Owners Manual

FW2800 and FW2900 Series

Hydraulic Elevating Fifth Wheels

• Operation

• Maintenance Procedures

• Troubleshooting

XL-FW428-01 Rev A

OPERATING INSTRUCTIONS

Notes, Cautions, and Warnings

You must read and understand all of the safety procedures presented in this manual

before starting any work on the SAF-HOLLAND product.

NOTE: Work shop safety requirements are defined by federal and/or state

Occupational Safety and Health Act in the United States, or equivalent laws

in other countries. This manual is written based on the assumption that

OSHA or other applicable employee safety regulations are followed by the

location where work is performed.

Proper tools must be used to perform the maintenance and repair procedures

described in this manual. Many of these procedures require special tools.

Throughout this manual, you will notice the terms “NOTE”, “IMPORTANT”,

“CAUTION”, and “WARNING” followed by important product information. So that

you may better understand the manual, those terms are as follows:

NOTE: Includes additional information to enable accurate and easy performance

of procedure.

IMPORTANT: Includes additional information that if not followed could lead

to hindered product performance.

Used without the safety alert symbol, indicates a potentially

hazardous situation which, if not avoided, may result in property

damage.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Fifth Wheel Design and Intended Use

1. For pulling trailers with standard SAE kingpins which are in good condition and

securely mounted or locked in position in the trailer.

2. For on-highway hauling applications.

3. Within the capacities stated in SAF-HOLLAND literature.

4. As recommended in SAF-HOLLAND literature (available from www.safholland.us).

Holland Fifth Wheels are NOT Designed or Intended For

1. Use with non-SAE kingpins, such as kingpins which are bent, improper size or

dimensions, not secured to maintain SAE configuration, or which are installed in

warped trailer bolster plates.

2. Tow-away operations which damage or interfere with the proper operation of the

fifth wheel.

3. The attachment of lifting devices.

4. The transport of loads in excess of rated capacity.

5. Off-highway applications and use.

6. Applications other than recommended.

2 SAF-HOLLAND, Inc. XL-FW428-01 Rev A

OPERATING INSTRUCTIONS

Before You Begin

IMPORTANT: This unit is not intended for operation on public streets and

highways with the fifth wheel in the up position. Do not operate

this unit on public highways unless the fifth wheel manual

secondary lock is engaged. The fifth wheel must be in the full down

position and the lockdown pins (option -87) fully engaged.

IMPORTANT: Towing a trailer in the elevated position raises the center of

gravity and increases the risk of vehicle rollover. To avoid rollover,

do not travel at excessive speeds and do not make sudden turns

or maneuvers.

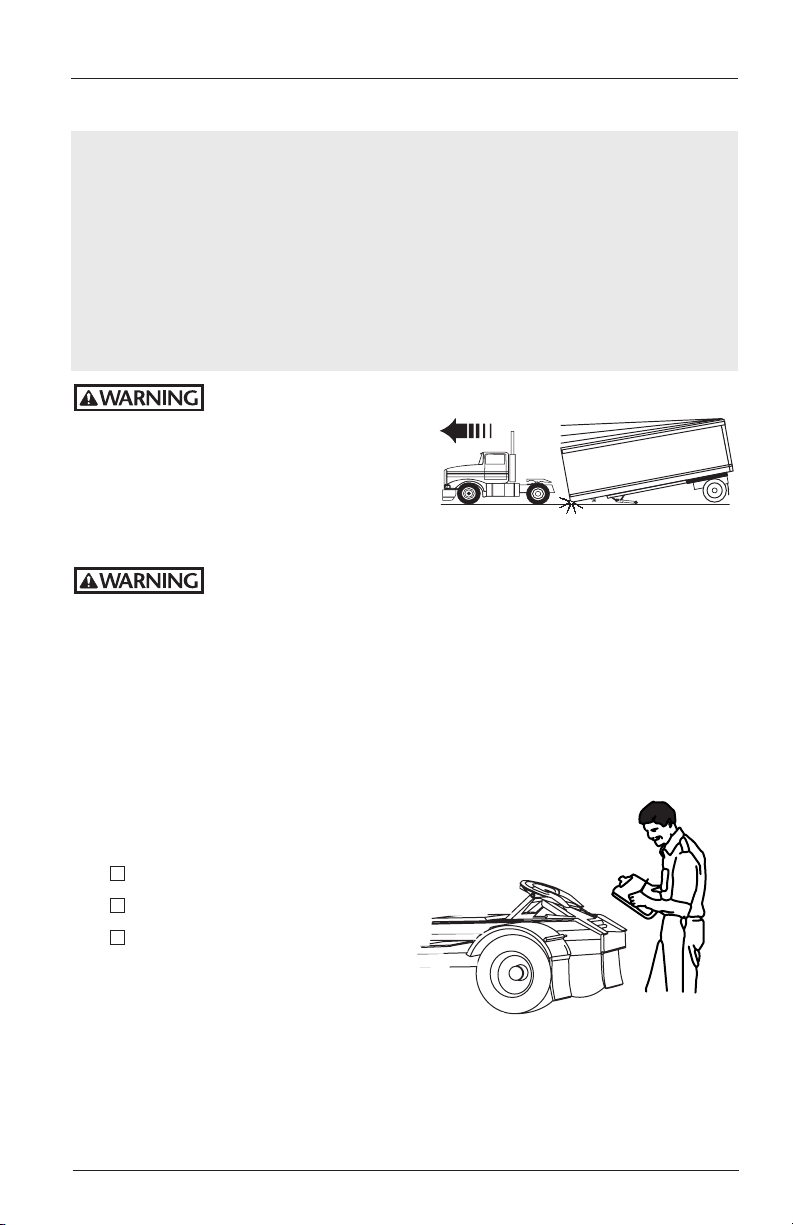

Failure to lower fifth wheel to full down position and engage

lockdown pins prior to

moving a coupled tractor

will increase vehicle

instability which, if not

avoided, could result in

serious unjury or death.

Failure to properly couple the fifth wheel according to these

instructions could result in tractor and trailer separation, causing

death or serious injury to others.

Fifth Wheel Inspections

1. Inspect the fifth wheel and mounting.

3

Tighten loose fasteners.

3

Replace missing fasteners.

3

Repair/replace missing,

cracked or otherwise

damaged components.

2. Inspect the lock jaws. If they

appear dry, apply grease to the

lock jaws and the front of the throat.

3. Tilt the ramps down.

XL-FW428-01 Rev A SAF-HOLLAND, Inc. 3

OPERATING INSTRUCTIONS

continued

General Coupling Procedures

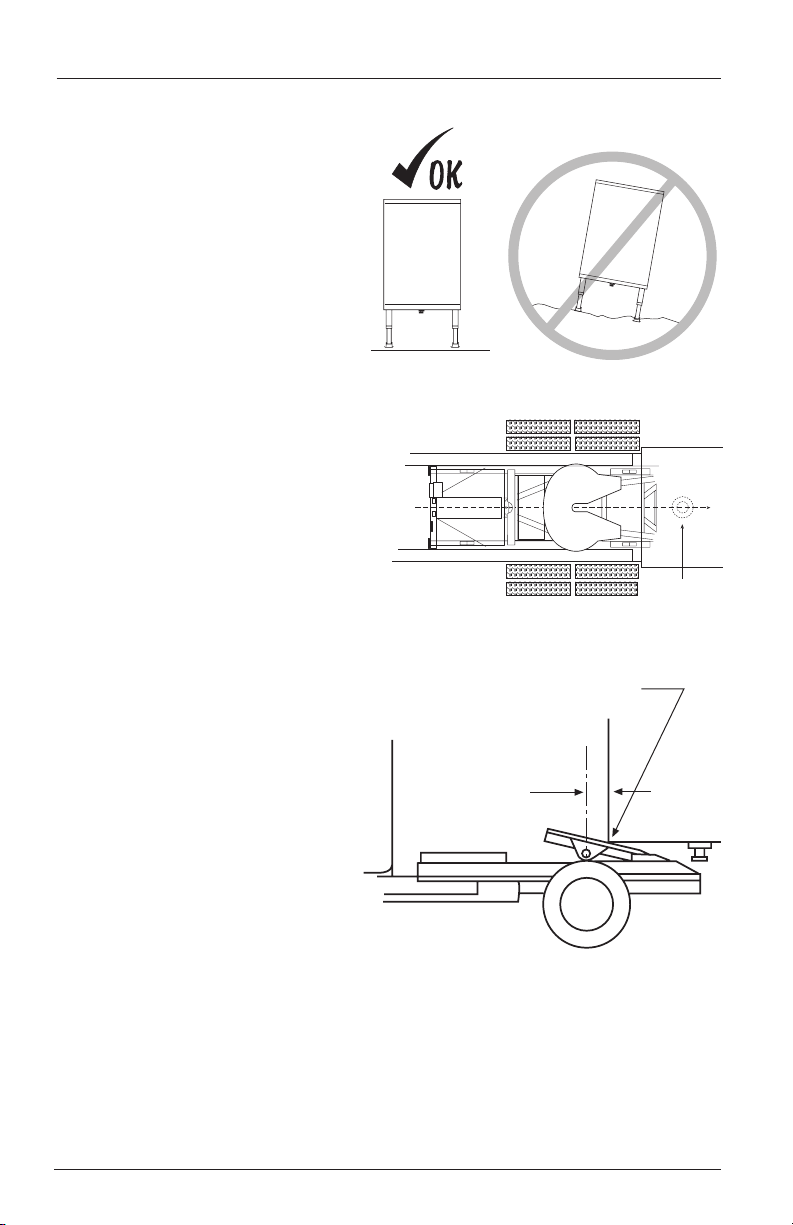

1. Make sure coupling area is flat,

level and clear of persons and

obstacles.

2. Center fifth wheel with kingpin and

back up straight.

3. Back tractor close to trailer

and STOP.

INITIAL CONTACT OF TRAILER WITH

FIFTH WHEEL AT THIS POINT

4˝ APPROX.

TRAILER

(TOP)

KINGPIN

continued

4 SAF-HOLLAND, Inc. XL-FW428-01 Rev A

OPERATING INSTRUCTIONS

continued

General Coupling Procedures

4. Chock trailer wheels.

5. Connect brake lines

and light cord.

6. Support slack in lines

to prevent interference.

7. Set trailer brakes.

NOTE: Follow operating instructions for the landing gear that is installed on

your trailer to raise or lower landing gear and trailer.

8. Adjust the trailer height so the fifth

wheel will lift the trailer. The trailer

should contact the fifth wheel 4˝ – 6˝

behind the fifth wheel bracket pin. If

the trailer landing gear needs to be

raised or lowered for proper coupling

height, use low gear.

continued

4˝- 6˝

OK

FIFTH WHEEL

MUST LIFT

TRAILER

➠

➠

FIFTH WHEEL

TILTED DOWN

USE LOW

GEAR

Wrong

FIFTH WHEEL

WILL NOT

LIFT TRAILER

continued

XL-FW428-01 Rev A SAF-HOLLAND, Inc. 5

OPERATING INSTRUCTIONS

General Coupling Procedures continued

continued

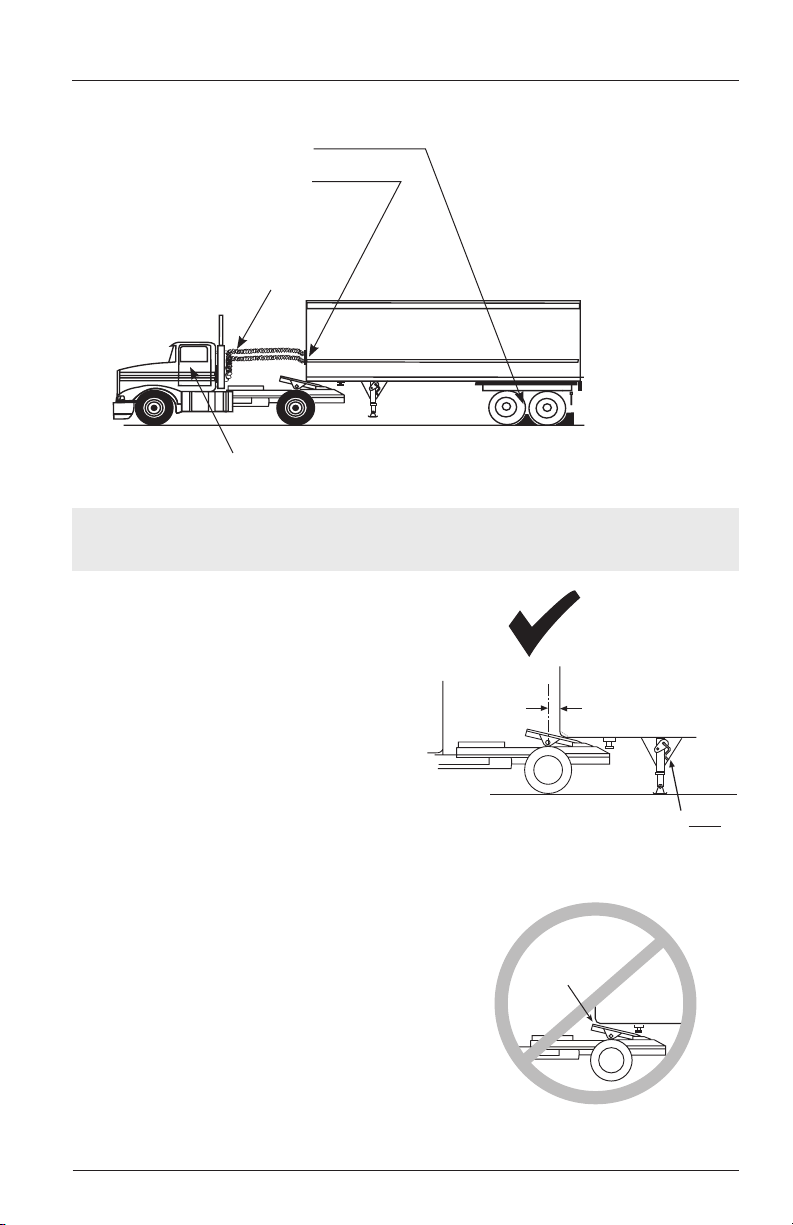

9. Slowly back into the trailer.

BACK INTO TRAILER

SLOWLY

10. Do a pull test as an

INITIAL CHECK.

➠

➠

PULL TEST

➠

PULL FORWARD WITH TRACTOR

DO NOT

BACK INTO

TRAILER FAST

➠ ➠ ➠ ➠

11. Visual Inspection. GET OUT OF THE TRACTOR!

VISUALLY check that the lock is CLOSED!

DO NOT RELY ON SOUND.

1

3

➠

NO GAP!

2

3

WITHOUT

PULL TEST

➠

View looking into

the throat of the

fifth wheel

➠

Bolster plate

is flush with

the fifth wheel

LOCKS COMPLETELY CLOSED

AROUND KINGPIN

If you do not obtain a proper couple, repeat the coupling sequence.

NOTE:

DO NOT use any fifth wheel that fails to operate properly.

Failure to properly couple the fifth wheel according to these

instructions could result in tractor trailer separation, if not

avoided, could result in serious injury or death.

6 SAF-HOLLAND, Inc. XL-FW428-01 Rev A

Kingpin

Trailer

bolster plate

continued

OPERATING INSTRUCTIONS

continued

Coupling Procedures for Over-The Road Use

For private yard operation (yard-spotter) coupling instructions, proceed to page 9. The

two steps below are required for operation of this fifth wheel on public streets.

IMPORTANT: This unit is not intended for operation on public streets and

highways with the fifth wheel in the up position. Do not operate

this unit on public highways unless the fifth wheel manual

secondary lock is engaged. The fifth wheel must be in the full

down position and the lockdown pins (option -87) fully engaged.

Failure to lower fifth wheel to full down position and engage

lockdown pins prior to moving a coupled tractor will increase vehicle

instability which, if not avoided, could result in serious injury or death.

1. Unhook and engage the secondary lock for operation on public streets.

1˝ MAXIMUM

ROD VISIBLE

HANDLE IS IN

2. Place the fifth wheel in the full down position and engage the top plate lock

down pins.

NOTE: The fifth wheel must be fully lowered to allow the lockdown pins to

engage. If the wheel is up too high, put the transmission in neutral and

engage the power take off (PTO). Set the engine speed to 1,000 to 1,200

r.p.m. and operate the control valve to lower the trailer and fifth wheel

until they are all the way down.

To engage the pins, move the handle from the “Yard Use” position (handle

pointing toward the front of the tractor), to the “Highway Use” position (handle

pointing toward the rear of the tractor) as shown below. This operation is also

illustrated on the instruction label located directly above the handle on the left

front side of the fifth wheel frame assembly.

FIFTH WHEEL IN FULL DOWN POSITION

HANDLE IN “HIGHWAY USE” POSITION

“YARD USE” POSITION

continued

XL-FW428-01 Rev A SAF-HOLLAND, Inc. 7

OPERATING INSTRUCTIONS

continued

Coupling Procedures for Over-The Road Use continued

3. Confirm that the lockdown pins

are in the extended position. Both

pins should be fully extended through

the fifth wheel assembly frame rails and

through the lockdown plates.

NOTE: Follow operating instructions for

the landing gear that is installed

on your trailer to raise or lower

landing gear and trailer.

4. Retract landing gear in accordance with

manufacturer’s instructions.

5. Check the brake lines and light cord.

Remove the wheel chocks and continue

with a pre-trip inspection.

LOCK PINS EXTENDED

(FOR HIGHWAY USE)

USE

LOW

GEAR

USE

HIGH

GEAR

SECURE

CRANK

continued

8 SAF-HOLLAND, Inc. XL-FW428-01 Rev A

OPERATING INSTRUCTIONS

continued

Coupling Procedures for Private Yard

(Yard-Spotter) Operation

1. Before raising the fifth wheel,

confirm that the lockdown pins

are in the retracted position. Both

pins should be fully retracted.

2. Put the transmission in neutral and

engage the power take-off (PTO).

3. Set the engine speed to 1,000 to 1,200 r.p.m.

and operate the control valve to raise the trailer

to the full height of the fifth wheel.

4. Disengage the PTO, remove the blocks, and

release the the trailer brakes.

LOCK PINS RETRACTED

General Uncoupling Procedures

1. Position the tractor and trailer on firm,

level ground – clear of obstacles and people.

2. Set the trailer brakes.

3. Slowly back the tractor tightly against the trailer.

(FOR YARD USE)

4. Set the tractor brakes.

5. Chock the trailer wheels.

6. Disconnect the brake lines and light cord.

Attach the brake line to a dummy coupling

to keep the line clean.

continued

XL-FW428-01 Rev A SAF-HOLLAND, Inc. 9

OPERATING INSTRUCTIONS

support

may be required.)

continued

Uncoupling Procedures for Over-The Road Use

For uncoupling procedures for Yard-Spotter operations, proceed to Step 1, Page 11.

NOTE: Follow operating instructions for the landing gear that is isntalled on

your trailer to raise or lower landing gear and trailer.

1. Extend landing gear in accordace with

manufacturer’s instructions.

USE

2. Switch to low gear and crank

an additional 4-8 turns.

HIGH

GEAR

Do not raise the trailer off the

fifth wheel.

3. Pull the secondary lock handle

and hook it on the rib (located on

the right side of the fifth wheel).

Proceed to step 4 on page 11.

USE

LOW

GEAR

SECURE

CRANK

Firm ground.

(Additional

10 SAF-HOLLAND, Inc. XL-FW428-01 Rev A

continued

OPERATING INSTRUCTIONS

continued

Uncoupling Procedures for Private Yard

(Yard-Spotter) Operation

1. Put the transmission in neutral and engage the PTO.

NOTE: The PTO must be engaged (pumped down) when lowering the fifth wheel.

2. Set the engine speed to 1,000 to 1,200 r.p.m. and operate the control valve to

lower the trailer until it rests on the trailer supports (landing gear).

3. Disengage the PTO.

4. Return to the tractor cab and push the fifth wheel lock

control valve and hold it in as you pull slowly out

from the trailer.

Never push the fifth wheel lock control

valve when the wheel is up or while

traveling.

Failure to lower fifth wheel to full

down position and engage lockdown

pins prior to pushing the fifth wheel

lock control valve could result in tractor

trailer separation which, if not avoided,

could result in serious injury or death.

FIFTH WHEEL

LOCK CONTROL

WARNING

NEVER PUSH WHEN WHEEL

IS UP OR WHILE TRAVELING.

TRAILER CAN SEPERATE

AND CAUSE DEATH OR

SERIOUS INJURY.

FIFTH WHEEL LOCK

CONTROL VALVE

continued

XL-FW428-01 Rev A SAF-HOLLAND, Inc. 11

TROUBLESHOOTING

PROBLEM: Will not lift.

POSSIBLE CAUSE SOLUTION

Insufficient oil ..............................................Check oil level. The tank should contain 4˝ of oil in the

down position. If low, add oil.

PTO not engaged ........................................Engage the PTO. Check the shifter for

proper operation.

Engine r.p.m. too low ..................................Increase to 1,000 to 1,200 r.p.m.

Control valve ...............................................Check for full throw.

Load exceeds capacity .................................Reduce the weight of the trailer.

Flow restriction ............................................ Check for ruptured or collapsed hoses; check oil filter;

clear the lines.

Pump is losing prime ................................... Raise the oil tank and/or line above the pump inlet.

Pump is running hot .................................... PTO left in gear; disengage when not in use.

Oil foaming (contains air) ...........................Tighten all fittings and check for leaks.

PROBLEM: Raises or lowers slowly.

POSSIBLE CAUSE SOLUTION

PTO not engaged ........................................Engage the PTO.

Engine r.p.m. too low .................................. Increase to 1,000 to 1,200 r.p.m.

Control valve ...............................................Check for full throw.

Incorrect pressure ........................................Raising pressure circuit should be 1,800 p.s.i.; lowering

circuit pressure should be 150 p.s.i.

Flow restricted .............................................Check for ruptured or collapsed hoses, check oil filter,

clear lines.

PROBLEM: Oil tank is overflowing.

POSSIBLE CAUSE SOLUTION

Too much oil in the system ......................... Check oil level. Tank should contain 4˝ of oil in the

down position.

Oil foaming (contains air) ...........................Tighten all fittings and check for leaks.

12 SAF-HOLLAND, Inc. XL-FW428-01 Rev A

TROUBLESHOOTING

continued

PROBLEM: Will not lower.

POSSIBLE CAUSE SOLUTION

PTO not engaged ........................................PTO must be engaged when lowering unit.

Engine r.p.m. too low .................................. Increase to 1,000 to 1,200 r.p.m.

PROBLEM: Will not stay in raised position.

POSSIBLE CAUSE SOLUTION

Pressure loss ................................................Air in hydraulic oil. Let stand until clear. Tighten fittings

and check for leaks. Check oil level.

Pressure loss ................................................Leak in system. Tighten fittings and check for leaks.

Pressure loss ................................................Damaged hydraulic cylinder. Isolate and pressurize to

check. Repair or replace.

Pressure loss ................................................Faulty valves. Clean and reassemble, or, replace

control and release valves in manifold.

PROBLEM: Cracking or breaking of lift arms.

POSSIBLE CAUSE SOLUTION

Rough terrain ..............................................Improve road surface.

Overload ......................................................Reduce trailer weight.

Lack of lubrication .......................................Lubricate per maintenance instructions.

Worn shafts, bushings,

and housings ............................................. Replace

Incorrect pressure ........................................Lifting circuit pressure should be 1,800 p.s.i.

PROBLEM: Fifth wheel will not unlock properly.

POSSIBLE CAUSE SOLUTION

Accumulated grease and

dirt in mechanism ..................................... Steam clean thoroughly and lubricate with light,

rust-resistant oil.

Insufficient lubrication .................................Lubricate thoroughly with light, rust-resistant oil.

Faulty release air cylinder ............................Replace air filter and/or cylinder.

Worn or damaged parts. .............................Rebuild or replace.

continued

XL-FW428-01 Rev A SAF-HOLLAND, Inc. 13

MAINTENANCE INSTRUCTIONS

Weekly

1. Apply grease to all fittings.

2. Be sure the fifth wheel top plate is lubricated.

3. Check the hydraulic oil level.

4. Check the operation of the fifth wheel locking mechanism.

Monthly

1. Steam clean the entire unit thoroughly.

2. Inspect the elevating fifth wheel assembly and its mounting. Check the truck

frame for proper bolt torque; missing or damaged bolts; and broken, distorted, or

missing parts.

3. Check the fifth wheel locking mechanism for proper operation using a Holland

TF-TLN-1000 lock tester. Lubricate the locking mechanism with a light, rustresistant oil. When checking, move the lock tester fore and aft when it’s closed in

the locks. If play exceeds 3/8˝, rebuild or replace the top plate. See your Holland

distributor for top plates or rebuild kits.

4. Relubricate the assembly.

5. Inspect for leaks in the hydraulic system. Seal or replace any components, as

required.

6. Check the oil filter. Replace if necessary.

7. Check free play and pivot points in the elevating fifth wheel assembly. If free play

exceeds 1/8˝, replace the torque frame and/or shaft, as required.

continued

14 SAF-HOLLAND, Inc. XL-FW428-01 Rev A

MAINTENANCE PROCEDURES

continued

As-Needed Lubrication

IMPORTANT: Always maintain adequate lubrication in fifth wheel locking

mechanism, if it appears dry, apply grease to lock jaw and

front of throat directly, or through the lube tube grease fitting

located near the front left side of the fifth wheel.

LUBE THE CAM TRACK

Recommended Greases

A “low temp” grade recommended

for -30ºF or lower such as:

1. Cato Oil and Grease #5213

2. Craftsman Chemical Co. #LTF 2

3. Mystic LP-200 or equivalent

LUBE THE LOCKS

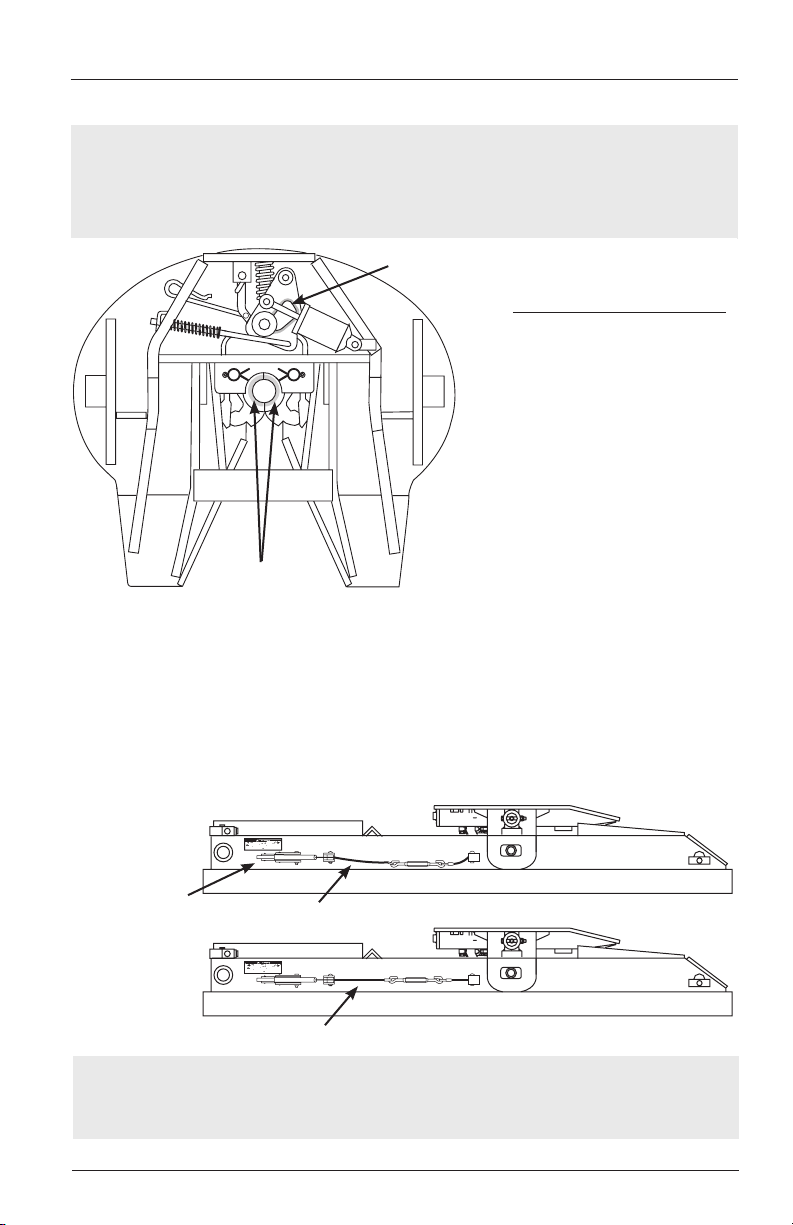

Check Top PlateLockdown Mechanism Cables

1. With the handle in the “Highway Use” position, the cable should be moderately

tight and not sagging excessively. If the cable is loose, rotate the turnbuckle to

tighten the cable.

2. After tightening, cycle the handle from the “Yard Use” position to the “Highway

Use” position several times to confirm that the pins are extending and retracting, as

described on page 8. Also confirm that the cables are not binding or being pinched.

HANDLE IS IN

THE HIGHWAY

USE POSITION

CABLE IS LOOSE - TIGHTEN BY ROTATING TURNBUCKLE

CABLE IS TIGHT - NO ADJUSTMENT NEEDED

NOTE: Do not use any fifth wheel that does not operate properly. If your

fifth wheel does not operate properly, contact your nearest Holland

Representative for assistance.

continued

XL-FW428-01 Rev A SAF-HOLLAND, Inc. 15

and maintenance of this product. Read and understand

E n g i n e e r i n g Y o u r R o a d t o S u c c e s s

this information.

IMPORTANT: Enclosed is important information for the operation

Failure to properly install, operate, or maintain

WARNING

this fifth wheel could result in tractor and trailer

separation which, if not avoided, could result in

serious injury or death.

SAF-HOLLAND USA, Inc. SAF-HOLLAND Canada Limited

888.396.6501 Fax 800.356.3929 519.537.3494 Fax 800.565.7753

Western Canada

604.574.7491 Fax 604.574.0244

XL-FWFW428-01 Rev A · 2009-07-07 · Amendments and errors reserved · © SAF-HOLLAND, Inc.

Loading...

Loading...