LANDING

OPERATING INSTRUCTIONS &

MAINTENANCE PROCEDURES

GEAR

Challenger Series - Model 50000

Contender Series - Model 51000

Fast Gear Series - FG4000

1XL-LG330-01 Rev. B

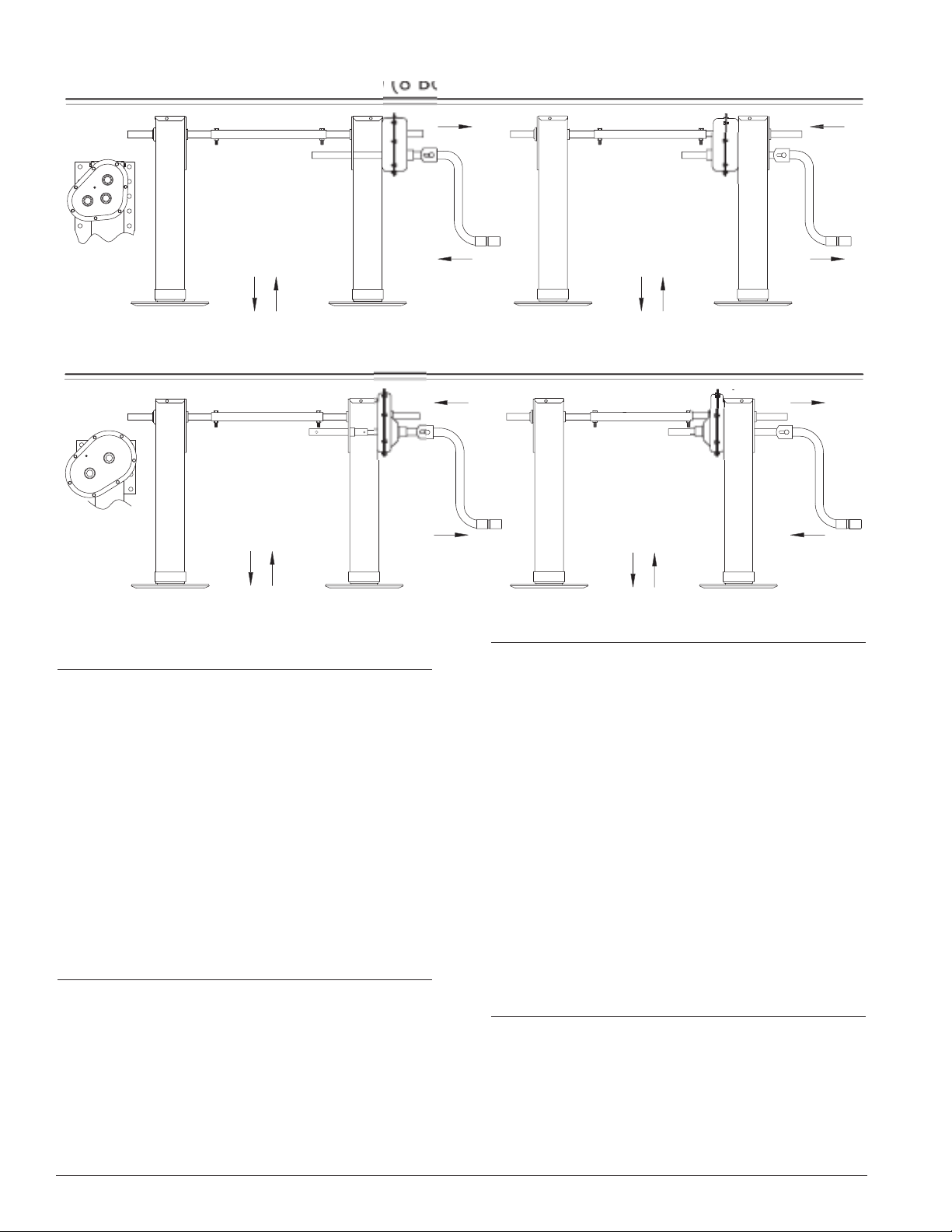

TO REMOVE TRACTOR

CONVENTONAL

PUSH CRANK IN FOR HIGH SPEED.

PULL CRANK OUT FOR LOW SPEED.

ROTATE CRANK COUNTERCLOCKWISE

TO EXTEND LANDING GEAR.

RO

TATE CRANK CLOCKWISE

T

O RETRACT LANDING GEAR.

CCW

CW

REVERSE

PULL CRANK OUT FOR HIGH SPEED.

PUSH CRANK IN FOR LOW SPEED

ROTATE CRANK CLOCKWISE

TO EXTEND LANDING GEAR.

RO

TATE CRANK COUNTERCLOCKWISE

T

O RETRACT LANDING GEAR.

HIGH

CW

LOW

HIGH

CCW

LOW

OPERATION

CONVENTONAL

PUSH CRANK IN FOR LOW SPEED.

PULL CRANK OUT FOR HIGH SPEED.

ROTATE CRANK CLOCKWISE

T

O EXTEND LANDING GEAR.

RO

TATE CRANK COUNTERCLOCKWISE

T

O RETRACT LANDING GEAR.

CW

CCW

HIGH

LOW

PULL CRANK OUT FOR LOW SPEED.

PUSH CRANK IN FOR HIGH SPEED

ROTATE CRANK COUNTERCLOCKWISE

T

O EXTEND LANDING GEAR.

RO

TATE CRANK CLOCKWISE

T

O RETRACT LANDING GEAR.

CWCCW

HIGH

LOW

OPERATION

Fast Gear

FROM TRAILER:

1. Position the trailer so that the landing gear

shoes will rest on a firm level surface when

landing gear is extended.

2. Shift landing gear to high gear and extend

landing gear until shoes contact ground.

3. Shift landing gear to low gear and lift trailer

approximately (1) inch.

4. Unlock fifth wheel, uncouple air lines, and

drive the tractor out from under the trailer.

LUBRICATION – STANDARD:

When manufactured, the landing gears have

been adequately greased with high quality

lubricant. It will be necessary to periodically

supplement this lubricant to maintain

satisfactory performance. Use a molybdenum

type grease with appropriate temperature

range for your operating conditions. Gearbox

leg has (3) grease fittings; leg without gearbox

has (2) gr

Prior to lubrication, extend legs approximately

1.

(2) inches fr

For optimum per

2.

lube both legs at all grease fittings.

ease fittings.

om maximum r

mance, ever

for

etracted position.

y (6) months

TO CONNECT TRACTOR

TO TRAILER:

1. Ensure that the trailer is at a sufficient height

to allow coupling of the tractor and trailer.

2. Connect air lines from tractor to trailer, then

lock trailer brakes and back tractor under

trailer, then lock fifth wheel.

3. Retract landing gears to fully retracted

position.

4. Store crank on the crank holder.

2

3. Add 1/4-lb grease at each grease fitting.

LUBRICATION – NoLube:

No additional grease is required.

XL-LG330-01 Rev. B

TROUBLE SHOOTING:

mal trailer operating service, certain components such as shafts, bushings, bearings, gears, and

In nor

screw and nut assemblies are subject to wear and will require replacement.

However, under extreme usage condition exceeding AAR-931 Durability Requirements the same

components may r

equire replacement more frequently.

Landing gears hard to crank–check the following:

PROBLEM SOLUTION

1. Cross driveshaft in a bind or tight Bolts must be loose and cross driveshaft free to

between shafts. move in slots provided.

2. To determine which leg turns hard Remove cross driveshaft bolt and crank each leg

on the jack shaft.

3. Inadequate lubrication. (See Lubrication Instructions).

4. Alignment. Legs must be timed together, parallel to each other

and perpendicular to the trailer crossmembers.

5. Upper housing or retracting tube may be bent. Replace damaged part.

6. Screw and nut assembly may have excessive Disassemble and inspect for wear. If screw and/or

wear and be hard to turn or inoperable. nut show considerable wear, then replace entire

retracting tube assembly.

7. Check for proper clearance between pinion Minimum end play 1/32˝.

and bevel gear.

8. Excessive wear or damage to pinion, bevel, Replace damaged gears.

input, idler and/or output gears.

9. Landing gear jack shafts and/or shift shaft Check to see if trailer mounting bracket has

binding. sufficient size clearance hole to miss landing gear

boss or shift shaft.

10. Bent retracting screw. Replace entire retracting tube assembly.

11. Damaged thrust bearing. Replace.

12. Damaged collar. Replace.

13. Damaged shift lock boss and/or shaft Replace.

bearing boss.

Weld blow through where strut bracket is Grind weld as required and re-weld.

14.

welded to housing. (With no-load on landing

gear, the retract tube should have free play

inside housing.)

15. Impact to jack shaft end has pressed bearing Press boss back into position.

boss into gearbox half.

Trouble Shooting/General:

1. Right-hand leg (gearbox leg) operates but Broken cross driveshaft bolt or damaged cross

left-hand leg does not move. driveshaft. Replace damaged part.

2. Legs will not operate when turning jack shaft. Damaged pinion or bevel gear. Replace damaged part.

3. Right-hand leg will not operate, shift shaft Damaged input, idler, and/or output gear. Replace

will turn but jack shaft does not turn. damaged part.

4. Leg locked and will not turn. Bent retracting screw or damaged riser nut and

screw. Replace entire retracting tube assembly.

5. Right-hand leg will not stay fully shifted in Shift lock ball and shift lock spring missing or

low gear. damaged shift lock spring. Replace missing or

damaged part.

6. Noisy gearbox. Check that shift shaft movement is 1˝ when shifted

between gears.

XL-LG330-01 Rev. B

3

CAUTIONS:

Landing gears are designed to meet T.T.M.A. recommended practice RP-4 and A.A.R.-931 requirements.

When operating the landing gears, it is necessary to observe some cautions. By doing so you will ensure long

ouble free service.

tr

Do not over extend or over retract landing gears.

1.

2. Never drop trailer on landing gears. Always extend landing gears until sand shoes

contact ground, then lift trailer approximately 1 inch before removing tractor

CAUTION

from trailer.

3. Always ensure that landing gear shoes or foot pads will rest on a hard ground

surface or concrete pad. If necessary, place shoes on a support plank to prevent

the landing gears from sinking into the ground surface. (This is especially

important with liquid cargo where a shift in the contents could overturn the

trailer!).

4. Always retract landing gears fully before moving the trailer.

5. Always store the crank on the crank holder after extending or retracting the

landing gear

.

6. Replace all damaged or missing parts.

7. Failure to replace worn or damaged riser nut and retracting screw assembly could

cause a failure.

1950 Industrial Blvd. • P.O. Box 425 • Muskegon, MI 49443-0425 • Phone 888-396-6501 • Fax 800-356-3929

Copyright © March 2005 • The Holland Group, Inc.

Holland USA, Inc. Facilities:

Dumas, AR Muskegon, MI

Holland, MI Warrenton, MO

Monroe, NC Wylie, TX

Ph: 888-396-6501 Fax: 800-356-3929

4

Holland International, Inc.

Holland, MI

Phone: 616-396-6501

Fax: 616-396-1511

HOLLAND USA, INC.

www.thehollandgroupinc.com

Holland Hitch of Canada, Ltd.

Woodstock, Ontario • Canada

Phone: 519-537-3494

Fax: 800-565-7753

Holland Equipment, Ltd.

Norwich, Ontario • Canada

Phone: 519-863-3414

Fax: 519-863-2398

Holland Hitch Western, Ltd.

Surrey, British Columbia • Canada

Phone: 604-574-7491

Fax: 604-574-0244

XL-LG330-01 Rev. B

Loading...

Loading...