FIFTH WHEEL

OWNER’S

MANUAL

FW2800 and FW2900 Series

Hydraulic Elevating

Fifth Wheel

Installation, Operation,

Maintenance Procedures and

Comprehensive Warranty

TECHNOLOGY

XL-FW488 Rev A

Questions or Comments?

Call

www.thehollandgroupinc.com

FIFTH WHEELS

1-888-396-6501

INSTALLATION INSTRUCTIONS

When welding, use a procedure which assures a sound, good quality

cause distortion and damage, and underwelding may not develop sufficient strangth. A

low hydrogen process and AWS E70XX filler metal are recommended. Take precautions

to ensure that the tractor electrical system is not damaged by the welding.

weld and which protects the operator and others. Overwelding may

Fifth Wheel Design and Intended Use:

1. For pulling trailers with standard SAE kingpins which are in good condition and

securely mounted or locked in position in the trailer.

2. Within the capacities stated in Holland literature.

3. As recommended in Holland literature (available from Holland or Holland distributors).

Holland Fifth Wheels are NOT Designed or Intended For:

1. Use with non-SAE kingpins, such as kingpins which are bent, improper size or

dimension, not secured to maintain SAE configuration, or which are installed in

warped trailer bolster plates.

2. Tow-away operations which damage or interfere with the proper operation of the

fifth wheel.

3. The transport of loads in excess of rated capacity.

4. Applications other than recommended.

Installation

General Recommendations

1. Every user and installer using Holland products either recommended or not

recommended by Holland, must ensure that the installation procedure used is

appropriate for the vehicle, product and application.

2. Consult the Holland literature for fifth wheel capacities and applications.

3. Determine the range of proper fifth wheel positions. Proper positioning of the fifth

wheel is important for weight distribution, swing clearance and handling characteristics.

The center of the kingpin locks must always be positioned on or

ahead of the tractor rear axle or bogie centerline. Failure to do so

can result in loss of vehicle control.

4. Use Grade 8, 5/8˝ minimum diameter bolts and Grade “C” locknuts for mounting.

5. Bolt holes can be 1/32˝ larger in diameter than the bolt fastener. Bolts must be

adequately tightened using charted torque ranges in foot-pounds for the

recommended Grade 8, 5/8˝ diameter bolts. Larger diameter Grade 8 bolts and

coated fasteners may be used.

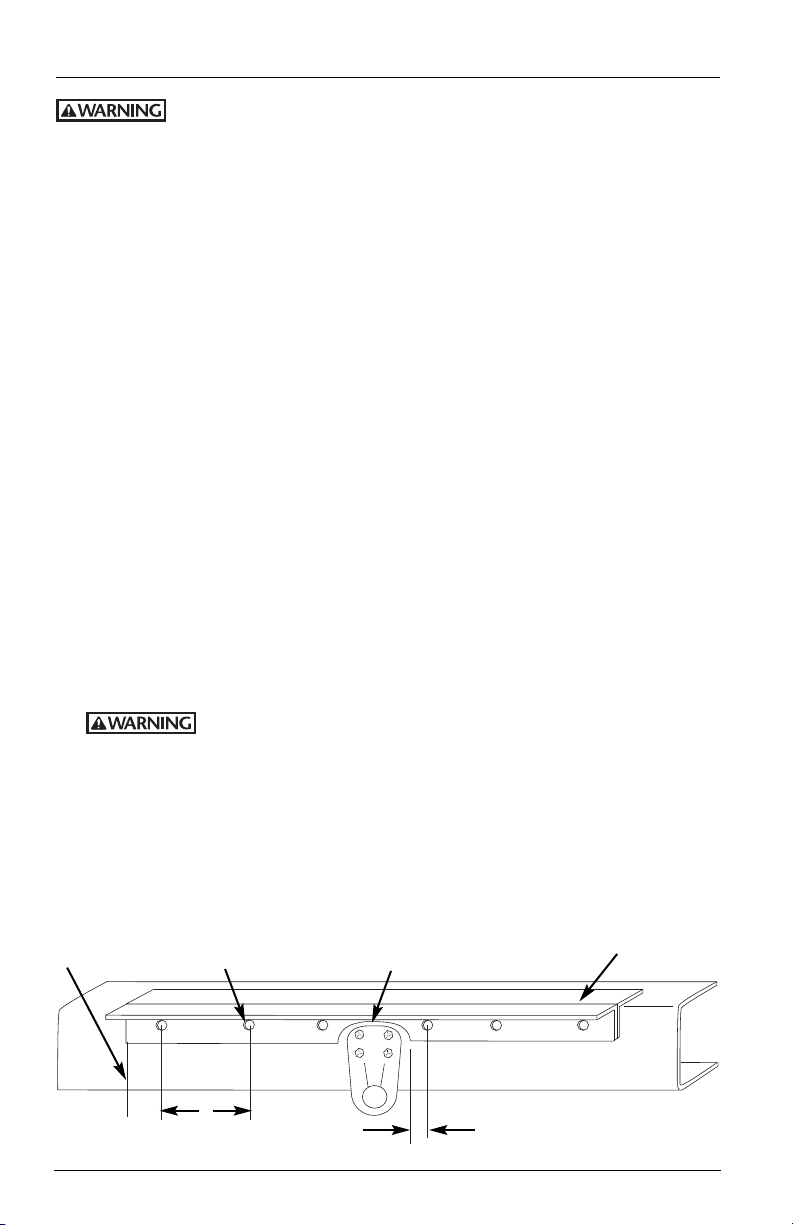

Figure 1

1˝ min. from

hole to the end

of the angle.

Holes drilled for

5/8˝ mounting

bolts.

Angle cut out for tractor

frame interference. 1˝

minimum for radius.

Lift wheel

mounting base.

1

⁄2˝ mounting required

8˝

Maximum

hole spacing

2

1˝ – 1

between 1˝ and 11⁄2˝ of

angle cut out.

XL-FW488 Rev A

INSTALLATION INSTRUCTIONS

APPROX. 1˝ APPROX. 1˝

FIFTH WHEEL MOUNTING FRAME

MOUNTING ANGLE MARK ANGLES HERE

PIVOT LOCATION

continued

6. The bolts attaching the fifth wheel mounting angles to the truck frame require

hardened steel washers under both the bolt and under the locknut, unless flanged

head bolts or flanged head locknuts are employed.

7. A minimum of 5 bolts should be applied to attach each mounting angle to the

tractor frame rail, and the distance between bolts should not exceed 8˝, except

when cutouts are required in the mounting angles (see Figure 1).

8. Whenever a cutout is made on the mounting angle, such as required to bypass

spring hangers, a 1˝ minimum radius should be used and bolts should be placed

within 1-1/2˝, but not closer than 1˝ of the cut, fore and aft (see Figure 1).

9. When initially positioning the fifth wheel for frame holes, the full length of the fifth

wheel mounting angles should seat flush on the top and side surfaces of the trucktractor frame rails where channel-type rails are employed. There should not be a

gap over the top of the truck frame rails. The base of the fifth wheel assembly and

of the mounting angle members should seat flush on the top of the frame rail to

prevent flexing and to give uniform weight distribution. It is also recommended to

chamfer or smooth any sharp edges and corners of mounting materials wherever

contact is made with the tractor frame.

10. Review “System Check” found on page 8.

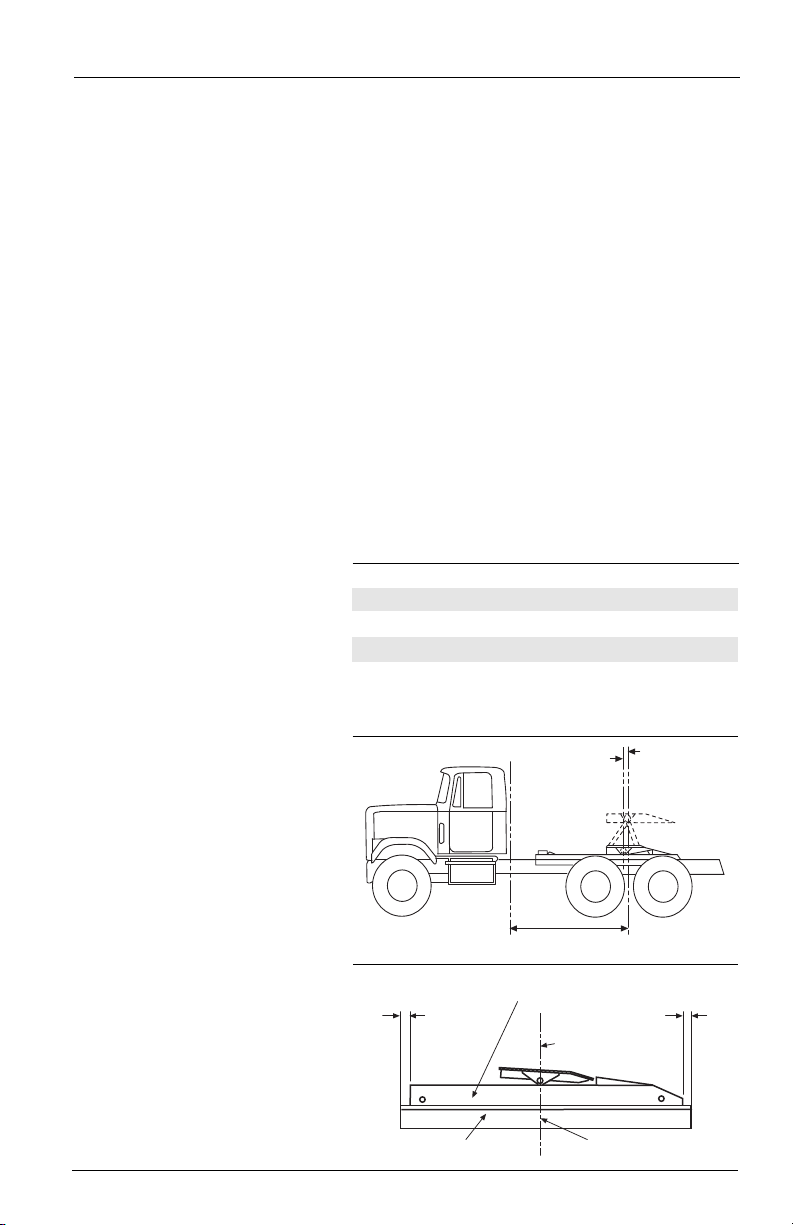

Detailed Information

1. Remove the shipping lugs

from the bottom of the unit.

2. Determine the proper fifth

wheel position on the tractor:

A. Verify that the tractor has

sufficient “Cab to Axle”

(C.A.) clearance for the

elevating fifth wheel

model selected, as listed

Chart 1 and Figure 2.

in

B. Locate the pivot point of

the fifth wheel (when it’s

in the down position) on

the given mounting

angles by positioning the

angles approximately 1˝

beyond each end of the

fifth wheel assembly

frame. Once this has been

completed, mark the pivot

point of the fifth wheel on

both angles (see Figure 3).

Chart 1

Cab to Axle Requirements and Mounting Location

MODEL CAB TO AXLE* LOCATION (A)

MINIMUM MOUNTING

FW2800-X 72˝ 10˝

FW2800-5X 77˝ 10˝

FW2900-X 60˝ 6˝

FW2900-5X 65˝ 7˝

* Based on a 102˝ wide, square corner trailer, with a 36˝

kingpin setting. More or less cab to axle clearance may be

required for other nose configurations, kingpin settings,

refrigeration units, etc.

Figure 2

(A)

FIFTH WHEEL

MOUNTING

LOCATION

CAB TO AXLE

CLEARANCE

CENTERLINE

OF THE REAR

AXLE/BOGIE

Figure 3

XL-FW488 Rev A

3

INSTALLATION INSTRUCTIONS

5˝x 5˝

ANGLE

SPACER

FRAME RAILS

FIFTH WHEEL MOUNTING FRAME

TRUCK

FRAME

RAIL

3/8˝

(9.53mm)

MINIMUM

ANGLE

HARDENED

STEEL WASHERS

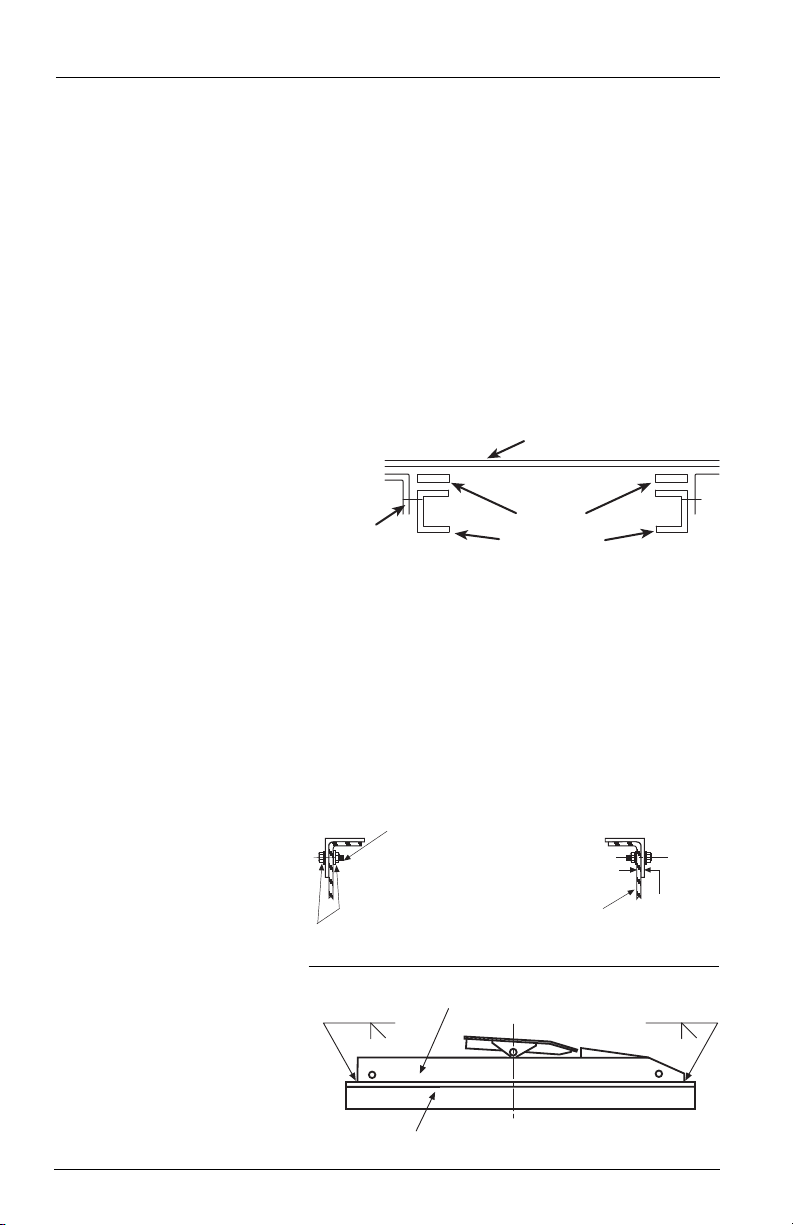

The full length of the fifth wheel mounting angle should

seat flush on the truck frame when mounting to prevent

flexing of mounting angle and to give uniform weight

distribution along truck frame rail.

.63” diameter Grade 8 bolts

minimum size.

Tightening torque to bolt

manufacturer charts.

Hardened steel washers or

flanged locknuts. .63”

diameter Grade “C” locknuts.

3/8˝ 3/8˝

FIFTH WHEEL MOUNTING FRAME

MOUNTING ANGLE

continued

C. Take the marked angles and position them on the tractor frame.

NOTE: The marked angles will no longer be symmetrical. It is critical

to make certain that the angles are notaccidentally reversed.

D. Line up the marks of both angles with the imaginary centerline of the rear

axle/bogie. Use the dimension listed under “Mounting Location (A)” in Chart 1

for the elevating fifth wheel model selected, and offset the angle forward (toward

the cab) by that distance.

NOTE: The offsetting of the angles is necessary to allow for the horizontal (forward)

movement of the wheel when elevating. When the wheel is in its maximum vertical

condition, the pivot point of the wheel will be in line with the imaginary centerline

of the rear axle/bogie and the centerline markings made on the angles in Step 2B,

above (see Figure 2).

3. Once the proper position of the angles is known, mark the angles in all areas of

interference between the angles and the tractor frame. For example, mark the areas

of the angle needed to be cut out to clear bolts, rivets, spring hangers, etc.

NOTE: A spacer may be

required to obtain

Figure 4

clearance between the

hydraulic cylinder (and

hoses) and the

transmission or cross

members. If a riser is

needed, it may be

necessary to use 5˝x 5˝

angles.

4. Remove the angles from the tractor frame and machine any interference areas in

accordance with the “

Installation: General Recommendations” found on the page 2.

5. Clamp the mounting angles tightly to the tractor frame. Be certain to check

clearances of cutouts. Drill holes in accordance with the “Installation: General

Recommendations” found on the page 2.

6. Remove the clamps and fasten the angles, in accordance with the “General

Information”. In addition, see Figure 5.

7. Position the fifth wheel

Figure 5

on the mounting angles

with the top plate pivot

on the marked location.

Verify that there are no

interferences and that

the fifth wheel frame

seats flush on the

mounting angles. Tack

weld the fifth wheel to

the mounting angles.

8. Weld the ends of the

fifth wheel assembly

frame to the top of the

mounting angles with

two 3/8˝ groove welds,

as shown in Figure 6.

4

Figure 6

XL-FW488 Rev A

INSTALLATION INSTRUCTIONS

5/16˝

3-8

1

/2˝

3/8˝

3-8

1

/2˝

FIFTH WHEEL

MOUNTING FRAME

MOUNTING ANGLE

continued

9. Remove the rear pivot shaft (see corresponding fifth wheel’s parts list — pages 11

through 12 — in combination with Chart 2 — to find the rear pivot shaft):

Chart 2

Rear Pivot Shaft Identification

FIFTH WHEEL REAR PIVOT SHAFT REAR PIVOT SHAFT

PART NUMBER PART NUMBER DETAIL NUMBER

FW2800-X XA-2895 Detail #7

FW2900-X XA-2895 Detail #7

FW2800-5X XA-2895 Detail #37

FW2900-5X XA-2895 Detail #37

10. Using a lifting device, pick up the rear support assembly (see corresponding fifth

wheel parts list in combination with Chart 3 to find the rear support assembly). For

safety, block out the assembly after it is lifted.

Chart 3

Rear Support Assembly Identification

FIFTH WHEEL ASSEMBLY ASSEMBLY

PART NUMBER PART NUMBER DETAIL NUMBER

FW2800-X XA-2808-B Detail #2

FW2900-X XA-2908-B Detail #2

FW2800-5X XA-2808-B Detail #32

FW2900-5X XA-2908-B Detail #32

11. Use air pressure to extend the cylinder rod(s) approximately 12˝. Be sure to cover

the cylinder rod(s) to protect from weld splatter.

12. Weld the fifth wheel frame to the mounting angles per

skip welds inside the frame, and 3/8˝ groove skip welds on the outside. Make the

skip welds 3˝ long on approximately 8-1/2˝ centers (i.e. weld 3˝ bead, skip 5-1/2˝).

Make inside skip welds opposite to the outside welds.

REAR SUPPORT REAR SUPPORT

Figure 7. Make 5/16˝ fillet

Figure 7

13. Reassemble the rear pivot shaft removed in Step 9.

XL-FW488 Rev A

5

POWER TAKE OFF (PTO) AND

HYDRAULIC PUMP INSTALLATION

General Information

1. Hydraulic fifth wheels require certain hydraulic components for operation. These

components should have the following characteristics:

A. Pump – Single cylinder, 17 gallon/minute @ 1300 r.p.m.

B. Power Take Off – Compatible with transmission and pump, and with an

output as close as possible to engine speed (i.e. 1-to-1 ratio).

C. Hose and Fittings – Should be of good quality and selected to handle the

maximum pump output at 2,000 p.s.i.

Hydraulic Oil – Selection of the proper oil is a prime requirement for

D.

satisfactory system performance and life.

Detailed Information

1. Install the PTO in accordance with the PTO manufacturer’s instructions. In the

absence of instructions, proceed as follows:

A. Start the tractor and listen to the transmission. After installation, the

transmission should sound similar.

B. Shut off the tractor and drain the transmission fluid.

C. Remove the transmission cover plate from the PTO installation point.

D. Check the PTO and transmission gears for proper width, diameter, and

location.

E. Install studs in the transmission.

F. Install gaskets and sufficient shims on the transmission.

G. Install the PTO. Draw the nuts evenly while checking the gear backlash. When

fully tightened, the backlash should be .008˝– .012˝. If the backlash is

incorrect, remove the PTO and add or remove the required shims.

H. Check for free shifting. If free, refill the transmission to the proper level.

I. Install the PTO shift controls.

J. Start the tractor. Engage the PTO and listen to the transmission. If any

unusual noises occur, inspect and correct using the shimming procedure

outlined above in Step F.

2. Install the hydraulic pump per the manufacturer’s recommendations.

Hydraulic Component Installation

1. Install the oil tank and brackets. The tank should be located as close to the pump

as possible, with the bottom of the tank higher than the inlet port on the pump.

2. Install the hydraulic control valve.

A. Manual – Locate the valve in the cab at a convenient operation location.

Then, route the hydraulic hoses through the cab to the pump, tank, and

manifold.

B. Air Operated – If your unit was purchased with the optional air operated

control valve kit (RK-2800-50), install as follows (refer to FIGURE 8 for the

following steps):

1. Mount the control valve/air cylinder assembly in a convenient location,

between the manifold and air valve.

2. Mount the lift control valve in the cab in a location were it will not be

accidentally activated.

3. With hoses, connect the air supply from a location recommended by the

chassis manufacturer.

6

XL-FW488 Rev A

POWER TAKE OFF (PTO) AND

LIFT CONTROL VALVE

FROM

TRACTOR

AIR SUPPLY

HYDRAULIC MANIFOLD

ADJUSTABLE

COUPLING

CONTROL VALVE/AIR CYLINDER ASSEMBLY

HYDRAULIC PUMP INSTALLATION

Hydraulic Component Installation continued

NOTE: Hose and fittings for these connections are to be supplied by the

customer/installer.

4. Connect the air lines from the lift control valve to the control valve/air

cylinder.

5. Connect the hydraulic hoses from the hydraulic valve to the hydraulic

manifold.

6. Operate the air lift control valve in both the up and down position, and

inspect the hydraulic control valve. In either position, the hydraulic

control valve must be fully actuated. If not, adjust the coupling until full

stroke is achieved (see

Figure 8

Figure 8.)

continued

3. Install all hydraulic hoses and fittings (as shown in the piping diagrams on pages

9 and 10) for the model selected. Use care to assure that all hoses and fittings are

clear and free from foreign material and that all joints are properly sealed.

4. Fill and bleed the hydraulic system.

A. Have, on hand, sufficient hydraulic oil for the model selected. The

approximate system volumes are given below:

MODEL: SYSTEM VOLUME

FW2800-X 71/2gallons

FW2800-5X 12 gallons

FW2900-X 6 gallons

FW2900-5X 91/2gallons

NOTE: These volumes ar

installation to installation. They ar

approximately 2-1/2 gallons reserve in the oil tank when the system is

filled and bled.

XL-FW488 Rev A

e approximate and will vary somewhat from

e designed to provide

7

POWER TAKE OFF (PTO) AND

HYDRAULIC PUMP INSTALLATION

B. Fill the oil tank (approximately 5 gallons), taking precautions not to let

foreign material into the tank. After the tank is filled, loosen the inlet fitting

on the pump until the oil drips out. Retighten the fitting. Start the engine and

shift the PTO into gear. Operate the engine at 1000 to 1200 r.p.m.

1.

Single Cylinder Models – Operate the hydraulic control valve to

completely raise the fifth wheel.

2. Twin Cylinder Models – Operate the hydraulic control valve to raise the

fifth wheel approximately one-third of it’s total height. Stop and refill the

oil tank. Raise the fifth wheel to two-thirds total height, and again fill the

oil tank. Raise to full height.

C. Check the fluid level in the oil tank. Be sure that it contains four inches of oil

(approximately half full) and add or remove oil if necessary.

D. Take the PTO out of gear and loosen the pipe plug on the front end of the

cylinder enough to let air bleed out. When oil starts to drip, retighten the

plug. Engage the PTO and lower the fifth wheel.

E. Completely raise and lower the fifth wheel. Disengage the PTO and check the

oil level in the tank.

5. System Check

A. Double check the fifth wheel installation

1. Are all fittings tight?

2. Are all mounting bolts properly tightened?

3. Is the fifth wheel frame properly welded to the mounting angle?

4. Is the oil tank approximately half full with oil?

5. Has the transmission been refilled with transmission fluid?

B. Lubricate the unit. Apply Dura Slide

the fifth wheel, and grease all of the grease fittings at pivot points in the

elevating fifth wheel mechanism.

C. Install the operating instructions in the tractor cab.

D. Check the proper operation of the fifth wheel locking mechanism by coupling

several times to a trailer or with a Holland TF-TLN-5001 lock tester. (The lock

tester may be used prior to lubricating the top plate.) Also test the operation

of the manual secondary lock.

E. Check the operation of the system in accordance with the operating

instructions by lifting, moving, and spotting a loaded trailer.

F. Shut the system down and check the hydraulic system for leaks. Also,

examine the mechanical components to assure that there are no interferences

with any components of the tractor frame.

TM

or grease to the top bearing surface of

continued

8

XL-FW488 Rev A

FW2800-X and FW2900-X

AIR PIPING

FOR FIFTH

WHEEL LOCKS

TO FIFTH WHEEL TOP PLATE LOCKS

FROM TRACTOR

AIR SUPPLY

1

2

3

4

5

12

13

PTO

GEAR

PUMP

14 and 15

(OPTIONAL)

16

(OPTIONAL)

26

10

3

9

7

6

8

ALL PARTS INSIDE THIS BOX

ARE PRE-ASSEMBLED

26

21

23

22

20

26

25

24

21

25

24

See page

8

11

27 27

18

19

17

ITEM PART NO. QTY DESCRIPTION

1 XB-2556 1 Fifth wheel lock control valve

2* XB-01786 1 Filler cap and breather

3* XA-01909 2 Mounting brackets

4* XB-01730 1 Oil tank

5 XB-02208 1 Pipe coupler – 11/4˝ NPT

6 XB-02209 1 90° reducing elbow

7 XB-2798-1 1 3/4˝ pipe nipple

8 XB-2783 1 Hydraulic oil filter

9 XB-2793 1 Straight male hose fitting 3/4˝-14 NPT, 5/8˝ I.D. hose

10 XB-2785 1 5/8˝ I.D. medium pressure oil hose, 51/2ft. long

11 XB-2790 1 Male adapter – 15/8˝-12 JIC, 11/4˝-111/2˝ NPTF

12 XB-2795 1 Straight swivel fitting 15/8˝-12 JIC x 11/8˝ I.D. hose

13 XB-2786-1 1 11/8˝ I.D. medium pressure oil hose, 51/2˝ long

14 XB-2781-1 1 (Optional) power take-off

15 XB-2781-1-A 1 (Optional) power take-off with air operated shifter

16 XB-04476 1 (Optional) hydraulic gear pump

17 XB-2794-1 1 Straight male hose fitting 1˝-11-1/2˝ NPT x 11/8˝ I.D. hose

18 XB-04478 1 Reducer bushing 1˝-11-1/2˝/1/2˝-14 NPT

19 XB-2791 1 Straight male hose fitting 1/2˝-14 NPT x 1/2˝ I.D. hose

20 XB-2937 1 11/6˝-12 JIC, 1/2˝ I.D. hose, SAE 37° flare

21 XB-2934 2 90° elbow 11/6˝-12 JIC, 3/4˝-14 NPT

22 XB-2782-1 1 Control valve

23

XB-2932 1 1

1

/

6

˝-12 JIC, 5/8˝ I.D. hose, 37° flare (JIC) swivel

24 XB-2939290° elbow 7/8˝-14 JIC, 1/2˝-14 NPT

25 XB-2938 2 SAE 37° flare (JIC) swivel, 7/8˝-14 JIC, 1/2˝ I.D. hose

26 XB-2784 3 1/2˝ I.D. medium pressure oil hose

27 XB-2792 2 Straight male hose fitting, 3/4˝-14 NPT, 1/2˝ I.D. hose

*Items 2, 3, and 4 are available individually or as XA-01911 tank assembly.

SINGLE CYLINDER ELEVATING FIFTH WHEEL

Piping Diagram Parts List

XL-FW488 Rev A

9

FW2800-SX and FW2900-5X

AIR PIPING

FOR FIFTH

WHEEL LOCKS

TO FIFTH WHEEL TOP PLATE LOCKS

FROM TRACTOR

AIR SUPPLY

1

2

3

4

5

6

7

8

XB-2790-3 FLANGE KIT

PTO

GEAR

PUMP

9 and 10

(OPTIONAL)

11

(OPTIONAL)

XB-2790-3

FLANGE KIT

13

13

3

17

15

18

14

16

12

A

LL PARTS INSIDE THIS BOX

ARE PRE-ASSEMBLED

See page 9

18

13

20

19

21

19

18

13

19

22

20

19

22

ITEM PART NO. QTY DESCRIPTION

1 XB-2556 1 Fifth wheel lock control valve

2* XB-01786 1 Filler cap and breather

3* XA-01909 2 Mounting brackets

4* XB-01730 1 Oil tank

5 XB-01924 1 Pipe reducer, 11/2˝ NPT to 11/4˝ NPT

6 XB-0257 1 Straight male hose fitting, 11/2˝ NPT, 13/8˝ I.D. hose

7 XB-2786 1 13/8˝ I.D. medium pressure oil hose, 51/2˝ ft.

8 XB-04479 1 90° split flange fitting, 11/4˝ flange, 13/8˝I.D. hose

9 XB-2781-1 1 (Optional) power take-off

10 XB-2781-1-A 1 (Optional) power take-off with air operated shifter

11 XB-04477 1 (Optional) hydraulic gear pump

12 XB-04480-1 1 90° split flange fitting, 11/4˝ flange, 3/4˝ I.D. hose

13 XB-2785-2 4 3/4˝ I.D. high pressure oil hose

14 XB-01788 1 90° elbow, 11/4˝ NPT

15 XB-0255 1 Pipe nipple, 11/4˝ NPT x 2˝ long

16 XB-2783-A 1 Oil filter

17 XB-0181 1 Reducing bushing, 11/4˝ x 3/4˝ NPT

18 XB-2794-2 3 Straight male hose fitting, 3/4˝ NPT, 3/4˝ I.D. hose

19 XB-0258-1 4 37° flare fitting, 11/16˝-12 JIC, 3/4˝ I.D. hose

20 XB-2934 2 90° elbow, 3/4˝-14 NPT, 11/16˝-12 JIC

21 XB-2782-1 1 Control valve

22 XB-2933 2 90° male elbow, 1/2˝-14 NPT, 11/6˝-12 JIC

*Items 2, 3, and 4 are available individually or as XA-01911 tank assembly.

TWIN CYLINDER ELEVATING FIFTH WHEEL

Piping Diagram Parts List

10

XL-FW488 Rev A

FW2800-X, FW2900-X, FW2800-X-87 and FW2900-X-87

HYDRAULIC CYLINDER PARTS

BRONZE

BUSHING

VEE

PACKING

R

OD

SCRAPER

26

13

12

11

(4 REQ.)

14

15

4*

2

0

24

2

1

2

5*

20

2

4

2

2

5*

23

21

1

7

(4 REQ.)

19

19

21

20

1

9

1

6

5*

3*

1

8

2*

22

1*

10

9 6*

7

8

27

27

29*

28*

29*

28*

ITEM PART NO. QTY DESCRIPTION

10 XA-2894 1 Front pivot shaft

11 XA-2928 4 Male connector

12 XB-2930 1 Hydraulic pump piping manifold

13 XB-C-38-C-214 2 Hex head bolt, 3/8˝-16 x 21/4˝

14 XB-2936 1 Hose assembly

15 XB-2936-1 1 Hose assembly

16 XA-2811 1 Clevis sub-assembly

17 XA-0861 4 Bronze bearing

18 XB-H-38-C 1 45° grease fitting

19 XB-H-38 5 Grease fitting

20 XB-0103 3 Lock nut, 1/2˝-13

21 XB-BR-12-C-4 3 Hex head bolt, 1/2˝-13 x 4˝

22 XB-767 2 Grease fitting

23 XA-2893 1 Axle shaft

24 XA-2809 2 Fifth wheel pivot shaft

* 25A XA-2801-AX-1 1 Fifth wheel top plate sub-assembly

* 25B XA-2801-AX-1

* 25C

XA-2801-07486-1

* 25D

XA-2801-07486-1

26 RK-2774 N/A Hydraulic cylinder rod bearing rebuild kit

27 XB-338 2 Lock nut,

3/8˝-16

* 28C XA-06245 2 Rest pad

* 28D XA-06245

* 29C XA-09498 2 Riser block

* 29D XA-09498

ITEM PART NO. QTY DESCRIPTION

* 1A XA-2806-2 1 Frame sub-assembly

* 1B XA-2906

* 1C XA-06288

* 1D XA-08172

* 2A XA-2808-B 1 Rear support assembly

* 2B XA-2908-B

* 2C XA-2908-B

* 2D XA-2808-B

* 3A XA-2807-B 1 Front support assembly

* 3B XA-2907-B

* 3C XA-2907-B

* 3D XA-2807-B

* 4A XA-2810-1 1 Cylinder sub-assembly

* 4B XA-2710-1

* 4C XA-2710-87

* 4D XA-2810-87

* 5A XA-2756-2 2 Wheel

* 5B XA-2756-3

* 5C XA-2756-3

* 5D XA-2756-2

* 6A XA-292-14 2 Mounting angle

* 6B XA-292-12

* 6C XA-292-12

* 6D XA-292-14

7 XA-2895 1 Rear pivot shaft

8 XB-6834 1 HHCS, 1/2-20 x 3/4˝

9 XB-21-S-375-3000 1 Rollpin

* An item with an “A” suffix denotes parts

used on FW2800-X.

An item with a “B” suffix denotes parts

used on FW2900-X.

An item with a “C” suffix denotes parts

used on FW2900-X-87.

An item with a “D” suffix denotes parts

used on FW2800-X-87.

SINGLE CYLINDER ELEVATING FIFTH WHEEL

Parts Explosion

XL-FW488 Rev A

11

FW2800-SX and FW2900-5X

HYDRAULIC CYLINDER PARTS

BRONZE

BUSHING

V

EE

P

ACKING

ROD

SCRAPER

56

34*

45

44*

43

42

(2 REQ.)

46

34*

31*

39

47

33*

35

32*

55

51

52 (2 REQ.)

35

53

41

(8 REQ.)

51

50

5

4

50

48

(4 REQ.)

50

54

51

49

(10 REQ.)

49

40 36*

37

38

41

ITEM PART NO. QTY DESCRIPTION

* 42 XB-338 2 Hex head lock nut, 3/8˝-16

43 XB-2930-A 1 Hydraulic pump piping manifold

* 44A XB-08894 2 HHCS, 3/8˝-16 x 23/4˝

* 44B XB-C-38-C-214 2 Hex head bolt, 3/8˝-16 x 21/4˝

45 XB-2936 2 Hose assembly

46 XB-2936-1 2 Hose assembly

47 XA-2811 2 Clevis sub-assembly

48 XA-0861 4 Bronze bearing

49 XB-H-38 10 Grease fitting

50 XB-0103 4 Lock nut, 1/2˝-13

51 XB-BR-12-C-4 4 Hex head bolt, 1/2˝-13 x 4˝

52 XB-767 2 Grease fitting

53 XA-2893 1 Axle shaft

54 XA-2809 2 Fifth wheel pivot shaft

55 XA-2801-AX-1 1 Fifth wheel top plate sub-assembly

56 RK-2774 N/A Hydraulic cylinder rod bearing rebuild kit

ITEM PART NO. QTY DESCRIPTION

* 31A XA-2806-2 1 Frame sub-assembly

* 31B XA-2906-1 1 Frame sub-assembly

* 32A XA-2808-B 1 Rear support assembly

* 32B XA-2908-B 1 Rear support assembly

* 33A XA-2807-2-B 1 Front support assembly

* 33B XA-2907-1-B 1 Front support assembly

* 34A XA-2810-1 2 Cylinder sub-assembly

* 34B XA-2710-1 2 Cylinder sub-assembly

35 XA-2756-2 2 Wheel

* 36A XA-292-10 2 Mounting angle

* 36B XA-292-15 2 Mounting angle

37 XA-2895 1 Rear pivot shaft

38 XB-6834 1 HHCS, 1/2-20 x 3/4˝

39 XA-2894-2 1 Front pivot shaft

40 XB-21-S-375-3000 1 Rollpin

41 XB-2928 8 Male connector

* An item with an “A” suffix denotes parts used on FW2800-5X.

* An item with a “B” suffix denotes parts used on FW2900-5X.

TWIN CYLINDER ELEVATING FIFTH WHEEL

Parts Explosion

12

XL-FW488 Rev A

Parts Explosion

ITEM PART NO. QTY DESCRIPTION

14 XB-T-69-A 3 Lock Nut, 1/2˝-20

15 XB-PW-1732-1-116 3 Washer, 1/2˝

16 XA-1705-11 1 Cam Plate S/A

17 XB-CX-58-F-134 1 HHCS, 5/8˝-18 x 1-3/4˝

18 XA-2524-R-13-X 1 Air Cyl. S/A for XA-2801-AX-1

19 XB-01996 1 90° Street Elbow

20 XB-2083 2 HHCS, 1/2˝-20 x 1-3/4˝

21 XB-T-49 1 Washer, 1/2˝

22 XA-1029 1 Roller

23 XB-GT-13-1 1 Extension Spring

24 XA-1704-X 1 Lock Set

25 XB-10267 1 Washer, 9/16˝

ITEM PART NO. QTY DESCRIPTION

1 XA-1707-16 1 Handle S/A Release

2 XB-1028-1 1 Spring

3 XB-5 2 Cotter Pin, 1/4˝ x 2˝

4 XA-3544-1-A 1 Handle S/A

5 XA-1703-F 1 Yoke

6 XA-1313 2 Lock Pin

7 XA-3528 1 Lock Bar

8 XB-2149 1 Torsion Spring

9 XA-1507-1 1 Cam Roller

10 XB-1030-1 2 Washer

11 XB-21-S-500-2750 1 Roll Pin

12 XB-1505 1 Spring

13 XA-1706-1 1 Yoke Shaft

4

13

12

5

11

7

8

1

0

16

9

10

1

7

2

0

25

22

21

14

20

14

18

15

2

1

24

23

3

3

6

6

1

5

15

1

4

19

XA-2801-AX-1

TOP PLATE

XL-FW488 Rev A

13

OPERATING PROCEDURES

Failure to read, understand and follow the important information

contained in these instructions may result in a hazardous condition or

cause a hazardous condition to develop.

elative to tractor-trailer operations, there are other checks, inpsections and

R

procedures not listed here, which are necessary, prudent and/or required by law. The

following is in addition to these and pertains to the fifth wheel only.

Perform these procedures with the area clear of obstacles and other personel.

Check Equipment Prior to Use

1. Make sure fifth wheel is properly lubricated.

2. Make sure secondary lock is disengaged (see Figure 1).

3. Make sure the fifth wheel locks are open.

4. Make sure the fifth wheel ramps are in the down position (see

Figure 2).

FOR NORMAL YARD USAGE

All elevating fifth wheels when towing trailers in the elevated

position are less stable than conventional tractor-trailers and are

sensitive to speed and maneuvers.

Coupling Procedures

1. Place handle in “Yard Use” position to retract top plate lockdown pins. To retract

pins, move handle from the “Highway Use” position (handle pointing toward rear

of tractor), to the “Yard Use” position (handle pointing toward front of tractor) as

shown on instruction label located above the handle on the left front side of the

fifth wheel frame assembly.

2. Confirm lockdown pins are in the retracted position. Both pins should be fully

retracted through the fifth wheel assembly frame rails and through lockdown plates

(see Figure 4).

3. Back up close to the trailer, centering the kingpin on the throat of the fifth wheel.

STOP.

4. Block the trailer’s wheels. Connect air lines and set the trailer brakes.

5. Check to see that the trailer is at the proper height for coupling. The front of the

bolster plate should contact the fifth wheel approximately 4 inches to the rear of

the fifth wheel’s articulation point. If not, raise or lower the fifth wheel to obtain

this position (see Figure 2).

6. Back under the trailer, engaging the fifth wheel locks with the trailer kingpin. Pull

forward to test the completeness of the coupling as an INITIAL check. Set the tractor

brakes.

A direct visual inspection assures proper coupling. The trailer plate

must be on the top plate of the fifth wheel and the locks closed on

the kingpin as shown in Figure 3.

7. Put transmission in neutral and engage power take-off (PTO).

8. Set engine speed to 1000 to 1200 r.p.m. and operate control valve to raise the trailer

to full height of fifth wheel. Release the control lever to hold fifth wheel height.

9. Disengage PTO, remove blocks, release trailer brakes and “MOV-ON”.

Uncoupling Procedures

m suppor

1. Position the trailer in the desir

landing gear.

2. Set the trailer brakes. T

3. Put transmission in neutral and engage PTO. NOTE: The PTO must be engaged

(pumped down) when lowering the fifth wheel.

14

ed location, one that assur

ractor brakes should be r

eleased.

es fir

t for the

XL-FW488 Rev A

OPERATING PROCEDURES

MANUAL

SECONDARY

LOCK HANDLE

SECONDARY

LOCK

SECONDARY LOCK

DISENGAGED

SECONDARY LOCK

ENGAGED

4" APPROX.

INITIAL CONTACT OF

TRAILER WITH FIFTH

W

HEEL AT THIS POINT

LOCKS

CLOSED

VIEW LOOKING INTO

THROAT OF FIFTH WHEEL

BOLSTER PLATE

FLUSH WITH

FIFTH WHEEL

KINGPIN PROTRUDES

BELOW LOCKS

LOCK PINS

EXTENDED

(FOR HIGHWAY

USE)

LOCK PINS

RETRACTED

(FOR YARD USE)

continued

4. Set engine speed to 1000 to 1200 r.p.m. and operate control valve to lower the

trailer until it rests on the landing gear.

5. Disengage the PTO, block the trailer wheels, disconnect and store the air lines and

light cord.

6. Check to see if the secondary lock is engaged. If it is engaged, release it by pulling

the secondary lock handle. To keep the lock open, place the handle loop end in the

parking hole of the top plate. This holds the lock away from the yoke. (See figure 1)

7. Push the fifth wheel lock control valve and hold in as you pull slowly out from the

trailer and “MOV-ON”.

FOR OVER-THE-ROAD YARD USAGE ON PUBLIC STREETS

AND HIGHWAYS

Coupling Procedures

1. Place fifth wheel in the full down position and engage top plate lockdown pins. To

XL-FW488 Rev A

Figure 1

Figure 2

Figure 3 Figure 4

This unit is not recommended for operation on public streets and

highways with the fifth wheel in the up position, Do not operate

engage pins, move handle from the “Yard Use” position (handle pointing toward

front of tractor), to the “Highway Use” position (handle pointing toward rear of

tractor) as shown on instruction label located directly above the handle on the left

front side of the fifth wheel frame assembly.

this unit on public streets and highways unless the fifth wheel is in

the full down position and the lockdown pins are fully engaged.

15

CABLE IS LOOSE - TIGHTEN BY ROTATING TURNBUCKLE

CABLE IS TIGHT - NO ADJUSTMENT NEEDED

OPERATING PROCEDURES

continued

Coupling Procedures continued

2. Confirm lockdown pins are in the extended position. Both pins should be fully

extended through fifth wheel assembly frame rails and through lockdown plates

(see Figure 4).

3. Back up close to the trailer, centering the kingpin on the throat of the fifth wheel.

STOP.

4. Block the trailer’s wheels. Connect air lines and set the trailer brakes.

5. Check to see that the trailer is at the proper height for coupling. The front of the

bolster plate should contact the fifth wheel approximately 4 inches to the rear of

the fifth wheel’s articulation point. If not, raise or lower the trailer landing gear to

obtain this position (see Figure 2).

6. Back under the trailer, engaging the fifth wheel locks with the trailer kingpin. Pull

forward to test the completeness of the coupling as an INITIAL check. Set the

tractor brakes.

A direct visual inspection assures proper coupling. The trailer plate

must be on the top plate of the fifth wheel and the locks closed

on the kingpin as shown in Figure 3.

7. Engage manual secondary lock. To engage the secondary lock, remove the handle

loop end from the parking hole in the top plate and allow the handle to move in

which causes the secondary lock to pivot behind the locking yoke. (See figure 1).

8. Fully retract the trailer landing gear.

9. Remove blocks, release trailer brakes and “MOV-ON”.

Uncoupling Procedures

1. Position the trailer in the desired location, one that assures firm support for the

landing gear.

2. Set the trailer brakes. Tractor brakes should be released.

3. Extend trailer landing gear to ground to support trailer.

4. Block trailer wheels, disconnect and store air lines and light cord.

5. Check to see if the secondary lock is engaged. If it is engaged, release it by pulling

the secondary lock handle. To keep the lock open, place the handle loop end in the

parking hole of the top plate. This holds the lock away from the yoke (see Figure 1).

6. Push the fifth wheel lock control valve and hold in as you pull slowly out from the

trailer and “MOV-ON”.

Maintenance

1. Check top plate lockdown mechanism cables. With handle in “Highway Use”

position cable should be moderately tight and not sagging excessively. If cable is

loose, rotate turnbuckle to tighten cable (see

2. After tightening, cycle handle from “Yard Use” to “Highway Use” position several

times to confirm pins are extending and retracting as described above and to

confirm cables are not binding or being pinched.

Figure 5

16

Figure 5).

XL-FW488 Rev A

XL-FW488 Rev A

17

18

XL-FW488 Rev A

WARRANTY

COMMERCIAL

PRODUCTS

WARRANTY

olland warrants all Commercial Products (products

H

other than those normally used for personal, family,or

household purposes) manufactured by it, when

properly installed, to be free from defects in material

and workmanship under normal use and service for a

period of two (2) years from the date of manufacture,

with the exception of elevating fifth wheels for which

the warranty period is 180 days.

This warranty is void with respect to any product

which has been altered in any way from its

manufactured condition, such as intentional

modification, accident, corrosion,misuse, failure to

provide necessary and reasonable maintenance and is

exclusive of normal wear.

The sole responsibility of Holland under this warranty

is limited to repairing or replacing at the factory any

part or parts which are returned, with transportation

charges prepaid,and are found to be defective to the

satisfaction of Holland.Written authorization from

Holland must be obtained prior to returning any part

or parts. No charges for transportation or for labor

performed on Holland products by unauthorized

persons will be allowed under this warranty.

XL-FW488 Rev A

Holland shall not be liable, in any event, for proximate,

incidental, consequential or other damages, including

but not limited to damages for loss of production

or injury to persons or property arising out of any

breach of this warranty.

THERE ARE NO WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING THE WARRANTY OF

MERCHANTABILITY OR A WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE

EXTENDING BEYOND THAT SET FORTH ABOVE.

Warranty

19

20

Copyright © July 2005 • The Holland Group, Inc.

maintain this fifth wheel could result in

tractor and trailer separation causing death

or serious injury to others.

operation, and maintenance of this product. Read and

Failure to properly install, operate, or

understand this information.

IMPORTANT: Enclosed is important information for the installation,

XL-FW488 Rev A

Loading...

Loading...