

2. Using the control station, put the platform in the down

and open position (Figure 21).

3. Remove the filler cap and add recommended hydraulic

fluid to pump reservoir. Check that the hydraulic fluid is

at the proper fill level, half full (Figure 22).

IMPORTANT: Always use the correct grade of hydraulic

fluid. Refer to the chart below for

recommended hydraulic fluid or contact

your SAF-HOLLAND representative.

TEMPERATURE RECOMMENDED FLUIDS

RANGE MANUFACTURER TYPE

Above 0° C

(32° F)

-25 to 65° C

(-15 to 150° F)

-35 to 50 ° C

(-30 to 120° F)

-45 to 40° C

(-50 to 100° F)

Any

Any Esso, Exxon

Mobil, Shell

Exxon, Esso Shell,

Petro--Can

Any Esso, Exxon,

Shell

AW-32

ISO 32

HYDRAUL 50

DTE 11

DONAX TD

Low Viscosity

UNIVIS N15

TELLUS T15

MV ARCTIC 15

MIL-H-5606

UNIVIS J-13

UNIVIS HV1 13

FLUID #4

Figure 21

TLV MODEL IN

DOWN AND OPEN

POSITION

Figure 22

FILLER CAP

14

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

11. Routine Service and Inspection

11.1 Daily Inspection

1. Daily or before each trip, inspect the liftgate for damage

to mounting assemblies, mechanical parts, and hydraulic

components and hoses. Any noticeable defects must be

repaired prior to operation to avoid damage and possible

injury. Inspect and verify the condition of the following

key components:

• Torsion springs – are not broken or rusted

• Stowage lock mechanism – is in working order

• Attaching plates – no bends and/or cracked welds

are present

• Deck extension – no cracked welds are present

• Pivot points – no pin movement caused by excessive wear

• Pivot points – all pins and bushings are present and in

good working order

• Shackles – are in proper orientation and proper

platform presentation

• Platform – no bends are present

• Platform – no weld cracks are present

• Flipover – no bends are present

• Flipover – no weld cracks are present

• Control switch – is in properly operational

• Control switch – no damage is present

• Control switch – have no noticeable corrosion

• Hydraulic hoses – have no leaks

• Hydraulic hoses – are secured properly

• Hydraulic hoses – no rub or abrasion marks are present

• Cylinders – have no leaks

• Cylinders – no damage is present

2. Inspect and replace any decals that have been removed

or have become illegible.

11.2 Monthly Inspection

1. Every 1000 cycles or 30 days, whichever occurs first, lubricate

all pivot points using EP2 chassis grease. In severe winter

conditions, it may be necessary to lubricate more frequently.

2. Lubricate linkage pivot points with light spray lubricant.

3. Check oil level in reservoir (1/2" [13 mm] from top of

tank with cylinders retracted).

4. Verify electrical connections, coat with non aerosol

dielectric grease or equivalent.

Routine Service and Inspection

2. Lubricate linkage pivot points with light spray lubricant.

3. Inspect all decals. Replace any decals that are not clearly

visible or legible.

11.4 Alternate Year Inspection

1. Every 24,000 cycles or two (2) years, whichever occurs

first, inspect all pivot points for wear. Replace any pins

or parts that show signs of wear.

2. Replace any worn hydraulic hoses, leaking fittings or

leaking cylinders.

IMPORTANT: Review General Safety Precautions before

working on hydraulic or electrical components.

11.5 Monthly Hydraulic and Electrical Inspection

1. Inspect and remove the coil from the valve and look for signs of

corrosion. If corrosion is present, clean and repair as necessary.

2. Inspect to ensure all hydraulic hoses are tight and not

leaking. If hoses are showing signs of wear, replace as

necessary. After torquing the hydraulic hoses, SAF-HOLLAND

recommends putting a line across the fittings for a future

visual reference that will indicate loose fittings.

3. Inspect the filler cap for signs of damage. The foam baffle

on the inside of the cap should be flat and in place. Inspect

all wire connections on toggles, push buttons or any other

controls attached to the liftgate. Clean and apply dielectric

grease to all electrical components to help reduce corrosion.

4. Inspect all wiring and wiring connections to ensure they

are tight and free of corrosion. If the pump has foreign

debris, clean the entire pump and wire connections. Once

you are satisfied that all components are clean, apply

non-aerosol dielectric grease to all connections. If any

wires show signs of deterioration, replace as required.

5. SAF-HOLLAND recommends that you flush and replace

the hydraulic oil every year to ensure contaminates are

flushed from the system. Remove the pump tank and

wipe free with a lint free cloth. If present, clean reservoir

magnet of contaminants. Remove the strainer and flush.

Replace the strainer. Remove any contaminates.

NOTE: To reduce downtime, bring in your liftgate every

two to three (2-3) months for quick and simple

inspections. Daily inspections while doing the circle

check on your vehicle will spot any concerns

before they become serious failures.

11.3 Yearly Inspection

1. Change the oil and oil filter. When filling pump reservoir, use

a funnel with a fine mesh screen . Use only recommended

hydraulic fluid (refer to Section 15).

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

15

Troubleshooting

12. Troubleshooting

PROBLEM POSSIBLE CAUSE RESOLUTION

Platform lowers slowly or does not lower.

Flow control valve incorrectly installed. Check location and direction of arrow on valve.

Electrical connections loose, disconnected or corroded. Check connections and wire condition.

Battery does not have enough voltage to activate

solenoid properly.

Restriction/blockage of hydraulic hose.

Flow control valve blocked. Clean or replace valve.

Mechanical components seized or damaged.

Incorrect or contaminated oil in system.

Hydraulic system not plumbed properly.

Verify voltage and recharge or replace battery.

Ensure that cables are in good condition with

secure connections.

Check hoses for external damage or pinching.

Check for blockages in hoses.

Lubricate all pivot points and replace all

damaged items.

Oil should be clean and for the appropriate

geographical climate.

Check to see that the hose connected to the ‘A’

port is plumbed to the rod end of the cylinder.

Unit will not lift capacity load.

Oil expels from reservoir while loading.

Pump will not operate.

Hydraulic cylinder leaking internally. Replace seals or complete cylinder.

Relief valve setting too low. Adjust relief valve setting.

Hydraulic pump worn. Change worn parts or pump.

Too much oil in reservoir. Ensure level of oil allows displacement of rods.

Wrong flow control fitting.

Motor is not running when lowering platform.

(Power down option only)

Master disconnect switch is turned off Verify the main power is turned on.

Battery does not have enough voltage/current.

Electrical wiring to pump is loose, disconnected

or corroded

Remote control switch broken or shorted. Check wiring to switch.

Solenoid switch on pump faulty. Check solenoid switch.

Electrical coupling to trailer not complete

(Tractor/Trailer vehicles only).

Check that the number stamped on flow control

valve is correct as per the appropriate schematic.

Check for power at the "down" coil

Verify voltage and recharge or replace battery.

Ensure that cables are in good condition with

secure connections.

Check wiring to pump.

Connect coupling.

16

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Troubleshooting

PROBLEM POSSIBLE CAUSE RESOLUTION

Verify voltage and recharge or replace battery.

Battery does not have enough voltage/current.

Insufficient oil in reservoir.

Defective actuating coil on valve. Replace actuating coil.

Liftgate is overloaded. Reduce the load on the platform.

Ensure that cables are in good condition with

secure connections.

With platform on ground, fill tank within 2" (50 mm)

of top with Dextron III Automatic Transmission Fluid.

Platform will not raise.

Platform will not raise smoothly.

Platform creeps down when stationary.

Hose or fitting leak. Check and re-torque fittings.

Leaking check valve or relief valve. Clean, adjust or replace valve.

Worn piston seals. Replace seals.

Worn or scored piston. Replace cylinders.

Pivot points seized. Lubricate.

Pump is worn out. Replace pump.

Broken pump shaft or coupler. Replace shaft or coupling as necessary.

Insufficient oil in reservoir. Fill reservoir.

Operate ‘Raise Control’ for a few seconds at

Air lock in hydraulic system.

Undue mechanical wear or lack of lubrication. Lubricate pivots, replace worn parts.

Cylinder seal leak. Replace seals or cylinder if scored.

Worn or dirty check valve. Clean or replace valve.

Hose or fitting leak Replace hose or tighten fitting

Battery does not have enough voltage/current.

Liftgate is overloaded. Reduce load on platform.

top of stroke. Repeat two (2) times, pausing

between operations.

Verify voltage and recharge or replace battery.

Ensure that cables are in good condition with

secure connections.

Faulty cable connections: Electrical connections

corroded or disconnected.

Platform raises slowly.

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Pump motor not grounded adequately. Check grounding to truck frame.

Hose leaking. Tighten or replace hoses.

Cylinder internal leak. Replace seals or replace cylinder.

Lack of lubrication or undue mechanical wear. Lubricate all pivot points and replace worn parts.

Incorrect relief valve setting. Check relief valve setting.

Worn pump. Replace pump.

Check connections.

17

Pump Hydraulic and Electrical Diagram

13. Pump Hydraulic and Electrical Diagrams

Power Down Option

Figure 23

A PORT (C1) (UP)

(TOP VIEW)

BLACK WIRE

FROM CONTROL

(2W2P) (DOWN)

B PORT (C2) (DOWN)

(SIDE VIEW)

WHITE WIRE FROM TOGGLE (4W2P) (UP)

POWER FROM BATTERY

(END VIEW)

POWER FROM

CONTROL (GREEN)

18

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Gravity Down Option

Figure 24

Pump Hydraulic and Electrical Diagram

OUTLET PORT

(TOP VIEW)

BLACK WIRE FROM

CONTROL (DOWN)

POWER FROM CONTROL

(GREEN)

POWER FROM BATTERY

(SIDE VIEW)

WHITE WIRE FROM

TOGGLE (UP)

(END VIEW)

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

19

Pump Hydraulic Schematic

14. Pump Hydraulic and Electrical Schematic

Power Down Option

Figure 25 (Hydraulic Schematic)

34 BAR

500 PSI

A (UP)B (DOWN)

BLACK WIRE

(2W2P)

WHITE WIRE

(4W2P)

Figure 26 (Electrical Schematic)

193 BAR

2800 PSI

1.98 CC/REV

0.121 IN3/REV

2W2P

VALVE

COIL FLOW

PORT B

BLACK (DOWN)

FLOW PORT B

MOTOR START

SOLENOID

GREEN (POWER)

20

WHITE (UP)

FLOW PORT A

4W2P VALVE COIL FLOW PORT A

+ 12V DC BATTERY(+VE)

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Gravity Down Option

Figure 27 (Hydraulic Schematic)

OUTLET PORT

3/8-19 BSPP REF

172 BAR

2500 PSI

Pump Hydraulic Schematic

7.57 LPM

2.0 GPM

Figure 28 (Electrical Schematic)

2.31 CC/REV

0.137 TN3/REV

2W2P

VALVE

COIL

BLACK (DOWN)

MOTOR START

SOLENOID

GREEN (POWER)

WHITE (UP)

+ 12V DC BATTERY(+VE)

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

21

Liftgate Assembly - Exploded View

15. Liftgate Components

23

25

(30 1/2") (29 1/2")(30") (28 3/4")

26

31

28

24

22

21

14

20

16

7

10

9

8

18

17

12

5

4

3

2

1

13

6

19

27

30

29

22

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Liftgate Assembly - Parts Lists

TLV 2748W

DETAIL DESCRIPTION

1 Outer Platform Assembly XB-59906-28 XB-59906-28 1

2 Pin XB-59906-49 XB-59906-49 4

3 Connector XB-59906-48 XB-59906-48 4

4 Inner Platform Assembly XB-59906-29 XB-59906-29 1

5 Shackle, Curbside XB-59906-34 XB-59906-34 2

6 Spring, Curbside XB-59906-46 XB-59906-46 1

7 Spring, Roadside XB-59906-47 XB-59906-47 1

8 Lock Plate, Pin XB-59906-45 XB-59906-45 2

9 Lock Plate, Pin XB-59906-44 XB-59906-44 2

10 Adjunct-Arm XB-59906-33 XB-59906-33 2

11 Spacer XB-59906-38 XB-59906-38 2

12 Spacer XB-59906-39 XB-59906-39 2

13 Hose, Gravity Down XB-59906-54 N/A 1

14 Lock Plate, Pin XB-59906-43 XB-59906-43 2

15 Lift Frame XB-59906-32 XB-59906-32 1

16 Cylinder XB-59906-50 2046100000180 1

17 Pin XB-59906-31 XB-59906-31 2

18 Right Angle Return Air Joint XB-59906-30 XB-59906-30 1

19 Bracket, Cylinder & Lift Arm XB-59906-35 XB-59906-35 1

20 Spacer XB-59906-37 XB-59906-37 2

21 Lock Plate, Pin XB-59906-41 XB-59906-41 2

22 Lock Plate, Pin XB-59906-42 XB-59906-42 2

23 Mounting Plate XB-59906-51 XB-59906-51 1

24 Insert, Roller Opener 2112360004130 2112360004130 1

25 Install Strap, Long XB-59906-52 XB-59906-52 1

26 Install Strap, Short XB-59906-53 XB-59906-53 1

27 Lock Chain Assembly XB-59906-40 XB-59906-40 1

28 Extension Plate 2112200003560 2112200003560 1

29 Pump Box 2112360003570 AK-62864-01 1

30A 2" Step Bumper XA-50044 XA-50044 2

30B 3" Step Bumper XA-50045 XA-50045 2

31 Shackle, Roadside XA-55906-55 XA-55906-55 1

GRAVITY DOWN

TLV 2748W

POWER DOWN QTY

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

23

Hydraulics Part List

16. Hydraulic Components

Gravity Down Option

6

5

4

3

2

1

7

DETAIL DESCRIPTION PART NO. QTY

1 90° Fitting, Air Hose XB-59906-30 1

2 Air Hose, Gravity Down XB-59906-54 1

3 Fitting, 90° Elbow, -6 Orb / 1/4" Fnpt XB-57030 1

4 Flow Control Valve, 2.0 Gpm XB-50032 1

5 Adapter 1/4" Male Pipe/-4 Male Jic XB-51529 1

6 Hose Asssembly, 60" Lg XA-51610-60 1

7 Control Station XA-58359-01 1

24

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Power Down Option

Hydraulics Parts List

1

6

3

4

5

2

7

DETAIL DESCRIPTION PART NO. QTY

1 Fitting, 90° Elbow, -6 Orb / -4 Jic XB-51918 1

2 Hose Assembly, 60" Lg XB-59906-60 1

3 Fitting, 90° Elbow, -6 Orb / 1/4" Fnpt XB-57030 1

4 Flow Control Valve, 2.0 Gpm XB-50032 1

5 Adapter 1/4"Male Pipe/-4 Male Jic XB-51529 1

6 Hose Assembly, 72" Lg XA-51610-07200 1

7 Control Station XA-58359-01 1

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

25

Notes

26

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Notes

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

27

From fifth wheel rebuild kits to suspension bushing repair kits,

SAF-HOLLAND Original Parts are the same quality components used

in the original component assembly.

SAF-HOLLAND Original Parts are tested and designed to provide

maximum performance and durability. Will-fits, look-alikes or, worse

yet, counterfeit parts will only limit the performance potential and

could possibly void SAF-HOLLAND’s warranty. Always be sure to spec

SAF-HOLLAND Original Parts when servicing your

SAF-HOLLAND product.

SAF-HOLLAND USA

www.safholland.us

SAF-HOLLAND CANADA

WESTERN CANADA

www.safholland.ca

SAF-HOLLAND MEXICO

www.safholland.com.mx

info@safholland.com

SAF-HOLLAND USA, INC.

1950 Industrial Blvd., Muskegon, MI 49442

www.safholland.com

888.396.6501

·

519.537.3494

·

604.574.7491

·

52.55.5362.8743

·

Fax 800.356.3929

·

Fax 800.565.7753

·

Fax 604.574.0244

·

Fax 52.55.5362.8743

·

XL-TG10156UD-en-US Rev A · 2013-04-18 · Amendments and errors reserved. © SAF-HOLLAND, Inc.

Loading...

Loading...