Service Manual for Drum Brake Axles

Tapered and Parallel Spindle Axles

XL-TA10006OM-en-US Rev B

Contents

Contents Page

Introduction ......................................................................... 3

Warranty .............................................................................. 3

Notes, Cautions, and Warnings ............................................. 3

Section 1 – General Safety Instructions ................................ 4

Section 2 – Model Identification........................................... 5

Section 3 – Identification Tag ............................................... 5

Brake Components Parts List Prior to November 30, 2012 ..... 6

Brake Components Parts List After November 30, 2012 ......... 7

Section 4 – Hubs, Bearings and Seal Removal ....................... 8

Section 5 – Bearing Inspection ........................................... 10

Section 6 – Hubs, Bearings and Seal Installation ................. 11

Section 7 – Hub Bearing Adjustment .................................. 13

Section 8 – Hub Cap Installation ........................................ 15

Section 9 – Filling Hub with Lubricant (Oil Based) .............. 15

Introduction

This manual provides the necessary information for the maintenance,

inspection, and safe operation of the SAF® axle/brake system.

Read this manual before using or servicing this product and

keep it in a safe location for future reference. Updates to this

manual, which are published as necessary, are available on

the internet at www.safholland.us.

Use only SAF-HOLLAND

SAF-HOLLAND INTEGRAL™ disc brake axle. A list of technical

support locations that supply SAF-HOLLAND® Original Parts

and an Aftermarket Parts Catalog are available on the internet

at www.safholland.us or contact Customer Service at 888-396-6501.

Warranty

Refer to the complete warranty for the country in which the

product will be used. A copy of the written warranty is included

with the product or available on the internet at www.safholland.us.

®

Original Parts to service your

Contents Page

Section 10 – Retracting the Brake Shoes or Slack

Adjuster Control Arm(s).................................. 16

Section 11 – Brake Shoe Removal ...................................... 17

Section 12 – Brake Shoe Installation .................................. 19

Section 13 – Brake Adjuster Removal ................................. 22

Section 14 – Brake Adjuster Installation ............................. 22

Section 15 – S-Camshaft and Bearing Removal Procedure ... 23

Section 16 – S-Camshaft and Bearing Installation .............. 24

Section 17 – Brake Adjustment Procedure .......................... 26

Section 18 – ABS Sensor Replacement Procedure ............... 27

Section 19 – Axle Alignment Inspection .............................. 27

Section 20 – Routine Service Schedule ............................... 28

Section 21 – Torque and Lubrication Specifications ............. 29

Section 22 – Troubleshooting Chart .................................... 30

Notes, Cautions, and Warnings

Before starting any work on the unit, read and understand all

the safety procedures presented in this manual. This manual

contains the terms “NOTE”, “IMPORTANT”, “CAUTION”, and

“WARNING” followed by important product information. These

terms are defined as follows:

NOTE: Includes additional information to enable accurate

and easy performance of procedures.

IMPORTANT: Includes additional information that

if not followed could lead to hindered

product performance.

Used without the safety alert symbol,

indicates a potentially hazardous

situation which, if not avoided, could

result in property damage.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury.

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

3

General Safety, Maintenance and Inspection Instructions

1. Safety Instructions

General and Servicing Safety Instructions

Read and observe all Warning and Caution hazard alert

messages. The alerts provide information that can help prevent

serious personal injury, damage to components, or both.

Failure to follow the instructions and safety

precautions in this manual could result in

improper servicing or operation leading

to component failure which if not avoided

could result in death or serious injury.

All installation should be performed by a properly

technician using proper/special tools, and safe procedures.

NOTE: In the United States, workshop safety requirements

are defined by federal and/or state Occupational

Safety and Health Act (OSHA). Equivalent laws

could exist in other countries. This manual is written

based on the assumption that OSHA or other

applicable employee safety regulations are followed

by the location where work is performed.

IMPORTANT: Use only SAF-HOLLAND

®

Original Parts to

service your SAF-HOLLAND

disc brake axle.

Failure to maintain your SAF-HOLLAND®

INTEGRAL™ disc brake with SAF-HOLLAND

Original Parts can result in brake or wheel

bearing failure which, if not avoided,

could result in death or serious injury.

Properly support and secure the vehicle and axles from

unexpected movement when servicing the unit.

Failure to properly support the vehicle

and axles prior to could create a crush

hazard which, if not avoided, could result

in death or serious injury.

If possible, unload the trailer before performing any

service procedures.

After re-positioning the brake chamber, brake adjuster

and/or ABS system as instructed in this manual, ALWAYS

consult the manufacturer’s manual for proper operation.

IMPORTANT: Key components on each axle system

including but not limited to suspension,

brake adjuster, brake chambers, bearings,

hubs, and drums require information

supplied by the original manufacturer of

the components to ensure proper and safe

operation of the axle system.

Failure to follow the original manufacturer’s

instructions regarding spring brake or air

pressure control could allow an

uncontrolled release of energy which

could result in death or serious injury.

Service both roadside and curbside of an axle. Worn parts

should be replaced in sets. Key components on each axle’s

braking system, such as friction material, rotors and drums

will normally wear over time.

trained

®

INTEGRAL™

Operational and Road Safety Instructions

The wheel contact surfaces between the wheel and hub

MUST NOT receive additional paint.

IMPORTANT: The wheel contact surfaces MUST be clean,

smooth and free from grease.

Failure to keep wheel and hub contact surfaces

clean and clear of foreign material could

allow wheel/hub separations which, if not

avoided, could result in death or serious injury.

Only the wheel and tire sizes approved by the trailer builder

can be used.

Before operating the vehicle, ensure that the maximum

permissible axle load is not exceeded and that the load

is distributed equally and uniformly.

Make sure that the brakes are not overheated from

continuous operation.

Failure to minimize the use of brakes during

overheating conditions could result in

deterioration of brake efficiency which,

if not avoided, could result in death or

serious injury.

®

The parking brake MUST NOT be immediately applied when

the brakes are overheated.

If the parking brake is immediately applied

to the brakes when overheated, the brake

drums or discs could be damaged by different

stress fields during cooling.

Observe the operating recommendation of the trailer

manufacturer for off-road operation of the installed axles.

IMPORTANT: The definition of OFF-ROAD means driving

on non-asphalt/non-concrete routes,

such

as gravel roads, agricultural and forestry tracks,

on construction sites and in gravel pits.

IMPORTANT: Off-road operation of axles beyond

the approved application design could

result in damage and impair suspension

system performance.

SAF® axles require routine service, inspection and maintenance

to maintain optimum performance, operational and road

safety, and to recognize natural wear and defects before

they become serious. Please refer to the Service Manual

for Drum Brake Axles XL-TA1000060M-en-US which can

be found at www.safholland.us or contact our customer

service group at 888-396-6501.

4

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

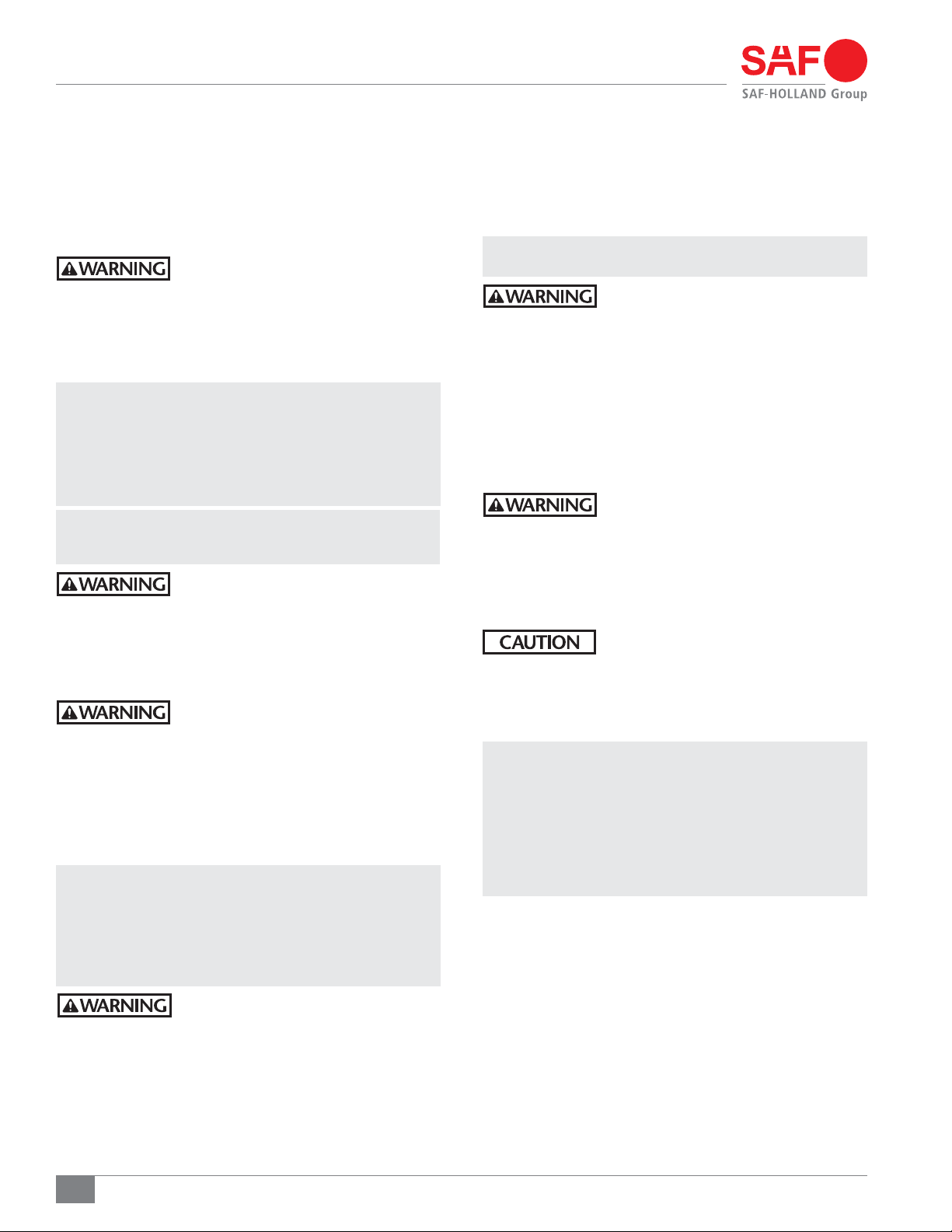

Model and Serial Number

2. Model Identification

The Drum Brake Axle Serial Tag is located near the center of

the axle tube (Figure 1).

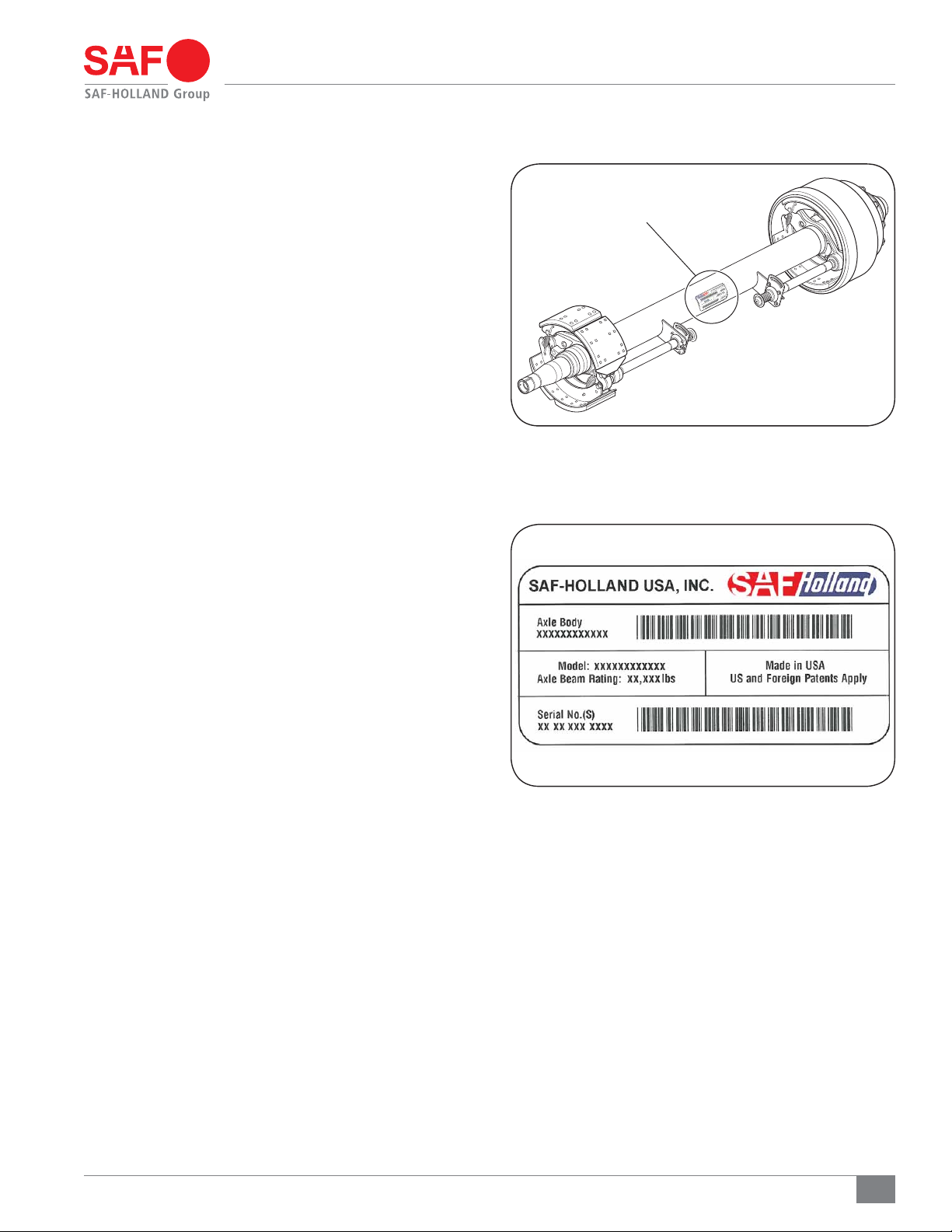

3. Identification Tag

The sample tag shown will help you interpret the information

on the SAF-HOLLAND USA Inc

number, axle body part number, axle beam rating, and serial

number are listed on the tag (Figure 2).

Record your tag numbers below for future quick reference.

®

. serial number tag. The model

Figure 1

SERIAL NUMBER TAG LOCATED

NEAR CENTER OF AXLE TUBE

Figure 2

Axle Body Part Number _________________________________

Model Number _______________________________________

Axle Beam Rating _____________________________________

Serial Number _______________________________________

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

5

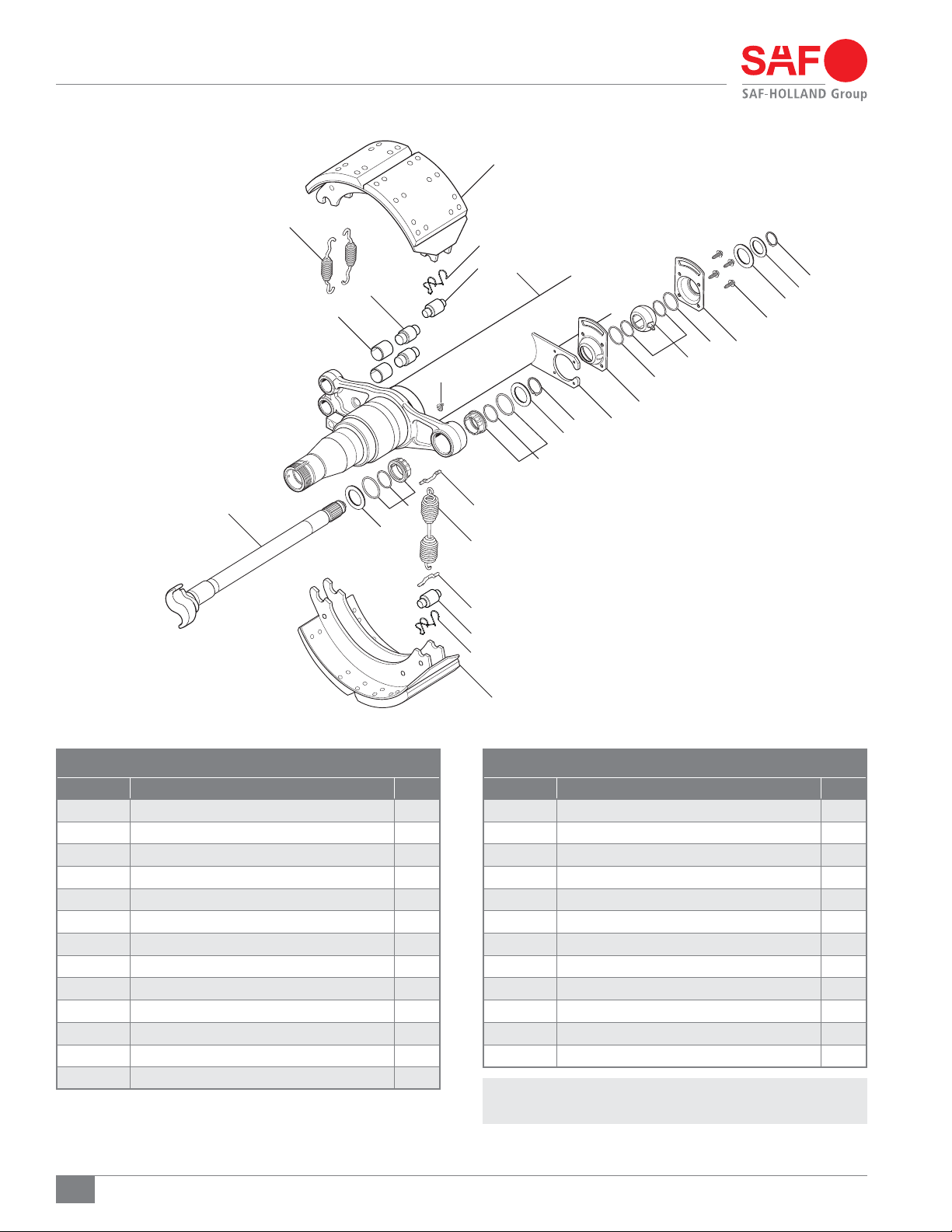

Brake Components Parts List – Prior to November 30, 2012

5

16

8

1

9

4

3

2

12

6

13

25

23

24

22

20 21

19

20

17 LH AND 18 RH (NOT SHOWN)

AXLE

BRACKET

10 LH AND

11 RH (NOT SHOWN)

12

BRAKE COMPONENTS

ITEM DESCRIPTION QTY

1 Axle Body Assembly 1

2 Fitting, Lubrication 2

3 Bushing, Anchor Pin 4

4 Pin, Anchor 4

5 Brake Shoe Assembly 4

6 Bearing Assembly, S-Cam-Spider inboard 2

7 Bearing Assembly, S-Cam-Spider Outboard 2

8 Retainer, Roller 4

9 Roller, Brake Shoe 4

10 S-Camshaft, Left-Hand 1

11 S-Camshaft, Right-Hand (not shown) 1

12 Washer, S-Cam Bearing-Outboard 4

13 Retainer Ring 2

7

14

15

14

9

8

5

TAPERED SPINDLE AXLE SHOWN

BRAKE COMPONENTS

ITEM DESCRIPTION QTY

14 Return Spring Pin 4

15 Spring, Return-Hub/Drum 2

16 Spring, Anchor Pin 4

17 Housing, S-Cam Bearing, Left-Hand Slotted 1

18 Housing, S-Cam Bearing, Right-Hand Slotted 1

19 Bearing Assembly S-Camshaft 2

20 O-Ring, S-Camshaft Bearing Seal-Inboard 4

21 Housing, S-Cam Bearing 2

22 Screw, Thread Rolling Tapping 8

23 Washer, Shaft End 2

24 Washer, Shaft End 2

25 Retaining Ring 2

NOTE: Refer to Drum Brake Axle Parts Manual XL-TA10058PM-en-US for

axle component and service kit part numbers.

6

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

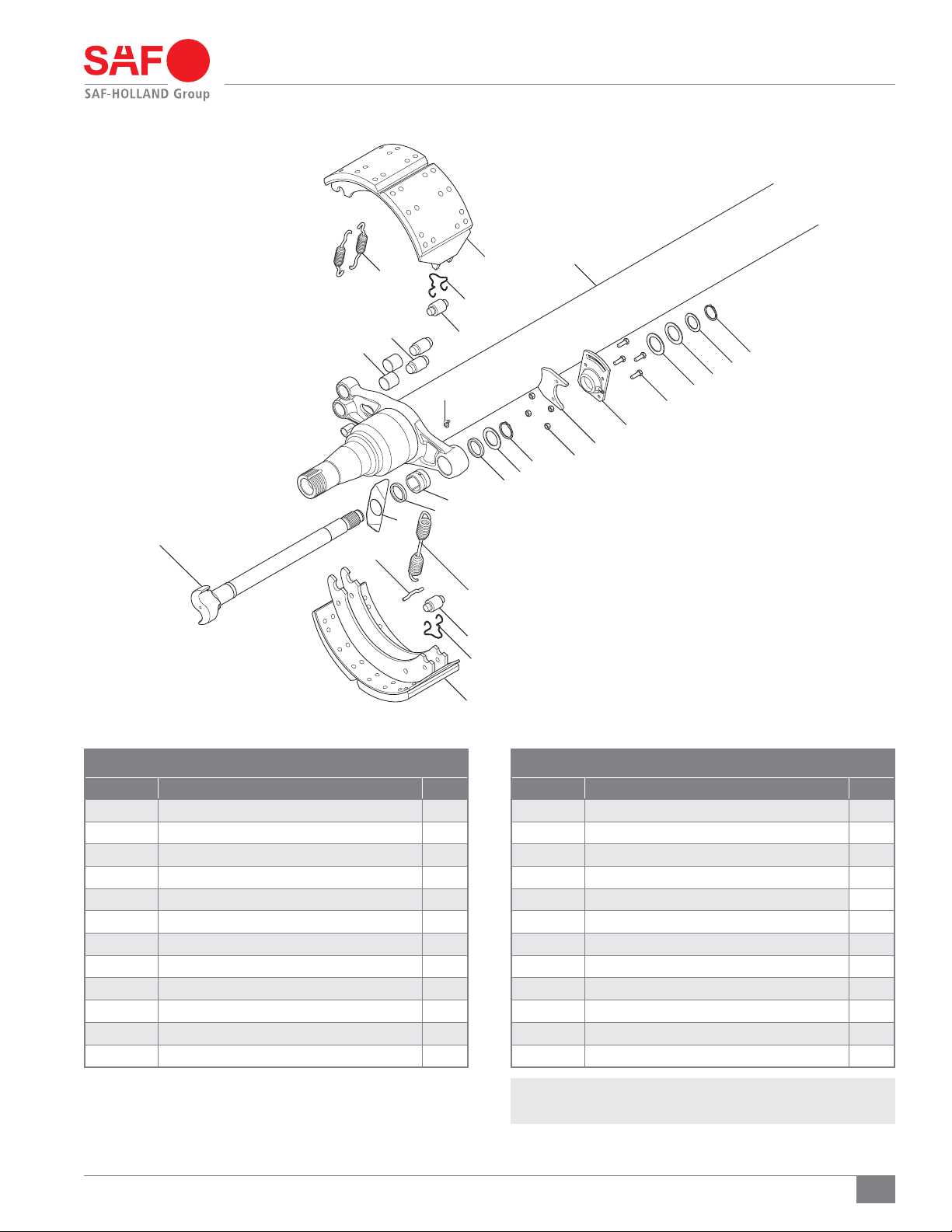

Brake Components Parts List – After November 30, 2012

10 LH AND

11 RH (NOT SHOWN)

16

4

3

7

24

14

5

8

9

2

12

7

6

15

9

8

5

13

1

19

21

22

22

20

17 LH & 18 RH (NOT SHOWN)

AXLE

BRACKET

TAPERED SPINDLE AXLE SHOWN

23

BRAKE COMPONENTS

ITEM DESCRIPTION QTY

1 Axle Body Assembly 1

2 Fitting, Lubrication 2

3 Bushing, Anchor Pin 4

4 Pin, Anchor 4

5 Brake Shoe Assembly 4

6 Bushing, Cam Bearing 2

7 Cam Seal, Spider 4

8 Retainer, Cam Roller 4

9 Roller, Brake Shoe 4

10 S-Camshaft, Left-Hand 1

11 S-Camshaft, Right-Hand (not shown) 1

12 Washer, S-Cam Bearing-Outboard 2

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

BRAKE COMPONENTS

ITEM DESCRIPTION QTY

13 Retainer Ring 2

14 Return Spring Pin 4

15 Spring, Return-Hub/Drum 2

16 Spring, Anchor Pin 4

17 Cam Bearing Kit - Left-Hand 1

18 Cam Bearing Kit - Right-Hand (not shown) 1

19 Nut, Lock 8

20 Bolt, Hex Head Cap 8

21 Washer, Shaft End 2

22 Washer, Shaft End 4

23 Retaining Ring 2

24 Guide PLate, Brake Roller Shoe 2

NOTE: Refer to Drum Brake Axle Parts Manual XL-TA10058PM-en-US for

axle component and service kit part numbers.

7

Hubs, Bearings, and Seal Components

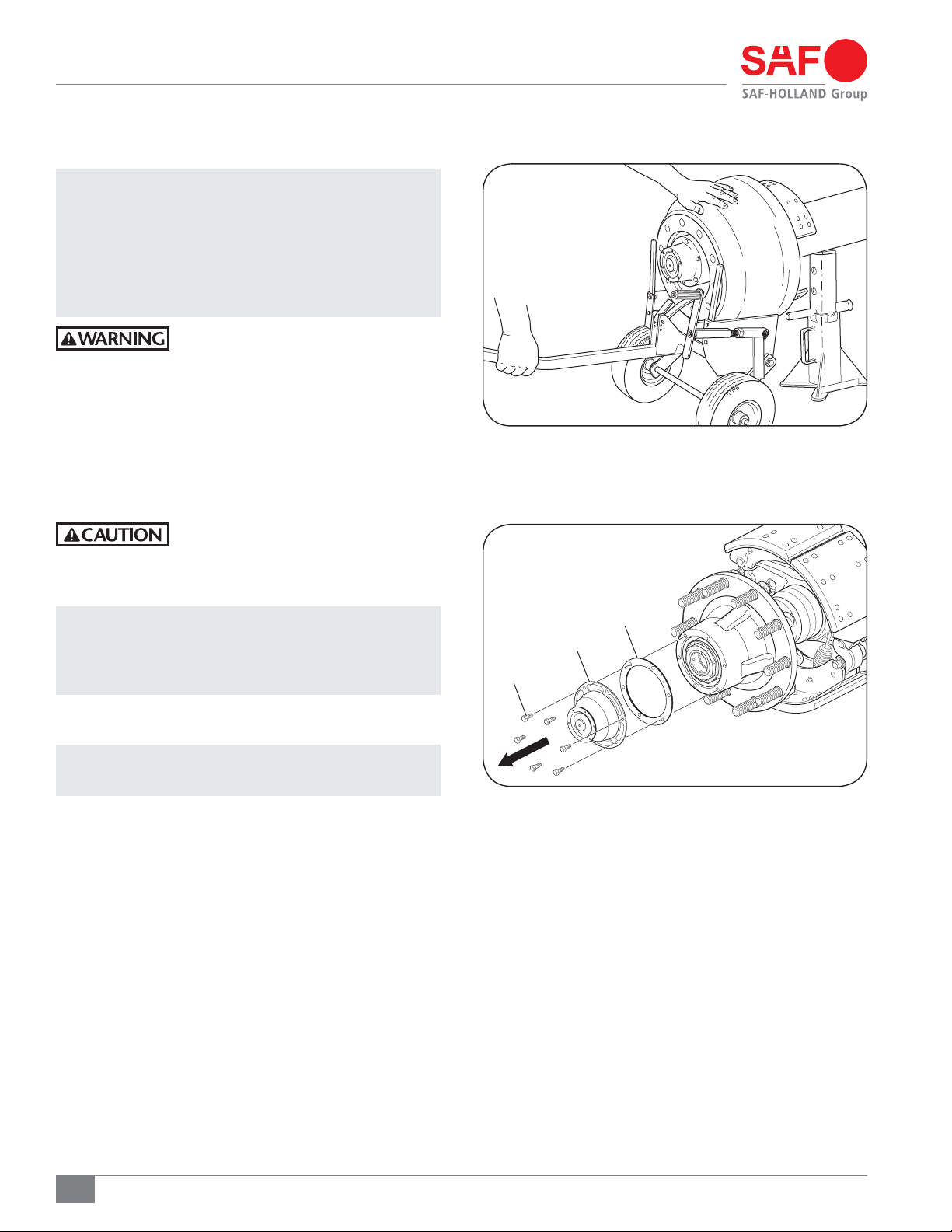

4. Hubs, Bearings and Seal Removal

NOTE: Before you begin any axle/brake service procedures,

park the vehicle on a level surface. Block the wheels

to prevent the vehicle from moving. Support the

vehicle and axle(s) with safety stands. DO NOT work

under a vehicle supported only by jacks. Jacks can

slip or fall over. Serious personal injury and damage

to components can result.

Failure to properly support the vehicle and

axles prior to commencing work could

create a crush hazard which, if not avoided,

could result in death or serious injury.

1. Release trailer brakes and cage spring brakes according

to spring brake manufacturer’s instructions. Remove tire

and wheel assembly to access hub and drum.

2. Remove drum from hub using support device such as a

drum dolly (Figure 3).

Failure to support weight during installation

or removal of brake drum could create a

crush hazard which, if not avoided, could

result in minor to moderate injury.

NOTE: It is necessary to retract brake shoes in accordance

with brake adjuster’s manufacturer manual to

allow brake drum to clear brake shoes during

brake drum removal.

Figure 3

Figure 4

HUB CAP

GASKET

HUB CAP

BOLTS (6)

3. Remove the hub cap and gasket by removing six (6)

bolts (Figure 4).

NOTE: Be prepared to collect lubrication fluid when

removing the hub cap.

8

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

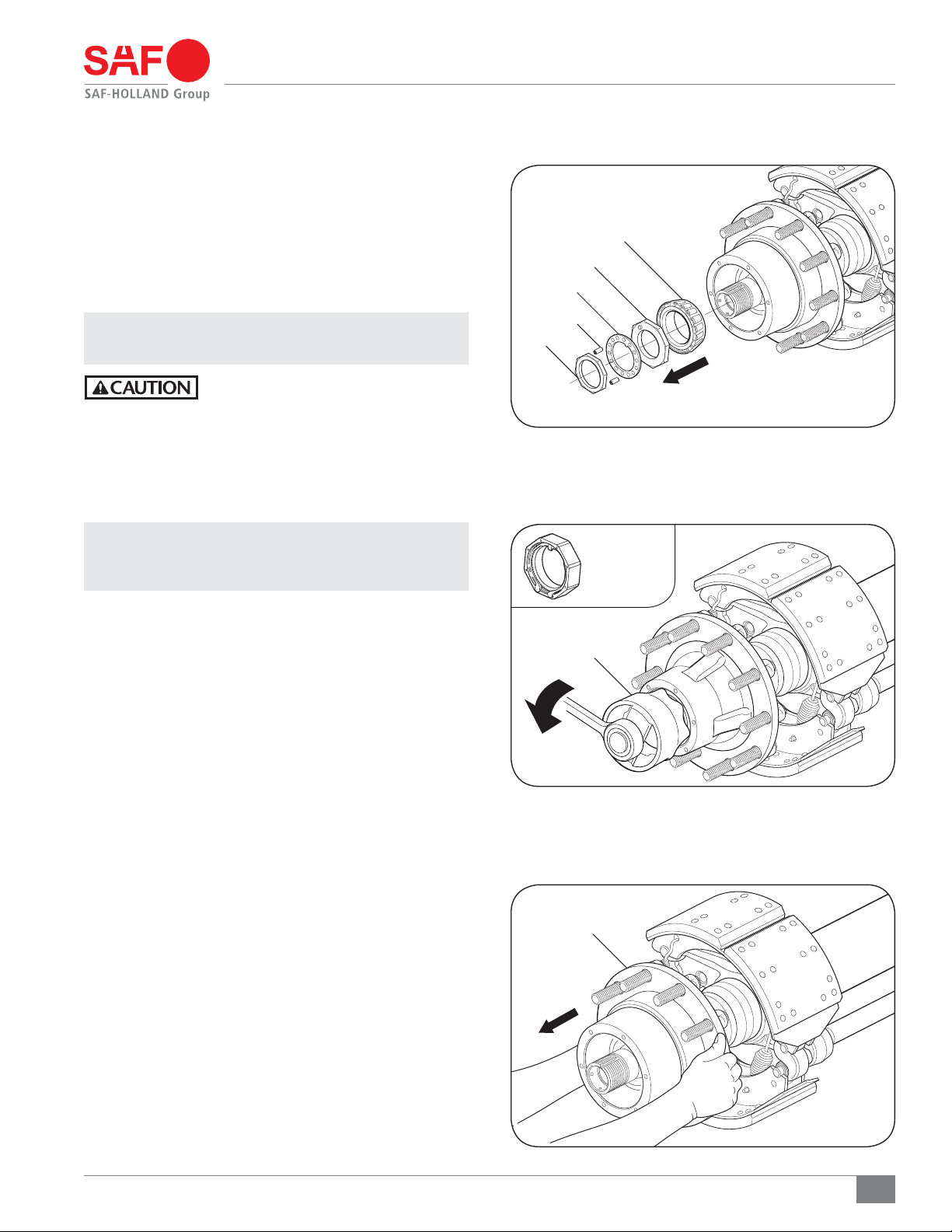

Hubs, Bearings, and Seal Components

4. Remove set screws (Figure 5).

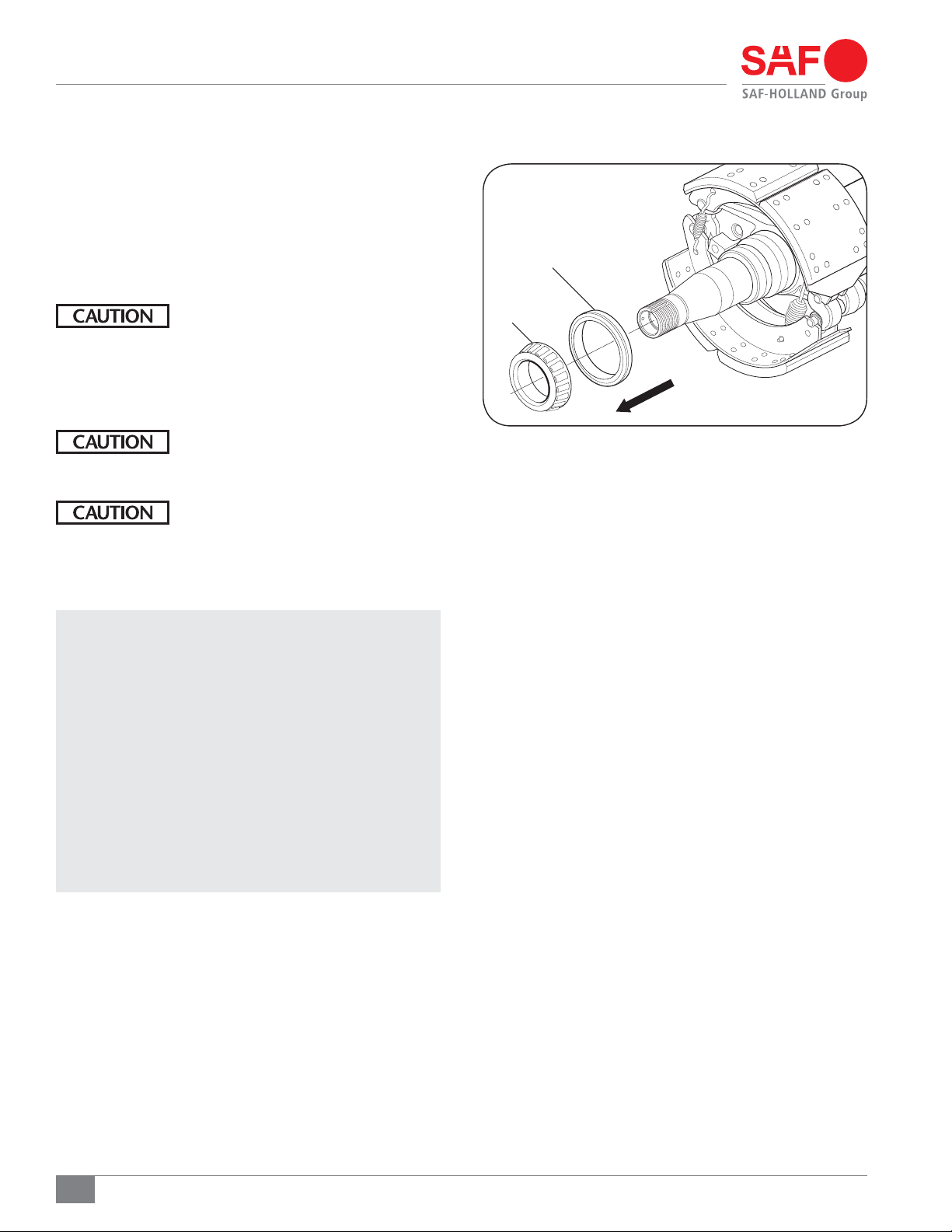

5. Remove the axle nut from the spindle using a wrench

with the axle nut socket. If the unit is equipped with

®

a Pro-Torq

(Figure

spindle nut, remove nut and skip Step 5.

6).

6. Release the axle washer and inner axle nut from the

spindle (Figure 6).

7. Remove the outer hub bearing from the spindle (Figure 6).

NOTE: With axle nut, washer, and inner nut removed, it is

possible to access the outer bearing.

DO NOT hit steel parts with a steel

hammer as parts could break, sending

flying steel fragments in any direction

creating a hazard which, if not avoided,

could result in minor to moderate injury.

8. Grasp the hub assembly with both hands and pull the

hub assembly off the axle spindle (Figure 7).

NOTE: Depending on the type of hub seal, the hub seal

and inner bearing could remain on spindle or come

off with hub assembly.

Figure 5

OUTER HUB BEARING

INNER AXLE NUT

AXLE WASHER

SET SCREWS

AXLE NUT

3-PIECE SPINDLE NUT SHOWN

Figure 6

PRO-TORQ®

SPINDLE NUT

AXLE NUT

SOCKET

Figure 7

HUB ASSEMBLY

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

9

Hubs, Bearings, and Seal Components

the inside of the hub (Figure 8).

10. Remove the hub seal from the hub bore using a pry bar.

A spindle mount hub seal can be driven off the spindle by

striking the ring from the back side or prying off with a

crow’s foot bar. Discard the used hub seal and use a new

hub seal during re-assembly being careful not to gouge

the spindle shoulder (Figure 8).

DO NOT use a chisel to cut the seal. The

shoulder can be damaged, resulting in

a leak which could lead to wheel end

and/or brake failure.

5. Bearing Inspection

Thoroughly clean bearings. DO NOT mix

a synthetic base grease or oil with an

organic/mineral base lubricant.

DO NOT spin dry hub bearings with

compressed air. Bearing damage

could result.

Figure 8 9. Remove the inner hub bearing from the spindle or from

HUB SEAL

INNER HUB

BEARING

1. After removing the hub assembly, clean excess grease

from the bearings.

IMPORTANT: A bearing which has been removed from

a vehicle should be cleaned with solvent.

When cleaning DO NOT use steam or water

which will cause bearings to rust.

IMPORTANT: Bearings that are rusted, flaked, pitted, or

have damaged cages should be replaced. It

is recommended to replace all questionable

bearings and ALWAYS replace the cup and

cone as a matched set. NEVER re-assemble

a tapered roller bearing in a damaged or

worn housing or on damaged or worn

spindles. Housings or spindles should

be replaced and NOT re-machined if the

bearing journal is worn.

10

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Hubs, Bearings, and Seal Components

6. Hubs, Bearings and Seal Installation

6.1. Spindle mounted Hub Seal Installation

instructions. (Refer to 8.2. for hub

mounted Hub Seal instructions).

1. Before installing the hub seal on the axle spindle, inspect

the machined spindle seal surface for nicks, scratches,

burrs or marks. If needed, use crocus cloth or emery cloth

to repair any damaged areas.

2. Clean the threads and keyway thoroughly with a wire

brush to avoid false bearing adjustments and to avoid

introduction of contaminants into the lubricant cavity.

3. Thoroughly clean the spindle and spindle threads of rust,

dirt, grease or any other contaminants that could damage

the hub seal and cause it to leak.

NEVER install a spindle mounted hub

seal in the hub and then force it onto the

axle spindle by tightening the axle nut.

Damage to seal will result.

4. The seal assembly should be placed on the spindle so the

words “Oil Bearing Side” are exposed to the oil (Figure 9).

5. Drive the hub seal into place using the seal installation

tool and hammer. Rotate the hub seal installation tool in

1/4-turn intervals with every hammer tap until the seal is

properly seated with the metal face of the seal flush with

the inner shoulder of the axle spindle (Figure 10).

6. Apply a thin coat of oil to the O.D. of the seal.

7. Prepare the hub. Remove the old lube and thoroughly

clean the hub cavity and hub bore. Inspect the inner hub

bore for roughness. If needed, use emery cloth to remove

any burrs or old bore sealant.

Figure 9

AXLE SPINDLE

INNER SHOULDER

KEYWAY

HUB SEAL

Figure 10

HUB SEAL

INSTALLATION TOOL

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

11

Hubs, Bearings, and Seal Components

8. Install the inner and outer bearing cups into hub (Figure 11).

9. Pre-lube the inner bearing with the lubricant that is

being retained and place it into the hub.

Failure to lubricate bearing correctly and

maintain proper lubrication could result

in bearing damage.

NOTE:

If using grease and not oil for hub lubrication, the

inner and outer bearing, and the hub cavity MUST be

pre-packed with grease before installation. Lubricate

wheel end components with grease specified in

lubrication table in Section 21.

10. Push the hub onto the spindle until it contacts the seal.

Pre-lube the outer bearing with the lubricant that is

being retained and place it into the hub.

Support the hub against the spindle inner

shoulder until the outer bearing and

adjusting nut are installed. DO NOT ram

the hub into the bearing shoulder, which,

if not avoided could damage the hub seal.

6.2. Hub Mounted Hub Seal

Installation Instructions

1. Remove all burrs from the hub bore and spindle.

Thoroughly clean hub cavity and spindle.

2. Place the hub on a smooth, hard surface in a horizontal

position. Pre-lube the inner bearing with the lubricant

that is being retained and place it into the hub bearing

cup (Figure 12).

Figure 11

INNER BEARING

HUB

OUTER

BEARING CUP

INNER

BEARING CUP

Figure 12

INNER

BEARING

HUB BEARING CUP

HUB

NOTE: When using grease, pre-pack the inner bearing

before placement into the hub.

3. With the correct head on the hub seal installation tool,

place the hub seal on the installation tool, so that the

words “Lube Side” face the inner bearing. Place the tool

(with the seal correctly mounted in the tool head) into

the hub bore. Use a three to five pound hammer to drive

against the end of the tool. Drive seal into bore until

complete bottoming is assured (Figure 13). Remove

Installation Tool and apply a thin layer of lubricant on

the I.D. surface of the seal. Ensure the inner bearing

rotates freely. Install a new seal if the seal is crooked or

damaged or after installation.

NOTE: DO NOT apply lubricant to the O.D. of the seal.

12

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

Figure 13

HUB SEAL

INSTALLATION

TOOL

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Hubs, Bearings, and Seal Components

4. Align the hub bore to the center of spindle with mechanical

supports. Gently push the hub assembly onto the spindle

until the seal is seated against the bearing shoulder. Rotate

the hub and lightly strike to ensure that the seal is properly

seated against bearing shoulder.

5. Pre-lube the outer bearing with the lubricant that is being

retained and place into the hub.

NOTE: When using grease, pre-pack the hub cavity. The

grease fill amount should be to a three o’clock

and nine o’clock level. This is to ensure a 50% hub

cavity fill. Use a template to hold grease in place

while filling the hub cavity (Figure 14).

7. Hub Bearing Adjustment

7.1. Hub Bearing Adjustment

Using 3-Piece Axle Nut

1. Install the bearing inner-axle adjustment nut finger tight

against the outer bearing (Figure 15).

2. While rotating the hub assembly, tighten the inner axle

adjustment nut to 200 ft.-lbs. (271 N•m).

3. Back off the inner axle adjustment nut one full turn and

then re-torque nut to 50 ft.-lbs. (68 N•m) while rotating

the hub assembly.

4. Back off inner axle nut approximately 1/4 turn and install

the axle lock washer (Figure 16). DO NOT include

socket backlash in the 1/4 turn.

5. Install the lock washer. If the hole in the washer is not

aligned with the pin on the inner nut, turn the washer

around and re-install. If the pin and hole are still not

aligned, slightly adjust parts as needed.

6. Install the outer axle nut finger tight against the axle

lock washer (Figure 16).

7. Tighten the outer axle nut to 300-400 ft.-lbs. (406-541 N•m).

Figure 14

PRE-PACK

HUB CAVITY

WITH GREASE

PRE-PACK

OUTER BEARING

WITH GREASE

GREASE LEVEL

TEMPLATE

Figure 15

OUTER BEARING

INNER AXLE NUT

Figure 16

AXLE LOCK WASHER

OUTER AXLE NUT

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

13

Hubs, Bearings, and Seal Components

8. Check the wheel bearing end play as follows:

a. Attach the magnetic base of a dial indicator to

spindle. Touch dial indicator stem to hubcap gasket

face (Figure 17).

b. Reading Number One – Slightly rotate wheel-end

in both directions while pushing inward until dial

indicator does not change. Set the dial indicator to

zero (Figure 17).

c. Reading Number Two − Slightly rotate hub in both

directions while pulling outward until dial indicator

does not change (Figure 17).

d. End play is the difference between reading number

one and reading number two.

IMPORTANT: Final adjustment should allow the wheel to

rotate freely with 0.001" to 0.005" (0.025

mm to 0.0127 mm) end play. If end play is not

within specification, re-adjustment is required.

Failure to maintain proper hub bearing

adjustment could allow bearing failure

and wheel-end separation which, if not

avoided, could result in death or serious injury.

Figure 17

HUB ASSEMBLY

DIAL INDICATOR

Figure 18

NOTE: If wheel bearing end play needs adjustment,

remove outer nut and lock washer. Tighten or

loosen inner nut as needed. Return to Step 6.

9. Install

set screw into an accessible threaded hole in the

lock washer. Set screw MUST contact the inner adjusting

nut. Tighten to 16-20 in.-lbs. (1.8-2.2 N•m) (Figure 19).

7.2. Hub Bearing Adjustment

Using Pro-Torq

The unit could be equipped with a Pro-Torq® spindle nut

(Figure 18). Refer to Stemco® “Pro-Torq® Installation

Instructions” (Part No. 09-571-006) which can be found

at www.stemco.com for more information.

®

Axle Nut

PRO-TORQ®

SPINDLE NUT

Figure 19

OUTER HUB BEARING

INNER AXLE NUT

AXLE WASHER

SET SCREWS

AXLE NUT

14

3-PIECE SPINDLE NUT SHOWN

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Hubs Cap Installation

O

I

L

L

E

V

E

L

O

I

L

L

E

V

E

L

F

U

L

L

A

D

D

F

U

L

L

A

D

D

8. Hub Cap Installation

1. Install the hub cap assembly, making sure the hub cap

gasket is in place (Figure 20).

When installing hub cap, make sure the

hub cap gasket is not bent or damaged.

DO NOT over torque. This can crush

the hub cap gasket and cause a leak.

2. Install the six (6) bolts to secure the hub cap assembly

(Figure 18). Tighten bolts to 12-16 ft.-lbs. (16-21 N•m).

9. Filling Hub With Lubricant (Oil Based)

IMPORTANT: DO NOT mix oil lubricant with grease

lubricant. If your bearing assembly has been

lubricated with grease DO NOT add oil.

Failure to correctly lubricate bearings could

damage bearings which, if not avoided,

could result in death or serious injury.

1. Remove plug and fill the hub to the FULL mark with

the specified lubricant (oil), through the hole in the

hub cap (Figure 21).

2. Allow the oil to flow through the bearings and level off.

3. Insert the plug into the hole in the hub cap (Figure 22).

Figure 20

HUB CAP GASKET

HUB CAP

BOLTS (6)

Figure 21

IMPORTANT: Axles equipped with a centralized tire inflation

system MUST use a vented hub cap.

OIL FILL LEVEL

Figure 22

HUB CAP

PLUG

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

15

Retracting Brake Shoes or Brake adjuster Arm

drum dolly jack (Figure 23).

Failure to support weight during installation

or removal of brake drum could create a

crush hazard which, if not avoided, could

result in minor to moderate injury.

Failure to uncage spring brakes in accordance

with manufacturer’s instructions after

servicing is complete will prohibit proper

brake function which could result in

uneven brake system component wear.

10. Retracting the Brake Shoes or

Brake Adjuster Control Arm(s)

IMPORTANT: Refer to brake adjuster’s manufacturer’s

procedures for proper adjustment of the

brake adjusters.

Figure 234. Re-install drum on hub using support device such as a

Failure to operate with proper brake

adjuster position could render brakes

inoperable which, if not avoided, could

result in death or serious injury.

NOTE: When servicing the brakes, in some instances it

could be necessary to fully retract the brake shoes

in order to remove the brake drum.

NOTE: When removing the S-Camshaft, it is necessary to

retract the brake adjuster control arm(s) from the

clevis so the brake adjuster can be removed from

the S-Cam shaft.

In both of the notes above, the brake shoes or the brake

adjuster control arm(s) are retracted by turning the adjusting

nut manually on the automatic brake adjuster.

16

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Brake Shoe Replacement

11. Brake Shoe Removal

NOTE: Before you begin any axle/brake service procedures,

park the vehicle on a level surface. Block the wheels

to prevent the vehicle from moving. Support the

vehicle and axle(s) with safety stands. DO NOT work

under a vehicle supported only by jacks. Jacks can

slip or fall over. Serious personal injury and damage

to components can result.

Failure to properly support the vehicle and

axles prior to commencing work could

create a crush hazard which, if not avoided,

could result in death or serious injury.

1. Release trailer brakes and cage spring brakes according

to spring brake manufacturer’s instructions. Remove tire

and wheel assembly to access hub and drum.

2. Remove drum from hub using support device such as a

drum dolly (Figure 24).

Failure to support weight during installation

or removal of brake drum could create a

crush hazard which, if not avoided, could

result in minor to moderate injury.

Figure 24

Figure 25

NOTE: It is necessary to retract brake shoes in accordance

with brake adjuster’s manufacturer’s manual to

allow brake drum to clear brake shoes during

brake drum removal.

3. Using the brake spring pliers, unhook both brake

retaining springs from the brake shoes (Figure 25).

4. Press down on the lower brake shoe to disengage it

from the anchor pin. Move the lower shoe to the side

of the anchor bracket and lift the upper and lower shoes

(still connected by brake return spring) from the anchor

pins (Figure 26).

IMPORTANT: The brake return spring, brake shoe rollers

and roller retaining clips will remain on

the brake shoes during this procedure.

RETAINING SPRING

BRAKE SPRING PLIERS

Figure 26

UPPER BRAKE SHOE

ANCHOR PINS

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

LOWER BRAKE SHOE

17

Brake Shoe Replacement

5. Discard the used brake hardware.

IMPORTANT: Brake hardware such as brake rollers,

roller retaining clips and brake return

springs experience fatigue during their

normal lifespan and could not have the

same performance characteristics as

new components. Since most of these

brake components are supplied new

with the brake overhaul kit, the existing

components should not be re-used.

6. With the brake shoes off, inspect the S-Camshaft and

S-Camshaft bushings for wear. Verify that S-Cam-to-bushing

radial free play is within specification by using a dial

indicator and moving S-Camshaft back and forth.

(Figure 27) Rotate the S-Camshaft in all directions

when checking for radial free play.

NOTE: Use a dial indicator to verify that S-Cam-to-bushing

free play is 0.030" (0.76 mm) or less.

If radial free play is less than 0.030" (0.76 mm):

DO NOT replace the bushings and seals.

If radial free play is more than 0.030" (0.76 mm):

Replace the bushings and seals.

7. Inspect brake shoes and components for wear:

a. Inspect the spider for expanded anchor pin holes and

for cracks. Brake spiders cannot be repaired and must

be replaced with new axle assembly.

b. Inspect the S-Camshaft bracket for broken welds, cracks

and correct alignment. Replace damaged brackets.

c. Inspect the anchor pins for corrosion and wear.

Replace worn or damaged anchor pins.

Figure 27

Figure 28

WEAR LIMIT

mm)

1/4" (6

MINIMUM

S-CAMSHAFT

DIAL INDICATOR

S-CAM ENDANCHOR PIN END

NOTE: Follow brake shoe manufacturer specifications

for minimum brake shoe thickness and maximum

brake drum inner diameter. A general guideline for

replacing brake shoes is when the lining thickness

is 1/4" (6 mm) or less, or when the lining rivets

have begun to contact the drum (Figure 28).

Failure to replace brake shoes that are

excessively worn could result in damage

to brake drum or other components

d. Inspect the brake shoes for wear, expanded rivet holes,

broken welds and correct alignment. Replace shoes as

a set with any of the above conditions.

18

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Brake Shoe Replacement

8. Inspect brake drums for wear.

DO NOT operate the vehicle with the

brake drum worn or machined beyond

the discard dimension indicated by the

drum manufacturer. The brake system

could not operate correctly. Damage

to components, death or serious injury,

could result.

Replace the brake drum if it is out-of-round.

DO NOT turn or re-bore a brake drum

beyond manufacturers recommendations.

Doing so could decrease the strength and

capacity of the drum which, if not avoided,

could result in brake component damage.

a. Inspect the brake drums for cracks, severe heat checking,

heat spotting, scoring, pitting and distortion. Replace

drums as required.

b. Measure the inside diameter of the drum in several

locations with a drum caliper or internal micrometer

(Figure 29).

c. If brake drum is excessively worn or out of round

replace brake drum.

Failure to replace an out of round brake

drum could result in damage to brake

drum or other components.

Figure 29

MEASURE INNER DRUM

DIAMETER TO DETERMINE

WEAR AND OUT OF ROUND

IN ACCORDANCE WITH BRAKE

DRUM MANUFACTER’S MANUAL.

Figure 30

BRAKE SHOE ROLLER

RIBS

12. Brake Shoe Installation

1. Install the brake shoe roller into the roller retainer

(Figure 30).

2. Install the roller and roller retainer into the brake shoe

ribs (Figure 30).

3. Coat anchor pins (ends only) completely with lubricant

(Never-Seez

spider (Figure 31).

®

) and install (if removed) in the brake

ROLLER

RETAINER

Figure 31

ANCHOR PINS

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

19

Brake Shoe Replacement

4. Install return spring pin into brake shoe ribs (Figure 32).

5. Connect the hub/drum return spring to the upper and

lower brake shoes (Figure 33).

6. Position the roller of the upper brake shoe up against the

S-Cam, then place the other end of the shoe against the

anchor pin (Figure 34).

Failure to control spring pressure during

brake shoe installation could create a

pinch hazard which, if not avoided, could

result in minor to moderate injury.

Figure 32

RETURN SPRING PIN

Figure 33

HUB/DRUM

RETURN SPRING

20

Figure 34

UPPER BRAKE SHOE

S-CAM

ANCHOR PINS

LOWER BRAKE SHOE

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Brake Shoe Replacement

7. Position the roller of the lower brake shoe up against the

S-Cam, then place the other end of the shoe against the

anchor pin (Figure 35).

8. Install the two (2) brake anchor pin springs using the

anchor pin pliers (Figure 36).

9. Make sure the brake linings are clean.

10. Re-install drum using support device such as a drum dolly

jack (Figure 37).

Failure to support weight during installation

or removal of brake drum could create a

crush hazard which, if not avoided, could

result in minor to moderate injury.

11. Adjust the brakes as described in Section 17.

Figure 35

UPPER BRAKE SHOE

S-CAM

ANCHOR PINS

LOWER BRAKE SHOE

Figure 36

Figure 37

SPRING PLIERS

BRAKE ANCHOR PIN SPRING

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

21

Brake Adjuster Replacement

13. Brake Adjuster Removal

NOTE: Maintenance procedures in this section require

re-positioning of the brake adjuster. Consult the

manufacturer’s manual for procedures to properly

operate brake adjusters.

1. Remove the cotter pins that secure the brake adjuster/brake

chamber clevis pins (Figure 38). Remove the clevis pins.

2. Remove the retaining ring and washer that secure the

brake adjuster to the S-Camshaft (Figure 39).

3. Remove the self-adjusting brake adjuster from the spline

end of the brake S-Camshaft.

4. Rotate adjusting mechanism to back the brake adjuster

out of the clevis in accordance with brake adjusters

manual.

14. Brake Adjuster Installation

1. Apply an even coat of anti-seize compound to splined

surface of S-Camshaft.

2. Position the spacing washers on both sides of the brake

adjuster, then install the brake adjuster onto the S-Camshaft

spline and secure the brake adjuster on the S-Camshaft

by assembling the retaining ring (Figure 40).

3. Align the brake adjuster to the clevis and pin together

using the clevis pins and cotter pins (Figure 38).

4. Apply service and spring brake several times. Final

brake adjustment is required to ensure proper initial

brake operation. The brake adjuster will then seek

the proper working stroke during normal operating

conditions. Refer to brake adjuster and brake chamber

manufacturers' procedures for proper adjustment.

Figure 38

CLEVIS PINS

Figure 39

S-CAM SPLINE

CLEVIS PINS

SPACING WASHERS

CLEVIS

BRAKE ADJUSTER

BRAKE ADJUSTER

COTTER PINS

RETAINING RING

COTTER PINS

22

Figure 40

BRAKE ADJUSTMENT NUTBRAKE CHAMBER

CLEVIS

PUSH ROD JAM NUT

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

S-camshaft Replacement

15. S-Camshaft and Bearing

Removal Procedure

1. Remove the brake shoes and brake adjuster as described

in Section 11 and 13, respectively.

2. Remove the retaining ring from the spider end of the

S-Camshaft (Figures 41).

3. Remove the S-Camshaft by sliding it out of the S-Camshaft

bearing housing and bearings. It could be necessary to

tap the end of the shaft with a soft mallet to release it

from the bearings (Figure 41).

4. Remove existing bolts securing the S-Camshaft bearing

housing to the axle bracket (Figure 42).

5. Inspect bearings assembly for wear and deterioration.

Replace as necessary.

Figure 41

BRAKE SPIDER

RETAINING RING

Figure 42

S-CAMSHAFT BEARING HOUSING

AXLE BRACKET

S-CAMSHAFT

AXLE BRACKET

BOLTS (4)

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

23

S-camshaft Replacement

16. S-Camshaft and Bearing Installation

1. Attach the S-Cam bearing housing bracket to (Figure 43)

the axle bracket, securing it with the four (4) nuts and

bolts (Figure 44). Tighten the nuts to 15-22 ft.-lbs.

(20-30 N•m).

2. Install the S-Camshaft bearing into the brake spider,

ensuring that the bearing is centered (Figure 45).

Failure to center S-Camshaft bearing into

the brake spider could not allow grease

flow to bearing which, if not avoided,

could result in premature bearing failure.

3. Install the guide plate, brake roller shoe and cam seal

on the S-Camshaft and slide S-Camshaft and washer

assembly through the S-Camshaft bearing in the brake

spider (Figure 45).

Figure 43

S-CAMSHAFT

BEARING HOUSING

Figure 44

S-CAMSHAFT BEARING HOUSING

AXLE BRACKET

Figure 45

BOLTS (4)

SPIDER GREASE FITTING

NUTS (4)

S-CAM BEARING

CAM SEAL

GUIDE PLATE, BRAKE ROLLER SHOE

S-CAMSHAFT

24

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

S-camshaft Replacement

5. Install the cam seal washer and retaining ring onto

S-Camshaft and slide S-Camshaft into the S-Camshaft

bearing housing bracket (Figure 46).

6. Install the brake shoes and brake adjusters as described

in Section 12 and 14, respectively.

7. Inspect S-Camshaft installation to ensure that the correct

S-Camshaft has been installed on the required side of the

axle for proper operation (Figure 47).

Figure 46

HOUSING BRACKET

S-CAM BEARING

RETAINING RING

WASHER

CAM SEAL

BRAKE SPIDER

GUIDE PLATE, BRAKE ROLLER SHOE

S-CAMSHAFT

Figure 47

CORRECT S-CAMSHAFT INSTALLED

WHEEL ROTATION

INCORRECT S-CAMSHAFT INSTALLED

WHEEL ROTATION

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

S-CAM ROTATION

S-CAM ROTATION

25

Brake Adjustment

8. Lubricate the S-Camshaft bearings with grease specified

in the Lubrication Table in Section 21 (Figure 48).

17. Brake Adjustment Procedure

1. Verify that the spring brakes are caged prior to beginning

adjustment procedure.

2. Adjust the brake adjuster until the brake lining contacts

the brake drum, then back off 1/2 turn.

3. Apply the service brakes using normal operating pressure

(average line pressure should be 90 psi, but not less than

80 psi). Check the following while brake pressure is applied.

• The optimum distance of push rod travel should be

approximately 1.5"-1.75" (38-44 mm) (Figure 49).

• Angle between the push rod and the brake adjuster

with brake applied, should be

• Brake lining to drum contact. A 0.010" feeler gauge

should not fit between the lining and the drum

contact area.

4. Release the air pressure from the service brake system

and check to see that all brakes release to the normal

relaxed position. If all brakes do not properly release, Refer

to Troubleshooting Chart in Section 22.

Failure to adjust brakes in accordance

with manufacturer’s instructions prior

to placing trailer back in service will

prohibit proper brake function which,

if not avoided, could result in uneven

brake system component wear.

95°-100° (Figure 50).

Figure 48

S-CAMSHAFT LUBRICATION

FITTING LOCATIONS

BRAKE ADJUSTER

S-CAMSHAFT

S-CAM BEARING HOUSING

Figure 49

5. Uncage spring brakes

Failure to uncage spring brakes in

accordance with manufacturers's

instructions after servicing is complete

will prohibit proper brake function which,

if not avoided, could result in death or

serious injury.

26

.

OPTIMUM PUSH ROD TRAVEL APPROX. 1.75"-2.0" (38-44

mm)

Figure 50

95-100O

O

95-100

(WITH BRAKES APPLIED)

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

ABS Sensor Replacement

18. ABS Sensor Replacement Procedure

18.1 Sensor Removal

NOTE: ABS sensors MUST match the system. DO NOT mix

sensors from different manufacturers.

1. Manually release the brakes.

2. Remove brake drum assembly as described in Section 4.

3. Disconnect the ABS sensor connector and remove the

sensor from the sensor holder by pulling straight out

(Figure 51).

4. Remove the sensor retaining spring clip, if necessary.

18.2 Sensor Installation

NOTE: Be sure to use the correct spring clip for the sensor

being installed.

1. Install the sensor retaining spring clip, if removed, into

the sensor holder.

2. Install the ABS sensor into the spring clip and sensor

holder. Push the sensor in until it contacts the tone ring

(Figure 52).

3. Connect the ABS sensor connector.

4. Re-install drum using support device such as a drum dolly

jack (Figure 37).

5. Adjust brakes as described in Section 17.

Figure 51

Figure 52

ABS SENSOR

CONNECTOR

ABS SENSOR

CONNECTOR

SPRING CLIP

ABS SENSOR

HOLDER

ABS SENSOR

HOLDER

19. Axle Alignment Inspection

NOTE: Alignment can be achieved using an optical device

designed specifically for this purpose. Follow

the instructions in the optical device operating

instructions to align the axles.

1. To manually align the axles attached to your trailer, first

pull the trailer in a straight line for a sufficient distance

to release/clear any binds in the suspension.

NOTE: A straight, unbound suspension is the position of

a suspension during normal operations.

Using the alignment procedures per the suspension

manufactuer’s recommendations, align the axles to the

following specifications.

2. Measure the distance from the king pin to the centerline

of the spindles on each side of the front axle. Dimensions

A and B MUST be equal to within 1/8" (4 mm) (Figure

53, A and B).

3. Measure the distance from the centerline of the spindles

of the front axle to the centerline of the spindles of each

additional axle. Dimension C and D must be equal to

within 1/16" (1 mm) (Figure 53, C and D).

Figure 53

KING PIN

A=B

C=D

A

B

D

C

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

27

Routine Service Schedule

20. Routine Service Schedule

WHICHEVER OCCURS FIRST PERIODIC CHECKS

AFTER FIRST

MILEAGE INTERVALS

TIME INTERVALS

VISUAL INSPECTION FOR WEAR/DAMAGE

Check brake linings for wear. • •

Check S-Camshaft for proper operation. • •

Check brake adjusters for correct function. • •

Check air brake system for leaks (brake applied). • •

Check axle structural components for cracks or damage. • •

Check hub lubrication level for excessive leakage. • •

MECHANICAL

Attention: Torque check wheel nuts after the first thirty

(30) miles (50 km) and 100 miles (150 km) (repeat also

after every wheel removal). •

Torque check all nuts and bolts to recommended setting. • •

Check and adjust wheel bearing end play. • •

Pack hub bearings with fresh lubricant (also after every

brake lining replacement, check hub bearing wear). •

Lubricate S-Camshaft bearing bushings. • •

SAFETY INSPECTION

Check brake lining to drum clearance for correct

adjustment – re-adjust clearance if necessary. Check

service brake and parking brake for performance. • •

CHECK

3,000 MILES

AFTER FIRST

MONTH EVERY MONTH EVERY 6 MONTHS EVERY 12 MONTHS

EVERY 10,000

MILES

EVERY 50,000

MILES

EVERY 100,000

MILES

SPECIAL SERVICE CONDITIONS

Service at specified time intervals, e.g. trailer used for storage or frequently left standing for

Vehicles with long standing periods.

Vehicles used under extreme conditions.

Warranty claims will only be accepted as long as the operation and maintenance instructions have been complied with and if SAF-HOLLAND approved spare parts have been fitted.

several days at a time.

Service at suitably reduced intervals, e.g. trailer operating in continuous multi-shifts or in

off-road construction sites.

28

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

21. Torque and Lubrication Specifications

Torque and Lubrication

TORQUE SPECIFICATIONS

COMPONENT TORQUE VALUE

Grease Fitting, Spider 20-50 in-lbs (2-6 N•m)

Axle, Inner Nut Refer to Section 7

Axle, Outer Nut 300-400 ft.-lbs. (406-542 N•m)

Air Chamber Nuts 80-125 ft.-lbs. (108-169 N•m)

Hubcap Bolts 12-16 ft.-lbs. (16-21 N•m)

Self-Threading Screw 15-22 ft.-lbs. (20-30 N•m)

LUBRICATION SPECIFICATION

COMPONENT SURFACE TO BE LUBRICATED TORQUE VALUE

S-Camshafts

S-Camshaft Bearings (Four

(4) Grease Fittings per Axle)

Lithium Complex

Grease

S-Camshafts S-Camshaft Spline NeverSeez

Brakes

Brakes − Brake

Adjuster

Brake Shoe Rollers anchor Pins

Brake Adjuster

Grease Fitting

NeverSeez

Lithium Complex

Grease

80/90 Gear Oil or

Lithium Complex

Axle Bearings and Hubs

* Oil lubed bearings and hubs should remain lubricated with oil, grease lubed

bearings and hubs should remain lubricated with grease.

NOTE: Intervals are based upon normal operations. Reduce intervals to

compensate for abnormal operations or severe conditions. During

inactive periods, sufficient lubrication must be performed for

equipment preservation.

Grease*

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

29

Troubleshooting

22. Troubleshooting Chart

PROBLEM POSSIBLE CAUSE RESOLUTION

Brake shoes bound up at anchor pins Lubricate brake operating parts

Brake hoses Restricted Replace hoses

Brakes out of adjustment Adjust brakes

Brakes will not release

No brakes or insufficient brakes

(NOTE: All of the possible causes would result

in brake lockup.)

Dog tracking

Uneven tire wear

Grabbing brakes

Excessive heat cracks on drum

ABS inoperable Refer to ABS manufacturer’s service literature

Slow brake application or release

Damaged brake assembly Replace or repair as required

Open cutout cocks at rear of tractor cab or push

Source of air supply shut off at tractor

Low brake line pressure Check air pressure gauge on tractor - inoperative

Brake lines between tractor and trailer not

properly coupled Properly couple brake lines

Reservoir drain cock open Close drain cock

Leaf spring broken Replace complete spring

Bent Axle Replace or straighten axle

Frame or suspension out of alignment Straighten frame or align axles

Over or under inflation Inflate to proper pressure

Loose wheel stud nuts or clamps Tighten wheel stud nuts or clamps

Loose or tight wheel bearing adjustment Adjust bearings

Axle bent or out of alignment Straighten, align or replace axle

Tires not properly matched Match tires

Improper acting brakes Correct brakes as required

Rapid Stopping Apply brakes slowly when approaching stop

High-speed driving on turns Reduce speed

Oil, grease or foreign material on brake lining Reline brakes

Brakes out of alignment Adjust brakes

Brake drum out-of-round Replace brake drum

Damaged brake chamber or internal assembly Replace brake chamber/internal assembly

Leaky or broken hose between relay valve and

brake chamber Replace or Repair as required

Rapid stopping or poor air flow to brakes Replace drum

Out of adjustment Adjust brakes

Binding S-Cam, anchor pins or chamber rod end pin Lubricate and free up

Damaged brake assembly/brake drum out-of-round Replace or repair as required

Lack of lubrication Lubricate brake operating parts

Excessive travel in brake chamber push rod Adjust brakes

Restiction in hose or lines Replace hoses

Defective brake valve Replace brake valve

control valve “IN”

30

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Notes

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

31

From fifth wheel rebuild kits to suspension bushing repair kits,

SAF-HOLLAND Original Parts are the same quality components used

in the original component assembly.

SAF-HOLLAND Original Parts are tested and designed to provide

maximum performance and durability. Will-fits, look-alikes or, worse

yet, counterfeit parts will only limit the performance potential and

could possibly void SAF-HOLLAND’s warranty. Always be sure to spec

SAF-HOLLAND Original Parts when servicing your

SAF-HOLLAND product.

SAF-HOLLAND USA

www.safholland.us

SAF-HOLLAND CANADA

WESTERN CANADA

www.safholland.ca

SAF-HOLLAND MEXICO

www.safholland.com.mx

info@safholland.com

SAF-HOLLAND USA, INC.

1950 Industrial Blvd., Muskegon, MI 49442

www.safholland.com

888.396.6501

·

519.537.3494

·

604.574.7491

·

52.55.5362.8743

·

Fax 800.356.3929

·

Fax 800.565.7753

·

Fax 604.574.0244

·

Fax 52.55.5362.8743

·

XL-TA10006OM-en-US Rev B · 2014-03-13 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF, and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Loading...

Loading...