Owners Manual

FW31 and XA-311 Series

®

Fifth Wheels

with Traditional Slider

• Operation

• Maintenance Procedures

• Comprehensive Warranty

XL-FW436-01 Rev B

GENERAL SAFETY INFORMATION

Notes, Cautions, and Warnings

You must read and understand all of the safety procedures presented in this manual

before starting any work on the SAF-HOLLAND product.

NOTE: In the United States, work shop safety requirements are defined by federal

and/or state Occupational Safety and Health Act or equivalent laws in other

countries. This manual is written based on the assumption that OSHA or other

applicable employee safety regulations are followed by the location where work is

performed.

Proper tools must be used to perform the maintenance and repair procedures

described in this manual. Many of these procedures require special tools.

Throughout this manual, you will notice the terms “NOTE”, “IMPORTANT”,

“CAUTION”, and “WARNING” followed by important product information. So that

you may better understand the manual, those terms are as follows:

NOTE: Includes additional information to enable accurate and easy performance

of procedure.

IMPORTANT: Includes additional information that if not followed could lead

to hindered product performance.

Used without the safety alert symbol, indicates a potentially

hazardous situation which, if not avoided, may result in property

damage.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Fifth Wheel Design and Intended Use

1. For pulling trailers with standard SAE kingpins which are in good condition and

securely mounted or locked in position in the trailer.

2. For on-highway hauling applications.

3. Within the capacities stated in SAF-HOLLAND literature.

4. As recommended in SAF-HOLLAND literature (available from www.safholland.us).

Holland Fifth Wheels are NOT Designed or Intended For

1. Use with non-SAE kingpins, such as kingpins which are bent, improper size or

dimensions, not secured to maintain SAE configuration, or which are installed in

warped trailer bolster plates.

2. Tow-away operations which damage or interfere with the proper operation of the

fifth wheel.

3. The attachment of lifting devices.

4. The transport of loads in excess of rated capacity.

5. Off-highway applications and use.

6. Applications other than recommended.

2 SAF-HOLLAND, Inc. XL-FW436-01 Rev B

OPERATION INSTRUCTIONS

➠

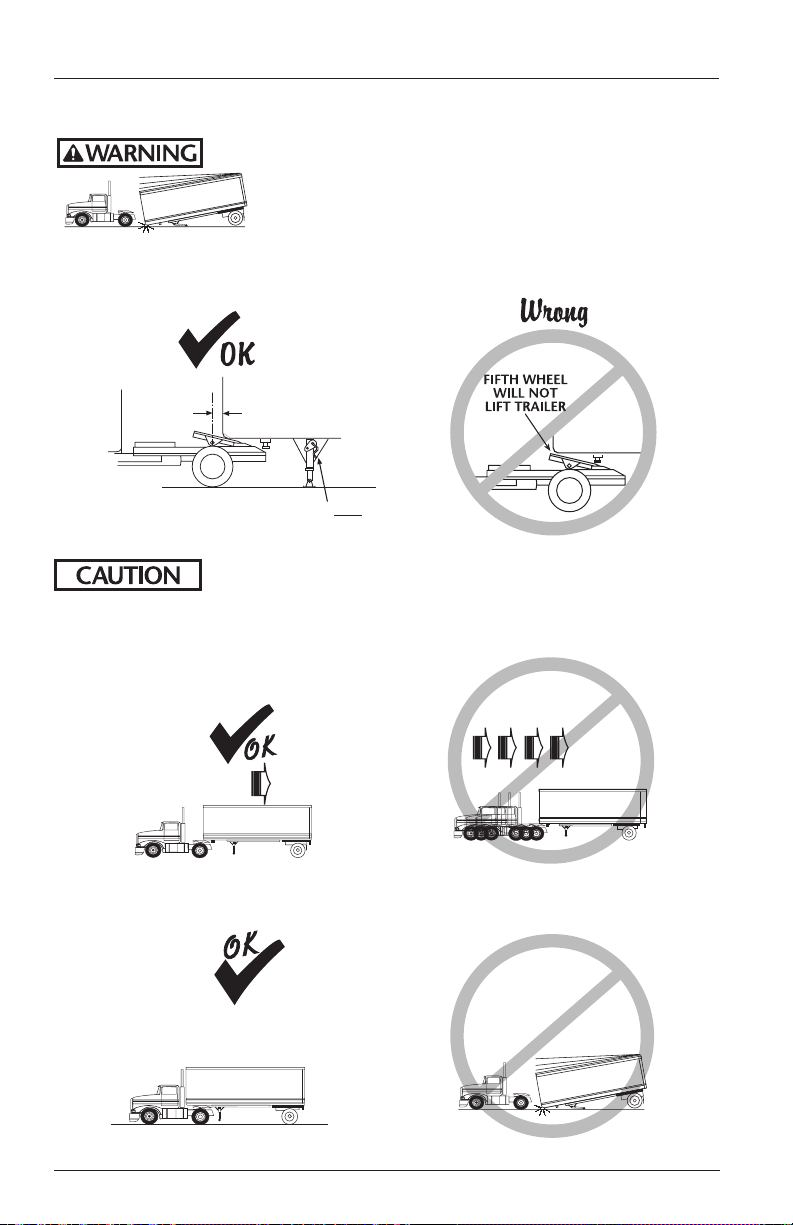

Failure to properly install, operate, or maintain this fifth

wheel may result in tractor and trailer separation which, if

not avoided, could result in death or serious injury.

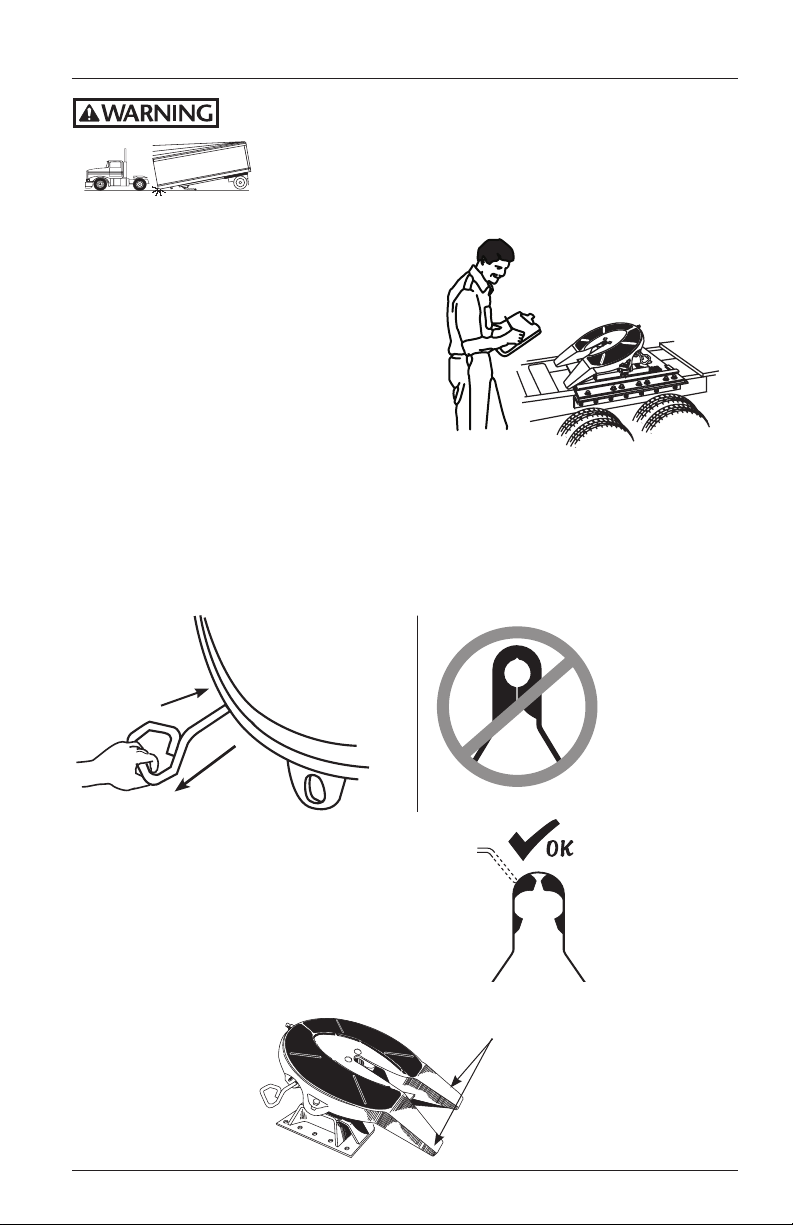

Fifth Wheel Inspections

1. Inspect the fifth wheel and mounting.

• Confirm that the lube plates

are in place and firmly attached.

• Tighten loose fasteners.

• Replace missing fasteners.

• Repair/replace missing,

cracked or otherwise

damaged components.

• For sliding fifth wheels, make sure both plungers

are fully engaged (see Page 14).

2. Make sure the lock is open. To open the lock, pull the release handle all the way

out. If Air Release equipped, set tractor brakes and actuate the fifth wheel control

valve to open the locks.

Grease

fitting

location

If locks are closed,

pull release

handle all the

way out.

Locks are closed

and the fifth

wheel is locked.

DO NOT

attempt to

couple!

3. Inspect the lock jaws. If they appear dry,

apply grease to lock jaws and front of throat

directly or through the lube tube grease

fitting. Coupled lock jaws and front of throat

can be lubricated through lube tube grease

fitting (see page 15).

4. Tilt the ramps down.

XL-FW436-01 Rev B SAF-HOLLAND, Inc. 3

TILT

DOWNWARD

The locks are

open and ready

to couple.

OPERATION INSTRUCTIONS con ti nu ed

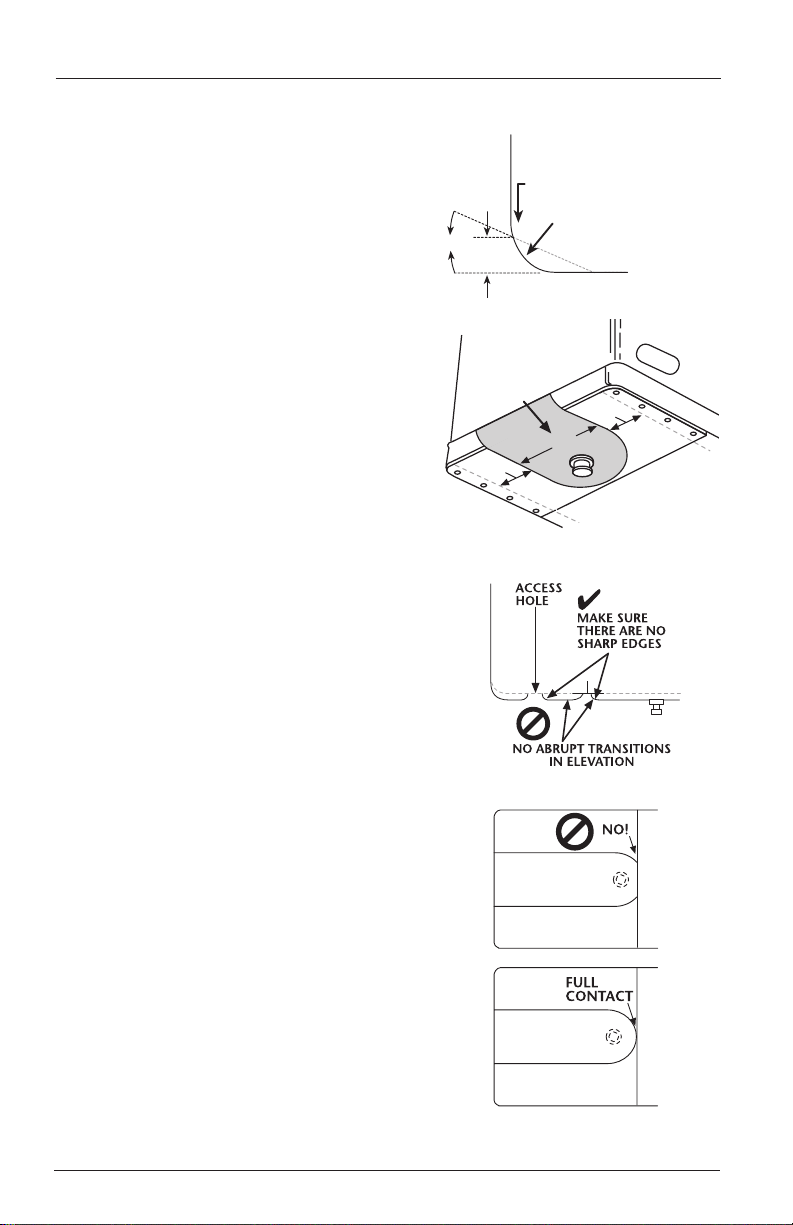

Trailer Upper Coupler Inspections

1. Inspect the leading edge of the trailer

bolster/skid plate. It must be free of

any square or sharp edges.

2. Make sure there are no bolts or nuts

extending below the bolster/skid plate

within 6˝ of the fifth wheel travel path

while coupling.

3. The area that is supported by the fifth

wheel should be free of any large

holes or gouges.

4. Any access holes that the fifth wheel

passes below should have chamfered

or radius edges.

5. Check that any splits from the skid

plate to bolster plate are welded

adequately and that there are no

sharp edges or abrupt changes in

elevation.

6. The upper coupler should extend

adequately rearward to maintain full

contact with the fifth wheel during

tight turning. If it does not, at a

minimum, the rear edges should be

chamfered or radius edges.

20ϒ

2˝

min.

Keep path of fifth

wheel free of

large holes

& gouges

6˝min.

✔

CHAMFERED (Preferred)

or LARGE RADIUSED

LEADING EDGE

6˝min.

40˝

Keep bolts and nuts

clear of this area

7. Make sure that any upper coupler

residual grease is free of heavy coarse

grit.

8. Ensure that the upper coupler fifth

wheel contact surface is free of rust.

Do not paint the contact area! The

area should be conditioned with rust

inhibitor such as a light oil.

9. Inspect the kingpin for excessive wear

and damage (use Holland tool TF-0110

Kingpin Gage) along with bolster bow

(see SAE 1700).

✔

4 SAF-HOLLAND, Inc. XL-FW436-01 Rev B

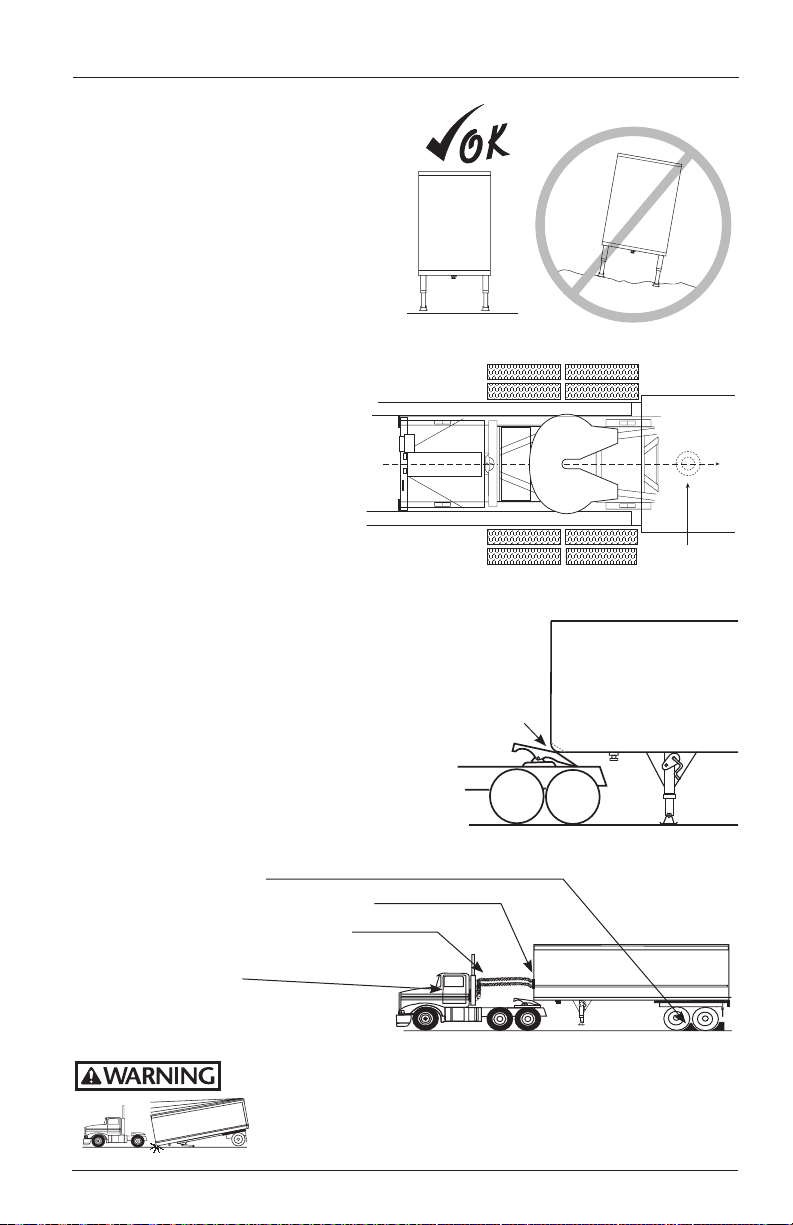

OPERATION INSTRUCTIONS

➠

Coupling Procedures

1. Make sure the coupling area is

flat, level, and clear of persons and

obstacles.

2. Center the fifth wheel with the

kingpin and back up straight.

3. Back the tractor close to the

trailer and STOP.

continued

TRAILER

(TOP)

KINGPIN

Back in and

STOP!

4. Chock trailer wheels.

5. Connect brake lines and light cord.

6. Support slack in lines to prevent

interference.

7. Set trailer brakes.

Failure to properly install, operate, or maintain this fifth

wheel may result in tractor and trailer separation which, if

not avoided, could result in death or serious injury.

XL-FW436-01 Rev B SAF-HOLLAND, Inc. 5

OPERATION INSTRUCTIONS

➠

Coupling Procedures continued

Failure to properly install, operate, or maintain this

fifth wheel could result in tractor and trailer separation,

causing death or serious injury to others.

8. Adjust the trailer height so the fifth wheel will lift the trailer.

The trailer should contact the fifth wheel 4˝ – 6˝ behind the fifth wheel bracket pin.

continued

➠

FIFTH WHEEL

4˝- 6˝

MUST LIFT

TRAILER

➠

FIFTH WHEEL

TILTED DOWN

Attempting to couple with the trailer at an improper height

could result in a false or improper coupling.

9. Slowly back into the trailer.

BACK INTO TRAILER

SLOWLY

USE LOW

GEAR

➠

10. Do a pull test as an INITIAL CHECK.

➠

➠

PULL TEST

➠

DO NOT

BACK INTO

TRAILER FAST

➠ ➠ ➠ ➠

WITHOUT

PULL TEST

➠

PULL FORWARD WITH TRACTOR

6 SAF-HOLLAND, Inc. XL-FW436-01 Rev B

Loading...

Loading...