FIFTH WHEEL

OWNER’S

MANUAL

FW35-S09623 Series

Fifth Wheel

Installation, Operation, Inspection,

Maintenance Procedures and

Comprehensive Warranty

TECHNOLOGY

XL-FW504 Rev A

Questions or Comments?

Call

www.thehollandgroupinc.com

FIFTH WHEELS

1-888-396-6501

INSTALLATION INSTRUCTIONS

General Safety Information

It is important to read, understand, and follow the important information contained in

these installation instructions. Failure to do so may result in a hazardous condition or

cause a hazardous condition to develop.

All welding should be performed by an AWS certified welder using a low hydrogen

process and AWS E70XX filler metal. Failure to weld correctly may cause distortion,

damage, and/or result in insufficient strength and subsequent joint failure which,

if not avoided, could result in death or serious injury.

Prior to welding take precautions to ensure that the tractor electrical system is not

damaged due to the welding process.

Safety Signal Words

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided,

1. Keep Work Area Clean. Cluttered areas and benches invite accidents.

2. Keep fingers away from all potential pinch points in the fifth wheel.

3. All fifth wheel maintenance must be performed by a qualified service technician

using proper tools and safe procedures.

4. Use only genuine Holland parts.

Use Safety Goggles. Glasses or goggles not in compliance with ANSI or CSA can

5.

cause serious injury when damaged or broken.

Wear Proper Apparel. Do not wear loose clothing, gloves, neckties, jewelry (rings,

6.

wristwatches, etc.) that can get caught in moving parts. Non-slip footwear is

recommended.

may result in property damage.

Fifth Wheel Design and Intended Use:

1. For pulling trailers with standard SAE kingpins which are in good condition

and securely mounted or locked in position in the trailer.

2. For on-highway hauling applications.

3. Within the capacities stated in Holland literature.

4. As recommended in Holland literature (available from Holland or Holland

distributors).

Holland Fifth Wheels are NOT Designed or Intended For:

1. Use with non-SAE kingpins, such as kingpins which are bent, improper size or

dimensions, not secured to maintain SAE configuration, or which are installed in

warped trailer bolster plates.

2. Tow-away operations which damage or interfere with the proper operation of

the fifth wheel.

3. The attachment of lifting devices.

4. The transport of loads in excess of rated capacity.

5. Off-highway applications and use.

6. Applications other than recommended.

2

XL-FW504 Rev A

INSTALLATION INSTRUCTIONS

continued

Installation

General Recommendations

1. Every user and installer using Holland products either recommended or not recommended by

Holland, must thoroughly satisfy himself that the installation procedure used is appropriate

or the vehicle, product and application.

f

2. Consult the Holland literature for fifth wheel capacities and applications.

. Consult the tractor manufacturer’s body builder’s book and the latest SAE and D.O.T.

3

standards for additional installation methods. Holland recommends the

aintenance Practice 603Bfor installation procedures.

M

4. Determine the proper fifth wheel position, or, in the case of a sliding fifth wheel, the range of

proper positions. Proper positioning of the fifth wheel is important for weight distribution,

swing clearance and handling characteristics. See SAE J701a for proper placement, as well as

the tractor manufacturer’s body builder’s book.

5. Use Grade 8, 5/8˝ minimum diameter bolts and Grade “C” locknuts for mounting.

6. Bolt holes can be 1/32˝ larger in diameter than the bolt fastener. Bolts must be adequately

tightened using charted torque ranges in foot-pounds for the recommended Grade 8, 5/8˝

diameter bolts. Larger diameter Grade 8 bolts and coated fasteners may be used.

7. The bolts attaching the fifth wheel mounting angles to the truck frame require hardened

steel washers under both the bolt and under the locknut, unless flanged head bolts or

flanged head locknuts are employed.

8. A minimum of 5 bolts are required to attach each mounting angle to a frame rail, and the

distance between bolts must not exceed 8˝, except when cutouts are required in the

mounting angles.

9. Whenever a cutout is made on the mounting angle, such as required to bypass spring

hangers, a 1˝ minimum radius should be used and bolts should be placed within 1-1⁄2˝, but

not closer than 1˝ of the cut, fore and aft.

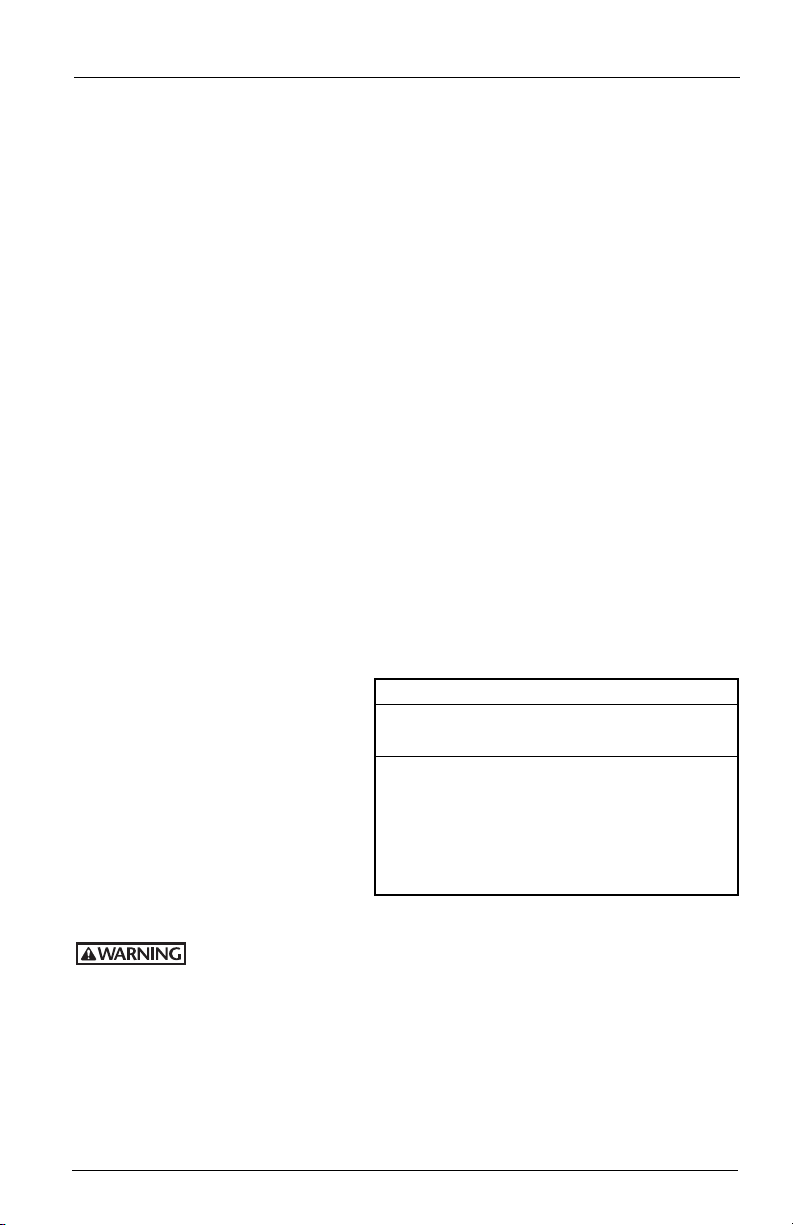

10. The mounting angle should have a minimum thickness as shown in

steel specification ASTM A 36.

11. When initially positioning the fifth wheel for frame holes, the full length of the fifth wheel or

slider mounting angles should seat flush on the top and side surface of the truck-tractor

frame rails where channel-type rails

are employed. There should not be a

gap over the top of the truck frame

rails. The base of the fifth wheel

assembly and of the mounting angle

members should seat flush on the top

of the frame rail to prevent flexing

and to give uniform weight

distribution. It is also recommended

to chamfer or smooth sharp edges

and corners of mounting materials

wherever contact is made with the

tractor frame.

12. If the fifth wheel is to be mounted using a mounting plate (bracket with mounting base),

result in structural failure of the installation with a potential loss of the fifth wheel assembly,

mounting structure, and/or trailer and may result in death or serious injury.

13. Trailer pick-up ramps ar

14. When mounting to aluminum frames, follow the tractor manufactur

15. Review, in addition, the specific information on the following pages for each type of fifth

CHART 1 for minimum plate thickness recommendations.

refer to

Do not use U-bolts in fifth wheel installations. Use only new Grade 8 bolts and

new Grade C lock nuts, sized 5/8˝ minimum diameter. Failure to do so may

ecommended at the r

e r

Holland has available a stationary mounting angle intended for use with aluminum frames.

Contact Holland or Holland distributors for availability.

wheel mounting, as well as “

publication.

Inspection and Lubrication Prior to Use” on page 8 of this

Fifth Wheel Mounting Angle Mounting Plate

Vertical Capacity Thickness Thickness

12,000 lbs. 1/4˝ 1/4˝

20,000 lbs. 5/16˝ 1/4˝

40,000/45,000 lbs. 5/16˝ 5/16˝

50,000/55,000 lbs. 3/8˝ 3/8˝

62,500/70,000 lbs. 1/2˝ 1/2˝

100,000 lbs. 3/4˝ 3/4˝

165,000 lbs. 3/4˝ 1˝

ear of the tr

CHART 1

Minimum Minimum

uck-tractor frame.

T.M.C. Recommended

Chart 1 and should be

ecommendations.

s r

er’

XL-FW504 Rev A

3

INSTALLATION INSTRUCTIONS

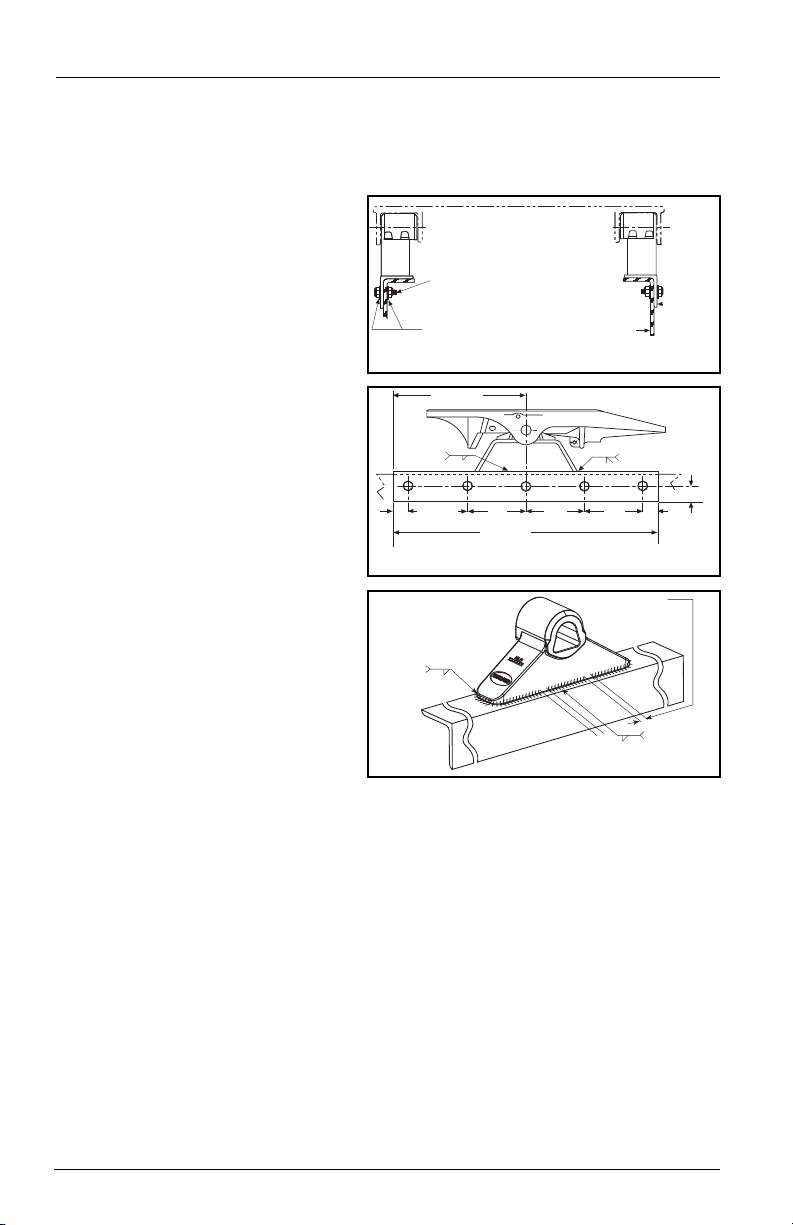

The full length of the fifth wheel mounting

angle should seat flush on the truck frame

when mounting to prevent flexing of

mounting angle and to give uniform

weight distribution along truck frame rail.

5/8˝ diameter Grade 8 bolts minimum size,

tightening torque to bolt manufacturer

c

harts.

Hardened steel washers or flanged lock

nuts (5/8˝ diameter Grade “C” lock nuts).

HDN. STEEL WASHERS

T

RUCK FRAME RAIL

See Chart 1

for minimum

mounting

angle

t

hickness

18.00˝ MIN.

3

6.00˝ MIN.

1

.00˝ MIN.

D

OUBLE PASS MIN.

BOTH ENDS

8.00˝ MAX. TYP.

(50.8mm)

2.00˝

(203.2mm)

1

/4˝

BOTH SIDES

8.00

˝

(

203.2mm)

(

203.2mm)

8

.00

˝

(

203.2mm)

8.00˝

(

914.4mm)

2.00˝

(

50.8mm)

1/2˝

(457.2 mm)

3

5

/1

6

GAP

1

/4˝-1/2˝ in 4 places

5

/16

Both ends

continuous

Both sides

center of

bracket

continued

Stationary Fifth Wheel Installation

Prior to proceeding with the installation of the stationary fifth wheel assembly, carefully

review the “General Safety Information” section on page 2.

Bracket with Mounting Angle

(see Figure 1A, 1B, and 1C):

1. Holland brackets with mounting

angle are provided with the bracket

welded in the center of a 36˝ long

angle with a 4˝ minimum

horizontal and 3-1/2˝ minimum

vertical leg size, and to a specific

tractor frame width. Verify that the

bracket and tractor frame width are

the same.

2. In addition to the information

given in “Installation: General

Recommendations” on page 3, follow

the recommendations in FIGURE 1.

Bracket for Angle Mounting

(see Figure 1A, 1B, and 1C):

1. Holland brackets for angle

mounting are intended to be

welded to mounting angles at the

time of installation.

2. See “Installation: General Recommen-

dations” on page 3, for angle

thickness and material (use 4˝

minimum horizontal and 3-1/2˝

minimum vertical leg size).

The recommended length of

each mounting angle is 36˝. It is

recommended that each angle

extend a minimum length of 18˝ forward of the fifth wheel pivot point, and not less

than 12˝ to the rear. If angles shorter than 36˝ are required, the special

recommendations of the tractor manufacturer should be obtained.

3. In addition to the information given in

follow the recommendations given in FIGURES 1A, 1B, and 1C. The following

sequence is suggested for both fabricated and cast brackets:

A. Securely position the mounting angle to the tractor frame.

B. Bolt the angles to the tractor as shown in FIGURES 1A and 1B.

C. Position the brackets on the angles and verify the correct spacing to mount

the fifth wheel.

D. For fabricated brackets (a welded asssembly), weld the bracket to the mounting

angle with 1/4˝ fillet welds on both sides, and 1/2˝ groove welds on both ends,

as shown in FIGURES 1A and 1B. The welds should be continuous around the

bracket and joined at the corners.

E. For cast brackets (single piece), weld with 5/16˝ fillet weld, as shown in

FIGURE 1C. The welds must be continuous ar

4

FIGURE 1C

(Cast Brackets Only)

WELDING DETAILS

“Installation: General Recommendations,”

FIGURE 1A (End View)

FIGURE 1B (Side View)

ound the bracket ends.

XL-FW504 Rev A

INSTALLATION INSTRUCTIONS

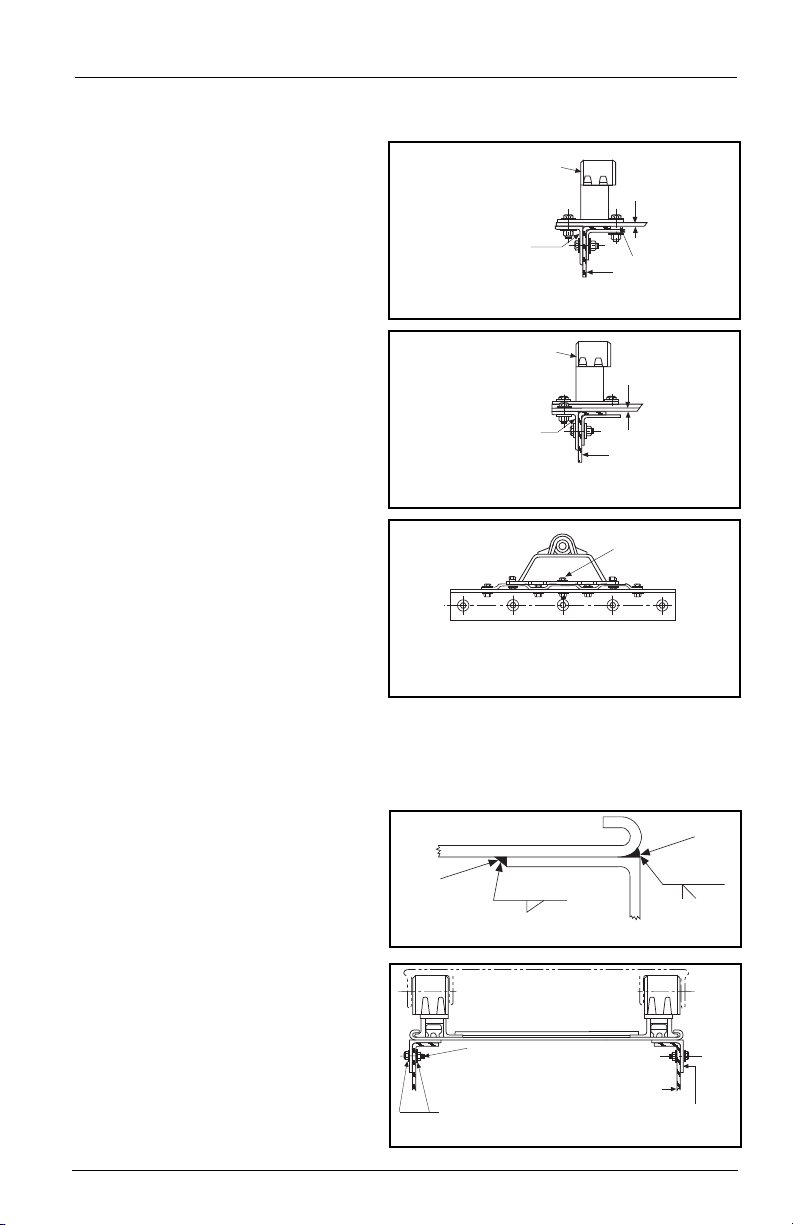

FIFTH WHEEL

SUPPORT BRACKET

FLAT MOUNTING PLATE

See Chart 1 for

minimum thickness

INBOARD ANGLE

T

RACTOR FRAME

SPACER

Attach the outboard angle to

tractor frame with hardware

listed in Figure 1A. Attach

mounting plate to angle

with same number of bolts

(

in addition to attachment to

fifth wheel support bracket).

Attach the outboard angle to

tractor frame with hardware

l

isted in Figure 1A. Attach

mounting plate to angle with

same number of bolts (in

a

ddition to attachment to

fifth wheel support bracket).

CORRUGATED

M

OUNTING PLATE

See Chart 1 for

minimum thickness

TRACTOR FRAME

FIFTH WHEEL

SUPPORT BRACKET

CENTER

BOLT

Attach bracket and mounting plate as shown.

Use center bolt of sufficient length to bolt through

bracket, mounting plate and mounting angle.

3/8˝ 3 - 8.50˝

5/16˝

3 - 8.50˝

INSIDE

WELD

OUTSIDE

WELD

See Chart 1 for min.

mounting angle

thickness

HARDENED STEEL

WASHERS

The full length of the fifth wheel mounting

angle should seat flush on the truck frame

when mounting to prevent flexing of

mounting angle and to give uniform

weight distribution along truck frame rail.

5/8” diameter Grade 8 bolts minimum size.

Tightening torque to bolt manufacturer charts.

Hardened steel washers or flanged locknuts.

5/8” diameter Grade “C” locknuts.

TRUCK FRAME RAIL

Stationary Fifth Wheel Installation continued

Bracket with Mounting Base

(See Figures 2A, 2B, and 2C):

1. Holland brackets with mounting

base are intended for installation

on either corrugated or flat

mounting plates.

continued

2. In addition to the information

given in “Installation: General

FIGURE 2A

Recommendations,” on page 3,

follow the recommendations in

FIGURES 2A, 2B, and 2C.

3. See “Installation: General

Recommendations” on page 3

for angle thickness and material.

The mounting angle should be 1˝

longer than the mounting plate,

FIGURE 2B

and be 36˝ minimum length.

Use 3˝ minimum horizontal and

3 -1/2˝ minimum vertical leg size.

Longer horizontal legs may be

required with narrow frame widths.

FIGURE 2C

Sliding Fifth Wheel Installation

Prior to proceeding with the installation of the sliding fifth wheel assembly,

carefully review the

Inboard Angle Mounting

(See Figures 3 and 4):

1. Angles must be installed on the

sliding fifth wheel base plate to

facilitate mounting. See “Installation:

General Recommendations,” on page

3, for angle thickness and material.

“General Safety Information” section on page 2.

FIGURE 3

2. Use a mounting angle which is at

least 2˝ longer than the slide base

plate and 36˝ minimum length.

Use 4˝ minimum horizontal and

3-1/2˝ minimum vertical leg size.

The fifth wheel top plate and support

bracket may be removed fr

base plate for ease of handling.

XL-FW504 Rev A

om the

FIGURE 4 (End View)

5

INSTALLATION INSTRUCTIONS

1.00˝

(25.4 mm) MIN.

CENTER LINE OF

TRACTOR REAR

A

XLE(S) OR

BOGIE

P

LATE LENGTH PLUS 2.00˝ MIN. (50.8 mm)

4.00˝

(101.6 mm)

m

ax.

1˝ min. 6 bolts equally spaced

FORWARD TRAVEL

T

RUCK FRAME RAIL

T

he full length of the fifth wheel mounting angle should seat flush on

the truck frame when mounting to prevent flexing of mounting angle

and to give uniform weight distribution along truck frame rail.

5/8˝ diameter Grade 8 bolts minimum size,

tightening torque to bolt manufacturer charts.

Hardened steel washers or flanged locknuts.

5/8˝ diameter Grade “C” locknuts.

HARDENED STEEL

WASHERS

continued

Sliding Fifth Wheel Installation continued

Inboard Angle Mounting continued

3. Position the angles on the slide

plate for the required frame width.

Be sure to keep the plate centered

left to right, and front to rear on

the mounting angles.

4. Weld as shown in FIGURE 3. Make

F

5/16˝fillet welds inside and 3/8˝

IGURE 4 (Side View)

groove welds on the outside with

skip welds 3˝ long on

approximately 8-1/2˝ centers (weld

3˝, skip 5-1/2˝). Weld inside

opposite skips on the outside. ALSO

The plate to the top of the

WELD:

angle at the ends of the plate.

5. Attach the slider plate and

mounting angles to the tractor

using recommendations in

“General Recommendations”

and in FIGURE 4.

6. Reassemble the fifth wheel top

plate and bracket sub-assembly to

the slider base plate if they were

removed previously.

Outboard Angle Mounting

(See Figures 5 and 6):

1. If angles are not installed, see “Installation: General Recommendations,” on page 3, for

thickness and material. Use 3˝ minimum horizontal and 3-1/2˝ minimum vertical

leg size. Longer horizontal legs may be required with narrow frame widths. The

recommended length of each mounting plate is the same length as the slide base

mounting plate.

2. In addition to the information given in

on page 2, follow the recommendations in FIGURE 5 and FIGURE 6. The following

sequence is suggested:

A. Securely position the mounting angles to the tractor frame and attach as shown

in FIGURE 5. Follow the bolting recommendations as shown in FIGURE 4. Angles

must be flush with the top of the tr

B. Locate the slide base and center left to right and fr

angles. Clamp in place and drill 21/32˝ diameter holes using the mounting

plate as a template if holes are not provided in the angle.

C. Align holes in the slide plate with outboard angle mounting holes and bolt

using Grade 8 fasteners, hardened steel washers and Grade C locknuts, properly

tightened, (see

6

FIGURE 6). Use all mounting holes on the fifth wheel.

“Installation: General Recommendations,”

uck frame.

ear on the mounting

ont to r

XL-FW504 Rev A

FIGURE 5

FIGURE 6

INSTALLATION INSTRUCTIONS

PLUNGER ADJ. BOLT

POCKET

PLUNGER

RACK

BRACKET CAP

1/8”

1/4”-1/2”

Locate and weld the

rear slide stops per steps

2 through 5 above.

Weld the forward side

in the center only

to avoid interference

with the bracket.

TYP.

5/16˝

Dimensions apply

after welding.

TYP.

5/16˝

SLIDE STOP

continued

Sliding Fifth Wheel Installation continued

Adjustment of Sliding Bracket Locking Plungers

The slide locking plungers are given a preliminary adjustment during factory assembly.

However, due to variations introduced during mounting (such as frame and material

tolerances) a final adjustment must be made at the time of installation.

Adjust the locking plungers at installation, after one month of service,

and at recommended maintainence intervals. by use of the adjusting

bolts provided on both sides. Failure to do so may result in accelerated wear of

components, lower service life, improper load transfer, or improper load distribution.

To adjust locking plungers:

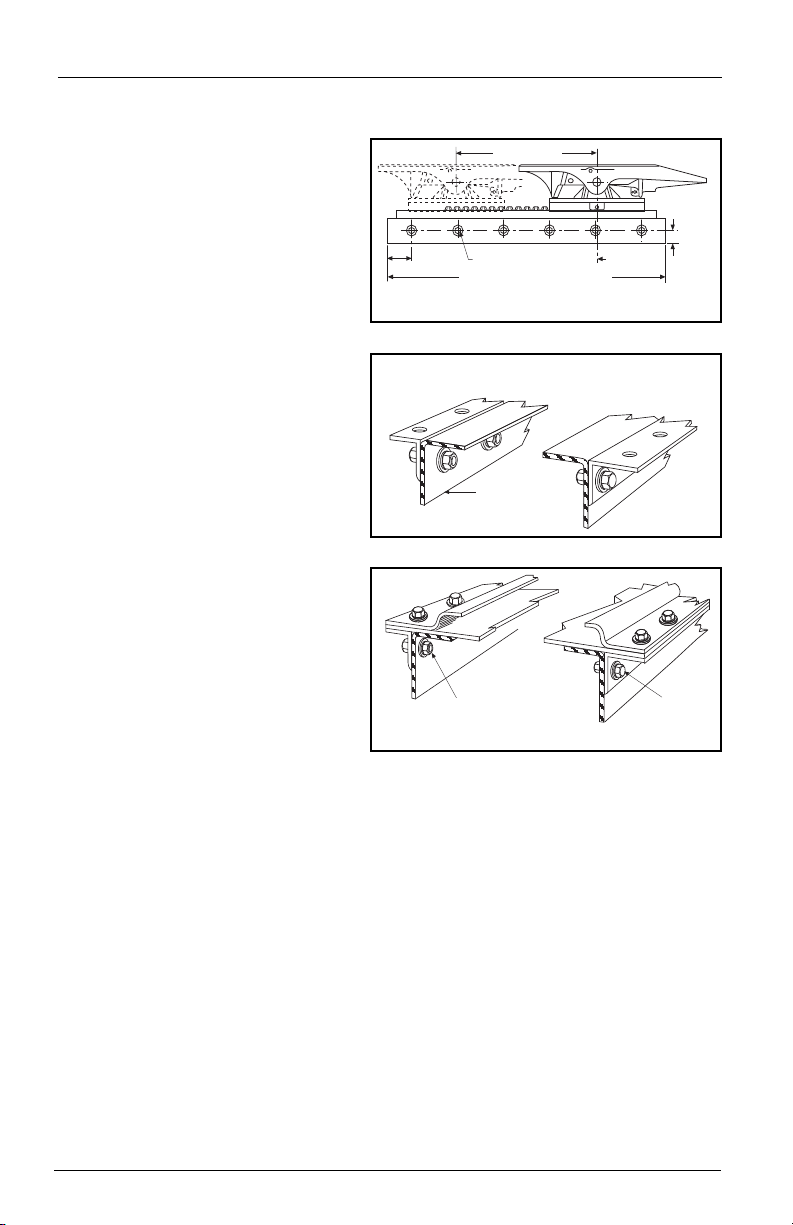

1. Loosen lock nut and turn adjusting bolt

out (counterclockwise). See FIGURE 7.

2. Disengage and engage the locking

plungers. Check that the plungers are

securely seated without binding.

3. Turn the adjusting bolt in (clockwise)

until it contacts the rack. Turn the bolt

an additional 1/2 turn then tighten the

locking nut securely.

FIGURE 7

(Outside View)

Prior to proceeding with the installation of the sliding fifth wheel assembly, carefully

review the

“General Safety Information” section on page 2.

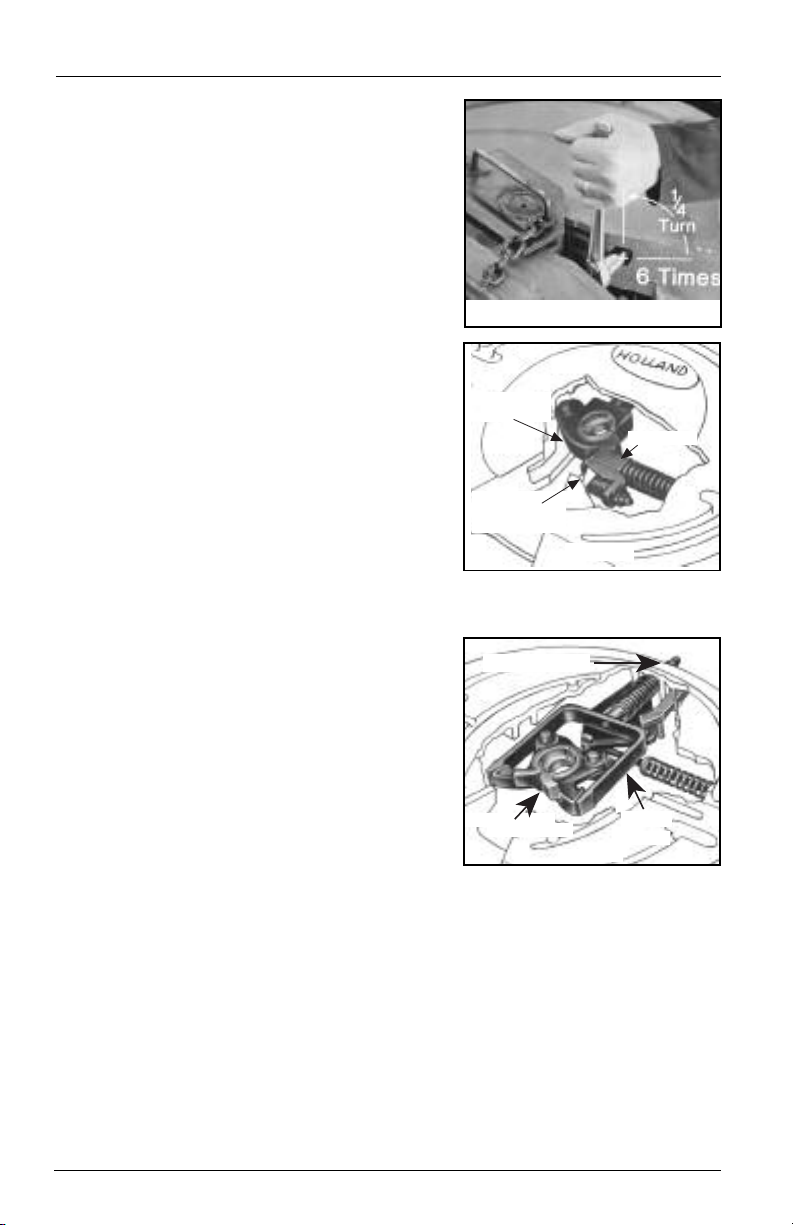

Installation of Slide Stops

1. It is the responsibility of the installer

to insure that slide stops are installed

properly at all four corners of the

slider plate.

2. Slide the bracket to the full rear

position and engage the plungers in

the rack.

3. Locate rear stops under the curled

edge allowing some clearance to the

bracket (approximately 1/8˝). Clamp

in place. This should position the

stops approximately 1/4˝ to 1/2˝

from the edge of the rear of the plate,

FIGURES 8A and 8B.

see

4. Slide bracket ahead out of the way

and weld the stops in place as shown

in FIGURES 8A and 8B. The welds

should be 5/16˝ fillet.

5. Slide the bracket to the full r

position and check for clearance.

bracket seat properly into the rack

with all teeth engaged.

6. Repaint as required.

XL-FW504 Rev A

Make sure the plungers on the sliding

ear

FIGURE 8A

FIGURE 8B (Rear End View)

7

INSTALLATION INSTRUCTIONS

continued

Attachment of Air-Activated Slide Release – If Required

1. Mount the cab control valve in accordance with the instructions provided. It should

be readily accessible to the driver, but protected to prevent accidental activation.

2. Attach an air line, using appropriate fittings to the “air” or “in” port of the valve.

Use an air source recommended by the tractor manufacturer. Use fittings and lines

of suitable pressure rating.

3. Connect an air line between the “cyl” or “out” port of the valve and the active side

of the air cylinder. A bulkhead fitting may be placed at the front of the slide base

plate, if desired. Use fittings and lines of suitable pressure rating and be sure line is

run so as not to interfere with any other operation or component.

4. Check operation of the valve and cylinder.

Inspection and Lubrication Prior to Use

1. Review the installation. Be sure all nuts and bolts are in place and properly

tightened. Be sure all necessary steps were properly followed and that all

components removed to facilitate installation are reinstalled.

2. Check the fifth wheel locking mechanism with a Holland TF-TLN-5001 (2˝) or

TF-TLN-1500 (3-1/2˝) Lock Tester. Examine for proper locking as described in the

“Operating Instructions” of this manual. This must be done to assure that the

mechanism has not been damaged by shipment, handling, or storage.

Failure to properly install, operate, or maintain this fifth wheel could

result in tractor and trailer separation causing death or serious injury

to others.

3. Apply grease to the bearing surface of the support bracket through the grease

fittings on the side or front of the fifth wheel pockets. The top plate must

be lifted up slightly to ensure proper application of grease. (NOTE: This is not

required on Holland LowLube and NoLube top plates.)

4. Apply a generous coating of grease to the top of the fifth wheel plate, where it will

contact the trailer plate. (

NoLube top plates.)

5. Apply a generous coating of grease to the front lock and lock jaws.

8

NOTE: This is not required on Holland LowLube and

XL-FW504 Rev A

OPERATING INSTRUCTIONS

1. Failure to read, understand, and follow the important information

contained herein may result in a hazardous condition or cause a

hazardous condition to develop.

2. Relative to tractor-trailer operations, there are other checks,

inspections, and procedures not listed here, which are necessary,

prudent, and/or required by law. The following is in addition to

these, and pertains to the fifth wheel only.

3. Perform these procedures with the area clear of obstacles and other

personnel.

Coupling Procedures

1. Check out the equipment before coupling.

A. Make sure that the fifth wheel is properly lubricated, that the locks are open,

and that the ramps are tilted down in the proper position.

B. Make sure the mounting of the fifth wheel to the tractor frame is in good

condition and is tight.

2. Back up close to the trailer, centering the kingpin on the throat of the fifth wheel.

STOP.

3. Block the trailer wheels, connect the brake lines and light cord. Be sure any slack in

the lines is supported so the brake lines do not become tangled. Set the trailer

brakes.

4. Check to see that the trailer is at the proper height for coupling. The leading edge

of the trailer upper coupler plate should initially contact the fifth wheel top bearing

surface 4" to 6" behind its pivot axis as the tractor backs under the trailer. Using low

gear, raise or lower the trailer landing gear as required to obtain this position.

Attempting to couple with the trailer at an improper height could

result in a false or improper coupling and cause damage to the tractor,

fifth wheel, or trailer.

5. Back under the trailer, keeping the trailer kingpin centered in the throat of the fifth

wheel.

6. After picking up the trailer with the fifth wheel —

until the fifth wheel locks firmly on the kingpin. Stopping helps prevent hitting the

kingpin too hard.

7. Back up tightly against the kingpin. Then pull forward to test the completeness of

the coupling as an INITIAL check.

STOP — then continue backing

XL-FW504 Rev A

9

OPERATING INSTRUCTIONS

WHEN LOCKED WITH LOCKS PROPERLY ADJUSTED,

THE YOKE WILL BE SEATED AS SHOWN AND THE

NUT AND WASHER WILL BE SNUG AGAINST THE

FIFTH WHEEL.

BOLSTER PLATE

FLUSH WITH

FIFTH WHEEL

LOCKS

CLOSED

KINGPIN PROTRUDES

BELOW LOCKS

PLUNGER

NO GAP

BOLSTER PLATE FLUSH WITH FIFTH WHEEL

WHEN LOCKED, SWINGING LOCK (JAW) MUST BE

AROUND KINGPIN AND LOCKING PLUNGER MUST

BE VISIBLE AS SHOWN AS VIEWED FROM THE

REAR OF THE TRACTOR.

continued

Coupling Procedures continued

A direct visual inspection is required to assure proper coupling. Improper

coupling can pass the initial pull test. Sound is unreliable. Do not take for

granted that you are properly couple. Get out of the cab and look.

8. Visually check to see that the kingpin

is in the fifth wheel locks, not

overhanging the fifth wheel or caught

in a grease groove. There should be no

gap between the trailer bolster plate

and the fifth wheel. (See FIGURE 1 and

FIGURE 2A.) Check for proper coupling

by looking into the throat of the fifth

wheel. Check the locks as shown in

FIGURE 1 for Type “A” locks and

FIGURES 2A and 2B for Type “B” locks.

If you do not obtain a

proper coupling, repeat

this sequence. Do not use any fifth wheel

which fails to operate properly.

9. If your fifth wheel is equipped with a

manual secondary lock, engage it.

10. Using low gear, retract the landing

gear until unloaded. Then, shift to

high gear and continue cranking until

they are fully retracted. Fold down or

remove the crank handle and place it

in the crank handle holder.

11. Check the brake lines and light cord.

12. Remove the wheel blocks and continue

with pre-trip inspection.

TYPE ‘A’ LOCK

FIGURE 1

TYPE ‘B’ LOCK

VIEW LOOKING INTO

THROAT OF FIFTH WHEEL

FIGURE 2A

TYPE ‘B’ LOCK

10

FIGURE 2B

XL-FW504 Rev A

OPERATING INSTRUCTIONS

UNLOCKED

(RELEASED)

LOCKED

(ENGAGED)

UNLOCKED

(RELEASED)

LOCKED

(ENGAGED)

continued

Uncoupling Procedures

1. Set trailer brakes with tractor protection switch.

2. Back into the kingpin and set emergency brake on the tractor.

3. Block the trailer wheels.

4. Wind down the landing gears in high gear until they touch the ground. Shift to low

gear and crank a few extra turns. Do not raise the trailer off the fifth wheel. It may

be necessary to provide a base for the landing gear in poor parking conditions. Fold

down or remove the crank handle and place it in the crank handle holder.

5. Disconnect the light cord and brake lines. Attach the dummy air coupling to keep

foreign material from entering the brake lines.

6. Unlock the fifth wheel, including the manual secondary lock if so equipped.

7. Release the tractor emergency brake and pull out slowly from under the trailer. Let

the trailer slide down the fifth wheel and pick-up ramps, being careful that the

trailer landing gear touches the ground with minimal impact.

NOTE: When uncoupling the Type A fifth wheel, it is normal for the release handle to

move to the closed position. It is not necessary to pull the release handle to recouple.

Sliding Procedure for a Sliding Fifth Wheel

1. Stop the tractor and trailer in a straight line on level

ground. Lock the trailer brakes.

The trailer must be stopped and the trailer

brakes locked to prevent damage to the

tractor or trailer by uncontrolled sliding of the fifth wheel.

2. Release slide locking plungers as detailed below for

the type of slide release:

A. Air Slide Release - put cab control valve to the

unlock position.

B. Manual Slide Release - pull release lever. See

FIGURE 3.

3. Check to see that both plungers have released as

shown in

FIGURE 3 and 4. If plungers do not come

out, lower the landing gear to relieve pressure on

the plungers. This also allows the fifth wheel to slide

easier.

4. Drive the tractor forward or backward slowly to

position the fifth wheel.

5. After sliding the fifth wheel to the desired setting,

engage the slide locking plungers as below:

A. Air Slide Release - put control valve in lock

position to retract plungers.

B. Manual Slide Release - trip release arm to allow

plungers to retract.

6. Visually check to see that both plungers are retracted

and fully engaged. Leaving the trailer brakes locked

and moving the tractor slightly may be necessary to

engage the plungers in the rack teeth. Raise the

landing gear to the fully retracted position.

Do not operate the vehicle if the plungers are not fully engaged and

landing gears are not fully retracted, as damage to the tractor, trailer,

and landing gears may occur.

XL-FW504 Rev A

MANUAL SLIDE RELEASE

FIGURE 3

FIGURE 4

AIR SLIDE RELEASE

11

INSPECTION PROCEDURE

Your Holland fifth wheel (or rebuild kit) is equipped with an

tractors with sufficient clearance between the tires and fifth wheel release handle.

After installation or rebuilding of the fifth wheel, the vehicle must be inspected to

insure proper clearance between the handle and the fifth wheel.

EXTENDED LENGTH RELEASE HANDLE. It is only to be used on

Inspection Procedure

After mounting the fifth wheel to the tractor frame, measure the distance between the

fifth wheel release handle and tractor tires with the release handle in the “open” or

“ready-to-couple” position. Rotate (“articulate”) the fifth wheel forward, as shown in

Figure 2, and measure the clearance.

1. Verify that the fifth wheel handle is in the “open” or “ready-to-couple” position.

EXTENDED

RELEASE

HANDLE

(XA-S09623)

8.0˝

2. Verify that the fifth wheel handle-to-tractor tire clearance is 3/0˝ or greater, as shown.

RELEASE

HANDLE

3.0˝

MINIMUM

TRACTOR TIRE

If the clearance in any position is less than .30˝, the extended handle

used, and a standard length release handle must be used. Contact Holland at

(888) 396-6501 for assistance.

3. If you are rebuilding a FW35-S09623-1 or FW35-S09623-2 fifth wheel, follow all

instructions in Holland publication XL-FW290. EXCEPTION: Use the extended

release handle (XA-S09623) for Item 23 in place of the standar

(XA-07171-1).

LOCKS OPEN

“READY TO COUPLE”

CANNOT be

elease handle

d r

12

XL-FW50

4

Rev A

MAINTENANCE PROCEDURES

1. Failure to read, understand, and follow the important information

contained herein may result in a hazardous condition or cause a

hazardous condition to develop.

2. All maintenance must be performed by a qualified person using

proper tools and safe procedures.

3. All maintenance must be performed while the tractor is uncoupled

from the trailer.

As-Needed Lubrication

1. Keep a water-resistant lithium-base grease applied to the trailer contact surface of

the fifth wheel plate.

2. Apply grease to the bearing surface of the support bracket through the grease

fittings on the side of the fifth wheel plate. The plate must be lifted up slightly to

relieve weight on the bracket while applying grease.

3. Spray diesel oil on the rack and slide path of the bracket on sliding fifth wheels.

Periodic Inspections and Adjustments

NOTE: All of the following must be performed every 30,000 miles or 3 months,

whichever comes first. Perform the inspections after steam cleaning to assure a good

inspection.

Inspection — General

1. Inspect the fifth wheel mounting. Check torque and replace any missing or

damaged bolts. Check for broken or distorted components and repair or replace as

needed.

2. Inspect the fifth wheel assembly for bent, worn or broken parts. Replace with

HOLLAND parts only.

Fifth Wheel Locking Mechanism Inspection and Adjustment

1. Check the operation of the fifth wheel locking mechanism using a HOLLAND

TF-TLN-1000 (2˝ kingpin) or TF-TLN-1500 (31/2˝ kingpin) Lock Tester. Inspect for

proper locking as described in the “Operating Instructions” in this manual.

Do not use any fifth wheel which does not operate properly.

2. Check adjustment of the fifth wheel locks and adjust as required. Use the procedure

as follows for the appropriate locking mechanism. If the locks cannot be properly

adjusted due to wear, the fifth wheel must be rebuilt or replaced. Contact your

HOLLAND Distributor to order the appropriate rebuilding kit or fifth wheel.

Improper adjustment can cause improper locking of the mechanism.

XL-FW504 Rev A

13

MAINTENANCE PROCEDURES

SPLIT LOCKS

LOCK ADJ. NUT

YOKE

S

WINGING

LOCK

LOCK

ADJUSTMENT

SCREW

PLUNGER

continued

Type “A” Lock Adjustment

The lock adjustment screw is found in the crotch

on the right side as shown (FIGURES 1 & 2).

1. Close the locks with the lock tester.

2. Tighten the adjustment screw by turning

clockwise until tight, using a 1/2˝ Allen

wrench or Allen socket extension.

3. Loosen the adjustment screw by turning it

counterclockwise 11⁄2turns. The locks are

now properly adjusted.

FIGURE 1

4. Verify this adjustment by locking and

unlocking several times.

FIGURE 2

Type “B” Lock Adjustment

1. Close the locks and insert a 2˝ plug

(HOLLAND P/N TF-0237) in the locks.

2. Check for a tight fit. The plug should be snug,

but you should be able to rotate it by applying

some force.

3. If the plug fits loosely, tighten by rotating the

nut on the shank counterclockwise. It may be

necessary to tap the end of the yoke shank

lightly to allow the nut to seat against the top

plate.

4. Repeat this procedure until the plug fits snug but can still be rotated. The locks are

now properly adjusted.

5. Verify proper operation of the locking mechanism using the lock tester.

FIGURE 3

14

XL-FW50

4

Rev A

MAINTENANCE PROCEDURES

PLUNGER

ADJ. BOLT

POCKET

PLUNGER

RACK

Relubrication After Inspection and Adjustment

Relubricate by applying a light rust-resistant oil to all moving parts.

Fifth Wheel Sliding Mechanism Inspection and Adjustment

1. Adjustment of Locking Plungers:

A. Loosen lock nut and turn

adjusting bolt (counterclockwise).

See FIGURE 4.

B. Disengage and engage the locking

plungers. Check that the plungers

are securely seated without binding.

Turn adjusting bolt in (clockwise) until

it contacts the rack. Turn adjusting

bolt an additional 1/2 turn, then

tighten the locking nut securely.

2. When Locking Plungers Won’t Release

to Permit Sliding of the Fifth Wheel:

A. Check the air cylinder for proper

operation and replace if necessary.

B. Check plunger adjustment.

C. If adjusted plunger binds on the

pocket (FIGURE 5), grind the top

plunger edges 1/16˝, reinstall and

adjust as above. Use a HOLLAND

TF-TLN-2500 Spring Compressor

to remove and reinstall the plunger.

3. When Locking Plungers Are Too Loose:

A. Check plunger adjustment.

B. Check the plunger springs for proper compression. Replace is necessary.

C. Check for plunger wear and replace if necessary. Use a HOLLAND TF-TLN-2500

Spring Compressor to remove and reinstall the plungers. Adjust the plungers as

described above.

Proper adjustment of the sliding bracket locking plungers must be

performed at installation and maintained at regular intervals by use of

the adjusting bolts provided on both sides. Proper adjustment is required for proper

operation and for proper load transfer and distribution.

COMMERCIAL PRODUCTS WARRANTY

HOLLAND warrants all Commercial Products (products

other than those normally used for personal, family

or household purposes) manufactured by it, when

properly installed, to be free from defects in material

and workmanship under nor

period of two (2) years from the date of manufactur

with the exception of elevating fifth wheels for which

the warranty period is ninety (90) days. This warranty

is void with respect to any product which has been

altered in any way from its manufactured condition,

such as intentional modification, accident, cor

misuse, failure to provide necessary and reasonable

maintenance and is exclusive from normal wear. The

sole responsibility of HOLLAND under this warranty is

limited to repairing or replacing at the factory any part

or parts which are returned, with transportation

charges prepaid, and are found to be defective to the

XL-FW504 Rev A

mal use and service for a

osion,

r

satisfaction of HOLLAND. Written authorization fr

HOLLAND must be obtained prior to returning this

warranty. HOLLAND shall not be liable in any event,

for proximate, incidental, consequential or other

damages, including but not limited to damages for

e,

loss of production or injury to persons or property arising

out of any breach of this warranty.

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING THE WARRANTY OF MERCHANTABILITY OR

A WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE

EXTENDING BEYOND THAT SET FORTH ABOVE.

Holland reserves the right, without giving prior notice, to

change specifications and dimensions as designs are altered

or improved. Options other than those shown may be

provided. Contact the factory for information.

FIGURE 4

CHECK FOR POSSIBLE

INTERFERENCE

FIGURE 5

continued

om

15

16

XL-FW50

4

Rev A

XL-FW504 Rev A

17

18

XL-FW50

4

Rev A

WARRANTY

5-YEAR

COMPREHENSIVE

WARRANTY

olland warrants all fifth wheel commercial products

H

other than those normally used for personal, family,or

(

household purposes) manufactured after July 1,1990, to

be free from defects in material or workmanship for a

period of 5 years from the date of manufacture, except

elevating fifth wheels, which will carry a 180-day

warranty.This warranty covers only defects in materials

or workmanship and does not cover failures due to any

of the following:

1. Normal wear

2. Improper installation

3. Intentional modification

4. Accident

This warranty does not guarantee a particular service

life of the product since service life will vary with

application, degree of use, operating environment, level

of maintenance, and other factors beyond our control.

Holland’s sole responsibility for any fifth wheel product

or part determined by Holland to be defective and

covered by this warranty is limited to repairing or

replacing the product or part, and to providing an

allowance to be applied to the labor cost of removal

and replacement.

Prior authorization from Holland must be obtained

before replacing or returning any part, or incurring any

labor cost for removal.

incurred in parts, labor,or transportation by

unauthorized persons will be allowed under this

warranty. Holland reserves the right to request the

return of any part or fifth wheel assembly (with

transportation charges prepaid) claimed to be covered

by this warranty.

Holland shall not be liable, in any event, for proximate,

incidental, consequential,special, or other damages,

including — but not limited to — damages for loss of

production, loss of profits, loss of opportunity,or injury

to persons or property arising out of any breach of this

warranty.

THERE ARE NO WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING THE WARRANTY OF

MERCHANT

A PARTICULAR PURPOSE, OR ANY OTHER

ARRANTY EXTENDING BEYOND THA

W

FORTH ABOVE.

ABILITY, WARRANTY OF FITNESS FOR

5. Corrosion

6. Misuse

7. Failure to provide

reasonable maintenance

No charges for expense

Warranty

T SET

XL-FW504 Rev A

19

20

Copyright © July 2005 • The Holland Group, Inc.

maintain this fifth wheel could result in

tractor and trailer separation causing death

or serious injury to others.

operation, and maintenance of this product. Read and

Failure to properly install, operate, or

understand this information.

IMPORTANT: Enclosed is important information for the installation,

XL-FW504 Rev A

Loading...

Loading...