FIFTH WHEEL

OWNER’S

MANUAL

FW6000 and FW6200 Series

Fifth Wheel

Installation, Operation,

Maintenance Procedures and

Comprehensive Warranty

TECHNOLOGY

XL-FW485 Rev A

Questions or Comments?

Call

www.thehollandgroupinc.com

FIFTH WHEELS

1-888-396-6501

INSTALLATION INSTRUCTIONS

Failure to read, understand and follow the important information

contained herein may result in a hazardous condition or cause a

hazardous condition to develop.

Fifth Wheel Design and Intended Use:

1. For pulling trailers with standard SAE kingpins which are in good condition and

securely mounted or locked in position in the trailer.

2. Within the capacities stated in Holland literature.

3. As recommended in Holland literature (available from Holland or Holland distributors).

Holland Fifth Wheels are NOT Designed or Intended For:

1. Use with non-SAE kingpins, such as kingpins which are bent, improper size or

dimension, not secured to maintain SAE configuration, or which are installed in

warped trailer bolster plates.

2. Tow-away operation.

3. The attachment of lifting devices.

4. The transport of loads in excess of rated capacity.

5. Applications other than recommended.

Installation

General Recommendations

1. Every user and installer using Holland products either recommended or not

recommended by Holland, must thoroughly satisfy himself that the installation

procedure used is appropriate for the vehicle, product and application.

2. Consult the Holland literature for fifth wheel capacities and applications.

3. Consult the tractor manufacturer’s body builder’s book and the latest SAE and

D.O.T. standards for additional installation methods. Holland recommends the

T.M.C. Recommended Maintenance Practice 603B for installation procedures.

4. Determine the proper fifth wheel position. See SAE J701a for proper placement, as

well as the tractor manufacturer’s body builder’s book.

Note: The center of the kingpin locks must always be positioned on or ahead of the truck

rear axle.

5. Use Grade 8, 1/2˝ minimum diameter bolts and Grade “C” locknuts for mounting.

6. Bolt holes can be 1/32˝ larger in diameter than the bolt fastener. Bolts must be

adequately tightened using charted torque ranges in foot-pounds for the

recommended Grade 8, 1/2˝ diameter bolts. Larger diameter Grade 8 bolts and

coated fasteners may be used.

7. The bolts attaching the fifth wheel mounting angles to the truck frame require

hardened steel washers under both the bolt and under the locknut, unless flanged

head bolts or flanged head locknuts are employed.

8. Whenever a cutout is made on the mounting angle, such as required to bypass

suspension components, a 1˝ minimum radius should be used and bolts should be

placed within 1-1⁄2˝, but not closer than 1˝ of the cut, fore and aft.

Do not use U-bolts in fifth wheel installation.

ecommended at the rear of the truck-tractor frame.

9. Trailer pick-up ramps ar

10. When mounting to aluminum frames, follow the truck manufacturer’s

recommendations. Holland has available a stationary mounting angle intended for

use on aluminum frames; contact Holland or Holland Distributors for availability

11. Review, in addition, the specific information on the following pages for each type of

fifth wheel mounting, as well as “

e r

.

Inspection and Lubrication Prior to Use”.

2

XL-FW485 Rev A

INSTALLATION INSTRUCTIONS

continued

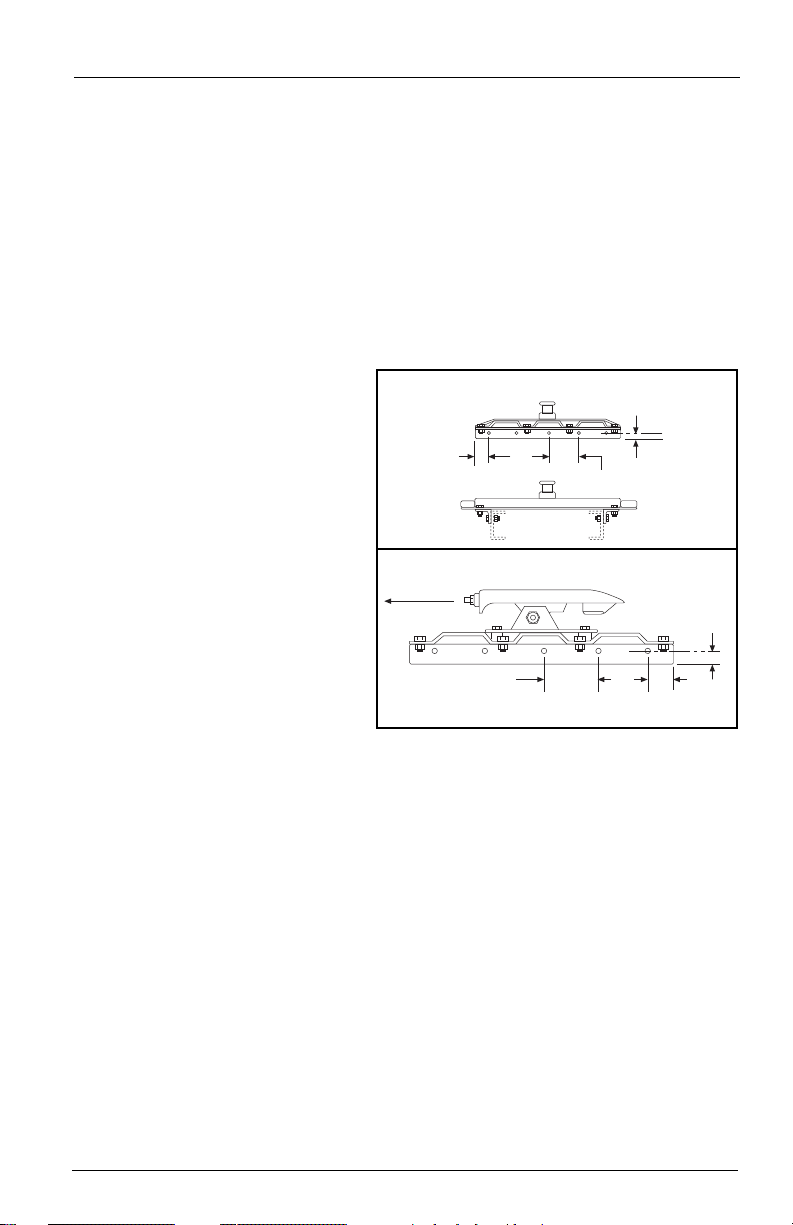

Tractor Coupler Mounting (Kingpin or Fifth Wheel)

Straight Frame - Without a Body:

In addition to the general installation recommendations listed above, the

following specific recommendations should be followed:

1. If a folding kingpin is to be installed, see additional procedures under “Tractor Coupler

Mounting (Kingpin or Fifth Wheel) - Non-Straight Frame - With or Without a Body,” on the

next page.

2. Attach the mounting plate (kingpin or fifth wheel plate) to the frame using a fulllength mounting angle, ASTM A36, 3˝ x 3˝ x 5/16˝ minimum on each side.

3. When initially positioning the coupler plate for frame holes, the full length of the

mounting plate should seat flush on the top and side surface of the truck-trailer

frame rails to prevent flexing

and give uniform weight

distribution. There should not

be a gap over the top of the

truck frame rails. It is also

recommended to chamfer or

smooth sharp edges and corners

of mounting materials whenever

contact is made with the trucktractor frame. See

mounting diagrams. A

minimum of four (4) Grade 8˝,

1/2˝ diameter (minimum) bolts

must be used to attach each

mounting angle to the frame.

The distance between the bolts

must not exceed 8˝, except

when cutouts are required in

the mounting angles.

Figure 1 for

FRONT OF

VEHICLE

KINGPIN ATTACHMENT

1˝ MIN.

2˝

8˝ MAX.

FIFTH WHEEL ATTACHMENT

8˝ MIN.

Figure 1

1˝ MIN.

2˝

XL-FW485 Rev A

3

INSTALLATION INSTRUCTIONS

25/8˝

26˝

20˝

40˝

31/4˝

3

1

/4˝

9

7

/8˝

27/8˝

continued

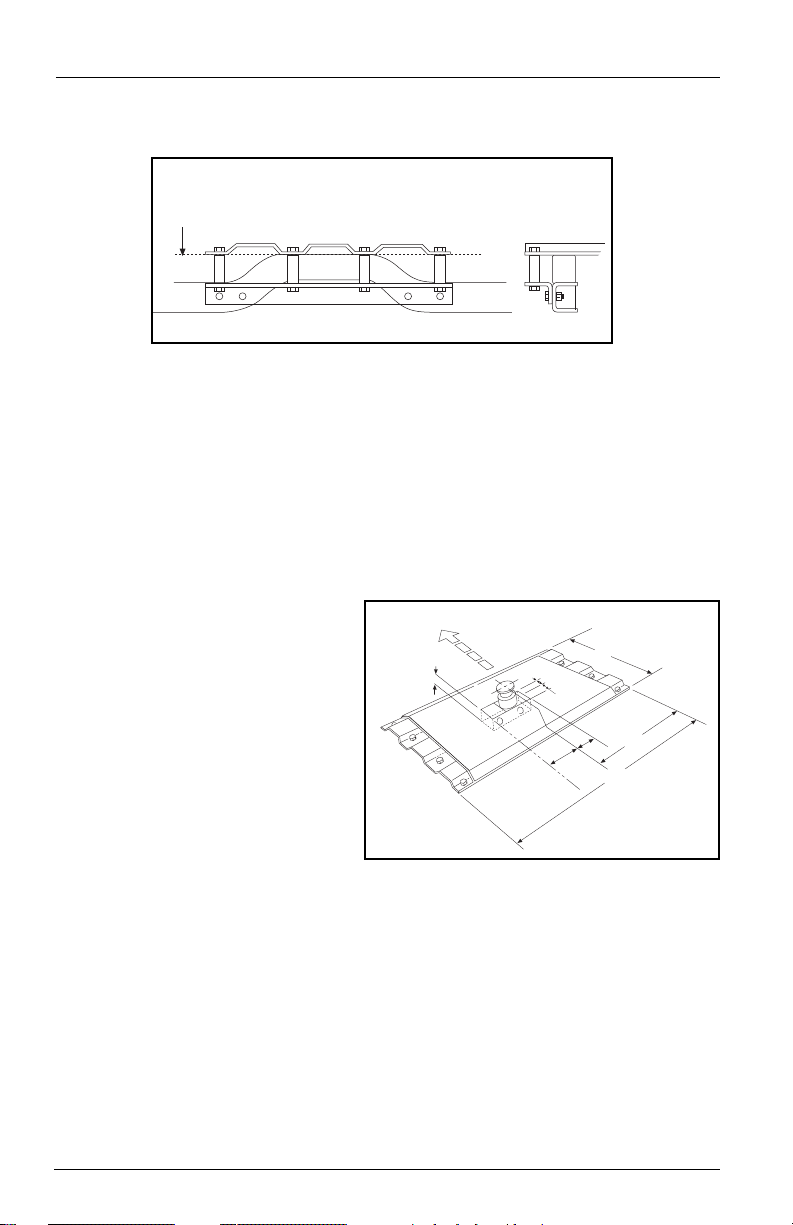

Tractor Coupler Mounting (Kingpin or Fifth Wheel)

Non-Straight Frame – With or Without a Body:

PREFERRED MOUNTING METHOD

BODY FLOOR

Figure 2

1. Full Angle Mounting – Preferred

In addition to the general installation recommendations listed on the previous

page, the following specific recommendations must be followed:

A. If a folding kingpin is to be installed, the following procedures must be

completed before going to step C:

1. The 40˝ dimension of the kingpin plate must be installed parallel with the

rear axle with the upright kingpin centered between the pickup sides.

2. Check under the floor in the area where the kingpin is to be located to avoid

interference with the differential, drive shaft or frame cross members. The

area should be clear 3˝ below the floor when the springs are fully bottomed.

3. Cut a hole in the truck floor

to receive the folding

kingpin box (see

Figure 4).

NOTE: The folding kingpin base is

offset. Cut three sides of the floor and

fold the flap down and out of the way.

B. Initially position the coupler

plate in the box or on the frame in

the desired position (at least 2˝

ahead of the rear axle). If possible,

the coupler plate should be

attached using a full-length

mounting angle (3˝ x 3˝ x 5/16˝

minimum, ASTM A-36) on each

side (see

Figure 2).

C. A minimum of four (4) Grade 8, 1/2" diameter (minimum) bolts must be applied

to attach each mounting angle to the frame rail.

D. Proper length tube spacers (3/4˝ I.D. x 1 1/2˝ O.D. recommended) must be used

to shim the distance between the mounting angle and the coupler mounting

plate (minimum of 4 per side).

FRONT OF TRUCK

Figure 4

4

XL-FW485 Rev A

INSTALLATION INSTRUCTIONS

1/4 2 – 6

TYP.

3/16 2 – 6

TYP.

continued

ACCEPTABLE MOUNTING METHOD

BODY FLOOR

Figure 3

2. Tab Mount - Acceptable

In addition to the general installation recommendations listed on the previous page,

the following specific recommendations must be followed:

A. If a full-length mounting angle is impractical, an angle TAB mount, as shown in

Figure 3, is acceptable. The angle TABS should be 3˝ x 3˝ x 3/8˝ x 3˝ long

minimum, using an ASTM A36 steel. A minimum of 4 TABS per side are required.

B. The TABS must be attached to the tractor frame using 1/2" diameter (minimum)

Grade 8 fasteners.

C. Proper length tube spacers (3/4˝ I.D. x 1 1/2˝ O.D. recommended) must be used

to shim the distance between the TAB angles and the coupler mounting plate.

Tractor Coupler Mounting – Kingpin or Fifth Wheel Mount:

The kingpin mounting box is designed to be attached to the trailer frame by welding. It

is imperative, therefore, that the attachment is substantial enough to develop the full

strength of the hitch.

When welding, use a procedure which assures a sound, good quality

cause distortion and damage and underwelding may not develop sufficient strength. A

low hydrogen process and AWS E70XX filler metal are recommended. Take precautions

to insure that the trailer electrical system is not damaged by the welding.

1. Weld as shown in Figure 5, making 1/4˝ fillet welds on the inside and 3/16˝ fillet welds

on the outside, with skip welds 2˝ long on approximately 6" centers (weld 2˝, skip

4˝). Weld inside opposite skips on the outside.

2. Install and adjust inner box to required height. Use the six (6) Grade 5 fasteners

provided (2 each hole series) and tighten to 65 ft. - lbs.

3. When installing a fifth wheel

on a trailer mounting box, be

certain that the open end of

the fifth wheel faces the front

of the trailer (see

XL-FW485 Rev A

weld and which protects the operator and others. Over-welding may

Figure 7A).

Figur

e 5

5

F

RONT OF VEHICLE

CORRECT ENGAGEMENT

M

ounting Box

for Fifth Wheel

t

o Trailer

C

HECK NO. 3

N

o Space

between Fifth

W

heel and

Kingpin Plate

No Space

Bed of

Truck

Space

S

PACE

INCORRECT ENGAGEMENT

Mounting Box

for Fifth Wheel

to Trailer

Bed of Truck

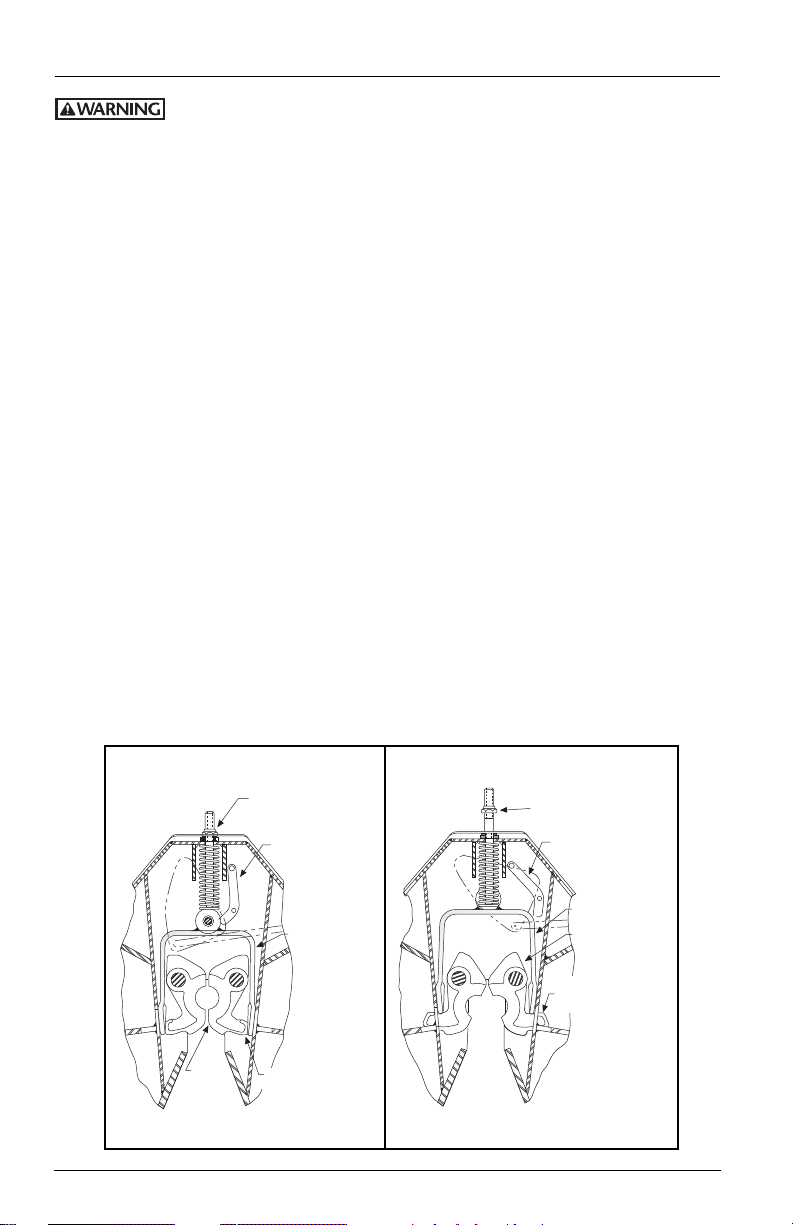

OPERATING INSTRUCTIONS

LOCKS SHOWN IN CLOSED POSITION

CHECK NO. 1

Nut Seated on

Fifth Wheel

CHECK NO. 2

Secondary Lock

Behind Yoke

Yoke

Yoke Flush with

Ends of Locks

Locks

LOCKS SHOWN IN OPEN POSITION

NOTE:

Nut away from

Fifth Wheel

NOTE:

Secondary Lock

away from Yoke

Yoke

NOTE: Locks

Extend through

Window to Open

Locks

SOLID

STUD

YES!

PIPE

RELEASE

HANDLE

RELEASE

HANDLE

NO!

ADJUSTING

BOLT & NUT

NO!

PUSH

TOWARD

TRAILER

Relative to tractor/trailer operations, there are other checks, inspections,

and procedures not listed here, which are necessary, prudent, and/or

required by law. The following is in addition to these, and pertains to the fifth wheel only.

Perform these procedures with the area clear of obstacles and other personnel.

Coupling Procedures

1. Check out the equipment before coupling.

A. Make sure that the fifth wheel is properly lubricated, that the locks are open,

and that the ramps are tilted in the proper position.

B. Make sure the mounting of the fifth wheel is in good condition and is tight.

C. Make sure the power/brake line and breakaway line (if the trailer is equipped

with electric brakes) and clear of the coupling area.

2. If the tractor is equipped with a body, lower the tailgate.

3. Back up close to the trailer, centering the kingpin on the crotch of the fifth wheel.

STOP!

4. Chock the trailer wheels.

5. Check the trailer height for coupling. The fifth wheel should just touch the kingpin

plate; adjust the landing gears as necessary.

6. Back

7. Visually check to see that the kingpin is in the fifth wheel lock.

8. Visually check that the locks are properly locked on the kingpin by the following (3) checks.

slowly under the trailer, keeping the kingpin centered in the crotch of the fifth

wheel until the fifth wheel locks firmly on the kingpin. Pull forward to check the

completeness of the coupling as an initial check.

CHECK 1

The adjustment nut must be seated against the fifth wheel (see Figure 6A).

CHECK 2

The secondary lock must be behind the yoke (see Figure 6A).

Figure 6A Figure 6B

6

XL-FW485 Rev A

F

RONT OF VEHICLE

CORRECT ENGAGEMENT

M

ounting Box

for Fifth Wheel

t

o Trailer

C

HECK NO. 3

N

o Space

between Fifth

W

heel and

Kingpin Plate

No Space

Bed of

Truck

Space

S

PACE

INCORRECT ENGAGEMENT

Mounting Box

for Fifth Wheel

to Trailer

Bed of Truck

OPERATING INSTRUCTIONS

SOLID

STUD

YES!

PIPE

RELEASE

HANDLE

RELEASE

HANDLE

NO!

ADJUSTING

BOLT & NUT

NO!

PUSH

TOWARD

TRAILER

Coupling Procedures continued

CHECK 3

The fifth wheel must be flush with the kingpin plate (see Figure 7A).

A direct visual inspection is required to assure proper coupling. Do not

use any fifth wheel which does not operate properly.

continued

9. Connect the

power/brake

Figure 7A

line(s).

10. If the trailer is

equipped with

electric brakes,

connect the

breakaway switch

line.

11. Retract the

landing gears,

raise the tailgate,

Figure 7B

pick up the wheel

chocks.

Uncoupling Procedure

1. Set trailer brakes and chock trailer wheels.

2. Lower the landing gear; when the foot pad contacts the ground, crank two or three

additional turns to reduce the vertical load on the fifth wheel. Do not raise the fifth

wheel off the kingpin plate.

3. If the truck/tractor is equipped with a body, lower the tailgate.

4. Disconnect the power/brake line and, if the

trailer is equipped with electric brakes,

unhook the breakaway switch line. Do not

disconnect at the switch.

5. Open the fifth wheel locks by . . .

A. pulling the release handle or . . .

B. from the driver’s side, slide a pipe

release handle over the solid stud,

located next to the adjusting bolt and

push toward the rear of the vehicle

(see

handle.

6.

Drive away from the trailer slowly.

e 8

Figur

). Remove and stor

7. Raise the tailgate if so equipped.

XL-FW485 Rev A

e the

Figure 8

7

MAINTENANCE PROCEDURES

1/4 2 – 6

TYP.

3/16 2 – 6

TYP.

1. All maintenance must be performed by a qualified person using

proper tools and safe procedures.

2. All maintenance must be performed while the tractor is uncoupled

from the trailer.

As-Needed Lubrication

1. Keep a water-resistant lithium-base grease applied to the trailer contact surface of

the fifth wheel plate.

2. Lubricate all moving parts with a light, rust-resistant oil.

3. Apply a light grease through the grease zerks at the pivot points and the cam.

Periodic Inspections and Adjustments

NOTE: All of the following must be performed every 30,000 miles or 3 months, whichever

comes first. Perform the inspections after steam cleaning to assure a good inspection.

Inspection — General

1. Inspect the fifth wheel and the kingpin mountings. Check torque and replace any

missing or damaged bolts. Check for broken or distorted components and repair or

replace as needed.

2. Inspect the fifth wheel assembly for bent, worn or broken parts. Replace with

HOLLAND parts only.

Fifth Wheel Locking Mechanism Inspection and Adjustment

1. Check the operation of the fifth wheel locking mechanism using a HOLLAND

TF-TLN-1000 (2˝ kingpin) or TF-TLN-1500 (31/2˝ kingpin) Lock Tester. Inspect for

proper locking as described in the “Operating Instructions” in this manual.

Do not use any fifth wheel which does not operate properly.

2. Check adjustment of the fifth wheel locks and adjust as required. The lock adjusting

nut is located at the front edge of the fifth wheel (see Figure 6A on page X). With

the wheel locked around the lock tester, tighten or loosen the nut until the rubber

washer seats snugly against the fifth wheel (but can still be turned by hand).

Viewed from the adjusting nut, a counter-clockwise rotation of the nut will allow

the yoke (see Figure 6A) to move in and tighten the locks on the kingpin. A

clockwise rotation will pull the yoke out and loosen the locks. Remove and reinsert

the lock tester to verify proper adjustment and coupling.

3. Relubricate by applying a light, rust-resistant oil to all moving parts.

8

XL-FW485 Rev A

XL-FW485 Rev A

9

10

XL-FW485 Rev A

WARRANTY

COMMERCIAL

PRODUCTS

WARRANTY

olland warrants all Commercial Products (products

H

other than those normally used for personal, family, or

household purposes) manufactured by it, when

properly installed, to be free from defects in material

and workmanship under normal use and service for a

period of two (2) years from the date of manufacture,

with the exception of elevating fifth wheels for which

the warranty period is 180 days.

This warranty is void with respect to any product

which has been altered in any way from its

manufactured condition, such as intentional

modification, accident, corrosion, misuse, failure to

provide necessary and reasonable maintenance and is

exclusive of normal wear.

The sole responsibility of Holland under this warranty

is limited to repairing or replacing at the factory any

part or parts which are returned, with transportation

charges prepaid,and are found to be defective to the

satisfaction of Holland.Written authorization from

Holland must be obtained prior to returning any part

or parts. No charges for transportation or for labor

performed on Holland products by unauthorized

persons will be allowed under this warranty.

XL-FW485 Rev A

Holland shall not be liable, in any event, for proximate,

incidental, consequential or other damages, including

but not limited to damages for loss of production

or injury to persons or property arising out of any

breach of this warranty.

THERE ARE NO WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING THE WARRANTY OF

MERCHANTABILITY OR A WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE

EXTENDING BEYOND THAT SET FORTH ABOVE.

Warranty

11

12

Copyright © July 2005 • The Holland Group, Inc.

maintain this fifth wheel could result in

tractor and trailer separation causing death

or serious injury to others.

operation, and maintenance of this product. Read and

Failure to properly install, operate, or

understand this information.

IMPORTANT: Enclosed is important information for the installation,

XL-FW485 Rev A

Loading...

Loading...