Coupling Procedures

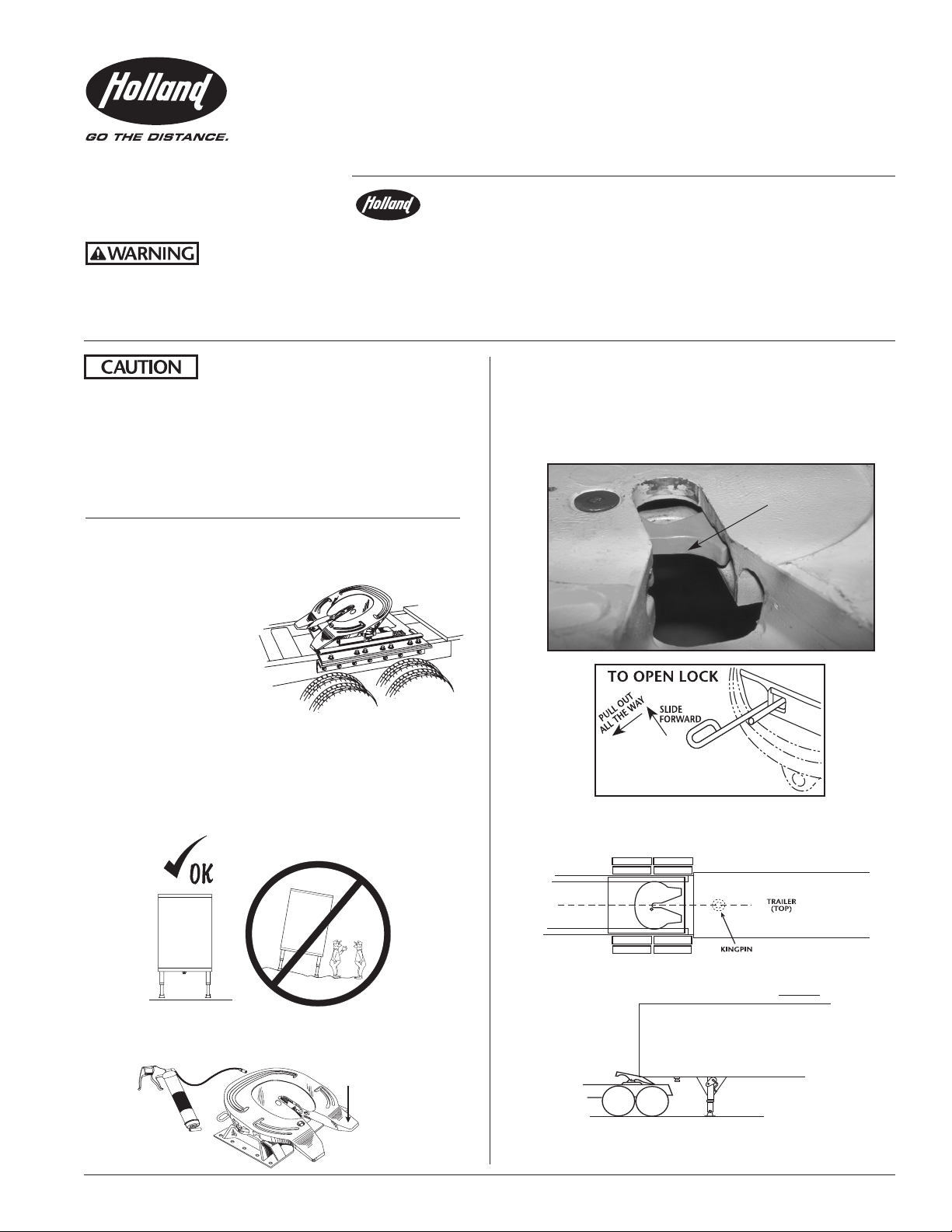

1. Inspect the fifth wheel mounting.

• Tighten loose

fasteners

• Replace missing

fasteners

• Repair/replace

cracked

components

NOTE: If you have a sliding fifth wheel, make sure

both plungers are fully engaged (locked).

(See Page 4, Figure 4B)

2. Make sure coupling area is flat, level and clear

of persons and obstacles.

3. Lubricate the fifth wheel-to-trailer contact

surface with grease. Tilt the ramps down.

XL-FW421-02

TILT

DOWNWARD

4. Make sure the locks are open. To open locks,

slide the handle forward and pull it out to the

maximum extension. The lock will swing to

the open position. Note: When you first receive

your fifth wheel, you may have to pry open the lock.

5. Center fifth wheel with kingpin.

6. Back tractor close to trailer and STOP.

LOCK OPEN

POSITION

ACTUATING FINGER

1

FLEETMASTER

XA-201-A-80-L AIR RELEASE

OPERATING INSTRUCTIONS &

MAINTENANCE PROCEDURES

OPERATING INSTRUCTIONS

This air release option fifth wheel

top plate is not intended to be

mounted onto low mount stationary brackets (Part

No. XA-7586 and XA-7886). Low mount brackets

do not provide sufficient clearance for the air

cylinder which can be damaged when the fifth

wheel is articulated.

You must read and understand the following instructions before operating your fifth

wheel. Failure to follow all of the important maintenance procedures contained in

these instructions may result in a hazardous condition or cause a hazardous condition to develop.

All maintenance must be performed by a qualified person using proper tools and safe procedures.

All maintenance must be performed while the tractor is uncoupled from the trailer.

7. Chock trailer wheels.

8. Connect brake lines and light cord.

9. Support slack in lines

to prevent interference.

10. Set trailer brakes.

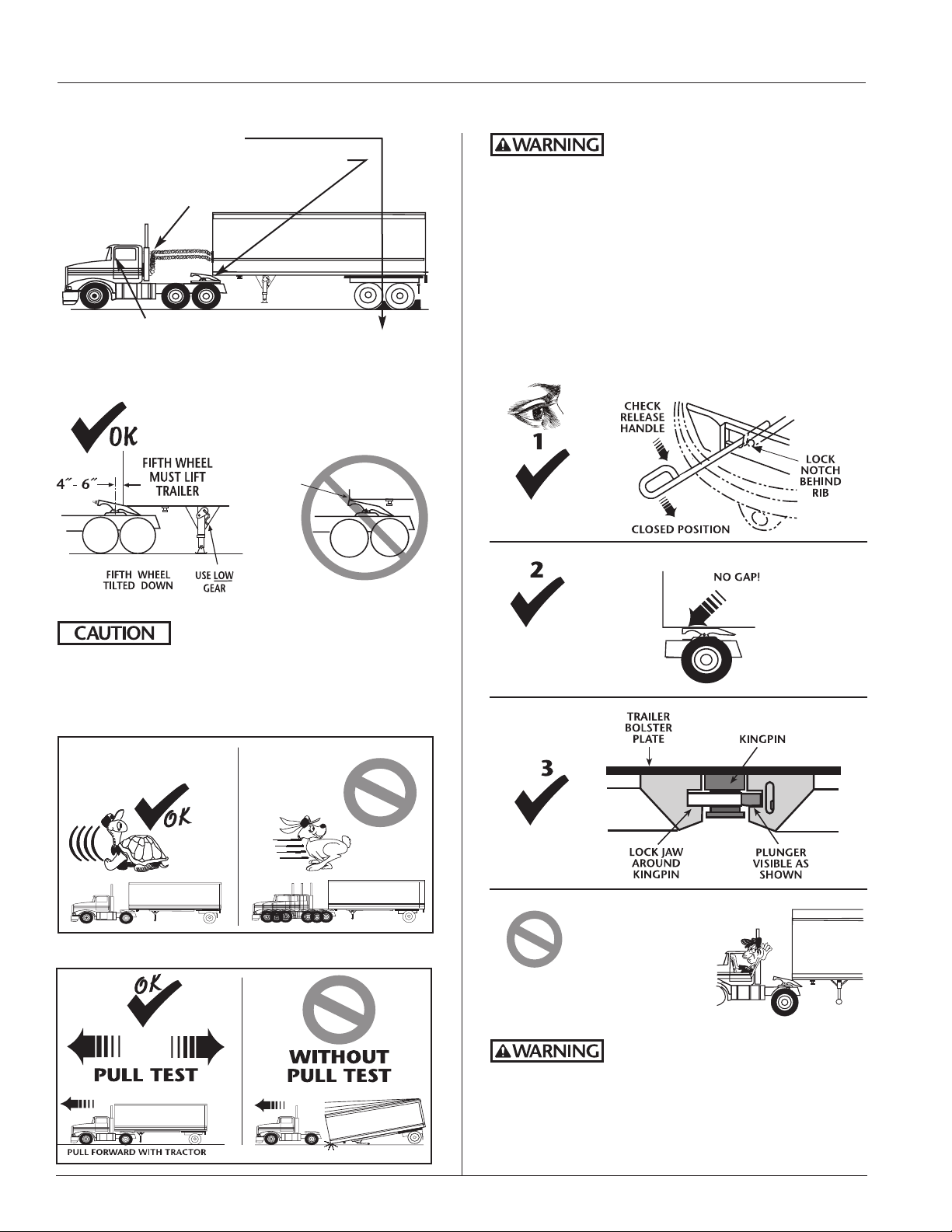

11. Adjust trailer height so fifth wheel will lift trailer.

Trailer should contact fifth wheel 4˝–6˝ behind

fifth wheel bracket pin.

12. Slowly back into trailer.

13. Do a pull test as an INITIAL CHECK.

Wrong

FIFTH WHEEL

WILL NOT LIFT

TRAILER

BACK INTO TRAILER

SLOWLY

à

à

à

à

à

à

DO NOT

BACK INTO

TRAILER FAST

14. Visual Inspection.

GET OUT OF THE TRACTOR!

VISUALLY check that the lock is CLOSED!

DO NOT

RELY ON

SOUND

à

à

2

A direct visual inspection is

required to assure proper

coupling. Improper coupling can pass the initial

pull test. Sound is unreliable. DO NOT take for

granted that you are properly coupled. Get out of

the cab and look. An improperly coupled truck and

trailer could result in seperation and may cause

death or serious injury to others.

If you do not obtain a proper

couple, repeat the coupling

sequence. DO NOT use any fifth wheel that fails to

operate properly. An improperly coupled truck and

trailer could result in seperation and may cause

death or serious injury to others.

OPERATING INSTRUCTIONS

Coupling Procedures (con’t.)

Attempting to couple with the

trailer at an improper height

could result in a false or improper coupling and

cause damage to the tractor, fifth wheel, or trailer.

XL-FW421-02

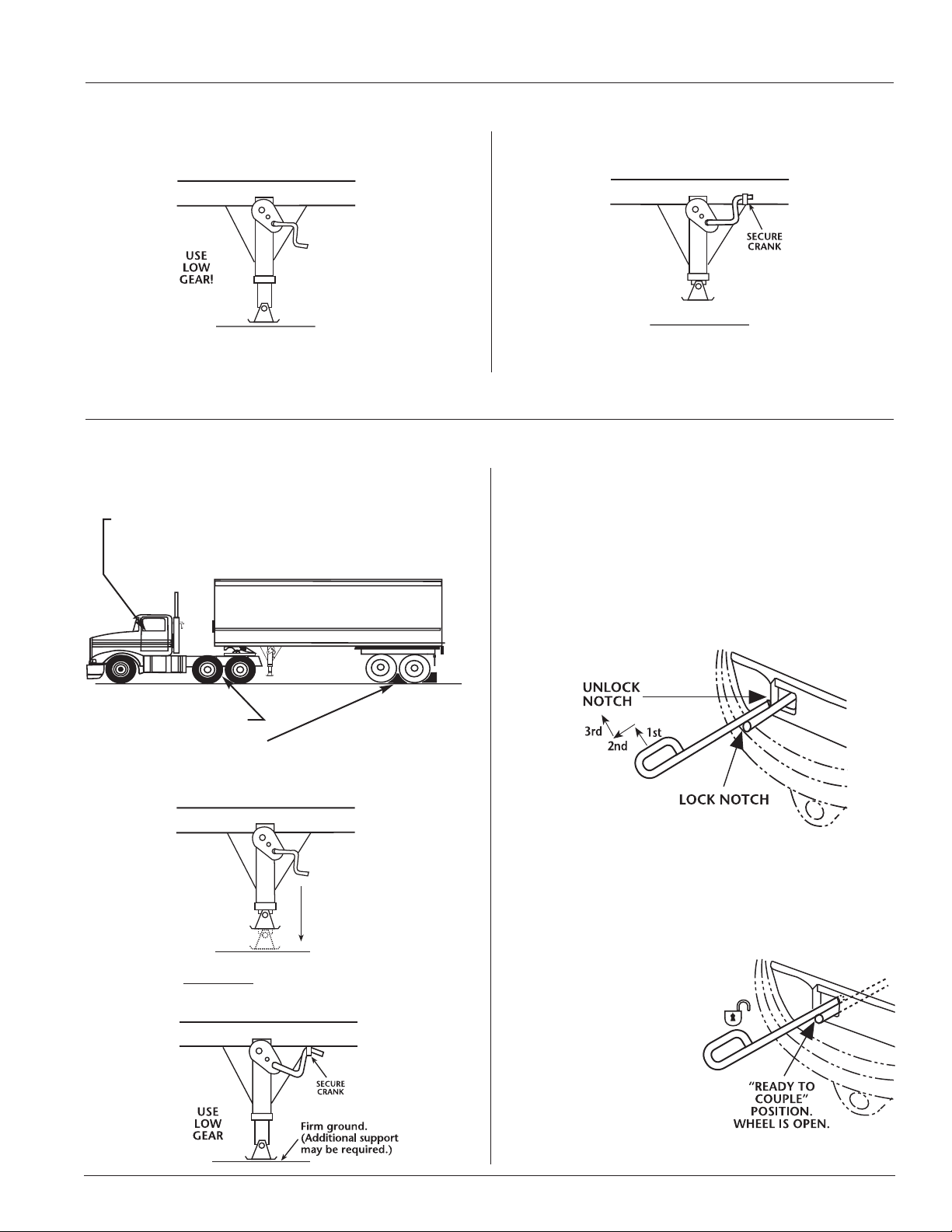

8. Disconnect brake lines and light cord. Attach

brake line to dummy coupling to keep line clean.

9. Actuate the fifth wheel control valve to open

the locks.

10. Slowly pull out from the trailer.

IF MANUAL RELEASE IS REQUIRED, FOLLOW

INSTRUCTIONS BELOW:

Release tractor brakes and slowly drive away

from the trailer. Let the trailer slide down the

fifth wheel and pick-up ramps, being careful

that the trailer landing gear touch the ground

with minimal impact.

NOTE: It is

normal after

uncoupling for

the release

handle to come

off the unlock

notch and move

to a “ready to

couple” position.

1. Position tractor and trailer on firm, level

ground clear of obstacles and persons.

2. Set trailer brakes.

3. Slowly back tractor tightly against trailer.

4. Set tractor brakes.

5. Chock trailer wheels.

6. Lower landing gear until pads just touch the

ground.

7. Switch to low gear

and crank an additional 4-

8 turns. Do not raise trailer off the fifth wheel.

USE

HIGH

GEAR

3

OPERATING INSTRUCTIONS

Coupling Procedures (con’t.)

15. Retract landing gear until pads come off the

ground.

16. Switch to high gear, fully retract and secure

crank handle.

17. Re-check brake lines and light cord. Remove

wheel chocks, continue with pre-trip inspection.

OPERATING INSTRUCTIONS

Uncoupling Procedures

XL-FW421-02

Loading...

Loading...